Patents

Literature

506 results about "Lightening holes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lightening holes are holes in structural components of machines and buildings used by a variety of engineering disciplines to make structures lighter. The edges of the hole may be flanged to increase the rigidity and strength of the component. The holes can be circular, triangular, elliptical, or rectangular and should have rounded edges, but they should never have sharp corners, to avoid the risk of stress risers, and they must not be too close to the edge of a structural component.

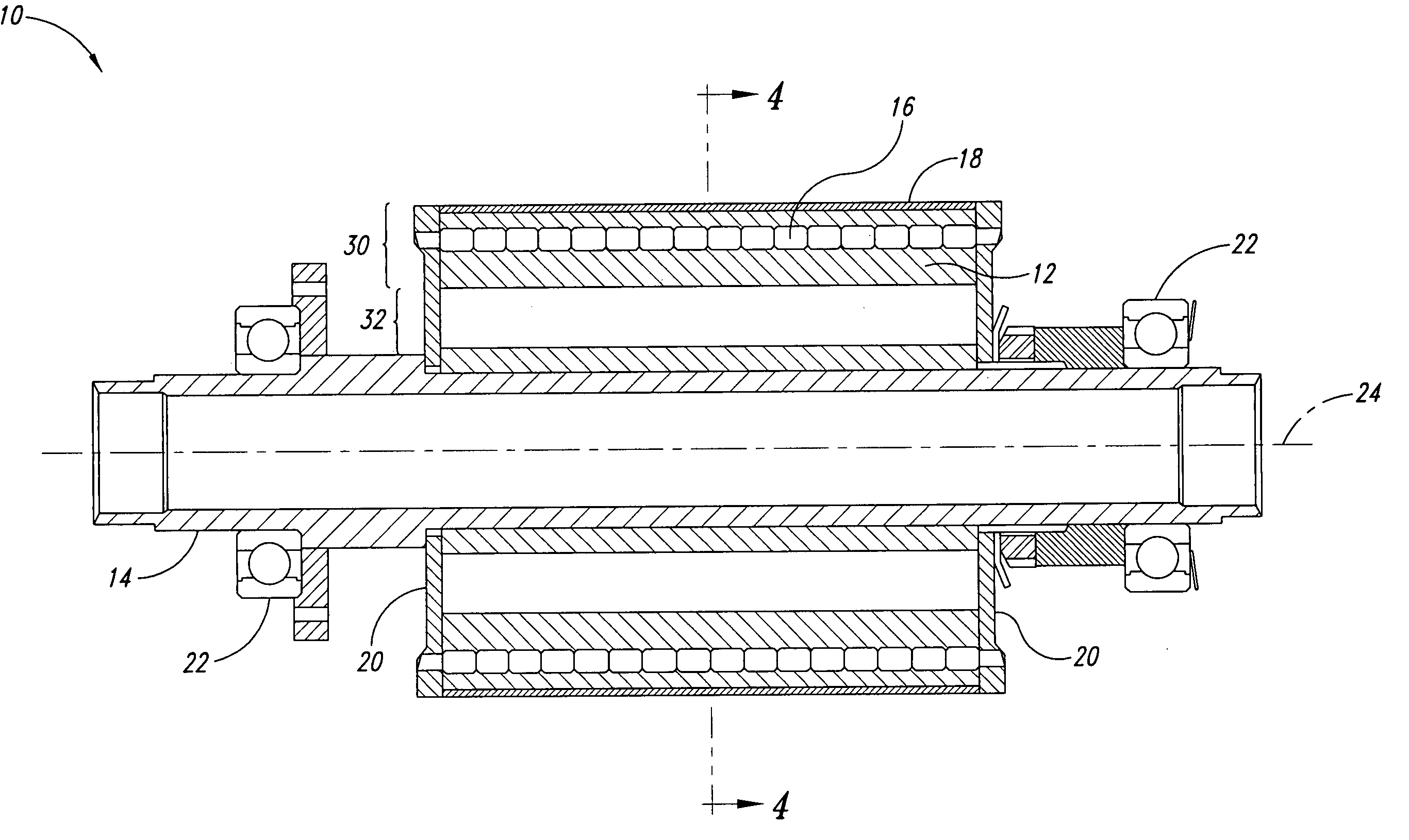

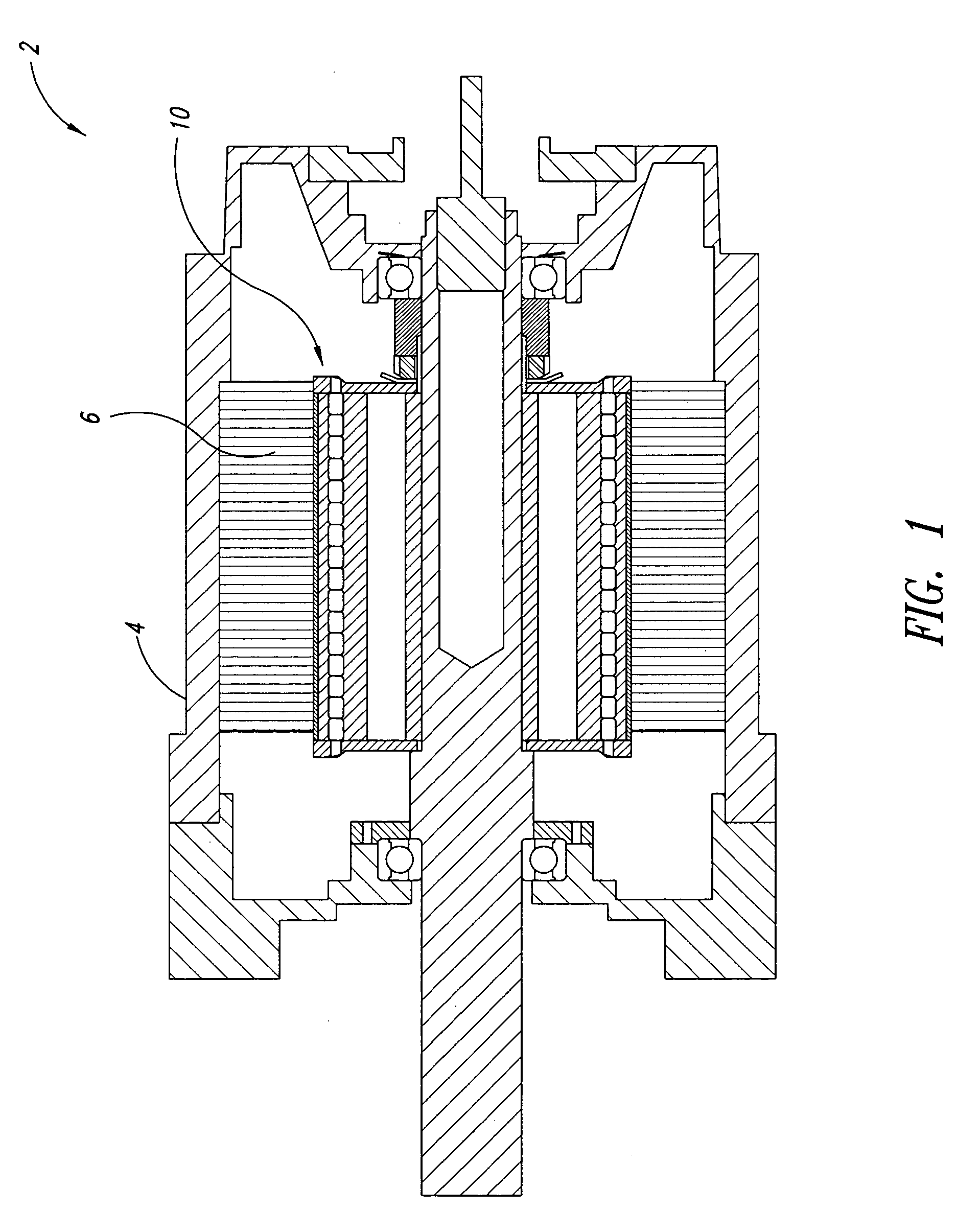

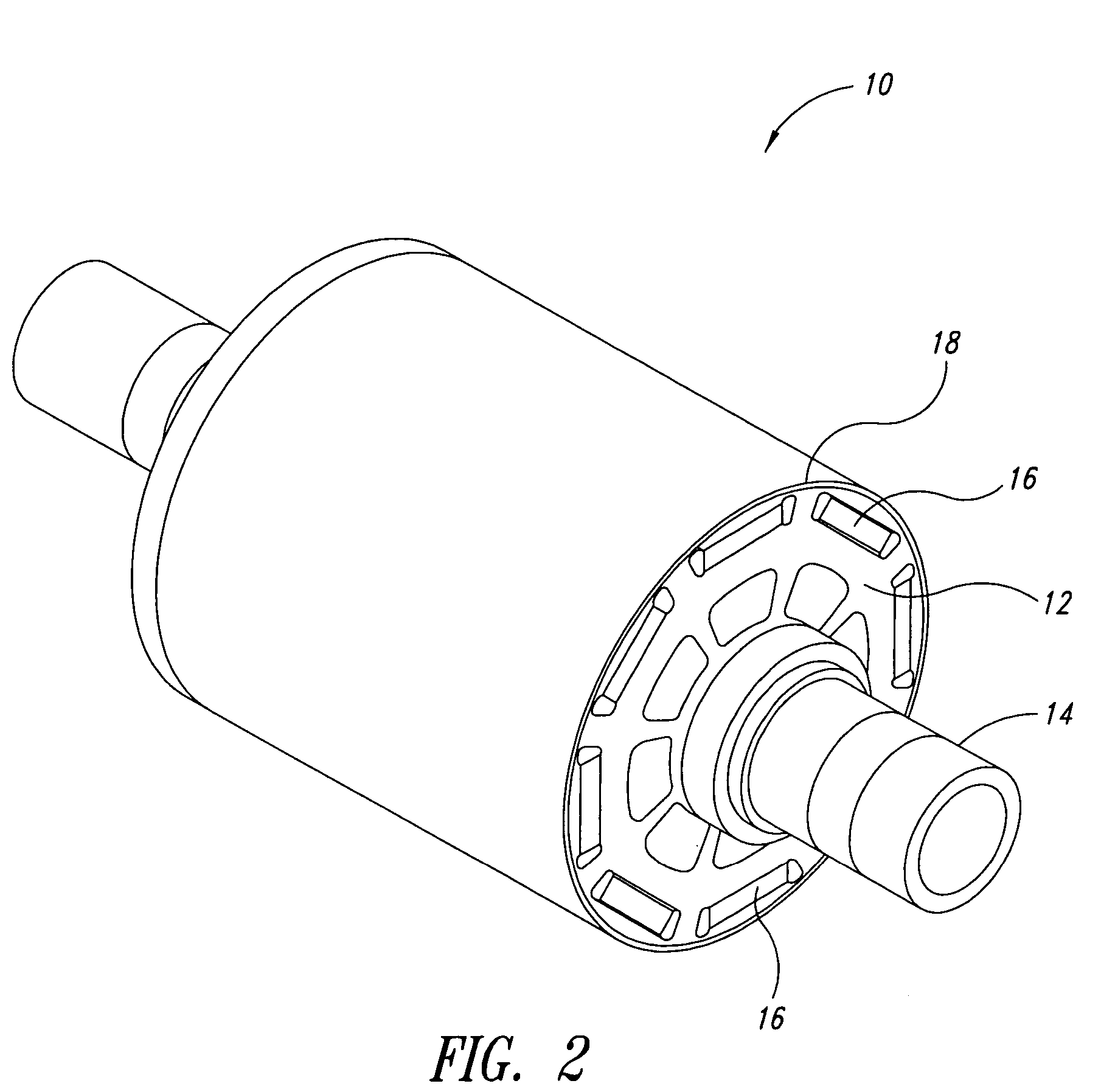

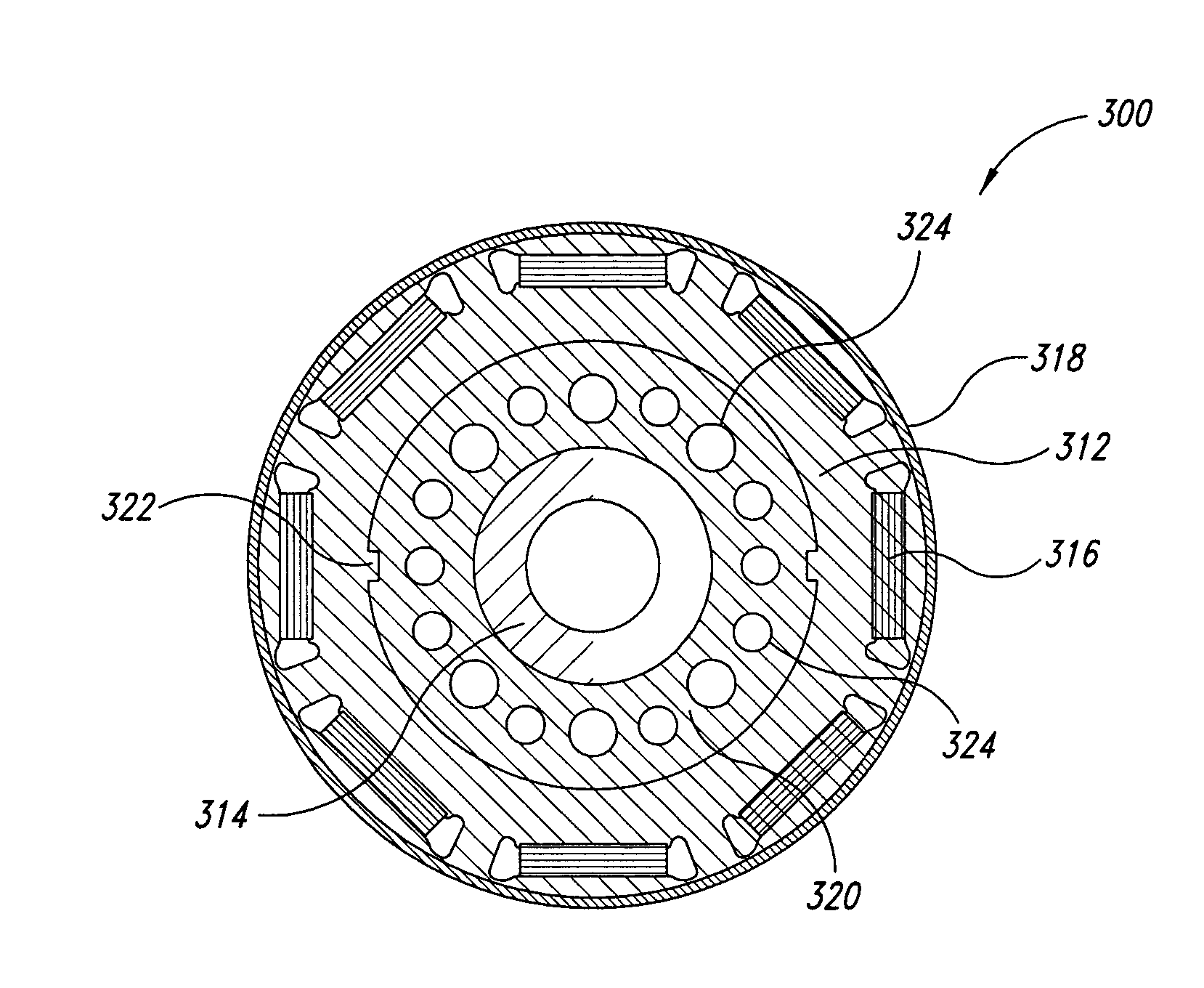

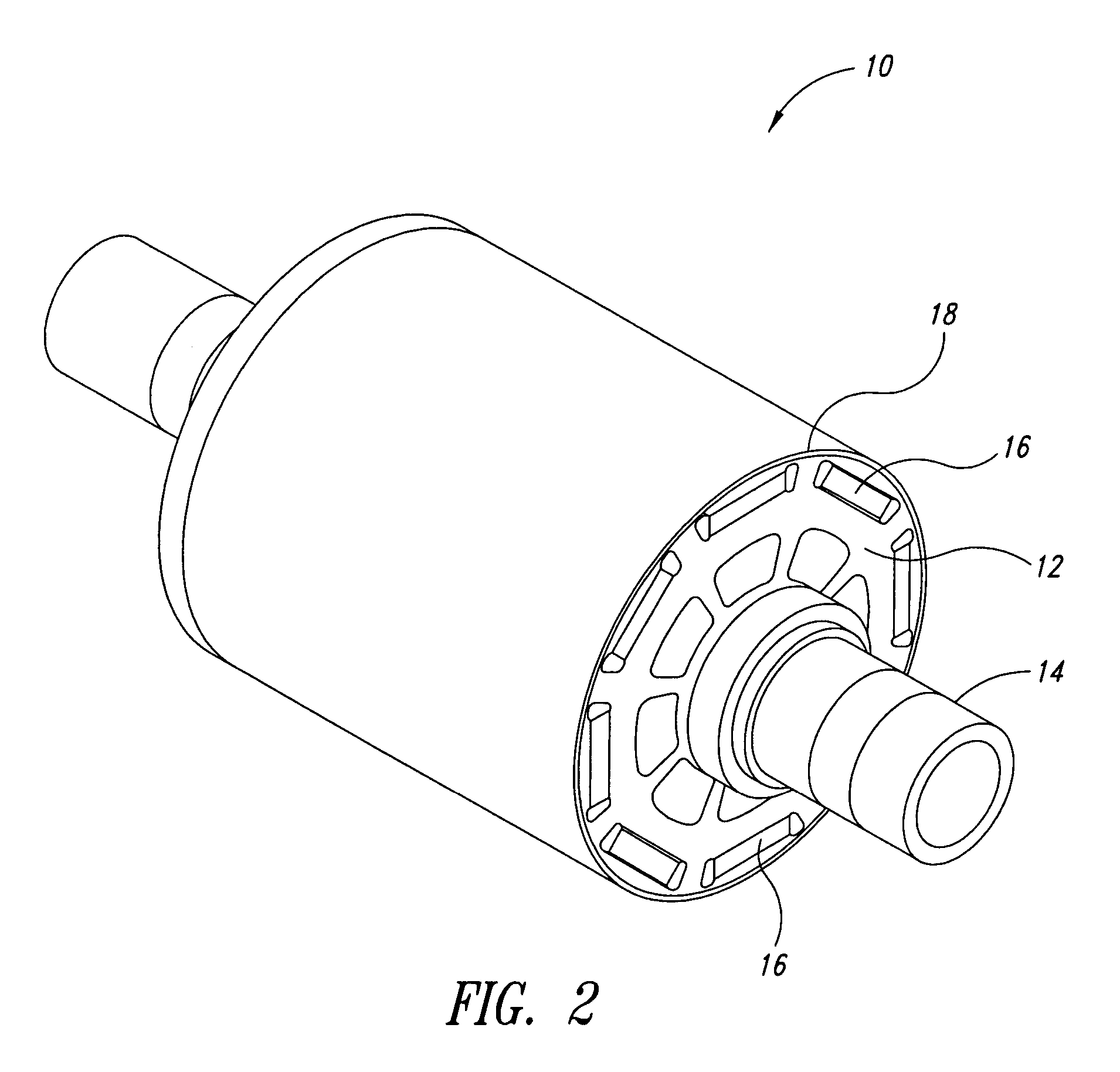

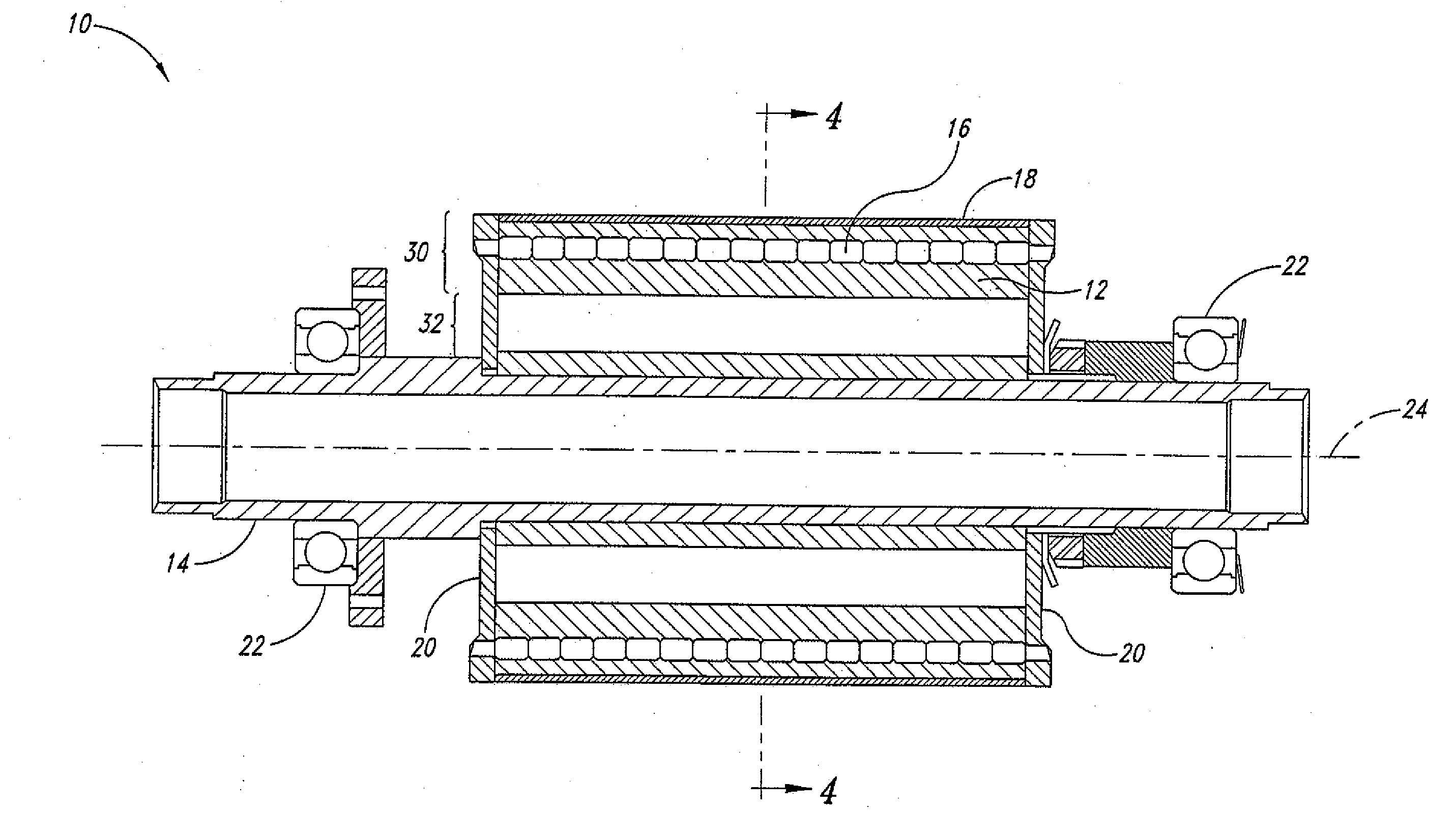

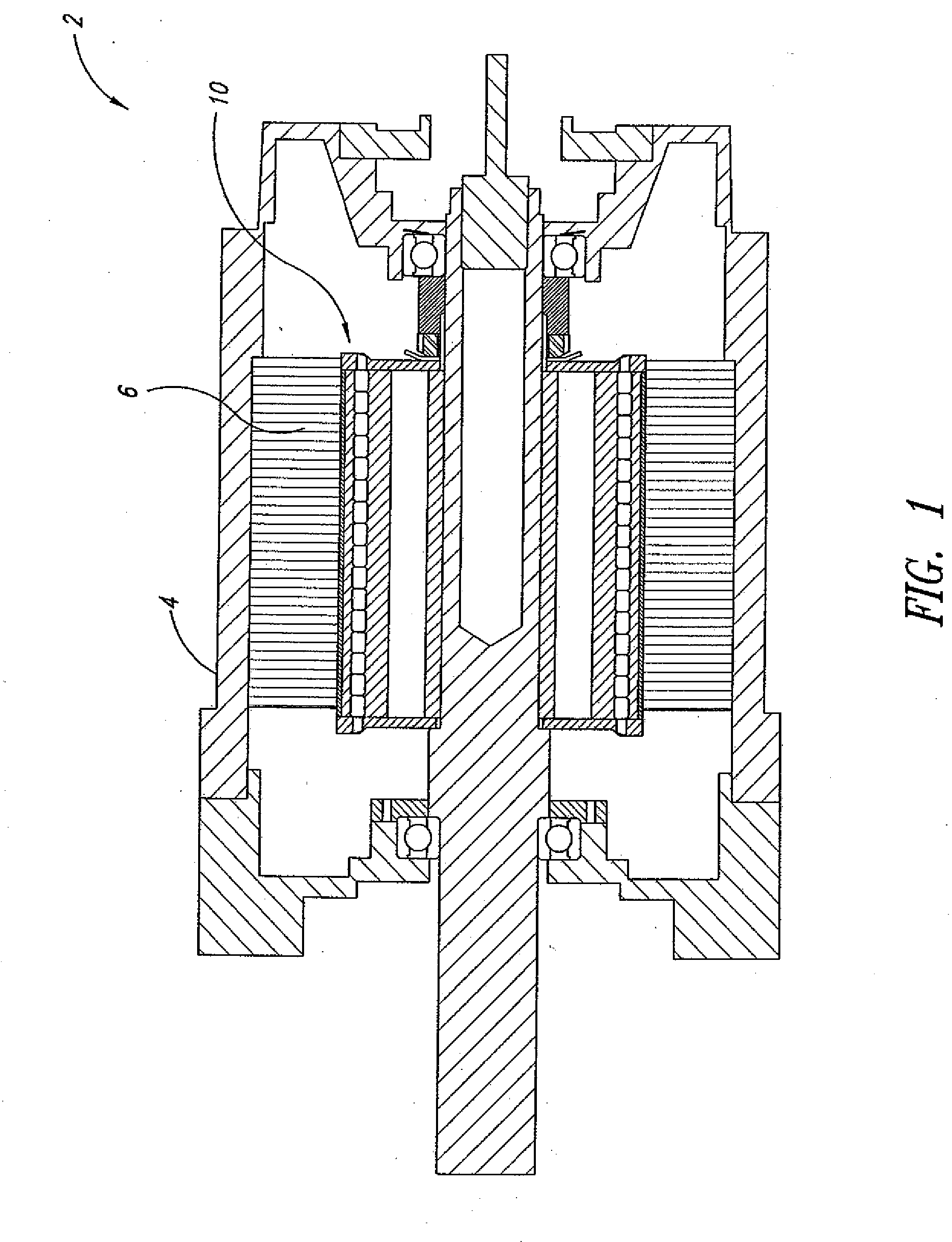

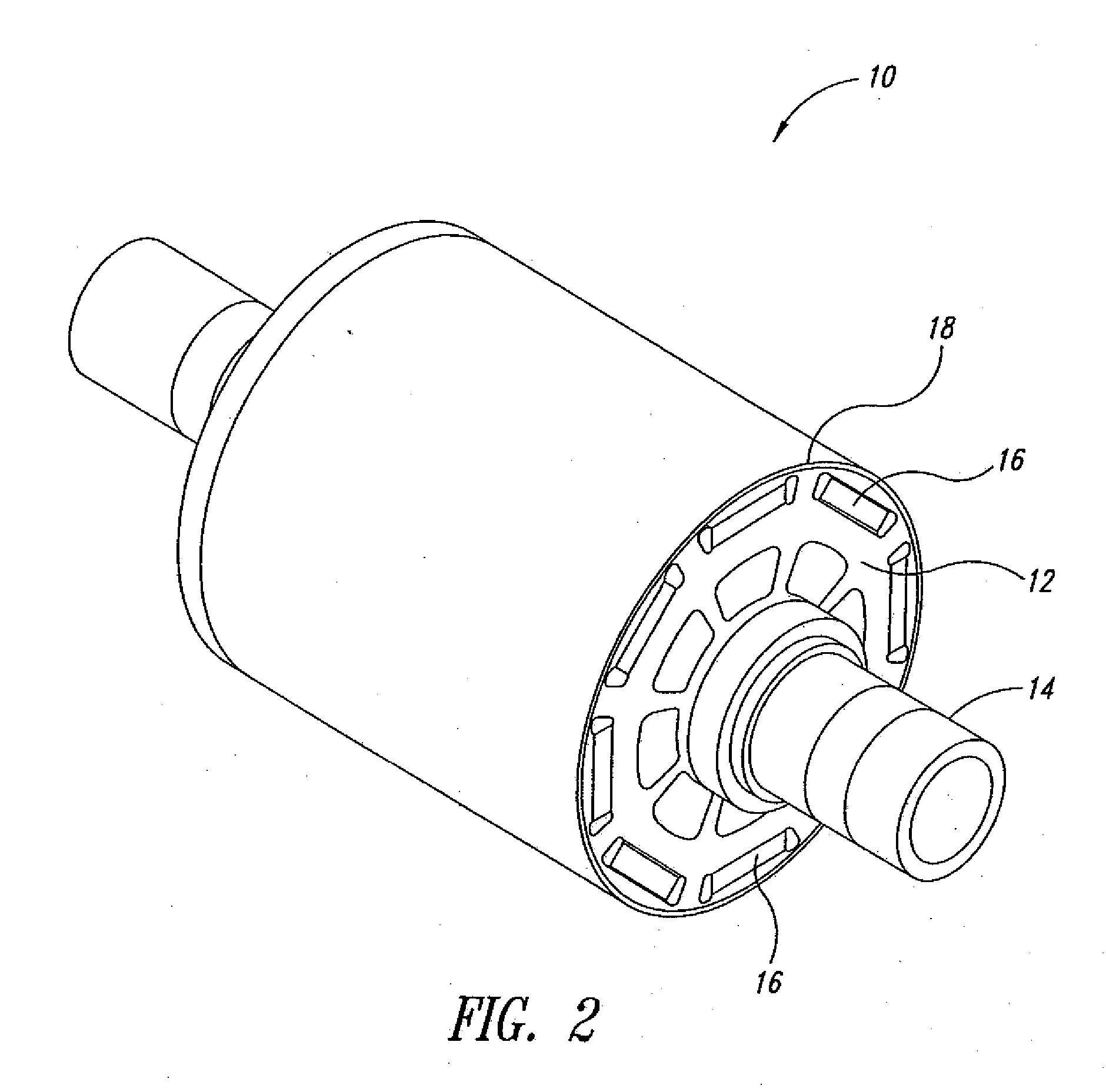

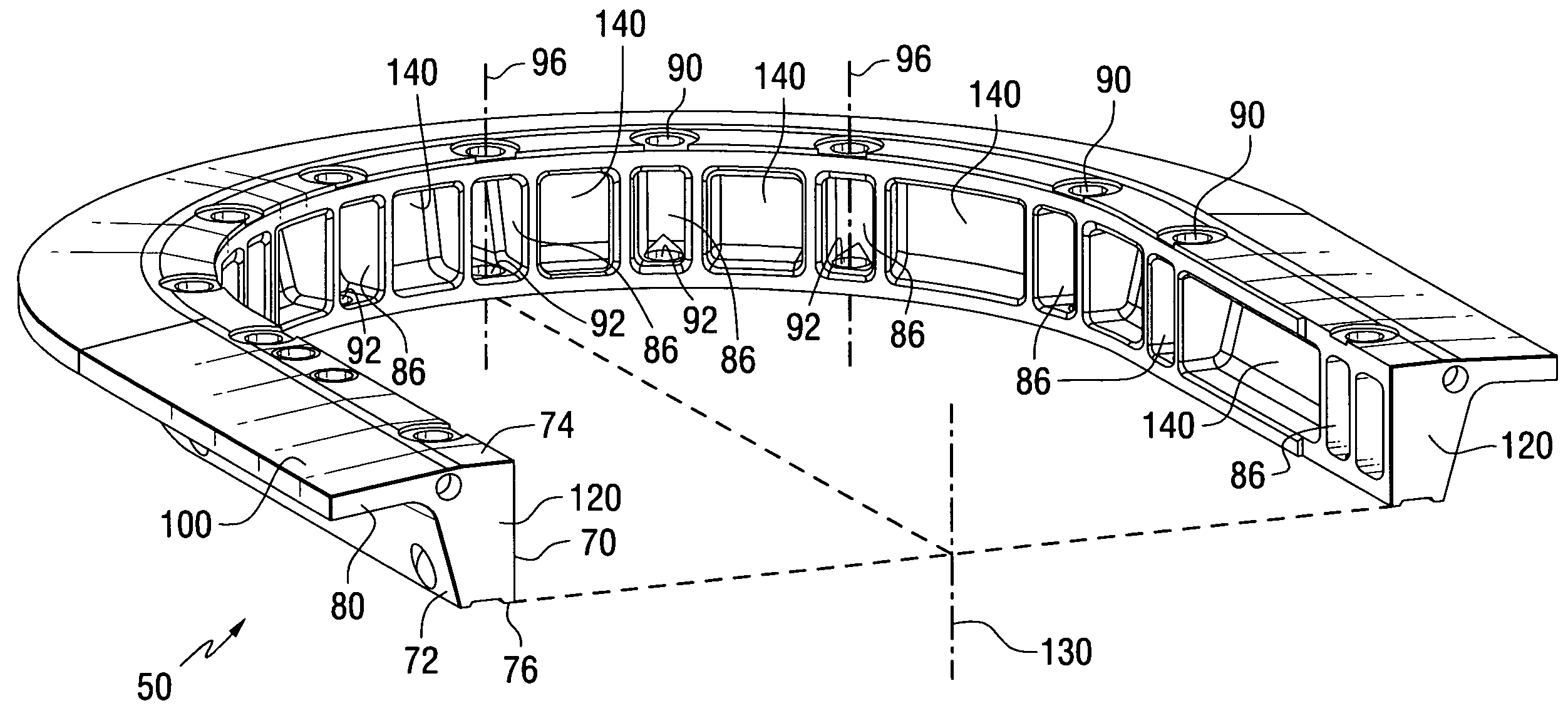

Rotor hub and assembly for a permanent magnet power electric machine

InactiveUS20060022541A1Reduce weightIncrease speedMagnetic circuit rotating partsMechanical energy handlingElectric machineEngineering

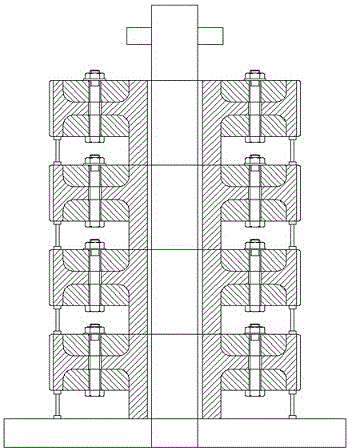

A rotor assembly for use in an electric motor or generator where the mass of the rotor assembly is reduced with respect to conventional rotor assemblies. In addition, the rotor assembly is configured to be scalable to different sized electric motors. Within the rotor assembly, the rotor hub, the shaft, and the permanent magnets can independently or collectively be modified to have a reduced mass. In one aspect, a portion of the rotor hub adjacent to the shaft is configured with passages and spokes. In another aspect, an intermediate hub with lightening holes is provided between the shaft and the rotor hub. In yet another aspect, a large diameter hollow shaft replaces a portion of the rotor hub. In yet another aspect, the permanent magnets are configured to have an arc-shape, which permits the thickness of the magnets to be reduced without reducing the efficiency of the magnets.

Owner:SIEMENS VDO AUTOMOTIVE CORP

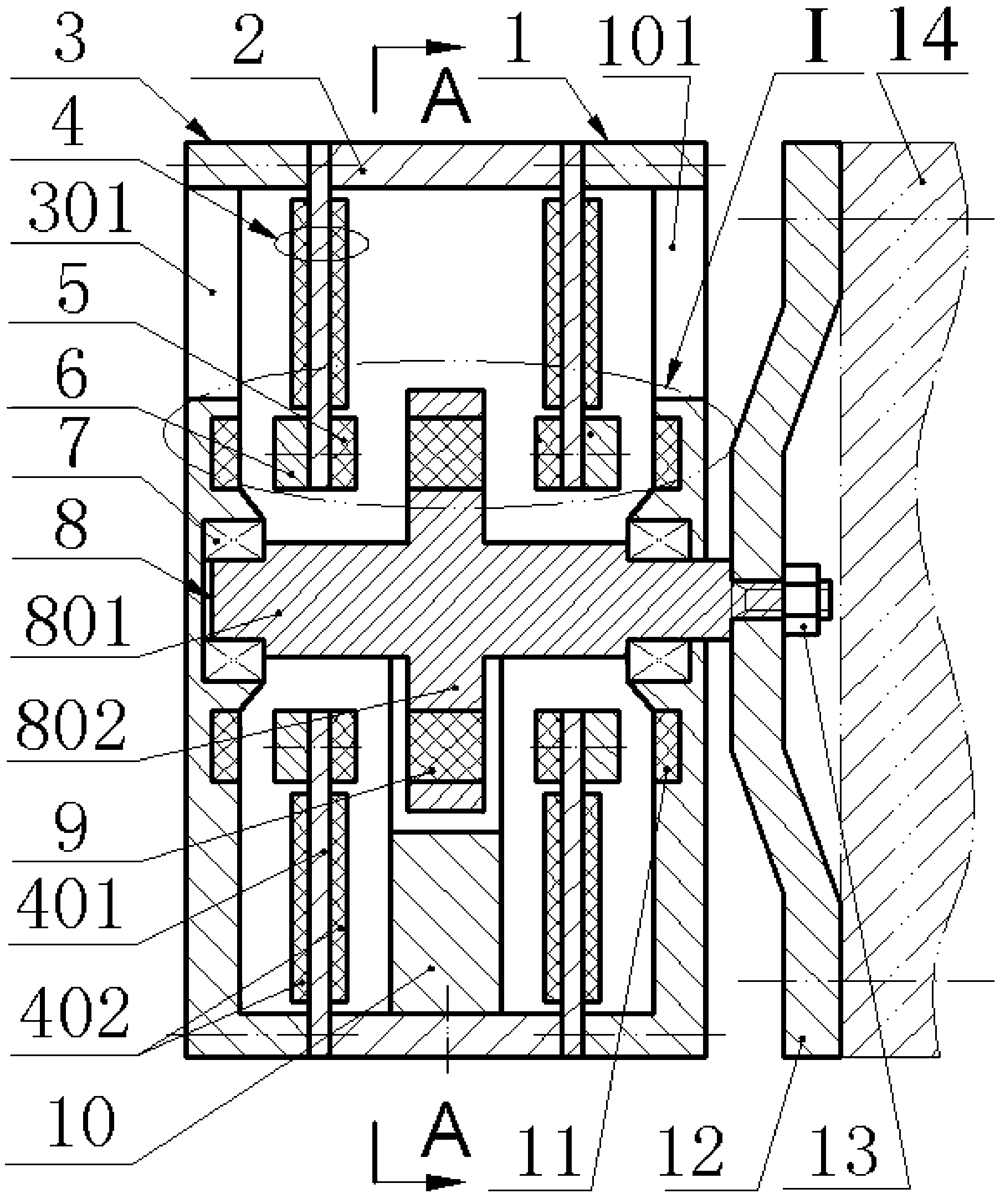

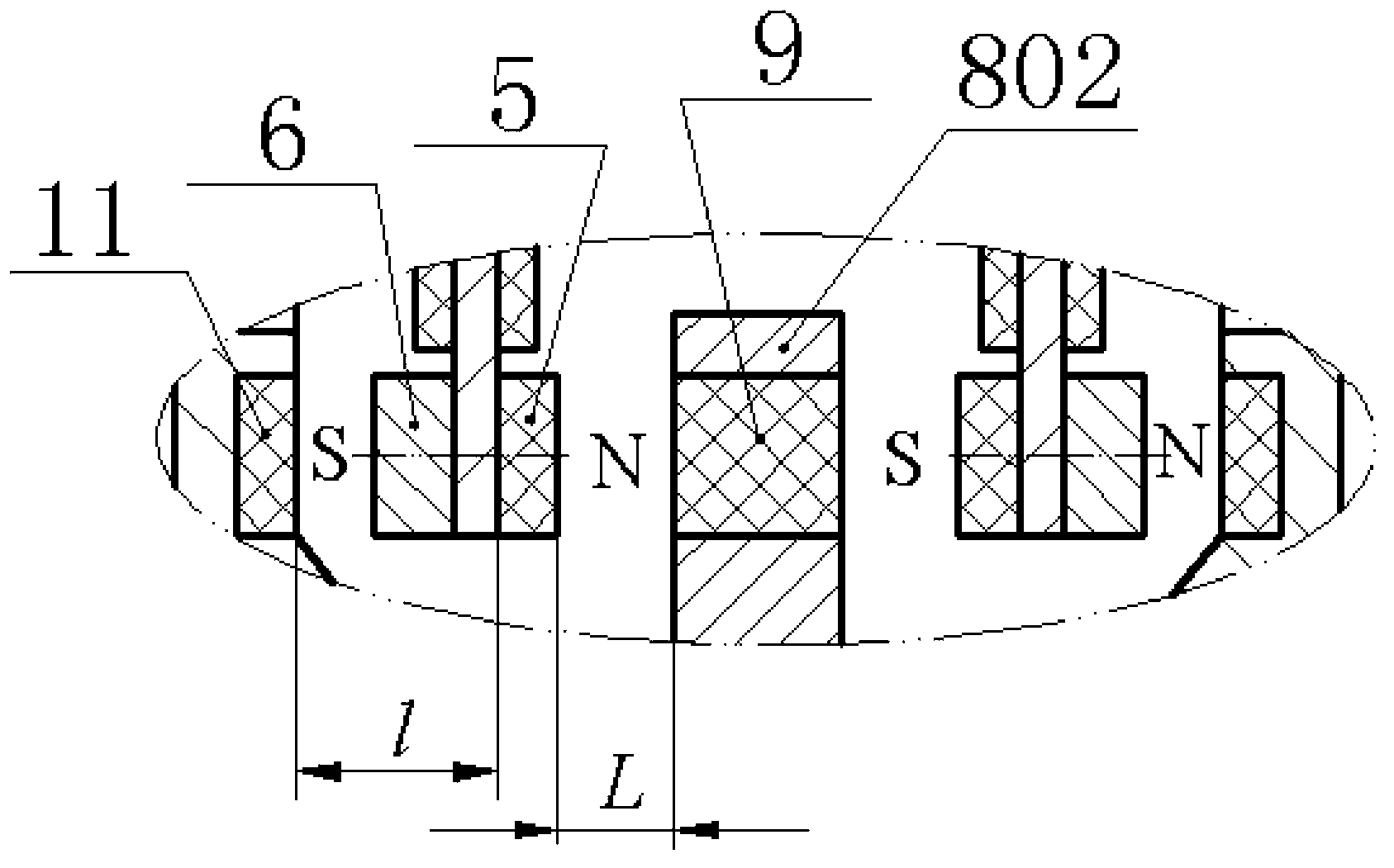

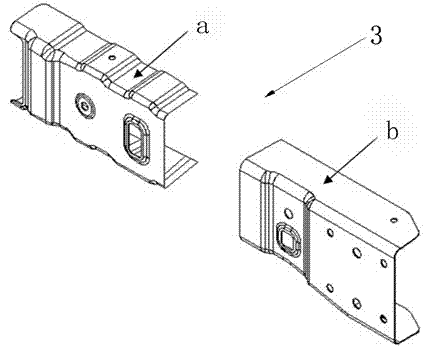

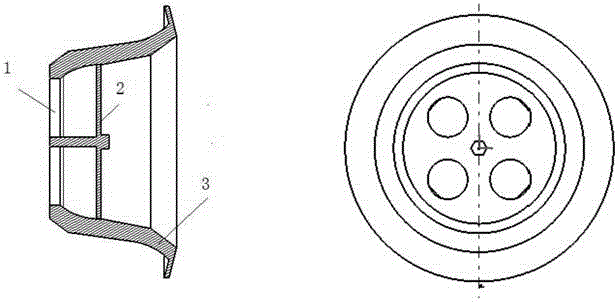

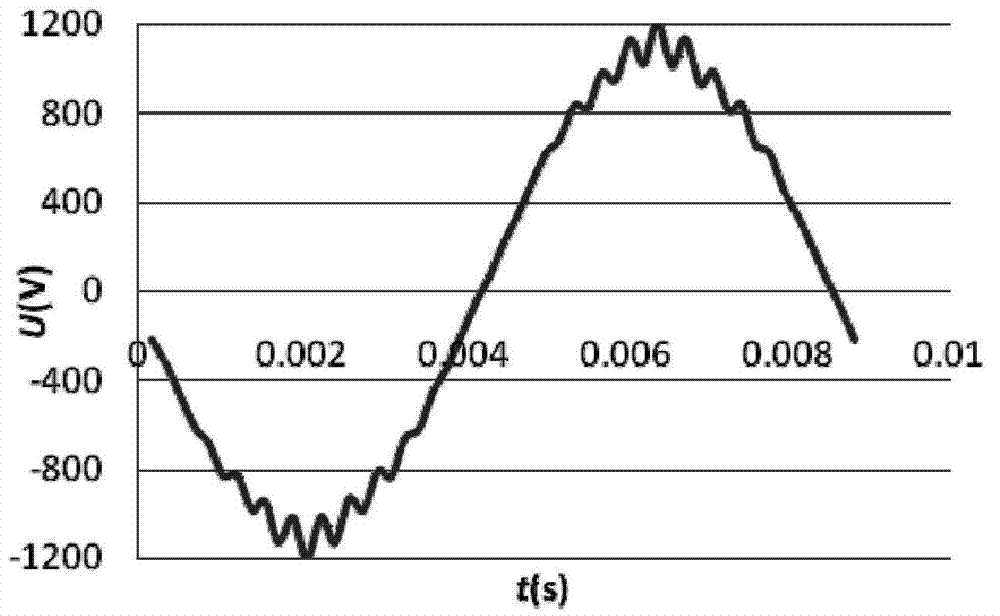

Shaft-end overhung piezoelectric cantilever beam electric generator

InactiveCN103259452AEffect of small axial bending deformationImprove reliabilityPiezoelectric/electrostriction/magnetostriction machinesNew energyEngineering

The invention relates to a shaft-end overhung piezoelectric cantilever beam electric generator, and belongs to the technical field of new energy resources and power generation. A left end cover and a right end cover are respectively installed at two ends of a shell body through screws. A semi-annular balancing weight is installed on the lower side of the interior of the shell body through a screw. The upper portion of the left end cover and the upper portion of the right end cover are respectively provided with a lightening hole. A magnet I and a bearing are embedded in the inner side of the bottom wall of the left end cover. A magnet I and a bearing are embedded in the inner side of bottom wall of the right end cover. A piezoelectric vibrator is arranged between the left end cover and the shell body in a compression joint mode. A piezoelectric vibrator is arranged between the right end cover and the shell body in a compression joint mode. A magnet II and a frequency-modulation mass block are installed at the free end of each piezoelectric vibrator. A rotating shaft of a rotor is installed on the left end cover and the right end cover through bearings. A connecting disc is installed at one end of the rotating shaft through a nut. A magnet III is embedded in a rotating disc of the rotor. The shaft-end overhung piezoelectric cantilever beam electric generator has the advantages that the piezoelectric vibrators are motivated for electric generation and external fixing and supporting are not needed; the shaft-end overhung piezoelectric cantilever beam electric generator is an integrated type individual component, so that the structure of a rotating body does not need to be changed, and the shaft-end overhung piezoelectric cantilever beam electric generator is convenient to install and maintain; the shaft-end overhung piezoelectric cantilever beam electric generator is high in reliability, strong in power generation capacity, and wide in velocity zone.

Owner:ZHEJIANG NORMAL UNIVERSITY

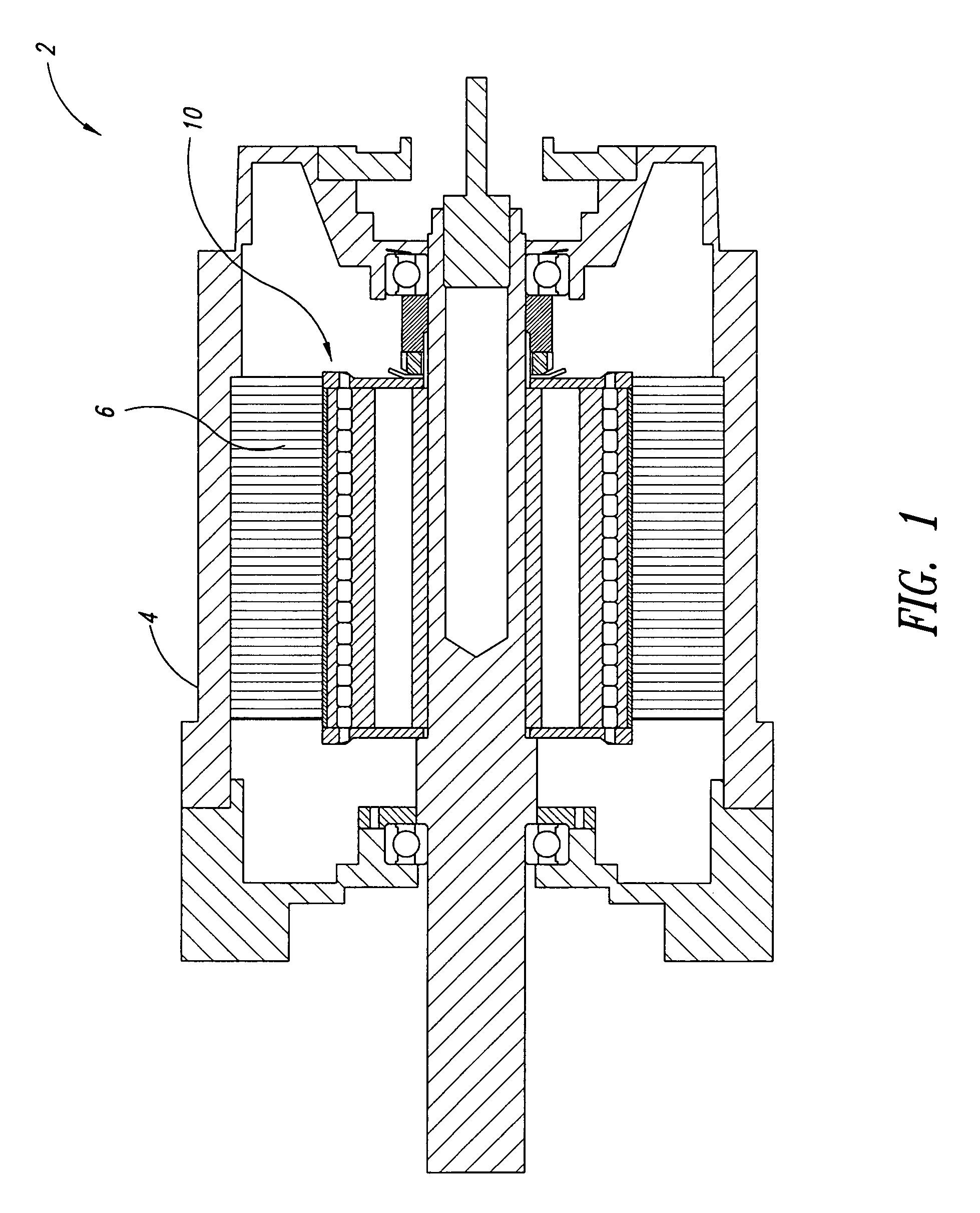

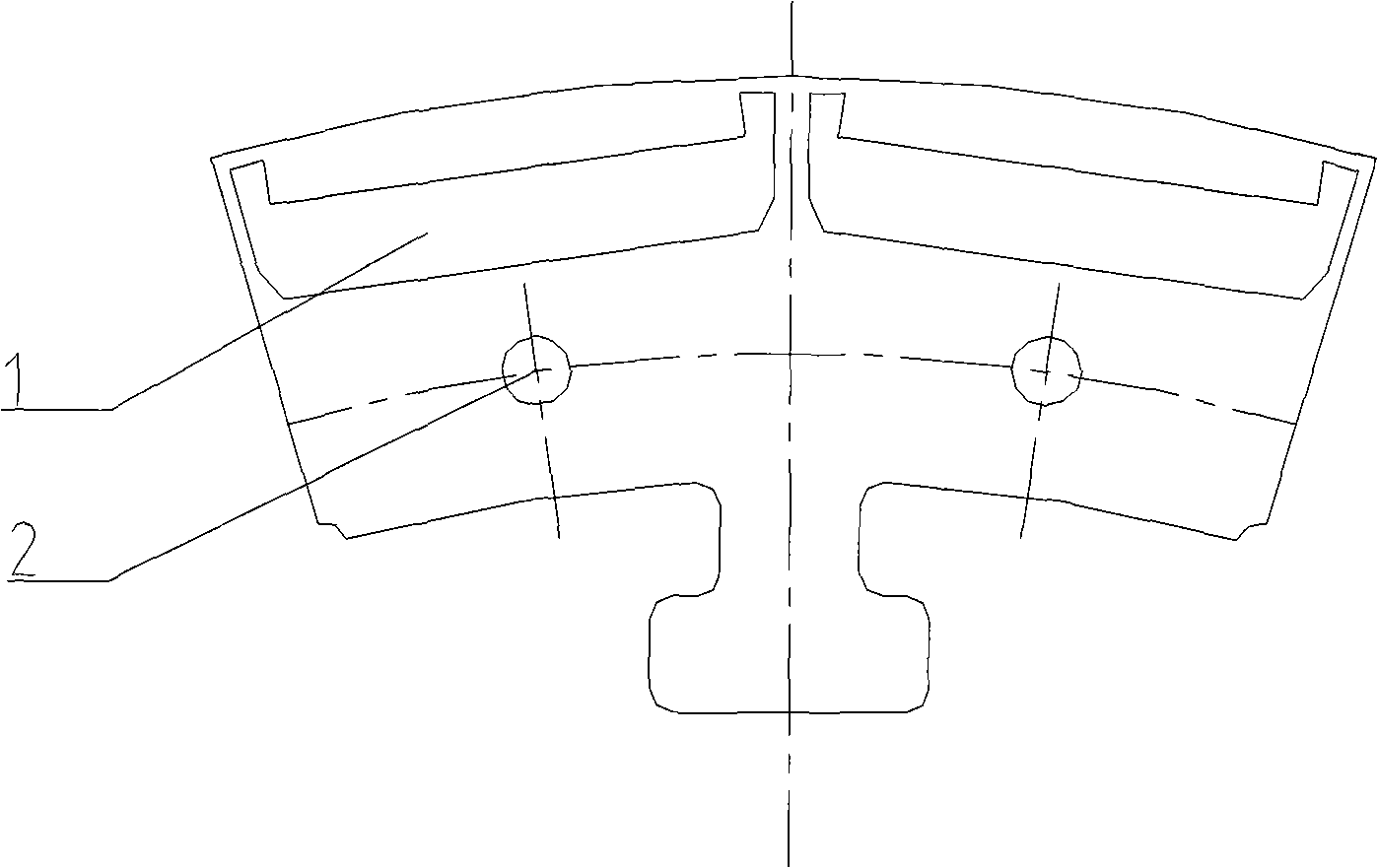

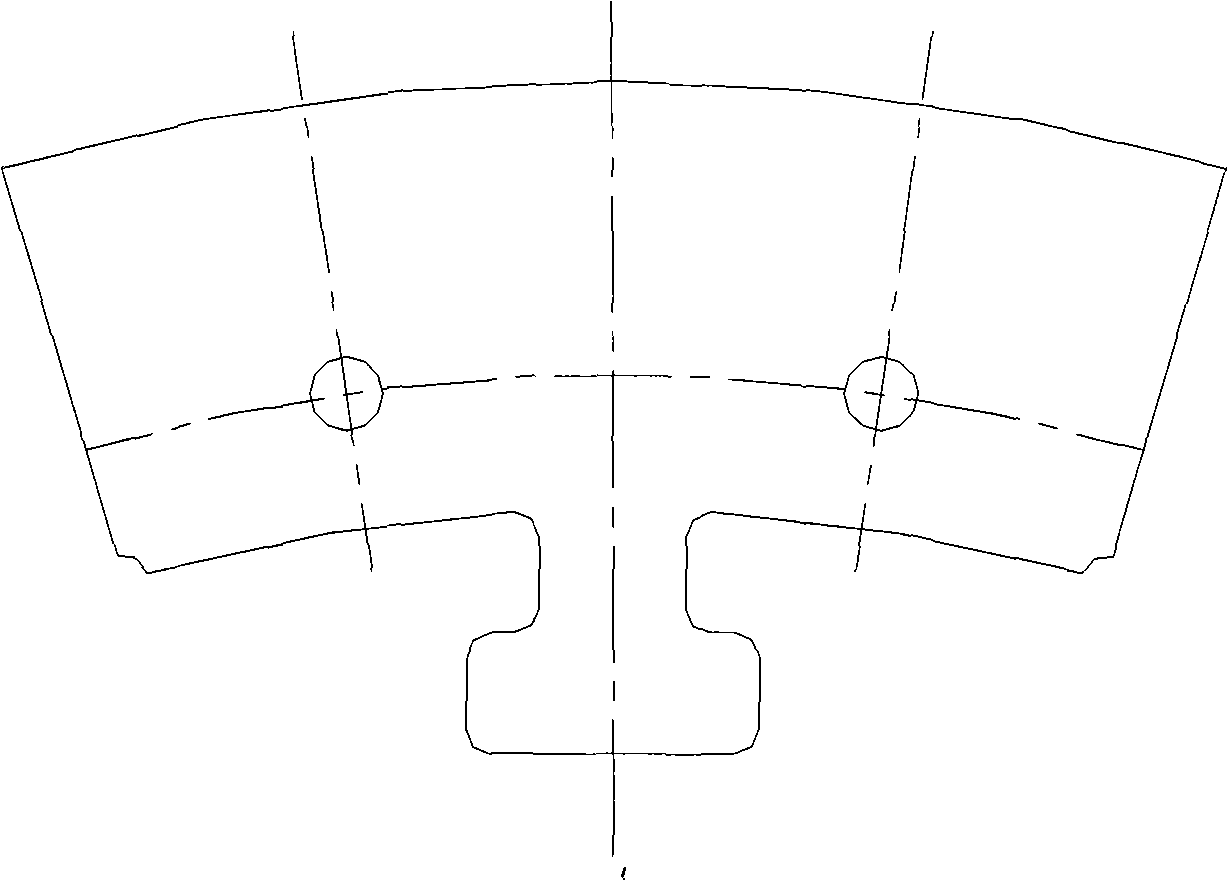

Rotor assembly for a permanent magnet power electric machine

ActiveUS7098569B2Reduce weightIncrease speedMagnetic circuit rotating partsElectric machineEngineering

Owner:CONTINENTAL AUTOMOTIVE SYST INC

Rotor hub and assembly for a permanent magnet power electric machine

InactiveUS20070273232A1Reduce weightIncrease speedMagnetic circuit rotating partsMechanical energy handlingElectric machineEngineering

A rotor assembly for use in an electric motor or generator where the mass of the rotor assembly is reduced with respect to conventional rotor assemblies. In addition, the rotor assembly is configured to be scalable to different sized electric motors. Within the rotor assembly, the rotor hub, the shaft, and the permanent magnets can independently or collectively be modified to have a reduced mass. In one aspect, a portion of the rotor hub adjacent to the shaft is configured with passages and spokes. In another aspect, an intermediate hub with lightening holes is provided between the shaft and the rotor hub. In yet another aspect, a large diameter hollow shaft replaces a portion of the rotor hub. In yet another aspect, the permanent magnets are configured to have an arc-shape, which permits the thickness of the magnets to be reduced without reducing the efficiency of the magnets.

Owner:CONTINENTAL AUTOMOTIVE SYST INC

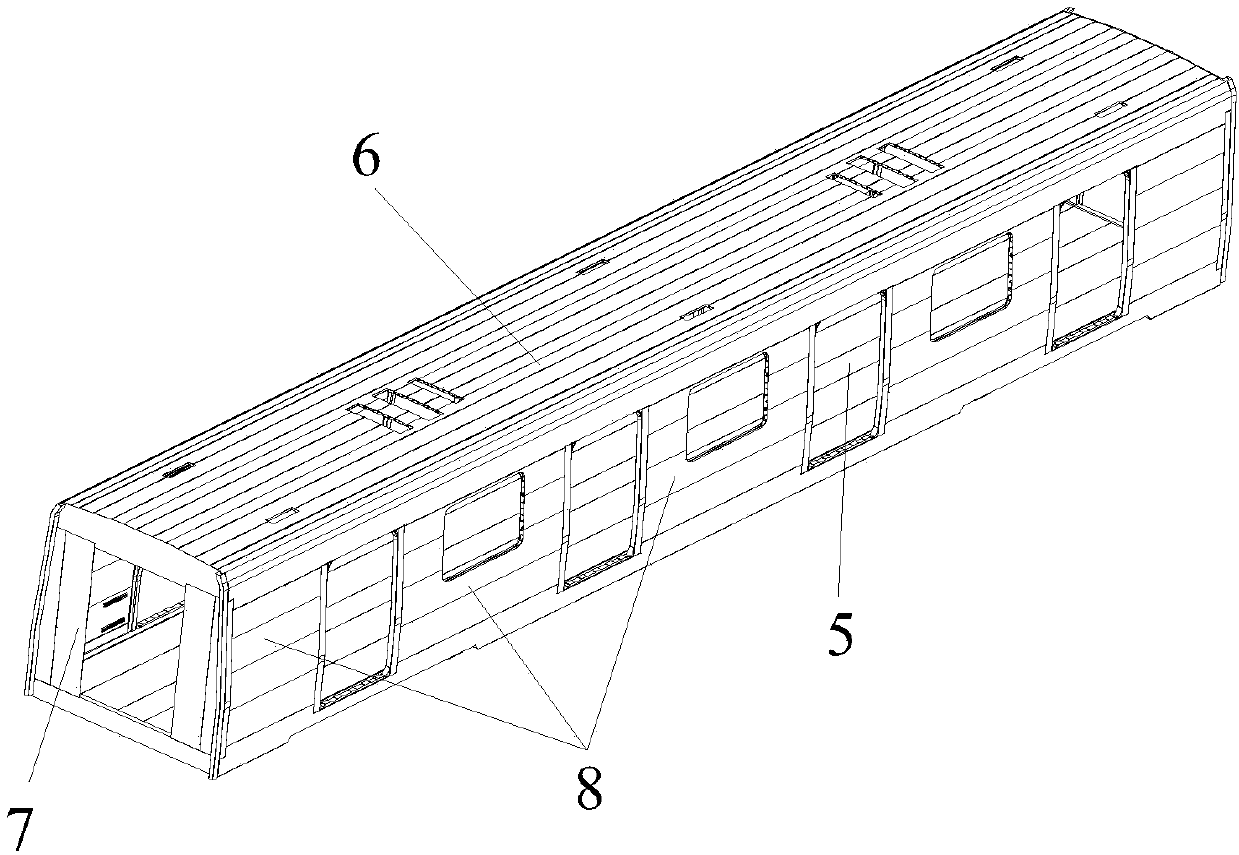

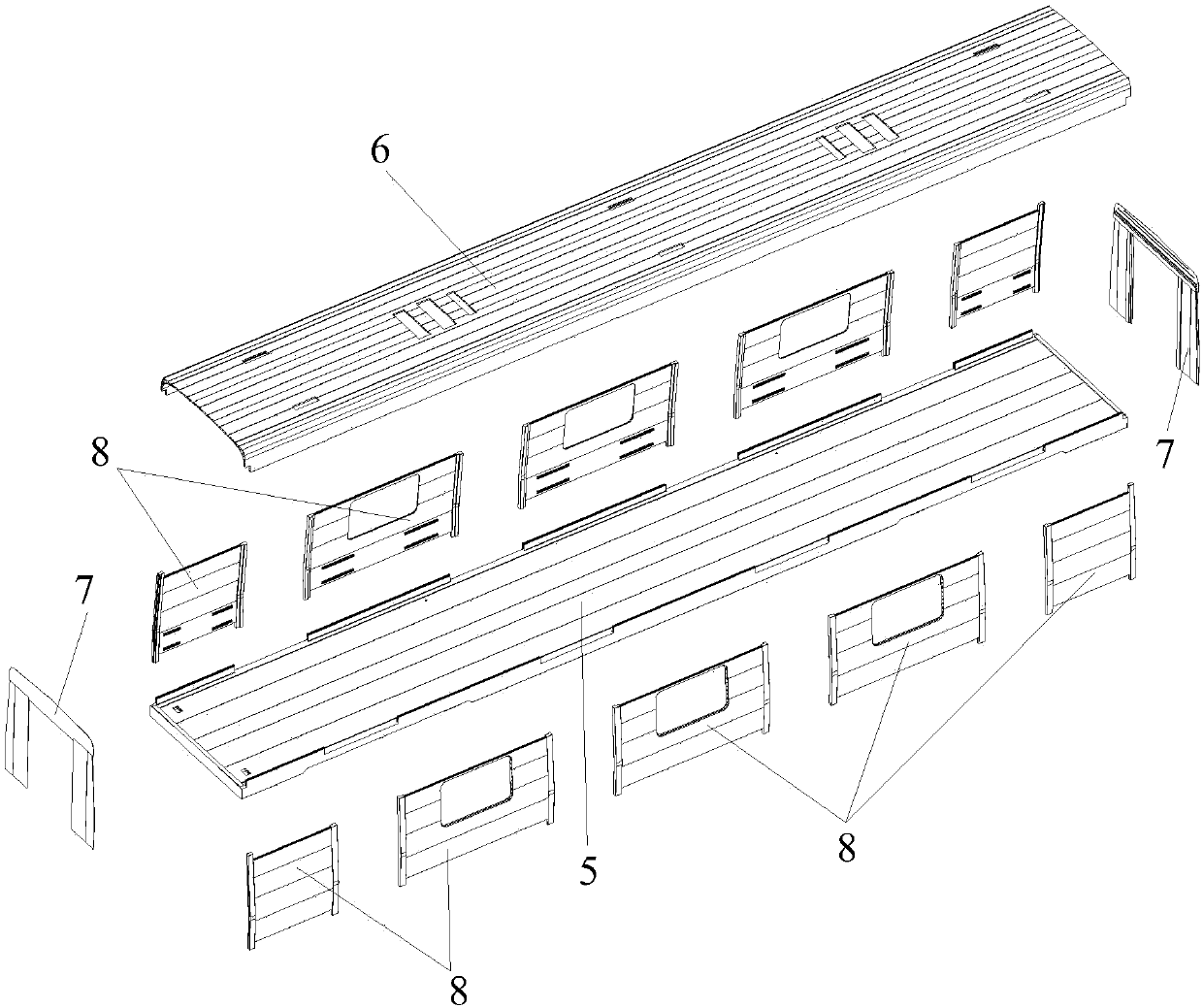

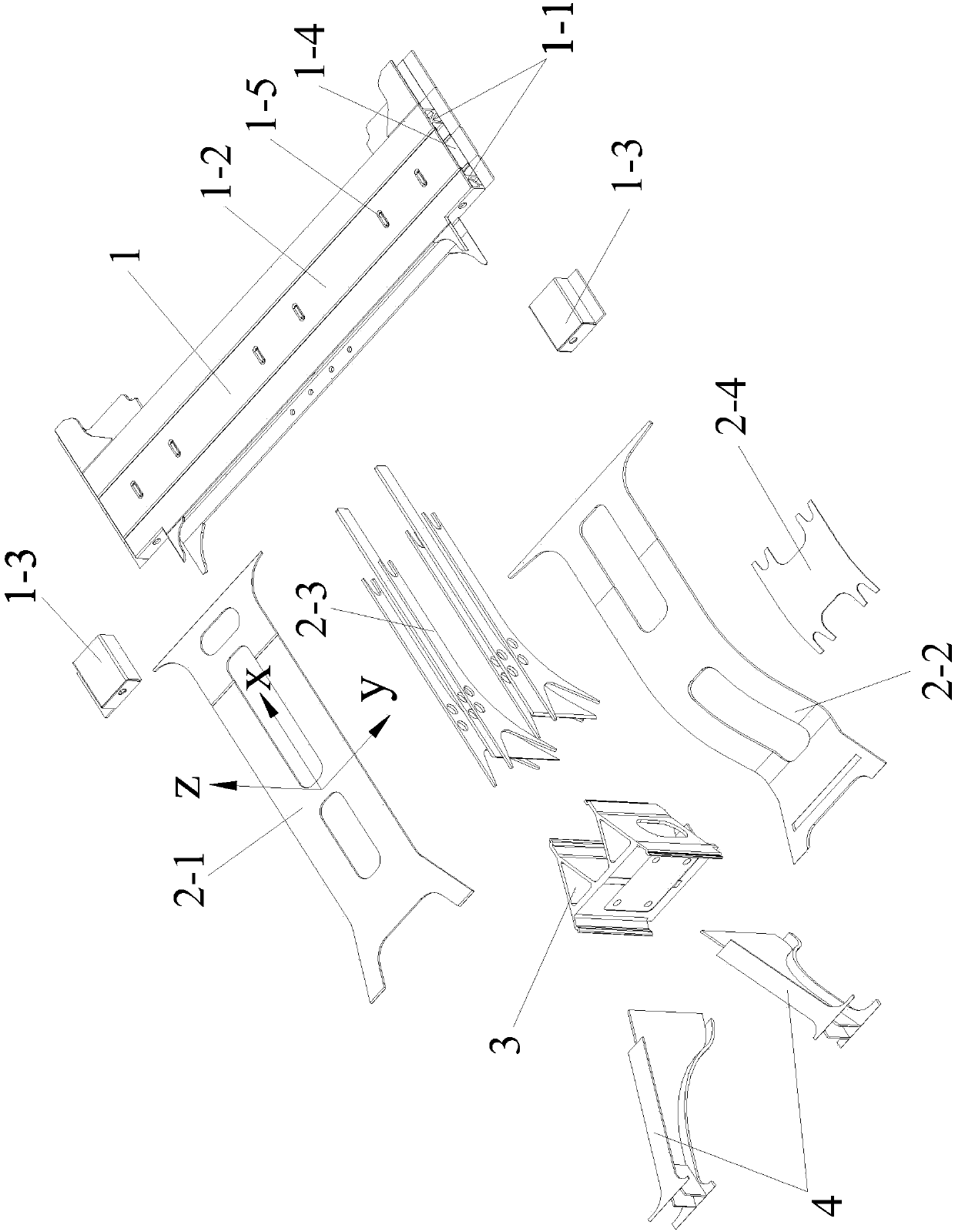

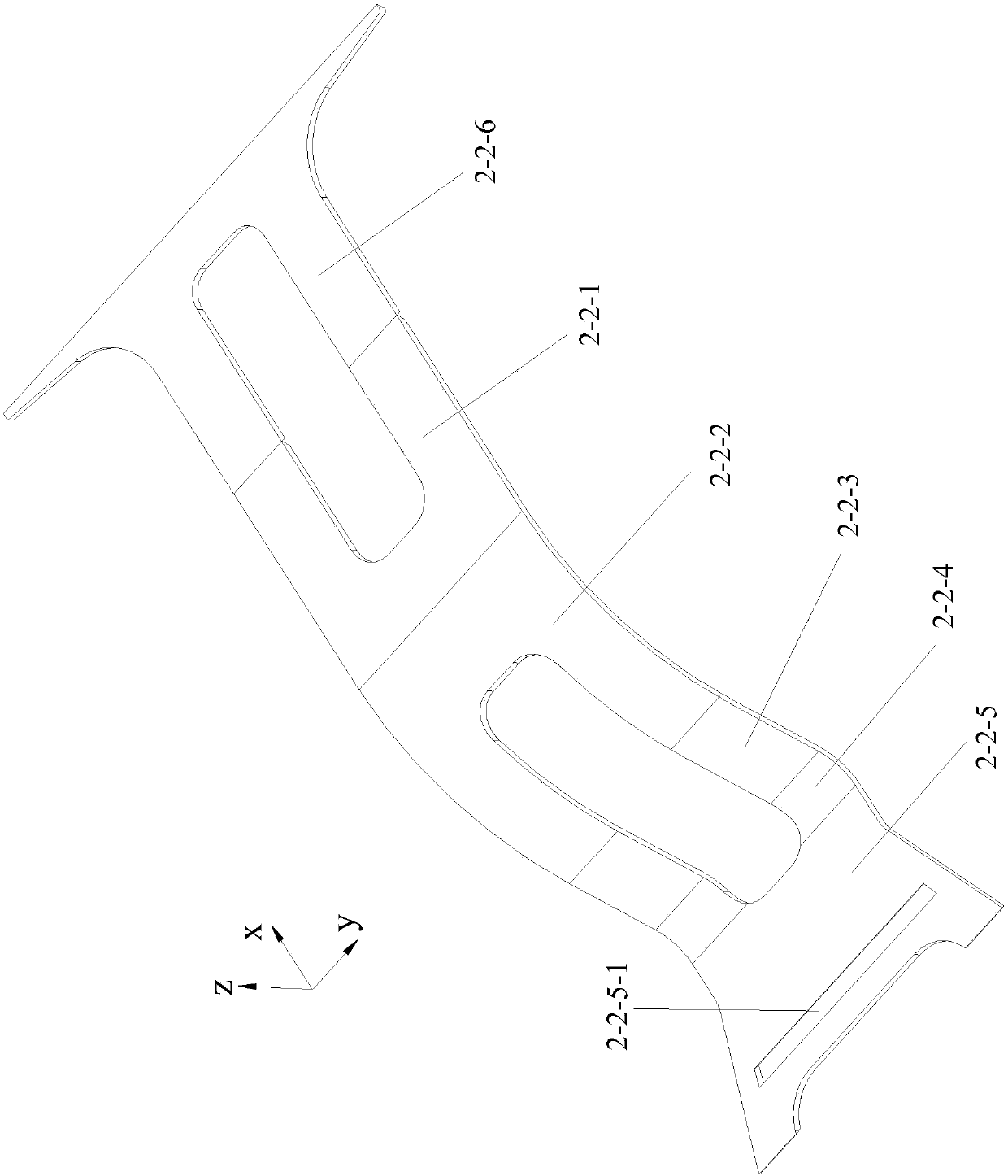

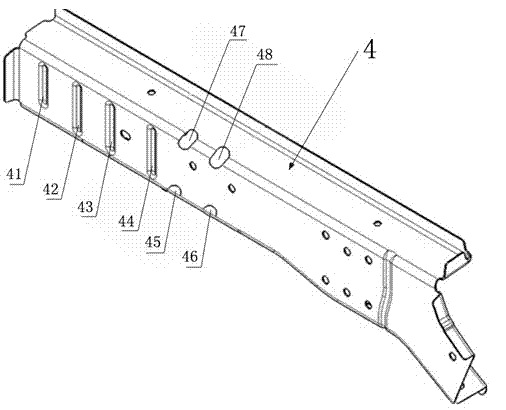

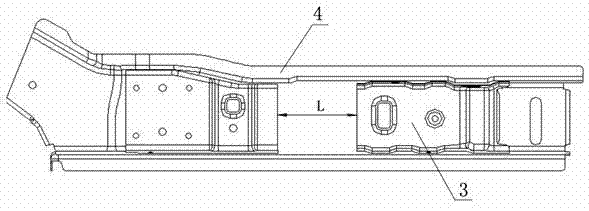

Light-weight metro vehicle body with novel traction sleeper buffer structure

ActiveCN107856688AImprove accessibilityImprove welding qualityRailway roofsUnderframesEngineeringUltimate tensile strength

The invention provides a light-weight metro vehicle body with a novel traction sleeper buffer structure and belongs to the field of full-aluminum product metro vehicle body devices. The light-weight metro vehicle body comprises a chassis, a vehicle roof, two end walls, multiple side wall boards and a full-aluminum product traction sleeper buffer device. The chassis comprises a rectangular floor frame jointly defined by two side beams and two end beams and a floor located in the floor frame. The traction sleeper buffer device comprises a sleeper beam, a traction beam, a draw gear installation seat and two buffer beams. A traction beam lower cover plate and a buffer beam lower cover plate of the full-aluminum product traction sleeper buffer device of the light-weight metro vehicle body are both made of a profile aluminum plate material which is low in density, light in weight and good in bending performance, the draw gear installation seat is made from aluminum plates high in yield stress, other straight plate structures are all made of an aluminum plate material high in yield stress, overall selected materials of the traction sleeper buffer device meet the strength standard, and theprocessing property of welding and manufacturing of the traction sleeper buffer device is the best; and all lightening holes can be simultaneously used as auxiliary holes in the inner cavity weldingoperation process, so that the accessibility and welding quality of inner cavity welding joints are improved.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

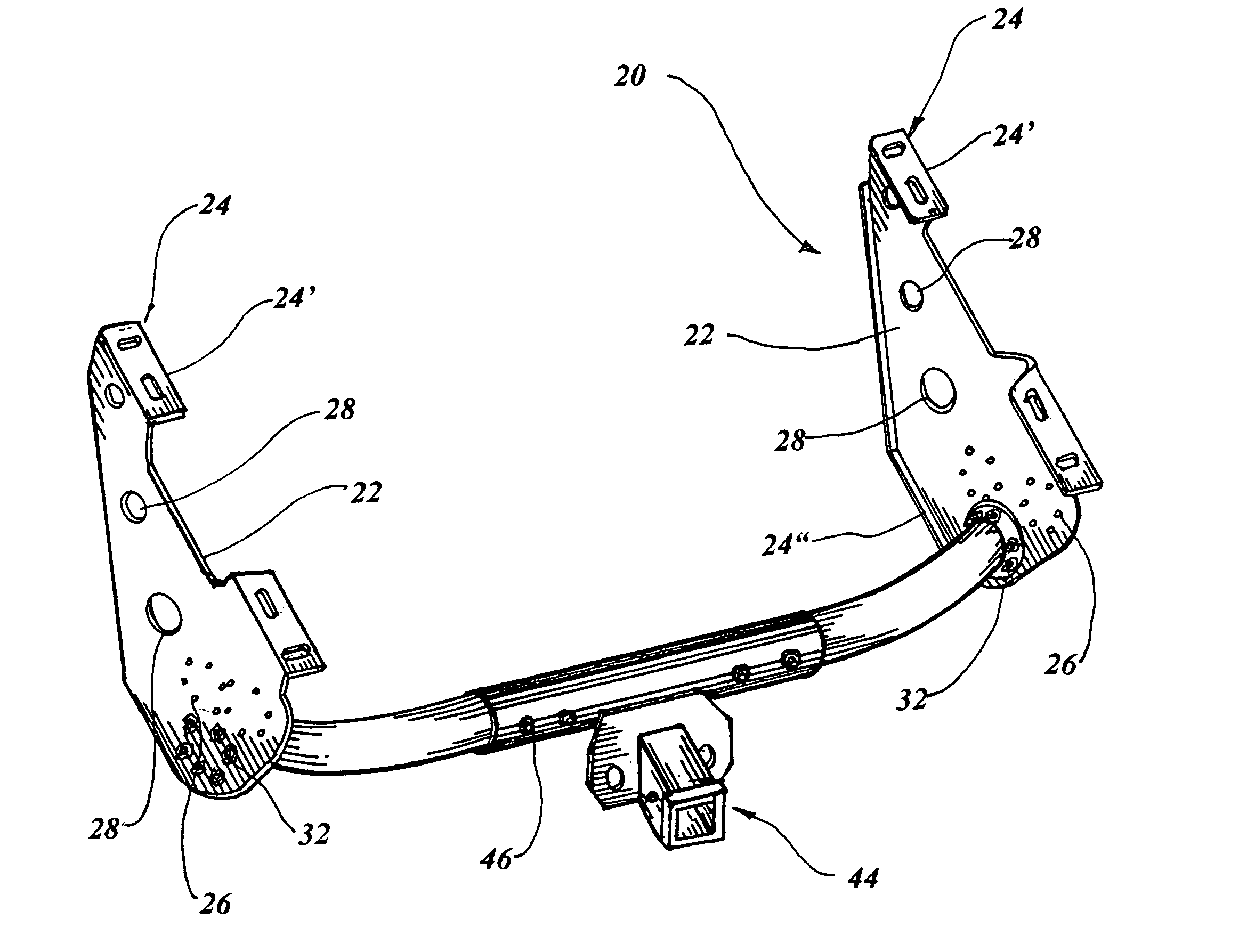

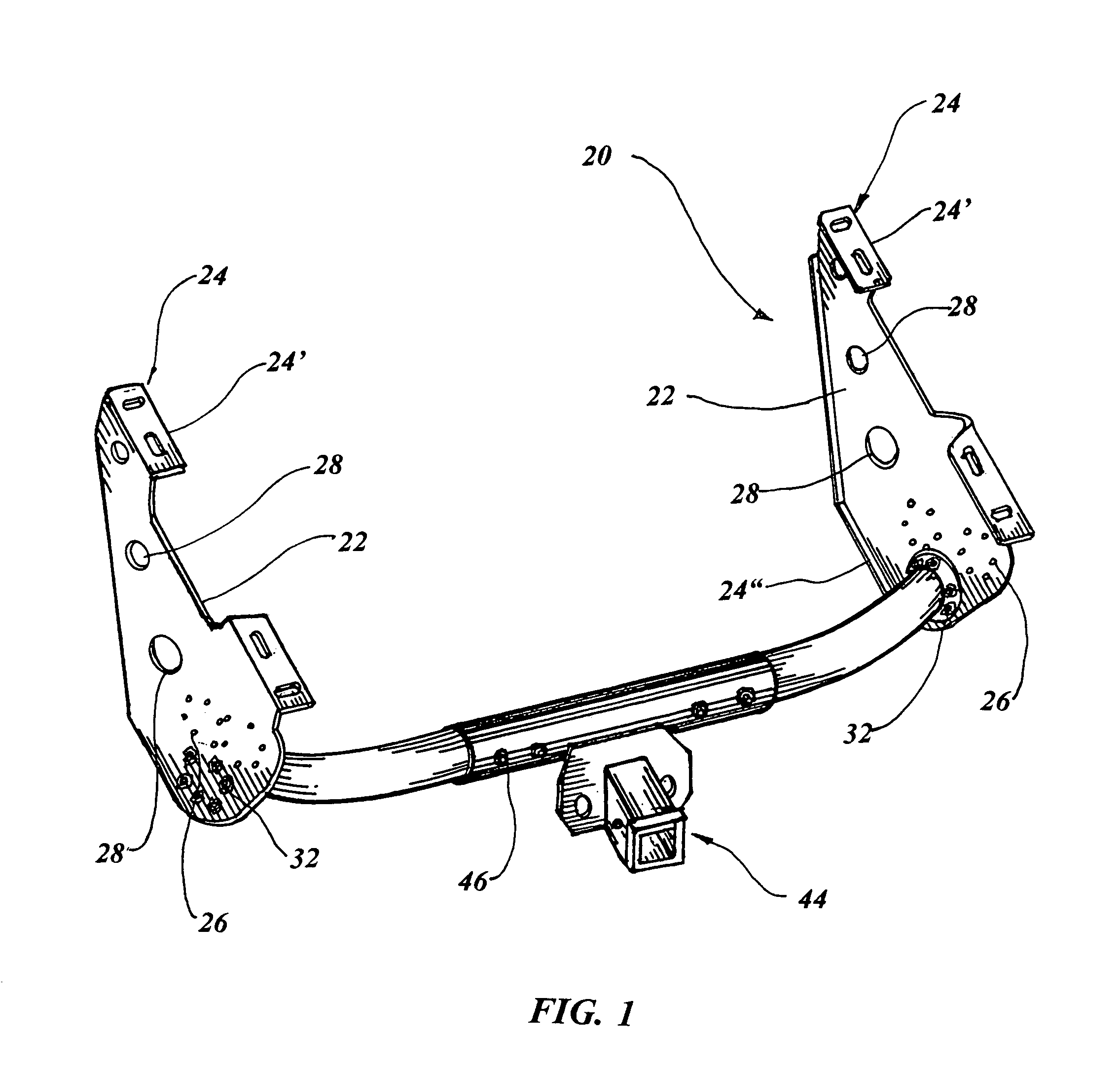

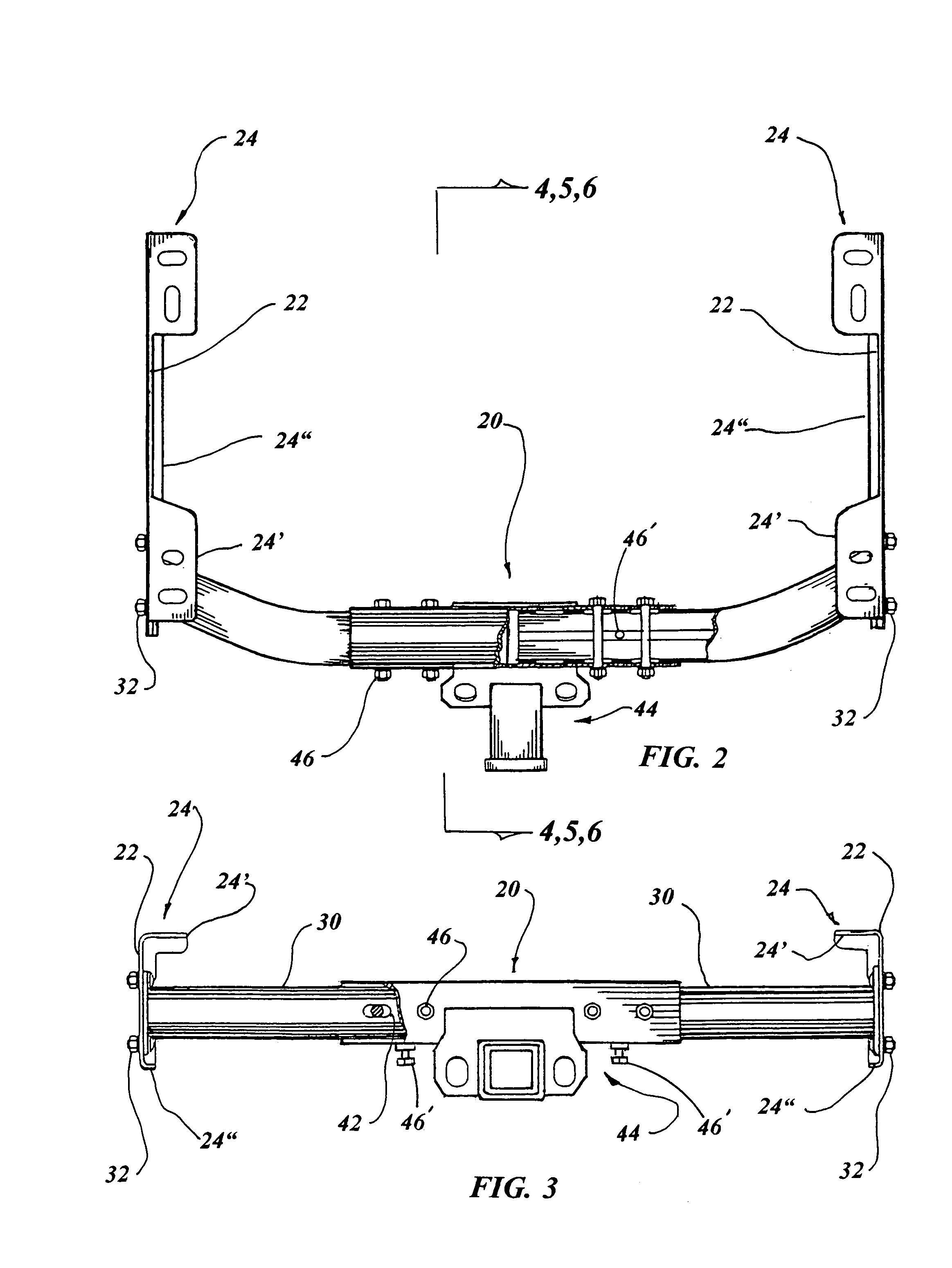

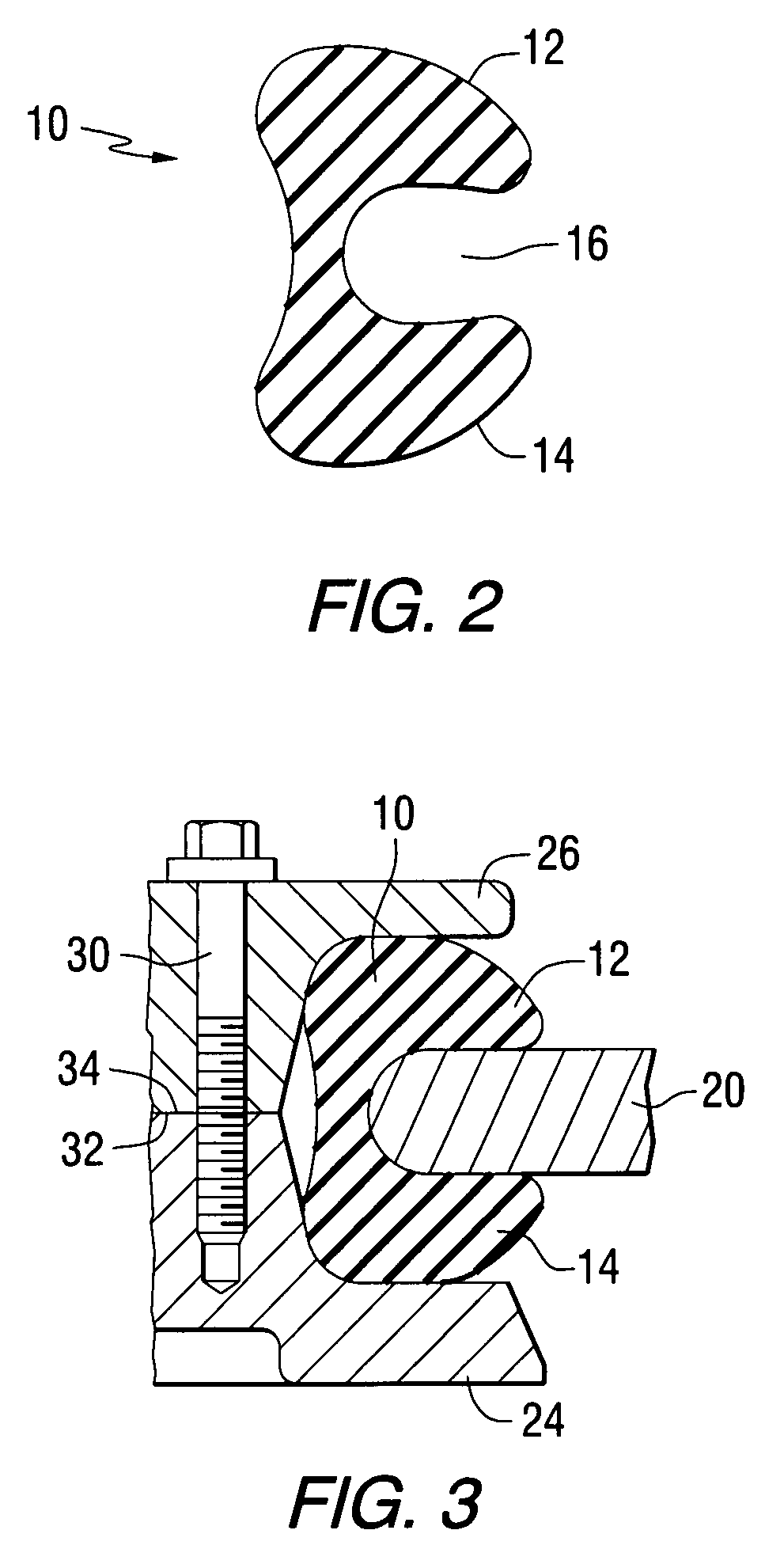

Adjustable receiver hitch

An adjustable receiver hitch (20) for receiving a hitch ball mounted, trailer ball mount that is attached onto the frame of a motor vehicle for pulling a trailer. A pair of frame mounting brackets (22) are configured for attachment onto the frame of the motor vehicle, with each mounting bracket further having flanges (24), lightening holes (28), and a plurality of bracket thru-holes (26). A pair of hitch mounting arms (30) are connected to the frame mounting brackets and interface with a selected set of the holes (28) for height adjustment of the receiver hitch relative to the motor vehicle frame. A box hitch (44) is adjustably attached onto each mounting arm by inserting the arms into a tubular sleeve (50) or (52) which is a connecting element of the box hitch. A receiver box (48) is connected on the lower surface of the tubular sleeve for receiving the hitch ball mounted on the trailer ball mount.

Owner:CHENG JOHN C +1

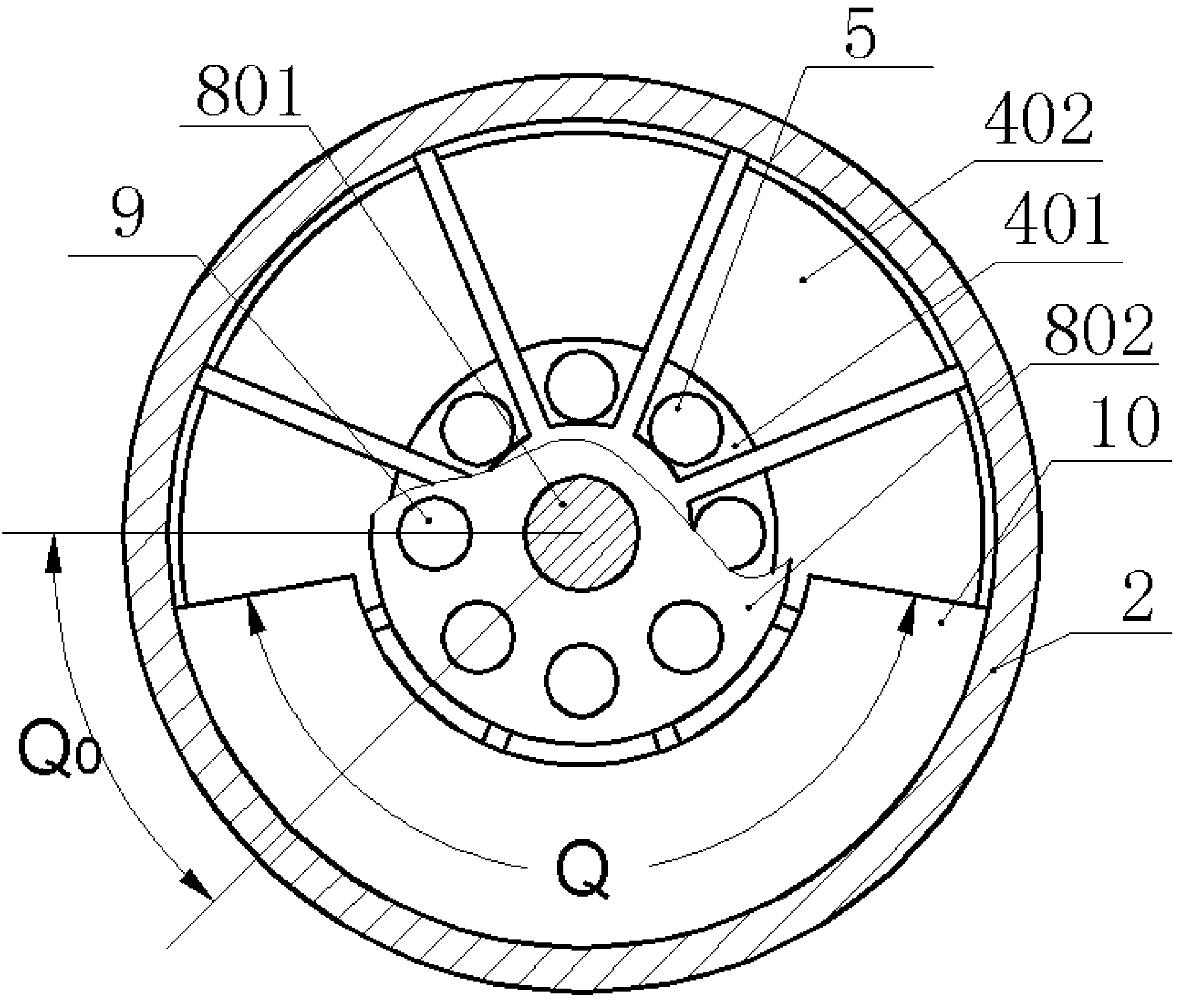

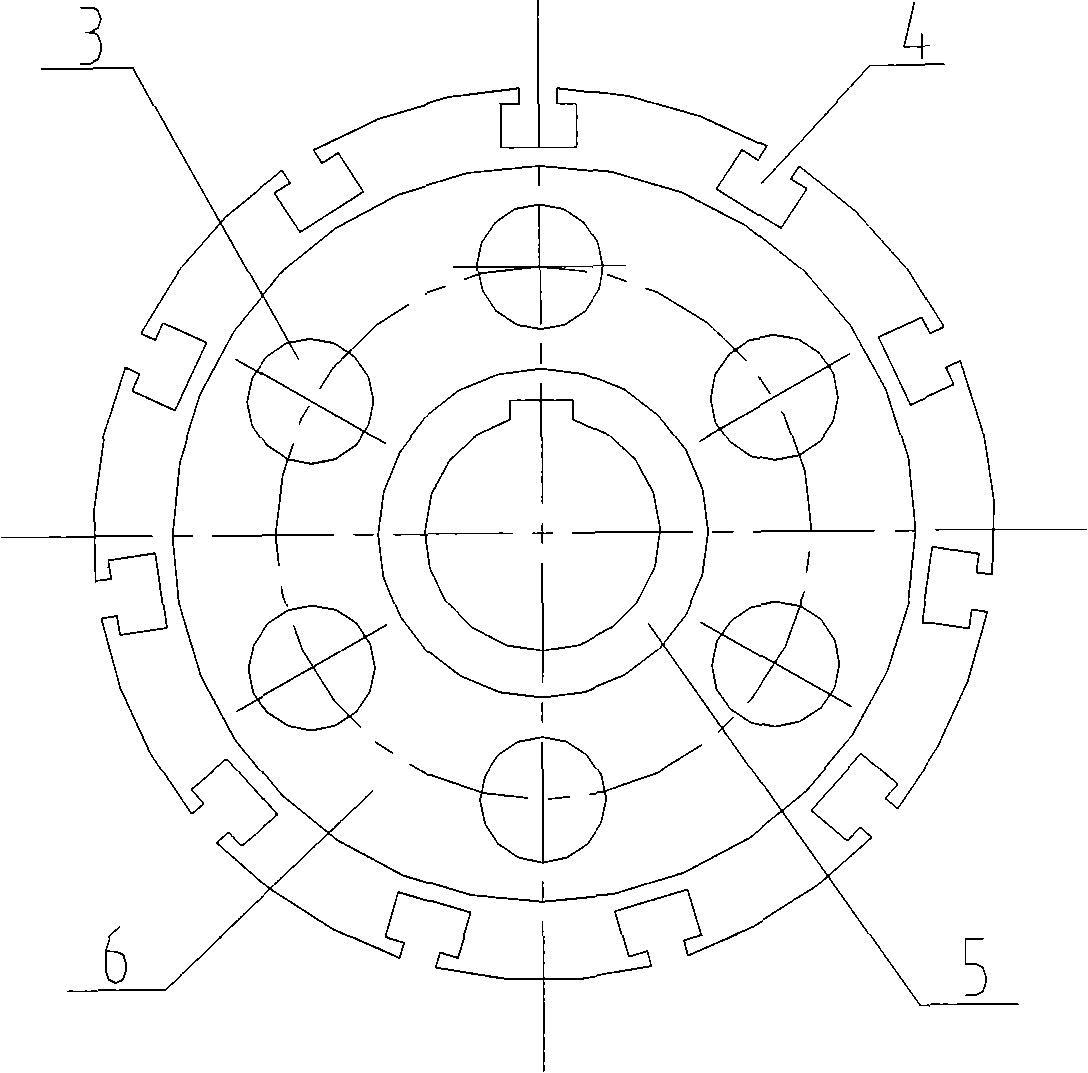

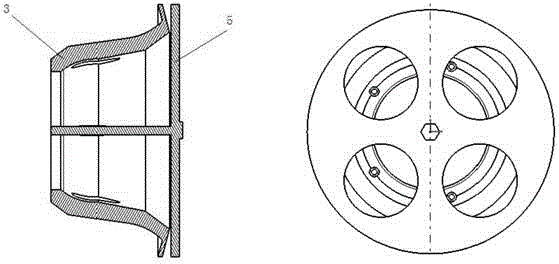

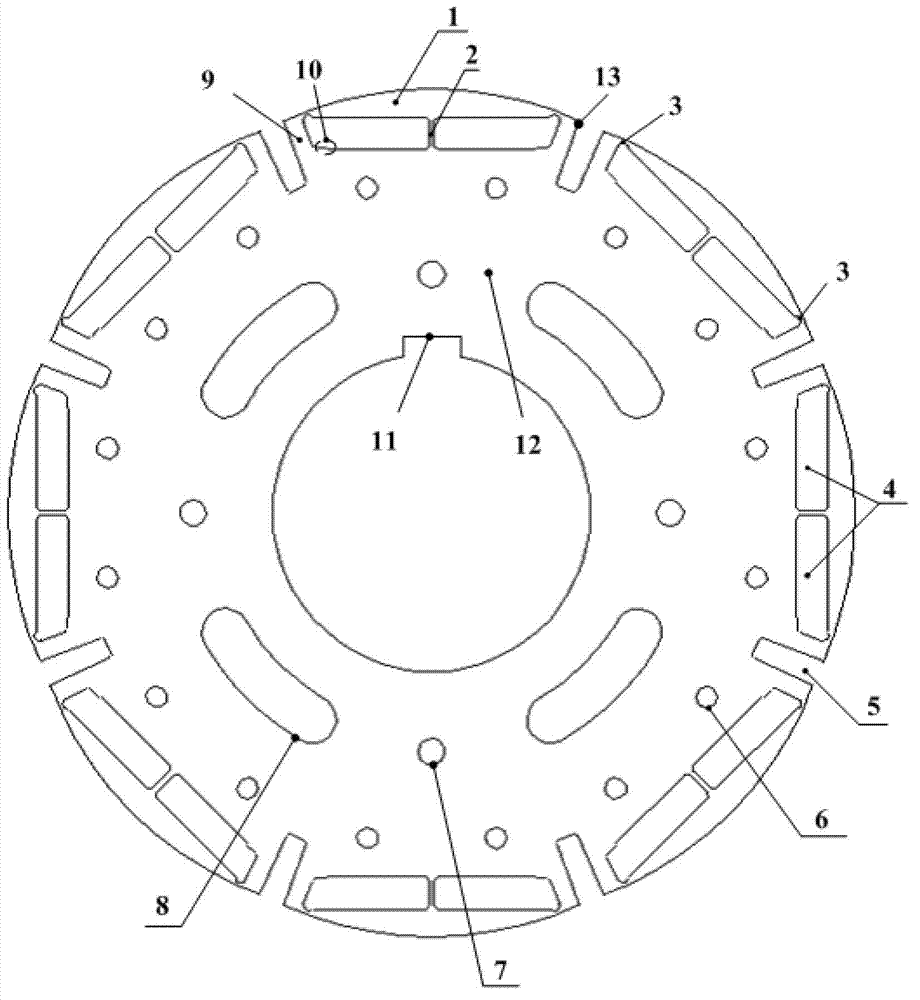

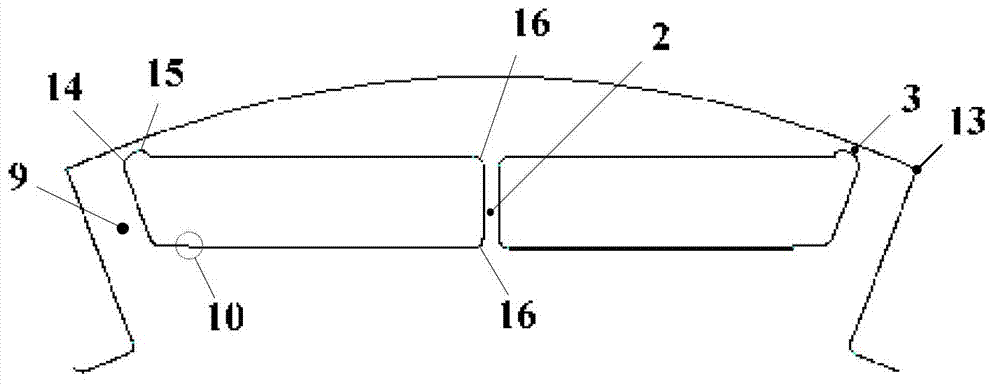

Combined rotor structure of permanent magnet wind power generator

InactiveCN101359847AGuaranteed partial loss of fieldIncrease profitMagnetic circuit rotating partsSynchronous machine detailsPunchingMagnetic poles

The invention provides a combined rotor structure of a permanent magnet wind power generator, which belongs to the technique field of permanent magnet wind power generator, and adopts the technical proposal that: fan-shaped punching sheets are laminated to form a magnetic pole, a permanent magnet is inserted into a permanent magnet groove reserved on the fan-shaped magnetic pole along the axial direction of a motor, and an air magnetic shield bridge is formed in the fan-shaped magnetic pole, the whole magnetic pole is inserted into a dovetail groove of a rotor support along the axial direction, rotor lightening holes are evenly distributed at supporting spoke positions along the circumferential direction, both sides of the magnetic pole are added with a magnetic pole pressing plate respectively, the magnetic pole and the magnetic pole pressing plates are fastened together by bolts through location holes, and location wedges are wedged into gaps of the magnetic pole and the support from both sides along the axial direction to ensure that the magnetic pole and the support are combined into one body, so the magnetic pole with the built-in permanent magnet can be completed.

Owner:SHENYANG POLYTECHNIC UNIV

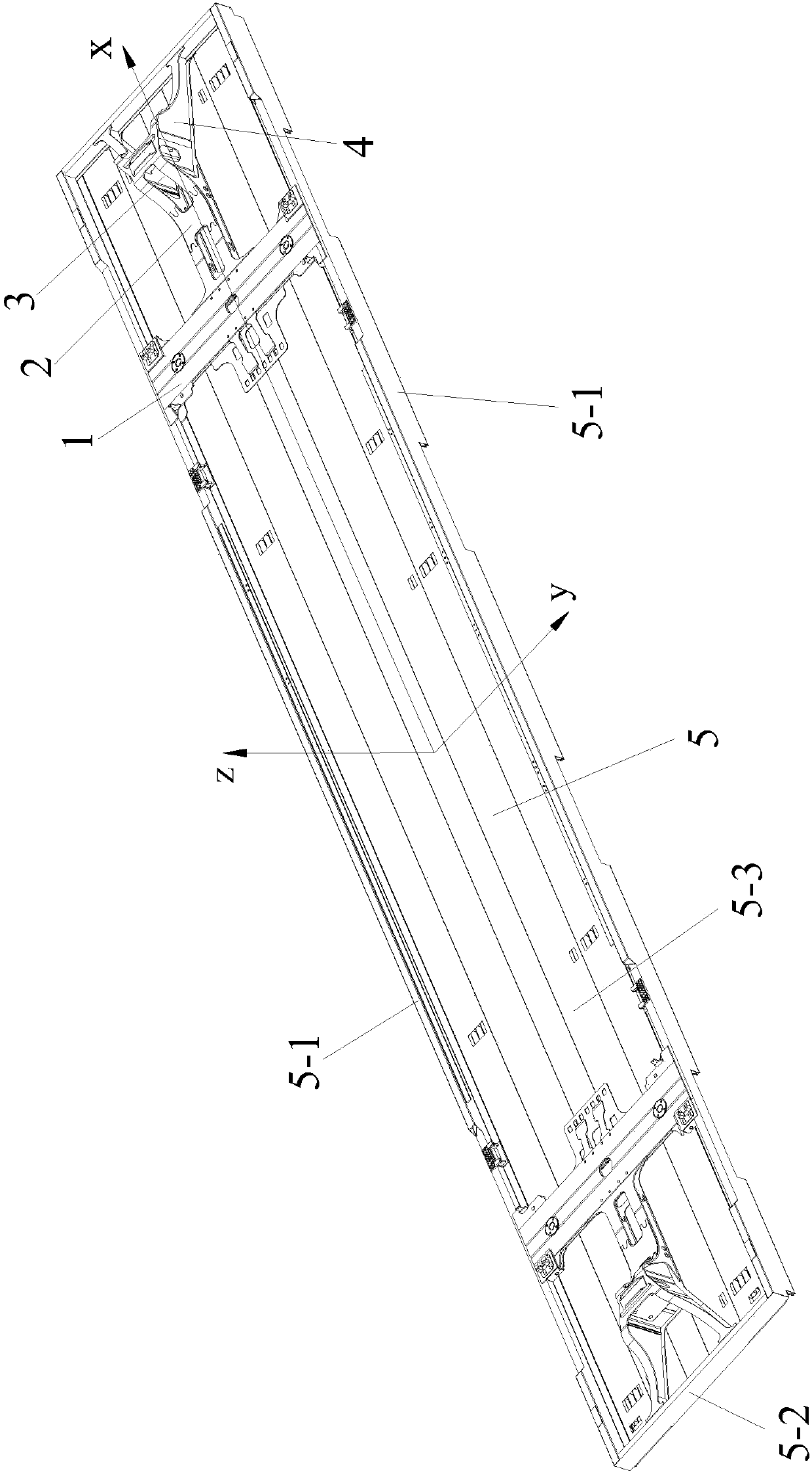

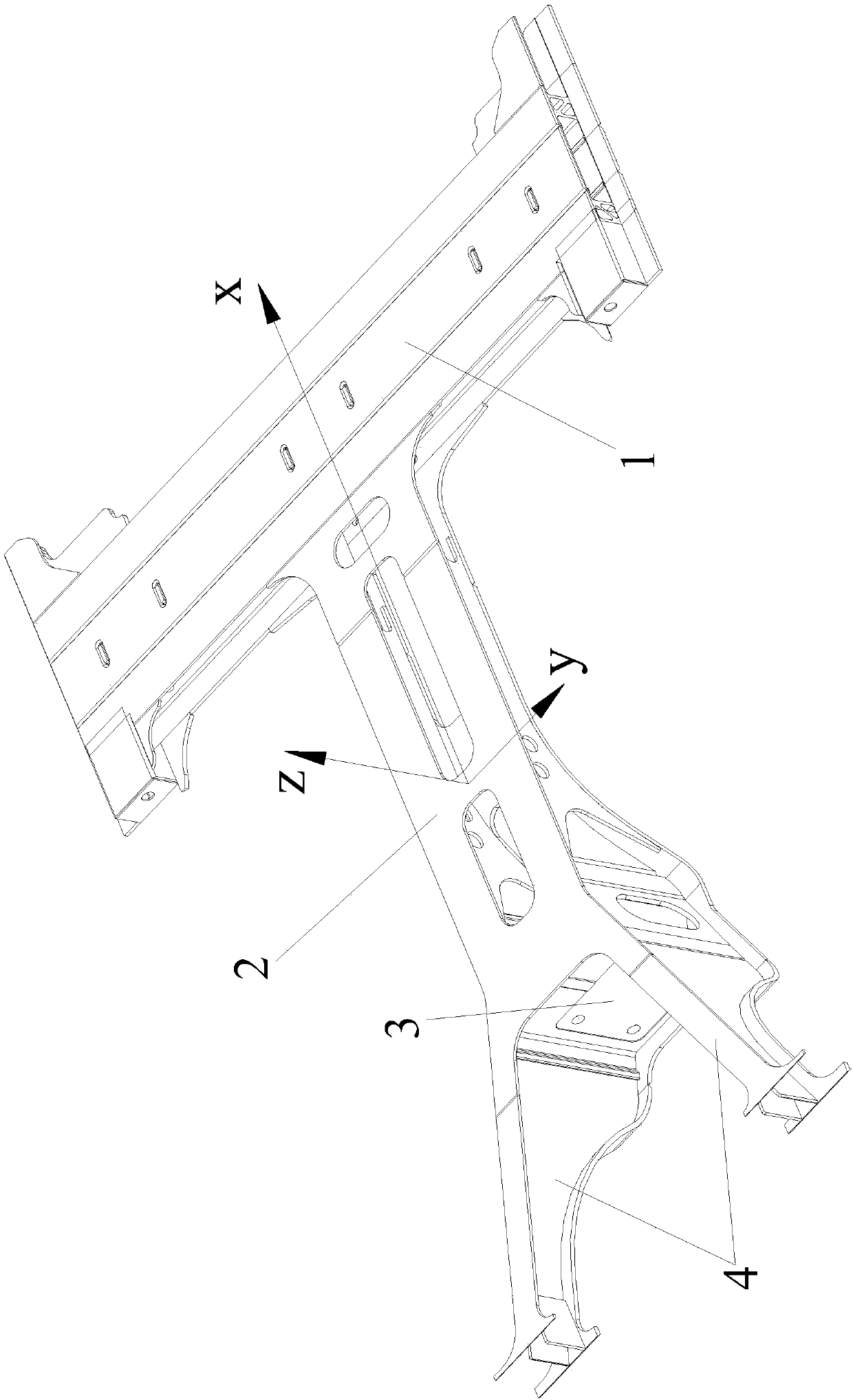

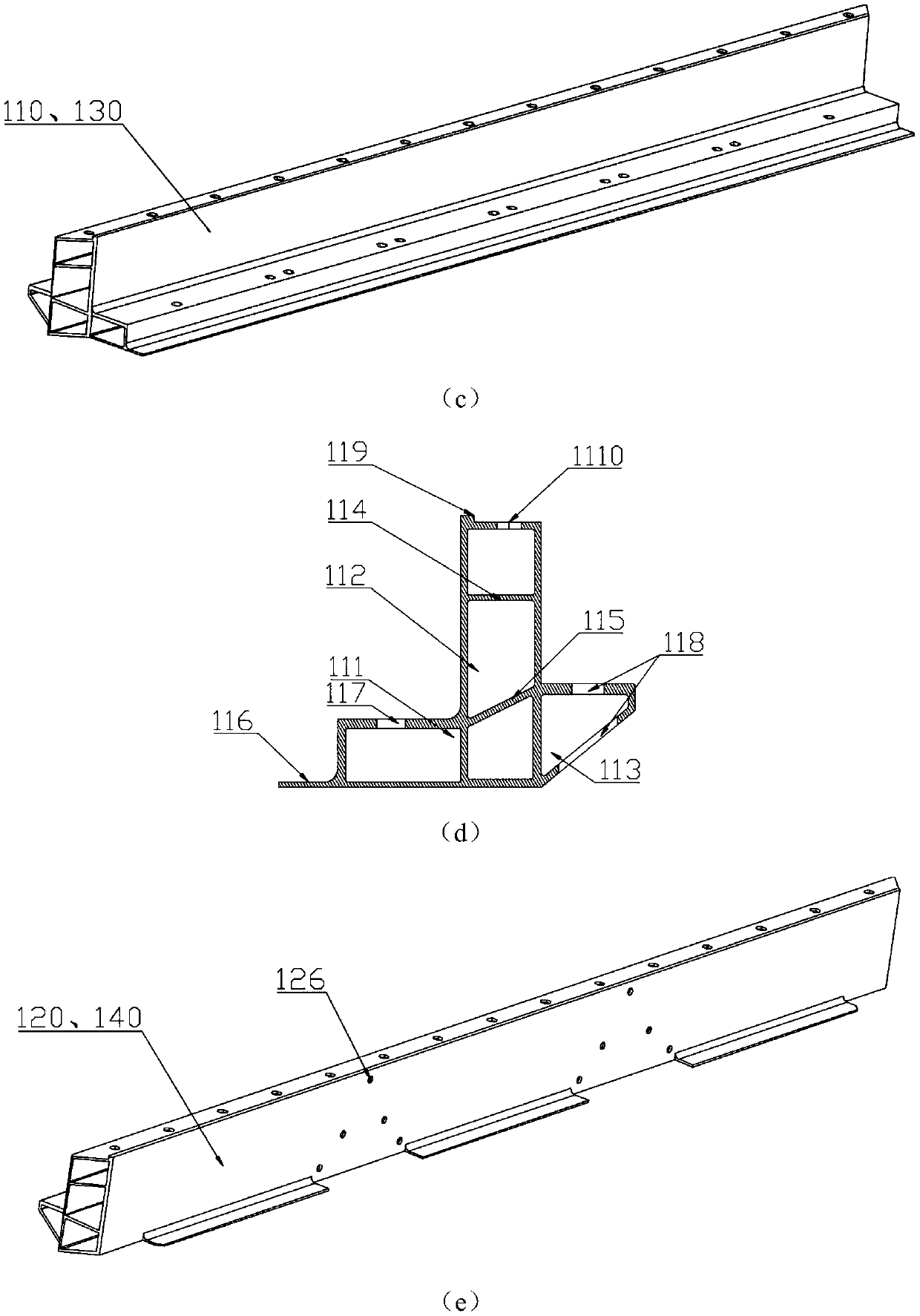

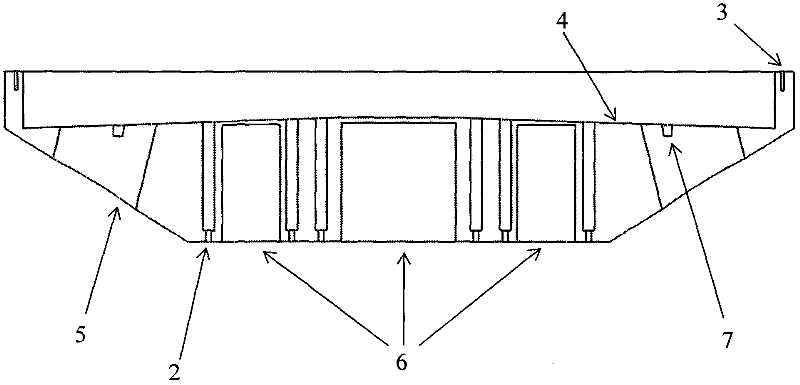

Traction sleeper buffer device of all-aluminum railway vehicle

ActiveCN107901938AImprove accessibilityImprove welding qualityUnderframesEngineeringUltimate tensile strength

The invention provides a traction sleeper buffer device of an all-aluminum railway vehicle and belongs to the field of traction sleeper buffer devices for railway vehicles. The traction sleeper bufferdevice comprises a sleeper beam, a traction beam, a drag gear installation seat and two buffer beams. A lower traction beam cover board and lower buffer beam cover boards of the traction sleeper buffer device are all made of an EN AW 5083 type aluminum plate material which is low in density, low in weight and good in bending performance, the drag gear installation seat is made from EN AW 6005A aluminum plates high in yield stress, other straight plate structures are all made of an EN AW 6082 type aluminum plate material high in yield stress, so that the overall selected materials of the traction sleeper buffer device meet the strength standard, and the welding and manufacturing processing property of the traction sleeper buffer device is the best. All lightening holes can be used as auxiliary holes at the same time in the inner cavity welding operation process, and therefore the accessibility and welding quality of an inner cavity welding joint are improved.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

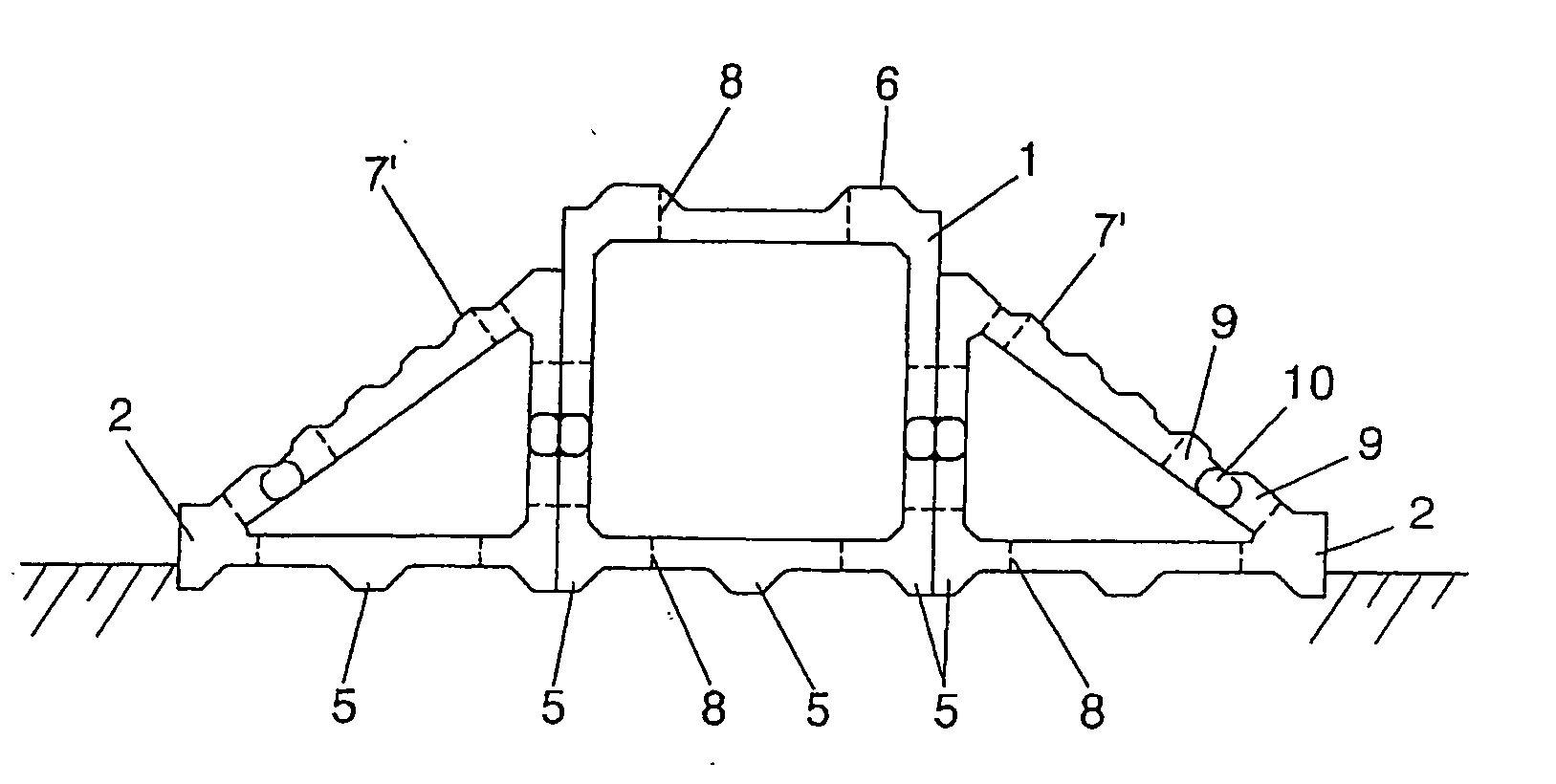

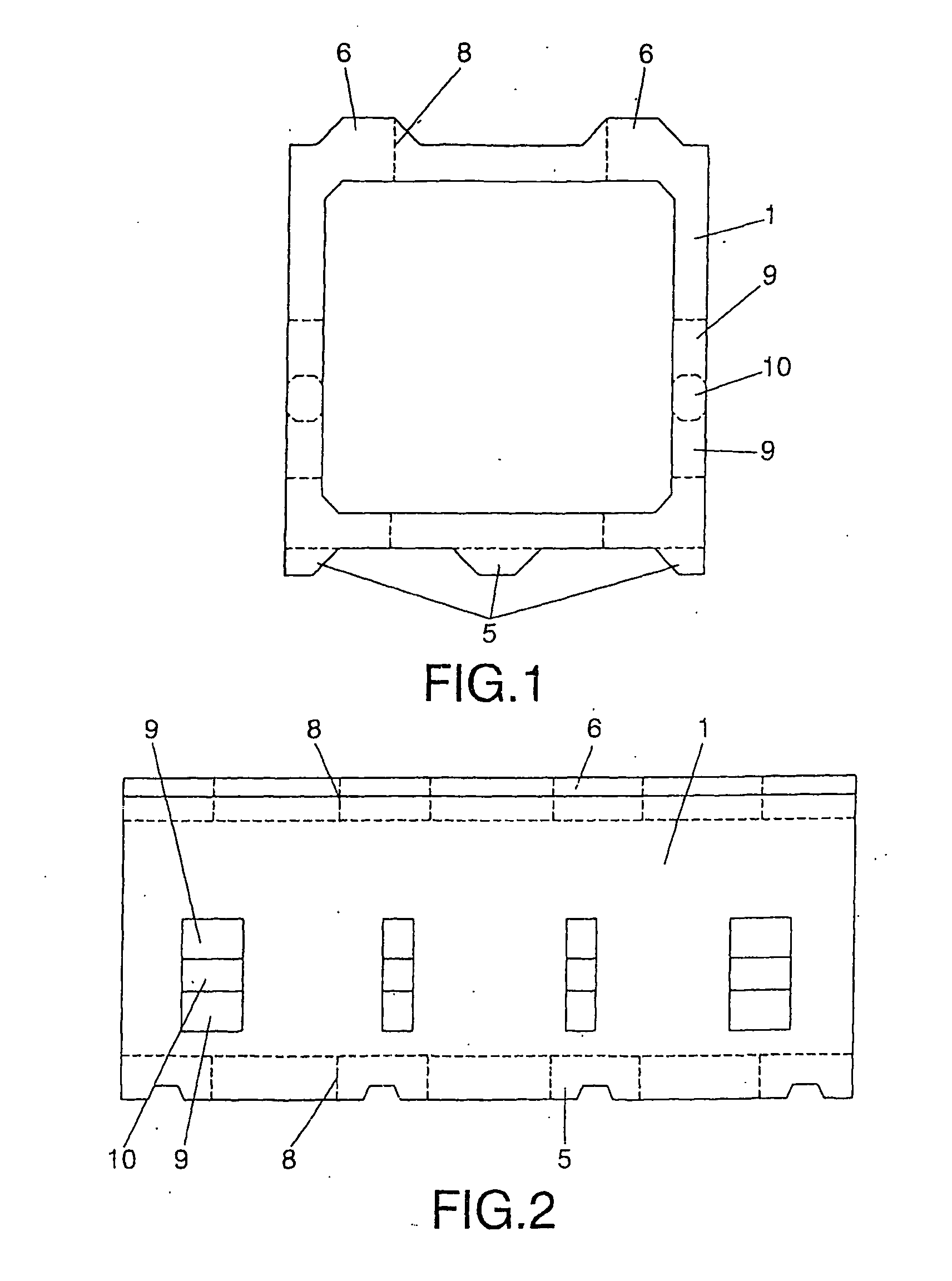

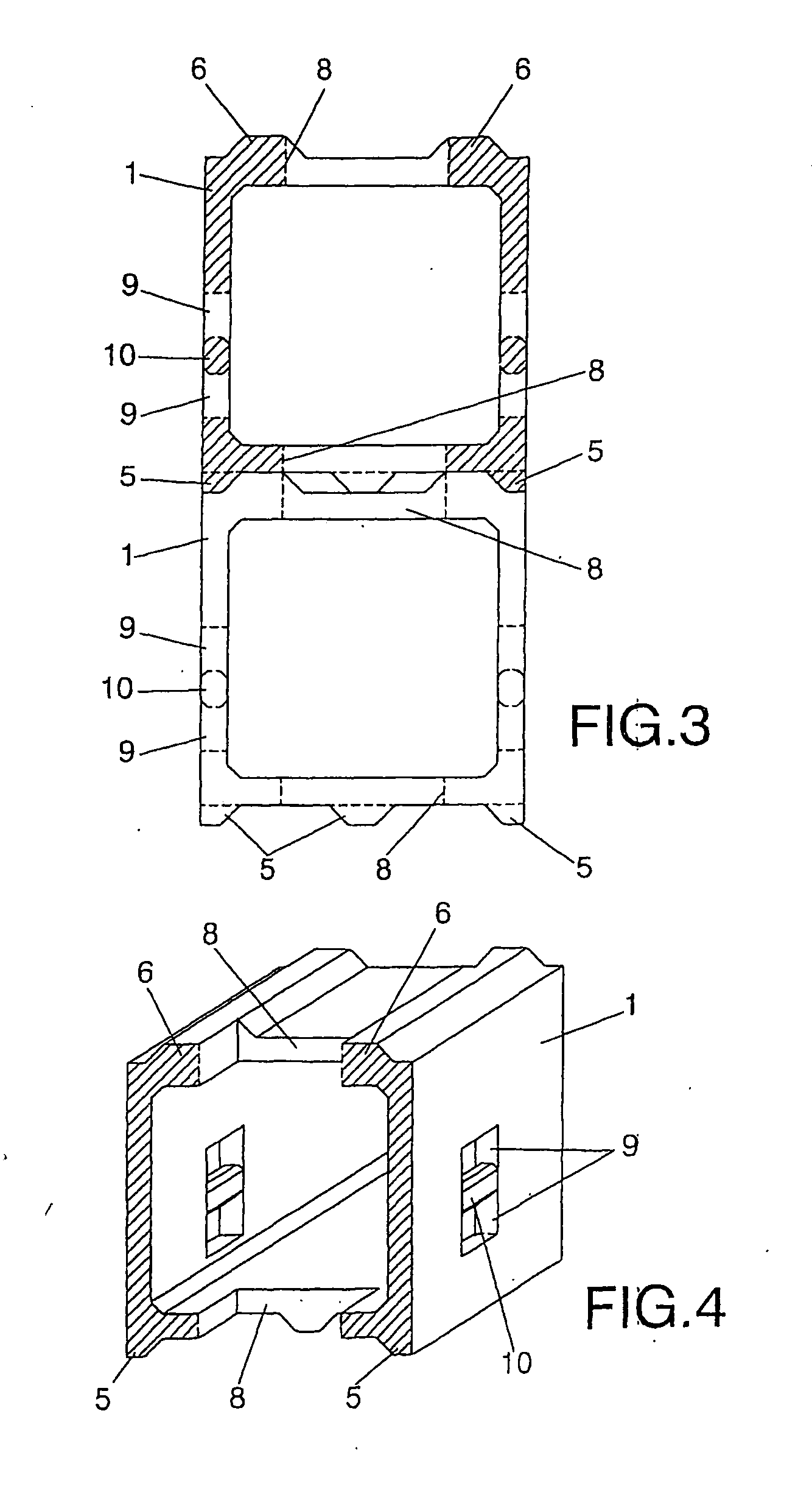

Modular dike for shore protection

InactiveUS20060275081A1Economic and advantageEfficient managementArtificial islandsBreakwatersCouplingEngineering

The invention relates to a modular dike which is intended for shore protection. The inventive dike is based on a reduced number of different prismatic, tubular modules including one quadrangular-section module, two triangular-section modules and a straight trapezoidal-section module. The aforementioned modules are equipped with tongue-and-groove coupling means for the stacking thereof and lateral fixing means such that it is possible to produce a dike of any width, height and section. Moreover, the modules have a thickness of the order of 2.5 metres, a similar height and a length of between 6 and 12 metres. In this way, the dimensions of the modules are suitable for the standard containers that are used to transport goods by road and, more specifically, the constituent modules of the dike can be transported by road on the standard transport network used for the containers. Furthermore, the modules are provided with large lightening holes and, following installation, the modules can be stabilised using, among other means, sand-filled geotextile bags which are disposed therein.

Owner:UNIV POLITECNICA DE VALENCIA

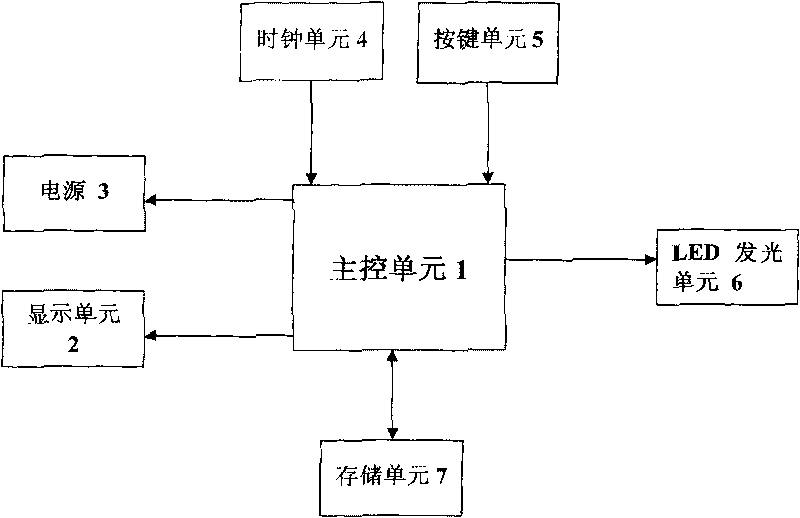

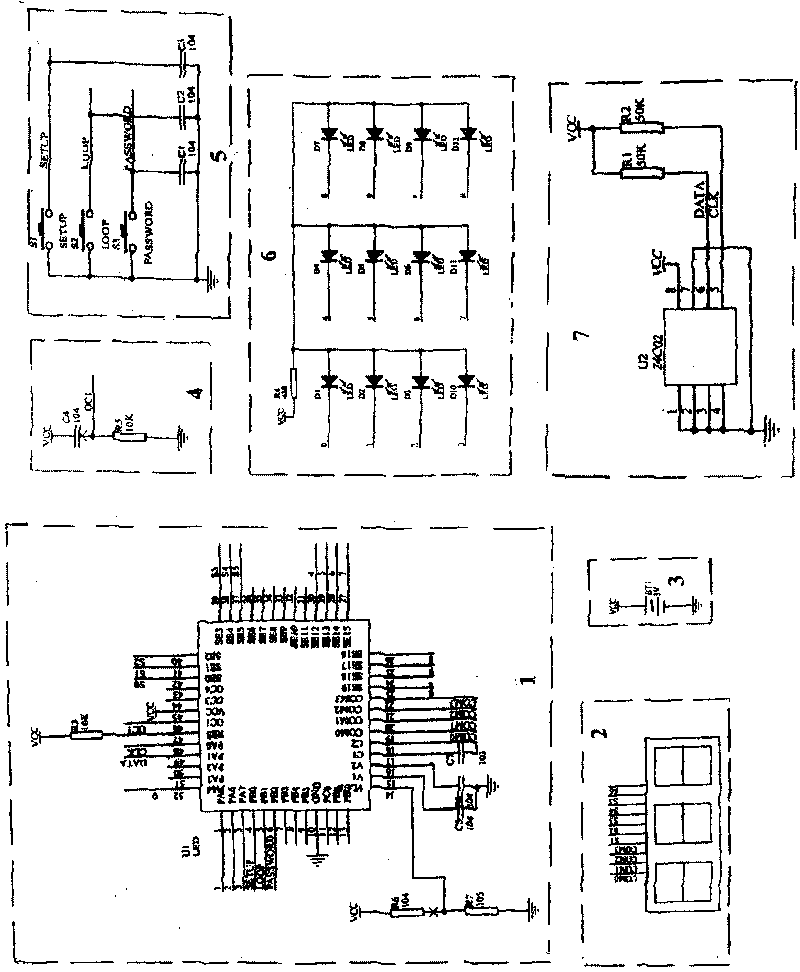

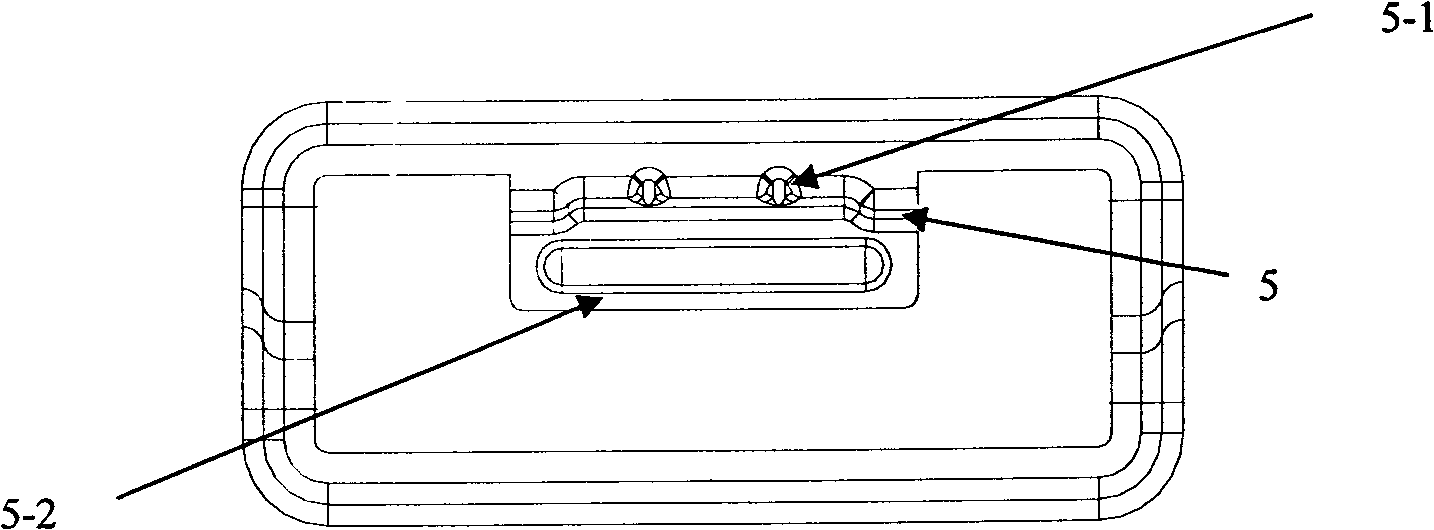

Key of optical coded lock

The invention relates to a key, in particular to a key for an optical coded lock, which is matched with the optical coded lock. The key comprises a shell, a button, a plurality of lightening holes and a lock control switch controlling device, wherein the button and the lightening holes are arranged on the shell; the lock control switch controlling device is arranged in the shell and comprises a power supply, a clock unit, a button unit, a main control unit and an LED lightening unit; the power supply, the clock unit and the button unit are respectively connected with the main control unit; the main control unit is connected with the LED lightening unit; the button on the shell is arranged corresponding to the button unit; and an LED lamp on the LED lightening unit is matched with a plurality of lightening holes on the shell. The invention has the beneficial effect that the key unlocks through remote control by one button and has convenient use, and solves the problems in the prior art that a long code needs to be input once for unlocking every time, is too fussy and easy to forget, and is especially inconvenient for old people and children to use.

Owner:方荣光

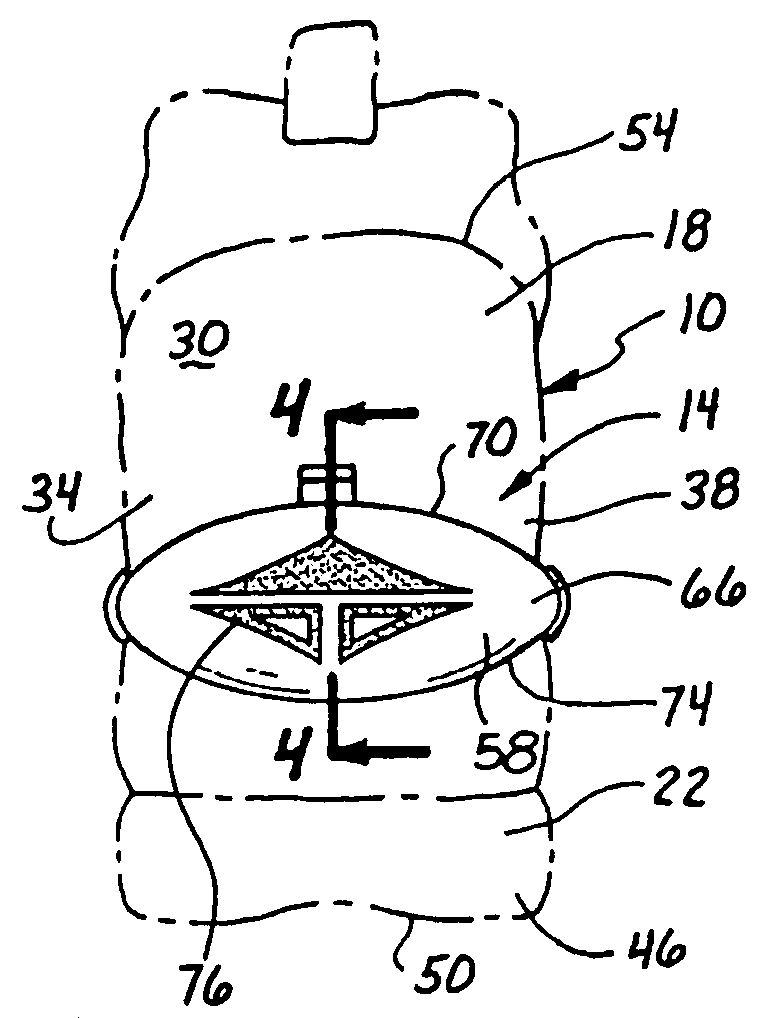

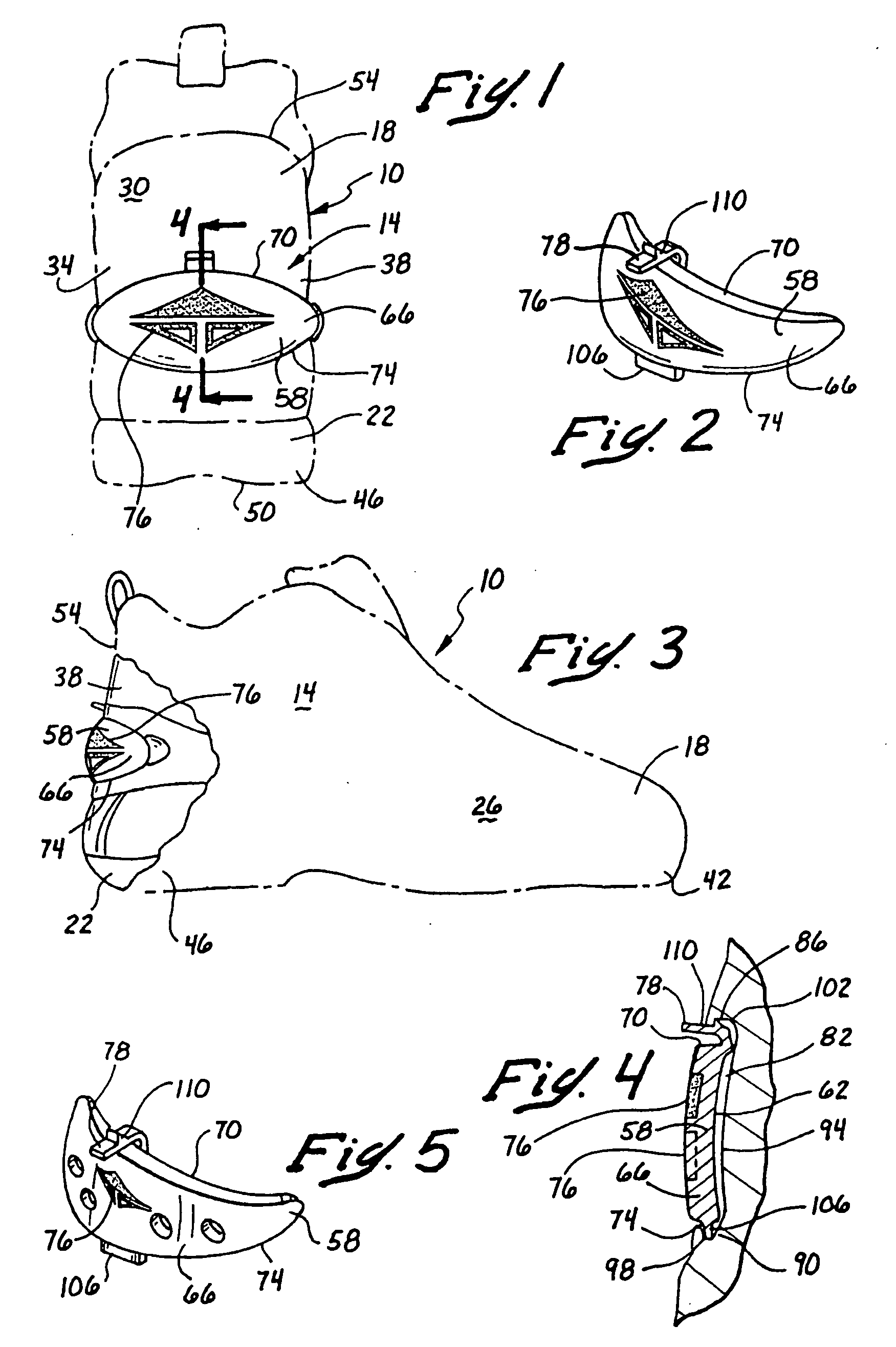

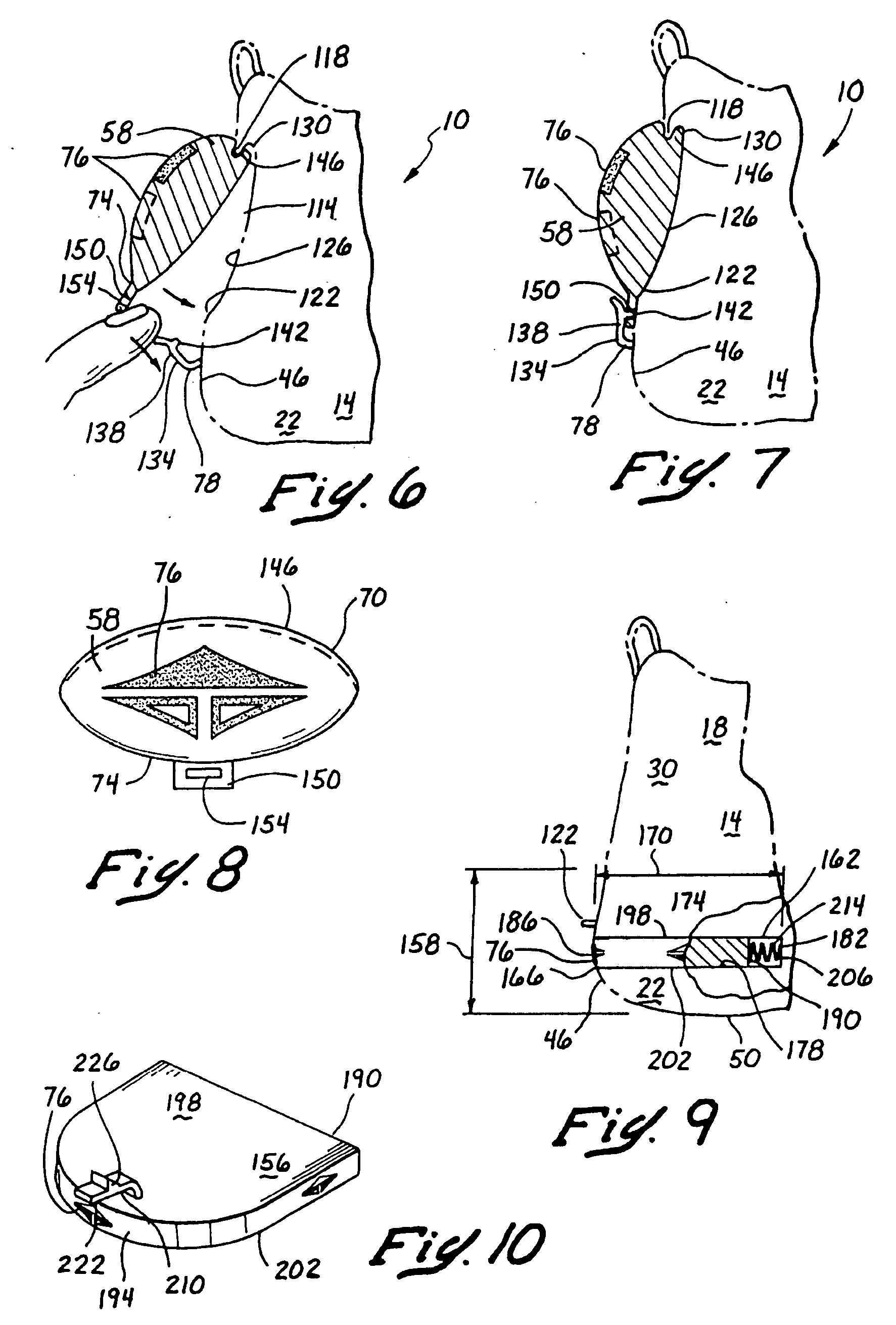

Variable weight athletic shoe with magnetic inserts

A variable weight athletic shoe is described is removably fitted with training weights of varying heaviness or the weights may be left off entirely without damaging the aesthetic appeal or functional aspects of the shoe. The weights are of various sizes and are quickly and securely coupled to the rear portion of the heel-enclosing section of the shoe with several types of attachment clips and latches. The weights also include magnetic inserts provided for health-enhancing reasons. In other variants of the invention, shoe weights are removably attached within cavities in the heel or arch sections of the shoe sole. Weights may also be attached across the instep of the athletic shoe. The shoe weights may be covered in various protective and decorative coverings and may contain lightening holes to achieve the desired weight in a given size.

Owner:JACK SABAT

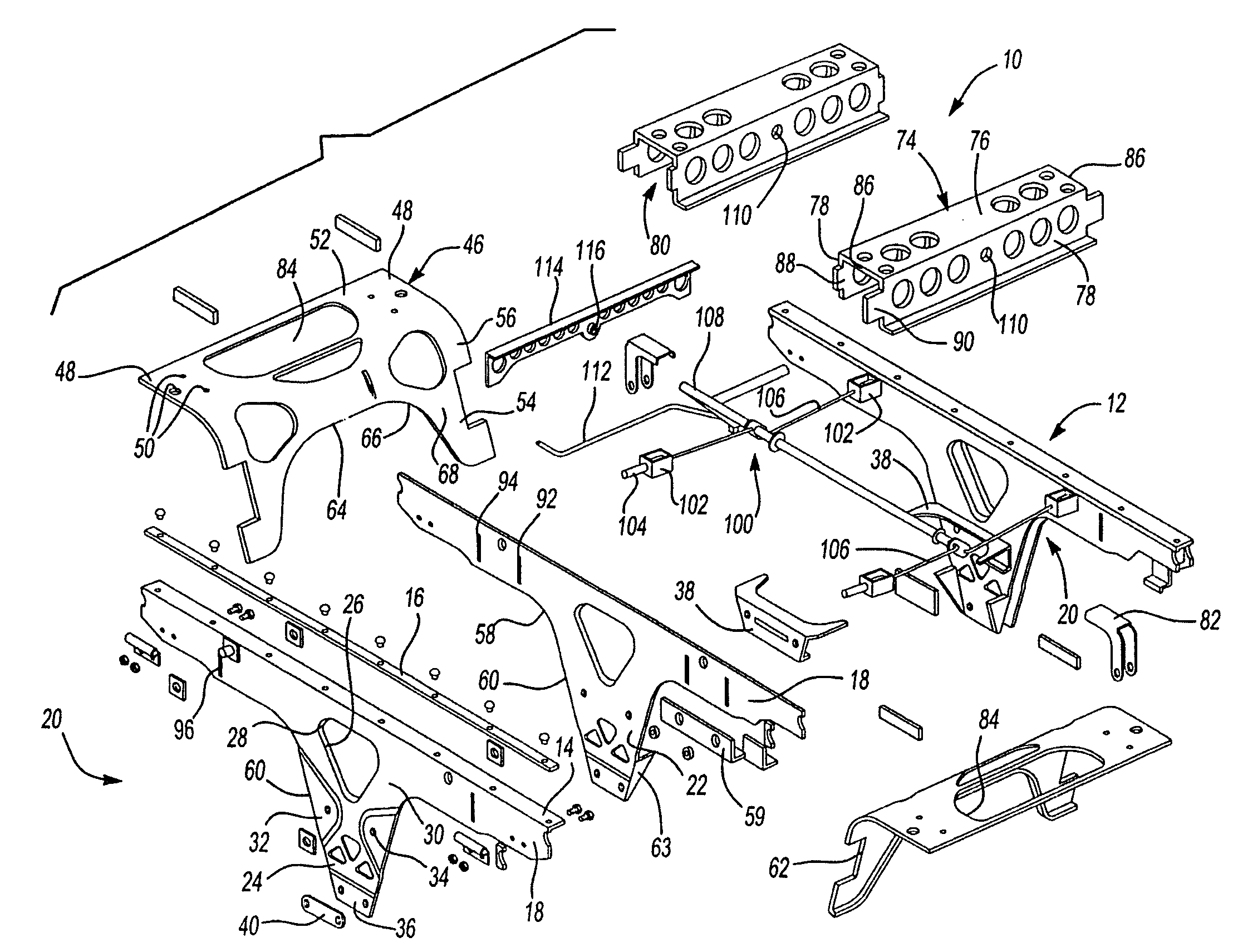

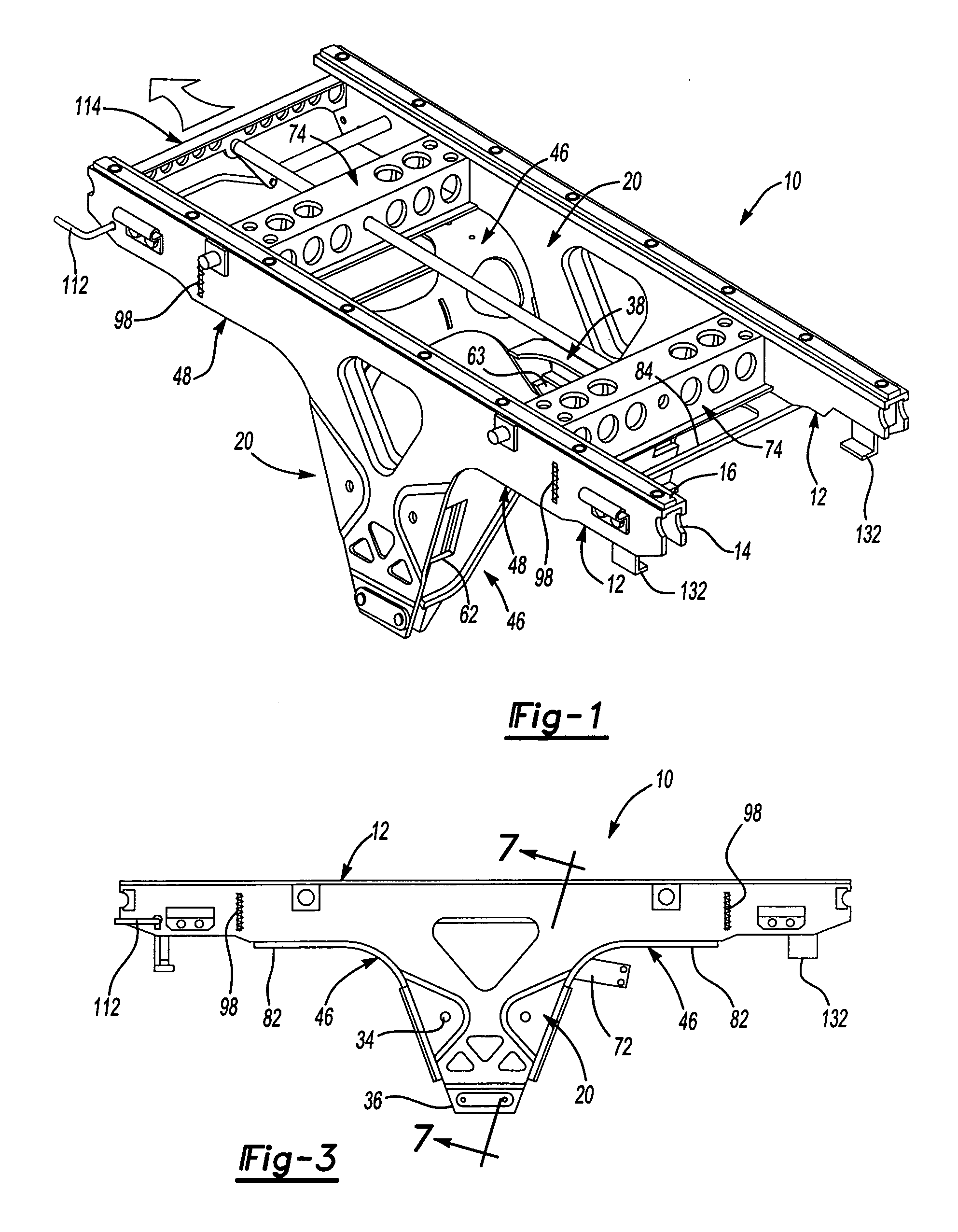

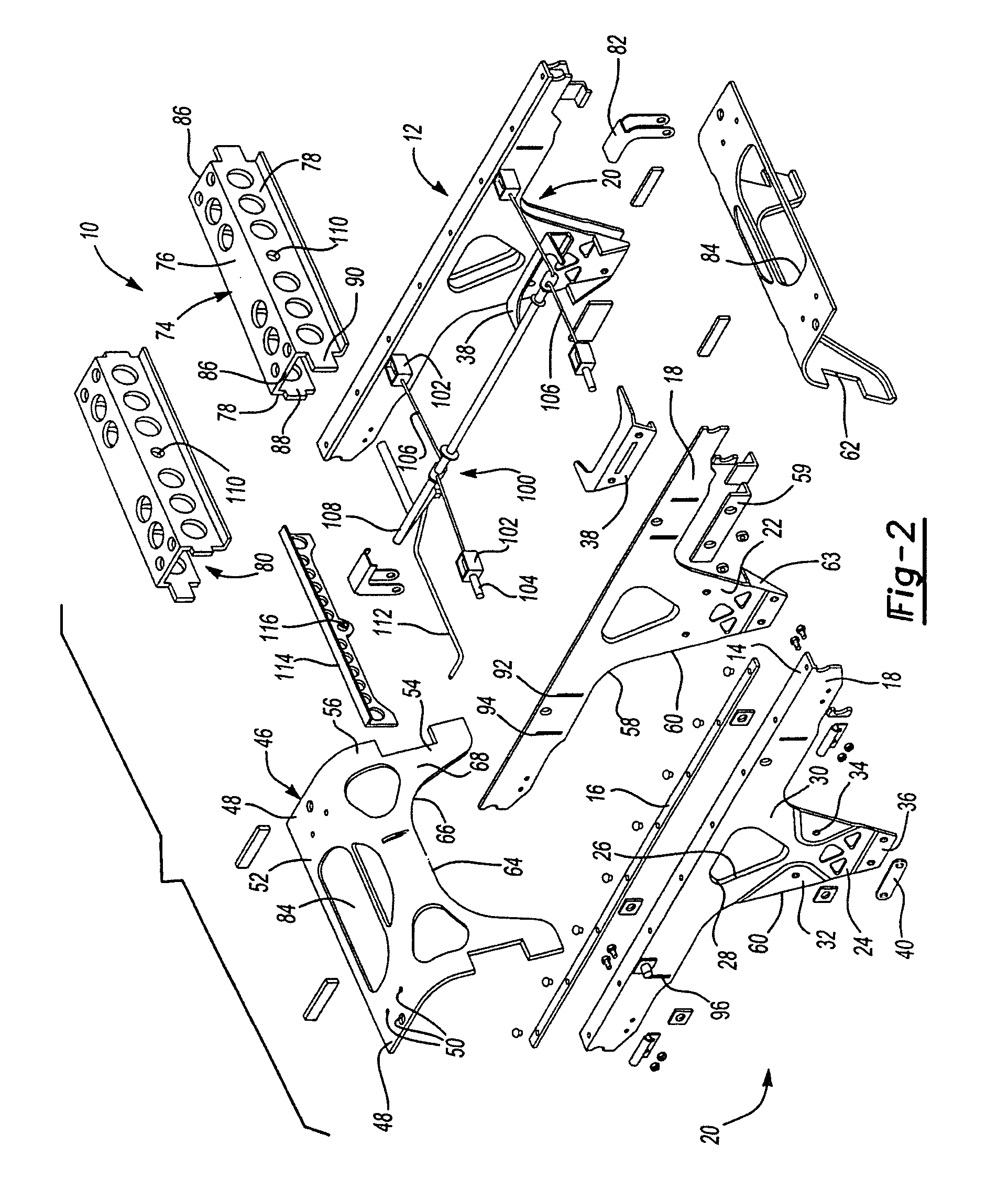

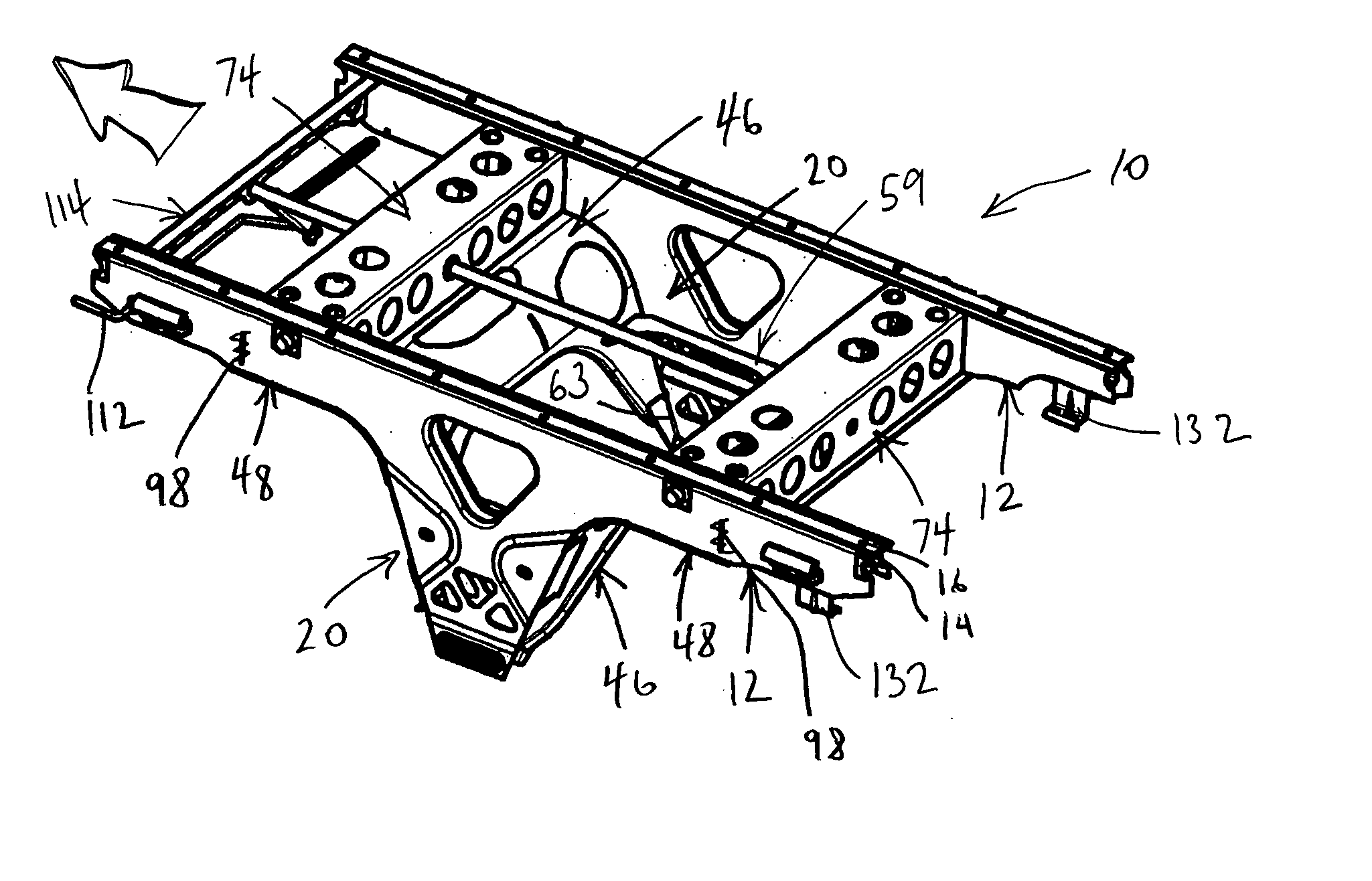

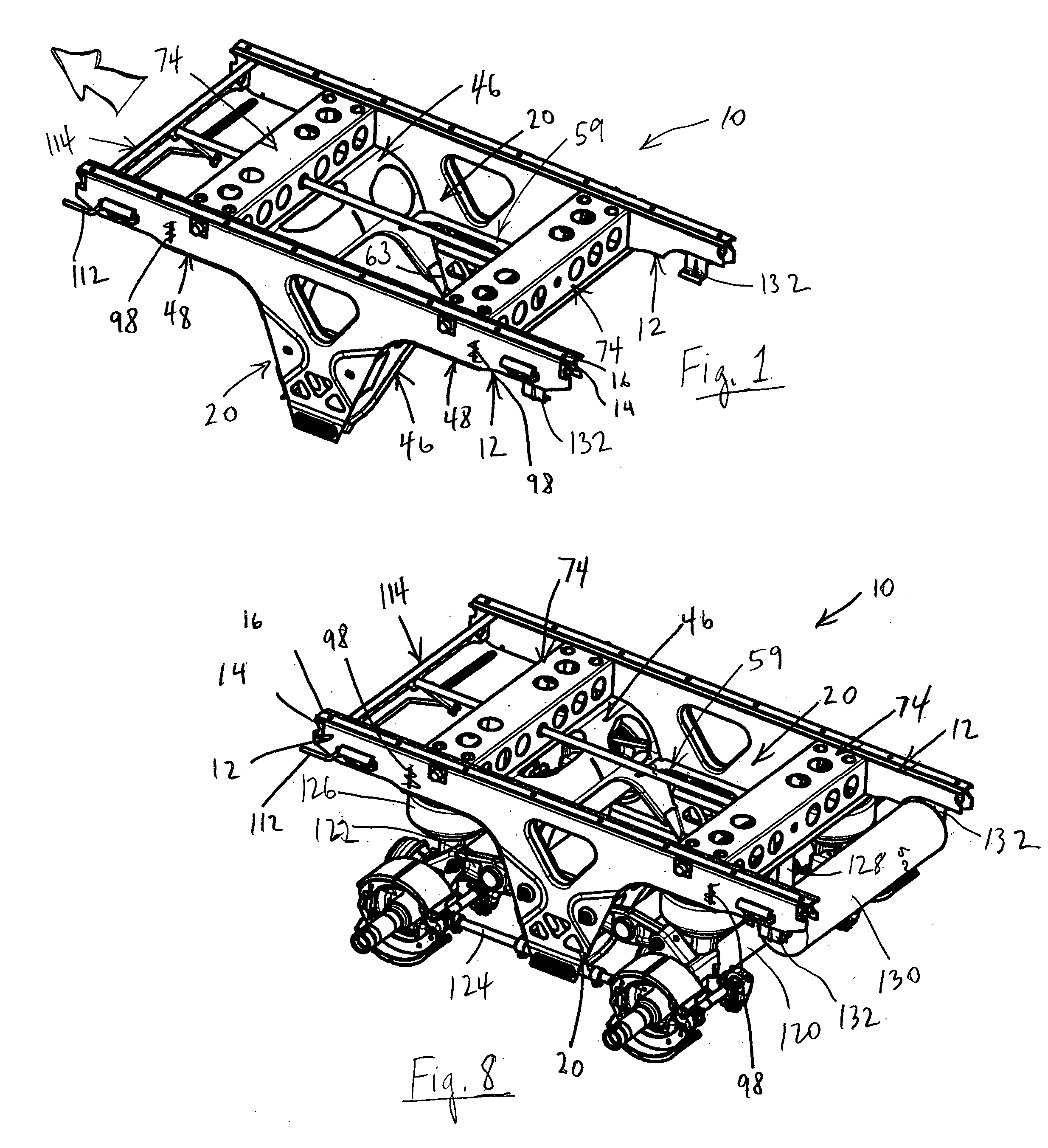

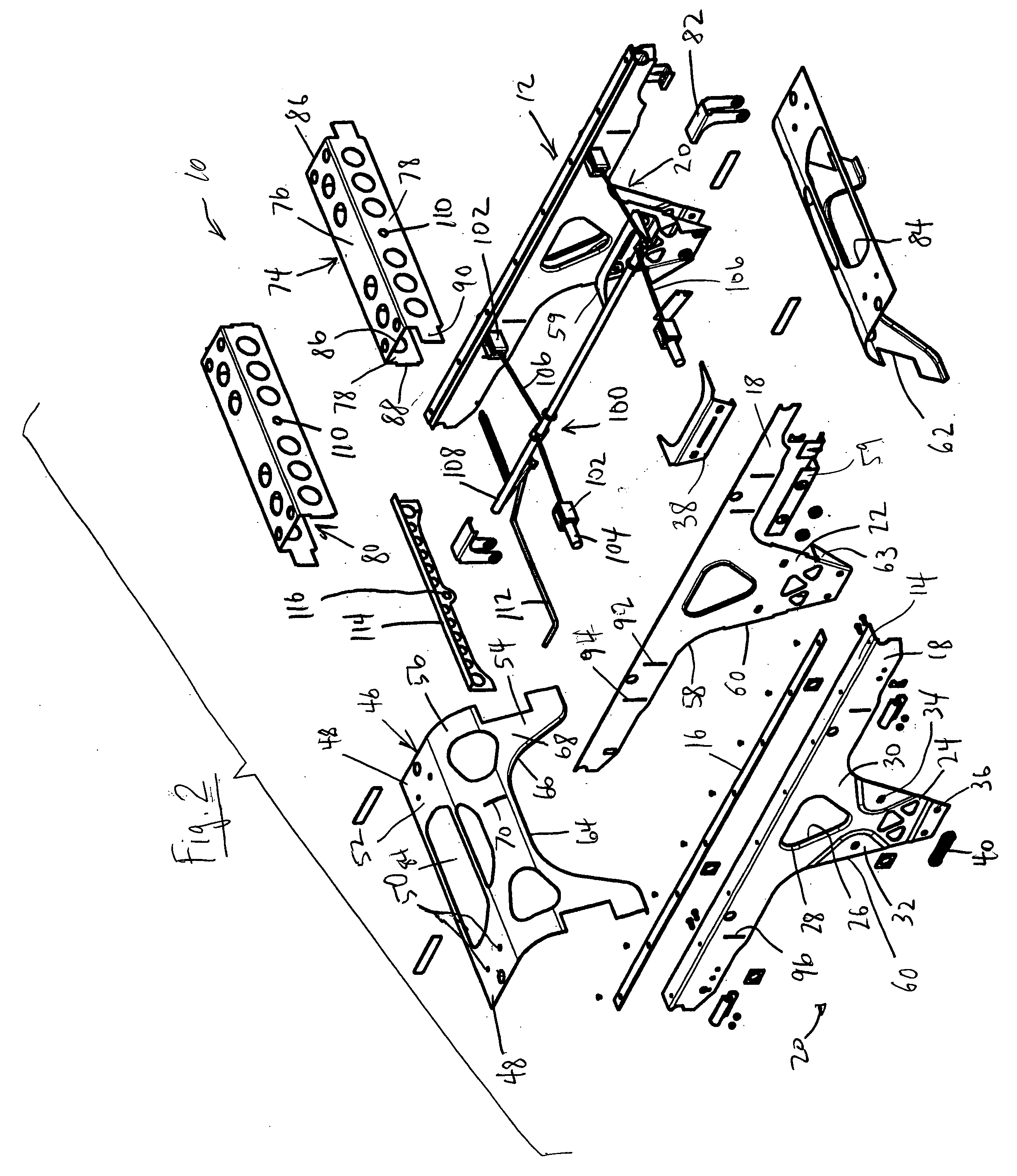

Lightweight reinforced tractor-trailer slider

ActiveUS7207593B2Improve structural rigidityEasy to manufactureUnderstructuresConvertible cyclesAir springControl arm

A tractor-trailer slider includes spaced apart longitudinal side rails having control arm supports extending downwardly from the side rails for supporting the slider. Portions of the longitudinal side rails and the control arms supports are integrated using one or more common plates. Lightening holes and edge of the slider are flanged to reinforce the walls. Coining and ribbing are also used for additional reinforcement. Lateral cross-members extend between the longitudinal side rails. The lateral cross-members have tabs on opposing ends that are received in an interlocking relationship with complementary elongated slots in the longitudinal side rails. Air spring supports arranged at forward and rearward portions of the slider are secured to the longitudinal side rails, the control arm supports, and the lateral cross-members to provide a structurally rigid frame. The air spring supports provide spaced apart air spring mounting pads.

Owner:ARVINMERITOR TECH

Crane and arm frame thereof

Owner:TAICANG LIBIAO INTELLIGENT TECH CO LTD

Lower shell of steel-aluminum hybrid battery pack

The invention discloses a lower shell of a steel-aluminum hybrid battery pack. The lower shell comprises a frame structure, cross beams, longitudinal beams, bottom plates and middle lifting lugs; themiddle lifting lugs penetrates through the cross beams and the bottom plates from top to bottom and are fixed to the cross beams and the bottom plates, and each of the middle lifting lugs comprises amiddle lifting lug body of a cylindrical hollow structure, wherein the top end of the middle lifting lug body is matched with a middle lifting lug nut, and the lower end of the middle lifting lug bodyis sequentially installed in a middle lifting lug reinforcing plate and a middle lifting lug sleeve in a penetrating mode; the frame structure is formed by splicing four frames, the four frames are divided into two groups, and each group of frames are the same in structure and are oppositely arranged; the cross beams are formed by embedding an inverted U-shaped thin-wall structure with a lightening hole into an inverted T-shaped thin-wall structure with a lightening hole, and the frame structure is made of aluminum alloy; the cross beams, the longitudinal beams, the middle lifting lugs and the bottom plates are all made of steel. According to the invention, the advantages of aluminum alloy and high-strength steel are fully absorbed, the lightweight and low-cost design of the battery packbox body is realized, the welding deformation is small, the connection strength is high, and the processing efficiency is high.

Owner:JIANGSU UNIV

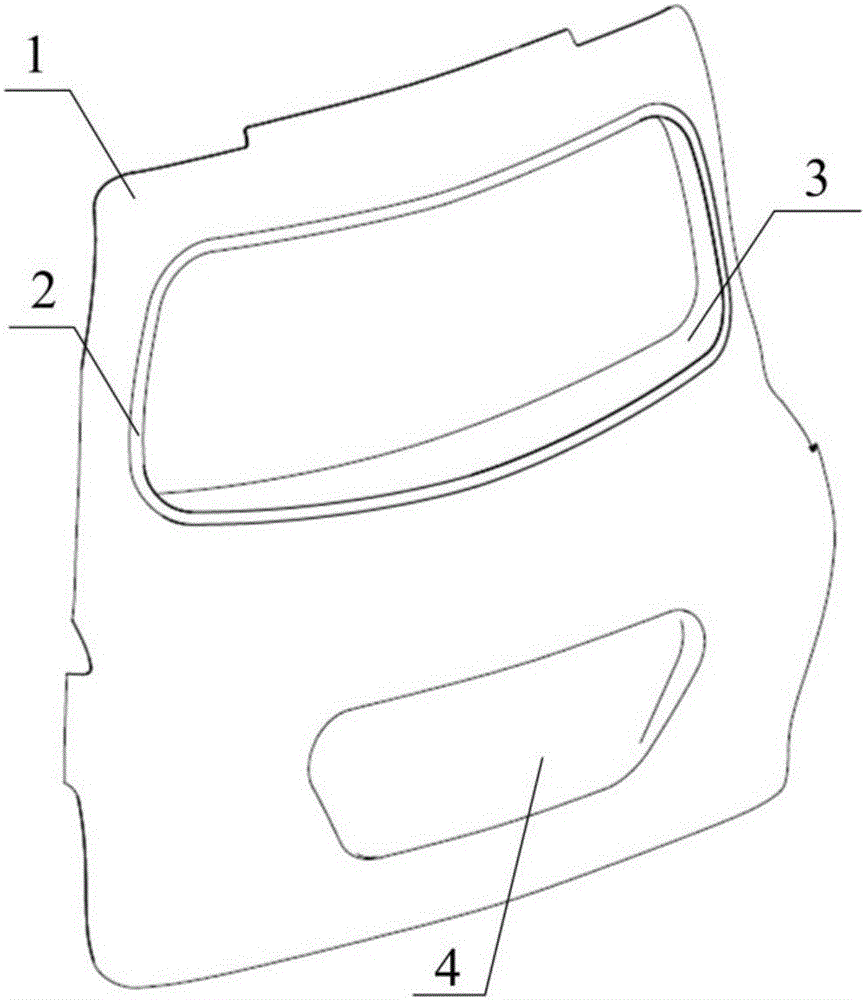

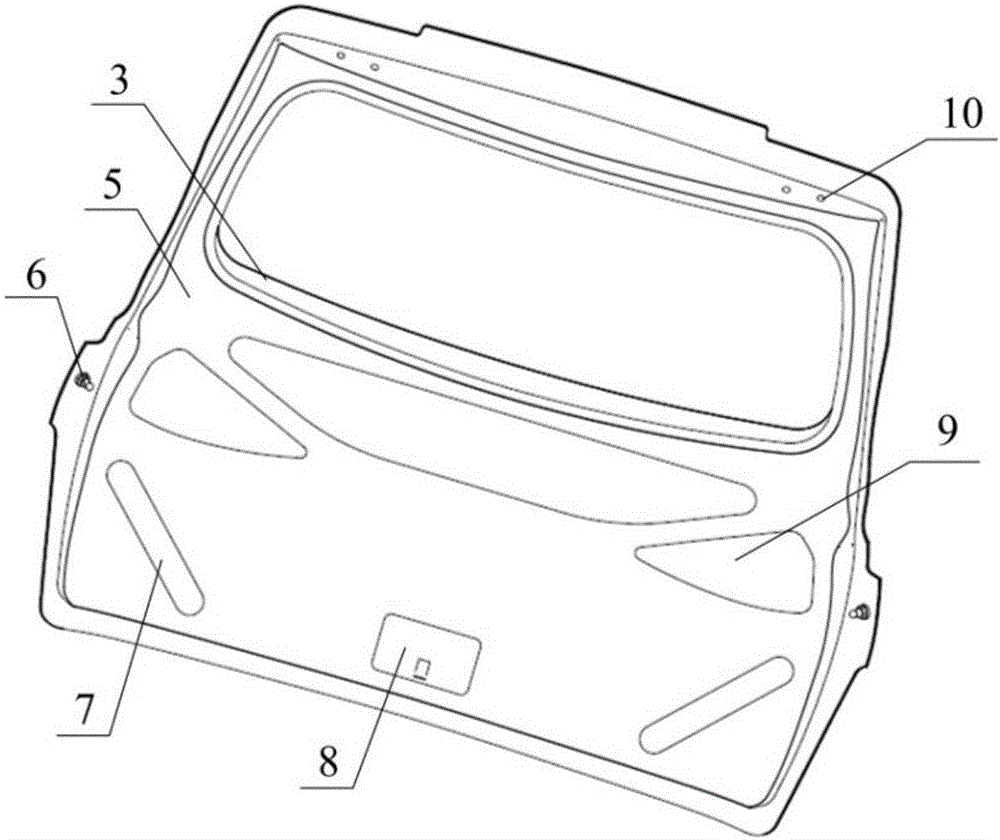

Automobile tail door made of composite material

InactiveCN105711106AReduce in quantityReduce the number of moldsDomestic articlesDoorsCarbon fibersResin matrix

An automobile tailgate made of resin-based composite material, which includes an automobile tailgate outer panel, a tailgate window edge, a vehicle window inner frame, a tailgate license plate frame, an automobile tailgate inner panel, a tailgate hydraulic cylinder mounting support, and an inner panel reinforcement Ribs, tailgate latches, inner panel weight-reducing holes, tailgate hinge mounting holes. It is made of large-tow carbon fiber or glass fiber material, combined with low-viscosity resin, using resin transfer molding (RTM) process. The weight of the tailgate is further reduced through the topologically optimized weight-reduction holes on the inner panel of the tailgate. The strength and rigidity of the inner panel are enhanced through the reinforcing rib at the bottom of the inner panel of the tailgate. Use the tailgate hydraulic cylinder mounting brackets, tailgate latch and tailgate hinge mounting holes to mount composite automotive tailgates to the vehicle body. Due to the use of fiber-reinforced composite materials with high specific strength and specific stiffness, combined with the modular and lightweight design concept, the weight of the vehicle is greatly reduced, the number of parts of the tailgate is reduced, and energy saving and emission reduction are realized.

Owner:BEIHANG UNIV

Preparation method for wide thermoplastic prepreg and hot compression rolls for preparing same

The invention discloses a preparation method for a wide thermoplastic prepreg and hot compression rolls for preparing the same. Each of the hot compression rolls comprises a hot compression roll body and a hollow rotating shaft sleeving the same, wherein a hot compression roll heating layer is arranged on the inner surface of the hot compression roll body; end baffle plates for fixedly connecting the hot compression roll body and the hot compression roll heating layer are arranged at two ends of the hollow rotating shaft; an inner sealed space is formed by virtue of the two end baffle plates; a vacuum opening is formed in each of the end baffle plates, a reinforcing plate is arranged between the hollow rotating shaft and the hot compression roll heating layer, and a plurality of round lightening holes are uniformly formed in the reinforcing plate. The preparation method disclosed by the invention combining the advantages of a melting method and a film method prepreg preparation method is high in continuity, high in method realizability, and high in energy consumption utilization ratio; the damage of fibers is little, the preparation method is easy to industrialize, and the quality of the prepreg is excellent; by adopting the special hot compression rolls, the structural stability of the hot compression rolls in a wide pre-impregnating preparation process is guaranteed, and the quality of the prepreg is not affected.

Owner:SHAANXI TIANCE NEW MATERIAL TECH

Automobile longitudinal beam inner plate assembly

The invention discloses an automobile longitudinal beam inner plate assembly, which comprises a longitudinal beam inner plate and a reinforcement which is connected to the inner side of the longitudinal beam inner plate through a bolt, and is characterized in that: the reinforcement is a groove-shaped structural member which is integrally formed; the side face of the reinforcement is provided with a first lightening hole and a second lightening hole; and the side face of the reinforcement between the first lightening hole and the second lightening hole is also provided with a first boss and a second boss. The assembly is rational in structural design and difficult for bending deformation, and can fully absorb collision energy, so that acceleration peak in a collision process of a vehicle is reduced, and the integrity of the automobile and the safety of passengers are protected.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

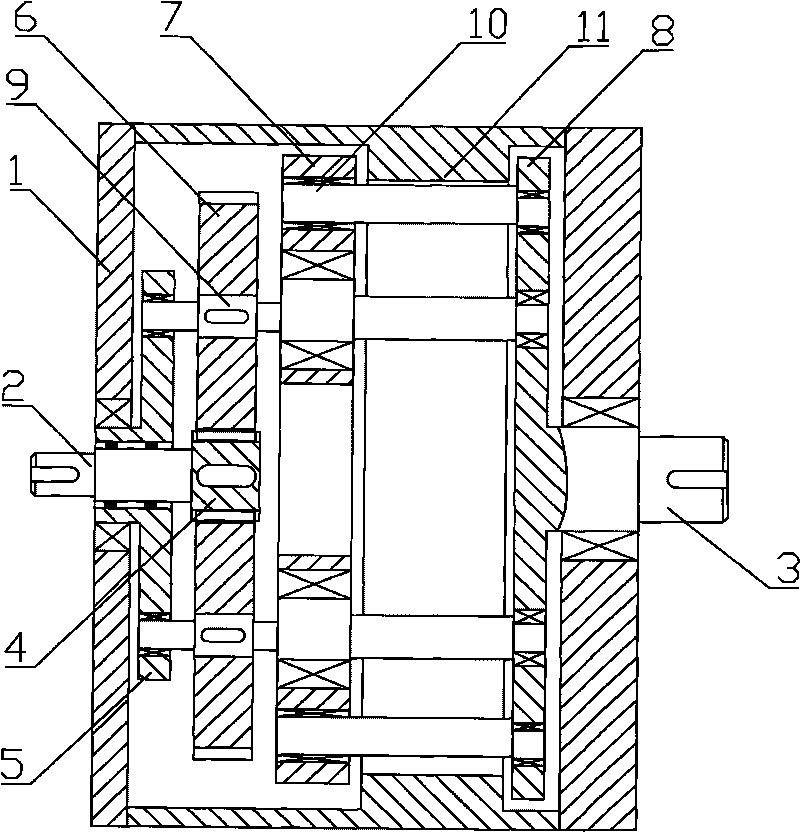

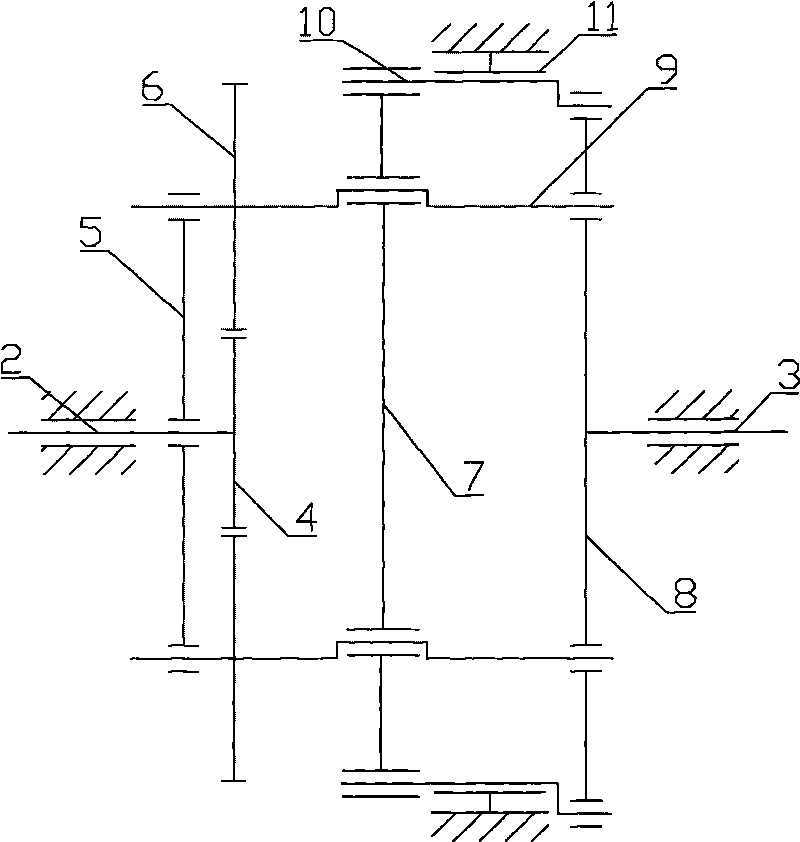

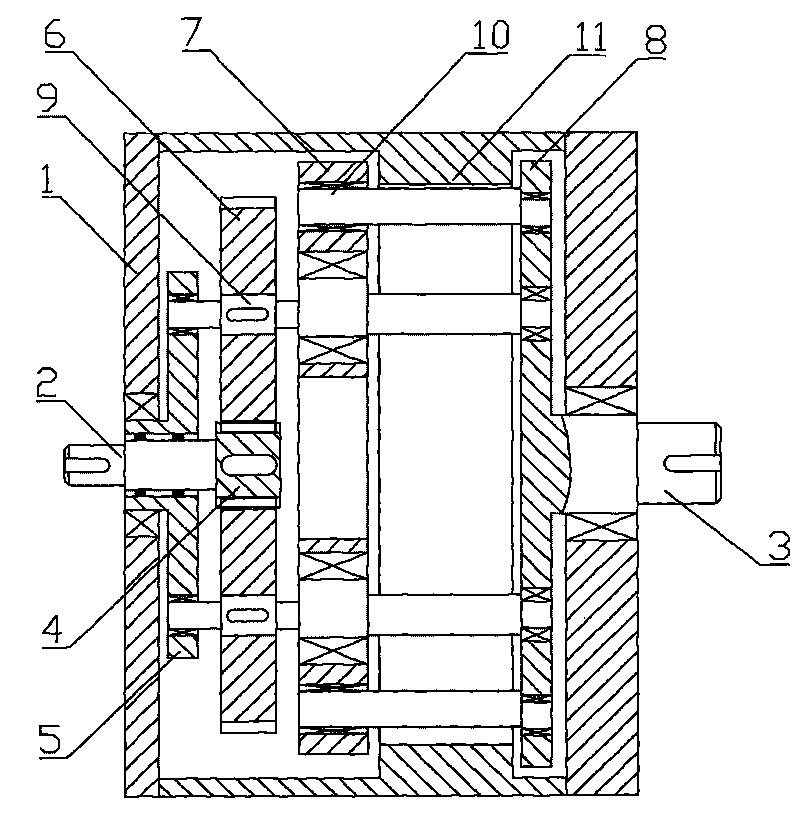

Hypocycloid RV transmission device

InactiveCN101718329ARealize large transmission ratio transmissionImprove stress conditionsToothed gearingsStress conditionsGear wheel

The invention discloses a hypocycloid RV transmission device comprising a shell, a power input shaft and a power output shaft. The power input shaft and the power output shaft are coaxially arranged and are in running fit with the shell; a support disc, a driven gear, a pin tooth installation disk and an output disk are axially juxtaposed in the shell in sequence; and the shell is provided with a hypocycloid gear. The hypocycloid RV transmission device retains the advantage of the RV transmission and improves and overcomes the disadvantages of the RV transmission. A pinwheel is adopted by the hypocycloid RV transmission device to do planetary motion, and only one pin tooth installation disk provided with a lightening hole is used by the hypocycloid RV transmission device, thus the weight of the hypocycloid RV transmission device is effectively reduced. Two ends of the pinwheel are respectively arranged on the pin tooth installation disk and the output disk, thus the vibration of the hypocycloid RV transmission device is effectively decreased, and the dynamic performance of the hypocycloid RV transmission device is improved. The hypocycloid RV transmission device adopts a crankshaft and the pinwheel to output simultaneously, thus the stressing condition of a rotating arm bearing is improved, and the bearing capacity of the rotating arm bearing is enhanced. Due to the appropriate tooth choose and pinwheel diameter increase, the bearing capacity of the rotating arm bearing can be further enhanced. The invention has simple and compact structure and low manufacturing cost and is convenient to maintain.

Owner:CHONGQING UNIV

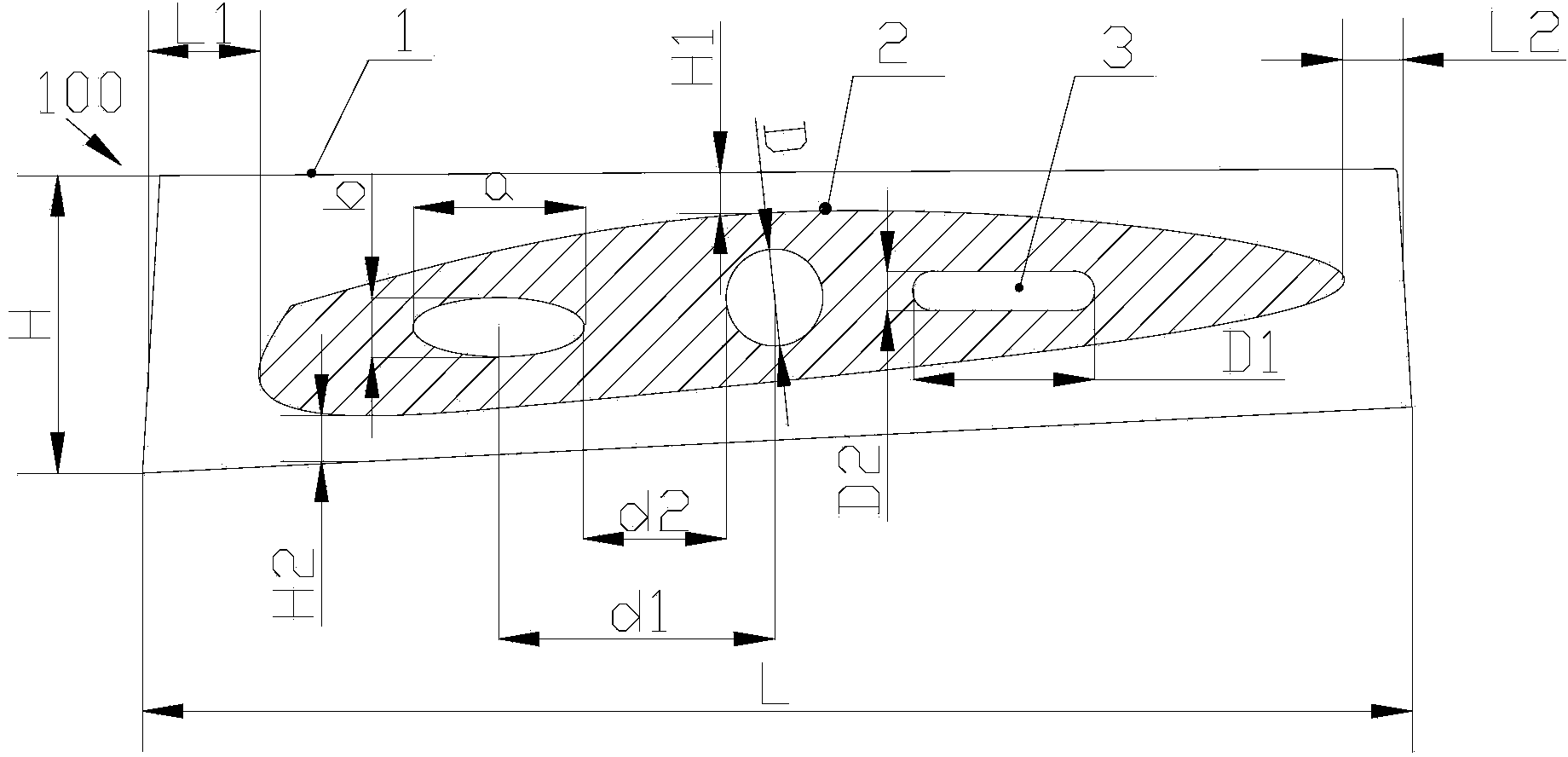

Machining method for helicopter fairing supporting piece

ActiveCN105081681ASave resourcesSolve the clamping problemPositioning apparatusMetal-working holdersNumerical controlMachine tool

The invention relates to a machining method for a helicopter fairing supporting piece. The method includes the steps that firstly, preprocessing is conducted; secondly, a positioning clamp is installed at the clamping installation location 1, areas except for a middle pressure plate 2 and the clamping installation location 1 are subjected to rough turning, and the allowance is 1mm; thirdly, the middle pressure plate 2 is removed, four lateral clamping plates 4 are installed, a part 3 is fixed from the outer side, and the residual unprocessed areas in the first step are subjected to rough turning, finish turning and finish milling; fourthly, the part and the positioning clamp are connected through cooperation of a sunken hole machined in the second step and a corresponding threaded hole in the positioning clamp, the lateral clamping plates 4 are removed, the residual area of secondary finish turning is subjected to finish turning, and the residual portions, except for a lightening hole, of the part 3 are machined; and fifthly, an outer end pressure plate 5 is installed at the outer end face of the part 3, and the lightening hole in the outer end pressure plate 5 is subjected to rough milling and finish milling. The clamping purpose is reasonably achieved in machining, resources of tools and numerically-controlled machine tools are saved, cycling time is greatly shortened, and a good effect is achieved.

Owner:HARBIN

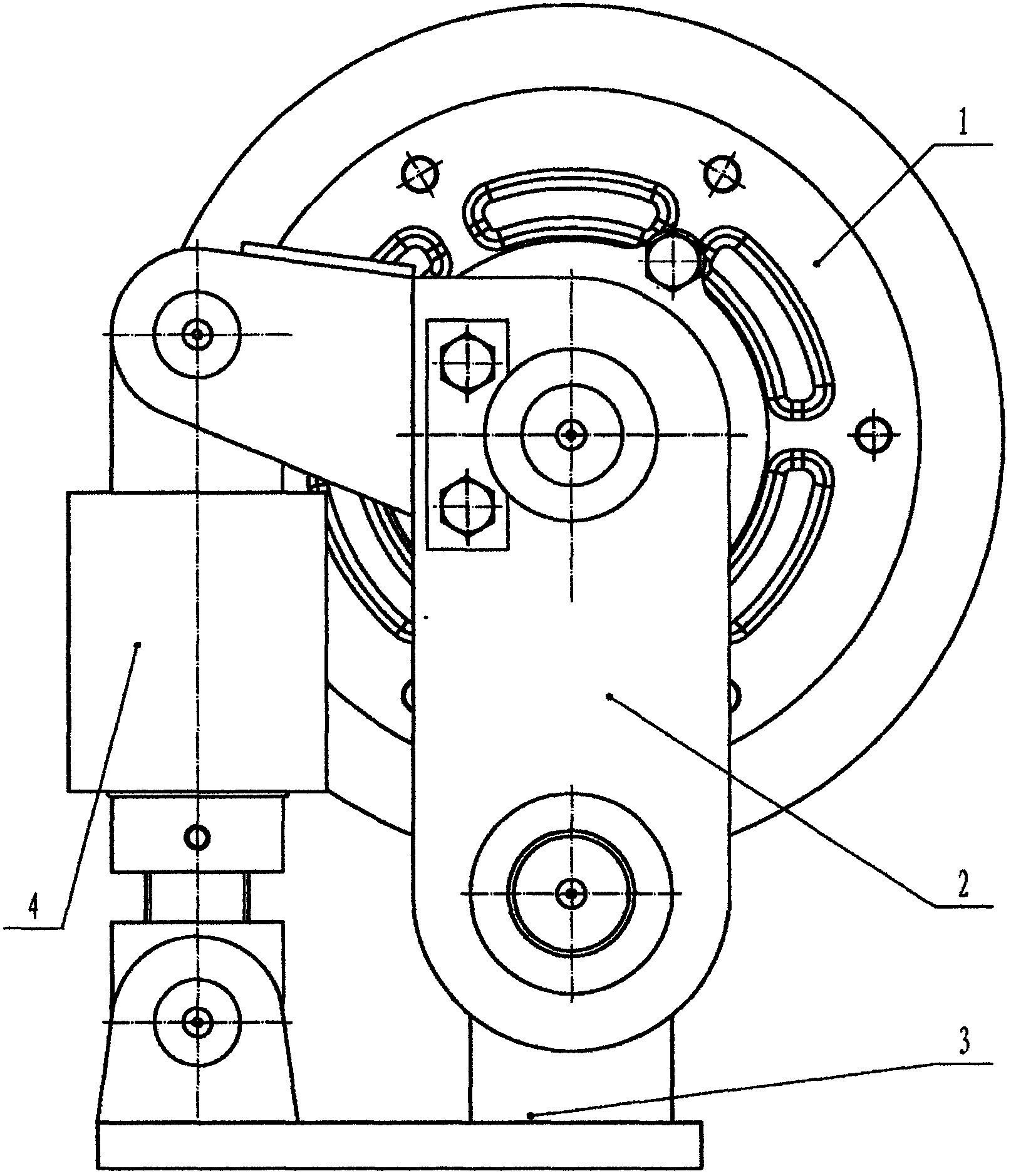

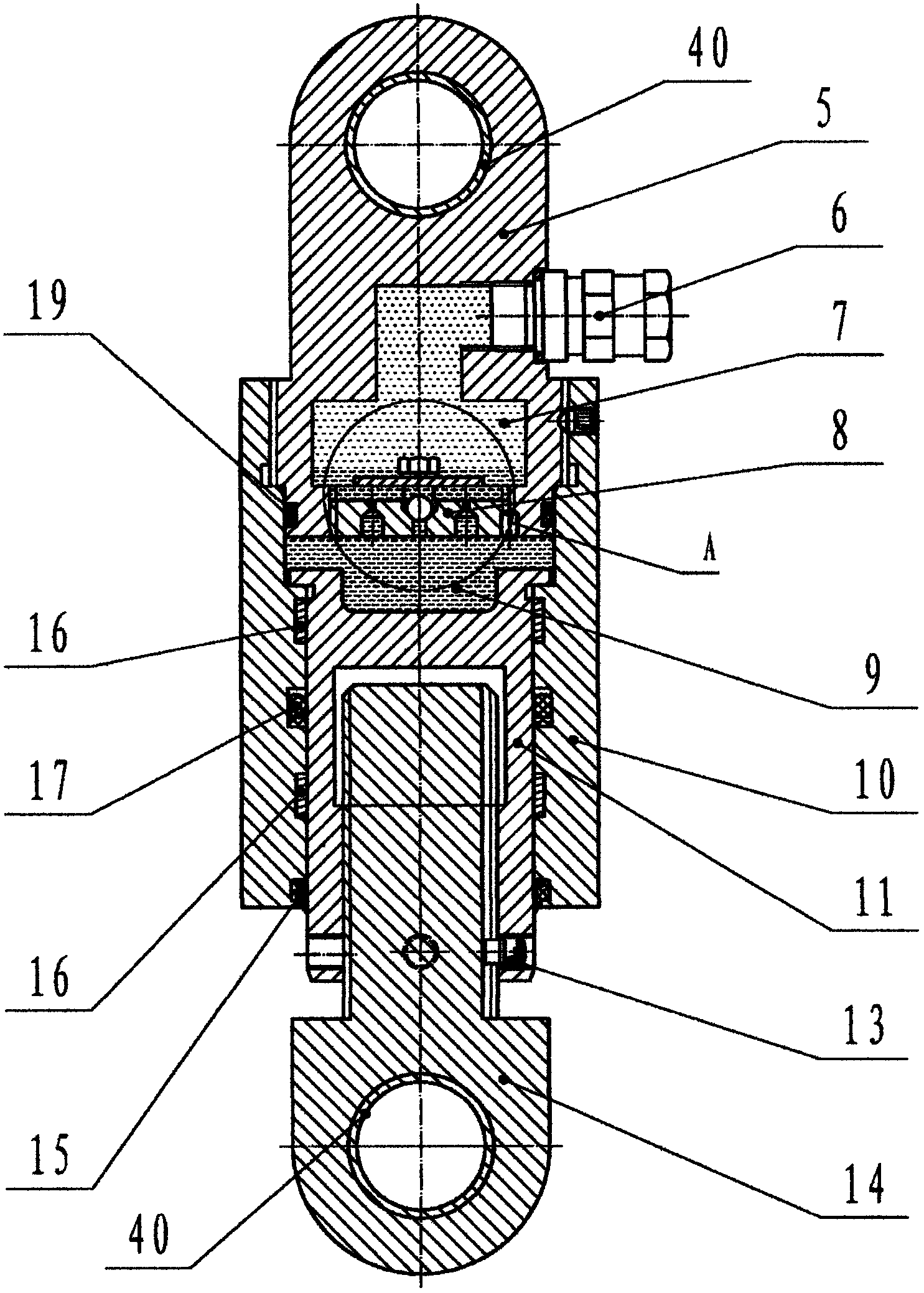

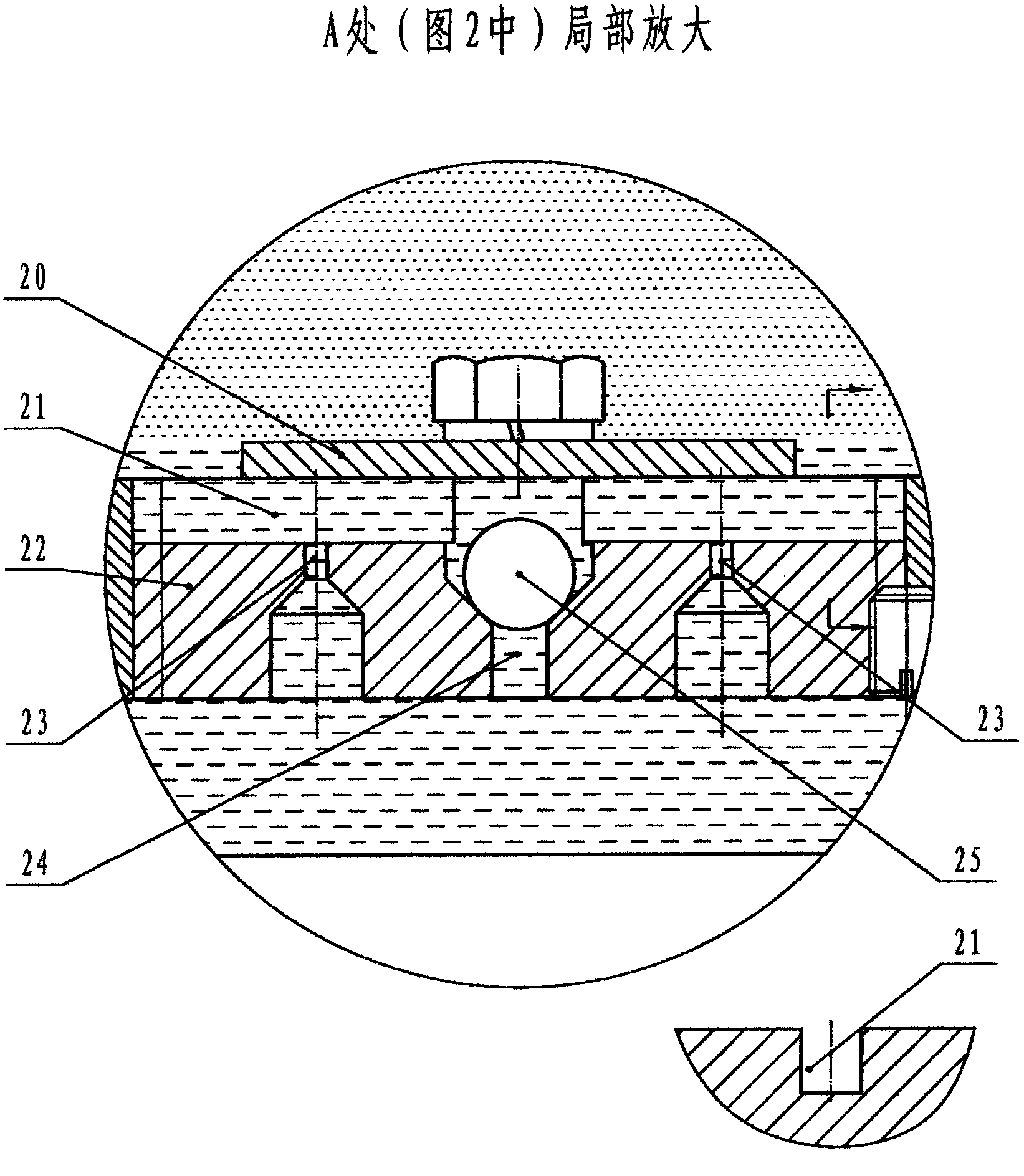

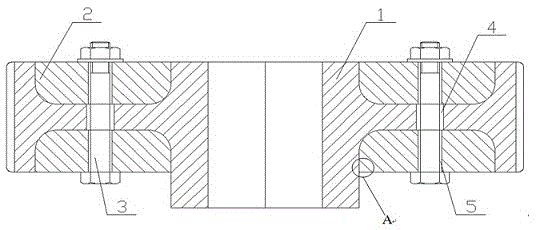

Light roller cage ear with gas spring hydraulic damper

InactiveCN102701047ASolving Elasticity ProblemsSolve the adjustmentSpringsElevatorsNitrogenGas spring

The invention provides a light roller cage ear with a gas spring hydraulic damper. The roller cage ear is formed by hinging a base, a bracket and a damper, wherein a roller component is arranged on the bracket; the damper consists of a cylinder, a damping valve, a plunger and a damper length adjusting rod; the damping valve is connected with the cylinder; high-pressure nitrogen is filled in the upper part of an air chamber; hydraulic oil is filled in the lower part of the air chamber; the roller component comprises light hubs with lightening holes and clamping rings; bolts penetrate through bolt holes on the clamping rings and hubs and are matched with the semi-circular grooves on a corrosion-resisting roller to form a circular hole, and the corrosion-resisting rollers are fixed on the hubs. The roller cage ear has the advantages that the impact energy can be quickly absorbed by the damper, the bearing capacity is high, the damping performance is high, the impact on a tank channel is small, the initial elasticity and the length of the damper can be conveniently adjusted, and the damper is fully sealed and is long in service life; the roller component is simple in structure, rubber wheels are easily replaced, the hubs have a fully-sealed structure, and the service life of a bearing is long; besides, the roller cage ear is light in weight and long in service life and is not required to be maintained.

Owner:北京中煤昊翔高新技术有限公司 +1

Carburizing and quenching deformation control method for gears of large-sized heavy-load locomotive

ActiveCN104651857AEasy wayUniform sizeSolid state diffusion coatingFurnace typesEngineeringHeavy load

The invention provides a carburizing and quenching deformation control method for gears of a large-sized heavy-load locomotive. The method comprises the steps of laminating two steel plates with the same shapes with spoke plates of gears to sunken parts on two sides of the spoke plates of the gears by virtue of a compensation method, penetrating lightening holes in the spoke plates of the gears by bolts to fix the upper and lower steel plates and avoid relative displacement, sequentially charging the gears of the heavy-load locomotive into a furnace according to design requirements of a conventional process, and carrying out carburizing and quenching. According to the method, two sides of the spoke plates of the gears are clamped and compressed by the upper and lower steel plates, so that the bending of the spoke plates is avoided, the temperature differences among parts of the gears are uniformed, the large thermal stress and the large structural stress caused due to different sectional dimensions are reduced, and therefore, the deformation of the gears is reduced; furthermore, the carburization can be effectively prevented, the manufacturing cost for coating a seepage-proofing agent and maintaining machining allowance is lowered, the production cycle is shortened, and the production efficiency is improved.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

High-speed permanent magnetic wind driven generator rotor sheet

InactiveCN102820721AHigh strengthImprove reliabilityMagnetic circuit rotating partsWind drivenElectric machine

The invention relates to a high-speed permanent magnetic wind driven generator rotor sheet, wherein a permanent magnet groove below each rotor magnetic pole is of a double section symmetrical structure which is isolated by an intermediate magnetic bridge; an axial ventilation slot is formed between the adjacent two magnetic poles; and the excircle of the rotor magnetic pole is an eccentric circular arc, the permanent magnet groove is provided with a permanent magnet mounting and locating step, tightening screw vents, lamination location holes and waist-shaped lightening holes are uniformly distributed in the rotor sheet, and a keyway is formed in the inner circle of the rotor sheet. After the integral round rotor sheet is adopted, a rotor has a simpler structure, a permanent magnet is not needed to be fixed through other measures, and the rotor sheet is easy to process and produce; the intermediate magnetic bridge can be used for effectively improving the rotor strength, and accordingly, the operation reliability of the rotor is improved; the eccentric circular arc of the rotor magnetic pole and the structural parameters of the magnetic bridge are adjusted, the output performance of a generator can be effectively improved, and the anti-demagnetizing performance of a motor is improved under the short circuit condition; and the ventilation slot is formed between the rotor poles, so the ventilation and heat dissipation capabilities of the whole generator can be effectively improved.

Owner:HARBIN ELECTRIC MASCH CO LTD

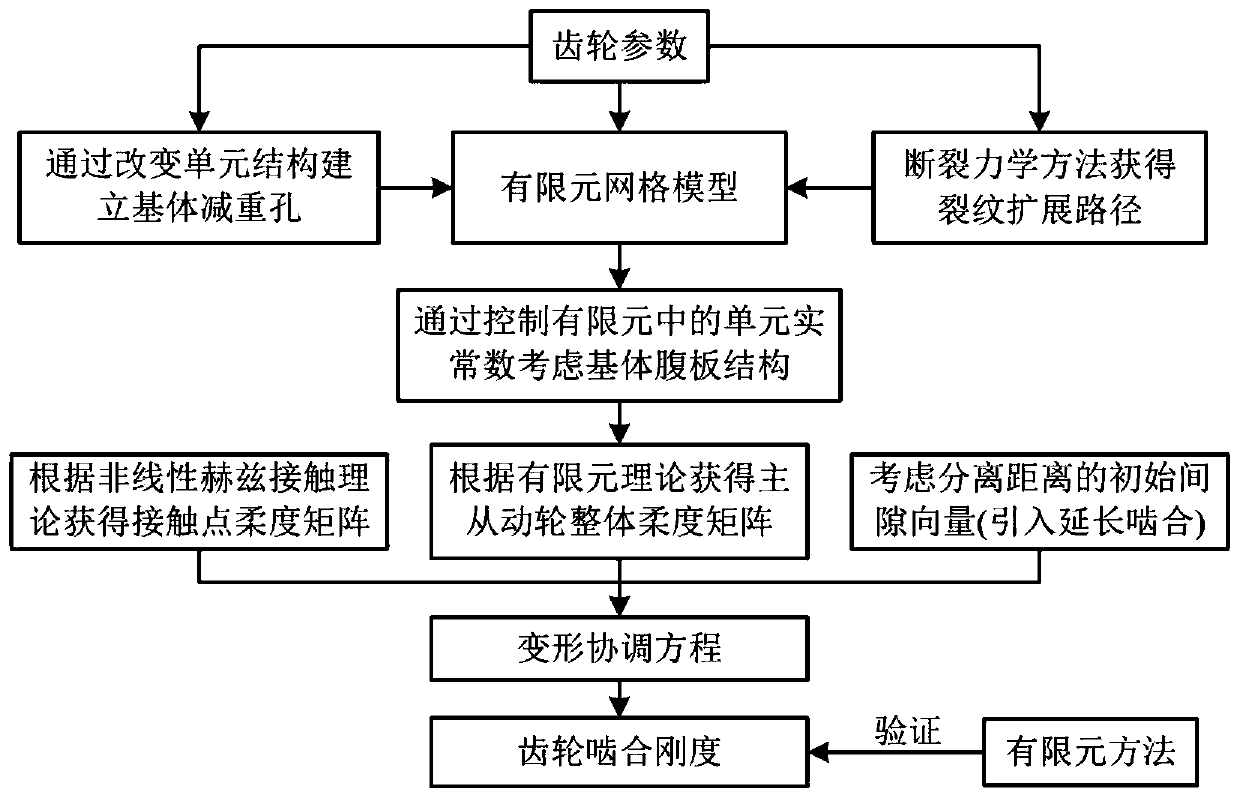

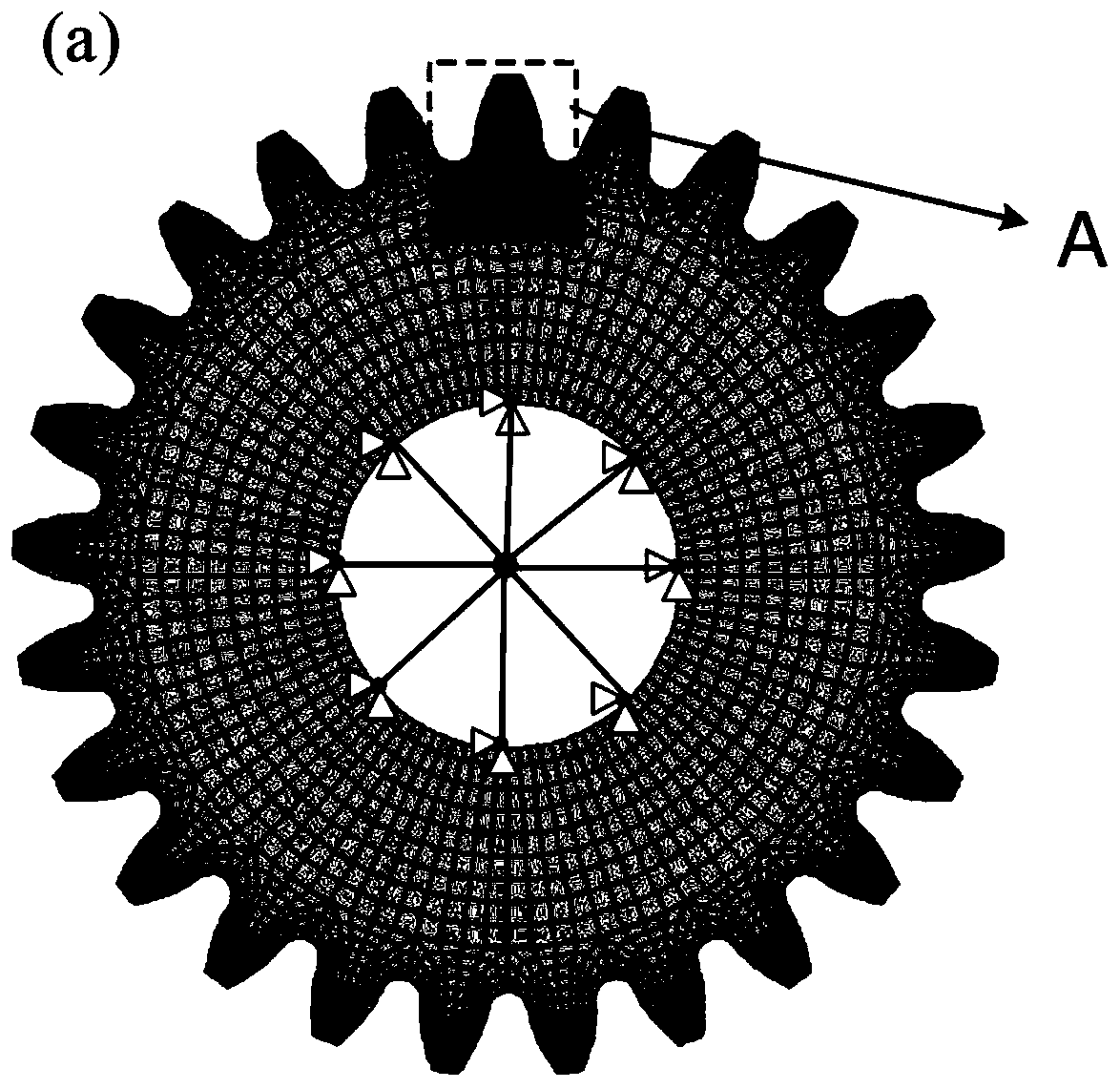

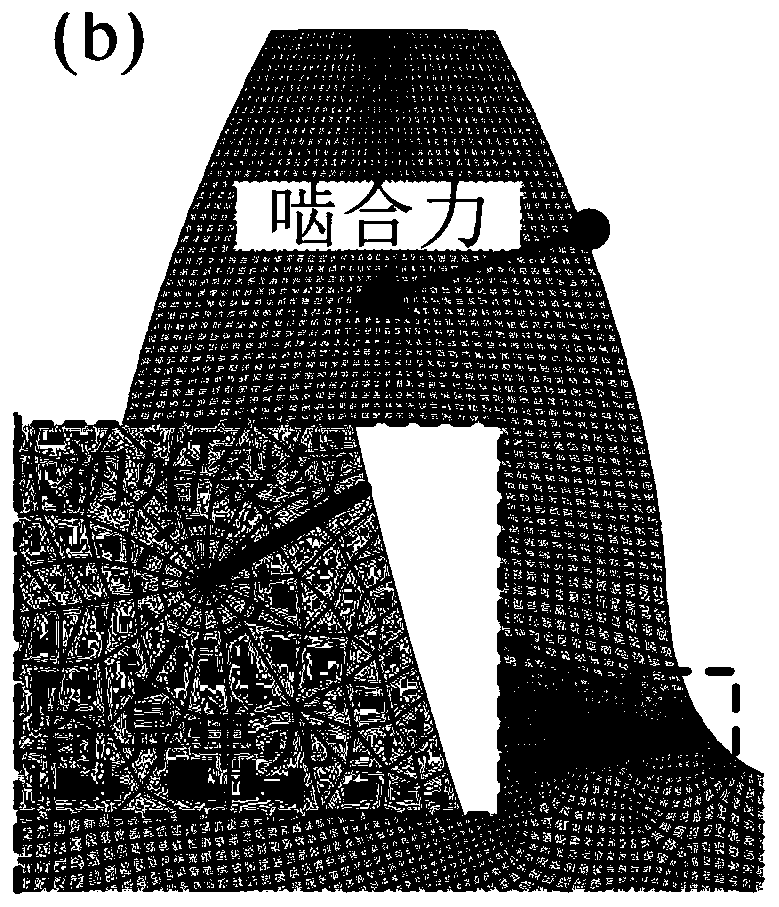

A straight gear meshing stiffness calculation method considering a complex matrix and a crack propagation path

ActiveCN109726520AHigh meshing stiffnessHigh precisionSpecial data processing applicationsDrive wheelWeb structure

The invention relates to a straight gear meshing stiffness calculation method considering complex matrix and crack propagation, and the method comprises the steps: obtaining an overall flexibility matrix of a driving wheel and a driven wheel of a meshing gear based on a finite element theory, and determining an overall flexibility matrix of a possible contact point at each meshing position; Introducing a nonlinear Hertz contact theory, and calculating a contact flexibility matrix of possible contact points at each meshing position; And introducing the overall flexibility matrix, the contact flexibility matrix and the initial gap vector of the possible contact point into a deformation coordination equation, and calculating the meshing stiffness of the meshing position. According to the method, crack propagation paths obtained through fracture mechanics can be considered at the same time, and the influence of a complex matrix structure (including a web structure and a lightening hole structure) on the meshing rigidity of the straight gear can be considered at the same time. According to the method, the straight gear meshing stiffness considering the gear web structure, the lighteninghole structure and the crack propagation path can be calculated at the same time. The result of the method is verified by adopting a three-dimensional contact finite element method, and the result shows that the method disclosed by the invention has higher precision for calculating the meshing stiffness of the crack-containing complex matrix gear.

Owner:NORTHEASTERN UNIV

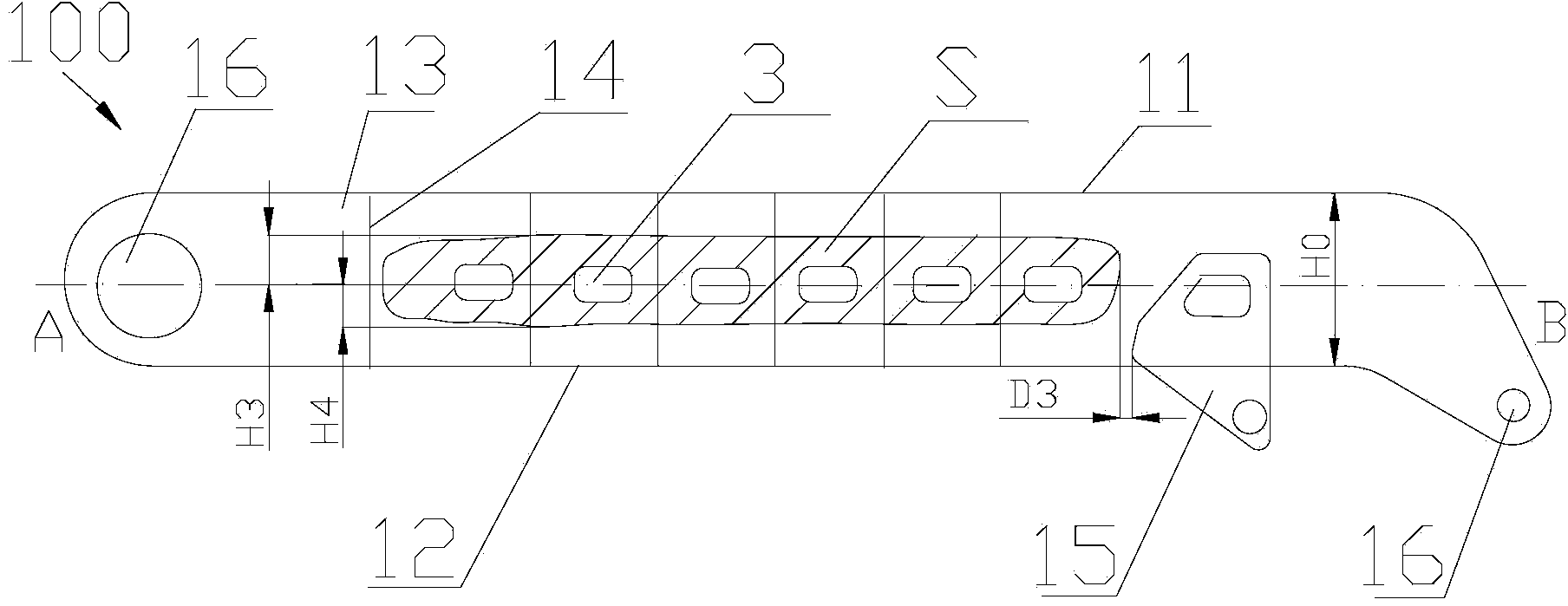

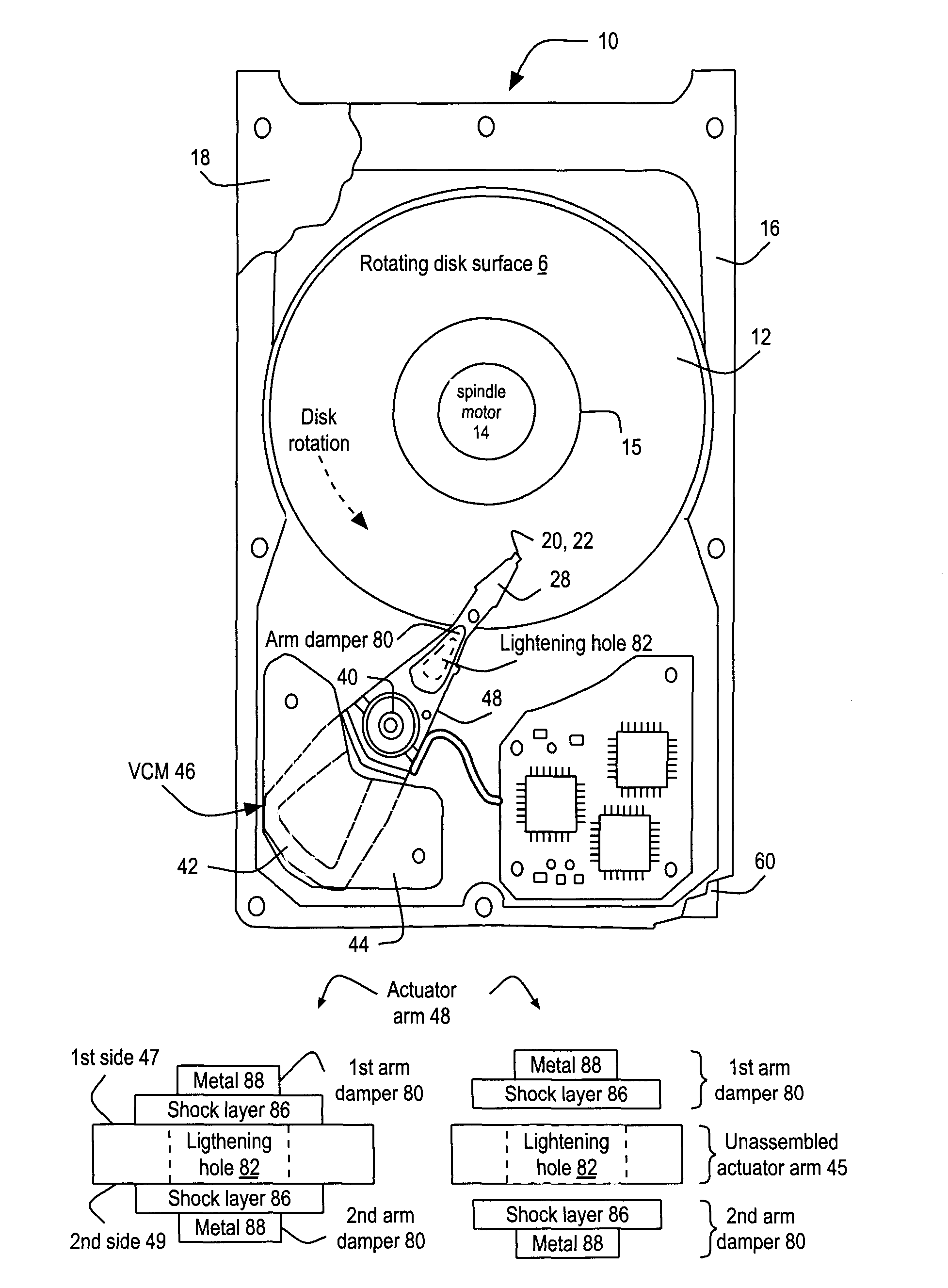

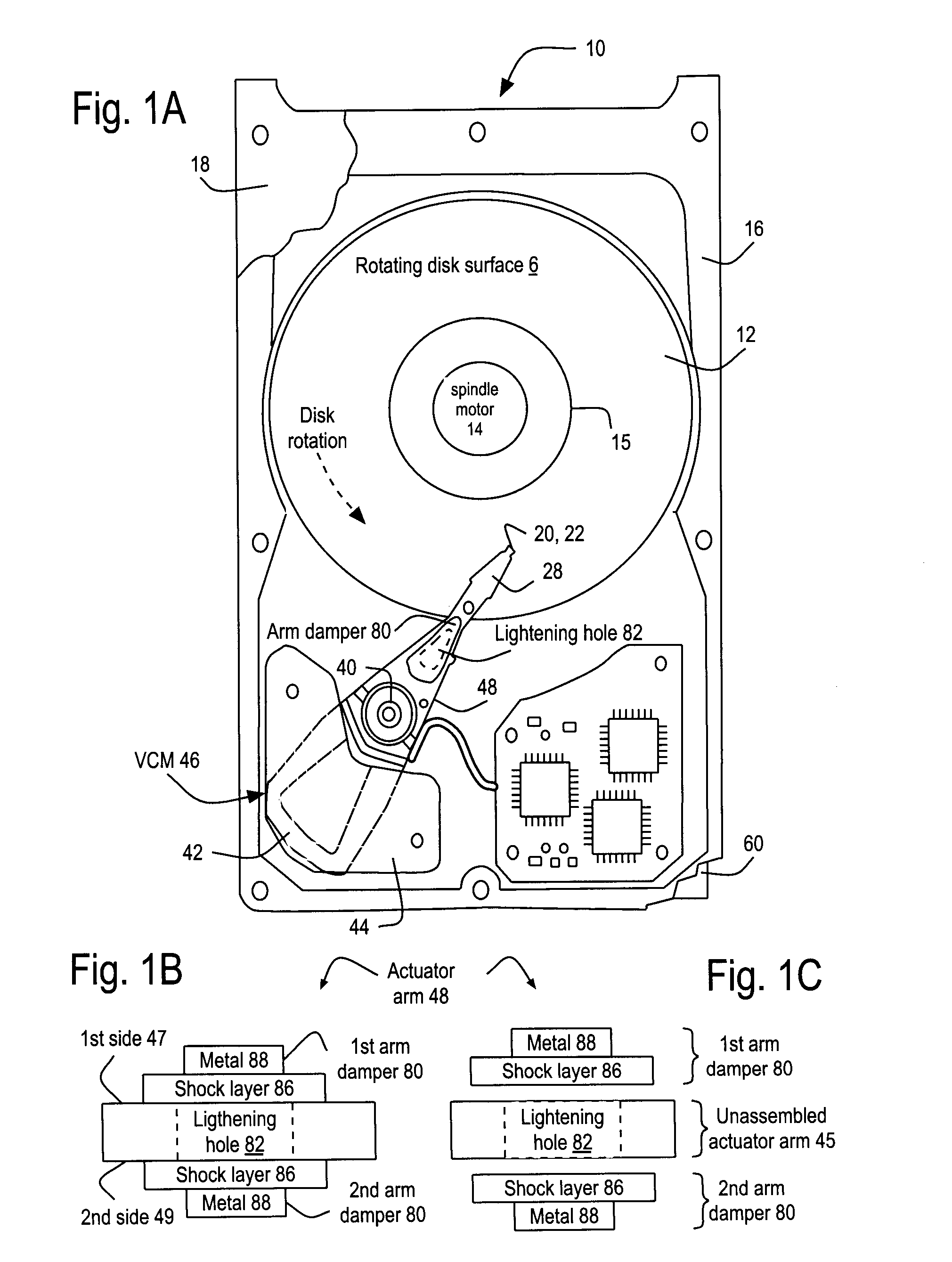

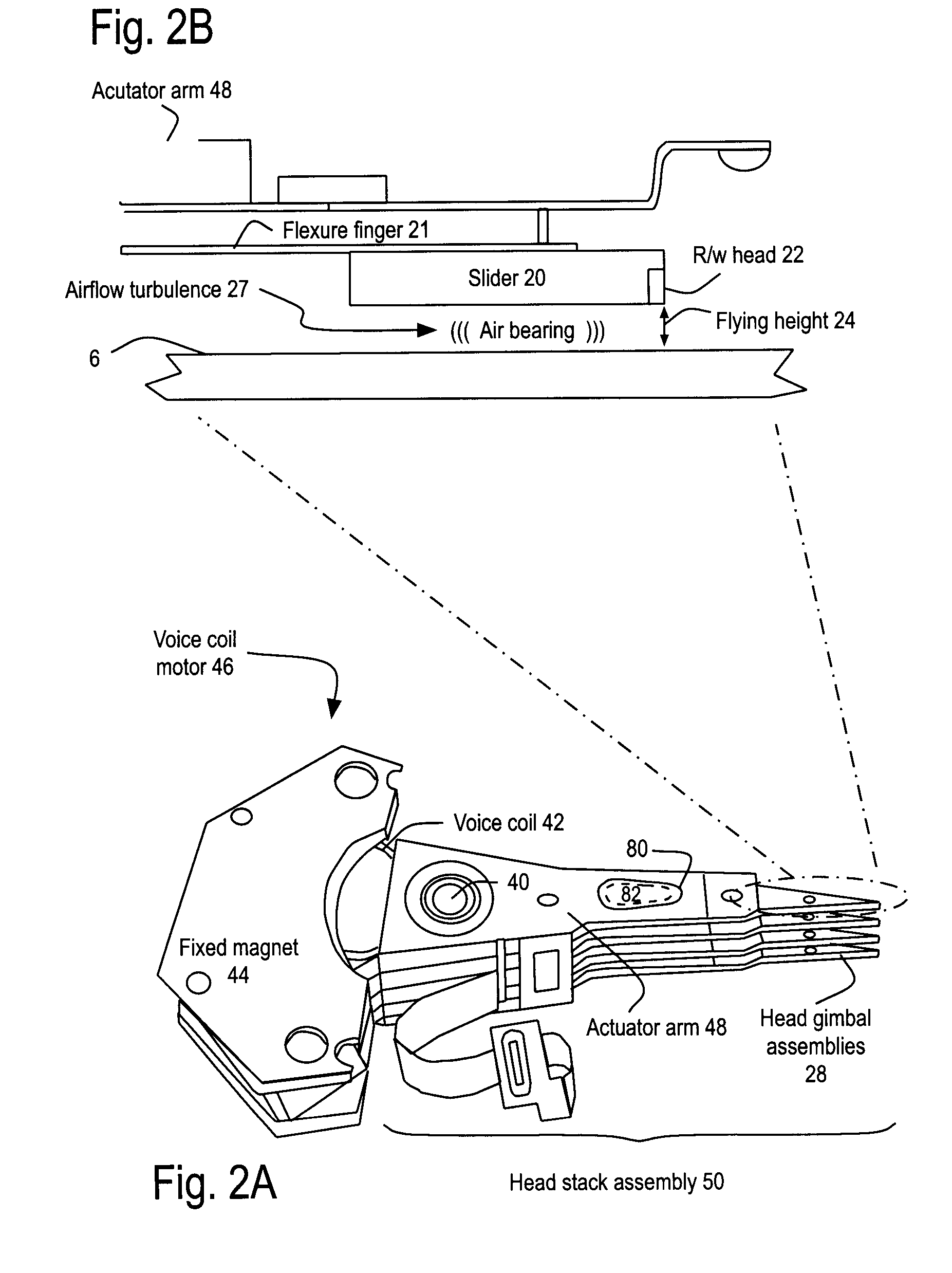

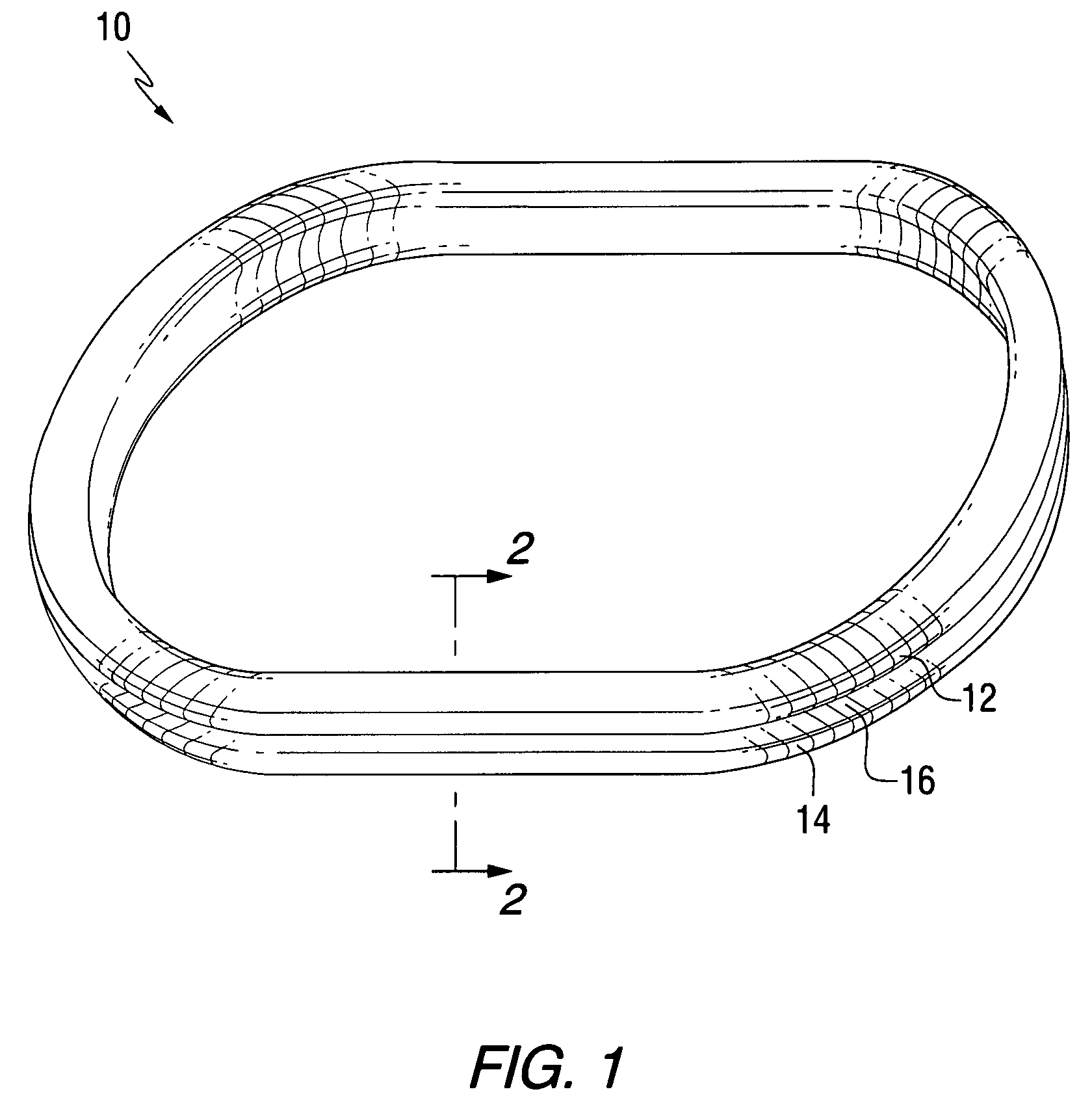

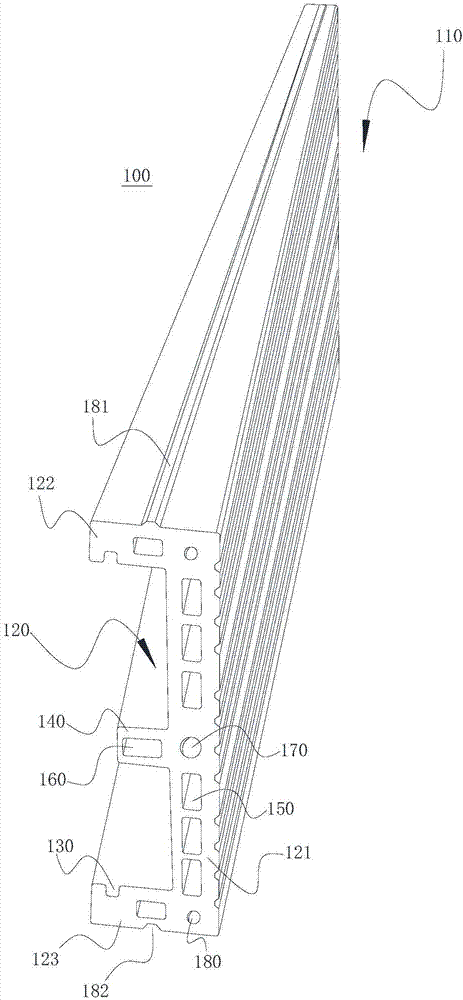

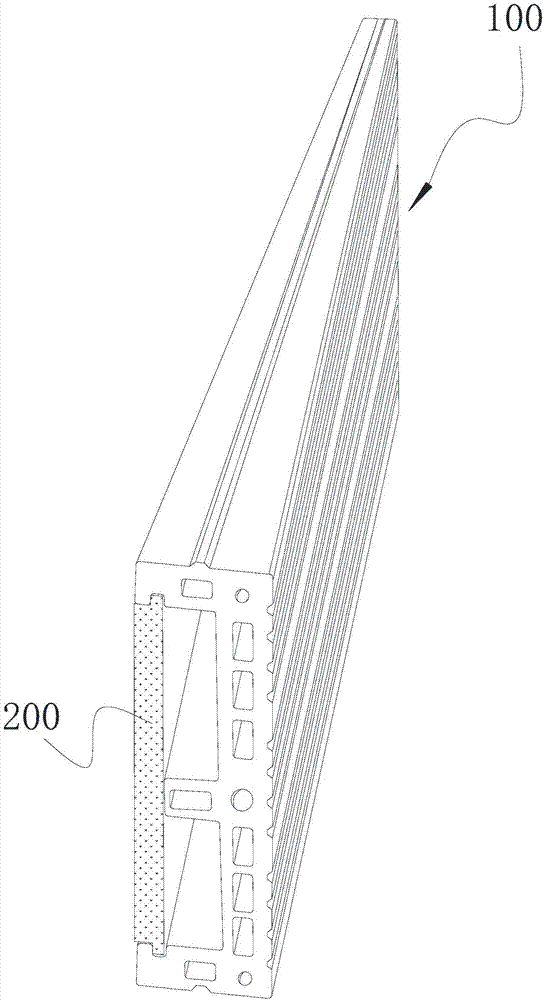

Method and apparatus for at least one actuator arm damper covering at least one lightening hole in a hard disk drive to reduce track mis-registration (TMR)

InactiveUS20110211280A1Reduce the total massReduce turbulenceRecord information storageStructure of arm assemblyHard disc driveActuator

This application discloses a hard disk drive, a head stack assembly, an actuator arm, and an arm damper configured for coupling to an actuator arm to create the head stack assembly used in the hard disk drive. The actuator arm has two arm dampers covering a lightening hole on either side of the actuator arm and configured to reduce the effects of airflow turbulence and mechanical vibration in the hard disk drive. Also disclosed, methods of operating the hard disk drive and of manufacturing for the head stack assembly and the hard disk drive.

Owner:SEAGATE TECH INT

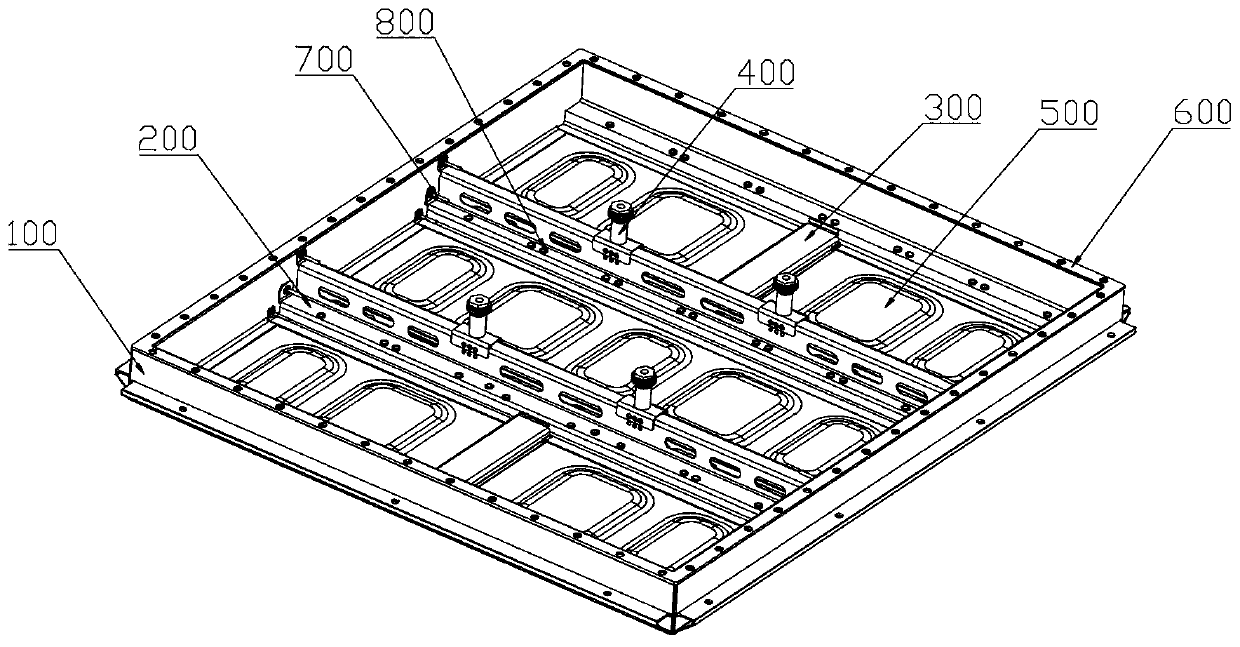

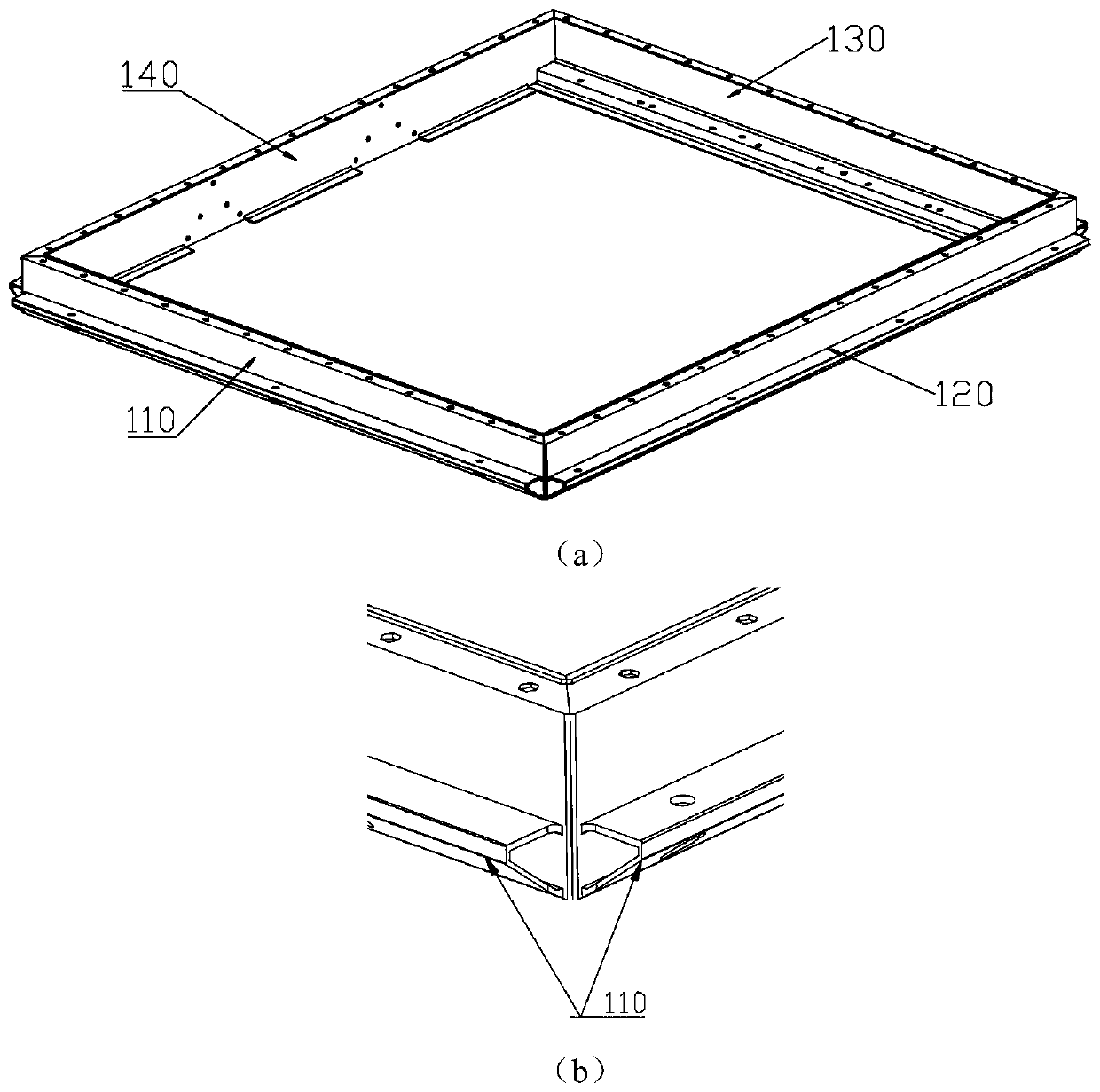

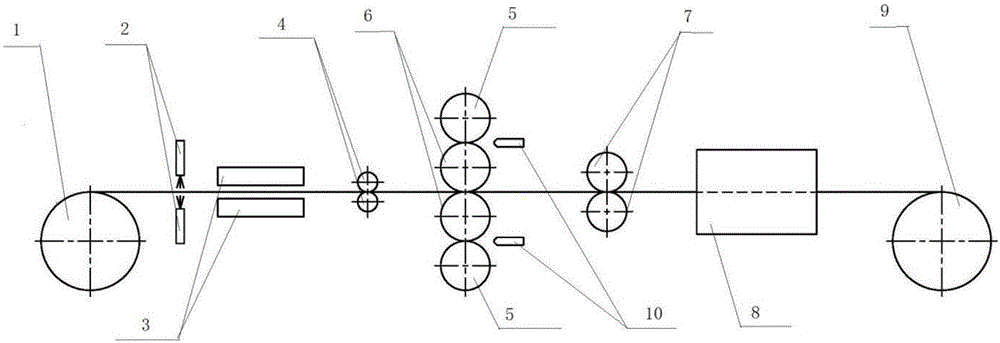

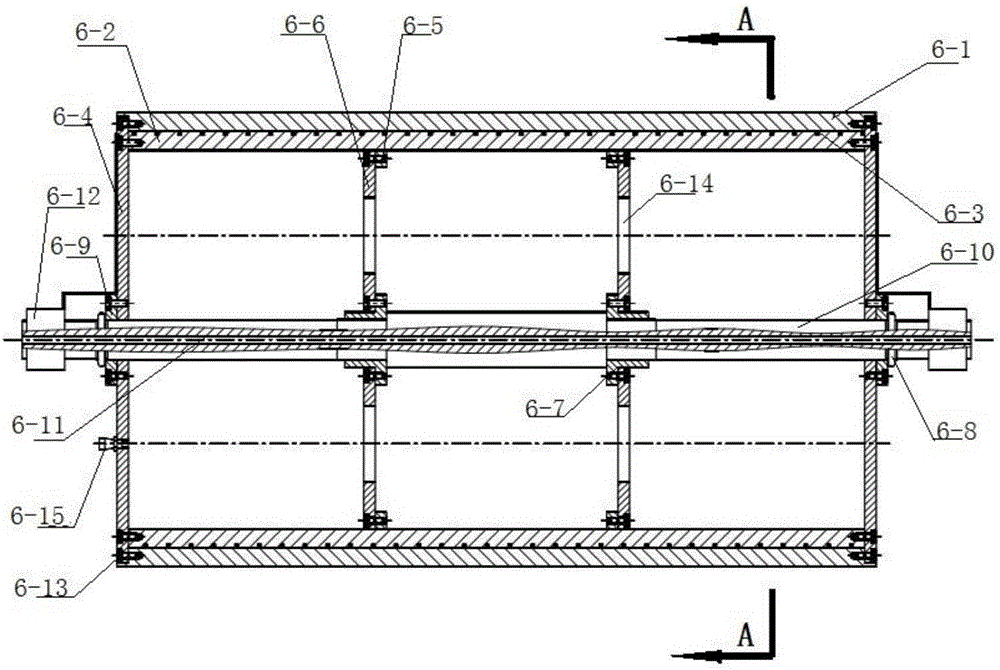

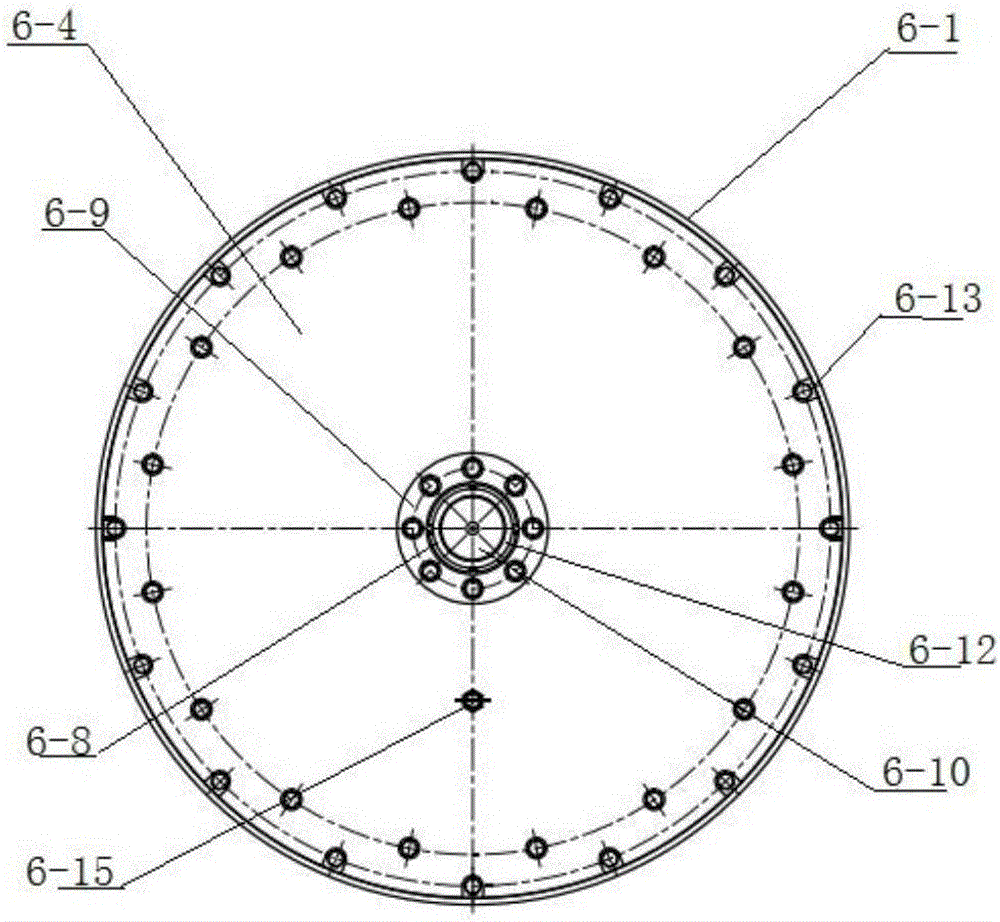

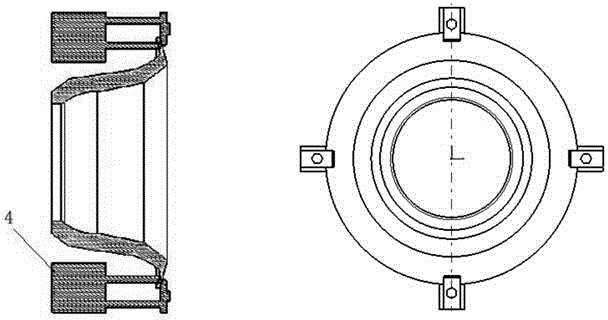

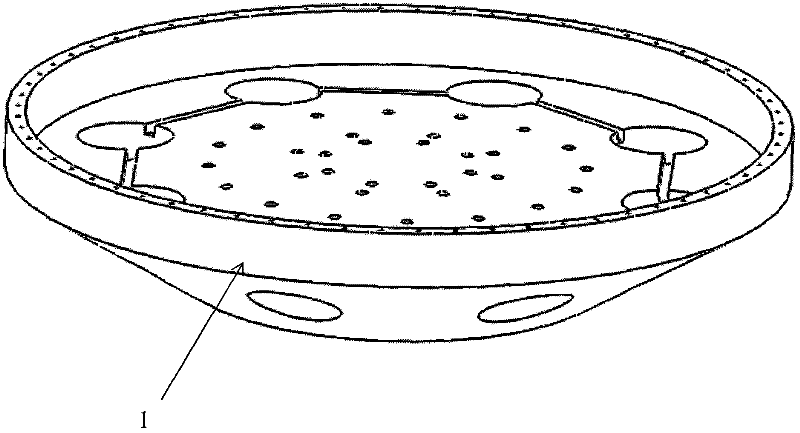

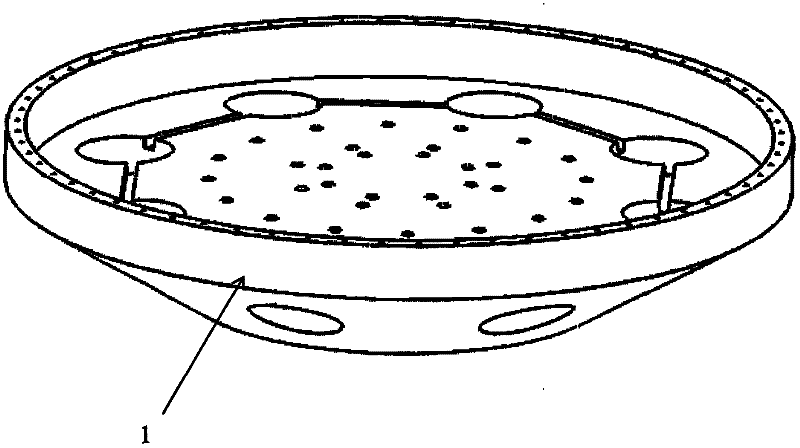

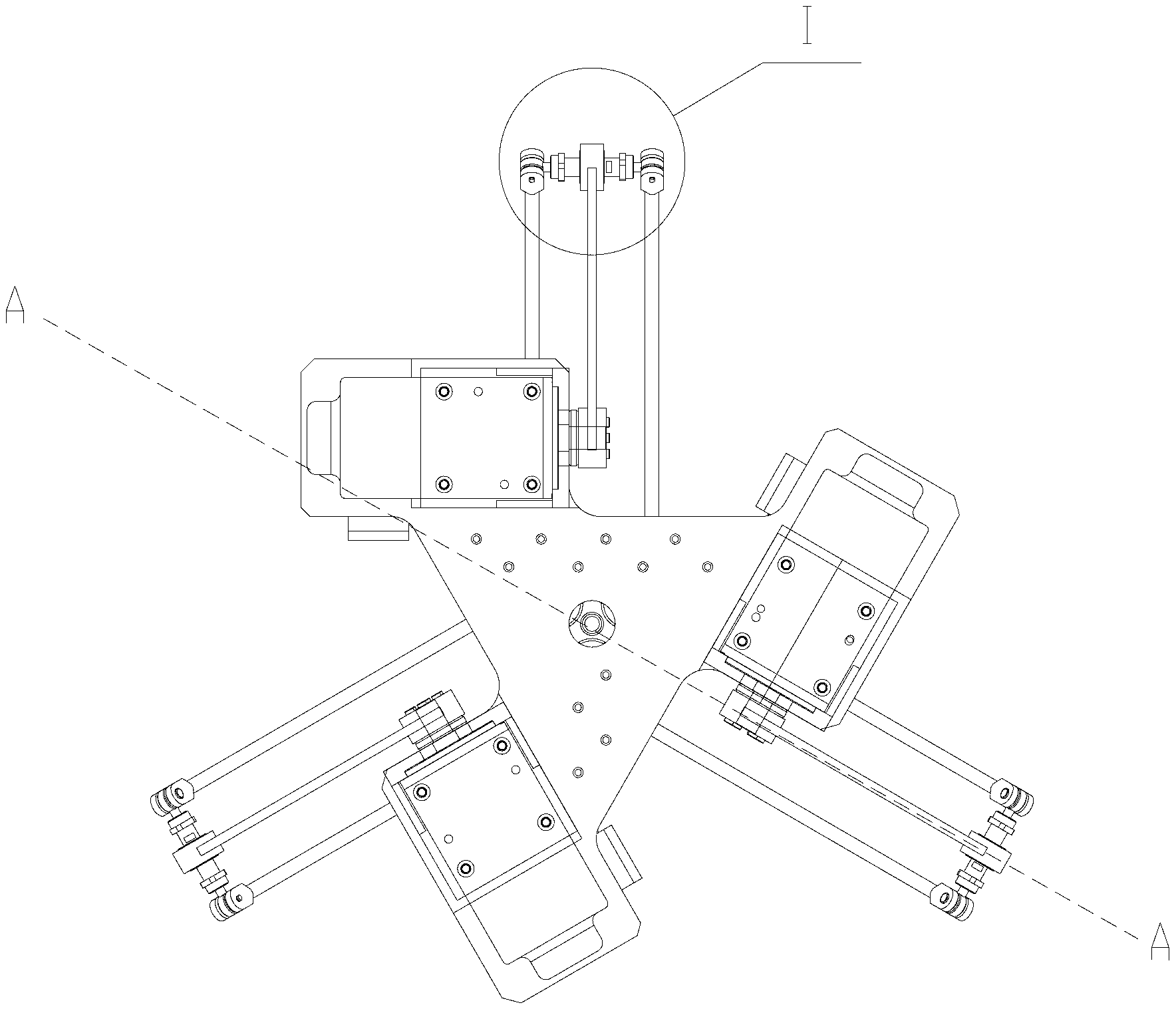

High-frequency anti-water-leakage satellite vibration test clamp for large interface expanding

ActiveCN102539095AOptimize the leak-proof methodLeak-proof way safeVibration testingLeaking waterResonance

A high-frequency anti-water-leakage satellite vibration test clamp (1) for large interface expanding is mainly used for expanding the interface size of phi 990mm of a vibration platform to be more than double so as to adapt to installation of a large interface of more than phi 2000mm of a satellite, and is capable of preventing the vibration platform from being damaged by water leakage of a satellite water tank. Furthermore, the high-frequency anti-water-leakage satellite vibration test clamp can meet the requirements of a satellite high-frequency vibration test when first-order resonance frequency of the clamp reaches more than 200Hz. Under the condition that the height and the quality are controlled, the clamp expands the original interface (2) of phi 990mm to be more than double and enables the interface to be an interface (3) of phi 2100mm in a mode that the number of lightening holes of an entity is increased or decreased, high rigidity and frequency are ensured, and the defects that the height cannot be reduced due to a rib plate type clamp without a large expanded interface and accordingly the frequency and the rigidity are remarkably reduced are overcome. A top inclined plane (4) of the clamp inclines from the center to an edge lightening hole and is combined with an edge slant lightening hole (5), a central blind hole type lightening hole (6) and a flow guide groove (7) to enable water leaked from the satellite water tank to flow along the top inclined plane and to be led out of a vibration platform range through the gradient of the edge lightening hole, thereby protecting and preventing vibration platform from being damaged by leaked water and removing complicated work of waterproof cover paving on the clamp due to the fact that an original clamp aims at protecting the vibration platform. The high-frequency anti-water-leakage satellite vibration test clamp for the large interface expanding has the advantages of being low in manufacture cost, excellent in performance, convenient and visual in use, strong in adaptability and generality and the like.

Owner:SHANGHAI INST OF SATELLITE EQUIP

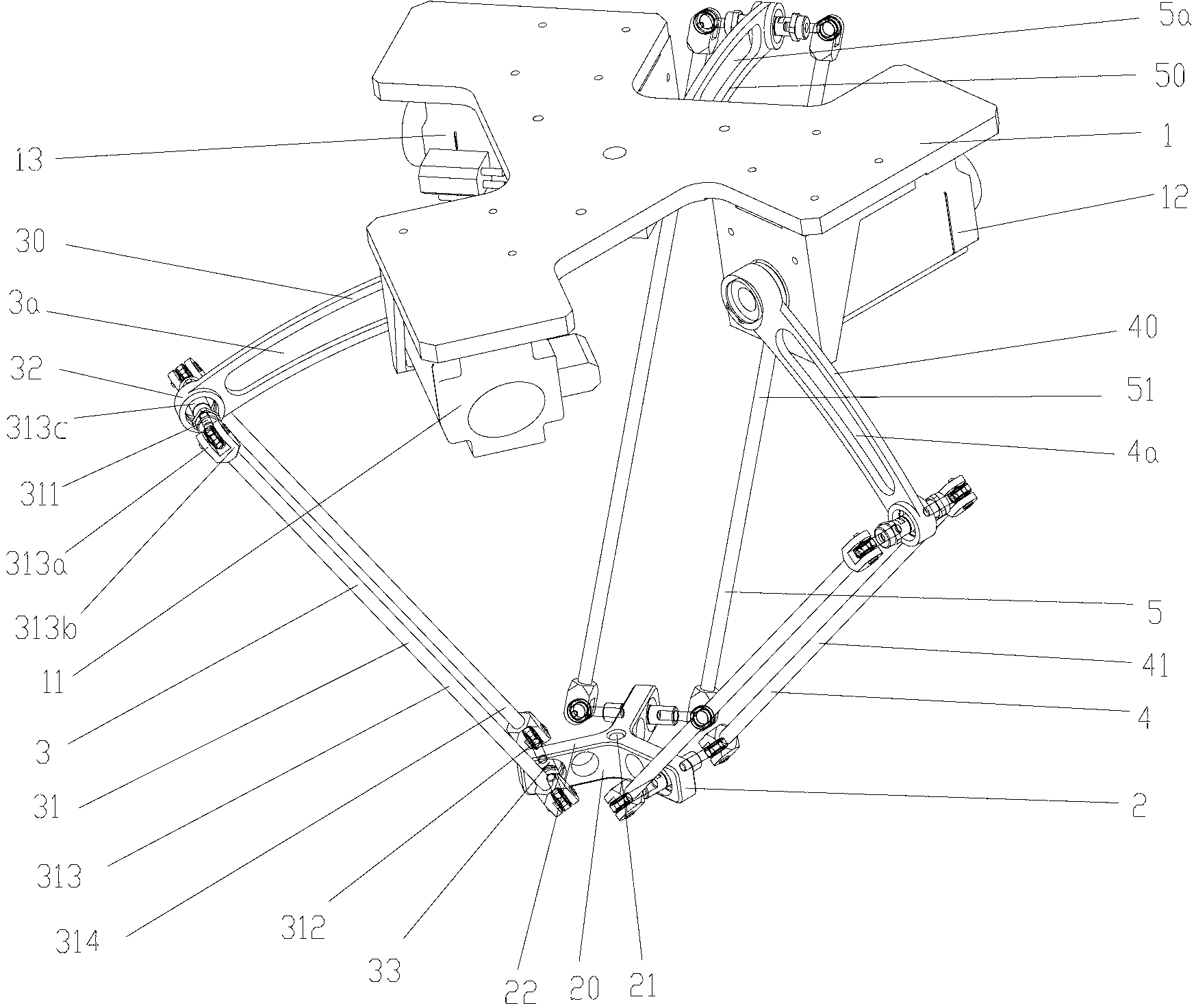

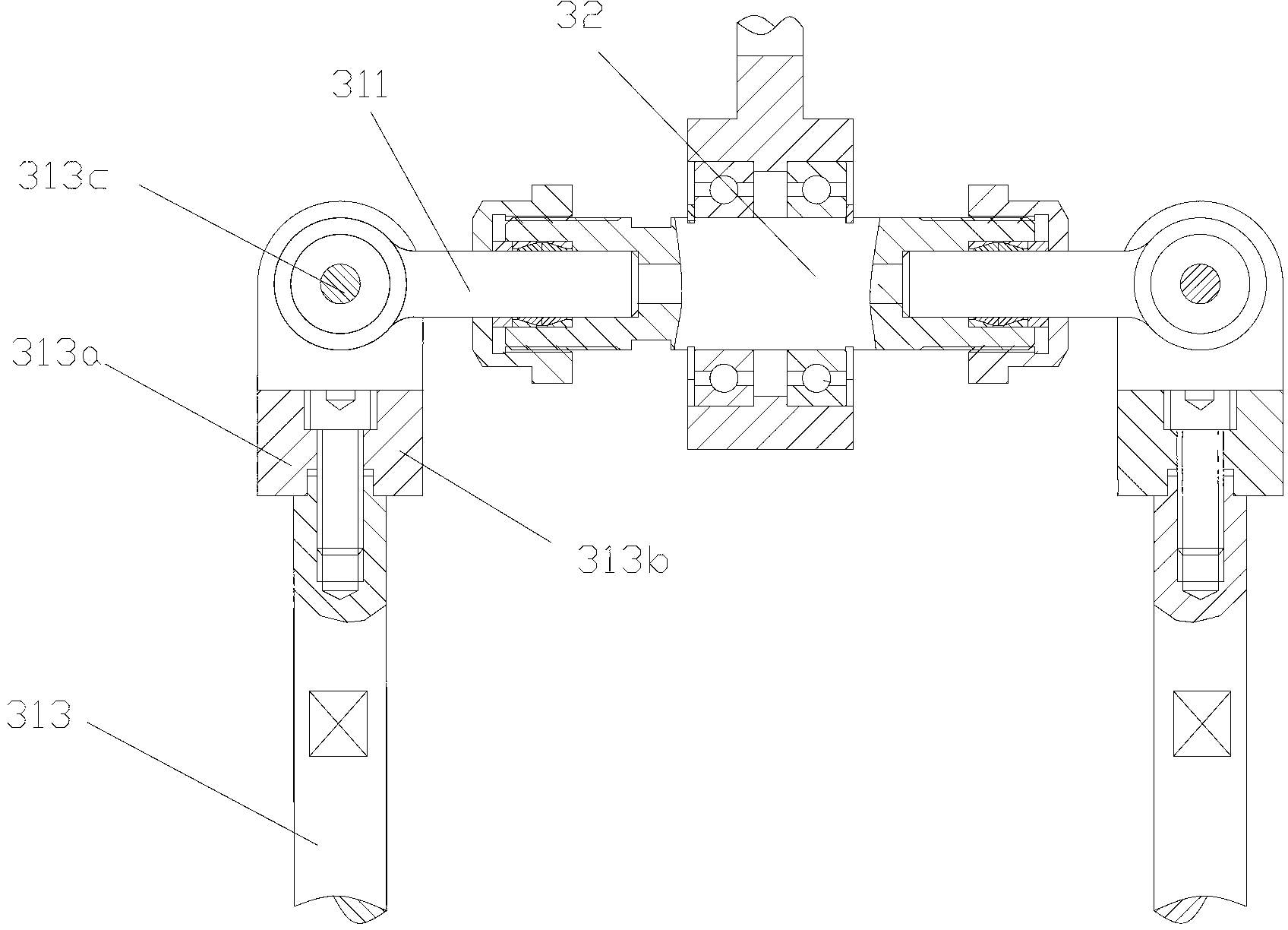

Parallel robot

InactiveCN103231362AReduce weightIncrease stiffnessProgramme-controlled manipulatorEngineeringIndustrial robot

The invention discloses a parallel robot and belongs to the field of industrial robots. The parallel robot comprises a static platform, a dynamic platform and three branched chains installed between the static platform and the dynamic platform. The three branched chains are formed by a first branched chain, a second branched chain and a third branched chain, wherein the first branched chain, the second branched chain and the third branched chain are of the same structure. The first branched chain, the second branched chain and the third branched chain are provided with a first driving rod, a second driving rod and a third driving rod respectively, every two of the first branched chain, the second branched chain and the third branched chain form the same angle, the first branched chain, the second branched chain and the third branched chain are distributed on a plane in an equant mode, and the first driving rod, the second driving rod and the third driving rod are respectively provided with a first lightening hole, a second lightening hole and a third lightening hole. The parallel robot achieves two-dimensional movement of a tail end dynamic platform of the three branched chains through spatial arrangement, effectively improves mechanism overall stiffness, simultaneously is provided with the lightening holes, and effectively reduces weight of the branched chains.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

Clamp member for a marine propulsion device

A clamp member is provided with numerous lightening holes which comprise cavities and depressions formed on an inner surface of the clamp member. Bolt holes are provided through upper and lower surfaces of the clamp member and extend through the cavities. A reduced volume of the clamp member allows it to be manufactured from materials that are generally heavier than aluminum, but less susceptible to galvanic corrosion.

Owner:BRUNSWICK CORPORATION

Lightweight reinforced tractor-trailer slider

ActiveUS20050205324A1Improve structural rigidityEasy to manufactureUnderstructuresConvertible cyclesAir springControl arm

A tractor-trailer slider includes spaced apart longitudinal side rails having control arm supports extending downwardly from the side rails for supporting the slider. Portions of the longitudinal side rails and the control arms supports are integrated using one or more common plates. Lightening holes and edge of the slider are flanged to reinforce the walls. Coining and ribbing are also used for additional reinforcement. Lateral cross-members extend between the longitudinal side rails. The lateral cross-members have tabs on opposing ends that are received in an interlocking relationship with complimentary elongated slots in the longitudinal side rails. Air spring supports arranged at forward and rearward portions of the slider are secured to the longitudinal side rails, the control arm supports, and the lateral cross-members to provide a structurally rigid frame. The air spring supports provide spaced apart air spring mounting pads.

Owner:ARVINMERITOR TECH

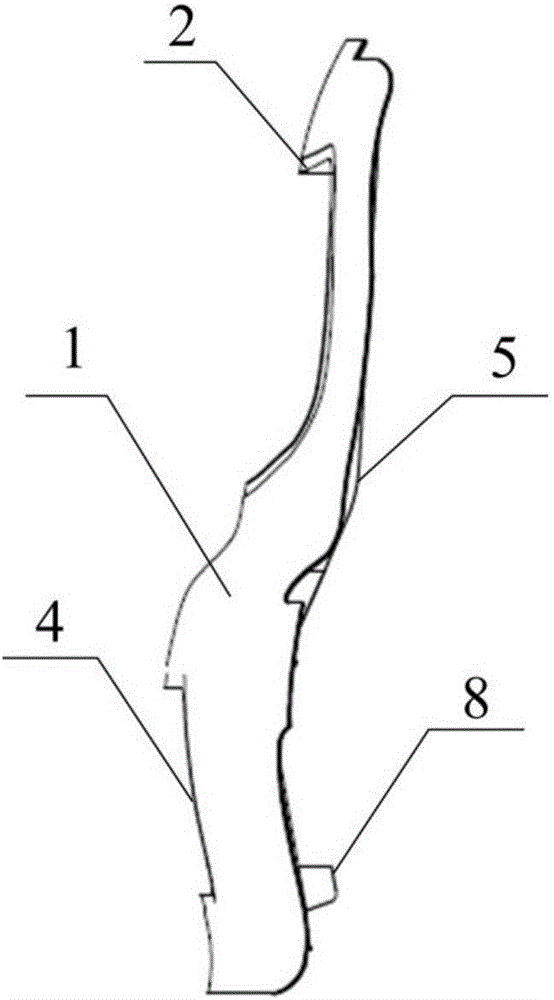

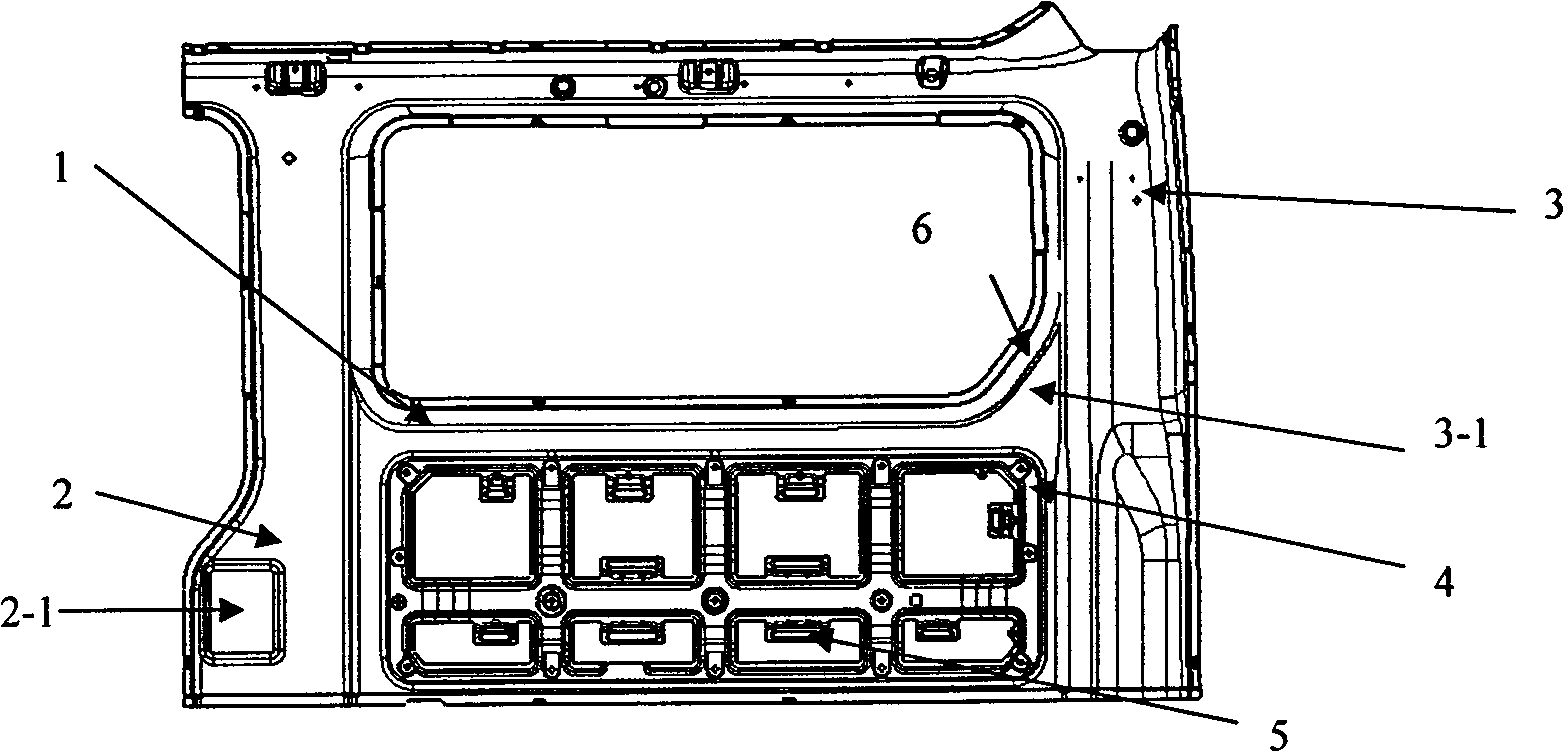

Vehicle side-wall inner-plate

InactiveCN101357649AStable supportSolve the deformationSuperstructure subunitsEngineeringOblique angle

The invention discloses an automobile side wall internal plate. A plate body thereof is a rectangular stamping component and the front end of the plate body is a C post while the rear end thereof is a D post. The middle upper part of the plate body is provided with a rear side window frame and the middle lower part of the plate body is provided with lightening holes. A plurality of lightening holes are distributed in the middle lower part of the plate body and a support leg slantwise extending to the outside is left on the edge of the lightening hole. After the installation, the support leg supports between a right side wall internal plate and a right side wall external plate. The support leg is provided with a glue storage groove of which two ends take the shape of a closed arc, and the support leg is also provided with a strengthening rib. The position which is close to the middle position of the D post and at the underside of the rear side window frame is an inward oblique angle so as to cause the D post to take the shape of a trumpet. The automobile side wall internal plate of the invention has simple structure and comparatively high strength and can overcome the defects of insufficient strength and support, easy deformation of the external plate and the influence on the service life of an automobile body.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

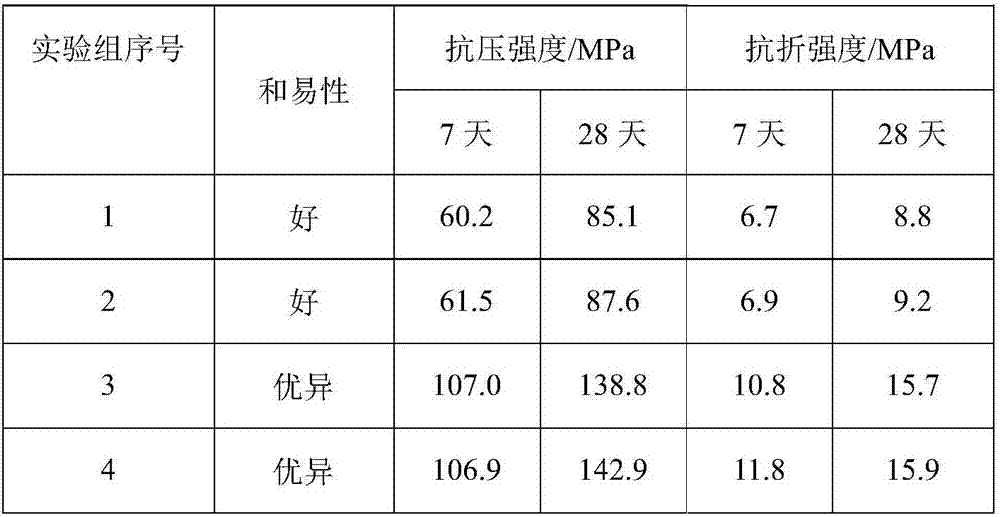

Acoustic shielding backing plate and concrete thereof

PendingCN107445553AImprove securityImprove support stabilityNoise reduction constructionFiberEngineering

The invention relates to the technical field of construction materials, and provides an acoustic shielding backing plate and concrete thereof. The concrete is prepared from the following raw materials: a gelling material, aggregate, admixture, fibers and an additive, and has excellent durable mechanical performance. The acoustic shielding backing plate comprises a backing plate body, wherein an acoustic shielding slot is formed in the backing plate body along the length direction of the backing plate body, and first lightening holes are respectively formed in the bottom wall, first side wall and second side wall of the acoustic shielding slot along the length direction of the backing plate body; a male groove and a female groove are respectively formed in the side, far from the acoustic shielding slot, of the first side wall and the second side wall along the length direction of the backing plate body, and are matched in shapes; reinforcing holes are formed in the first side wall, the second side wall and a stiffener; and the impact resistance and bending strength of the backing plate can be remarkably reinforced by implanting reinforcing ribs, injecting a grouting material and plugging a grouting socket with concrete, and the durability and the stability can be greatly improved, and the absolute safety of the backing plate can be guaranteed. The acoustic shielding backing plate has an excellent supporting effect and an acoustic shielding effect.

Owner:SICHUAN SHUANGTIE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com