Shaft-end overhung piezoelectric cantilever beam electric generator

A cantilever beam, generator technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problem of reducing the axial vibration displacement of the piezoelectric vibrator and adapting the speed Low capacity, low power generation efficiency, etc., to achieve the effect of effective speed bandwidth, small influence of axial bending deformation, and strong power generation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

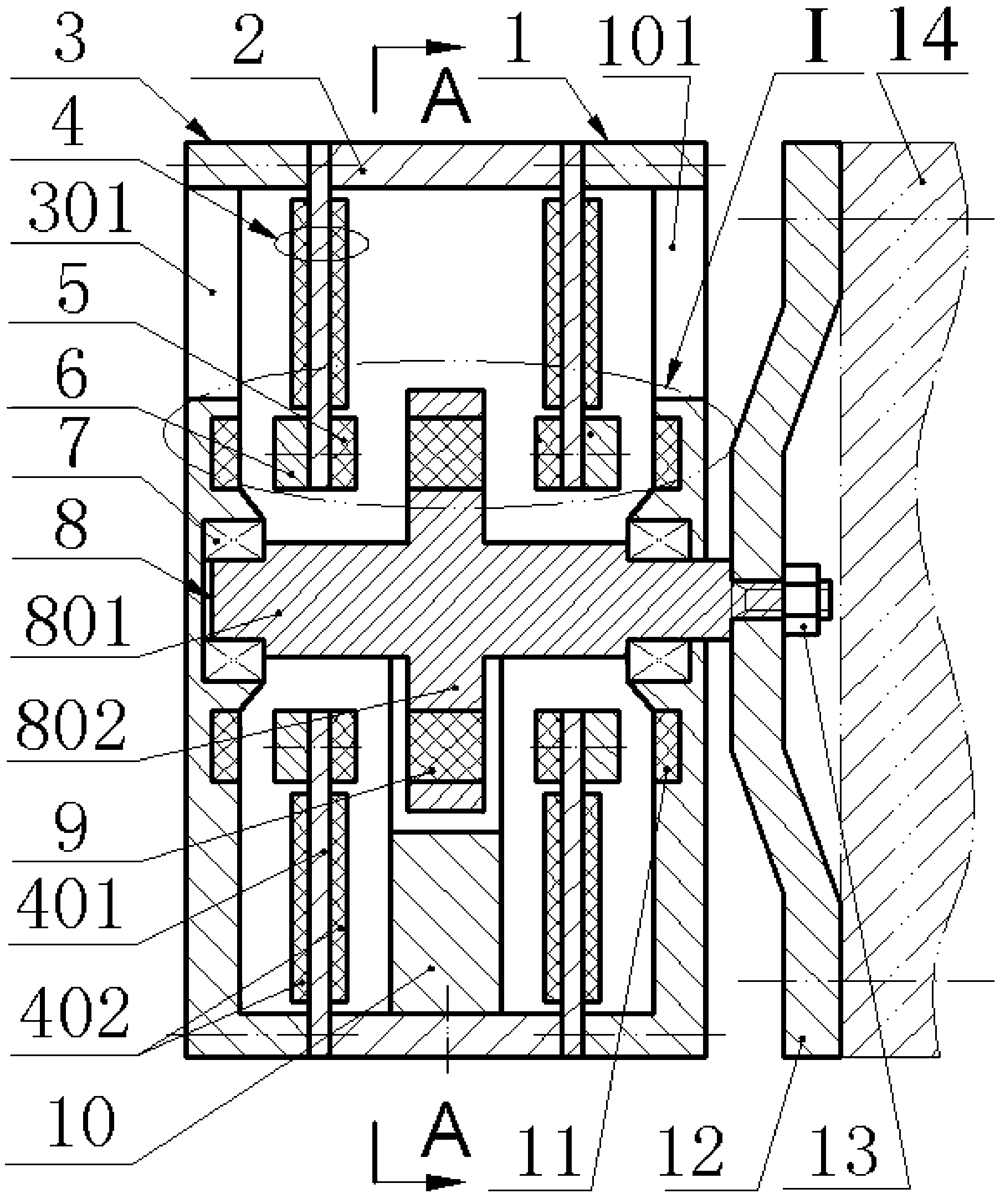

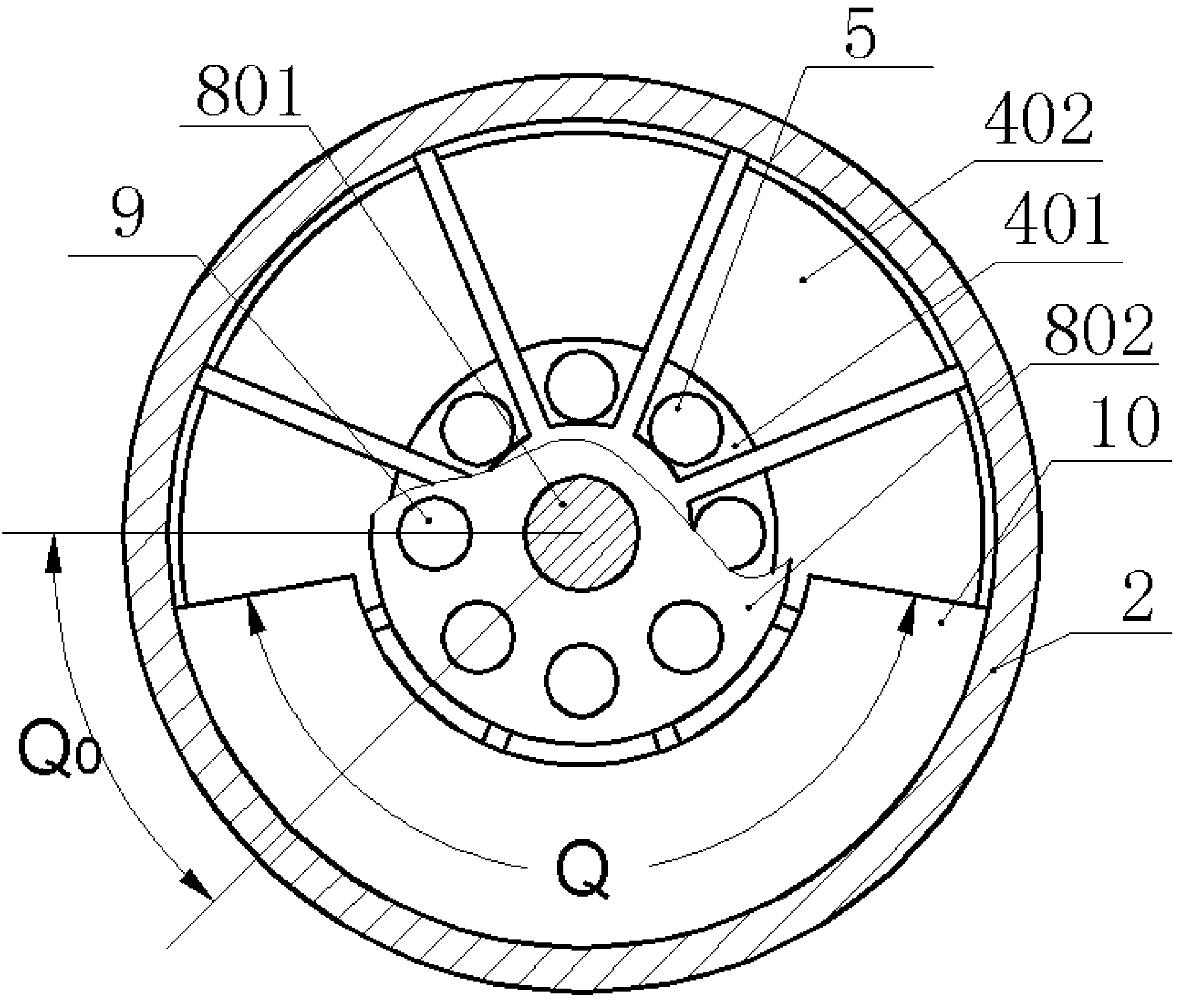

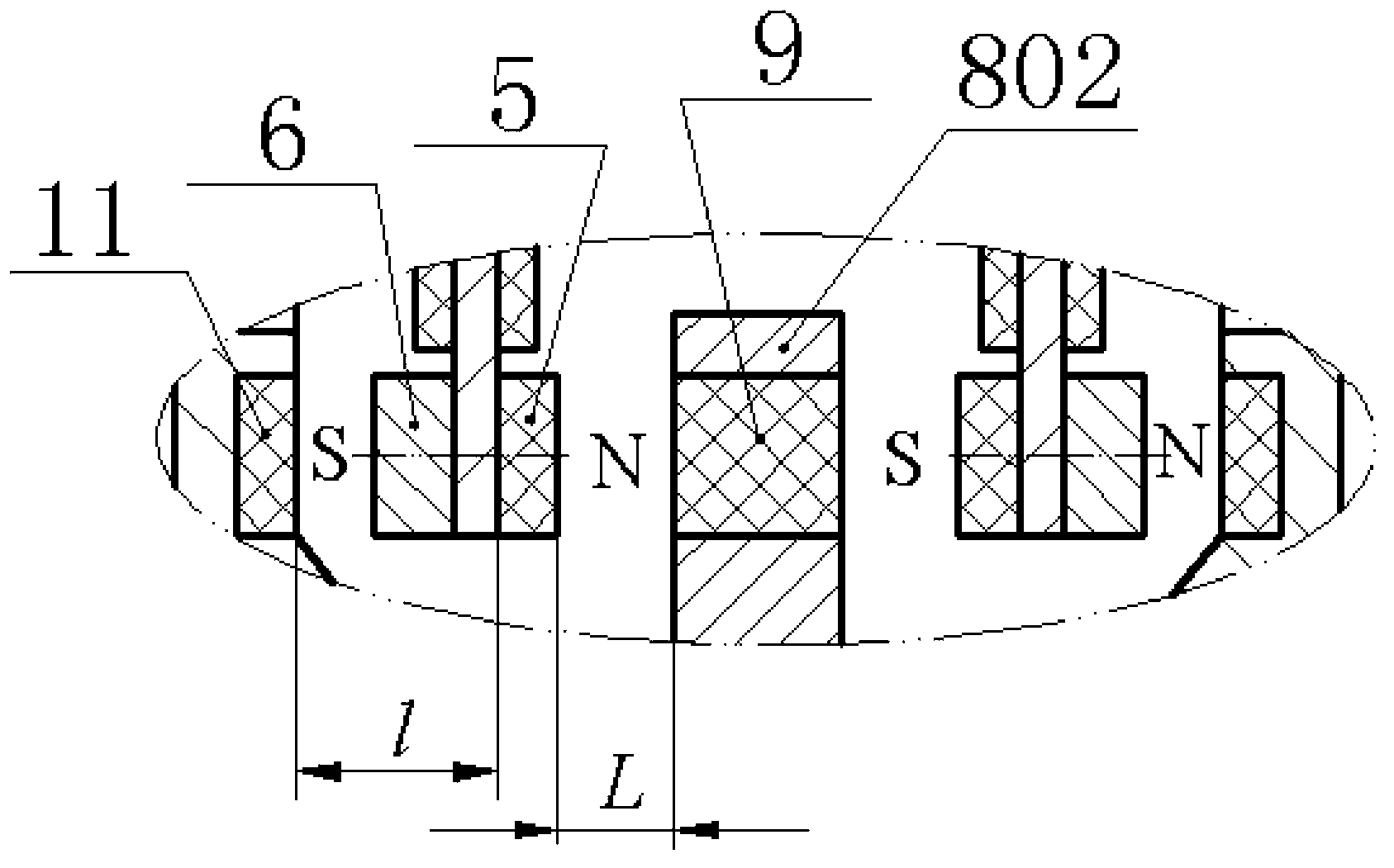

[0016] The left end cover 3 and the right end cover 1 are respectively installed on the two ends of the housing 2 by screws, and the inner lower side of the housing 2 is equipped with a semi-circular counterweight 10 by screws; the upper part of the left end cover 3 and the right end cover 1 A lightening hole 301 and a lightening hole two 101 are respectively provided, and the inside of the bottom wall of the left end cover 3 and the right end cover 1 are inlaid with a circular magnet 11 and a bearing 7; the left end cover 3 and the right end cover 1 are inlaid with Metal substrates 401 are crimped between the housings 2, and the metal substrates 401 and the piezoelectric wafers 402 bonded on their sides form sector-shaped piezoelectric vibrators 4, and the free ends of the piezoelectric vibrators 4 are mounted with round Shaped magnet 2 5 and frequency modulation mass block 6, the rotating shaft 801 of rotor 8 is installed on the left end cover 3 and the right end cover 1 by b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com