Patents

Literature

545results about How to "Reduce centrifugal force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

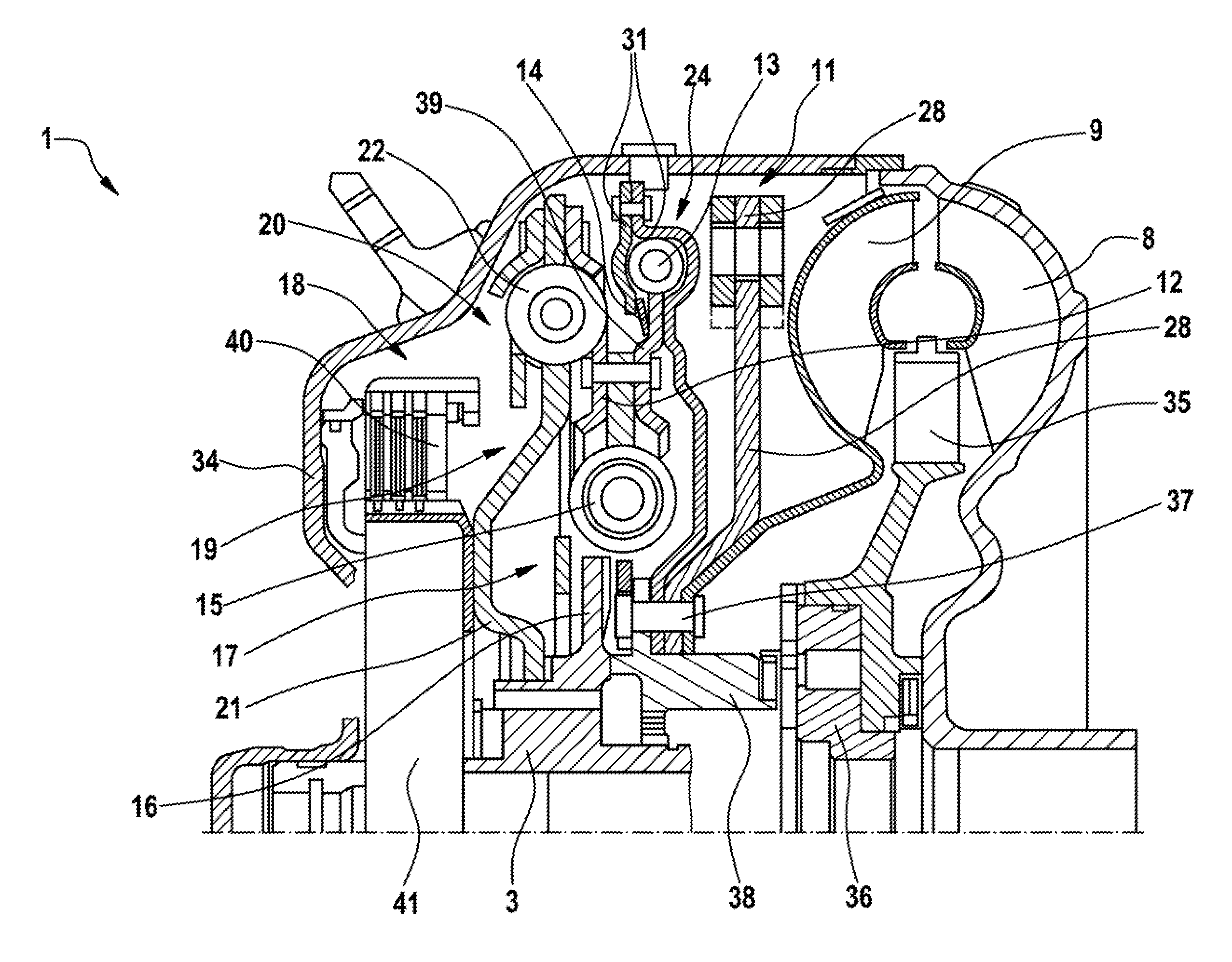

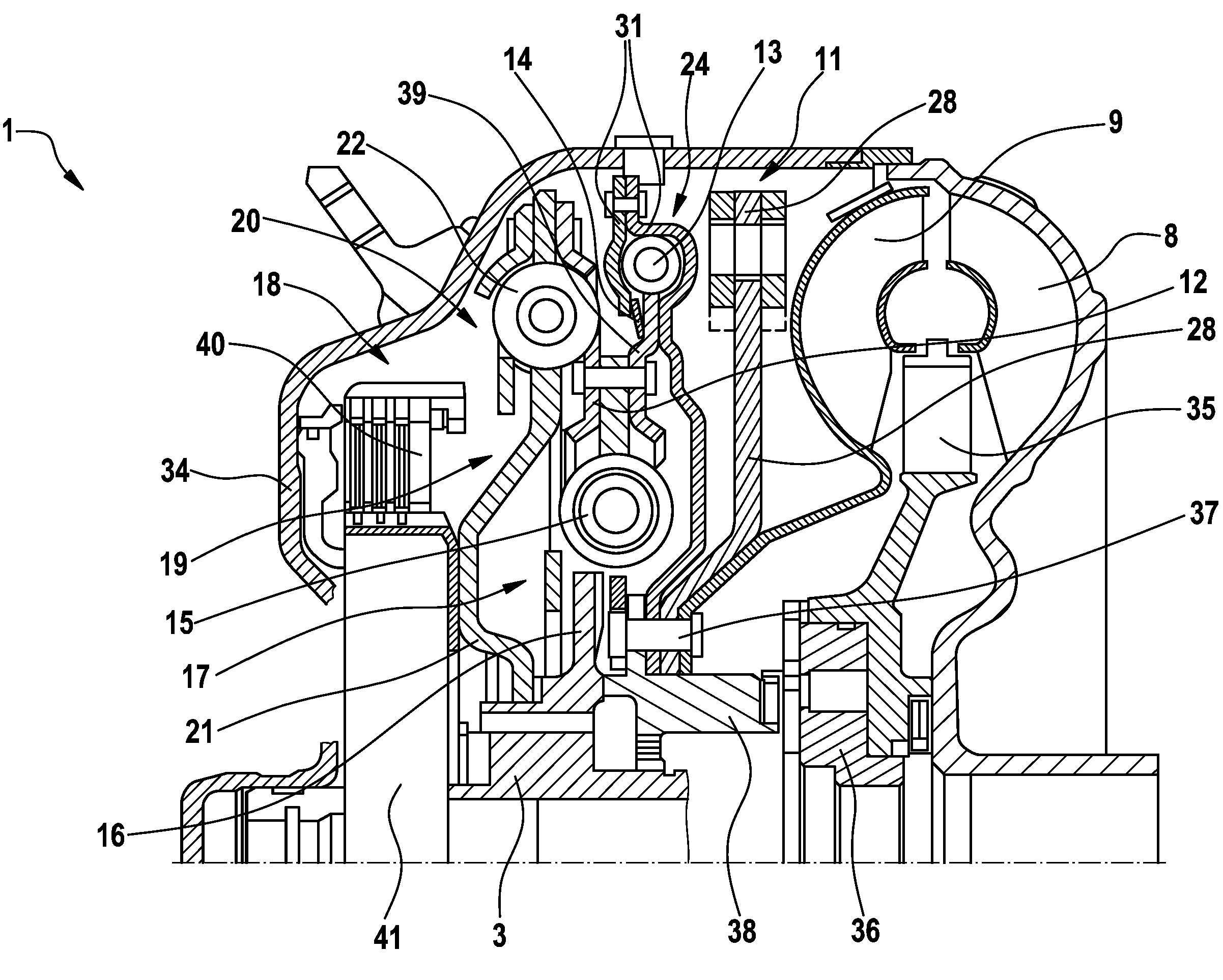

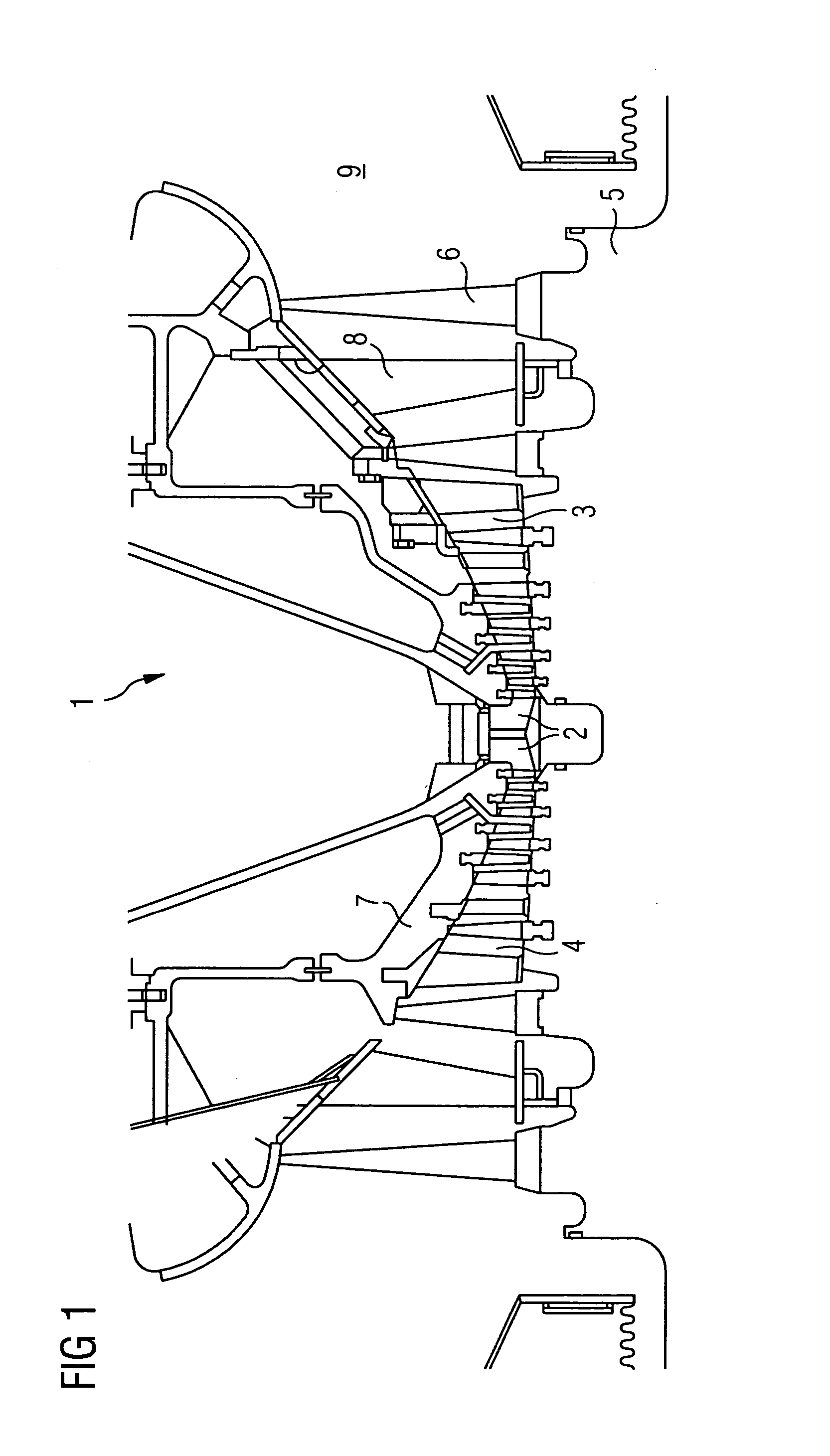

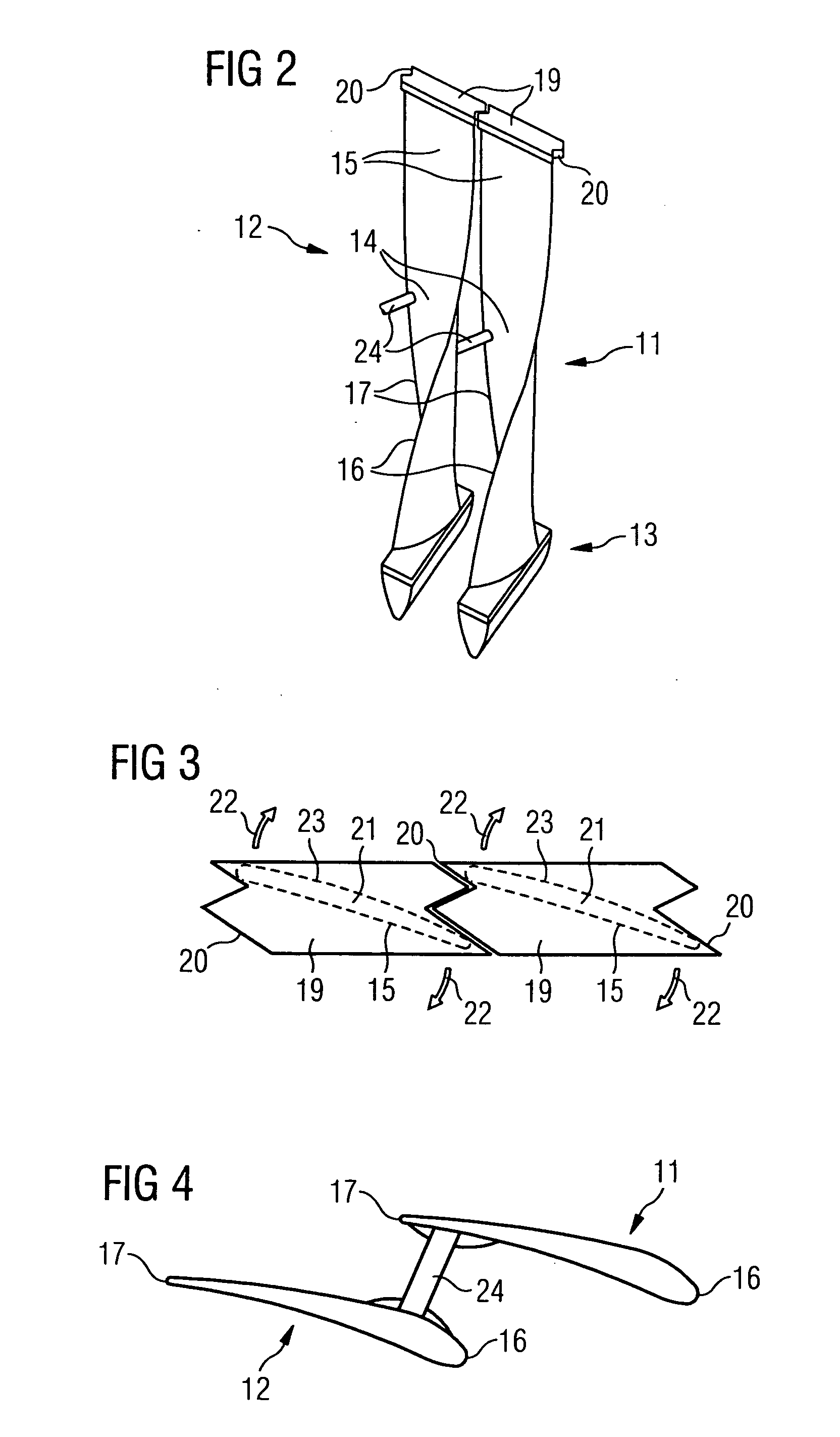

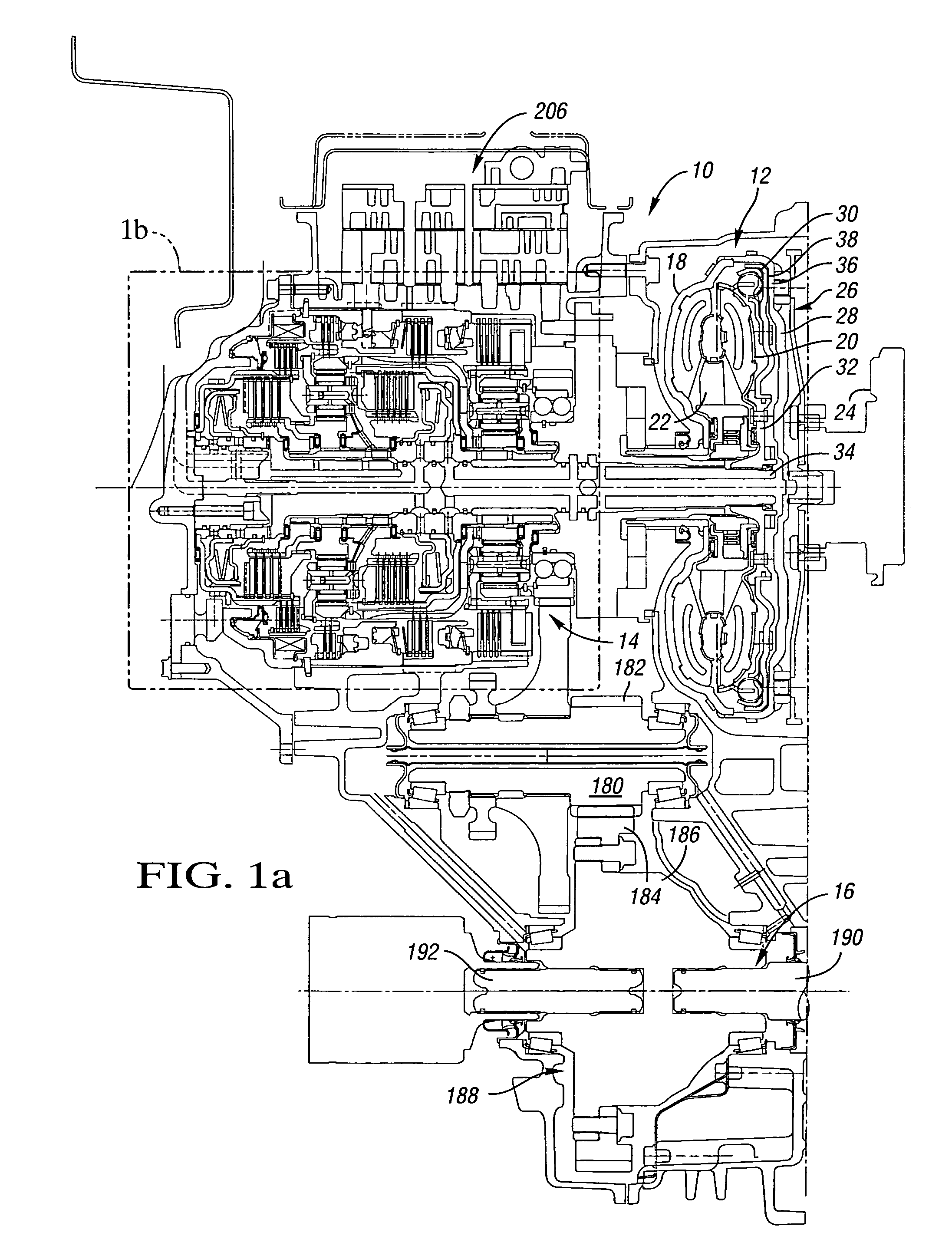

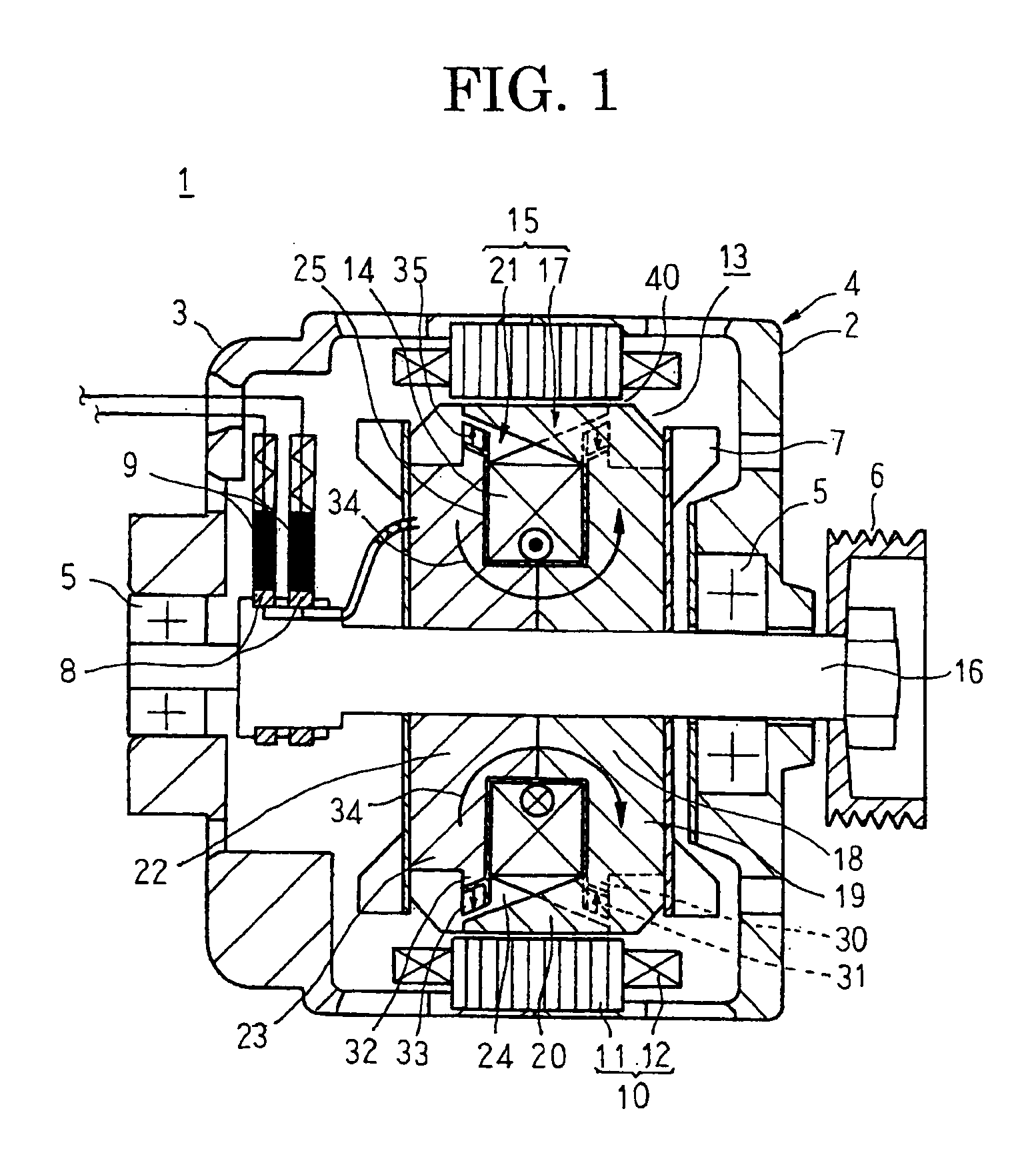

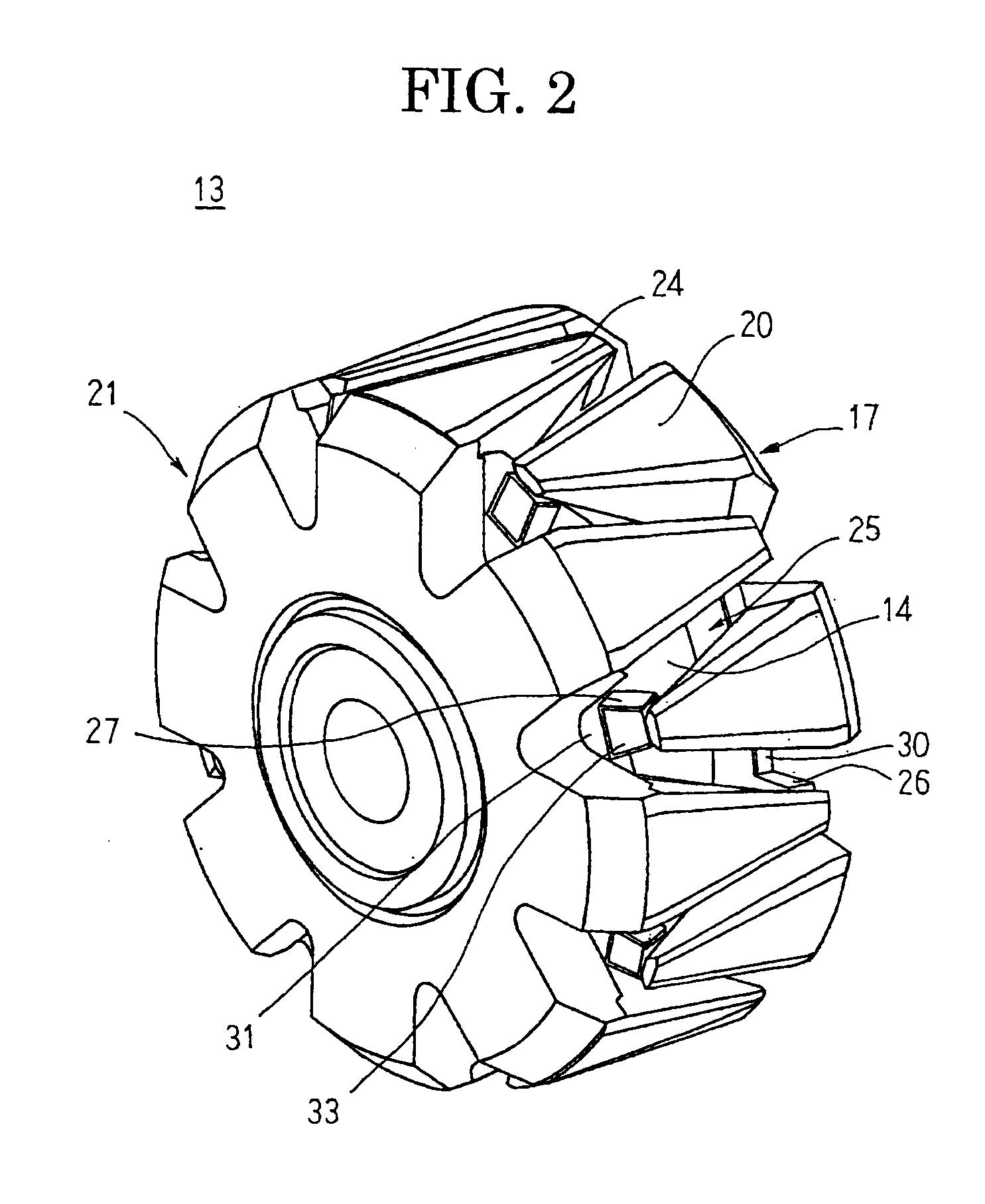

Hydrodynamic torque converter

ActiveUS20110192692A1Simplify designVibration angle be reduceYielding couplingRotary clutchesImpellerPower flow

A hydrodynamic torque converter (1), comprising a turbine wheel (9) driven by an impeller (8) and connected to an output part, and comprising a housing (34), in which a torsional vibration damper (19) having several damper stages (17, 20) and a centrifugal force pendulum (11), and also a converter lockup clutch (18) connecting a housing and an output part (3), are accommodated. In order to avoid any striking of the pendulum masses of the centrifugal force pendulum in internal combustion engines having large oscillating angles driving the torque converter, a turbine damper is connected in the power flow upstream of the centrifugal force pendulum.

Owner:SCHAEFFLER TECH AG & CO KG

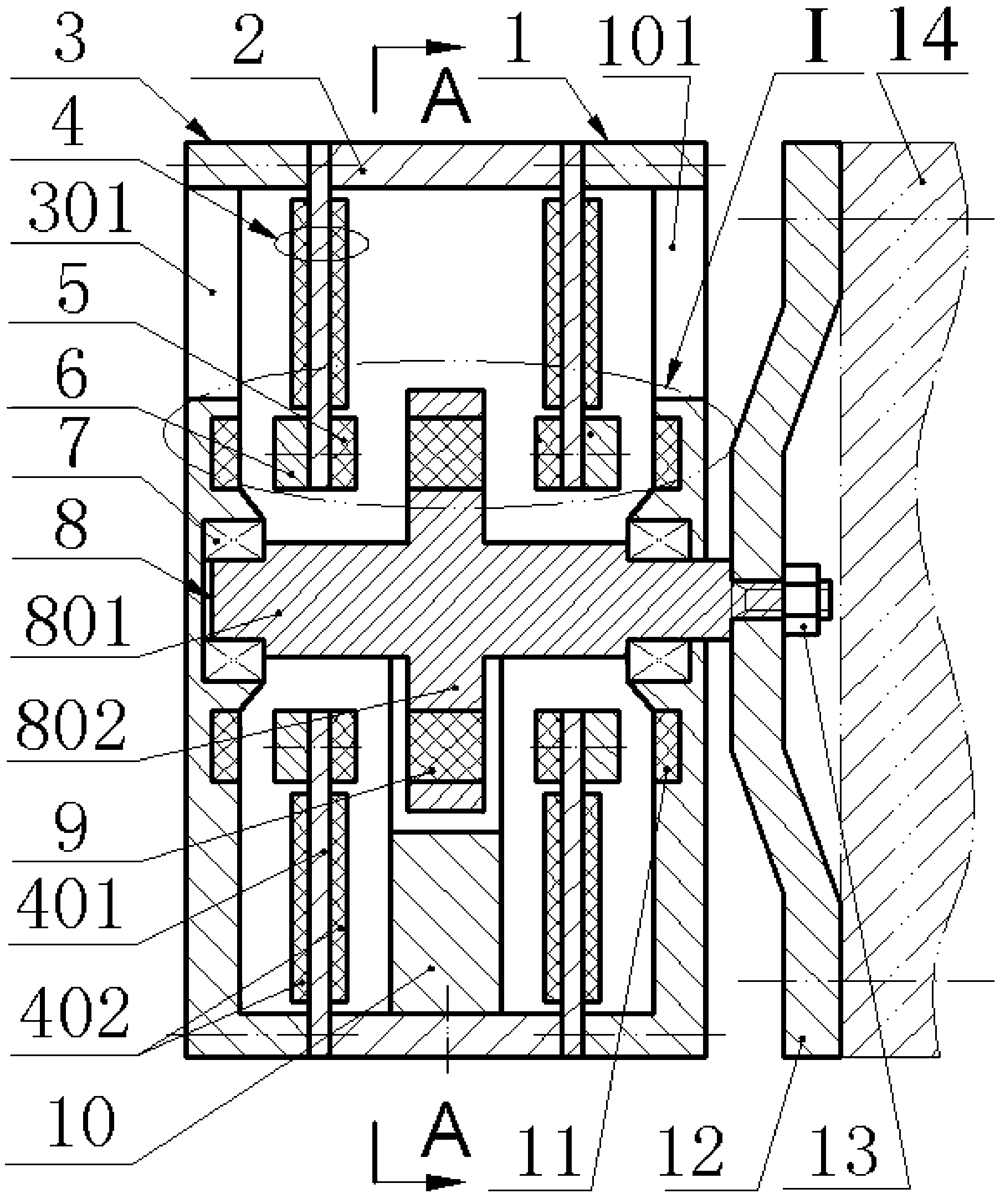

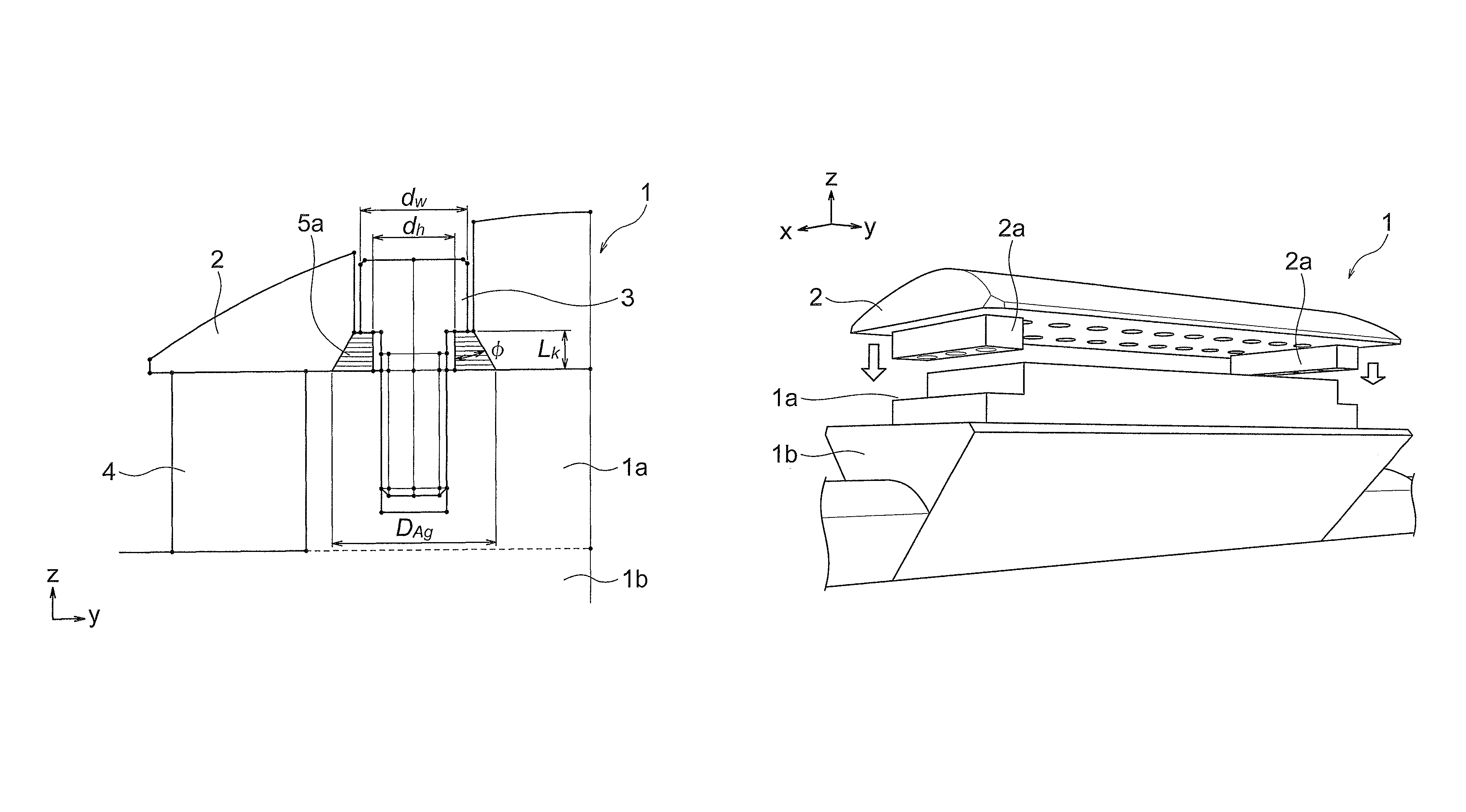

Shaft-end overhung piezoelectric cantilever beam electric generator

InactiveCN103259452AEffect of small axial bending deformationImprove reliabilityPiezoelectric/electrostriction/magnetostriction machinesNew energyEngineering

The invention relates to a shaft-end overhung piezoelectric cantilever beam electric generator, and belongs to the technical field of new energy resources and power generation. A left end cover and a right end cover are respectively installed at two ends of a shell body through screws. A semi-annular balancing weight is installed on the lower side of the interior of the shell body through a screw. The upper portion of the left end cover and the upper portion of the right end cover are respectively provided with a lightening hole. A magnet I and a bearing are embedded in the inner side of the bottom wall of the left end cover. A magnet I and a bearing are embedded in the inner side of bottom wall of the right end cover. A piezoelectric vibrator is arranged between the left end cover and the shell body in a compression joint mode. A piezoelectric vibrator is arranged between the right end cover and the shell body in a compression joint mode. A magnet II and a frequency-modulation mass block are installed at the free end of each piezoelectric vibrator. A rotating shaft of a rotor is installed on the left end cover and the right end cover through bearings. A connecting disc is installed at one end of the rotating shaft through a nut. A magnet III is embedded in a rotating disc of the rotor. The shaft-end overhung piezoelectric cantilever beam electric generator has the advantages that the piezoelectric vibrators are motivated for electric generation and external fixing and supporting are not needed; the shaft-end overhung piezoelectric cantilever beam electric generator is an integrated type individual component, so that the structure of a rotating body does not need to be changed, and the shaft-end overhung piezoelectric cantilever beam electric generator is convenient to install and maintain; the shaft-end overhung piezoelectric cantilever beam electric generator is high in reliability, strong in power generation capacity, and wide in velocity zone.

Owner:ZHEJIANG NORMAL UNIVERSITY

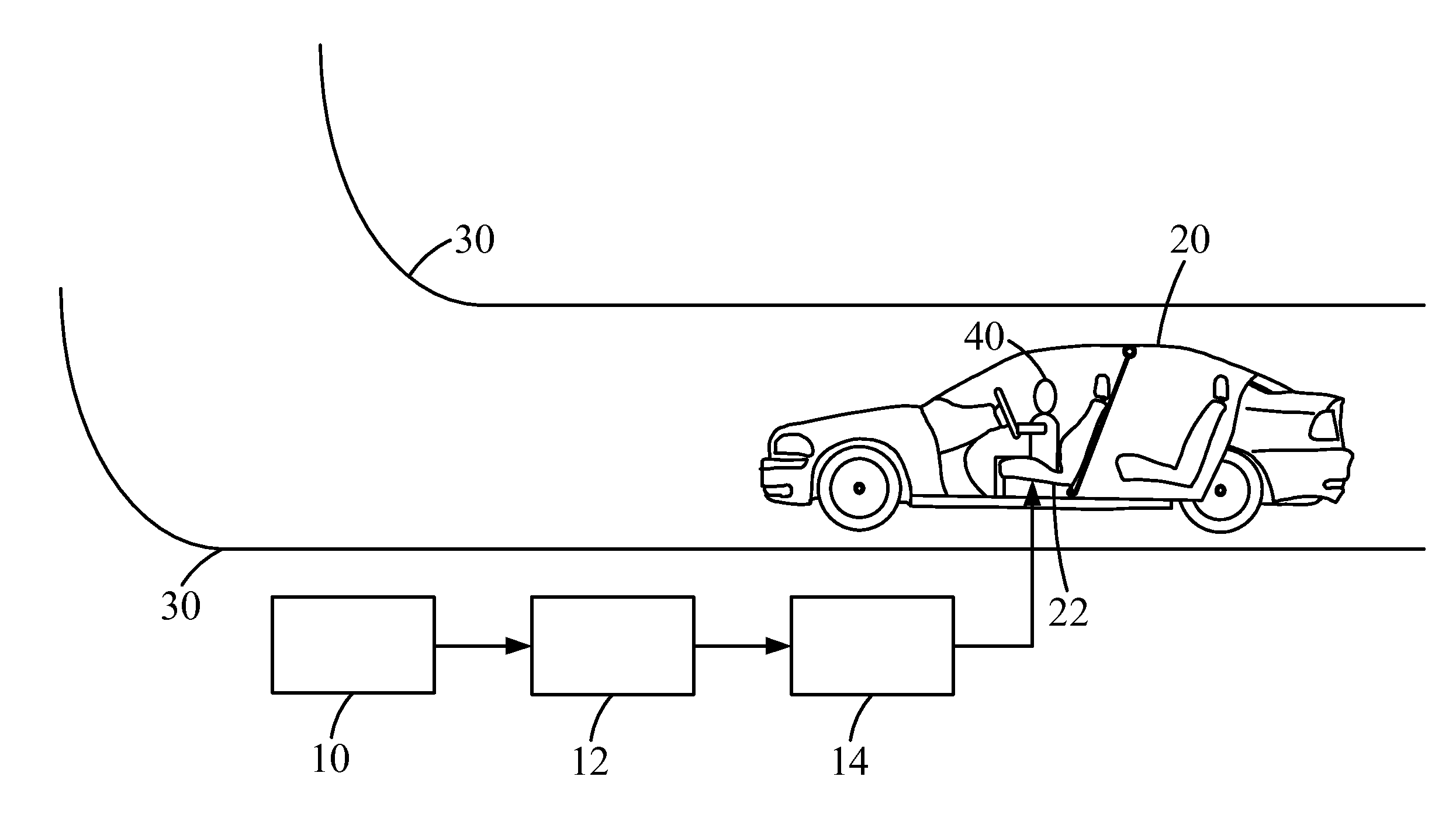

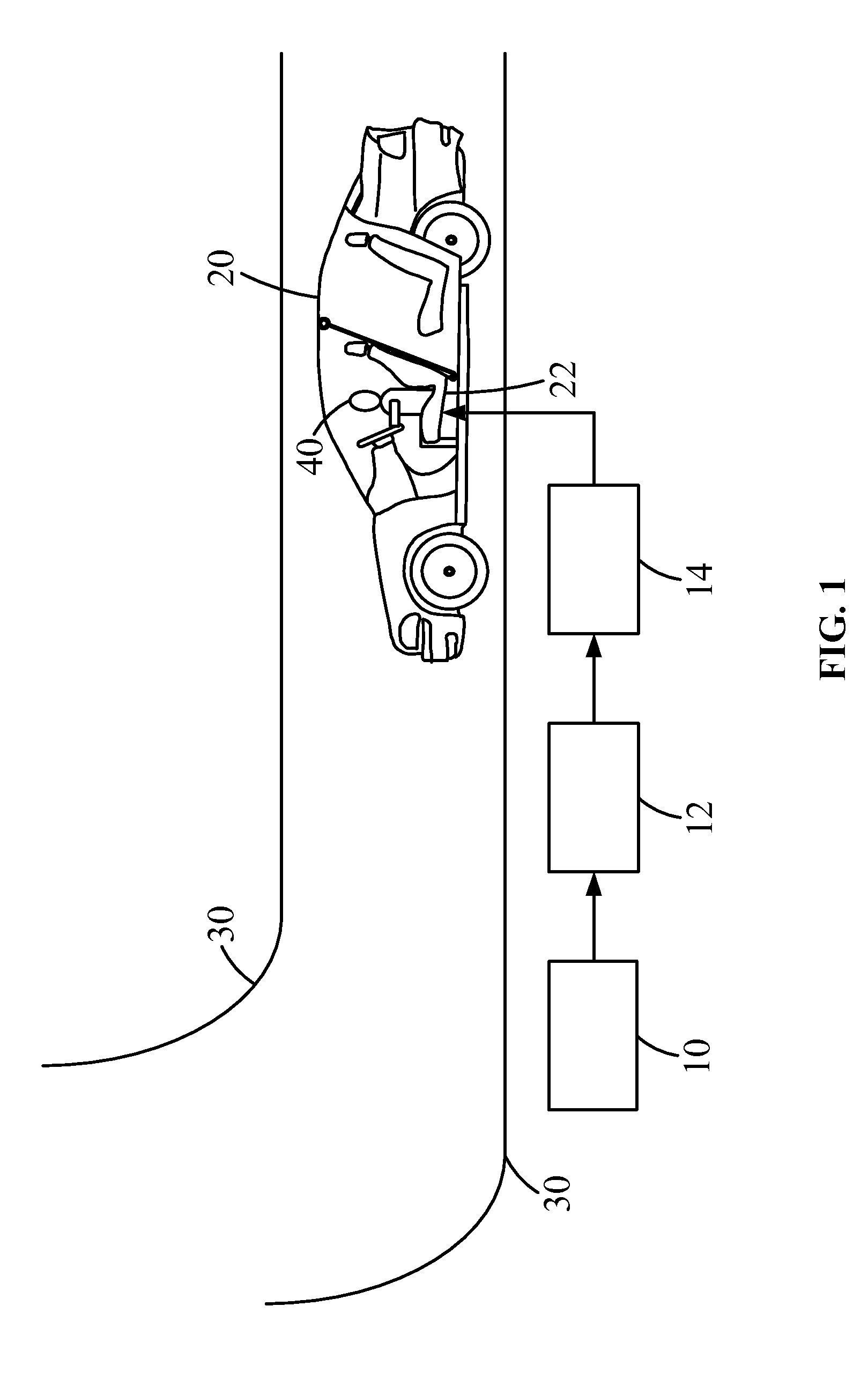

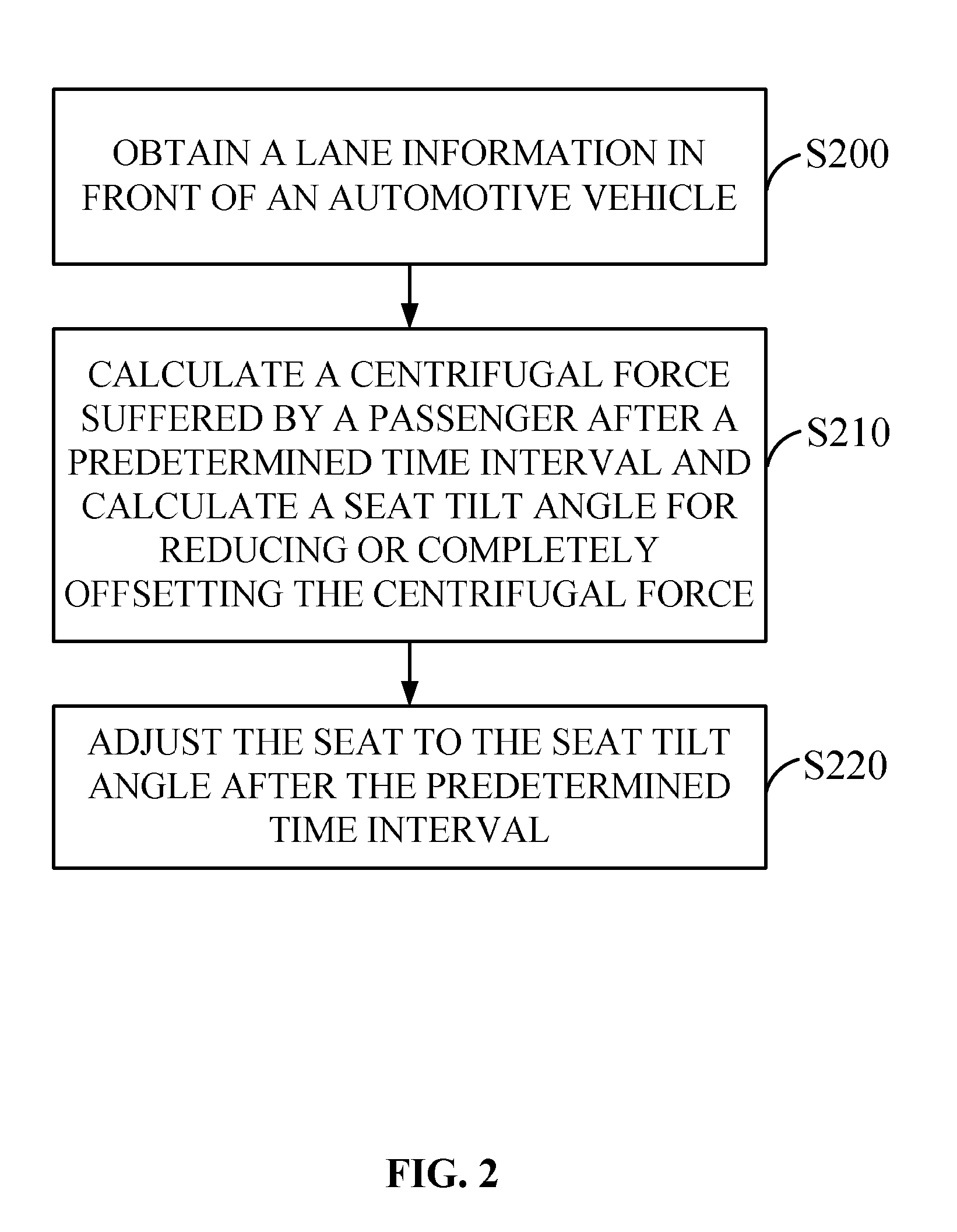

Autonomous seat system of automotive vehicle and performing method thereof

InactiveUS20130006478A1Reduce centrifugal forceDigital data processing detailsPower-operated mechanismMobile vehicleCentrifugal force

An autonomous seat system of an automotive vehicle and a performing method thereof are disclosed. The system and the method are aimed to reduce discomfort of a passenger due to centrifugal forces resulted from vehicle's turning motion. The autonomous seat system of the automotive vehicle includes a lane prediction unit, a control unit, and a seat adjusting unit. The lane prediction unit is utilized for obtaining lane information in front of the automotive vehicle. According to the lane information the control unit calculates the centrifugal force which the passenger experiences while sitting in a seat of the automotive vehicle, and a seat tilt angle which is required for the seat to compensate the centrifugal force after a predetermined time interval. The seat adjusting unit adjusts the seat to the seat tilt angle after the predetermined time interval so as to reduce or eliminate the ill-effect on the passenger resulted from the centrifugal force.

Owner:NAT TAIWAN UNIV OF SCI & TECH

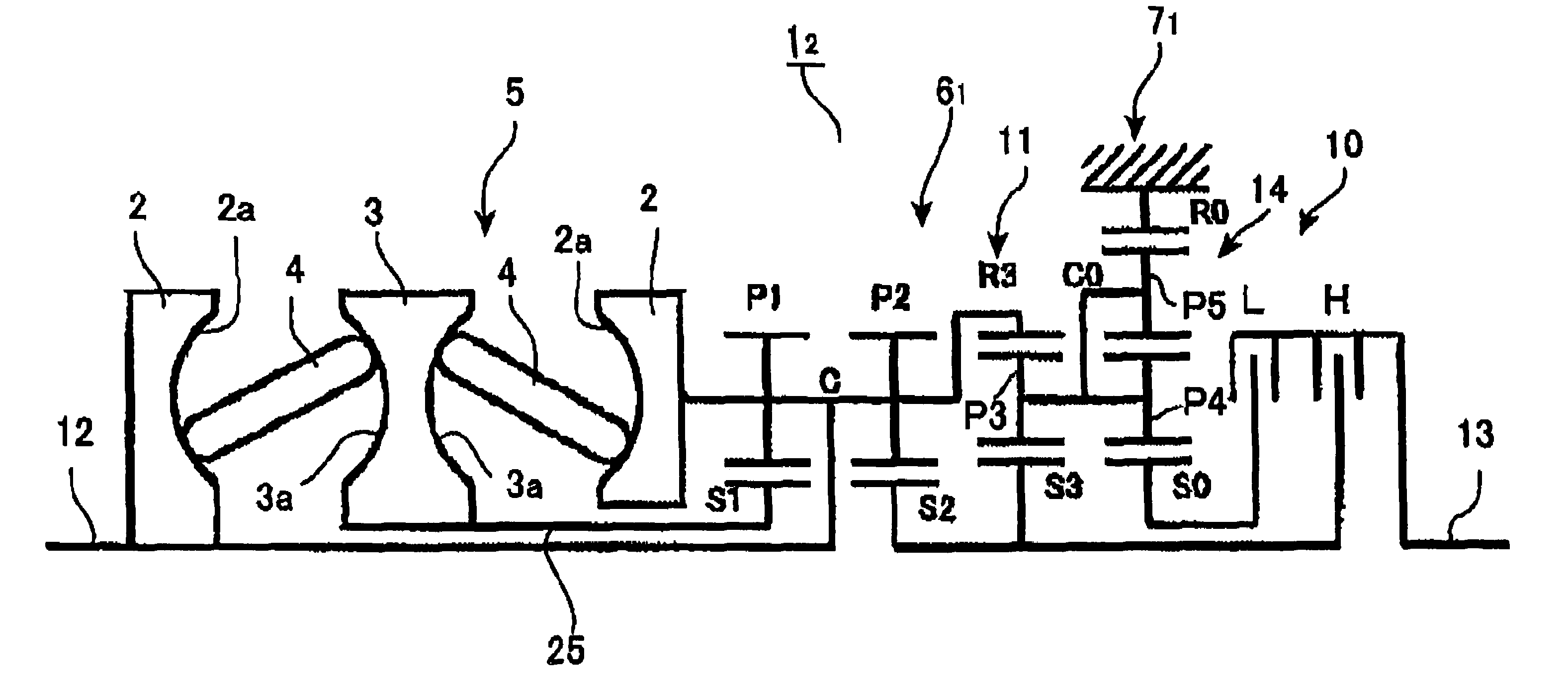

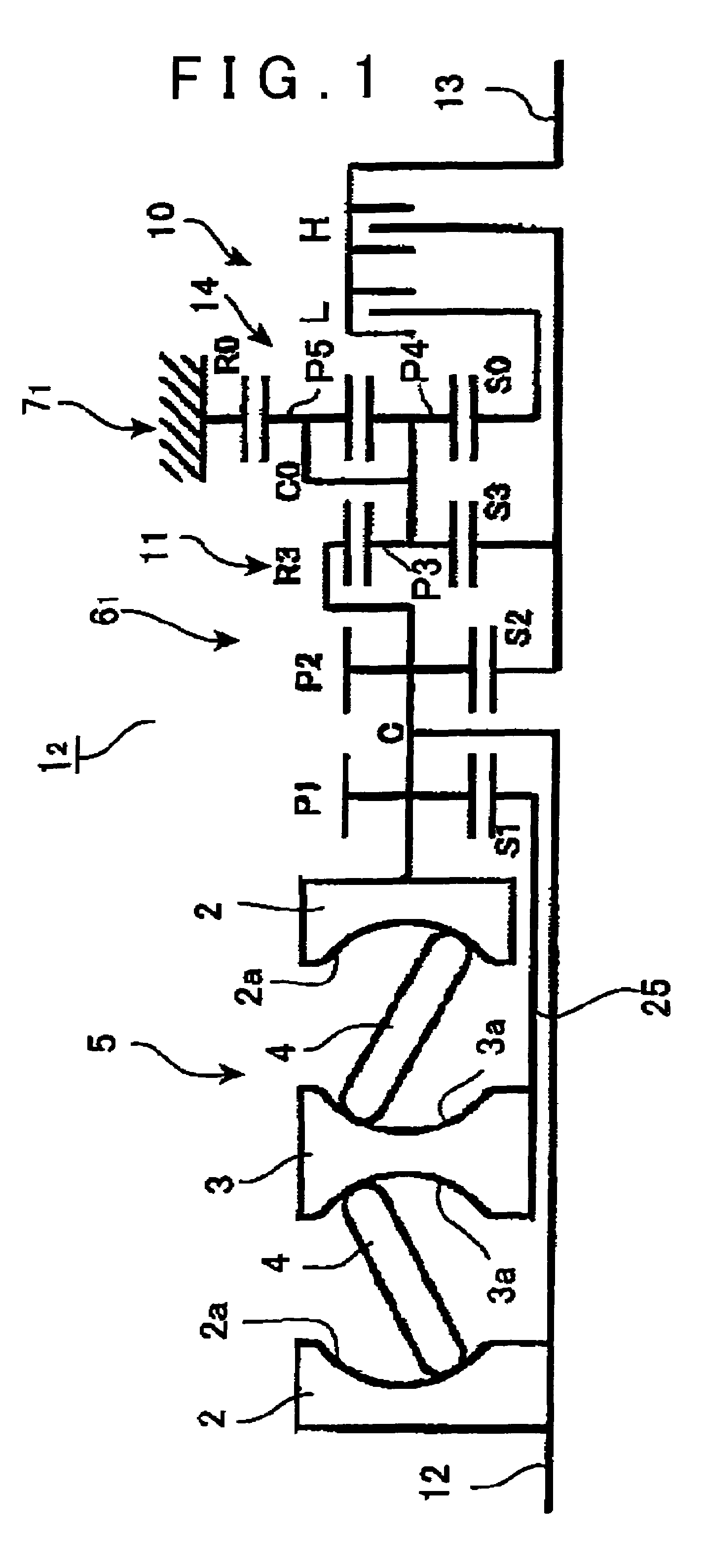

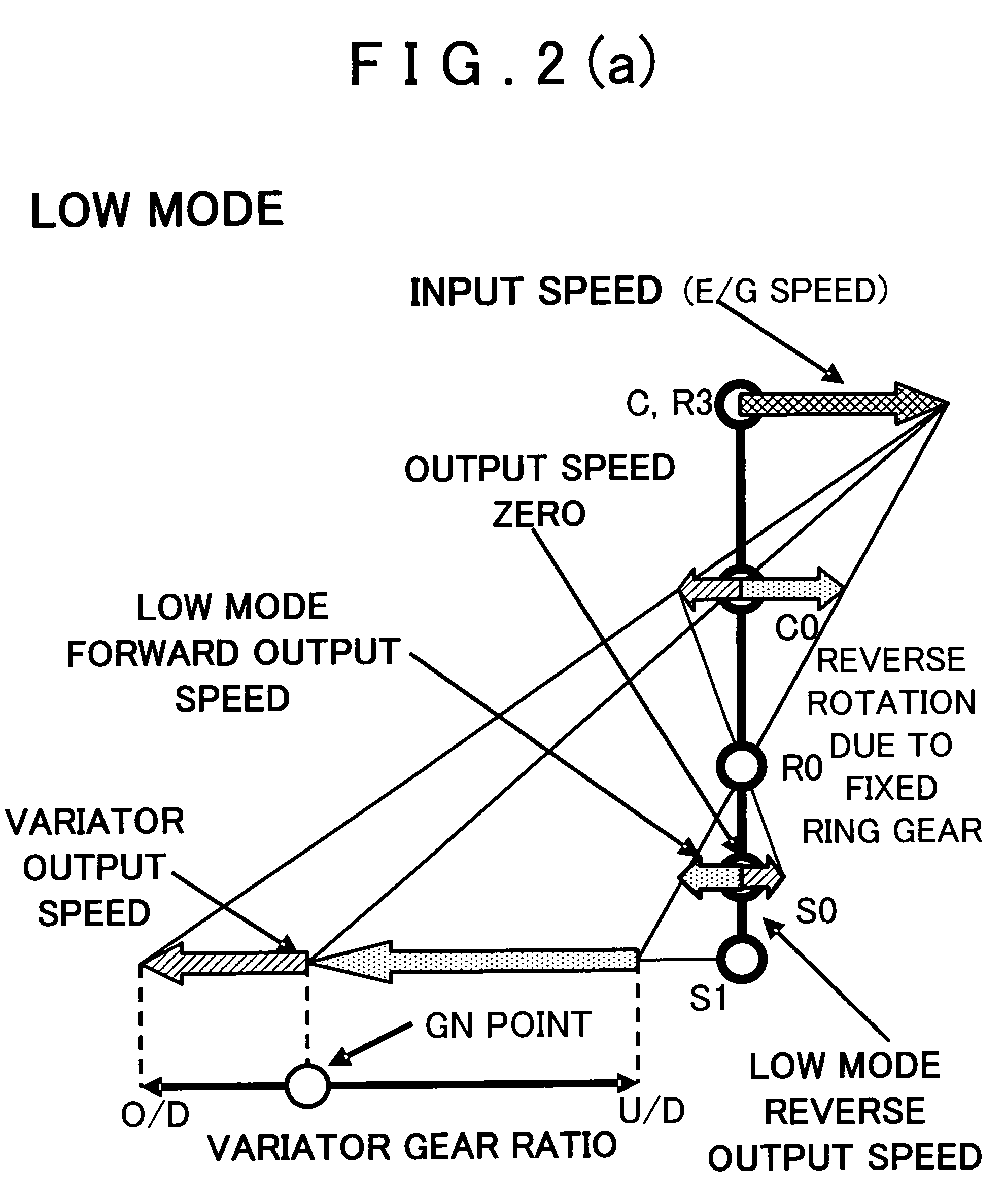

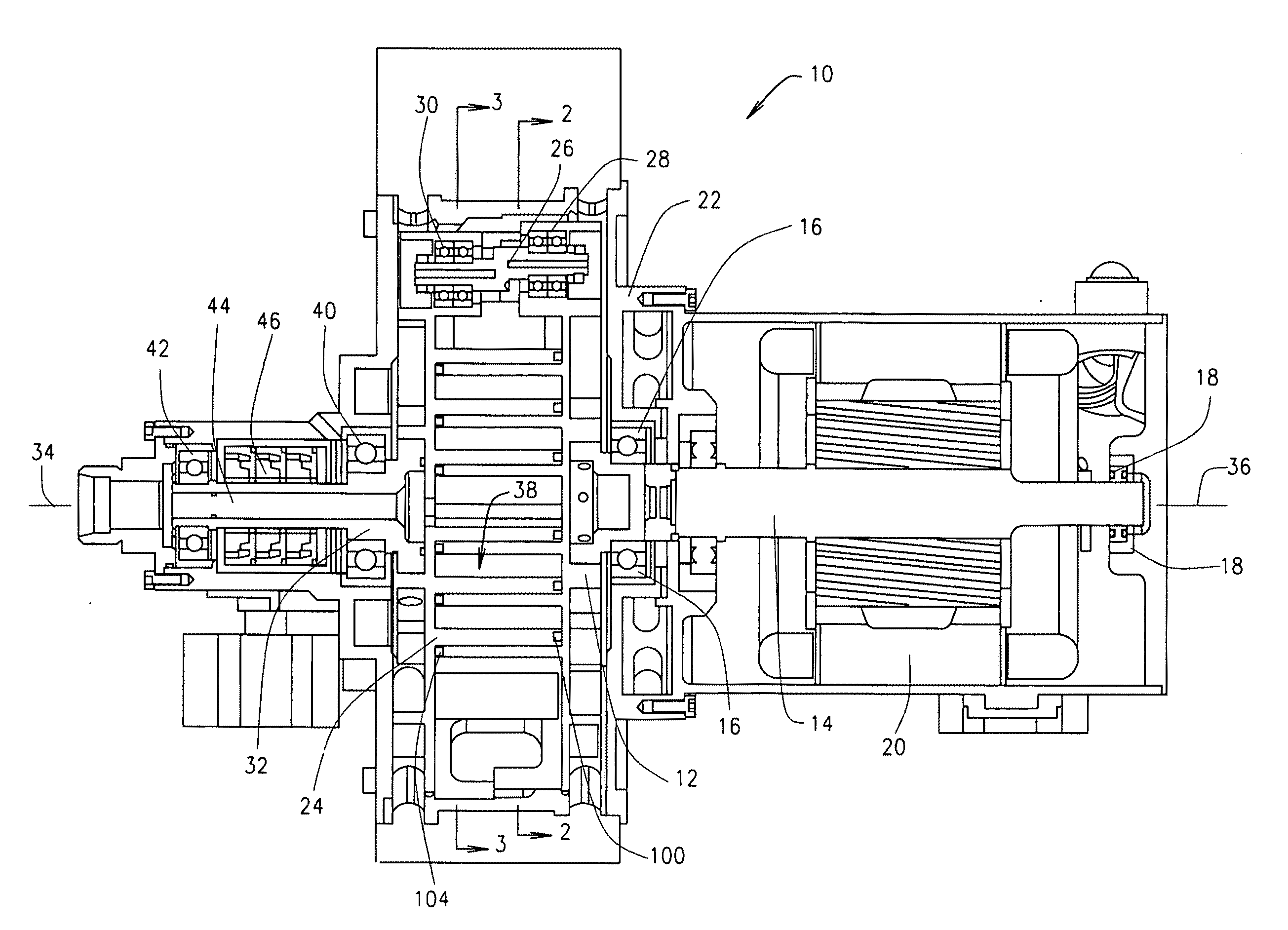

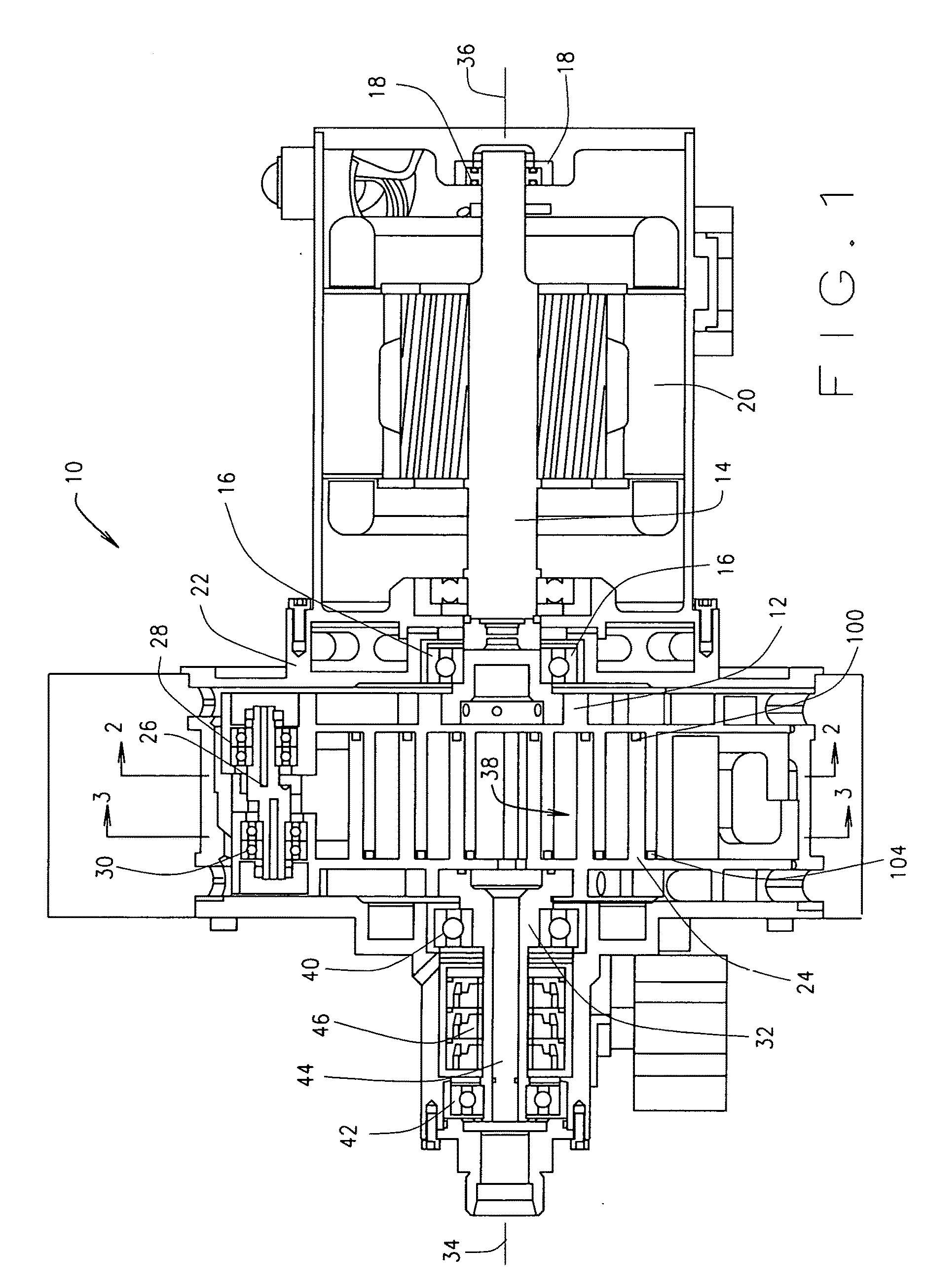

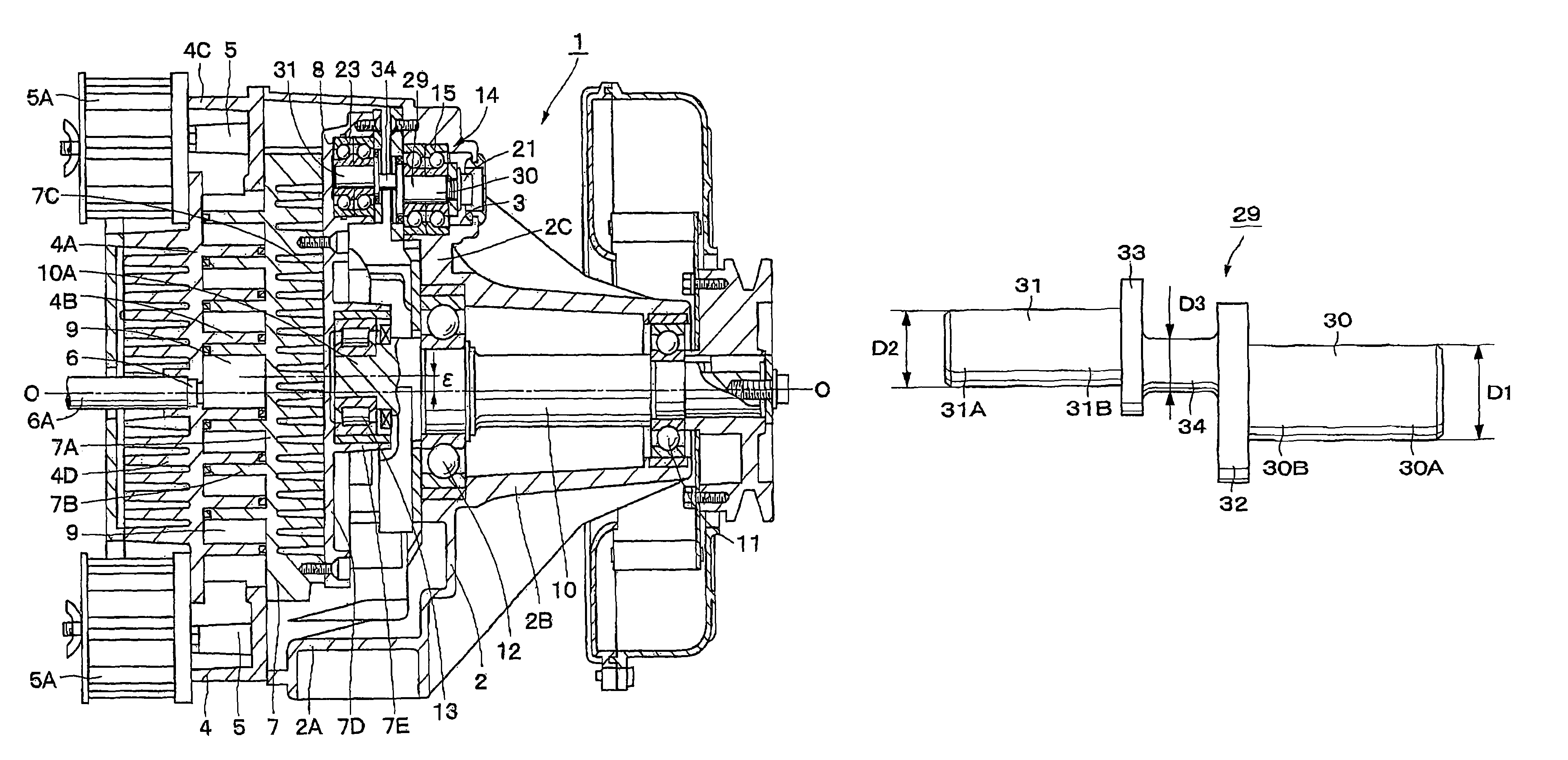

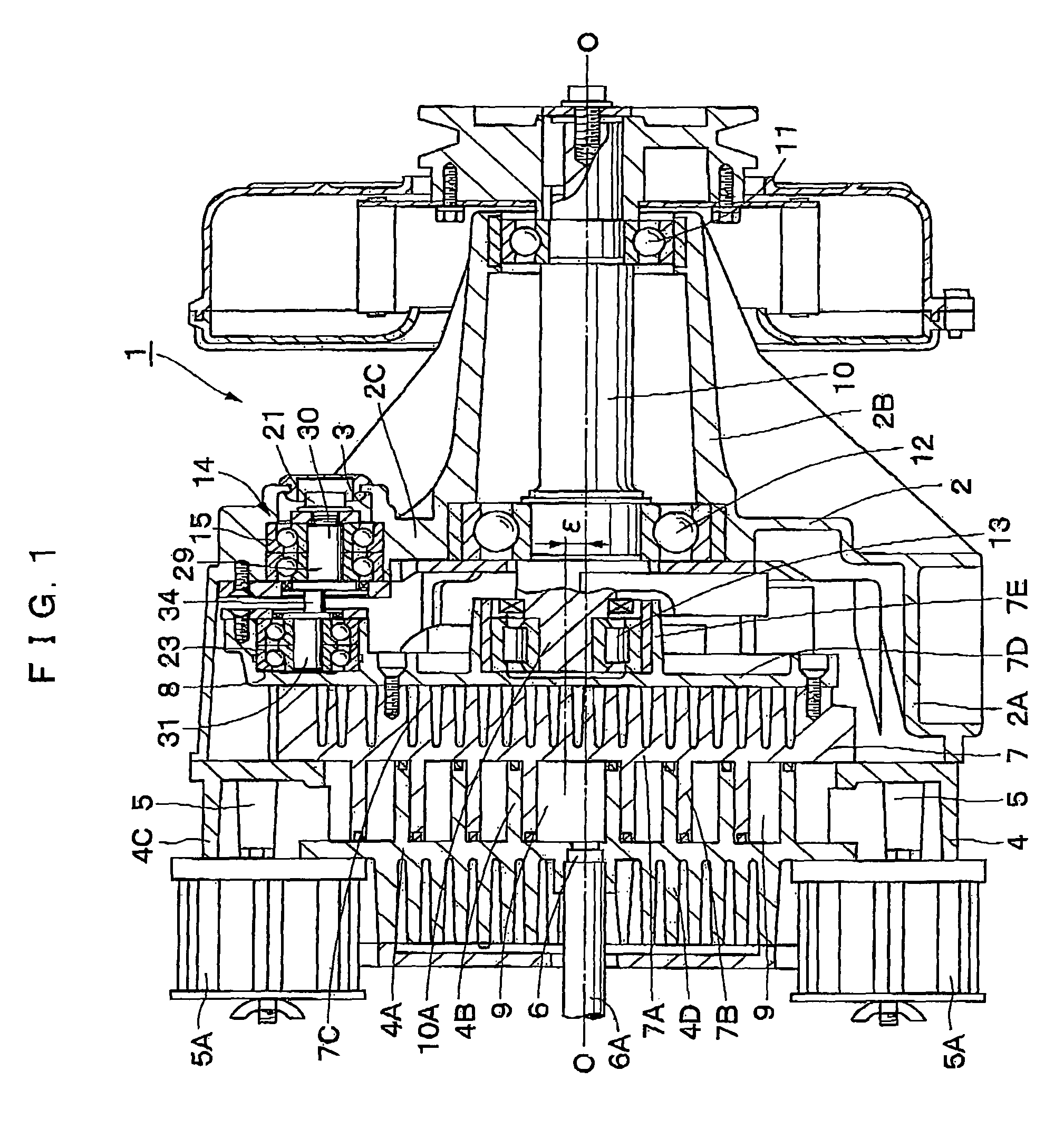

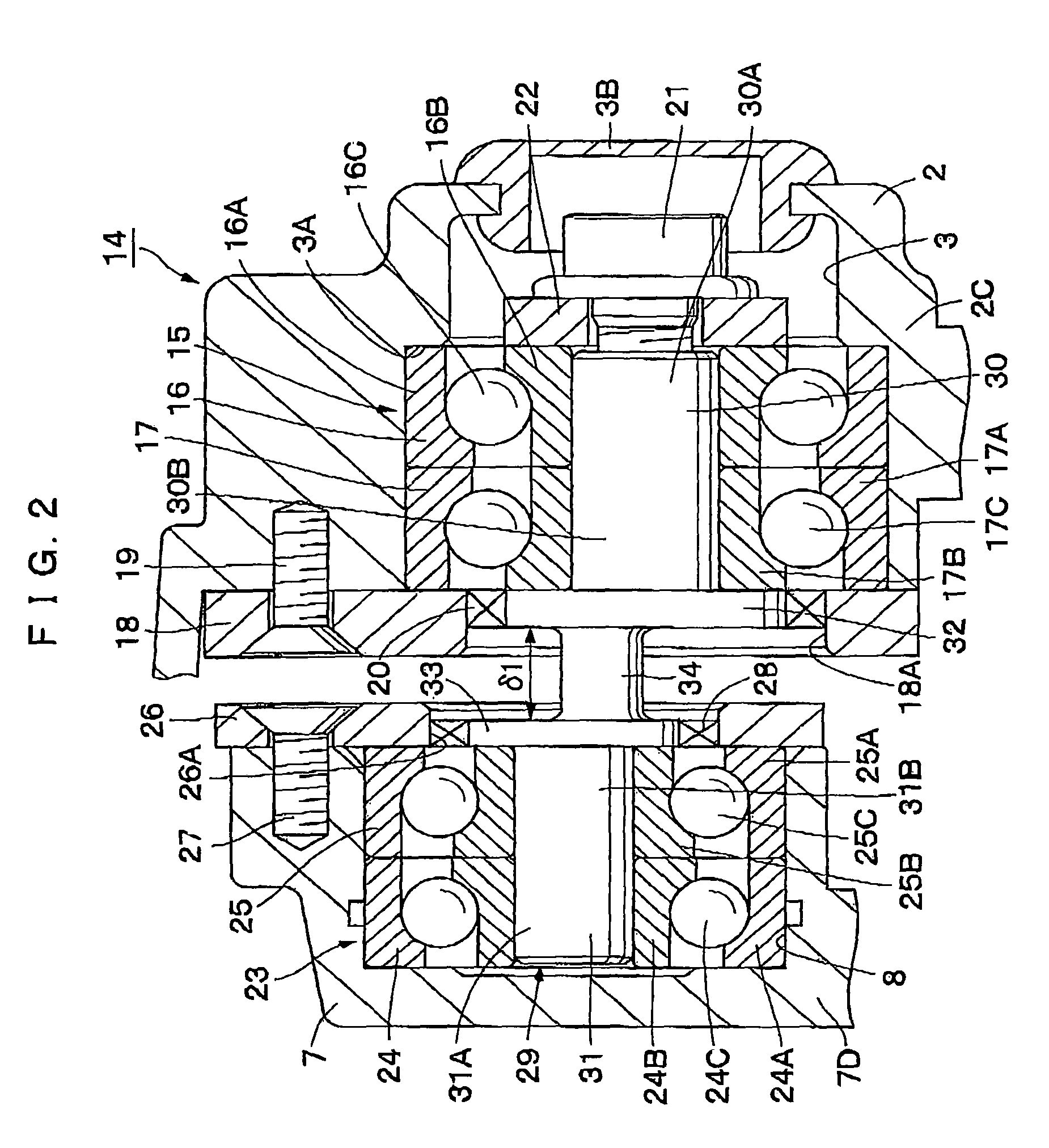

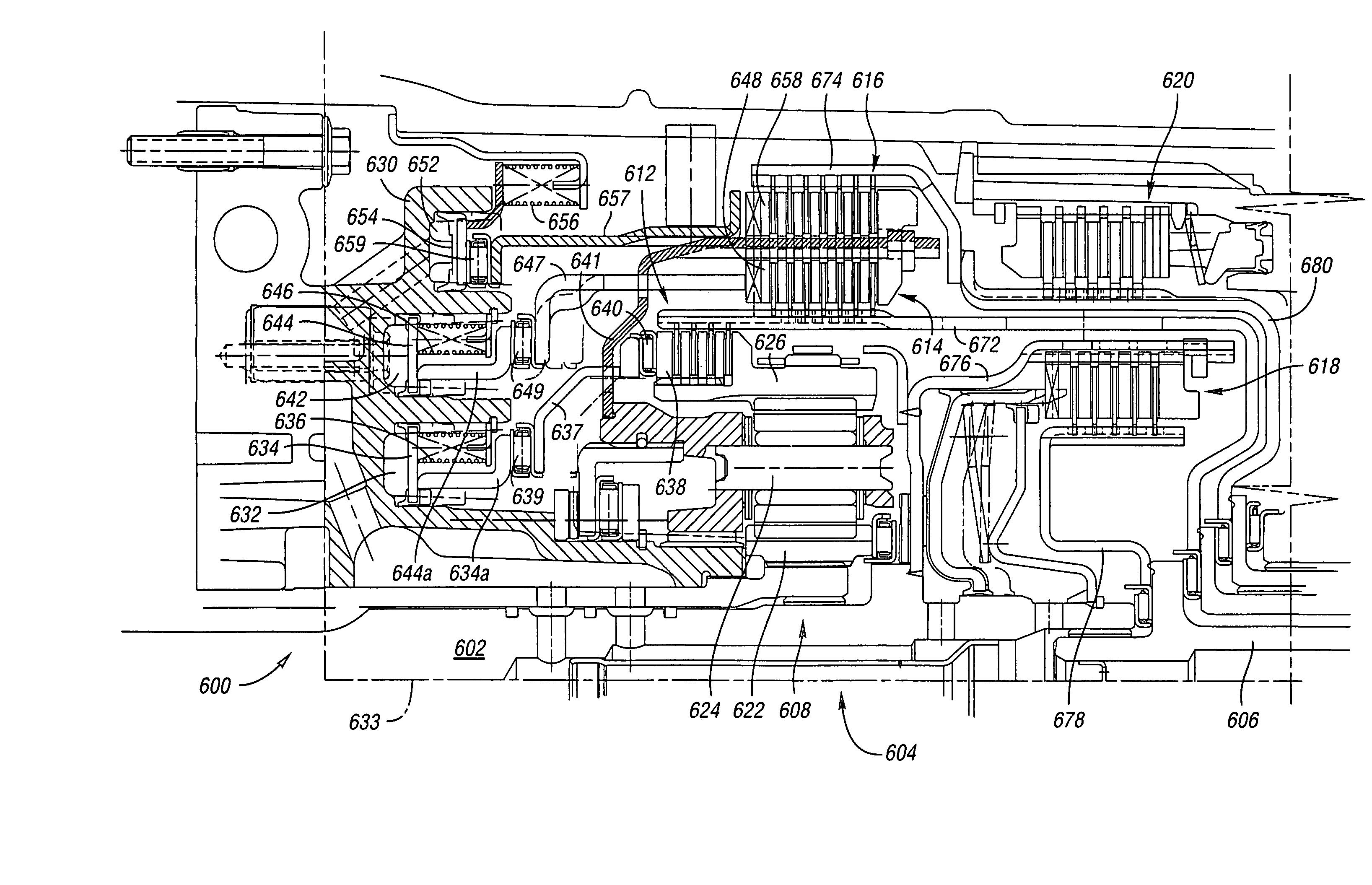

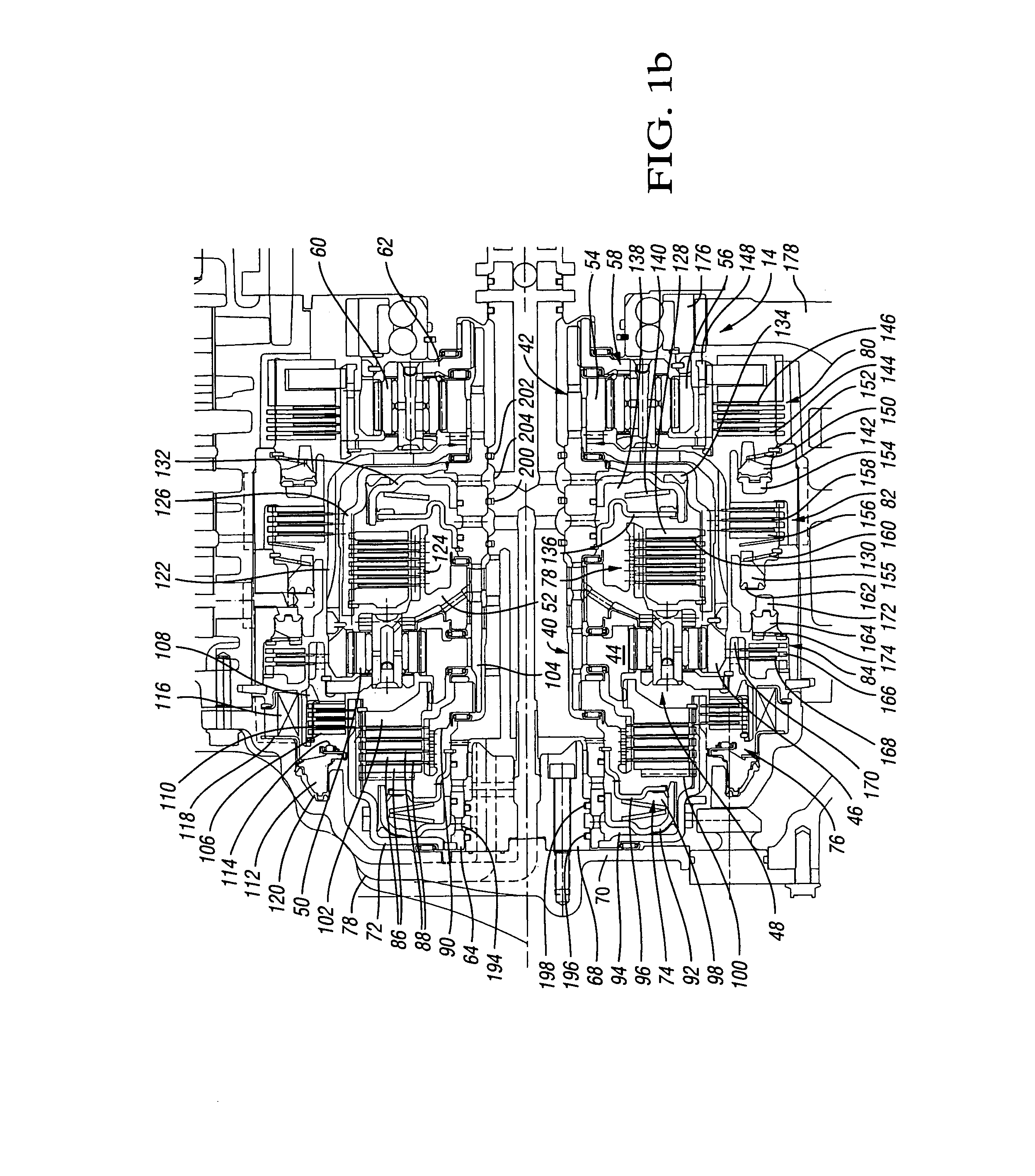

Continuously variable transmission

ActiveUS7335126B2Increase the lengthReduces bending of the pinion shaftGearingCommon carrierEngineering

Rotation of an input shaft is directly transmitted to a front carrier of a planetary gear mechanism, and rotation, which is speed-changed and reversed by a toroidal-type continuously variable speed change unit, is transmitted to a first sun gear. When a Low clutch is applied, rotation of an output carrier of a simple planetary gear unit is transitted to a counter gear mechanism via a common carrier, and then output at an output shaft. When a High clutch H is applied, rotation of a second sun gear is transmitted to the output shaft. Thus, the pinion shaft is shortened and the service life span of a supporting bearing is increased as compared with a planetary gear mechanism that has a three-step pinion.

Owner:EQUOS RES

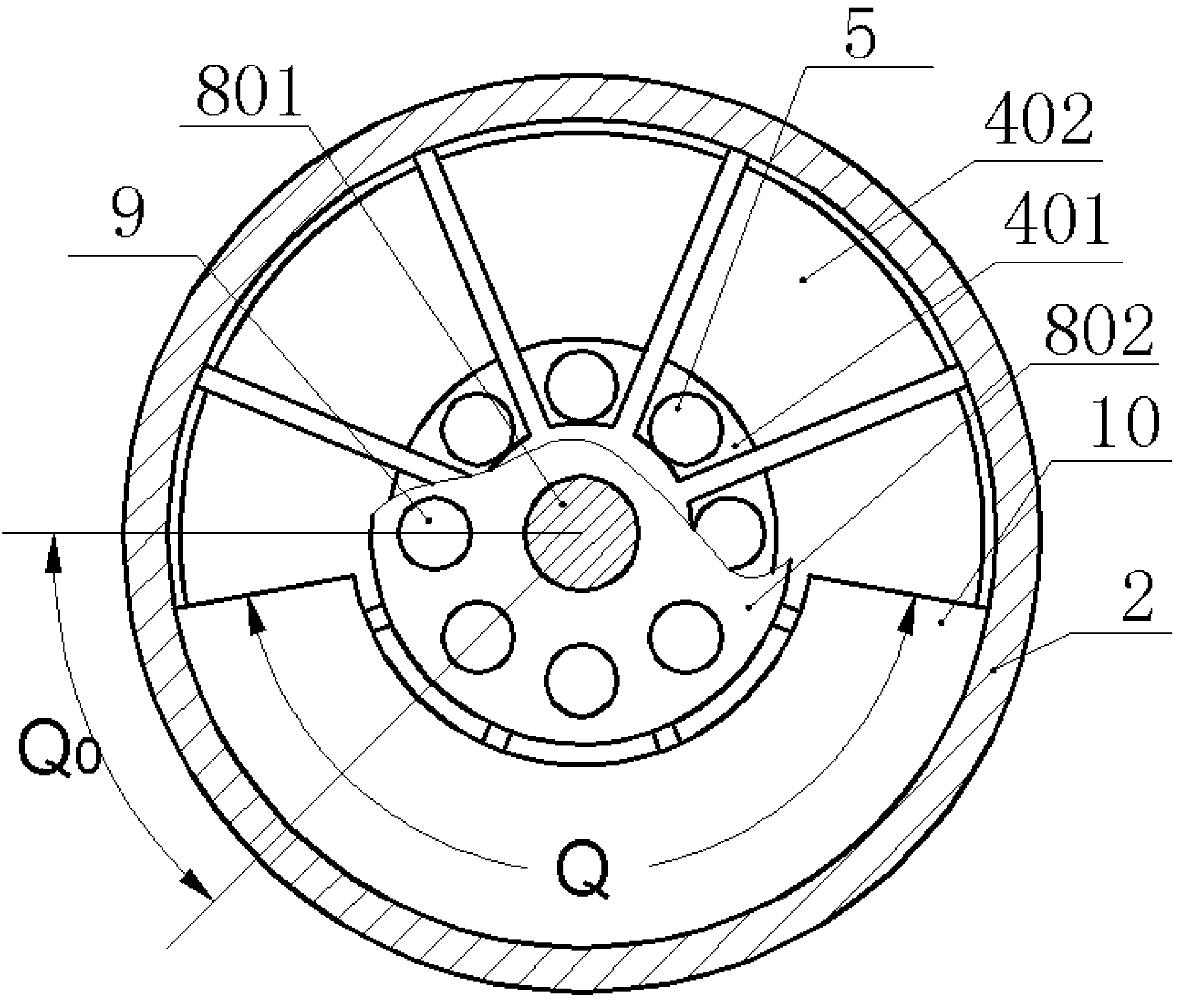

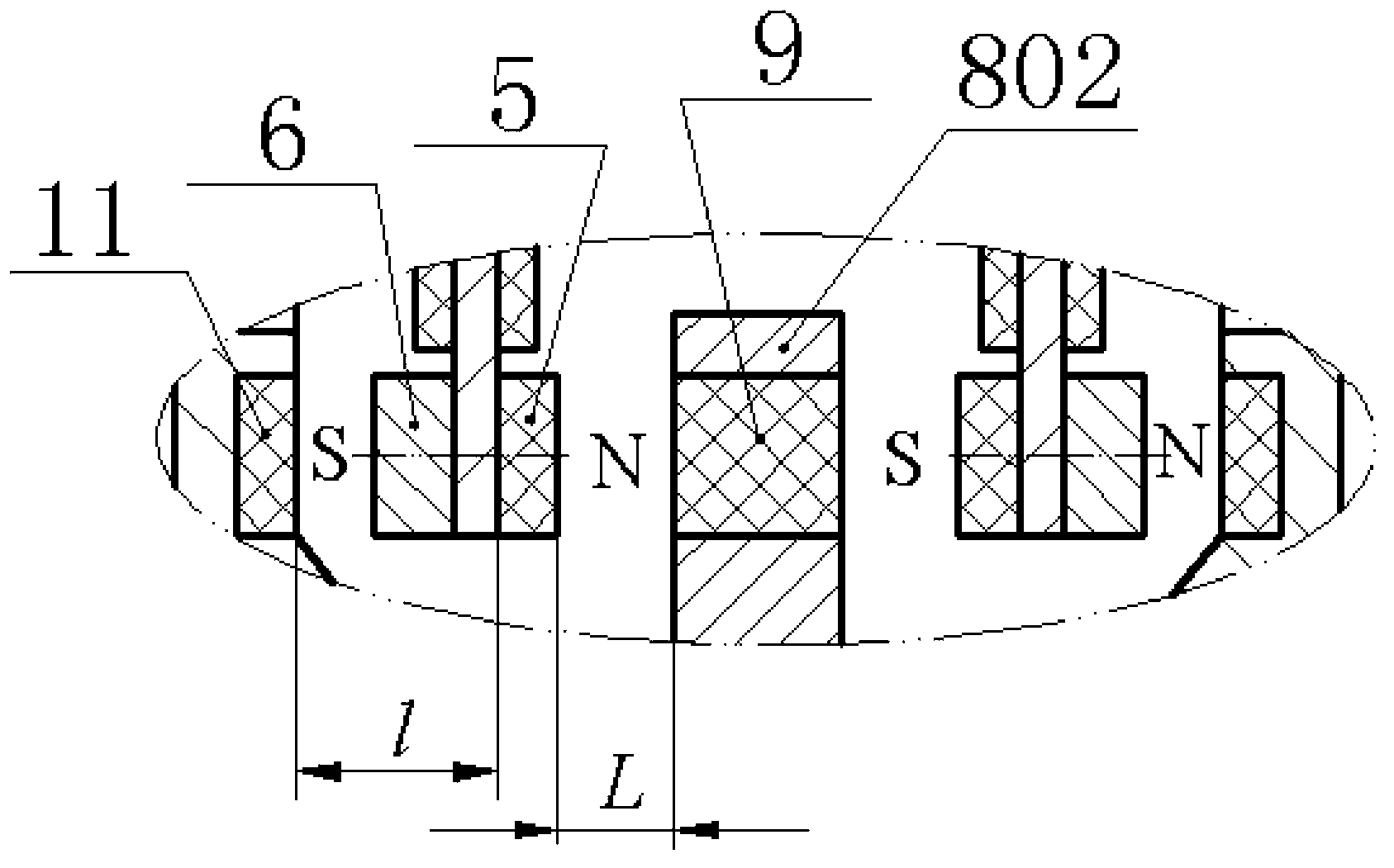

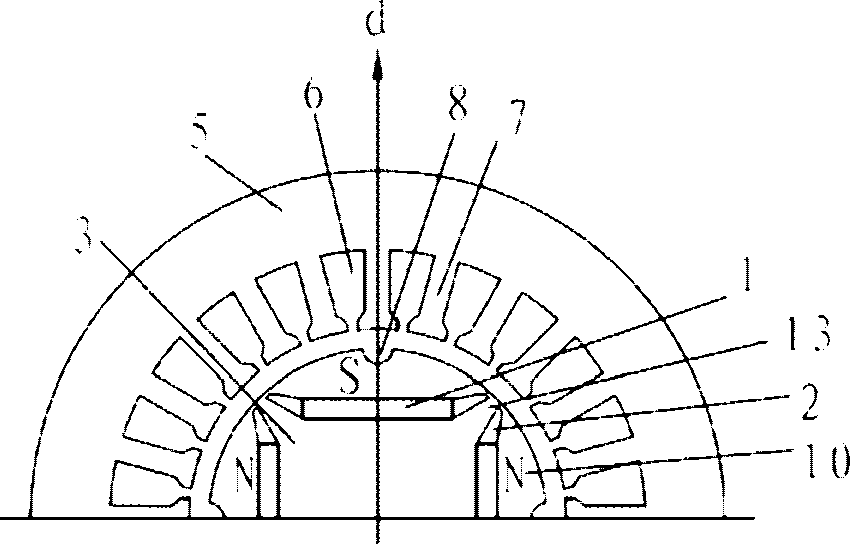

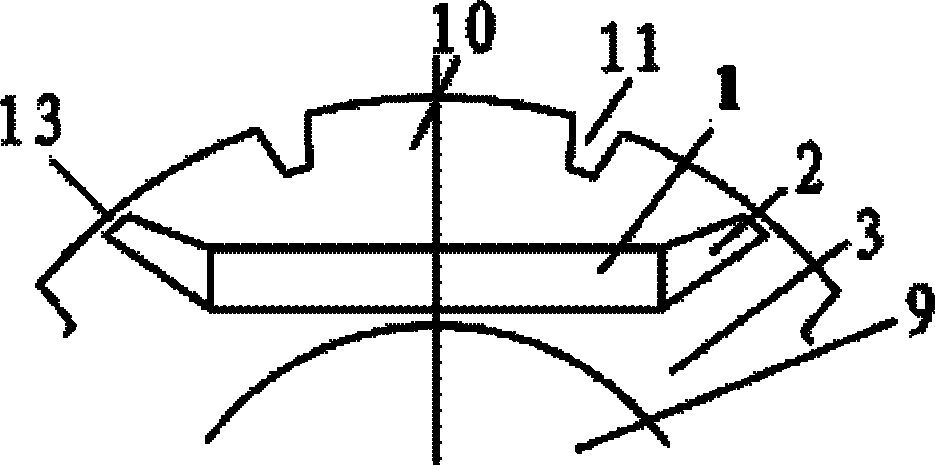

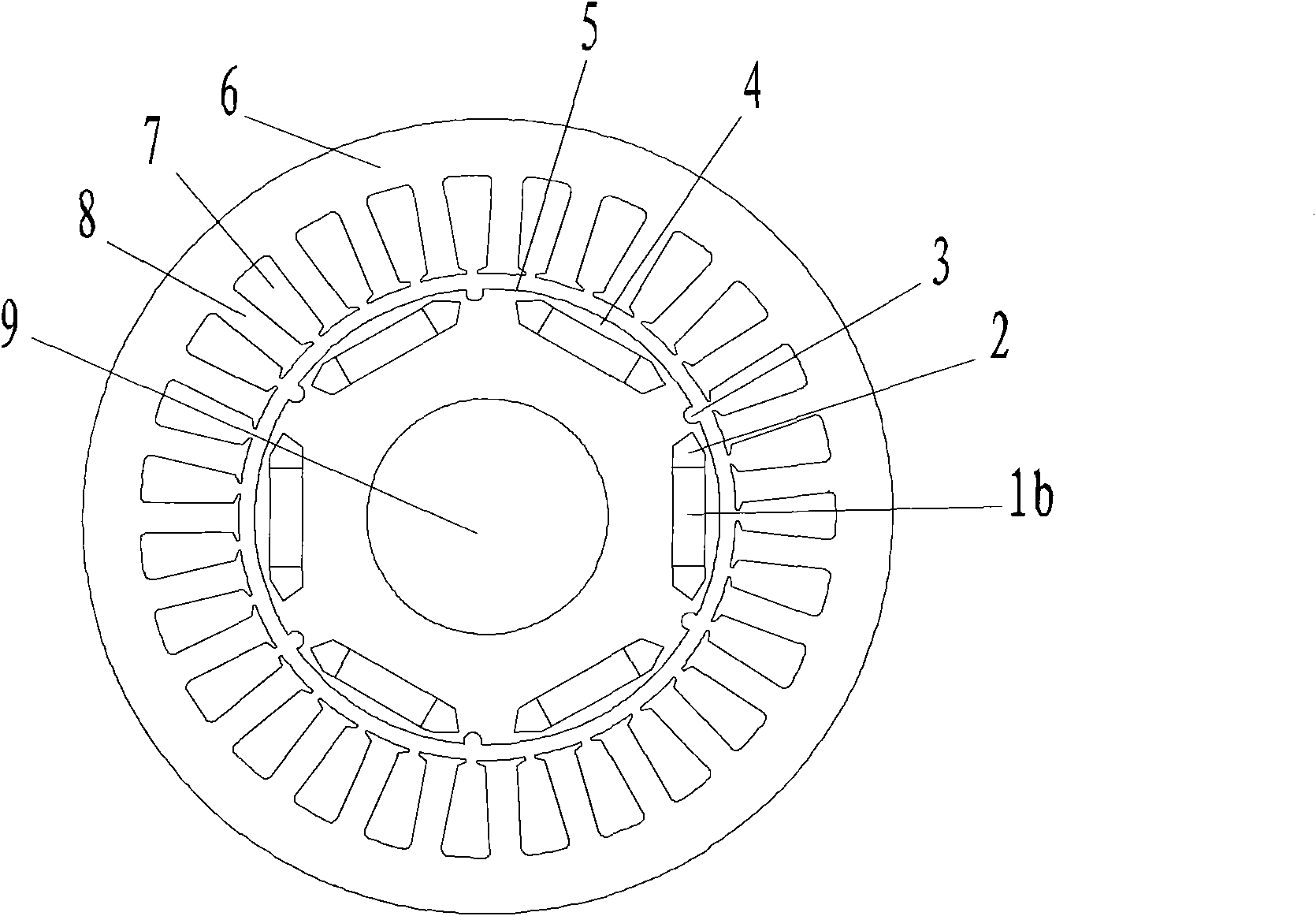

Built-in permanent-magnetic motor rotor and motor comprising same

InactiveCN102355071AReduce noiseImproved air gap magnetic field waveformMagnetic circuit rotating partsSynchronous machinesWave shapeControl theory

The invention discloses a built-in permanent-magnetic motor rotor, which comprises a rotating shaft and a rotor iron core, wherein the rotor iron core comprises a pole shoe, at least one permanent magnet body is arranged inside the pole shoe, and the outer circle of the pole shoe is provided with a plurality of grooves. The invention also discloses a motor, which comprises a stator and the rotor. Due to the adoption of the built-in permanent-magnetic motor rotor, the waveform of an air gap field of the motor can be improved, fundamental wave times of the cogging torque fluctuation can be increased, the cogging fundamental wave and the ultra-harmonics torque amplitude can be reduced, and the torque fluctuation caused by the cogging can be reduced.

Owner:苏州和鑫电气股份有限公司

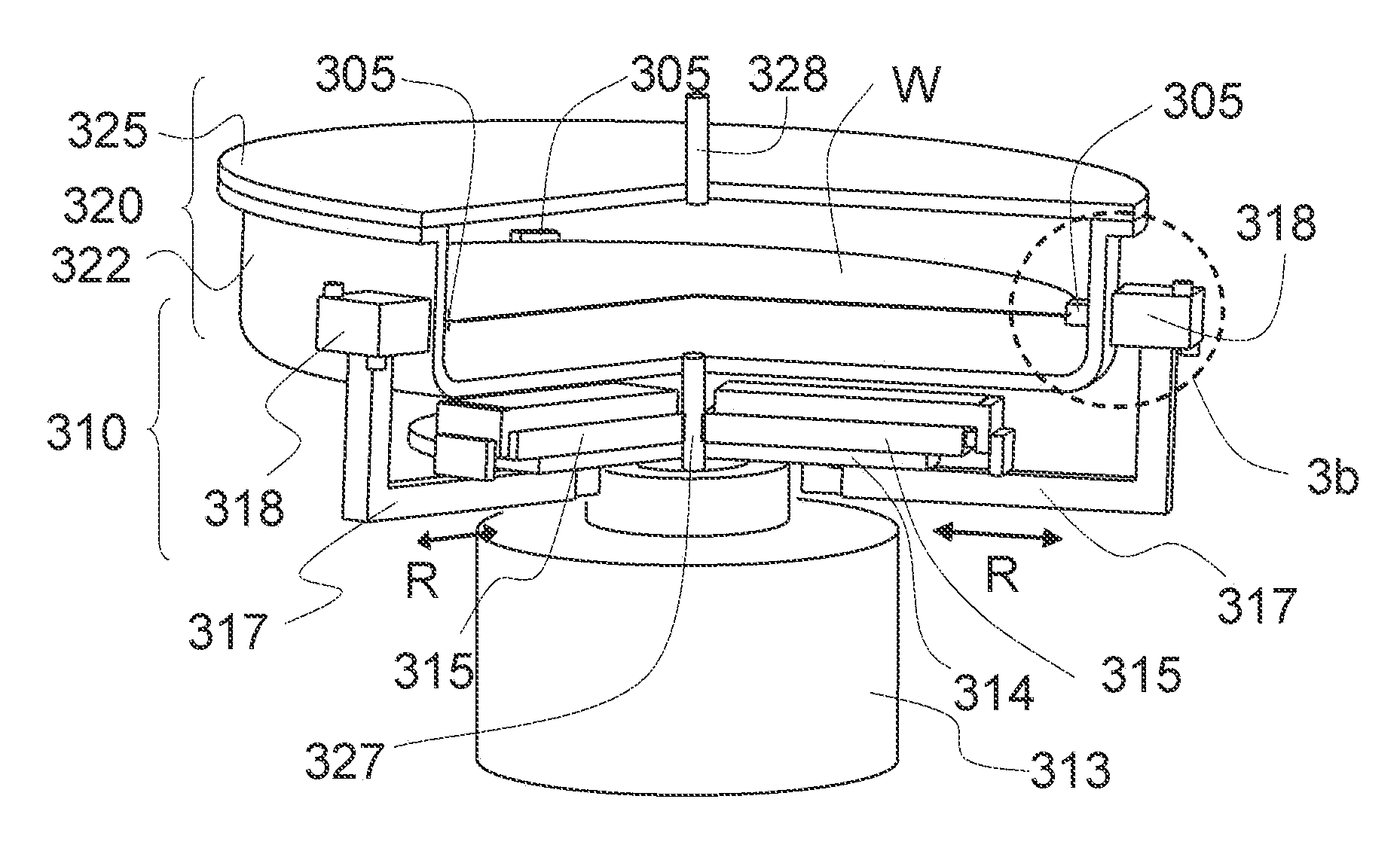

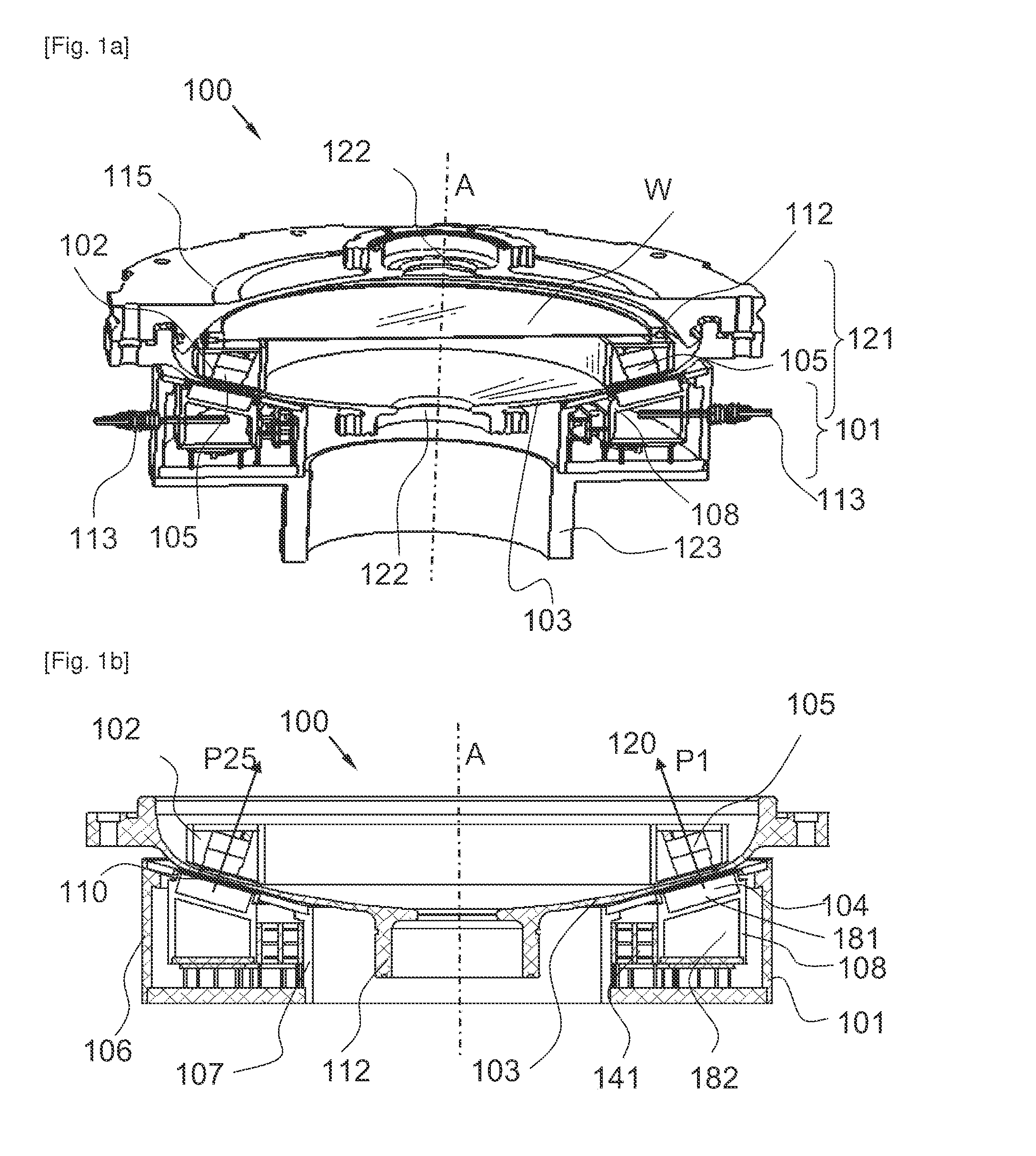

Device for treating disc-like article and method for operating same

InactiveUS20110250044A1Reduces cryogenic effortReduce the temperatureSemiconductor/solid-state device manufacturingMagnetic tension forceCoupling

A device for supporting and rotating a disc-like article includes:a first rotor including a support for supporting the disc-like article, wherein the first rotor is located within a process chamber,a second rotor connected to a drive mechanism for rotating the second rotor, wherein the second rotor is coupled to the first rotor by magnetic forces without touching the first rotor, and the second rotor is located outside the process chamber and a wall is arranged between the first rotor and the second rotor, andat least one magnetic couple, wherein the couple includes a first coupling part and a second coupling part, wherein the first coupling part includes a coupling magnet mounted to the first rotor and the second coupling part includes a high temperature superconducting material,wherein the magnetic couple(s) are arranged and / or formed so that no degree of freedom remains between the first and second rotor so that the first rotor moves together with the second rotor. A method for operating such device is disclosed.

Owner:LAM RES AG

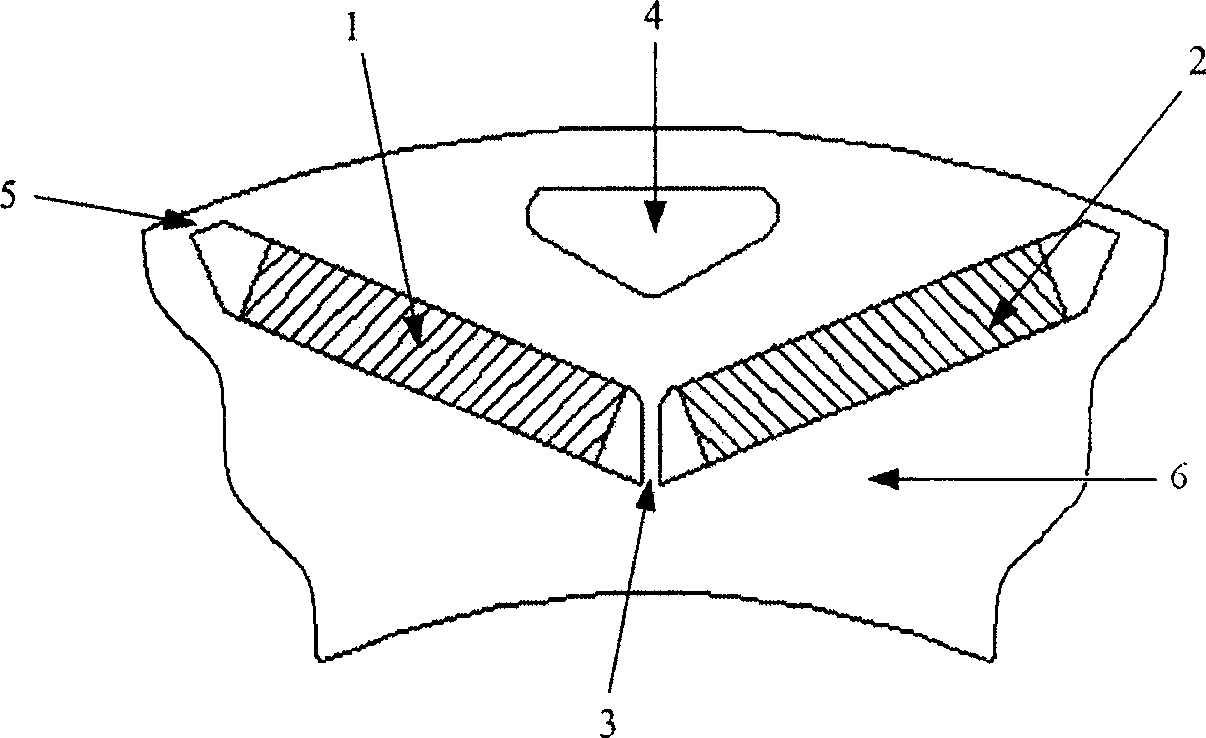

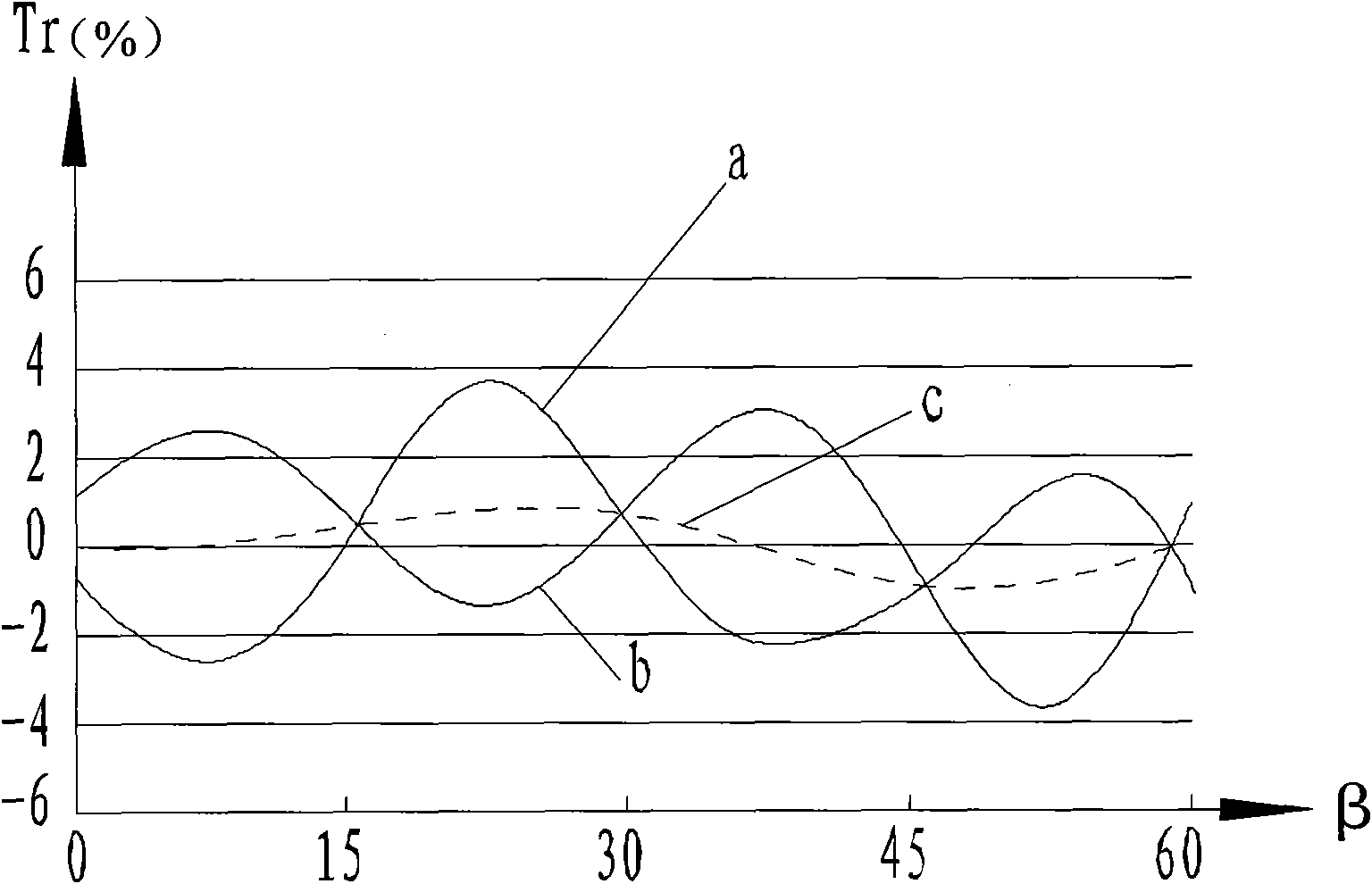

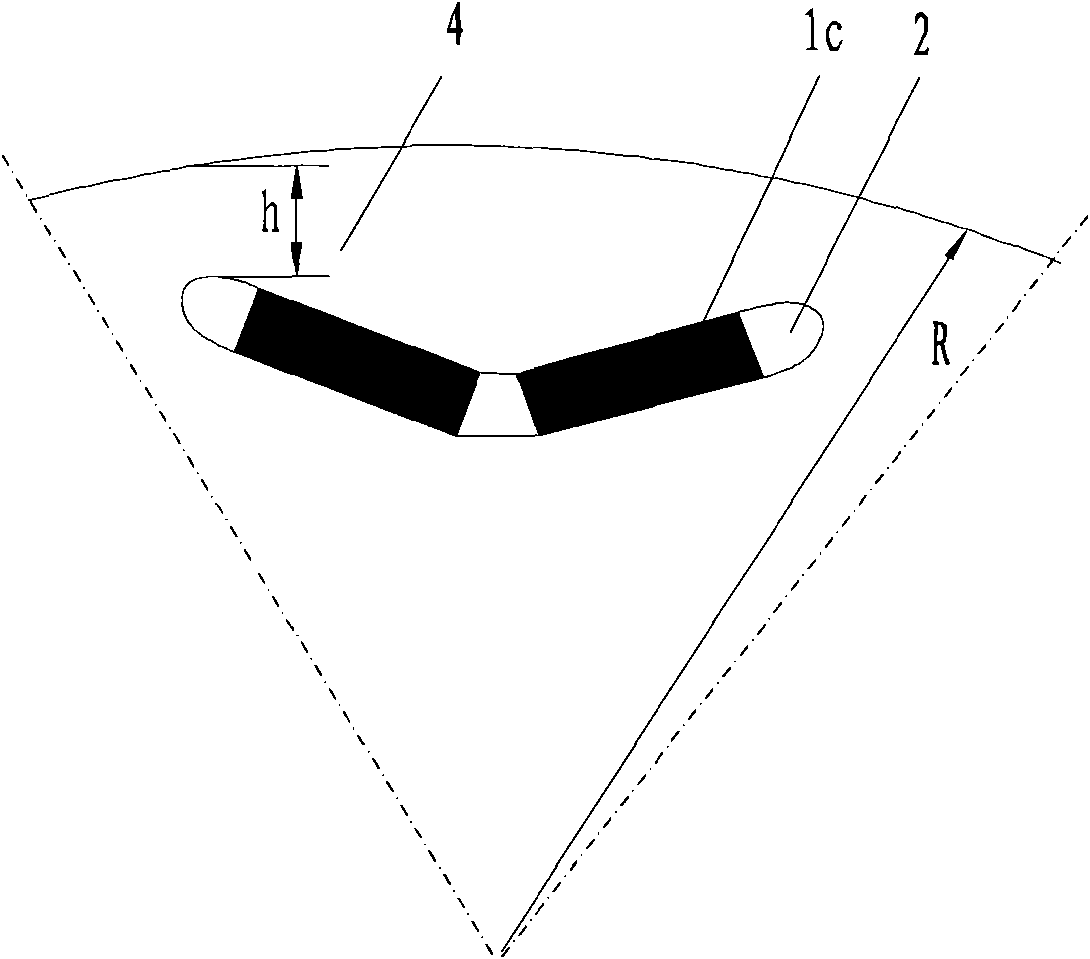

'V' type builti-in rotor of permanent megnet dynamo

InactiveCN1835340AIncrease the maximum safe operating speedReduce weightMagnetic circuit rotating partsStress pointWave shape

The invention converts built-in type rotor structure in conventional 'I'type to built-in type rotor structure in 'V'type, as well as sets up reinforced ribs between magnetic poles and sets up accessory pores above the said reinforced ribs. Changing distribution of deformation on surface of rotor diameter, the rotor structure in 'V'type makes maximal centrifugal stress point shift to reinforced ribs of rotor. The maximal centrifugal stress point is tensile stress restricted by tensile strength of material of rotor core. Since tensile strength of material of rotor core is larger than yield strength, thus, operating mechanical property of rotor at high speed is enhanced remarkably. Moreover, the said accessory pores can control waveform of air gap field, lightens weight of rotor, reduces centrifugal force, vibration and noise as well as improves operating mechanical property and other performances of motor.

Owner:SHANGHAI UNIV

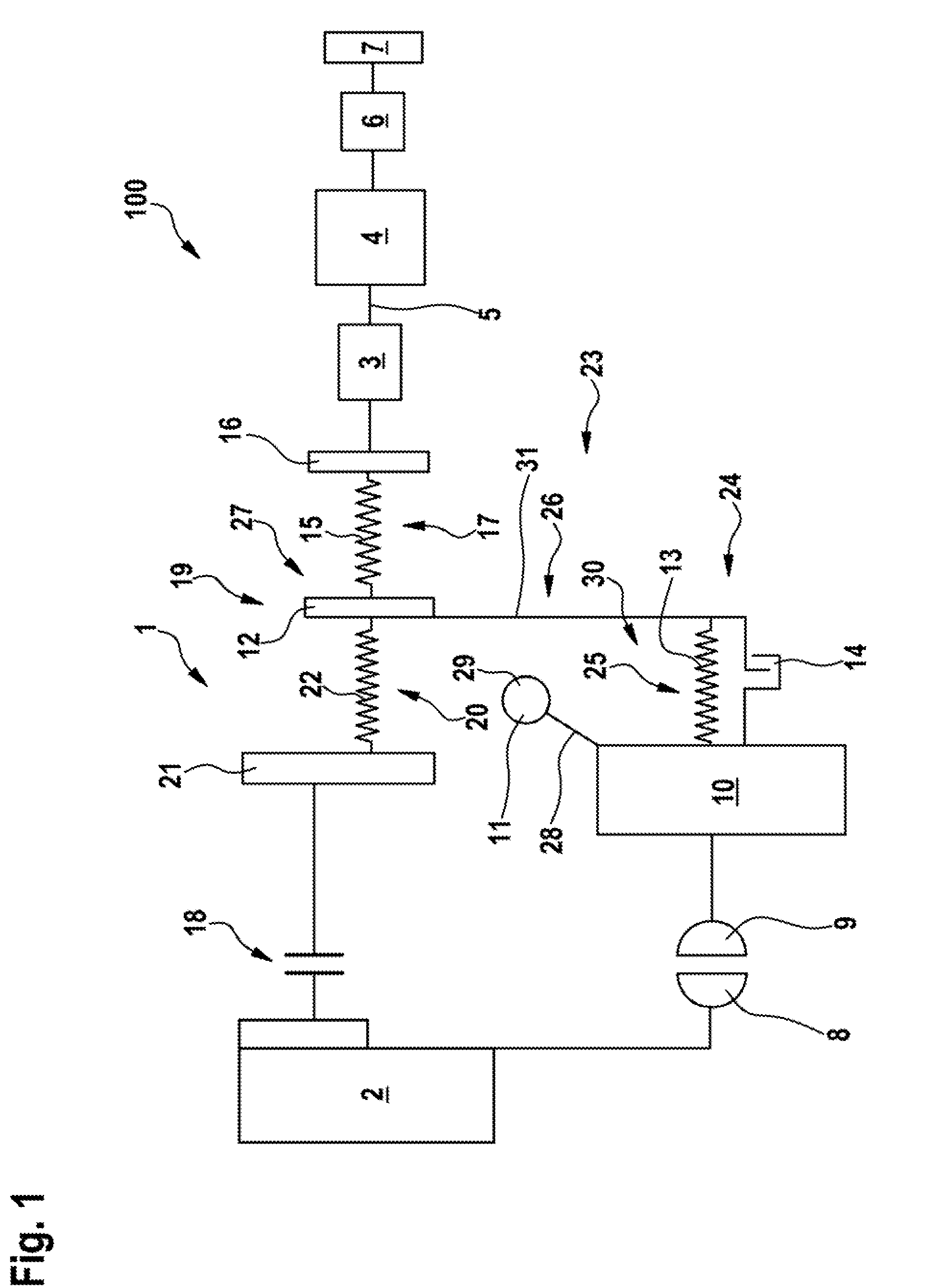

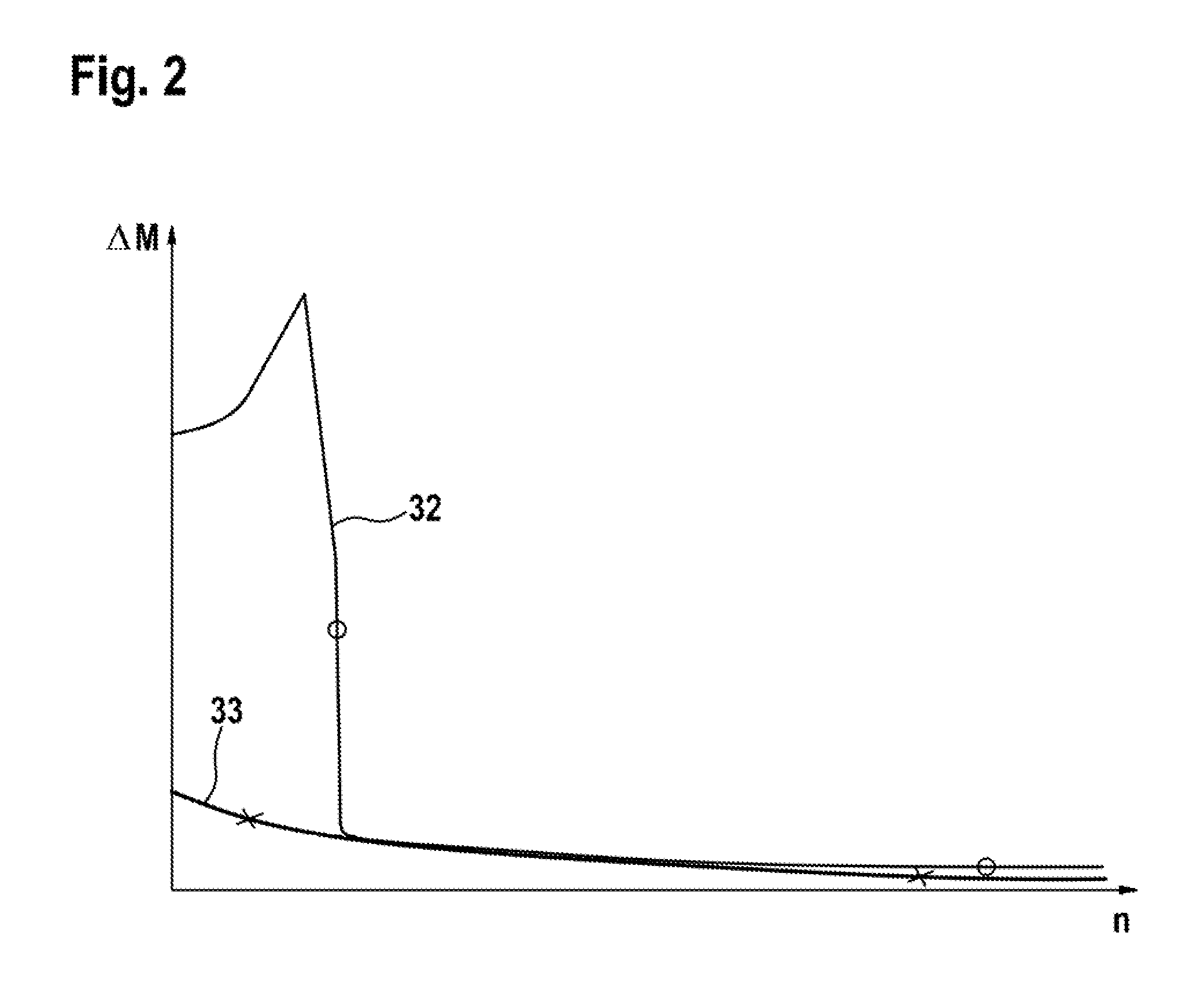

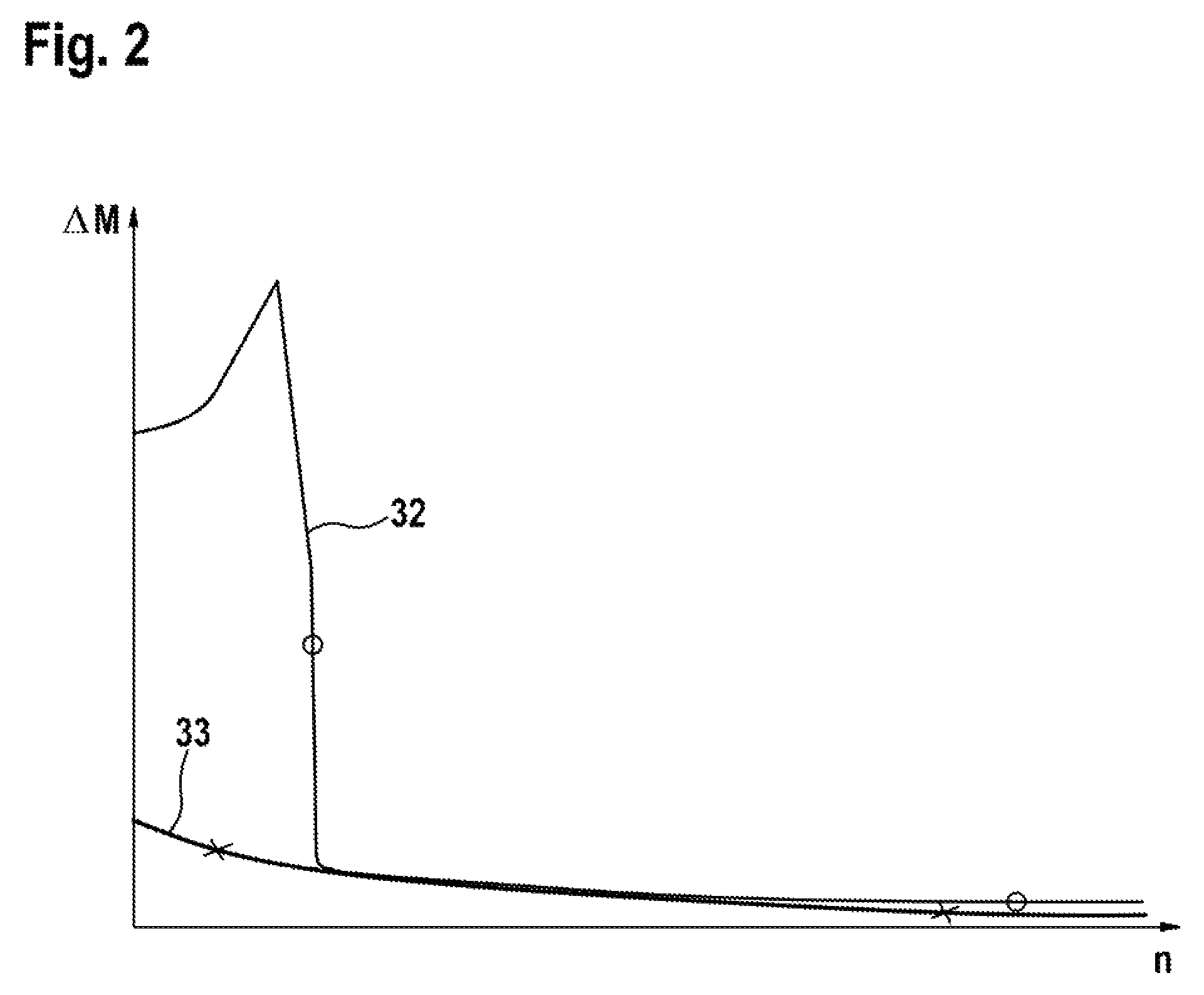

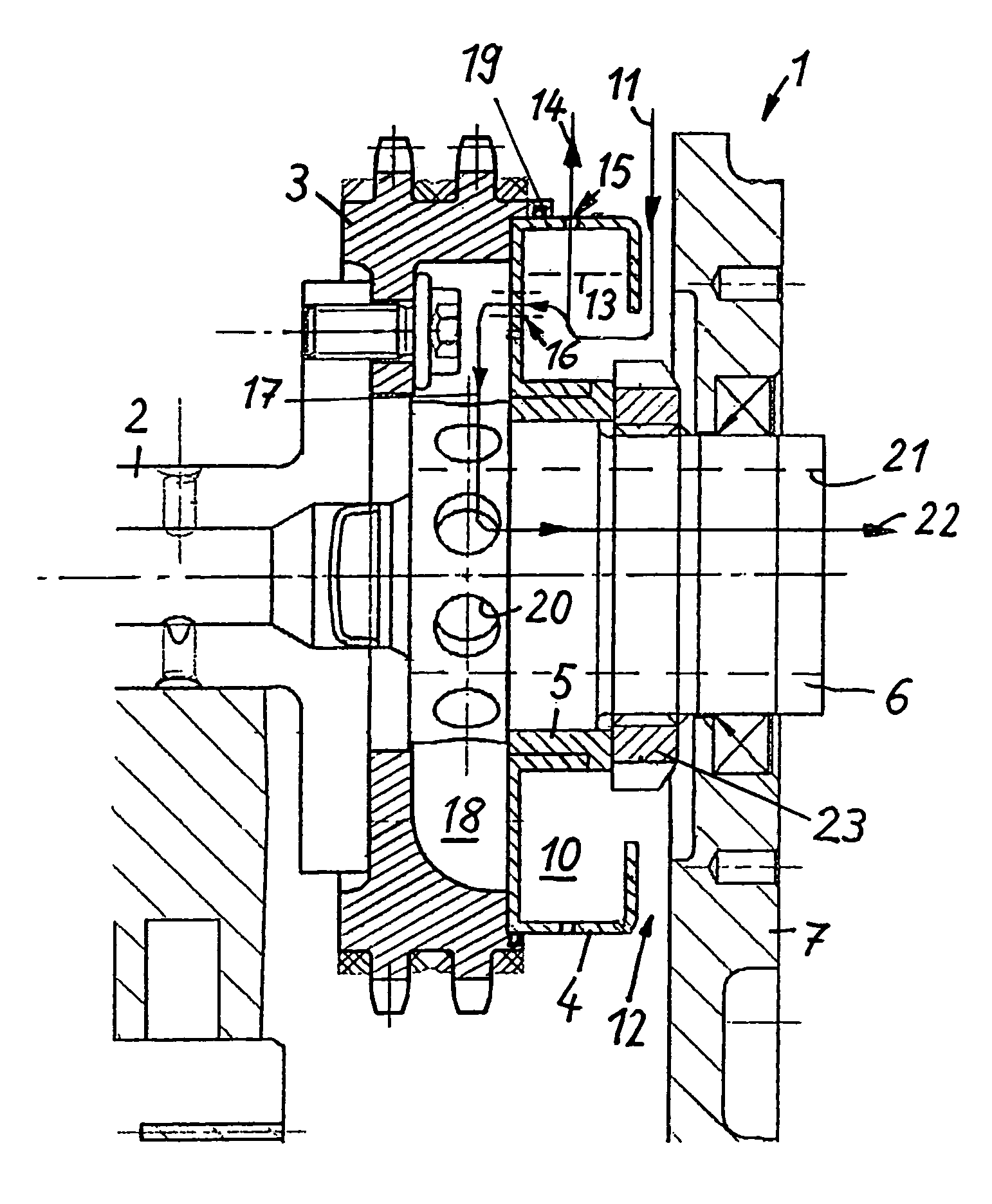

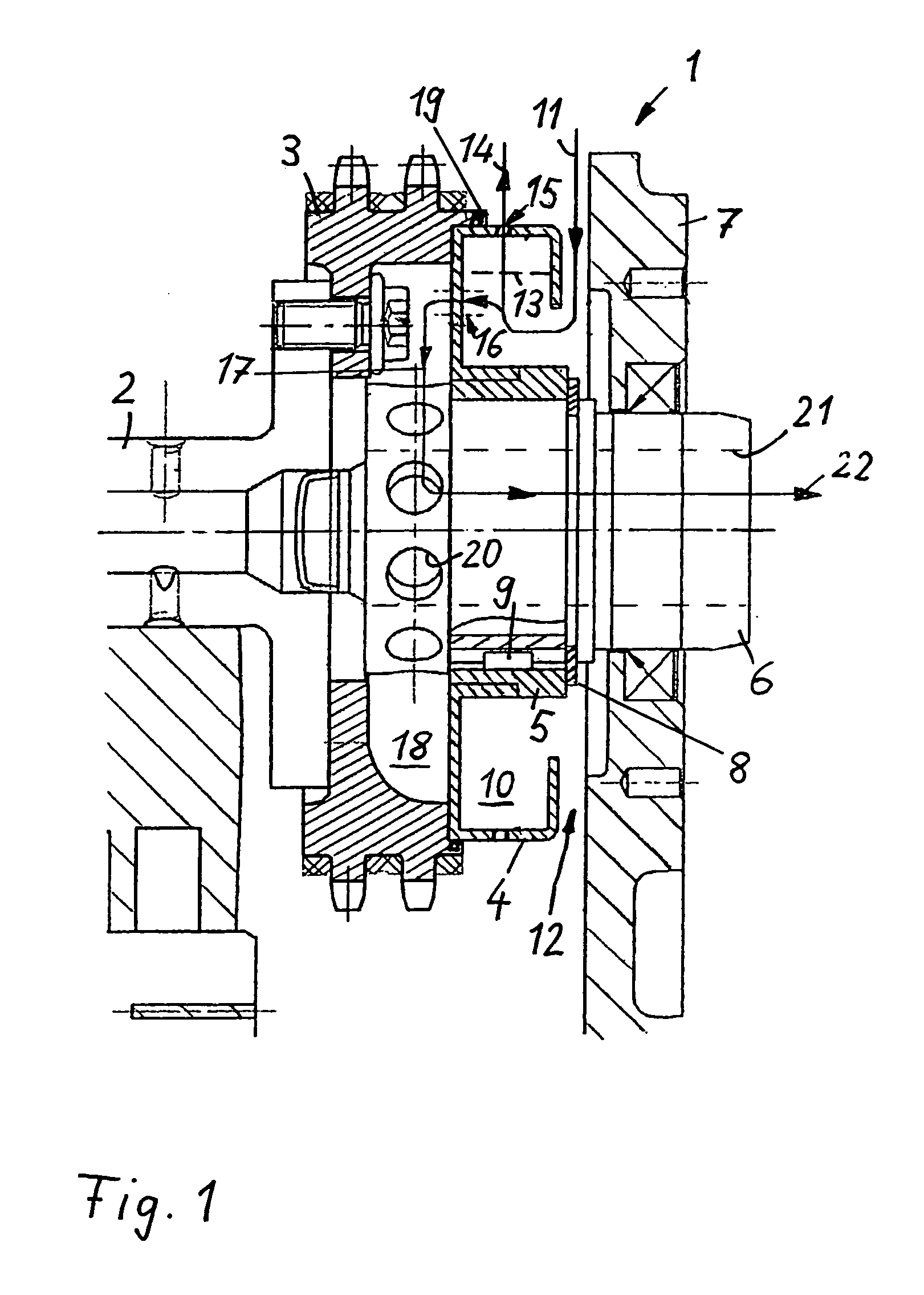

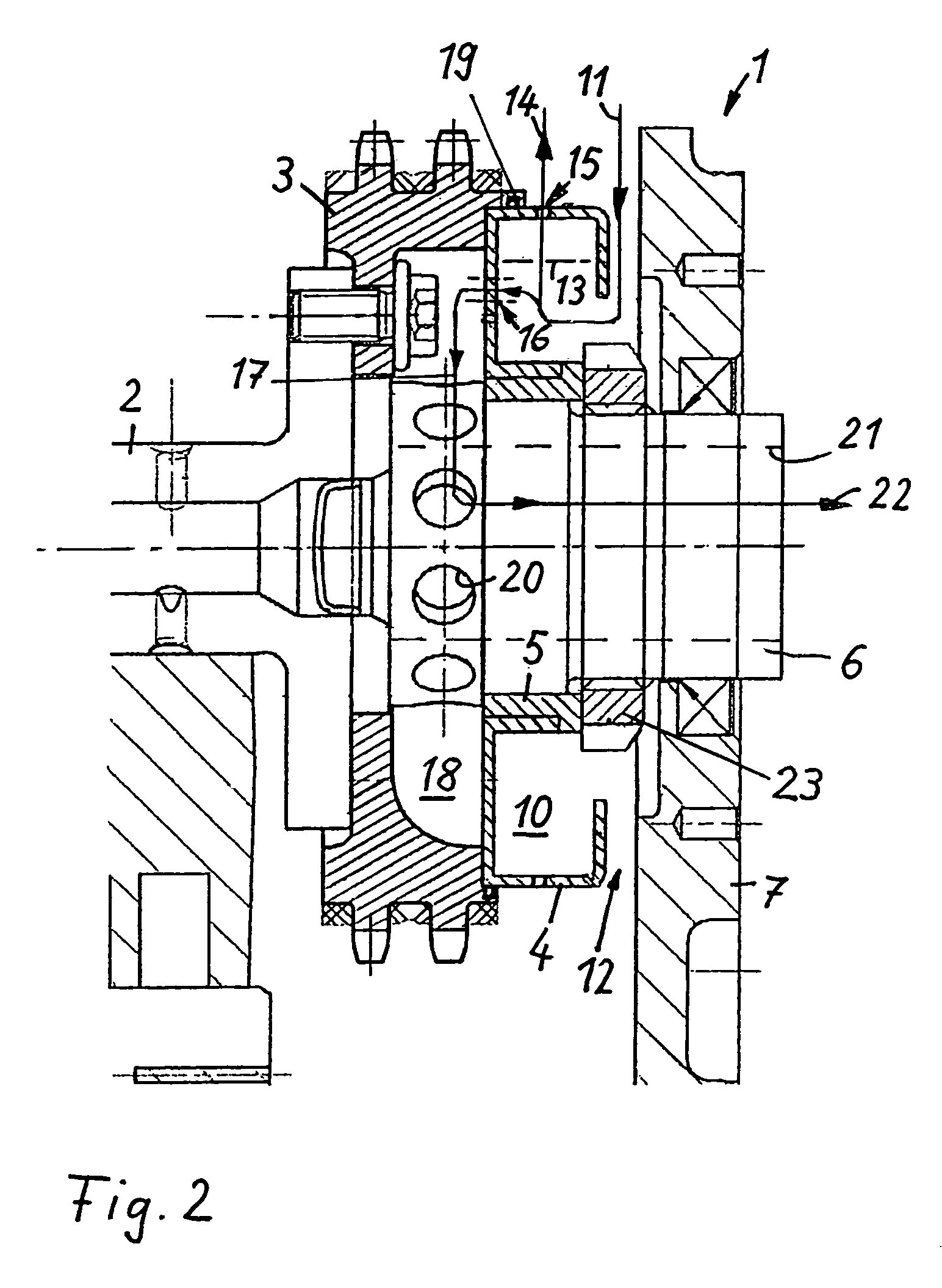

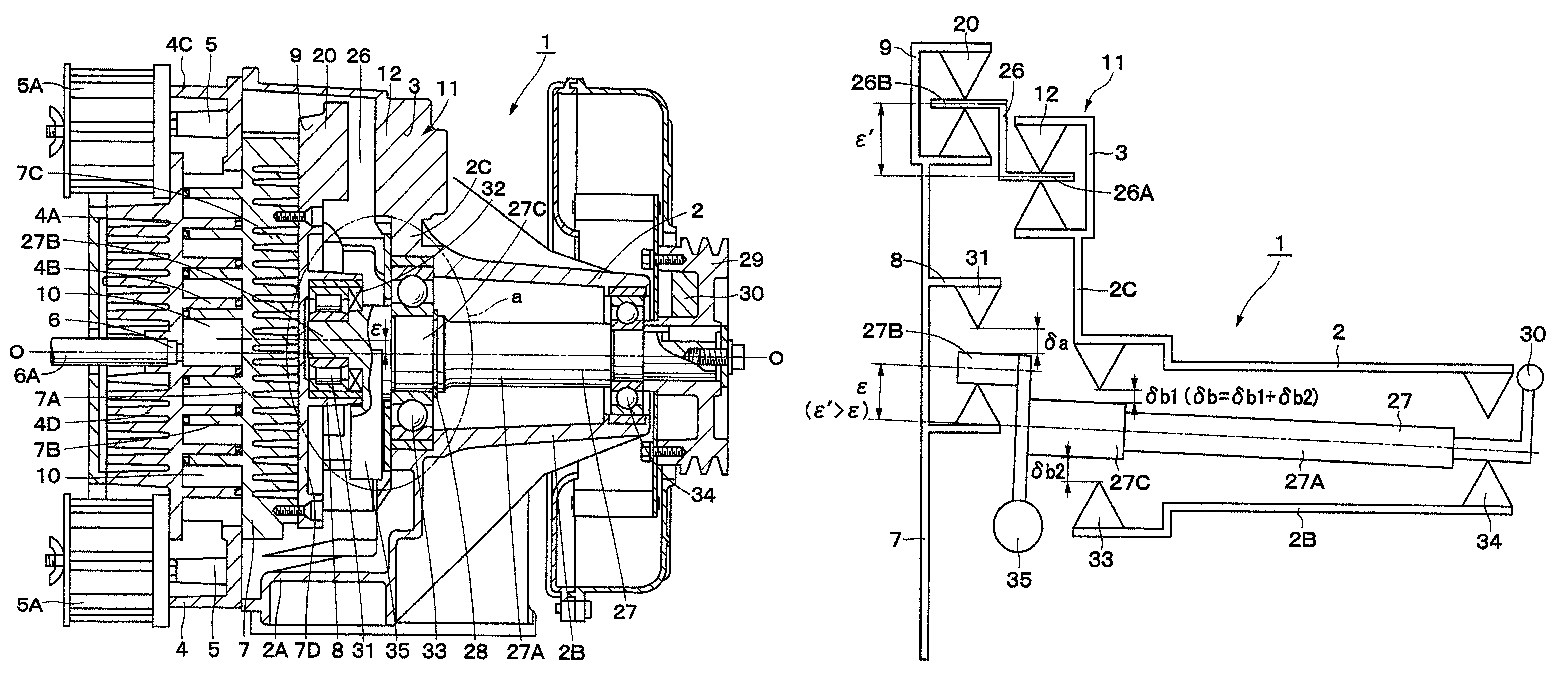

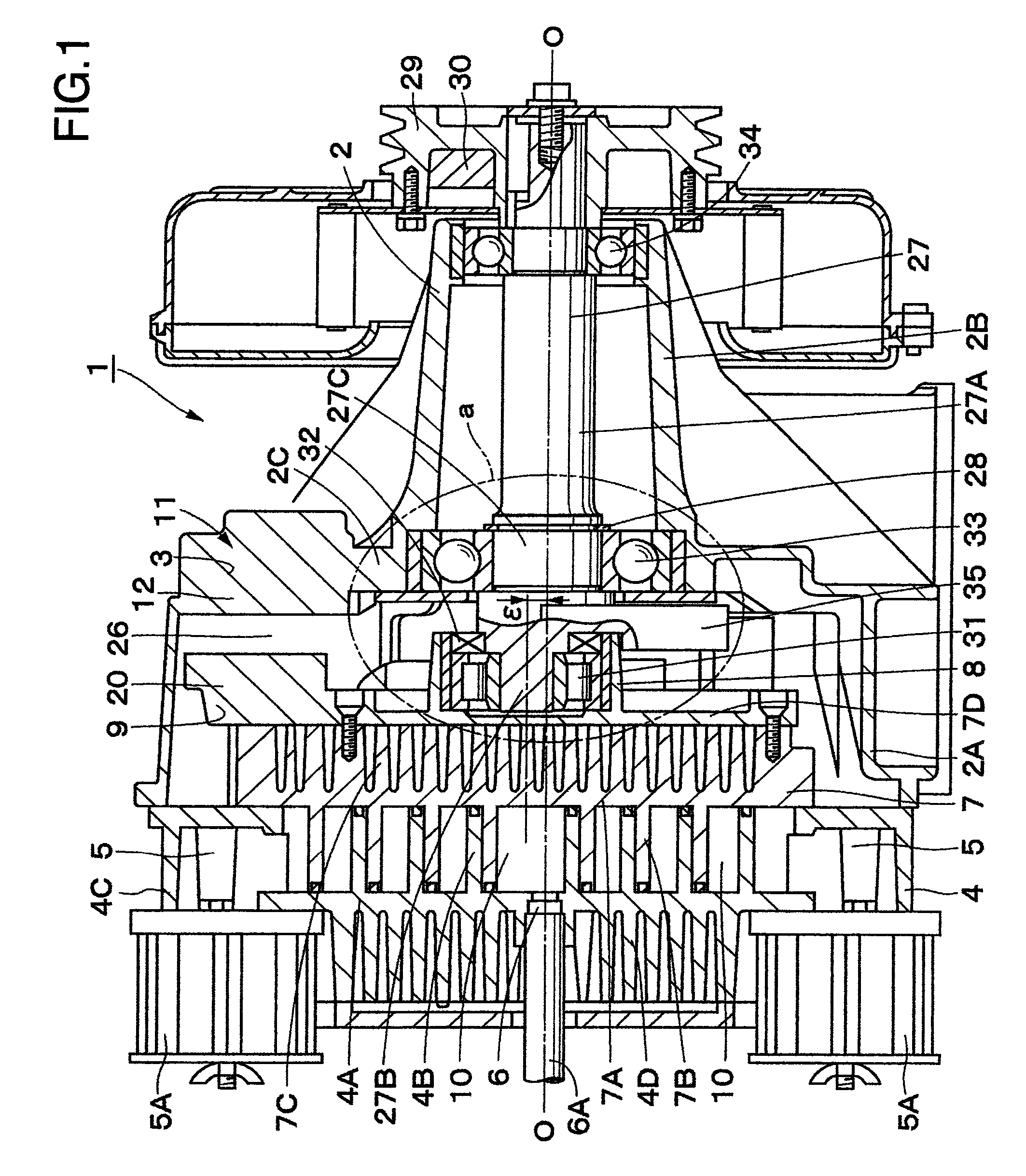

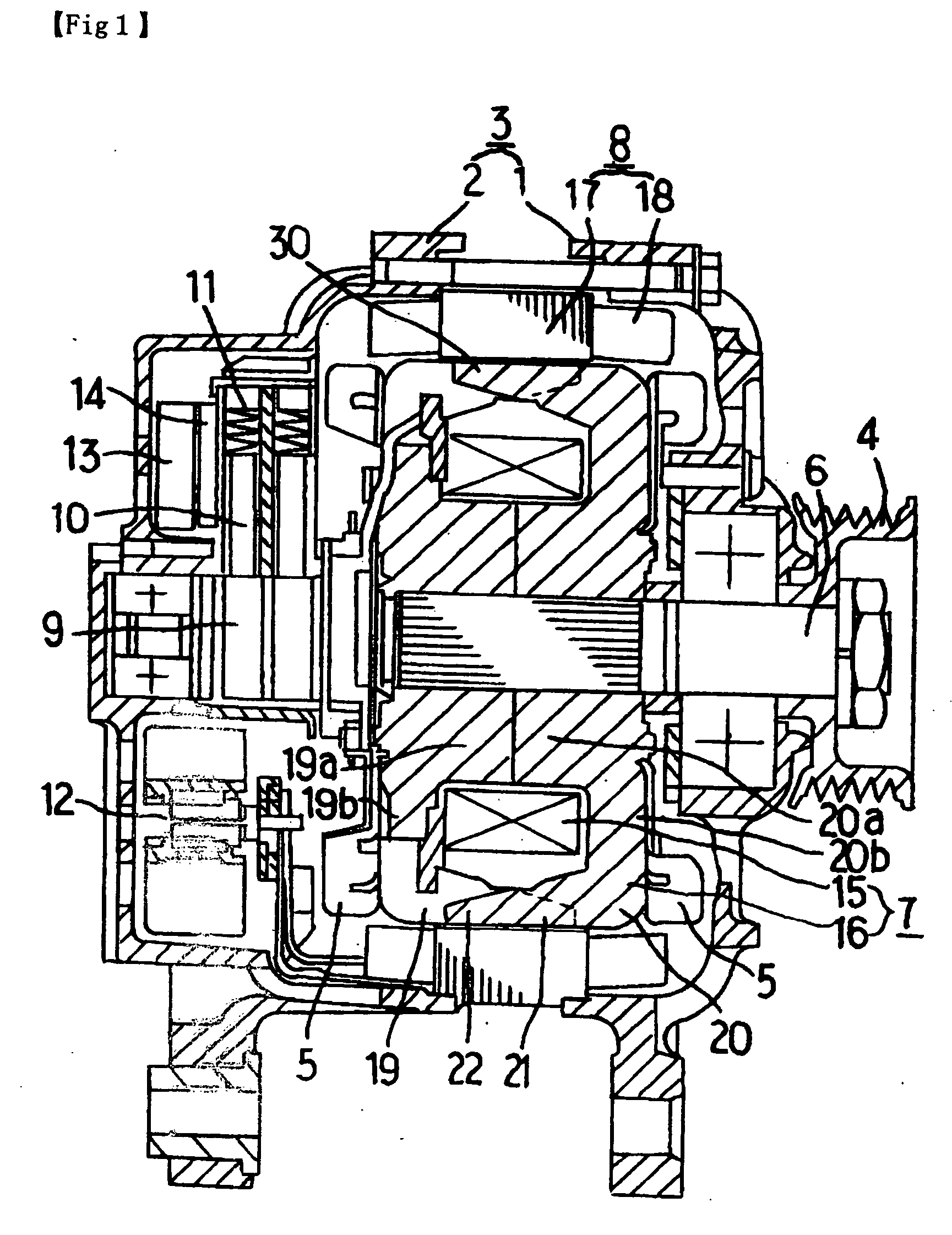

Hydrodynamic torque converter

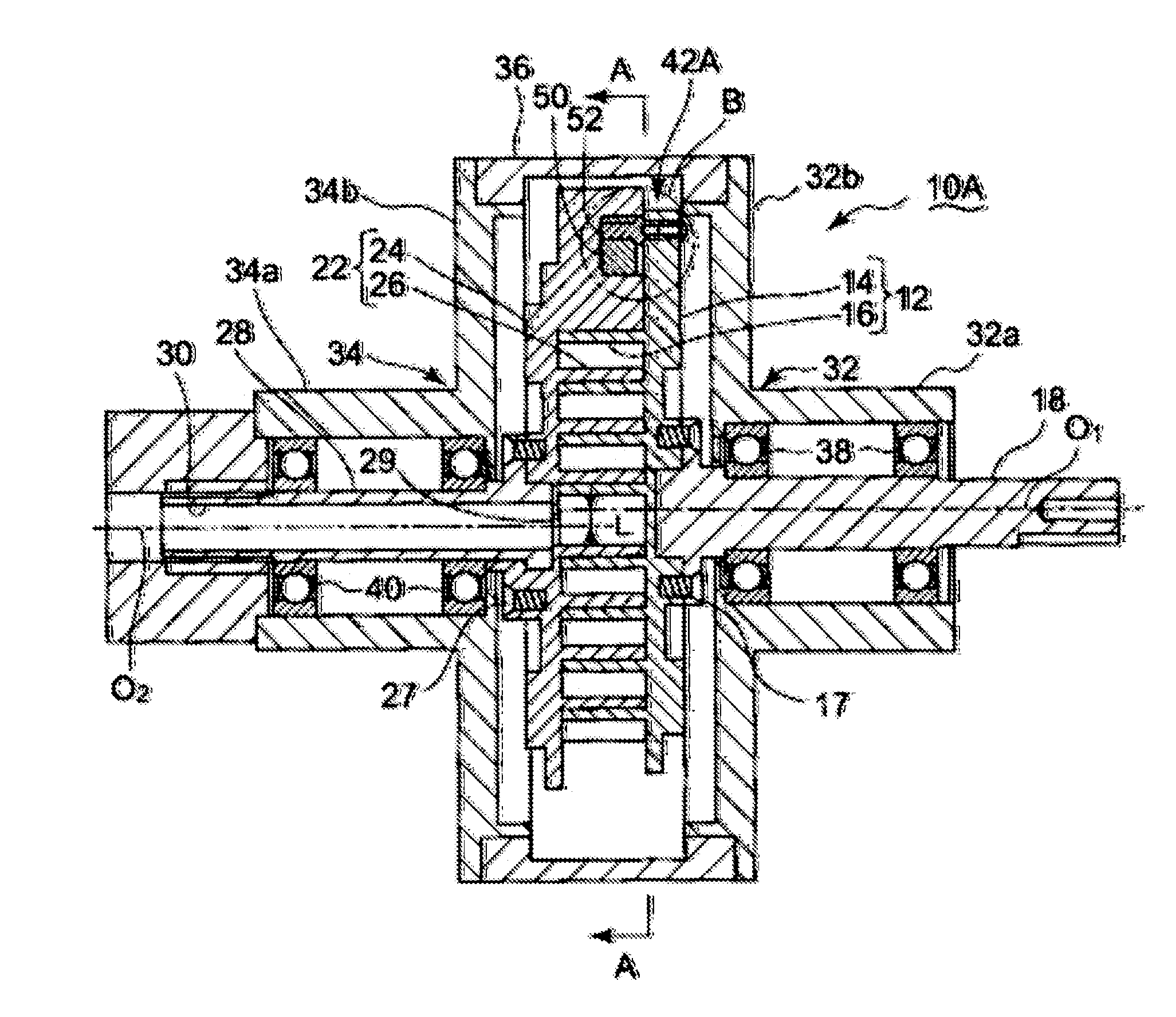

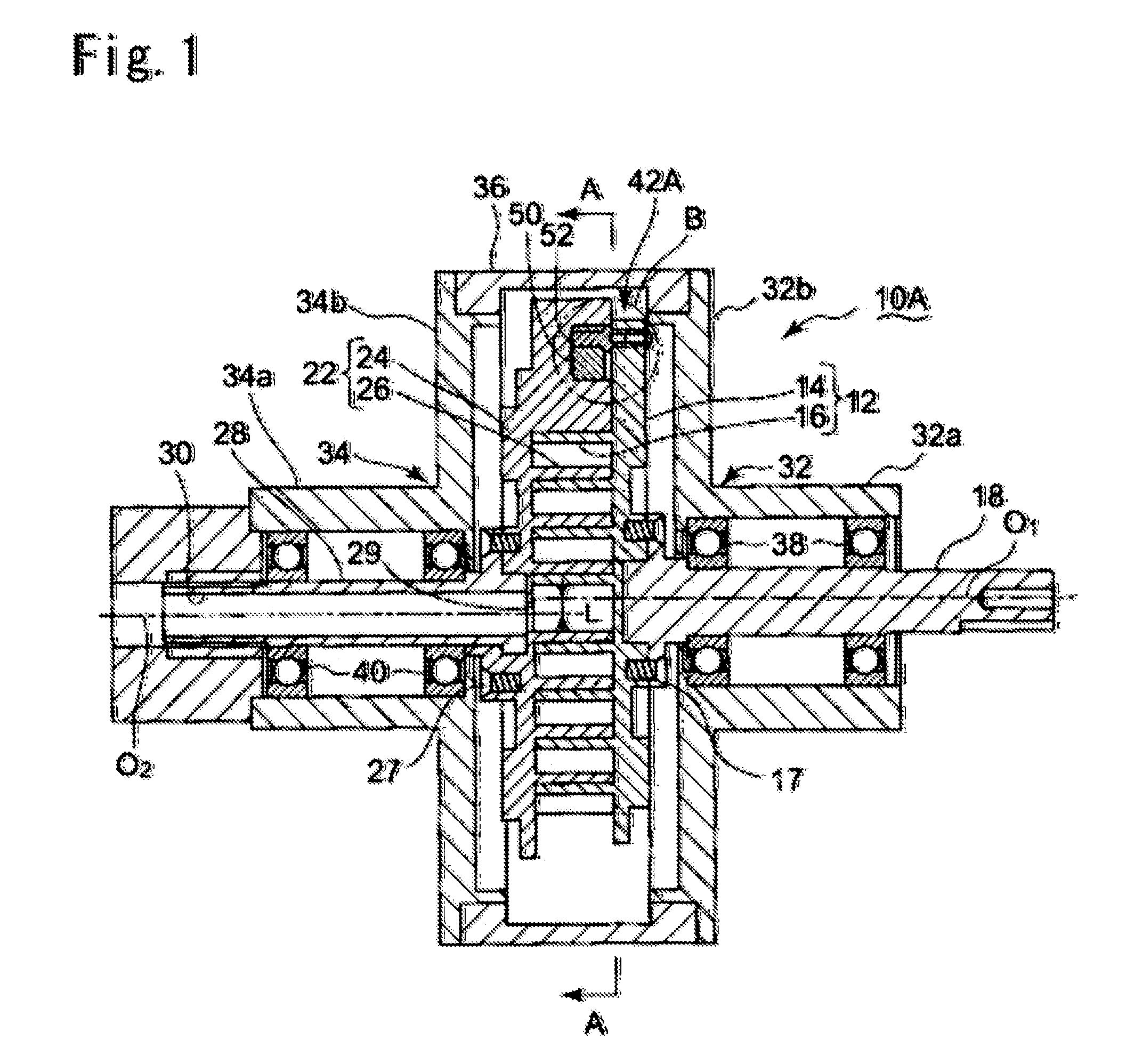

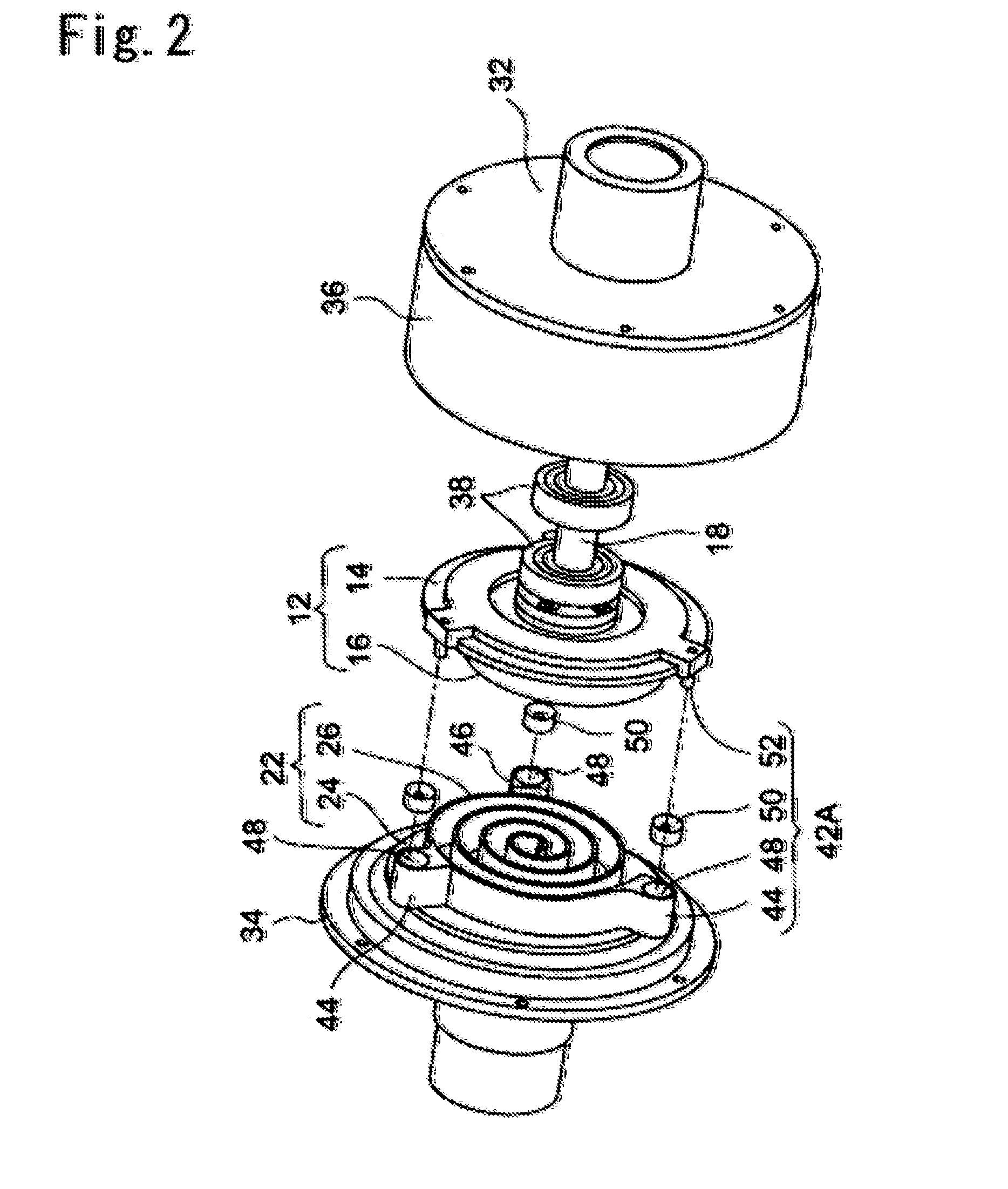

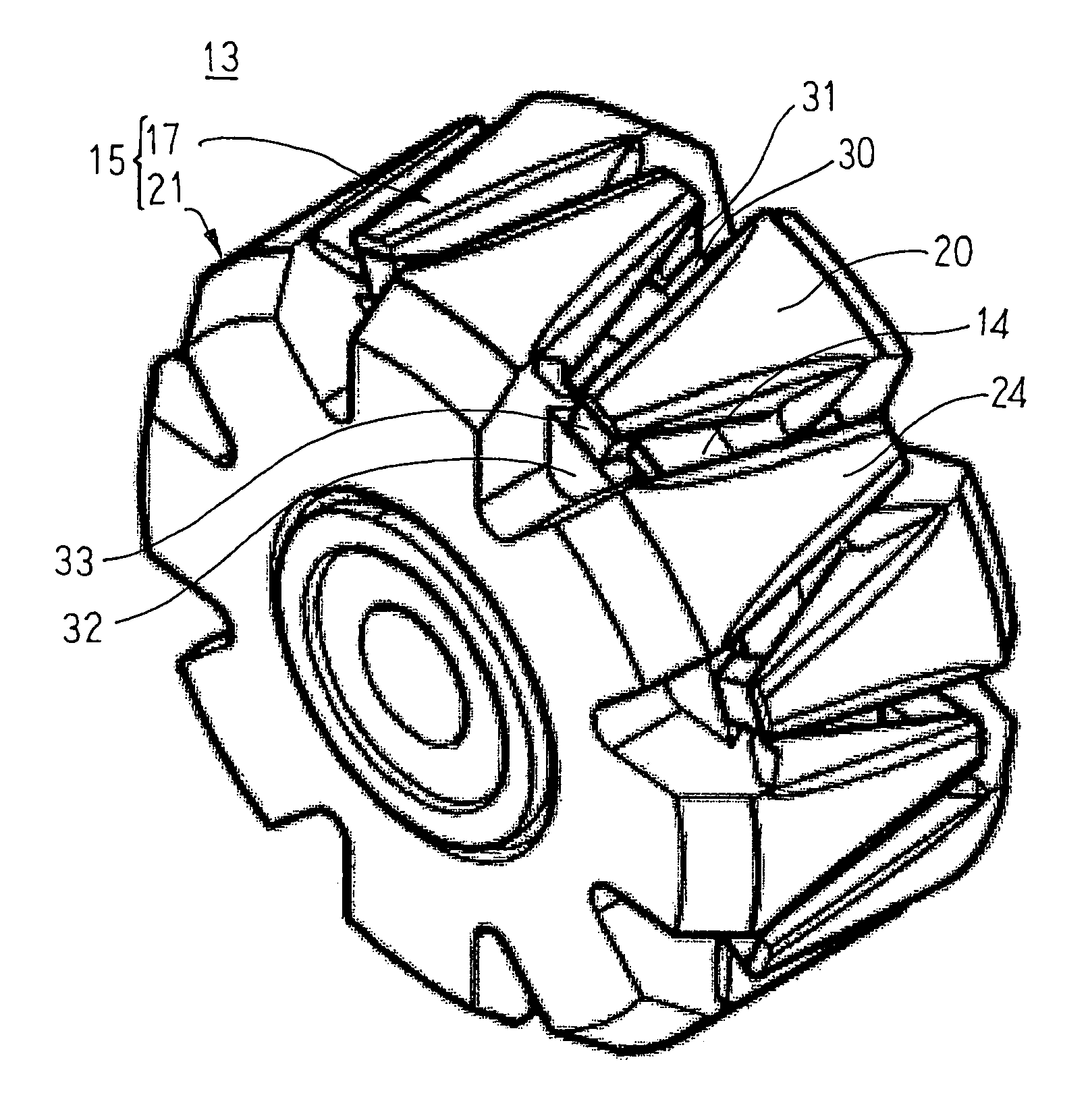

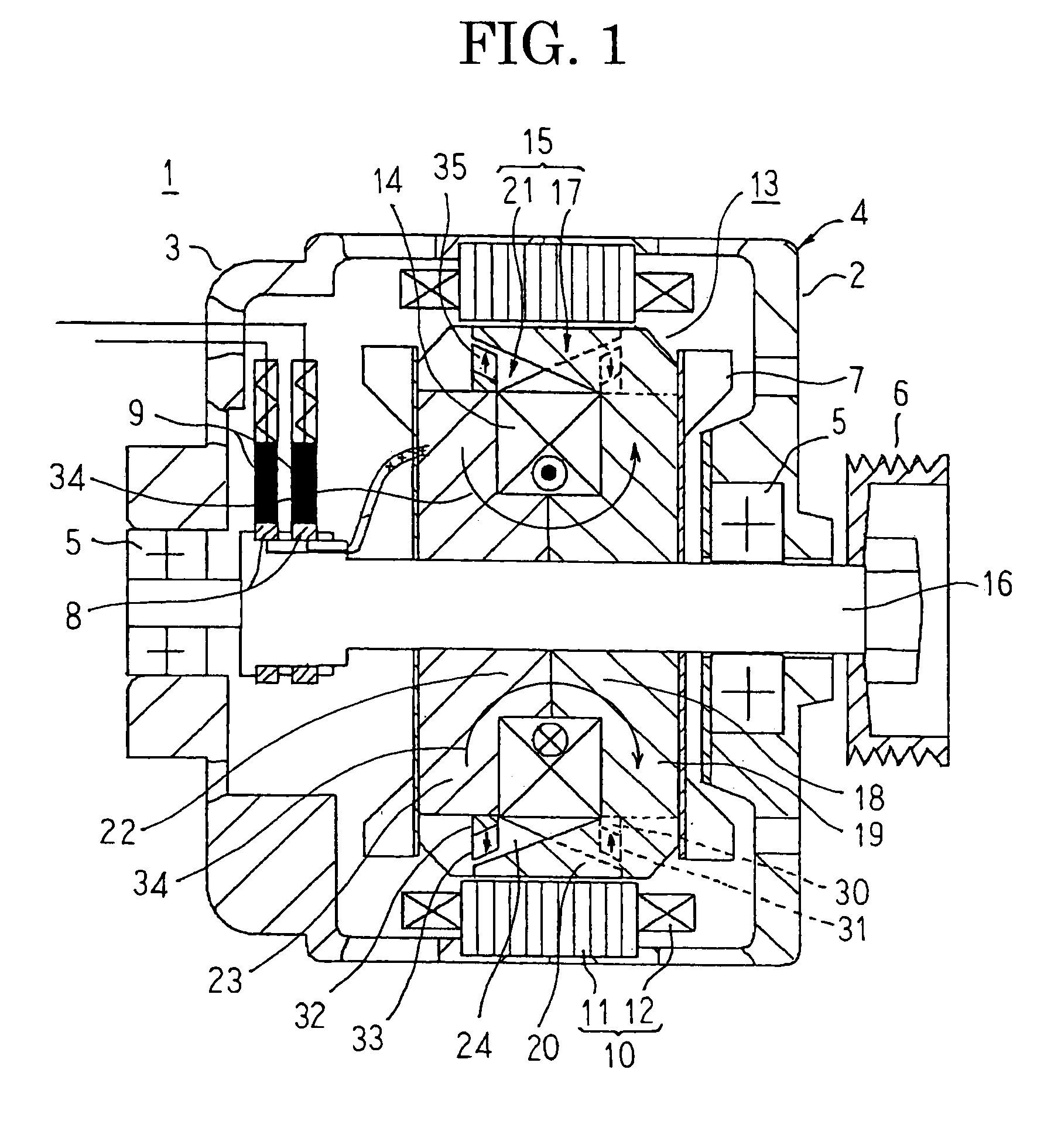

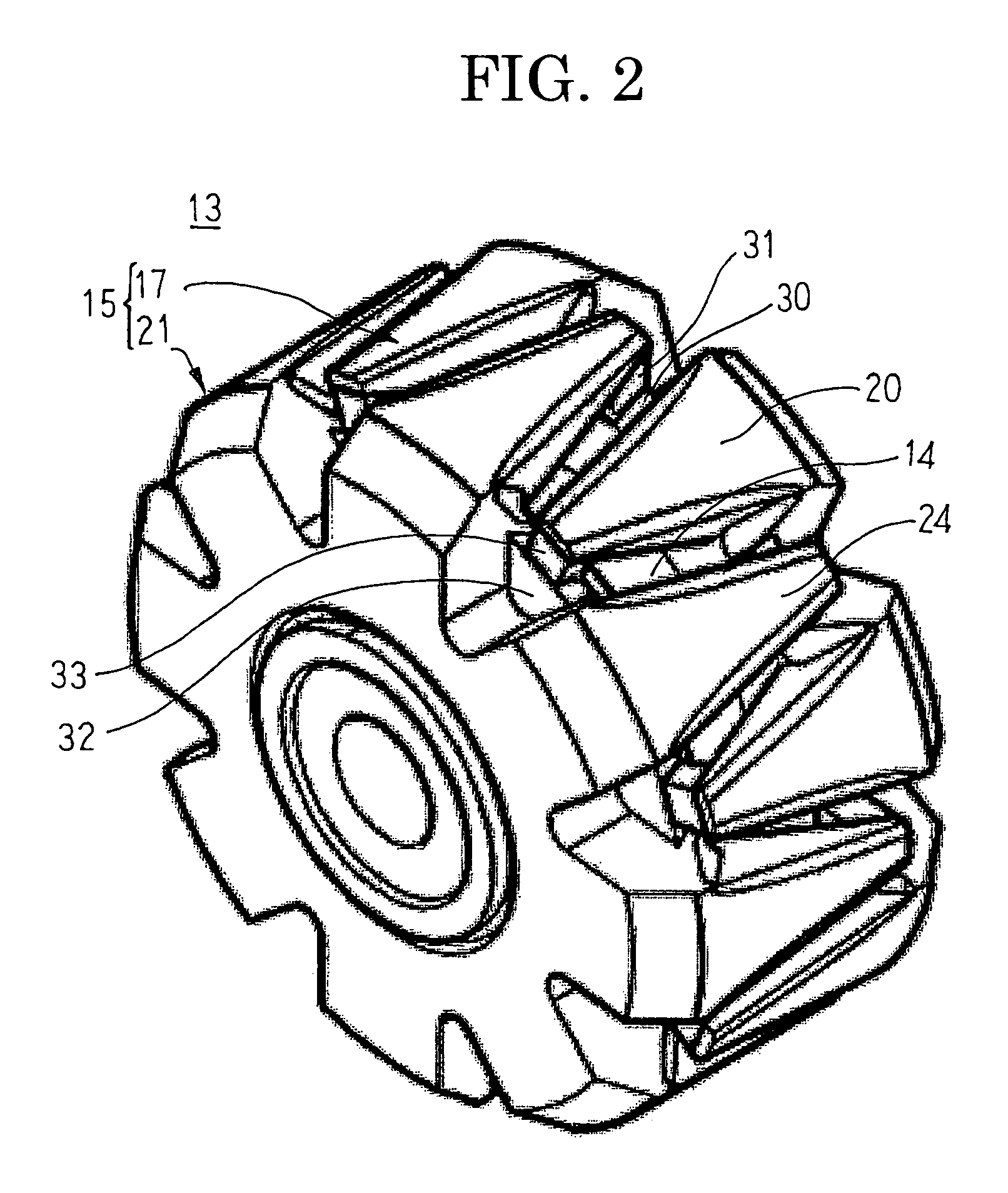

ActiveUS8342306B2Simple designReduce centrifugal forceRotating vibration suppressionYielding couplingTurbine wheelExternal combustion engine

A hydrodynamic torque converter (1), comprising a turbine wheel (9) driven by an impeller (8) and connected to an output part, and comprising a housing (34), in which a torsional vibration damper (19) having several damper stages (17, 20) and a centrifugal force pendulum (11), and also a converter lockup clutch (18) connecting a housing and an output part (3), are accommodated. In order to avoid any striking of the pendulum masses of the centrifugal force pendulum in internal combustion engines having large oscillating angles driving the torque converter, a turbine damper is connected in the power flow upstream of the centrifugal force pendulum.

Owner:SCHAEFFLER TECH AG & CO KG

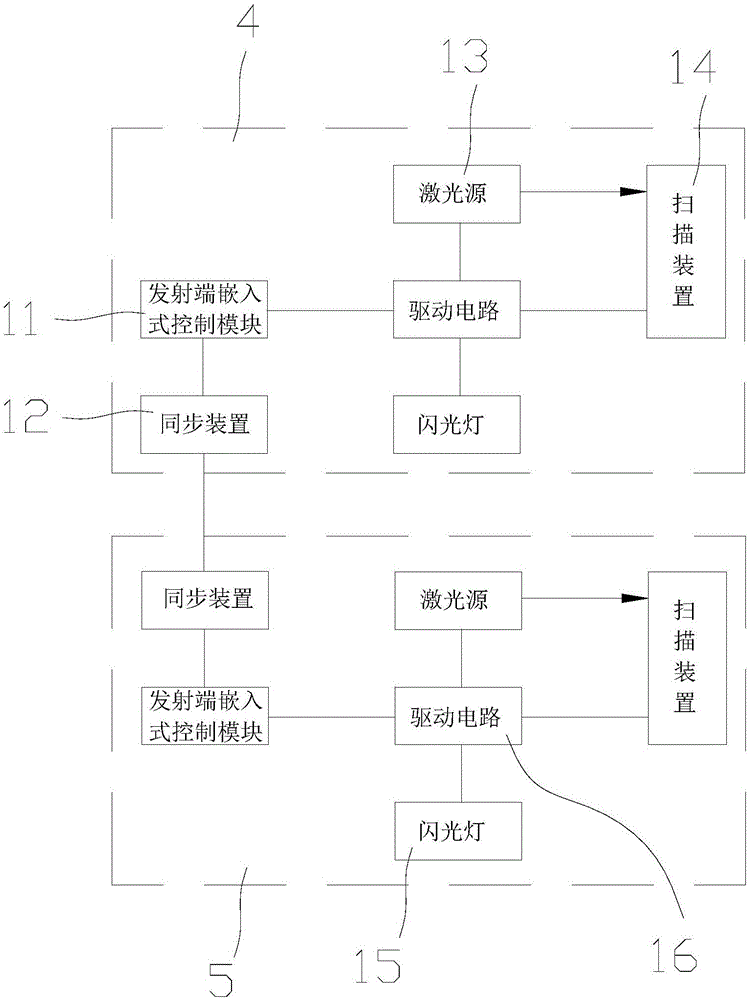

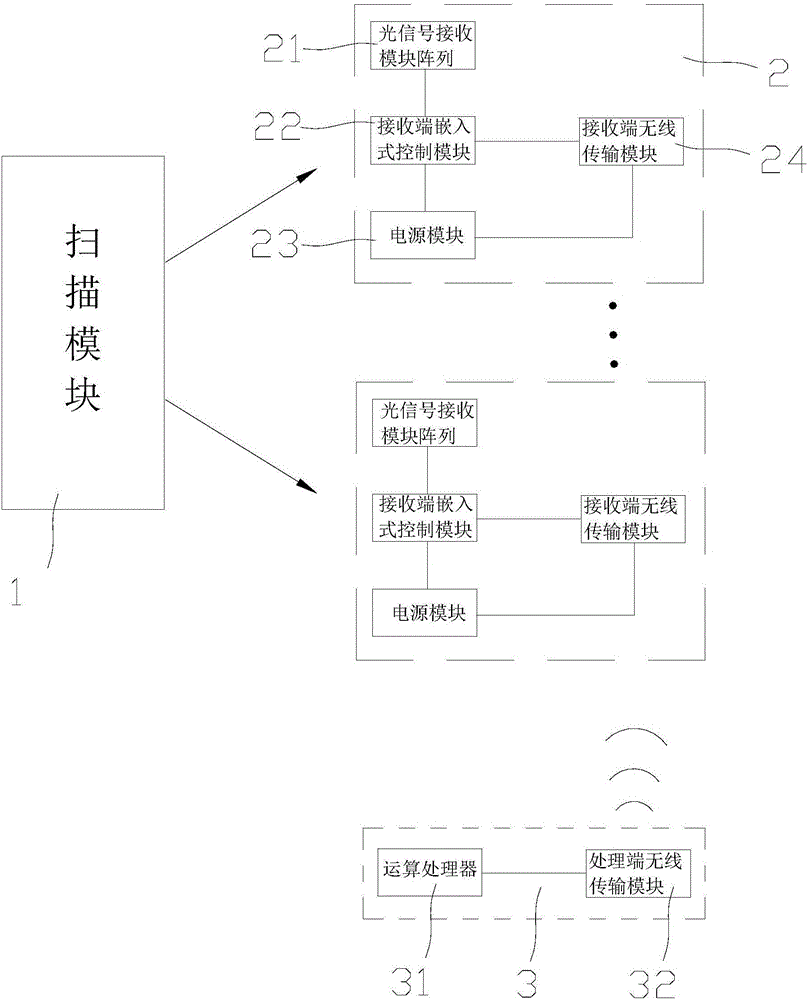

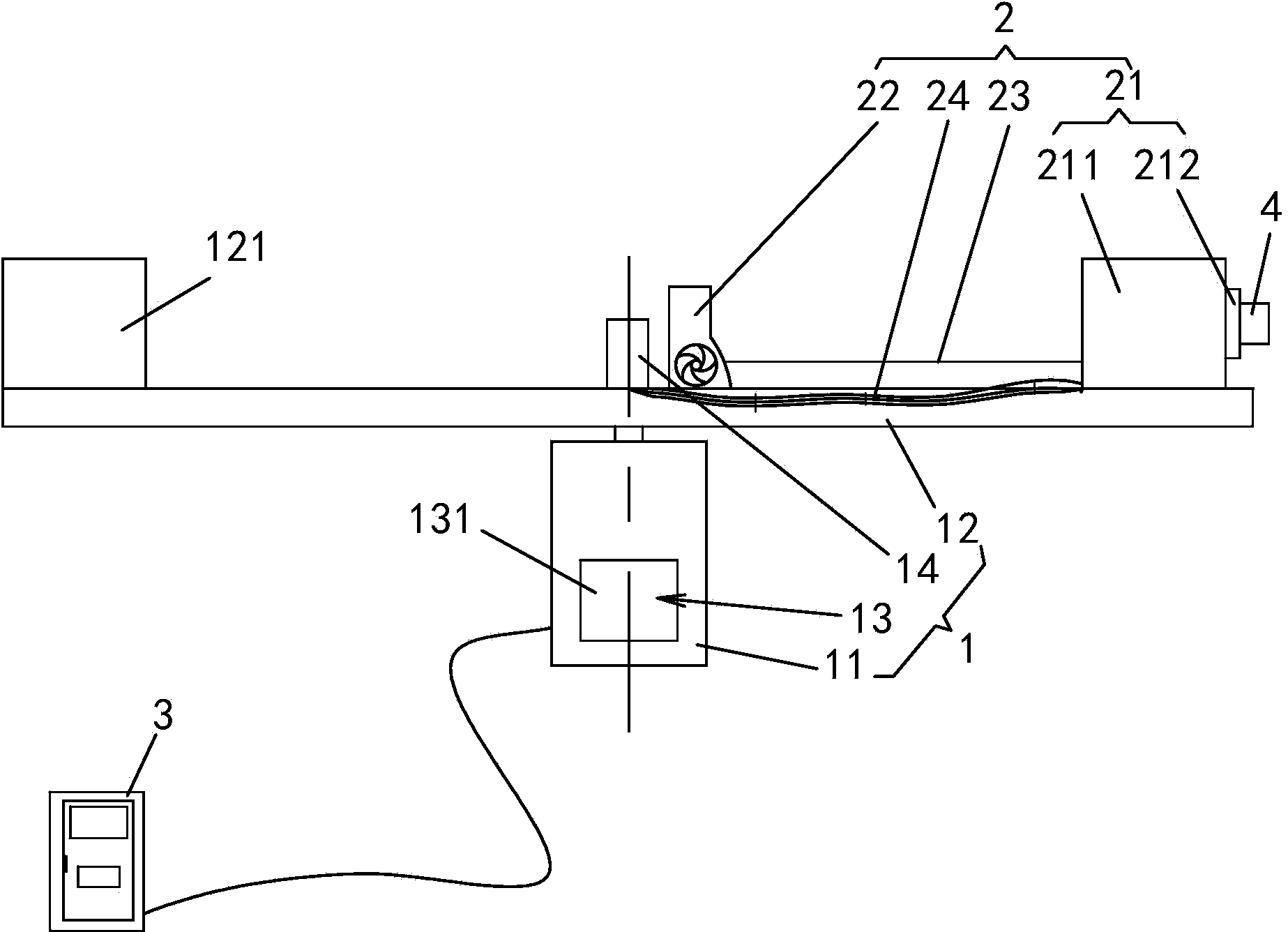

Method and system for positioning interactive space

PendingCN105824004AReduce in quantityImprove real-time performanceActive open surveying meansPosition fixationMicrocomputerEngineering

The invention provides a method and a system for positioning an interactive space. The system includes a scanning module, a receiving module and processing module. The receiving module includes an optical signal receiving module array. Compared with prior art, the system uses the method of scanning longitudes and latitudes in an alternative and successive manner, which simplifies computational complexity and at the same time reduces the number of measuring devices and has a simpler structure. The adoption of a rotary polyhedron, a scanning vibrating mirror, and a microcomputer electric reflector enables quality reduction of a rotator, is conducive to reduce centrifugal force generated from the rotation or vibration of the rotator, and increases device stability. The usage of a 2D controllable microcomputer electric reflector further reduces the number of the rotors to one, which further simplifies devices. The periodic flash of a flash lamp can enable the system to better determine a scanning period and prevent data chaos among different periods. An emit light ray processing module can increase or decrease emitting angles of a laser, which enlarges a scanning range.

Owner:VR TECH (SHENZHEN) LTD

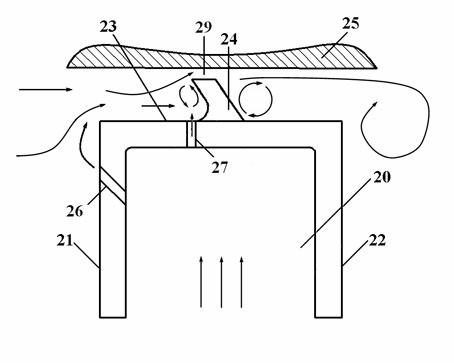

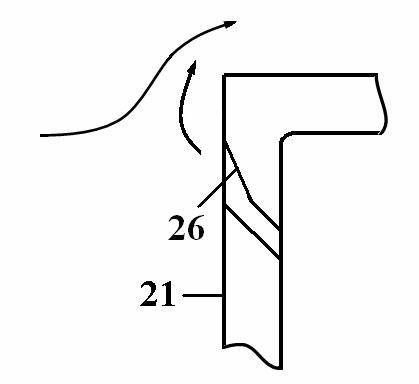

Centrifugal oil separator in an internal combustion engine

InactiveUS7309308B2Reduce weightImprove retentionCombination devicesDispersed particle filtrationEngineeringInternal combustion engine

In a centrifugal oil separator in an internal combustion engine including a centrifuge housing which is placed in a rotationally fixed manner onto a rotating centrifuge shaft, the centrifuge housing is manufactured from plastic and a metal bushing is integrated into the centrifuge housing and is slipped onto the centrifuge shaft.

Owner:DAIMLER AG

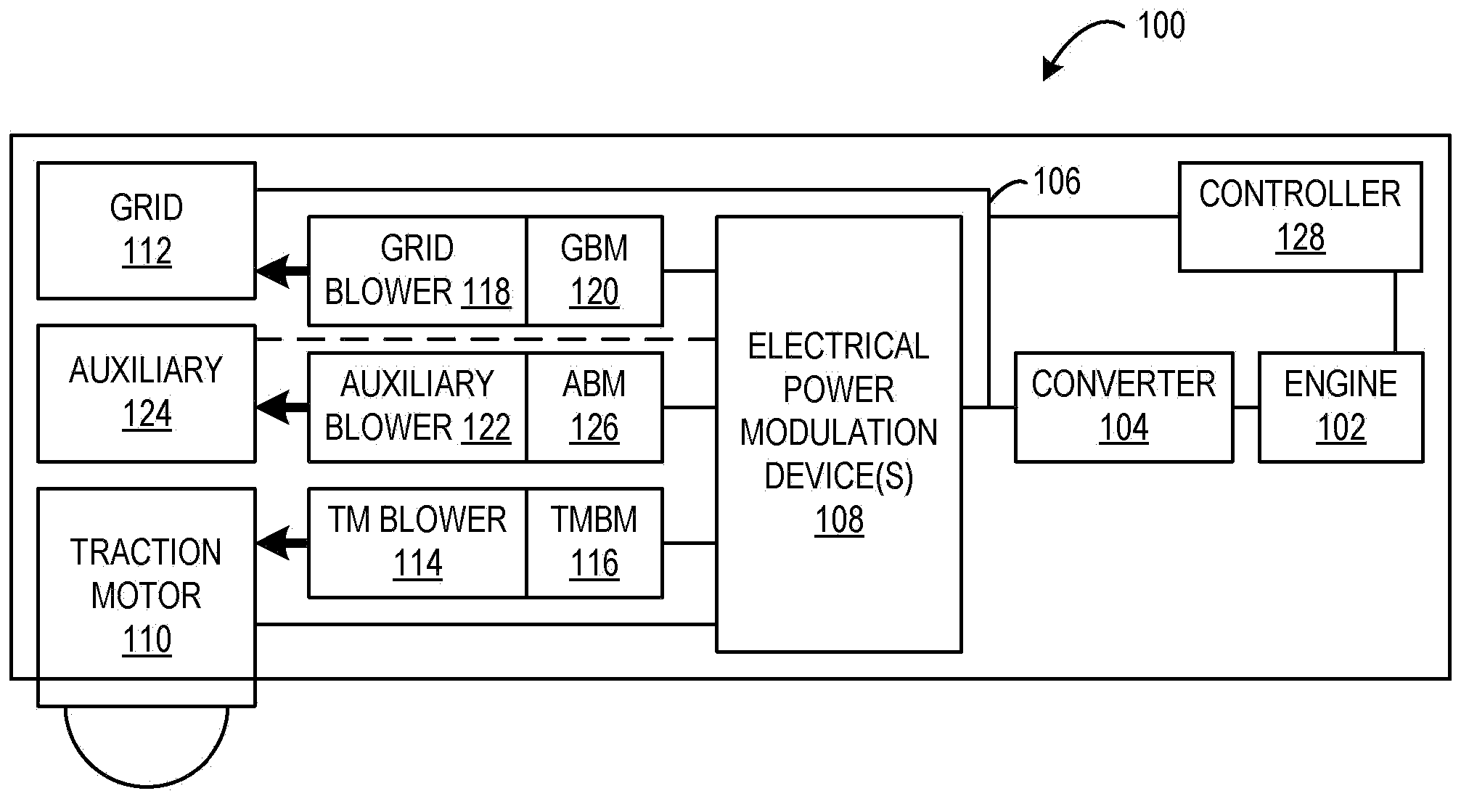

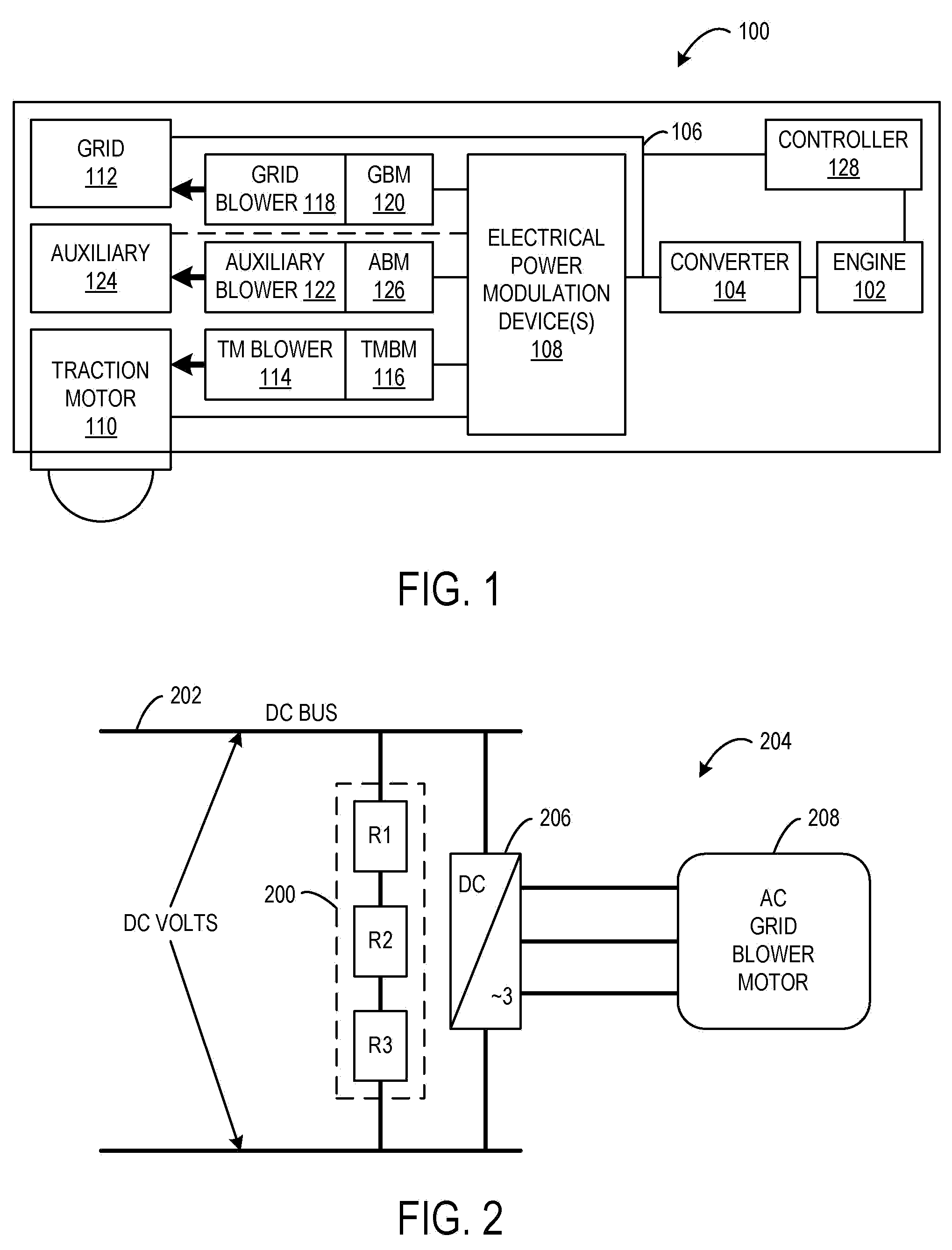

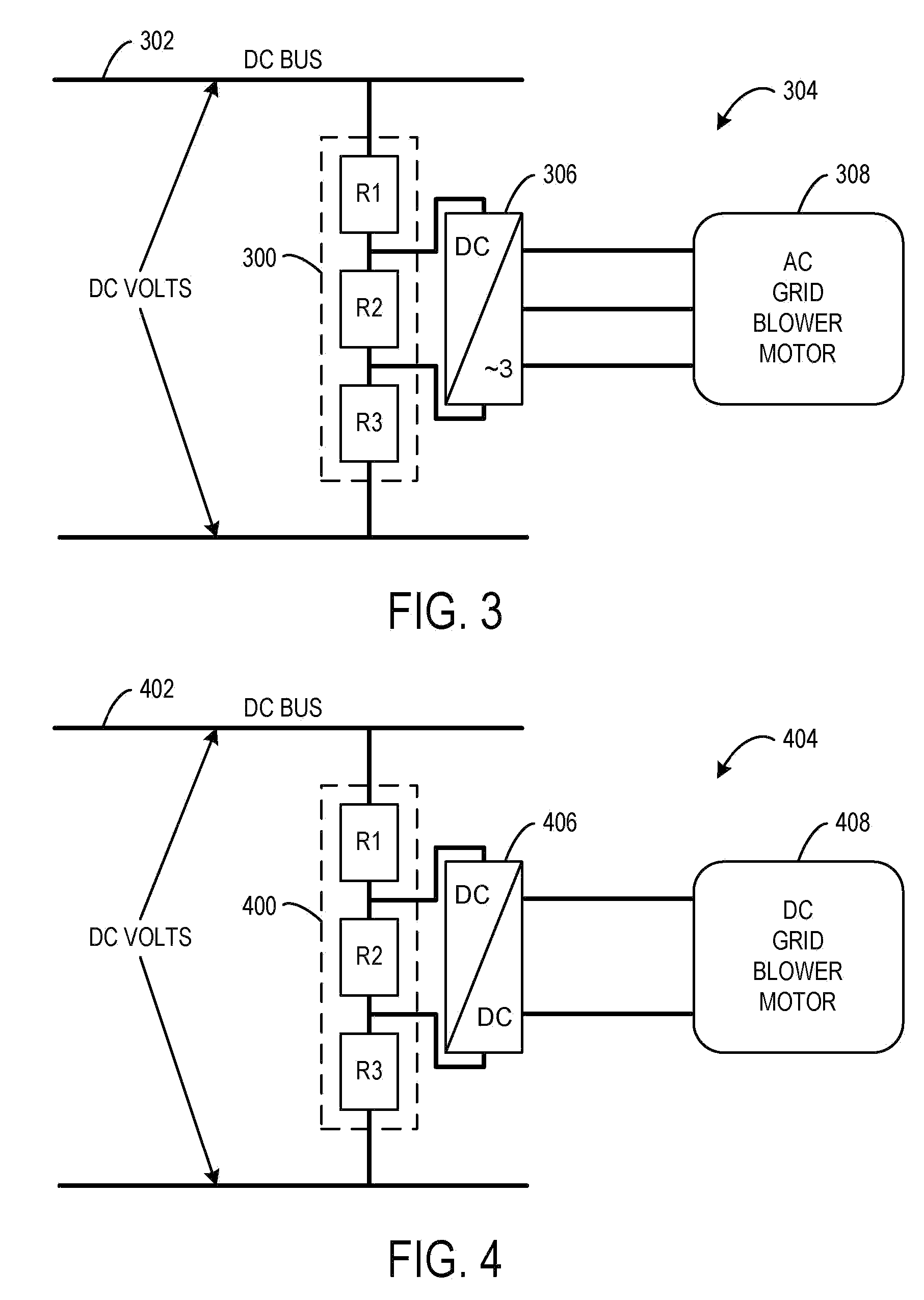

Variable-Speed-Drive System for a Grid Blower

ActiveUS20090293760A1Enhance forced-air cooling effectExtended service lifeDC motor speed/torque controlDigital data processing detailsElectrical resistance and conductancePower modulation

A drive system for a grid blower of a vehicle is provided. The system includes: an electrical bus, a grid of resistive elements connected to the electrical bus, the grid of resistive elements configured to thermally dissipate electrical power generated from braking of the vehicle, the electrical power being transmitted on the electrical bus to the grid of resistive elements, an electrical power modulation device configured to modify electrical power received from at least one of the electrical bus and the grid of resistive elements, and a grid blower motor coupled to an output of the electrical power modulation device, wherein a speed of the grid blower motor varies based on the electrical power that has been modified by the electrical power modulation device.

Owner:GE GLOBAL SOURCING LLC

Turbine cooling blade with blade tip leakage prevention structure

InactiveCN102678189ASimple structureLight in massBlade accessoriesMachines/enginesLeading edgeTurbine blade

The invention relates to a turbine cooling blade with a blade tip leakage prevention structure. A blade body is internally provided with a cooling channel; a blade tip partition rib extending from the front edge of the blade body to the tail edge of the blade body is arranged on the outer surface of a blade tip plate of the blade body; and more than one jet hole communicated with the cooling channel is distributed on the blade tip plate from the front edge to the tail edge of the blade body and is positioned at one side or two sides of the blade tip partition rib along the extending direction of the blade tip partition rib. According to the turbine cooling blade with the blade tip leakage prevention structure, the blade tip partition rib is arranged on the outer surface of the blade tip plate from the front edge to the tail edge of the blade body; when in use, the blade tip partition rib is positioned in a gap between the turbine blade and the sealing structure so as to replace the existing blade tip girdle structure, so that gas loss in the blade tip gap can be reduced, and no blade tip girdle structure is needed; and at the same time, the structure of the blade tip partition rib is simple, so that the blade tip partition rib can be rapidly maintained when being abraded or damaged after long time work of the turbine blade; and therefore, the turbine blade has high maintainability.

Owner:HENAN UNIV OF SCI & TECH

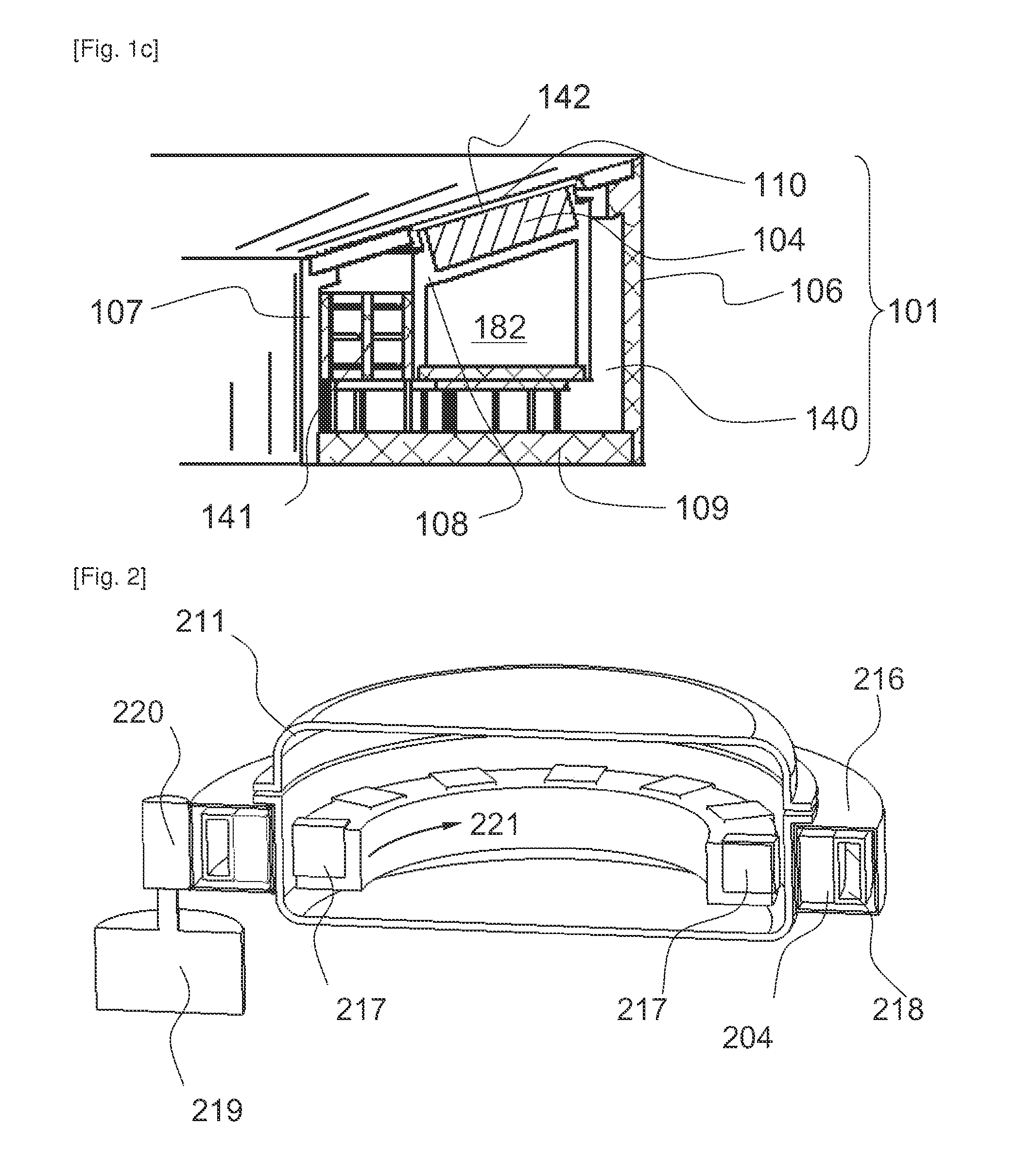

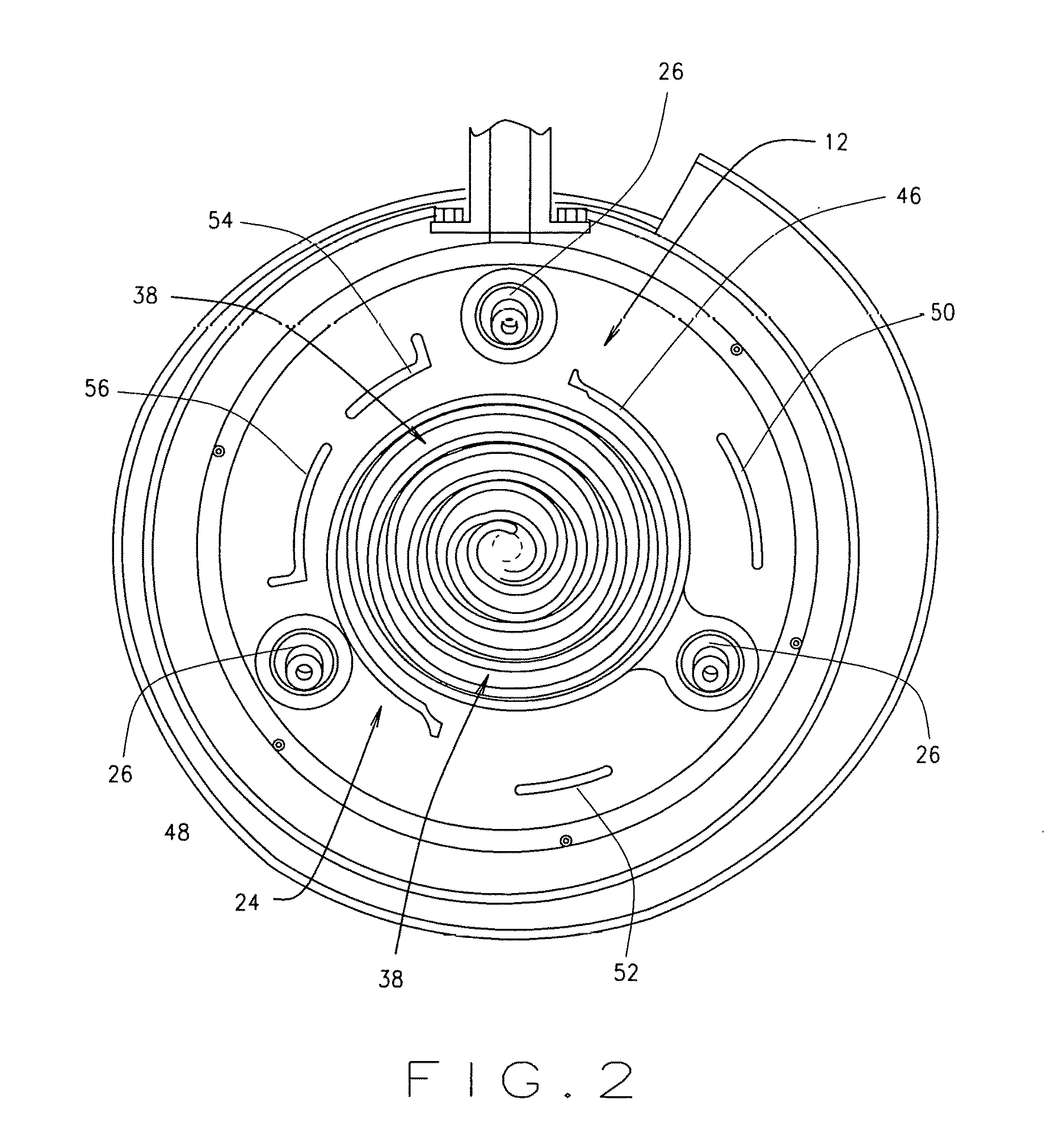

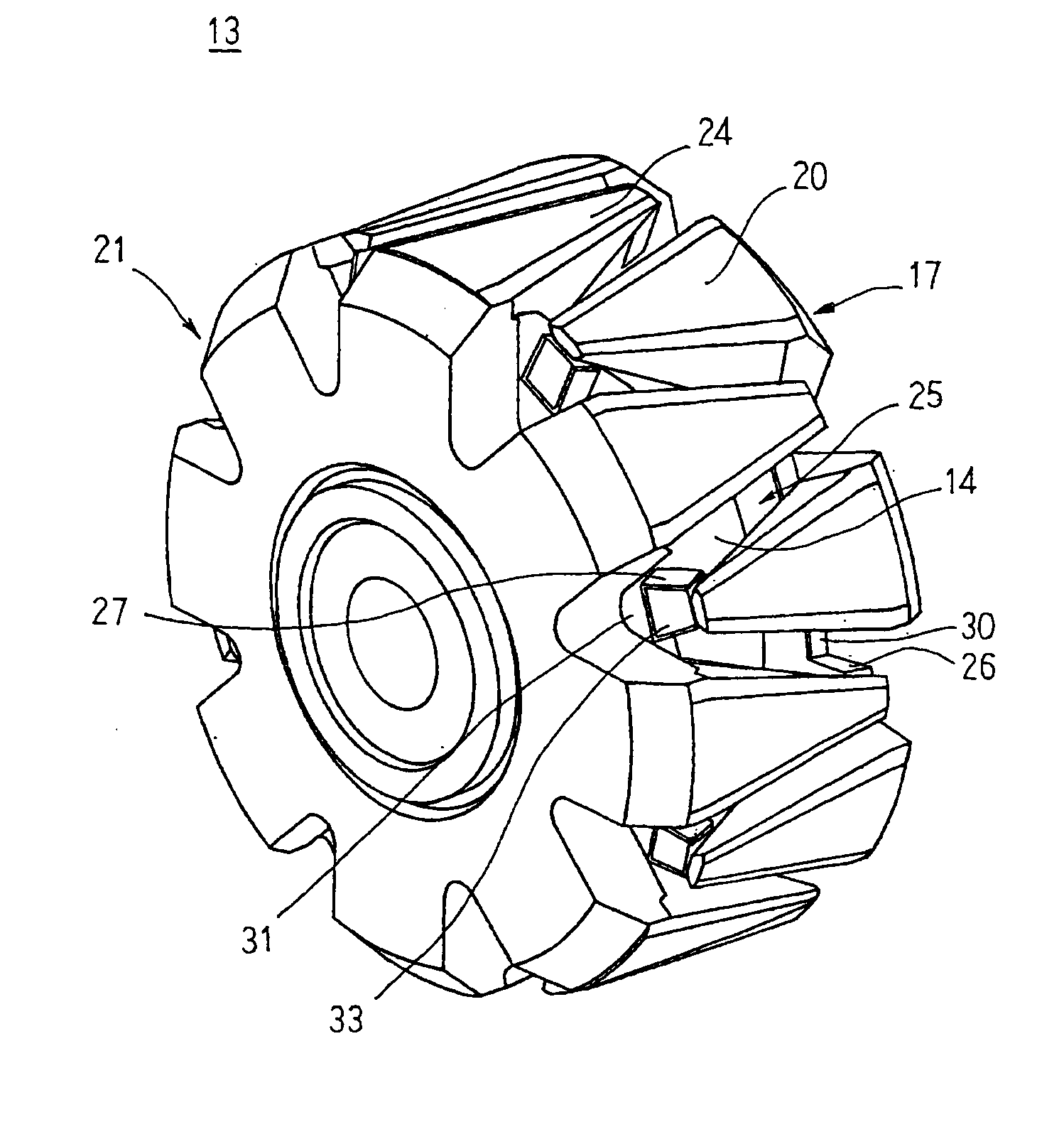

Scroll type device incorporating spinning or co-rotating scrolls

ActiveUS20170051741A1Reduce axial loadReduce centrifugal forceRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsEngineeringElectric motor

Owner:AIR SQUARED

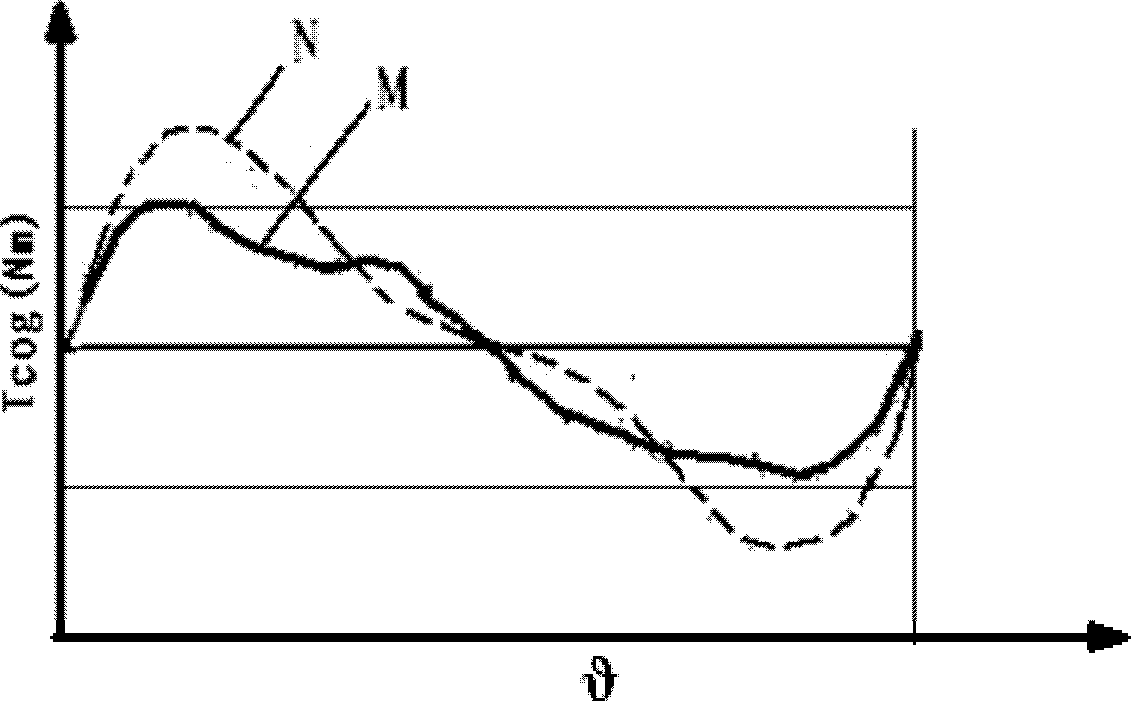

Permanent magnet drive motor for solar tracking system

ActiveCN101917076AReduced resultant torque fluctuationSmall torque fluctuationMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsSEMI-CIRCLEDrive motor

The invention relates to a permanent magnet drive motor for a solar tracking system, which comprises an enclosure, a stator and a rotor which are arranged in the enclosure, wherein, the stator comprises a stator core and a stator winding which are fixed on an inner wall of the enclosure, and the stator core comprises a stator magnetic yoke, a stator slot and stator teeth; the rotor comprises a rotating shaft and a rotor core, and a permanent magnet slot is uniformly arranged along the periphery of the rotor core; the permanent magnet slot is internally inlaid with radial magnetized rectangular strip magnetic steel, the radial magnetized rectangular strip magnetic steel and a pole piece form a permanent magnet pole, and an excircle of a rotor pole piece is in a concentric or excentric arc curved surface shape to form uniformly or non-uniformly symmetrical air gap; semi-circle grooves are arranged on two ends of the permanent magnet slot in which one of two pieces of adjacent radial magnetized rectangular strip magnetic steel is arranged; and rectangular supporting bars are radially inserted in the permanent magnet slot in which the V-shaped radial magnetized rectangular strip magnetic steel is arranged. The permanent magnet drive motor has the characteristics of high efficiency, high output power, high reliability, low moment fluctuation and the like.

Owner:苏州和鑫电气股份有限公司 +1

Scroll-type fluid machine that reduces centrifugal force of an orbiting scroll

InactiveUS8186980B2Reduce centrifugal forceYielding couplingEngine of arcuate-engagement typeEngineeringCentrifugal force

A scroll-type fluid machine comprising: a casing; a fixed scroll; an orbiting scroll; and an auxiliary crank device in which to prevent the orbiting scroll from being rotated, wherein the auxiliary crank device comprises: a fixed-side bearing body provided on either a casing side or a fixed scroll side; an orbiting-side bearing body provided on an orbiting scroll side; and an auxiliary crank shaft in which a fixed-side shank is rotatably supported with the fixed-side bearing body, and an orbiting-side shank is rotatably supported with the orbiting-side bearing body; a tip of the fixed-side shank of the auxiliary crank shaft is fixed in a radius direction, and a tip of the orbiting-side shank of the auxiliary crank shaft is fixed in a radius direction; and a deformative portion is provided between the tip of the fixed-side shank and the tip of the orbiting-side shank of the auxiliary crank shaft.

Owner:HITACHI LTD

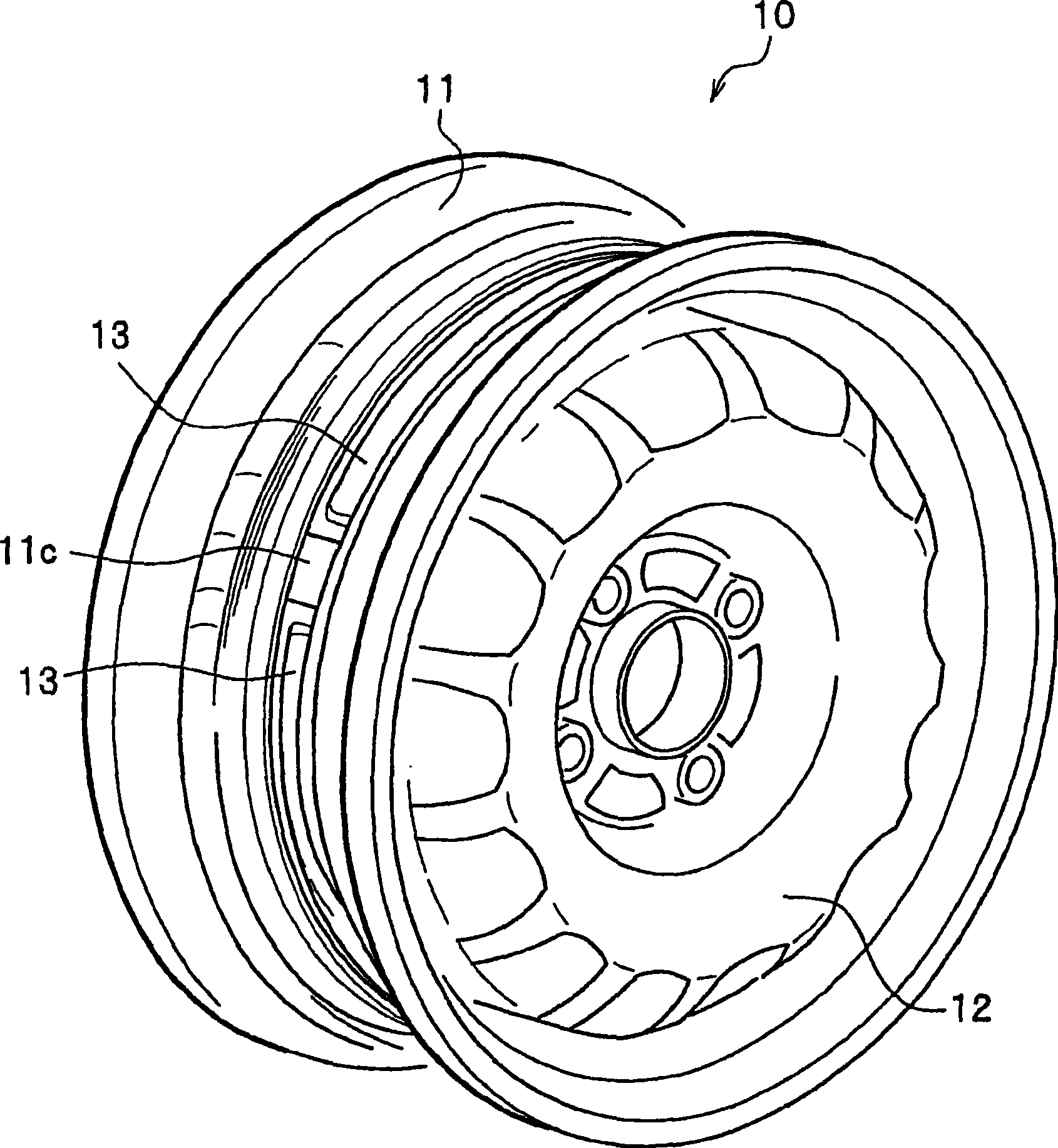

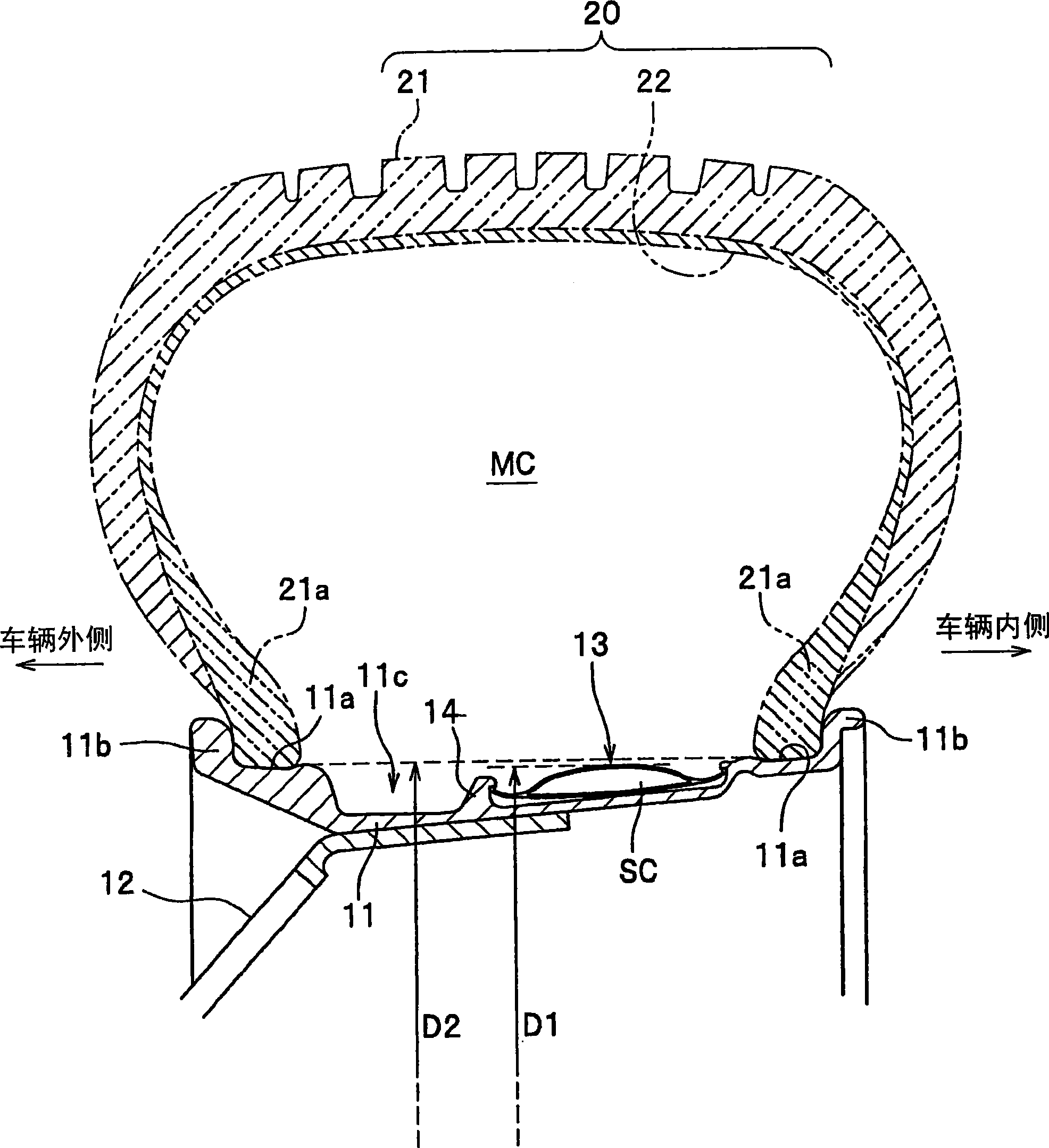

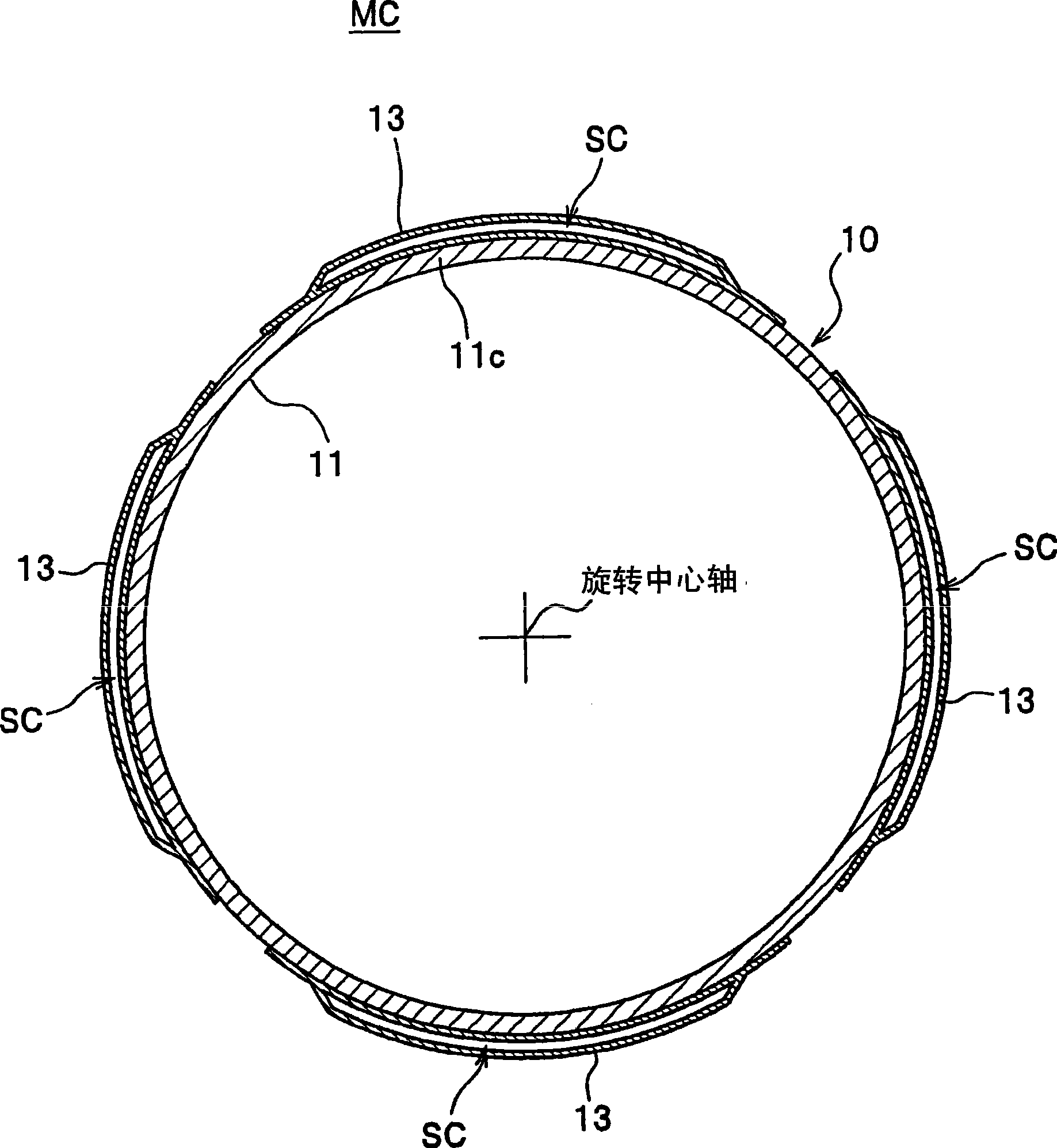

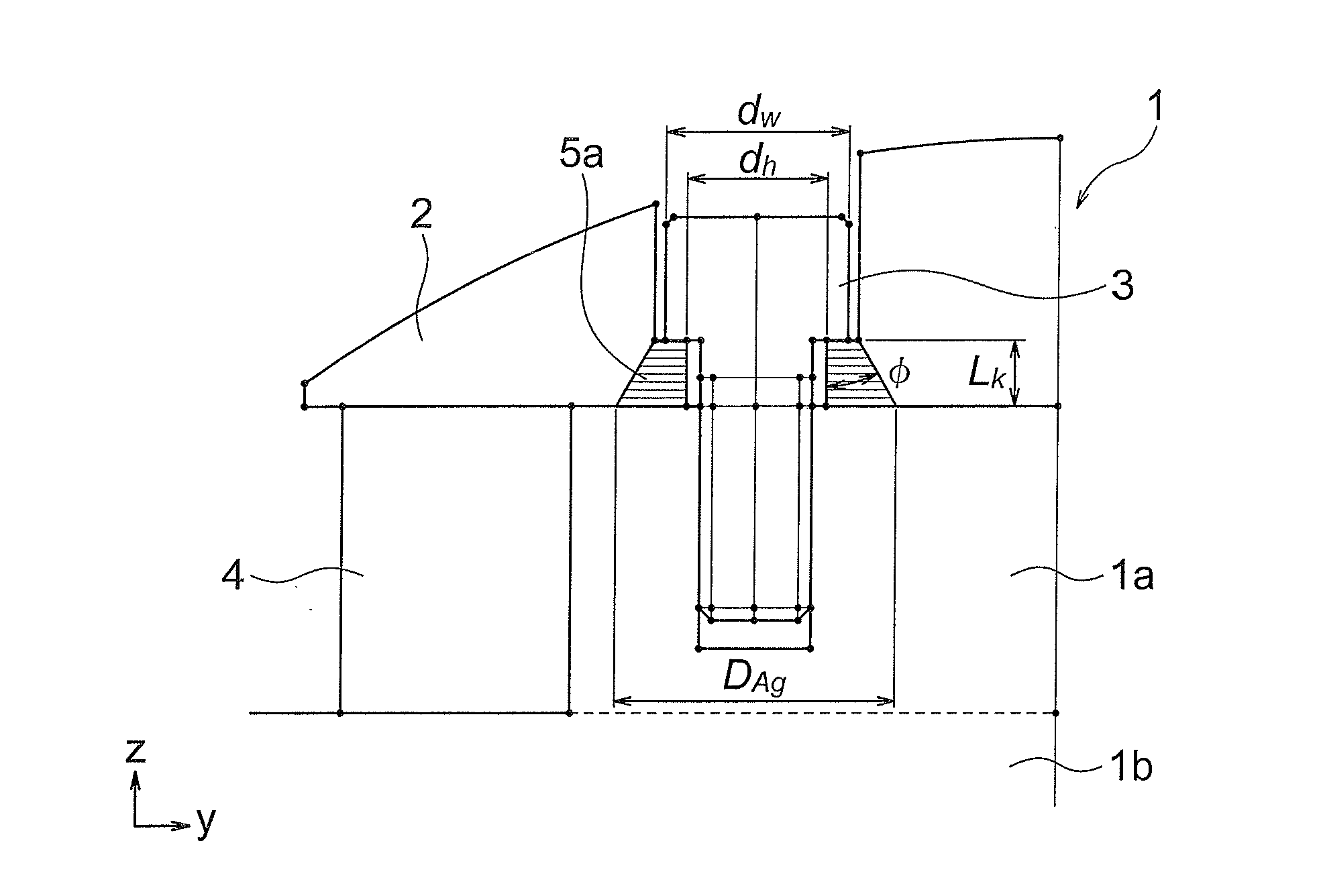

Vehicle wheel

The present invention provides a vehicle wheel, wherein a sub air chamber (13C) is provided with a plurality of tyre beads (31) concavely facing the sub air chamber (SC) side and extending along wheel circumferential direction, and a plurality of tyre beads (32) concavely facing the sub air chamber (SC) side and extending along wheel width direction on a bottom plate (25a) of a sub air chamber component (13A), in addition, a fovea is formed locally from the bottom plate (25a) to an upper plate (25b), and an upper butt-jointing portion (binding portion) (33A) is formed on several positions of the fovea bottom for jointing the bottom plate (25a) and the upper plate (25b). In the sub air chamber (13C) of the transfiguration embodiment, in the center of the wheel width direction, at least one of the bottom plate (25a) and the upper plate (25b) of the sub air chamber (13) is formed with tyre beads (30) in a direction crossed with a first longitudinal wall surface (15) and a second longitudinal wall surface (16) extending in a row along the circumferential direction of the wheel, and the butt-jointing portion (33A) is divided into eleven parts with equal interval.

Owner:HONDA MOTOR CO LTD +1

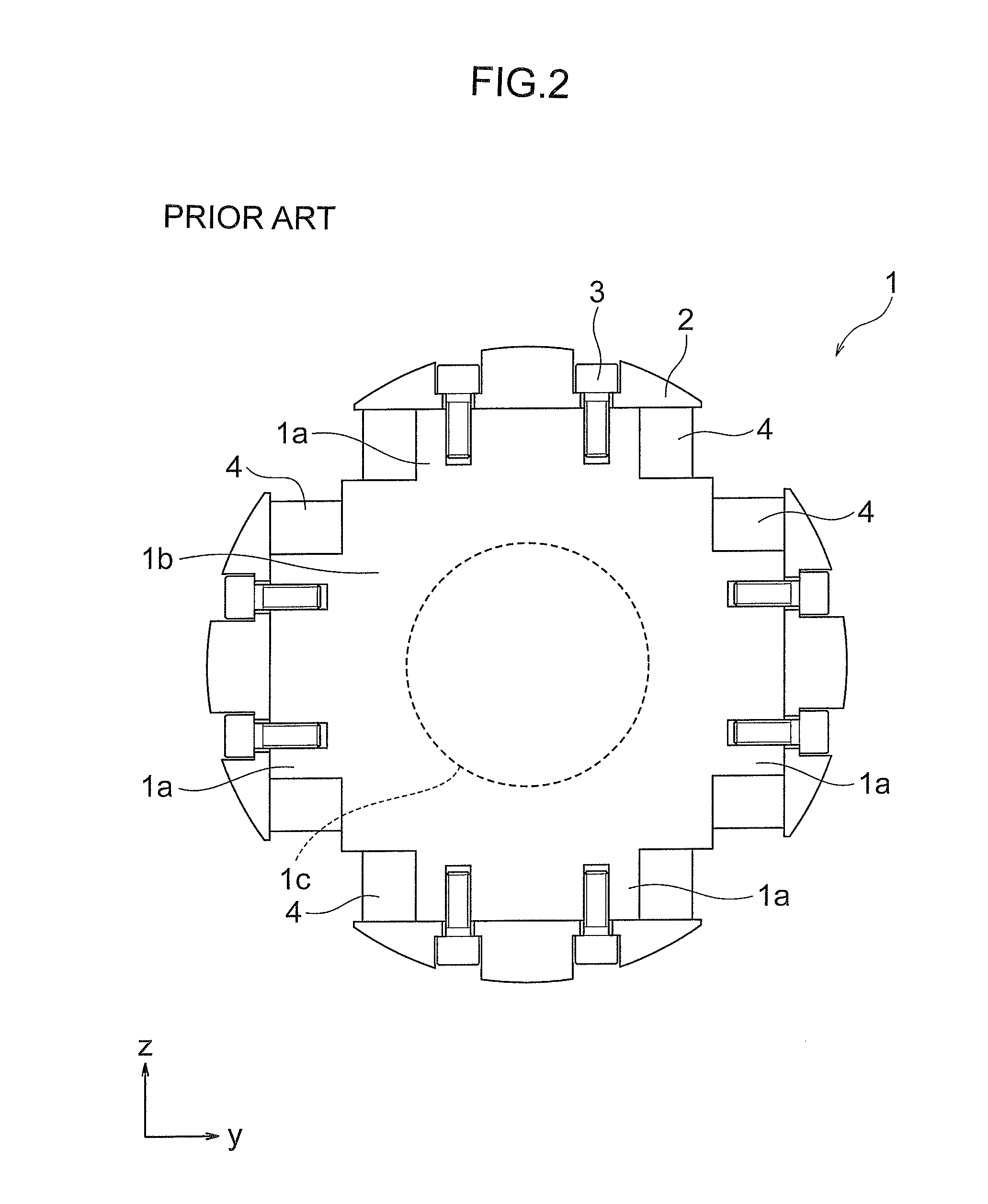

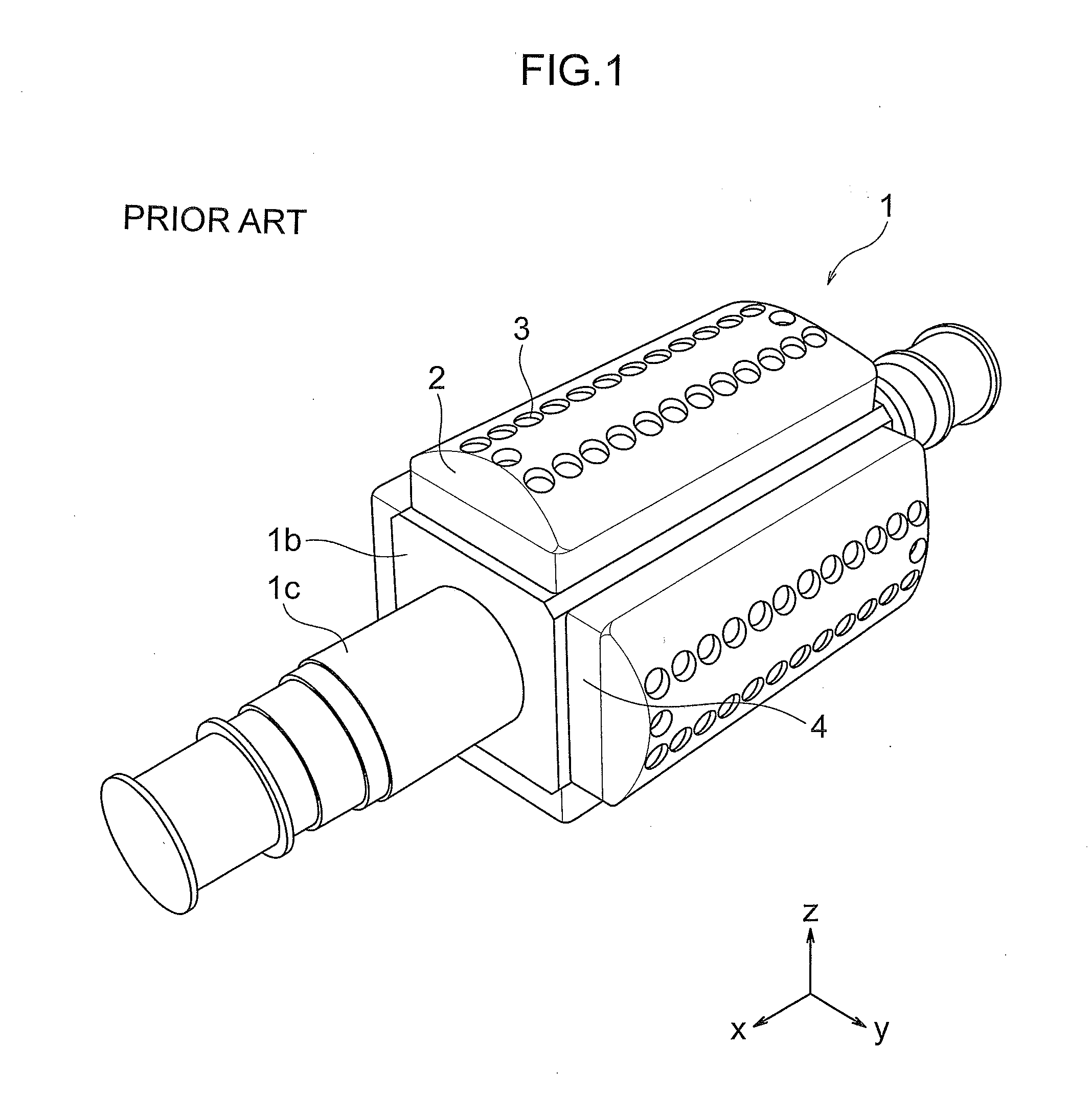

Electrical rotating machine

ActiveUS9077223B2Reduced strengthReduce centrifugal forceMagnetic circuit rotating partsElectric machineEngineering

An electrical rotating machine is provided with a salient-pole rotor, which is composed of magnetic field pole bodies integrally formed with a shaft and pole shoes constituting magnetic field pole heads. Each pole shoe is fixedly joined on the corresponding one of the magnetic field pole bodies with a plurality of bolts. Each pole shoe or its corresponding magnetic field pole body is provided with at least one protrusion or recess for restricting a conically-shaped compression domain in a compression domain that occurs in the pole shoe when the pole shoe is joined on the corresponding magnetic field pole body with the bolts.

Owner:HITACHI IND PROD LTD

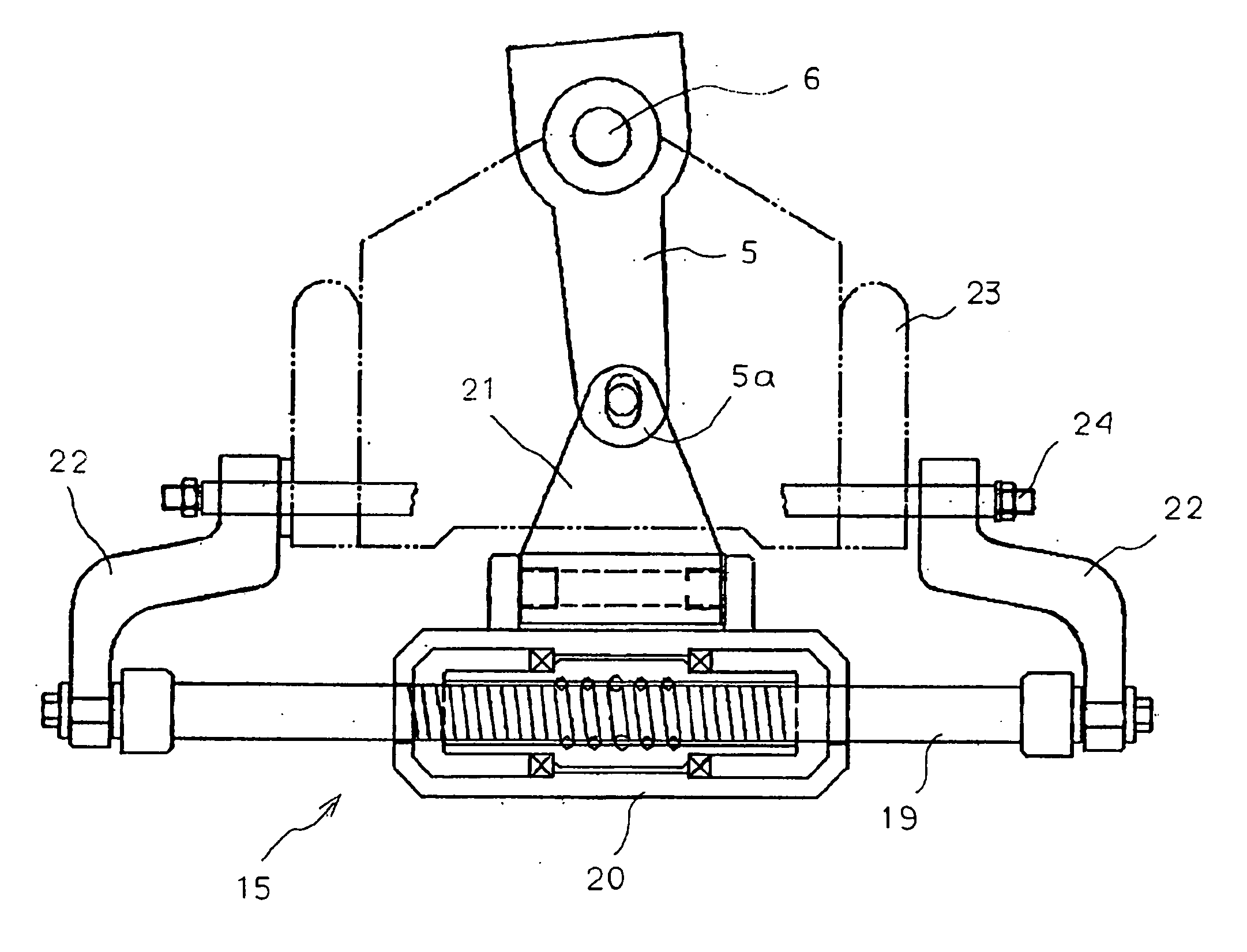

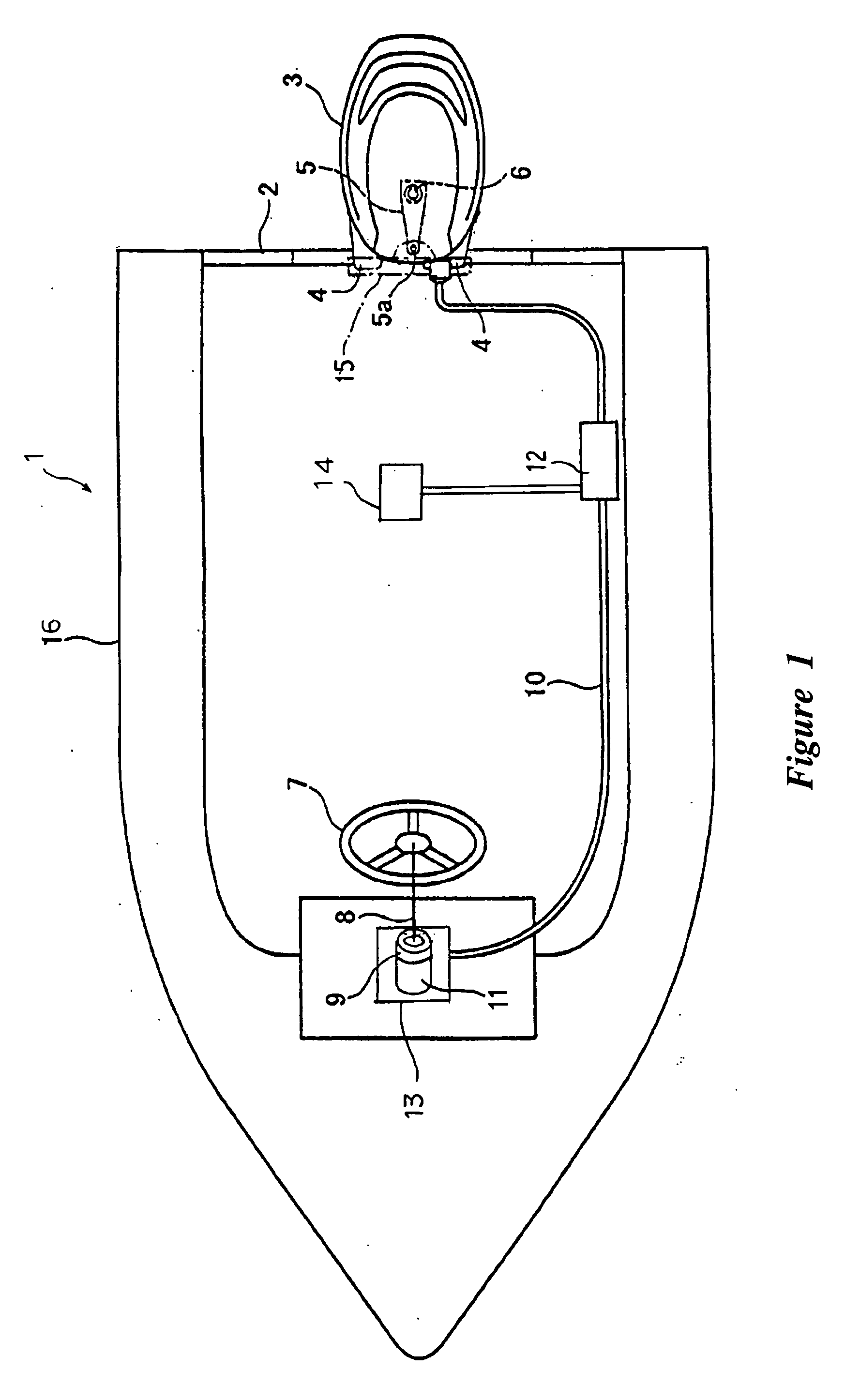

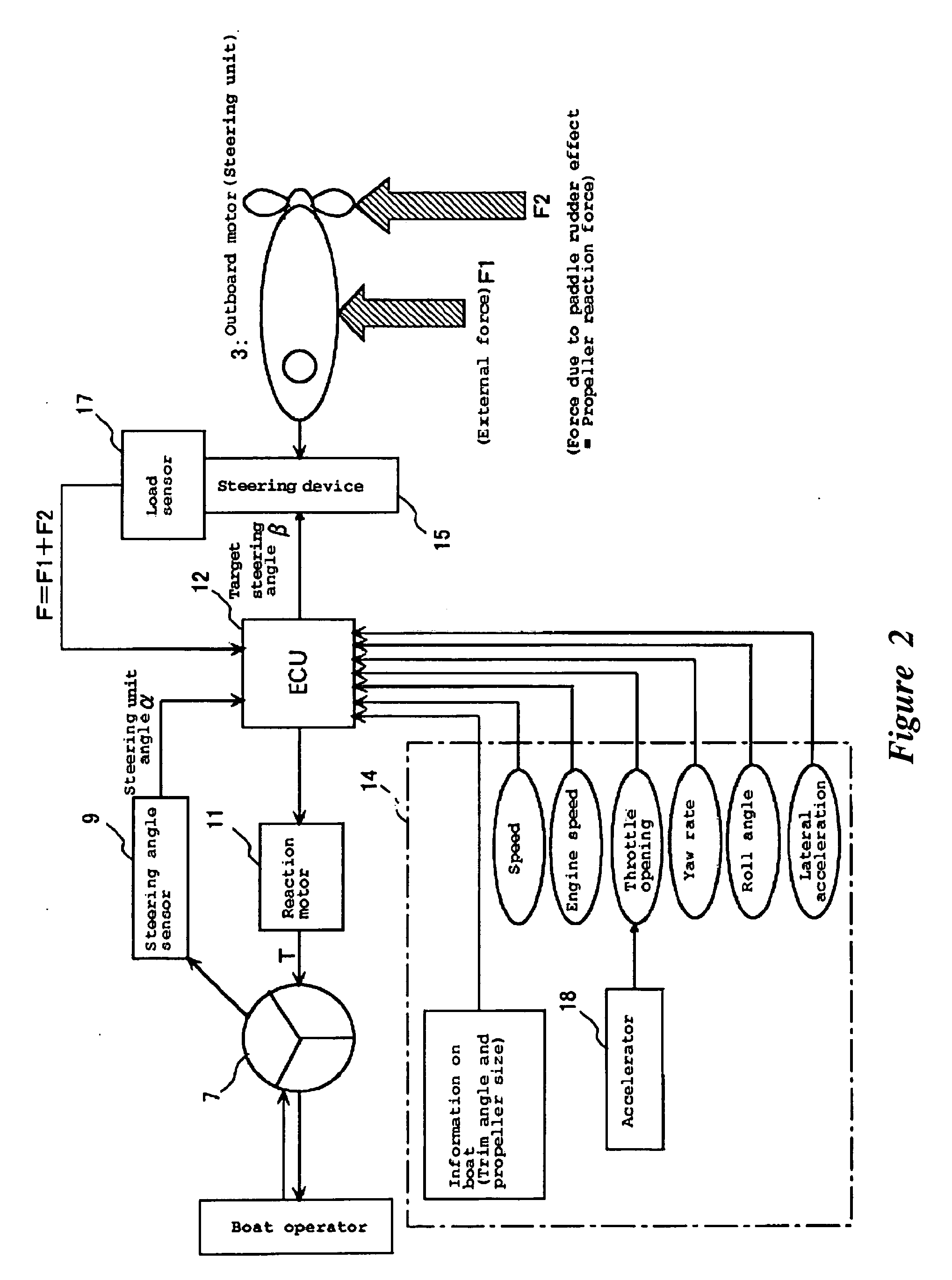

Steering method and steering system for boat

ActiveUS20070066156A1Reduce centrifugal forceAuxillariesPropulsion power plantsSteering angleSteering wheel

A steering method for a boat with a marine propulsion unit at the stern is provided in which a reaction torque is applied to a steering wheel in response to external force to the boat. The steering method includes: detecting a steering angle and the behavior of the boat; determining whether or not the turning of the steering wheel is in an initial phase based on the detected steering angle and the behavior of the boat; and applying the reaction torque to the steering wheel in response to the determination.

Owner:YAMAHA MARINE KK

Scroll type fluid machine

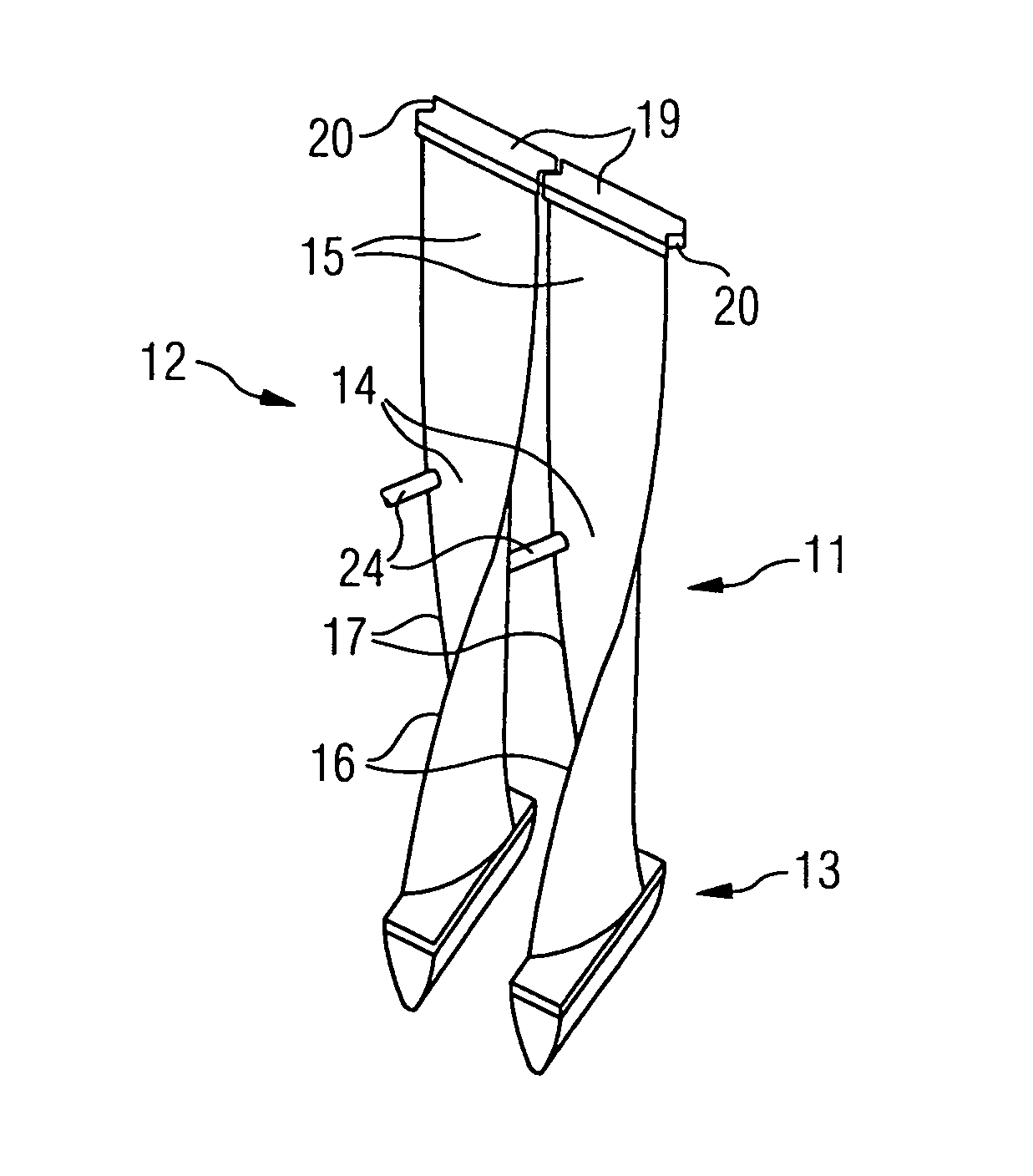

InactiveUS20120288393A1Easy to slideIncreased durabilityEngine of arcuate-engagement typePump componentsEngineeringSolid of revolution

To realize an increase in lifespan and a reduction in cost in an interlocking mechanism that causes a driving scroll and a driven scroll to rotate synchronously, a through hole is drilled into a peripheral edge portion of a driving scroll side end plate, and a pin member is fixed to the through hole. A base is provided on a driven scroll side spiral projection that faces the through hole. A columnar recessed portion is carved into an opposing surface of the base, and an aluminum rotary body is loosely fitted into the recessed portion. An eccentric hole is drilled into the rotary body, and the pin member is loosely fitted into the eccentric hole. The interlocking mechanism is disposed in an odd number at equal intervals on an outer edge portion of the scroll end plate such that loads exerted on the rotary body act in an identical plane.

Owner:ANEST IWATA CORP

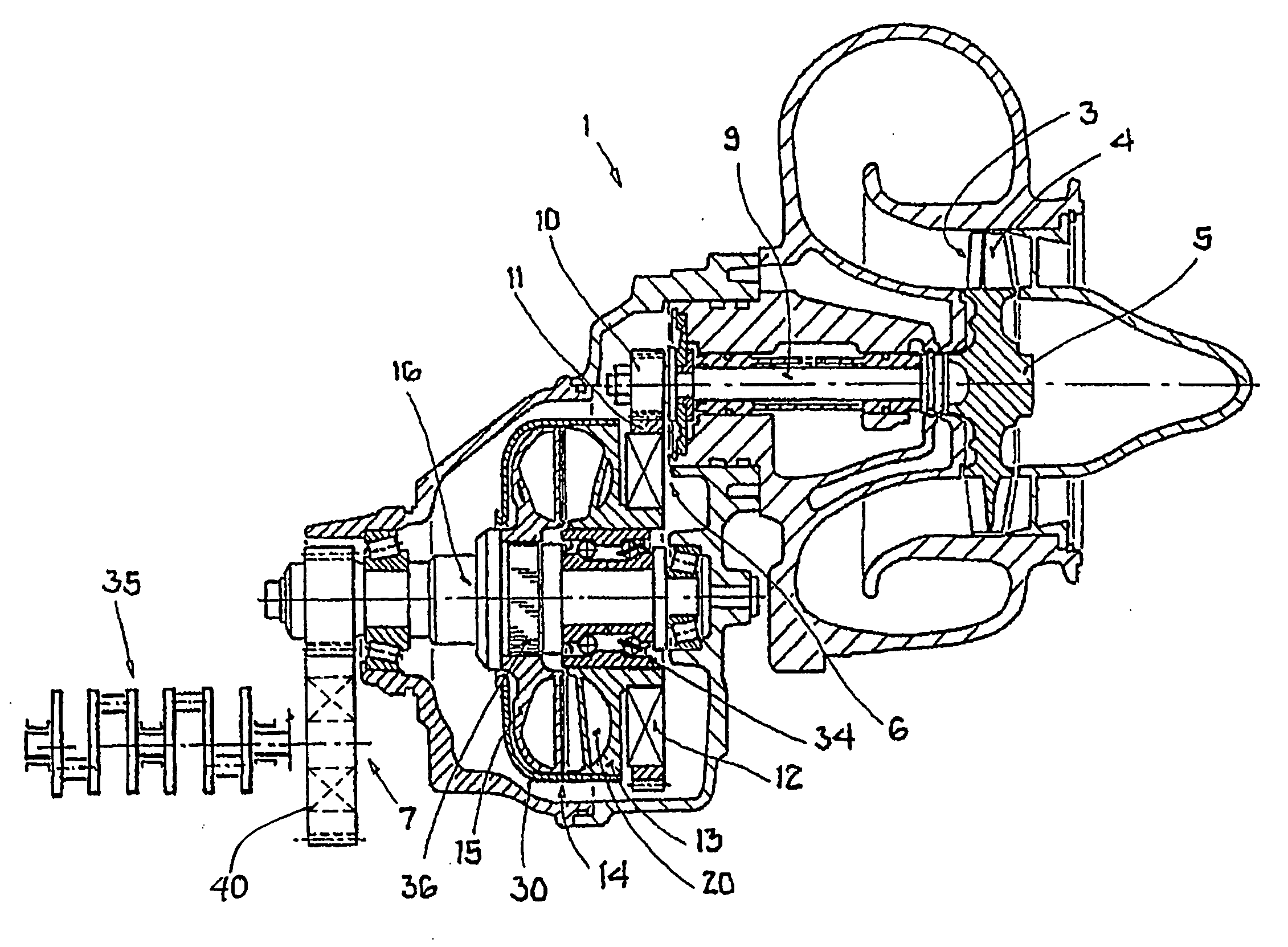

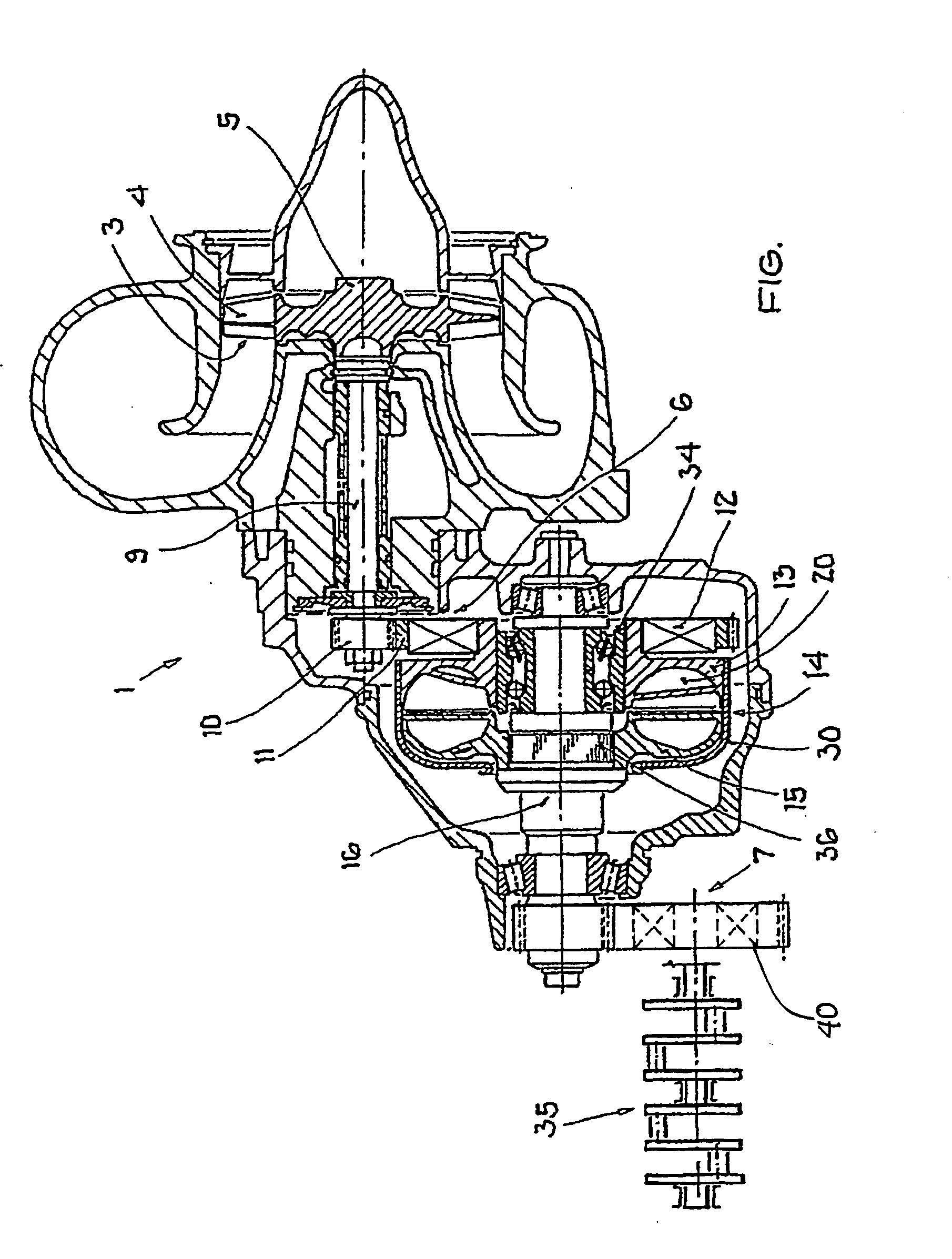

Moving-blade row for fluid-flow machines

InactiveUS20040191068A1Avoid vibrationReduce quality problemsPump componentsBlade accessoriesLeading edgeTrailing edge

The invention relates to a moving-blade row of a fluid-flow machine, the moving-blade row having individual adjacent moving blades which each have a moving-blade root and a moving-blade center region and also a moving-blade tip and a leading edge and a trailing edge, the moving blades being mechanically connected to one another in the moving-blade center region by supporting elements in such a way that undesirable vibrations of the moving blades are effectively avoided.

Owner:SIEMENS AG

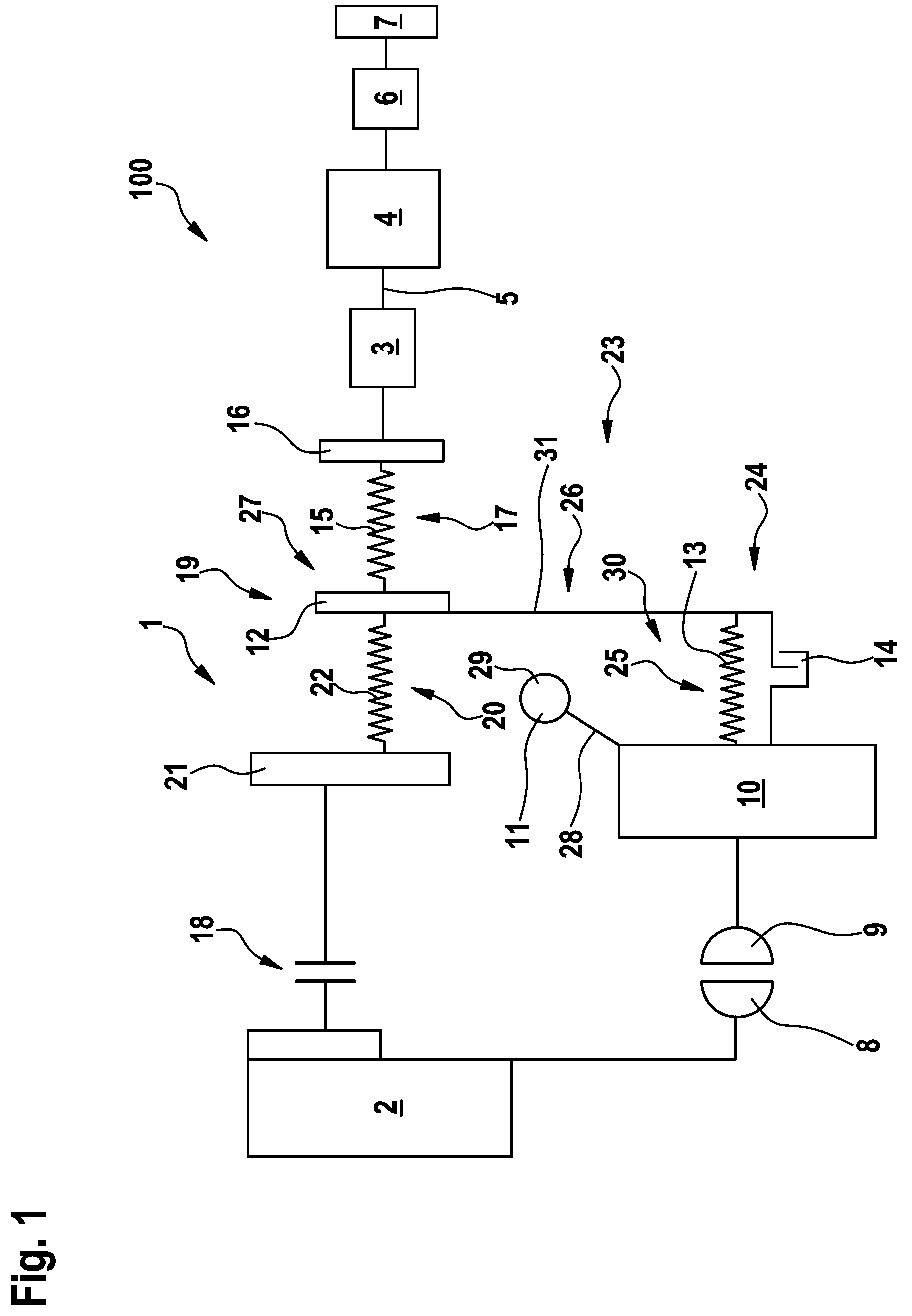

Turbocompound engine drive

InactiveUS20090139231A1Reduce centrifugal forcePoor efficiencyInternal combustion piston enginesHot gas positive displacement engine plantsExhaust gasPower transmission

In a turbocompound engine drive including an engine with a crankshaft, an exhaust gas turbine operatively connected to the crankshaft via a reduction gear structure and a hydrodynamic clutch providing together for a power transmission path between the engine a freewheel is integrated into the power transmission path between the turbine and the crankshaft of the engine for disconnecting the turbine from the engine when the turbine speed is lower than the comparable engine speed to prevent the turbine from being driven by the engine.

Owner:DAIMLER AG

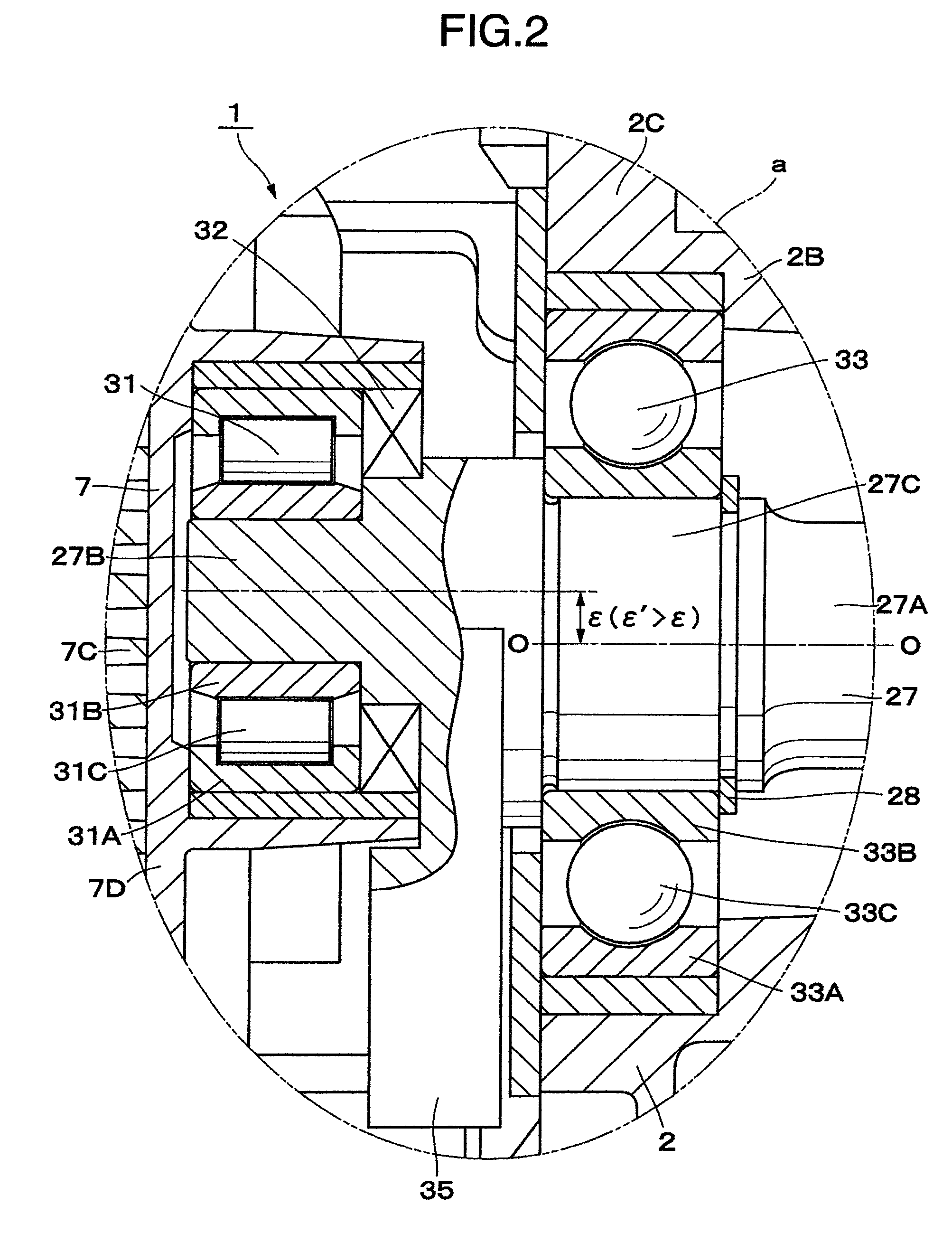

Bearings of a scroll type machine with crank mechanism

ActiveUS8328544B2Reduce centrifugal forceEngine of arcuate-engagement typeOscillating piston enginesDouble ValueDrive shaft

The invention reduces a centrifugal force of an orbiting scroll which acts on an auxiliary crank mechanism. A crank pin which is eccentric from a main shaft portion is formed in a drive shaft and attached to an orbiting bearing which is provided in a back face side of an orbiting scroll. The main shaft portion of the drive shaft is rotatably supported by a main bearing. An internal gap of the main bearing is set to a value which is larger than a value obtained by subtracting the double value of an eccentric amount difference between an eccentric amount of an auxiliary crank shaft and an eccentric amount of the drive shaft from an internal gap of the orbiting bearing.

Owner:HITACHI IND EQUIP SYST CO LTD

Vibration and centrifugation composite-testing equipment

InactiveCN104075863AReduce centrifugal forceReduce adverse effectsVibration testingCentrifugationControl signal

Vibration and centrifugation composite-testing equipment is characterized by comprising a centrifuge and an air-cooling electric vibrating table, wherein the centrifuge comprises a base, a rotating arm and a driving device; both ends of the rotating arm extend outwards; one end of the rotating arm serves as a load end; the other end of the rotating arm is provided with a balance weight to serve as a balance end; an electric brush is arranged in the center of rotation of the rotating arm; the air-cooling electric vibrating table comprises a vibrating table main unit and a blower; the vibrating table main unit is arranged at the load end of the rotating arm; the blower is arranged at the middle section of the rotating arm and is connected with the vibrating table main unit through a hard pipe; the vibrating table main unit is connected with the electric brush through a conductor group fixed on the rotating arm so as to be connected with a power supply and input / output control signals through the electric brush. The vibration and centrifugation composite-testing equipment adopts a design of integration of the centrifuge and the air-cooling electric vibrating table and ensures that a test piece can receive the actions of vibration force and centrifugal force, thereby achieving the purpose of carrying out vibration and centrifugation composite testing and filling a gap in the field.

Owner:苏州苏试广博环境可靠性实验室有限公司

Dynamoelectric machine

ActiveUS20100096941A1Facilitates holdingHolding of the permanent magnets is facilitatedSynchronous generatorsWindingsMagnetic polesEngineering

A dynamoelectric machine including first and second permanent magnets held by first and second magnet seats on first and second yoke portions so as to face inner circumferential surfaces of tip end portions of first and second claw-shaped magnetic pole portions. The first and second permanent magnets are magnetically oriented in a reverse direction to orientation of a magnetic field that the field coil produces. The dynamoelectric machine enables permanent magnet holding reliability to be increased, induced voltage during no-load de-energization to be suppressed, and thermal demagnetization of magnets due to high-frequency magnetic fields that are induced by stator slots to be avoided.

Owner:MITSUBISHI ELECTRIC CORP

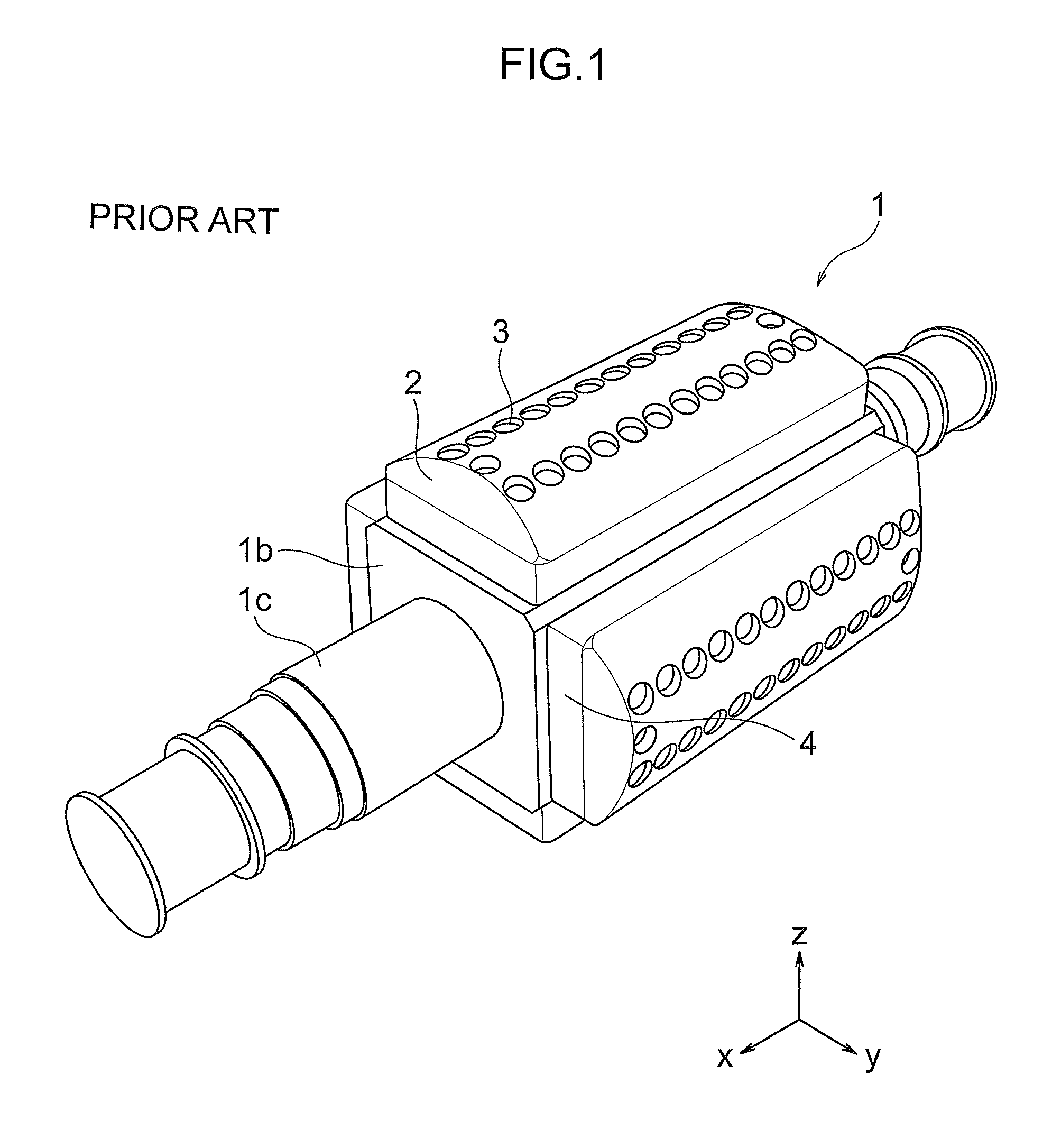

Electrical Rotating Machine

ActiveUS20140333174A1Reduced strengthReduce centrifugal forceMagnetic circuit rotating partsMagnetic circuit stationary partsEngineeringPole piece

An electrical rotating machine is provided with a salient-pole rotor, which is composed of magnetic field pole bodies integrally formed with a shaft and pole shoes constituting magnetic field pole heads. Each pole shoe is fixedly joined on the corresponding one of the magnetic field pole bodies with a plurality of bolts. Each pole shoe or its corresponding magnetic field pole body is provided with at least one protrusion or recess for restricting a conically-shaped compression domain in a compression domain that occurs in the pole shoe when the pole shoe is joined on the corresponding magnetic field pole body with the bolts.

Owner:HITACHI IND PROD LTD

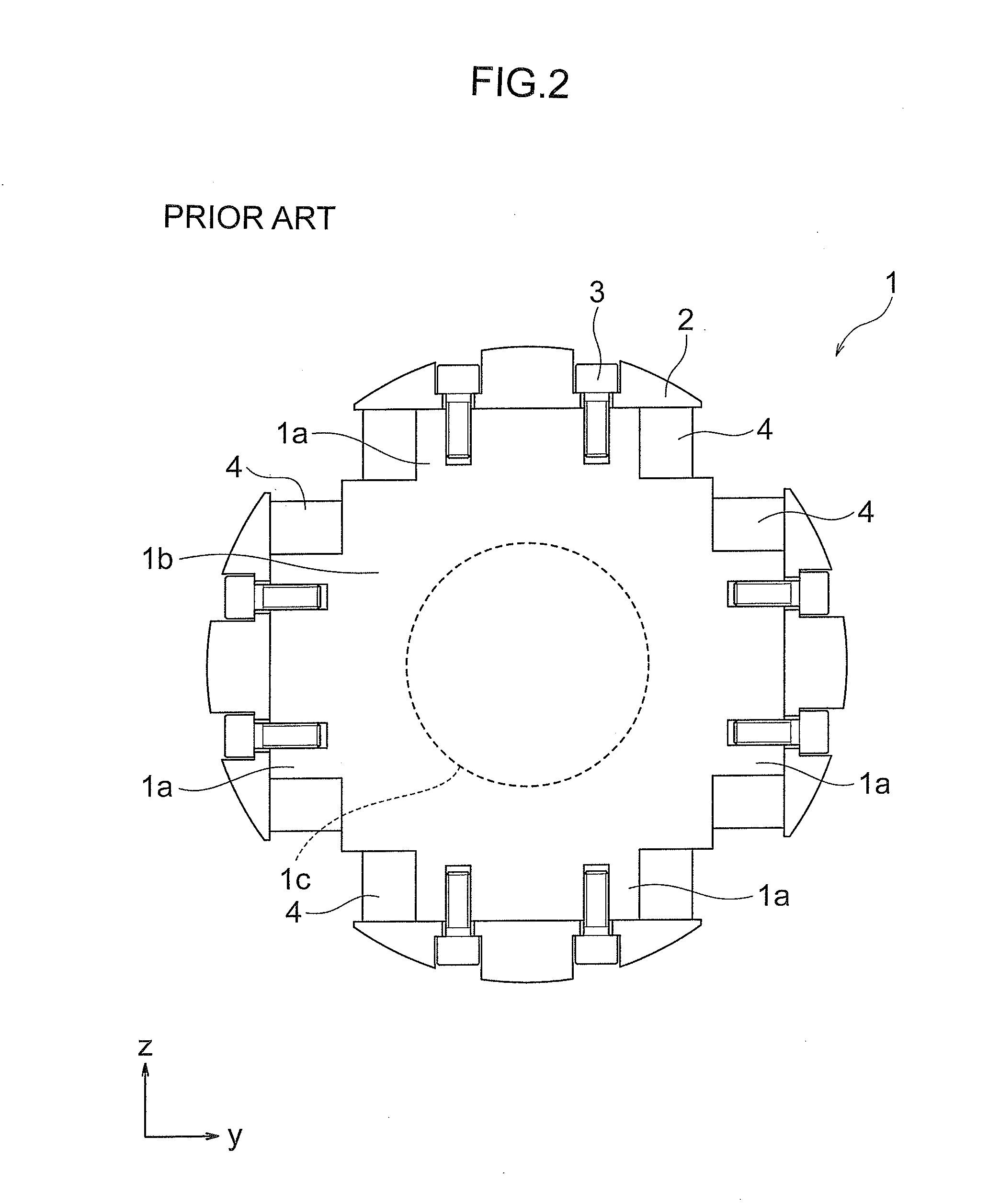

Planetary transmission having a rotating-type torque-transmitting mechanism with a stationary piston

ActiveUS7070532B2Reduced axial space requirementsLess spaceMechanical actuated clutchesFluid actuated clutchesMechanical engineeringPiston

A planetary transmission has a plurality of rotating-type torque-transmitting mechanism that are operable to connect a rotating input mechanism with one or more planetary gear members. At least two of the rotating-type torque-transmitting mechanisms are radially stacked and axially aligned. At least one of the radially stacked rotating torque-transmitting mechanisms has an apply piston that is slidably mounted in a stationary transmission housing, an apply plate that is rotatable with a portion of the torque-transmitting mechanism, and a bearing disposed therebetween to accommodate relative rotation therebetween.

Owner:GM GLOBAL TECH OPERATIONS LLC

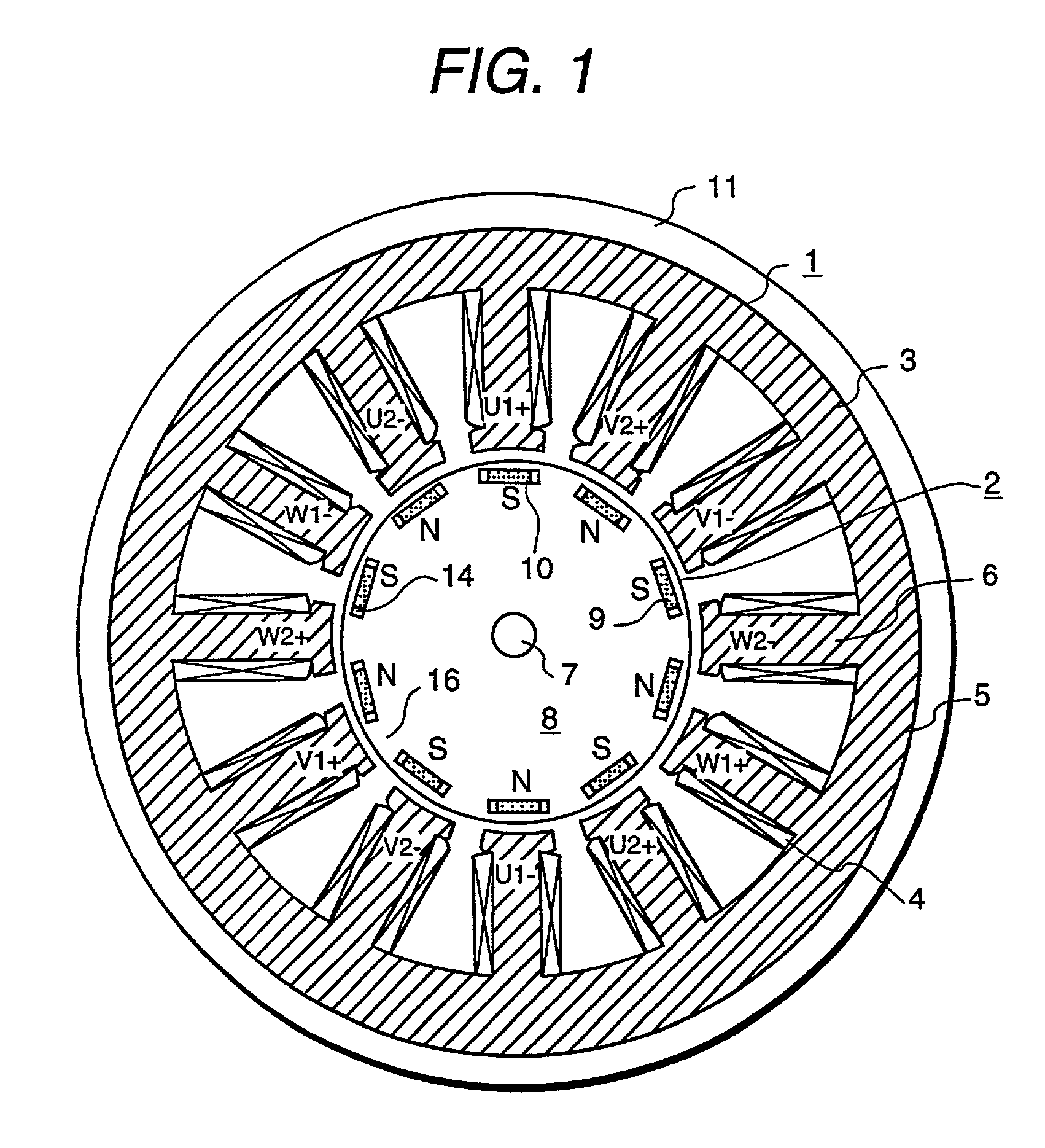

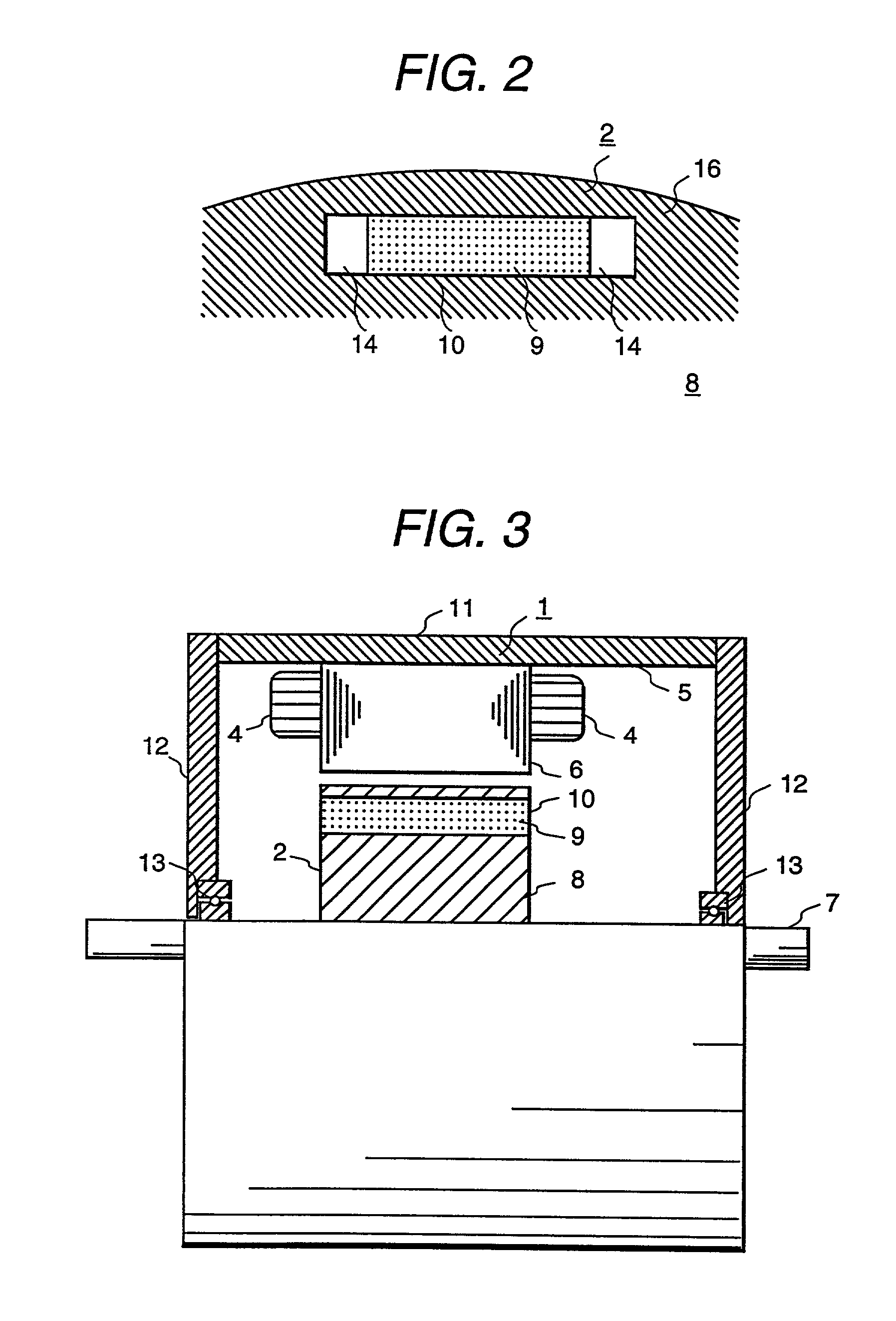

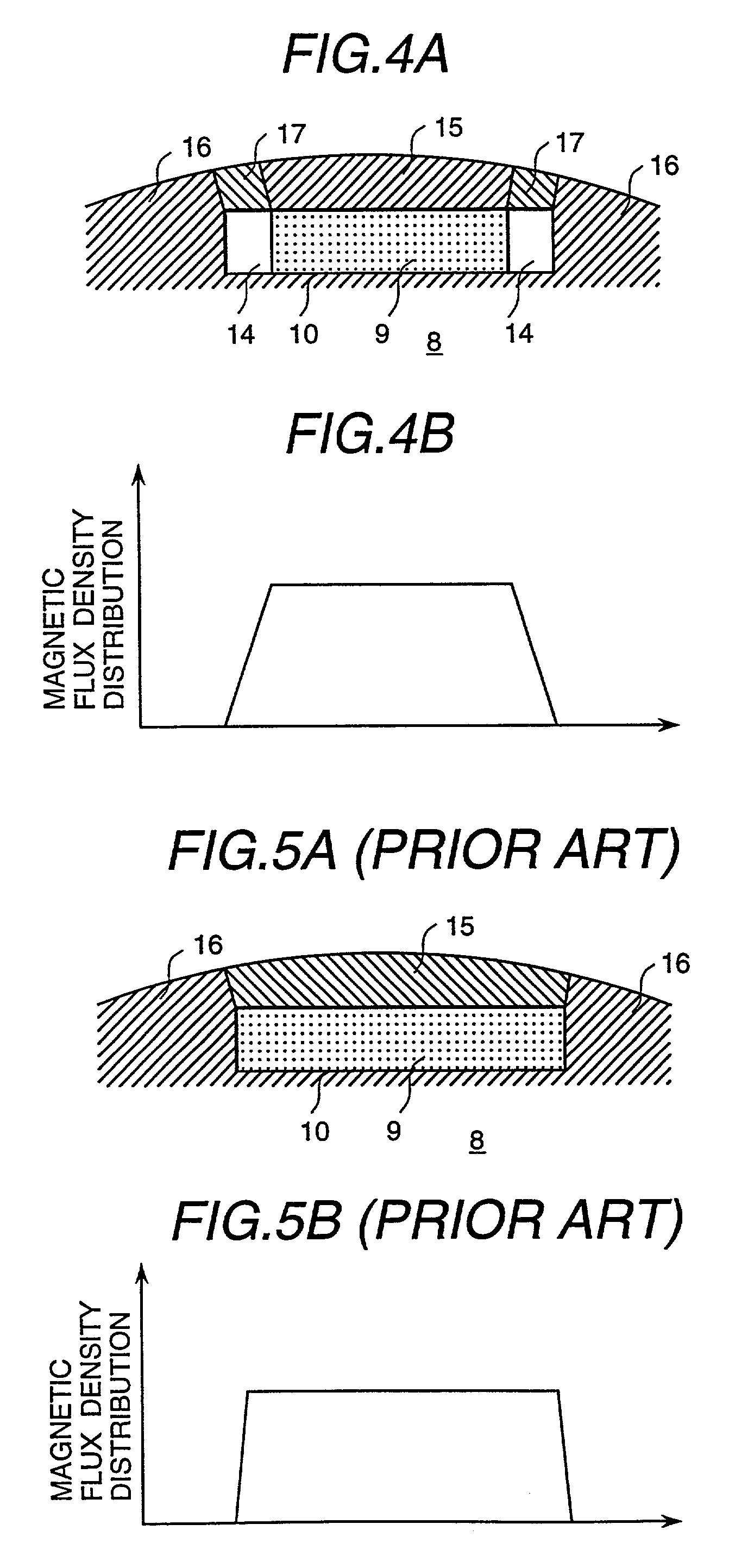

Permanent magnet electric rotating machine and electomotive vehicle using permanent magnet electric rotating machine

InactiveUS20010002094A1Reduce pulsationReduce centrifugal forceMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsMagnetic polesMagnetic flux density distribution

A magnetic gap is provided between permanent magnet of a rotor and an auxiliary magnetic pole portion which is adjacently arranged to the permanent magnet to a peripheral direction. A change in a magnetic flux density distribution of a surface of the rotor is performed moderately and a cogging torque and a torque pulsation are restrained. By obtaining a reluctance torque according to the auxiliary magnetic pole, a permanent magnet electric rotating machine in which the cogging torque and the torque pulsation are restrained can be obtained and further an electromotive vehicle having the permanent magnet electric rotating machine can be provided.

Owner:HITACHI LTD +1

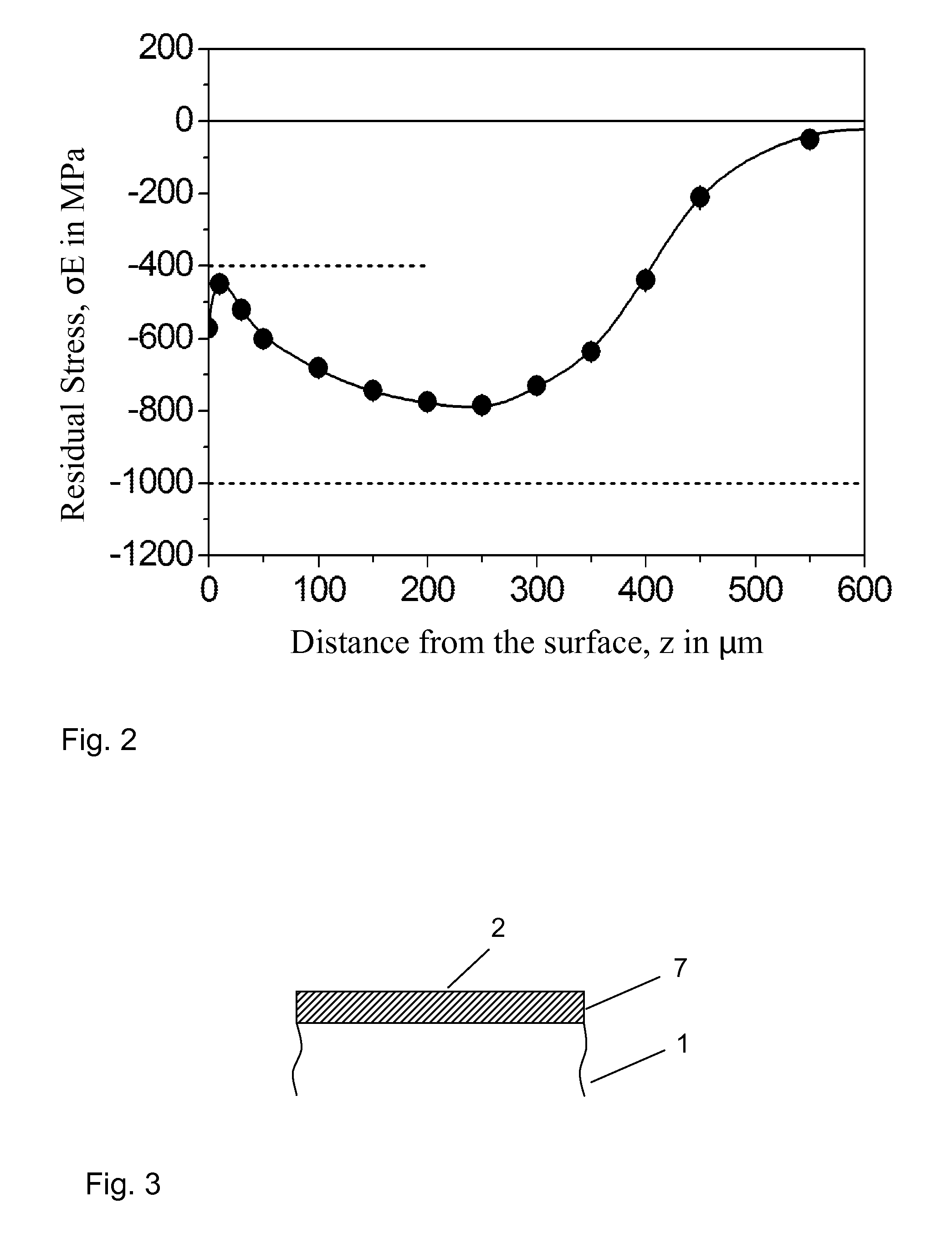

Rolling-element bearing and method of manufacturing thereof

ActiveUS20140212082A1Good cyclical loadabilityReduce manufacturing costRolling contact bearingsShaftsRolling-element bearingHeat treated

A rolling-element bearing includes an inner ring made of steel and having an inner-ring raceway, an outer ring having an outer ring raceway, and ceramic rolling elements which roll on the inner-ring raceway and on the outer-ring raceway. The inner ring has been subjected to a heat treatment to harden it. The heat treatment is concluded with the performance of a final heat-treatment step at a predetermined temperature. In the inner ring, compressive residual stresses are formed in an outer layer by cold working in the region of the inner-ring raceway. The inner ring also has been subjected to a bluing treatment.

Owner:AB SKF

Dynamoelectric machine

ActiveUS20100207476A1Reduce assembly man-hoursEasy to assembleSynchronous generatorsWindingsBobbinMagnetic poles

A dynamoelectric machine includes first and second magnet seat portions disposed to project from portions of first and second yoke portions that face respective inner circumferential surfaces near tip ends of second and first claw-shaped magnetic pole portions, and magnet housing portions disposed integrally to extend axially outward from outer circumferential portions of a pair of flange portions of a bobbin, extend near the first and second yoke portions that face the inner circumferential surfaces near the tip ends of the first and second claw-shaped magnetic pole portions, and be held by the first and second magnet seat portions. First and second permanent magnets are housed and held in the first and second magnet housing portions, are disposed to face the inner circumferential surfaces near the tip ends of the second and first claw-shaped magnetic pole portions, and the first and second permanent magnets are respectively magnetically oriented in a reverse direction to a direction of a magnetic field that the field coil produces.

Owner:MITSUBISHI ELECTRIC CORP

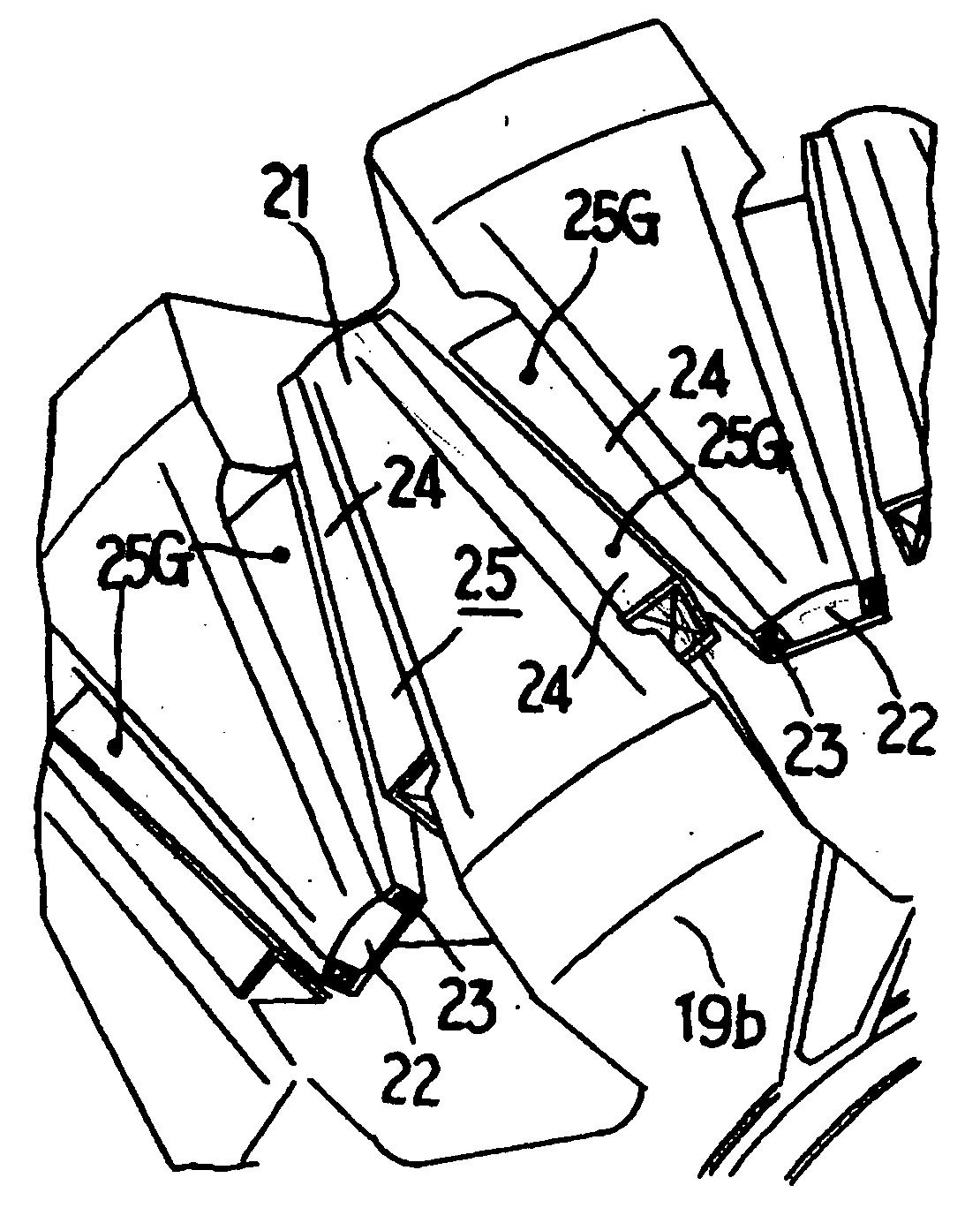

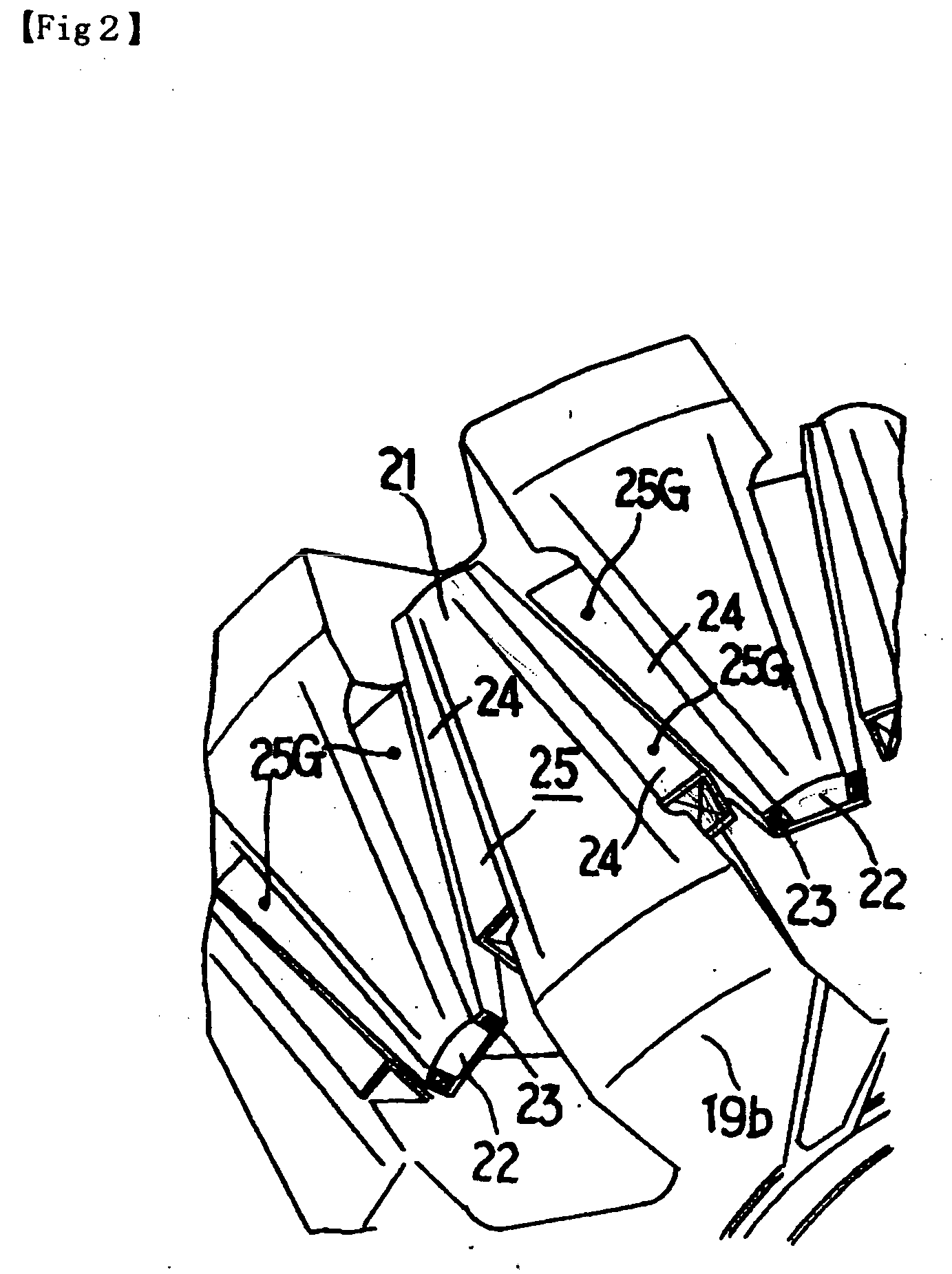

Rotor of electric rotating machine

InactiveUS20060097605A1Improve efficiencyAvoid Flux LeakageSynchronous generatorsMagnetic circuit rotating partsMachining deformationMagnetic poles

Deformation and vibration of claw magnetic poles in rotor are reduced. A rotor includes: a rotor coil 15 for generating a magnetic flux by applying a current; a pole core comprised of a first pole core body 19 and a second pole core body 20 that are disposed so as to cover the rotor coil 15, each being provided with claw-shaped claw magnetic poles 21, 22 engaging with each other; and a magnet assembly 25 composed of a magnet 23 for reducing leakage of magnetic flux and a magnet-holding member 24 for supporting the magnet 23 on the claw magnetic poles 21, 22. Center of gravity 25G of the magnet assembly 25 is located on the base part side nearer than the center of the claw magnetic poles 21, 22.

Owner:MITSUBISHI ELECTRIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com