Patents

Literature

48results about How to "Reduce load fluctuation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

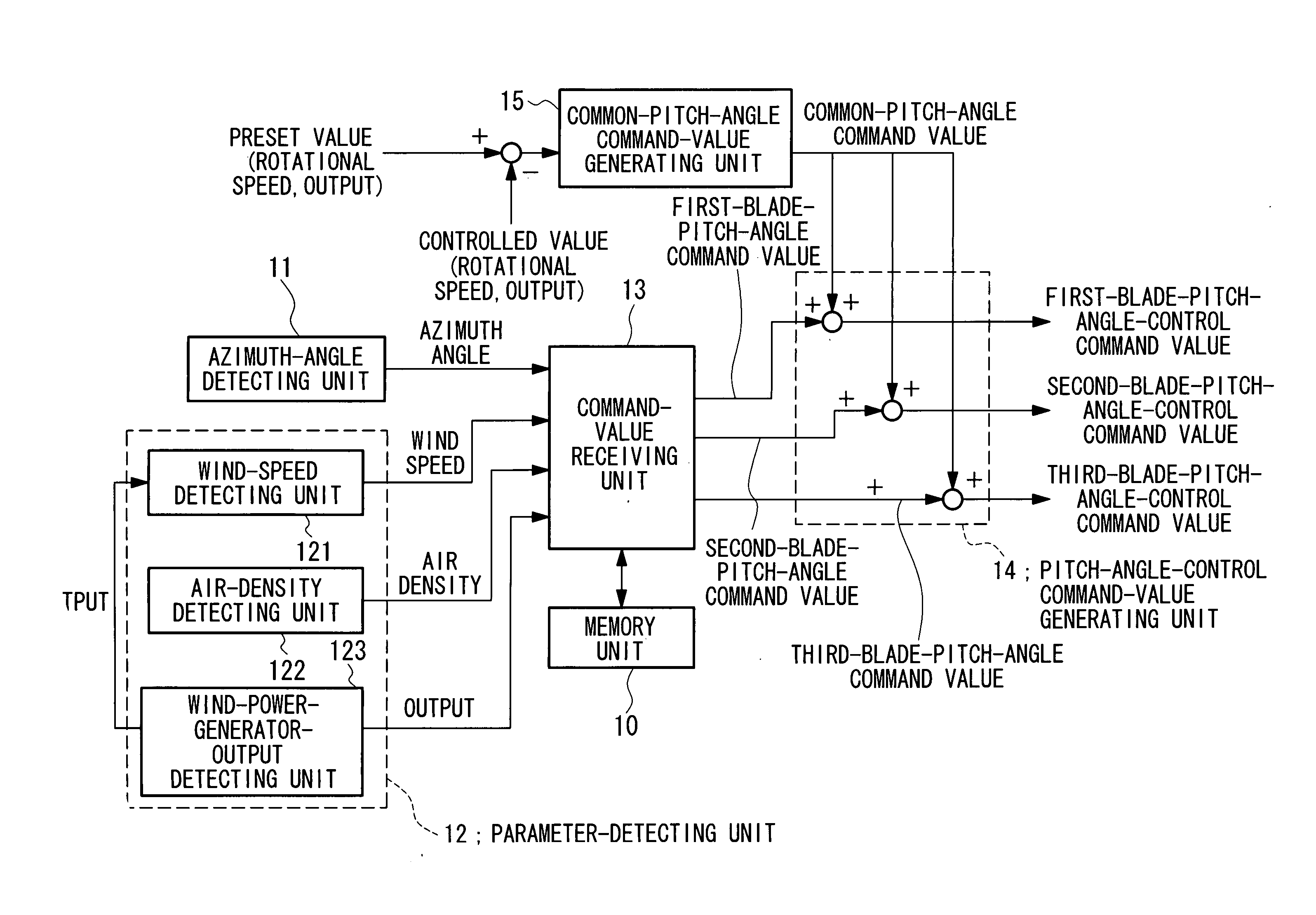

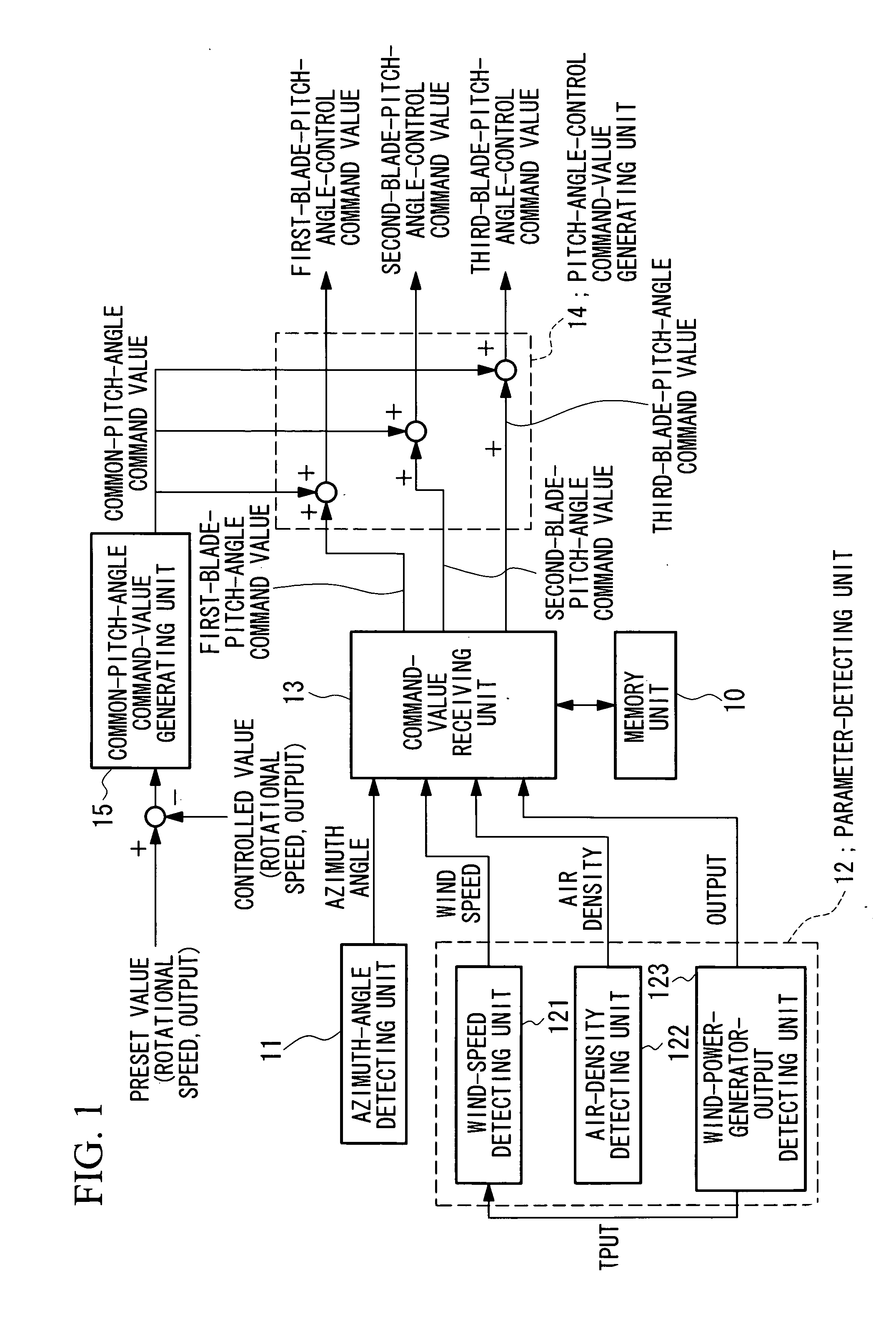

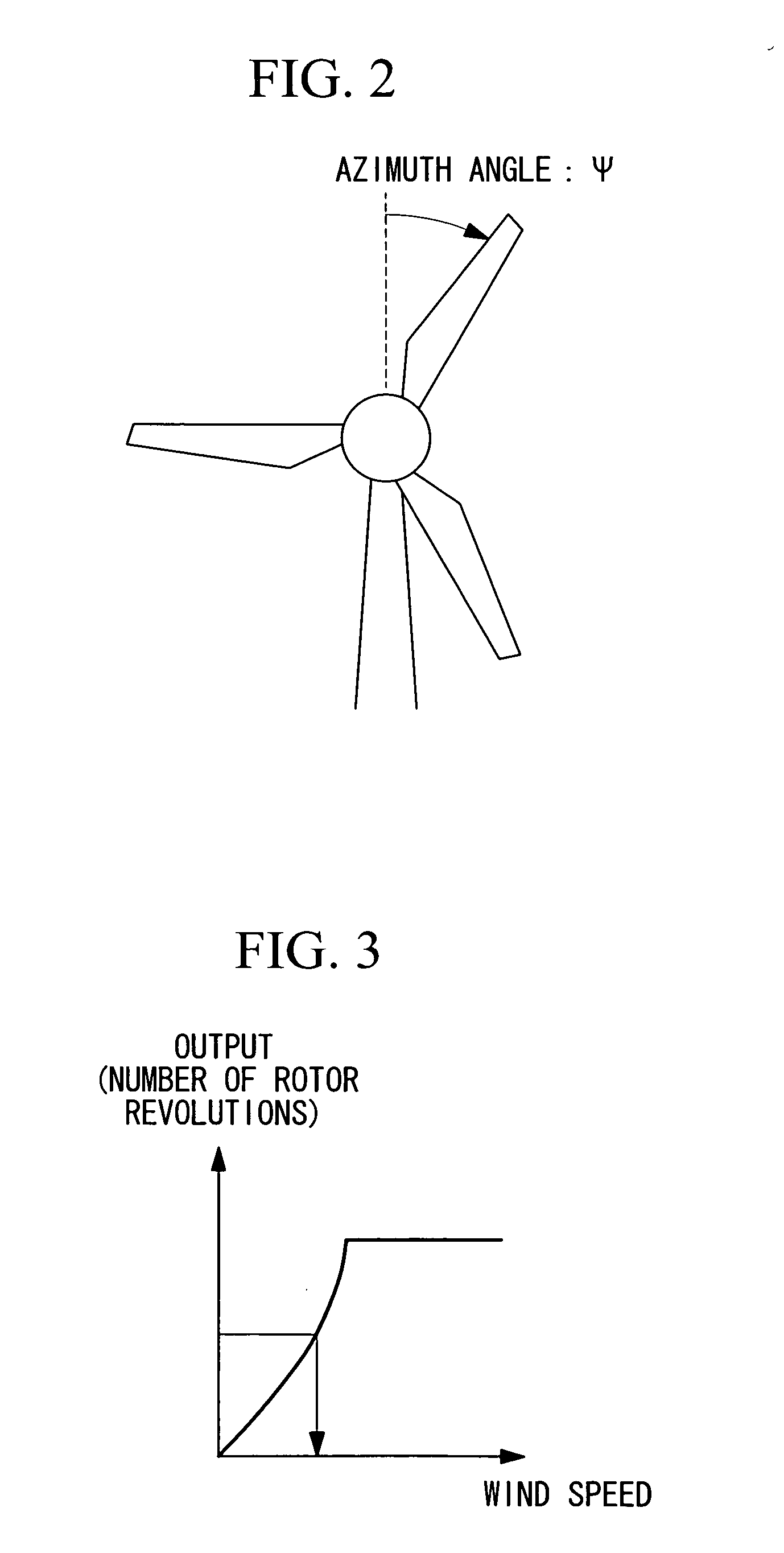

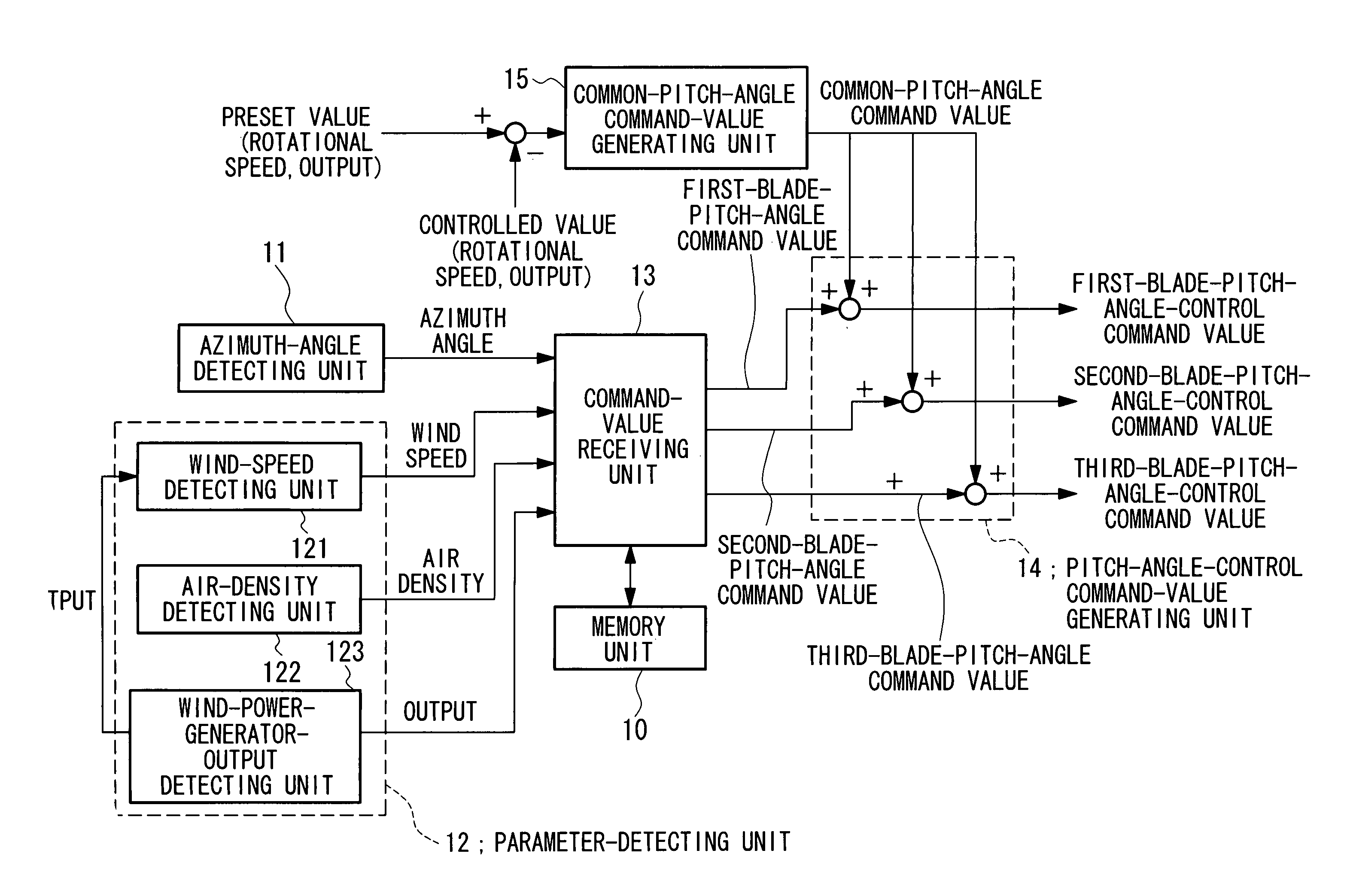

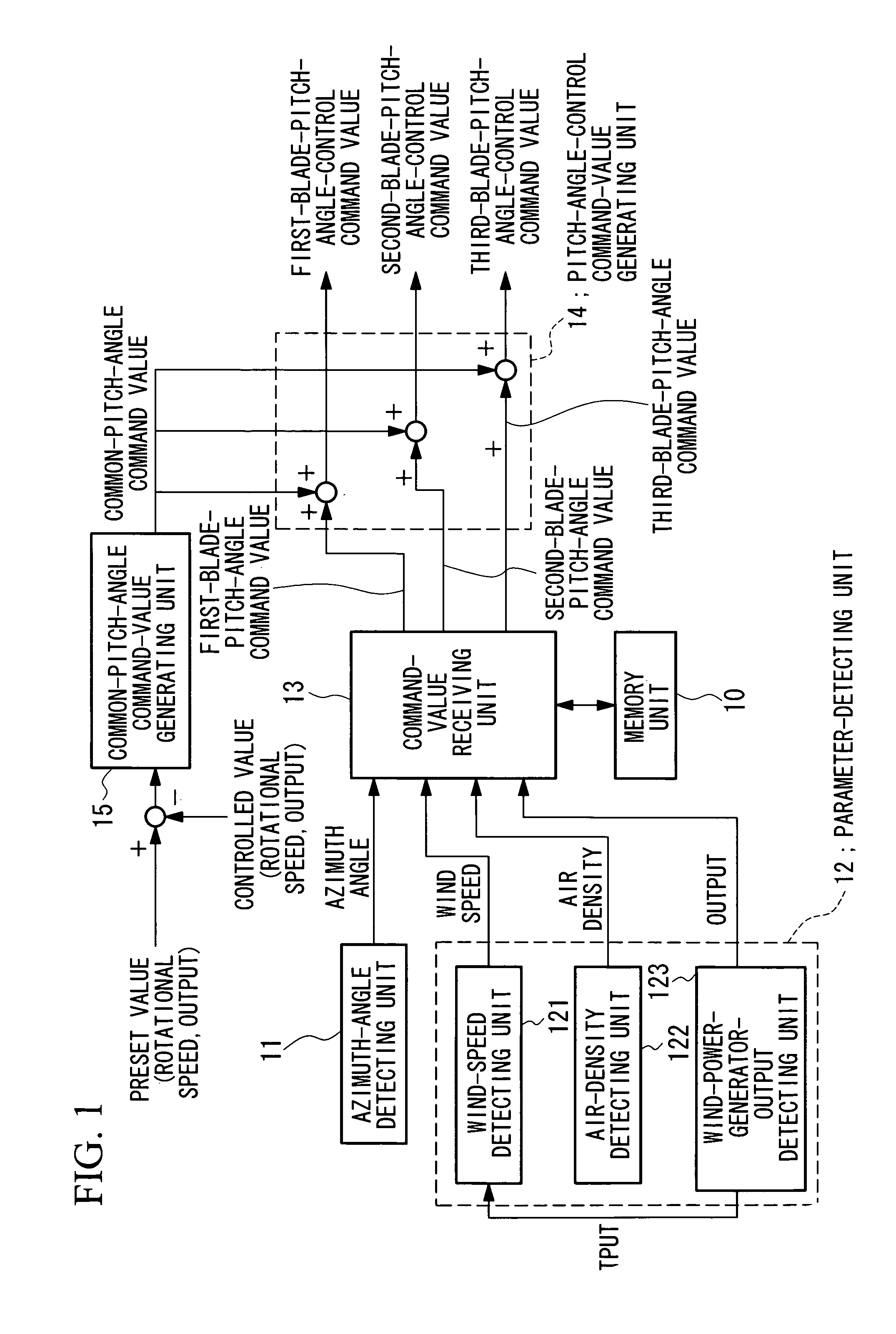

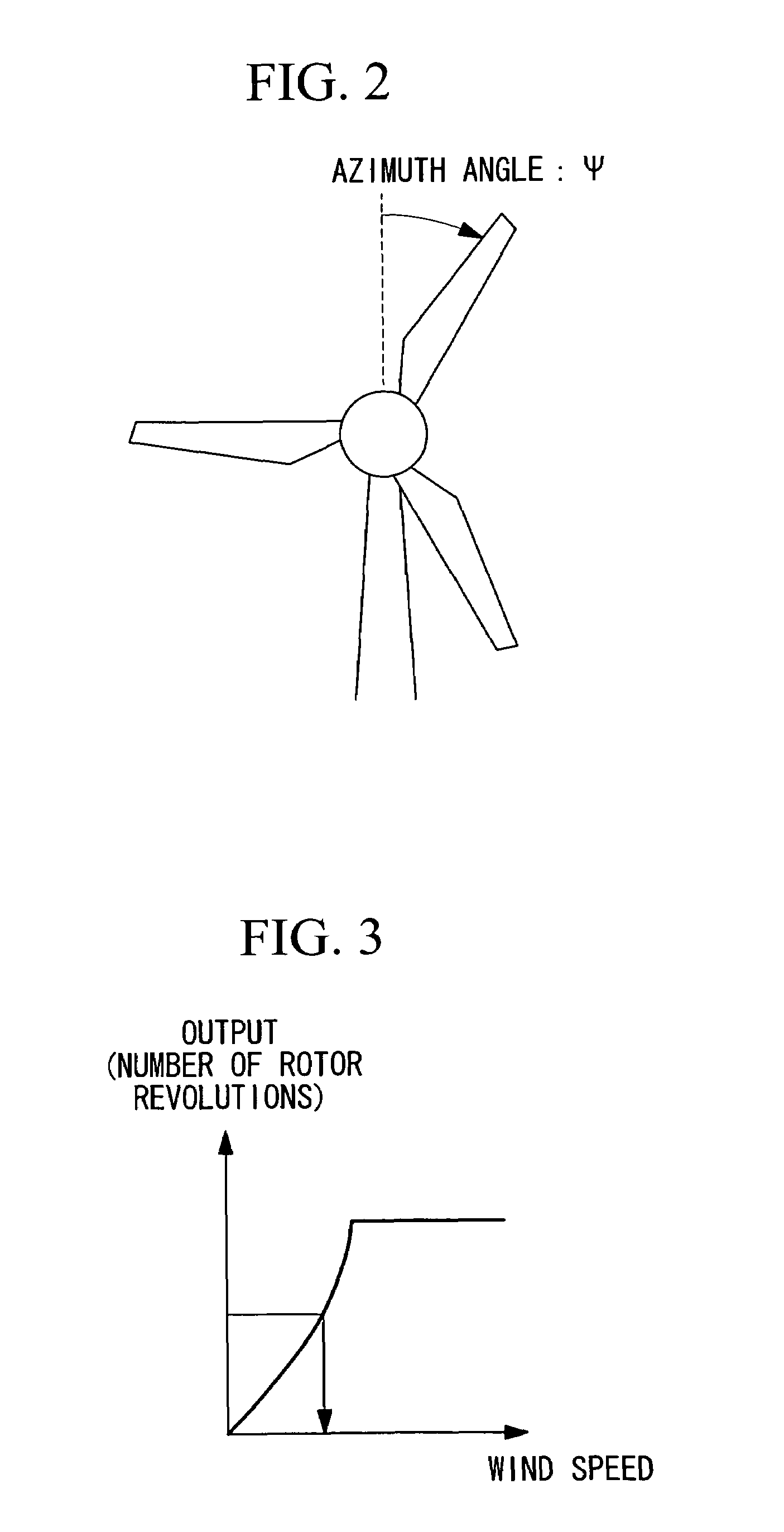

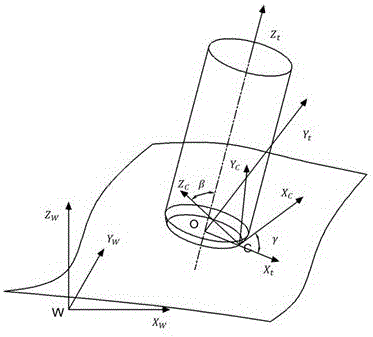

Blade-pitch-angle control device and wind power generator

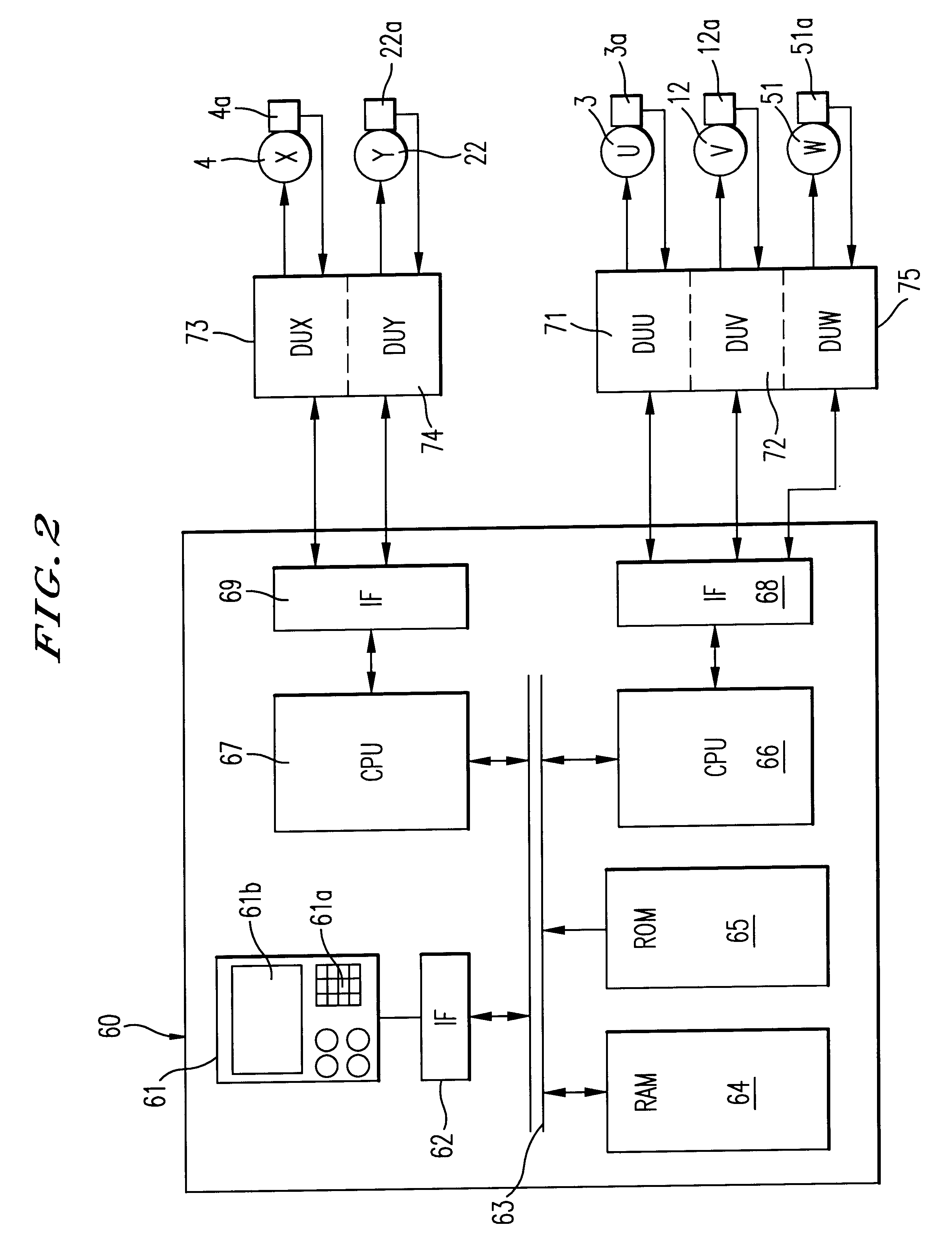

ActiveUS20070041837A1Improve accuracyReduce load fluctuationPropellersWind motor controlEngineeringBlade pitch

A blade-pitch-angle control device includes a memory unit in which predetermined parameters that affect the load fluctuation of blades, azimuth angles, and pitch-angle command values are stored in association with each other; an azimuth-angle detecting unit that detects the azimuth angle of each of the blades; a parameter-detecting unit that detects the predetermined parameters; a command-value receiving unit that receives pitch-angle command values for each of the blades from the memory unit, the pitch-angle command values being selected on the basis of the azimuth angle of each blade detected by the azimuth-angle detecting unit and the predetermined parameters detected by the parameter-detecting unit; and a pitch-angle-control command-value generating unit that generates pitch-angle-control command values for individually controlling the pitch-angle of each blade on the basis of the pitch-angle command values and a common-pitch-angle command value.

Owner:MITSUBISHI HEAVY IND LTD

Blade-pitch-angle control device and wind power generator

ActiveUS7452185B2Improve accuracyReduce load fluctuationPropellersWind motor controlEngineeringBlade pitch

Owner:MITSUBISHI HEAVY IND LTD

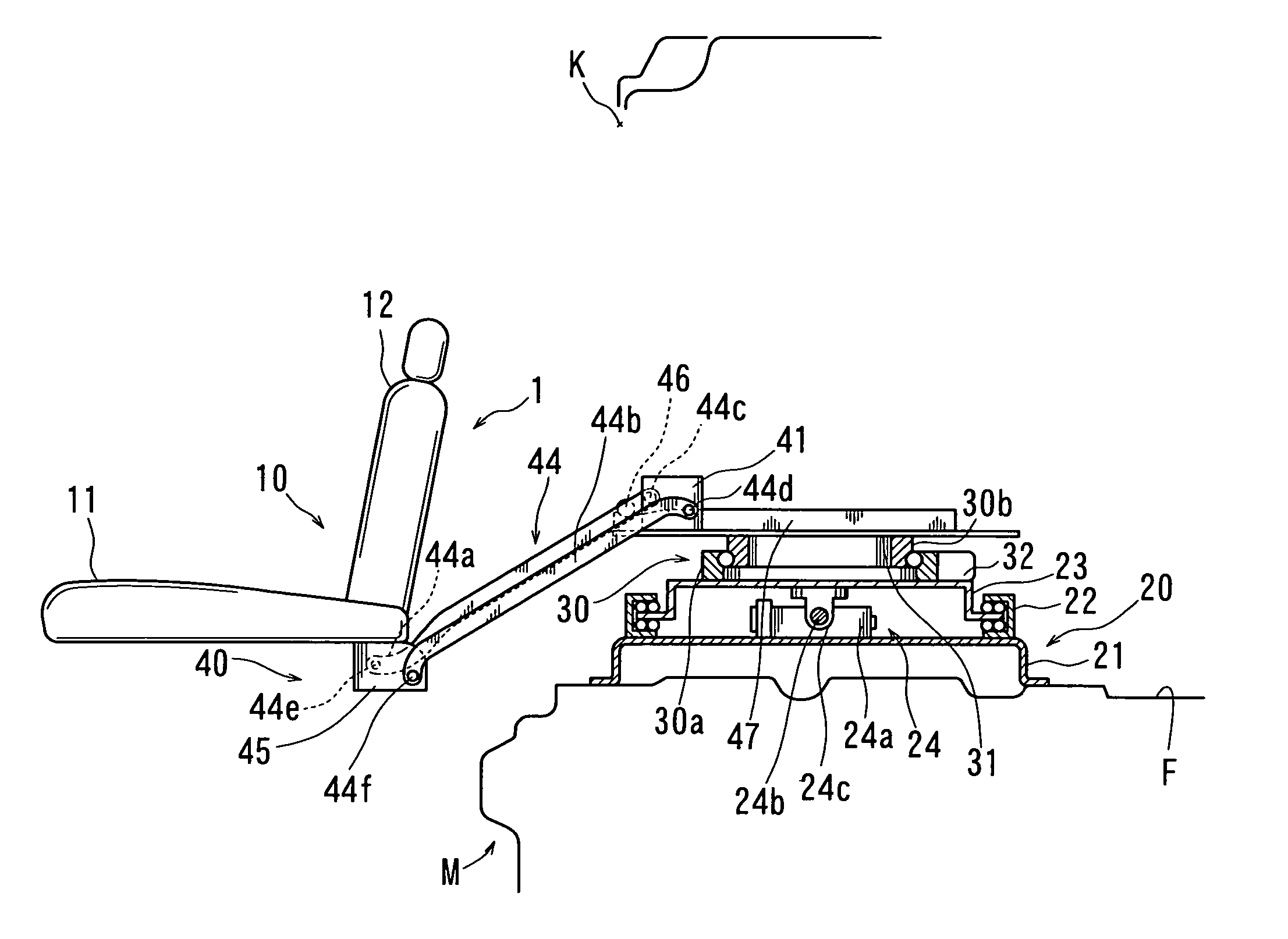

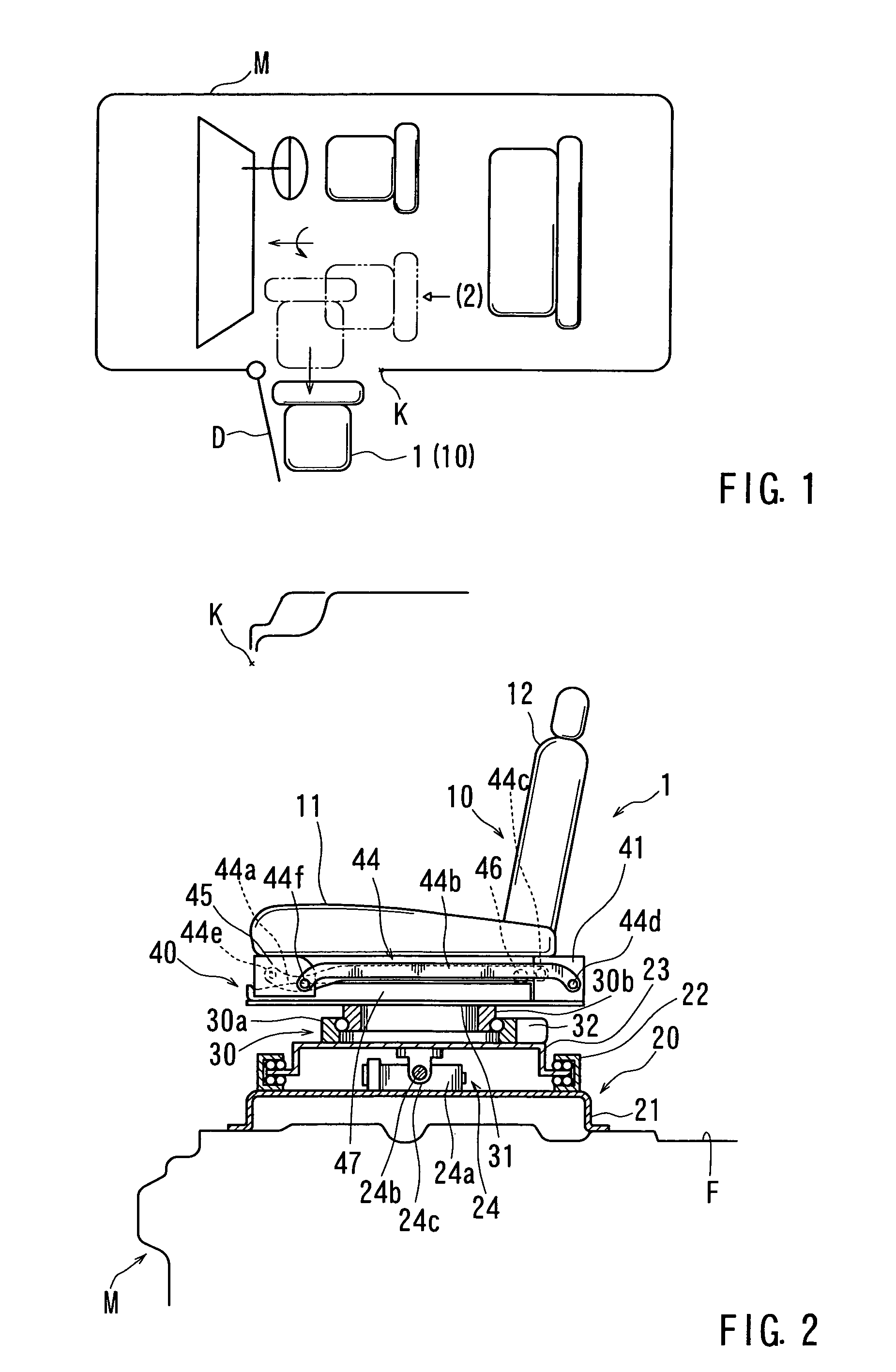

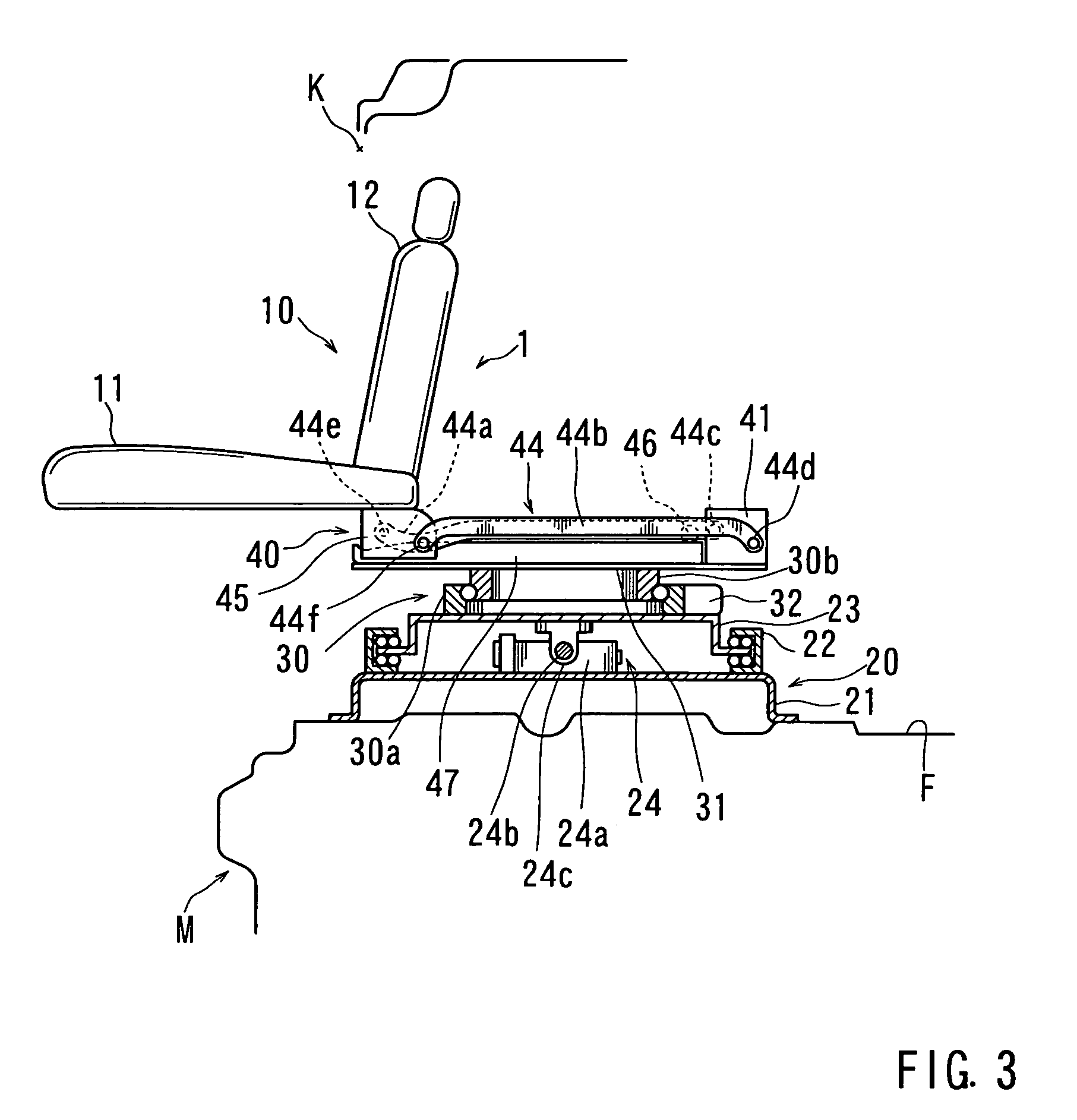

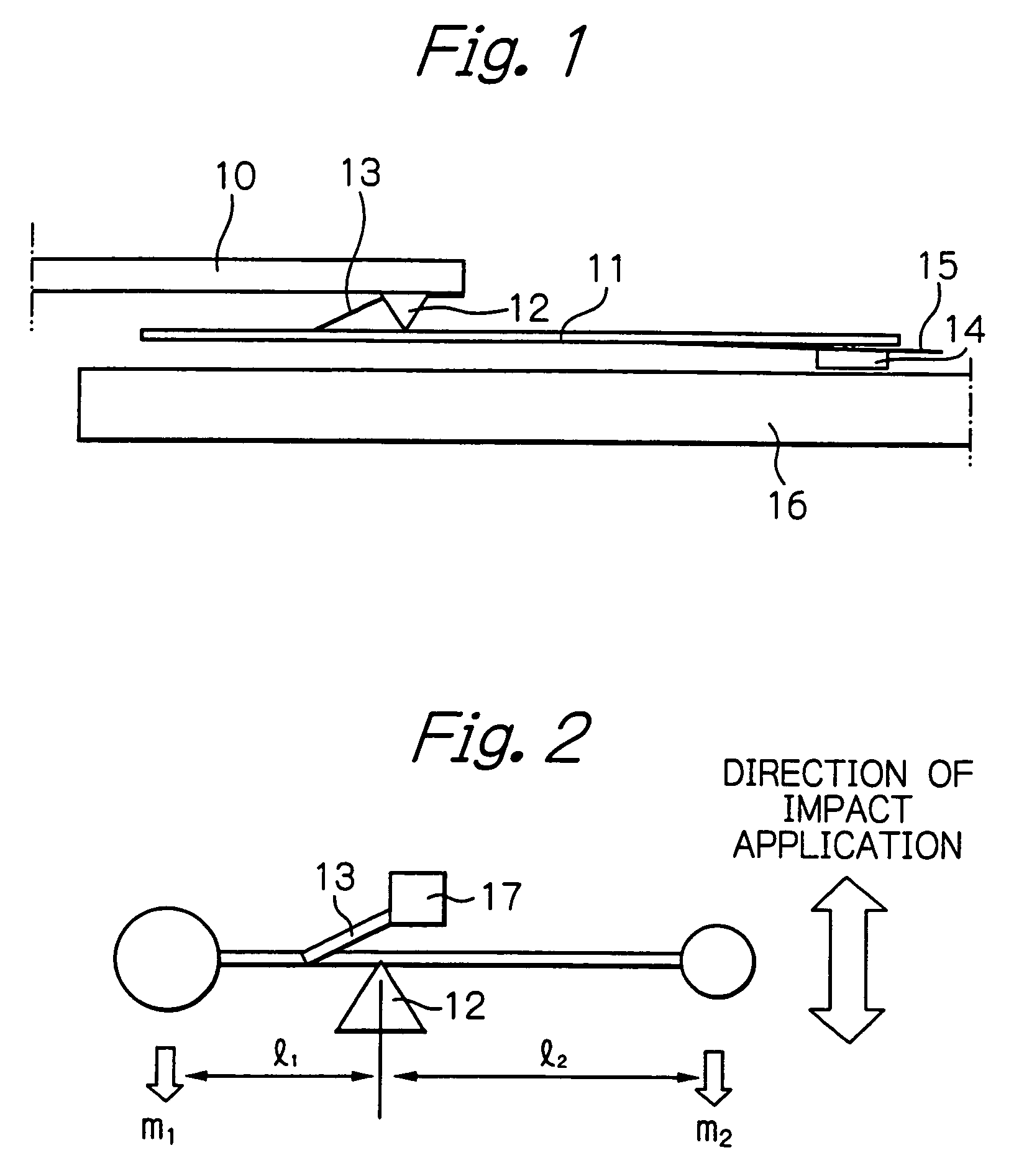

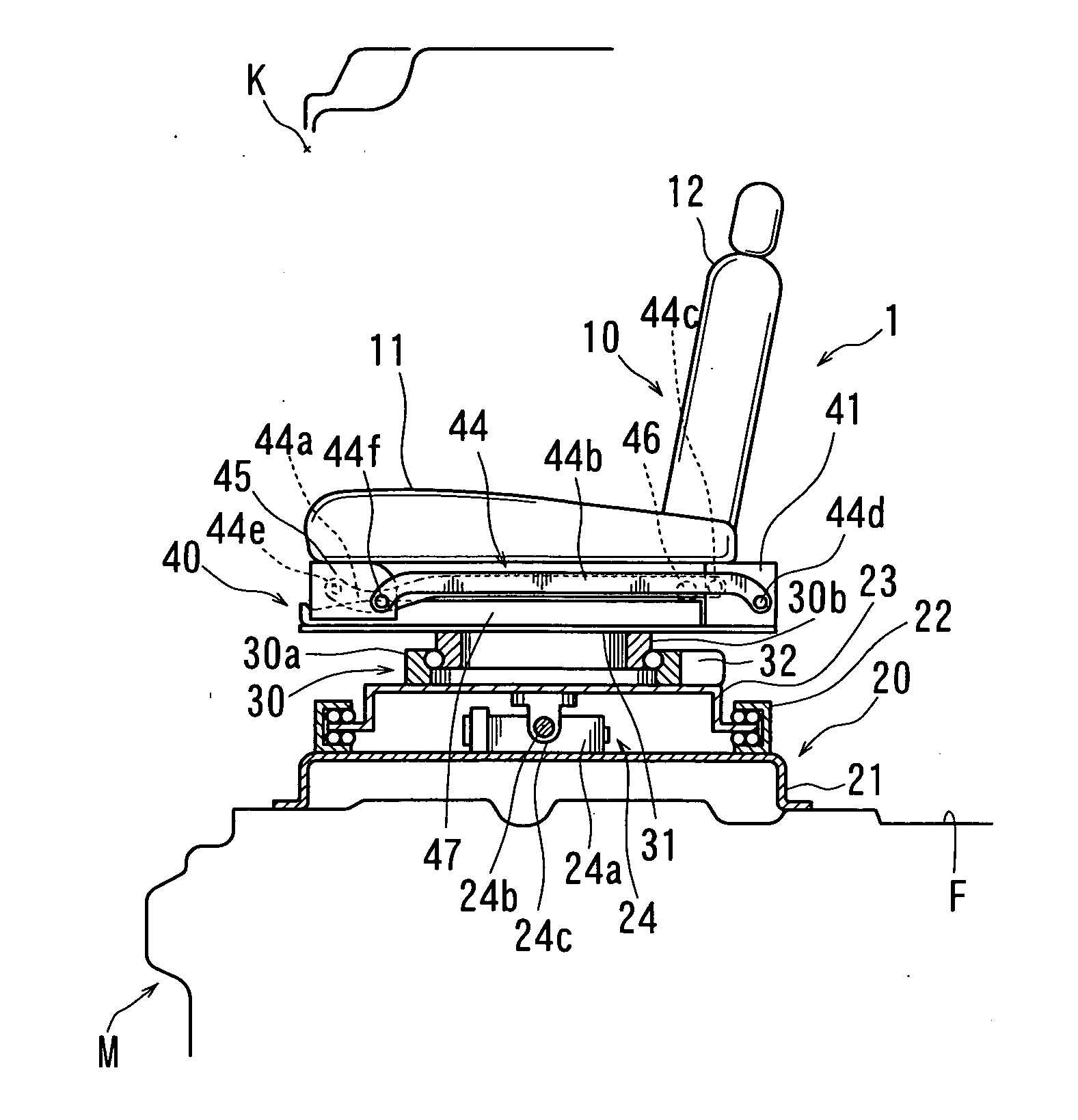

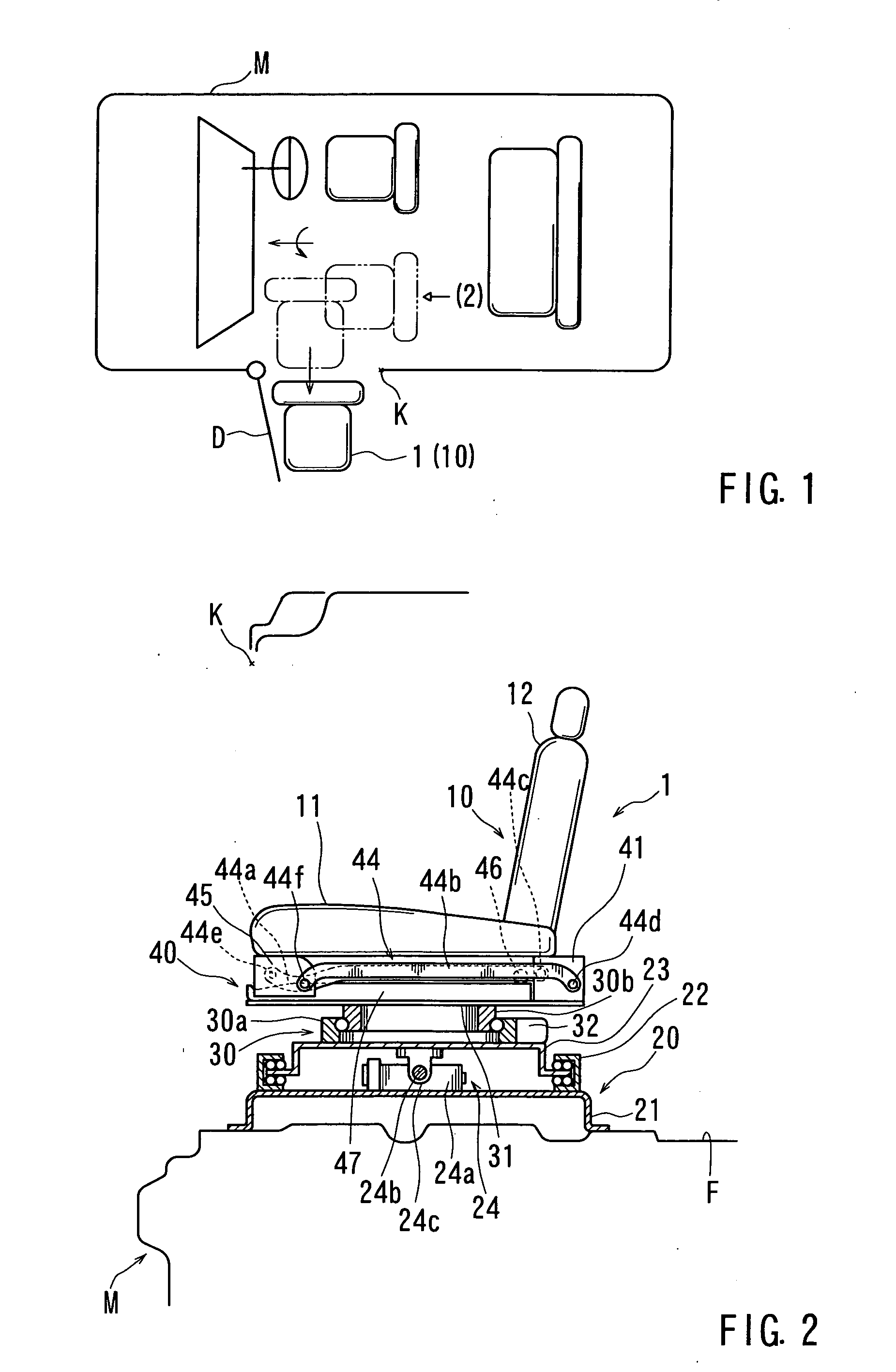

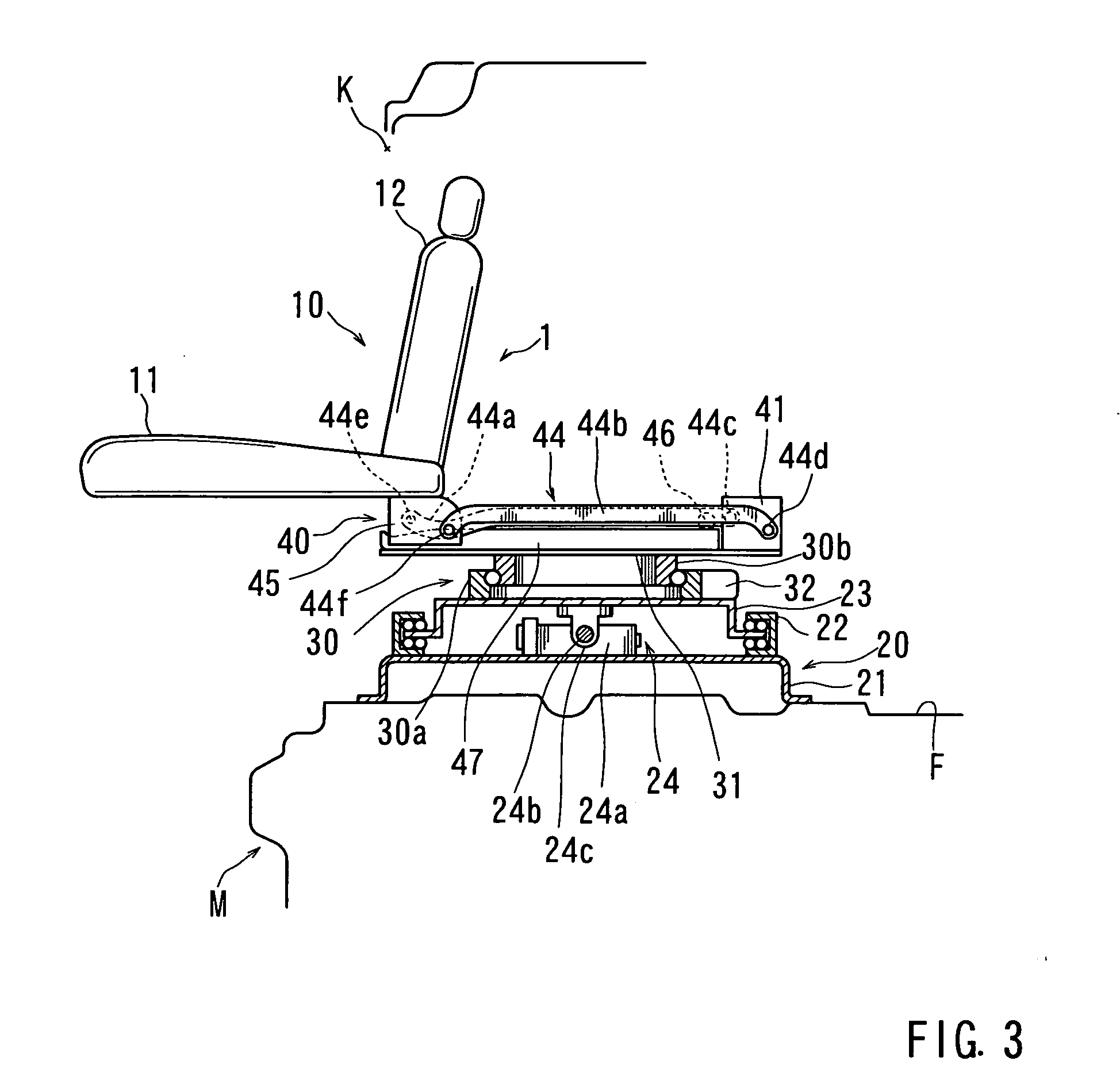

Seat moving device for vehicle

ActiveUS7316441B2Reduce volatilityReduce load fluctuationSeating furnitureMonocoque constructionsEngineeringCam

It is one object of this invention to provide a technique that is effective in diminishing the range of fluctuation of a load applied to a drive source when a seat main body in a vehicle seat moving apparatus is moved between a raised position and a lowered position.For this purpose, this invention provides a vehicle seat moving apparatus constructed as follows. Provided on a rotation base 31, for rotating a seat main body 10 between a position where it faces the front side of the vehicle and a position where it faces a door opening, is a widthwise slide base 41 that moves horizontally in the vehicle width direction while the seat main body 10 faces the door opening. The seat main body 10 is supported by the slide base 41 via four-bar linkage mechanisms 44. Guide rollers 46 are attached to upper link arms 44a of the four-bar linkage mechanisms 44. The guide rollers 46 are placed on cam surfaces of cam plates 47 provided to the rotation base 31. The cam surfaces have continuously extending inclined guide surfaces 47b that guide such that the guide rollers 46 move obliquely upwards when the widthwise slide base 41 moves.

Owner:TOYOTA SHATAI KK

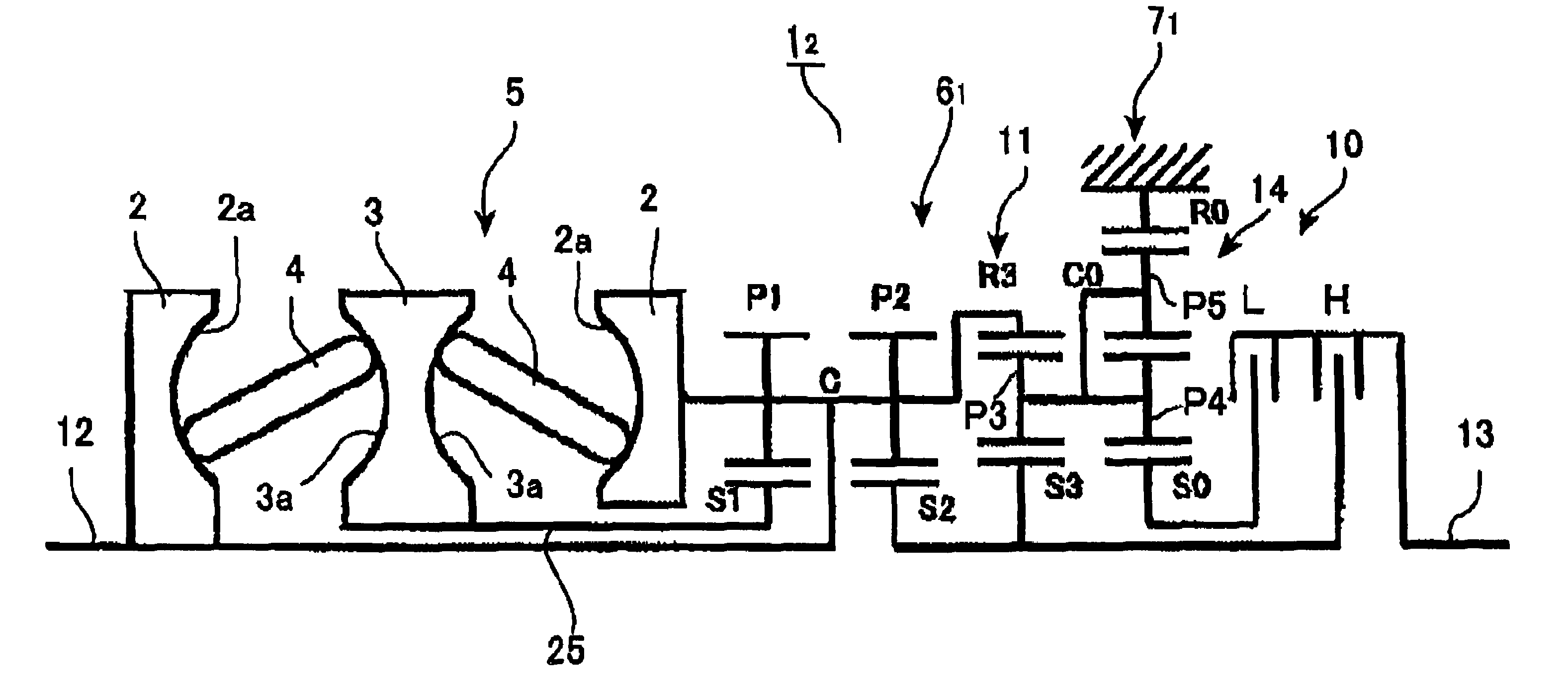

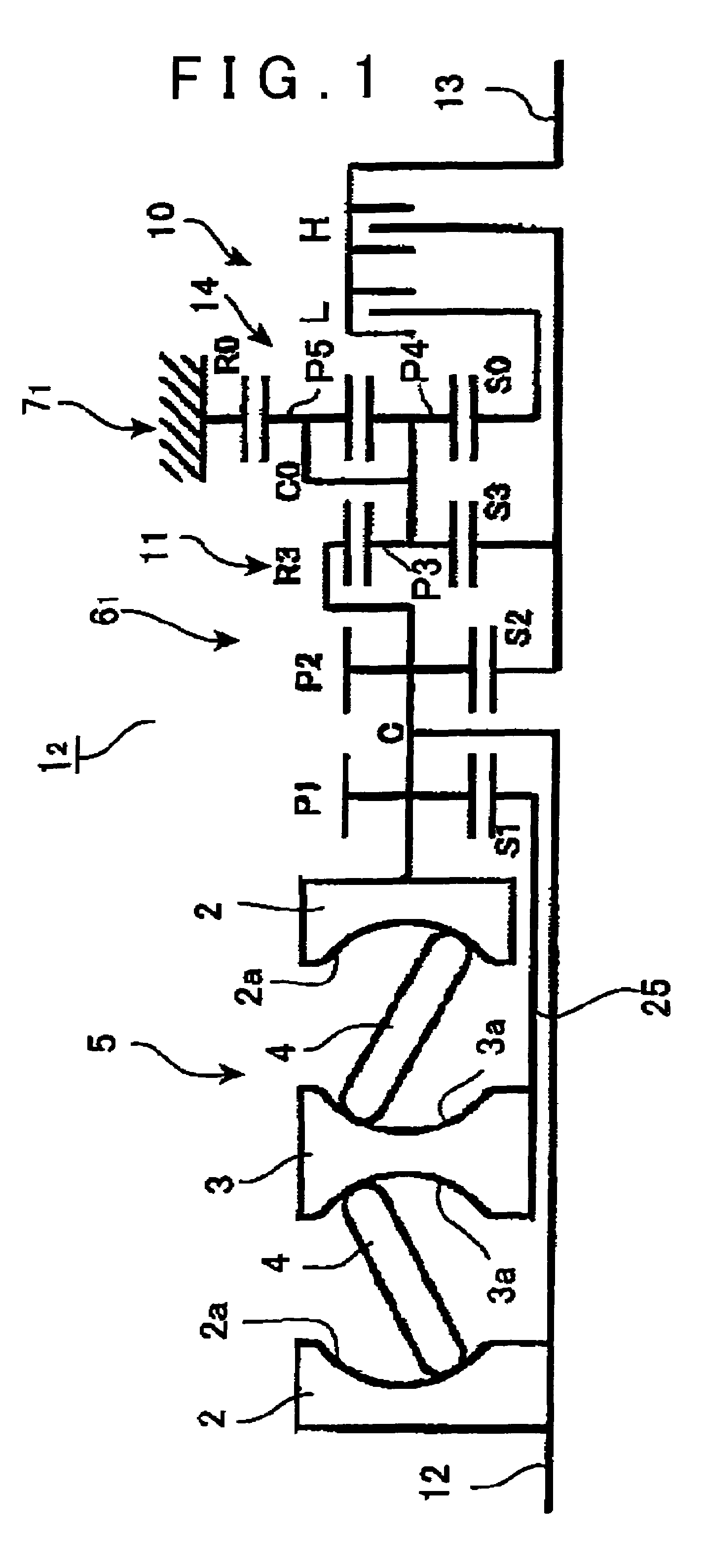

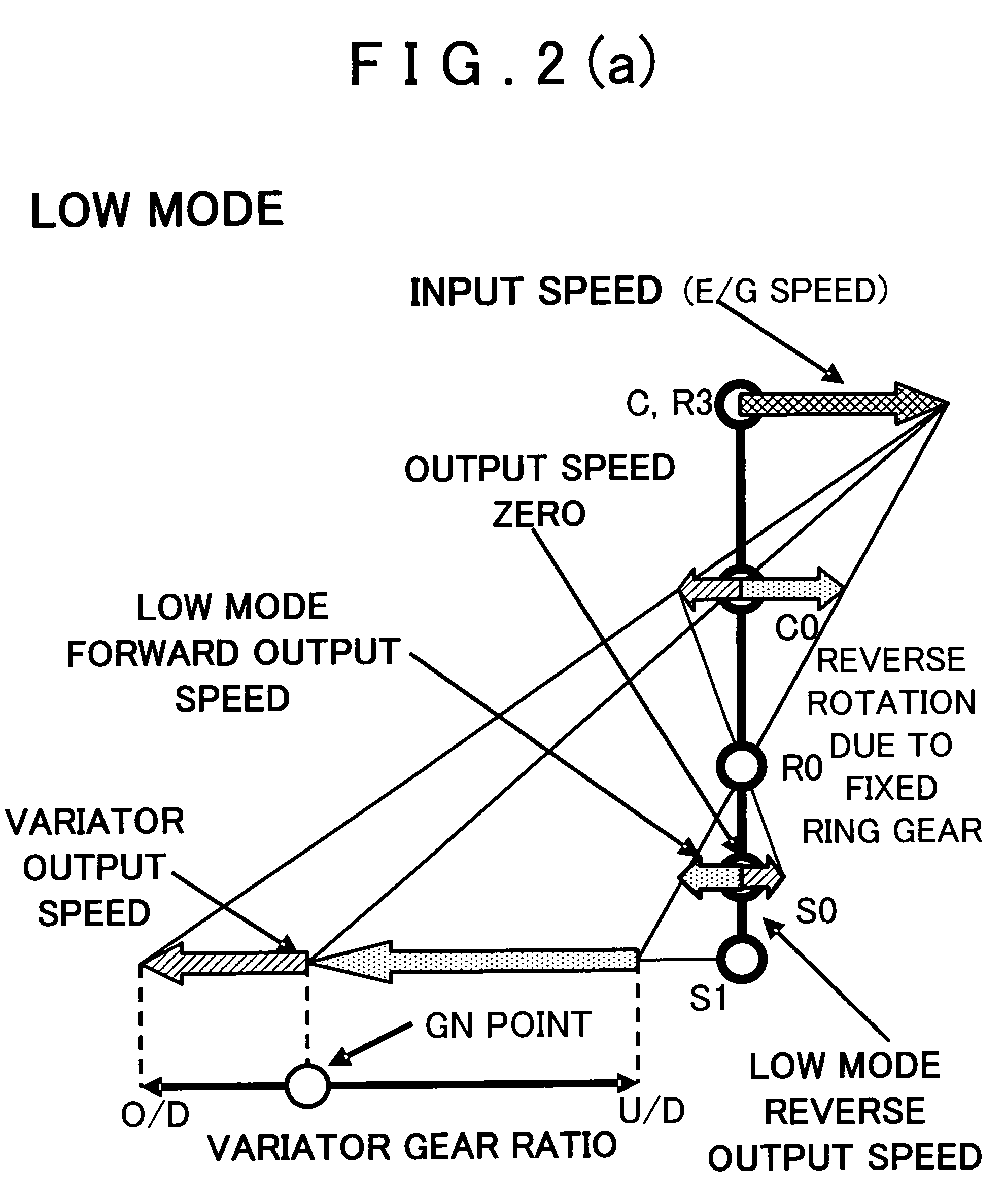

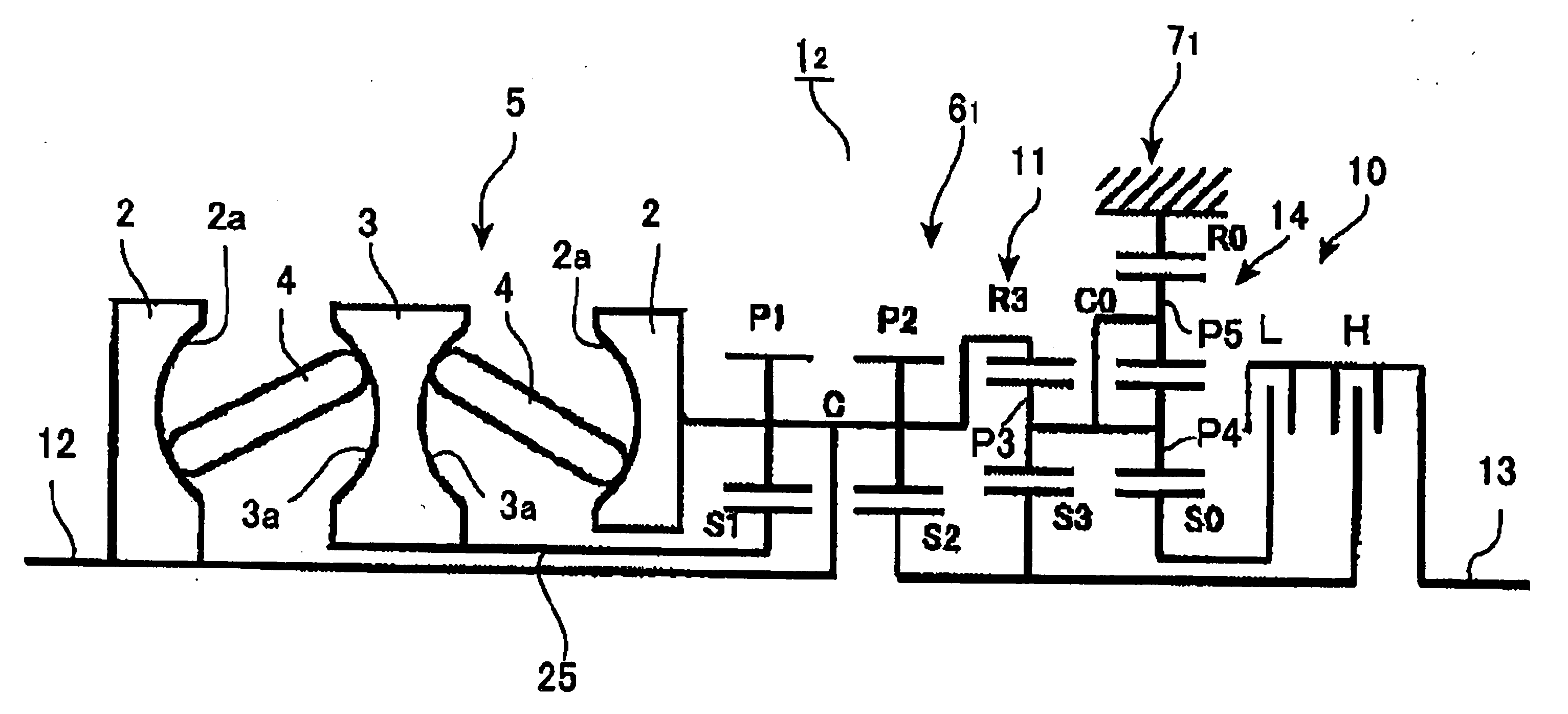

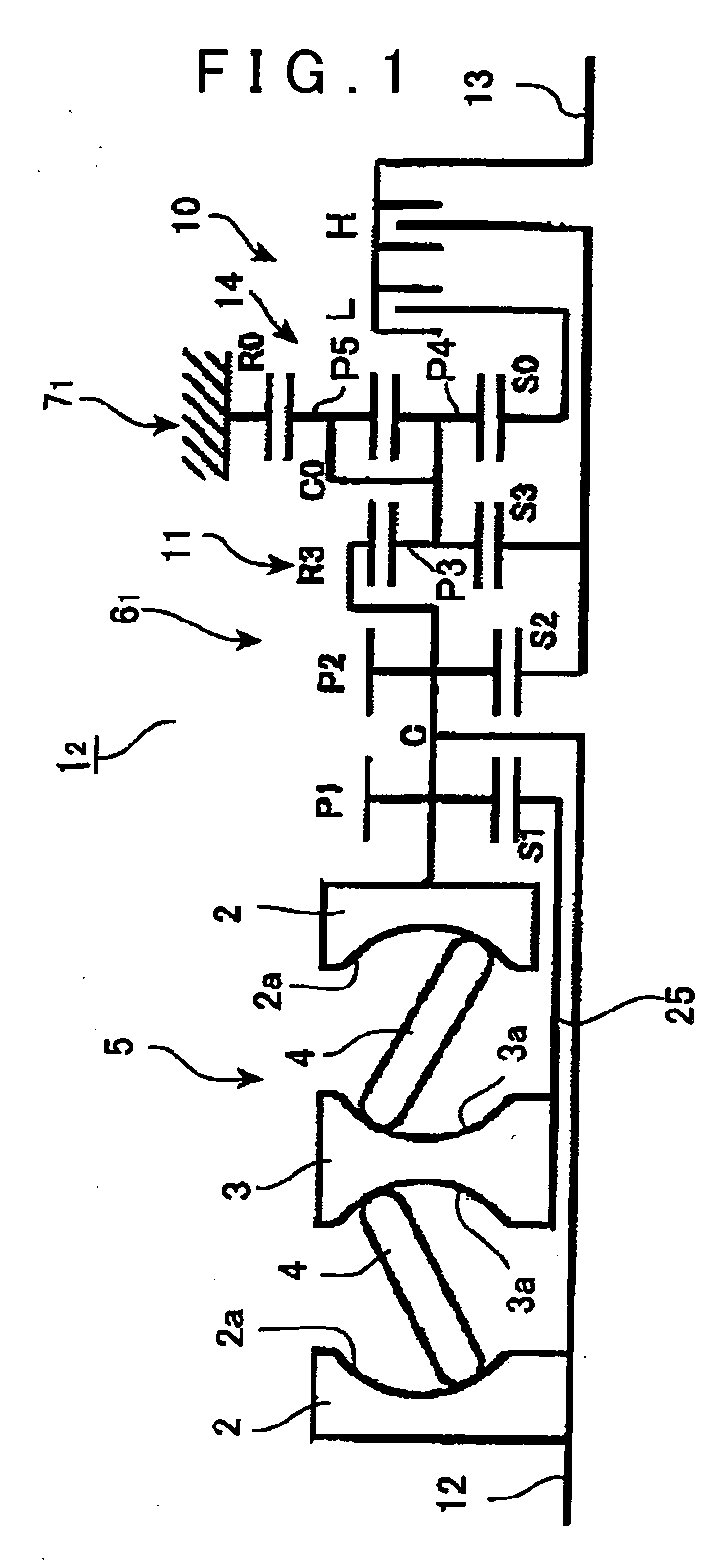

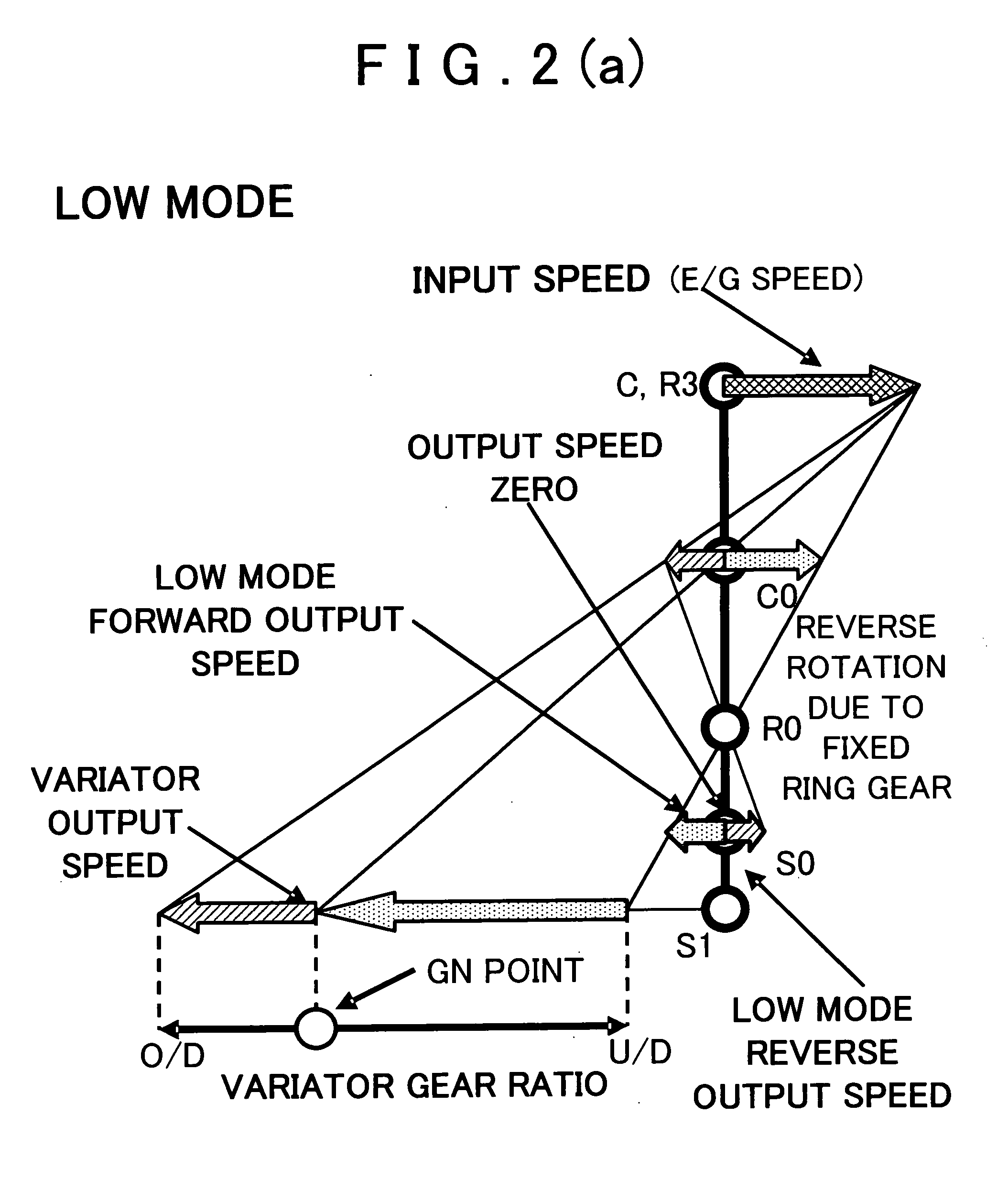

Continuously variable transmission

ActiveUS7335126B2Increase the lengthReduces bending of the pinion shaftGearingCommon carrierEngineering

Rotation of an input shaft is directly transmitted to a front carrier of a planetary gear mechanism, and rotation, which is speed-changed and reversed by a toroidal-type continuously variable speed change unit, is transmitted to a first sun gear. When a Low clutch is applied, rotation of an output carrier of a simple planetary gear unit is transitted to a counter gear mechanism via a common carrier, and then output at an output shaft. When a High clutch H is applied, rotation of a second sun gear is transmitted to the output shaft. Thus, the pinion shaft is shortened and the service life span of a supporting bearing is increased as compared with a planetary gear mechanism that has a three-step pinion.

Owner:EQUOS RES

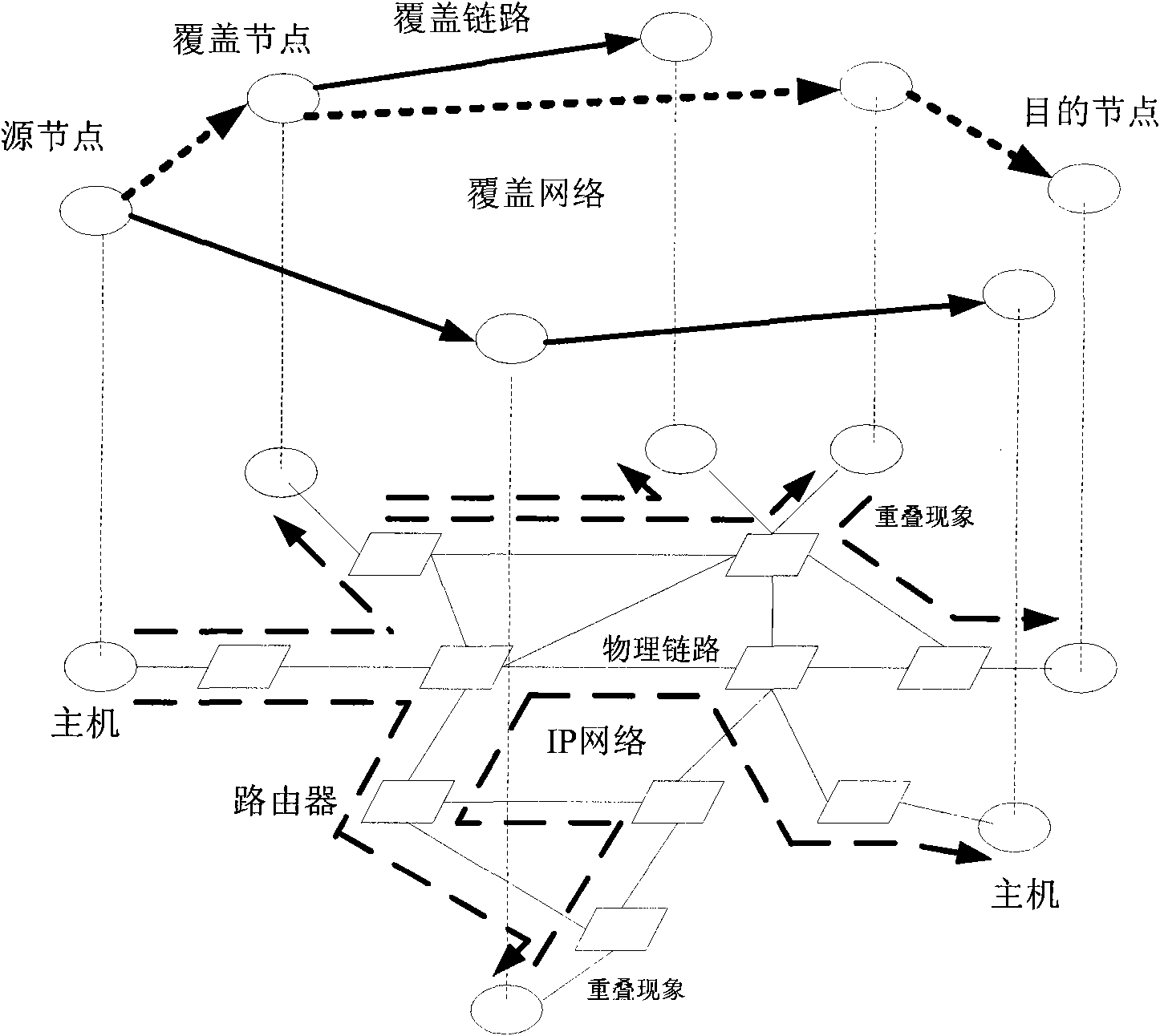

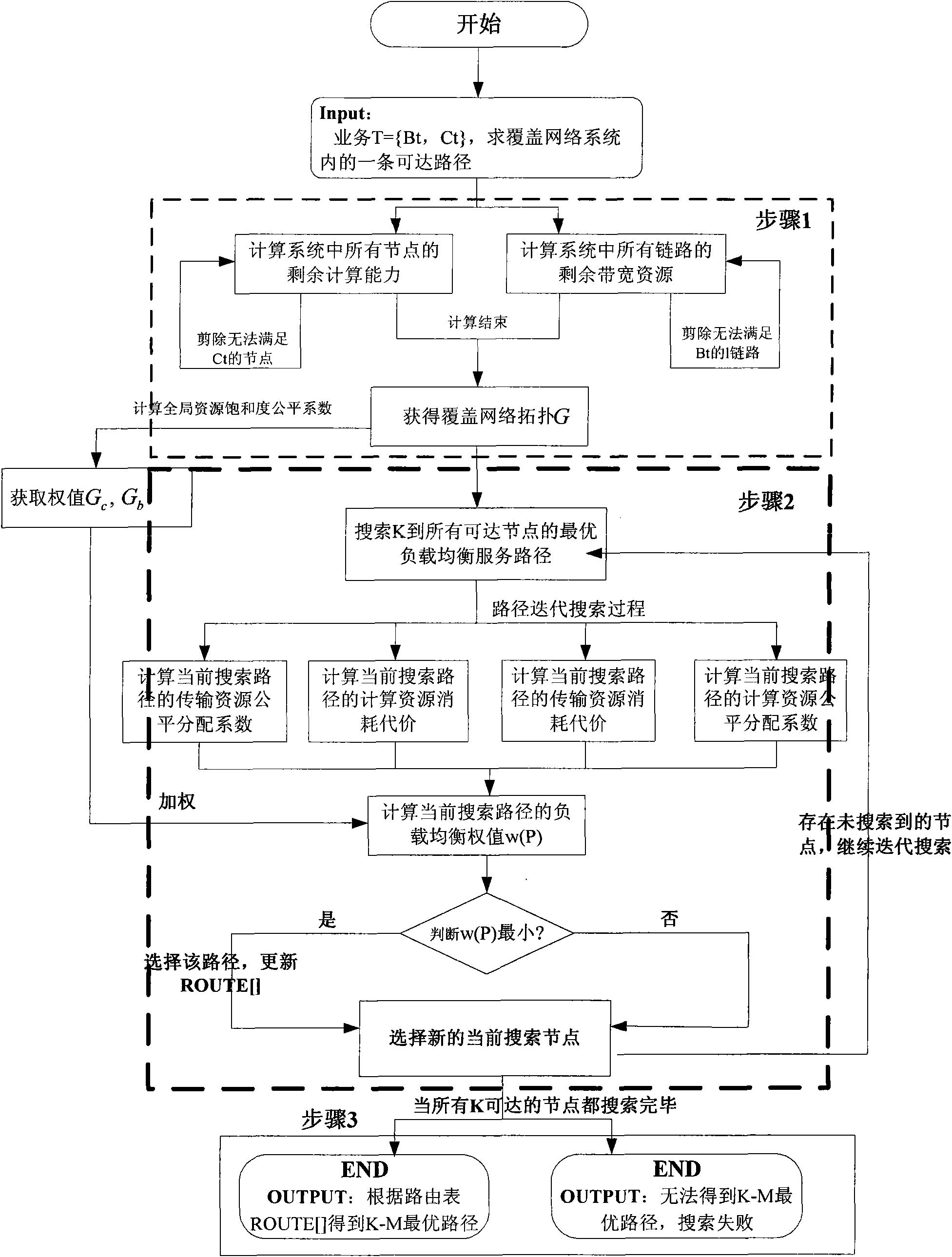

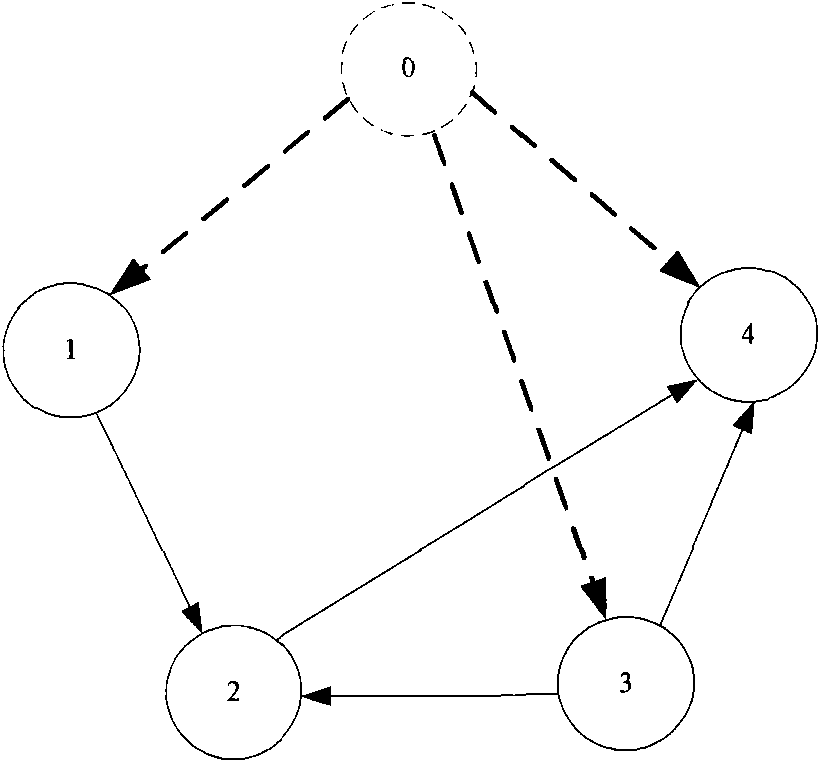

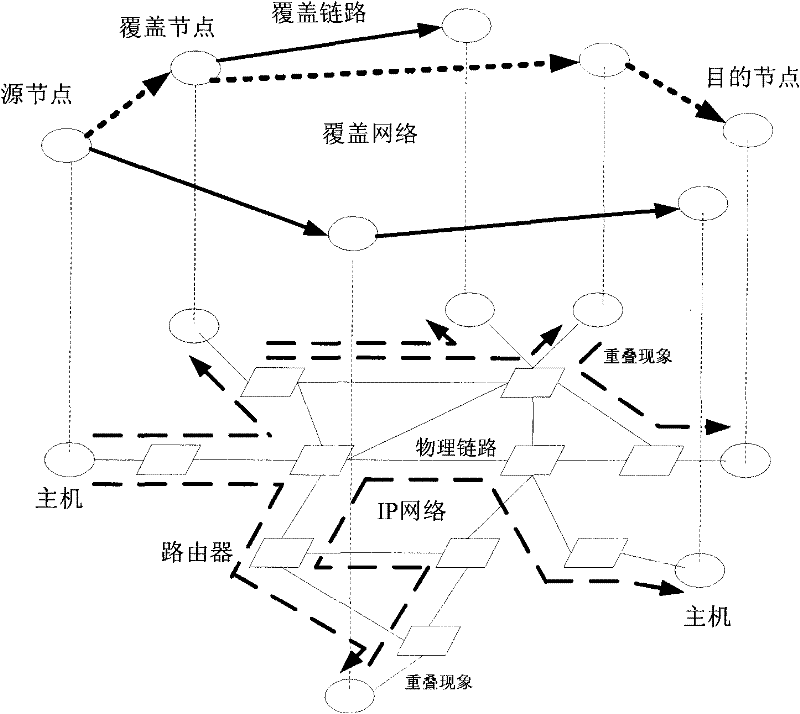

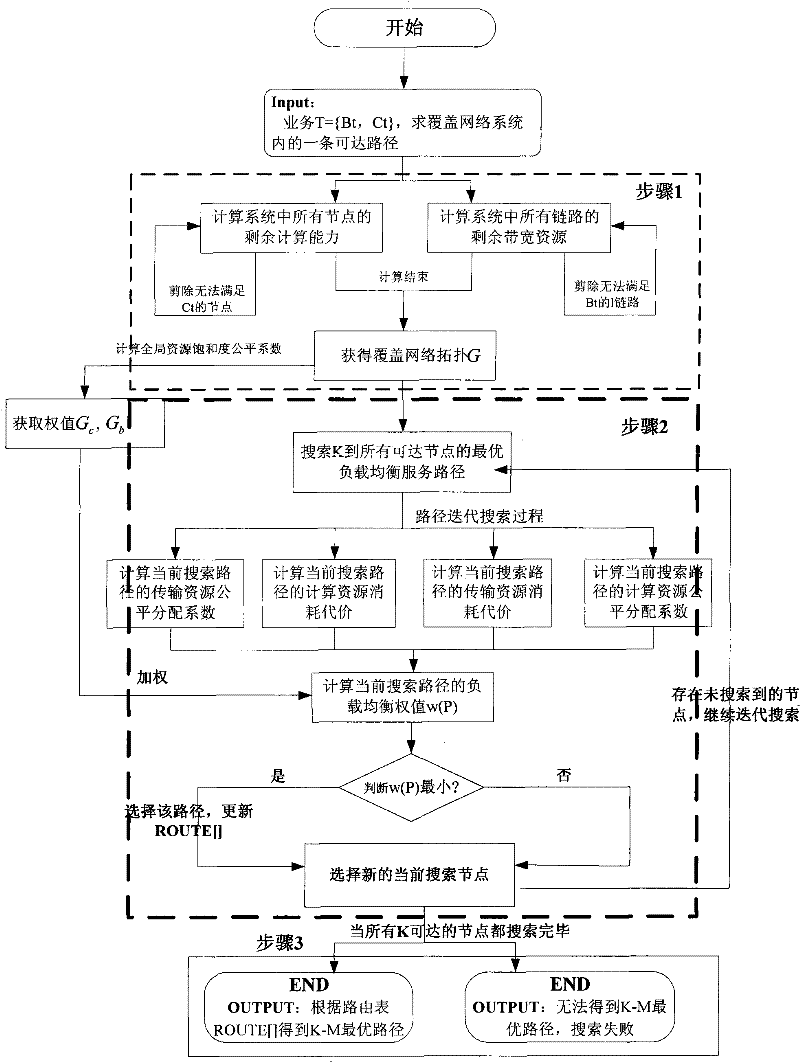

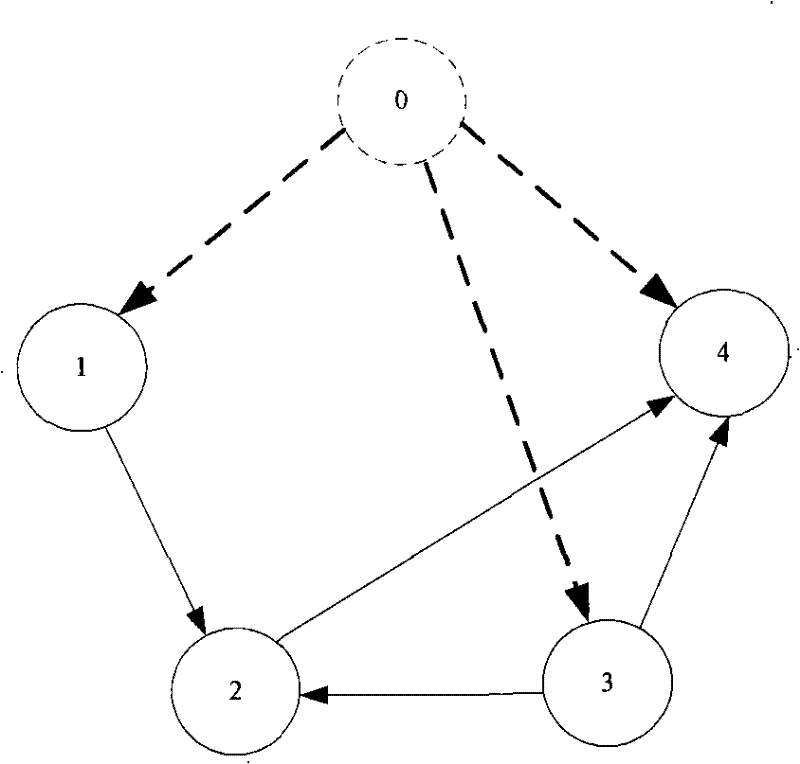

QoS (Quality of Service) route distributing method for realizing load balance in overlay network

InactiveCN102055663AReduce blocking rateConducive to optimizing the distributionData switching networksQuality of serviceDistribution method

The invention relates to the technical field of network communication, in particular to a QoS (Quality of Service) route distributing method for realizing load balance in an overlay network. The method comprises the steps of: introducing resource fair index representing path bottleneck degree, establishing a new load balance utility function, correcting a QoS bound term weight by adopting an adaptive system load state weighting method, and searching an optimal load balance service path. Compared with the traditional route method for load balance in the overlay network, the invention has the advantages of lowering the fluctuation degree RLCD (Residual Link Capacity Deviation) and RNCD (Residual Node Capacity Deviation) of the network load distribution, and being capable of improving the QoS service success rate (QSSR).

Owner:WUHAN UNIV

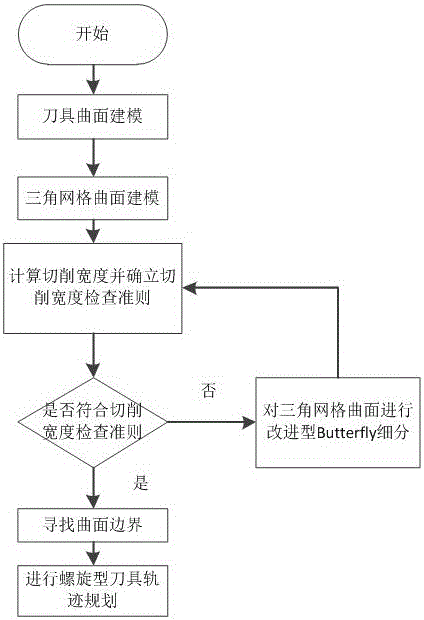

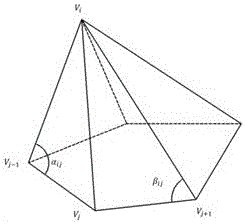

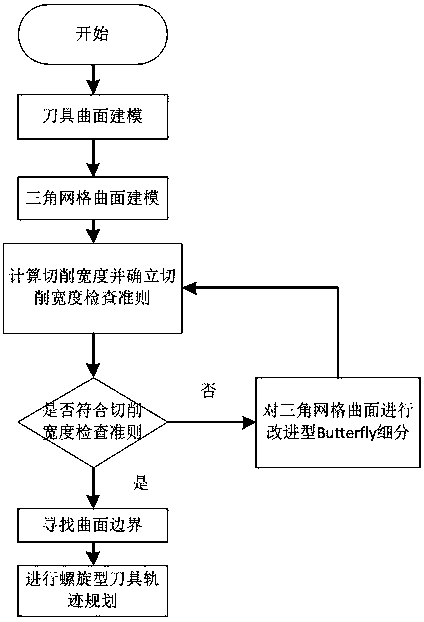

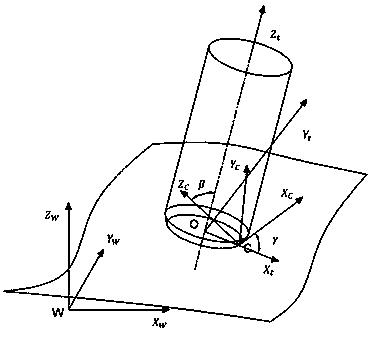

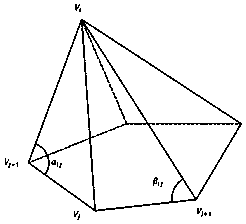

Grid free-form surface toroidal cutter path planning method based on improved Butterfly subdivision

The invention discloses a grid free-form surface toroidal cutter path planning method based on improved Butterfly subdivision. The method comprises the steps of toroidal cutter surface modeling and triangular grid free-form surface modeling. Besides, the cutter surface of a cutter contact point (CC point) and a workpiece surface are geometrically analyzed with combination of the geometrical features of the toroidal cutter. The minimum front inclination angle of the cutter is calculated according to the principle of cutting cutter interference so as to obtain the maximum width of a cutting path, based on which subdivision is performed on the triangular grid surface by adopting the improved Butterfly subdivision method so that the line space of the cutter path is enabled to meet the width requirement of the cutting path. Planning of the spiral cutter path cutter contact point (CC point) is performed line by line along the boundary of the triangular grid with a surface contour curve acting as an initial cutter path so that the position of a cutter center (CL point) is finally solved according to the toroidal cutter geometrical model. The method is applied to high-speed machining so that continuity of the formed cutter path can be enhanced, cutter load fluctuation can be reduced, and cutting stability can be enhanced and the service life of the cutter can be prolonged under the premise of guaranteeing the cutting quality.

Owner:ZHEJIANG UNIV

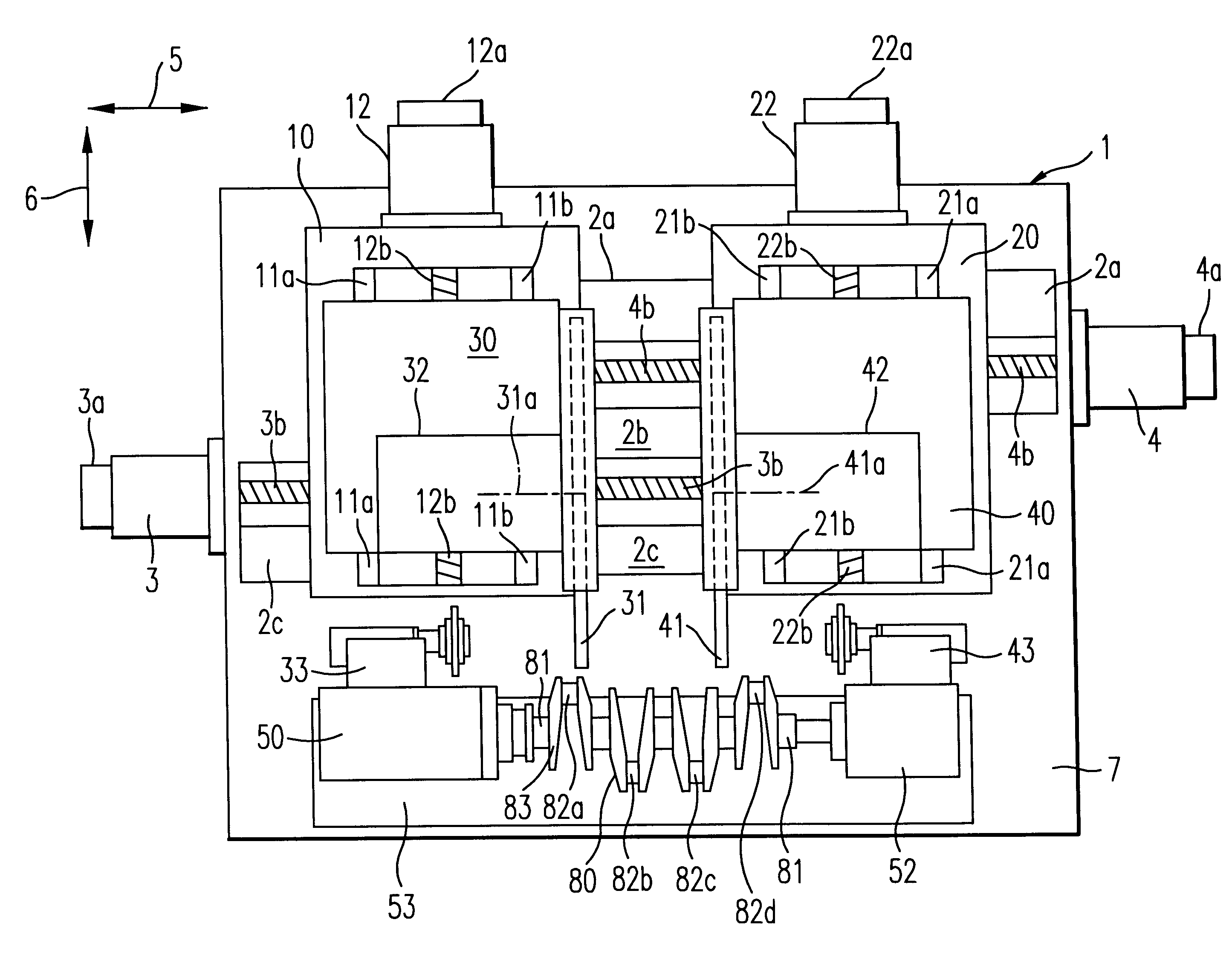

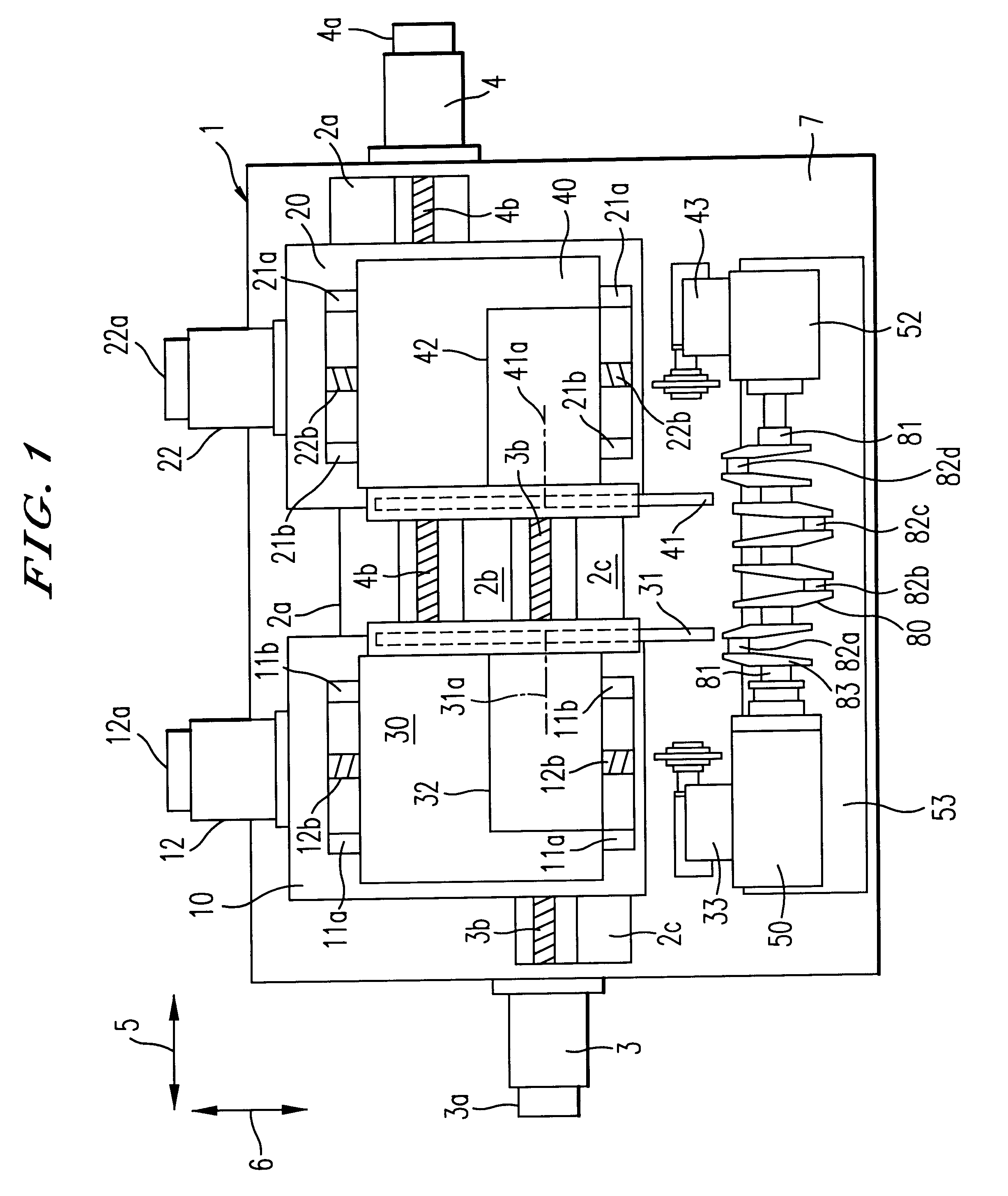

Apparatus for and a method of machining two portions

InactiveUS6334806B1Inhibit deteriorationReduce load fluctuationRevolution surface grinding machinesGrinding feed controlRotational axisCrankshaft

A grinding machine includes a spindle head for rotatably driving a crankshaft around a journal center as a rotational axis and, two wheel heads that support respective two grinding wheels and that advance and retract in a direction perpendicular to the rotational axis independently with each other. Two of plural pin portions of the rotating crankshaft are simultaneously ground by the respective two grinding wheels, in which rotational phases of the two pin portions are different from each other. Further, the rotational phases of the two pin portions are stored as a combination in a memory. The two pin portions are simultaneously ground in accordance with the combination by the respective two grinding wheels.

Owner:TOYODA MASCH WORKS LTD

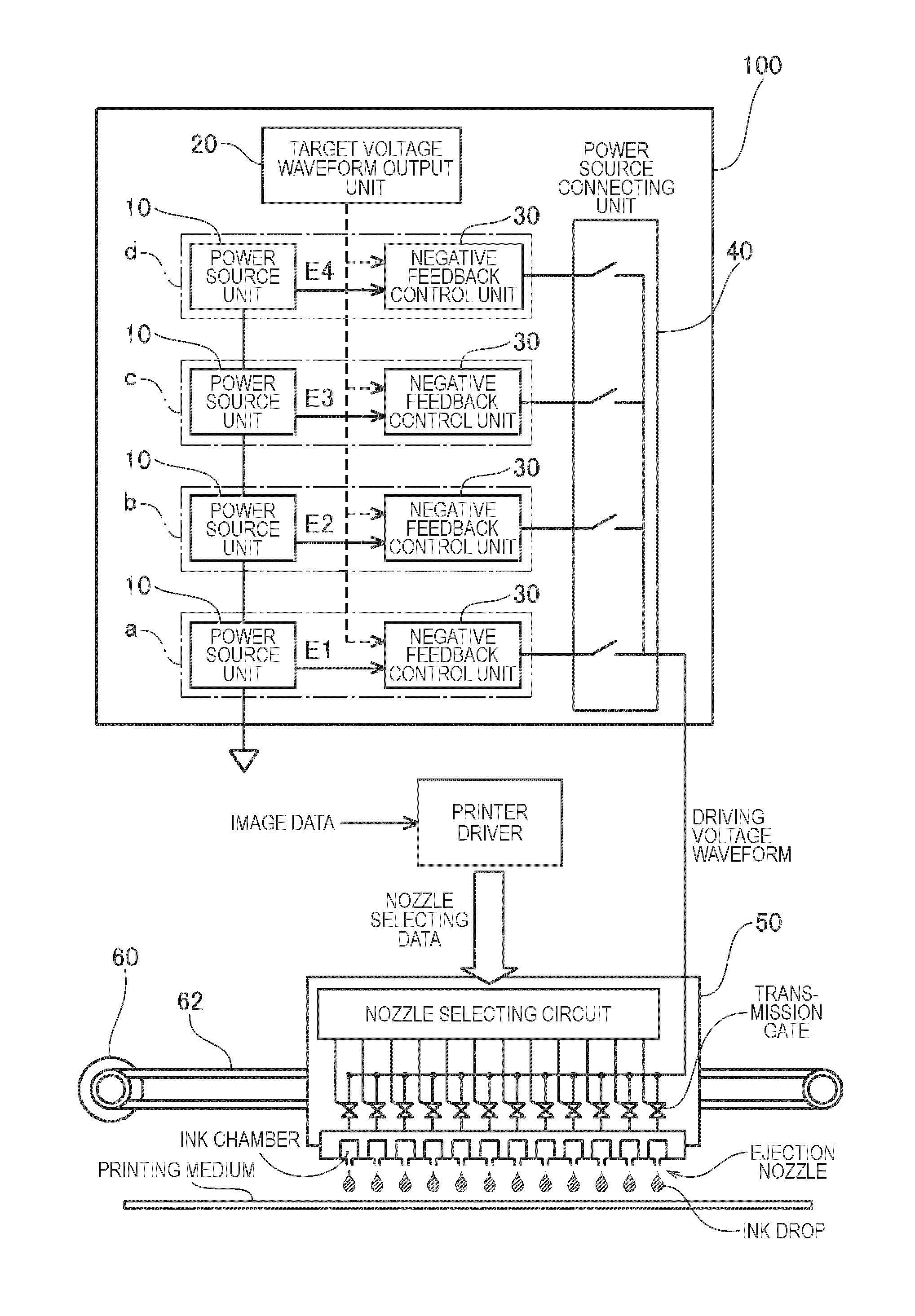

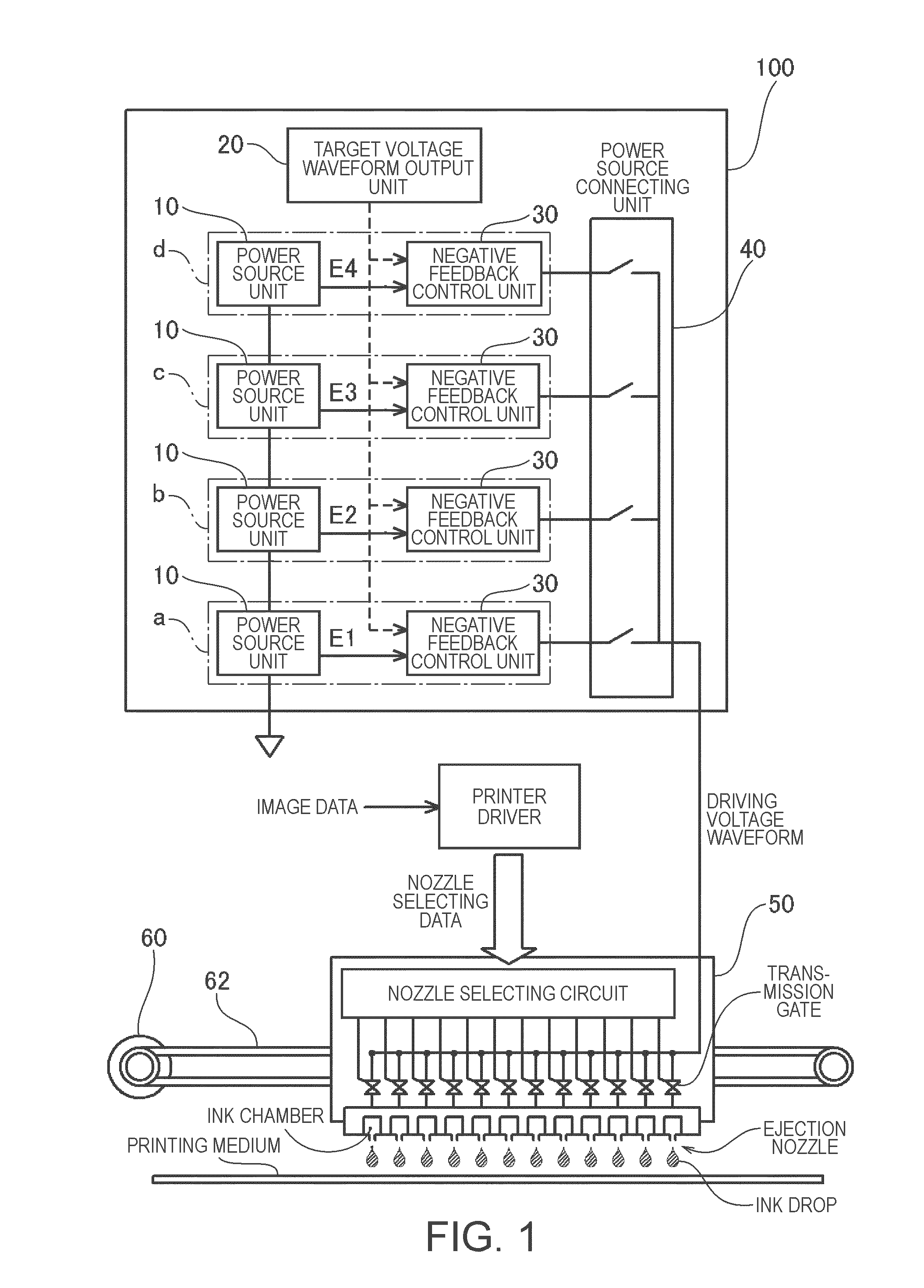

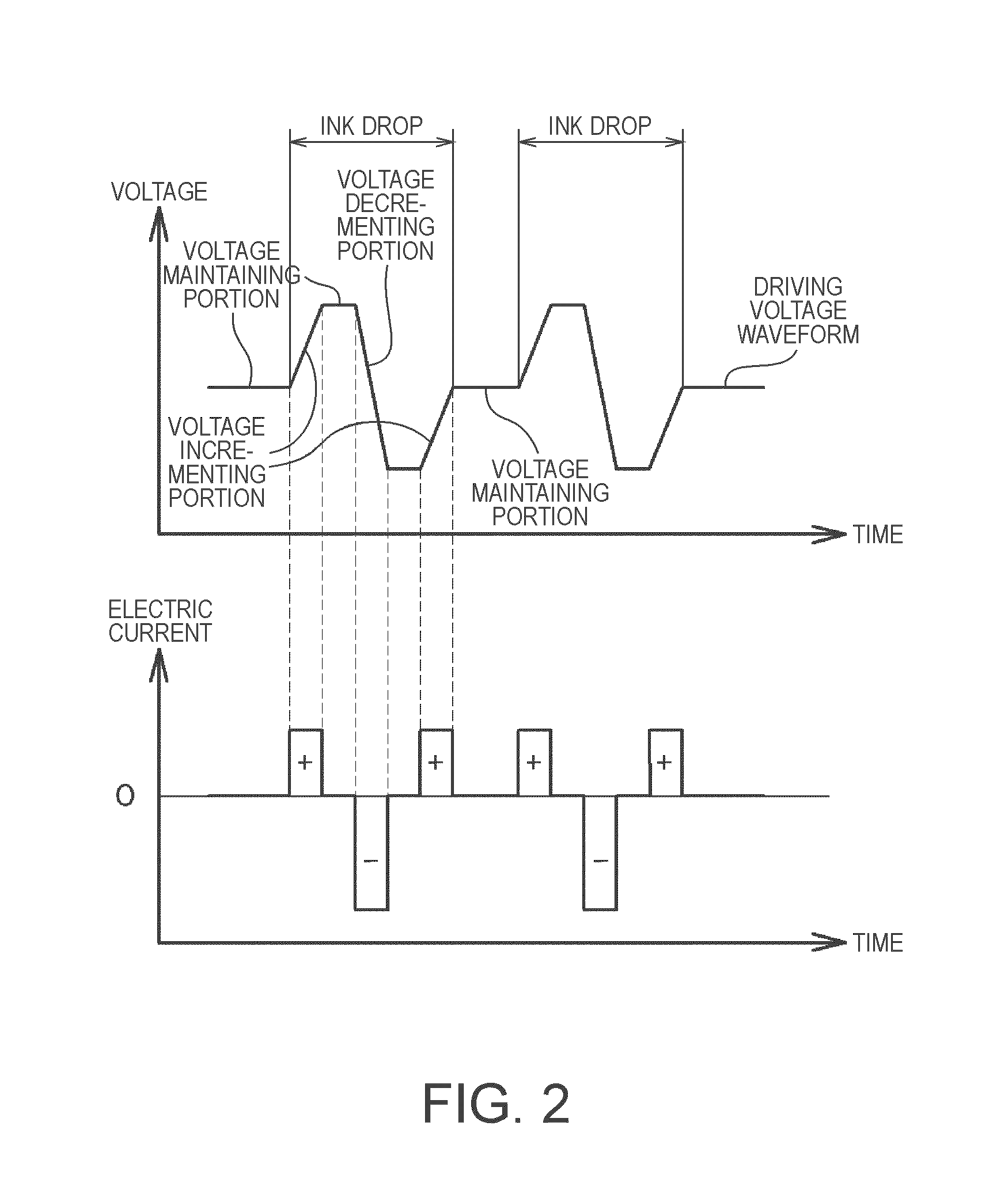

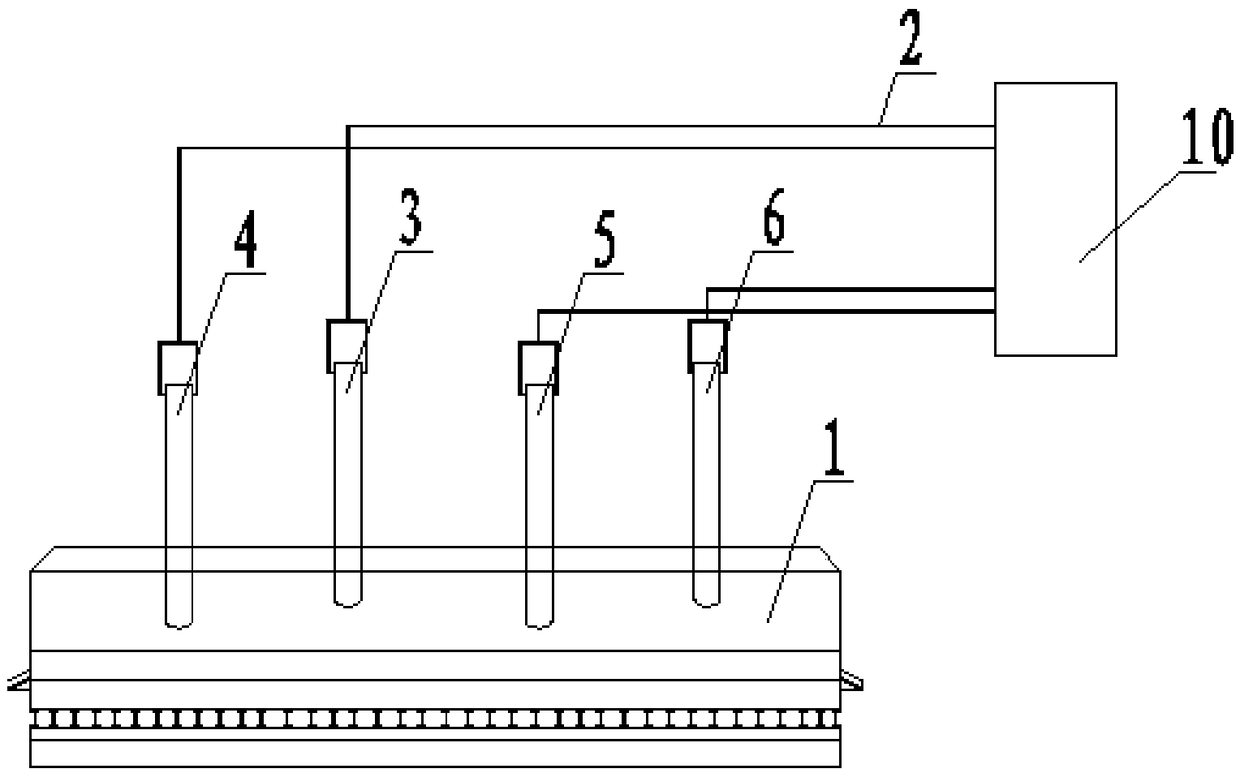

Driving circuit for fluid jet head, driving method for fluid jet head, and fluid jet printing apparatus

ActiveUS20100103211A1Reduce the impactStable supplyDc network circuit arrangementsOther printing apparatusNegative feedbackEngineering

An ejection head driving circuit that supplies a driving voltage waveform to an ejection head has ejection nozzles that cause fluid to be ejected. A target voltage waveform output unit outputs a target voltage waveform to the ejection head. Power source units generate electric power at different voltage values. Negative feedback control units supply electric power from the respective power source units to the ejection head and perform a negative feedback control of the voltage values so that the voltage value to be applied to the ejection head matches the target voltage waveform. A power source connecting unit selects one of the power source units on the basis of the voltage value applied to the ejection head or the voltage value of the target voltage waveform, connects the selected power source unit to the ejection head, and disconnects the remaining power source units from the ejection head.

Owner:SEIKO EPSON CORP

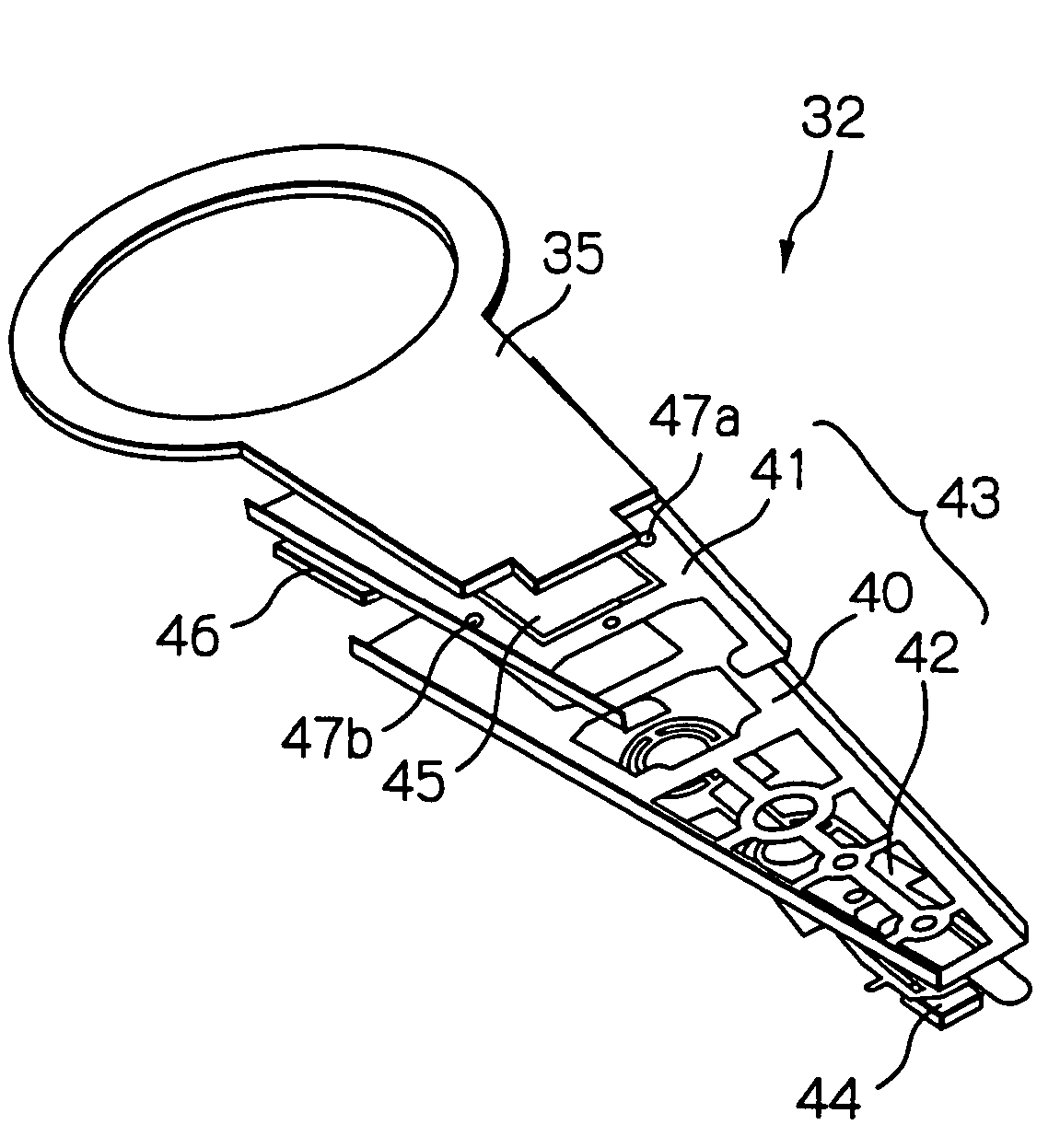

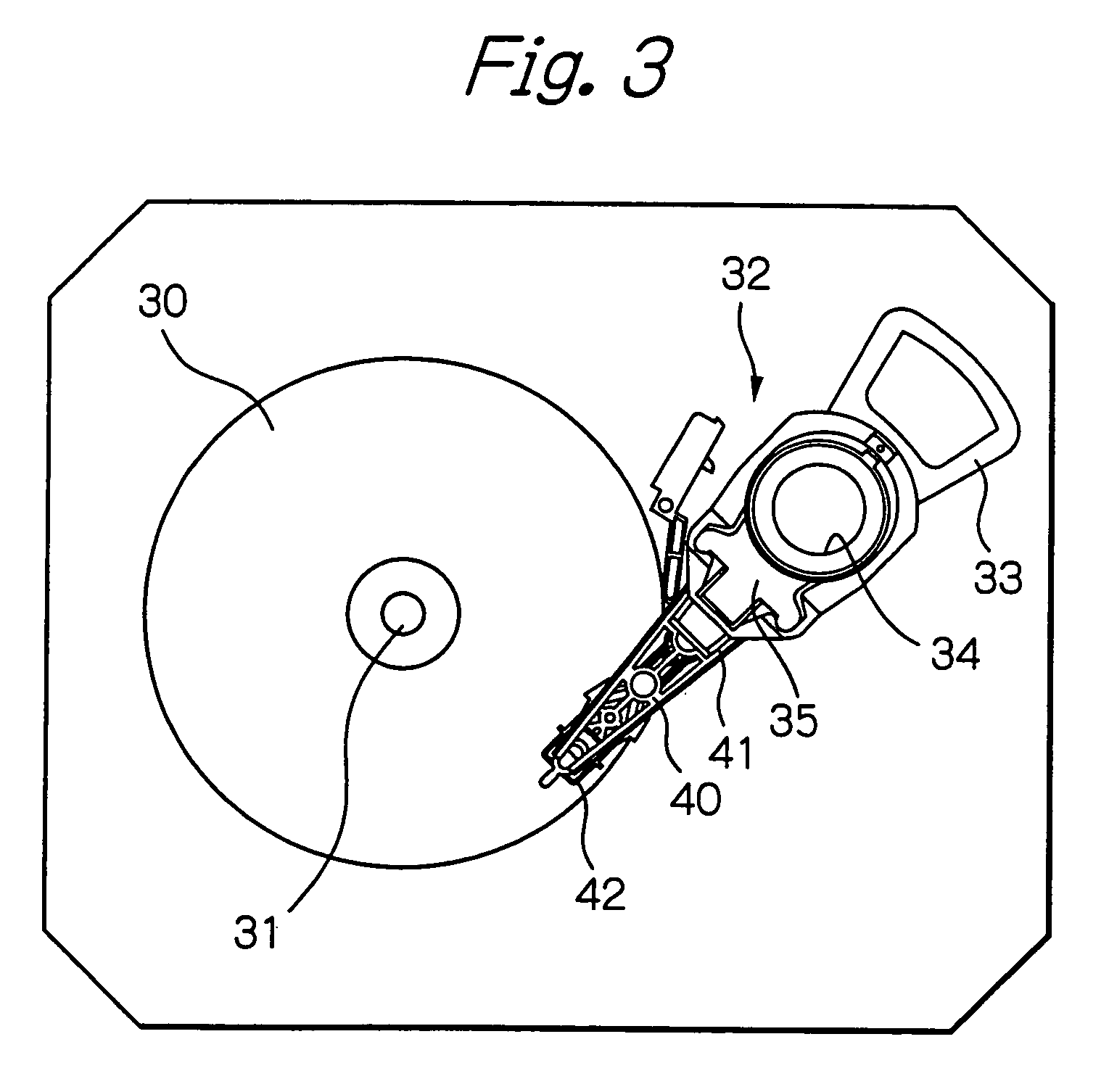

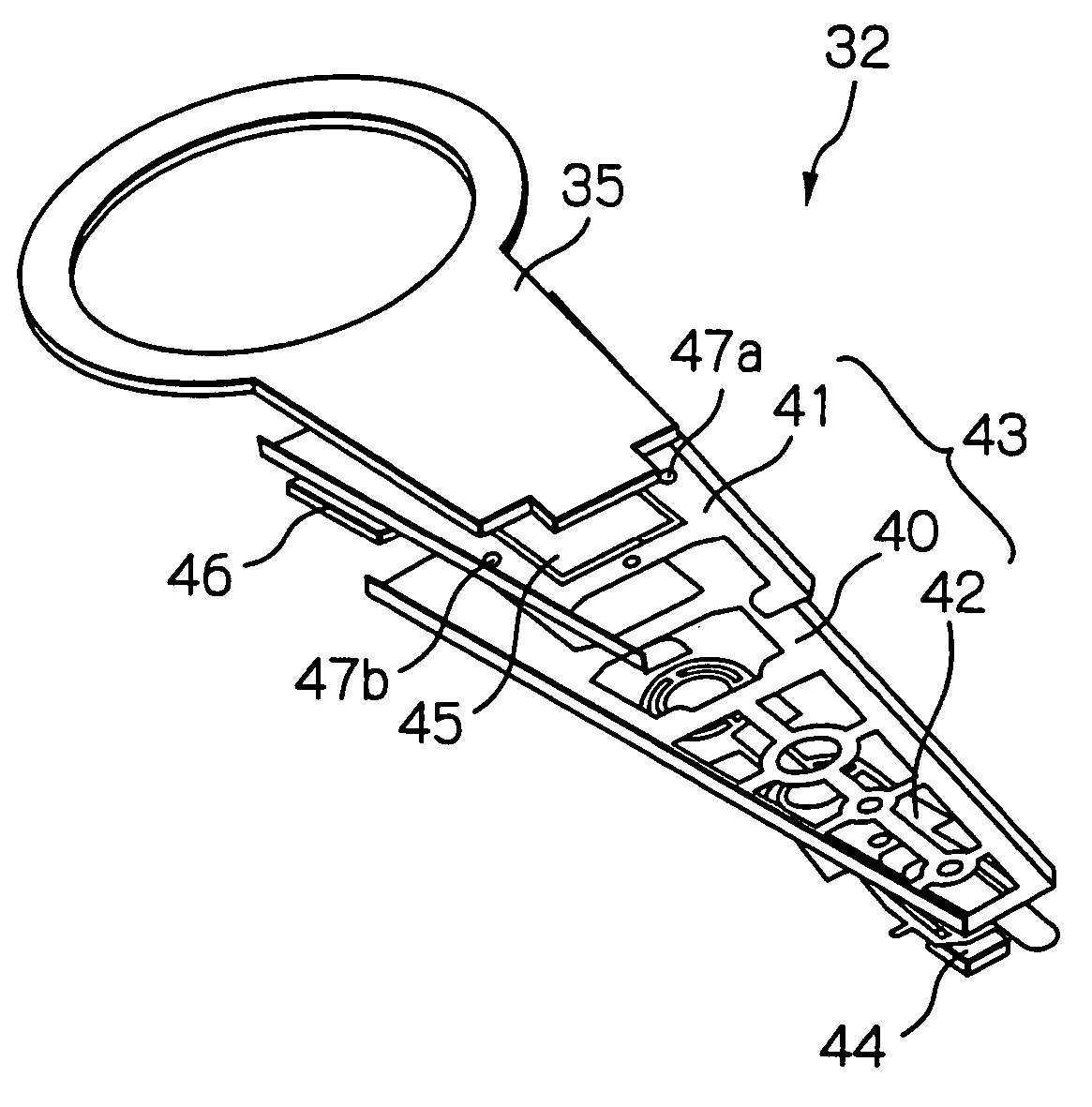

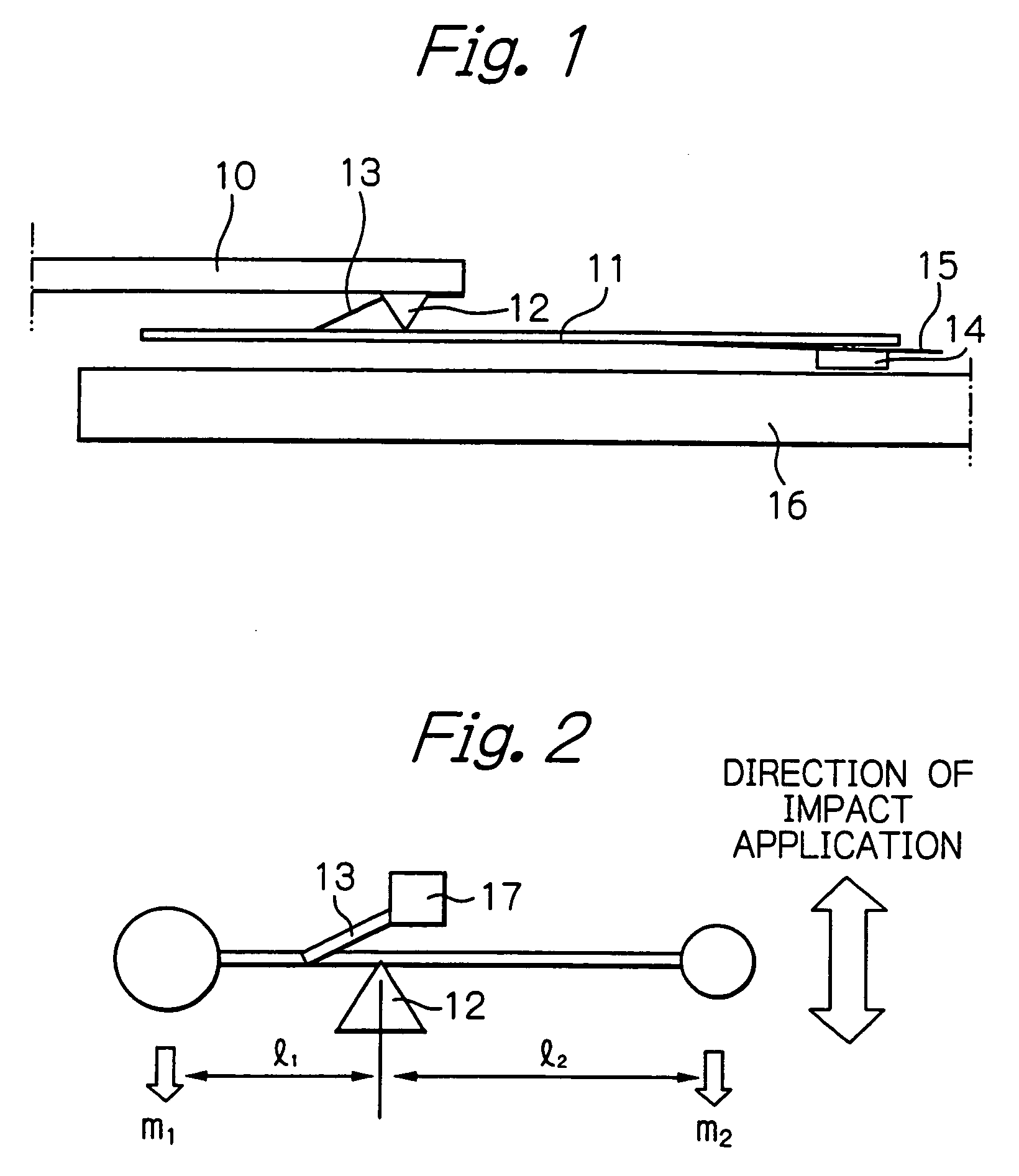

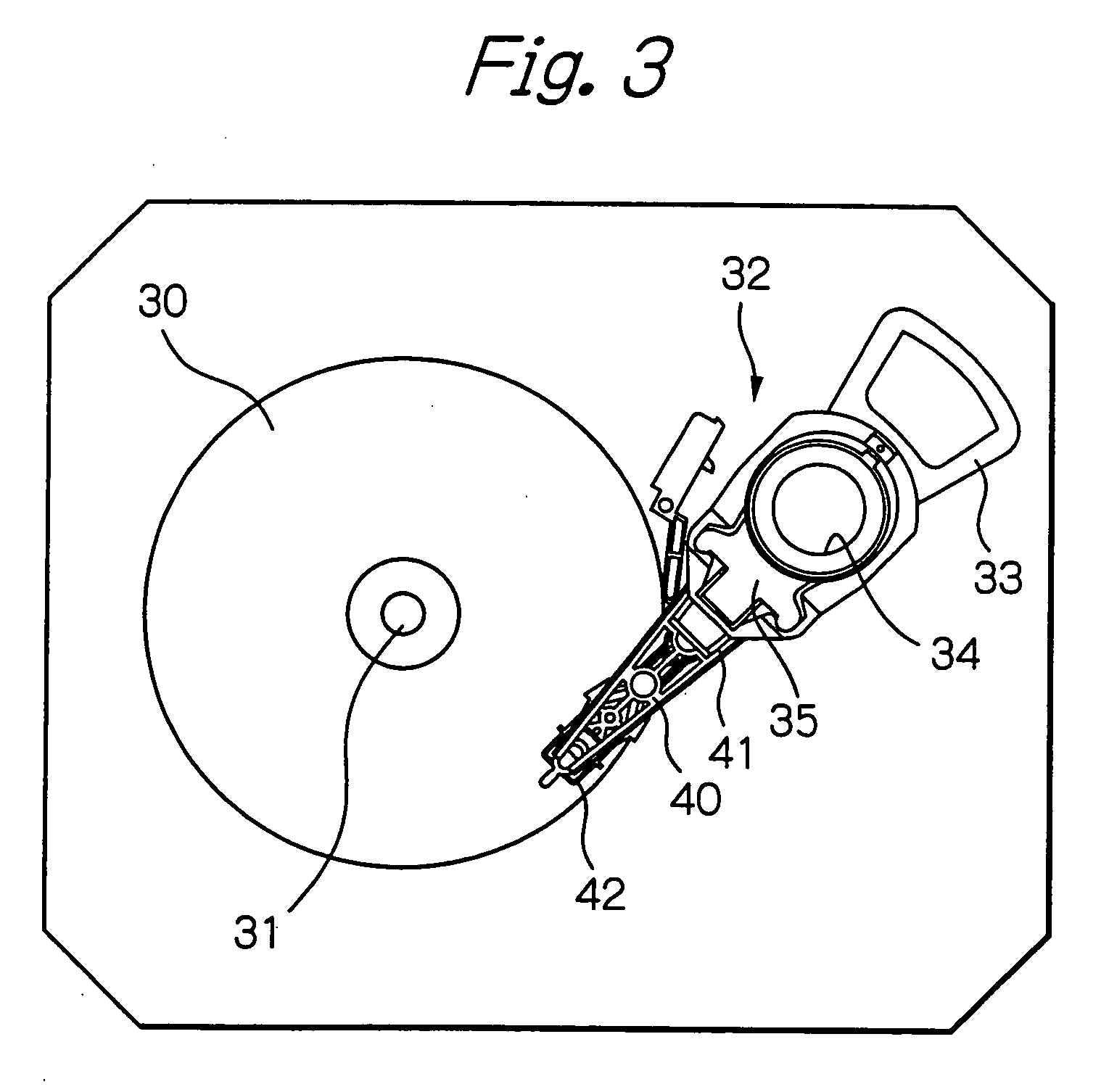

Head supporting mechanism including two load beams with ribs overlapped with each other

InactiveUS7333299B2Impact-resistance is enhancedImprove rigidityRecord information storageMounting/attachment of transducer headStructural engineeringSecond rib

Owner:TDK CORPARATION

Suspension, head supporting mechanism, head arm assembly and disk drive device with the head arm assembly

InactiveUS20050128644A1Impact-resistance is enhancedImprove rigidityRecord information storageMounting/attachment of transducer headSecond ribHead parts

Owner:TDK CORPARATION

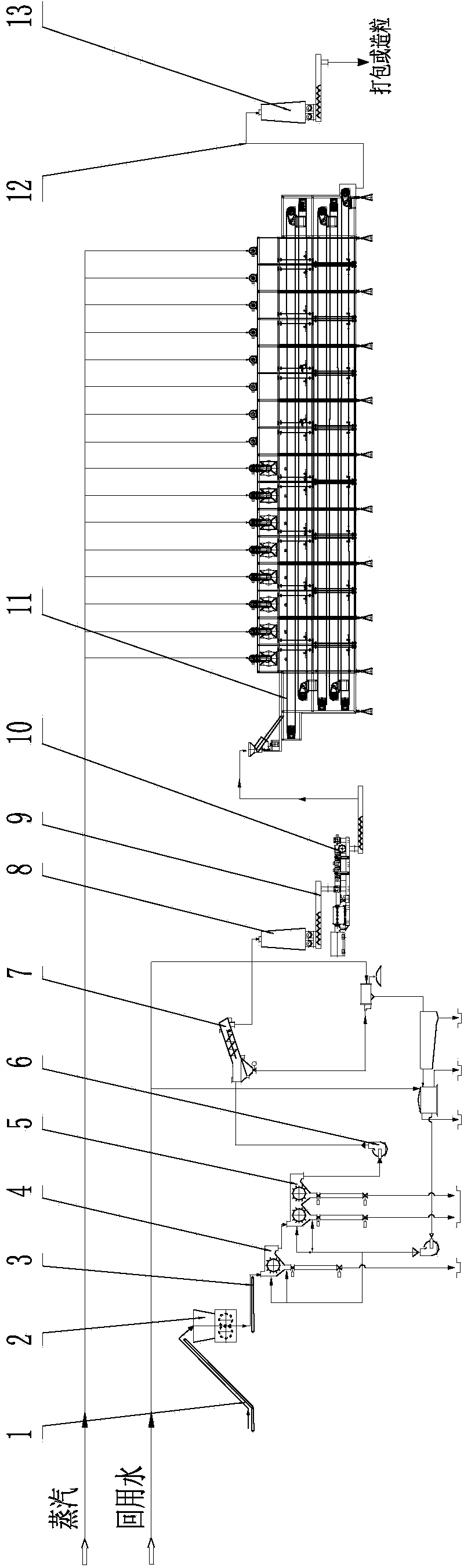

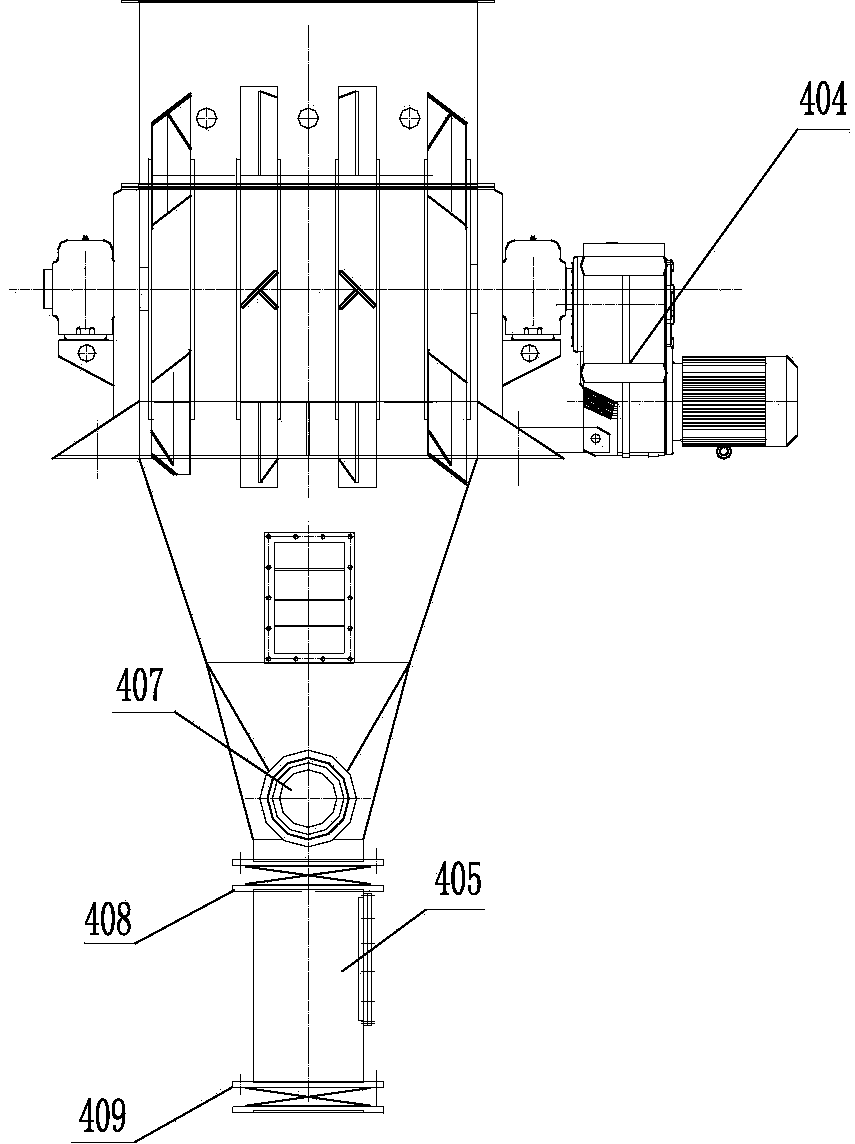

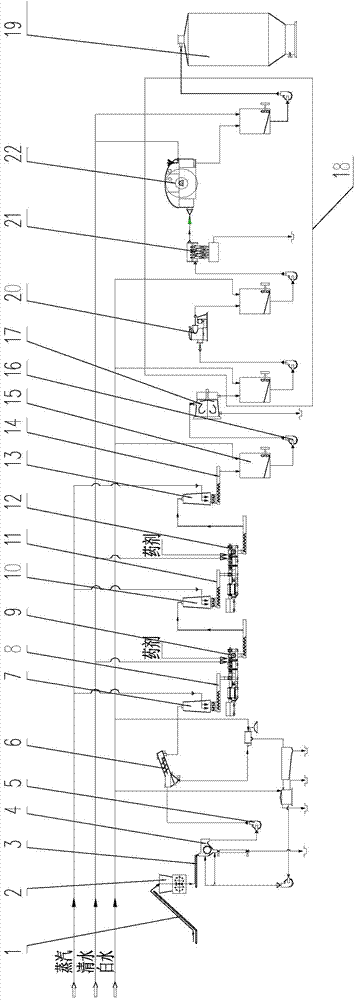

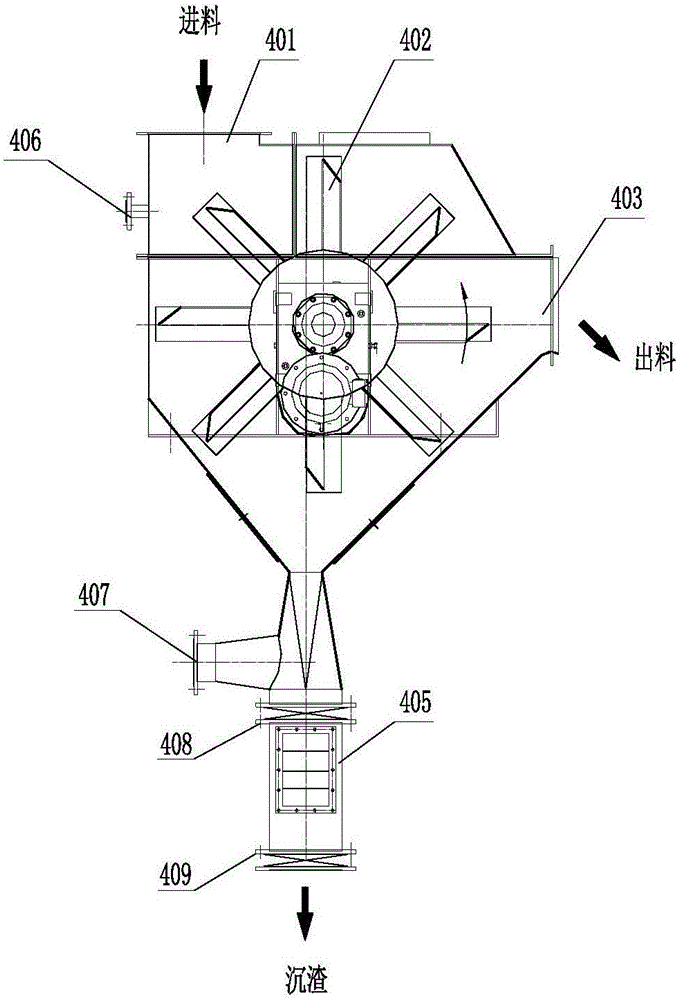

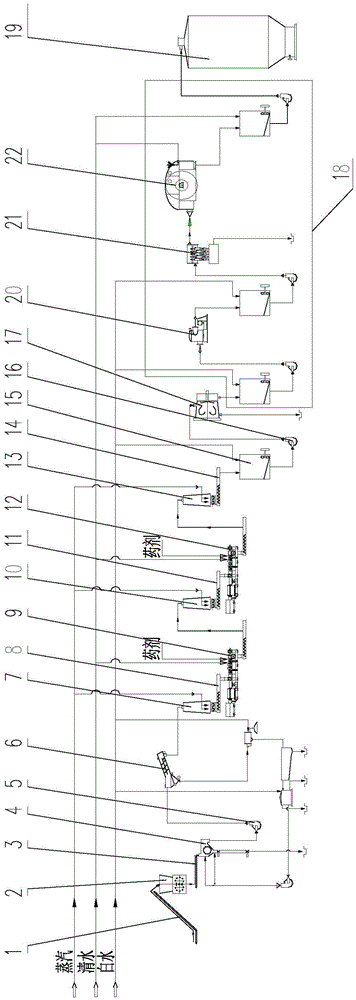

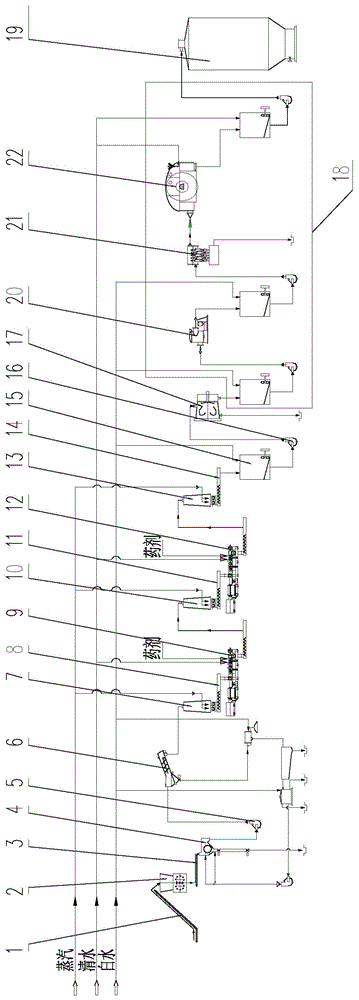

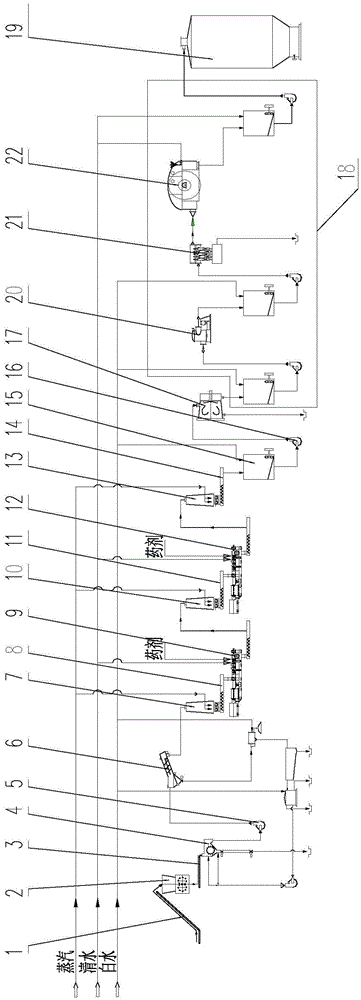

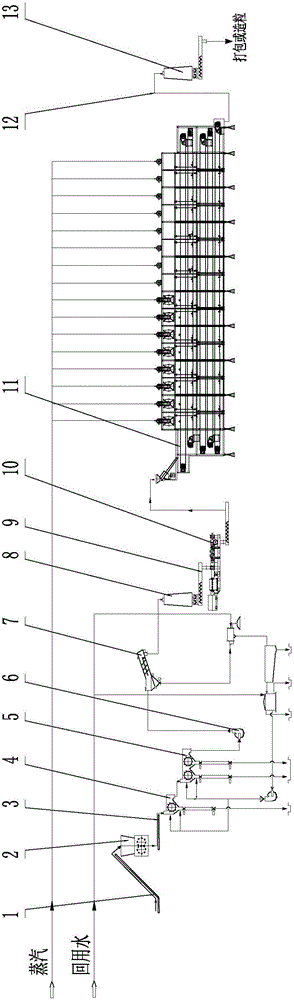

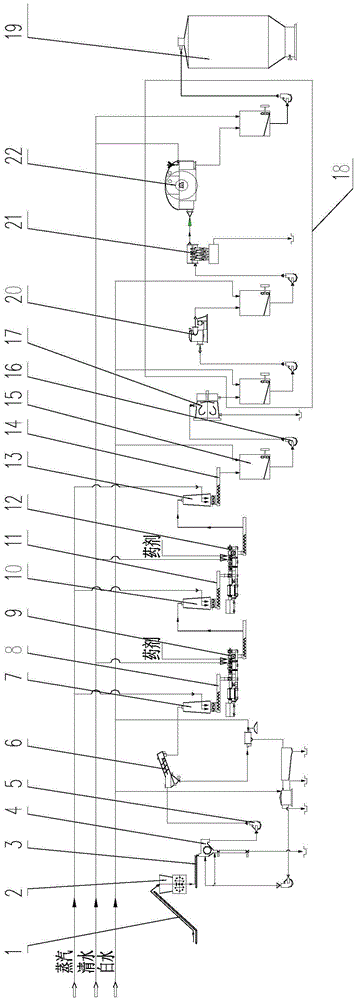

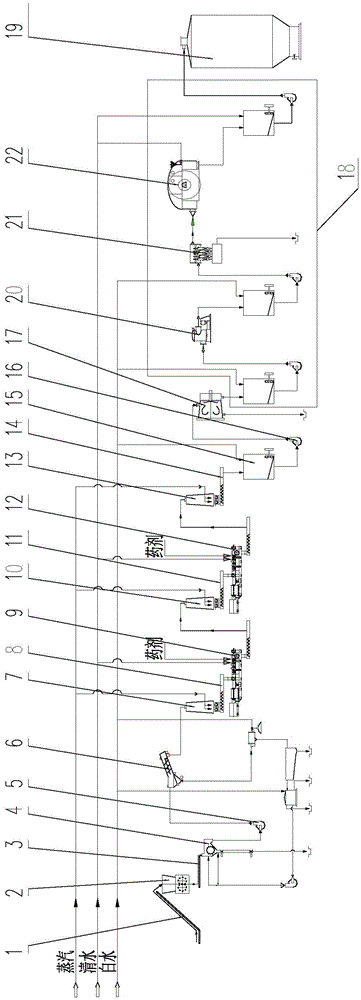

Thin film type waste plastic recycling, reusing, washing and purifying method

ActiveCN104139471AEfficient removalReduce consumptionPlastic recyclingWet separationFiberProcess engineering

The invention discloses a thin film type waste plastic recycling, reusing, washing and purifying system and method. The method comprises the steps that a shredding machine is adopted to shear waste materials with a mechanical shear, the waste materials are preliminarily washed, sedimentation is carried out, and heavy impurities are removed; then, the waste materials are washed through multiple stages of drums in a multi-drum washing separation device, the upgoing flowing speed of washing water injected from lower water inlets is controlled, light impurities mixed into the materials or different materials with different proportions are effectively removed or are extracted through washing, and a double-screw impregnator is utilized for shearing, kneading and evenly forming obtained plastic pieces into small pieces and particles to be dried and stored for standby. According to the thin film type waste plastic recycling, reusing, washing and purifying method and system, solid waste of a paper-making factory can be comprehensively utilized, waste paper fibers and waste plastic are respectively recycled and reused, automation and large-scale industrial production can be achieved, the rate of multipurpose utilization can reach more than 90%, water consumption can be reduced by 50% to 80% through washing water cyclic utilization, environmental pollution is reduced, production continuity is ensured, the production space is saved, and the thin film type waste plastic recycling, reusing, washing and purifying system and method are of remarkable significance.

Owner:JIANGSU JINWO MACHINERY

Continuously variable transmission

ActiveUS20060189432A1Increase the lengthReduces bending of the pinion shaftGearingCommon carrierEngineering

Rotation of an input shaft is directly transmitted to a front carrier of a planetary gear mechanism, and rotation, which is speed-changed and reversed by a toroidal-type continuously variable speed change unit, is transmitted to a first sun gear. When a Low clutch is applied, rotation of an output carrier of a simple planetary gear unit is transitted to a counter gear mechanism via a common carrier, and then output at an output shaft. When a High clutch H is applied, rotation of a second sun gear is transmitted to the output shaft. Thus, the pinion shaft is shortened and the service life span of a supporting bearing is increased as compared with a planetary gear mechanism that has a three-step pinion.

Owner:EQUOS RES

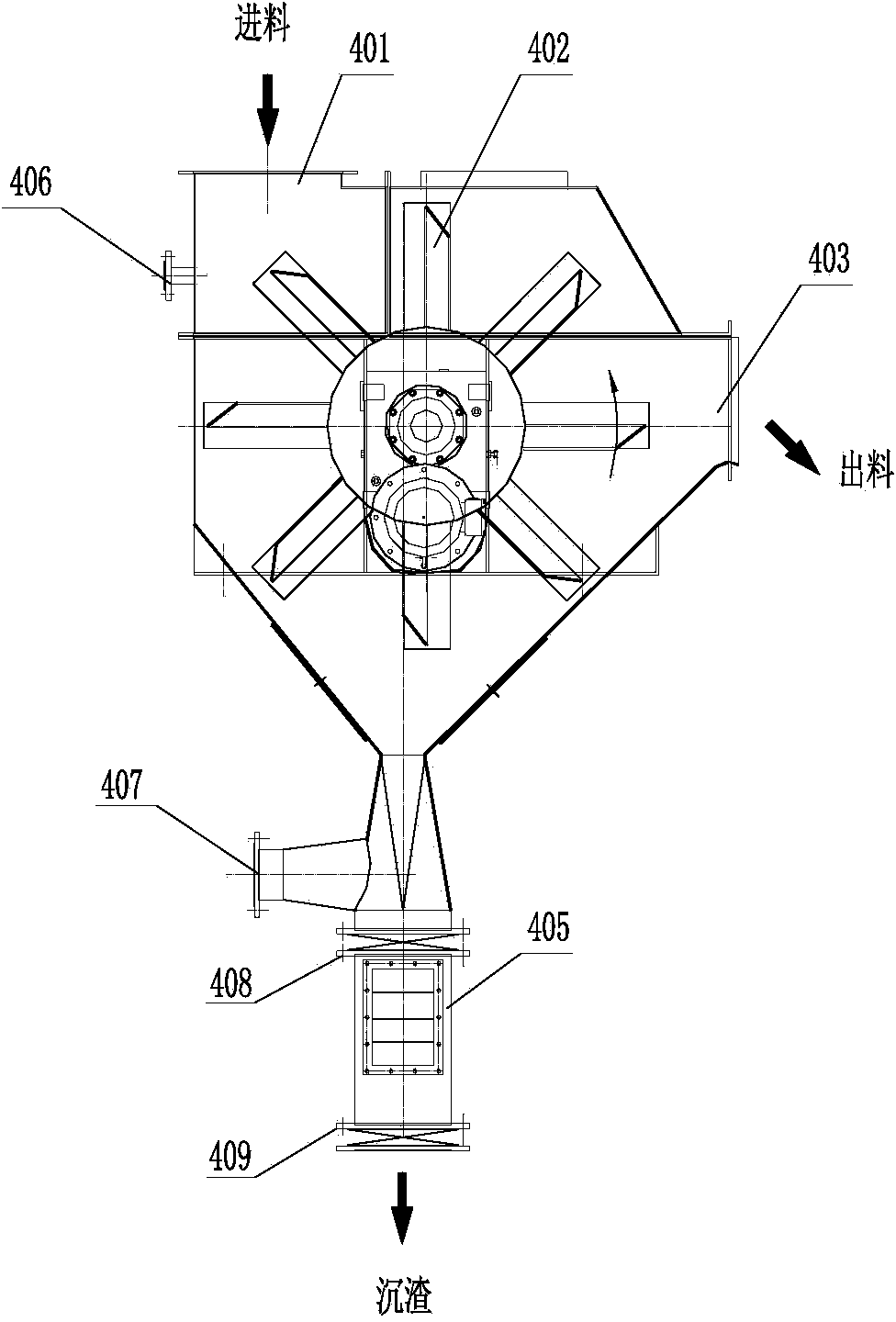

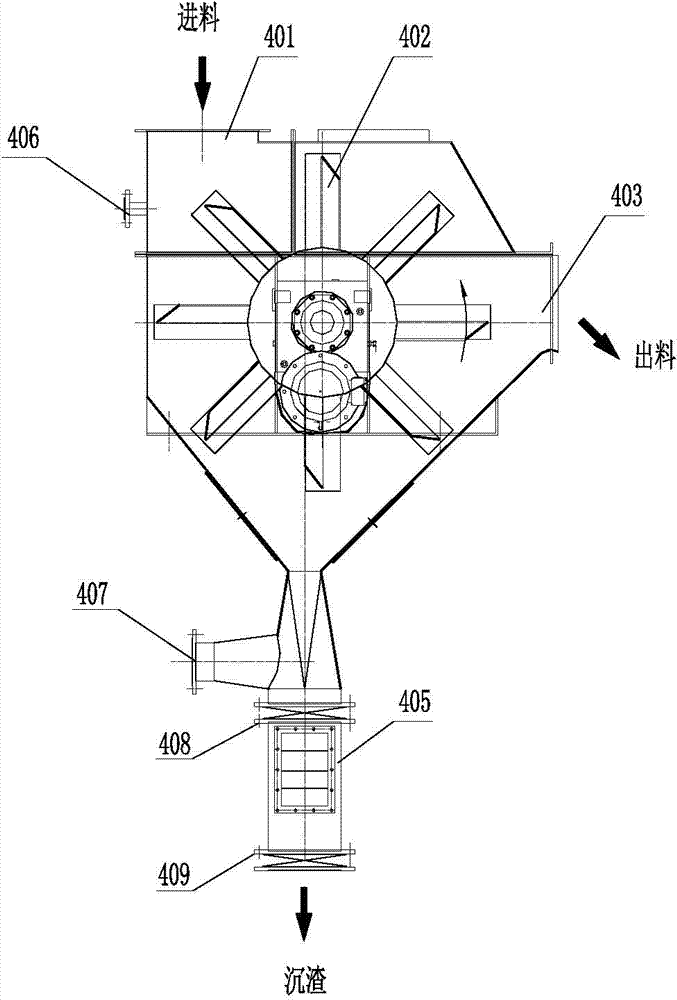

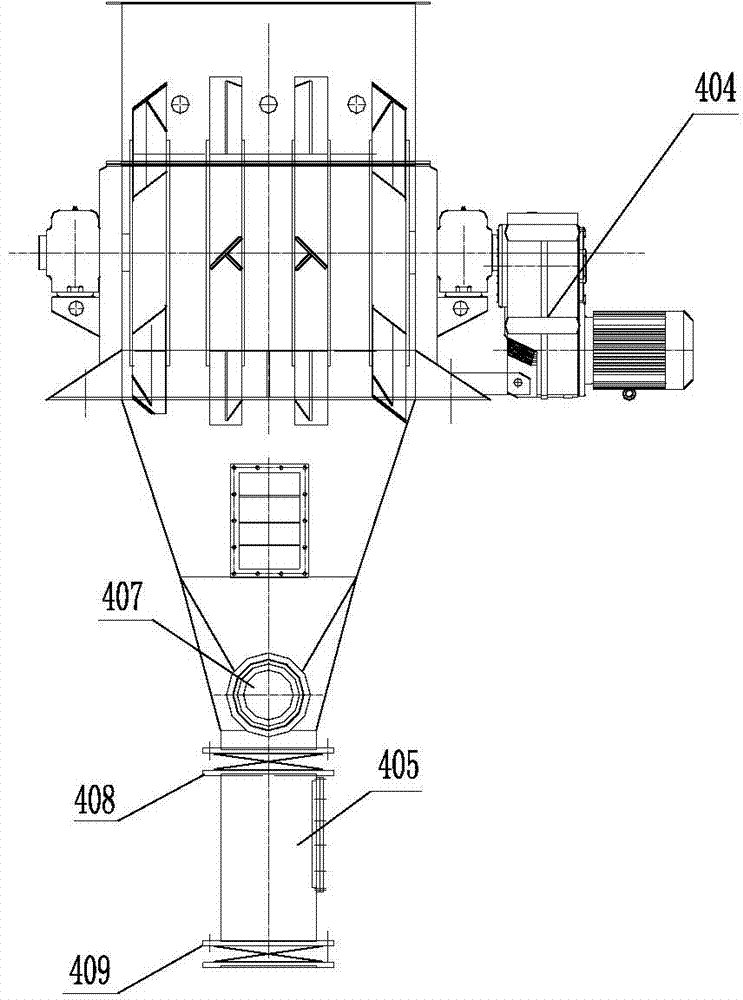

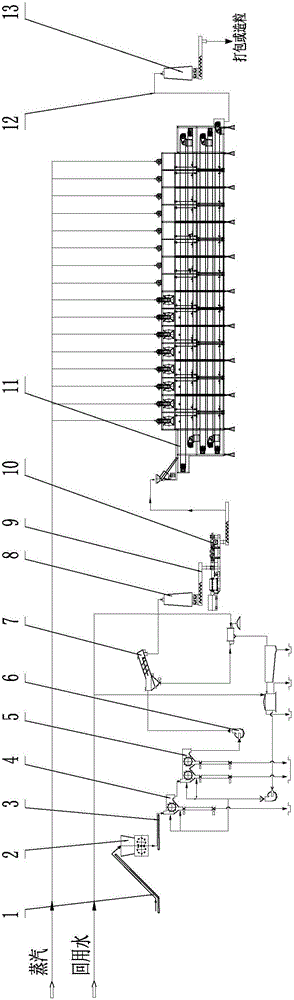

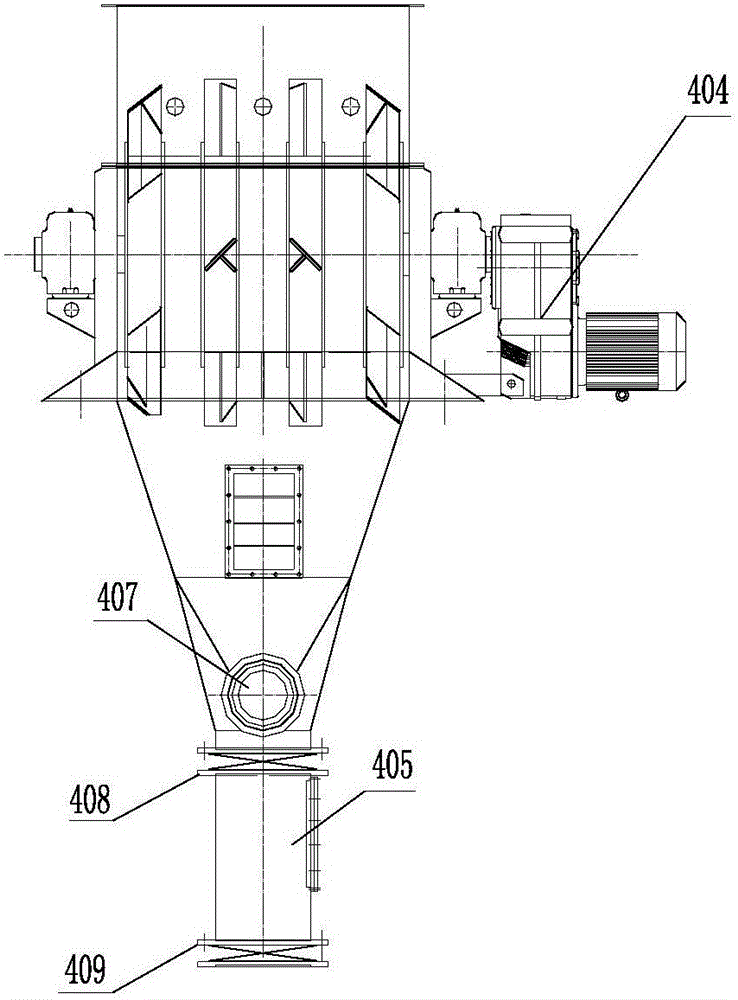

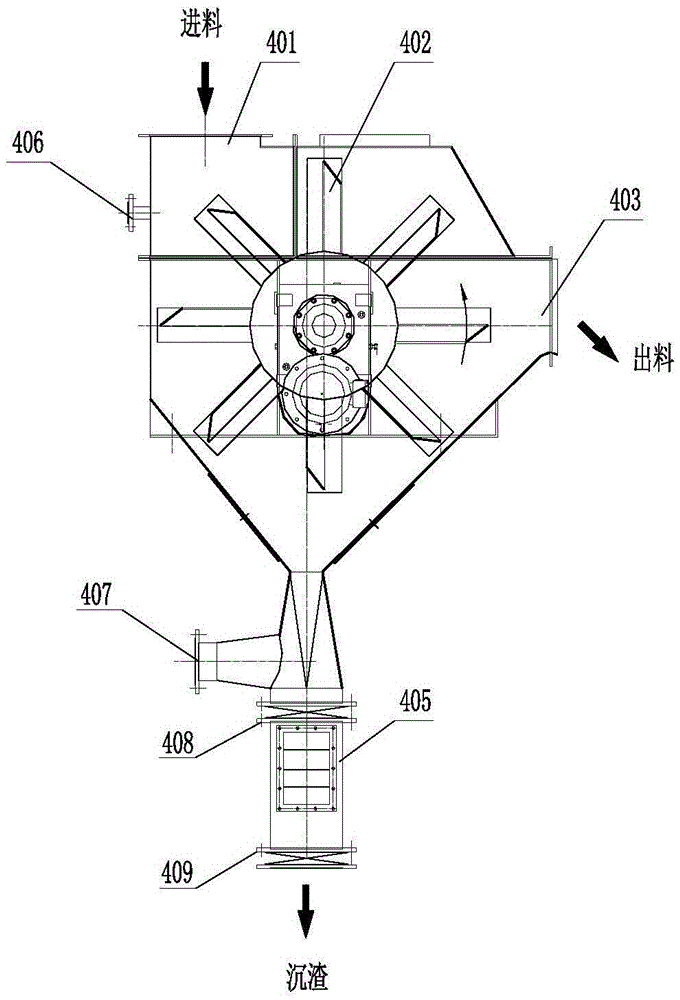

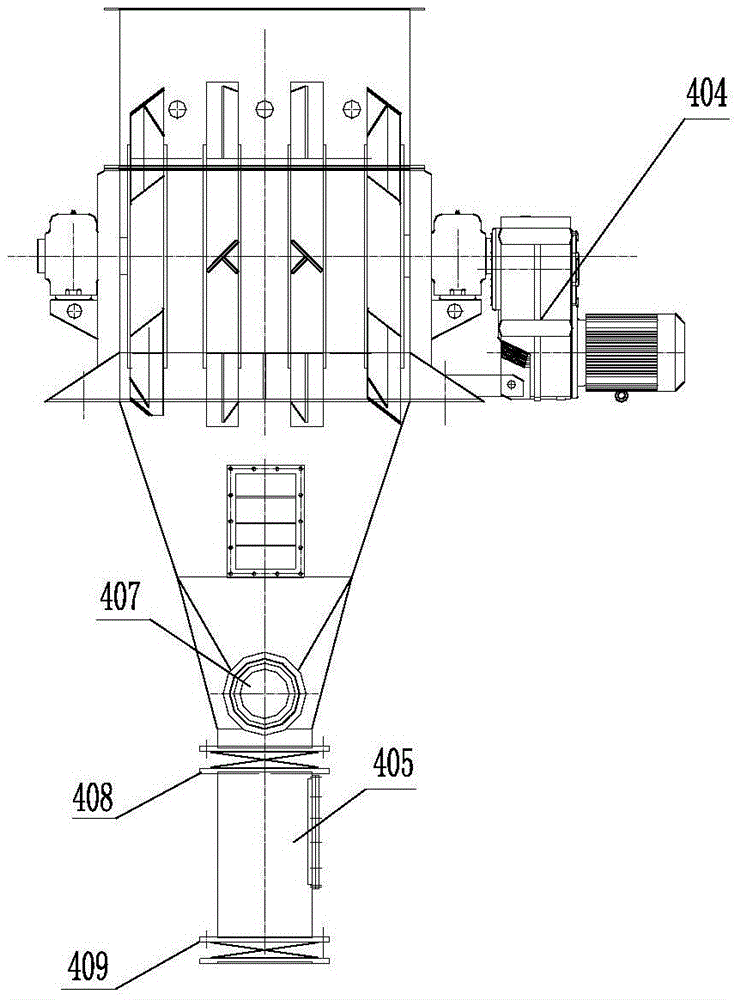

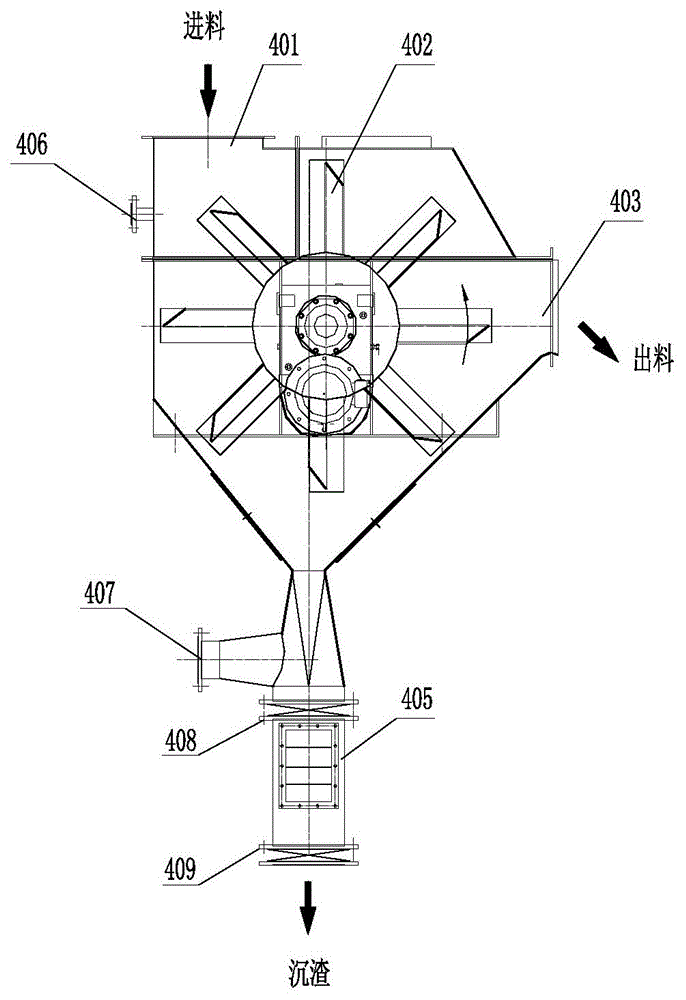

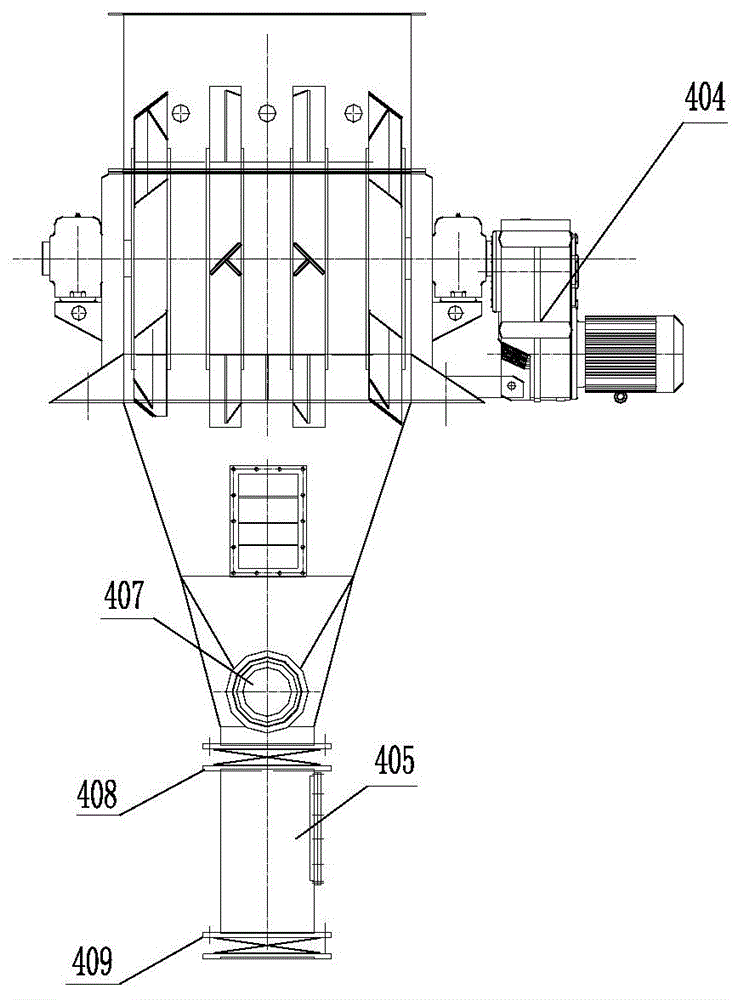

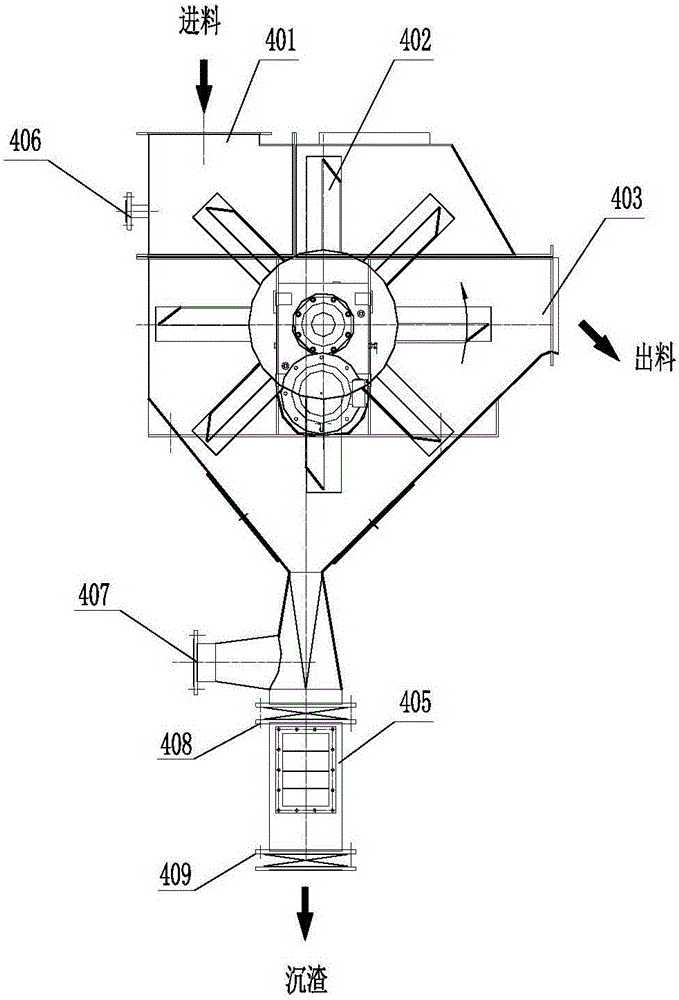

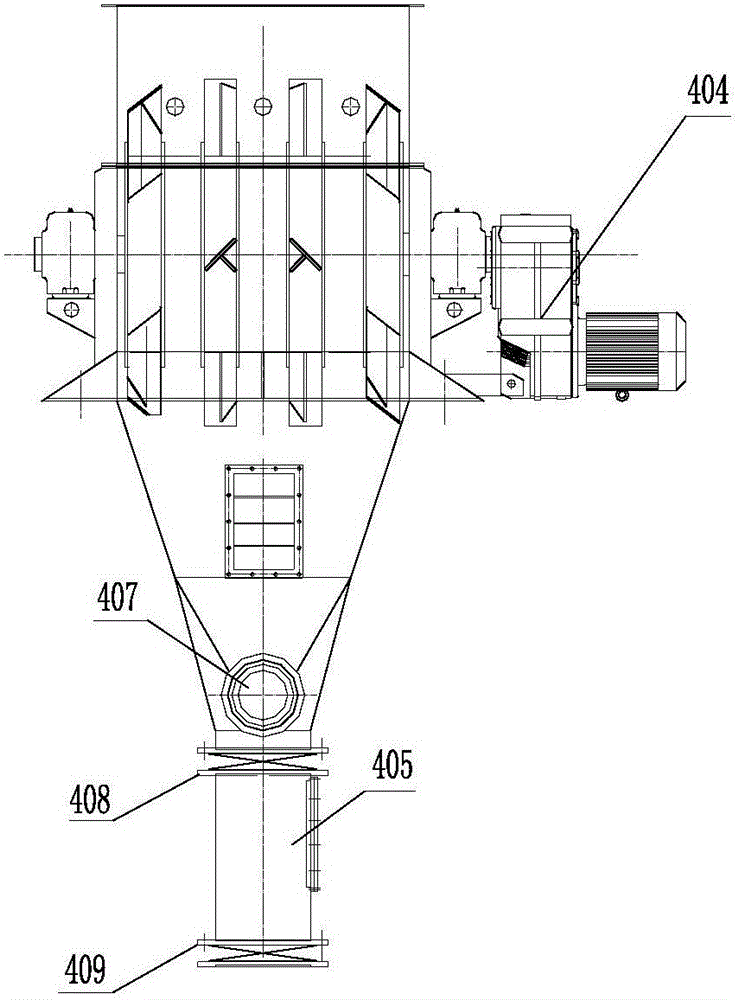

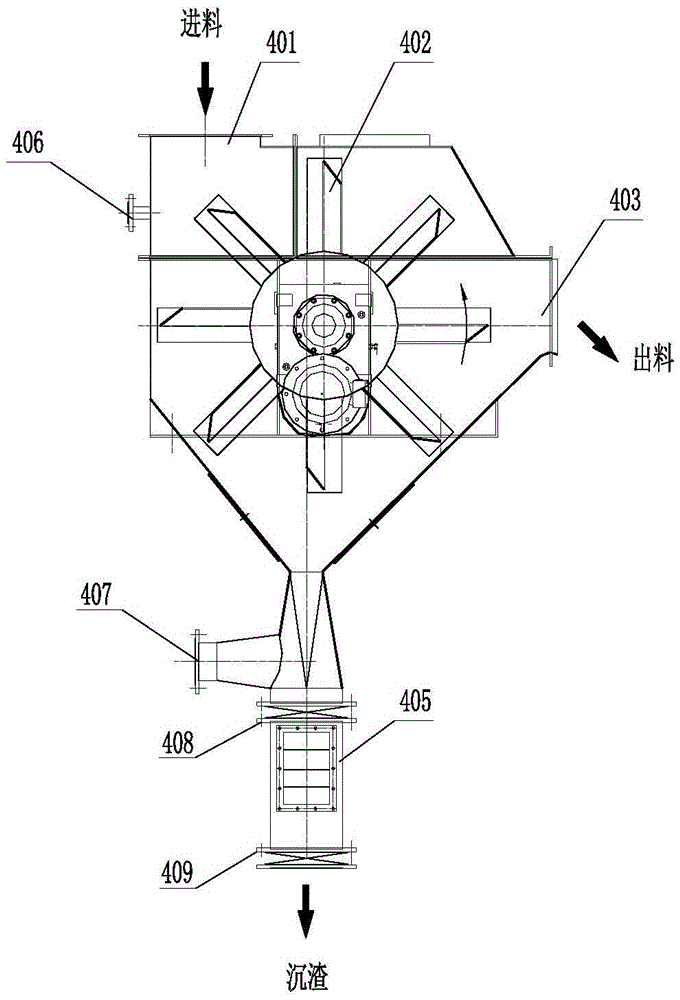

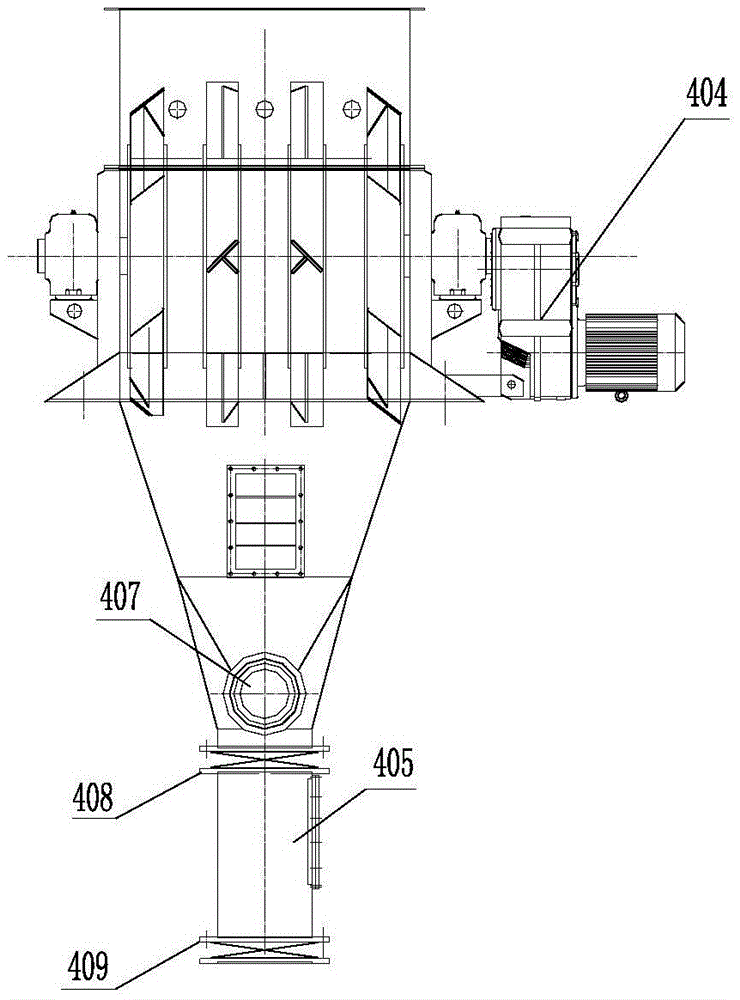

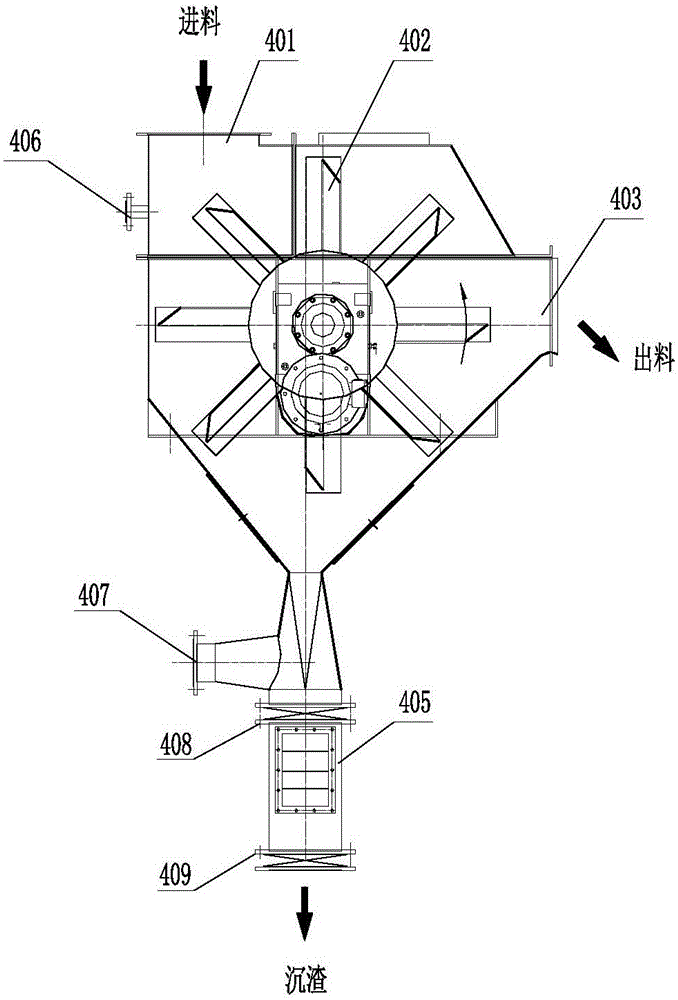

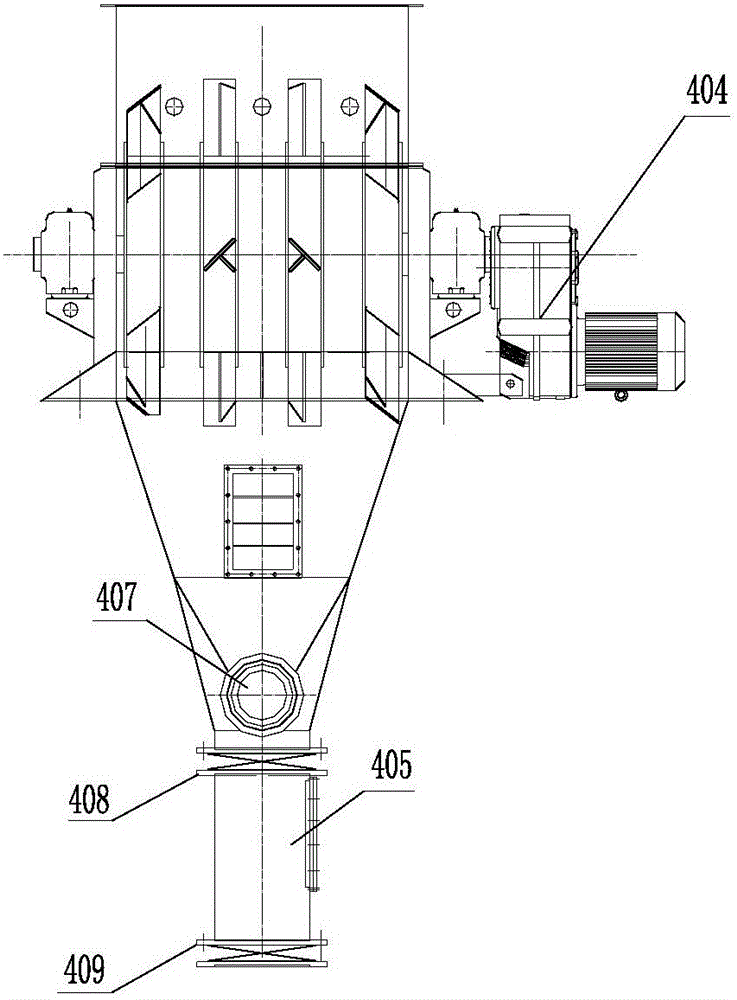

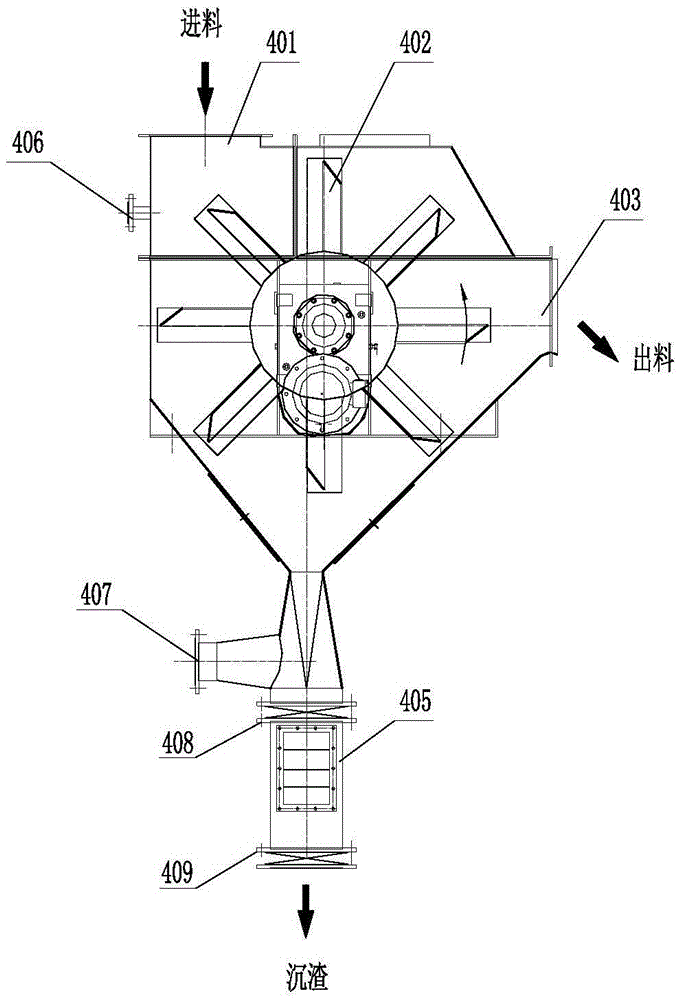

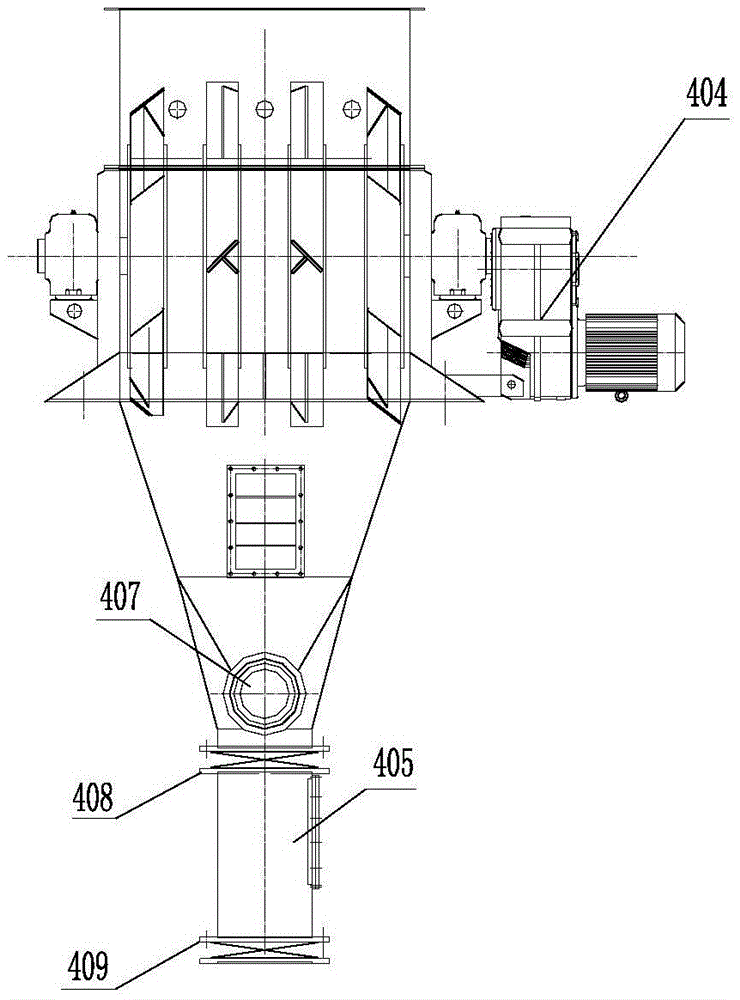

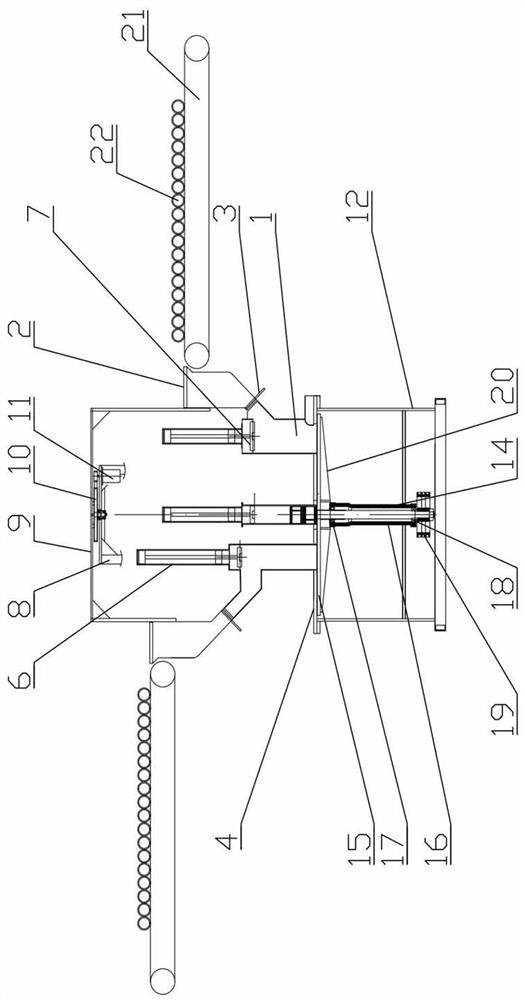

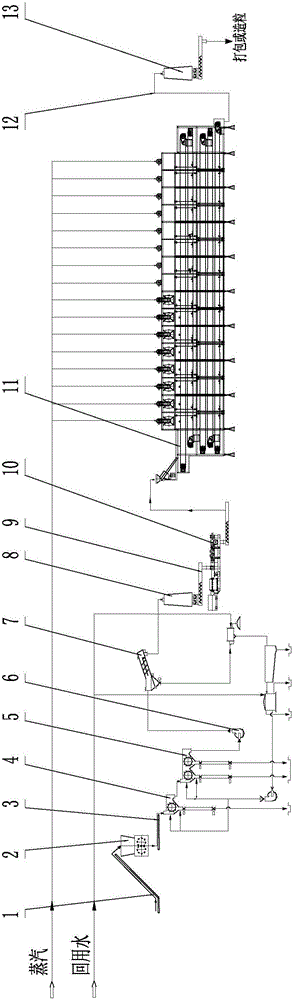

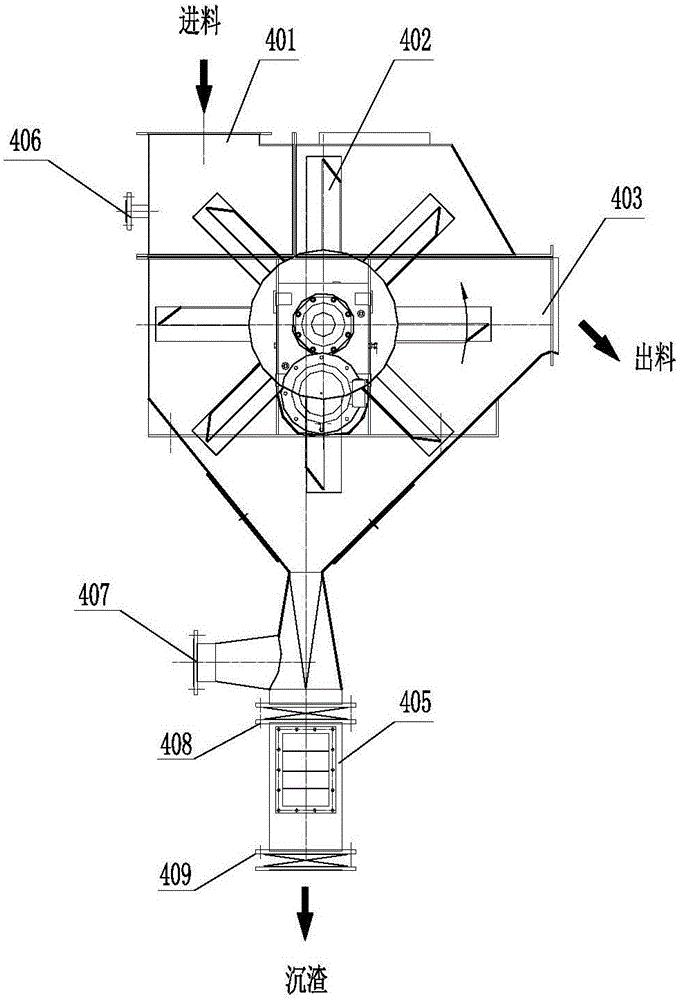

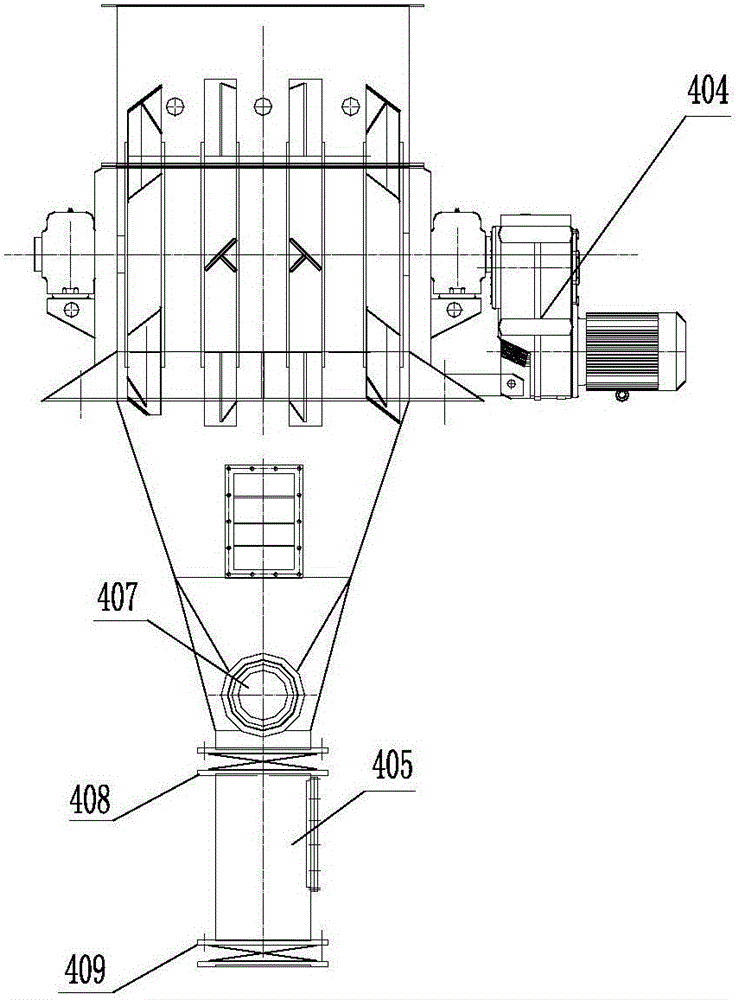

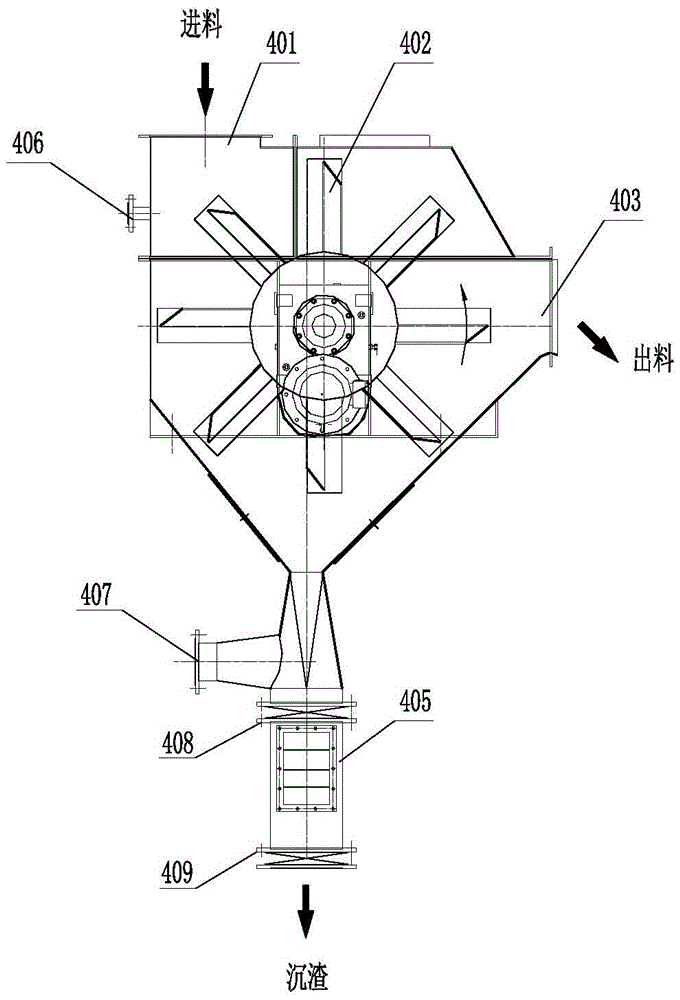

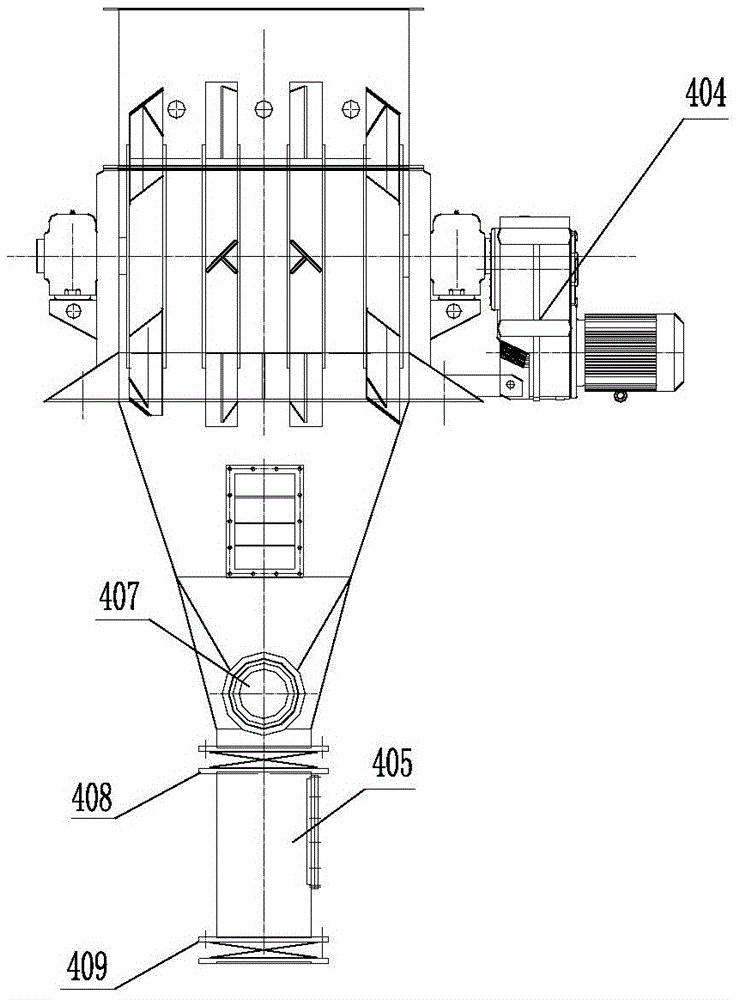

Wet-strength waste paper recycling chemical mechanical pulping system

ActiveCN104120613AReduce consumptionImprove chemical reaction efficiencyPaper recyclingWaste paper working-upChemical treatmentFiber

The invention discloses a wet-strength waste paper recycling chemical mechanical pulping system. In the material process running direction, the system comprises first conveying equipment, a crusher, second conveying equipment, a tumbler-type washing machine, an oblique spiral dehydrator, a steaming bin, a third spiral conveyer, a first double-screw impregnator, a first reaction bin, a fourth spiral conveyer, a second double-screw impregnator, a second reaction bin, a fifth spiral conveyer, a latency chest, a pulp pump, a fiber separator, a purification, filtration and concentration device and a pulp storage device. The uniform-discharging-type reaction bins are used for achieving uniform discharging so as to reduce the load fluctuation amplitude; the rotary material-poking-type steaming bin is used for eliminating the bridging phenomenon, sufficiently steaming materials so as to soften the materials and reducing chemical consumption; the double-screw impregnators are used for dissociating wet-strength waste paper gradually, achieving high-concentration mixing and homogeneous immersion of chemical agents and pulp and improving the chemical reaction efficiency. The problems that when the wet-strength waste paper is recycled for pulping, the dissociation rate is low and the strength is greatly reduced are solved through the effects of mechanical strength and chemical treatment.

Owner:JIANGSU JINWO MACHINERY

Seat moving device for vehicle

ActiveUS20060131943A1Avoid damageReduce volatilityMovable seatsMonocoque constructionsCamMobile device

It is one object of this invention to provide a technique that is effective in diminishing the range of fluctuation of a load applied to a drive source when a seat main body in a vehicle seat moving apparatus is moved between a raised position and a lowered position. For this purpose, this invention provides a vehicle seat moving apparatus constructed as follows. Provided on a rotation base 31, for rotating a seat main body 10 between a position where it faces the front side of the vehicle and a position where it faces a door opening, is a widthwise slide base 41 that moves horizontally in the vehicle width direction while the seat main body 10 faces the door opening. The seat main body 10 is supported by the slide base 41 via four-bar linkage mechanisms 44. Guide rollers 46 are attached to upper link arms 44a of the four-bar linkage mechanisms 44. The guide rollers 46 are placed on cam surfaces of cam plates 47 provided to the rotation base 31. The cam surfaces have continuously extending inclined guide surfaces 47b that guide such that the guide rollers 46 move obliquely upwards when the widthwise slide base 41 moves.

Owner:TOYOTA SHATAI KK

Recycling, washing and purifying method of multi-drum film type waste plastic

The invention discloses a recycling, washing and purifying method of multi-drum film type waste plastic. After a waste material is shorn by mechanical scissors through a shredding machine, sediments are primarily washed to remove heavy impurities; and then, the waste material is washed through a multi-stage drum in a multi-drum washing and separating device, and an upper flowing speed of washing water injected in each lower water inlet is controlled, so that light impurities mixed in the material are effectively removed, or different materials with a specific gravity difference are separated through washing, and a double-screw dipping machine is used for uniformly shearing and rolling obtained plastic pieces to small pieces and granular particles to dry and store for future use. The method and the system can realize comprehensive utilization of solid wastes of a paper mill, recycling of waste paper fibers and the waste plastic and automatic large-scale industrial production, can reach a comprehensive utilization rate of above 90%, can reduce the water consumption by 50-80% through recycling of the washing water, reduces the environmental pollution, guarantees the production continuity, saves the production space, and has prominent significance.

Owner:JIANGSU JINWO MACHINERY

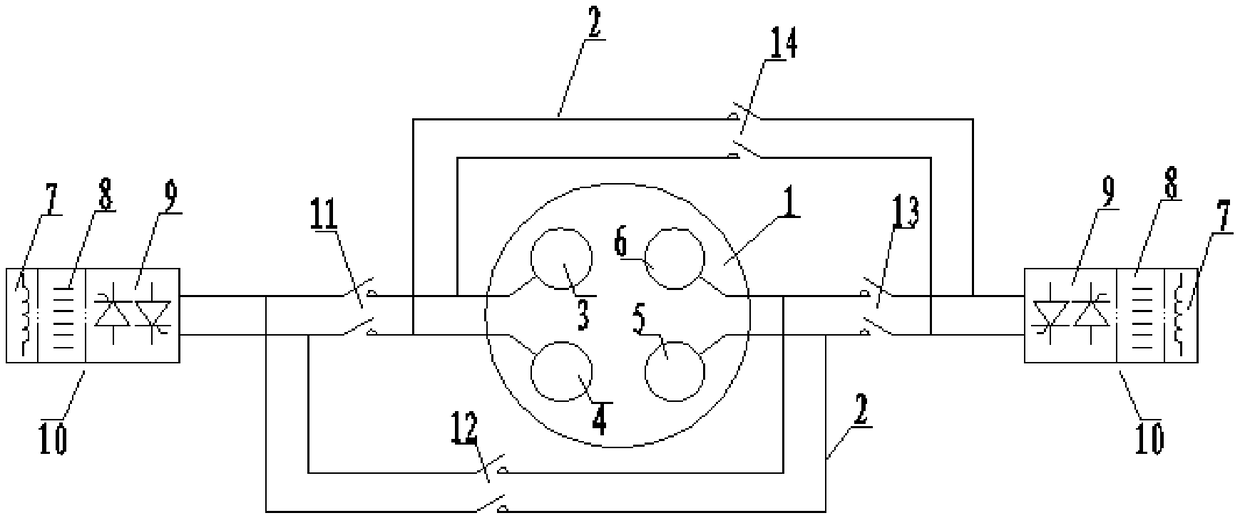

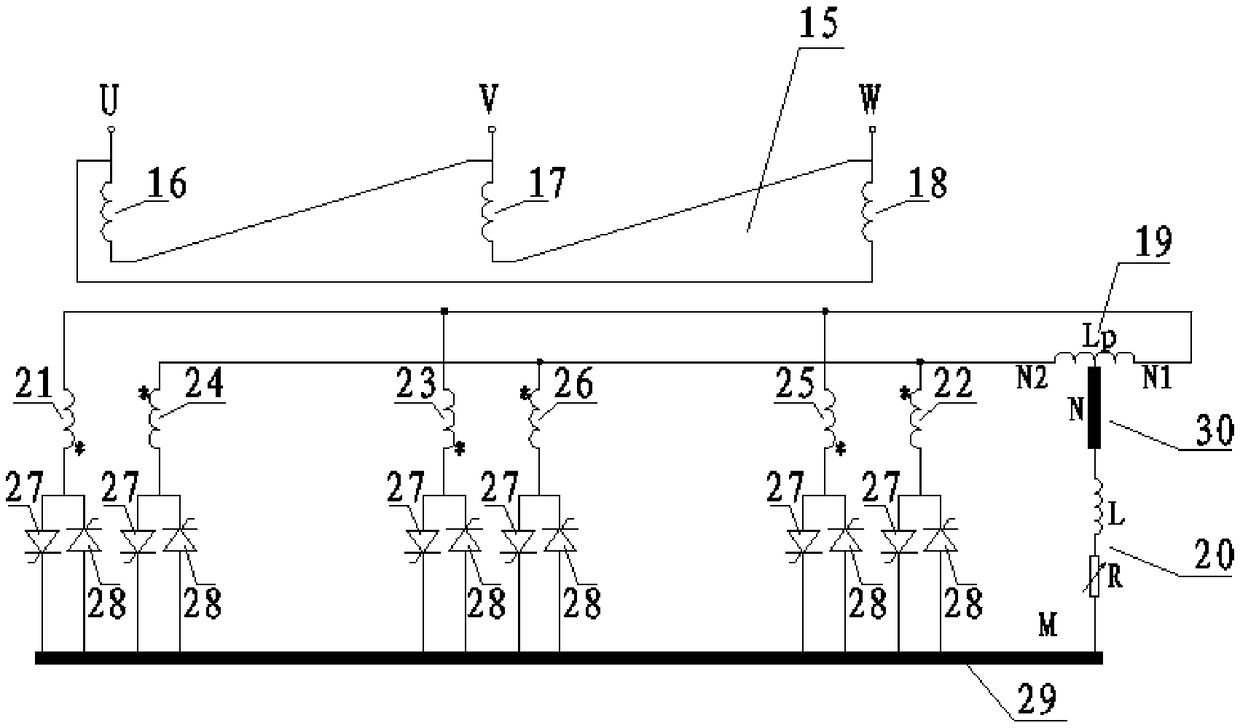

Variable direct-current loop iron alloy ore heat stove

ActiveCN109000481AAvoid or reduce electrode disconnection accidentsGuaranteed smooth productionIncreasing energy efficiencyCrucible furnacesElectrical conductorControl objective

The invention provides a variable direct-current loop iron alloy ore heat stove. The variable direct-current loop iron alloy ore heat stove mainly comprises an ore heat stove body, N sets of rectifying voltage-regulating power supply systems, and a redundant mutually-backup group, wherein N pairs of smelting electrodes extend into the ore heat stove body for heating, melting and smelting cores; the N sets of rectifying voltage-regulating power supply systems are connected with the smelting electrodes for separately controlling polarity switching of the smelting electrodes; the redundant mutually-backup group is arranged on a connecting conductor for converting control objectives of each set of the rectifying voltage-regulating power supply systems. When the variable direct-current loop iron alloy ore heat stove works, N sets of the rectifying voltage-regulating power supply systems separately control polarity switching of N pairs of the smelting electrodes to realize uniform roasting of each pair of smelting electrodes. The technical scheme adopted by the invention solves the problem that accidents such as electrode breakage in a production process due to the fact that roasting forpositive and negative electrodes is out of step in the prior art.

Owner:大连重工机电设备成套有限公司 +1

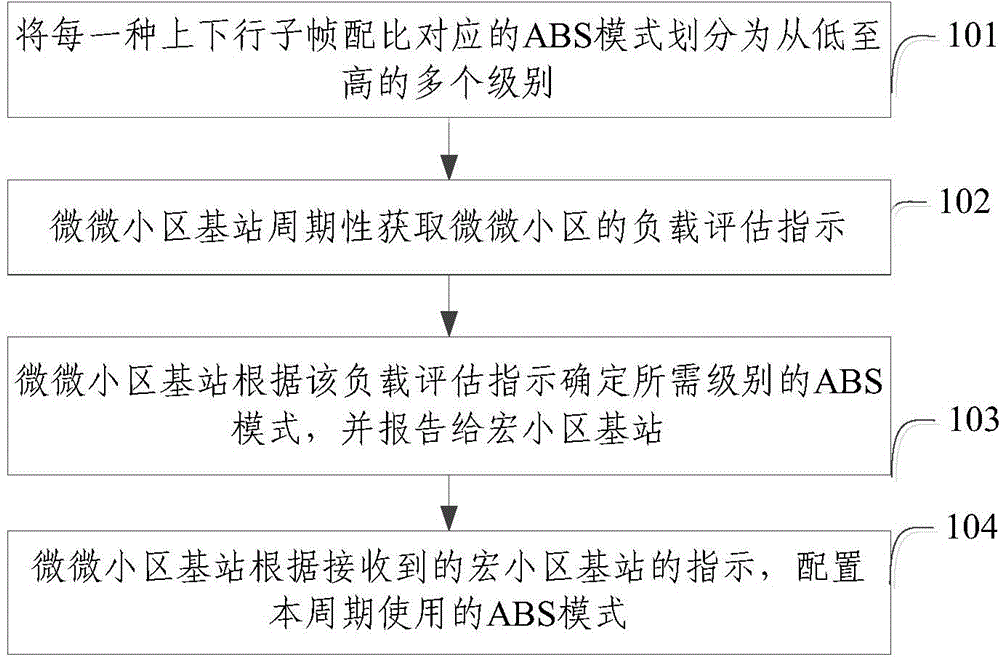

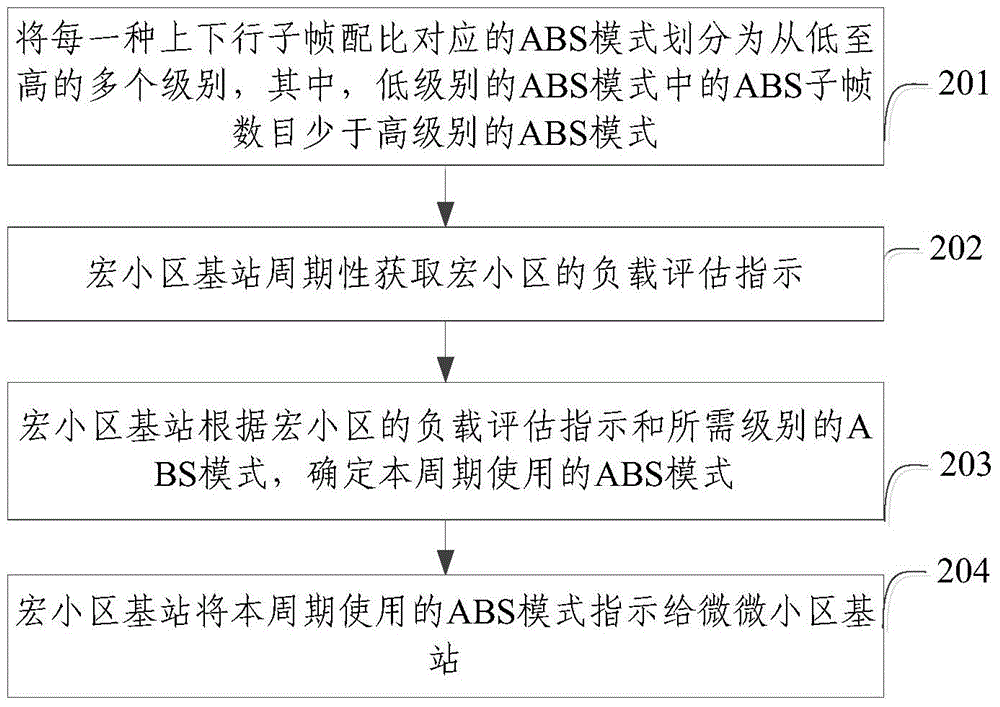

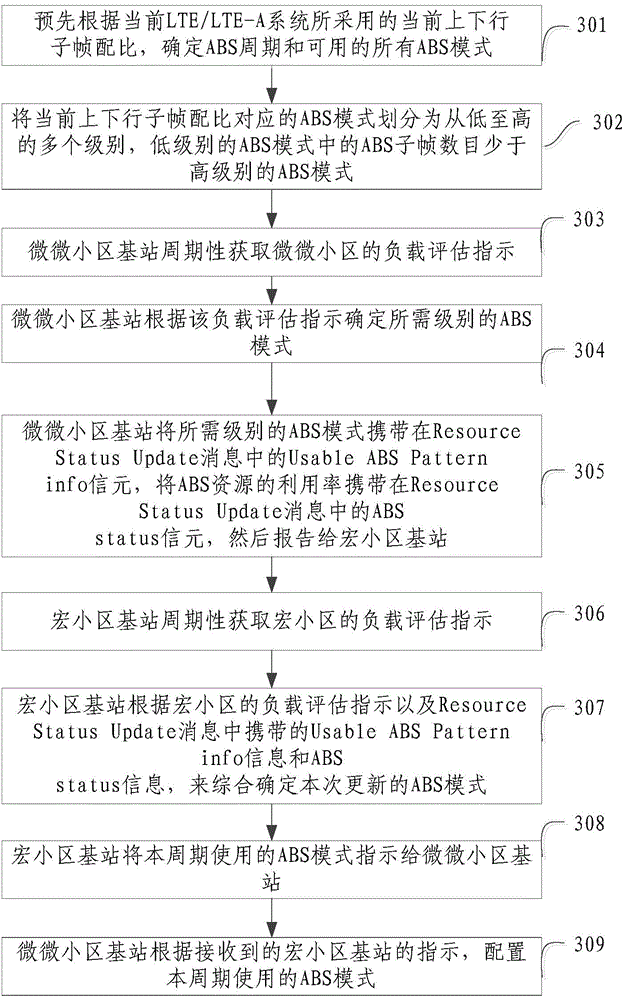

Downlink interference coordinating method and base stations

InactiveCN104581736AOptimizationHigh interference coordination performanceNetwork planningMacrocellPicocell

The invention provides a downlink interference coordinating method and base stations. Following processing is performed in a macro cell base station: dividing ABS modes matched with and corresponding to each uplink subframe and each downlink subframe into multiple levels from a low level to a high level, wherein the number of ABS subframes in the low-level ABS mode is smaller than that in the high-level ABS mode; periodically acquiring a macro cell load on assessing instruction by the macro cell base station, determining the ABS mode used in the period according to the macro cell load on assessing instruction as well as a required-level ABS mode reported by a picocell base station, and indicating to the picocell base station. By the downlink interference coordinating method, dynamic interference coordination can be carried out.

Owner:POTEVIO INFORMATION TECH

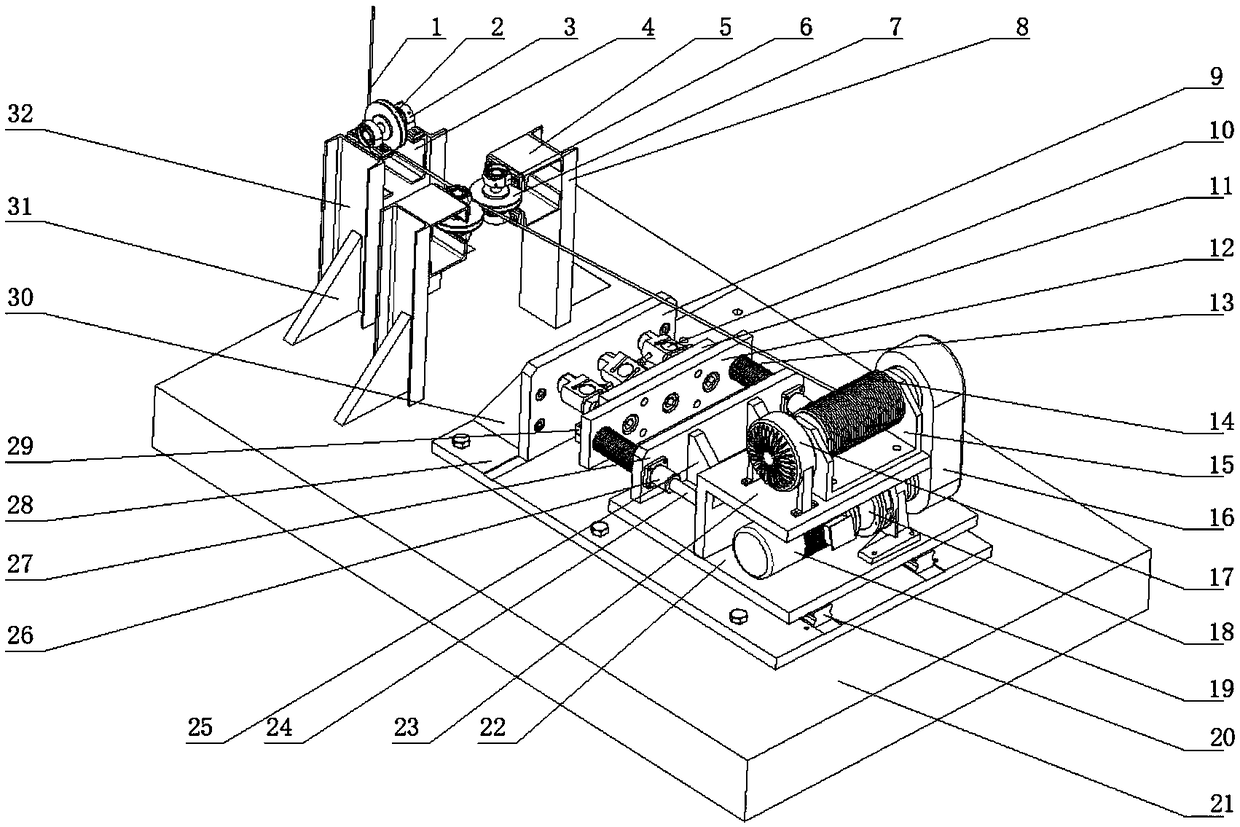

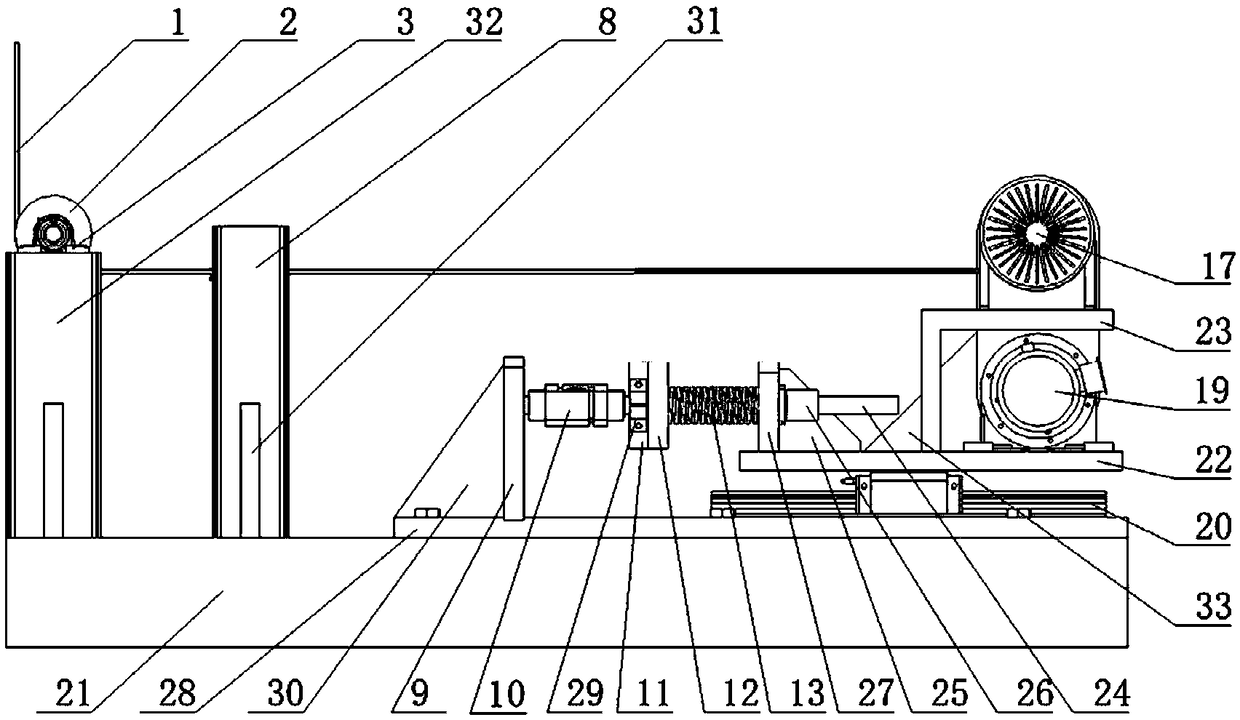

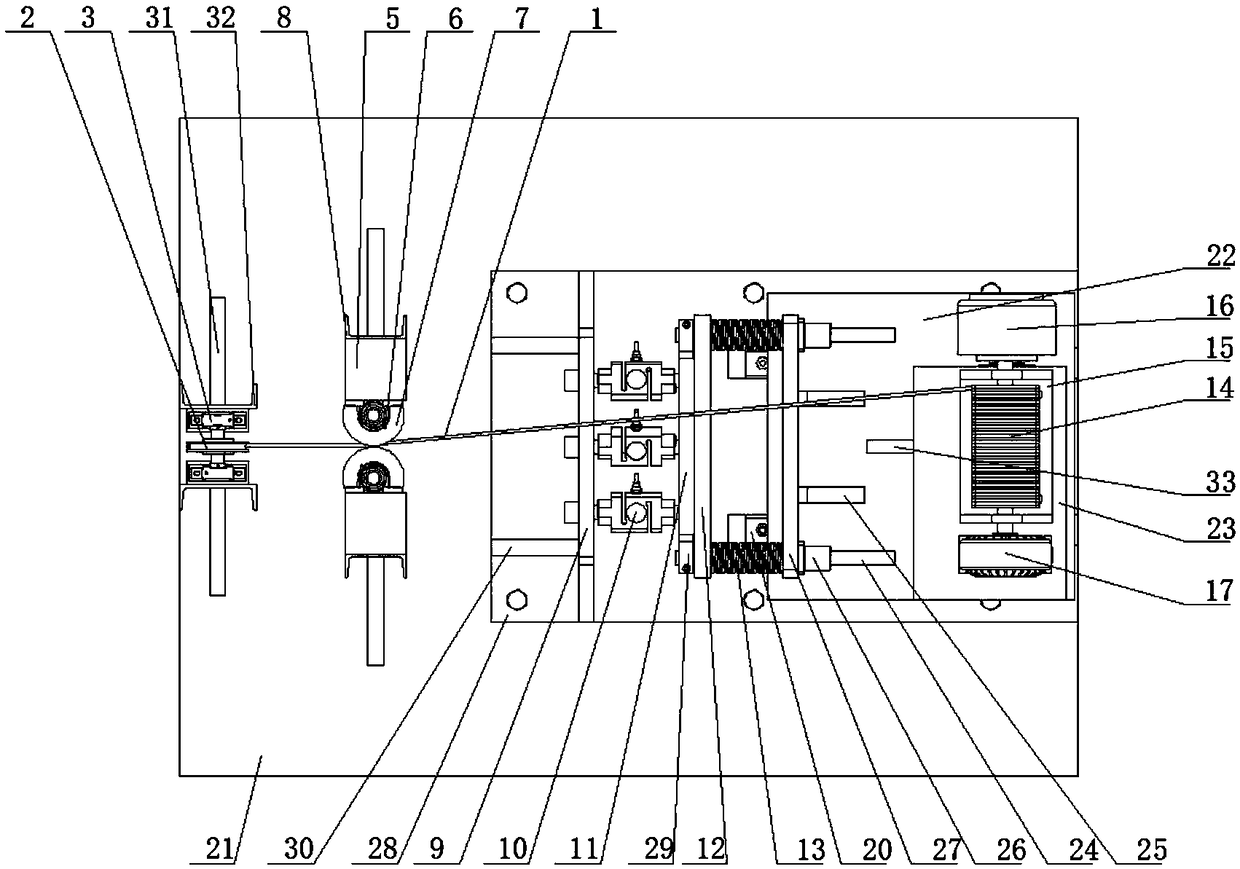

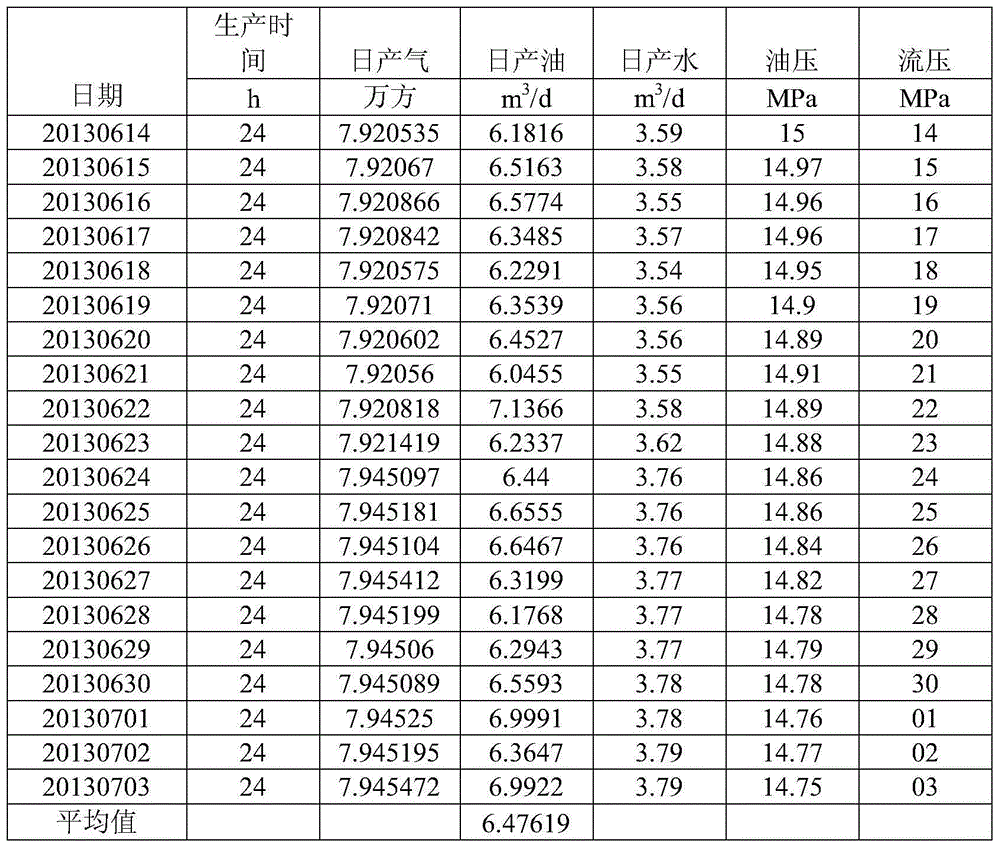

Load simulation test device of oil pumping unit

PendingCN109283002ASimple structureOptimal control programStructural/machines measurementControl systemEngineering

The invention relates to a load simulation test device of an oil pumping unit. The device comprises a control system, a load simulation system, a slide damping platform and a load guide mechanism. Theload simulation mechanism provides a load through a servo motor and a magnetic powder brake, and a force-measuring sensor feeds back and adjusts the magnitude of the load. A damping force-measuring platform is provided with a mold spring and a linear slide rail assembly moving along a fixed guide rod so that the fluctuation generated by instantaneous impact in an equipment operating process is effectively reduced, and the accuracy and the sensitivity of control of the load by the system are improved. According to the digital load simulation test device of the oil pumping unit, through cooperation of a torque control mode of the servo motor and the magnetic powder brake, various oil pumping conditions can be simulated more accurately and conveniently.

Owner:杭州中油智井装备科技有限公司

Mesh Freeform Surface Annular Tool Path Planning Method Based on Improved Butterfly Subdivision

The invention discloses a grid free-form surface toroidal cutter path planning method based on improved Butterfly subdivision. The method comprises the steps of toroidal cutter surface modeling and triangular grid free-form surface modeling. Besides, the cutter surface of a cutter contact point (CC point) and a workpiece surface are geometrically analyzed with combination of the geometrical features of the toroidal cutter. The minimum front inclination angle of the cutter is calculated according to the principle of cutting cutter interference so as to obtain the maximum width of a cutting path, based on which subdivision is performed on the triangular grid surface by adopting the improved Butterfly subdivision method so that the line space of the cutter path is enabled to meet the width requirement of the cutting path. Planning of the spiral cutter path cutter contact point (CC point) is performed line by line along the boundary of the triangular grid with a surface contour curve acting as an initial cutter path so that the position of a cutter center (CL point) is finally solved according to the toroidal cutter geometrical model. The method is applied to high-speed machining so that continuity of the formed cutter path can be enhanced, cutter load fluctuation can be reduced, and cutting stability can be enhanced and the service life of the cutter can be prolonged under the premise of guaranteeing the cutting quality.

Owner:ZHEJIANG UNIV

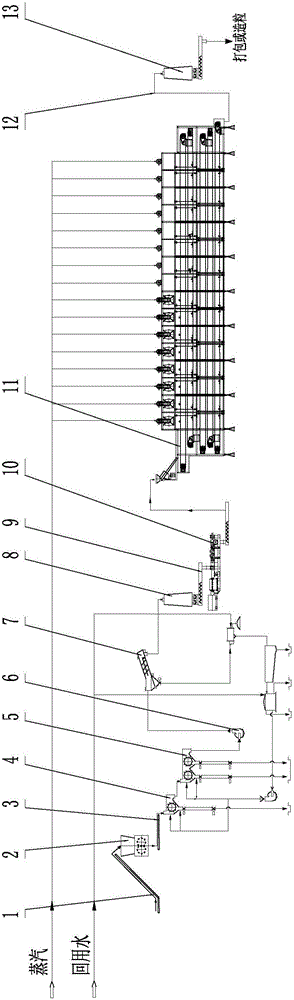

Pulping system for recycling wet-strength recycled paper

ActiveCN105648817AReduce consumptionImprove chemical reaction efficiencyPaper recyclingWaste paper working-upChemical treatmentHigh concentration

The invention discloses a chemical mechanical pulping system for recycling wet-strength recycled paper. The system comprises first conveying equipment, a crusher, second conveying equipment, a drum washing machine, an oblique spiral dehydrator, a steaming bin, a third screw conveyer, a first double-screw impregnator, a first reaction bin, a fourth screw conveyer, a second double-screw impregnator, a second reaction bin, a fifth screw conveyor, a latency chest, a stock pump, a fiber separator, a purifying, screening and concentrating device and a pulp storage device in the running direction of the material procedure. The even feeding type reaction bins are utilized for achieving even feeding and reducing the load fluctuation range; the rotary stirring type steaming bin is utilized for eliminating a bridging phenomenon, materials are fully steamed and softened, and chemical consumption is reduced. The double-screw impregnators are utilized for gradually dissociating the wet-strength recycled paper, high-concentration mixing and homogenizing impregnation of a chemical additive and pulp are achieved, and the chemical reaction efficiency is improved. By means of the function of mechanical strong force and chemical treatment, the problems that during wet-strength recycled paper recycling, pulping and dissociating rate is low, and the strength is greatly reduced are solved.

Owner:JIANGSU JINWO MACHINERY

Chemical mechanical pulping method for recycling of wet strength waste paper

ActiveCN104099795AReduce consumptionImprove chemical reaction efficiencyPretreatment with water/steamPretreatment with alkaline reacting compoundsChemical treatmentProcess engineering

The invention discloses a chemical mechanical pulping method for recycling of wet strength waste paper. The method comprises a material preparation section, a steaming section, a first squeezing dipping chemical mechanical treatment section, a second squeezing dipping chemical mechanical treatment section, a latency and re-defibering section and a purification, screening and concentration section. According to the method, wet strength waste paper fiber dissociation and re-pulping are realized while the original pulp strength is not reduced under the action of mechanical strength and chemical treatment; furthermore, at the two squeezing dipping chemical mechanical treatment sections in series connection, a wet strength agent in the waste paper can be oxidized under the acidic condition firstly, and then hydrolysis is further promoted under the alkaline condition, so that the chemical bonding among molecules of the wet strength agent and between the wet strength agent and pulp fibers are destroyed more effectively, and the fiber dissociation rate and the re-pulping yield are effectively increased. The problems that the wet strength waste paper recycling, pulping and dissociation rate is low and the strength is substantially reduced are solved, and continuous, large-scale, low-water-consumption, low-energy-consumption, pollution-free and environment-friendly pulping can be realized.

Owner:JIANGSU JINWO MACHINERY

Recycling and reusing washing and purifying system for film type waste plastics

The invention discloses a recycling and reusing washing and purifying system and a washing and purifying method for film type waste plastics. A shredding machine is adopted; after waste materials are cut by using a mechanical shear, dregs are washed preliminarily and heavy impurities are removed; then in a multi-drum type washing separation device, washing is carried out through multiple stages of drums; besides, the ascending flow velocity of washing water injected from all lower water inlets is controlled; light impurities mixed in the materials are removed effectively or different materials with proportion differences are washed and separated; furthermore, a twin-screw impregnator is used for cutting and rubbing obtained plastic sheets uniformly into small pieces and granular particles; and the pieces and the particles are dried and stored for use. The method and the system can achieve comprehensive utilization of solid wastes of a paper mill, recycling and reusing of waste paper fiber and waste plastics and automatic and large-scale industrial production; the comprehensive utilization rate can reach more than 90%; the water consumption can be reduced by 50-80% through recycling of the washing water; the environmental pollution is reduced; the continuity in production is guaranteed; the production space is saved; and remarkable significance is achieved.

Owner:JIANGSU JINWO MACHINERY

Wet-strength wastepaper recycling double-pH-value chemical and mechanical pulping method

ActiveCN105568726AReduce consumptionImprove chemical reaction efficiencyPretreatment with water/steamPretreatment with alkaline reacting compoundsChemical treatmentFiber

The invention discloses a wet-strength wastepaper recycling double-pH-value chemical and mechanical pulping method. The method includes a material preparation section, a steaming section, a first extrusion and impregnation chemical and mechanical treatment section, a second extrusion and impregnation chemical and mechanical treatment section, a latency and re-defibering section and a purification, screening and concentration section. Wet-strength wastepaper fiber dissociation re-pulping is achieved while original pulp strength is not reduced through the mechanical strong force effect and the chemical treatment effect. Furthermore, on the two extrusion and impregnation chemical and mechanical treatment sections connected in series, a wet strength agent in wastepaper is oxidized under the acid condition firstly, hydrolysis is further promoted under the alkaline condition, chemical bonding between molecules of the wet strength agent and between the wet strength agent and pulp fibers is more effectively damaged, and the fiber dissociation rate and the re-pulping yield are effectively increased. The problems that the wet-strength wastepaper recycling pulping dissociation rate is low and strength is greatly decreased are solved, and continuous, large-scale, low-water-consumption and low-energy-consumption pollution-free and environment-friendly pulping can be achieved.

Owner:JIANGSU JINWO MACHINERY

Multi-drum type recycling and reusing washing and purifying system for film type waste plastics

ActiveCN105728170AEfficient removalReduce consumptionPlastic recyclingWet separationSpecific gravityWater cycle

The invention discloses a recycling and reusing washing and purifying system and a washing and purifying method for film type waste plastics. A shredding machine is adopted; after waste materials are cut by using a mechanical shear, dregs are washed preliminarily and heavy impurities are removed; then in a multi-drum type washing separation device, washing is carried out through multiple stages of drums; besides, the ascending flow velocity of washing water injected from all lower water inlets is controlled; light impurities mixed in the materials are removed effectively or different materials with proportion differences are washed and separated; furthermore, a twin-screw impregnator is used for cutting and rubbing obtained plastic sheets uniformly into small pieces and granular particles; and the pieces and the particles are dried and stored for use. The method and the system can achieve comprehensive utilization of solid wastes of a paper mill, recycling and reusing of waste paper fiber and waste plastics and automatic and large-scale industrial production; the comprehensive utilization rate can reach more than 90%; the water consumption can be reduced by 50-80% through recycling of the washing water; the environmental pollution is reduced; the continuity in production is guaranteed; the production space is saved; and remarkable significance is achieved.

Owner:JIANGSU JINWO MACHINERY

Wet-strength waste paper recycling chemi-mechanical pulping system

ActiveCN105544264AReduce consumptionImprove chemical reaction efficiencyPaper recyclingWaste paper working-upChemical treatmentHigh concentration

Owner:JIANGSU JINWO MACHINERY

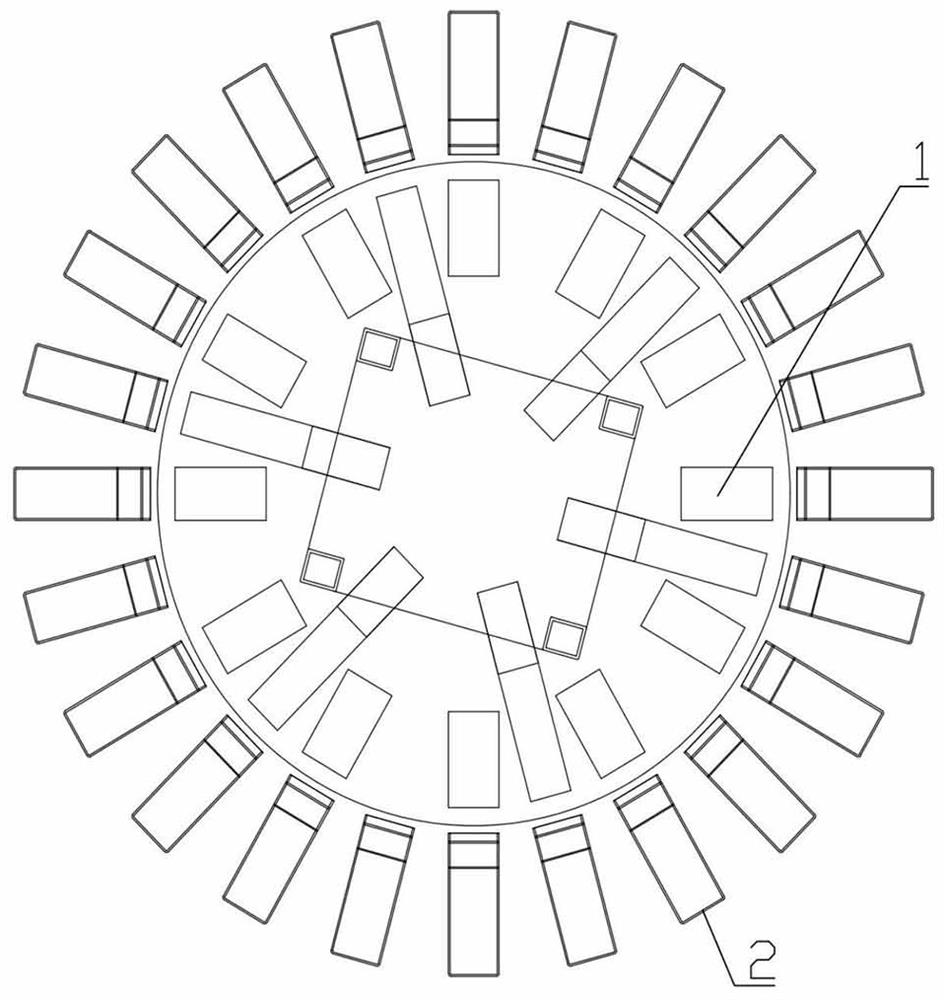

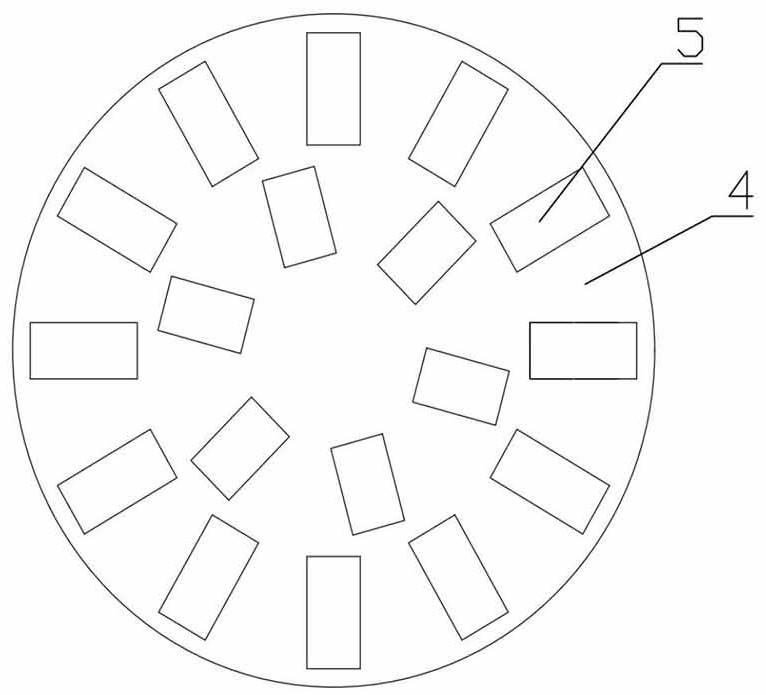

Feeding mechanism, cutter cutting assembly and wood shaving machining device

ActiveCN113334519AIncrease the areaPrecise dockingWood working apparatusWood shavingsStructural engineering

The invention relates to the technical field of wood shaving machining, in particular to a feeding mechanism, a cutter cutting assembly and a wood shaving machining device. The feeding mechanism comprises material pressing bins, rotary feeding bins and a material baffle, and at least two circles of reference annular belts are distributed on the outer side of a reference axis at intervals from inside to outside. One material pressing bin with an outlet located at the reference point position is arranged at the position corresponding to each reference point position, the end faces of the outlets of all the material pressing bins are located on the horizontal reference plane, a feeding inlet is formed in the upper portion of each material pressing bin, one rotary feeding bin is arranged at each feeding inlet, and all the rotary feeding bins can rotate around the reference axis. The lower portion of each rotary feeding bin is provided with a conveying opening capable of being in butt joint with the corresponding feeding inlet. The feeding mechanism is reasonable and compact in structure and convenient to use, through the arrangement of the material pressing bins and the rotary feeding bins, feeding can be conducted on at least two layers of annularly-formed machining openings, so that the material slicing area of a cutter is increased, the machining efficiency is improved, and the characteristics of use safety, efficiency and convenience are achieved.

Owner:TREEZO NEW MATERIAL TECH GRP CO LTD

Flow-velocity-decreasing multi-drum type film waste plastic recycling method

The invention discloses a flow-velocity-decreasing multi-drum type film waste plastic recycling method. The flow-velocity-decreasing multi-drum type film waste plastic recycling method is characterized by comprising the following steps: shearing waste materials by a shredding machine via mechanical shears, preliminarily washing the sheared waste materials, and settling the the washed waste materials to remove heavy impurities; then, washing the waste materials through a multi-stage drum in a multi-drum type washing and separating device, controlling upward flow velocity of washing water injected from each lower water inlet, effectively removing light impurities mixed in the materials or separating out different materials with specific gravity difference by washing and separating; shearing, rubbing and leveling obtained plastic sheets into small sheets and aggregate particles by a double-screw impregnation machine; and drying and storing the small sheets and aggregate particles for later use. The method and a system can realize comprehensively utilizing solid wastes of a paper mill and recycling waste paper fibers and waste plastic separately, and can realize automatic and large-scale automatic production, wherein a comprehensive utilization rate can be 90% or higher; and moreover, water consumption can be reduced by 50-80% by circulating washing water, so that environmental pollution is reduced, production continuity is guaranteed, the production space is saved, and the significance is remarkable.

Owner:JIANGSU JINWO MACHINERY

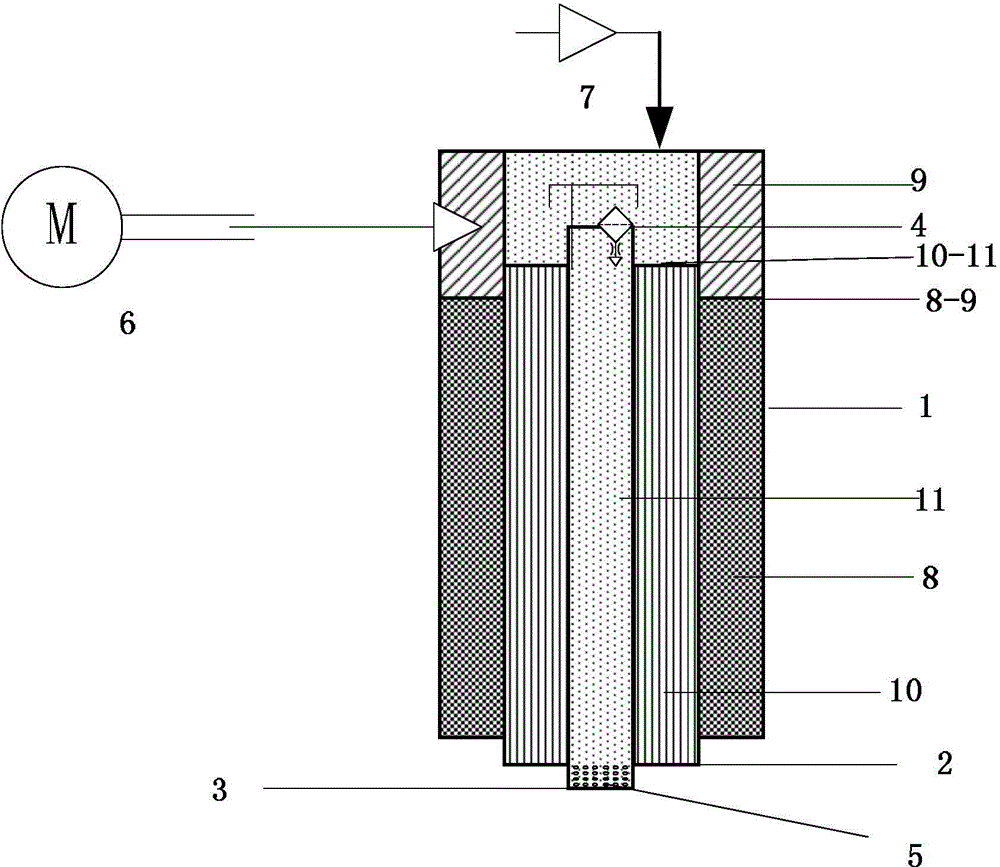

Method for exploiting oil sand through paraffin media

InactiveCN104533365AReduce consumptionRelease stabilityInsulationFluid removalParaffin waxLiquid water

The invention provides a method for exploiting oil sand through paraffin media. In at least one period, the method includes the following steps: a central tube is arranged on an oil deposit section in an oil well shaft, a sleeve is arranged outside the central tube, and annular space between the central tube and the sleeve is used for containing liquid water; a steam hole is formed in the upper end of the central tube, the position of the steam hole is higher than a working liquid level of the liquid water in the annular space between the central tube and the sleeve, and a steam outlet hole is formed in the lower end; the paraffin media are injected into annular space between the shaft and the sleeve to maintain the reservoir pressure, and are heated through a heating system; the liquid water is continuously injected into the annular space between the central tube and the sleeve; heat exchanging is carried out between the paraffin media and the liquid water to generate steam, and the steam enters the central tube through the steam hole of the central tube and flows out from the steam outlet hole to be in contact with an oil deposit for heat exchanging; when the steam injection amount meets the oil field steam flooding period heat supply requirement, heating is stopped, water is supplied, and oil extraction is carried out after a well is shut. The method is stable in steam generation, free of pollution, convenient to maintain and low in investment.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

QoS (Quality of Service) route distributing method for realizing load balance in overlay network

InactiveCN102055663BReduce blocking rateConducive to optimizing the distributionData switching networksQuality of serviceNetwork communication

The invention relates to the technical field of network communication, in particular to a QoS (Quality of Service) route distributing method for realizing load balance in an overlay network. The method comprises the steps of: introducing resource fair index representing path bottleneck degree, establishing a new load balance utility function, correcting a QoS bound term weight by adopting an adaptive system load state weighting method, and searching an optimal load balance service path. Compared with the traditional route method for load balance in the overlay network, the invention has the advantages of lowering the fluctuation degree RLCD (Residual Link Capacity Deviation) and RNCD (Residual Node Capacity Deviation) of the network load distribution, and being capable of improving the QoS service success rate (QSSR).

Owner:WUHAN UNIV

Double-pH-value wet-strength waste paper recycling pulping method

ActiveCN105648818AReduce consumptionImprove chemical reaction efficiencyPaper recyclingWaste paper working-upMaterials preparationPollution

The invention discloses a double-pH-value wet-strength waste paper recycling pulping method. The method includes a material preparation work section, a steaming work section, a first extrusion and dipping chemical-mechanical treatment section, a second extrusion and dipping chemical-mechanical treatment section, a latency and re-defibering section and a purification, screening and concentration section. According to the method, fiber dissociation and re-pulping of wet-strength waste paper are achieved under the effects of strong mechanical force and chemical treatment without reducing the strength of raw paper pulp; furthermore, in the two serial extrusion and dipping chemical-mechanical treatment sections, a wet-strength agent in the waste paper is oxidized under the acidic condition, and then hydrolysis is further promoted under the alkaline condition, so that chemical bonding between molecules of the wet-strength agent and chemical bonding between the wet-strength agent and pulp fibers are effectively damaged, and the fiber dissociation rate and the re-pulping yield are effectively increased. The problems that in wet-strength waste paper recycling pulping, the dissociation rate is low and strength is substantially reduced are solved, and continuous, large-scale, pollution-free and environment-friendly pulping with low water consumption and energy consumption can be achieved.

Owner:JIANGSU JINWO MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com