Patents

Literature

82results about How to "Improve chemical reaction efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dental Bleaching Gel Composition Containing Vegetative Enzymes

InactiveUS20090220919A1Improve defectsImprove energy absorptionCosmetic preparationsGum massageDecompositionNuclear chemistry

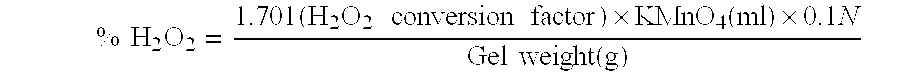

This invention is related to a kind of teeth bleaching formulation containing the vegetative enzymes extracted from plant tubers with extensively applications in cosmetic dentistry. The enzymes are susceptible to promote the decomposition (dissociation) of peroxide compounds, thus the intermediate hydroxyl free radicals are generated to turn the unpleasant stained tooth into light or colorless appearance effectively. The composition of a whitening gel may comprising 2˜50 wt % of hydrogen peroxide, 0.003˜3 wt % vegetative enzyme extract, and transferring to alkalinity approximately pH 8˜13 to achieve the high efficiency dental bleaching usage.

Owner:YANG JEN CHANG +4

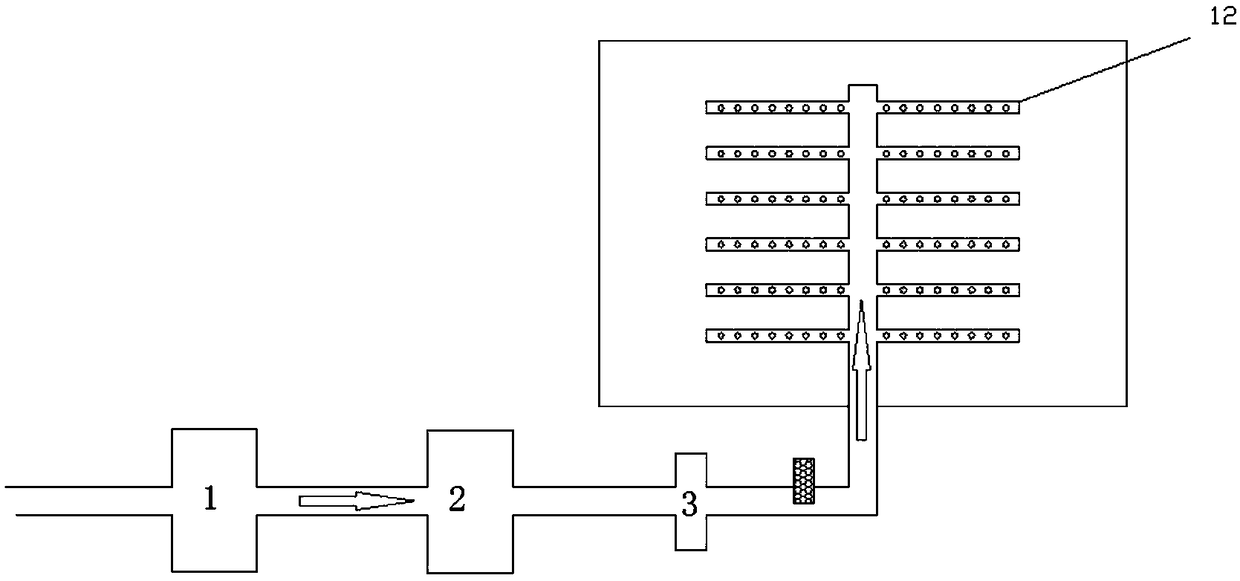

Air purification device

ActiveCN105180272ASolve the problem of longevitySolve the real problemMechanical apparatusLighting and heating apparatusParticulatesWater baths

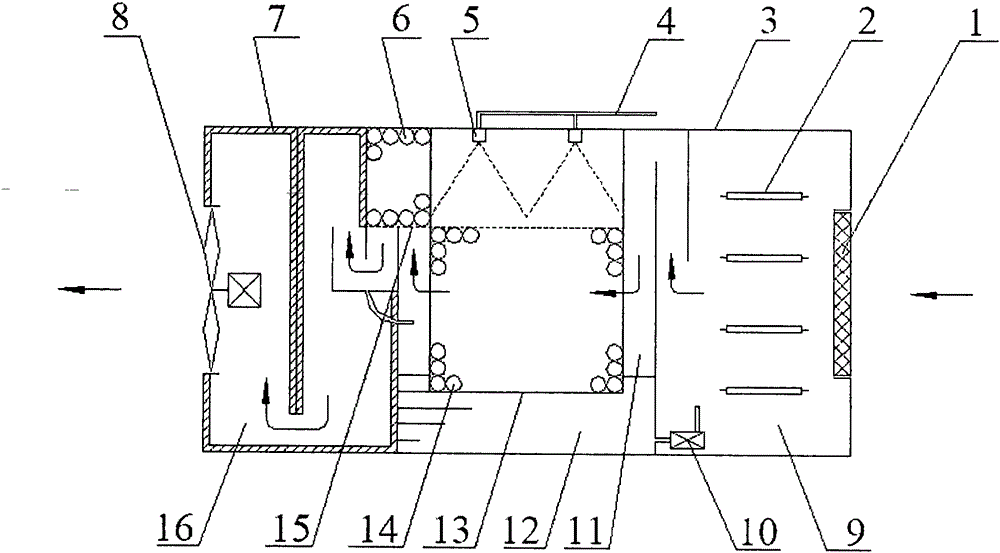

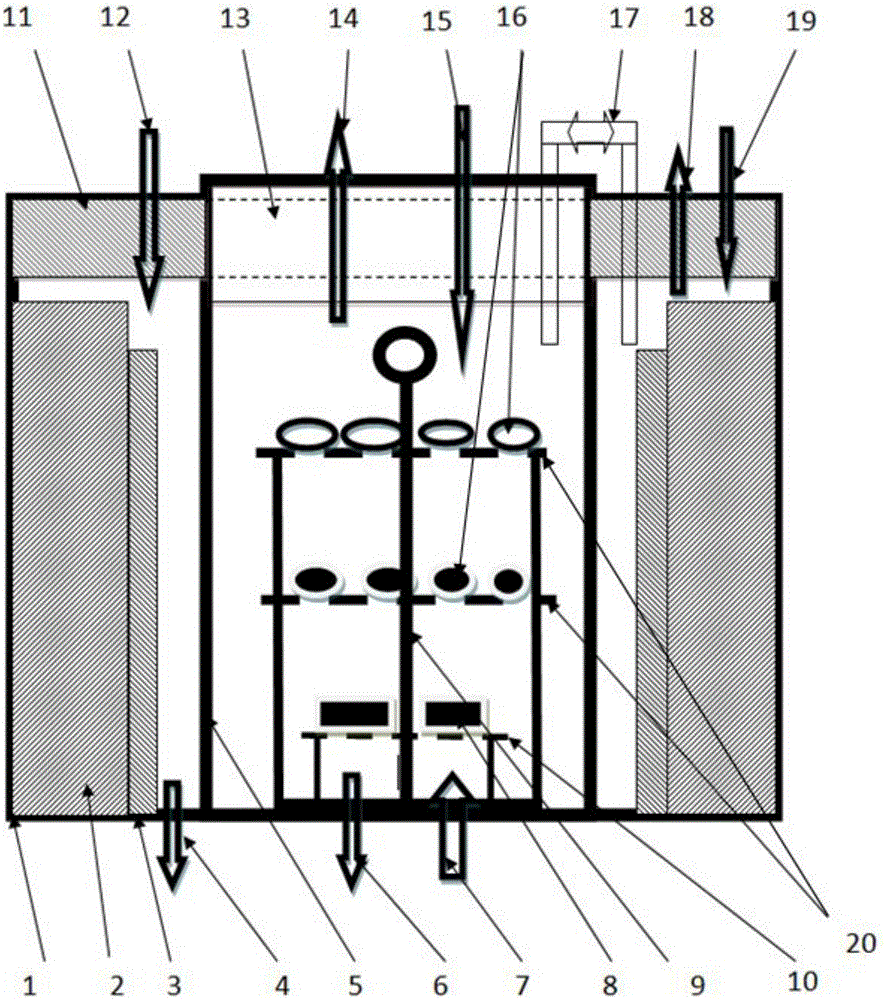

The invention relates to the technical field of air purification, in particular to an air purification device. The air purification device comprises a host, an ozone system, a spraying system, a water bath system, a dehumidification system and an adsorption system. The host comprises a box, and an inner cavity of the box is sequentially divided into a front chamber, a middle chamber and a rear chamber; a filter is arranged at an air inlet of the front chamber; a draught fan is arranged at an air outlet of the rear chamber. The front chamber is provided with the ozone system. The spraying system is arranged on the top of the middle chamber. The water bath system is arranged in the middle of the middle chamber. The dehumidification system is arranged in a channel between the middle chamber and the rear chamber. The rear chamber is provided with the adsorption system. The air purification device can capture PM2.5 particles in air, decompose formaldehyde and conduct disinfection and sterilization. Besides, the service life problem of 'saturation' in the use of filtering and adsorbing materials is solved, the efficiency of chemical reactions is high, and the sterilization effect is efficient.

Owner:李志国

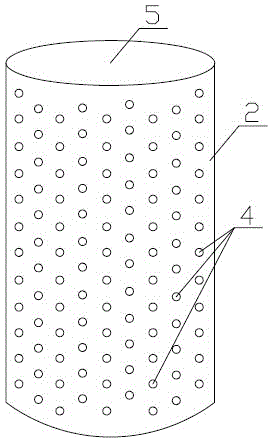

Preparation method and production equipment of acrylonitrile-based carbon fiber spinning solution

ActiveCN101736442AResolve Radial DifferencesImprove delivery qualityFibre chemical featuresChemical reactionAcrylonitrile

The invention discloses a preparation method and production equipment of an acrylonitrile-based carbon fiber spinning solution. The preparation method comprises the step of carrying out a polyreaction in a tubular reactor, wherein a turbulent plate or a cross over disk is arranged in a tube cavity of the tubular reactor, and a device for controlling the temperature of the tube cavity is arranged on the outer wall of the tube cavity. Because components including the turbulent plate or the cross over disk are arranged in the tube cavity of the tubular reactor adopted by the preparation method of the invention, central and peripheral materials can crosswise flow, the radial difference of the materials in a tube is effectively solved, the fluid transportation quality is improved, heat transfer and mass transfer are provided, the chemical reaction efficiency is improved and the flow resistance is relatively lower, thereby improving the uniformity of polymers and realizing continuous industrial production.

Owner:KINGFA SCI & TECH CO LTD +1

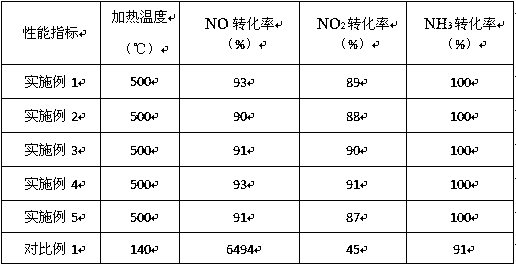

Regeneration method and equipment of selective catalytic reduction (SCR) denitration catalyst

InactiveCN104923316AEasy accessExtended service lifeSulfur-dioxide/sulfurous-acidCatalyst regeneration/reactivationLow activityProcess engineering

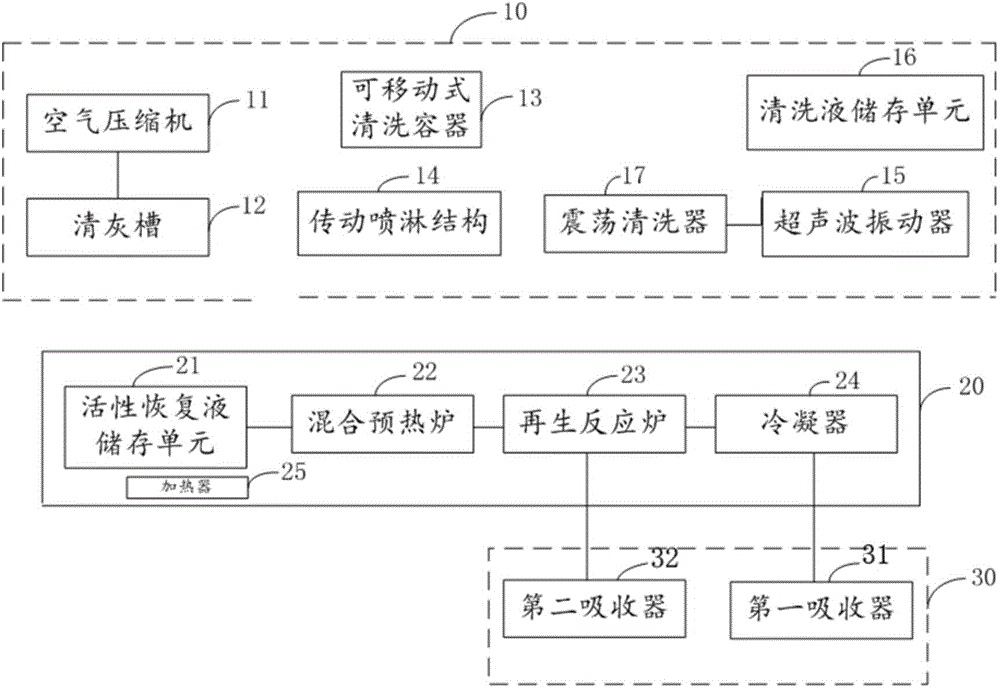

The invention provides a regeneration method and regeneration equipment of a selective catalytic reduction (SCR) denitration catalyst. The regeneration method includes: 1) front-section cleaning process by removing dust and impurity particles on the catalyst; 2) activation process by immersing the dried SCR denitration catalyst in an activation liquid for activation reaction; 3) drying process by drying the SCR denitration catalyst in order to avoid the activated catalyst from deactivation and damage; and 4) re-forging process by placing the dried deactivated catalyst in a furnace, allowing mixed gas to pass through a mixing preheating furnace and then enter a regeneration reactor, and carrying out heat treatment regeneration of the deactivated catalyst in the furnace. The method solves the problems of low activity of the regenerated catalyst, low practicability and complex operation and so on in the prior art.

Owner:湖北大清科技有限公司

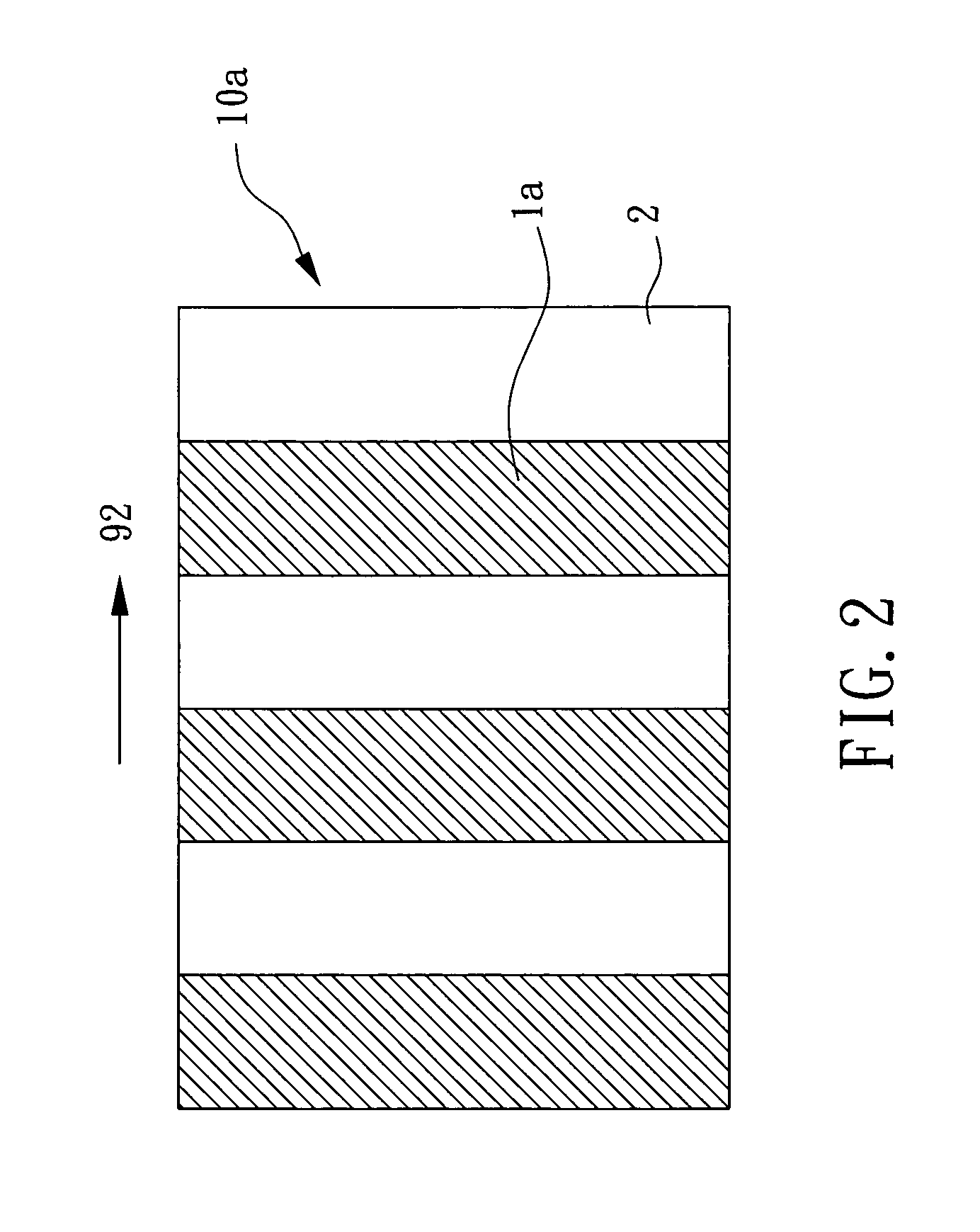

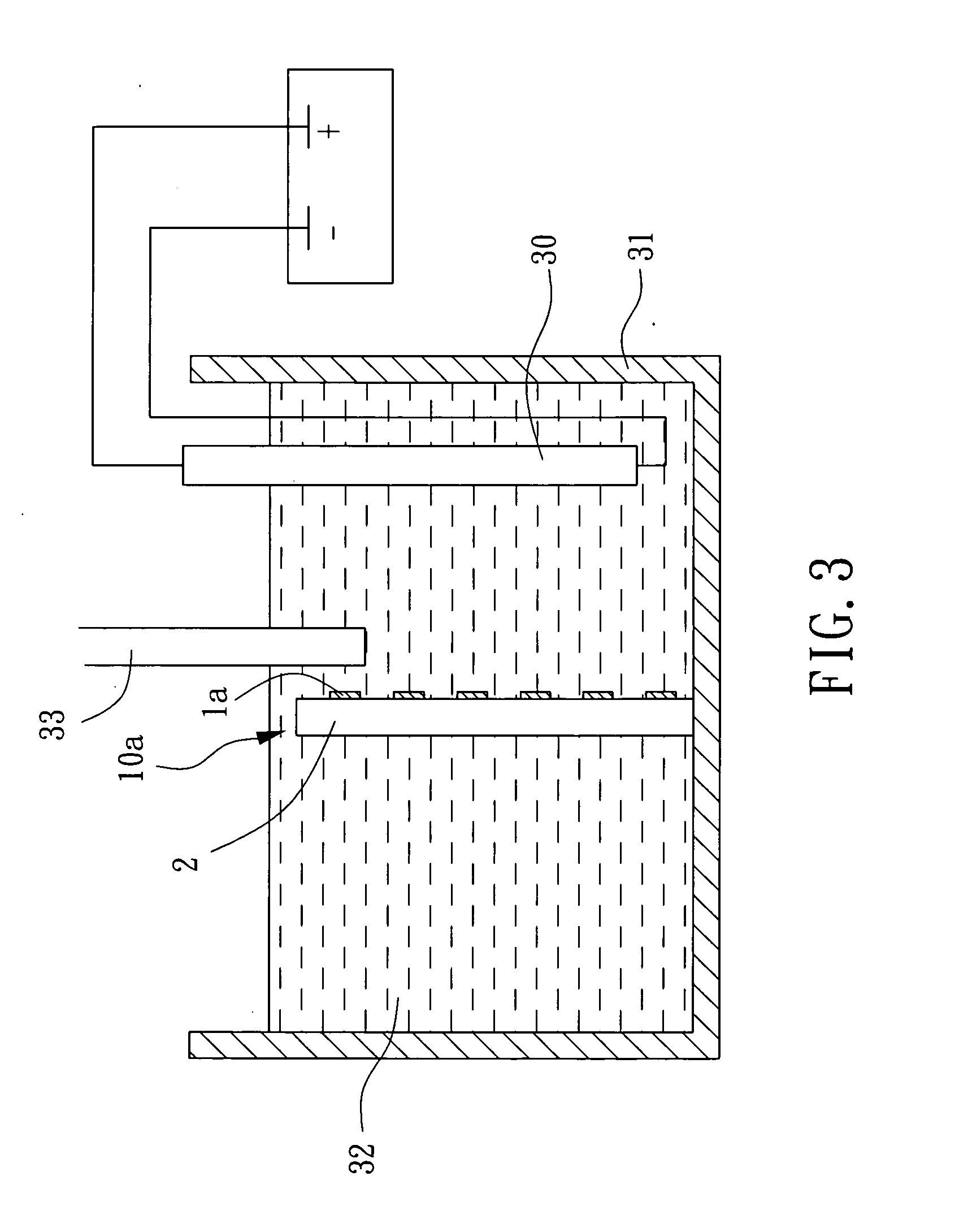

Photocatalyst carrier

InactiveUS20050130839A1High chemical activityImprove chemical reaction efficiencyMetal/metal-oxides/metal-hydroxide catalystsElectronic transmissionElectron hole

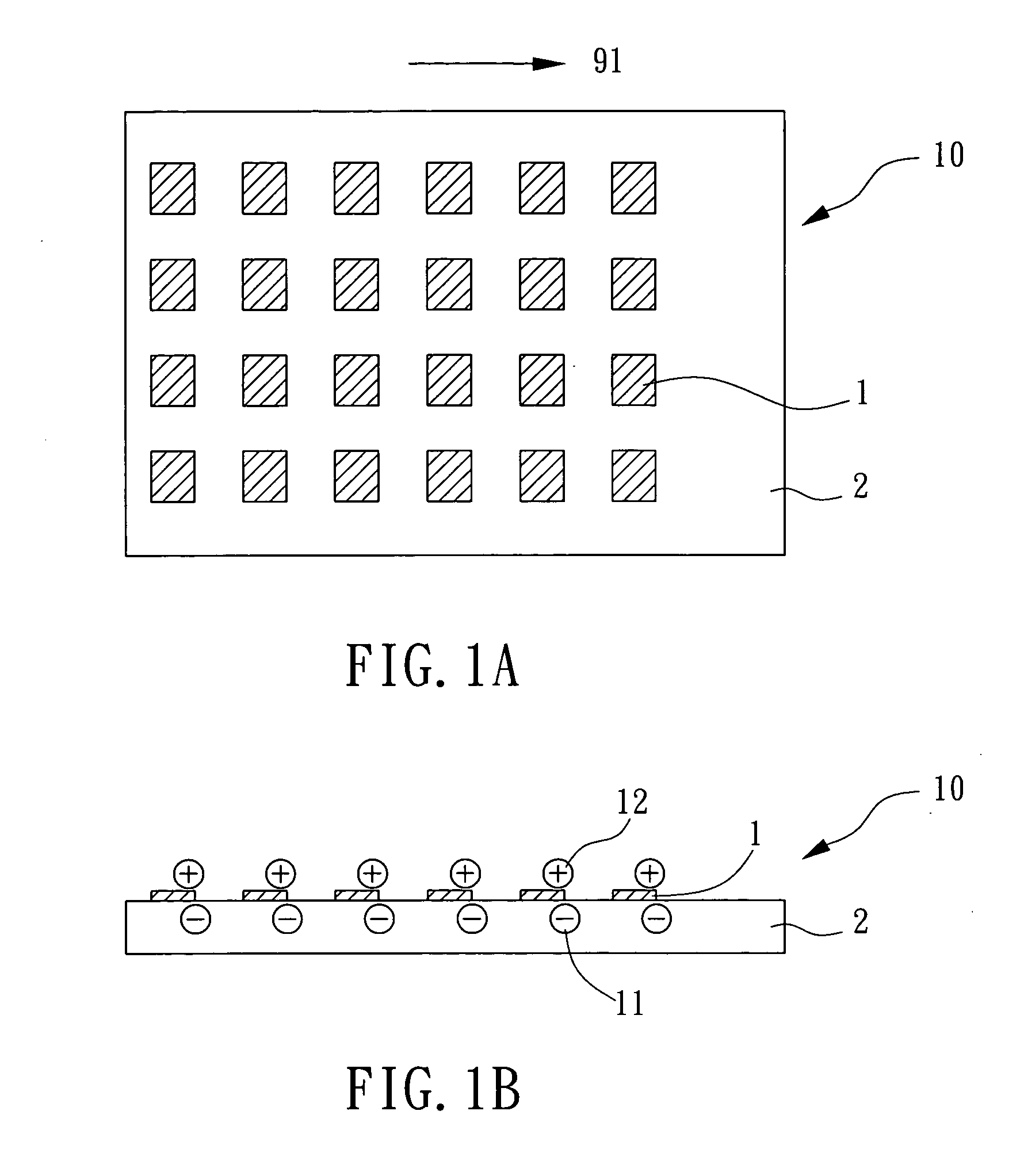

A photocatalyst carrier comprises a carrier and a photocatalyst, wherein the carrier having a surface is made of an electric conductive material, and the photocatalyst is coated unevenly onto the surface to form a plurality of photocatalyst electrodes. By applying the concept of electronic transmission, the existence probability of the electron-hole pair is increased for enabling the reactant to perform an oxidation-reduction reaction on the photocatalyst and carrier respectively so as to enhance the photocatalyst activity.

Owner:IND TECH RES INST

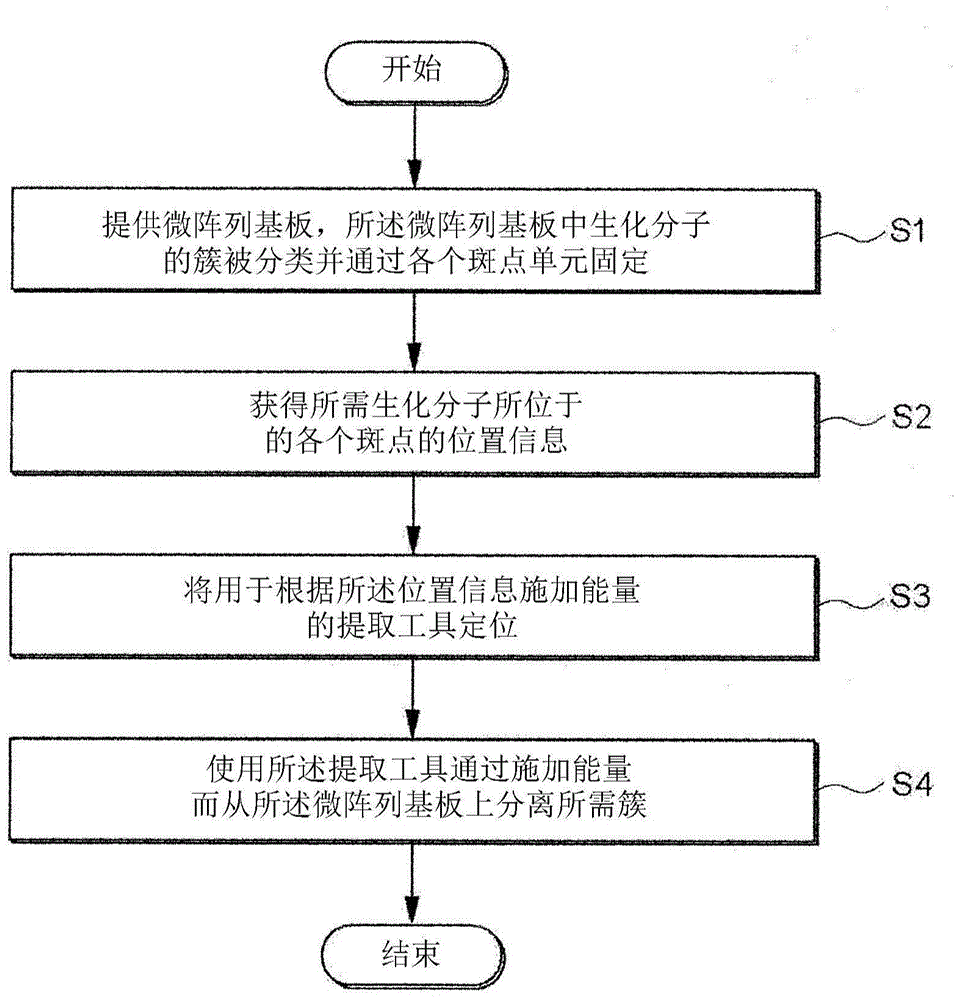

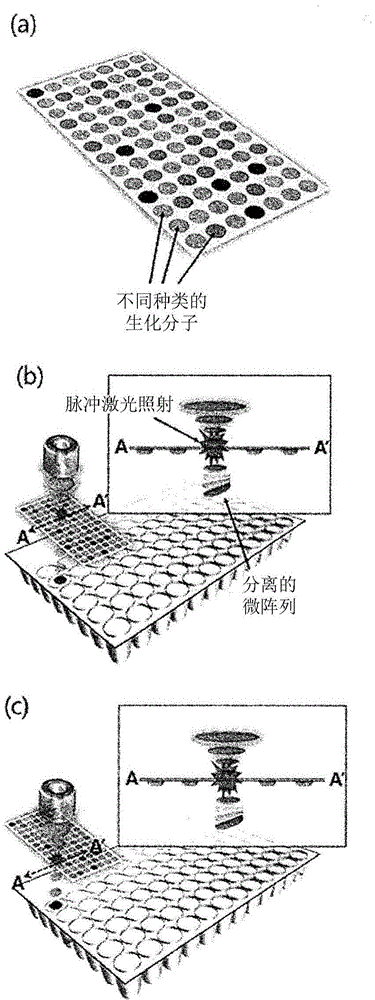

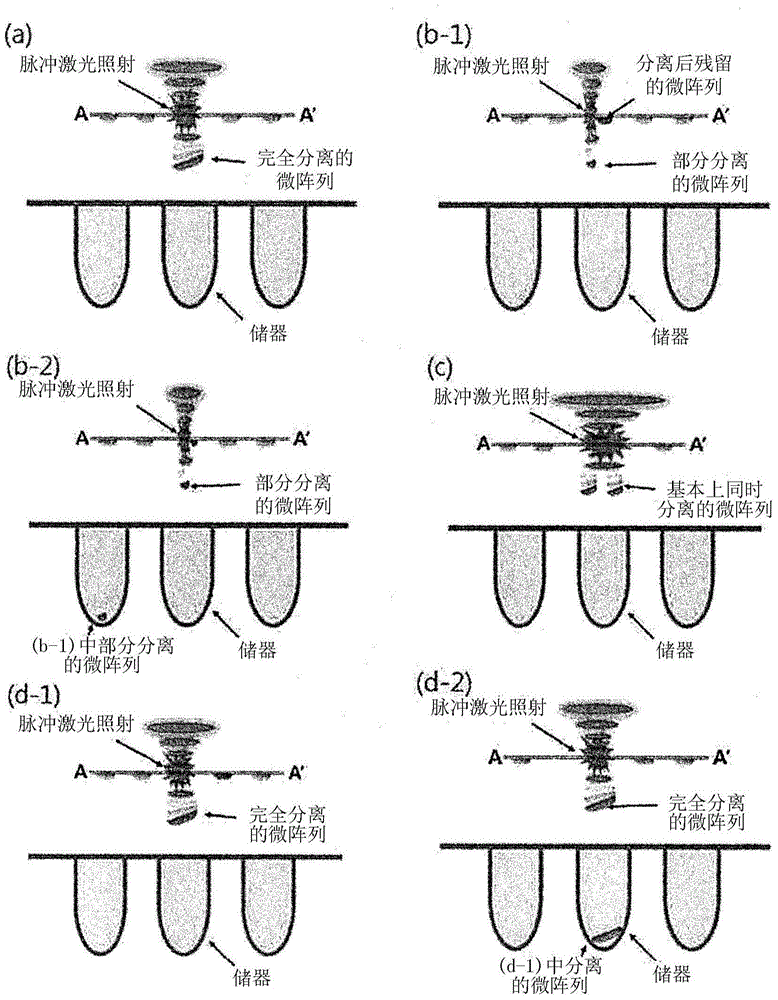

Method for isolating biochemical molecules on microarray substrate

ActiveCN104884957AImprove application efficiencyReduce complexitySequential/parallel process reactionsMicrobiological testing/measurementBiochemistryCluster based

Provided is a method for isolating biochemical molecules on a microarray substrate, comprising the steps of: providing the microarray substrate on which clusters of different types of biochemical molecules are attached by being classified by individual spot units which are regularly arranged; acquiring the information on the location of the individual spot in which a desired cluster among the clusters of biochemical molecules is located; placing an extraction tool for applying energy so as to isolate the desired cluster based on the information on the location; and applying energy in a contact or non-contact manner using the extraction tool so as to isolate the desired cluster from the microarray substrate.

Owner:SEOUL NAT UNIV R&DB FOUND

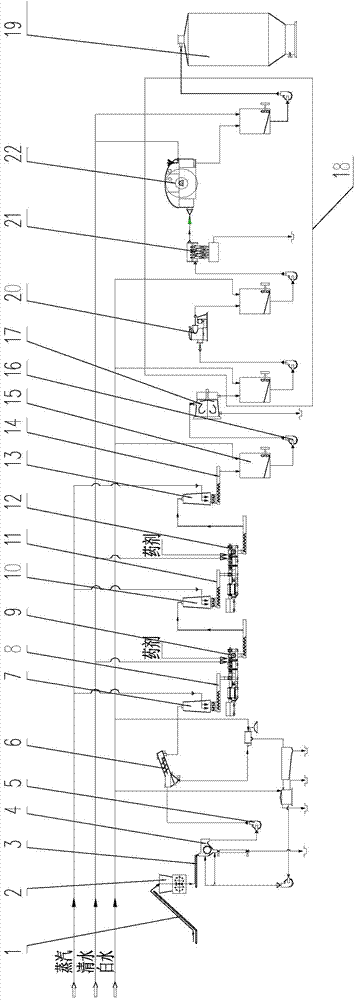

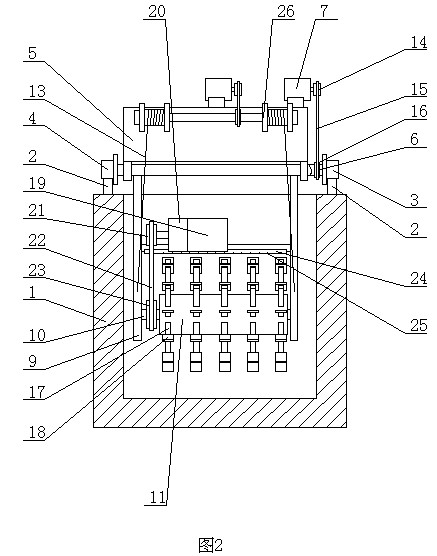

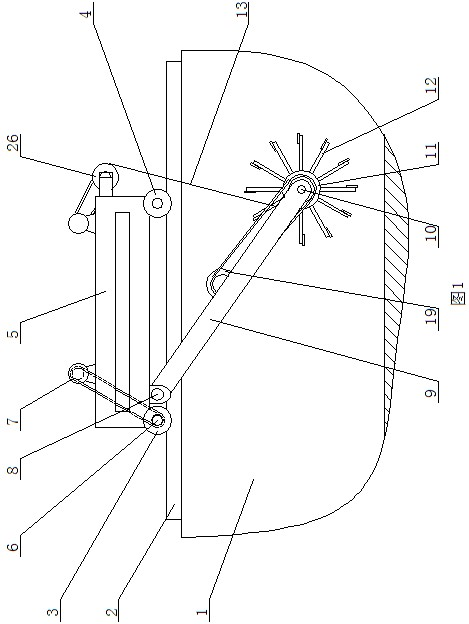

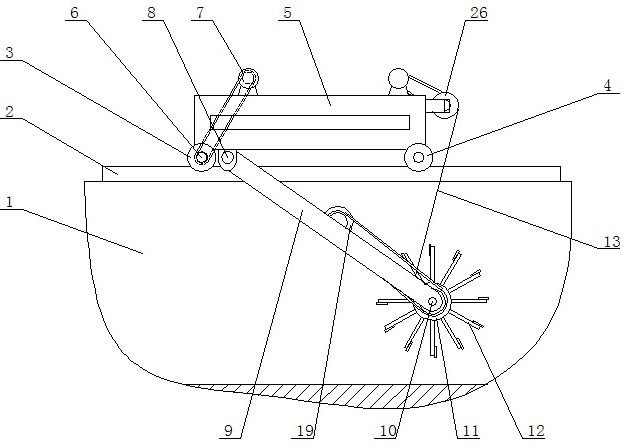

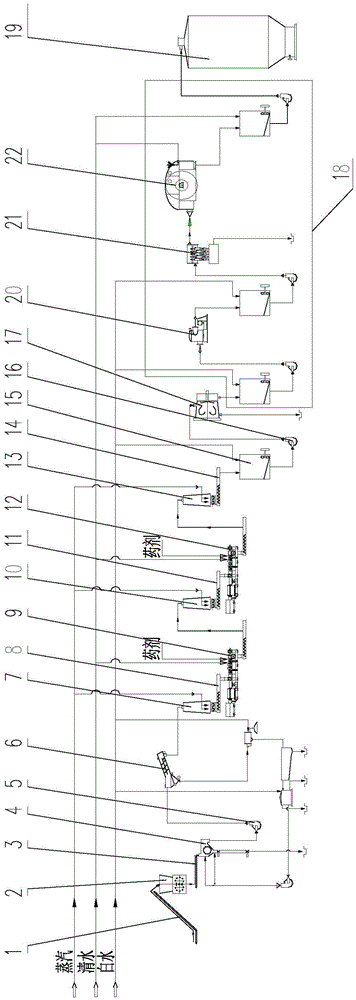

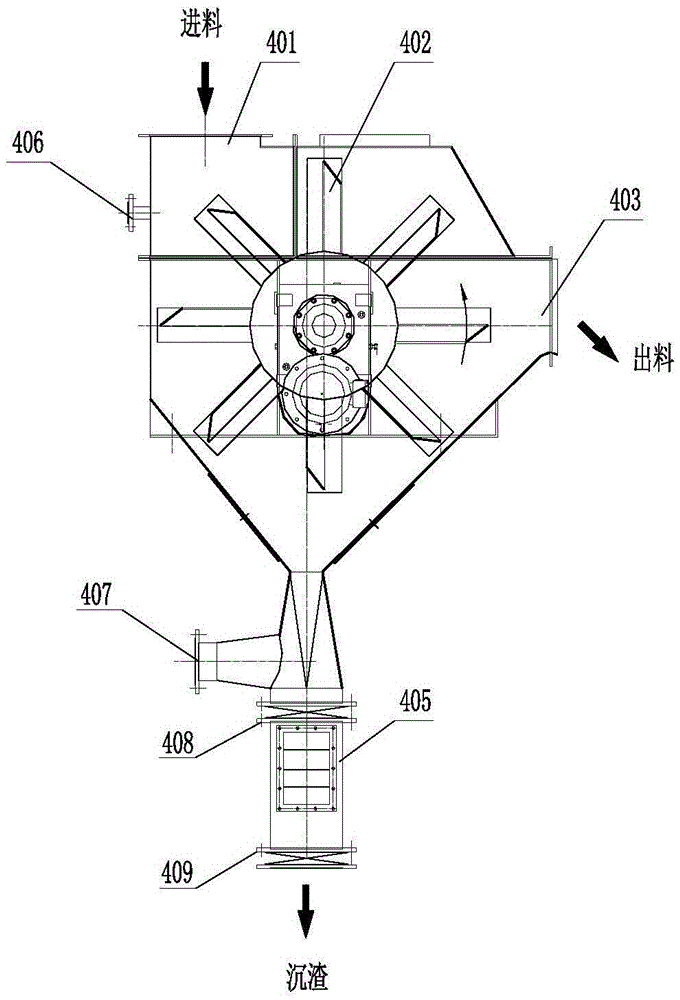

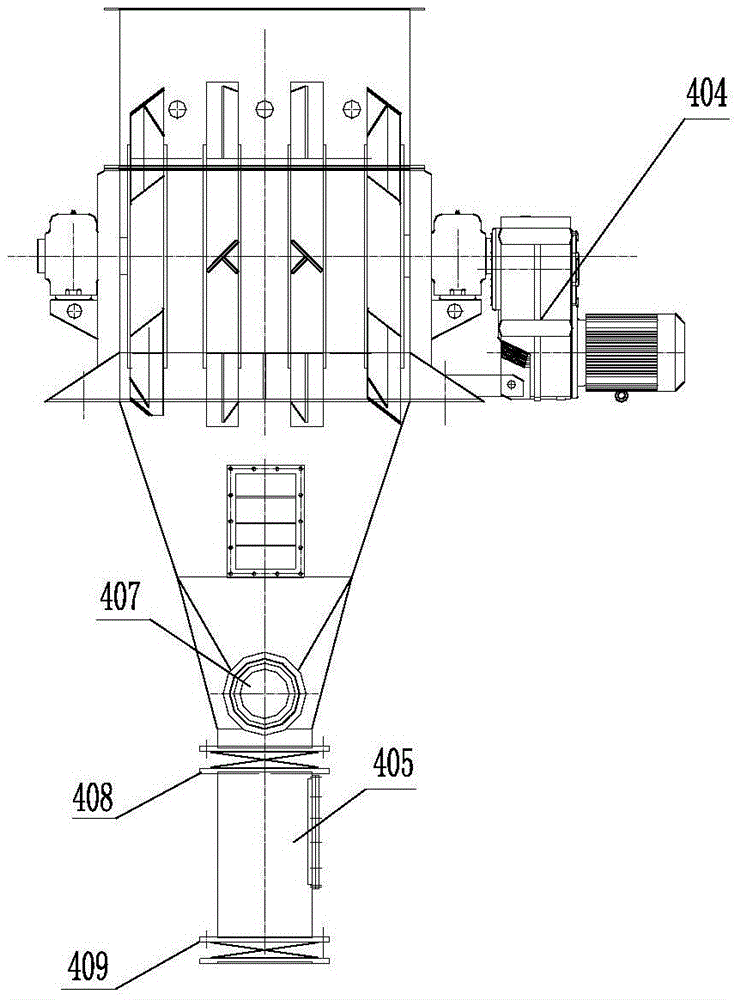

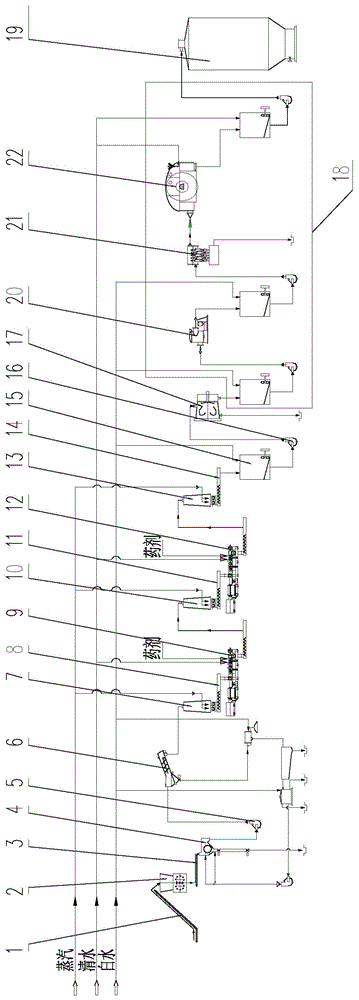

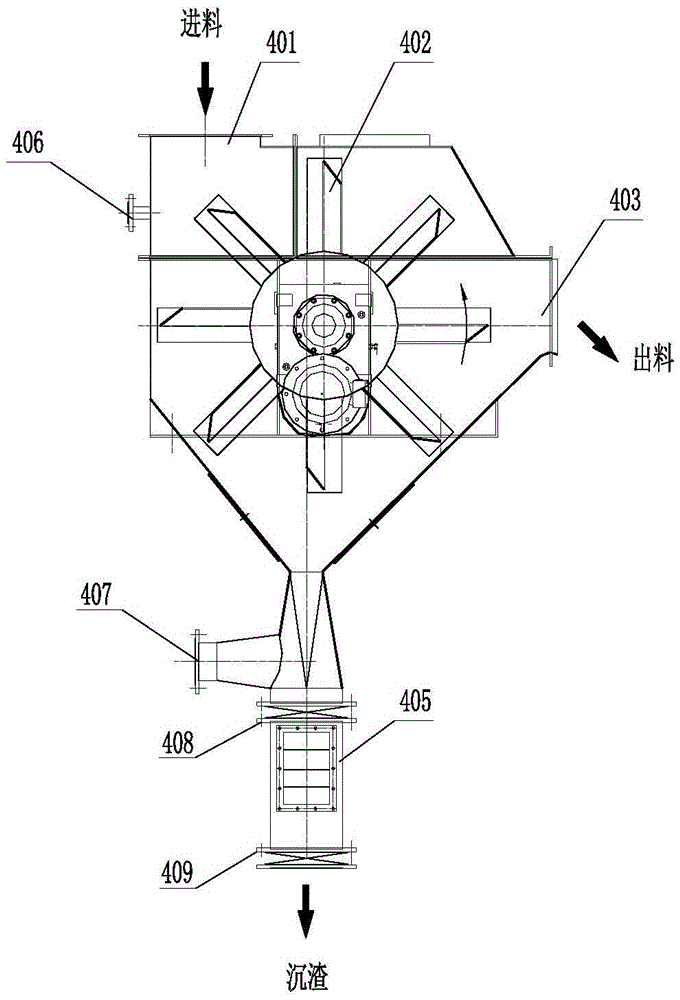

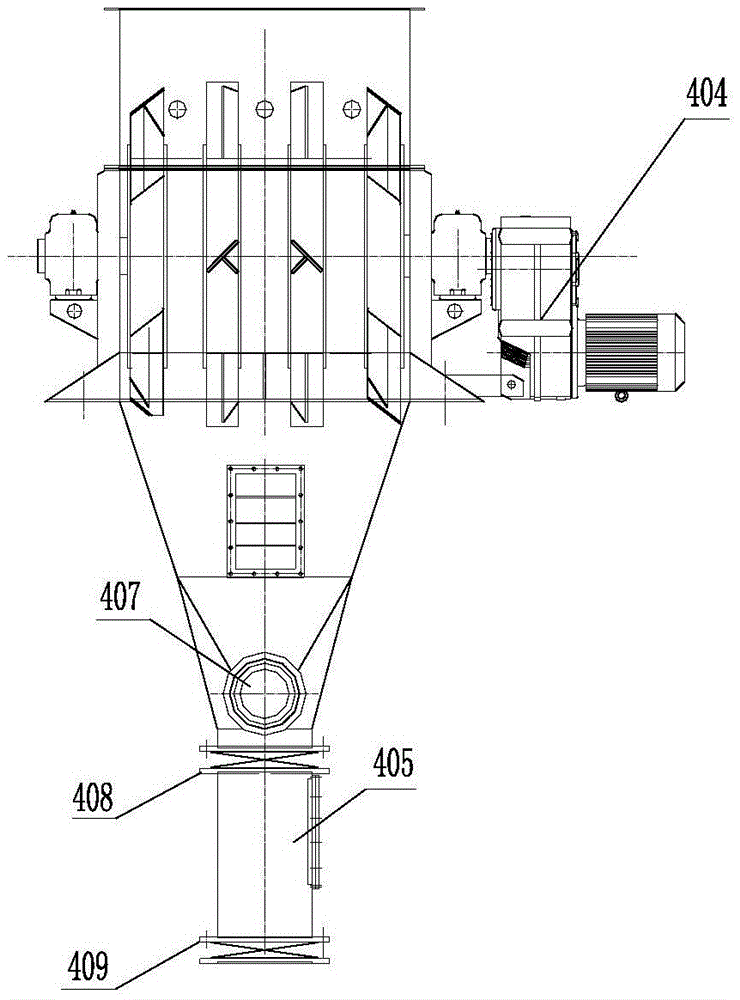

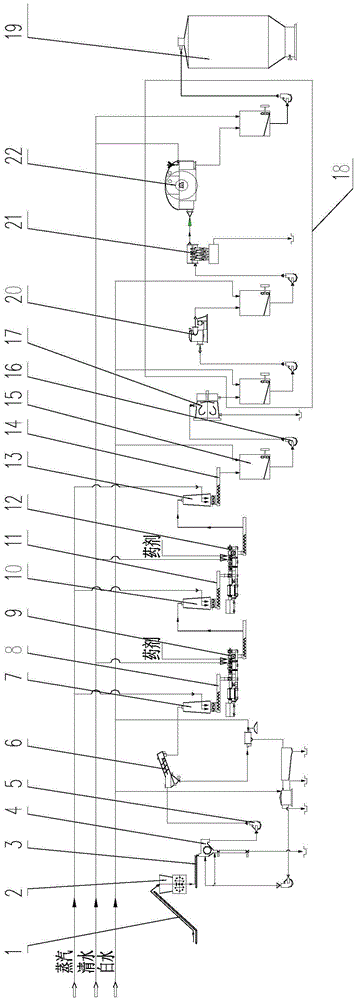

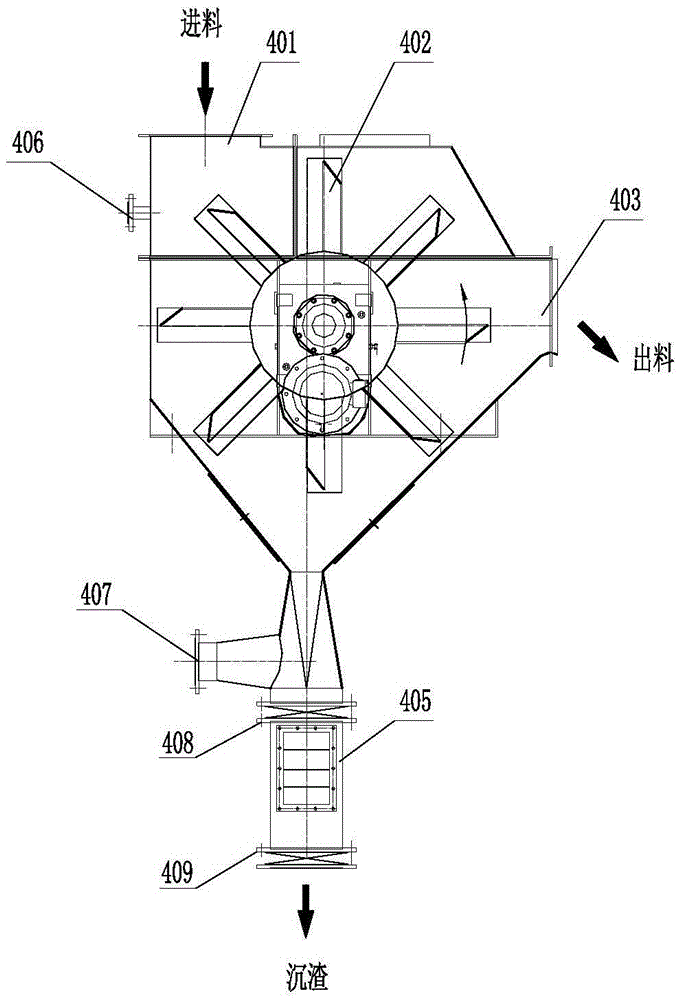

Wet-strength waste paper recycling chemical mechanical pulping system

ActiveCN104120613AReduce consumptionImprove chemical reaction efficiencyPaper recyclingWaste paper working-upChemical treatmentFiber

The invention discloses a wet-strength waste paper recycling chemical mechanical pulping system. In the material process running direction, the system comprises first conveying equipment, a crusher, second conveying equipment, a tumbler-type washing machine, an oblique spiral dehydrator, a steaming bin, a third spiral conveyer, a first double-screw impregnator, a first reaction bin, a fourth spiral conveyer, a second double-screw impregnator, a second reaction bin, a fifth spiral conveyer, a latency chest, a pulp pump, a fiber separator, a purification, filtration and concentration device and a pulp storage device. The uniform-discharging-type reaction bins are used for achieving uniform discharging so as to reduce the load fluctuation amplitude; the rotary material-poking-type steaming bin is used for eliminating the bridging phenomenon, sufficiently steaming materials so as to soften the materials and reducing chemical consumption; the double-screw impregnators are used for dissociating wet-strength waste paper gradually, achieving high-concentration mixing and homogeneous immersion of chemical agents and pulp and improving the chemical reaction efficiency. The problems that when the wet-strength waste paper is recycled for pulping, the dissociation rate is low and the strength is greatly reduced are solved through the effects of mechanical strength and chemical treatment.

Owner:JIANGSU JINWO MACHINERY

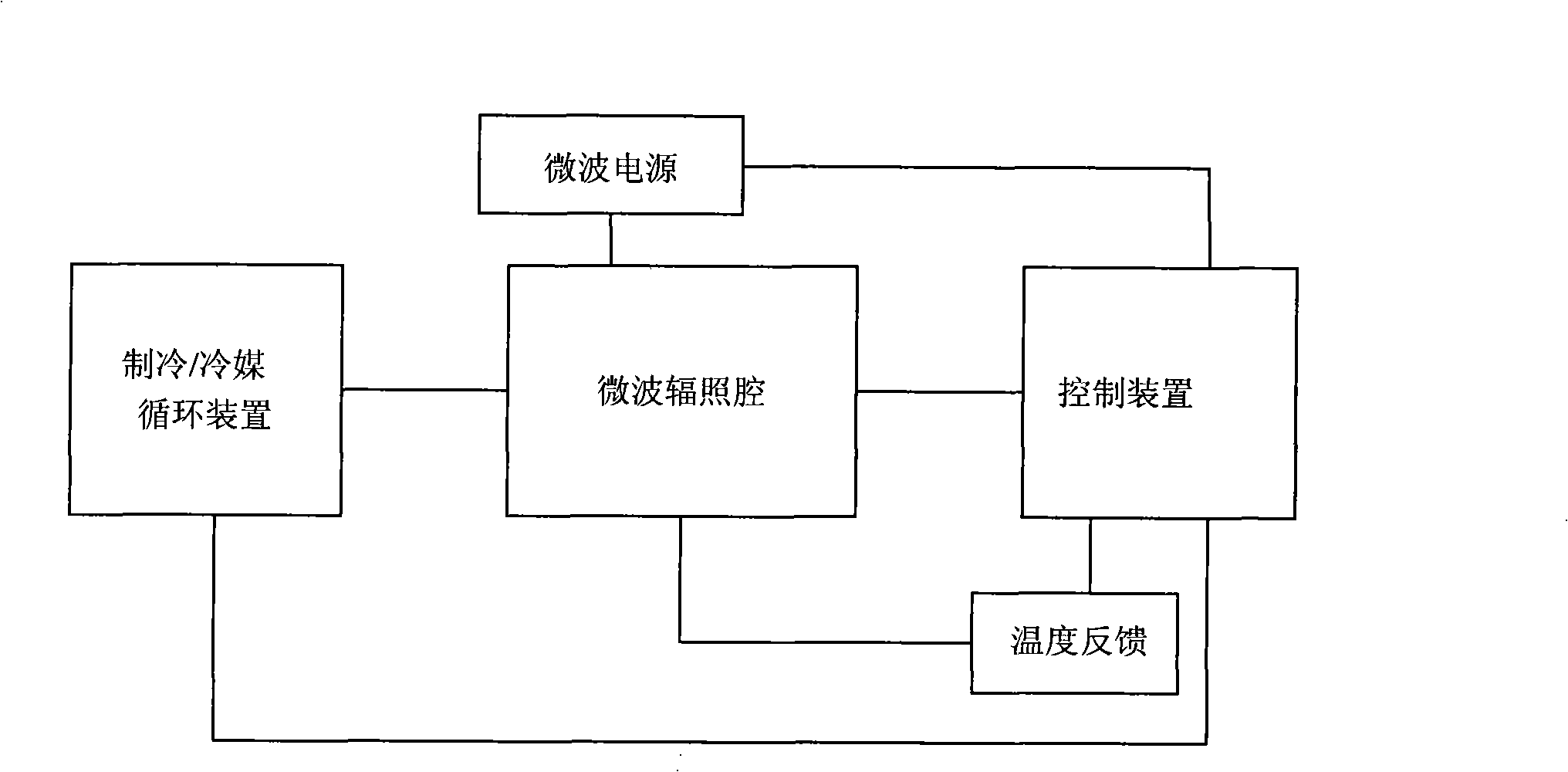

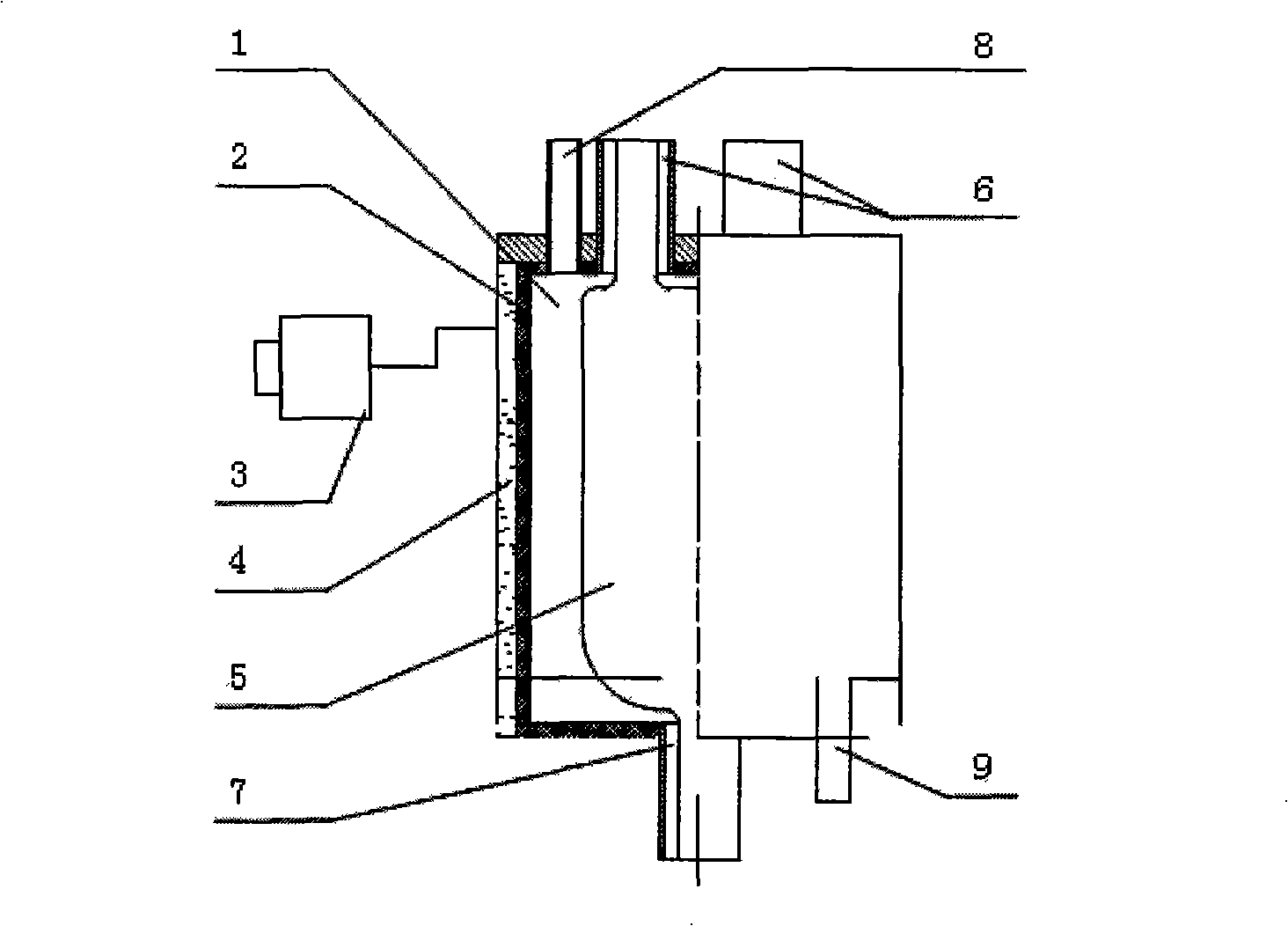

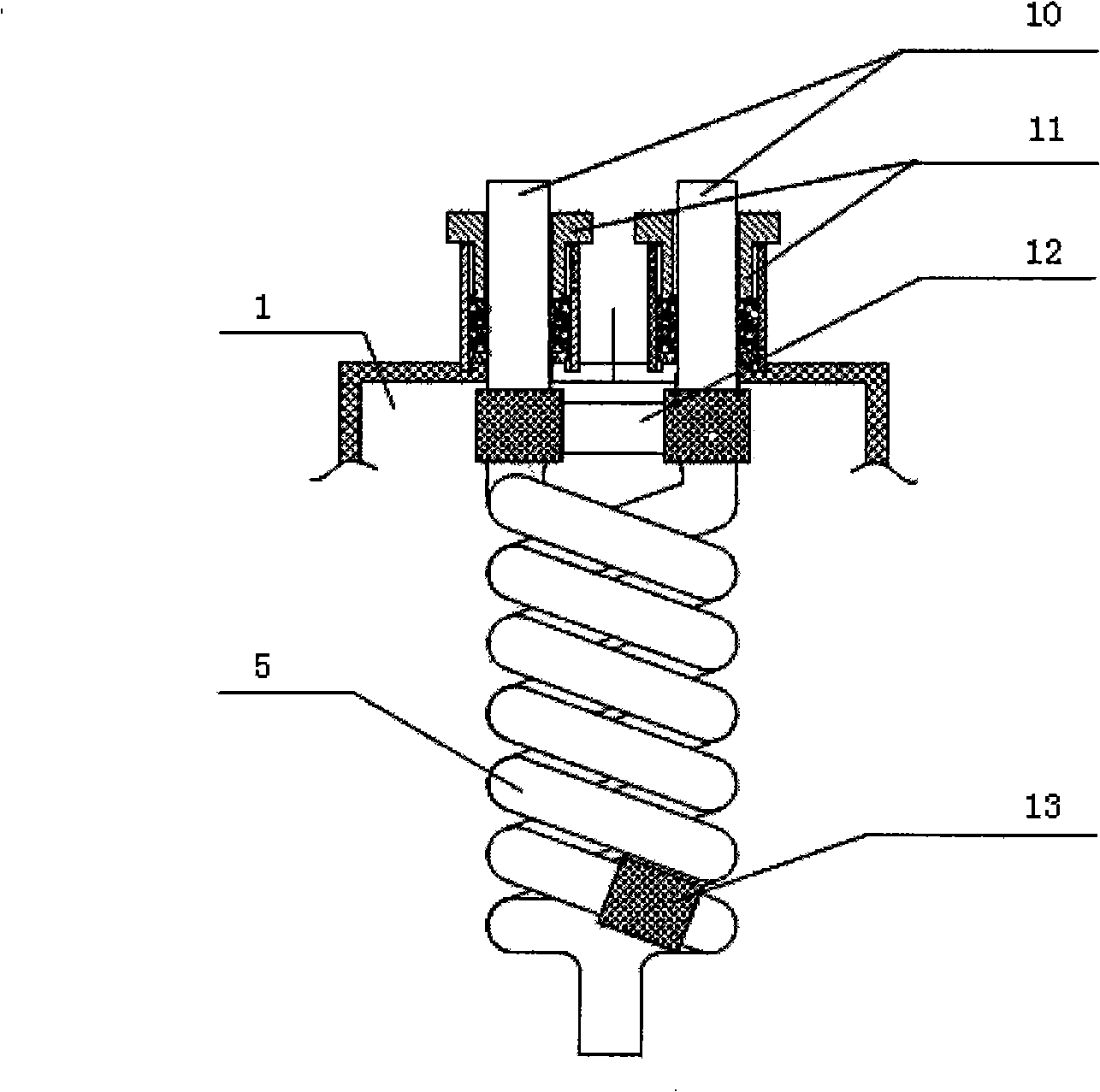

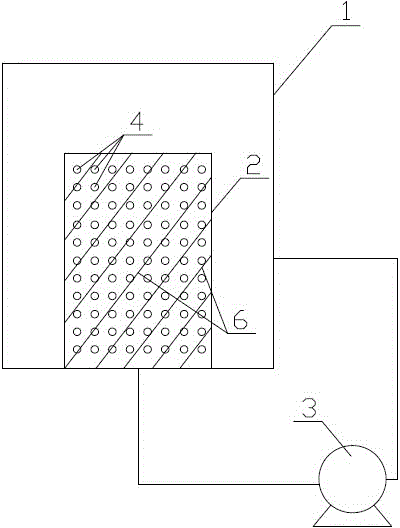

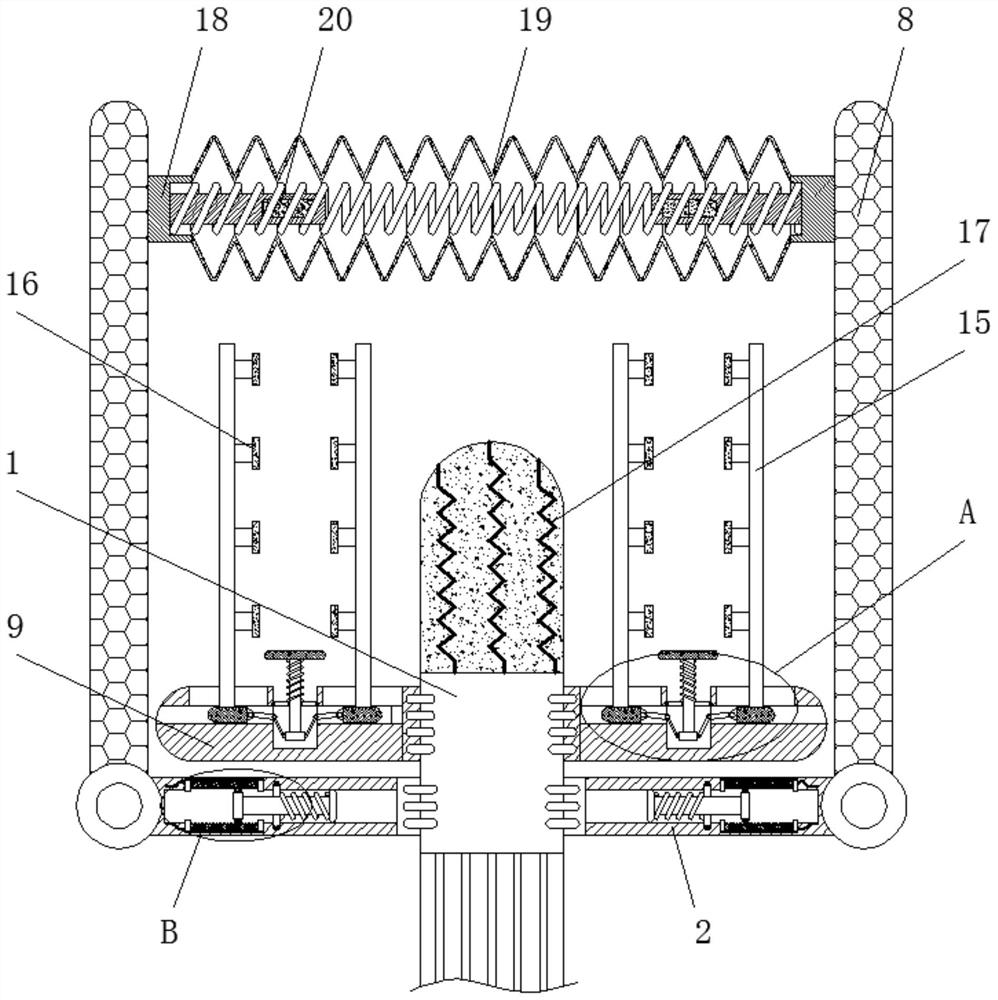

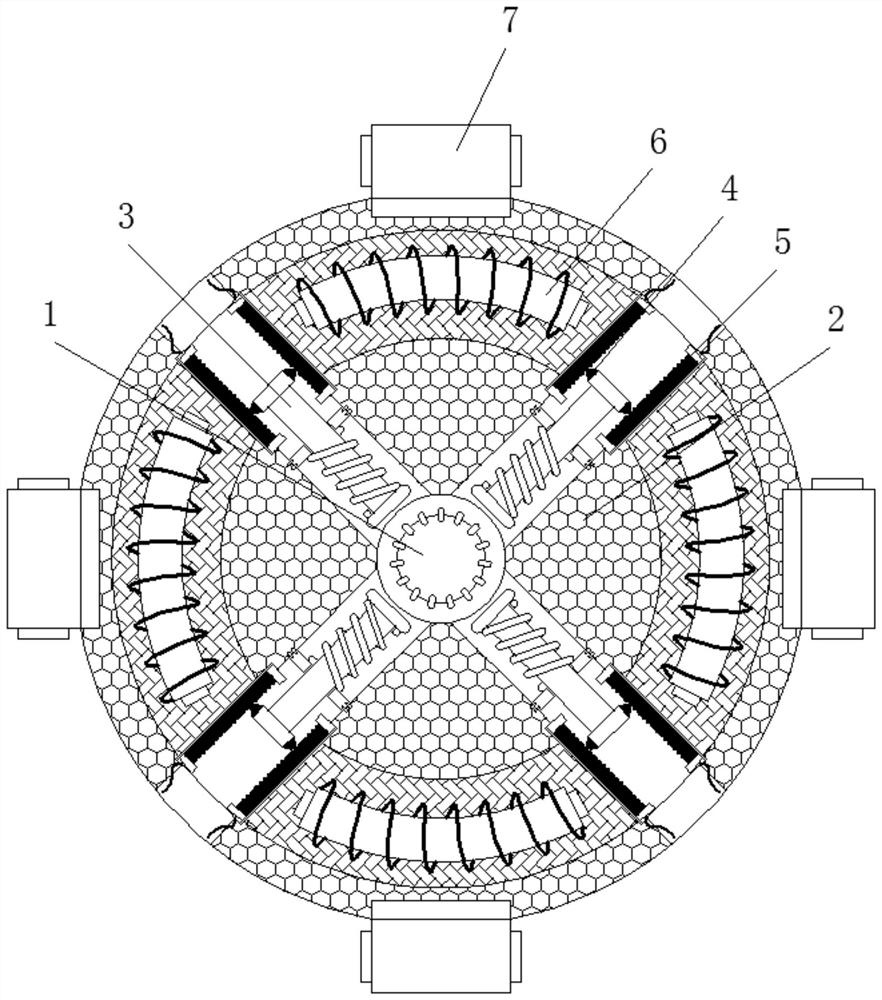

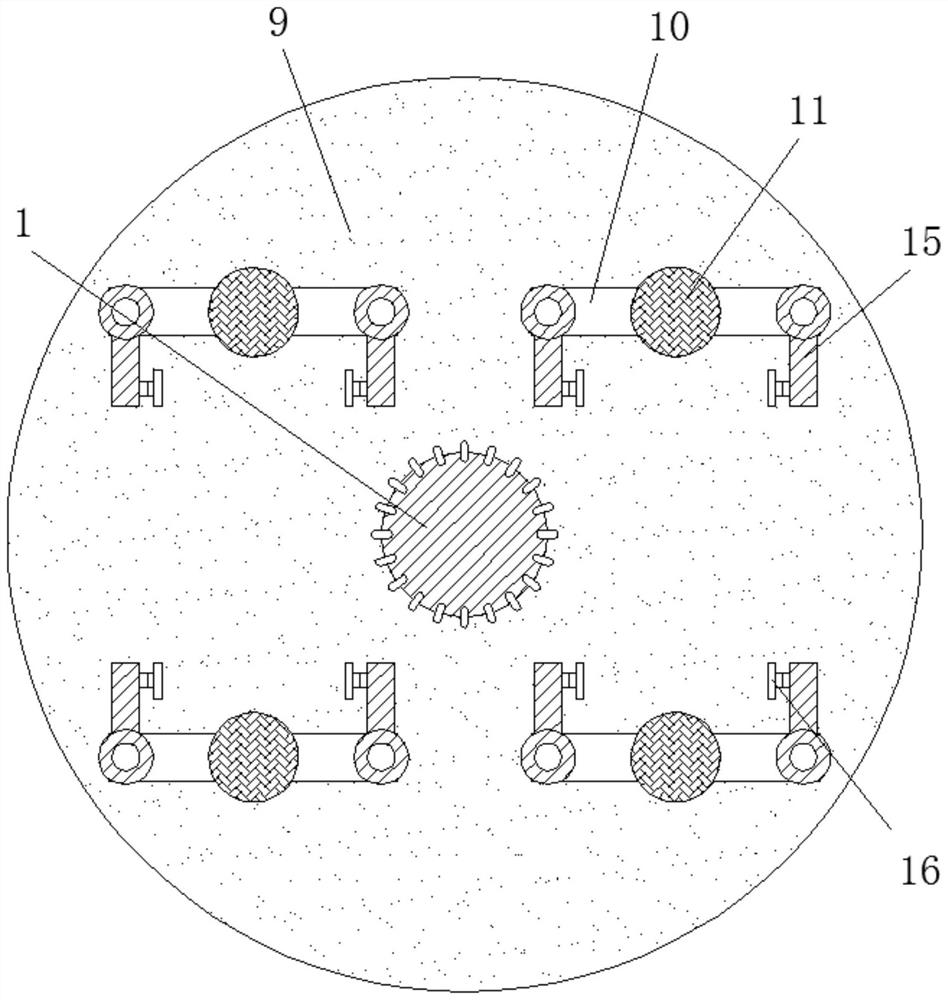

Refrigeration and microwave irradiation integrated microwave chemical reaction apparatus

InactiveCN101342475AImprove chemical reaction efficiencyIncrease temperatureEnergy based chemical/physical/physico-chemical processesChemical reactionMicrowave irradiation

The present invention relates to a microwave chemical reaction device in the chemical research and the chemical field, in particular to a microwave chemical reaction device for research, pilot test and output magnification of microwave chemical reaction under relatively low temperature. The present invention provides a microwave chemical reaction device with integrated refrigeration and microwave radiation, which comprises a microwave radiating cavity, an embedded microwave reactor, a microwave power, a magnetic control pipe and a refrigerating device; the embedded microwave reactor is arranged in the microwave radiating cavity; the microwave radiating cavity is directly connected with the refrigerating device for continuous refrigeration of the microwave radiating cavity; the microwave power and the magnetic control pipe are connected with the microwave radiating cavity. The present invention can provide high-strength and high-intensity microwave radiation and ensures that the reaction system is under the low temperature or superlow temperature condition while greatly increasing the chemical reaction speed, thus providing full reaction activated energy, increasing the reaction speed and overcoming the damages of high temperature on reactants or target molecule structure, activity and shape.

Owner:BEIJING ANNAN SCI & TECH

Chemical modification method and chemical modification device for aramid fibers

ActiveCN104894850ASolve the problem of limited modification effectImprove joint forceFibre typesPolymer scienceInterlaminar shear

The invention relates to a chemical modification method and a chemical modification device for aramid fibers and belongs to the technical field of chemical synthetic fiber modification. The method includes preparation of a surface modification treatment agent, modification treatment and washing drying, a specific acyl chloride active reaction reagent or anhydride active reaction reagent is dissolved in an anhydrous strong-polar organic solvent so as to subject the aramid fibers to chemical modification, surface performance of the modified aramid fibers can be improved remarkably, joint force between the aramid fibers and an epoxy resin matrix is enhanced significantly, and interlaminar shear strength of the modified aramid fibers can reach 50-59MPa. In addition, softness and dispersibility of the fibers are improved while the aramid fibers are subjected to surface modification, and application performance of the fibers is improved.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

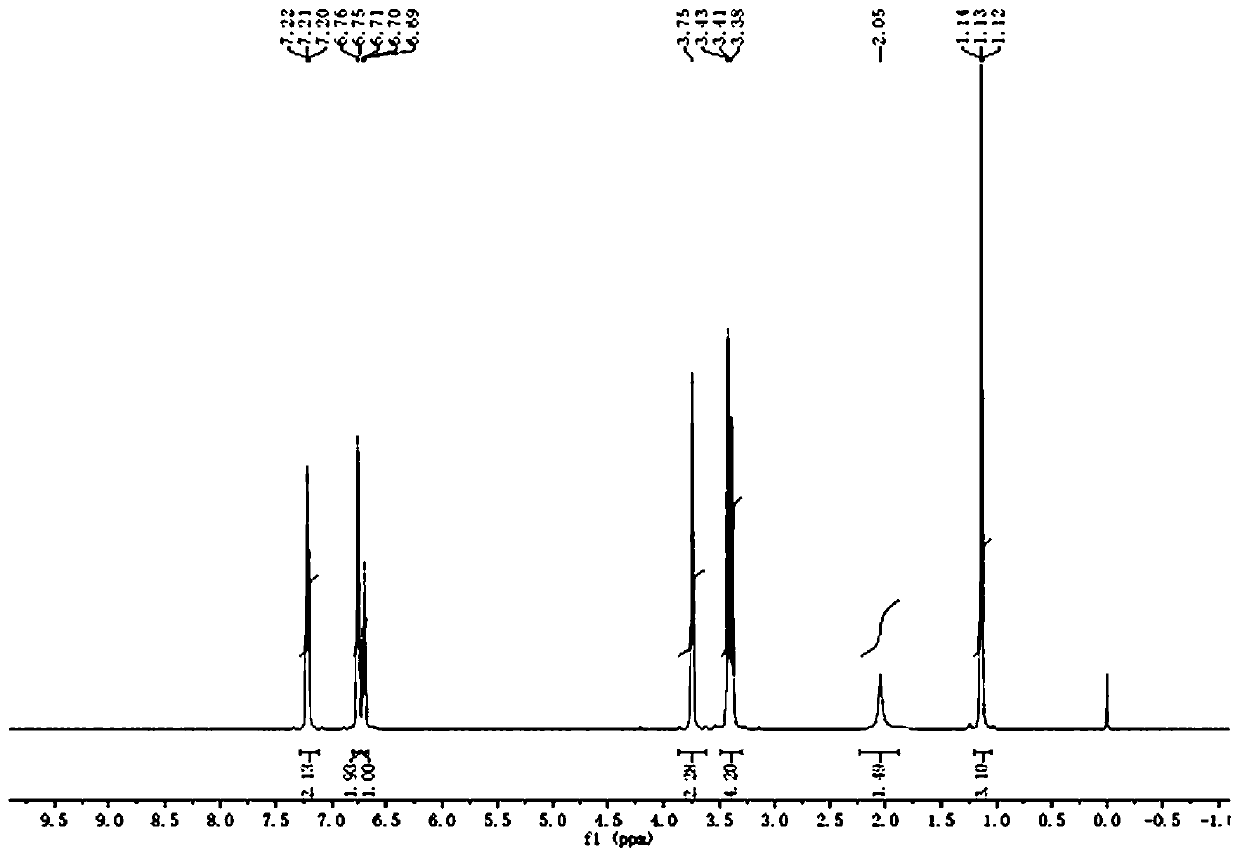

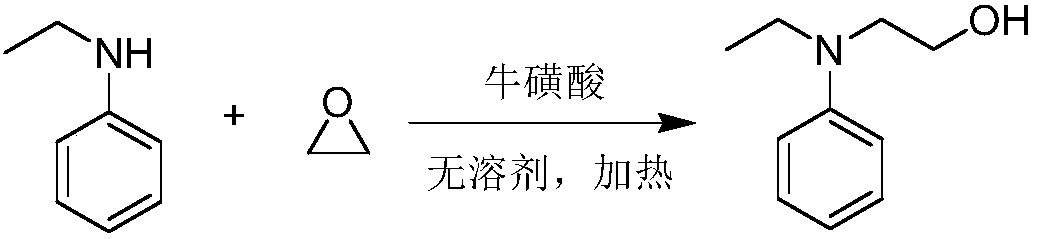

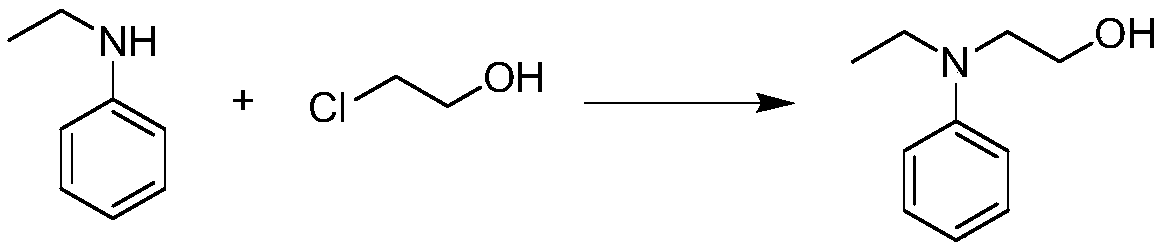

Method for preparing N-ethyl-N-hydroxyethylaniline

InactiveCN108117492AReduce dosageImprove catalytic performanceOrganic compound preparationAmino-hyroxy compound preparationEthylene oxideSolvent

The invention discloses a method for preparing N-ethyl-N-hydroxyethylaniline. The method comprises the following steps: by taking N-ethylaniline and ethylene oxide as raw materials, in the absence ofa solvent, under catalysis of taurine, performing programmed heating, directly synthesizing N-ethyl-N-hydroxyethylaniline, cooling, and discharging, thereby obtaining a finished product. The method iseasy in raw material obtaining, good in atom economy, gentle in reaction condition, green and environment-friendly, simple and efficient and applicable to industrial production.

Owner:JIANGSU YUANDA XIANLE PHARMA

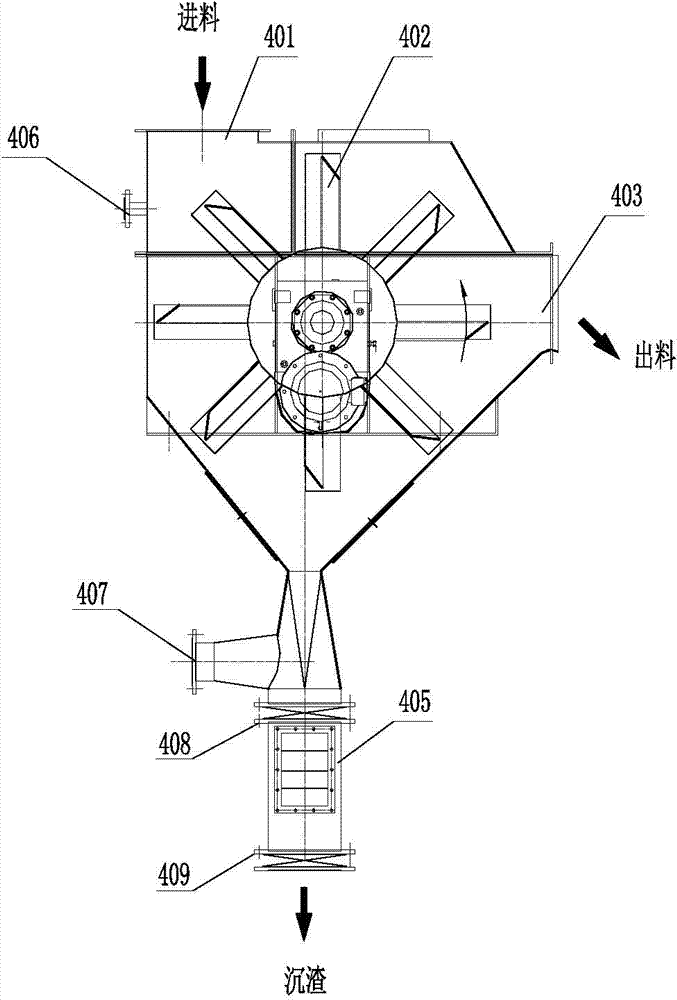

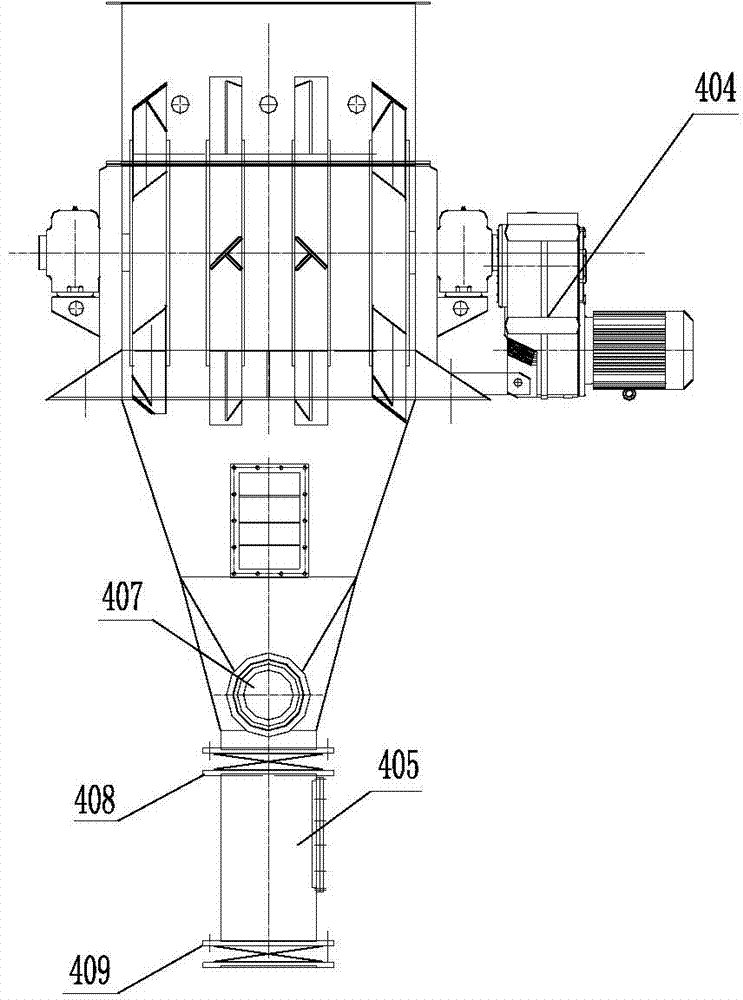

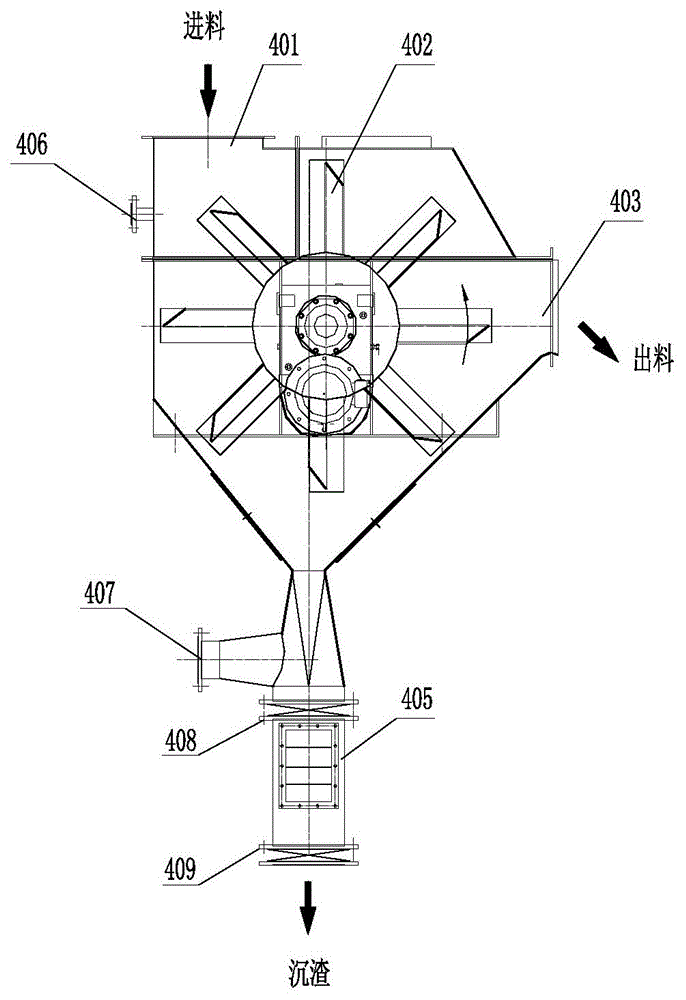

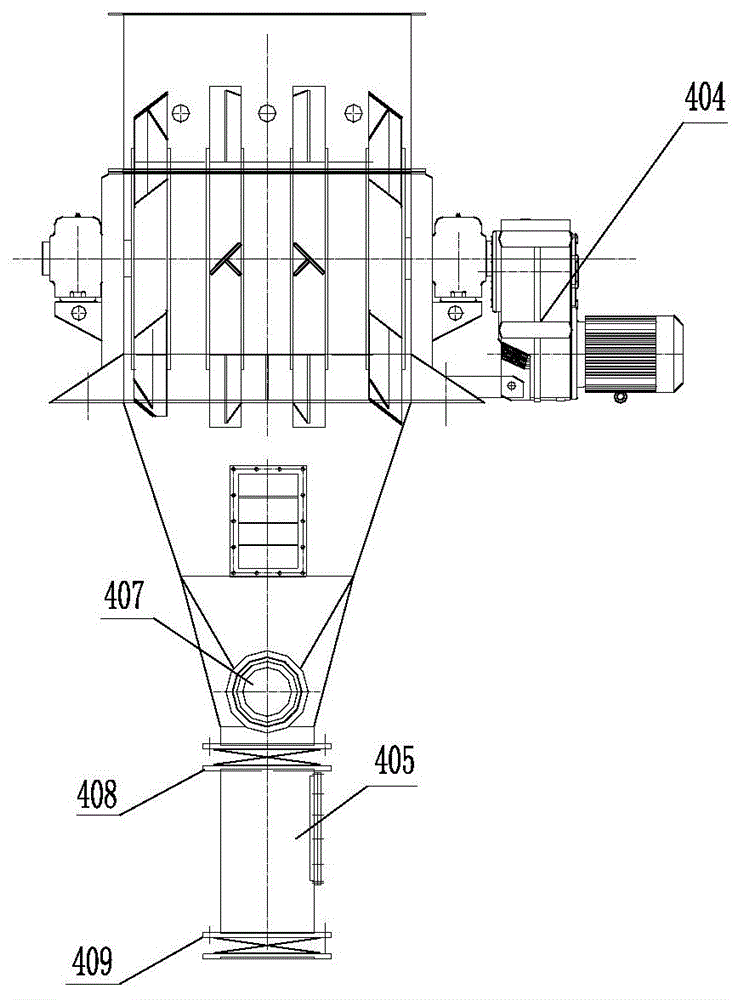

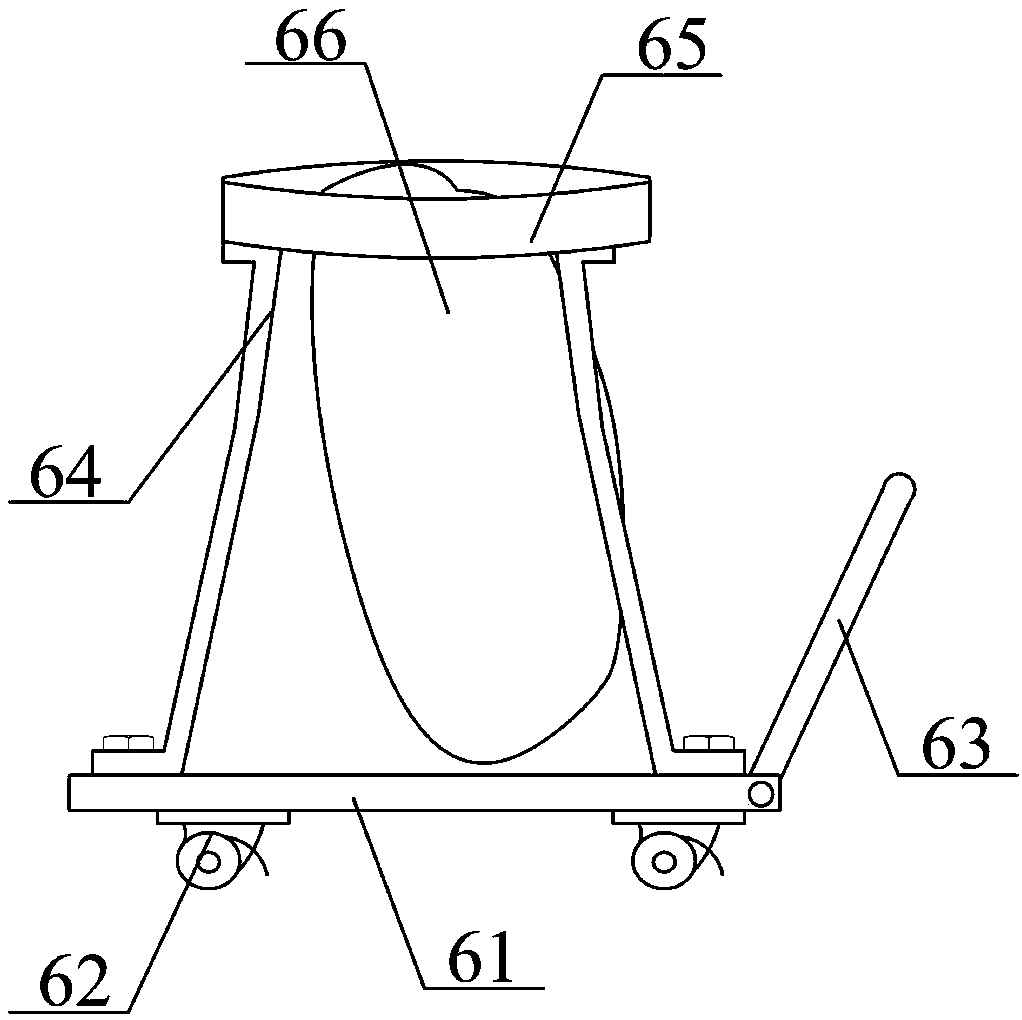

Hanging arm sludge mixing device

InactiveCN102284255AStir wellEasy to cleanRotary stirring mixersMixer accessoriesDrive wheelDrive shaft

The invention discloses a suspension arm type sludge stirring device, which comprises a stirring tank, guide rails are arranged on both sides of the top of the stirring tank, a driving wheel and a driven wheel are installed on the guide rail, the driven wheel is installed on a walking frame, and a driving shaft is passed between the driving wheels Connection, the drive shaft is connected with the travel motor through the travel transmission device, the hinge shaft is installed at the lower part of the travel frame, the two sides of the hinge shaft are hinged with the upper end of the cantilever, the stirring shaft is installed at the lower end of the cantilever, the stirring roller is installed on the stirring shaft, and the stirring teeth are set on the stirring roller , A stirring motor is installed on the cantilever, the stirring motor is connected to the stirring shaft through a stirring transmission device, a hoist is installed on the walking frame, and the hoist is connected to the cantilever through a noose. The present invention can adjust the position of the agitator according to the needs, carry out stratification and regional agitation of the sludge, does not need to be driven by a high-power motor, reduces energy consumption, and is beneficial to reduce the load of the motor, prevents the motor from burning out, and can agitate The sludge everywhere in the pool is evenly stirred, there is no mixing dead angle, and the sludge is easy to clean.

Owner:杨升华

Method for preparing anion template flocculant TPAS (Tissue Plasmogen Activator)

InactiveCN107759731ATargetedImprove chemical reaction efficiencyWater/sewage treatment by flocculation/precipitationChemistryPolypropylene

The invention discloses a method for preparing an anion template flocculant TPAS (Tissue Plasmogen Activator). The method comprises the following steps: with ultrasonic waves as an initialization mode, and by taking acrylamide and sodium p-styrenesulfonate as main raw materials, and polypropylene ammonium chloride PAAC (Polyallyl Acetate) as a template agent, preparing a water solution, adjustingthe pH value by using sodium hydroxide or hydrochloric acid, introducing a sufficient amount of nitrogen, initializing a polymerization reaction in an ultrasonic reactor, after the reaction is completed, performing aging treatment in a water bath pot, taking out a polymer obtained through synthesis, cleaning with alcohol, drying, and powdering, thereby obtaining the anion template flocculant TPAS.The method is simple in process procedure, short in reaction cycle, free of damage to instrument equipment, safe and environmental-friendly, free of toxic or side effect, low in cost, excellent in product property, and good in flocculation effect in treating hematite wastewater.

Owner:CHONGQING UNIV

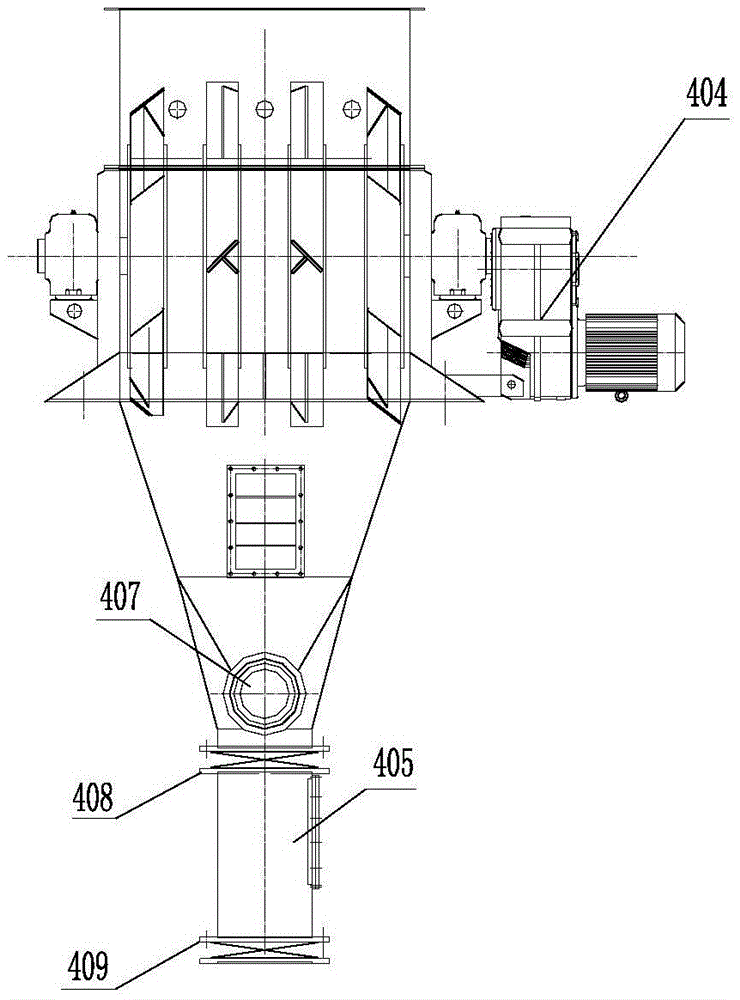

Production apparatus for aluminium oxide catalyst carrier

InactiveCN104338505AAchieve periodic swingImprove bindingCatalyst carriersCatalyst activation/preparationChemical reactionBinding force

A disclosed production apparatus for an aluminium oxide catalyst carrier comprises a kettle body, and the kettle body is provided with a motor, a decelerator, a feed pipe a , a safety valve, a feed pipe b, a stirrer, a discharge port, supporting legs, a heating pipe, a heating interlayer and a heat inlet pipe; and the production apparatus is characterized in that the kettle body is provided with a sampler, the sample is disposed on the kettle body, and a sealing cover is arranged between the sampler and the kettle body; the stirrer in the kettle body is provided with a kettle-bottom stirring paddle, the kettle-bottom stirring paddle is arranged at the lowest end of the stirrer, and a roller is arranged between the kettle-bottom stirring paddle and the kettle bottom. The technological effects comprise that 1, the pH value variation of a solution in the reaction kettle can be rapidly known through the sampler, and periodic swing of pH value can be realized by employing different feeding manners; 2, the stirrer is added with a transverse stirring shaft, the stirring manner is increased, the binding force of solution molecules is enhanced, and the chemical reaction efficiency is improved; and 3, reactants are layered and heavy substances sink because of different specific gravity of various molecules in the solution, but the kettle-bottom stirring paddle helps to reduce the phenomenon; and the reaction kettle is extremely convenient for control on the pore size of the catalyst carrier.

Owner:TIANJIN RUNWO WATER SUPPLY INSTALLATION ENG

Pulping system for recycling wet-strength recycled paper

ActiveCN105648817AReduce consumptionImprove chemical reaction efficiencyPaper recyclingWaste paper working-upChemical treatmentHigh concentration

The invention discloses a chemical mechanical pulping system for recycling wet-strength recycled paper. The system comprises first conveying equipment, a crusher, second conveying equipment, a drum washing machine, an oblique spiral dehydrator, a steaming bin, a third screw conveyer, a first double-screw impregnator, a first reaction bin, a fourth screw conveyer, a second double-screw impregnator, a second reaction bin, a fifth screw conveyor, a latency chest, a stock pump, a fiber separator, a purifying, screening and concentrating device and a pulp storage device in the running direction of the material procedure. The even feeding type reaction bins are utilized for achieving even feeding and reducing the load fluctuation range; the rotary stirring type steaming bin is utilized for eliminating a bridging phenomenon, materials are fully steamed and softened, and chemical consumption is reduced. The double-screw impregnators are utilized for gradually dissociating the wet-strength recycled paper, high-concentration mixing and homogenizing impregnation of a chemical additive and pulp are achieved, and the chemical reaction efficiency is improved. By means of the function of mechanical strong force and chemical treatment, the problems that during wet-strength recycled paper recycling, pulping and dissociating rate is low, and the strength is greatly reduced are solved.

Owner:JIANGSU JINWO MACHINERY

Chemical mechanical pulping method for recycling of wet strength waste paper

ActiveCN104099795AReduce consumptionImprove chemical reaction efficiencyPretreatment with water/steamPretreatment with alkaline reacting compoundsChemical treatmentProcess engineering

The invention discloses a chemical mechanical pulping method for recycling of wet strength waste paper. The method comprises a material preparation section, a steaming section, a first squeezing dipping chemical mechanical treatment section, a second squeezing dipping chemical mechanical treatment section, a latency and re-defibering section and a purification, screening and concentration section. According to the method, wet strength waste paper fiber dissociation and re-pulping are realized while the original pulp strength is not reduced under the action of mechanical strength and chemical treatment; furthermore, at the two squeezing dipping chemical mechanical treatment sections in series connection, a wet strength agent in the waste paper can be oxidized under the acidic condition firstly, and then hydrolysis is further promoted under the alkaline condition, so that the chemical bonding among molecules of the wet strength agent and between the wet strength agent and pulp fibers are destroyed more effectively, and the fiber dissociation rate and the re-pulping yield are effectively increased. The problems that the wet strength waste paper recycling, pulping and dissociation rate is low and the strength is substantially reduced are solved, and continuous, large-scale, low-water-consumption, low-energy-consumption, pollution-free and environment-friendly pulping can be realized.

Owner:JIANGSU JINWO MACHINERY

Preparing method of copper oxide/carbon nanofiber flexible compound coal gas desulfurizer

InactiveCN109999626AImprove adsorption capacityImprove responseDispersed particle separationPorosityCarbon nanofiber

The invention belongs to the technical field of preparation of coal chemical desulfurizer, and discloses a preparing method of a copper oxide / carbon nanofiber flexible compound coal gas desulfurizer.The preparing method comprises the following steps of dissolving polyacrylonitrile in a solvent N,N-dimethyl formamide (DMF), adopting cupric oxalate as an active component CuO precursor, and mixing cupric oxalate with the polymer solution; using an electrospinning technique to synthesize a cupric oxalate / polyacrylonitrile fiber compound material; finally conducting microwave high-temperature annealing on the compound material to obtain the copper oxide / carbon nanofiber flexible compound coal gas desulfurizer. The desulfurization material process route is simple, the preparing method is easy to implement, and the requirement of the desulfurizer for industrialization performance can be met; on the other hand, the polymer fibers with high flexibility and porosity are adopted to serve as carriers to construct a multi-stage microscopic pore structure of the desulfurizer, and thus the adsorption capability and desulfurization activity of the desulfurizer can be improved.

Owner:TAIYUAN UNIV OF TECH

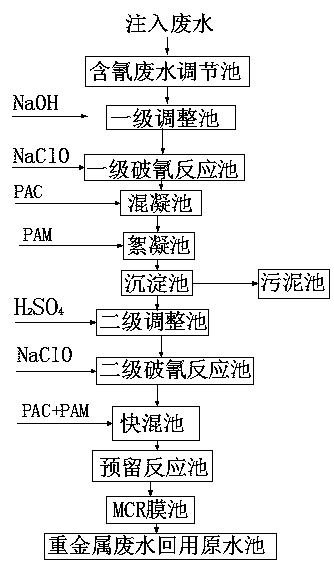

Electric plating cyanide-containing waste water treatment method

InactiveCN108751492AImprove the efficiency of cyanide treatmentEasy to control pHWater contaminantsWaste water treatment from metallurgical processLiquid wasteChemical reaction

The invention discloses an electric plating cyanide-containing waste water treatment method, which comprises the following steps of S1, cyanide-containing waste water regulation; S2, primary regulation; S3, primary cyanide breaking; S4, waste liquid coagulation; S5, waste liquid flocculation; S6, waste liquid precipitation; S7, secondary regulation; S8, secondary cyanide breaking reaction; S9, waste liquid fast mixing; S10, waste liquid reserved reaction; S11, MCR membrane pool reaction; S12, heavy metal waste water reuse in a raw water pool. A primary cyanide breaking reaction pool is used for performing pretreatment on the waste liquid; a secondary cyanide breaking reaction pool is used for performing secondary cyanide breaking treatment on saturated and untreated substances in the wastewater; the waste water cyanide breaking treatment efficiency is improved; an MCR membrane is a membrane reactor and is used for improving the chemical reaction efficiency in the process; meanwhile, the treated waste water can be cyclically utilized; the water resource pollution is further reduced; the goals of energy saving, emission reduction and consumption reduction are realized; the life environment of residents around a factory can be ensured.

Owner:ANHUI DEQI ENVIRONMENTAL PROTECTION TECH CO LTD

Wet-strength wastepaper recycling double-pH-value chemical and mechanical pulping method

ActiveCN105568726AReduce consumptionImprove chemical reaction efficiencyPretreatment with water/steamPretreatment with alkaline reacting compoundsChemical treatmentFiber

The invention discloses a wet-strength wastepaper recycling double-pH-value chemical and mechanical pulping method. The method includes a material preparation section, a steaming section, a first extrusion and impregnation chemical and mechanical treatment section, a second extrusion and impregnation chemical and mechanical treatment section, a latency and re-defibering section and a purification, screening and concentration section. Wet-strength wastepaper fiber dissociation re-pulping is achieved while original pulp strength is not reduced through the mechanical strong force effect and the chemical treatment effect. Furthermore, on the two extrusion and impregnation chemical and mechanical treatment sections connected in series, a wet strength agent in wastepaper is oxidized under the acid condition firstly, hydrolysis is further promoted under the alkaline condition, chemical bonding between molecules of the wet strength agent and between the wet strength agent and pulp fibers is more effectively damaged, and the fiber dissociation rate and the re-pulping yield are effectively increased. The problems that the wet-strength wastepaper recycling pulping dissociation rate is low and strength is greatly decreased are solved, and continuous, large-scale, low-water-consumption and low-energy-consumption pollution-free and environment-friendly pulping can be achieved.

Owner:JIANGSU JINWO MACHINERY

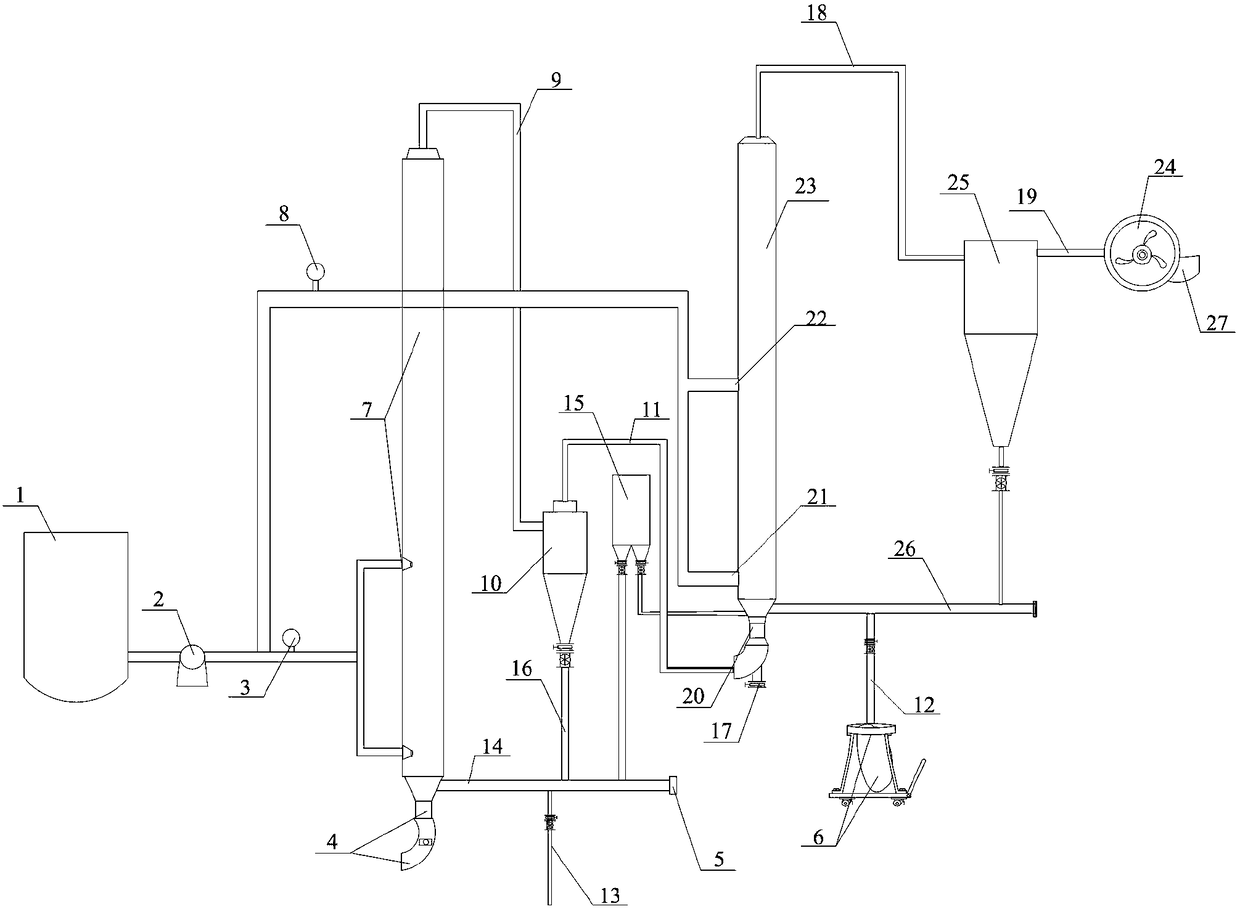

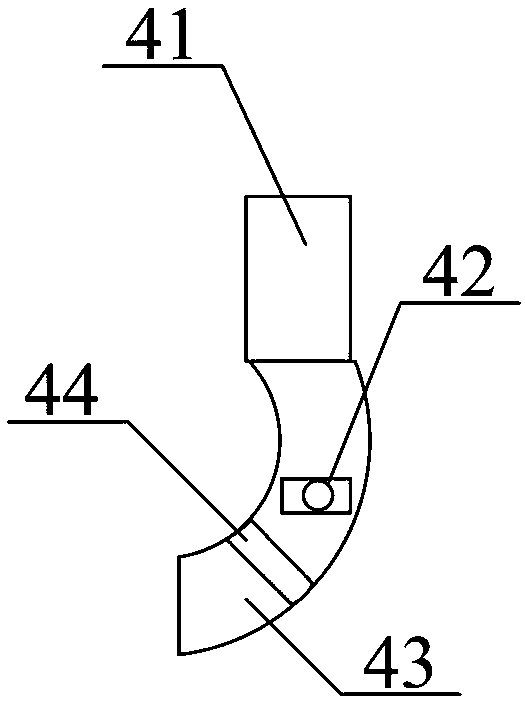

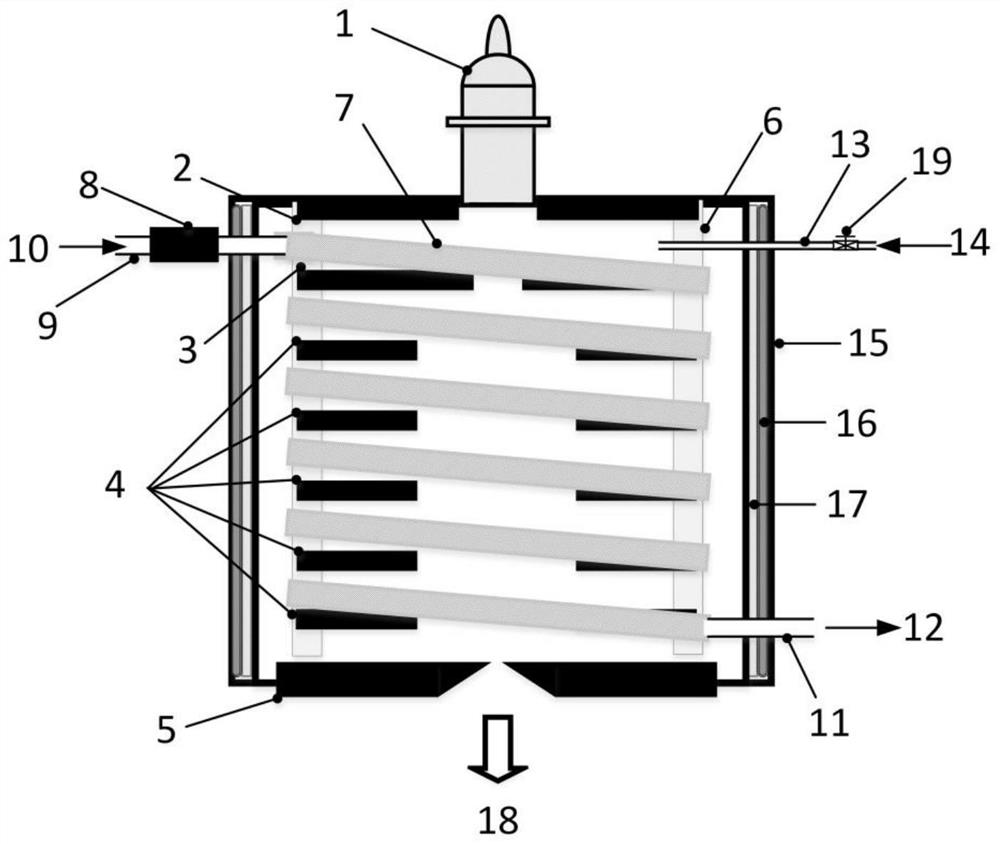

Kiln gas semi-dry process defluorination desulphurization dedusting equipment

ActiveCN108371880AImprove the effect of desulfurization and defluorinationShorten drying timeCombination devicesGas treatmentFlue gasTower

The invention provides kiln gas semi-dry process defluorination desulphurization dedusting equipment. The kiln gas semi-dry process defluorination desulphurization dedusting equipment comprises a technology water tank, a technology water pump, a first stage technology water flowmeter, a defluorination tower Venturi segment structure, a leakproof cap, a waste dust packaged conveying vehicle structure, a defluorination tower structure, a second stage technology water flowmeter, a defluorination tower outlet flue, a cyclone separator, a cyclone separator outlet flue, a discharge pipe, a first stage smoke discharge pipe, a defluorination tower material return inclined groove, a lime powder cabin structure, a first stage connecting pipe, a hand-operated valve, a desulphurization outlet flue, asmoke outlet pipe, a desulphurization Venturi segment, a desulphurization lower layer nozzle, a desulphurization upper layer nozzle, a desulphurization tower, a flue gas induced draught fan, a cloth bag dedusting cylinder structure, a desulphurization material return inclined groove, and a second stage smoke discharge pipe. According to the kiln gas semi-dry process defluorination desulphurizationdedusting equipment, the defluorination tower and the desulphurization tower are adopted, it is beneficial for defluorination and then desulphurization, interaction of defluorination and desulphurization is avoided, defluorination and desulphurization effect is improved; the mechanical valve, a flue gas inlet pipe, and a filter screen are adopted, so that it is beneficial for control of smoke introduction speed.

Owner:济南国器工程技术有限公司

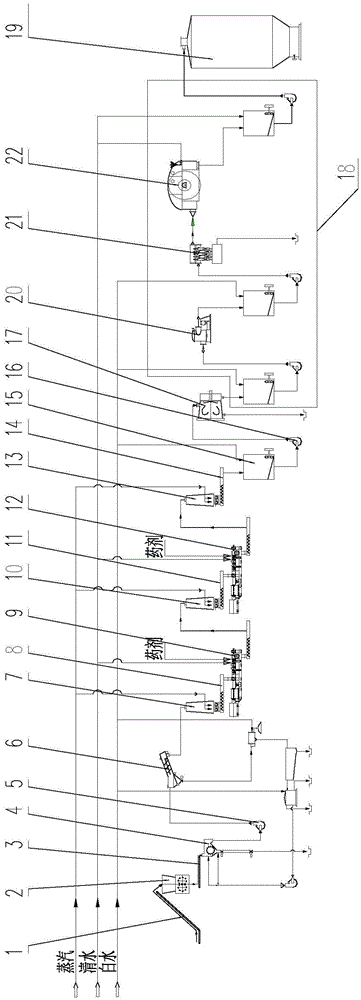

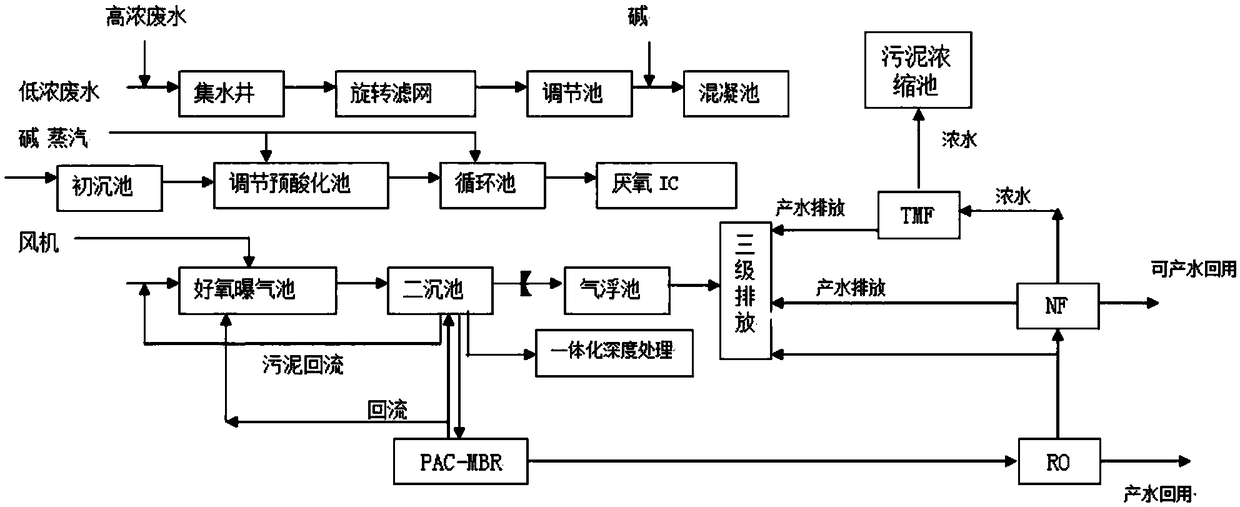

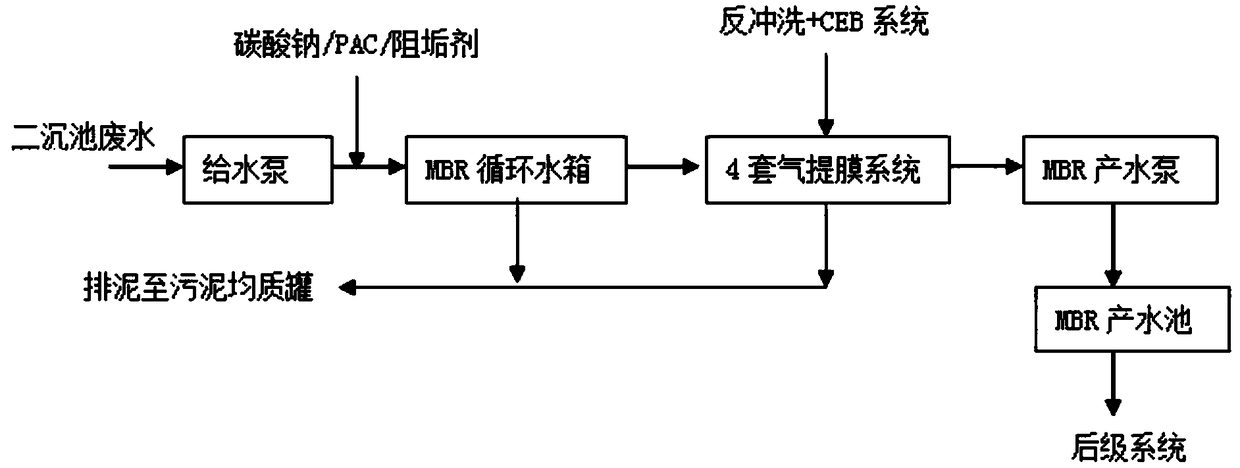

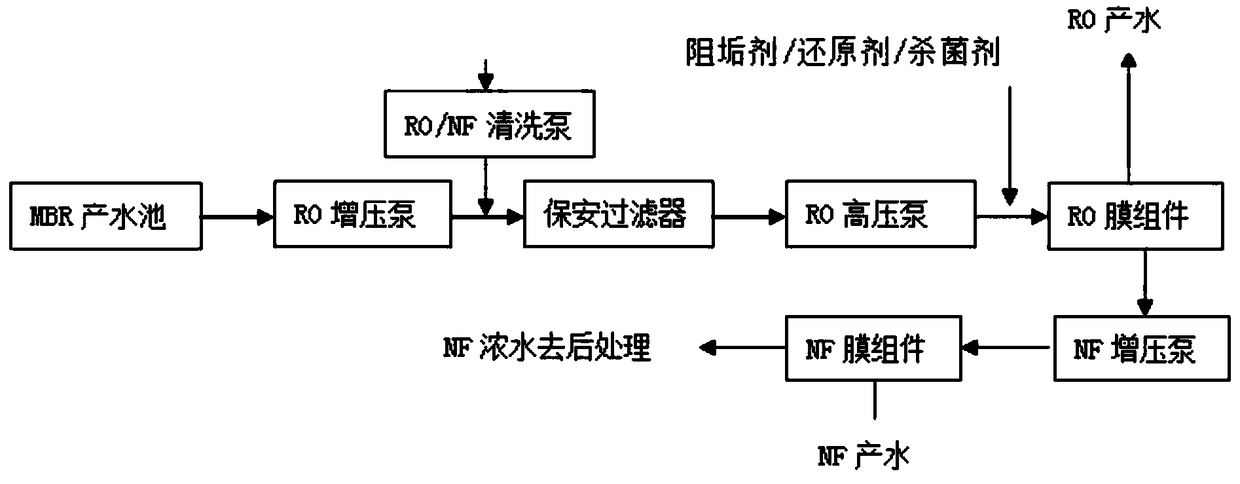

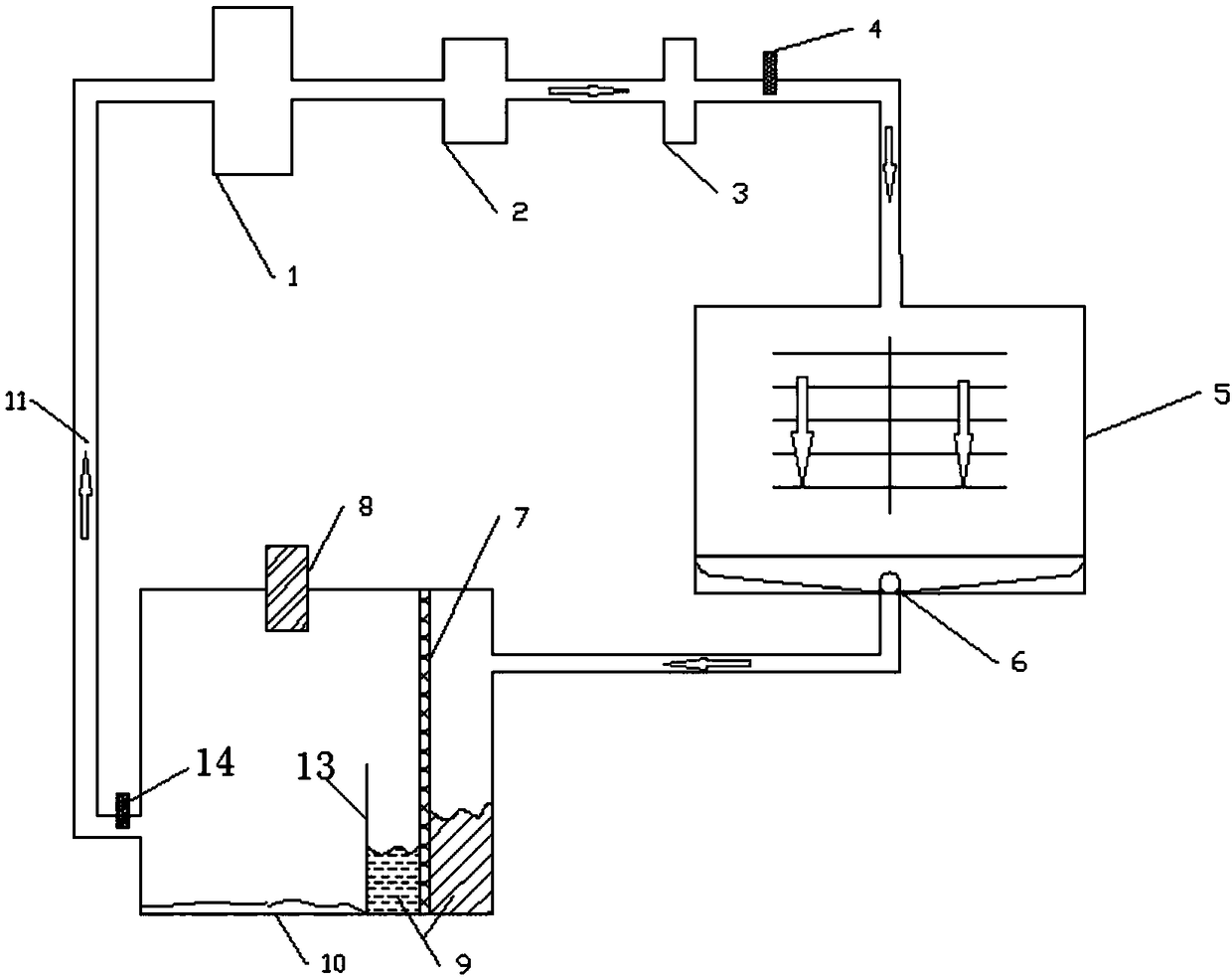

Reclaimed water recycling device of reconstituted tobacco wastewater and technology thereof

PendingCN108821520AIncrease concentrationGood removal effectSludge treatment by de-watering/drying/thickeningWater treatment parameter controlChemical reactorReverse osmosis

The invention relates to a reclaimed water recycling device of reconstituted tobacco wastewater and a technology thereof. The device is characterized by comprising a biochemical treatment system and an advanced treatment system. The biochemical treatment system comprises a water collecting well, a rotary filter screen, an adjusting tank, a coagulating basin, a primary sedimentation tank, a regulating pre-acidification tank, a circulating pool, an anaerobic pond, an aerobic tank and a secondary sedimentation tank. The advanced treatment system comprises a membrane bioreactor (MBR), a reverse osmosis system (RO), a nanofiltration system (NF) and a membrane chemical reactor (TMR). An effluent from the secondary sedimentation tank of the biochemical treatment system firstly passes through themembrane bioreactor for mud-water separation, and then produced water enters the reverse osmosis system to be treated for recycling. Concentrated water enters the nanofiltration system to be treated,and the produced water is directly discharged. A polymeric flocculant is added into the concentrated water and the concentrated water passes through the membrane chemical reactor, COD is greatly reduced; and then the concentrated water is uniformly mixed with the produced water from the nanofiltration system, thus achieving up-to-standard discharge. When the concentrated water in the membrane chemical reactor reaches a certain solid content, the concentrated water is intermittently discharged into a sludge thickener.

Owner:杭州利群环保纸业有限公司

Etching clamping device for promoting metal etching and separating invalid particles

ActiveCN112616260AGood etching effectHigh ion purityRotary stirring mixersTransportation and packagingEngineeringStructural engineering

The invention relates to the technical field of computer software and hardware, and discloses an etching clamping device for promoting metal etching and separating invalid particles. The etching clamping device comprises a transmission shaft, the surface of the transmission shaft is fixedly connected with a mounting frame, the interior of the mounting frame is slidably connected with a sliding rod, and the end part of the sliding rod is fixedly connected with a metal contact; and the side face of the metal contact is slidably connected with a resistor strip, an electromagnetic rod is fixedly connected to the interior of the mounting frame, and rotating shafts are fixedly connected to the periphery of the mounting frame. When the mounting frame rotates, the stirring rod performs conical stirring, so that the centrifugal force of an upper-end solution is large, the centrifugal force of a lower-end solution is small, metal ions can be accumulated in the center of the lower end, light impurities can float on the periphery of the upper end of the solution, and when the mounting frame does not rotate, the stirring rod can return to the original shape; therefore, the effects that invalid particles can be separated and the purity of ions participating in the reaction is relatively high are achieved.

Owner:湖北中培电子科技有限公司

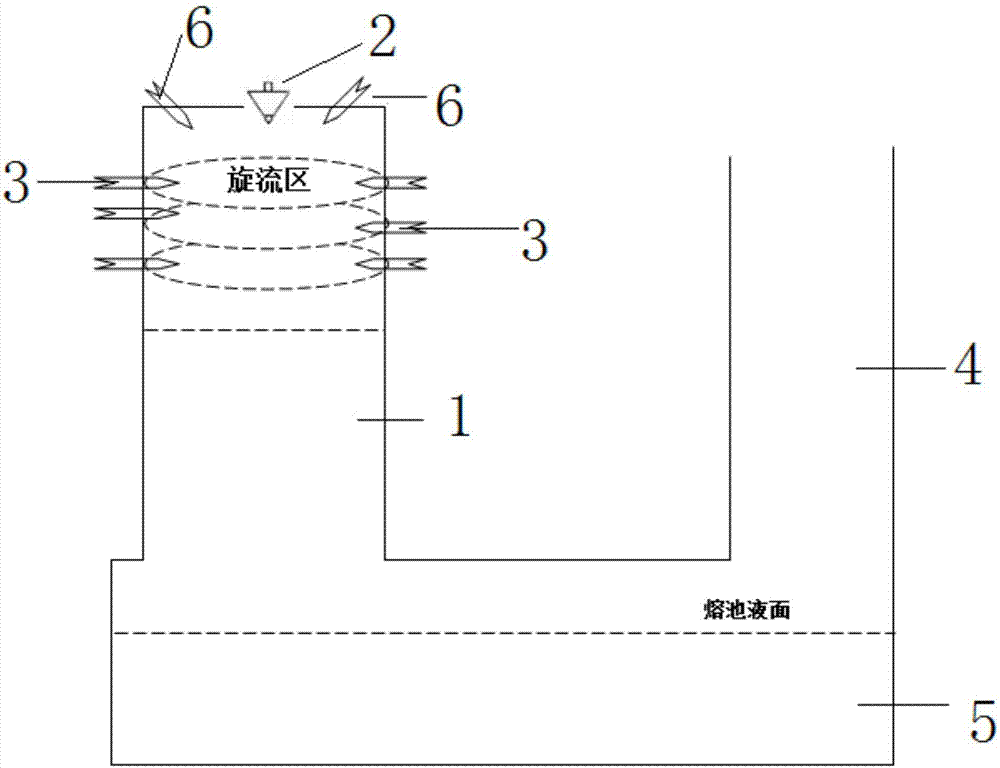

A swirl flash smelting process

Owner:TIANJIN FLASH IRONMAKING TECH CO LTD

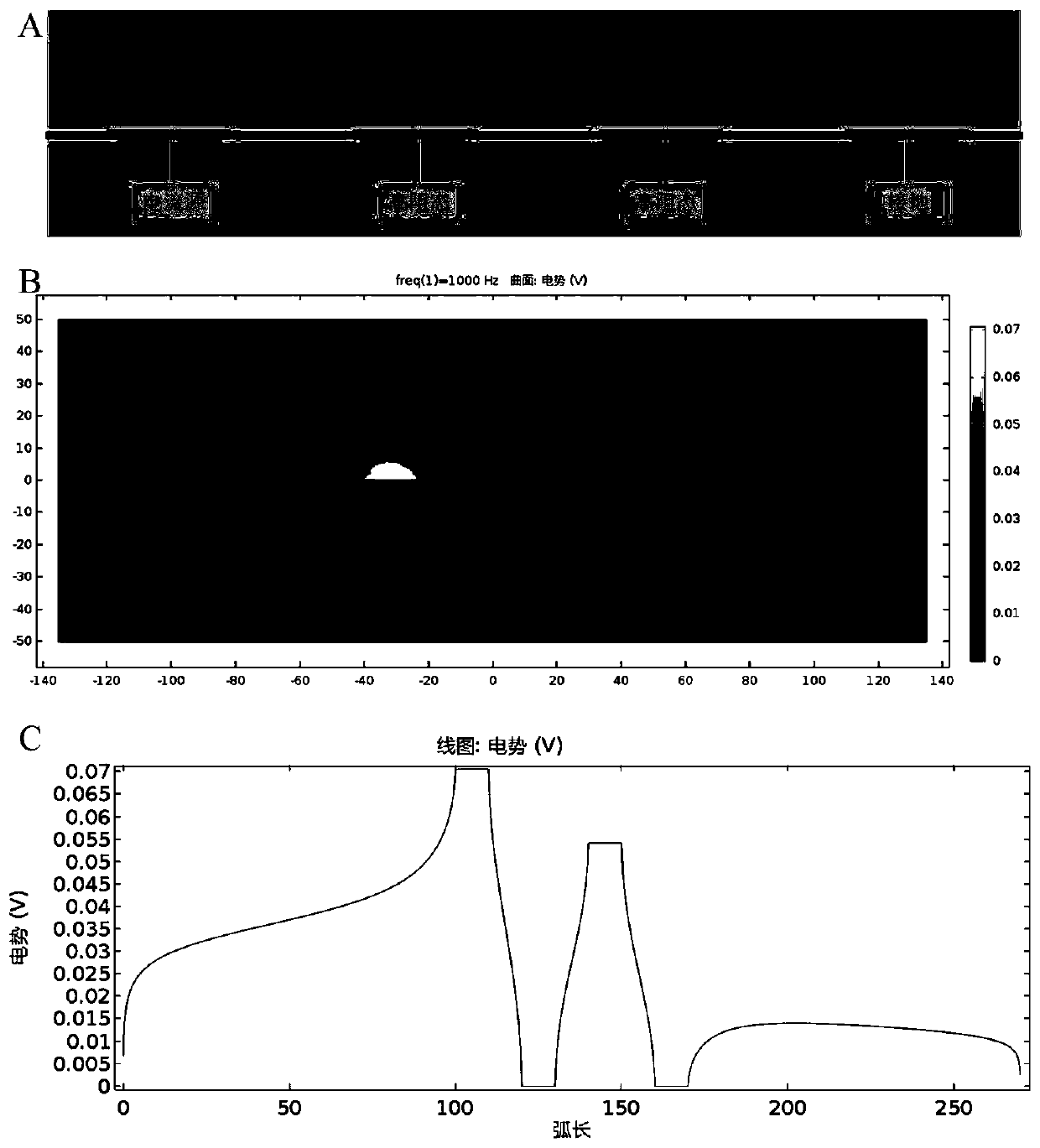

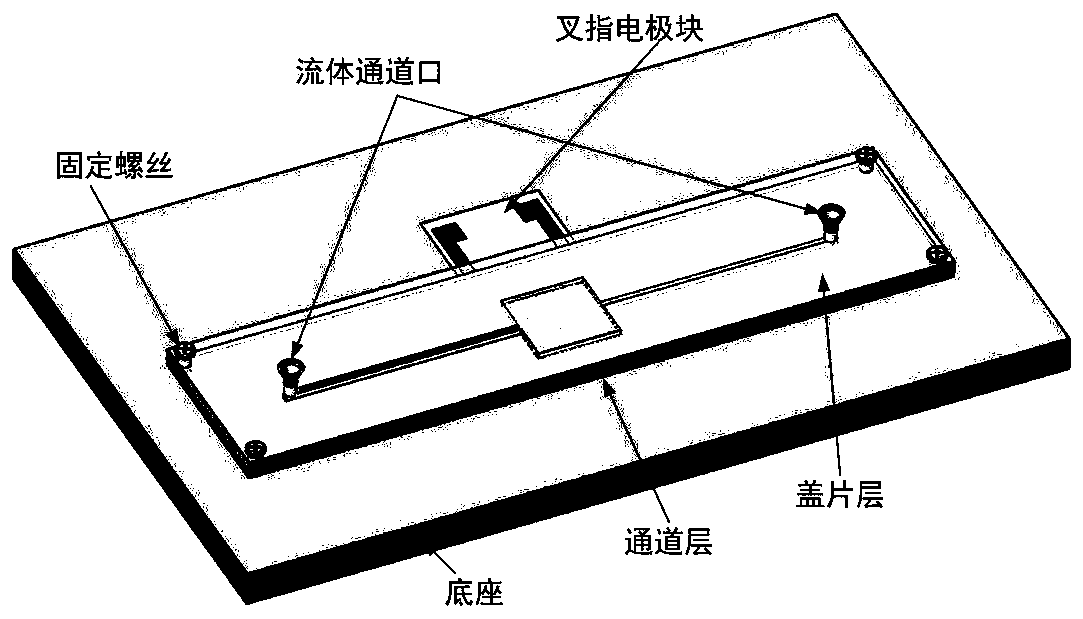

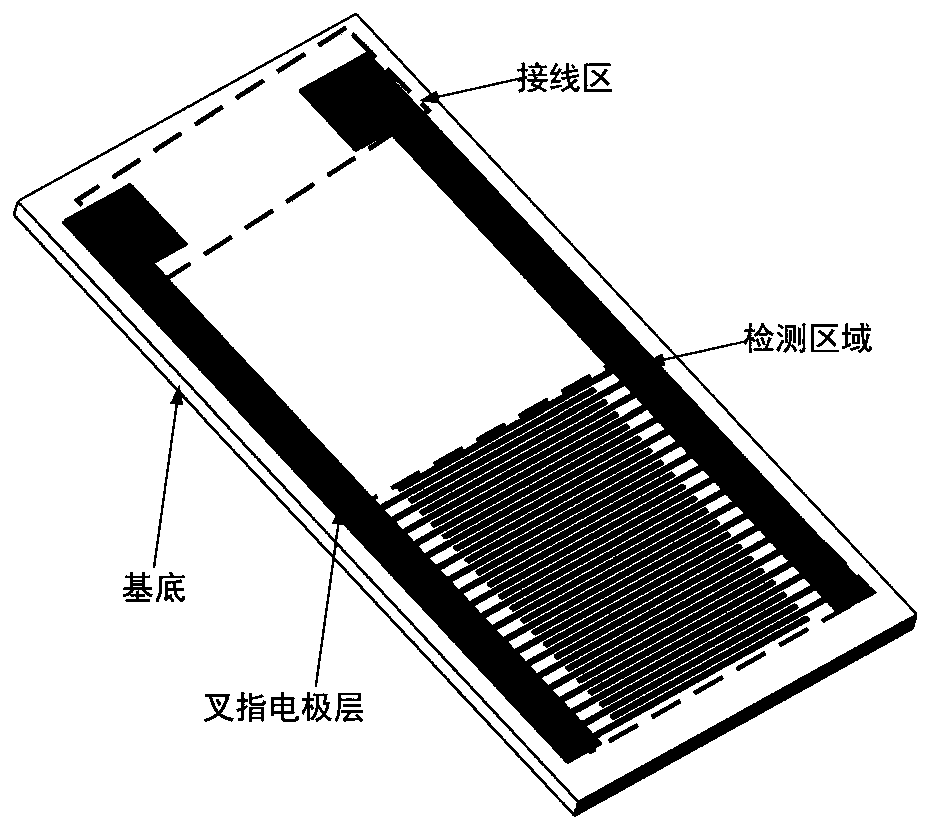

Interdigital electrode chip

InactiveCN110632138ARealize online detectionEasy to detectChemical/physical/physico-chemical microreactorsMaterial electrochemical variablesEngineeringCover glass

The invention discloses an interdigital electrode chip. The interdigital electrode chip comprises a base, an interdigital electrode block, a channel layer and a cover glass layer; an interdigital electrode block placing groove is formed in the base, and the interdigital electrode block is matched with the interdigital electrode block placing groove in shape; after the interdigital electrode blockis put into the interdigital electrode block placing groove, the upper surface of the interdigital electrode block is flushed with the upper surface of the base; the interdigital electrode block comprises a substrate and an interdigital electrode layer arranged on the substrate; and the interdigital electrode layer comprises a first electrode and a second electrode. The interdigital electrode chipdisclosed by the invention has the beneficial effects that the interdigital electrode chip is used for realizing online detection on reactants in a flow chemical microchannel reaction and can be accessed to any position of a reaction channel and detection and monitoring on dynamic changing processes of reactant concentrations and reactive states of multiple regions in a reaction process are realized.

Owner:JIANGNAN UNIV

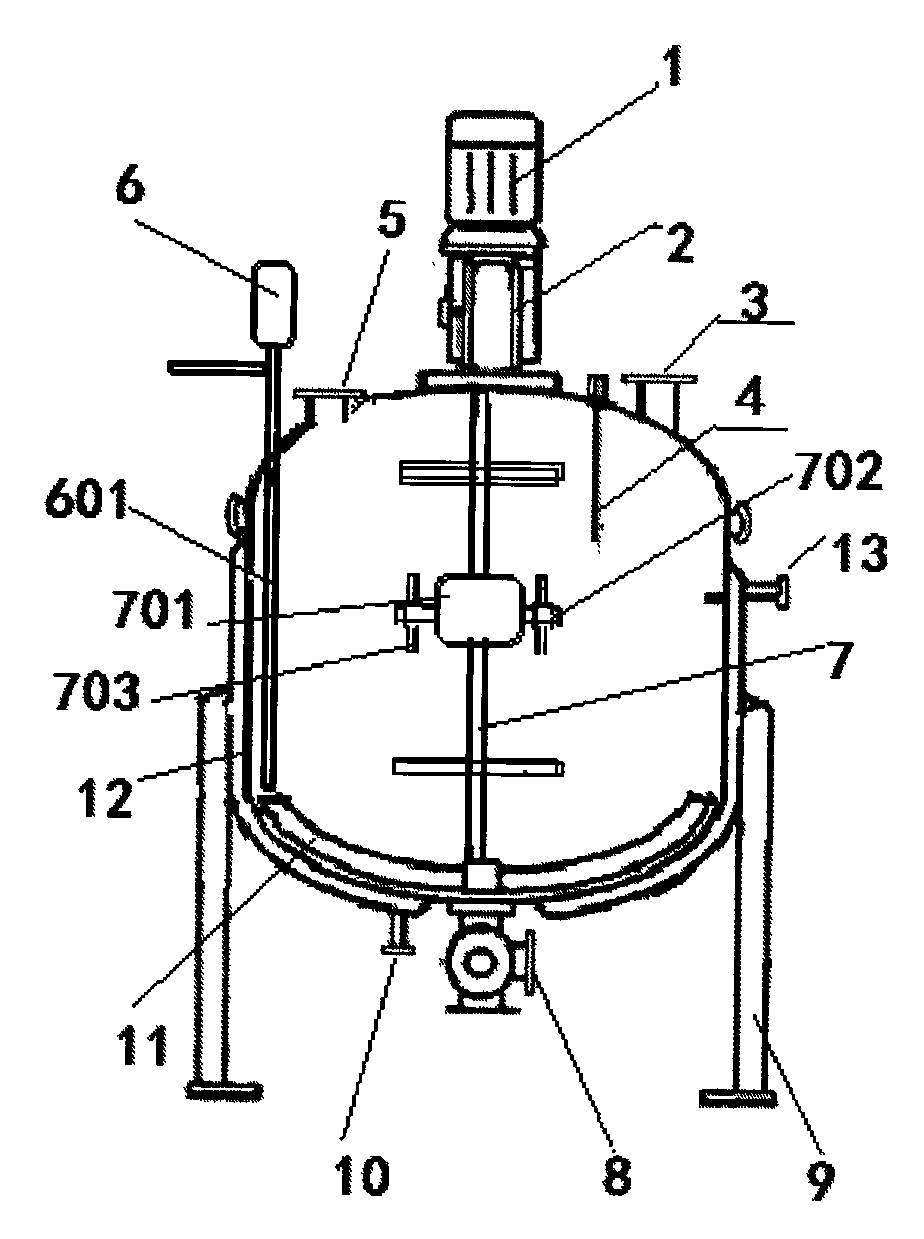

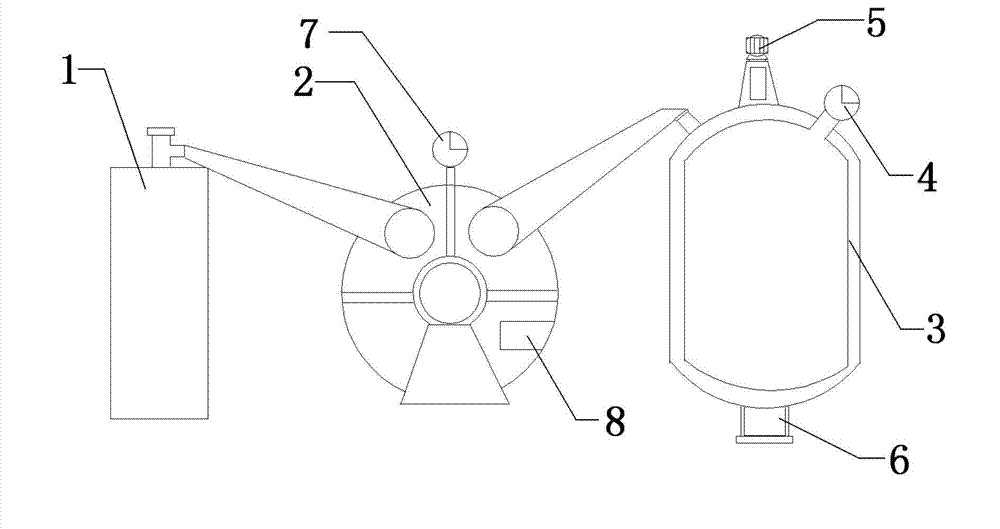

Pressurization reaction kettle

InactiveCN103706298AMonitor differential pressureEnsure safetyPressure vessels for chemical processChemical reactionNitrogen

A pressurization reaction kettle comprises a nitrogen bottle, a pressurization gas pump and a reaction kettle body, the edge of the top of the reaction kettle body is provided with an opening communicated with a port at one side of the pressurization gas pump, and a port at the other side of the pressurization gas pump is communicated with the nitrogen bottle; the edge of the top of the reaction kettle body is provided with a feeding port, and the edge of the bottom of the reaction kettle body is provided with a discharging port; the edge of the top of the reaction kettle is provided with a first pressure gauge; the top of the pressurization gas pump is provided with a second pressure gauge; and the side surface of the pressurization gas pump is provided with a monitoring device. The pressurization reaction kettle can increase the chemical reaction efficiency by increasing the reaction pressure, can effectively monitor a pressure difference between the reaction kettle body and the pressurization gas pump, can timely sound a warning when abnormity appears, improves the work efficiency, and guarantees the safety of a worker.

Owner:天津百科生物化学有限公司

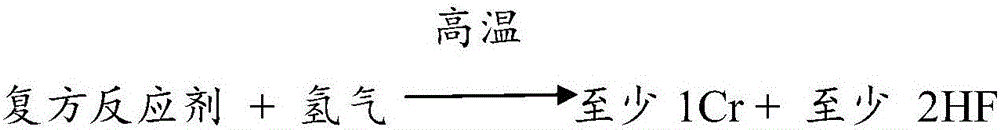

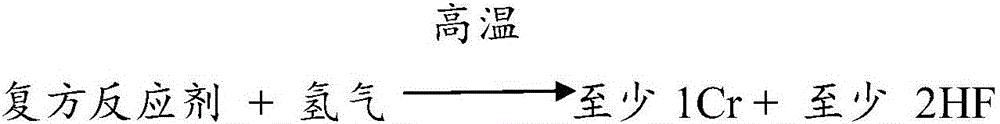

Novel indirect-type high-temperature hydrogen fluoride ionized gas cleaning reactant, technology and device

The invention provides a novel indirect-type high-temperature hydrogen fluoride ionized gas cleaning reactant. A compound dominated by solid-state CrF2, metal Cr and solid-state ammonium bifluoride form the compound reactant according to the mass ratio of (3.0-20.0):(80.0-97.0):(0.3-3.0). The invention further provides a cleaning device and technology. The cleaning reactant, device and technology are innovated, the compound dominated by the solid-state metal fluoride CrF2, the metal Cr and the solid-state ammonium bifluoride are adopted to form the compound reactant, the reactant is reacted with hydrogen in a sealed high-temperature reactor to form hydrogen fluoride gas, oxide on the part surfaces is removed through the produced hydrogen fluoride gas, reaction gas leakage can be prevented, the purposes of efficient hydrogen fluoride ionized gas cleaning and subsequent high-temperature vacuum removal of remaining fluoride on the workpiece surfaces can be achieved at the same time by operating gas pressure change in the reactor, using safety is guaranteed, and a good working environment is created.

Owner:力航

Graphene catalytic plate capable of efficiently purifying automobile exhaust and preparation method

InactiveCN107737526AIncrease surface areaImprove chemical reaction efficiencyGas treatmentDispersed particle separationCvd grapheneOxide

The invention belongs to the technical field of automobile exhaust treatment, and particularly relates to a graphene catalytic plate capable of efficiently purifying automobile exhaust and a preparation method. Metal oxide and graphene are prepared into slurry, the slurry is then foamed and shaped into the shape of a plate, forming fine holes, a metal catalyst is sprayed on the surface after sintering, and a heating wire is arranged on the plate. The outstanding advantages are as follows: by connecting the heating wire, graphite heats, the graphite particles, serving as a heating source, are catalyzed by the metal oxide in situ to rapidly promote nitrogen oxide, ammonia and the like to be reduced into nitrogen and water, and thereby the efficiency of automobile exhaust treatment is increased.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Wet-strength waste paper recycling chemi-mechanical pulping system

ActiveCN105544264AReduce consumptionImprove chemical reaction efficiencyPaper recyclingWaste paper working-upChemical treatmentHigh concentration

Owner:JIANGSU JINWO MACHINERY

Device for fast clearing scale of smoke cooker

The invention discloses a device for fast clearing scale of a smoke cooker. The device for fast clearing the scale of the smoke cooker solves the problems that a smoke cooler in the prior art is not through in clearing and is frequently washed, and has the beneficial effects of solving the problem that water resource waste is caused by frequency washing, and consequently the construction progressis affected, improving the washing efficiency and shortening the clearing time. According to the scheme of the device for fast clearing the scale of the smoke cooker, the device for fast clearing thescale of the smoke cooker comprises a chemical agent device which is connected with the inlet end of the smoke cooler sequentially through a circulating water pump and a heater; the outlet end of thesmoke cooler is connected with a precipitation pond through a pipeline; and the precipitation pond is connected with the chemical agent device through a circulating pipeline.

Owner:POWERCHINA SEPCO1 ELECTRIC POWER CONSTR CO LTD

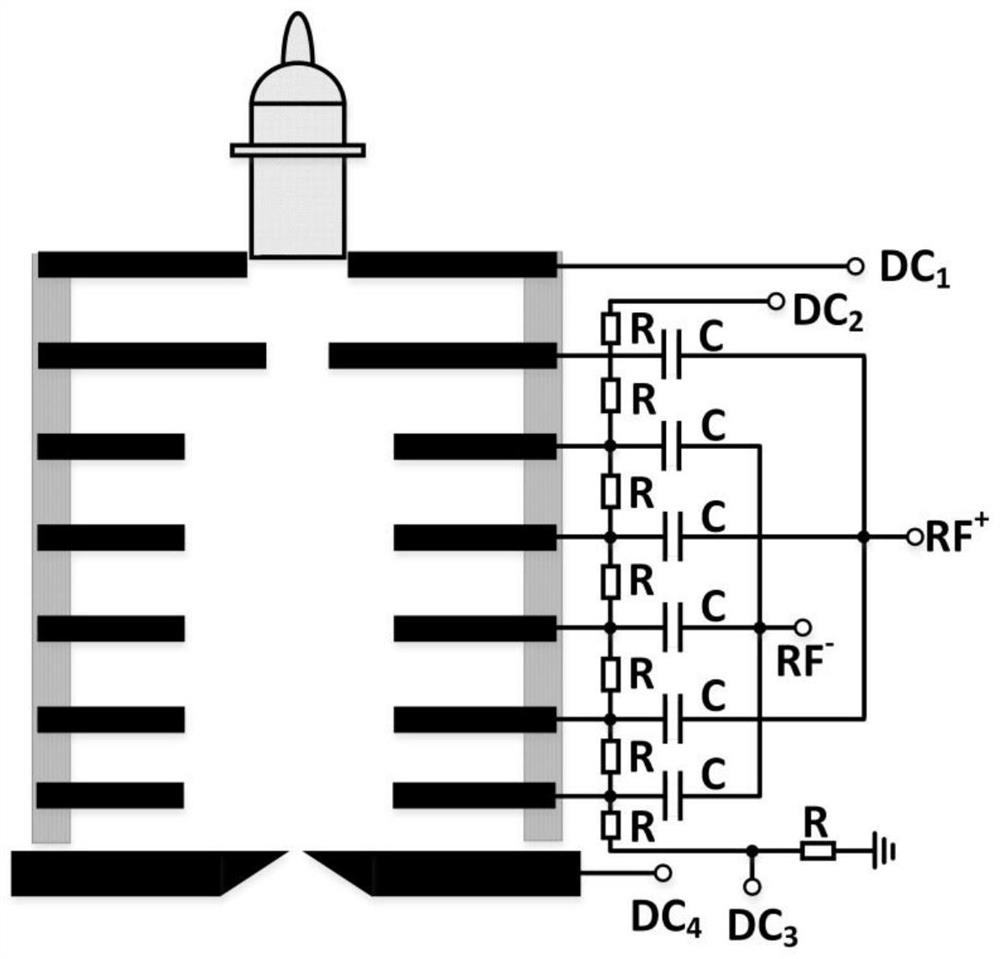

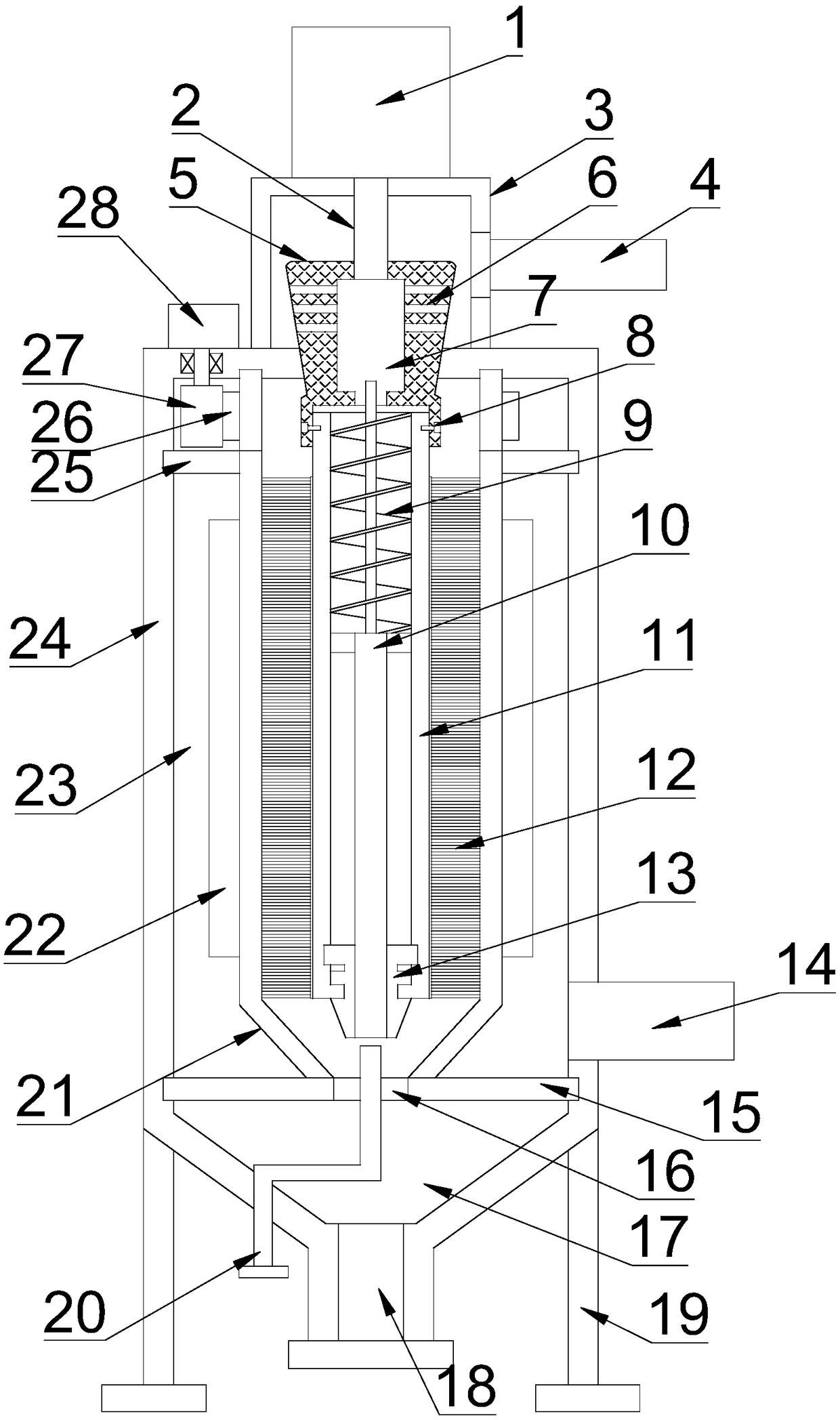

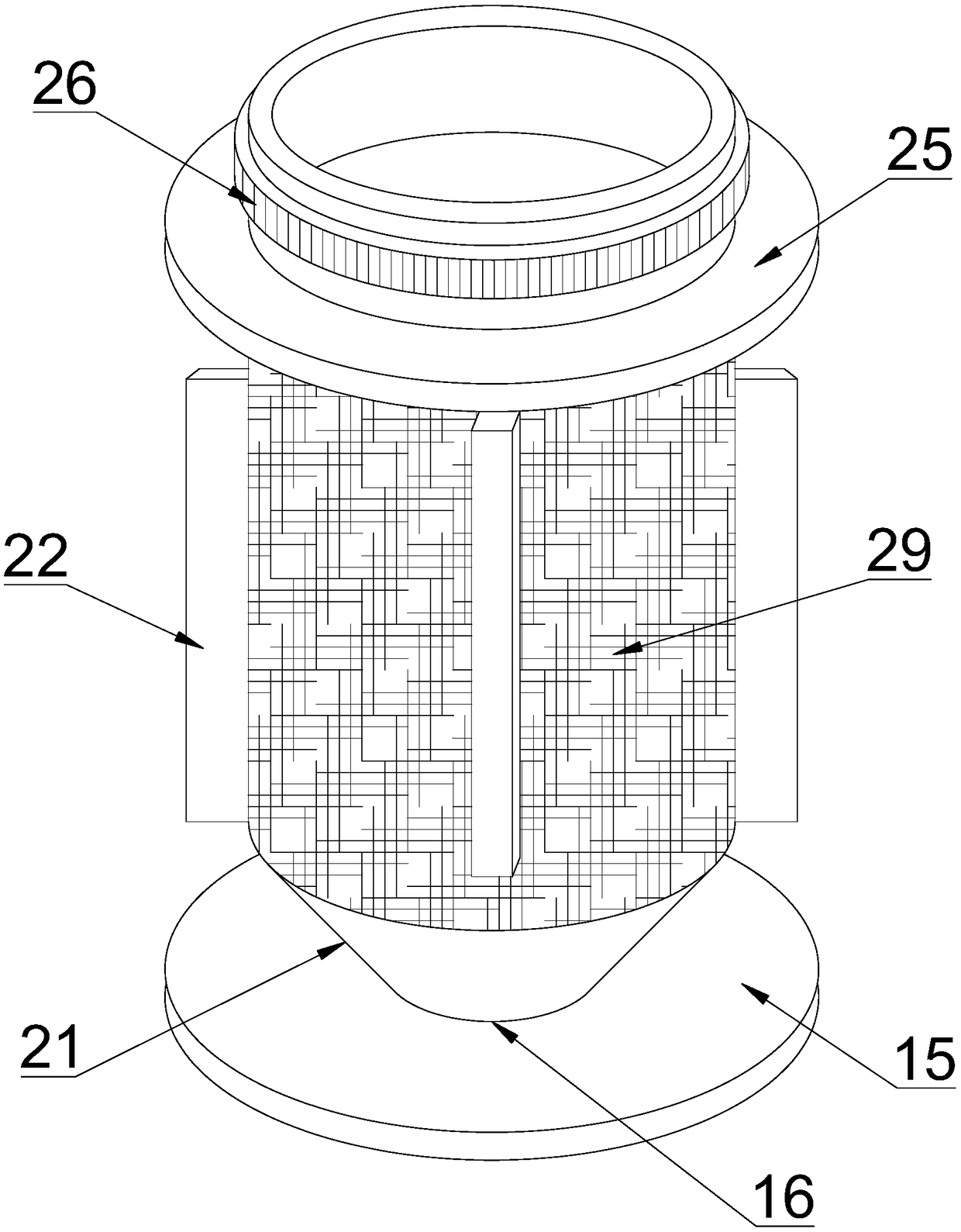

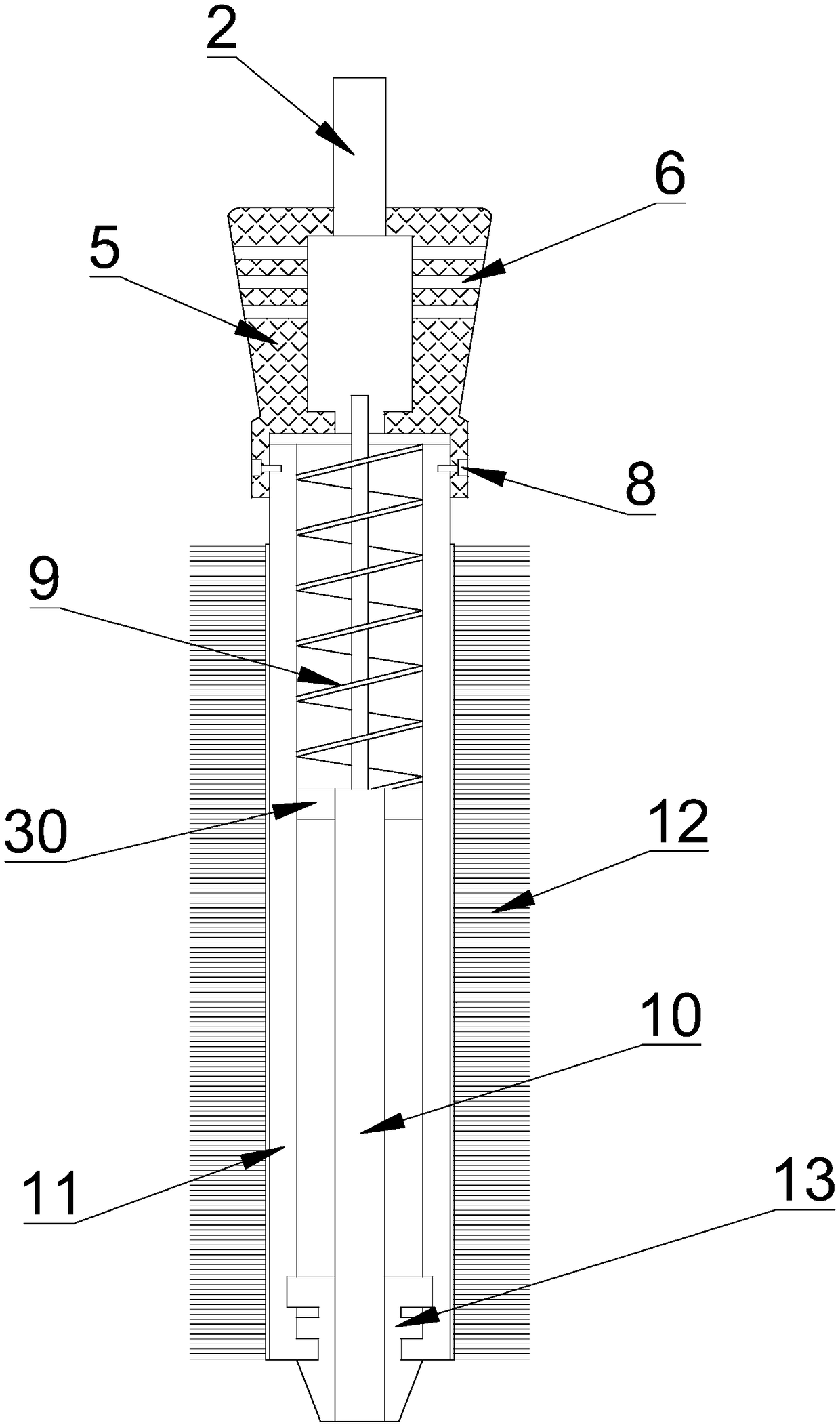

In-source membrane sample introduction radio frequency enhanced chemical ionization source

ActiveCN112908829AIncreased internal surface areaAccelerated precipitationSamples introduction/extractionIon sources/gunsChemical ionizationSilica gel

The invention relates to a mass spectrometry instrument, in particular to an in-source membrane sample introduction radio frequency enhanced chemical ionization source. The chemical ionization source specifically structurally comprises an ionization source cavity, a vacuum ultraviolet lamp, a gas sample introduction tube, a tubular membrane, a silica gel electric heating tape, a liquid sample introduction tube, a repulsion electrode, a radio frequency electrode and a differential electrode. The ionization source can work in three modes: a single photon ionization mode, a chemical ionization mode and a radio frequency enhancement mode. High-sensitivity analysis of the volatile organic compounds in the water is achieved through ionization in the ionization source, and the permeability of the volatile organic compounds in the water passing through the tubular membrane is improved through heating of the liquid sample feeding pipe and the ionization source. Reagent gas can be introduced in a chemical ionization mode, ionization is carried out firstly under ultraviolet irradiation, sample molecules permeating out of the membrane and reagent ions are subjected to charge transfer or proton transfer reaction, and the ionization efficiency is greatly improved. The introduction of the radio frequency electric field can improve the collision frequency of ion molecules and improve the yield of the ion molecule reaction, thereby improving the sensitivity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Chemical mixed reaction vessel for separating turbulent flow

InactiveCN109046205AEasy to addImprove cleaning efficiencyHollow article cleaningChemical/physical/physico-chemical stationary reactorsChemical reactionEngineering

The invention discloses a chemical mixed reaction vessel for separating a turbulent flow. The reaction vessel comprises a flow guiding cylinder, a cleaning brush, a rotating cylinder and a reaction tank, wherein the reaction tank is installed on a support, the rotating cylinder is installed inside the reaction tank, a lower division plate is welded at the bottom end of the rotating cylinder, an upper division plate is welded on an outer wall of the upper part of the rotating cylinder, a segment between the upper division plate and lower division plate of the rotating cylinder is provided witha filter screen cylinder, a side wall of the filter screen cylinder is provided with a plurality of filter holes, a bottom side of the reaction tank is connected with a liquid discharge pipe, which iscommunicated with a solution cavity, a gear ring is welded on an outer wall of the rotating cylinder at the upper part of the upper division plate, and a side face of the gear ring is meshed with a gear; the cleaning brush is arranged inside the rotating cylinder. The reaction vessel disclosed by the invention has a firm structure, is convenient for operation, addition of feed liquid and an adjuvant, full reaction of a solution and separation of residues, improves the cleaning efficiency of the cleaning brush to an inner wall of the rotating cylinder, avoids blocking the filter screen cylinder, and is conducive to fully mixing the solution and improving the chemical reaction efficiency as well.

Owner:杨康峰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com