Method for preparing N-ethyl-N-hydroxyethylaniline

A technology of hydroxyethylaniline and ethylaniline, which is applied in the field of chemical synthesis, can solve the problems of large environmental pollution and many by-products, and achieve the effects of high chemical reaction efficiency, high utilization rate and good catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

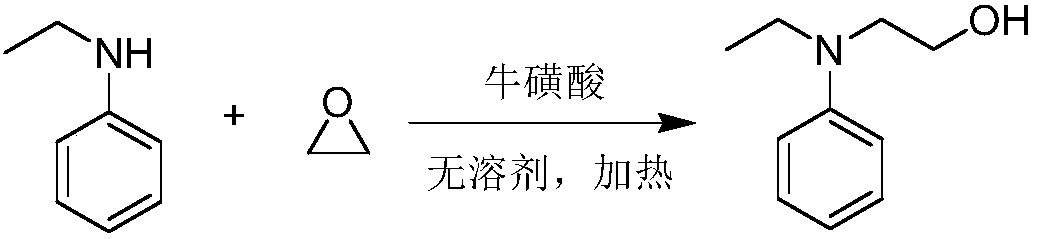

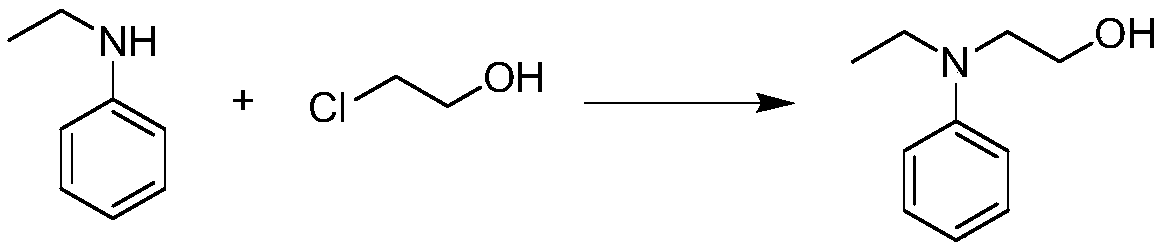

Method used

Image

Examples

Embodiment 1

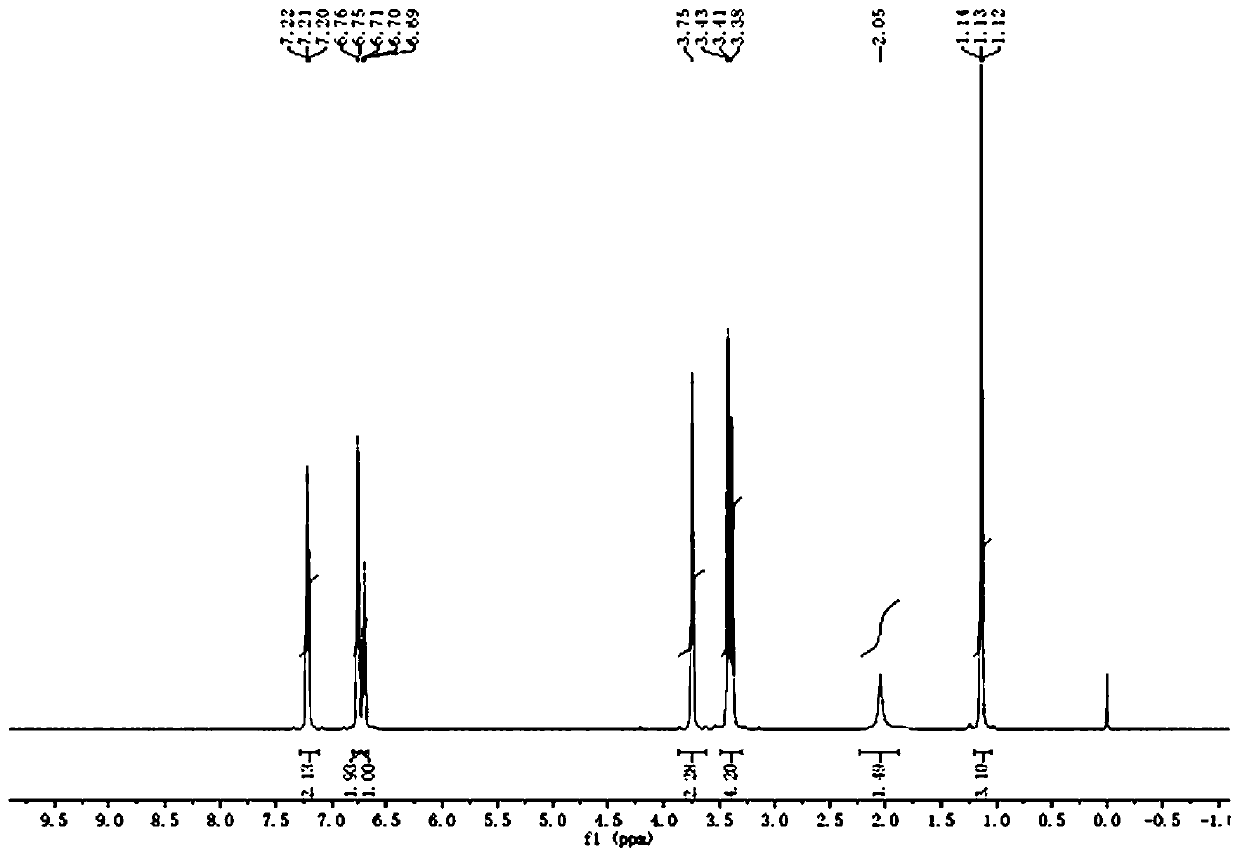

[0050] Purging the autoclave with nitrogen, under nitrogen protection, add the N-ethylaniline of 121g (1mol), the oxyethane of 44g (1mol), 1.2g (9.6mmol) taurine, close the autoclave lid, And tighten it, turn on the heating, raise the temperature to 90°C at a heating rate of 1°C / min, stop heating, raise the reaction temperature to 100°C and react for 6h, after the reaction is completed, cool to 40°C, and discharge to obtain N-ethyl-N- Hydroxyethylaniline 162g, yield 98.2%. 1 H NMR (400MHz, CDCl 3 )δ7.21(t, J=4.0Hz, 2H), 5.76(d, J=4.0Hz, 2H), 5.70(t, J=4.0Hz, 1H), 3.75(s, 2H), 3.43-3.48( m, 4H), 2.05(s, 1H), 1.13(t, J=4.0Hz, 3H).

Embodiment 2

[0052]Purging the autoclave with nitrogen, under the protection of nitrogen, add 121g (1mol) of N-ethylaniline, 46.2g (1.05mol) of ethylene oxide, 0.6g (4.8mmol) of taurine, close the autoclave Cover and tighten, turn on the heating, raise the temperature to 110°C at a heating rate of 1.5°C / min, stop heating, raise the reaction temperature to 140°C and react for 2 hours, after the reaction is completed, cool to 40°C, and discharge to obtain N-ethyl- N-hydroxyethylaniline 163.4g, yield 99%.

Embodiment 3

[0054] Purging the autoclave with nitrogen, under the protection of nitrogen, add 121g (1mol) of N-ethylaniline, 46.2g (1.05mol) of ethylene oxide, 0.91g (7.3mmol) of taurine, close the autoclave Cover and tighten, turn on the heating, raise the temperature to 100°C at a heating rate of 1.3°C / min, stop heating, raise the reaction temperature to 130°C for 3.5 hours, after the reaction is completed, cool to 40°C, and discharge to obtain N-ethyl -N-Hydroxyethylaniline 163.8g, yield 99.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com