Patents

Literature

2020 results about "Atom economy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Atom economy (atom efficiency/percentage) is the conversion efficiency of a chemical process in terms of all atoms involved and the desired products produced. Atom economy is an important concept of green chemistry philosophy, and one of the most widely used metrics for measuring the "greenness" of a process or synthesis. Atom economy can be written as: atom economy=(Molecular Weight of desired product)/(Molecular Weight of all reactants)×100% For a multi-step process, where the intermediates are formed in one step and consumed during a later step: A+B→C C+D→E E+F→G atom economy=Mᵣ(G)/(Mᵣ(A)+Mᵣ(B)+Mᵣ(D)+Mᵣ(F)) Atom economy is a different concern than chemical yield, because a high-yielding process can still result in substantial byproducts.

Method for preparing ethanediol from polyhydroxy compounds

ActiveCN101735014ARaw material resources are renewableMeet the requirements of sustainable developmentOrganic compound preparationCatalyst activation/preparationHydrogen pressureCobalt

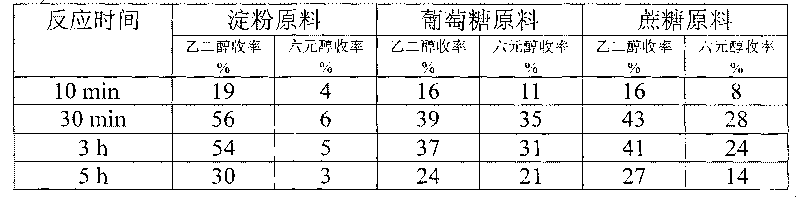

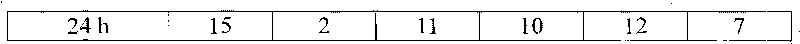

The invention provides a method for preparing ethanediol from polyhydroxy compounds comprising starch, hemicellulose, cane sugar, glucose, fructose and fructosan. The method comprises the following steps of: taking the polyhydroxy compounds as reaction raw materials, and taking metals, carbides, nitrides, and phosphides of transition metals in families VIII, IX and X, such as ferrum, cobalt, nickel, ruthenium, rhodium, palladium, iridium, platinum, molybdenum and tungsten as catalytic active components to form a polymetallic catalyst; and performing further catalytic conversion under a hydrothermal condition that the temperature is 120 to 300 DEG C and the hydrogen pressure is 1 to 13 MPa to prepare the ethanediol from the polyhydroxy compounds with high efficiency, high selectivity and high yield. The method for preparing the ethanediol from the polyhydroxy compounds has the outstanding advantages of renewable raw materials, environment-friendly reaction process, and atom economical efficiency. Simultaneously, compared with other techniques taking biomasses as the raw materials, the method has the advantages of simple process and high yield.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing ethylene glycol from cellulose

ActiveCN101723802ALow costWide variety of sourcesOrganic compound preparationCatalyst activation/preparationHydrogen pressurePolyethylene glycol

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

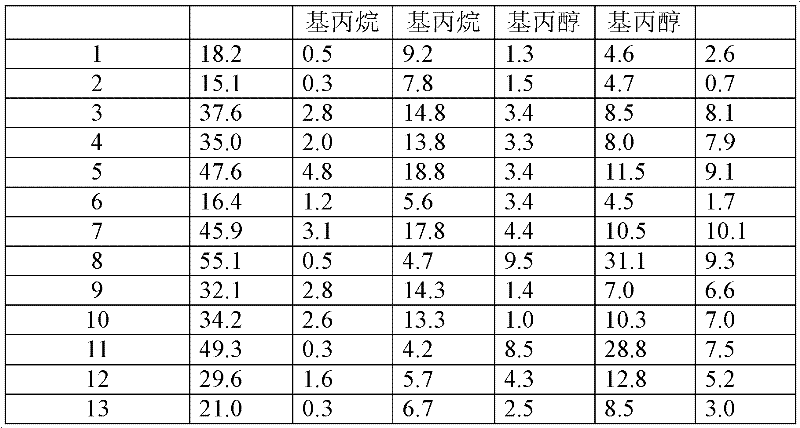

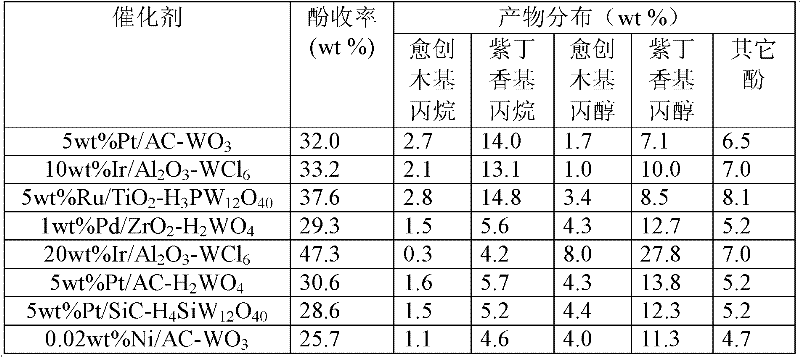

Application of tungsten-based catalyst in lignin catalytic hydrogenation for producing aromatic compound

ActiveCN102476980AWide variety of sourcesLow costCatalyst carriersOrganic compound preparationIridiumHydrogen pressure

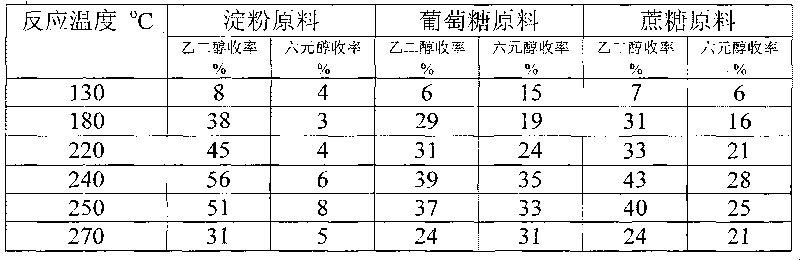

The invention relates to hydrocracking of lignin, and specifically relates to a method for applying a tungsten-based catalyst to catalyze lignin hydrocracking for producing an aromatic compound. The catalyst comprises a main active component of non-zero-valent tungsten, and a second metal component of a small amount of one or more transition metals selected from zero-valent nickel, cobalt, ruthenium, iridium, palladium, platinum, iron, and copper. According to the method, raw materials such as lignin, biomass hydrolysis residue, lignosulfonate, and alkaline lignin are subject to catalytic hydrogenation under a hydrothermal condition with a temperature of 120 to 450 DEG C and a hydrogen pressure of 1 to 20MPa; the raw materials are cracked into C6-C9 phenolic compounds with high selectivity. A maximal phenol yield reaches 55.6%. Compared to existing technologies, according to the invention, renewable natural biomasses are adopted as raw materials, such that the raw materials are cheap, and have wide sources; inorganic acid and alkali are not required, such the production of a large amount of alkaline solution in traditional lignin catalysis is avoided; the tungsten-based catalyst is cheap; the reaction process is green, and has atom economical characteristics.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

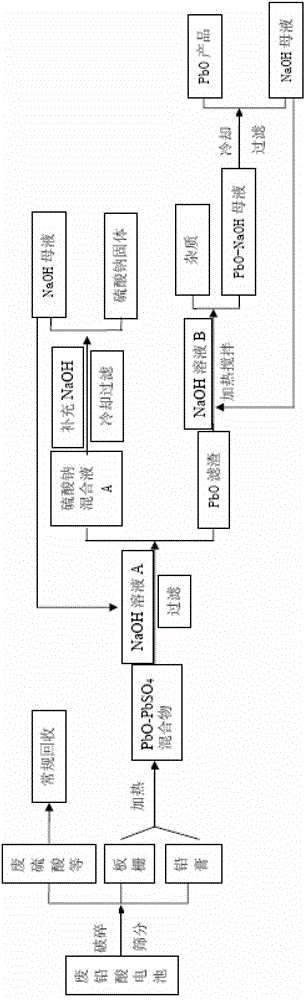

Method for producing lead oxide by recovering waste lead-acid batteries based on atom economy way

ActiveCN103146923AImprove recycling efficiencyMeet the needs of high-purity PbOProcess efficiency improvementChemical industryLead oxide

The invention provides a method for producing lead oxide by recovering waste lead-acid batteries based on an atom economy way and belongs to the field of chemical industry for clearing and recovering waste lead-acid batteries. The method comprises the steps of: heating lead paste and lead powder of the lead-acid batteries, and then carrying out solid phase mixing reaction, sodium hydroxide alkaline desulfurization and sodium hydroxide leaching to directly obtain a lead-bearing alkaline solution and filter residue; and carrying out purification and cooling crystallization on the solution so as to obtain high-purity lead oxide and a by-product sodium sulfate so as to eliminate the defect that a large quantity of chemical raw materials are required to be consumed in a conventional synthesis process of the lead oxide so that the method is a clean and energy-saving new technology and has a large-scale industrial application prospect.

Owner:BEIJING UNIV OF CHEM TECH

Method of preparing ethylene glycol from cellulose

ActiveUS7960594B2High yieldHigh selectivityOxygen-containing compound preparationOrganic compound preparationCelluloseIridium

A method for preparing ethylene glycol from cellulose uses the cellulose as the feed for the reaction. The cellulose conversion is performed over catalysts which are composed of the metallic state, carbides, nitrides, or phosiphides of molybdenum or tungsten, and metallic cobalt, nickel, ruthenium, rhodium, palladium, iridium, and platinum of the group 8, 9, or 10 transition metals. The catalytic conversion of cellulose is conducted at 120 to 300° C. and hydrogen pressure 1 to 12 MPa under the hydrothermal conditions to achieve the high efficiency, high selectivity, and high yield of ethylene glycol. Compared to the existing method of preparing ethylene glycol from ethylene, the method, using the renewable raw material for the reaction, is friendly to the environment, and has high atom economy.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Methods for preparing ethylene glycol from polyhydroxy compounds

ActiveUS20120172633A1High yieldHigh selectivityOxygen-containing compound preparationOrganic compound preparationHydrogen pressureHeteropoly acid

This invention provides methods for producing ethylene glycol from polyhydroxy compounds such as cellulose, starch, hemicellulose, glucose, sucrose, fructose, fructan, xylose and soluble xylooligosaccharides. The methods uses polyhydroxy compounds as the reactant, a composite catalyst having active components comprising one or more transition metals of Groups 8, 9, or 10, including iron, cobalt, nickel, ruthenium, rhodium, palladium, iridium, and platinum, as well as tungsten oxide, tungsten sulfide, tungsten hydroxide, tungsten chloride, tungsten bronze oxide, tungsten acid, tungstate, metatungstate acid, metatungstate, paratungstate acid, paratungstate, peroxotungstic acid, pertungstate, heteropoly acid containing tungsten. Reacting at a temperature of 120-300° C. and a hydrogen pressure of 1-13 MPa under hydrothermal conditions to accomplish one-step catalytic conversion. It realizes efficient, highly selective, high yield preparation of ethylene glycol and propylene glycol from polyhydroxy compounds. The advantage of processes disclosed in this invention include renewable raw material and high atom economy. At the same time, compared with other technologies that converts biomass raw materials into polyols, methods disclosed herein enjoy advantages including simple reaction process, high yield of targeted products, as well as easy preparation and low cost for the catalysts.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Tungsten carbide catalysts, their preparation and application in synthesis of ethylene glycol from cellulose

ActiveUS20100255983A1Improve efficiencyHigh selectivityOxygen-containing compound preparationOrganic compound preparationHydrogen pressureCobalt

Tungsten carbide catalysts are used in preparation of ethylene glycol by hydrogenating degradation of cellulose. The catalyst includes tungsten carbide as main catalytic active component, added with small amount of one or more transition metals such as nickel, cobalt, iron, ruthenium, rhodium, palladium, osmium, iridium, platinum, and copper as the second metal, supported on one or more porous complex supports such as active carbon, alumina, silica, titanium dioxide, silicon carbide, zirconium oxide, for conversion of cellulose to ethylene glycol. The catalyst realizes high efficiency, high selectivity, and high yield in the conversion of cellulose to ethylene glycol at the temperature of 120-300° C., hydrogen pressure of 1-10 MPa, and hydrothermal conditions. Compared to the existing industrial synthetic method of ethylene glycol using ethylene as feedstock, the invention has the advantages of using renewable raw material resources, environment friendly process, and excellent atom economy.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method of preparing ethylene glycol cellulose

ActiveUS20100256424A1High yieldHigh selectivityOxygen-containing compound preparationOrganic compound preparationCelluloseIridium

A method for preparing ethylene glycol from cellulose uses the cellulose as the feed for the reaction. The cellulose conversion is performed over catalysts which are composed of the metallic state, carbides, nitrides, or phosiphides of molybdenum or tungsten, and metallic cobalt, nickel, ruthenium, rhodium, palladium, iridium, and platinum of the group 8, 9, or 10 transition metals. The catalytic conversion of cellulose is conducted at 120 to 300° C. and hydrogen pressure 1 to 12 MPa under the hydrothermal conditions to achieve the high efficiency, high selectivity, and high yield of ethylene glycol. Compared to the existing method of preparing ethylene glycol from ethylene, the method, using the renewable raw material for the reaction, is friendly to the environment, and has high atom economy.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

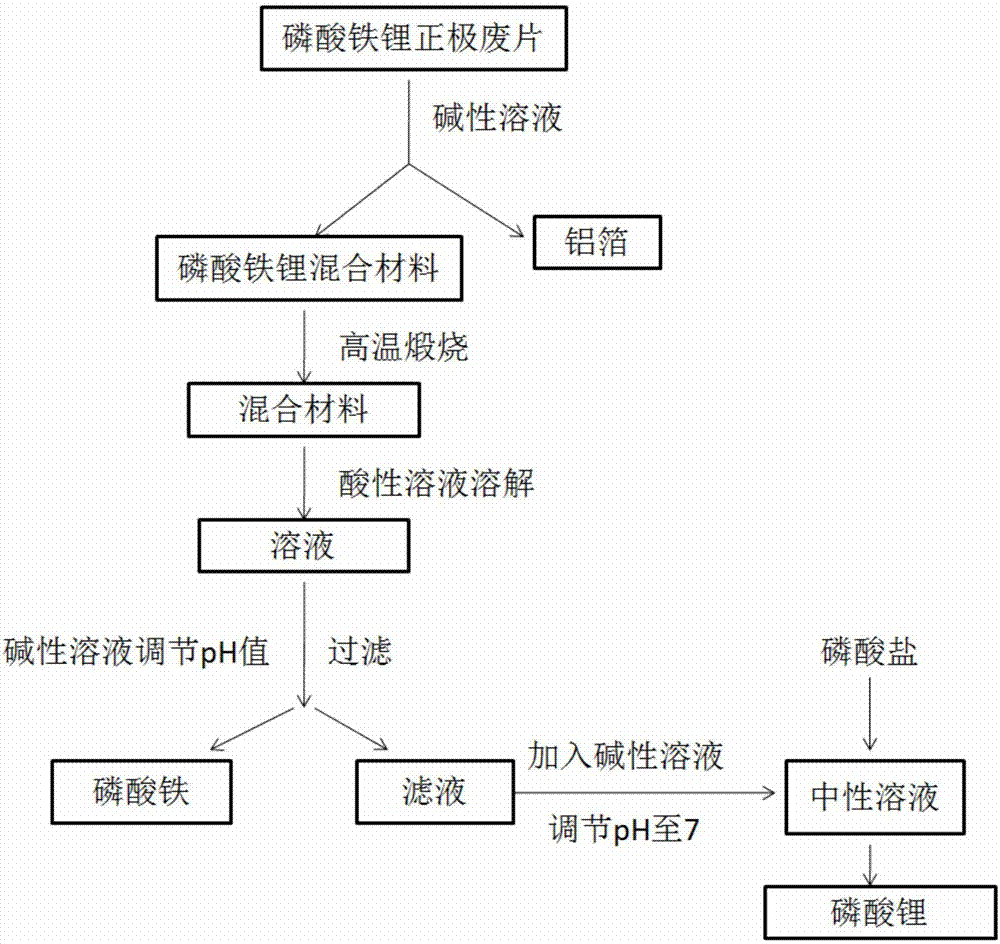

Method for recycling lithium, iron and current collector-aluminum foil in positive electrode material of waste lithium iron phosphate battery

InactiveCN107190150AComplete exfoliationEasy to recycleWaste accumulators reclaimingProcess efficiency improvementPhosphateMixed materials

The invention discloses a method for recycling lithium, iron and current collector-aluminum foil in a positive electrode material of a waste lithium iron phosphate battery. The method comprises the steps that firstly, the positive electrode material of the waste lithium iron phosphate battery is arranged in an alkaline solution to be subjected to stirring and ultrasonic treatment, and after a lithium iron phosphate positive electrode mixed material completely disengages from aluminum foil, the aluminum foil is directly recycled after being separated from the alkaline solution; then the lithium iron phosphate positive electrode mixed material is filtered and separated out from the alkaline solution and then is subjected to roasting, ball milling and screening; then the lithium iron phosphate positive electrode mixed material is immersed in acid liquor to be dissolved, the pH value is adjusted, the iron element is deposited in the form of iron phosphate, and filtering and separating are conducted; the filter liquor is continuously adjusted to the neutralization, then phosphate is added, and the lithium element is deposited in the form of lithium phosphate. The method is simple and effective, the main elements of iron, lithium and current collector-aluminum foil in the positive electrode material of the waste lithium iron phosphate battery can be effectively recycled, the recycling rate is high, low-concentration acid liquor and low-concentration alkaline liquor are adopted, secondary pollution is not generated, the valuable elements are all recycled, and atom economy is achieved.

Owner:XIANGTAN UNIV

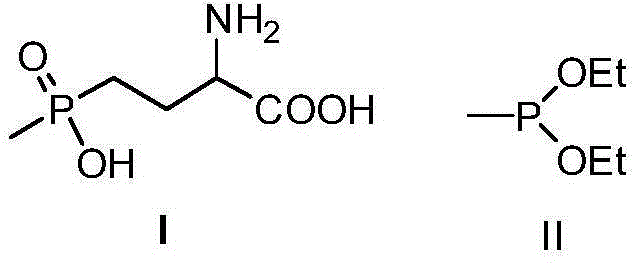

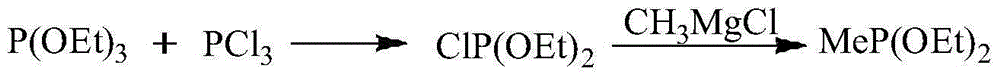

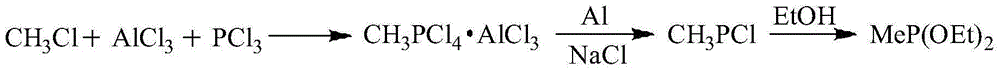

Recycling process of sodium tetrachloroaluminate in phosphinothricin production

ActiveCN105217667ASolve processing problemsReduce pollutionAluminium chloridesWater/sewage treatment by flocculation/precipitationAluminium chlorohydrateSewage treatment

The invention discloses a recycling process of sodium tetrachloroaluminate in phosphinothricin production. The process comprises the following steps that 1, mismatching and precipitation are carried out; 2, solids are filtered; 3, cooling precipitation is carried out; 4, reutilization is carried out; 5, cyclic utilization is carried out; 6, aluminum polychlorid is prepared. Sodium tetrachloroaluminate solid waste is changed into treasure, alchlor obtained after mismatching is recycled, the problem of treatment of sodium tetrachloroaluminate solid waste is solved, pollution to environment is reduced, no three waste is discharged, the atom economy of a reaction is improved, and large-scale production of phosphinothricin is facilitated. A mismatching agent and a poor solvent adopted in the process are low in price and easy to obtain, the whole process is easy and convenient to operate, and especially suitable for industrial production. Further prepared polymerization alchlor can be adopted as a water purifying agent, and is wide in application range and especially suitable for sewage treatment of chemical plants.

Owner:ANHUI COSTAR BIOCHEM CO LTD

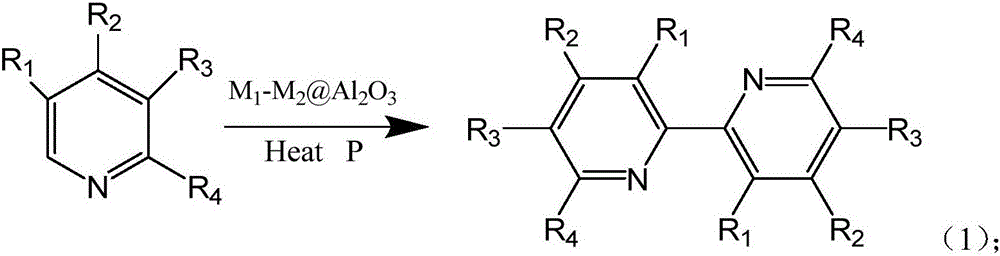

Synthesis method of 2,2'-dipyridine by using supported bimetal nano catalyst

ActiveCN105859610ANo pollution in the processIncrease productivityOrganic chemistryHeterogenous catalyst chemical elementsChemical industryNano catalyst

The invention discloses a synthesis method of 2,2'-dipyridine by using a supported bimetal nano catalyst. The method is characterized in that the supported bimetal nano catalyst M1-M2@Al2O3 is utilized to catalyze the direct coupling reaction of pyridine so as to synthesize the 2,2'-dipyridine. The supported bimetal nano catalyst M1-M2@Al2O3 uses Al2O3 as a supporter and any two different metals M1 and M2 as active components, wherein M1 and M2 are respectively and independently selected from noble metals Pd, Pt, Ru, Au, Ag and Rh, or non-noble metals Ni, Cu, Fe, Zn and Co. By using the supported bimetal nano catalyst in direct coupling production of 2,2'-dipyridine from pyridine, the method has high production efficiency, conforms to the atom economy principle in chemical industry production, does not generate any pollutant which is harmful to the environment, and thus, is a green chemical-industry intermediate production technique.

Owner:HEFEI UNIV OF TECH

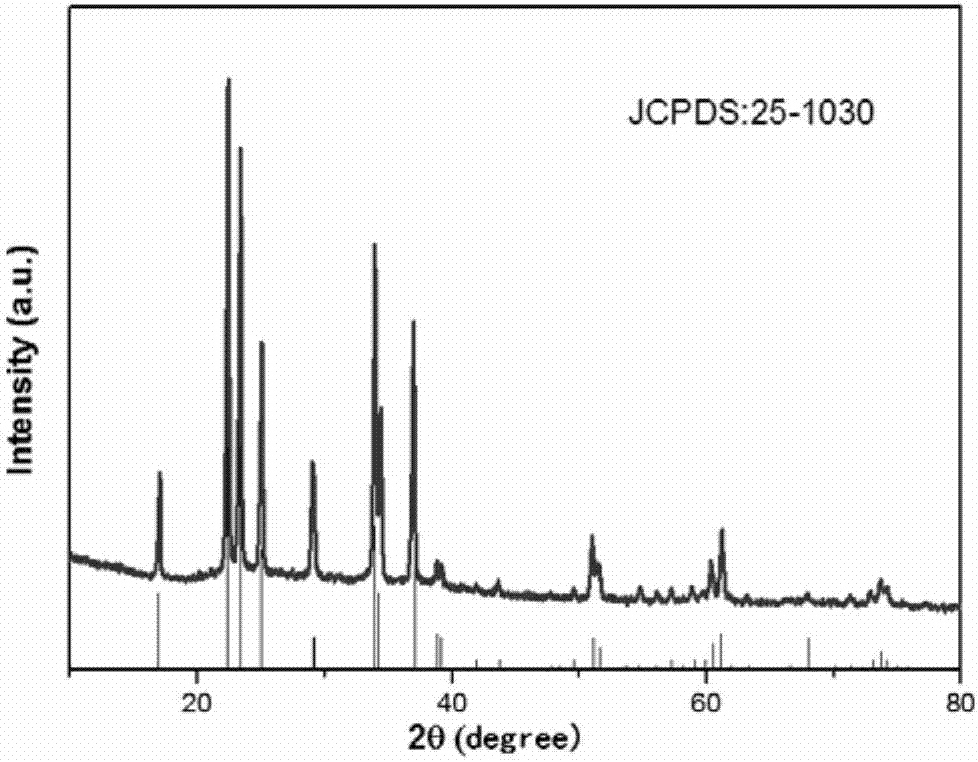

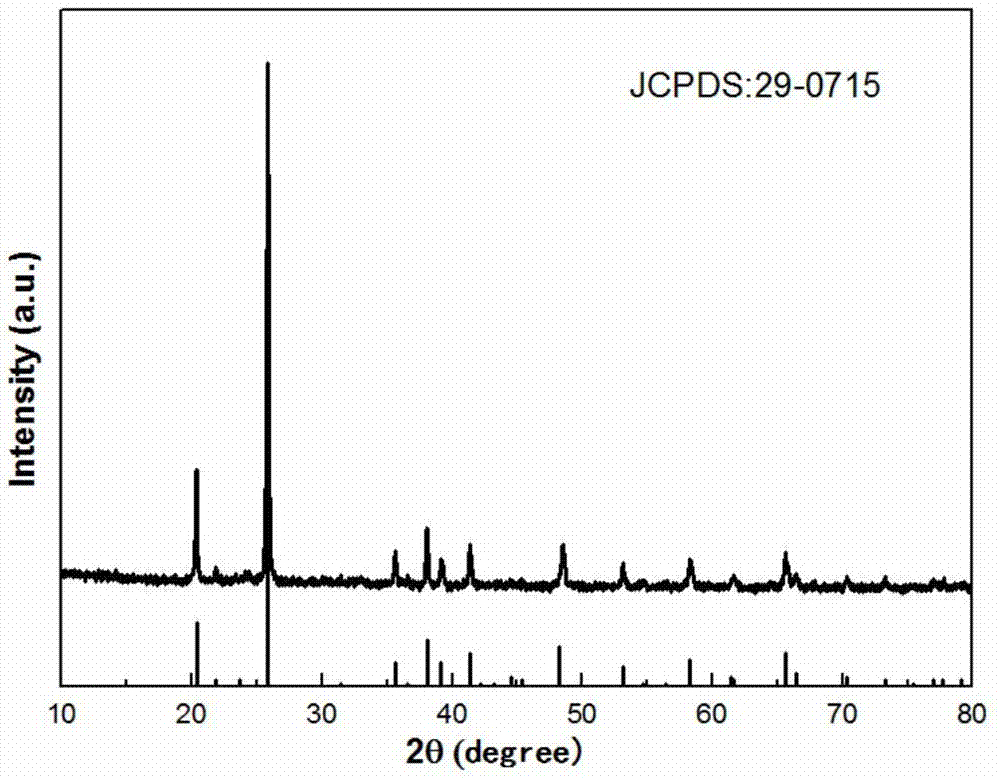

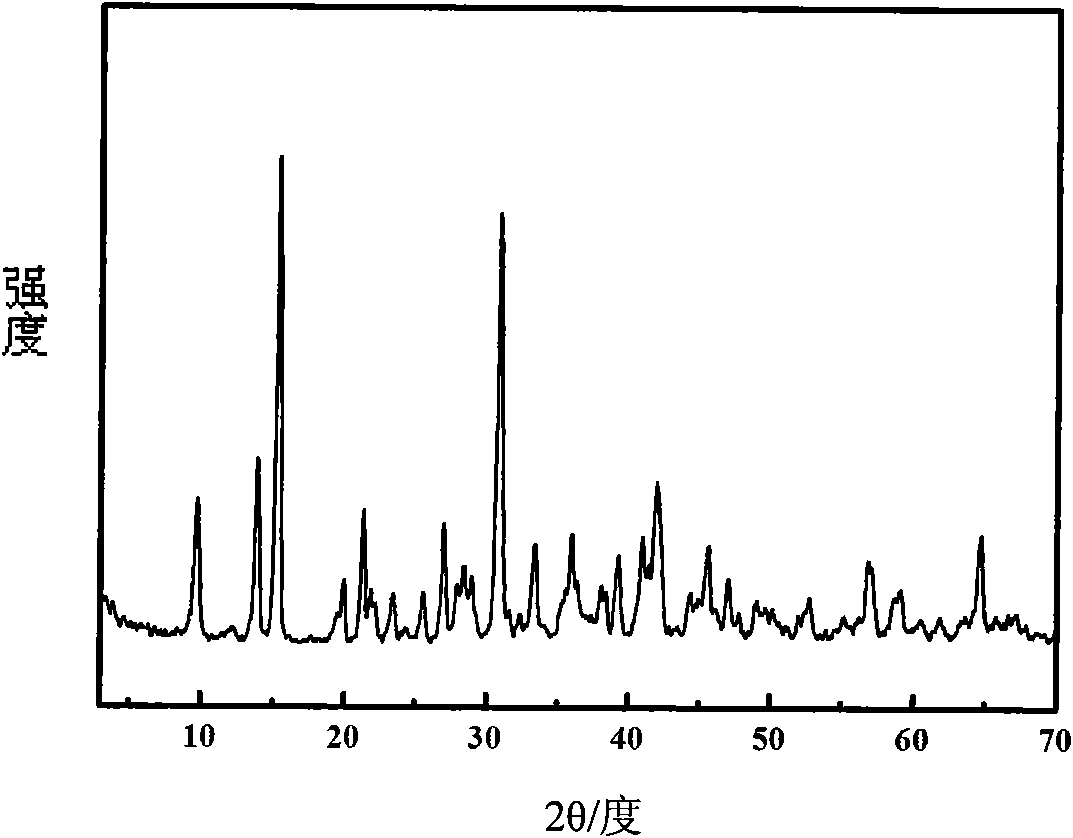

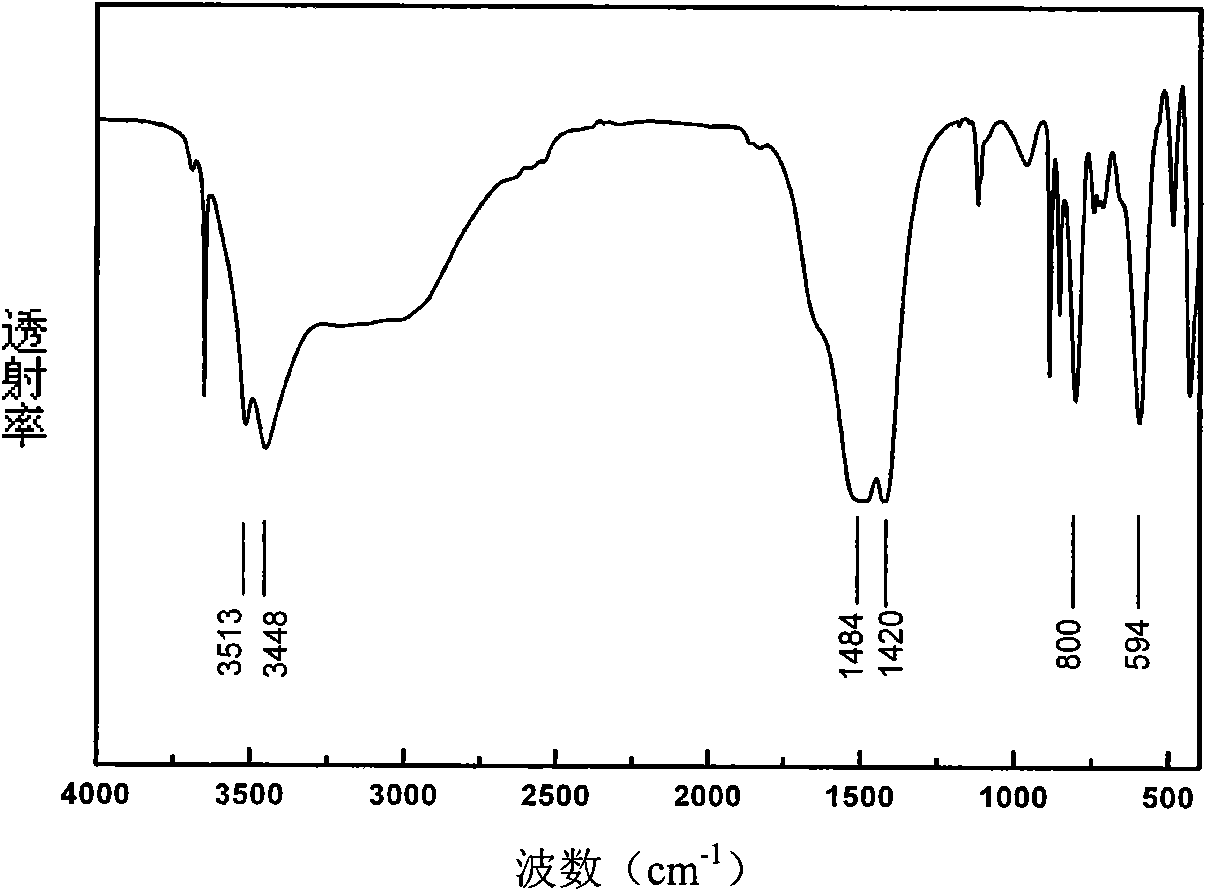

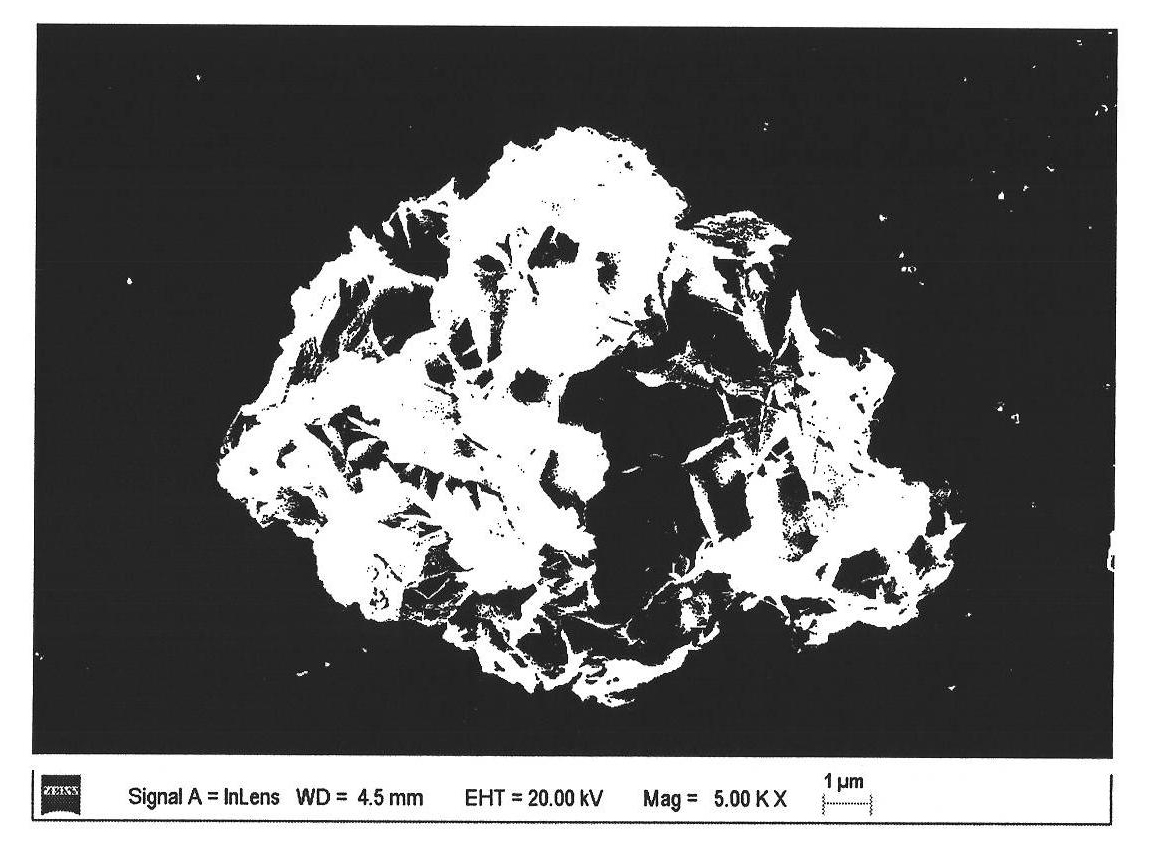

Atom economic preparation method for laminated composite metal hydroxide

The invention discloses an atom economic preparation method for laminated composite metal hydroxide, and belongs to the technical filed of the preparation of inorganic non-metal functional materials. In the method, the laminated composite metal hydroxide is prepared from metal hydroxide, ammonium salt and ammonia water serving as raw materials through atom economical reaction in a reactor. Due to the adoption of the ammonium salt and the ammonia water in the reaction process, the reaction temperature is reduced and the reaction condition is milder and is controlled easily; the ammonium in the ammonium salt and the ammonia water used in the reaction can be recycled in the post-treatment; the metal hydroxide and the corresponding ammonium salt with negative ion An- are used in the reaction, and other raw materials such as NaOH and the like are not used; and all the raw materials take part in the reaction to generate the target product and the atom economy is 100 percent, so the reaction belongs to the typical atom economic reaction. In the production process, side products are not generated, and the product can be dried to form pure product without washing so as to greatly save water resource and protect the environment.

Owner:临沂万新海纳材料科技有限公司

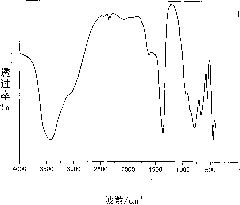

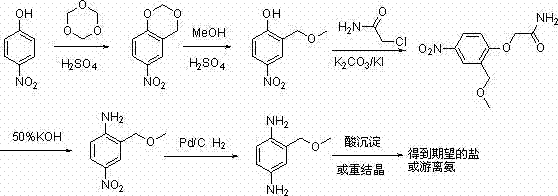

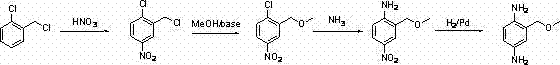

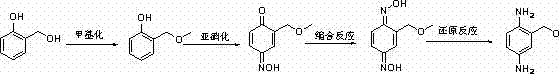

Method for preparing 2-( methoxyl-methyl) phenyl-1,4-diamine

ActiveCN104744272AEasy to operateHigh yieldOrganic compound preparationAmino-hyroxy compound preparationHydrogenEconomic benefits

The invention relates to a method for preparing 2-(methoxyl-methyl) phenyl-1,4-diamine. The method comprises the following steps: by taking o-nitrobenzyl alcohol as a raw material, performing methylation and hydrogenation reduction reaction so as to obtain 2-(methoxyl methyl) aniline, performing azo reaction on 2-( methoxyl methyl) aniline by taking an aniline substance as a coupling agent so as to obtain 2-(methoxyl methyl)-5-azo aniline, performing hydrogenolysis reaction on 2-(methoxyl methyl)-5-azo aniline in the presence of a hydrogenation catalyst so as to generate 2-(methoxyl methyl) phenyl-1,4-diamine and a corresponding coupling agent, separating and purifying, thereby respectively obtaining 2-(methoxyl methyl) phenyl-1,4-diamine and a corresponding coupling agent. The method has the characteristics that the atom economy property is good, a small amount of the tree wastes can be generated, the raw materials are cheap, auxiliary materials can be recycled and reused, the aspects such as operation simplification, pollution reduction and economic benefit increase are remarkably improved, and the method is applicable to industrial production.

Owner:ZHEJIANG DINGLONG TECH

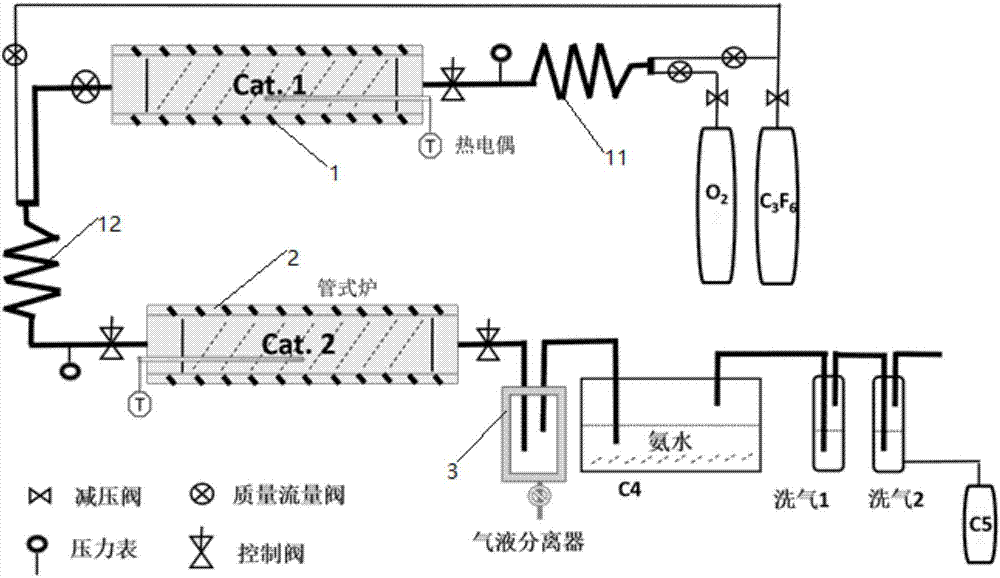

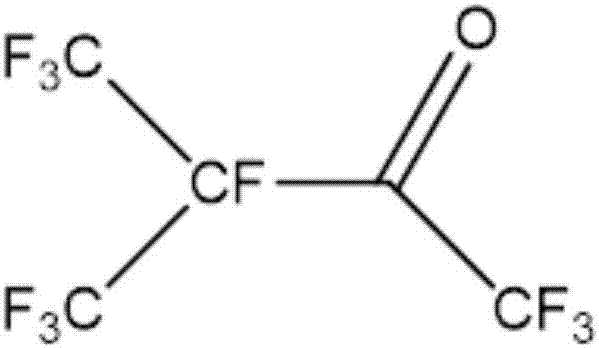

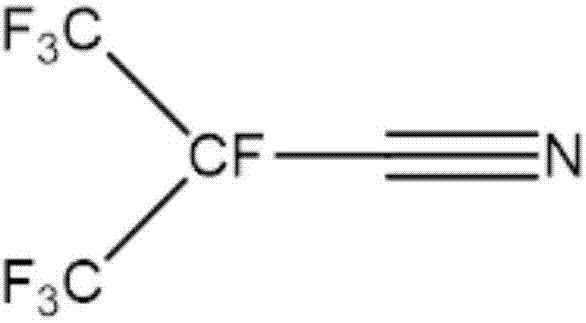

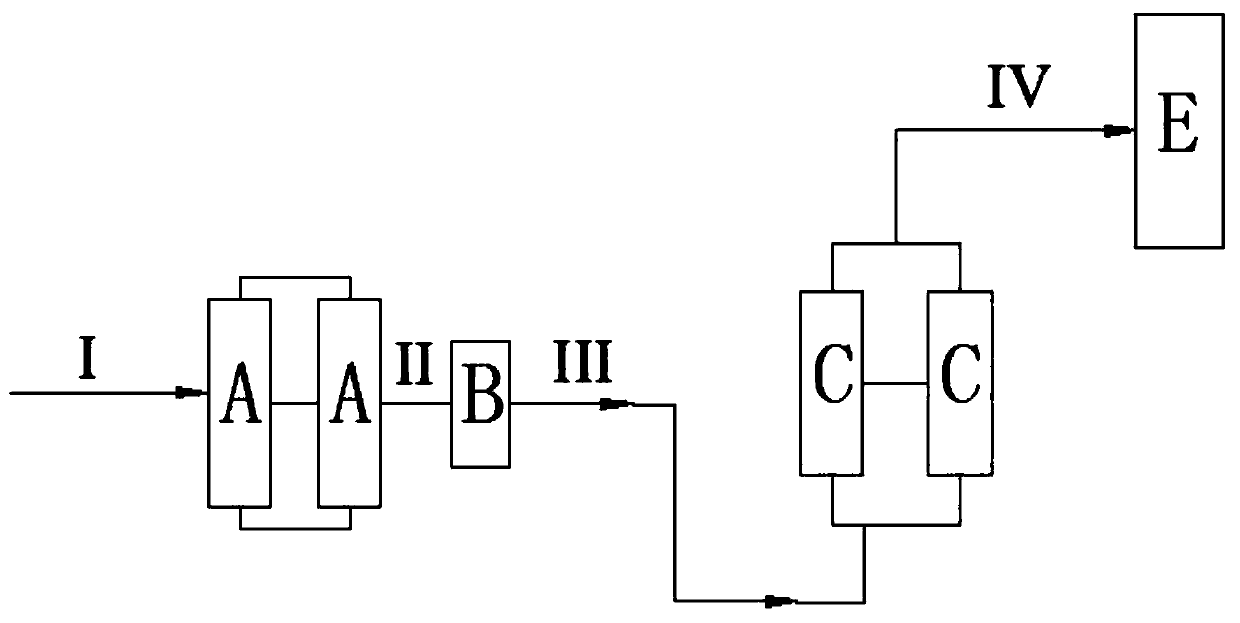

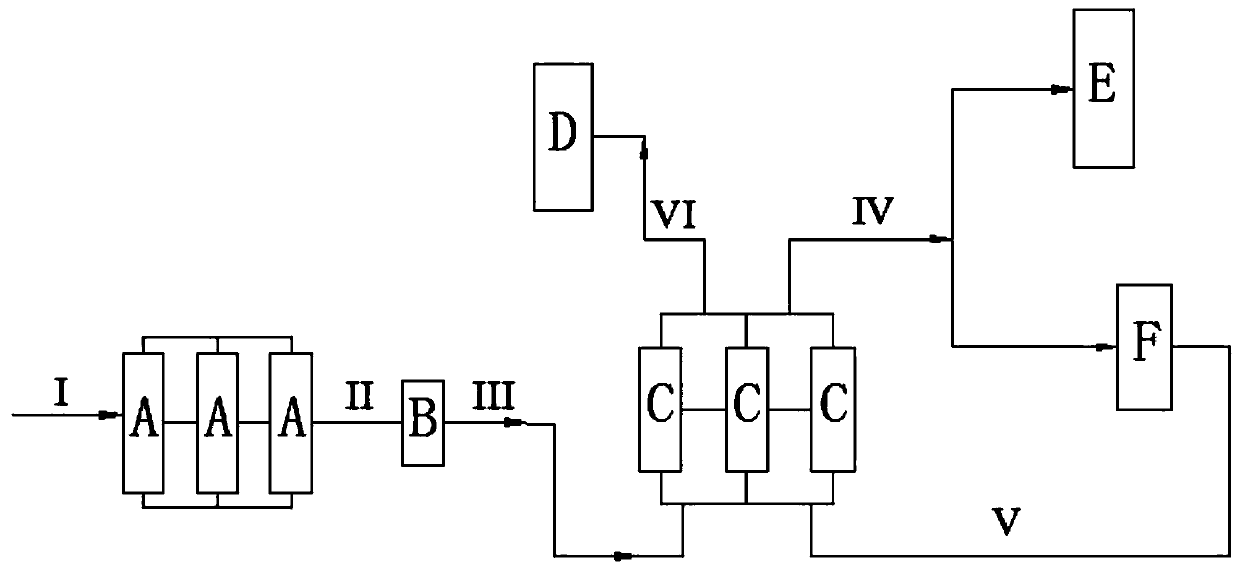

Environmentally-friendly insulating gas combined production technology and industrial production device thereof

ActiveCN106946669AReduce manufacturing costReduce the discharge of three wastesOrganic compound preparationCarboxylic acid amides preparationFixed bedProcess engineering

The invention discloses an environmentally-friendly insulating gas combined production technology and an industrial production device thereof. The combined production technology comprises the following steps: 1, carrying out a contact reaction on oxygen and HFP in a first fixed bed reactor under a catalyst condition or a catalyst-free condition; 2, mixing a gas product flowing out of the first fixed bed reactor with the HFP, allowing the gas product and the HFP to enter a second fixed bed reactor, and carrying out a contact reaction in the second fixed bed reactor under the action of a catalyst; and 3, carrying out separation on the effluent of the second fixed bed reactor to prepare a C5 product and a C4 product. Combined production of two novel environmentally-friendly insulating gases is realized from cheap raw materials comprising perfluoropropylene and oxygen at an atom economy of 80-90%, so the production cost is greatly reduced, and the discharge of three wastes in the production process is reduced.

Owner:STATE GRID CORP OF CHINA +3

Clean preparation method for basic magnesium carbonate

InactiveCN101935059ASave waterTypical Atom Economy ReactionMagnesium carbonatesSynthesis methodsWater source

The invention relates to a clean preparation method for basic magnesium carbonate, which prepares the basic magnesium carbonate by taking natural mineral brucite or synthesized magnesium hydroxide as raw materials and by performing the atom economic reaction of the raw material and CO2. All atoms in the raw materials participate in the reaction, and a target product is generated; the economical efficiency of the atoms is 100 percent; and thus, the reaction is a typical atom economic reaction. A reaction process avoids using raw materials such as dolomite, magnesite or brine, and sodium carbonate which are usually used by the conventional synthesis method, so that a product has no impurities, the pure product can be directly obtained without drying, a washing link is removed, a great amount of water source is saved, and the environment is protected.

Owner:BEIJING UNIV OF CHEM TECH

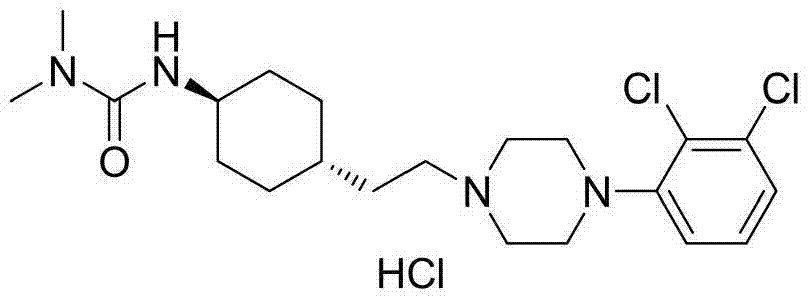

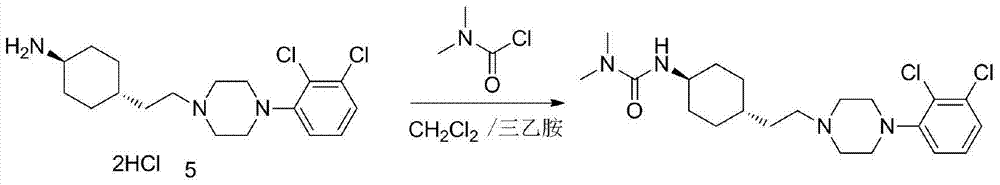

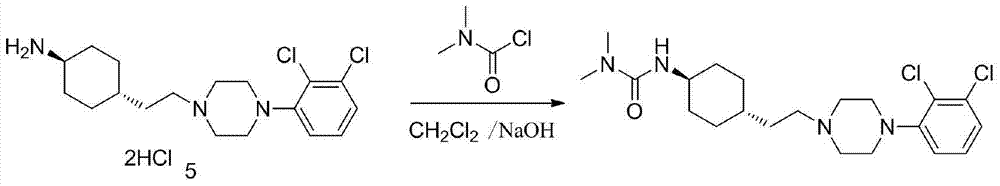

3-cyclohexyl-1,1-dimethylurea compound as well as preparation method and application thereof

ActiveCN104496854AAtom economy is highHigh purityUrea derivatives preparationOrganic compound preparationCariprazineDimethylurea

The invention discloses a 3-cyclohexyl-1,1-dimethylurea compound as well as a preparation method and application thereof. The 3-cyclohexyl-1,1-dimethylurea compound is used for preparing an antischizophrenic drug cariprazine. Compared with the prior art and report literatures, the preparation method of the 3-cyclohexyl-1,1-dimethylurea compound has the remarkable advantages of being free of removal of protecting groups such as Boc group, high in atom economy, low in cost and easy in getting of raw materials, mild in reaction condition, stable in yield, simple and convenient to operate, controllable in product quality, high in product purity, less in three waste pollution and easy to produce industrially. The structure formula of the 3-cyclohexyl-1,1-dimethylurea compound is as shown in (I) in the specification.

Owner:SHANGHAI INST OF PHARMA IND CO LTD +1

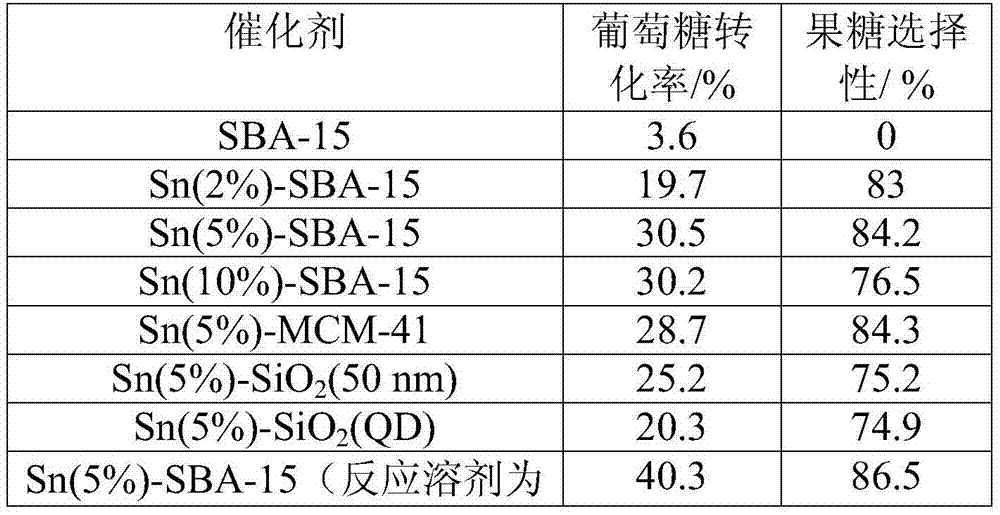

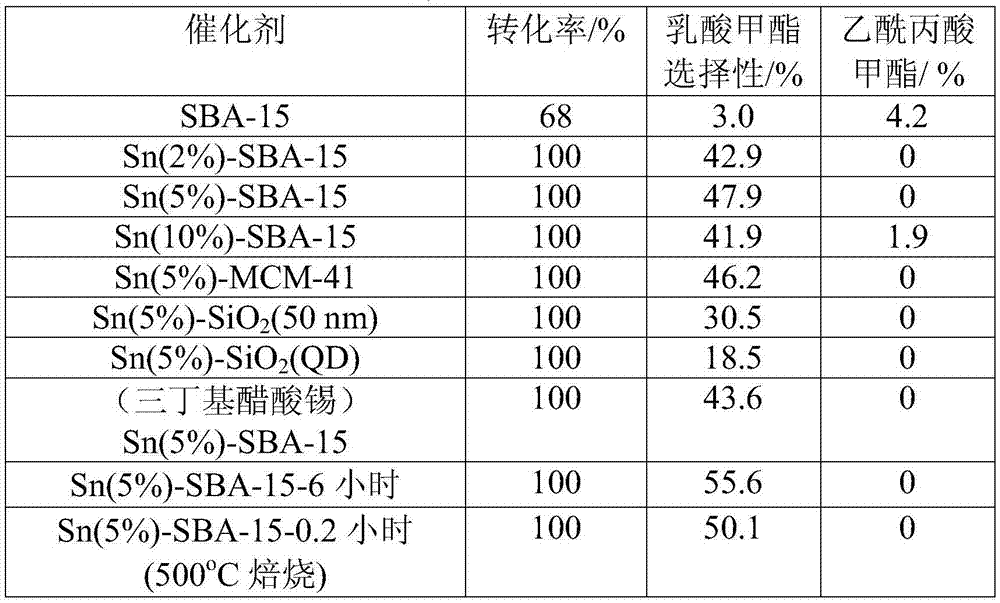

Preparation method of tin based catalyst, tin based catalyst and application of tin based catalyst

ActiveCN106861747AEasy to prepareSingle active siteMolecular sieve catalystsOrganic compound preparationIsomerizationIon exchange

The invention provides preparation of a tin based catalyst and an application of the tin based catalyst in catalytic conversion of carbohydrates. According to the method, the tin based catalyst is prepared by an ion exchange method and is applied in a reaction for preparation of lactic acid ester through isomerization and catalytic conversion of the carbohydrates, and at the temperature of 80-210 DEG C and through a one-step catalytic conversion process, fructose or lactic acid ester is prepared from the carbohydrates with high efficiency, high selectivity and high yield. The reaction provided by the invention has the remarkable advantages of raw materials as renewable resources and high atom economy. At the same time, the catalyst preparation process has the advantages of being simple and feasible to implement and low in cost. In addition, compared with other technologies for preparing fructose or lactic acid ester by using biomass as raw material, the process has the advantages of simple reaction process, high space-time yield and convenience in industrialized production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method and device for blast furnace coal gas fine desulfurization and purification

InactiveCN110819393AReduce difficultyImprove the efficiency of adsorption and desulfurizationSulfur preparation/purificationGas purification by catalytic conversionThermodynamicsSulfide

The invention provides a blast furnace coal gas fine desulfurization and purification method, which comprises that S1, blast furnace coal gas enters a conversion unit under a positive pressure, and the organic sulfur in the blast furnace coal gas is converted into hydrogen sulfide; S2, the obtained material enters a cooling unit and is cooled; and S3, the cooled stream enters an adsorption unit filled with an adsorption material, and the sulfide in the blast furnace coal gas is adsorbed and removed to form purified coal gas. According to the invention, the low-concentration sulfides in blast furnace coal gas are enriched into sulfur-rich concentrated gas to convert the working condition with large-capacity and low-concentration sulfides into the working condition with small-capacity and high-concentration sulfides, so that the desulfurization effect can be improved, the desulfurization investment cost and the operation cost can be reduced, the sulfur element in the blast furnace coal gas can be recovered, the atom economy is high, and the secondary pollution is reduced.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

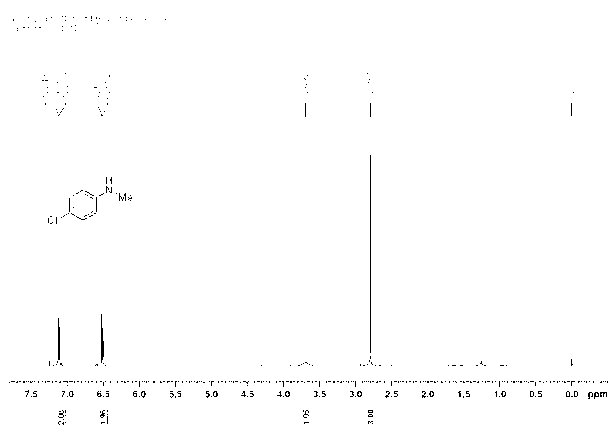

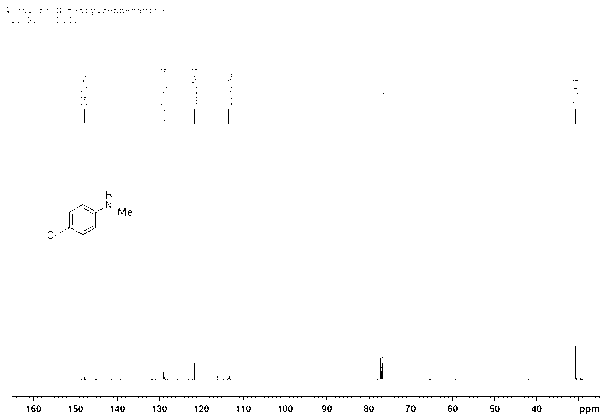

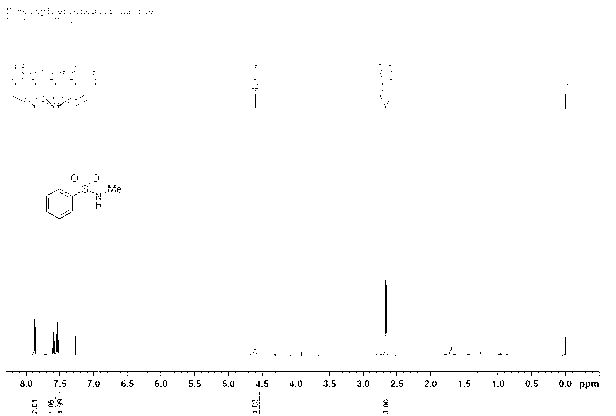

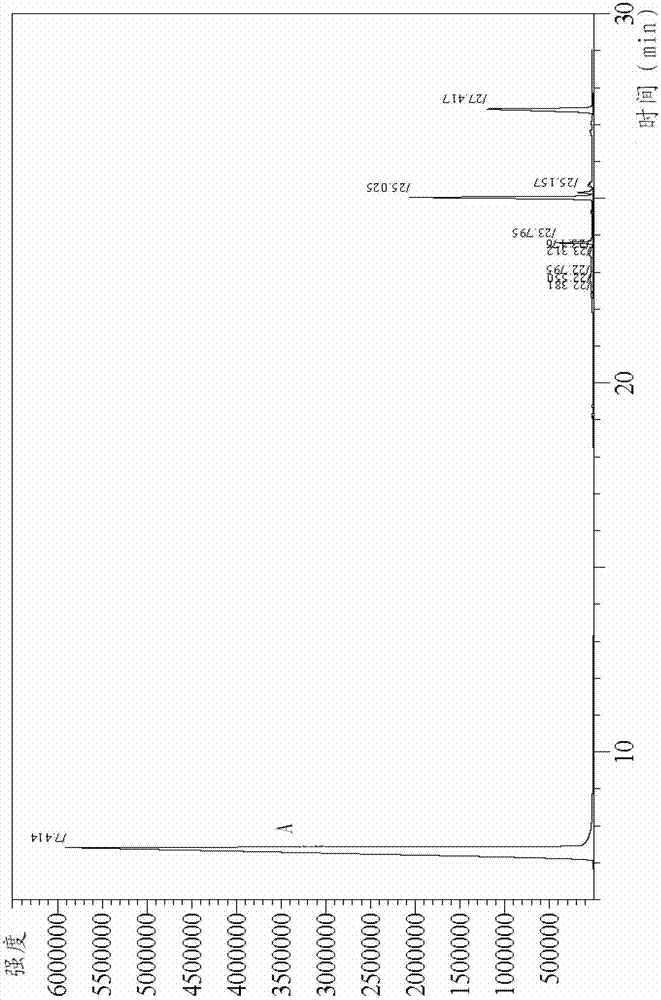

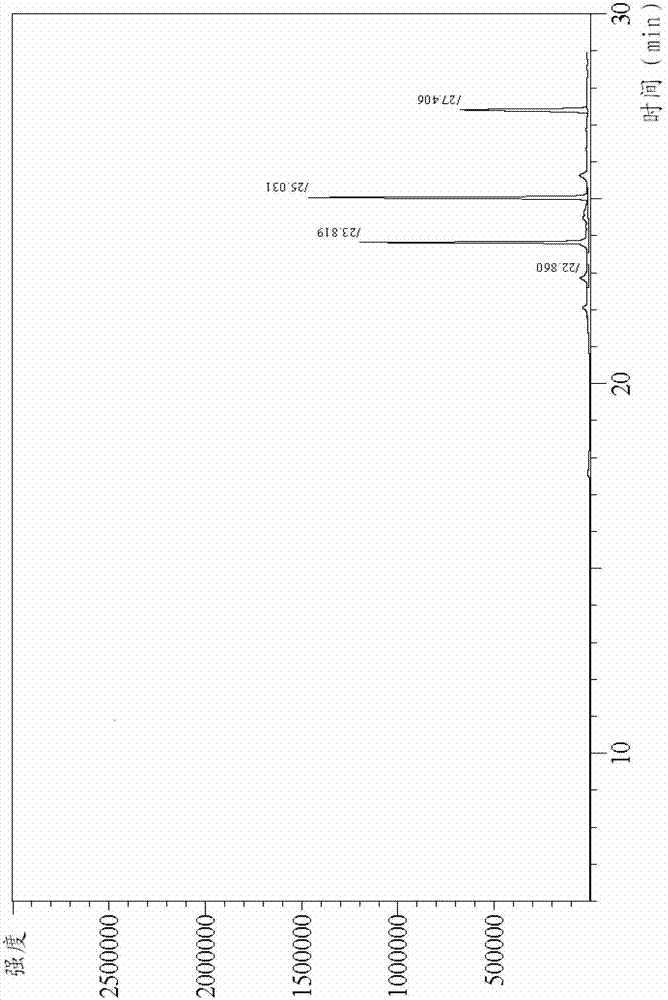

Method for realizing selective N-methylation of primary amine

InactiveCN103172523ANo harmImprove economyOrganic compound preparationSulfonic acid amide preparationIridiumNitrogen gas

The invention relates to a method for realizing selective N-methylation of primary amine, which comprises the following steps: in a nitrogen gas protective atmosphere or in the air, adding a primary amine derivative, a metal iridium or ruthenium complex, methanol and alkali into a reaction vessel; reacting the reaction mixture at 100-150 DEG C for several hours, and then cooling to room temperature; and performing rotary evaporation to remove the solvent, and then performing column separation to obtain a target compound. Compared with the prior art, the reaction shows the following remarkable advantages: 1) the methanol is used as an alkylation agent, thereby avoiding the use of virulent haloalkane and dimethyl sulfate; 2) the reaction only generates water as the byproduct, thereby causing no environmental hazard; 3) the reaction is high in atom economy; 4) the reaction shows absolute selectivity, and the reaction only generates mono-methyl products and generates no bis-methyl products; and 5) the reaction shows wide substrate universality and is effective for various primary amine derivatives.

Owner:NANJING UNIV OF SCI & TECH

Allantoin synthesizing process

The invention relates to a new technique to prepare allantoin, in a stirring state, adding hydrogen peroxide solution containing a proper amount of metallic salt catalyst or resin loading metallic salt catalyst to oxalic dialdehyde water solution, to oxidize the oxalic dialdehyde into glyoxalic acid; adding a proper amount of raw material urea to the obtained glyoxalic acid solution and completing catalytic condensation reaction under the condition of heating and stirring; filtering and recovering the catalyst, cooling, pump-filtering, washing, recrystallizing and drying to obtain the finished product allantoin. It has larger yield at 56% or so; reduces the urea dosage; the new catalyst is simple to prepare and has high catalytic activity, able to be repeatedly used for 10 times above; it is a new green technique.

Owner:NINGXIA UNIVERSITY

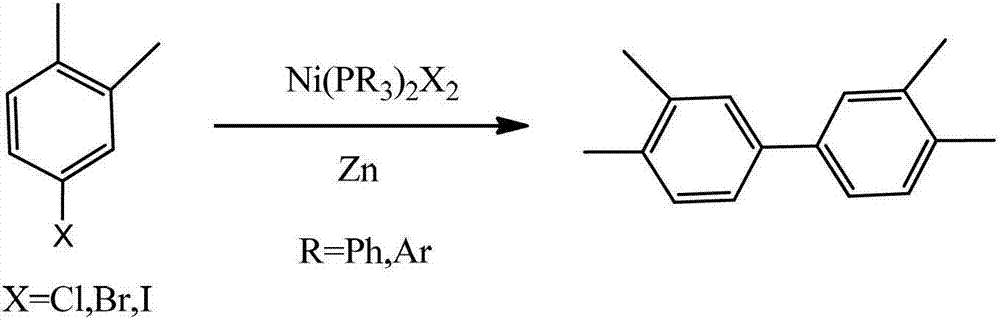

Preparation method of tetramethyl biphenyl

ActiveCN103086837AReduce manufacturing costLow equipment requirementsHydrocarbon by hydrocarbon condensationMetal catalystAcid anhydride formation

The invention provides a preparation method of tetramethyl biphenyl, which comprises the following steps: mixing o-xylene, oxidizer, additive and metal catalyst, and reacting to obtain the tetramethyl biphenyl, wherein the additive is organic acid and / or organic acid anhydride, and the oxidizer is inorganic oxidizer and / or organic oxidizer containing metal cation. Compared with the prior art of synthesizing tetramethyl biphenyl from halogenated o-xylene, the invention uses the o-xylene for direct coupling to obtain the tetramethyl biphenyl. The raw material o-xylene is cheap and accessible, and the preparation of the halogenated o-xylene is not needed, so the invention lowers the production cost, is simple to operate and has the advantages of mild reaction conditions and low facility request; and under the action of the catalyst, the o-xylene is directly coupled to prepare the tetramethyl biphenyl, and all the carbon atom frameworks of the o-xylene enter the product, so the invention also has the advantage of high economical efficiency of atoms.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

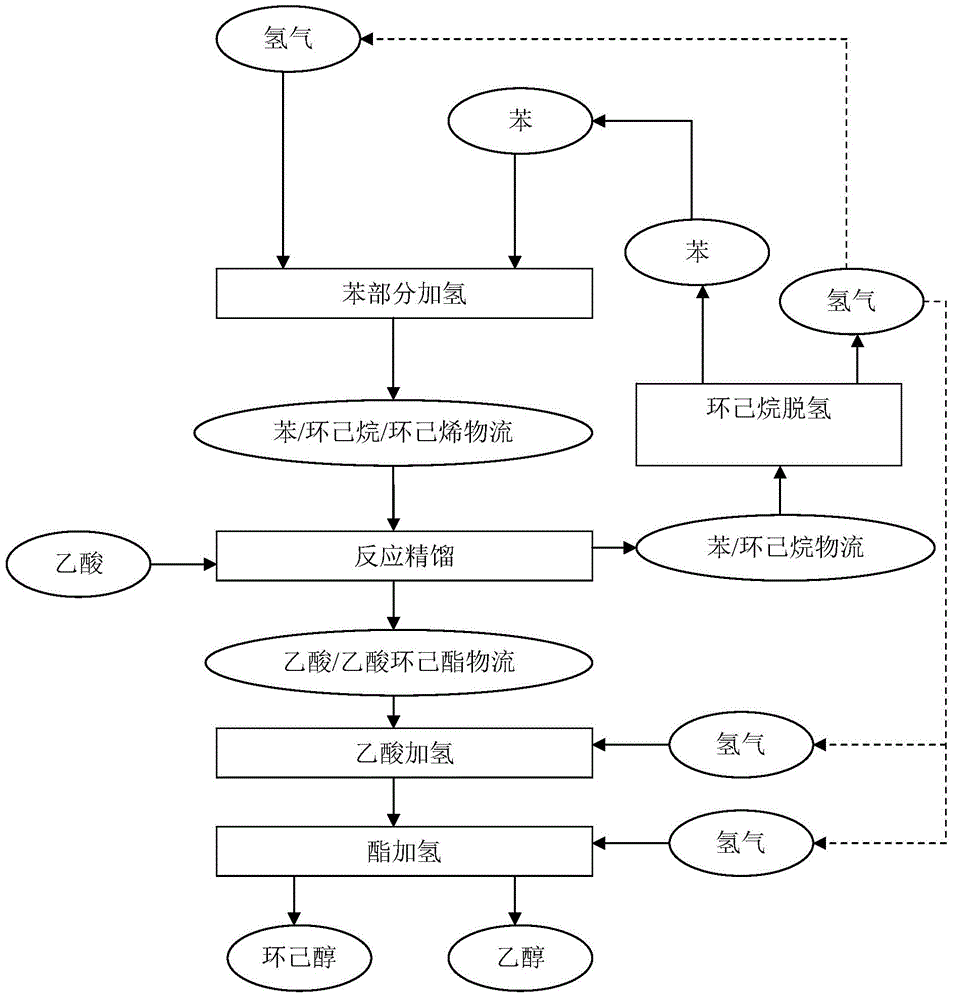

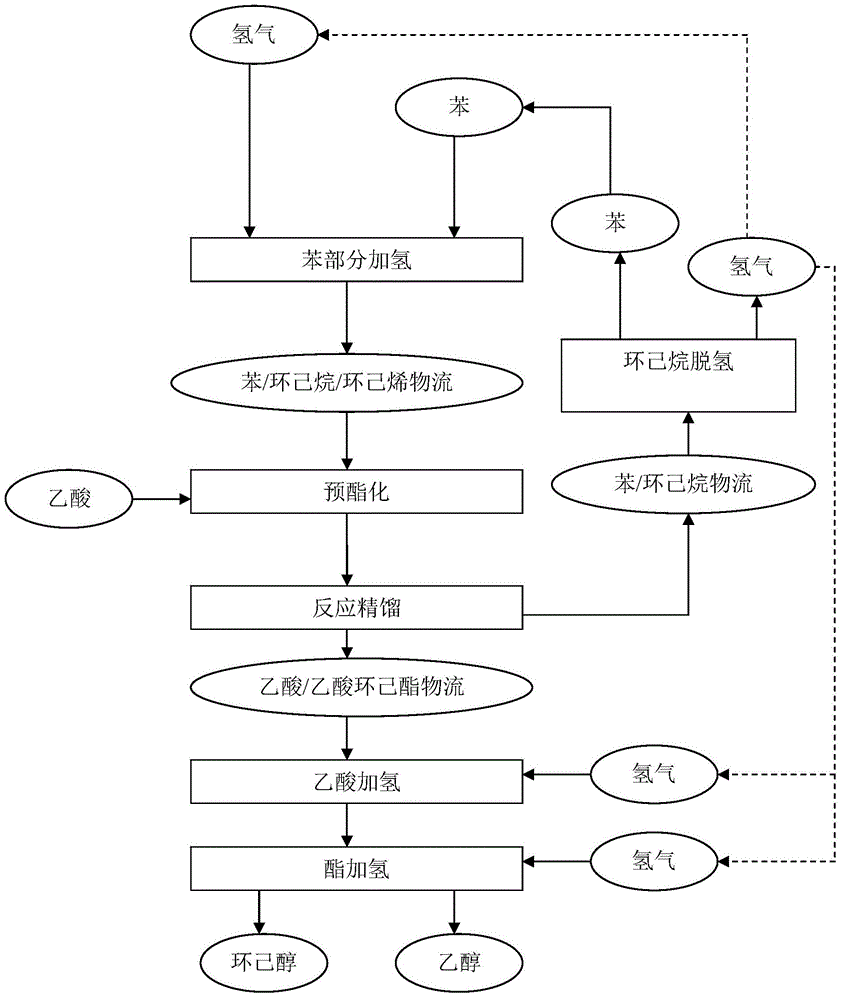

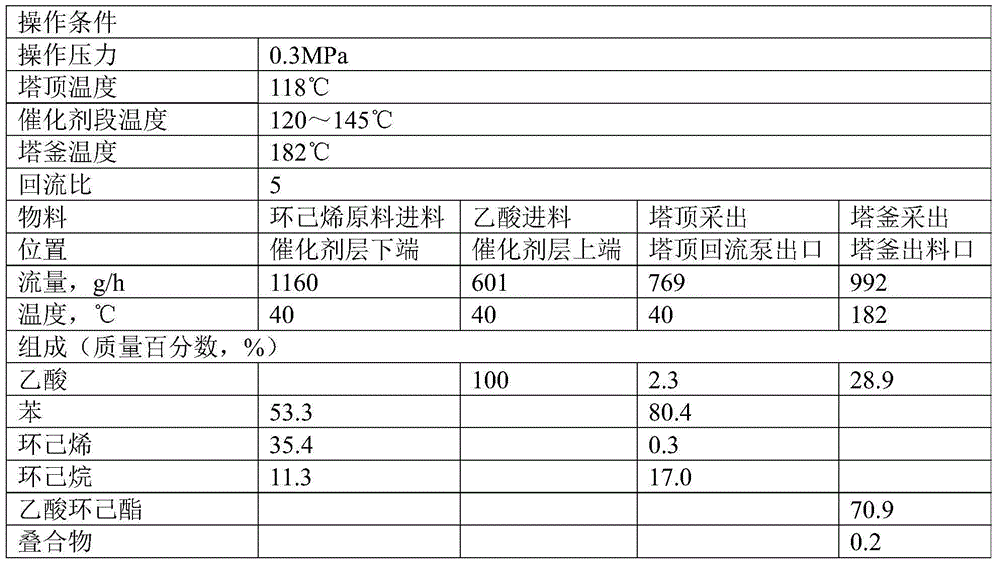

Method for coproducing cyclohexanol and alkanol

InactiveCN104557465AImprove efficiencyLow costOrganic compound preparationCarboxylic acid esters preparationBenzeneAcetic acid

The invention provides a method for coproducing cyclohexanol and alkanol. The method comprises the following steps: preparing benzene and / or cyclohexane into cyclohexene, carrying out addition-esterification on the cyclohexene in a catalytic distillation tower, obtaining carboxylic acid / cyclohexyl carboxylate material flow at the bottom of the tower, hydrogenating the material flow to obtain the cyclohexanol and the alkanol. The esterification and hydrogenation reactions in the method have high conversion rate and selectivity, and high atom economy; the process is environment-friendly; the alkanol is coproduced when the cyclohexanol is produced, in particular, when acetic acid is used, the cheap acetic acid is converted into ethanol with high cost and large market capacity in an indirect manner, so as to increase the economical efficiency of the process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing titanium-based catalyst and synthesizing epoxypropane and dicumyl peroxide

InactiveCN103212437AOvercoming multiple and environmental pollution problemsSolve pollutionMolecular sieve catalystsOrganic compound preparationCorrosionHydrogen peroxide

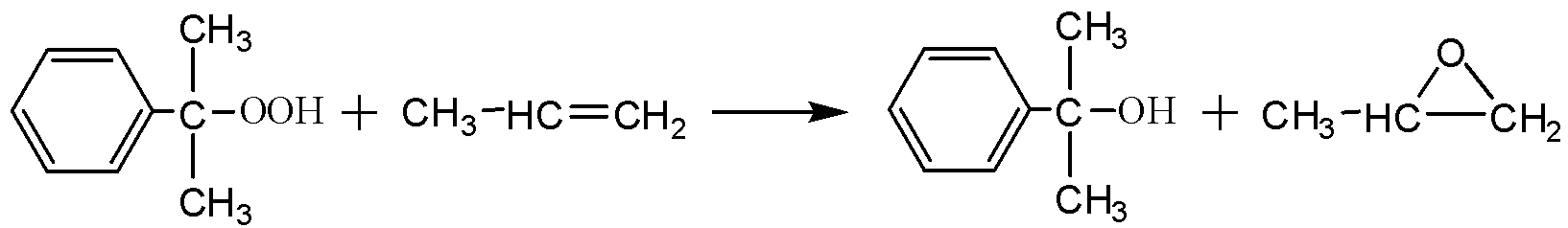

The invention discloses a method for preparing a titanium-based catalyst and synthesizing epoxypropane and dicumyl peroxide. According to the method, when the epoxypropane is synthesized on the basis of the titanium-based molecular sieve based catalyst, a byproduct, namely dimethyl-benzyl carbinol is continuously recycled to synthesize and prepare dicumyl peroxide; the problems of equipment corrosion, large quantity of byproducts and environmental pollution caused by the traditional chlorohydrins method and an indirect oxidation method are solved; the problem of environmental pollution caused by inorganic-salt-containing wastewater produced in a process of preparing the dicumyl peroxide by reducing cumyl hydroperoxide by using inorganic matters, such as water-soluble sulfur compounds is solved; and therefore the method is a synthesis process with high atom economy and has a favorable industrial application prospect.

Owner:DALIAN UNIV OF TECH

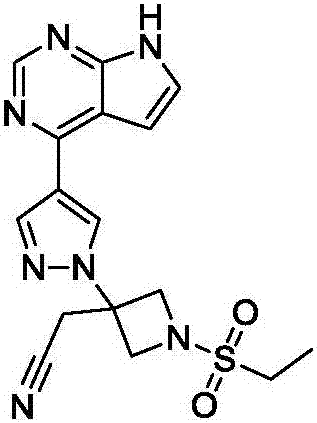

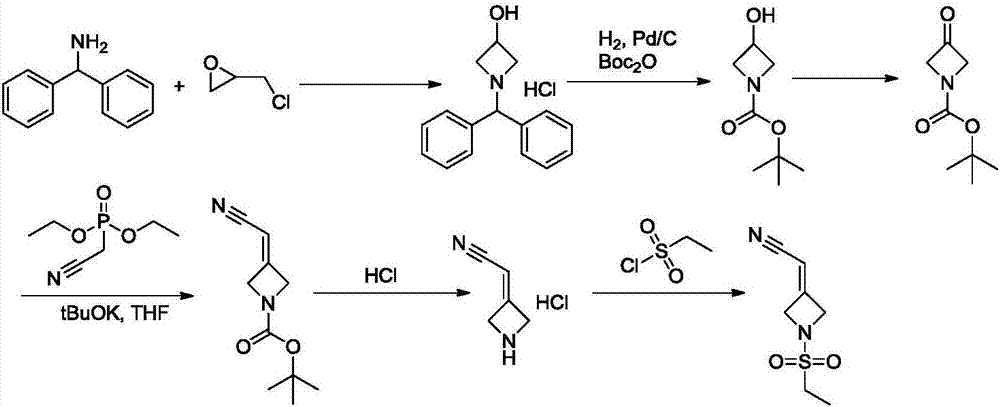

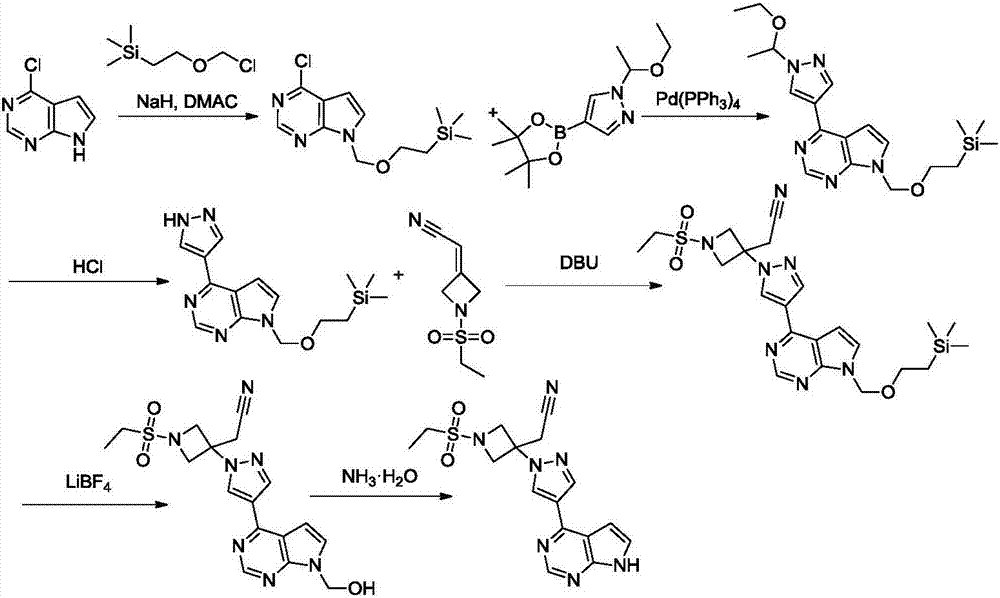

New synthesis methods of JCK inhibitor baricitinib and intermediate thereof

ActiveCN106946917AImprove efficiencyAtom economy is highGroup 3/13 element organic compoundsBulk chemical productionWittig reactionSynthesis methods

The present invention provides a new synthesis method of a baricitinib compound 11. According to the present invention, by using a compound 1 as a staring raw material, the amino group is protected by directly using ethanesulfonyl chloride, and direct cyclization is directly performed by using the effect of an alkali to obtain a key intermediate compound 3 so as to avoid the use of other protection groups and substantially improve the route efficiency and the atomic economy; during the compound 5 preparation, a Wittig reaction is performed by using triphenylphosphine acetonitrile so as to avoid the use of strong alkali and improve the reaction yield; the completely-new neopentyl glycol borate derivative compound 8 has good stability and good crystallinity so as to simplify the separation and purification process; and the route is simple to operate and has the high yield, the purity of the obtained product is high, and the synthesis method is suitable for amplification production. The formulas 1-11 are defined in the specification.

Owner:HANGZHOU CHEMINSPIRE TECH CO LTD

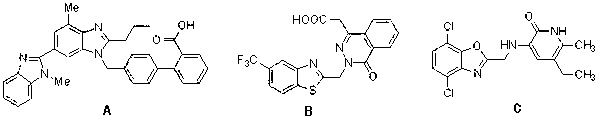

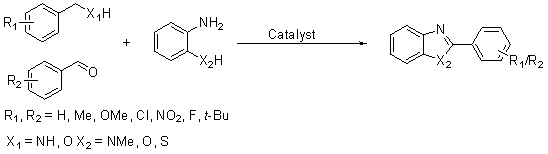

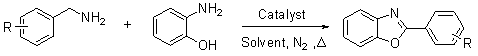

Method for preparing 2-substituted benzoxazole compound

The invention discloses a method for preparing a 2-substituted benzoxazole compound. According to the method, a benzylamine compound or a benzaldehyde compound or a benzyl alcohol compound, and o-toluidine-N-methyl-o-phenylenediamine, ortho-aminophenol and o-aminobenzenethiol serve as raw materials, metals palladium, platinum or ruthenium serves as a catalyst, and N,N-dimethylformamide, N,N-dimethylacetamide or N-methylpyrrolidone serves as a solvent. The method comprises the following preparation steps: (1) mixing the raw materials; (2) reacting; (3) separating and extracting; and (4) drying and concentrating. An oxidant and a hydrogen acceptor are not required in the whole preparation process, and the used partial catalysts can be recycled. The method is high in atom economy, simple in aftertreatment and mild in reaction conditions and has a certain industrial application prospect.

Owner:EAST CHINA UNIV OF SCI & TECH

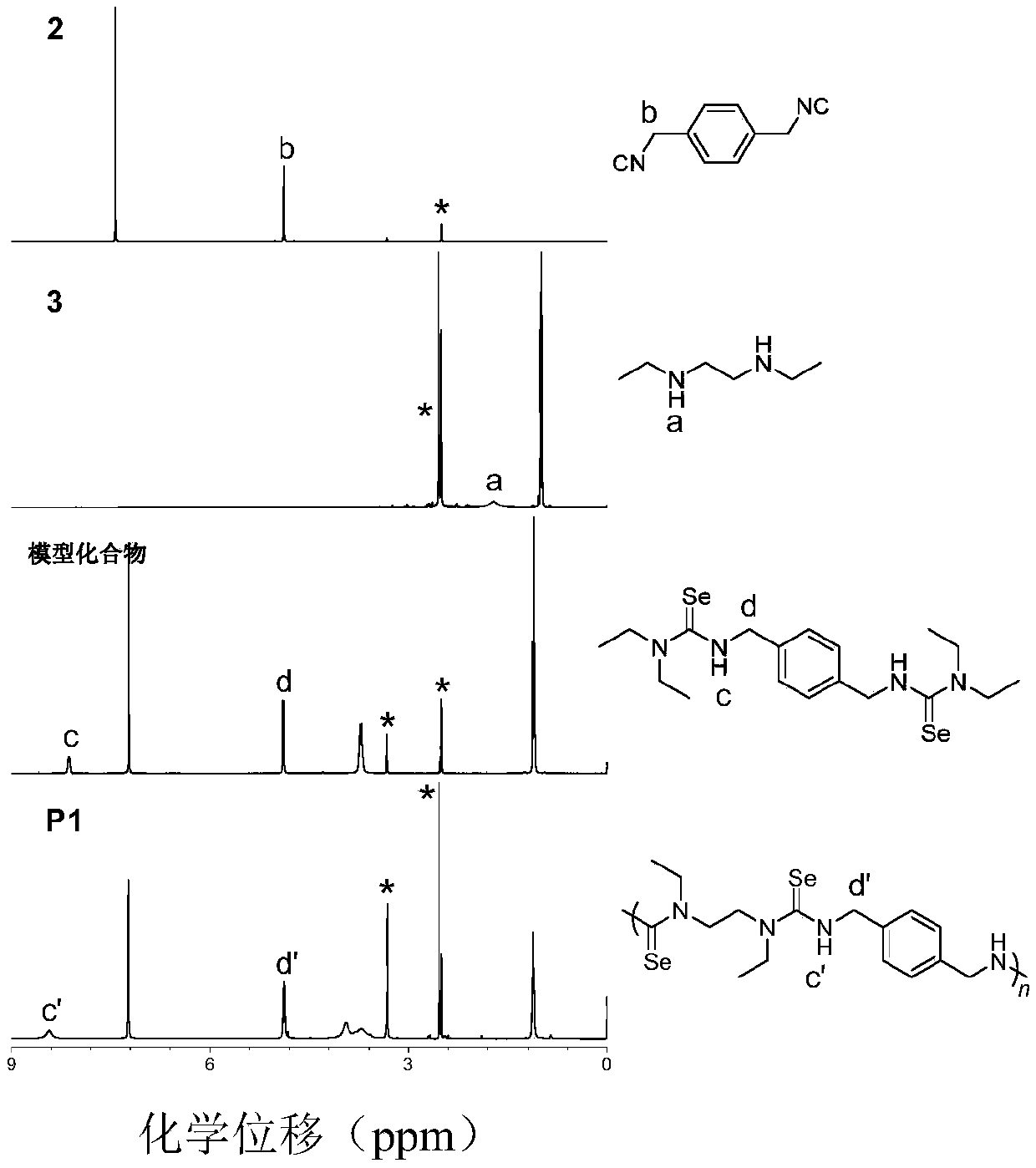

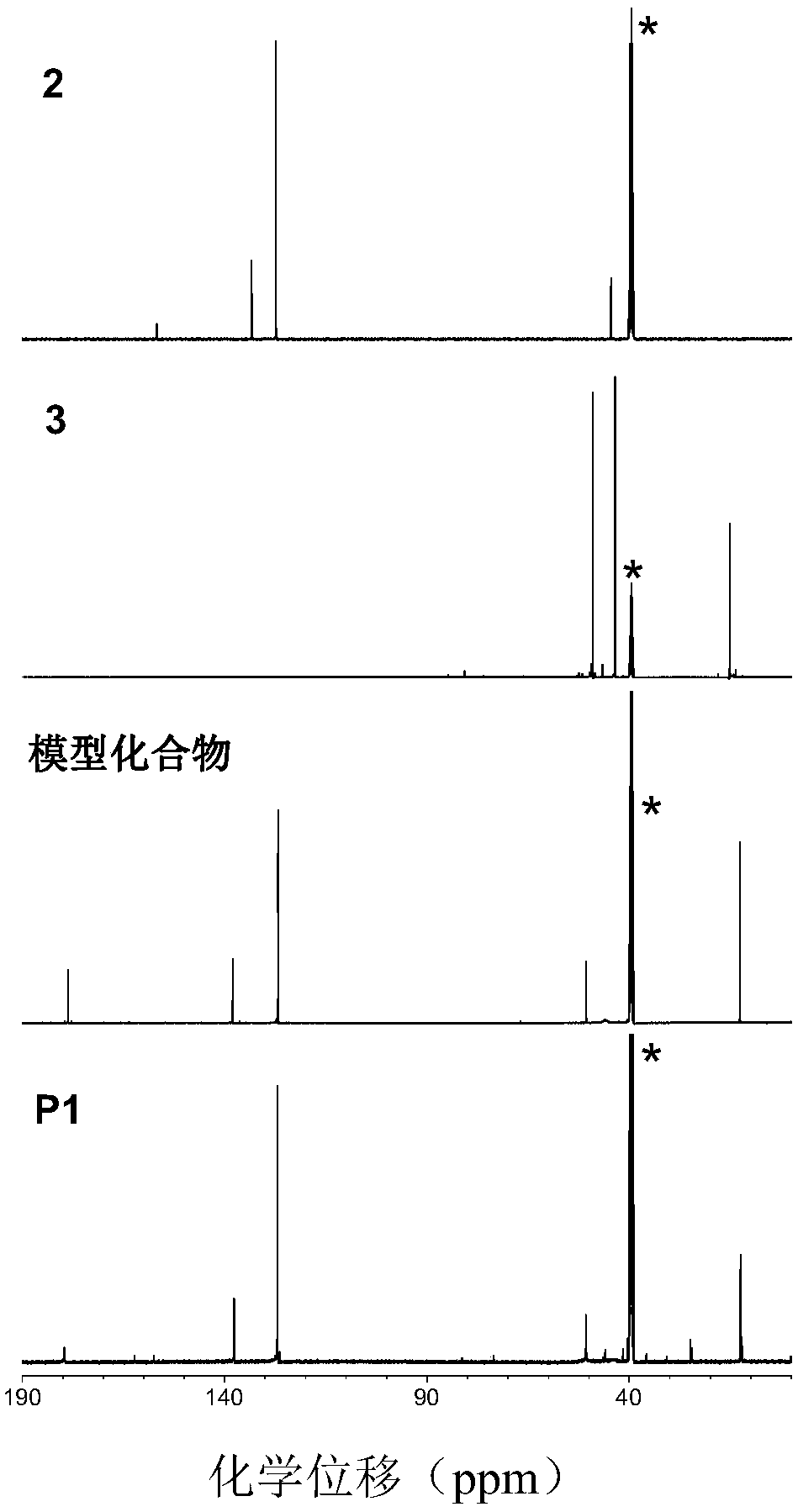

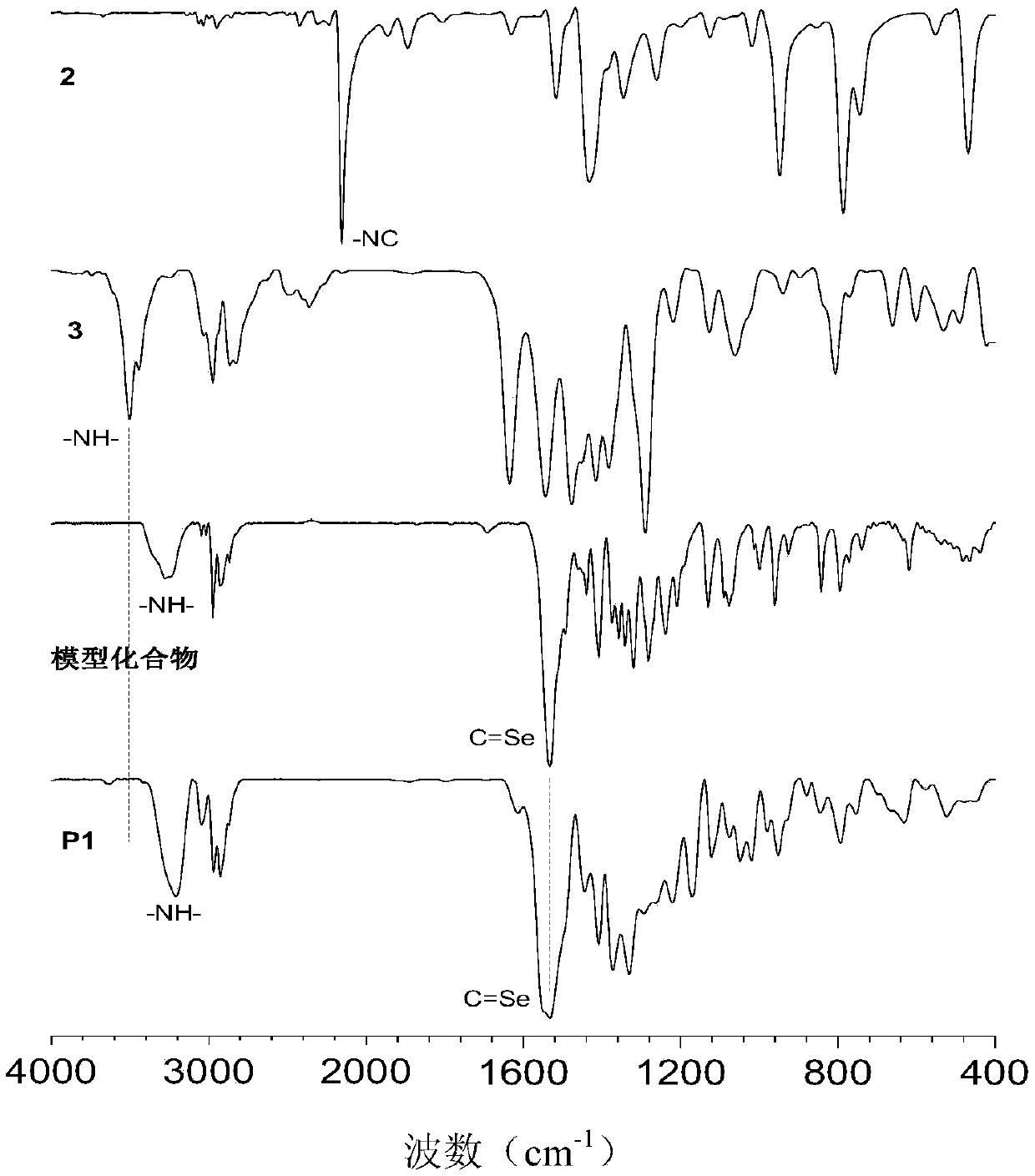

Method for preparing polyselenourea/polyselenoamide through multi-component polymerization of elemental selenium, isonitrile/alkyne and amine

The invention belongs to the technical field of preparation of selenium-containing polymers, and discloses a method for preparing polyselenourea / polyselenoamide through multi-component polymerizationof elemental selenium, isonitrile / alkyne and amine. The method comprises: carrying out a reaction on elemental selenium, a binary triple bond compound and a diamine in an organic solvent under an inert atmosphere, and subsequently treating to obtain a selenium-containing polymer, wherein the binary triple bond compound is binary isonitrile or binary alkyne, and the selenium-containing polymer is polyselenourea or polyselenoamide. According to the present invention, the method has characteristics of mild reaction conditions, high efficiency, energy saving, no catalyst, no by-product generation,atomic economy, green chemistry, low monomer toxicity, high atom utilization rate and high yield (more than or equal to 90%); the group has strong tolerance, and a variety of functional groups can beintroduced into the monomer; and the polyselenourea / polyselenoamide is stable, and can be degraded under specific conditions.

Owner:SOUTH CHINA UNIV OF TECH

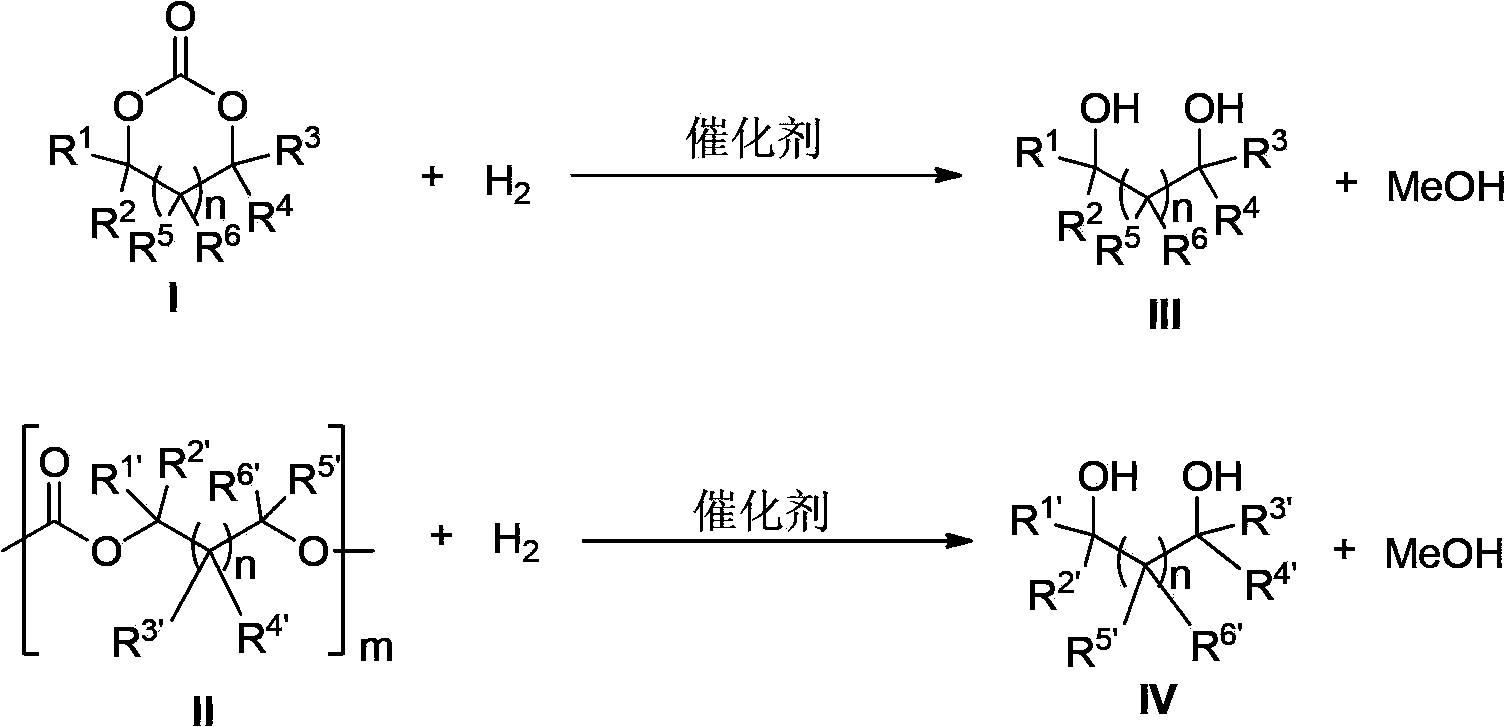

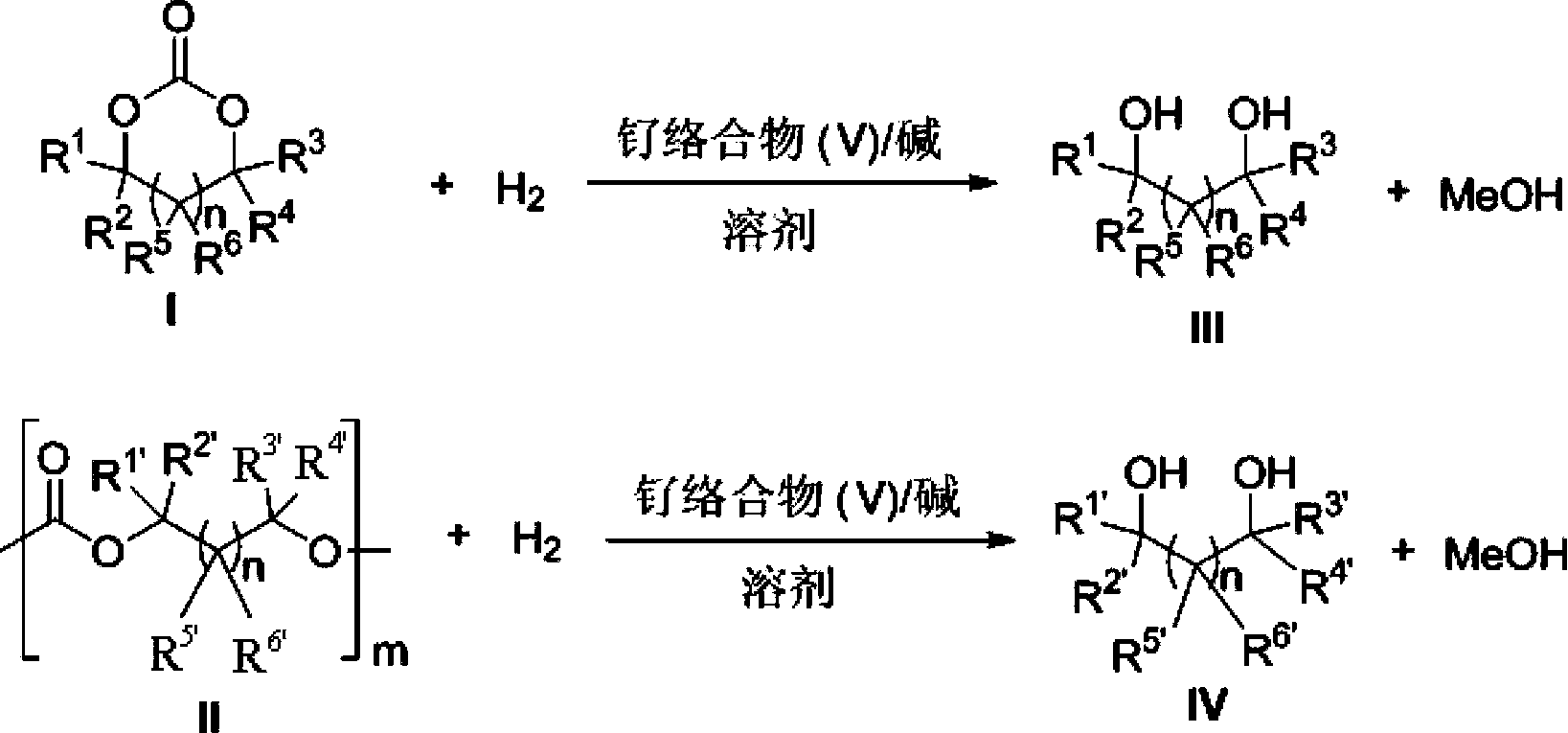

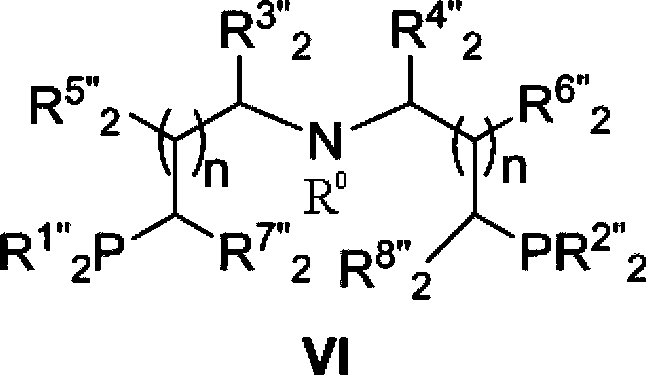

Novel ruthenium complex and method for preparing methanol and diol

ActiveCN103772142AFacilitate large-scale industrial productionImprove efficiencyRuthenium organic compoundsOrganic compound preparationOrganic solventHydrogen atmosphere

The invention provides a method for preparing methanol and diol from cyclic carbonates and polycarbonates. The method comprises: in hydrogen atmosphere, in an organic solvent, and in the presence of a ruthenium complex (Ru(L)XYY') and an alkali, performing hydrogenation reduction reaction on a cyclic carbonate or a polycarbonate, so as to obtain methanol and diol, wherein all groups in the formula are defined in the specification. The invention also provides the ruthenium complex formed by ruthenium and a tridentate amino diphosphine ligand. The invention also provides a method for preparing deuterated methanol and deuterated diol by employing the above preparation method. The method provided by the invention is high in efficiency, high in selectivity, economic, environment-friendly, and simple for operation, can be performed under mild conditions, and has complete atom economy.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

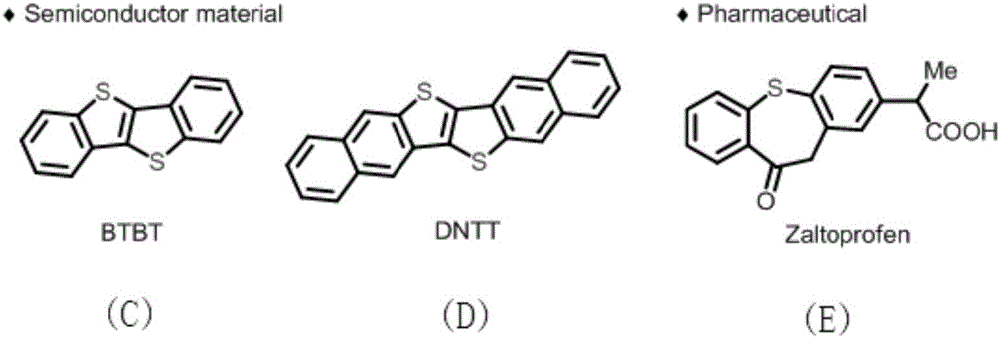

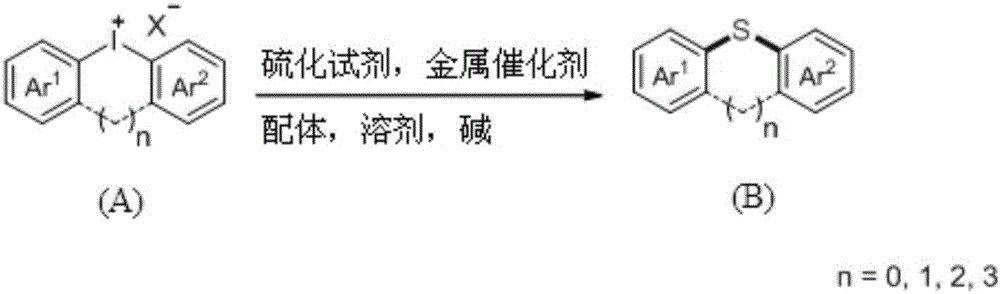

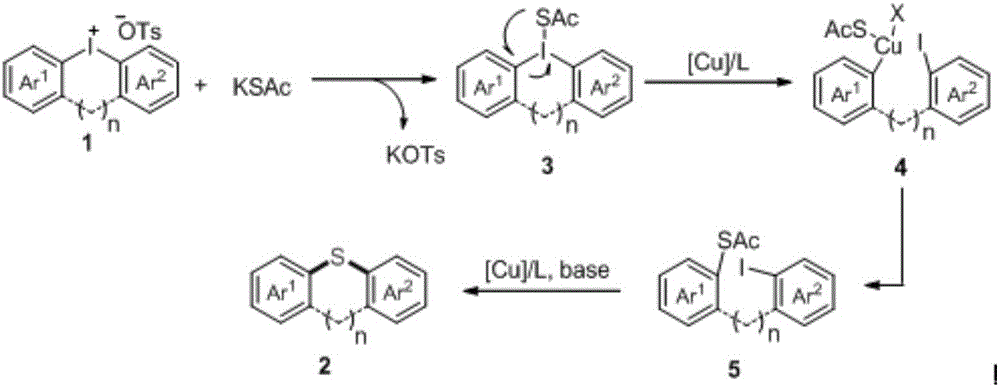

Diaryl thioether compound, and synthetic method and application thereof

The invention discloses a diaryl thioether compound, and a synthetic method and an application thereof. Various diaryl thioether compounds can be obtained through a reaction of a reaction raw material high iodine salt in dimethyl sulfoxide at 60-100DEG C under the action of an odorless sulfuration reagent, an alkali, a metal catalyst and a ligand for 3-12h. Sulfur is introduced in the later stage, so poisoning of sulfur to the metal catalyst and incompatibility of an oxidant in the early stage reaction are avoided; the above inorganic sulfur source is nontoxic and odorless; and two aryl groups in the high iodine salt are fully used, so the atom economy of the method is fully shown. The diaryl thioether compound prepared through the method can be further used to synthesize a photoelectric material BTBT and an anti-inflammatory drug zaltoprofen.

Owner:EAST CHINA NORMAL UNIV

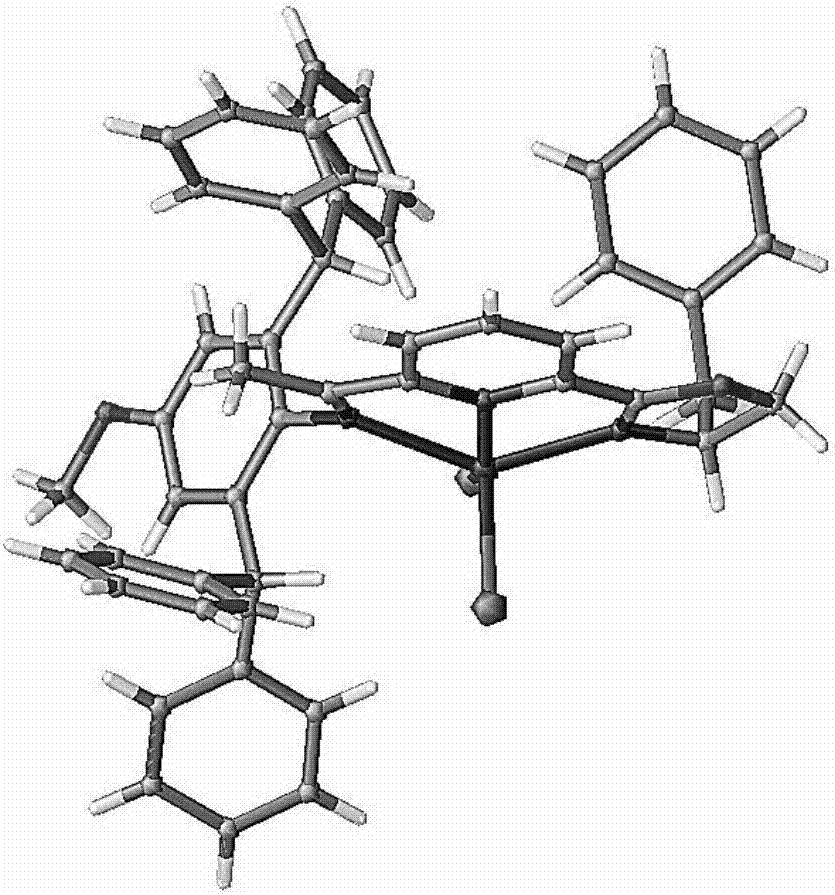

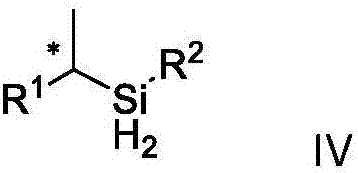

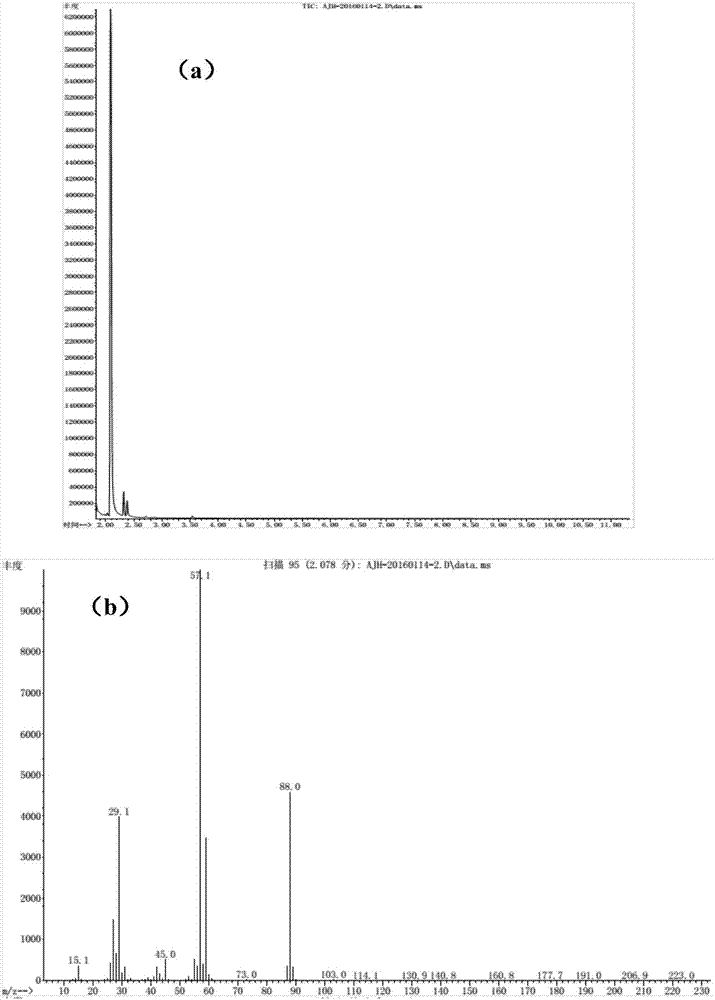

Chirality dihydrogen silane compound and synthetic method and application thereof

ActiveCN107235995AHigh selectivityHigh efficiency and high selectivitySilicon organic compoundsPreparation by oxidation reactionsSilanesEnantio selectivity

The invention discloses a chirality dihydrogen silane compound. The chirality dihydrogen silane compound is as shown in the formula IV. In the formula IV, X represents a chiral carbon atom. The invention further discloses a synthetic method for the chirality dihydrogen silane compound. The method comprises the following steps: using olefin shown in the formula I and silane shown in the formula II as raw materials, and using a chiral CoX2-OIP complex compound as a catalyst, in the existence of a reducing agent, reacting to obtain the chirality dihydrogen silane compound shown in the formula IV. The synthetic method is suitable for different types of the olefins, the reaction condition is moderate, the operation is simple and convenient, and the atomic economy is high. The reaction does not need to be added with any other toxic transition metal ions, the reaction yield is better and is 53%-97% generally, and the enantio-selectivity is higher and is 81%-99% and gt generally. The provided chirality dihydrogen silane compound shown in the formula IV can be used for synthesizing a chiral alcohol compound, a chiral silicon alcohol compound, a chiral polysubstituted silane compound and so on.

Owner:ZHEJIANG UNIV

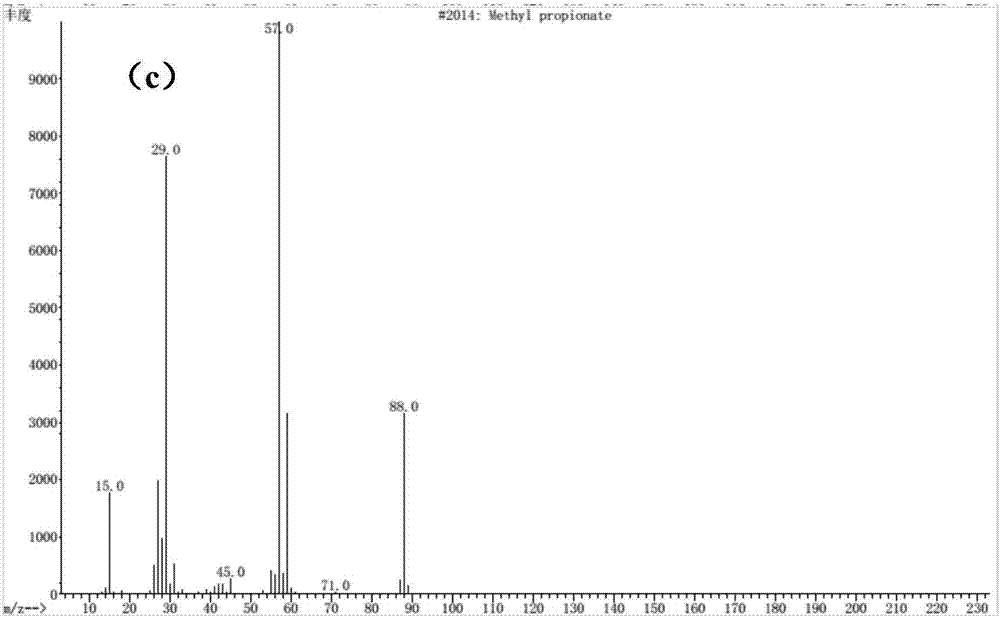

Methyl propionate preparation method

ActiveCN108003024ANo generationAtom economyPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsFixed bedReaction temperature

The invention relates to a methyl propionate preparation method, which comprises carrying out a reaction on raw materials including ethylene, carbon monoxide and methanol in a fixed bed reactor at a reaction temperature of 150-250 DEG C, wherein a reaction pipe is filled with a ruthenium-loaded metal oxide catalyst, and the reaction pipe with the catalyst is placed in the fixed bed reactor. According to the present invention, the reaction has the 100% atomic economy, does not produce by-products, and uses the noble metal-loaded metal oxide or the molecular sieve as the catalyst, wherein the catalyst is easily prepared and efficiently catalyzes the reaction, and the yield of methyl propionate can reach over 80% .

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com