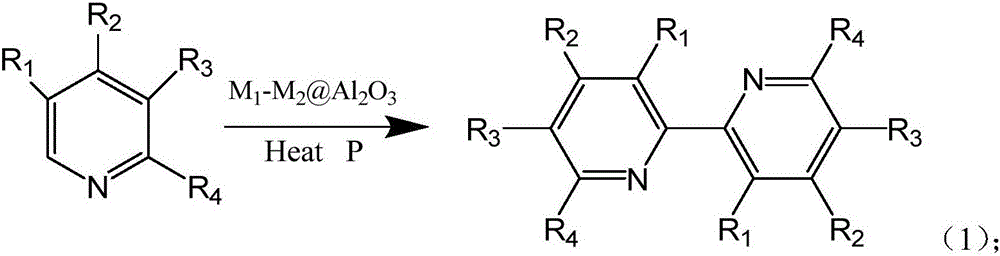

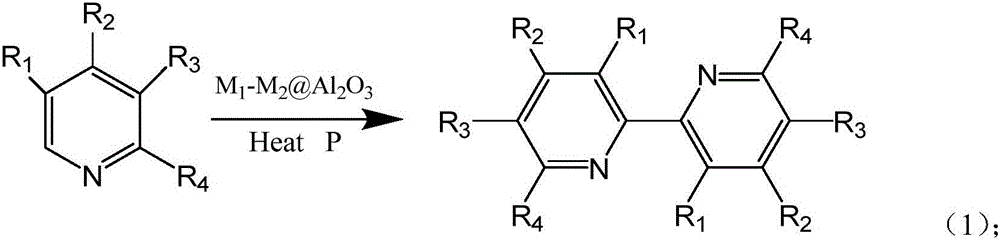

Synthesis method of 2,2'-dipyridine by using supported bimetal nano catalyst

A bimetallic nanometer and synthesis method technology, which is applied in the synthesis field of 2,2'-bipyridine, can solve the problems of complex synthesis route of metal complex catalyst, inconsistent nature pollution, limited production and application value, etc., and achieves high catalytic performance. Activity and product selectivity, easy recovery and reuse, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: In-situ loading method Pd@γ-Al 2 o 3 Preparation and catalytic reaction of metal nanocatalysts

[0032] (1) Preparation of catalyst

[0033] Weigh 2.00g PdCl 2 Put it into a container, add 20mL of deionized water, stir until completely dissolved; weigh 4g of γ-Al 2 o 3 Add it to the above solution, stir for 4 hours to form a paste, dry at 75°C for 12 hours, take out the above solid and grind it evenly, and put the ground particles in a nitrogen-hydrogen mixed atmosphere (the volume ratio of nitrogen and hydrogen is 1:1) 450 ℃ activation treatment for 4h, that is, to obtain 5.03g supported metal nanocatalyst Pd@γ-Al 2 o 3 .

[0034] (2) Catalytic synthesis of 2,2'-bipyridine

[0035] Catalyst 4g and 40g pyridine prepared by step (1) are added in autoclave, with N 2 Replace the O in it 2 Finally, seal the autoclave; start the autoclave to stir, and heat to the autoclave temperature of 400 ° C; stop heating after 8 hours of reaction, until the autoclav...

Embodiment 2

[0036] Example 2: Cu@γAl in situ loading method 2 o 3 Preparation and catalytic reaction of metal nanocatalysts

[0037] (1) Preparation of catalyst

[0038] Weigh 5.34g CuCl 2 2H 2 Put O into a container, add 20mL of deionized water, stir until completely dissolved; weigh 5g of γ-Al 2 o 3 Add it to the above solution, stir for 4 hours to form a paste, dry at 75°C for 12 hours, take out the above solid and grind it evenly, and put the ground particles in a nitrogen-hydrogen mixed atmosphere (the volume ratio of nitrogen and hydrogen is 1:1) 450 ℃ activation treatment for 5h, that is, 6.89g supported metal nanocatalyst Cu@γ-Al was obtained 2 o 3 .

[0039] (2) Catalytic synthesis of 2,2'-bipyridine

[0040] Catalyst 4g and 30g pyridine prepared by step (1) are added in autoclave, with N 2 Replace the O in it 2 Finally, seal the autoclave; start the autoclave to stir, and heat to the autoclave temperature of 400 ° C; stop heating after 10 hours of reaction, until the ...

Embodiment 3

[0041] Example 3: In-situ loading method Pd-Ni@γ-Al 2 o 3 (Pd and Ni molar ratio is 2:1) preparation and catalytic reaction of bimetallic nanocatalysts

[0042] (1) Preparation of catalyst

[0043] Weigh 2.34g PdCl 2 and 1.92g Ni(NO 3 ) 2 ·6H 2 O was put into a container, added 30mL of deionized water, and stirred until completely dissolved; weighed 4g of γ-Al 2 o 3 , added to the above solution and stirred for 4 hours to form a paste, dried at 75°C for 12 hours, the above solid was taken out and ground evenly, and the ground particles were placed in a nitrogen-hydrogen mixed atmosphere (the volume ratio of nitrogen and hydrogen was 1:1) 500 After activating at ℃ for 5.5h, 5.59g of supported bimetallic nanocatalyst Pd-Ni@γ-Al was obtained 2 o 3 .

[0044] (2) Catalytic synthesis of 2,2'-bipyridine

[0045] Catalyst 5.0g and 50g pyridine prepared by step (1) are added in the autoclave, with N 2 Replace the O in it 2 Finally, seal the autoclave; start the autoclave ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com