Preparation method of tetramethyl biphenyl

A technology of tetramethylbiphenyl and o-xylene, applied in the direction of condensation hydrocarbon production with dehydrocarbons, organic chemistry, etc., can solve the problem of increased reaction cost and reaction process, difficulties in the separation of halogenated o-xylene, post-treatment cumbersome and other issues, to achieve high atom economy, low equipment requirements, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

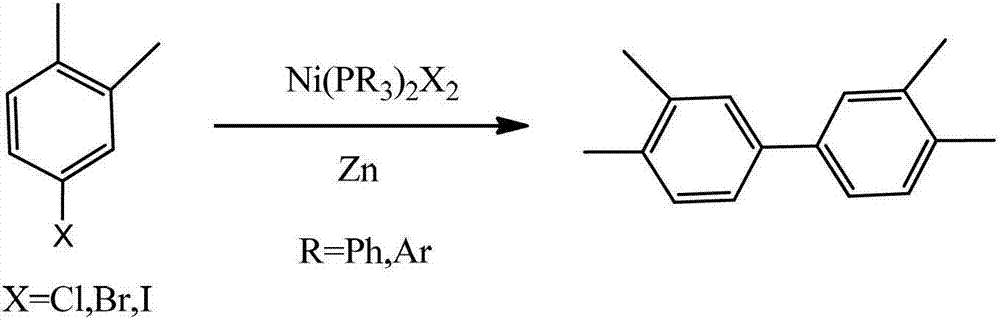

[0026] The invention provides a preparation method of tetramethyl biphenyl, which comprises: mixing o-xylene, an oxidant, an additive and a metal catalyst, and reacting to obtain tetramethyl biphenyl; the additive is an organic acid and / or an organic Acid anhydride; the oxidant is an inorganic oxidant and / or an organic oxidant containing an oxidizing transition metal cation.

[0027] Wherein, the inorganic oxidant may be an inorganic oxidant well-known to those skilled in the art, and there is no particular limitation, and the organic oxidant containing an oxidizing transition metal cation is a well-known oxidizing transition metal cation known to those skilled in the art The organic oxidizing agent of the metal cation may be used, and is not particularly limited. The oxidant in the present invention is preferably potassium persulfate, sodium persulfate, ammonium persulfate, potassium hydrogen persulfate, sodium hydrogen persulfate, copper acetate, copper nitrate, copper sulfa...

Embodiment 1

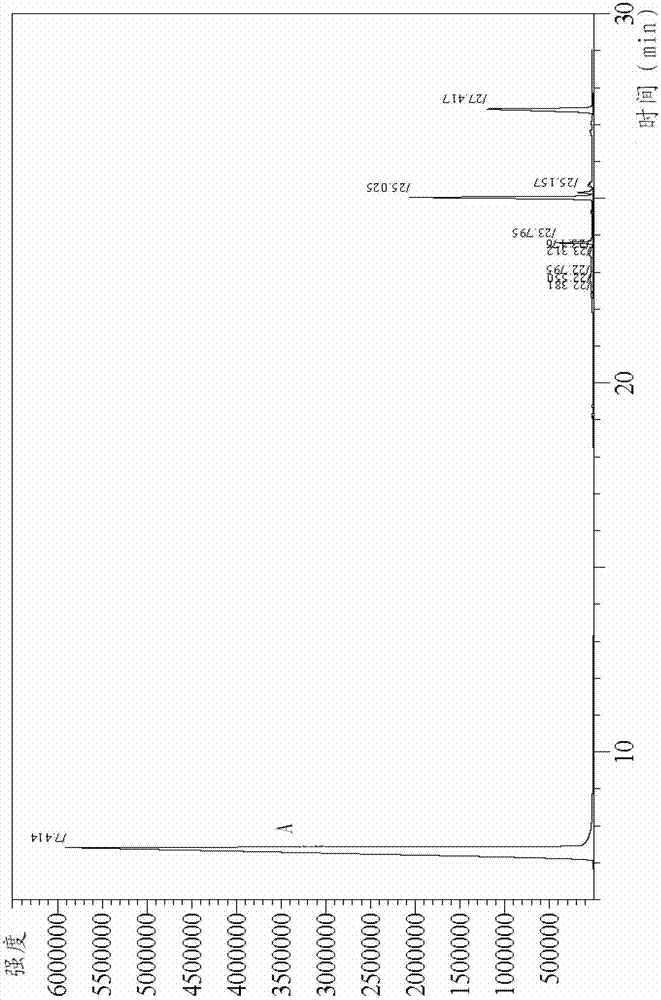

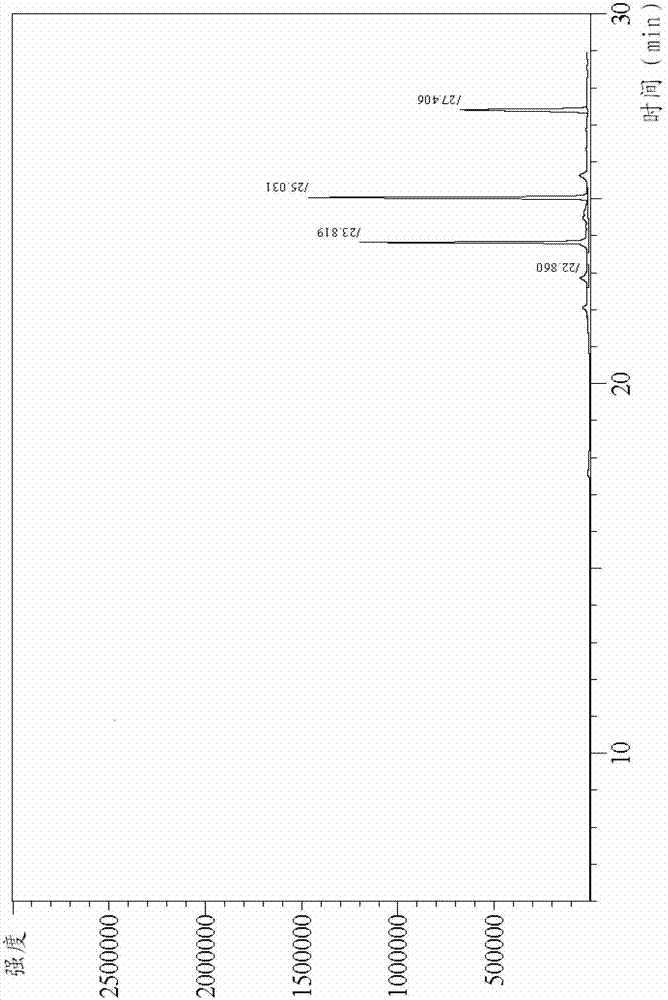

[0043] Mix 56.0 mg (0.2 mmol) of palladium acetate, 6.48 g (24 mmol) of potassium persulfate, 6.0 ml (50 mmol) of o-xylene and 1.5 ml (20 mmol) of trifluoroacetic acid, heat to 45 ° C, stir the reaction for 13 h, and then use saturated The acid in the system is neutralized by sodium bicarbonate, and the organic phase is analyzed by gas chromatography, and the conversion rate of o-xylene to tetramethyl biphenyl is 27.3%, of which 3,3′,4,4′-tetramethylbiphenyl , The molar ratio of 2,2',3,3'-tetramethylbiphenyl to 2,3,3',4'-tetramethylbiphenyl is 0.09:1.07:1, such as figure 1 shown, where A is o-xylene, figure 2 Gas chromatogram of mixed tetramethylbiphenyl standard sample.

Embodiment 2

[0045] Mix 56.0 mg (0.2 mmol) palladium acetate, 2.16 g (8 mmol) potassium persulfate, 6.0 ml (50 mmol) o-xylene and 1.5 ml (20 mmol) trifluoroacetic acid, heat to 45 ° C, stir the reaction for 13 h, and then use saturated The acid in the system was neutralized by sodium bicarbonate, and the organic phase was analyzed by gas chromatography, and the conversion rate of o-xylene to tetramethyl biphenyl was 11.8%, of which 3,3′,4,4′-tetramethylbiphenyl The molar ratio of 2,2',3,3'-tetramethylbiphenyl to 2,3,3',4'-tetramethylbiphenyl is 0.07:0.79:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com