Patents

Literature

257 results about "Organic acid anhydride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An organic acid anhydride is an acid anhydride that is an organic compound. An acid anhydride is a compound that has two acyl groups bonded to the same oxygen atom. A common type of organic acid anhydride is a carboxylic anhydride, where the parent acid is a carboxylic acid, the formula of the anhydride being (RC(O))₂O. Symmetrical acid anhydrides of this type are named by replacing the word acid in the name of the parent carboxylic acid by the word anhydride. Thus, (CH₃CO)₂O is called acetic anhydride. Mixed (or unsymmetrical) acid anhydrides, such as acetic formic anhydride (see below), are known, whereby reaction occurs between two different carboxylic acids. Nomenclature of unsymmetrical acid anhydrides list the names of both of the reacted carboxylic acids before the word "anhydride" (for example, the dehydration reaction between benzoic acid and propanoic acid would yield "benzoic propanoic anhydride").

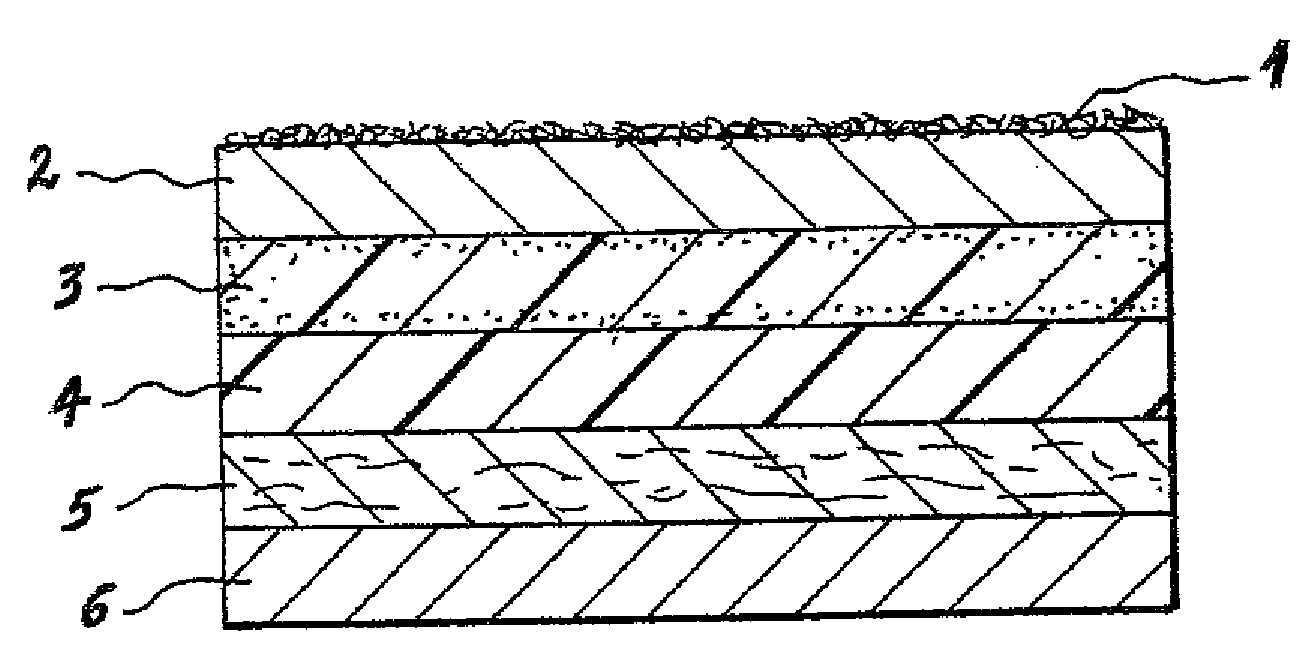

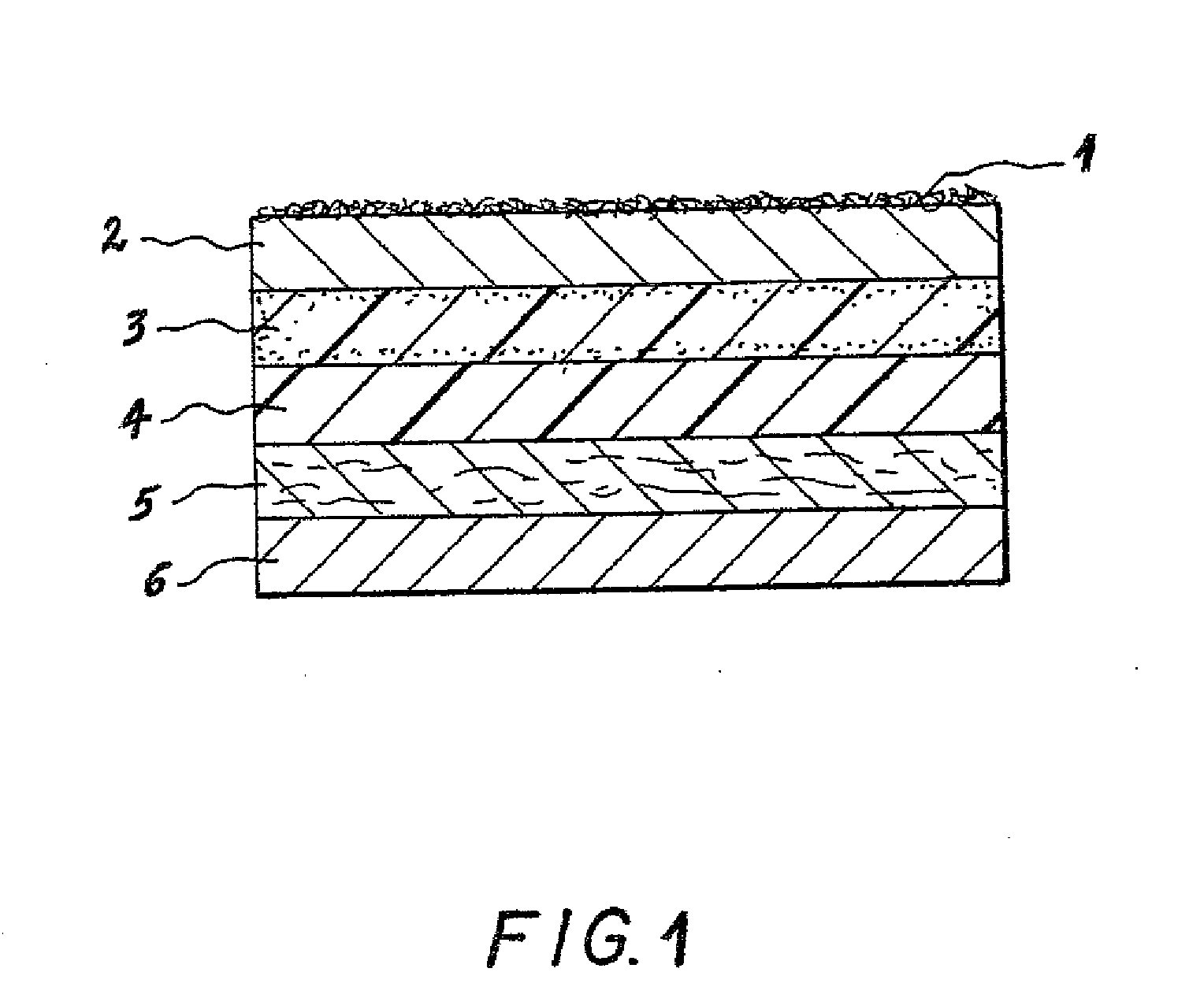

Carpet Tiles and Methods Of Making Same

InactiveUS20080233336A1Strong adhesionHigh bonding strengthWood working apparatusSurface layering apparatusBrickPolyolefin

Modular carpet tiles having multiple layers are described, including a laminate layer having a compatibilizing agent. The laminate layer can include at least one polyolefin functionalized with at least one unsaturated organic acid and / or at least one unsaturated organic acid anhydride, such as maleic anhydride. The functionalized polyolefin can have an acid number from about 5 to about 55 mg KOH / g. Methods of making the tiles are also described.

Owner:MANNINGTON MILLS

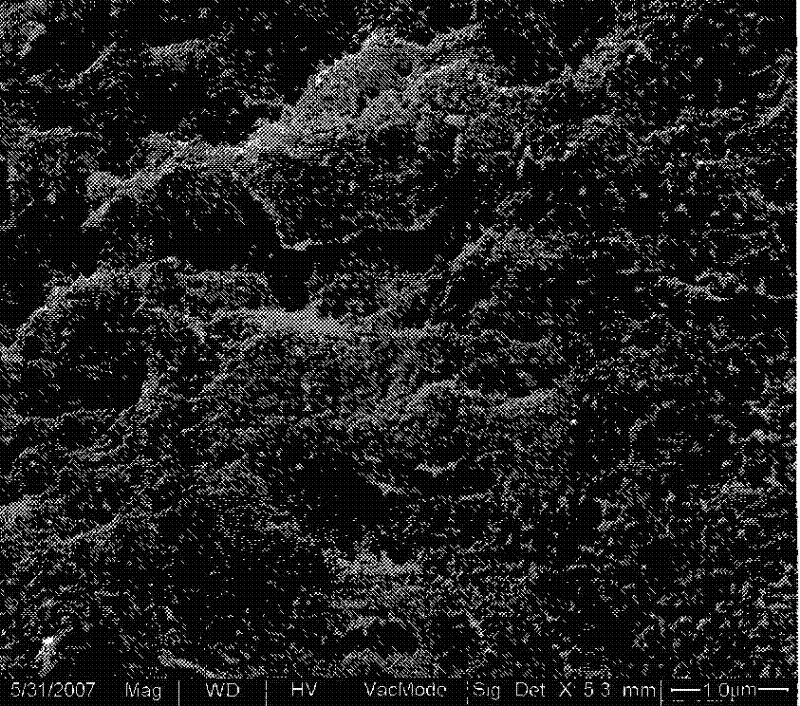

Preparation method of multidimensional hybrid composite of glass fibre/ grapheme- carbon nano tube/ epoxy resin

InactiveCN102304274AIncreased interlaminar shear strengthImprove interface strengthCarbon nanotubeResin matrix

The invention relates to a preparation method of multidimensional hybrid composite of glass fibre / grapheme-carbon nano tube / epoxy resin. In the method, after grapheme-carbon nano tube network structure is subjected to surface carboxylation, diamine or polyamine is introduced on the grapheme-carbon nano tube network structure; the grapheme-carbon nano tube connected with the amino is modified by micromolecule aromatic polybasic anhydride compound to prepare the carbon nano tube carried with an anhydride group; the grapheme-carbon nano tube is dispersed in the epoxy resin matrix by ultrasonic oscillation and high-speed stirring; organic acid anhydride curing agent is adopted for curing; and the obtained epoxy resin polymer containing the grapheme-carbon nano tube serves as the matrix to be compounded with glass fiber processed by silane coupling agent to form a multifunctional hybrid composite structure connected by covalent bonds. The multidimensional hybrid composite is convenient to prepare, the application range of the glass fiber, the grapheme, the carbon nano tube and the epoxy resin is widened, so that the hybrid composite can be widely applied on the aspects of aerospace, traffic transportation, electronic industry, civil facilities, building, chemical engineering and the like, can be industrially produced on a large scale, has low cost and is friendly to environment.

Owner:TONGJI UNIV

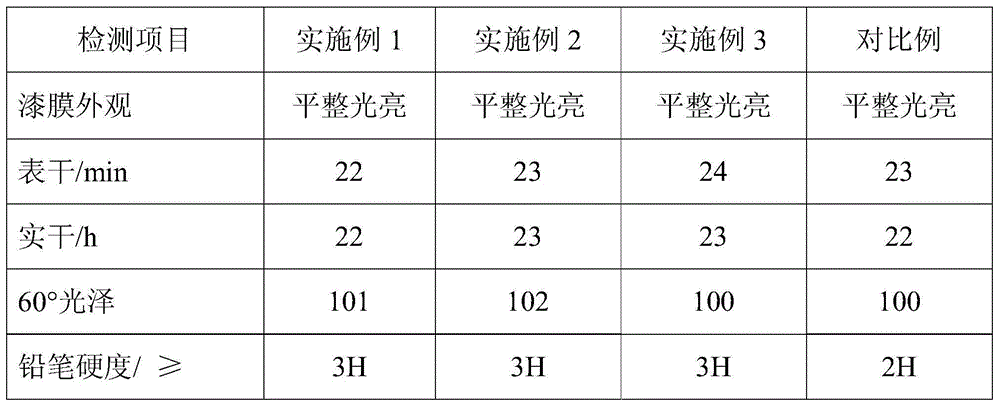

Isocyanate modified alkyd resin and preparation method thereof

The invention relates to isocyanate modified alkyd resin and a preparation method thereof. Isocyanate is utilized to modify alkyd resin, and the alkyd resin containing an ammonia ester structure is synthesized. The basic formula comprises, by weight: 20-33% of plant oil, 5-8% of polyatomic alcohol, 2-8% of organic acid anhydride, 5-10% of the isocyanate, 0.02-0.5% of catalyst, 35-50% of solvent and 3-8% of terminator. Varnish and enamel paint prepared by the isocyanate modified alkyd resin are better than ordinary middle-long-oil-degree alkyd resin paint in aspects of dryness, hardness, water resistance and the like, and are better than double-component polyurethane paint in aspects of toxicity, application property, odor and the like. The isocyanate modified alkyd resin is widely applied to the surfaces of products made of wood, metal, plastic and the like to have functions of protection and decoration. Due to the fact that the isocyanate modified alkyd resin is both hard and soft, the isocyanate modified alkyd resin has certain resistance to stone strike, can serve as primer and repair paint of agricultural vehicles and trucks, and has good market prospects accordingly.

Owner:UNION FOSHAN CHEM

Electroconductive metal paste

InactiveCN1478285AEasy high reproducibilityInhibition of agglomerationConductive materialMetal-working apparatusMetal particleAcid anhydride formation

This invention provides a low-temperature sintering conductive paste for high density circuit printing which can form a fine circuit having good adhesive force, a smooth surface and low resistance when applied on a substrate and then baked; the conductive paste of the invention uses, as conductive media, in combination with metal fillers having an average particle diameter of 0.5 to 20 mum, ultrafine metal particles having an average particle diameter of not larger than 100 nm, which are set in the state that the surfaces thereof are coated with one compound or more having a group comprising a nitrogen, oxygen, or sulfur atom and capable of coordinate-bonding by a lone pair existing in the atom, as a group capable of coordinate-bonding to a metal element contained in the ultrafine metal particles, and are dispersed uniformly in a resin composition comprising a heat curable resin component, an organic acid anhydride or a derivative thereof or an organic acid, and one or more organic solvent; and thereby it enables low-temperature sintering of the ultrafine metal particles during a heat treatment at a low temperature.

Owner:HARIMA CHEM INC +1

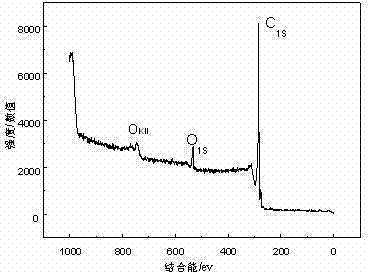

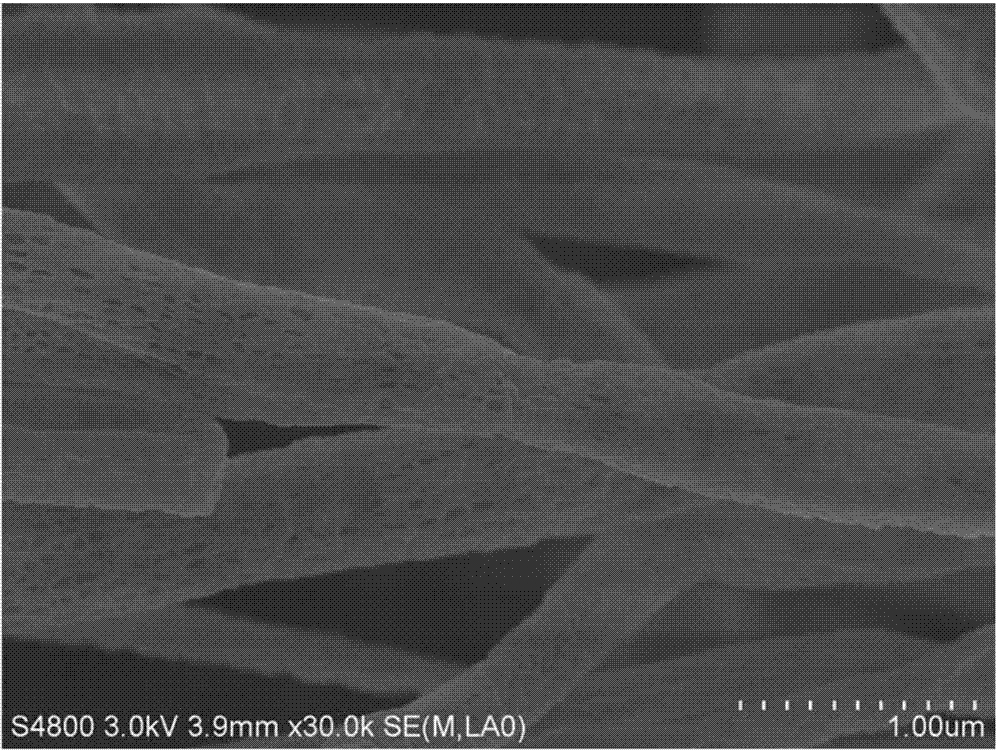

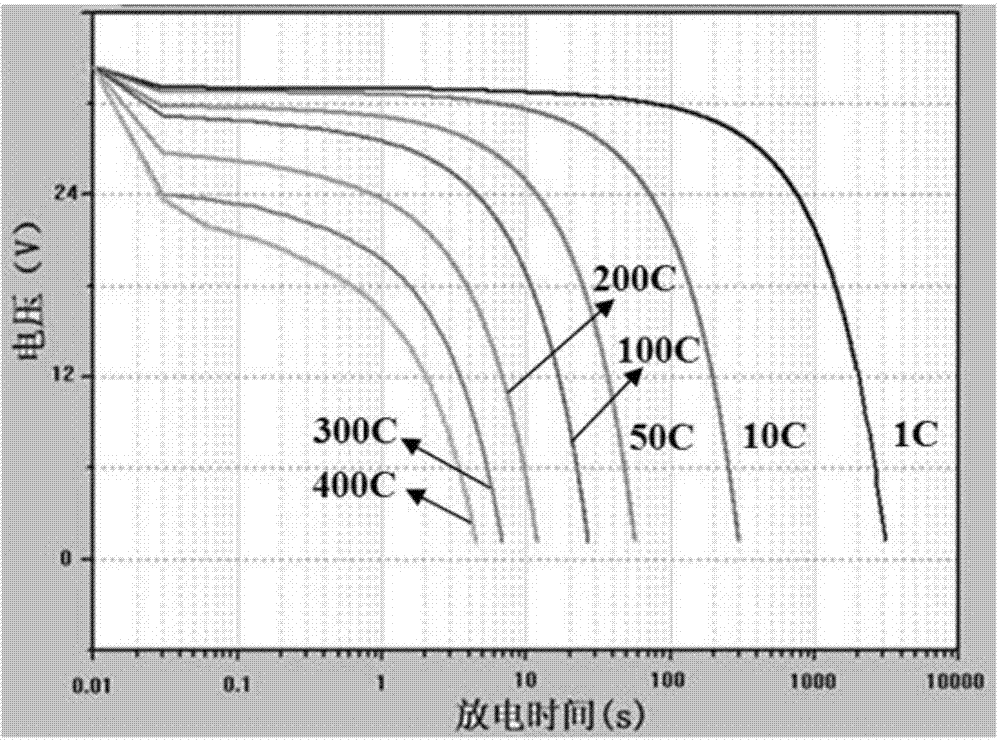

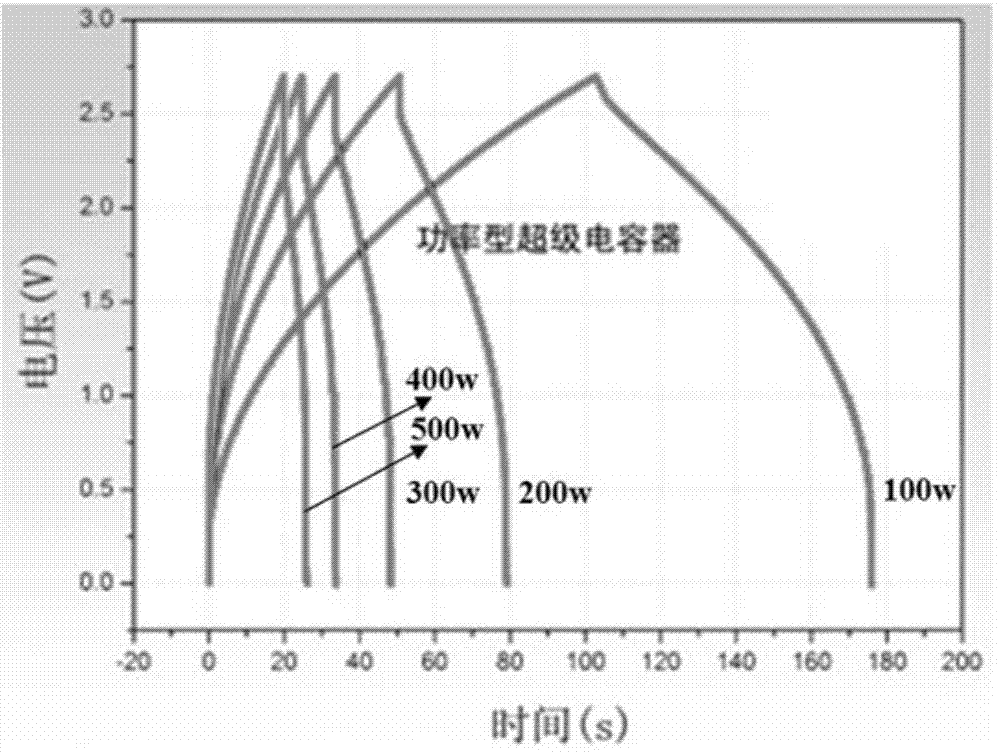

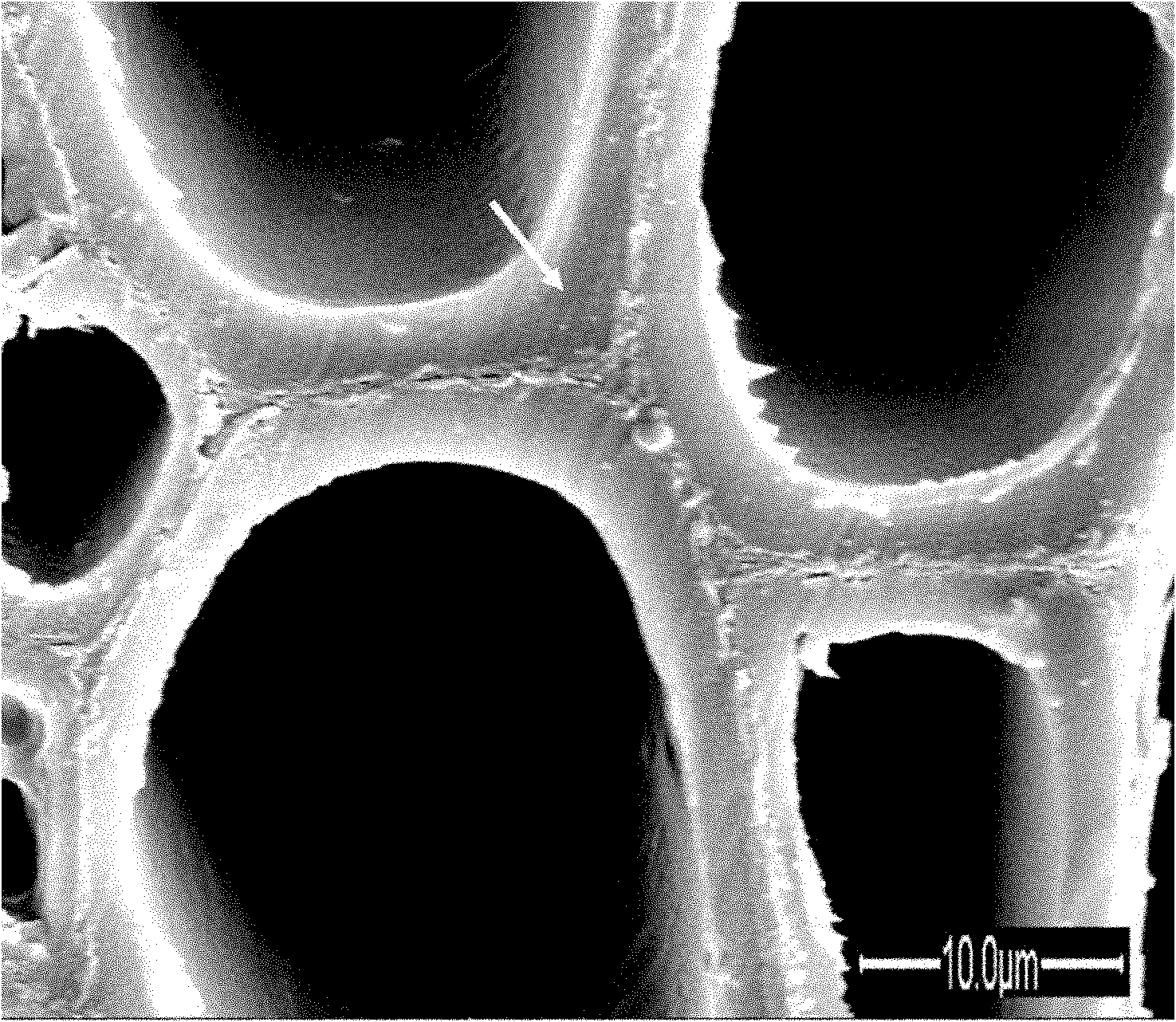

Method for preparing polyimide porous nanofiber electrode diaphragm

ActiveCN104752665AImprove stabilityHigh mechanical strengthHybrid capacitor separatorsCell component detailsMetal oxide nanoparticlesAcid anhydride formation

The invention discloses a method for preparing a polyimide porous nanofiber electrode diaphragm. The method comprises the following steps: carrying out condensation reaction by adopting binary organic amine and binary organic acid anhydride in an organic solvent, thereby obtaining a polyamide acid solution; adding a soluble metal salt to prepare a spinning precursor, preparing a polyamide acid-metal salt electrostatic spinning fiber diaphragm by virtue of high-voltage electrostatic spinning, and performing thermal imidization treatment, thereby obtaining a polyimide-metallic oxide fiber composite diaphragm; and dissolving the composite diaphragm in an inorganic acid aqueous solution for performing acid treatment, so that metallic oxide nanoparticles are converted into soluble metal salts so as to be dissolved in the inorganic acid aqueous solution so as to obtain the polyimide nano / micron porous fiber diaphragm. The method has the advantages that according to the polyimide nano / micron porous fiber diaphragm, the mechanical strength, thermal stability, liquid holdup, permeability, wettability and migration rate of conductive ions of the diaphragm can be effectively improved, and the liquid junction resistance of the diaphragm and electrolyte and the contact resistance of the diaphragm and the electrode can be reduced, so that the electrochemical performance of a supercapacitor is improved.

Owner:锦州凯美能源有限公司

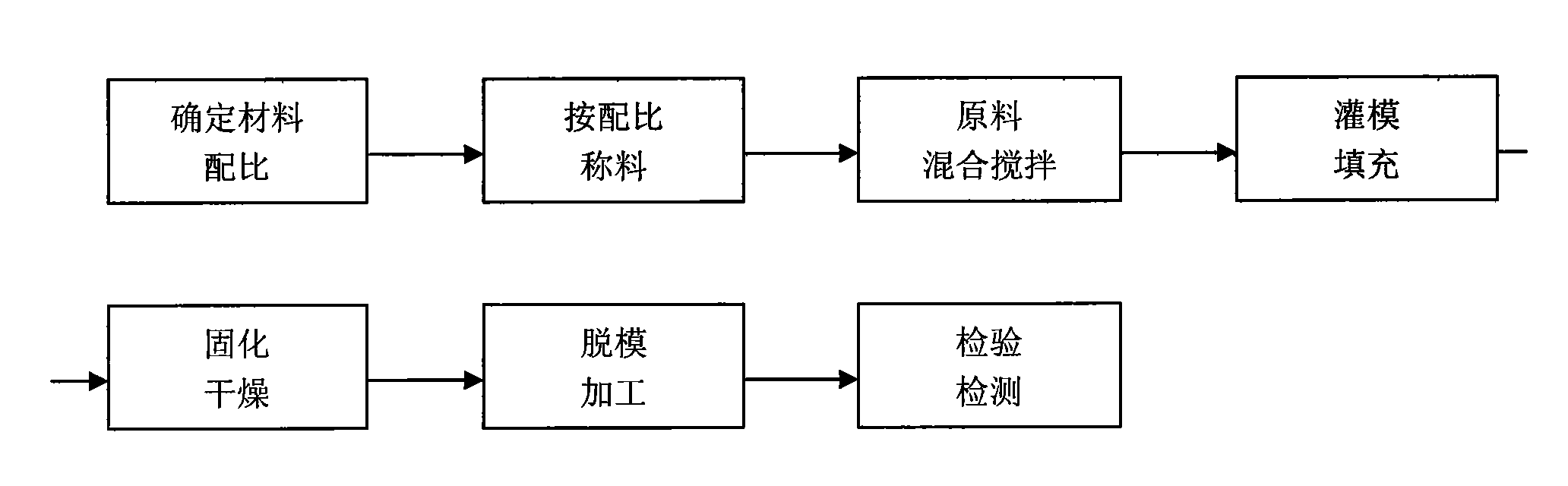

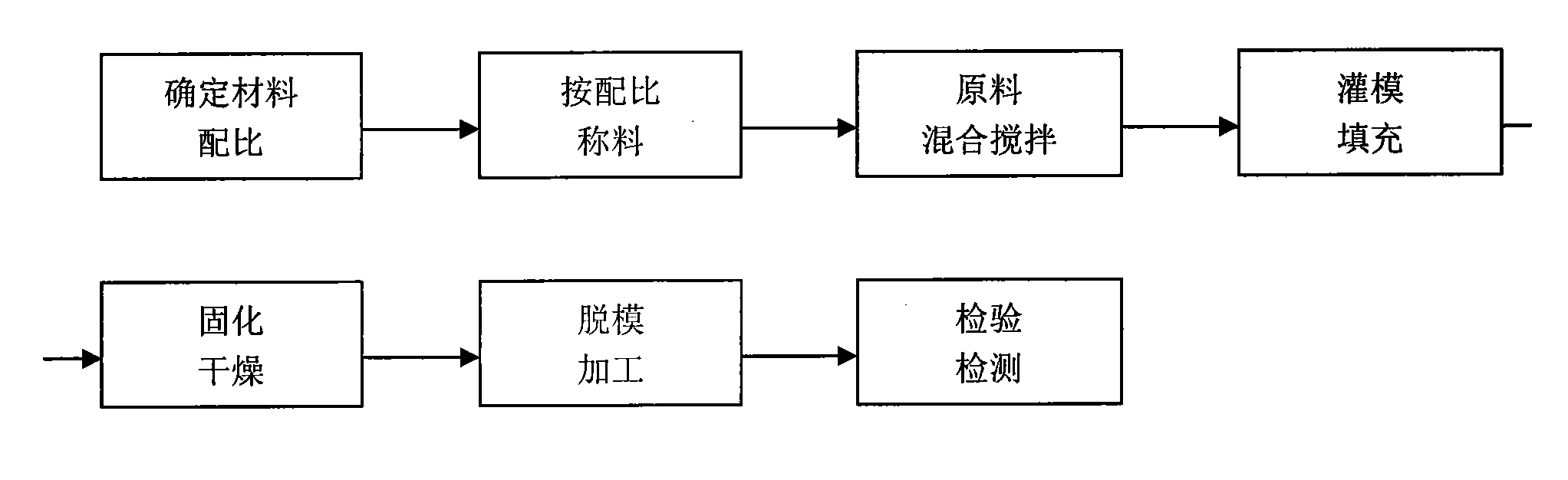

Machinable solid buoyancy material and preparation method thereof

The invention relates to a machinable solid buoyancy material and a preparation method thereof. The machinable solid buoyancy material belongs to a functional nonmetallic material and comprises the following components in part by mass: 100 parts of epoxy resin, 15 to 55 parts of amine epoxy curing agent and 30 to 130 parts of glass beads, wherein the epoxy resin is bisphenol S type epoxy resin or glycidol epoxy resin; and the amine epoxy curing agent is polyamide 650, polyamide 651, tertiary nitrogen type organic amine or quaternary nitrogen type organic amine, bismaleimide, low molecular weight polyacrylamide, imidazoles or organic acid anhydride compounds. The preparation method comprises the following steps of: heating the epoxy resin and the amine epoxy curing agent, weighing the epoxy resin and the amine epoxy curing agent, blending and stirring the epoxy resin and the amine epoxy curing agent, adding the glass beads, stirring again, kneading the materials, after taking the material out, coating a mould release agent on the inner wall of a die and sticking mould release paper; filling the material into the die; covering by using a cover; curing the die in a drying oven; and separating the material from the die on a demoulding machine. The machinable solid buoyancy material can meet the requirements on underwater projects, permanent buoys and the like.

Owner:710TH RES INST OF CHINA SHIPBUILDING IND CORP

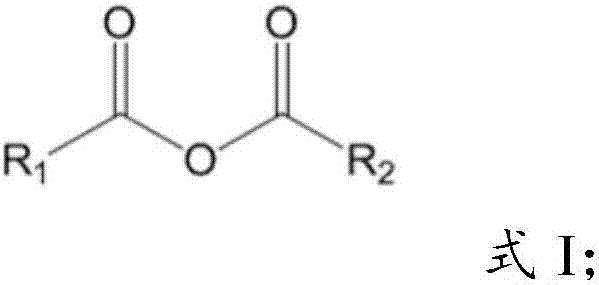

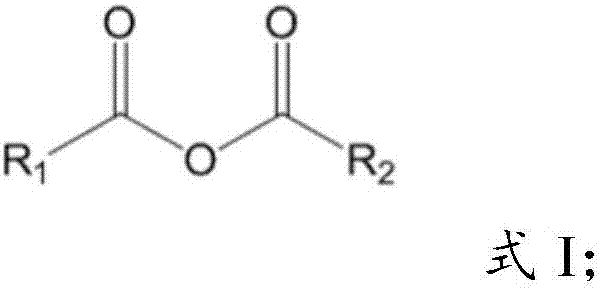

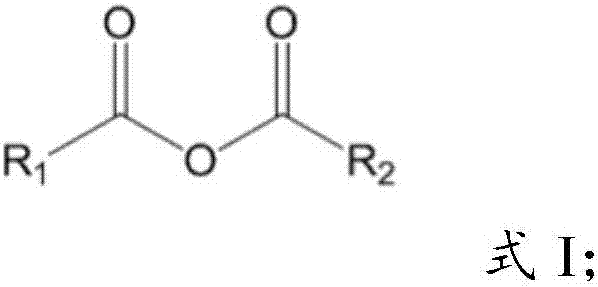

Purification method of lithium bis(fluorosulfonyl)imide

The invention provides a purification method of lithium bis(fluorosulfonyl)imide. The method comprises the following steps of (1) dissolving a lithium bis(fluorosulfonyl)imide crude product in an organic solvent; filtering to remove insoluble substances and obtain filter liquid; (2) mixing the filter liquid and organic acid anhydride and then heating to obtain mixed liquid, wherein the organic acid anhydride has a structure shown as a formula I, and in the formula I, R1 and R2 are independently selected from C1-C5 alkyls or C1-C5 halogen alkyls; (3) performing evaporation treatment on the mixed liquid to remove the organic solvent and obtain an intermediate product; (4) crystallizing the intermediate product in a low-polarity organic solvent to obtain a lithium bis(fluorosulfonyl)imide pure product, wherein the polarity of the low-polarity organic solvent is lower than 4. The purification method provided by the invention has the advantages that the organic acid anhydride is used for removing moisture in the lithium bis(fluorosulfonyl)imide crude product; other impurities are not introduced; the recrystallization is performed through solvent polarity regulation. The purification method provided by the invention has the advantages that the process is simple; the obtained lithium bis(fluorosulfonyl)imide has high purity.

Owner:JIANGSU GUOTAI SUPER POWER NEW MATERIALS

Starch esters and method of preparation

A lipophilic starch is provided along with methods of making the same. The starch is prepared by modifying the starch with an organic acid anhydride reagent, such as octenyl succinic anhydride, drying the modified starch to a moisture content of less than 15% by weight, and then heat treating the dried starch at a temperature of at least 100° C. for at least one minute.

Owner:KANSAS STATE UNIV RES FOUND

Method for preparing organic cellulose acid ester by solid acid catalysts

The invention discloses a method for preparing organic cellulose acid ester by solid acid catalysts, relating to the technical field for preparing organic cellulose acid ester. In the invention, the organic cellulose acid ester refers to cellulose formic acid, cellulose acetate, cellulose propionate, cellulose acetate butyrate, cellulose acetate propionate, cellulose acetate butyrate and cellulose acetate propionate butyrate. Three solid acids, namely, SO42- / MxOy solid acid, biomass carbon-based solid acid, phosphorus-aluminum molecular sieve solid acid; the organic acid is used as solvent and the organic acid anhydride is used as esterifying agent; the using amount of the catalyst is 0.01-5% of the reaction liquid; the organic cellulose acid ester is prepared under the conditions that the reaction temperature is 15-90 DEG C and the reaction time is 0.5-72 h. The method adopts the novel environment-friendly solid acid catalyst; the obtained product has good quality; the catalyst is easy to separate, recover and recycle; no device corrosion exists and the environment is protected.

Owner:CHANGMAO BIOCHEMICAL ENG CO LTD +1

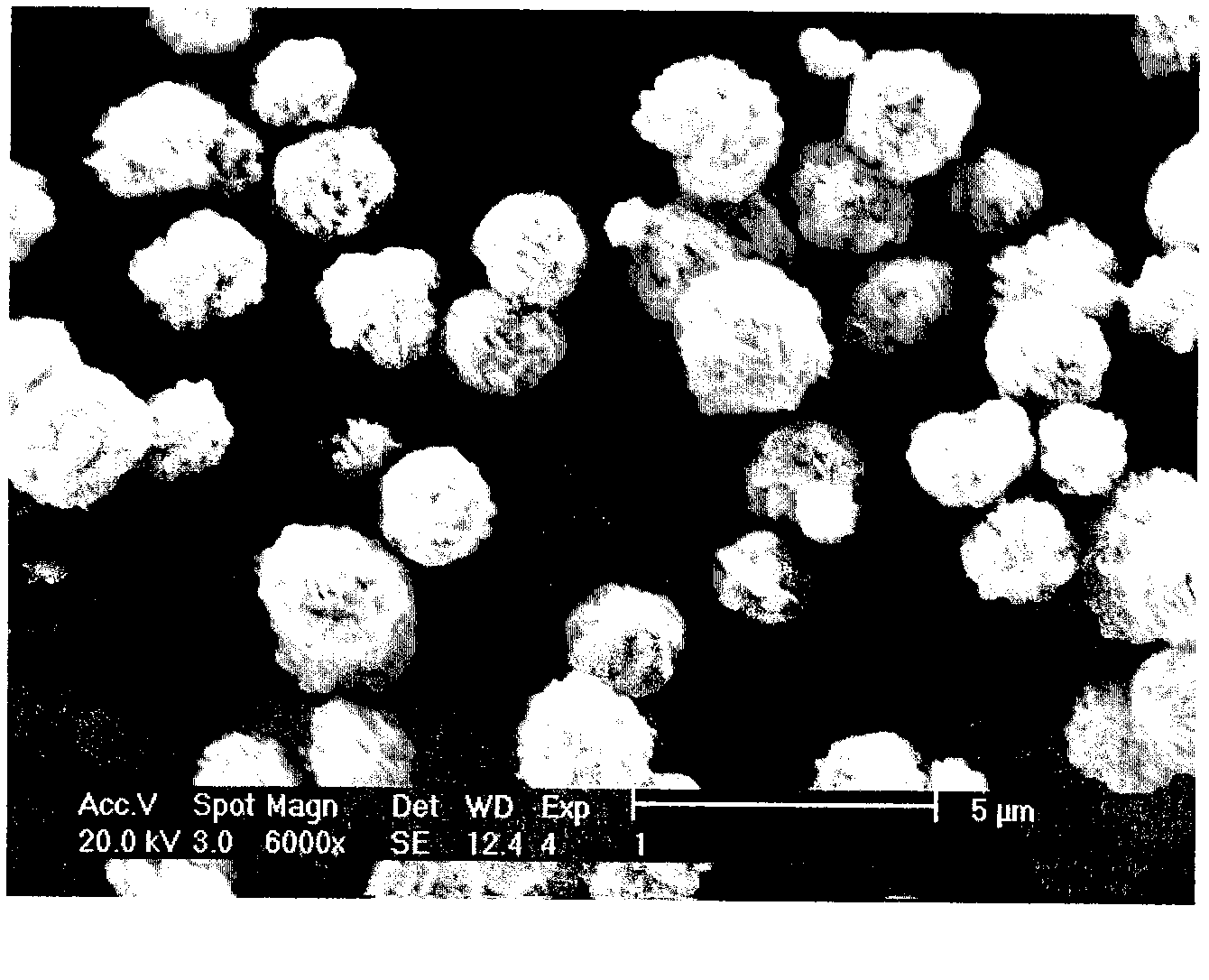

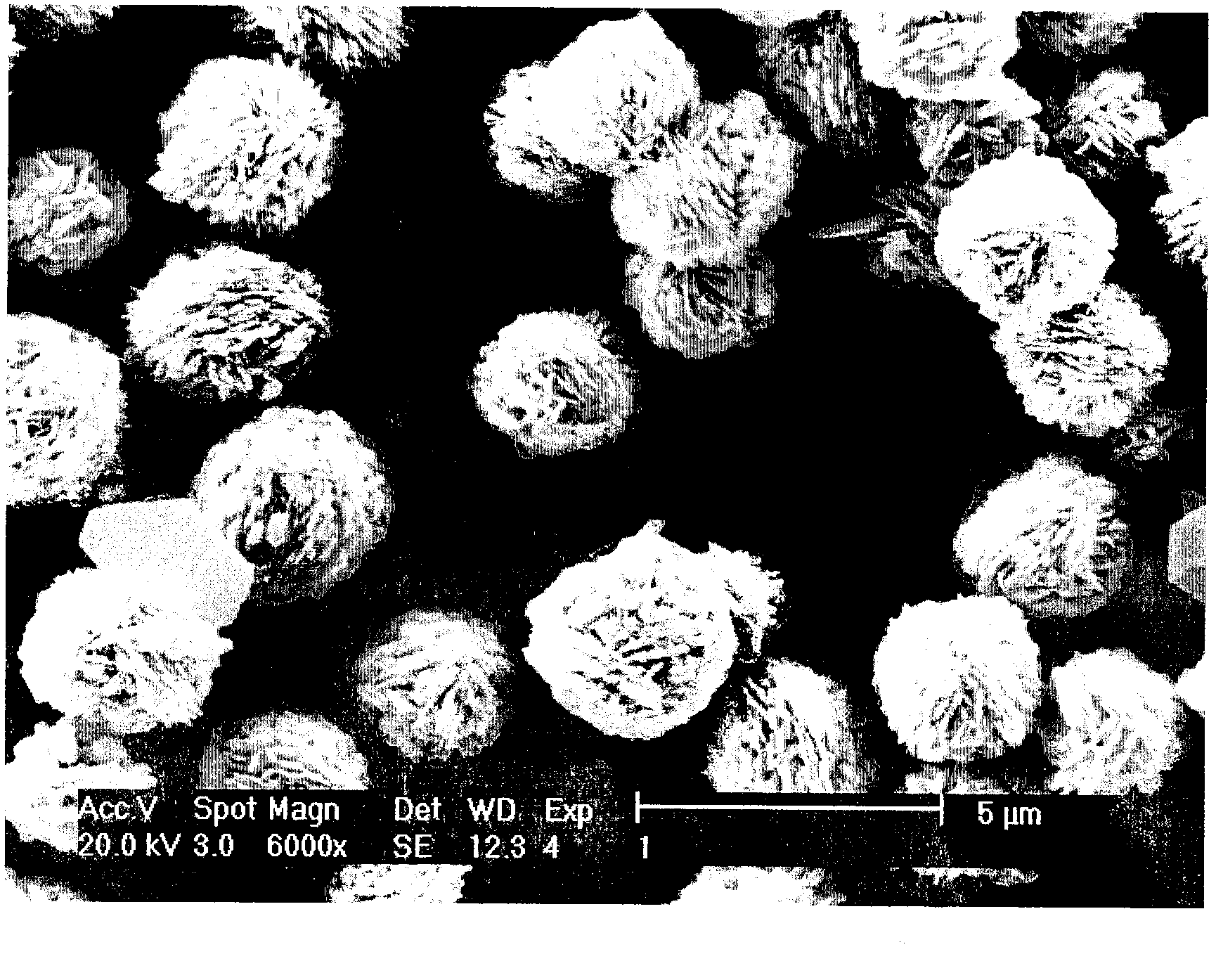

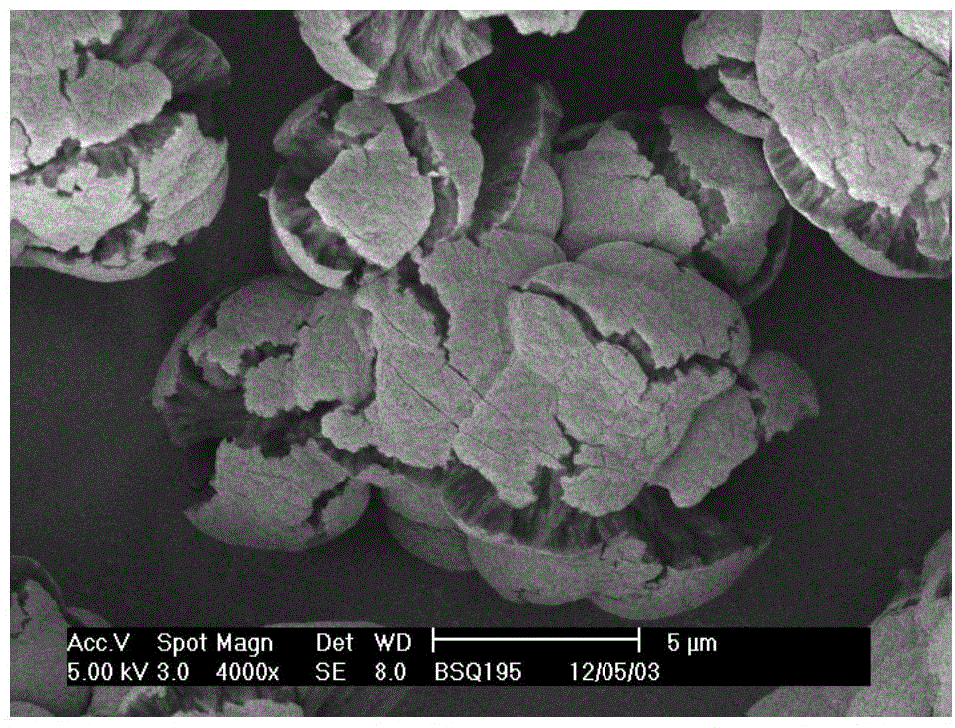

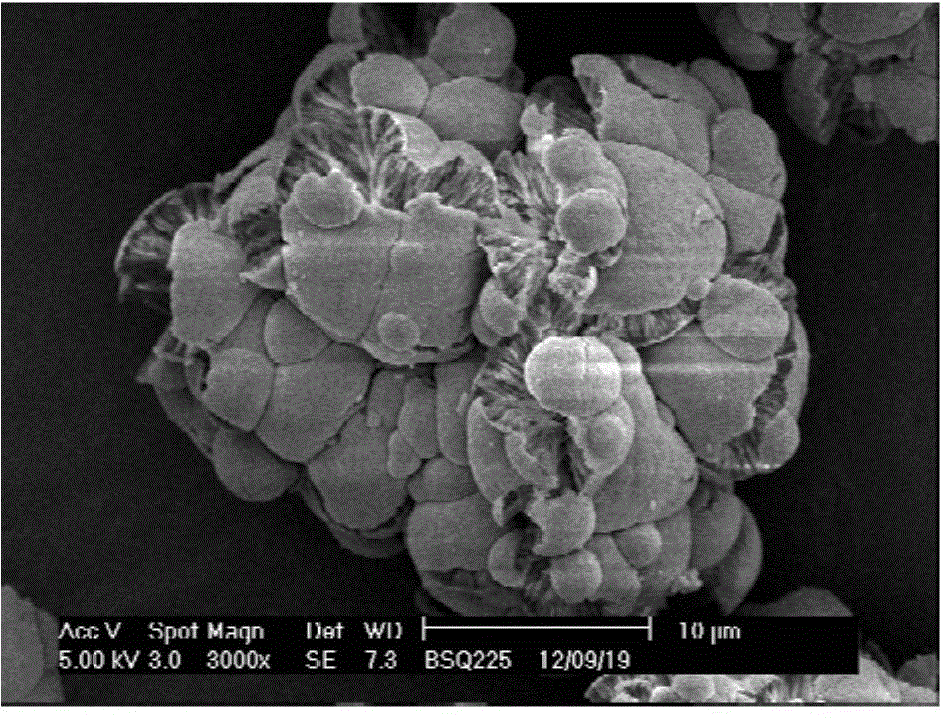

Flower-like spherical silver powder preparing method

InactiveCN103273082ANo pollution in the processSimple processSpherical shapedAcid anhydride formation

The invention discloses a flower-like spherical silver powder preparing method which includes steps that: (1) 1-50g / L silver nitrate solutions and 1-200g / L ferrous sulfate reductant solutions are prepared; (2) complexing agents are added into the silver nitrate solutions and the silver nitrate solutions with the complexing agents are evenly mixed, wherein the complexing agents are binary and n-nary (n>2) organic acids, organic acid anhydrides or organic acid salts, the ratio of carboxyl group concentration and silver ion concentration of the mixed silver nitrate solutions is 0.1:1-1:1, and the silver nitrate solutions and the ferrous sulfate reductant solutions are cooled to be at 0-20 DEG C; (3) reductants are added into the silver nitrate solutions and are continuously stirred until the color of the solutions does not change any more; and (4) deionized water is used for washing for several times after centrifugal separation or natural setting, absolute ethyl alcohol is used for washing for several times, and then the silver nitrate solutions are dried in vacuum on the condition of 0-80 DEG C to obtain flower-like spherical silver powder. The flower-like spherical silver powder obtained in the flower-like spherical silver powder preparing method has good sphericity degree and has a rough surface and narrow particle size distribution, and the number of pieces of the flower-like silver powder can be freely adjusted.

Owner:昆山西微美晶电子新材料科技有限公司

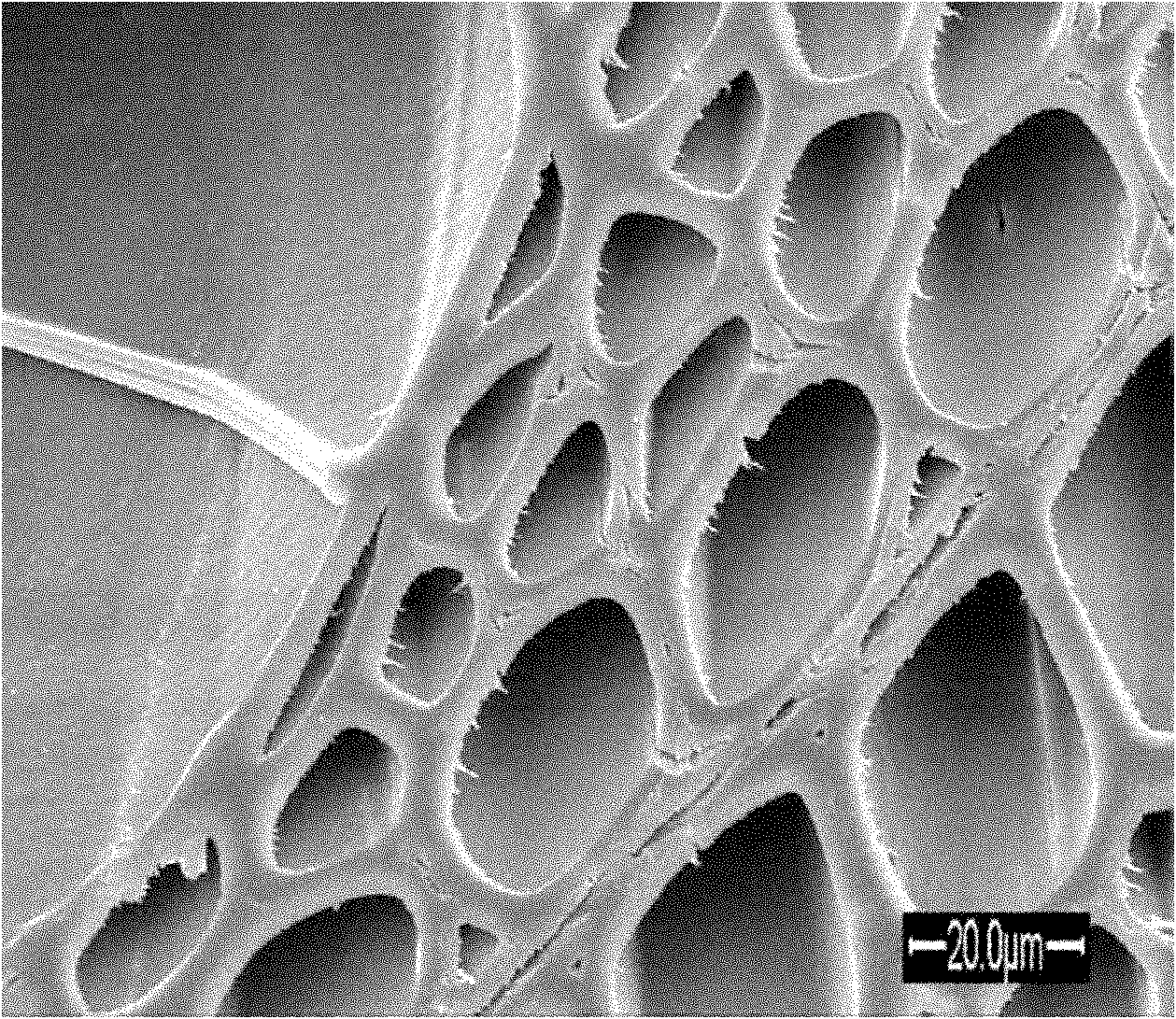

Method for modifying wood by filling grafted cell walls with organic monomers and polymerization-filling cell cavities

InactiveCN101954662AIncreased durabilityImprove mechanical propertiesPressure impregnationWood impregnation detailsCell cavityCell wall

The invention discloses a method for modifying wood by filling grafted cell walls with organic monomers and polymerization-filling cell cavities, which relates to a wood modification method. The invention solves the problem of difficulty in simultaneously enhancing mechanical properties and durability of wood in the existing wood modification method. The method comprises the following steps: 1, preparing organic acid anhydride solution; 2, soaking the wood with the organic acid anhydride solution; 3, filling grafted wood cell walls with organic acid anhydride by heating; 4, preparing the organic polymerizable monomer solution; 5, soaking the wood with the organic polymerizable monomer solution; and 6, carrying out polymerization-filling on the wood cell cavities with the monomers by heating. Since organic function micromolecules firstly enter the wood cell walls, the method realizes filling and bonding and eliminates a great deal of hydroxyl groups in the cell walls, thereby enhancing wood durability; and the wood cell cavities are soaked by the organic polymerizable monomers to initiate the polymerization and realize the filling of the cell cavities, so that the wood has higher mechanical properties and durability.

Owner:NORTHEAST FORESTRY UNIVERSITY

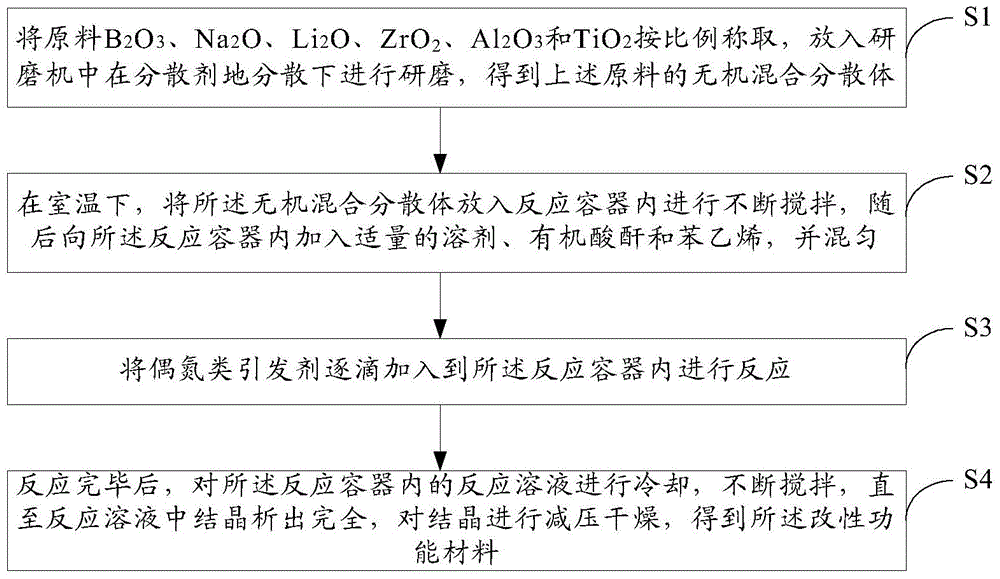

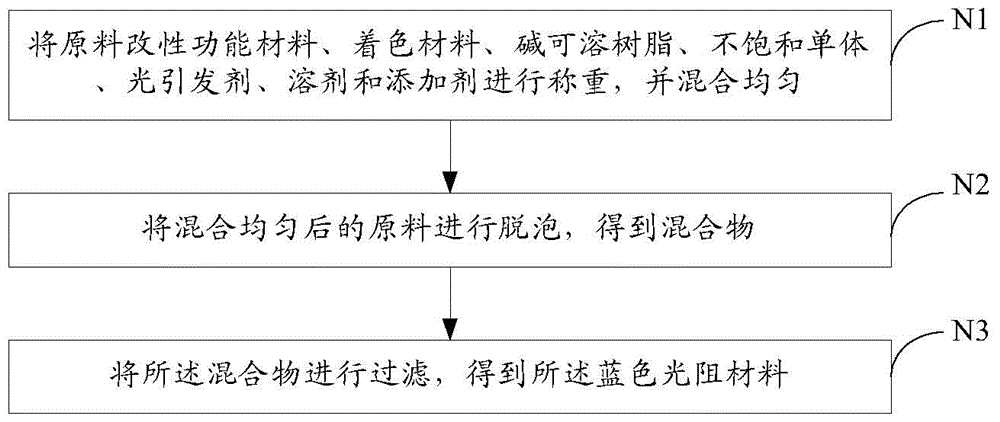

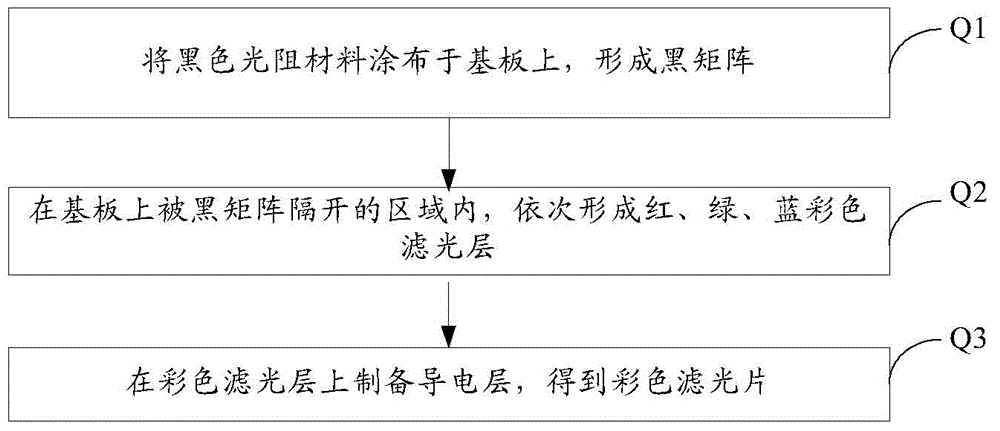

Modified function material, blue photoresist material and color filter as well as preparation methods thereof and display device

PendingCN103555003AImprove air qualityImprove immunityOptical filtersPhotosensitive materials for photomechanical apparatusColor gelDisplay device

The embodiment of the invention provides a modified function material, a blue photoresist material and a color filter as well as preparation methods of the modified function material, the blue photoresist material and the color filter and a display device, belongs to the field of liquid crystal displays, and aims to improve the air quality in the environment. The modified function material comprises an inorganic mixed dispersion body and a coating layer on the outer part of the inorganic mixed dispersion body; the inorganic mixed dispersion body is formed by mixing and dispersing B2O3, Na2O, Li2O, ZrO2, Al2O3 and TiO2 by a dispersant; the coating layer is a copolymer generating by styrene and organic acid anhydride by the inorganic mixed dispersion body. The modified function material, the blue photoresist material and the color filter as well as the preparation methods of the modified function material, the blue photoresist material and the color filter, and the display device can be used for producing the color filter.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

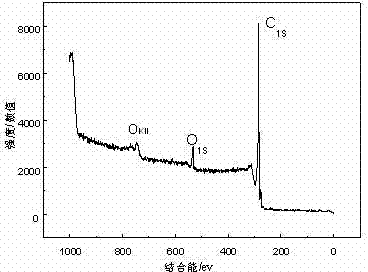

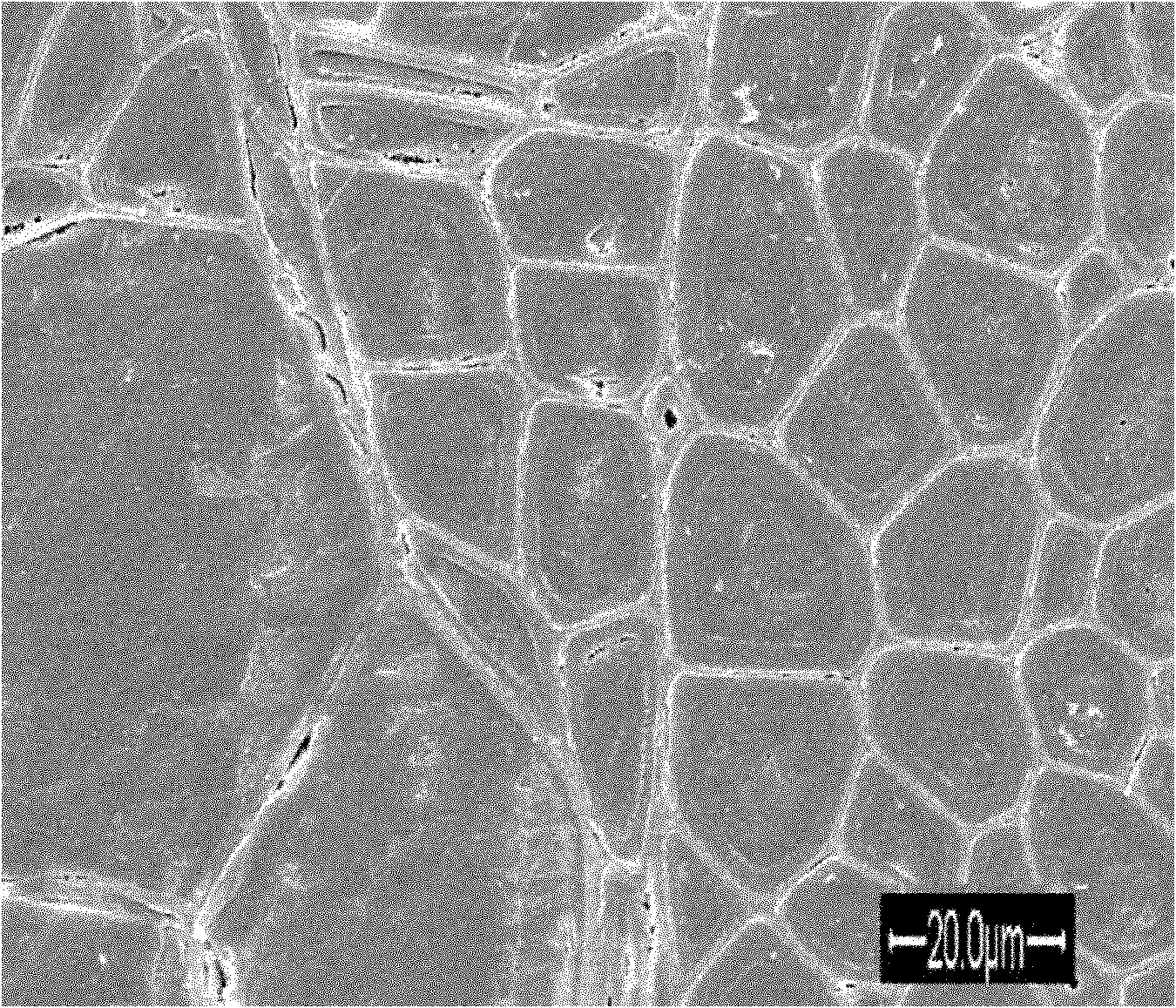

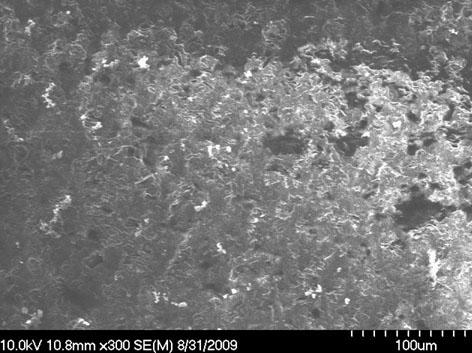

Preparation method of glass fiber/carbon nanotube/epoxy resin multi-dimensional hybrid composite material

InactiveCN102276795AIncreased interlaminar shear strengthImprove interface strengthResin matrixCarbon nanotube

The invention relates to a preparation method of a glass fiber / carbon nanotube / epoxy resin multi-dimensional hybrid composite material. The preparation method provided by the invention comprises the following steps of: treating glass fiber with a silane coupling agent; carrying out surface carboxylation and chlorination on carbon nanotubes, then introducing diamine or polyamine to the carbon nanotubes, and modifying the carbon nanotubes connected with an amino group by a polybasic anhydride compound to prepare the carbon nanotubes carrying an anhydride group; dispersing the treated carbon nanotubes in an epoxy resin matrix by ultrasonic oscillation and high-speed stirring, and curing with an organic anhydride curing agent; and compounding the obtained carbon-nanotube-containing epoxy resin polymer used as a matrix with the coupling-agent-treated glass fiber to form a multi-dimensional hybrid composite material structure linked through covalent bonds. The preparation method provided by the invention has the advantages that: the composite material is convenient to prepare, the dispersion of the carbon nanotubes in epoxy resin is improved, and the strength and toughness of the carbon nanotubes are utilized to toughen epoxy resin and to improve the bonding strength with the base surface of the glass fiber, thereby enhancing the overall performance of the glass fiber / carbon nanotube / epoxy resin multi-dimensional hybrid composite material and broadening the applications of the glass fiber, carbon nanotubes and epoxy resin.

Owner:TONGJI UNIV

Preparation method of nano-SiO2 modified alkyd resin

InactiveCN105622908AGood storage stabilityDoes not affect transparencyPolyester coatingsResin-Based CompositeSolvent

The invention relates to a preparation method of nano-SiO2 modified alkyd resin. The nano-SiO2 modified alkyd resin comprises, by weight, 30-60% of fatty acid, 6-20% of polyol, 4-10% of diol, 2-8% of nano-silica, 12-35% of organic acid anhydrides, 0.01-0.5% of an esterification catalyst and 30-45% of a solvent. The nano-SiO2 modified alkyd resin prepared in the invention has good storage stability, and a coating layer prepared by using the nanometer composite resin has excellent hardness, wear resistance, scratch resistance, ultraviolet resistance and ageing resistance and does not influence the transparence or the compatibility of the resin, and can be widely applied in surface coating and protection of woodenware, metals, plastics and other products.

Owner:UNION FOSHAN CHEM +1

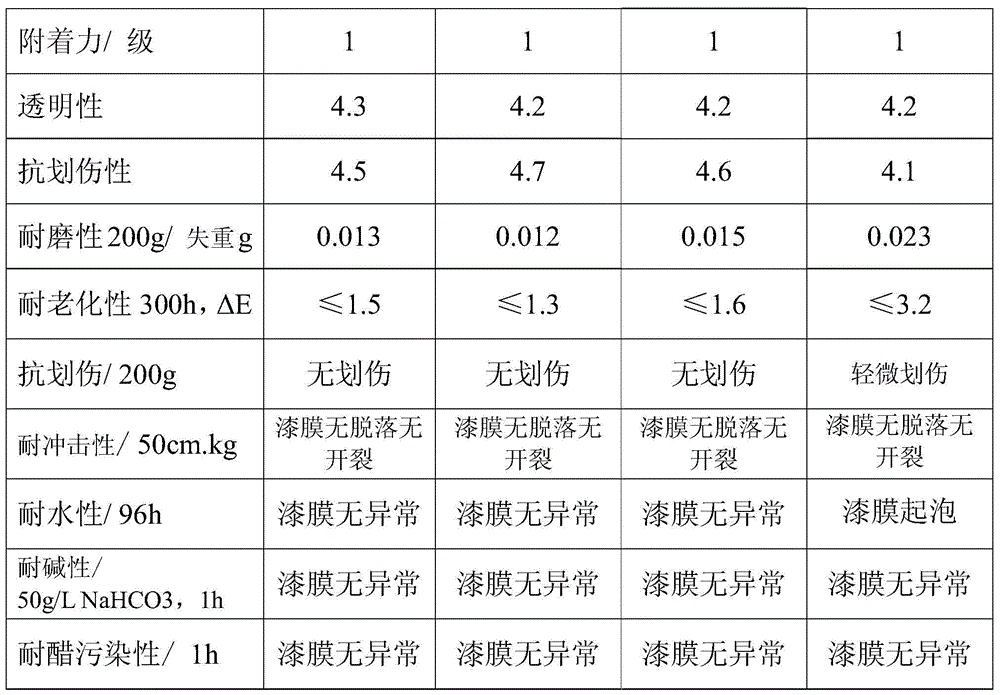

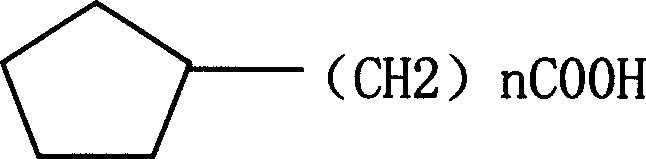

Water-soluble corrosion-retarding neutralizer and its preparation process

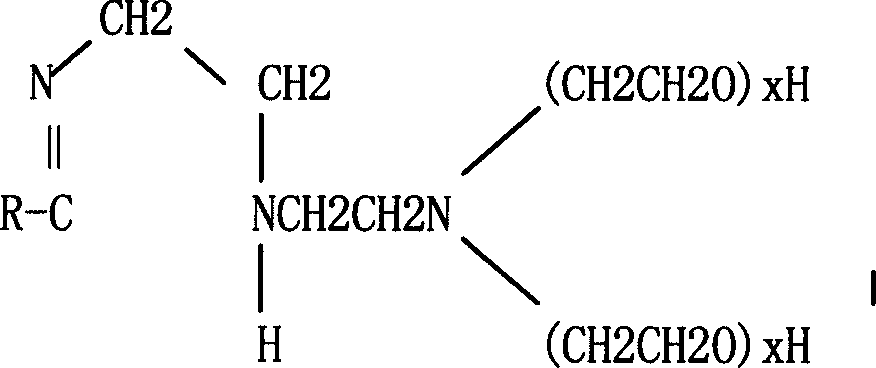

The invention relates to a water-soluble neutralizing agent mainly for oil-extraction plant low-temperature light oil position metallic conservation, which is prepared form naphthenic acid, polyenamine and organic acid anhydrides or ethylene oxide as raw material through mixing with neutralization agent and dissolvent.

Owner:PETROCHINA CO LTD

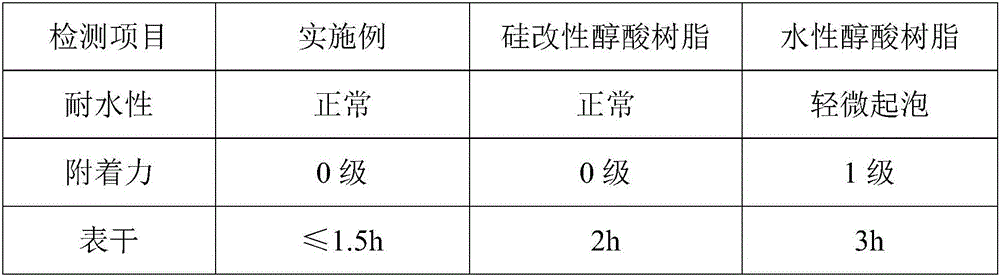

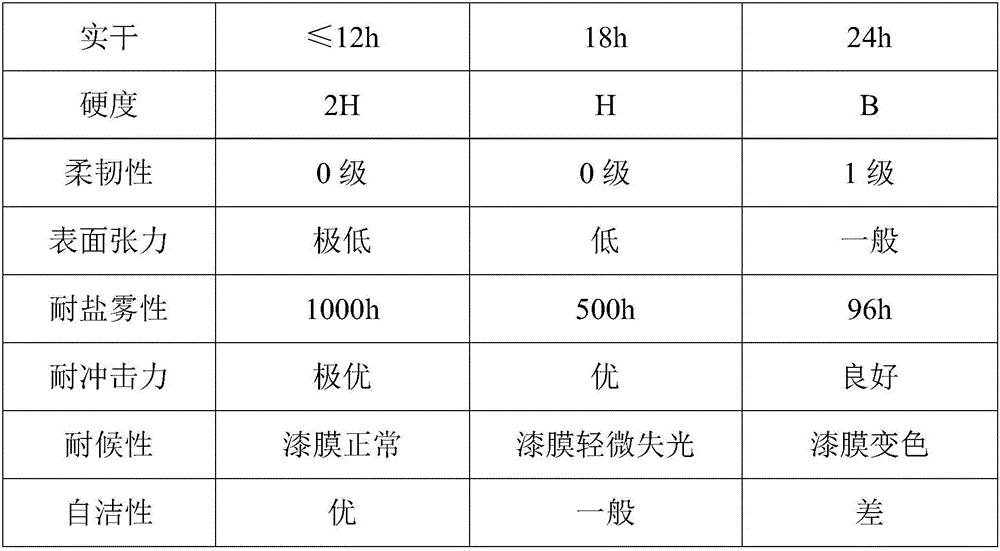

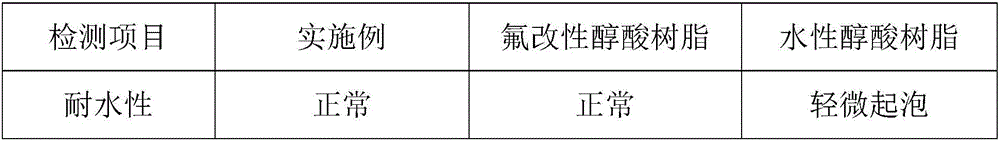

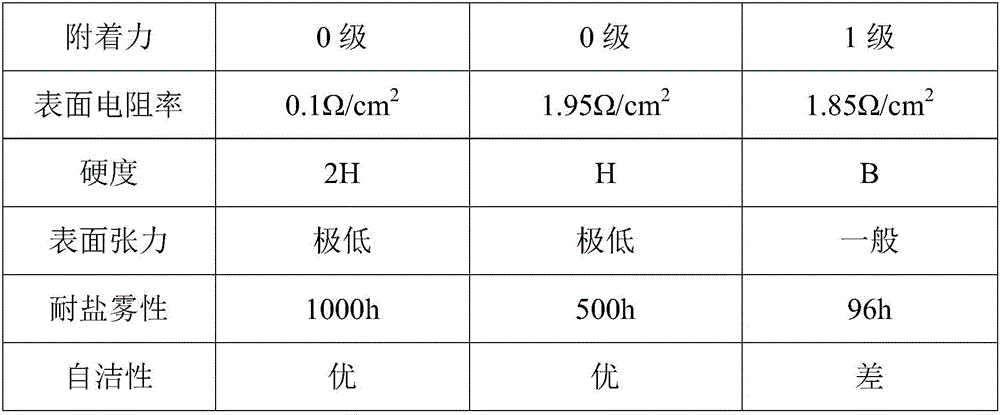

Fluorine-silicon modified waterborne alkyd resin and preparing method thereof

ActiveCN106117449AWith shielding protectionImprove thermal stabilityAntifouling/underwater paintsPaints with biocidesAcid anhydride formationStain

The invention relates to a fluorine-silicon modified waterborne alkyd resin and a preparing method thereof. The fluorine-silicon modified waterborne alkyd resin is prepared from vegetable oil fatty acid, organic acid anhydride, polyol, fluorinated allyl monomers, isocyanate, hydroxyl-terminated organic silicon, acrylic monomers and deionized water. Single-component waterborne paint, double-component waterborne paint and room-temperature curing paint can be blended with the fluorine-silicon modified waterborne alkyd resin prepared through the method. The prepared fluorine-silicon modified waterborne alkyd resin has the performance such as high adhesion, stain resistance, high hardness, water resistance, durability, hydrophobicity and self-cleaning performance, and can be widely applied to waterborne wood paint, waterborne industrial paint, waterborne anti-fouling paint, waterborne corrosion resistance paint, waterborne special engineering paint such as radar dome materials, wind power generation, nuclear power and vessel paint and the like.

Owner:湖南大禹防水建材科技有限公司

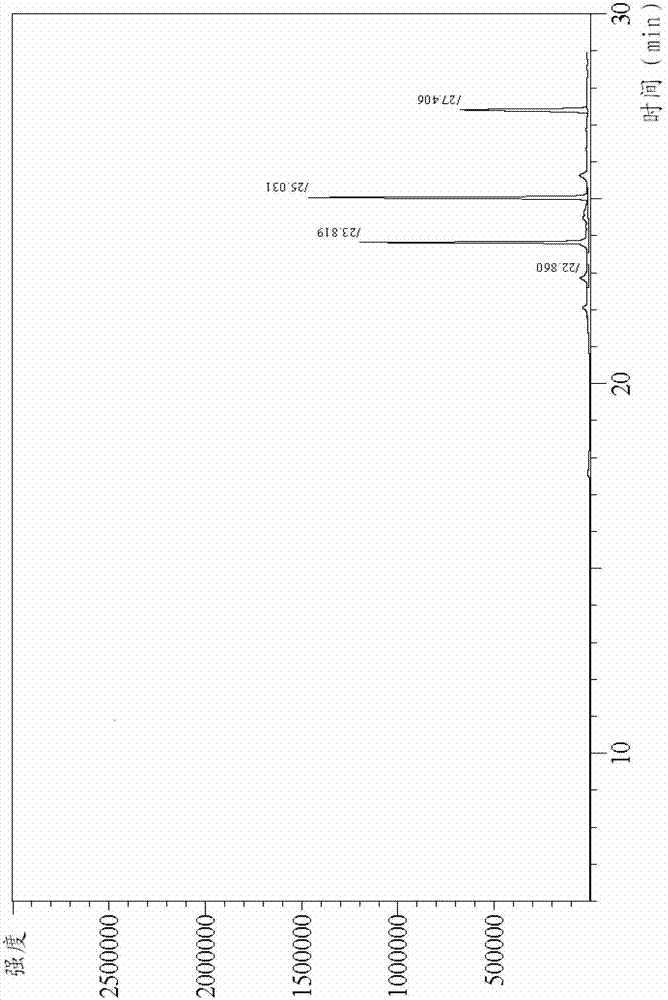

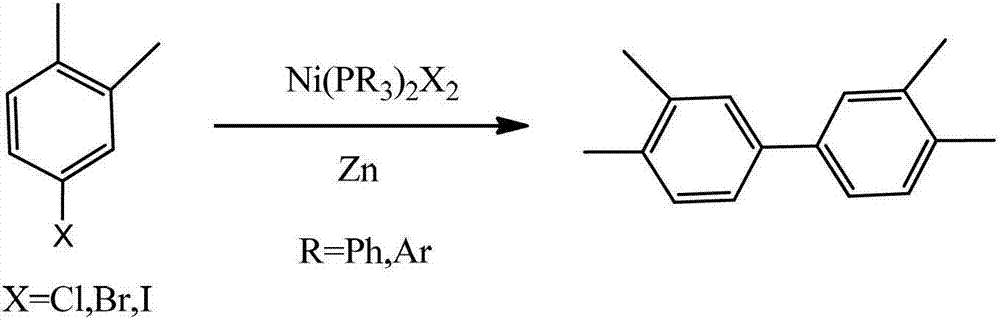

Preparation method of tetramethyl biphenyl

ActiveCN103086837AReduce manufacturing costLow equipment requirementsHydrocarbon by hydrocarbon condensationMetal catalystAcid anhydride formation

The invention provides a preparation method of tetramethyl biphenyl, which comprises the following steps: mixing o-xylene, oxidizer, additive and metal catalyst, and reacting to obtain the tetramethyl biphenyl, wherein the additive is organic acid and / or organic acid anhydride, and the oxidizer is inorganic oxidizer and / or organic oxidizer containing metal cation. Compared with the prior art of synthesizing tetramethyl biphenyl from halogenated o-xylene, the invention uses the o-xylene for direct coupling to obtain the tetramethyl biphenyl. The raw material o-xylene is cheap and accessible, and the preparation of the halogenated o-xylene is not needed, so the invention lowers the production cost, is simple to operate and has the advantages of mild reaction conditions and low facility request; and under the action of the catalyst, the o-xylene is directly coupled to prepare the tetramethyl biphenyl, and all the carbon atom frameworks of the o-xylene enter the product, so the invention also has the advantage of high economical efficiency of atoms.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Flame retardant aromatic polycarbonate resin composition

ActiveUS20050154103A1Improve flame retardant performanceMaintain good propertiesSolesFibre treatmentPhosphonium saltAlkaline earth metal

An aromatic polycarbonate resin composition comprising: 100 parts by weight of a resin component (A) mainly comprising an aromatic polycarbonate, 0.1 to 200 parts by weight of a solid inorganic compound (B), at least one compound (C) selected from the group consisting of an organic acid, an organic acid ester, an organic acid anhydride, an organic acid phosphonium salt and an organic acid ammonium salt, 0.001 to 1 part by weight of at least one organic acid metal salt (D) selected from the group consisting of an organic acid alkali metal salt and an organic acid alkaline earth metal salt, and 0.01 to 1 part by weight of a fluoropolymer (E), wherein compound (C) is present in an amount wherein a mixture of compounds (B) and (C) exhibits a pH value of from 4 to 8.

Owner:RP TOPLA

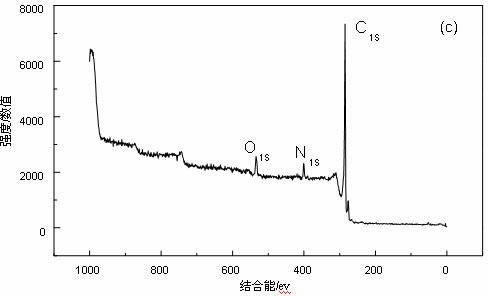

High performance epoxy resins composite material and preparation thereof

InactiveCN101407620AGood dispersionEasy to manufactureInorganic pigment treatmentCarbon nanotubeCarboxylic acid

The invention belongs to the technical field of nano materials, and particularly relates to a high-performance epoxide resin composite material and a preparation method. Carboxylic acid, chloroformylation, amination or hydroxylation are carried out to the carbon nano tube; and the carbon nano tube is modified by small molecular aromatic polyanhydride compound so as to prepare the carbon nano tube which carries acid anhydride group. The carbon nano tube is dispersed in epoxide resin substrate by ultrasonic oscillation and high-speed stirring, is cured by adopting organic acid anhydride curing agent so as to obtain the carbon nano tube / epoxide resin composite material. The invention leads the preparation of the carbon nano tube / epoxide resin composite material to be more convenient, the activity of taking part in reaction of the carbon nano tube is endowed, and acid anhydride group of the carbon nano tube and the epoxide resin group of the epoxide resin generate chemical cross linking, thus improving the dispersion of the carbon nano tube in the epoxide resin and obtaining high-performance epoxide resin composite material. Compared with the control sample, all the mechanical performance indexes of the cured composite material are improved by 5 percent to 300 percent and the volume resistivity is reduced by 3 to 9 order of magnitude.

Owner:TONGJI UNIV

Method for preparing anti-scratch matt alkyd resin

The invention relates to a method for preparing anti-scratch matt alkyd resin. The anti-scratch matt alkyd resin comprises the following components in percentage by weight: 17 to 35 percent fatty acid, 16 to 30 percent of polyhydric alcohol, 18 to 40 percent of organic acid anhydride, 0 to 2 percent of esterifying catalyst, and 30 to 45 percent of solvent. The anti-scratch matt alkyd resin is synthesized by terephthalic acid or isophthalic acid with a symmetric structure and neopentyl glycol, diglycol and pentaerythritol by a polymer method, and has the characteristics of quick dryness, easy extinction, good transparency and the like. A PU () high-grade matt wood painted tool made by the anti-scratch matt alkyd resin is soft in hand feel, plump and smooth, and rigid with soft, gives people the feeling of elegance and comfort, adapts to modern aesthetic view, and is popular in market and clients. The anti-scratch matt alkyd resin can be widely applied to the surface of woods, metal, plastic and other products for protecting and decorating.

Owner:UNION FOSHAN CHEM

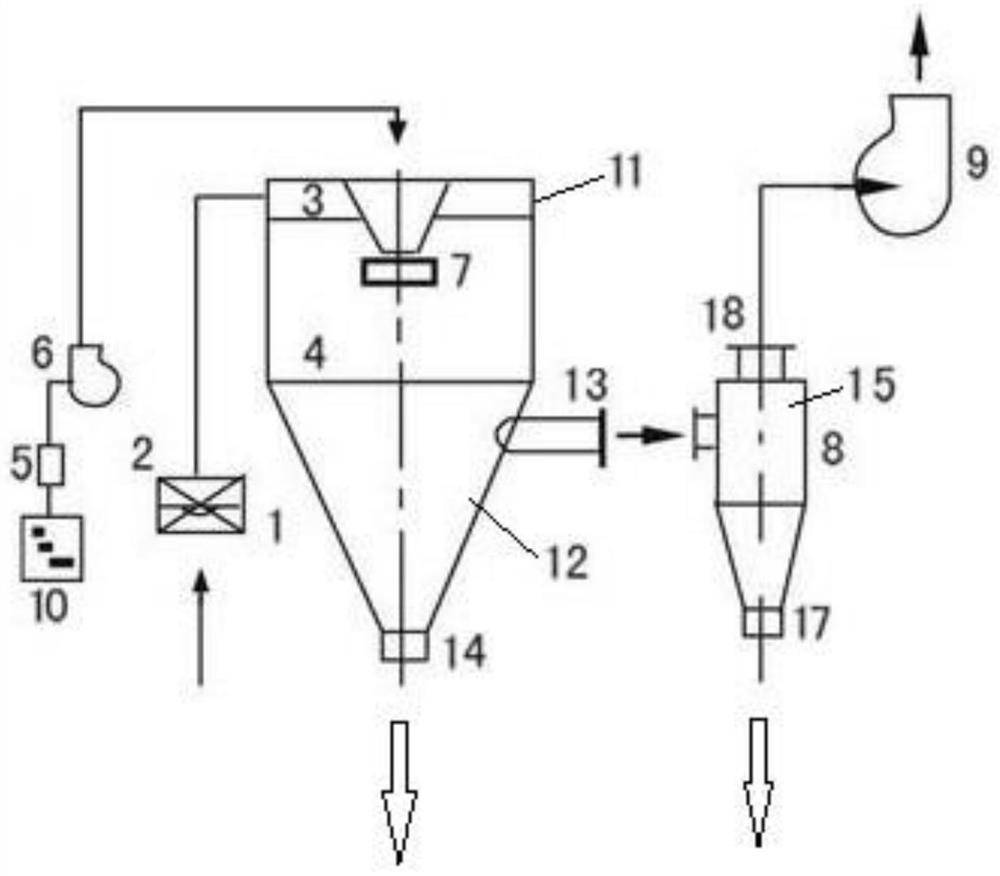

Preparation method of sucrose-6-ester

PendingCN112218874AThorough responseImprove conversionEsterified saccharide compoundsSugar derivativesSucrosePhysical chemistry

The invention provides a preparation method of sucrose 6 ester. The preparation method comprises the following steps: preparing a reaction solution of sucrose and an organic tin compound; atomizing the reaction solution to form small liquid drops; fully mixing and contacting the droplets with a gasified dehydration medium, and carrying out dehydration reaction on the droplets so as to generate anintermediate mixture containing the sucrose organic tin ester droplets; separating the intermediate mixture to obtain a sucrose organic tin ester solution and a dehydrated gas-liquid mixture; recovering the sucrose organic tin ester solution obtained in the separation step and circulating the sucrose organic tin ester solution to the atomization step and the dehydration step for multiple times; and carrying out acylation reaction on the sucrose organic tin ester solution and organic anhydride to generate sucrose 6 ester. According to the method, rapid and efficient dehydration of the esterification reaction can be realized in an extremely short time, the sucrose organic tin ester intermediate is efficiently prepared, decomposition of carbohydrates and side reactions in the system are reduced to a great extent, the energy consumption is low, the product yield is high, the selectivity is high, and the sucrose reaction degree is more thorough.

Owner:ANHUI JINGHE IND

Graphene-modified waterborne anticorrosive coating

ActiveCN106590401AImprove mechanical propertiesStrong mechanical propertiesAnti-corrosive paintsPolyurea/polyurethane coatingsAcid anhydride formationMechanical property

The invention relates to a grapheme-modified waterborne anticorrosive coating. The grapheme-modified waterborne anticorrosive coating is composed of a grapheme-modified waterborne alkyd resin, pigment and filler, a cosolvent, a leveling agent, a dispersing agent, a wetting agent, a defoaming agent, a thickening and anti-settling agent, a flash rust inhibitor, a pH value regulator and deionized water, wherein the graphene polyurethane-modified waterborne alkyd resin is prepared from vegetable oil or fatty acid, organic acid anhydride, dimethylolpropionic acid, polyol, grapheme, polyisocyanate and deionized water through a reaction. The prepared grapheme-modified waterborne anticorrosive coating integrates the advantages of grapheme and polyurethane, has properties like high hardness, good adhesion, good chemical resistance, antistatic performance, corrosion resistance, aging resistance and good mechanical properties, and is endowed with excellent corrosion resistance, aging resistance, excellent mechanical properties and antistatic performance.

Owner:广东科迪新材料科技有限公司 +1

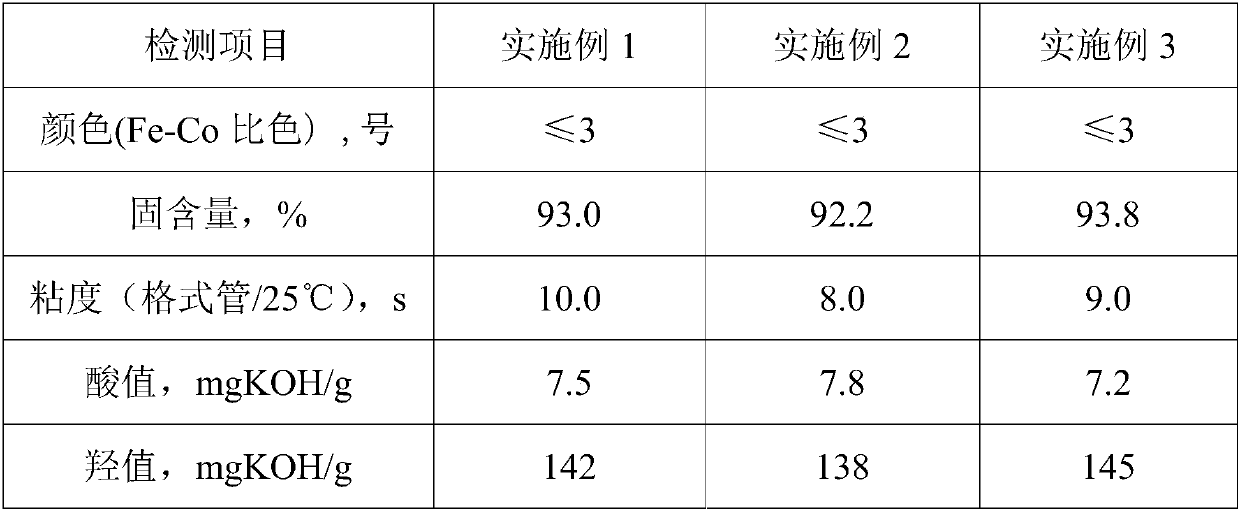

High-solid low-viscosity alkyd resin for removing odor and preparation method of alkyd resin

InactiveCN107828053AControl growthNarrow molecular weight distributionPolyurea/polyurethane coatingsPolyester coatingsBenzoic acidKetone

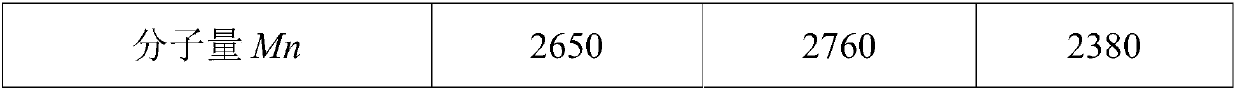

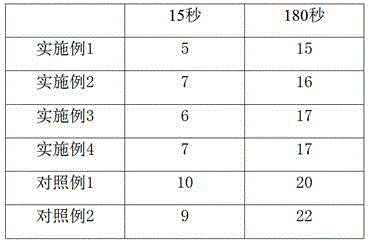

The invention relates to high-solid low-viscosity alkyd resin for removing odor. The alkyd resin is prepared from a vegetable oil fatty acid, an organic acid anhydride, benzoic acid, a polyhydric alcohol, an esterification catalyst, glycidyl tertiary carbonate, a reflux solvent and a diluting solvent through a step-by-step polycondensation reaction. The invention also provides a preparation methodof the high-solid low-viscosity alkyd resin for removing odor. The alkyd resin prepared by the invention is free of benzene and ketone, has a solid content of 93+ / -2%, viscosity (Gardner-Holdt tube / 25 DEG C) of less than or equal to 10s, an acid value of less than or equal to 8mg KOH / g, a hydroxyl value of larger than or equal to 135mg KOH / g and a number-average molecular weight Mn of 2200-3000,has excellent adhesive force, water resistance, chemical resistance, wear resistance and scratch resistance, and has the characteristics of high solvent volatilization speed, high drying speed and thelike in the film forming process. The leveling property and the transparency of a coated film are good; no solvent is left after the film is coated for 24 hours; and the odor removing effect is achieved. The alkyd resin is widely applied to surface decoration and protection of products such as woodware, metals, plastics and the like.

Owner:UNION FOSHAN CHEM +2

Phosphate silkete penetrating agent and preparation method thereof

InactiveCN104611923AImprove permeabilityNo irritating smellFibre treatmentPhosphoric Acid EstersPhosphate

The invention relates to a phosphate silkete penetrating agent and a preparation method thereof, and belongs to the technical field of textile auxiliary agents. The phosphate silkete penetrating agent comprises the following components in parts by weight: 5 parts of fatty alcohol, 1-4.5 parts of fatty alcohol-polyoxyethylene ether, 1-1.5 parts of a phosphorylation reagent and 1-2 parts of organic acid anhydride. As substances such as phosphorus pentoxide, organic acid anhydride and fatty alcohol-polyoxyethylene ether which are relatively gentle in reaction and easy in reaction speed control are adopted to react, the phosphate silkete penetrating agent which is small in bubble, good in permeability and free of irritant smell can be prepared.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

Fluorine-modified water-borne alkyd resin and preparation method thereof

InactiveCN105669908AImprove performanceNo pollution in the processCoatingsEpoxyAcid anhydride formation

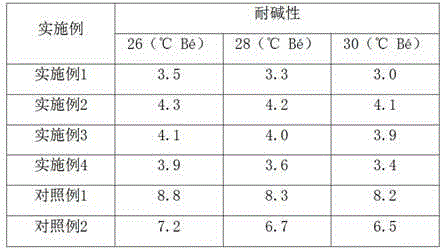

The invention relates to a fluorine-modified water-based alkyd resin and a preparation method thereof. Its components are composed of vegetable oil fatty acids, organic acid anhydrides, polyols, epoxy resins, fluorine monomers, acrylic monomers and deionized water; The fluorine-modified water-based alkyd resin prepared by the invention can be formulated into one-component water-based coatings, two-component water-based coatings, and normal-temperature curing coatings. The fluorine-modified water-based alkyd resin prepared by the present invention has good adhesion, stain resistance, water resistance, alkali resistance, durability, hydrophobicity, low dielectric constant and other properties, and is widely used in marine fields, wood Coatings, anti-fouling and water-repellent coatings, which can also be used in radome materials, have enormous application potential.

Owner:UNION FOSHAN CHEM +1

Cellulose derivatives

InactiveCN1482142AReduce the burden of pollutionEfficient removalTobacco smoke filtersThin material handlingParticulatesCellulose acetate

Owner:DAICEL CHEM IND LTD

Amino acid racemization method

InactiveCN1569815AGood racemization effectComplete racemizationOrganic compound preparationAmino-carboxyl compound preparationReaction speedSolvent

Disclosed is an amino acid racemization method which consists of dissolving the L-amino acid in organic acid solvent, acylating with organic acid anhydride, thus achieving a L-amino racemization ratio of 100% with a fast reaction speed and high yield, the acid anhydride and organic acid solvent can be reclaimed for circulation use.

Owner:何佺

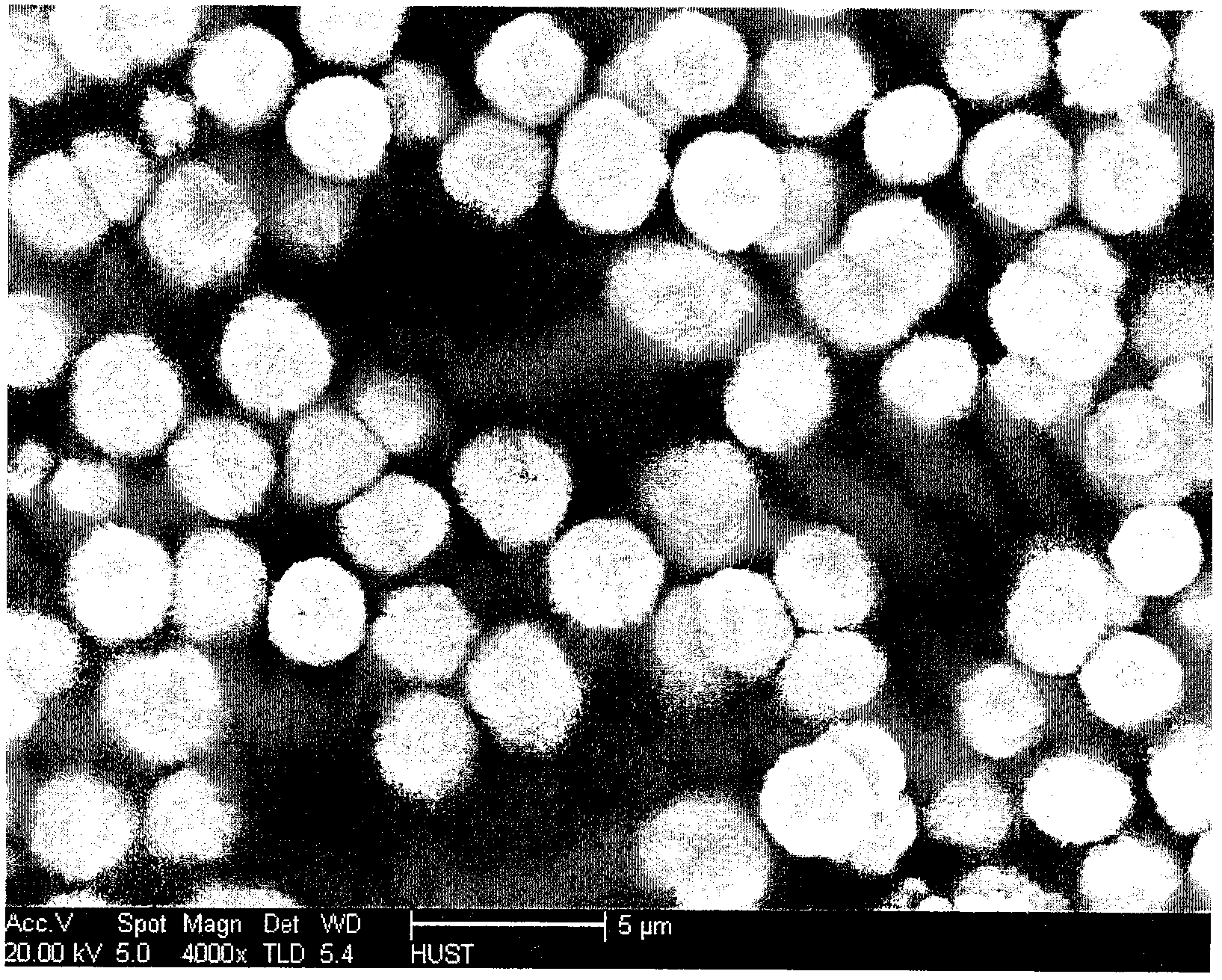

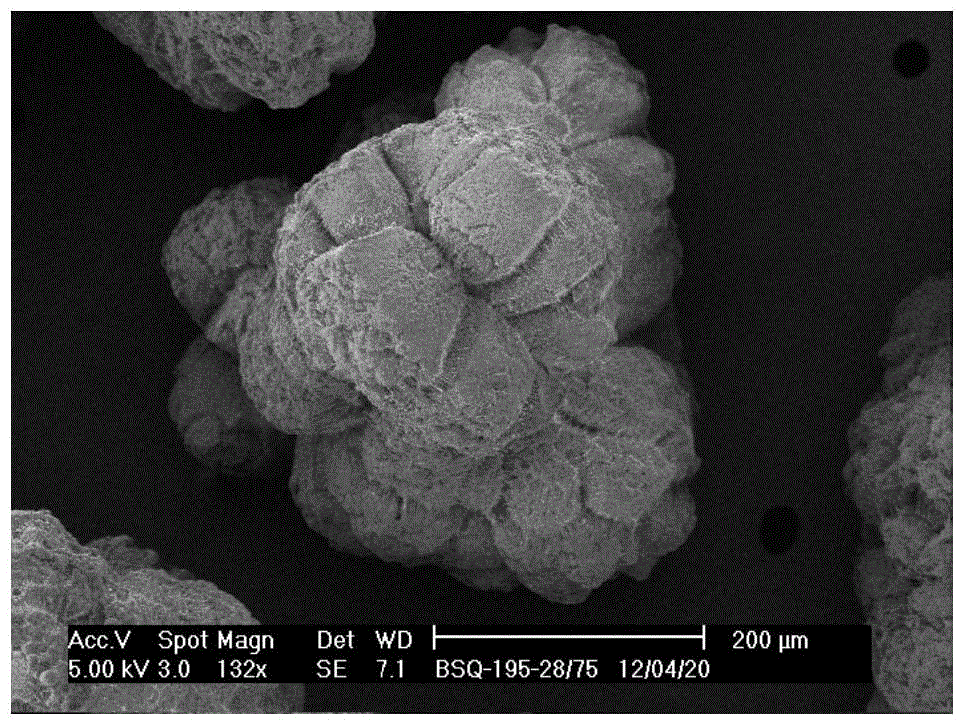

Catalyst component for polymerization of ethylene, catalyst and preparation method of catalyst component

The invention provides a catalyst component for polymerization of ethylene. The catalyst component comprises reactants of the following components: (1) magnesium compounds; (2) organic acid anhydride; (3) acetic ester compounds; (4) cyclic ketone compounds; and (5) titaniferous compounds. When organic acid anhydride / acetic ester / cyclic ketone compounds are introduced into a system to be used as compounding electron donors, spherical / ellipsoidal magniferous / titaniferous solid particles can be prepared. Through slurry polymerization of ethylene on a catalyst disclosed by the invention, spherical / ellipsoidal powder particles can be obtained, and besides, the powder particles have very high powder bulk density.

Owner:CHINA PETROLEUM & CHEM CORP +1

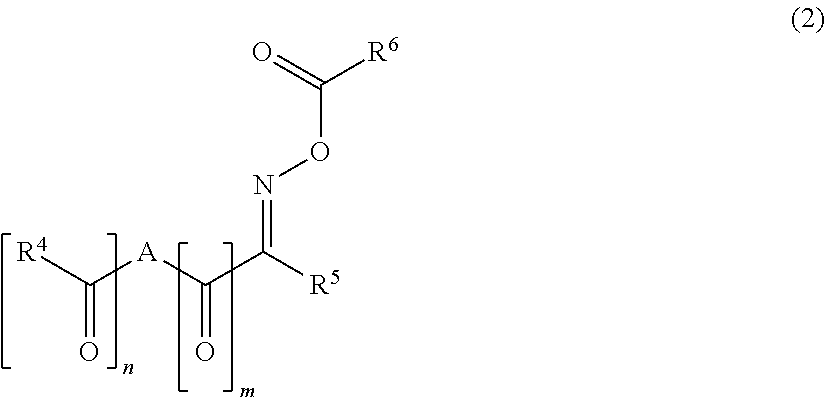

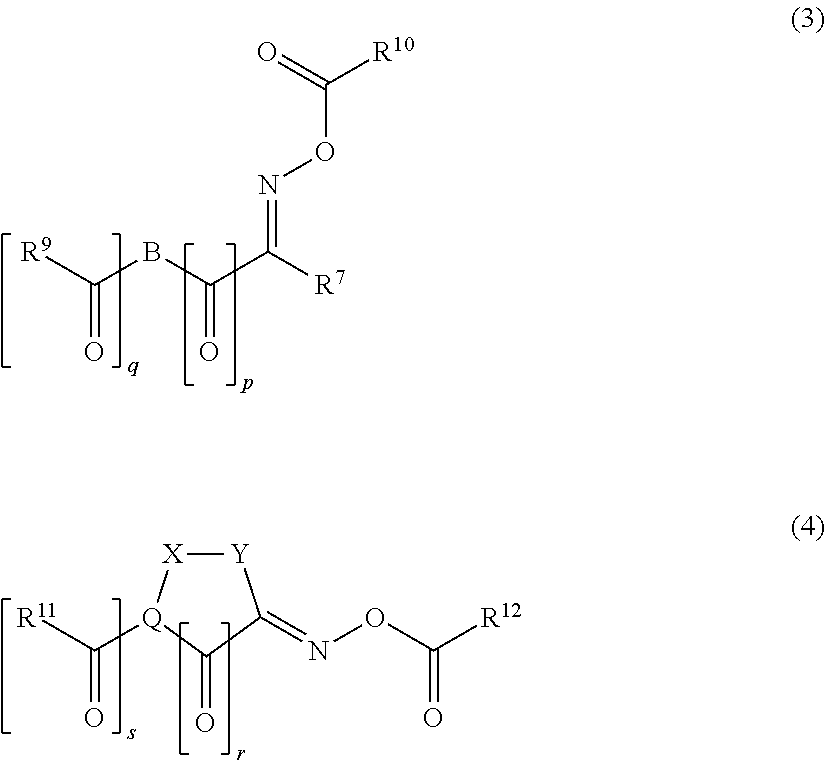

Polymerizable composition, cured film, color filter, method of producing color filter and solid-state image sensor

ActiveUS20110294049A1Improve power generation efficiencyIncreasing wavelengthPhotosensitive materialsOptical filtersAcid anhydride formationOxime

The invention provides a polymerizable composition including an oxime ester photopolymerization initiator, an organic acid anhydride having a molecular weight of 300 or less, and a polymerizable compound.

Owner:FUJIFILM CORP

Graphene-modified water-based fluorine alkyd resin and preparation method thereof

The invention relates to graphene-modified water-based fluorine alkyd resin and a preparation method thereof. The graphene-modified water-based fluoroalate resin consists of vegetable oil fatty acid, organic acid anhydride, polyatomic alcohol, polybasic acid, dimethylolpropionic acid, a fluoroelene monomer, a neutralizing agent, polyisocyanate, grapheme, an acrylic monomer and deionized water. The graphene-modified water-based fluorine alkyd resin prepared by the preparation method provided by the invention has good adhesion, stain resistance, water resistance, alkali resistance and wear resistance, good electrical conductivity, excellent antistatic performance and the like, and is widely used for water-based wood coatings, water-based industrial coatings, water-based anti-fouling coatings, water-based anti-corrosion coatings and water-based special function coatings.

Owner:英德科迪颜料技术有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com