High-solid low-viscosity alkyd resin for removing odor and preparation method of alkyd resin

A clean-odor alkyd resin, high-solid low-viscosity technology, applied in coatings, polyester coatings, polyurea/polyurethane coatings, etc. It is difficult to solve problems such as wood lacquer, and achieve the effect of excellent adhesion, soft hand feeling and fast drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

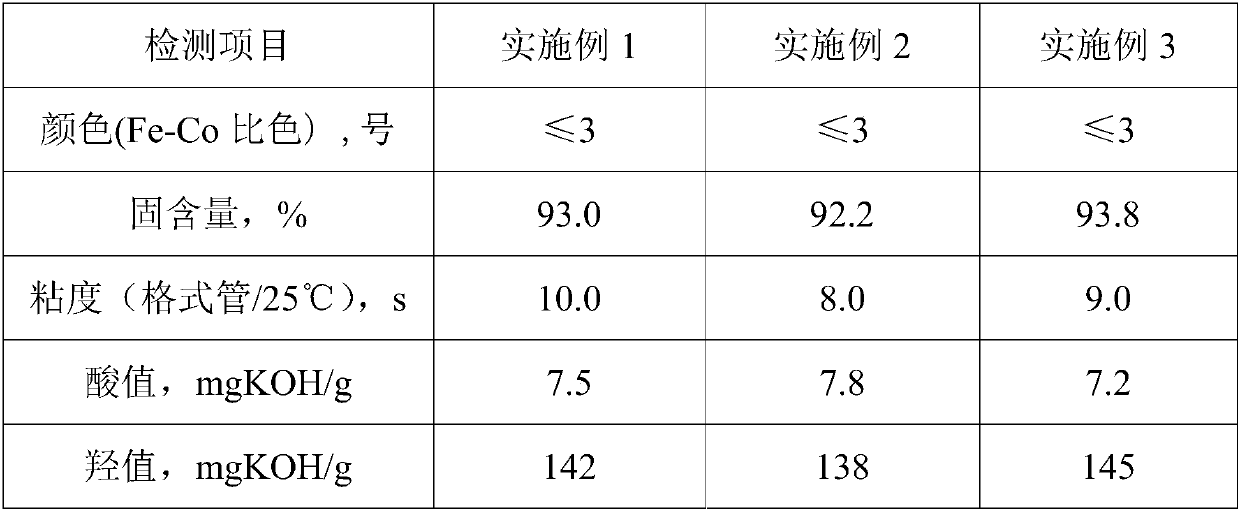

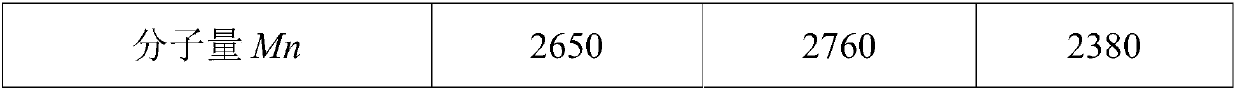

Examples

Embodiment 1

[0038] A high-solid and low-viscosity net-odor alkyd resin, the preparation process of which is as follows:

[0039] a), by weight percentage, sequentially add 23.5 parts of castor oil, 7.2 parts of isophthalic acid, 26.5 parts of phthalic anhydride, 3.0 parts of adipic acid, 10 parts of glycerin, 5 parts of trimethylolpropane, 1,4-butanediol Add 4.5 parts into the reaction kettle, start heating, when the material in the kettle is completely melted, feed N 2 , start stirring and raise the temperature to 120°C, add 0.5 part of organotin catalyst, then raise the temperature to 165°C~180°C, add 6.0 parts of benzoic acid and 3.5 parts of reflux solvent, keep the reaction for 2~3 hours, and remove the water brought out by the reflux reaction 6.2 parts, and the cooled reflux solvent is transported to the top of the packed tower with a circulation pump and gets back to the reactor;

[0040] b), when the separated water is very little, add C 10 10.0 parts of glycidyl tert-carbonate ...

Embodiment 2

[0043] A high-solid and low-viscosity net-odor alkyd resin, the preparation process of which is as follows:

[0044] a), by weight percentage, sequentially add 25.0 parts of soybean oil, 18.0 parts of phthalic anhydride, 12.0 parts of adipic acid, 4.5 parts of maleic anhydride, 12 parts of glycerin, 5.2 parts of trimethylolpropane, and 4.0 parts of neopentyl glycol into the In the reaction kettle, start heating, when the material in the kettle is completely melted, feed N 2 , start stirring and raise the temperature to 120°C, add 0.4 parts of rare earth catalyst, then raise the temperature to 165°C~180°C, add 6.0 parts of benzoic acid and 3.2 parts of reflux solvent, keep the reaction for 2~3h, and remove 5.8 parts of water brought out by the reflux reaction Parts, and the cooled reflux solvent is transported to the top of the packed tower with a circulation pump and returned to the reactor;

[0045] b), when the separated water is very little, add C 10 8.0 parts of glycidyl...

Embodiment 3

[0048] A high-solid and low-viscosity net-odor alkyd resin, the preparation process of which is as follows:

[0049] a), by weight percentage, sequentially add 22.6 parts of soybean oil, 24.0 parts of phthalic anhydride, 7.8 parts of terephthalic acid, 4.2 parts of adipic acid, 13.5 parts of trimethylolpropane, and 6.0 parts of 1,6-hexanediol into In the reaction kettle, start heating, when the material in the kettle is completely melted, feed N 2 , start stirring and raise the temperature to 120°C, add 0.4 parts of organotin catalyst, then raise the temperature to 165°C~180°C, add 6.0 parts of benzoic acid and 3.0 parts of reflux solvent, keep the reaction for 2~3h, and remove the water brought out by the reflux reaction 6.0 parts, and the cooled reflux solvent is transported to the top of the packed tower with a circulating pump and gets back to the reactor;

[0050] b), when the separated water is very little, add C 10 12.0 parts of glycidyl tert-carbonate and 4.0 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com