Patents

Literature

315results about How to "Control growth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soft tissue implants and anti-scarring agents

InactiveUS20050142162A1Guaranteed functionImprove clinical outcomesPeptide/protein ingredientsAntipyreticChinBiomedical engineering

Soft tissue implants (e.g., breast, pectoral, chin, facial, lip, and nasal implants) are used in combination with an anti-scarring agent in order to inhibit scarring that may otherwise occur when the implant is placed within an animal.

Owner:ANGIOTECH INT AG (CH)

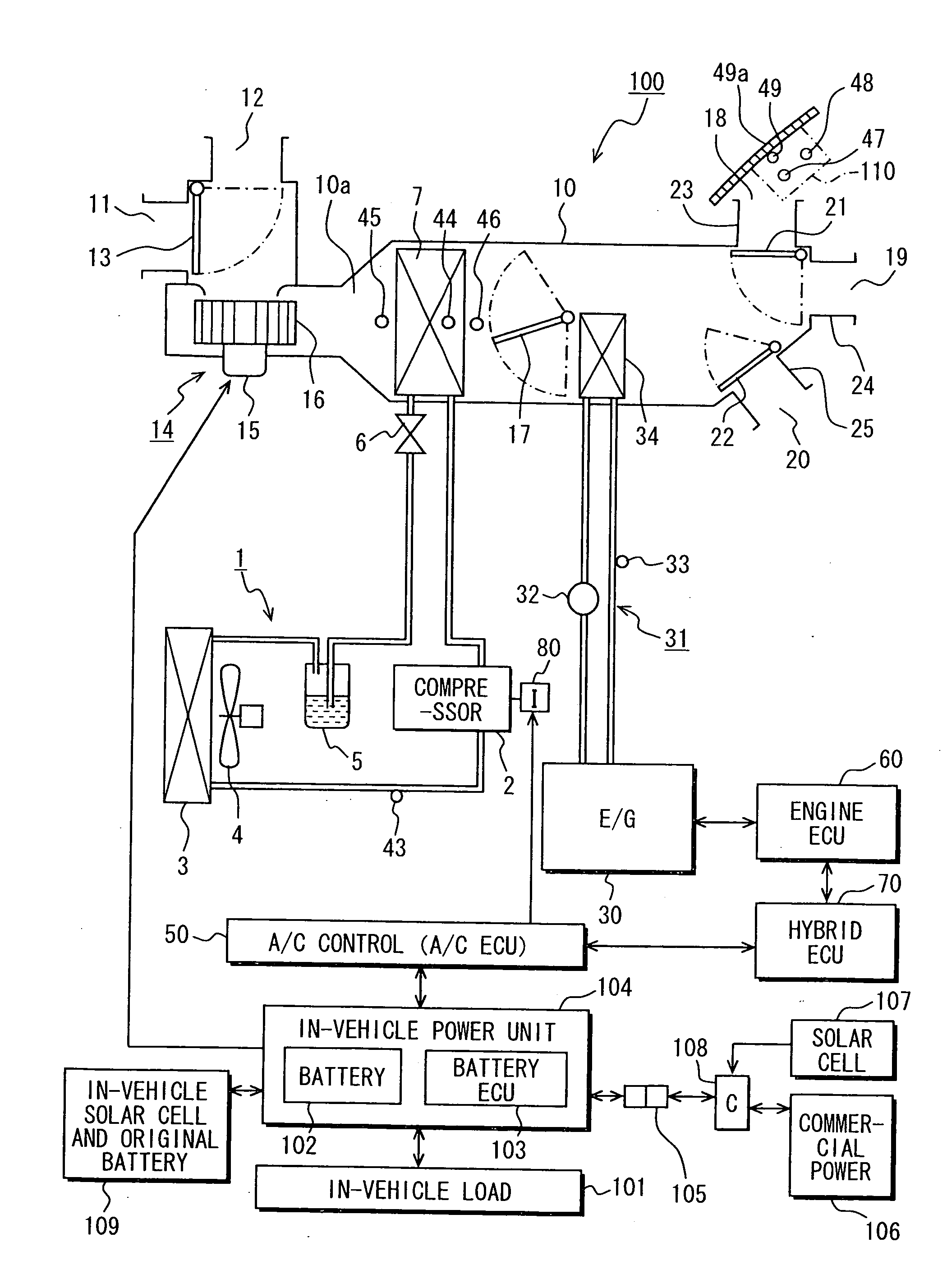

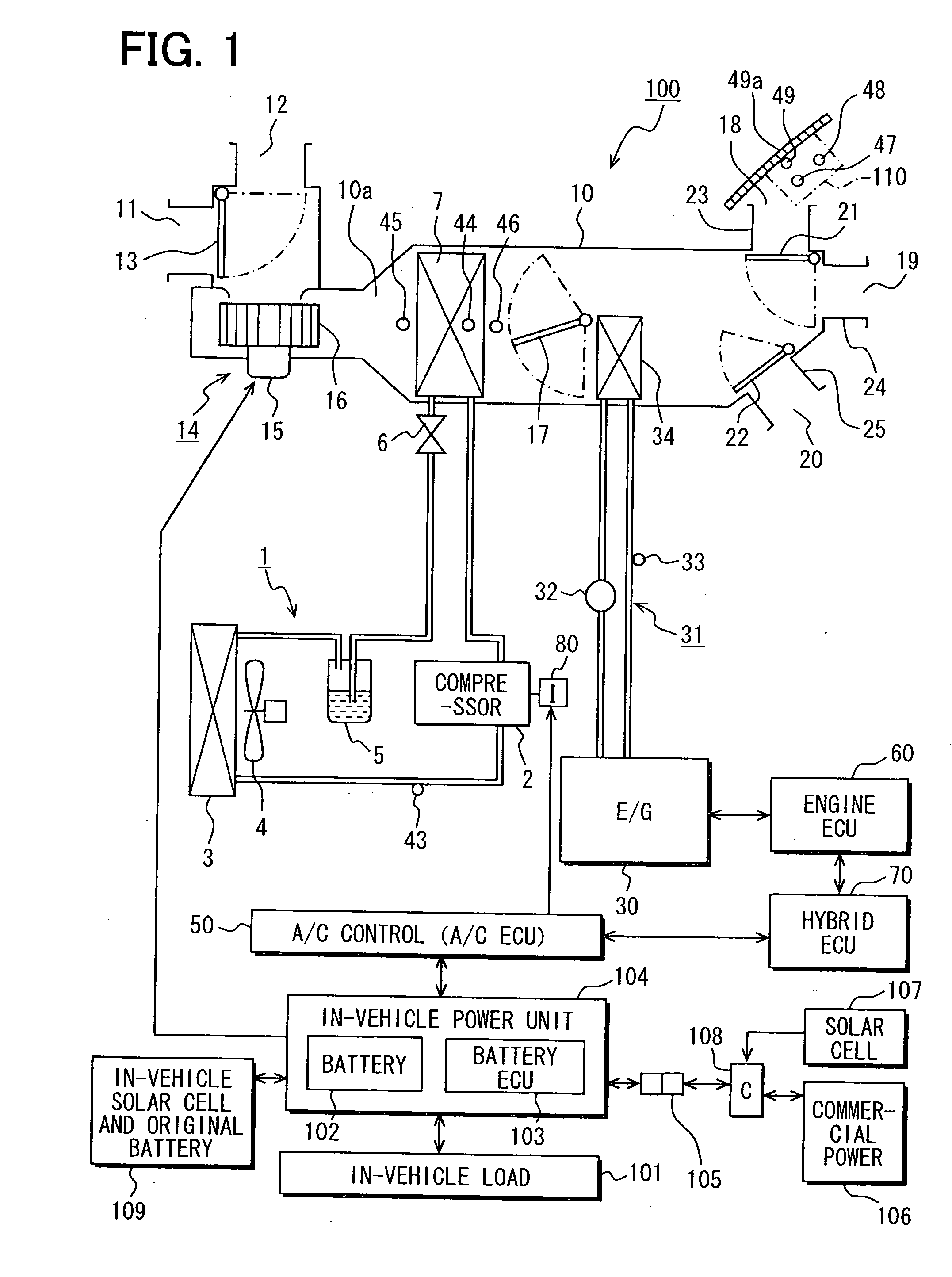

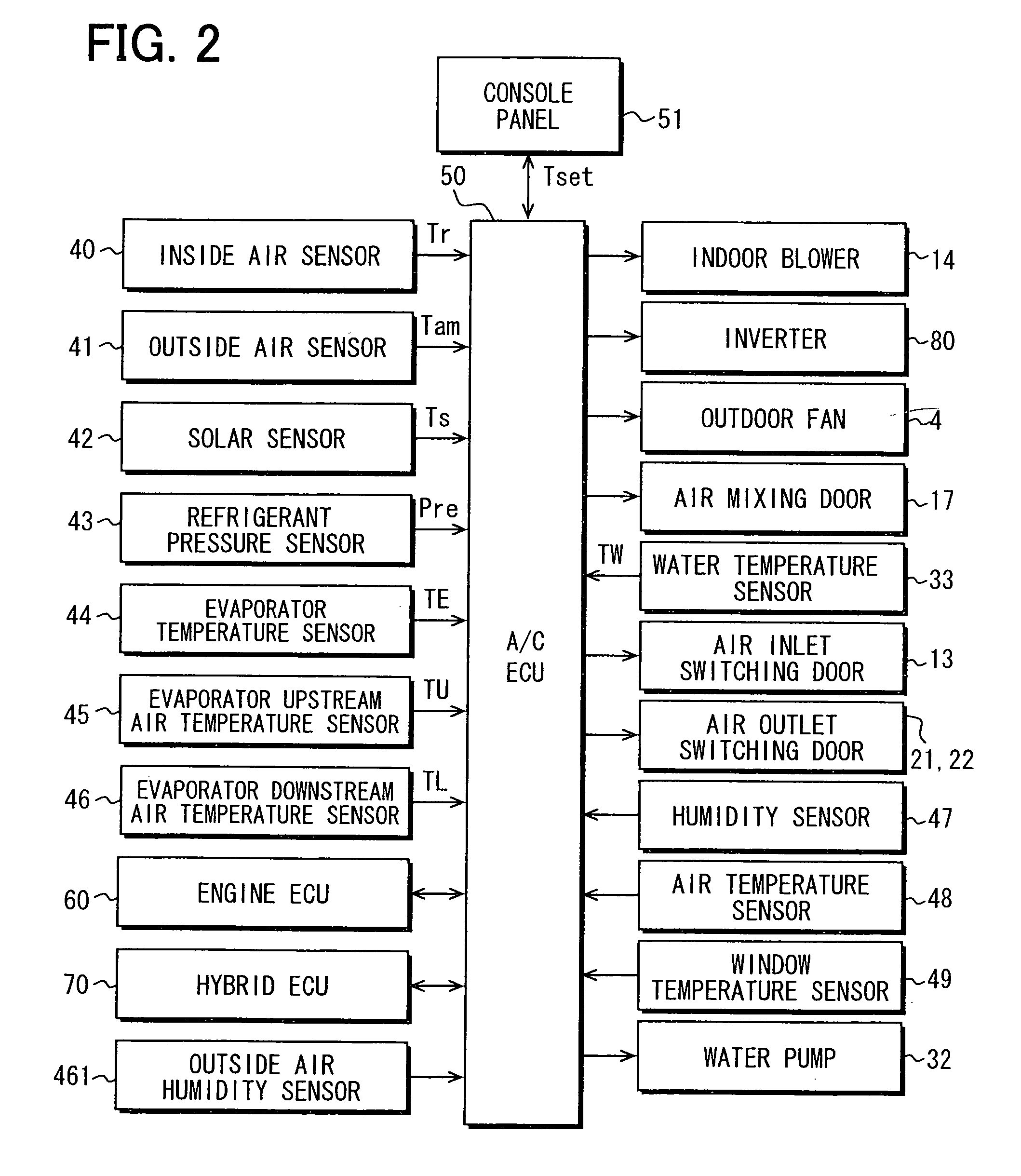

Air-conditioning device for vehicle

InactiveUS20110067422A1Control generationControl growthAir-treating devicesRefrigeration safety arrangementElectrical batteryIn vehicle

An air-conditioning device for a vehicle includes a blower and an estimating portion. The blower is disposed in an air-conditioning case, and performs a dry control for a heat exchanger arranged in a passenger compartment of the vehicle by sending air. The blower uses one of power supplied from an external power source, power supplied from the battery having residual quantity equal to or larger than a predetermined quantity, or power supplied from an in-vehicle solar cell, while the vehicle is parked. The estimating portion estimates an approximate elimination of odor generated from the heat exchanger by starting the sending of air, and stops the blower based on the estimation.

Owner:DENSO CORP

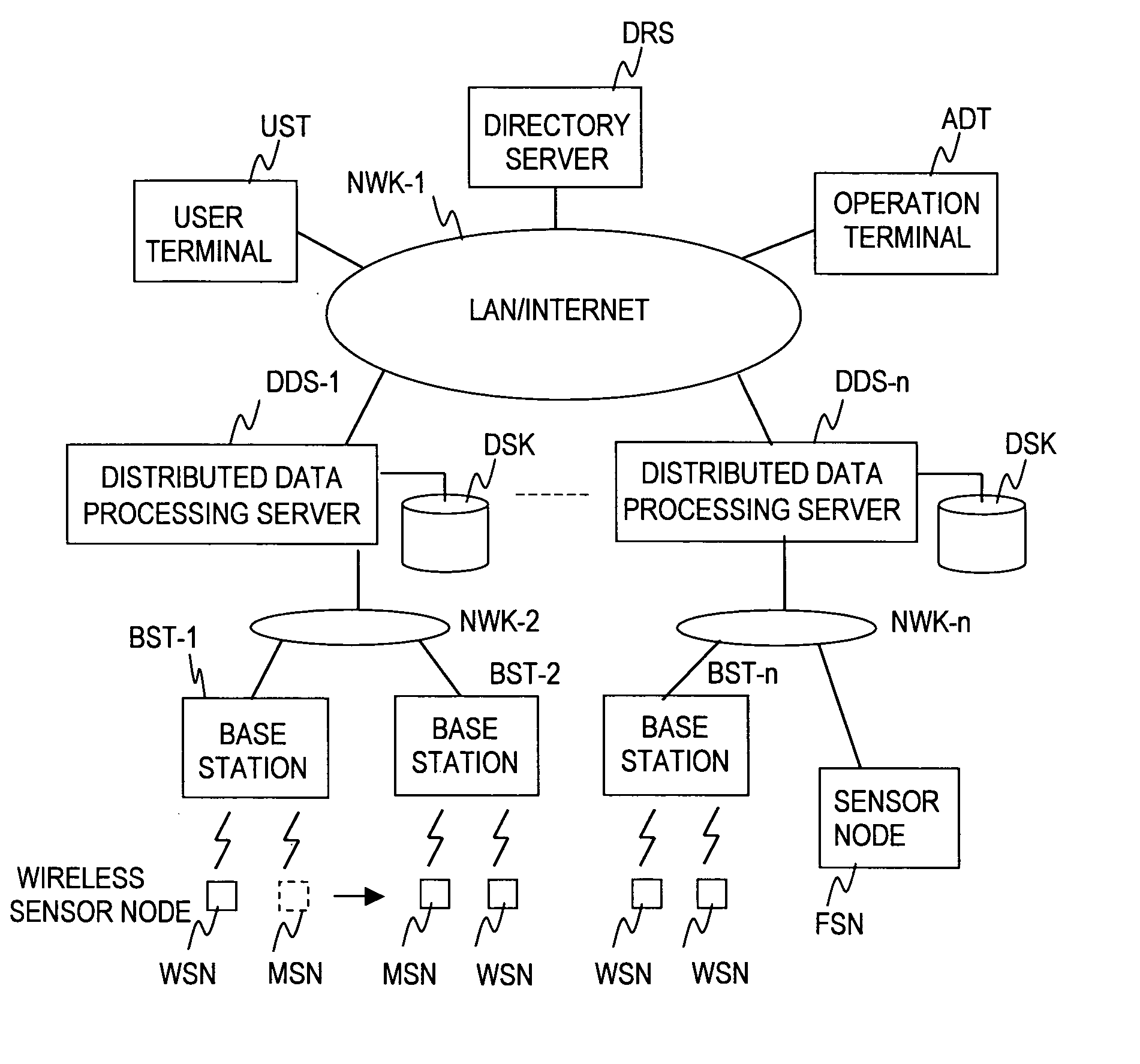

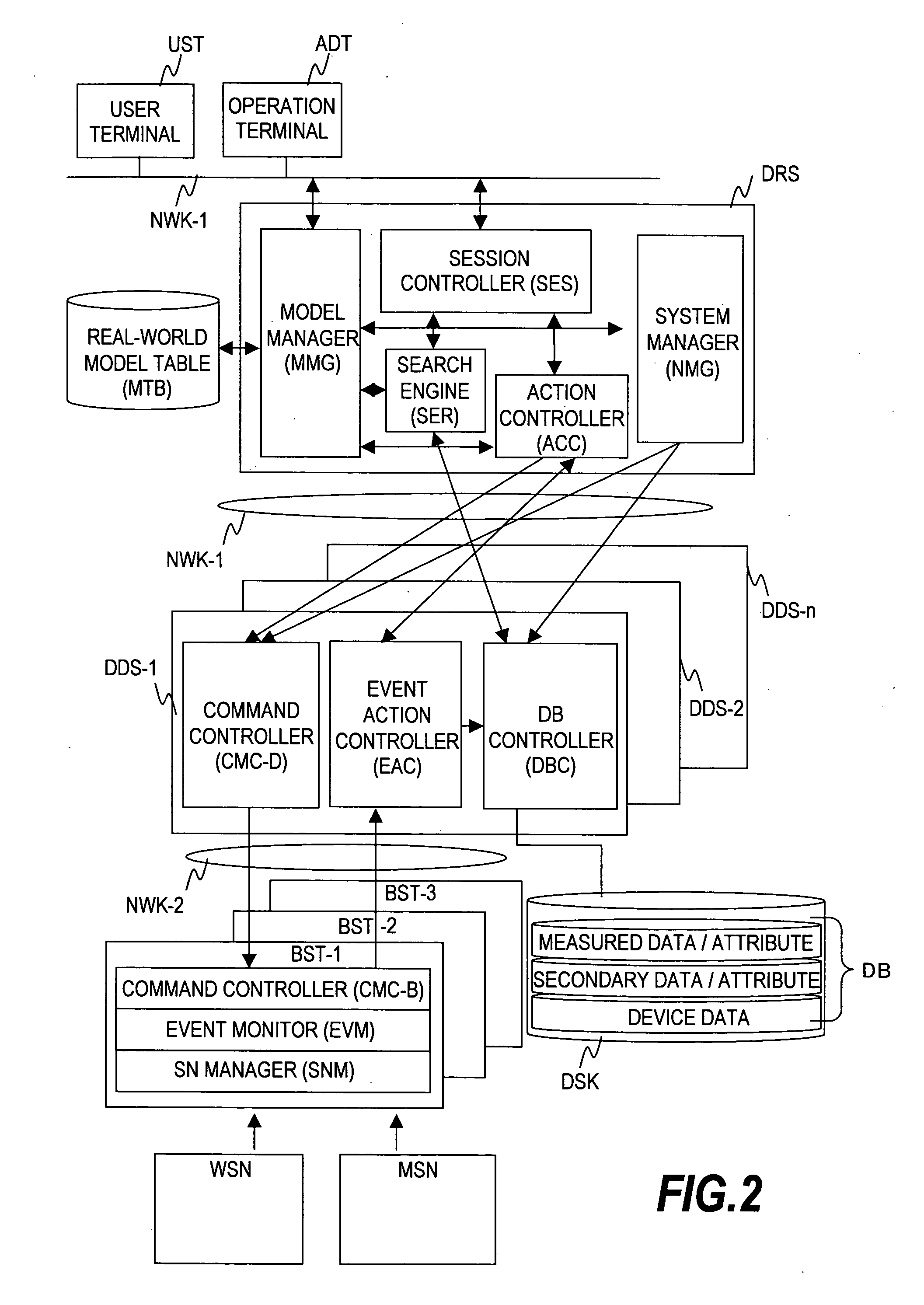

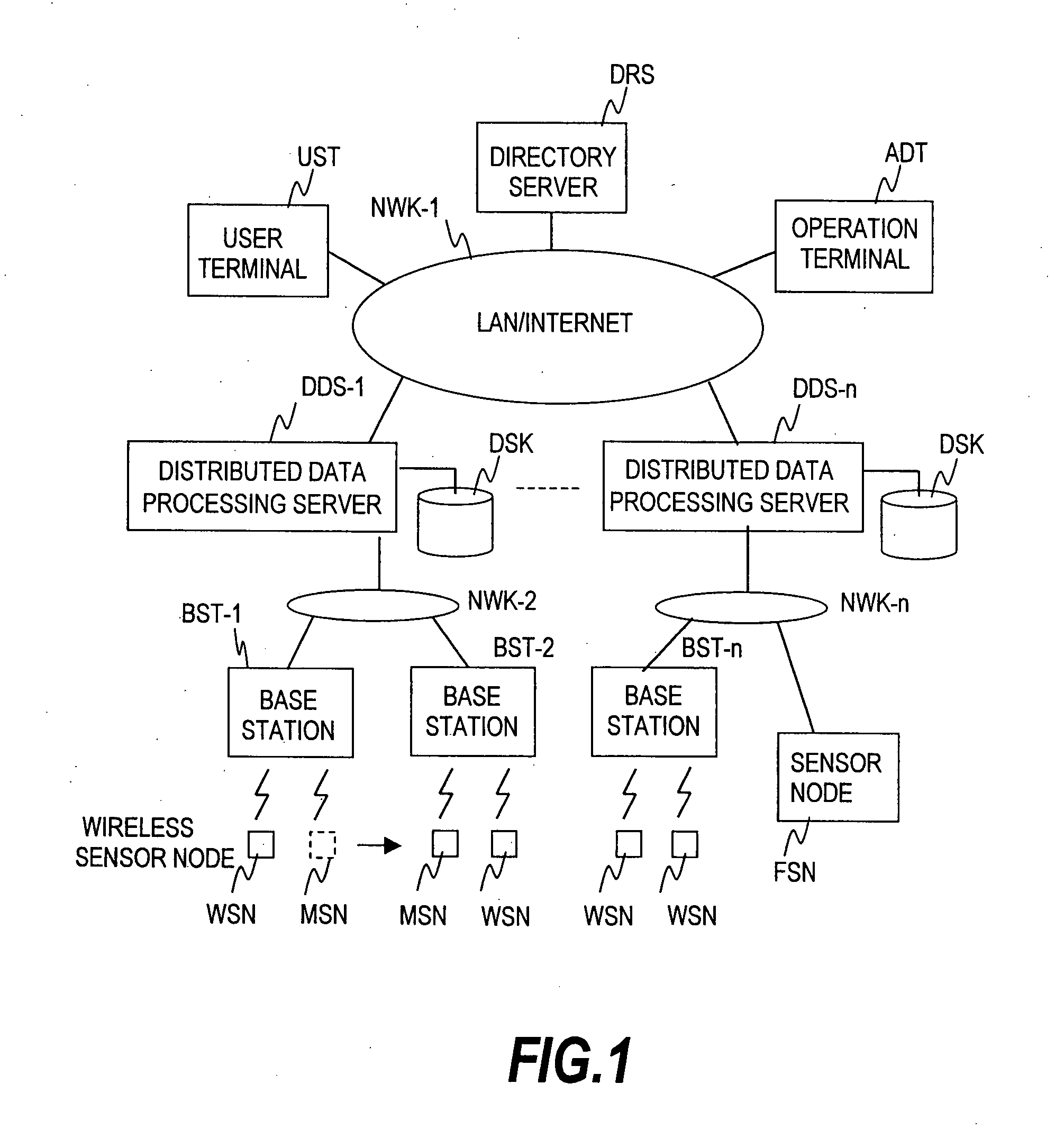

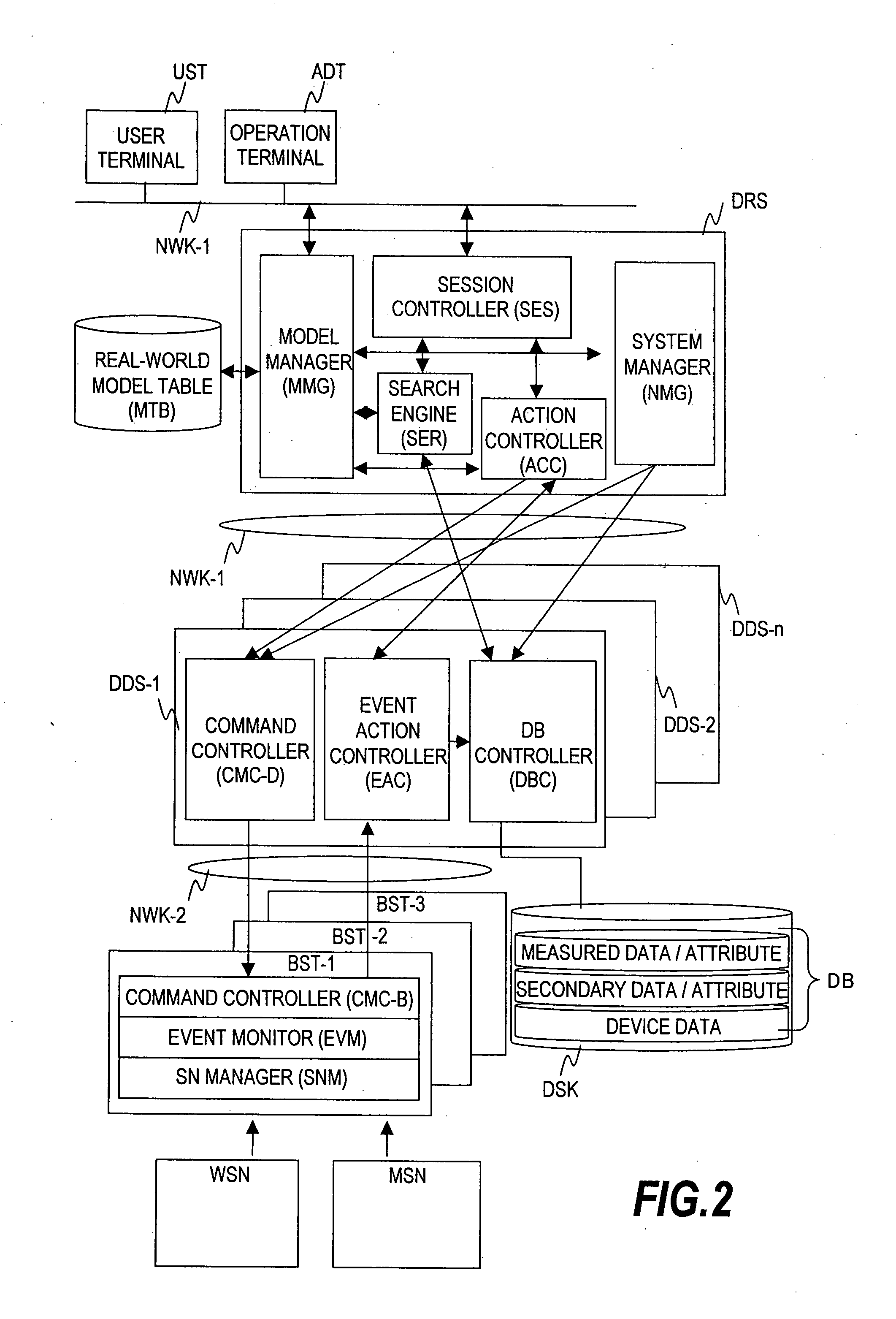

Sensor network system and data retrieval method for sensing data

InactiveUS20060161645A1Easily and quickly necessary informationAvoid loadTelephonic communicationDigital computer detailsTime informationSensing data

This invention enables to easily retrieve real-time information from a large number of sensors connected to a network. The sensor network system of this invention includes distributed data processing servers for collecting data from plural sensors at a predetermined frequency, a management server for maintaining a location of sensor data, user terminals for requesting data to the management server, and a first network for connecting with the management server, user terminals and plural distributed data processing servers. The management server includes a model table having model names previously set and information link pointers for indicating which distributed data processing server collects data corresponding to the model names, and a search engine for acquiring data requested by the user terminals from the distributed data processing servers corresponding to the information link pointers based on the model table and for responding to the user terminals with the data.

Owner:HITACHI LTD

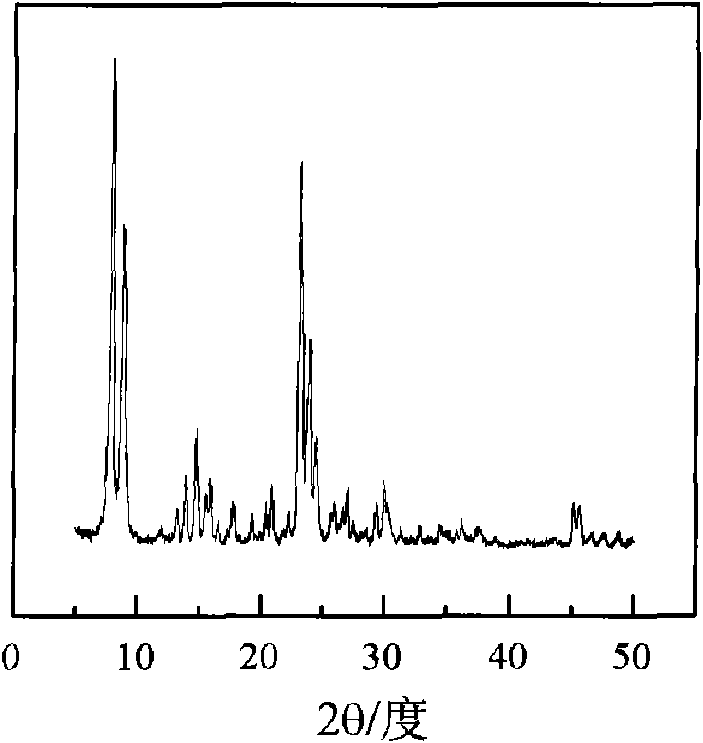

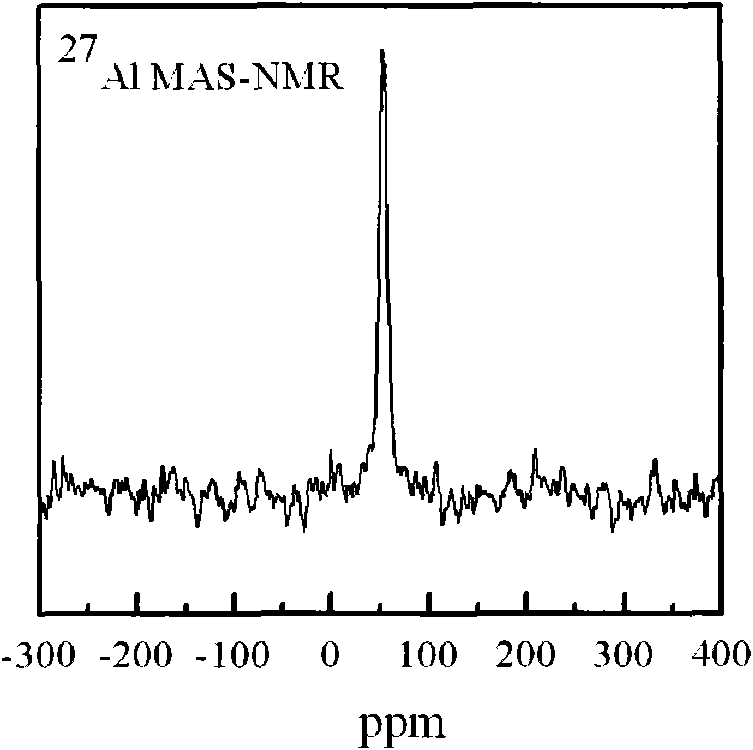

ZSM-5 type molecular sieve for catalyst for reaction for preparing propylene from methanol and/or dimethyl ether

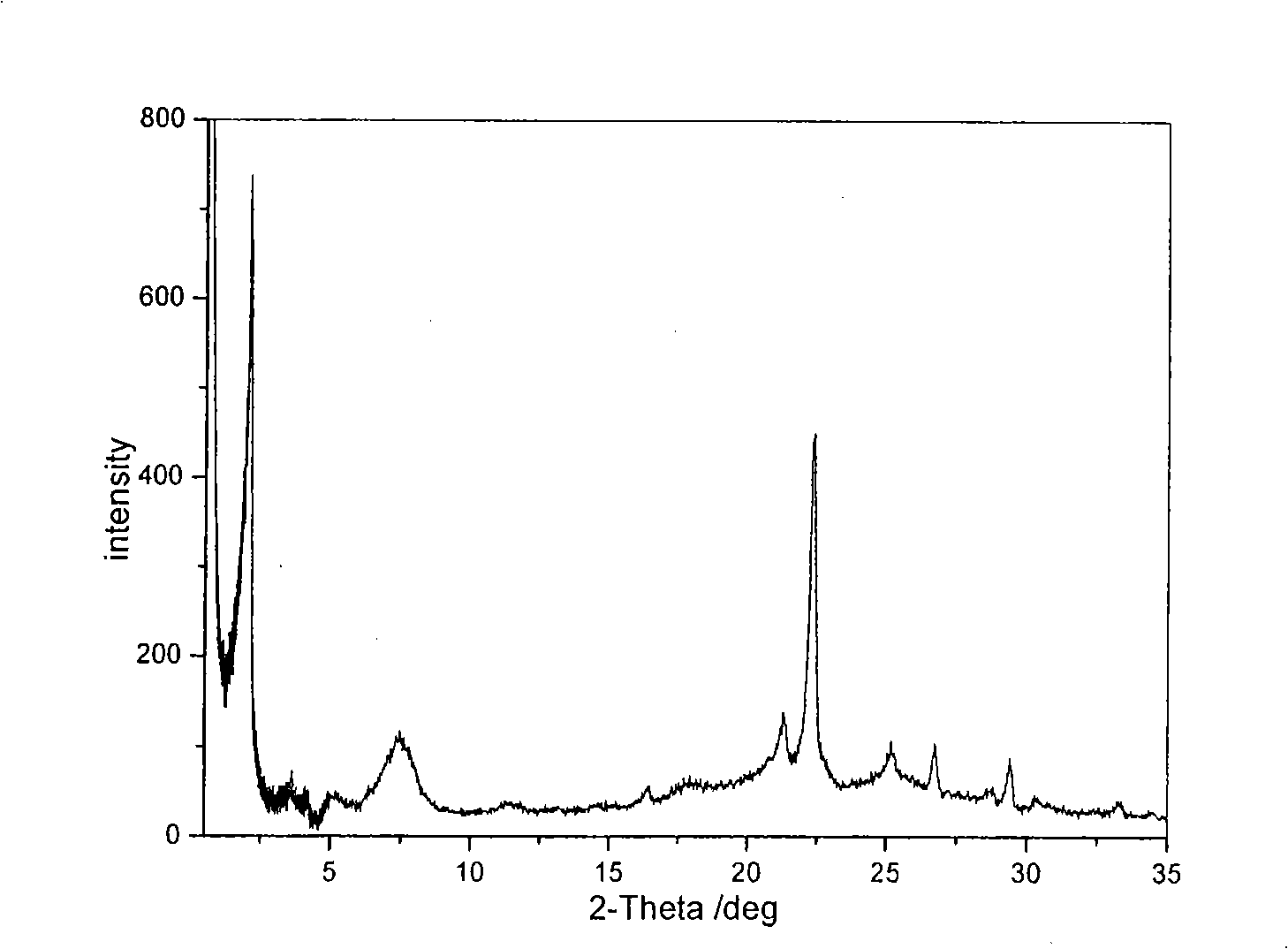

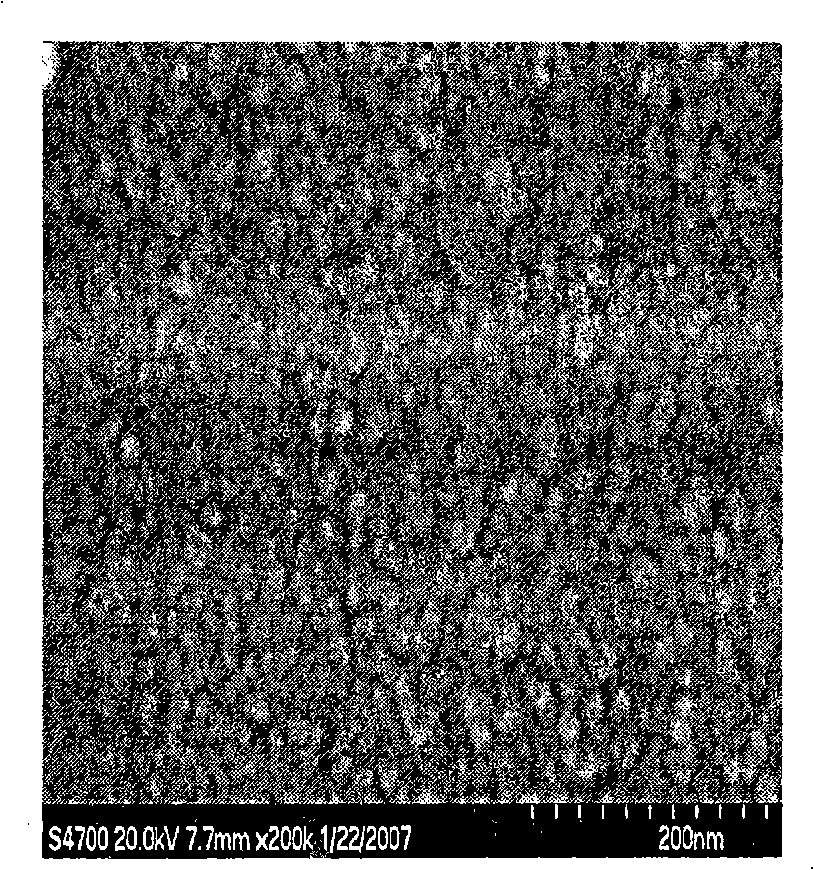

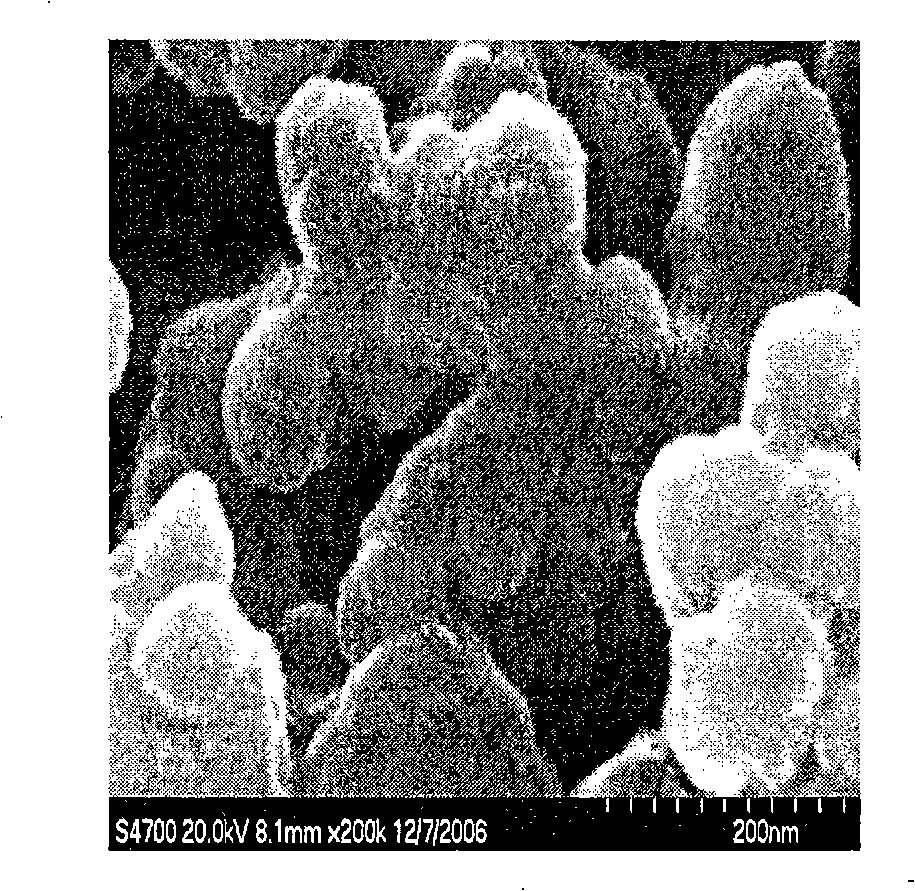

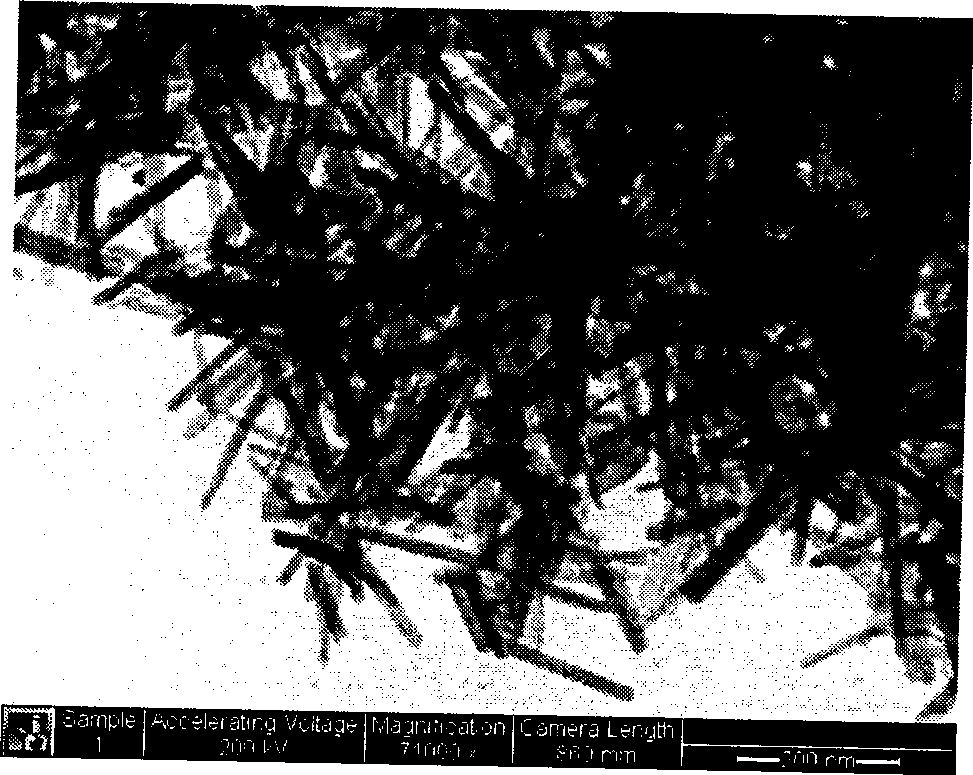

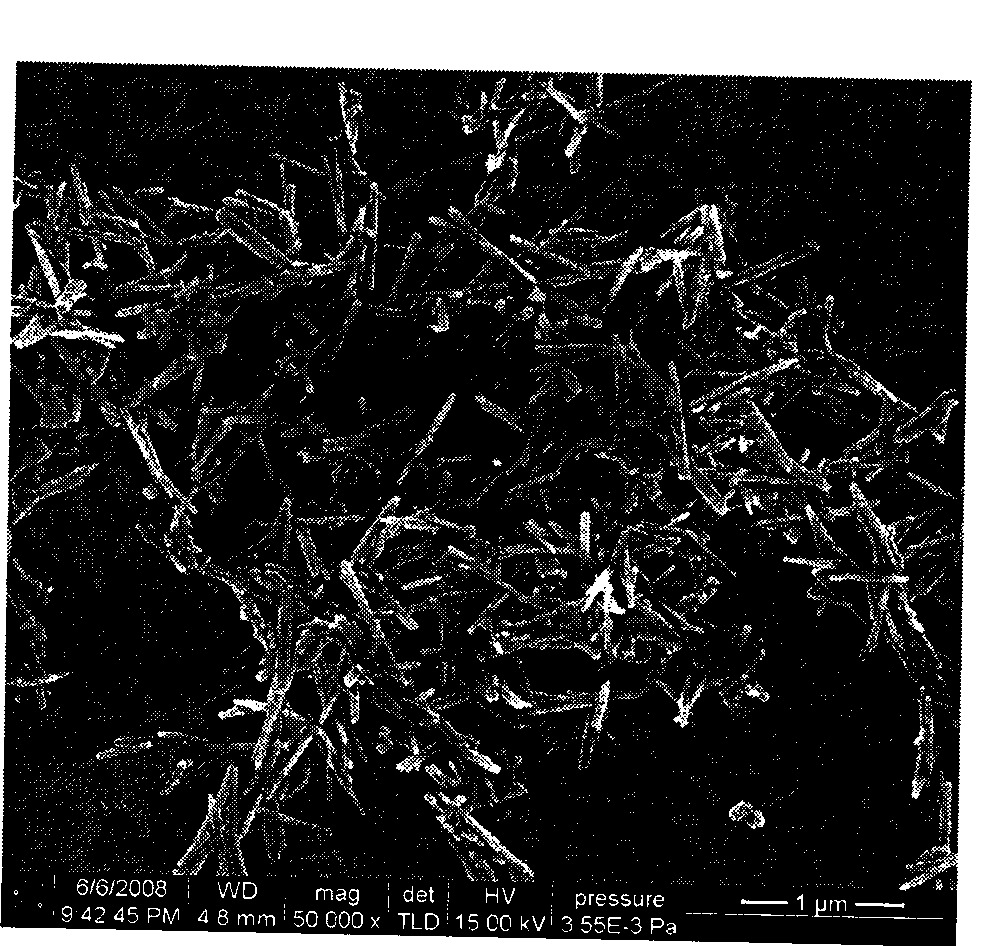

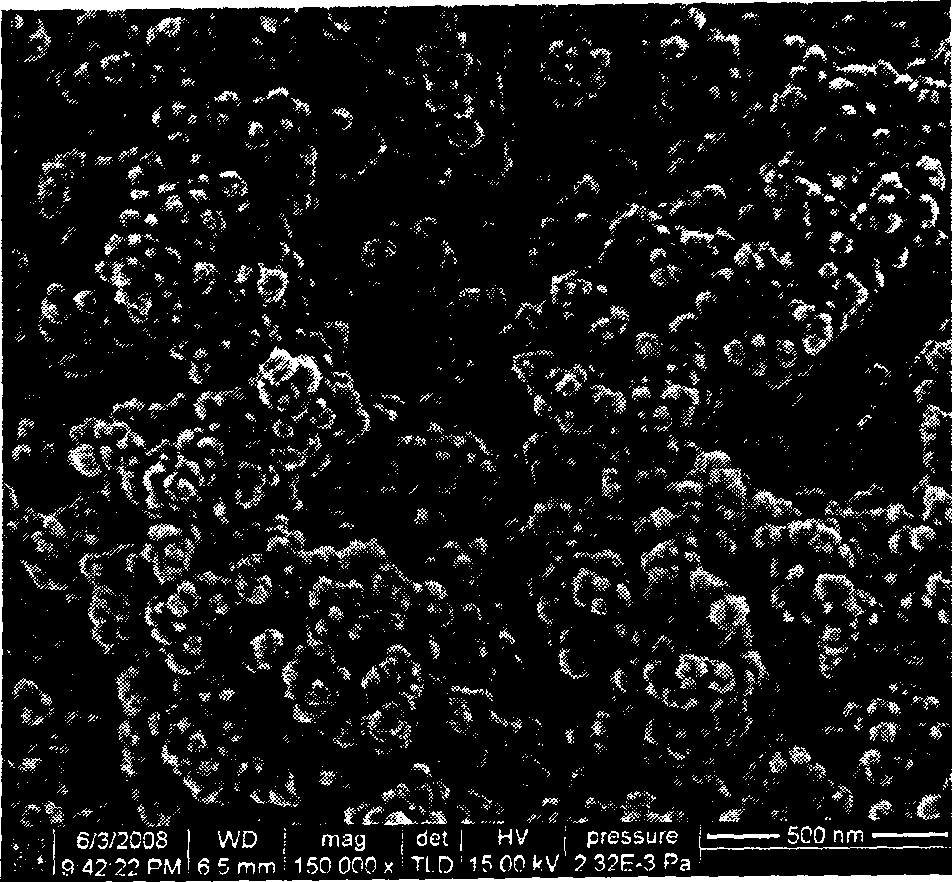

ActiveCN101624192AImprove diffusion abilityHigh P/E ratioMolecular sieve catalystsHydrocarbon from oxygen organic compoundsDispersitySilicon

The invention provides a ZSM-5 type molecular sieve for a catalyst for a reaction for preparing propylene from methanol and / or dimethyl ether, which has a silica alumina ratio of 250-1,150 and a grain diameter of 65-250nm. A preparation method of the molecular sieve comprises the following steps: (1) mixing an aluminum source and an organic directing agent and stirring an obtained mixture at constant temperature of 0-30 DEG C for 2-24 hours; (2) adding a silicon source and an organic addition agent to the mixed solution obtained in the step (1) and continuing stirring the mixed solution to obtain gel; (3) stirring the gel obtained in the step (2) at 35-95 DEG C and then carrying out a crystallization reaction for 24-240 hours at 60-200 DEG C, wherein in the raw materials for synthesizing the molecular sieve, and the molar ratio of OH<-1> to SO2 to AL2O3 to H2O to the organic directing agent to the organic directing agent is (0.1-0.35):1:(0.0005-0.01):(10-25):(0.1-0.6):(0.5-8). The ZSM-5 type catalyst has the characteristics of controllable grain size, adjustable silica alumina ratio, high dispersity, and the like and has higher propylene selectivity and P / E ratio in the reaction for preparing low carbon olefin from the methanol and / or the dimethyl ether.

Owner:DATANG INT CHEM TECH RESINST

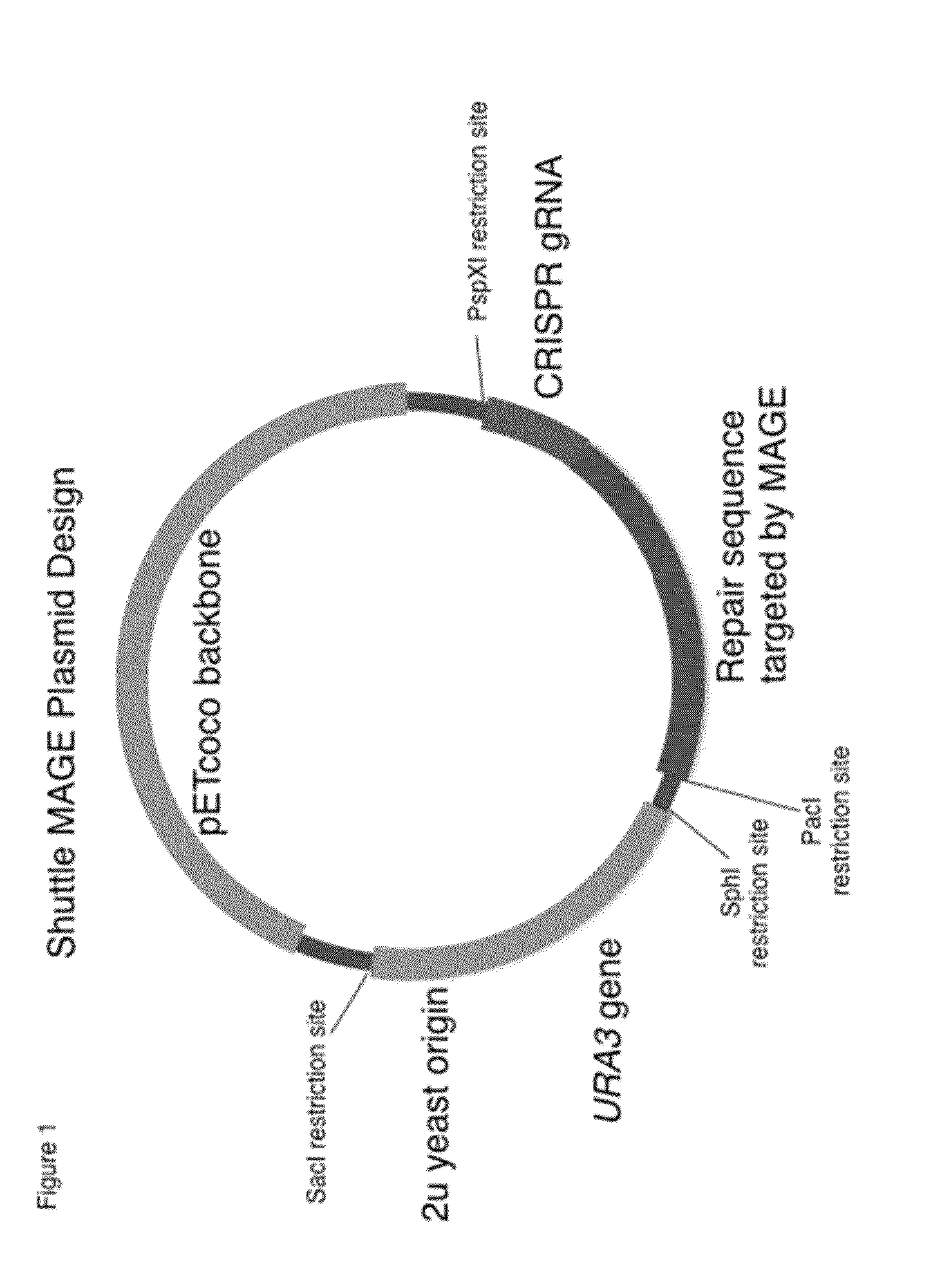

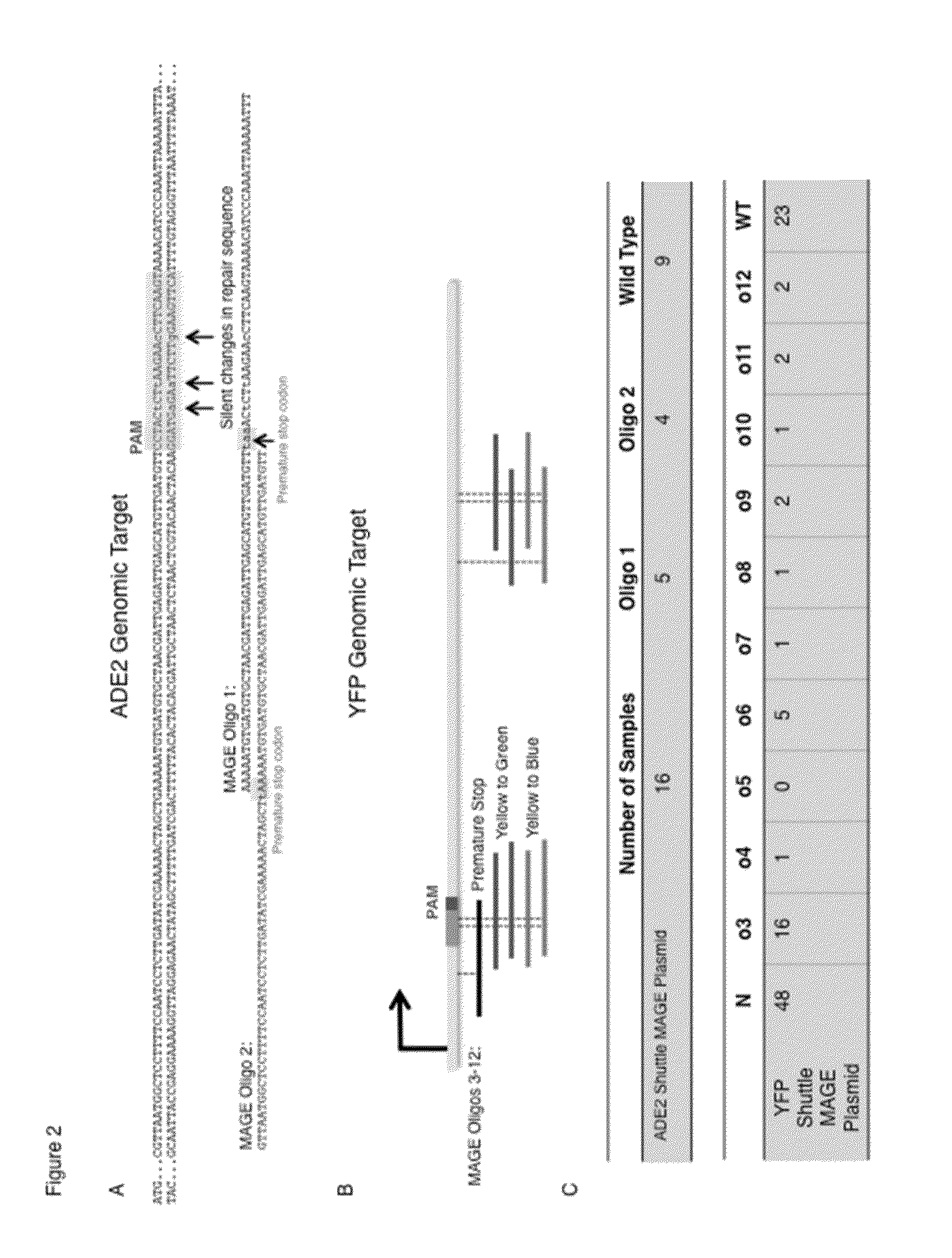

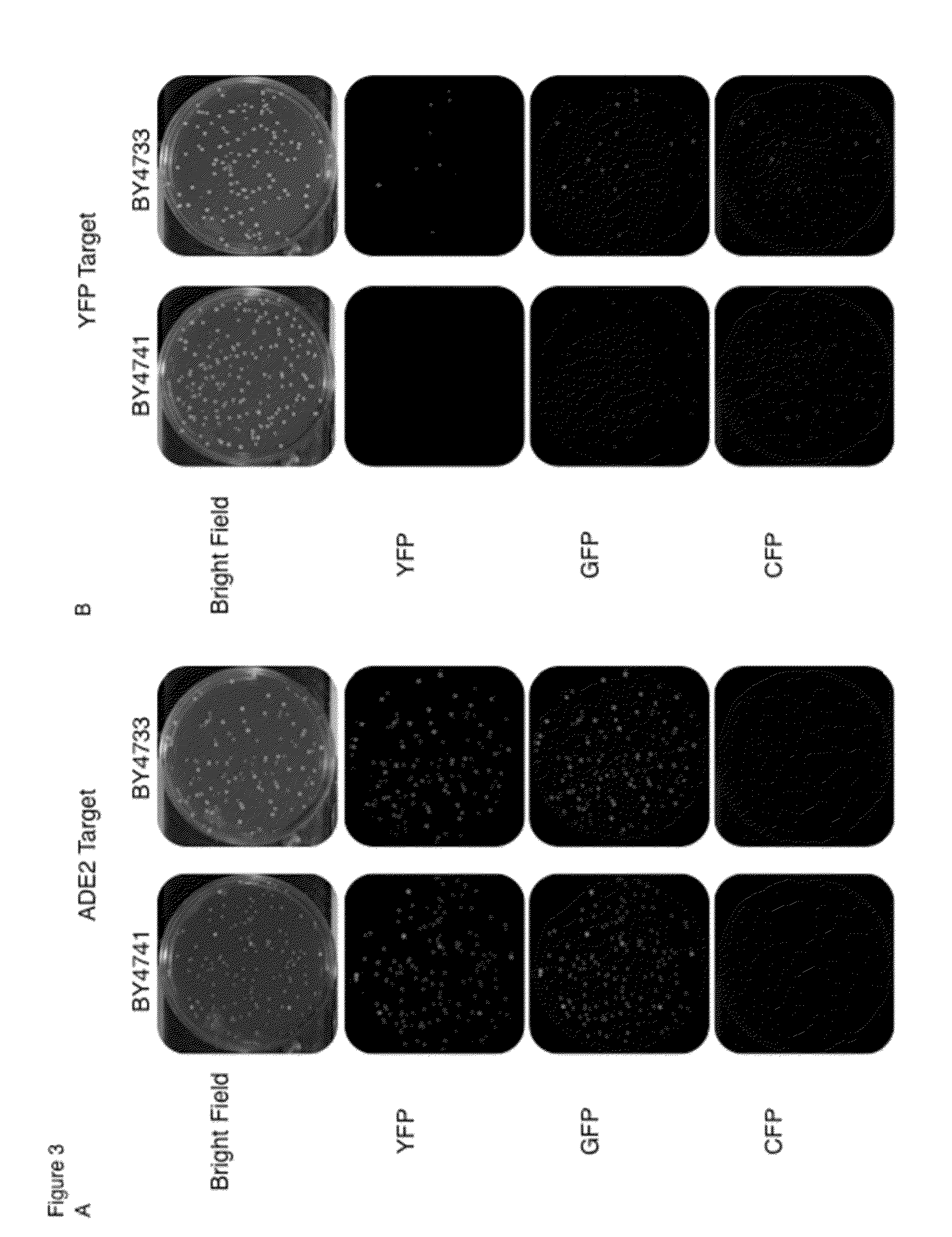

Processes and host cells for genome, pathway, and biomolecular engineering

ActiveUS20160186168A1High energy valueIncrease probabilityBacteriaUnicellular algaeBiotechnologyGenomic engineering

Owner:ENEVOLV

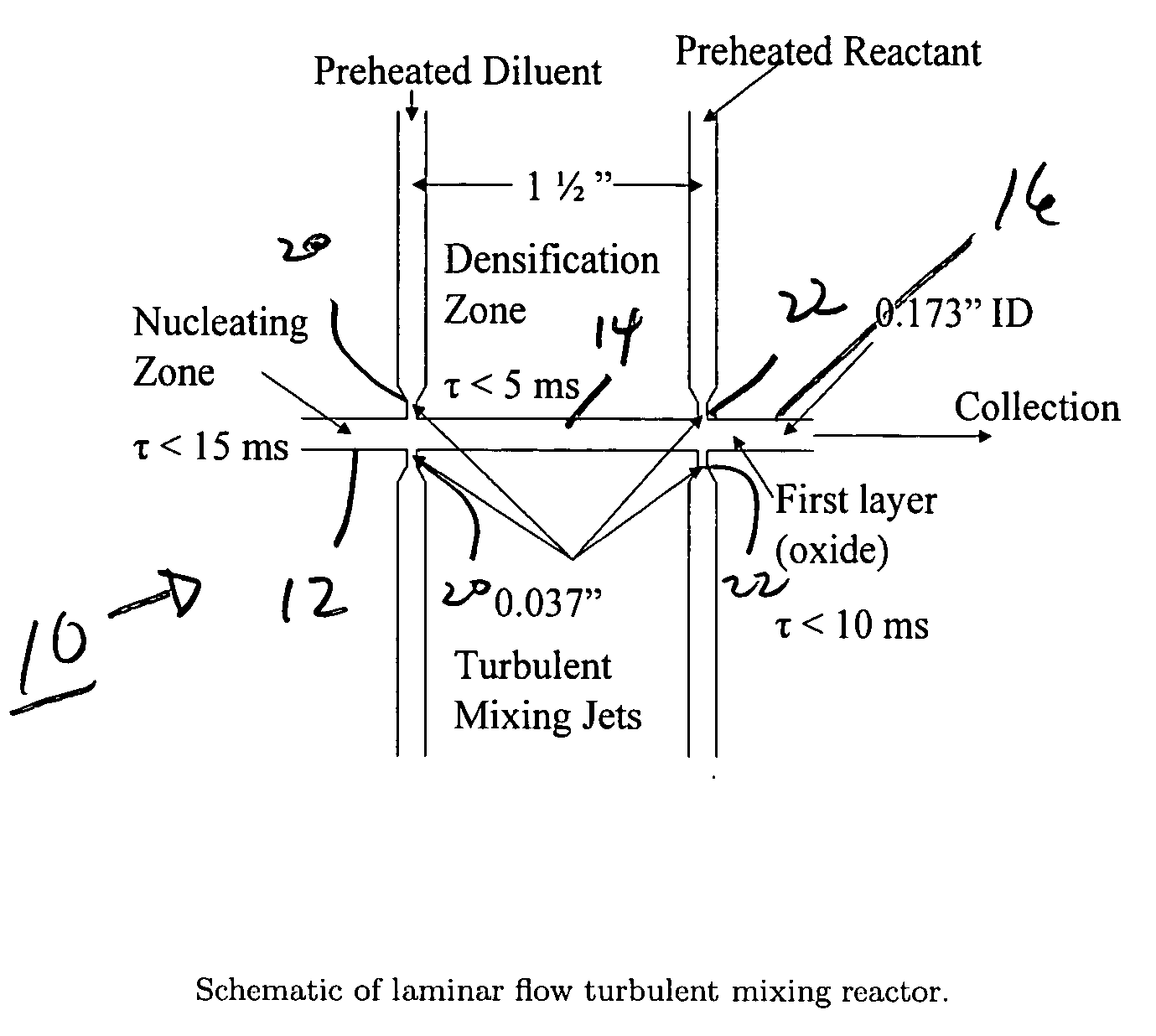

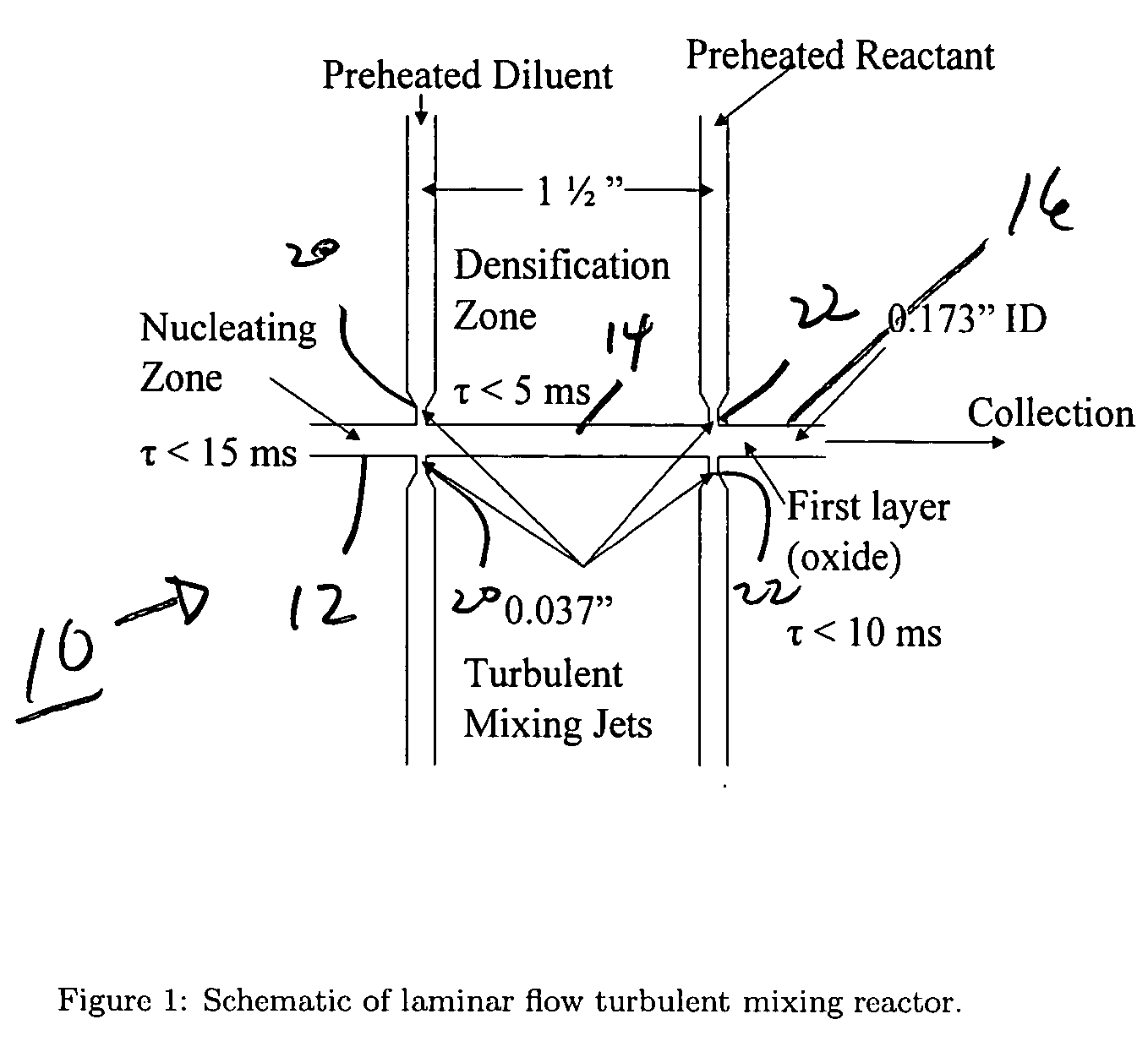

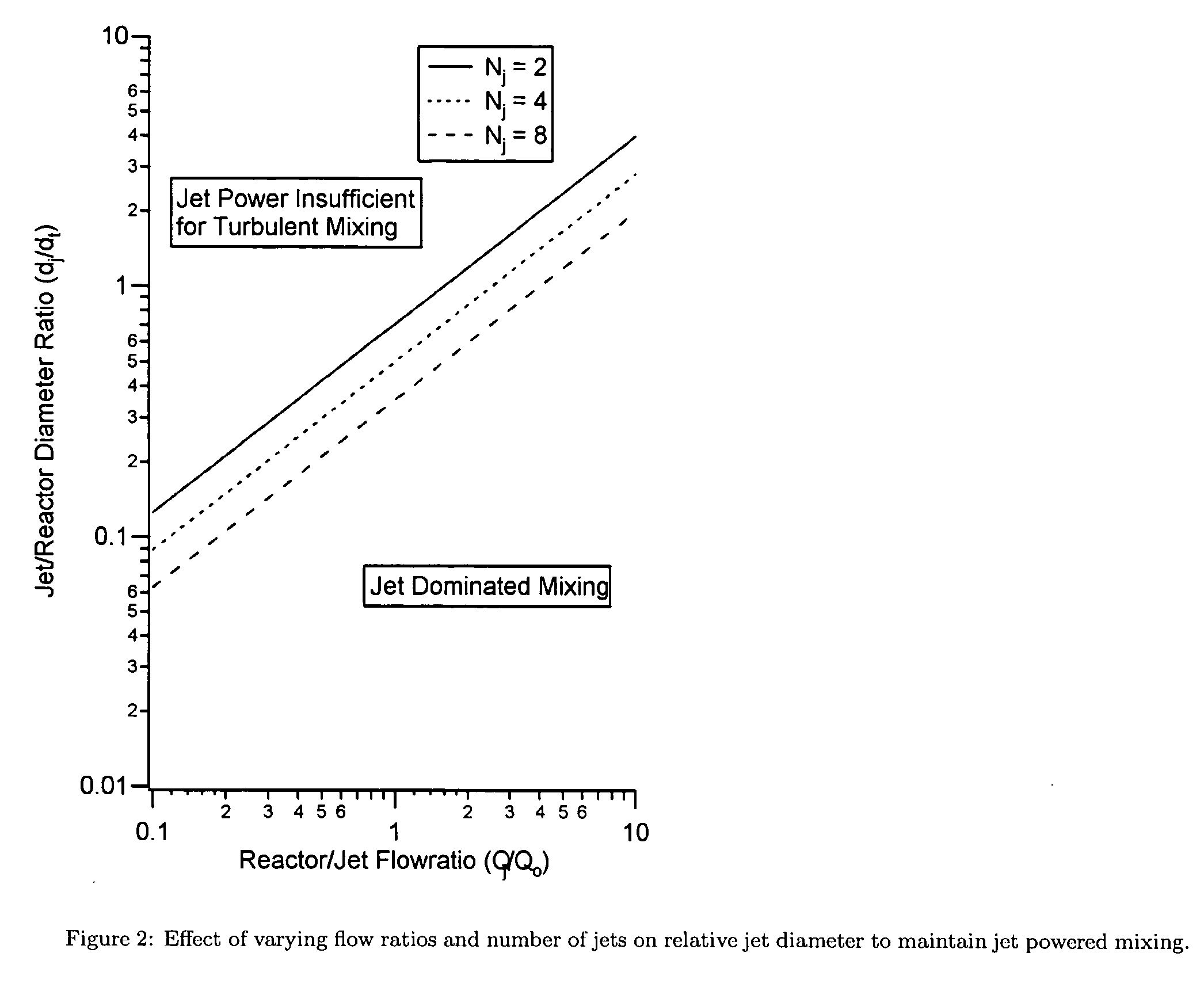

Turbulent mixing aerosol nanoparticle reactor and method of operating the same

InactiveUS20060024435A1Improve throughputKeep full controlMaterial nanotechnologyLiquid surface applicatorsThermal energyNanoparticle

A nanoparticle reactor comprises a nucleation and core growth region providing a laminar flow of reactants in which the reactants thermally decompose to produce a supersaturated vapor that nucleates aerosol particles into particle cores. Nozzle(s) turbulently mix a preheated diluent into the heated reactants. The mixed preheated diluent and heated reactants flow into a core densification region where particle growth is quenched, coagulation limited and sufficient thermal energy for densification of the cores of the particles is provided. Nozzles turbulently mix a preheated additional reactant. A jet and chemical injection and layer formation region is used to develop the particle cores.

Owner:CALIFORNIA INST OF TECH

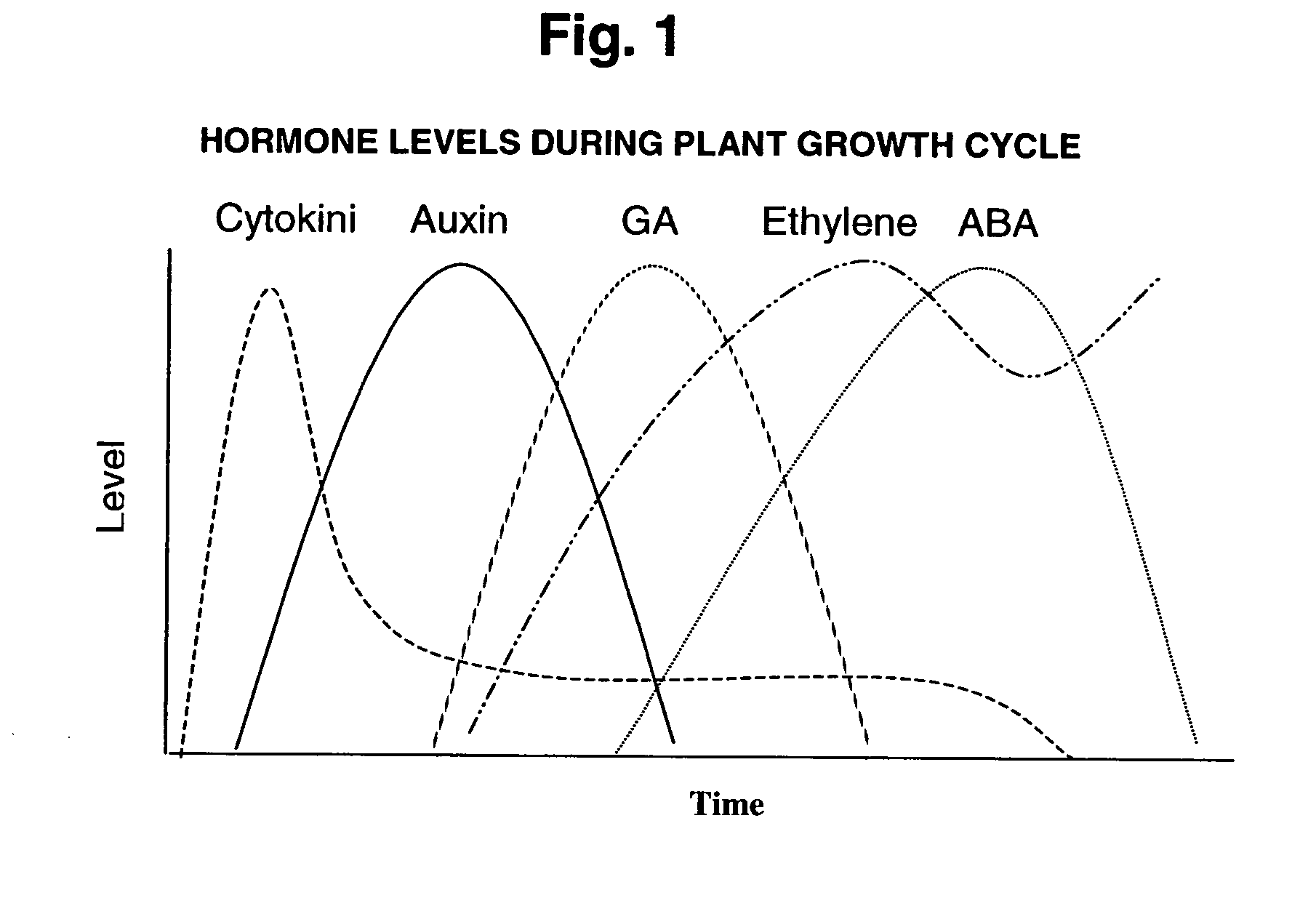

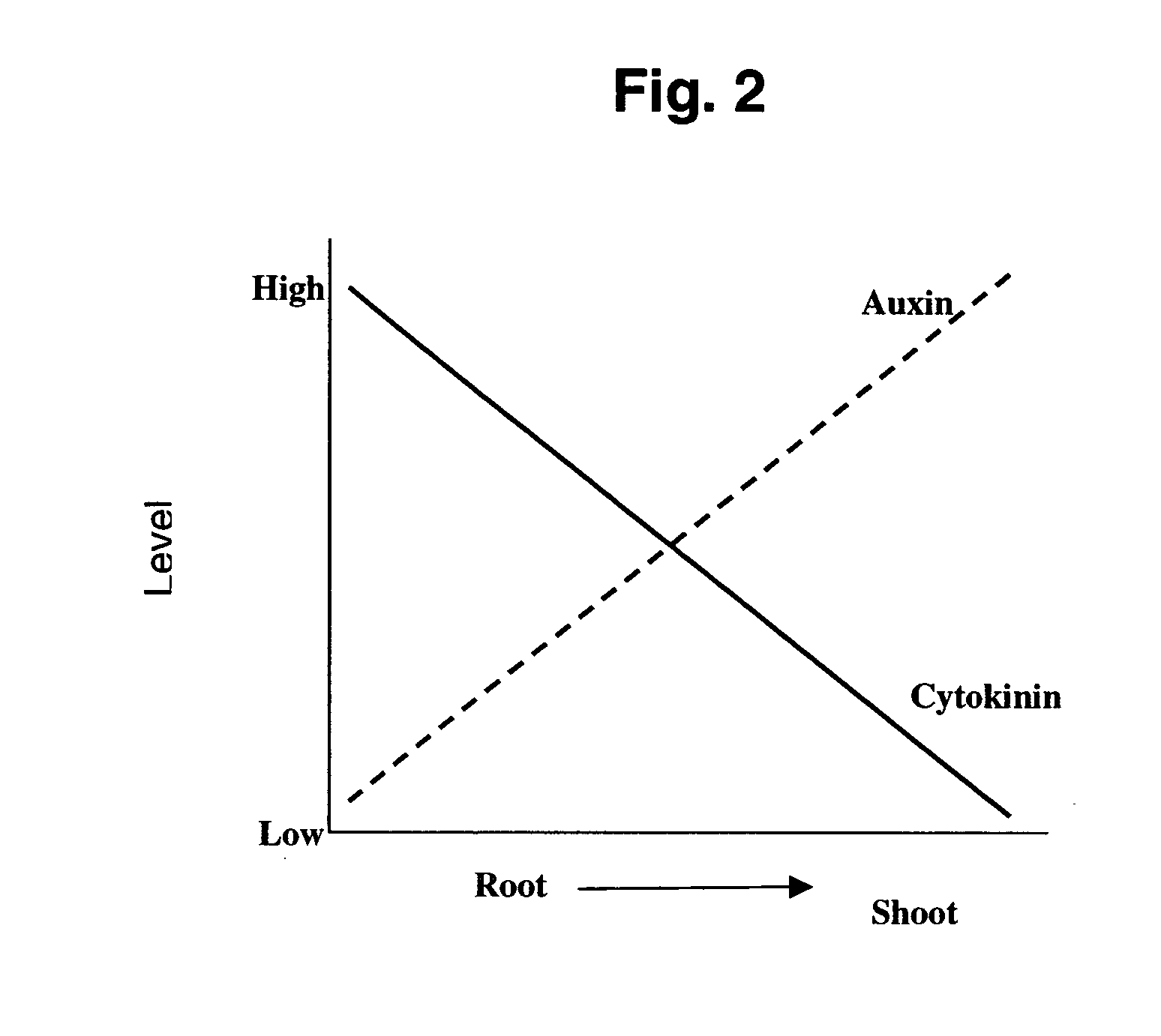

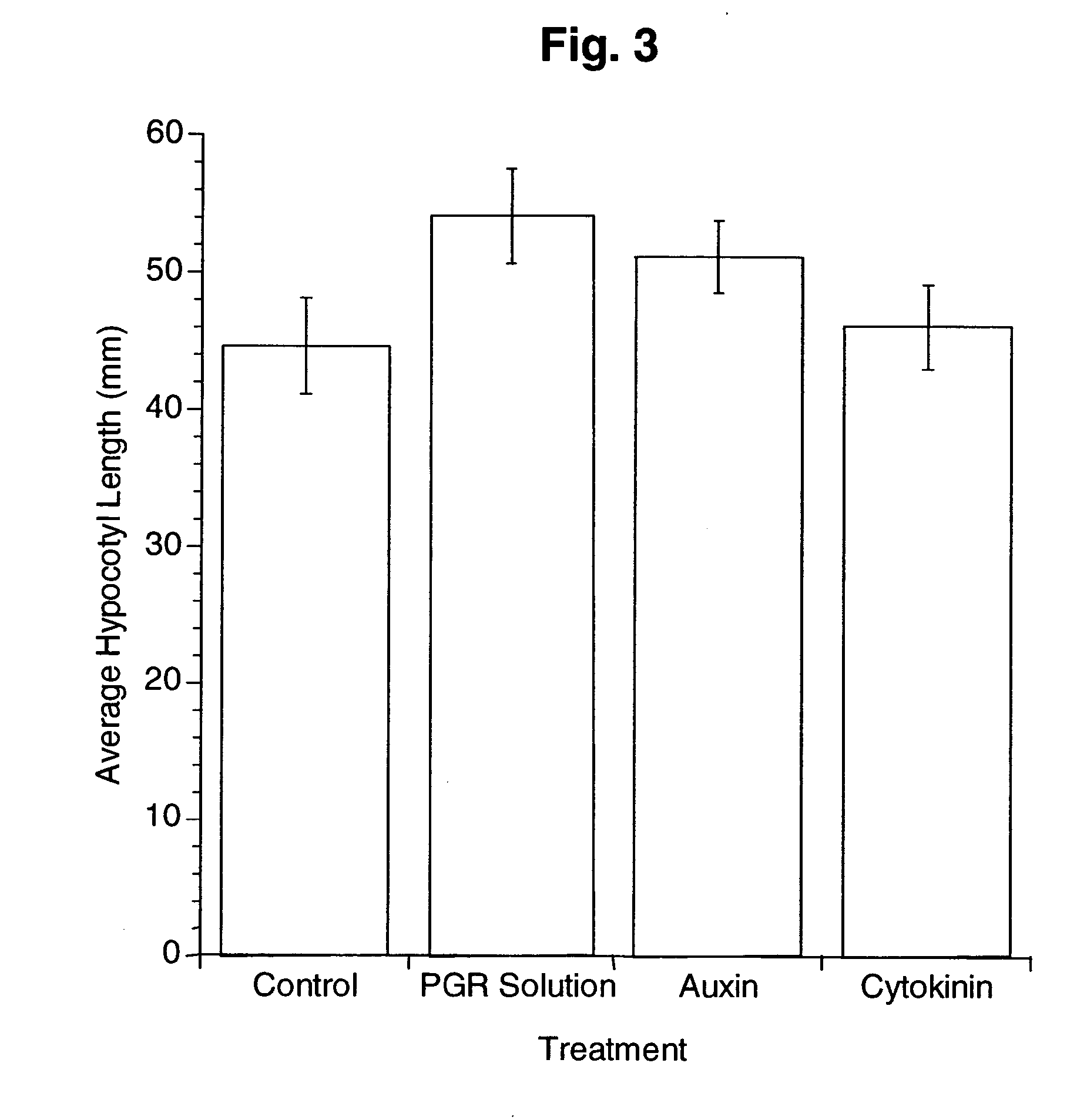

Methods for improving growth and crop productivity of plants by adjusting plant hormone levels, ratios and/or co-factors

ActiveUS20050197253A1Improve architectureIncrease crop yieldBiocideAnimal repellantsCytokininDisease

In agriculture when temperature and moisture deviate from the norm two things happen, plant growth suffers and disease flourishes. The Stoller model for plant growth states that proper hormone balance is necessary for optimum growth and performance. When growth conditions deviate from the norm, hormone balance is altered and plant growth suffers. This invention presents evidence to support this model and explain the relationship between hormone levels and plant growth. A clear understanding of this relationship will facilitate crop treatments aimed to eliminate these problems. Although we cannot control the climate, we can control the damage caused by environmental stresses by manipulating the levels and / or ratio of plant hormones in the different plant tissues. By adjusting the levels and / or ratios of hormones, particularly auxin and cytokinins in the root tissue, we can assist the plant in overcoming or compensating for this environmental stress.

Owner:STOLLER ENTERPRISES INC

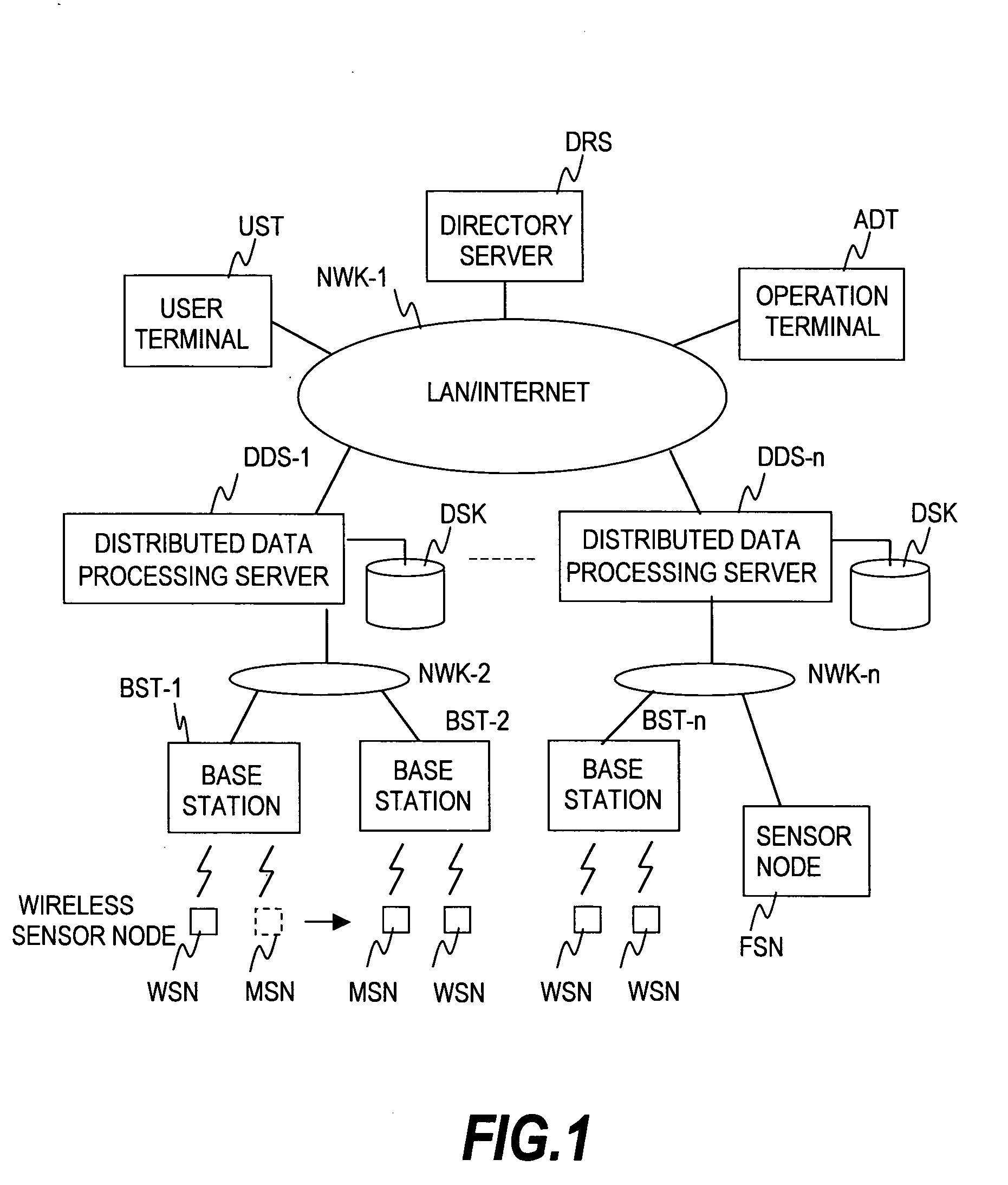

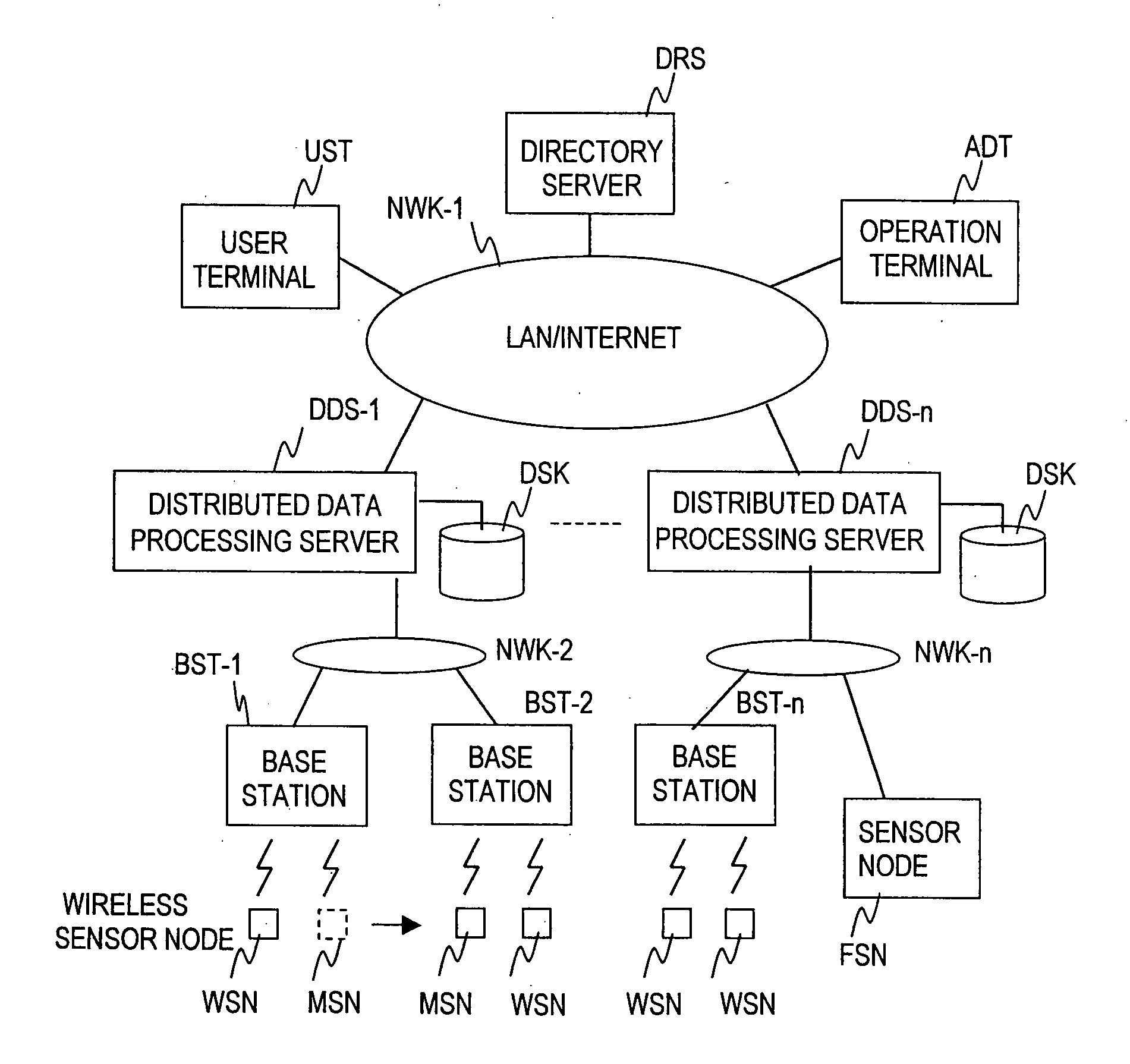

Sensor network system and data retrieval method for sensing data

InactiveUS20070198708A1Easy retrievalEasily and quickly necessary informationDigital computer detailsTelephonic communicationSensing dataData retrieval

A data retrieval method for sensing data for retrieving, from user terminals, data transmitted from a plurality of sensor nodes, the data retrieval method including: a step for storing in distributed servers the data sent from the plurality of sensor nodes, a step for setting information link pointers for indicating model names previously set and link pointers of data corresponding to the model names, a step for a management server connected through a network with the distributed servers and the user terminal to accept the reference requests for data acquired from the user terminals, and a step for the management server to acquire data from the distributed servers set as the information link pointers based on the data reference request from among the data stored in the distributed servers and to respond to the user terminal.

Owner:HITACHI LTD

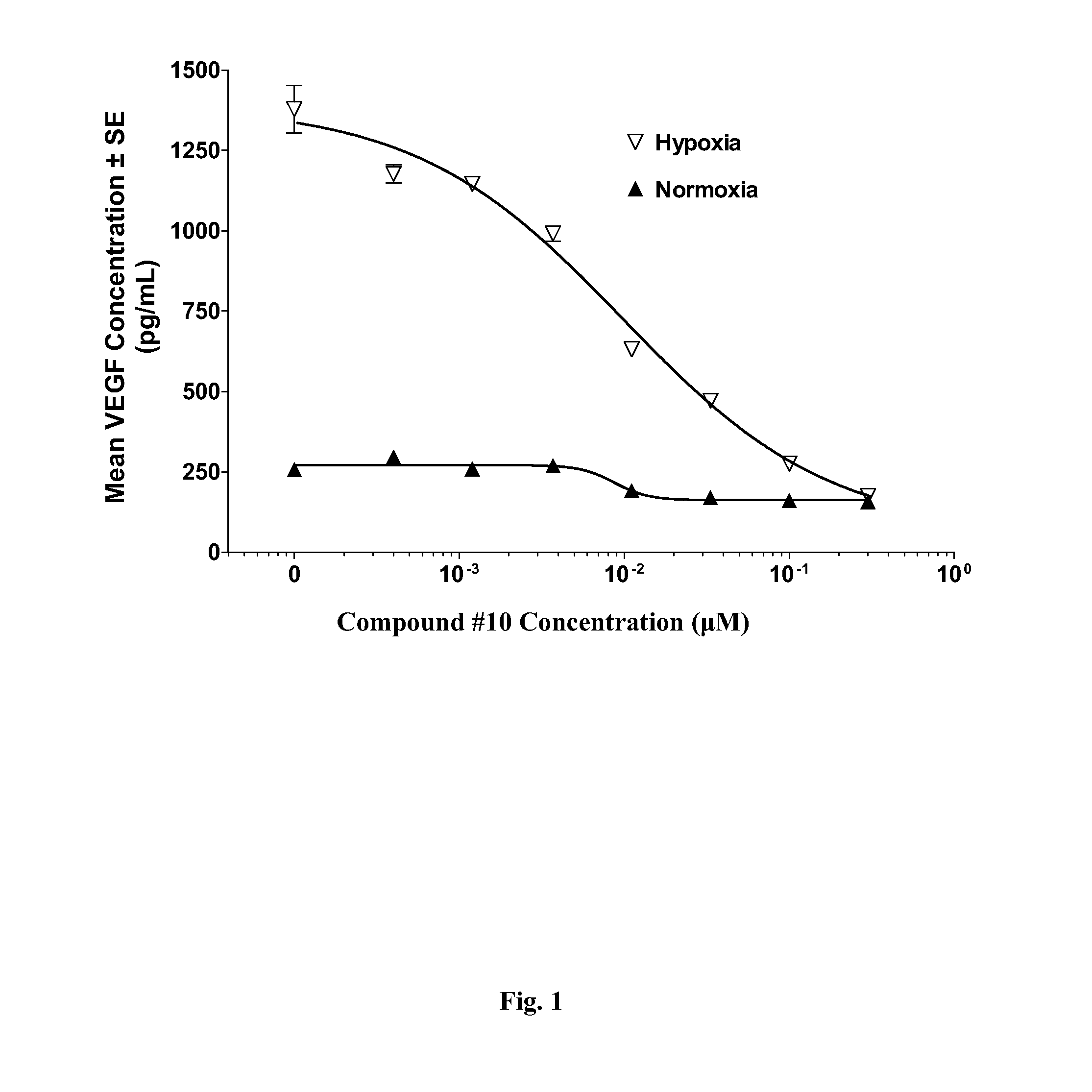

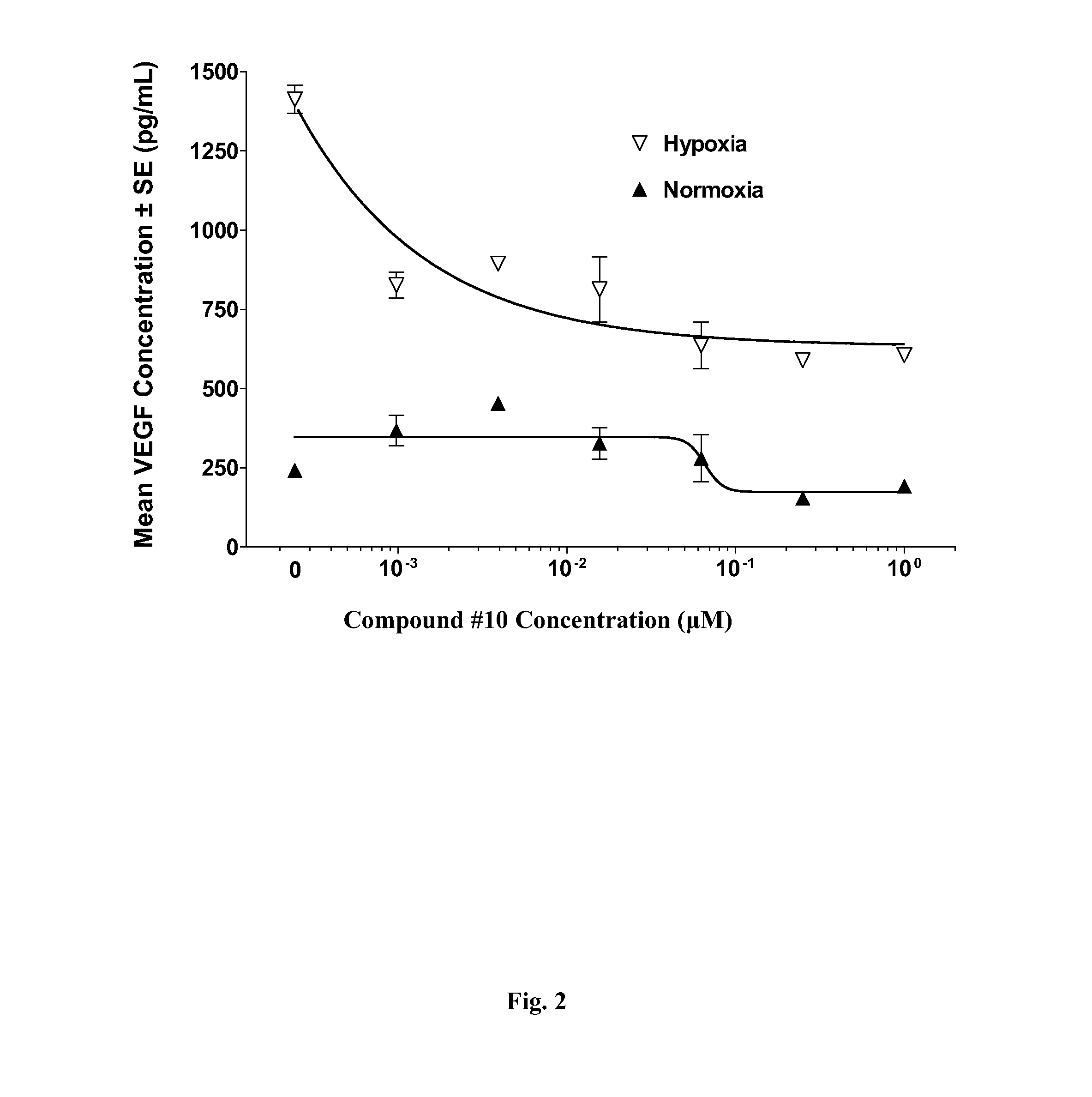

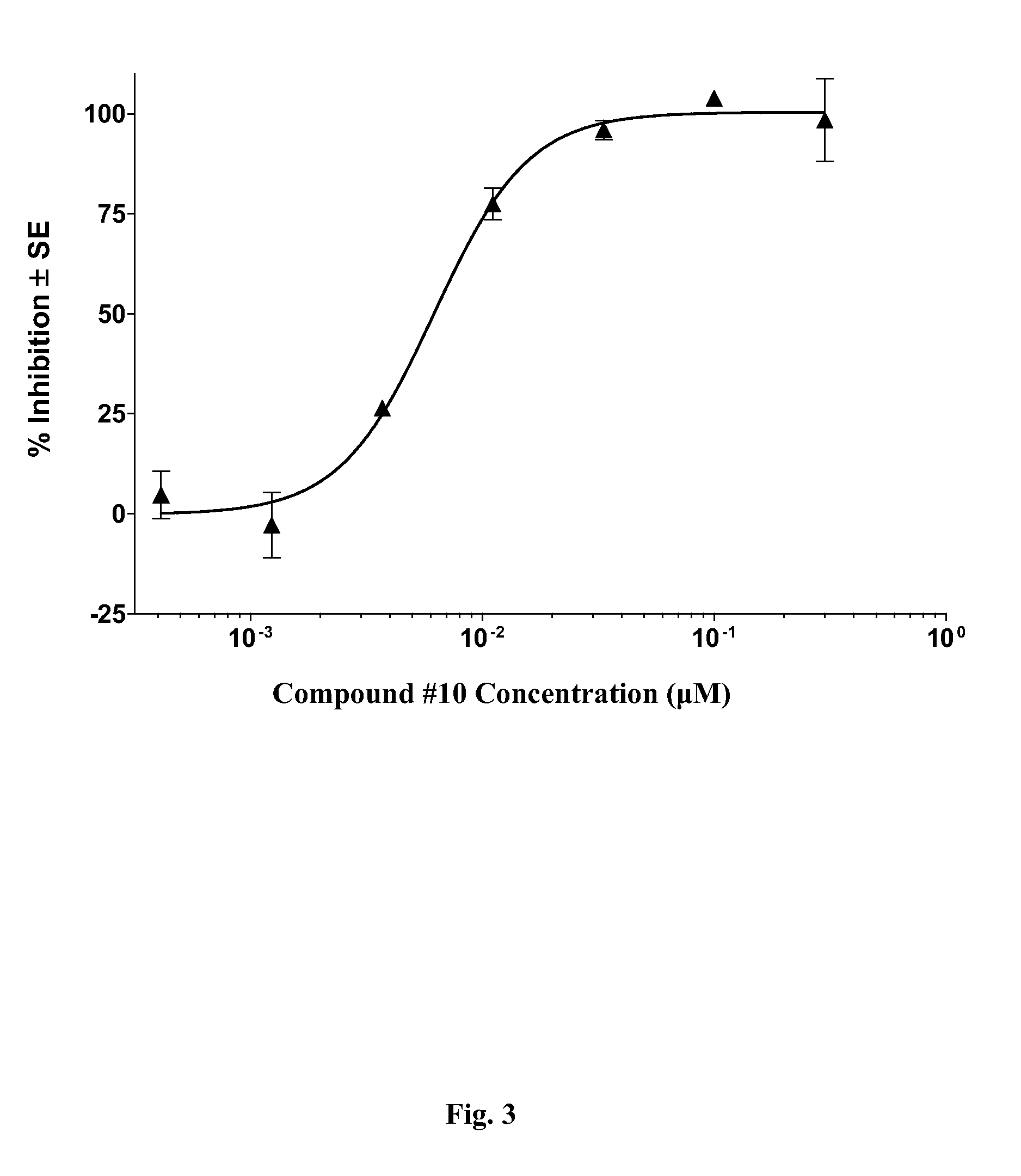

Methods for treating brain tumors

InactiveUS20120157402A1Limiting solid tumor growthLimiting tumor-related inflammationBiocideCarbohydrate active ingredientsBrain tumorCancer research

Methods for treating brain tumors involving the administration of a compound that selectively inhibits pathological production of human VEGF are described. The compound can be administered as a single agent therapy or in combination with one or more additional therapies to a human in need of such treatment.

Owner:PTC THERAPEUTICS INC

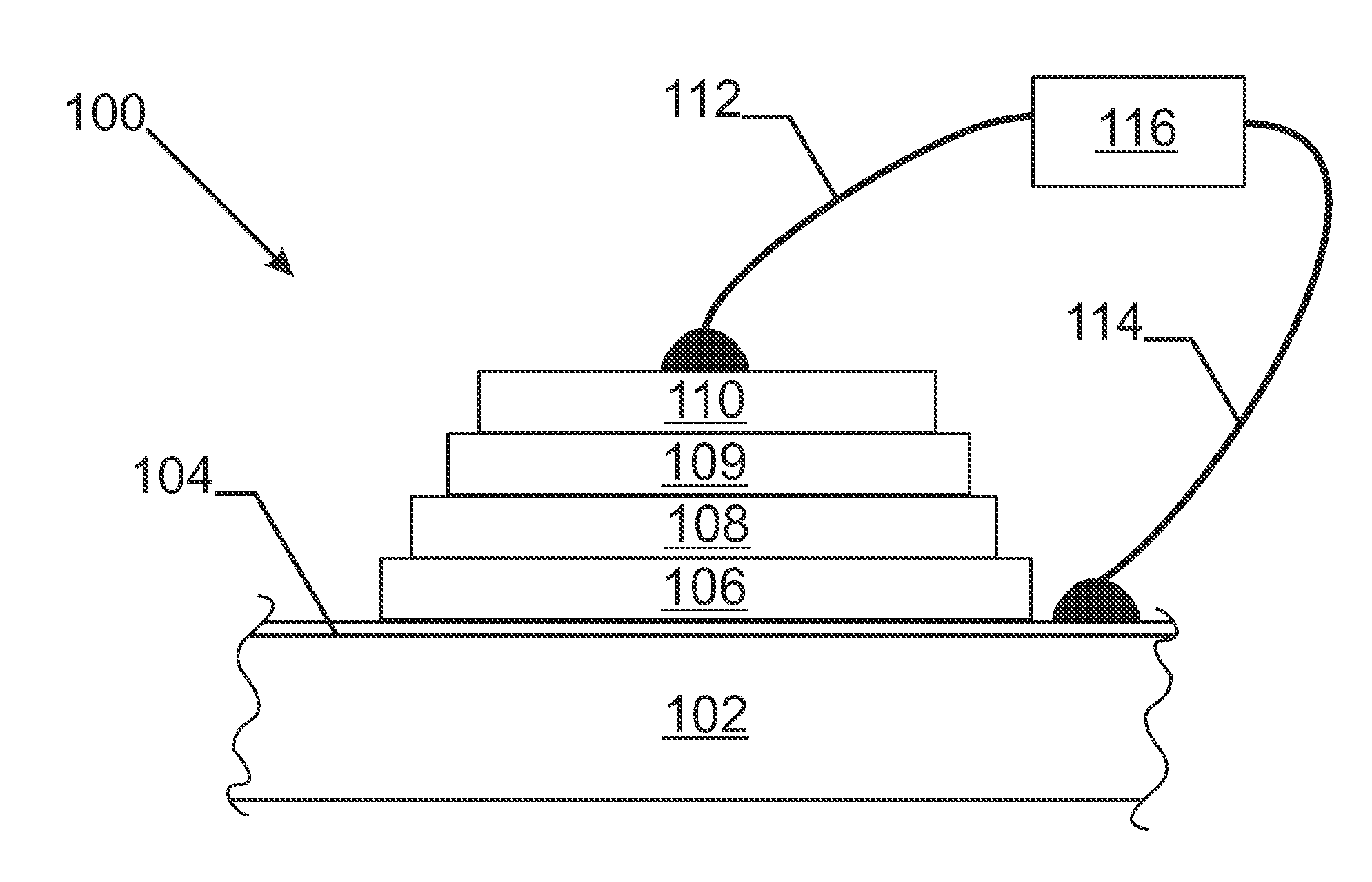

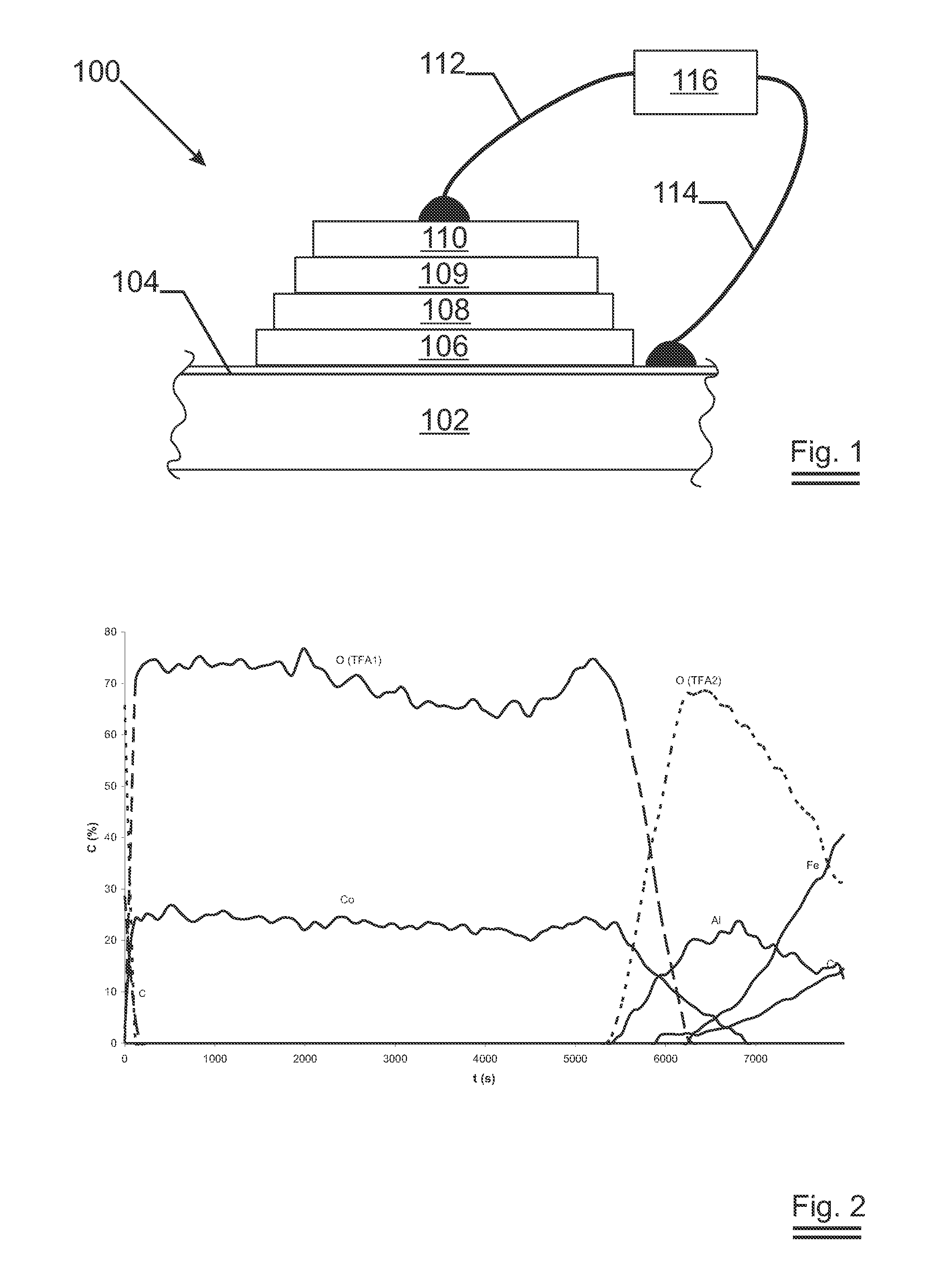

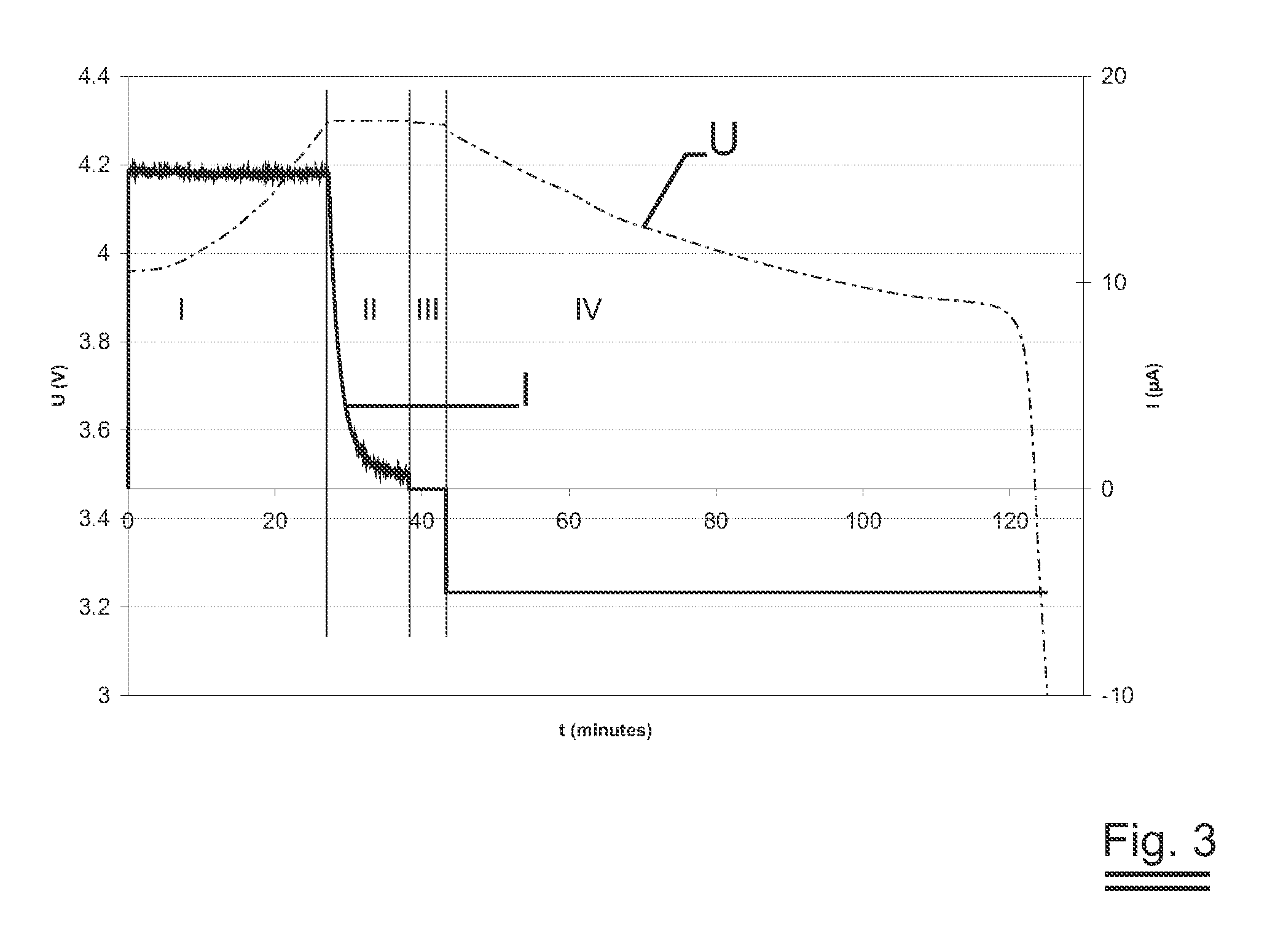

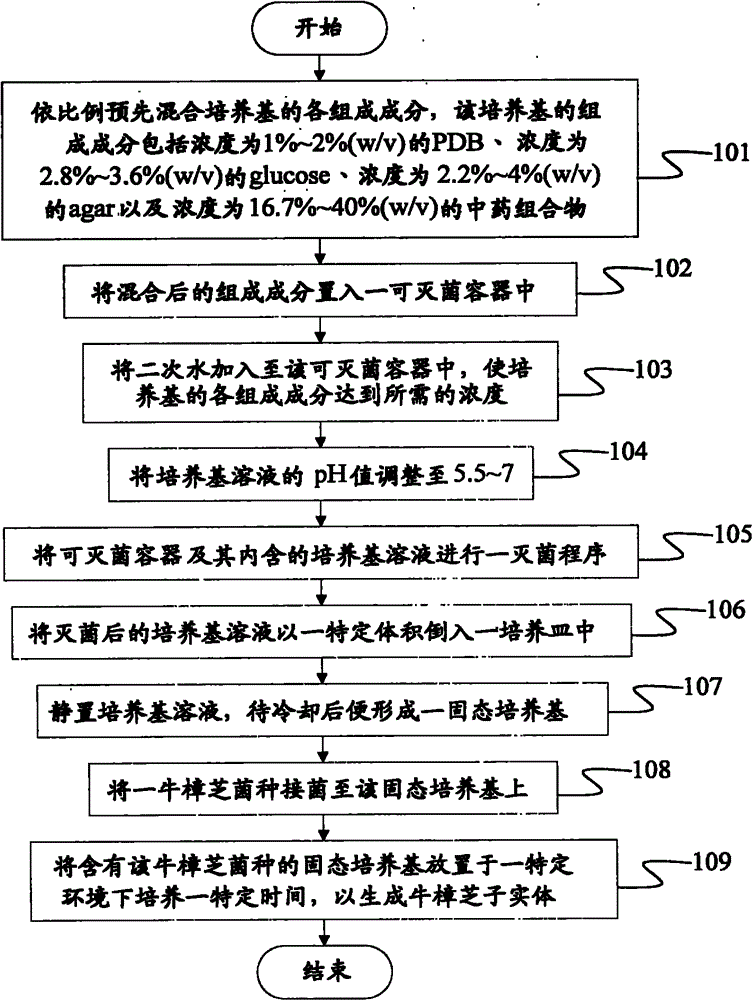

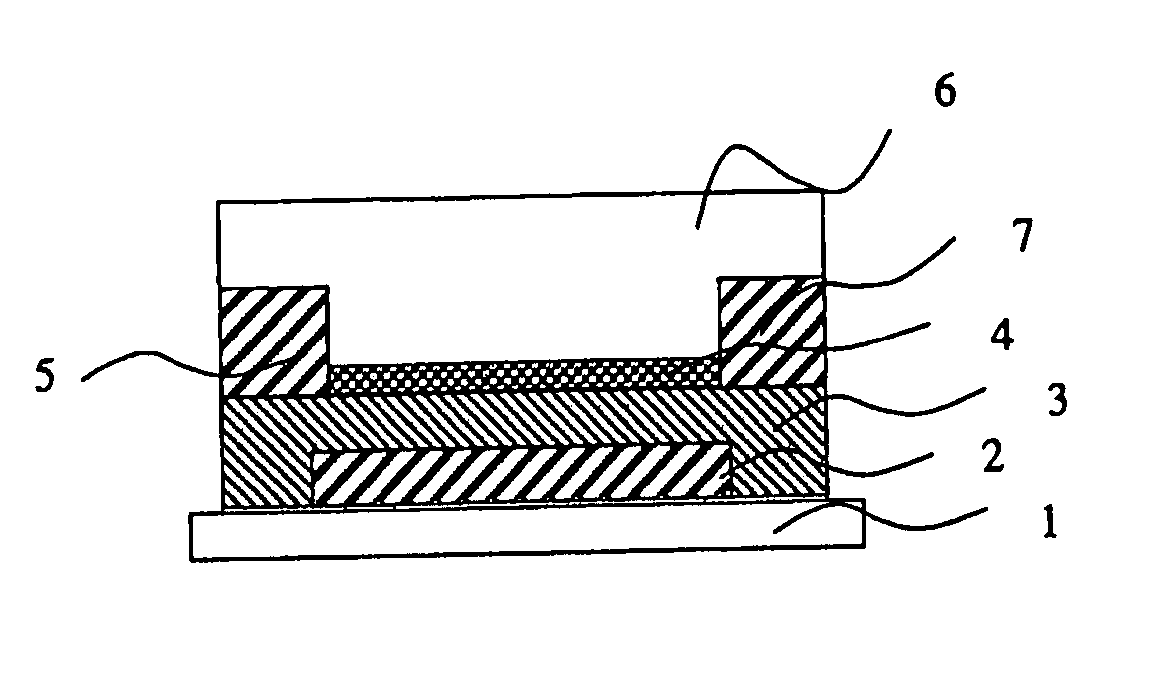

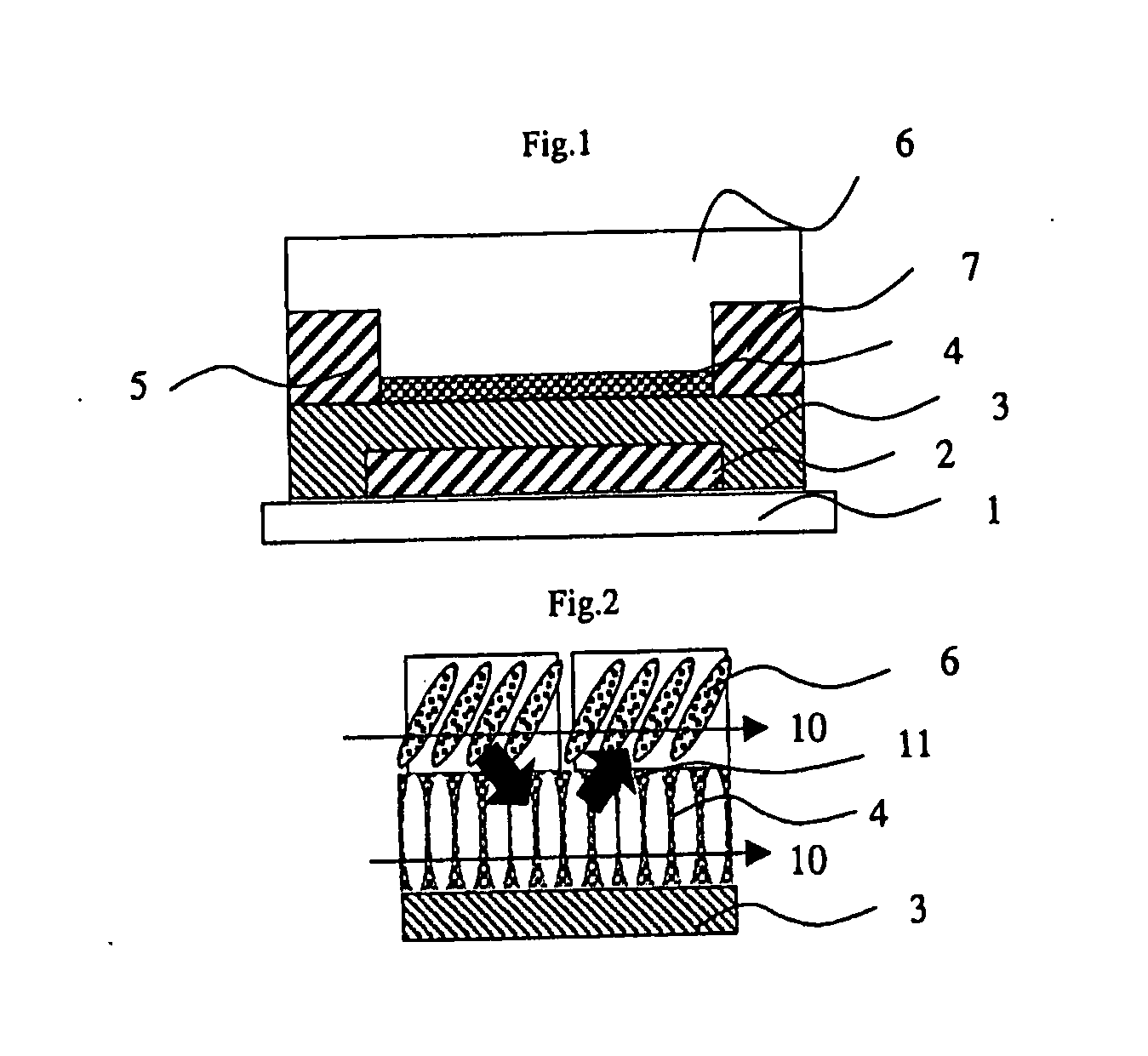

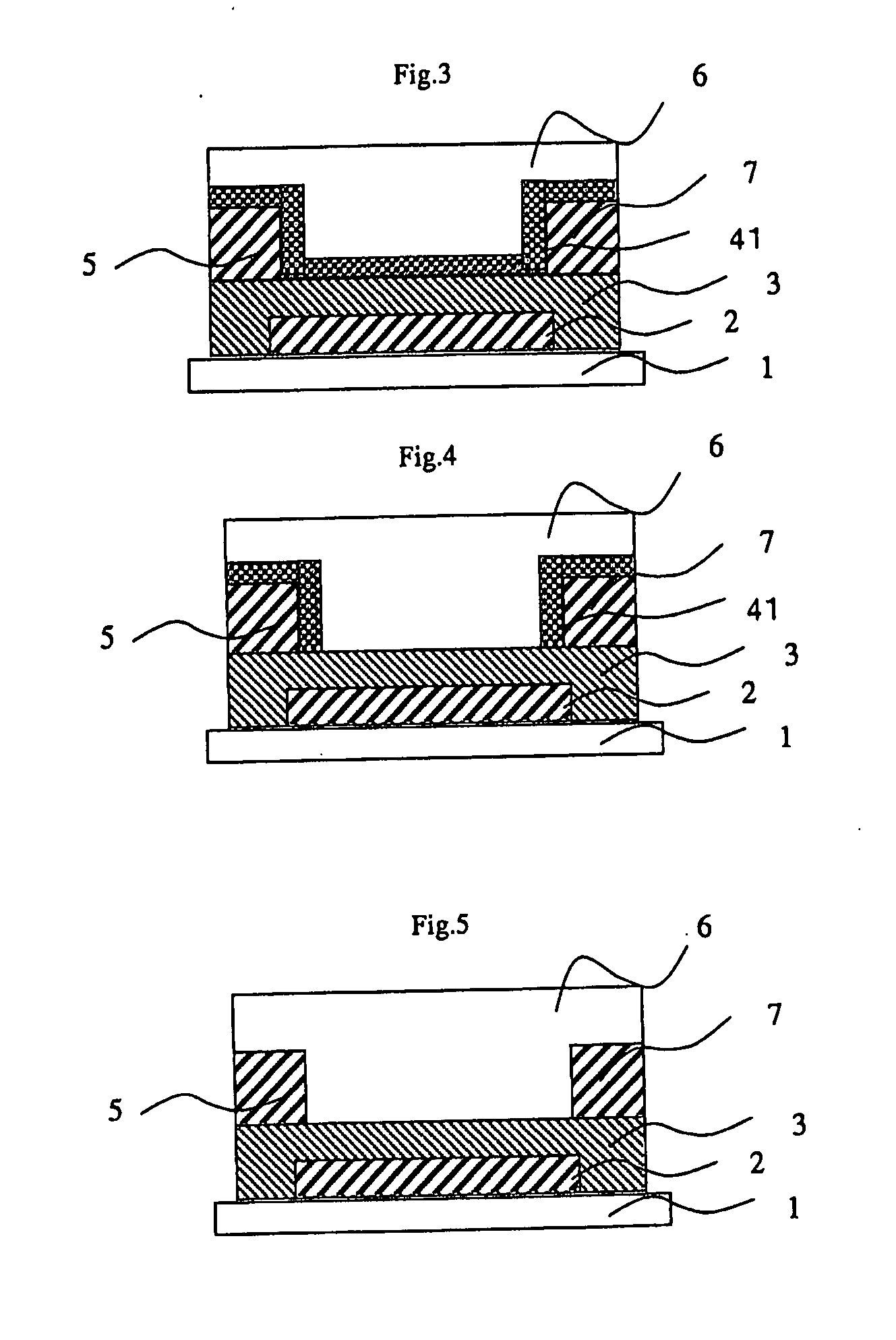

Substrate for lithium thin film battery

InactiveUS20100104942A1Easy to keepAvoid lostAlkaline accumulatorsActive material electrodesAll solid stateOxygen

When attempting to make a lithium ion-switching device such as a high-efficiency, all-solid state, thin film battery the choice of carrier substrate is all important. As such a substrate must withstand a high temperature under an oxidising atmosphere to crystallise certain layers making up the device, the substrate should not oxidise thereby ruling out most metals. The invention now describes a class of ternary alloys of which the oxidation rate is limited and that are useable to produce thin film batteries on. At least one element with a high affinity to oxygen (Al, Mg, Zn or Si) is present in the alloy. The other two metallic elements reduce the growth of the oxide of this first element. In addition the thus formed oxide scale turns out to be an effective barrier to lithium. Surprisingly, the scale shows nanoscopic voids that allow for sufficient electrical contact with the device layers, thereby eliminating the need for a separate current collector. As the ternary alloy can be made in a flexible foil, it can advantageously be used in a roll-to-roll process.

Owner:CYMBET CORP

Newborn infant formulas and feeding methods

InactiveUS20050175759A1Reducing occurrence and extent of insulin resistanceReduce generationMalt preparationFood preparationDiseaseCoronary artery disease

Disclosed are newborn infant formulas comprising fat, carbohydrate, and from 0.5 to 2.5 g of protein per 100 ml of formula, wherein the formula has a caloric density of from 25 to 50 kcal per 100 ml of formula. Also disclosed are methods of administering the infant formulas to provide newborns with optimal nutrition, to reduce the occurrence or extent of insulin resistance in an individual later in life, to reduce the occurrence or extent of atherosclerosis or coronary artery disease in an individual later in life, or combinations thereof, by feeding newborn infants the newborn infant formula described herein.

Owner:UNIV COLLEGE OF LONDON

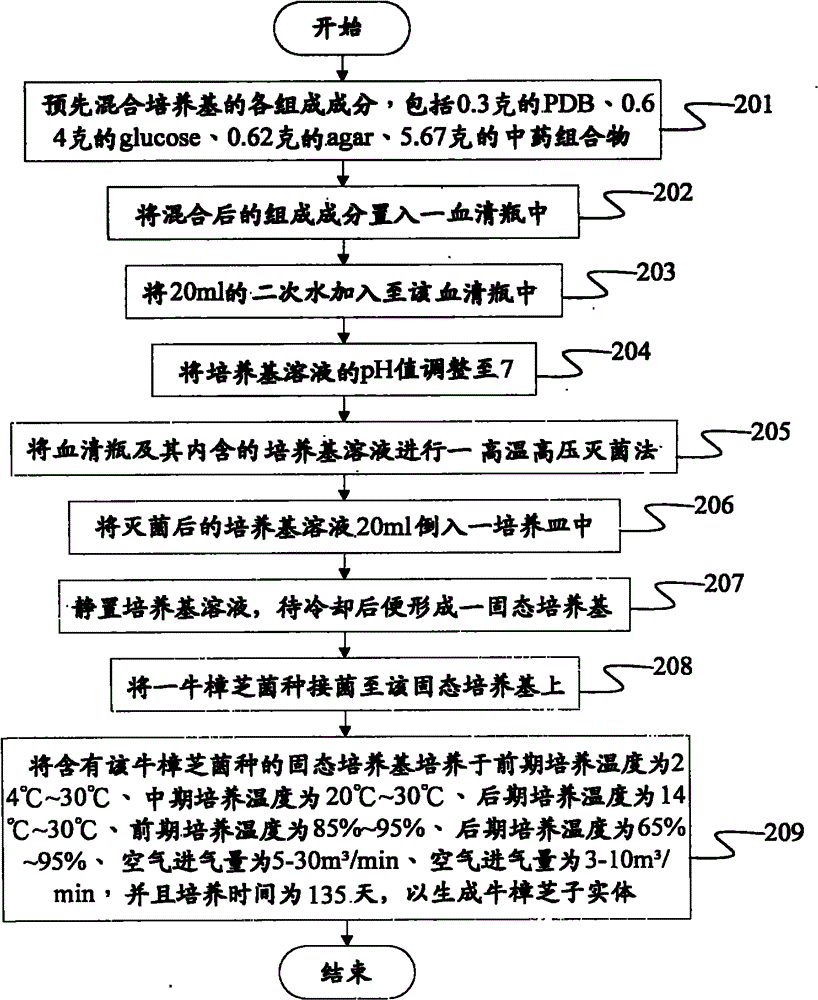

Culture medium for culturing fruiting bodies of Antrodia cinnamomea and cultural method thereof

ActiveCN102746054AReduce incubation timeImprove the success rate of cultivationHorticultureFertilizer mixturesCulture mediumsAgar

The invention discloses a culture medium for culturing fruiting bodies of Antrodia cinnamomea and a cultural method thereof. The culture medium comprises potato dextrose broth (PDB) with a concentration of 1-2%(w / v), glucose with a concentration of 2.8-3.6%(w / v), agar with a concentration of 2.2-4%(w / v) and a Chinese medicine composition with a concentration of 16.7-4.%(w / v). The cultural method comprises the following steps: preparing a solid culture medium according to the ratio of the ingredients, inoculating an Antrodia cinnamomea strain to the solid culture medium, putting the solid medium containing the Antrodia cinnamomea strain in a specific environment to culture for a certain period to generate the fruiting bodies of Antrodia cinnamomea, wherein the fruiting bodies of Antrodia cinnamomea obtained by the cultural method have same index components as wild Antrodia cinnamomea.

Owner:GANQUAN BIOLOGICAL TECH

Newborn infant formulas and feeding methods

InactiveUS20070254062A1Reducing occurrence and extent of insulin resistanceReduce generationAnimal feeding stuffPharmaceutical non-active ingredientsDiseaseCoronary artery disease

Disclosed are newborn infant formulas comprising fat, carbohydrate, and from 0.5 to 2.5 g of protein per 100 ml of formula, wherein the formula has a caloric density of from 25 to 50 kcal per 100 ml of formula. Also disclosed are methods of administering the infant formulas to provide newborns with optimal nutrition, to reduce the occurrence or extent of insulin resistance in an individual later in life, to reduce the occurrence or extent of atherosclerosis or coronary artery disease in an individual later in life, or combinations thereof, by feeding newborn infants the newborn infant formula described herein.

Owner:UNIV COLLEGE OF LONDON

Prepn of nanometer aggregated zirconia powder for hot spraying

InactiveCN1637080AControl growthStructure does not growLiquid surface applicatorsCoatingsThermal sprayingMass ratio

The preparation process of nanometer aggregated zirconia powder for spraying includes: mixing nanometer zirconia powder stabilized with 20-60 nm granularity yttrium oxide and adhesive in the mass ratio of 95:5 to 98:2 and adding pure water of 1-1.3 times the mixture weight to compound slurry; spraying at 110-300 deg.c to form micron level aggregated powder; and final plasma nodulizing or sintering to form compact powder of 40-90 micron granularity and with the nanometer crystal structure maintained. The obtained powder may meet the technological requirement of plasma spraying or flame spraying. The technological process is simple, great in output, safe, reliable, low in cost and suitable for continuous industrial production.

Owner:WUHAN UNIV OF TECH

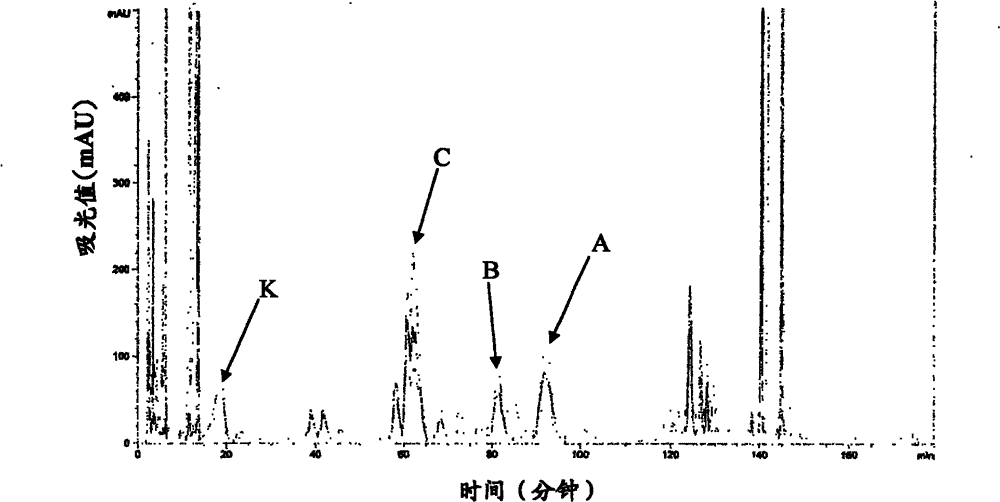

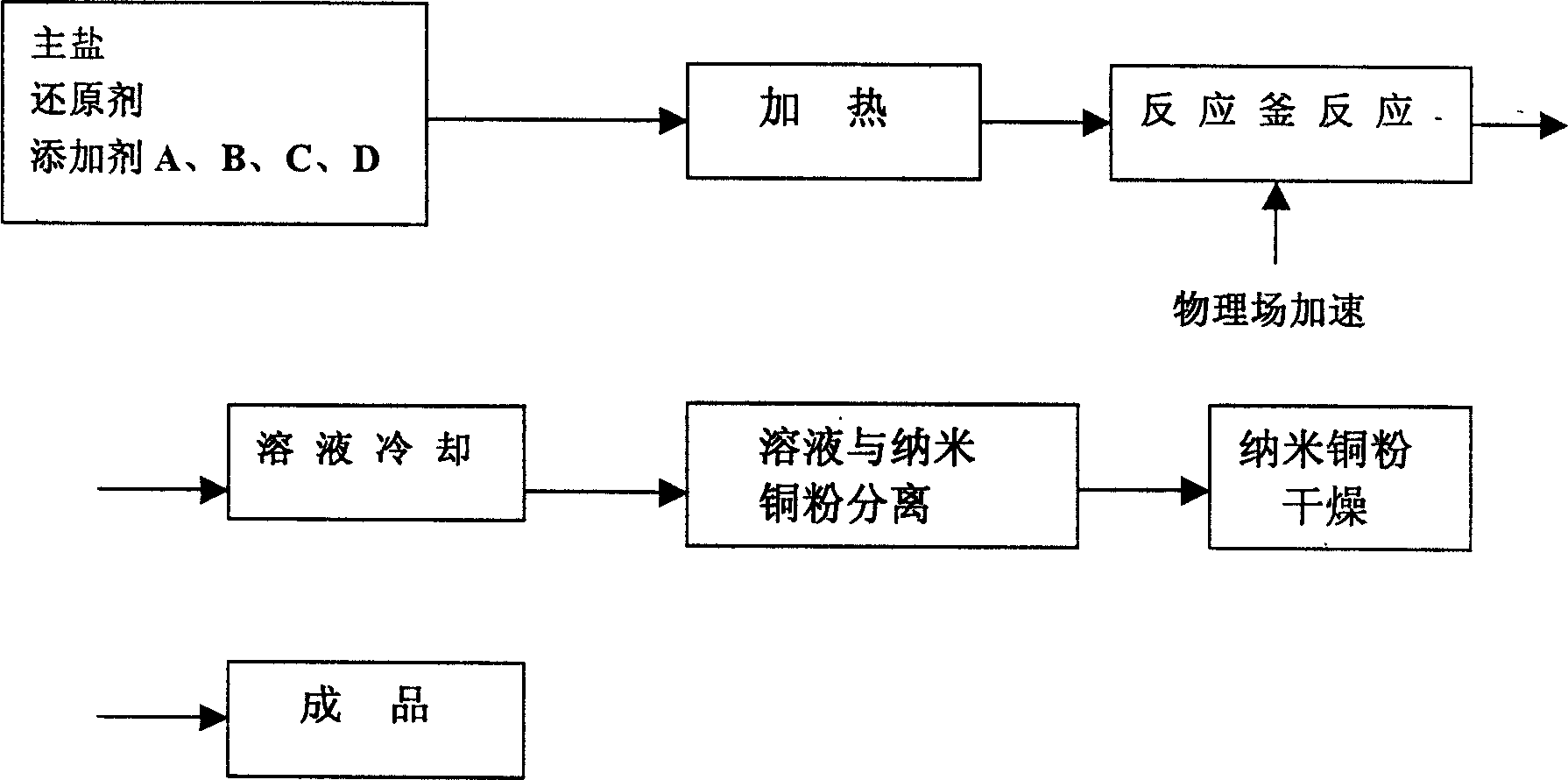

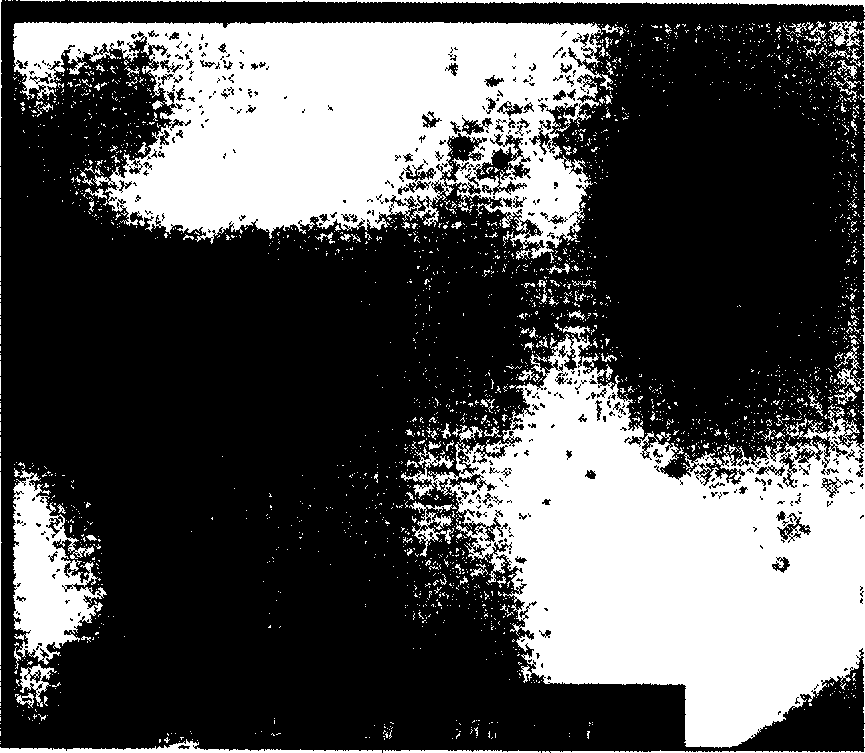

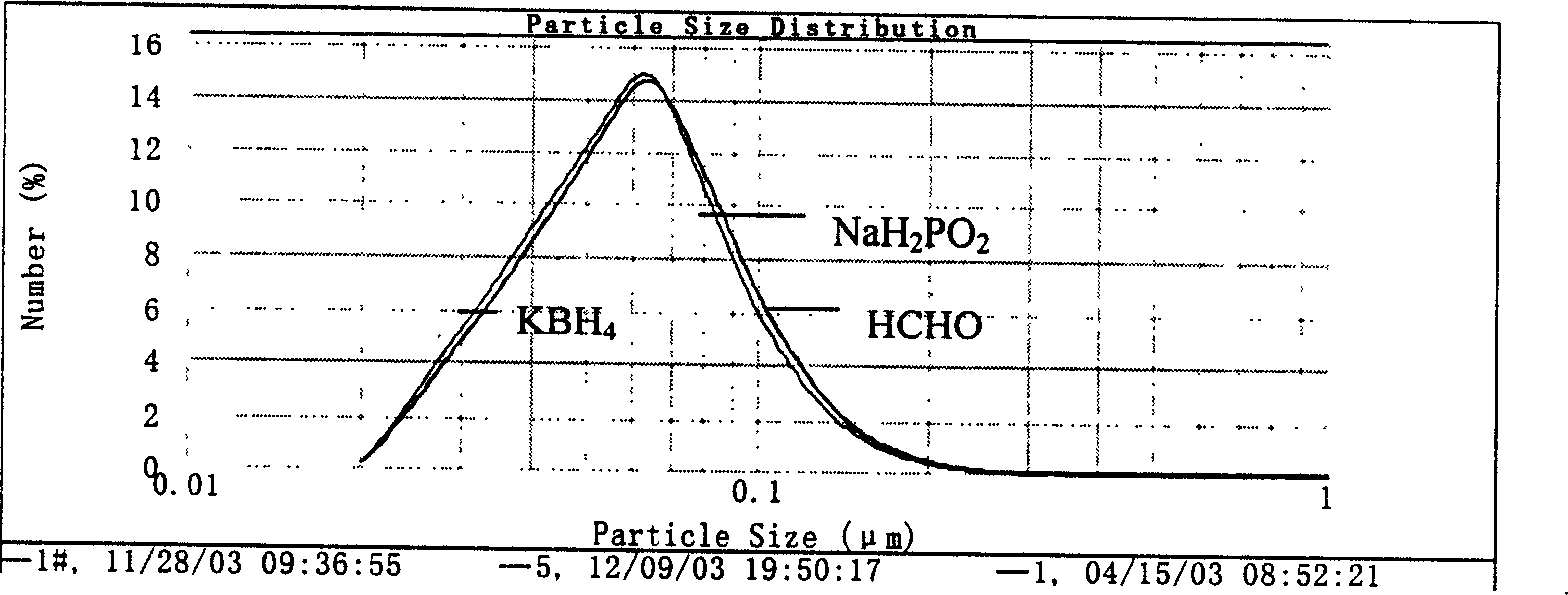

Method for preparing nanometer copper powder by chemical reduction in water solution

The present invention is chemical reduction process of preparing nanometer copper powder in water solution, and relates to electrochemical process for preparing powdered material. The preparation process adopts the proper combination of main salt, reductant and additives, the main salt is copper sulfate or copper chloride, the reductant is sodium hypophosphorate, sodium borohydride and formaldehyde, and the additives include silver nitrate or palladium chloride, gelatin or SDBS, potassium sodium tartrate or triethanolamine and sodium hydroxide or potassium hydroxide. During the preparation, outer ultrasonic field is applied. The preparation process is simple and high in preparation speed, and has no coagulation of copper powder to ensure the medium powder size smaller than 100 nm for ideal use effect of the nanometer copper powder.

Owner:UNIV OF SCI & TECH BEIJING

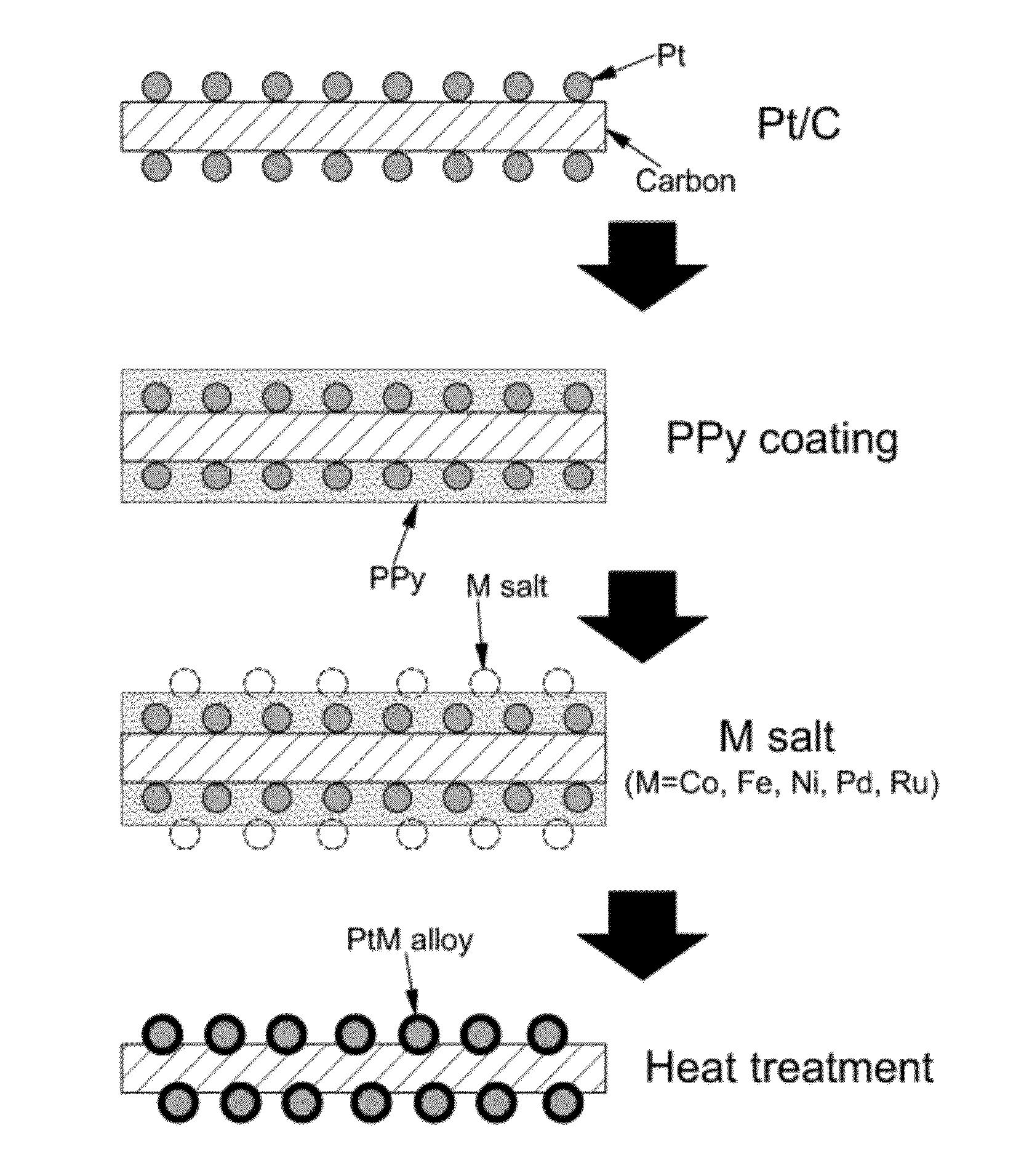

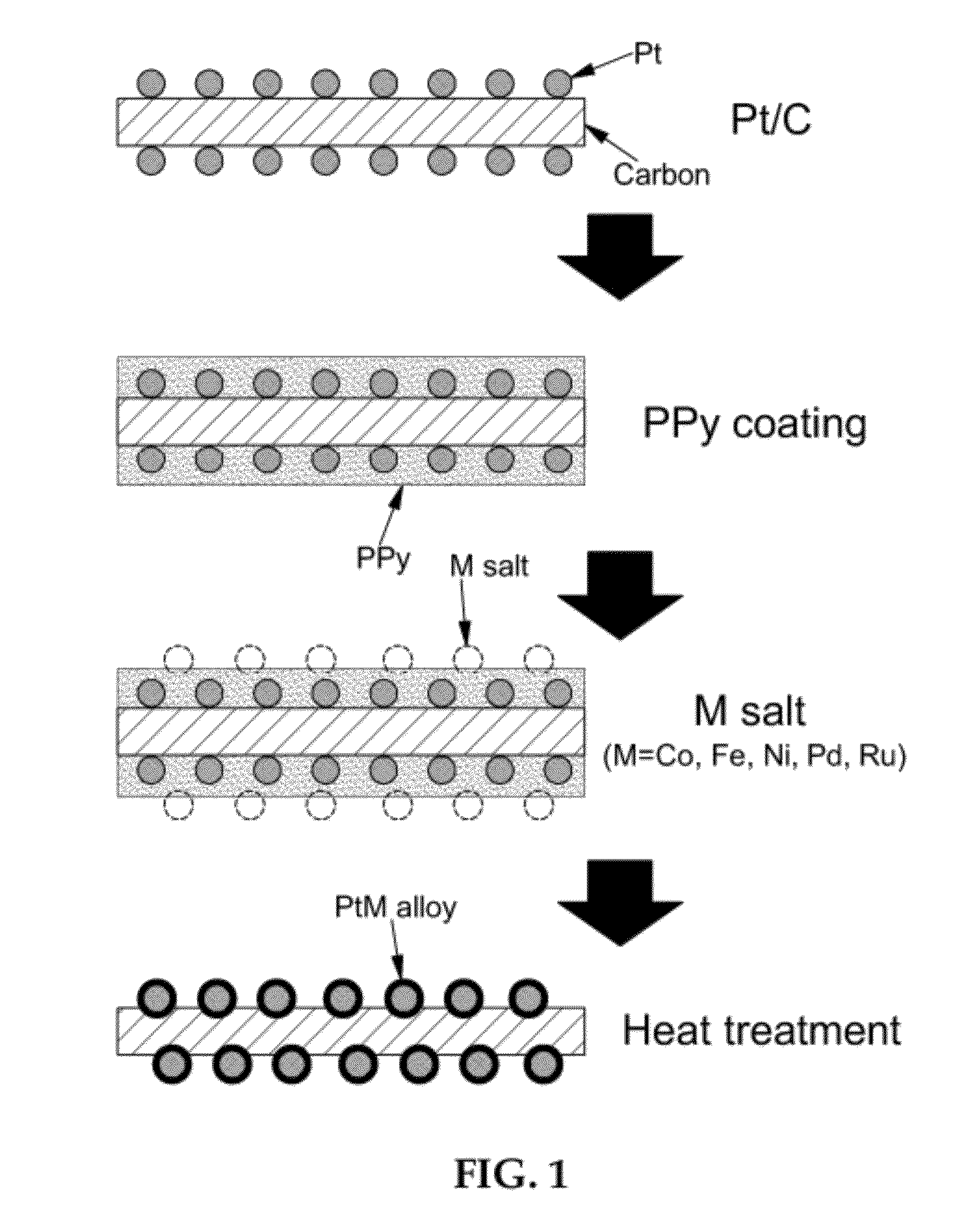

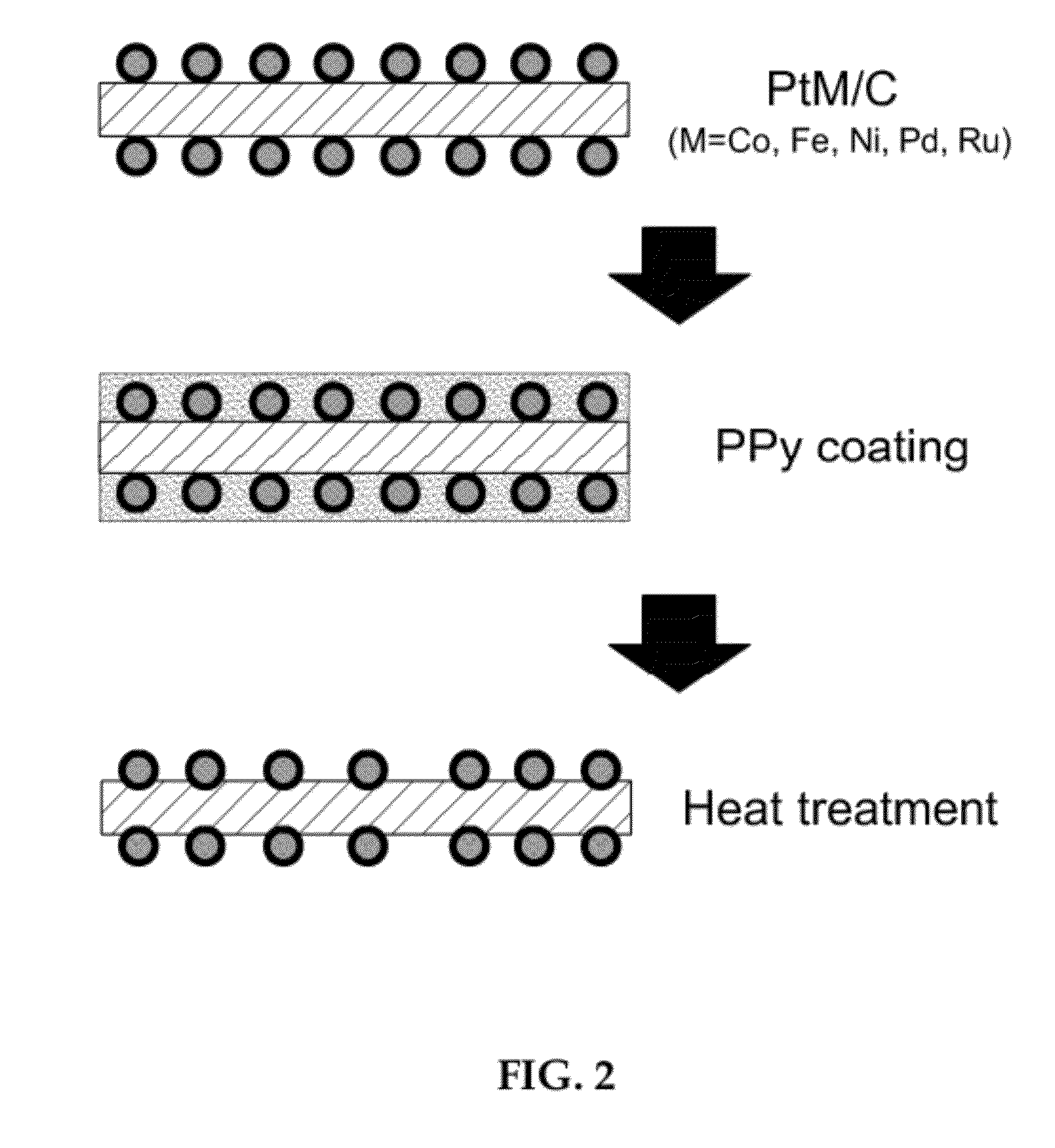

Preparing an alloy catalyst using conductive polymer coating

ActiveUS20120135137A1Improve concentrationReduced dissolving out of transition metalMaterial nanotechnologyCell electrodesDispersityConductive polymer

Techniques herein prepare an alloy catalyst using a protective conductive polymer coating. More particularly, an alloy catalyst is prepared by: preparing a platinum catalyst supported on carbon; coating the surface of the platinum catalyst with a conductive polymer; supporting a transition metal salt on the coated catalyst; and heat treating the catalyst on which the transition metal salt is supported. Also, an alloy catalyst may be prepared by: preparing a platinum-transition metal catalyst supported on carbon; coating the surface of the platinum-transition metal catalyst with a conductive polymer; and heat treating the coated catalyst. Accordingly an alloy catalyst with superior dispersity can be prepared by increasing the degree of alloying of the catalyst through heat treatment while preventing the increase of catalyst particle size through carbonization of the conductive polymer. The prepared catalyst may be useful, for example, for a fuel cell electrode.

Owner:HYUNDAI MOTOR CO LTD +2

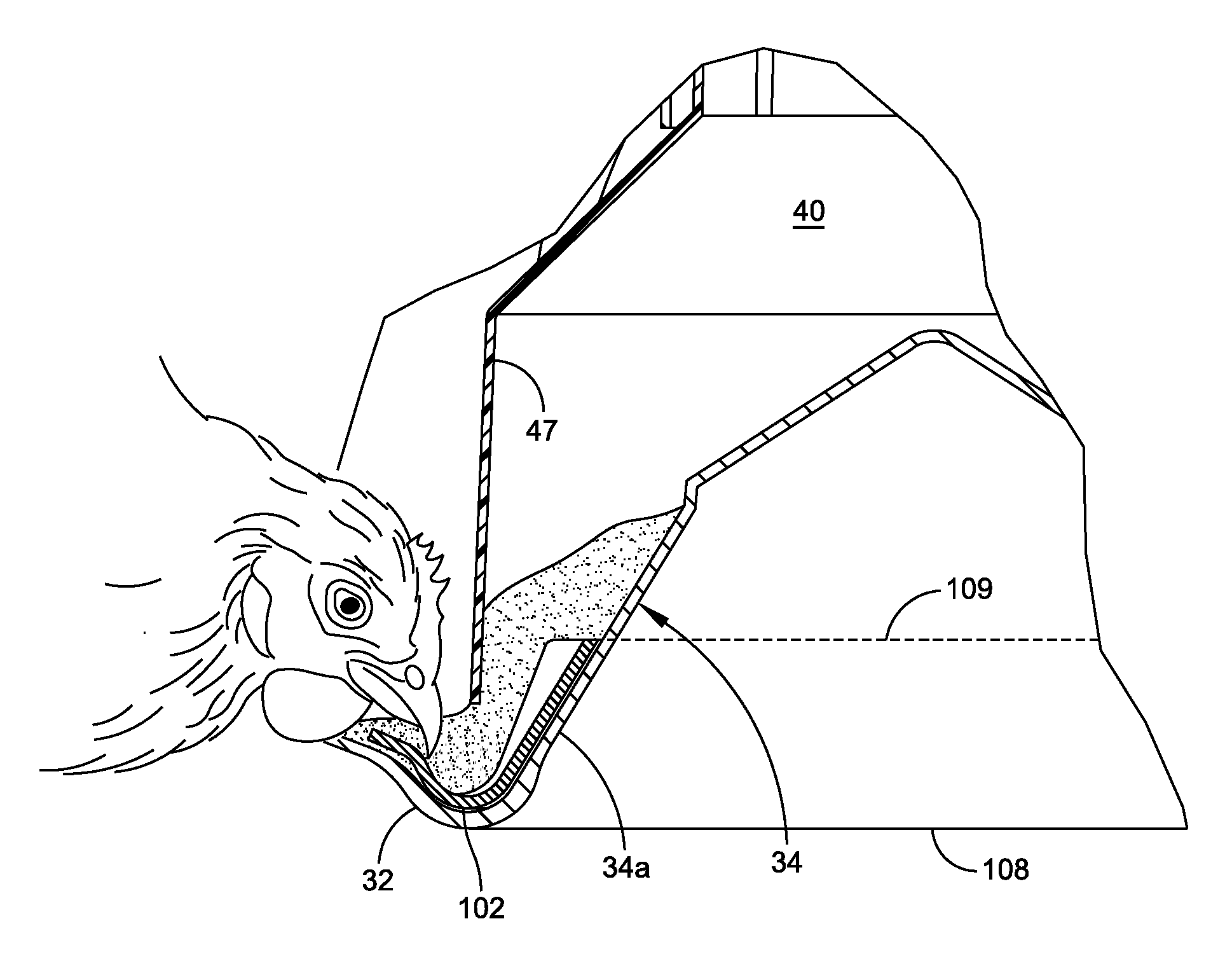

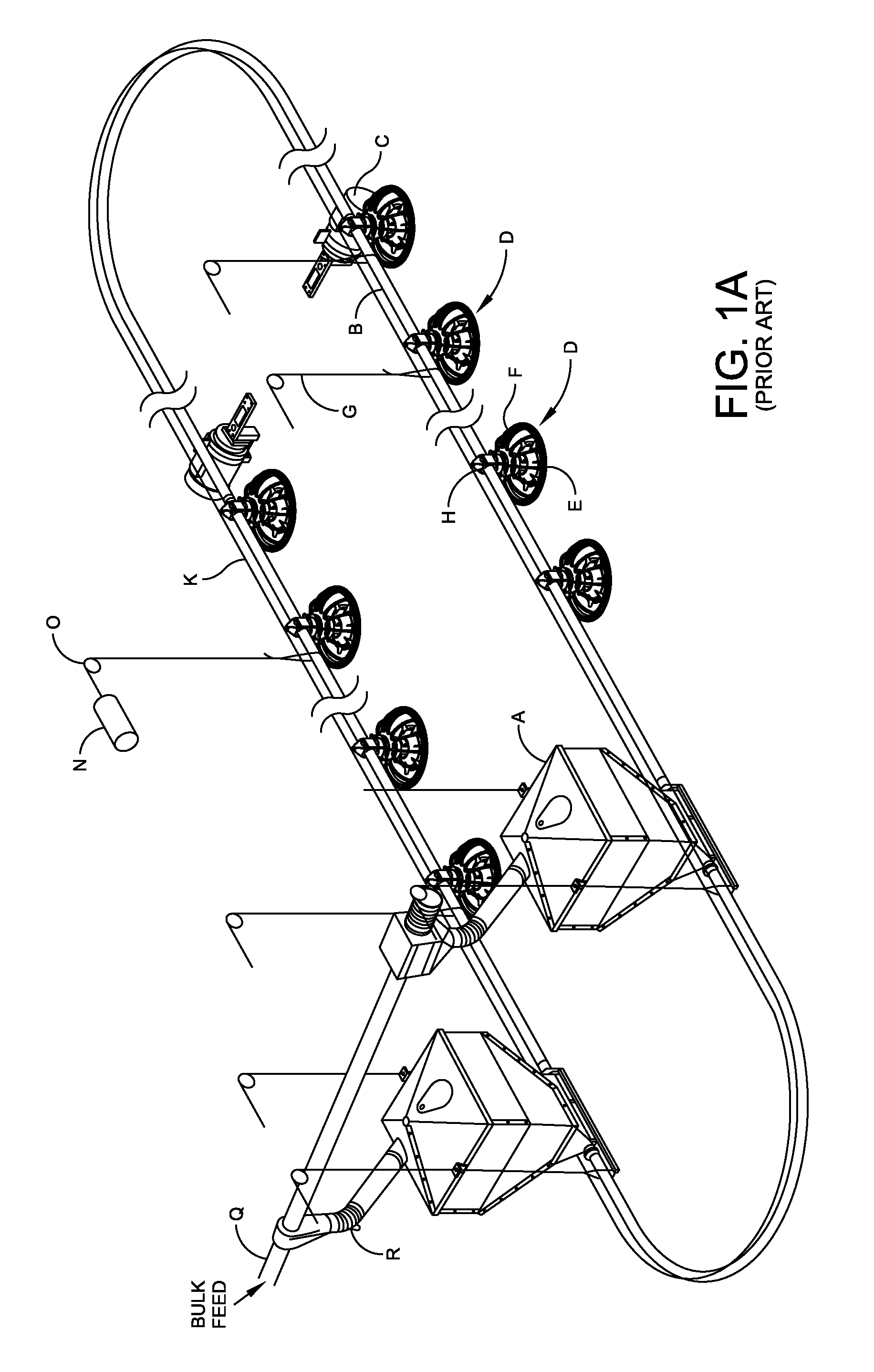

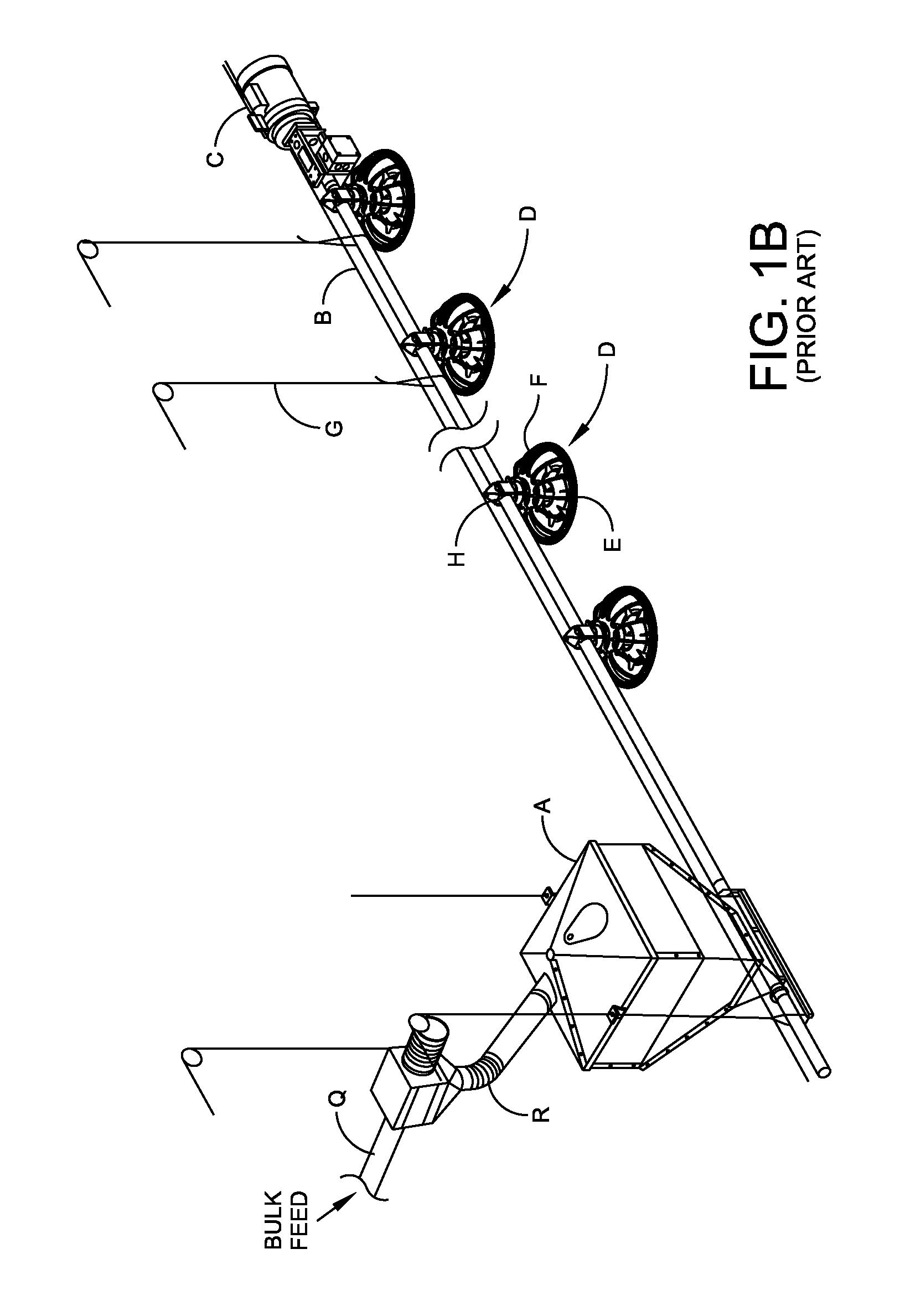

Poultry feeder with beak grooming device

ActiveUS20130139755A1Easily replaceableEasy to replaceAnimal feeding devicesAnimal housingGrowth controlEngineering

A poultry feeder with beak growth control device is provided. In one embodiment, the feeder includes a feeder pan, a feeder tower, and a beak grooming ring. The grooming ring is removably inserted in the feeder and has an annular shape complementary configured to engage a corresponding shape of the feeder pan. Preferably, the grooming ring has a self-supporting structure that retains its complementary shape to the feeder pan independently of the pan when removed therefrom. The grooming ring is insertable and removable from feeder as a separable unit from the feeder and operable to abrade the beak while the birds feed, thereby controlling its growth and length.

Owner:VALCO IND INC

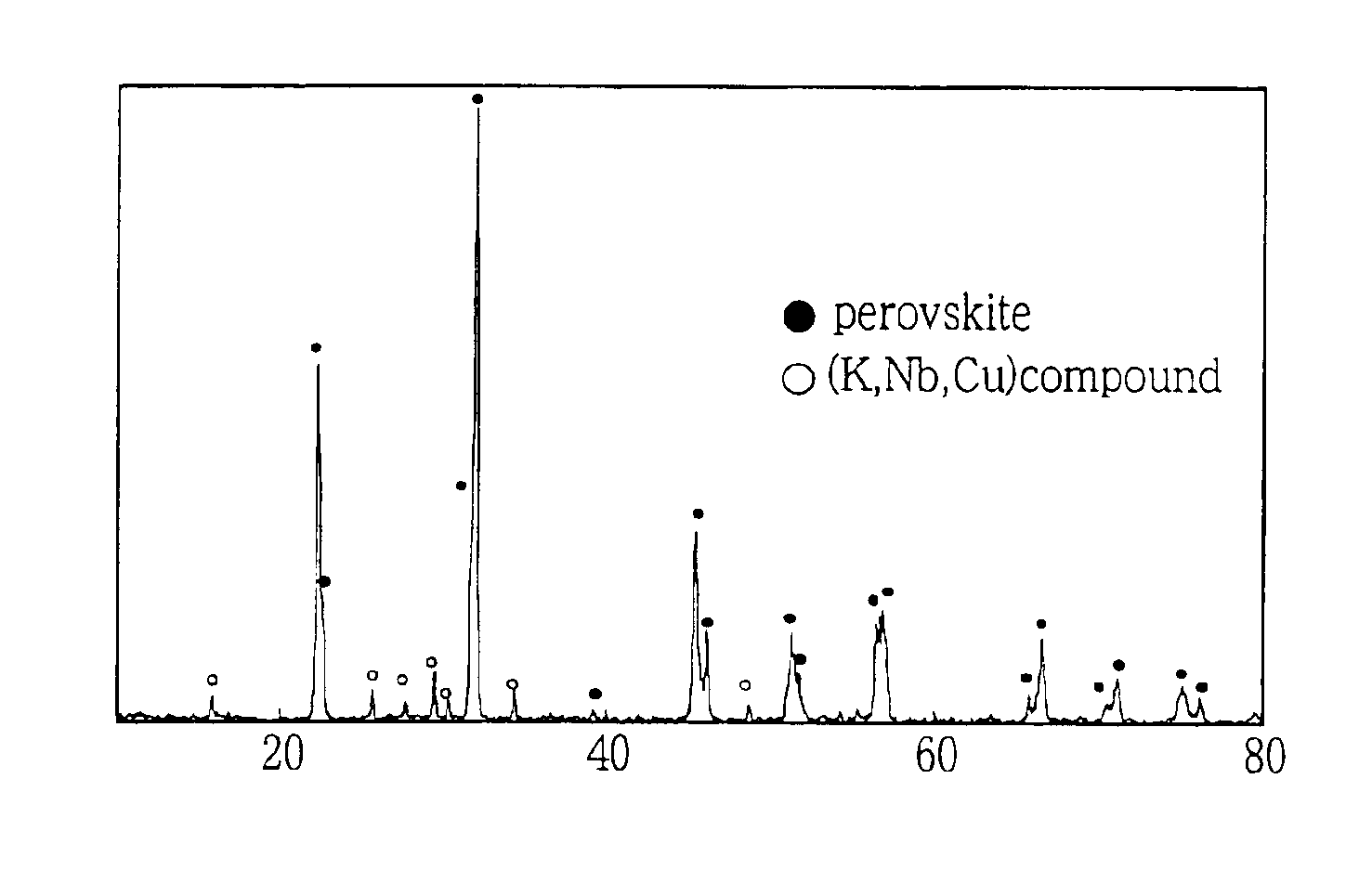

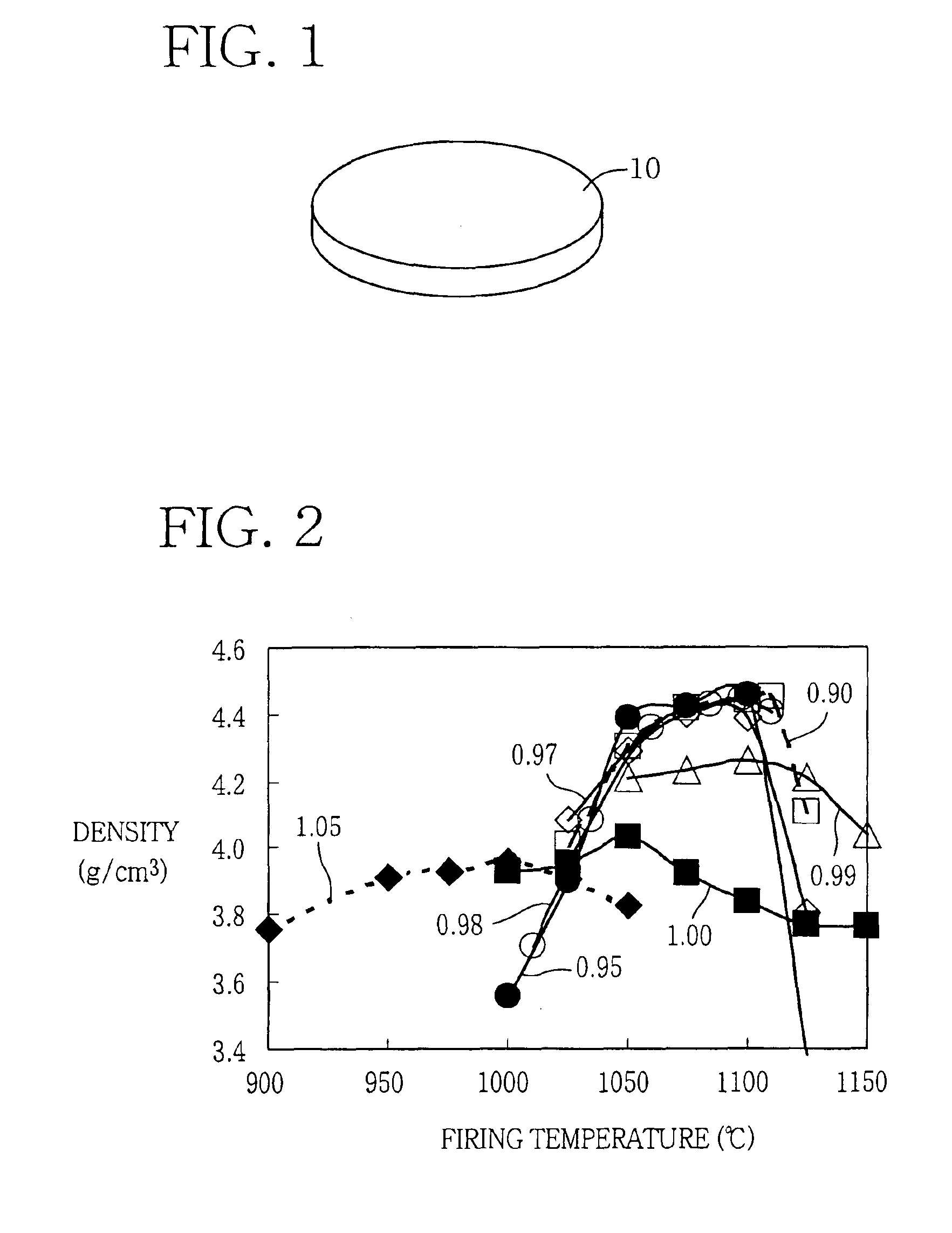

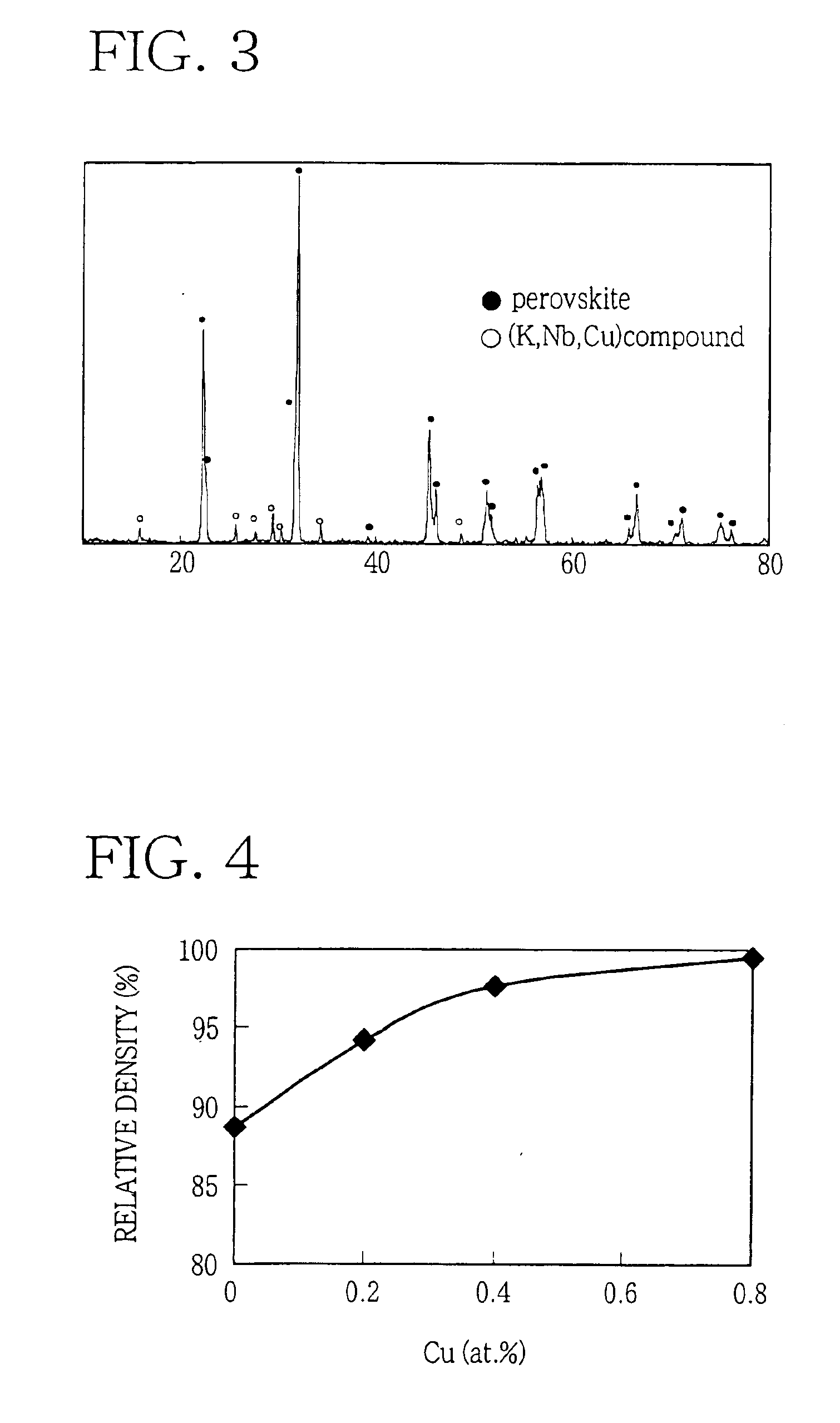

Lead-free piezoelectric ceramic composition wherin Cu is contained in (KxA1-x)y(Nb1-zBz)O3perovskite compound, and process of preparing the same

InactiveUS6884364B2Improve sintering performanceImprove sinterabilityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionAbnormal grain growthSecondary component

A lead-free piezoelectric ceramic composition wherein a suitable amount of Cu is contained in a perovskite compound of a non-stoichiometric composition represented by a formula (KxA1-x)y(Nb1-zBz)O3, wherein “A” represents at least one of Na and Bi, while “B” represents at least one of Ta and Ti, and wherein 0<x≦1, 0<y<1, and 0≦z≦1, so that by-products such as KaCubNbcOd and KaCubTacOd are produced as a result of reaction of (Nb1-zBz) with Cu in the process of calcination of a starting material, and the by-products restrict melting and abnormal grain growth of (KxNa1-x)(Nb1-zTaz) O3 during firing of a calcined body, thereby improving sinterability of the fired body, while restricting volatilization of alkali components and melting of KNbO3, thereby increasing the density and improving the piezoelectric properties of the fired body. The ceramic composition is prepared by firing a starting composition including the perovskite composition as a primary component, and a secondary component in the form of at least one of compounds KaCubNbcOd, KeCufTagOh and KiCujTikOl.

Owner:NORITAKE CO LTD +1

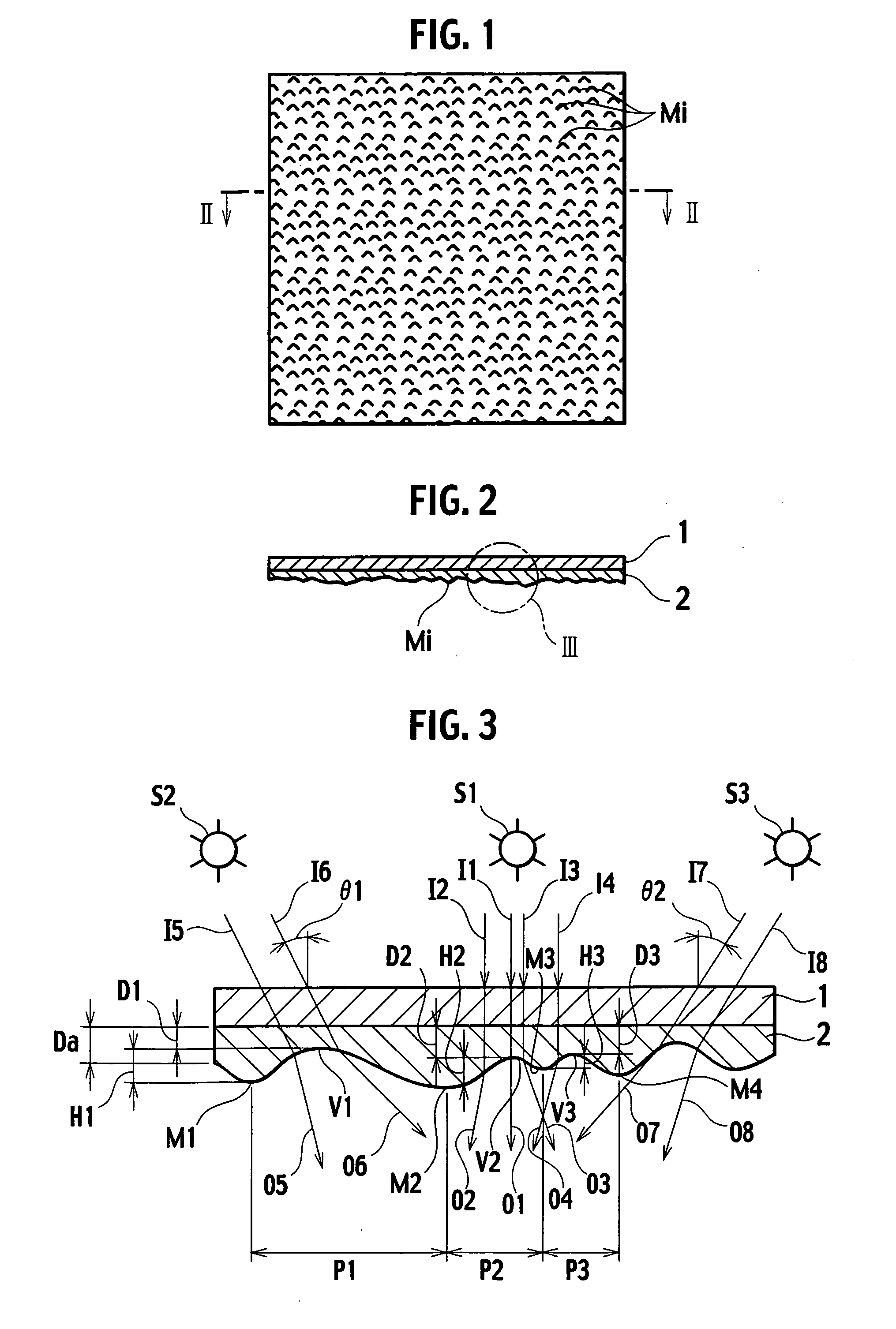

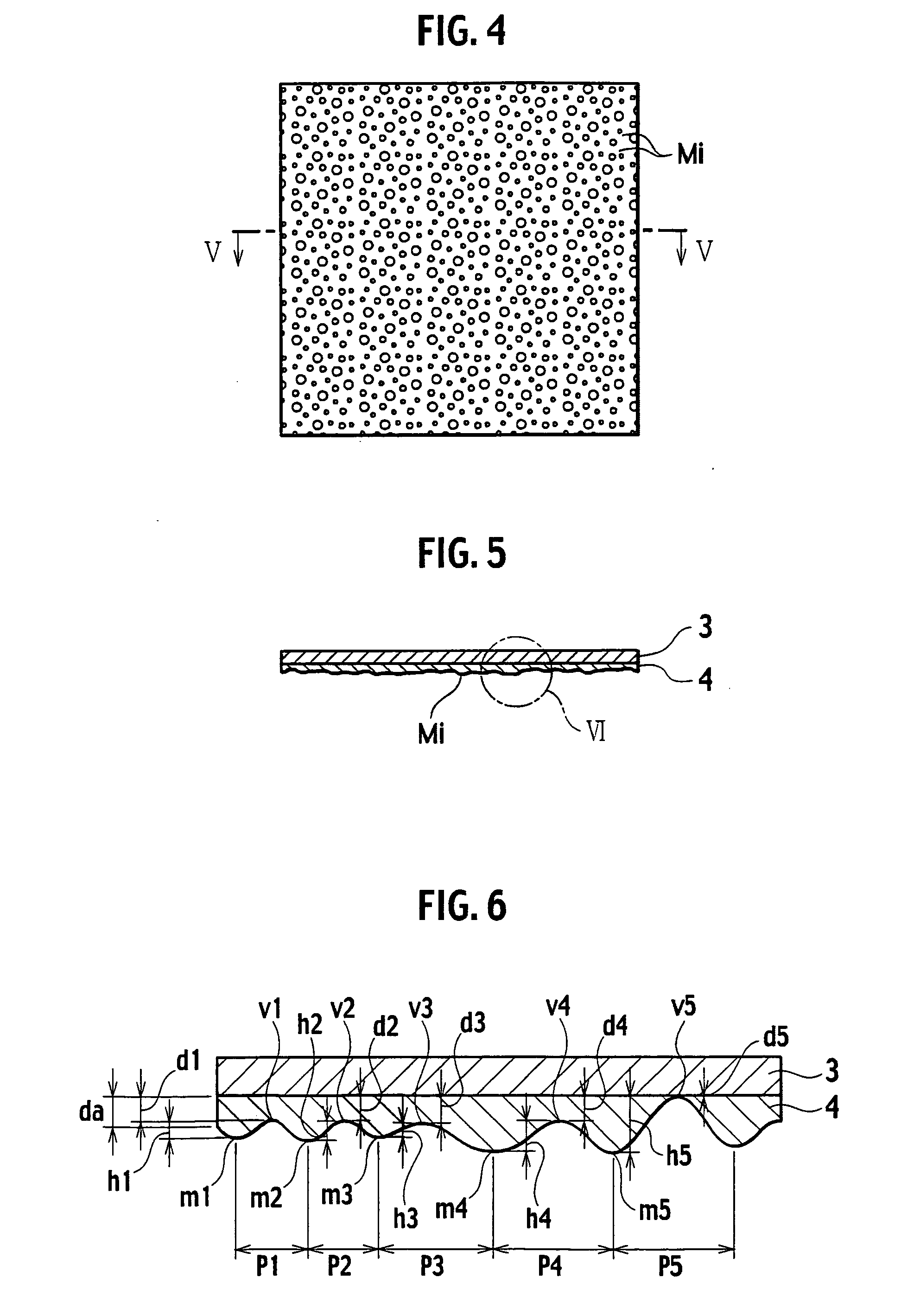

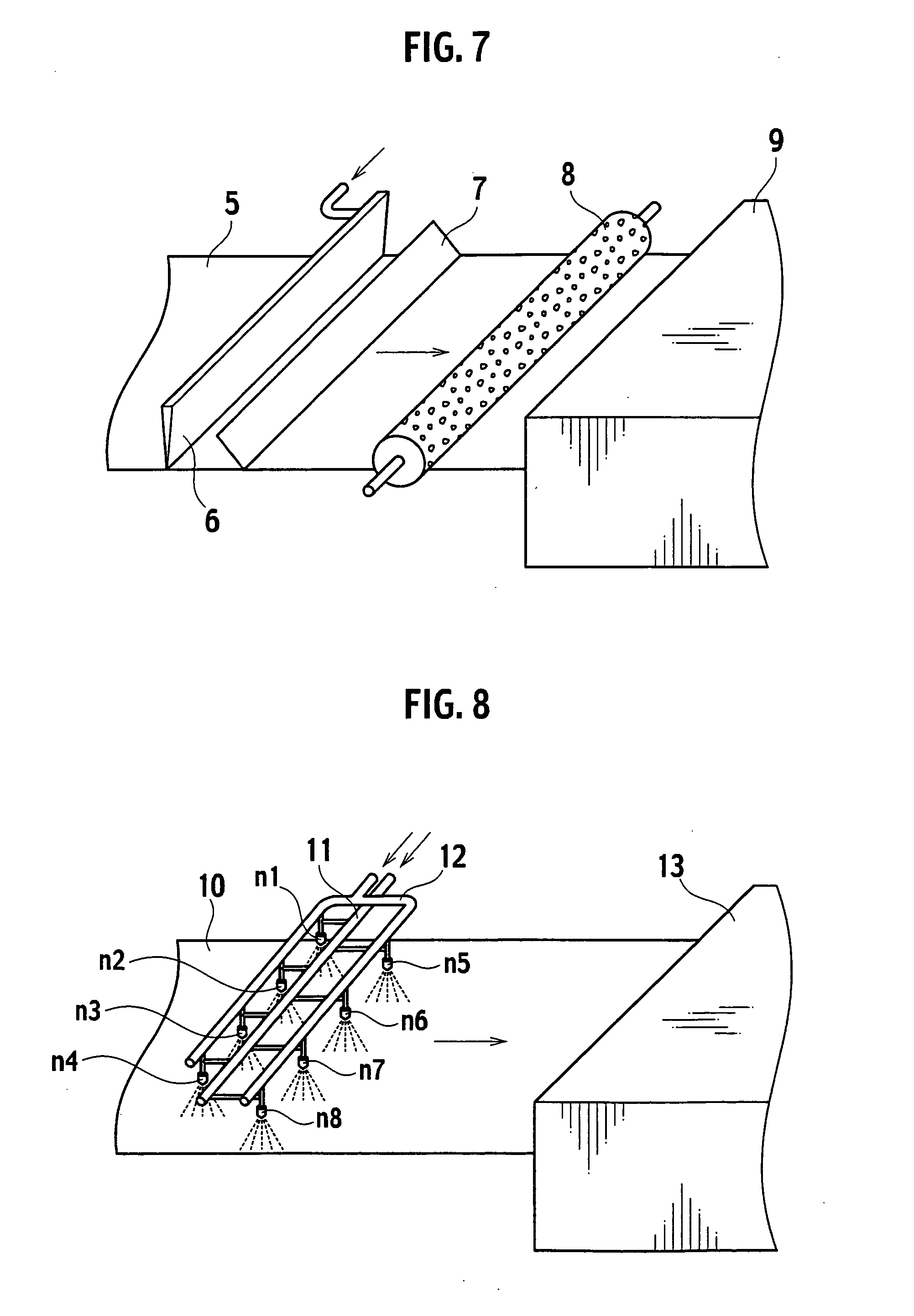

Light-scattering composite agricultural film

InactiveUS20060057343A1AdhesivenessImprove adhesionAgricultural articlesClimate change adaptationUltravioletOptical transmittance

A transparent base film and a transparent resin layer are provided. An ultraviolet absorbent is contained in at least either of the base film and the resin layer, and a transmittance of an ultraviolet ray with a wavelength of 380 nm is set at 60% or less. On a surface of the resin layer, numerous irregularities are provided, in which an total luminous transmittance is 85% or more, and a diffuse transmittance is 6% or more.

Owner:JTS CO LTD

Porous carbon electrode with conductive polymer coating

InactiveUS8164881B2Improve Capacitive PerformanceSimple materialElectrode manufacturing processesLiquid electrolytic capacitorsCapacitancePolymer science

An extremely high-performance polyaniline electrode was prepared by potentiostatic deposition of aniline on hierarchically porous carbon monolith (HPCM), which was carbonized from mesophase pitch. A capacitance value of 2200 F g−1 of polyaniline was obtained at a power density of 0.47 kW kg−1 and an energy density of 300 Wh kg−1. This active material deposited on HPCM also has an advantageous high stability. These superior advantages can be attributed to the backbone role of HPCM. This method also has the advantages of not introducing any binder, thus contributing to the increase of ionic conductivity and power density. High specific capacitance, high power and energy density, high stability, and low cost of active material make it very promising for supercapacitors.

Owner:MAX PLANCK GESELLSCHAFT ZUR FOERDERUNG DER WISSENSCHAFTEN EV

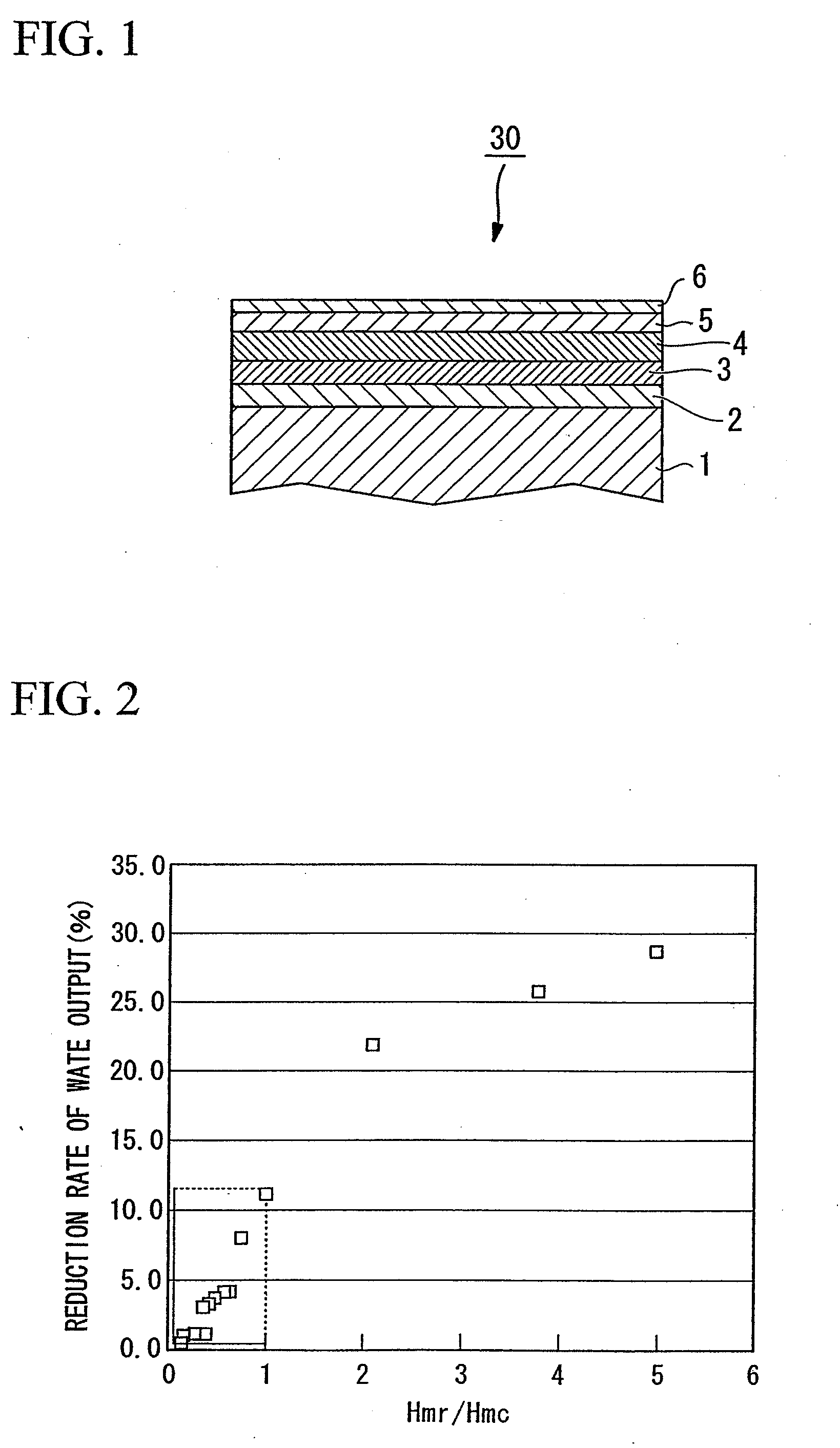

Magnetic recording medium, production process thereof, and magnetic recording and reproducing apparatus

InactiveUS20090142625A1Improve signal-to-noise ratioImprove recording densityDifferent record carrier formsMagnetic materials for record carriersColloidal silicaRocking curve

The present invention provides a magnetic recording medium which enables improvement of the layer quality of magnetic layer grown on the surface of a soft magnetic underlayer by conducting excellent control of crystal orientation by imparting an optimal half-width of the Rocking curve (Δθ50), as well as obtainment of SNR that suppresses generation of TA and enables realization of high-density recording. The magnetic recording medium includes a soft magnetic underlayer, an orientation control layer, a perpendicular magnetic recording layer, and a protective layer, which are disposed on top of a non-magnetic substrate; wherein the magnetic anisotropy ratio (Hmr / Hmc) of the soft magnetic underlayer is 1 or less, and Δθ50 is 1 to 6 degrees. The soft magnetic underlayer is formed on the primary surface of the non-magnetic substrate where the primary surface has been polished one substrate at a time by a sheet-type texture processing device using polishing tape and a slurry containing colloidal silica abrasive grain.

Owner:SHOWA DENKO KK

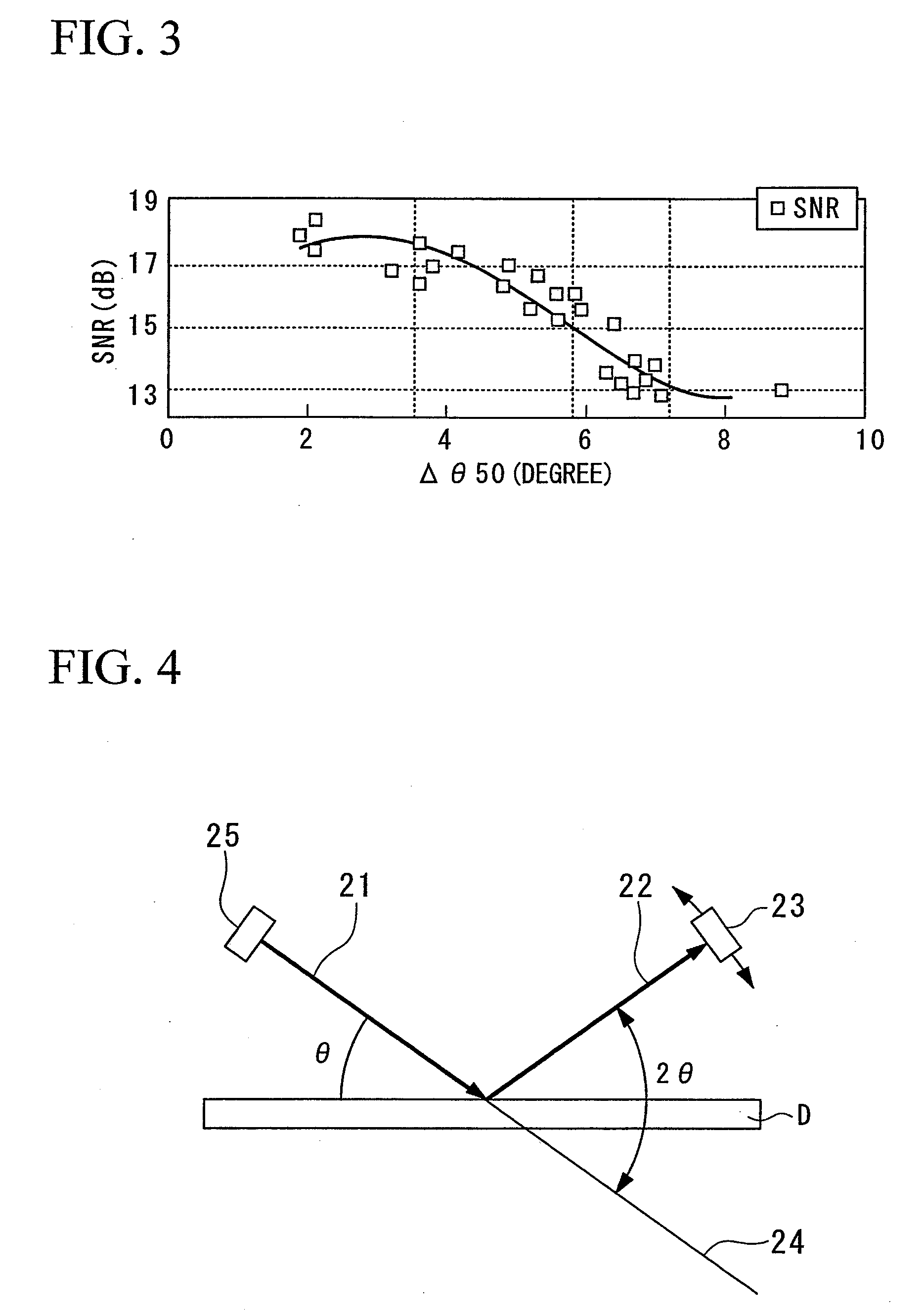

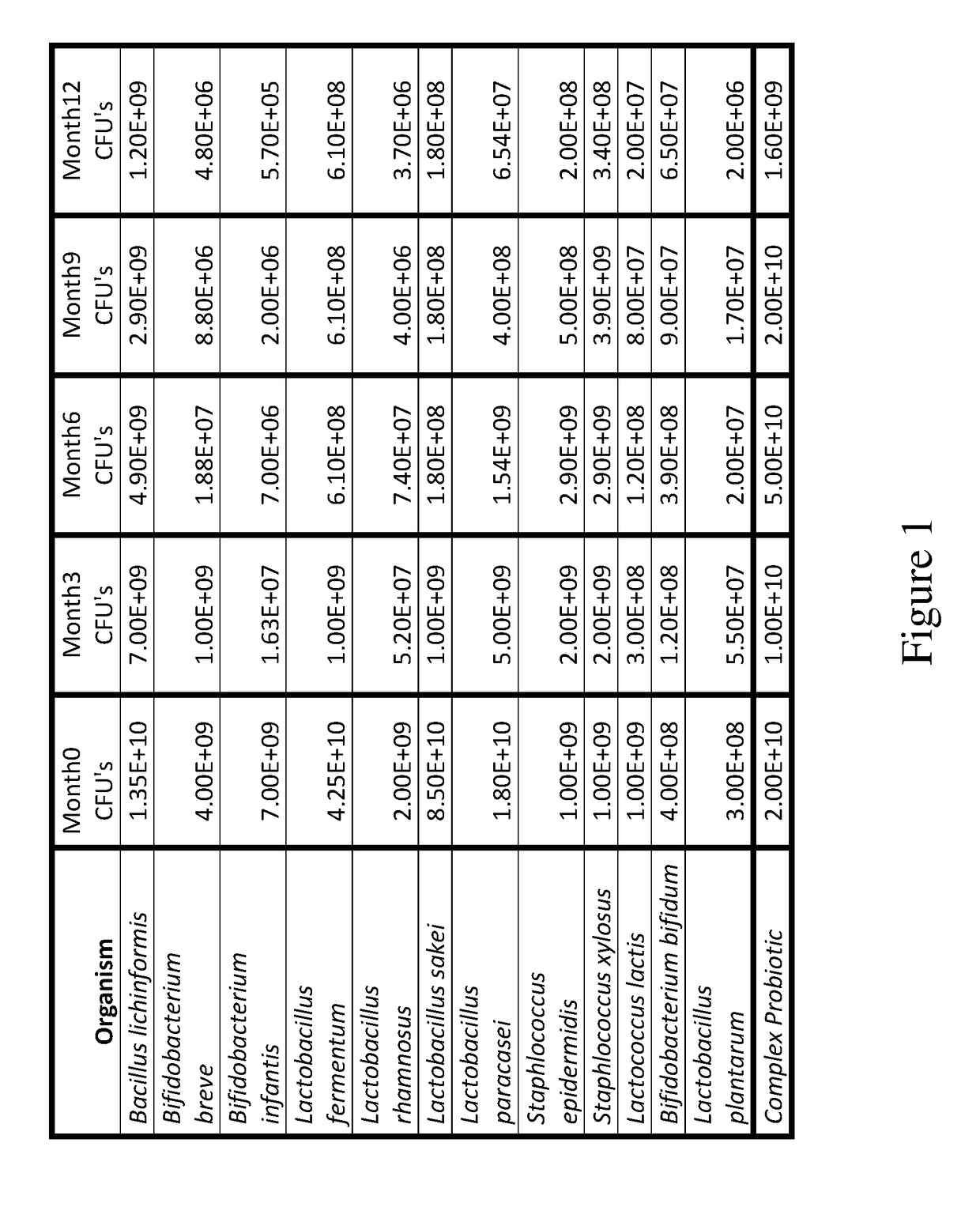

Skin microbiome colonizer formulations and methods for use

ActiveUS20180325968A1Prevent acneControl growthOrganic non-active ingredientsViral/bacteriophage medical ingredientsMicrobiomeMedicine

A system for treating and maintaining the health of the skin of a user. The system may include a topical formulation and an oral formulation. The topical formation may include various probiotic organisms selected for enhancing and treating the skin of a user. The oral formulation may include various probiotic organisms for enhancing and treating the skin of the user. The topical formulation and the oral formulation may be used cooperatively and simultaneously to produce a beneficial, synergistic effect.

Owner:MORRIS SHAYNE K

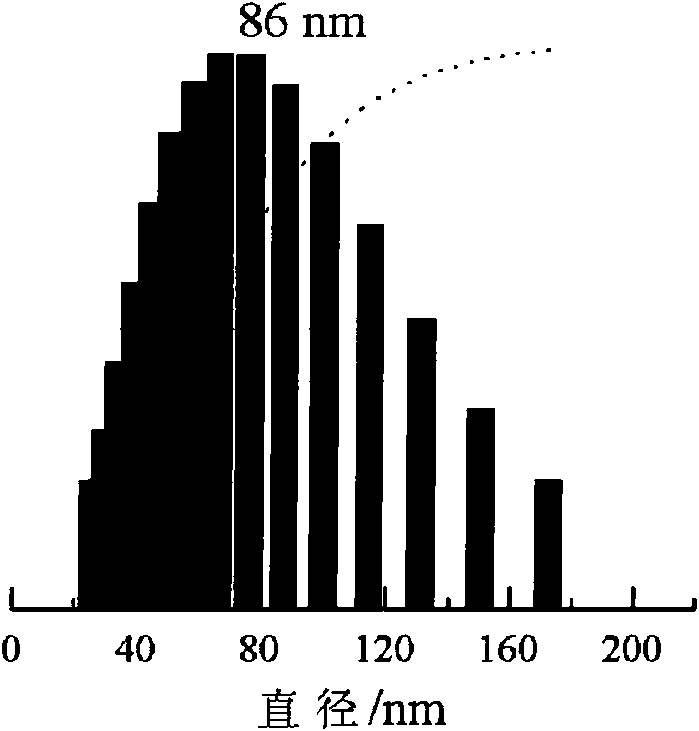

Nano composite meso-microporous molecular sieve and preparation method thereof

InactiveCN101311117ASimple processSave energyCrystalline aluminosilicate zeolitesMolecular sieveAmmonium hydroxide

The invention relates to a nano-composite molecular sieve and a preparing method thereof. Silica sol and sodium metaaluminate are taken as silicon source and aluminum source respectively, and step-by-step synthesis of crystallization is adopted by utilizing surfactant hexadecyl trimethyl ammonium bromide (CATB) and tetraethyl ammonium hydroxide (TEAOH) used for synthesizing a porous Beta molecular sieve as a template agent; in the first step of crystallization, an additive is added for controlling the solvent of the silicon source and the aluminum source to synthesize nano Beta latex; low-temperature dynamic crystallization is adopted in the second step; at the temperature of 30 to 40 DEG C, a composite molecular sieve is synthesized; finally a Beta / MCM-41nano-composite molecular sieve with grain size being 50 to 100 nanometers is produced after the processing steps of filtering, washing, drying and roasting.

Owner:BEIJING UNIV OF CHEM TECH

Organic Thin Film Transistor and Its Fabrication Method

InactiveUS20080042129A1High device propertyEasy to transportSolid-state devicesSemiconductor/solid-state device manufacturingSilane compoundsOptoelectronics

An organic TFT comprising an organic thin film, a gate electrode formed on one surface of the organic thin film through a gate insulating film, source / drain electrodes formed on both sides of the gate electrode and on one surface of the organic thin film or on the other surface, and a film of an organic silane compound positioned between the organic thin film and the gate insulating film and / or between the organic thin film and the source / drain electrodes.

Owner:SHARP KK

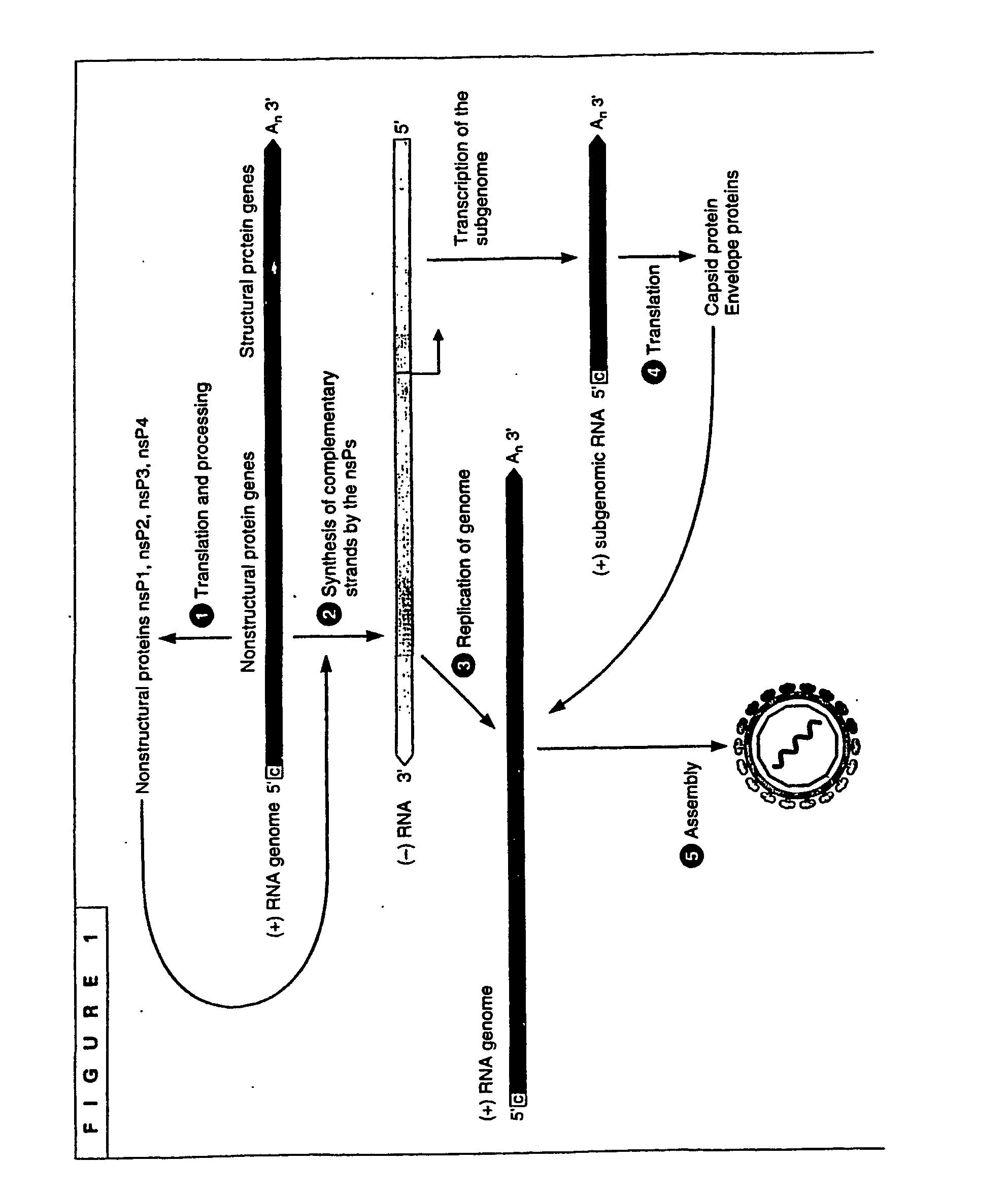

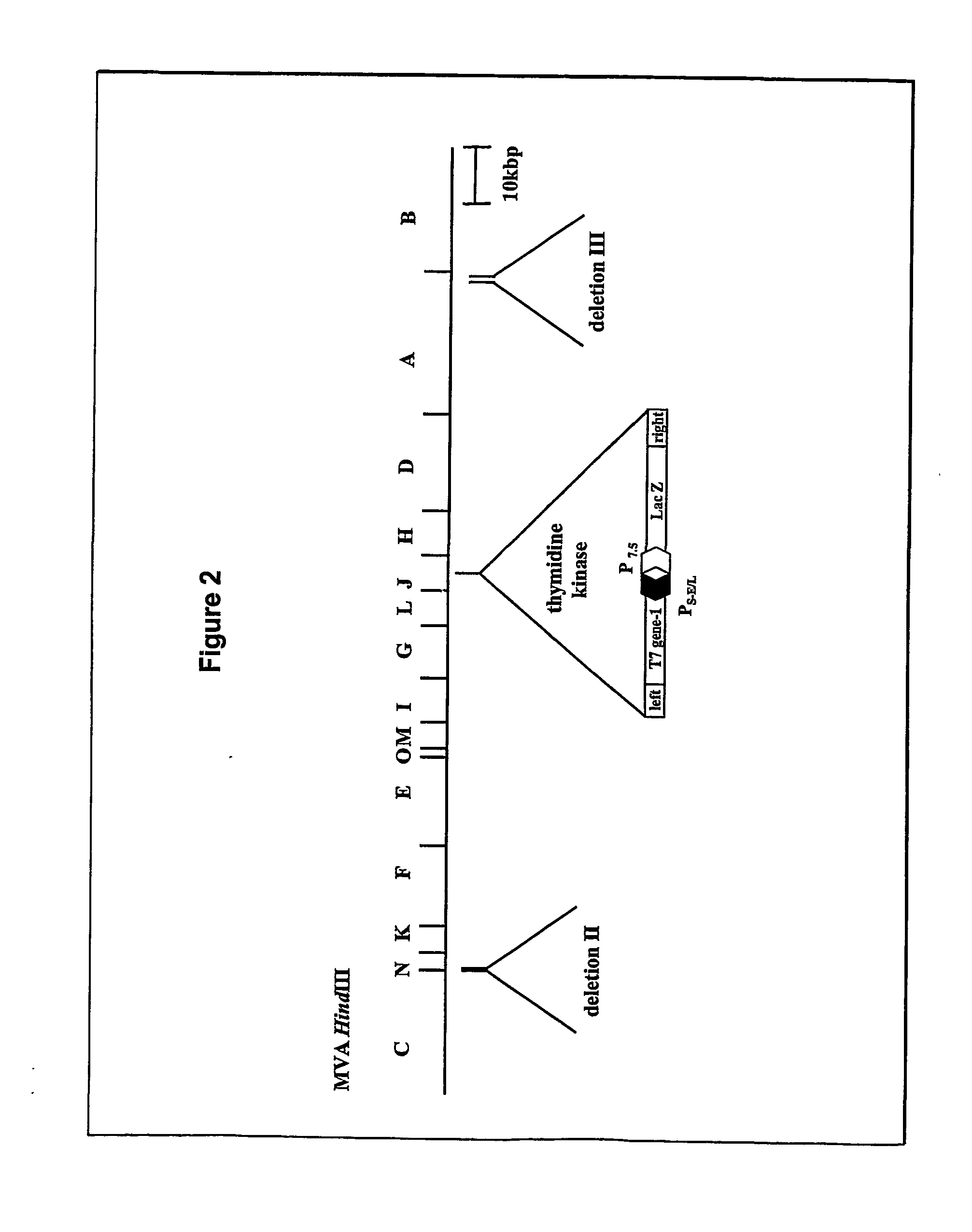

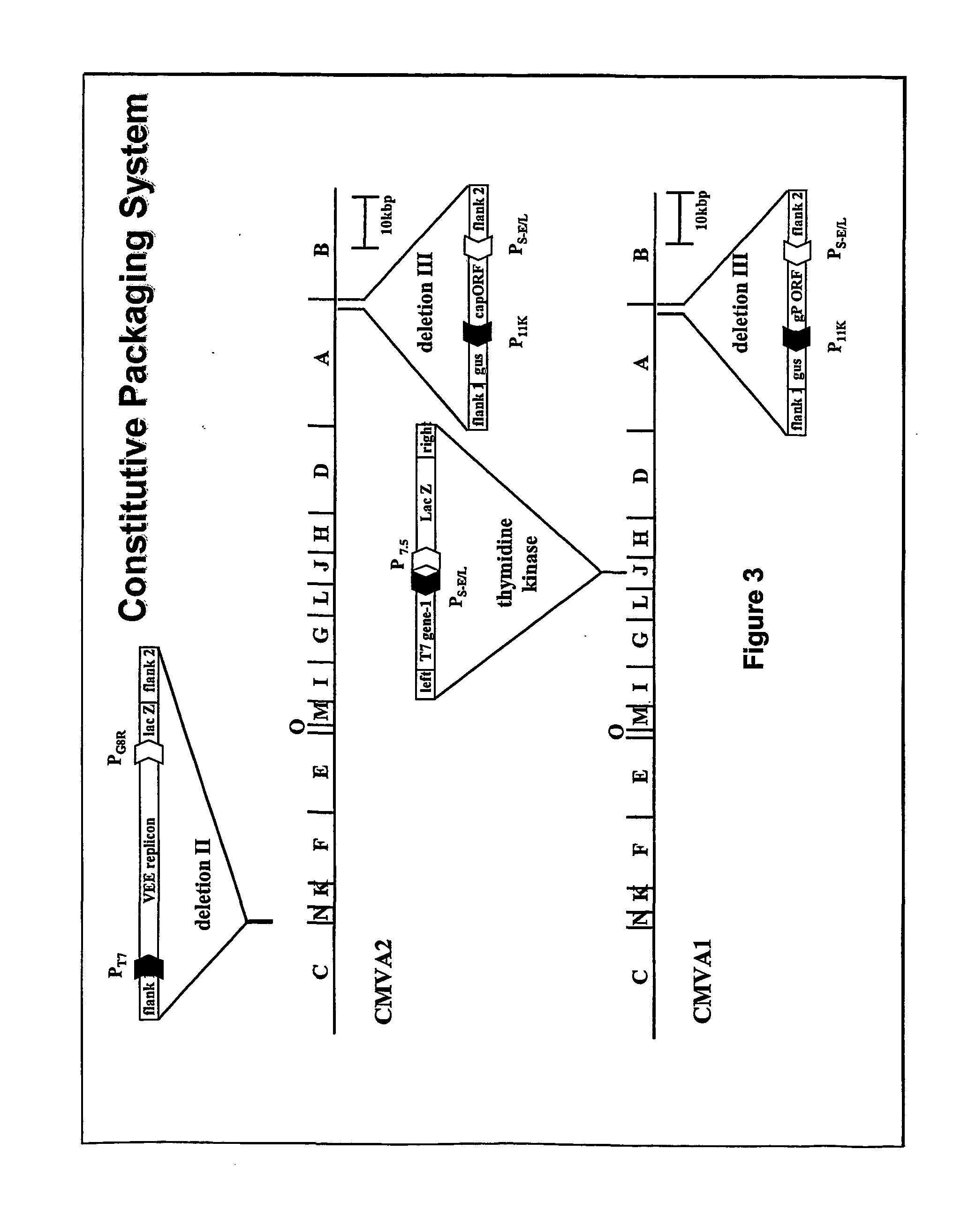

Packaging of positive-strand rna virus replicon particles

InactiveUS20040029279A1Great titerProbability of generatingFungiSsRNA viruses positive-sensePharmaceutical formulationViral vector

The invention generally relates to recombinant polynucleotides, positive-strand RNA virus (psRNAV) recombinant expression vectors, and packaging systems. The packaging systems are based on the expression of helper functions by coinfecting re-combinant poxvirus vectors comprising recombinant polynucleotides. Methods for obtaining psRNAV replicon particles using these packaging systems are disclosed. Immunogenic compositions and pharmaceutical formulations are provided that comprise replicon particles of the invention. Methods for generating an immune response or producing a pharmaceutical effect are also provided.

Owner:WYETH HOLDINGS CORP

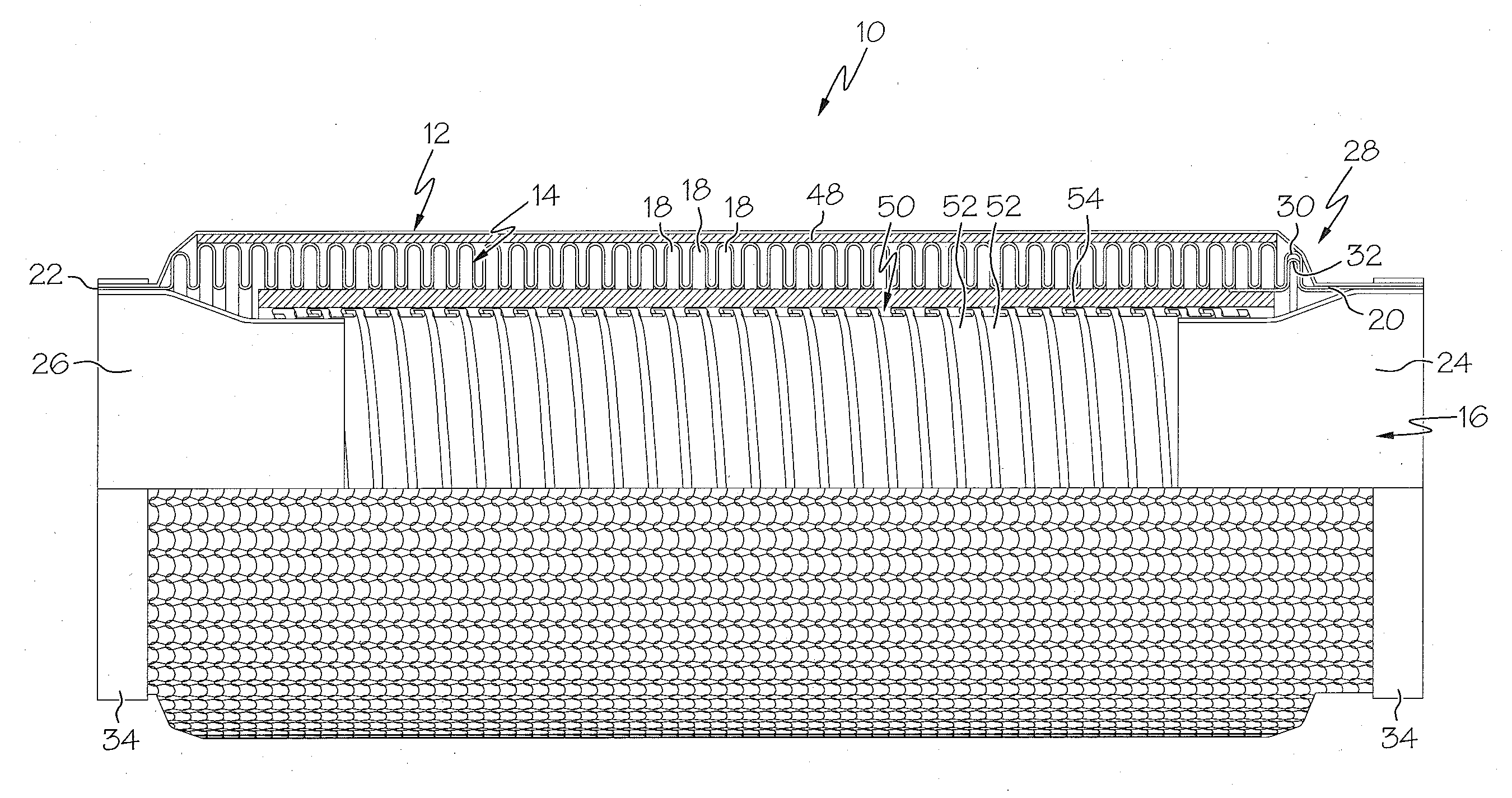

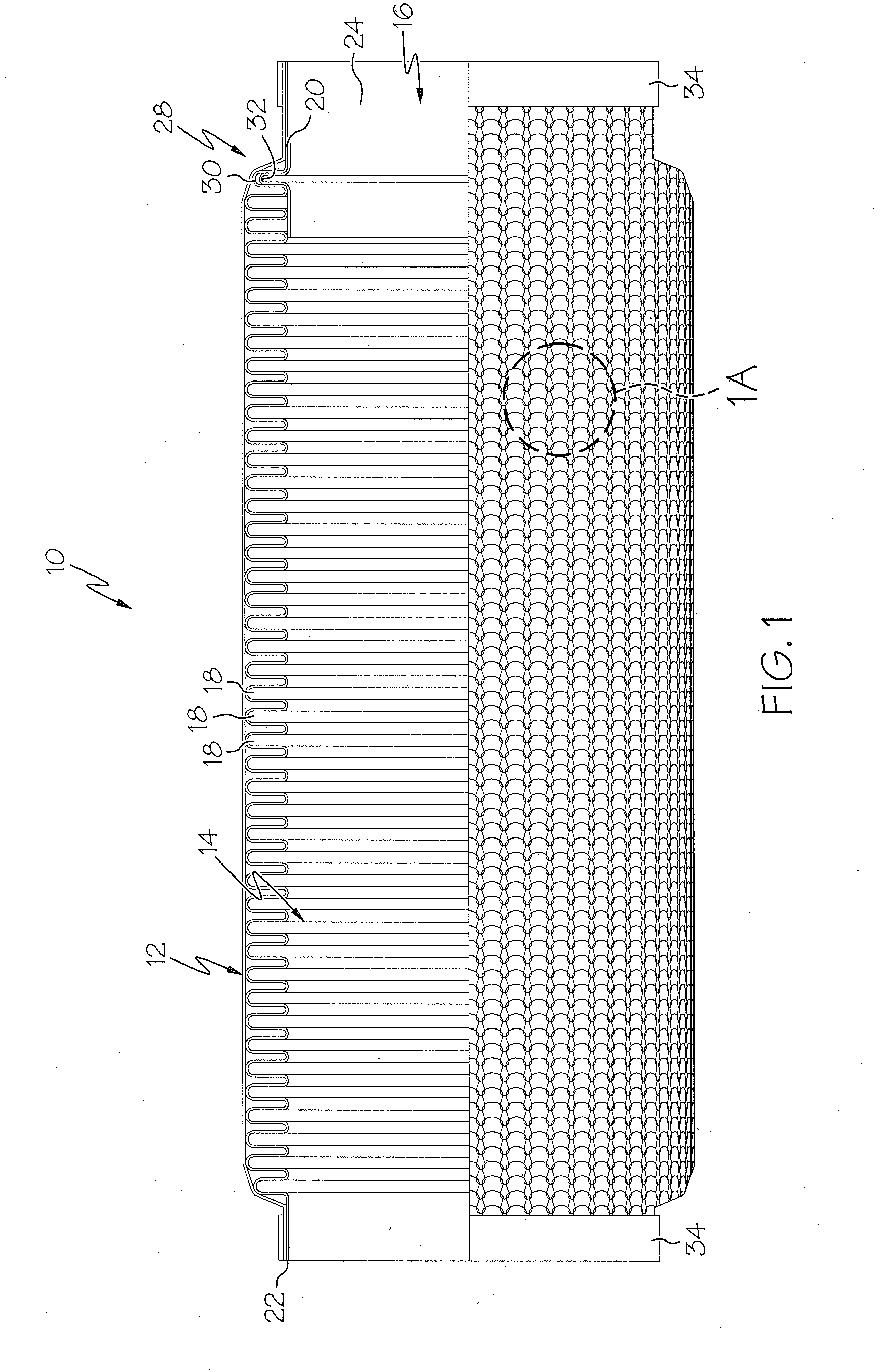

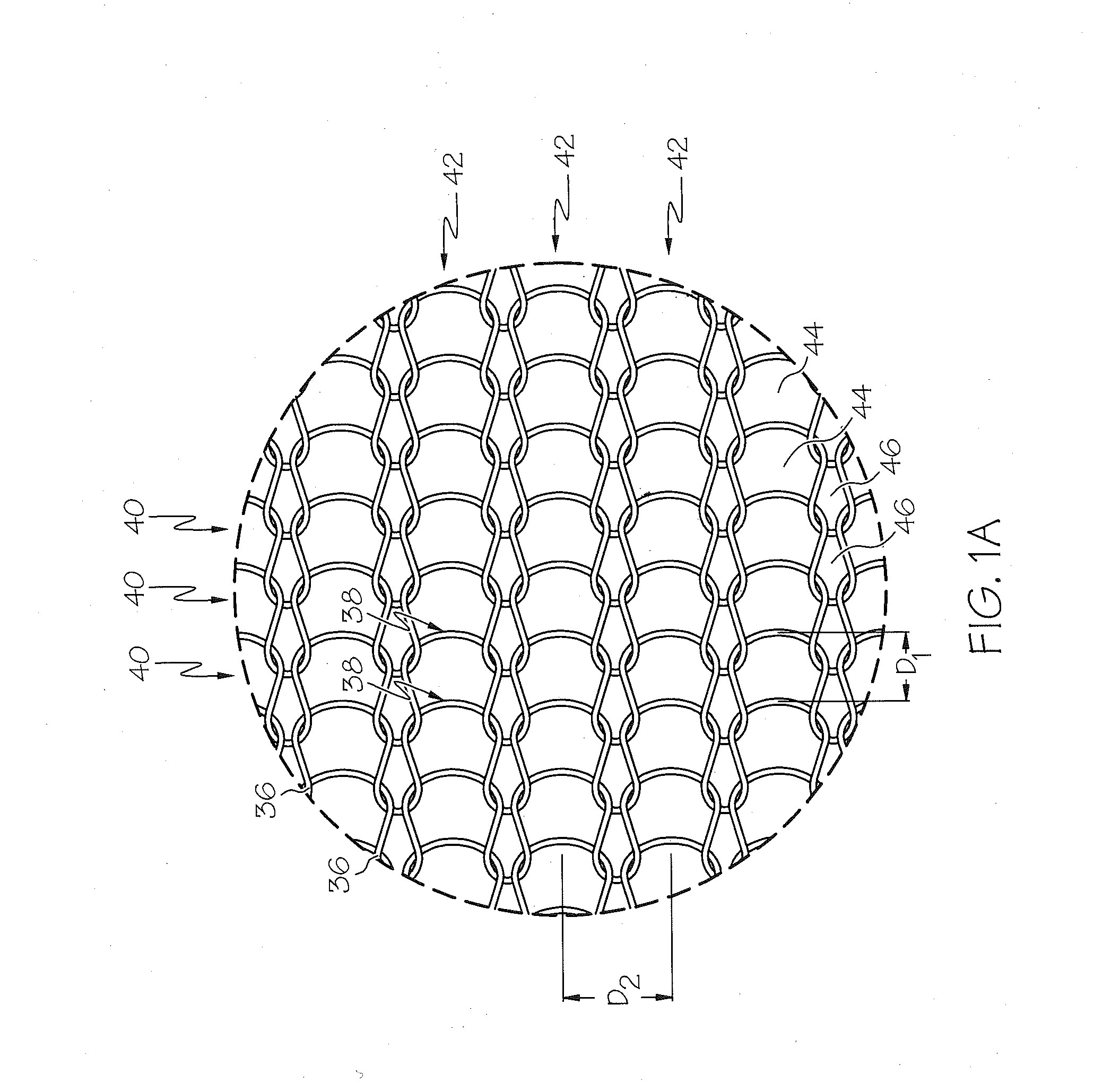

Frequency-controlled exhaust bellows assembly

InactiveUS20130015652A1Counteract vibrationControl growthSleeve/socket jointsPipeline expansion-compensationLongitudinal growthEngineering

An exhaust connection coupler is provided having a flexible conduit portion, a cover made of a generally porous and flexible knitted metallic wire mesh material surrounding the conduit portion and a retainer for combining end parts of the conduit portion and cover. The cover may be constructed of a series of stockinette stitches formed in a continuous round-and-round manner in a seamless tubular configuration. The cover can be selected from a group of covers designed to be applied to the coupler, the particular cover being chosen for its weight or stiffness so as to selectively control the natural frequency of the coupler. Additionally, the loosely knitted configuration of the cover is designed to provide resistance limiting longitudinal growth of the coupler while enabling compression and angular flexibility. Further, the coupler may include one or more spacers for providing separation between the cover and the conduit portion.

Owner:TRU FLEX

Method for producing high-purity nano-zinc oxide by ammonia method using electrolytic zinc acid-leaching residues

ActiveCN102863007AGrowth inhibitionSmall particle sizeZinc oxides/hydroxidesNanotechnologyElectrolysisZno nanoparticles

The invention discloses a method for producing high-purity nano-zinc oxide by an ammonia method using electrolytic zinc acid-leaching residues. The method comprises the following steps of: adding slaked lime being 1-5% of the mass of electrolytic zinc acid-leaching residues before a leaching step to perform activation, then leaching with ammonia-ammonium bicarbonate solution, adding 0.3-0.5kg of sodium fluorosilicate to per cubic meter of ammonia-ammonium bicarbonate solution, and refining after performing purification and impurity removal. According to the method for producing high-purity nano-zinc oxide by ammonia method using electrolytic zinc acid-leaching residues, the electrolytic zinc acid-leaching residues can be leached efficiently, the high-purity nano-zinc oxide with the purity up to above 99.7% can be obtained, and the high-purity nano-zinc oxide has high practical value and economic value; all the valuable and harmful heavy metals in the electrolytic zinc acid-leaching residues are leached and utilized, so that the obtained final leaching residues are converted from electrolytic zinc acid-leaching residues as high hazard wastes into ordinary solid wastes, the environment is protected, and the resources are rationally utilized.

Owner:SICHUAN JUHONG TECH

A silver containing chitosan fiber having antimicrobial function and preparation method

InactiveCN1308509CNon-oxidizingWill not oxidize and turn blackArtifical filament manufactureFiberBacteria

This invention relates to a silver-bearing crustamine fabric with anti-biotic action and its preparing method, which is composed of 90.0-99.9 percent of crustamine powder in weight and 0.1-10 percent of insoluble silver compounds particles. The invention has great anti-biotic action, and can be used as medical dressing to restrict the bacteria on wound.

Owner:JIAXING UNIV

Preparation of nano hydroxylapatite powder

InactiveCN101486452AShape is easy to controlUniform particle sizePhosphorus compoundsPhosphateApatite

The invention relates to a method for preparing a nanometer hydroxyl apatite powder by utilizing hydrothermal solution, which pertains to the chemical field. Cheap calcium nitrate and phosphate which are easy to purchase in the market are taken as raw materials, the two saline solutions are mixed in accordance with certain Ca / P ratio, after adjustment and mixing by using ammonia, the pH value of the suspension comes to a certain range and then the suspension is put into a reaction kettle; under the conditions of certain stirring speed, heating temperature and holding time, reaction happens and hydroxyl apatite is generated; and the acicular or bulbiform nanometer hydroxyl apatite powder is obtained after filtration, being cleaned by a certain solvent and drying under certain conditions. The preparation method is simple and easy to be operated and has good repeatability; the obtained power has high purity and narrow particle size range and is suitable for being popularized and applied in various fields such as hard tissue repair, wastewater treatment, chromatography filler, and the like.

Owner:CHONGQING UNIV

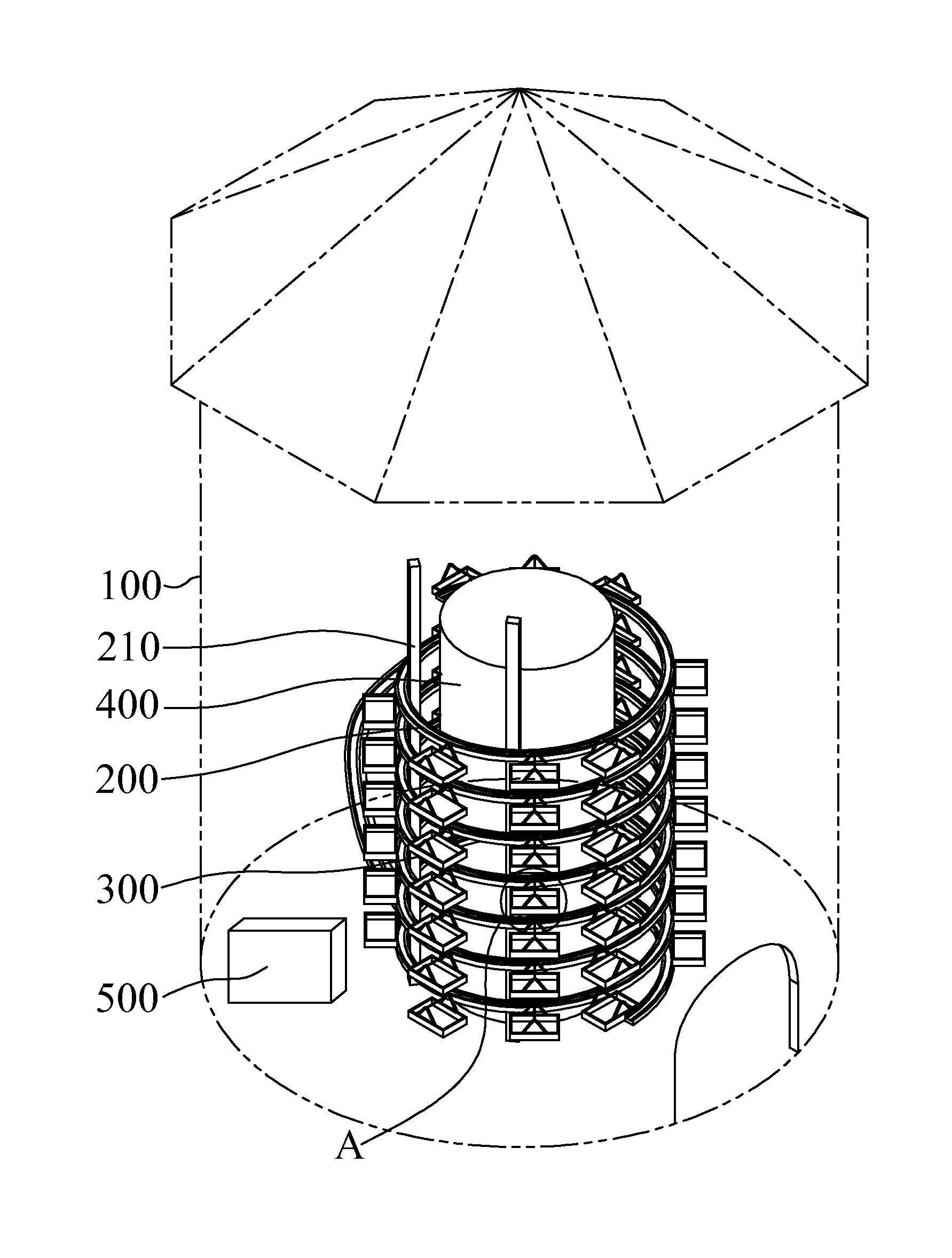

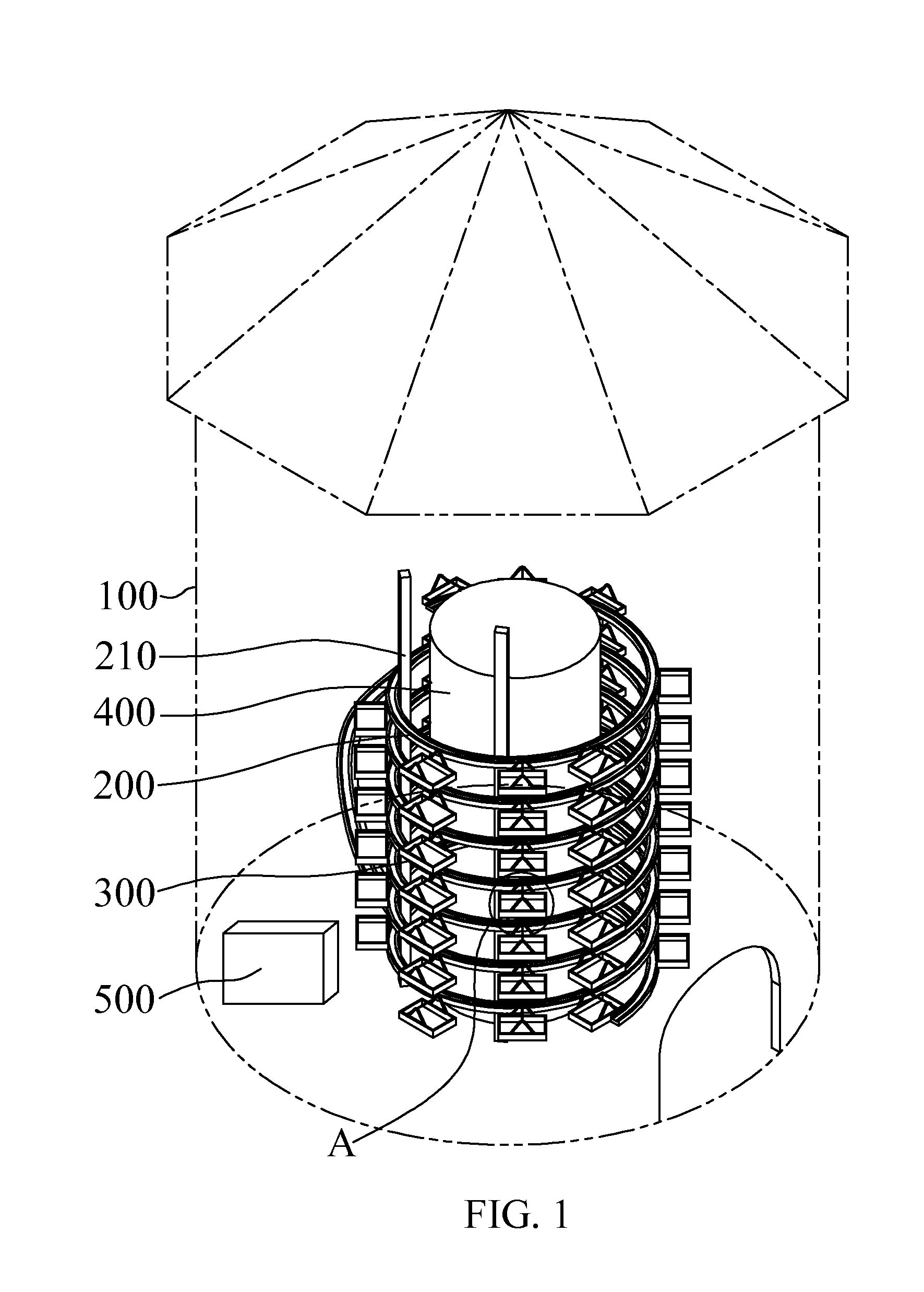

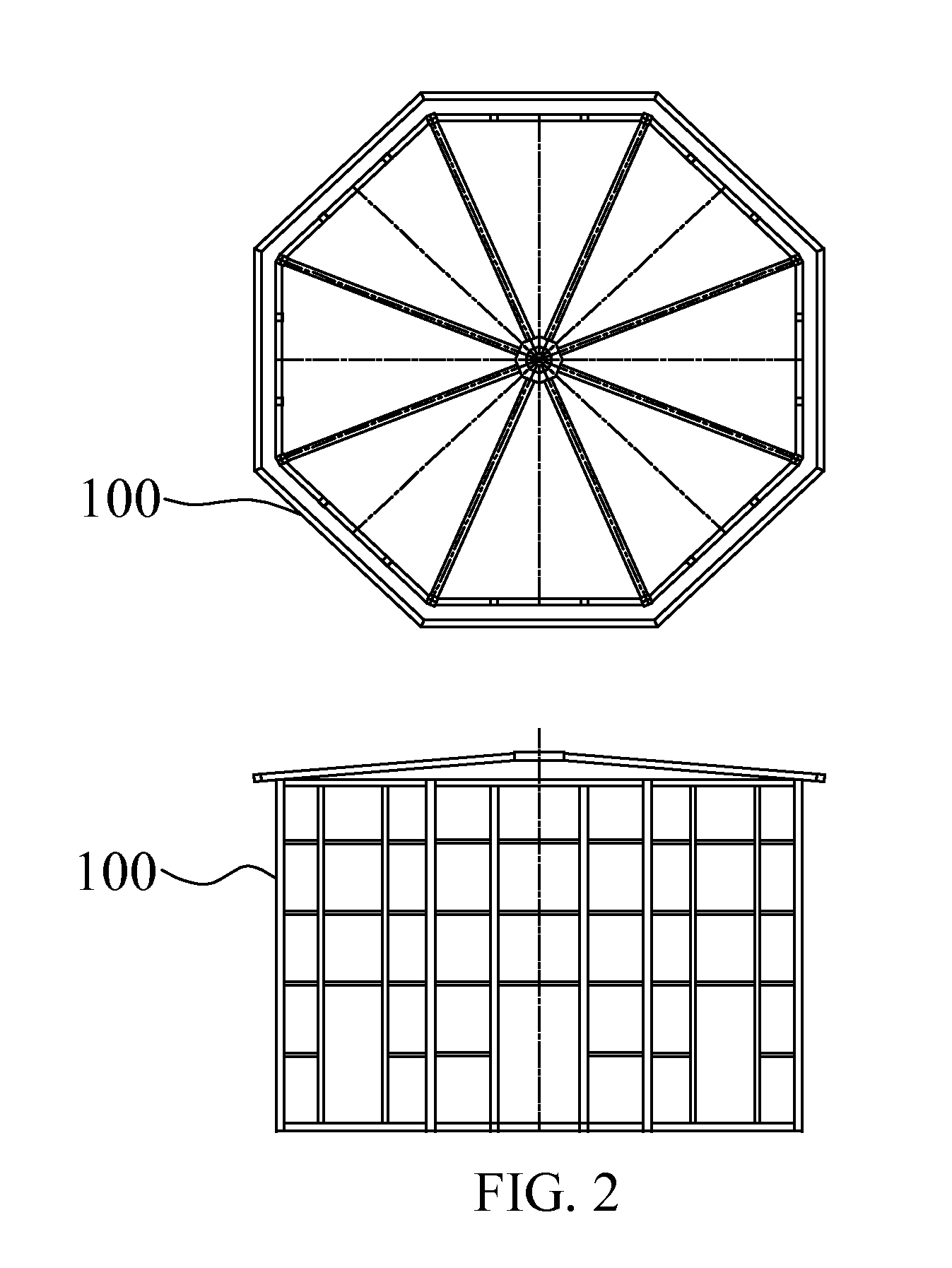

Vegetable tower

InactiveUS20110130871A1Control growthQuality improvementDigital data processing detailsWatering devicesFertilizerCarbon dioxide

The present invention discloses a vegetable tower, which comprises a main body. A main spiral slide guide is disposed inside the main body and vegetable growing bins can be hung on the main spiral slide guide via a plurality of chains and then slipped downstream along the main spiral slide guide by means of gravity. The vegetable growing bins further comprises several supply tubes and supply inlets. A main control module is built inside the main body, and it can automatically ascend and descend inside the main body to perform identifying, feeding, catching images and measuring functionalities. The main control module can feed the vegetable growing bins with water, fertilizer, CO2. The central management module and the main control module are integrated to be an automatic planting-care system to make the growths of the vegetables under well control.

Owner:UNIVERSAL CARBON CONTROL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com