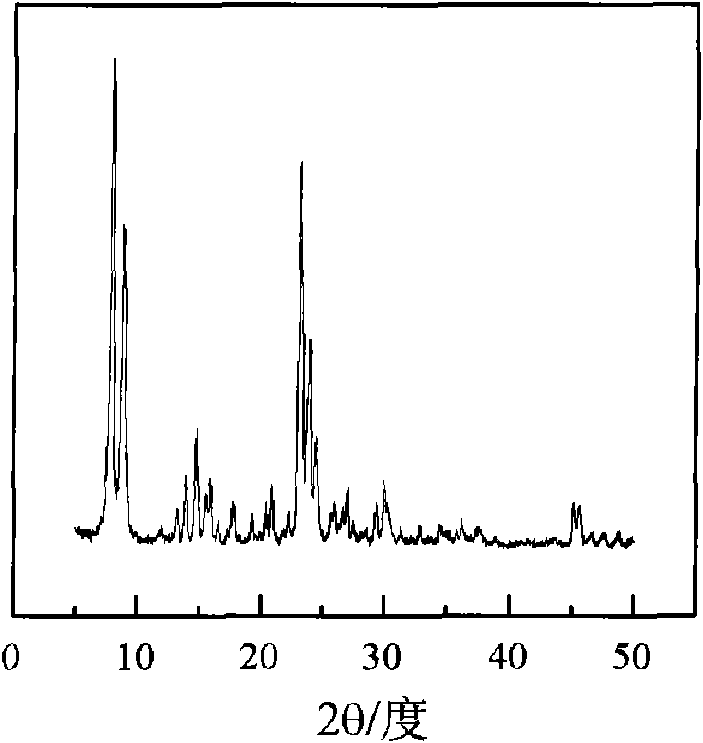

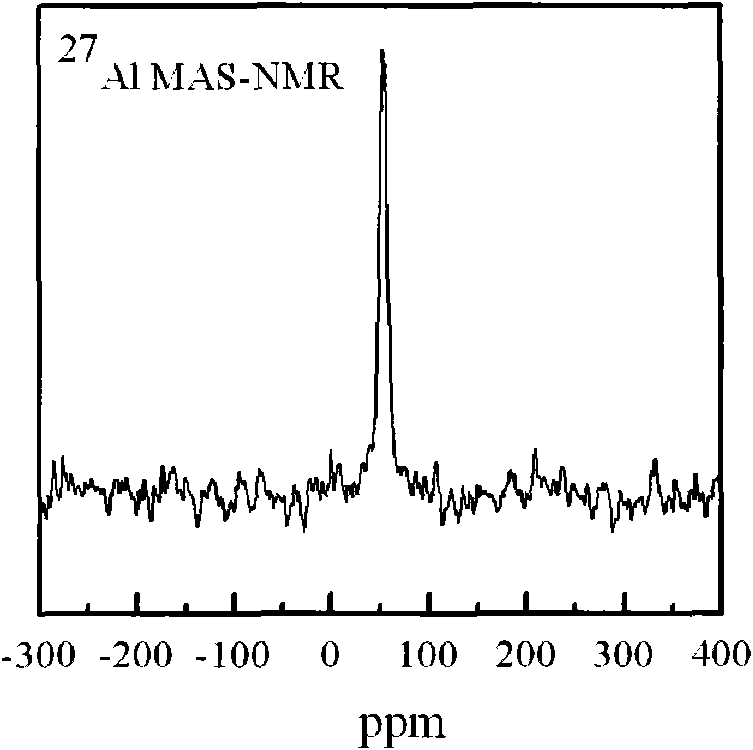

ZSM-5 type molecular sieve for catalyst for reaction for preparing propylene from methanol and/or dimethyl ether

A technology of ZSM-5 and molecular sieve, which is applied in physical/chemical process catalysts, molecular sieve catalysts, organic chemistry, etc., can solve the problems of low propylene selectivity and low mass ratio of propylene to ethylene, and achieve high propylene selectivity and high P /E ratio, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with specific embodiments, and the given examples are only for clarifying the present invention, not for limiting the scope of the present invention.

[0037] The ZSM-5 catalyst synthesized according to the raw materials and conditions recorded in Table 1 and Table 2 was calcined and ammonium exchanged to obtain hydrogen-form ZSM-5, which was pressed into tablets and sieved to 20-40 mesh, and evaluated on a fixed-bed reaction device . Catalytic evaluation conditions are: methanol or dimethyl ether and deionized water mixed feed, its mass ratio is methanol and / or dimethyl ether: water = 2: 1, and its liquid space velocity is 1 hour -1 , the amount of catalyst used is 3g, the reaction temperature is 480°C, and the pressure of the reaction system is less than 50 kPa. The reaction product is detected by FID, and the catalytic performance and physicochemical properties of the catalyst are listed in...

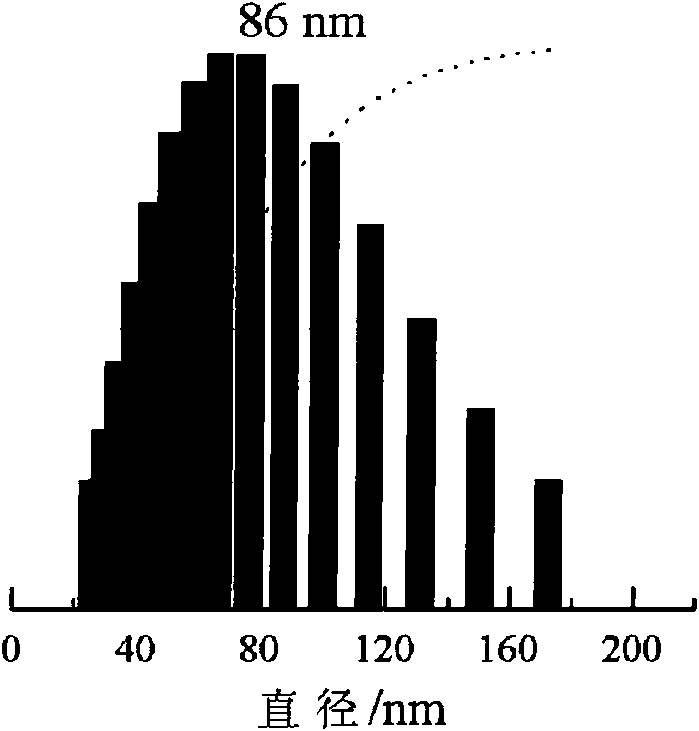

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com