Patents

Literature

145results about How to "Adhesiveness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

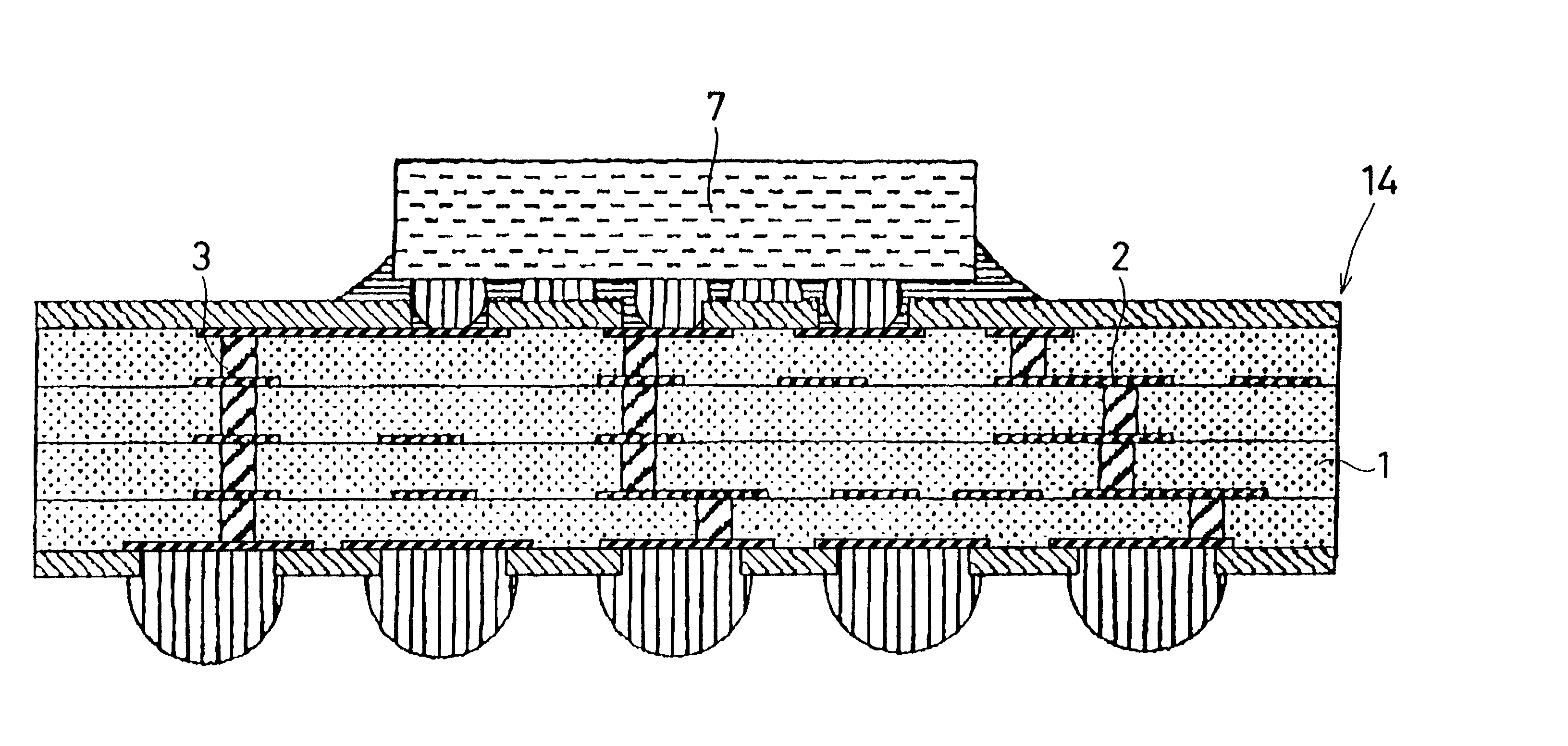

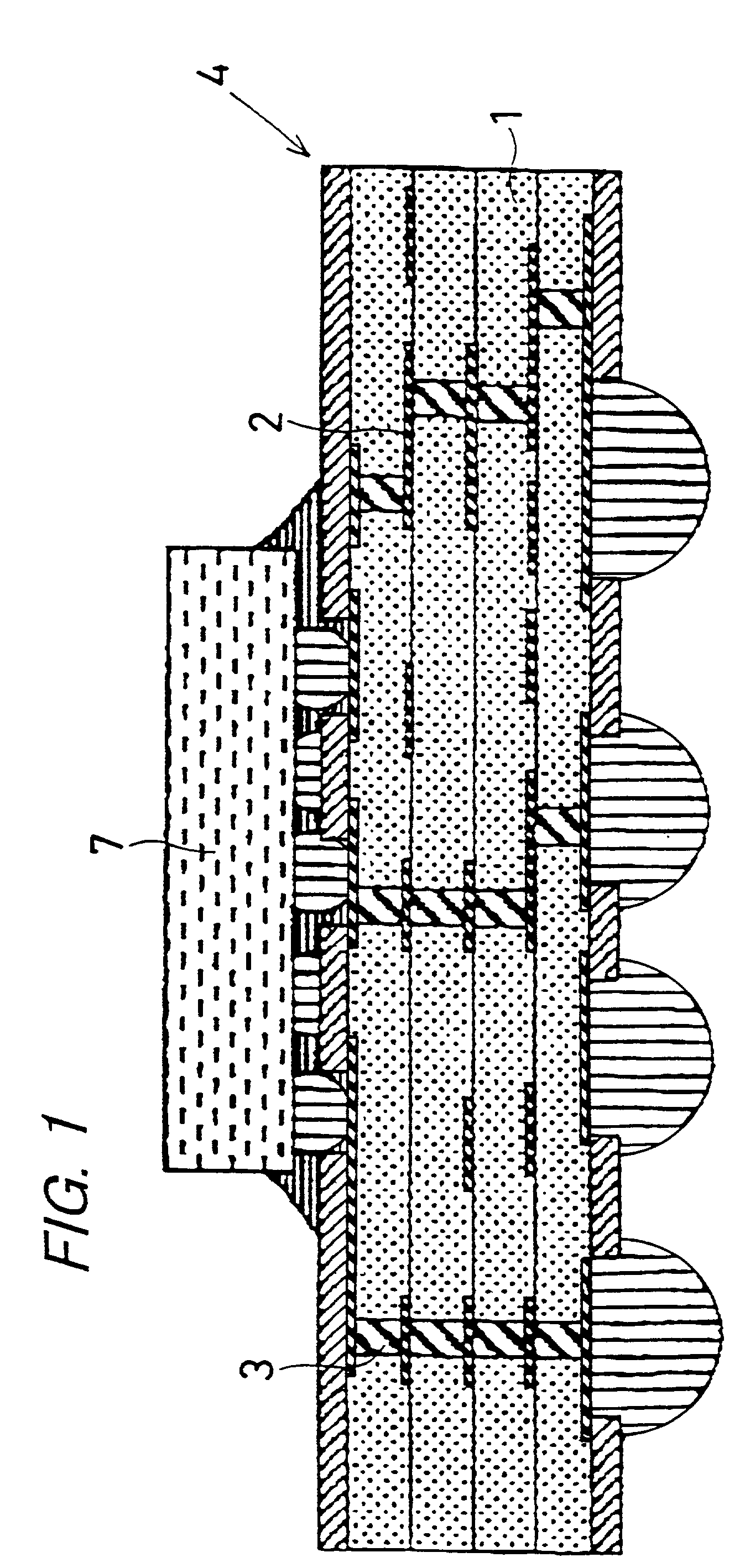

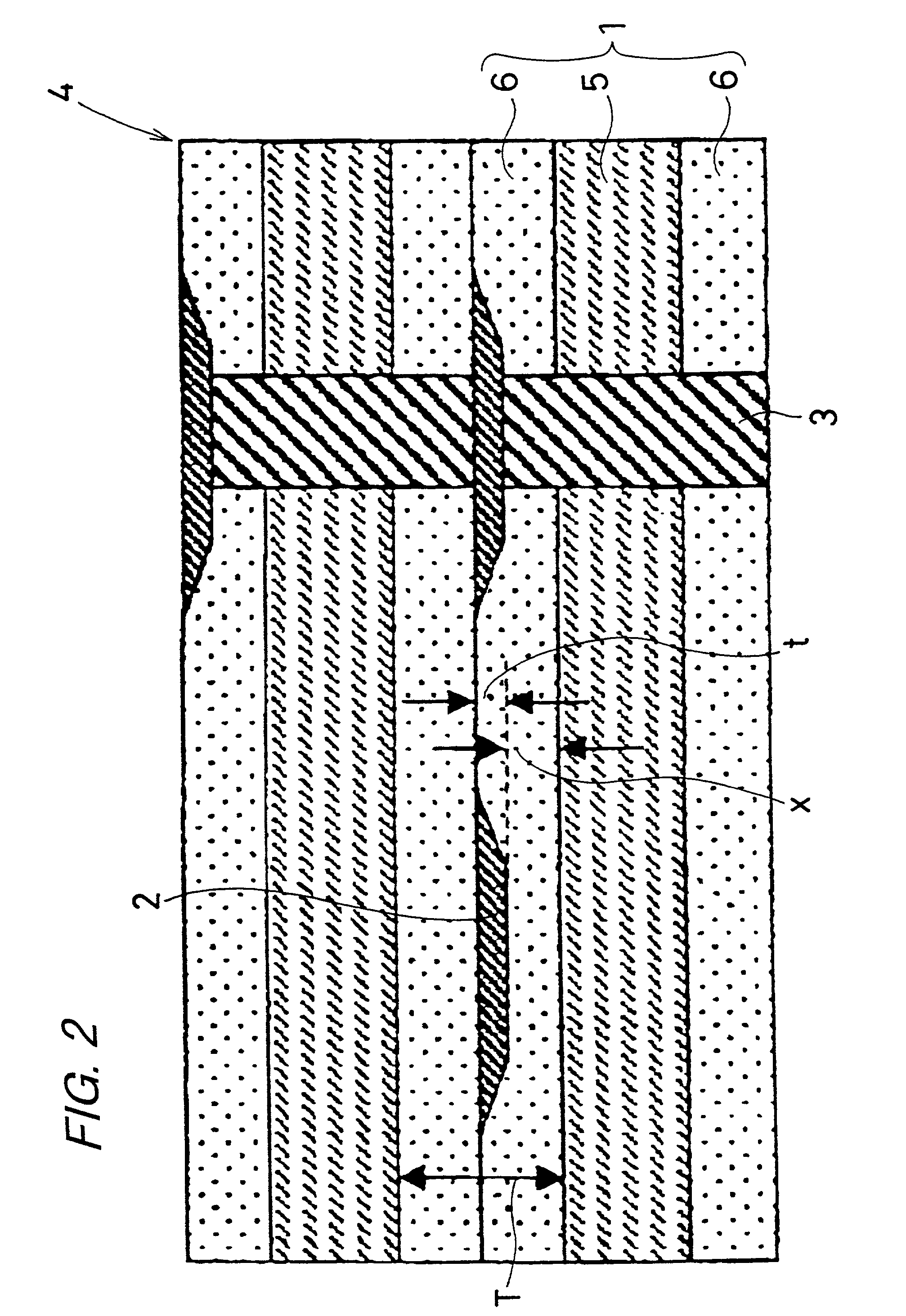

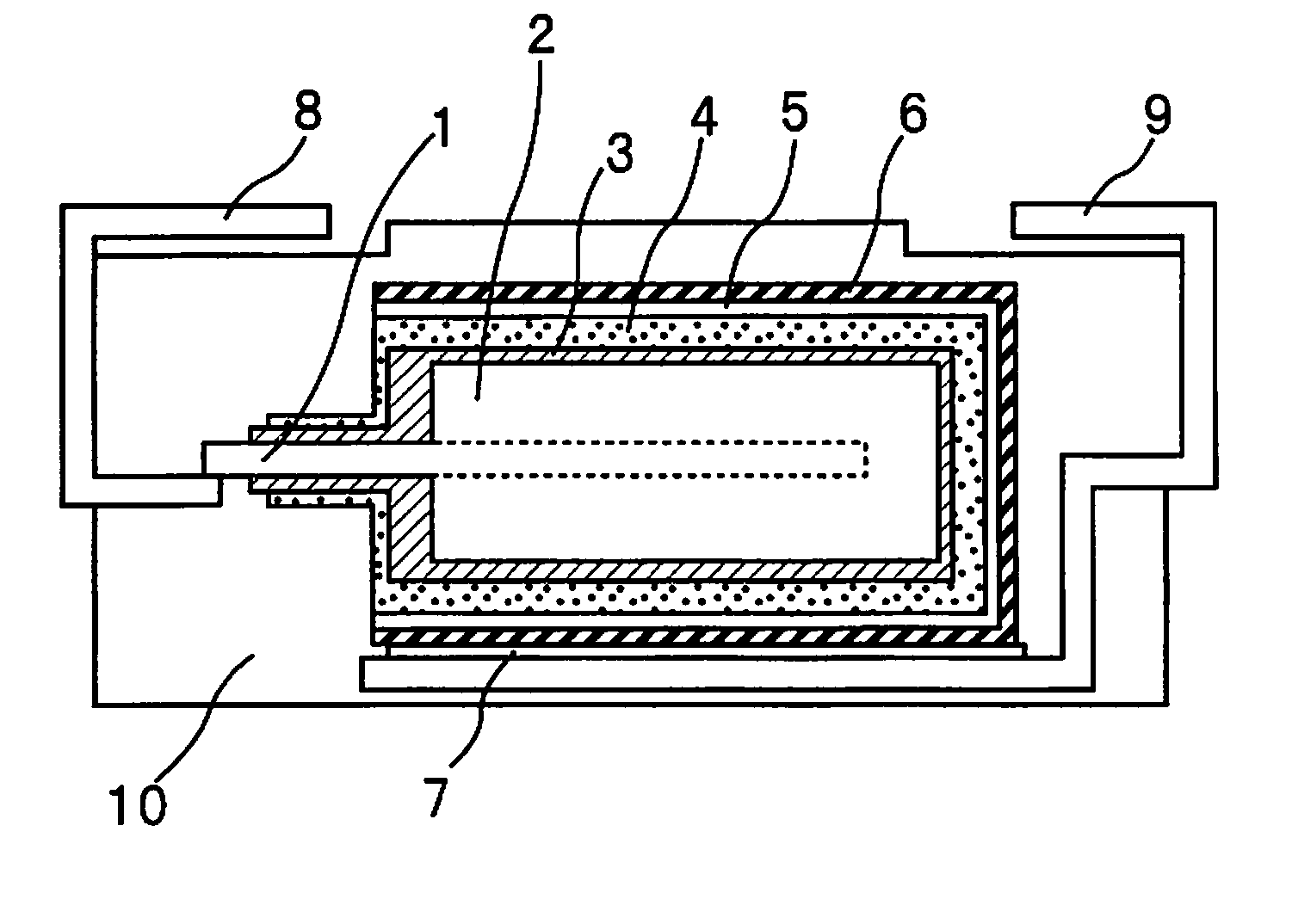

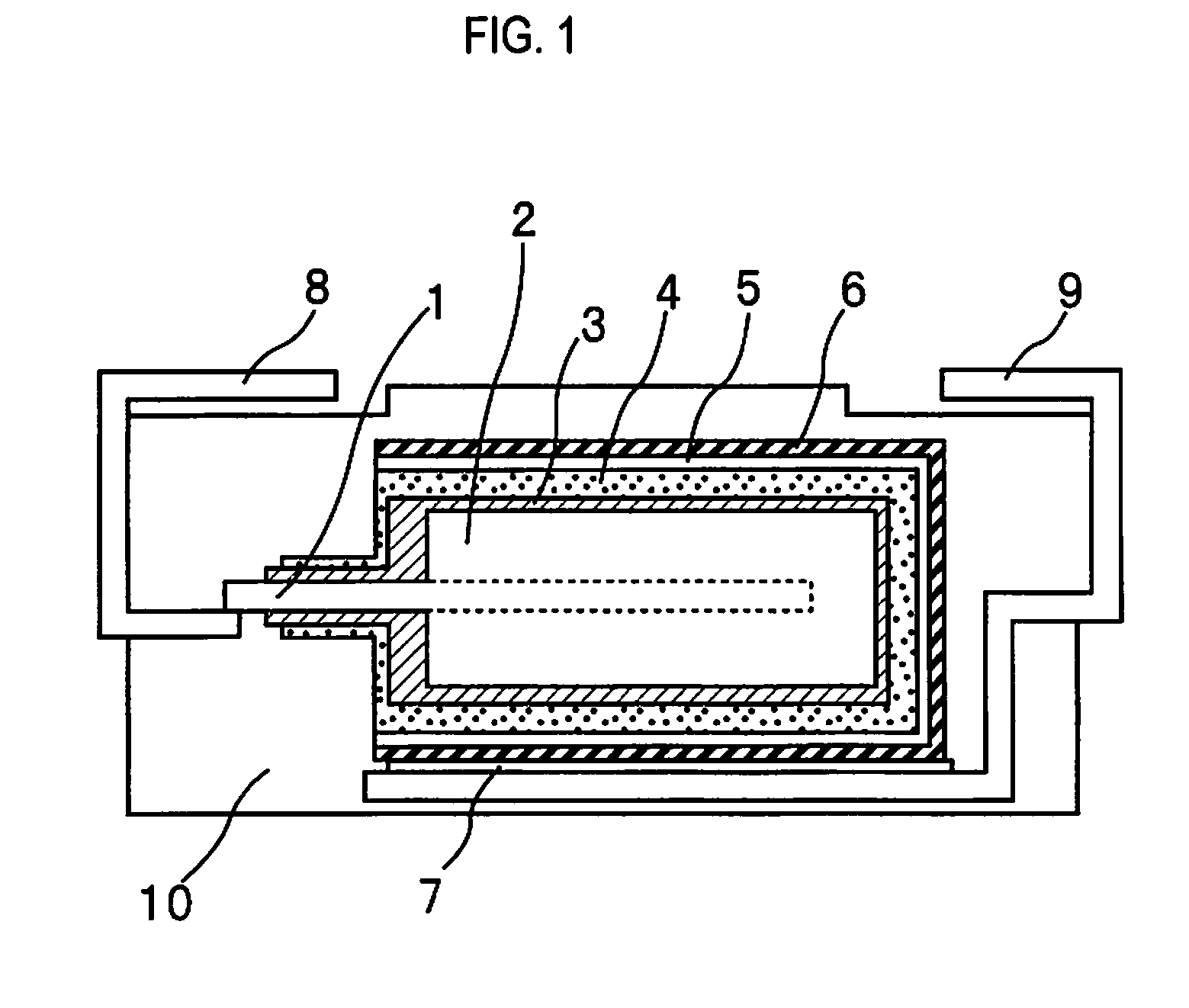

Multi-layer wiring substrate

InactiveUS20020172021A1Excellent in high-frequency characteristicAdhesivenessSemiconductor/solid-state device detailsSolid-state devicesMetallic foilHigh density

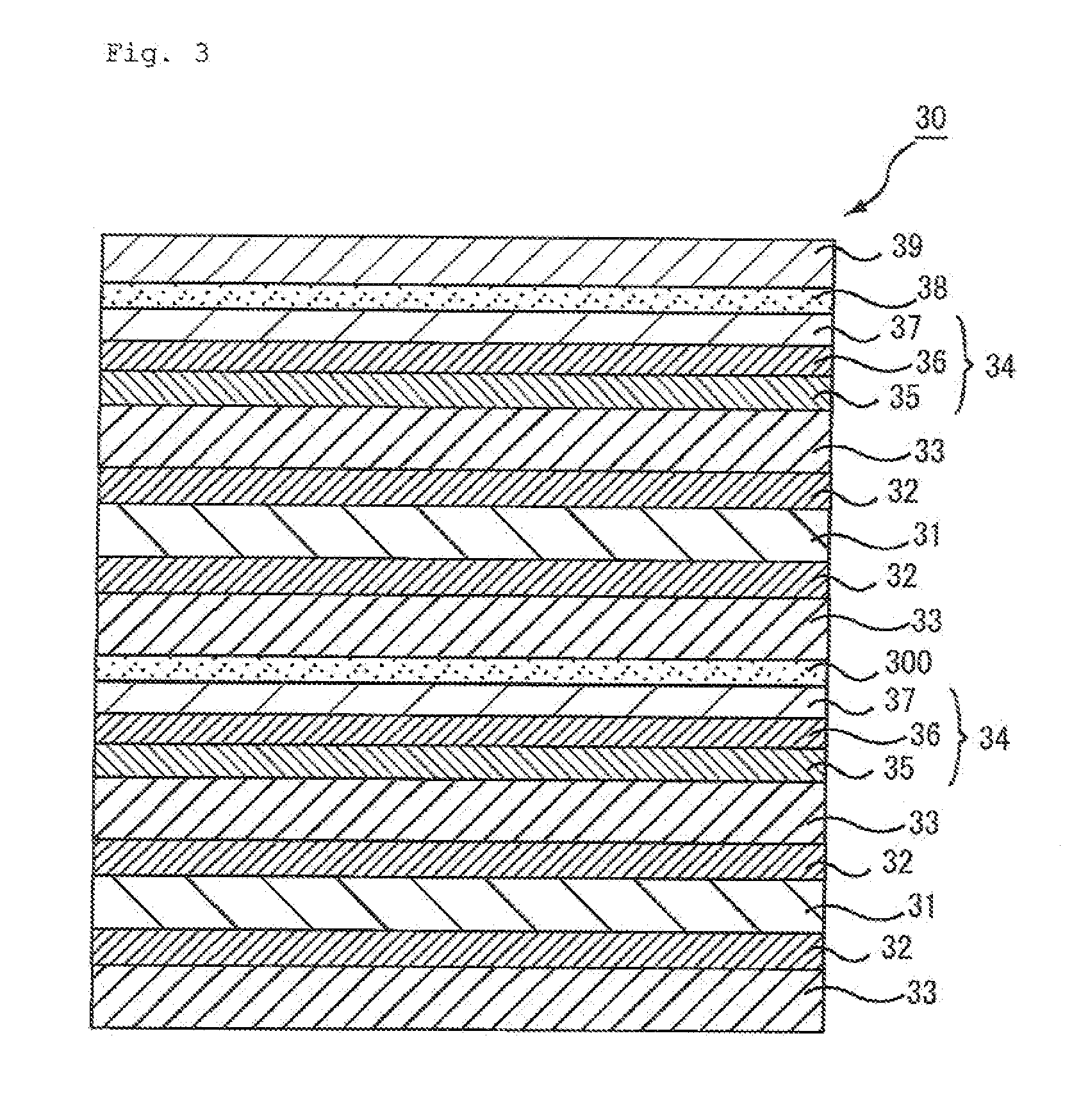

An object of the invention is to satisfy all of a high-density wiring package, soldering thermal resistance, an insulating property and high-frequency transmission characteristics. The invention is a multi-layer wiring substrate having a lamination of a plurality of dielectric layers which are each provided with a wiring conductor made of a metallic foil on at least one of upper and bottom surfaces of the dielectric layer, the wiring conductors between which the dielectric layer is disposed being electrically connected with each other via a through conductor formed in the dielectric layer; on this occasion, the dielectric layers each individually are composed of a liquid crystal polymer layer and cladding layers made of a polyphenyleneether-type organic substance and formed on upper and bottom surfaces of the liquid crystal polymer layer.

Owner:KYOCERA CORP

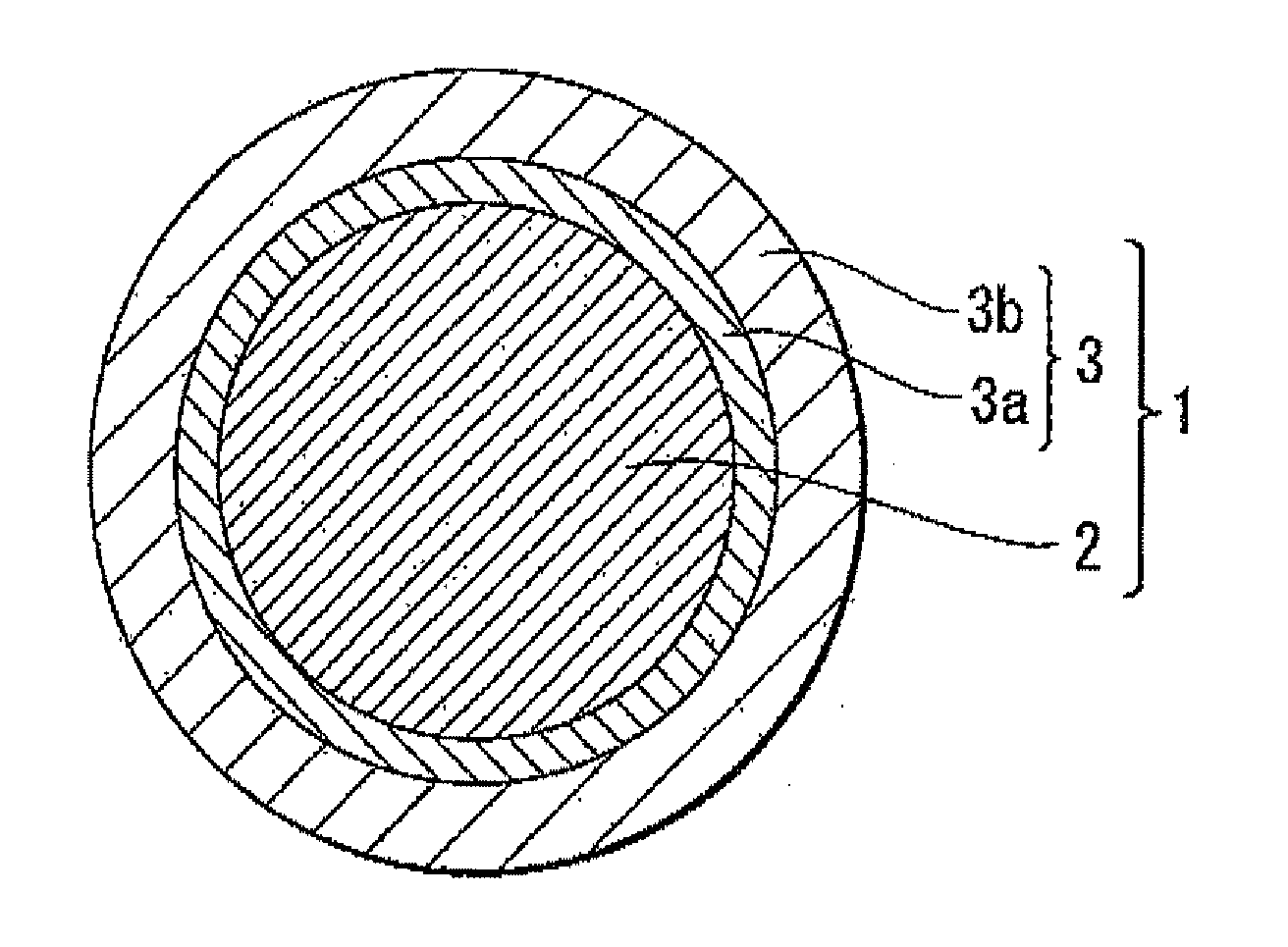

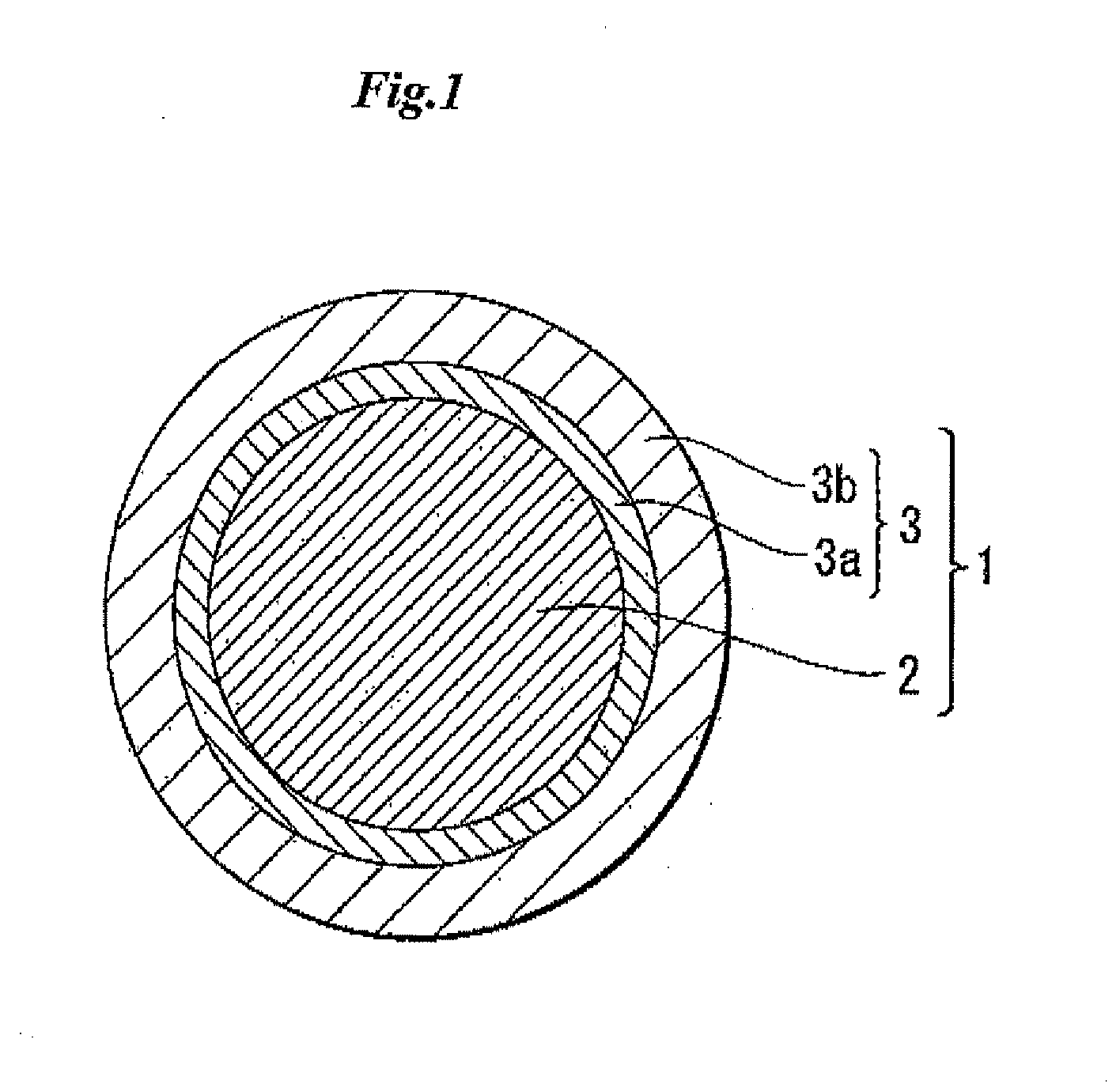

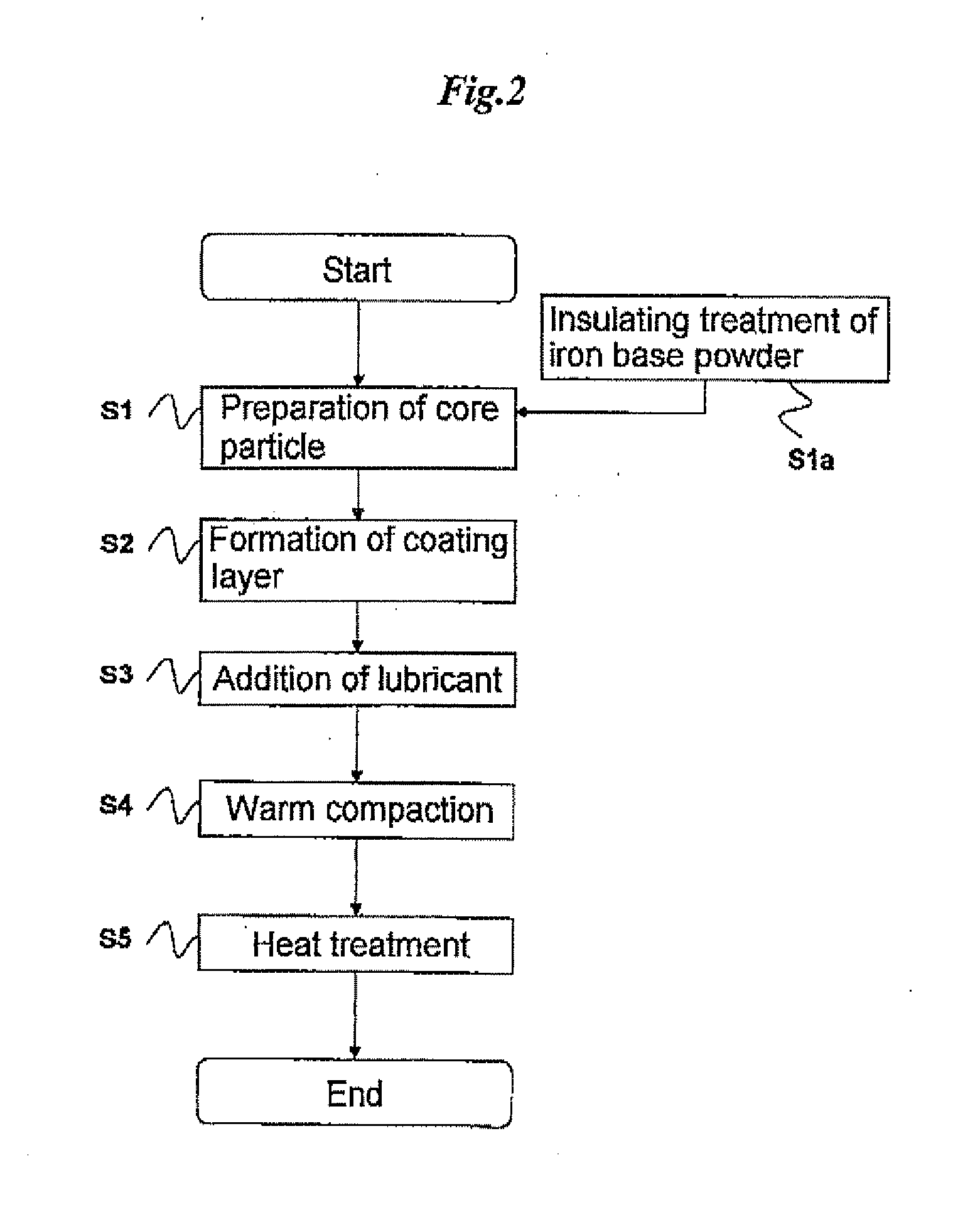

Powder magnetic core

ActiveUS20120082844A1High performanceHigh heat resistanceSynthetic resin layered productsMetal-working apparatusBrown iron oxideMagnetic core

A powder magnetic core having a high electrical resistivity and a high magnetic flux density, including at least a composite magnetic particle the composite magnetic particle including: a core particle containing iron as the main component; and an insulating passivation layer formed on the core particle, wherein: the insulating passivation layer at least has an inner layer formed on the core particle and the outermost layer formed on the inner layer; and the outermost layer contains iron oxide as the main component.

Owner:TDK CORPARATION

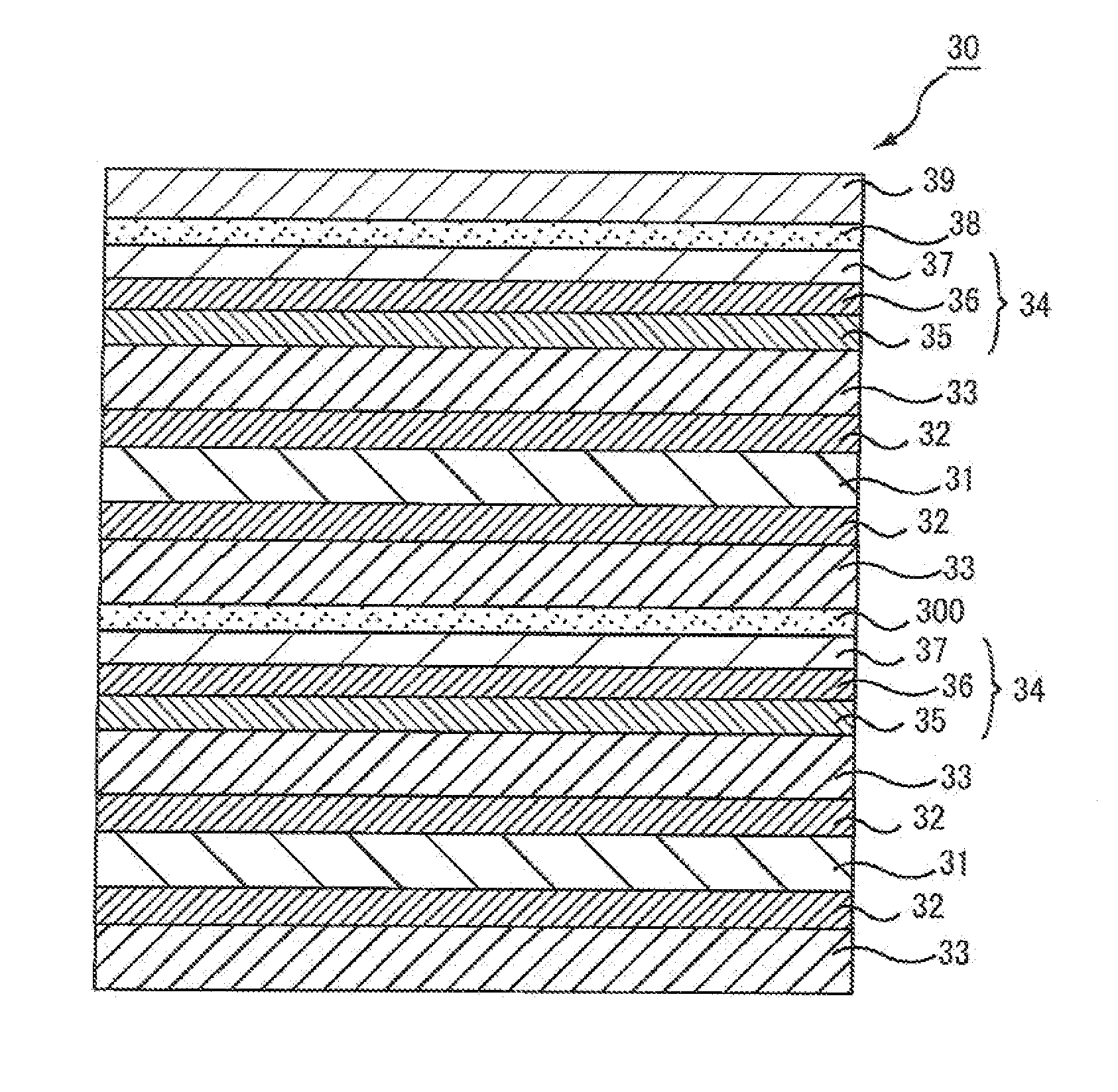

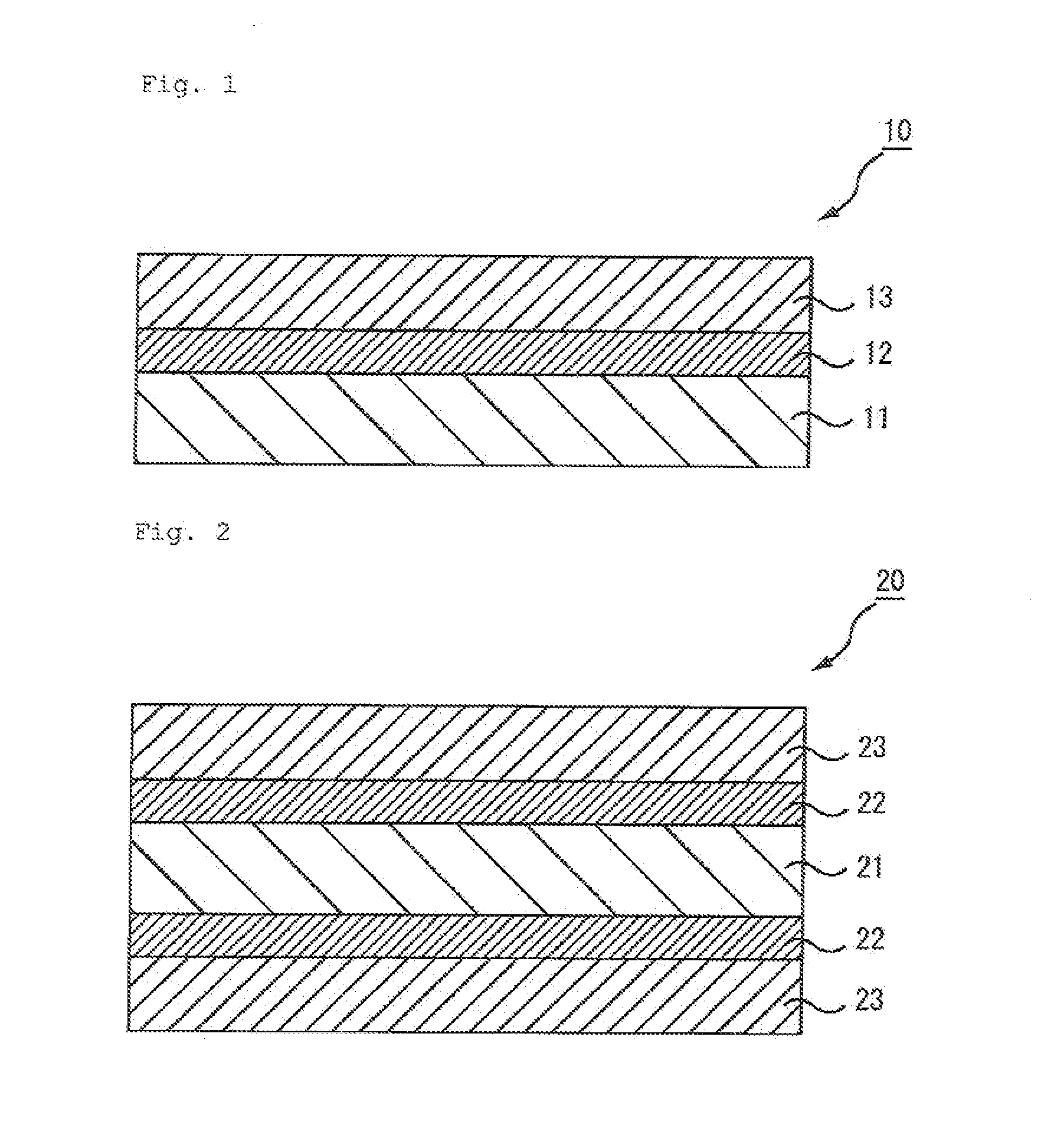

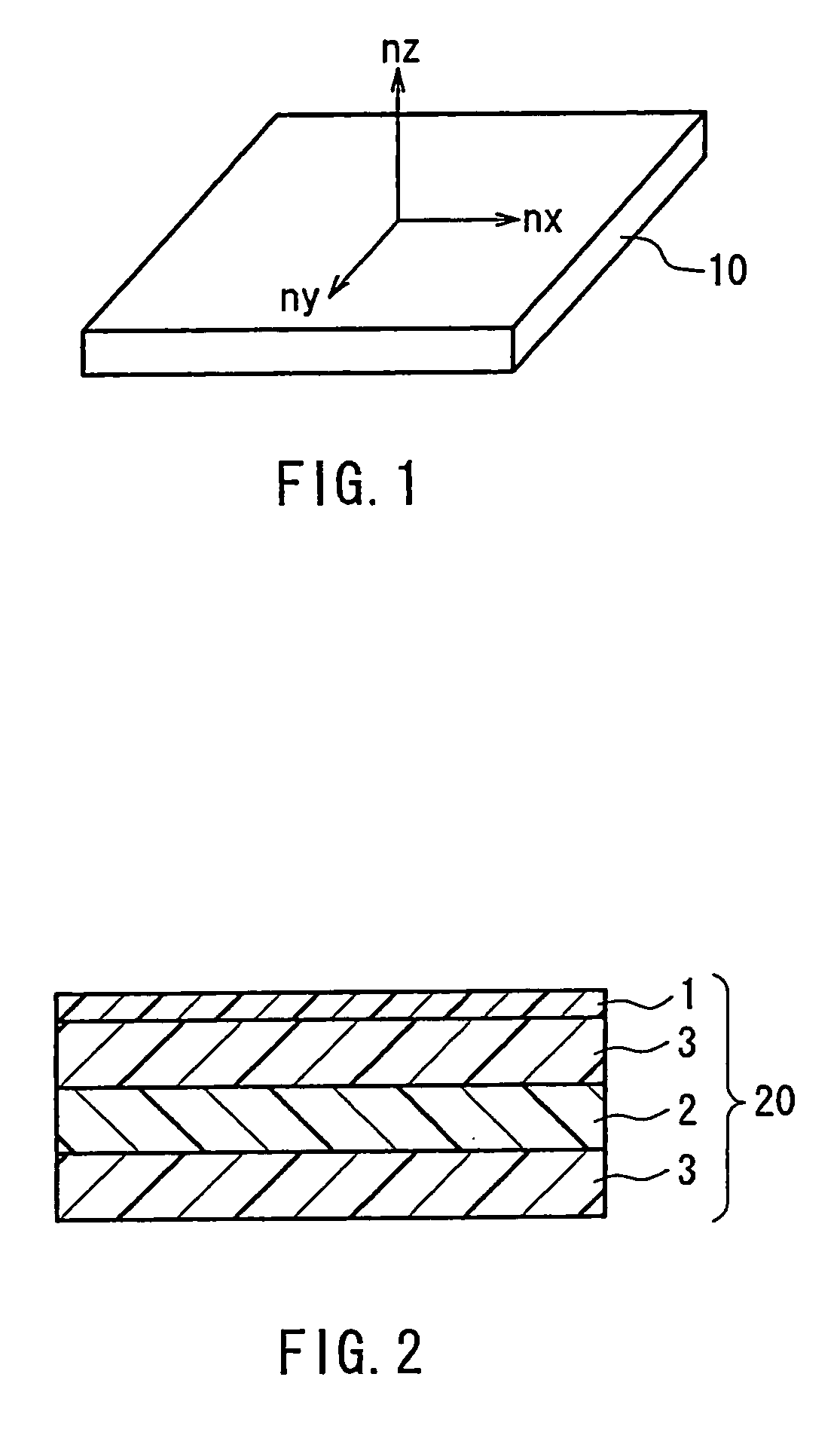

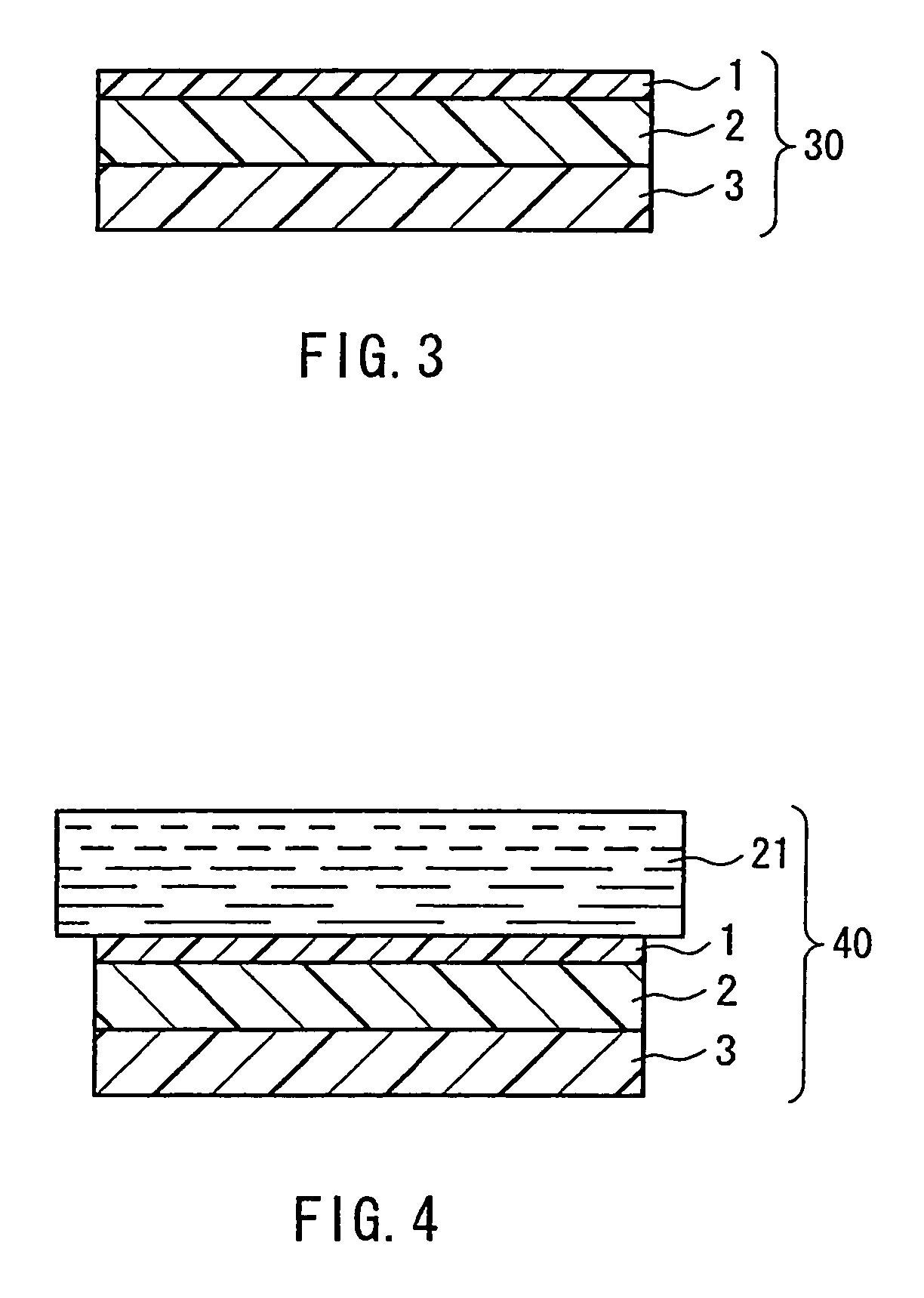

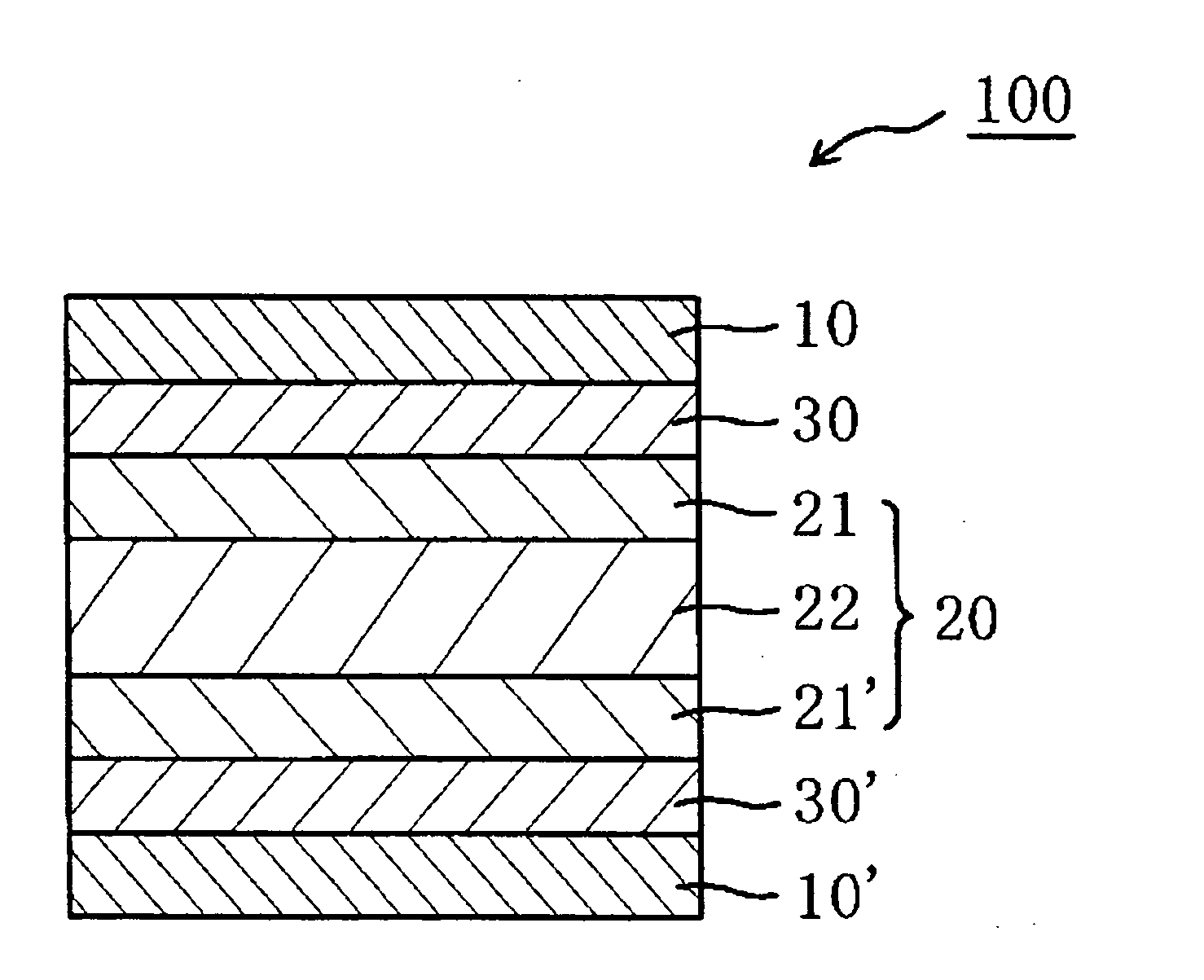

Optical layered body, polarizer and image display device

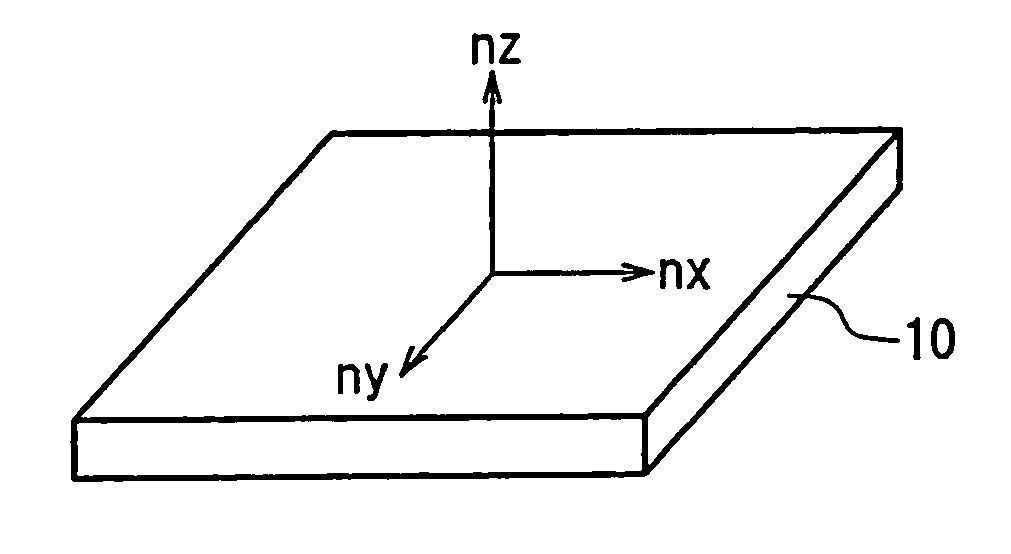

ActiveUS20130194211A1AdhesivenessImprove adhesionSynthetic resin layered productsPolarising elementsPolyesterRefractive index

Provided is an optical layered body that includes a polyester base, a primer layer formed thereon, and a hard coat layer formed on the primer. The polyester has a retardation of not less than 8000 nm, and a difference (nx−ny) of 0.07 to 0.20 between a refractive index (nx) in a slow axis direction that is a high refractive index direction and a refractive index (ny) of a fast axis direction that is orthogonal to the slow axis direction, a refractive index (np) of the primer, the refractive index (nx) in the slow axis direction of the polyester, and the refractive index (ny) in the fast axis direction of the polyester satisfy ny<np<nx, and a refractive index (nh) of the hard coat, the refractive index (nx) in the slow axis direction of the polyester, and the refractive index (ny) in the fast axis direction of the polyester satisfy ny<nh<nx.

Owner:DAI NIPPON PRINTING CO LTD

Shrink film, process for producing the same, printing ink, print produced therewith and process for producing print

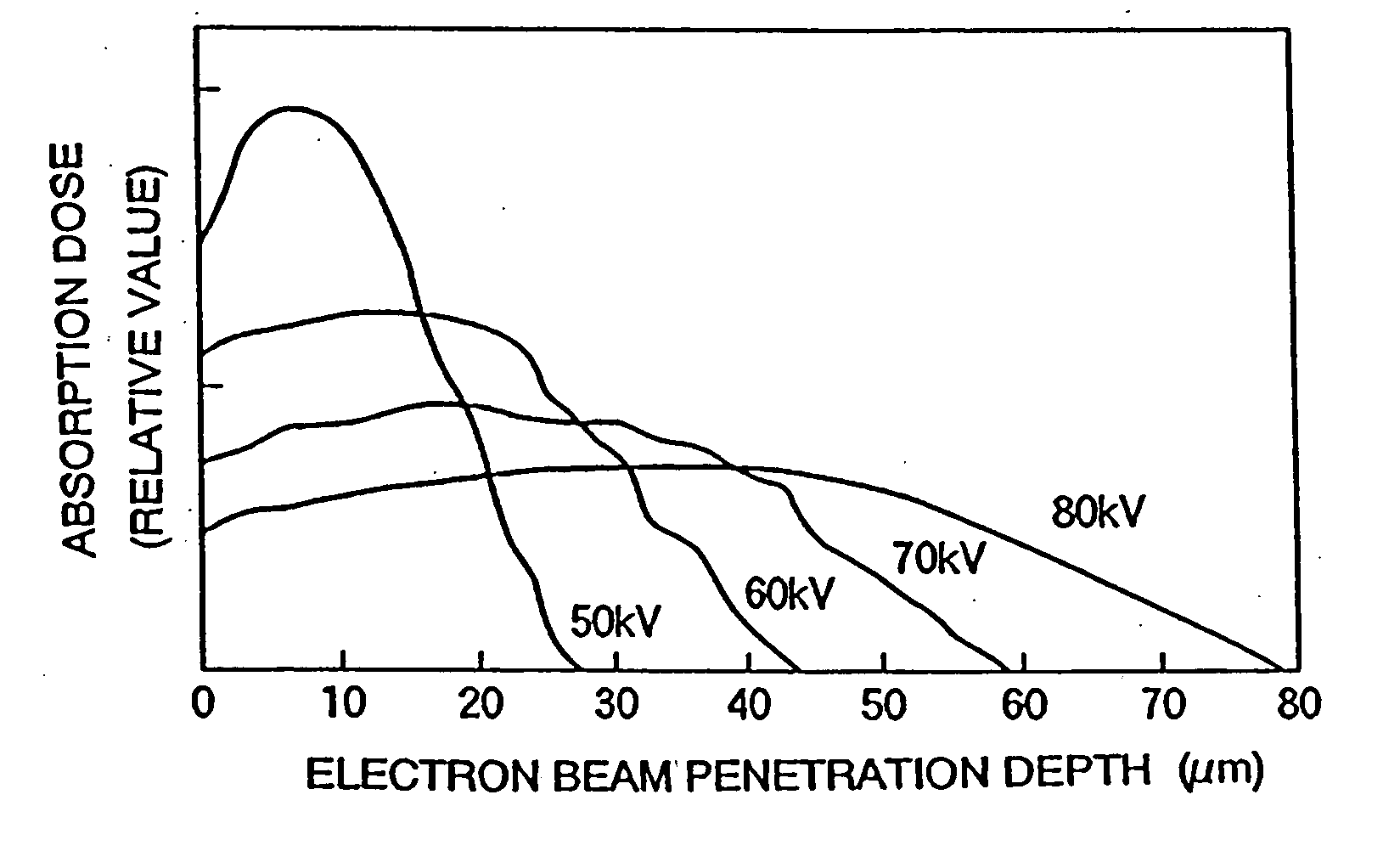

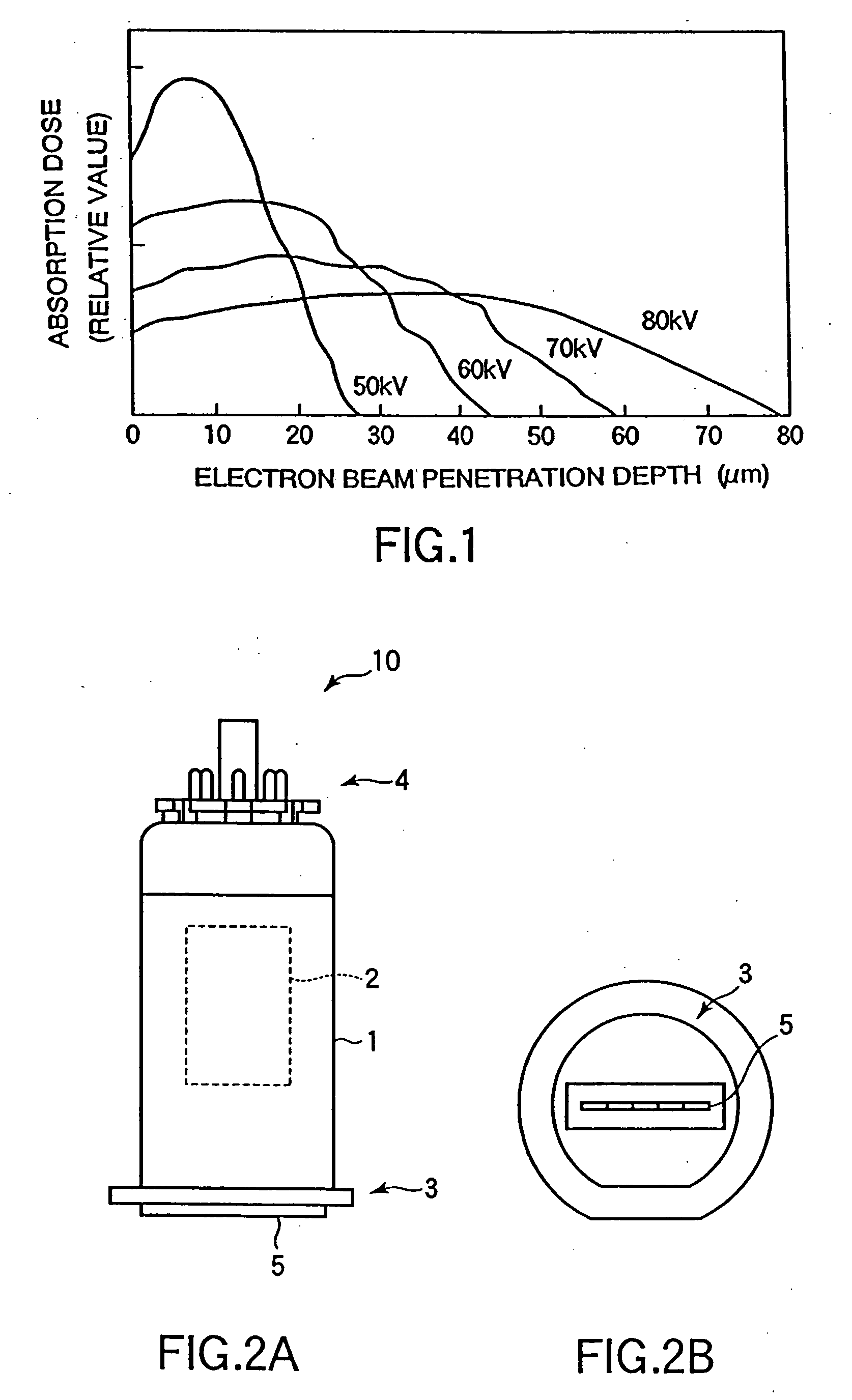

InactiveUS20050191439A1Short timeIncrease production capacityLayered productsDuplicating/marking methodsPrinting inkPlastic film

A coating material of an electron beam curable type is printed or coated onto a substrate of a heat shrinkable plastic film. Then, the coating material is cured by electron beam irradiation to form a coating layer. As a consequence, a shrinkable film including the substrate and the coating layer disposed thereon is obtained.

Owner:TOYO INK SC HOLD CO LTD +1

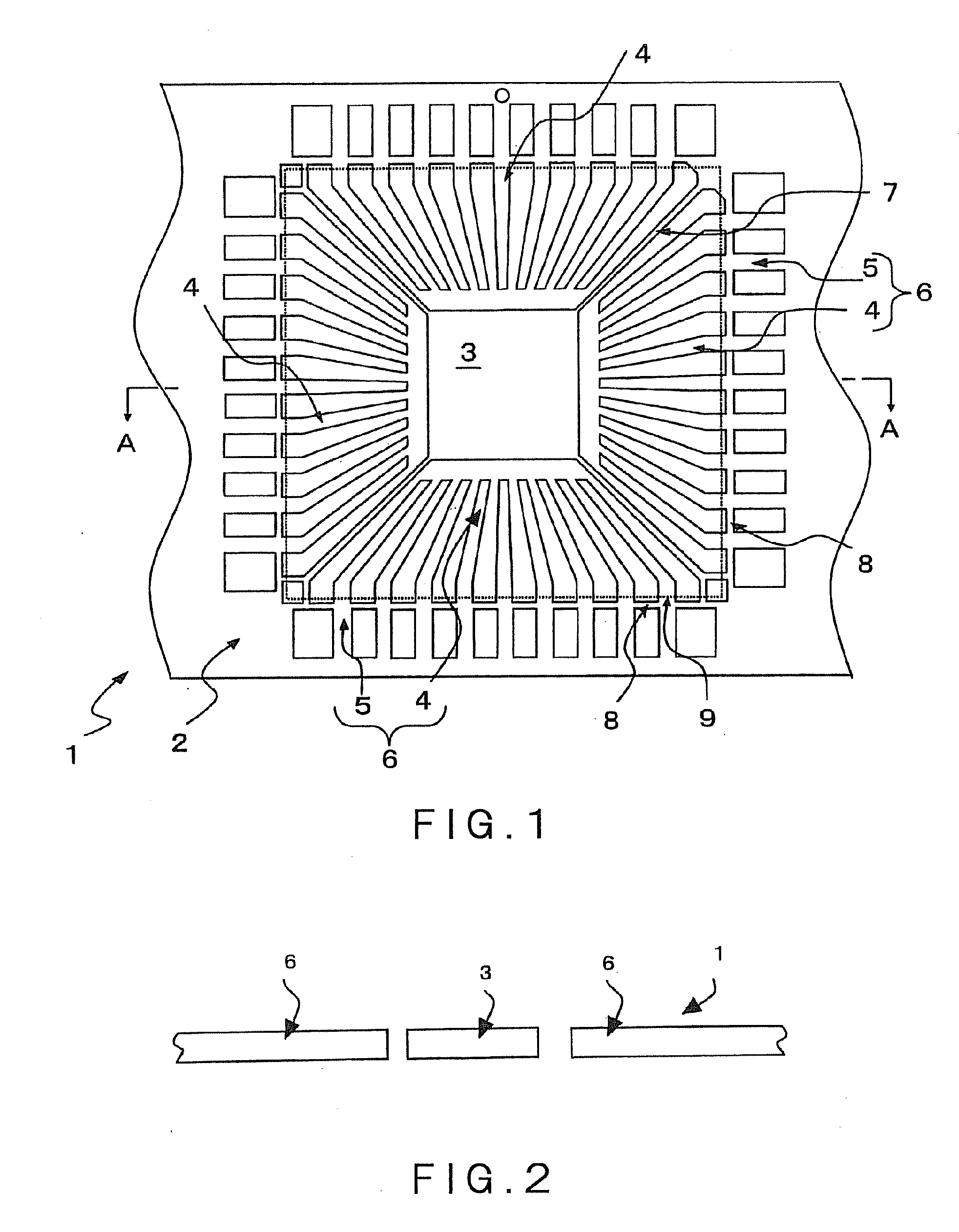

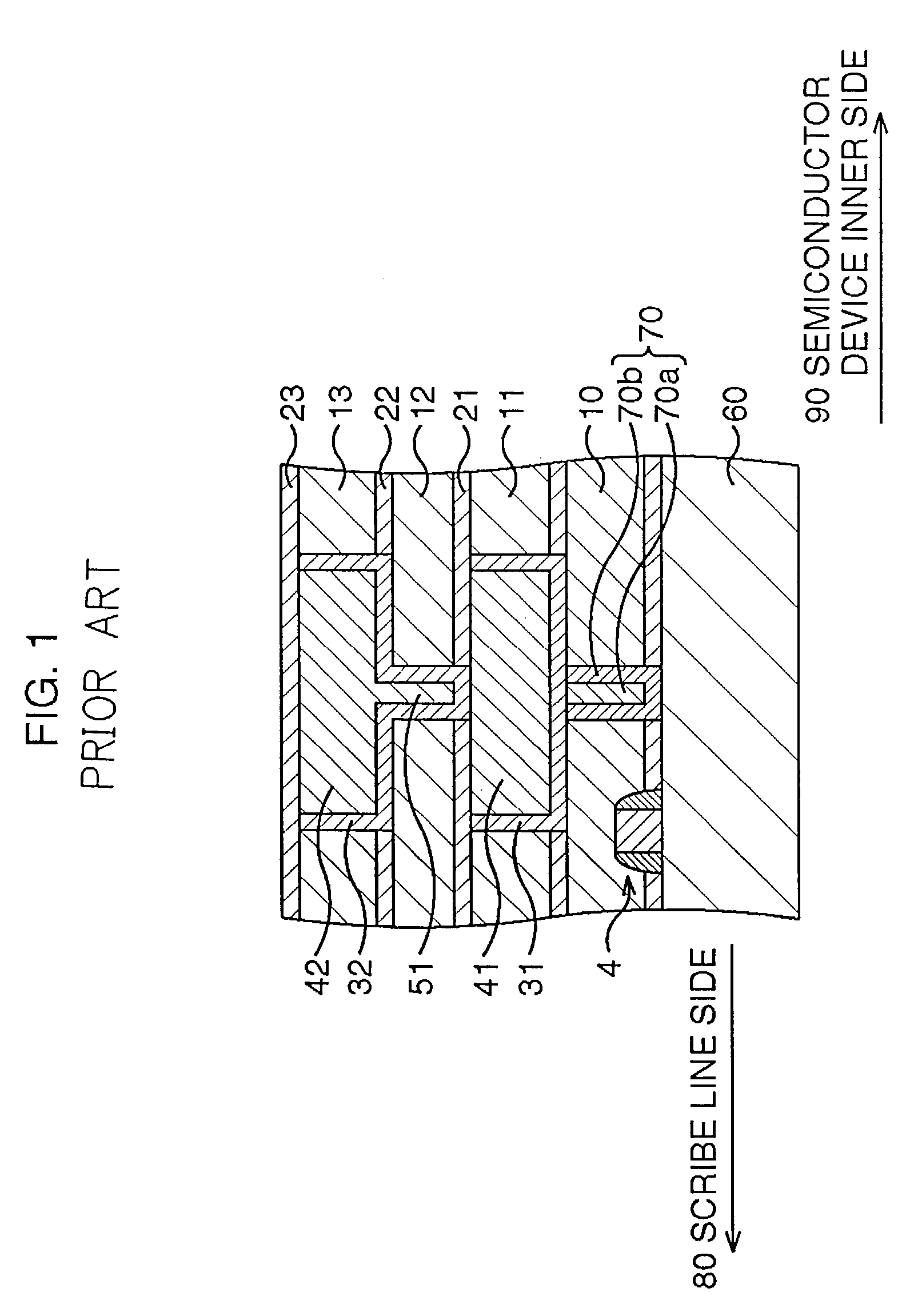

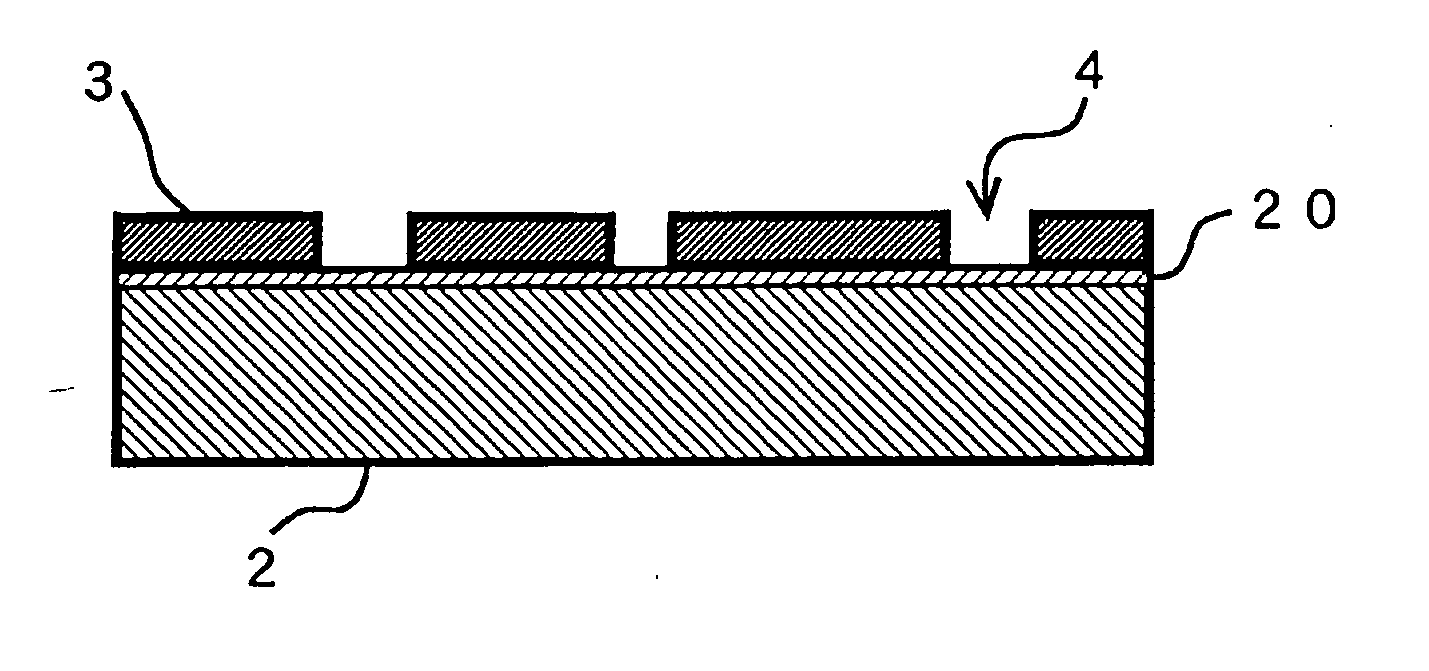

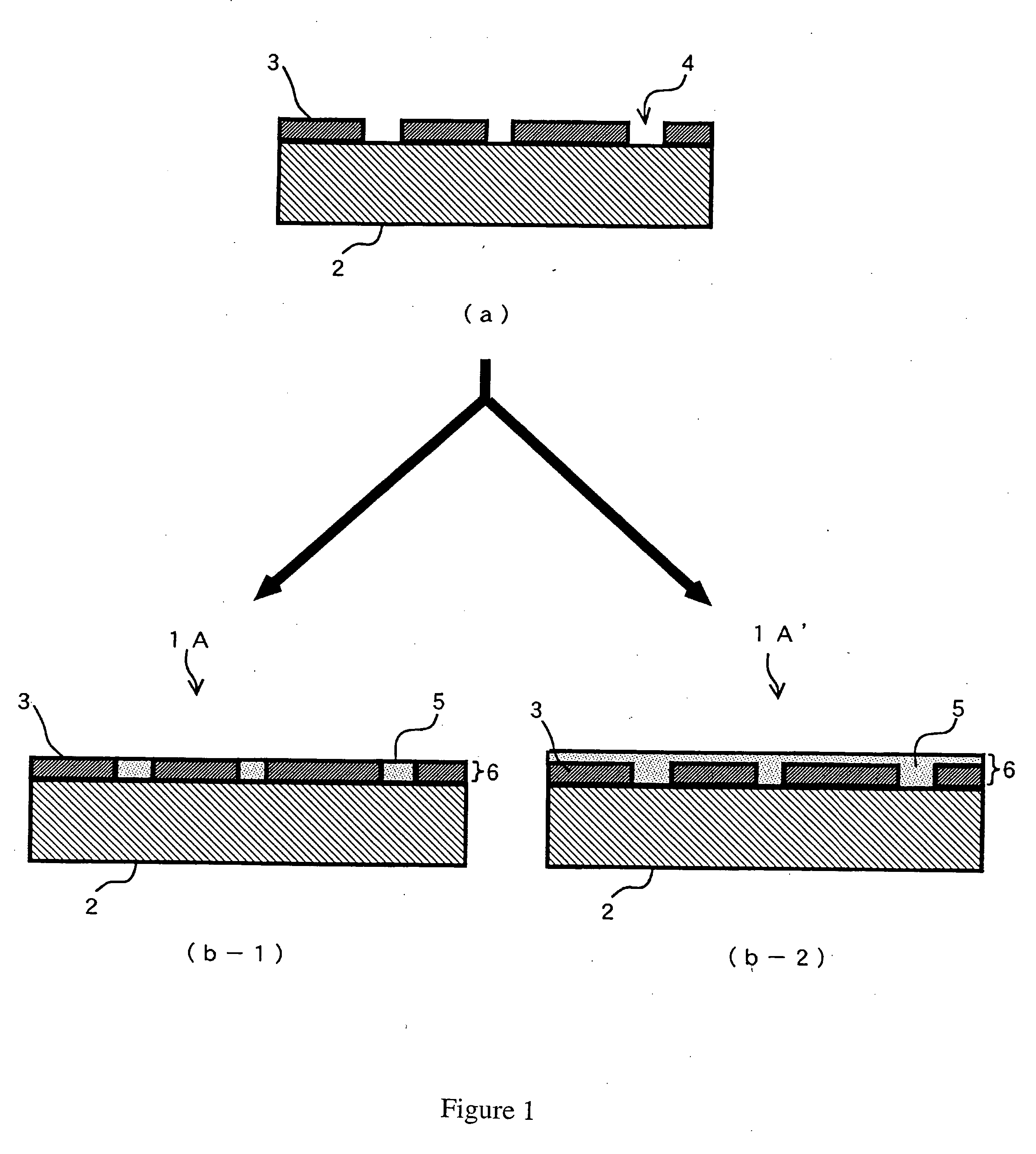

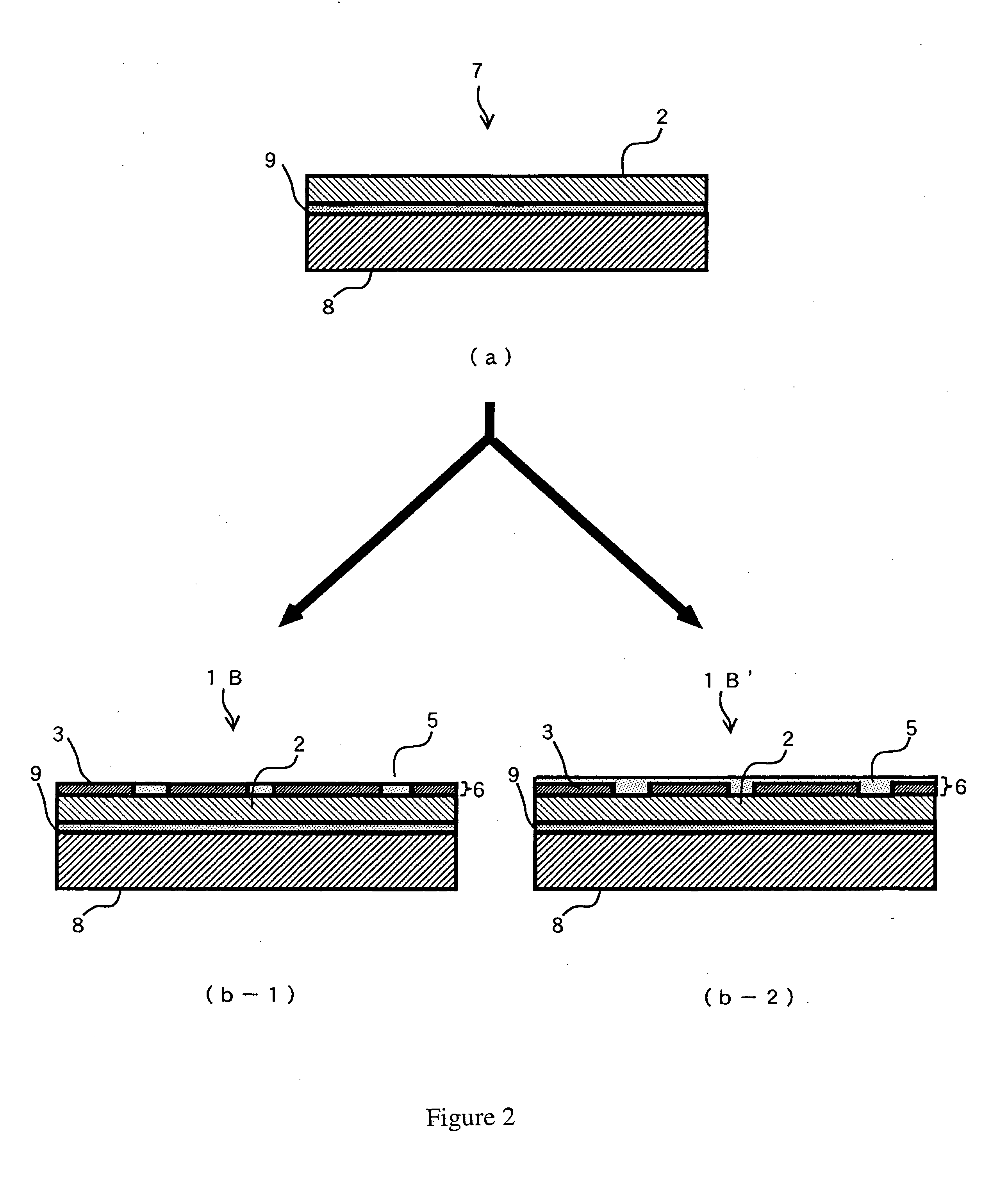

Circuit member, manufacturing method of the circuit member, and semiconductor device including the circuit member

InactiveUS20090146280A1Improve reliabilityImprove adhesionSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

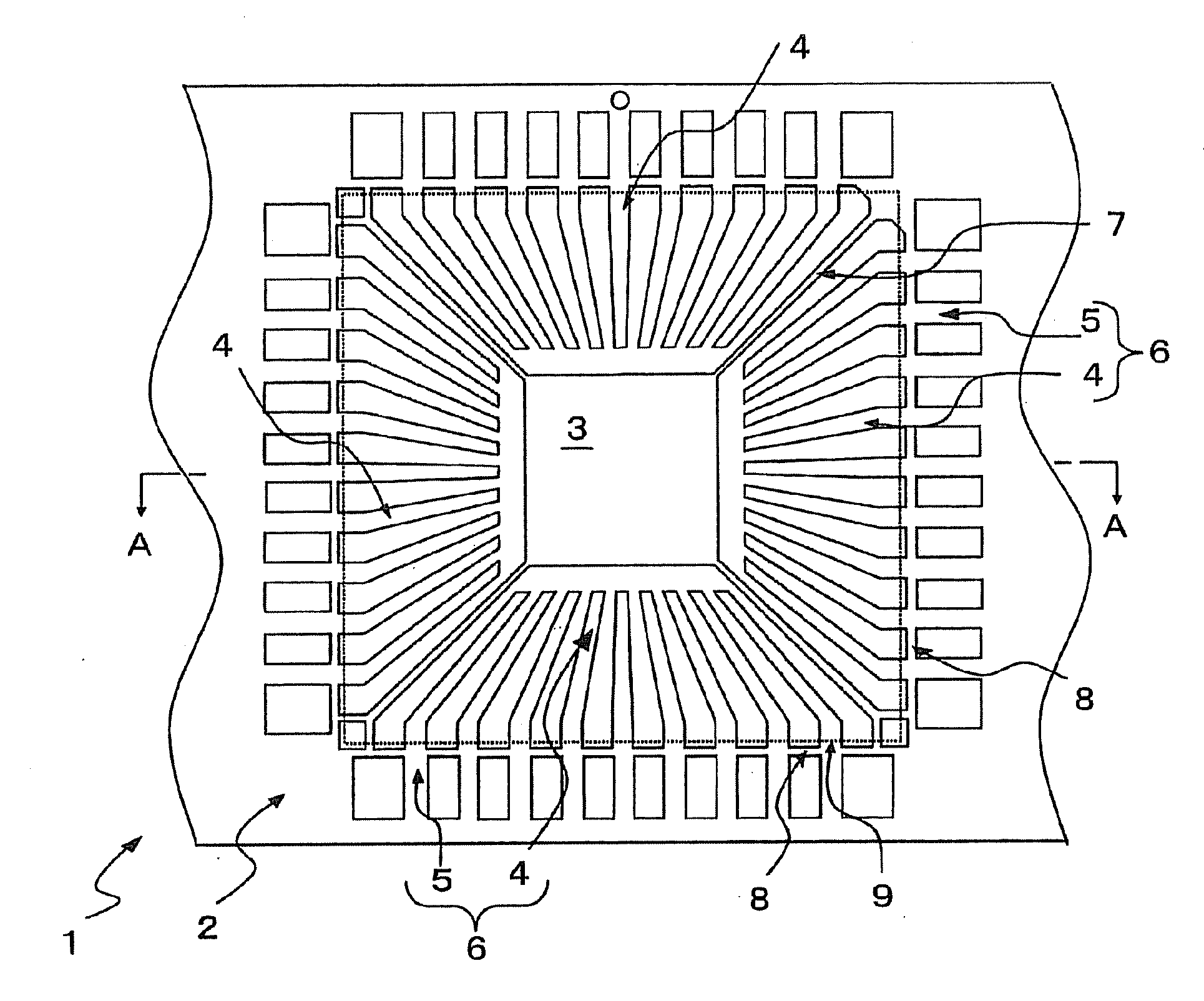

A circuit member 20 includes a lead frame material 1 having a die pad 3, a lead part 6 to be electrically connected with a semiconductor chip 30, and an outer frame 2 configured to support the die pad and the lead part. The lead frame material includes a resin sealing region 9. Roughened faces 10A to 10C and 11A to 11C, each having an average roughness Ra of 0.3 μm or greater, are formed on a surface in the resin sealing region of the lead frame material. The surface of the lead frame material except for the resin sealing region is a flat and smooth face. A two-layer plated layer 12A formed by laminating a Ni plated layer 13 and a Pd plated layer 14 in this order or a three-layer plated layer 12B formed by laminating the Ni plated layer 13, the Pd plated layer 14 and an Au plated layer 15 in this order is formed on the whole surface of the lead frame material.

Owner:DAI NIPPON PRINTING CO LTD

Temperature-resistant, corrosion-resistant and high-adhesion adhesive and preparation method thereof

ActiveCN102559120AImprove impact resistanceImprove heat resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesCelluloseThermoplastic

The invention discloses a temperature-resistant, corrosion-resistant and high-adhesion adhesive and a preparation method thereof, and belongs to the technical field of adhesives. The temperature-resistant, corrosion-resistant and high-adhesion adhesive consists of two components, i. e., an adhesive A and an adhesive B, in the weight ratio of 100:1-10, wherein the adhesive A consists of chemical plasticizing vinyl ester resin, a polymerization inhibitor, a low shrinkage agent, a free radical curing solvent, gas-phase silicon dioxide, inorganic filler, a coupling agent, a defoaming agent, color paste or paint, a promoter and a promotion additive; and the adhesive B consists of phthalic ester, peroxide and inertial powder filler. The adhesive provided by the invention has the performance of heat resistance, corrosion resistance, penetration resistance, adhesion, positioning, impact resistance and the like, can be formed into different types at normal temperature, and medium and high temperature, is easy and convenient to operate, can bring the unique advantage of the adhesive into full play on some occasions requiring to paying attention to corrosion resistance, adhesion, heat resistance and the like, and is suitable for mutual adhesion among a continuous cellulose material, a concrete material, a metal material, stone, FRP (Fiber Reinforce Plastic), thermoplastic plastic and the like.

Owner:浙江天和树脂有限公司 +1

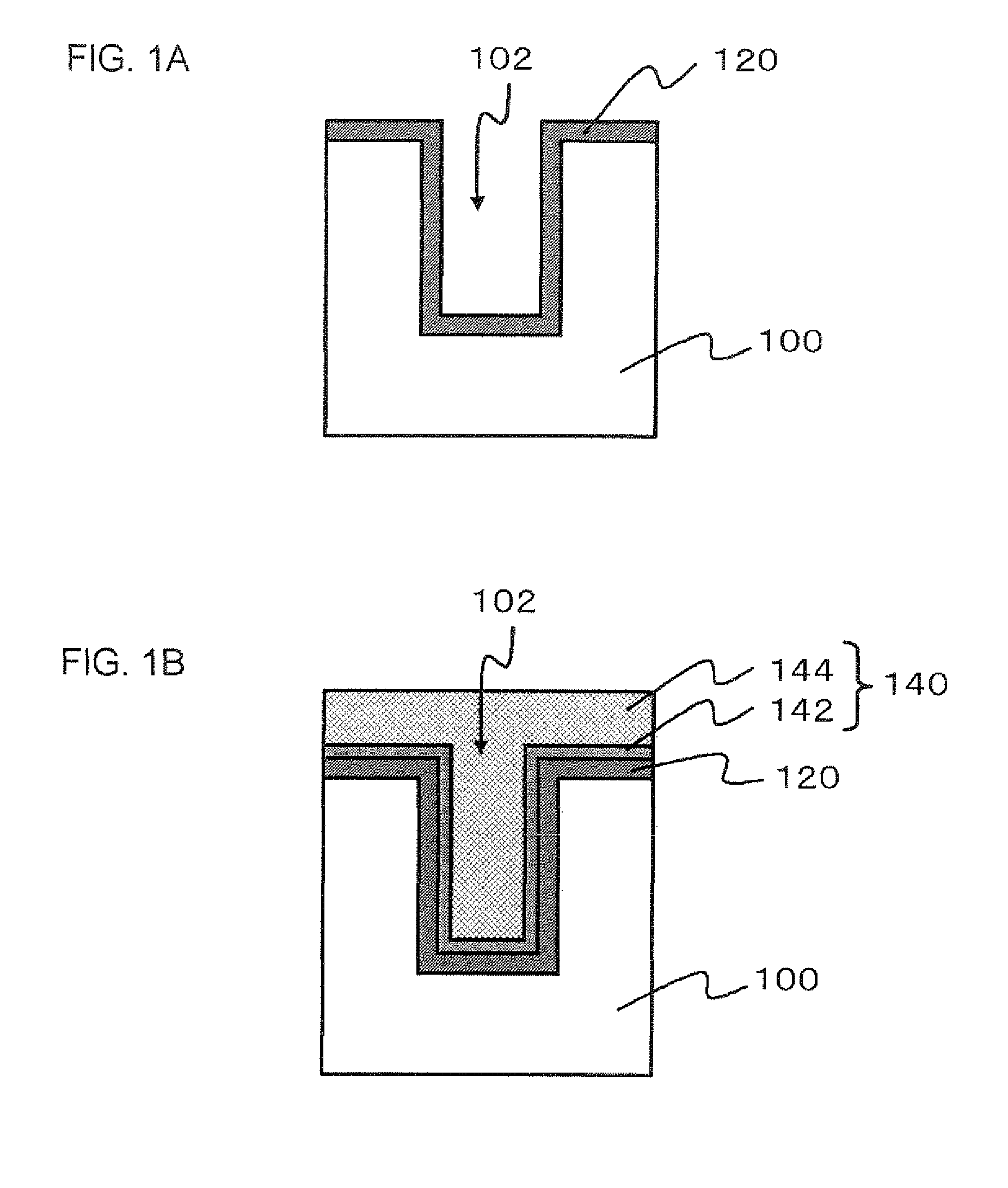

Semiconductor device and method of manufacturing the same

InactiveUS20100078820A1Improve metal resistanceAdhesivenessSemiconductor/solid-state device detailsSolid-state devicesAlloySemiconductor

A metal barrier film which contains an additive element is formed on the side face and on the bottom of a trench formed in an insulating film; a seed film is formed over the metal barrier film; a plated layer (Cu film) is formed using the seed film as a seed so as to fill up the trench with a metal film; the metal barrier film and the metal film are annealed to thereby form therebetween an alloy layer which contains a metal composing the metal barrier film, the additive element, and a metal composing the metal film, and to thereby allow the additive element to diffuse into the metal film.

Owner:RENESAS ELECTRONICS CORP

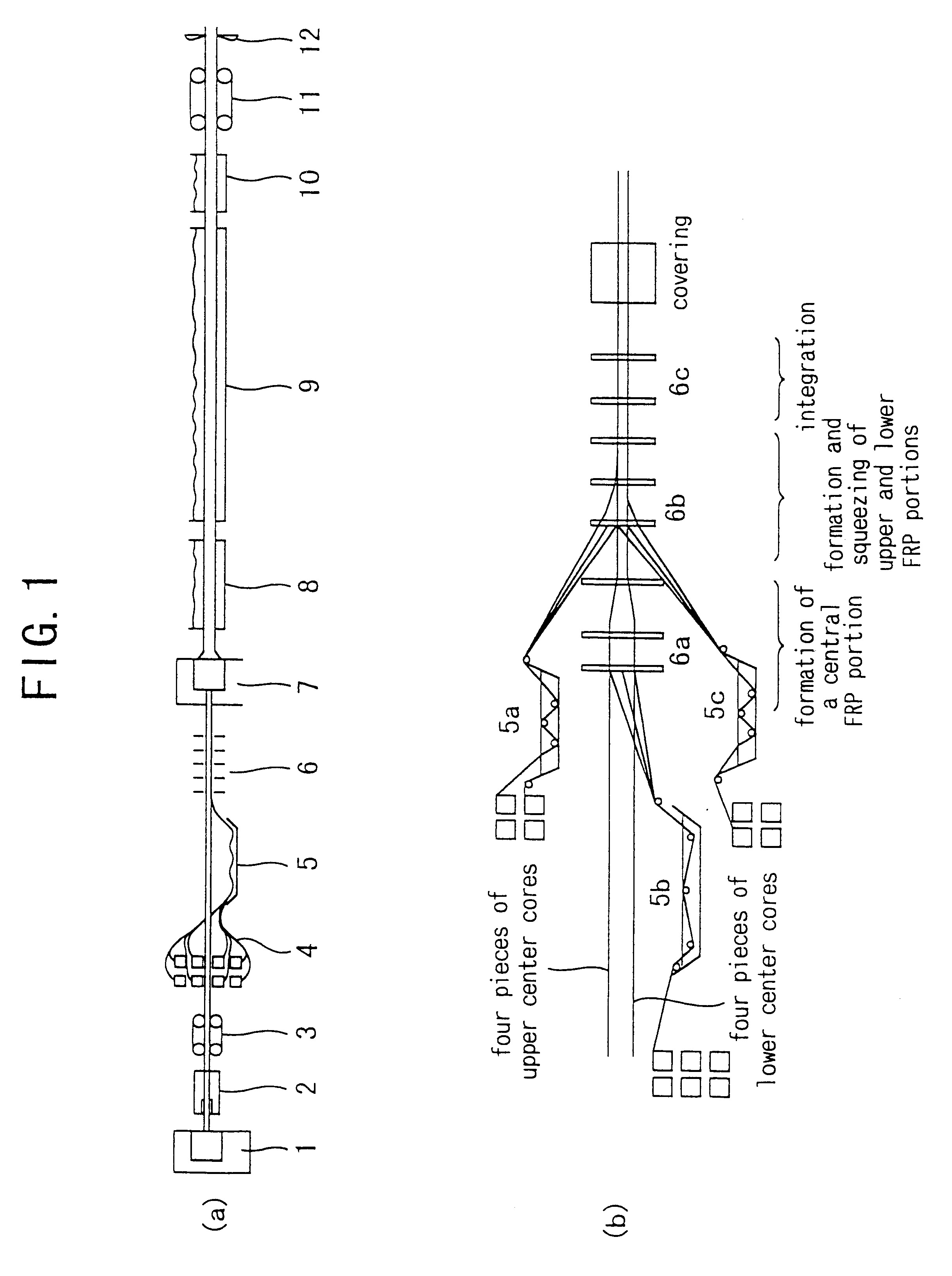

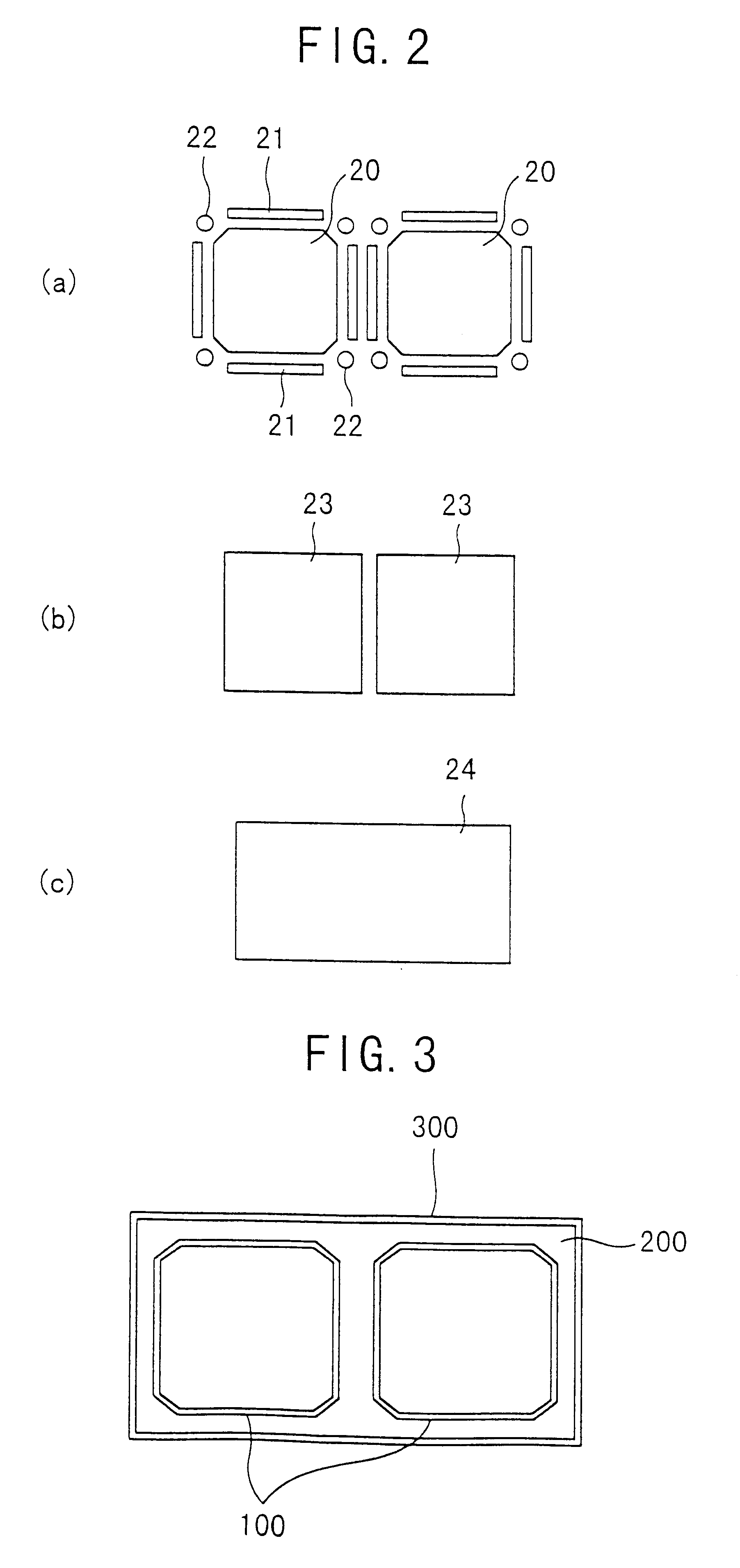

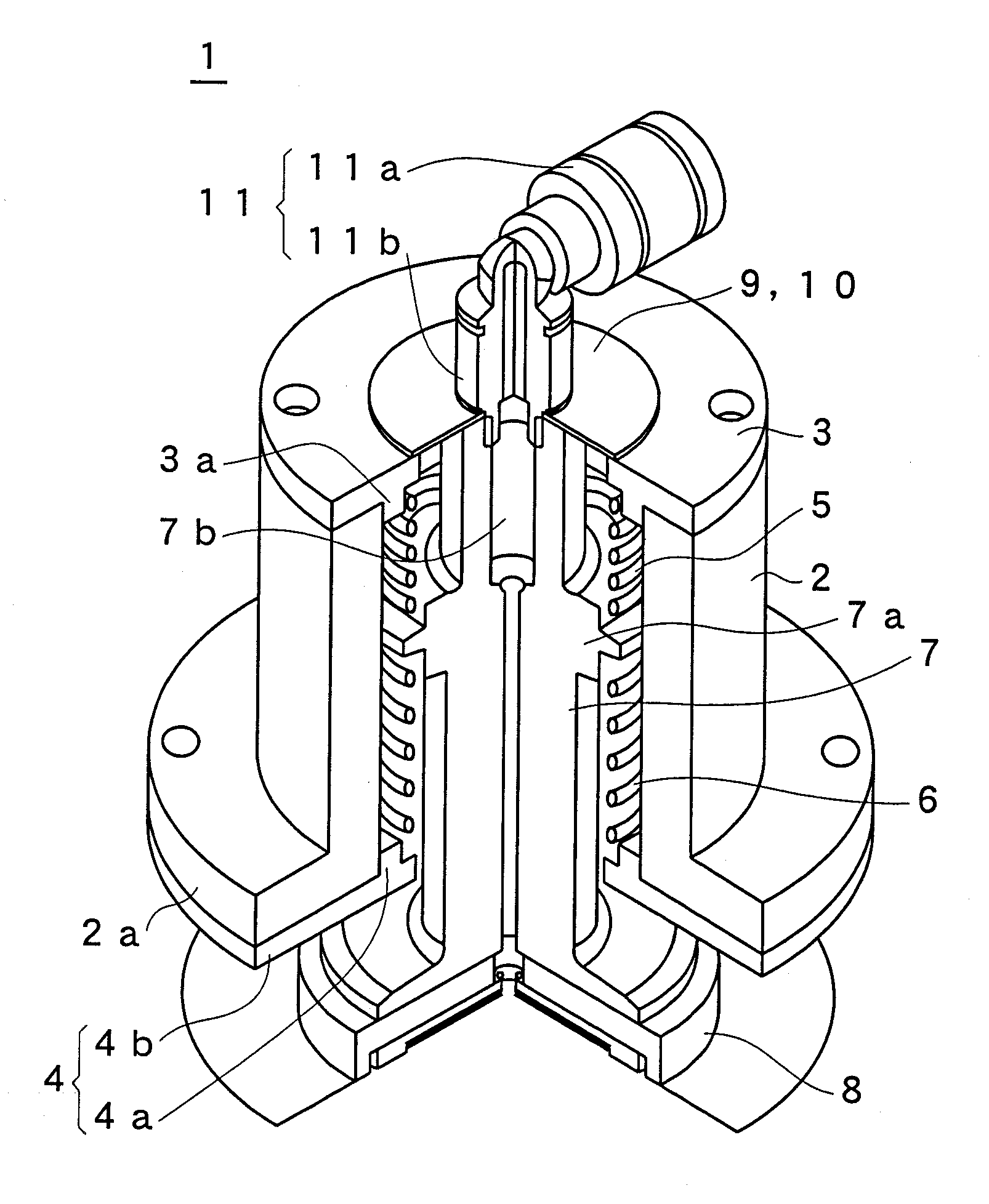

Fiber-reinforced composite hollow structure, method for production thereof, and apparatus therefor

InactiveUS6607798B1Prevent saggingUniform coverageEnvelopes/bags making machineryWrappers shrinkageEngineeringFiber-reinforced composite

Center cores are formed by extrusion-molding ABS resin. Seven pieces of the center cores, which are juxtaposed to each other in the horizontal direction, are supplied by a pultruder, and reinforcing long-fibers impregnated with an unsaturated polyester resin are allowed to pass through dispersion guides and squeezing nozzles, to thus squeezing-mold a fiber-reinforced composite hollow structure having FRP made legs. A final squeezing nozzle is disposed in a cross head die through a cooling jacket, and the hollow structure thus molded is allowed to pass therethrough to be covered with the ABS resin in a state in which the outer periphery of the hollow structure is heated. The hollow structure thus covered is subjected to cooled-sizing through a plurality of horizontal and vertical pairs of rollers, and then cured in a hot curing tank. The surface covered with the ABS resin is subjected to a surface-treatment of imparting irregularities for giving an antislipping function to the surface. A thermoplastic resin-made protective cap is fitted to an end of the center core. The apparatus for manufacturing a composite hollow structure has a plurality of pairs of rotatable and heat-resisting sizing rollers. The plurality of pairs of the sizing rollers are disposed in the pultruding direction while being gradually cooled in the order from those positioned on the upstream side to those positioned on the downstream side for sizing the softened outer layer covering the outer periphery of the intermediate layer.

Owner:UBE NITTO KASEI CO LTD

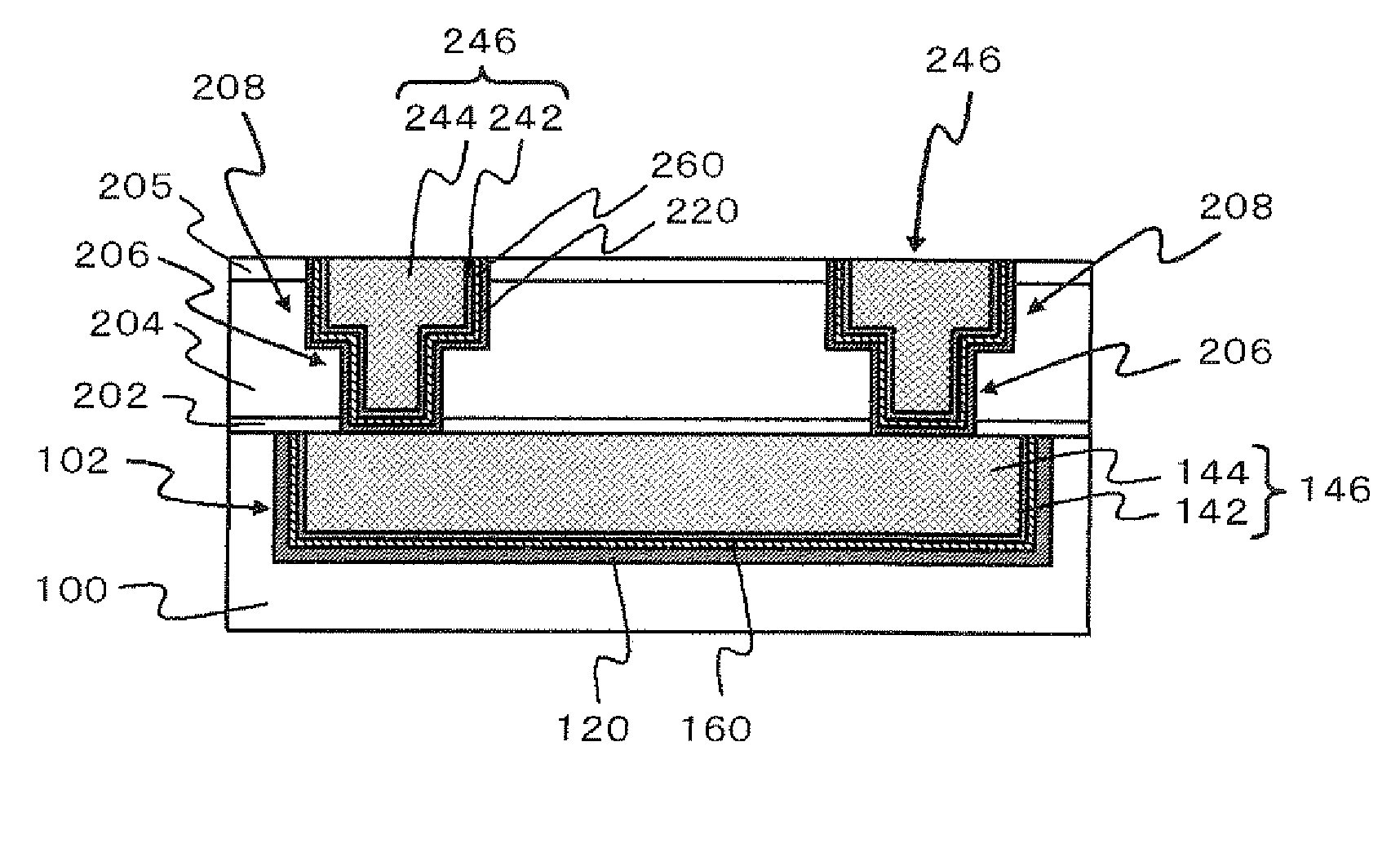

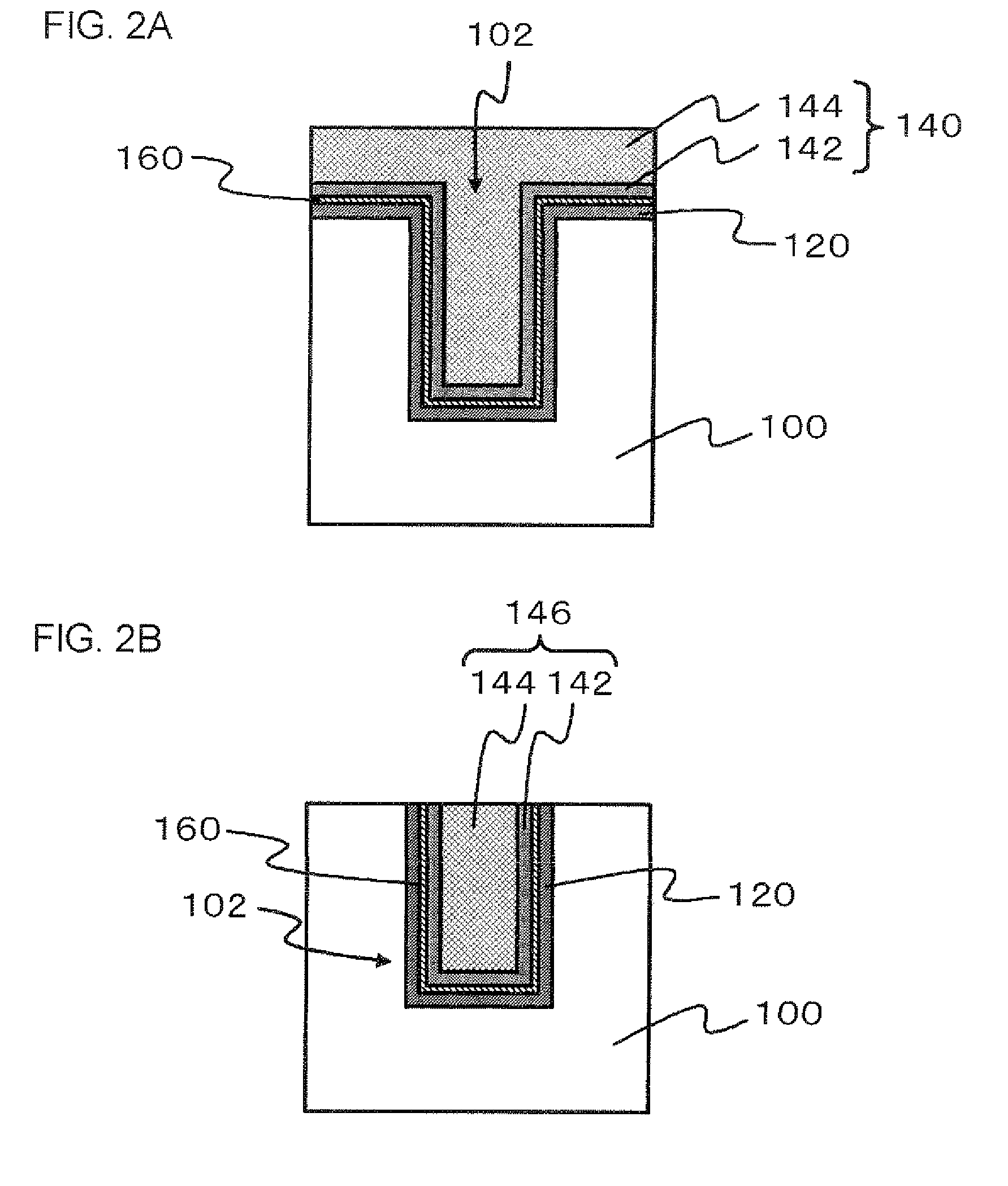

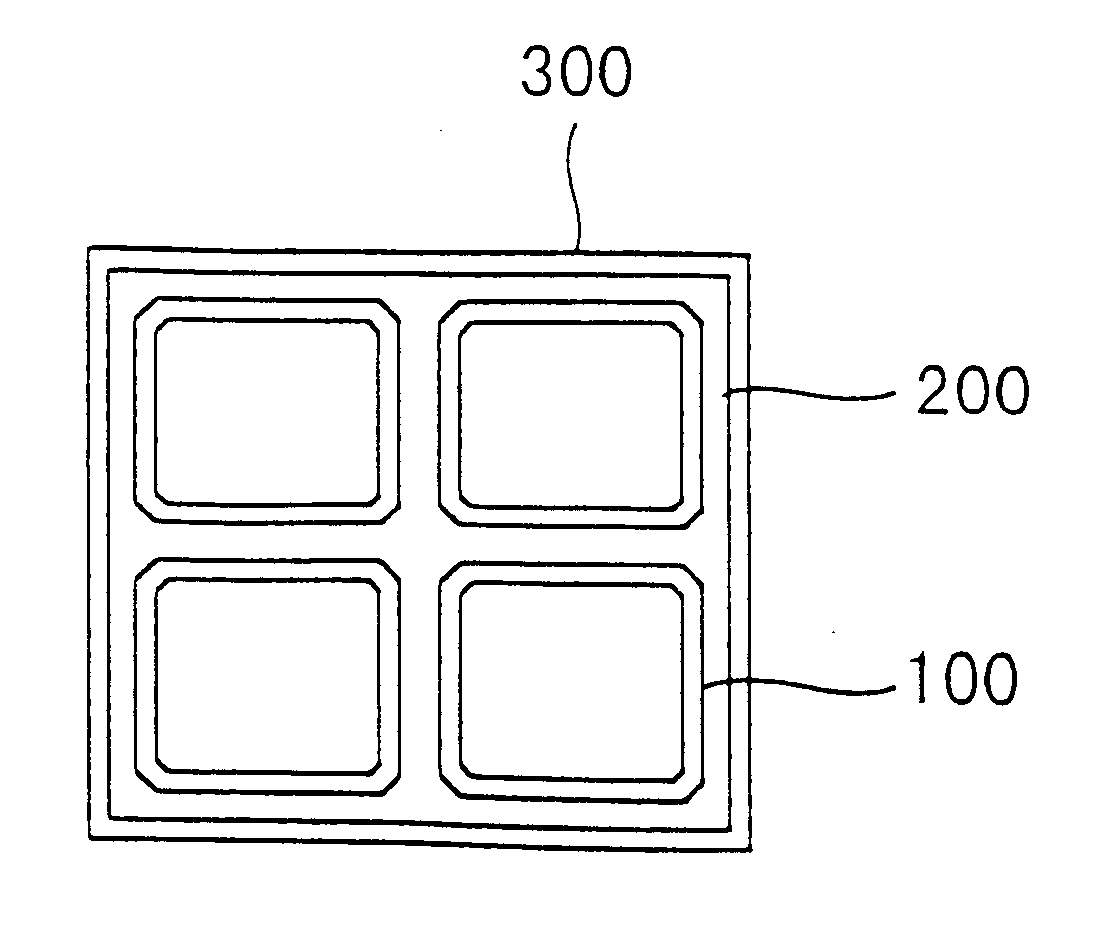

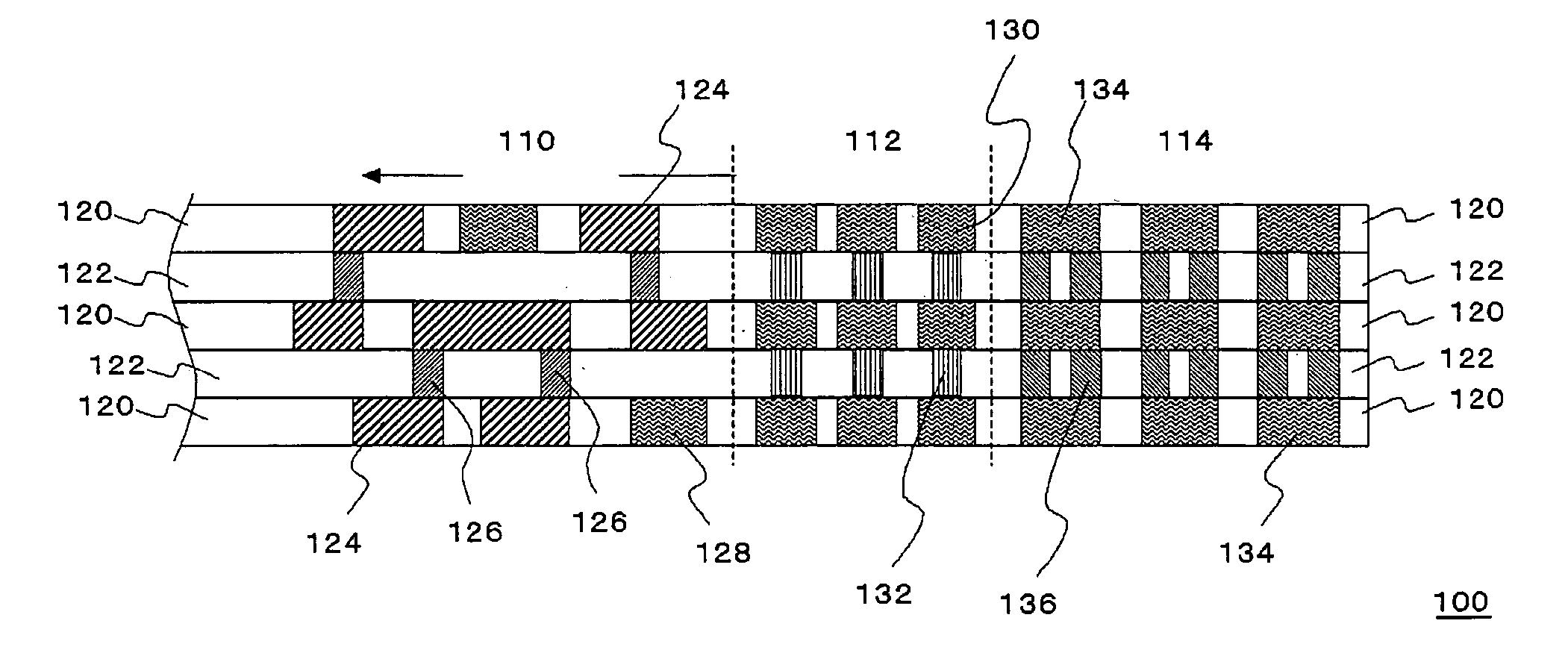

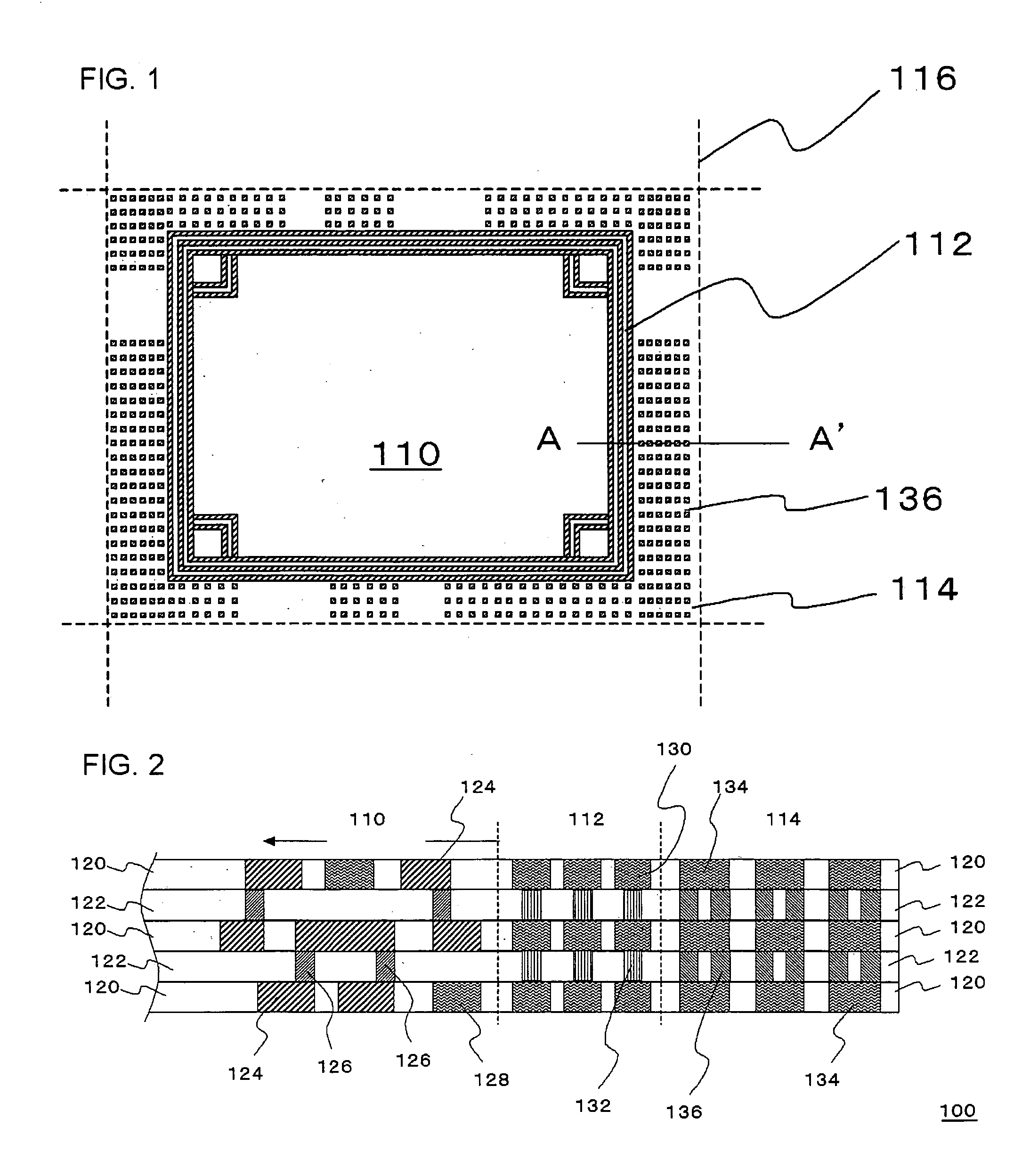

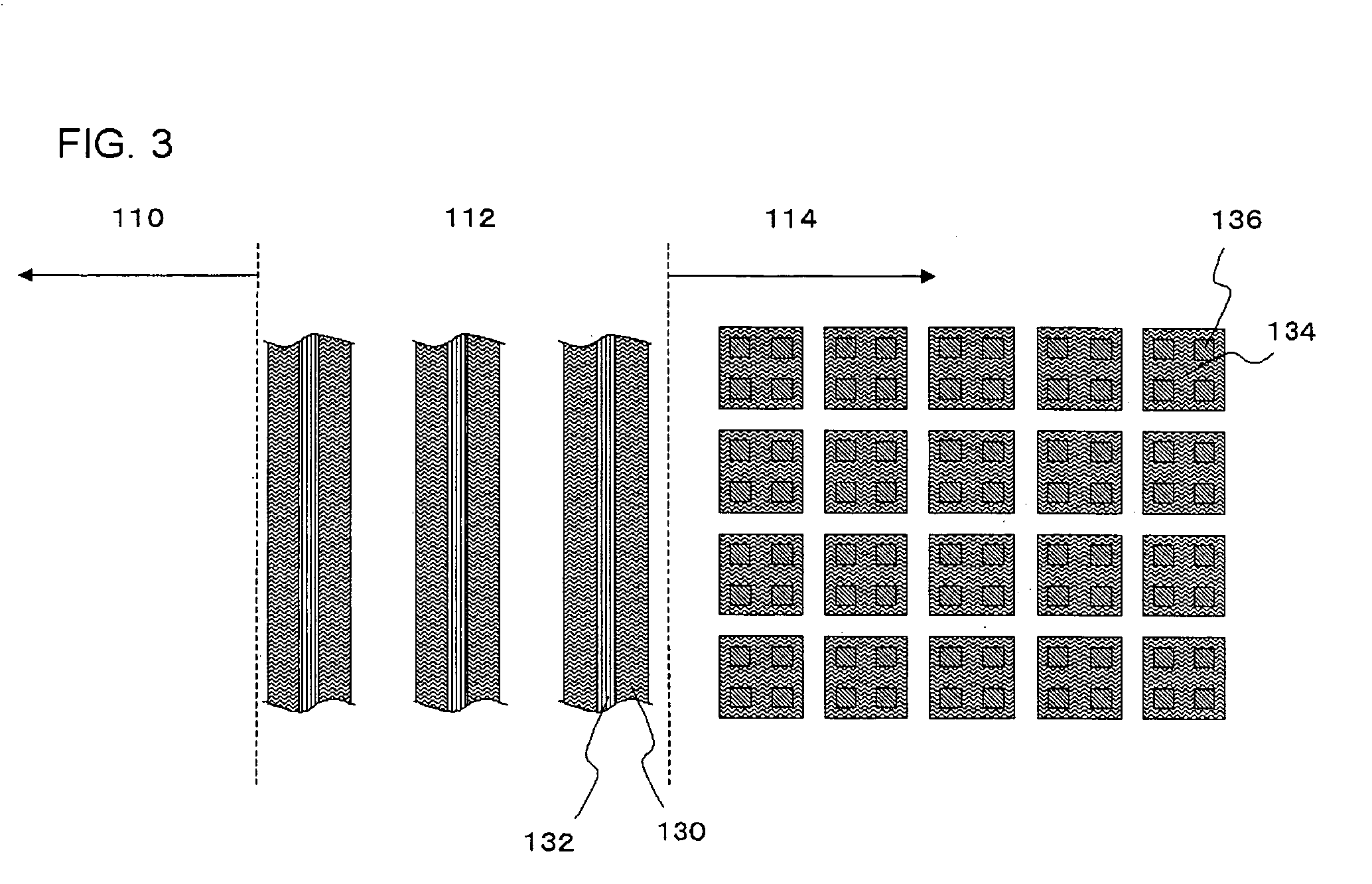

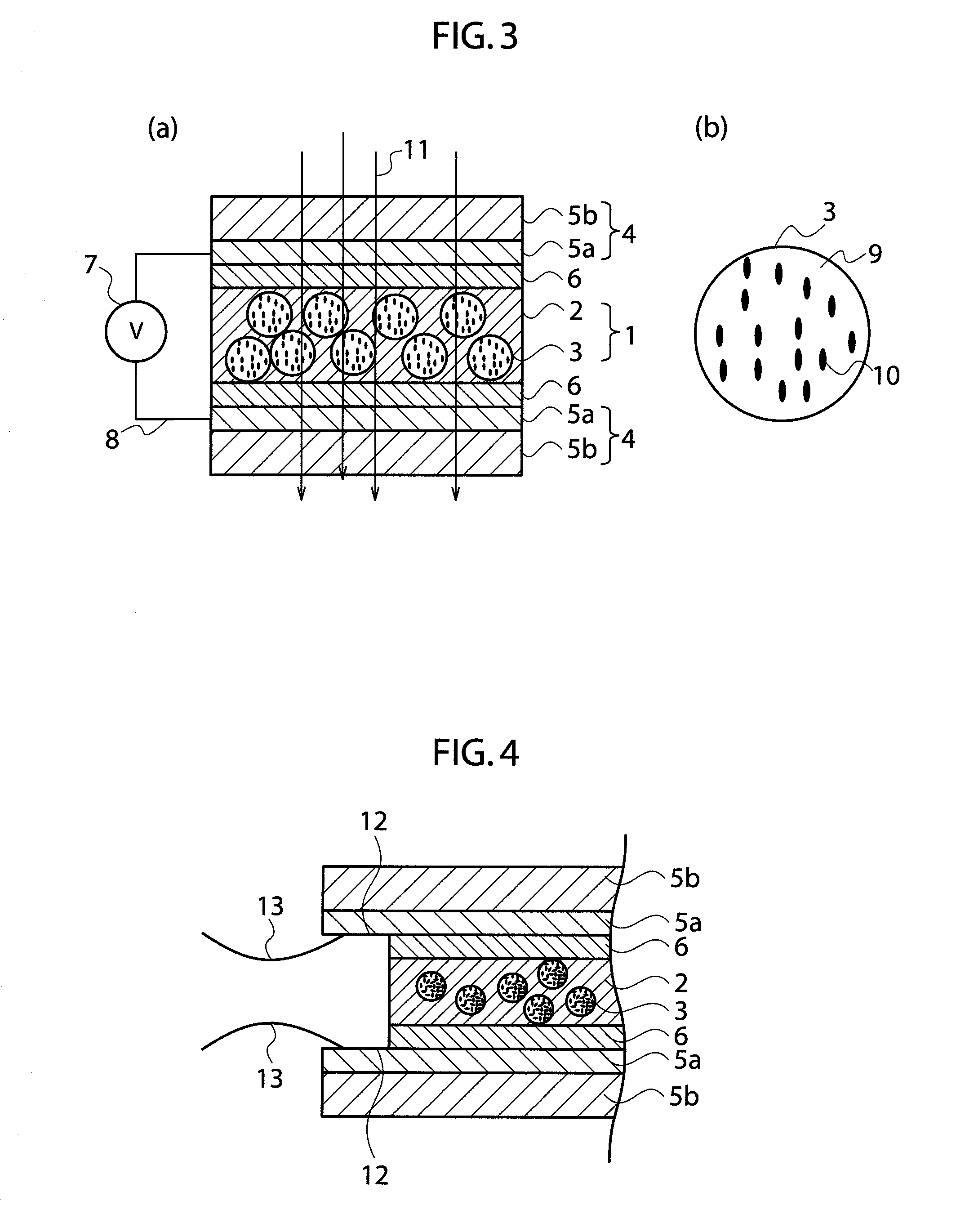

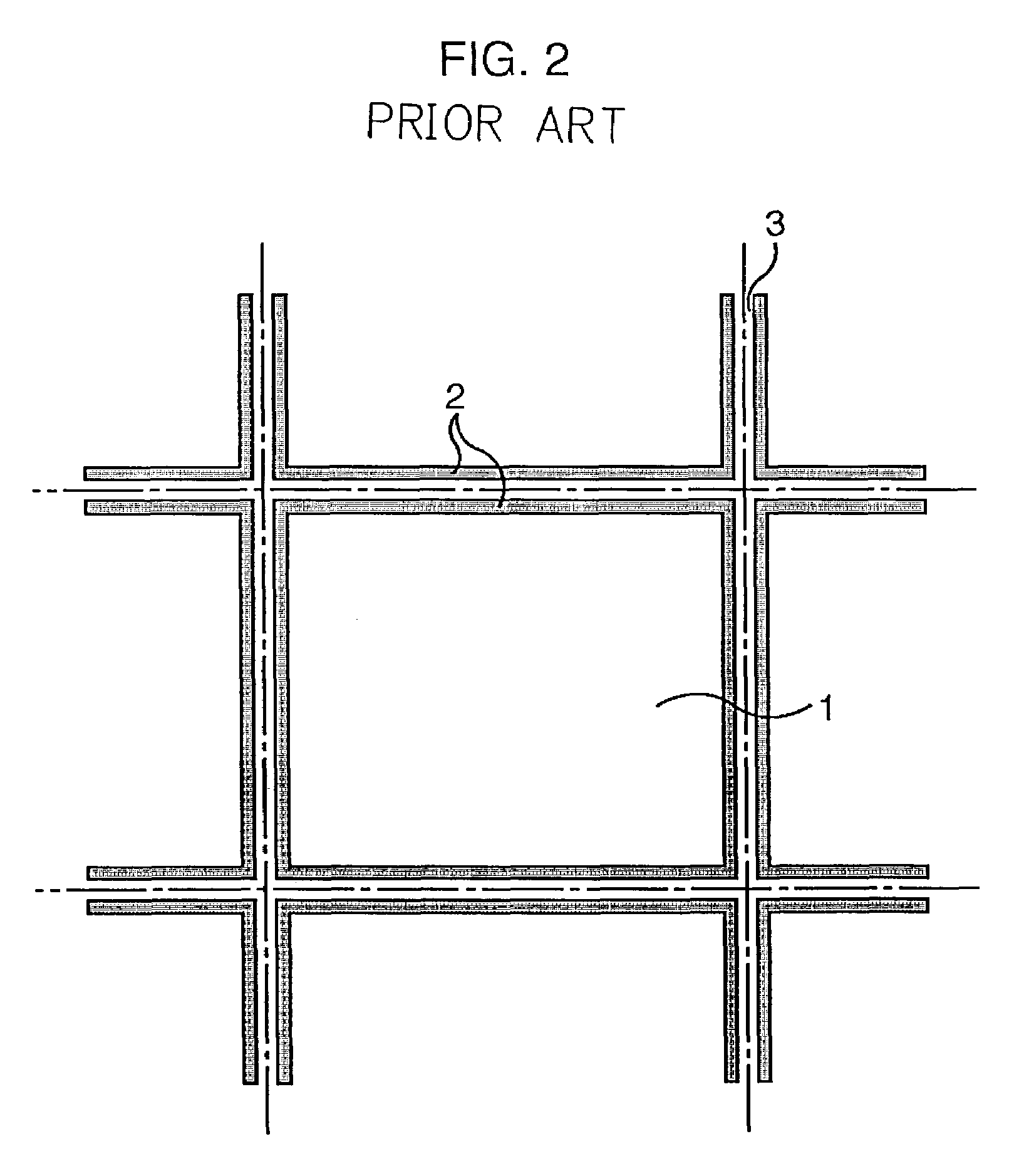

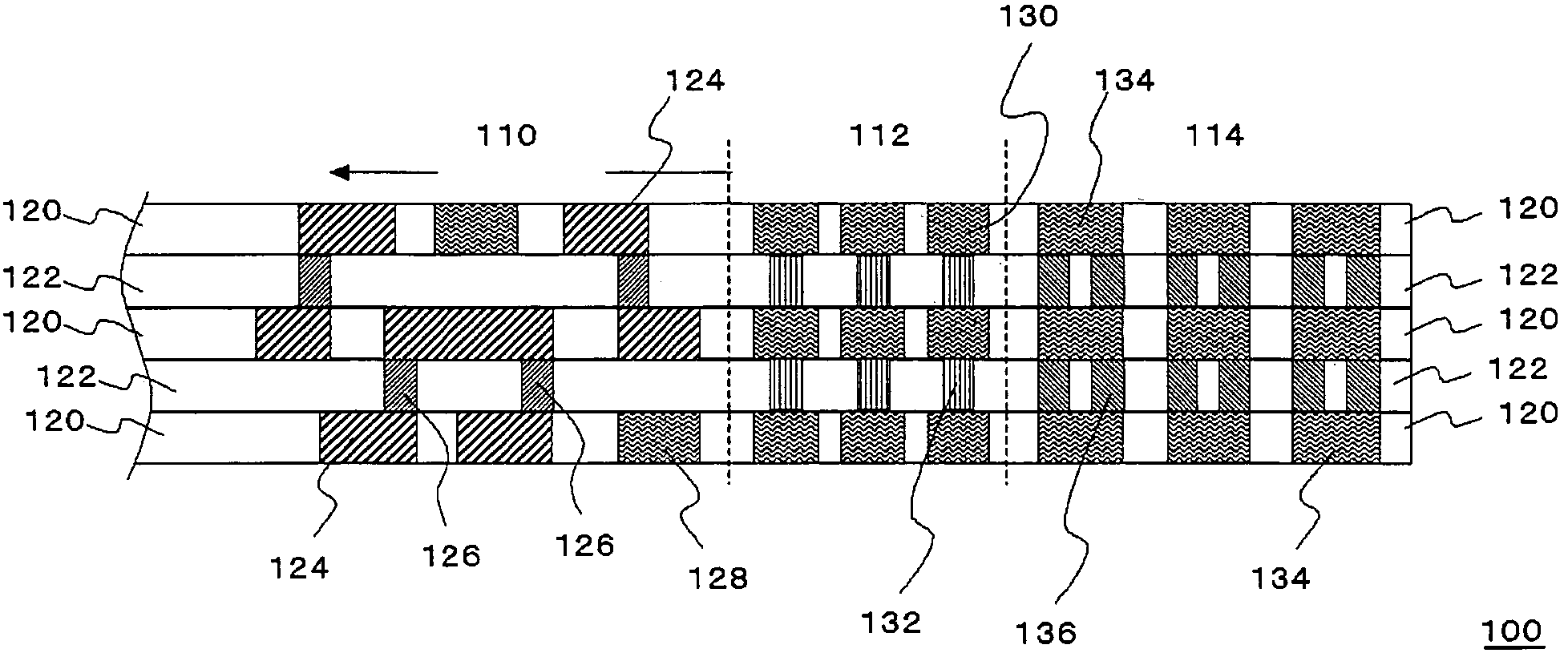

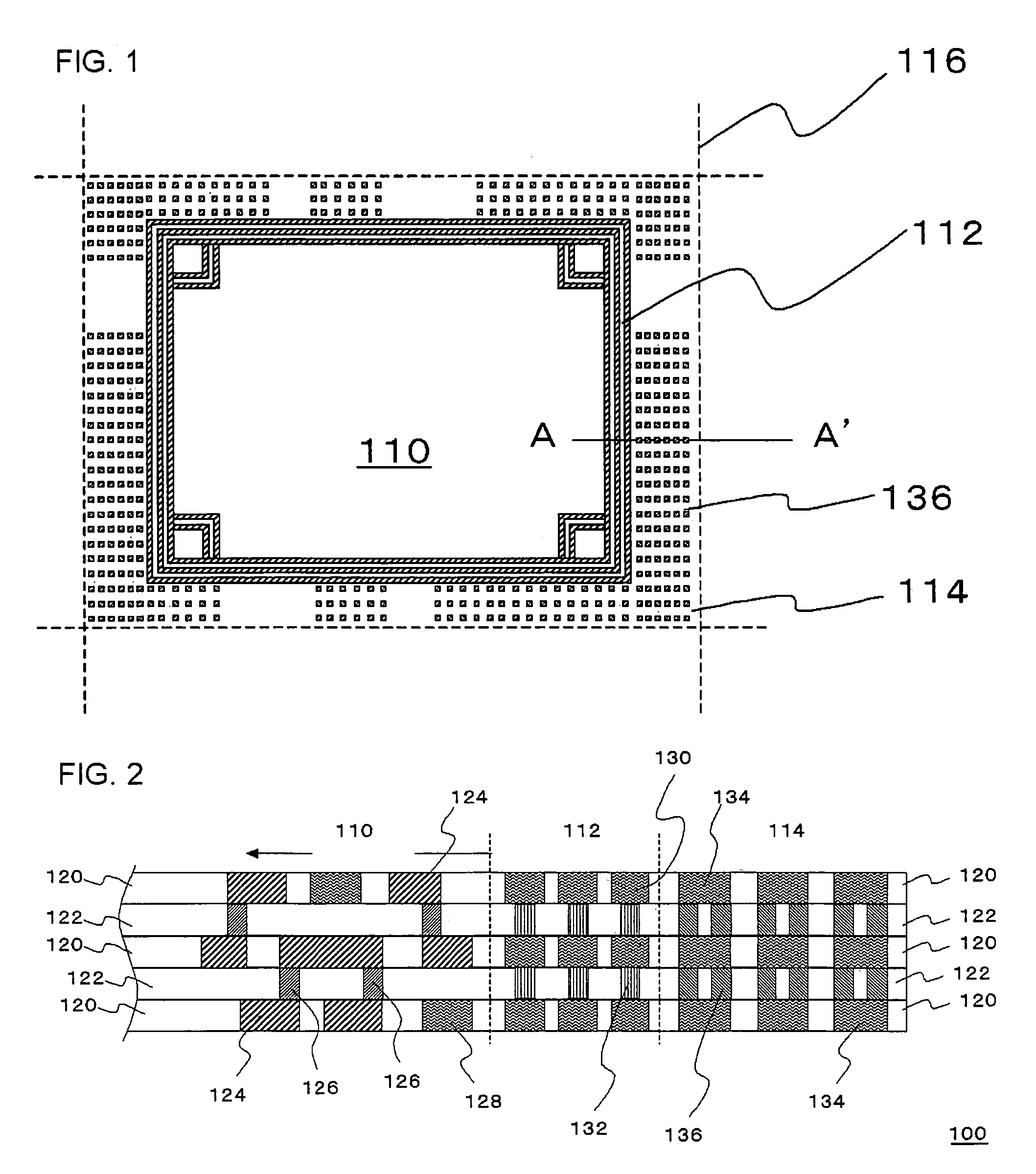

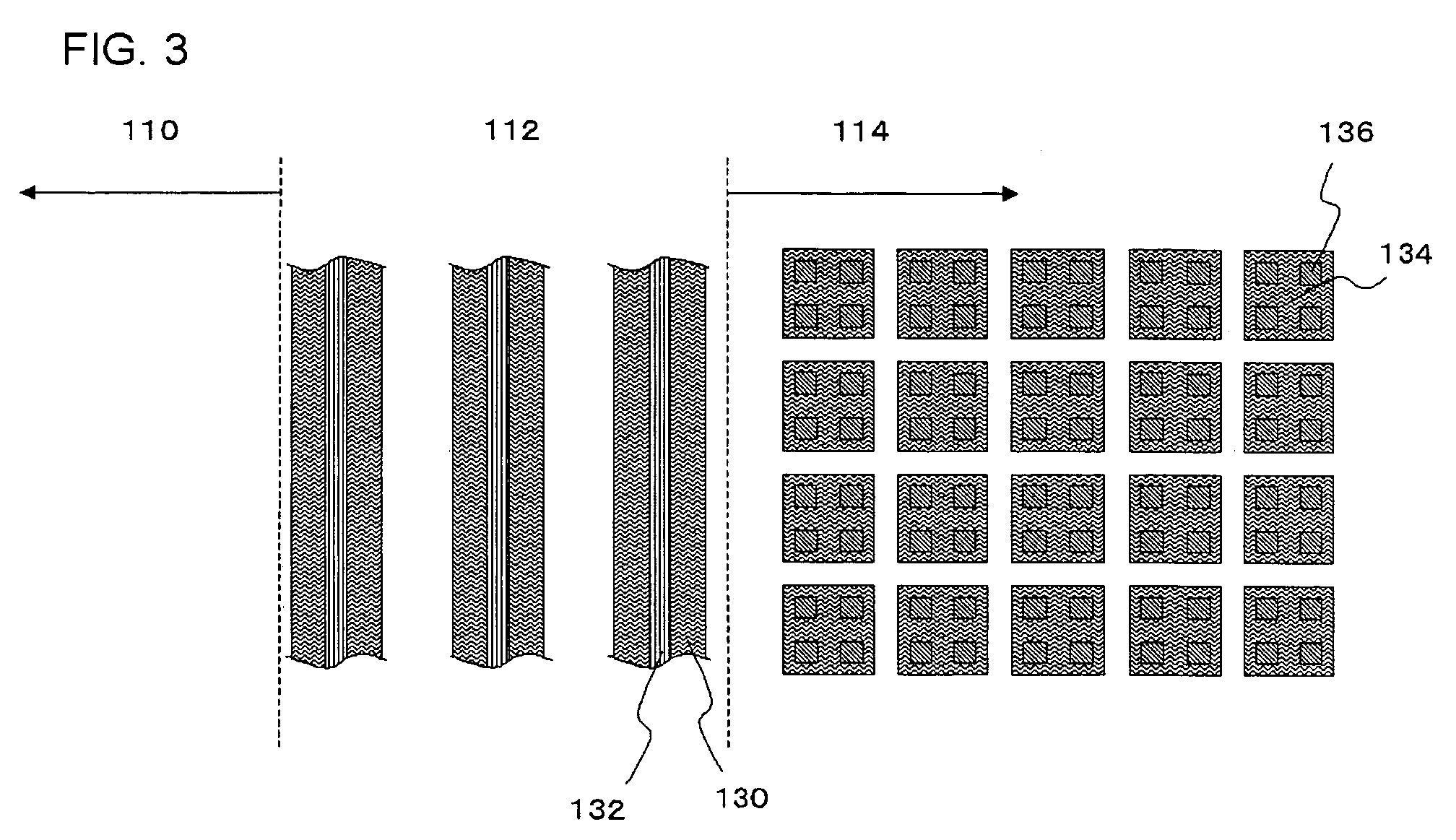

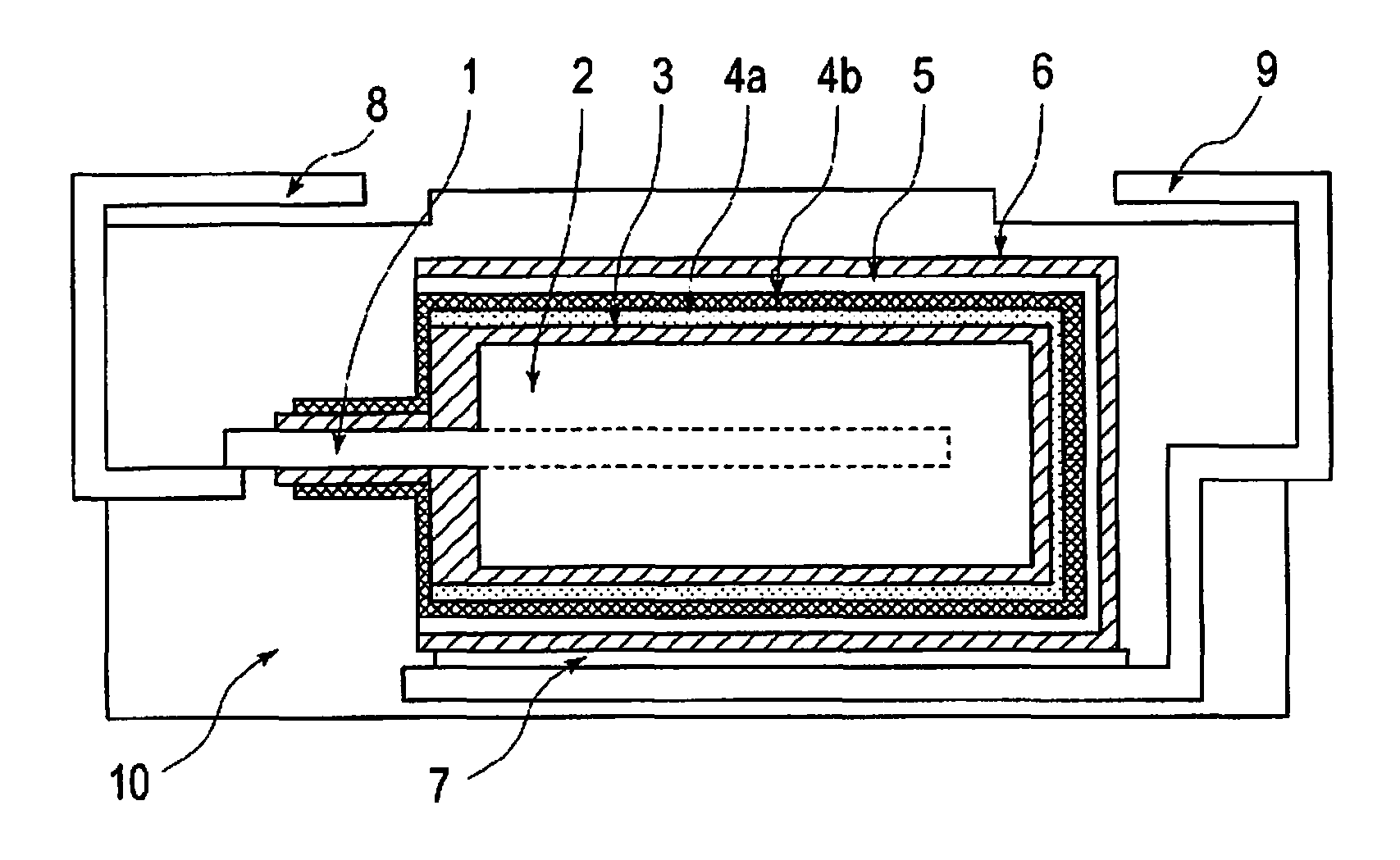

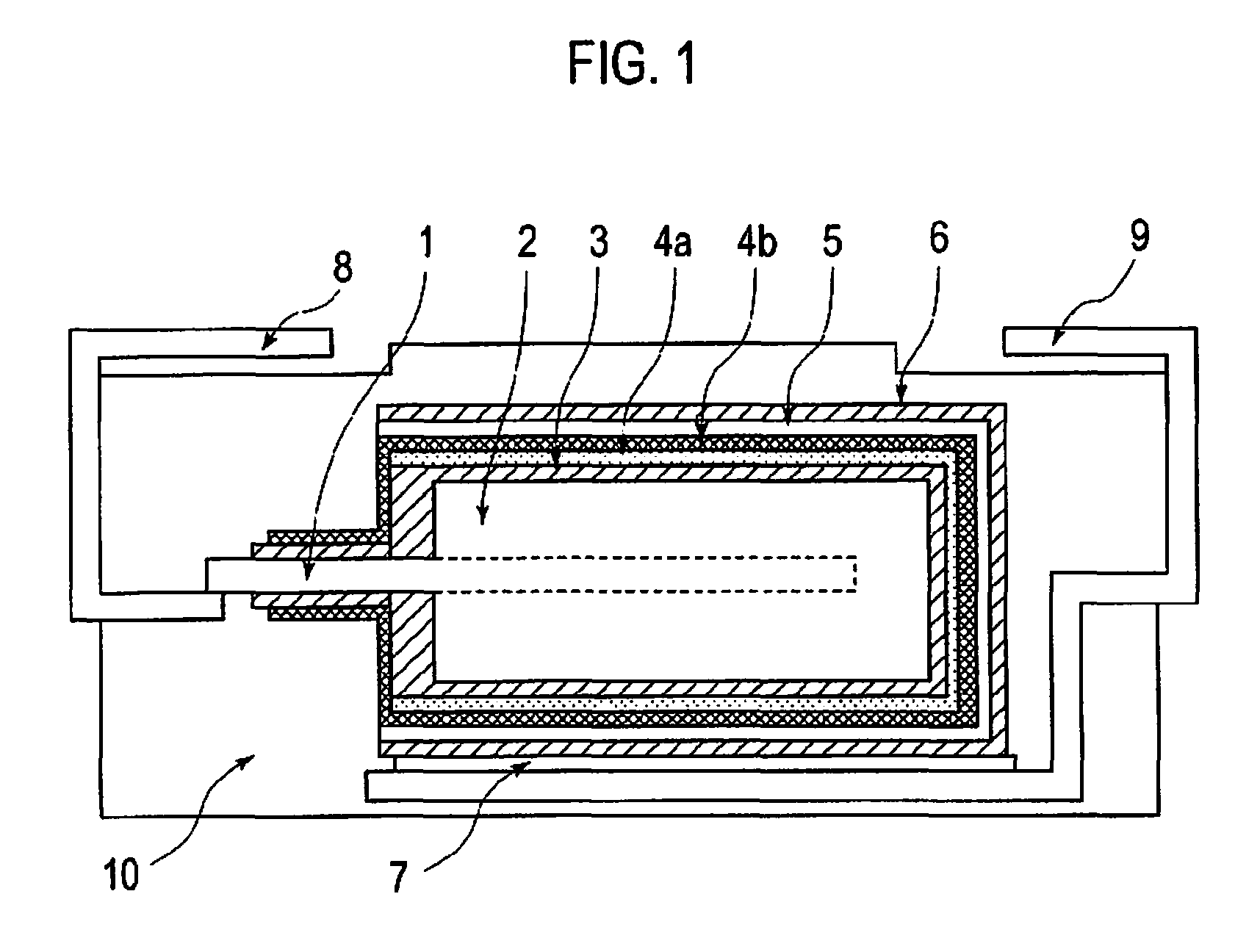

Semiconductor device

ActiveUS20060022224A1Improve adhesionSpeed up the processSemiconductor/solid-state device detailsSolid-state devicesDielectricInter layer

The semiconductor device 100 includes a multilayer wiring structure formed on the semiconductor substrate. The multilayer wiring structure includes at least a first inter layer dielectric film 120 in which interconnects 124 are formed, and at least a second inter layer dielectric film 122 in which vias 126 are formed. The multilayer wiring structure includes a circuit region 110 in which the interconnects 124 and the vias 126 are formed, a seal ring region 112 formed around the circuit region 110 and in which seal rings surrounding the circuit region 110 in order to seal the circuit region 110 are formed, and a peripheral region 114 formed around the seal ring region 112. The semiconductor device 100 further includes dummy vias 136 formed of a metal material, formed in the second interlayer dielectric film 122 at the peripheral region 114.

Owner:RENESAS ELECTRONICS CORP

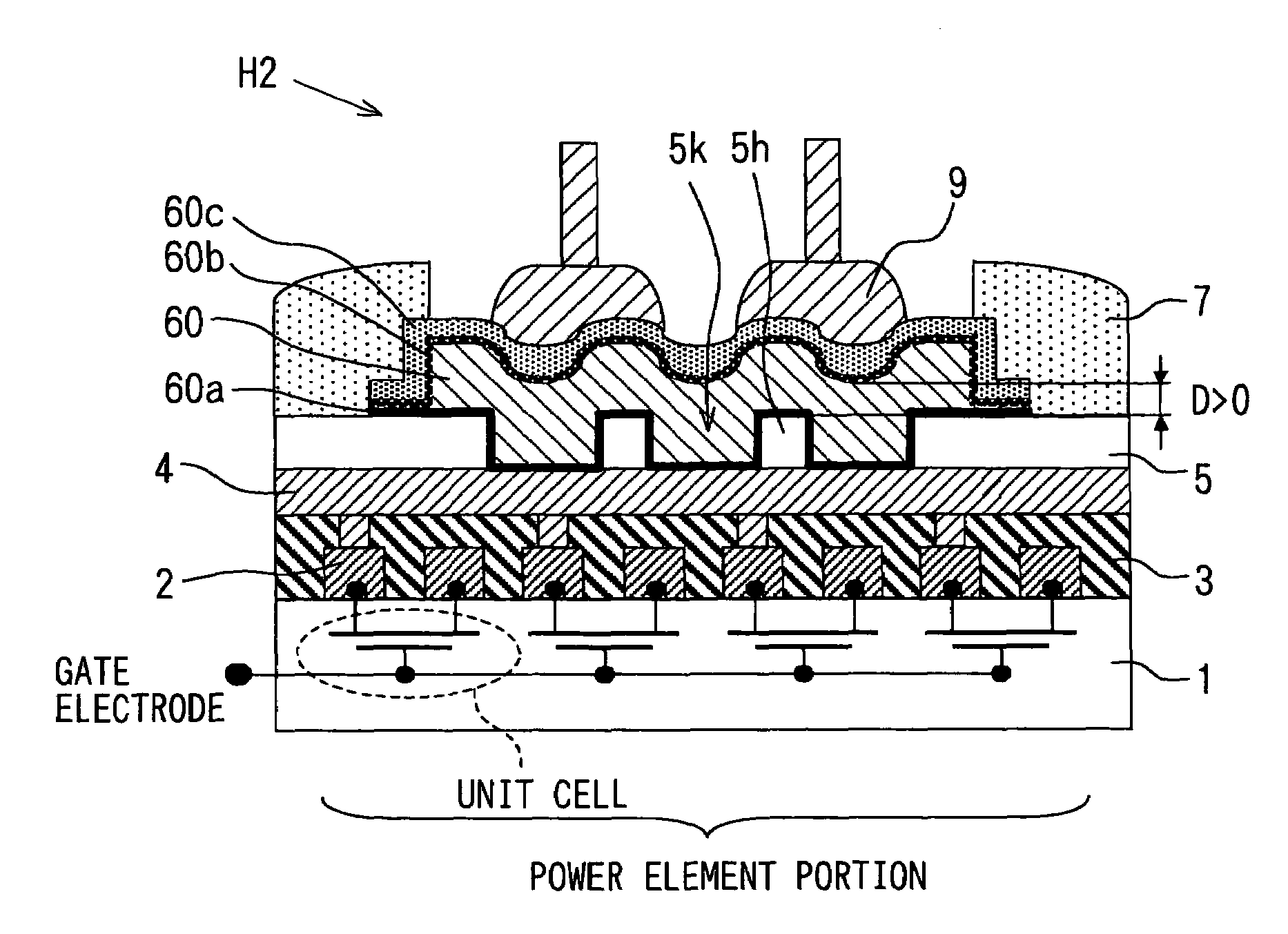

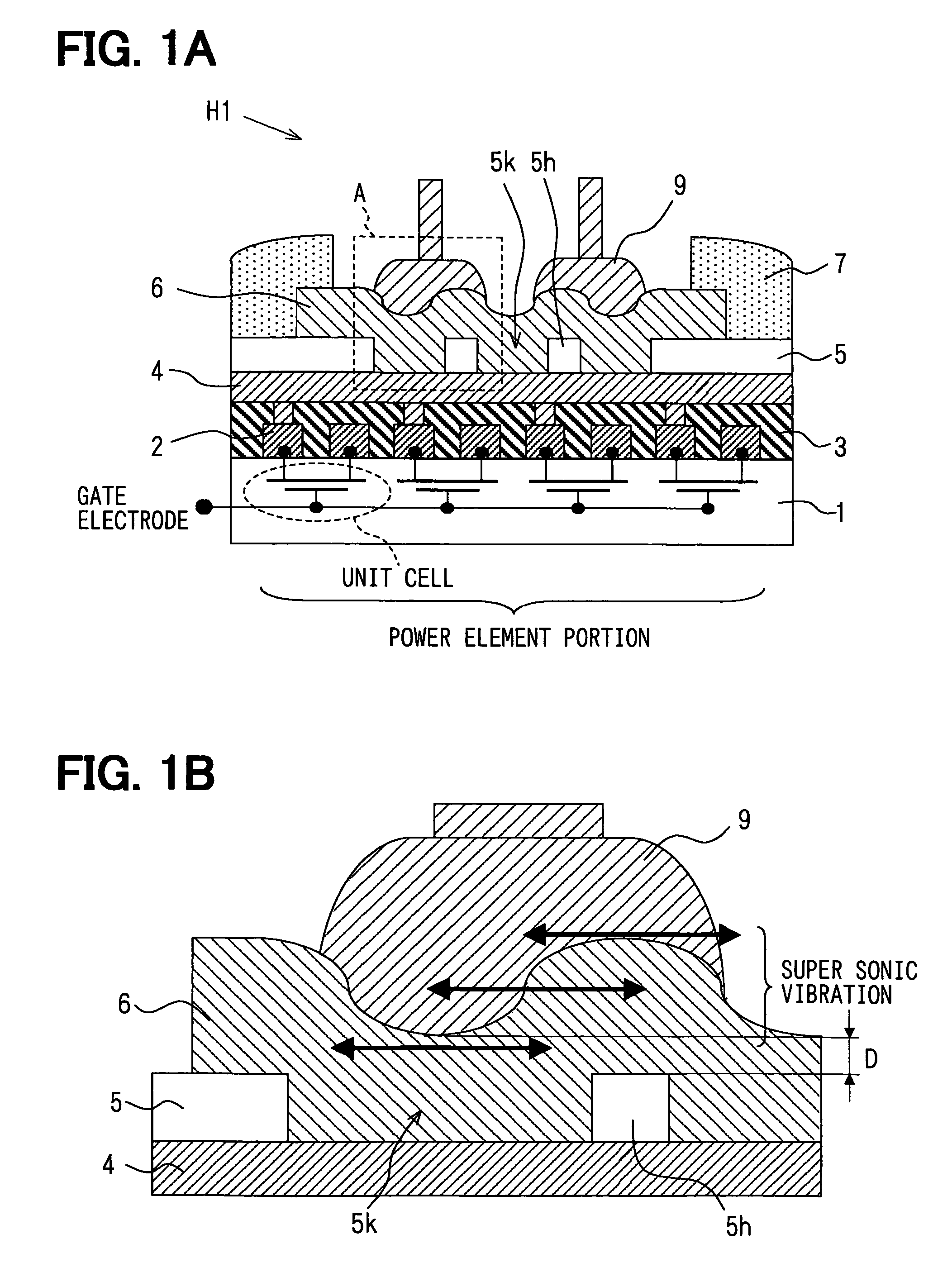

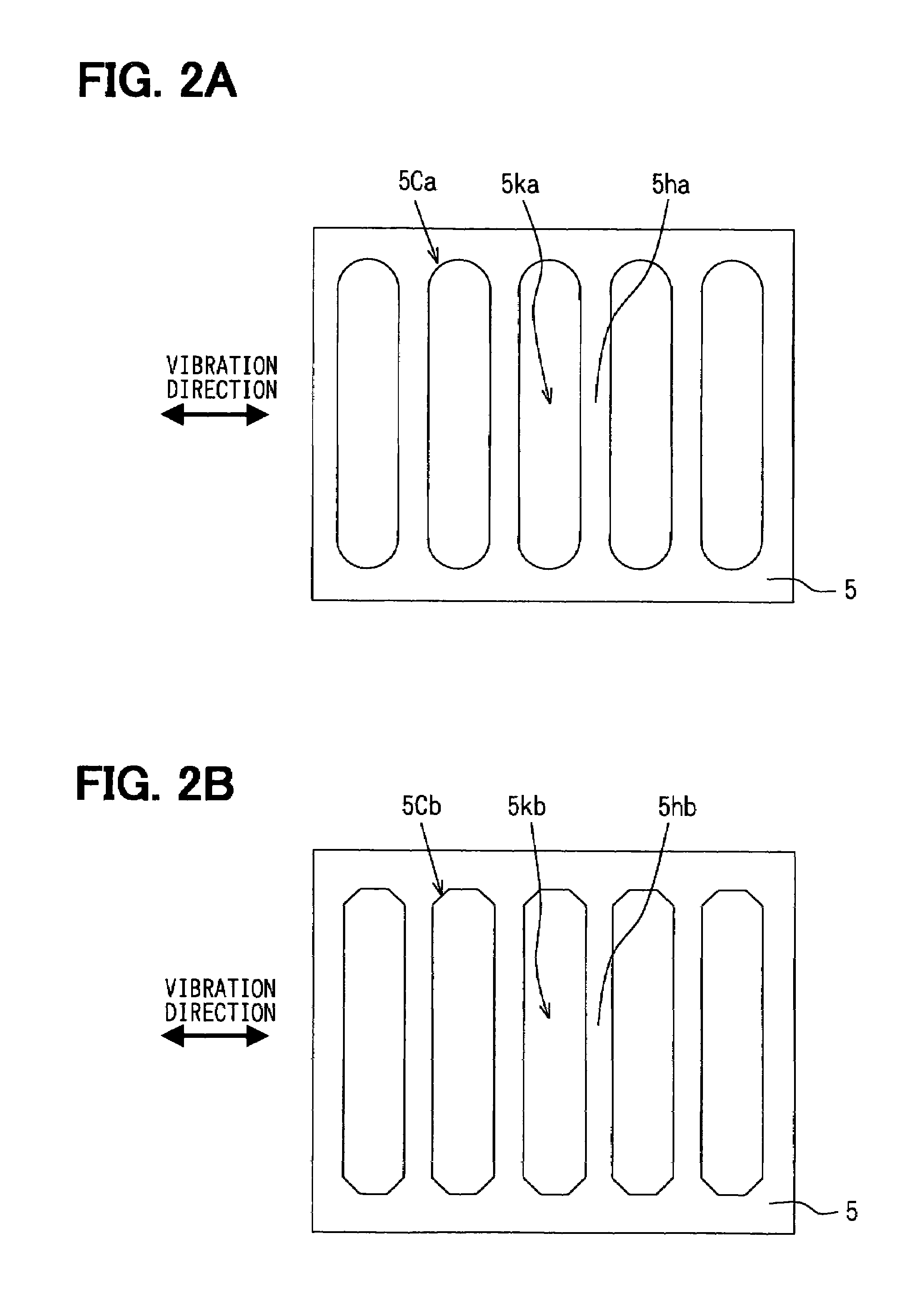

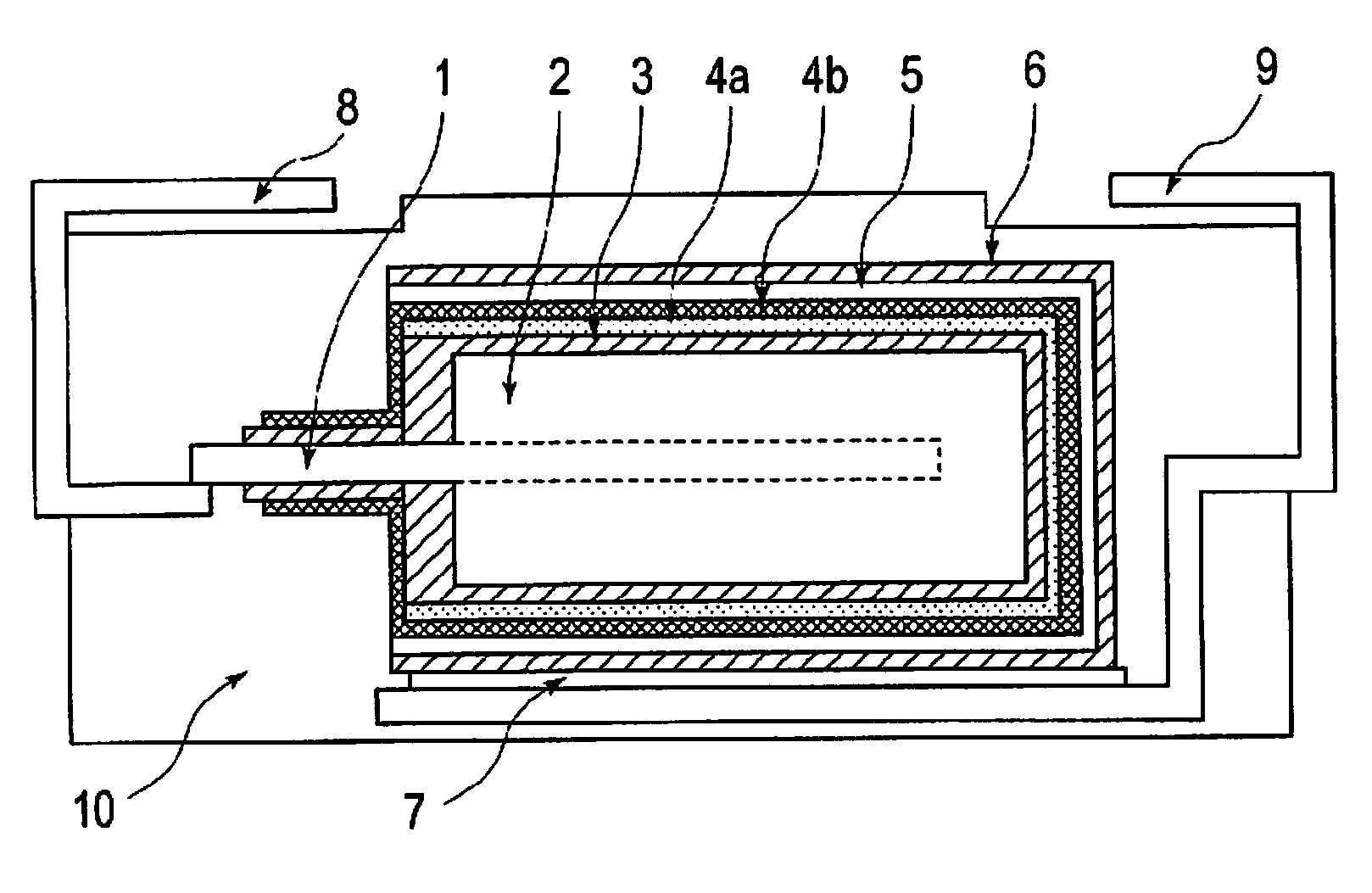

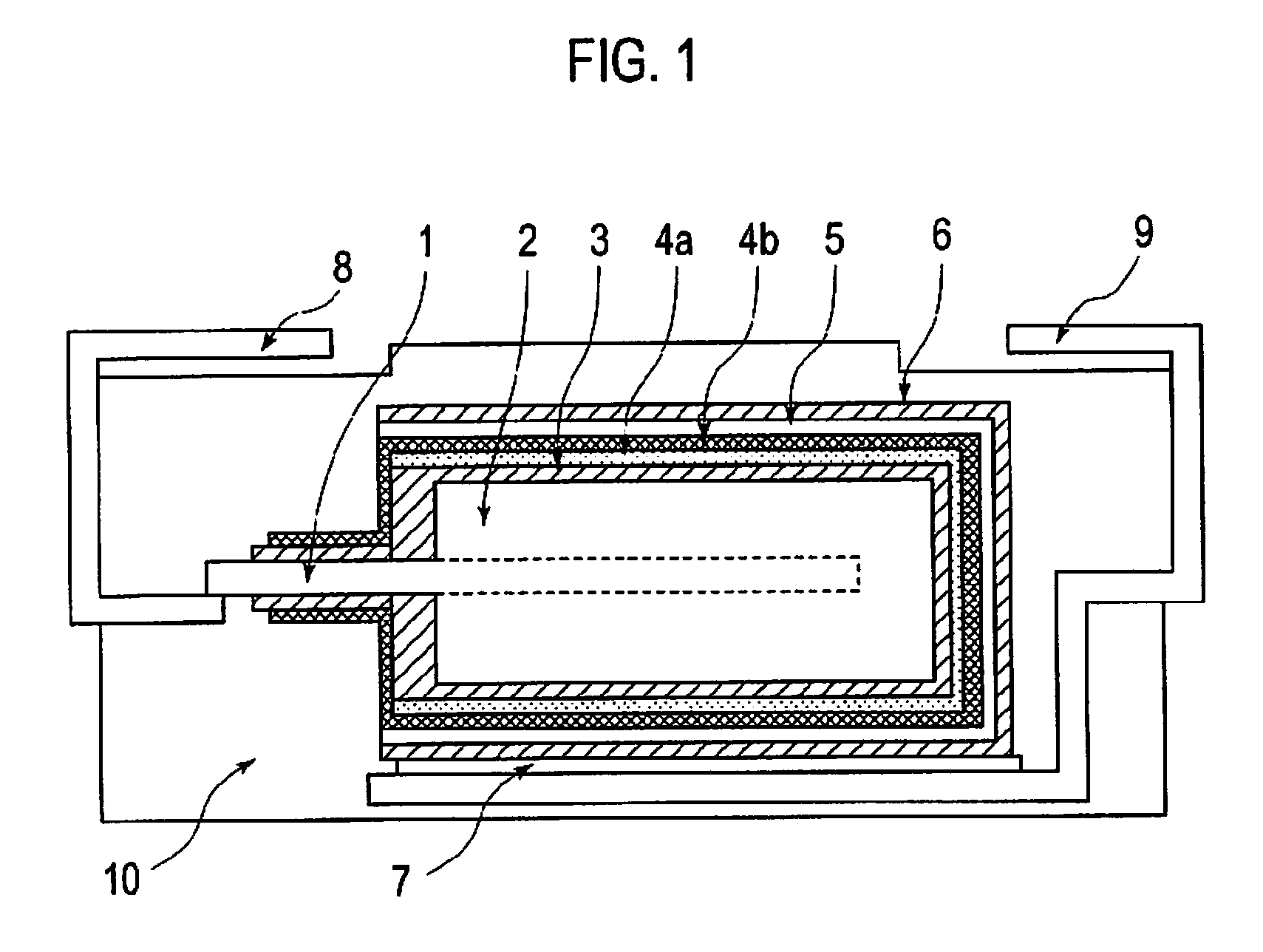

Integration type semiconductor device and method for manufacturing the same

InactiveUS7420283B2AdhesivenessHigh mechanical strengthSemiconductor/solid-state device detailsSolid-state devicesTectorial membraneSemiconductor

A semiconductor device includes: a plurality of power MOS cells on a semiconductor substrate; a plurality of lead wires connecting to a source and a drain of each power MOS cell through a contact hole; a plurality of collecting electrodes connecting in parallel with the lead wires through a via hole; an interlayer protection film on the collecting electrode; a thick film electrode connecting to the collecting electrode through the opening; and a terminal protection film having an opening for bonding connection. The openings are formed in the interlayer protection film such that a portion between the openings becomes a beam shape

Owner:DENSO CORP

Solid electrolytic capacitor

ActiveUS20090128997A1Reduce capacitanceAdhesivenessAnodisationSolid electrolytic capacitorsElectrolysisConductive polymer

An aspect of the invention provides a solid electrolytic capacitor that comprises: an anode formed of a valve metal or an alloy mainly made of a valve metal; a dielectric layer formed on a surface of the anode; a first conducting polymer layer formed on the dielectric layer, the first conducting polymer layer containing a non-ionic surfactant; a second conducting polymer layer formed on the first conducting polymer layer; and a cathode layer formed on the second conducting polymer layer.

Owner:SANYO ELECTRIC CO LTD

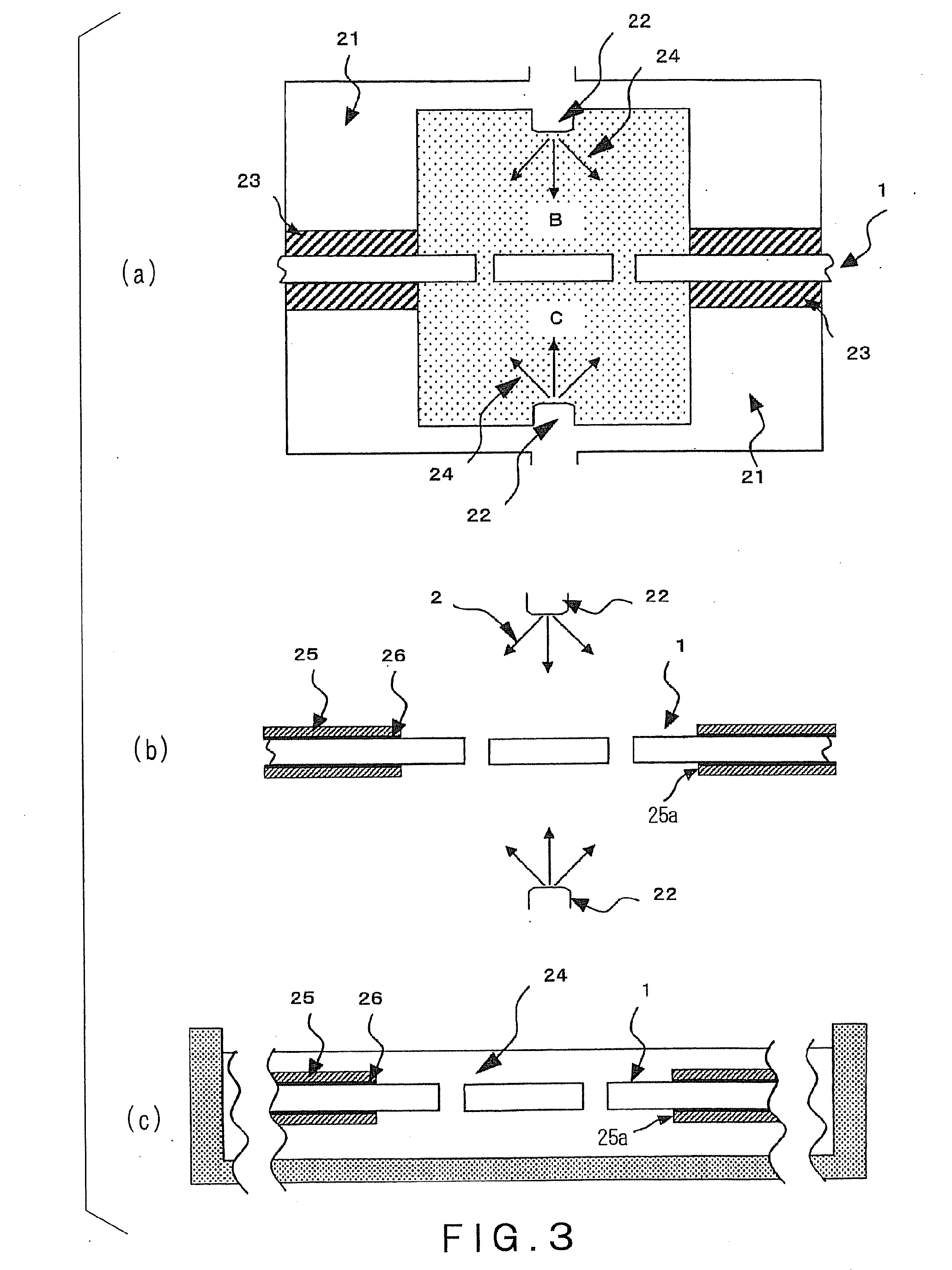

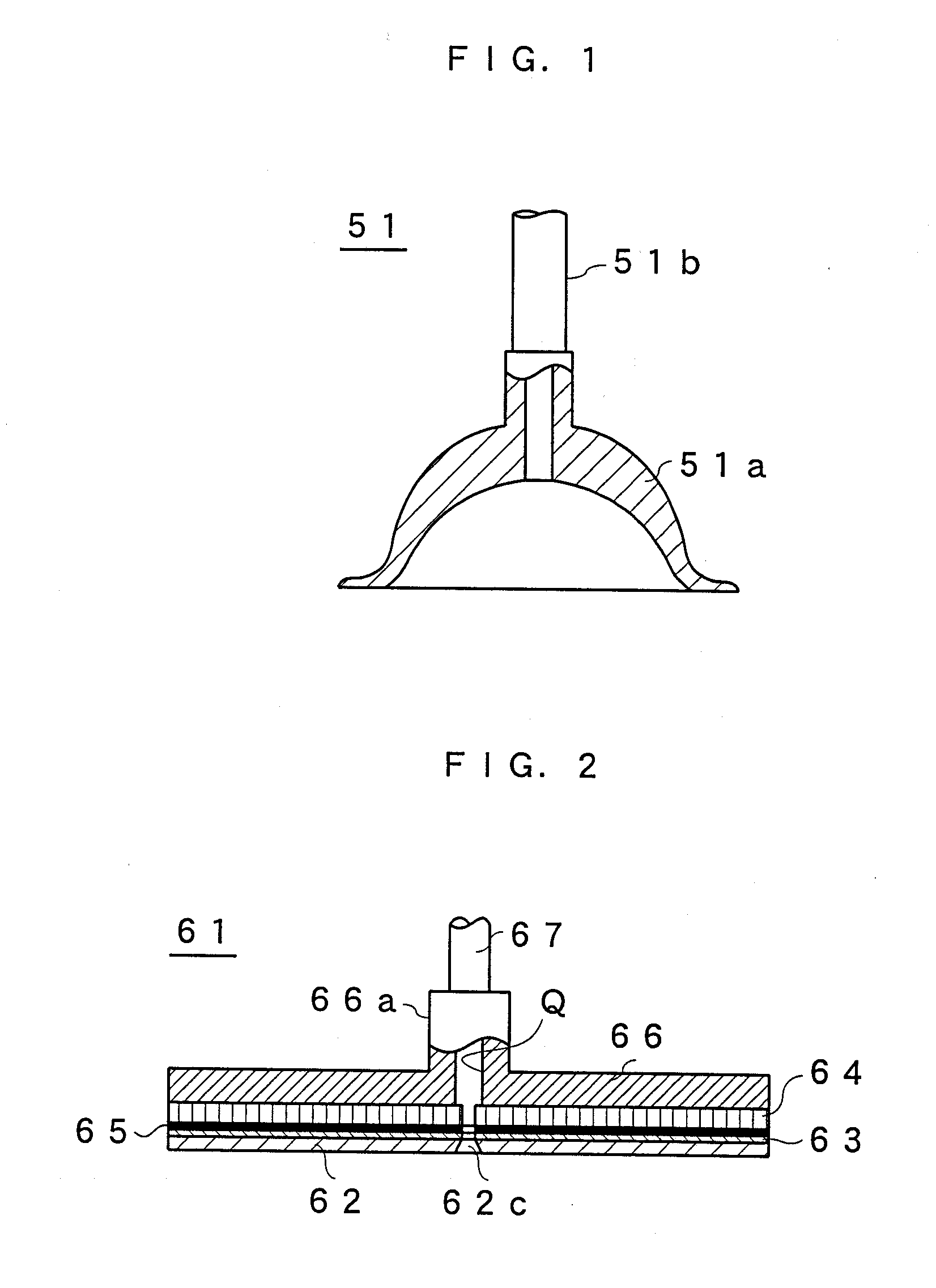

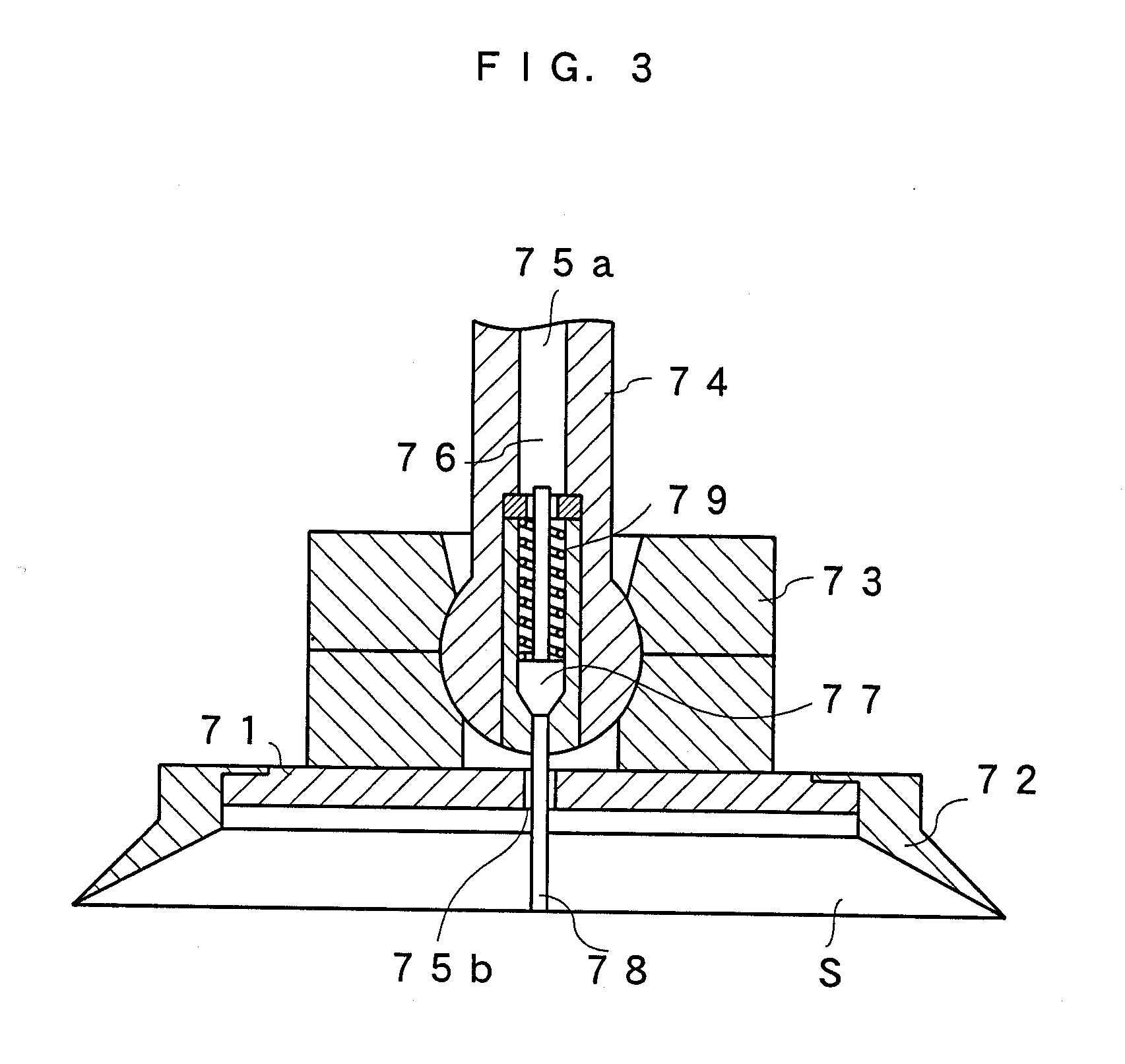

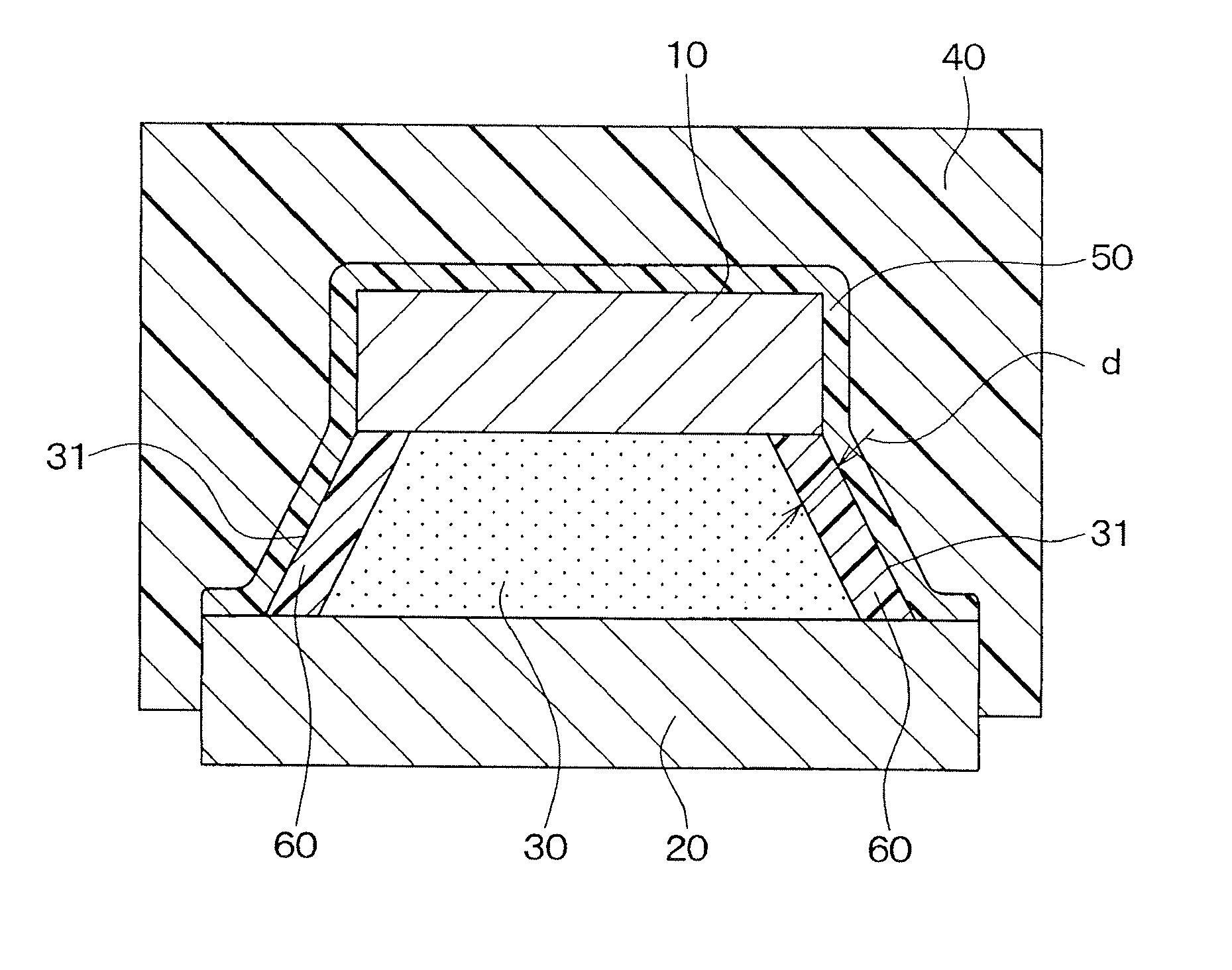

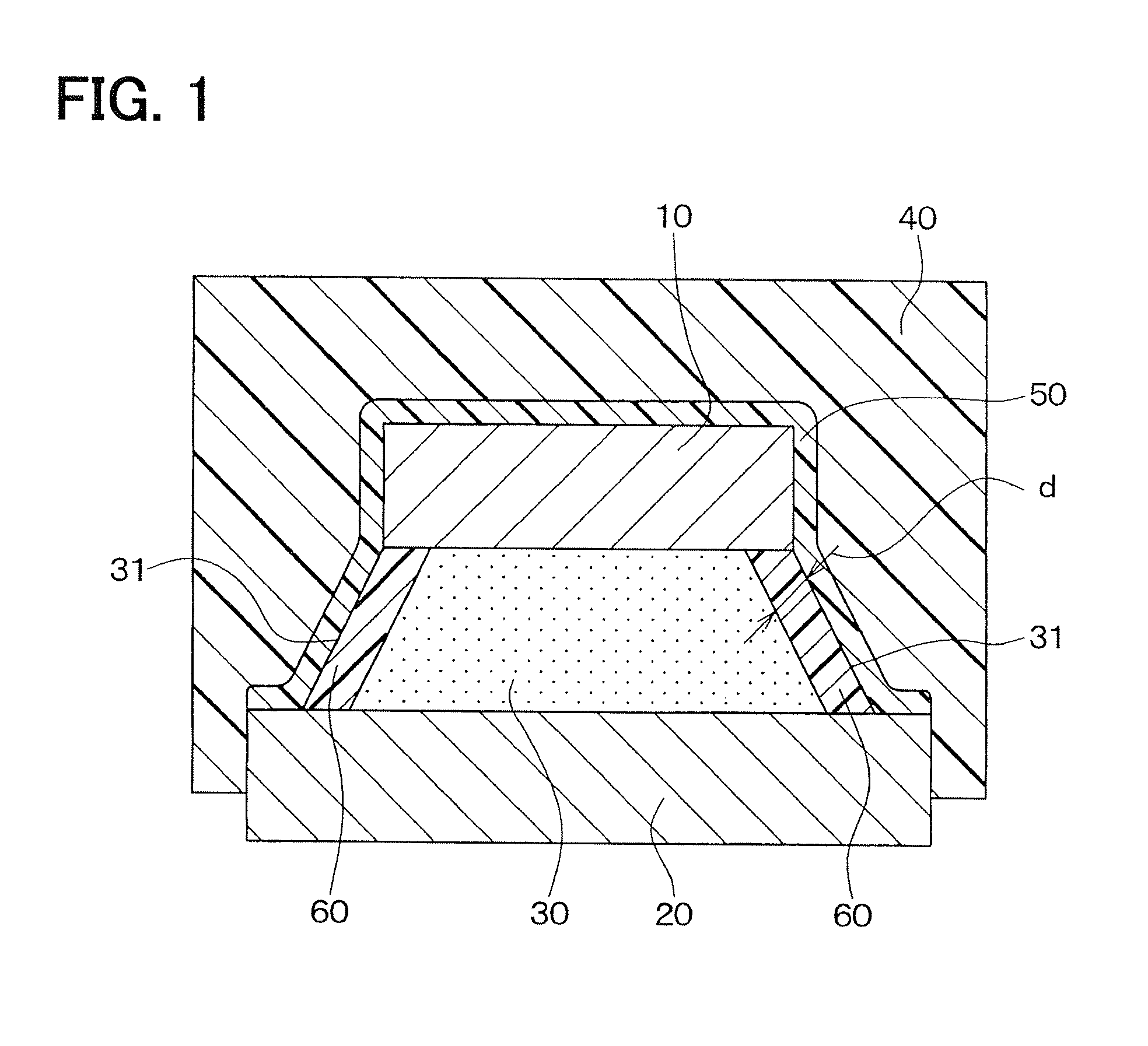

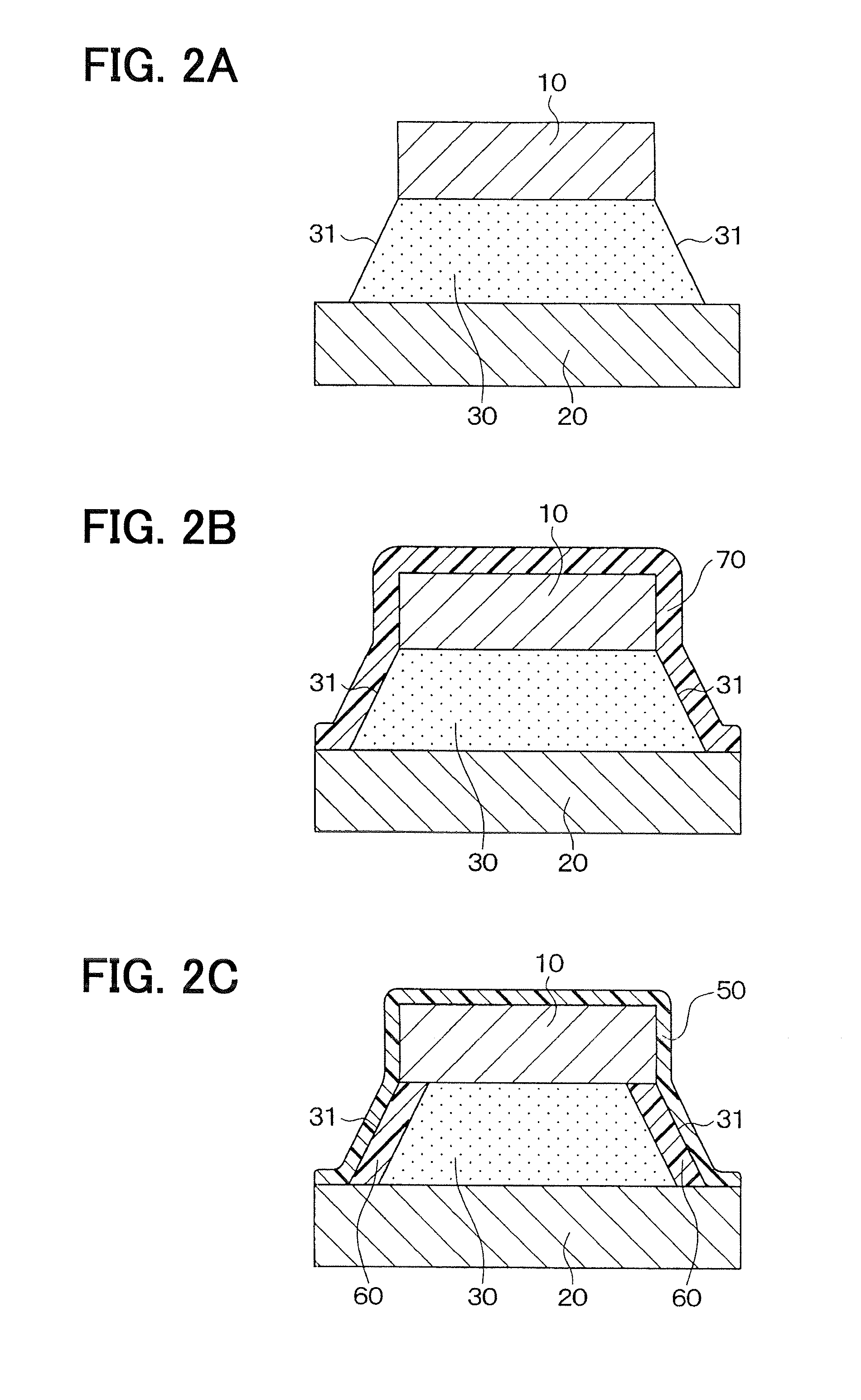

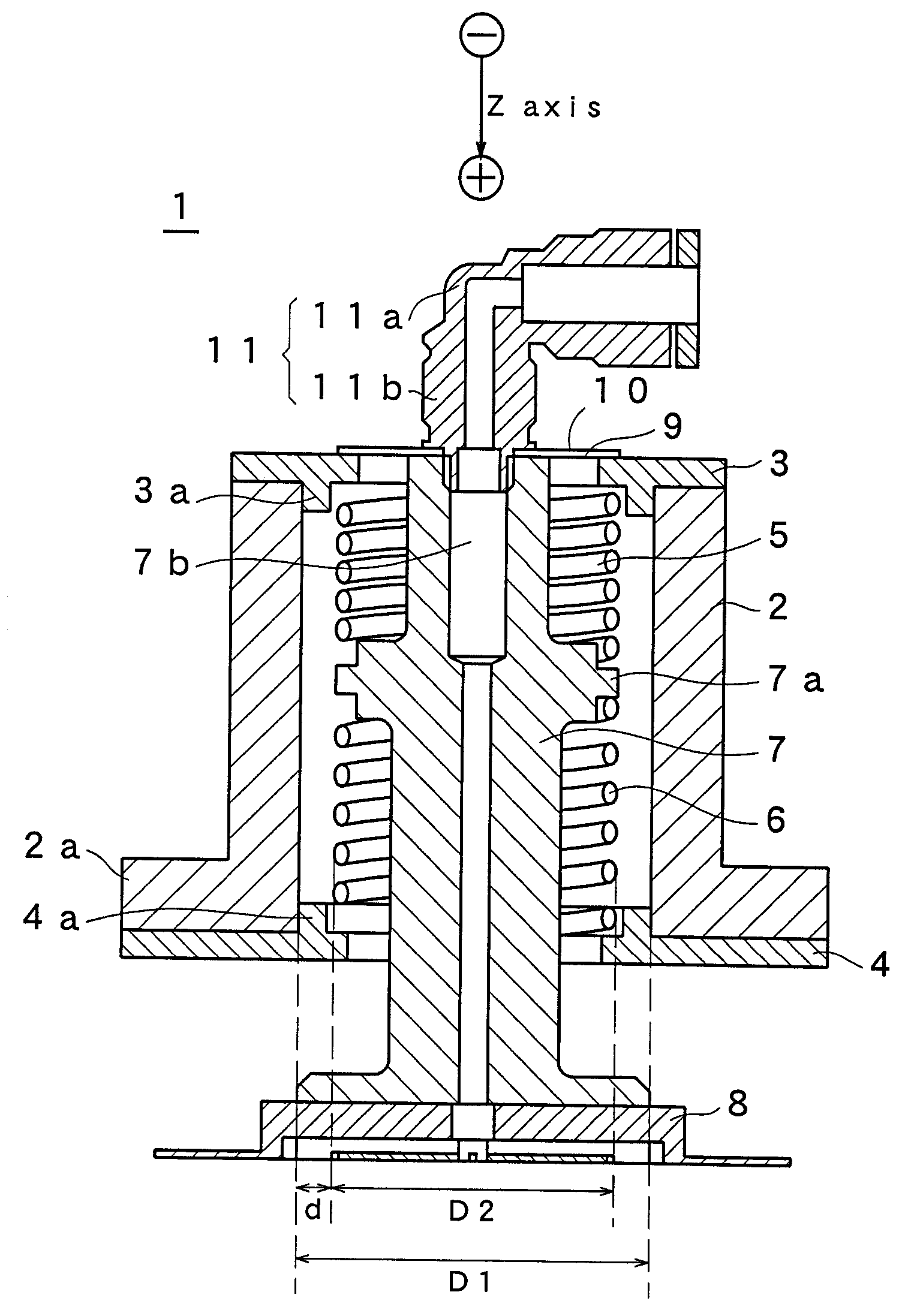

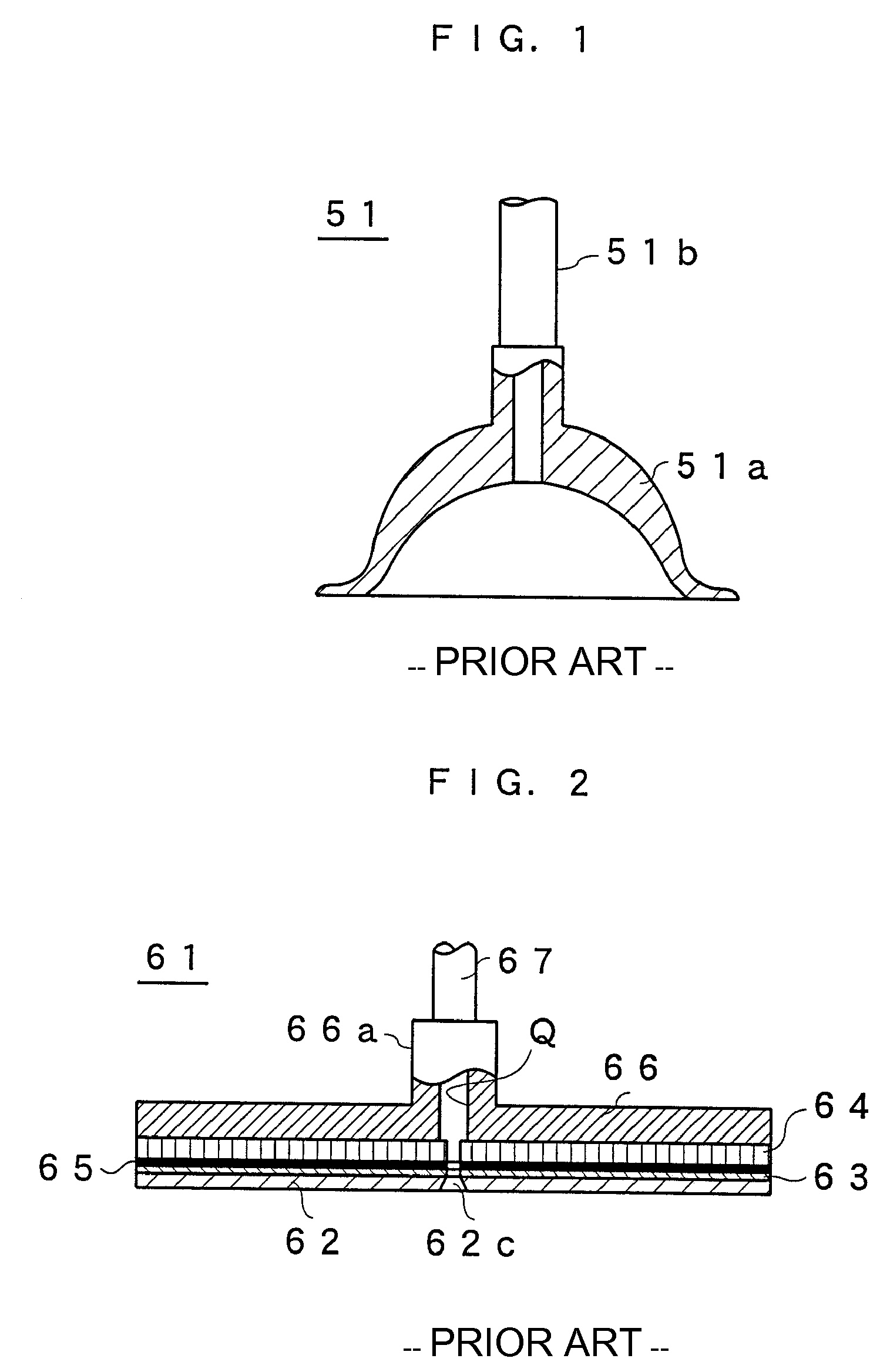

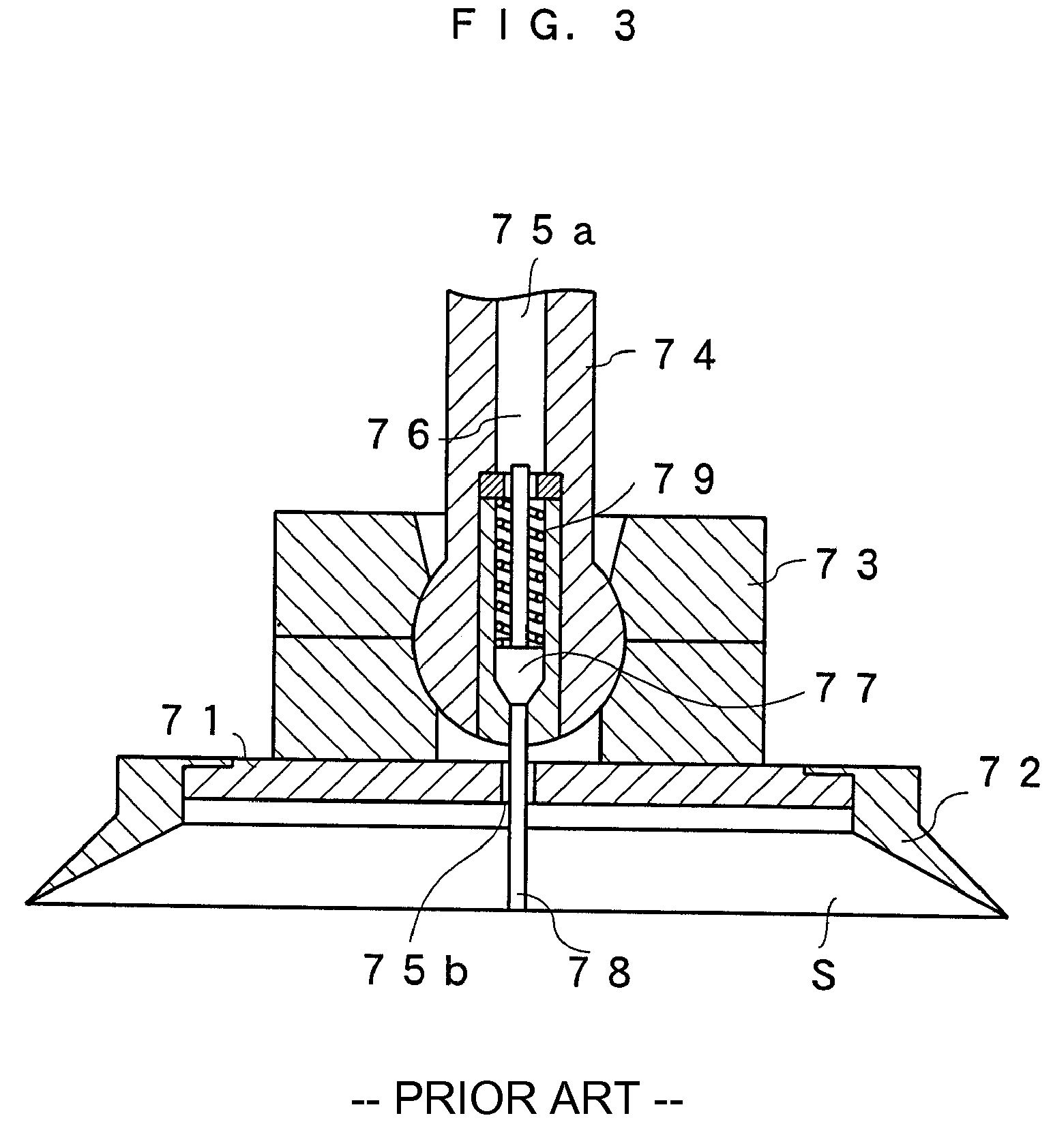

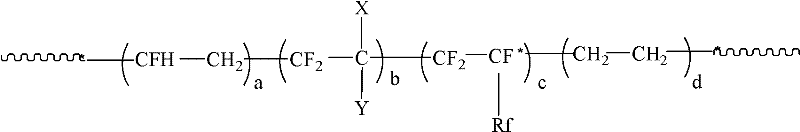

Vacuum Suction Head, And Vacuum Suction Device And Table Using The Same

InactiveUS20070200377A1AdhesivenessImprove adhesionGripping headsSemiconductor/solid-state device manufacturingLiquid-crystal displayEngineering

A vacuum suction head of the present invention can be applied to a large-sized liquid crystal display panel and can reliably suck an object to be sucked even if the object has undulation or flexure. The suction head has a shaft, which holds a suction pad, and gas is charged into and discharged from the suction pad through a suction hole. A casing holds the shaft through first and second springs so as to be movable in the axial direction. Since the suction pad is elastically supported by the springs, the suction pad can reliably suck the object to be sucked having undulation or flexure. The vacuum suction head can be used for a vacuum suction device and a working table.

Owner:MITSUBOSHI DIAMOND IND CO LTD

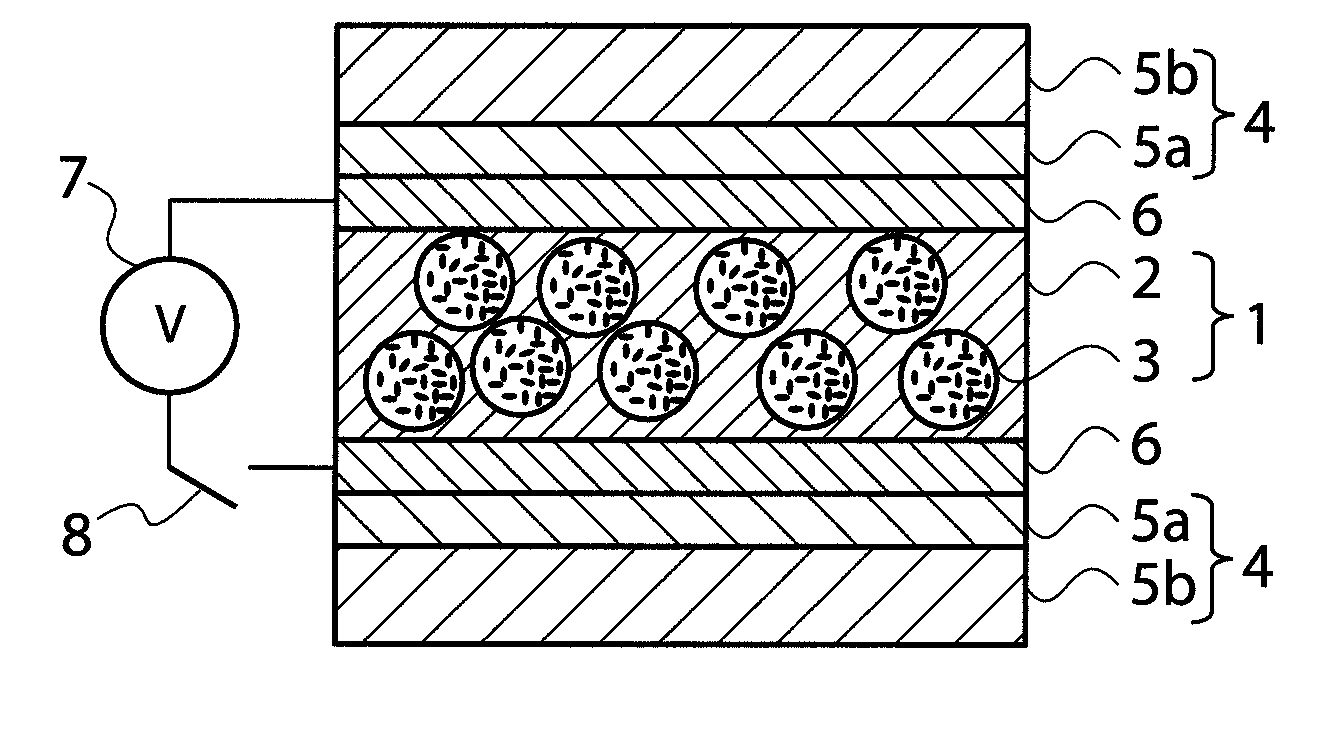

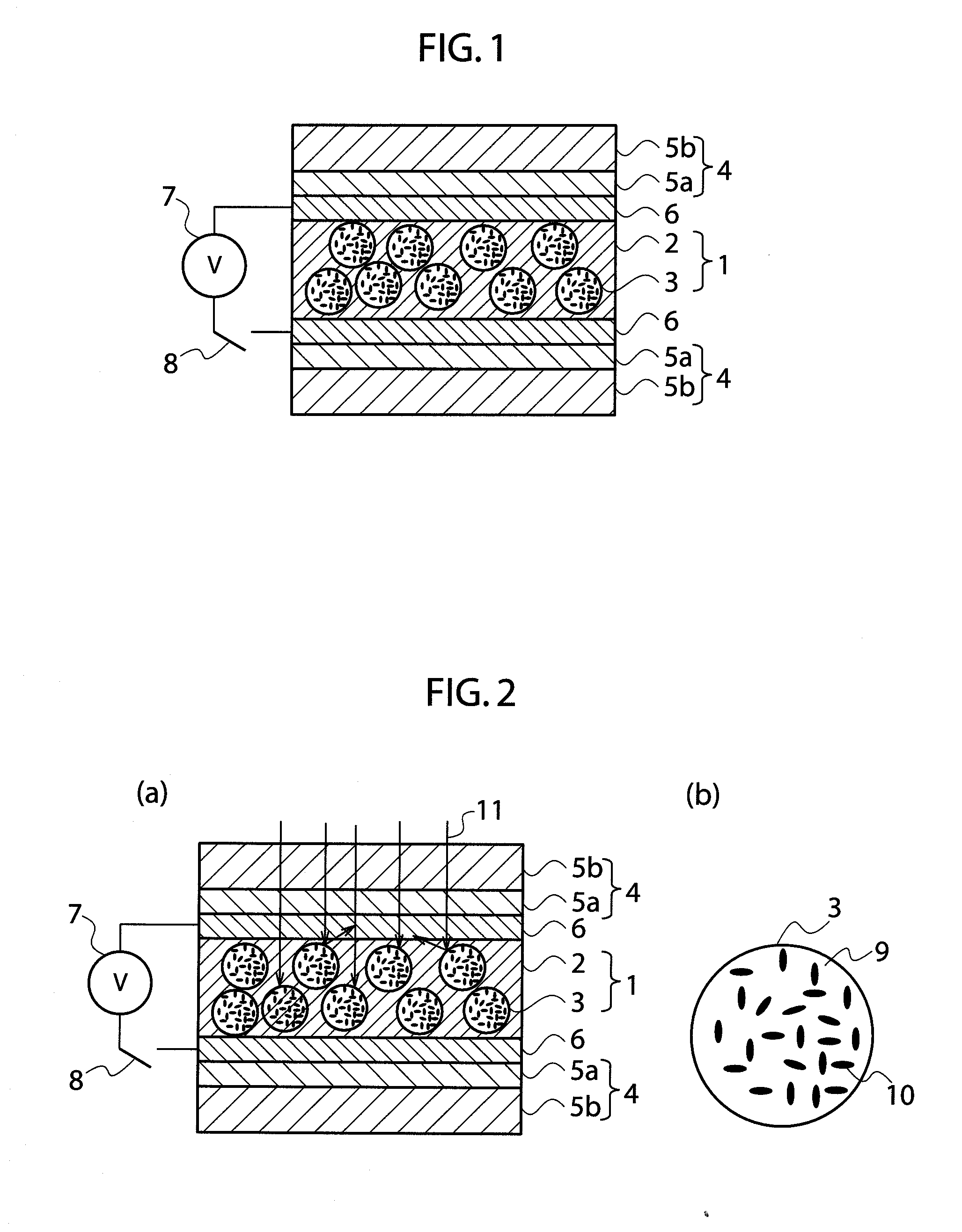

Light control film

ActiveUS20100309544A1AdhesivenessStable functionStatic indicating devicesNon-linear opticsPhosphoric Acid EstersControl layer

Disclosed is a light control film comprising:two transparent electroconductive resin substrates; anda light control layer sandwiched between the two transparent electroconductive resin substrates, the light control layer containing:a resin matrix; anda light control suspension dispersed in the resin matrix,wherein the light control film has a primer layer on the light control layer side of at least one of the transparent electroconductive resin substrates, and the primer layer is formed by using a phosphoric ester having in the molecule thereof one or more polymerizable groups. By virtue of the above constitution, the light control film has an improved adhesion between a film matrix and a substrate, and has a stable light control function.

Owner:RESONAC CORP

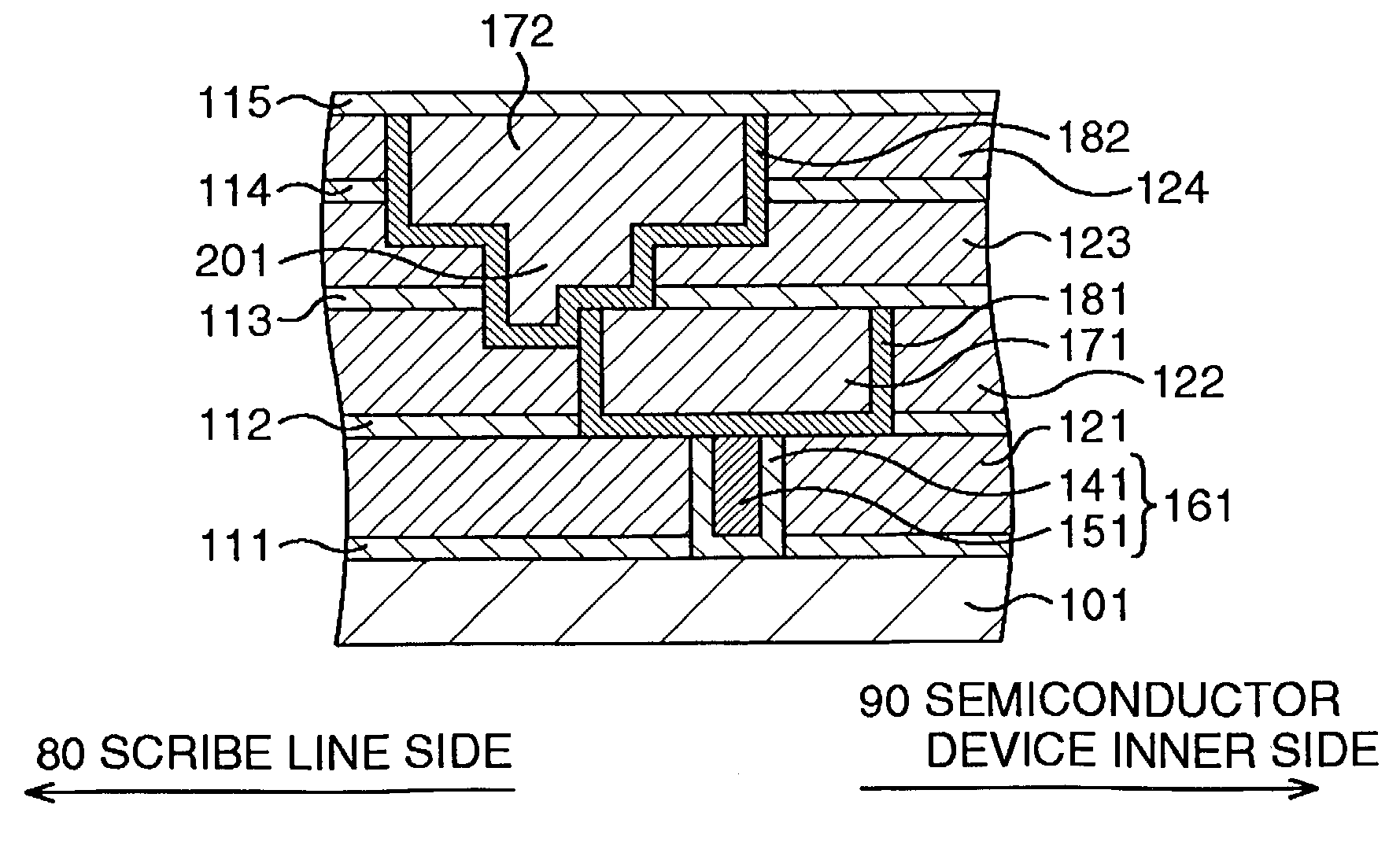

Semiconductor device and method for manufacturing the same

InactiveUS7119439B2Avoid crackingAvoid enteringSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorSilicon oxide

After formation of a contact pattern on a semiconductor substrate, a first wiring pattern composed of a first barrier metal film and a first conductor pattern is formed on the contact pattern. A moisture-proof ring is formed which has such a structure that an outer peripheral portion, covering a sidewall face on the outer peripheral side of the first conductor pattern, of the first barrier metal film, is in contact at the upper end portion with a barrier metal bottom face portion, covering the bottom face of a via contact portion, of a second barrier metal film. This results in formation of a barrier metal film such as Ta, TiN, or the like, with no discontinuation, in the whole region from the semiconductor substrate to an silicon oxide film being the uppermost layer, thereby improving adhesiveness for prevention of cracks and entry of moisture.

Owner:FUJITSU SEMICON LTD

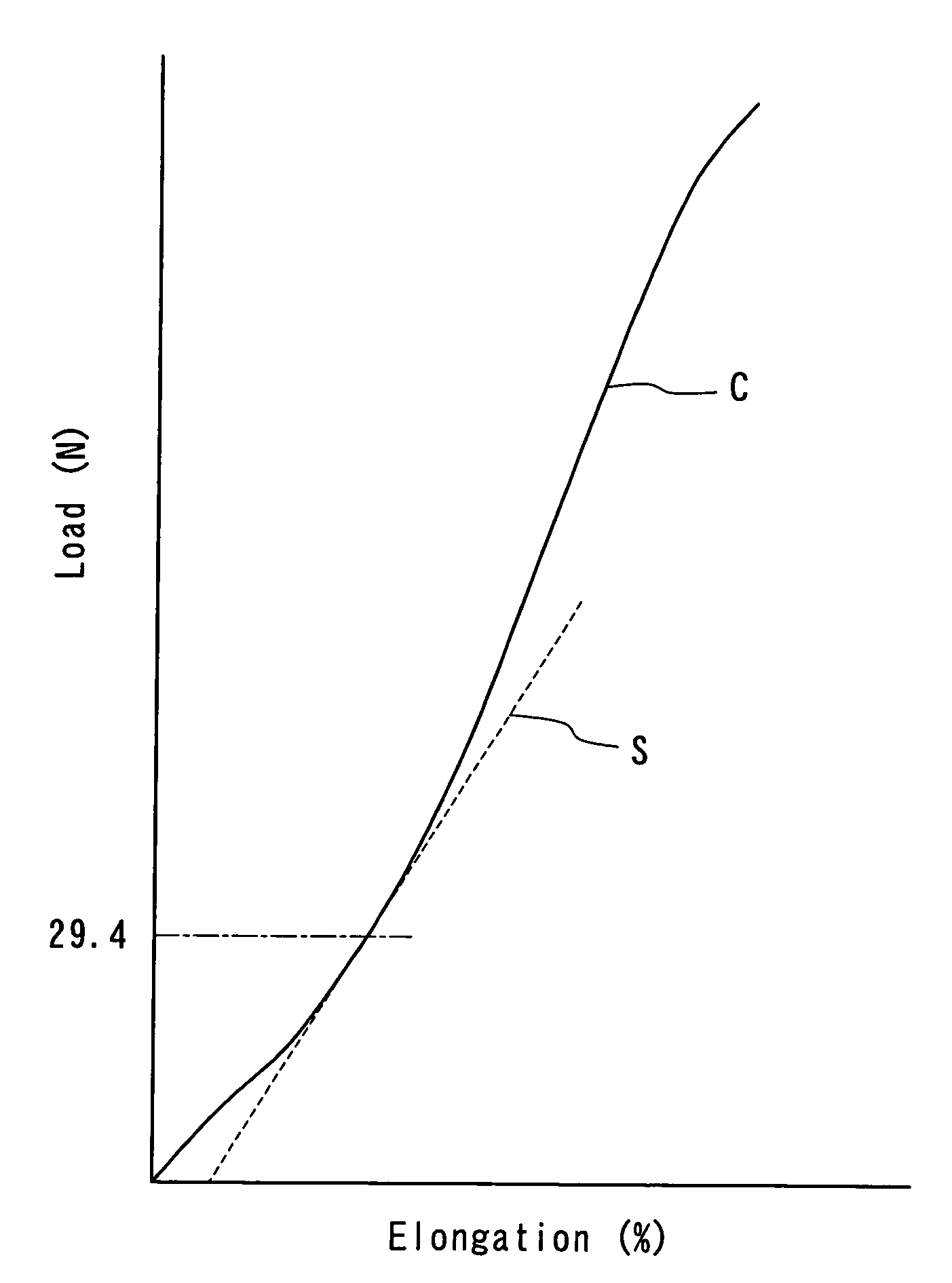

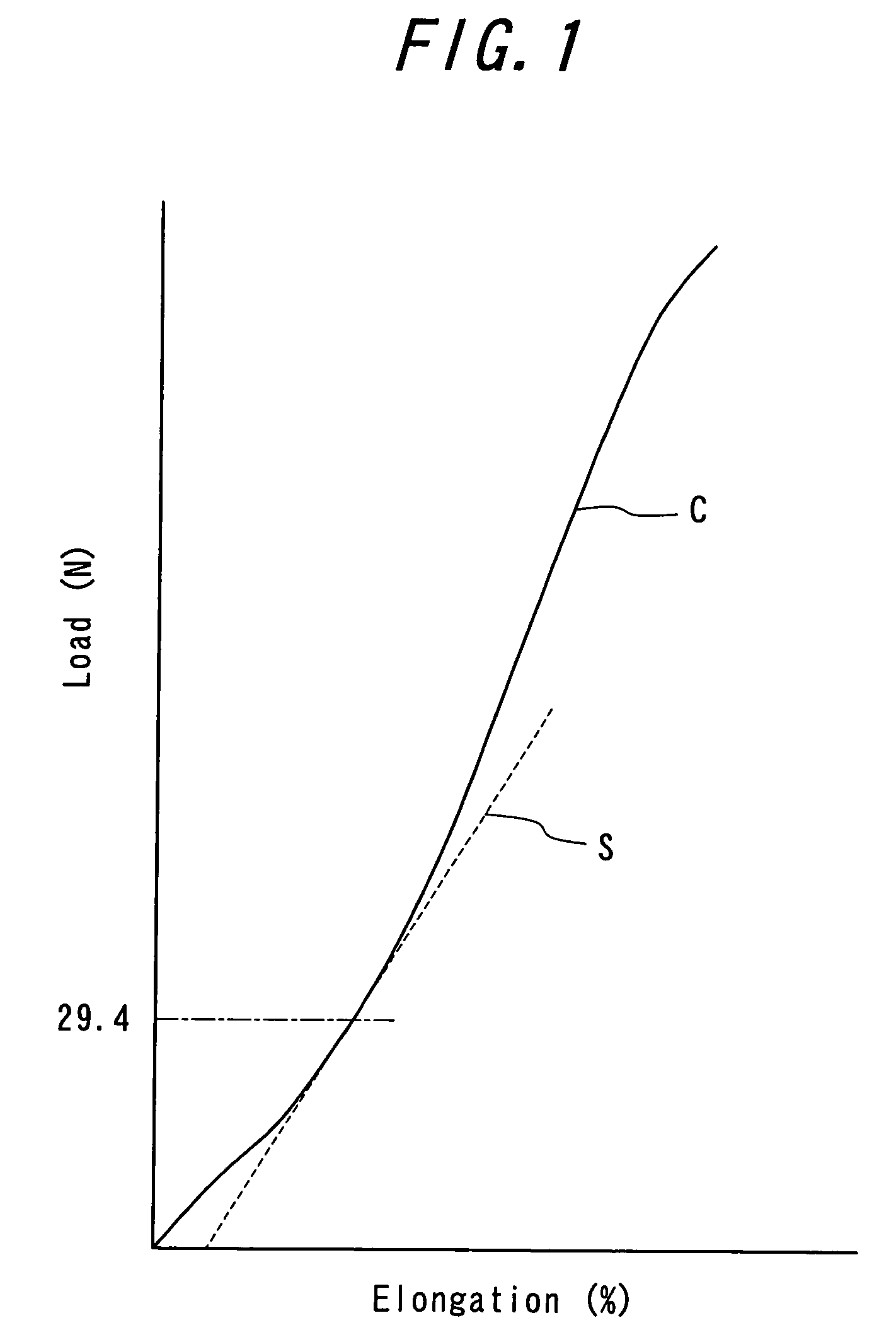

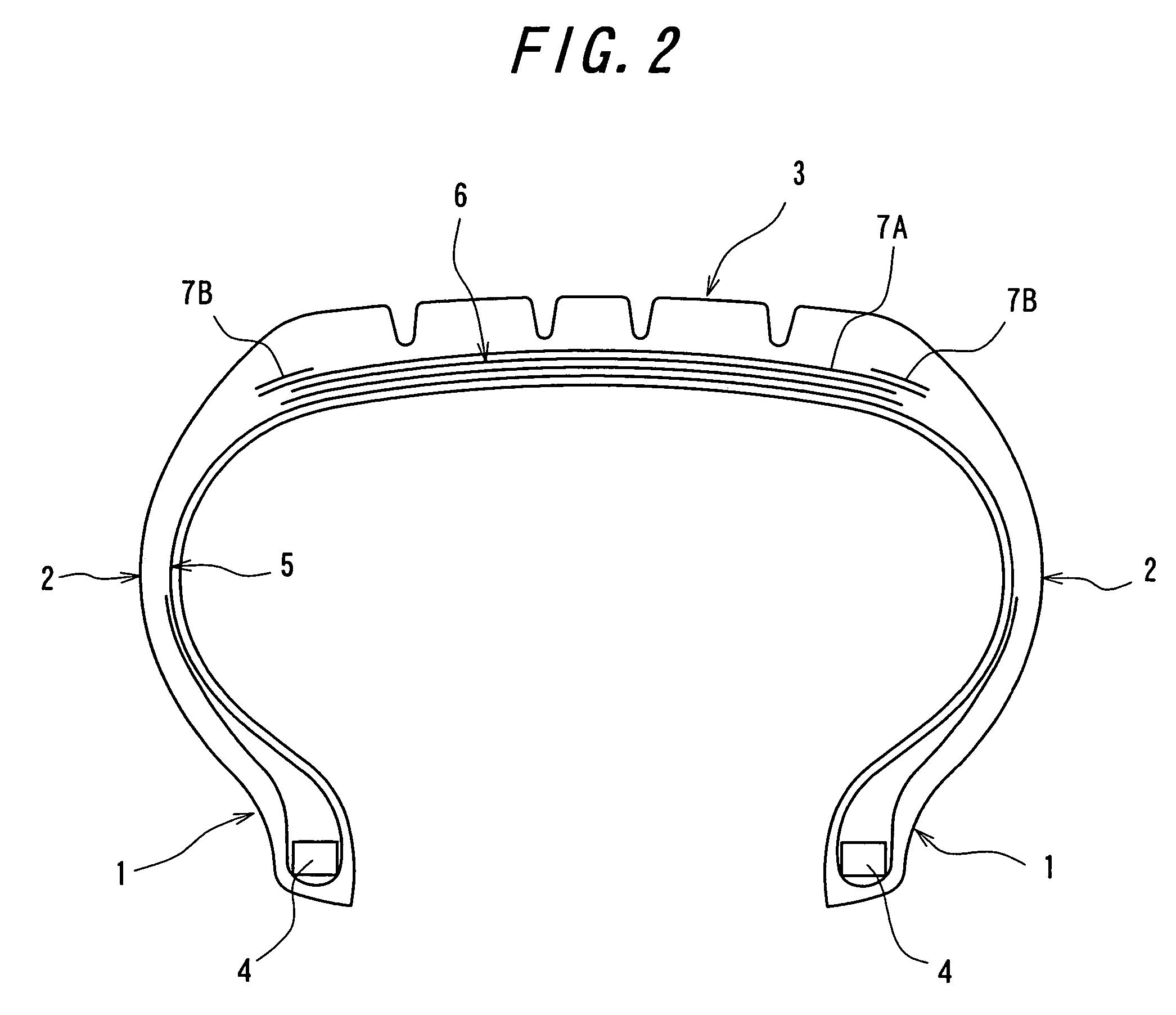

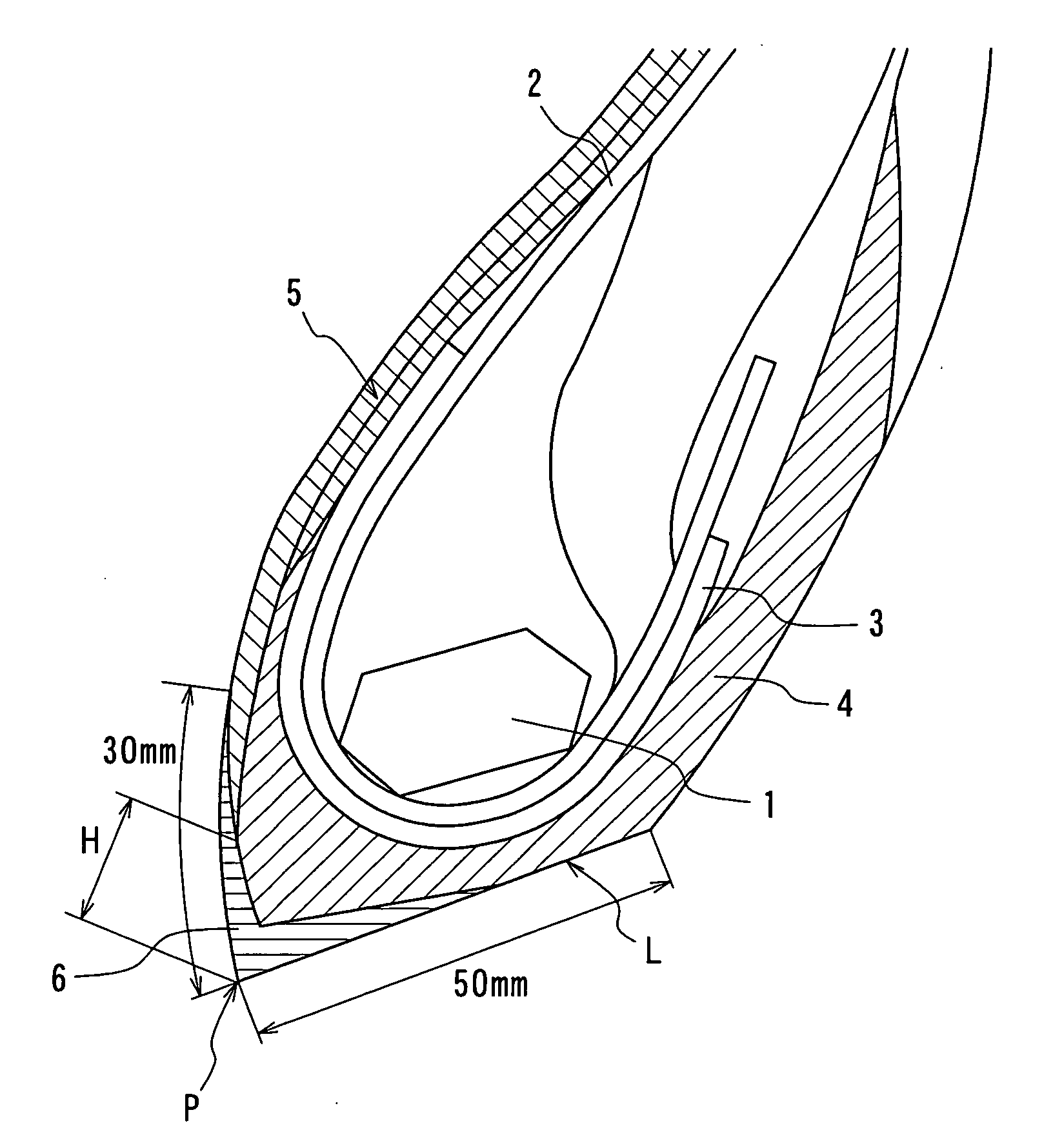

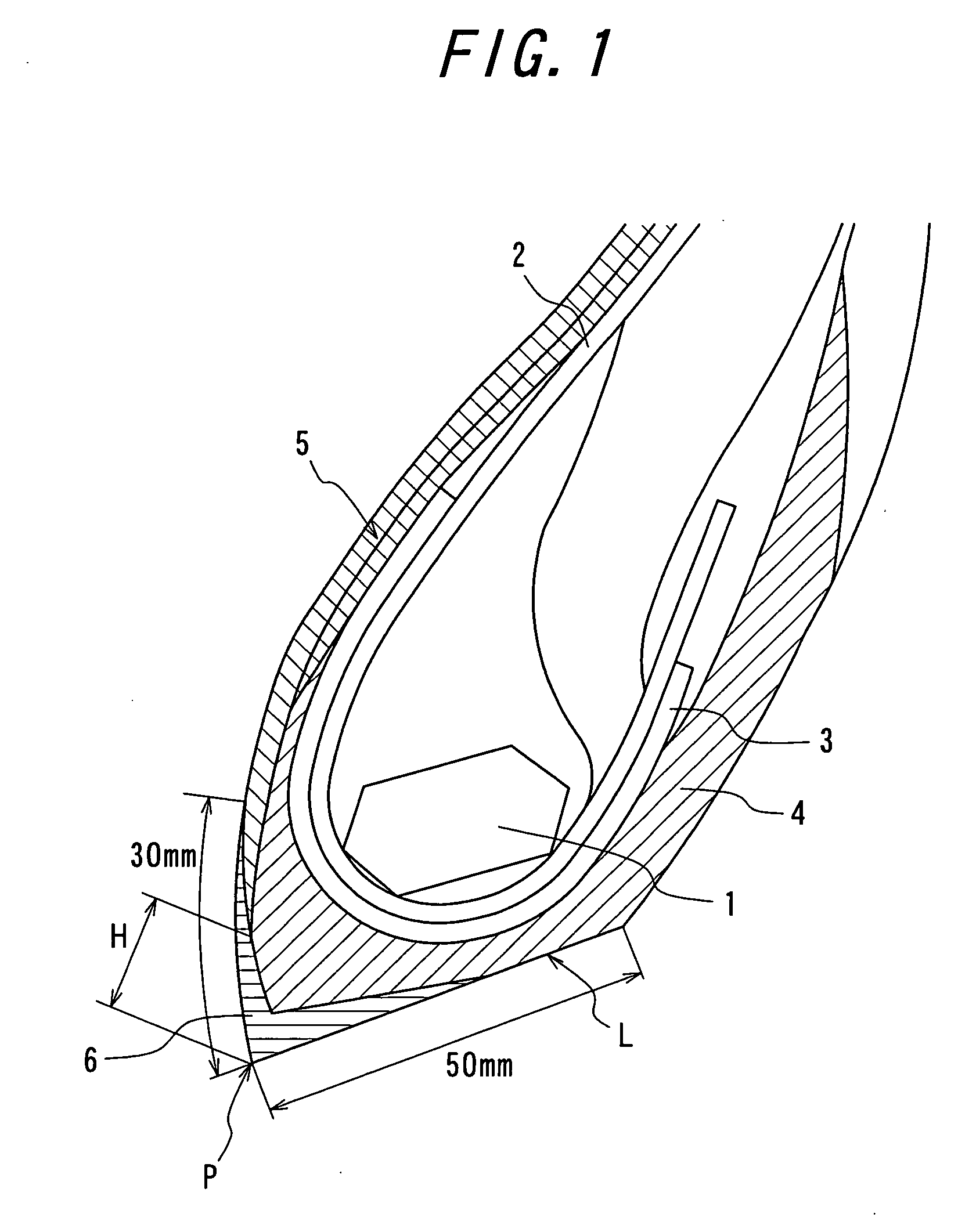

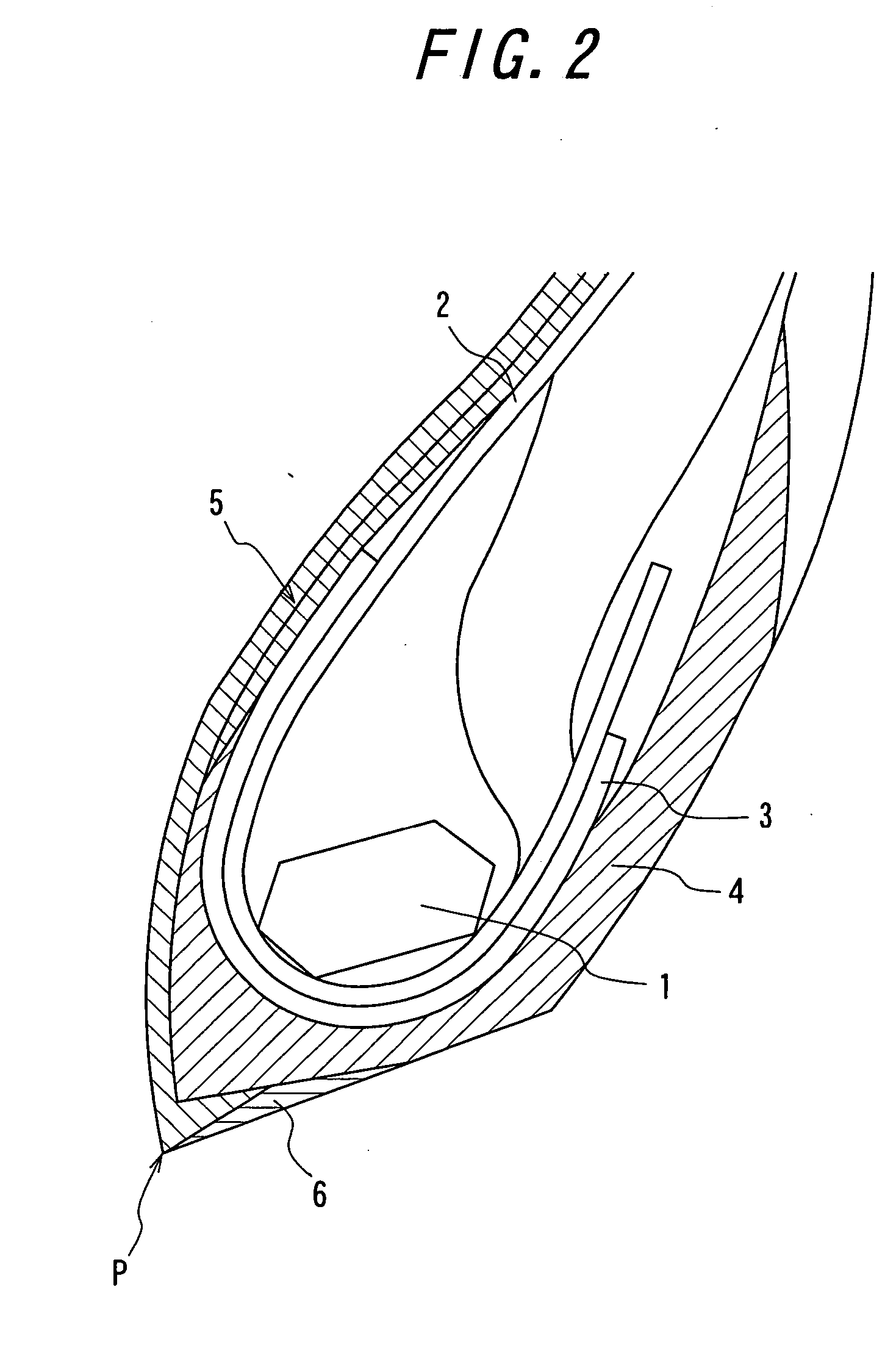

Pneumatic radial tire with polyethylene terephthalate cord belt reinforcing layer

ActiveUS7584774B2AdhesivenessInferior durabilityNon-macromolecular adhesive additivesFibre typesPolyethylene terephthalateEngineering

This invention relates to a pneumatic radial tire having low road noise and flat spot and a high high-speed durability, and more particularly to a pneumatic radial tire comprising a radial carcass (5), a belt (6) disposed outside a crown portion of the carcass in a radial direction and comprised of at least two belt layers, and a belt reinforcing layer (7A, 7B) disposed outside the belt in the radial direction, characterized in that the belt reinforcing layer 7A, 7B is formed by continuously and spirally winding a polyethylene terephthalate cord(s) in a circumferential direction of the tire, and this cord has an elastic modulus of not less than 2.5 mN / dtex·% under a load of 29.4 N measured at 160° C.

Owner:BRIDGESTONE CORP

Electronic device and method of manufacturing the same

ActiveUS20110192630A1High strengthHigh mechanical strengthLine/current collector detailsSemiconductor/solid-state device detailsElectrical conductorElectronic component

An electronic device includes an electronic component, a joining member to be mechanically joined with the electronic component, and a metal conductor located between the electronic component and the joining member to mechanically join the electronic component and the joining member. The metal conductor is made of porous noble metal to have pores, and includes an end surface without being covered by the electronic component and the joining member. Furthermore, a reinforcing resin is impregnated from the end surface of the metal conductor to the pores inside of the metal conductor, so as to mechanically reinforce the metal conductor.

Owner:DENSO CORP

Vacuum suction head, and vacuum suction device and table using the same

InactiveUS7665783B2AdhesivenessImprove adhesionGripping headsSemiconductor/solid-state device manufacturingLiquid-crystal displayEngineering

A vacuum suction head of the present invention can be applied to a large-sized liquid crystal display panel and can reliably suck an object to be sucked even if the object has undulation or flexure. The suction head has a shaft, which holds a suction pad, and gas is charged into and discharged from the suction pad through a suction hole. A casing holds the shaft through first and second springs so as to be movable in the axial direction. Since the suction pad is elastically supported by the springs, the suction pad can reliably suck the object to be sucked having undulation or flexure. The vacuum suction head can be used for a vacuum suction device and a working table.

Owner:MITSUBOSHI DIAMOND IND CO LTD

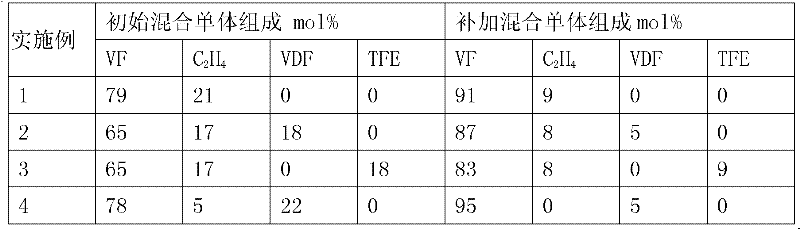

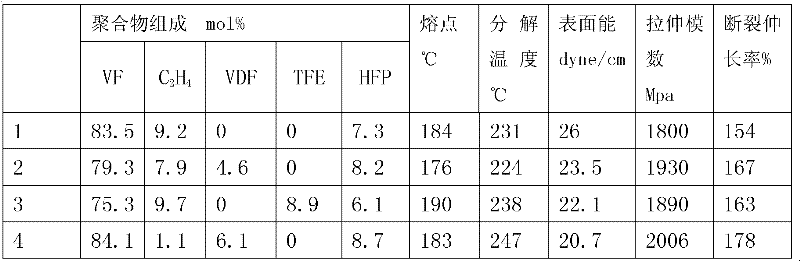

Melt-processable modified polyvinyl fluoride resin and preparation method thereof

The invention relates to a melt-processable modified polyvinyl fluoride (PVF) resin which is polymerized by vinyl fluoride, ethylene, one or more of CF2=CXY and one or more of CF2=CFRf. Reaction monomers are subjected to a copolymerization reaction under the action of an initiating agent in an aqueous phase or an emulsion, reaction temperature ranges from 40 DEG C to 100 DEG C, and reaction pressure ranges from 1 MPa to 10 MPa. According to the melt-processable modified polyvinyl fluoride resin, high-temperature performance of the PVF resin is kept, treatment temperature of the resin is reduced simultaneously, conventional melt processing can be used for processing the resin, and obtained thin-film materials have good combination properties.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

Semiconductor device

ActiveUS7294932B2Improve adhesionAdhesivenessSemiconductor/solid-state device detailsSolid-state devicesDielectricInter layer

The semiconductor device 100 includes a multilayer wiring structure formed on the semiconductor substrate. The multilayer wiring structure includes at least a first inter layer dielectric film 120 in which interconnects 124 are formed, and at least a second inter layer dielectric film 122 in which vias 126 are formed. The multilayer wiring structure includes a circuit region 110 in which the interconnects 124 and the vias 126 are formed, a seal ring region 112 formed around the circuit region 110 and in which seal rings surrounding the circuit region 110 in order to seal the circuit region 110 are formed, and a peripheral region 114 formed around the seal ring region 112. The semiconductor device 100 further includes dummy vias 136 formed of a metal material, formed in the second interlayer dielectric film 122 at the peripheral region 114.

Owner:RENESAS ELECTRONICS CORP

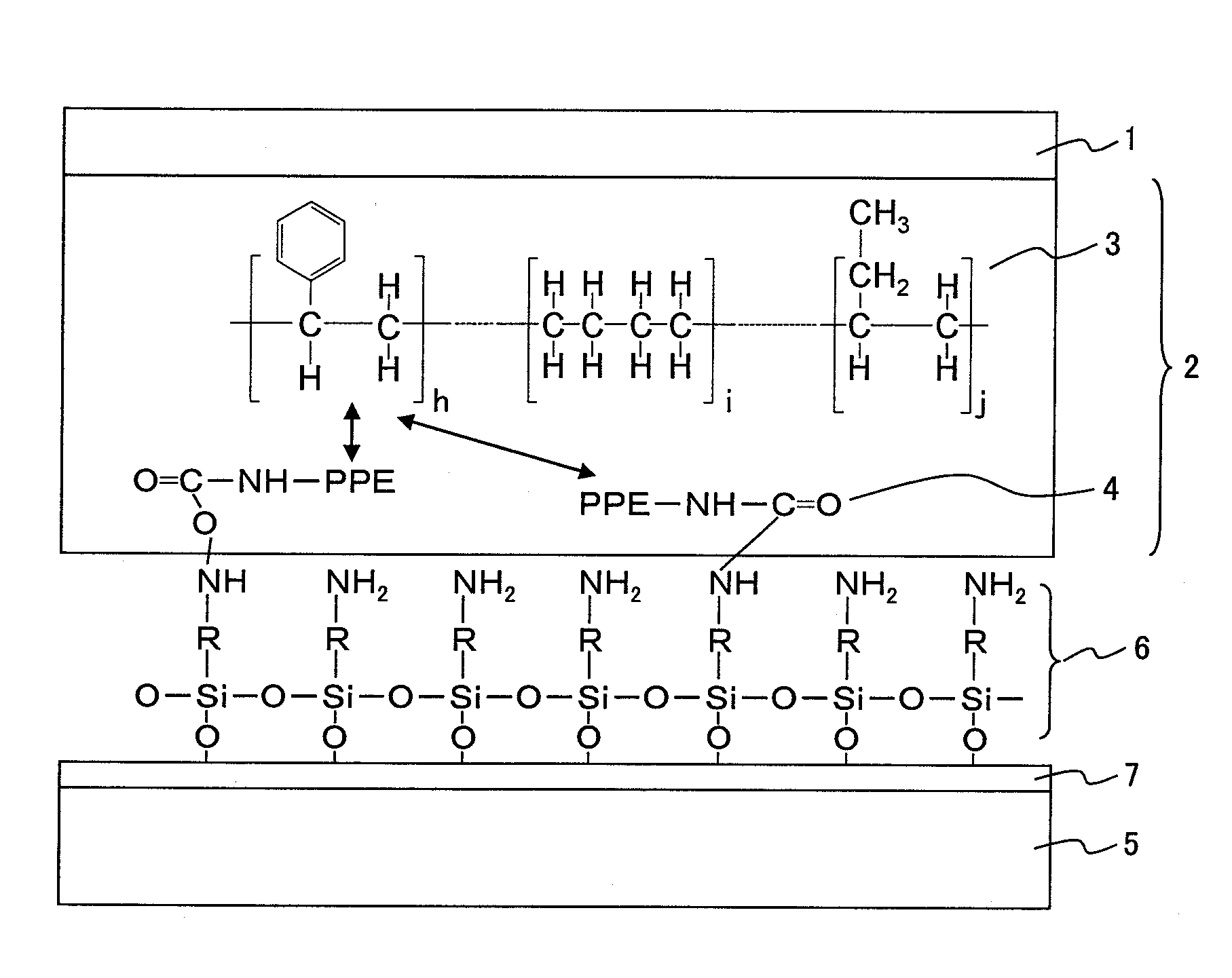

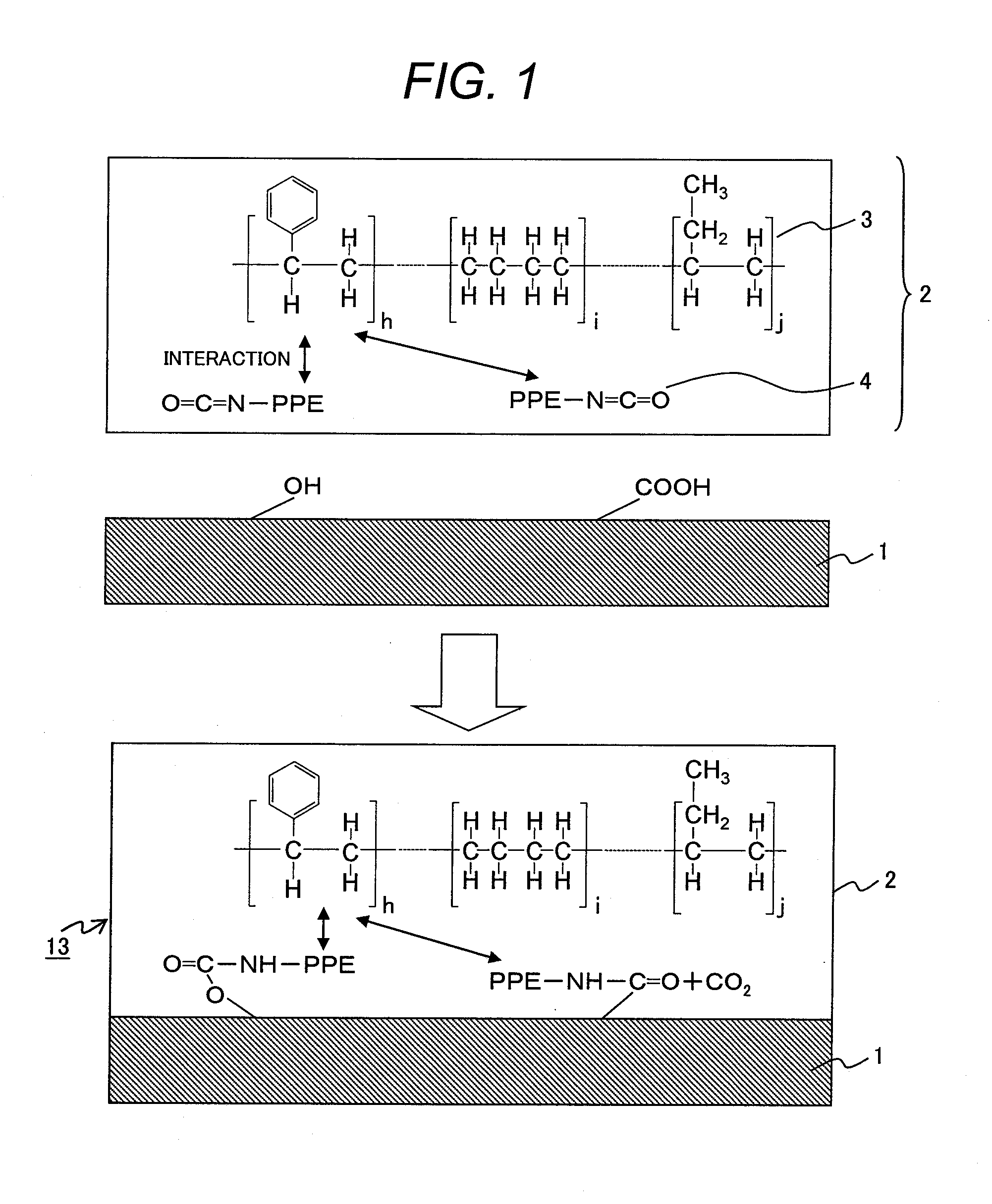

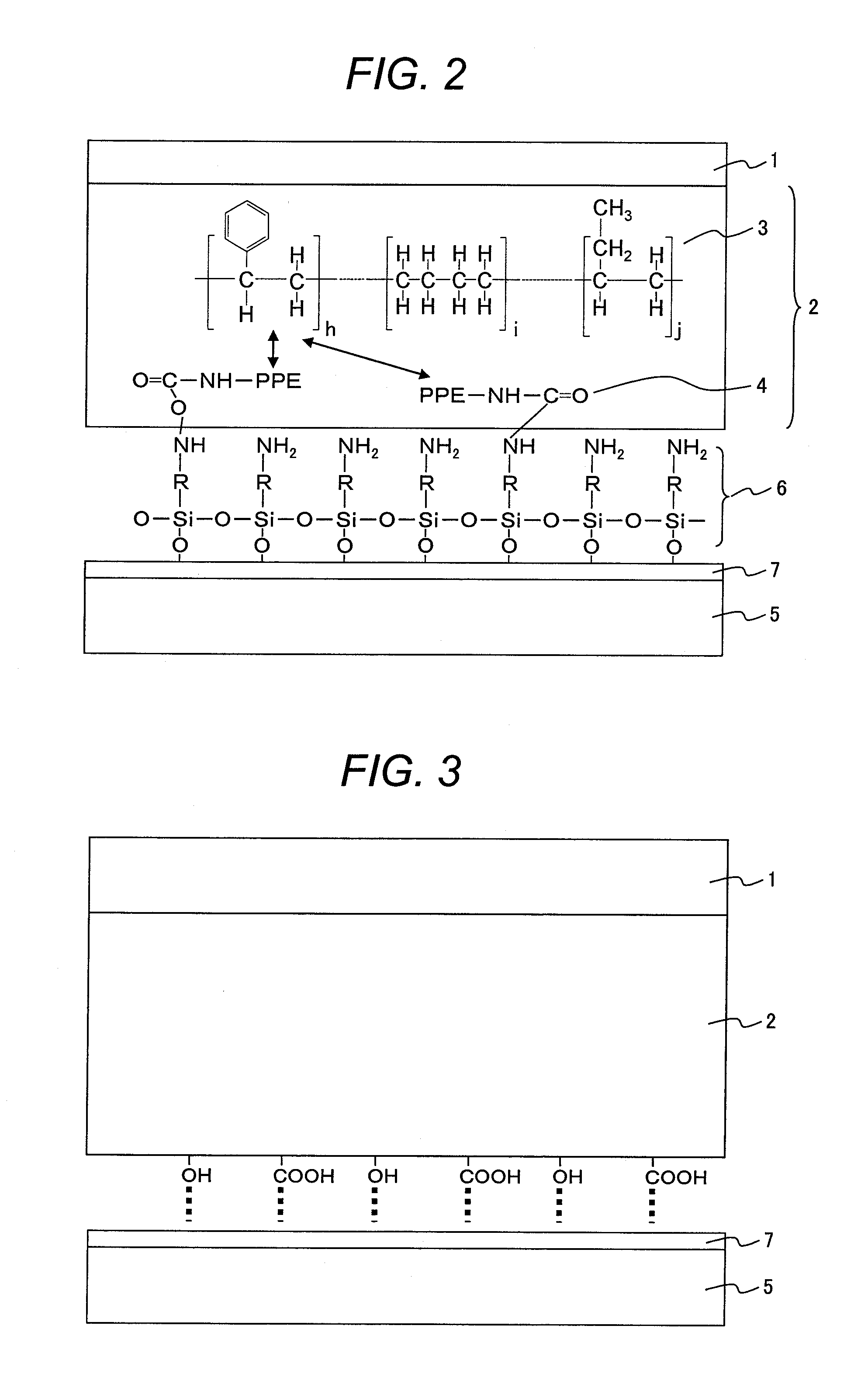

Thermoplastic resin composition, adhesive film and wiring film using the same

InactiveUS20120037410A1Simple methodImproved adhesive forceOrganic chemistryFilm/foil adhesivesChemical structureIsocyanate compound

A thermoplastic resin composition including a polyphenylene ether-based polymer having hydroxyl groups in its chemical structure and having 2,6-dimethylphenylene ether as a repeating unit, an isocyanate compound having a plurality of isocyanate groups in its structure; or a reaction product of the polyphenylene ether-based polymer having 2,6-dimethylphenylene ether as a repeating unit and the isocyanate compound having a plurality of isocyanate groups in its structure; and a hydrogenated styrene-based elastomer, and an adhesive film and a wiring film using the same are disclosed.

Owner:HITACHI METALS LTD

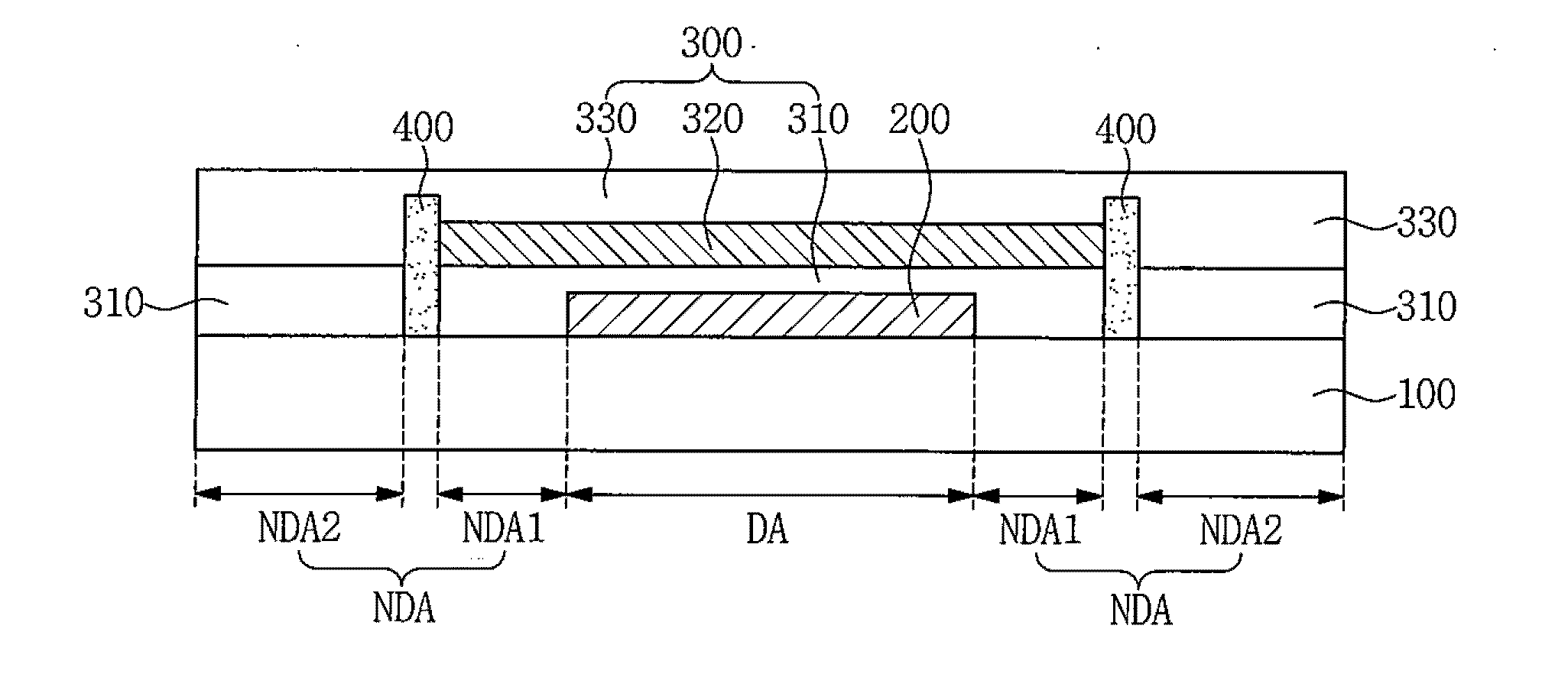

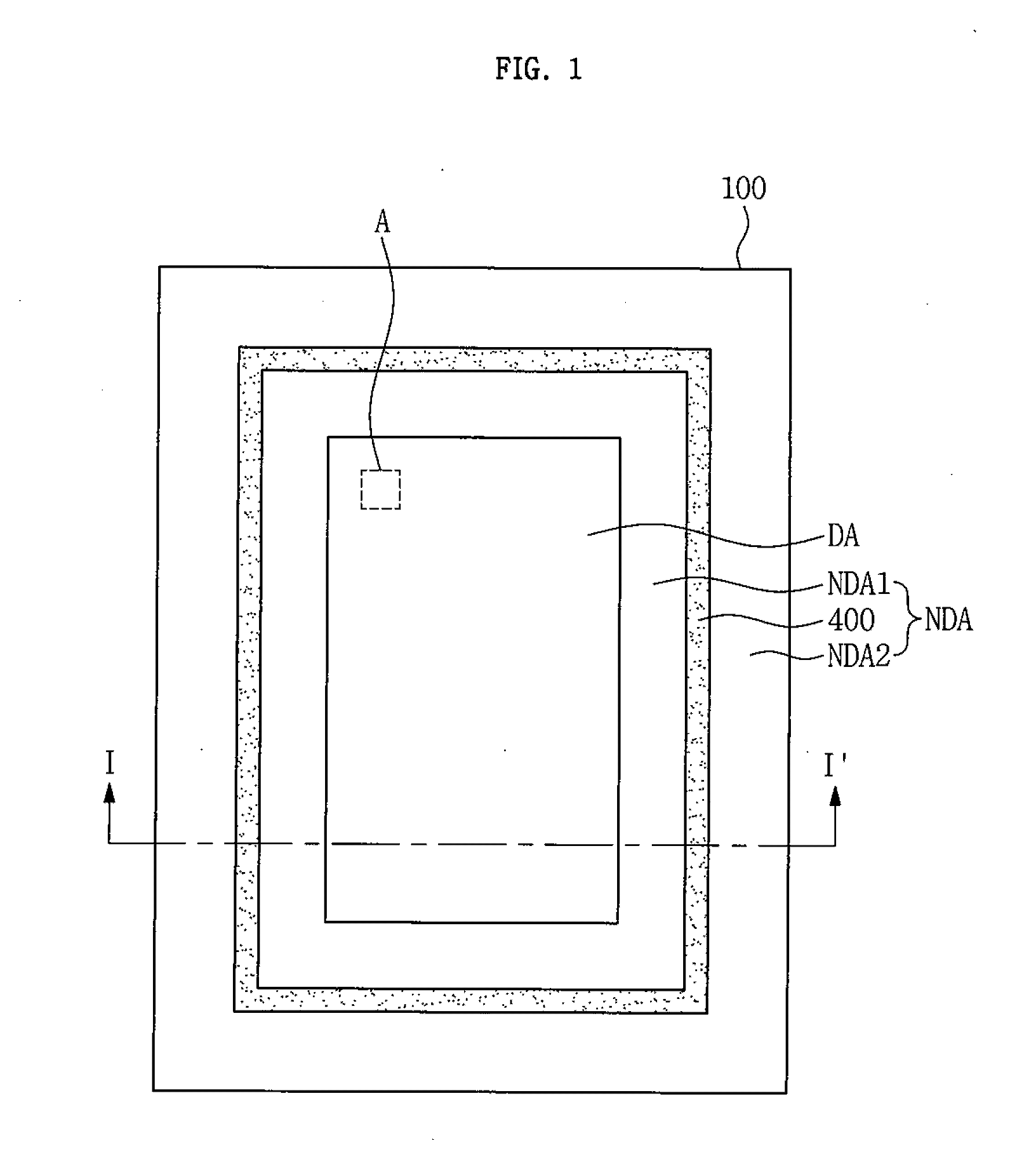

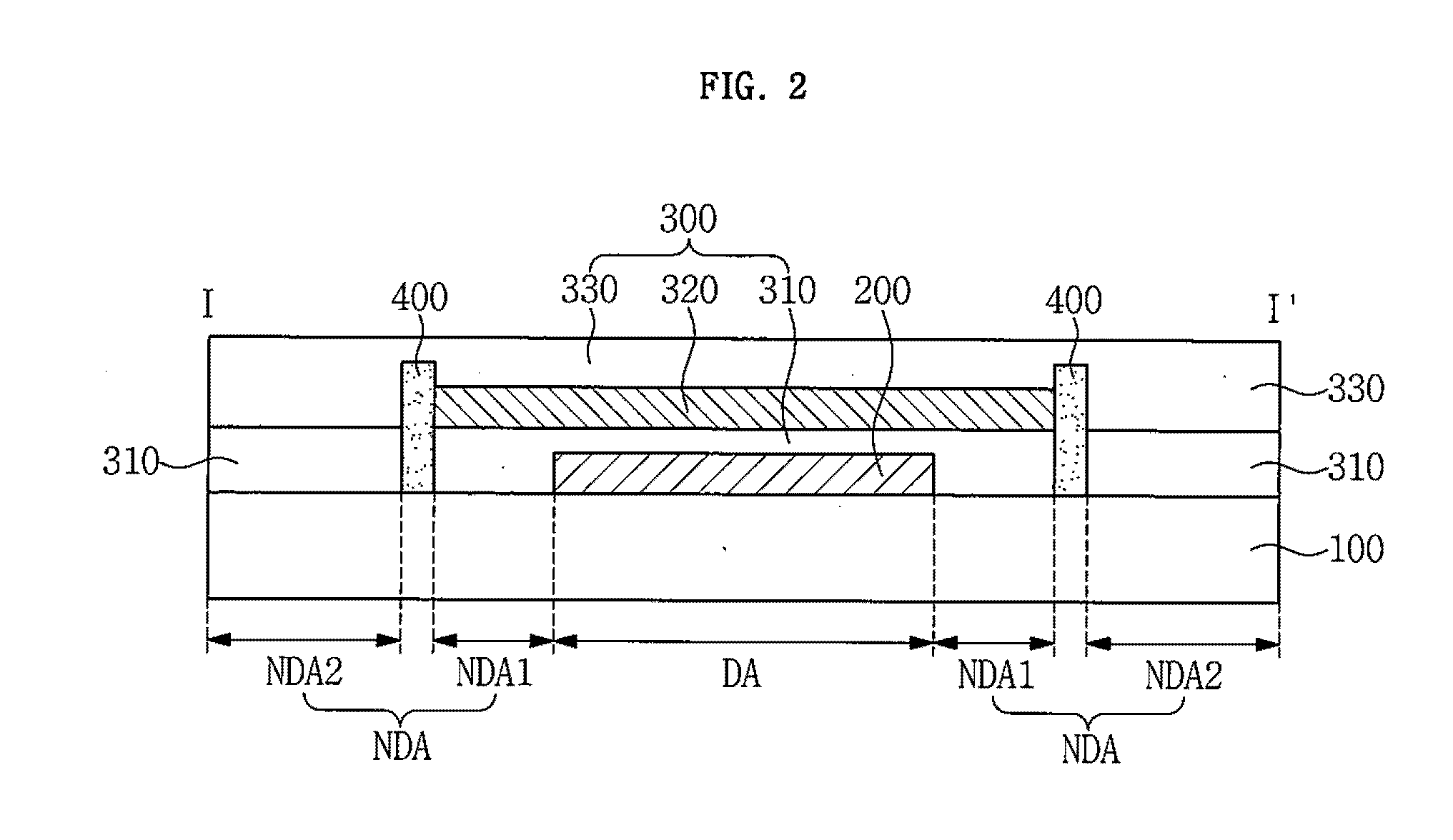

Organic light emitting diode display device and method of manufacturing the same

ActiveUS20160268547A1AdhesivenessPrevent moisture infiltrationSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceLight-emitting diode

A method of manufacturing an organic light emitting diode (OLED) display device includes: providing a substrate including a display area and a non-display area; forming an organic light emitting diode element in the display area; forming a barrier wall around the display area and spaced apart from the organic light emitting diode element; performing a plasma treatment on the substrate on which the organic light emitting diode element is formed; and forming a thin film encapsulation layer for coating the organic light emitting diode element, wherein forming the thin film encapsulation layer includes: forming at least one inorganic layer; and forming at least one organic layer inwardly of the barrier wall.

Owner:SAMSUNG DISPLAY CO LTD

Solid electrolytic capacitor

ActiveUS8027151B2Excellent storage propertiesAdhesivenessAnodisationSolid electrolytic capacitorsElectrolysisMetallurgy

Owner:SANYO ELECTRIC CO LTD

Polar-group-containing cyclized rubber and process for producing same

A main object of the invention is to provide a polar-group-containing cyclized rubber making it possible to improve remarkably the adhesiveness between paint and a molded product made of a nonpolar polymer such as polypropylene or polyethylene, and a process for producing the same. In order to attain the object, the invention provides a polar-group-containing cyclized rubber which has a polar group at a terminal of a polymer chain thereof, has a weight-average molecular weight of 1,000 to 1,000,000, and is obtained by cyclizing a conjugated diene polymer having the polar group at a terminal of a polymer chain thereof.

Owner:ZEON CORP

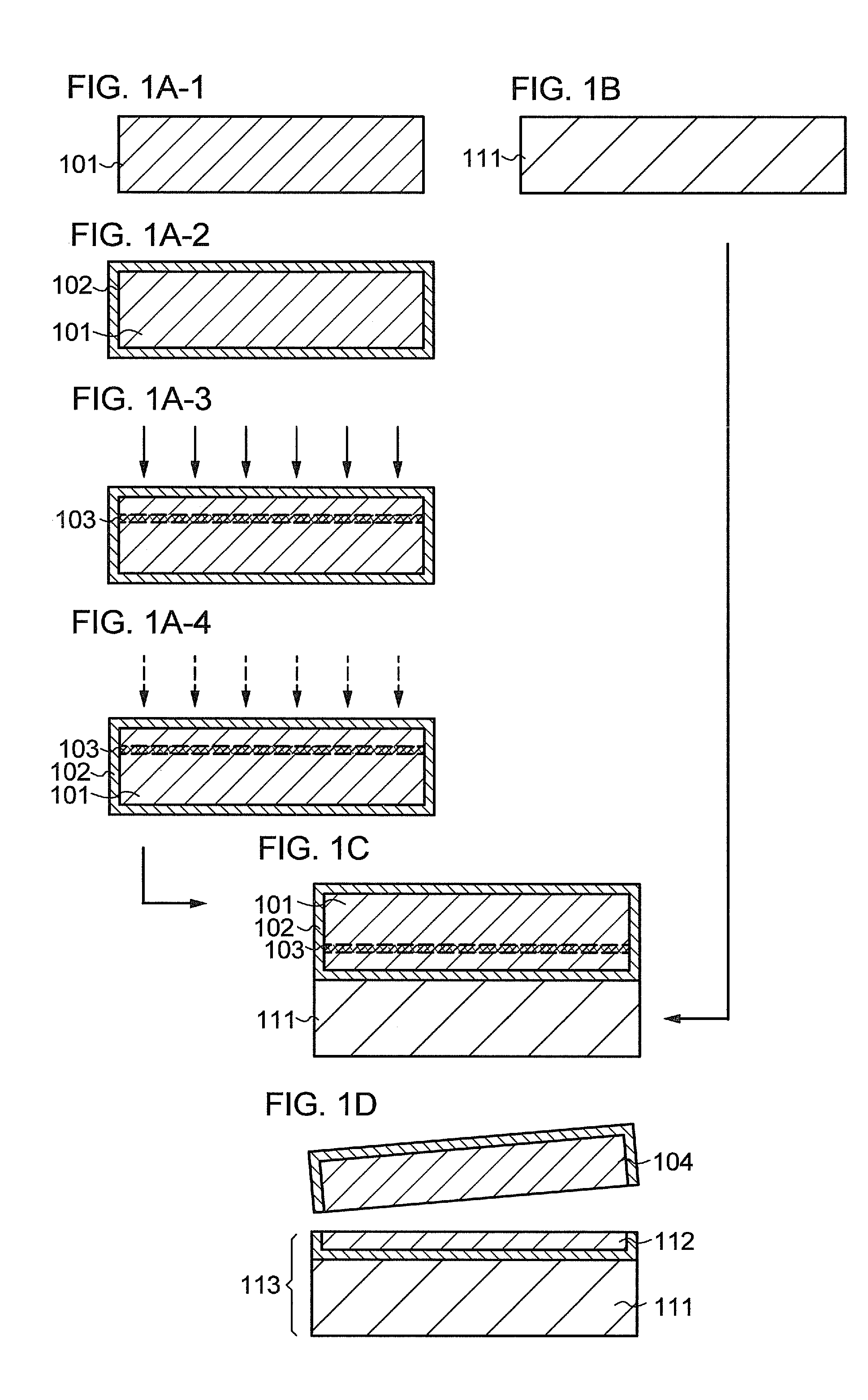

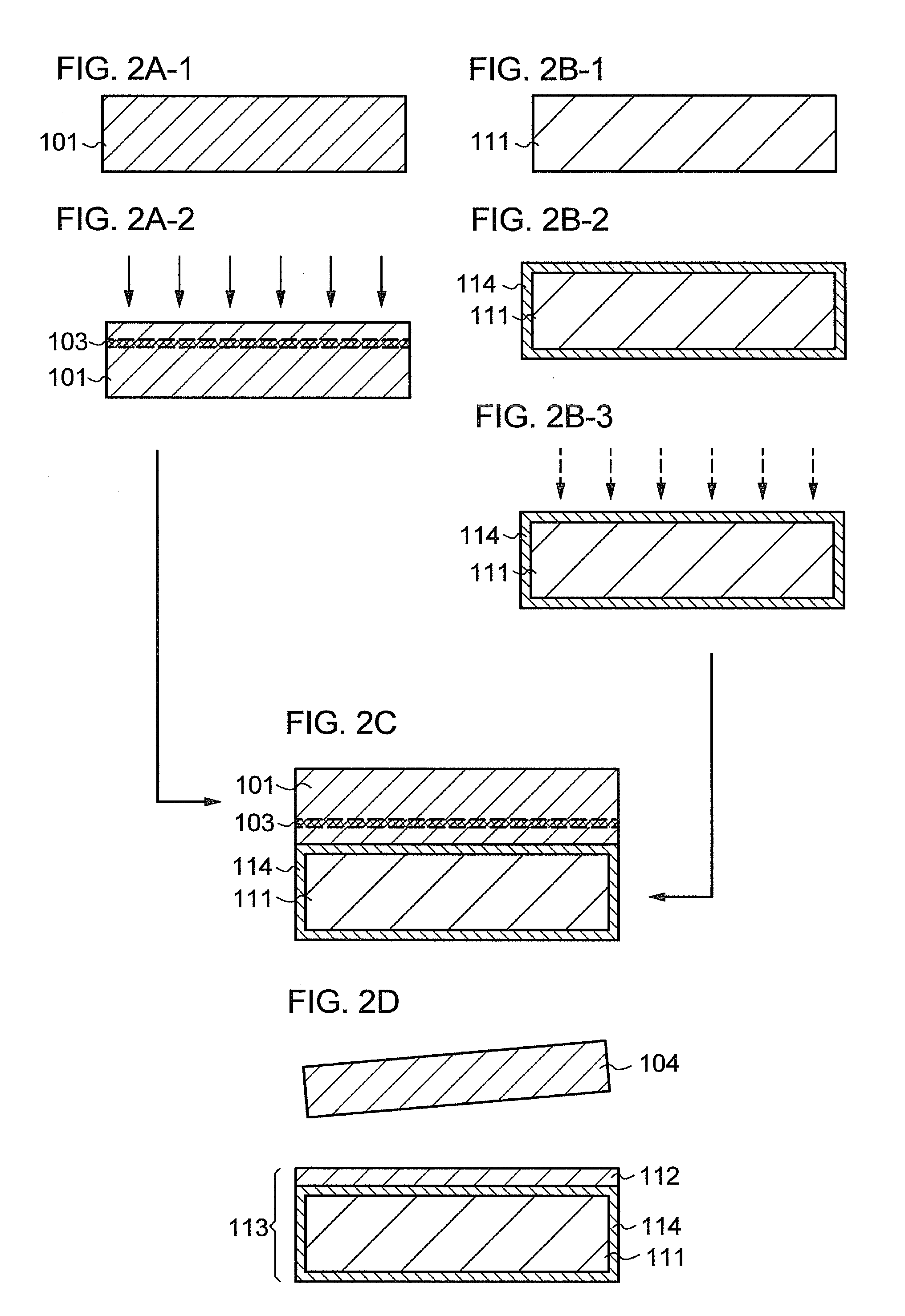

Method for manufacturing soi substrate

InactiveUS20090197391A1Improve adhesionHigh bonding strengthSolid-state devicesSemiconductor/solid-state device manufacturingSoi substrateSingle crystal

A method for manufacturing an SOI substrate is provided in which adhesiveness between a single crystal semiconductor substrate and a semiconductor substrate is improved; bonding defects are reduced; and sufficient bonding strength is provided in a bonding step and also in a process of manufacturing a semiconductor device. An insulating film including halogen is formed on a single crystal semiconductor substrate side in which an embrittlement layer is formed. The insulating film including halogen undergoes a plasma treatment. The insulating film including halogen and a face of a semiconductor substrate are bonded so as to face each other. A thermal treatment is performed to split the single crystal semiconductor substrate along the embrittlement layer, thereby separating the single crystal semiconductor substrate into a single crystal semiconductor substrate and the semiconductor substrate to which a single crystal semiconductor layer is bonded. The single crystal semiconductor layer bonded to the semiconductor substrate undergoes a planarization treatment.

Owner:SEMICON ENERGY LAB CO LTD

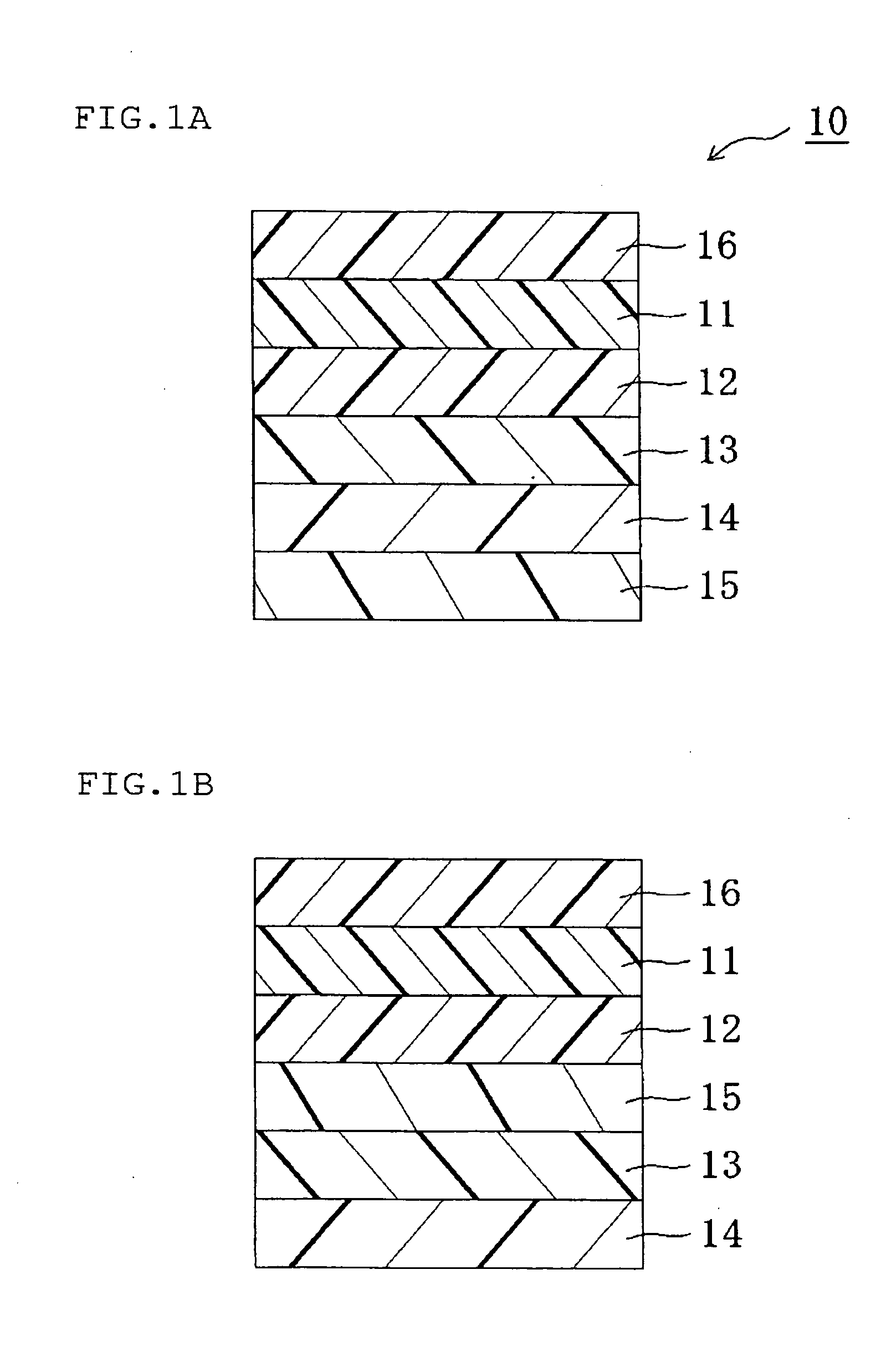

Optical film, method for producing the same, and image display device using the same

InactiveUS7223452B2Improve adhesionAdhesivenessLiquid crystal compositionsLayered productsSolubilitySolvent

An optical film, which includes a laminate of a base and a birefringent layer, and which is excellent in adhesiveness between the base and the birefringent layer, is provided. The birefringent layer is formed on the base by: coating a material of the birefringent layer on the base so as to form a coating film; stretching / shrinking the base so as to stretch / shrink the coating film; and solidifying the material of the coating film. The material is dispersed or dissolved previously in a solvent and coated in a form of solution, where the solvent used exhibits solubility with respect to the base, and in the coating step, the solvent is infiltrated into a part of the interior of the base, thereby obtaining an optical film with excellent adhesiveness between the base and the birefringent layer.

Owner:NITTO DENKO CORP

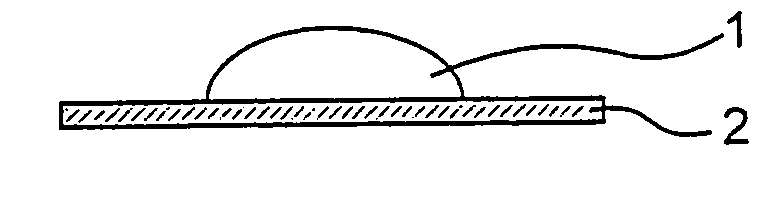

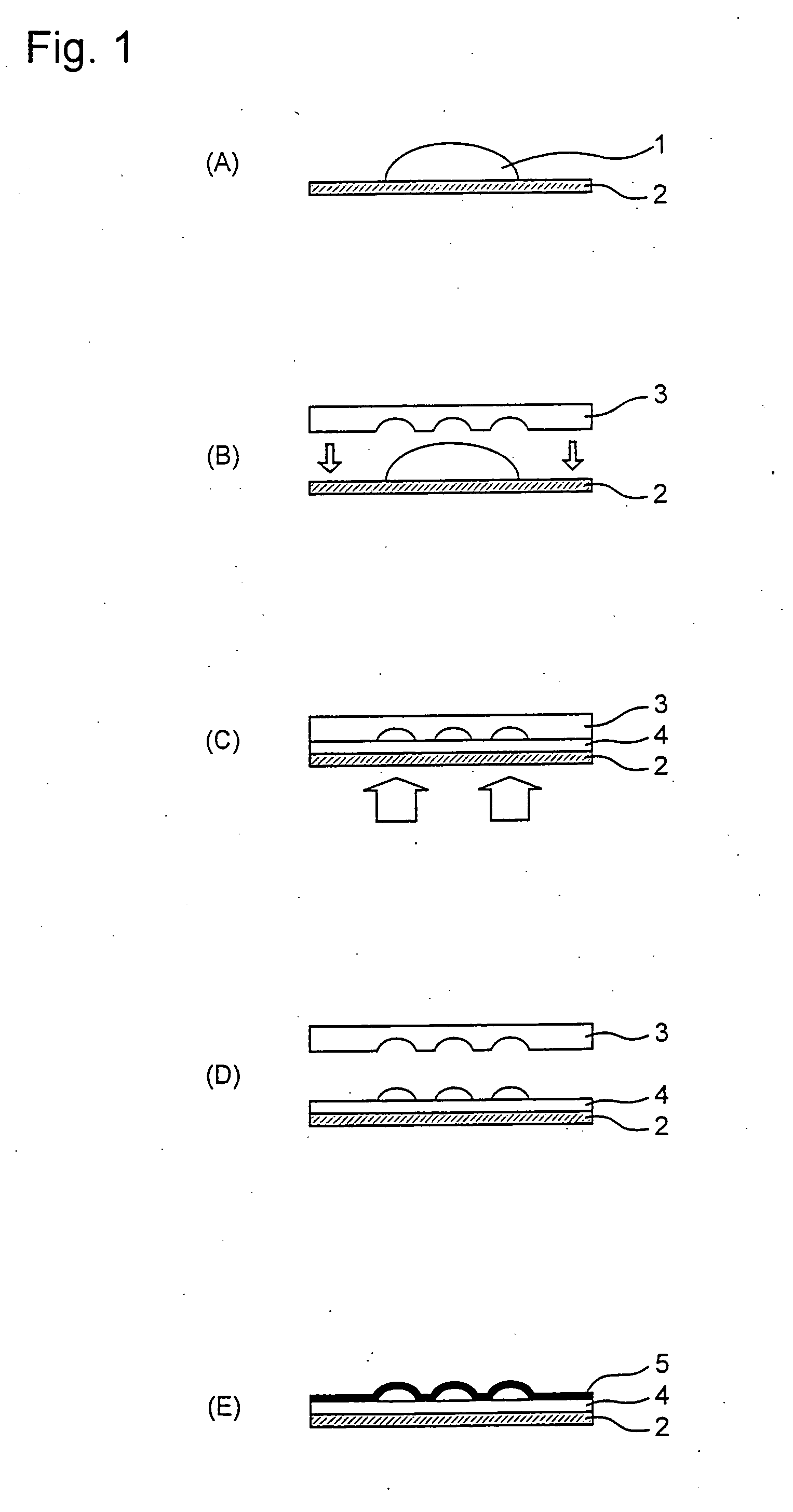

Microlens

InactiveUS20070172772A1Avoid separationAdhesivenessPhotomechanical apparatusOriginals for photomechanical treatmentHigh humidityInorganic compound

Provided is a microlens having an inorganic compound layer directly formed on the surface of a base lens material that is resistant to cracking and wrinkling of the inorganic compound layer under high-temperature and high-humidity environment and also to cracking of the base lens material by repeated temperature fluctuation, and an optical device using the microlens. A microlens, comprising a hardened product obtained by polymerization of a polymerizable composition containing a polymerizable monomer and metal oxide fine particles having an average diameter of 1 to 80 nm as essential components and an inorganic compound layer coated on the surface thereof. An optical device equipped with the microlens.

Owner:ORMON CORP

Solid electrolytic capacitor and method for manufacturing the same

ActiveUS20090161297A1AdhesivenessImprove adhesionSolid electrolytic capacitorsLiquid electrolytic capacitorsCarbon layerSilver paste

Solid electrolytic capacitors are provided with decreased equivalent series resistance (ESR). The solid electrolytic capacitors include: an anode containing a valve metal or an alloy that is mainly made of a valve metal; a dielectric layer formed on a surface of the anode; an electrolyte layer formed on the dielectric layer; a carbon layer formed on the electrolyte layer; and a silver paste layer formed on the carbon layer, wherein the silver paste layer contains a nonionic surfactant.

Owner:SANYO ELECTRIC CO LTD

Pneumatic tire

InactiveUS20070074799A1AdhesivenessSuppresses penetration of oxygenWithout separate inflatable insertsWith separate inflatable insertsEngineeringButyl rubber

This invention relates to a pneumatic tire provided at its bead portion with a rubber chafer (4) and covered at its inner surface with an innerliner (5), wherein a toe rubber (6) is further arranged on a toe end part of the bead portion so as to overlap with the rubber chafer (4) and the innerliner (5) and locate at least outside the innerliner (5) at the overlapped portion with the innerliner (5), and a rubber composition A containing at least one of butyl rubber and halogenated butyl rubber as 20-40 mass % of a rubber component is used in the toe rubber (6).

Owner:BRIDGESTONE CORP

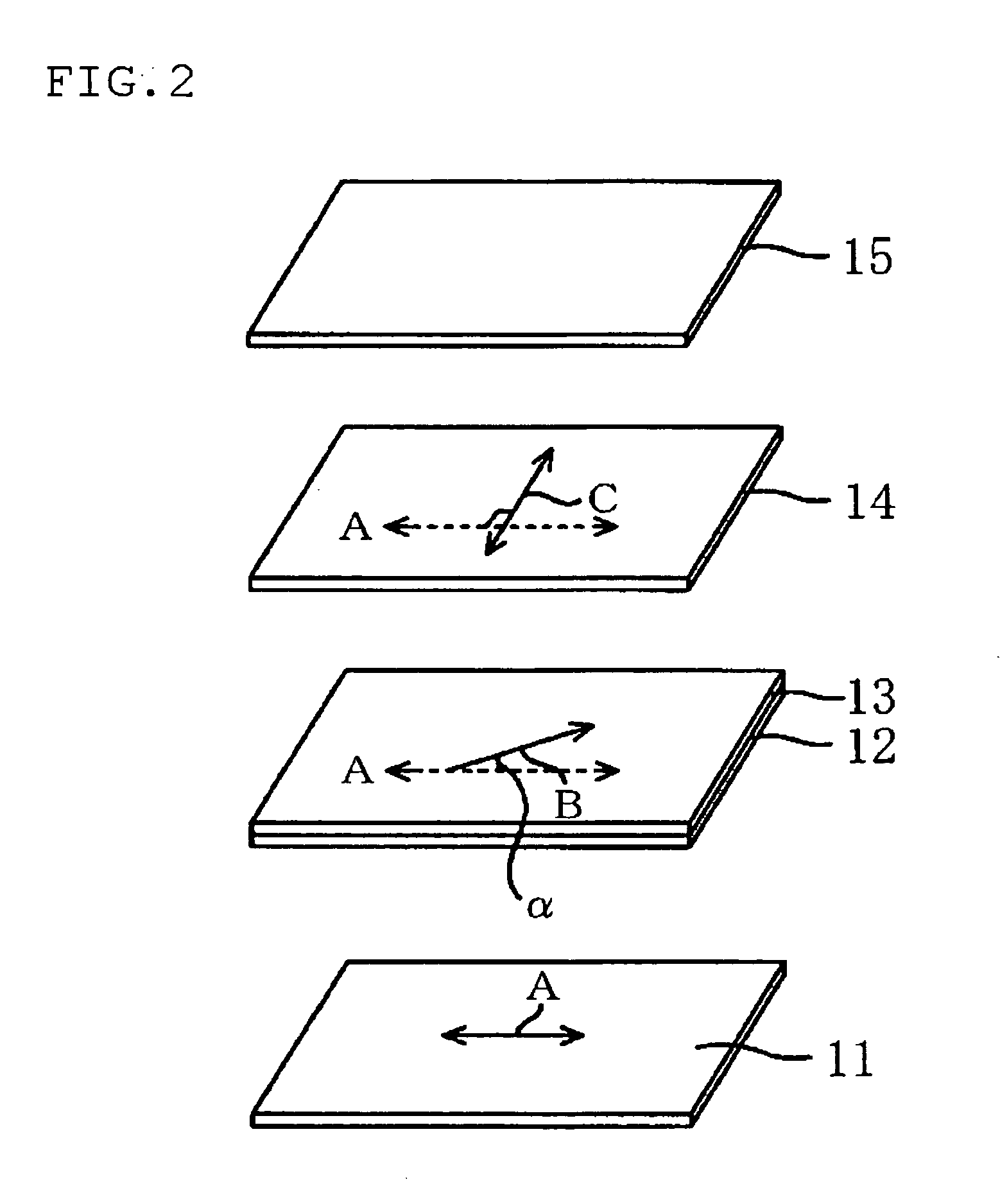

Method of producing elliptically polarizing plate and image display using the elliptically polarizing plate

InactiveUS20060203159A1Improve production efficiencyWaste is producedPolarising elementsNon-linear opticsTectorial membranePolarizer

The present invention provides a method of producing an elliptically polarizing plate including the steps of: forming a first birefringent layer on a surface of a transparent protective film; laminating a polarizer on a surface of the transparent protective film; forming a second birefringent layer on a surface of the first birefringent layer; and forming a third birefringent layer on a surface of the second birefringent layer. The first birefringent layer is arranged on the opposite side against the polarizer with respect to the transparent protective film. The step of forming the first birefringent layer includes the steps of: applying a liquid crystal material onto a substrate subjected to an alignment treatment; treating the applied liquid crystal material, so as to form the first birefringent layer on the substrate; and transferring the first birefringent layer onto a surface of the transparent protective film.

Owner:NITTO DENKO CORP

Copper foil provided with dielectric layer for forming capacitor layer, copper clad laminate for formation of capacitor layer using such such copper foil with dielectric layer, and method for producing such copper foil with dielectric layer for formation of capacitor layer

InactiveUS20060057420A1High dielectric constantImprove electrostatic capacityThermometers using material expansion/contactionSurface reaction electrolytic coatingCapacitanceCopper foil

To provide a dielectric-layer-provided copper foil or the like for extremely improving the product yield while making the most use of the increase effect of an electric capacity of a thin dielectric layer using the sputtering vapor deposition method. In the case of dielectric-layer-provided copper foils respectively having a dielectric layer on one side of a copper foil, the dielectric layer 6 is an inorganic-oxide sputter film having a thickness of 1.0 μm or less and formed on the one side of the copper foil in accordance with the sputtering vapor deposition method and the dielectric-layer-provided copper foils for respectively forming a capacitor layer, characterized in that a pit-like defective portion generated on the inorganic-oxide sputter film is sealed by polyimide resin are used.

Owner:MITSUI MINING & SMELTING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com