Patents

Literature

35results about How to "High density wiring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-layer wiring substrate

InactiveUS20020172021A1Excellent in high-frequency characteristicAdhesivenessSemiconductor/solid-state device detailsSolid-state devicesMetallic foilHigh density

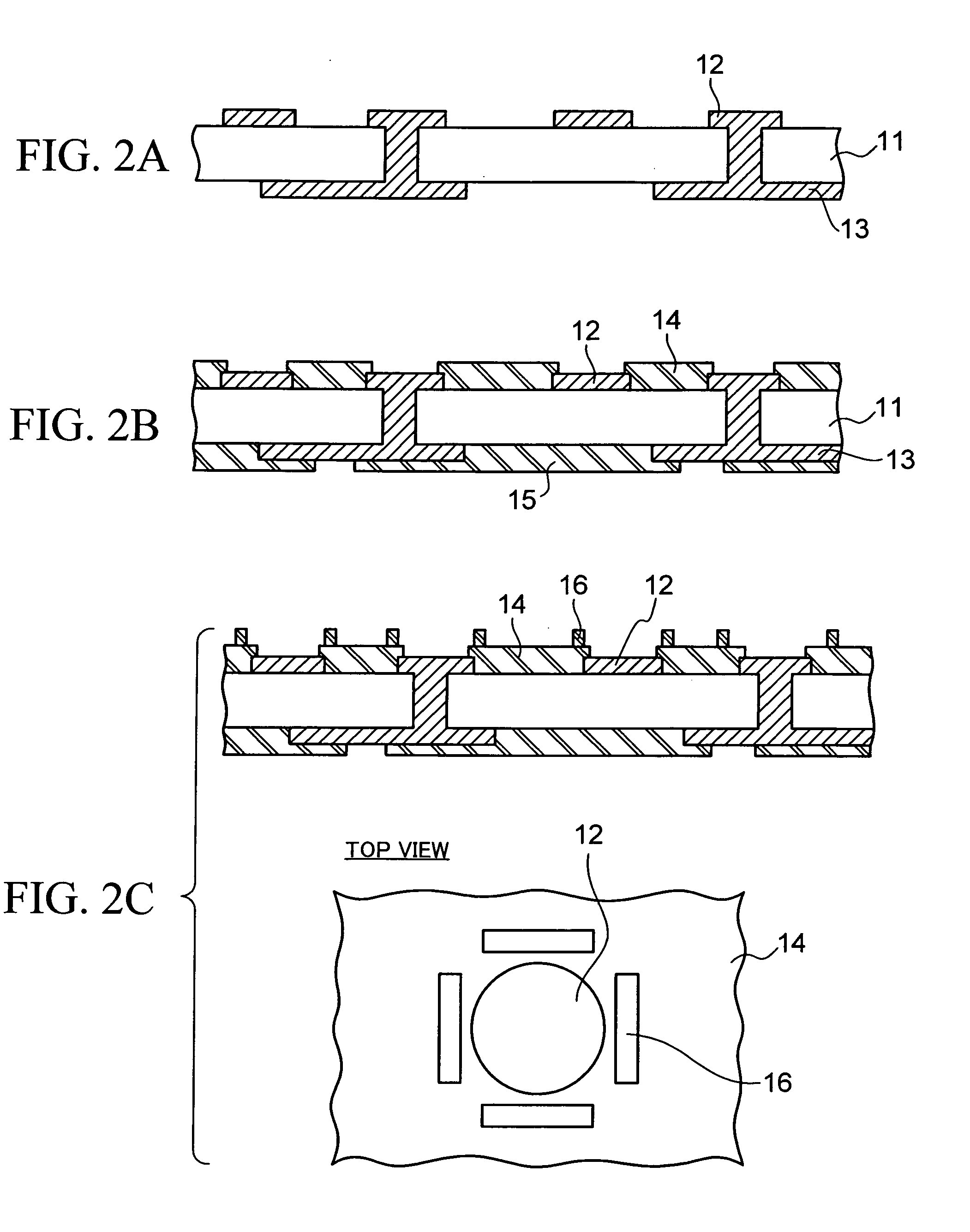

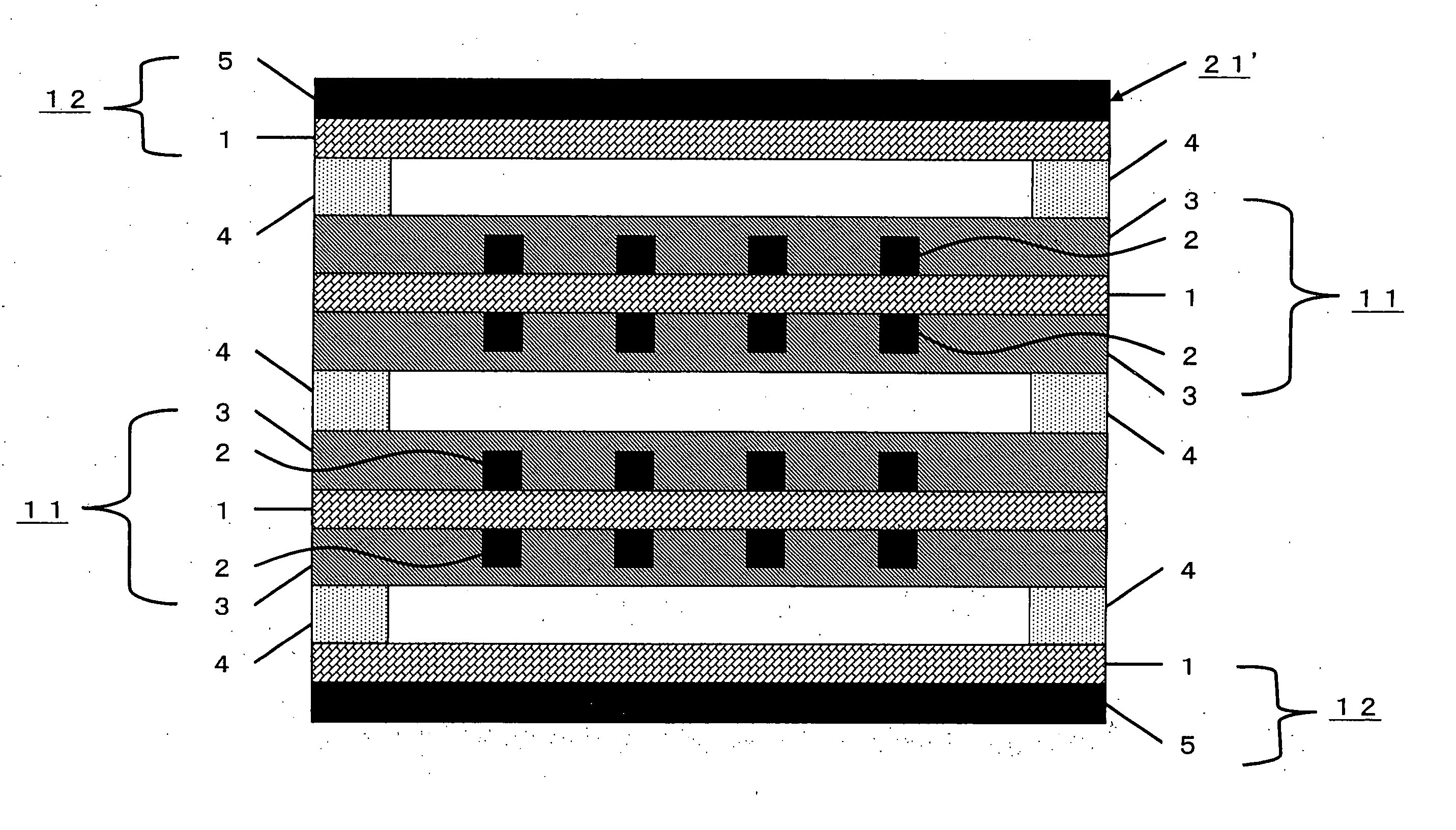

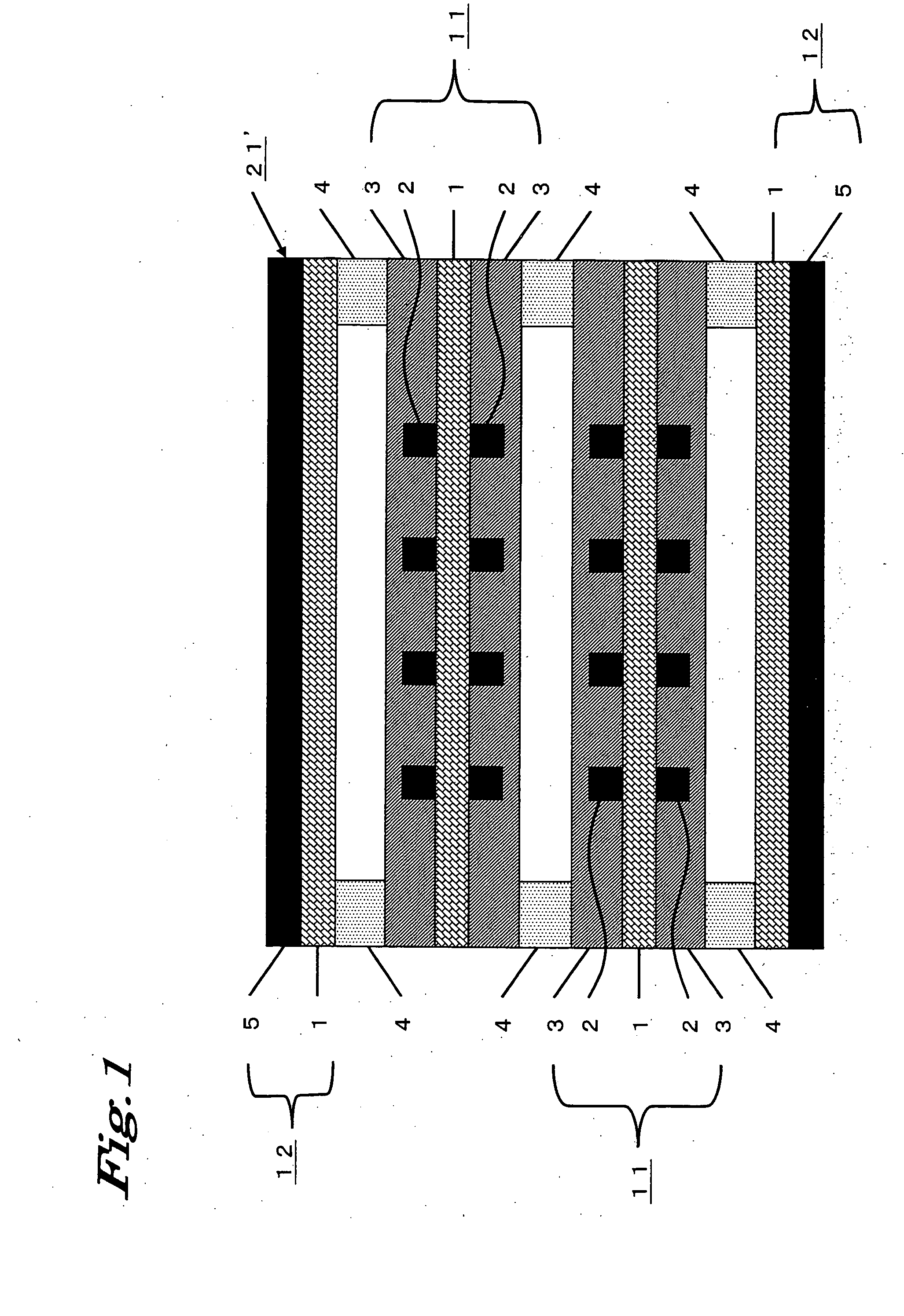

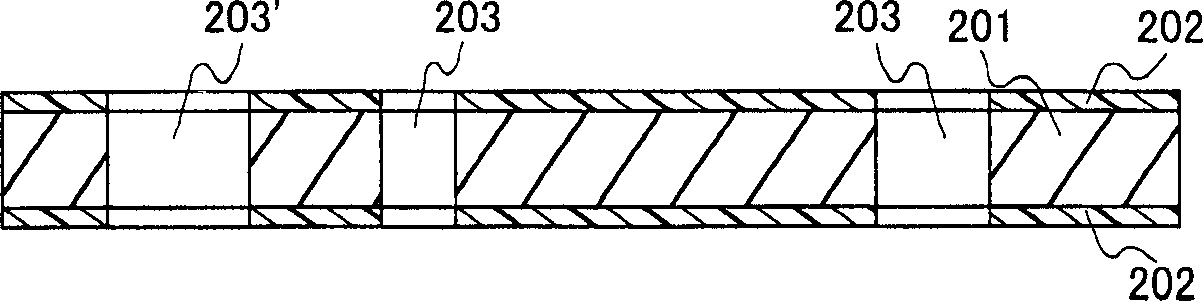

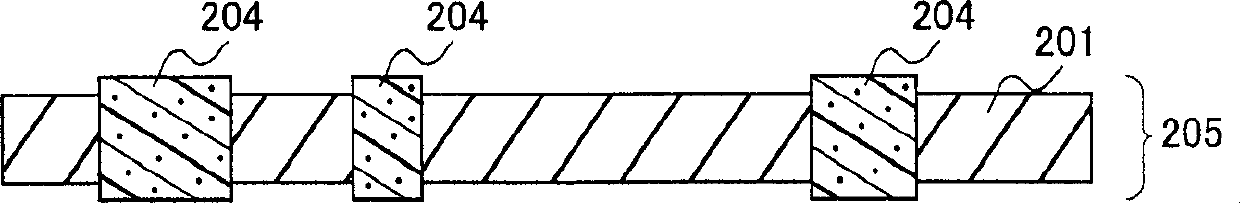

An object of the invention is to satisfy all of a high-density wiring package, soldering thermal resistance, an insulating property and high-frequency transmission characteristics. The invention is a multi-layer wiring substrate having a lamination of a plurality of dielectric layers which are each provided with a wiring conductor made of a metallic foil on at least one of upper and bottom surfaces of the dielectric layer, the wiring conductors between which the dielectric layer is disposed being electrically connected with each other via a through conductor formed in the dielectric layer; on this occasion, the dielectric layers each individually are composed of a liquid crystal polymer layer and cladding layers made of a polyphenyleneether-type organic substance and formed on upper and bottom surfaces of the liquid crystal polymer layer.

Owner:KYOCERA CORP

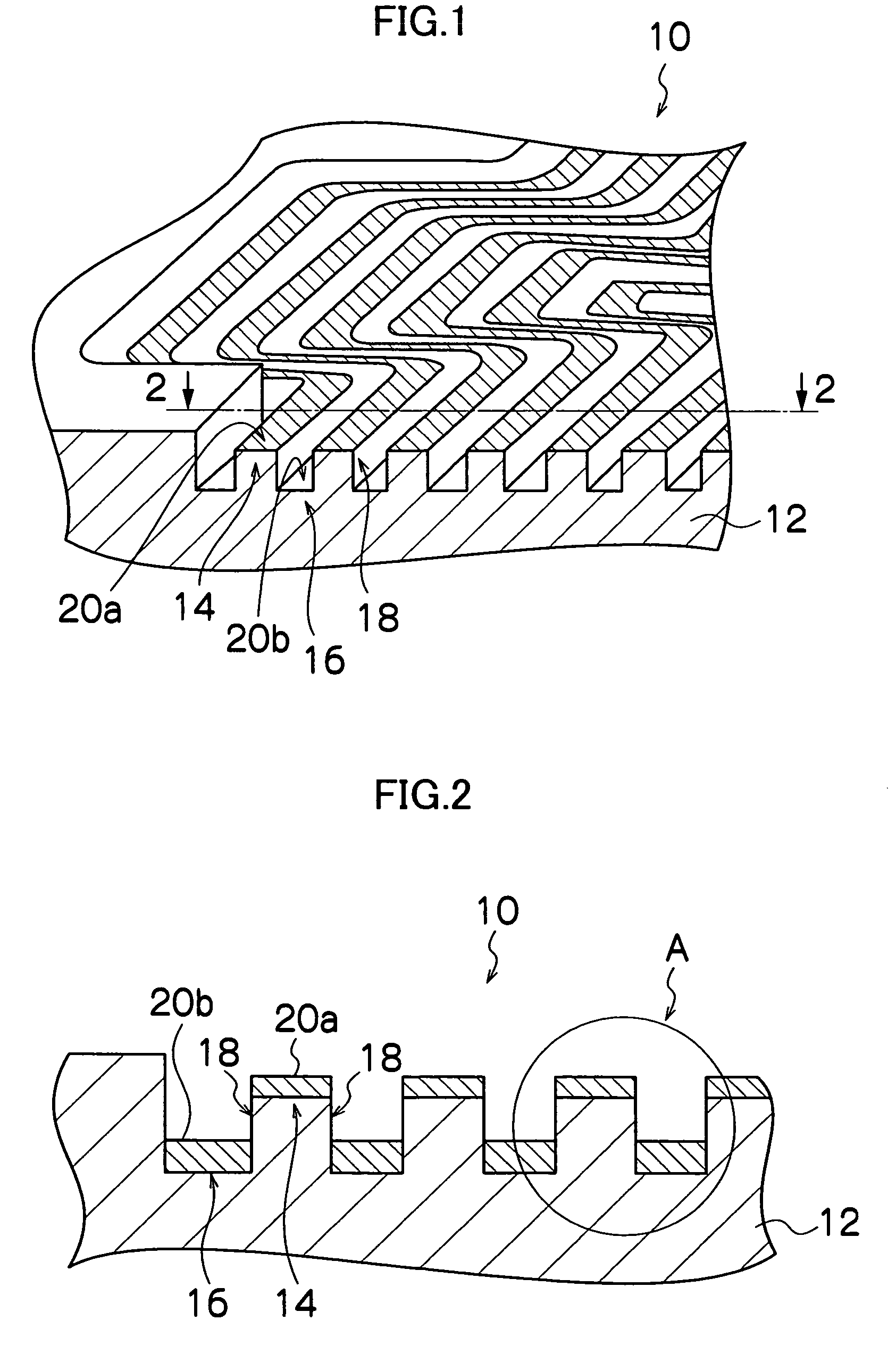

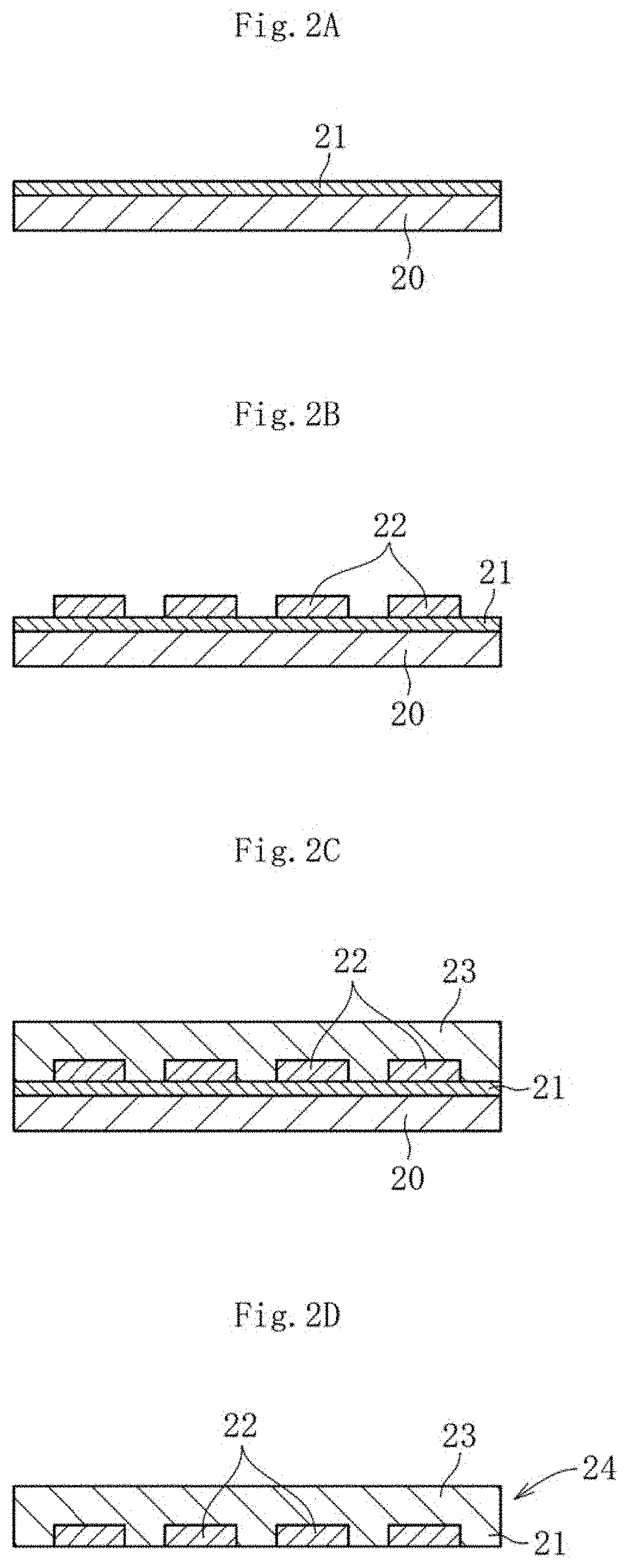

Wiring board and production method thereof

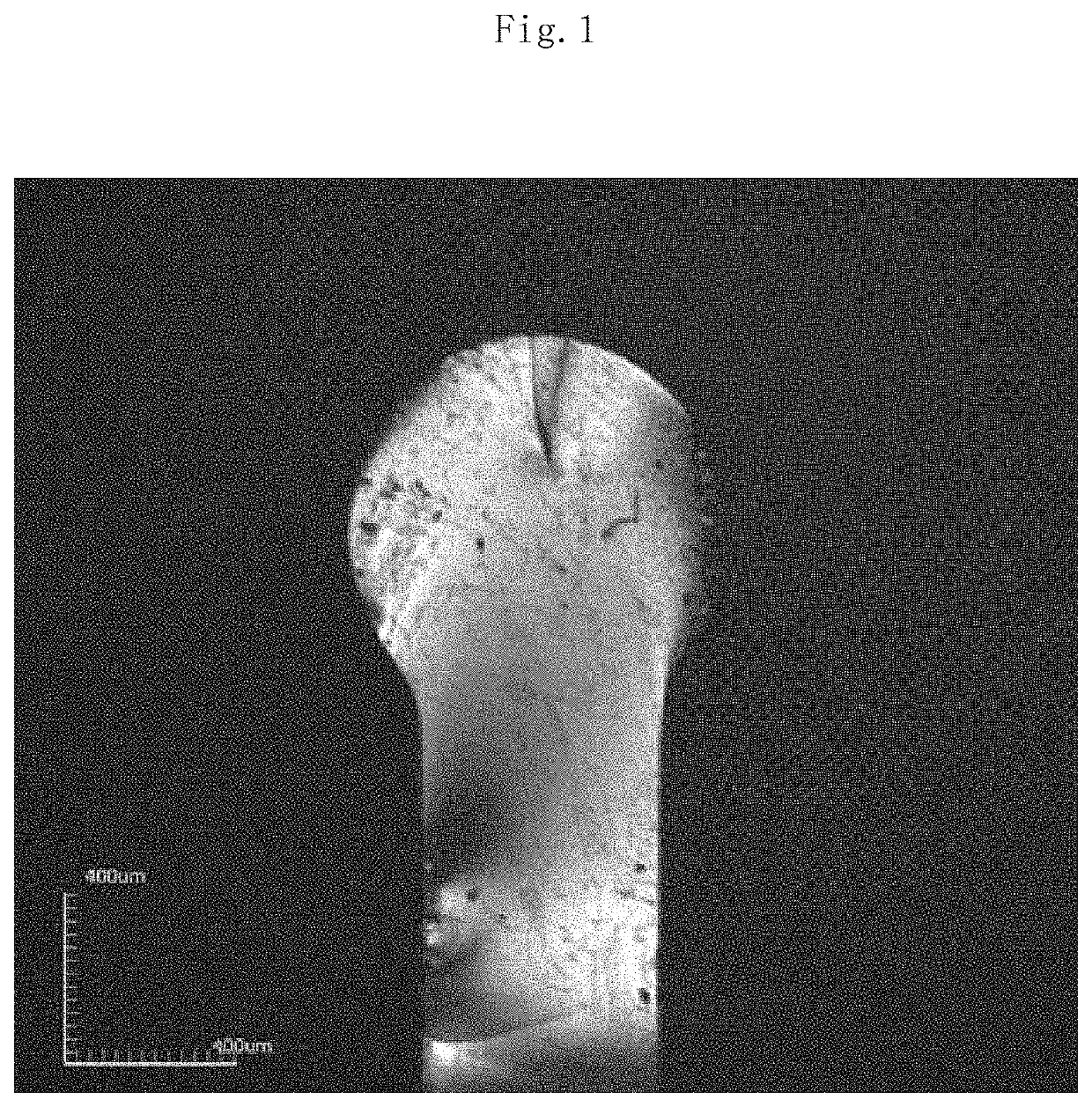

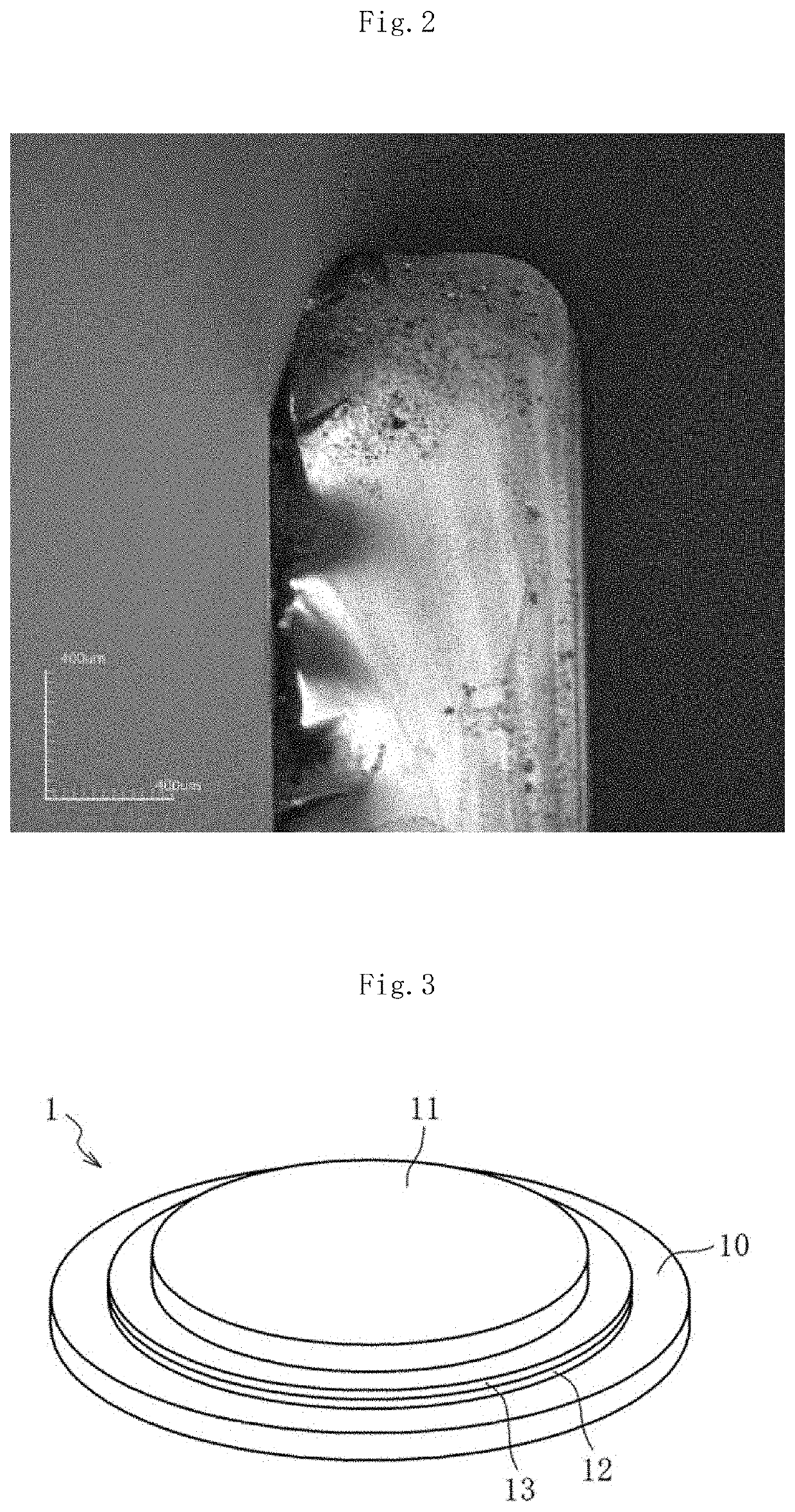

InactiveUS20060163725A1Reduced dimensional accuracy requirementsHigh-density wiringSemiconductor/solid-state device detailsSolid-state devicesResistAdemetionine

It is an object of the present invention to provide a wiring board having high-density wiring with a controlled shape without masking by a resist film and a production method thereof. In the present invention, the production method of a wiring board having copper wiring on an insulating substrate includes the steps of forming a metal seed layer on the insulating substrate, the metal seed layer having a roughened shape in a portion on which the copper wiring or a bump is to be formed, and forming an electroplated film of copper or an alloy of copper through electroplating on the portion of the metal seed layer having the roughened shape. A substance for suppressing the plating reaction is added to a plating bath to provide an angle of 90 degrees or smaller between a surface of the insulating substrate and a side of the electroplated film.

Owner:HITACHI CABLE

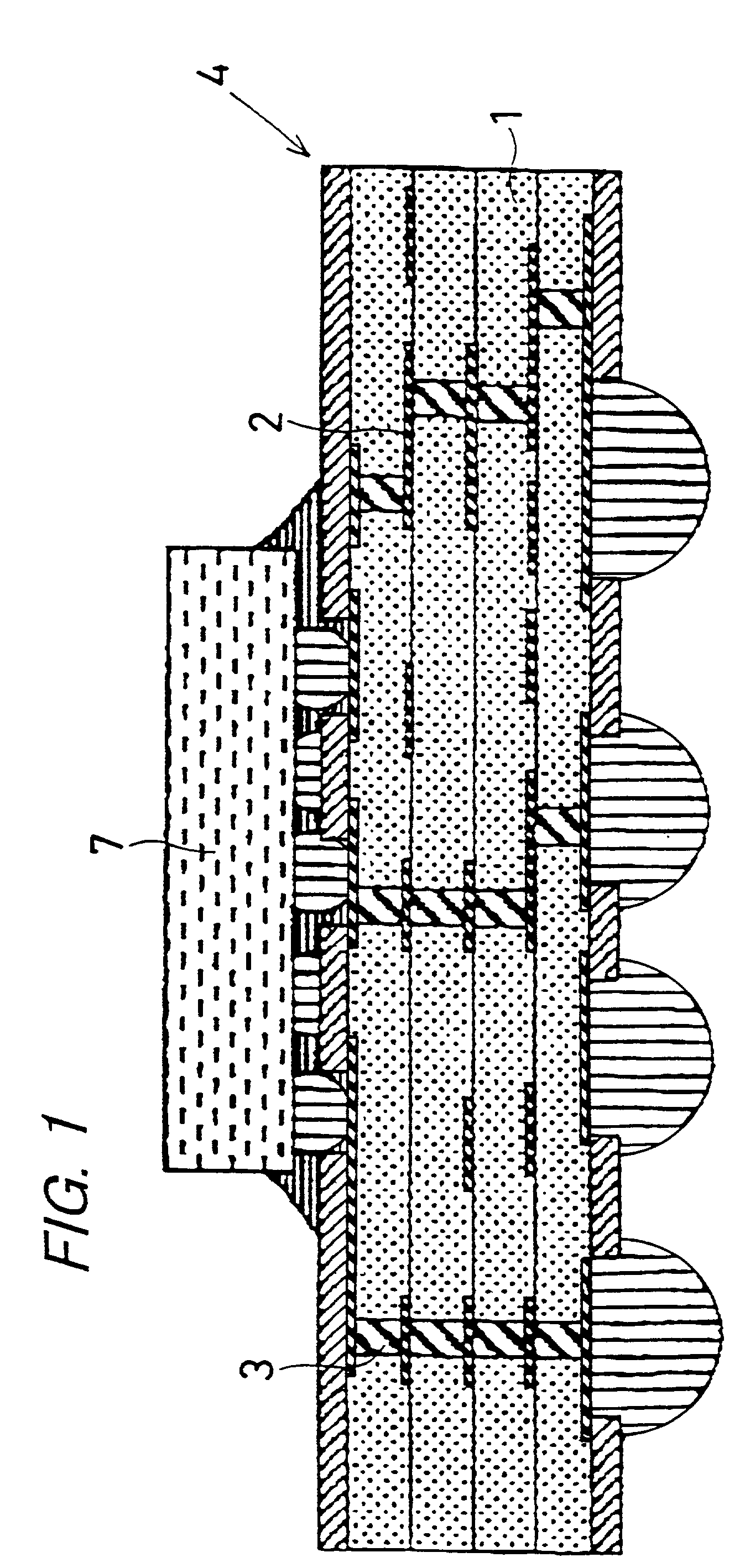

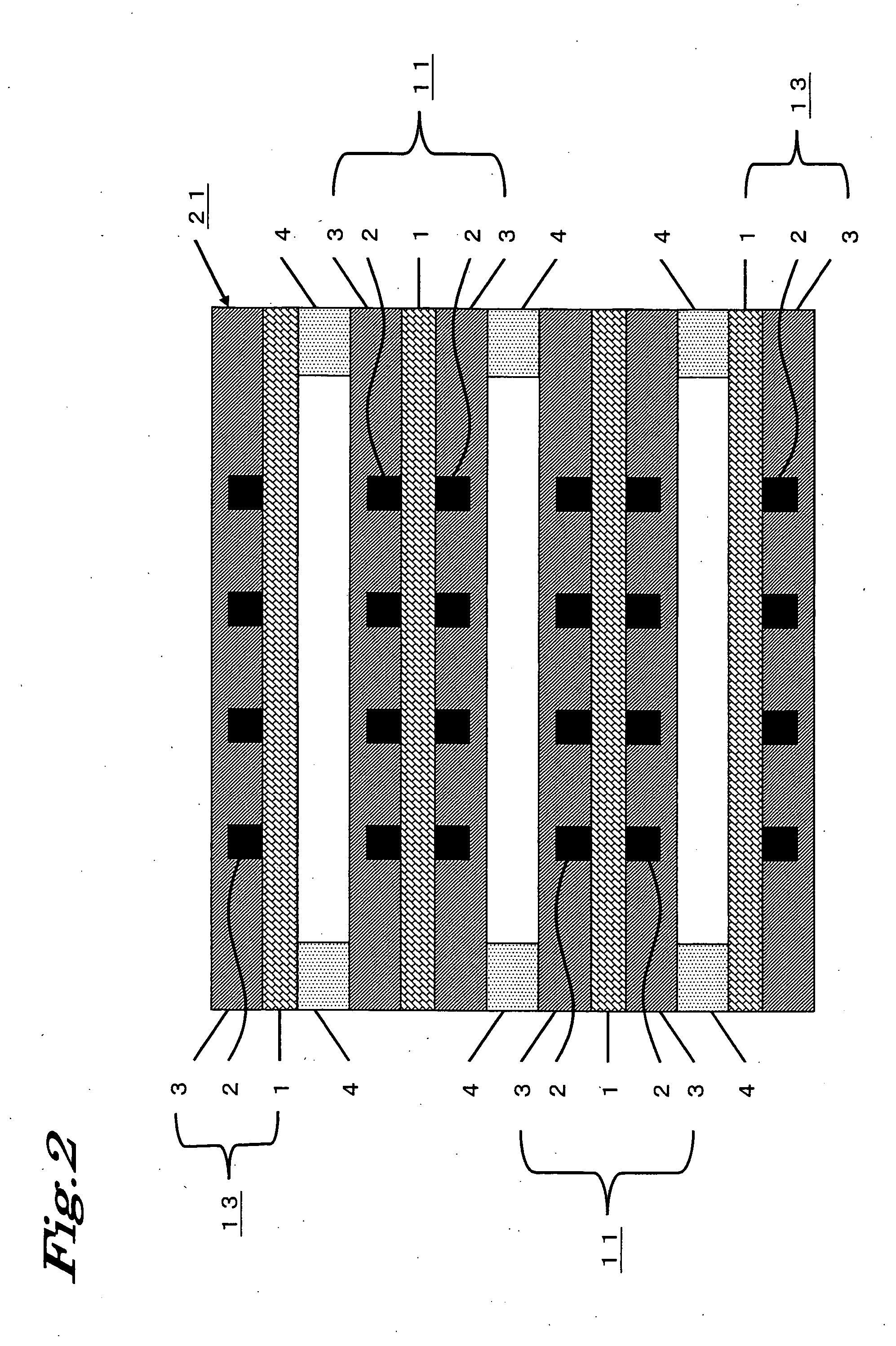

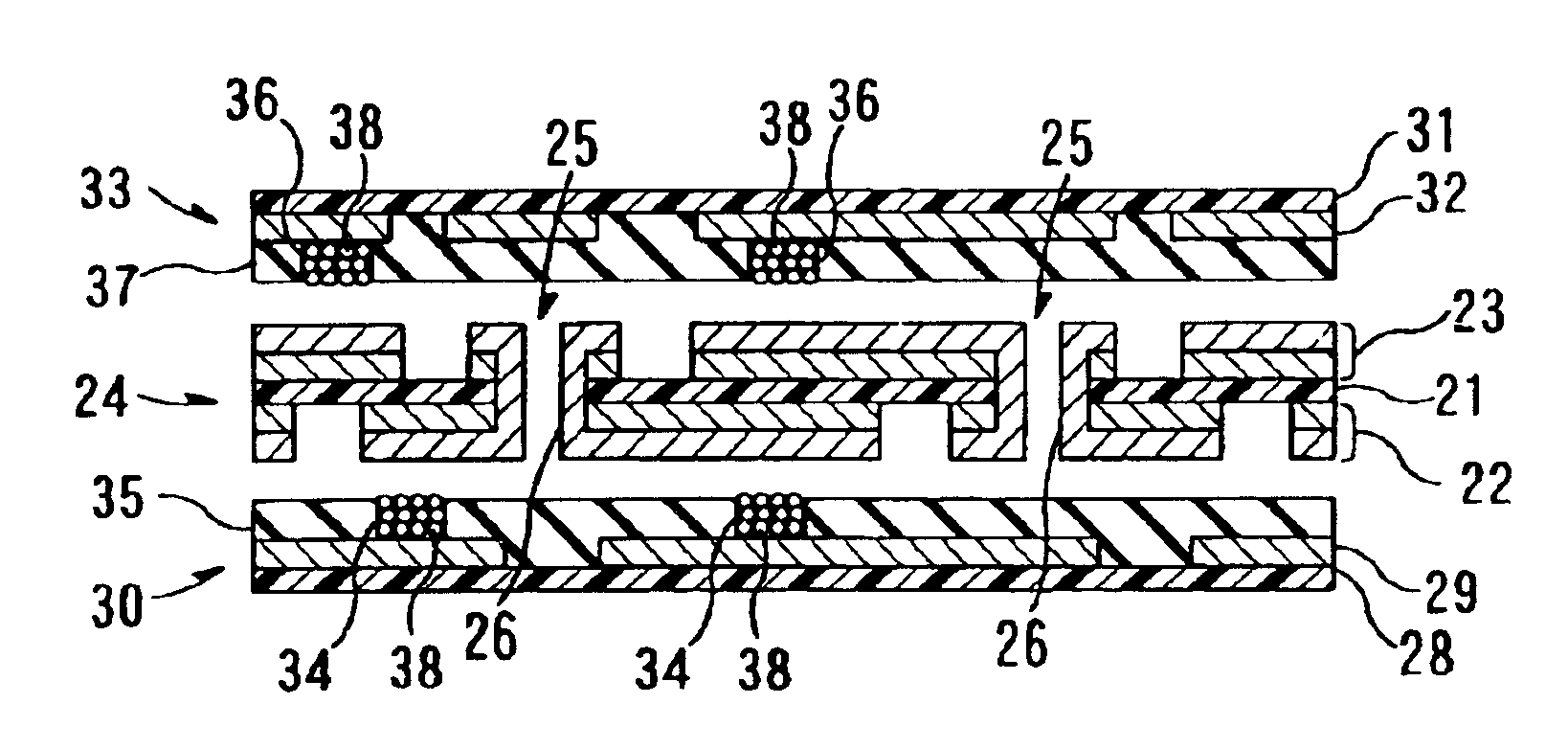

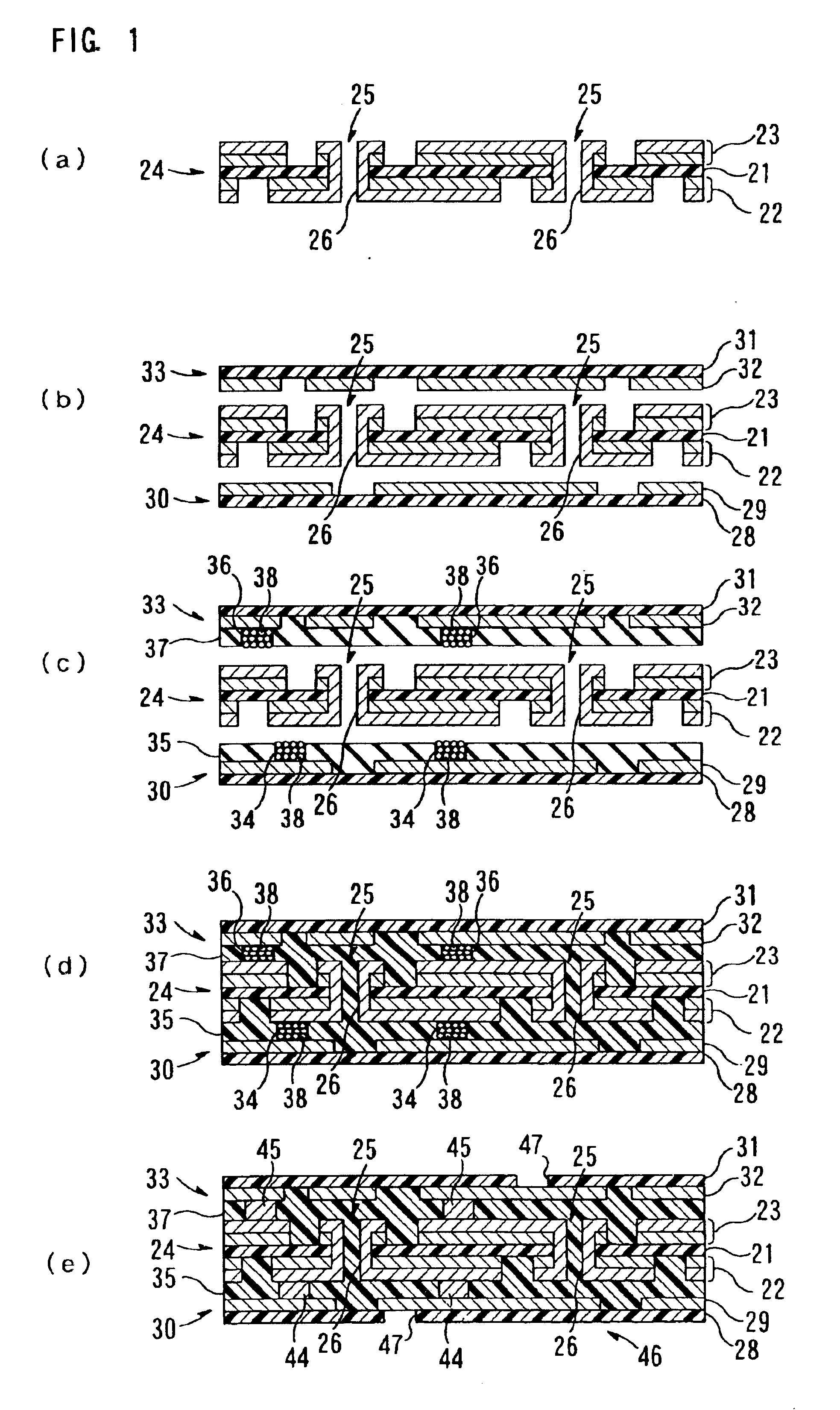

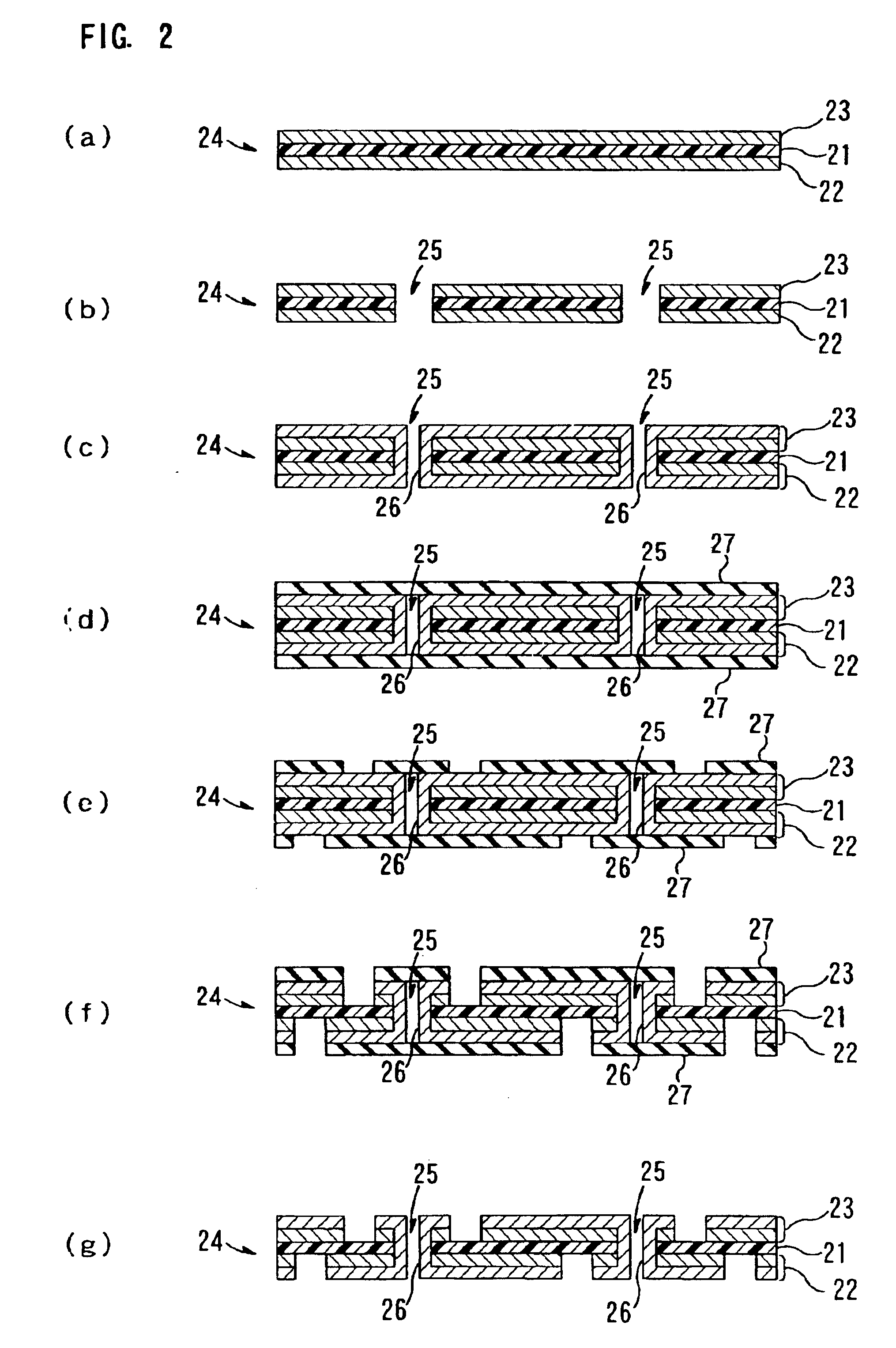

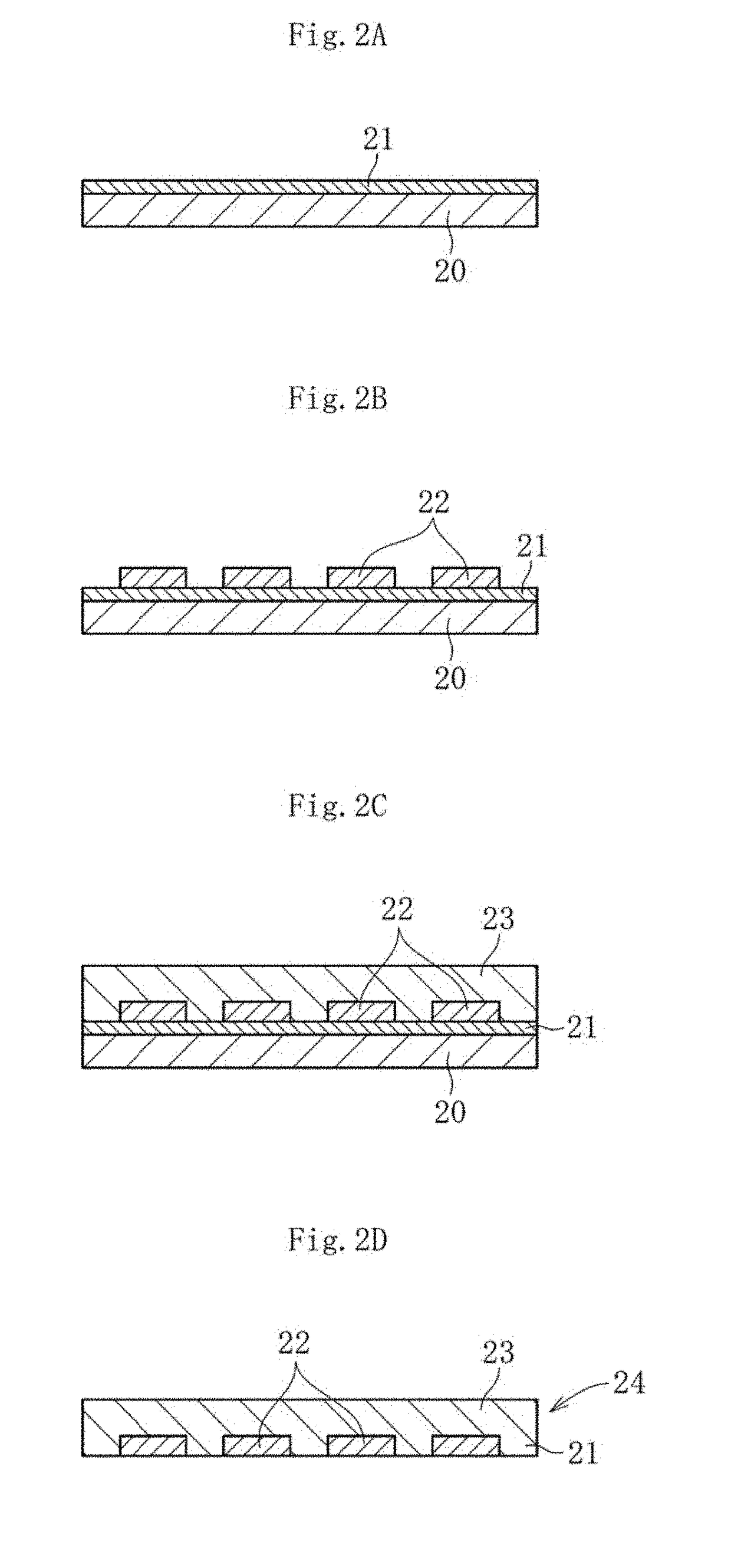

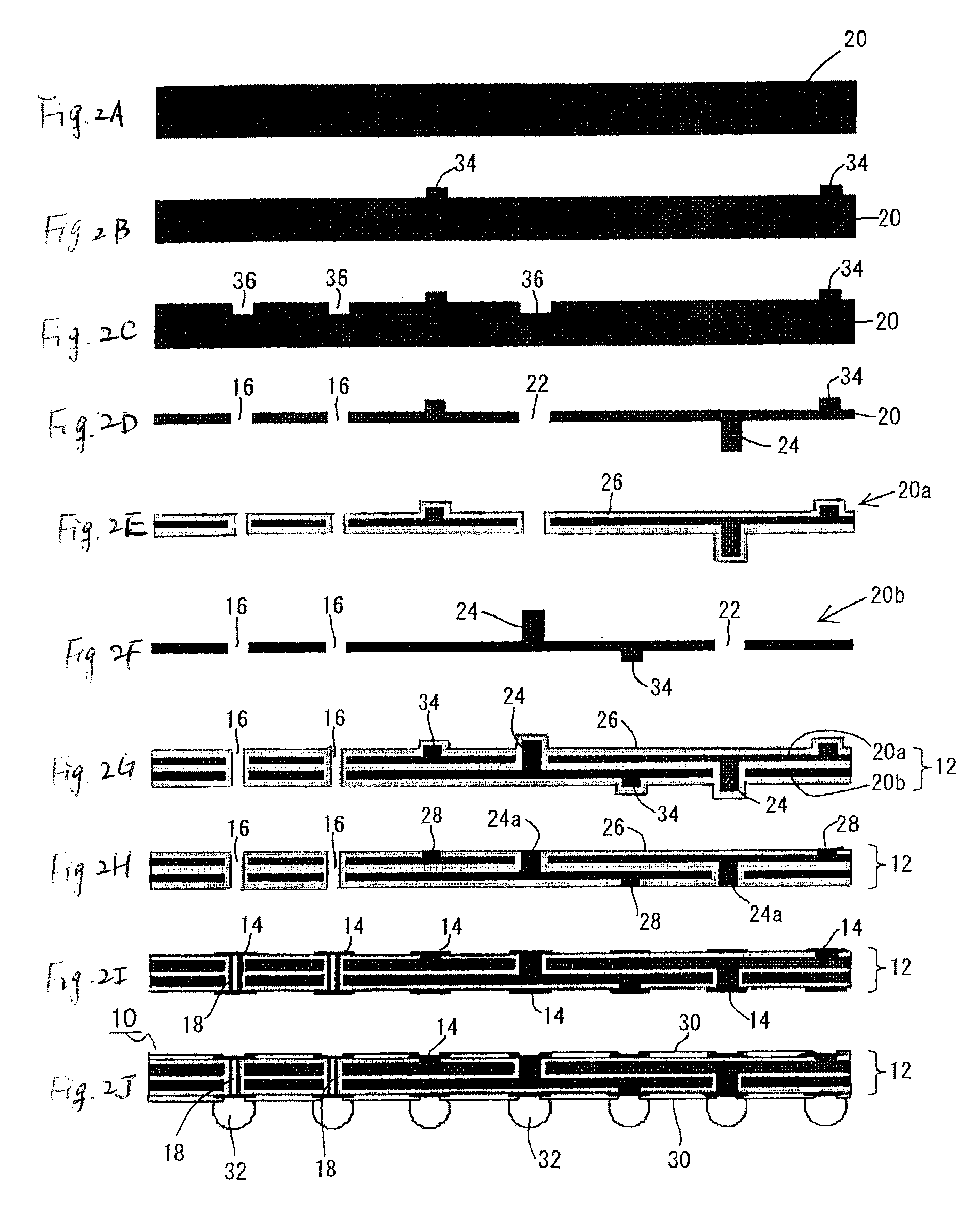

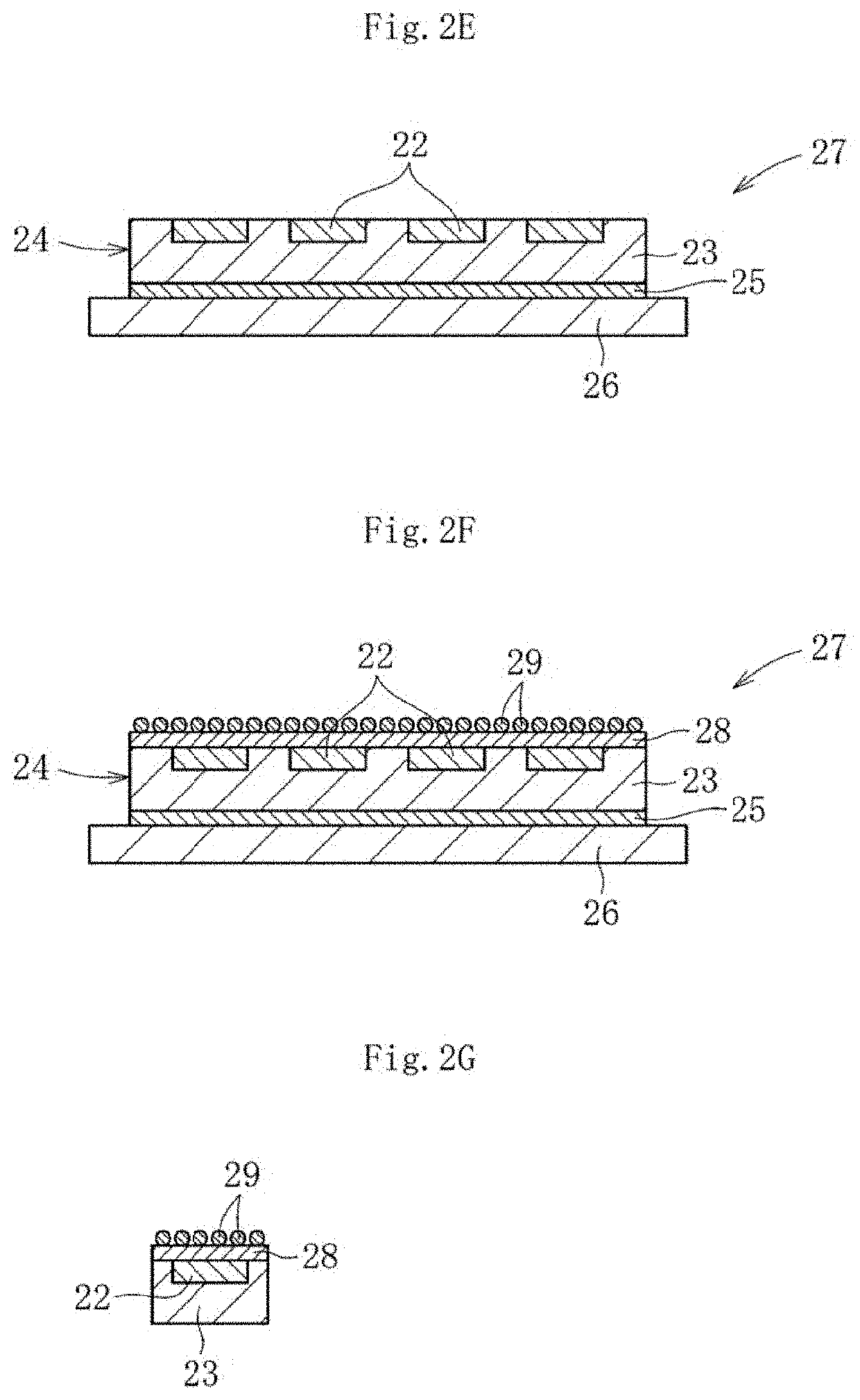

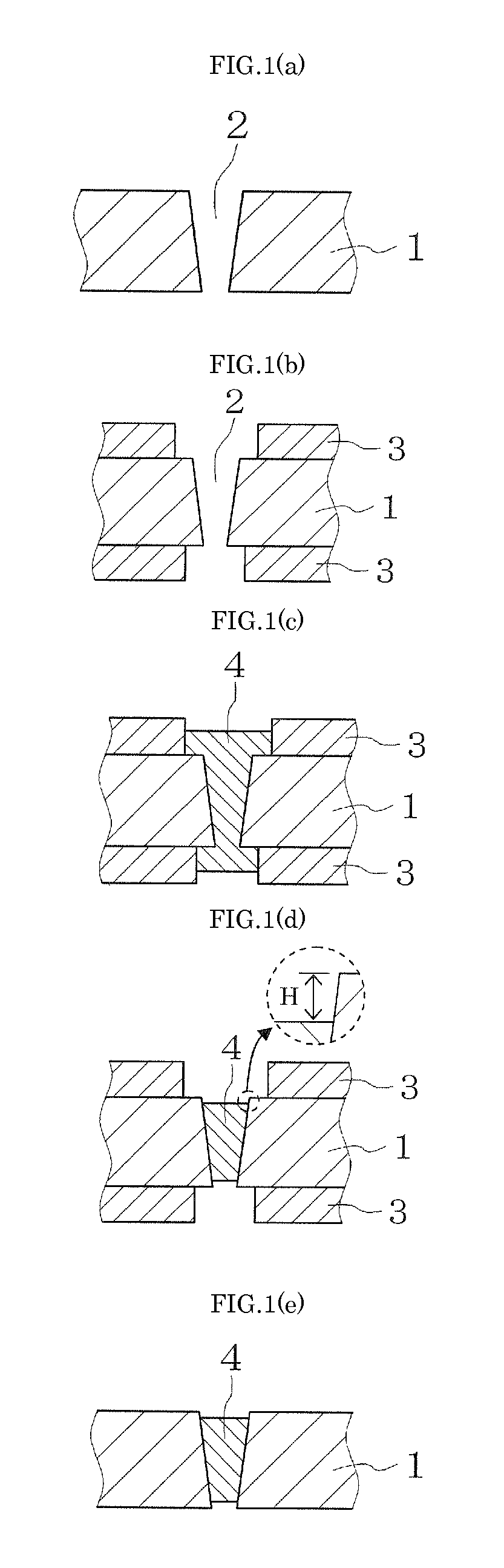

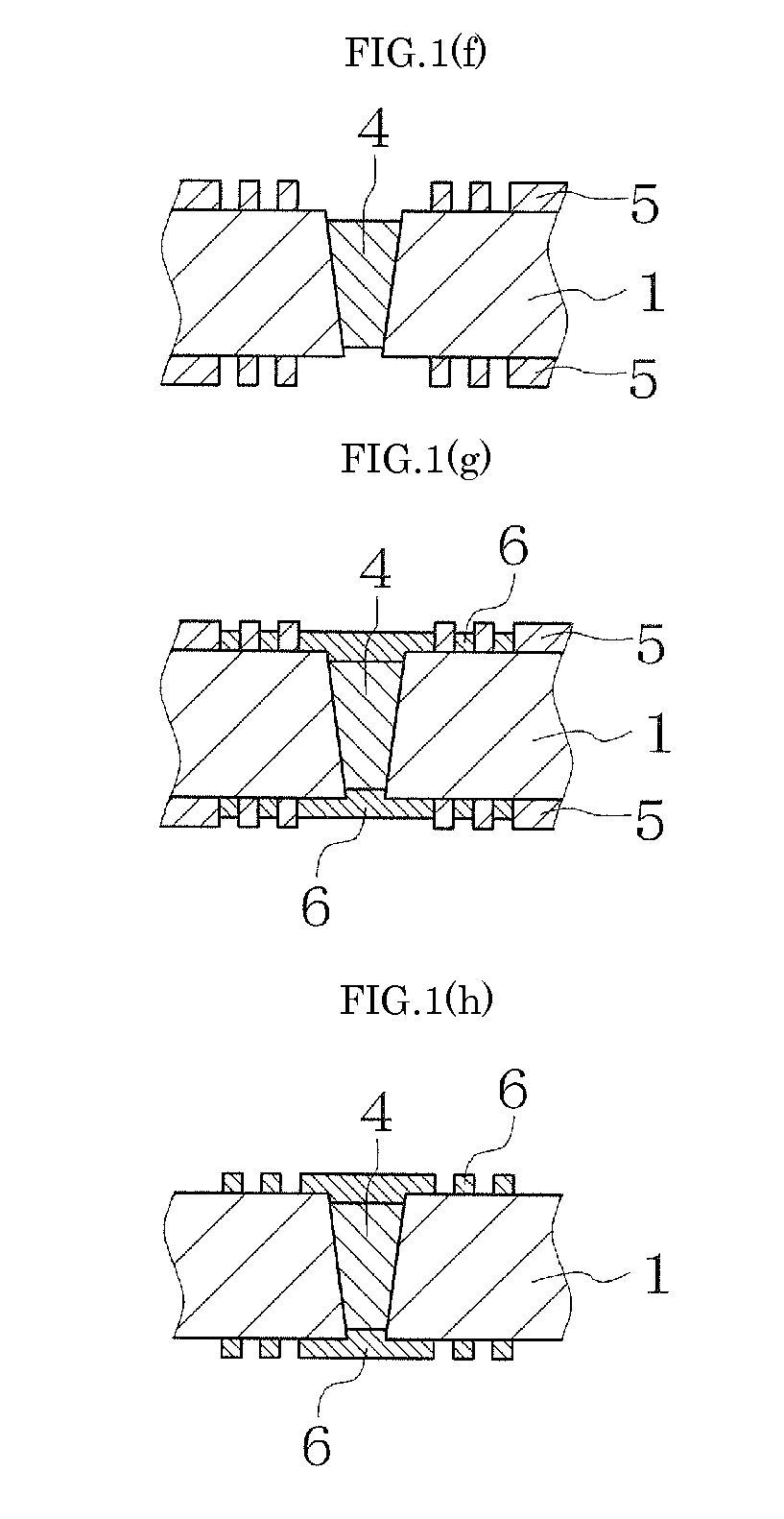

Method of manufacturing multilayer wiring board

InactiveUS20080184555A1Shorten the time periodIncrease productionPrinted circuit assemblingPrinted circuit aspectsIn planeEngineering

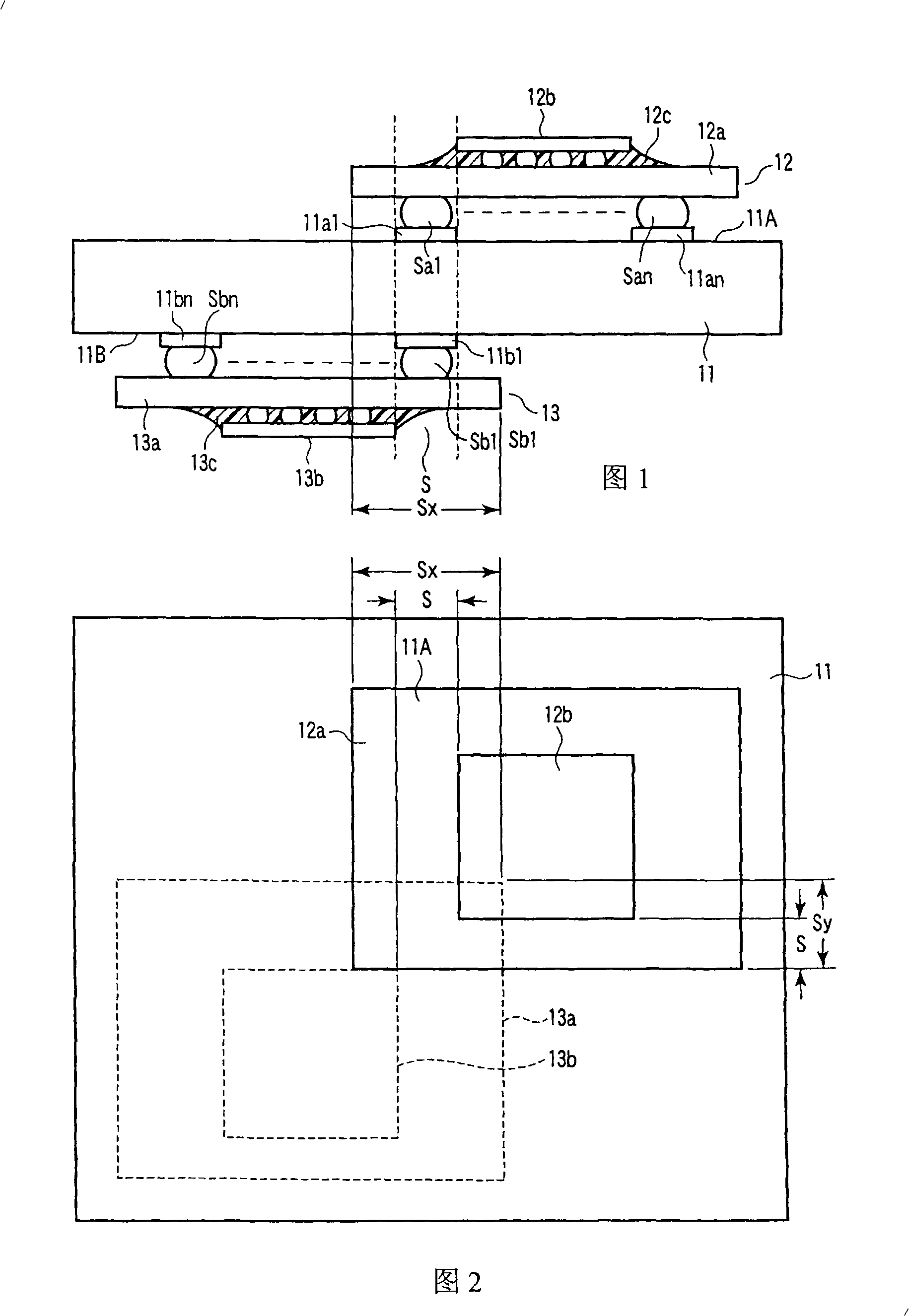

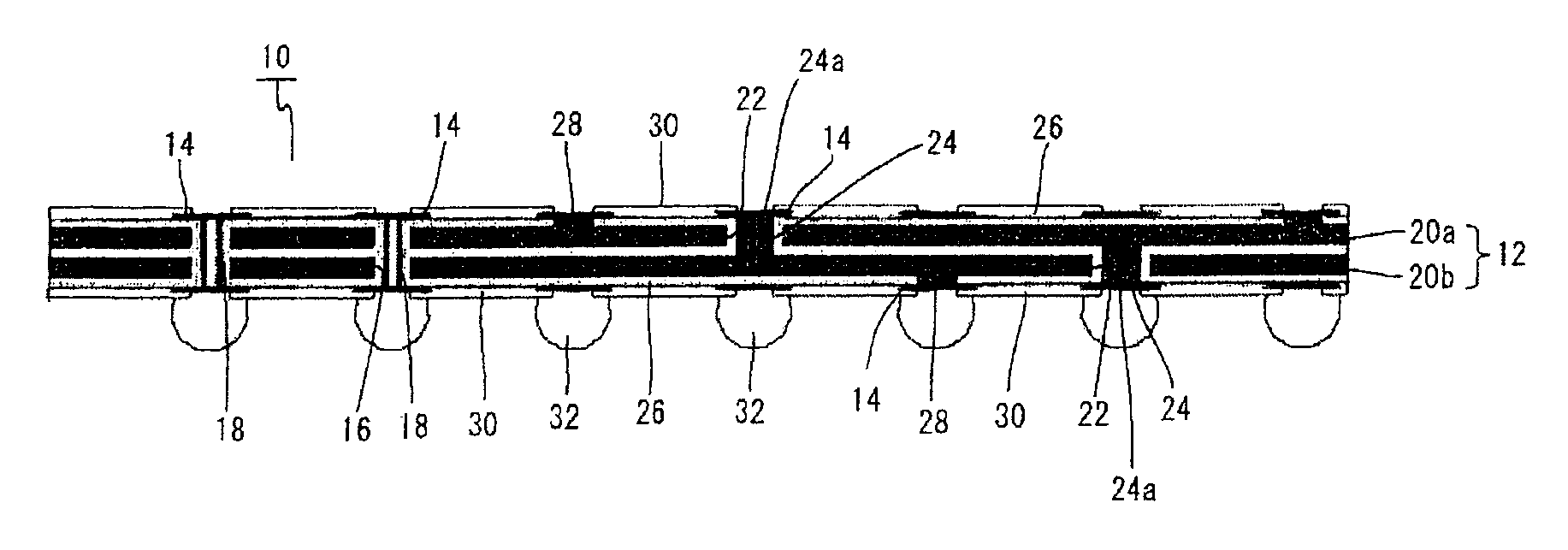

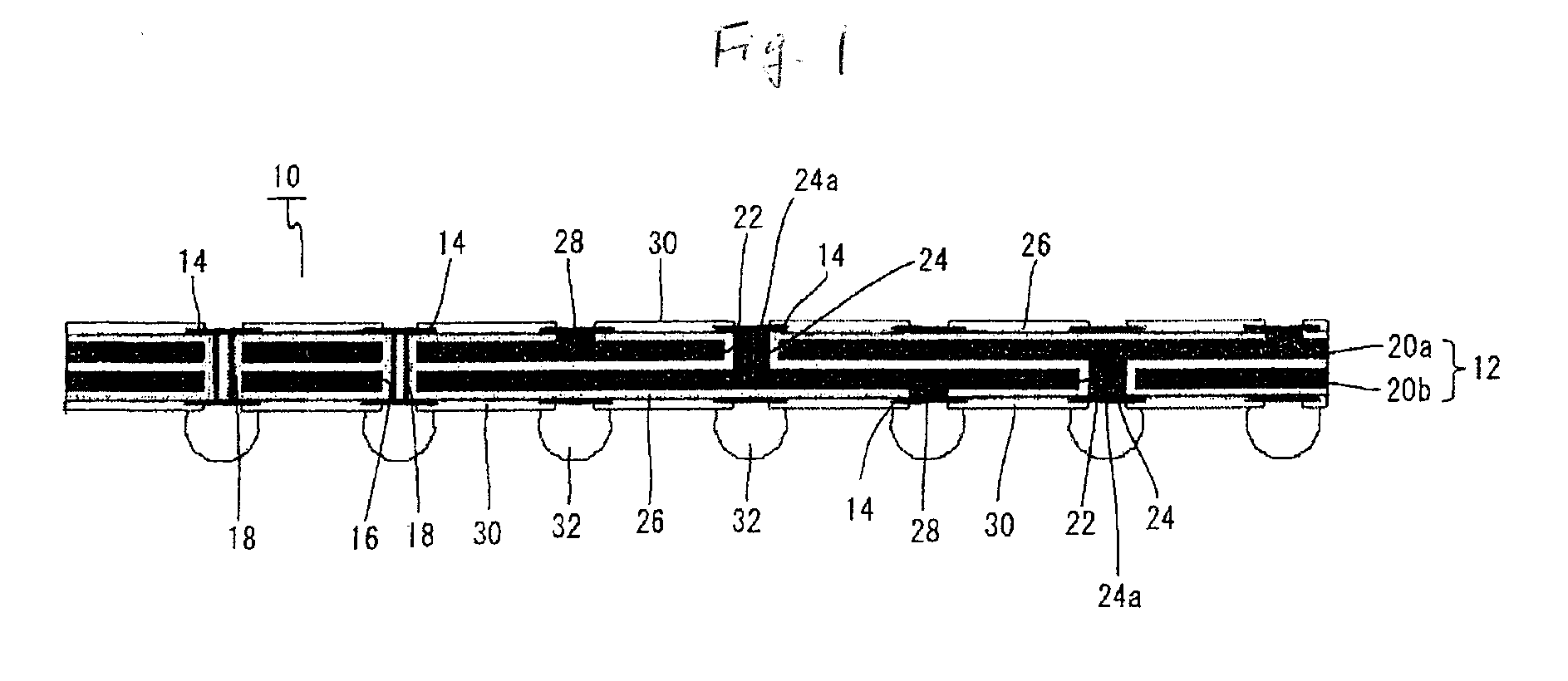

First, a plurality of wiring boards are fabricated at separate steps. The first wiring board includes a Cu post formed on a wiring layer on one surface of a substrate, and a first stopper layer formed at a desired position around the Cu post. The second wiring board includes a through hole for insertion of the Cu post therethrough, a connection terminal formed on a wiring layer on one surface of a substrate, and a second stopper layer that engages the first stopper layer and functions to suppress in-plane misalignment. The third wiring board includes a connection terminal formed on a wiring layer on one surface of a substrate. Then, the wiring boards are stacked up, as aligned with one another so that the wiring layers are interconnected via the Cu post and the connection terminals, to thereby electrically connect the wiring boards. Thereafter, resin is filled into gaps between the wiring boards.

Owner:SHINKO ELECTRIC IND CO LTD

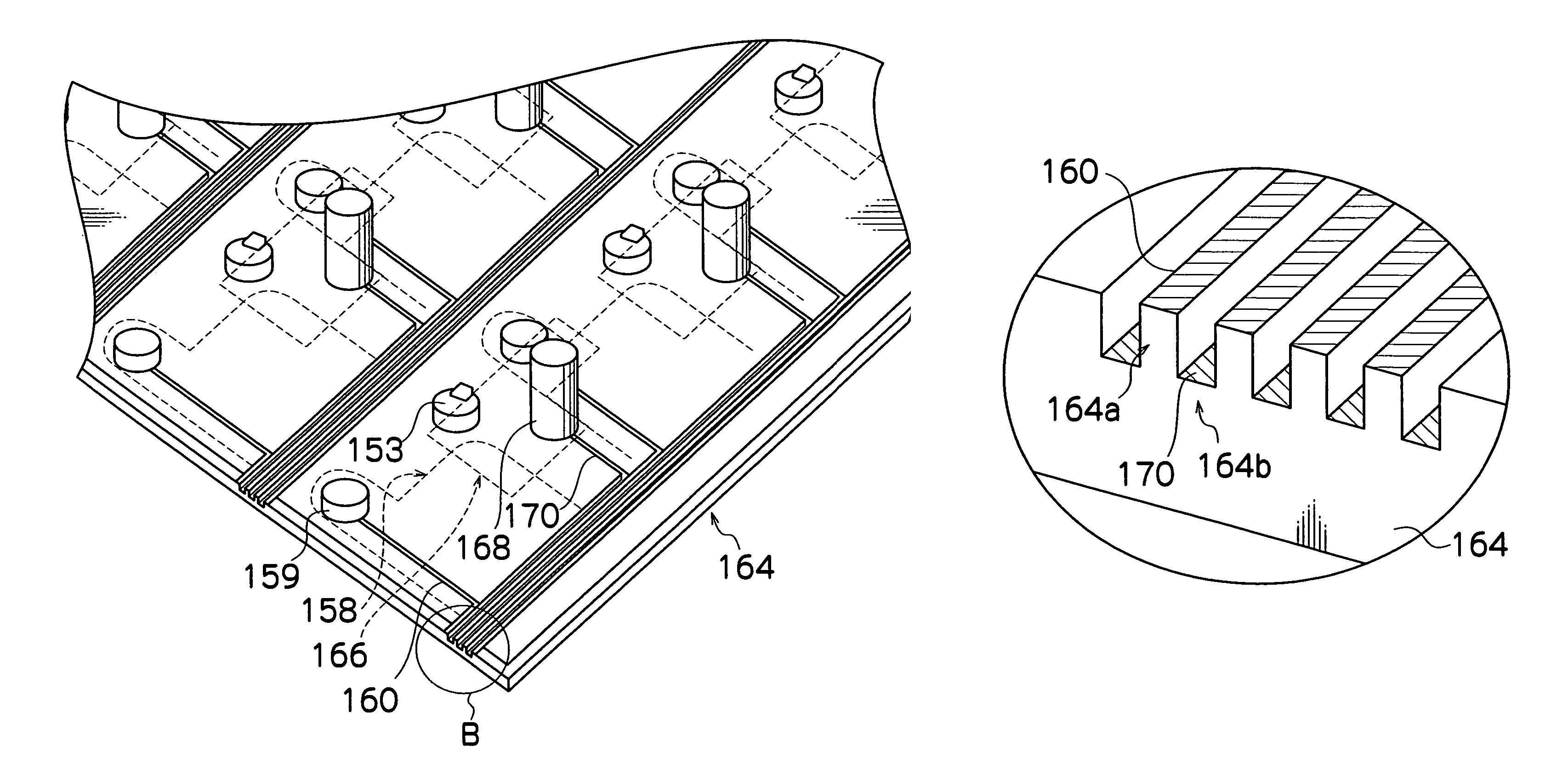

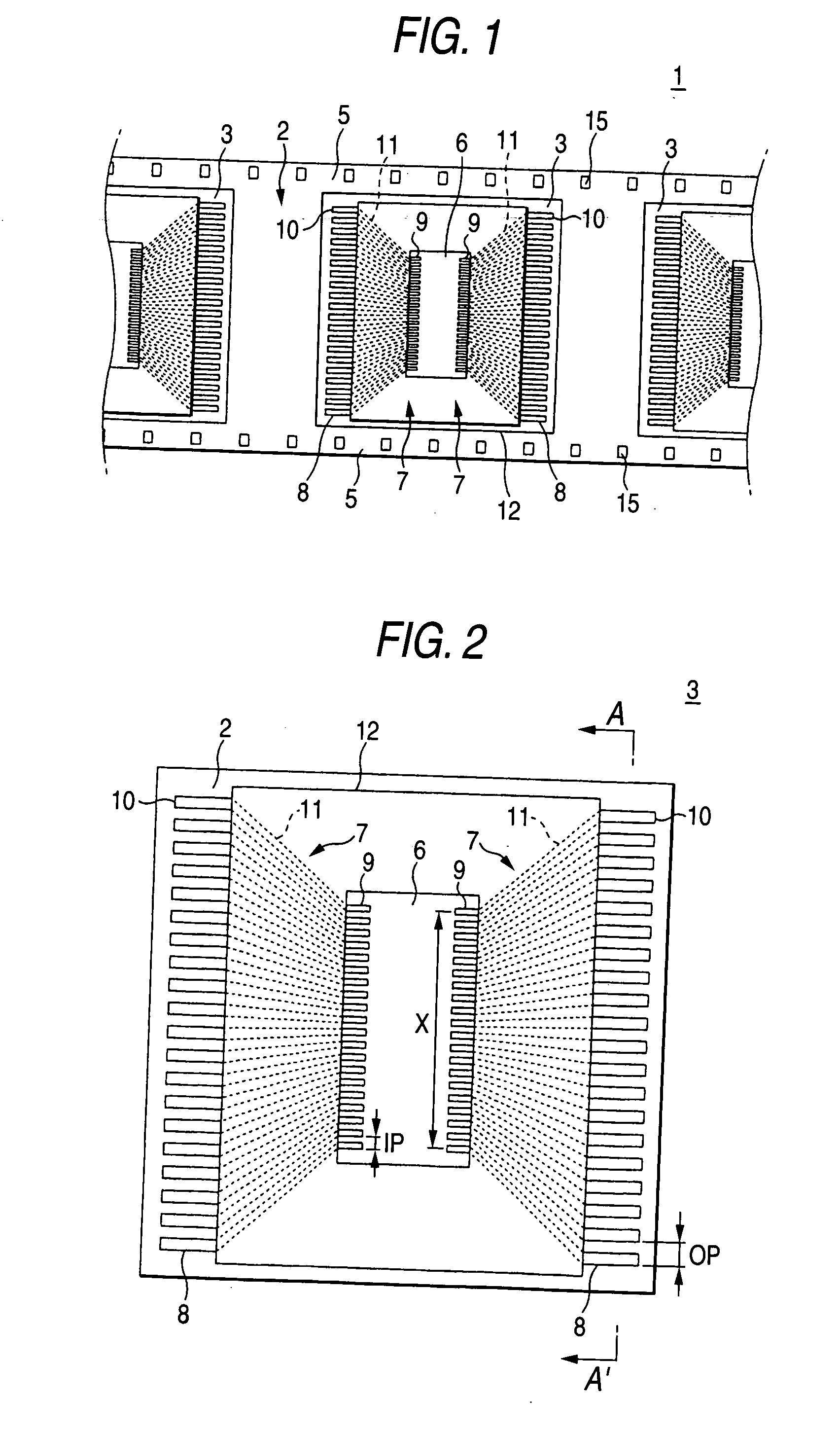

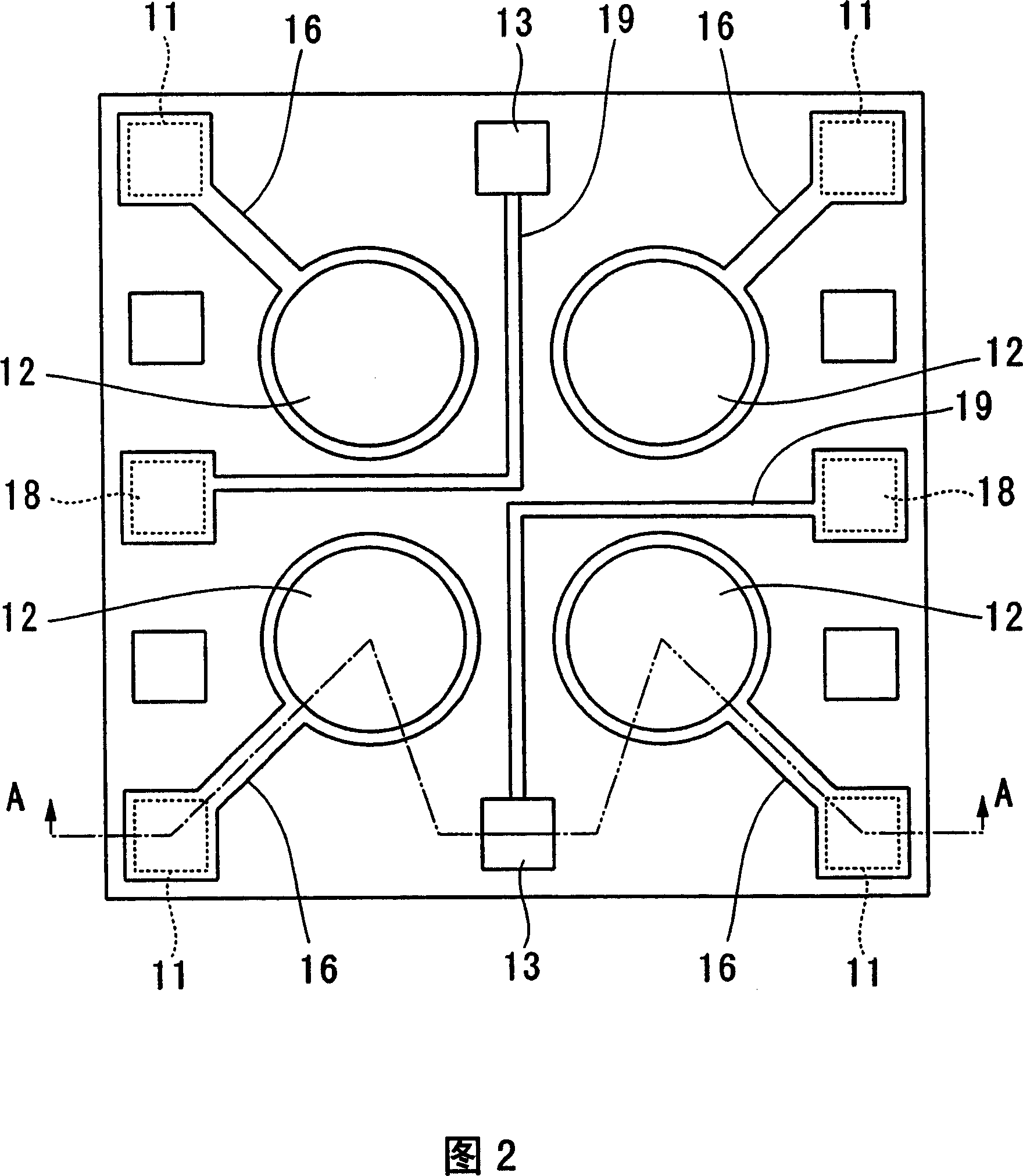

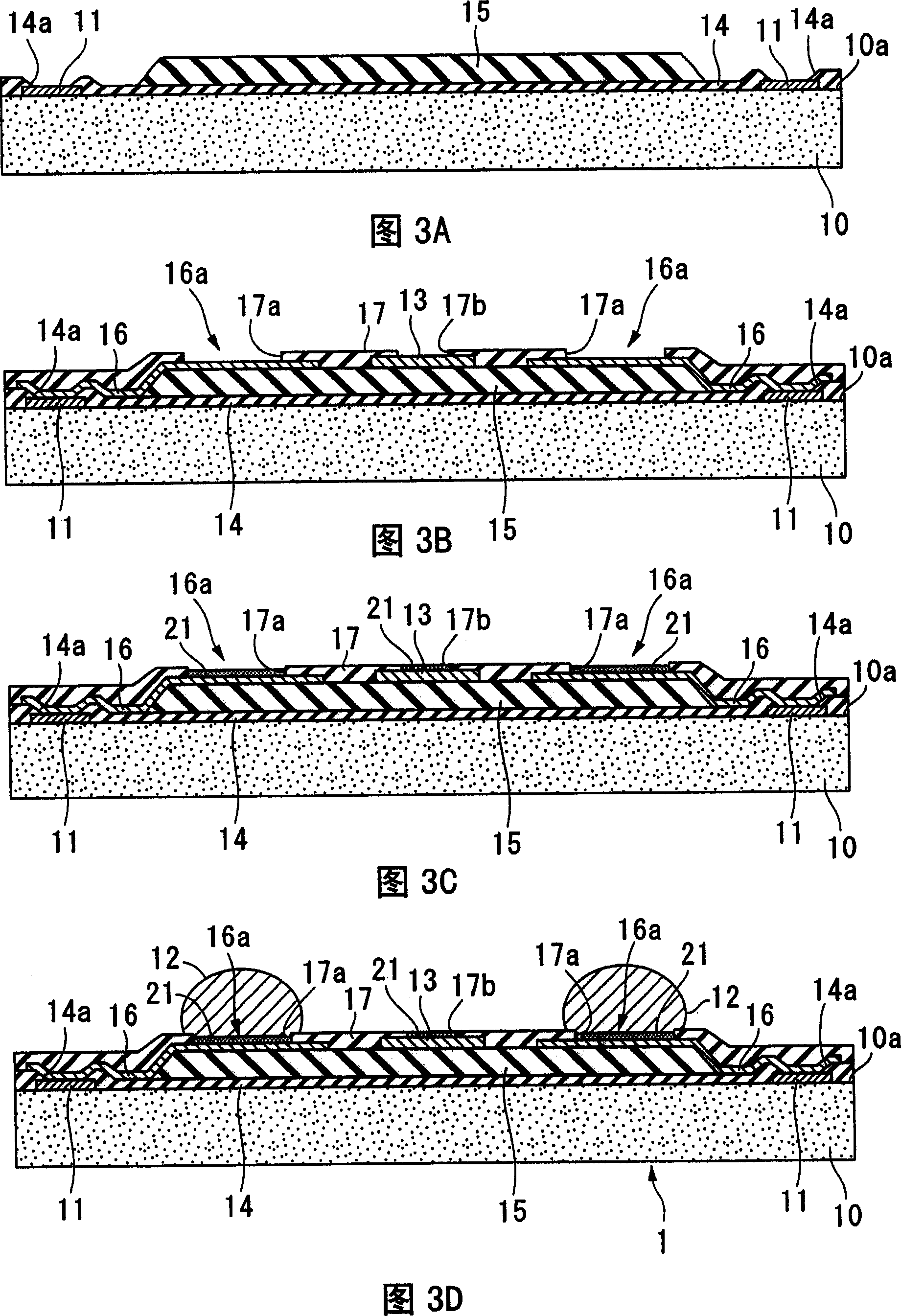

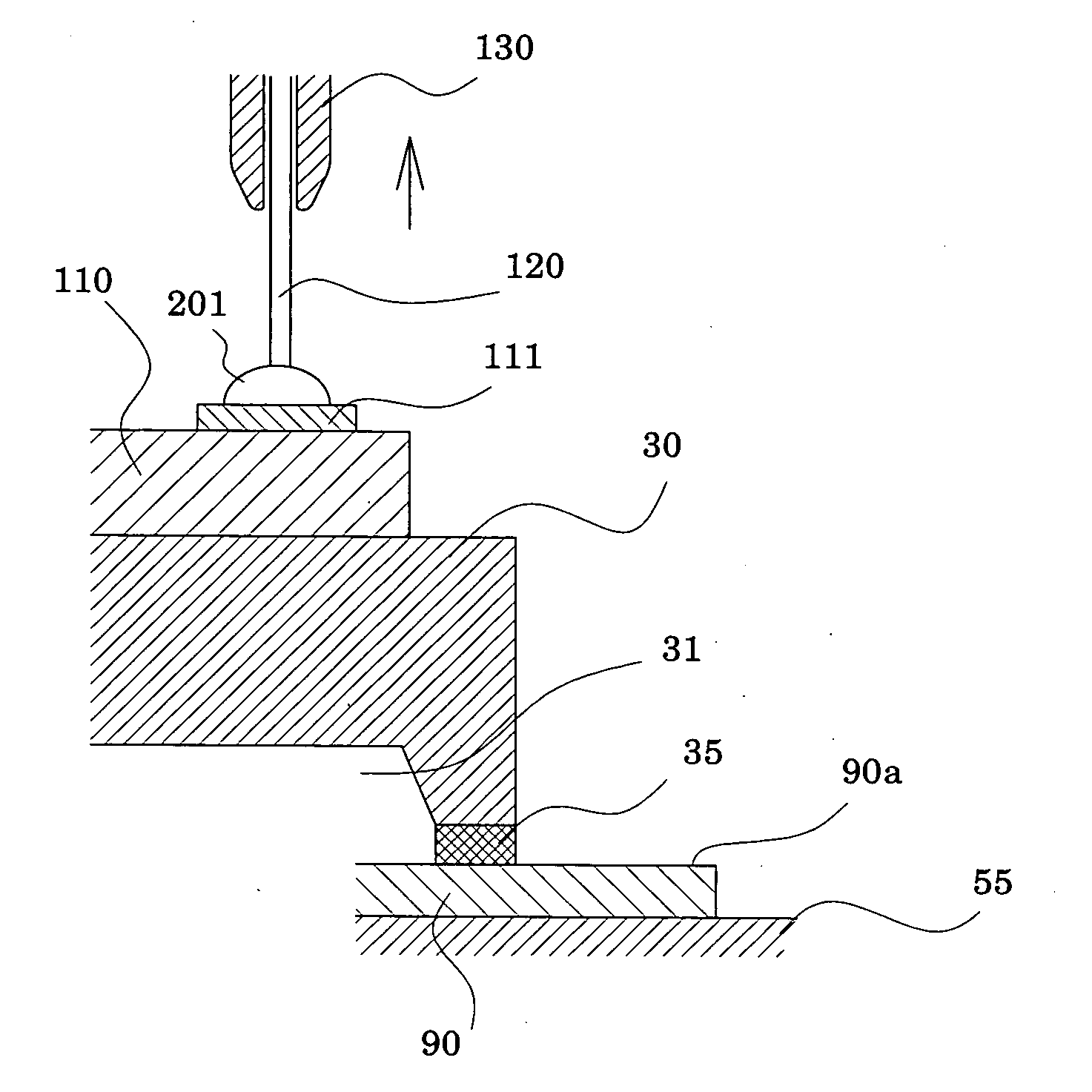

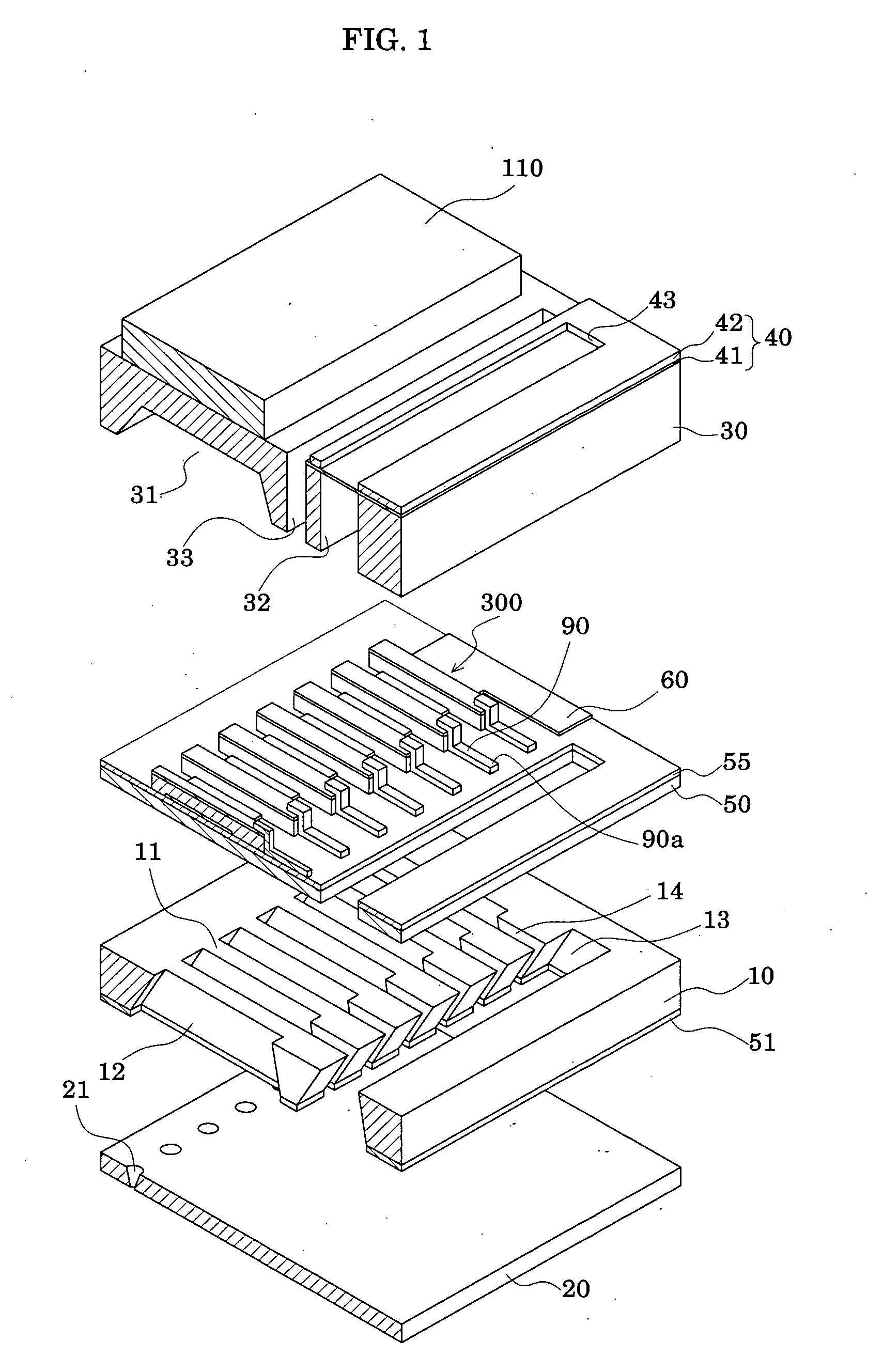

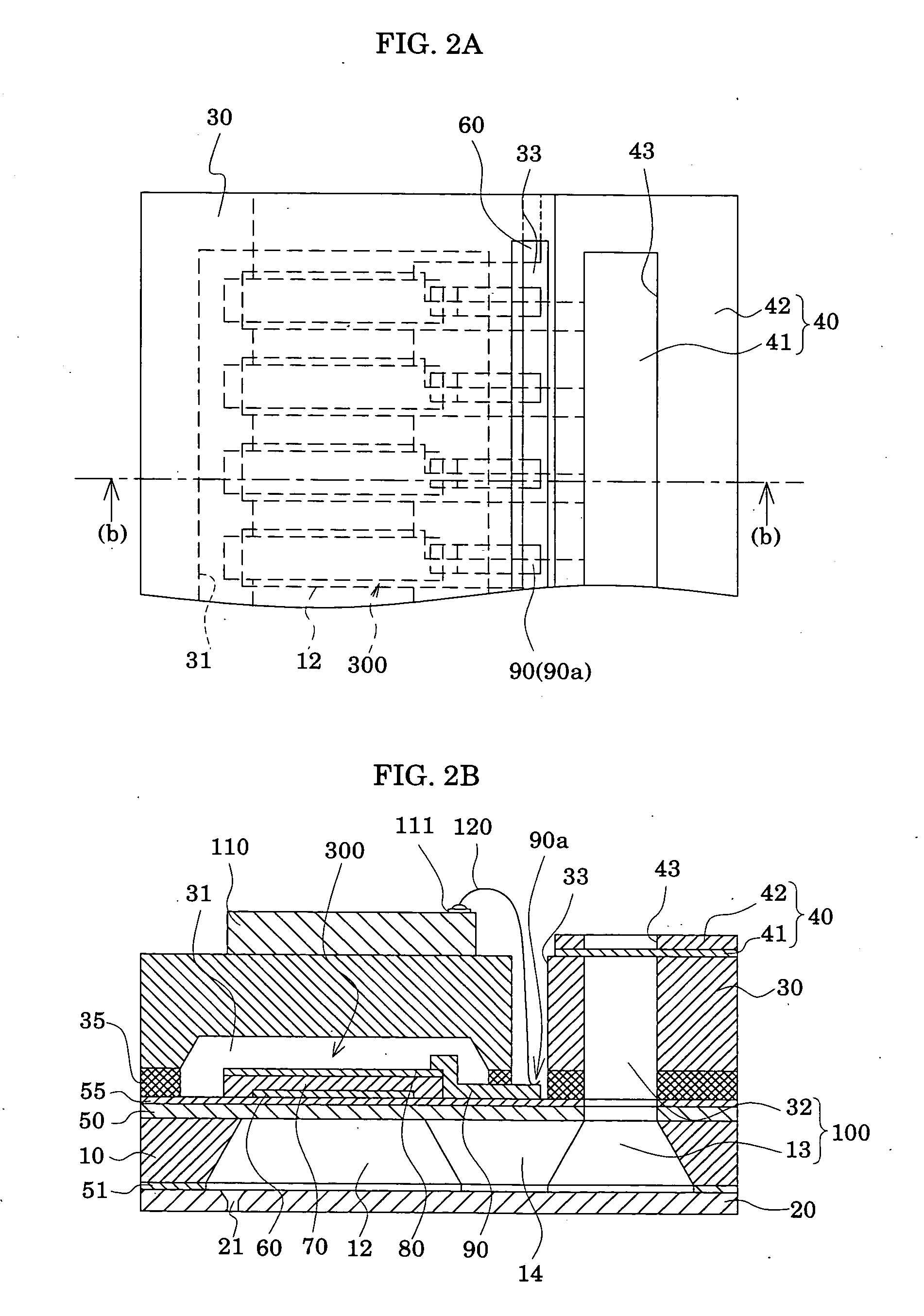

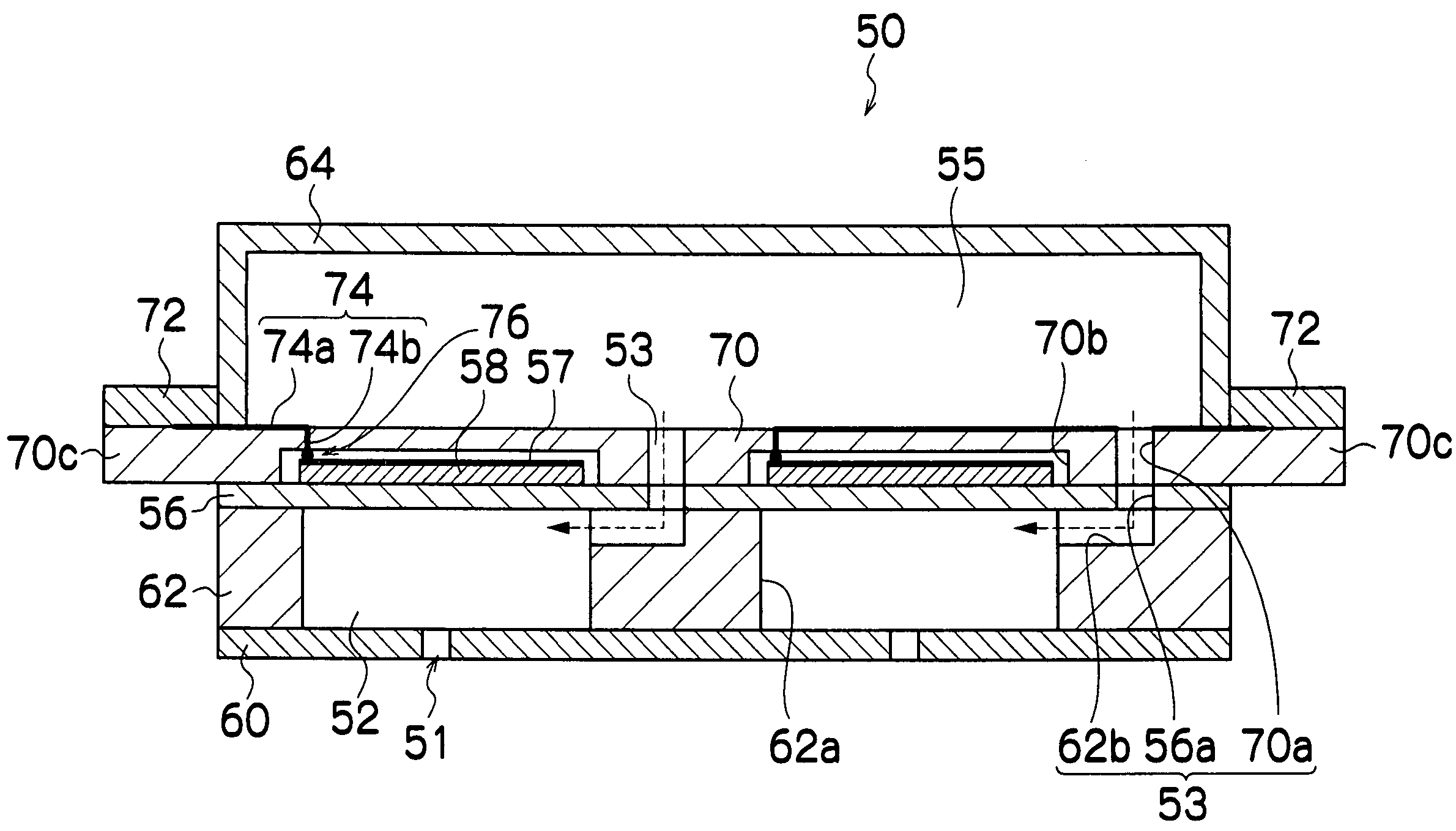

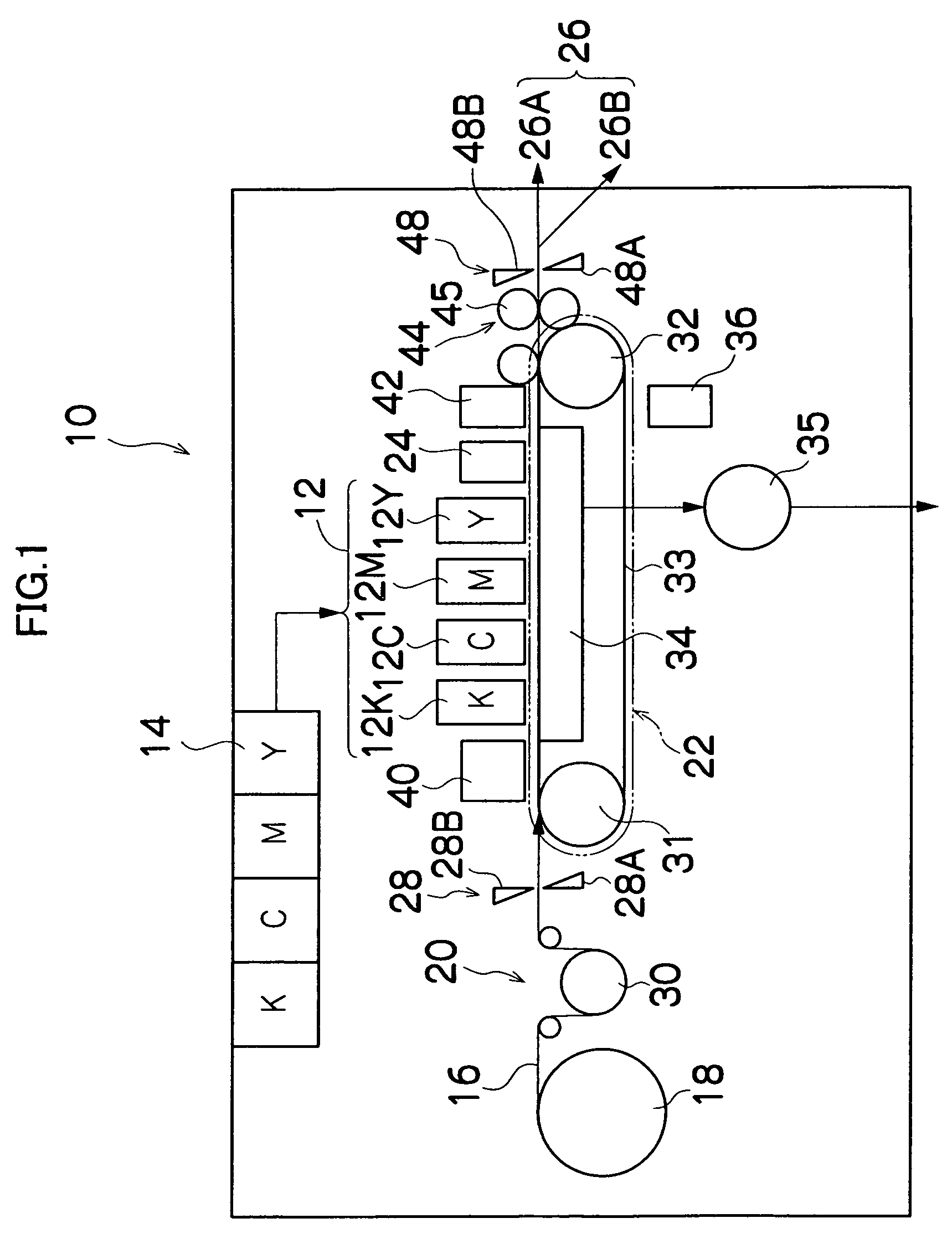

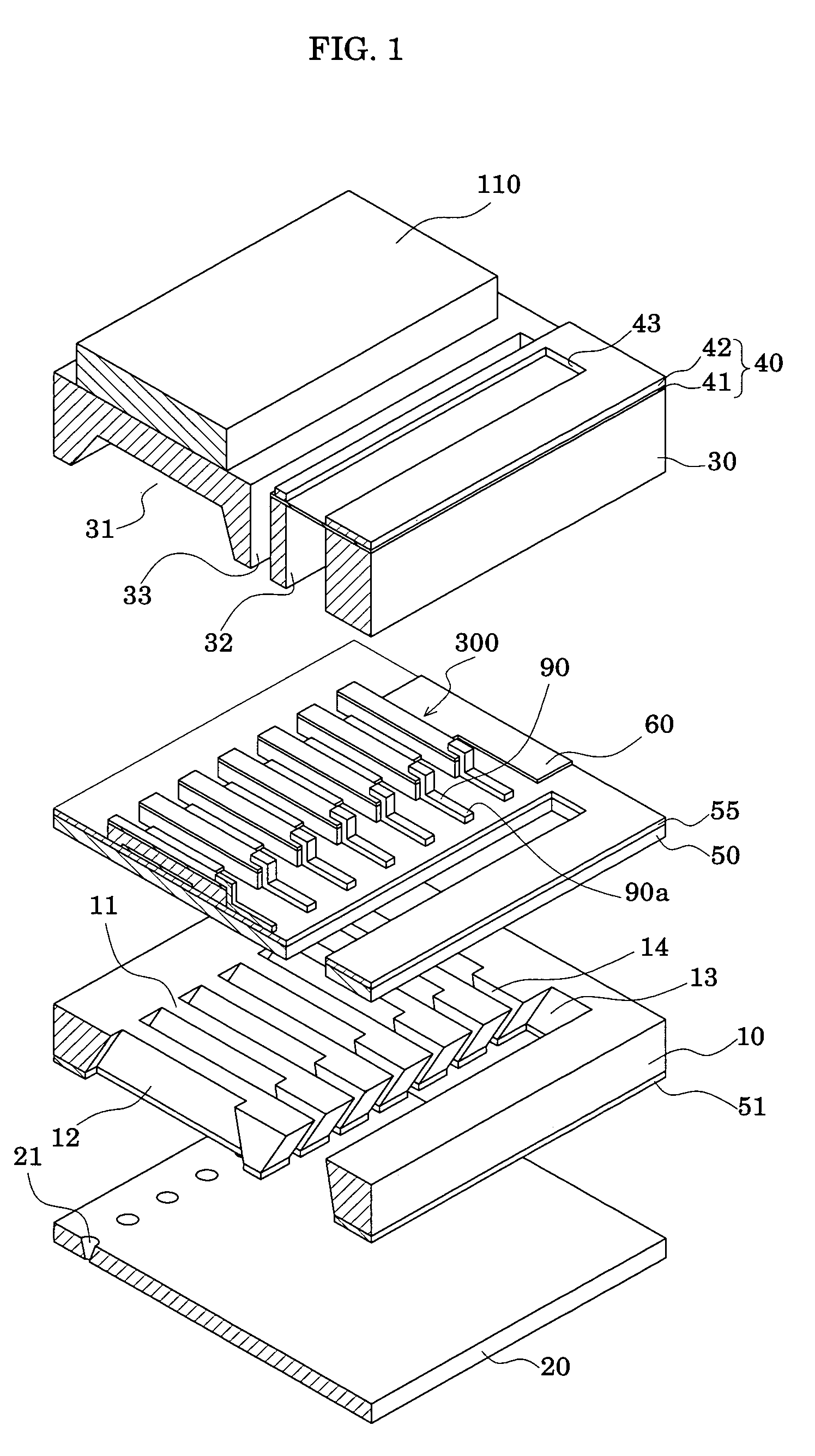

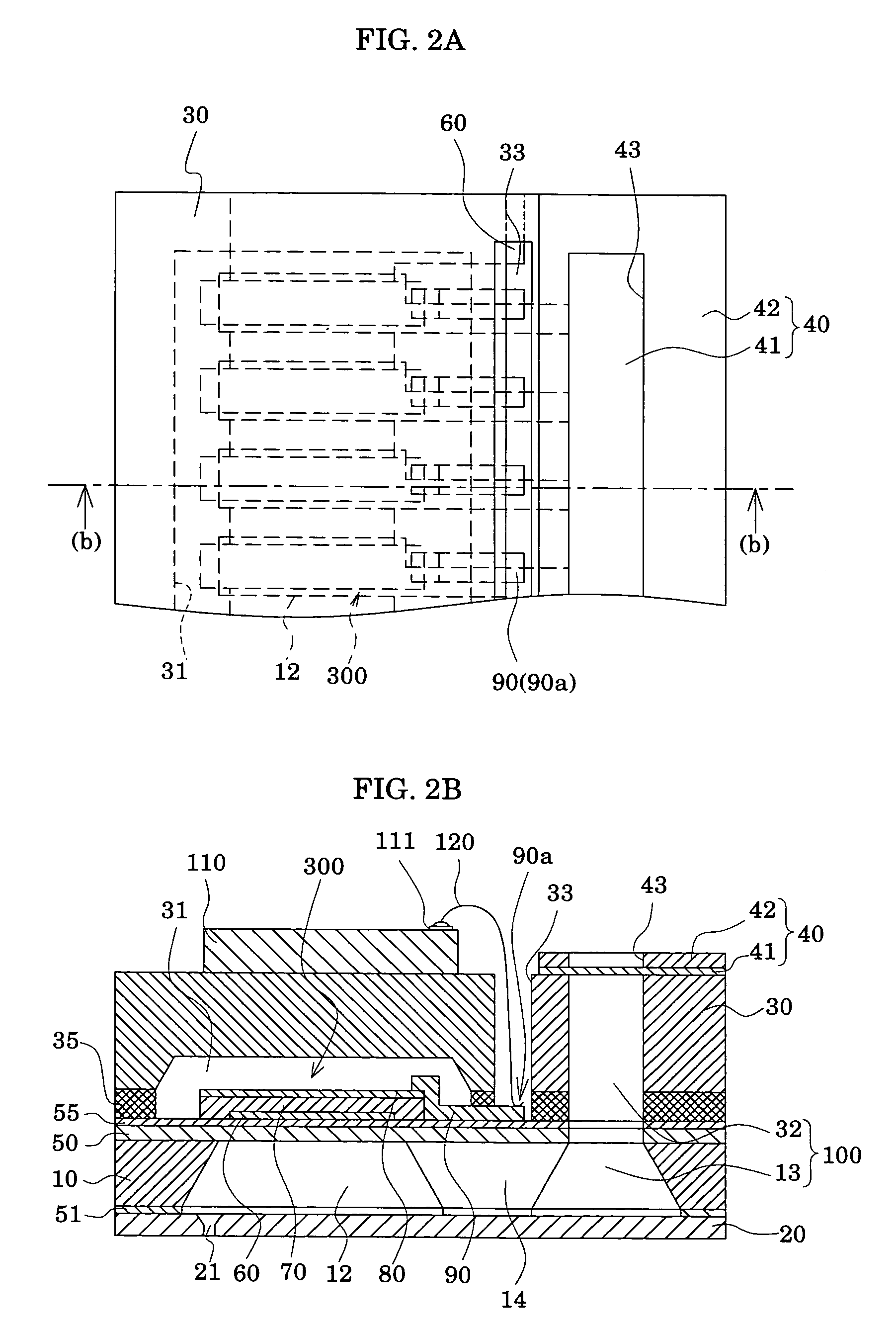

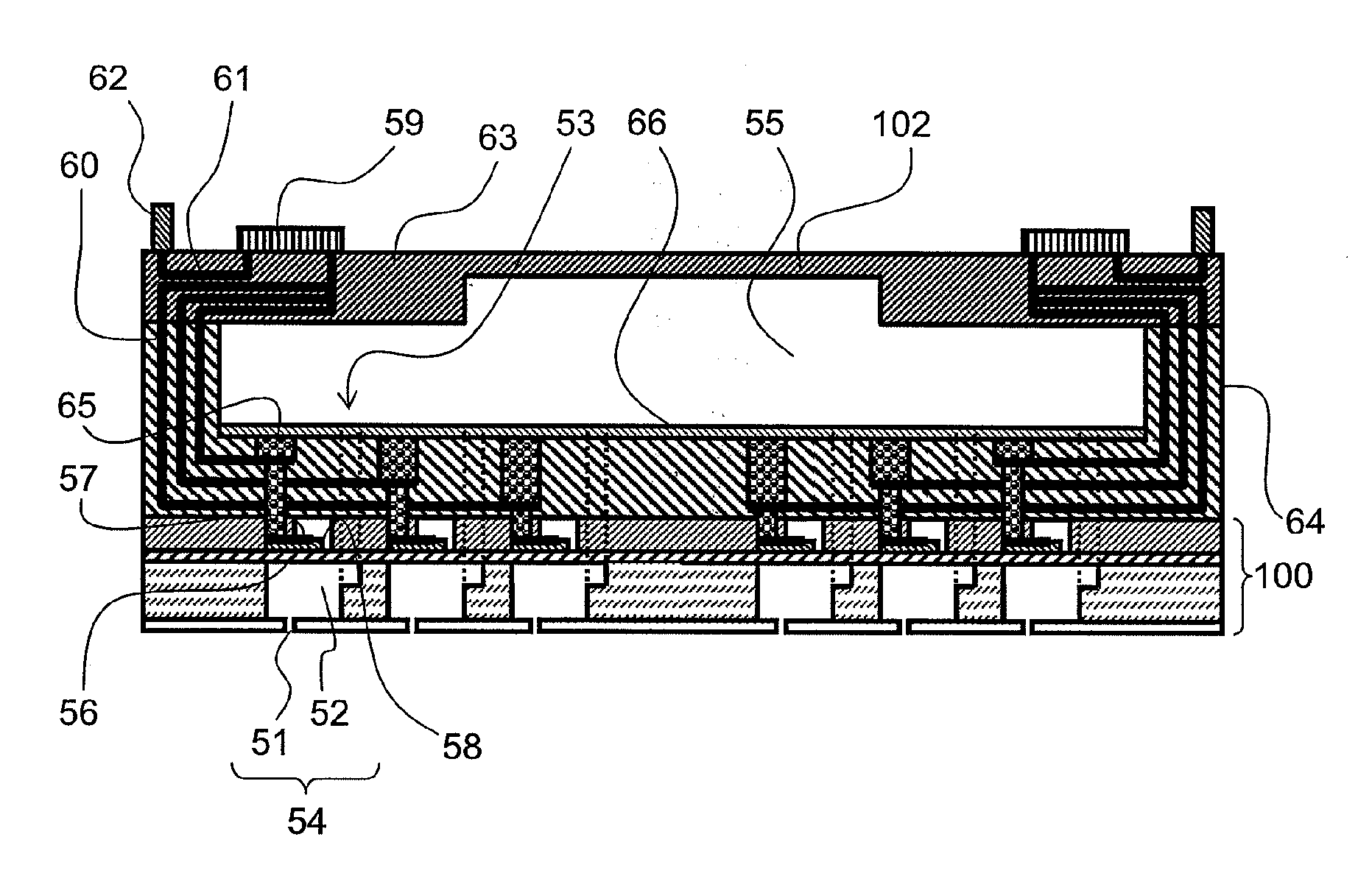

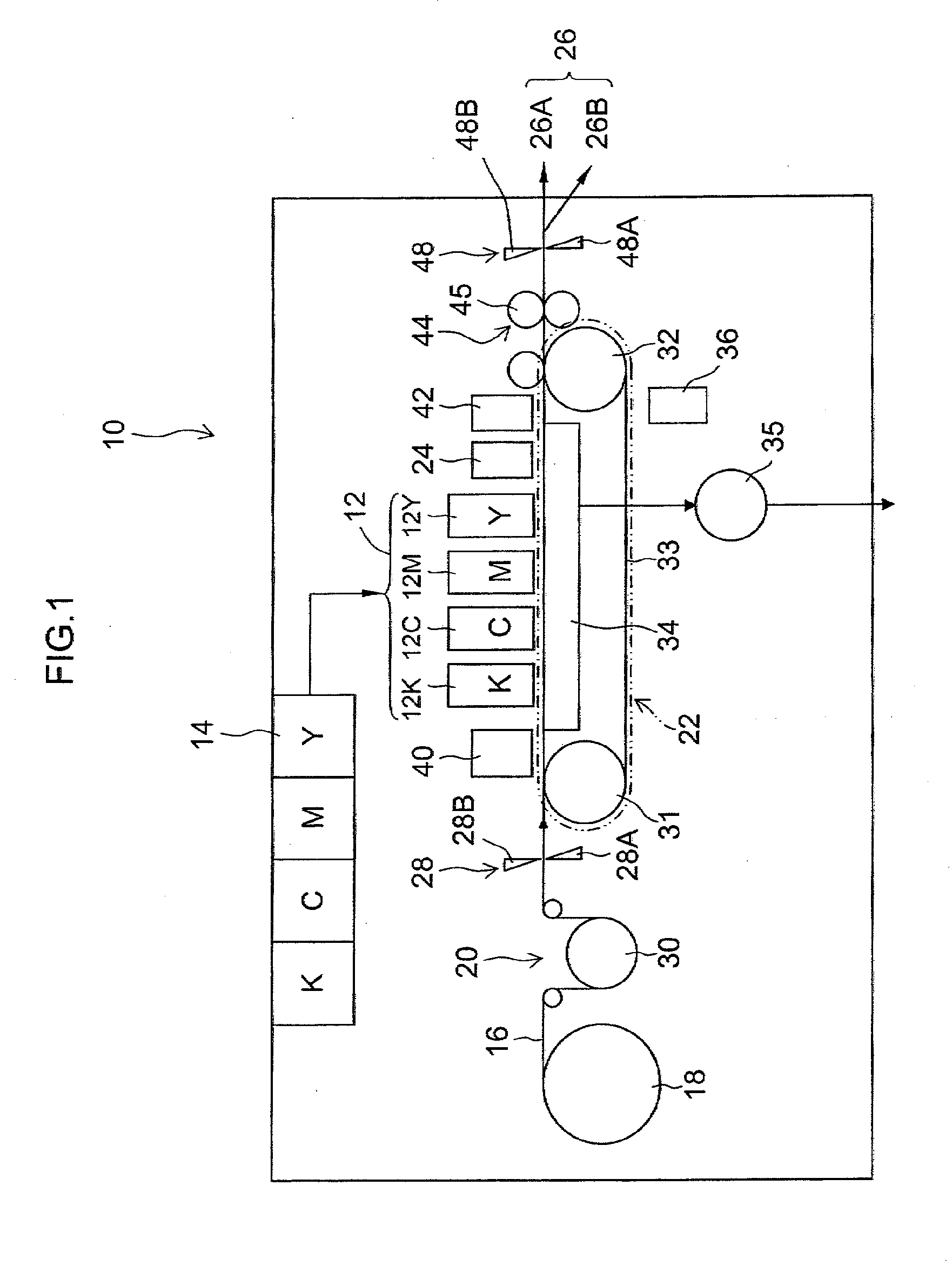

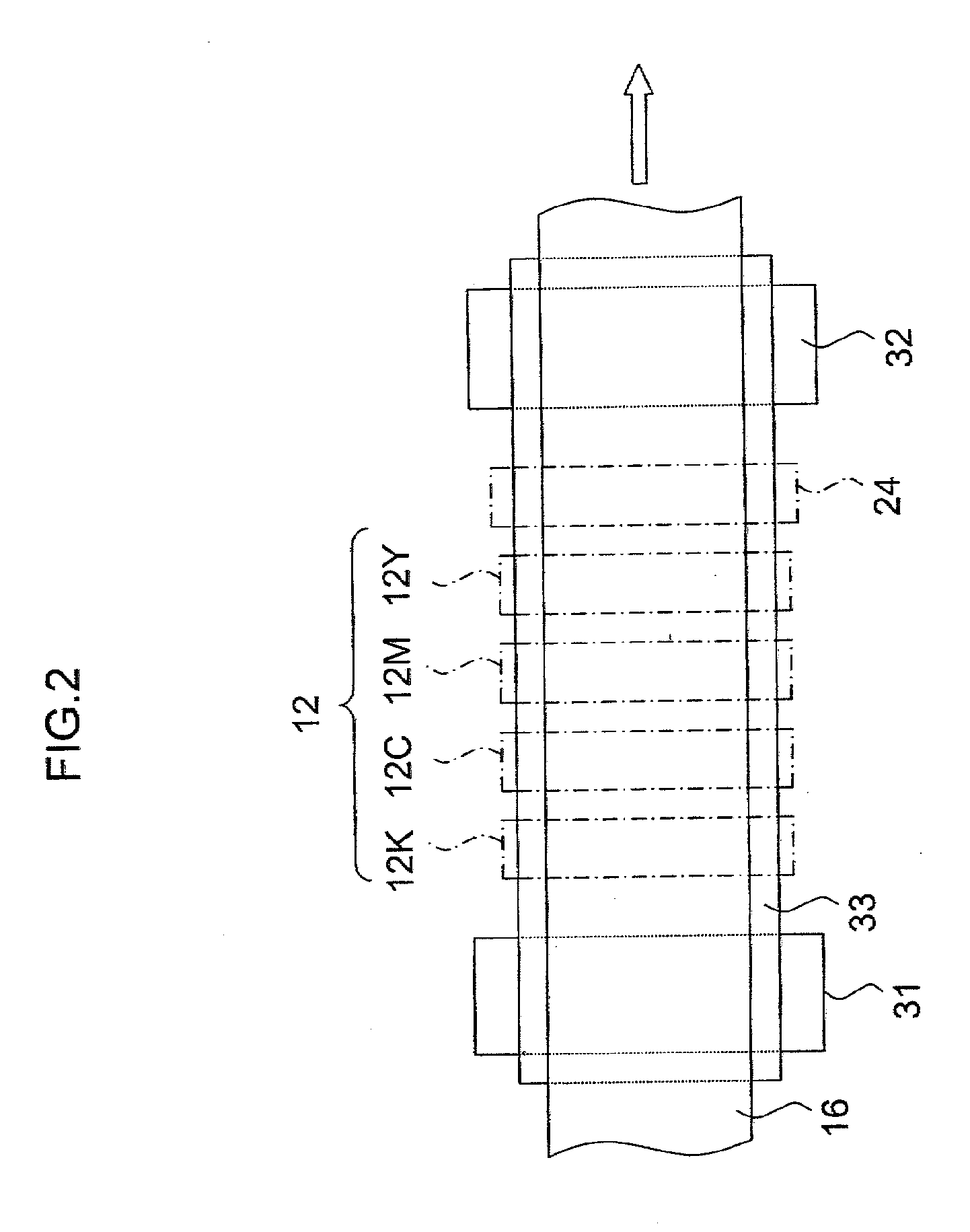

Liquid ejection head and image forming apparatus including liquid ejection head

InactiveUS20070211108A1High density arrangementReduce component countInking apparatusElectric wireBackplane

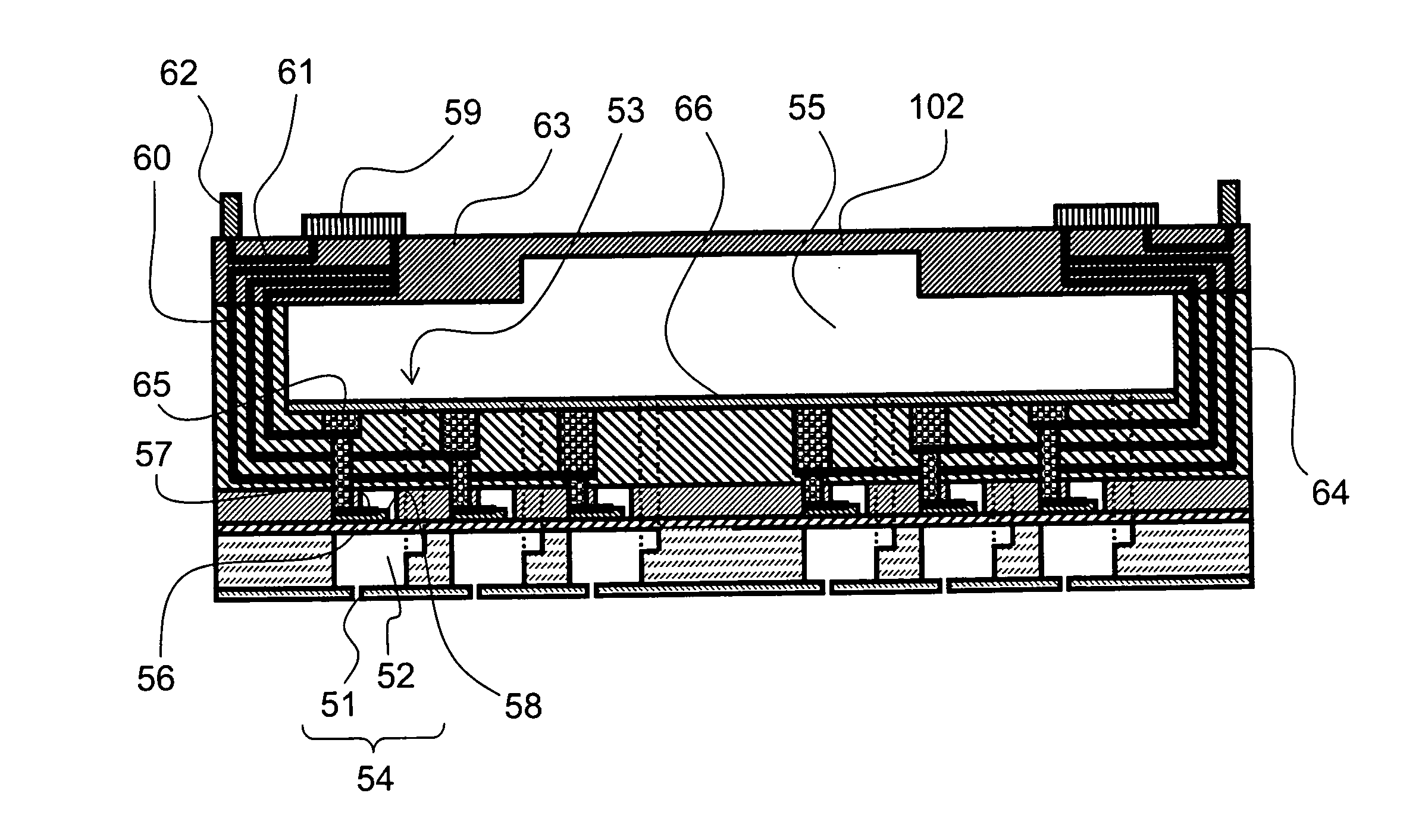

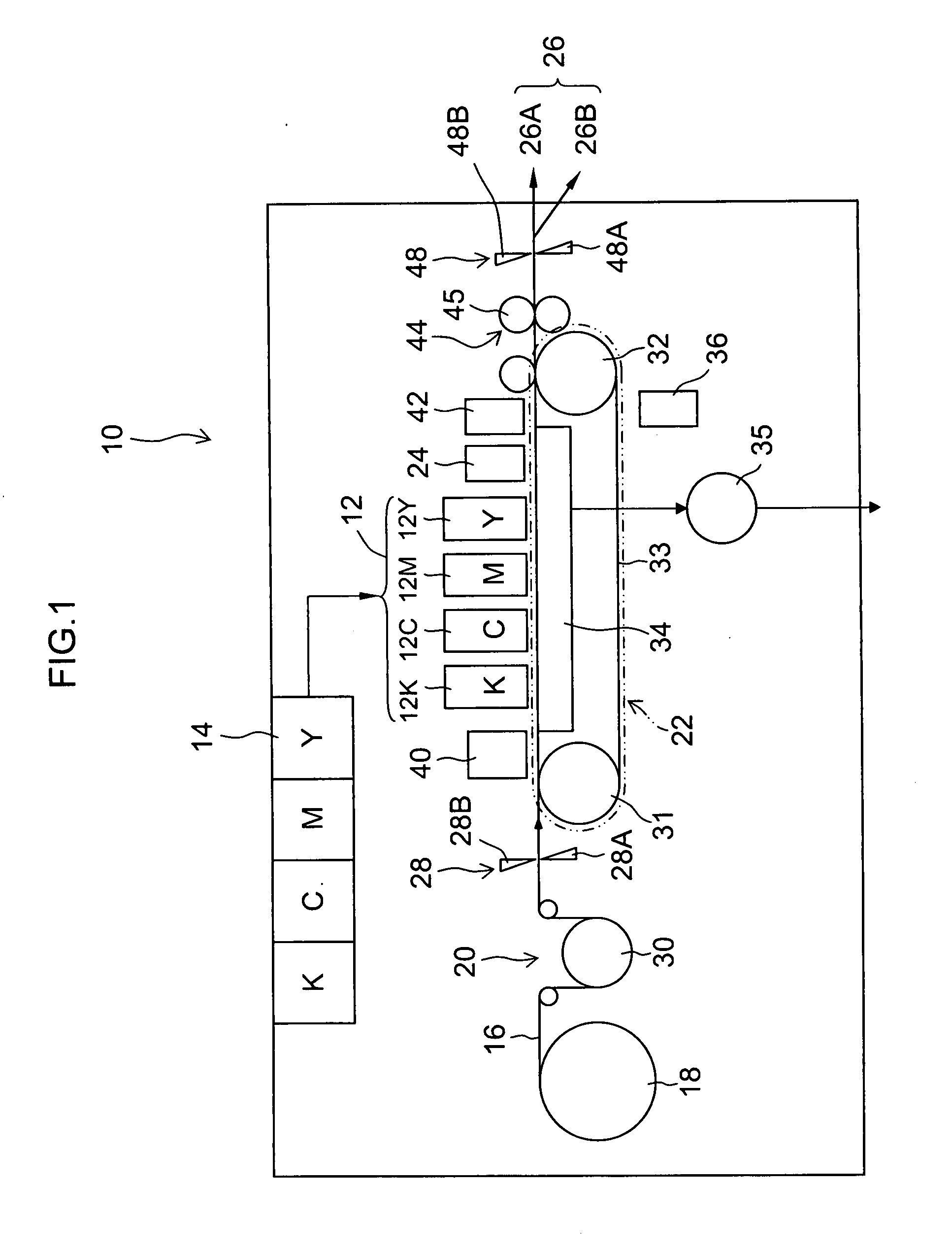

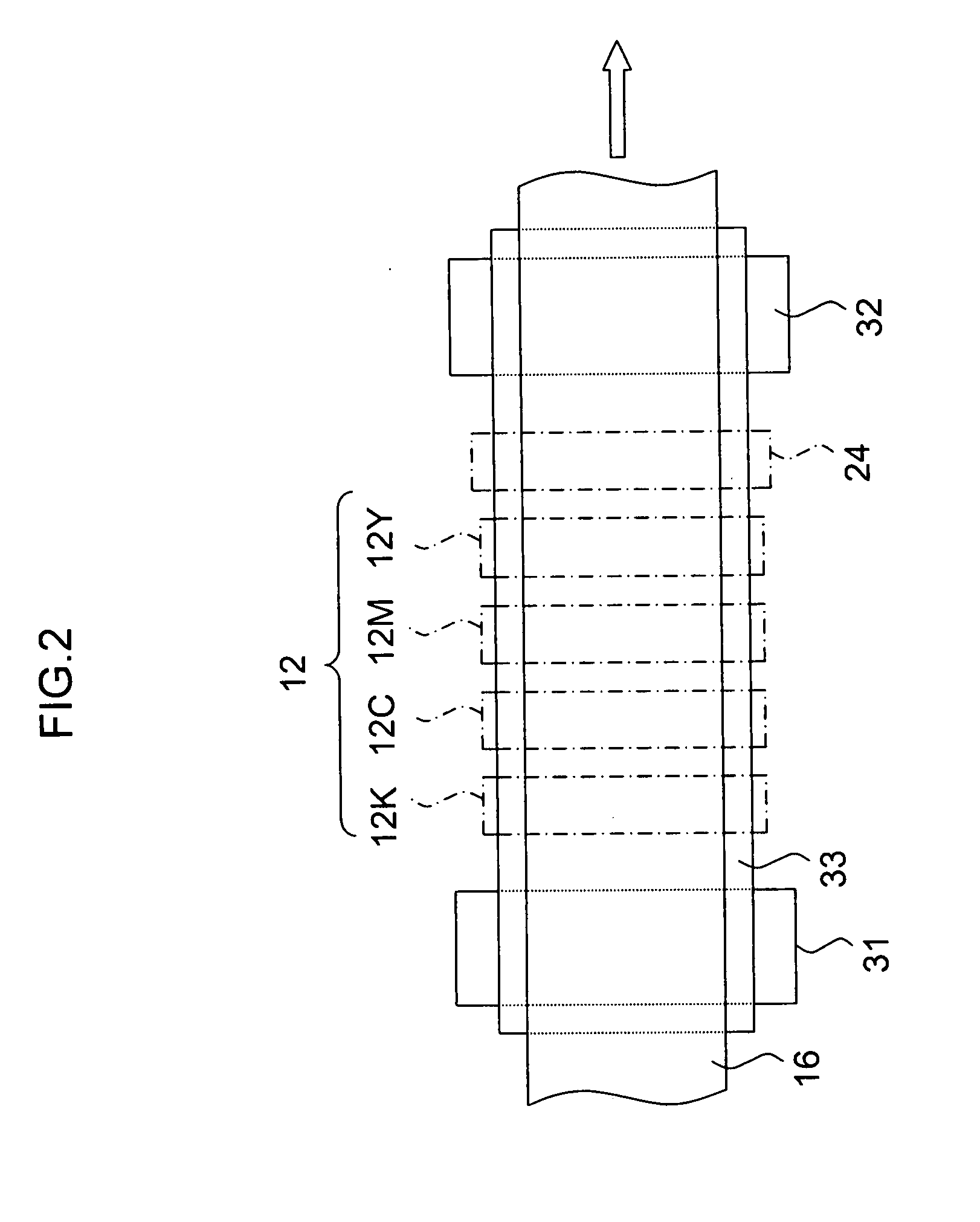

The liquid ejection head for ejecting liquid from nozzles includes: pressure chambers connecting to the nozzles; a common liquid chamber which is connected to the pressure chambers, is arranged across the pressure chambers from the nozzles, and is defined by at least a multi-layer wiring substrate which has a recess-shaped structure including a base section forming one of a ceiling and a floor of the common liquid chamber and a projecting section forming a side wall of the common liquid chamber; electrical wires which are formed at least partially inside the multi-layer wiring substrate; and a connection electrode which is provided in a top of the projecting section of the multi-layer wiring substrate.

Owner:FUJIFILM CORP

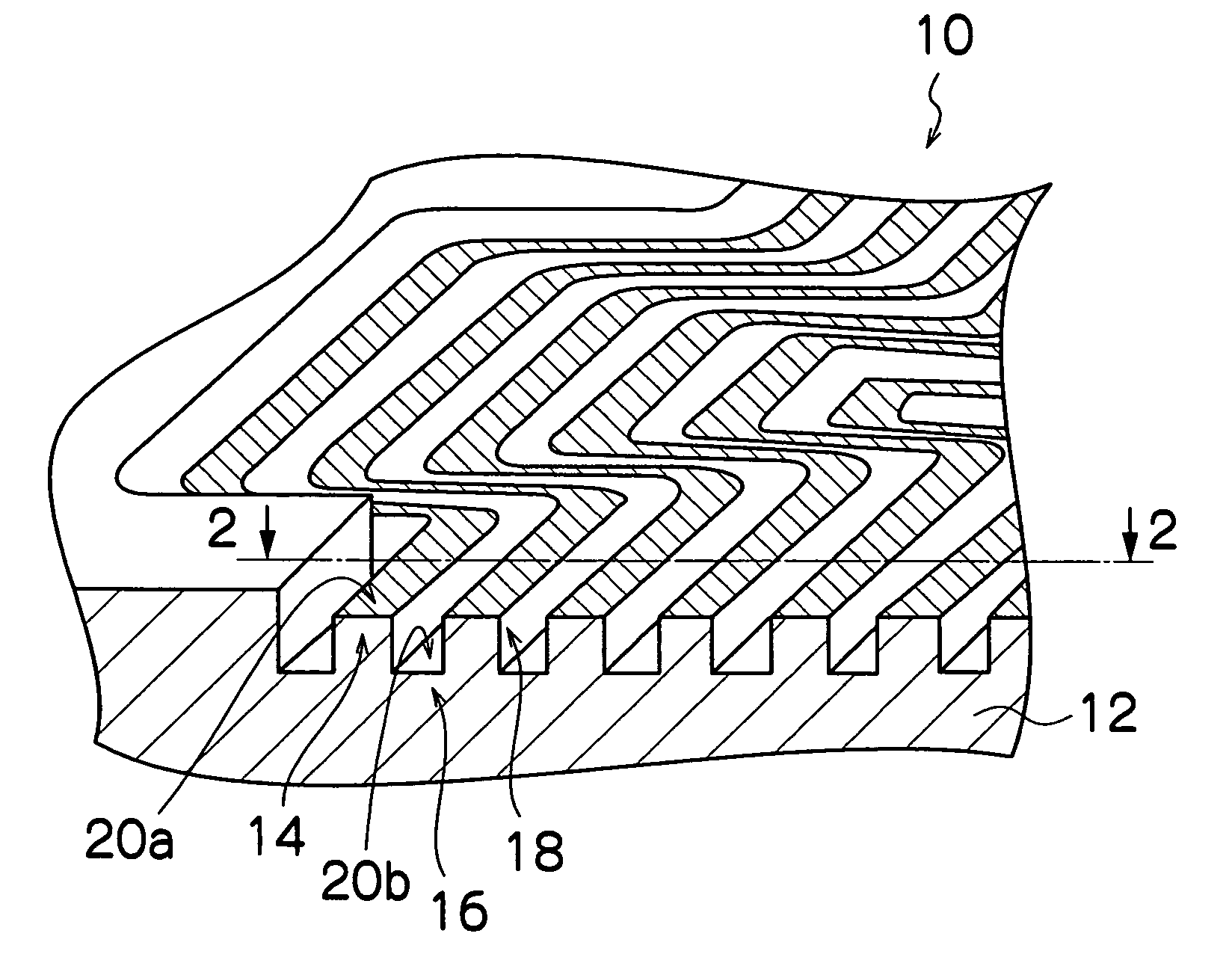

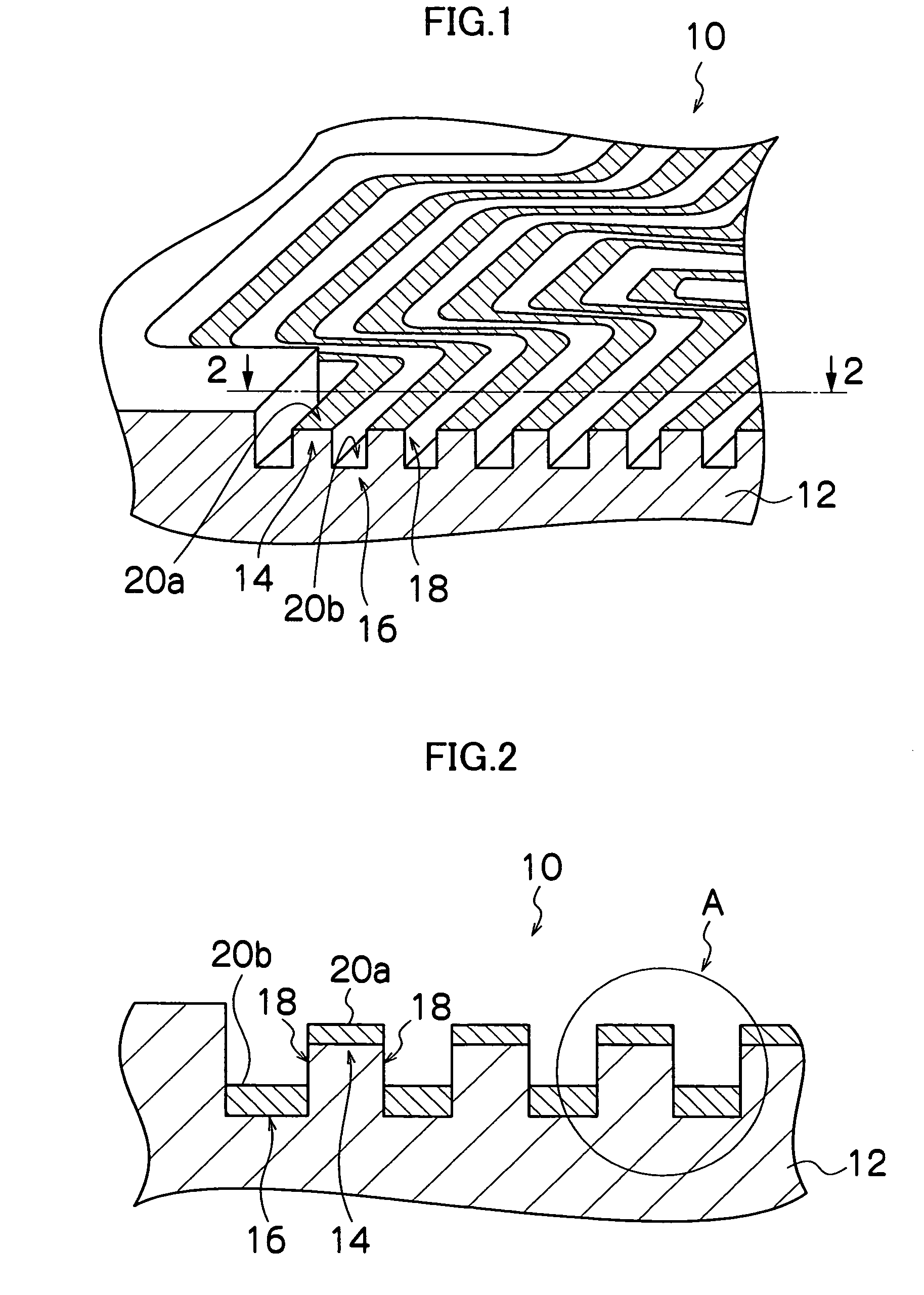

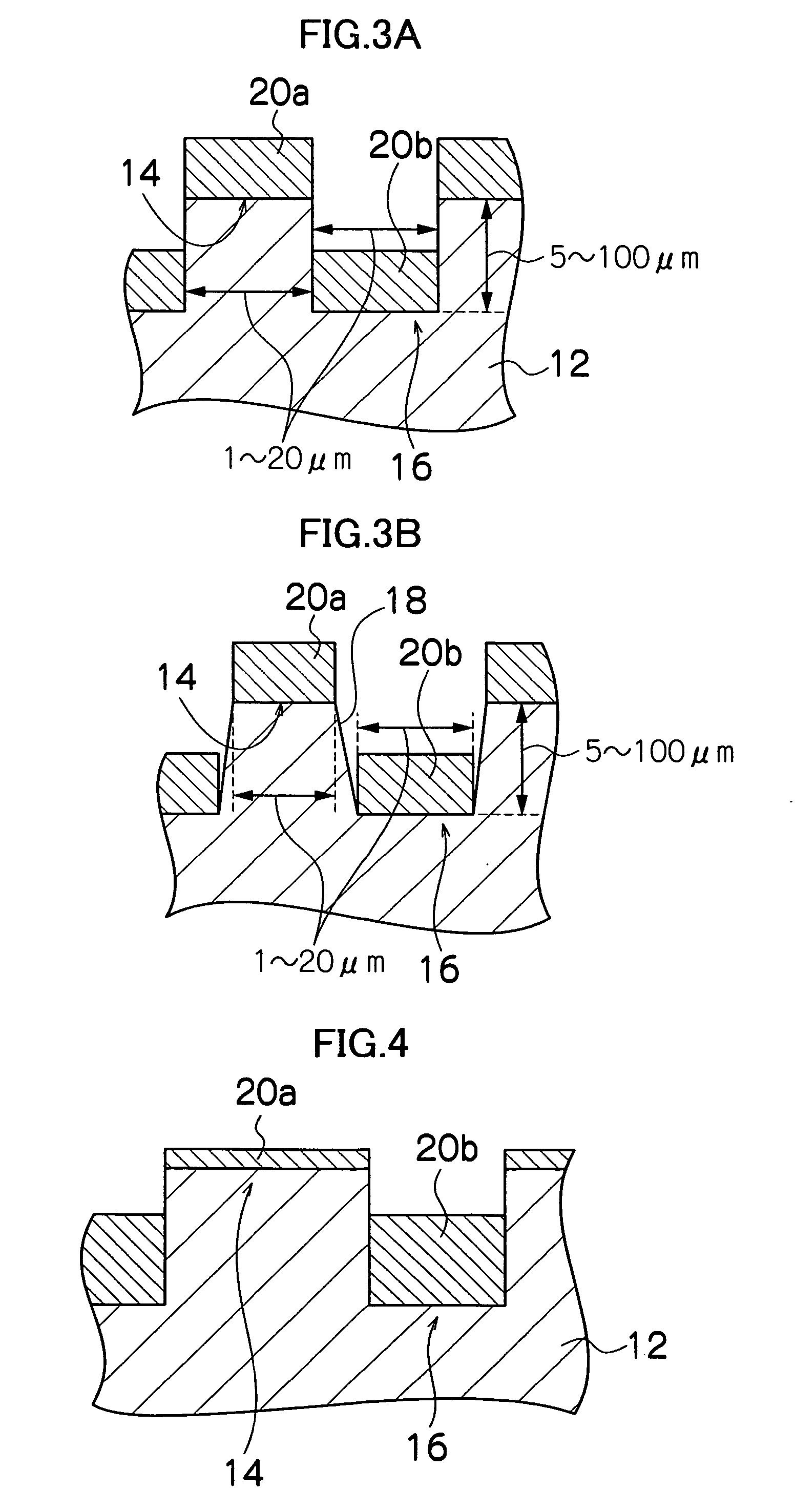

Wiring substrate, method of manufacturing wiring substrate, and liquid droplet ejection head

InactiveUS20070049130A1High-density wiring arrangementPrevent short-circuitingInking apparatusPrinted circuit aspectsEngineeringElectrical and Electronics engineering

Owner:FUJIFILM CORP

Method of manufacturing multilayer wiring board

InactiveUS7624501B2Shorten the time periodIncrease productionPrinted circuit assemblingPrinted circuit aspectsIn planeEngineering

First, a plurality of wiring boards are fabricated at separate steps. The first wiring board includes a Cu post formed on a wiring layer on one surface of a substrate, and a first stopper layer formed at a desired position around the Cu post. The second wiring board includes a through hole for insertion of the Cu post therethrough, a connection terminal formed on a wiring layer on one surface of a substrate, and a second stopper layer that engages the first stopper layer and functions to suppress in-plane misalignment. The third wiring board includes a connection terminal formed on a wiring layer on one surface of a substrate. Then, the wiring boards are stacked up, as aligned with one another so that the wiring layers are interconnected via the Cu post and the connection terminals, to thereby electrically connect the wiring boards. Thereafter, resin is filled into gaps between the wiring boards.

Owner:SHINKO ELECTRIC IND CO LTD

Hinge board and method for producing the same

InactiveUS20070062722A1Reduce thicknessAvoid disconnectionPrinted circuit assemblingPrinted circuit aspectsElectrical conductorPolyimide

A hinge board having a hinge bending part and a rigid part includes: not less than two flexible wiring boards including a polyimide sheet layer, a conductor layer having a circuit formed on both sides or one side of the polyimide sheet layer, and a coverlay film layer covering the conductor layer; and a bonding material for bonding the flexible wiring boards. At least one of the flexible wiring boards is a flexible double-sided wiring board including the conductor layers on both sides of the polyimide sheet layer. Moreover, the flexible wiring boards are bonded to each other in the rigid part by use of the bonding material in such a manner that a space part is formed between the flexible wiring boards in the hinge bending part.

Owner:NIPPON STEEL CHEMICAL CO LTD

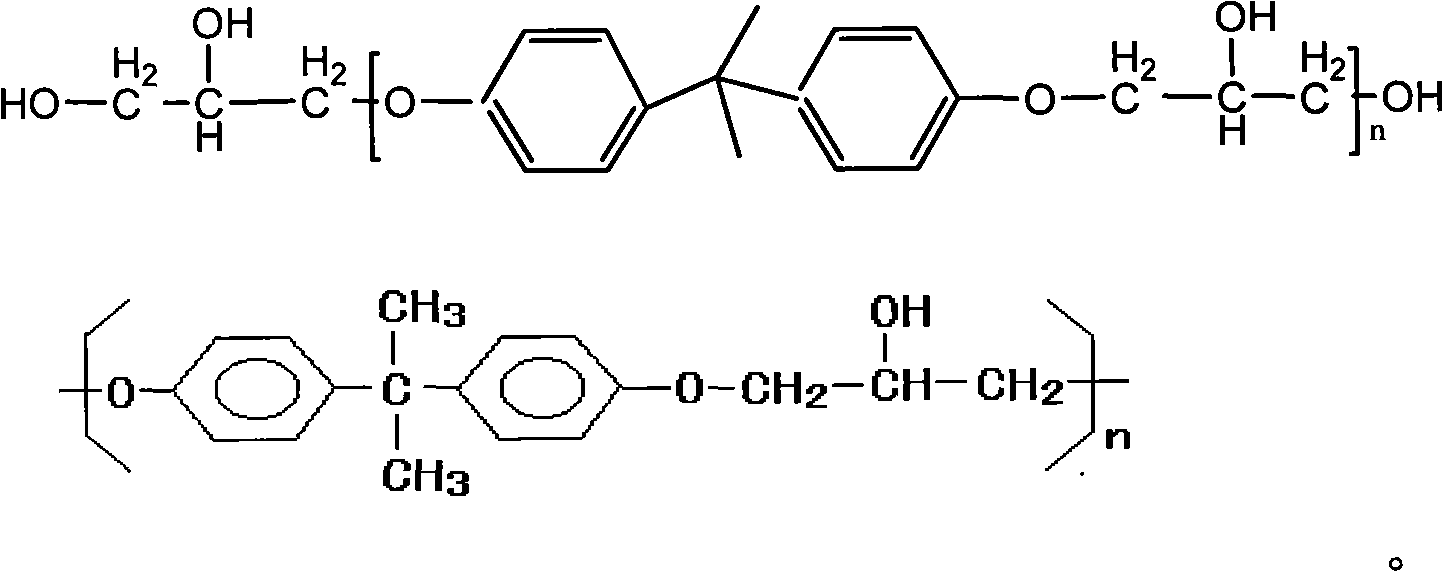

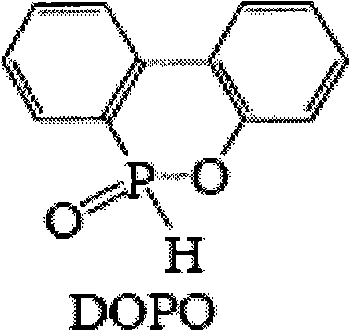

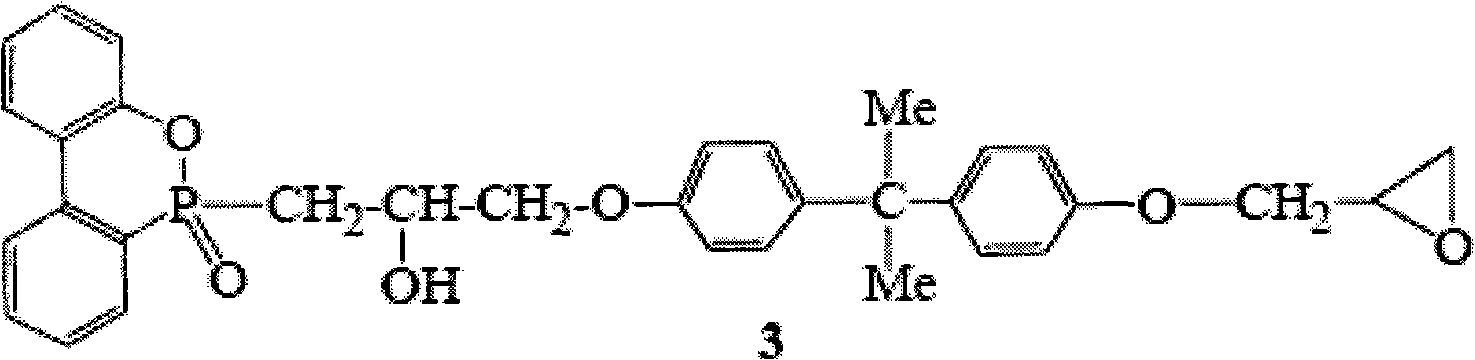

Halogen-free high heat-conducting resin composition and resin coated copper foil

InactiveCN101792573AImprove heat resistanceHigh peel strengthPrinted circuit detailsMetal layered productsEpoxyCopper foil

The invention discloses a halogen-free high heat-conducting resin composition and a resin coated copper foil. The halogen-free high heat-conducting resin composition comprises the following components in part by mass: 10 to 40 parts of phosphoric epoxy resin, 0 to 10 parts of UV blocking multifunctional epoxy resin, 5 to 35 parts of phenoxy resin, 50 to 80 parts of high heat-conducting filler, 1 to 10 parts of amine curing agent and 0.2 to 2 parts of accelerator. The halogen-free high heat-conducting resin composition provided by the invention does not contain halogen, is environment-friendly, and has high heat resistance and peeling strength and good reliability. Moreover, the invention provides a resin coated copper foil manufactured by using the composition, which replaces a common prepreg and a common copper foil, is used for manufacturing printed circuit board materials of metal base plates, flexible plates and multilayer laminated plates, realizes higher heat conductivity, fills the domestic bank in the aspect of high heat conductance of the resin coated copper foil, provides possibility for the light, thin, short, small and multifunctional development of electronic products, and can realize a high-performance material with high-density wire arrangement, thin shape, superfine aperture and high heat dissipation property.

Owner:GUANGDONG SHENGYI SCI TECH

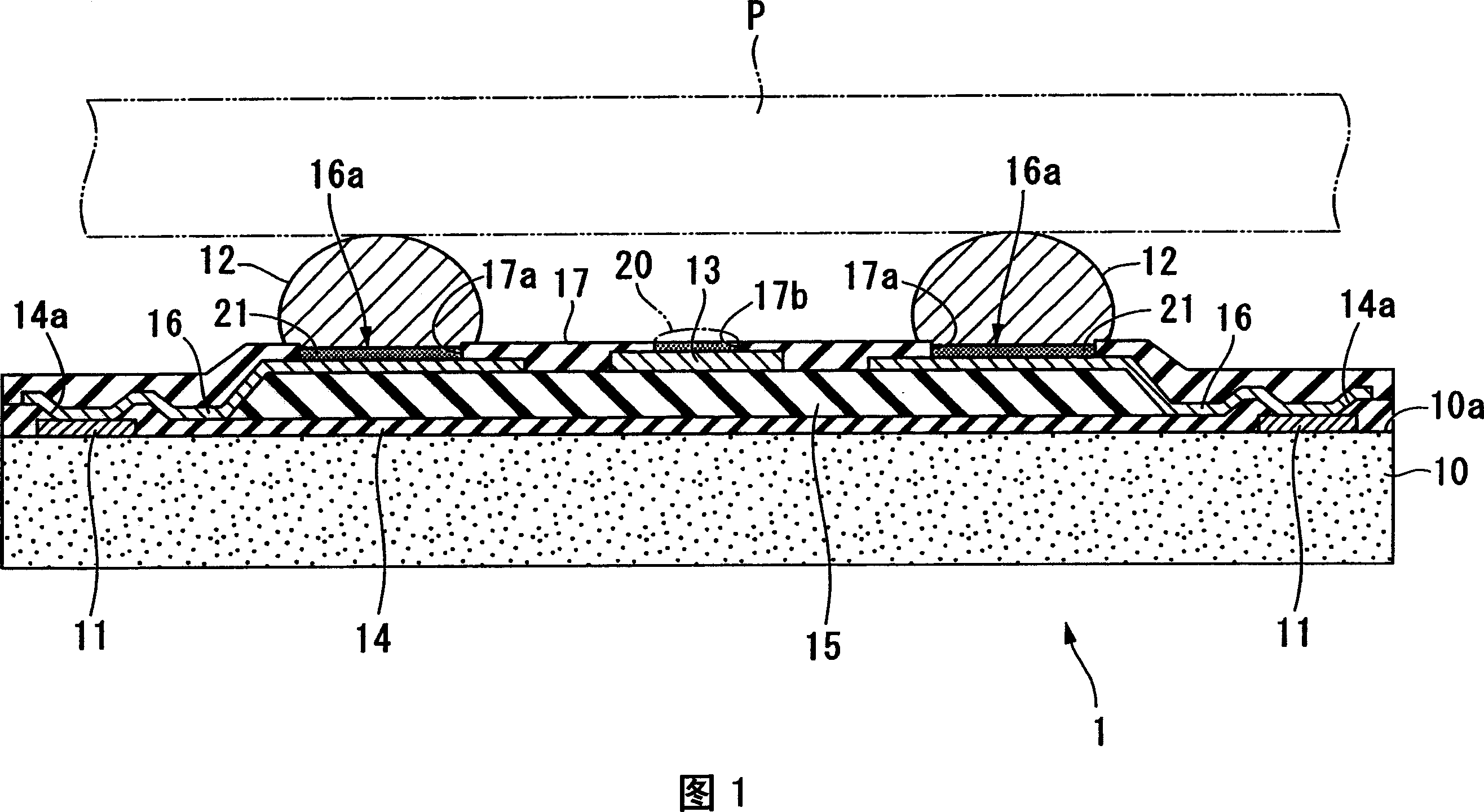

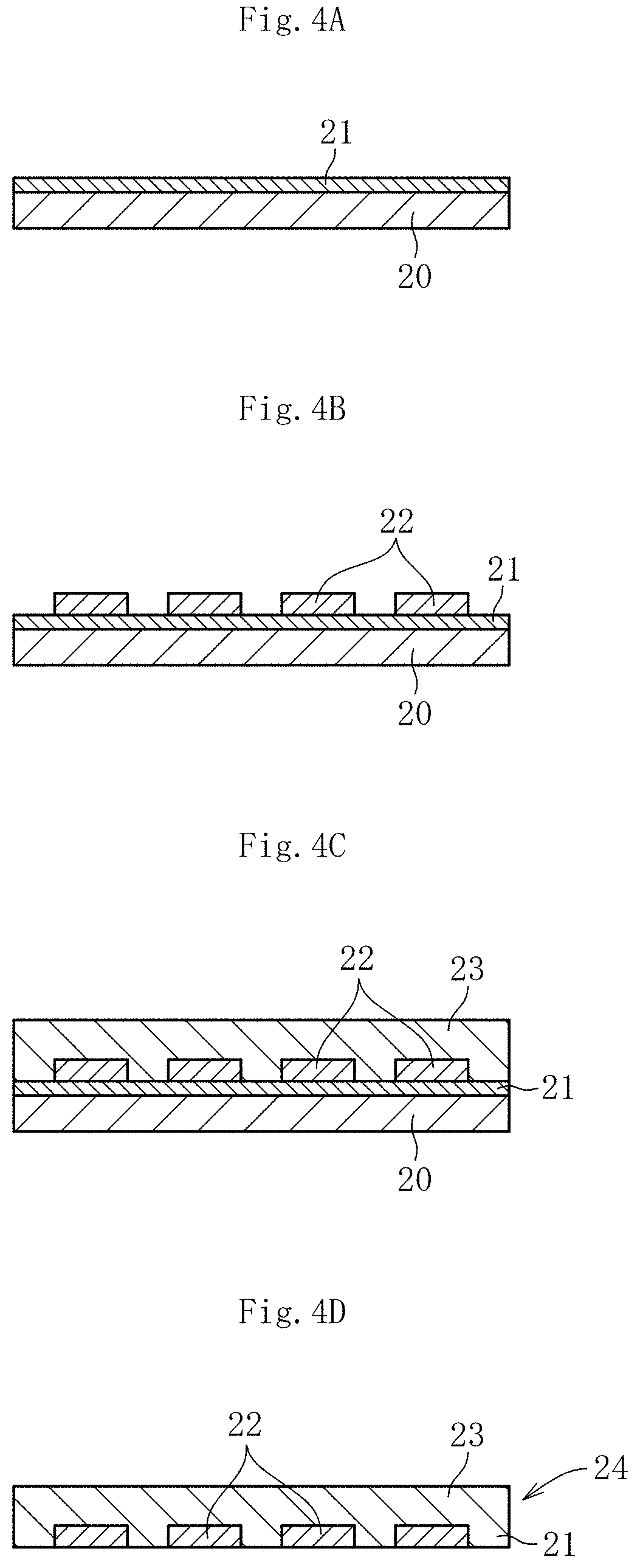

Optical waveguide substrate and substrate mounting photoelectric hybrid circuit

InactiveUS20100166363A1Reduce the number of partsLow costCoupling light guidesOptical waveguide light guideHigh densityPhotoelectric conversion

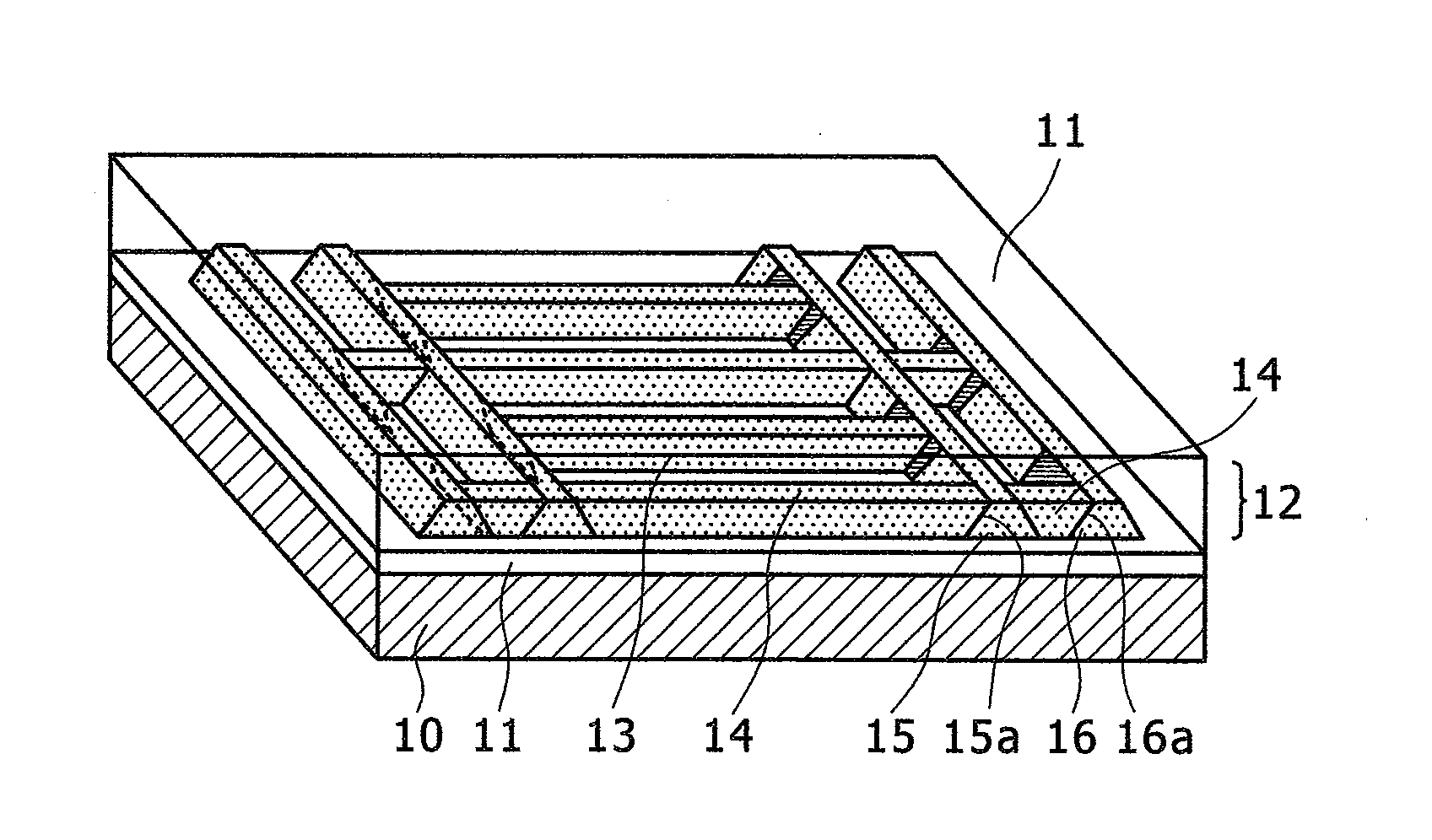

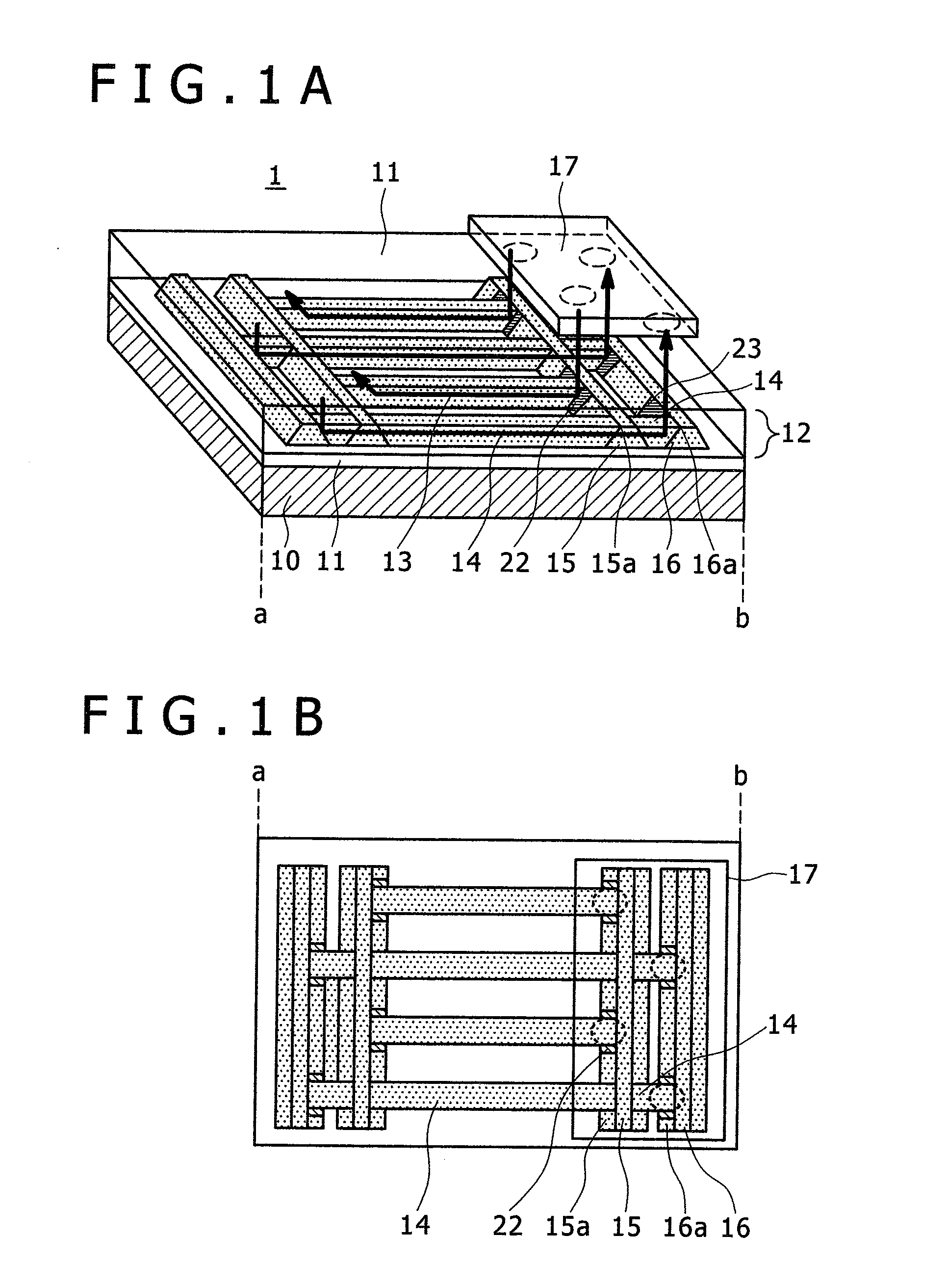

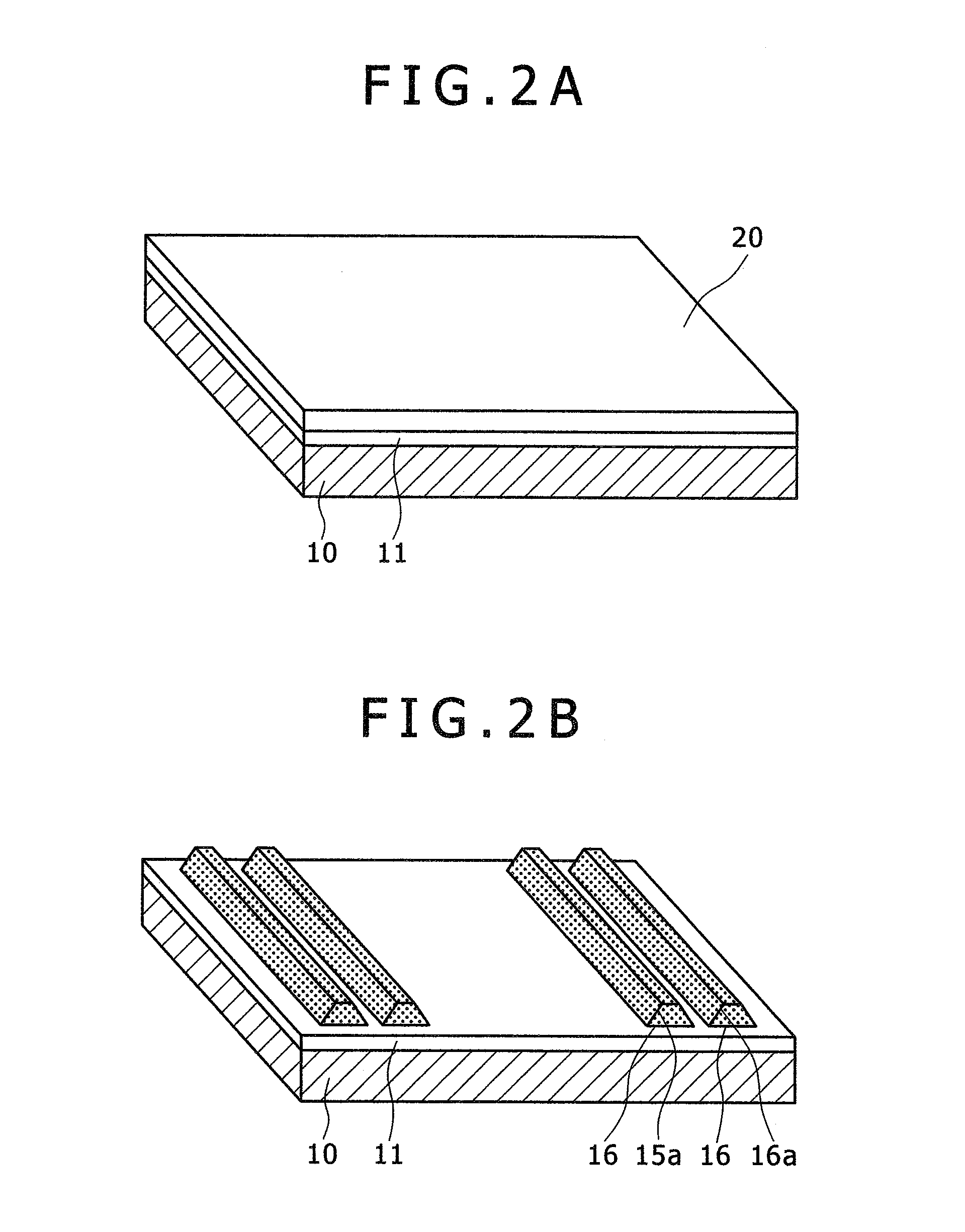

There are provided a substrate mounted with a photoelectric hybrid circuit having an optical path conversion mirror structure and optical waveguide wiring by reducing the number of parts and the number of fabrication steps, as well as most effectively implement high-density wiring for an optical connection between the optical waveguide and the photoelectric conversion element or optical waveguide array connector that are formed on the substrate, and a device. An optical waveguide layer 12 stacked on a substrate 10 and formed of a wiring core surrounded by a clad layer 11, and cores 15, 16 having tapered surfaces intersecting the respective wiring cores 13, 14 of the optical waveguide layer 12 perpendicularly are arranged, the tapered surfaces 15a, 16a of the cores 15, 16 having tapered surfaces are buried respectively in the wiring portion cores intersecting perpendicularly, and a first core 13 for turning the optical path of light propagating through the wiring portion core at the first core 15 with a tapered surface, and a second core 14 for turning the optical path of light passed through the first core 15 with a tapered surface at the second core 16 with a tapered surface are arranged alternately.

Owner:HITACHI CHEM CO LTD

Printed circuit board, electronic member mounting method and electronic device

InactiveCN101336045AHigh density installationHigh Density WiringPrinted circuit assemblingFinal product manufactureSemiconductor packageSemiconductor chip

According to one embodiment, a printed wiring board structure comprises a printed wiring board having first and second component mounting surfaces at front and back sides thereof, respectively, each for mounting a semiconductor package loading a semiconductor chip loaded on a substrate as a mounting component, a first semiconductor package mounted on the first component mounting surface, and a second semiconductor package mounted on the second component mounting surface, wherein the first and second semiconductor packages have a positional relationship such that the substrates are partially overlapped via the printed wiring board, and the semiconductor chips are not overlapped.

Owner:KK TOSHIBA

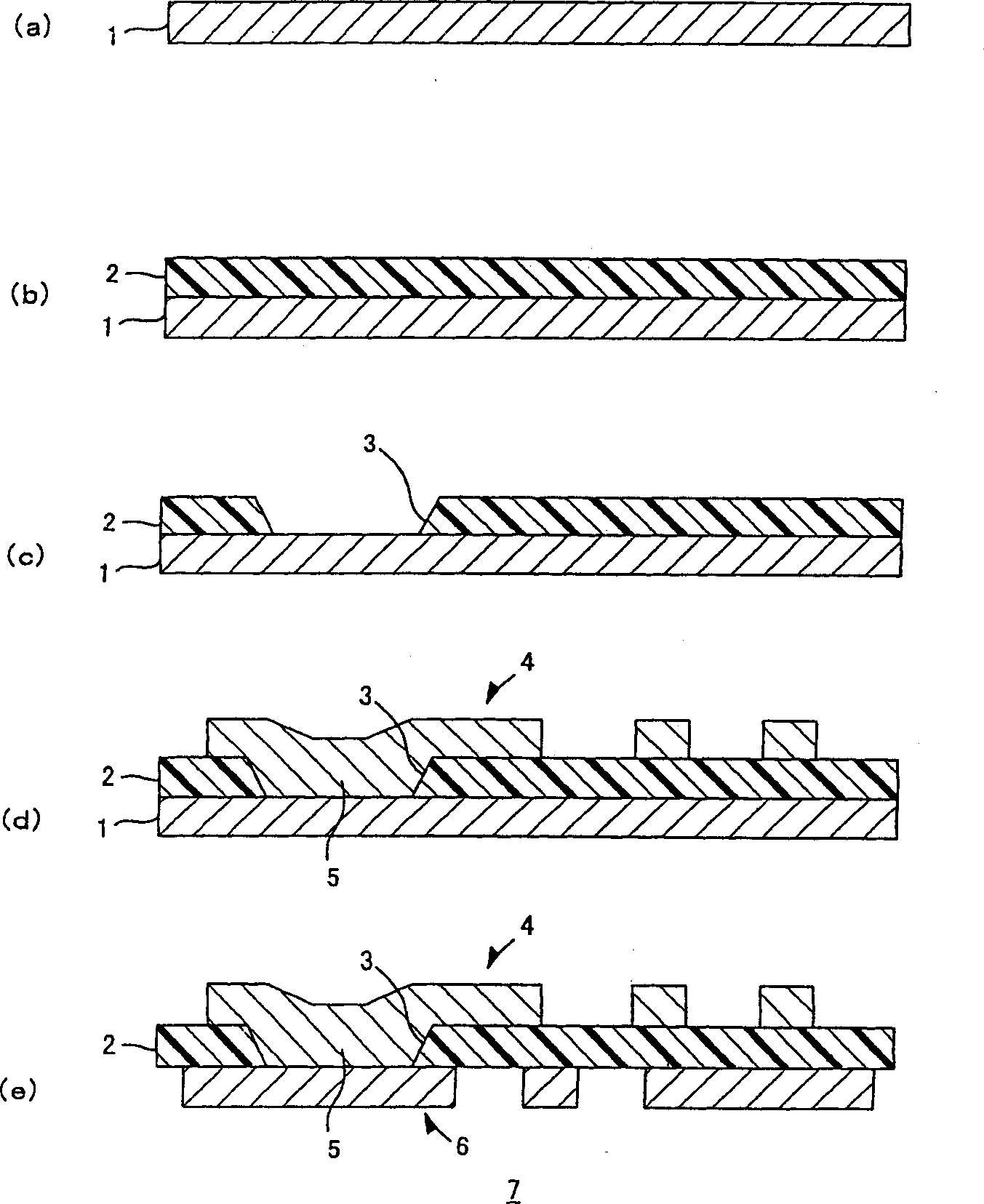

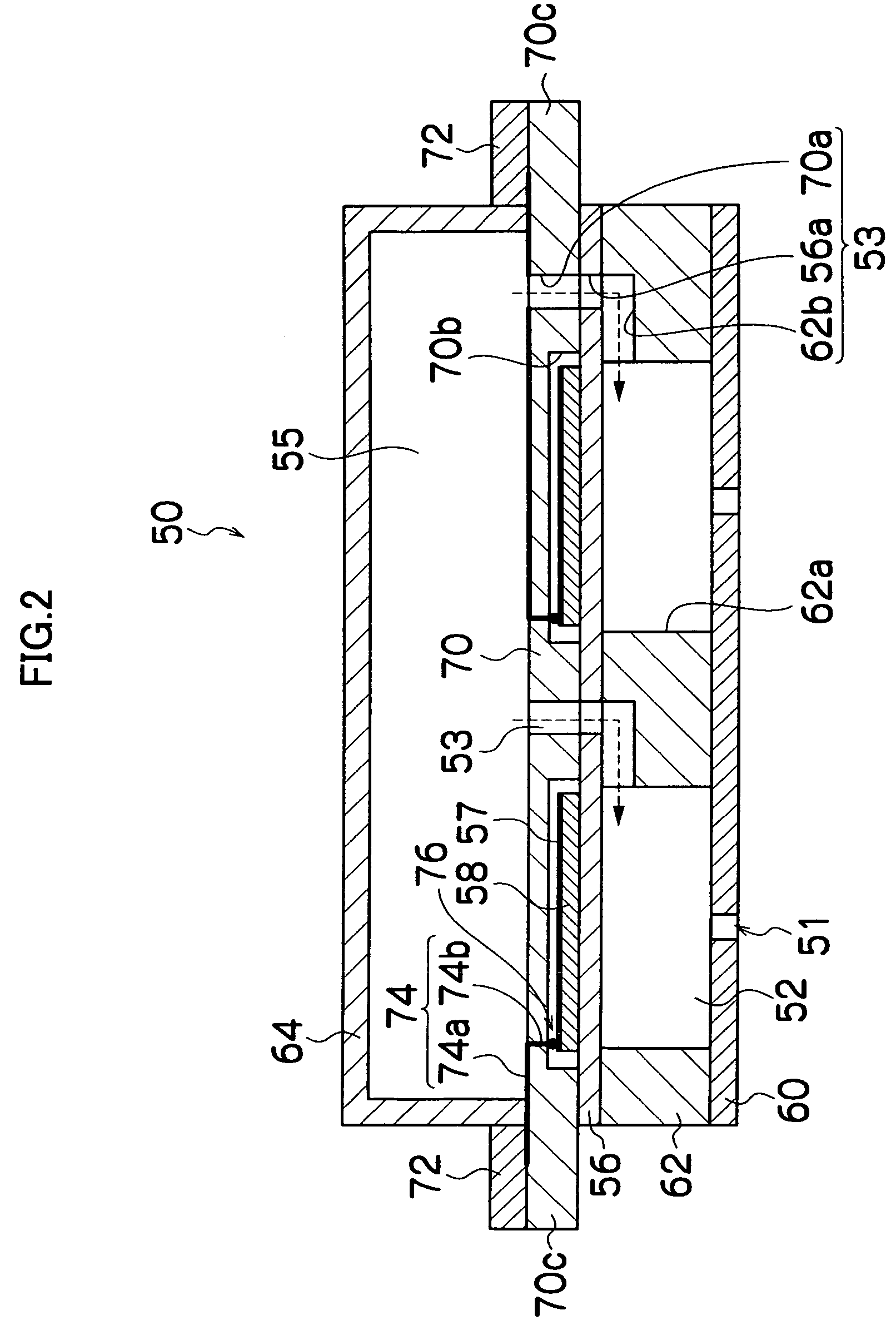

Multilayer flexible wiring circuit board and its manufacturing method

InactiveUS6887560B2Sufficient adhesive strengthIncrease adhesion strengthPrinted circuit aspectsLaminationEngineeringElectrical conductor

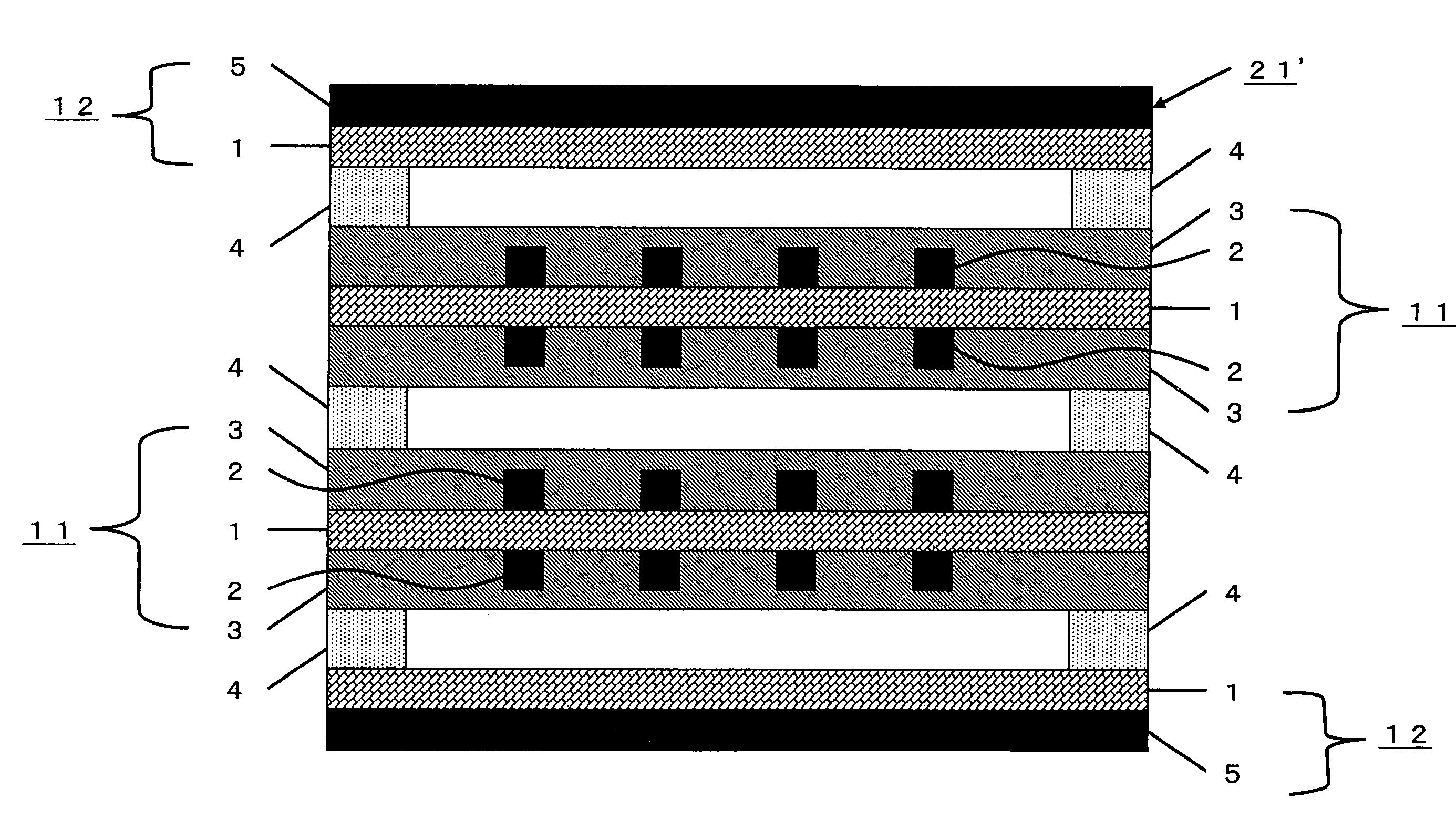

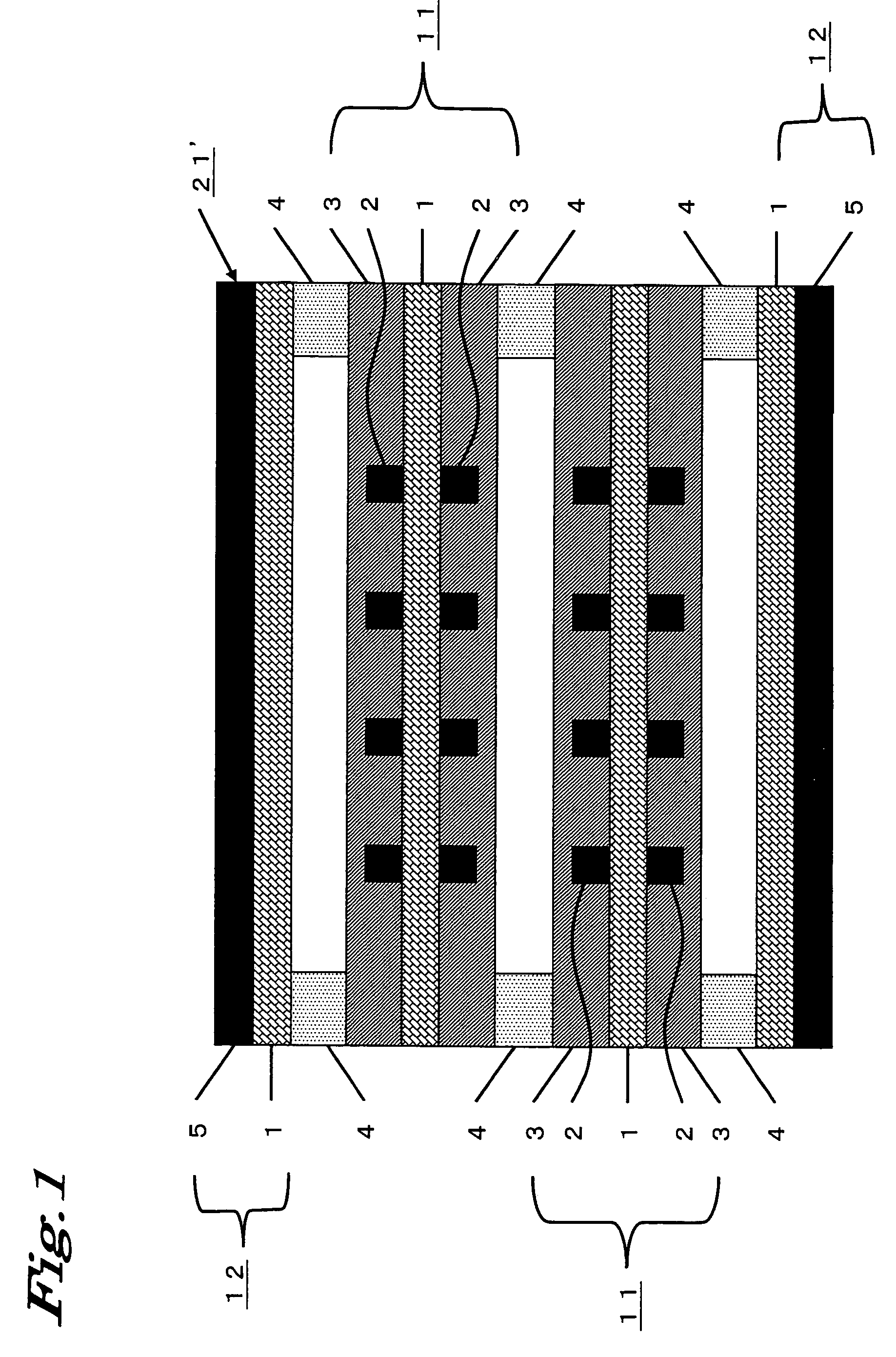

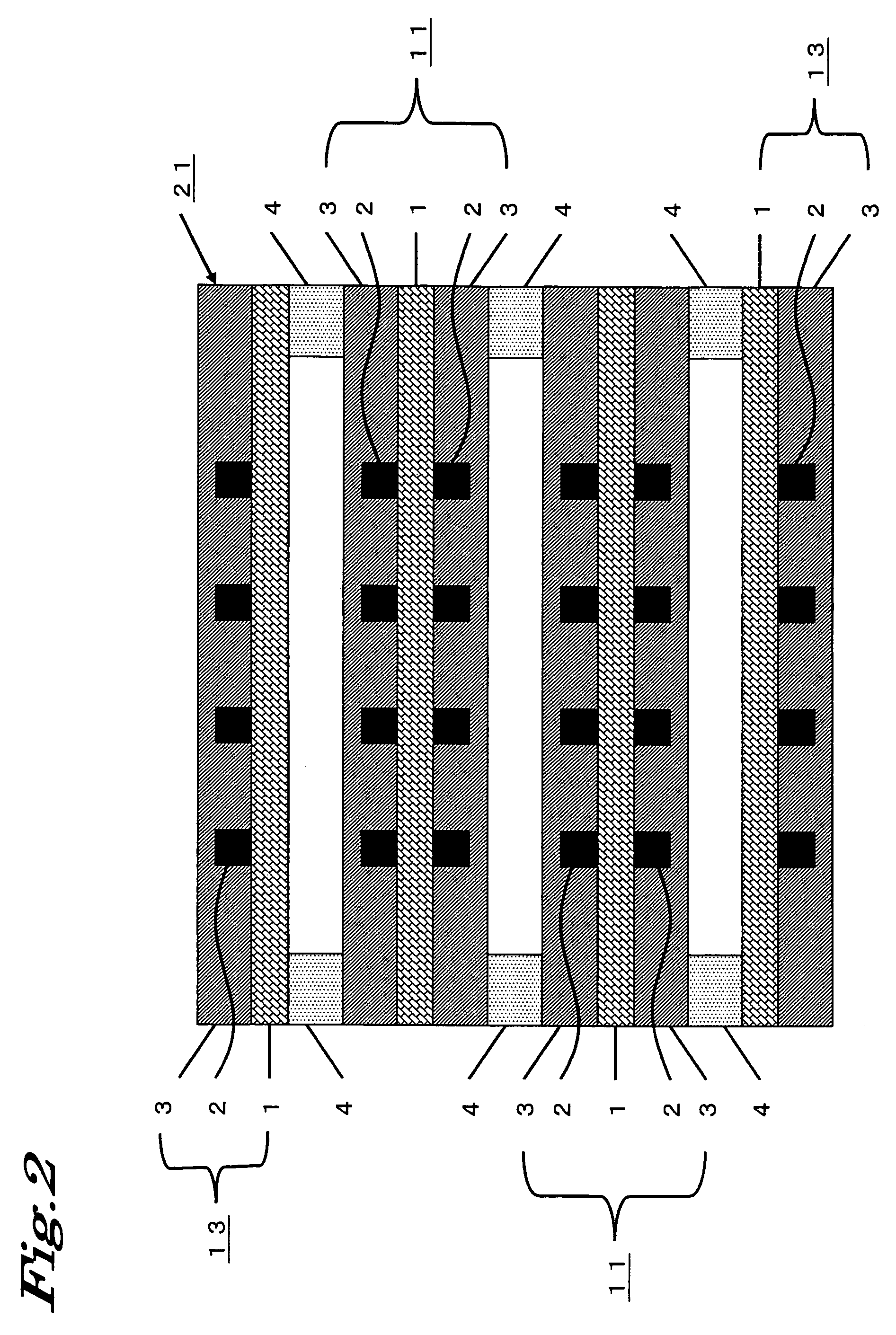

A multilayer flexible wired circuit board that can provide high density wiring and also can provide reduction in thickness and size, and a producing method thereof. A four-layered flexible wired circuit board is produced by preparing a double-sided substrate in which a first conductor layer and a second conductor layer are laminated on both sides of a first insulating layer; preparing a first single-sided substrate in which a third conductor layer is laminated on one surface of a second insulating layer and a second single-sided substrate in which a fourth conductor layer is laminated on one surface of a third insulating layer; bonding the first conductor layer and the third conductor layer to each other through a first thermosetting adhesive layer; and bonding the second conductor layer and the fourth conductor layer to each other through a second thermosetting adhesive layer.

Owner:NITTO DENKO CORP

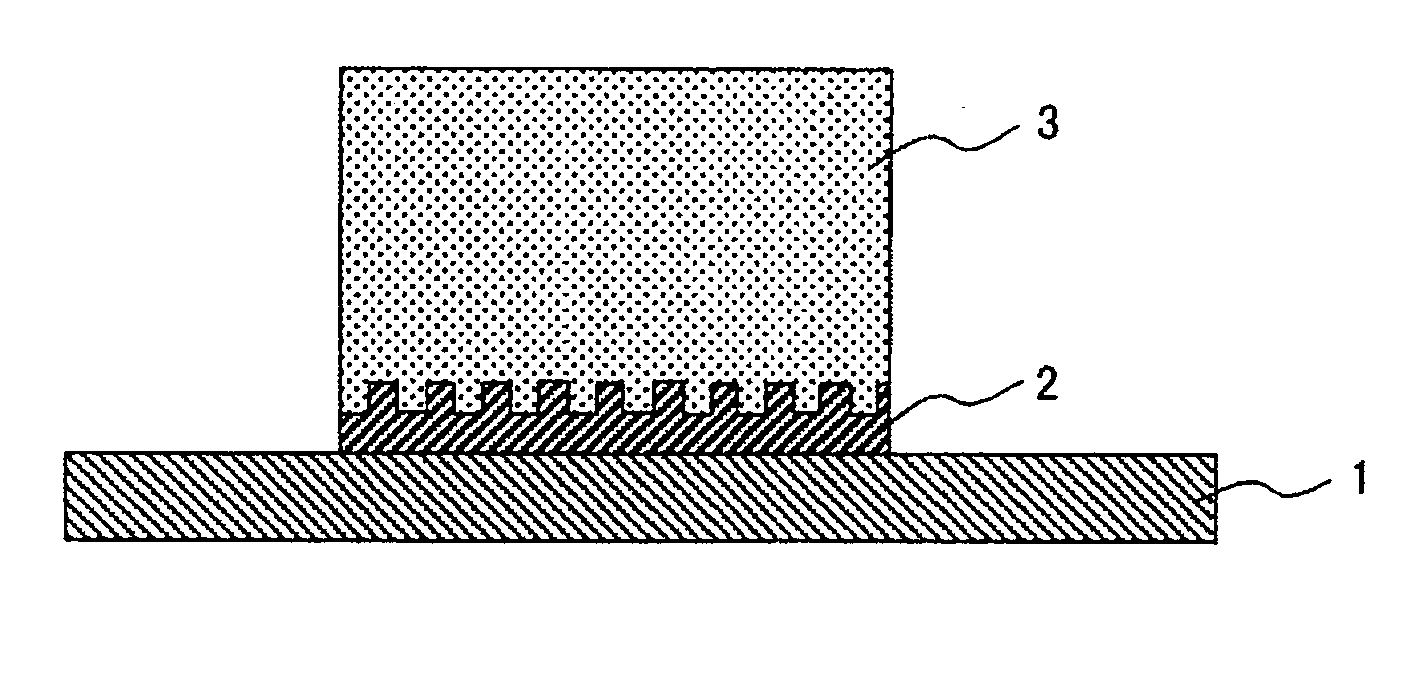

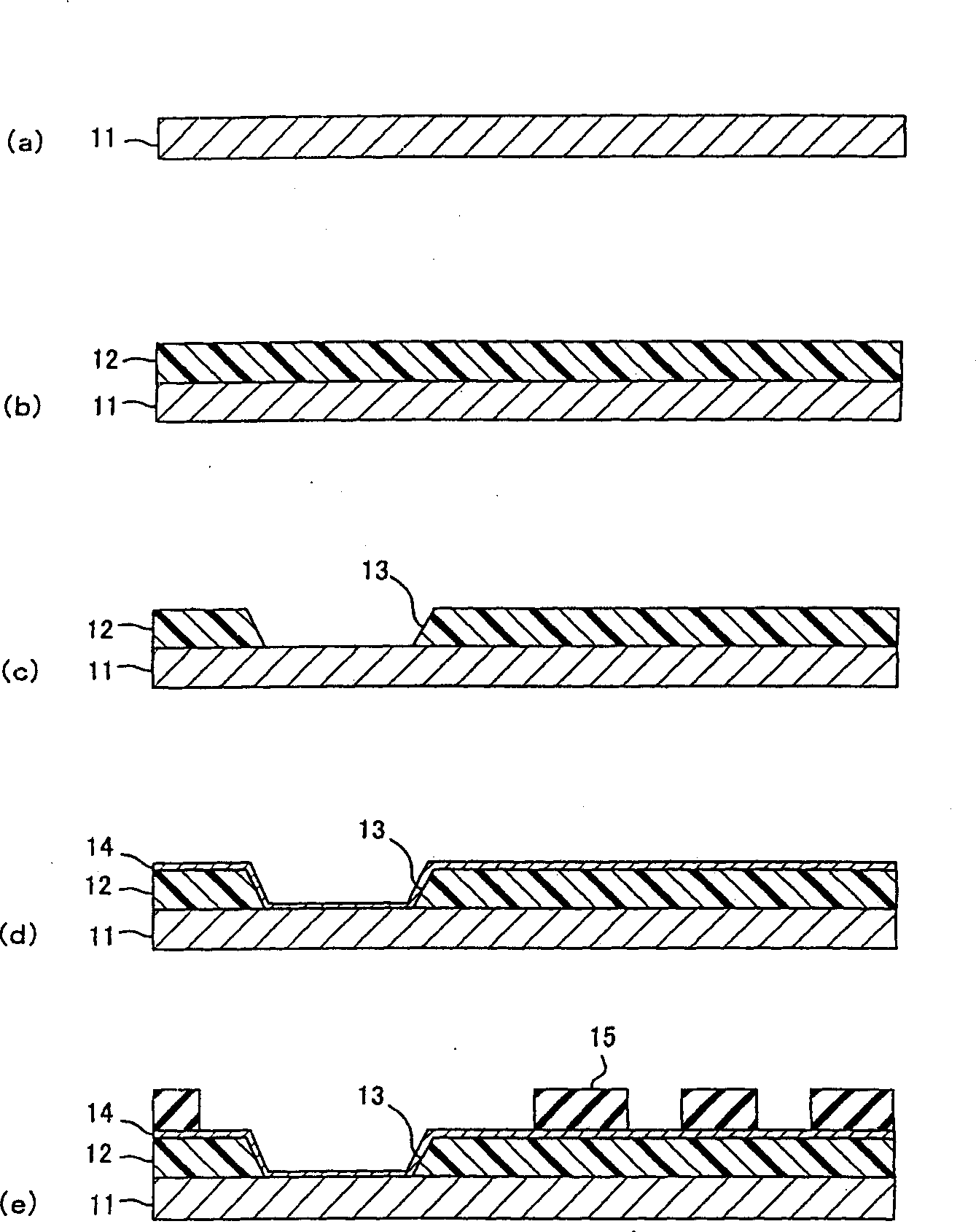

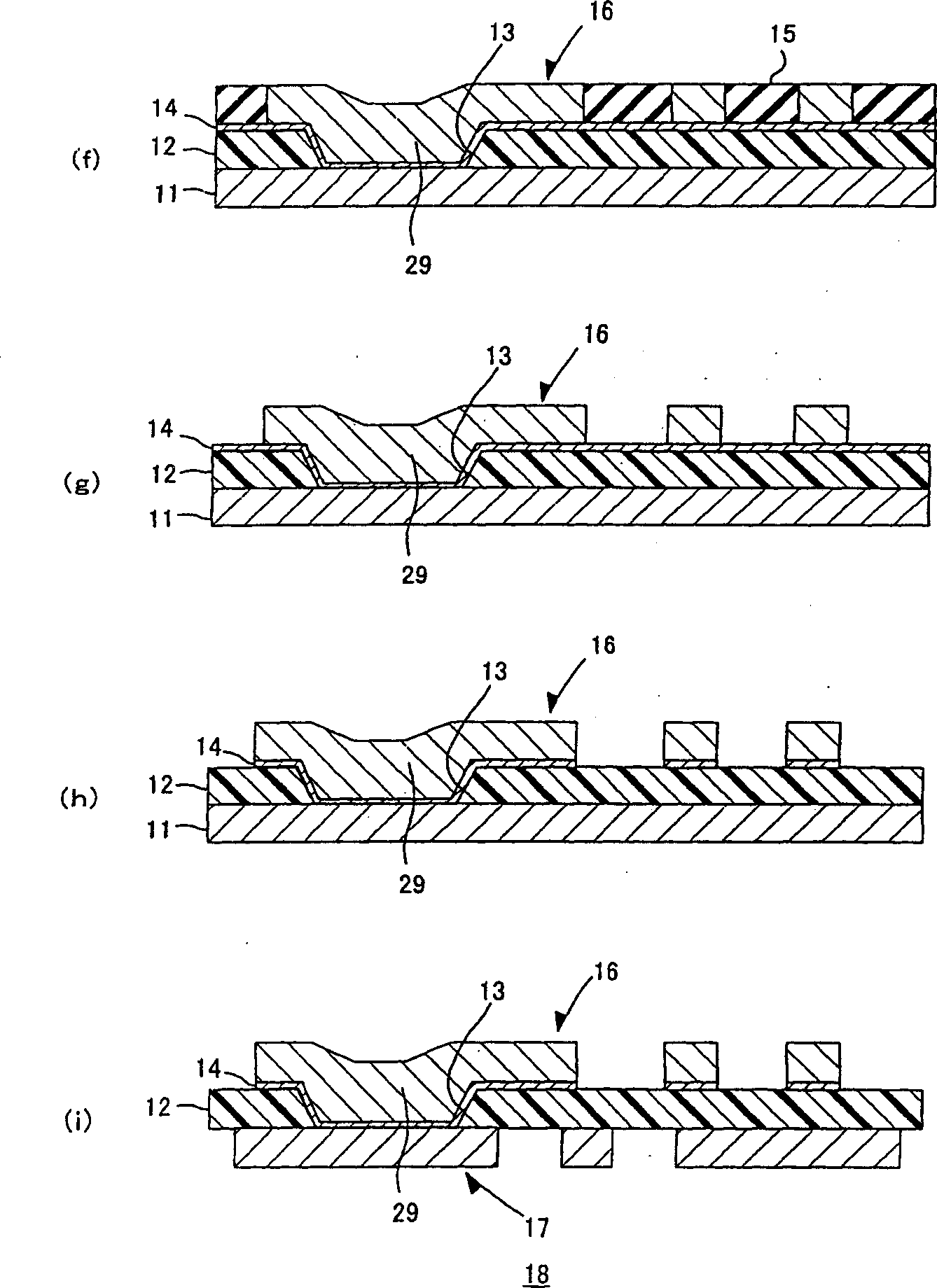

Method for mfg. multilayer printed wiring board and multilayer printed wiring board thereby

InactiveCN1347277ALow profileReduce weightInsulating substrate metal adhesion improvementPrinted circuit aspectsHigh densityMetal foil

To provide a method of producing a multilayer printed wiring board that can be intended to have low-profile, light-weight and high-density wiring of a printed wiring board, and a multilayer printed wiring board produced by the method of producing a multilayer printed wiring board, the double-sided substrate is produced by the steps of forming an insulating resin layer on a metal foil; of forming a via hole in the insulating resin layer; of forming a first circuit pattern on the insulating resin layer and forming a conductive layer in the via hole, by plating; and of etching the metal foil to form it into a second circuit pattern. The produced double-sided substrate is used as a core substrate for producing multilayer printed wiring board by a laminate-en-bloc or a build-up method.

Owner:NITTO DENKO CORP

Wiring substrate, method of manufacturing wiring substrate, and liquid droplet ejection head

InactiveUS8109612B2Reduce thicknessHigh-density wiringInking apparatusSecuring/insulating coupling contact membersEngineeringElectrical and Electronics engineering

Owner:FUJIFILM CORP

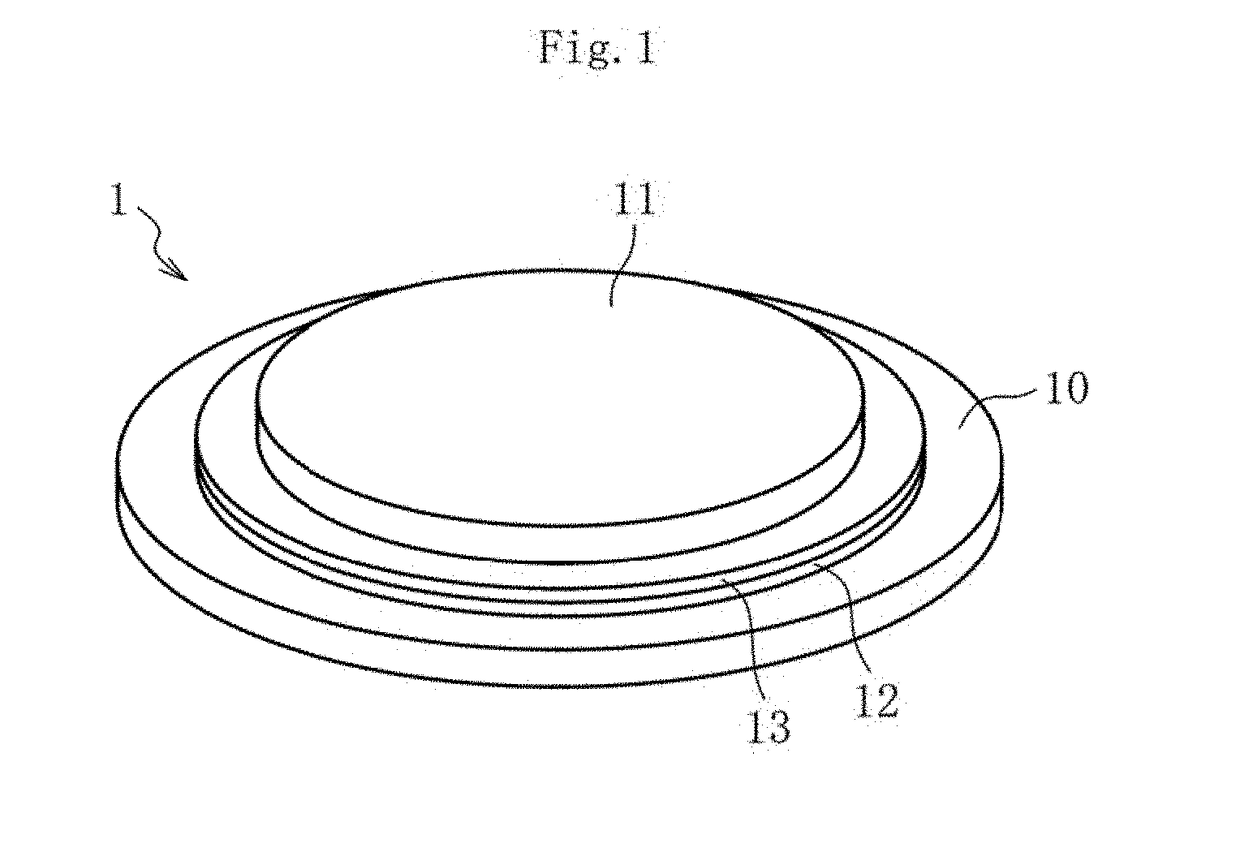

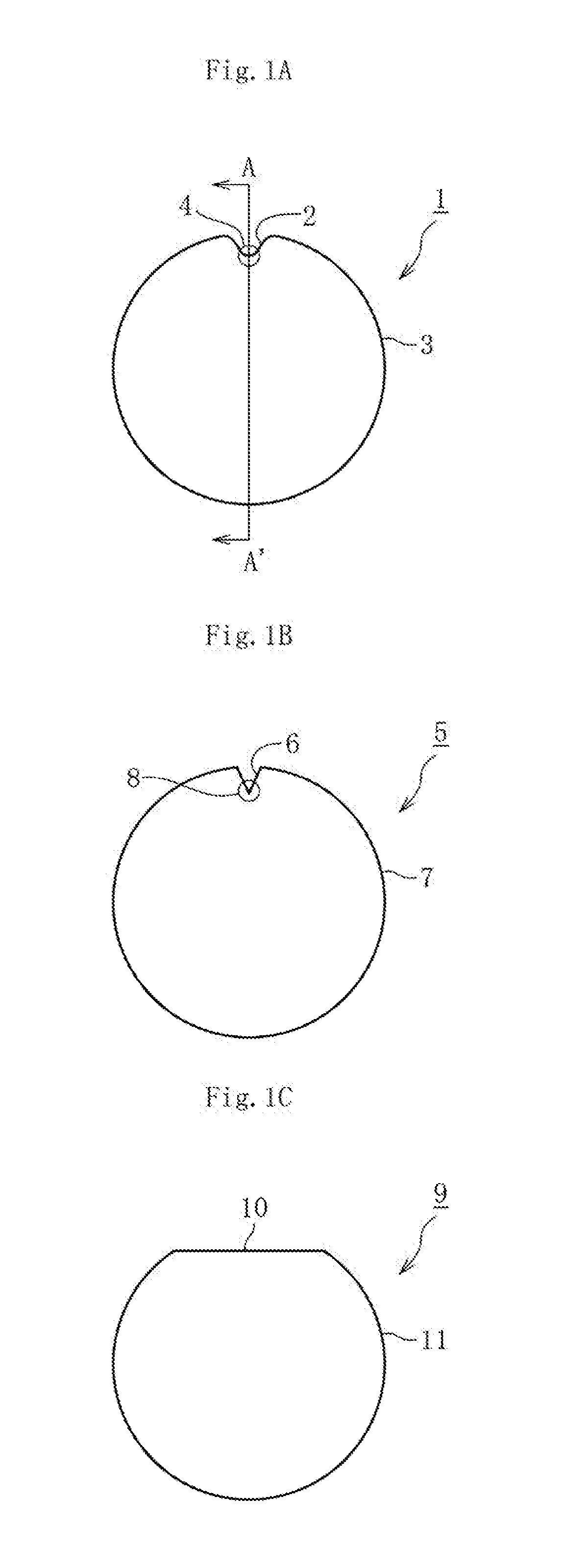

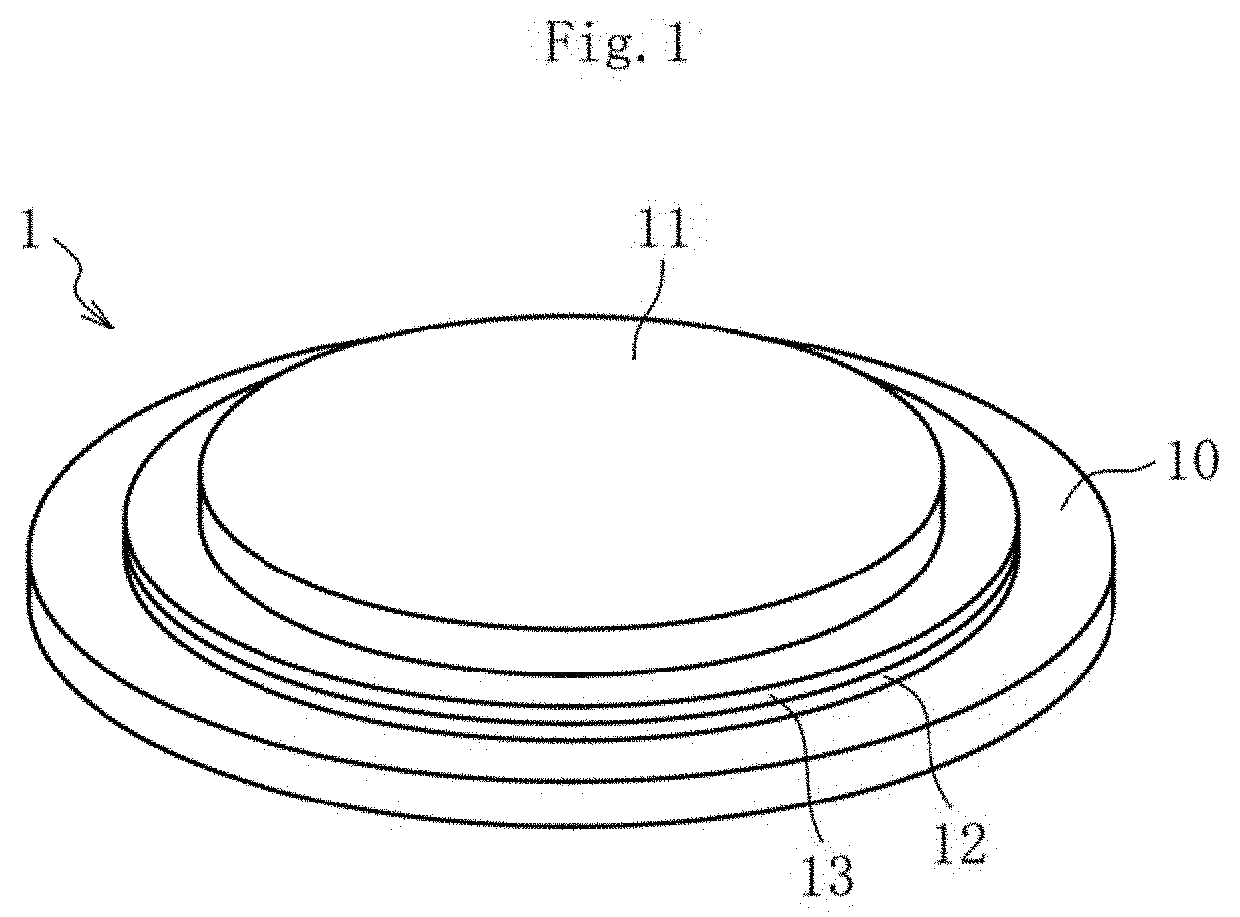

Glass substrate and laminate using same

ActiveUS20180339929A1Increase stiffnessImprove deformationSemiconductor/solid-state device detailsSolid-state devicesHigh densityTechnical object

A technical object of the present invention is to devise a glass substrate that is suitable for supporting a substrate to be processed to be subjected to high-density wiring and enables correct recognition of production information and the like, and a laminate using the glass substrate. In order to achieve the technical object, the glass substrate of the present invention has a total thickness variation of less than 2.0 μm and includes an information identification part formed of a plurality of dots.

Owner:NIPPON ELECTRIC GLASS CO LTD

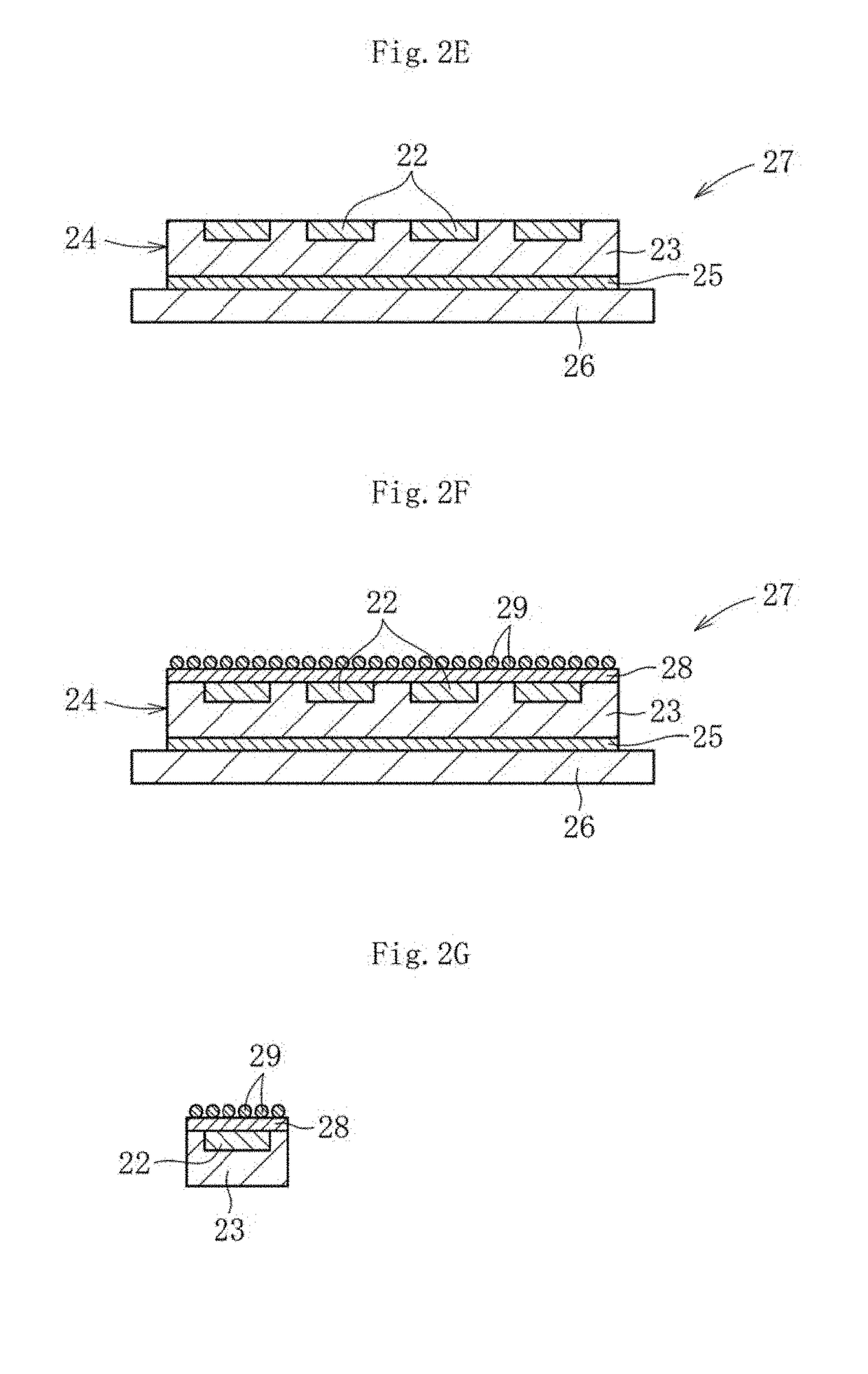

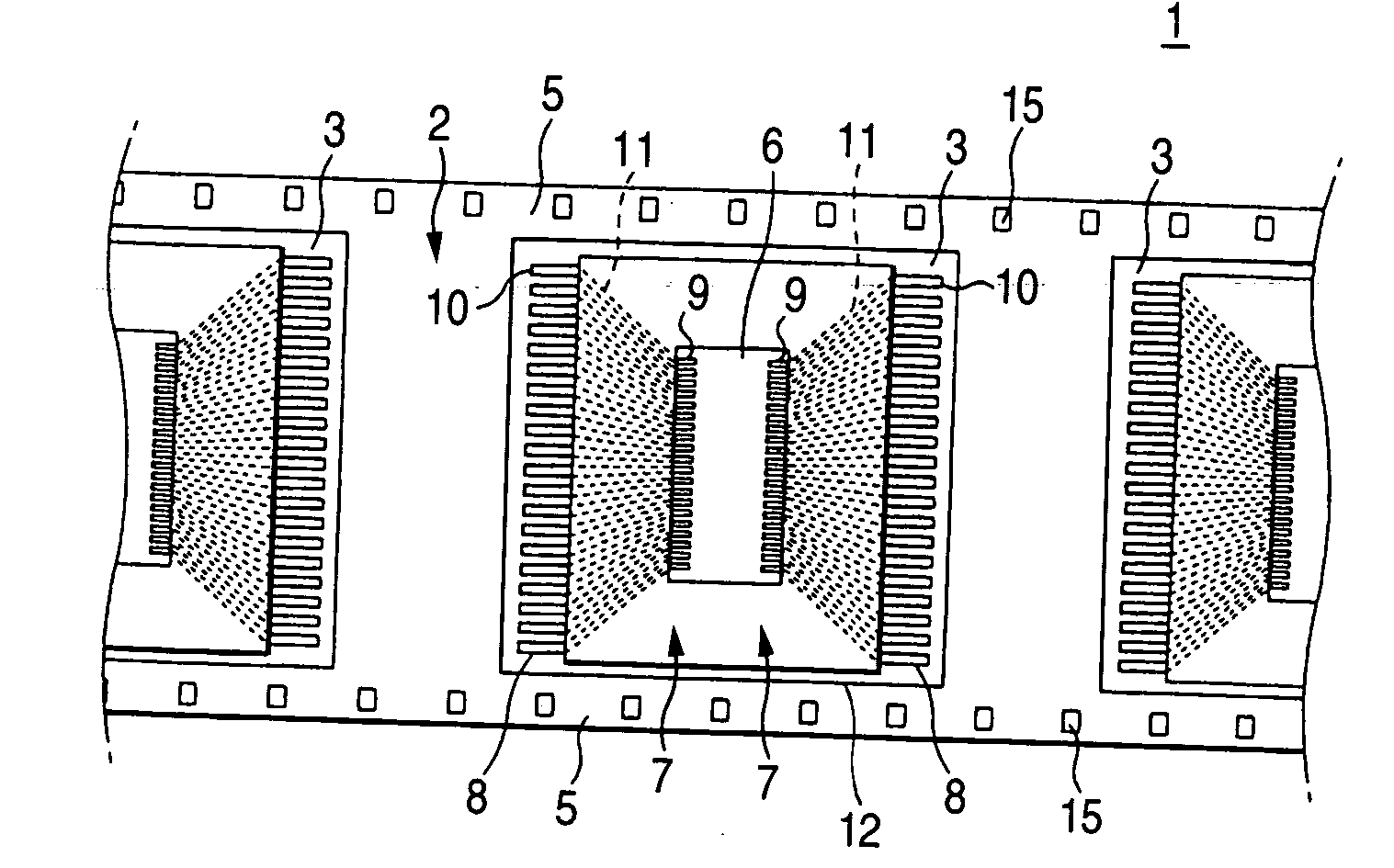

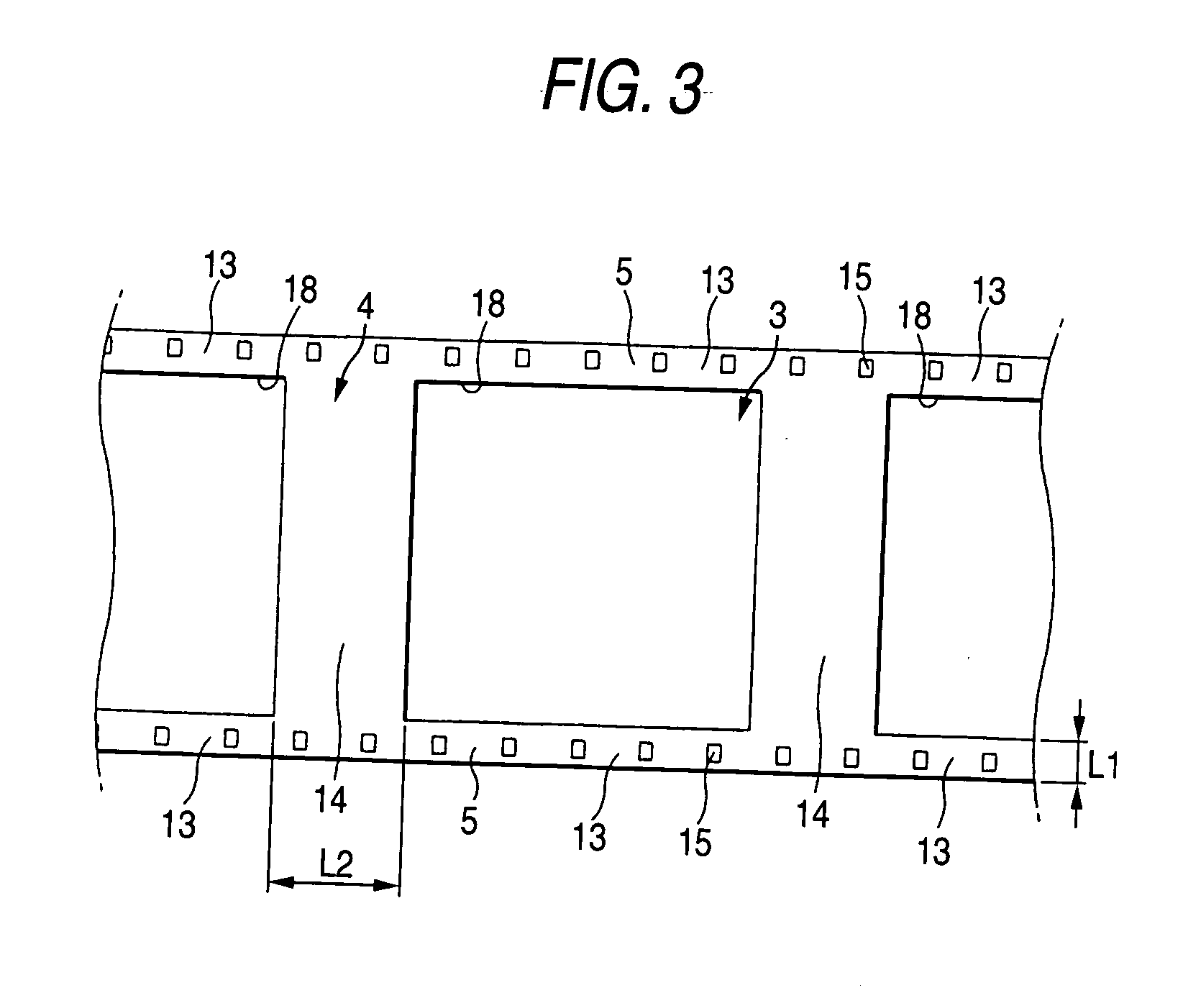

Tape carrier for TAB

InactiveUS20050230790A1Reduce weightReduce thicknessLine/current collector detailsSemiconductor/solid-state device detailsMagnetic tape

Electric conductor patterns having inner leads arranged at a pitch of not larger than 60 μm are formed on a front surface of an insulating layer of a tape carrier for TAB. A reinforcing layer of stainless steel foil is formed on a rear surface of the insulating layer so as to be extend along a lengthwise direction at opposite side edge portions in a widthwise direction of the insulating layer. Accordingly, both dimensional accuracy and positional accuracy can be improved at the time of carrying the tape carrier for TAB or at the time of mounting and bonding electronic parts though the insulating layer can be formed so as to be thin.

Owner:NITTO DENKO CORP

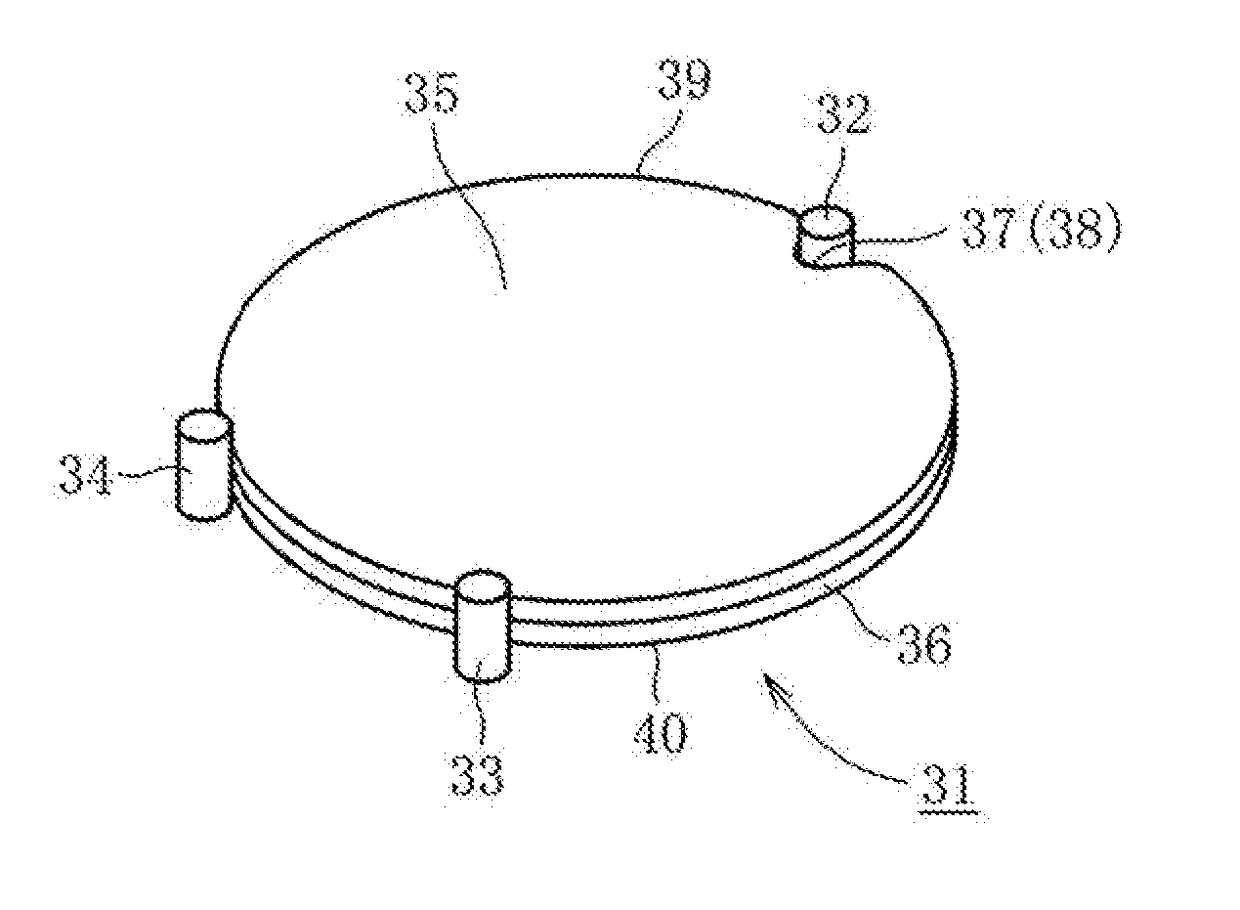

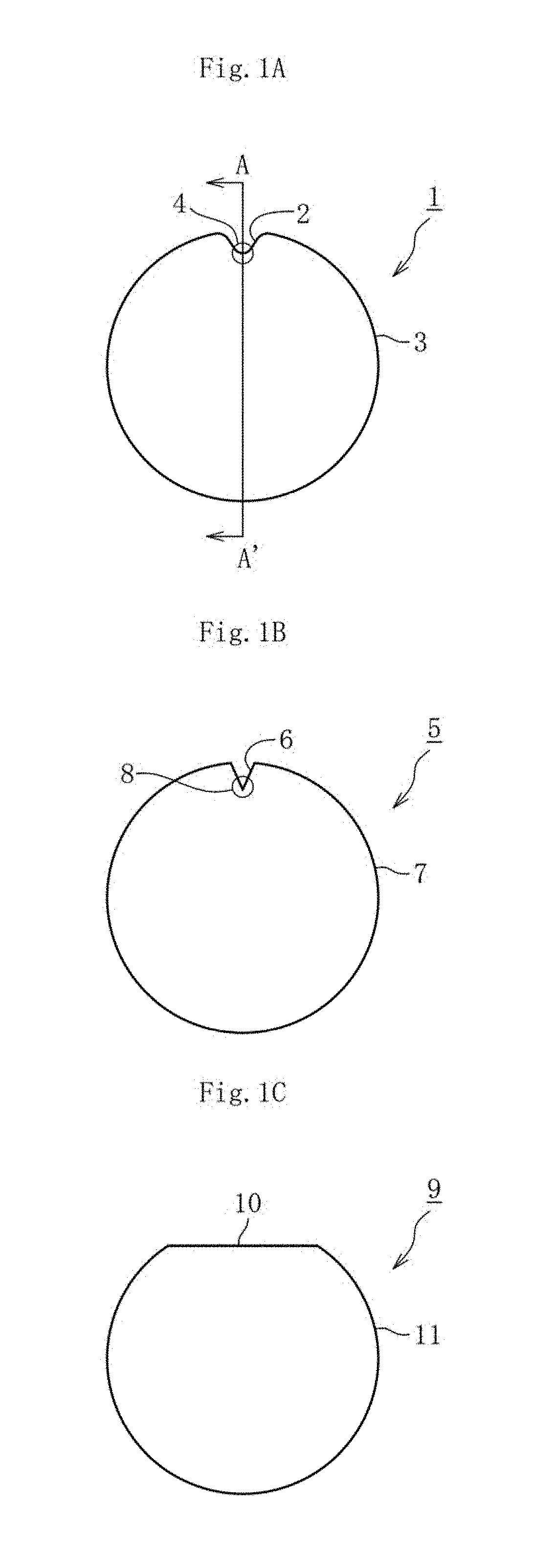

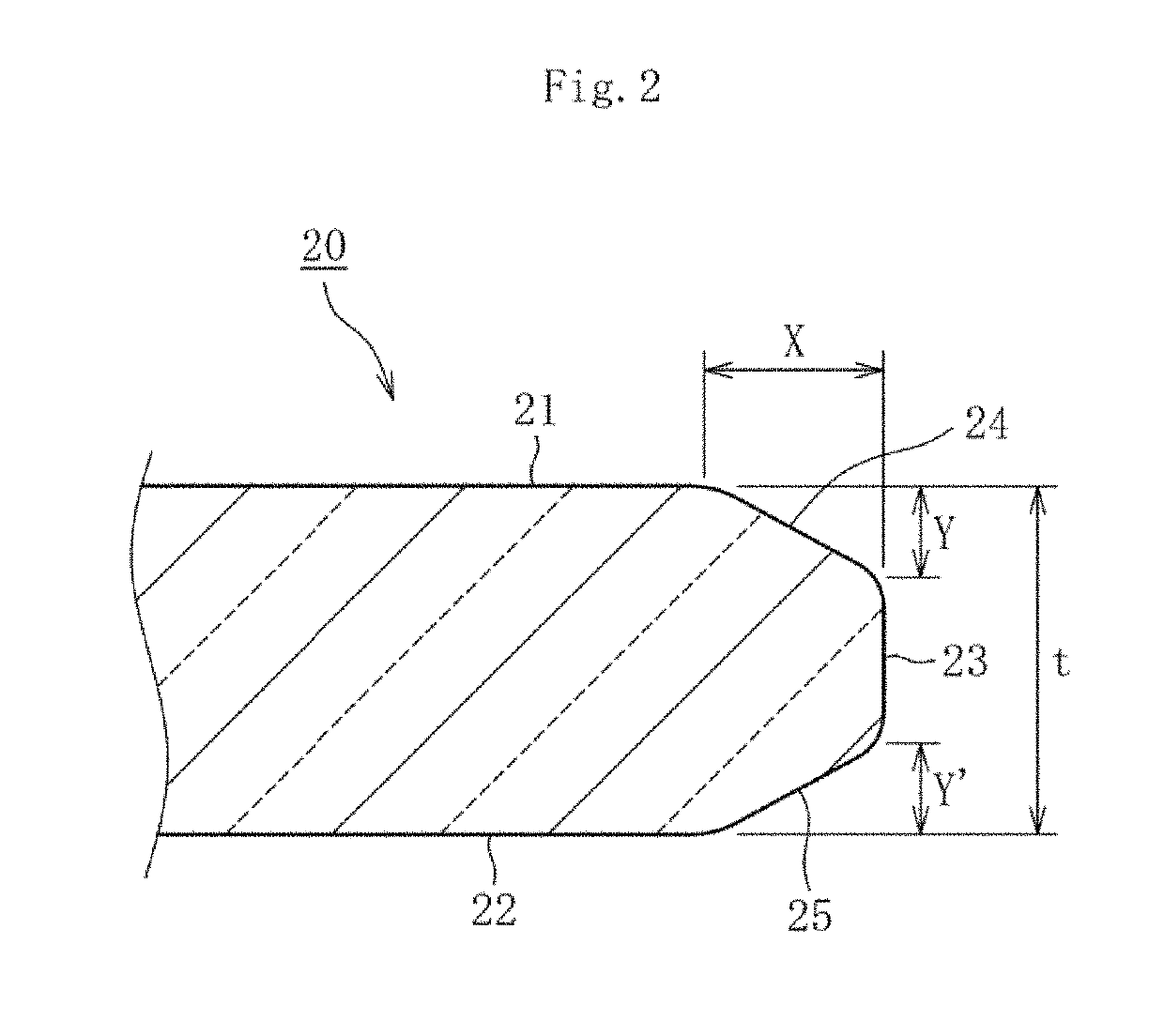

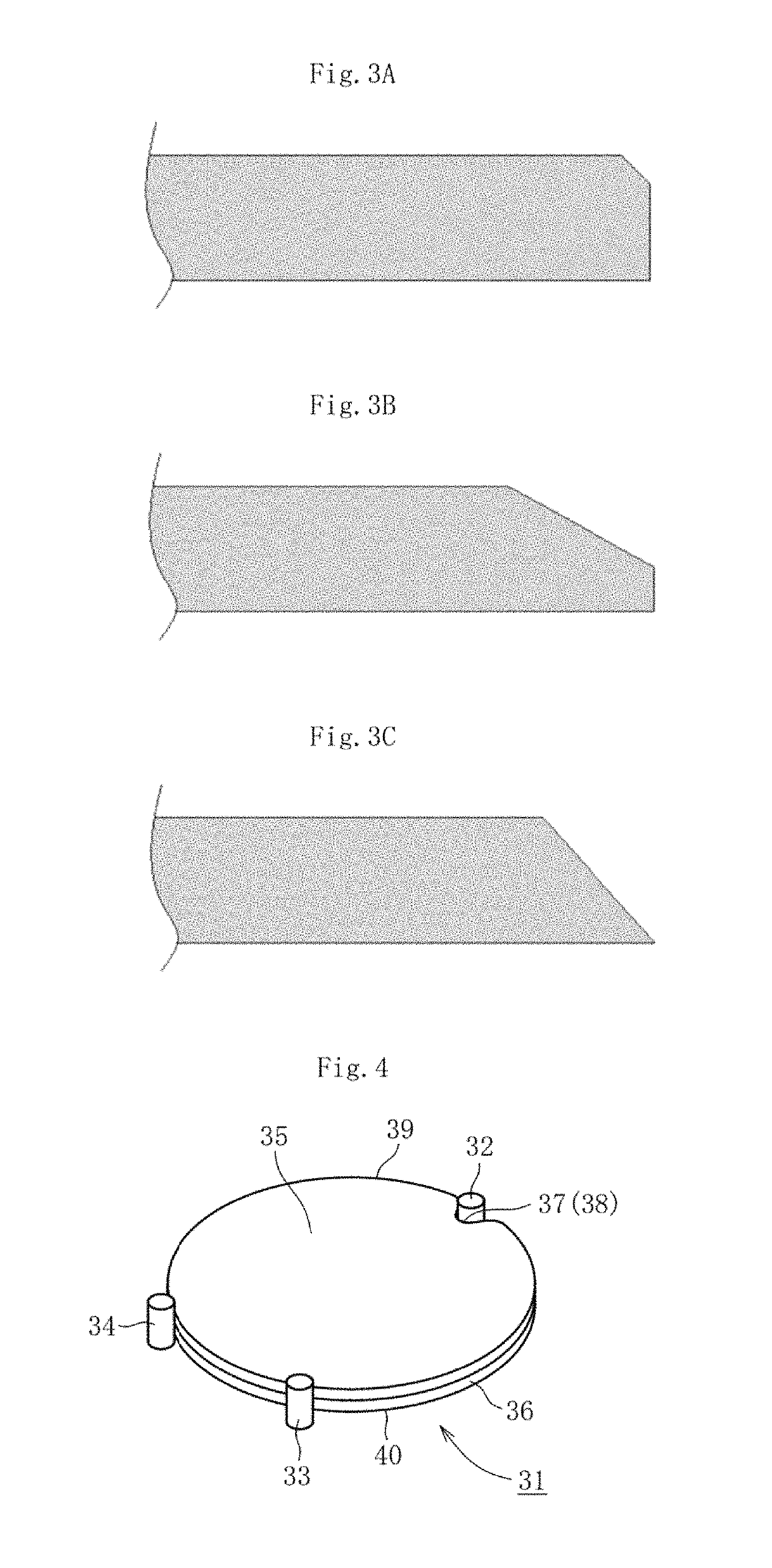

Glass sheet

ActiveUS20170334773A1Avoid changeSupported strongly and accuratelySemiconductor/solid-state device detailsSolid-state devicesTechnical objectMaterials science

A technical object of the present invention is to devise a glass sheet that facilitates position alignment with a substrate to be processed and is less liable to be broken during conveyance, or processing treatment of the substrate to be processed, to thereby contribute to an increase in density of a semiconductor package. In order to achieve the technical object, the glass sheet of the present invention includes, in a contour thereof: a contour portion; and a position alignment portion, in which all or part of an end edge region of the position alignment portion where a surface thereof and an end surface thereof intersect is chamfered.

Owner:NIPPON ELECTRIC GLASS CO LTD

Hinge board and method for producing the same

InactiveUS7381901B2Reduce thicknessAvoid disconnectionPrinted circuit assemblingPrinted circuit aspectsElectrical conductorMechanical engineering

A hinge board having a hinge bending part and a rigid part includes: not less than two flexible wiring boards including a polyimide sheet layer, a conductor layer having a circuit formed on both sides or one side of the polyimide sheet layer, and a coverlay film layer covering the conductor layer; and a bonding material for bonding the flexible wiring boards. At least one of the flexible wiring boards is a flexible double-sided wiring board including the conductor layers on both sides of the polyimide sheet layer. Moreover, the flexible wiring boards are bonded to each other in the rigid part by use of the bonding material in such a manner that a space part is formed between the flexible wiring boards in the hinge bending part.

Owner:NIPPON STEEL CHEMICAL CO LTD

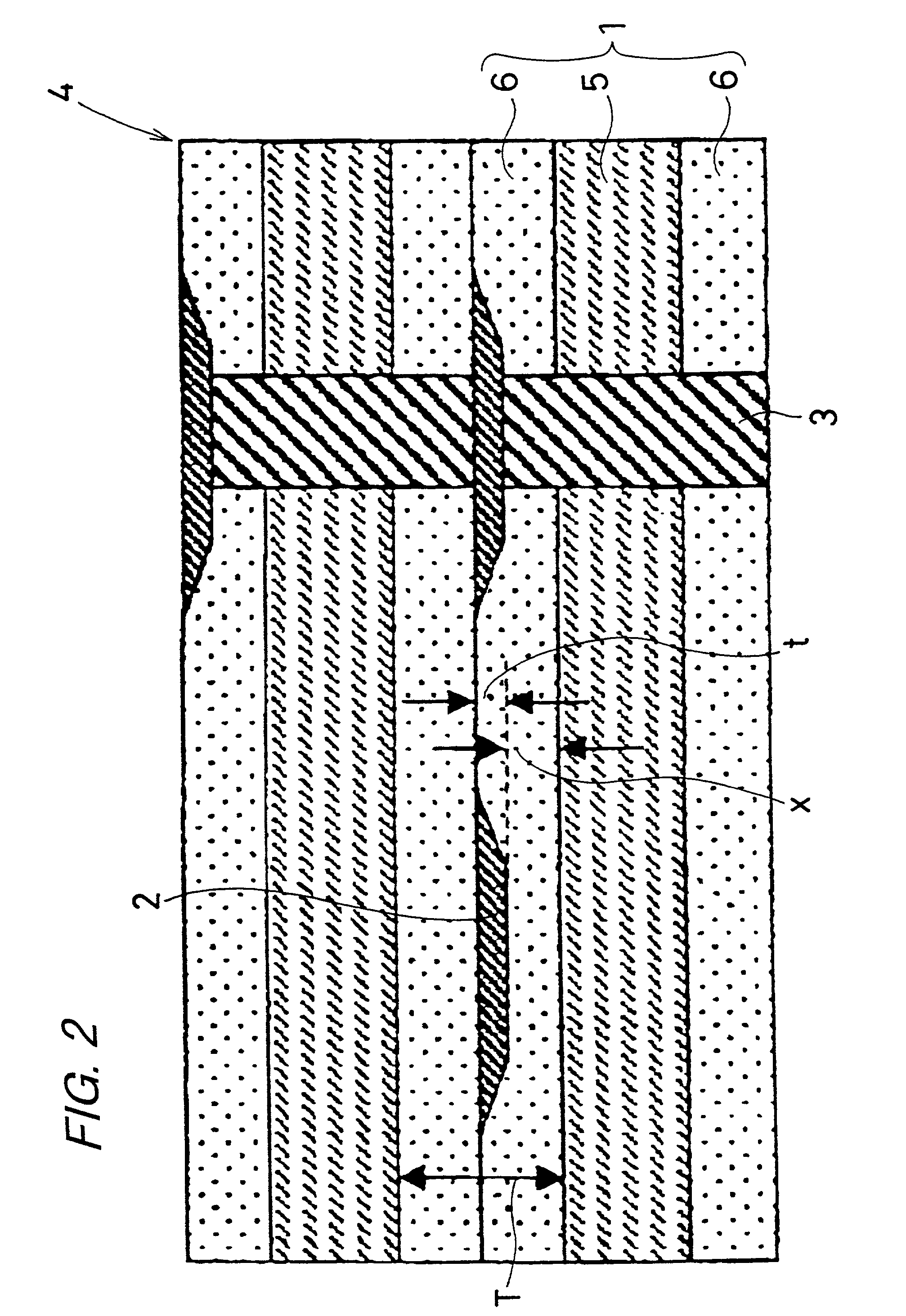

Circuit base board and method for mfg. same

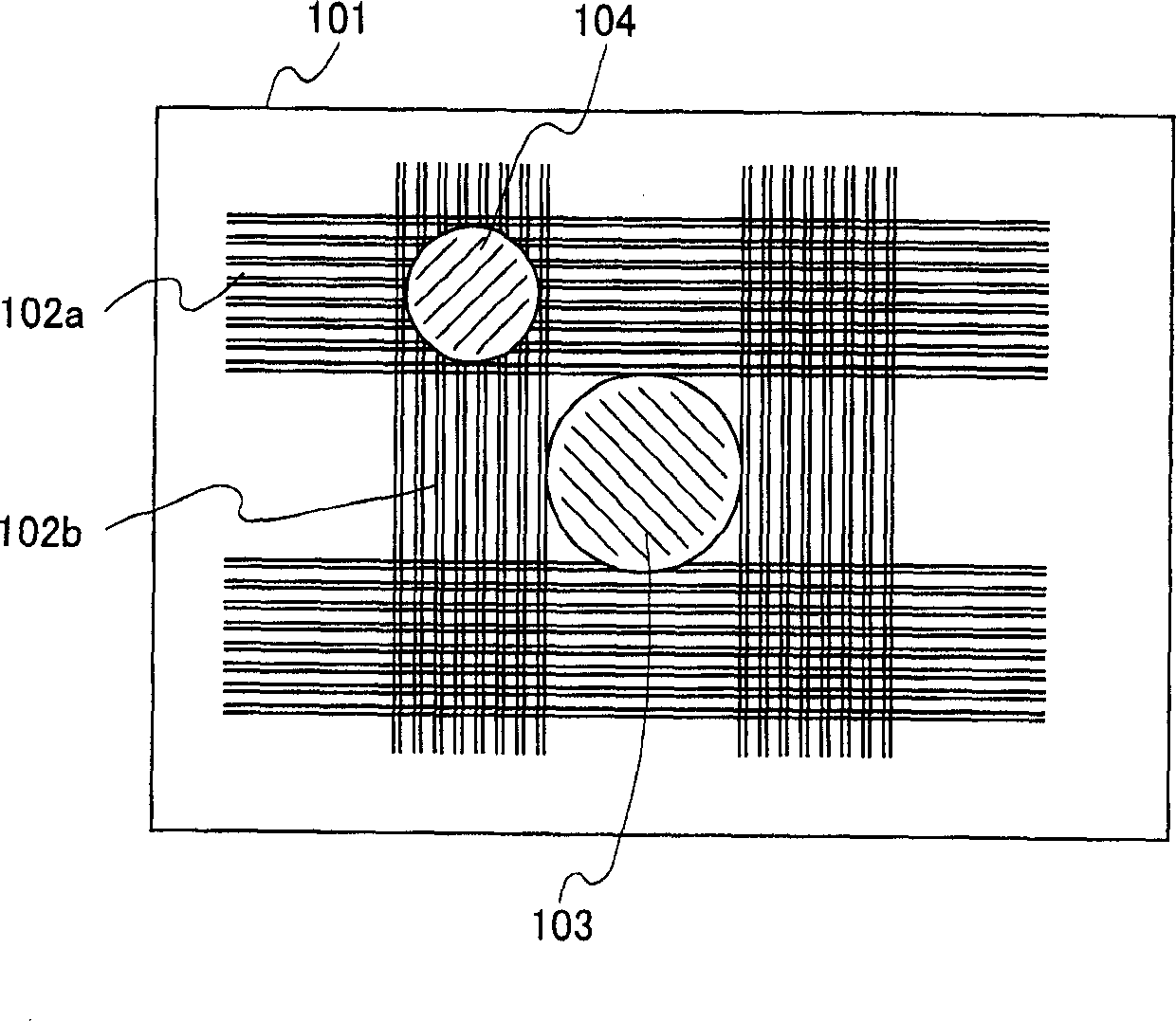

InactiveCN1360460AHigh density wiringSmall discretePrinted circuit aspectsElectrical connection printed elementsElectrical resistance and conductanceIn plane

A circuit board includes an electrical insulator layer formed of a reinforcer sheet (101) with density distribution in its in-plane direction, an electrical conductor filled in a plurality of inner via holes provided in the electrical insulator layer in its thickness direction, and a wiring layer connected to the electrical conductor. The inner via holes (104) provided in a high-density portion of the reinforcer sheet (101) are formed to have a smaller cross-section than the inner via holes (103) provided in a low-density portion of the reinforcer sheet. In this manner, it is possible to provide a circuit board that can achieve a high-density wiring and an inner via connection resistance with less variation, when a base material including a reinforcer sheet with density distribution in its in-plane direction such as a glass cloth formed of warps (102b) and wefts (102a) is used for an insulator layer.

Owner:PANASONIC CORP

Package for semiconductor device and method of manufacturing the same

ActiveUS20090151995A1High-density wiringLower the resistance valueSemiconductor/solid-state device detailsSolid-state devicesSemiconductorMetal

In a package for a semiconductor device, a core substrate has two metal plates, each of which includes a first through hole, a second through hole, a projection, and an insulating layer formed on its surface. The metal plates are stacked in a manner that the projections of the mutual metal plates enter the second through hole of the metal plate on a partner side, and the first through holes of the metal plates form a through hole penetrating the core substrate. A tip end of each of the projections of the metal plates is exposed to a surface of the metal plate on the partner side to form a first terminal portion, and a second terminal portion is exposed from the insulating layer and formed on a surface of the metal plate on a side where the first terminal portion of the metal plate on the partner side is exposed.

Owner:SHINKO ELECTRIC IND CO LTD

Semiconductor device, manufacturing method for semiconductor device, electronic component, circuit board, and electronic device

InactiveCN1979833AHigh density wiringSemiconductor/solid-state device detailsSolid-state devicesSilver plateEngineering

A semiconductor device, includes: a semiconductor substrate having an active face; a first electrode provided on or above the active face of the semiconductor substrate; an external connection terminal electrically connected to the first electrode and provided on or above the active face of the semiconductor substrate; and a connection terminal provided on or above the active face of the semiconductor substrate, wherein any of a gold plated film, a silver plated film, and a palladium plated film is formed on at least one of the external connection terminal and the connection terminal.

Owner:SEIKO EPSON CORP

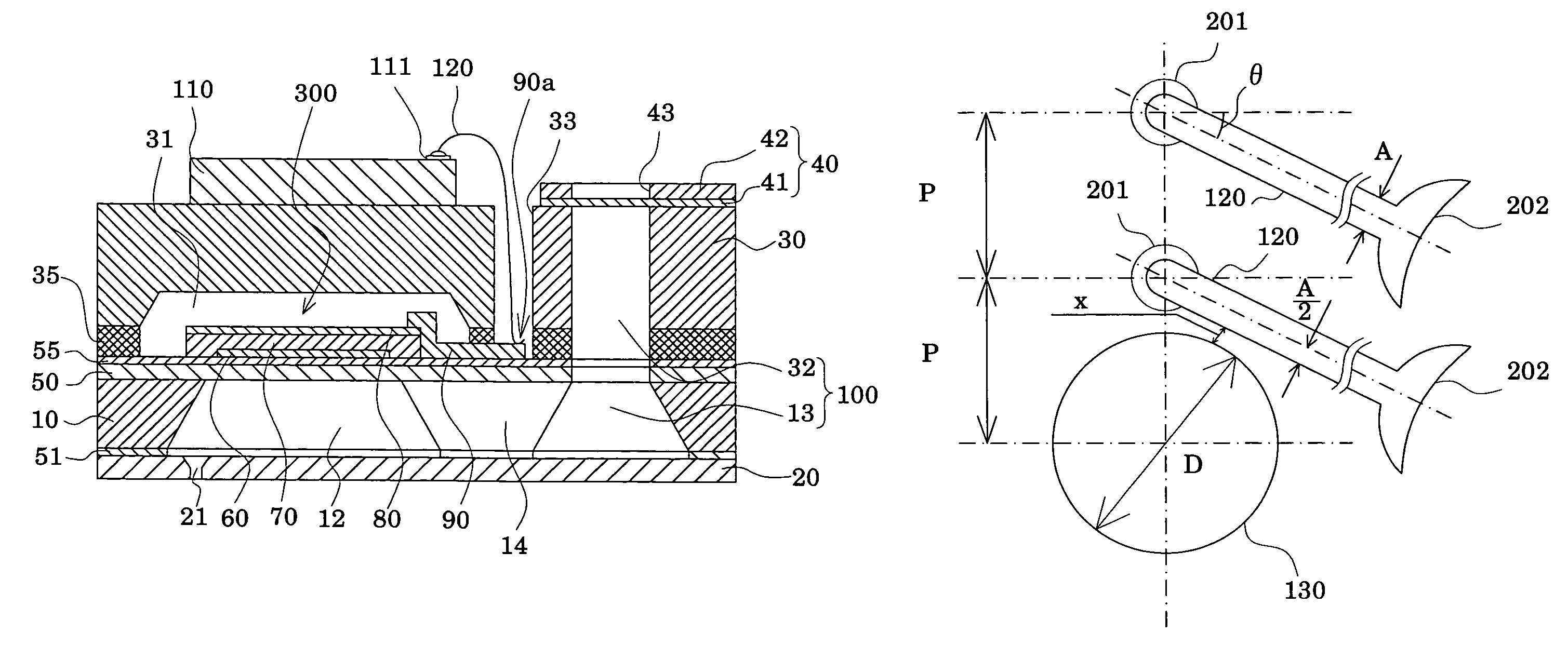

Bonding structure, actuator device and liquid-jet head

InactiveUS20060077227A1High-density wiring for devicesOptimizationSolid-state devicesPrintingLiquid jetActuator

A bonding structure comprising bonding wires having a diameter A, bonding pads to which the bonding wires are connected, and bonding portions which, as sites of connection, are arranged on a straight line, and wherein the pitch P of the bonding portions is set at XA+σ or more where 1.80≦X≦2.1, A is as defined above, and σ denotes a variation for the bonding procedure.

Owner:SEIKO EPSON CORP

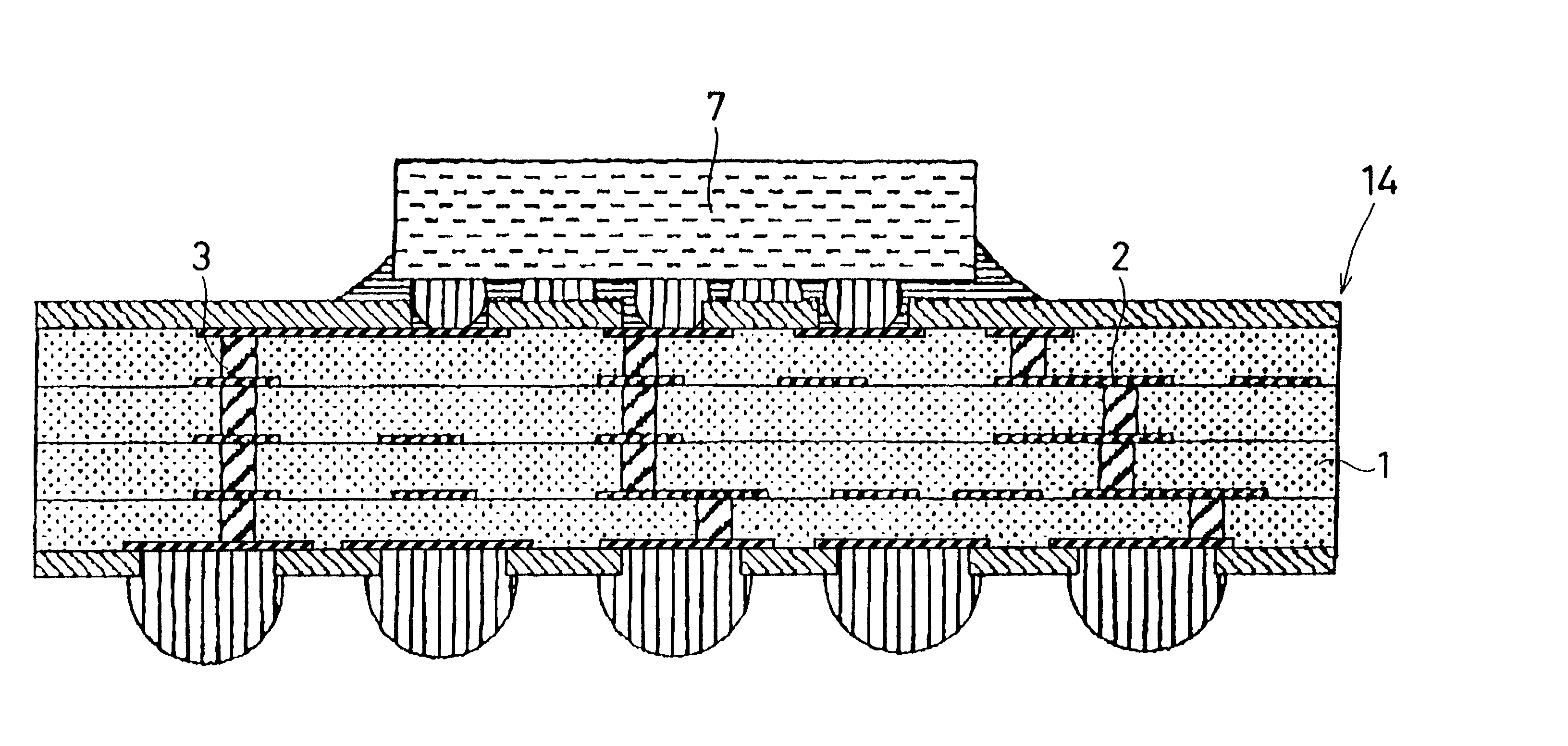

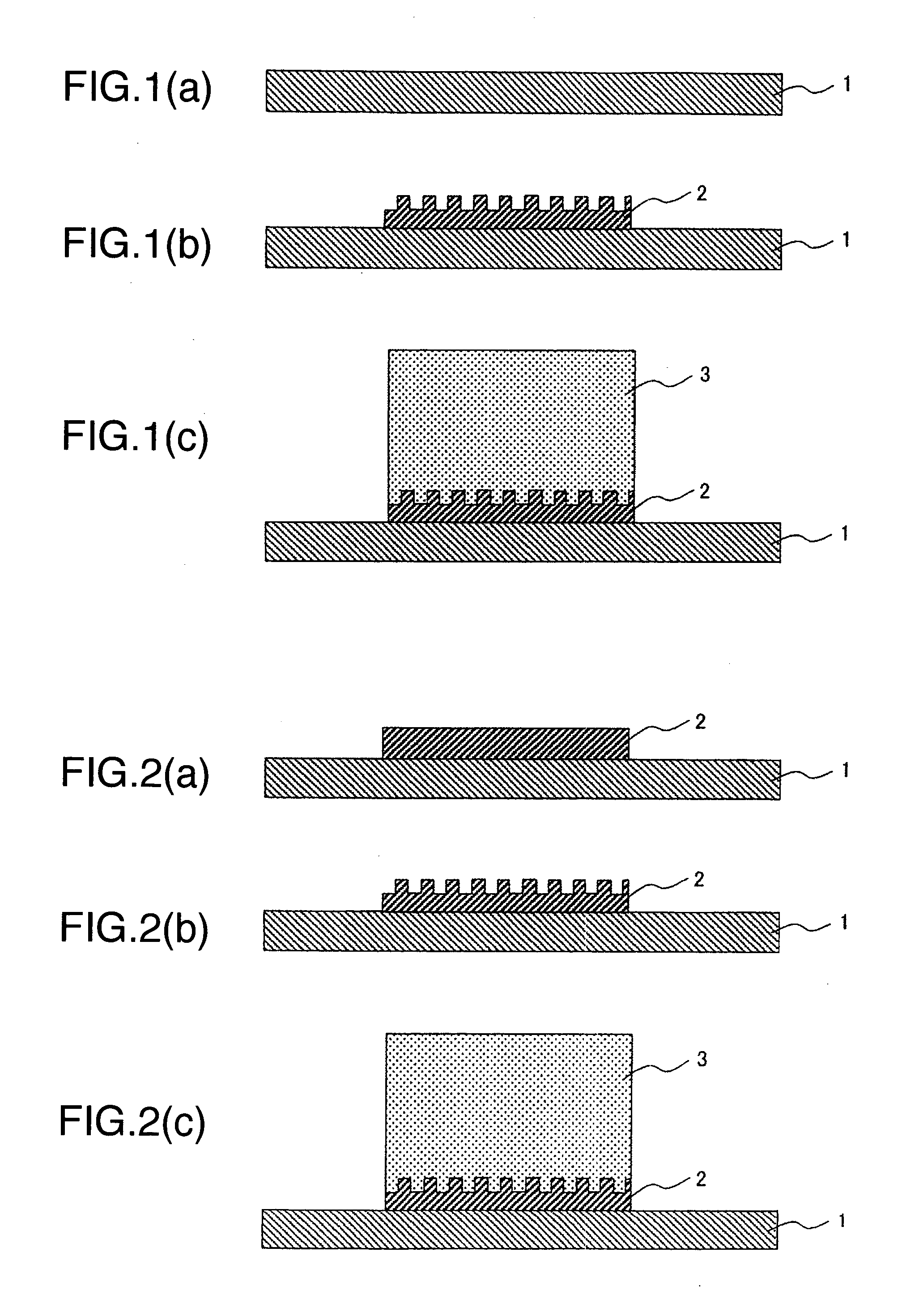

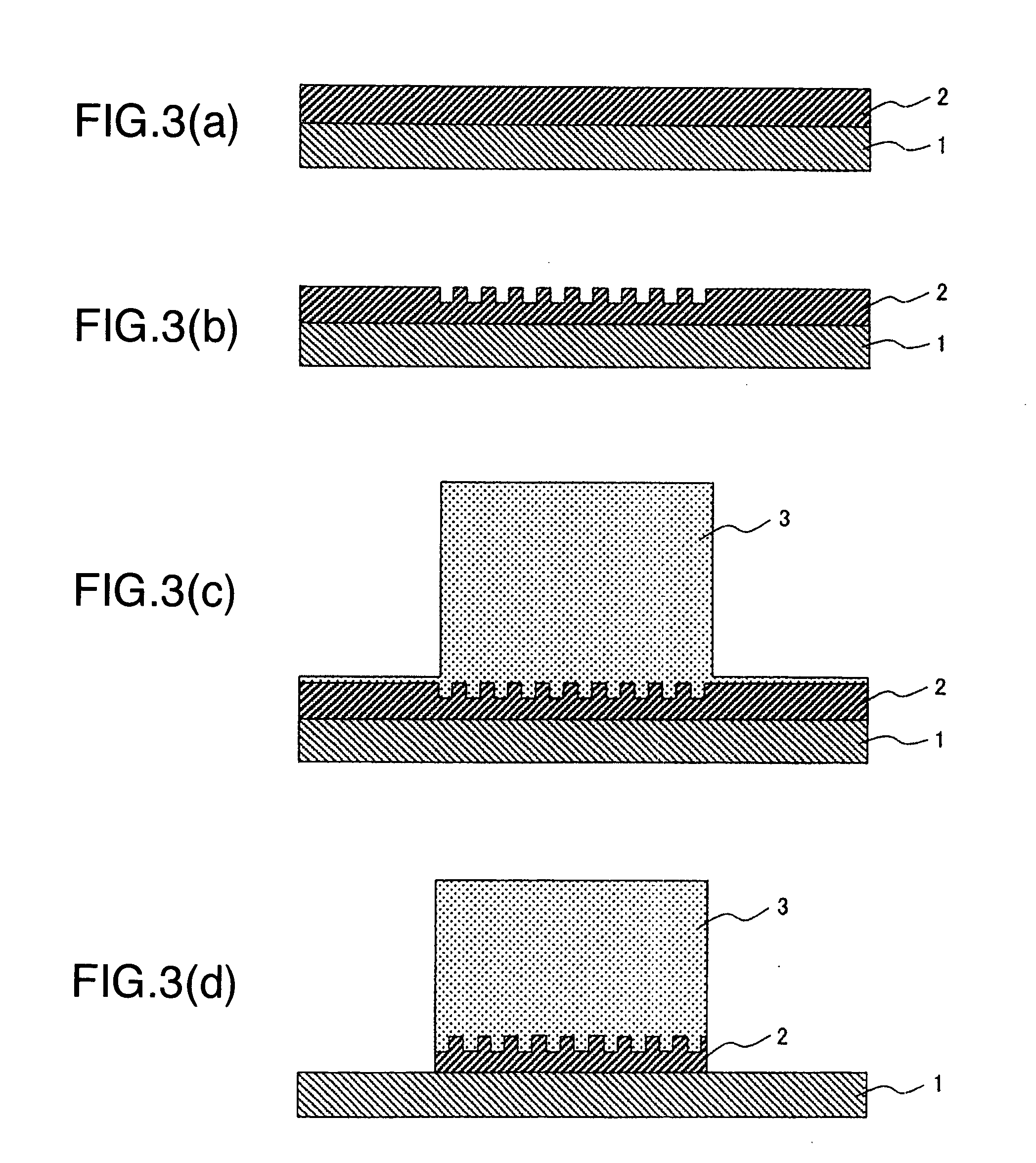

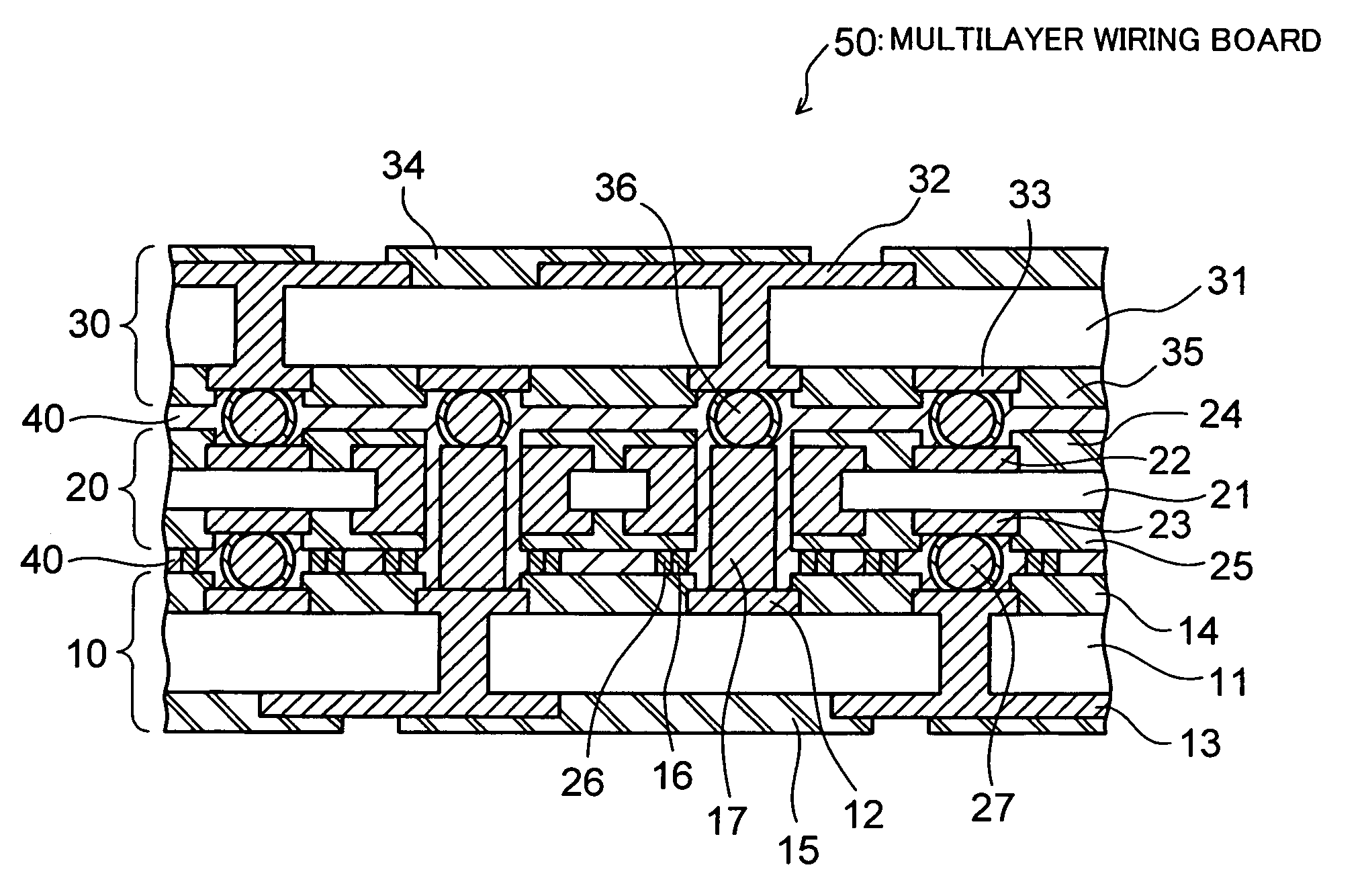

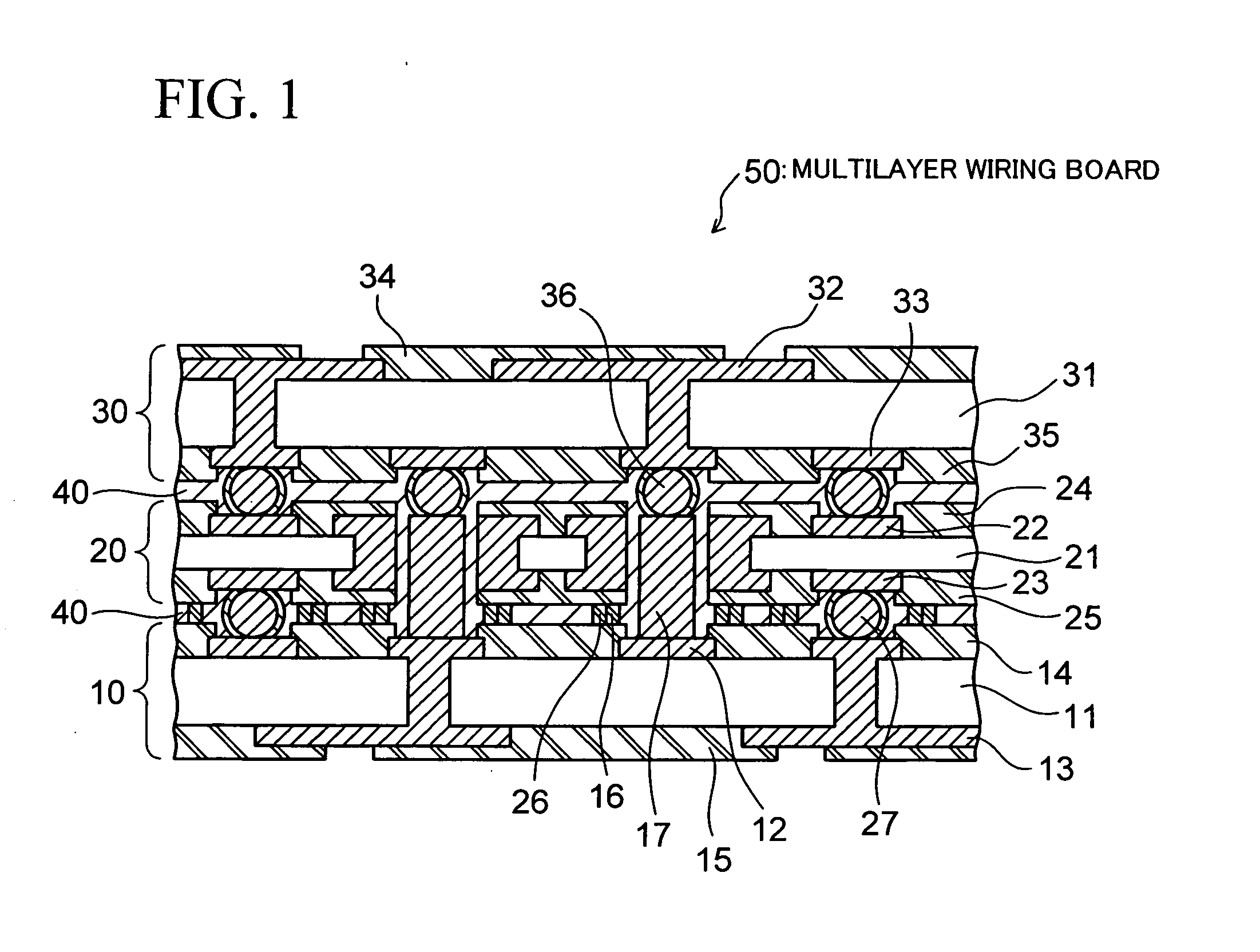

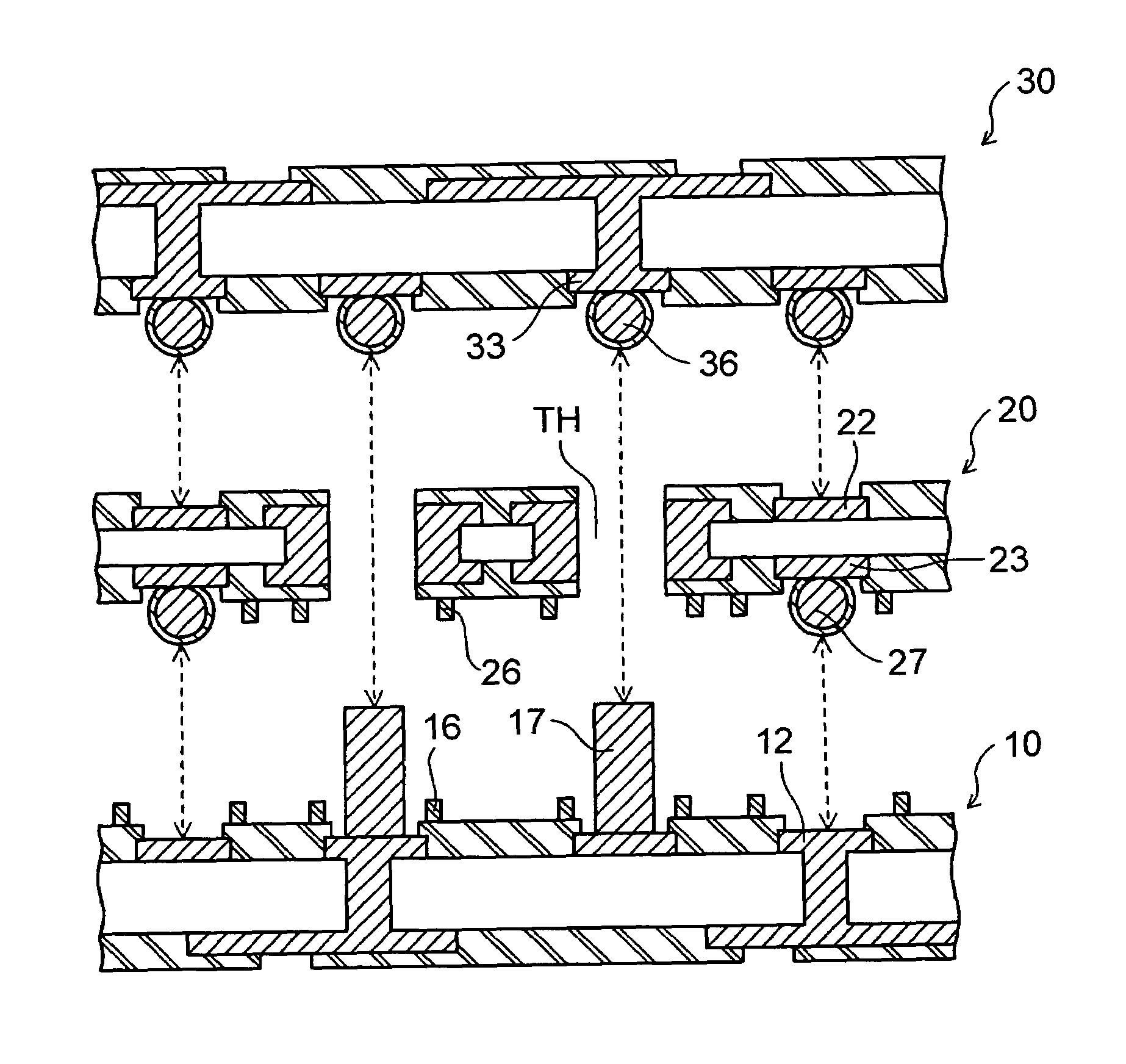

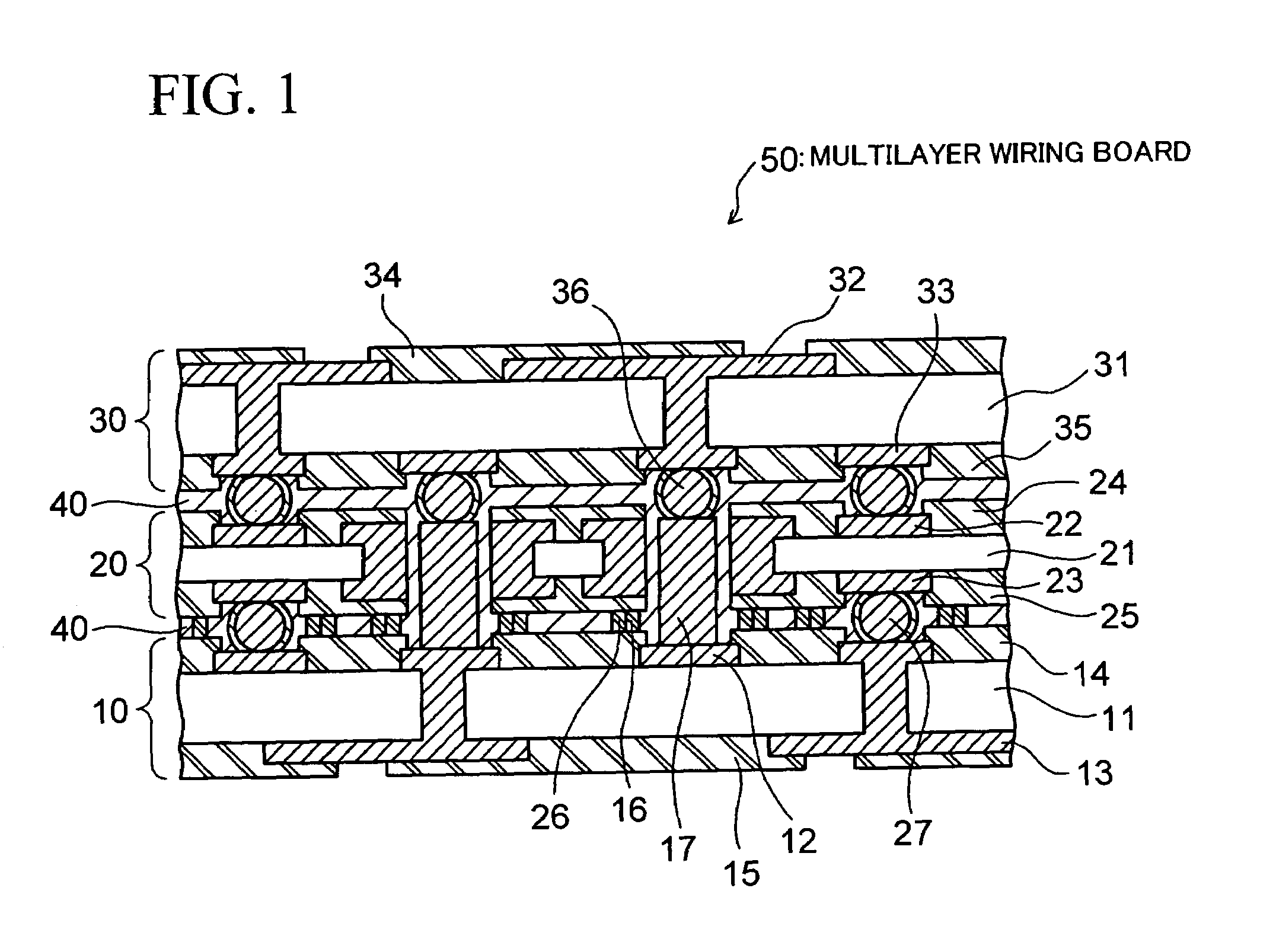

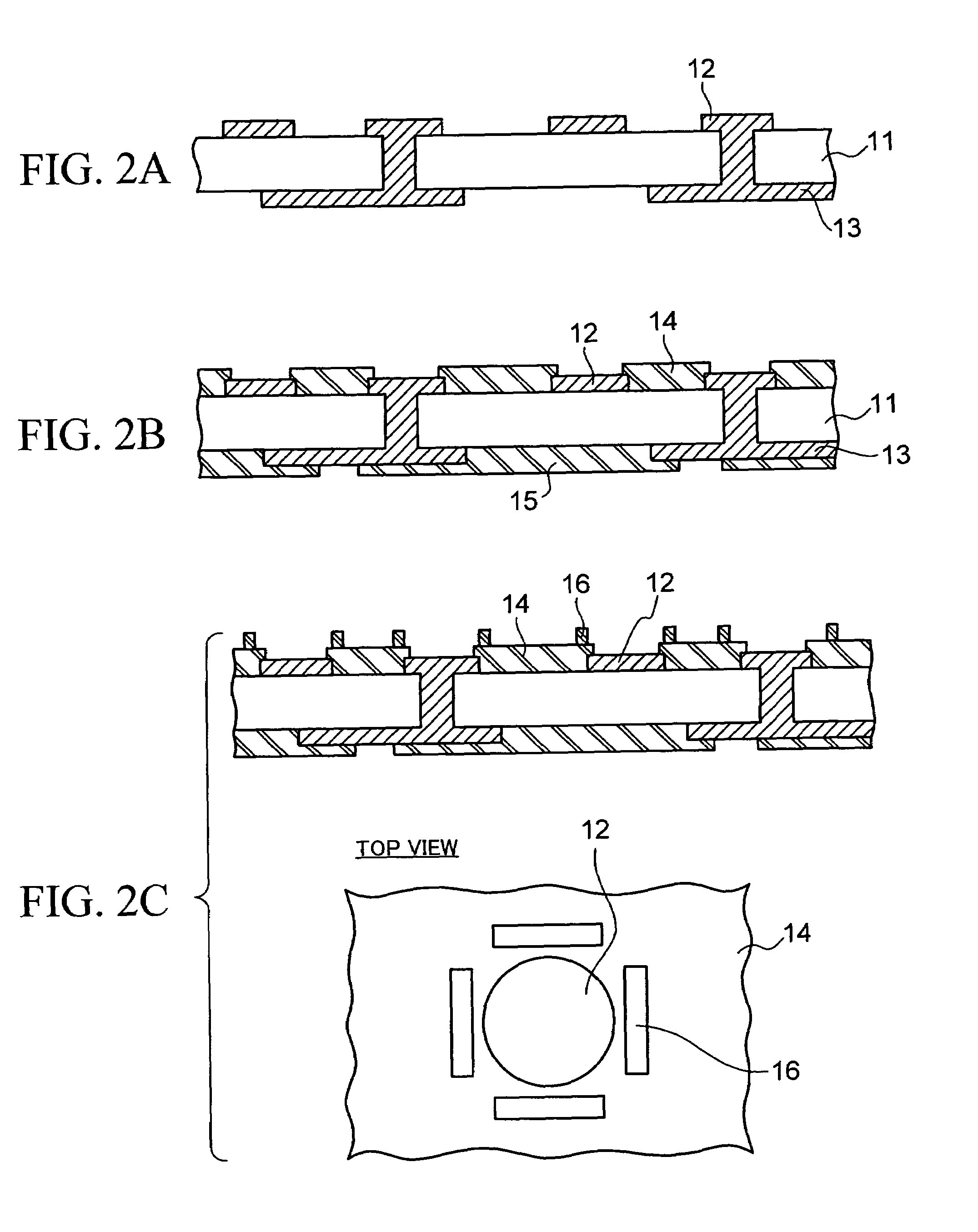

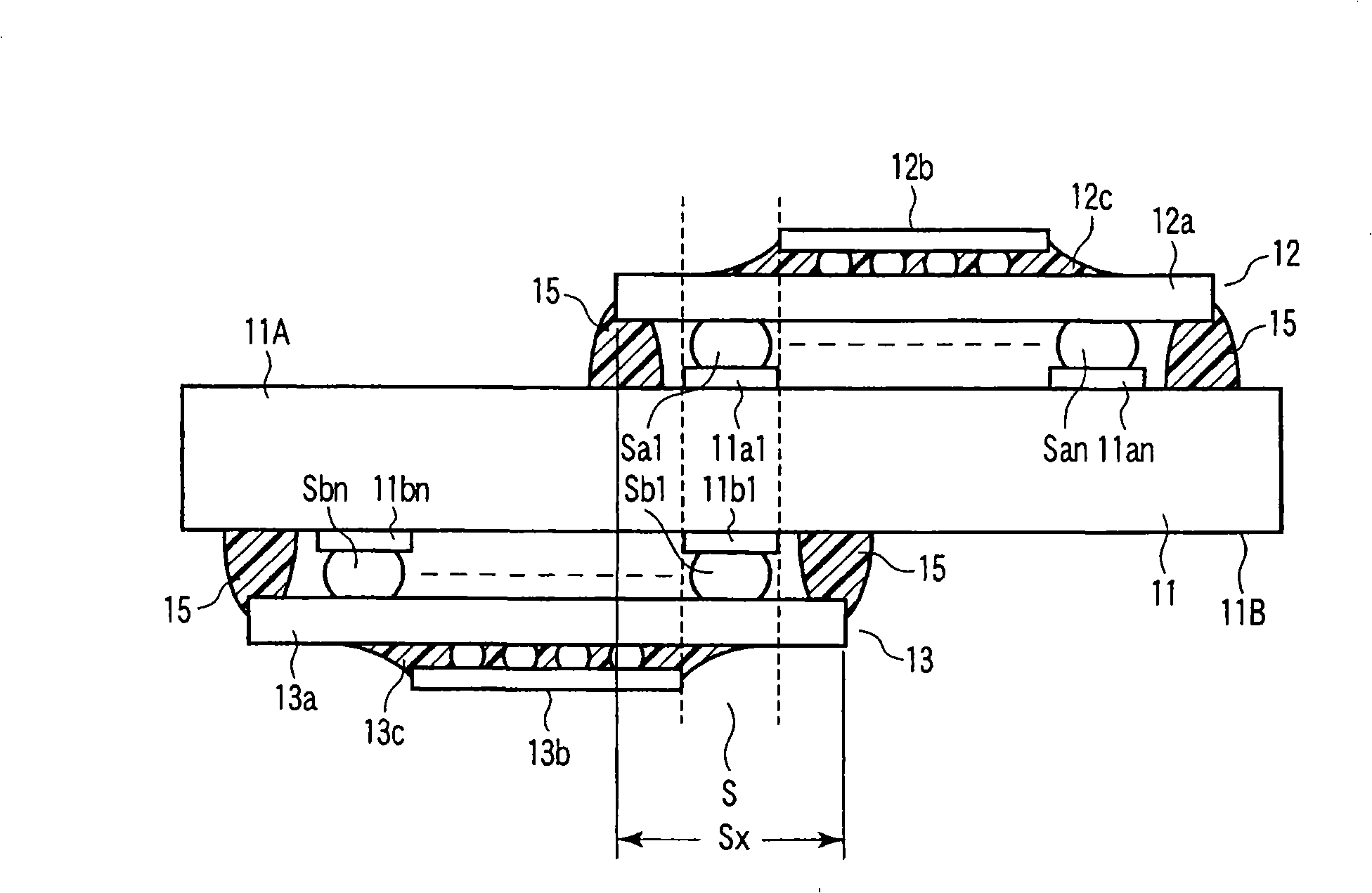

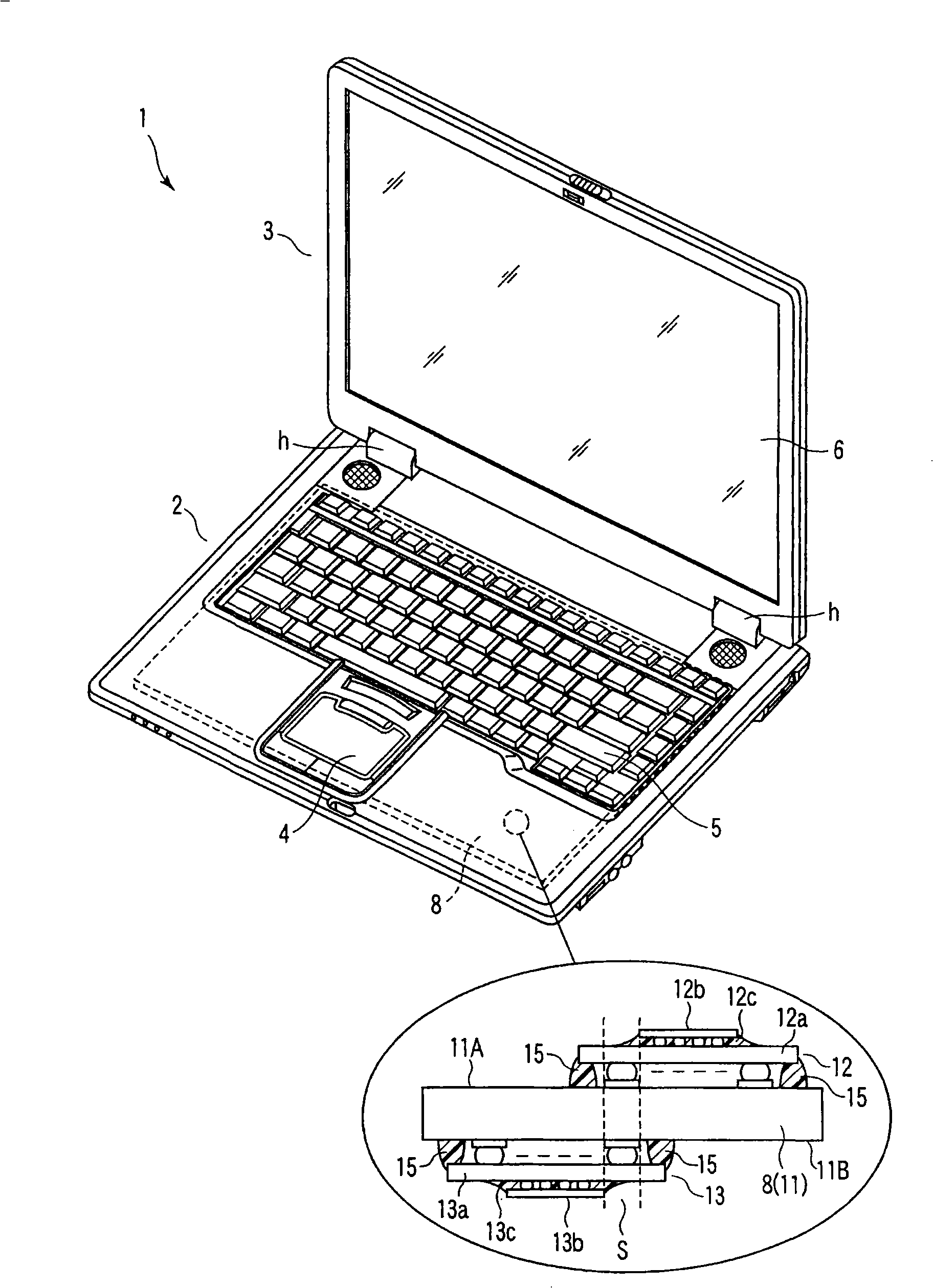

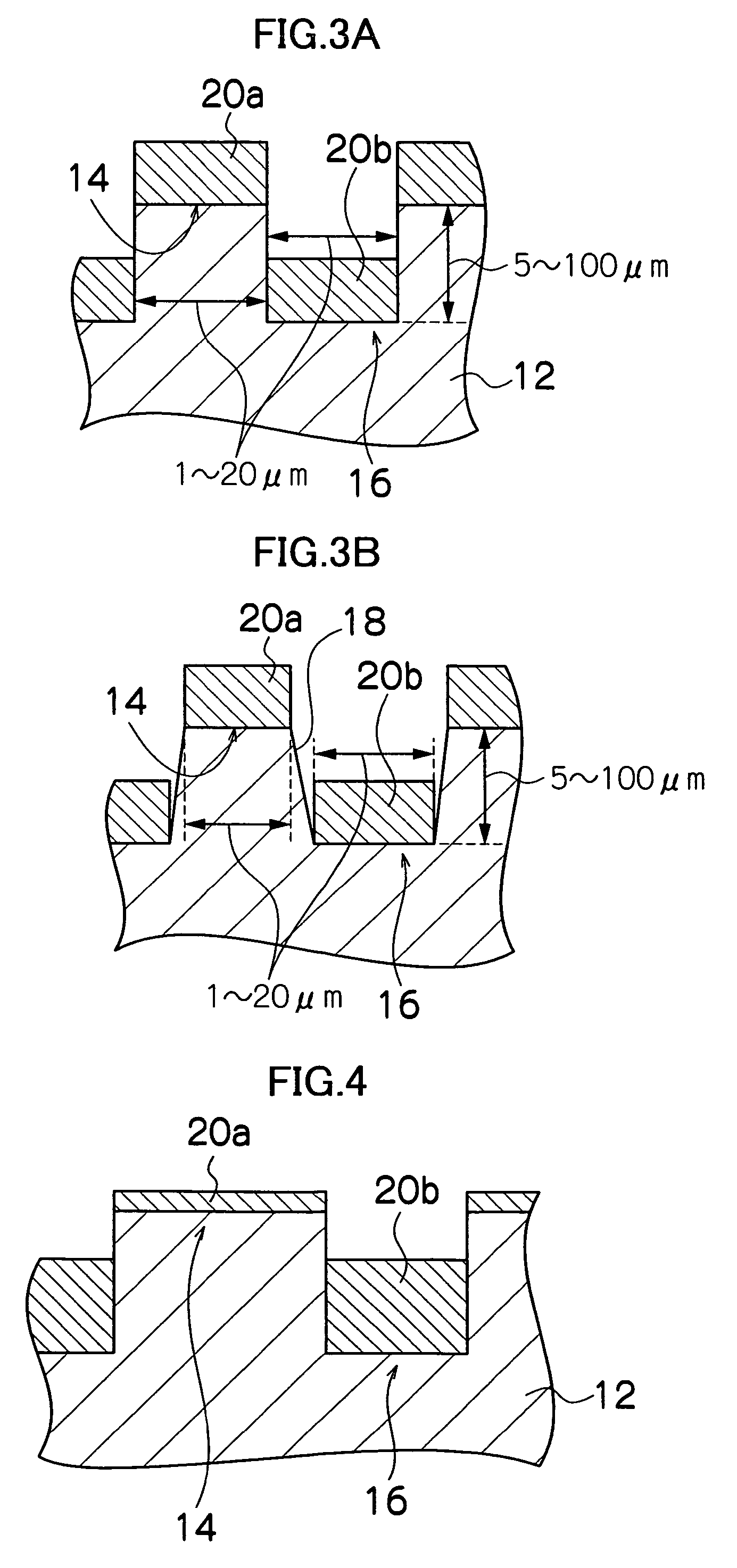

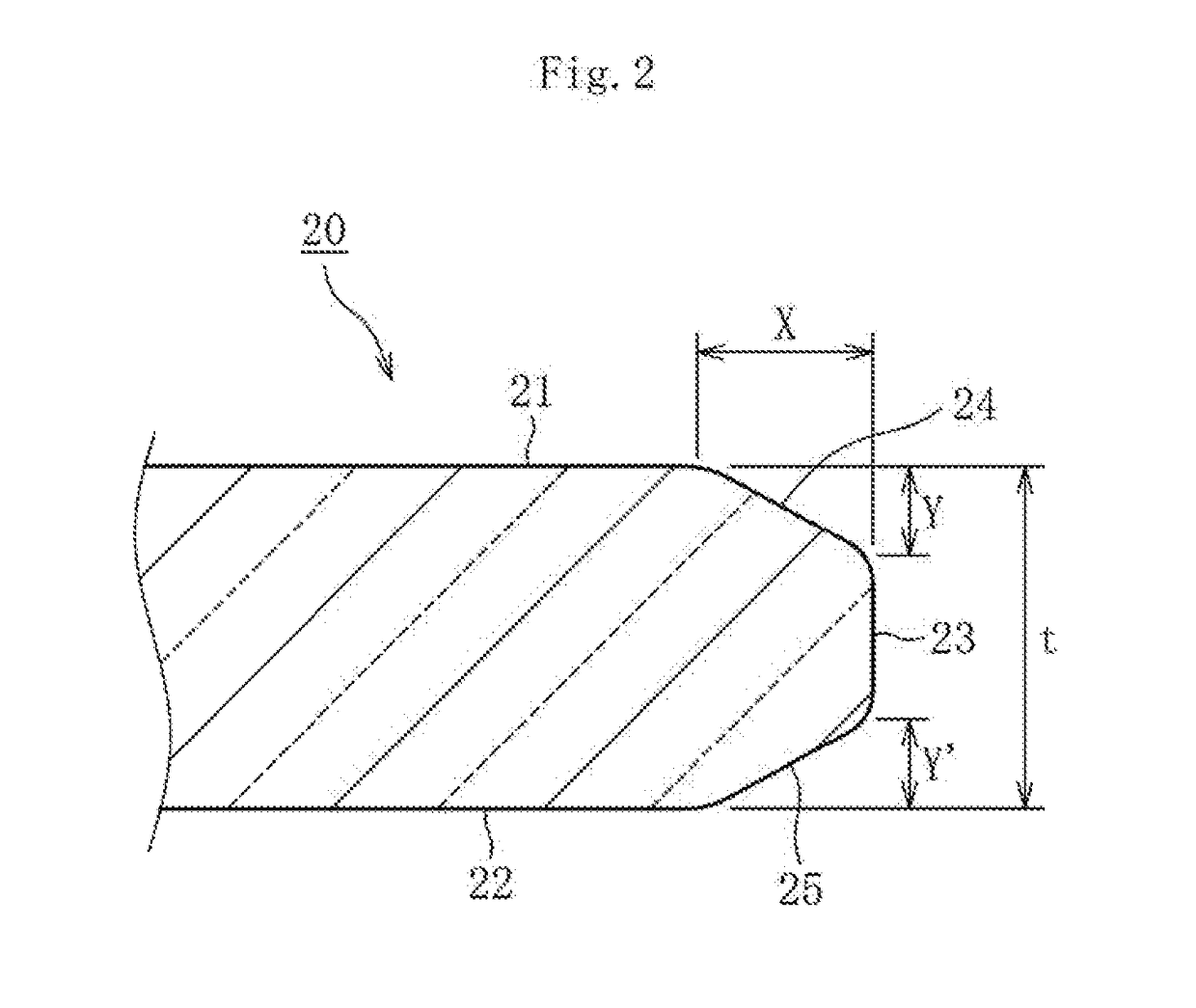

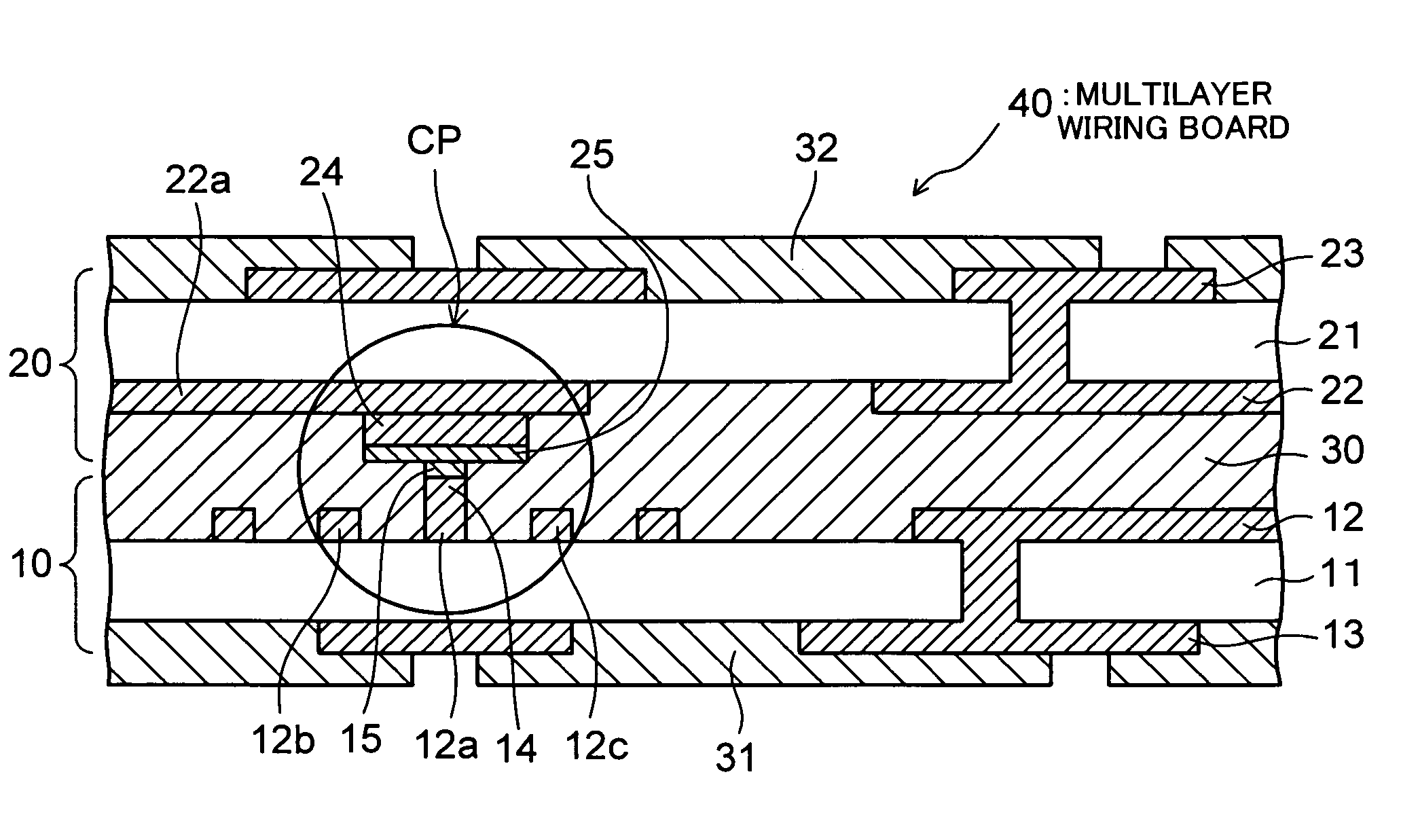

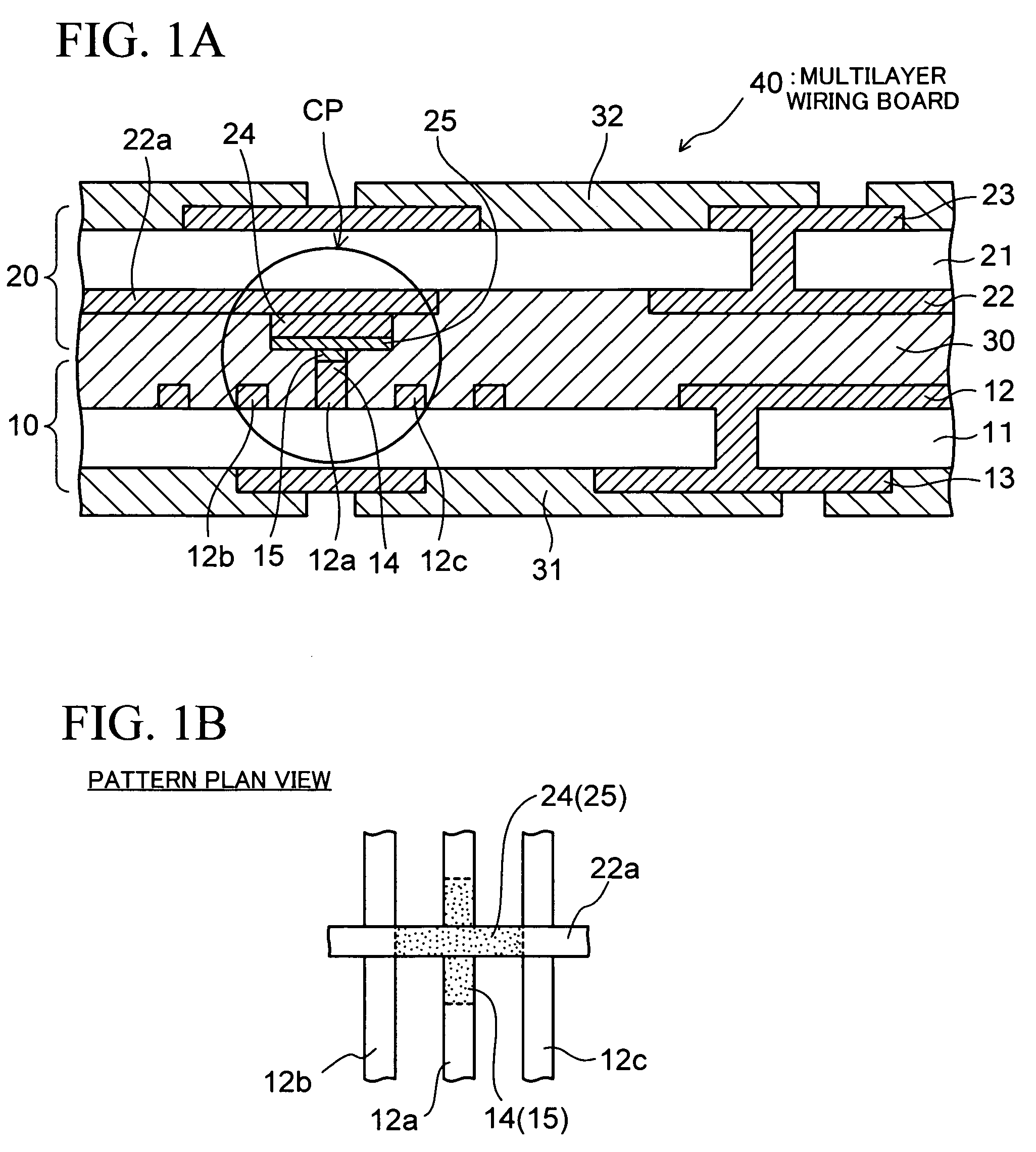

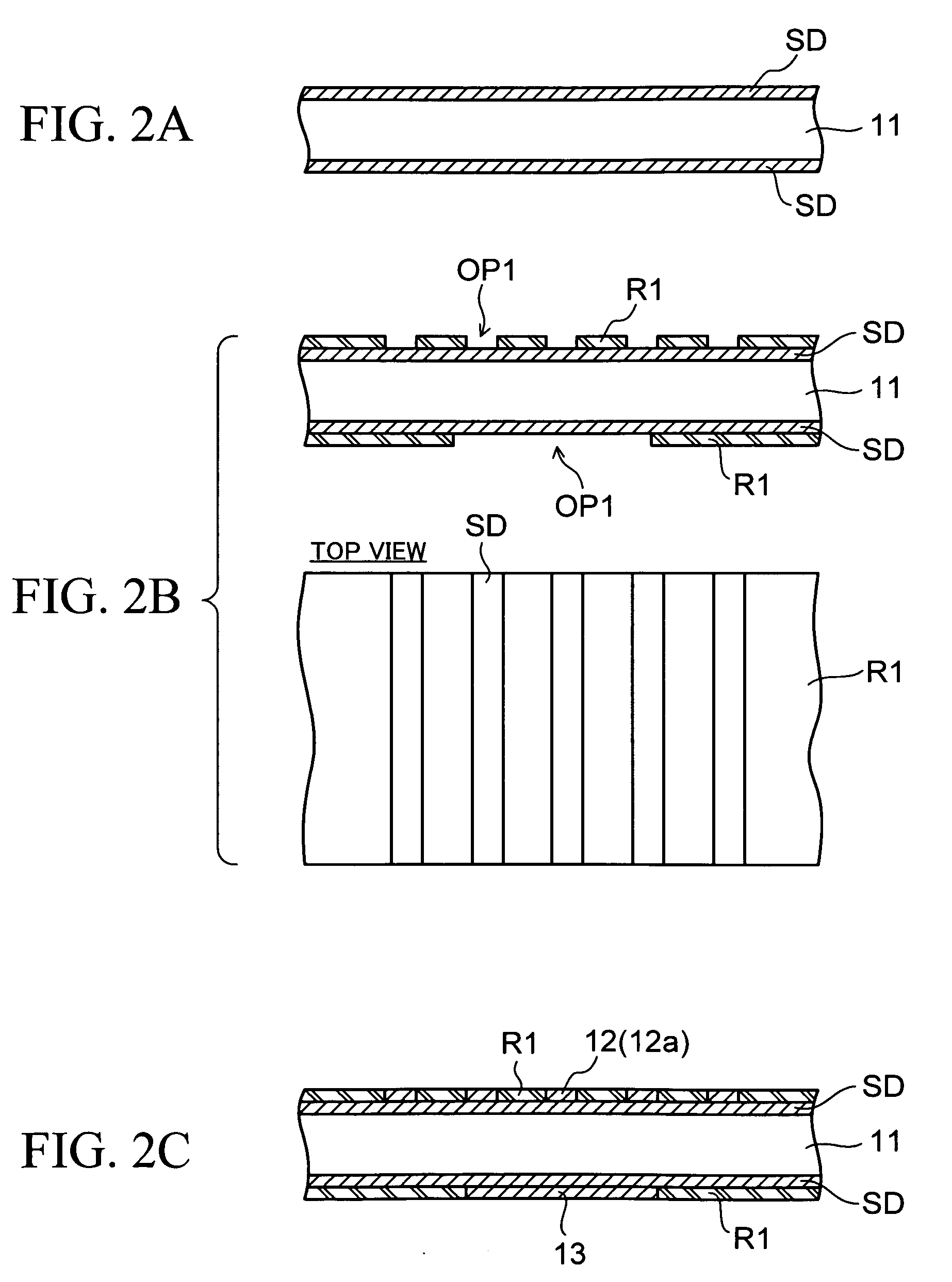

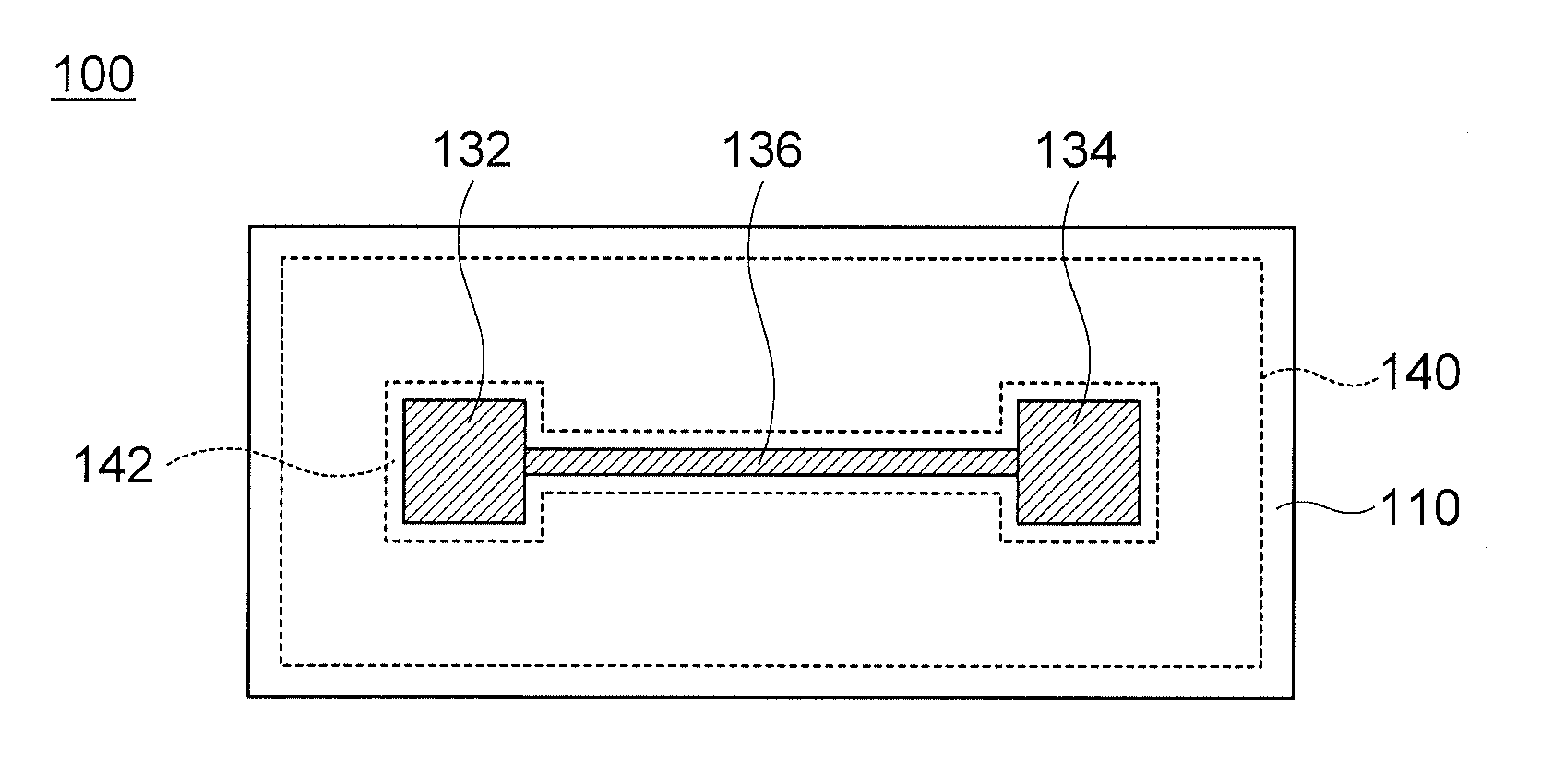

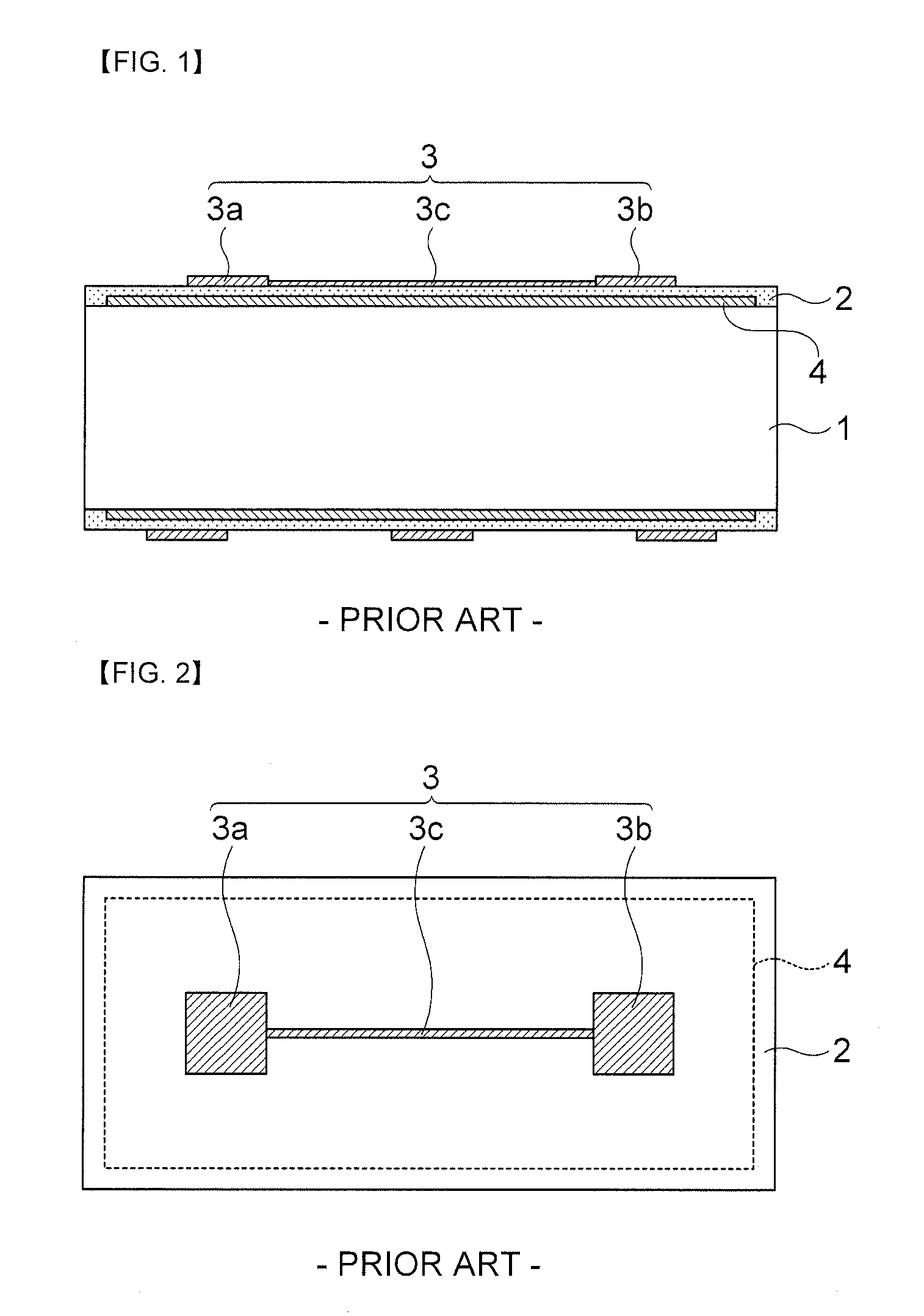

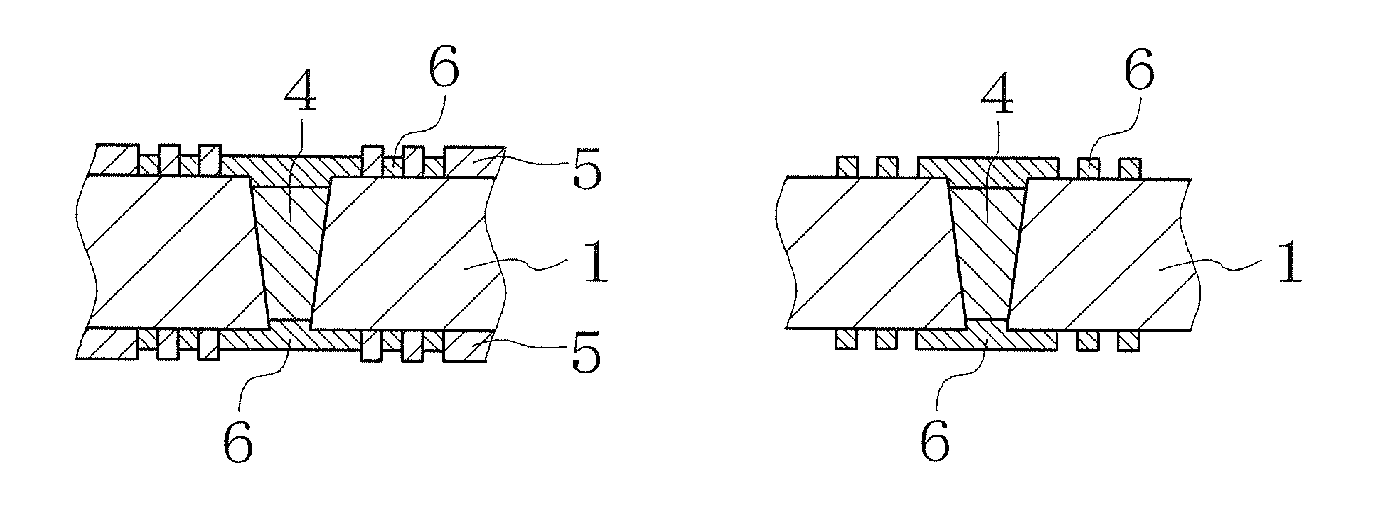

Multilayer wiring board and method of manufacturing the same

ActiveUS8026448B2High-density wiringEliminate needPrinted circuit assemblingPrinted circuit aspectsTectorial membraneElectrical and Electronics engineering

A multilayer wiring board includes at least two wiring boards having wiring layers containing wiring patterns formed on both sides. A pair of fin-shaped bumps are formed at desired positions on wiring patterns on the surfaces facing each other, of the wiring boards, so that the bumps assume a slender shape as seen in plan view and that the bumps intersect each other. The pair of fin-shaped bumps are electrically connected to form an inter-board connection terminal. Further, an insulating layer is formed between the wiring boards, and protection films are formed to cover the entire surface except pad areas defined at predetermined positions on outer wiring layers of the wiring boards.

Owner:SHINKO ELECTRIC IND CO LTD

Liquid ejection head and image forming apparatus

The liquid ejection head comprises: a plurality of pressure chambers connected to a plurality of nozzles from which liquid is ejected, the pressure chambers being arranged in a two-dimensional configuration; a diaphragm which constitutes a wall of each of the pressure chambers, the wall being located opposite to the nozzles; a plurality of piezoelectric elements disposed at positions corresponding to the pressure chambers on a surface of the diaphragm which is on an opposite side of the diaphragm from the pressure chambers, the piezoelectric elements causing portions of the diaphragm corresponding to the pressure chambers to deform; an intermediate plate which is located on a piezoelectric element side of the diaphragm where the piezoelectric elements are disposed and which forms a space around a periphery of each of the piezoelectric elements; electrical wires for electrically connecting drive circuits which drives the piezoelectric elements with drive electrodes of the piezoelectric elements, the electrical wires being disposed in the intermediate plate; and an ink pool section which is located across the intermediate plate from the diaphragm and which supplies the liquid to the pressure chambers.

Owner:FUJIFILM CORP

Bonding structure, actuator device and liquid-jet head

InactiveUS7399061B2High-density wiring for devicesOptimizationSolid-state devicesPrintingLiquid jetActuator

A bonding structure including bonding wires having a diameter A, bonding pads to which the bonding wires are connected, and bonding portions which, as sites of connection, are arranged on a straight line, and wherein the pitch P of the bonding portions is set at XA+σ or more where 1.80≦X≦2.1, A is as defined above, and σ denotes a variation for the bonding procedure.

Owner:SEIKO EPSON CORP

Glass sheet

ActiveUS10442729B2Avoid changeGood light transmissionSemiconductor/solid-state device detailsSolid-state devicesTechnical objectSemiconductor package

A technical object of the present invention is to devise a glass sheet that facilitates position alignment with a substrate to be processed and is less liable to be broken during conveyance, or processing treatment of the substrate to be processed, to thereby contribute to an increase in density of a semiconductor package. In order to achieve the technical object, the glass sheet of the present invention includes, in a contour thereof: a contour portion; and a position alignment portion, in which all or part of an end edge region of the position alignment portion where a surface thereof and an end surface thereof intersect is chamfered.

Owner:NIPPON ELECTRIC GLASS CO LTD

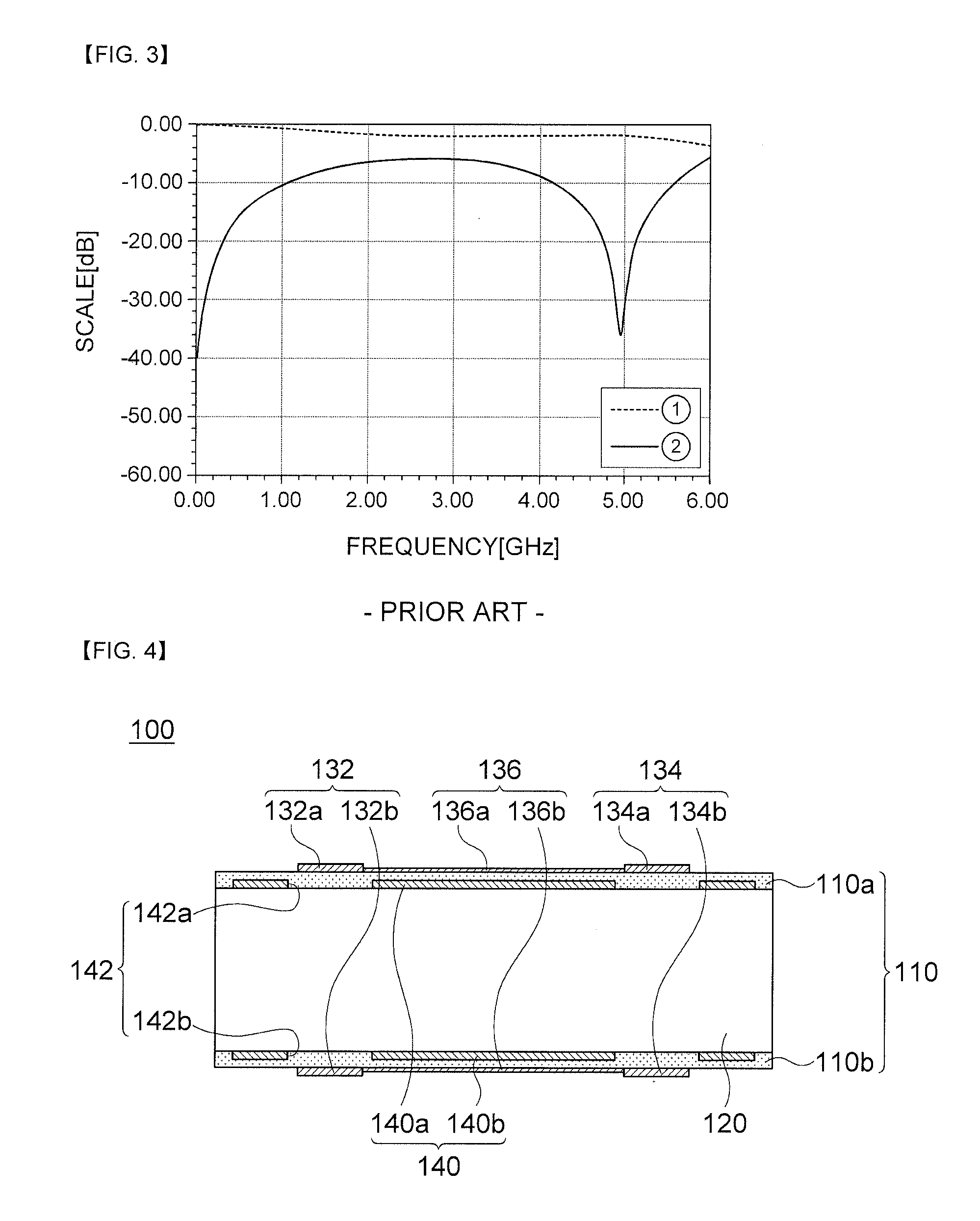

Printed circuit board

InactiveUS20130081868A1High-density wiringThin thicknessPrinted circuit assemblingHigh frequency circuit adaptationsHigh densityDielectric substrate

Disclosed herein is a printed circuit board, including: a dielectric substrate having a ground surface; a plurality of pads formed on the dielectric substrate; a transmission line transmitting a signal between the plurality of pads; and slots formed in partial regions of the ground surface correspondingly to the pads, thereby to improve signal transmitting characteristics and allow high-density wiring and thin thickness.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Glass substrate and laminate using same

ActiveUS10669184B2Increase stiffnessImprove deformationSemiconductor/solid-state device detailsSolid-state devicesHigh densityEngineering

A technical object of the present invention is to devise a glass substrate that is suitable for supporting a substrate to be processed to be subjected to high-density wiring and enables correct recognition of production information and the like, and a laminate using the glass substrate. In order to achieve the technical object, the glass substrate of the present invention has a total thickness variation of less than 2.0 μm and includes an information identification part formed of a plurality of dots.

Owner:NIPPON ELECTRIC GLASS CO LTD

Liquid ejection head and image forming apparauts including liquid ejection head

InactiveUS20110277319A1High density arrangementReduce component countPrinted circuit assemblingInking apparatusLiquid jetElectric wire

Owner:FUJIFILM CORP

Method of manufacturing glass sheet

ActiveUS10737965B2Avoid changeGood light transmissionSemiconductor/solid-state device detailsSolid-state devicesHigh densitySemiconductor package

A technical object of the present invention is to devise a glass sheet that is suitable for supporting a substrate to be processed to be subjected to high-density wiring and has high end surface strength, and a method of manufacturing the glass sheet, to thereby contribute to an increase in density of a semiconductor package. The glass sheet of the present invention has a total thickness variation of less than 2.0 μm, all or part of an end surface of the glass sheet including a melt-solidified surface.

Owner:NIPPON ELECTRIC GLASS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com