Printed circuit board, electronic member mounting method and electronic device

一种印刷线路板、电子设备的技术,应用在印刷电路零部件、印刷电路、印刷电路等方向,能够解决降低连接可靠性等问题,达到高密度安装连接可靠性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

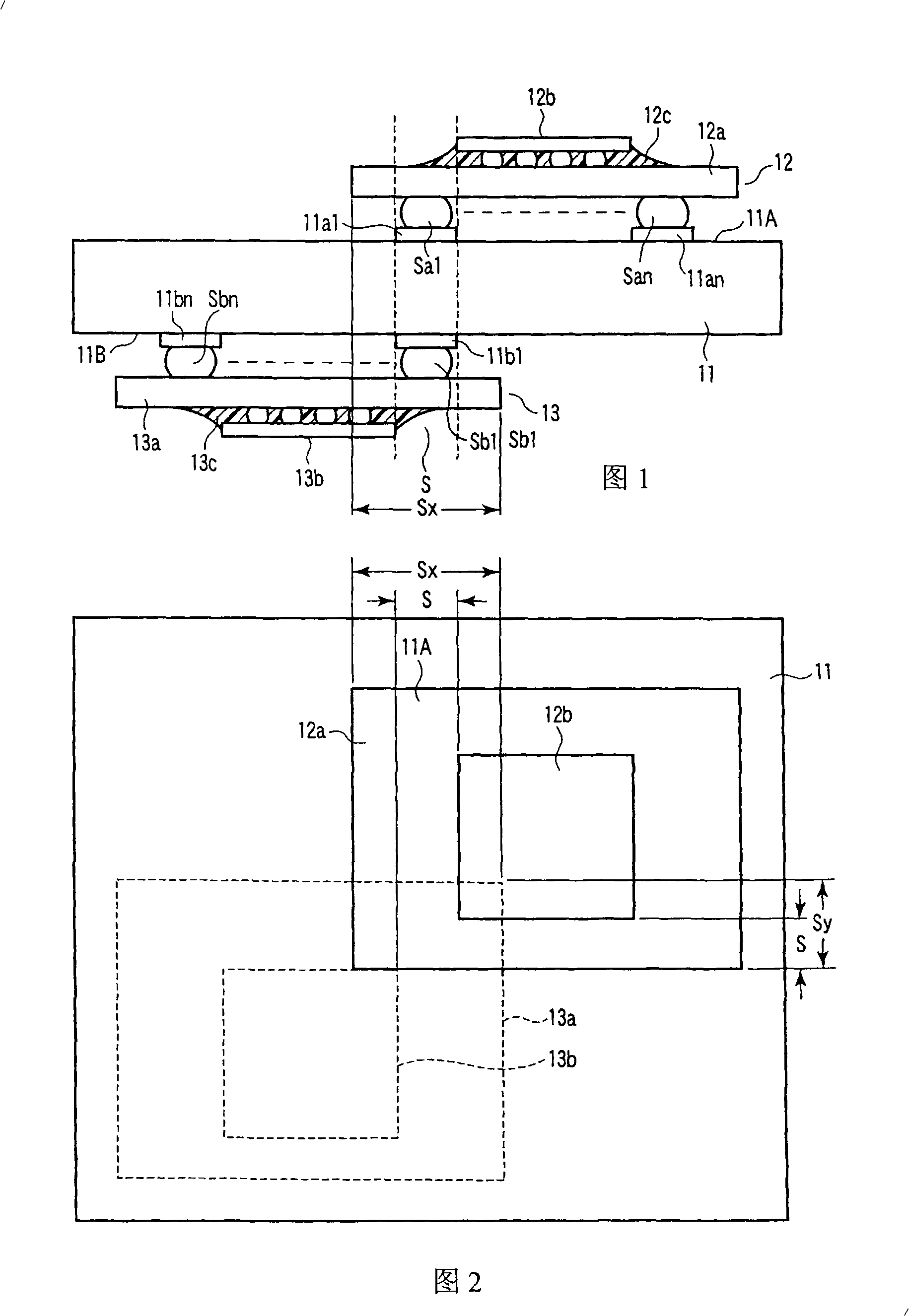

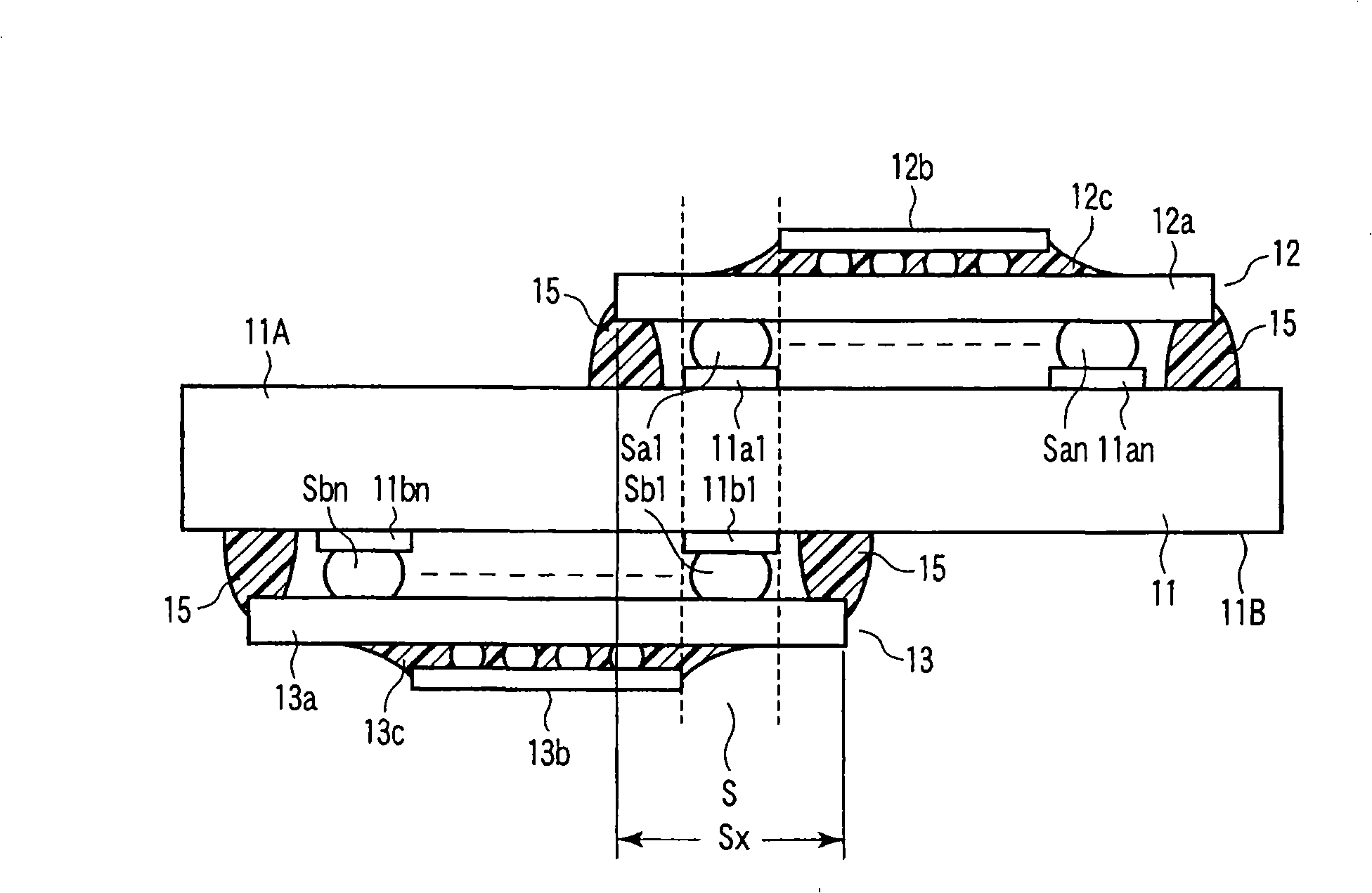

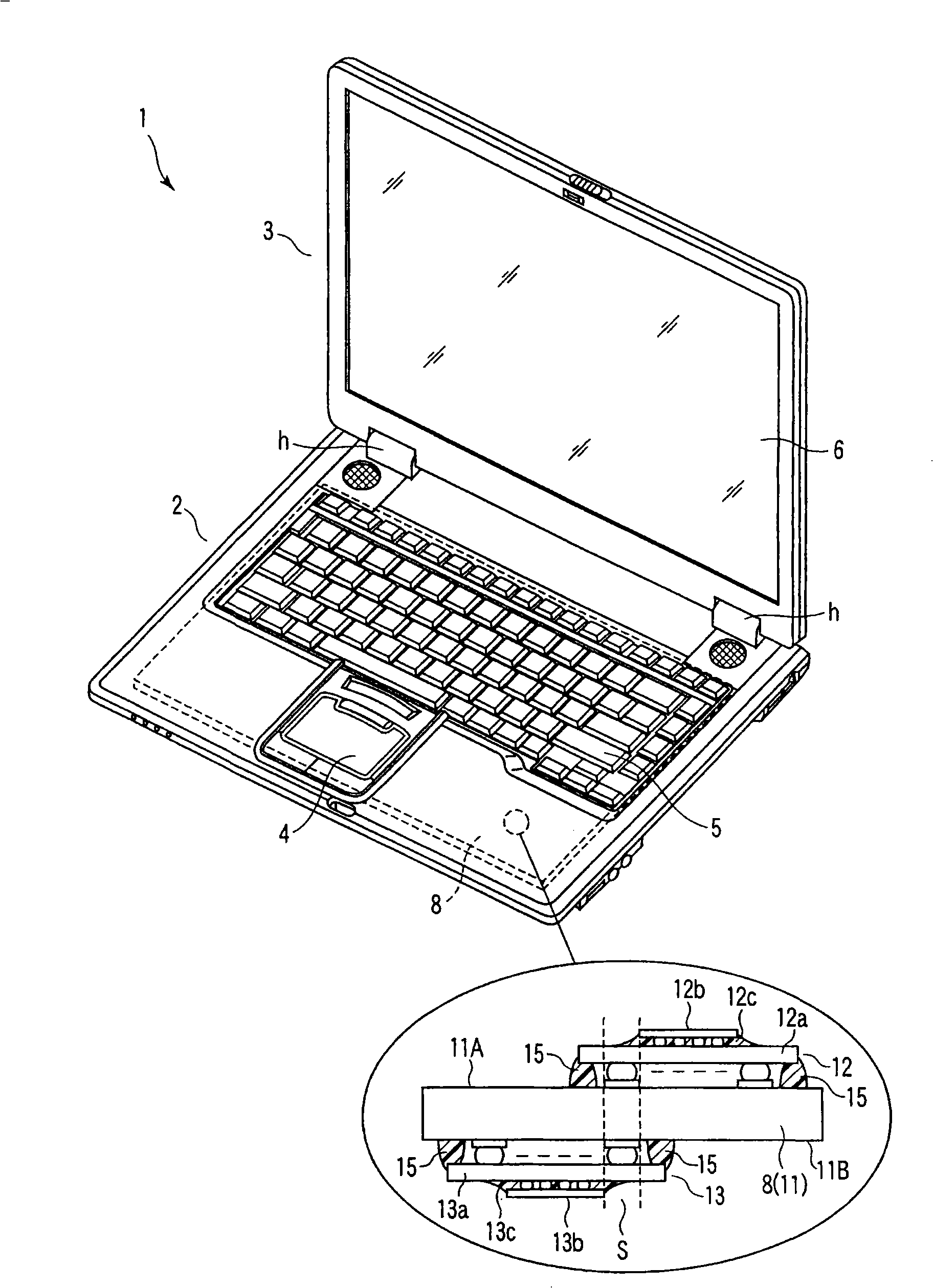

[0019] Hereinafter, various embodiments according to the present invention will be described with reference to the accompanying drawings. Generally, according to an embodiment of the present invention, a printed circuit board structure is provided, including:

[0020] A printed wiring board having first and second component mounting surfaces at its front and rear sides, each of which is used to mount a semiconductor package as a mounted component, the semiconductor package being loaded on Semiconductor chips on substrates;

[0021] a first semiconductor package mounted on the first component mounting surface; and

[0022] a second semiconductor component mounted on the second component mounting surface,

[0023] Wherein the first and second semiconductor components have a positional relationship such that the substrates are partially overlapped via the printed wiring board and the semiconductor chips are not overlapped.

[0024] According to the printed wiring board structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com