Circuit member, manufacturing method of the circuit member, and semiconductor device including the circuit member

a manufacturing method and circuit technology, applied in semiconductor devices, semiconductor/solid-state device details, electrical apparatus, etc., can solve the problems of cracking sealing resin, high possibility of serious damage to the life of society, and adhesion strength (or joining strength) between metals, so as to enhance the reliability of semiconductor devices, and improve the reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

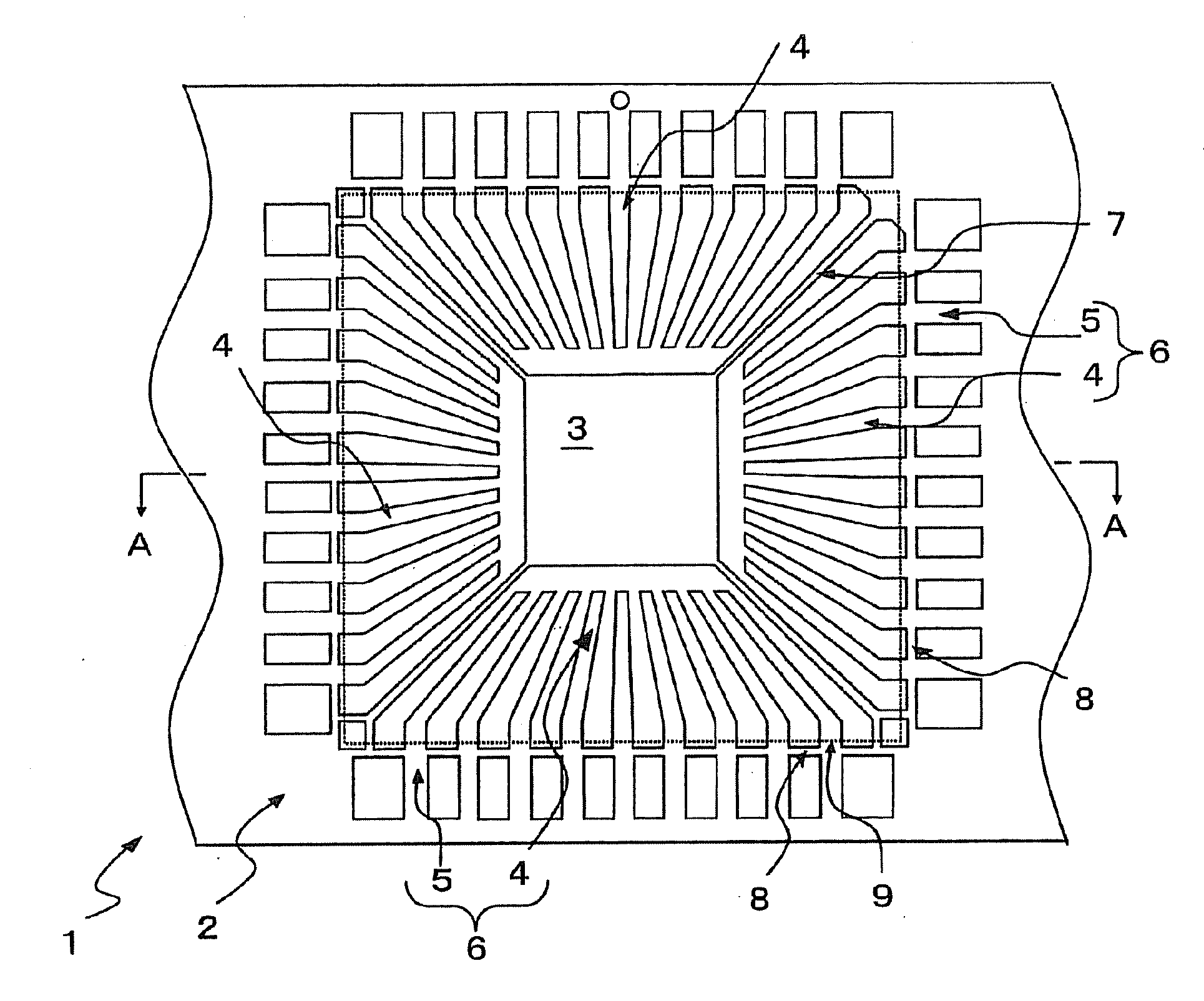

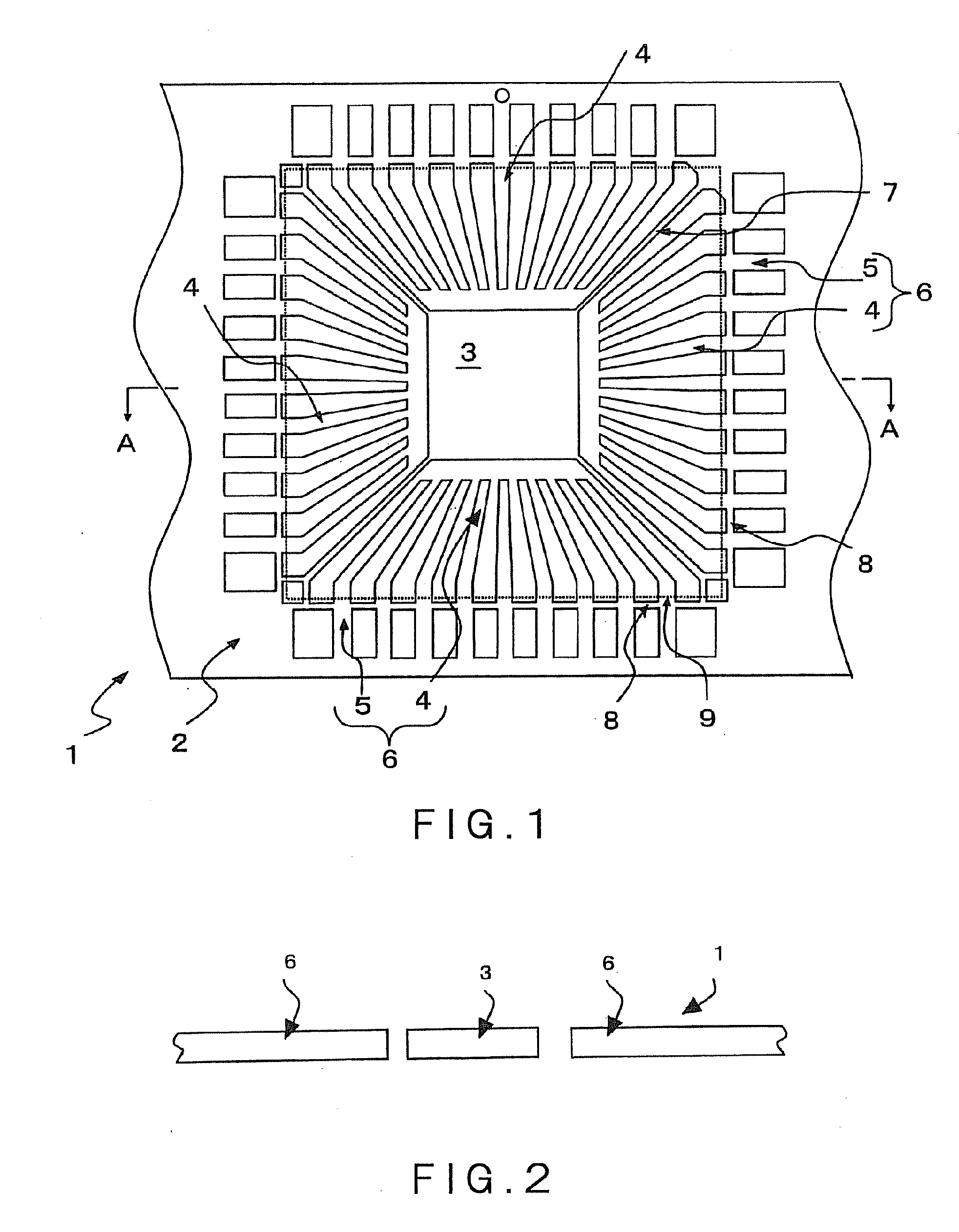

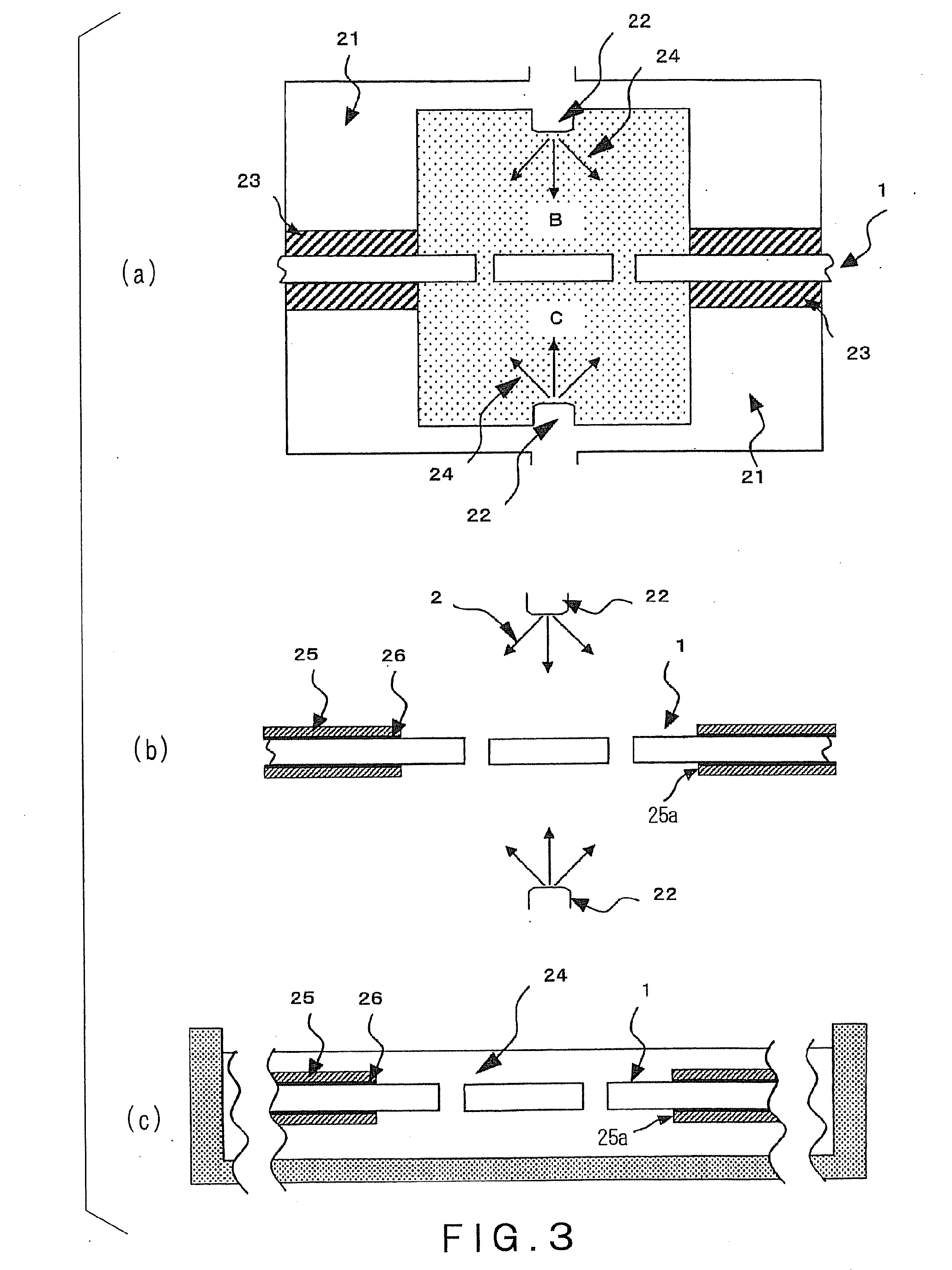

[0060]First of all, a first embodiment of the present invention will be described with reference to FIGS. 1 to 8. Of these drawings, FIG. 1 is a top view of the lead frame material of the QEP type, and FIGS. 2 to 8 are provided for illustrating the circuit member, a manufacturing method for the circuit member and a semiconductor device including the circuit member, respectively seen from a viewpoint corresponding to a cross section taken along line A-A of FIG. 1.

(Construction of the Circuit Member)

[0061]The lead frame material (lead frame body, lead frame member) 1 related to this embodiment is manufactured from a rolled copper plate or rolled copper alloy plate having an elongated plate-like or coil-like shape. In more detail, the lead frame material 1 is formed, in succession, in the rolled copper plate or rolled copper-alloy plate, by etching employing photolithography technology or punching with a press using a mold (mold tool, die), or the like means. That is to say, a pluralit...

second embodiment

[0092]Next a second embodiment according to the present invention will be described with reference to FIGS. 9 to 15. FIGS. 9 to 15 are provided for illustrating the circuit member, the manufacturing method for the circuit member and the semiconductor device including the circuit member, respectively related to the second embodiment and seen from a viewpoint corresponding to the cross section taken along line A-A of FIG. 1. It is noted that in the second embodiment shown in FIGS. 9 to 15, like parts in the first embodiment will be designated by like reference numerals, and repeated description thereof will be omitted below.

(Construction of the Circuit Member)

[0093]As shown in FIG. 9, the lead frame material (lead frame body, lead frame member) 1 related to the second embodiment has substantially the same construction as that of the first embodiment shown in FIG. 1. Therefore, the description about the lead frame material 1 of the second embodiment will now be omitted.

[0094]As shown i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| roughness Ra | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com