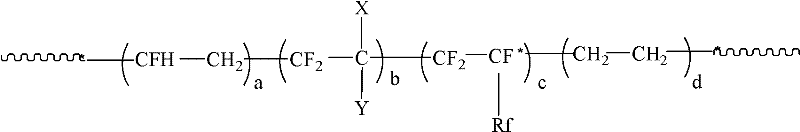

Melt-processable modified polyvinyl fluoride resin and preparation method thereof

A technology of polyvinyl fluoride resin and vinyl fluoride, which is applied in the field of modified polyvinyl fluoride resin and its preparation, can solve problems such as damage to ultraviolet resistance and resin decomposition, and achieve high bonding strength, good high temperature stability, and good durability The effect of high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

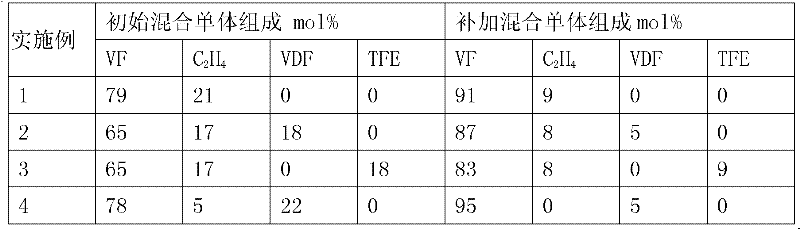

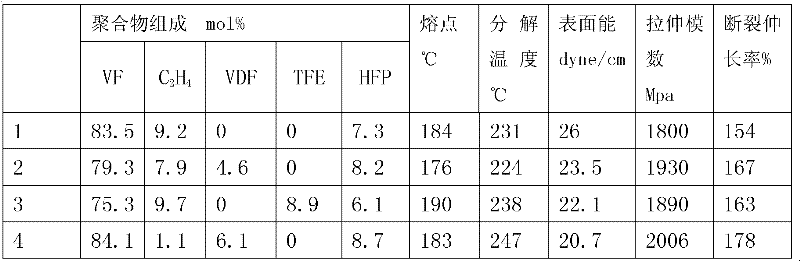

Embodiment 1-4

[0037] Add 6L of deionized water and 50g of 20% ammonium perfluorooctanoate aqueous solution into a 10L stainless steel polymerization kettle, replace the polymerization kettle three times by vacuuming and nitrogen charging, heat the reaction kettle to 90°C, and add Hexafluoropropylene (HFP) made the pressure of the reactor reach 0.2MPa, and mixed monomers (see Table 1 for the initial monomer composition) were added to the reactor in proportion to make the pressure of the reactor reach 2.1MPa, and 2g of ammonium persulfate was dissolved in 1L to The initiator solution was prepared in deionized water. Add the initiator solution into the reactor with a metering pump, initially add 125ml of the initiator once into the reactor, and then add 5ml of the initiator solution into the reactor every 5 minutes. During the polymerization process, a certain composition of mixed monomers was added to the reactor (the composition of the additional mixed monomers is shown in Table 1), and the ...

Embodiment 5-7

[0044] Add 6 liters of deionized water and 35 g of sodium dodecylbenzenesulfonate into the 10L reactor, start the stirring device, and vacuumize and replace it three times. Pass into mixed monomer (initial monomer composition sees Table 1), make the pressure in the reactor be 0.1MPa, add 800g perfluoropropyl vinyl ether (PPVE) monomer in the reactor by liquid feed valve, react The kettle was heated to 50°C, and the reaction kettle was supplemented with mixed reaction monomers until the pressure of the reaction kettle was 2.8MPa (see Table 1 for the composition of the additional monomer), and azodiisocyanurate with a concentration of 12wt% was added to the reaction kettle through a metering pump. Butylamidine dihydrochloride 50g initiator, start to react, continue to add mixed monomer in the reactor, keep the pressure in the reactor to be 2.8MPa, after reacting for 4 hours, stop heating, cool down, reclaim unreacted mixed Monomer, put the milky white slurry in the kettle into t...

Embodiment 8

[0050] Add 6L of deionized water and 50g of 20% perfluorooctanoic acid ammonium aqueous solution into a 10L stainless steel polymerization kettle, and replace it three times by evacuating and filling nitrogen to make the oxygen content in the polymerization kettle below 20ppm, and heat the reaction kettle to 9°C. First add VF into the kettle to make the pressure inside the kettle reach 2.1MPa, and then fill it with C 2 h 4 Make the kettle pressure reach 3MPa, and dissolve 2g of ammonium persulfate in 1L of deionized water to prepare an initiator solution. Add the initiator solution into the reactor with a metering pump, initially add 125ml of the initiator once into the reactor, and then add 5ml of the initiator solution into the reactor every 5 minutes. Add mixed monomers (VF / C) to the reactor during the polymerization process 2 h 4 The molar ratio is 4: 1), and the pressure in the reactor is kept constant. After the reaction was carried out for 3 hours, stop adding the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com