Patents

Literature

286 results about "Perfluorooctanoic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Perfluorooctanoic acid (PFOA) (conjugate base perfluorooctanoate)—also known as C8—is a perfluorinated carboxylic acid produced and used worldwide as an industrial surfactant in chemical processes and as a material feedstock, and is a health concern and subject to regulatory action and voluntary industrial phase-outs. PFOA is considered a surfactant, or fluorosurfactant, due to its chemical structure consisting of a perfluorinated, n-octyl "tail group" and a carboxylate "head group". The head group can be described as hydrophilic while the fluorocarbon tail is both hydrophobic and lipophobic; The tail group is inert and does not interact strongly with polar or non-polar chemical moieties; the head group is reactive and interacts strongly with polar groups, specifically water. The "tail" is hydrophobic due to being non-polar and lipophobic because fluorocarbons are less susceptible to the London dispersion force than hydrocarbons.

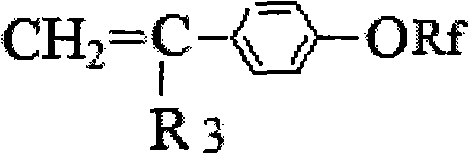

Method for preparing water-oil repellent fluorine-containing textile finishing agent

ActiveCN102060956ASmall particle sizeUniform compositionFibre treatmentCross-linkPerfluorooctanoic acid

The invention discloses a method for preparing a water-oil repellent fluorine-containing textile finishing agent, comprising the following steps of: adding a fluorine-containing alkyl (methyl) acrylate monomer, a higher fatty alcohol (methyl) acrylate monomer, a cross-linking monomer, an emulsifying agent, a solvent, a chain transfer agent and the like into a container in sequence, dropwise adding deionized water at 30-80 DEG C, shearing at high speed for pre-emulsification, carrying out high-pressure homogenization or ultrasound on a pre-emulsified solution, adding an initiator, and polymerizing for 0.5-8h at 50-80 DEG C. The obtained finishing agent has small particle size, uniform polymer composition and favorable properties of mechanical stability, pH stability, chemical stability, dilution stability and storage stability, and contains no components such as PFOS / PFOA (Perfluorooctane Sulfonates / Perfluorooctanoic Acid) and the like harmful to human bodies, and textiles finished with the finishing agent have favorable water-oil repellent property and has lower cost in comparison with like products.

Owner:JUHUA GRP

Watersoluble fluor resin non-stick paint and manufacture method thereof

InactiveCN101245209AHigh hardnessGood temperature distribution areaSpecial surfacesEmulsion paintsWater basedPerfluorooctanoic acid

The invention relates to a waterborne fluororesin nonstick coating, which is formed by 40 to 70 portions of modified polyte-trafluoroethylene (PTFE) water base resin, 10 to 30 portions of high temperature resistance pigment, 1 to 5 portions of fluororesin additive, 1 to 5 portions of surfactant and 20 to 40 portions of antiwear filler. The waterborne fluororesin nonstick coating uses synthesis propylene acid water base resin for modifying trafluoroethylene PTFE water base resin, adopts acrylic acid fat second polymerization method and does not use an addition agent, the entire fluorine caprylate compound which is harmful to human body in the modification process; the modified resin forms mosaic and perforating network structure, has good temperature dispersing region, solves the problem of the adhesiveness of the coating and the base material and the problems of baking and cracking, thus improving the hardness of nonstick coating. The NU aqueous fluorine resin of the invention does not stick to coating, can be coated on the surfaces of a microwave oven, an electric cooker, a nonstick pan and an electromagnetic pan, etc. to play the roles of protecting the surfaces from being stuck with food, and causing food and aluminum and other metals to be isolated.

Owner:TIANJIN COLOROAD COATING & CHEM

Corrosive liquid for preparing monocrystal silicon textured surface and method thereof

InactiveCN101634026AHigh thermodynamic stabilityGood chemical stabilityAfter-treatment detailsSemiconductor devicesPotassium hydroxidePerfluorooctanoic acid

The invention relates to a corrosive liquid for preparing monocrystal silicon textured surfaces and a method thereof. The corrosive liquid comprises an alkali solution, sodium silicate and isopropanol, and is characterized by also comprising a perfluoro octoate aqueous solution, wherein the perfluoro octoate aqueous solution has the volume percent of 0.2-1 percent and the concentration within a range of 5*10<-5>-5*10<-3>mol / L; the alkali solution has the mass percent of 1-2.5 percent, the sodium silicate has the mass percent of 0.1-2 percent, and the isopropanol has the volume percent of 0.3-2 percent; and the alkali solution is sodium hydroxide or potassium hydroxide or sodium carbonate. The corrosive liquid has low cost, pyramids formed on the prepared monocrystal silicon textured surfaces have small and uniform sizes, and the corrosive liquid is favorable for solar energy absorption and can be widely applied to the field of solar batteries.

Owner:BEIJING SOLAR ENERGY INST +1

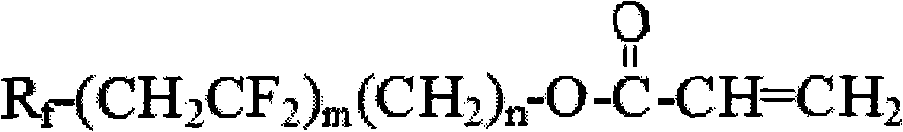

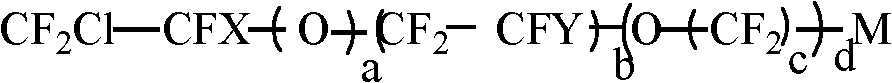

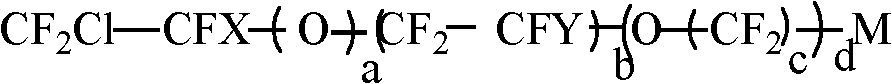

Preparation method of fluorine-containing polymer

InactiveCN102504063AEnvironmentally friendlyDoes not affect reaction ratePolymer scienceEmulsion polymerization

The invention discloses a preparation method of fluorine-containing polymer. The fluorine-containing polymer is obtained through the emulsion polymerization of fluorine-containing olefins monomer in the aqueous medium of fluorine-containing surfactant under the existence of initiator, wherein the weight percentage concentration of the fluorine-containing surfactant in the aqueous medium is 0.01-1%, the weight percentage concentration of the initiator in the aqueous medium is 0.001-1%, the reaction temperature is 10-120 DEG C and the pressure is 1-6.5MPa, and the reaction time is 3-15hours. The fluorine-containing surfactant satisfies a general formula shown in the specifications, wherein a is equal to 0 or 1; b is equal to 1 or 2; c is equal to 1, 2 or 3; d is equal to 1 or 2; X is C1, F or CF3; Y is H, F or CF3; and M is carboxylate or sulphonate. According to the method, perfluoro caprylic acid and derivatives thereof are not used in the method, so the method is environment-friendly; the preparation process can be conducted under wild temperature and pressure condition without affecting the reaction ratio of the polyreaction; and polymer powder with multiple grain sizes can be obtained, and thereby fluorine-containing polymer products at various grades can be prepared.

Owner:JUHUA GRP

Fluorine and silicon containing water and oil repellent finishing agent, preparation and application thereof

InactiveCN102094329AImprove performanceWater repellent retentionFibre treatmentPerfluorooctanoic acidCarbon chain

The invention discloses a fluorine and silicon containing water and oil repellent finishing agent which is synthesized from fluorine containing acrylic ester formed by fluorine containing alkyl with a shorter carbon chain and double-bond containing organic siloxane as basic structural units. On one hand, the advantages of a fluorine containing water and oil repellent finishing agent is retained; and on the other hand, the fluorine containing acrylic ester formed by the fluorine containing alkyl with a shorter carbon chain is selected so that perfluoro caprylic acid (PFOA) and salt thereof toxic to the environment are prevented from being generated in the degradation process of the fluorine and silicon containing water and oil repellent finishing agent. By combining the advantages of the silicon and the fluorine, the fluorine and silicon containing water and oil repellent finishing agent of the invention becomes a fabric finishing agent which has excellent performance and is environmentally friendly.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

Preparation of mixed glue nucleus solitarius shell-type fe3o4 nano solid phase extractive agent and application of the same

InactiveCN101130157AImprove stabilityPrevent oxidationOther chemical processesWater contaminantsMixed micellePerfluorooctanoic acid

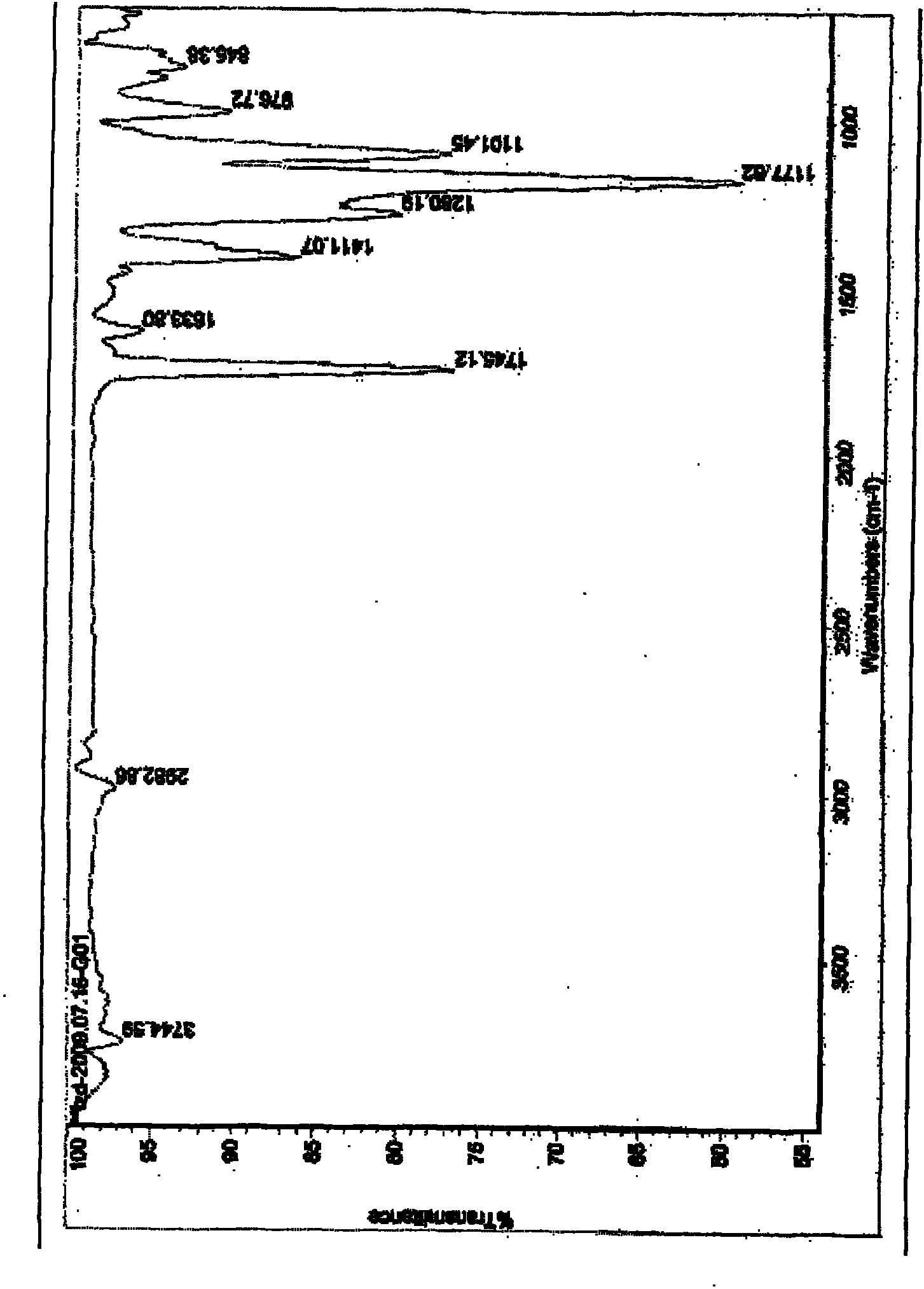

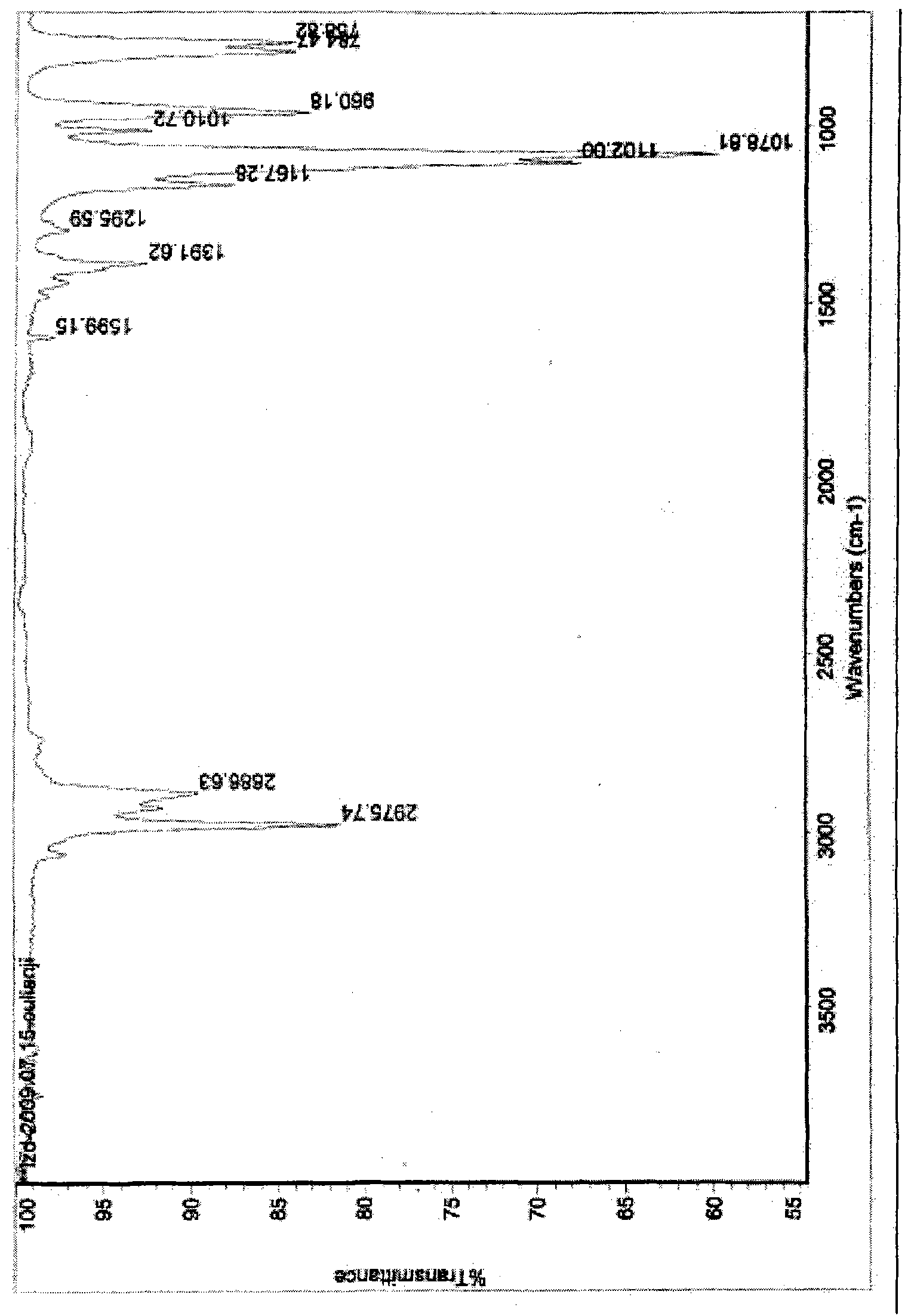

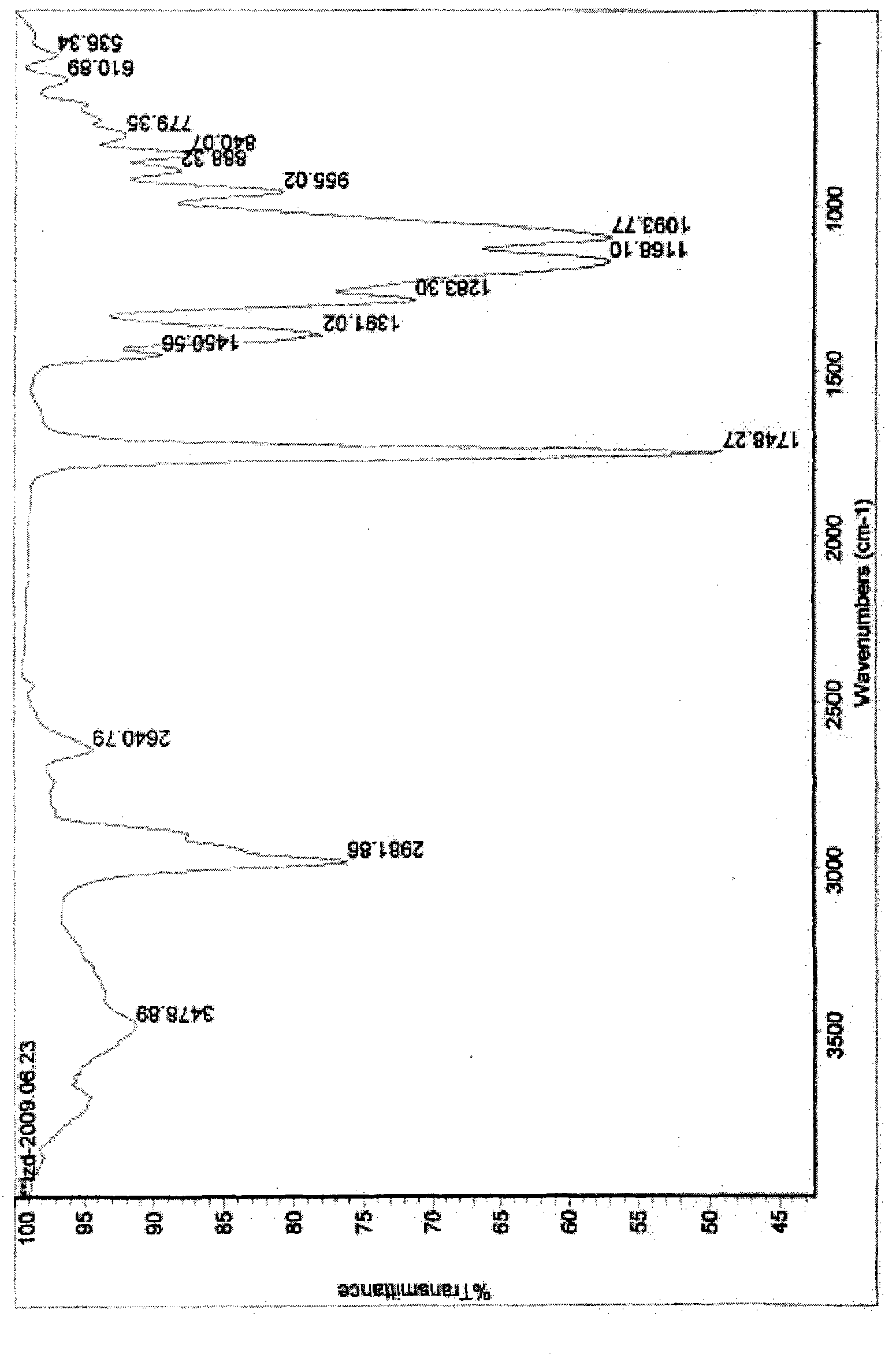

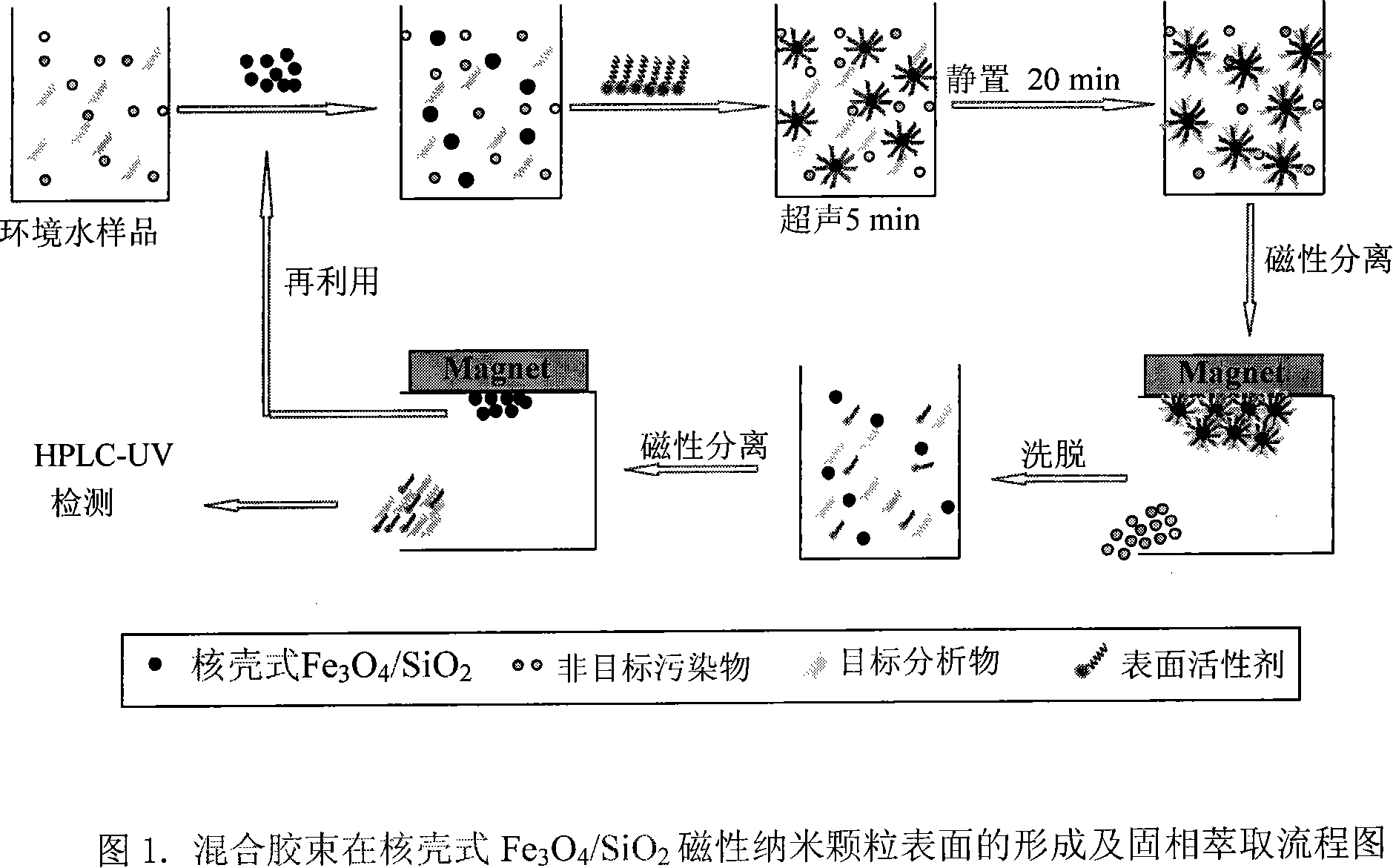

The invention relates to a new mixed micelle core-shell SiO2 / Fe3O4 nanometer solid phase extracting agent in the chemical analysis test instrument device field, which has the big specific surface area of the nanometer material, the strong magnetic separating property of the magnetic material, the good satiability of SiO2 shell layer and the good extraction property of the semi micelle and the absorption micelle, and is fit for the large scale batch preconditioning of bulk water sample, and has the small usage extracting agent, high efficient extraction, the simple operation, the high extracting speed, the friendly environment, the wide using range, the low cost and the reactivation property. Selecting bisphenol A(BPA), nonyl phenol(4-OP), octyl phenol (4-NP) as the represent of the hydrophobic pollution material and selecting perfluorine enanthic acid (PFHeA), perfluorooctanoic acid (PFOA), perfluorine octane sulfonic acid (PFOS), perfluorine n-nonanoic acid (PFDeA) or the like perfluorine compound as the represent of amphipathic nature pollution material, there are 0. 1g extracting agent and 50mg surface activator in 800ml environmental water simple, and the extracting ratio of the organic pollution materials is more than 90%.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

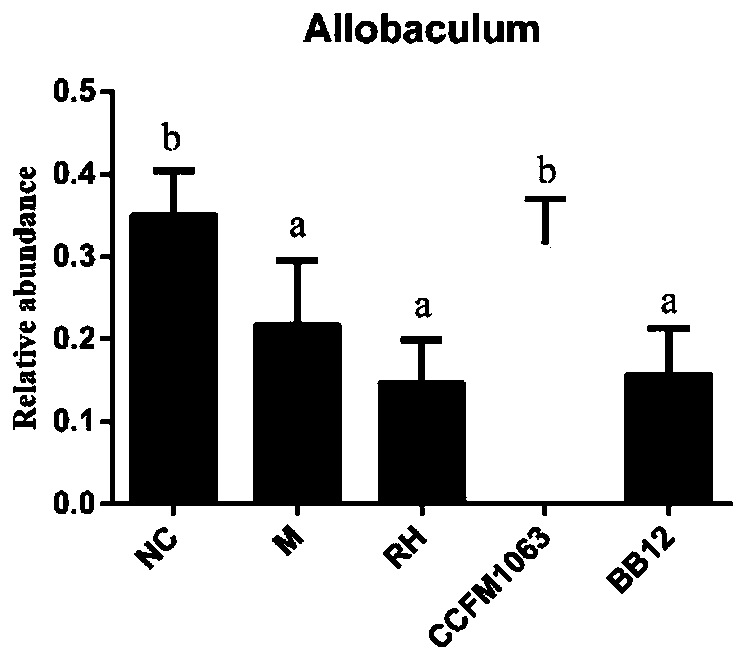

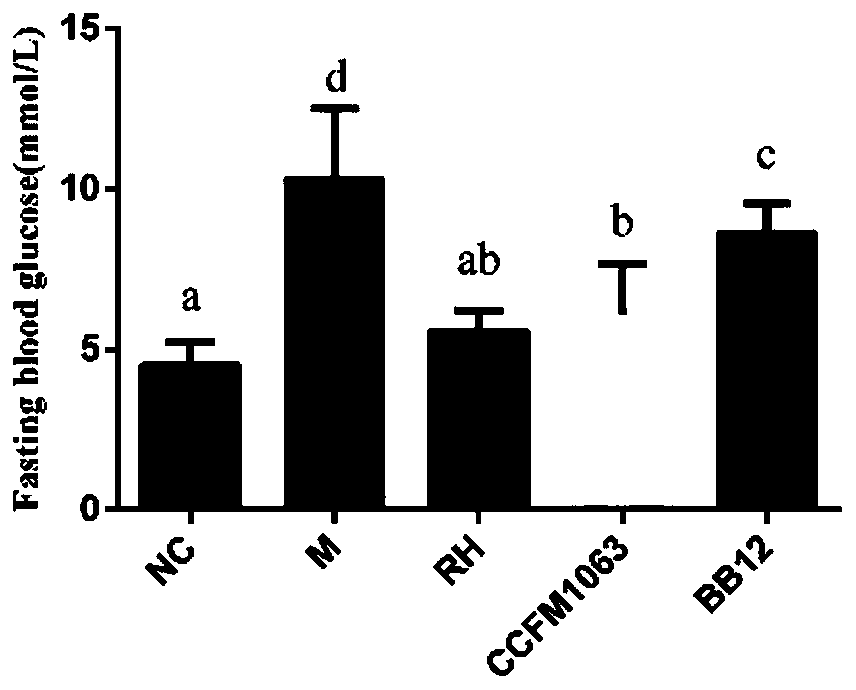

Bifidobacterium bifidum CCFM1063 and application thereof

ActiveCN110331119AImprove the immunityImprove pathological damageNervous disorderBacteriaPerfluorooctanoic acidAllobaculum

The invention discloses bifidobacterium bifidum CCFM1063 and application thereof. The bifidobacterium bifidum CCFM1063 can be rapidly planted in an intestinal tract, fasting blood-glucose and oral glucose tolerance caused by type II diabetes is significantly improved, and the area under the curve for glucose tolerance is reduced; total cholesterol in a serum increased and high-density lipoproteincholesterol reduced caused by the type II diabetes are significantly improved; the condition of insulin resistance caused by the significantly improved is significantly improved; the level of inflammation in type II diabetes liver tissue is significantly improved; pathological injuries of tissue such as pancreas and liver caused by the type II diabetes are significantly improved; the bifidobacterium bifidum CCFM1063 has higher adsorption capacity on perfluoro caprylic acid, and has the capacity of relieving toxicity of the perfluoro caprylic acid; and the constipation condition caused by the type II diabetes is significantly improved and the level of Allobaculum genus in the intestinal tract is improved, and functions of relieving anxiety and depression and colonitis are achieved.

Owner:JIANGNAN UNIV

Fluororesin having low residual amount of fluorinated emulsifier and process for its production

To provide a fluororesin which does not substantially contain perfluorooctanoic acid or its salt, and which has a low residual amount of a fluorinated emulsifier.A fluororesin which is obtained by emulsion-polymerizing a fluorinated monomer in an aqueous medium containing a fluorinated emulsifier of the formula (1):XCF2CF2(O)mCF2CF2OCF2COOAwherein X is a hydrogen atom or a fluorine atom, A is a hydrogen atom, an alkali metal or NH4, and m is an integer of from 0 or 1, and coagulating the obtained aqueous emulsion, followed by drying, wherein the residual amount of the fluorinated emulsifier of the formula (1) is at most 10 ppm.

Owner:ASAHI GLASS CO LTD

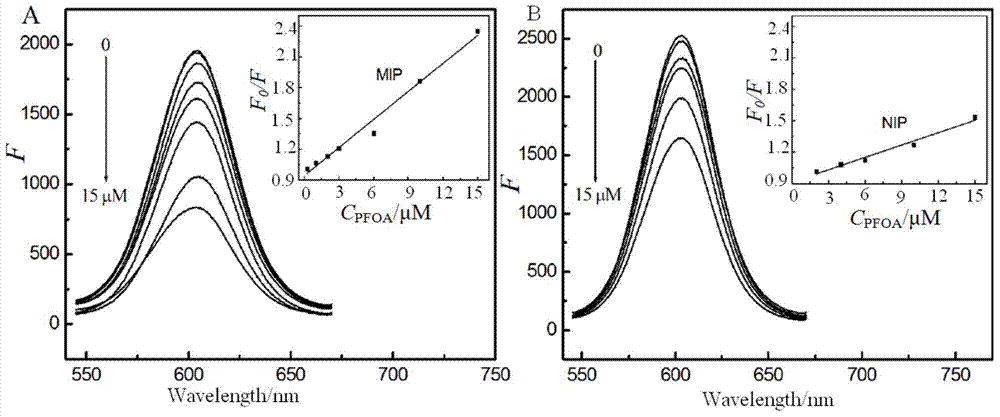

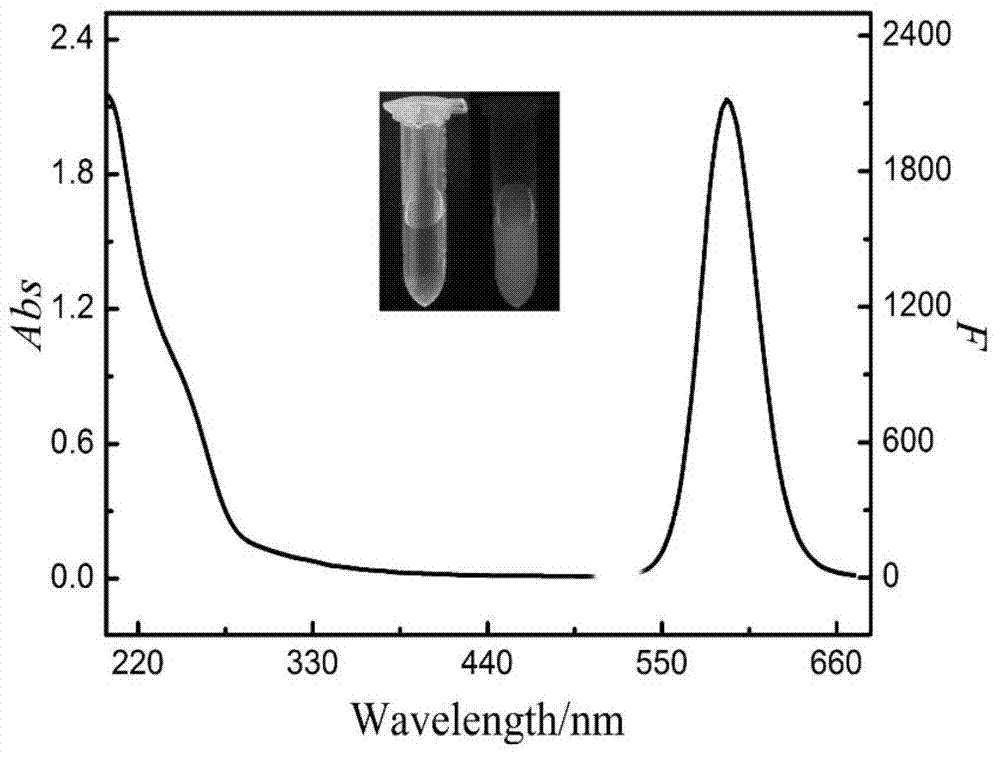

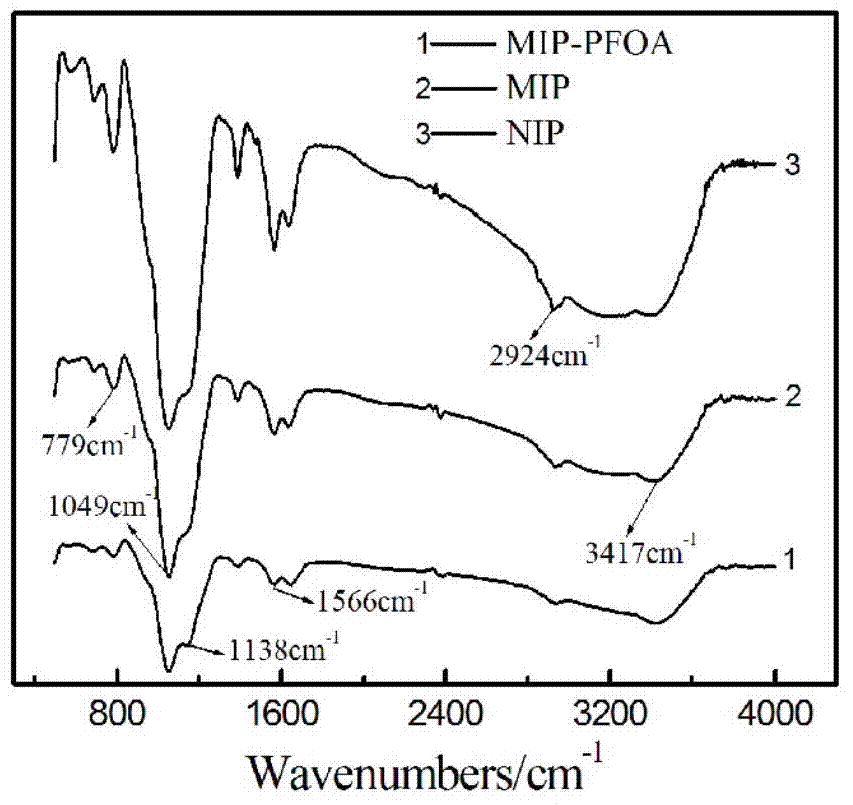

Molecularly imprinted polymer based on core-shell quantum dot and application thereof

InactiveCN104327271AImprove efficiencyQuick removalFluorescence/phosphorescenceFluorescencePerfluorooctanoic acid

The invention belongs to the technical field of preparation of molecularly imprinting fluorescent probes and especially relates to a CdTe / CdS quantum dot-molecularly imprinting polymer (QDs-MIP) and an application of the QDs-MIP as a fluorescent probe in detection and analysis of perfluorooctanic acid. The invention aims to solve a technical problem of providing a quick, simple, sensitive and high-selective method for detecting the perfluorooctanic acid and provides a quantum dot surface perfluorooctanic acid molecularly imprinting polymer and an application thereof. The polymer is a fluorescent molecularly imprinting polymer which is prepared by embedding a molecular recognition site into the surface of a TEOS-coated CdTe / CdS quantum dot with the perfluorooctanic acid as a template molecule. The molecularly imprinting polymer is high in sensitivity, is simple in detection, is high in selectivity and affinity and can be directly applied in detection of the perfluorooctanic acid in environment. The molecularly imprinting polymer not only can reduce a detection cost but also can increase detection efficiency.

Owner:SOUTHWEST UNIVERSITY +1

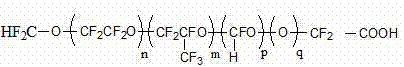

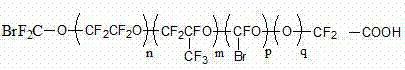

Fluorine-containing polymer and preparation method thereof

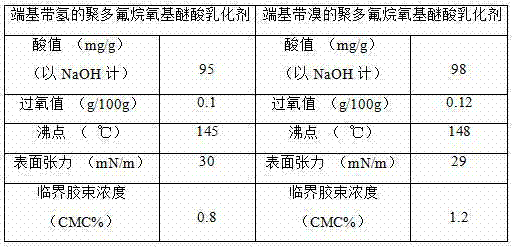

The invention discloses a fluorine-containing polymer and a preparation method thereof. One or more fluorinated monomers is / are subjected to liquid polymerization by using polyfluothane oxy ether acid as an emulsifier to obtain the fluorine-containing polymer free of perfluoro-octanoic acid or perfluoro-octylsulfonic acid, wherein the polyfluothane oxy ether acid is a halogen-terminated or hydrogen-terminated polyfluothane oxy ether acid emulsifier. The technical scheme mainly relates to the following three improvements: (1) the polyfluothane oxy ether acid or salt thereof selected instead of PFOA / PFOS as the fluorine-containing emulsifier can be effectively used in aqueous emulsion polymerization reaction of fluorinated monomers; (2) the prepared fluorine-containing polymer is free of perfluoro-octanoic acid or perfluoro-octylsulfonic acid, and thus, satisfies the environmental requirement; and (3) the fluorine-containing polymer conforms to the cost accounting, can greatly enhance the single-kettle yield of the equipment on the premise of not increasing the production equipment and personnel, and meanwhile, can enhance the polymerization time, polymerization yield and other production indexes.

Owner:成都晨光博达新材料股份有限公司

Method for preparing fluorine-containing polymer by using mixed fluorine-containing surfactant

The invention relates to a method for preparing a fluorine-containing polymer by using a mixed fluorine-containing surfactant. The method comprises the following steps of: performing homopolymerization or copolymerization by using a fluorine-containing olefin monomer or performing copolymerization on the fluorine-containing olefin monomer and the fluorine-fee olefin monomer under the effect of an initiator; adding 0.01-1% of mixed fluorine-containing surfactant to the reaction system, wherein the fluorine-containing surfactant is combined by a molecular weight fluorine-containing surfactant [Rf-(O)m-Rf'-COO]nAn+ and high molecular fluorine-containing surfactant [CF2=CF-(O)p-Rf1-(O)q-Rf2-COO]nAn+ containing unsaturated bonds. Without perfluoro caprylic acid as a dispersant, the method is high in safety and easy to control polymerization conditions, so that the environmental pollution by perfluoro caprylic acid is avoided, and the product system is good in stability and uniform in grain shape.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

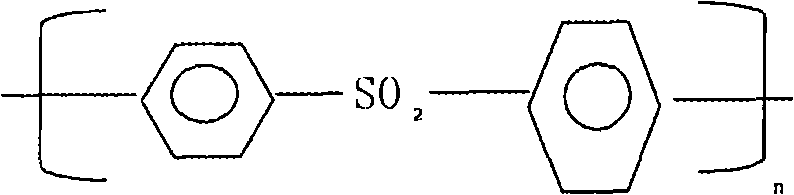

Water-based non-stick polyether sulphone coating containing no perfluorooctanoic acid and method for preparing same

The invention discloses a water-based non-stick polyether sulphone coating composition containing no perfluorooctanoic acid. The composition comprises (1) 8 to 25 weight percent of polyether sulphone, (2) 2 to 15 weight percent of fluorocarbon polymer containing no perfluorooctanoic acid, (3) 40 to 90 weight percent of water-based dispersant and (4) 0 to 20 weight percent of toner for coloring. The coating composition adopts distilled water as a thinner in spraying, reduces the use amount of an organic solvent, meets the requirement of environmental protection, contains no perfluorooctanoic acid (PFOA), and achieves the requirement of harmlessness to a human body.

Owner:INNOTEK TECH CHINA

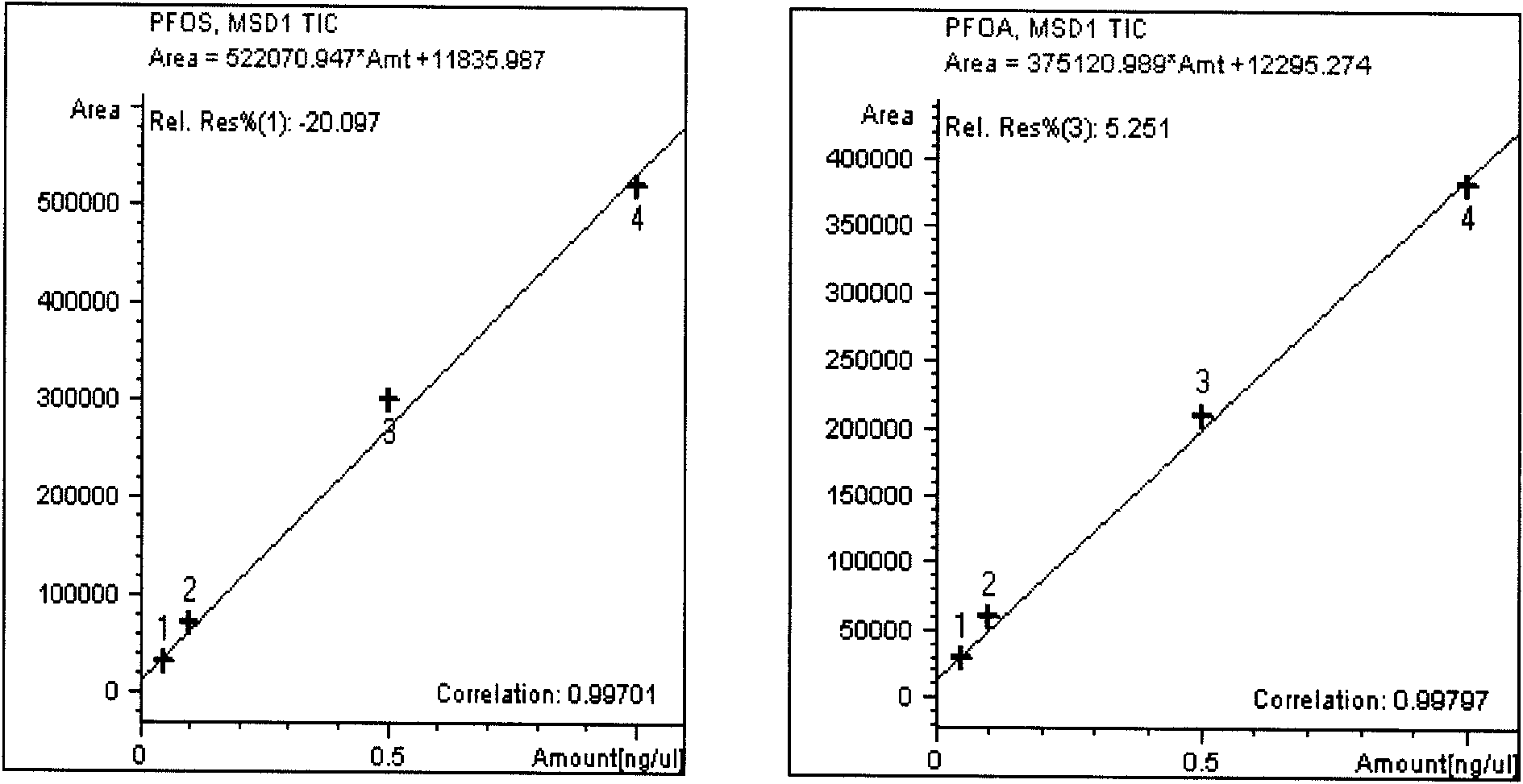

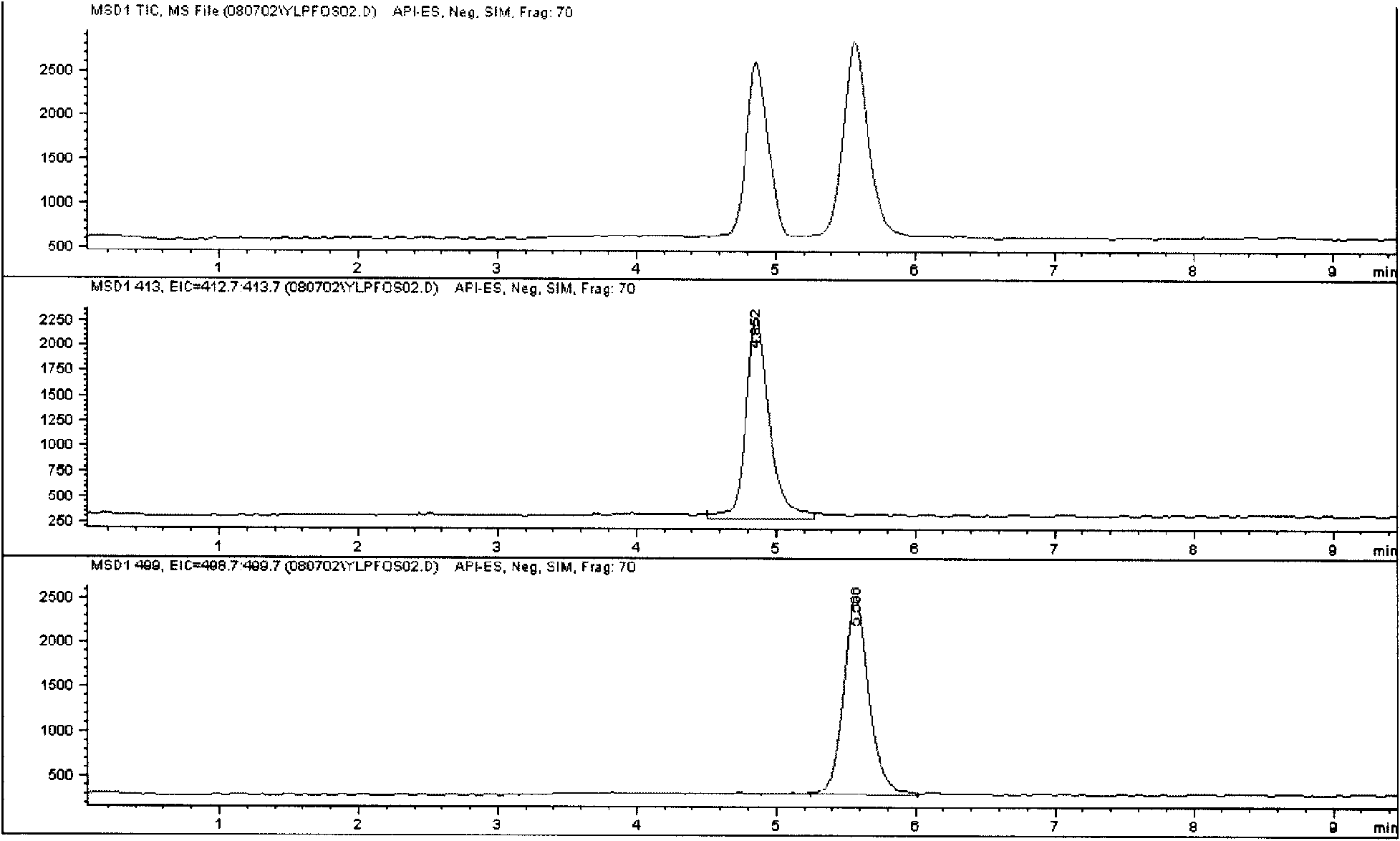

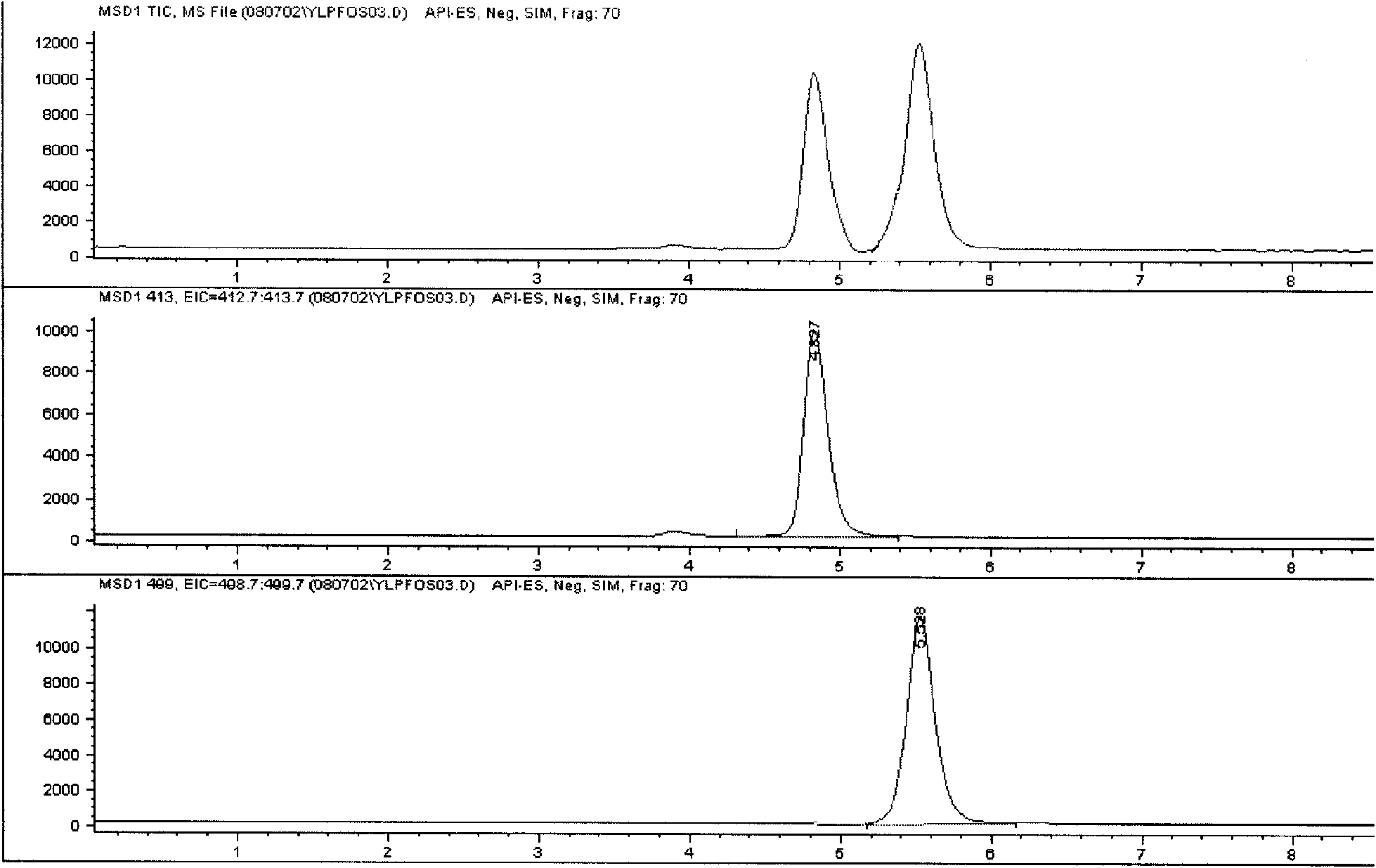

Method for rapidly detecting content of perfluor octyl sulfonic acid (PFOS) and perfluor octylic acid (PFOA)

The invention provides a method for rapidly detecting the content of perfluor octyl sulfonic acid (PFOS) and perfluor octylic acid (PFOA), which comprises the following steps: firstly, weighing a sample in a glass bottle, adding extract liquor, extracting and then filtering; then detecting the approximate content of PFOS and PFOA in the sample extract liquor by an HPLC-MS (directly carrying out mass spectrum (MS) detection without the process of a chromatographic column); if the content of the PFOS and the PFOA in the sample extract liquor is smaller than 50ppb, judging that a sample is feminine; and if the content of the PFOS and the PFOA in the sample extract liquor is larger than 50ppb, detecting the precise content of the PFOS and the PFOA in the sample by the HPLC-MS. The invention can rapidly detect the content of the PFOS and the PFOA in a plastic product, an electronic and electric product part and paper by a direct MS detection method, greatly improve the detecting speed and save the detecting time and cost and is worthy of popularizing.

Owner:江苏省优联检测技术服务有限公司

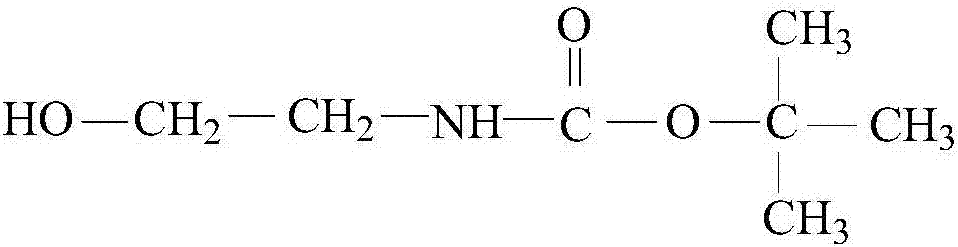

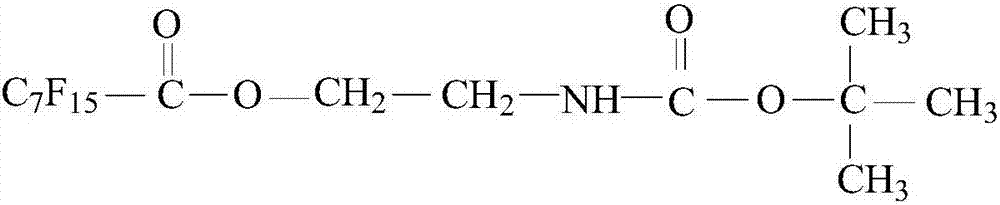

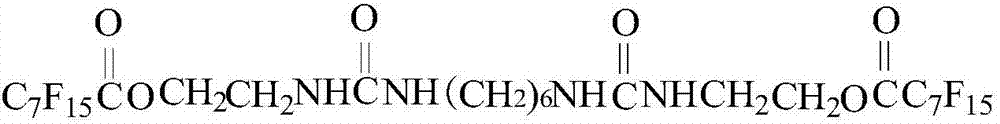

Preparation method of supercritical-carbon-dioxide thickening agent

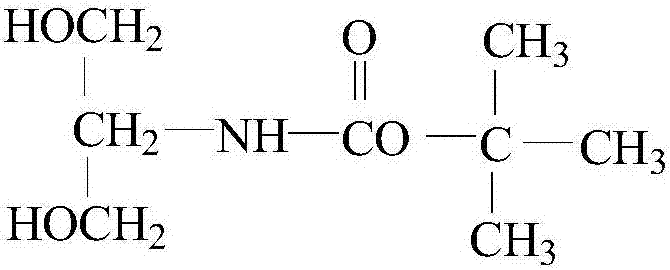

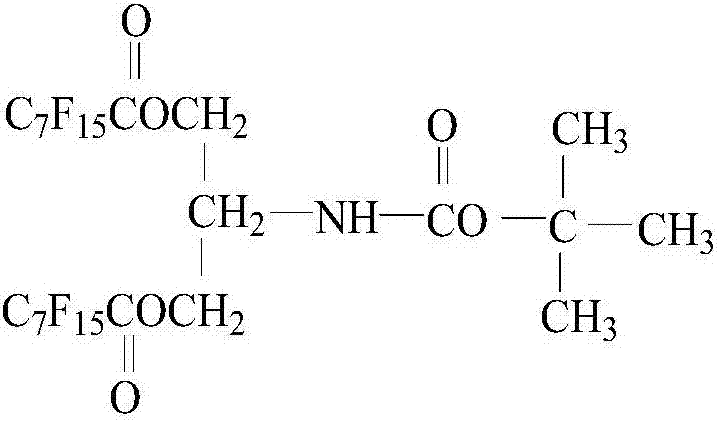

ActiveCN107253922AWell mixedUrea derivatives preparationCarbamic acid derivatives preparationRecovery methodCarbamate

The invention relates to a preparation method of a supercritical-carbon-dioxide thickening agent used for unconventional oil and gas reservoir development and aims to solve the problem that a conventional recovery method harms oil and gas reservoirs. According to the technical scheme, the method includes: adding deionized water into a bottle, adding ethanolamine, dropwise adding di-tert-butyl dicarbonate at 35 DEG C, performing reaction at 35 DEG C for 4 hours, and distilling to obtain an intermediate product (1) hydroxyethyl tert-butyl carbamate; adding the intermediate product (1) into a three-necked bottle, heating to 75 DEG C, dropwise adding perfluorooctanoyl fluoride, and performing reaction at 75 DEG C for 12 hours to obtain an intermediate product (2) ethyl perfluorooctanoate tert-butyl carbamate; adding dichloromethane and trifluoroacetic acid into the bottle, adding the intermediate product (2), performing reaction at 25 DEG C for 2 hours, performing extraction and vacuum drying, and adding 1, 6-hexamethylene diisocyanate to perform reaction for 10 minutes to obtain a final product (1, 6-diethyl perfluorooctanoate carbamido) hexane. The thickening agent can increase the viscosity of supercritical carbon dioxide and can be used for fracturing reformation and chemical reservoir oil displacement.

Owner:SOUTHWEST PETROLEUM UNIV

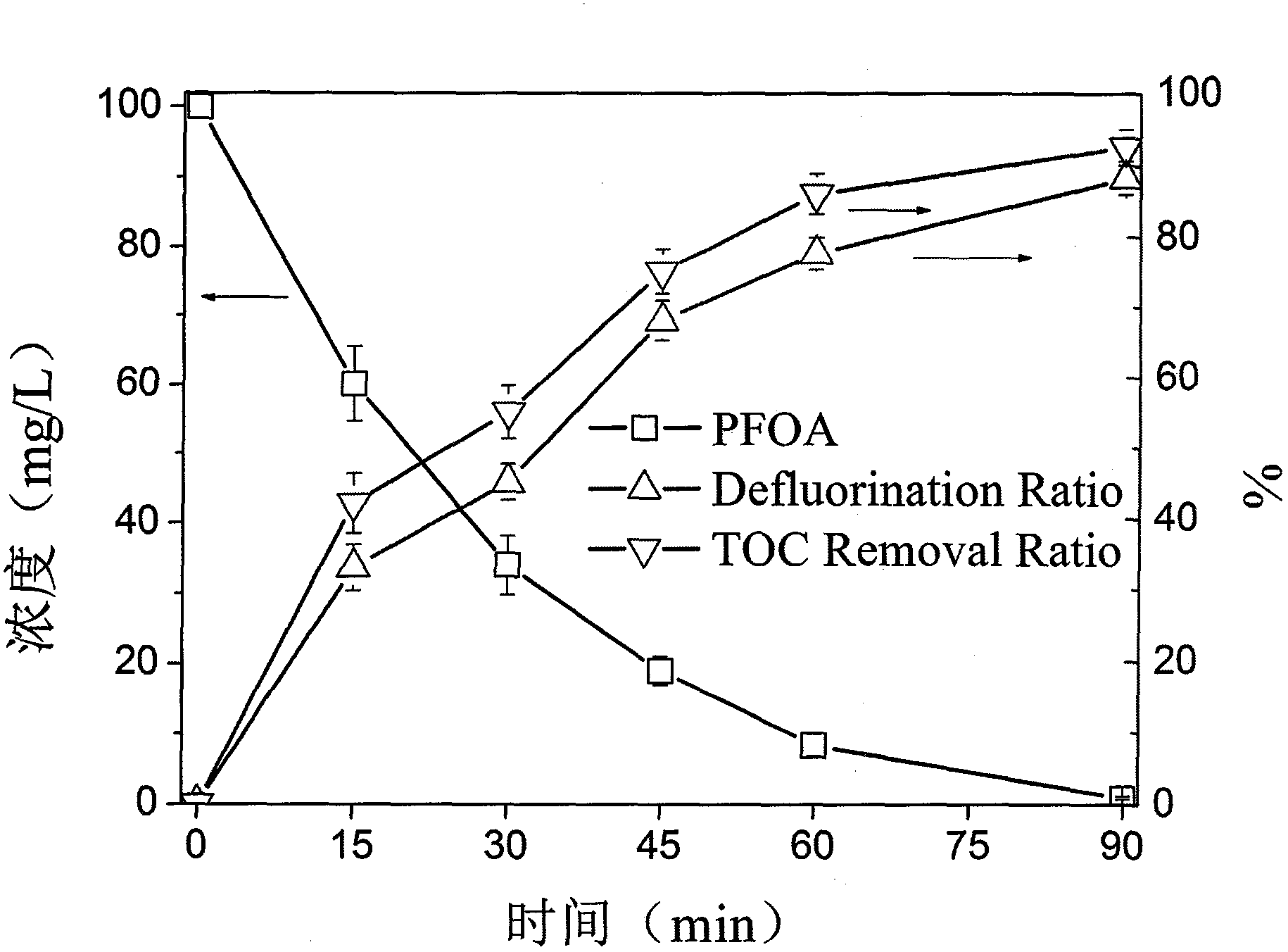

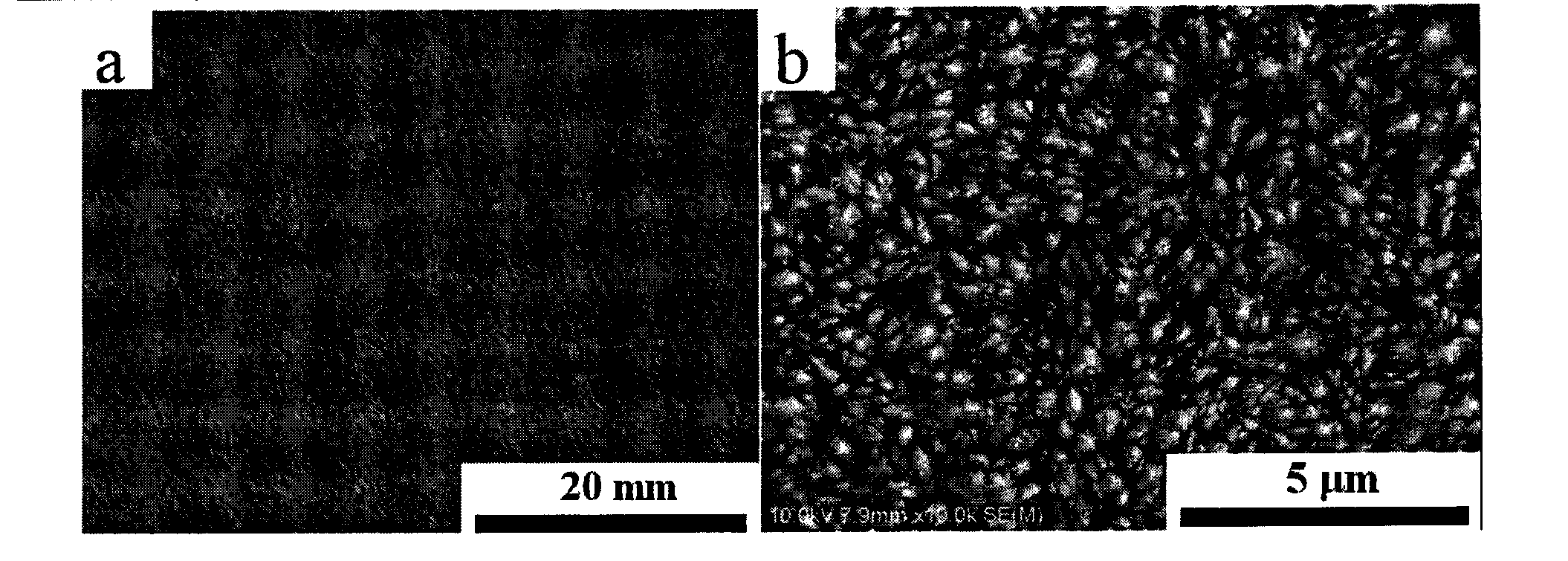

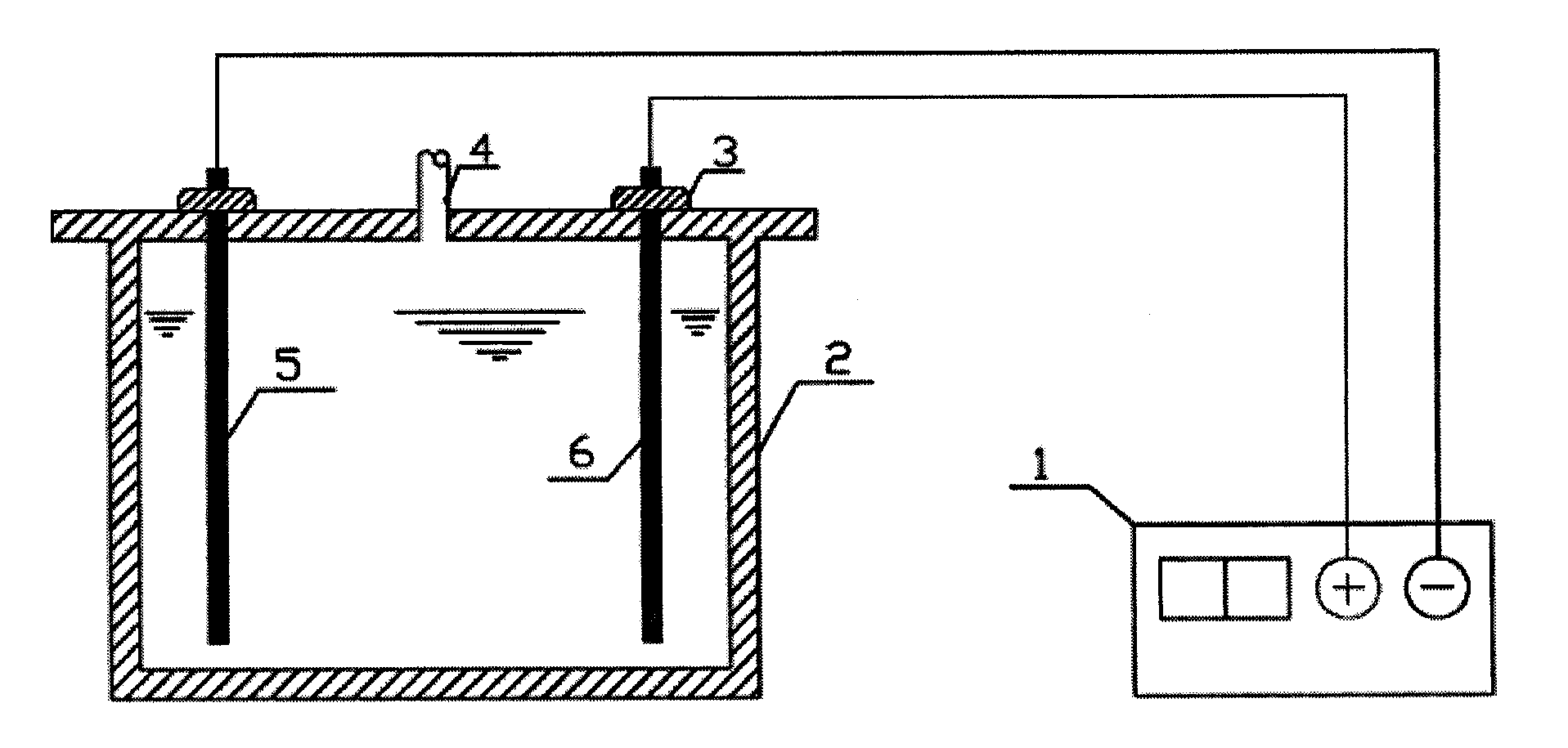

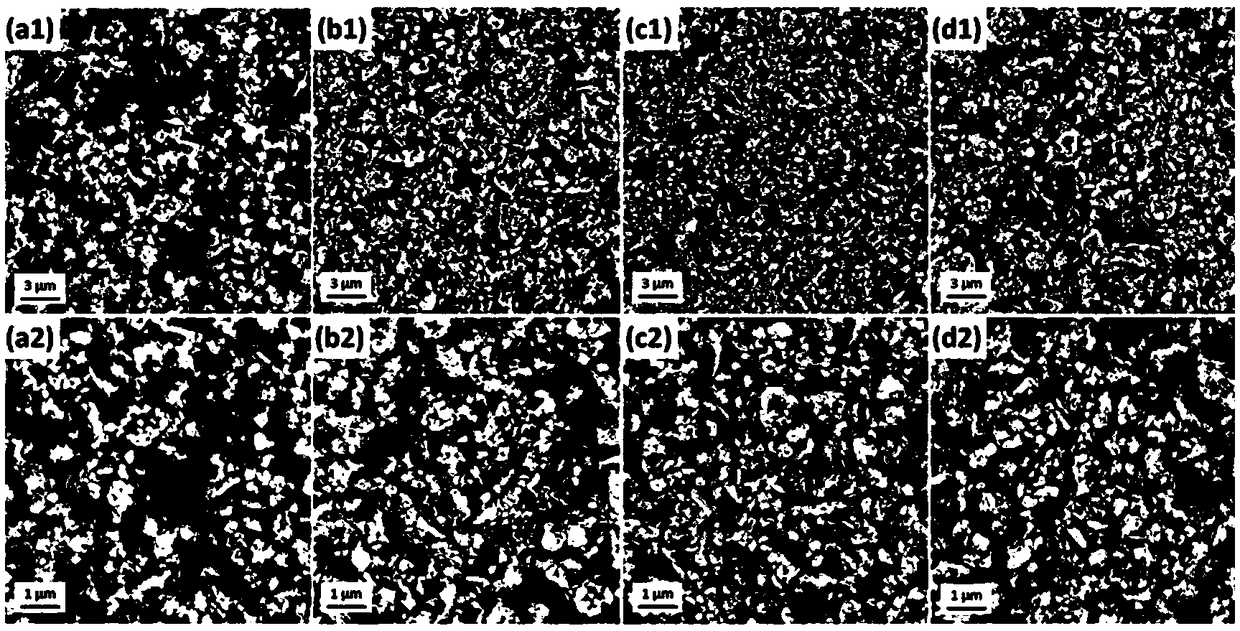

Preparation method of porous nanometer crystal electrodes and application of porous nanometer crystal electrodes

InactiveCN102701329AEasy to processStrong oxidation abilityWater contaminantsWater/sewage treatment by electrochemical methodsElectrolysisTreatment effect

The invention discloses a preparation method of porous nanometer crystal Ti / SnO2-Sn / Ce-PbO2 electrodes and a method for using the porous nanometer crystal Ti / SnO2-Sn / Ce-PbO2 electrodes for degrading and mineralizing perfluoro caprylic acid in water, and belongs to the technical field of electrochemistry. Waste water containing perfluoro caprylic acid is subjected to electrolytic oxidation treatment by using the porous nanometer crystal Ti / SnO2-Sn / Ce-PbO2 electrodes as anodes and Ti or 304 stainless steel as cathodes. The method is characterized in that the perfluoro caprylic acid can be efficiently mineralized under the mild condition. An electrochemical oxidation method is adopted, the technical flow process is simple, the operation is convenient, the reaction condition is mild, the treatment effect is good, in addition, stability and reliability are realized, and the industrial application is easy to realize. The adopted porous nanometer crystal Ti / SnO2-Sn / Ce-PbO2 electrodes have the advantages that the oxidation capacity is high, the service life is long, the processing is easy, the cost is low, and the like.

Owner:BEIJING NORMAL UNIVERSITY

Method for preparing suspension modified polytetrafluoroethylene

The invention discloses a method for preparing floating modified polytetrafluror-ethylene (PTFE) by adding a secondary comonomer which is perfluro propyl vinyl ether. Activator used in the method can be persulfate of alkali metals or alkaline-earth metals and a redox initiation system. The reaction temperature changes within a range of 5 DEG C -90 DEG C and the pressure is between 0.5-2.0MPa based on different activating system. The perfluro propyl vinyl ether is added by a vacuum absorption way, so as to avoid using perfluro octoate.

Owner:SHANGHAI 3F NEW MATERIAL TECH CO LTD

Fluorine elastomer containing high fluorine content and preparation process thereof

The present invention is fluoric elastomer with fluorine content higher than 70 %. The fluoric elastomer consists of the following copolymerized units: 1, 1-difluoro ethylene 30-60 wt%, perfluoro propylene 20-40 wt% and tetrafluoro ethylene 20-40 wt%. The present invention also relates to the preparation process of the fluoric elastomer with high fluorine content, and the preparation process is one emulsion polymerization process with water as medium, low molecular weight esters as chain transferring agent, persulfate as initiator, perfluoro caprylate as dispersant and borax as pH regulator.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

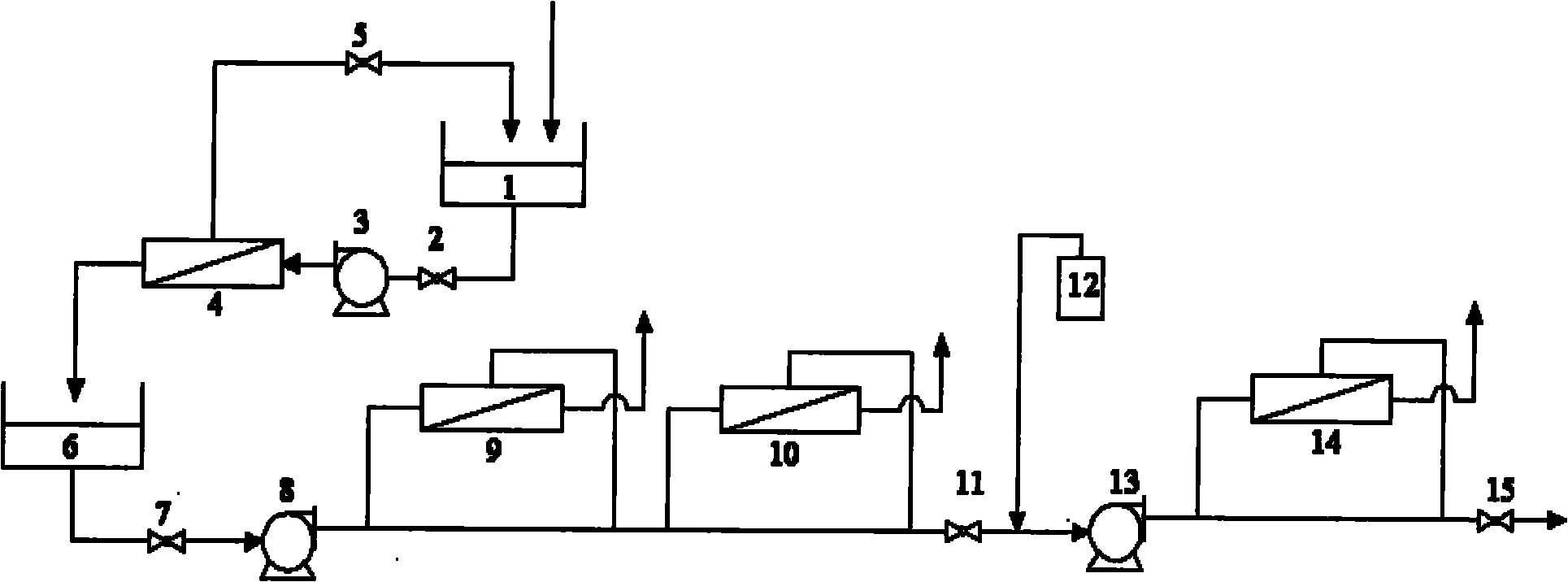

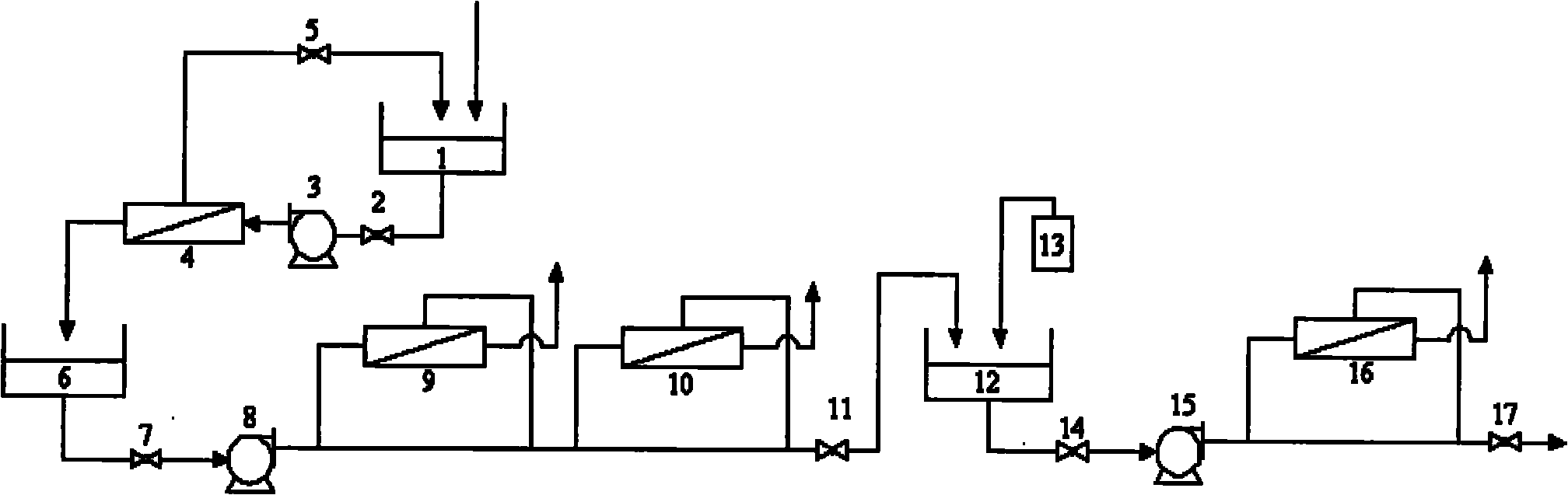

Method for treating wastewater with low-concentration ammonium perfluorooctanoate through all-film method

ActiveCN101928078AReduce recycling costsSimple operation processWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentHigh concentrationThree level

The invention belongs to the chemical wastewater treatment field, in particular relates to a method for treating wastewater with low-concentration ammonium perfluorooctanoate through all-film method which combines the ultra microfiltration technology and the nanofiltration technology. The method comprises the following steps: firstly adopting microfiltration or ultrafiltration to remove insoluble particles in the wastewater with low-concentration ammonium perfluorooctanoate; and secondly using a nanofiltration system to concentrate ammonium perfluorooctanoate in the pretreated and clarified wastewater, wherein the nanofiltration system is divided to three levels, each level adopts the concentrated water inner circulation mode to concentrate ammonium perfluorooctanoate to a higher concentration step by step, the permeate of each level of nanofiltration can be directly charged or used as the process water of other processes, and the zero emission of industrial wastewater can be realized. The method of the invention has simple operation, low energy consumption and no secondary pollution; and high-value-added perfluorooctanoic acid can be recycled and the industrial wastewater can meet the direct emission standard or the reuse standard.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

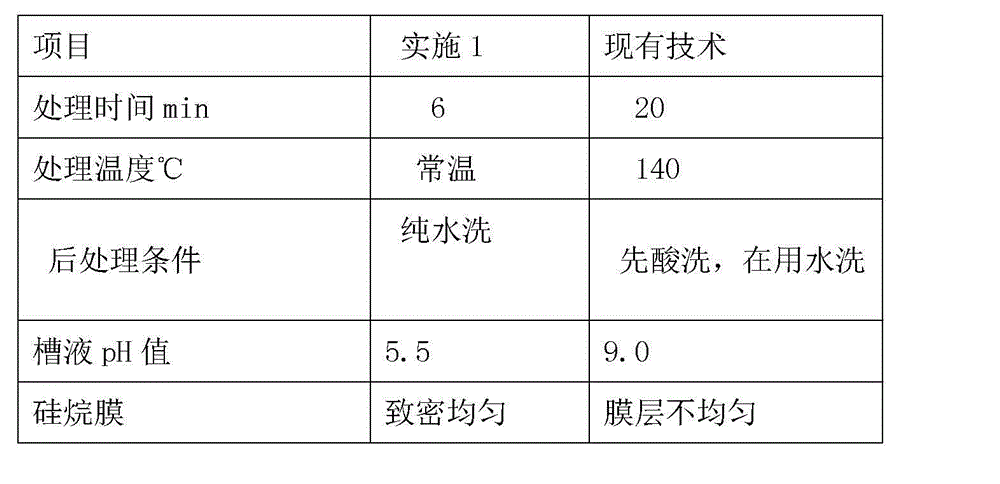

Modified silane surface pretreating agent containing polyoxyethylene octadecanol ether and preparation method of modified silane surface pretreating agent

ActiveCN102977774AOvercome CorrosivityOvercome uniformity issuesAnti-corrosive paintsPerfluorooctanoic acidChemistry

The invention discloses a modified silane surface pretreating agent containing polyoxyethylene octadecanol ether. The modified silane surface pretreating agent is prepared from the following raw material components in parts by weight: 100 parts of deionized water, 10-15 parts of modified coupling agent, 10-15 parts of ethanol, 30-40 parts of silane coupling agent 702, 20-30 parts of silane coupling agent KH-550, 1-2 parts of dicumyl peroxide, 0.002-0.003 part of sodium perfluorooctanoate, 0.3-0.5 part of tree ash, 4-6 parts of polyacrylic emulsion, 0.8-1.2 parts of polyoxyethylene octadecanol ether, 0.05-0.1 part of lanthanum triacetate and 0.2-0.3 part of phytic acid. The final product is obtained through modifying by using the coupling agent, compounding, adding additives, distributing, mixing and reacting. The modified silane surface pretreating agent provided by the invention has the characteristics of no toxicity, environment friendliness, convenience in use, compact and uniform silane membrane, strong adhesion and high corrosion resistance property.

Owner:蚌埠尚维知识产权运营有限公司

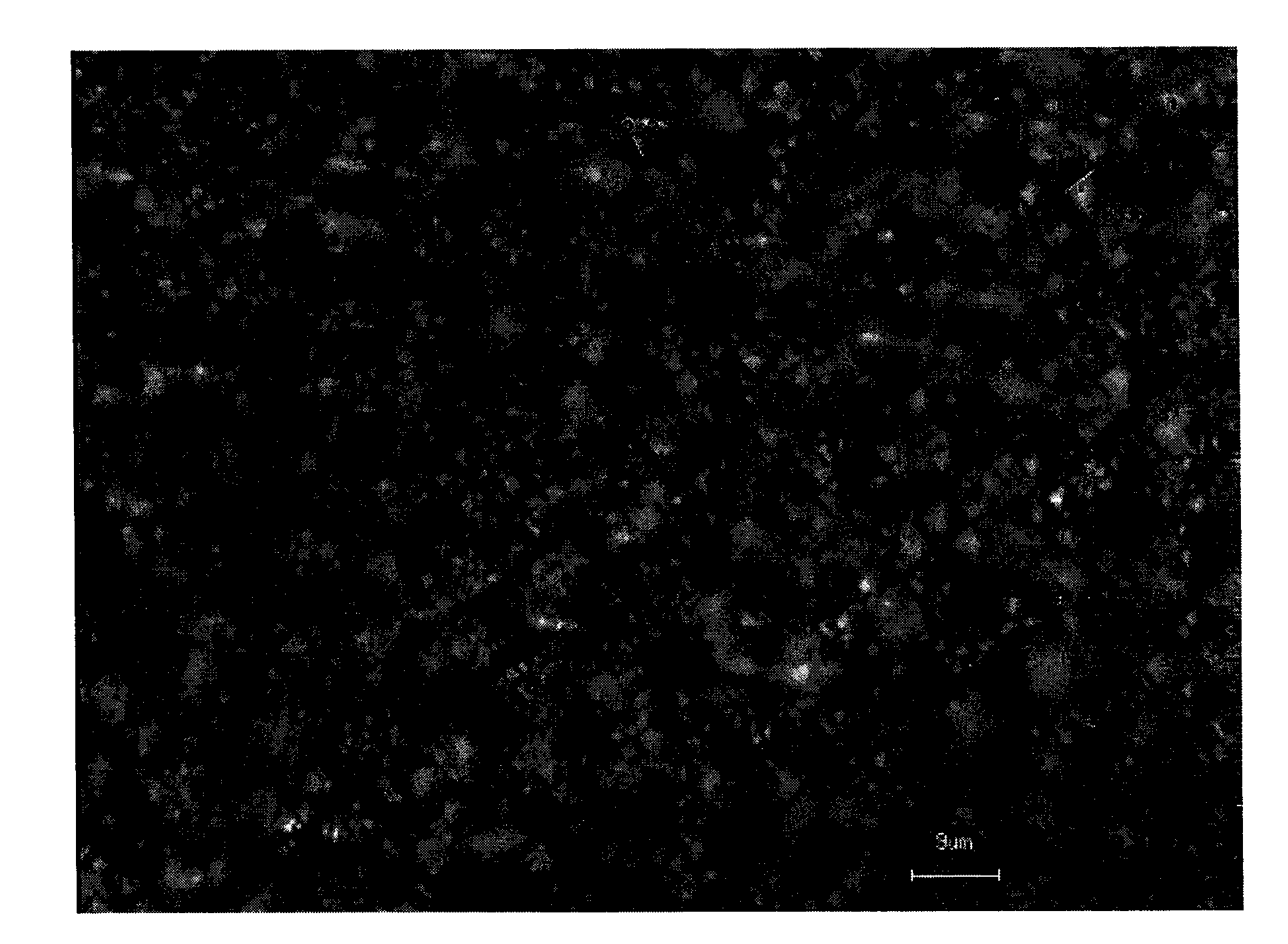

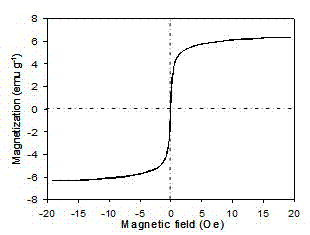

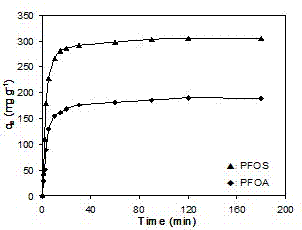

Preparation of magnetic mesoporous carbon nitride adsorbent and method for removing perfluorooctane compound in water

InactiveCN103170308ALarge specific surface areaGood for large area dynamic adsorptionOther chemical processesWater contaminantsIron sulfateAdsorption equilibrium

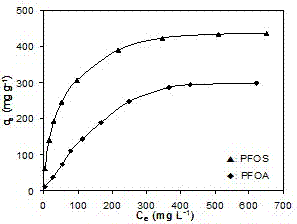

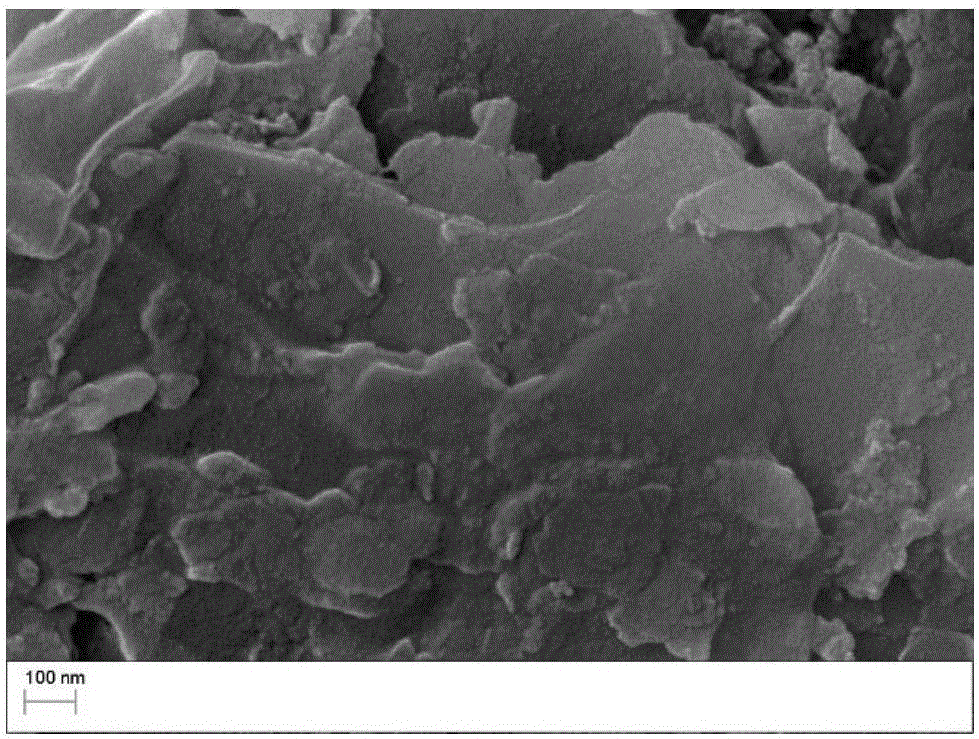

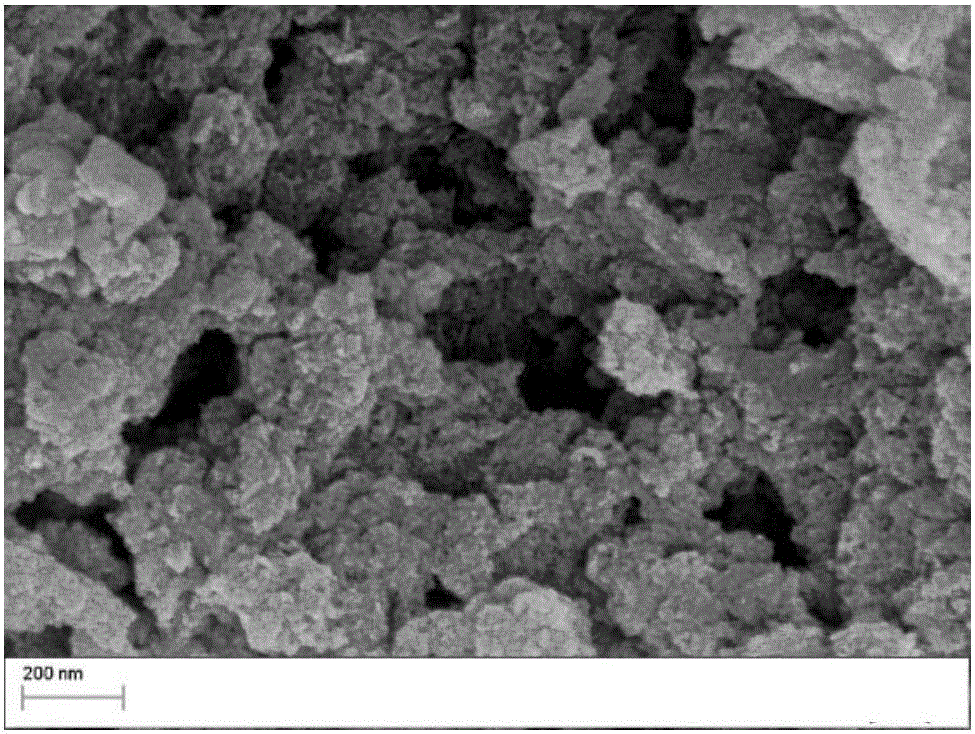

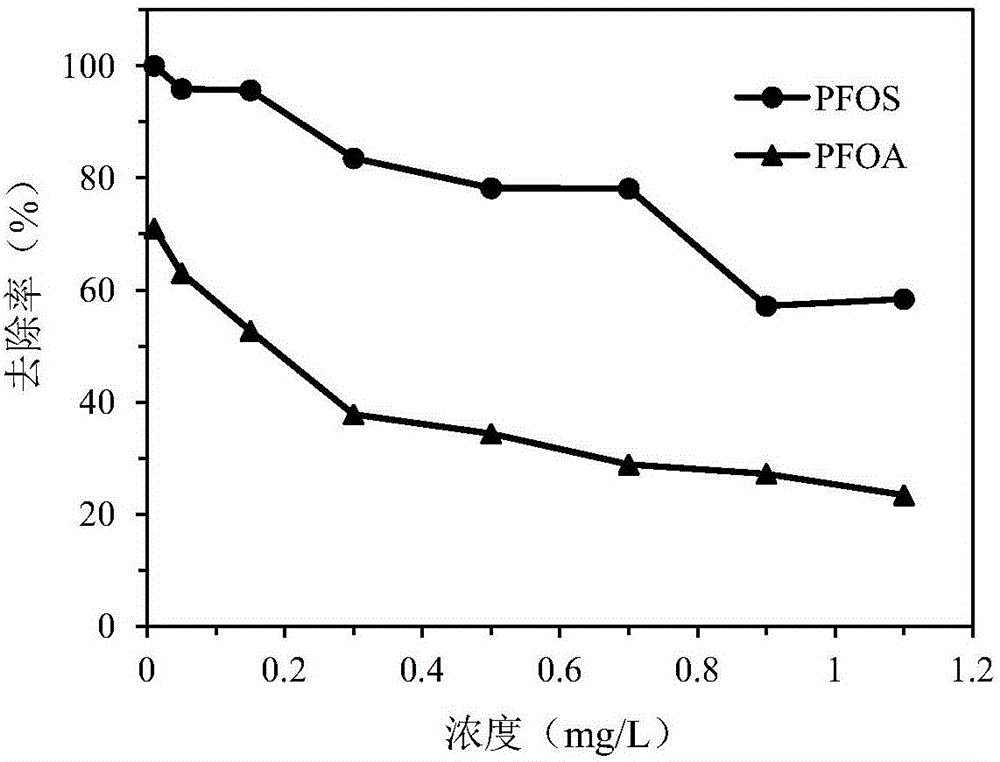

The invention discloses a preparation method of a magnetic mesoporous carbon nitride adsorbent and a method for removing perfluorooctane compounds in water. The method comprises the following steps of: based on mesoporous carbon nitride as a matrix, and ammonium ferrous sulfate and ammonium ferric sulfate as an iron source, adjusting the alkaline environment of the liquid by ammonia water; and performing co-precipitin reaction in water bath condition. The saturation magnetization of the magnetic mesoporous carbon nitride prepared is 6.37emu / g. The magnetic mesoporous carbon nitride is used for removing perfluorooctane compounds [PFOS (Perfluorooctane sulfonates)] and [PFOA (Perfluorooctanoic acid)] in water, so that a good removal effect is obtained and adsorption equilibrium is quickly realized. Meanwhile, the magnetic mesoporous carbon nitride adsorbent provided by the invention can be recovered by additionally applying a magnetic field to the benefit of repeated use. The adsorbent provided by the invention has an important meaning for adsorption removal of perfluorooctane compounds, and has a good application prospect in wastewater treatment.

Owner:NANJING UNIV OF SCI & TECH

Sludge-based activated carbon with effect of efficiently adsorbing PFOS (perfluorooctane sulfonate) and PFOA (perfluorooctanoic acid) and preparation method as well as application of sludge-based activated carbon

InactiveCN106732379AEasy to operateLow costSludge treatment by de-watering/drying/thickeningOther chemical processesActivated carbonSorbent

Owner:SOUTH CHINA UNIV OF TECH

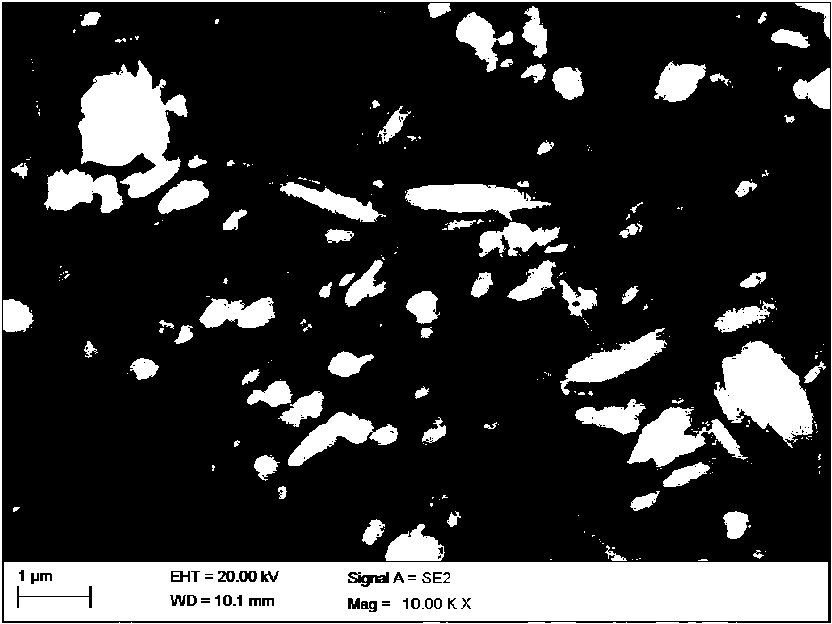

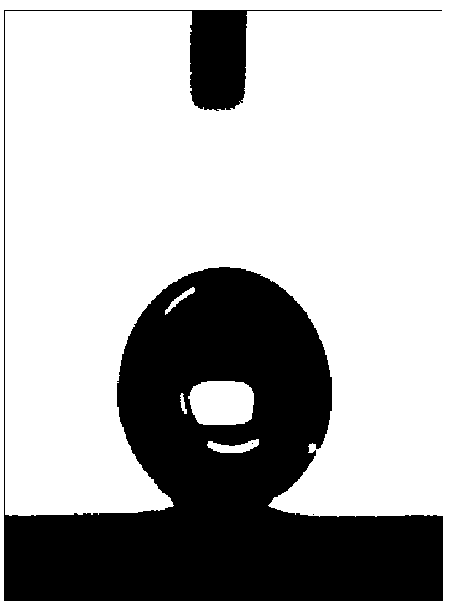

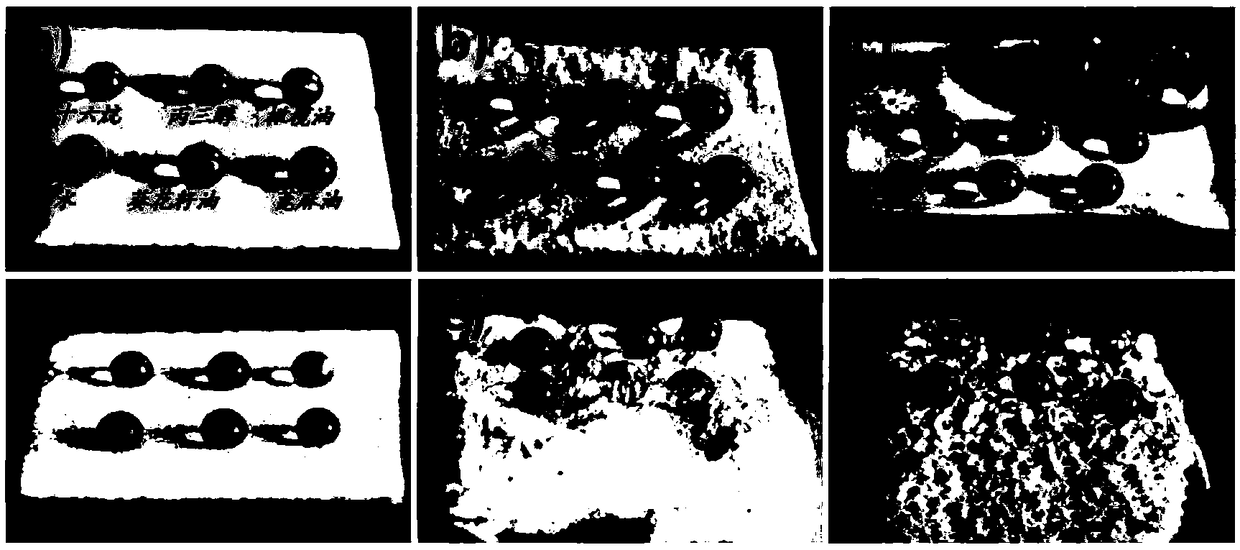

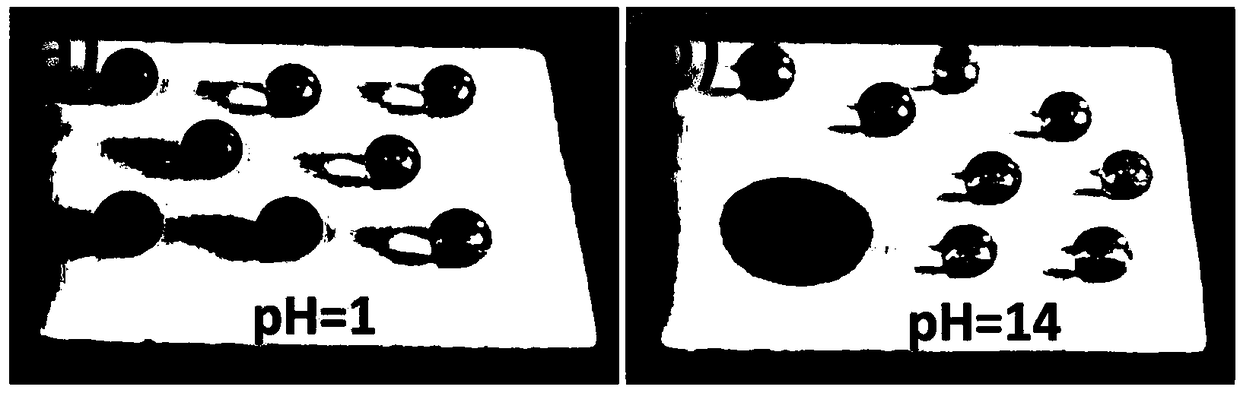

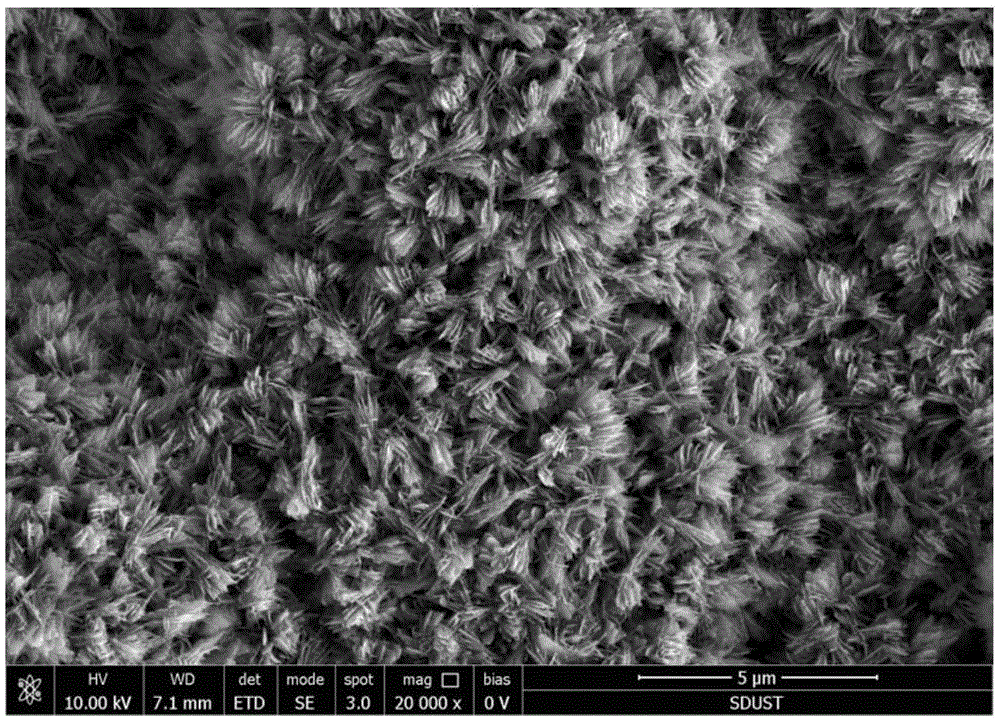

Reparation method for zinc super-hydrophobic surface

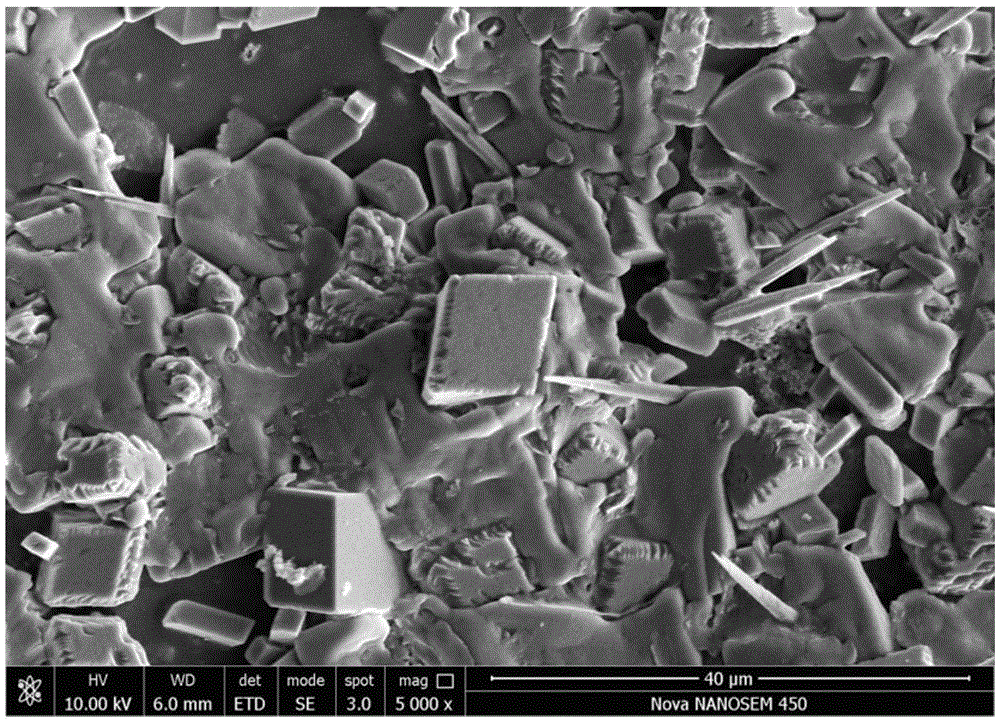

InactiveCN104195539AGood oleophobic effectSimple preparation processMetallic material coating processesPerfluorooctanoic acidNanometer size

The invention discloses a technology for preparing a zinc super-hydrophobic surface. The preparation method comprises the following steps: chemically etching a zinc sheet by virtue of hydrochloric acid to form a spherical rough structure on the surface of the zinc sheet; then, performing hydrothermal reaction to form a layer of uniform rod-shaped structure which is close to nanoscale on the surface of the spherical rough structure, wherein the rod-shaped structure is almost vertical to the surface of the zinc sheet; and finally, carrying out low-energy modification by using an absolute ethyl alcohol solution of perfluoro caprylic acid to obtain the super-hydrophobic surface with good lipophobicity. According to the preparation method, distilled water drops onto the chemically-modified zinc sheet surface to carry out contact angle measurement, wherein a contact angle of the zinc sheet surface and water is greater than 150 degrees, and a rolling angle is smaller than 10 degrees; and moreover, the surface has relatively good lipophobicity, and has a contact angle of 145.62 degrees with peanut oil.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for preparing fluorine-containing polymer without containing perfluorocaprylic acid

The invention belongs to the field of fluorine-containing polymer preparation, and provides a fluorine-containing emulsifying agent for replacing perfluorocaprylic acid and salt thereof. A2O3SCF2 (CF2OCF (CF3))n-1COOA, CF3CF2 (CF2OCF (CF3))n-1COOA, H3COOCF2 (CF2OCF (CF3))n-1COOA, in the formula, n is 1 to 4, and A is hydrogen atom, alkali metal or NH4. The invention also provides a method for preparing fluorine-containing polymer without containing perfluorocaprylic acid by using the fluorine-containing emulsifying agent. The fluorine-containing emulsifying agent of the invention has better emulsifying and dispersing effects, and the quality of an obtained product is in accordance with that of a reaction product in presence of PFOA.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

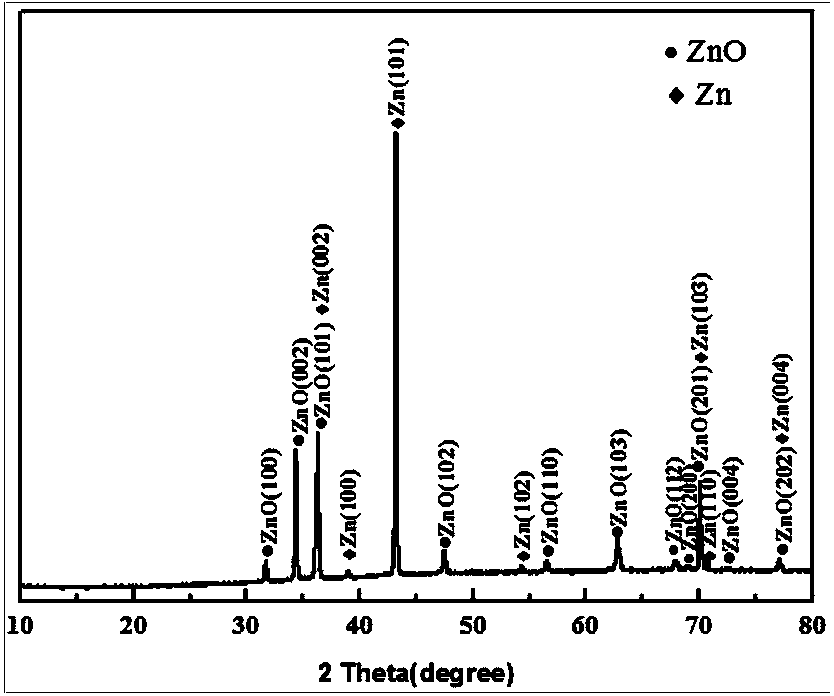

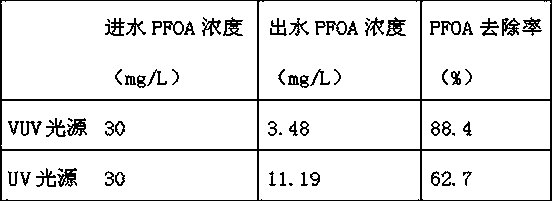

Method for nano-scale gallium oxide vacuum-ultraviolet photocatalytic degradation of perfluorooctanic acid

InactiveCN108264127AHigh catalytic activityEfficient degradationWater/sewage treatment by irradiationWater treatment compoundsEthylenediamineSemiconductor materials

The invention discloses a method for nano-scale gallium oxide vacuum-ultraviolet photocatalytic degradation of perfluorooctanic acid. The method comprises preparation of a nano-scale beta-Ga2O3 photocatalyst and photocatalytic degradation of perfluorooctanic acid based on the nano-scale beta-Ga2O3 photocatalyst. Through use of an ethylenediamine solution as an additive, the gallium salt forms bunchy nano-scale beta-Ga2O3 and has a specific surface area of 30-50 m<2> / g 3-5 times that of the commercial gallium oxide. The larger specific surface area means that more catalytic active sites are exposed so that the catalytic material has better catalytic activity. The method uses vacuum ultraviolet light as a light source, which has higher chemical energy with photogenerated electrons generatedby the catalytic material, and gallium oxide is used as a semiconductor material in the deep ultraviolet region and has a stronger absorption capacity for vacuum ultraviolet light, so that perfluorooctanoic acid can be degraded efficiently.

Owner:嘉兴市众盛环保科技有限公司

Preparation method of liquid carbon dioxide thickening agent

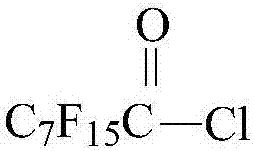

InactiveCN107043620ARelieve pressureImprove dissolutionUrea derivatives preparationOrganic compound preparationDistillationPerfluorooctanoic acid

The invention relates to a preparation method of a liquid carbon dioxide thickening agent for unconventional oil and gas reservoir development, and can solve the problem of damage to an oil and gas reservoir in a conventional mining mode. The preparation method has the technical scheme that methylbenzene and water are added into a bottle; then, serinol is added; terbutyloxycarbonyl anhydride is dropwise added at 0 DEG C; reaction is performed for 4h at 25 DEG C; distillation is performed to obtain an intermediate product (1); then, perfluoro caprylic acid is added into another bottle; thionyl chloride and N,N-dimethyl formamide are added at 75 DEG C; reaction is performed for 2h; distillation is performed to obtain an intermediate product (2); next, the intermediate product (1) is added into another bottle; the temperature is raised to 75 DEG C; the intermediate product (2) is dropwise added; reaction is performed for 12h at 75 DEG C to obtain an intermediate product (3); finally, dichloromethane and trifluoroacetic acid are added into the bottle; then, the intermediate product (3) is added; reaction is performed for 2h at 25 DEG C; after extraction and vacuum drying, hexamethylene diisocyanate is added to perform reaction for 2 minutes; a final product is obtained. The thickening agent can increase the carbon dioxide viscosity, and can be used for fracturing reformation.

Owner:SOUTHWEST PETROLEUM UNIV

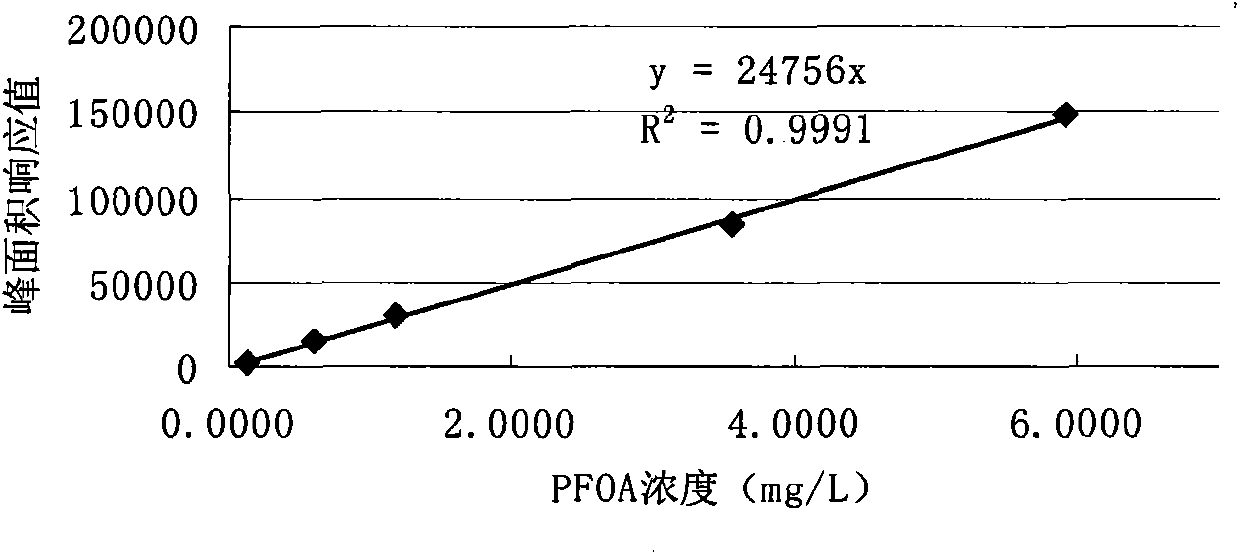

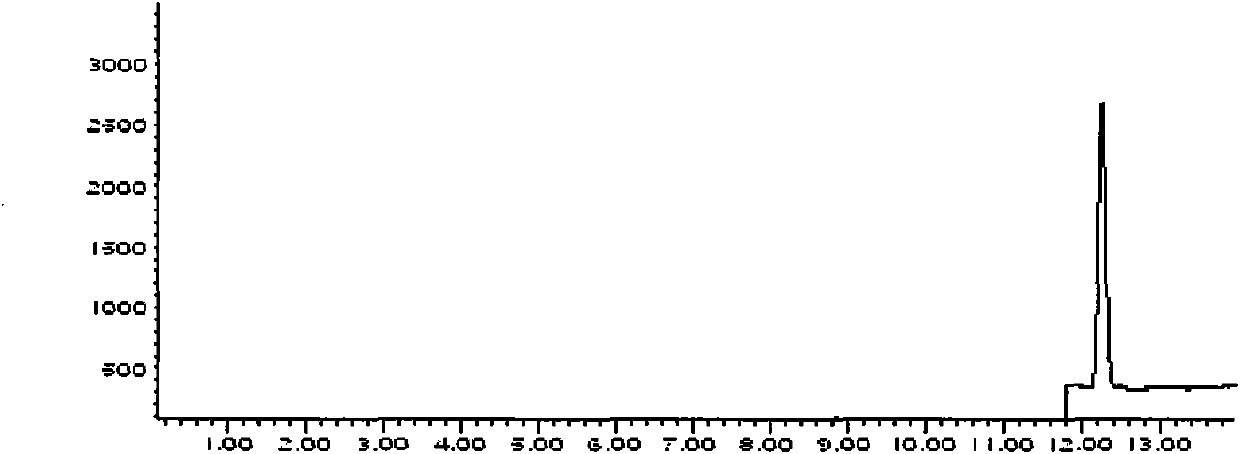

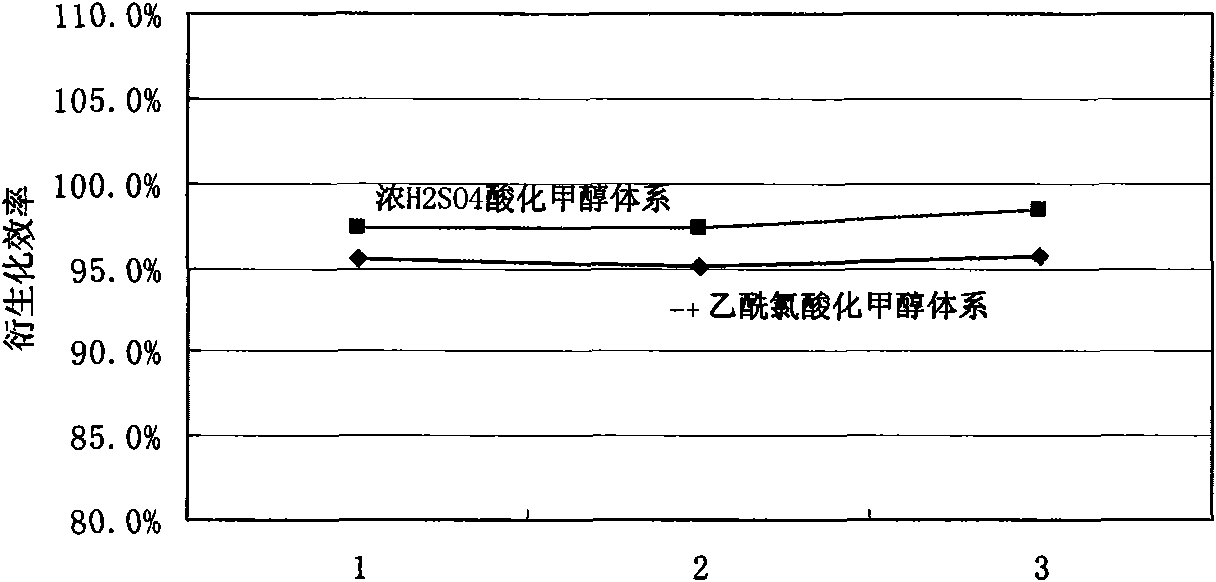

Method for quantitatively detecting perfluorooctanoic acid and salts thereof in fluororubber

InactiveCN101769909ASimple Quantitative DetectionEfficient quantitative detectionComponent separationGas phasePerfluorooctanoic acid

The invention provides a method for quantitatively detecting perfluorooctanoic acid and salts thereof in fluororubber. The method comprises steps of dissolving, depositing, solid phase extracting and deriving a sample, and then carrying out gas phase chromatography-mass spectrography measurement on the derivative. Counted as S / N=10, the limit of quantitative detection in the method of the invention is 0.04mg / kg, and related coefficient is 0.9991. The method in the invention has the characteristics of fast sample processing, high extraction efficiency, simple derivation step, small impurity interference and high sensitivity.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

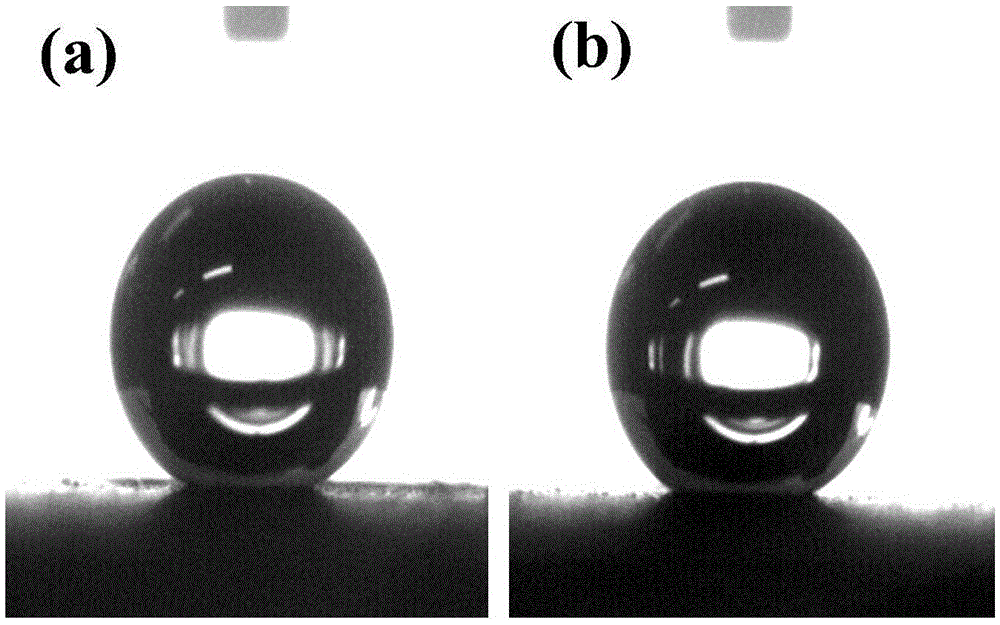

Preparation method and applications of super hydrophobic oleophobic material with pH responsiveness

ActiveCN109173345ALower free energyRich micro-nano rough structureLiquid separationSilanesThermal insulation

The invention discloses a preparation method and applications of a super hydrophobic oleophobic material with pH responsiveness. The preparation method comprises following steps: kaolin is added intoan ethanol solution of perfluorocapylic acid, after uniform mixing, an ethanol solution of silane is added, an obtained mixture is heated to 50 to 60 DEG C with stirring, thermal insulation is carriedout for 2 to 4h so as to obtain a suspending solution, the suspending solution is used for coating the surface of a substrate, and drying is carried out so as to obtain the super hydrophobic oleophobic material with pH responsiveness. The super hydrophobic oleophobic material possesses excellent super hydrophobicity and lipophobicity, and excellent wear resistance and corrosion resistance; in-suit or ex-situ pH induced material surface wetability change can be caused; a plurality of conversions between the hydrophobicity and lipophobicity can be realized. The super hydrophobic oleophobic material can be used for effective separation of a plurality of types of oil water mixtures, and especially treatment of oil-in-water emulsion, and the application prospect in treatment of leaked crude oil and purification of oil-containing waste water is promising.

Owner:西安奈微新材料有限公司

Preparing method of super-amphiphobic surface with scale preventing performance

The invention discloses a preparing method of a super-amphiphobic surface with scale preventing performance, relates to a preparing technology of the super-amphiphobic surface, and belongs to the field of metal material surface modification. The preparing method is a method for preparing a super-amphiphobic copper-zinc alloy layer on the surface of rolled steel. According to the preparing method, rolled steel serves as a substrate, firstly, a copper-zinc alloy layer is electrically deposited on the surface of the rolled steel, then a sample with the surface covered with the copper-zinc alloy layer is immersed in a beaker containing a mixed solution of potassium hydroxide and ammonium persulfate, and the beaker is placed in a water bath at a certain temperature to be insulated for corresponding time; and then at the room temperature, the treated steel sample is immersed in a perfluoro caprylic acid absolute ethyl alcohol solution with a certain concentration for several hours, and then the treated steel sample is taken out to be aired at the room temperature so that the super-amphiphobic surface can be obtained. The contact angle between the super-amphiphobic surface obtained through the method and water and the contact angle between the super-amphiphobic surface obtained through the method and glycerin both exceed 150 degrees, and the rolling angle between the super-amphiphobic surface obtained through the method and water and the rolling angle between the super-amphiphobic surface obtained through the method and glycerin are both smaller than 5 degrees. The scaling appearance of the super-amphiphobic sample in a mixed solution composed of CaCl2 and NaHCO3 is in a needle shape and is similar to an aragonite structure, and the super-amphiphobic sample has good scale preventing performance compared with a rhomb calcite structure on the surface of a steel base body.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Preparation method for special fluoroether oligomer

InactiveCN105111352AImprove surface activityImprove low temperature resistancePreparation from carboxylic acid halideTransportation and packagingAviationOligomer

The invention discloses a preparation method for a special fluoroether oligomer which is obtained by carrying out a photochemical polymerization reaction on a special fluorine-containing monomer mixture. The obtained fluoroether oligomer has many previously unimagined valuable applications. The fluoroether oligomer with the average molecular weight of 300-1500, the viscosity of about 1-20 cPs at 25 DEG C and the acidic value of about 70-100 is suitable for being used as a fluoroether surfactant and further can be used as a perfluoro caprylic acid substituent. The fluoroether oligomer with the average molecular weight over 1500 and the viscosity of about 20-500 cPs at 25 DEG C is further suitable for important applications of being processed as fluoroether oil and high-temperature-resistant lubricating oil and the like. The products or mixture thereof can be further used as an auxiliary for a polymerization process of special fluororubber, particularly low-temperature fluororubber. The low-temperature resistance can reach (-40) DEG C, so that the special fluoroether oligomer can be further accepted in markets of space flight and aviation and automobile industry.

Owner:江苏梅兰化工有限公司 +2

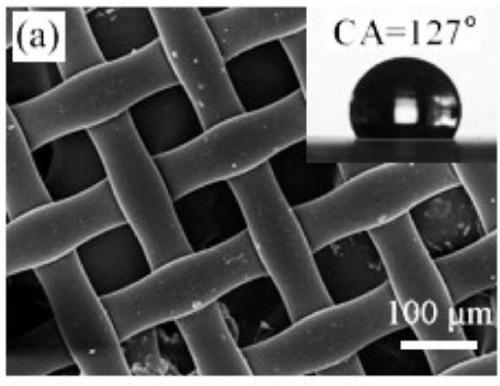

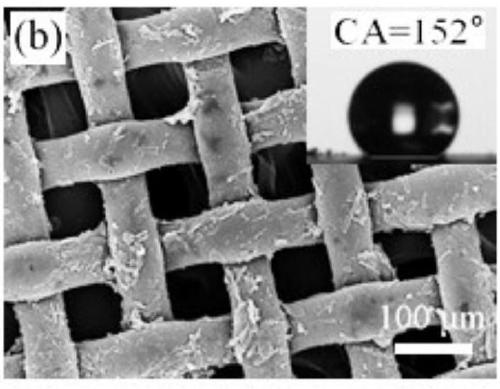

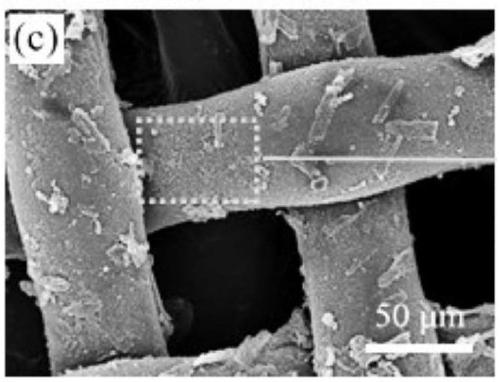

Oil-water separation material with pH responsiveness and multi-stage structure and preparation method of oil-water separation material

ActiveCN109364528AUniversalSmart and responsiveFatty/oily/floating substances removal devicesLiquid separationFiberPolyester

The invention provides an oil-water separation material with pH responsiveness and a multi-stage structure and a preparation method of the oil-water separation material. The method comprises the following steps of taking aminobenzene as a monomer, perfluorooctanoic acid as a dopant and ammonium persulfate as an oxidizing agent, taking a polyester screen mesh, porous sponge, cotton fabric, cotton and the like respectively as base materials, synthesizing a polyaniline composite material with a micro / nano multi-stage structure by adopting an in-situ chemical oxidation polymerization method, wherein the oil-water separation material has a large quantity of micro stagger polyaniline fiber on an overall woven mesh structure. Polyaniline and sponge are mutually compounded to form a novel materialwith super-hydrophobic / super-oleophilic performance. The polyaniline composite material synthesized in one step by adopting an aminobenzene in-situ chemical oxidation polymerization method is used for oil-water separation, the synthetic process is simple, and the raw materials are easy to obtain; the oil-water separation material has universality and can be applied to multiple kinds of base material surfaces; the material can be used for carrying out oil-water separation of an oil / water / oil three-phase system through adjusting and controlling a pH value, different organic solvents in water are absorbed, and can be discharged in an basic solvent without needing to draw support from external force.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com