Preparation method of supercritical-carbon-dioxide thickening agent

A carbon dioxide and supercritical technology, applied in the field of preparation of anhydrous fracturing fluid and supercritical carbon dioxide thickener, can solve the problems of reservoir damage, affecting fracturing stimulation, reducing reservoir permeability, etc. The effect of improving dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

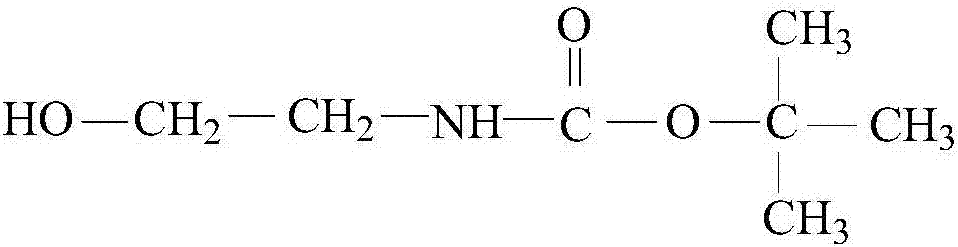

[0019] (1) Preparation of tert-butyl hydroxyethyl carbamate: Add 25ml of deionized water into the three-neck flask, then add 0.02mol ethanolamine, stir to dissolve completely, and then add 0.021mol di Di-tert-butyl carbonate, react at a constant temperature of 35 °C for 4 hours, add 30 mL of ethyl acetate to the solution for extraction, collect the upper organic phase, add anhydrous Na 2 SO 4 Dry, filter, and distill under reduced pressure to obtain the intermediate product (1) tert-butyl hydroxyethyl carbamate.

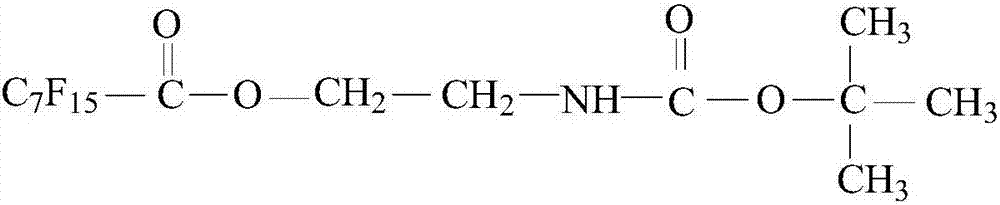

[0020] (2) Preparation of tert-butyl perfluorooctanoic acid ethyl carbamate: add tert-butyl hydroxyethyl carbamate and perfluorooctanoyl chloride to the three-neck flask, the molar ratio of tert-butyl hydroxyethyl carbamate perfluoro to octanoyl chloride 1:1.1, condensed and refluxed, heated to 75 ° C for 12 hours, added anhydrous ether, then added 5% NaOH solution, the solution was layered, extracted to obtain an organic phase, washed with distilled water several t...

Embodiment 2

[0024] (1) Preparation of tert-butyl hydroxyethyl carbamate: Add 25ml of deionized water into the three-necked flask, then add 0.02mol ethanolamine, stir to dissolve completely, and then add 0.023mol di Di-tert-butyl carbonate, react at a constant temperature of 35 °C for 4 hours, add 30 mL of ethyl acetate to the solution for extraction, collect the upper organic phase, add anhydrous Na 2 SO 4 Dry, filter, and distill under reduced pressure to obtain the intermediate product (1) tert-butyl hydroxyethyl carbamate.

[0025] (2) Preparation of tert-butyl perfluorooctanoic acid ethyl carbamate: add tert-butyl hydroxyethyl carbamate and perfluorooctanoyl chloride to the three-neck flask, the molar ratio of tert-butyl hydroxyethyl carbamate perfluoro to octanoyl chloride 1:1.2, condensed and refluxed, heated to 75°C and reacted for 12 hours, after adding anhydrous ether, then added 5% NaOH solution, the solution was layered, extracted to obtain an organic phase, washed with distil...

Embodiment 3

[0029] (1) Preparation of tert-butyl hydroxyethyl carbamate: Add 25ml of deionized water to the three-necked flask, then add 0.02mol ethanolamine, stir to dissolve completely, and then add 0.022mol di Di-tert-butyl carbonate, react at a constant temperature of 35 °C for 4 hours, add 30 mL of ethyl acetate to the solution for extraction, collect the upper organic phase, add anhydrous Na 2 SO4 Dry, filter, and distill under reduced pressure to obtain the intermediate product (1) tert-butyl hydroxyethyl carbamate.

[0030] (2) Preparation of tert-butyl perfluorooctanoic acid ethyl carbamate: add tert-butyl hydroxyethyl carbamate and perfluorooctanoyl chloride to the three-neck flask, the molar ratio of tert-butyl hydroxyethyl carbamate perfluoro to octanoyl chloride 1:1.1, condensed and refluxed, heated to 75 ° C for 12 hours, added anhydrous ether, then added 5% NaOH solution, the solution was layered, extracted to obtain an organic phase, washed with distilled water several tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com