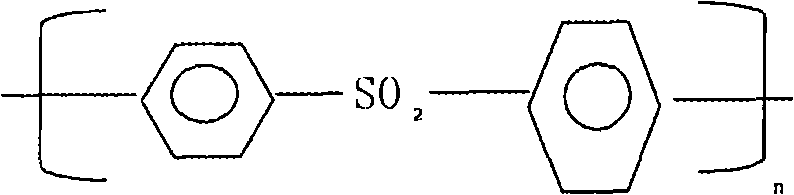

Water-based non-stick polyether sulphone coating containing no perfluorooctanoic acid and method for preparing same

A technology of non-stick coatings and perfluorooctanoic acid, applied in coatings, latex paints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0091] A kind of preparation method of waterborne polyethersulfone non-stick coating of the present invention, comprises the steps:

[0092] The composition of the present invention is ground for 30-40 hours to obtain the water-based polyethersulfone non-stick coating.

[0093] In a specific embodiment of the present invention, the grinding includes two or more stages,

[0094] In the first stage, 8-25wt% polyethersulfone and 40-90wt% aqueous dispersion are ground for 24-30 hours to obtain a ground polyethersulfone grinding liquid,

[0095] In the second stage, the polyethersulfone grinding liquid obtained in the first stage is mixed with the following components:

[0096] 2-15wt% fluorocarbon polymer without perfluorooctanoic acid, 0-20wt% coloring toner, optional 0.1-3wt% additives suitable for coloring toner,

[0097] The resulting mixture was milled for 6-10 hours to obtain the paint.

[0098] The present invention is an environment-friendly water-based polyethersulfone...

Embodiment 1

[0121] The present invention uses 80-mesh emery to roughen the electric rice cooker by light sandblasting. Then add appropriate water as the thinner of this paint, adjust to the appropriate spray viscosity, and then spray on the rice cooker base material, first preheat in an oven at 150°C-180°C for 3-5 minutes, and then put it in 380 ℃-400℃ oven, bake for 10-15min, after cooling, carry out various physical property tests.

[0122] Described coating composition formula is as follows table 1:

[0123] Table 1: Basic Paint Formulation 1

[0124] raw material

weight percentage (%)

Polyethersulfone①

14

PTFE micropowder②

8

N-Methylpyrrolidone

26

Ethylene glycol monobutyl ether

13

Rheological agent③

0.3

Titanium dioxide

8.3

carbon ink

0.4

Dispersant ④

0.1

Surfactant⑤

1.0

Anti-flowering agent⑥

0.1

28.8

...

Embodiment 2

[0133] The preparation method and application method of this embodiment are the same as in Example 1, except that the formula is as follows in Table 2:

[0134] Table 2: Basic Paint Formulation 2

[0135] raw material

weight percentage (%)

Polyethersulfone①

17

PTFE micropowder②

6

Tetrafluoroethylene / hexafluoropropylene copolymer

(FEP)③

3

N-Methylpyrrolidone

27

Ethylene glycol monobutyl ether

13

Rheological agent④

0.4

carbon ink

1.6

Pearl powder

0.7

Water-based aluminum paste

1.5

Dispersant ⑤

0.5

Surfactant⑥

1.1

Anti-flowering agent⑦

0.1

28.1

Total

100

[0136] Please refer to the performance examples for the physical property test data.

[0137] ① The degree of polymerization of polyethersulfone is 50, purchased from Gafone 3600RP of Gharda Chemicals in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melt viscosity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com