Patents

Literature

212 results about "Fluorocarbon Polymers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluorocarbon polymer, also called fluoropolymer or fluorinated polymer, any of a number of organic polymers whose large, multiple-unit molecules consist of a chain of carbon atoms to which fluorine atoms are appended.

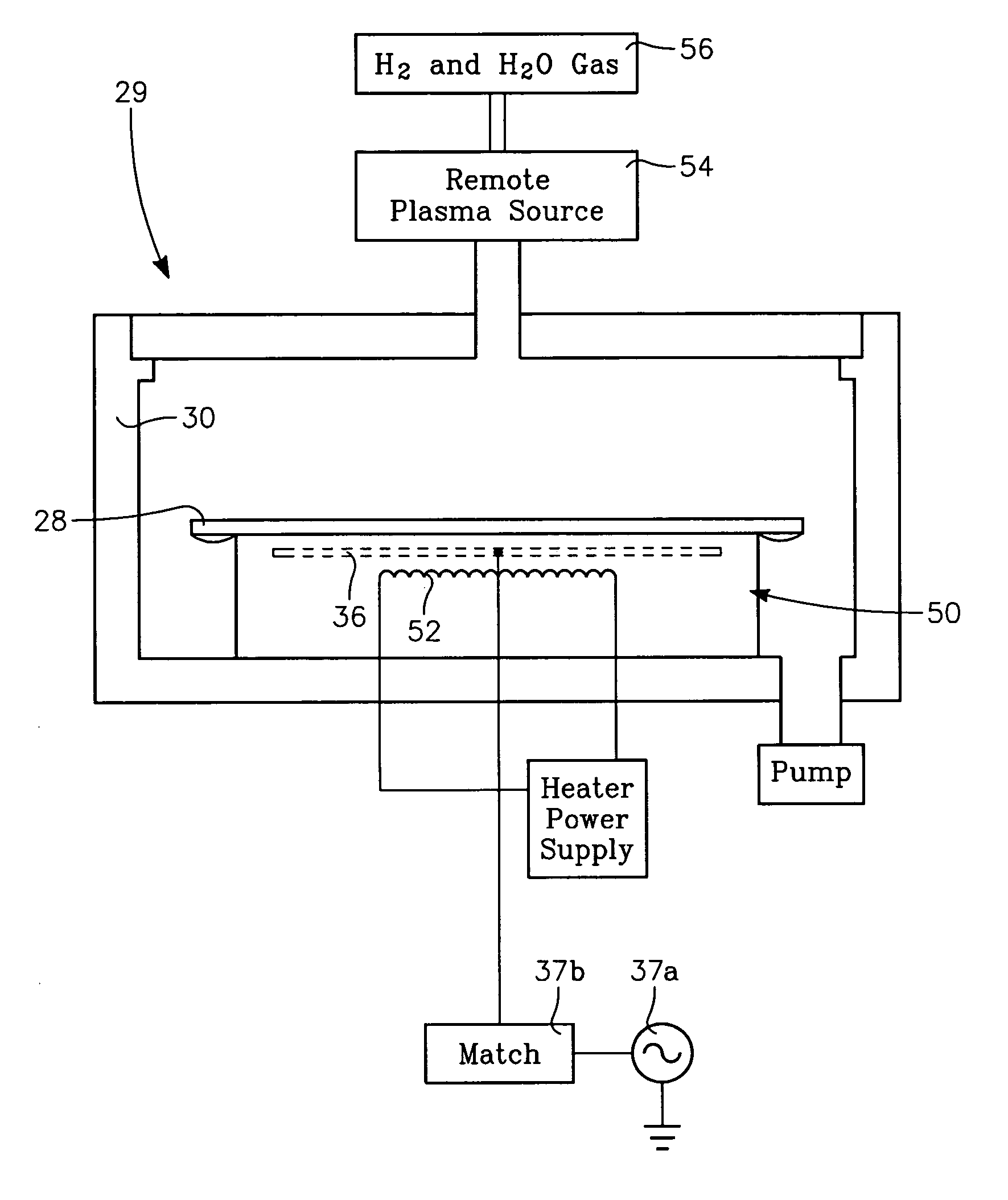

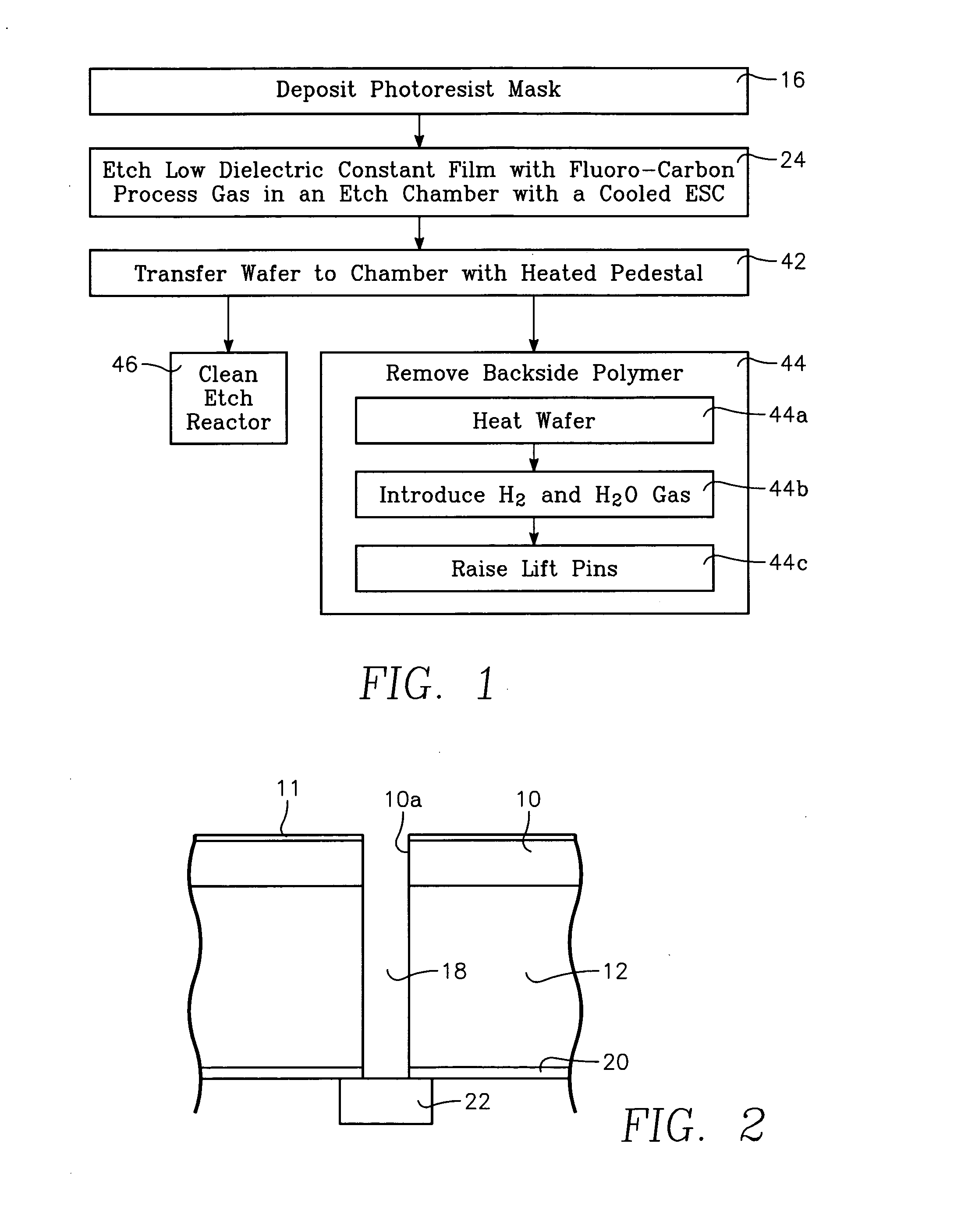

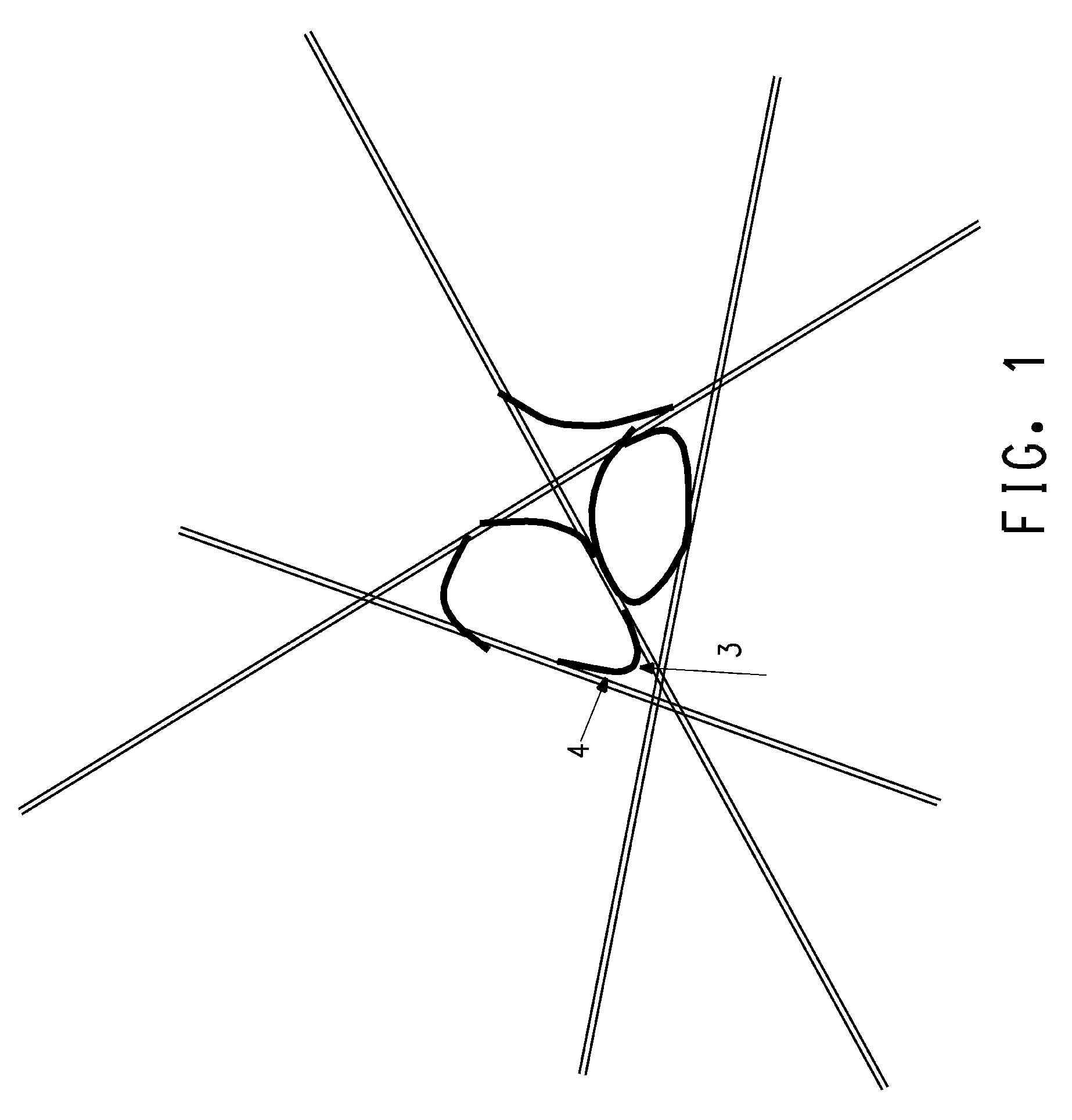

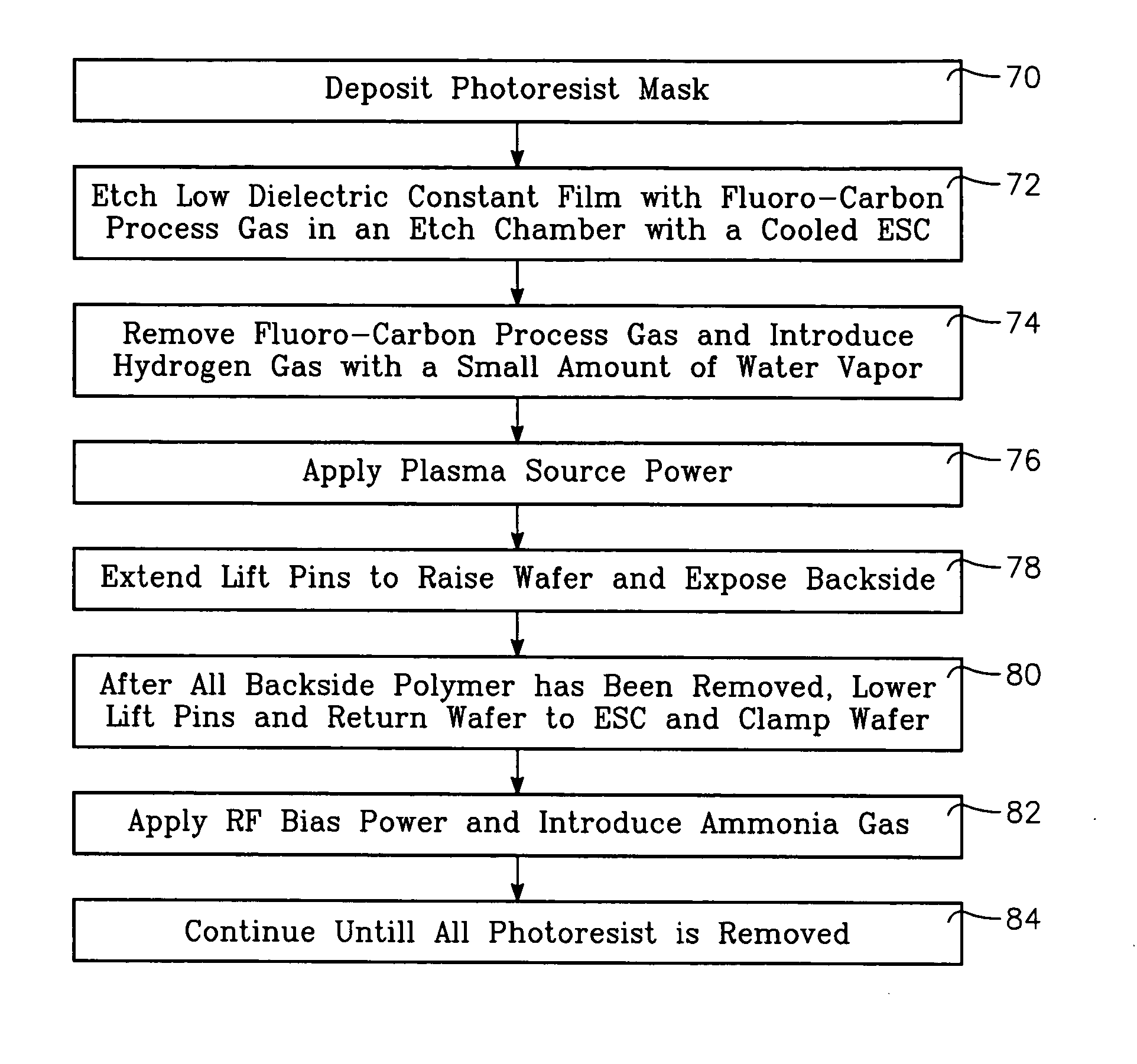

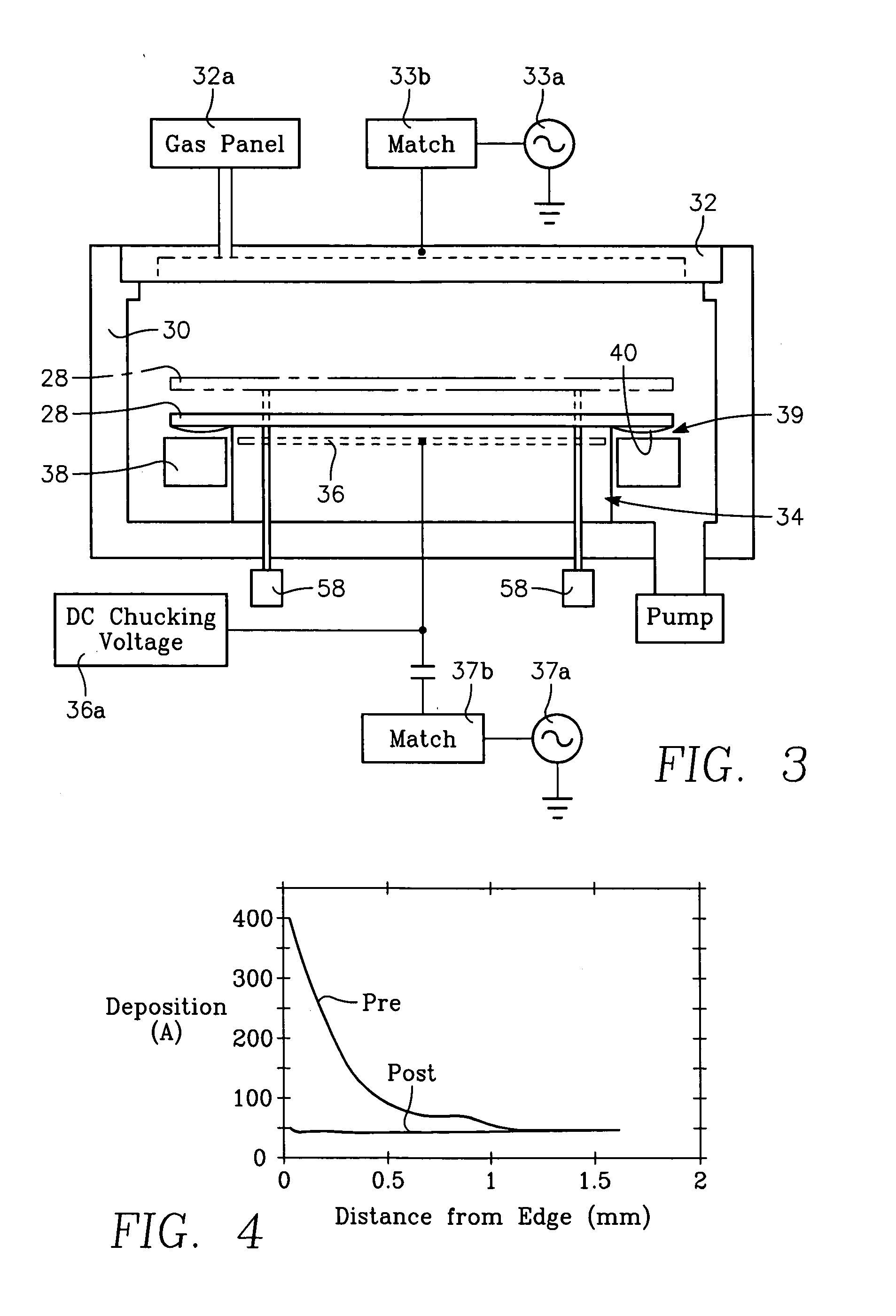

Plasma dielectric etch process including ex-situ backside polymer removal for low-dielectric constant material

A plasma etch process for etching a porous carbon-doped silicon oxide dielectric layer using a photoresist mask is carried out first in an etch reactor by performing a fluorocarbon based etch process on the workpiece to etch exposed portions of the dielectric layer while depositing protective fluorocarbon polymer on the photoresist mask. Then, in an ashing reactor, polymer and photoresist are removed by heating the workpiece to over 100 degrees C., exposing a peripheral portion of the backside of said workpiece, and providing products from a plasma of a hydrogen process gas to reduce carbon contained in polymer and photoresist on said workpiece until the polymer has been removed from a backside of said workpiece. The process gas preferably contains both hydrogen gas and water vapor, although the primary constituent is hydrogen gas. The wafer (workpiece) backside may be exposed by extending the wafer lift pins.

Owner:APPLIED MATERIALS INC

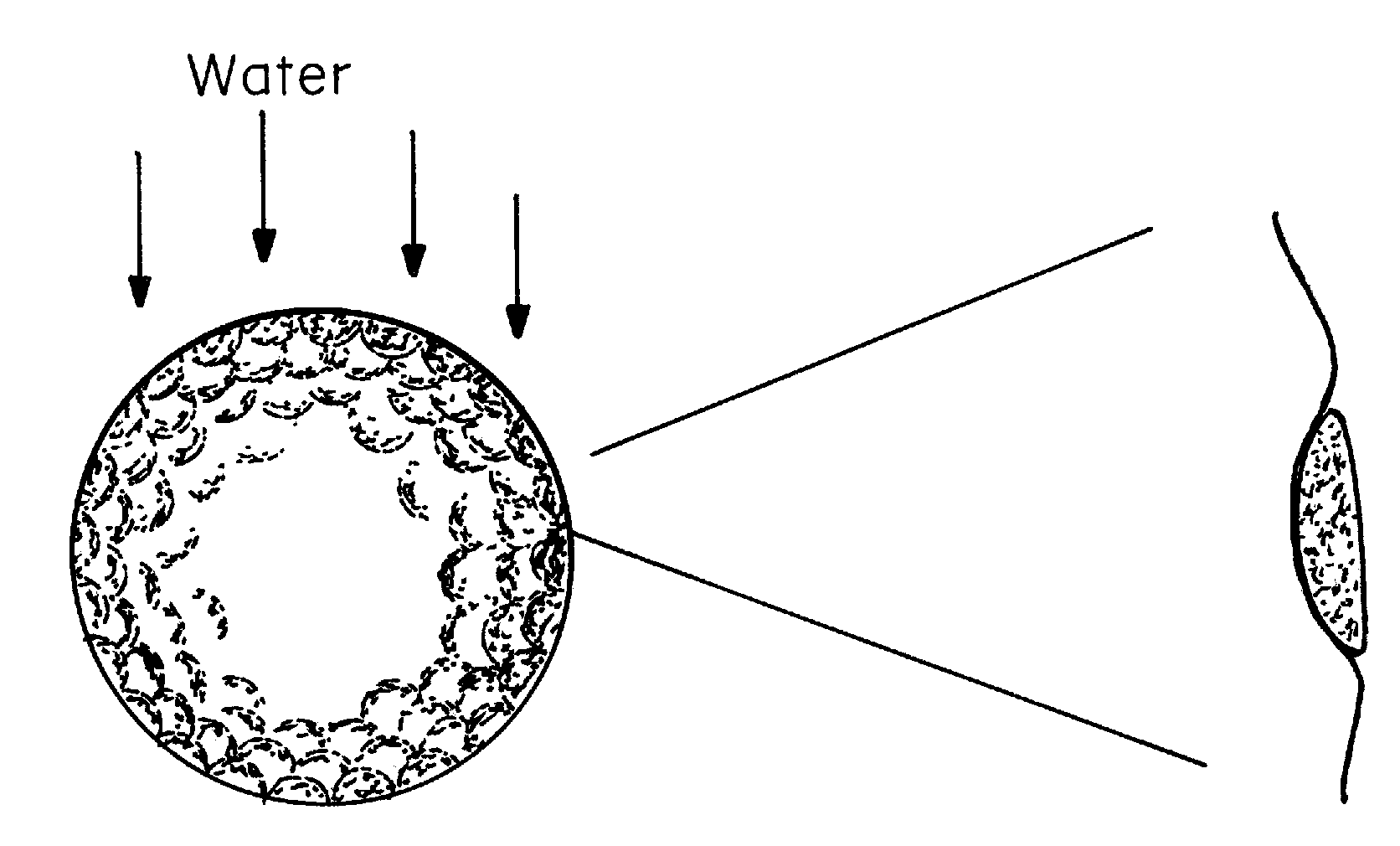

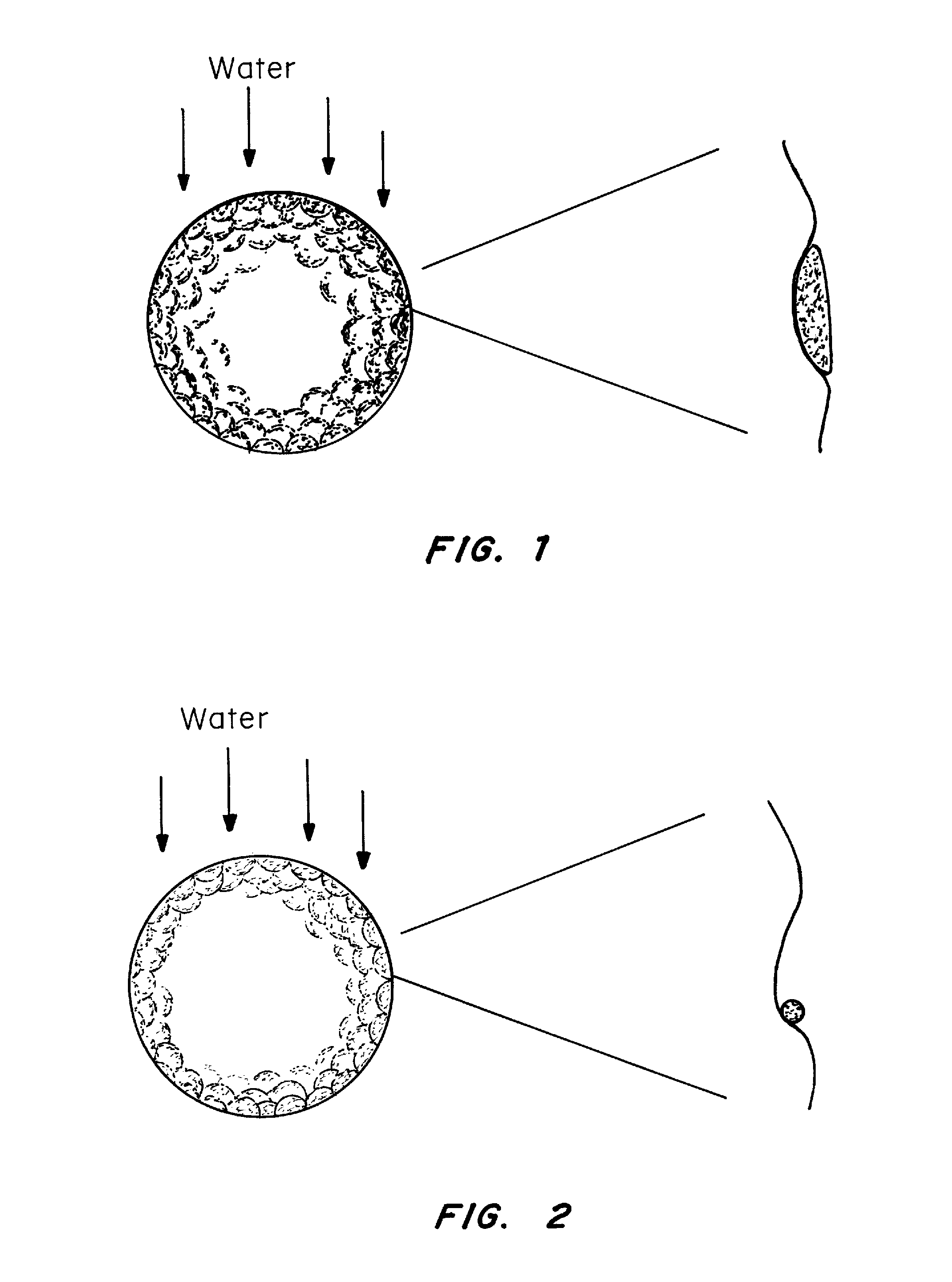

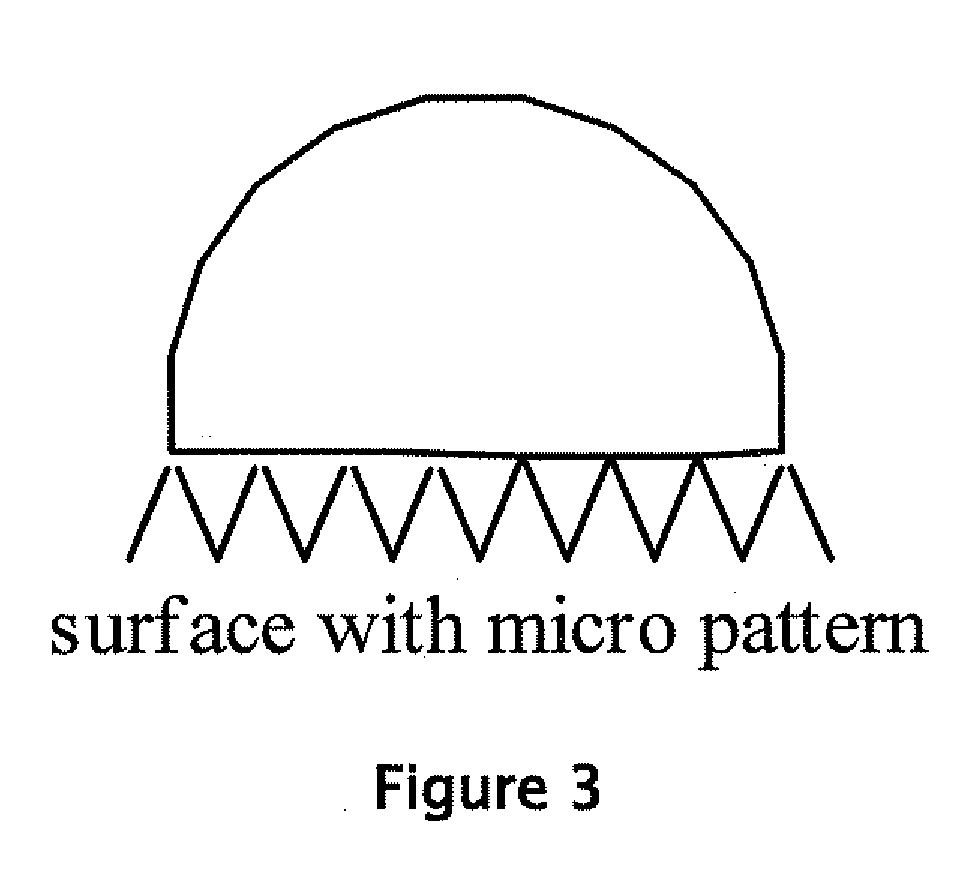

Water Repellant Golf Balls Containing a Hydrophobic or Superhydrophobic Outer Layer or Coating

InactiveUS20080280699A1Improve performanceSynthetic resin layered productsPaper coatingPolymer sciencePolyethylene glycol

Water-repellant, self-cleaning coatings and methods of making and using thereof are described herein. In one embodiment, a hydrophobic or super hydrophobic coating is applied to the surface of a golf ball to make the golf-ball water-repellant and self-cleaning. Suitable coating materials include silicone compounds, silicone compounds, nanoparticles, silanes, fluorocarbon polymers, perfluoroalkyl ethyl methacrylate (PPFEMA) coated polycaprolactone, hydrocarbons, polymer mats made of polystyrene and poly[tetrafluoroethylene-co-(vinylidene fluoride)-co-propylene] (PTVFP); polyethylene glycol with glucose and sucrose in conjunction with a hydrophobic substance; combinations of nanoparticles with polyethylene or polypropylene; high density polyethylene, technical waxes; films of rough particles of metal oxides, polymer binder layers containing a plurality of porous protrusions, and combinations thereof. Suitable coating techniques include, but are not limited to, spraying, dipping, painting, brushing, or wiping (such as applying the coating from a towel or sponge). The coating material or the outer layer of the golf ball may be modified to create nano- or micro roughness or patterns on the surface of the golf ball, which can induce the lotus effect. This roughness or pattern can be created using a variety of techniques known in the art including, but not limited to, etching, top / down methodologies, bottom / up methodologies, or combinations thereof.

Owner:JARVHOLM ERIK JONAS

Liquid water resistant and water vapor permeable garments

A water resistant garment is disclosed having regions of high MVTR while maintaining water resistance. The garment has a fabric layer adjacent one major surface of a nanofiber layer. The surface of the nanofibers are coated with a coating containing a fluorocarbon polymeric moiety and a resin binder or extender which is soluble in water and / or other solvents. The coated nanofiber layer has a contact angle of greater than 145°. The garment optionally includes a second fabric layer adjacent the other major surface of the nanofiber layer. The garment has regions having a Frazier air permeability of between about 0.5 m3 / min / m2 and about 8 m3 / min / m2, an MVTR of greater than about 500 g / m2 / day and a hydrostatic head of at least about 50 cmwc.

Owner:EI DU PONT DE NEMOURS & CO

Ceramic substrate for nonstick coating

InactiveUS20030059600A1Improve coating adhesionMore durableSynthetic resin layered productsPretreated surfacesFritAluminized steel

The present invention provides a new and useful nonstick coating for use on pure aluminum, alloys of aluminum, or aluminized steel surfaces. A nonstick coating according to the present invention includes a ceramic substrate disposed on an aluminum surface and a fluorocarbon polymer coating disposed on the ceramic substrate. The ceramic substrate, prior to firing, includes at least two layers: a first or bottom layer applied to the aluminum surface including an enamel ground coat; and a second or top layer applied over the enamel ground coat layer including a blend of one or more glass frits, non-ceramic refractory particles, and non-vitreous inorganic oxide particles. Upon firing, the ceramic substrate includes a continuous layer of vitreous enamel that is bonded to the aluminum surface. The exposed surface of the ceramic substrate has a micro-rough texture that is enriched with bonding sides for binder resins used in a fluorocarbon polymer primer layer. The ceramic substrate protects the aluminum surface from corrosion and mechanical damage and also protects the fluorocarbon polymer coating from abrasive wear.

Owner:FERRO CORP

Silicone polymer contact lens compositions and methods of use

InactiveUS20050288196A1Low vapor pressureImprove the immunitySenses disorderPharmaceutical delivery mechanismAlcoholCentistokes

The present invention is an eye preparation comprising a hydrophobic composition adapted for use on a contact lens inserted into a patient's eye and having a viscosity of 1 to 15,000 centistokes. The composition includes a silicone polymer, fluorinated silicone polymer, fluorocarbon polymer, fluorinated alcohol, or perfluorinated polyether composition, singly or blended, adapted to coat at least a portion of a contact lens inserted in a patient's eye. Silicone polymers for use in the invention include dimethicone, cyclomethicone, and silicone gums.

Owner:OCULARIS PHARMA

Hybrid coating compositions

InactiveUS6896934B2Easy to cleanImprove acid resistanceElectrolysis componentsVolume/mass flow measurementScreen printingFrit

The present invention provides a composition for use in forming an abrasion-resistant easy-to-clean coating on a substrate. The composition according to the invention includes a mixture of a fluorocarbon polymer component and an enamel-forming component. The enamel-forming component includes at least a first lead-free and cadmium-free glass frit. The first lead-free and cadmium-free glass frit includes from about 30% to about 50% P2O5, from about 15% to about 30% Al2O3, and from about 2% to about 40% X2O where X=Na and / or K. The present invention also provides a method of forming an abrasion-resistant easy-to-clean coating on a substrate. The method includes applying the composition according to the invention to a substrate and sintering the applied composition to fuse an abrasion-resistant easy-to-clean coating to the substrate. The method can be used to apply the composition to a variety of substrate materials such as metals, glass, ceramics, and stone, using a variety of application techniques such as wet spraying, screen printing, electrophoresis, dry electrostatic deposition, wet dipping, and flow coating.

Owner:FERRO FRANCE S A R L

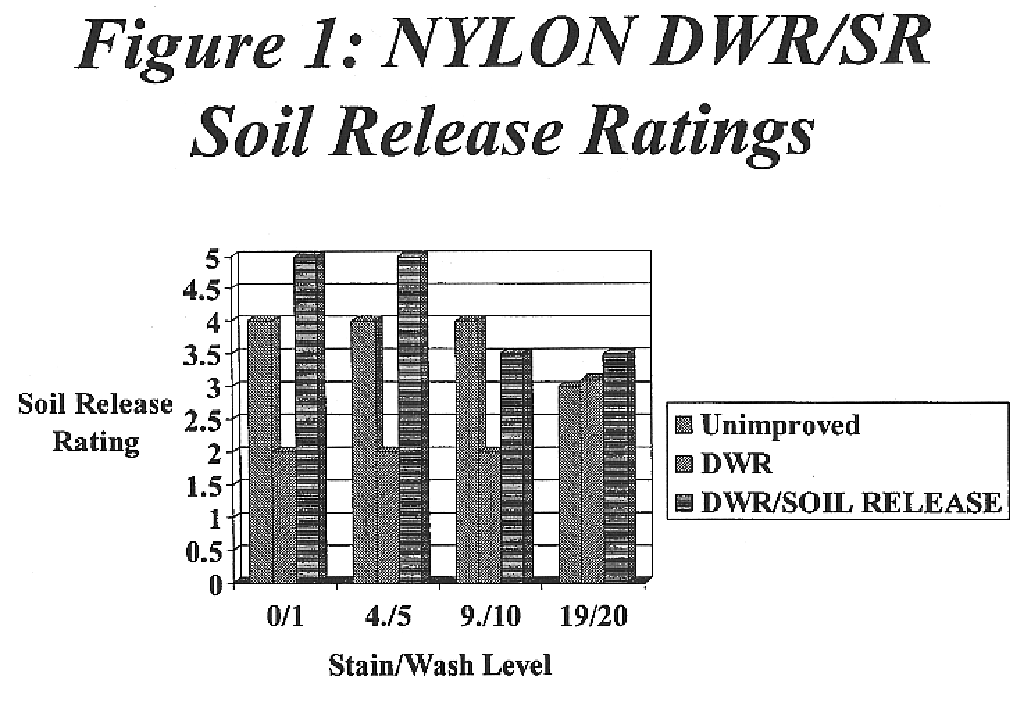

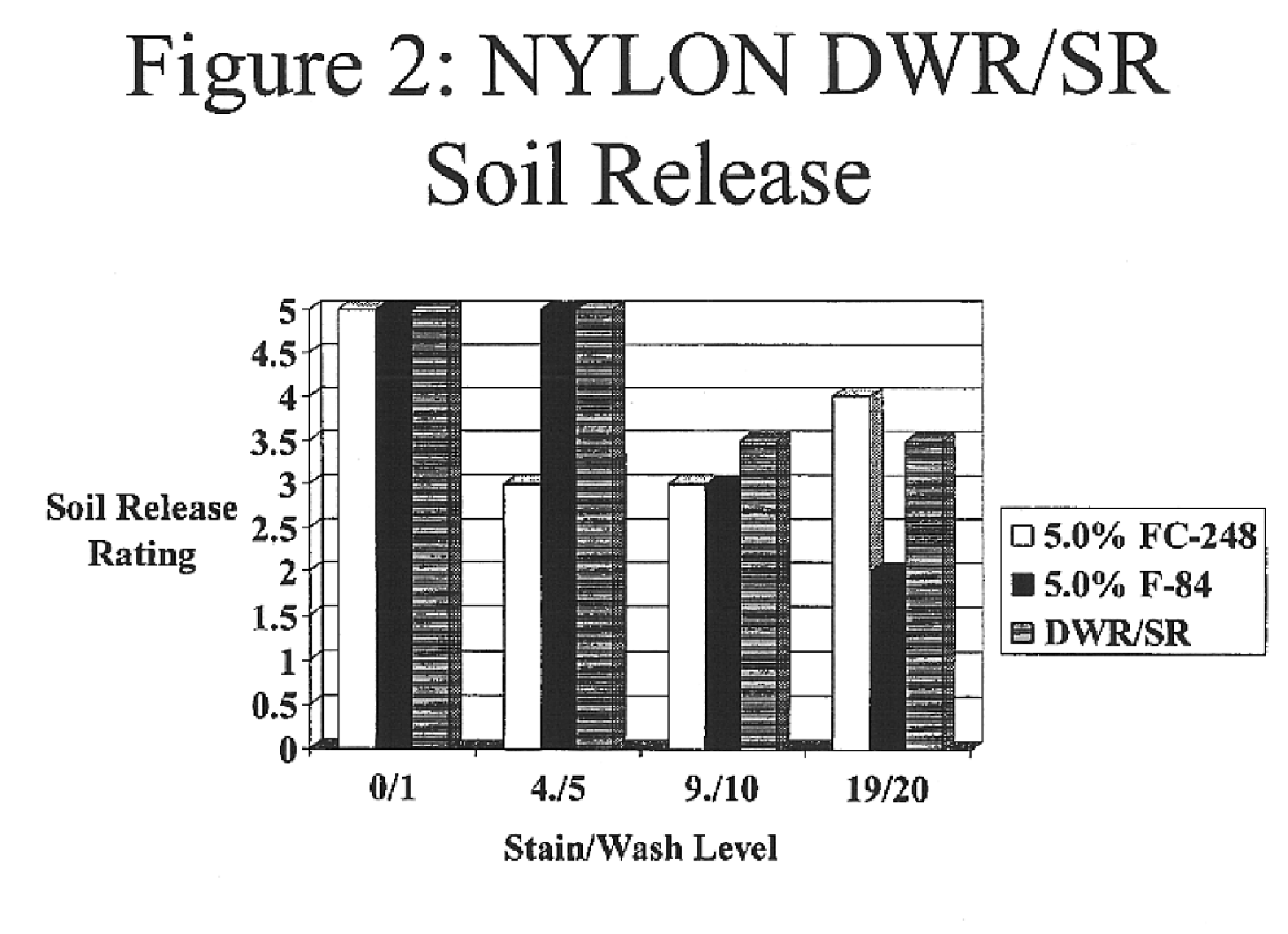

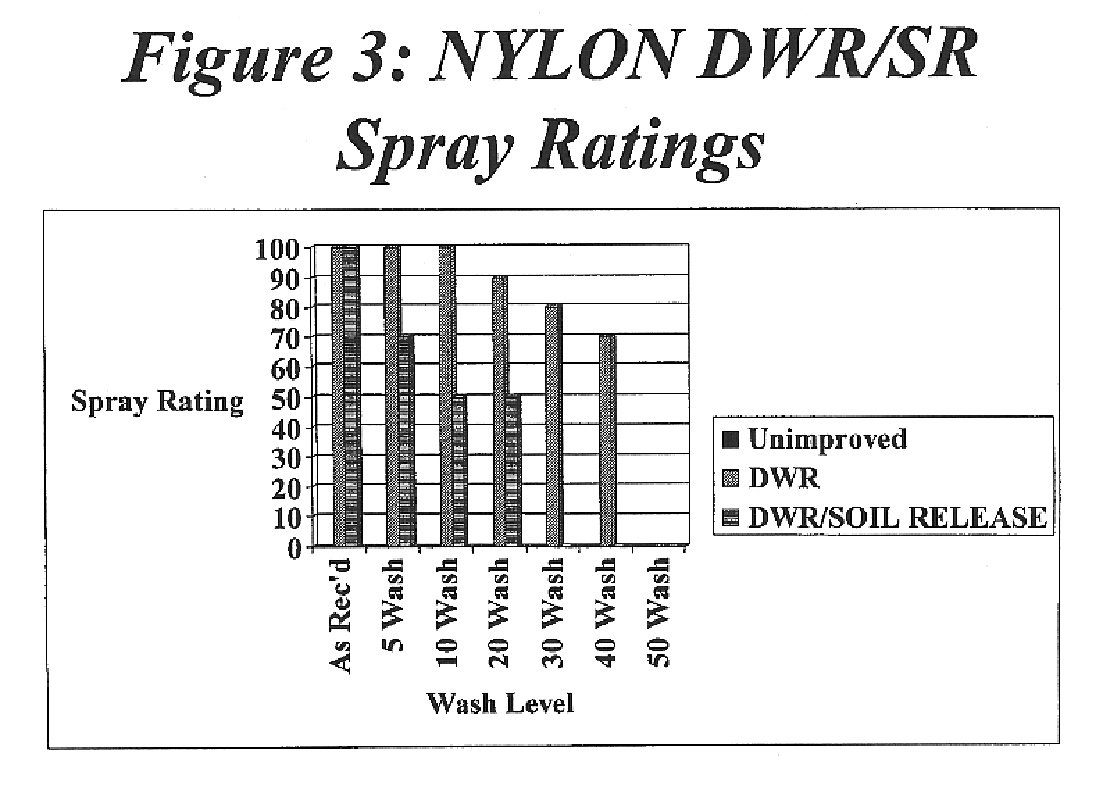

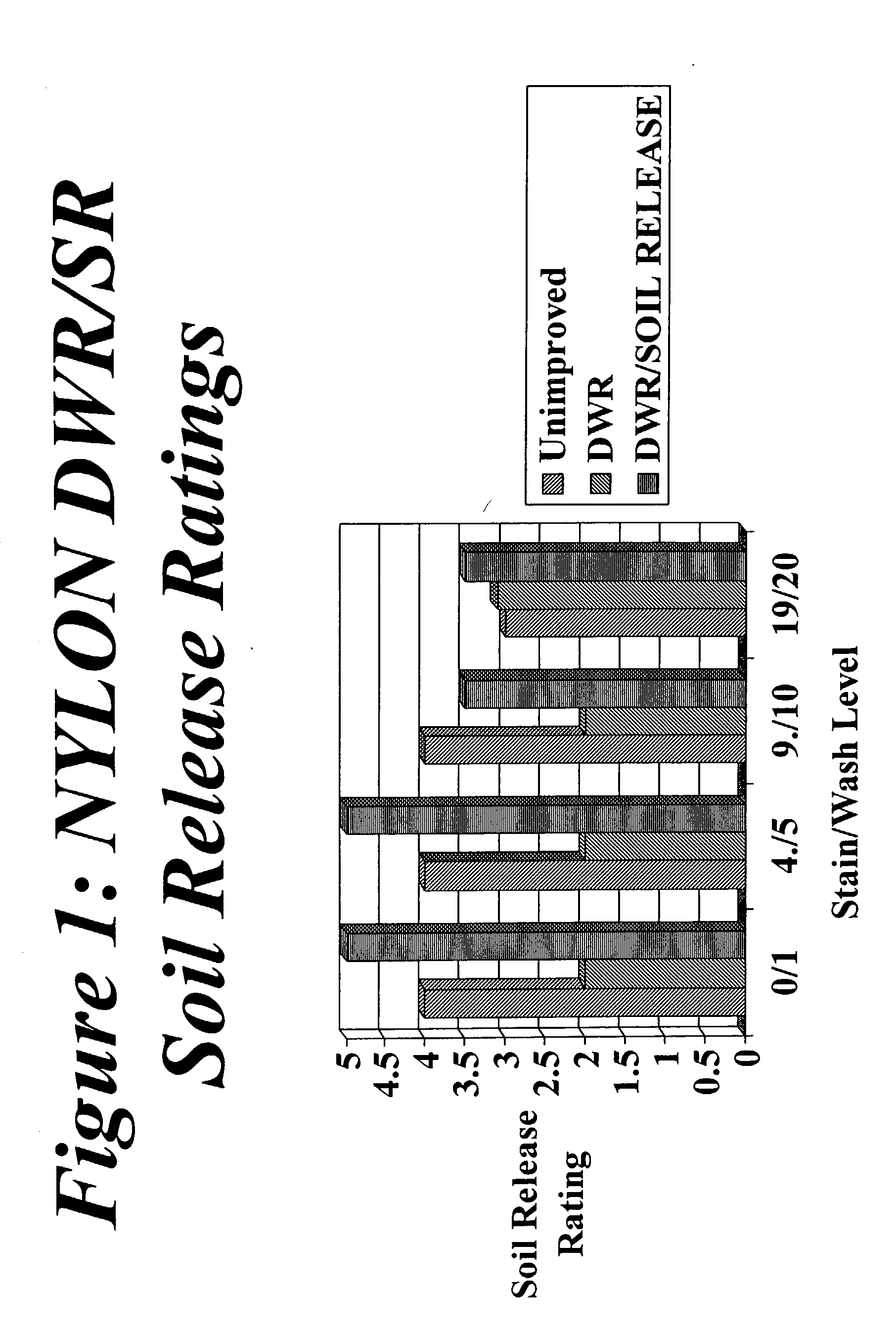

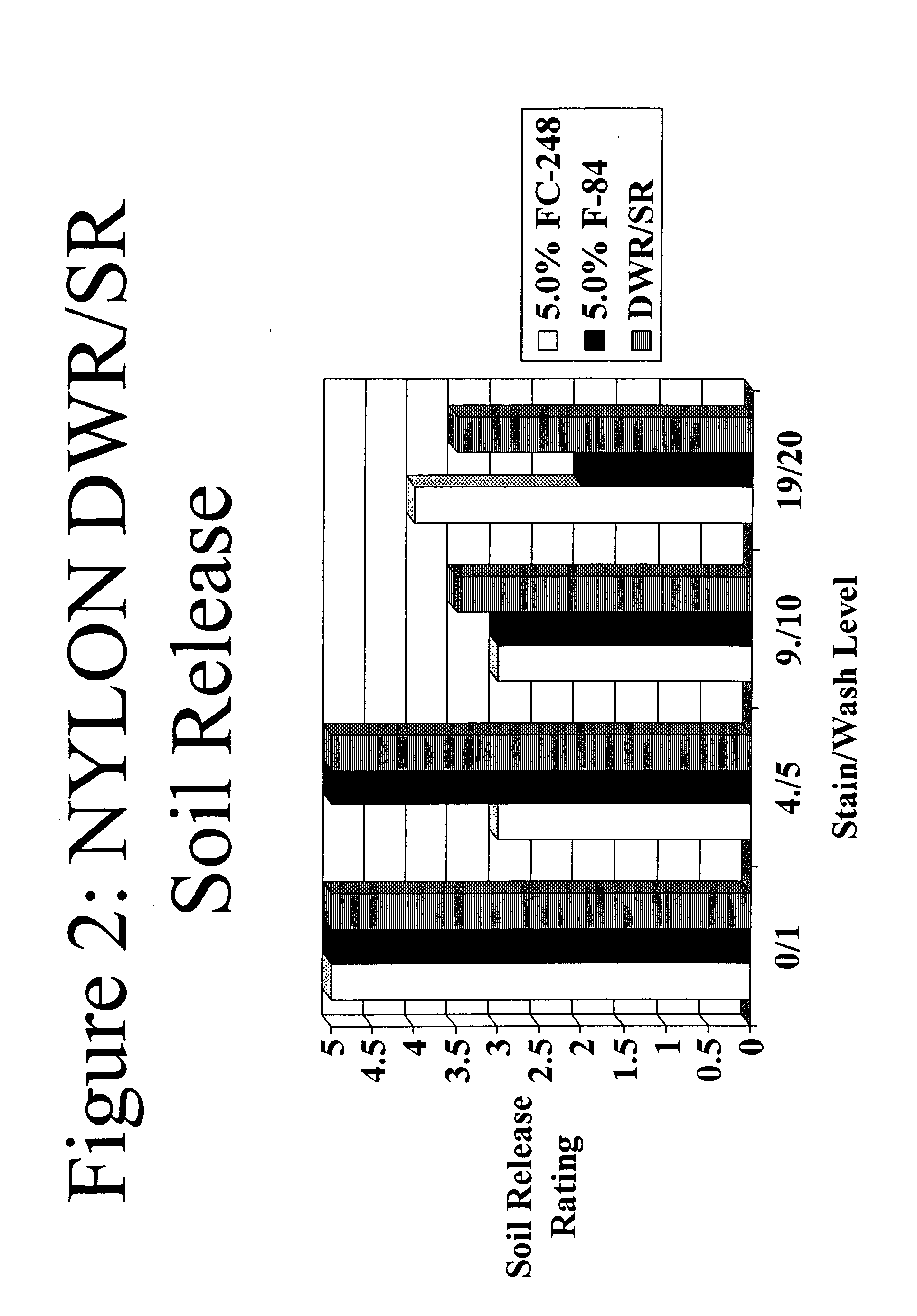

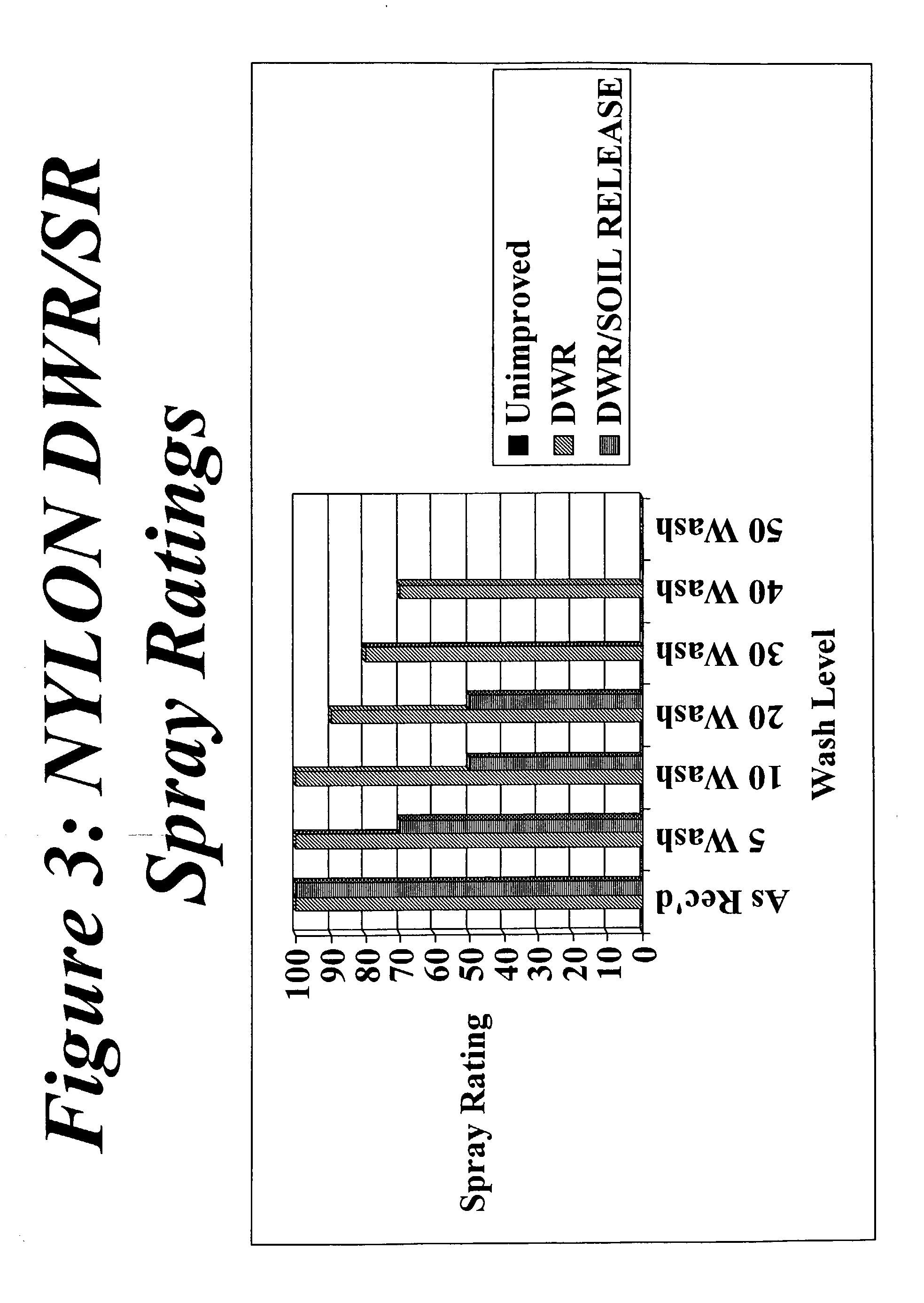

Method of producing textile substrates having improved durable water repellency and soil release

InactiveUS6818253B2Improved durable water and oil repellencyFacilitated releaseOther chemical processesSynthetic resin layered productsPolyesterAramides

Owner:MILLIKEN & CO

Textile substrates having improved durable water repellency and soil release and method for producing same

InactiveUS20030116744A1Improved durable water and oil repellencyFacilitated releasePhysical treatmentOther chemical processesPolyesterAramides

A process for imparting durable water and oil repellency and durable soil release characteristics comprises the application of an aqueous mixture having a water repellent component such as a fluorocarbon polymer and a separate hydrophilic soil release polymer to a textile substrate, followed by a drying step. Optionally, a curing or thermosetting step may also be employed, if desired. This process is carried out in a preferred embodiment in a generally mild pH, which allows the process to be performed on a wide variety of textile substrates that may not be capable of withstanding more extreme pH values. Polyamides, aramids, polyesters, and poly / cotton substrates, when treated according to the present process, have all yielded improved performance with respect to durable water and oil repellency and durable soil release characteristics. A novel mixture or bath and novel treated substrates are also disclosed.

Owner:MILLIKEN & CO

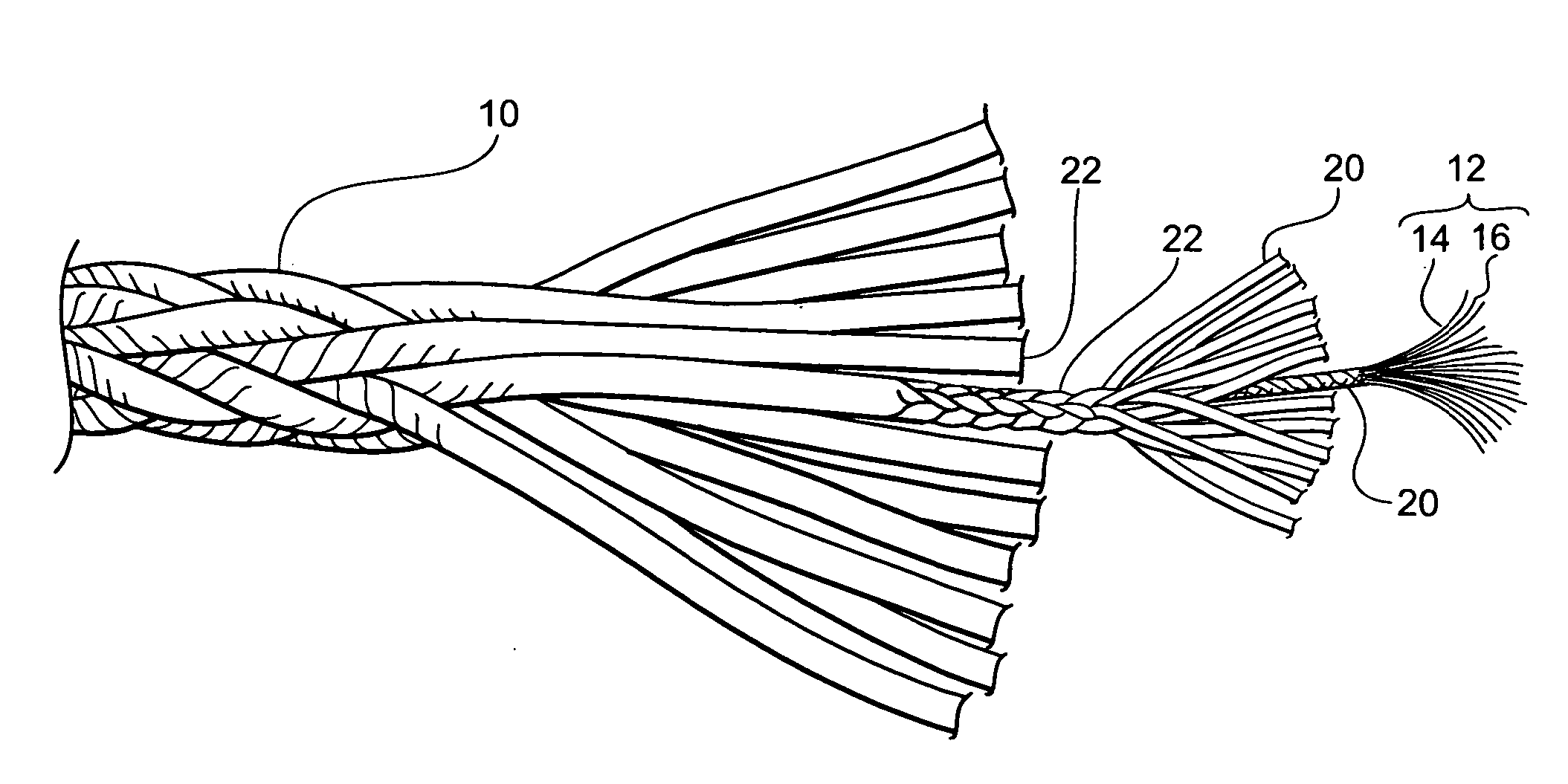

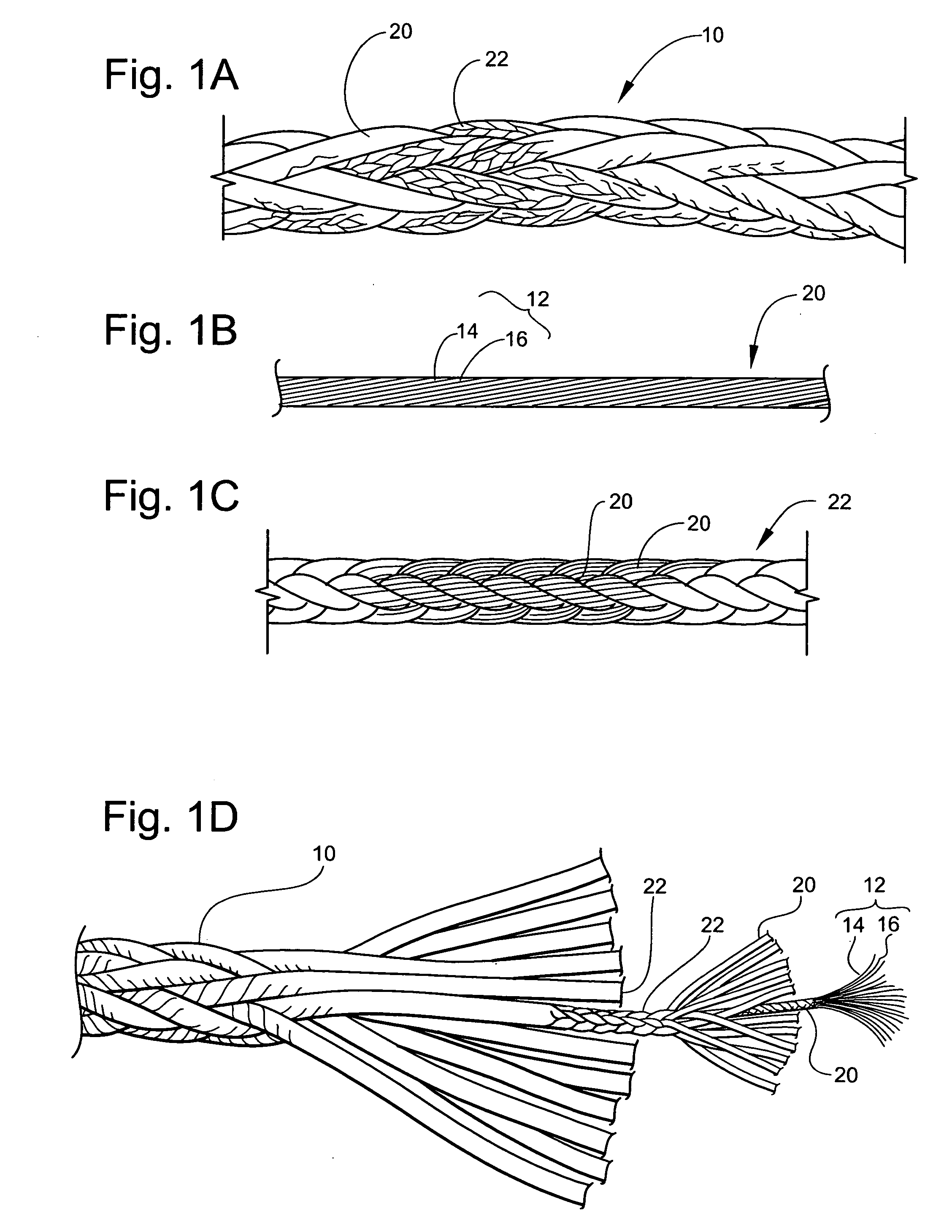

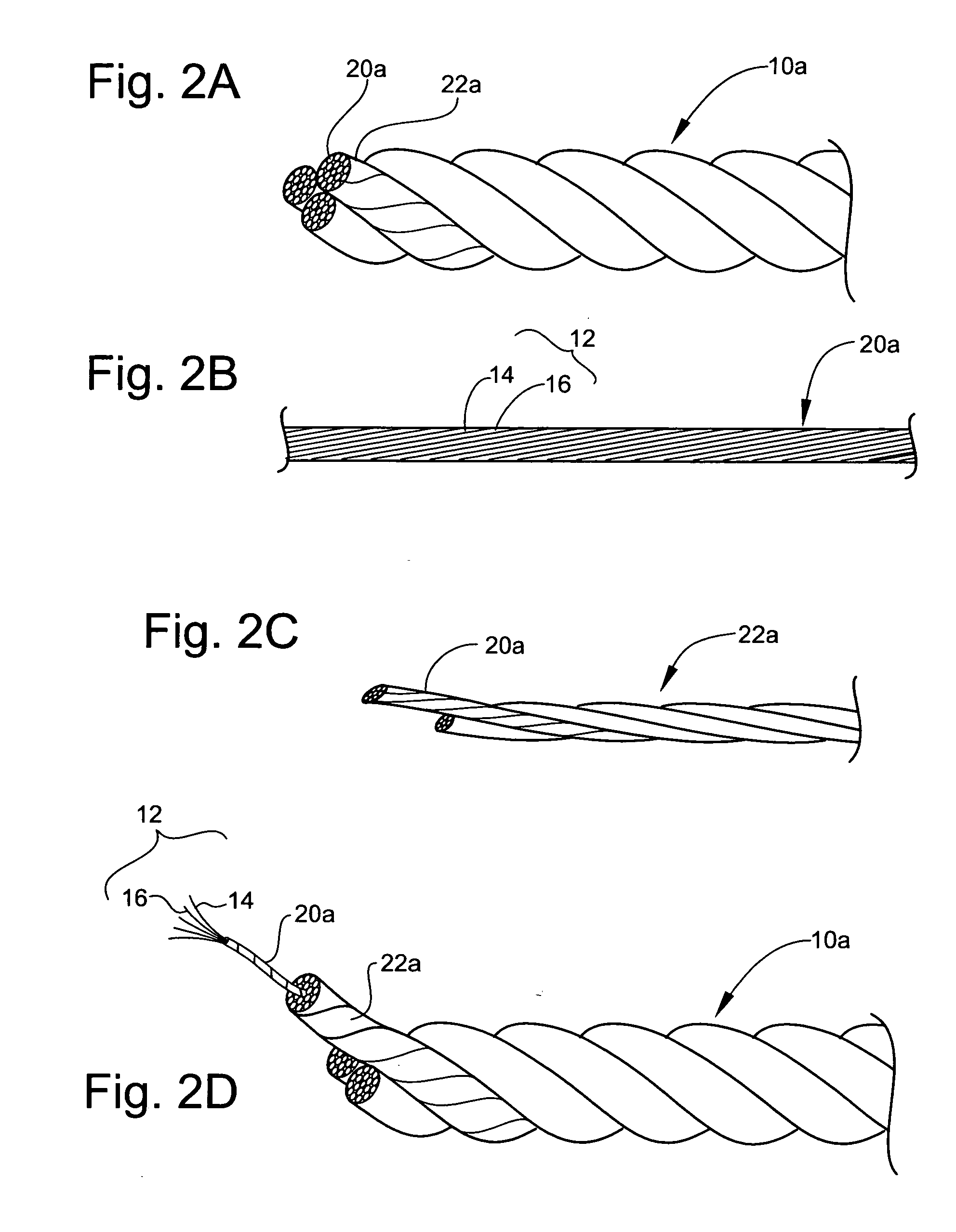

Rope

The instant invention is a rope. This rope includes a blend of filaments including a first filament, and a second filament. The second filament is fluorocarbon polymer filament.

Owner:CORTLAND CABLE

Ceramic substrate for nonstick coating

InactiveUS6638600B2Easy to optimizeImprove adhesionSynthetic resin layered productsPretreated surfacesFritAluminized steel

The present invention provides a new and useful nonstick coating for use on pure aluminum, alloys of aluminum, or aluminized steel surfaces. A nonstick coating according to the present invention includes a ceramic substrate disposed on an aluminum surface and a fluorocarbon polymer coating disposed on the ceramic substrate. The ceramic substrate, prior to firing, includes at least two layers: a first or bottom layer applied to the aluminum surface including an enamel ground coat; and a second or top layer applied over the enamel ground coat layer including a blend of one or more glass frits, non-ceramic refractory particles, and non-vitreous inorganic oxide particles. Upon firing, the ceramic substrate includes a continuous layer of vitreous enamel that is bonded to the aluminum surface. The exposed surface of the ceramic substrate has a micro-rough texture that is enriched with bonding sides for binder resins used in a fluorocarbon polymer primer layer. The ceramic substrate protects the aluminum surface from corrosion and mechanical damage and also protects the fluorocarbon polymer coating from abrasive wear.

Owner:FERRO CORP

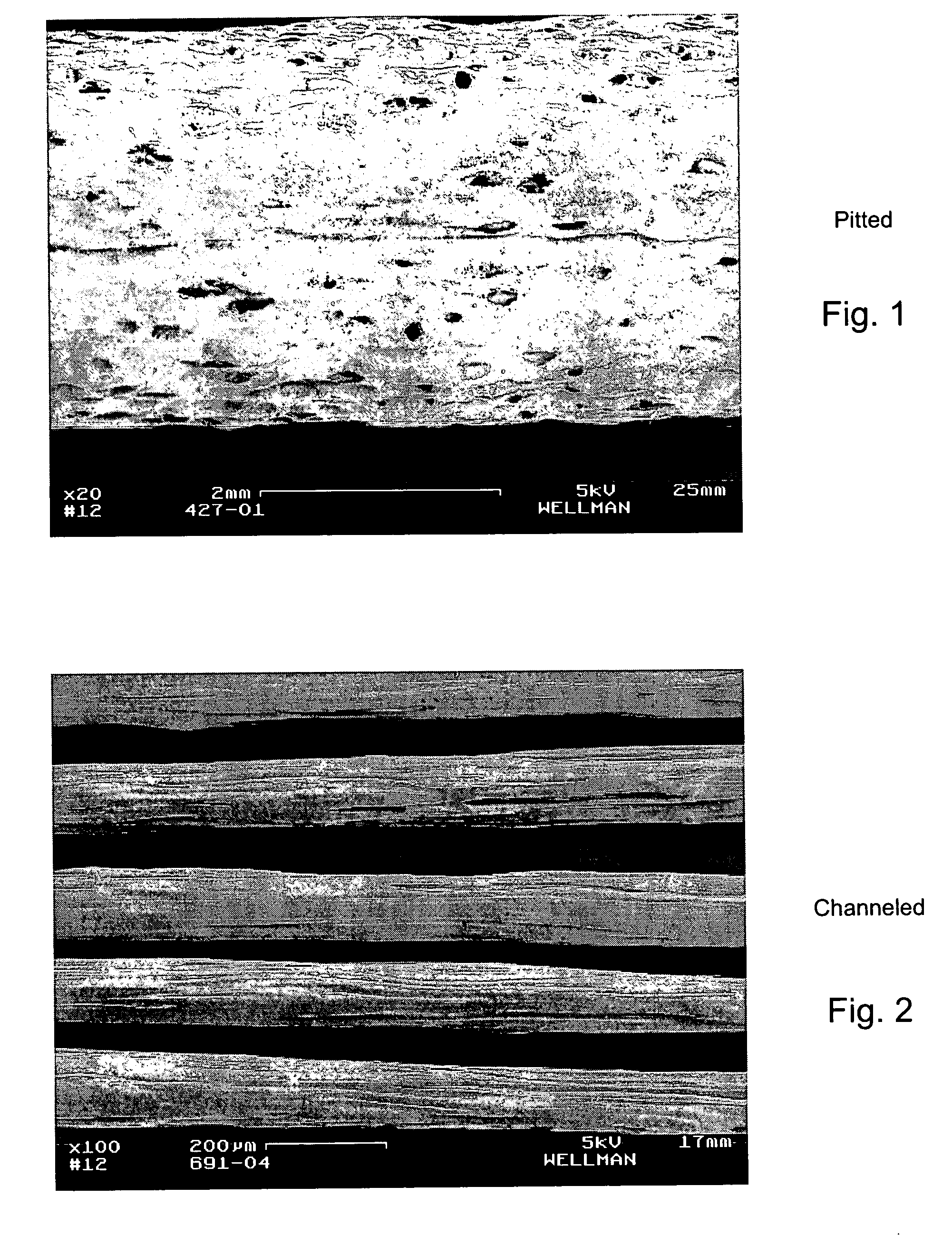

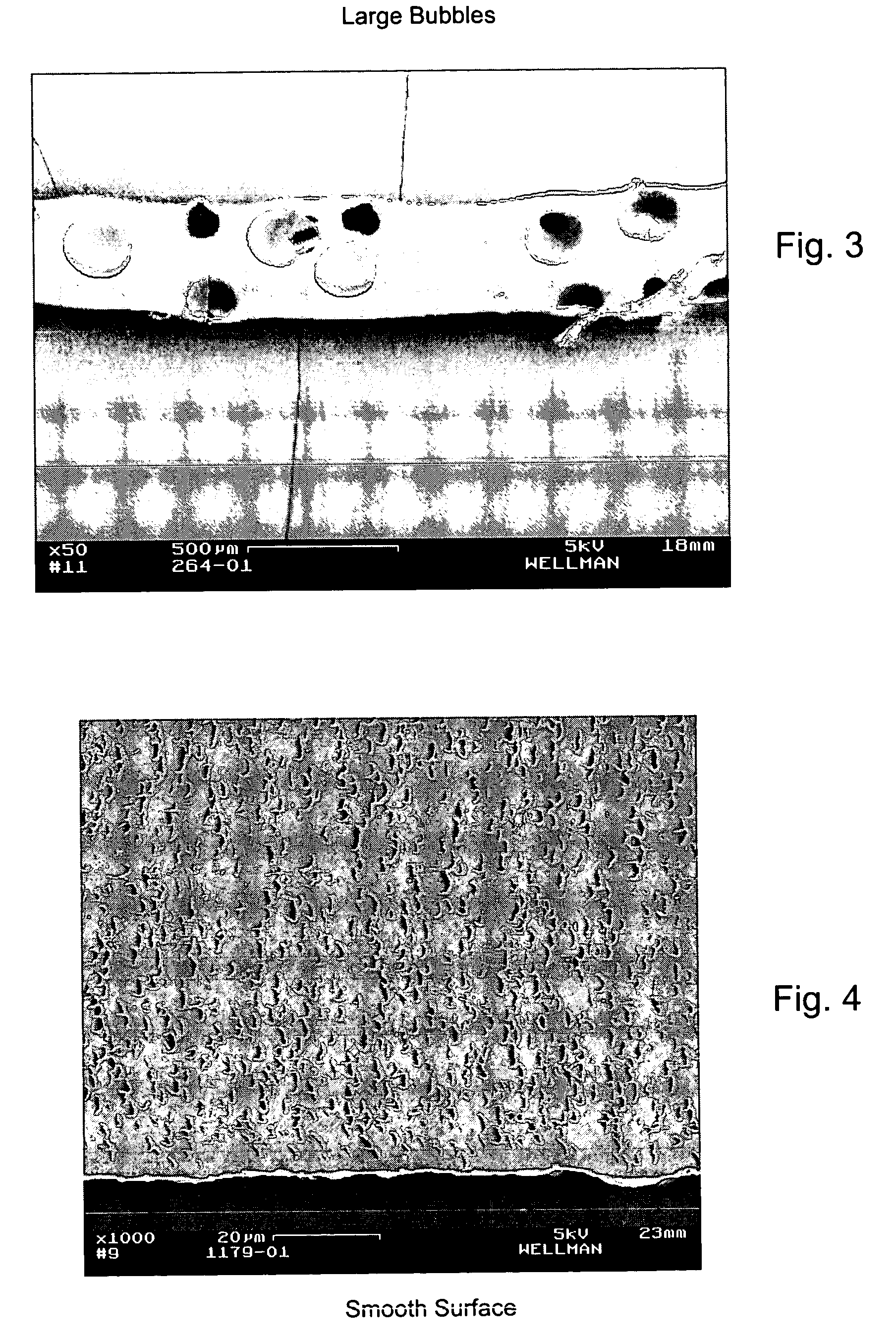

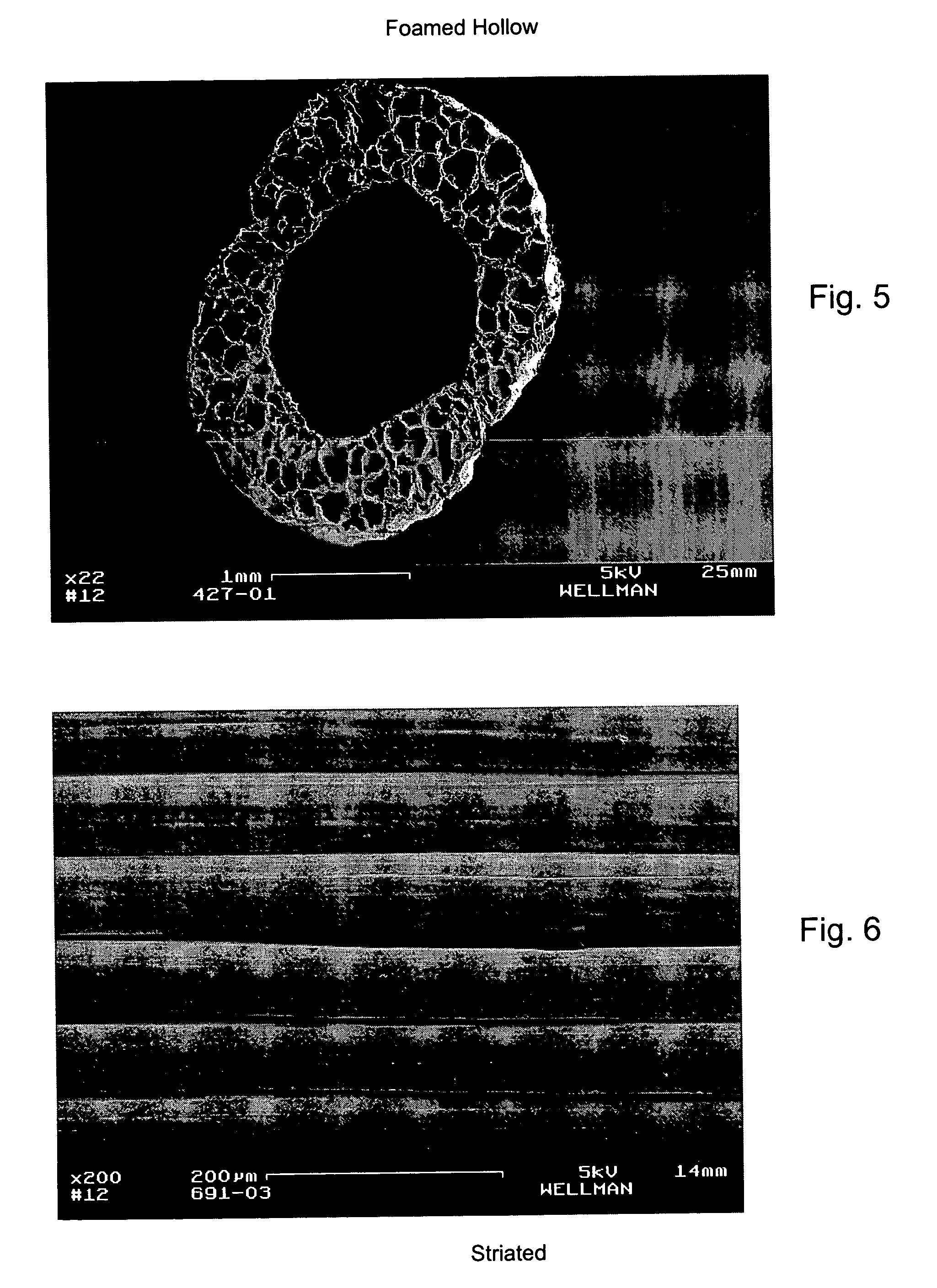

Low density light weight filament and fiber

InactiveUS20050221075A1Increase elasticityLow fiber densityNatural cellulose pulp/paperHollow filament manufactureFiberPolyester

A lightweight, low density fiber is disclosed along with a method of manufacture. The fiber includes a polyester copolymer for providing a greater elasticity than a corresponding monomer-based polyester, more than fifty percent functional void fraction in the form of foam-forming cells for reducing the density of the fiber as compared to a solid fiber, at least five void cells per axial cross section for increasing the structural integrity of the fiber as compared to less uniform foams, and submicron-sized particles of a fluorocarbon polymer, present in an amount less than 10 percent by weight.

Owner:FIBER IND INC

Liquid water resistant and water vapor permeable garments

A water resistant garment is disclosed having regions of high MVTR while maintaining water resistance. The garment has a fabric layer adjacent one major surface of a nanofiber layer. The surface of the nanofibers are coated with a coating containing a fluorocarbon polymeric moiety and a resin binder or extender which is soluble in water and / or other solvents. The coated nanofiber layer has a contact angle of greater than 145°. The garment optionally includes a second fabric layer adjacent the other major surface of the nanofiber layer. The garment has regions having a Frazier air permeability of between about 0.5 m3 / min / m2 and about 8 m3 / min / m2, an MVTR of greater than about 500 g / m2 / day and a hydrostatic head of at least about 50 cmwc.

Owner:EI DU PONT DE NEMOURS & CO

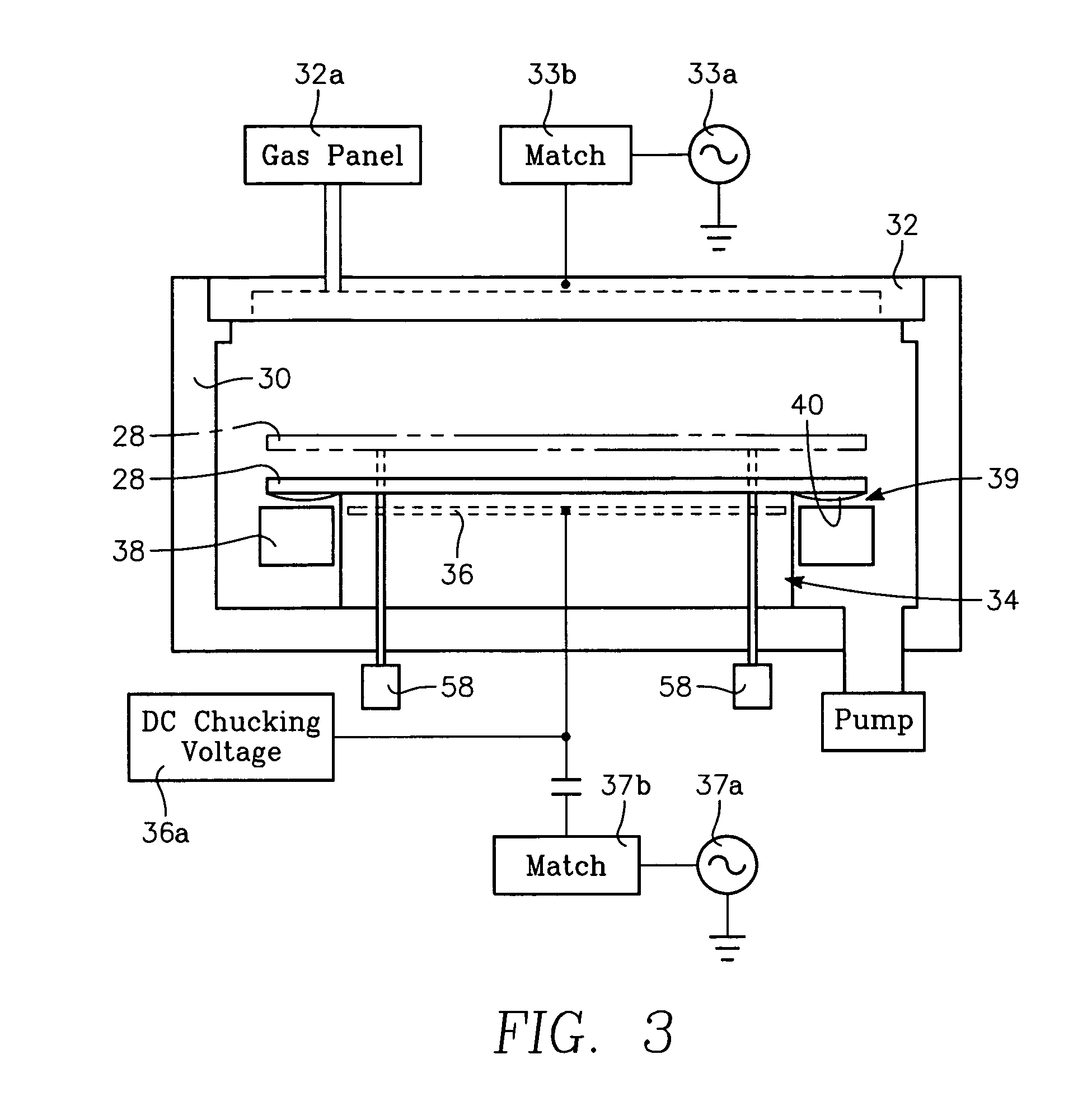

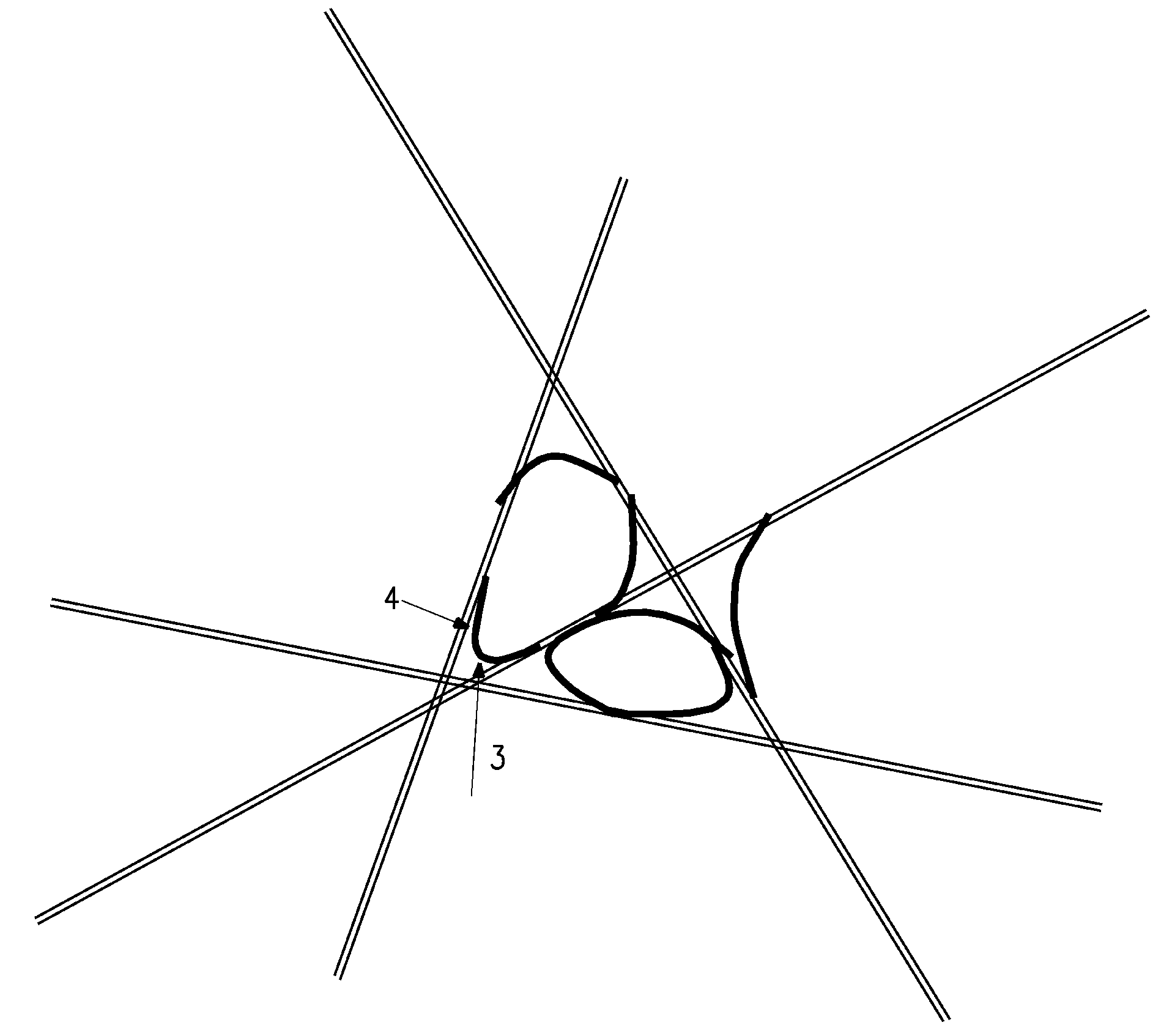

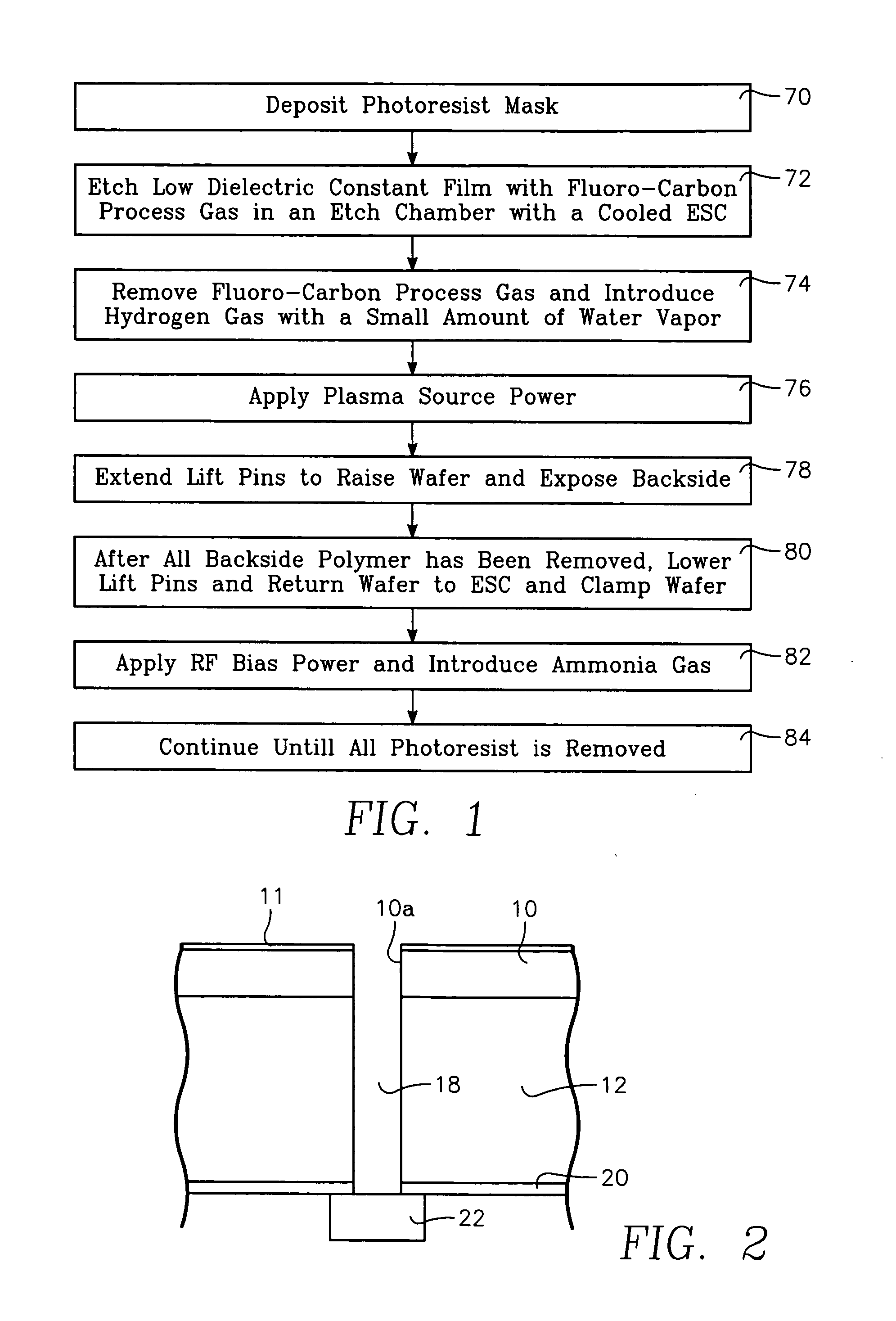

Plasma dielectric etch process including in-situ backside polymer removal for low-dielectric constant material

A plasma etch process with in-situ backside polymer removal begins with a workpiece having a porous or non-porous carbon-doped silicon oxide dielectric layer and a photoresist mask on a surface of the workpiece. The workpiece is clamped onto an electrostatic chuck in an etch reactor chamber. The process includes introducing a fluoro-carbon based process gas and applying RF bias power to the electrostatic chuck and RF source power to an overhead electrode to etch exposed portions of the dielectric layer while depositing protective fluoro-carbon polymer on the photoresist mask. The process further includes removing the fluoro-carbon based process gas and introducing a hydrogen-based process gas and applying RF source power to the overhead electrode. The lift pins in the electrostatic chuck are extended to raise the workpiece above the electrostatic chuck and expose a backside of the workpiece to plasma in the reactor chamber, so as to reduce polymer previously deposited on the backside, until the polymer has been removed from the backside.

Owner:APPLIED MATERIALS INC

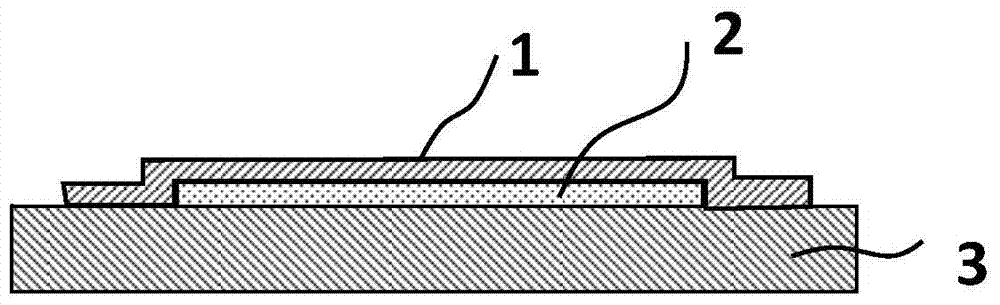

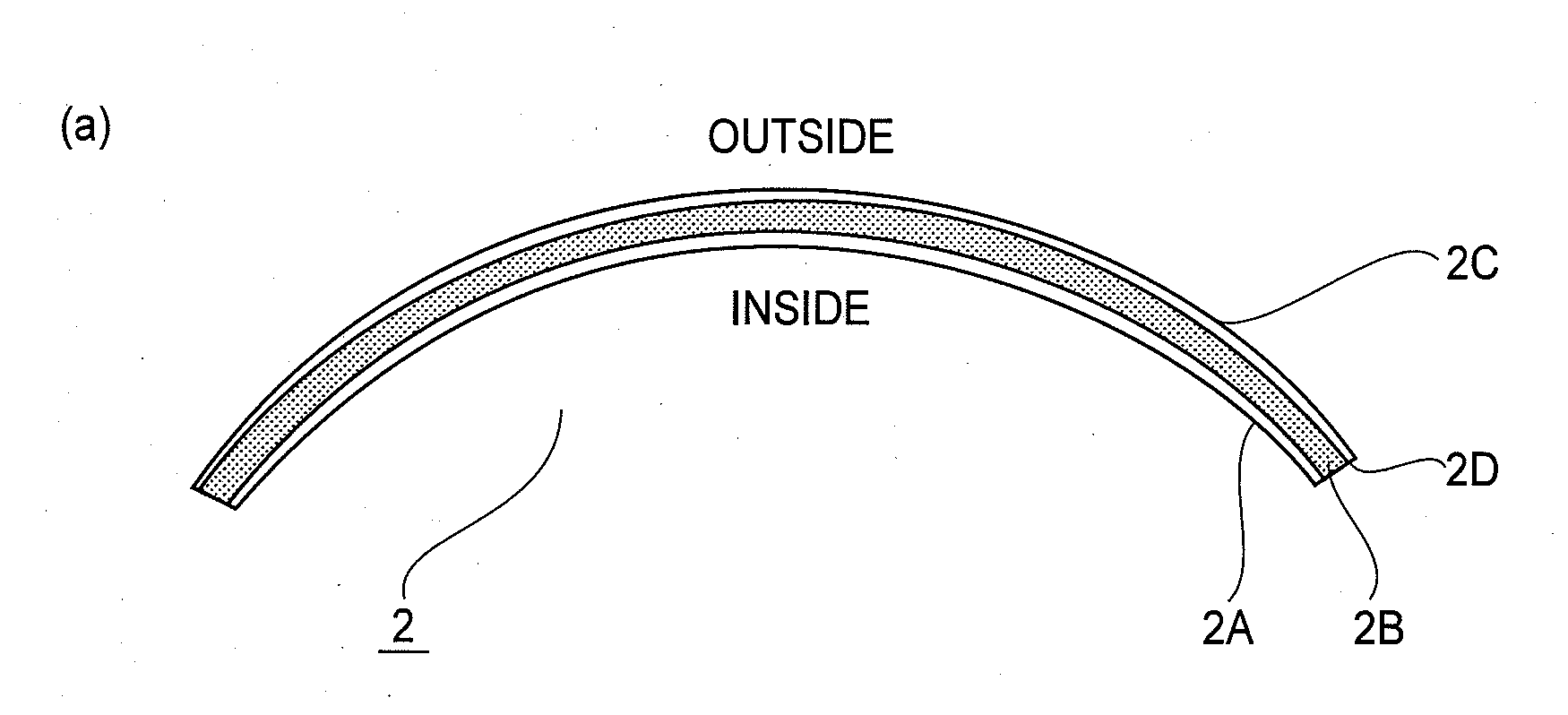

Organic electroluminescence device packaging structure and method and display device

ActiveCN103490019AImprove water and oxygen barrier performanceLower surface energySolid-state devicesSemiconductor/solid-state device manufacturingDisplay devicePolymer thin films

The invention provides an organic electroluminescence device packaging structure and packaging method and a display device, and belongs to the field of organic electroluminescence. The organic electroluminescence device packaging structure comprises a substrate used for bearing an organic electroluminescence device, the organic electroluminescence device located on the substrate and at least one film packaging layer covering the organic electroluminescence device, wherein the film packaging layer is composed of an inorganic film, a fluorocarbon polymer film and an organic polymer film located between the inorganic film and the fluorocarbon polymer film. Through the organic electroluminescence device packaging structure and packaging method, the water oxygen blocking capacity of the film packaging layer can be effectively improved, and therefore the service life of the OLED device is effectively prolonged.

Owner:BOE TECH GRP CO LTD

Liquid crystalline polyester composition

InactiveUS20120135228A1Difficult to formGood molding effectLiquid crystal compositionsGlass/slag layered productsPolyesterLiquid crystalline

Disclosed is a liquid crystalline polyester composition which contains a liquid crystalline polyester and mica and which provides a molded article hard to form blisters therein under a high temperature condition, even when it is molded at a high temperature. The liquid crystalline polyester composition is prepared by incorporating the mica and a fluorocarbon polymer whose flow start temperature is 330° C. or lower into the liquid crystalline polyester. The content of the mica in the liquid crystalline polyester composition is preferably from 15 to 100 parts by mass per 100 parts by mass of the liquid crystalline polyester, and the content of the fluorocarbon polymer in the liquid crystalline polyester composition is preferably from 0.2 to 10 parts by mass per 100 parts by mass of the liquid crystalline polyester.

Owner:SUMITOMO CHEM CO LTD

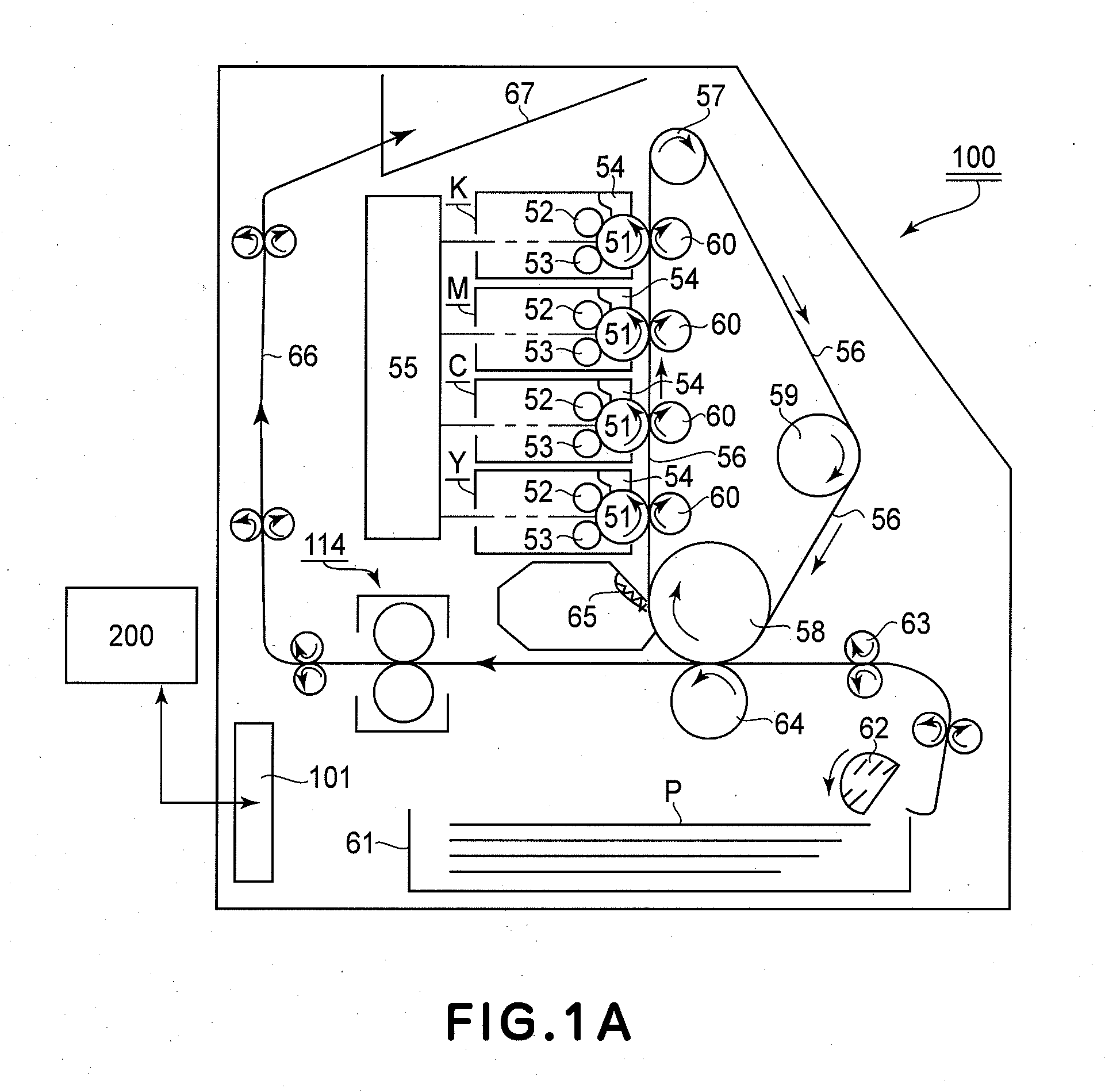

Ink-jet printer head and a manufacturing method thereof

InactiveUS20050088485A1Low mechanical strengthIncreased durabilityLiquid surface applicatorsCoatingsOrganic filmPolymer science

An ink-jet printer head is characterized by comprising an organic film coated on the surface of the nozzle plate for discharging ink, in which solid particles having abrasion resistance are dispersed, and a water-repellent film on the surface of the organic film, in which the chains of fluorocarbon polymer is grown. The head shows improved durability of the chains of the fluorocarbon polymer on the nozzle plate during cleaning of the nozzle surface.

Owner:RICOH KK

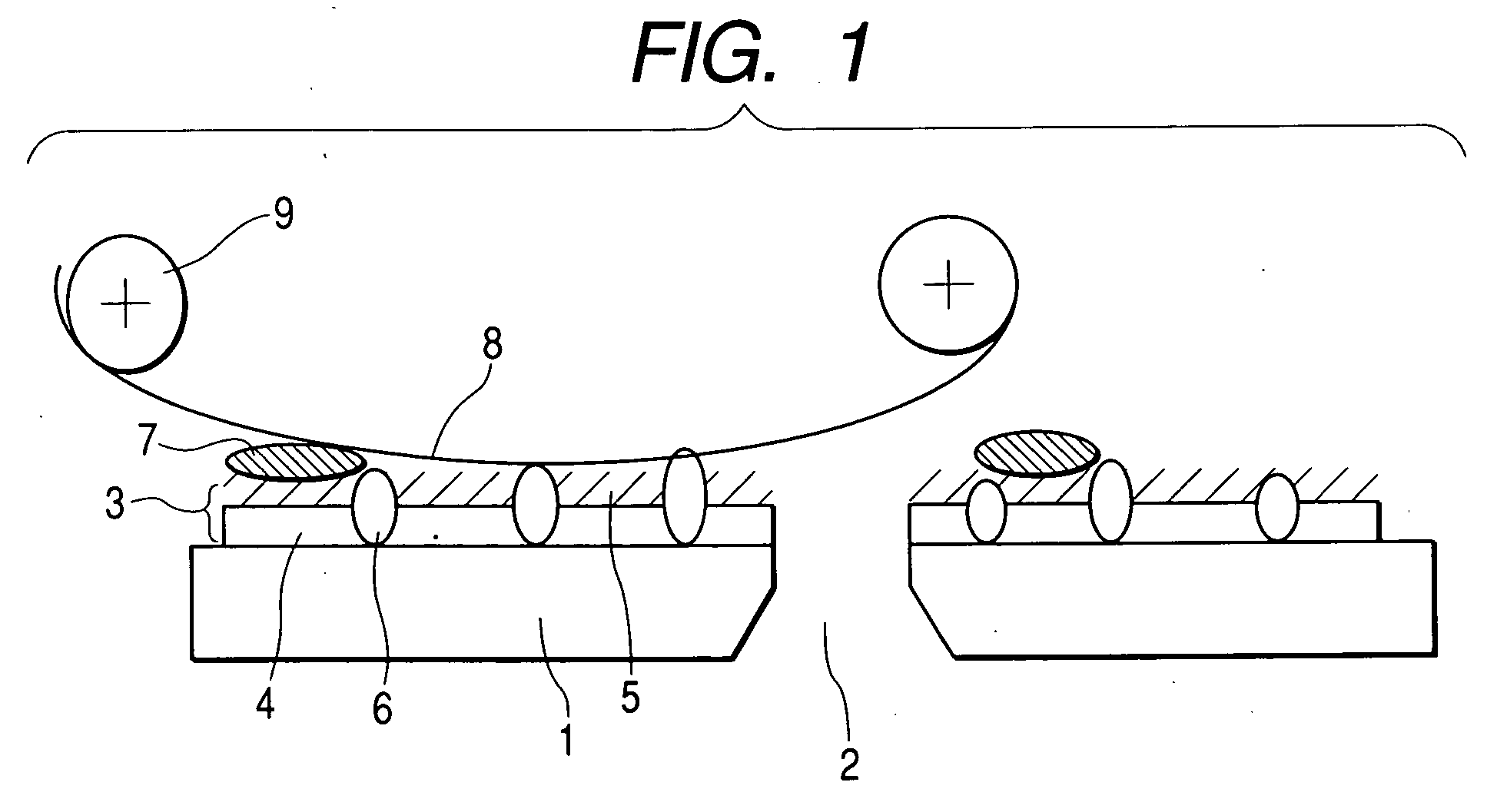

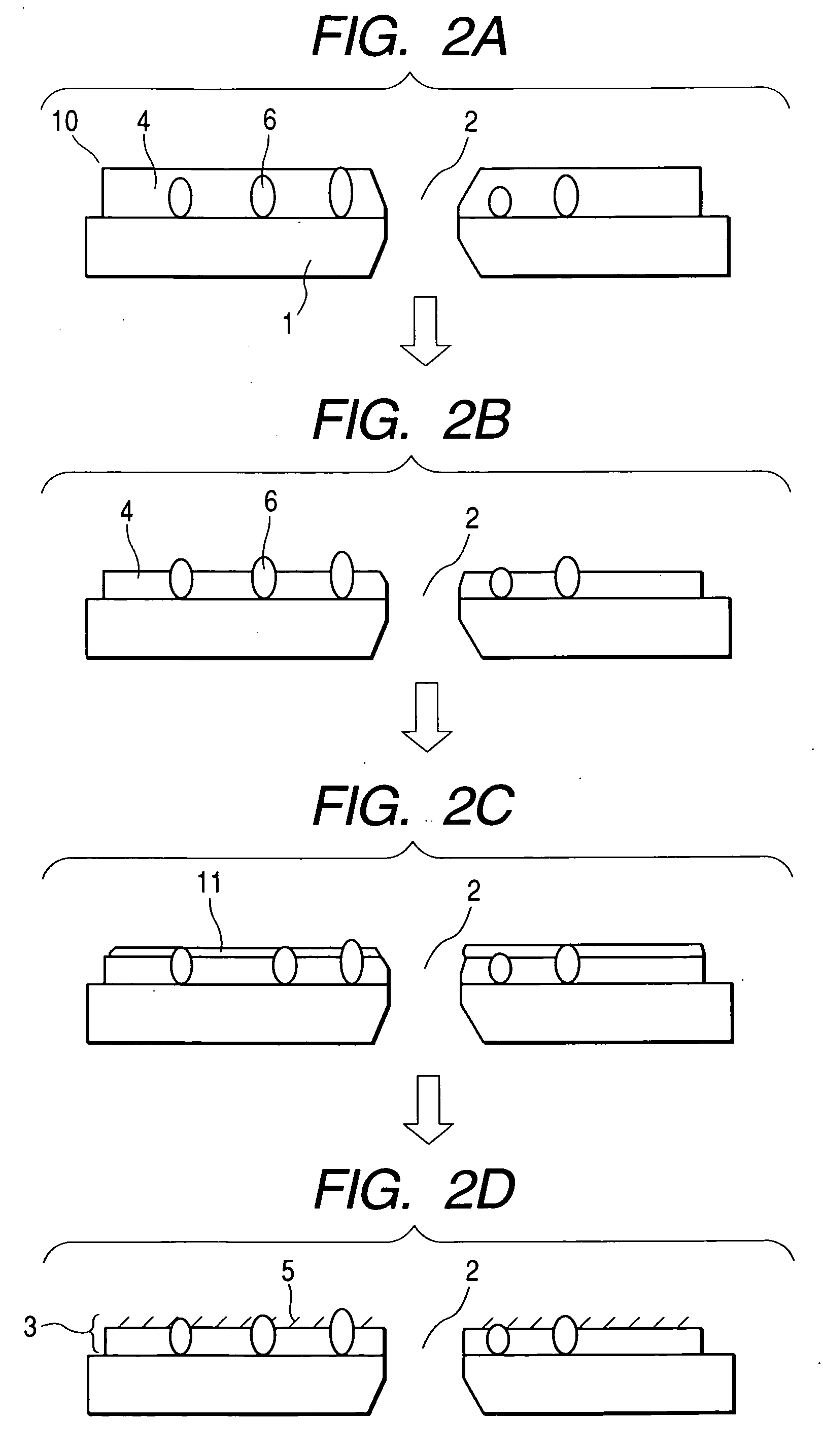

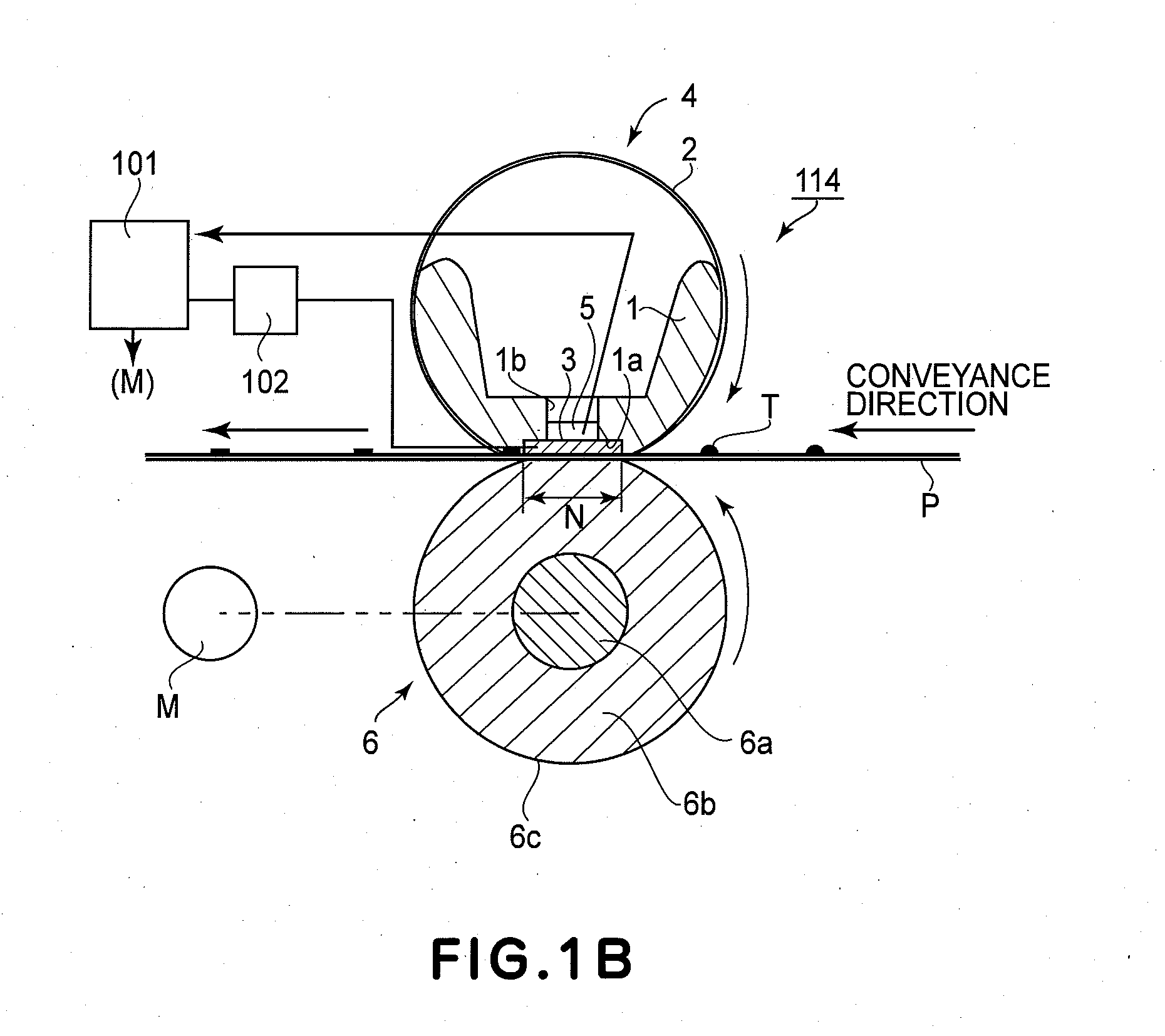

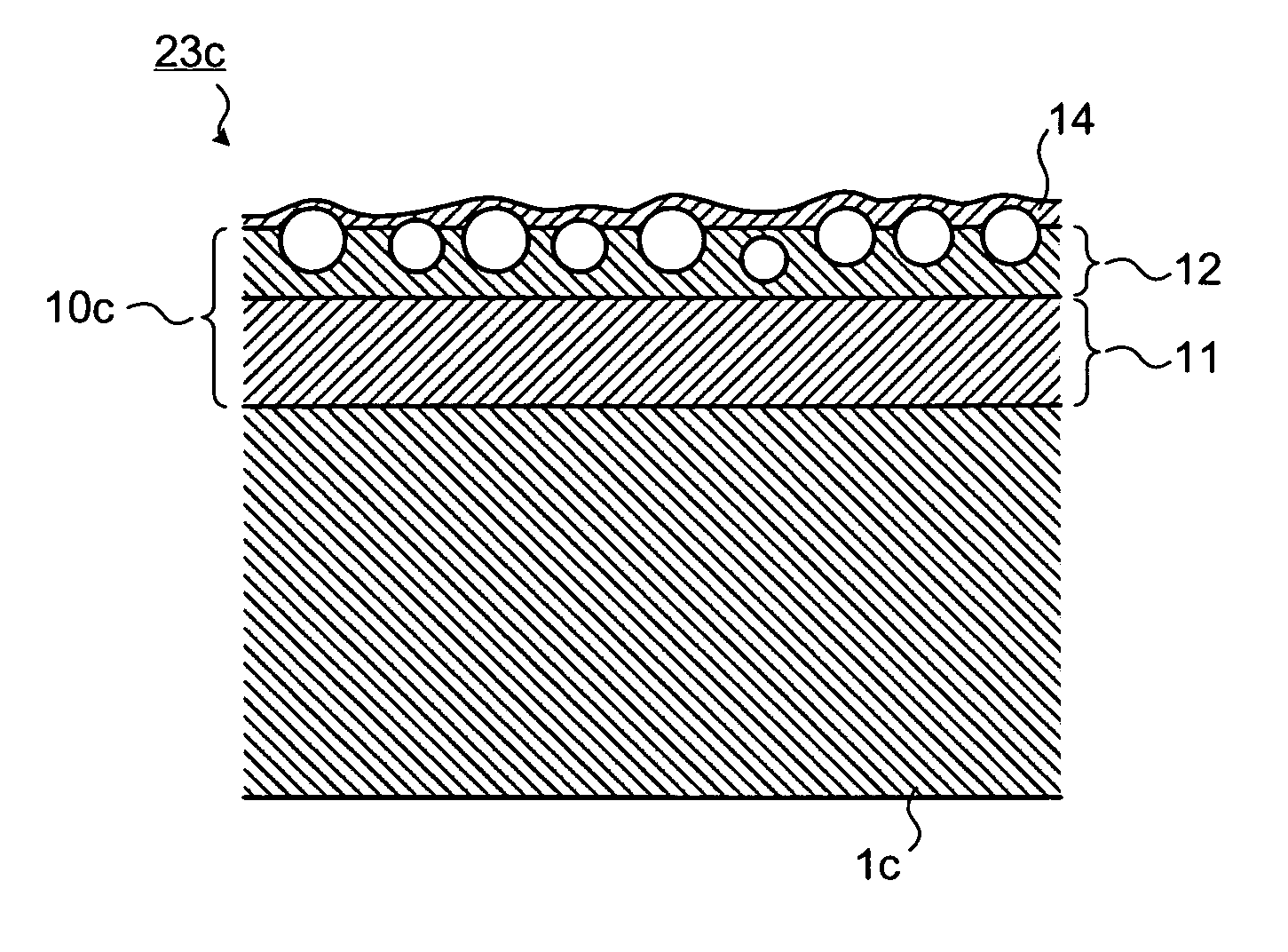

Rotatable fixing member, manufacturing method thereof and fixing device

InactiveUS20110082260A1Easy to crackAvoid crackingPretreated surfacesElectrographic process apparatusBiochemical engineeringFluorocarbon Polymers

A rotatable fixing member includes an elastic layer, a primer layer provided on the elastic layer, and a parting layer provided on the primer layer. The primer layer contains a crystalline fluorocarbon polymer having a functional group and has a thickness of 850 nm or less. The parting layer is a coating layer of a crystalline fluorocarbon polymer.

Owner:CANON KK

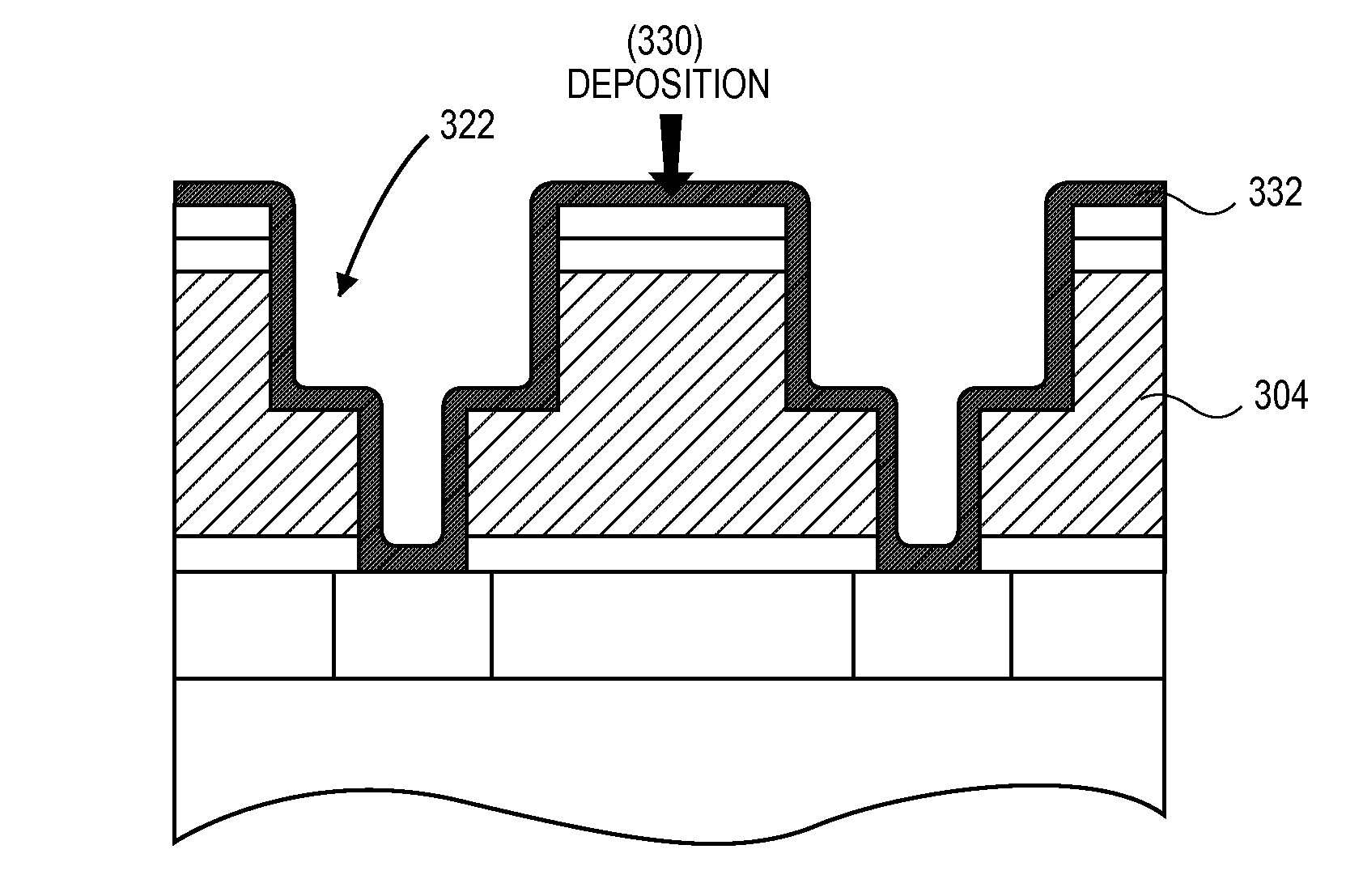

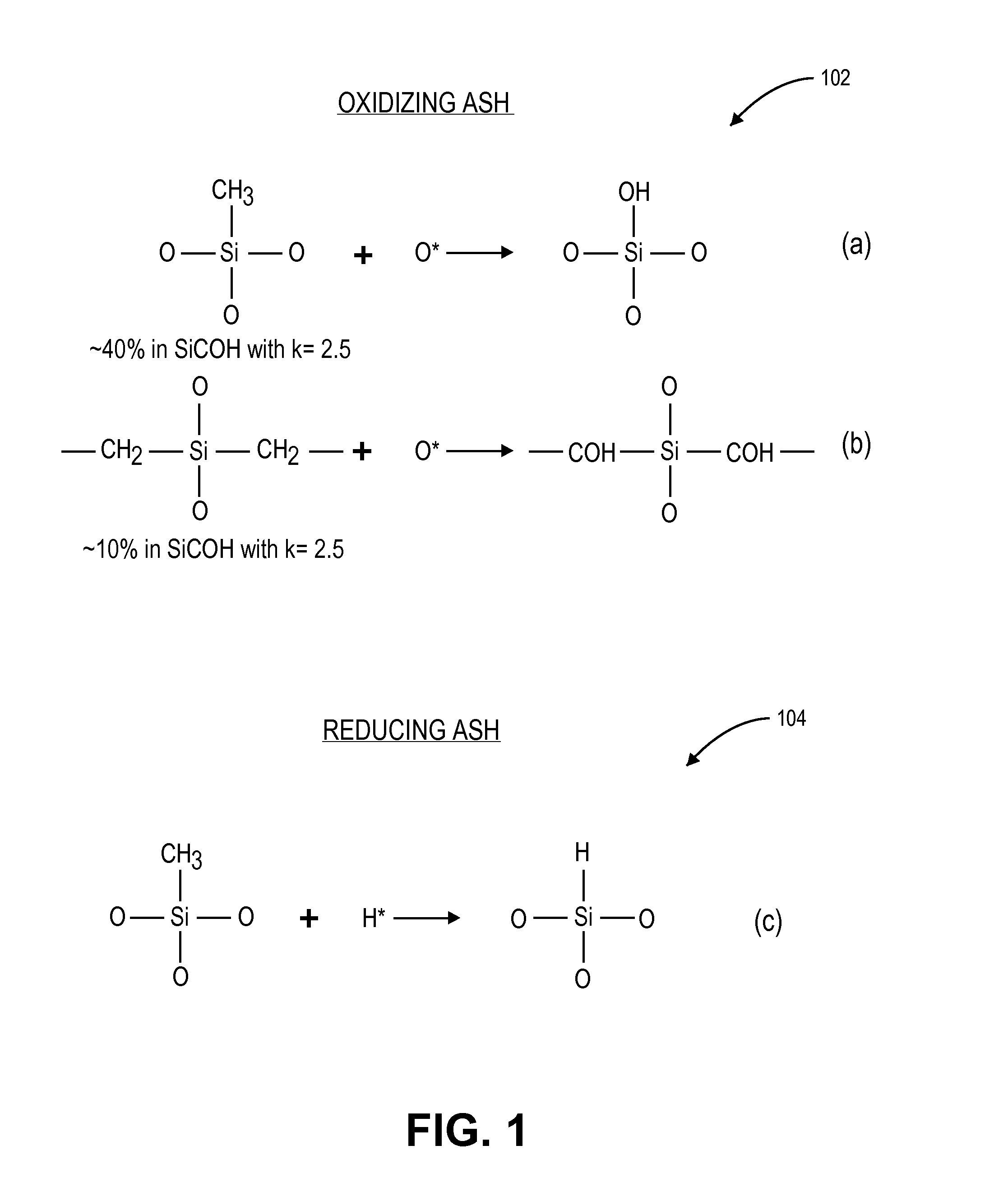

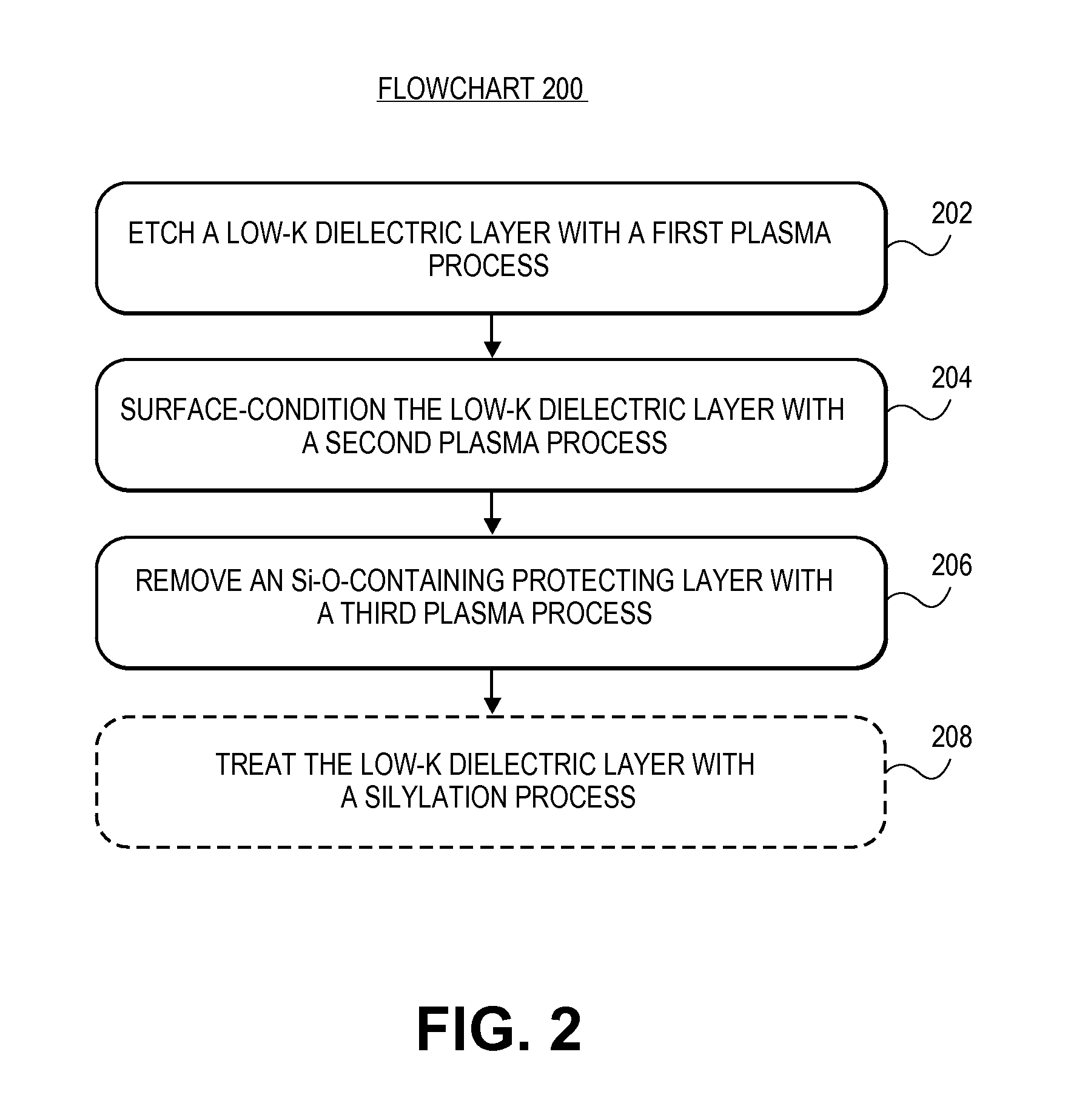

Post etch treatment (PET) of a low-k dielectric film

InactiveUS20130109187A1Solid-state devicesSemiconductor/solid-state device manufacturingSurface conditionsCompanion animal

Post etch treatments (PETs) of low-k dielectric films are described. For example, a method of patterning a low-k dielectric film includes etching a low-k dielectric layer disposed above a substrate with a first plasma process. The etching involves forming a fluorocarbon polymer on the low-k dielectric layer. The low-k dielectric layer is surface-conditioned with a second plasma process. The surface-conditioning removes the fluorocarbon polymer and forms an Si—O-containing protecting layer on the low-k dielectric layer. The Si—O-containing protecting layer is removed with a third plasma process.

Owner:APPLIED MATERIALS INC

Metered dose inhaler can coated two or more times with fluorocarbon polymers

A metered dose inhaler having part or all of its internal surfaces coated two or more times with a polymer comprising one or more fluorocarbon polymers, optionally in combination with one or more non-fluorocarbon polymers, containing an inhalation drug or a physiologically acceptable salt thereof, optionally an excipient and a fluorocarbon propellant. Also, a method for coating all or part of internal surfaces of a metered dose inhaler can comprising applying a first coat comprising a one or more fluorocarbon polymers to all or part of the internal the surfaces of a metered dose inhaler can. Subsequently, heating the first coat of fluorocarbon polymer and then applying a second coat comprising one or more fluorocarbon polymer on top of the first coat of fluorocarbon polymer. The two coats of fluorocarbon polymer are then heated to give a metered dose inhaler can that is more efficient in dispensing consistent doses of aerosol formulations.

Owner:EI DU PONT DE NEMOURS & CO +1

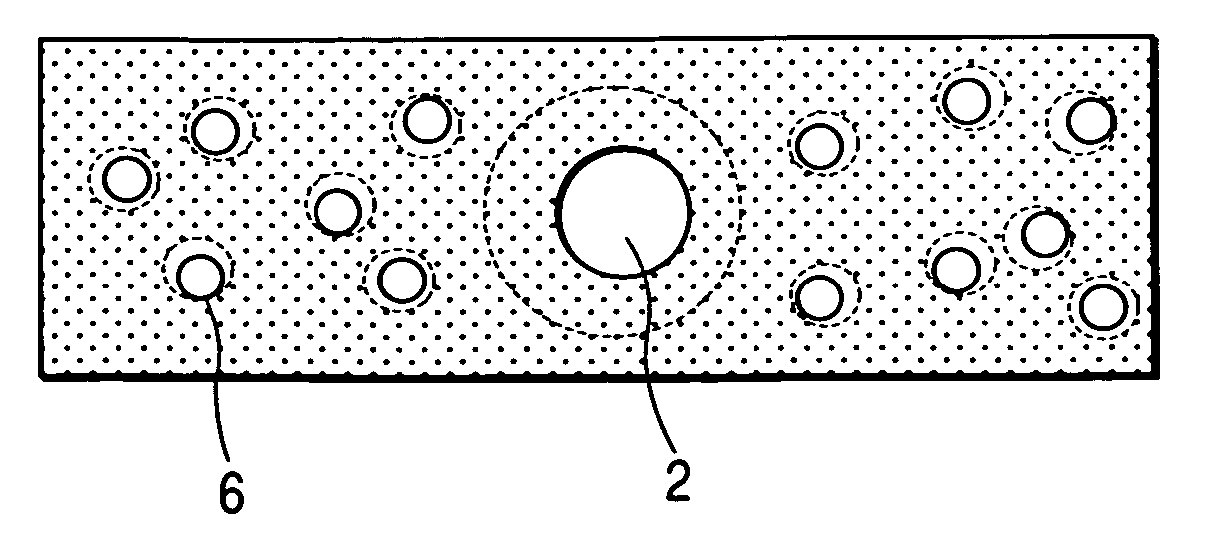

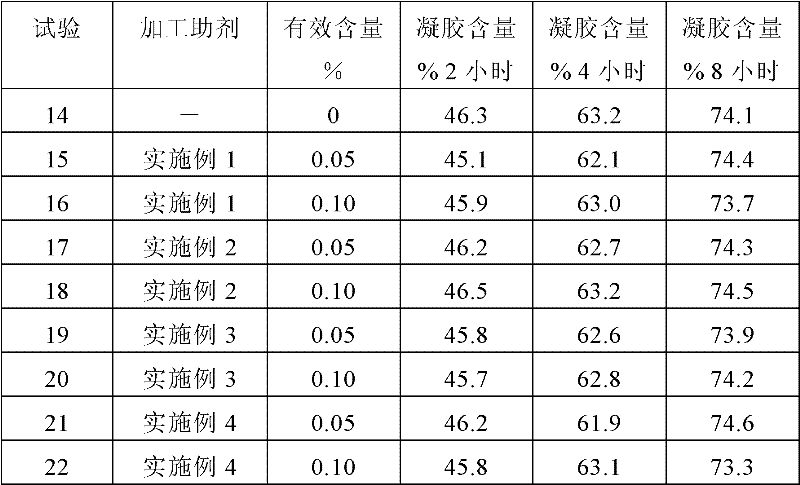

Fluoropolymer processing aid, silane-crosslinked polyethylene composition containing same and application thereof

ActiveCN102286157AInhibition of pre-crosslinkingIncrease extrusion speedCoatingsSurface finishProcedure Agents

The invention provides a fluoropolymer processing aid. The fluoropolymer processing aid is particles which are formed by a core part and a shell part and have average particle diameter of 0.2 to 1 micron, wherein the core part is made of fluorocarbon polymer, the shell part is made of MQ silicon resin, the ratio of M to Q is 0.5 to 0.9, and the weight ratio of the core part to the shell part is 20:80-45:55. The invention also provides a silane cross-linked polyethylene composition containing the processing aid and application of the fluoropolymer processing aid in silane cross-linked polyethylene extrusion molding. Not only the silane cross-linked polyethylene added with the fluoropolymer processing aid has high extrusion velocity, but also the extruded product has high surface finishment.

Owner:上海鲁聚聚合物技术有限公司

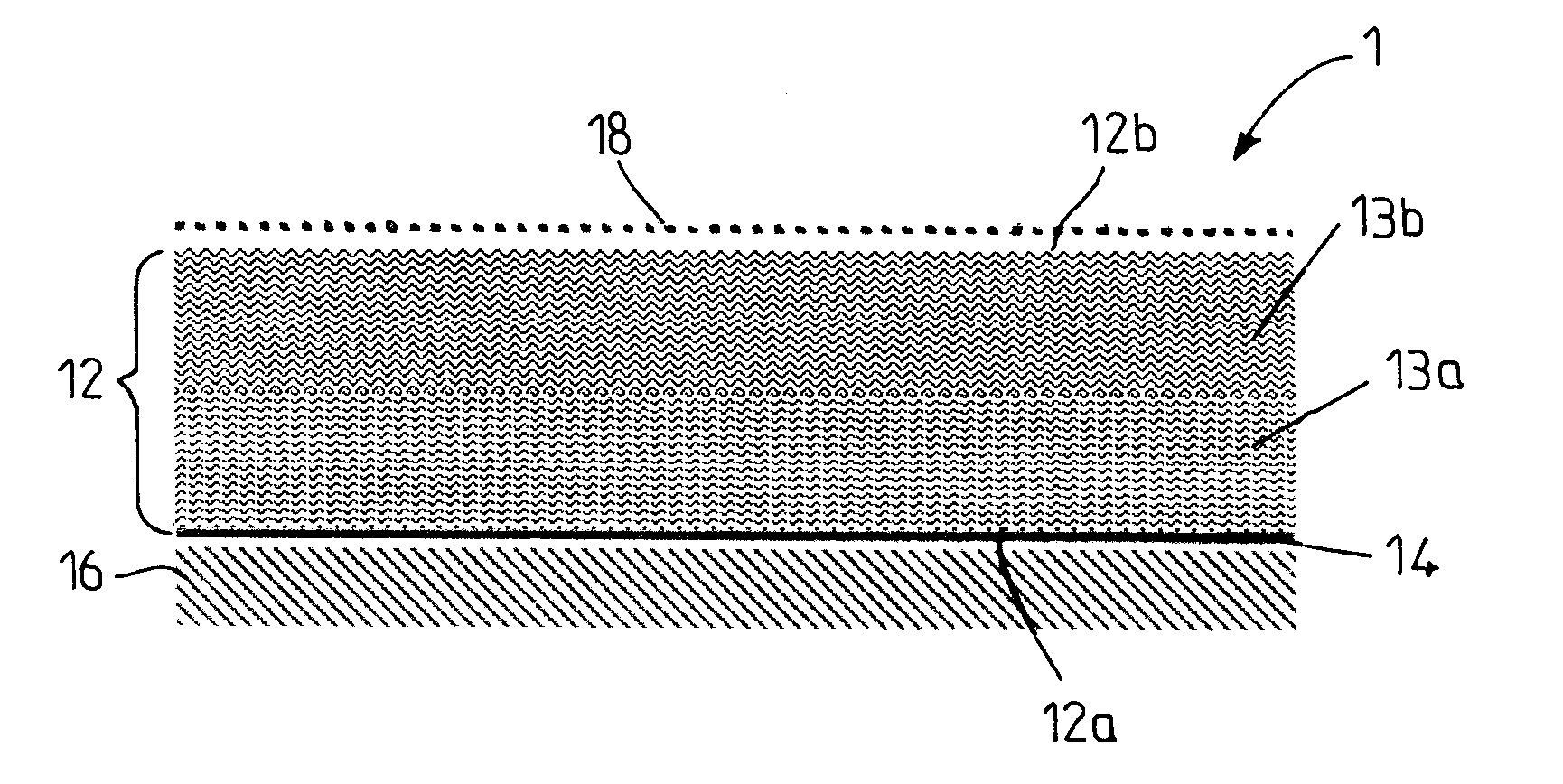

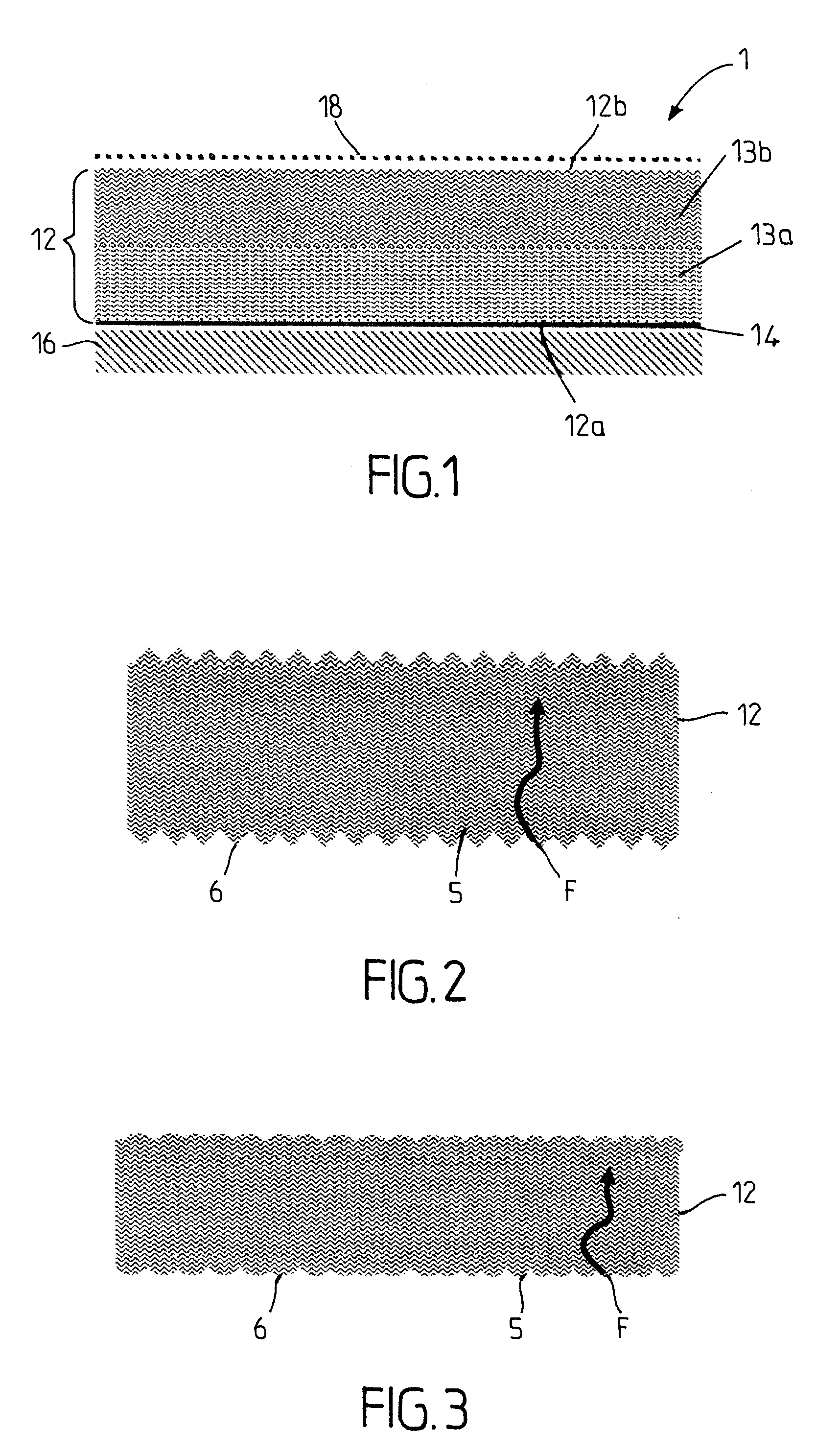

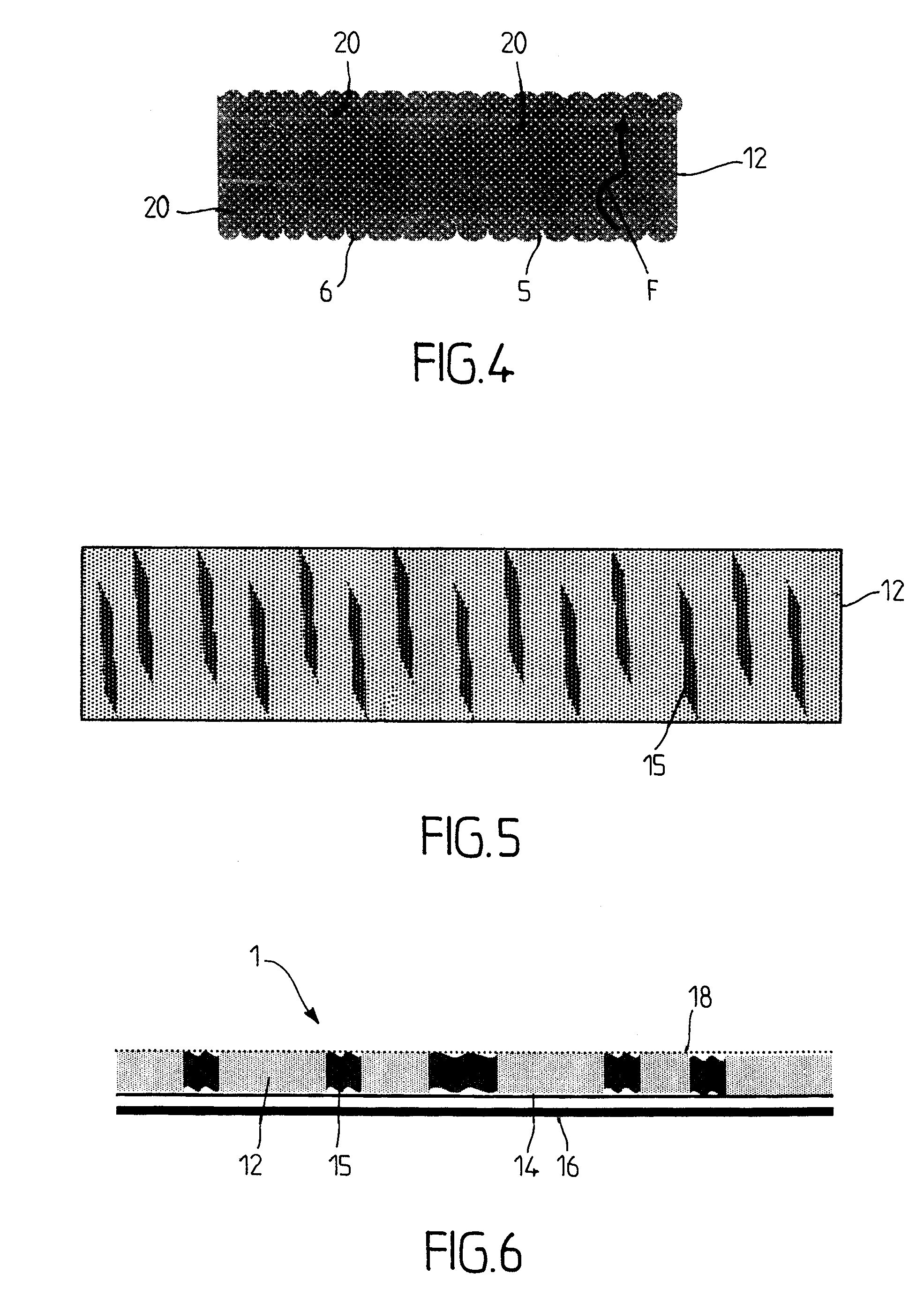

Adhesive tape made of silicone intended for medical applications

An adhesive tape (1) made of silicone is intended for medical applications. The tape (1) has a sheet material (12) based on nonwoven fibers, coated on an internal face (12a) intended to be in contact with the skin, with a barrier membrane (14) which adheres to the sheet material, based on crosslinked silicone polymer, and with a layer (16) of atraumatic and biocompatible silicone adhesive gel, and on an external face (12b), with a layer (18) of a nonstick and waterproof polymer based on a fluorosilicone or fluorocarbon polymer.

Owner:ADVANCED SILICONE COATING

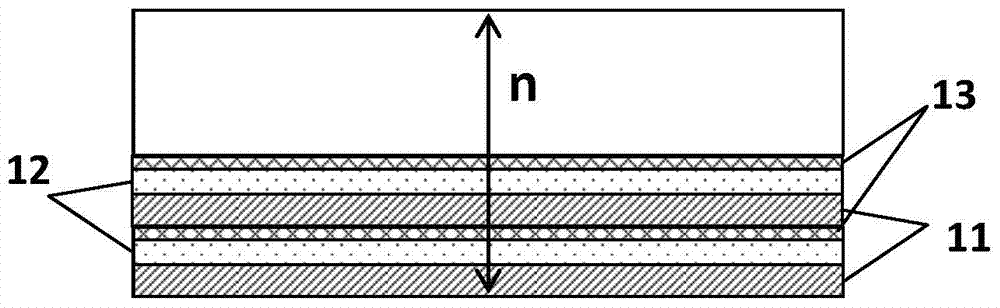

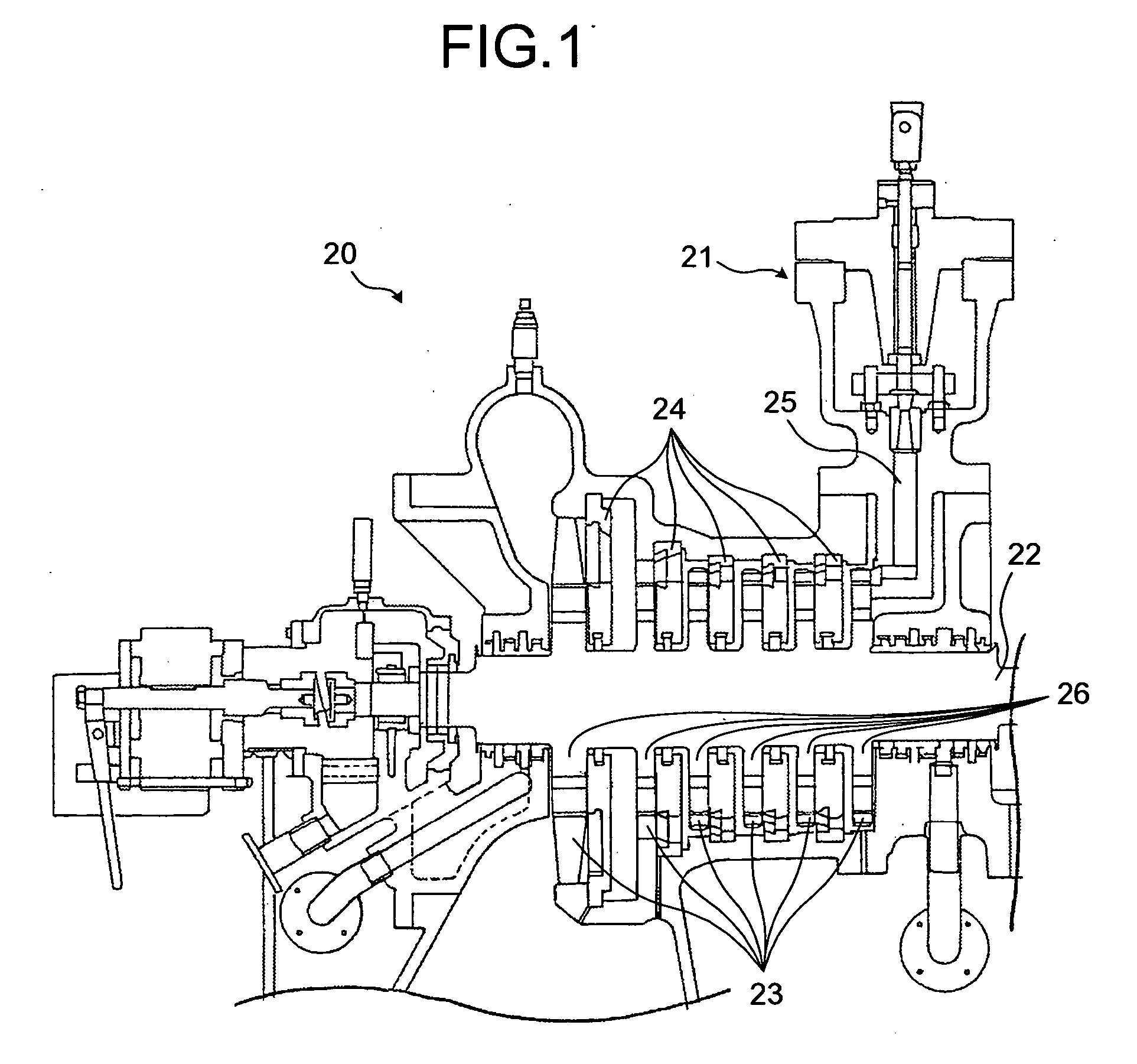

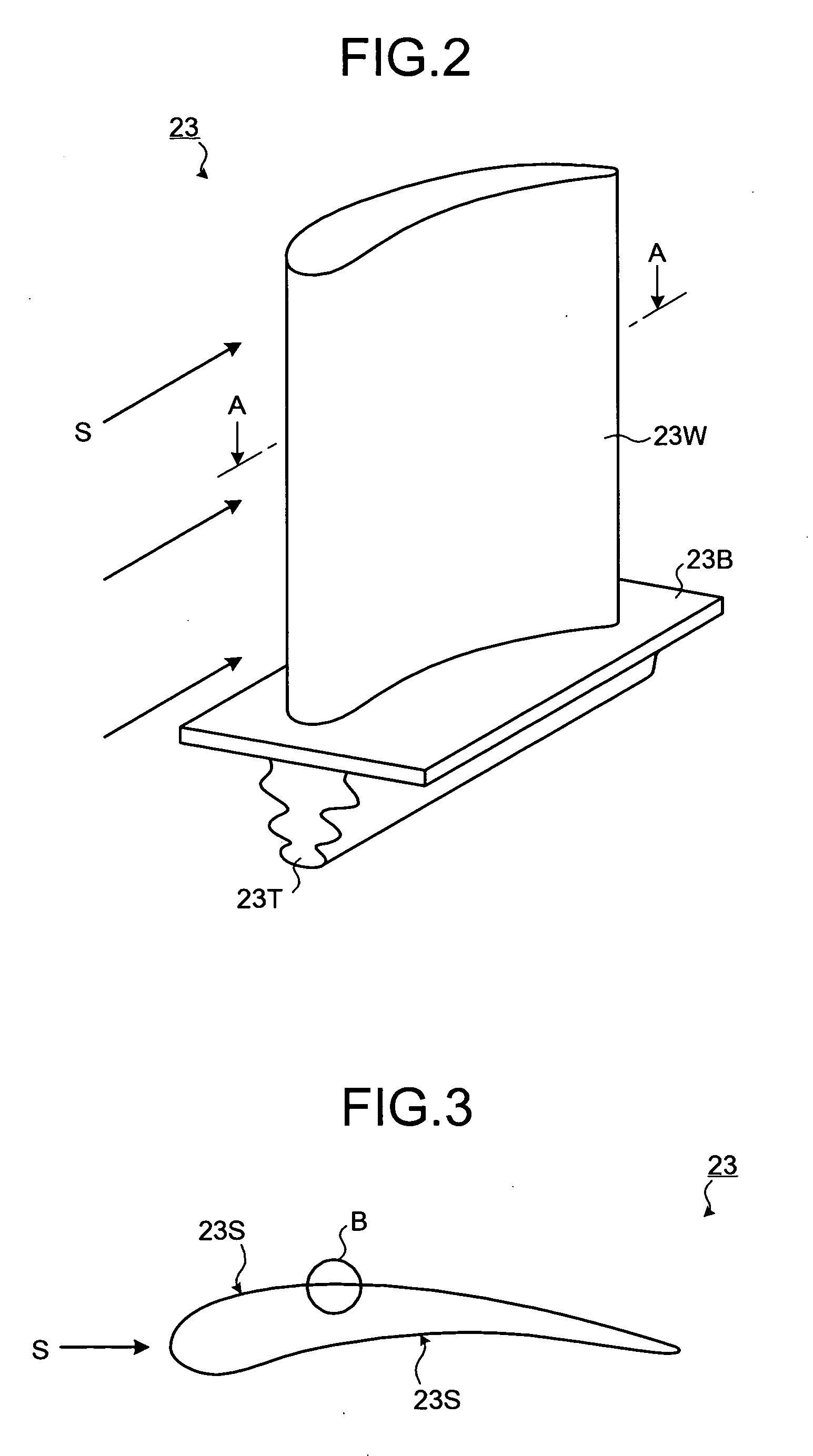

Rotating machine and parts of the same

InactiveUS20070054126A1Effectively preventing the particulatesElectrolytic coatingsBlade accessoriesParticulatesEngineering

The present invention provides parts of a rotation machine, which effectively prevent particulates, such as silica, iron oxide, and other particles, contained in a gas to adhere, in the rotating machines, which treat with the gases containing the particulates. An intermediated metal-plated film 11 and the plated film 12 containing the fluorocarbon polymer particles provided on the intermediate metal-plated film 11 are deposited on the surfaces of moving blades 23 used in a steam turbine. The plated film 12 containing the fluorocarbon polymer particles includes fluorocarbon polymer particles 13P made of any of Ni-based metals and a plated matrix 13M, and some of the fluorocarbon polymer particles 13P are exposed from the surfaces of the plated matrix 13M.

Owner:MITSUBISHI HEAVY INDUSTIES COMPRESSOR CORP

UV-curable solvent free compositions and use thereof in ceramic chip defect repair

InactiveUS20060069177A1Improve performance reliabilityPrevent product yieldImpression capsSemiconductor/solid-state device detailsThermoplasticElastomer

Solvent-free UV-curable polymer materials derived from miscible blends of reactive organic monomeric, oligomeric and low molecular polymeric systems and organic and inorganic fillers such as polytetrafluoroethylene and talc are provided to form polymer-filler composite compositions for use in the fabrication and repair of electronic components and microelectronic assembly processes. The composition contains a preformed thermoplastic or elastomeric polymer / oligomer with reactive end groups, a monofunctional and / or bifunctional acrylate monomer, a multifunctional (more than two reactive groups) acrylated / methacrylated monomer, a photoinitiator and a fluorocarbon polymer powder as an organic filler which is preferably PTFE and an inorganic filler such as talc. A nano-filler may also be used as the inorganic filler alone or in combination with another inorganic filler such as talc A method is also provided for repairing defects on ceramic substrates using the composition of the invention or other curable polymeric compositions.

Owner:TAIWAN SEMICON MFG CO LTD

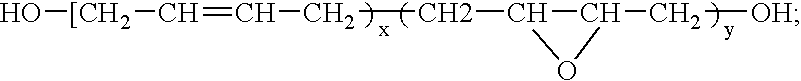

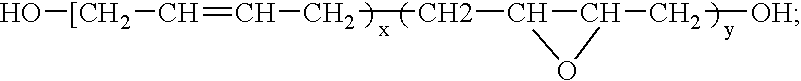

Water-based non-stick polyether sulphone coating containing no perfluorooctanoic acid and method for preparing same

The invention discloses a water-based non-stick polyether sulphone coating composition containing no perfluorooctanoic acid. The composition comprises (1) 8 to 25 weight percent of polyether sulphone, (2) 2 to 15 weight percent of fluorocarbon polymer containing no perfluorooctanoic acid, (3) 40 to 90 weight percent of water-based dispersant and (4) 0 to 20 weight percent of toner for coloring. The coating composition adopts distilled water as a thinner in spraying, reduces the use amount of an organic solvent, meets the requirement of environmental protection, contains no perfluorooctanoic acid (PFOA), and achieves the requirement of harmlessness to a human body.

Owner:INNOTEK TECH CHINA

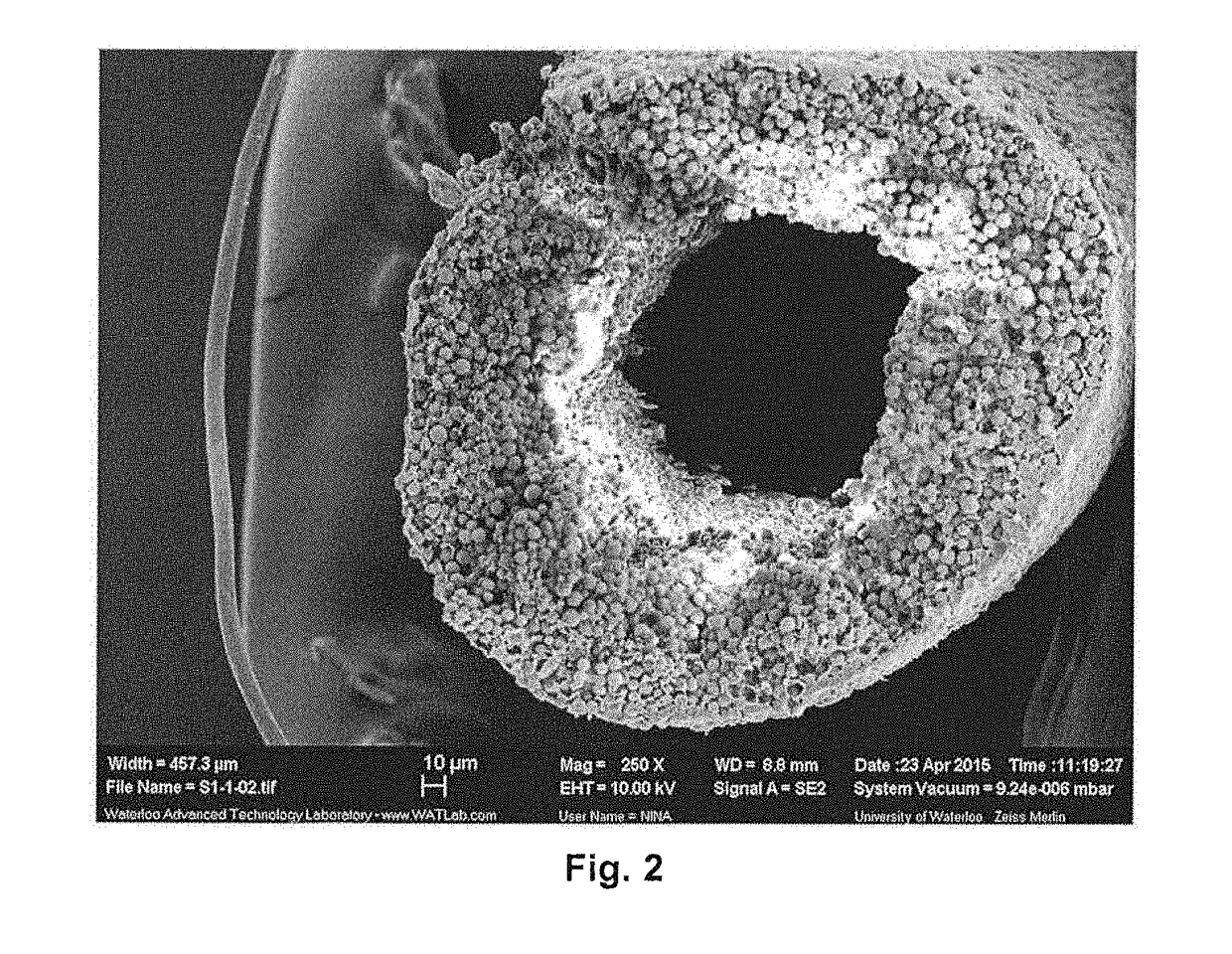

Solid phase microextraction coating

ActiveUS20170254732A1Other chemical processesPreparing sample for investigationAnalyteSolid-phase microextraction

The present disclosure provides an extraction coating for an SPME sampling instrument, where the extraction coating includes a sorptive material immobilized in a fluorocarbon polymer that is compatible with thermal-assisted desorption techniques, solvent-assisted desorption techniques, or both. The disclosure also provides SPME sampling instruments, methods of making an SPME sampling instrument, and methods of extracting an analyte from a sample matrix using the SPME coating.

Owner:JP SCI LTD +1

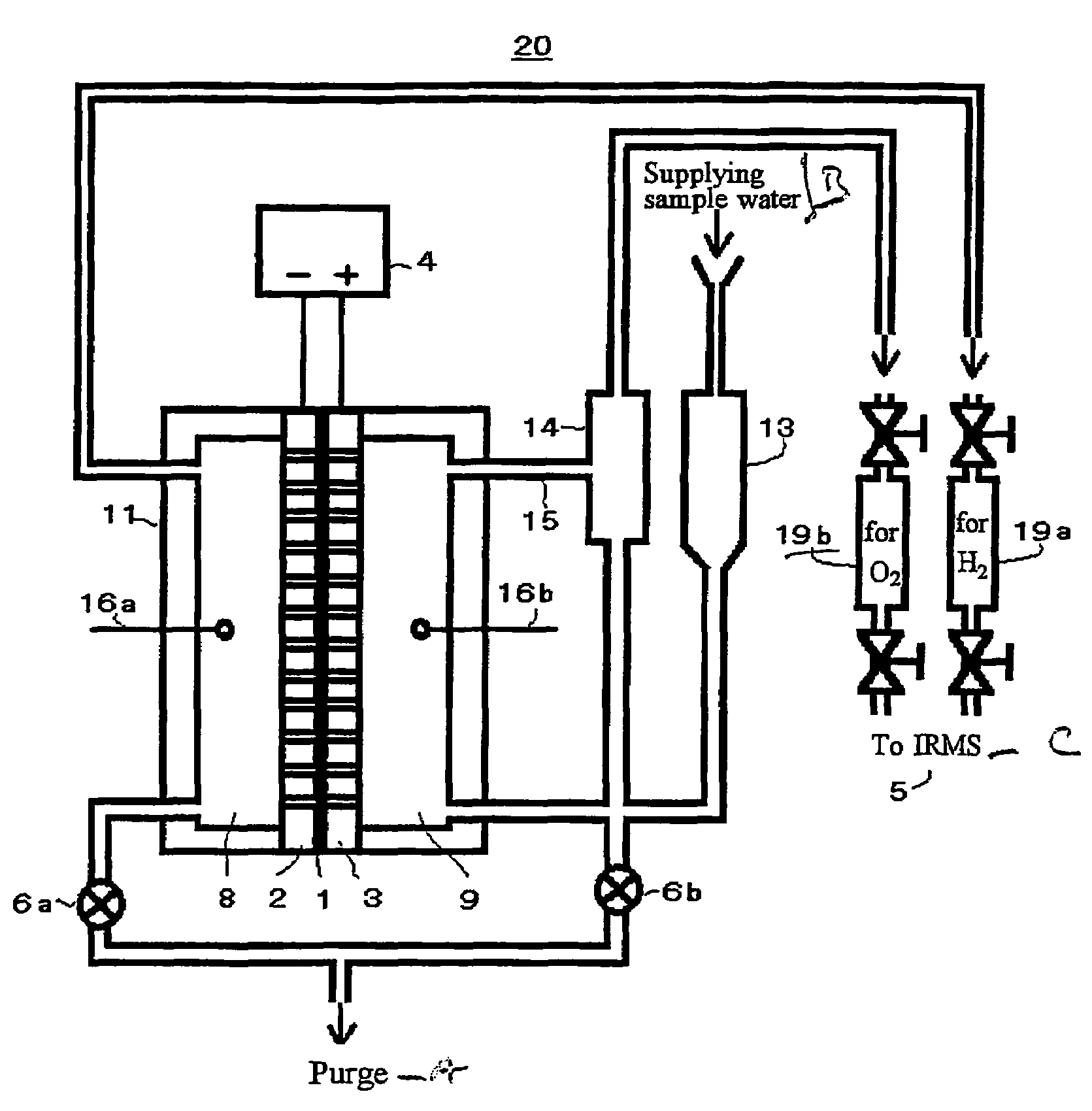

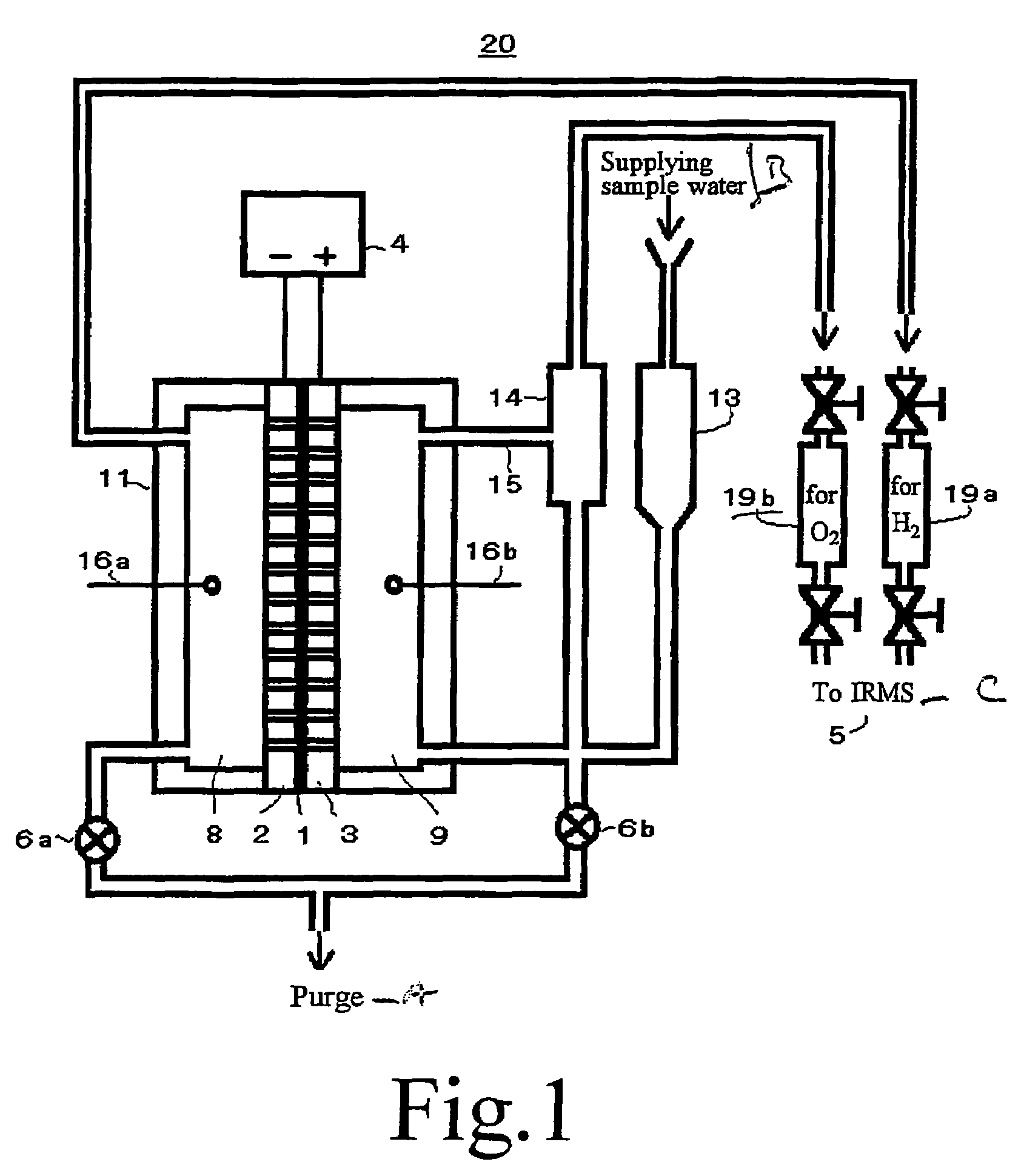

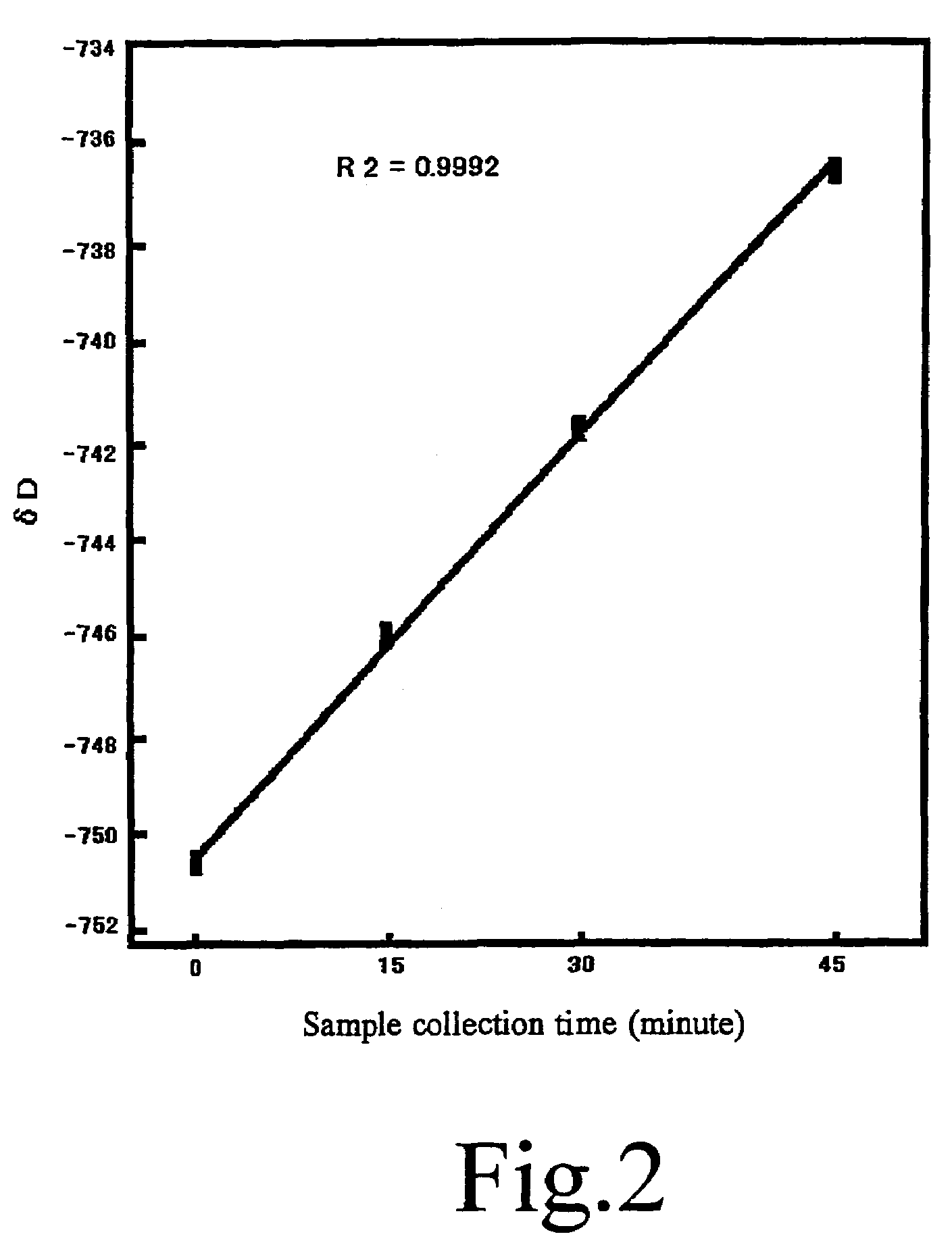

Water electrolysis method and device for determination of hydrogen and oxygen stable isotopic composition

Water electrolysis device determining stable isotopic composition of water and a water electrolysis method for stable isotopic composition of water capable of analyzing many samples easily, safely and at low cost in very short time, and rapidly analyzing 17O are provided. The water electrolysis device performing mass spectrometry of hydrogen or oxygen stable isotopic composition includes a proton exchange membrane of fluorocarbon polymer plated non-electrolytically with platinum, iridium, rhodium or iridium-rhodium alloy, and a cathode and an anode of porous titanium plated with platinum and sandwiching the proton exchange membrane, wherein water electrolyzes by introduction into the anode side chamber and supplying DC current between the anode and the cathode, and oxygen gas generated at the anode and hydrogen gas generated at the cathode respectively flows into an isotope ratio mass spectrometer. Water electrolysis method for stable isotopic composition of water using the water electrolysis device is also provided.

Owner:JAPAN SCI & TECH CORP

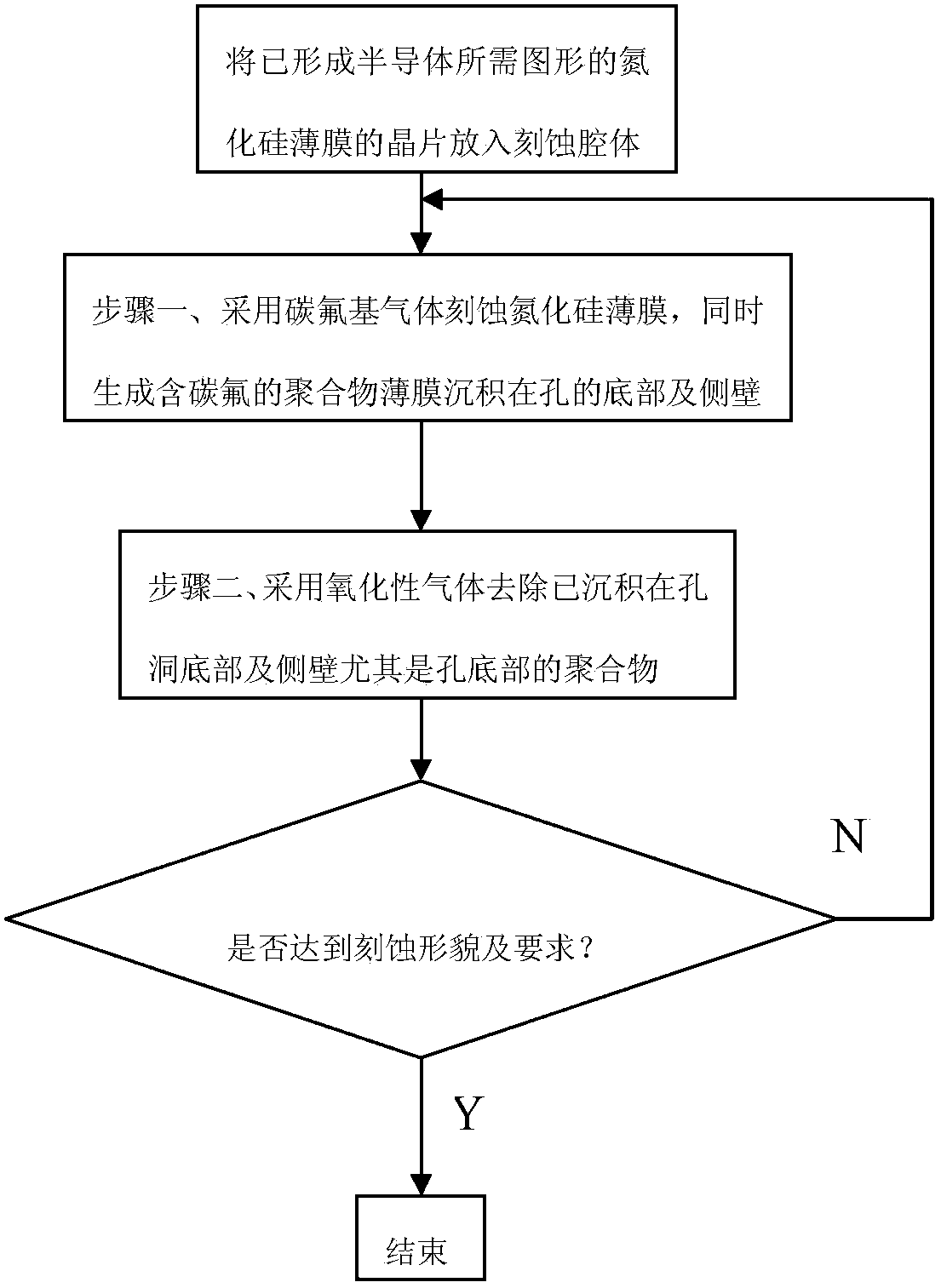

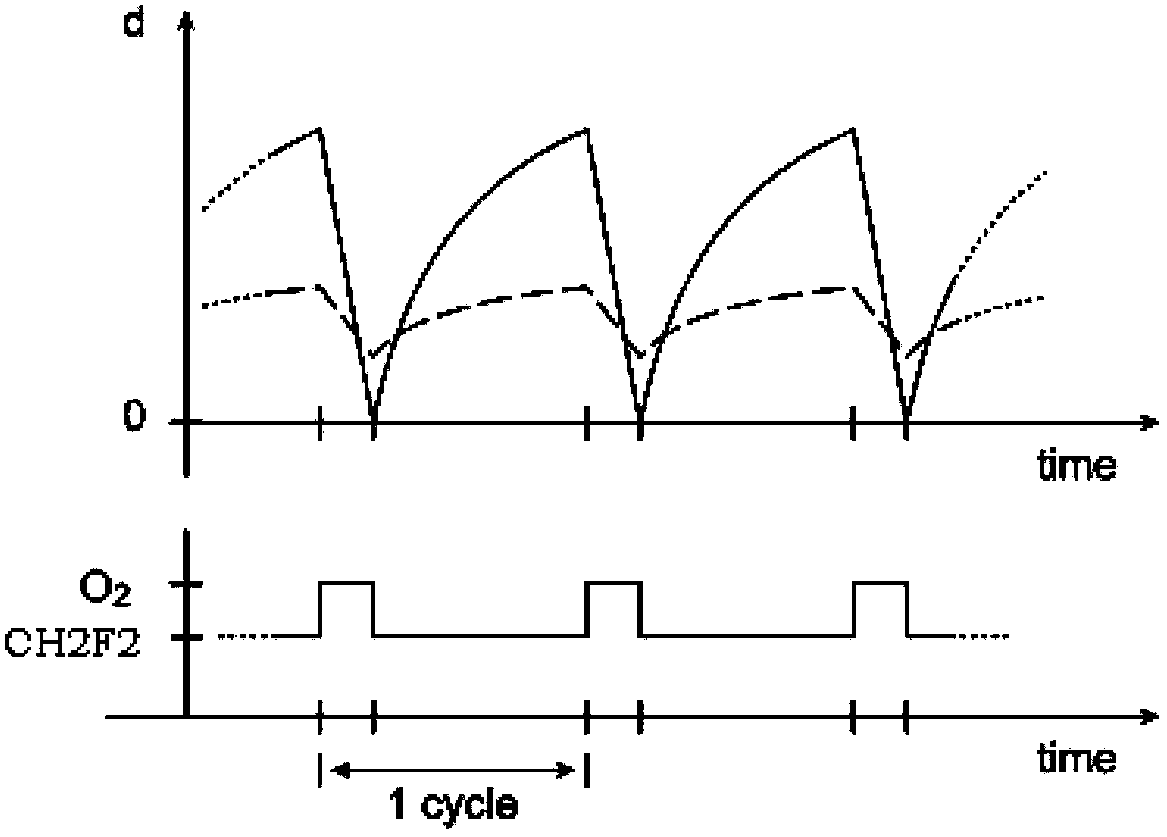

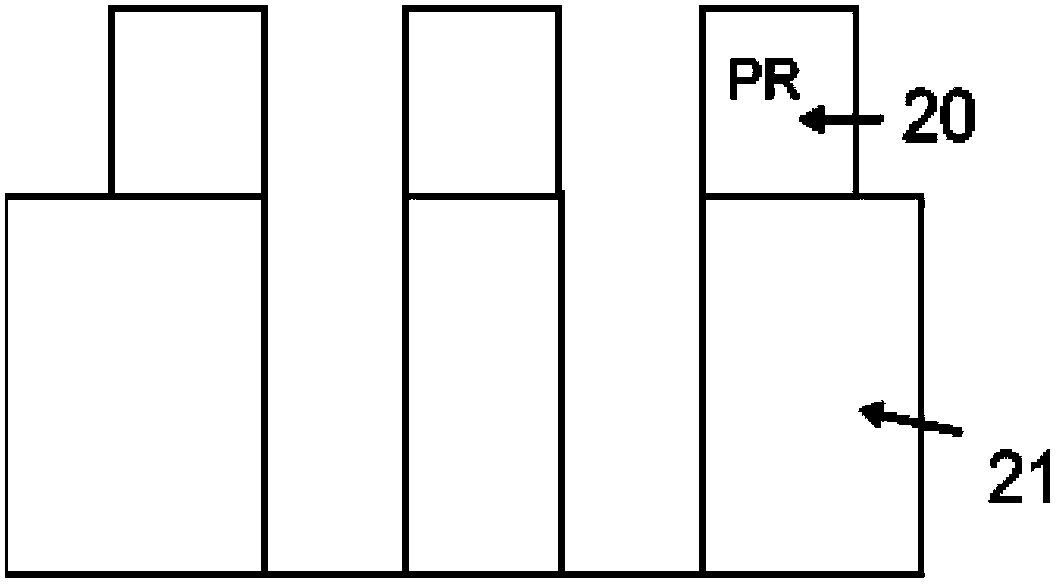

Circulating etching method of silicon nitride hole with high depth-to-width ratio

ActiveCN103578973AAdjust etch topographyAchieve anisotropySemiconductor/solid-state device manufacturingEtchingMetallurgy

A circulating etching method of a silicon nitride hole with high depth-to-width ratio comprises of the steps of 1 adopting a dry-method plasma process and fluorocarbon-based gas to perform silicon nitride thin film etching so as to form the hole and meanwhile generating a polymer depositing on the bottom and the side wall of the hole; 2 feeding oxidizing gas and diluting gas into an etching cavity. The deposition amount of fluorocarbon on the side wall of the deep hole can be controlled, the polymer depositing on the bottom of the deep hole can be removed so as to ensure continuous etching, and the two steps are repeatedly performed till the etching profile of the hole meets the requirement. When the fluorocarbon-based gas in the step 1 is increased and accordingly the fluorocarbon amount is increased, the hole is slightly oblique. When the oxidizing gas in the step 2 is increased, the hole is upright. Different hole etching profiles can be obtained as required by adjusting parameters to be between the two amounts.

Owner:SOI MICRO CO LTD

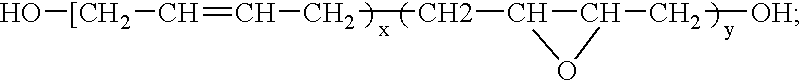

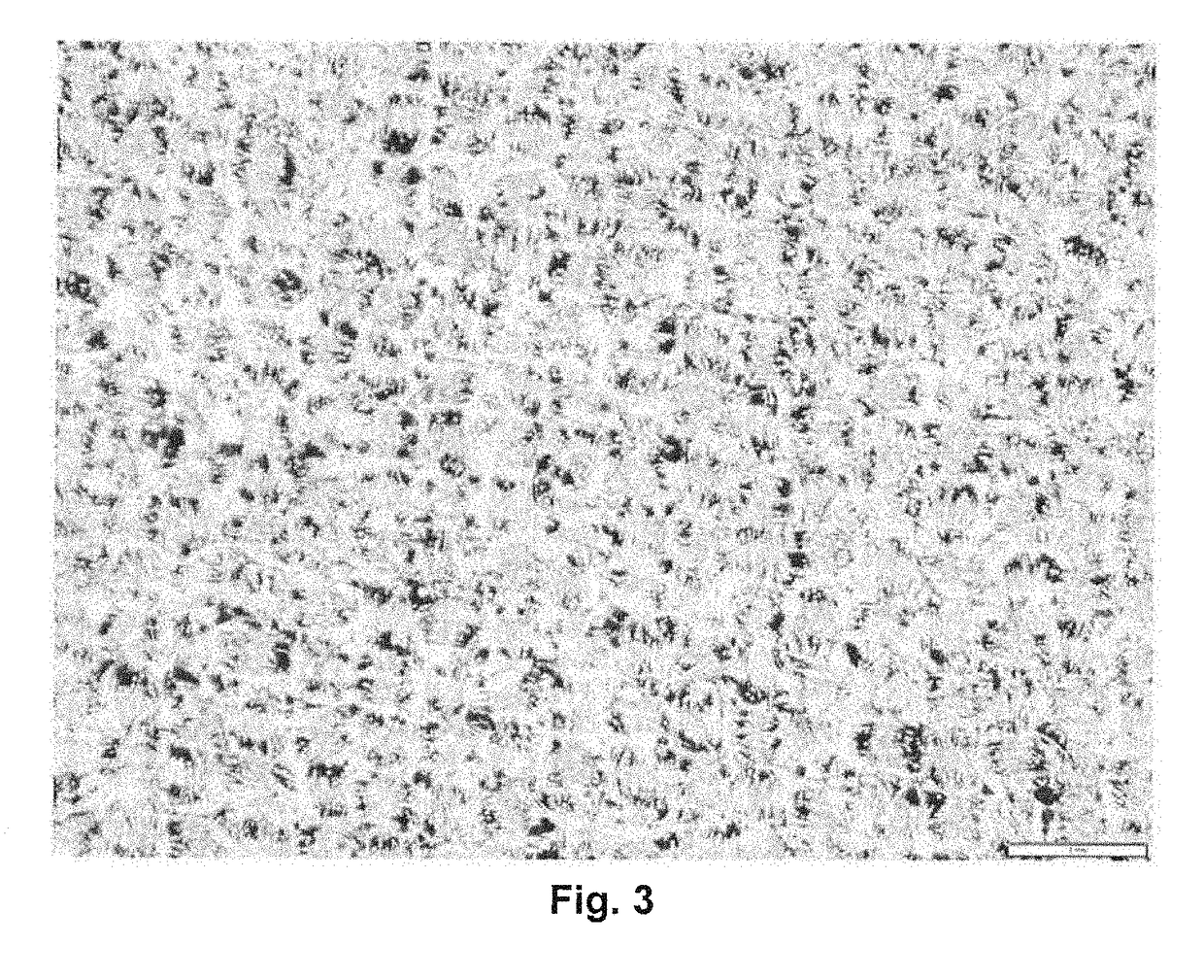

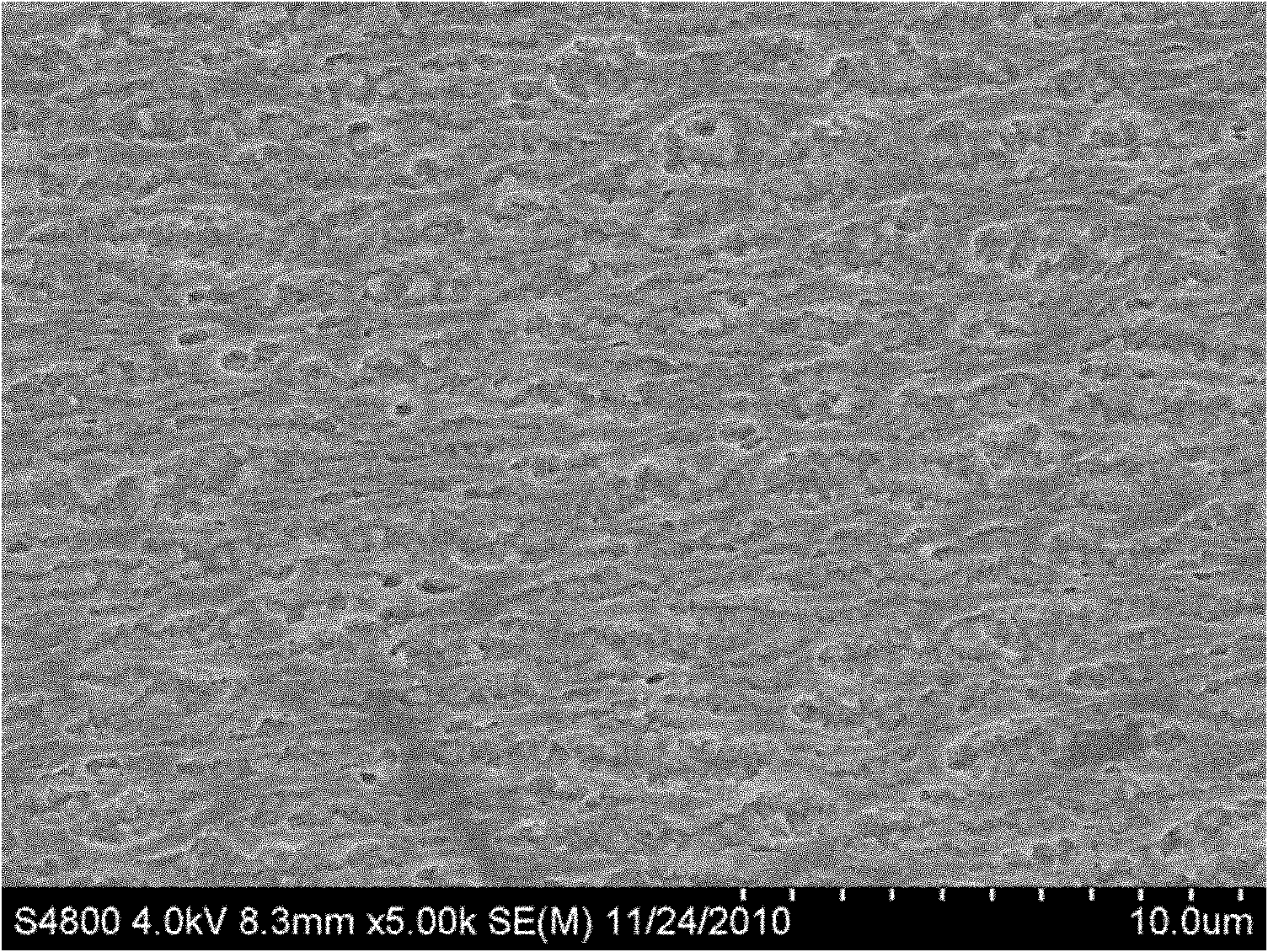

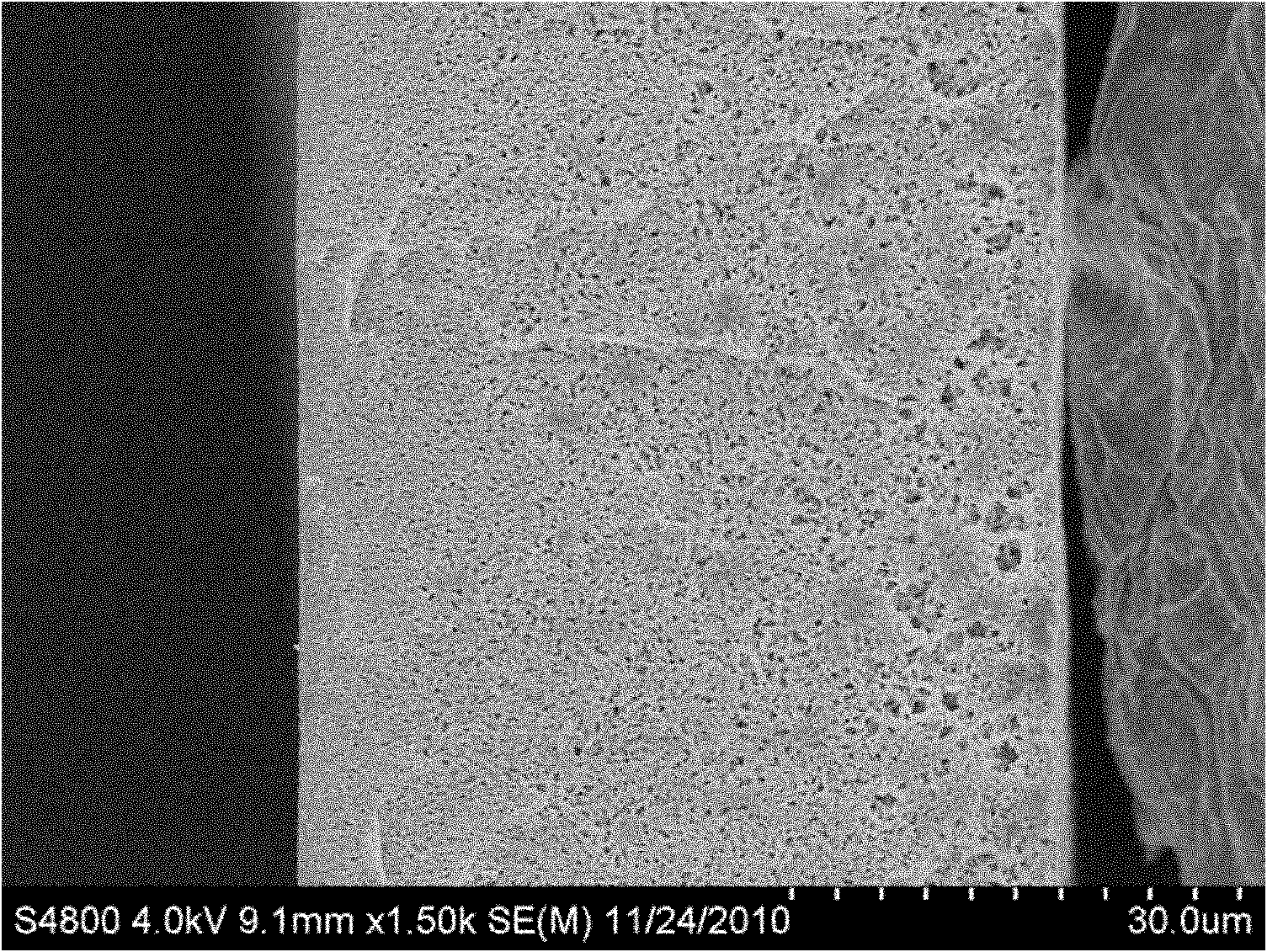

Method for preparing fluorocarbon polymer microporous film with interpenetrating network bicontinuous pore structure

ActiveCN102160969AOptimal Control StructureImprove throughputSemi-permeable membranesNon solventPolymer science

The invention discloses a method for preparing a fluorocarbon polymer microporous film with an interpenetrating network bicontinuous pore structure. The method comprises the following steps: dissolving the fluorocarbon polymer in a non-excellent solvent under conditions of constant temperature, constant humidity, constant time and constant stirring speed to prepare metastable state casting solution; defoaming the casting solution, controlling the evaporating time; curing to form by adopting a twice coagulating bath mode; and removing residual solvent, and airing to obtain the fluorocarbon polymer microporous film with the interpenetrating network bicontinuous pore structure. Compared with the prior art, in the invention, a method of combining non-solvent inductive phase separation and thermally induced phase separation is adopted to prepare a series of microporous films with the interpenetrating network bicontinuous pore structure, which have controllable structure and uniform section, and can completely eliminate large finger-type pores; and the microporous film has super large flux, high removal rating and excellent mechanical performance, can be particularly used as microfiltration films or superfiltration films, and can be applied to water resource purification and treatment.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

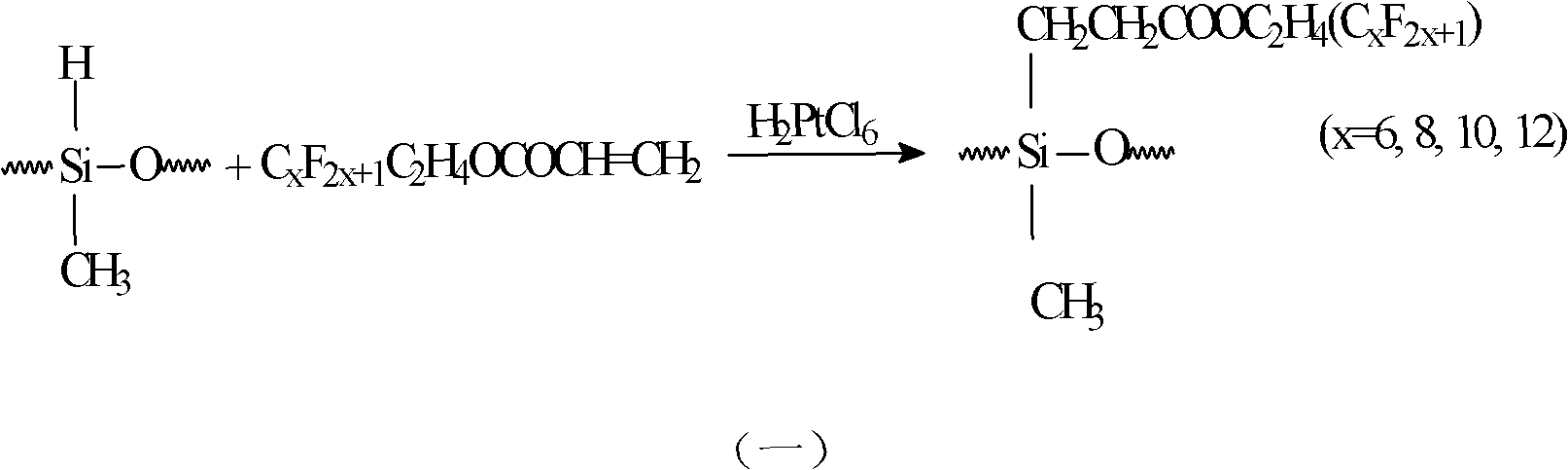

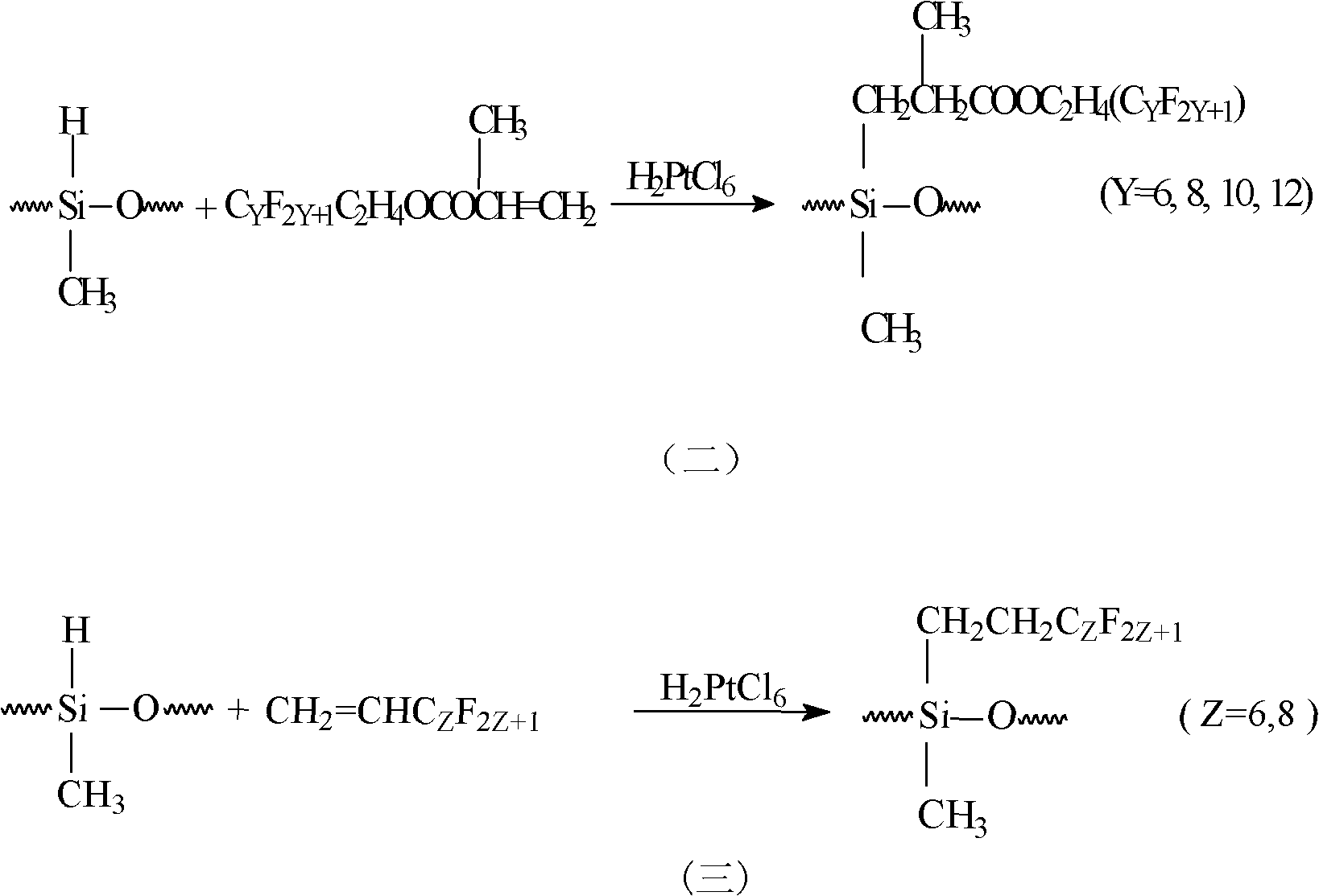

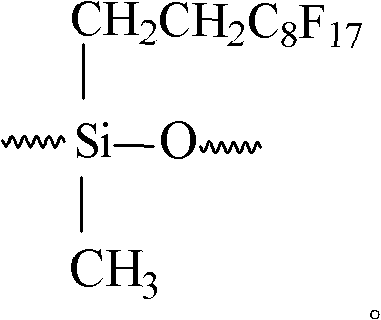

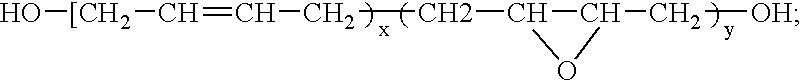

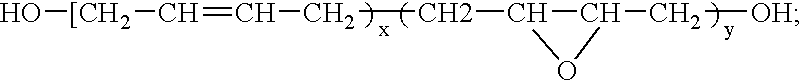

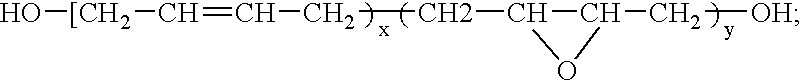

Low-surface energy fluorosilicone polymer and preparation method thereof

InactiveCN102134323ALower surface energyLow surface energyAntifouling/underwater paintsPaints with biocidesPolymer scienceSilicon oxygen

The invention discloses a low-surface energy fluorosilicone polymer and a preparation method thereof and relates to the field of organofluorine polymer paint. In the invention, an organosilicon polymer, perfluoroacyl monomers, a catalyst and a solvent are used as raw materials and are mixed in turn according to a mass part ratio of (60-80):(10-24):(0.0001-0.005):(30-50), the reaction product is purified, and thus, a high-fluoroacyl branched fluorosilicone polymer, which is one of the three perfluoroacyl monomers, or a high-fluoroacyl branched fluorosilicone polymer mixture of two or three of the three perfluoroacyl monomers. In the invention, because a catalytic reaction is performed by using a coordination compound of a transitional metal, the reaction conditions are mild, the process flow is short, the process is simple, the selectivity is high and the yield is high; the prepared polymer is a high-fluoroacyl branched fluorosilicone polymer; and the main chain of the polymer has a silicon-oxygen linear chain structure and has no other carbon-oxygen structure and the side chain is a perfluoroacyl with high fluorine content, so the low surface energy performance of organosilicon and fluorocarbon polymers can be fully played, and excellent low surface energy property can be realized.

Owner:WUHAN RES INST OF MATERIALS PROTECTION

UV-curable solvent free compositions and use thereof in ceramic chip defect repair

InactiveUS7329439B2Improve performance reliabilityAvoid YieldImpression capsSemiconductor/solid-state device detailsThermoplasticElastomer

Solvent-free UV-curable polymer materials derived from miscible blends of reactive organic monomeric, oligomeric and low molecular polymeric systems and organic and inorganic fillers such as polytetrafluoroethylene and talc are provided to form polymer-filler composite compositions for use in the fabrication and repair of electronic components and microelectronic assembly processes. The composition contains a preformed thermoplastic or elastomeric polymer / oligomer with reactive end groups, a monofunctional and / or bifunctional acrylate monomer, a multifunctional (more than two reactive groups) acrylated / methacrylated monomer, a photoinitiator and a fluorocarbon polymer powder as an organic filler which is preferably PTFE and an inorganic filler such as talc. A nano-filler may also be used as the inorganic filler alone or in combination with another inorganic filler such as talc. A method is also provided for repairing defects on ceramic substrates using the composition of the invention or other curable polymeric compositions.

Owner:TAIWAN SEMICON MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com