Rope

a technology of ropes and ropes, applied in the field of ropes, can solve the problems of rope failure, catastrophic failure of ropes, fiber material loosening a substantial amount of strength,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

first embodiment

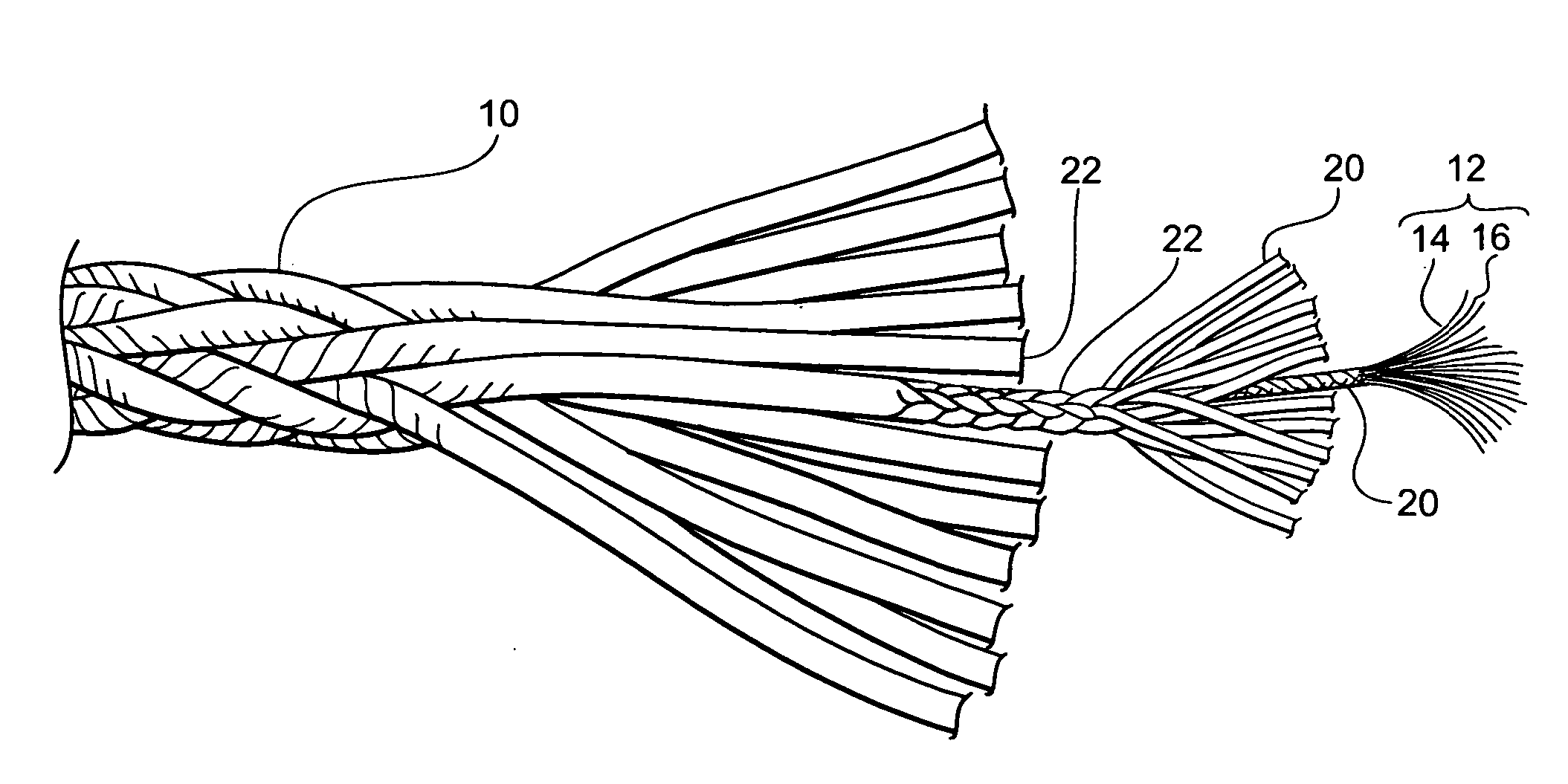

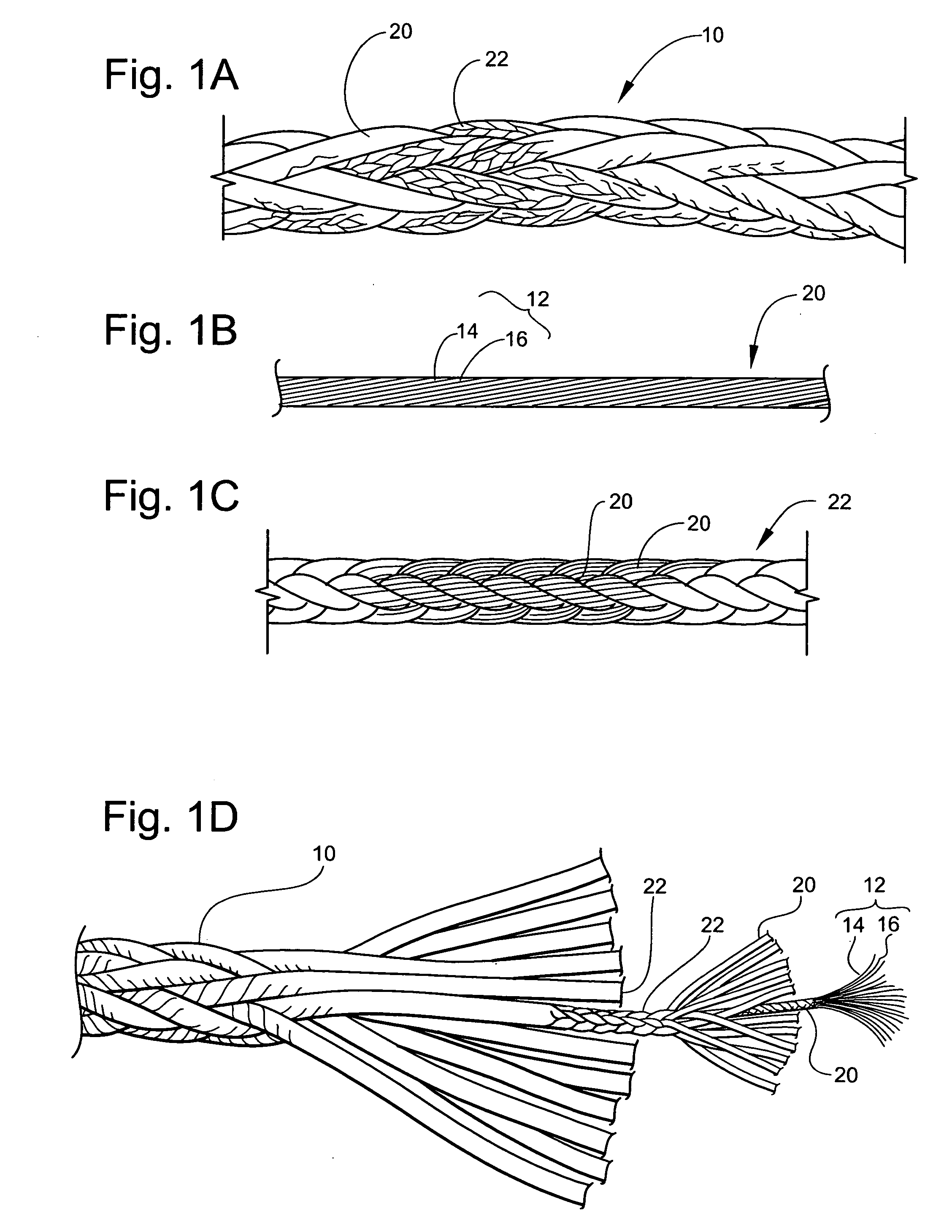

[0029] In construction of rope 10, referring to FIG. 1A-1D, the blend of filaments 12, which includes the first, and second filaments 14, and 16, respectively, is twisted together in a conventional manner to form a twisted yarn 20. The number of the first, and second filaments, 14, and 16 twisted together to form the twisted yarn 20 is not limited. Referring to FIG. 1c, a plurality of twisted yarns 20 is, then in turn, braided together in a conventional manner to from a braided strand 22. The number of twisted yarns 20 braided together to form the strand 22 is not limited. A plurality of braided strands is, subsequently, braided together in a conventional manner to form the rope 10. The number of braided strands 22 to form the rope 10 is not limited.

[0030] In an alternative construction of the first embodiment of rope 10, the blend of filaments 12, which includes first filament 14, second filament 16, and third filament (not shown) is twisted together in a conventional manner to for...

second embodiment

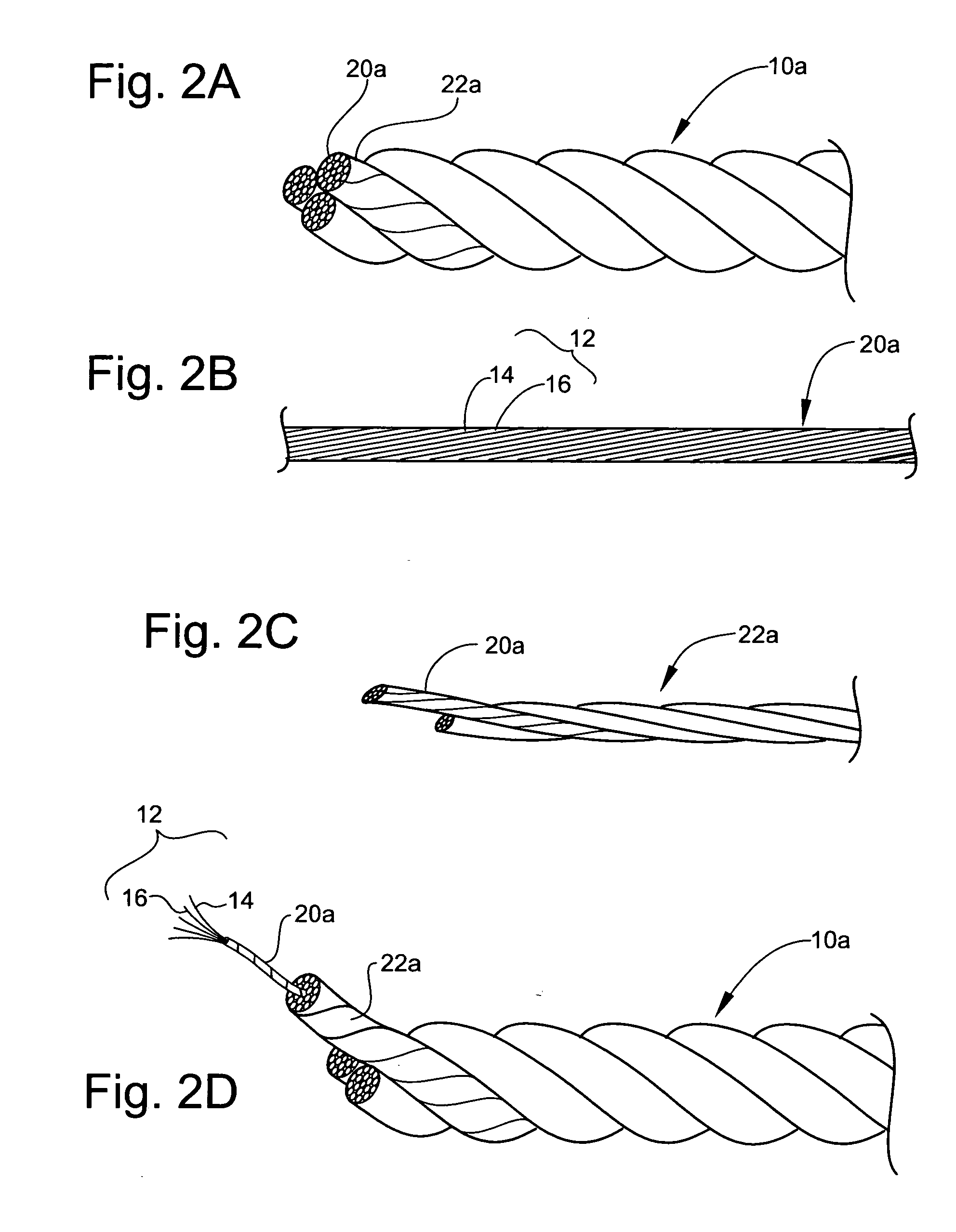

[0031] In construction of rope 10, referring to FIG. 2A-2D, the blend of filaments 12, which includes the first, and second filaments 14, and 16, respectively, is twisted together in a conventional manner to form a twisted yarn 20a. The number of the first, and second filaments, 14, and 16 twisted together to form the twisted yarn 20 is not limited. A plurality of the twisted yarns 20a is, then in turn, twisted together in a conventional manner to from a twisted strand 22a. The number of twisted yarns 20 twisted together to form the strand 22a is not limited. A plurality of twisted strands 22a is, subsequently, twisted together in a conventional manner to form the rope 10a. The number of twisted strands 22a to form the rope 10a is not limited.

[0032] In an alternative construction of the second embodiment of rope 10, the blend of filaments 12, which includes the first filament 14, second filament 16, and third filament (not shown) is twisted together in a conventional manner to form ...

third embodiment

[0033] In construction of rope 10, referring to FIG. 3A-3B, the blend of filaments 12, which includes the first, and second filaments 14, and 16, respectively, is aligned in a substantially parallel relation to each other, and then compacted under tension to form a core 24. The number of the first, and second filaments, 14, and 16 aligned and compacted together to form the core 24 is not limited. The Core 24 is, subsequently, covered by a covering 26. The covering 26 may include, but is not limited to, a synthetic polymer based product.

[0034] In an alternative construction of the third embodiment of rope 10, the blend of filaments 12, which includes the first filament 14, second filament 16, and third filament (not shown) is aligned in a substantially parallel relation to each other, and then compacted under tension to form a core 24. The number of the first filament 14, second filament 16, and third filament aligned and compacted together to form the core 24 is not limited. The Cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com