Organic electroluminescence device packaging structure and method and display device

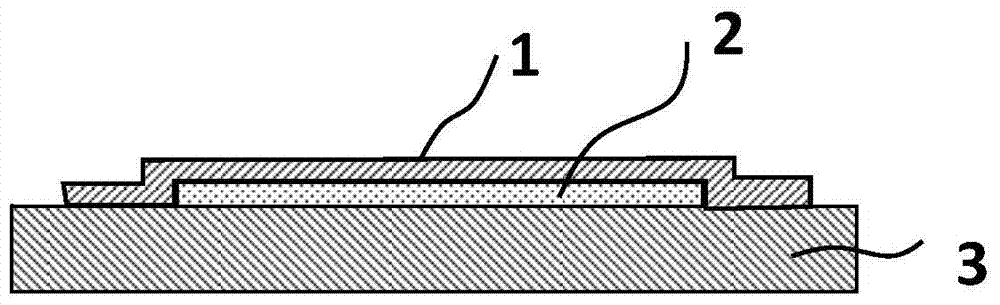

A technology of electroluminescent devices and packaging structures, which is applied in the direction of organic semiconductor devices, electric solid devices, electrical components, etc., can solve the problems of large internal stress, low elasticity of inorganic films, and peeling off, so as to improve the ability of blocking water and oxygen, Effect of extending life and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

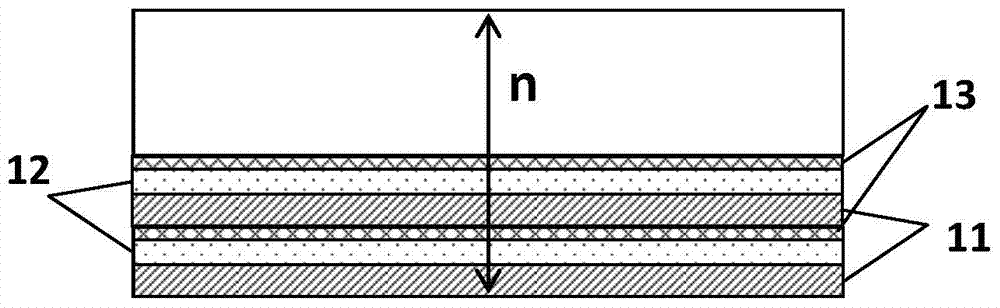

[0064] Example 1Al 2 o 3 (50nm) / PCP(50nm) / CFx(10nm)

[0065] The encapsulation method of the OLED device of the present embodiment comprises the following steps:

[0066] Step a: providing a substrate, which may be a quartz substrate or a glass substrate;

[0067] Step b: preparing the OLED device on the substrate;

[0068] Step c: Deposit a layer of Al on the substrate after step b by ion beam sputtering deposition 2 o 3 Thin films, the vacuum degree in the deposition chamber is 10 -6 Pa, deposition time is 10min, Al 2 o 3 The thickness of the film is 50nm;

[0069] Step d: using the method of chemical vapor deposition on the Al 2 o 3 Deposit a layer of polychlorinated p-xylene on the film, specifically, firstly sublimate the solid C-type polychlorinated-p-xylene at 100°C, and make the C-type polychlorinated-p-xylylene at 630°C on both sides The carbon-carbon bond of the chain is broken to generate a stable active monomer, and then the active monomer is introduced ...

Embodiment 2

[0072] Embodiment 2SiO (100nm) / polychlorinated p-xylene (200nm) / CFx (20nm)

[0073] The encapsulation method of the OLED device of the present embodiment comprises the following steps:

[0074] Step a: providing a substrate, which may be a quartz substrate or a glass substrate;

[0075] Step b: preparing the OLED device on the substrate;

[0076] Step c: Deposit a layer of SiO thin film on the substrate after step b by magnetron sputtering, and the vacuum degree in the deposition chamber is 10 -5 Pa, the deposition time is 10min, and the thickness of the SiO film is 100nm;

[0077] Step d: Deposit a layer of polychlorinated p-xylene on the SiO film by chemical vapor deposition, specifically, first sublimate the solid C-type polychlorinated-p-xylene at 100°C to make the C-type polychlorinated p-xylene The two side chain carbon-carbon bonds of substituted p-xylene are broken at 630°C to generate a stable active monomer, which is then introduced into the deposition chamber thr...

Embodiment 3

[0079] Embodiment 3SiON (100nm) / polychlorinated p-xylene (200nm) / CFx (20nm)

[0080] The encapsulation method of the OLED device of the present embodiment comprises the following steps:

[0081] Step a: providing a substrate, which may be a quartz substrate or a glass substrate;

[0082] Step b: preparing the OLED device on the substrate;

[0083] Step c: Deposit a layer of SiON film on the substrate after step b by magnetron sputtering, and the vacuum degree in the deposition chamber is 10 -5 Pa, the deposition time is 10min, and the thickness of the SiON film is 100nm;

[0084] Step d: Deposit a layer of polychlorinated p-xylene on the SiON film by chemical vapor deposition, specifically, first sublimate the solid C-type polychlorinated-p-xylene at 100°C to make the C-type polychlorinated p-xylene The two side chain carbon-carbon bonds of substituted p-xylene are broken at 630°C to generate a stable active monomer, which is then introduced into the deposition chamber thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com