Biodegradable baseplate used for soft light electron device and manufacturing method thereof

A kind of optoelectronic device, flexible technology, applied in semiconductor/solid-state device manufacturing, electric solid-state device, photovoltaic power generation, etc., can solve the problem of poor surface smoothness of flexible substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0168] Such as figure 1In the substrate structure shown, the flexible substrate 2 is shellac mixed with dual-curing adhesive, the dual-curing adhesive adopts a dual-curing system of free radical ultraviolet curing agent-thermal curing agent, and the conductive layer 1 is an ITO film.

[0169] The preparation method is as follows:

[0170] ①Use detergent, acetone solution, ethanol solution and deionized water to ultrasonically clean the glass substrate, and dry it with dry nitrogen after cleaning;

[0171] ② Stir the mixed solution of shellac-dual curing glue (dual curing glue accounted for 0.3% by mass) diluted 1:10 with ethanol for 20 hours, then spin-coat it on the surface of the glass substrate with a film thickness of about 100 microns;

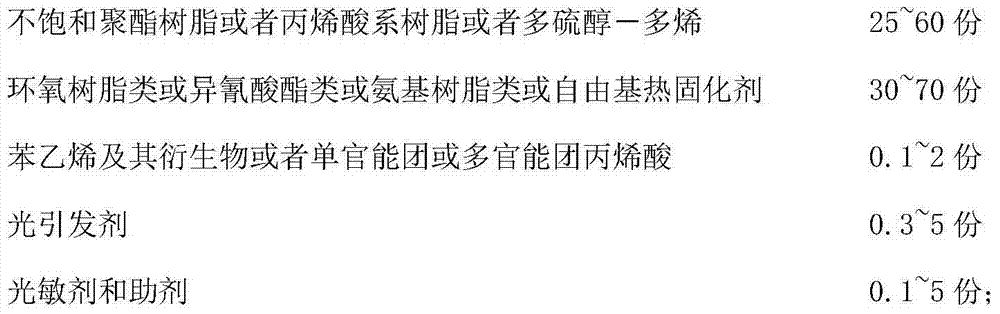

[0172] Wherein the proportioning ratio of dual curing rubber raw material components is:

[0173]

[0174] ③UV curing treatment on the surface of the substrate for 30 seconds;

[0175] ④Put the substrate into the oven at a temperatu...

Embodiment 2

[0181] Such as figure 1 In the substrate structure shown, the flexible substrate 2 is shellac mixed with dual-curing adhesive, the dual-curing adhesive adopts a dual-curing system of free radical ultraviolet curing agent-microwave curing agent, and the conductive layer 1 is carbon nanotubes.

[0182] The preparation method is as follows:

[0183] ①Use detergent, acetone solution, ethanol solution and deionized water to ultrasonically clean the glass substrate, and dry it with dry nitrogen after cleaning;

[0184] ② Stir the mixed solution of shellac-dual curing glue (dual curing glue accounted for 0.4% by mass) diluted 1:10 with ethanol for 20 hours, then spin-coat it on the surface of the glass substrate with a film thickness of about 300 microns;

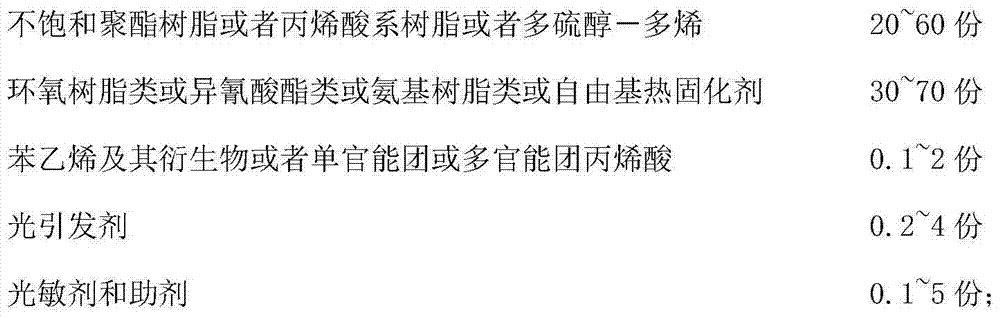

[0185] Wherein the proportioning ratio of dual curing rubber raw material components is:

[0186]

[0187] ③The substrate obtained in step ② is treated with ultraviolet light, and the treatment time is 30s;

[0188] ④ Put th...

Embodiment 3

[0194] Such as figure 1 In the substrate structure shown, the flexible substrate 2 is shellac mixed with dual-curing adhesive, the dual-curing adhesive adopts a dual-curing system of free radical ultraviolet curing agent-anaerobic curing agent, and the conductive layer 1 is silver nanowires.

[0195] The preparation method is as follows:

[0196] ① Clean the glass substrate with a surface roughness less than 1nm first, then use detergent, acetone, deionized water, and isopropanol to perform ultrasonic cleaning, and then dry it with dry nitrogen after cleaning;

[0197] ② Stir the mixed solution of shellac-dual curing glue (dual curing glue accounted for 0.5% by mass) diluted 1:10 with ethanol for 20 hours, then spin-coat it on the surface of the glass substrate, with a film thickness of about 500 microns;

[0198] Wherein the proportioning ratio of dual curing rubber raw material components is:

[0199]

[0200] ③UV curing the substrate obtained in step ② for 40 seconds; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com