Method for preparing pure-phase high-index vertically-oriented tin-based perovskite thin film based on phenylethyl amine chloride

A phenylethylammonium chloride and vertical orientation technology, applied in the field of solar cells, can solve the problems that the device stability and energy conversion efficiency cannot reach the ideal state at the same time, the decomposition of tin-based perovskite crystals, and the impact on energy conversion efficiency, etc. , to achieve the effect of facilitating energy supply, good water and oxygen isolation effect, and improving energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Provide a transparent conductive substrate of fluorine-doped tin oxide (FTO), and perform standardized cleaning;

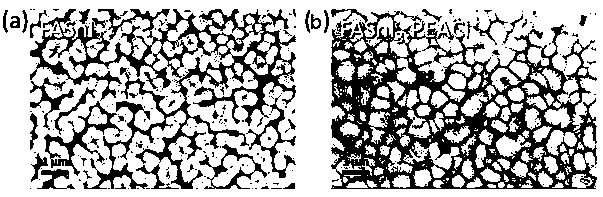

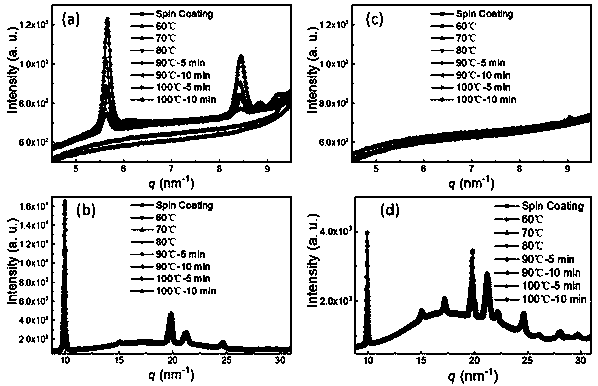

[0030] (2) Methyl iodide (FAI), stannous iodide (SnI 2 ) and stannous fluoride (SnF 2 ) was dissolved in dimethyl sulfoxide solution at a molar ratio of 1:1:0.1, phenethylamine chloride (PEACl) with a molar mass of 10 mol% was added, and stirred for 2-5 hours to obtain a tin-based perovskite precursor body solution;

[0031] (3) Treat the FTO with ozone for 30 min, then add nickel oxide (NiO x ) solution, rotated at 4000 rpm for 40 s, then annealed at 180 °C for 20 min to obtain a cured hole transport layer;

[0032] (4) After the perovskite precursor solution added with PEACl was treated with the anti-solvent of chlorobenzene, the perovskite layer film was rotated at a speed of 5000rpm for 70 seconds, anti-solvent treatment was performed for 50 seconds, and then the temperature gradient annealing treatment was performed, from 60 From ℃ to 100℃, fiv...

Embodiment 2

[0037] (1) Provide a transparent conductive substrate of fluorine-doped tin oxide (FTO), and perform standardized cleaning;

[0038] (2) Methyl iodide (FAI), stannous iodide (SnI 2 ) and stannous fluoride (SnF 2 ) was dissolved in dimethyl sulfoxide solution at a molar ratio of 0.9:1:0.1, and phenylethylammonium chloride (PEACl) with a molar mass of 10 mol% was added, and stirred for 2-5 hours to obtain a tin-based perovskite precursor body solution;

[0039] (3) Treat the FTO with ozone for 30 min, then add nickel oxide (NiO x ) solution, rotated at 4000 rpm for 40 s, then annealed at 180 °C for 20 min to obtain a cured hole transport layer;

[0040] (4) After the perovskite precursor solution added with PEACl was treated with the anti-solvent of chlorobenzene, the perovskite film was rotated at 5000rpm for 70 seconds, anti-solvent treatment was performed for 50 seconds, and then gradient annealing was performed. The temperature was raised to 100 °C, and five temperature ...

Embodiment 3

[0045] (1) Provide a transparent conductive substrate of fluorine-doped tin oxide (FTO), and perform standardized cleaning;

[0046] (2) Methyl iodide (FAI), stannous iodide (SnI 2 ) and stannous fluoride (SnF 2 ) was dissolved in dimethyl sulfoxide solution at a molar ratio of 1:1:0.1, phenethylamine chloride (PEACl) with a molar mass of 10 mol% was added, and stirred for 2-5 hours to obtain a tin-based perovskite precursor body solution;

[0047] (3) Treat FTO with ozone for 30 min, then add poly(3,4-ethylenedioxythiophene)-poly(styrenesulfonic acid) solution dropwise, rotate at 4000 rpm for 40 s, then anneal at 180 °C, Annealed for 20 min to obtain a cured hole transport layer;

[0048] (4) After the perovskite precursor solution added with PEACl was treated with the anti-solvent of chlorobenzene, the perovskite film was rotated at 5000rpm for 70 seconds, anti-solvent treatment was performed for 50 seconds, and then gradient annealing was performed. The temperature was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com