Plasma dielectric etch process including ex-situ backside polymer removal for low-dielectric constant material

a dielectric constant, exsitu backside technology, applied in the direction of photomechanical equipment, chemistry equipment and processes, instruments, etc., can solve the problems of oxidizing process doing catastrophic harm to the newer low dielectric constant insulator materials, difficult to remove all of the deposited polymer, and thinner photoresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

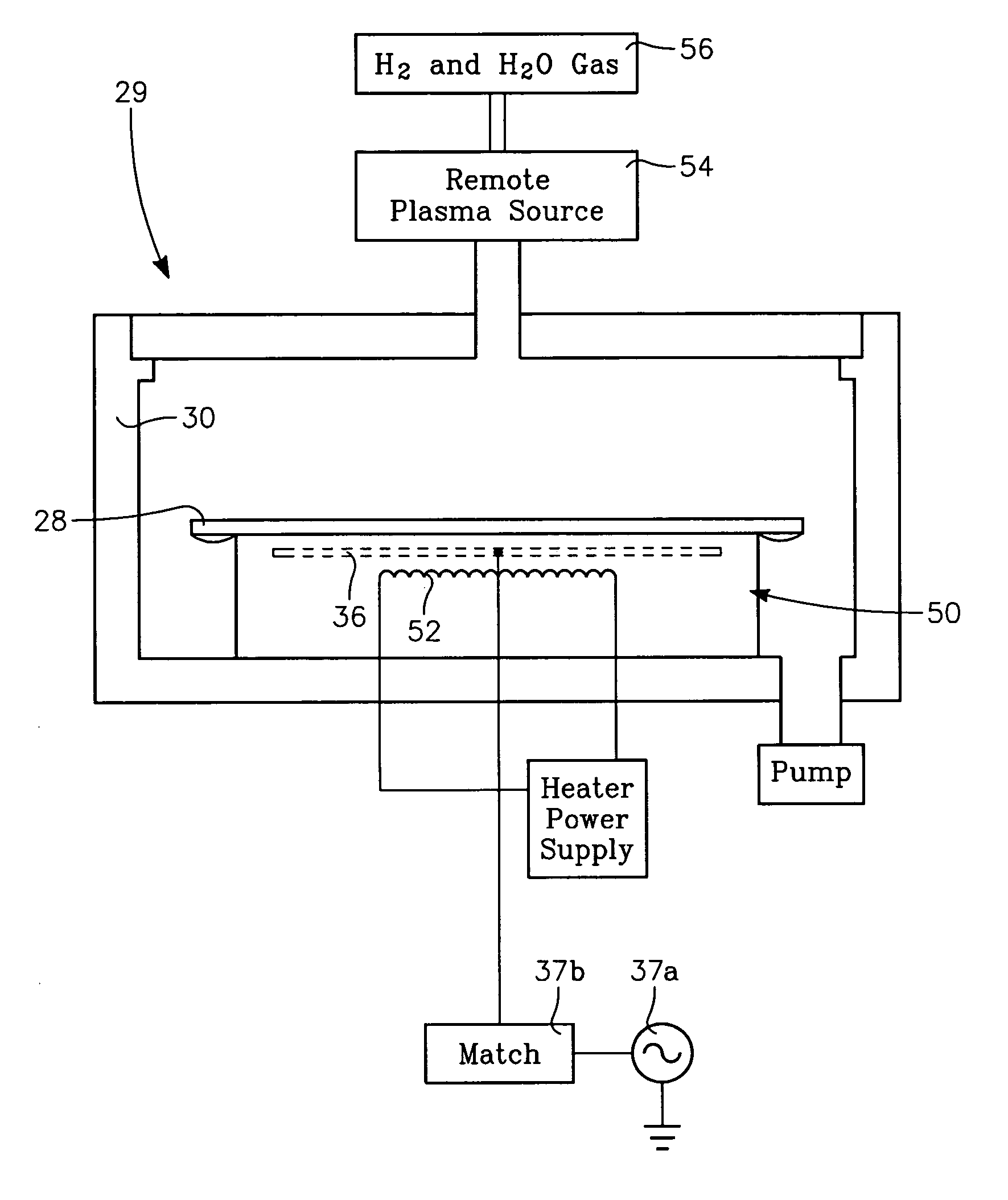

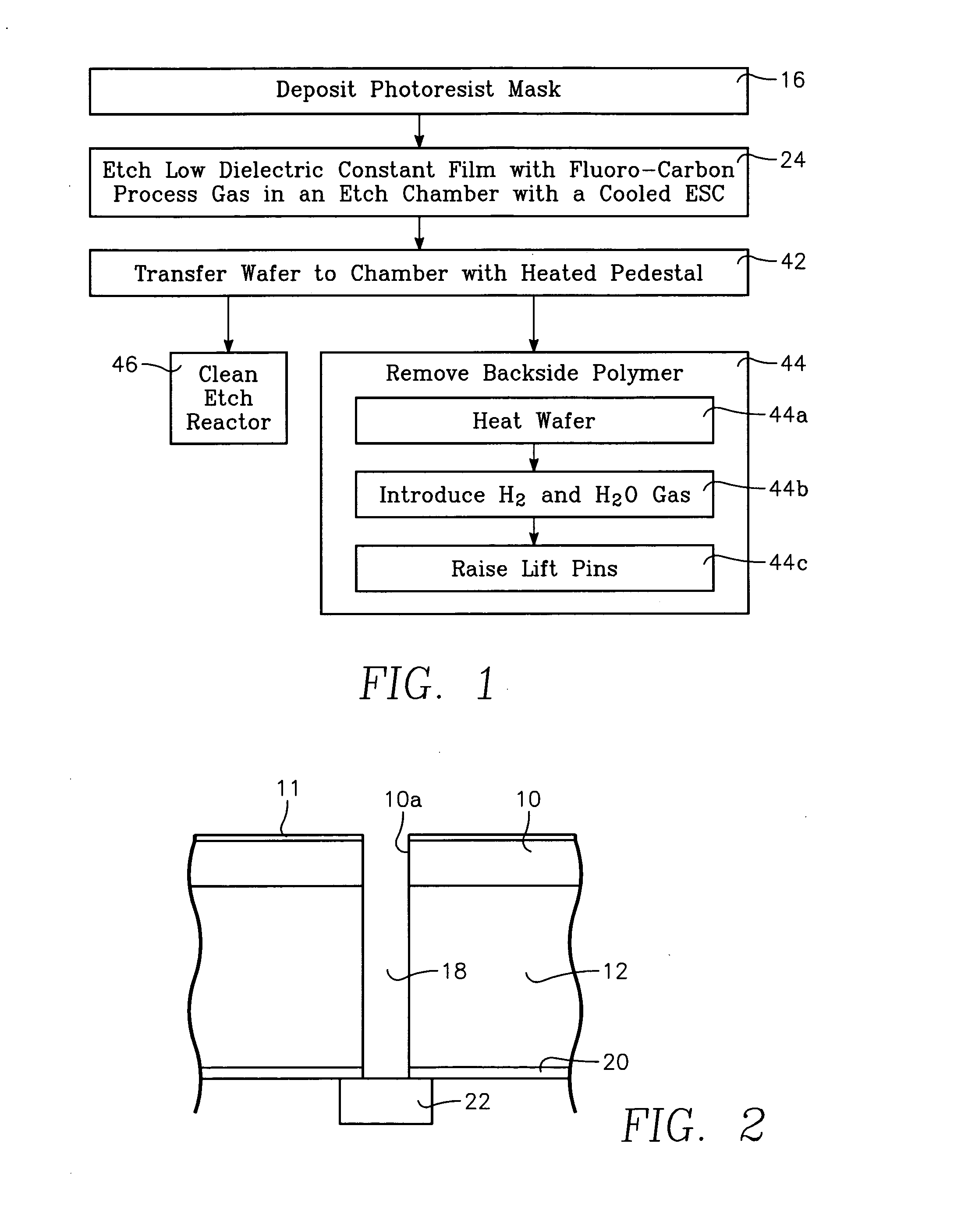

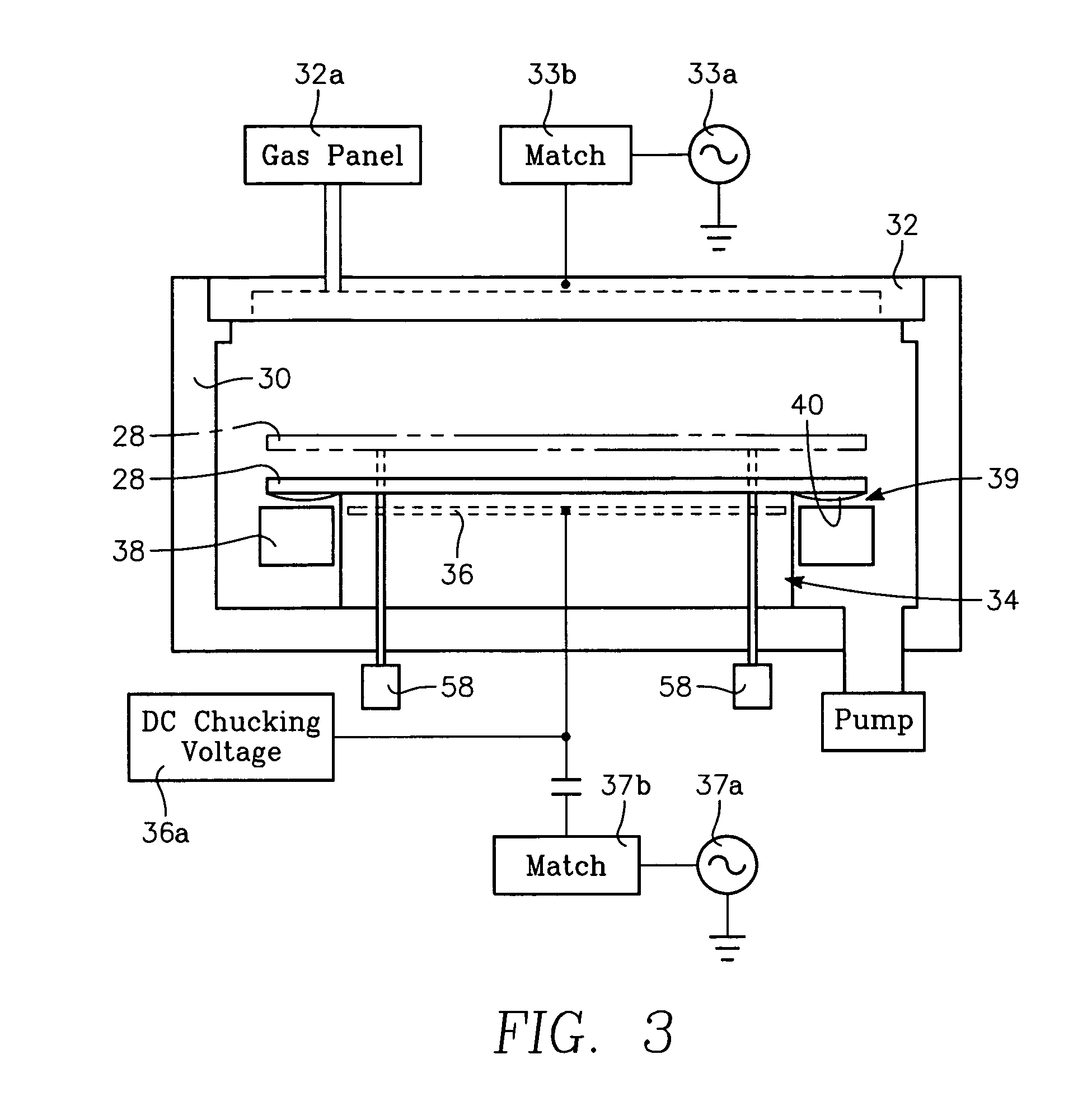

[0011] The invention is based upon our discovery of an etch process for a low dielectric constant material including a post etch polymer removal step that thoroughly removes both backside polymer and photoresist with no appreciable damage to the low dielectric constant insulator layer (e.g., porous carbon-doped silicon dioxide or a porous organo-silicate material), and does so in less than 60 seconds. An etch process embodying the invention is depicted in FIG. 1, while FIG. 2 depicts one example of a thin film structure that can be formed using the process of FIG. 1. A photoresist mask 10 depicted in FIG. 2 is deposited on a dielectric layer 12, the mask 10 having an aperture 10a corresponding to a feature 18 that is to be etched in the dielectric layer 12. This corresponds to the step of block 16 of FIG. 1. The feature may be a narrow via 18. The via 18 extends through the dielectric layer 12 and through a barrier layer 20 to expose the top surface of a copper line 22. The dielectr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| period of time | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com