Rotatable fixing member, manufacturing method thereof and fixing device

a technology of fixing member and manufacturing method, which is applied in the direction of electrographic process, coating, instruments, etc., can solve the problems of insufficient heat resistivity and durability, inability to obtain sufficient smoothness, and conventionally very difficult to form on the elastic, so as to prevent mud cracks, impair bonding properties, and cracks easily occur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

(7) Examples of Embodiment 1

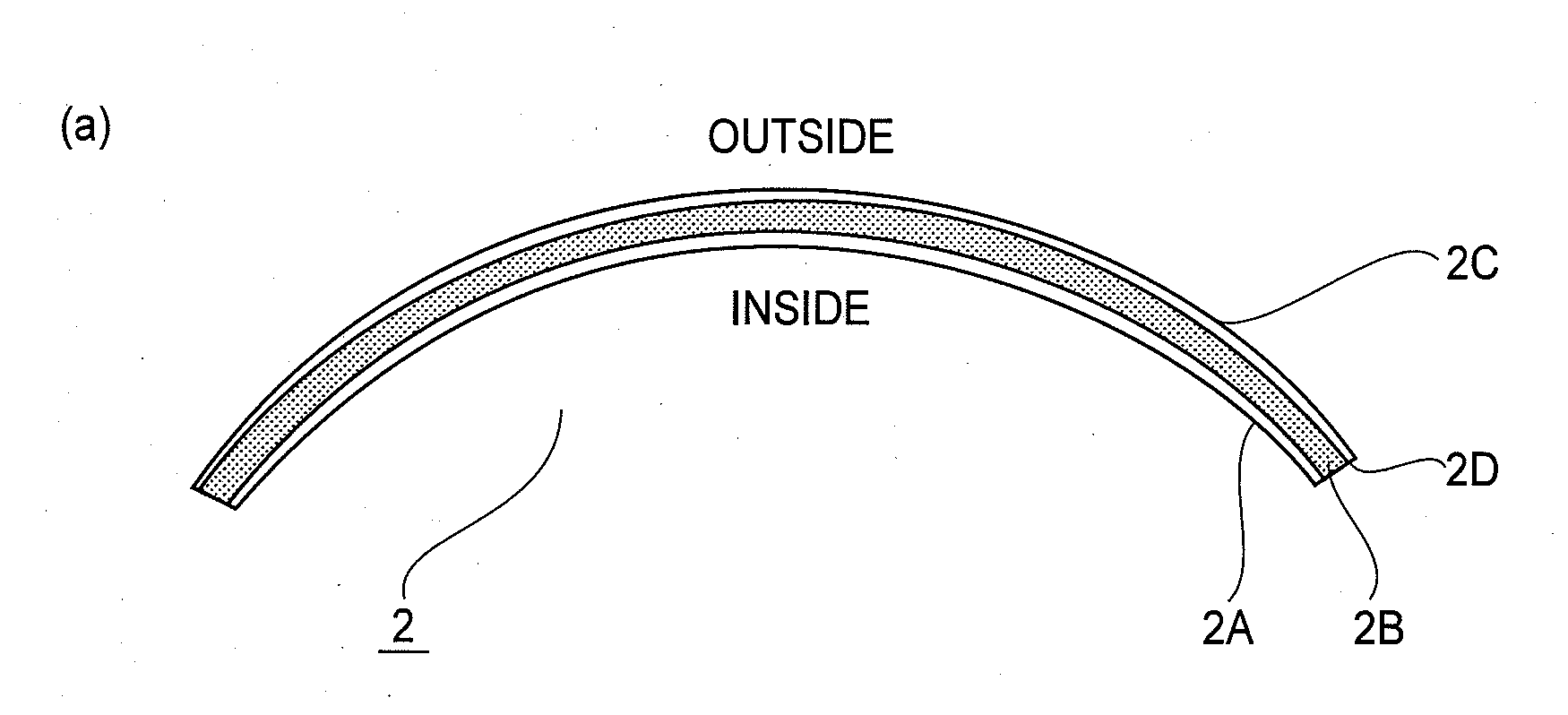

[0091]Specific examples of the fixing film 2 which is the rotatable fixing member in Embodiment 1 will be described.

(7-1) Fixing Film Manufacturing Method in Examples 1 to 3

[0092]The fixing films in Examples 1 to 3 have the same constitution except for their thicknesses.

(7-1-1) Preparation of Elastic Layer for Fixing Film

[0093]As the base material 2A, an SUS metal belt (flexible endless belt member) having a length of 240 mm, a thickness of 40 μm and an outer diameter of 30 mm was used. On an outer circumferential surface of the base material 2A2B, a high heat-resistant silicone rubber (“SE4400”, mfd. by Dow Corning Toray Co., Ltd.) which contained a heat-conductive filler in advance and had thermal conductivity of about 1 W / m·k was used. This silicone rubber was coated on the primer application area (300 μm in thickness and 230 mm in length) on the base material 2A by the ring coating method (FIG. 2(b)) to form a film and then the film was subjected to p...

embodiment 2

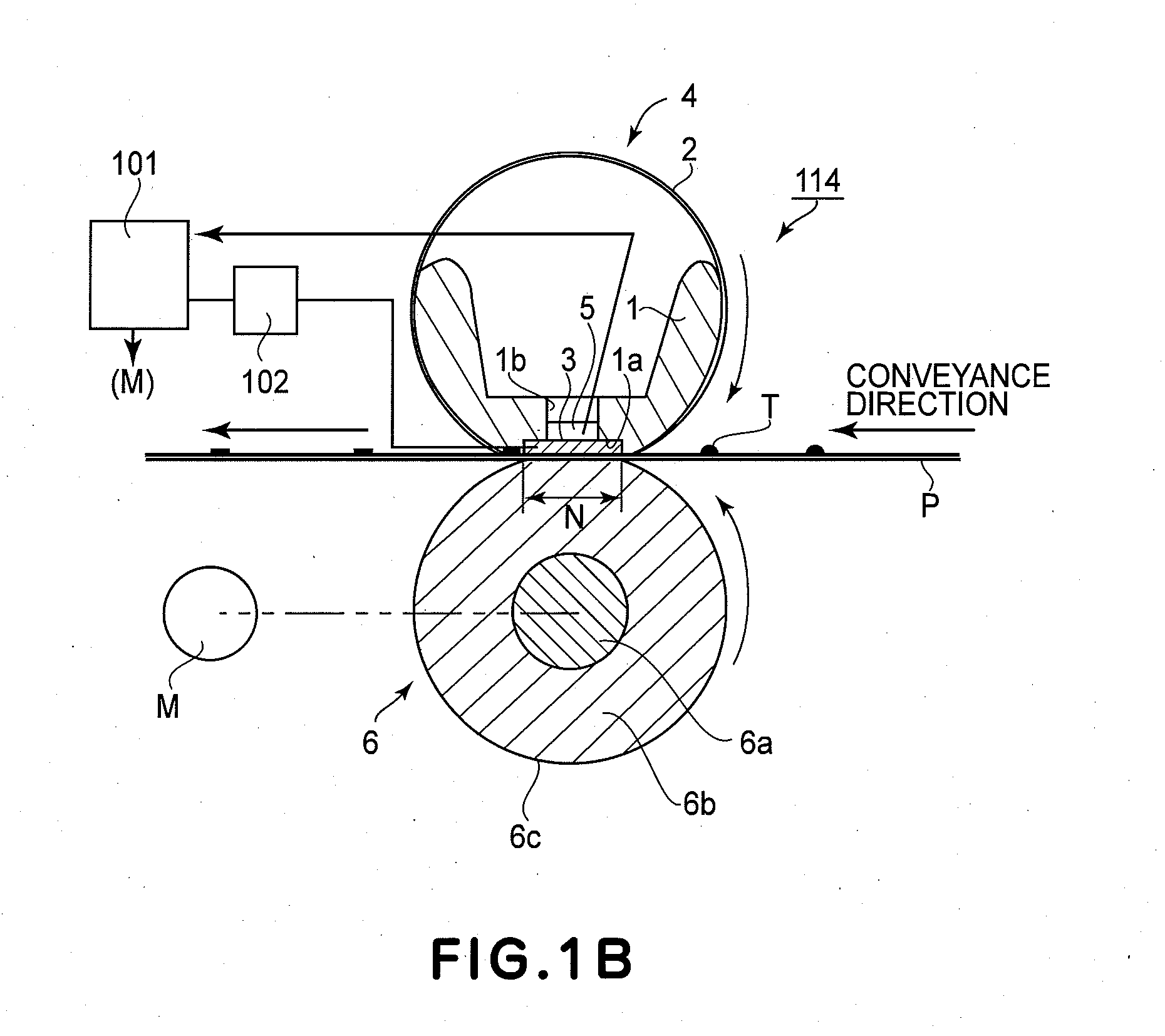

(2) Fixing Device 115

[0107]FIG. 7(a) is a schematic cross-sectional view of a principal part of a fixing device 115 in Embodiment 2. This fixing device 115 is of a so-called surface heating type fixing device and as the fixing roller for the fixing device of this type, the rotatable fixing member according to the present invention can be used. Referring to FIG. 7(a), a fixing roller 11 is the rotatable fixing member according to the present invention. An elastic pressing roller 12 is disposed below and in parallel to the fixing roller 11 and is pressed against the fixing roller 11 with a predetermined urging force by an unshown urging member. As a result, a fixing nip N2 with a predetermined width is created between the fixing roller 11 and the pressing roller 12. A heating unit 13 for externally heating the fixing roller 11 is disposed above and in parallel to the fixing roller 11. The heating unit 13 performs the function of applying heat from a ceramic heater 14 to the fixing rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com