Low-surface energy fluorosilicone polymer and preparation method thereof

A fluorosilicon polymer, low surface energy technology, applied in the field of low surface energy fluorosilicon polymer and its preparation, marine antifouling coating of fluorosilicon polymer, can solve the problem of low surface energy of silicone and fluorocarbon, no comparison Problems such as mature products, low surface energy of coatings, etc., to achieve the effects of mild reaction conditions, high yield and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

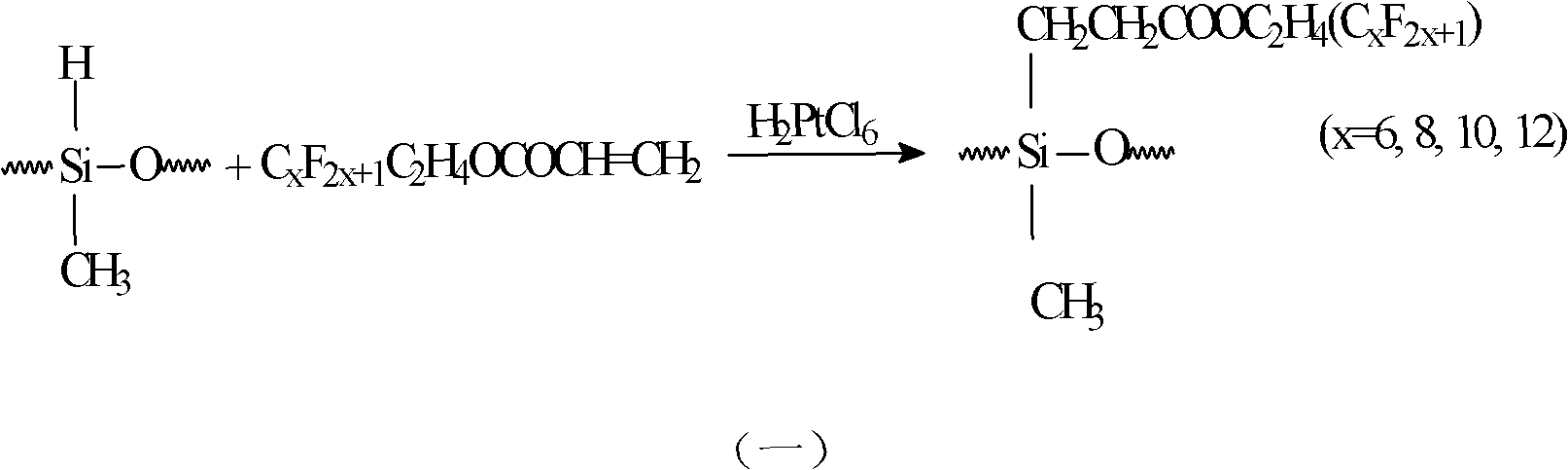

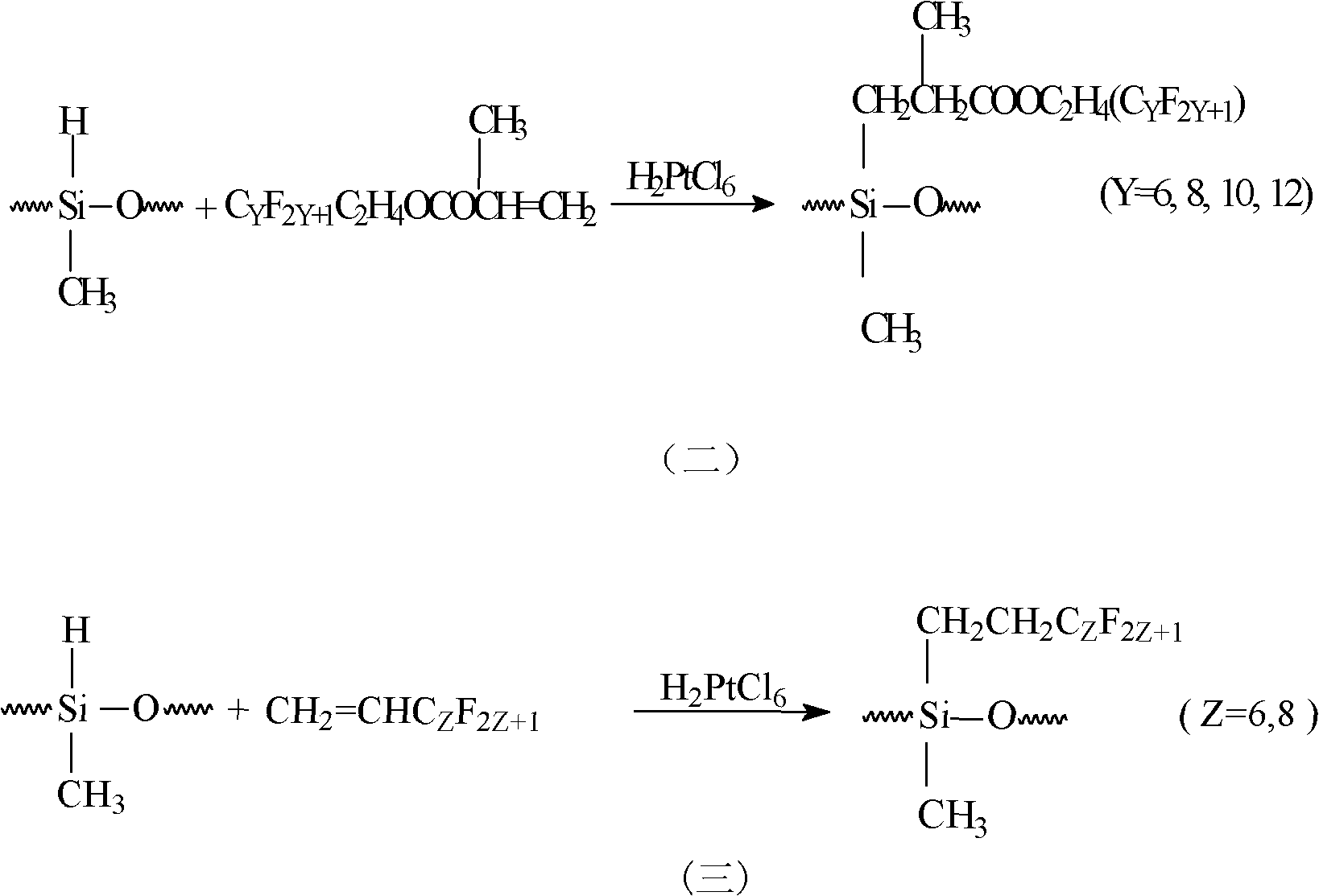

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Perfluoroalkyl monomers use: perfluorooctylethylene

[0027] (1) Weigh 60 parts of hydrogen-containing silicone oil after drying, 10 parts of perfluorooctylethylene (Z=8 in its general formula), 30 parts of xylene and 0.001 part of chloroplatinic acid.

[0028] (2) Add the weighing object into the pre-dried reaction kettle, and stir evenly.

[0029] (3) After the solution is mixed evenly, nitrogen gas is introduced for 15 minutes and then heated to 90°C for 28 hours.

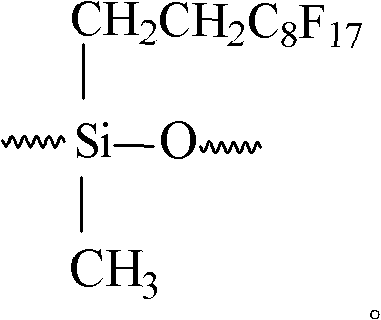

[0030] (4) After the reaction finishes, the catalyst is recovered, and the product obtained through extraction, vacuum distillation and rectification is to satisfy the high fluoroalkyl branched-chain fluorosilicon polymer of the present invention with the following structural formula:

[0031]

Embodiment 2

[0032] Example 2: Perfluoroalkyl monomers are used: perfluorohexyl ethyl acrylate and perfluorooctylethylene

[0033] (1) Weigh 80 parts of hydrogen-containing silicone oil after drying, 16 parts of perfluorohexyl ethyl acrylate (X=6 in the general formula), 8 parts of perfluorooctylethylene (Z=8 in the general formula), xylene 50 parts and 0.005 parts of chloroplatinic acid.

[0034] (2) Add the weighing object into the pre-dried reaction kettle, and stir evenly.

[0035] (3) After the solution is mixed evenly, nitrogen gas is introduced for 15 minutes and then heated to 110°C for 20 hours.

[0036] (4) After the reaction finishes, the catalyst is recovered, and the product obtained through extraction, vacuum distillation and rectification is to satisfy the high fluoroalkyl branched-chain fluorosilicon polymer mixture of the present invention with the following structural formula:

[0037]

Embodiment 3

[0038] Example 3: The use of perfluoroalkyl monomers: perfluorodecyl ethyl acrylate and perfluorohexyl ethyl methacrylate

[0039] (1) Weigh 75 parts of hydrogen-containing silicone oil after drying, 12 parts of perfluorodecyl ethyl acrylate (X=10 in the general formula), and 12 parts of perfluorohexyl ethyl methacrylate (Y=6 in the general formula) 6 parts, 40 parts of xylene and 0.003 parts of chloroplatinic acid.

[0040] (2) Add the weighing object into the pre-dried reaction kettle, and stir evenly.

[0041] (3) After the solution is uniformly mixed, nitrogen gas is introduced for 15 minutes and then heated to 120°C for 16 hours.

[0042] (4) After the reaction finishes, the catalyst is recovered, and the product obtained through extraction, vacuum distillation and rectification is to satisfy the high fluoroalkyl branched-chain fluorosilicon polymer mixture of the present invention with the following structural formula:

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com