Patents

Literature

142results about How to "Formation effect is good" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stemming and purpose thereof

Owner:XINJIANG BAYI IRON & STEEL

Low-surface energy fluorosilicone polymer and preparation method thereof

InactiveCN102134323ALower surface energyLow surface energyAntifouling/underwater paintsPaints with biocidesPolymer scienceSilicon oxygen

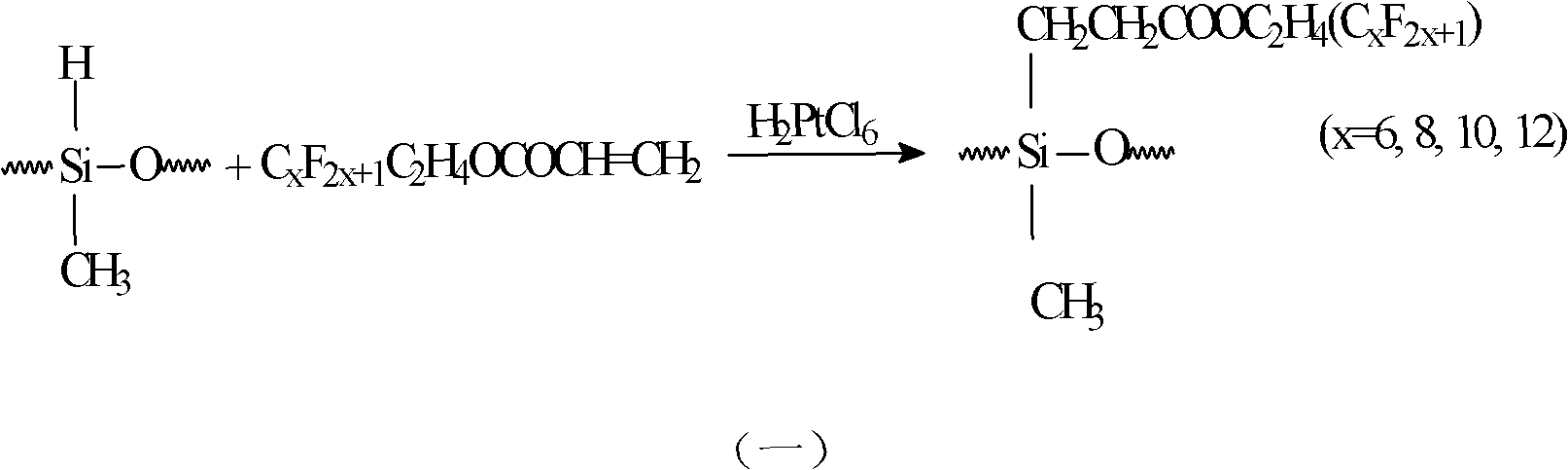

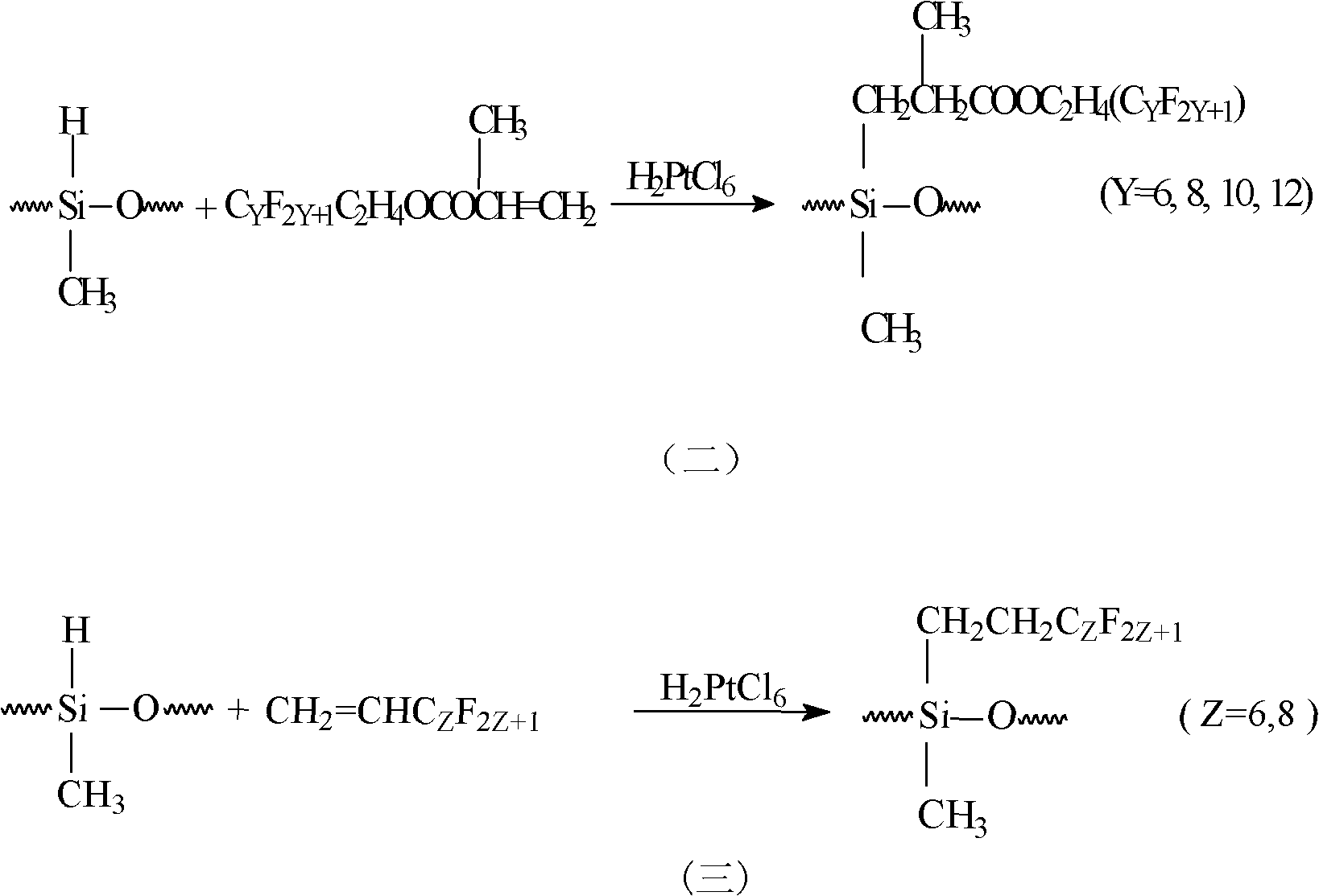

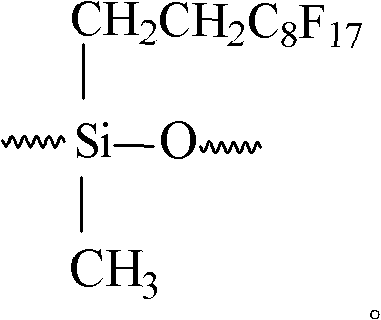

The invention discloses a low-surface energy fluorosilicone polymer and a preparation method thereof and relates to the field of organofluorine polymer paint. In the invention, an organosilicon polymer, perfluoroacyl monomers, a catalyst and a solvent are used as raw materials and are mixed in turn according to a mass part ratio of (60-80):(10-24):(0.0001-0.005):(30-50), the reaction product is purified, and thus, a high-fluoroacyl branched fluorosilicone polymer, which is one of the three perfluoroacyl monomers, or a high-fluoroacyl branched fluorosilicone polymer mixture of two or three of the three perfluoroacyl monomers. In the invention, because a catalytic reaction is performed by using a coordination compound of a transitional metal, the reaction conditions are mild, the process flow is short, the process is simple, the selectivity is high and the yield is high; the prepared polymer is a high-fluoroacyl branched fluorosilicone polymer; and the main chain of the polymer has a silicon-oxygen linear chain structure and has no other carbon-oxygen structure and the side chain is a perfluoroacyl with high fluorine content, so the low surface energy performance of organosilicon and fluorocarbon polymers can be fully played, and excellent low surface energy property can be realized.

Owner:WUHAN RES INST OF MATERIALS PROTECTION

Synthetic method of geopolymer

The invention discloses a synthetic method of geopolymer. Metakaolin is taken and added into expired phosphate group polishing liquor for being mixed for reacting, and a product is obtained after the reaction is ended. The applied expired phosphate group polishing liquor accounts for 70%-75% of the weight of metakaolin, wherein the expired phosphate group polishing liquor comprises the following vital components: 65%-75% of phosphoric acid, 8%-12% of sulfuric acid and 2%-5% of nitric acid. An excitant for the synthetic method is acidy, so that the synthesized geopolymer can be prevented from generating alkali-aggregate reaction, and the synthesized product is good in performance and excellent in quality; furthermore, the expired phosphate group polishing liquor is applied as the excitant for synthesizing the geopolymer to realize the recycling of wastes, so that not only is environment protected, but also cost of producing the geopolymer material is obviously lowered; moreover, the synthetic method disclosed by the invention is easy to operate, and concise in technological process.

Owner:GUANGXI UNIV

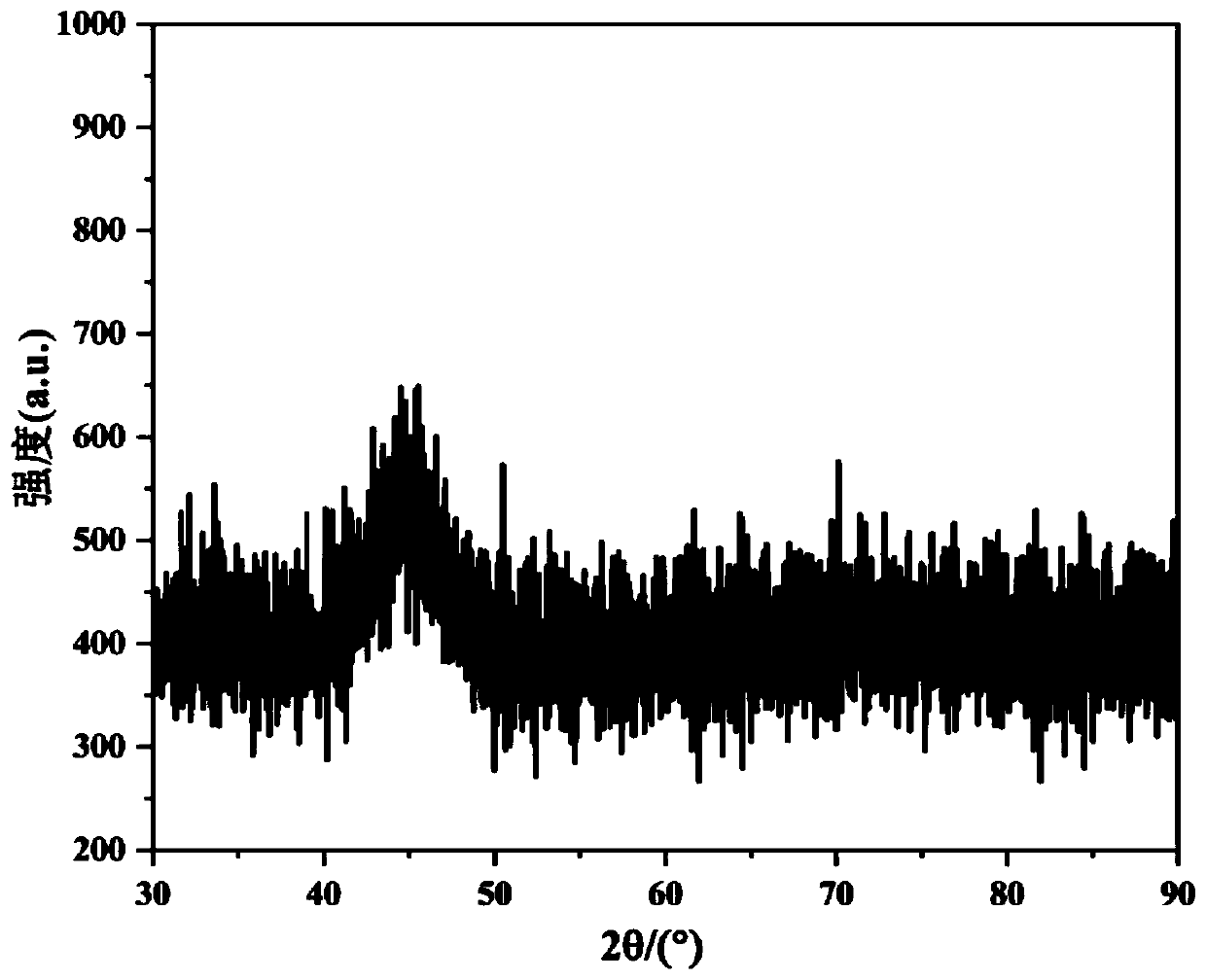

Ferrum-based amorphous nanocrystalline soft magnetic alloy and preparation method and application thereof

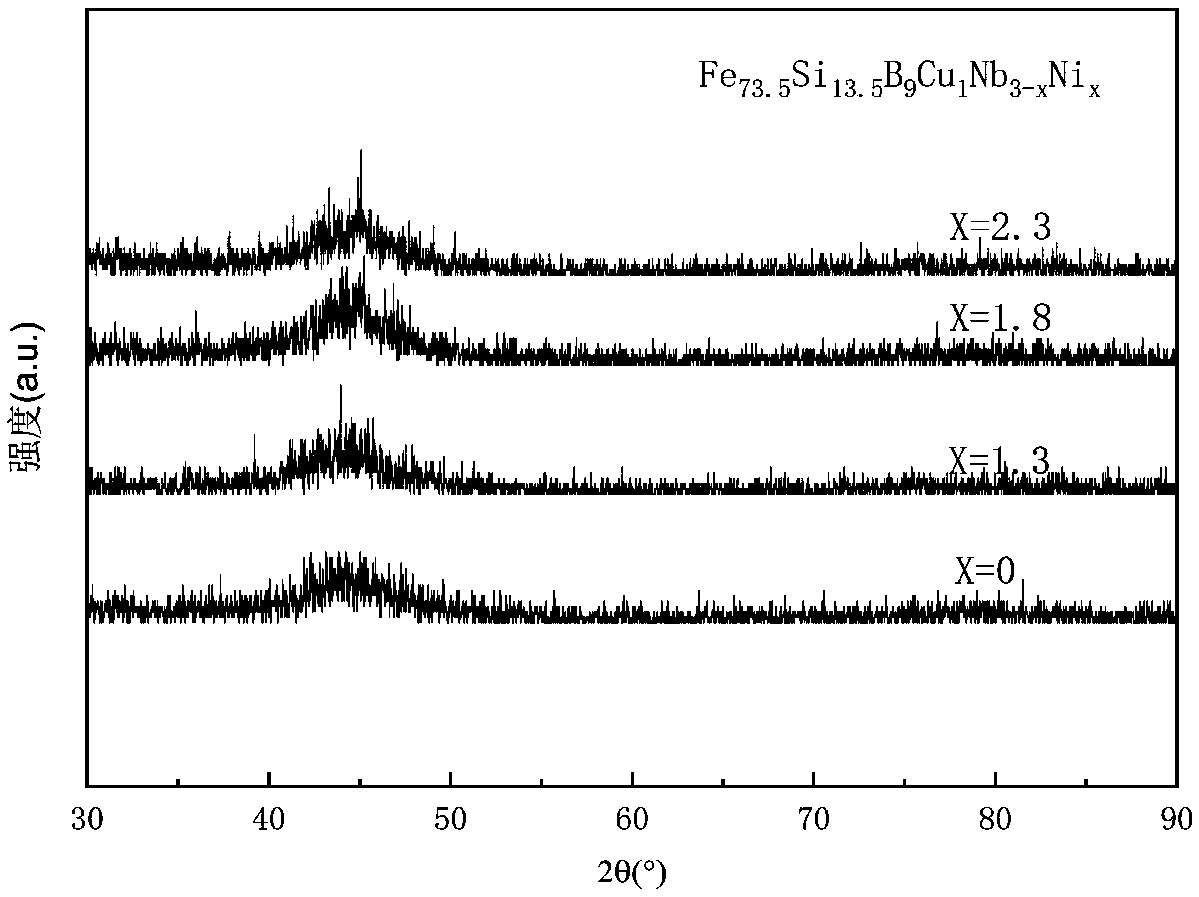

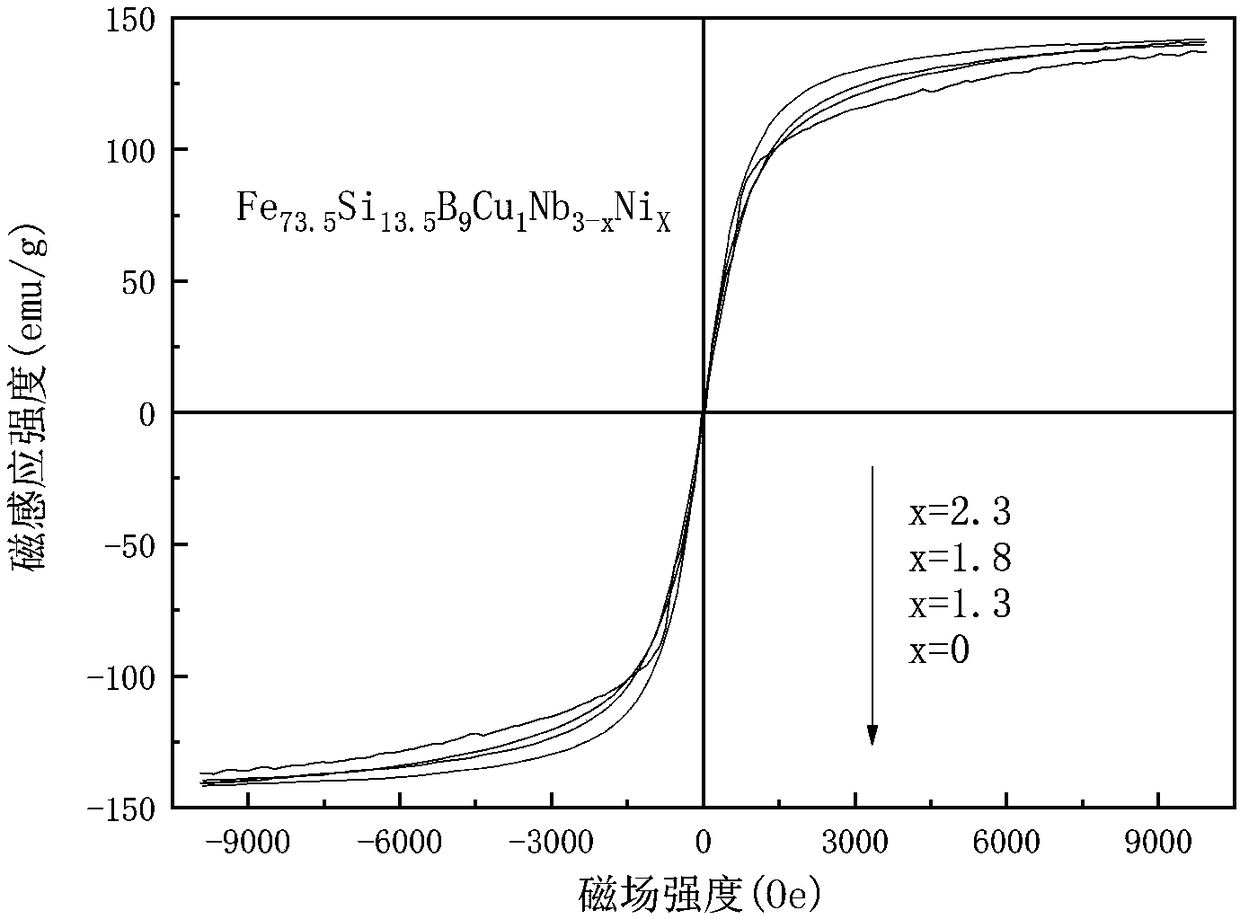

InactiveCN109440021AHigh saturation magnetic inductionLow coercivityInductances/transformers/magnets manufactureMagnetic materialsNiobiumIngot

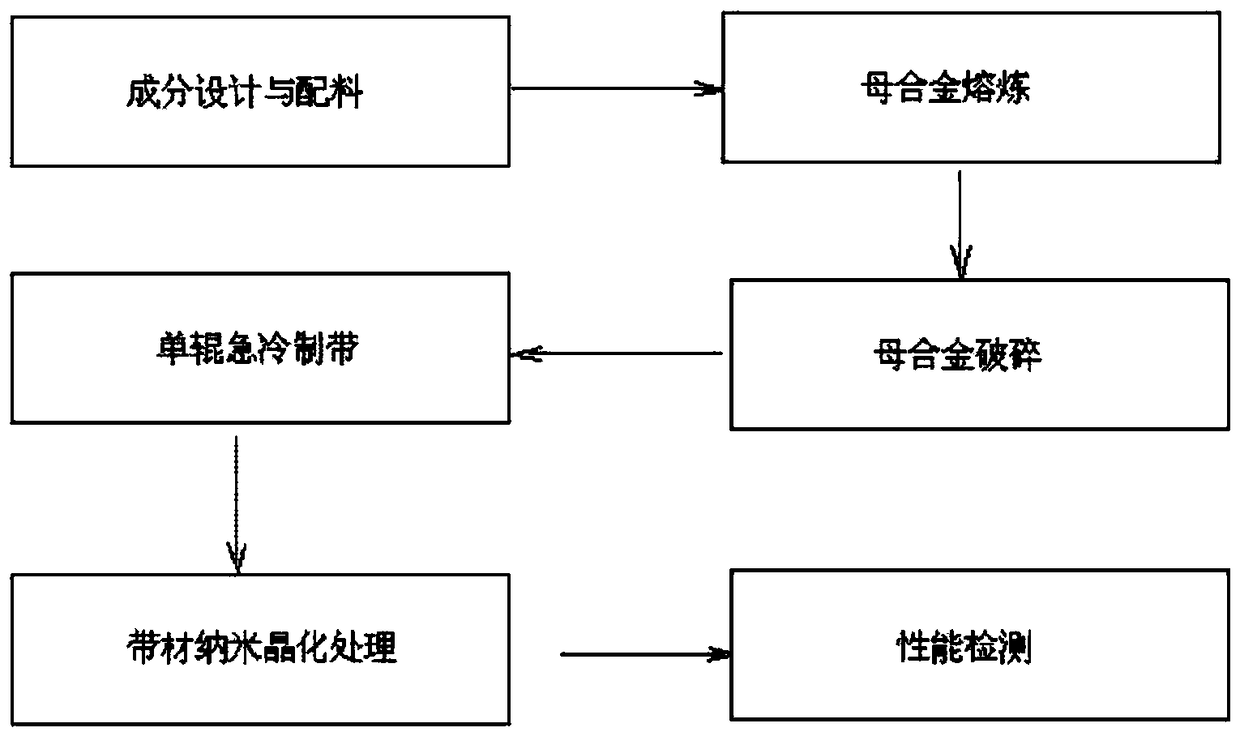

The invention belongs to the technical field of soft magnetic alloy function materials and discloses a ferrum-based amorphous nanocrystalline soft magnetic alloy and a preparation method and application thereof. The molecular formula of the ferrum-based amorphous nanocrystalline soft magnetic alloy is Fe73.5Si13.5B9Gu1Nb3-xNix, wherein the x is equal to 0, 1.3, 1.8 or 2.3. The preparation method comprises the steps that an alloy ingot is obtained after smelting of ferrum, silicon, boron source, copper, niobium and nickel; the alloy ingot is cleaned after being crushed, then strip-throwing is performed, and an amorphous alloy strip is obtained; and under the condition of vacuum or a protective atmosphere, the ferrum-based amorphous nanocrystalline soft magnetic alloy is obtained after the amorphous alloy strip is subjected to heat treatment with the temperature being 430-450 DEG C. An experiment result shows that, the prepared ferrum-based amorphous nanocrystalline soft magnetic alloysare all of completely-amorphous structures and have high saturation magnetic induction strength, low coercive force and other excellent soft magnetic properties, furthermore, the use amount of the expensive metal element Nb is reduced, and the material cost is significantly lowered.

Owner:GUANGDONG UNIV OF TECH

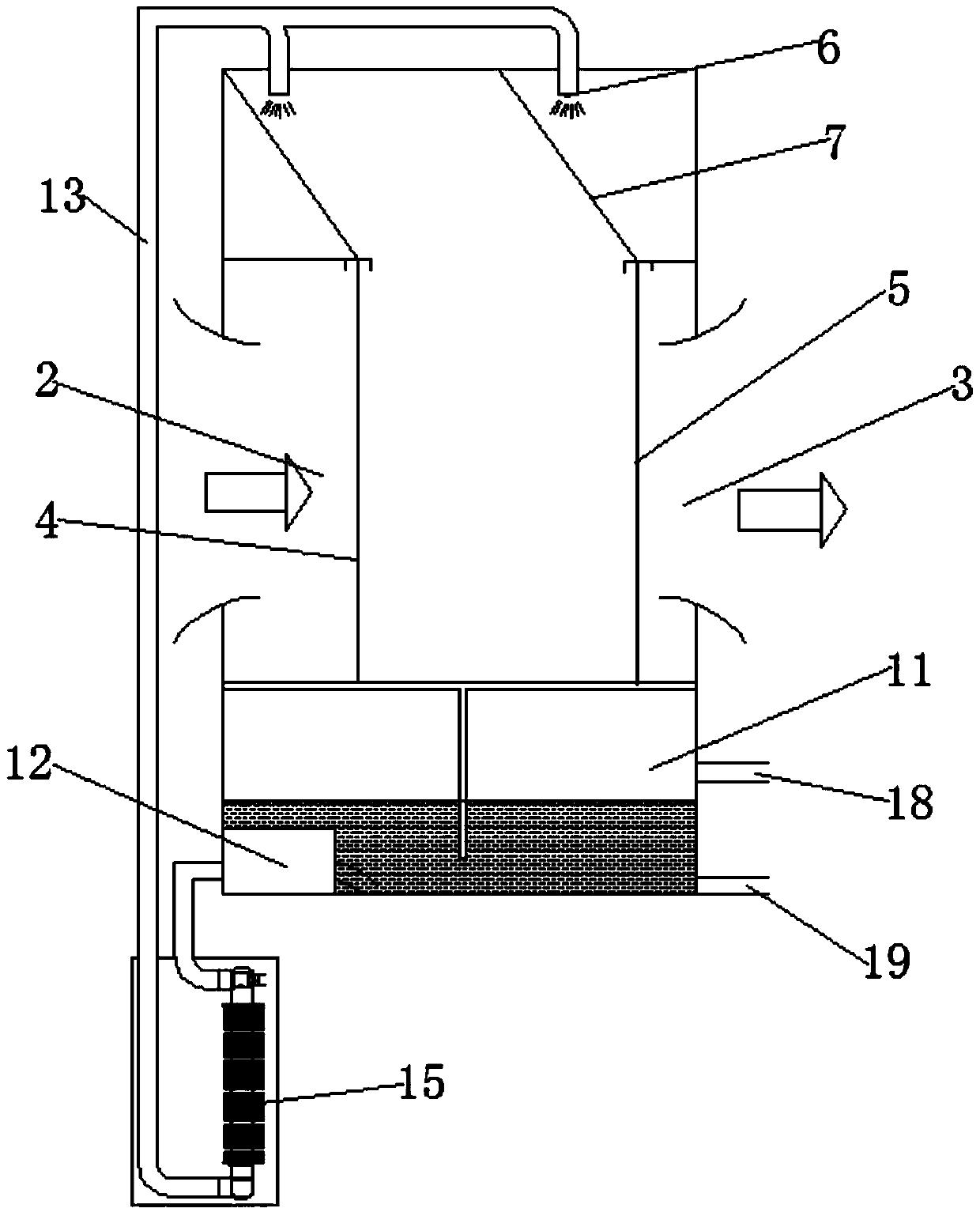

Method of processing active materials for use in secondary electrochemical cells

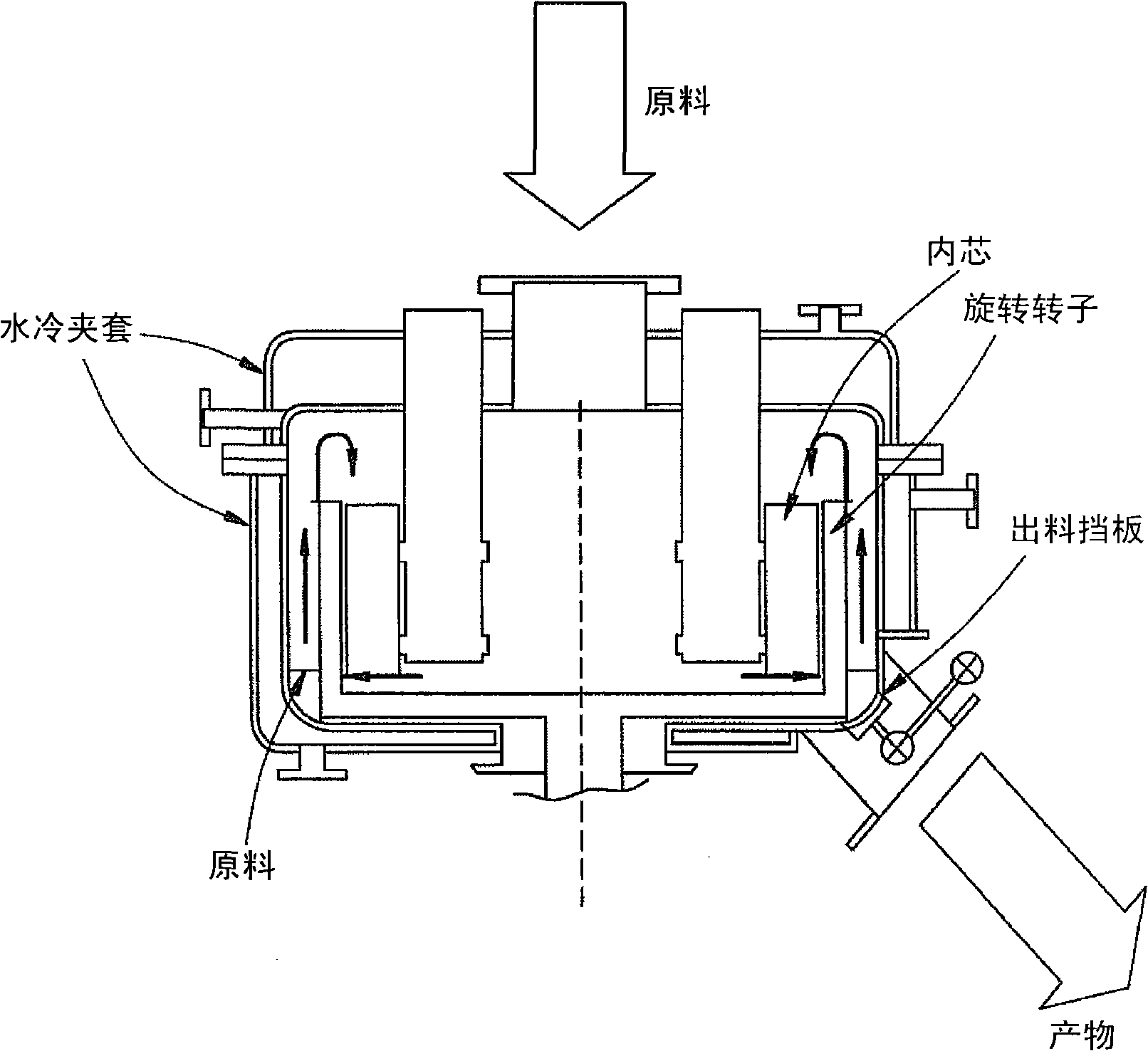

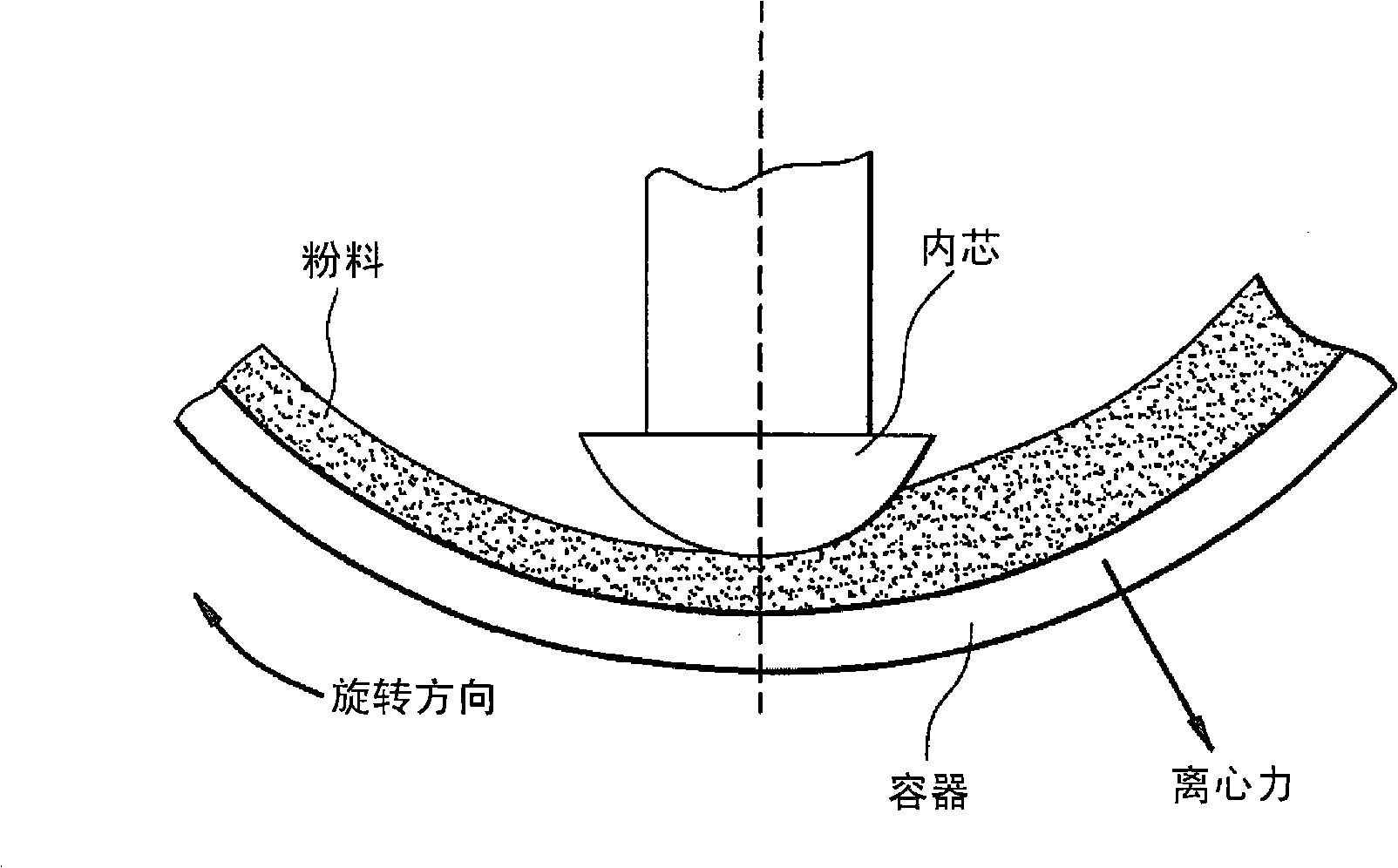

InactiveCN101542786AImprove physical propertiesFusion wellElectrode manufacturing processesLi-accumulatorsPhosphateElectrochemical cell

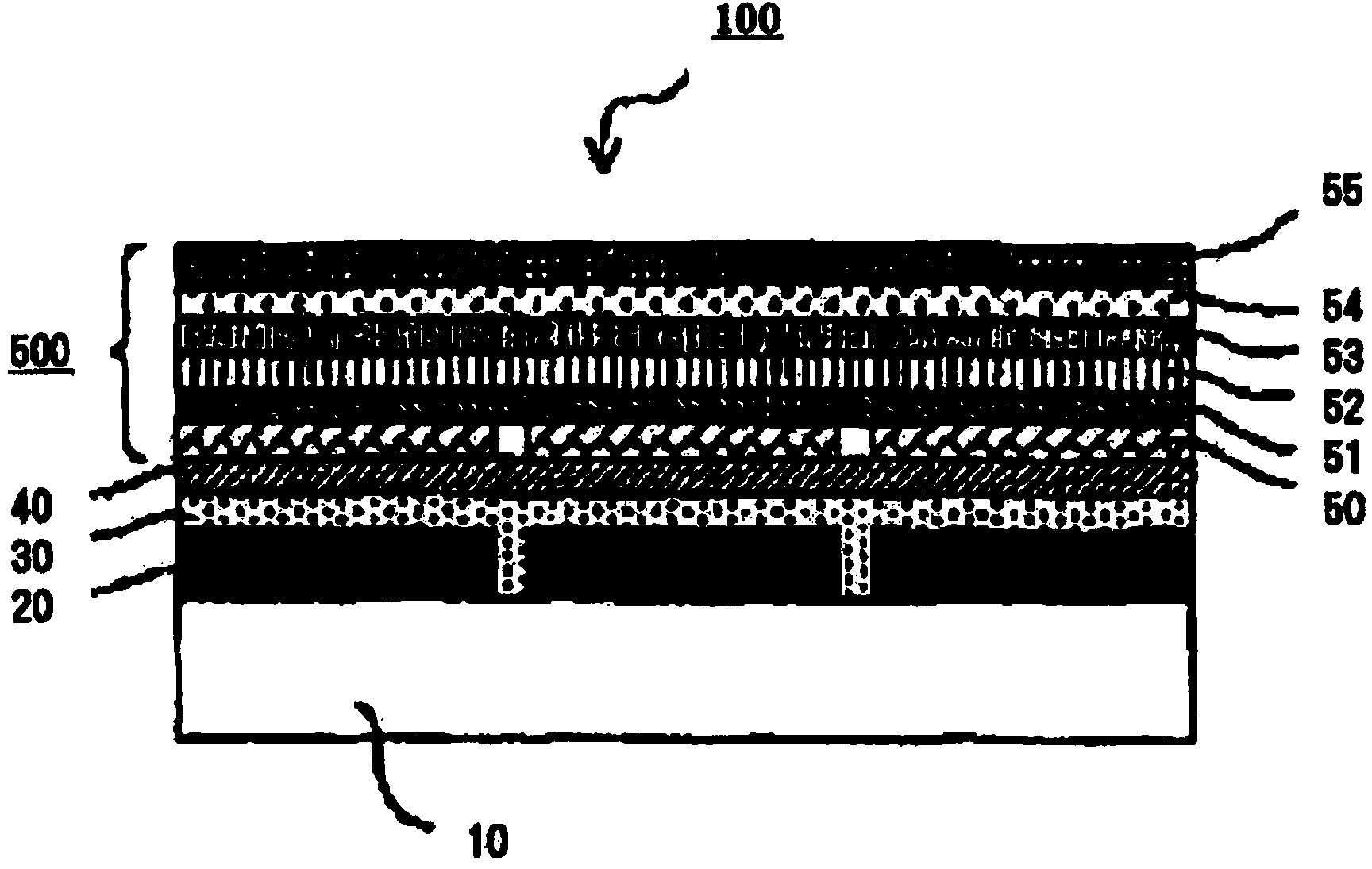

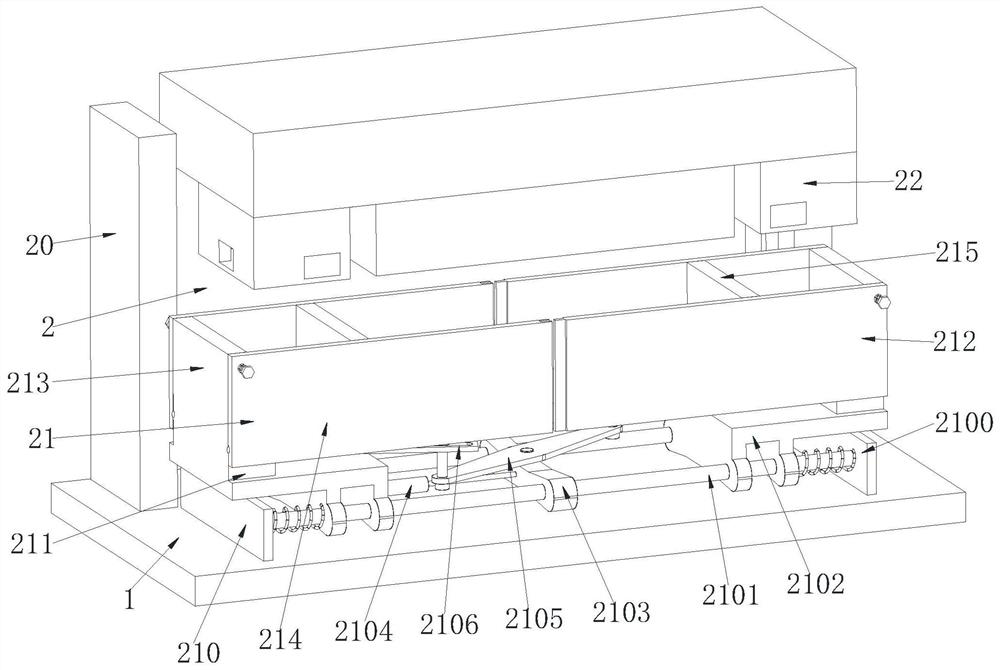

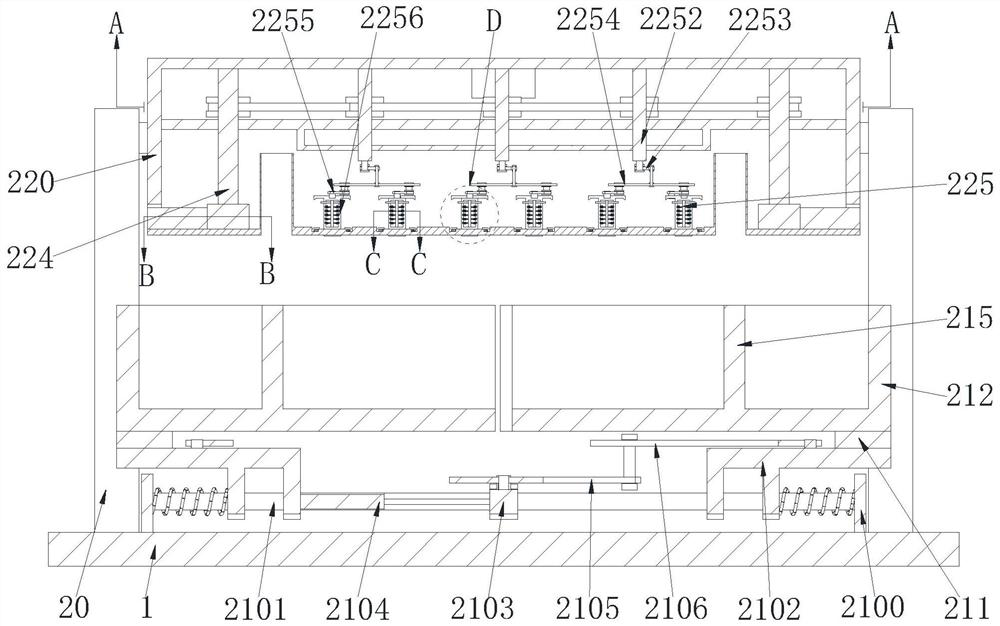

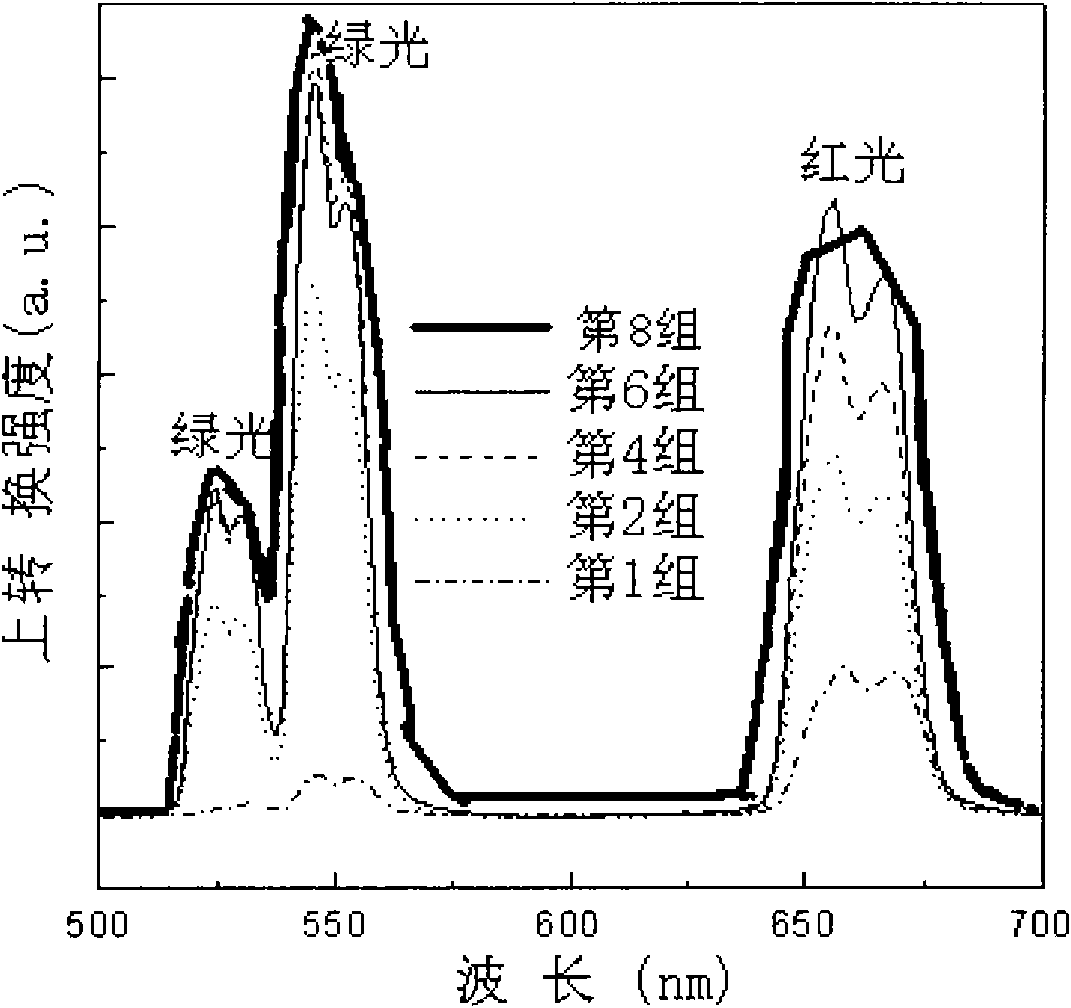

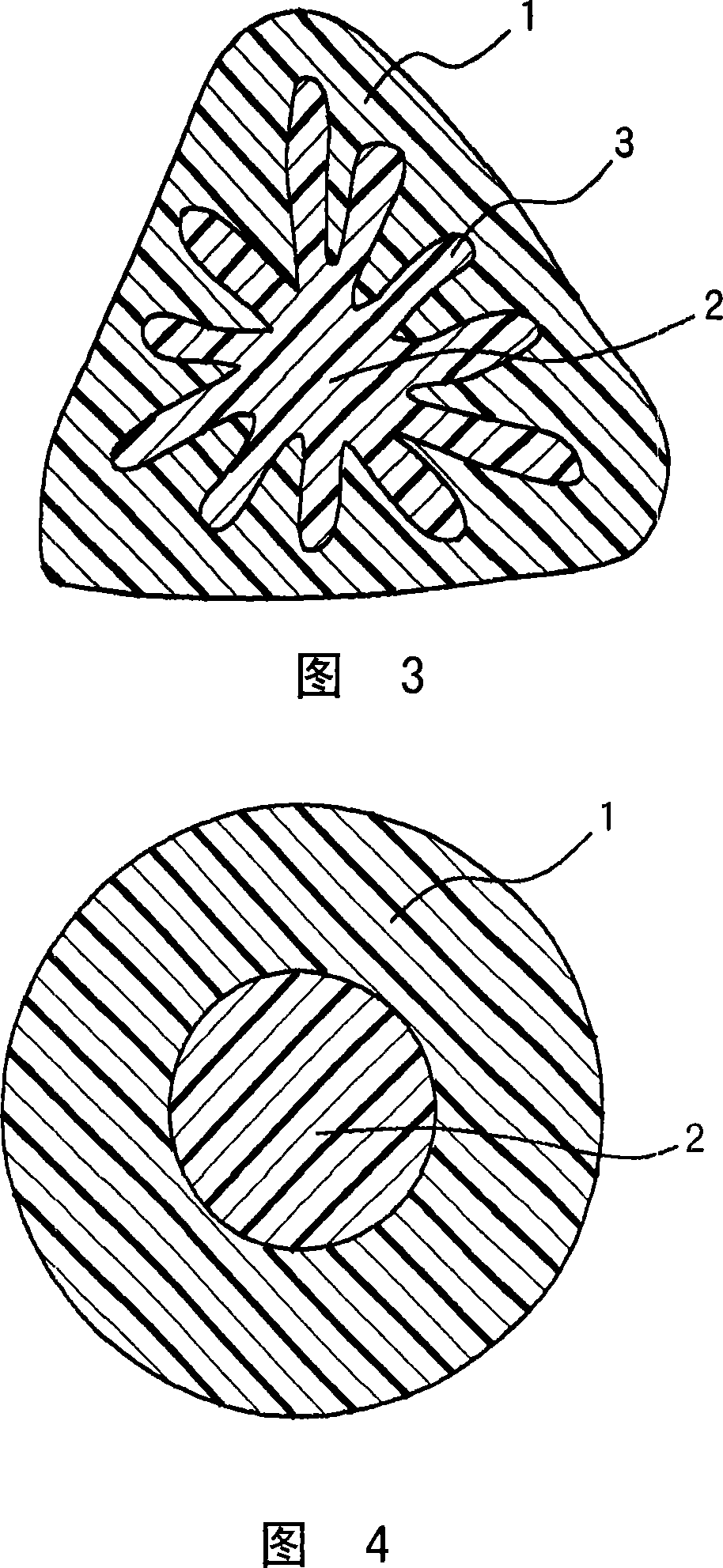

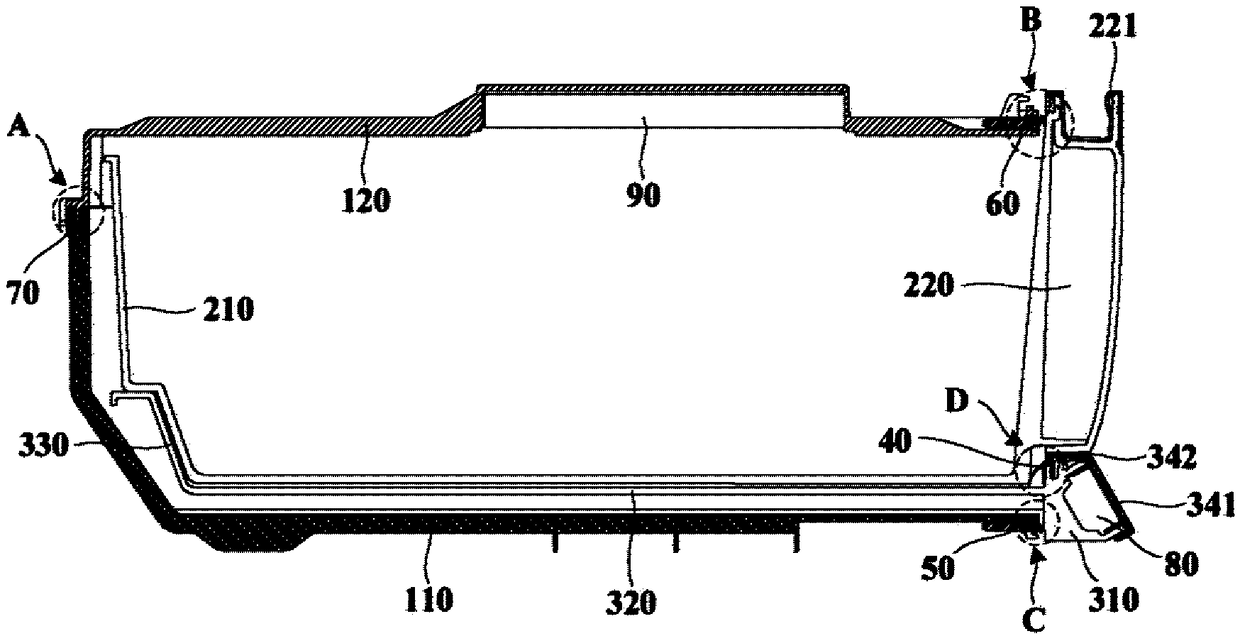

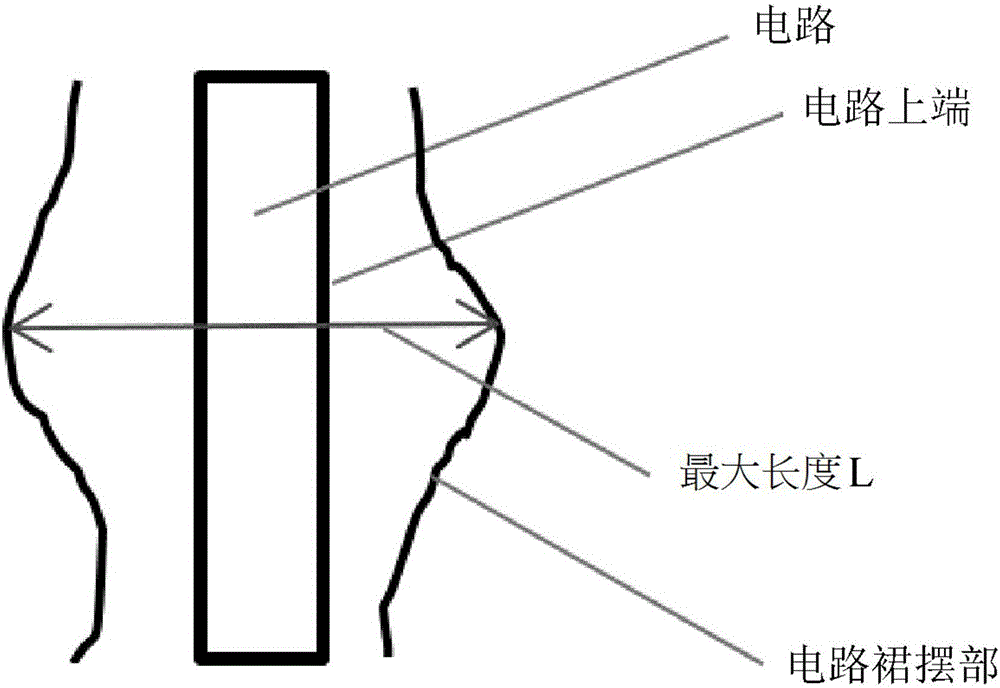

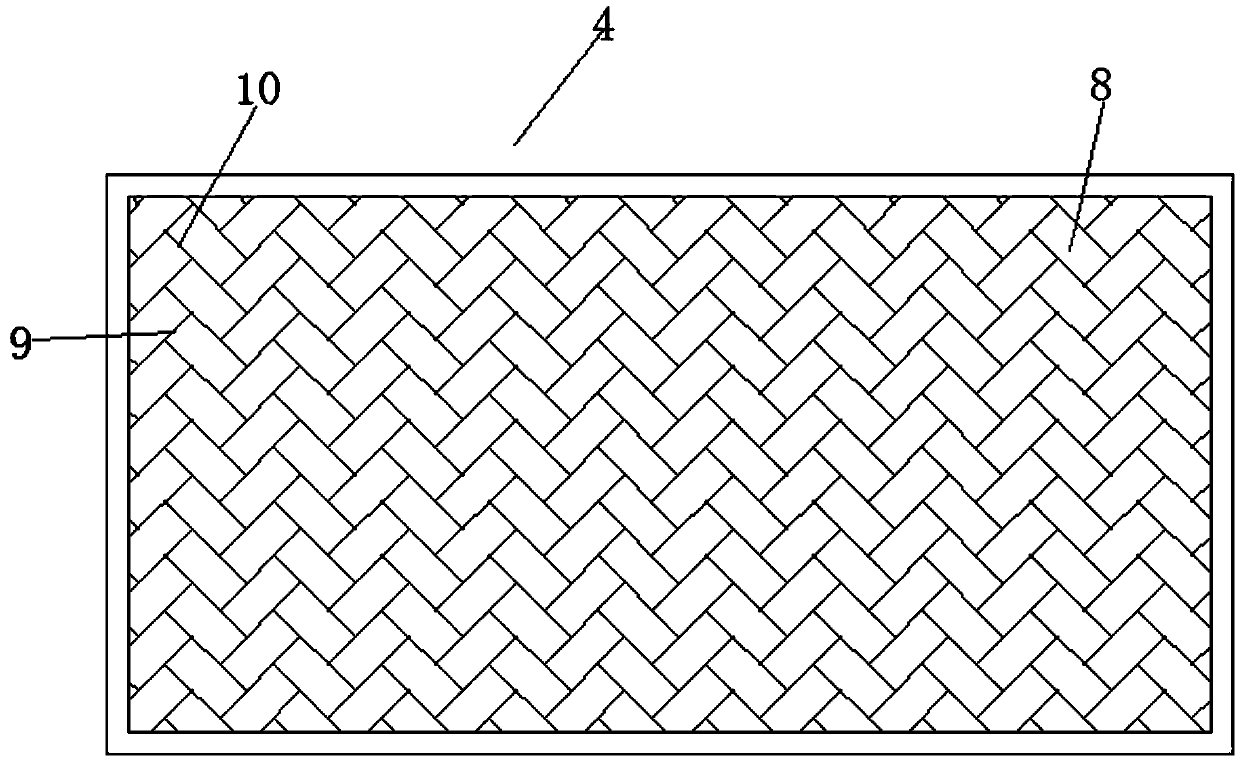

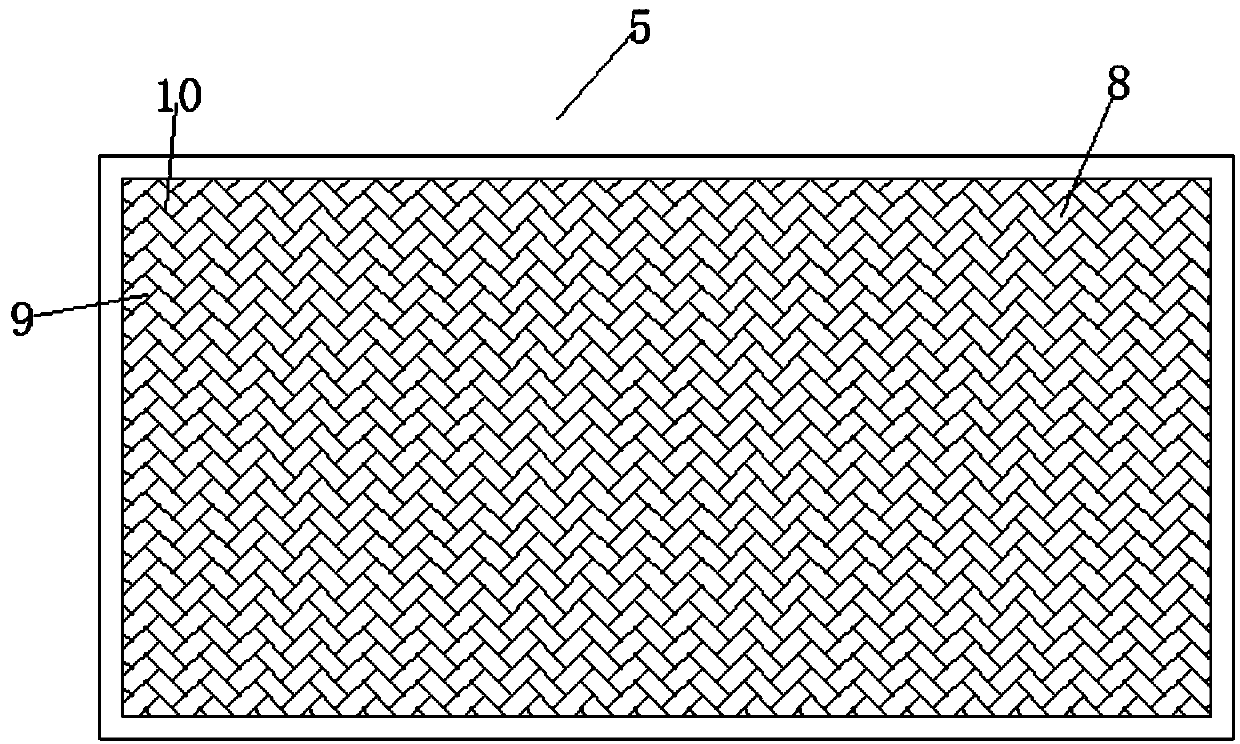

The present invention provides a method for the processing of particles of metal phosphates or particles of mixed metal phosphates and in particular lithiated metal phosphates and mixed metal phosphates. The processing occurs, for example using a mechanofusion system as depicted in Figures 1 and 2. In general, the powder materials are placed in a rotary container and are subjected to centrifugal force and securely pressed against the wall of the container. The material then undergoes strong compression and shearing forces when it is trapped between the wall of the container and the inner piece of the rotor with a different curvature (Figure 2). Particles of the material are brought together with such force that they adhere to one another. In the mechanofusion system, as indicated in Figure 2, the powder material is delivered through slits on the rotary walls. It is carried up above the rotors by the rotor-mounted circulating blades. Subsequently, the material returns again to the rotors where it is are subjected to strong compression and shearing forces from the inner pieces of the rotor. This cycle of both three-dimensional circulation and effective compression / shearing of the powder material is repeated at high speeds, thereby forming it into a composite electroactive material (powder).

Owner:VALENCE TECH INC

Colored resin composition, color filter, liquid crystal display device, organic el display device

ActiveCN103430099AFormation effect is goodExcellent developabilityMonoazo dyesDisazo dyesLiquid-crystal displayImaging quality

The purpose of the invention is to provide a display having high image quality; to provide a colored resin composition with which it is possible to prevent a reduction in image quality of the display; and to provide a color filter having excellent pixel color purity and transmittance, as well as a high-quality liquid crystal display device and an organic EL display device, by using such a colored resin composition. The invention relates to a colored resin composition comprising (A) a dye, (B) a solvent, (C) a binder resin, and (D) a chain transfer agent that contains a specific compound.

Owner:MITSUBISHI RAYON CO LTD

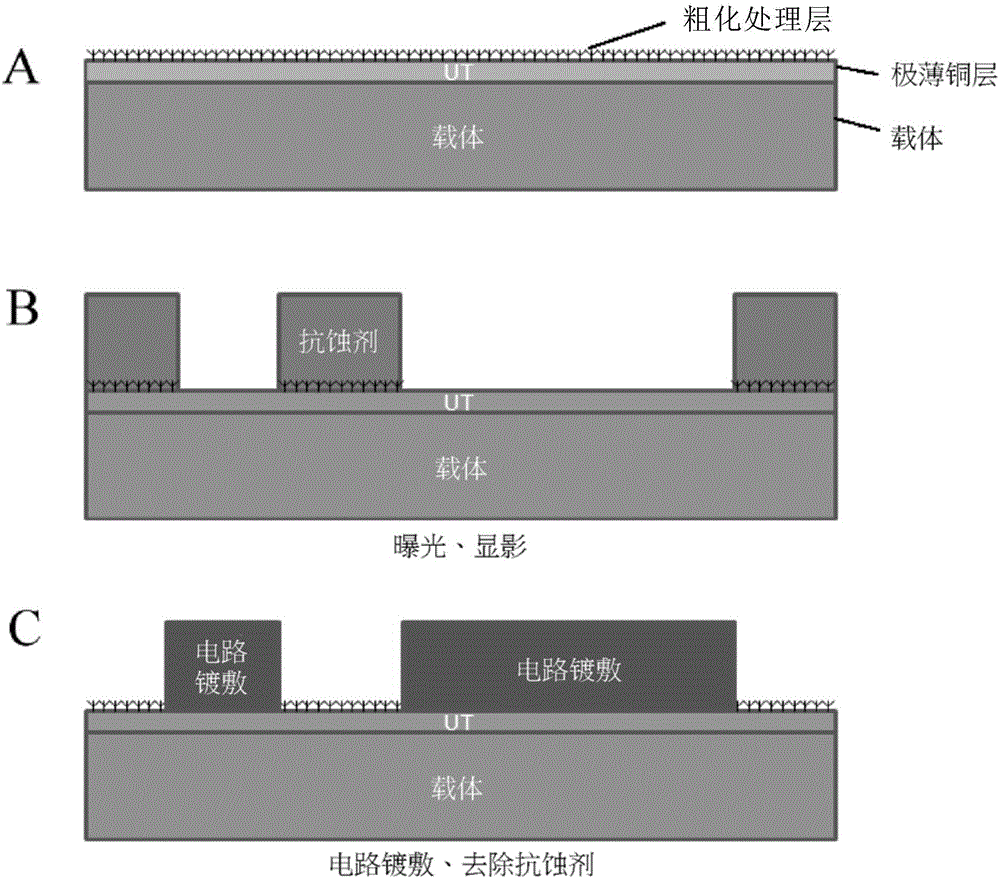

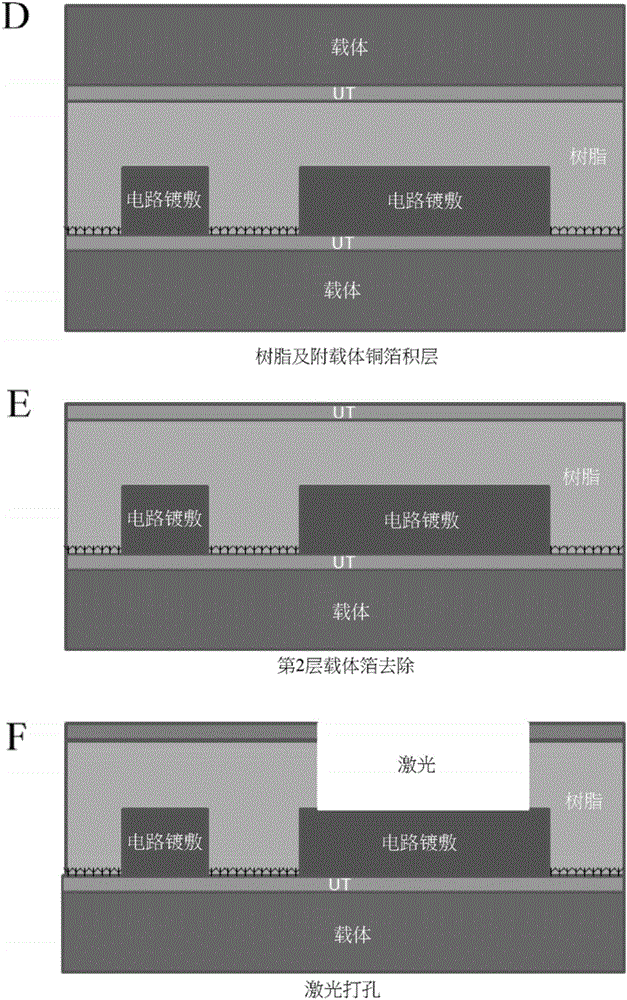

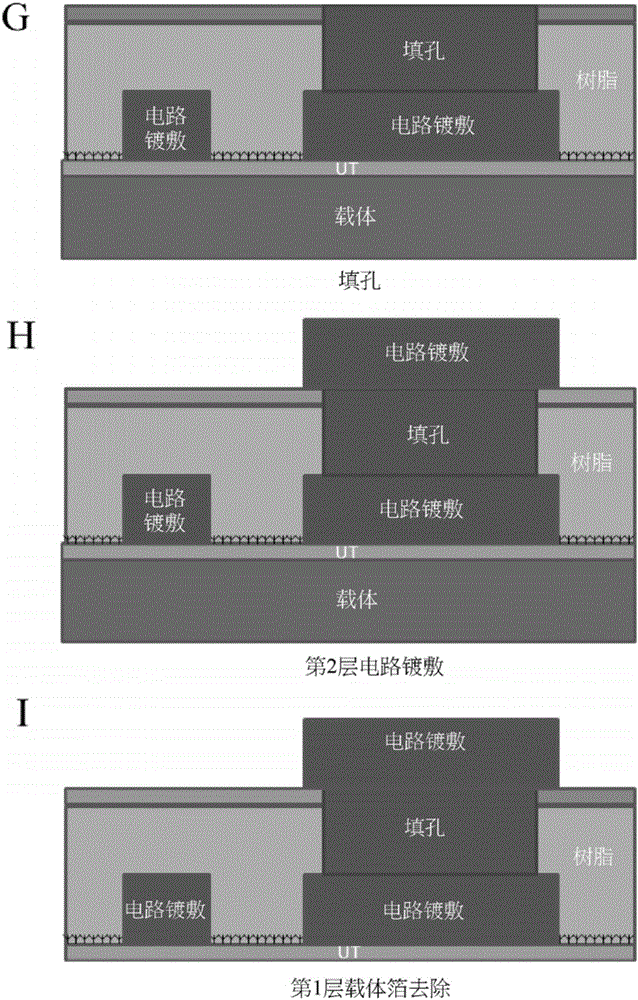

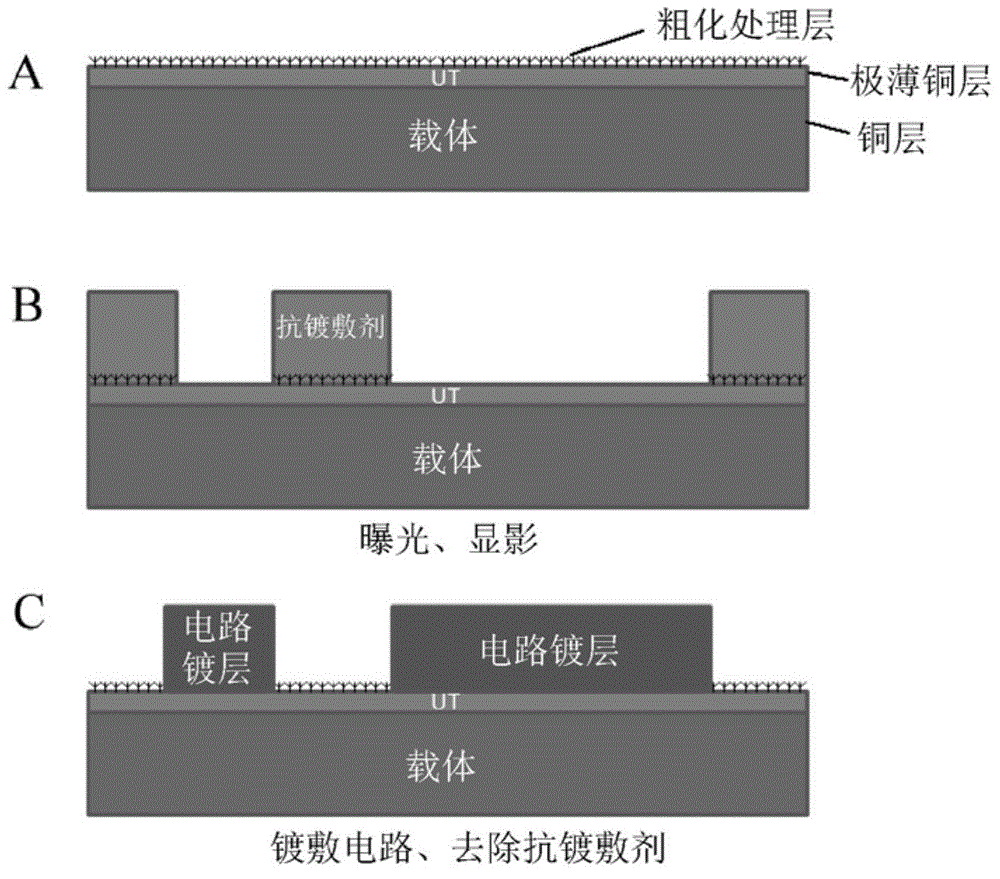

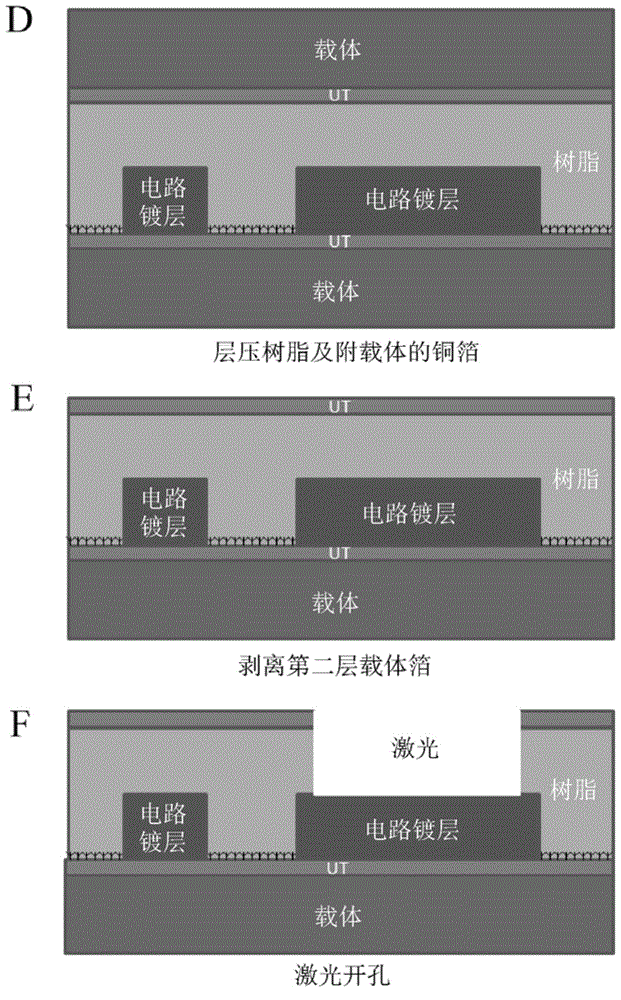

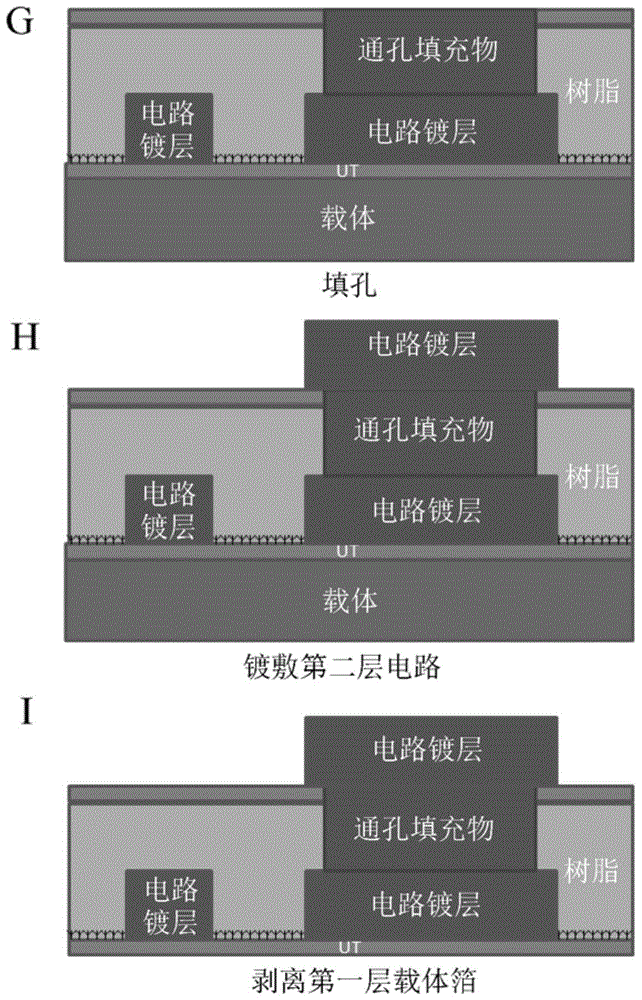

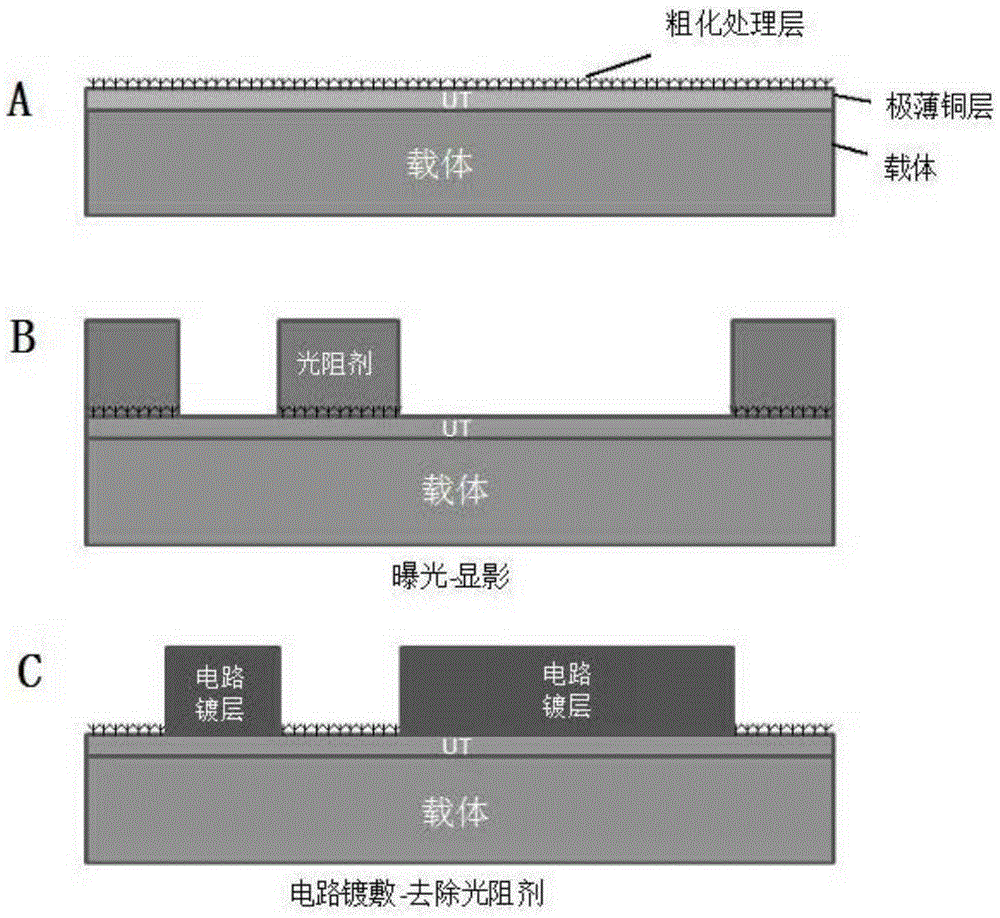

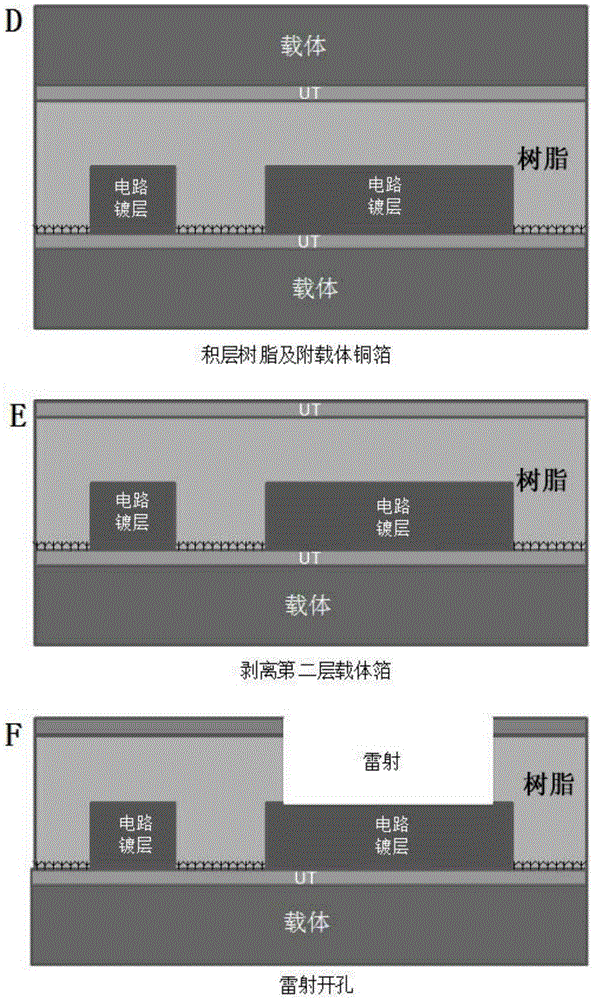

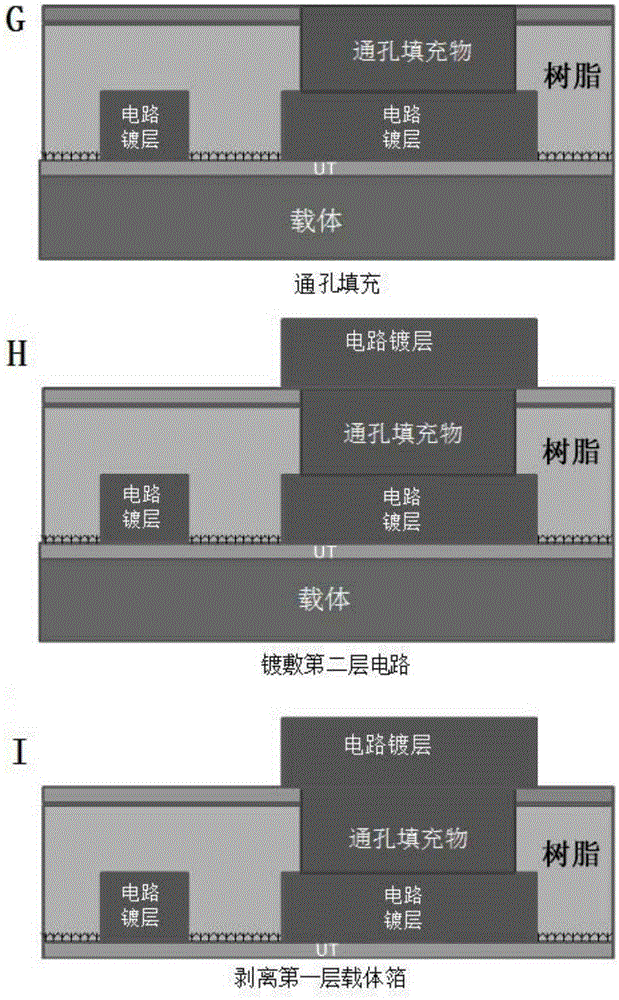

Carrier-Attached Copper Foil, Laminate, Method For Producing Printed Wiring Board, And Method For Producing Electronic Device

ActiveCN106455342AFormation effect is goodSynthetic resin layered productsPrinted circuit aspectsCopper foilTriazine

Provided herein is a carrier-attached copper foil having desirable fine circuit formability. The carrier-attached copper foil includes a carrier, an interlayer, and an ultrathin copper layer in this order, wherein D2-D1 is 0.30 to 3.83 [mu]m, where D1 is the gravimetrically measured thickness of the carrier-attached copper foil excluding the carrier and the interlayer, and D2 is the maximum thickness of the layer remaining on a bismaleimide-triazine resin substrate in case of detaching the carrier after the carrier-attached copper foil is laminated to the resin substrate from the ultrathin copper layer side by being heat pressed under a pressure of 20 kgf / cm2 at 220 DEG C for 2 hours.

Owner:JX NIPPON MINING & METALS CORP

Composite production process of steam pressured silicated product with steel slag and pyrite tailings

InactiveCN1357504AImprove stress resistanceImprove flexural strengthSolid waste managementBreaking strengthSteam pressure

Steel slag and pryite tailings in the weight ratio of 0.1-30 are mixed, ground and sieved with square-opening sieve to produce 80 micron fineness composite powder, which is used to replace, partially or even completely, gel material for steam pressured process of producing silicate product. The composite of the two industrial waste slag results in superior use effect and the product has tension and breaking strength 20% higher than that using one single slag.

Owner:SOUTH CHINA UNIV OF TECH

Fe-Si-B amorphous alloy strip, preparation method thereof and application of Fe-Si-B amorphous alloy strip in degradation of azo dye wastewater

InactiveCN109811278AFast degradation ratePromote degradationWater contaminantsWater/sewage treatment by oxidationAlloyDyeing wastewater

The invention belongs to the technical field of wastewater treatment, and discloses an Fe-Si-B amorphous alloy strip, a preparation method thereof and application of the Fe-Si-B amorphous alloy stripin degradation of azo dye wastewater. The composition of the Fe-Si-B amorphous alloy strip is FemSinBp, wherein m is larger than or equal to 75 and smaller than or equal to 83, n is larger than or equal to 7 and smaller than or equal to 15, p is larger than or equal to 7 and smaller than or equal to 15, and m+n+p is equal to 100; and preferably, the composition of the Fe-Si-B amorphous alloy stripis Fe78Si11B11. The invention further discloses a preparation method of the Fe-Si-B amorphous alloy strip and application of the Fe-Si-B amorphous alloy strip in degradation of the azo dye wastewater. The strip provided by the invention has relatively good corrosion resistance and relatively high catalytic activity, has very fast degradation rate to azo dyes and is low in cost.

Owner:SOUTH CHINA UNIV OF TECH

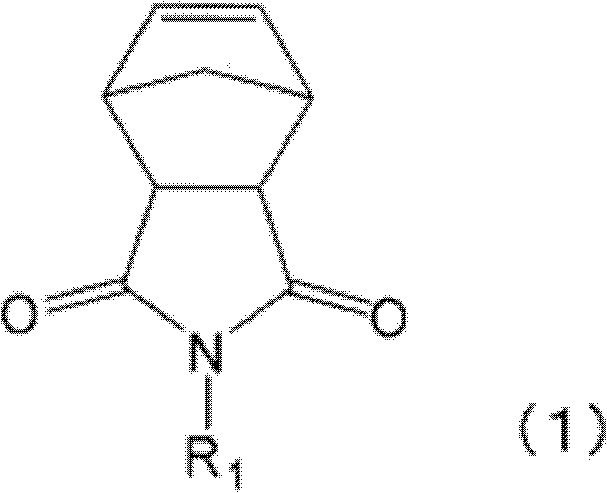

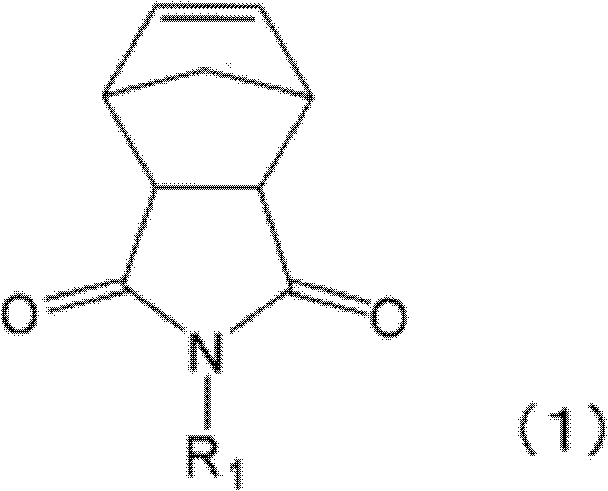

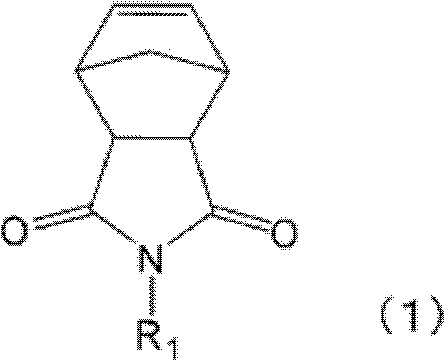

Polymer, hydrogen additive, resin composition, resin film, and electronic component

ActiveCN102365303AGood solubilitySmall water absorptionSemiconductor/solid-state device manufacturingOptical elementsSolventPolymer chemistry

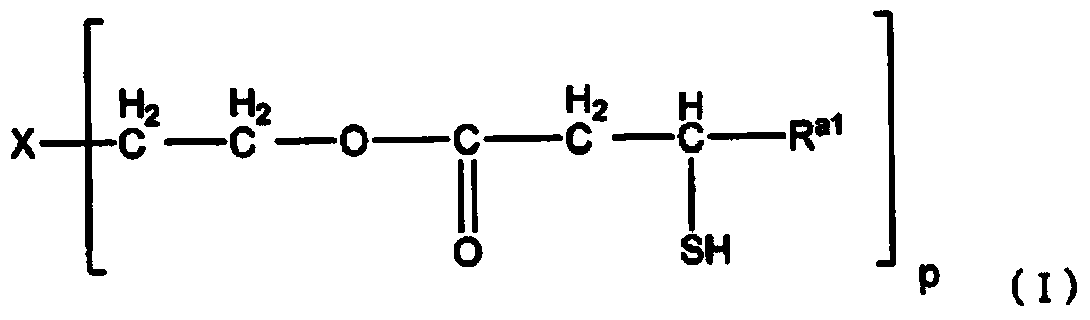

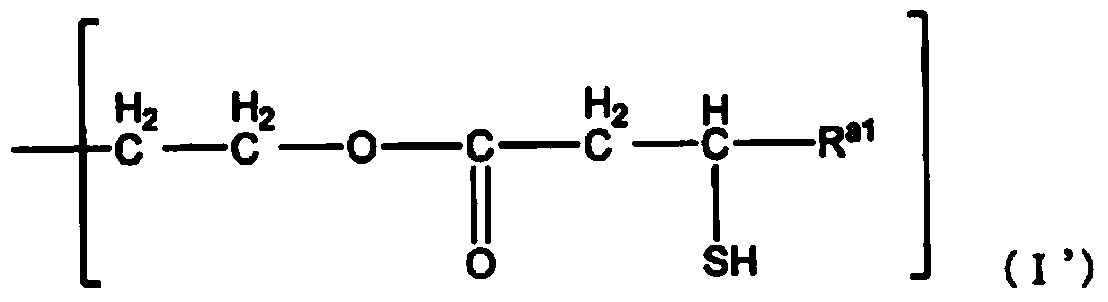

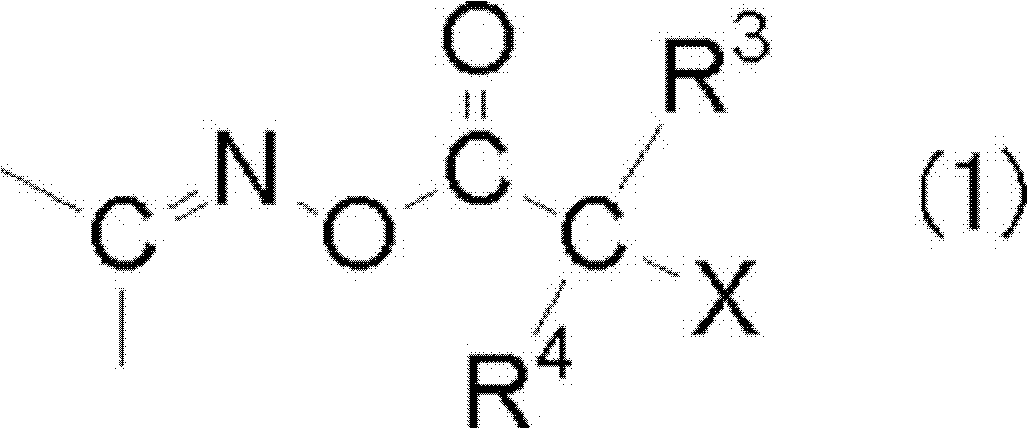

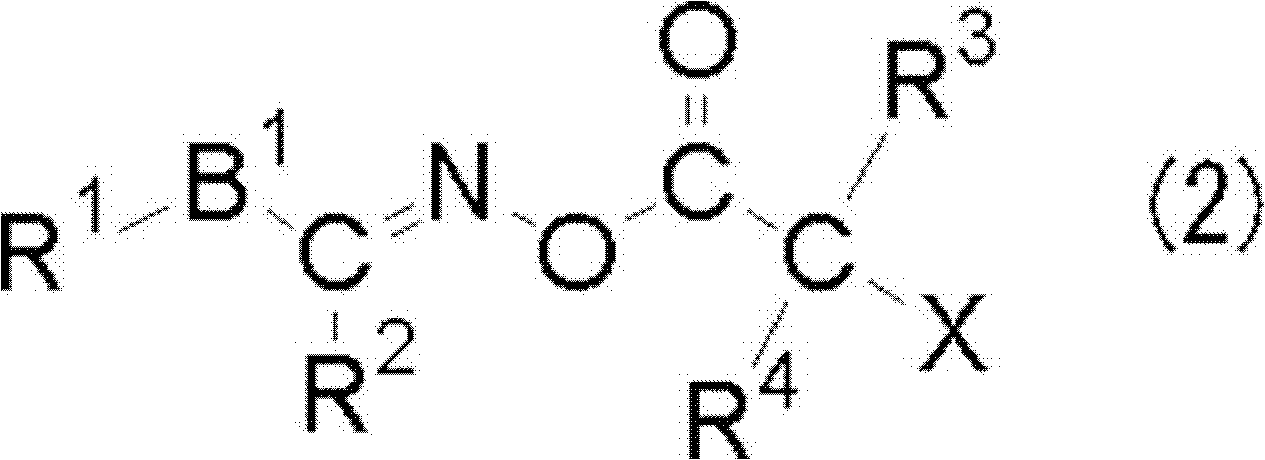

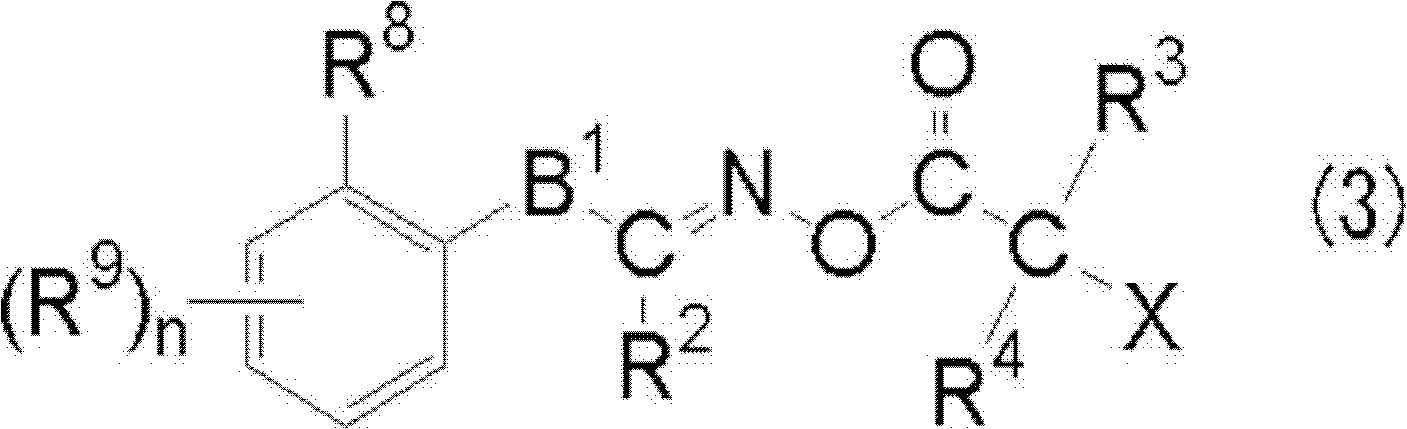

Provided is a polymer comprising a monomer polymerization unit represented by the general formula (1); whereby, a polymer that is highly soluble in solar solvents, exhibits low water absorption, and has a strong adherence to substrates, a hydrogen additive of said polymer, a resin composition using said polymer and / or said hydrogen additive, a resin film formed out of said resin composition, and an electronic component having said resin film can be obtained.

Owner:ZEON CORP

Copper foil with carrier, printed wiring board, laminate, electronic machine and method for manufacturing printed wiring board

ActiveCN104943270AGood circuit formationFormation effect is goodNon-metallic protective coating applicationMetallic pattern materialsWater contentCopper foil

The invention discloses a copper foil with a carrier, a printed wiring board, a laminate, an electronic machine and a method for manufacturing the printed wiring board. Specifically, the invention provides a copper foil with a carrier, and the copper foil has good circuit formability. The copper foil with the carrier sequentially has a carrier, an intermediate layer and an extremely thin copper layer, and when the copper foil with the carrier is heated at a speed of 30 DEG C / min to 500 DEG C, the water content that is less than generated is 160ppm / g.

Owner:JX NIPPON MINING & METALS CO LTD

Photopolymerizable composition, color filter, method for producing same, solid-state image pickup element, liquid crystal display device, lithographic printing original plate, and novel compound

ActiveCN102483572AReduced responseHigh sensitivityLiquid crystal compositionsOrganic chemistryArylHydrogen atom

Disclosed is a photopolymerizable composition which contains (A) a photopolymerization initiator that has a partial structure represented by general formula (1) and (B) a polymerizable compound. In general formula (1), R3 and R4 each independently represents a hydrogen atom, an alkyl group, an alkenyl group, an alkynyl group, an aryl group, a heteroaryl group or an alkoxy group,R3 and R4 may form a ring with each other,and X represents OR5, SR6, or NR17R18. The photopolymerizable composition is capable of forming a cured film that has high sensitivity, excellent curability with respect to the inner part of the film, and excellent adhesion to a supporting body. The cured film is able to maintain a patterned shape even during post-heating after development and has good pattern formability, while being suppressed in coloring due to heating or passage of time.

Owner:FUJIFILM CORP

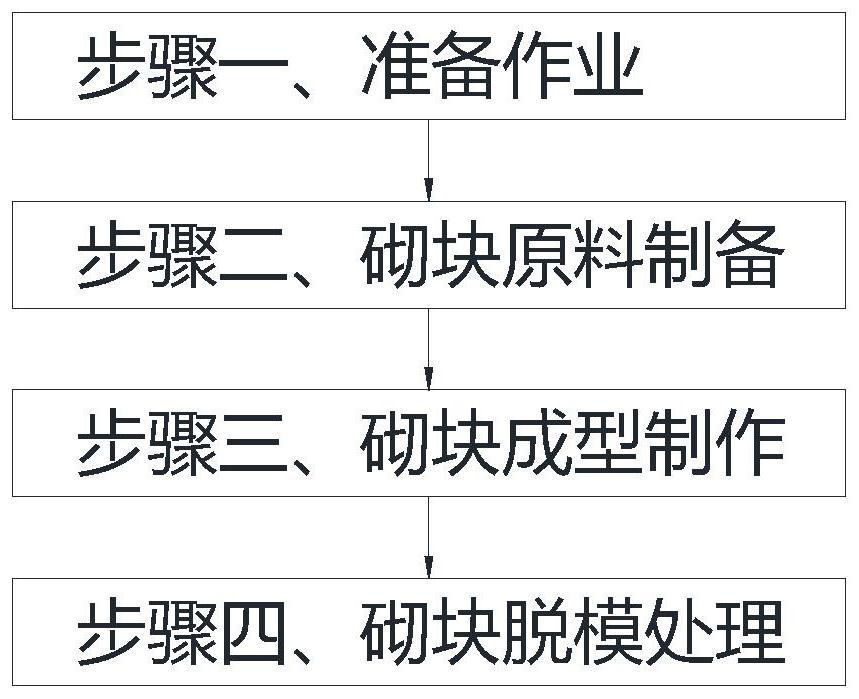

Aerated concrete block preparation and molding method

ActiveCN112109181AFormation effect is goodWell mixedDischarging arrangementPress rollersArchitectural engineeringMechanical engineering

Owner:山东铭城环保新材料科技有限公司

Nano self-emulsification system and preparation method thereof

InactiveCN104531114AImprove system stabilityFormation effect is goodDrilling compositionNanoparticlePolyethylene glycol

The invention discloses a nano self-emulsification system. The nano self-emulsification system is characterized by being prepared from a component (a) and a component (b): wherein the component (a) is a surfactant containing nanoparticles, the component (b) is an emulsifier containing an oil phase. The oil phase is a mixture of an emulsifier, polyethylene glycol and a mineral oil, the weight ratio of the nanoparticle hydrosol to the oil phase is 100:(30-60), preferably 100:(30-50) and more preferably 100:(35-45). The invention further provides a preparation method of the nano self-emulsification system.

Owner:CHINA PETROLEUM & CHEM CORP +1

Colored photosensitive resin composition, cured film, color filter, method for producing color filter, solid state imaging element, and image display device

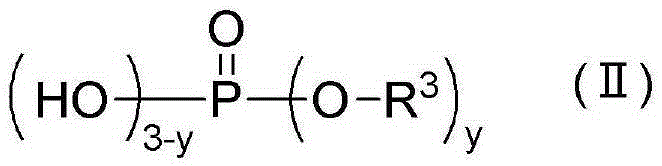

ActiveCN105324717AFormation effect is goodMonoazo dyesOptical filtersTricarboxylic acidPhosphoric acid

A colored photosensitive resin composition contains: (A) a pigment; (B) a basic dye derivative; (C-1) a phosphoric acid-based dispersing agent represented by general formula (II) or (C-2) a carboxylic acid-based dispersing agent resulting from reacting a polymer (POH) having a hydroxyl group at least at one terminus or a polymer (PNH2) having a primary amino group at least at one terminus, and a tricarboxylic acid anhydride or tetracarboxylic acid dianhydride; (D) a resin binder; (E) a photoinitiator; and (F) a polymerizable compound.

Owner:FUJIFILM CORP

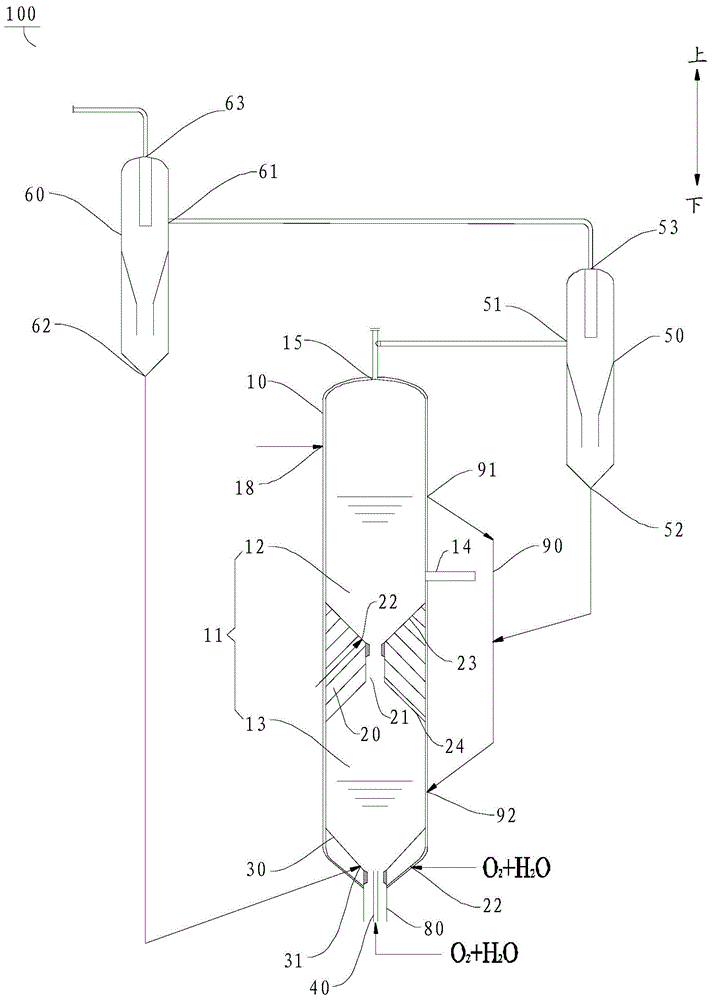

Fluid jet bed coal-to-synthetic gas gasification furnace

ActiveCN104017608AIncreased methane (CH

<sub>4</sub>

)contentExtended stayGranular/pulverulent flues gasificationSyngasSlag

The invention discloses a fluid jet bed coal-to-synthetic gas gasification furnace which comprises a furnace body, a spacer bush, an overflow pipe, a gas distribution plate and a center pipe, wherein a cavity is formed in the furnace body; the spacer bush is arranged in the cavity to divide the cavity into an upper cavity and a lower cavity; the overflow pipe is arranged at the outer side of the furnace body, one end of the overflow pipe is communicated with an inlet of the overflow pipe, and the other end of the overflow pipe is communicated with an outlet of the overflow pipe; the gas distribution plate is arranged in the lower cavity, and a slag discharge pipe which protrudes out of the lower cavity and discharges slag inside the lower cavity is arranged at the bottom of the gas distribution plate. According to the fluid jet bed coal-to-synthetic gas gasification furnace, the upper cavity and the lower cavity both form fluid jet beds, and the upper cavity and the lower cavity are communicated through a through hole; a solid material enters the upper cavity of the gasification furnace and then sufficiently contacts with a gasification agent and a synthetic gas, and the retention time of the solid material in the gasification furnace is prolonged, so that the methane (CH4) content, steam decomposition rate and carbon transformation rate of the synthetic gas are increased.

Owner:SHANGHAI YAOXING INVESTMENT MANAGEMENT

Injectable cartilage repair hydrogel and preparation method thereof

ActiveCN111184910AGood biocompatibilityFormation effect is goodPharmaceutical delivery mechanismTissue regenerationBenzoic acidMethacrylate

The invention relates to injectable cartilage repair hydrogel. The hydrogel is prepared from the following components in parts by weight: 5 to 15 parts of methacrylate gelatin, 1 to 10 parts of methacrylate hyaluronic acid, 1 to 2 parts of nano cellulose and 0.1 to 0.5 part of melanin nano particles loaded with 2-([1, 1-biphenyl]-4-ylcarbamyl) benzoic acid. According to the hydrogel disclosed by the invention, a catechol functionalized network is used as a paramagnetic metal ion chelating bracket, and the synthesized melanin base material has excellent biocompatibility and the capability of coordinating isolated paramagnetic metal centers. The base material is loaded with a cartilage repair promoting small molecular compound 2-([1, 1-biphenyl]-4-ylcarbamyl) benzoic acid. The nanoparticlesare dispersed into injectable hydrogel, so that the product can remarkably induce bone marrow mesenchymal stem cells to be differentiated into cartilage, has an extremely strong cartilage formation promoting effect, realizes detection of cartilage repair conditions in MRI, photoacoustic and photo-thermal multiple imaging modes, and enhancing application in medical clinics.

Owner:BEOGENE BIOTECH GUANGZHOU

Preparation method of germanium tellurite glass optical prefabricated rod output by green ray

InactiveCN101870557AFormation effect is goodImprove mechanical propertiesGlass making apparatusGlass productionLight sourceGermanium

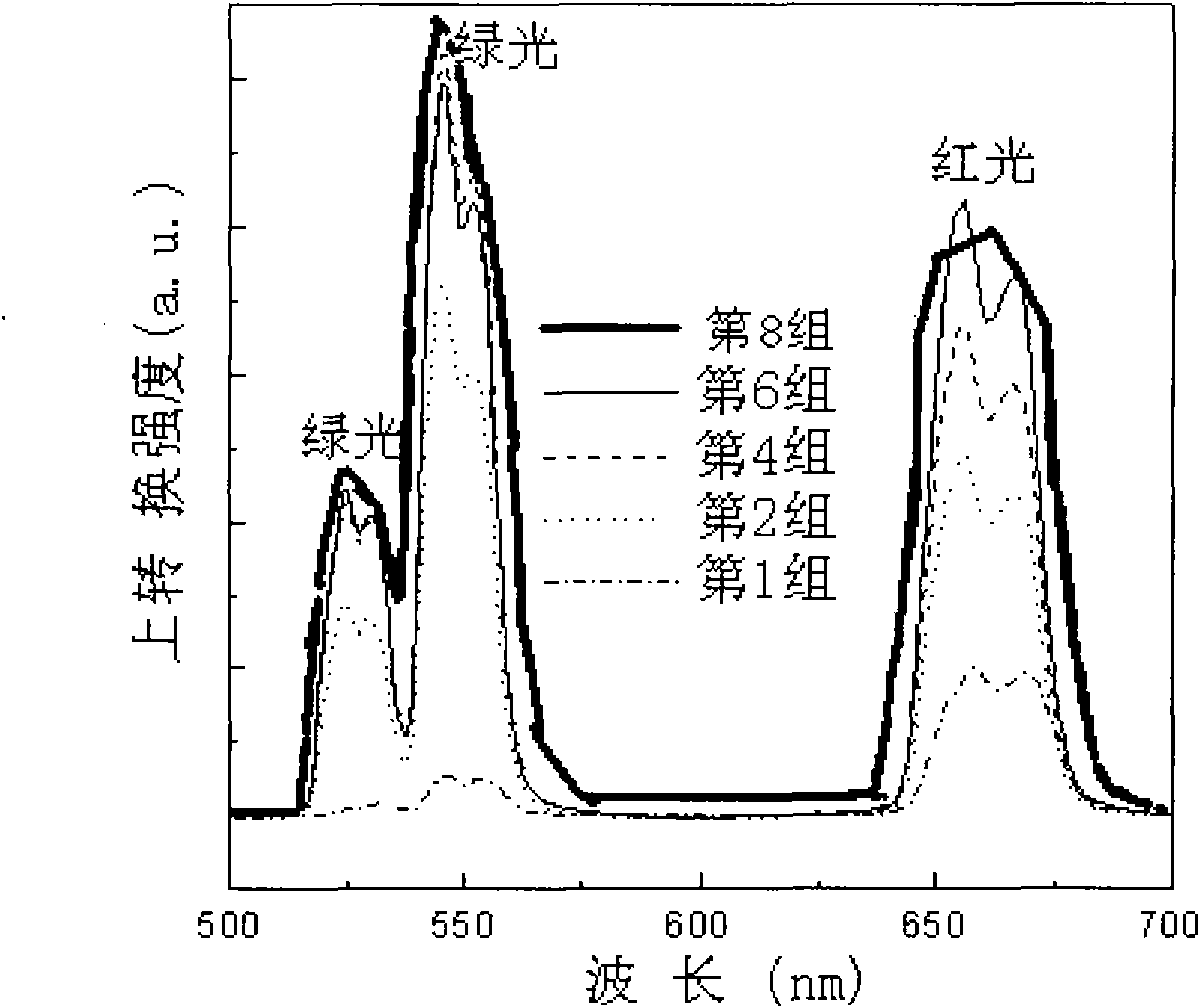

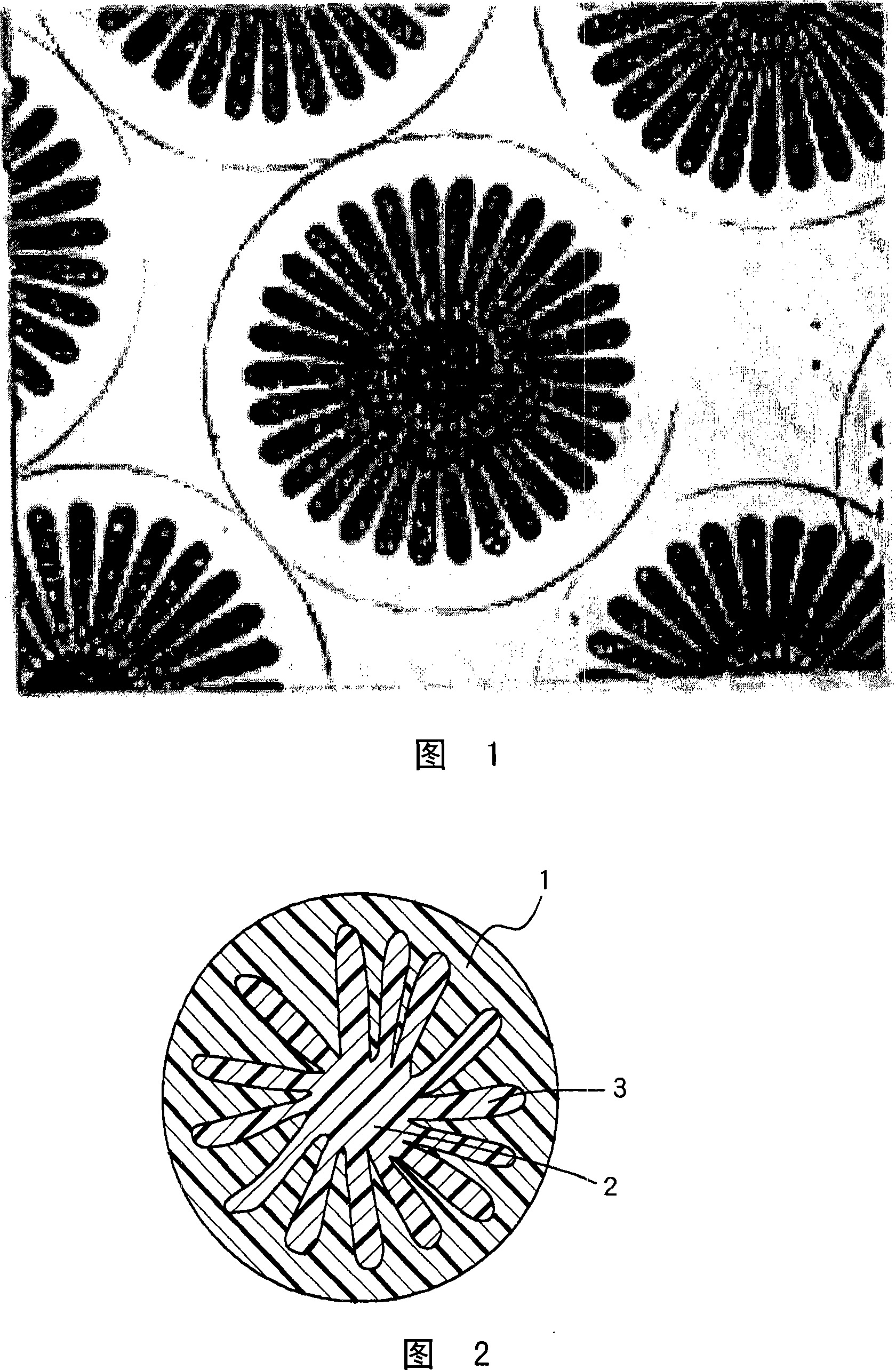

The invention relates to a preparation method of germanium tellurite glass optical prefabricated rod output by green ray, a component formula of the glass and a preparation method. The glass material has strong up-conversion green ray luminous intensity. When the luminous strength of the green ray is the greatest, the mixture ratio of the glass is as follows: 55mol% of TeO2, 3.75mol% of GeO2, 12mol% of ZnO, 50mol% of ZnCl2, 0.75mol% of Er2O3, and 3.5mol% of Yb2O3. The oxychloride tellurite glass prepared by the melting method is transparent, has favorable devitrification resistance capability, and excellent physical or chemical property; After the oxychloride tellurite glass with different contents of ZnCl2 is pumped by utilizing a semiconductor light source in a waveband of 980nm, the up-conversion green ray luminous intensity of the glass is dramatically improved. The glass can be applied to the up-conversion fibre optical laser and the color display device output by green ray.

Owner:柳祝平

Fabric and clothes for atopic dermatitis patients

InactiveCN1981078AIncrease productivityReduce stimulationOrnamental textile articlesGlovesPolymer scienceSingle fibre

It is intended to provide a fabric and clothes which can be obtained at a high productivity and are little irritative to atopic dermatitis patients. Namely, a fabric for atopic dermatitis patients, which is made of an EVOH-based fiber comprising an ethylene-vinyl alcohol copolymer having 25 to 70% by mol of ethylene copolymerized therein at a ratio of 70% or more of the fiber surface and can be in contact with affected parts of the atopic dermatitis patients and in which the hydroxyl content on the EVOH-based fiber surface amounts to 20 to 70% by mol, the Young's modulus of the EVOH-based fiber is 60cN / dtex or lower and the strand thickness of the EVOH-based fiber is 5 dtex or less, is prepared. The EVOH-based fiber may be a core-shell type compound fiber containing an ethylene-vinyl alcohol copolymer as the shell component, in particular, an ethylene-vinyl alcohol copolymer having 25 to 70% by mol of ethylene copolymerized therein as the shell component, and a crystalline thermoplastic resin having a melting point of 150 DEG C or higher as the core component.

Owner:KURARAY CO LTD

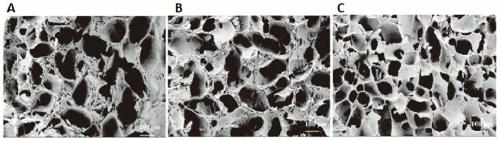

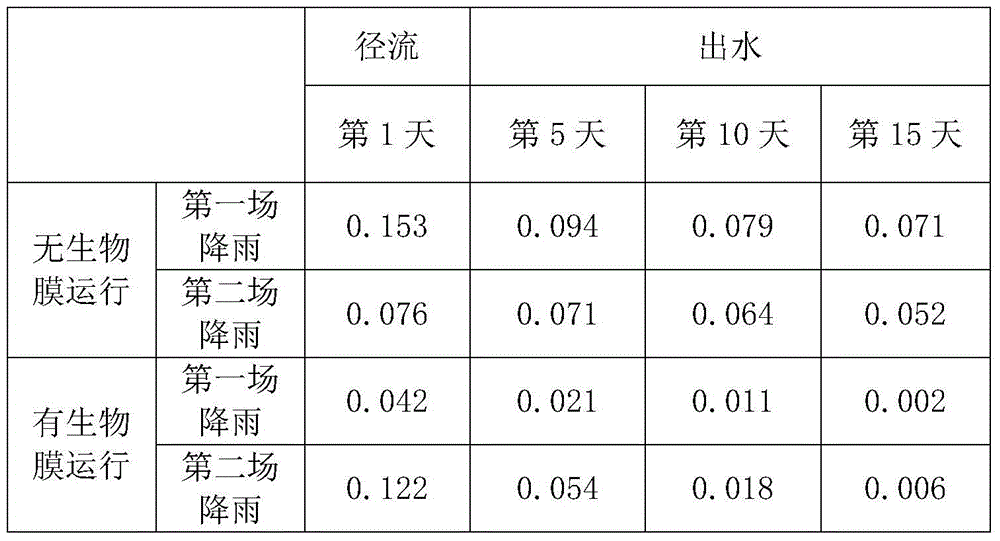

Bioretention pond capable of removing petroleum pollutants by using efficient biological film

InactiveCN105692914AGood removal effectEfficient conversionWater treatment compoundsWater contaminantsWash waterOil spill

The invention provides a bioretention pond capable of removing petroleum pollutants by using an efficient biological film, belonging to the field of environmental bioengineering. Aiming at the problem that the bioretention pond is poor in petroleum removal effect, the invention takes the conventional bioretention pond technology as a basis; efficient degradation microorganisms are inoculated and cultured by arranging a carrier material of the biological film at a specific bioretention area to generate a biological film system, so that effects of maintaining the long-term surviving of the microorganisms and enhancing the removal of the petroleum pollutants are achieved. The bioretention pond can be applied to storage and purification of rainwater or wash water of places such as a highway, a gas station, an automobile service factory, an oil depot and the like which have higher oil spill risk, and can reduce the damage of the petroleum pollutants to the water environment.

Owner:SHANDONG JIANZHU UNIV +1

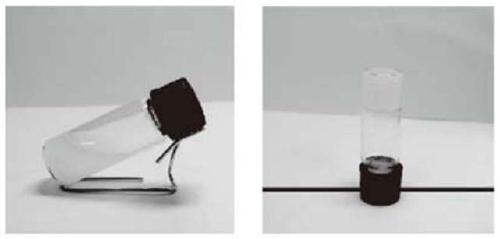

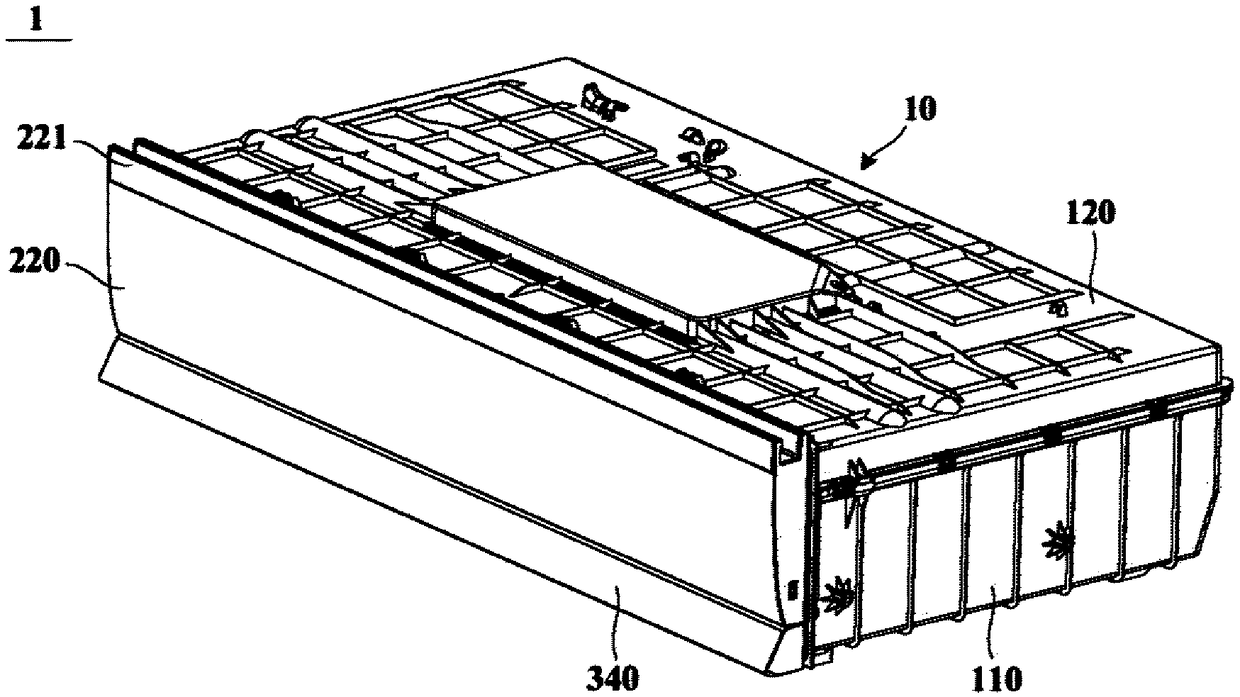

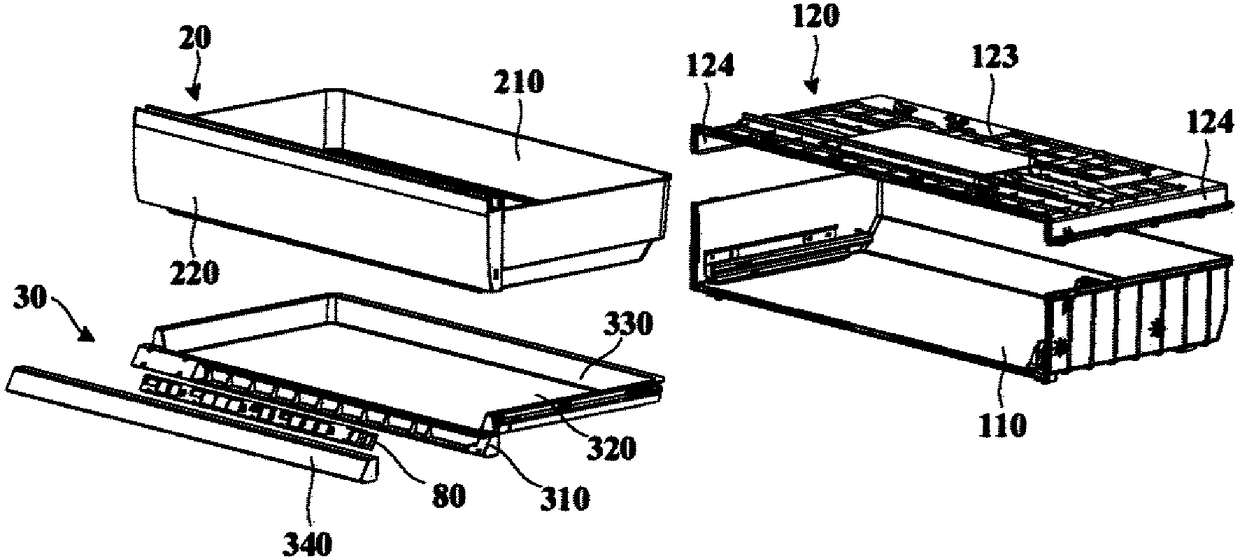

Cold storage and refrigeration device and drawer assembly thereof

PendingCN108397962AAvoid failureAvoid enteringLighting and heating apparatusDomestic refrigeratorsPush and pullEngineering

The invention relates to a cold storage and refrigeration device and a drawer assembly thereof. The drawer assembly comprises a seal bucket with an opening in the front end, a tray and a drawer; the seal bucket comprises a bucket body and a bucket cover, the tray is arranged to be inserted into the bottom of the seal bucket through the opening in the front end in a push and pull manner, the draweris borne on the tray, and is arranged to be inserted into the seal bucket in a push and pull manner along with the tray, and the drawer is provided with a drawer body and a front end plate arranged on the front side of the drawer body. The tray is located on the head of the outer side of the seal bucket when the drawer is in the completely closed state, the head of the tray and the drawer are inair tight seal through a seal part, the head of the tray and the front end of a bottom plate of the seal bucket are in air tight seal through a seal part, the front end plate and the front end of thebucket cover of the seal bucket are in air tight seal through a seal part, and the bucket body and the bucket cover are in air tight seal through a seal part, so that when the drawer is in the complete closing state, a sealed storage space is formed in the drawer. Manufacturing, maintaining or replacing and the like of all parts is facilitated, seal with the good effect and the higher level can beformed in the drawer.

Owner:HAIER SMART HOME CO LTD

Zirconium-based amorphous alloy and preparation method thereof

ActiveCN104498845AReduced mechanical propertiesFormation effect is goodMechanical propertyAmorphous metal

The invention discloses a zirconium-based amorphous alloy and a preparation method thereof. The zirconium-based amorphous alloy is low in cost, and is more suitable for industrialized production. High raw material purity and high vacuum degree required by conventional zirconium-based amorphous alloy preparation processes are not necessary. The zirconium-based amorphous alloy is (Zr(a)Cu(b)Al(c))(100-x)O(x), wherein a, b, c, and x are used for representing atom percentage, 57<=a<=76, 15<=b<=34, 9<=c<=28, and 50ppm<=x<=5000ppm. The zirconium-based amorphous alloy contains no Be which is harmful for bionts, and is excellent in mechanical properties and amorphous formation capability; requirement on vacuum degree and raw material purity is low, raw material cost is low, and application prospect is promising.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Copper foil with carrier, laminate, method of producing printed wiring board, and method of producing electronic devices

ActiveCN106257969AInhibits oxidative discolorationFormation effect is goodPrinted circuit secondary treatmentElectroforming processesInter layerCopper foil

The invention relates to a copper foil with a carrier, a laminate, a method of producing a printed wiring board, and a method of producing electronic devices. The invention provides the copper foil with the carrier having a small absolute value of the difference in releasing strength between the copper foil with a carrier prepared by laminating and hot-pressing the surface close to an ultra-thin copper layer of the copper foil with a carrier to an insulating substrate and used after the carrier is peeled off and the copper foil with a carrier prepared by laminating and hot-pressing the surface close to the carrier of the copper foil with a carrier to an insulating substrate and used after the ultra-thin copper layer is peeled off, while generation of swelling during laminating of the copper foil with a carrier to the insulating substrate by hot pressing is prevented, discoloring of the surface of the ultra-thin copper layer due to oxidation is prevented, and the circuit formability is high. A copper foil with a carrier, including a carrier, an intermediate layer, an ultra-thin copper layer, and a surface treated layer in this order, wherein no roughened layer is disposed on the surface of the ultra-thin copper layer, and the surface treated layer consists of Zn or a Zn alloy, the amount of Zn applied in the surface treated layer is 30 to 300 <mu>g / dm2, and if the surface treated layer is composed of the Zn alloy, the proportion of Zn in the Zn alloy is 51% by mass or more.

Owner:JX NIPPON MINING & METALS CORP

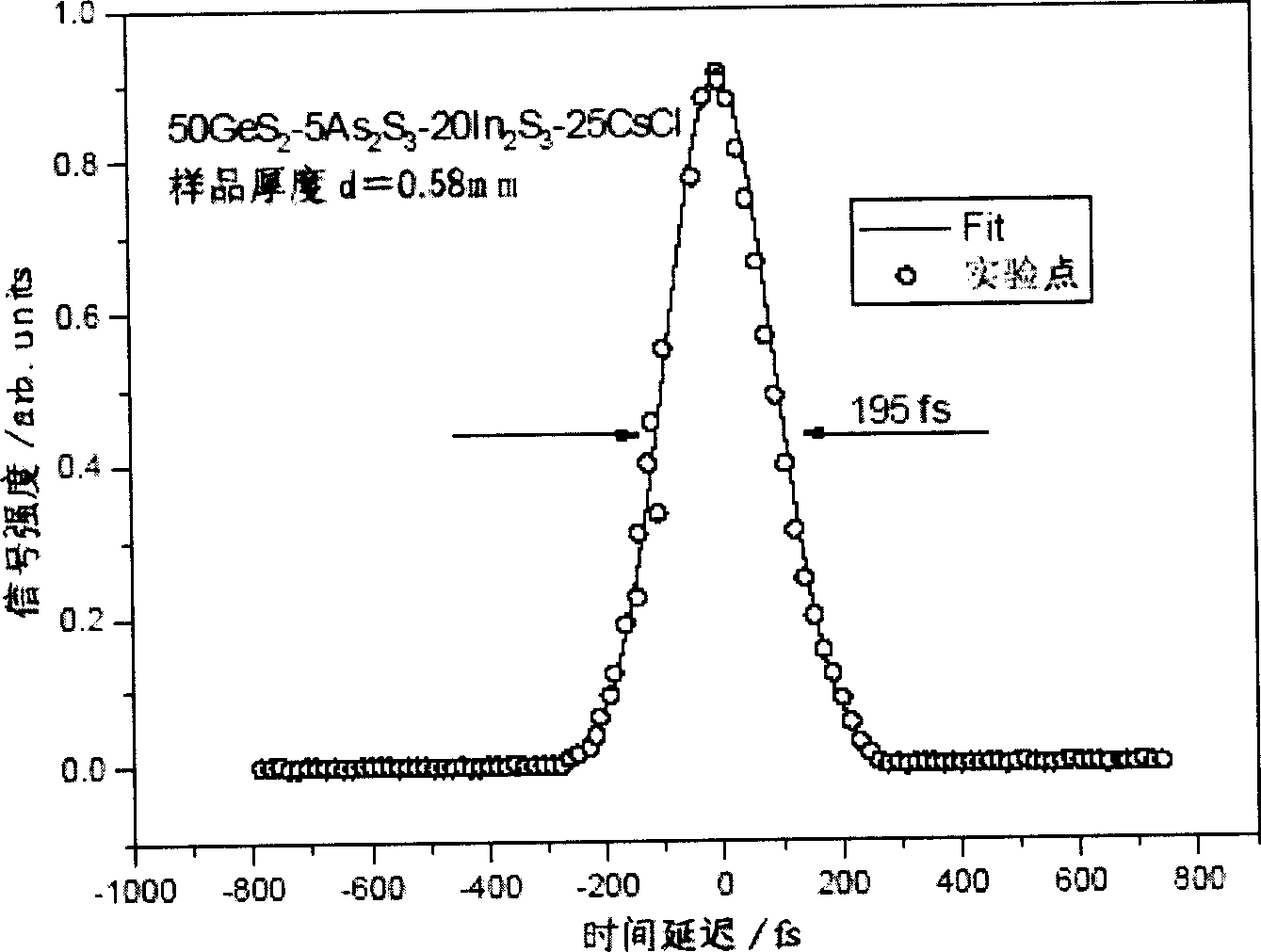

Sulfur halogen glass and its production for superfast light switch

A sulfur halogen glass for ultra-fast photo-switch and its production are disclosed. The sulfur halogen glass consists of In2S3 20í½35mol, MX 25í½40mol, As2S3 4í½10mol and GeS2 20-50mol. MX is mixture of any one kind or two kinds and above. It has better quality and glass forming ability, less consumption and larger linear optical refractive index.

Owner:WUHAN UNIV OF TECH

Preparation method of lithium vanadium phosphate/graphene/carbon composite positive electrode material

ActiveCN107706379AFormation effect is goodImprove performanceCell electrodesSecondary cellsCarbon compositesWater based

The invention specifically relates to a preparation method of a lithium vanadium phosphate / graphene / carbon composite positive electrode material. The preparation method comprises the steps of adding asoluble lithium compound, vanadium compound and phosphate into deionized water based on an appropriate proportion to prepare a solution; next, adding a proper amount of sodium citrate and graphene oxide; then putting a carbon substrate, the surface of which is attached with the vanadium compound, into the mixed solution in a horizontal manner to be immersed for several days, next, taking the immersed carbon substrate out and drying the substrate, and performing high-temperature calcining in protection atmosphere for a certain time, and then taking the product out and performing cooling; and repeatedly executing the above steps and finally performing low-temperature carbonization treatment and high-temperature synthesis treatment in sequence to obtain the lithium vanadium phosphate / graphene / carbon composite positive electrode material on the surface of the substrate. The lithium vanadium phosphate positive electrode material not only has the advantages of high specific capacity, high cycle performance, high rate capability and the like, but also combines the advantages of the low cost, green environmental protection and the like.

Owner:郴州博太超细石墨股份有限公司

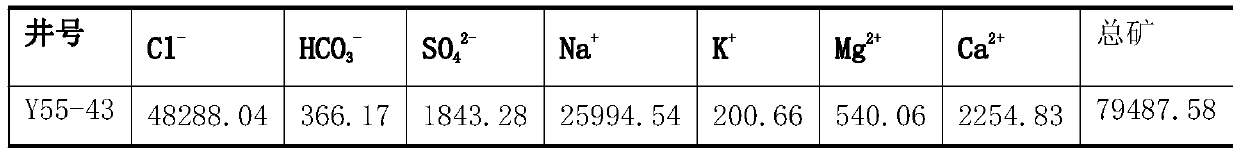

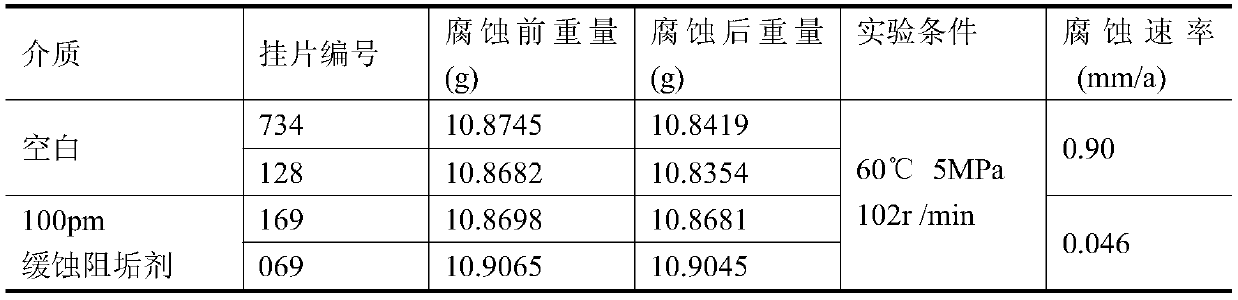

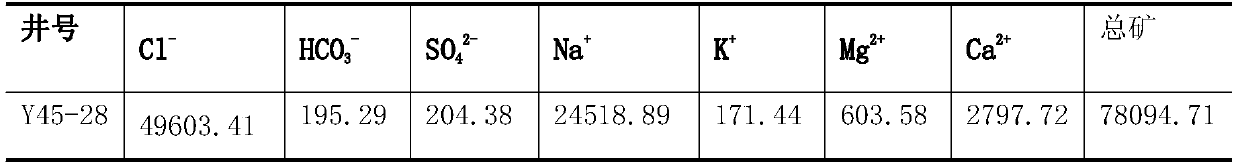

Corrosion and scale inhibitor

InactiveCN111472007AFormation effect is goodImprove anti-corrosion performanceOil fieldAqueous solubility

The invention belongs to the field of oilfield chemistry, and particularly provides a corrosion and scale inhibitor. The corrosion and scale inhibitor is prepared from, by mass percentage, 1.6-10% ofa water-phase scale inhibitor, 1-15% of an organic-phase corrosion inhibitor, 0.1-0.3% of a thickening agent, 9-15% of an emulsifier, 52-65% of oil and the balance water. The problem that common water-soluble scale inhibitors and oil-soluble corrosion inhibitors are poor in compatibility is solved. The corrosion and scale inhibitor can also achieve corrosion resistance and scale prevention of oilwells. Indoor experiments show that the corrosion inhibition rate of a system is larger than 90%, the scale prevention rate is larger than 80%, the effect is obvious, and the preparation process is simple. The corrosion and scale inhibitor has high thermodynamic and dynamic stability, is gradually released and demulsified after being injected into the wells, can be evenly dispersed in a produced aqueous medium while protecting the corrosion resistance of a shaft carbon steel pipe column, achieves effective scale prevention of a shaft, and also reduces the production and operation cost of oilfields.

Owner:PETROCHINA CO LTD

Method for manufacturing copper foil with carrier, method for manufacturing copper-clad laminate, method for manufacturing printed wiring board and method for manufacturing electronic device, and products thereof

ActiveCN105392297AFormation effect is goodImprove wettabilityCircuit precursor manufactureElectroforming processesCopper foilSilane coupling

The invention provides a method for manufacturing copper foil with carrier. The method comprises the following heating and processing steps: a copper foil with a carrier comprises a carrier, a middle layer, a ultrathin copper layer and a surface processing layer comprising a silane coupling processing layer, the copper foil with the carrier is performed a heating process for 1 hour to 8 hours at the heating temperature of 100 DEG C to 220 DEG C, or a heating process for 1 hour to 6 hours at the heating temperature of 100 DEG C to 220 DEG C, or a heating process for 2 hour to 4 hours at the heating temperature of 160 DEG C to 220 DEG C.

Owner:JX NIPPON MINING & METALS CO LTD

Inlet gas filter device and boiler provided with same

PendingCN109579040AIncreased maintenance difficultyReduce maintenance difficultyFluid heatersCombination devicesEngineeringFiltration

The invention relates to the technical field of purifying, in particular to an inlet gas filter device and a boiler provided with same. The inlet gas filter device provided by the invention is arranged at an air inlet of a first object, and comprises a filter mechanism and a water curtain forming mechanism, wherein the filter mechanism is provided with a gas inlet, a gas outlet, and at least a primary filter screen arranged between the gas inlet and the gas outlet; the gas outlet communicates with the gas inlet; and the water curtain forming mechanism is used for forming a water curtain on each stage of the filter screen. According to the inlet gas filter device provided by the invention, the water curtain is formed on each stage of the filter screen through the water curtain forming mechanism, so that the water curtain on the filter screen is in sufficient contact with inlet air of a first object, adhesion and filtration on dust in inlet air is realized by utilizing the adhesion of water; circulating water continuously flushes the filter screen, so that the filter screen is kept transparent, and therefore, the filter screen is prevented from being blocked as a result of too much dust; and the device does not need to dismount for maintaining, and circulating water only needs to change, so that maintenance is relatively simple, and maintenance cost is relatively low.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

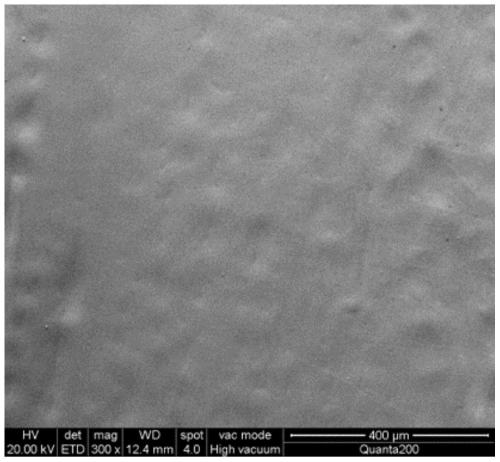

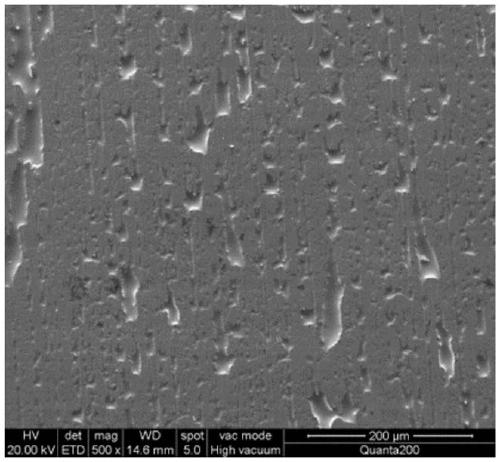

Corrosion prevention method for aluminum-based metal component, and corrosion-proof aluminum-based metal product produced by the method

InactiveCN101041899AEasy to confirmFormation effect is goodMetallic material coating processesMetal layered productsSodium molybdateSulfate

The present invention provides a corrosion prevention method for an aluminum-based metal component, which makes it easy to check the presence or absence of a chemically formed film on the component, and a corrosion-proof aluminum-based metal product produced by the method. In the method, the following treatment agent (A) is brought into contact with a surface of the aluminum-based metal component to chemically form the following film (B) on the surface of the aluminum-based metal component: (A) a treatment agent comprising an aqueous solution of zinc sulfate, an aqueous solution of ammonium fluoride and an aqueous solution of sodium molybdate which are mixed together; (B) a chemically formed film (B) comprising zinc fluoride, molybdenum and aluminum fluoride.

Owner:SUMITOMO RIKO CO LTD

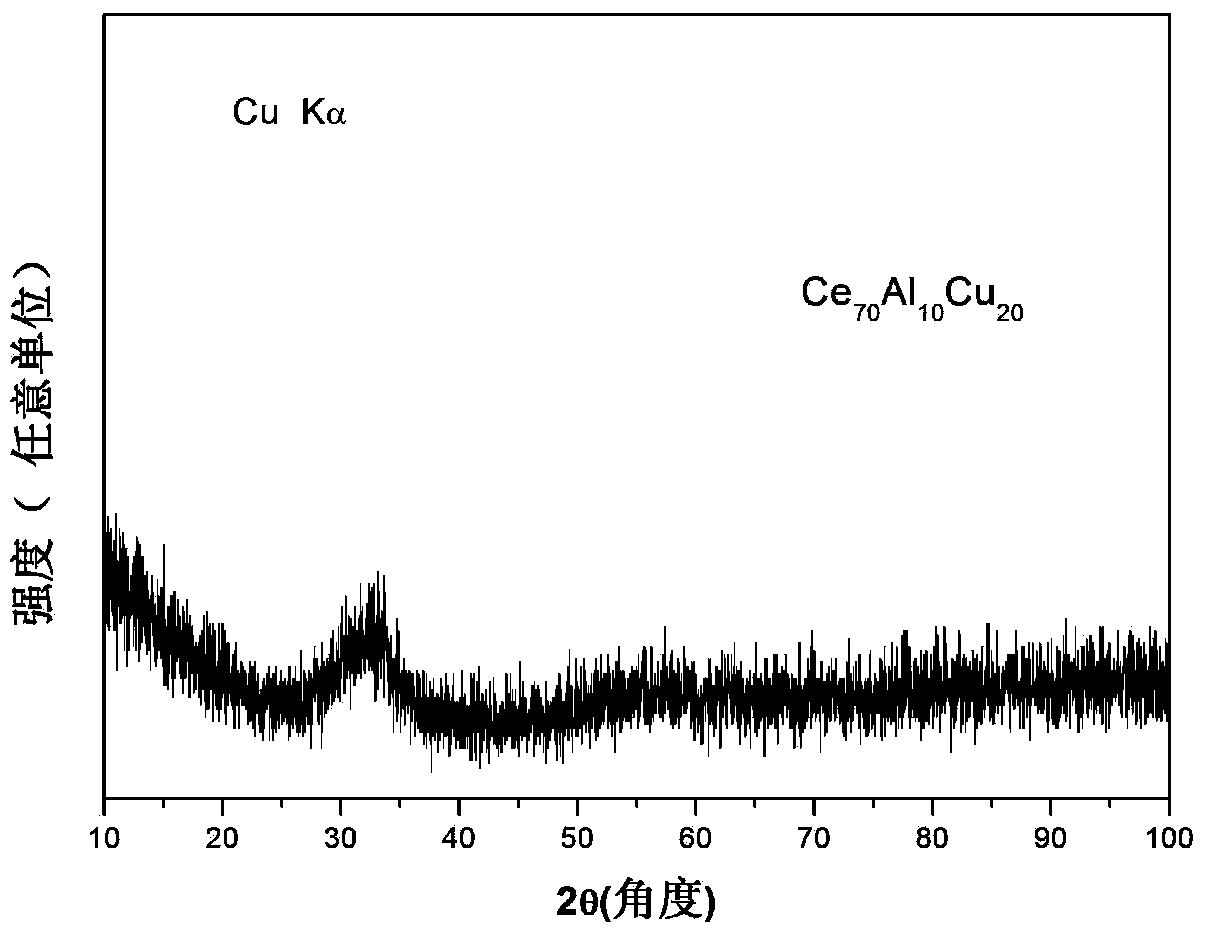

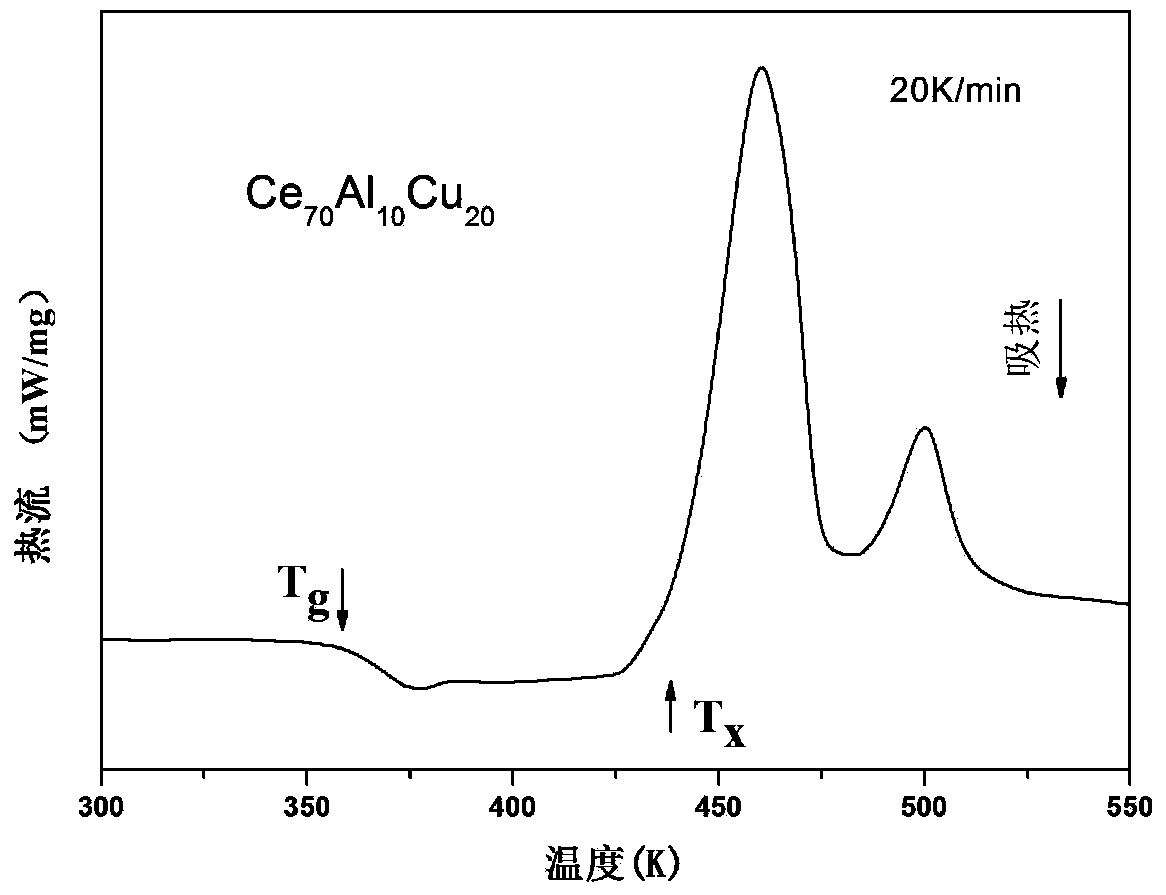

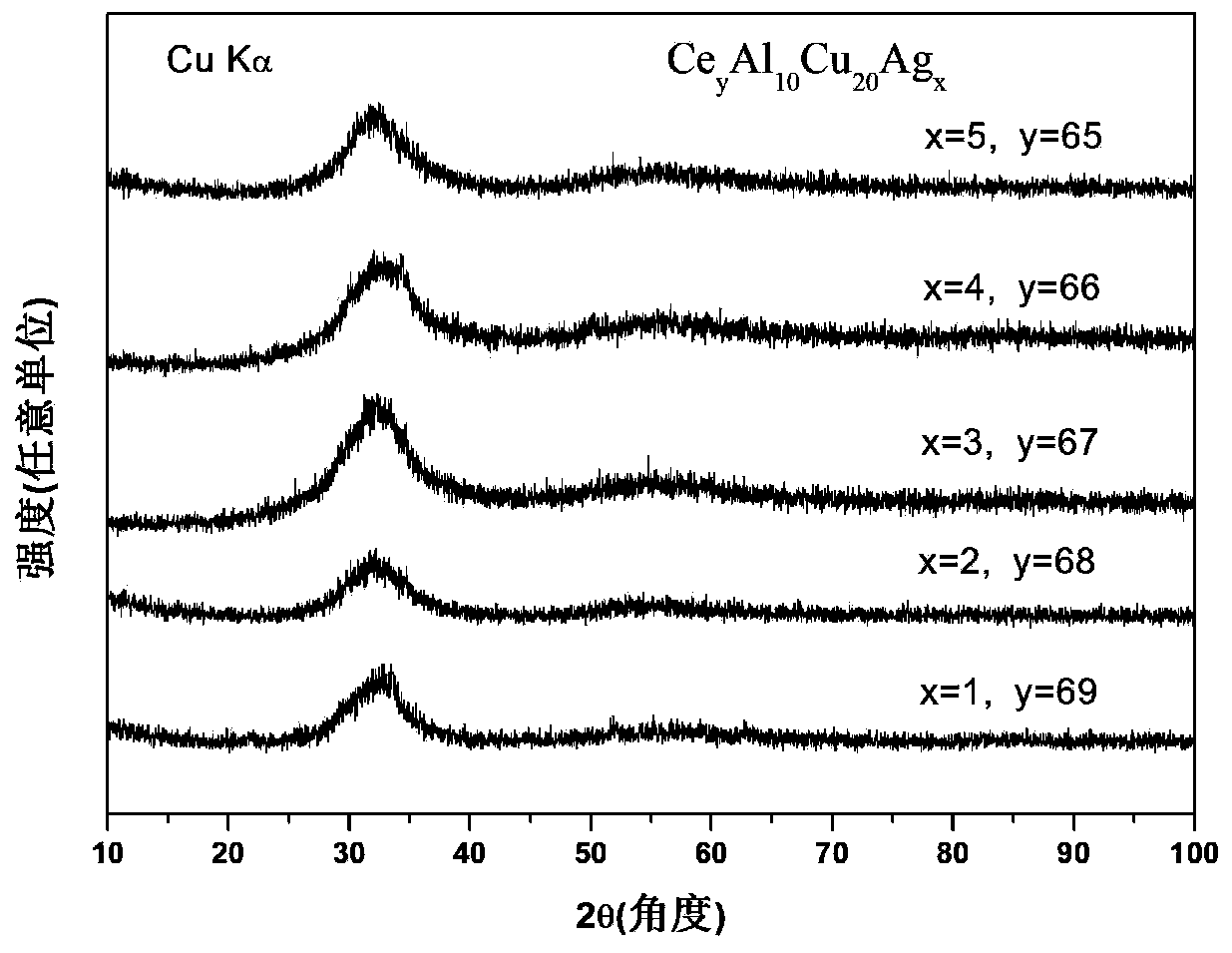

Ce-Al-Cu-Ag bulk amorphous alloy and preparation method thereof

ActiveCN103938126AImprove industrial applicabilityIncreased width and glass forming capacityAg elementLiquid phase

The invention relates to a Ce-Al-Cu-Ag bulk amorphous alloy with a low glass transition temperature and a wide supercooled liquid region. By taking Ce70Cu20Al10 as a basic component and the metal element Ag which belongs to the same main group with Cu as an alloying element, the composition of the alloy is determined by the follow formula: CeyAl10Cu20Agx, wherein x is the atomic percentage of the metal element Ag, y is the atomic percentage of Ce, x is greater than or equal to 1 but less than or equal to 5, y is greater than or equal to 65 but less than or equal to 69, and (x+y)=70. The alloy can form the bulk amorphous alloy with the critical dimension no less tan 3mm and the maximum supercooled liquid region reaching 95K. The alloy integrates low glass transition temperature, wide supercooled liquid region and good glass forming capacity. By means of the low glass transition temperature similar to a common polymer, the alloy can be used as an ideal material which researches phase change and structural relaxation of the metallic glass. By means of excellent conductivity and near-room-temperature super-plastic forming property, the alloy is expected to have a good application prospect in precise components and nano-meter fabrication.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com