Corrosion and scale inhibitor

A kind of anti-corrosion and anti-scaling agent technology, applied in the field of anti-corrosion and anti-scaling agent, can solve the problems of increasing the production cost of oil field, poor anti-corrosion and anti-scaling effect, poor compatibility, etc., to improve the effect of anti-corrosion and anti-scaling, Good film-forming effect and large selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

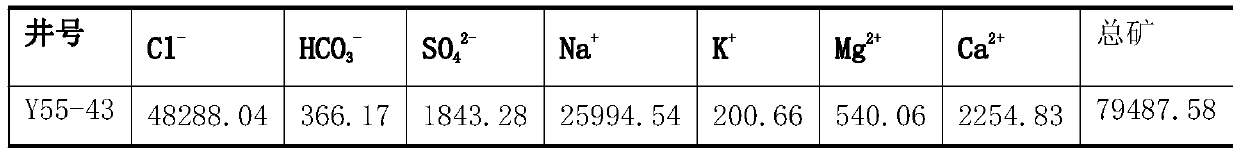

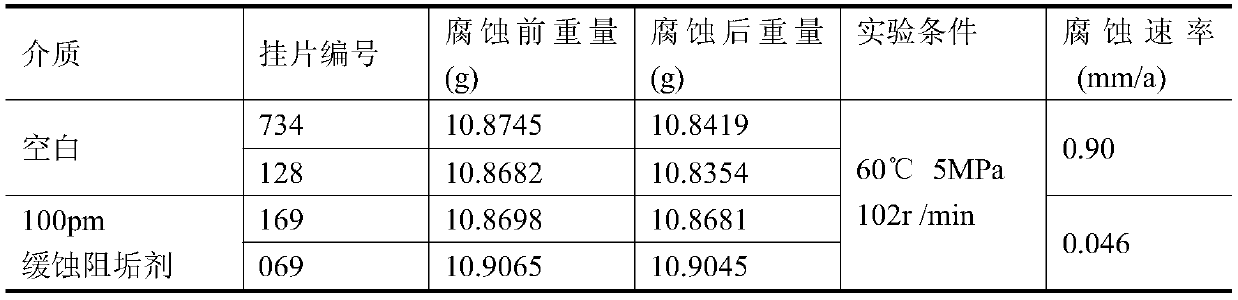

Examples

Embodiment 1

[0030] A corrosion and scale inhibitor, which is made of the following raw materials according to the following mass percentages: 1.6-10% of the water-phase scale inhibitor, 1-15% of the organic phase corrosion inhibitor, 0.1-0.3% of the thickener, emulsified Agent 9~15%, oil 52~65%, balance is water.

[0031] The water phase scale inhibitor is organic phosphonic acid, polycarboxylic acid acid scale inhibitor, and the organic phosphonic acid is aminotrimethylphosphonic acid, 2-phosphonic acid butane-1,2,4-tricarboxylic acid , one or several combinations of diethylenetriaminepentamethylphosphonic acid, polycarboxylic acid acid scale inhibitor is polymaleic anhydride.

[0032] The organic phase corrosion inhibitor is one or more combinations of imidazoline derivative corrosion inhibitors, phosphonic acid, phosphonic acid, mercaptobenzothiazole; the imidazoline derivative corrosion inhibitor is oleic acid sulfur One or more combinations of ureidoimidazoline and benzoic acid thio...

Embodiment 2

[0047]A kind of anticorrosion and antiscaling agent, it is made by following raw material by following mass percent: aqueous phase antiscaling agent 2-phosphonic acid butane-1,2,4-tricarboxylic acid (PBTCA) 8%, organic phase Corrosion inhibitor 12%, described organic phase corrosion inhibitor is the mixture of oleic acid thioureido imidazoline or phosphonic acid or oleic acid thioureido imidazoline and phosphonic acid, thickener 0.2%, described thickener is Carboxymethyl cellulose (CMC), starch, gelatin, sodium alginate, casein, guar gum, chitosan or one or more combinations, emulsifier sorbitan tristearate (Span-65 ) 9%, diesel oil 52%, and the balance is water.

[0048] The preparation method of described corrosion and scale inhibitor comprises the steps:

[0049] 1) First, in the emulsification reaction kettle, sequentially add the organic phase corrosion inhibitor oleic acid thioureidoimidazoline 12% and the emulsifier sorbitan tristearate (Span-65) 9%, secondly, the orga...

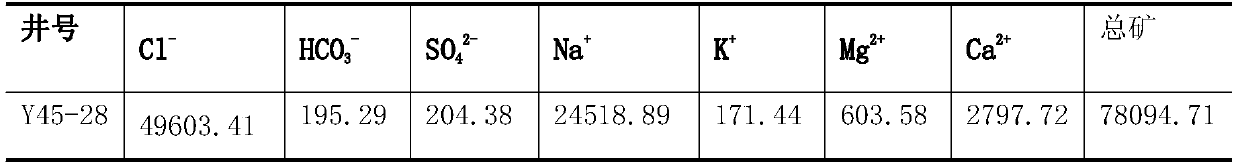

Embodiment 3

[0062] A kind of corrosion and scale inhibitor, it is made by following raw material by following mass percent: water phase scale inhibitor aminotrimethylphosphonic acid (ATMP) 5.8%, organic phase corrosion inhibitor 8%, described organic phase The corrosion inhibitor is one or more combinations of thioureidoimidazoline benzoate, phosphine carboxylic acid, and mercaptobenzothiazole, and the thickener is 0.2%, and the thickener is guar gum, gum arabic, soybean protein One or more combinations of glue, natural rubber, lanolin, agar, emulsifier propylene glycol fatty acid ester (PO-50) 12%, kerosene 60%, and the balance is water.

[0063] The preparation method of described corrosion and scale inhibitor comprises the steps:

[0064] 1) First, add 8% of organic phase corrosion inhibitor thioureidoimidazoline benzoate and 12% of emulsifier propylene glycol fatty acid ester (PO-50) in the emulsification reaction kettle in sequence, and then, the organic phase corrosion inhibitor and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com