Method of processing active materials for use in secondary electrochemical cells

A battery and electrode technology, applied in the field of electroactive material processing

Inactive Publication Date: 2009-09-23

VALENCE TECH INC

View PDF10 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, many known electroactive materials lack one or more of these properties

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Login to View More

Abstract

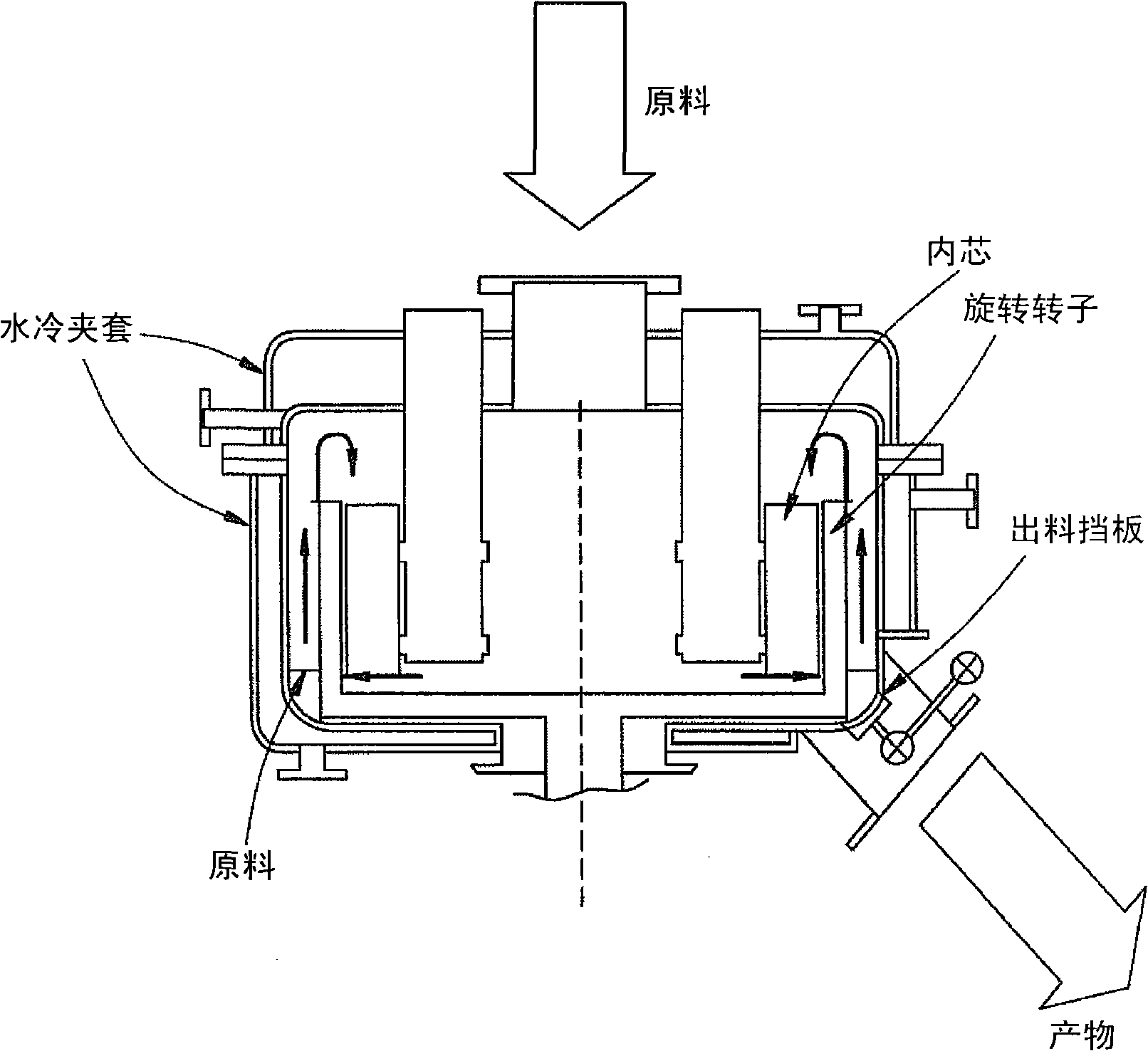

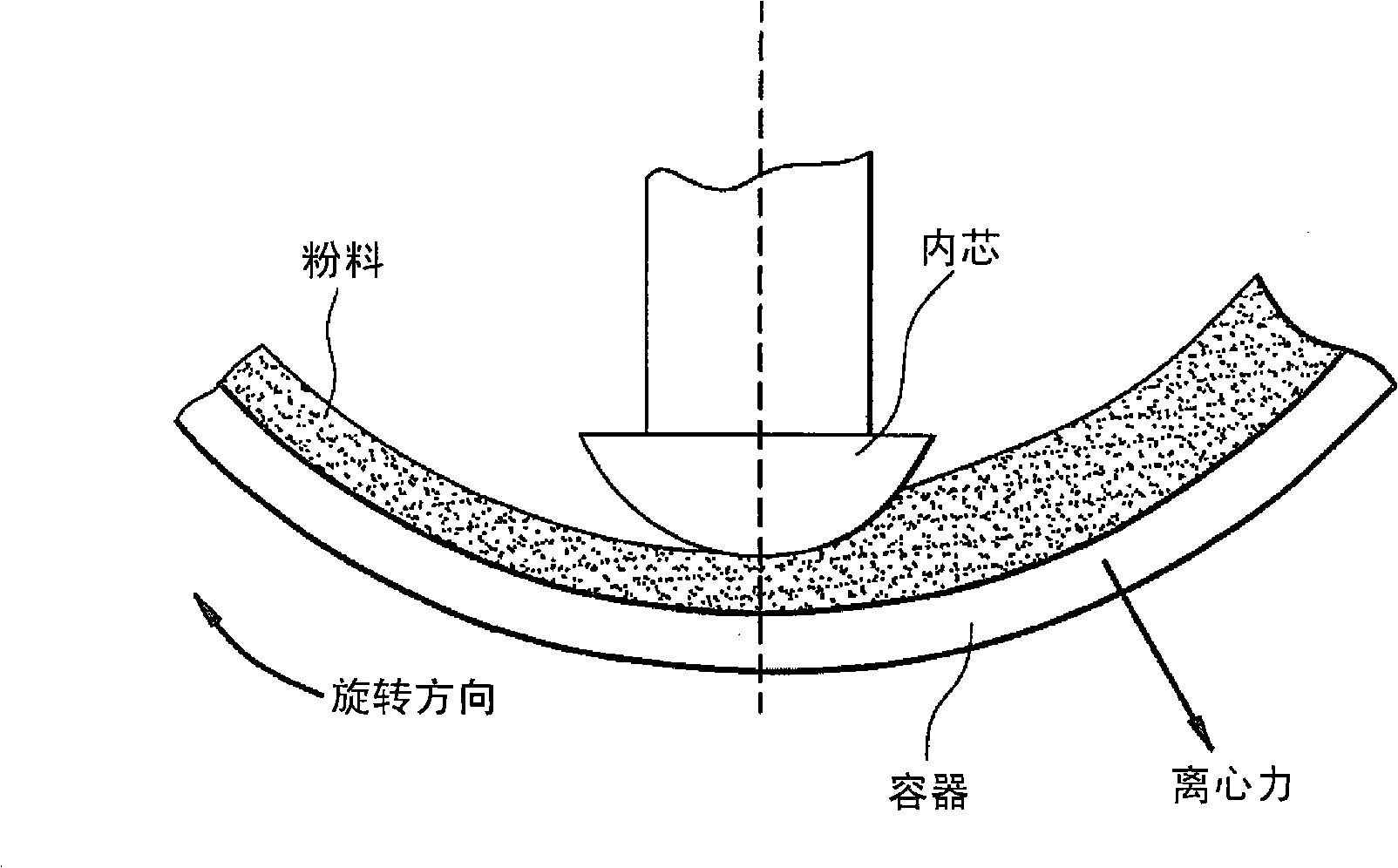

The present invention provides a method for the processing of particles of metal phosphates or particles of mixed metal phosphates and in particular lithiated metal phosphates and mixed metal phosphates. The processing occurs, for example using a mechanofusion system as depicted in Figures 1 and 2. In general, the powder materials are placed in a rotary container and are subjected to centrifugal force and securely pressed against the wall of the container. The material then undergoes strong compression and shearing forces when it is trapped between the wall of the container and the inner piece of the rotor with a different curvature (Figure 2). Particles of the material are brought together with such force that they adhere to one another. In the mechanofusion system, as indicated in Figure 2, the powder material is delivered through slits on the rotary walls. It is carried up above the rotors by the rotor-mounted circulating blades. Subsequently, the material returns again to the rotors where it is are subjected to strong compression and shearing forces from the inner pieces of the rotor. This cycle of both three-dimensional circulation and effective compression / shearing of the powder material is repeated at high speeds, thereby forming it into a composite electroactive material (powder).

Description

technical field [0001] The present invention relates to the processing of electroactive materials for the manufacture of electrodes and batteries. The electroactive material is processed using a mechanofusion process in which mechanical energy is applied to electroactive particles produced by a carbothermal reduction process. The mechanofusion process induces mechano-chemical reactions, resulting in novel electroactive particles. Background technique [0002] The variety of electrochemical cells or batteries is well known in the art. In general, a battery is a device that converts chemical energy into electrical energy through an electrochemical oxidation-reduction reaction. Batteries are used in many applications, especially as a power source for devices that cannot be practically powered by a central power source, such as a commercial power plant utilizing a utility transition line. [0003] Batteries generally consist of three components: the anode, which contains mate...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01M4/58H01M4/04H01M10/052H01M10/36

CPCY02E60/12H01M4/5825C01B25/37H01M4/043C01B25/45H01M10/052C01B25/455Y02E60/10

Inventor 董明

Owner VALENCE TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com