Preparation method of germanium tellurite glass optical prefabricated rod output by green ray

A technology of oxychlorotellurite and glass, applied in glass manufacturing equipment, glass production, manufacturing tools, etc., can solve problems such as poor chemical stability, reduce production costs, improve anti-devitrification ability, and improve up-conversion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

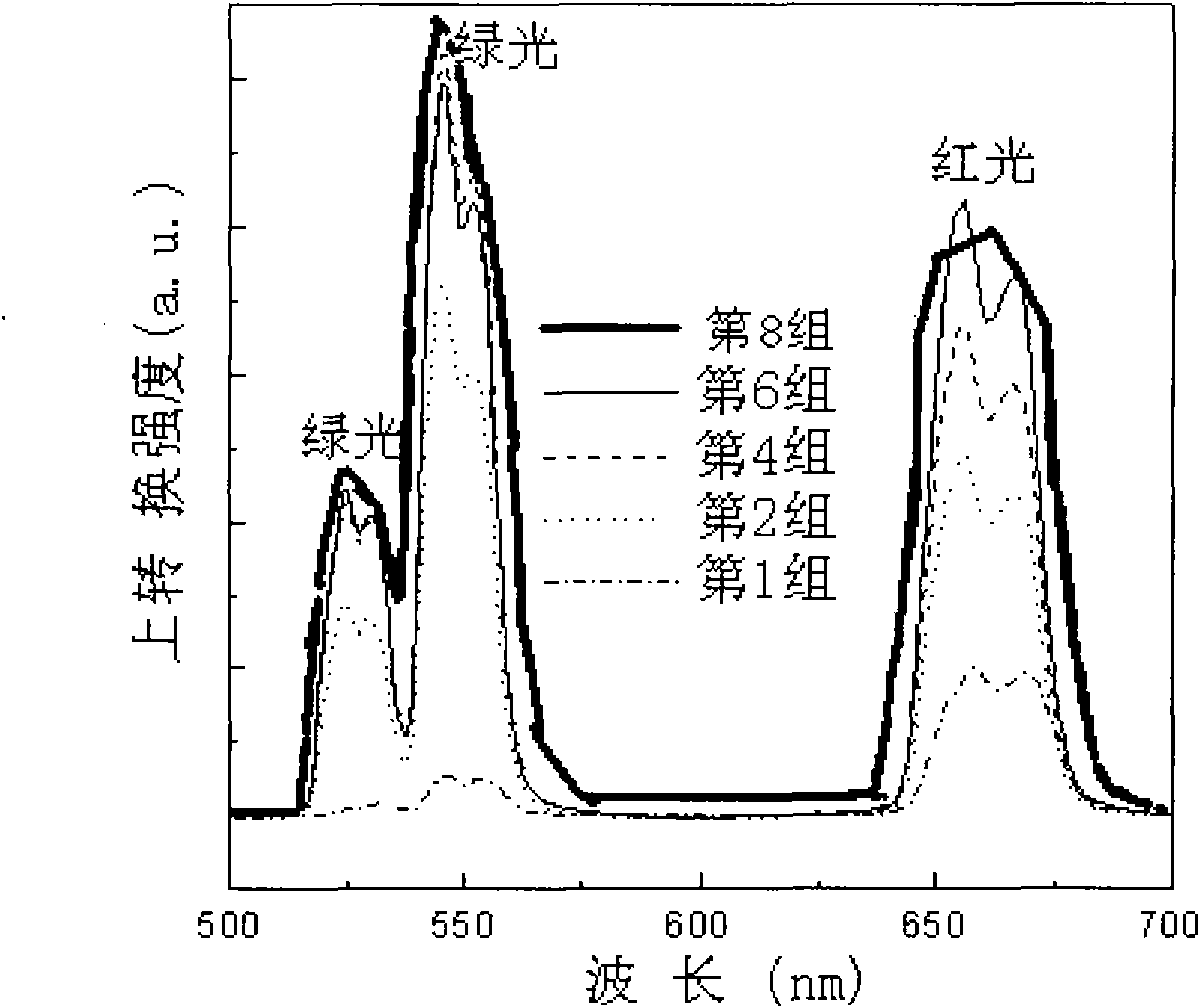

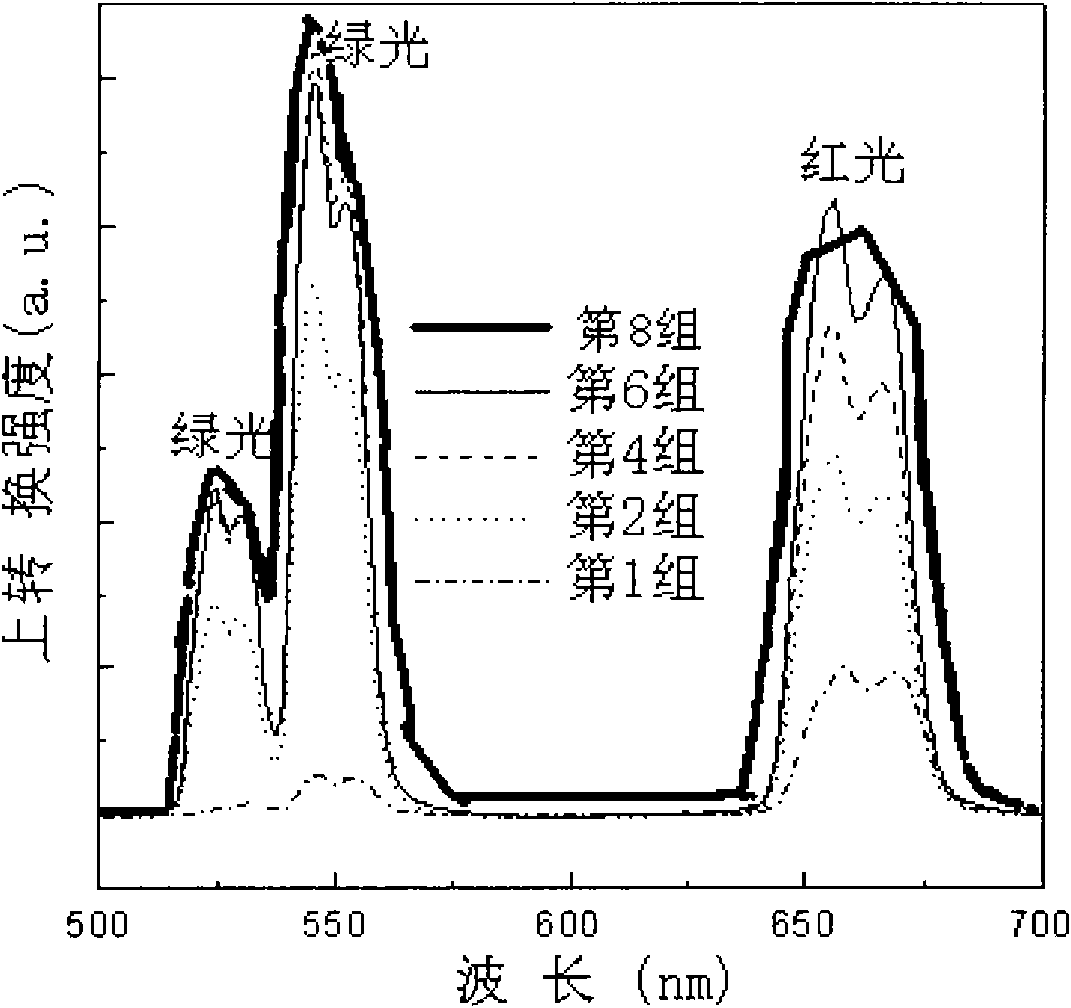

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in combination with specific embodiments.

[0012] First determine Er 3+ / Yb 3+ Formulation of co-doped oxychlorotellurite glasses. See Table 1 for the molar composition of the glass formulation.

[0013] Table 1: Formulation composition of oxychlorotellurite glass (mol%)

[0014] Ingredients name

Proportion range

best ratio

TeO 2

40~70

55

GeO 2

0~7.5

3.75

ZnO

4~20

12

ZnCl 2

0~50

50

Er 2 o 3

0.5~1.0

0.75

Yb 2 o 3

2~5

3.5

[0015] Concrete implementation example:

[0016] The first step: select a suitable glass formula (see Table 2);

[0017] Step 2: Melting Er 3+ / Yb 3+ The process of co-doped oxychlorotellurite glass: high-purity TeO 2 、GeO 2 , ZnO, ZnCl 2 、Er 2 o 3 and Yb 2 o 3 After the powdered raw materials are mixed evenly, they are put in a platinum crucible ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com