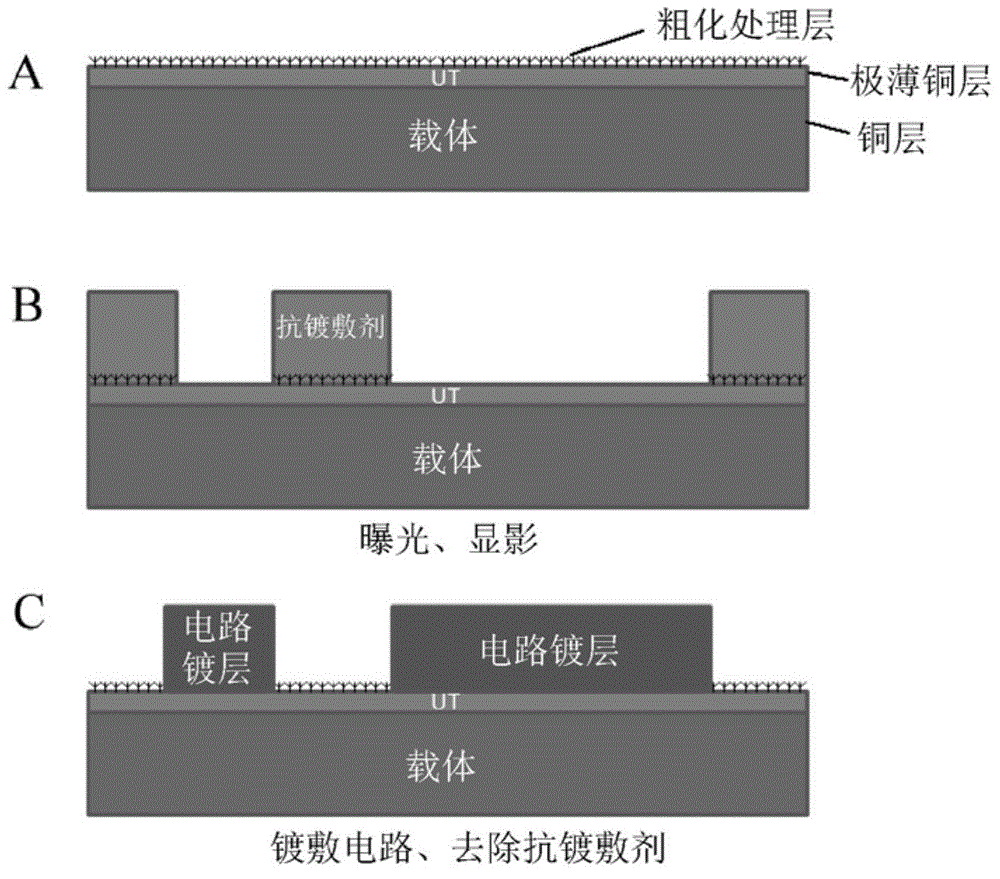

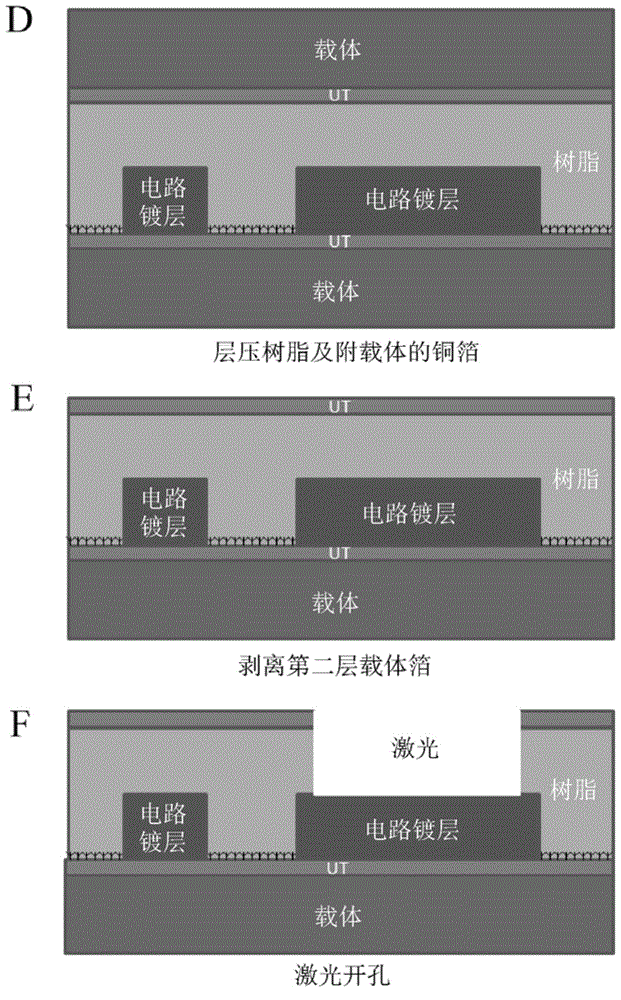

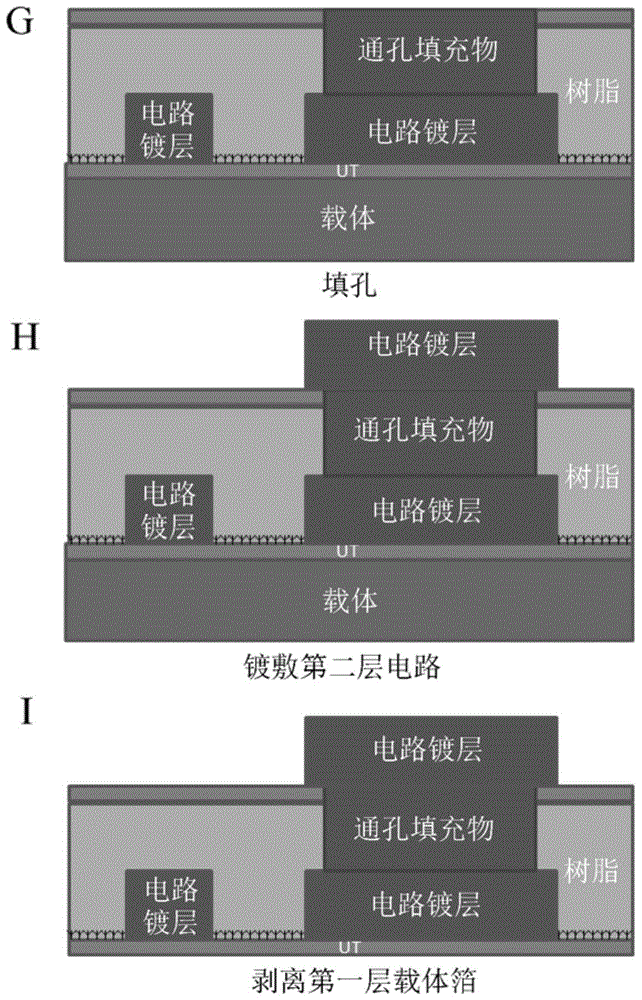

Copper foil with carrier, printed wiring board, laminate, electronic machine and method for manufacturing printed wiring board

A technology for printed wiring boards and manufacturing methods, applied in printed circuit parts, chemical instruments and methods, secondary processing of printed circuits, etc., can solve problems such as residues and poor insulation of circuit patterns, and achieve the effect of good circuit formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0331] Hereinafter, it demonstrates based on an Example and a comparative example. In addition, this Example is just an example, and is not limited to this example.

[0332] 1. Manufacture of copper foil with carrier

[0333] As a copper foil carrier, a 35-micrometer-thick long electrolytic copper foil (JTC manufactured by JX Nippon Oil Metal Co., Ltd.) and a 33-micrometer-thick rolled copper foil (C1100 manufactured by JX Nikko Nippon Oil Metal Co., Ltd.) were prepared. The glossy side (bright side) of the copper foil is subjected to nickel (Ni) or cobalt (Co) plating as metal plating using a roll-to-roll continuous plating line under the following conditions, followed by BTA treatment as chromate treatment or treatment with organic matter, thereby forming the intermediate layer. In addition, "degreasing" and "pickling" in Table 1 represent the pretreatment of performing nickel (Ni) plating on the surface of the carrier to be nickel-plated or cobalt-plated under the followi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com