Ferrum-based amorphous nanocrystalline soft magnetic alloy and preparation method and application thereof

A nanocrystalline soft magnetic, iron-based amorphous technology, applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc., can solve the problems that cannot be adapted to light weight, miniaturization, large volume, and low saturation magnetic induction intensity , to achieve the effect of optimizing soft magnetic properties, low coercivity, and high saturation magnetic induction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

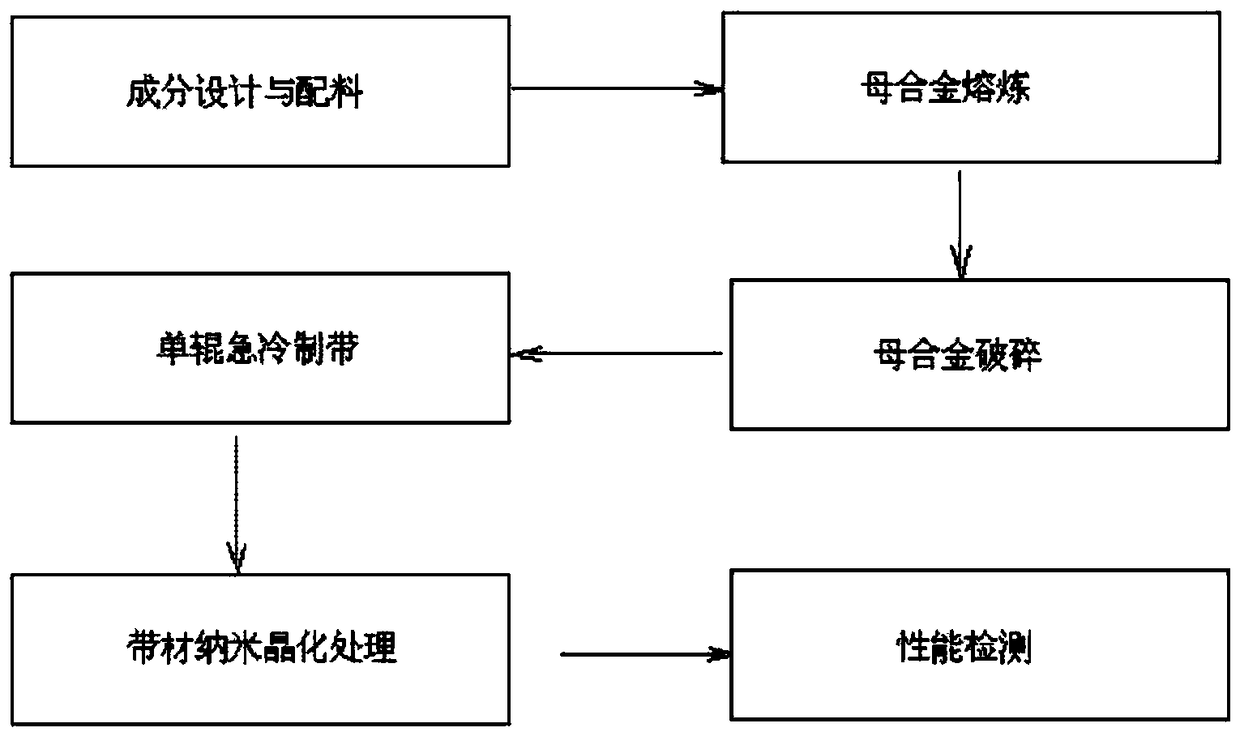

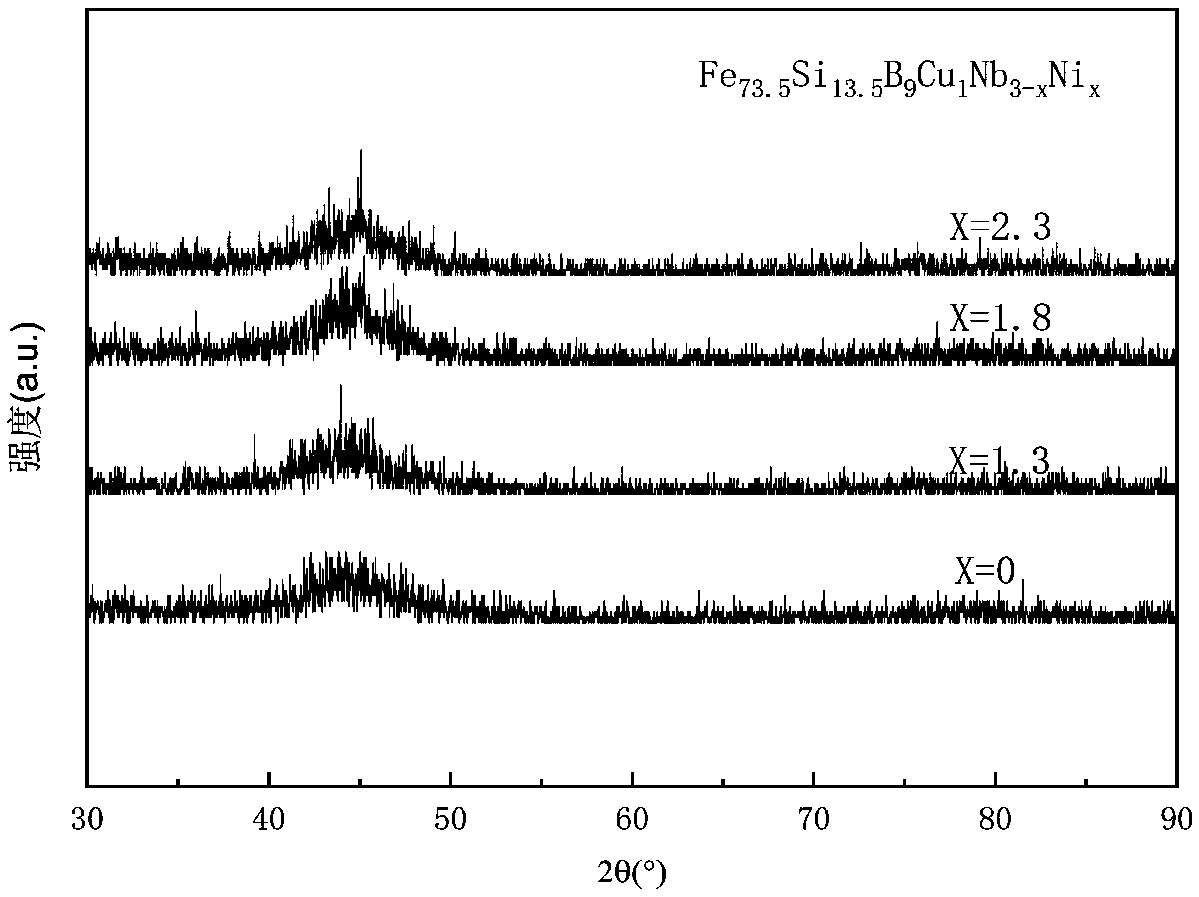

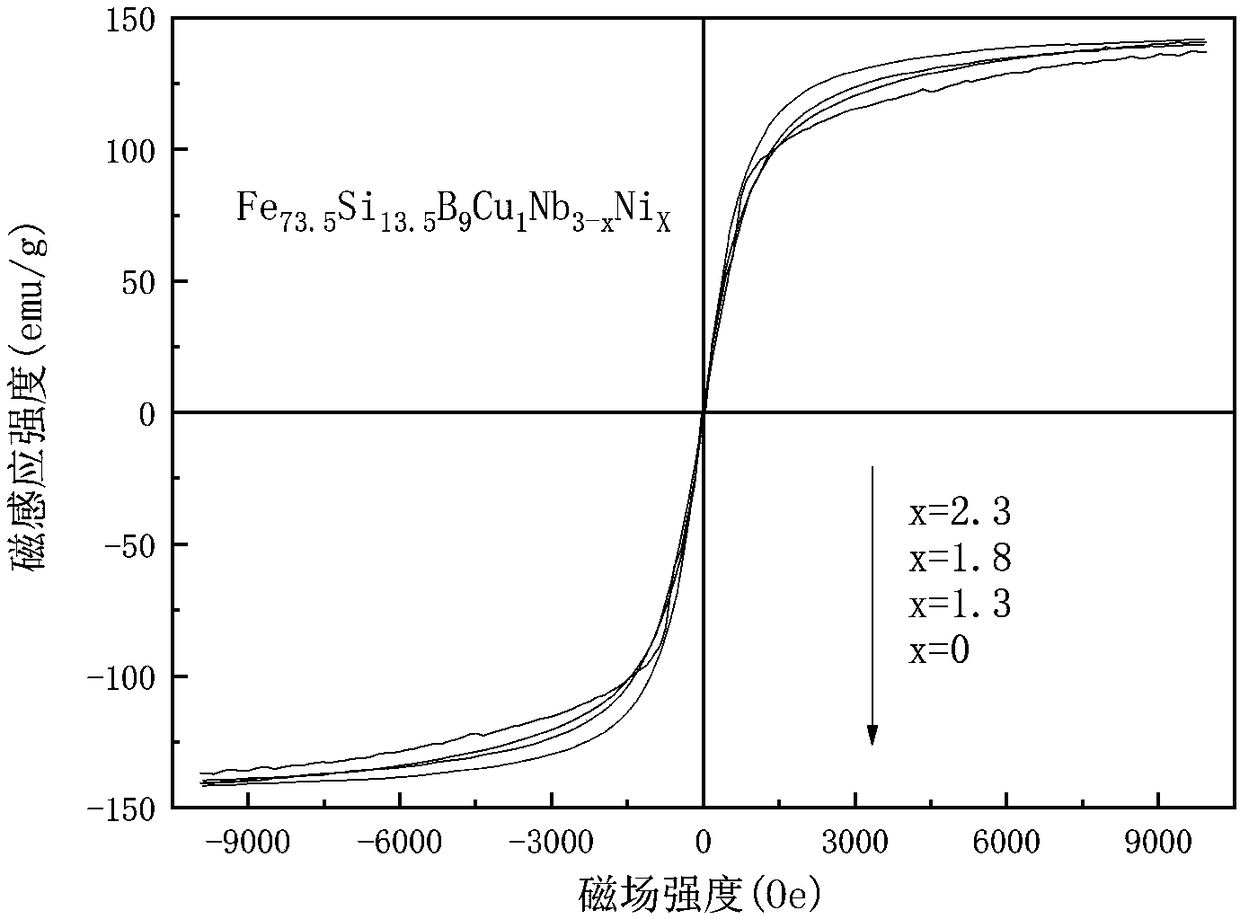

[0033] In this embodiment, the chemical formula of the iron-based amorphous nanocrystalline alloy is Fe 73.5 Si 13.5 B 9 Cu 1 Nb 1.7 Ni 1.3 . figure 1 It is a schematic diagram of the process flow for preparing the iron-based amorphous alloy in the present invention.

[0034] 1. Preparation:

[0035] (1) Master alloy raw material preparation: according to Fe 73.5 Si 13.5 B 9 Cu 1 Nb 1.7 Ni 1.3 The chemical formula converts atomic percentage to mass percentage, and weighs Fe (99.9%), FeB (17.51%) alloy, Si (99%) block, Cu (99.9%) block, Nb (99.9%) block and Ni (99.9%) in proportion. %).

[0036] (2) Master alloy smelting: Put the prepared raw materials into the vacuum arc melting furnace, and evacuate the furnace body to 5×10 -3 Then fill it with argon / nitrogen atmosphere for protection, and close the filling valve when the pressure in the furnace is 0.01Mpa higher than the atmospheric pressure. Heat and smelt the raw materials. After the raw materials are comple...

Embodiment 2

[0043] In this embodiment, the chemical formula of the iron-based amorphous nanocrystalline alloy is Fe 73.5 Si 13.5 B 9 Cu 1 Nb 1.2 Ni 1.8 .

[0044] 1. Preparation:

[0045] (1) Master alloy raw material preparation: according to Fe 73.5 Si 13.5 B 9 Cu 1 Nb 1.2 Ni 1.8 The chemical formula converts atomic percentage to mass percentage, and weighs Fe (99.9%), FeB (17.51%) alloy, Si (99%) block, Cu (99.9%) block, Nb (99.9%) block and Ni (99.9% %).

[0046] (2) Master alloy smelting: Put the prepared raw materials into the vacuum arc melting furnace, and evacuate the furnace body to 5×10 -3 Then fill it with argon / nitrogen protective atmosphere, and close the filling valve when the pressure in the furnace is 0.01Mpa higher than the atmospheric pressure. Heat and smelt the raw materials. After the raw materials are completely melted, continue to smelt for 3 minutes, then cool to solidify, quickly turn them over and repeat smelting 4 times to obtain an alloy ingot wi...

Embodiment 3

[0053] In this embodiment, the chemical formula of the iron-based amorphous nanocrystalline alloy is Fe 73.5 Si 13.5 B 9 Cu 1 Nb 0.7 Ni 2.3 .

[0054] 1. Preparation:

[0055] (1) Master alloy raw material preparation: according to Fe 73.5 Si 13.5 B 9 Cu 1 Nb 0.7 Ni 2.3 The chemical formula converts atomic percentage to mass percentage, and weighs Fe (99.9%), FeB (17.51%) alloy, Si (99%) block, Cu (99.9%) block, Nb (99.9%) block and Ni (99.9% %).

[0056] (2) Master alloy smelting: Put the prepared raw materials into the vacuum arc melting furnace, and evacuate the furnace body to 5×10 -3 Then fill it with argon / nitrogen atmosphere for protection, and close the filling valve when the pressure in the furnace is 0.01Mpa higher than the atmospheric pressure. Heat and smelt the raw materials. After the raw materials are completely melted, continue to smelt for 3 minutes, then cool to solidify, quickly turn them over and repeat smelting 4 times to obtain an alloy ingo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com