Colored photosensitive resin composition, cured film, color filter, method for producing color filter, solid state imaging element, and image display device

A photosensitive resin, color filter technology, applied in the direction of filters, optical components, chemical instruments and methods, etc., can solve problems such as coloring pattern 1 collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0632]

[0633] The compositions of the present invention are prepared by admixing the ingredients described above.

[0634] In addition, when preparing a composition, each component which comprises a composition may be prepared at once, and each component may be dissolved and dispersed in a solvent, and it may be prepared sequentially. In addition, there are no particular restrictions on the input sequence or operating conditions during deployment. For example, the composition can be prepared by dissolving and dispersing all the components in a solvent at the same time, and if necessary, two or more kinds of solutions and dispersions of the components can be prepared in advance, and these can be mixed at the time of use (at the time of coating). Prepared as a composition.

[0635] The composition prepared as described above can be used after being separated by filtration using a filter having a pore diameter of preferably 0.01 μm to 3.0 μm, more preferably about 0.05 μm to...

Embodiment

[0719] Examples are given below to further describe the present invention in detail. Materials, usage amounts, ratios, processing contents, processing procedures, etc. shown in the following examples can be appropriately changed unless they deviate from the gist of the present invention. Therefore, the scope of the present invention is not limited to the specific examples shown below. In addition, unless otherwise indicated, "%" and "part" are mass standards.

[0720]

Synthetic example 1

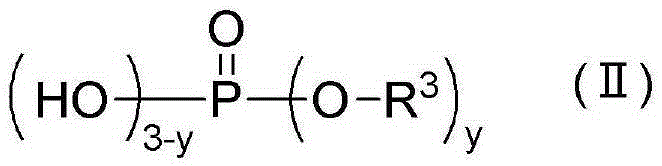

[0722] In a reaction vessel equipped with a condenser tube, a nitrogen inlet tube, and a stirrer on a three-neck round bottom flask, add 18.6 g of lauryl alcohol (manufactured by Nacalai Tesque Co., Ltd.), 57.1 g of ε-caprolactone monomer (manufactured by Wako Pure Chemical Industries, Ltd.) and 0.06 g of tetrabutyl titanate (manufactured by Tokyo Chemical Industry Co., Ltd.), after replacing the inside of the reaction vessel with nitrogen, heated and stirred at 120° C. for 3 hours. pass 1 H-NMR (Nuclear Magnetic Resonance, NMR) confirmed the disappearance of the lactone monomer. After the reaction solution was cooled to room temperature, it was mixed with 8.45 g of polyphosphoric acid having an orthophosphoric acid conversion content of 116%, the temperature was gradually raised, and it was heated and stirred at 80° C. for 6 hours to obtain R in the general formula (II). 3 A phosphoric acid-based dispersant (C-1) with a number average molecular weight of 760 and a ratio of y...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com