Bioretention pond capable of removing petroleum pollutants by using efficient biological film

A bioretention pond and biofilm technology, applied in the field of environmental bioengineering, can solve the problems of small number of microorganisms, limited removal effect, low conversion efficiency, etc., and achieve the effect of obvious effect, good effect, and easy maintenance and repair.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The selection of embodiment 1 biofilm carrier filler

[0028] Biofilm carrier fillers to be screened include zeolite, granular activated carbon, slag, diatomaceous earth, volcanic rock, PVC particles, PE particles, PS particles, PP particles and soft fibers, etc. According to the combination in Table 1, seven experiments with a volume of 1L were designed The chamber simulation device was operated for 30 days under the condition of 20°C and low water inflow of 40ml / hour, and the influence of different filler combinations on the formation of biofilm was observed. The test results (see Table 1) show that the formation of biofilm is the best when the upper filler is selected from zeolite and granular activated carbon, and the lower filler is selected from soft fiber carrier.

[0029] Table 1 Effect of biofilm carrier filler types on biofilm formation

[0030]

Embodiment 2

[0031] Example 2 Enrichment of High Efficiency Petroleum Hydrocarbon Degrading Bacteria

[0032] Prepare liquid medium according to the following steps: Take 100g soil sample, add 1000ml surface water, mix and shake for 10min, settle to get supernatant, make up 1000ml with surface water, add 0.2% peptone and 0.1% petroleum, 0.15MPa sterilize for 30min.

[0033] Collect 10 g of samples from the long-term oil-polluted soil around the oil field, dilute with 100 ml of the above-mentioned liquid medium, shake and mix, and after precipitation, take the supernatant and inoculate it into the liquid medium. 20°C, 30rpm acclimatization and enrichment culture for 5 days, then inoculated into new liquid medium, and continued acclimatization and enrichment culture. Continuous acclimatization and enrichment were carried out 5 times, and the obtained mixed flora was used as the strain for cultivating biofilm.

Embodiment 3

[0034] Embodiment 3 builds the bioretention pond with biofilm

[0035]A bioretention tank with biofilm carrier filler, the construction site is near the gas station, and the construction plan is: from top to bottom, there are planting soil layer (thickness 400mm), filter layer (thickness 300mm) and gravel layer (thickness 600mm) The planting soil layer is planted with herbs (Ophiopogon japonicus and clover) and shrubs (Buxus euonymus); the filter layer is composed of quartz sand, zeolite and granular activated carbon in a volume ratio of 7:2:1; the gravel layer is composed of gravel with a diameter of 20mm and soft The fiber carrier is composed of a volume ratio of 9:1; two PVC pipes with a diameter of 110mm are laid vertically, one PVC pipe reaches the middle of the filter layer, and the other PVC pipe reaches the middle of the gravel layer; the bottom is laid with a 70mm diameter PVC drain pipe and valve.

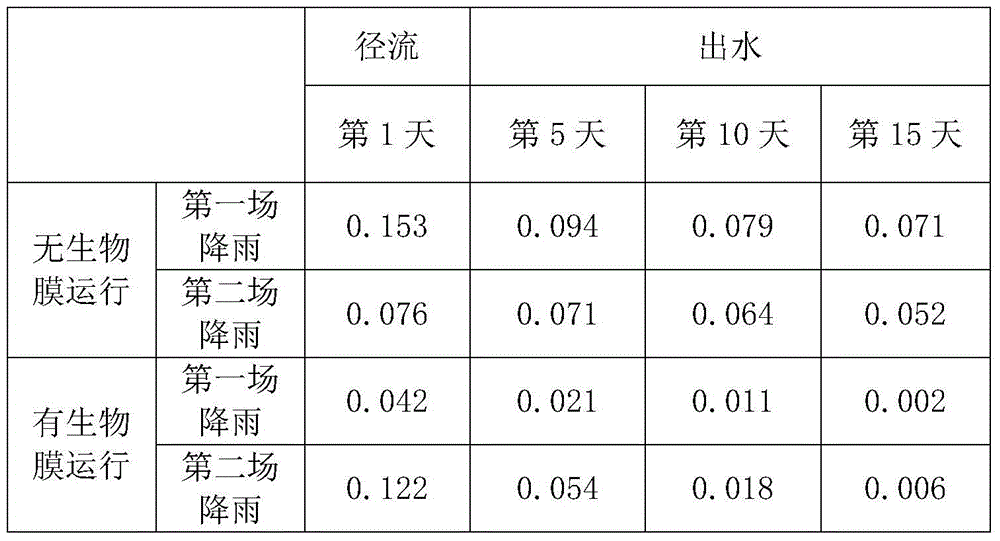

[0036] (1) No biofilm operation

[0037] After the bioretention tan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com