Fe-Si-B amorphous alloy strip, preparation method thereof and application of Fe-Si-B amorphous alloy strip in degradation of azo dye wastewater

A technology of amorphous alloys and azo dyes, applied in water pollutants, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of multiple treatment conditions and poor treatment effects, and achieve fast degradation rate, promotion of material transport and electron exchange, and the effect of excellent degradation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

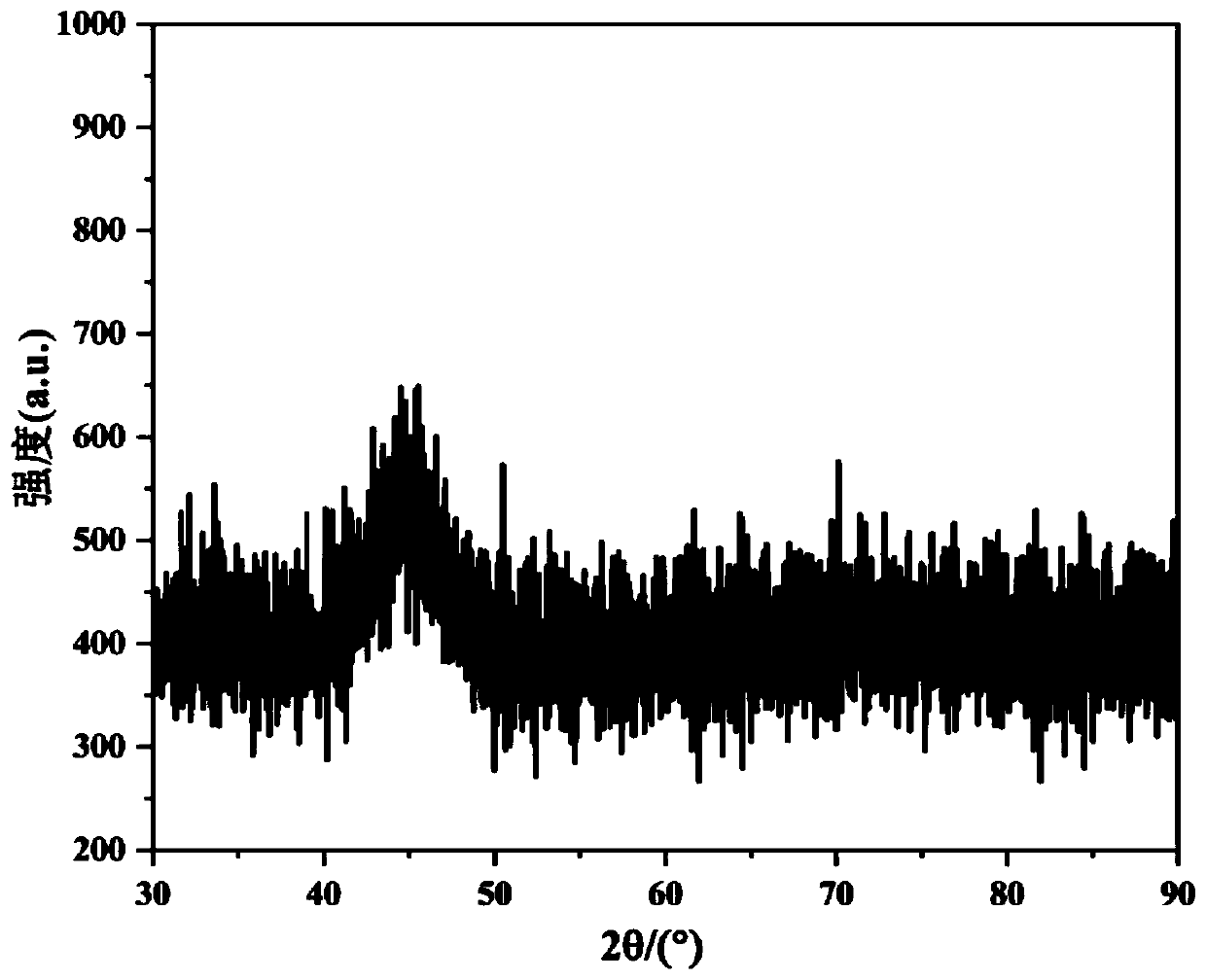

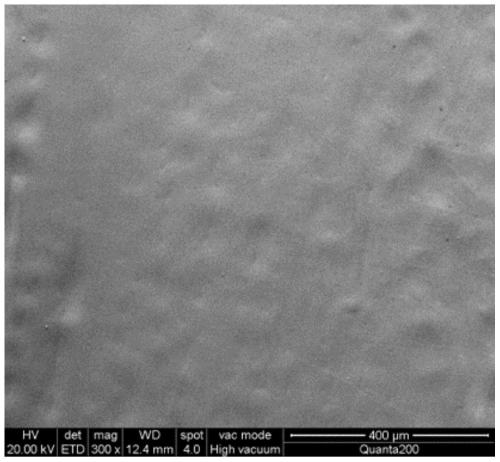

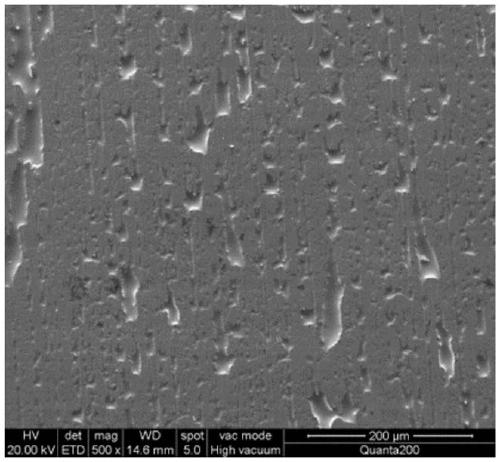

[0041] a kind of Fe 78 Si 11 B 11 A method for preparing an amorphous alloy strip, comprising the steps of:

[0042] 1) The composition of the amorphous alloy strip is Fe 78 Si 11 B 11 , is a component with strong amorphous forming ability; converted to the required mass of each element by atomic percentage, weighed Fe, Si, B, and placed Fe, Si, B in the water-cooled crucible of the melting furnace. Before smelting, vacuumize the smelting furnace (vacuum degree is 5×10 -3 Pa), and then began to clean the smelting furnace, filled with high-purity argon during the cleaning process, and then vacuumed again after each cleaning, cleaning 4 times. The arc melting of alloy raw materials is carried out under the protection of high-purity argon. Before smelting the alloy raw materials, it is necessary to arc-melt the sponge titanium ingot in the crucible. The purpose of this is to absorb the excess oxygen in the furnace cavity and prevent the sample from being oxidized during the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com