Patents

Literature

633 results about "Vanadium phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vanadium phosphates are inorganic compounds with the formula VOₓPO₄ as well related hydrates with the formula VOₓPO₄(H₂O)ₙ. Some of these compounds are used commercially as catalysts for oxidation reactions.

Lithium ion battery phosphatic composite cathode material and preparation method thereof

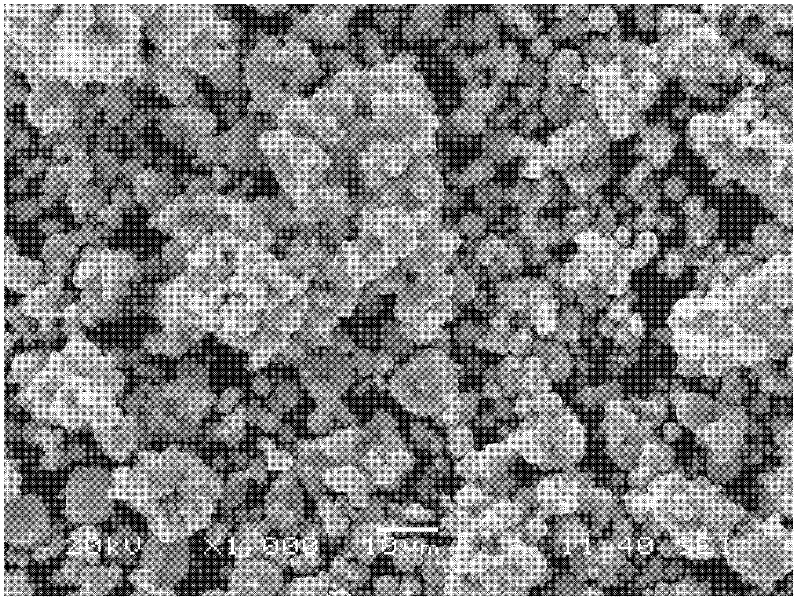

ActiveCN102244263AEasy to processImprove electrochemical performanceCell electrodesMicro structurePhosphoric acid

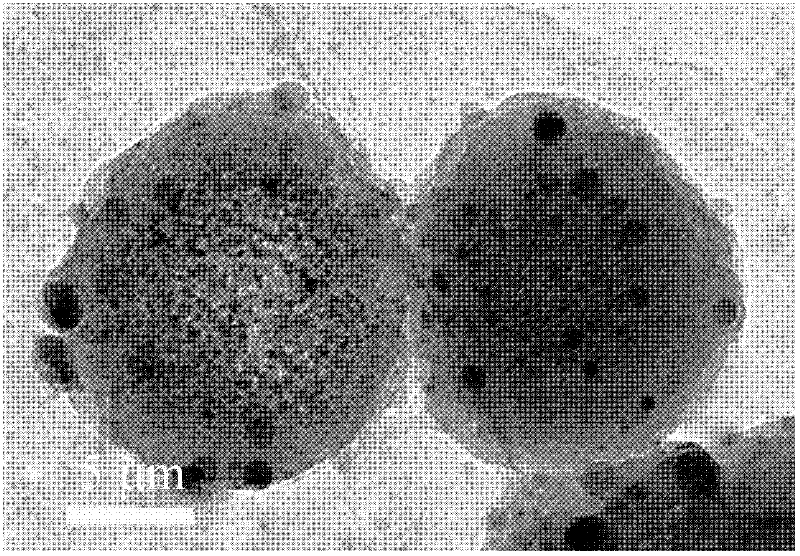

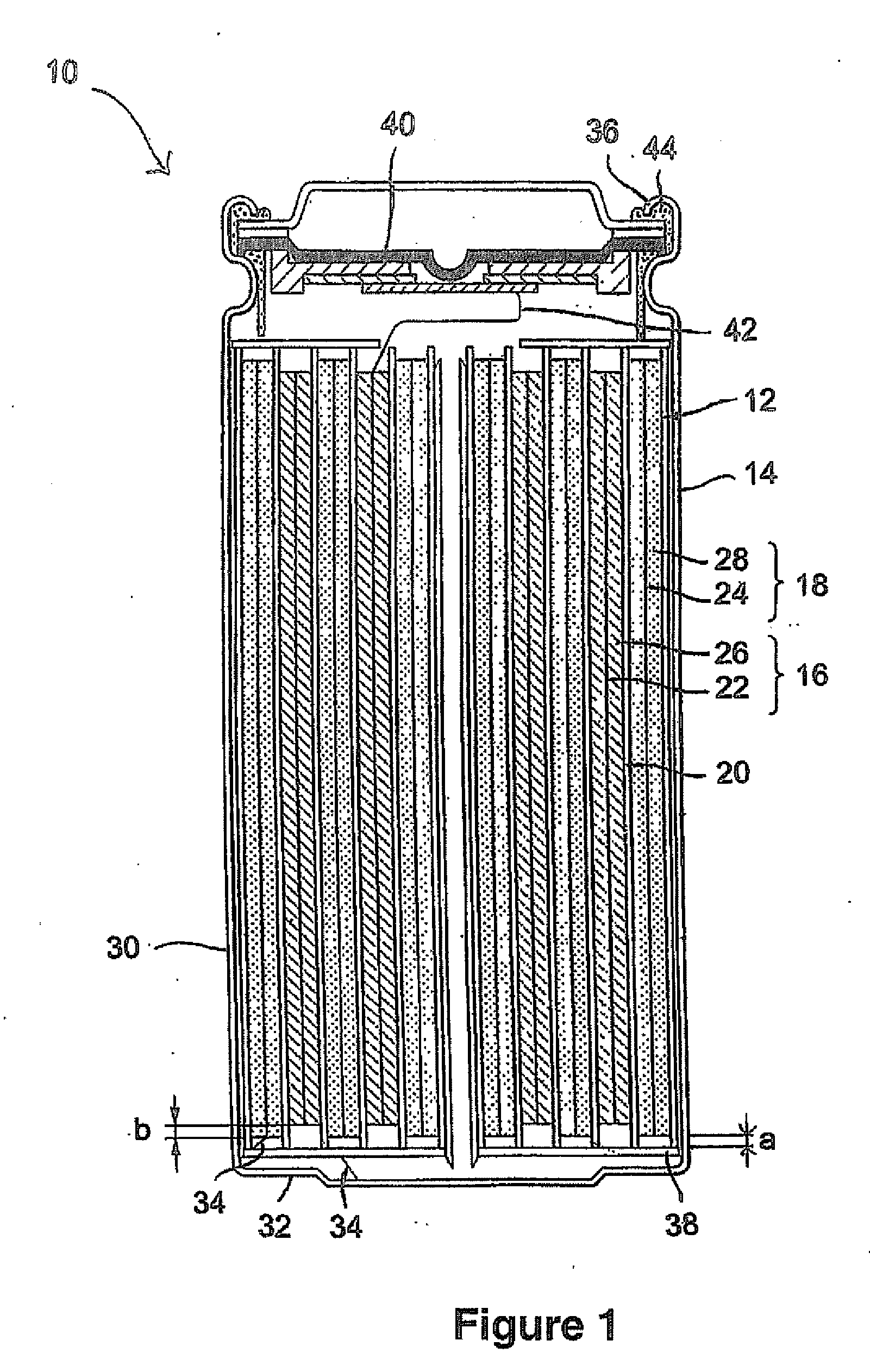

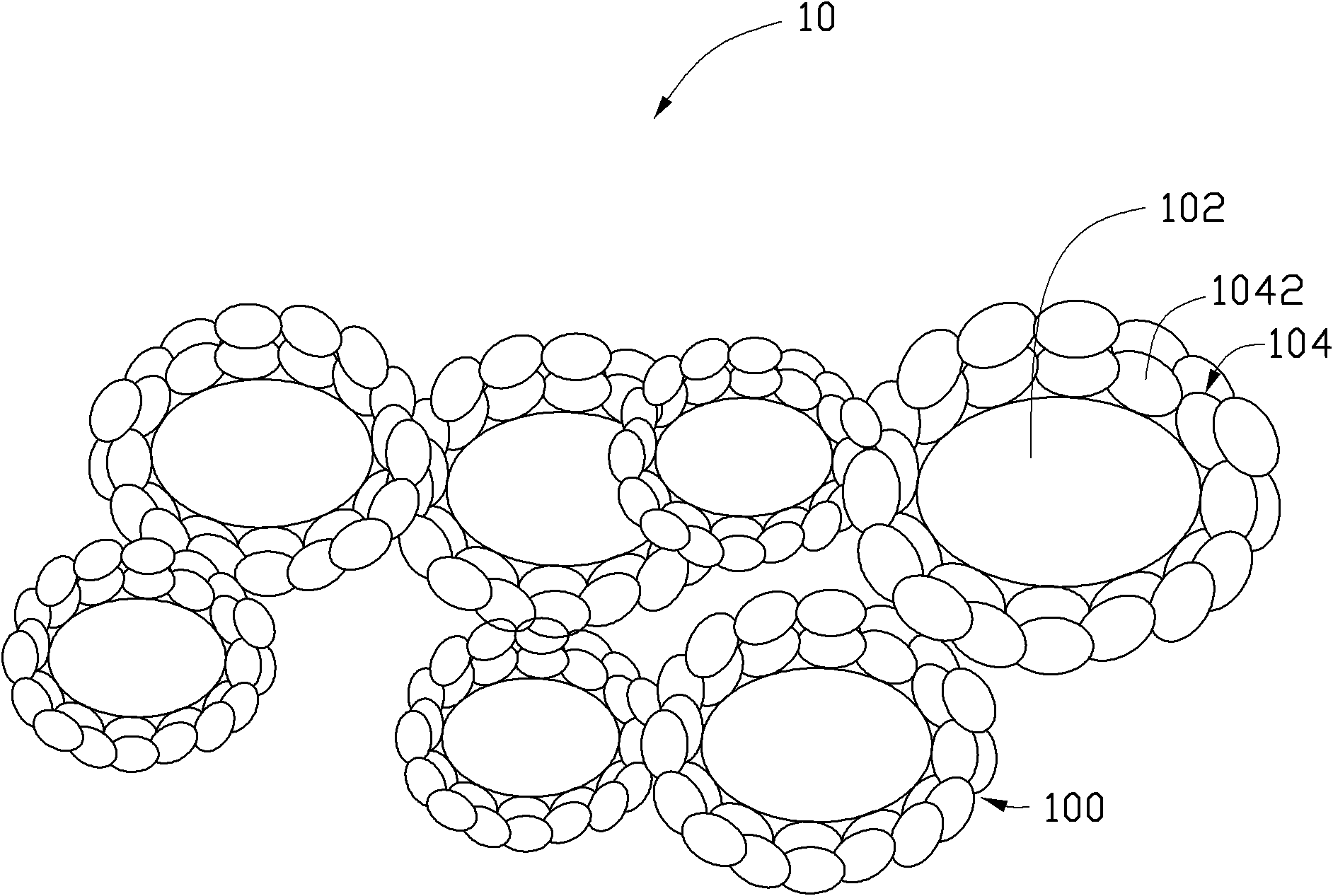

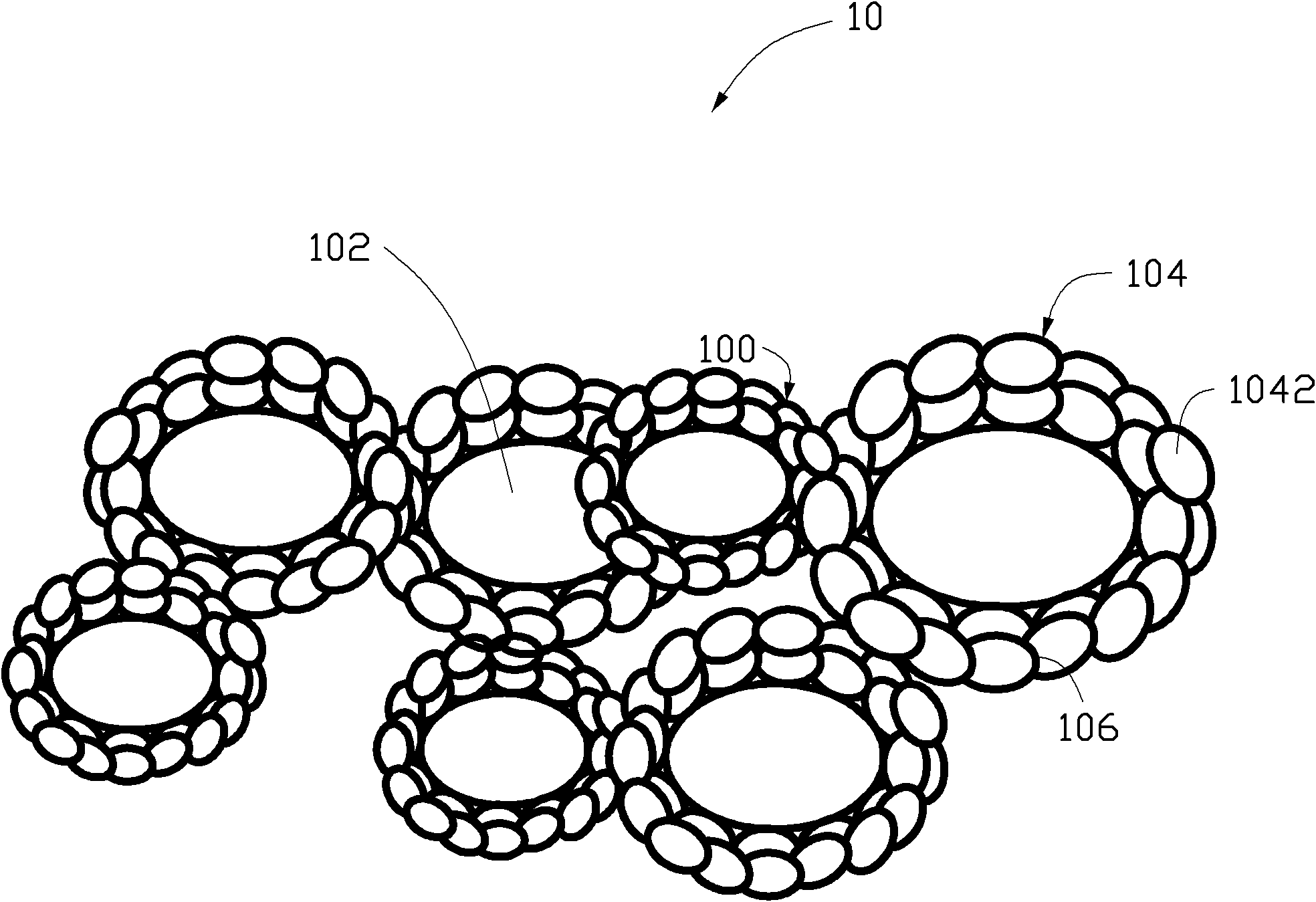

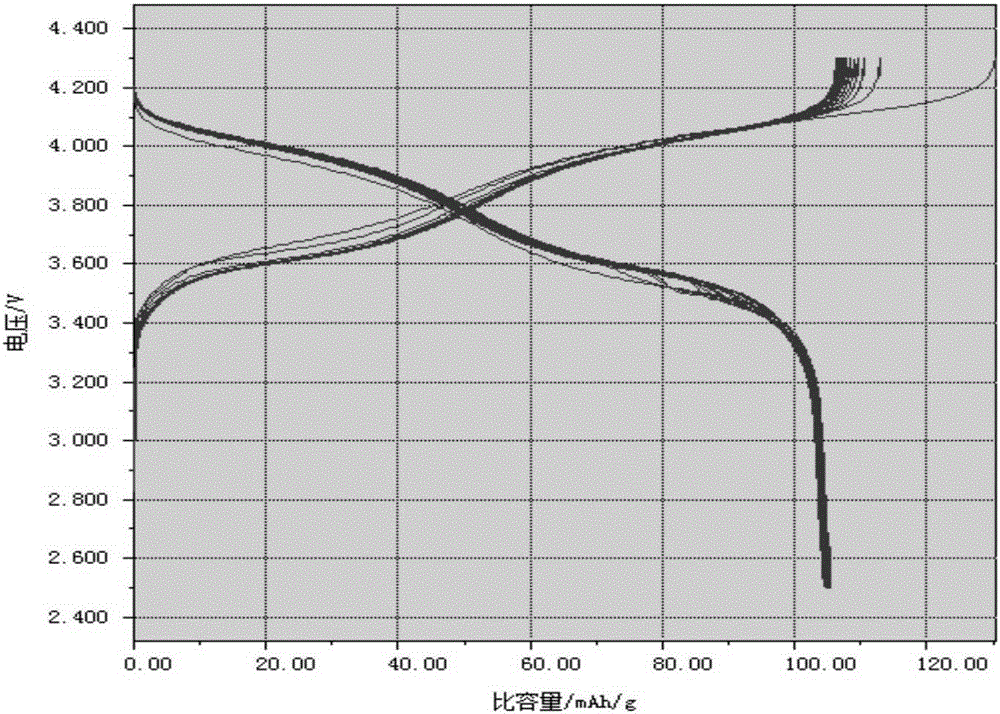

The invention discloses a lithium ion battery phosphatic composite cathode material and a preparation method thereof. The composite material is a multinuclear core shell structure composed of a plurality of cores and a housing layer, the cores are lithium iron phosphate particles wrapped by lithium vanadium phosphate and the housing layer is amorphous carbon. Preparation of the lithium iron phosphate particles wrapped by lithium vanadium phosphate comprises the following steps: preparing precursor sol with a sol gel method, adding lithium iron phosphate powder to disperse uniformly, carrying out spray drying on the above mixture, calcining the above resultant in inert gas, and followed by cooling and grinding to obtain the lithium iron phosphate particles wrapped by lithium vanadium phosphate. Preparation of the composite cathode material comprises the following steps: dissolving a carbon source compound into deionized water, adding core materials, dispersing the above resultant uniformly, carrying out second spray drying, calcining the above resultant in inert gas, and followed by cooling to obtain the composite cathode material. The composite material prepared in the invention has good electronic conduction performance, good ionic conduction performance and excellent electrochemistry performance. Because of existence of lithium vanadium phosphate, energetic density of a material is raised. Because of the multinuclear core shell structure like nano / micro structures, the composite material has good processing performance, and tap density of the material is greatly raised.

Owner:CENT SOUTH UNIV

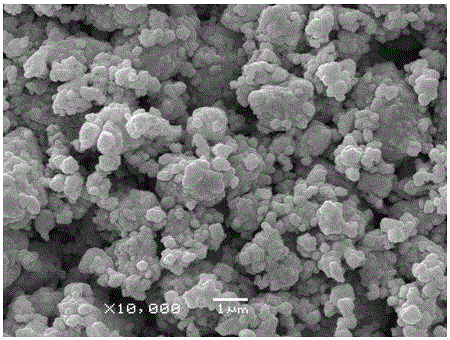

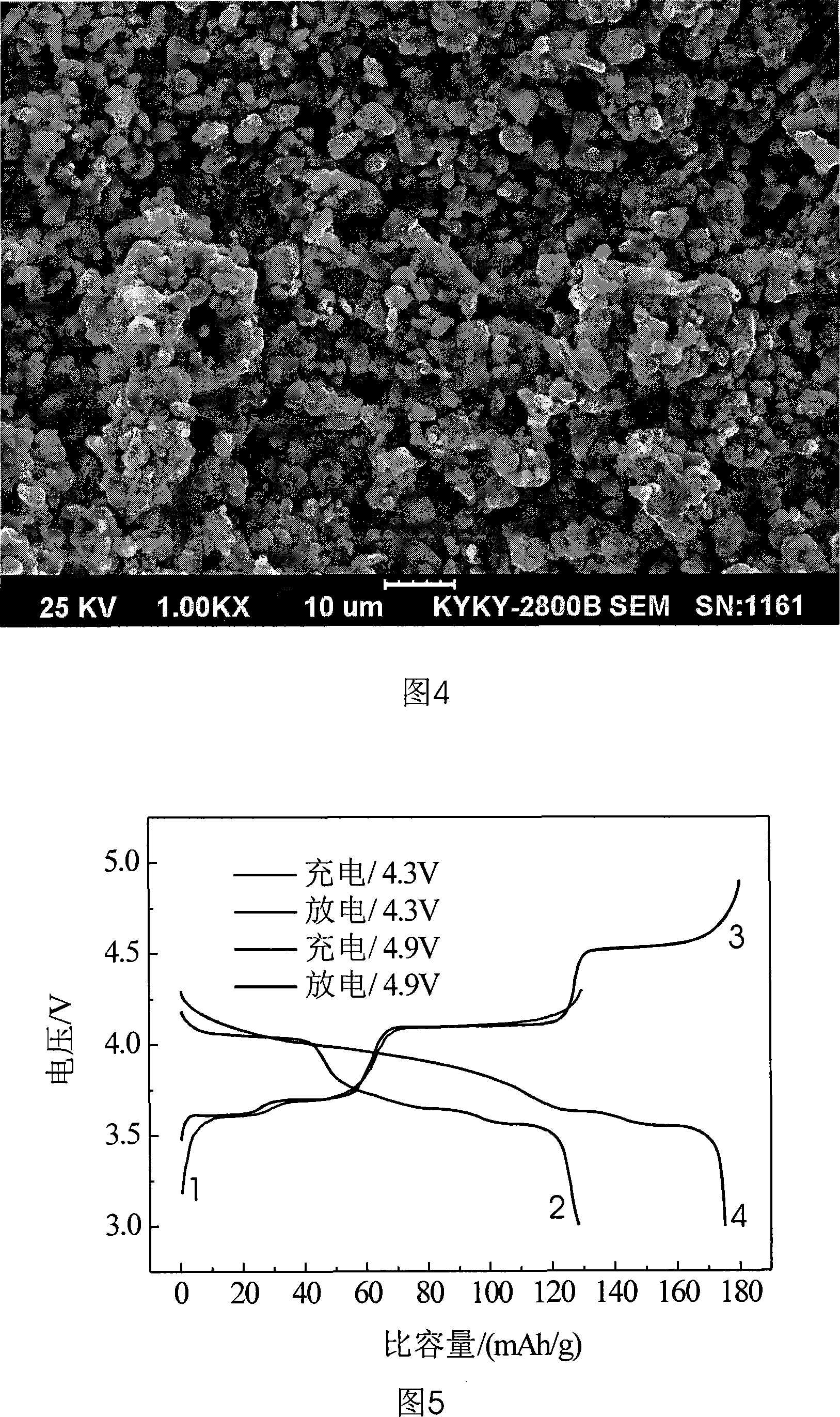

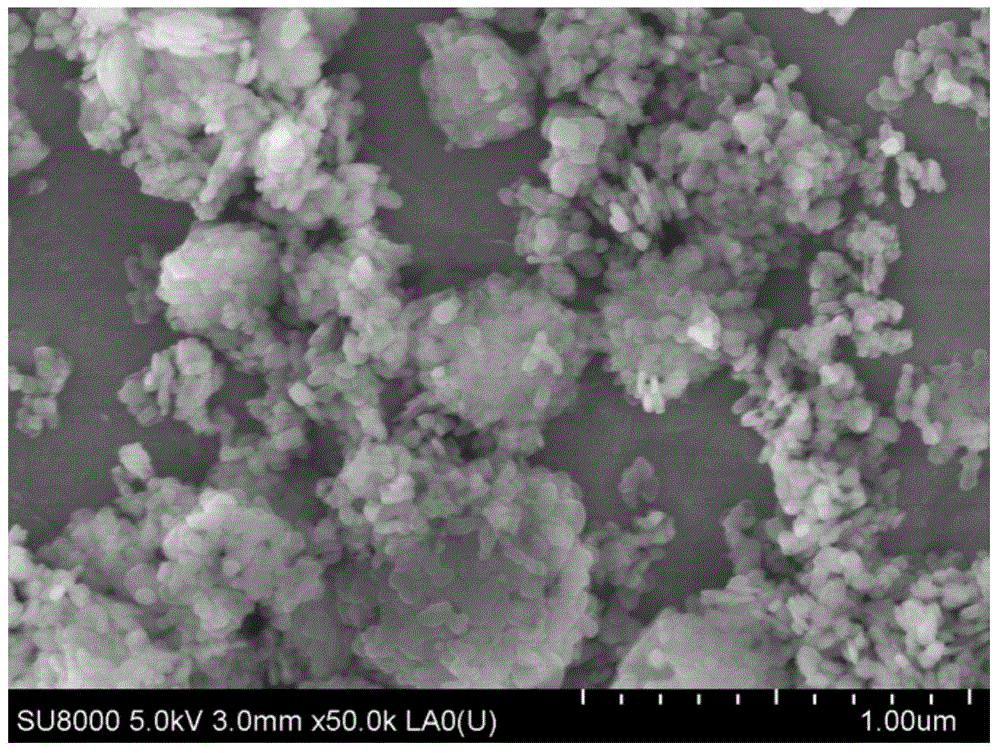

Preparation method of carbon coated vanadium sodium phosphate positive electrode material

InactiveCN105336924AEasy diffusion distanceImprove electrochemical performanceNon-aqueous electrolyte accumulatorsCell electrodesSodium phosphatesElectrical battery

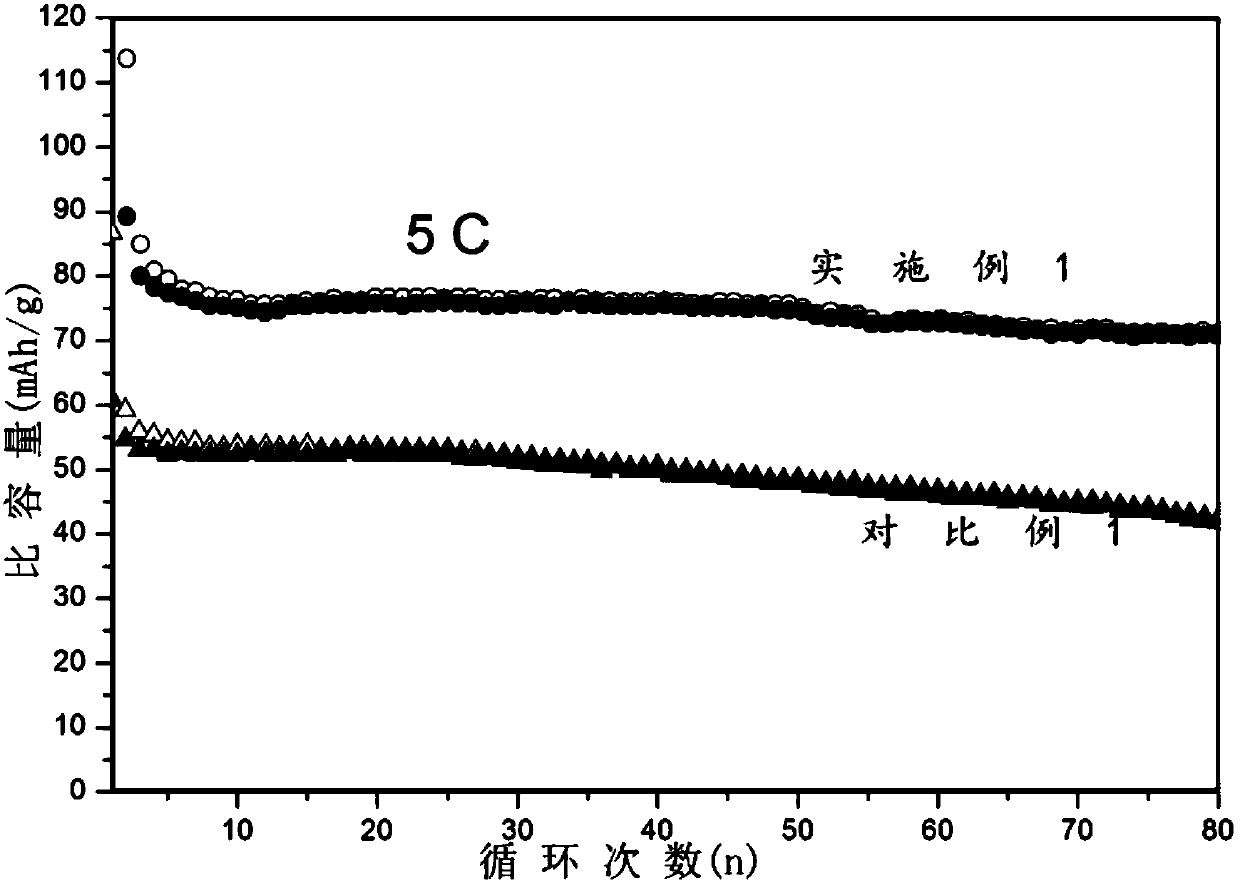

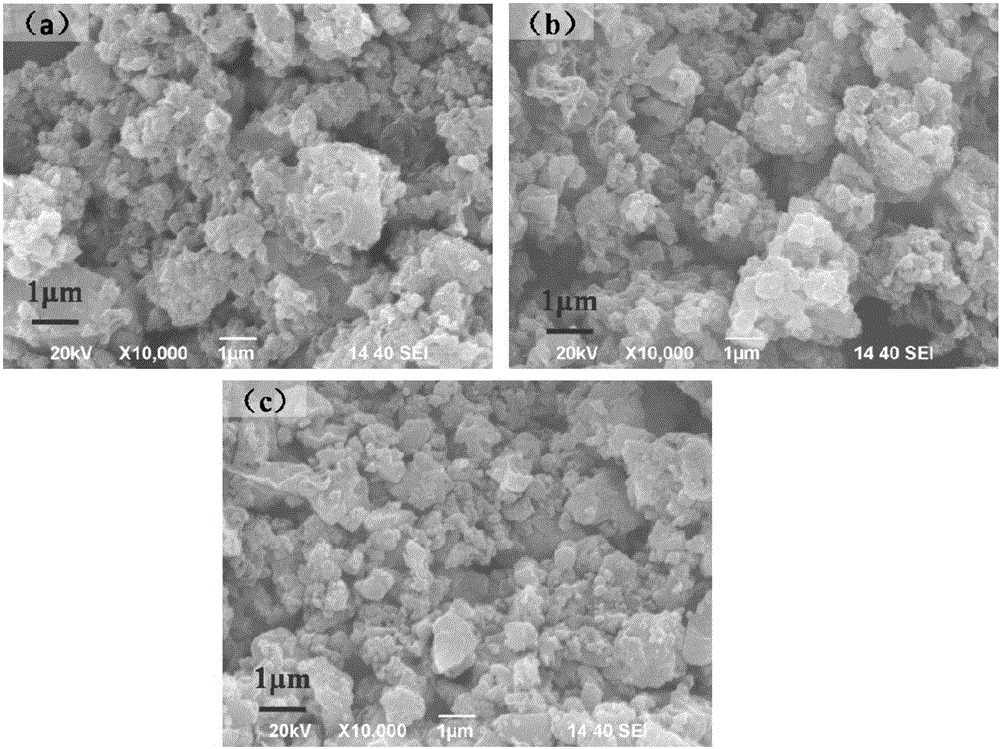

A preparation method of a carbon coated vanadium sodium phosphate positive electrode material comprises the steps: with glucose as a reducing agent and a carbon source and water as a dispersant, carrying out ball milling of NH4VO3, NaH2PO4.2H2O and glucose in water, carrying out spray drying, calcining, and thus obtaining the carbon coated vanadium sodium phosphate positive electrode material. The method has the advantages of low synthesis temperature, simple steps, easily obtained raw materials, and advantageous industrialization; the obtained carbon coated vanadium sodium phosphate positive electrode material has a structure with uniform primary particles, has the particle size of 100-200 nm, and has the characteristics of short sodium ion diffusion distance, fast transmission speed, high specific surface area, high electrical conductivity and fast ion transmission and the like. The obtained carbon coated vanadium sodium phosphate positive electrode material is assembled into a battery; in a voltage scope of 2.0-3.75 V and under 1 C multiplying power, the highest first charge and discharge capacity per gram can reach 93.5 mAh*g<-1>, the capacity retention rate can be up to 97.7% after cycling for 50 circles with the 1C multiplying power, and excellent electrochemical performance is showed.

Owner:CENT SOUTH UNIV

Material with mixture of ions with sodium vanadium phosphate cathode material coated by carbon and preparing method thereof

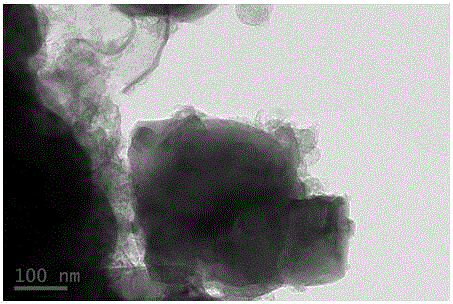

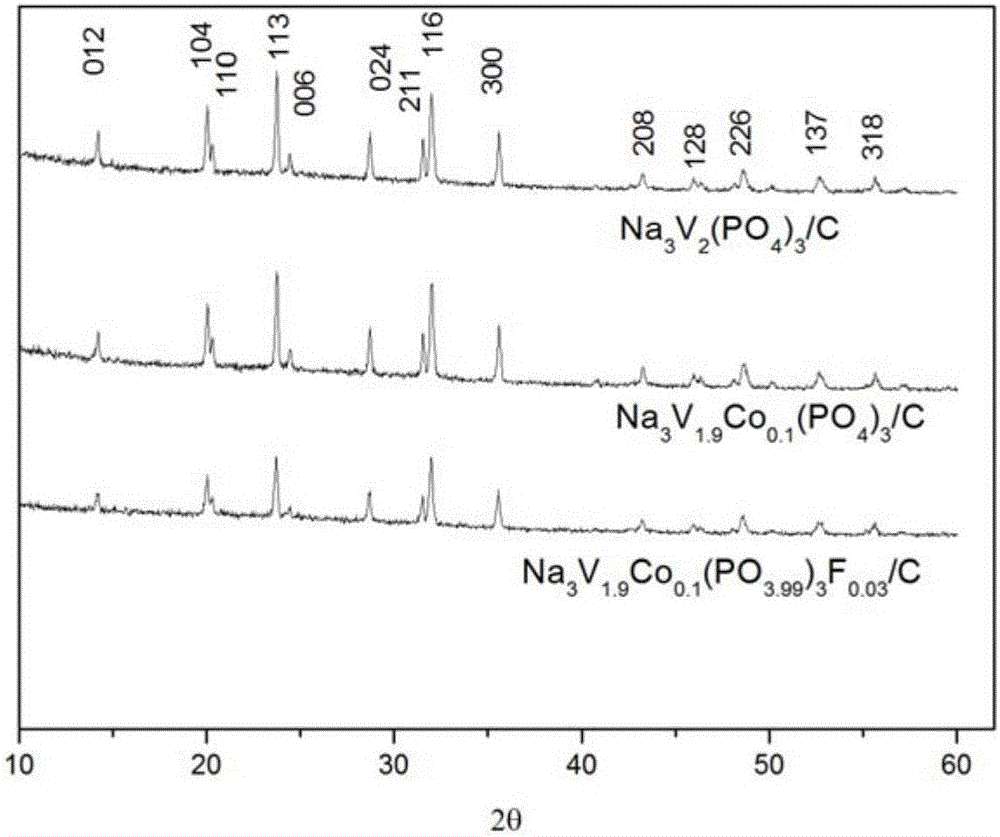

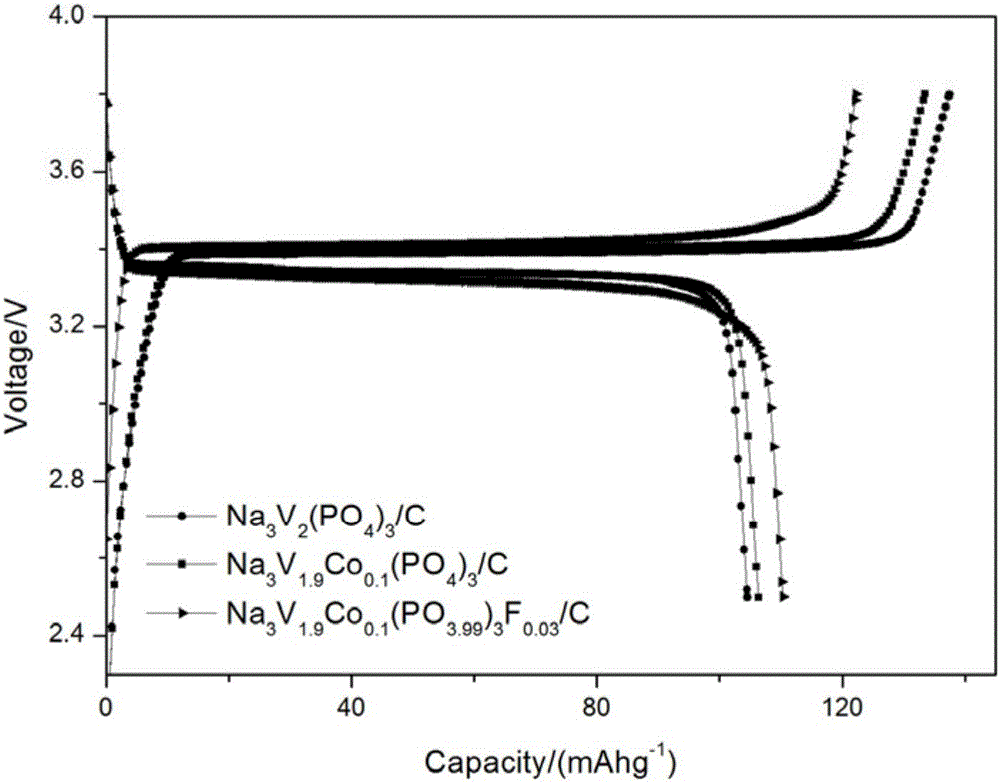

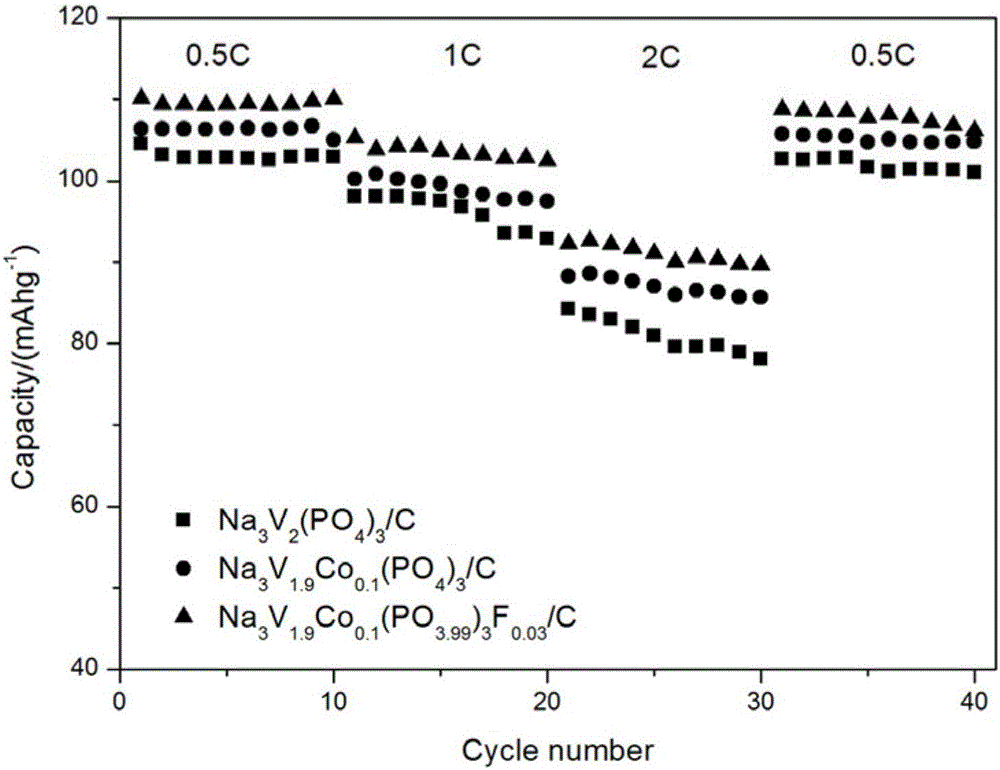

ActiveCN106328911AImprove electronic conductivityImprove electrochemical performanceCell electrodesSecondary cellsCarbon coatingPhysical chemistry

The invention discloses material with mixture of ions with sodium vanadium phosphate cathode material coated by carbon and a preparing method thereof, characterized in that the general formula of sodium vanadium phosphate cathode material is Na3V2-xMx(PO4-y)3Y3y / C, wherein 0<x<=0.2, 0><y<=0.05, M is Al, Fe, Cr, Ni, Co, Mg, Zn, La, Cu, Mn, Ti, Mo, Sn, Sr, Nb, Ce or Y, Y is For Cl. Through the carbon coating and the doping modification with ions for sodium vanadium phosphate cathode material, the electron conductivity of the material is improved and the electron-chemical property of material can be improved obviously.

Owner:HEFEI UNIV OF TECH

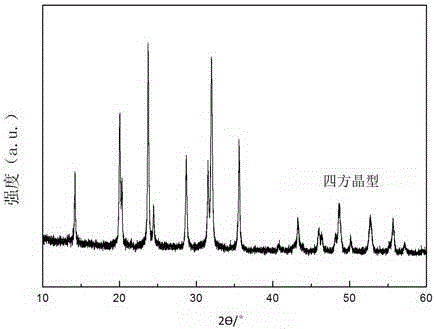

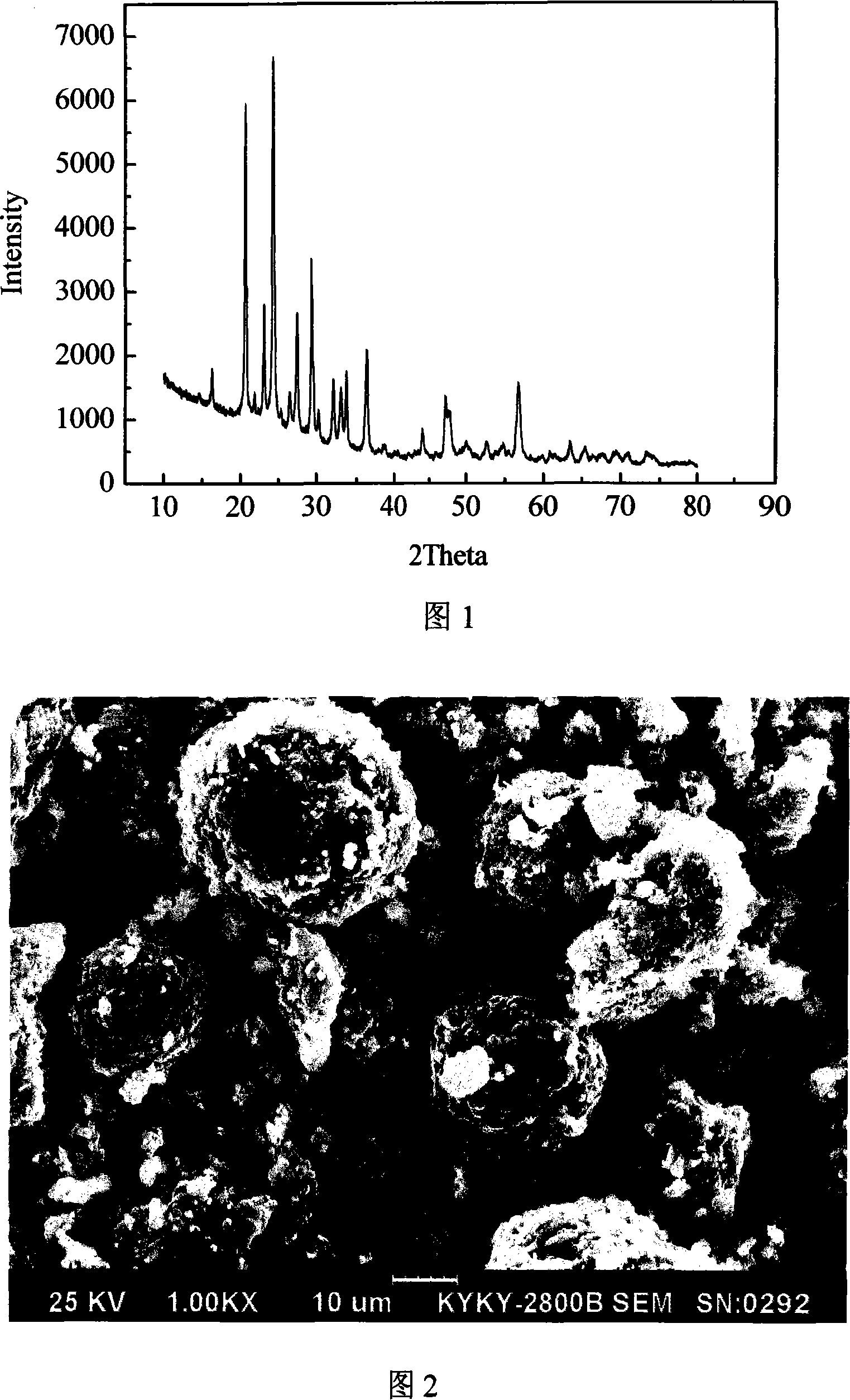

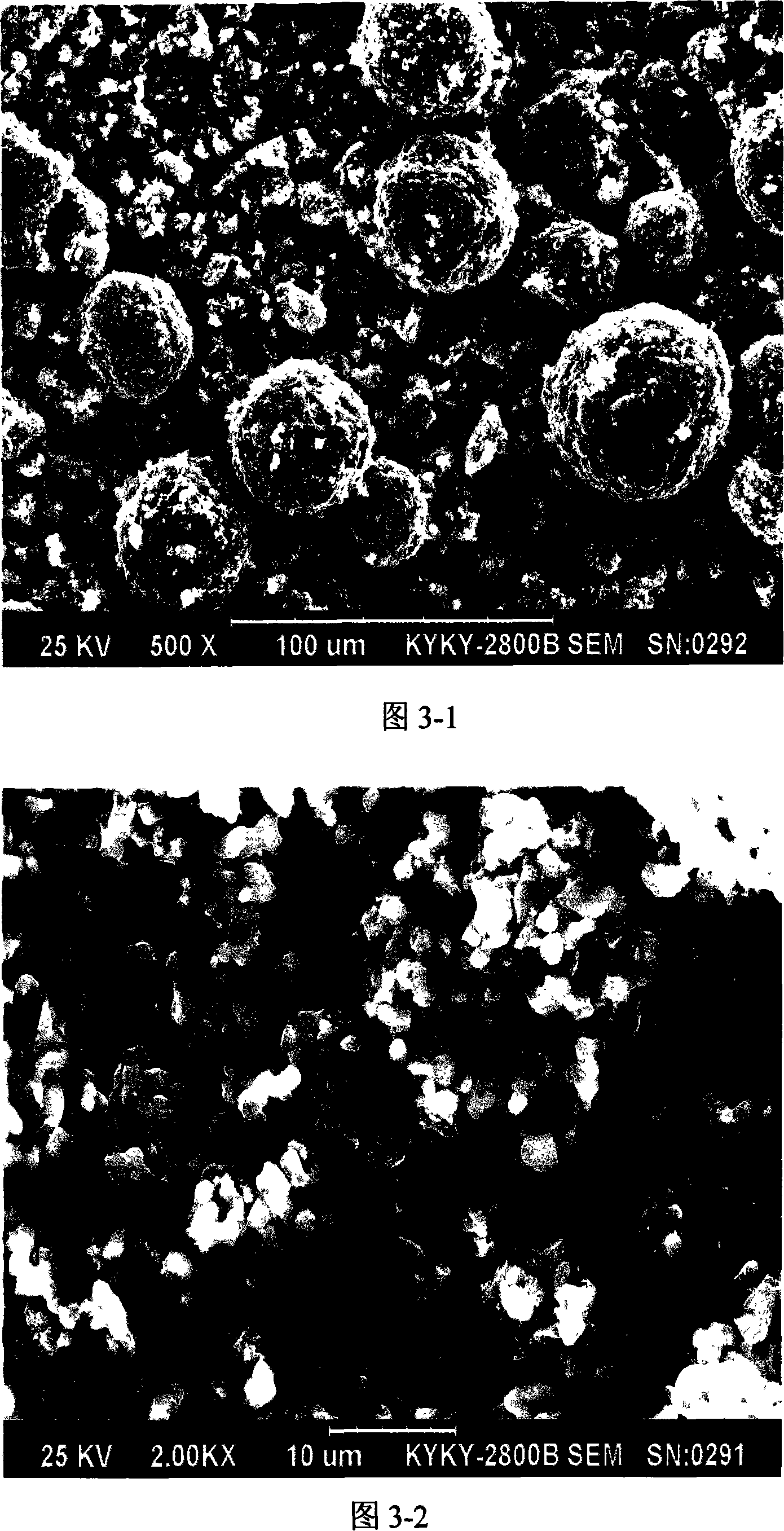

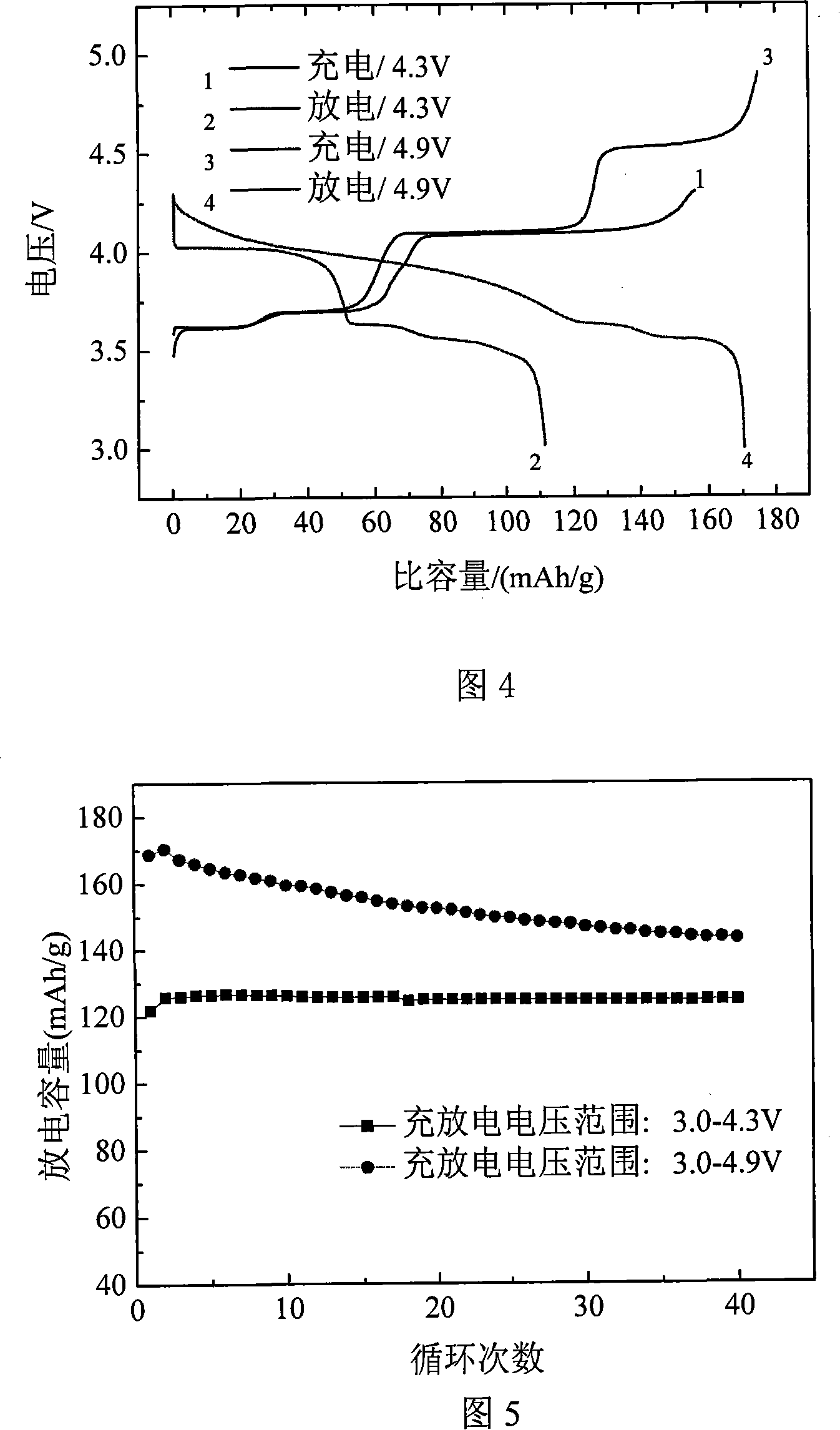

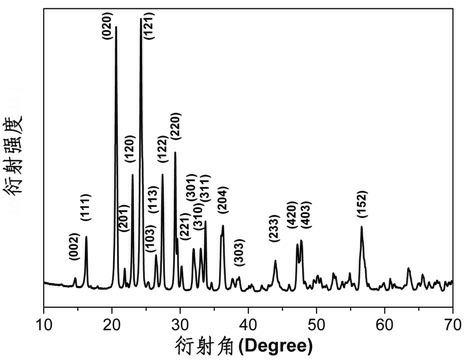

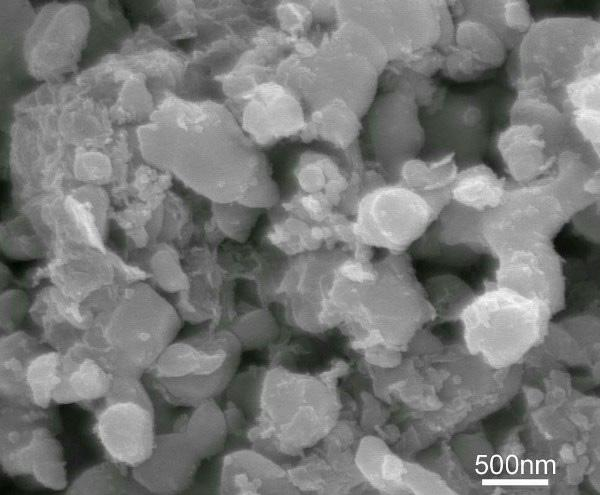

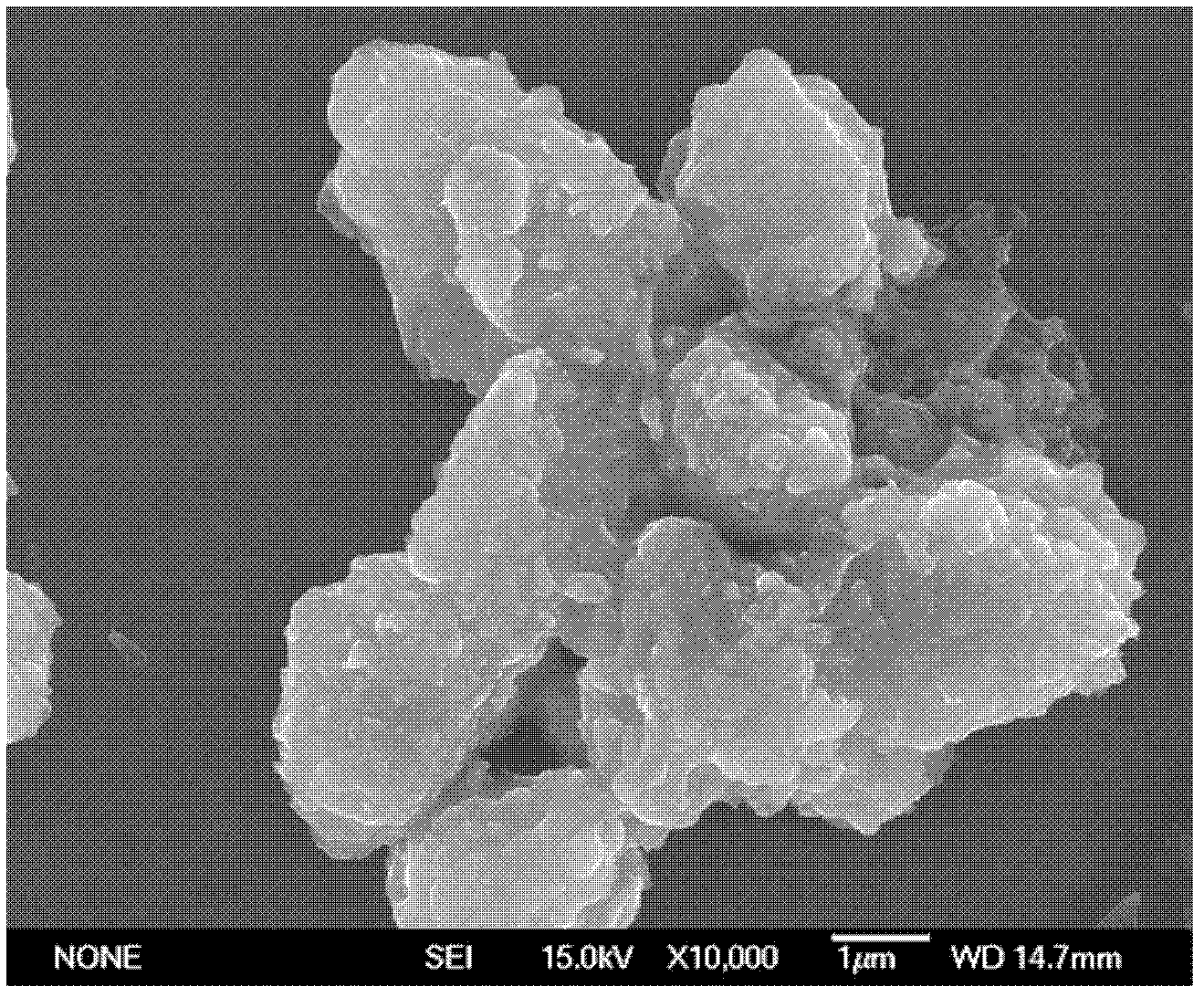

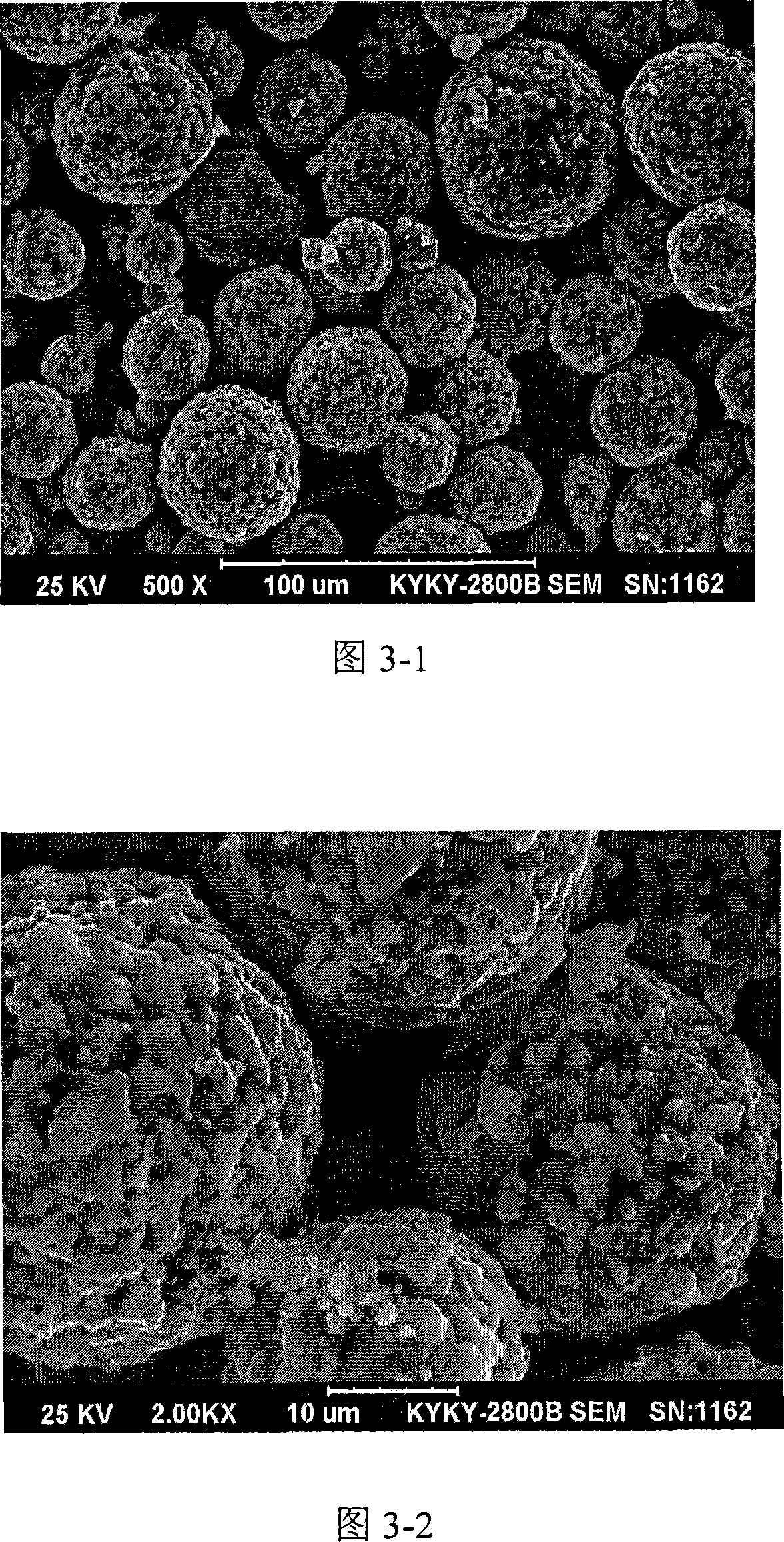

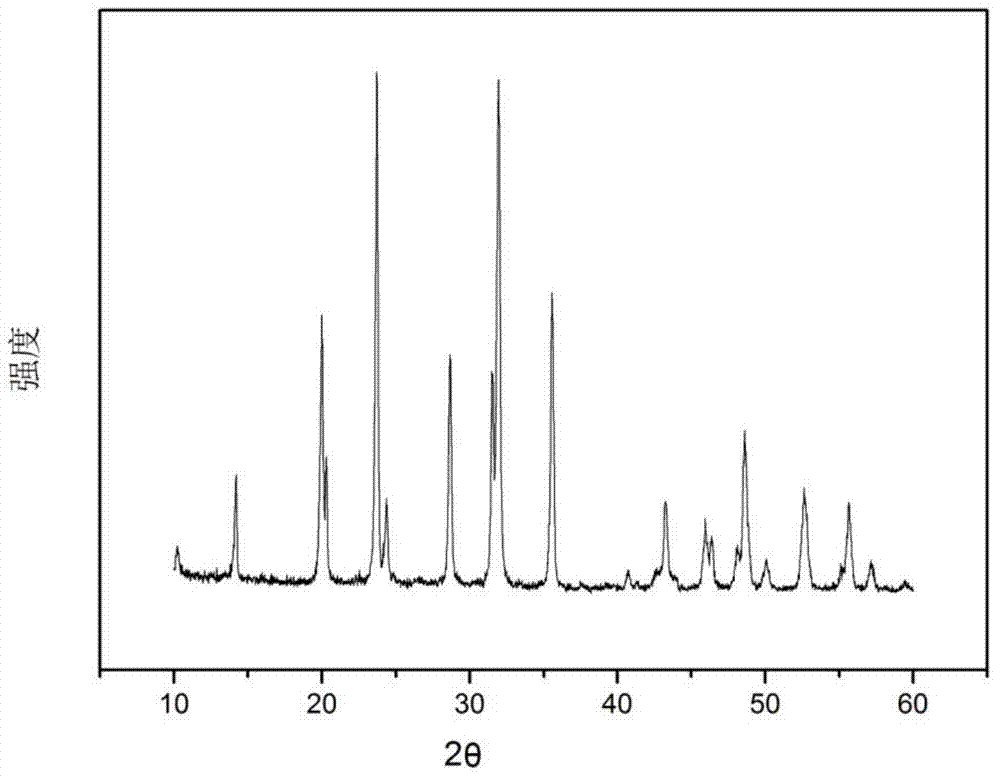

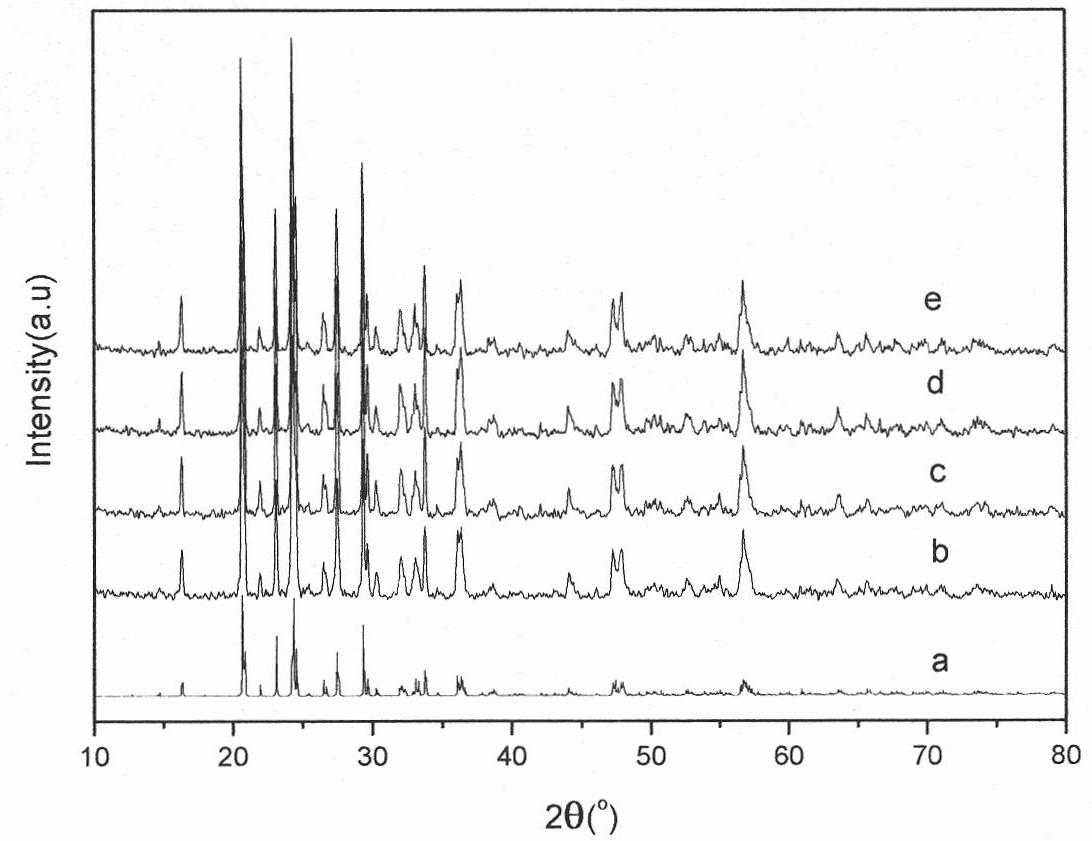

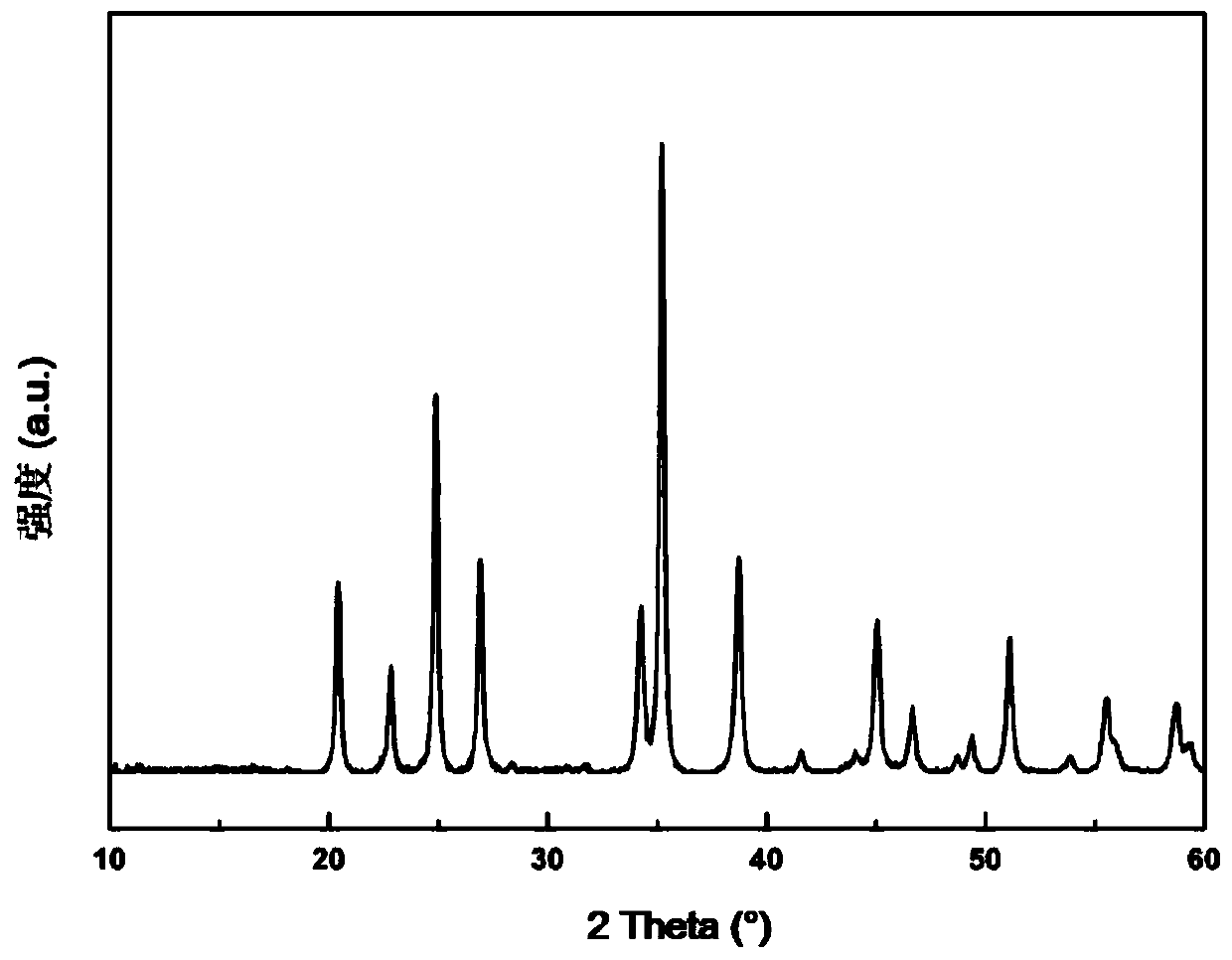

Cathode material Li3V2(PO4)3 of lithium ion battery and its making method

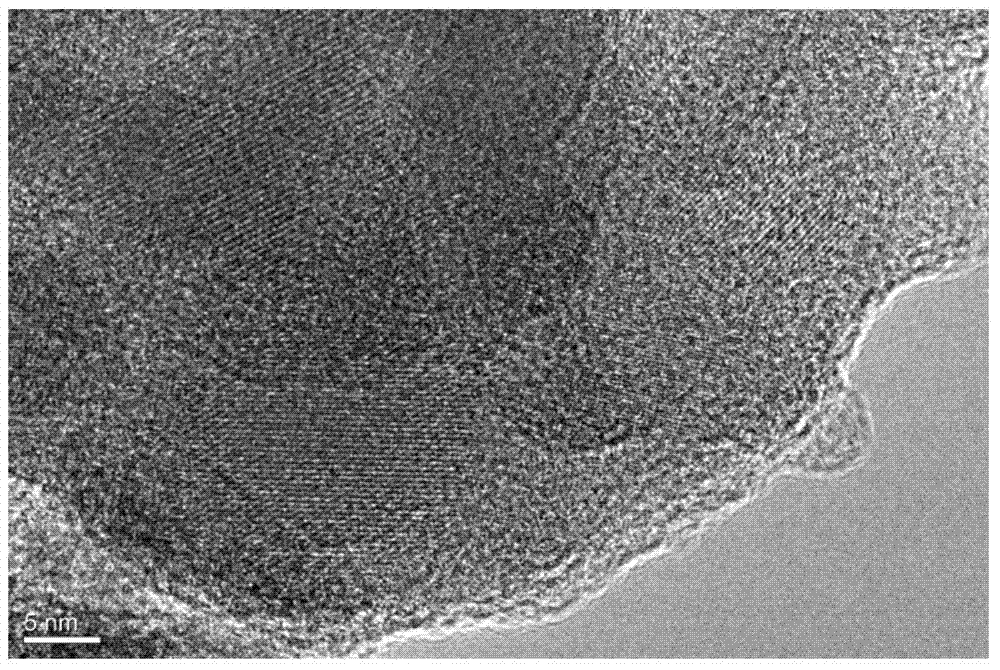

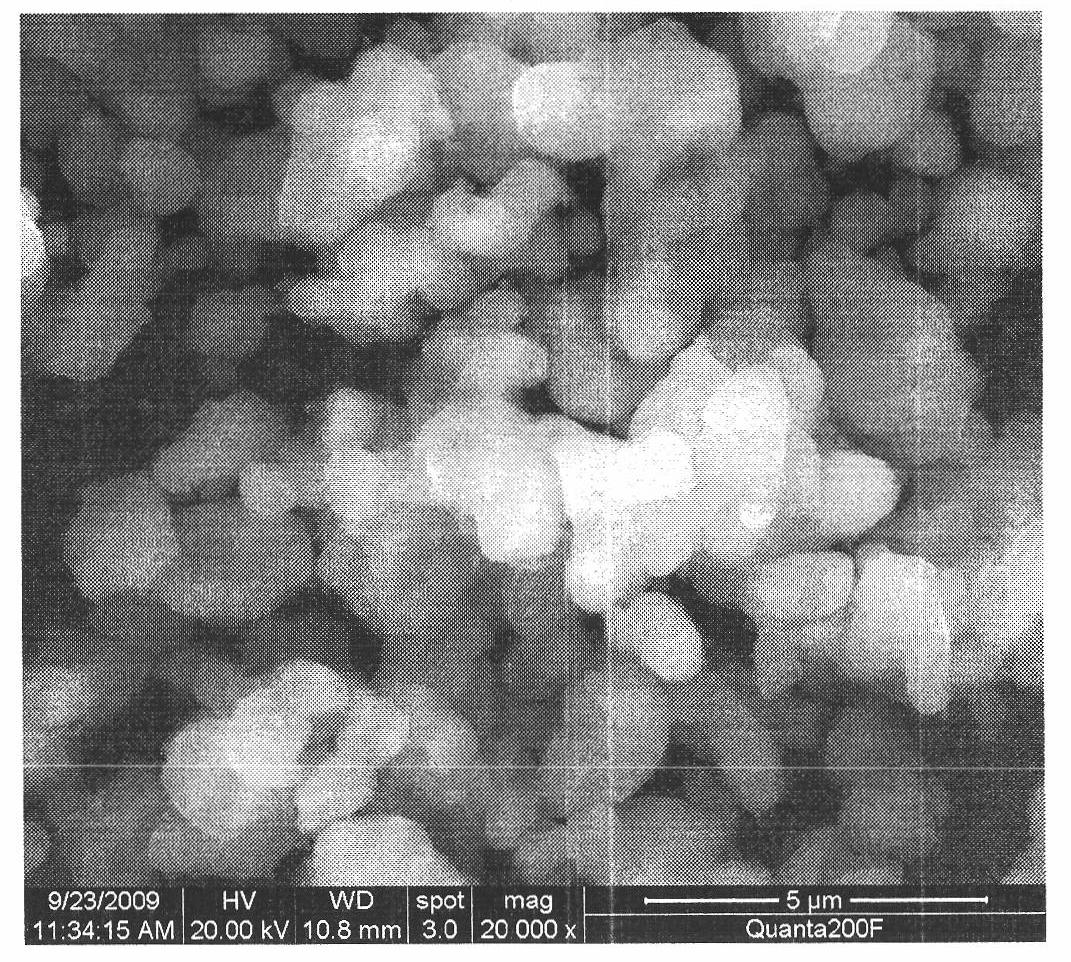

ActiveCN101106194ASmall and evenly dispersedAvoid reunionElectrode manufacturing processesChemical/physical/physico-chemical processesNanoparticlePhysical chemistry

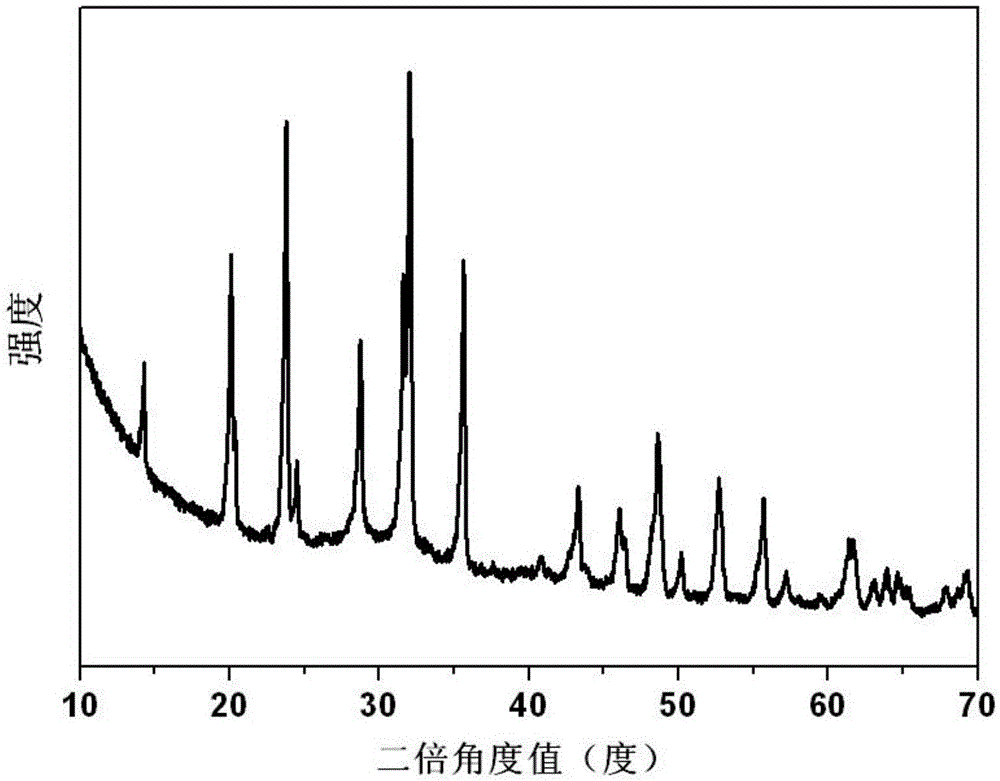

The invention discloses a lithium-ion battery positive material-lithium vanadium phosphate, and the preparation method thereof, the main technical proposal is to enhance the purity of positive material and simplify the synthesizing method. The positive material in the invention is provided with a base body of lithium vanadium phosphate, carbon materials are coated outside the base body, the positive material is provided with some microscopic features like spheres, semi-spheres with the length of long axis and short axis of 5-30 micron, diamonds, cones, flakes, laminates and / or blocks, the size thereof is 5-30 micron, and the specific surface area is 5-15m2 / g. The preparation method includes preparing nano particles, liquid mixing reacting, preparing precursors, pretreament, activated roasting, coating the organic materials which can be carbonized, and then high-temperature processing. Compared with the prior art, by utilizing the nano particle secondary-molding liquid method for synthesizing the positive material-lithium vanadium phosphate, the invention simplifies operation processes and reduces production cost, with the positive material with higher charging-discharging capacity and excellent cyclical steady.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

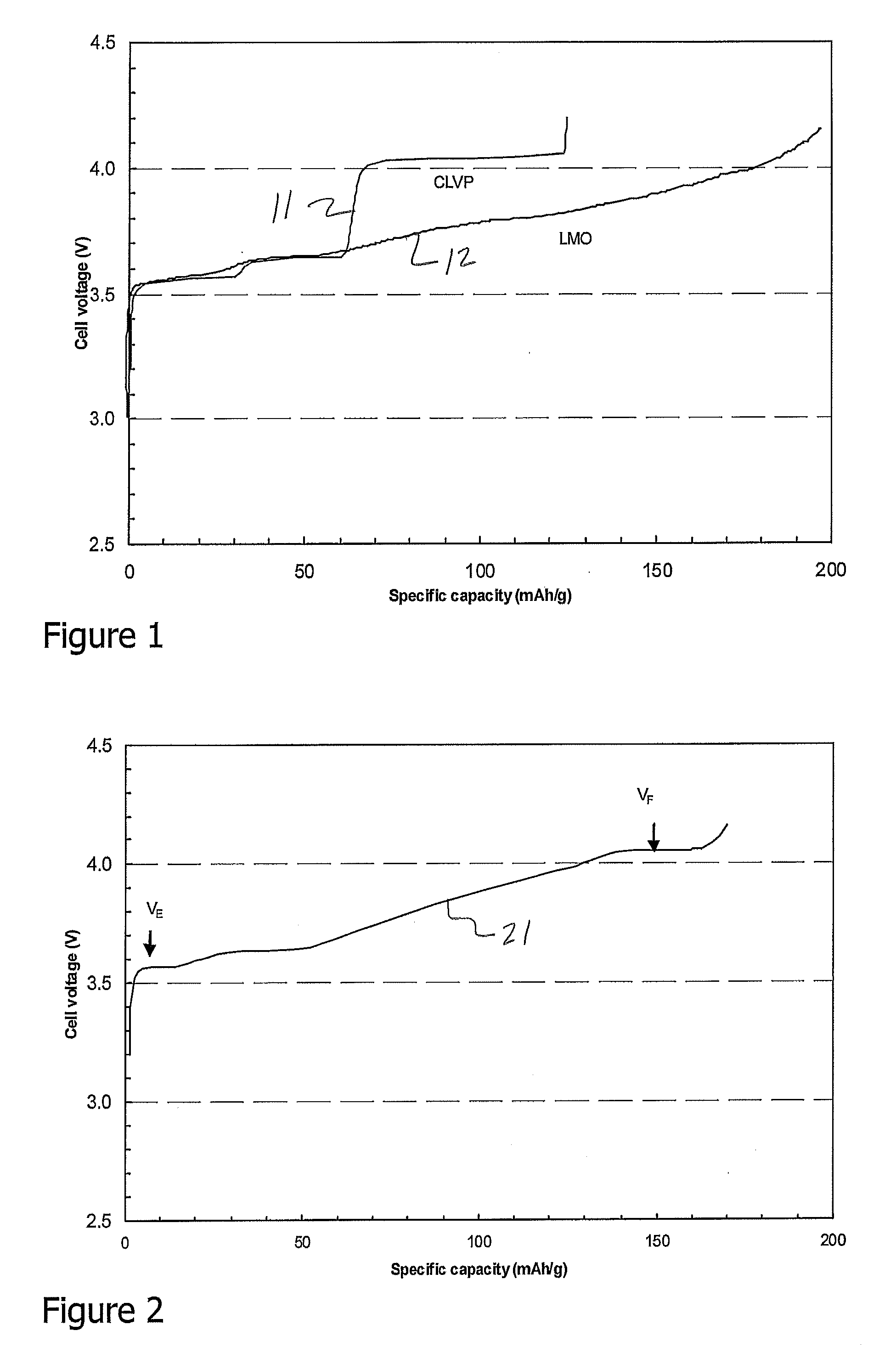

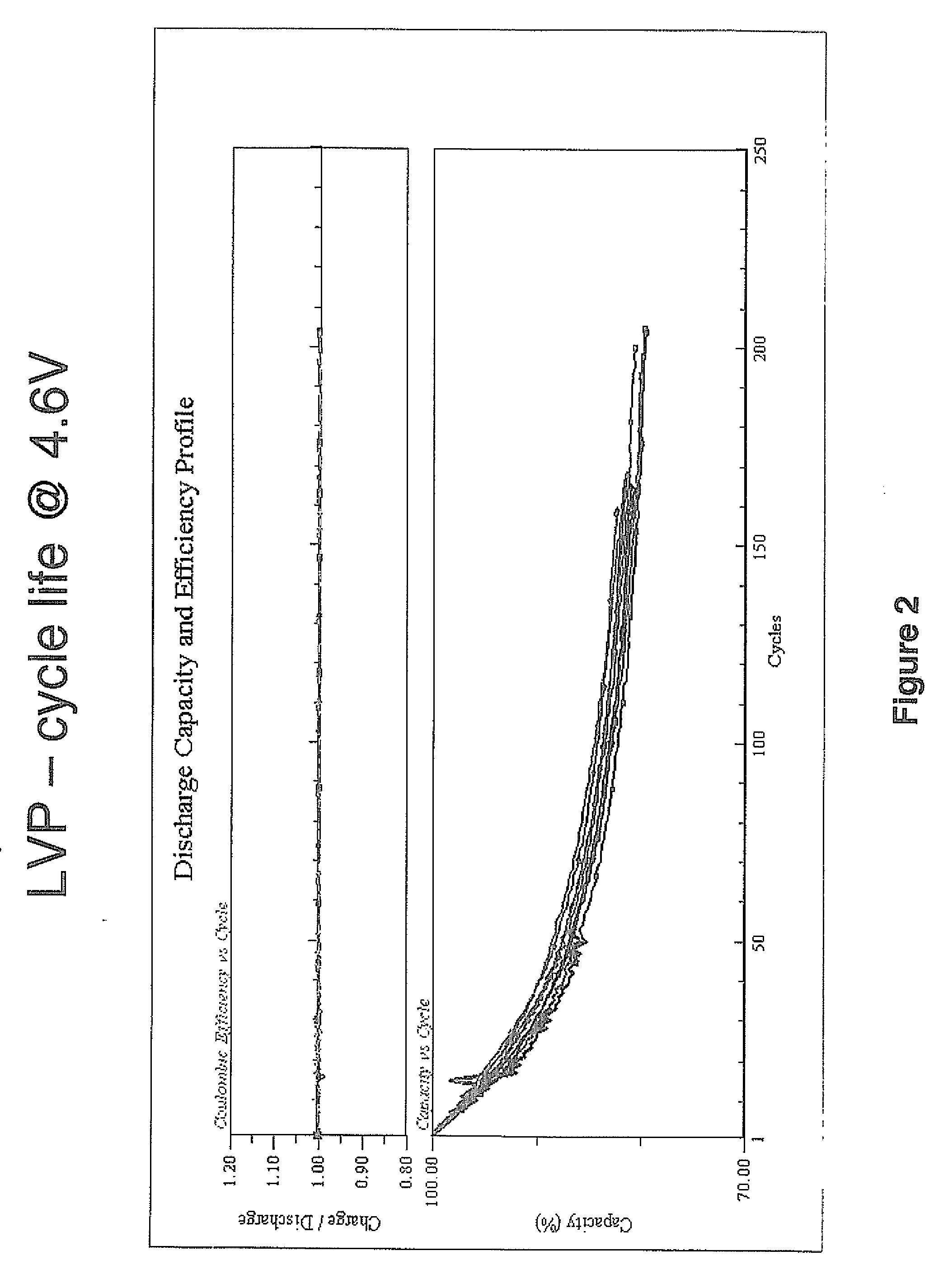

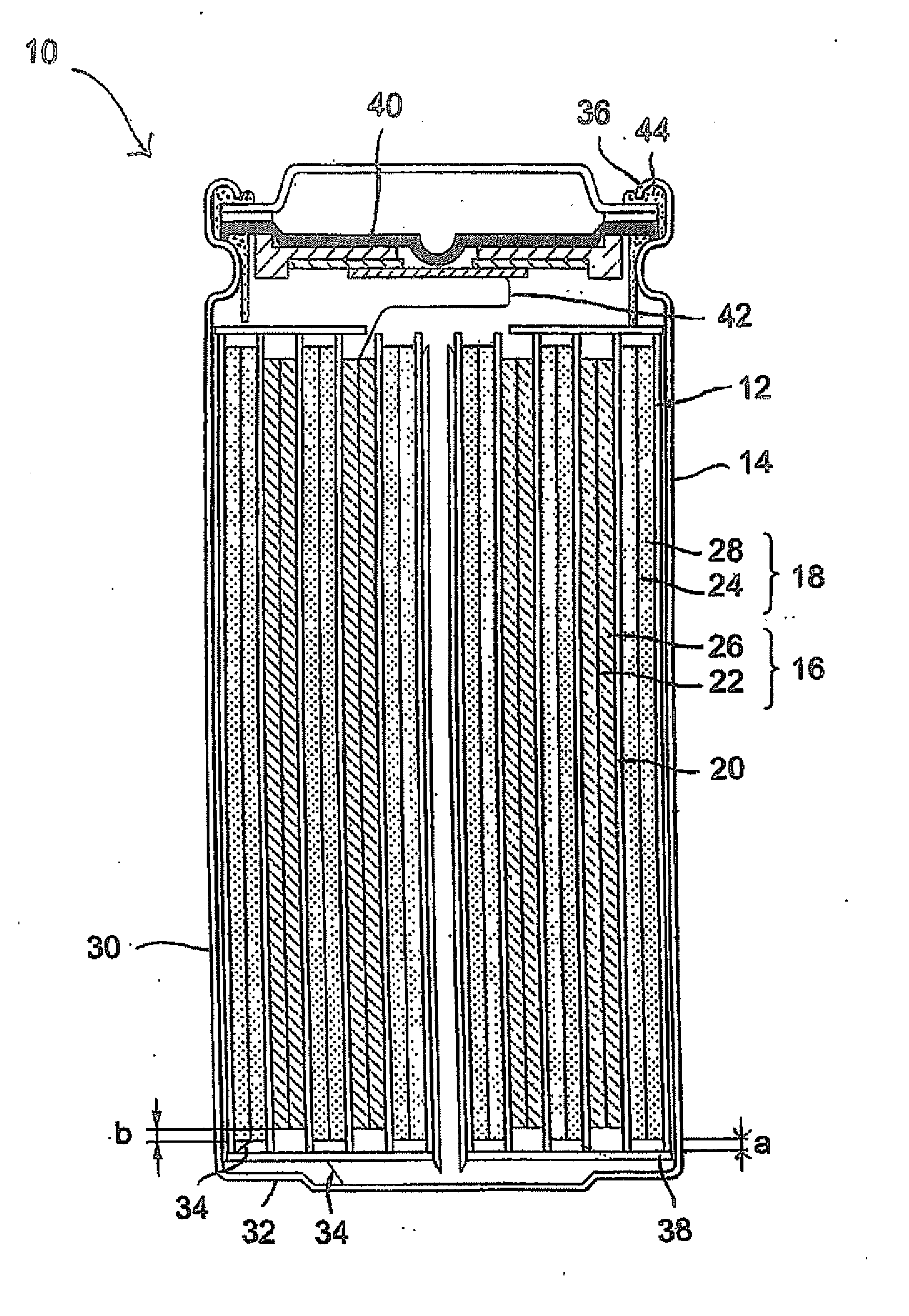

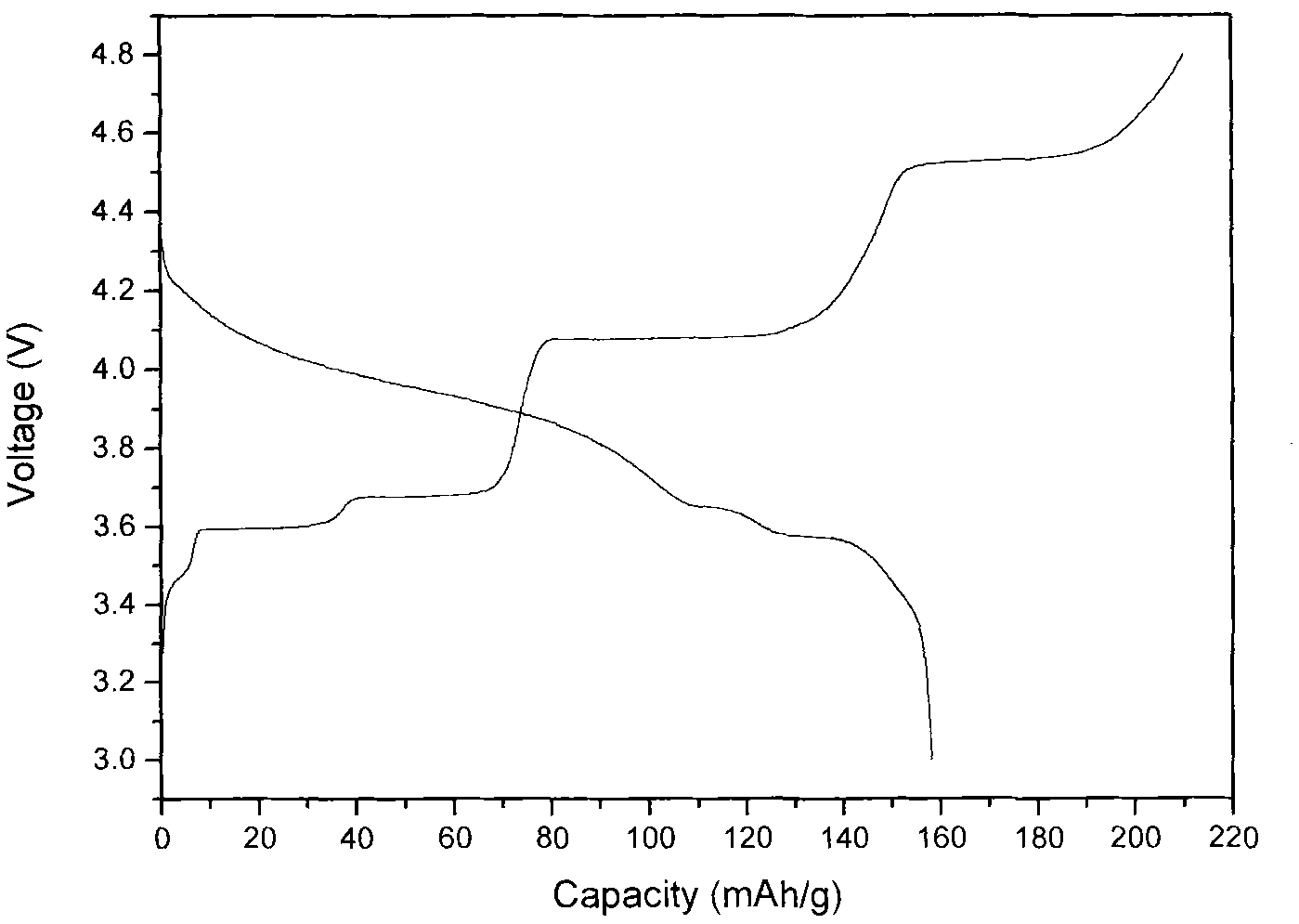

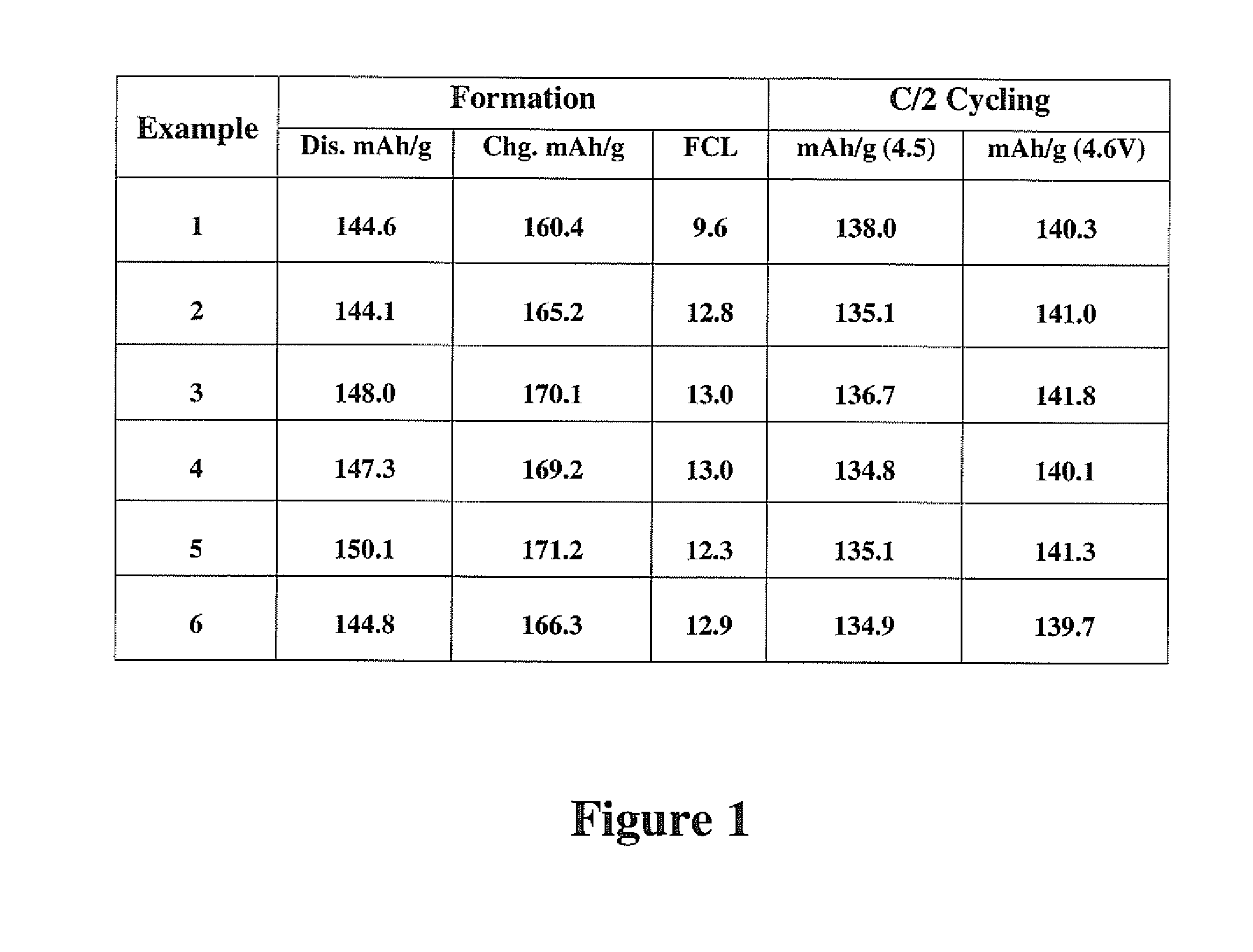

Process for making composite lithium powders for batteries

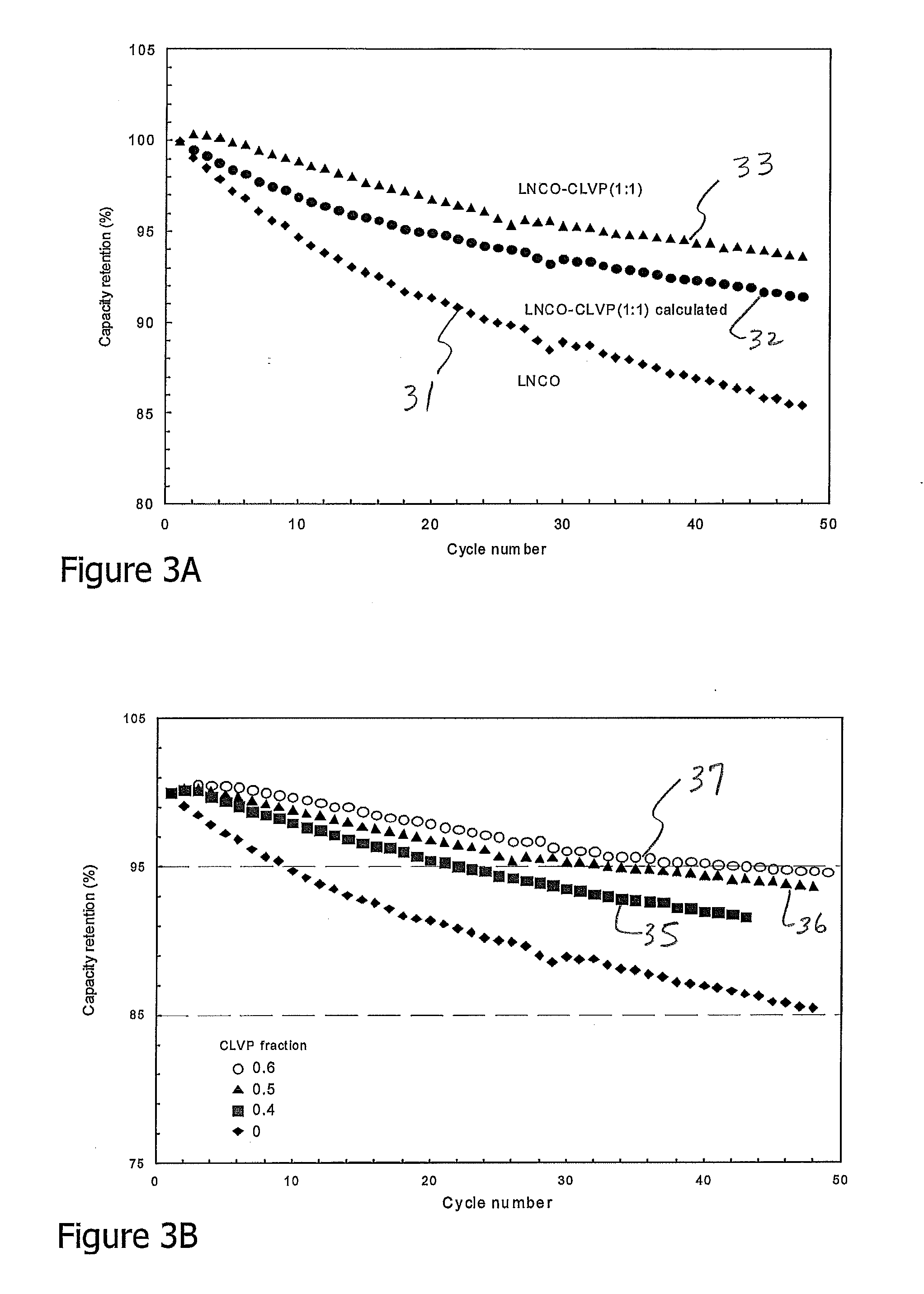

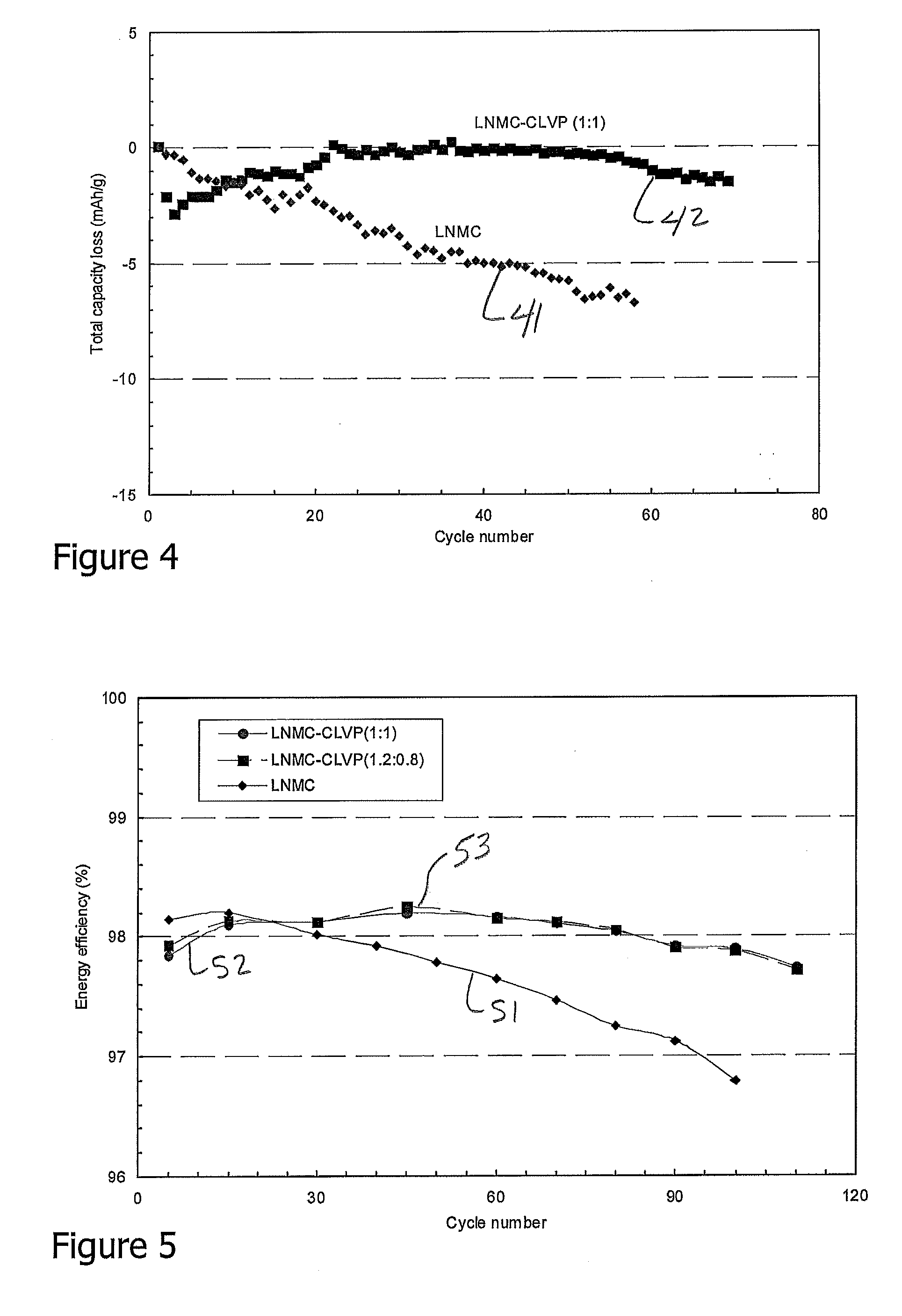

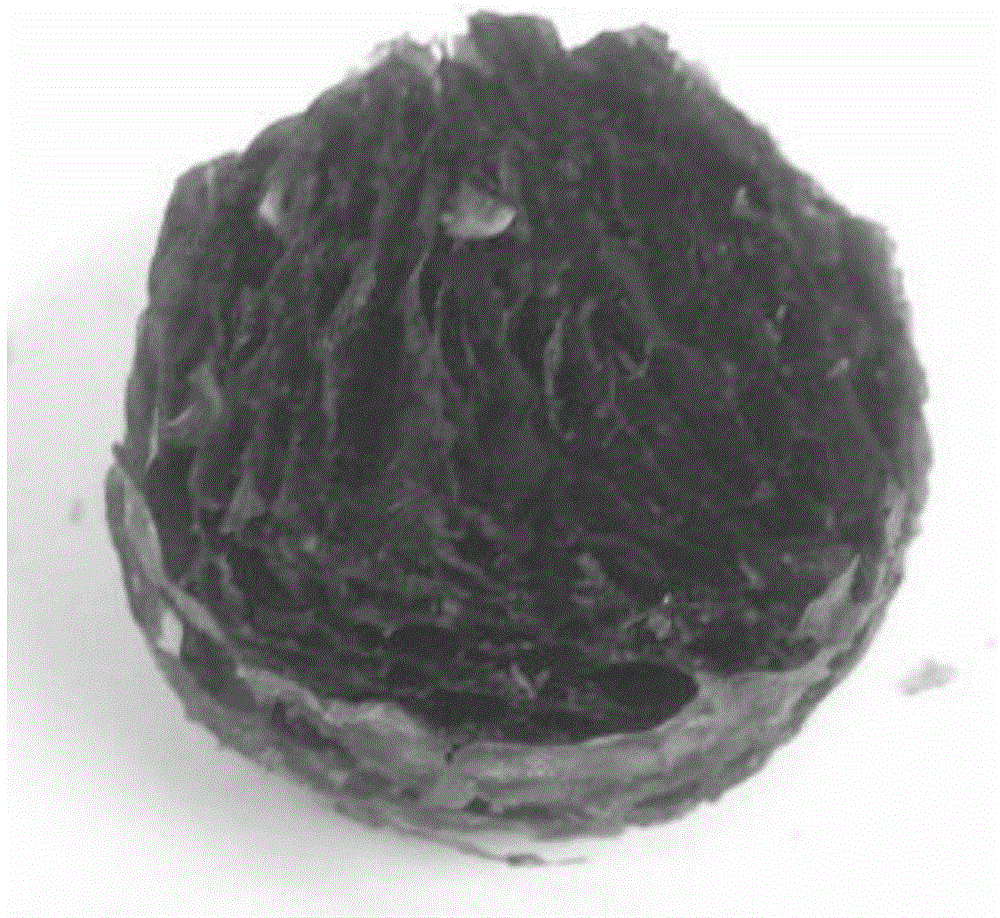

This invention relates to lithium-ion batteries and cathode powders for making lithium-ion batteries where the cathode powder comprises a blend or mixture of at least one lithium transition metal poly-anion and with one or more lithium transition-metal oxide powders. A number of different lithium transition-metal oxides are suitable, especially formulations that include nickel, manganese and cobalt. The preferred lithium transition metal poly-anion is carbon-containing lithium vanadium phosphate. Batteries using the mixture or blend of these powders have been found to have high specific capacity, especially based on volume, high cycle life, substantially improved safety issues as compared to lithium transition-metal oxides, per se, and an attractive electrode potential profile.

Owner:PYROTECK INC

Preparation method of three-dimensional porous vanadium phosphate sodium / carbon anode material

InactiveCN105932277ALarge specific surface areaImprove conductivityCell electrodesCarbon coatingCarbon composites

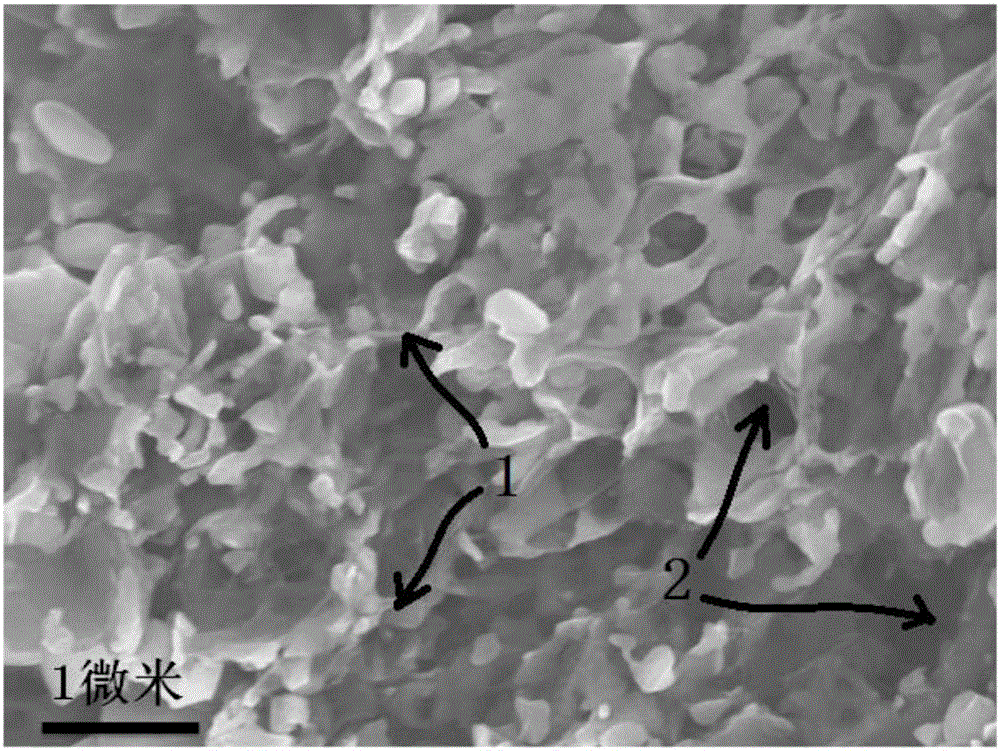

The present invention relates to the technical field of battery materials, and in particular relates to a preparation method of a three-dimensional porous vanadium phosphate sodium / carbon anode material. The method comprises the following steps: (1), dissolving a weighed vanadium source in a mixed solvent of deionized water and hydrogen peroxide, adding a sodium source, a phosphorus source and an organic complex until complete dissolution, pouring the reaction products in a reaction kettle for a hydrothermal reaction, wherein the molar ratio of Na:V:P is 3:2:3; and (2), after the hydrothermal reaction, drying the obtained three-dimensional precursor and then calcining in a gas mixture of argon and hydrogen (5%) at the temperature of 750 DEG C for 8h. The vanadium phosphate sodium / carbon composite material prepared by the invention has carbon coating to improve the electronic conductivity; and the three-dimensional structure porous structure improves the transmission efficiency of sodium ions between the electrode and the electrolyte, and plays a buffer role for deformation of sodium ions in the deintercalation process, and eventually greatly improves the cycle performance and rate performance of the material.

Owner:MAANSHAN YUCHI NEW ENERGY MATERIALS CO LTD

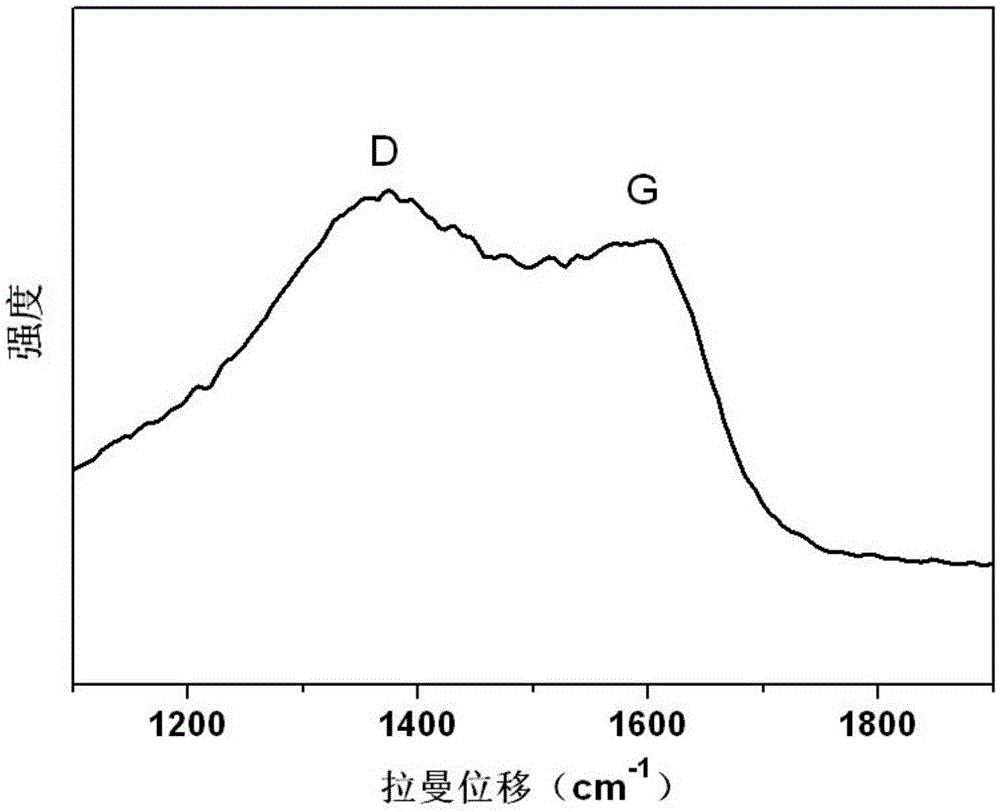

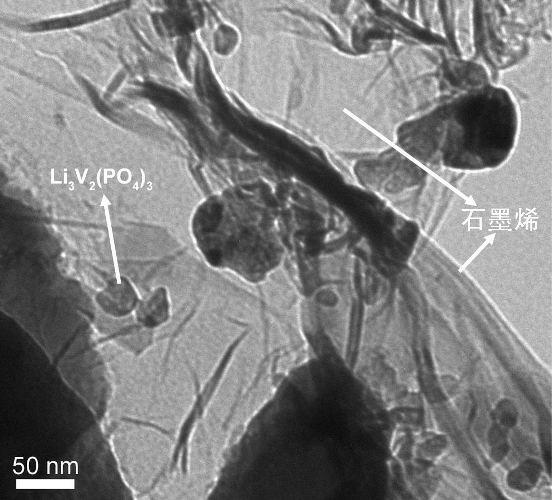

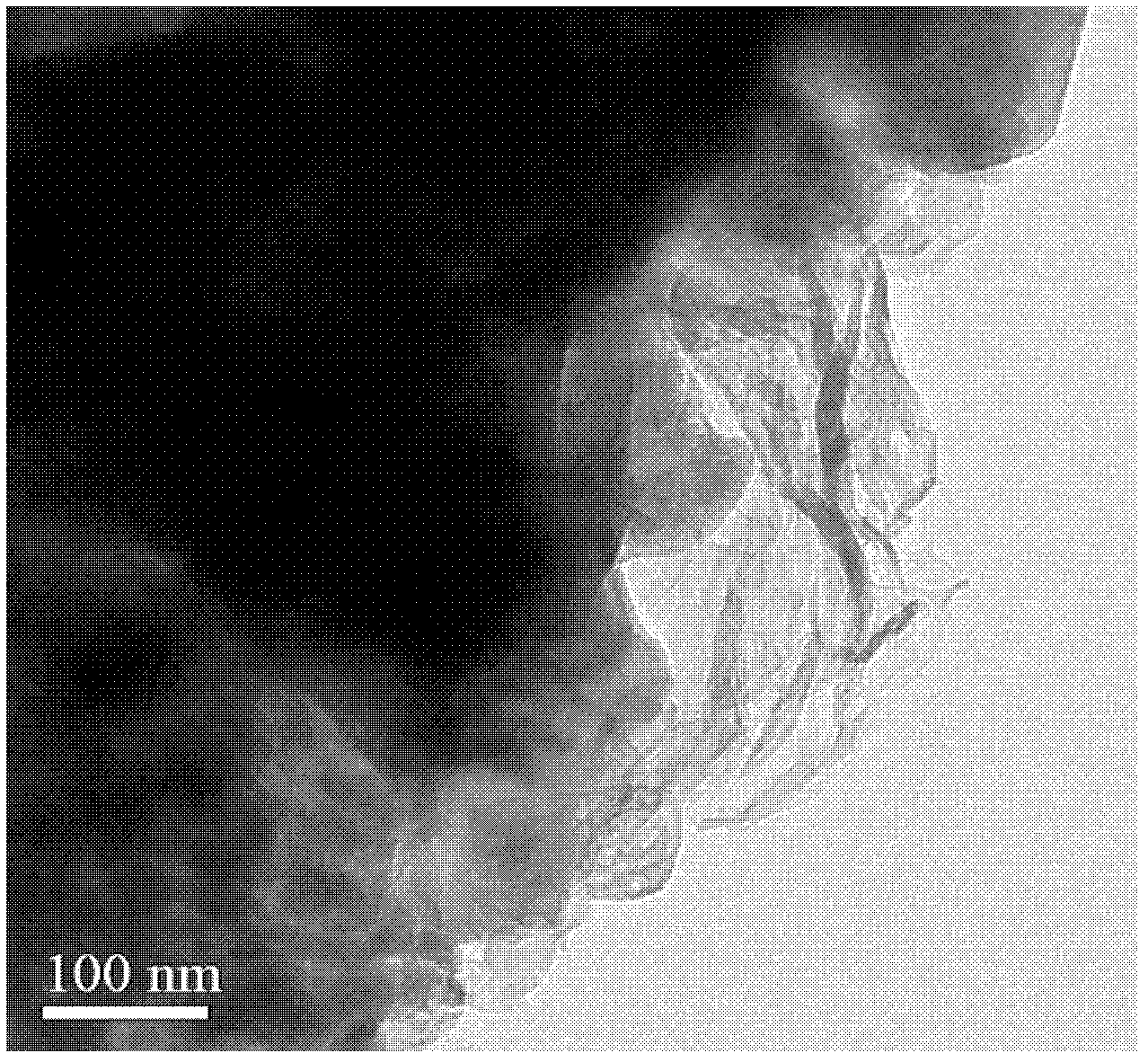

Lithium vanadium phosphate/graphene composite material and preparation method thereof

InactiveCN102386410AGrowth inhibitionThe preparation process is simple and flexibleCell electrodesBattery cellHeat treated

The invention discloses a lithium vanadium phosphate / graphene composite material and a preparation method thereof. The lithium vanadium phosphate / graphene composite material consists of lithium vanadium phosphate and graphene or graphene and other amorphous carbon. The preparation method comprises the following steps: mixing oxidized graphite and deionized water, performing ultrasonic treatment, or further adding a reducing agent and then performing ultrasonic treatment; and adding a material or colloidal sol precursor for synthesizing lithium vanadium phosphate, water bathing at 60-90 DEG C while stirring, continuing ultrasonic treatment, drying and grinding, performing heat treatment in the presence of inert or reducing gas, and naturally cooling to room temperature to obtain the lithium vanadium phosphate / graphene composite material. The composite material prepared by using the method disclosed by the invention is used as the lithium ion battery anode material, the specific capacity of the composite material is up to 115 mAh.g<-1> in case of charging / discharging at 10C multiplying factor, and the composite material has nearly no attenuation after 500 cycles. The method has simple synthesis process and good repetitiveness, and provides an anode material with high capacity and long service life for the application of high multiplying factor lithium ion batteries.

Owner:SHANGHAI UNIV

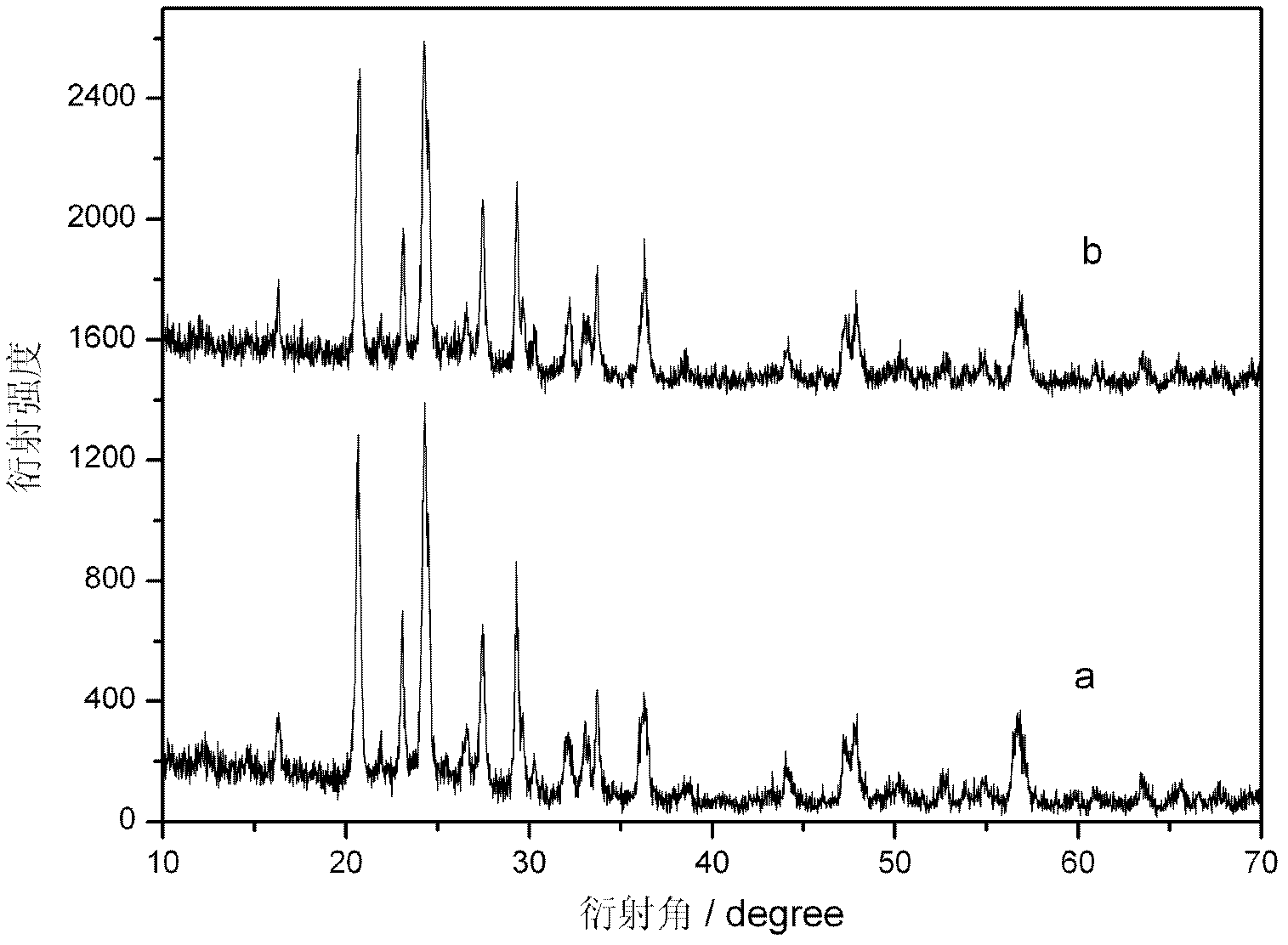

Preparation method of lithium vanadium phosphate (Li3V2(PO4)3)/graphene composite material for positive electrode of lithium ion battery

InactiveCN102623708AHigh purityHigh crystallinityCell electrodesAluminium-ion batterySodium-ion battery

The invention relates to a preparation method of a lithium vanadium phosphate (Li3V2(PO4)3) / graphene composite material for a positive electrode of a lithium ion battery. The method comprises the steps that firstly, a mixed precursor solution is prepared; pretreatment of spray drying is conducted and a precursor is obtained; and then the lithium vanadium phosphate positive electrode material of the lithium ion battery is prepared through a calcination reaction under an inert atmosphere condition. Compared with the prior art, the preparation method has the advantages that the combination mode of the Li3V2(PO4)3 and the graphene, the contents of carbon and the graphene, and the particle size of the material are effectively controlled, thereby improving the stability and the electrical conductive performance of the material.

Owner:SHANGHAI ZHIRONG TECH

Lithium ion cell anode material lithium vanadium phosphate and preparation method thereof

ActiveCN101145611ASmall and evenly dispersedAvoid reunionElectrode manufacturing processesPhosphorus compoundsHigh rateConductive materials

The invention discloses a lithium vanadium phosphate anode material used in a lithium battery and a preparation method thereof, and solves the technical problem that can improve the electrical conductivity and high-rate discharge property of the anode material. The inventive anode material comprises a matrix coated outside with a conductive nano-composite material with a particle size of 5-50 Mu m and a specific surface area of 5-25m<2> / g. The inventive anode material is prepared by the following steps: wet-method superfine ball mill, liquid-phase mixture reaction, spray drying, pretreatment, calcinations treatment, coating with conductive composite material, and fusion. Compared with the prior art, the invention can synthesize lithium vanadium phosphate anode material by the secondary molding liquid phase method of nanoparticles, and the product purity is high, the particle agglomeration is efficiently prevented. The synthetic lithium vanadium phosphate anode material has a discharge voltage about 4V, three discharge voltage platform zones, higher charge / discharge capacity, excellent rate discharge capability and loop stability, and low cost; and is suitable for the industrial production.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

Method for preparing uniform carbon-coated vanadium phosphate sodium material

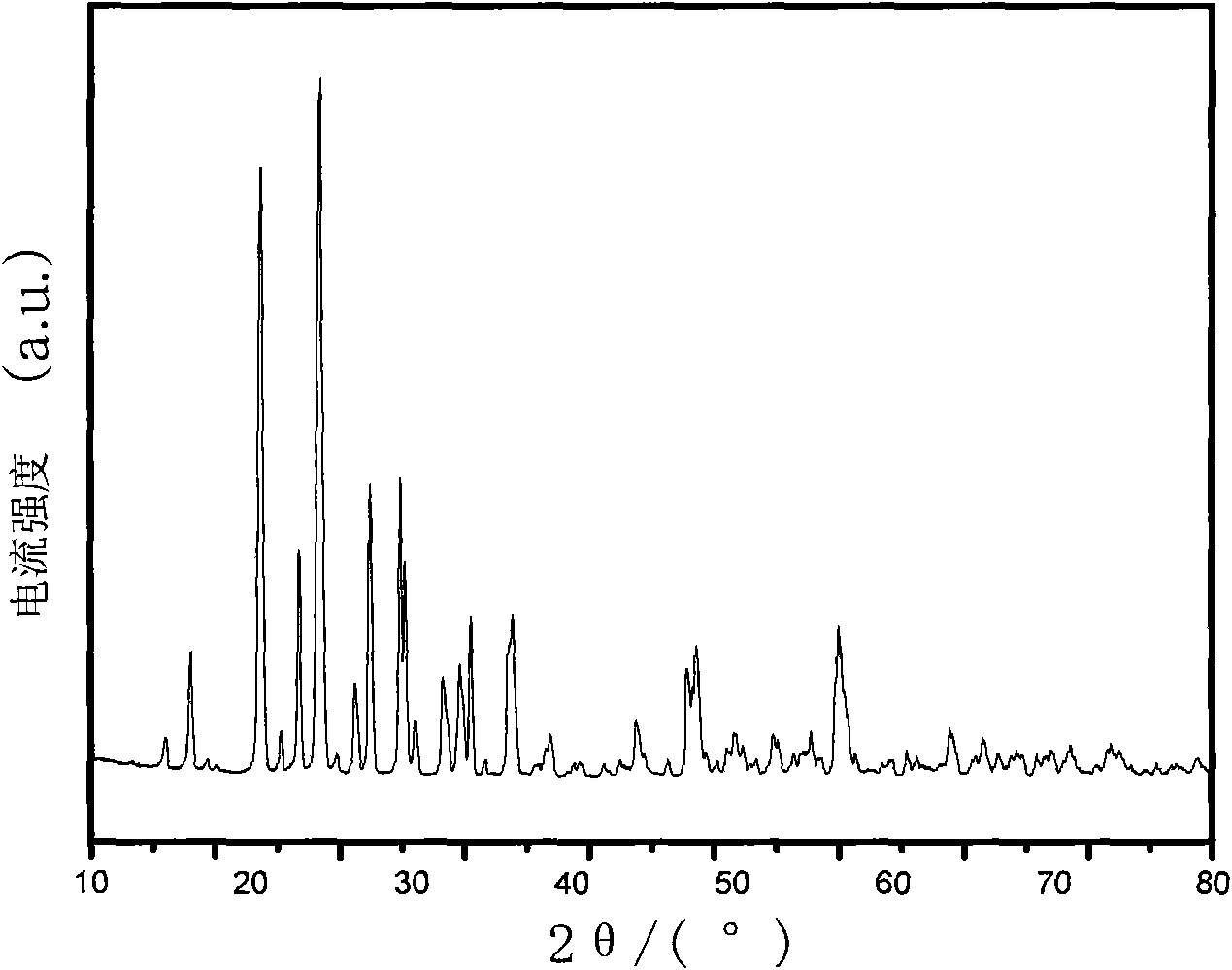

ActiveCN104733731AUniform sizeInhibition of agglomerationCell electrodesPhosphorus compoundsCarbon layerWater baths

The invention provides a method for preparing a uniform carbon-coated vanadium phosphate sodium material. The method comprises the following steps: dissolving V2O5, NH4H2PO4 and Na2CO3 or NH4VO3, H3PO4 and Na2CO3 in distilled water; uniformly mixing Na3V2(PO4)2 and glucose at a molar ratio of 2: (3-4); transferring the mixed solution into a hydrothermal reaction kettle, and carrying out the glycosidation reaction; cooling the hydrothermal reaction kettle at the room temperature, opening the hydrothermal reaction kettle, ultrasonic uniformly dispersing the obtained turbid liquid, magnetically stirring the turbid liquid in a water bath, and evaporating the water to obtain sol, and drying the sol in a drying oven to obtain gel; adequately grinding gel, and pre-burning the ground gel in argon; adequately grinding the pre-burned gel again, and calcining in argon to obtain the uniform carbon-coated Na3V2(PO4)3 material. The carbon-source glucose is added in the hydrothermal process, the surface of the particle is coated with a carbon layer, the conductivity of the material is improved, the clustering phenomenon of the particle in the sintering process can be inhibited, and a product with uniform size can be obtained.

Owner:TIANJIN UNIV

Process For Producing Electrode Active Material For Lithium Ion Cell

InactiveUS20090148377A1Reduce moisture contentPhosphatesElectrode thermal treatmentPhosphateElectrical battery

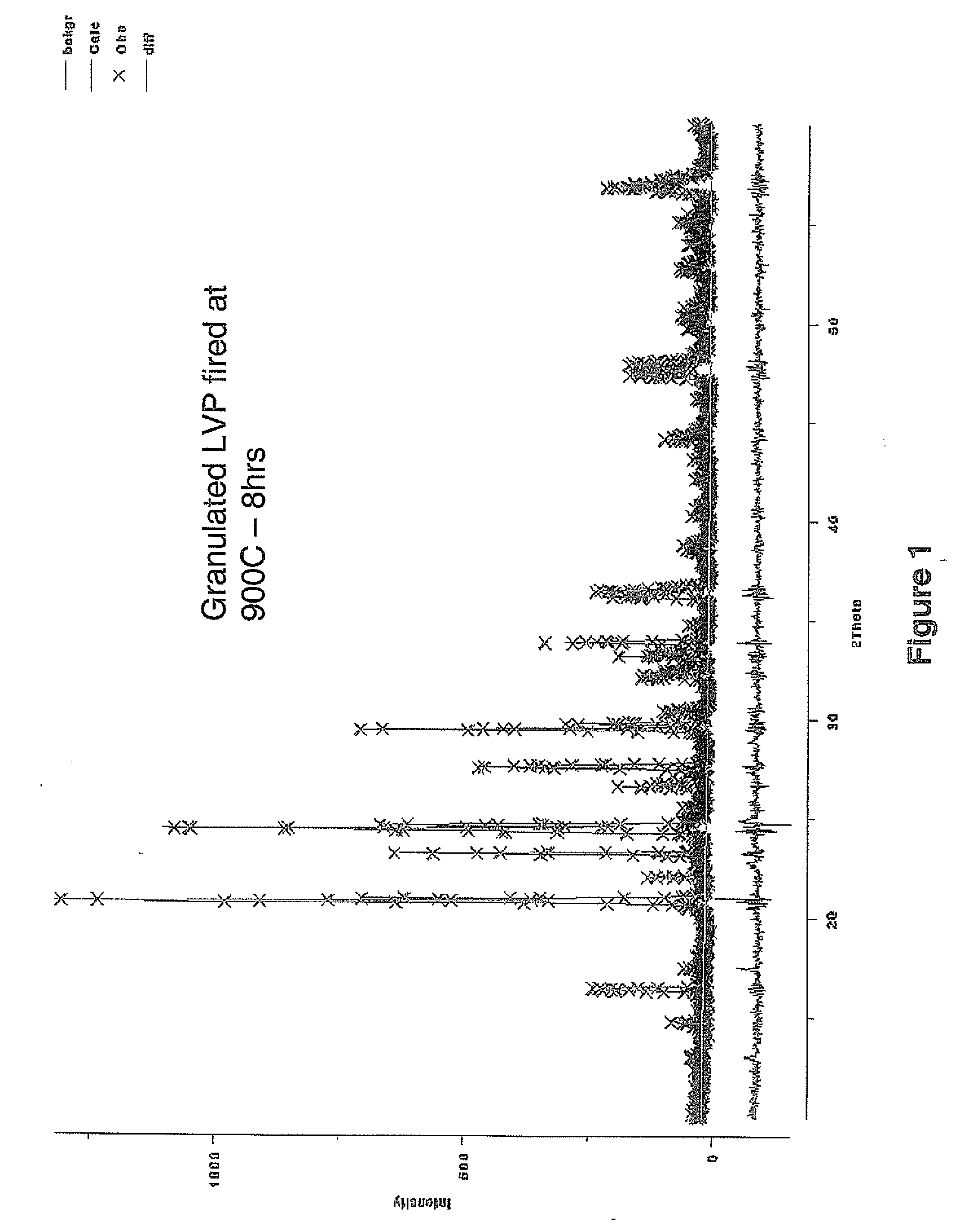

The present invention relates to a method for preparing a lithium vanadium phosphate material comprising mixing water, lithium dihydrogen phosphate, V2O3 and a source of carbon to produce a first slurry; wet blending the first slurry; spray drying the wet blended slurry to form a precursor composition; milling the precursor composition to obtain a milled precursor composition; compacting the milled precursor to obtain a compacted precursor; pre-baking the compacted precursor composition to obtain a precursor composition with low moisture content; and calcining the precursor composition with low moisture content at a time and temperature sufficient to produce a lithium vanadium phosphate. The lithium vanadium phosphate so produced can optionally be further milled to obtain the desired particle size. The electrochemically active lithium vanadium phosphate so produced is useful in making electrodes and batteries and more specifically is useful in producing cathode materials for electrochemical cells.

Owner:CARUS CORP +1

Positive pole material of lithium ion battery with nanometer structure and preparation method thereof

The invention discloses a positive pole material of a lithium ion battery with a nanometer structure and a preparation method thereof. The positive pole material is in a particle type core-shell structure, a core material consists of nanometer lithium iron phosphate, lithium vanadium phosphate or cobalt lithium oxide and graphene, and a shell material is porous carbon. The preparation method comprises the following steps of: taking lithium acetate, lithium oxalate, ammonium dihydrogen phosphate, ammonia metavanadate, phosphoric acid, lithium nitrate, cobalt nitrate and graphite oxide as raw materials, adopting a sol-gel method or a ball milling method to prepare a mixture, presintering the mixture in vacuum to obtain the core material, and mixing, grinding and calcining the core material with an organic carbon source to obtain the positive pole material with the particle type core-shell structure. The positive pole material has the advantages of good conductivity, good circulating performance, high capacity, small and uniform particle size, and simple preparation process and is easy for industrialized production.

Owner:深圳清研紫光科技有限公司

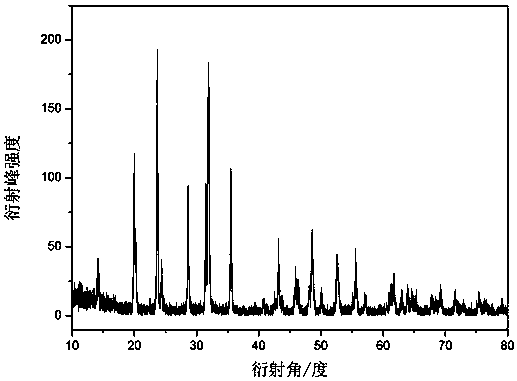

Method Of Making Active Materials For Use In Secondary Electrochemical Cells

InactiveUS20070160519A1Limit scopeElectrode manufacturing processesPhosphatesElectrochemical cellMaterials science

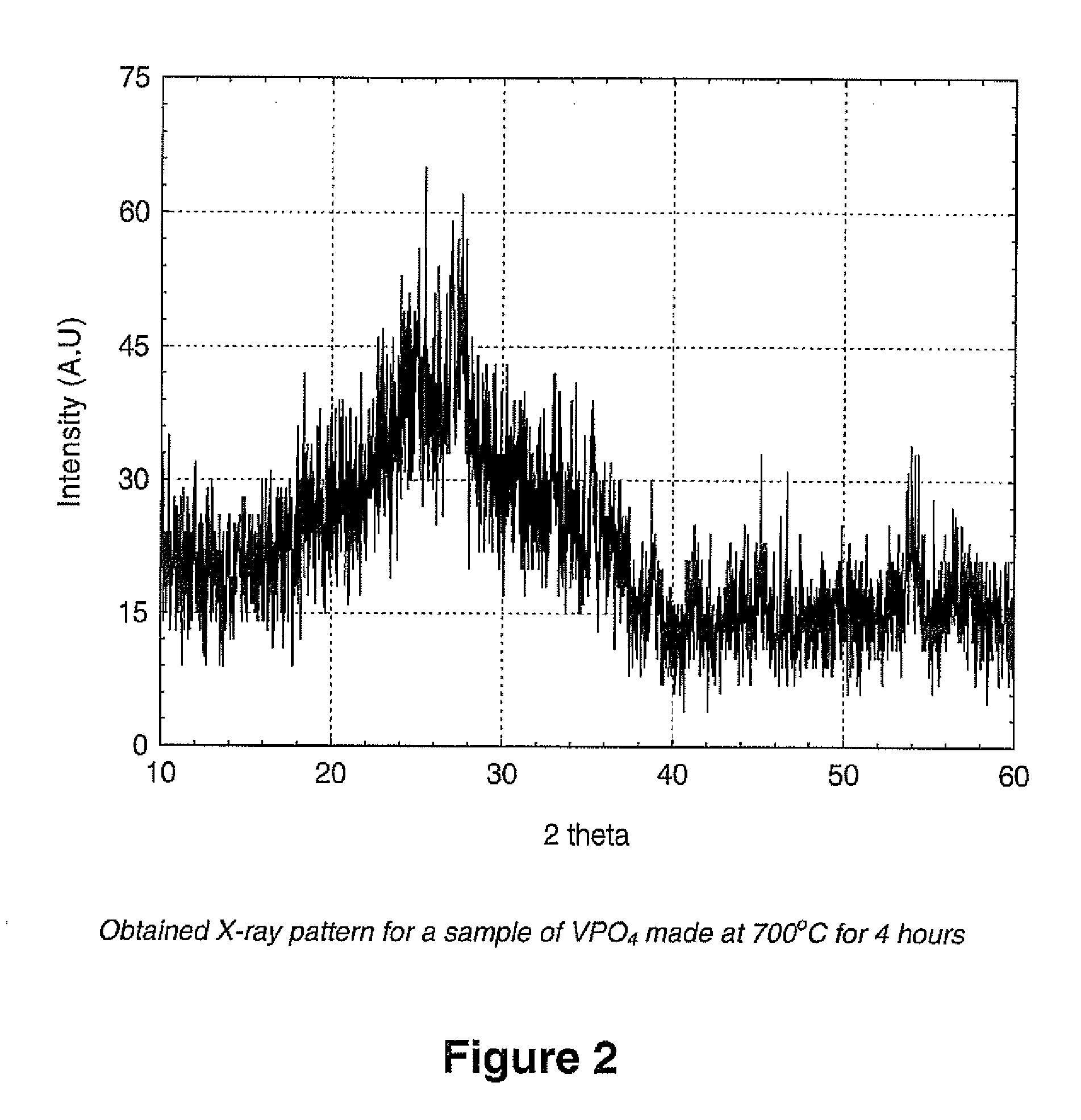

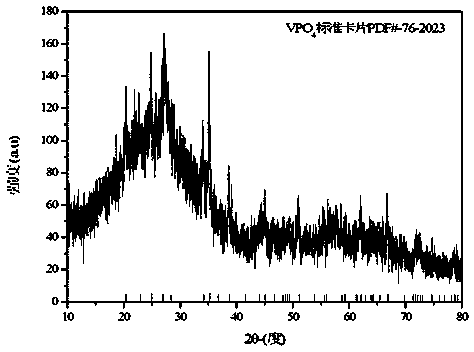

The present invention provides for the preparation of an “optimized” VPO4 phase or V—P—O / C precursor. The VPO4 precursor is an amorphous or nanocrystalline powder. The V—P—O / C precursor is amorphous in nature and contains finely divided and dispersed carbon. Throughout the specification it is understood that the VPO4 precursor and the V—P—O / C precursor materials can be used interchangeably to produce the final vanadium phosphates, with the V—P—O / C precursor material being the preferred precursor. The precursors can subsequently be used to make vanadium based electroactive materials and use of such precursor materials offers significant advantages over other processes known for preparing vanadium phosphate compounds.

Owner:VALENCE TECH INC

Lithium battery electrode material

ActiveCN101859891AImprove electrochemical performanceDiffuse fullyCell electrodesLithium vanadium phosphate batteryLithium iron phosphate

The invention discloses a lithium battery electrode material, comprising a plurality of uniformly distributed lithium iron phosphate / lithium vanadium phosphate composite particles. The material is characterized in that each lithium iron phosphate / lithium vanadium phosphate composite particle comprises a lithium vanadium phosphate particle and a lithium iron phosphate particle layer uniformly coated on the surface of the lithium vanadium phosphate particle, wherein, the lithium iron phosphate particle layer comprises a plurality of lithium iron phosphate particles.

Owner:TSINGHUA UNIV +1

Oxo-vanadium phosphate catalyst, and preparation method and application thereof

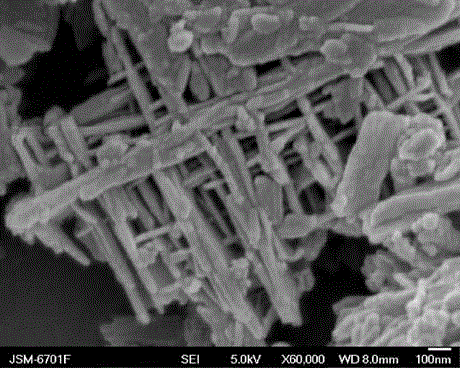

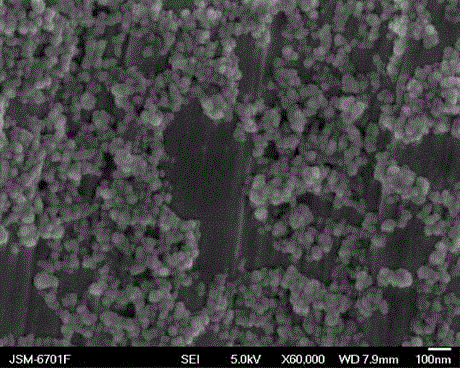

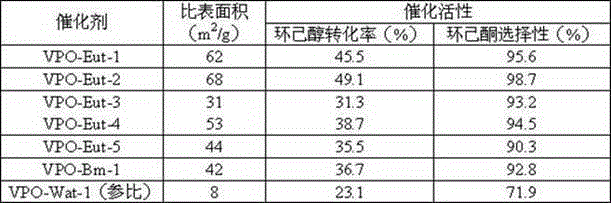

InactiveCN103551175ASmall particlesLarge specific surface areaPhysical/chemical process catalystsCarbonyl compound preparation by oxidationPtru catalystHydrogen phosphate

The invention relates to an oxo-vanadium phosphate catalyst, and a preparation method and application thereof. The catalyst is prepared through the following steps: preparing a precursor by performing ionothermal synthesis on vanadium pentoxide or metavanadate and phosphate or biphosphate used as raw materials in ionic liquid or eutectic mixture solvent at 120-180 DEG C under normal pressure; and then roasting. The synthesis method is operated under normal pressure, is safe and convenient, and has low requirements for equipment. The catalyst prepared through the method has a special spherical or claviform shape, has high specific surface area and can be used for cyclohexanol oxidation reaction.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

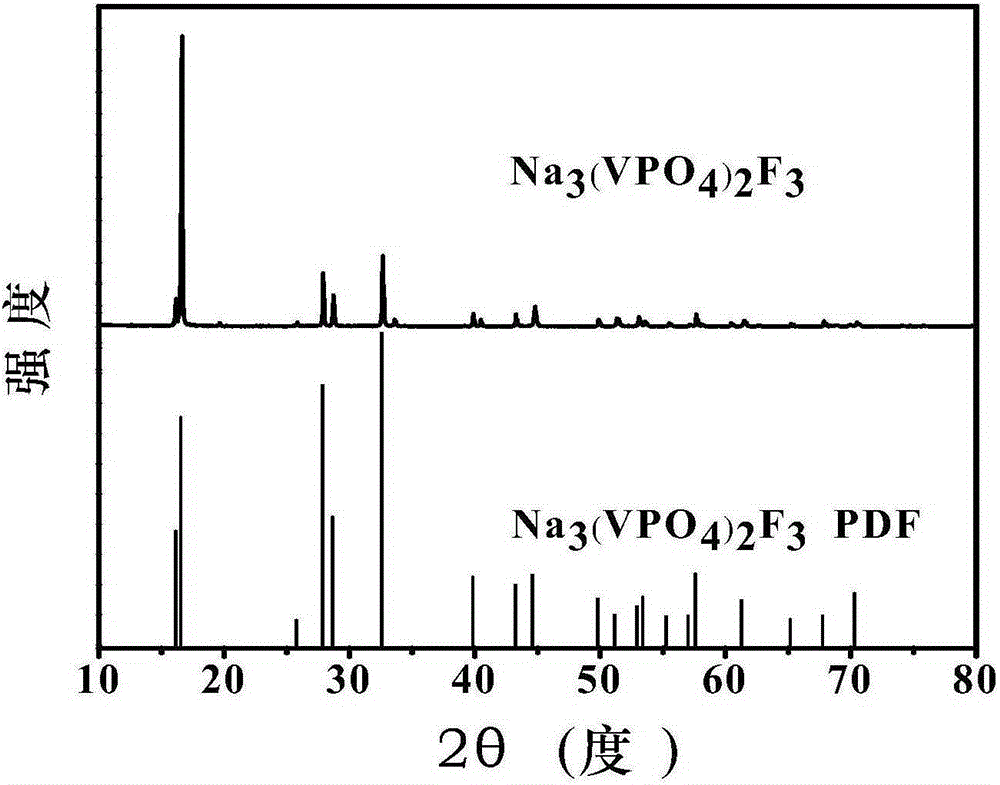

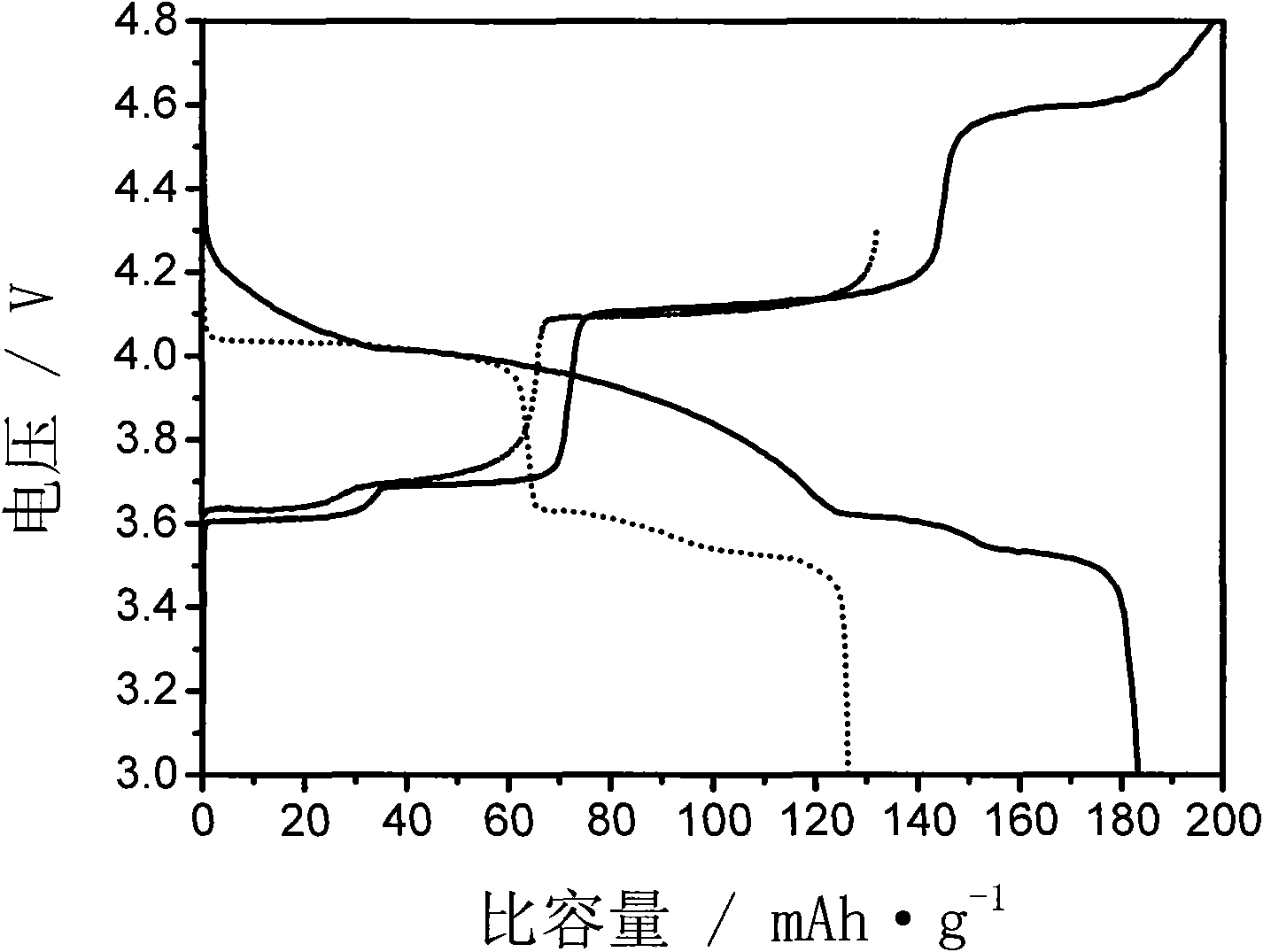

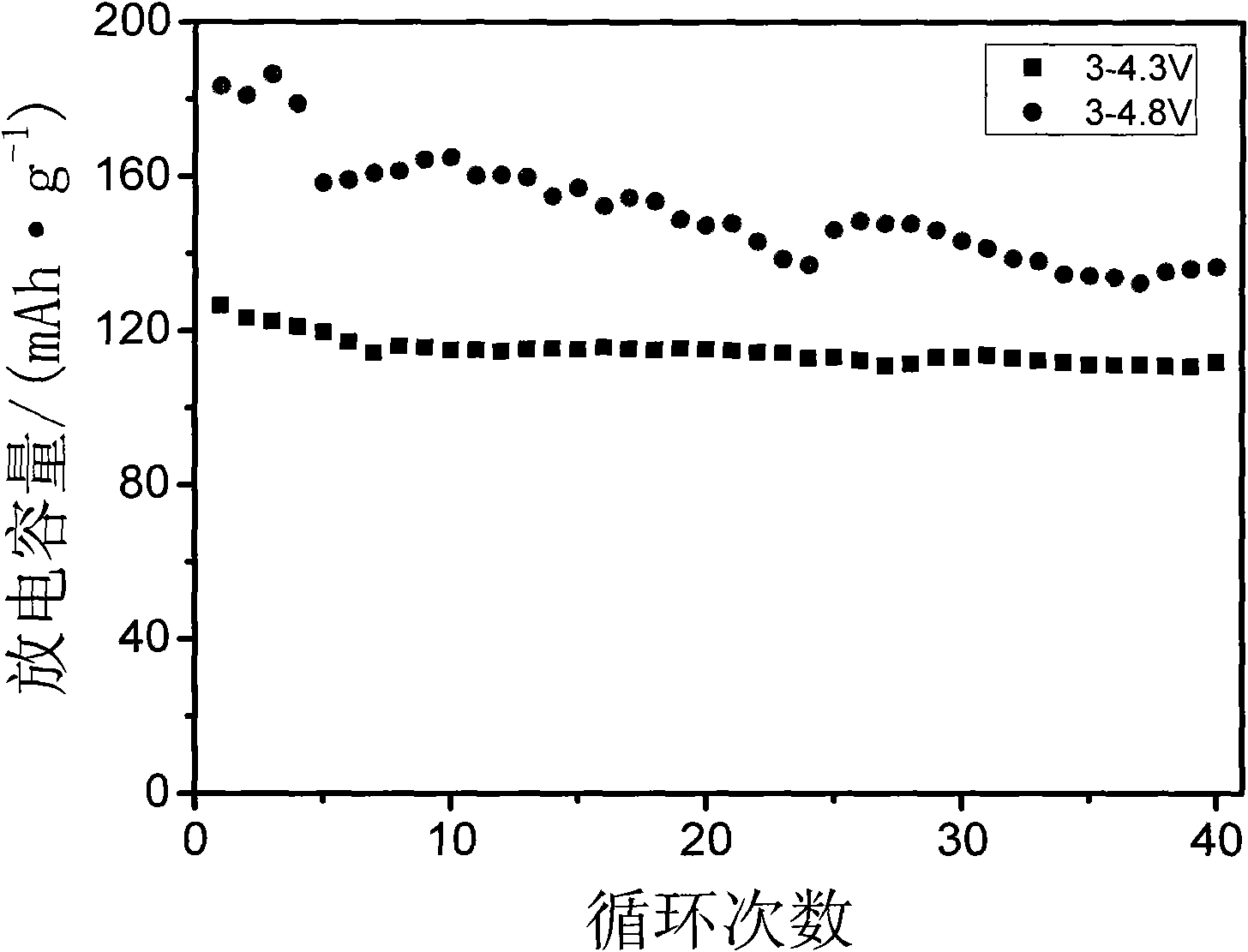

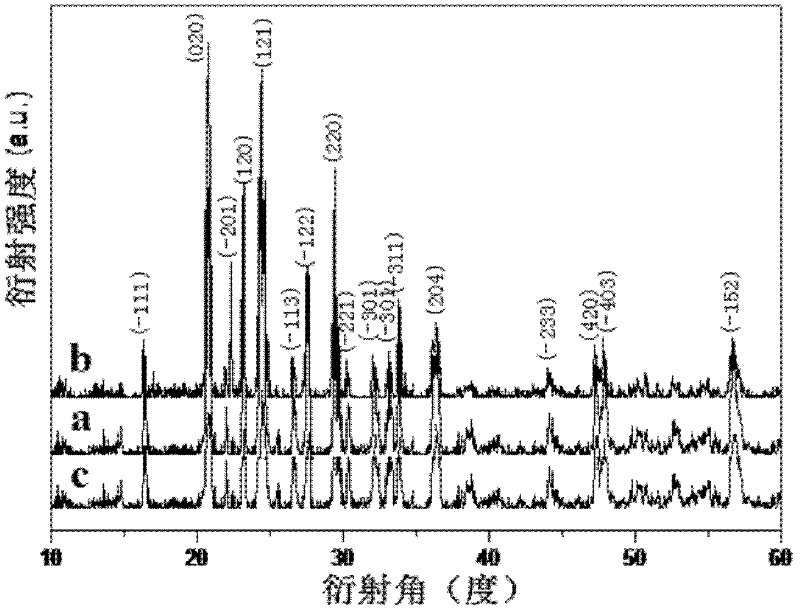

Sodium vanadium fluorophosphate as well as low-temperature environment-friendly preparation method and use thereof

InactiveCN106495124AImprove electrochemical performanceSynthesis temperature is lowCell electrodesPhosphorus compoundsAqueous solutionSpecific discharge

The invention belongs to the technical field of electrode materials and relates to sodium vanadium fluorophosphate as well as a low-temperature environment-friendly preparation method and use thereof. The preparation method comprises the steps of preparing a mixed water solution of a sodium source, a vanadium source, a phosphorus source and a fluorine source, reacting by virtue of the mixed water solution at 20-180 DEG C to obtain sodium vanadium fluorophosphate, wherein the vanadium source is a trivalent vanadium source and / or a tetravalent vanadium source; the chemical constitution of sodium vanadium fluorophosphate is Na3(VOxPO4)2F3-2x, and x is more than or equal to 0 and less than or equal to 1. According to the low-temperature environment-friendly preparation method, the mixed water solution of the sodium source, thephosphorus source, the fluorine source and the trivalent vanadium source and / or a tetravalent vanadium source can generate spontaneous reaction at 20-35 DEG C, the reaction can be accelerated at a temperature high than 35 DEG C and lower than 180 DEG C, and well-crystallized sodium vanadium fluorophosphate can be obtained. Sodium vanadium fluorophosphate can be used as an anode to be assembled into a battery, the specific discharge capacity is not lower than 100mAh / g, and the cycling stability is good.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

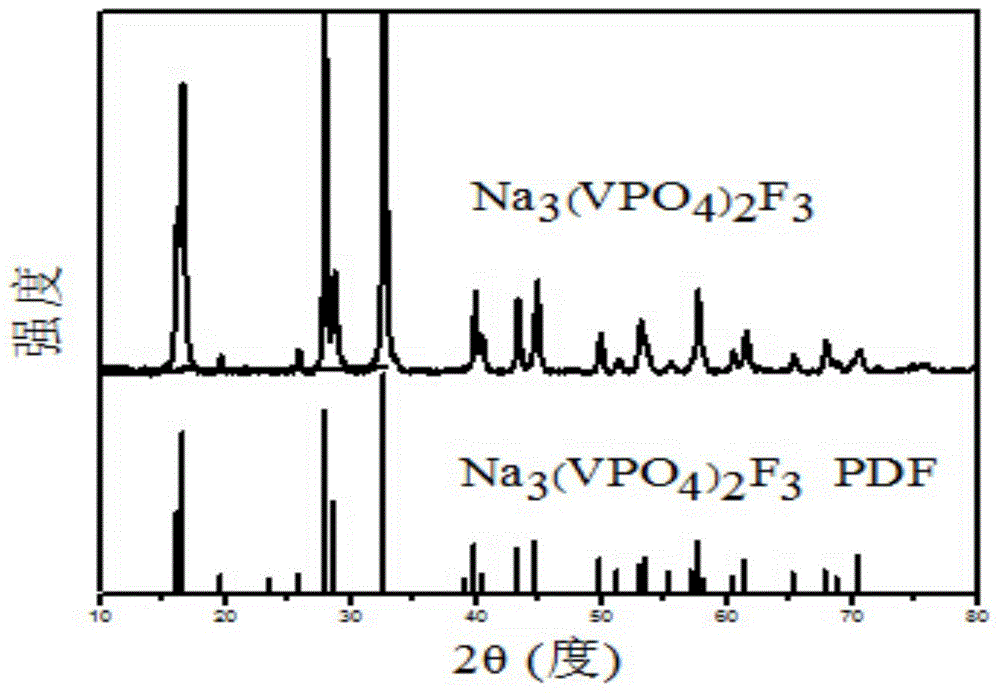

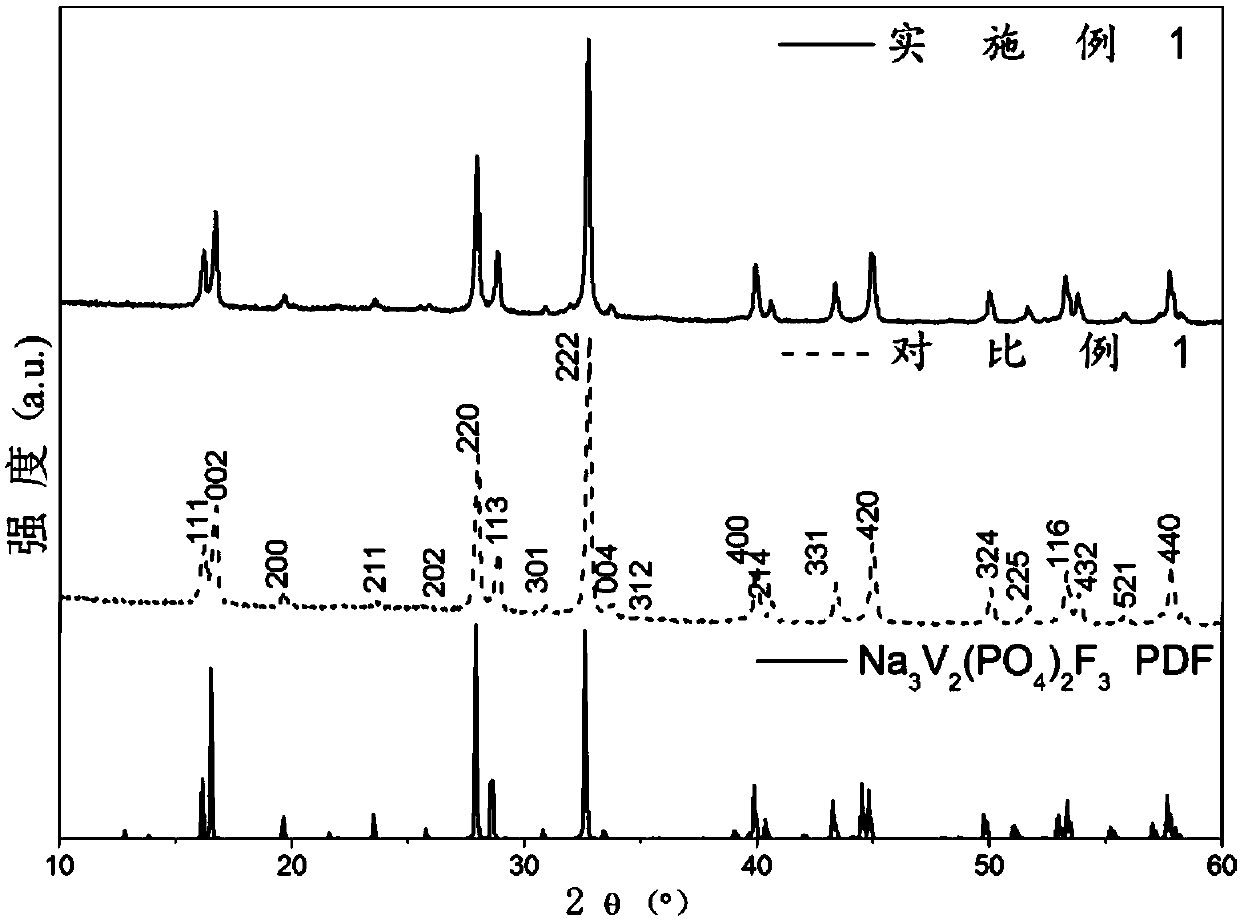

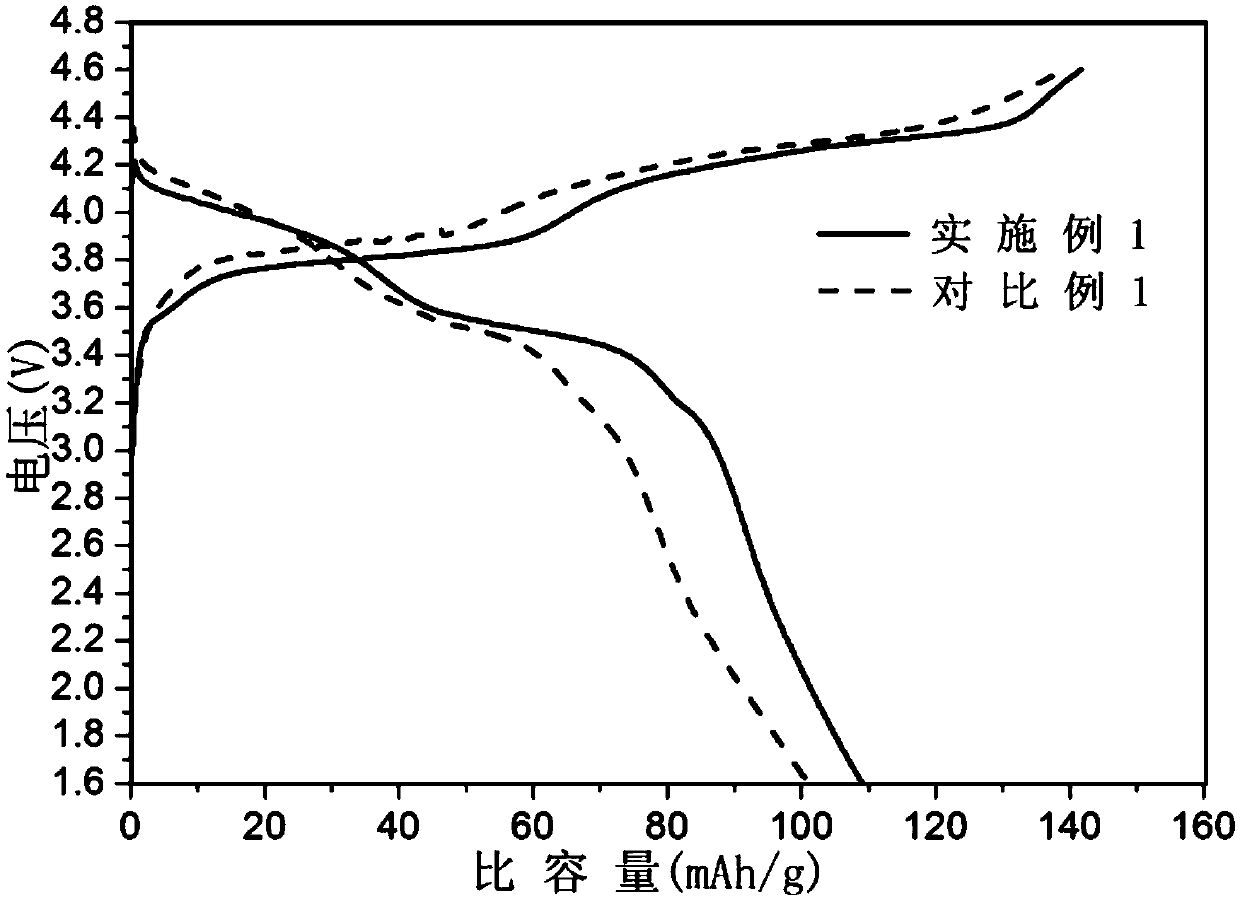

Sodium vanadium fluorophosphate, and preparation method and use thereof

ActiveCN105762356ASynthetic crystalline performance is goodImprove electrochemical performanceCell electrodesPhysical chemistryOrganosolv

The invention provides a preparation method and a use of sodium vanadium fluorophosphate. The preparation method of the sodium vanadium fluorophosphate comprises the following steps: dissolving or dispersing the following raw materials: a sodium source compound, a vanadium source compound, a phosphorus source compound and a fluorine source compound, in an organic solvent to obtain a mixture; and 2, transferring the mixture obtained in step 1 to a reaction kettle, heating the reaction kettle to 50-140DEG C, reacting the mixture, cooling the obtained product, washing the cooled product, and drying the washed product to obtain sodium vanadium fluorophosphate powder. Compared with high-temperature and complex-flow traditional technologies, the preparation method has the following advantage: the sodium vanadium fluorophosphate with good crystallinity and good electrochemical performances can be synthesized at a low temperature of 50-140DEG C only through a solvothermal reaction and precipitate washing short technology.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method of Making Active Materials For Use in Secondary Electrochemical Cells

InactiveUS20090068080A1Limit scopePhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesPre treatmentHigh pressure

The present invention provides for the two step preparation of lithium vanadium phosphate by pre-treatment of a mixture of precursor materials via high pressure at relatively low temperatures in water (hydrothermal pretreatment) and then calcining such hydrothermally pretreated precursors at relatively high temperatures for a period of time sufficient to produce lithium vanadium phosphate. The lithium vanadium phosphate so produced finds use in producing electrodes for electrochemical cells.

Owner:VALENCE TECH INC

Method for preparing lithium vanadium phosphate as lithium ion battery anode material

InactiveCN101651205AUniform particle size distributionHigh specific capacityElectrode manufacturing processesMuffle furnacesLithium vanadium phosphate batteryMicrowave sintering

The invention discloses a method for preparing lithium vanadium phosphate as a lithium ion battery anode material, which comprises the following steps: (1) preparing reaction precursor gel of an anodematerial by a sol-gel method; (2) presintering the reaction precursor gel prepared in the step (1); and (3) placing a material obtained by presintering into a microwave sintering furnace to sinter. The invention combines the sol-gel method with a microwave sintering method and can prepare a product with favorable electrode plate processing ability, electrical conductivity and electrochemical performance by sintering in tens of minutes. The method has high production efficiency, low energy consumption, easy control of technical parameter, favorable batch stability and low production cost and is suitable for mass industrial production.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Doped and modified sodium vanadium fluorophosphate cathode material and preparation method thereof

ActiveCN107819115AImproved magnification performanceImprove electrochemical performanceCell electrodesSecondary cellsPhosphateChemical measurement

The invention discloses a doped and modified sodium vanadium fluorophosphate cathode material and a preparation method thereof. According to the cathode material, the problems that an existing sodiumvanadium fluorophosphate cathode material is poor in rate capability and instable in cycle performance are solved. The nominal molecular formula of the cathode material is Na3V2-xCax(PO4)2F3, whereinx is more than 0 and less than or equal to 0.2. The preparation method comprises the following steps: uniformly dissolving a sodium source, a calcium source, a vanadium source, phosphate and a carbonsource into a deionized water medium in a stoichiometric ratio so as to obtain a mixed solution, and drying, so as to obtain a sodium vanadium fluorophosphate precursor, wherein the carbon source is used for controlling a V valence state in a compound; and carrying out thermal treatment on the precursor at 300-400 DEG C in an inert atmosphere, and sintering at 600-700 DEG C, so as to obtain the doped and modified sodium vanadium fluorophosphate cathode material. The material has relatively high ionic conductivity and electronic conductivity and therefore has excellent rate capability; the cycling stability of the material in electrochemical charging and discharging processes are enhanced; and the preparation craft process is simple.

Owner:UNIV OF SCI & TECH BEIJING

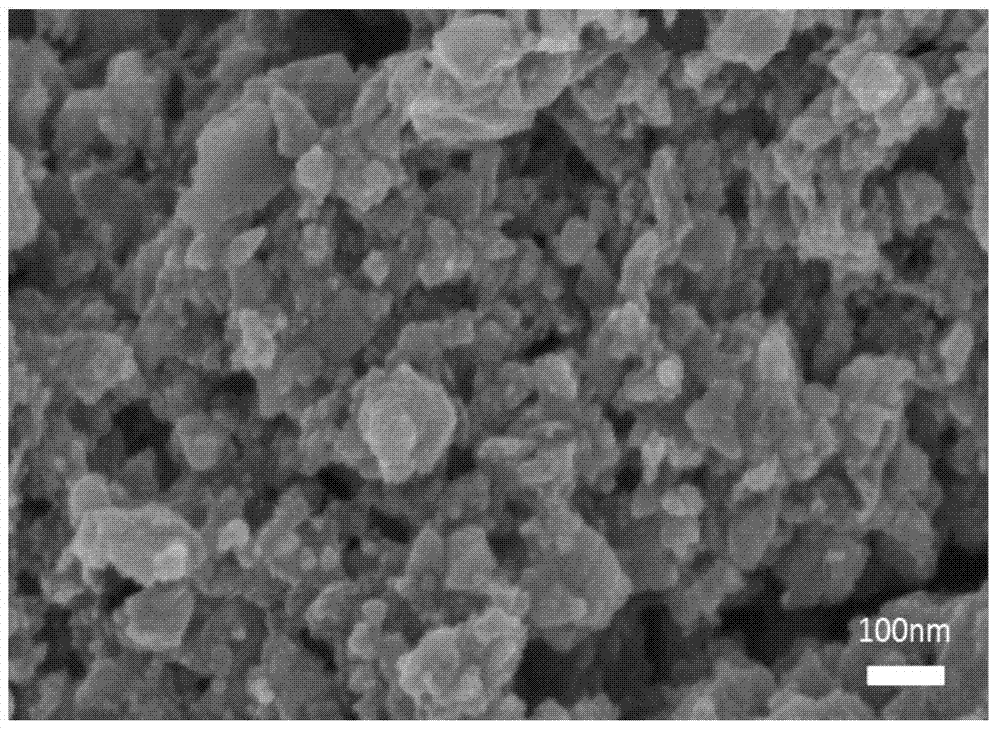

Vanadium phosphate sodium composite nano porous cathode material and method for preparing material by using freeze drying method

InactiveCN106025275ALarge specific surface areaHigh specific capacityMaterial nanotechnologyCell electrodesElectrochemical responseFreeze-drying

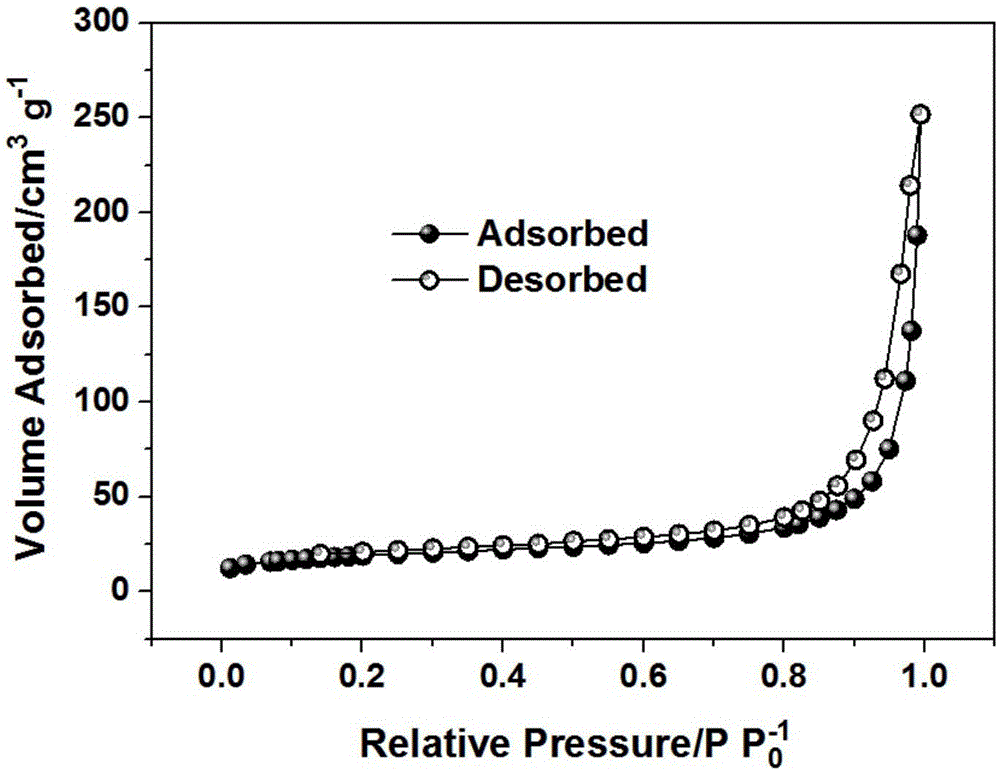

The invention discloses a vanadium phosphate sodium composite nano porous cathode material and a method for preparing the material by using a freeze drying method, which belong to the technical fields of a cell material and its preparation method. The method comprises the following steps: adding a certain amount of a vanadium source in a mixed solvent of deionized water and hydrogen peroxide, after stirring the materials and dissolving the materials, adding a sodium source, a phosphorus source and a carbon source with a stoichiometric ratio to form a mixing solution; then refrigerating the prepared mixing solution in liquid nitrogen to a solid, then performing vacuum drying on the material in a vacuum freeze drier; and finally putting a precursor obtained after freeze drying in mixing gas of argon and hydrogen for calcining to obtain the vanadium phosphate sodium composite nano porous cathode material. The prepared vanadium phosphate sodium composite nano porous cathode material has a three-dimensional porous structure and large specific surface area, and thereby is in favor of infiltration and transmission of an electrolyte, active sites of an electrochemical reaction are multiple, and high specific capacity and good multiplying power performance can be displayed.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for preparing cathode material lithium vanadium phosphate of lithium ion battery by using fast sol-gel method

InactiveCN101841024AAvoid overgrowthGrowth inhibitionCell electrodesCooking & bakingSodium-ion battery

The invention discloses a method for preparing a cathode material lithium vanadium phosphate of a lithium ion battery by using a fast sol-gel method, which specifically comprises the following steps of: (1) adding vanadic oxide into the solution of a reducing acid, heating the mixed solution to 60 to 80 DEG C and stirring the mixed solution for 10 to 50 minutes at a constant temperature to obtain blue solution; (2) adding lithium salts into the blue solution, wherein a stoichiometric ratio of the lithium salts to the vanadic oxide is 3-3.2: 2.9-3.05: 0.95-1.05; (3) treating an obtained powder material in an inert atmosphere at 200 to 400 DEG C for 2 to 4 hours to obtain a precursor; and (4) mixing and grinding uniformly the obtained precursor and another carbon source and cooling the mixture to obtain the cathode material lithium vanadium phosphate of the lithium ion battery. The method has the advantages that: (1) a synthesis process is simplified, the cost is reduced and the method is applied to industrial production; (2) the baking time is greatly shortened, the granularity of the product is reduced and the synthesized material has a nano-size; and (3) the carbon source is mixed before baking, carbon granules also can prohibit the growth of material granules and the synthesized material granules are uniform and fine.

Owner:NANCHANG UNIV

Synthesis of cathode active materials

The present invention relates to a method for preparing a lithium vanadium phosphate material comprising forming a aqueous slurry (in which some of the components are at least partially dissolved) comprising a polymeric material, an acidic phosphate anion source, a lithium compound, V2O5 and a source of carbon; wet blending said slurry, spray drying said slurry to form a precursor composition; and heating said precursor composition to produce a lithium vanadium phosphate. In one embodiment the present invention relates to a method for preparing a lithium vanadium phosphate which comprises reacting vanadium pentoxide (V2O5) with phosphoric acid (H3PO4) to form a partially dissolved slurry; then mixing with an aqueous solution containing lithium hydroxide; adding a polymeric material and a source of carbon to form a slurry; wet blending said slurry; spray drying said slurry to form a precursor composition; and heating said precursor composition for a time and at a temperature sufficient to produce a lithium vanadium phosphate compound. In an alternative embodiment the present invention relates to a method for preparing a lithium vanadium phosphate which comprises preparing an aqueous solution of lithium hydroxide; partially dissolving vanadium pentoxide in said aqueous solution; adding phosphoric acid to the aqueous solution; adding a polymeric material and a source of carbon to the solution containing vanadium pentoxide to form a slurry; spray drying said slurry to form a precursor composition; and heating said precursor composition for a time and at a temperature sufficient to form a lithium vanadium phosphate. The electrochemically active lithium vanadium phosphate so produced is useful in making electrodes and batteries.

Owner:VALENCE TECH INC

Carbon-coated lithium vanadium fluorophosphate lithium ion battery positive electrode material and preparation method thereof

ActiveCN109755514AHigh phase purityThorough responseCell electrodesSecondary cellsLithium-ion batteryCarbon coated

The invention provides a carbon-coated lithium vanadium fluorophosphate lithium ion battery positive electrode material and a preparation method thereof; the preparation method of the carbon-coated lithium vanadium fluorophosphate lithium ion battery positive electrode material comprises the following steps that a vanadium source, a phosphorus source and a carbon source are added into water to form a solution, and continuous stirring is carried out until a stable viscous solution is formed or rapid solidifying is performed; drying is performed on the viscous solution or the solid obtained in the last step, and heat treatment is performed in a non-oxidizing atmosphere, and then crushing and grinding are carried out to obtain the black carbon coated vanadium phosphate powder; mixing is carried out on the carbon-coated vanadium phosphate powder, lithium fluoride and a fluorine source to obtain precursor powder, and under the non-oxidizing atmosphere, sintering is carried out at 550-750 DEG C for 0.5-10h to obtain the carbon-coated lithium vanadium fluorophosphate material. The method is simple in process route, easy to operate, low in generating cost and capable of realizing large-scale production. The carbon-coated lithium vanadium fluorophosphate lithium ion battery positive electrode material prepared by the method is high in phase purity, uniform in particle sizes and excellent in electrochemical performance.

Owner:大连融科储能集团股份有限公司

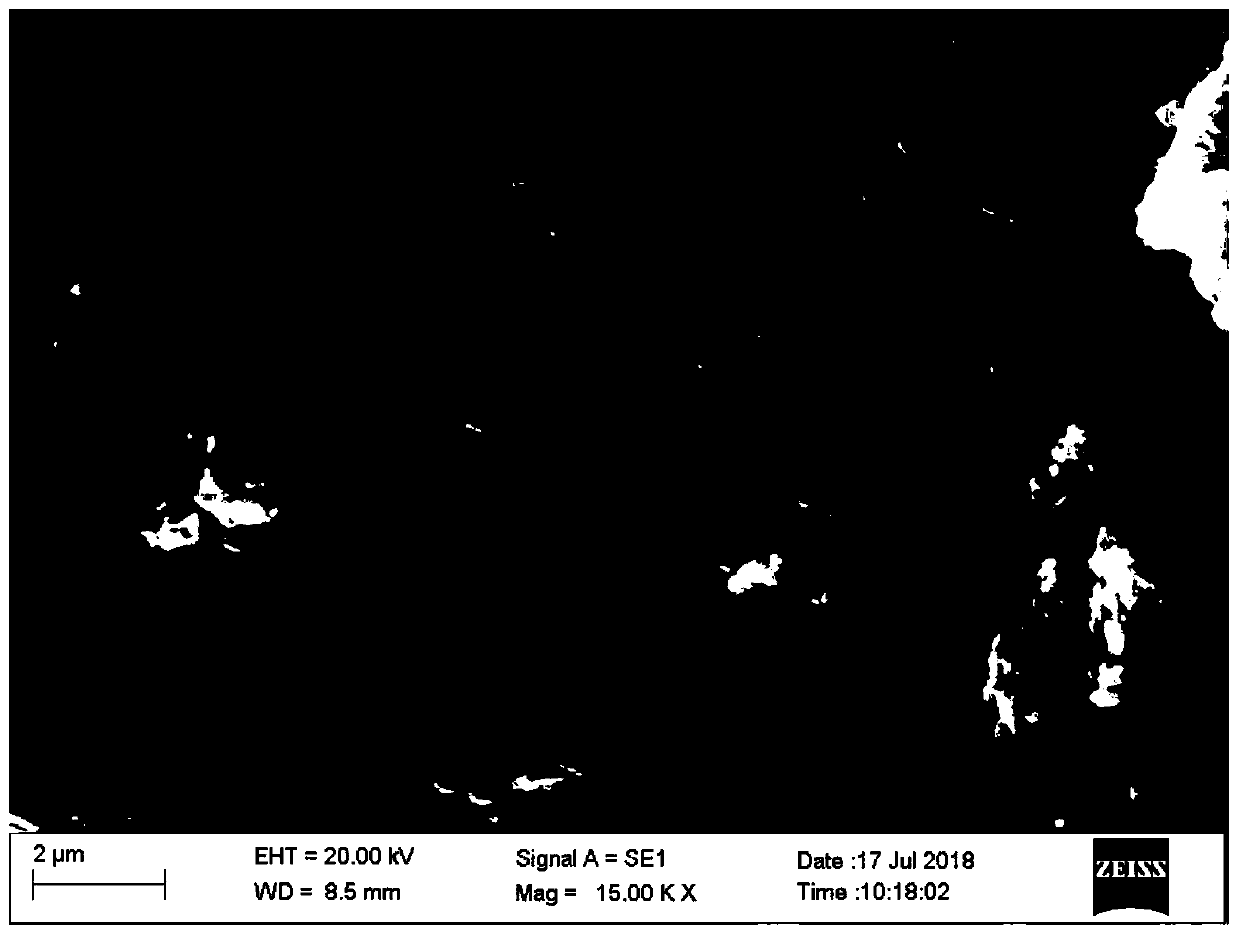

Porous spherical carbon-coated sodium vanadium phosphate composite positive electrode material and preparation method thereof

ActiveCN107611367AShort charge and discharge timeFully chargedMaterial nanotechnologyCell electrodesReaction temperatureCarbon coated

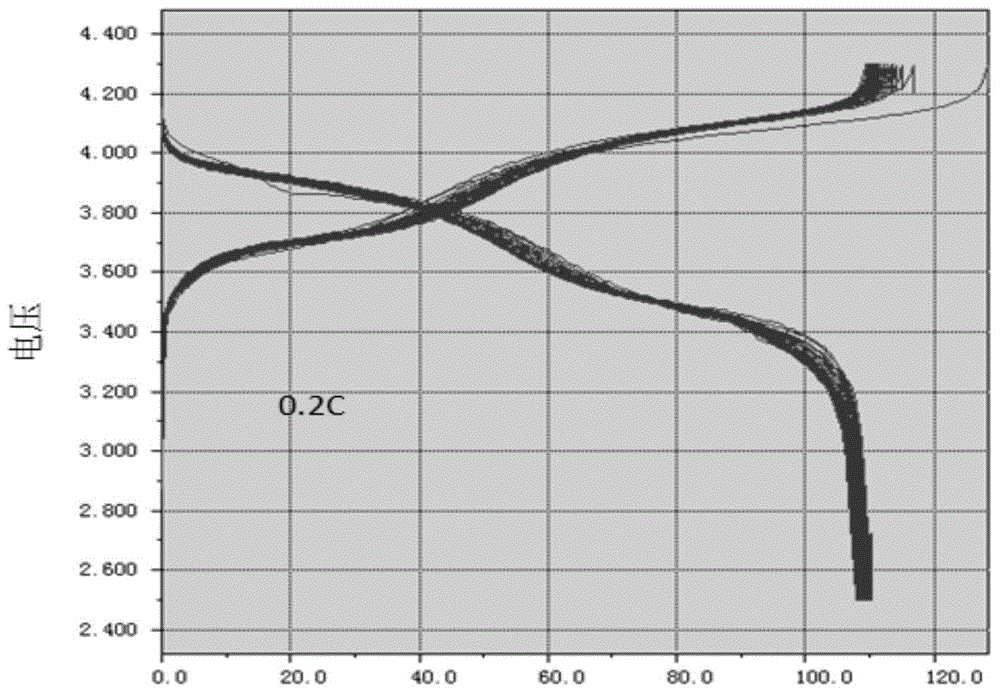

Disclosed are a porous spherical carbon-coated sodium vanadium phosphate composite positive electrode material and a preparation method thereof. The composite positive electrode material is prepared by the steps of (1) dissolving a vanadium source compound and a reducing agent into water, performing heating and then adding a phosphorus source compound and a sodium source compound to obtain a mixedsolution; (2) adding an organic solvent, wherein the polarity of the organic solvent is greater than that of water, and putting into a sealed container to be subjected to a heating reaction, and next, performing cooling, centrifuging, washing, depositing and drying to obtain precursor powder; and (3) performing mixing with glucose, and performing sintering and cooling on the mixture in protectiveatmosphere. The positive electrode material is spherical and has the primary granular diameter of 50-200nm; when the composite positive electrode material is assembled into a battery, the initial discharge capacity per gram at 0.2C and 10C within a voltage range of 2.0-3.8V can reach 110 mAh.g<-1> and 95 mAh.g<-1> respectively; the capacity retention rate can reach 99.47% at 10C rate after 100 cycles; and the method is simple and low in reaction temperature.

Owner:CENT SOUTH UNIV

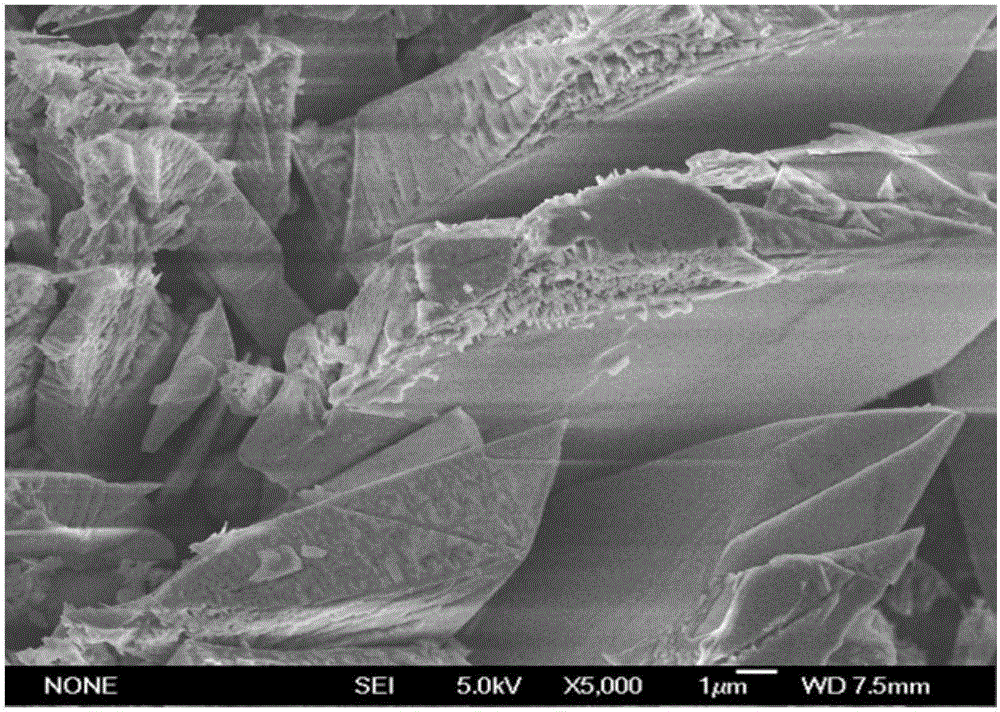

Preparation method for nano sheet-shaped lithium ion battery positive electrode material fluorine lithium vanadium phosphate

ActiveCN103840157AEasy to passEasy to embedMaterial nanotechnologyCell electrodesWater bathsLithium-ion battery

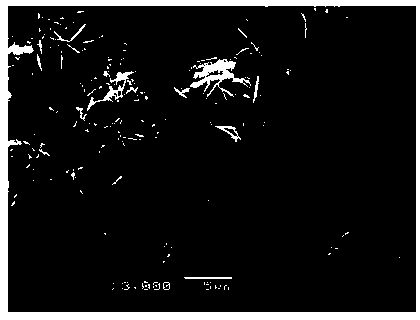

The invention provides a preparation method for a nano sheet-shaped lithium ion battery positive electrode material fluorine lithium vanadium phosphate. The preparation method comprises the following step: (1) dissolving a vanadium source, a phosphorus source and a reducing agent into water; (2) agitating in a water bath; (3) adjusting the pH to 2-12; (4) transferring the solution to a polytetrafluoroethylene tank; putting the polytetrafluoroethylene tank into a pyrolysis tank, and heating and reacting at 220-280 DEG C for 15-25 hours; cooling to a room temperature; (5) filtering and drying in vacuum; (6) arranging into an agate mortar to be grinded; then sintering under a non-oxidization atmosphere; cooling to the room temperature to obtain a crystallized-state vanadium phosphate precursor; (7) mixing the crystallized-state vanadium phosphate precursor with a lithium source and a fluorine source; uniformly grinding; and (8) arranging a mixture into a pipe type sintering furnace and sintering under the non-oxidization atmosphere; and cooling to the room temperature to obtain the nano sheet-shaped lithium ion battery positive electrode material fluorine lithium vanadium phosphate. According to the preparation method, the microcosmic appearance of the positive electrode material is in a sheet-shaped structure with the thickness being in a nano grade; the surface of a nano sheet is uniformly coated with carbon and the appearance of the material is special; the excellent electrochemical performance is represented.

Owner:CENT SOUTH UNIV

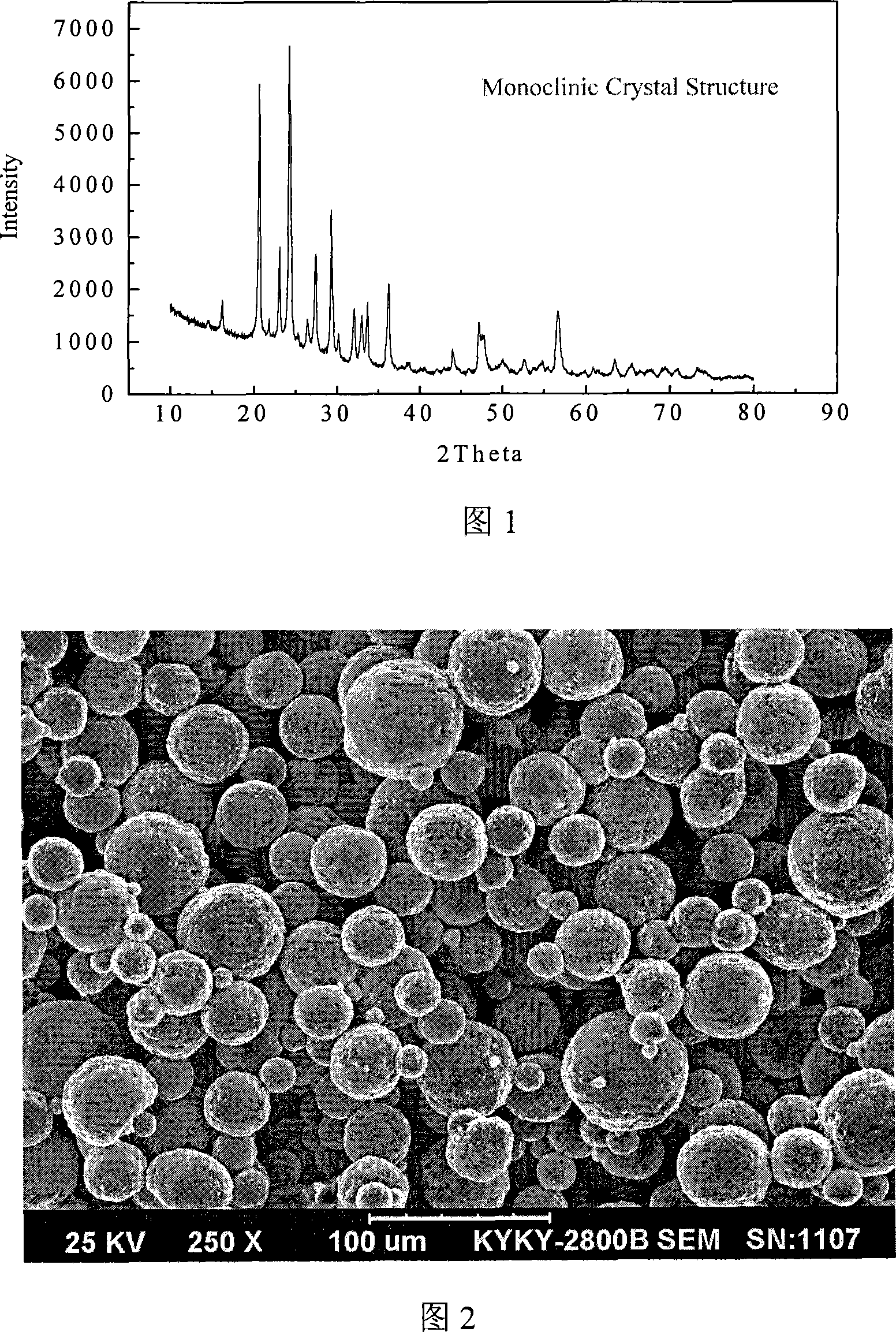

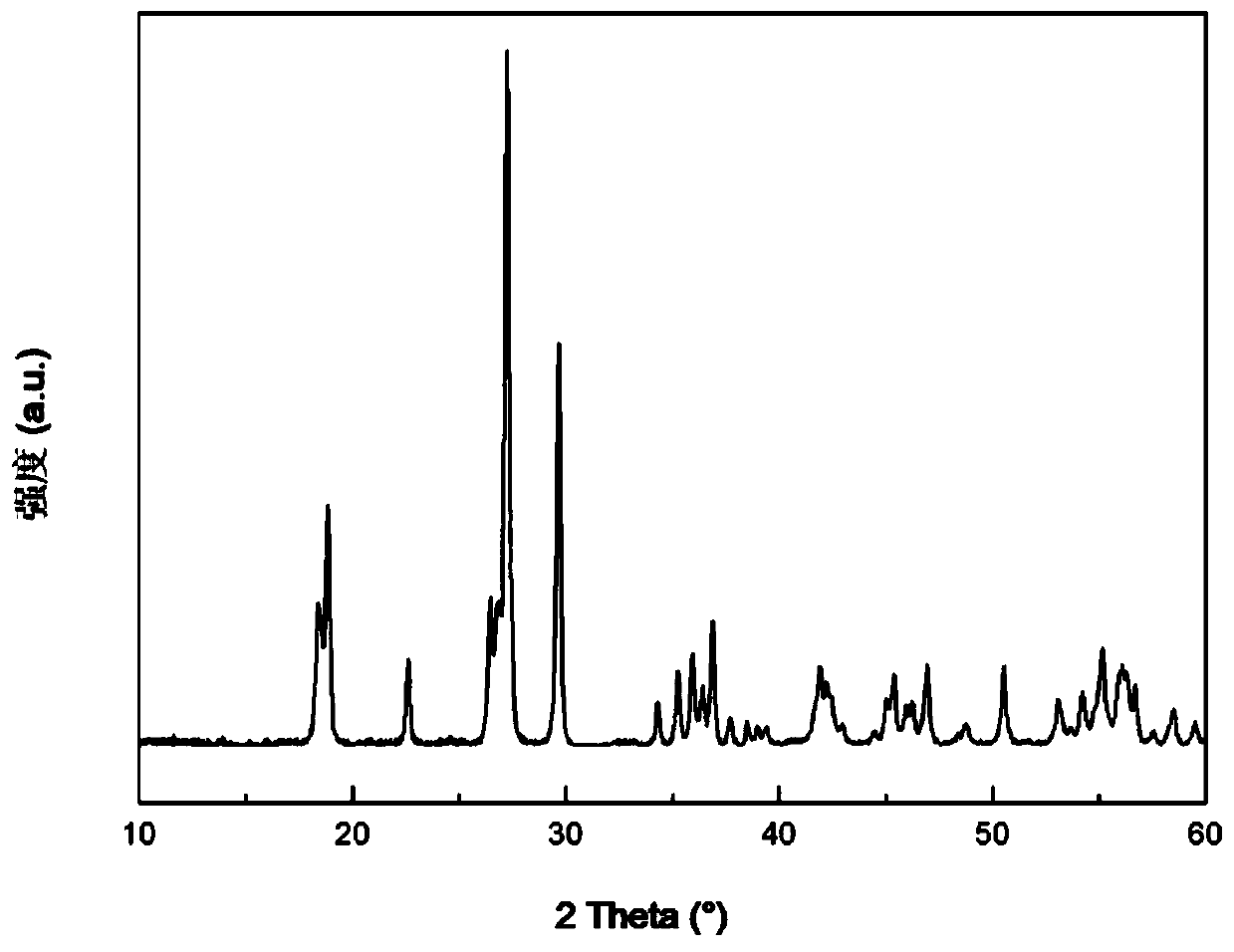

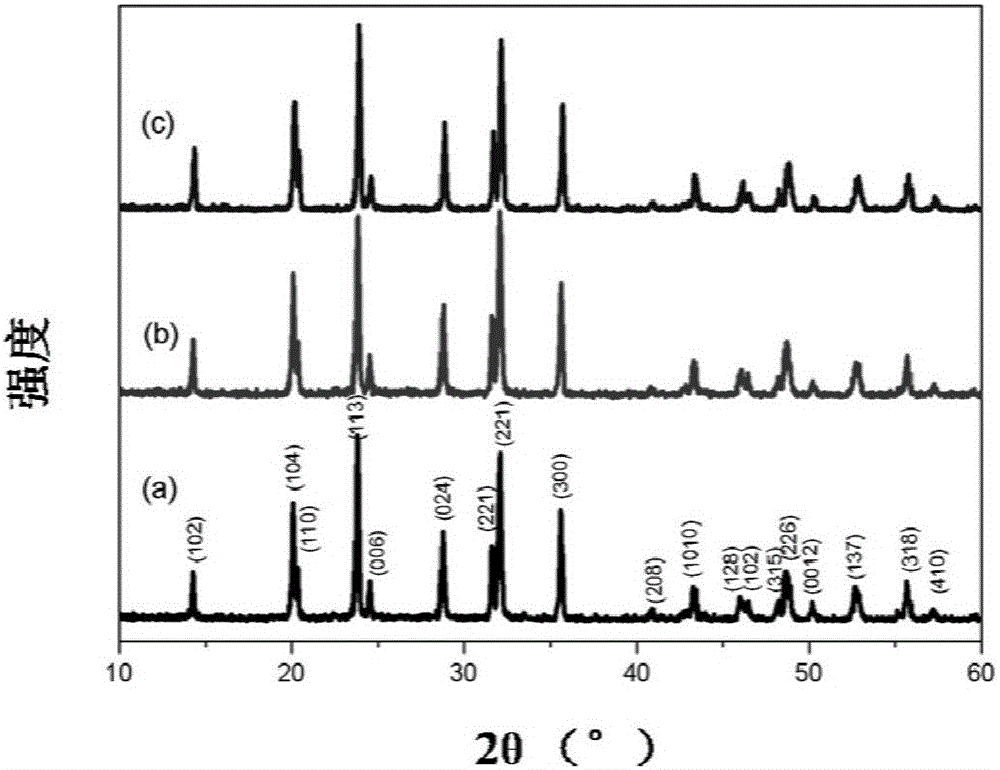

Vanadium sodium phosphate positive electrode material, sodium ion battery, preparation method therefor, and use thereof

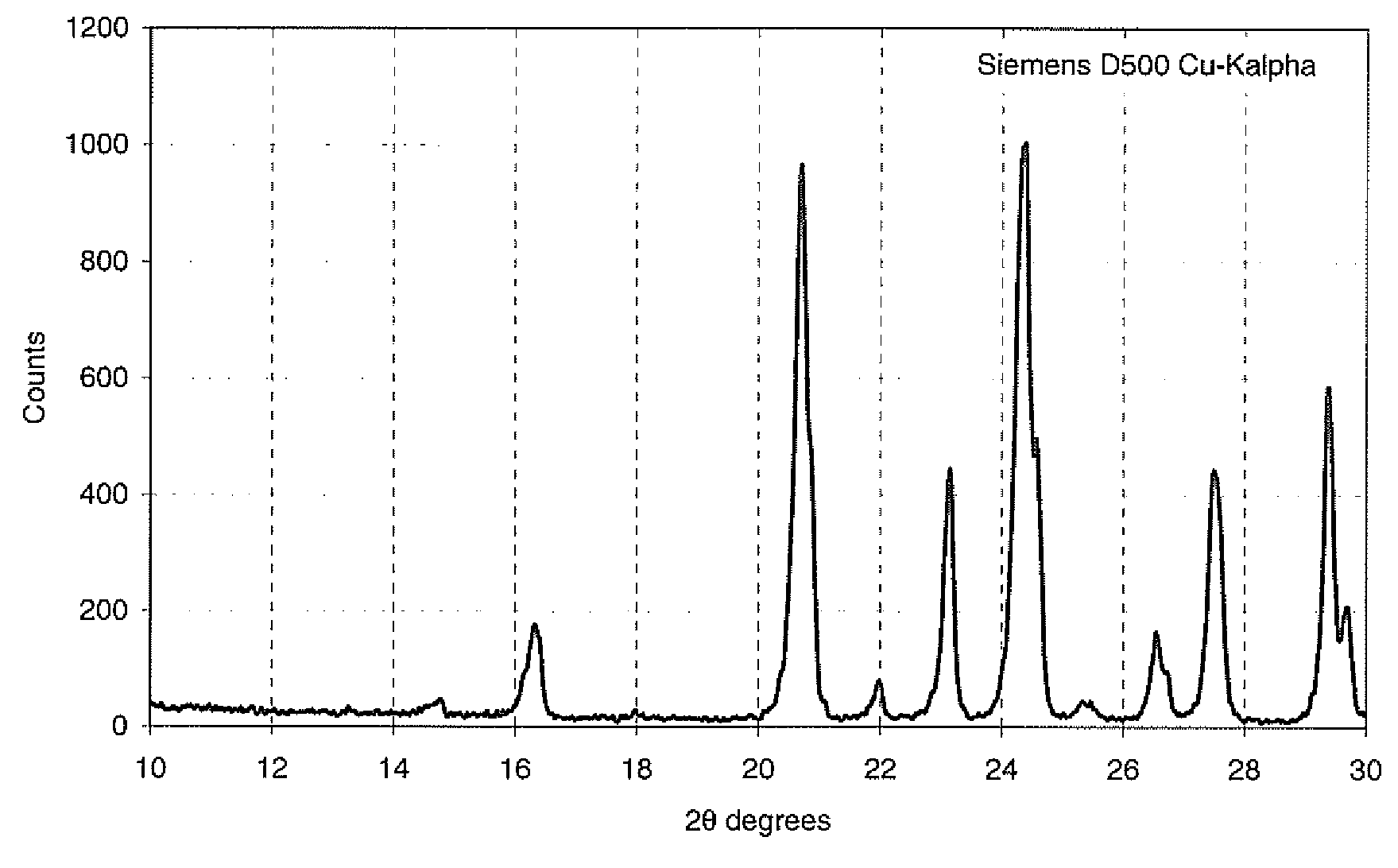

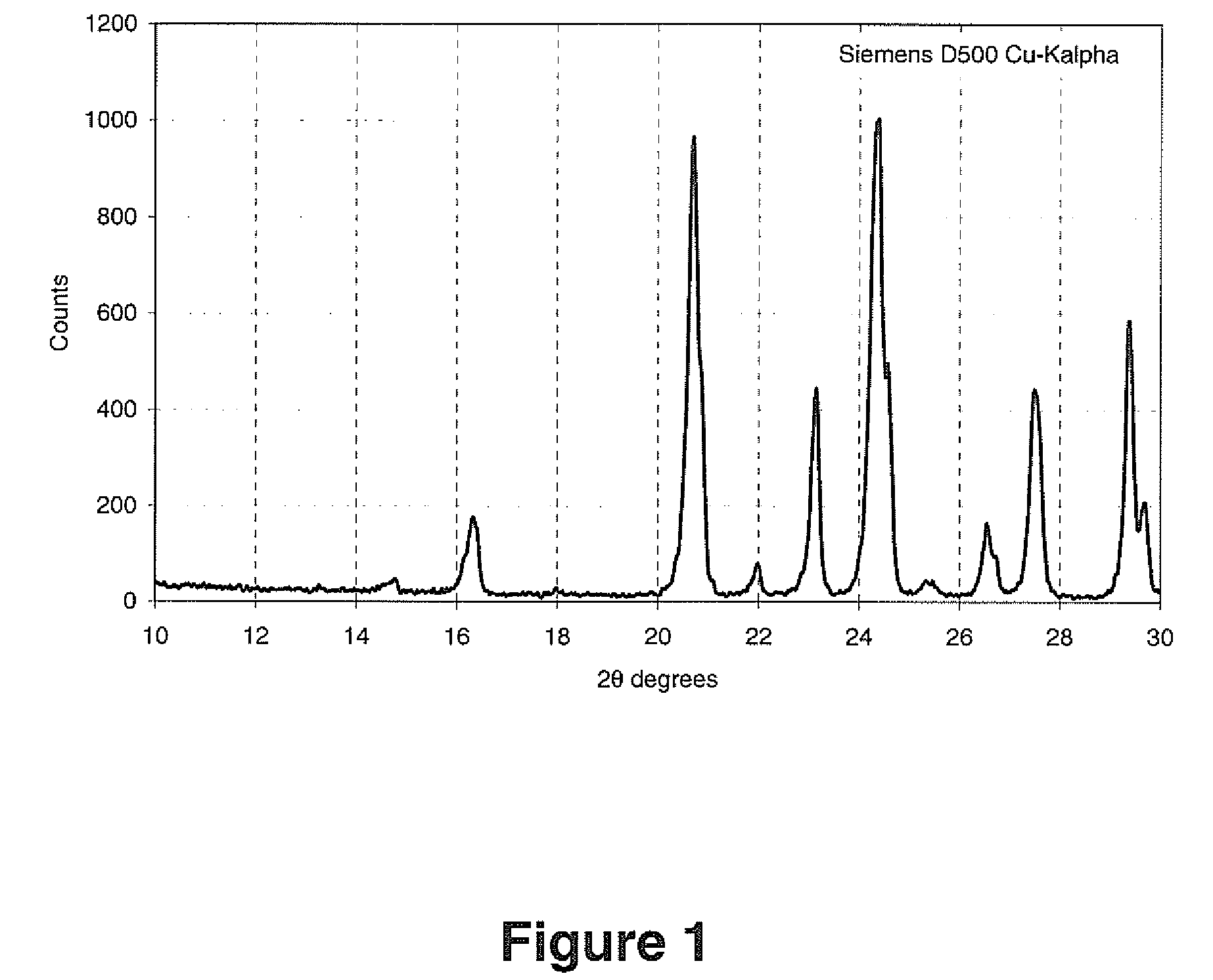

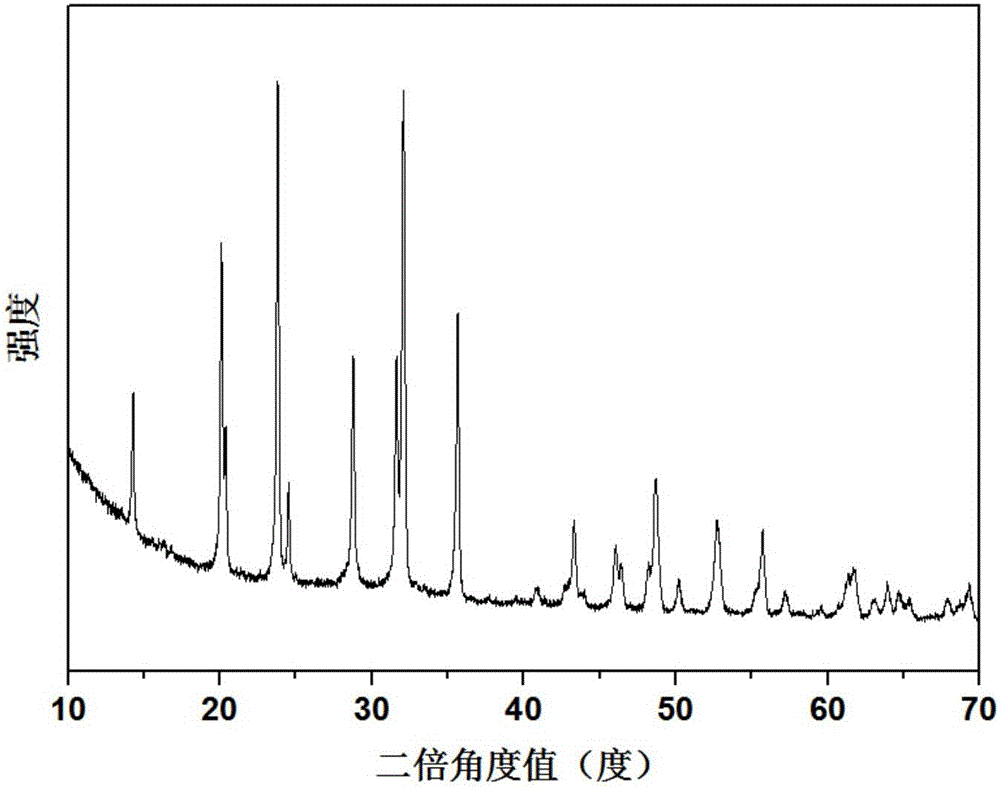

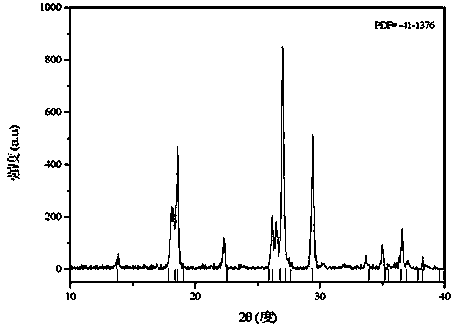

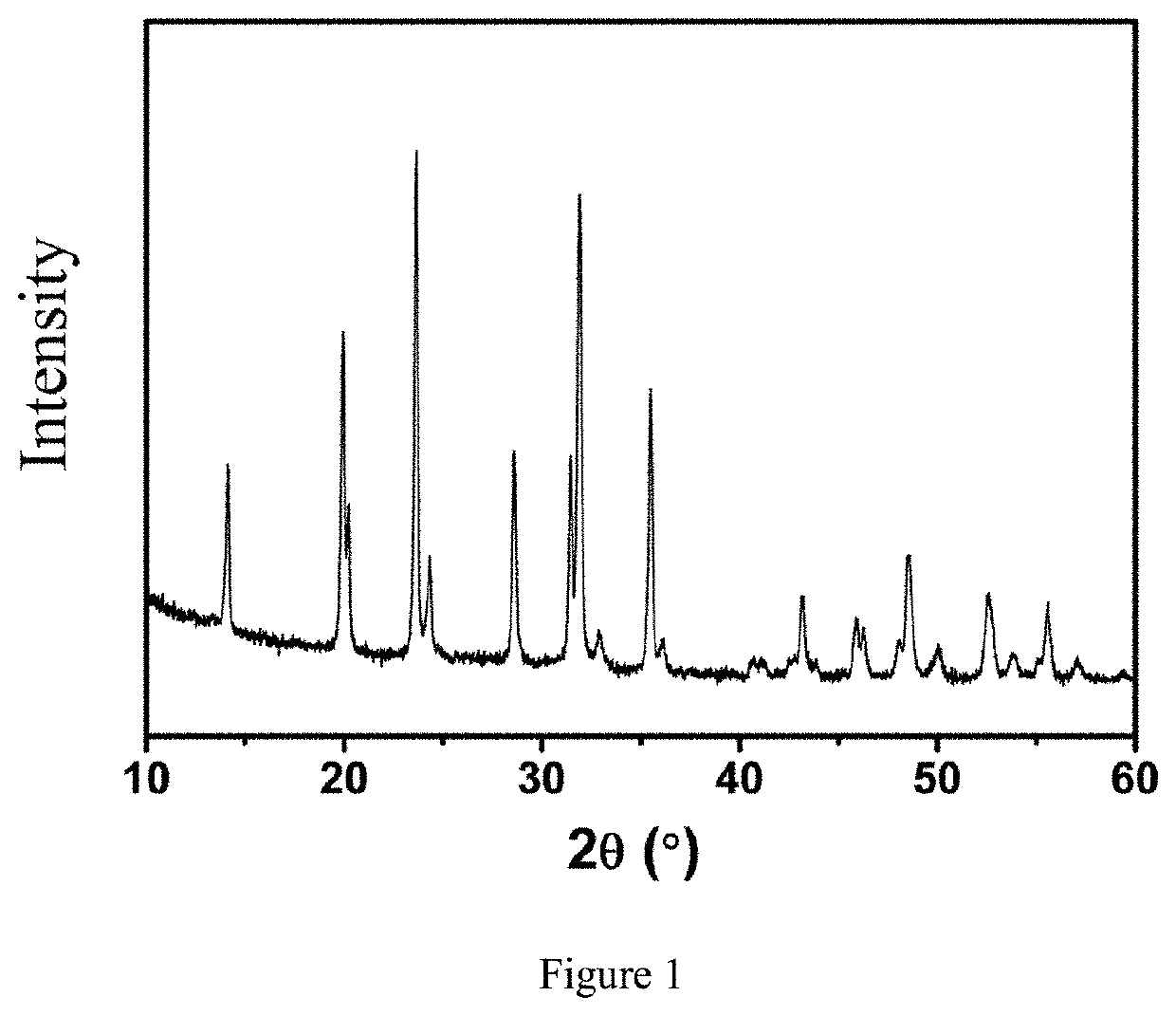

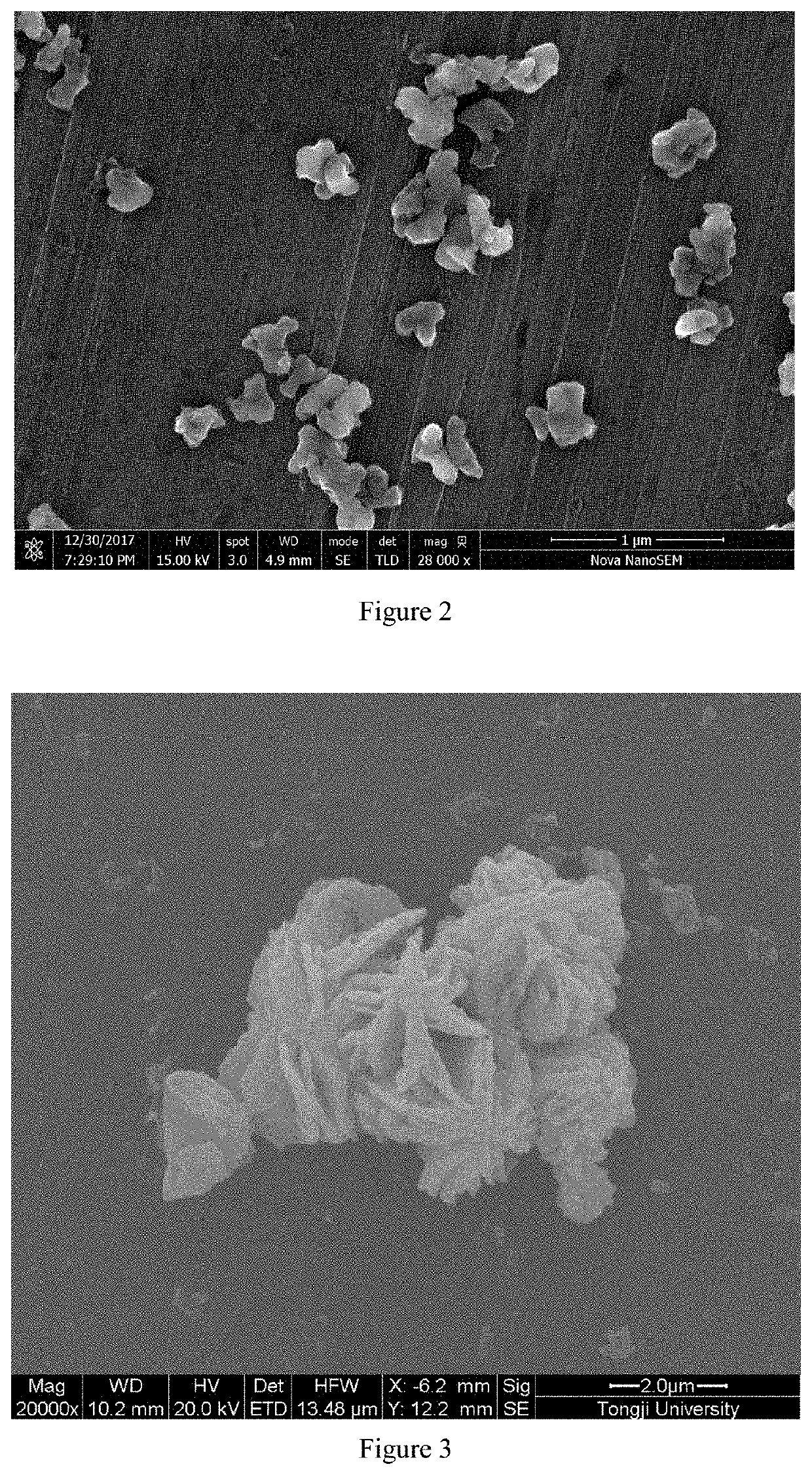

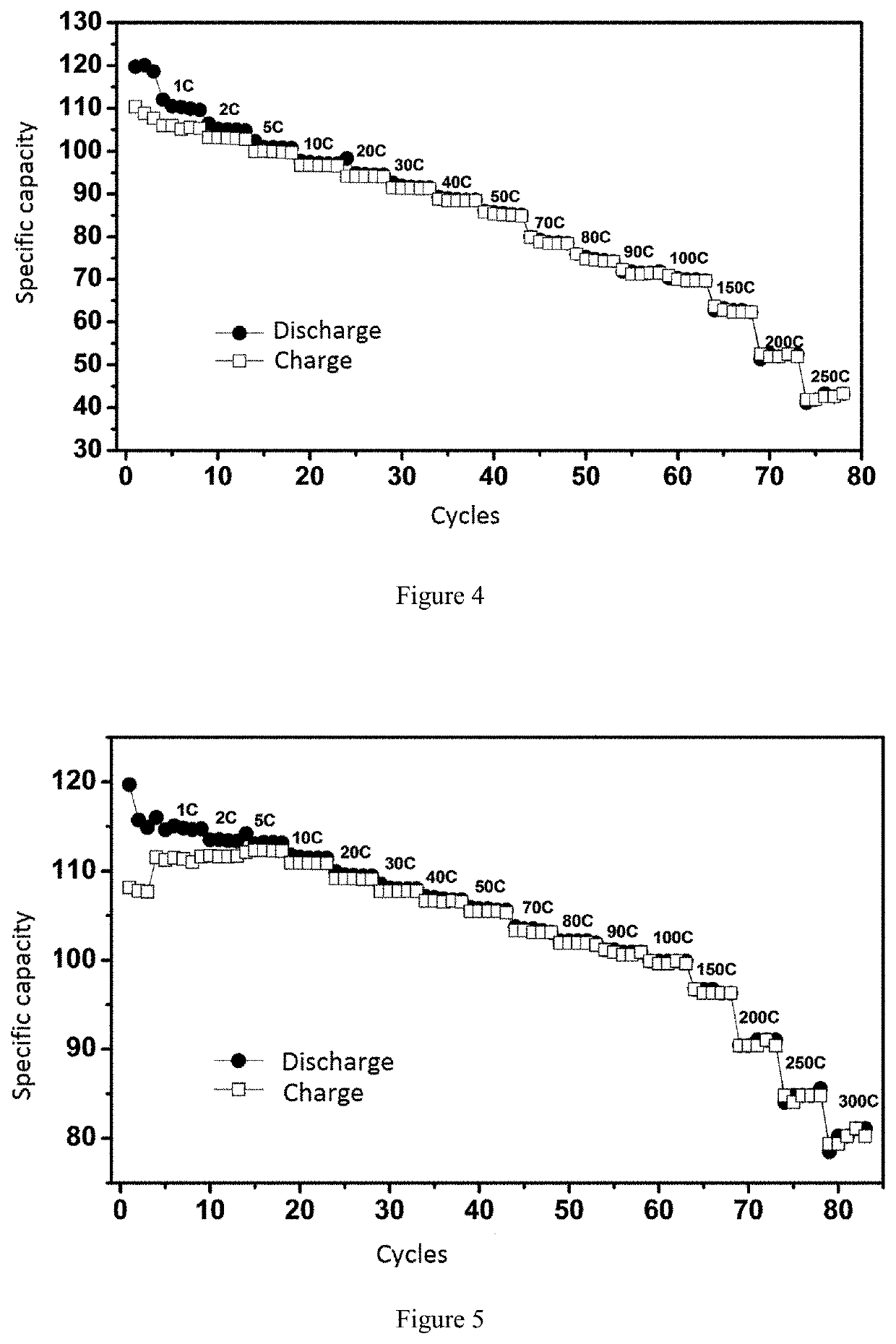

PendingUS20210167387A1High crystallinitySharp peakFinal product manufactureSmall-sized flat cells/batteriesSodium phosphatesSodium-ion battery

A vanadium sodium phosphate positive electrode material, a sodium ion battery, and a preparation method therefor and application thereof. The preparation method of the vanadium sodium phosphate positive electrode material comprises the following steps: (1) reacting an aqueous solution containing a vanadium source with a phosphorus source, a reducing agent, a sodium source, and a carbon source, the reaction comprising first performing a reaction of an aqueous solution of the vanadium source and the phosphorus source, and then perform a reaction with the reducing agent, or first performing a reaction of the aqueous solution of the vanadium source with the reducing agent and then performing a reaction with the phosphorus source; (2) drying and calcining the reaction liquid obtained in step (1). The vanadium sodium phosphate positive electrode material has a high dispersibility, and has stable circulation performance when used in a battery.

Owner:SHANGHAI ZIJIAN CHEM TECH CO LTD

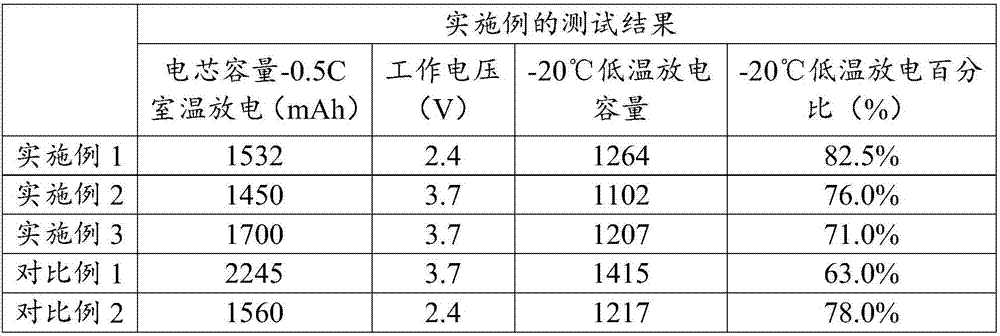

A cathode material, a lithium ion battery including the same and a preparing method of the lithium ion battery

InactiveCN107293727AIncrease energy densityHigh voltage platformCell electrodesSecondary cellsHigh energyCharge discharge

A cathode material is disclosed. The cathode material comprises lithium vanadium phosphate and a lithium ion battery cathode active compound. According to the cathode material, through blending the lithium vanadium phosphate and the lithium ion battery cathode active compound, present secondary lithium ion battery cathode materials are greatly improved, and characteristics of a high energy density, low-temperature discharging, high-current discharging and high-temperature safety of secondary lithium ion batteries are taken into account. In addition, a lithium ion battery including the cathode material is also disclosed. The lithium ion battery has a high energy density, a high voltage platform, long cyclic service lifetime, excellent low-temperature performance and good rate charge-discharge performance, and can meet energy density requirements of digital products and high-current charge-discharge requirements of electric tools. In addition, a preparing method of the lithium ion battery is also provided.

Owner:广州云通锂电池股份有限公司

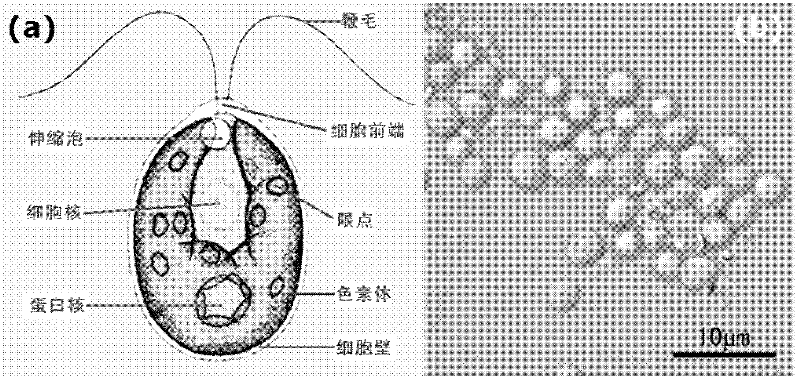

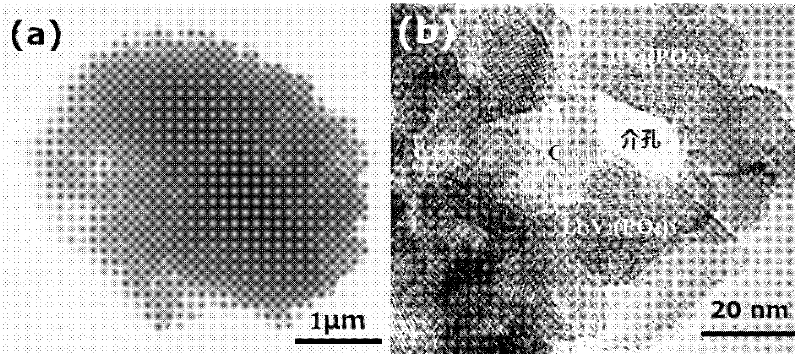

Biomimetic synthesis method of lithium vanadium phosphate/carbon nanometer composite mesoporous microspheres as positive electrode material of lithium ion battery

The invention relates to a preparation method of lithium vanadium phosphate / carbon nanometer composite mesoporous microspheres as positive electrode material of a lithium ion battery. The preparation method comprises the following steps: preparing hungry green algae cell solution from inexpensive green algae cells; adding vanadium oxalate solution into the hungry green algae cell solution dropwise; adding phosphate source and lithium source to obtain gel; drying to obtain lithium vanadium phosphate precursor; grinding lithium vanadium phosphate precursor; heating at about 450 DEG C in the nitrogen atmosphere; and heating to about 750 DEG C and preserving the temperature to obtain black powdered Li3V2(PO4)3 / C nanometer composite mesoporous microspheres. The lithium vanadium phosphate / carbon nanometer composite mesoporous microspheres prepared by the invention can be used as the positive electrode material of the lithium ion battery, and can be used for preparing portable or power lithium ion battery.

Owner:QILU UNIV OF TECH

Cathode material for sodium-ion battery, preparation method of cathode material and sodium-ion battery

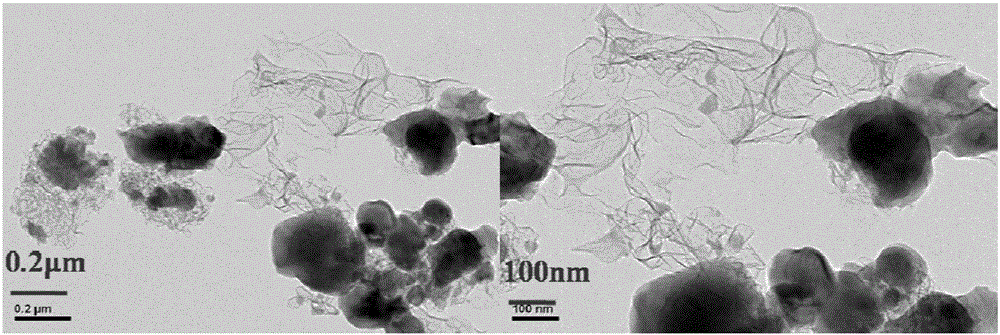

ActiveCN106025226AImprove electrochemical performanceRealize free transformationCell electrodesSecondary cellsSodium-ion batteryGraphene

The invention provides a cathode material for a sodium-ion battery, a preparation method of the cathode material for the sodium-ion battery and the sodium-ion battery. The method that a metal oxide catalyzes carbon sources to grow graphene in situ provided by the invention realizes the free conversions of the carbon sources, thereby being beneficial to industrial mass production. Furthermore, a certain amount of organic carbon sources are added in the synthesis process of Na3V2 (PO4)3(Sodium Vanadium Phosphate), and catalyzed to generate graphene under the effect of metal oxide, namely vanadium oxide at low temperature, and the graphene is uniformly coated on the surfaces of vanadium phosphate sodium particles to form a uniform carbon network layer, so that the conductivities of the material ions and electrons are enhanced to improve electrochemical performance of the material.

Owner:UNIV OF SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com