Method for preparing cathode material lithium vanadium phosphate of lithium ion battery by using fast sol-gel method

A technology of lithium ion battery and sol-gel method, which is applied in the field of lithium vanadium phosphate preparation lithium ion battery positive electrode material, can solve the problems of high equipment requirements, lower product roasting temperature, large material particles, etc., and achieve simplified synthesis process, roasting The effect of shortening the time and uniform material particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

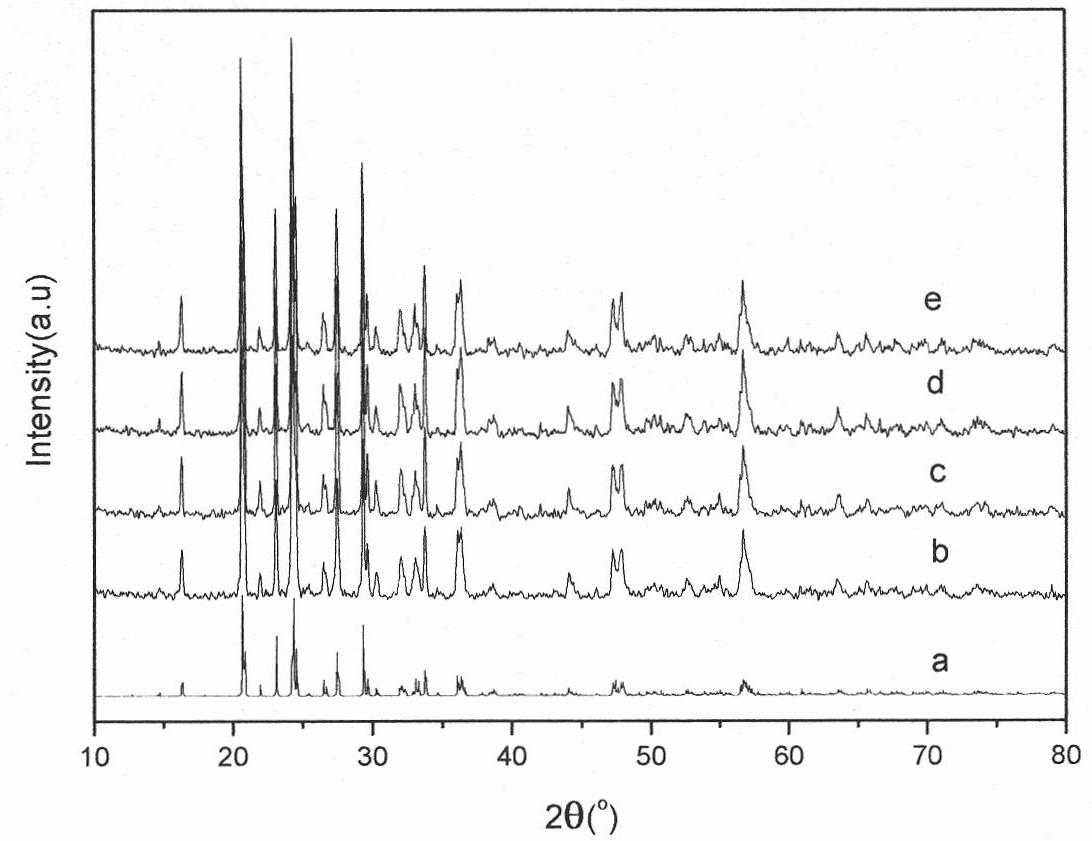

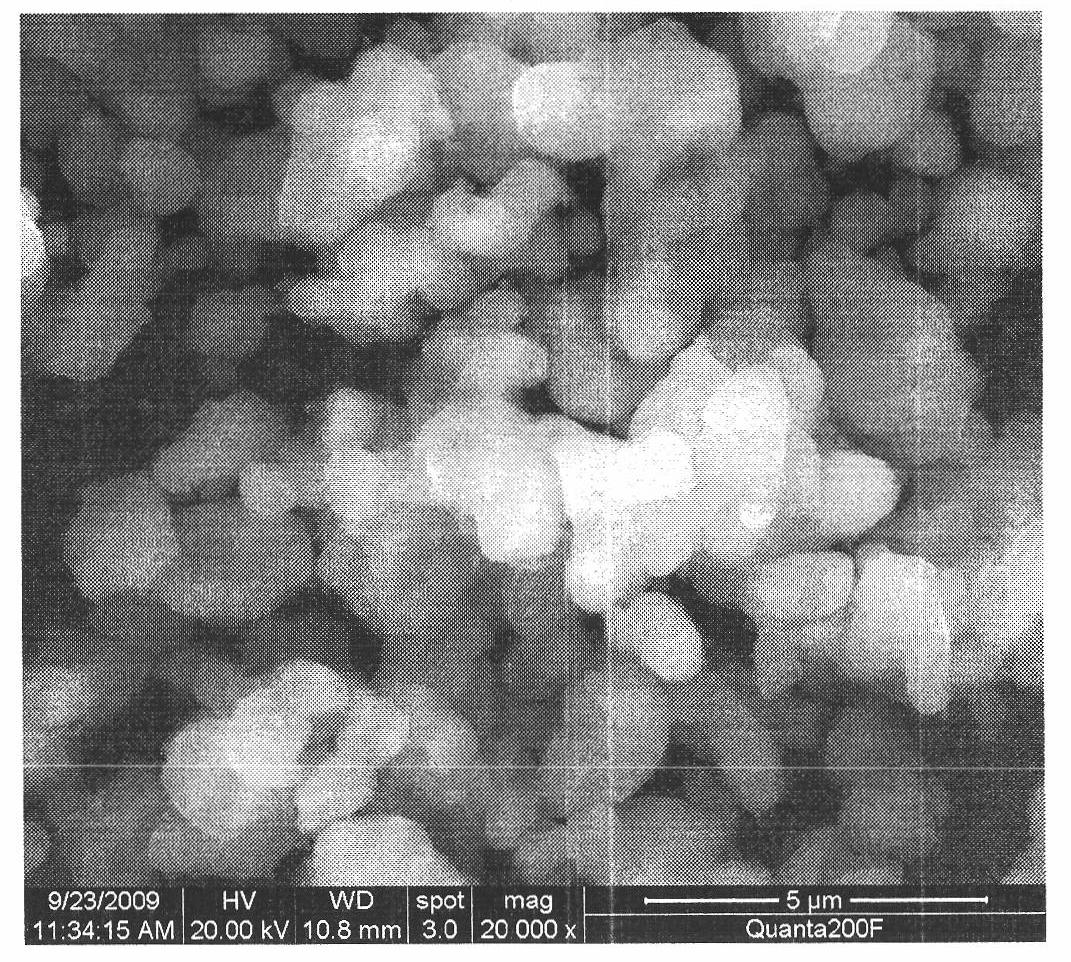

[0019] Dissolve 0.03 mol of vanadium pentoxide powder in a saturated solution of 0.1 mol of citric acid, stir at 60°C for 15 min, then add 0.093 mol of lithium acetate, 0.09 mol of diammonium hydrogen phosphate and 0.2 g of glucose, and continue stirring for 4 h. After drying at 100°C, pre-decompose at 300°C for 4 hours under the protection of argon, then mix 0.2g of polyaniline and grind for 2 hours, and then bake at 750°C for 4 hours under the protection of argon, and the finished Li is obtained after cooling. 3 V 2 (PO 4 ) 3 / C. The obtained product shows through X-ray diffraction analysis, see figure 1 As shown in b, without any impurities, it is pure phase Li 3 V 2 (PO 4 ) 3 . figure 2 It is the scanning electron microscope picture of the product. It can be seen from the picture that the size of the prepared product is at the nanometer level, the size is about 500-600nm, and the surface is covered with a layer of uniform nano-carbon particles.

Embodiment 2

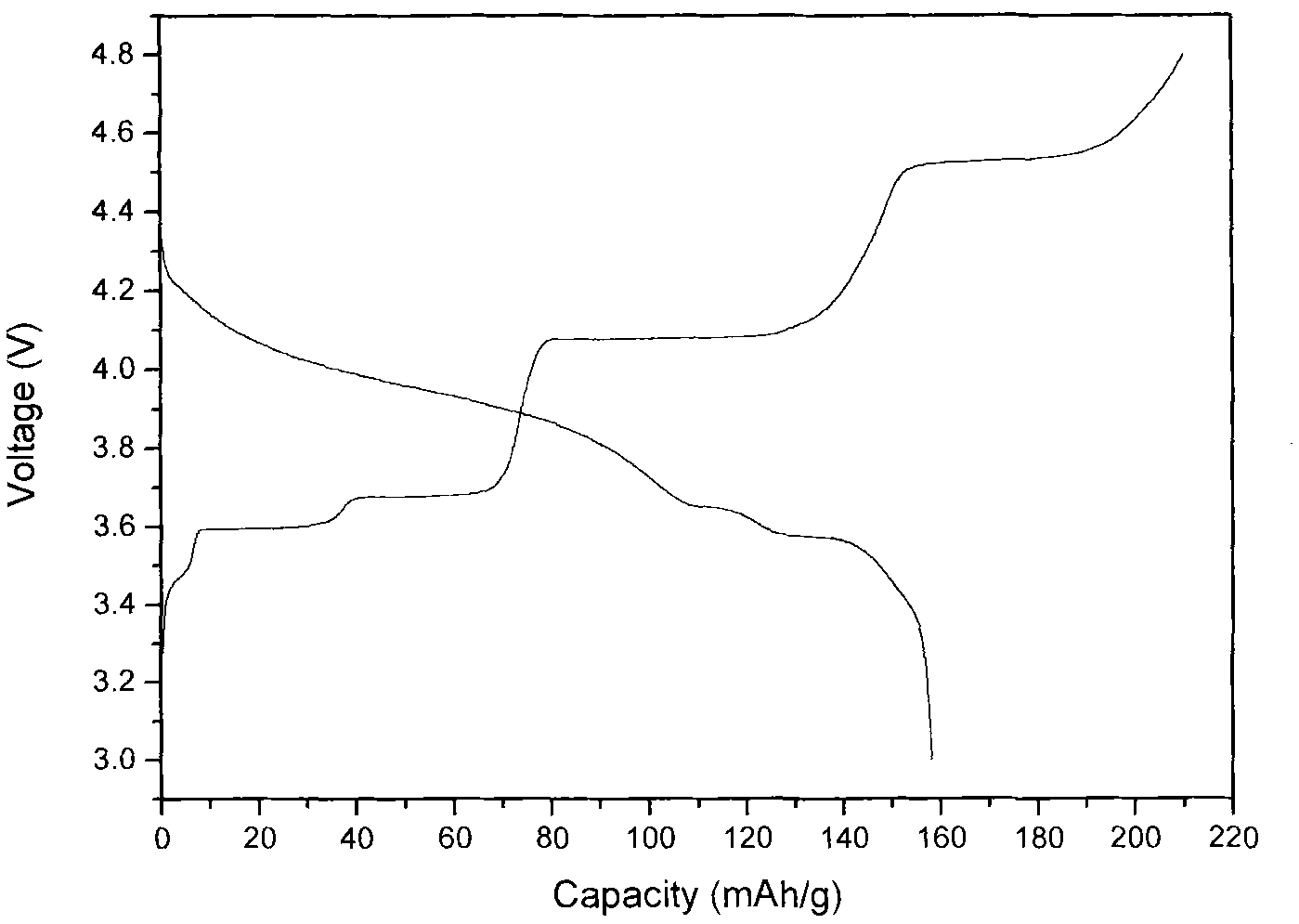

[0021] Dissolve 0.02 mol of vanadium pentoxide powder in a solution containing 0.06 mol of oxalic acid, stir at 80°C for 20 min, then add 0.06 mol of lithium chloride, 0.061 mol of ammonium dihydrogen phosphate and 0.25 g of glucose and continue stirring for 2 h, 100 After drying at ℃, pre-decompose at 350℃ for 3h under the protection of nitrogen, then mix 0.25g of acetylene black and grind for 1h, then roast at 800℃ for 3h under the protection of nitrogen, and the finished Li 3 V 2 (PO 4 ) 3 / C. The obtained product shows through X-ray diffraction analysis, see figure 1 As shown in c, without any impurities, it is pure phase Li 3 V 2 (PO 4 ) 3 . The first charge and discharge curve of the lithium vanadium phosphate positive electrode material is as follows: image 3 As shown, the discharge specific capacity can reach 158mAh / g in the range of 3.0-4.8V, and the charge-discharge voltage platform is consistent, indicating that the material has good reversibility.

Embodiment 3

[0023] Dissolve 0.05 mol of vanadium pentoxide powder in a solution containing 0.15 mol of oxalic acid, stir at 65°C for 30 min, then add 0.0765 mol of lithium carbonate, 0.145 mol of sodium phosphate and 1 g of polyethylene glycol (molecular formula 300) , continue to stir for 3 hours, after drying at 100°C, pre-decompose at 400°C for 2 hours under the protection of argon-hydrogen mixture gas, then mix Super P and grind for 2 hours, and then roast at 850°C for 2 hours under the protection of argon-hydrogen mixture gas, and after cooling, the finished Li 3 V 2 (PO 4 ) 3 / C. The obtained product shows through X-ray diffraction analysis, see figure 1 As shown in d, without any impurities, it is pure phase Li 3 V 2 (PO 4 ) 3 . The lithium vanadium phosphate positive electrode material is charged and discharged in the range of 3.0-4.8V, and the rate of 0.1C is as follows: Figure 4 As shown, the highest discharge capacity can reach 173mAh / g, and after 50 cycles, the capac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com