Carbon-coated lithium vanadium fluorophosphate lithium ion battery positive electrode material and preparation method thereof

A technology of carbon-coated lithium vanadium phosphate and lithium vanadium phosphate, which is applied in the field of carbon-coated lithium vanadium phosphate lithium-ion battery cathode materials and its preparation, can solve the problem of low phase purity and particle size of lithium vanadium phosphate Uneven diameter distribution, poor electrochemical performance and other problems, to achieve excellent electrochemical performance, uniform distribution of element components, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention discloses a method for preparing a positive electrode material of a carbon-coated vanadium phosphate lithium lithium ion battery, which comprises the following steps:

[0032] Step (1), take vanadium, the vanadium source that the molar ratio of phosphorus element is 0.95-1.05, phosphorus source and the carbon source (preferably 60-100%wt) that is metal vanadium total content 40-150%wt, under stirring condition Add vanadium source, phosphorus source and carbon source to water to form a homogeneous solution, control the vanadium concentration in the solution to 0.5-10mol / L, preferably 3-8mol / L, and continue stirring until a stable viscous solution or solid is formed; In the present invention, the molar ratio of vanadium to phosphorus is 0.95-1.05, and beyond this range, the crystal phase purity of the vanadium phosphate intermediate and lithium vanadium phosphate synthesized later cannot be guaranteed. The preferred molar ratio of vanadium to phosphorus is 1:...

Embodiment 1

[0043] This embodiment discloses a method for preparing a carbon-coated lithium vanadium phosphate lithium ion battery positive electrode material, comprising the following steps:

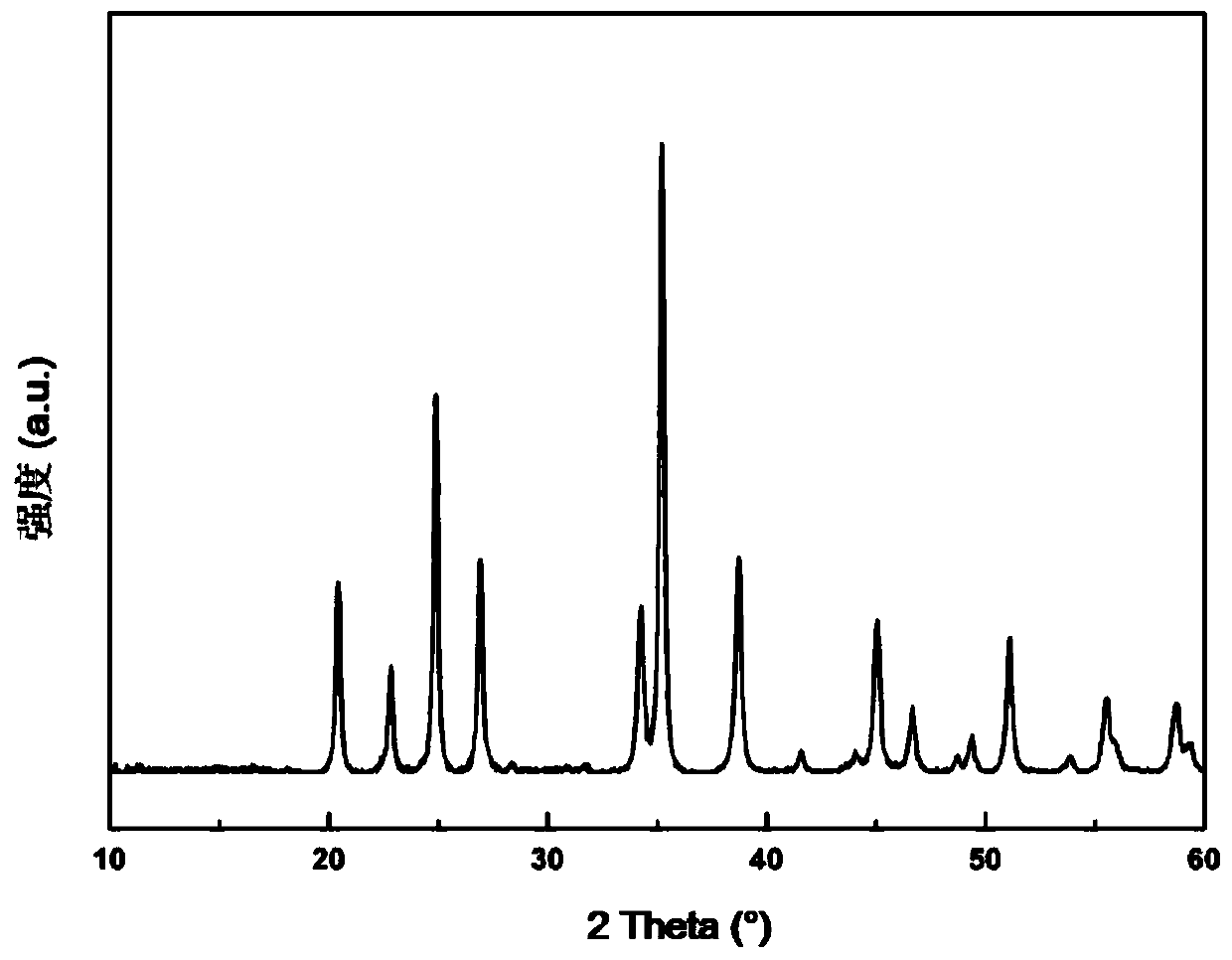

[0044] Add 165.9g of vanadium dioxide, 230.1g of ammonium dihydrogen phosphate, and 80g of glucose into 200mL aqueous solution in sequence, and mechanically stir at 90°C. After the solution forms a uniform dark green viscous liquid, transfer it to an oven at 80°C. After drying, the dried sample was pulverized and calcined at 850° C. for 6 hours under the protection of nitrogen. After cooling to room temperature, it was pulverized to obtain black vanadium phosphate. From XRD (such as figure 1 Shown) analysis shows that gained product is vanadium phosphate, and crystallinity is high, without its miscellaneous phase peak.

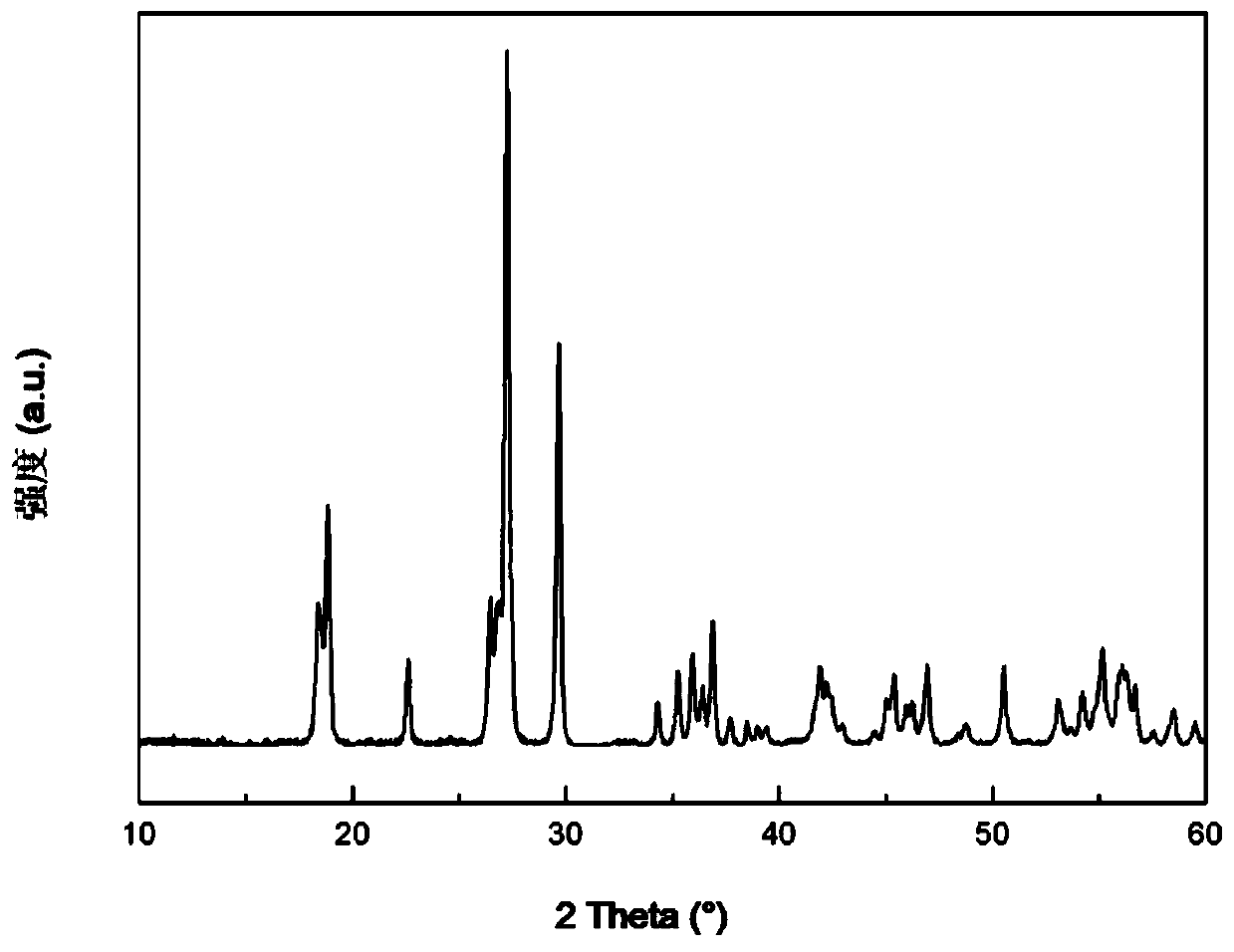

[0045] Analyze the element content of vanadium phosphate, mix vanadium phosphate and lithium fluoride at a ratio of 1:1 according to the vanadium content, and add 0.4% polytetrafl...

Embodiment 2

[0048] This embodiment discloses a method for preparing a carbon-coated lithium vanadium phosphate lithium ion battery positive electrode material, comprising the following steps:

[0049] Add 100g of ammonium metavanadate and 97.7g of concentrated phosphoric acid into 200mL of aqueous solution in turn, and mechanically stir at 70°C. After the solution forms a uniform dark red solution, add 50mL of sucrose solution with a concentration of 1.4g / L, and continue to stir until the The green viscous liquid solidifies quickly. The sample is taken out and transferred to an oven for drying at 80°C. Then the dried sample is pulverized and calcined at 800°C for 12 hours under the protection of nitrogen. After cooling to room temperature, it is pulverized to obtain black vanadium phosphate.

[0050] According to the vanadium content, vanadium phosphate and lithium fluoride were mixed at a lithium vanadium ratio of 1:1.05, and water was used as a solvent to obtain a lithium fluorovanadium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com