Emission peak-adjustable phosphate fluorescent powder for white-light LED (Light-Emitting Diode) and preparation method thereof

An emission peak, phosphate technology, applied in the field of fluorescent materials, can solve the problems of difficult to achieve device color rendering index and hinder the development of white light LED devices, and achieve the effect of wide excitation spectrum, high color rendering index and good luminous performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

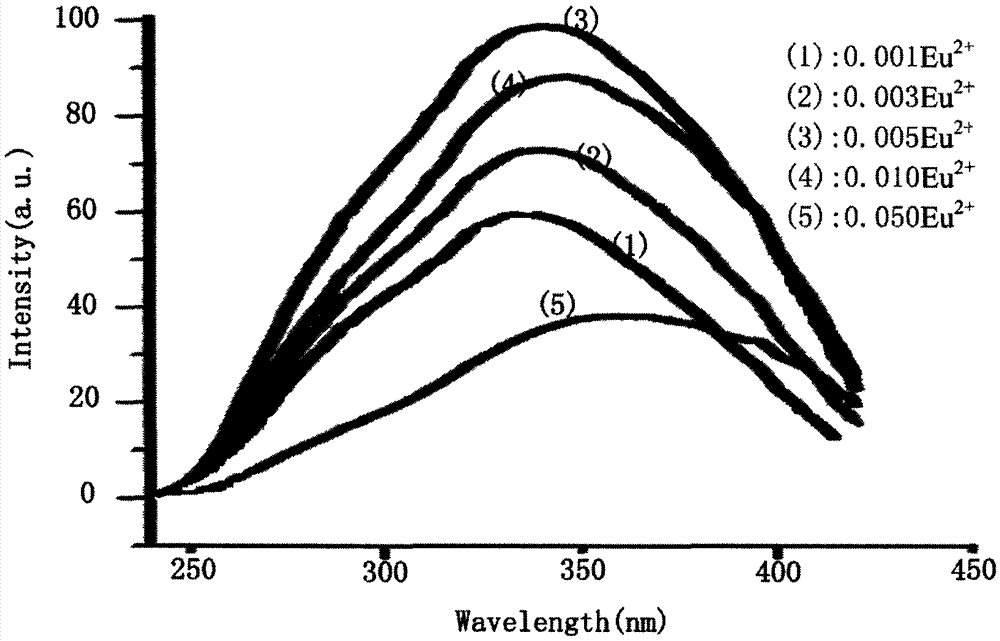

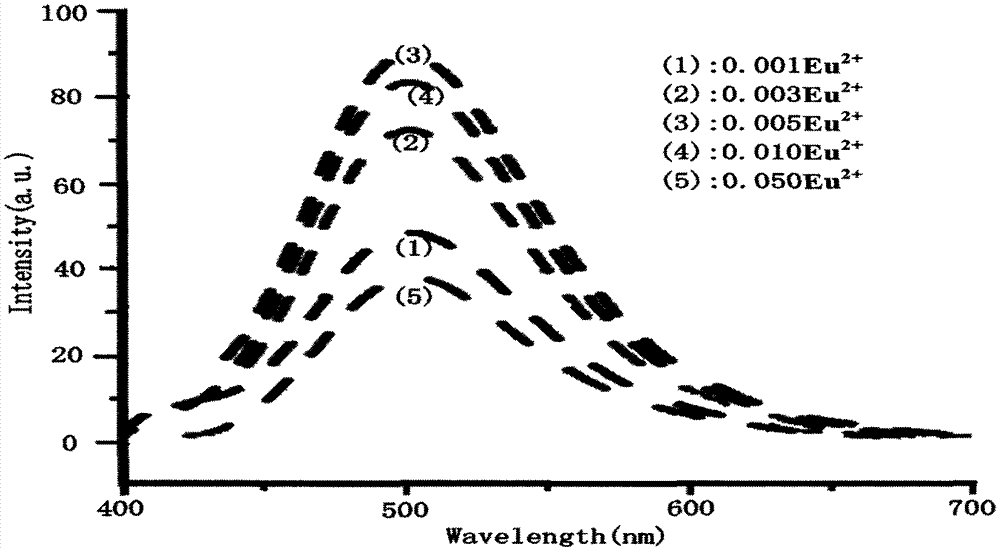

[0029] Implementation Example 1: Ca 8.991 La(PO 4 ) 7 :0.001Eu 2+ preparation of

[0030] First, according to the chemical formula Ca 9(1-x) La(PO 4 ) 7 :xEu 2+ The stoichiometric ratio of the reaction raw materials EuO, CaCO 3 , La 2 o 3 , (NH 4 ) 2 H(PO 4 ) in a molar ratio of 0.001:8.991:0.5:7; grind them in a mortar for 2 to 3 hours, and mix them thoroughly. Then put it into a crucible, compact it, and put it in an air high-temperature furnace, and sinter it at 1200°C for 8 hours; take it out after cooling, grind it to a certain particle size, put it into a crucible, and then reduce it in a reduction furnace at 1000°C for 8 hours; Cool to room temperature in a reducing atmosphere, take out the burnt material from the reduction furnace, crush it, wash it with deionized water, and bake it in an oven at 120-150°C for 6-8 hours to obtain the phosphate fluorescence pink.

Embodiment 2

[0031] Implementation Example 2: Ca 8.973 La(PO 4 ) 7 :0.003Eu 2+ preparation of

[0032] First, according to the chemical formula Ca 9(1-x) La(PO 4 ) 7 :xEu 2+ The stoichiometric ratio of the reaction raw materials EuO, CaCO 3 , La 2 o 3 , (NH 4 ) 2 H(PO 4 ) in a molar ratio of 0.003:8.973:0.5:7; grind them in a mortar for 2 to 3 hours, and mix them thoroughly. Then put it into a crucible, compact it, and put it in an air high-temperature furnace, and sinter it at 1200°C for 8 hours; take it out after cooling, grind it to a certain particle size, put it into a crucible, and then reduce it in a reduction furnace at 1000°C for 8 hours; Cool to room temperature in a reducing atmosphere, take out the burnt material from the reduction furnace, crush it, wash it with deionized water, and bake it in an oven at 120-150°C for 6-8 hours to obtain the phosphate fluorescence pink.

Embodiment 3

[0033] Implementation Example 3: Ca 8.955 La(PO 4 ) 7 :0.005Eu 2+ preparation of

[0034] First, according to the chemical formula Ca 9(1-x) La(PO 4 ) 7 :xEu 2+ The stoichiometric ratio of the reaction raw materials EuO, CaCO 3 , La 2 o 3 , (NH 4 ) 2 H(PO 4 ) in a molar ratio of 0.005:8.955:0.5:7; they were ground in a mortar for 2 to 3 hours, and thoroughly mixed. Then put it into a crucible, compact it, and put it in an air high-temperature furnace, and sinter it at 1200°C for 8 hours; take it out after cooling, grind it to a certain particle size, put it into a crucible, and then reduce it in a reduction furnace at 1000°C for 8 hours; Cool to room temperature in a reducing atmosphere, take out the burnt material from the reduction furnace, crush it, wash it with deionized water, and bake it in an oven at 120-150°C for 6-8 hours to obtain the phosphate fluorescence pink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com