Vehicle headlamp

A technology for headlights and vehicles, which is applied in the direction of vehicle lighting systems, headlights, vehicle components, etc., and can solve the problem of not being able to fully increase the luminosity of the driving beam, and not being able to realize small, lightweight and low-cost actuators, and actuator drive Increased power and other problems, to achieve the effect of small size and light weight, low cost, and increased power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

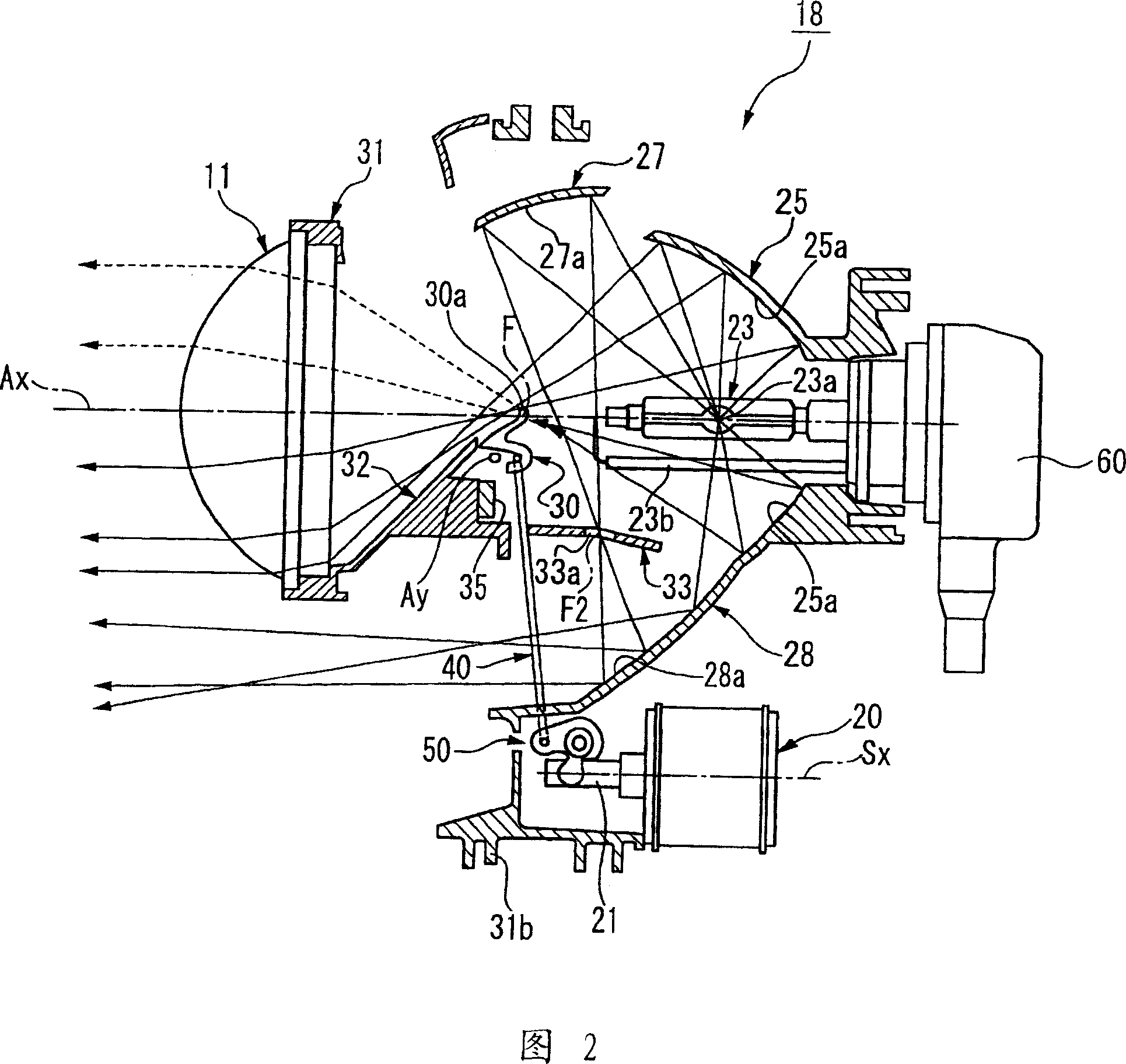

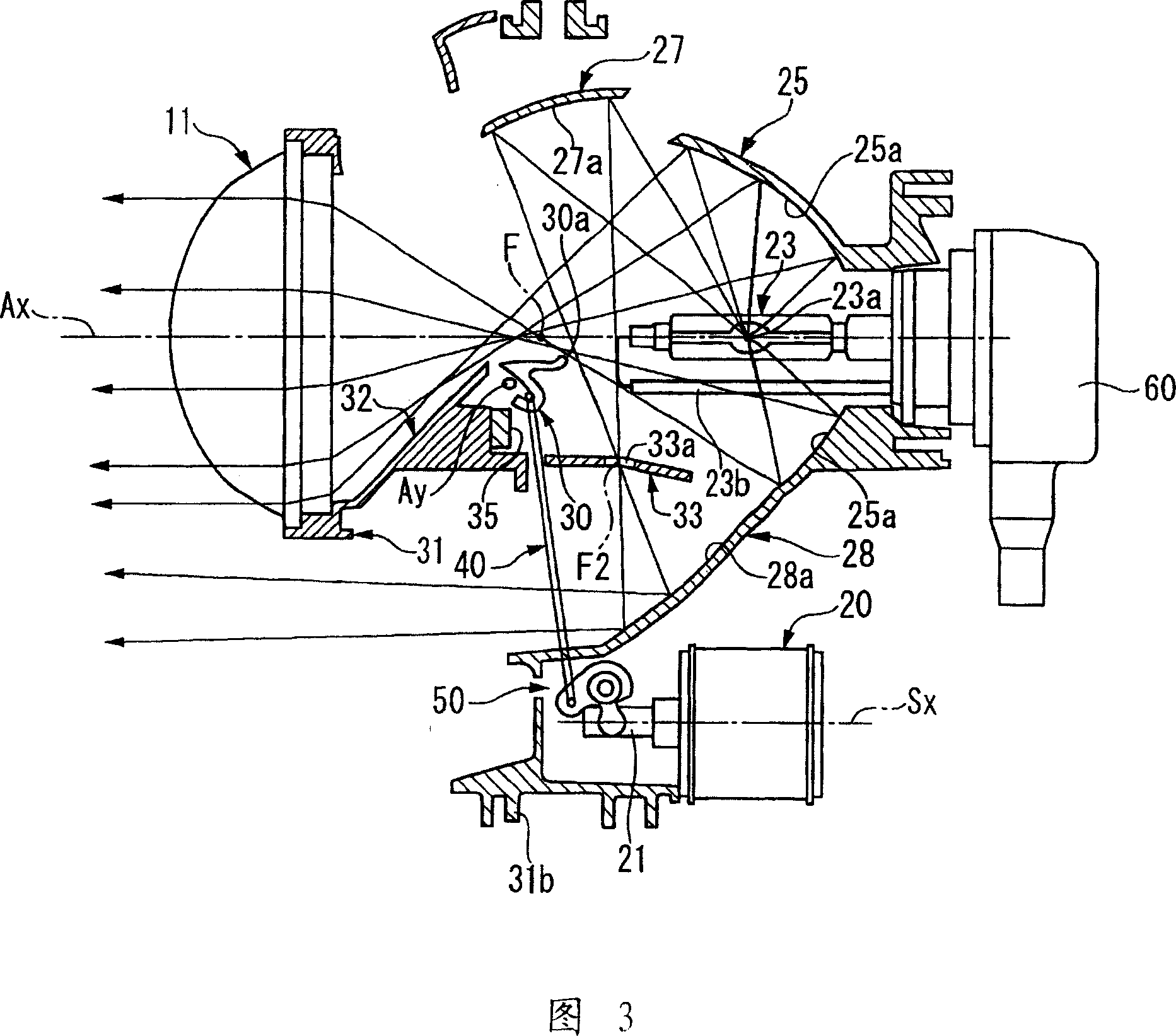

[0061] Hereinafter, preferred embodiments of the vehicle headlamp according to the present invention will be described in detail with reference to the accompanying drawings.

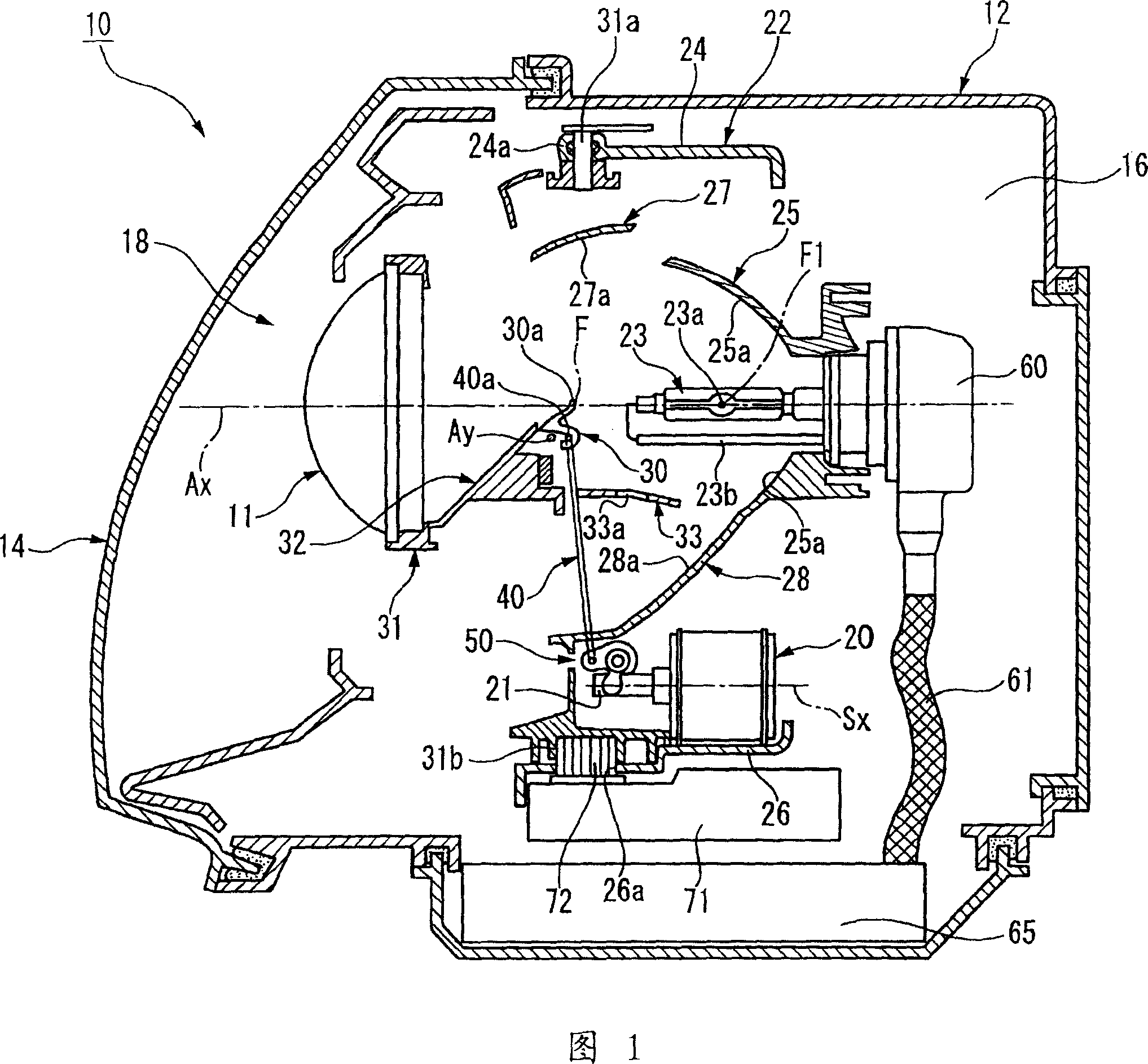

[0062] Fig. 1 is a schematic longitudinal sectional view of a vehicle headlamp according to an embodiment of the present invention.

[0063] The vehicle headlamp 10 of the present embodiment, as shown in FIG. Unit 18.

[0064] As shown in FIG. 1 , the lamp unit 18 is supported by the lamp body 12 via a frame 22 , and the frame 22 is supported by the lamp body 12 via an unillustrated dimming mechanism. The dimming mechanism is a mechanism for finely adjusting the installation position and installation angle of the lamp 18. In the stage after the alignment adjustment is performed, the central axis Ax of the lens of the lamp unit 18 is downward at about 0.5 to 0.6 degrees with respect to the front-rear direction of the vehicle. .

[0065] The frame 22 is formed in a substantially rectangular frame shape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com