Patents

Literature

122results about How to "Realization of small size and light weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

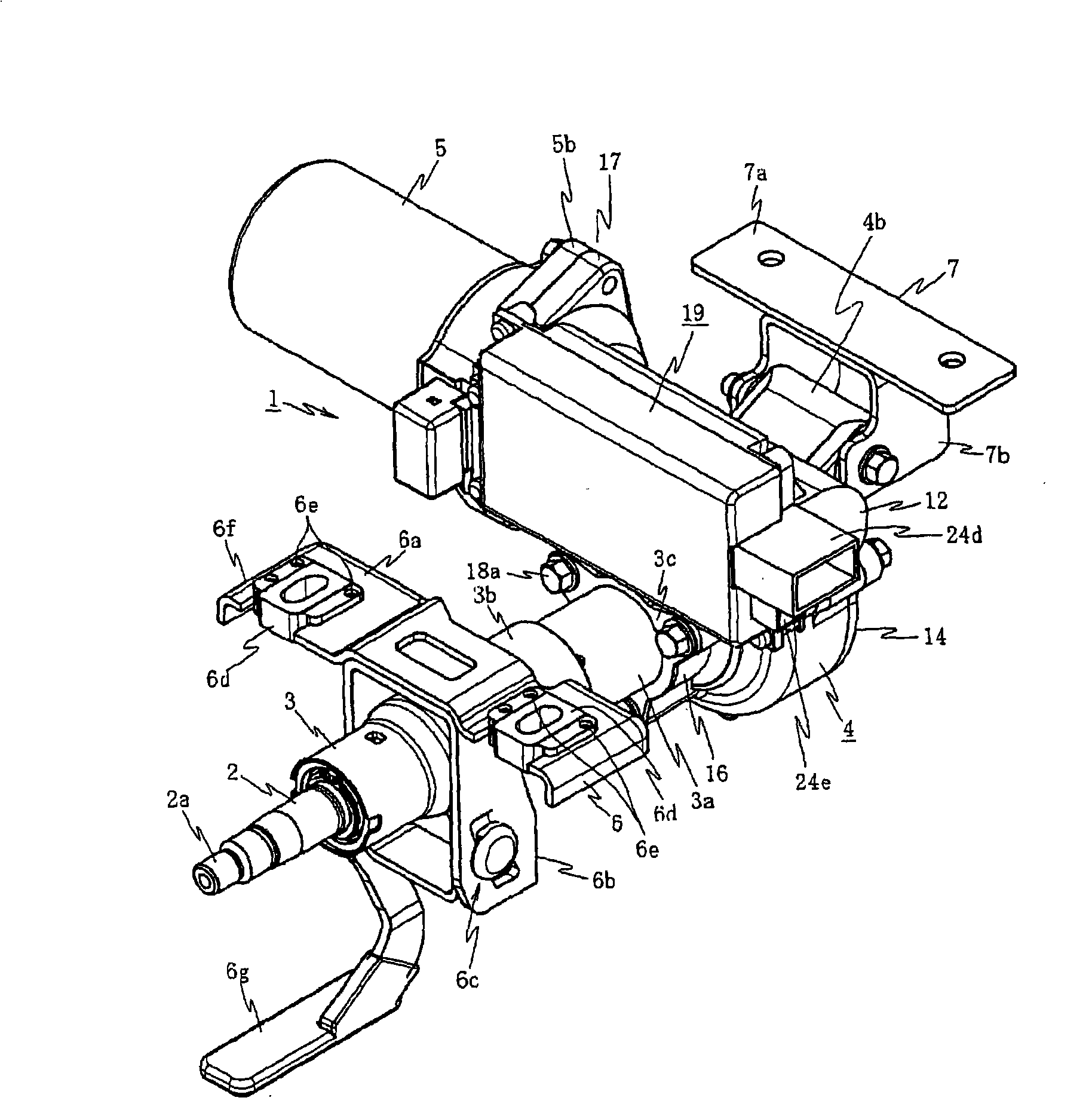

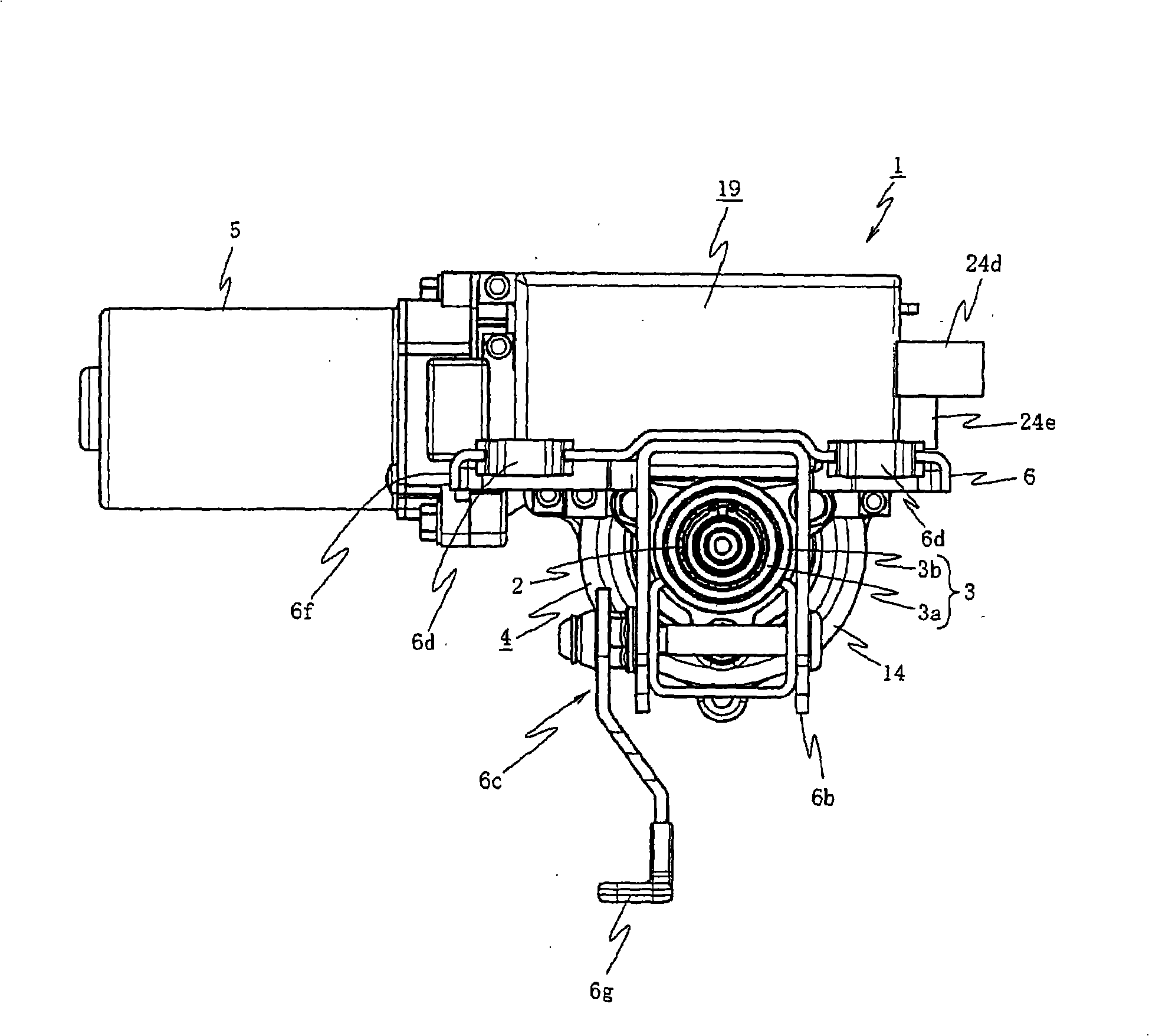

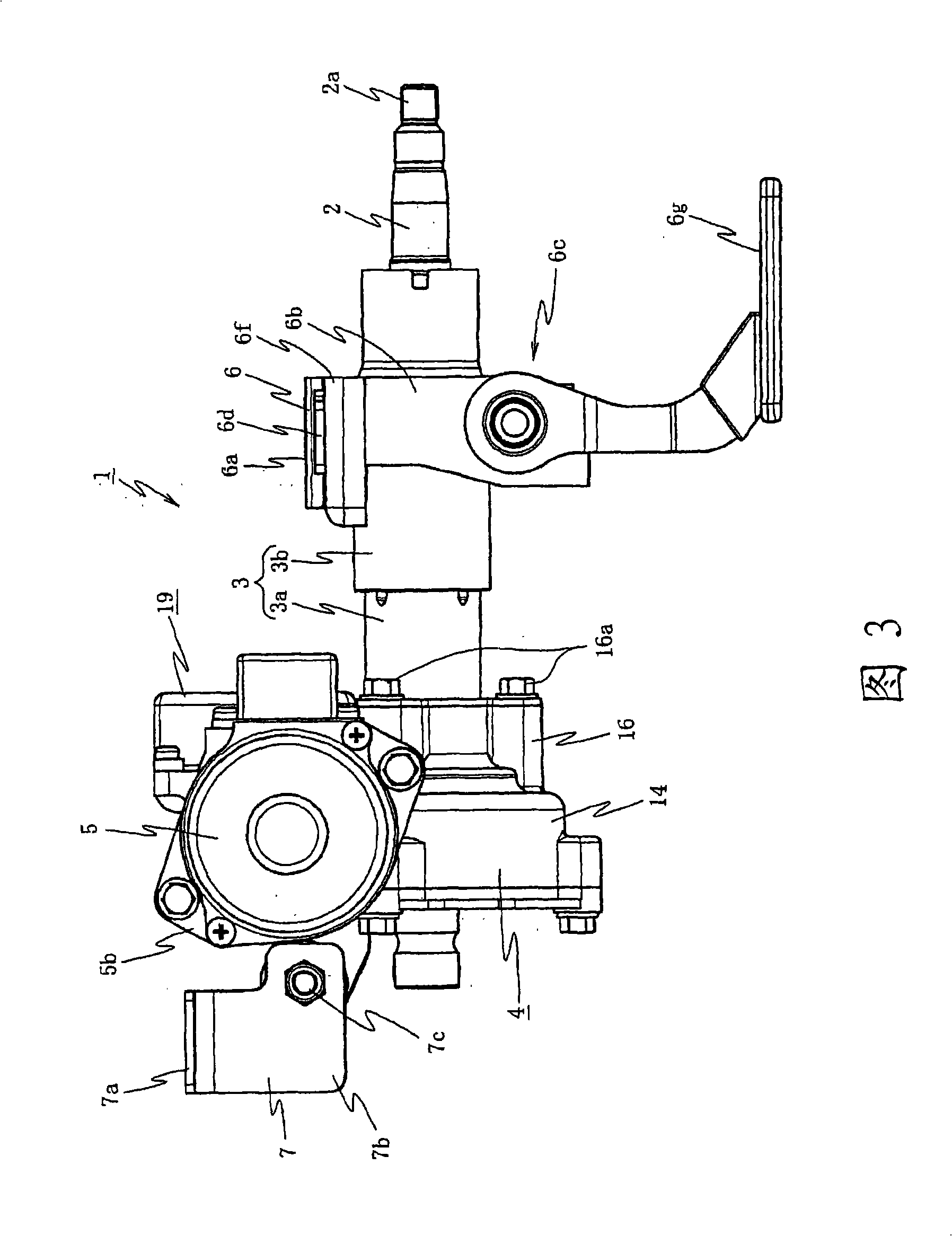

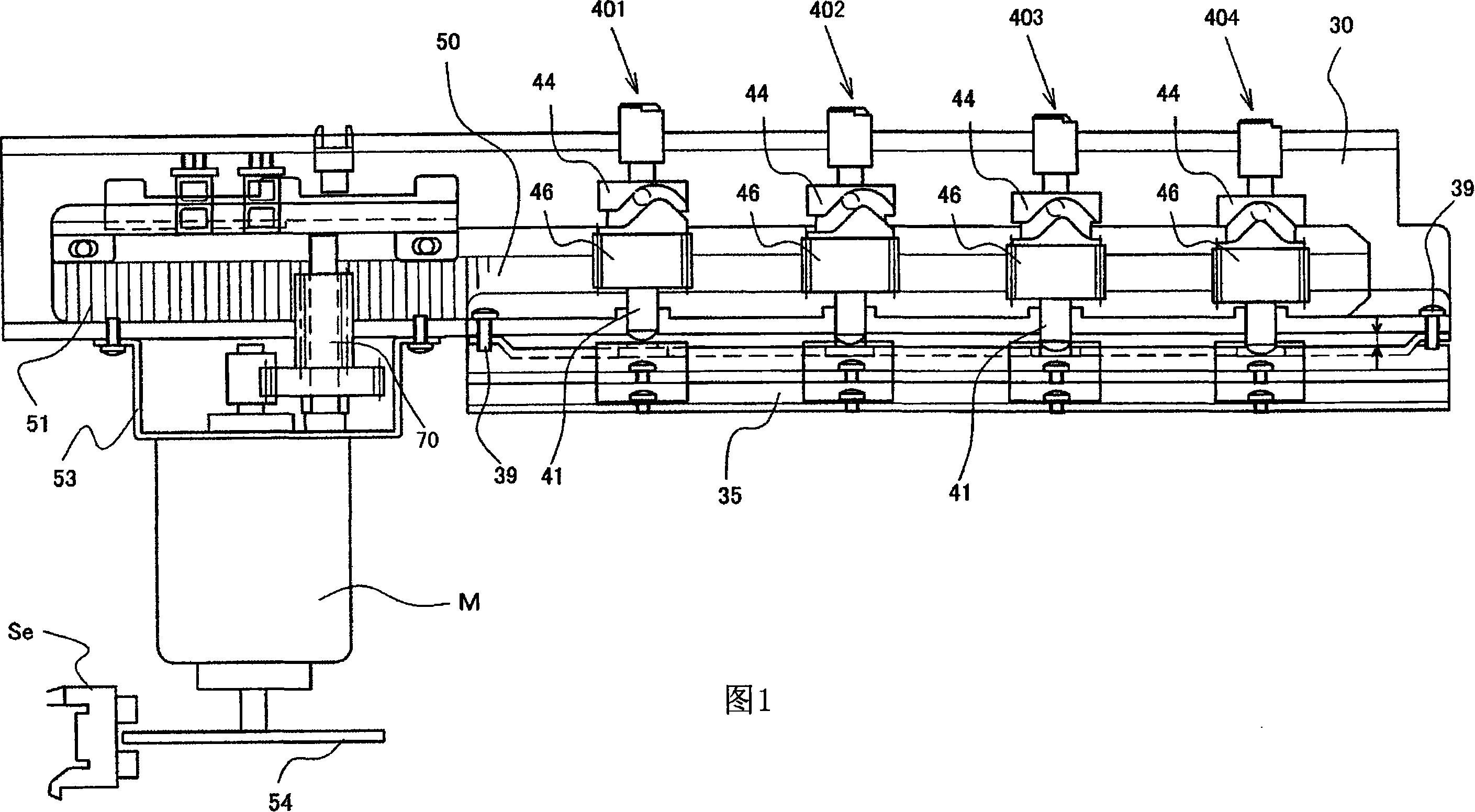

Electric power steering device and method of assembling the same

InactiveCN101410289AAvoid mixingShort electrical connection lengthToothed gearingsSteering columnsElectrical resistance and conductanceElectric power steering

To provide an electric power steering apparatus in which it is possible to minimize a connection distance between a control unit and an electric motor and surely prevent electric noise from mixing between the control unit and the electric motor as well as to minimize electric resistance and minimize an electric loss by directly connecting the control unit and connection terminals of the electric motor and a torque sensor. A motor control apparatus includes a steering column 3 having inserted therein a steering shaft 2 to which steering torque is transmitted, a reduction gear box 4 coupled to the steering shaft 2, and an electric motor 5 that transmits a steering assisting force to the steering shaft 2 via a reduction mechanism in the reduction gear box 4. The electric motor 5 and a control unit 19 including a control board mounted with a control circuit that controls to drive the electric motor 5 are provided side by side in the reduction gear box 4 and a connection terminal of the electric motor 5 is electrically connected to the control unit 19 directly.

Owner:NSK LTD

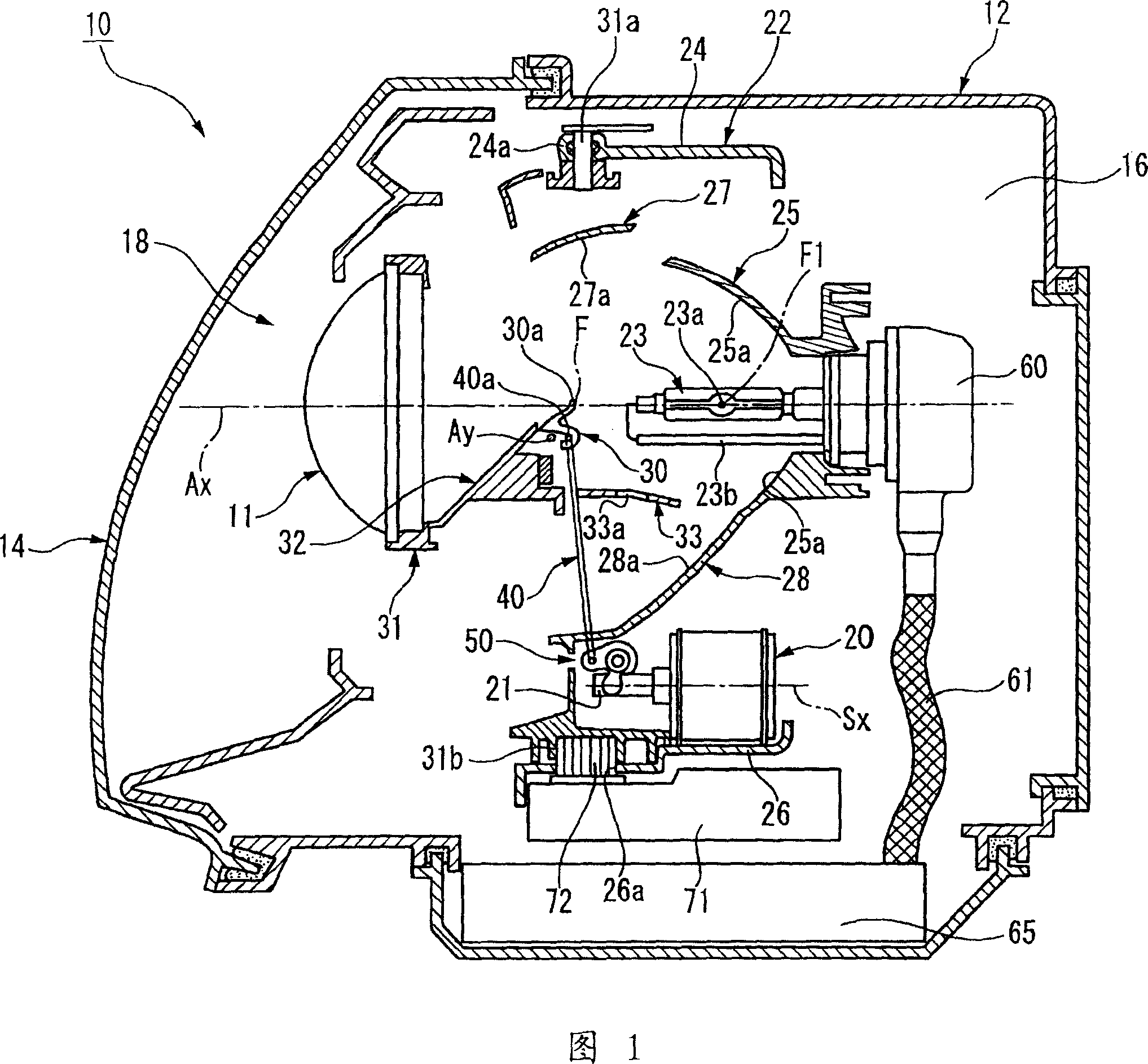

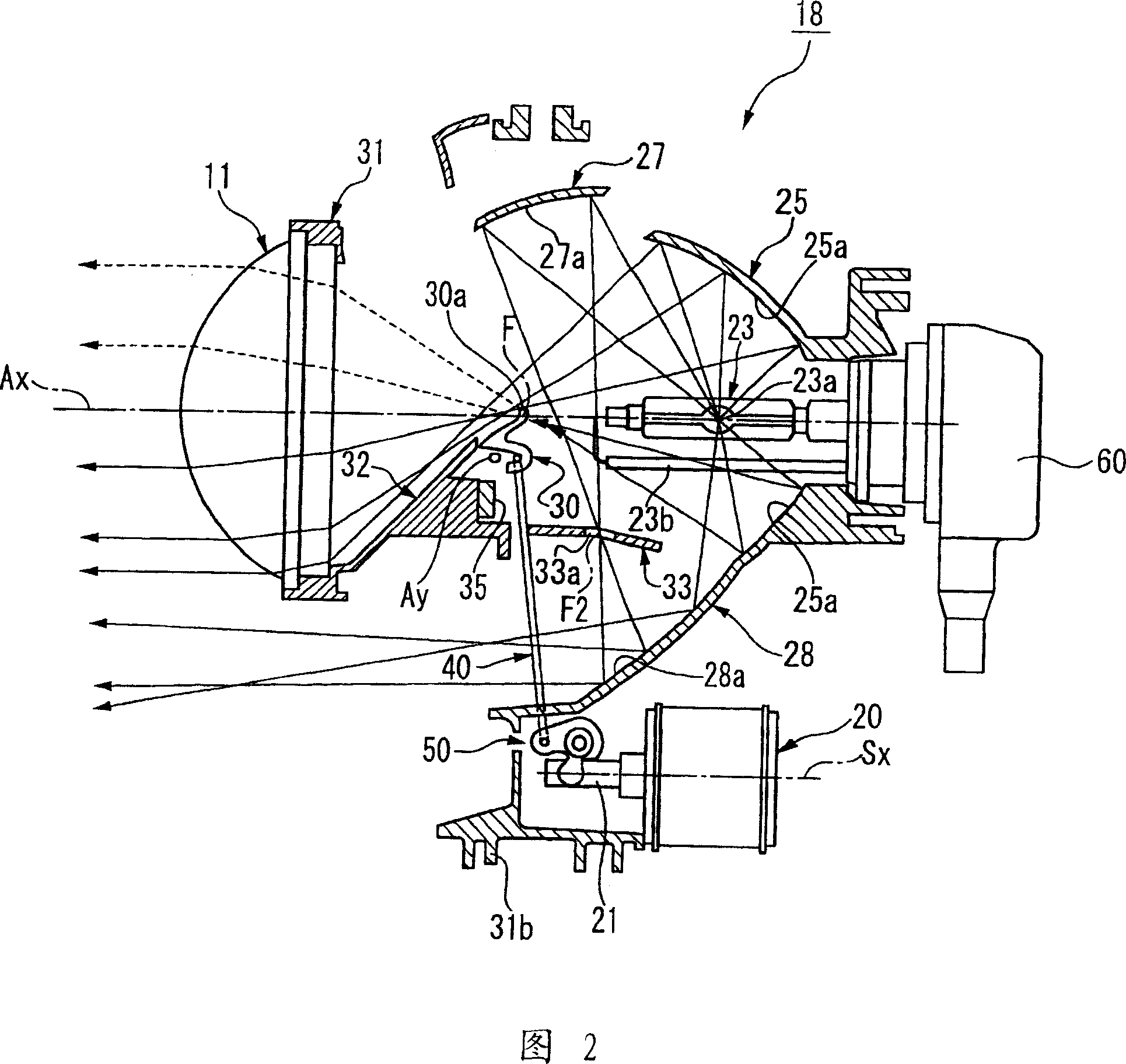

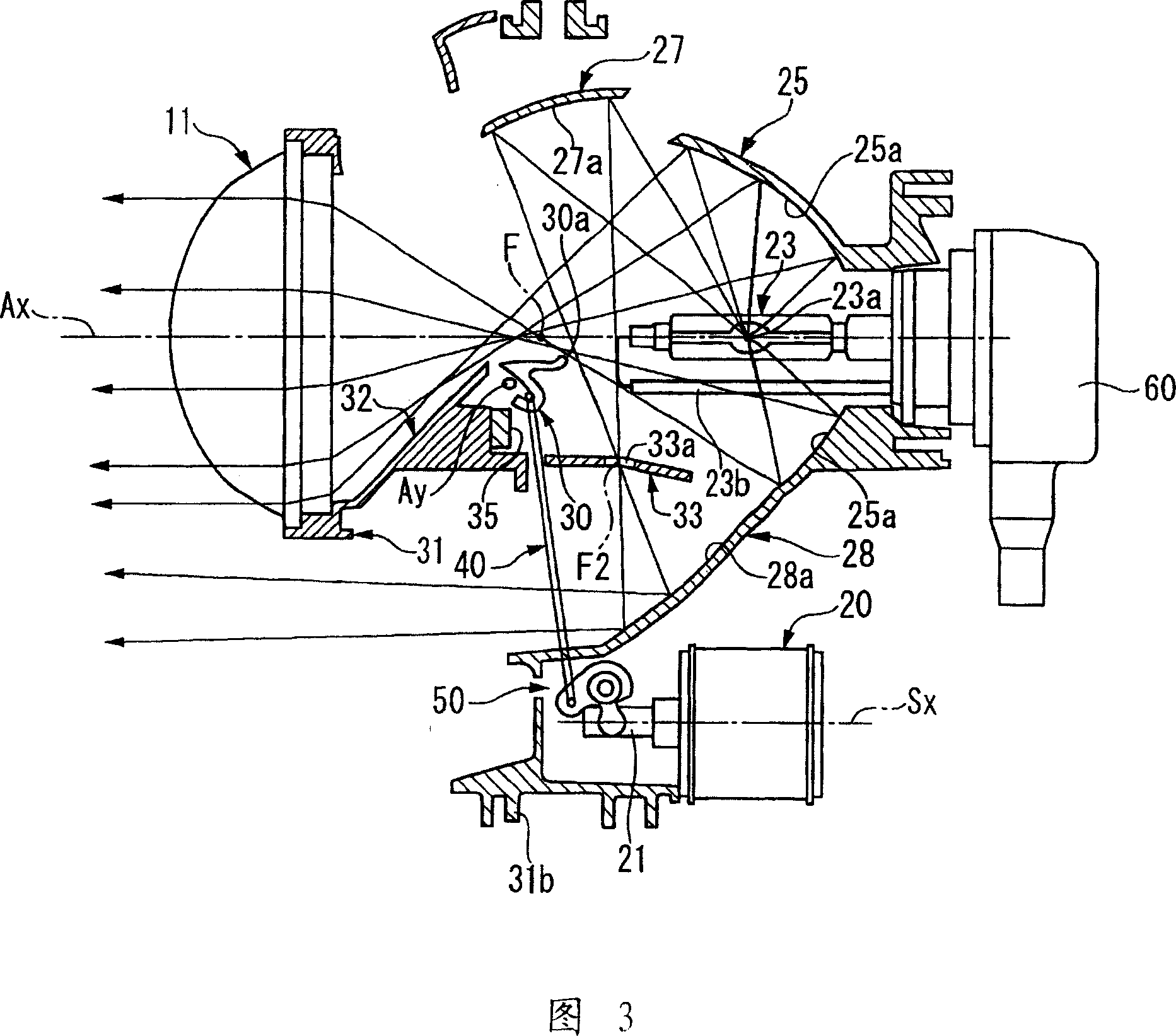

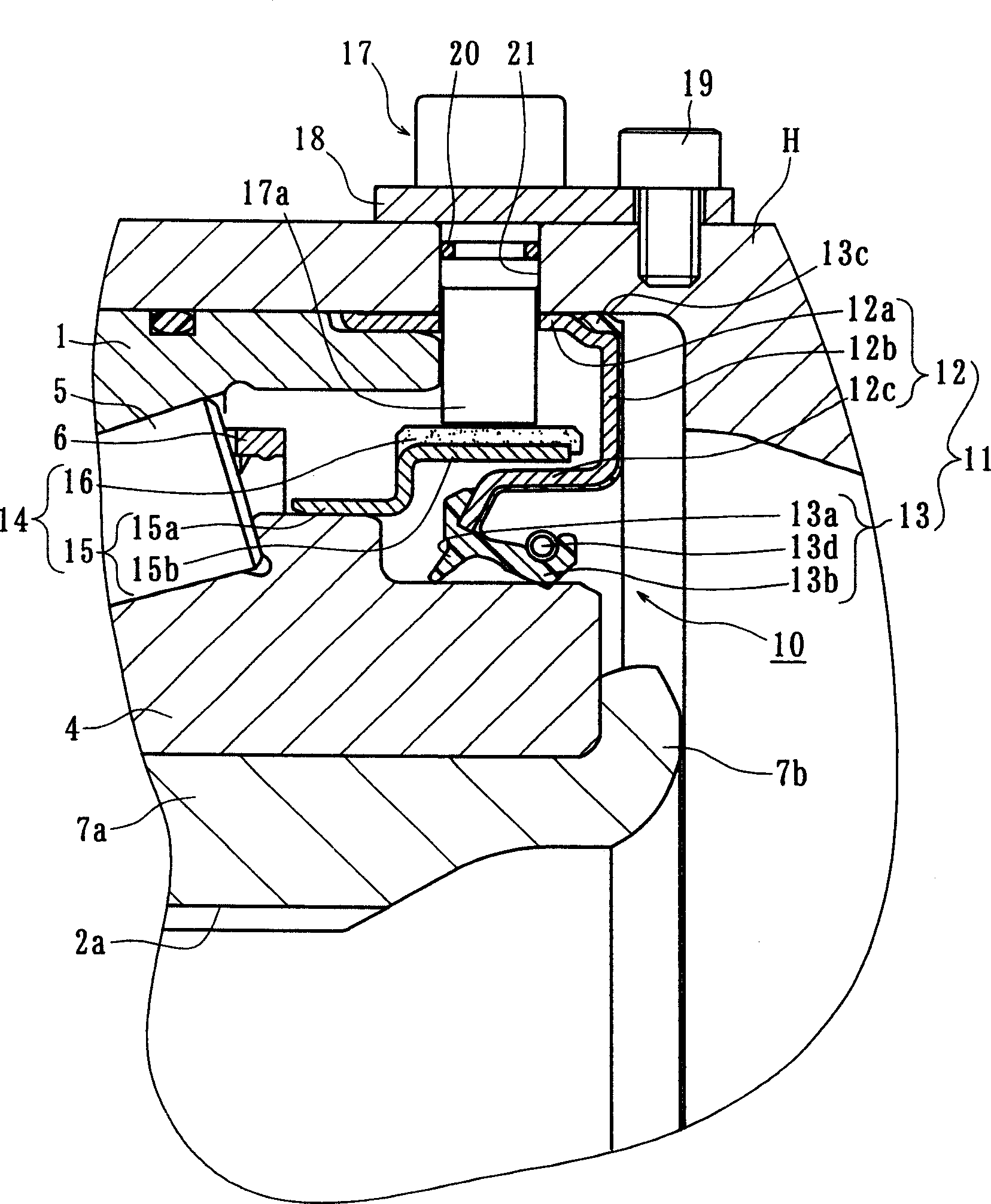

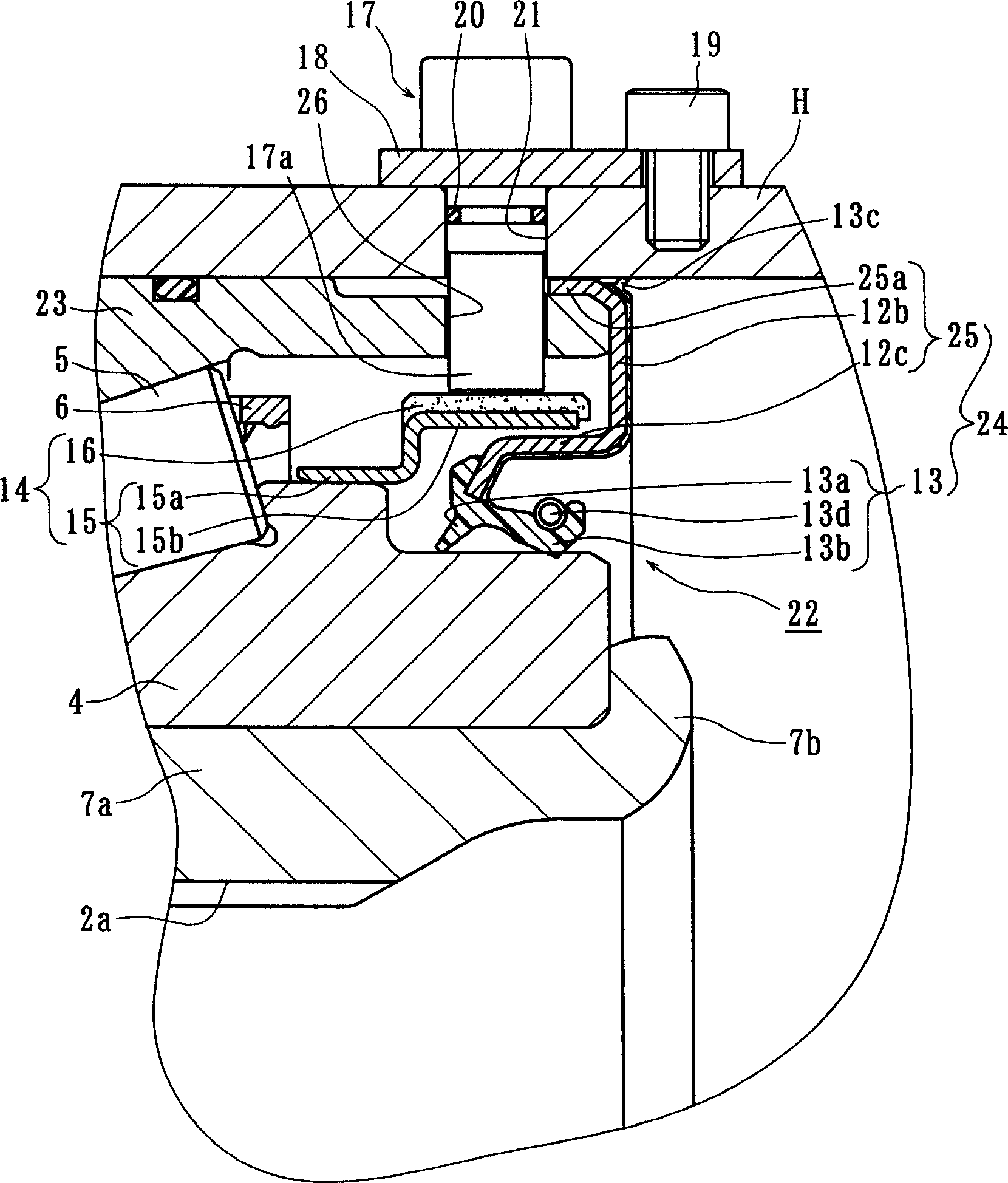

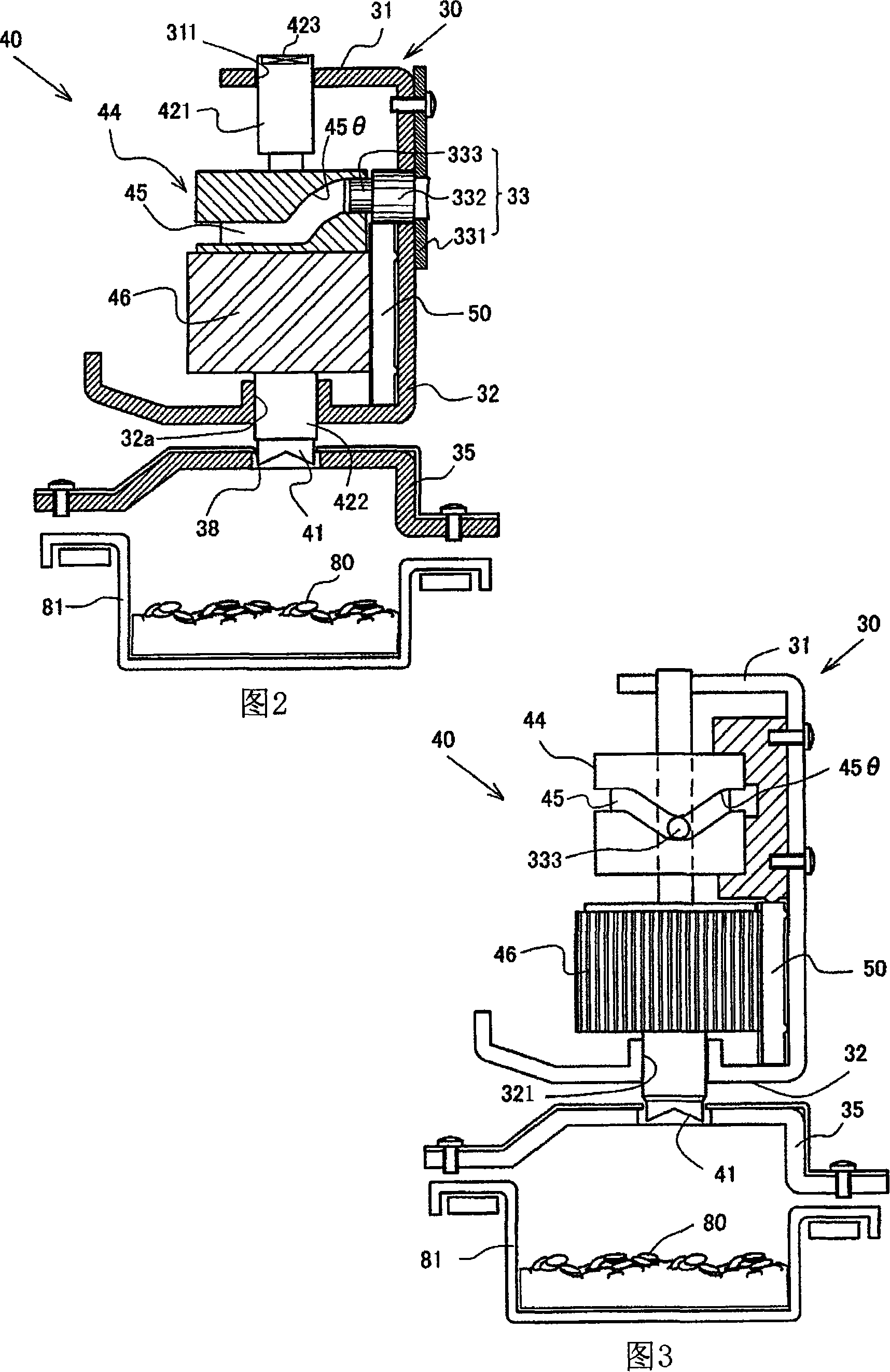

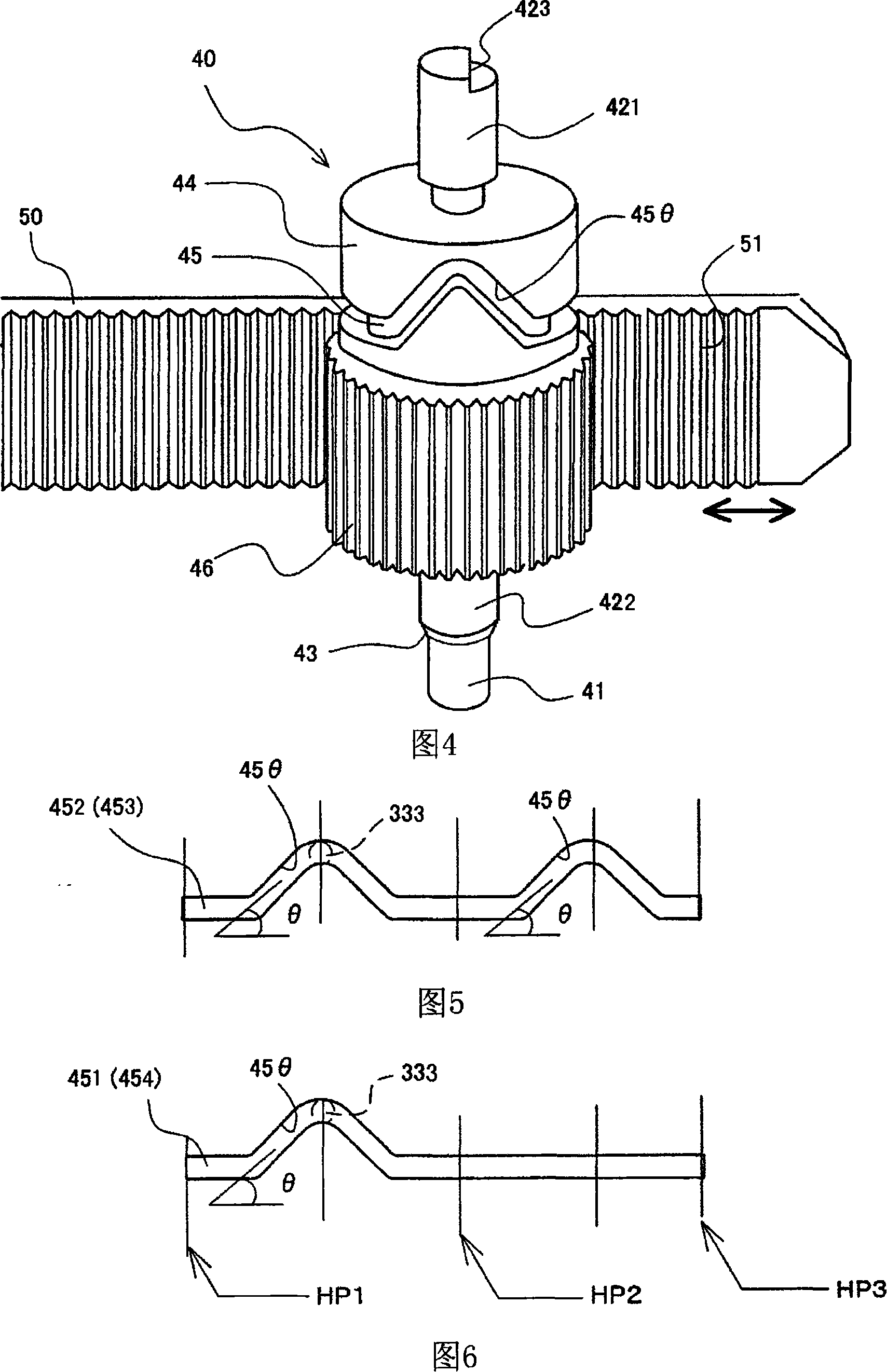

Vehicle headlamp

InactiveCN1928422AImprove rigidityReduce vibrationVehicle headlampsPoint-like light sourceRotational axisFree rotation

The invention provides a vehicle headlight with an actuator miniaturized and weight-saved and with luminance at irradiation effectively enhanced without adversely affecting on formation of a low-beam light distribution pattern, in a projector type one equipped with a movable shade. The vehicle headlight (10) is provided with a projection lens (11), a light source bulb (23), a reflector (25) reflecting direct light from the light source bulb (23) toward front, a movable shade (30), an actuator (20) moving the movable shade (30) between a shielding position and a shielding relaxation position. The movable shade (30) is installed in free rotation around a rotational axis line extended in a car width direction in the vicinity of a lens center axis (Ax), and the actuator (20) gives driving force to an end of a rod member (40) with the other end coupled with the movable shade (30) in a length direction through an operation direction changing mechanism (50) to rotate the movable shade.

Owner:KOITO MFG CO LTD

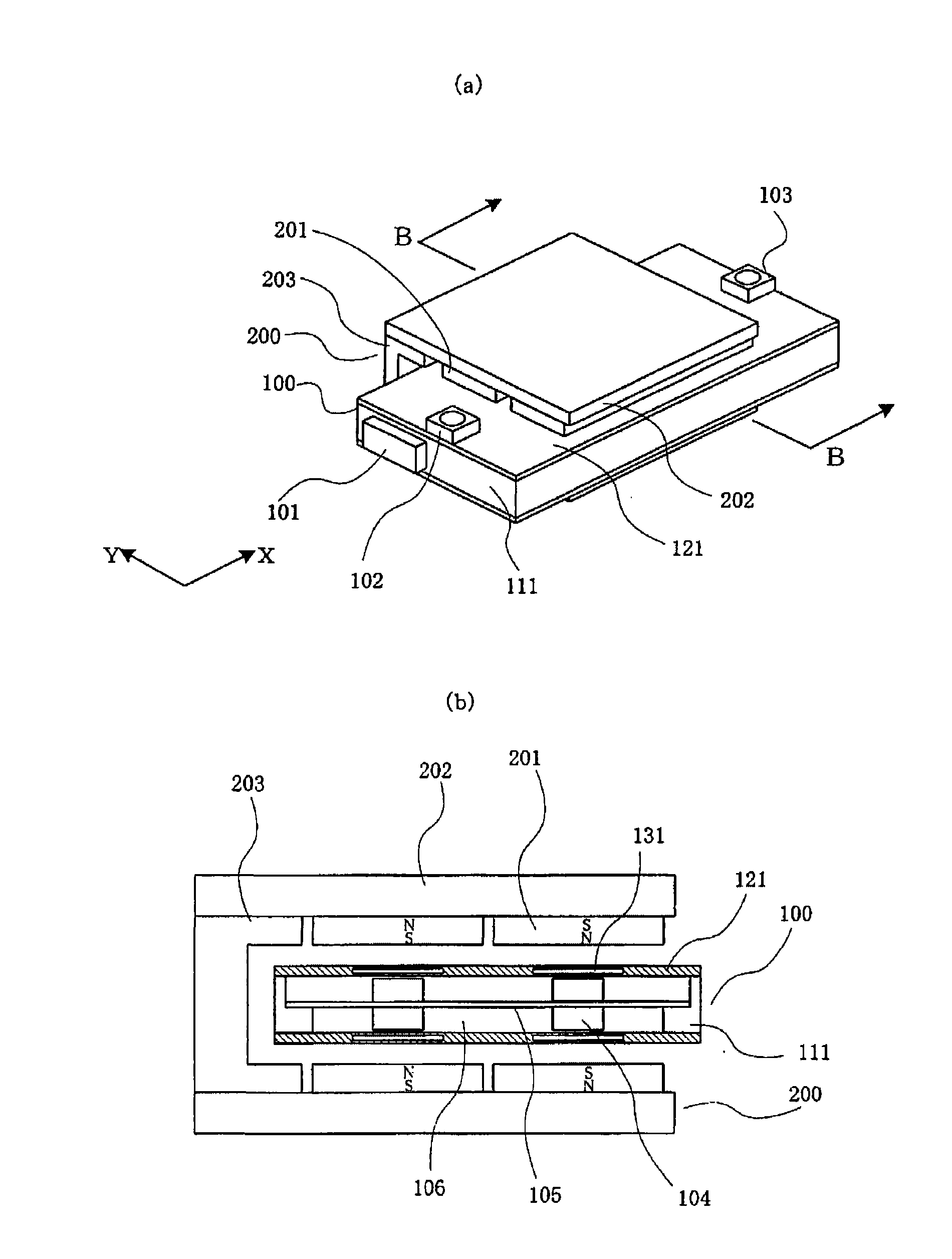

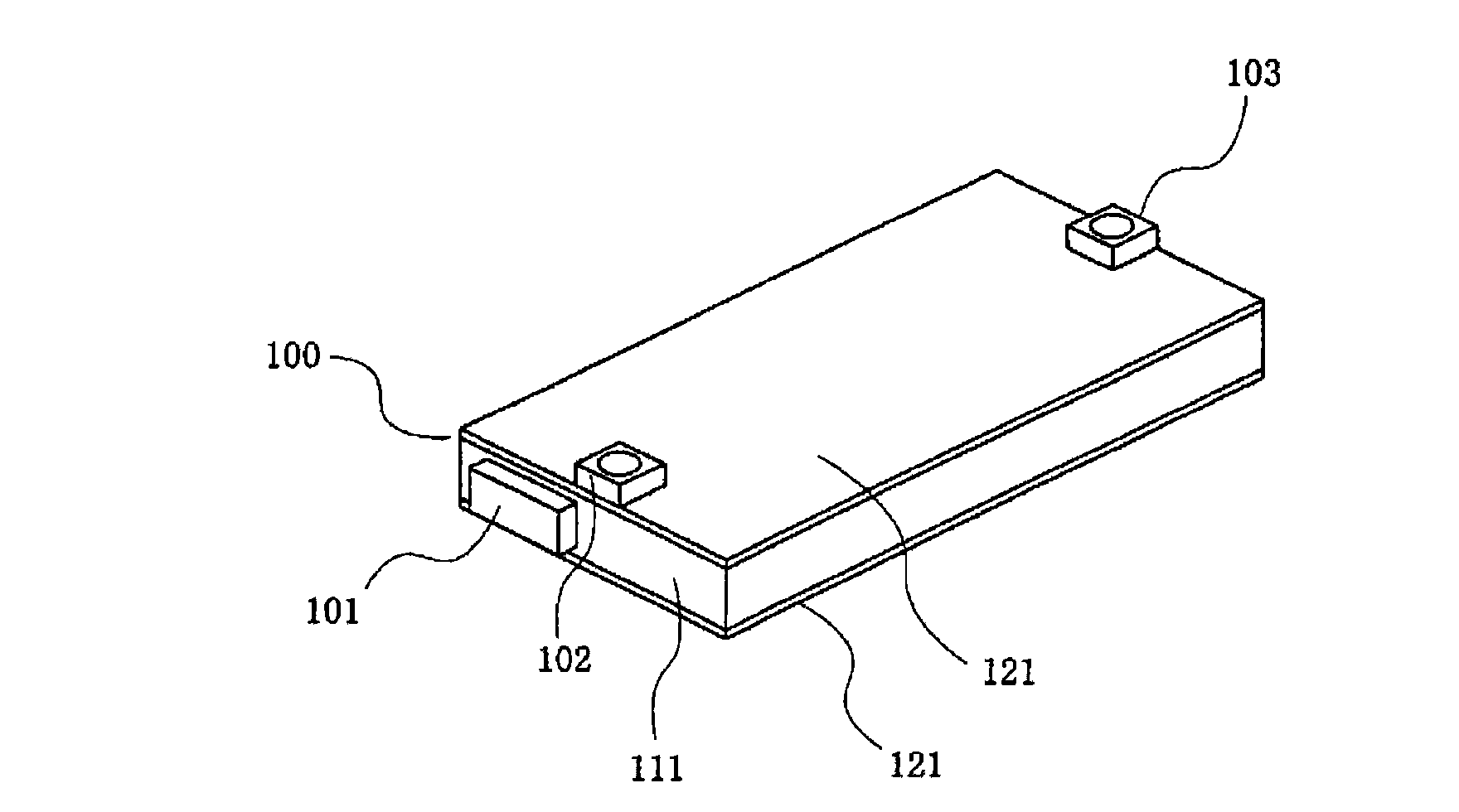

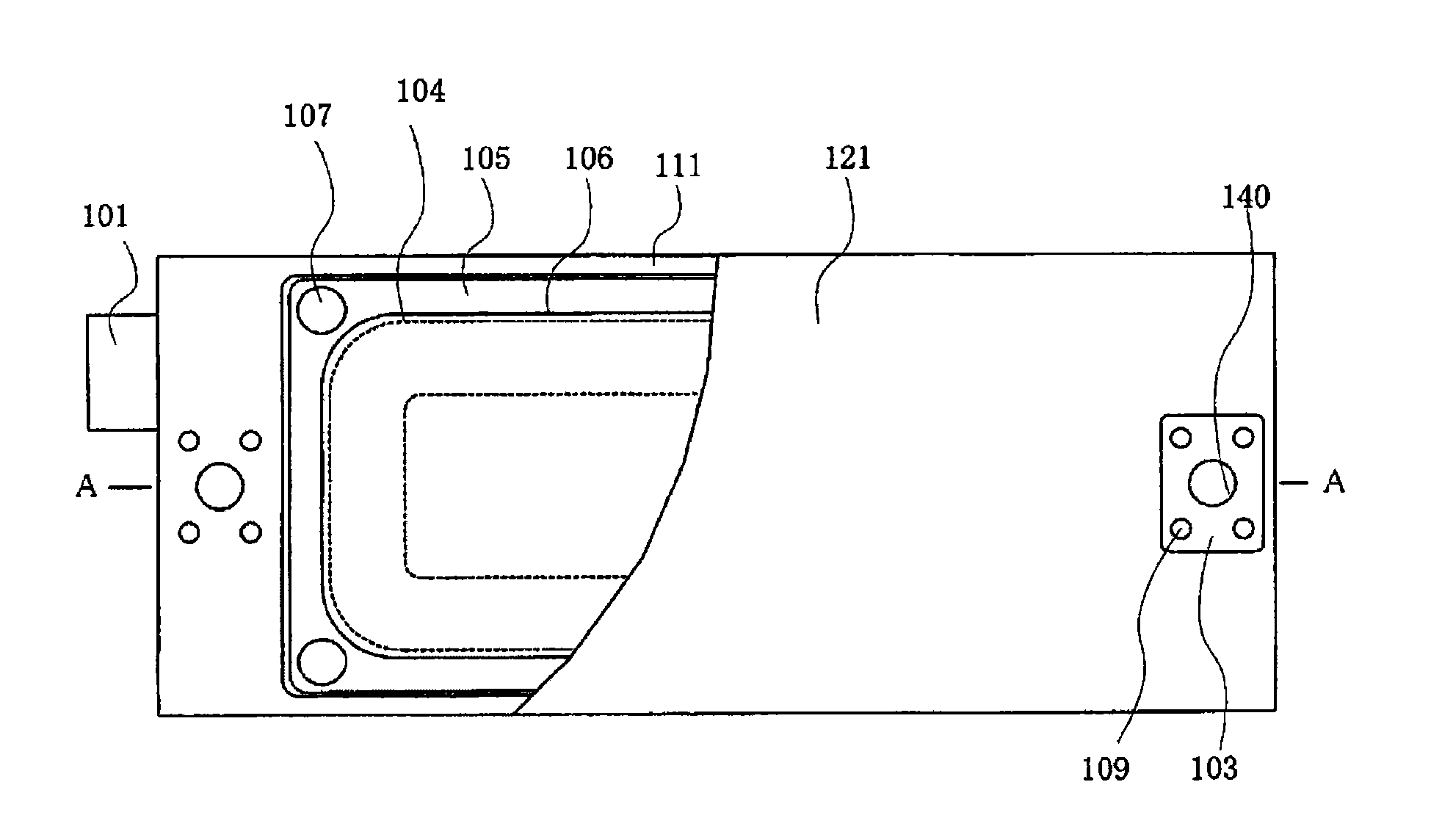

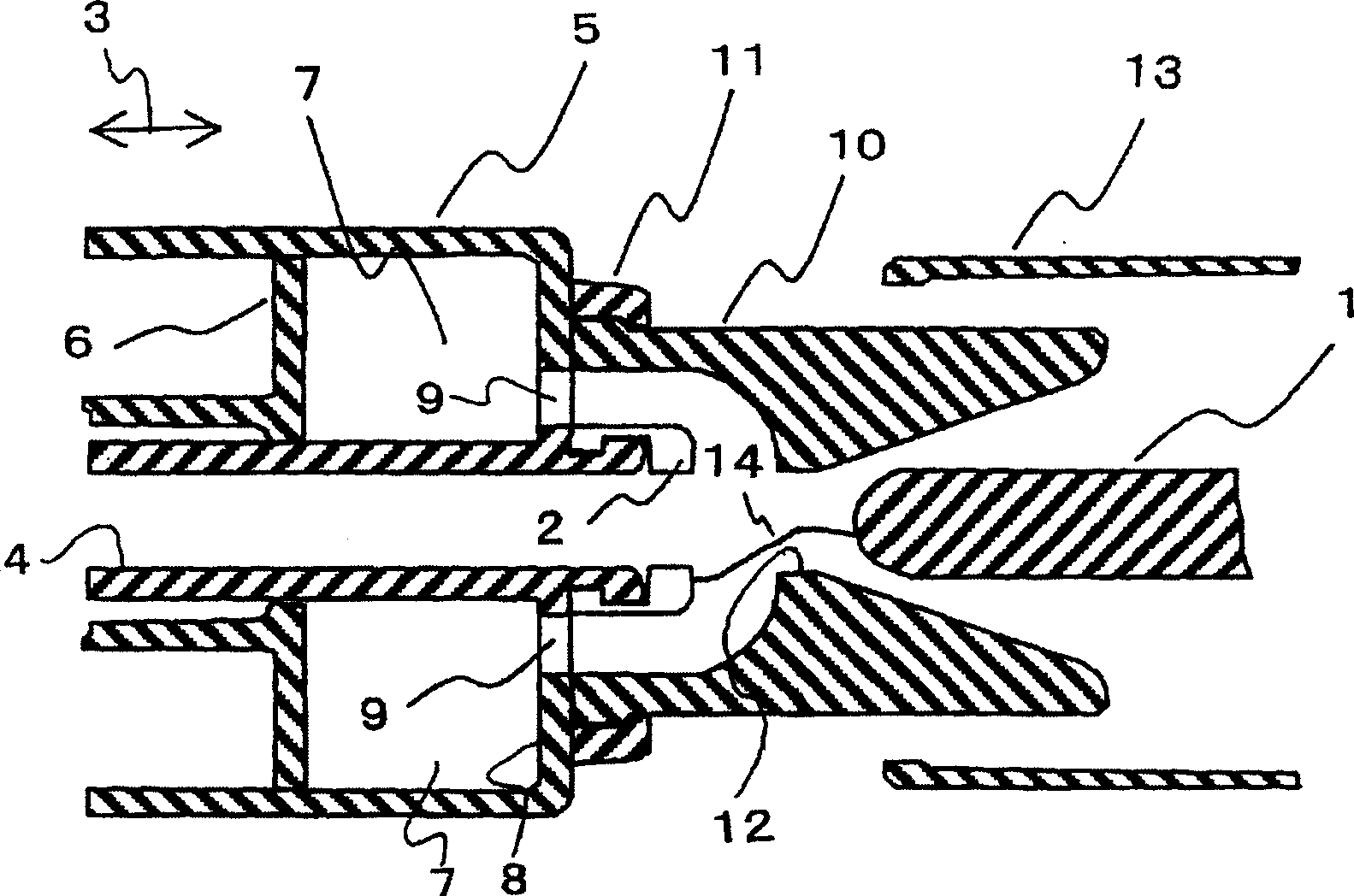

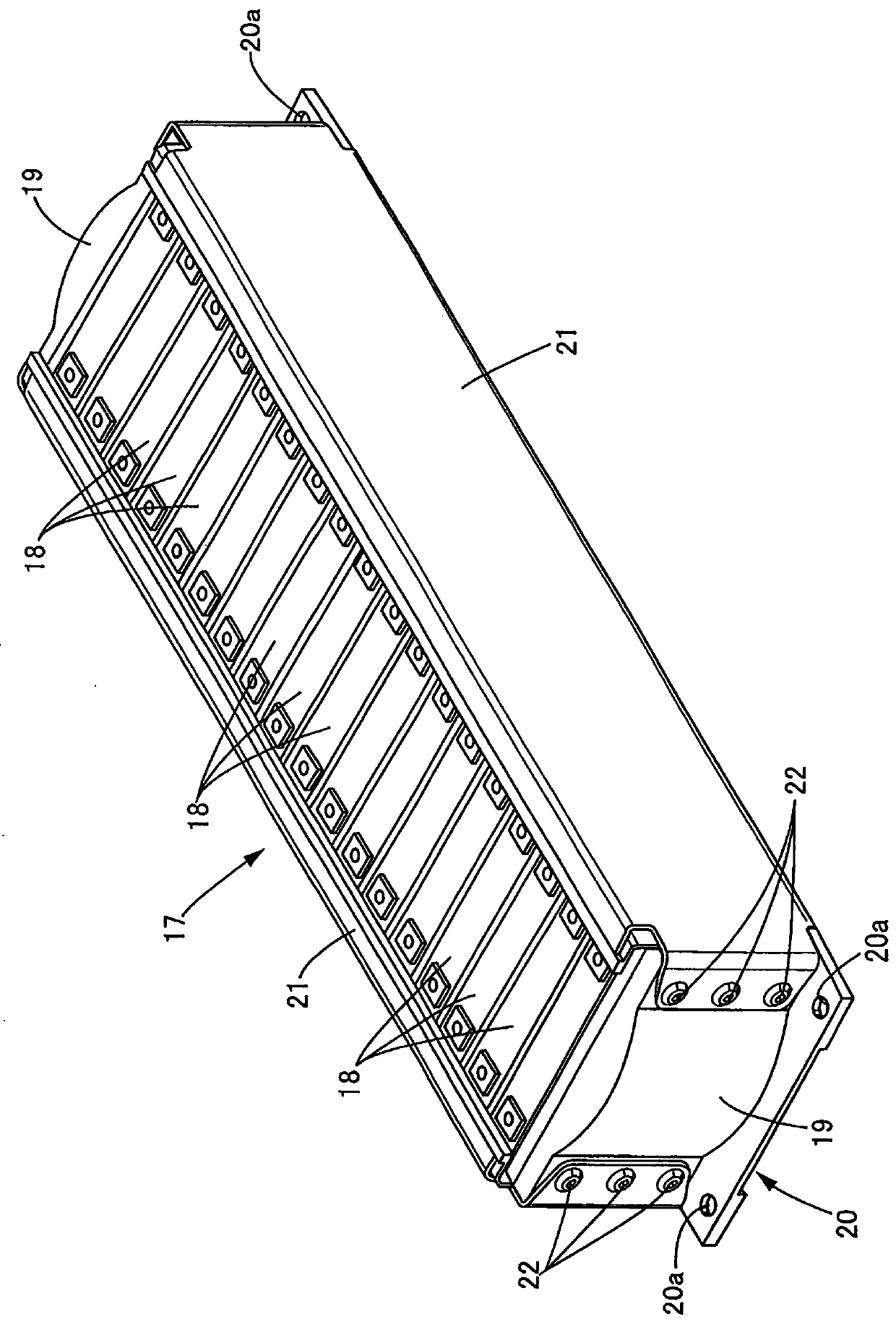

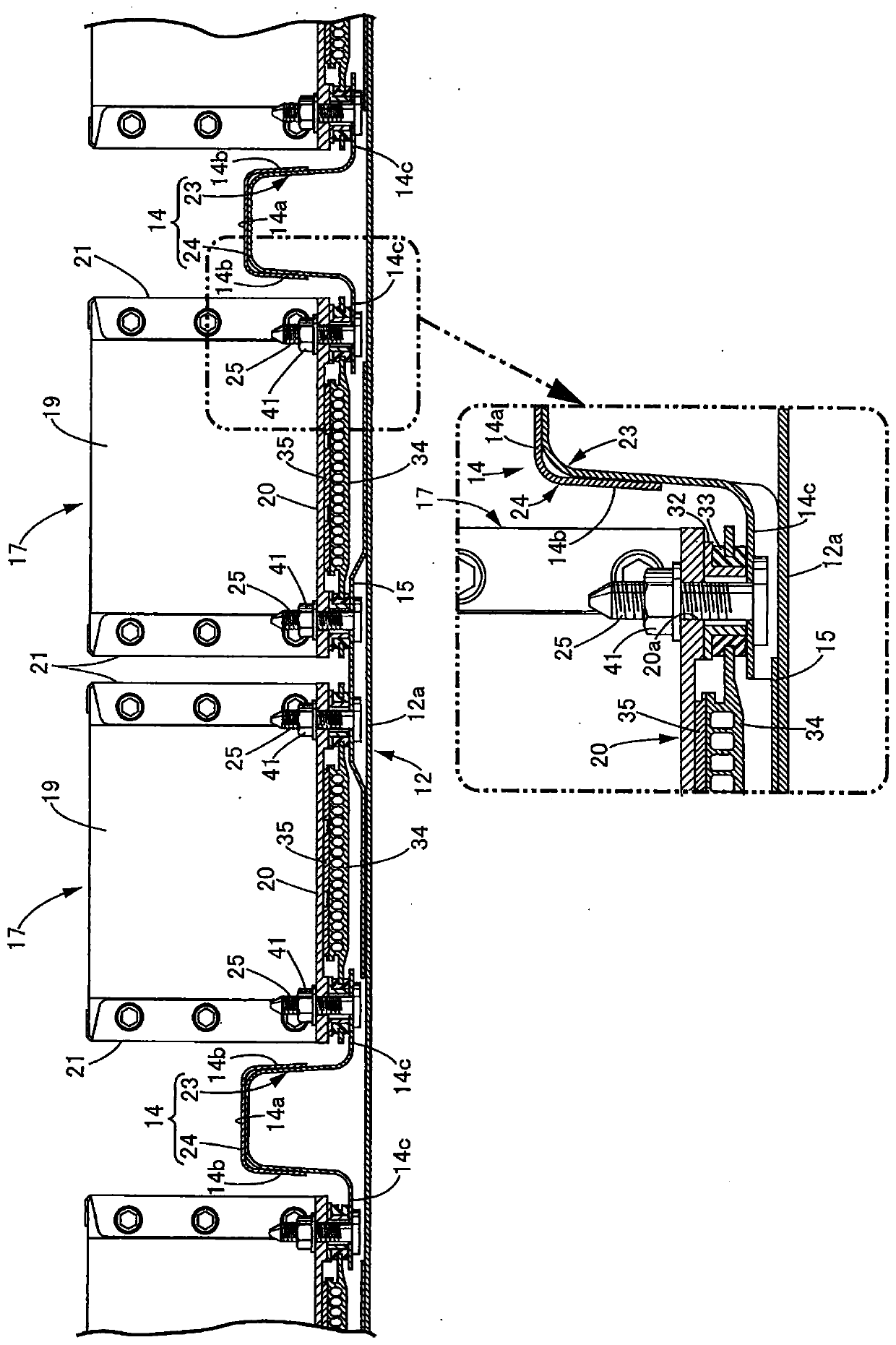

Canned linear motor armature and canned linear motor

InactiveCN101657956AEliminate insulation resistance reductionReduce temperature riseMagnetic circuitCooling/ventillation arrangementBrake forcePressure increase

A canned linear motor armature and a canned linear motor of water cooling type are provided. The insulation reliability of a canned linear motor armature is improved. The temperature rises of both the linear motor surface and the armature winding are reduced. Even if the coolant pressure increases, the can neither breaks nor deforms. The weight of the armature is lightened. The viscosity braking force is reduced. In the canned linear motor armature, the armature winding (104) is surrounded with a picture-frame-shaped case (111), both the openings of the case (111) are closed with flat can (121), and coolant passages (131) are provided inside the can (121) and on the top surface of the coil side of the armature winding (104).

Owner:YASKAWA DENKI KK

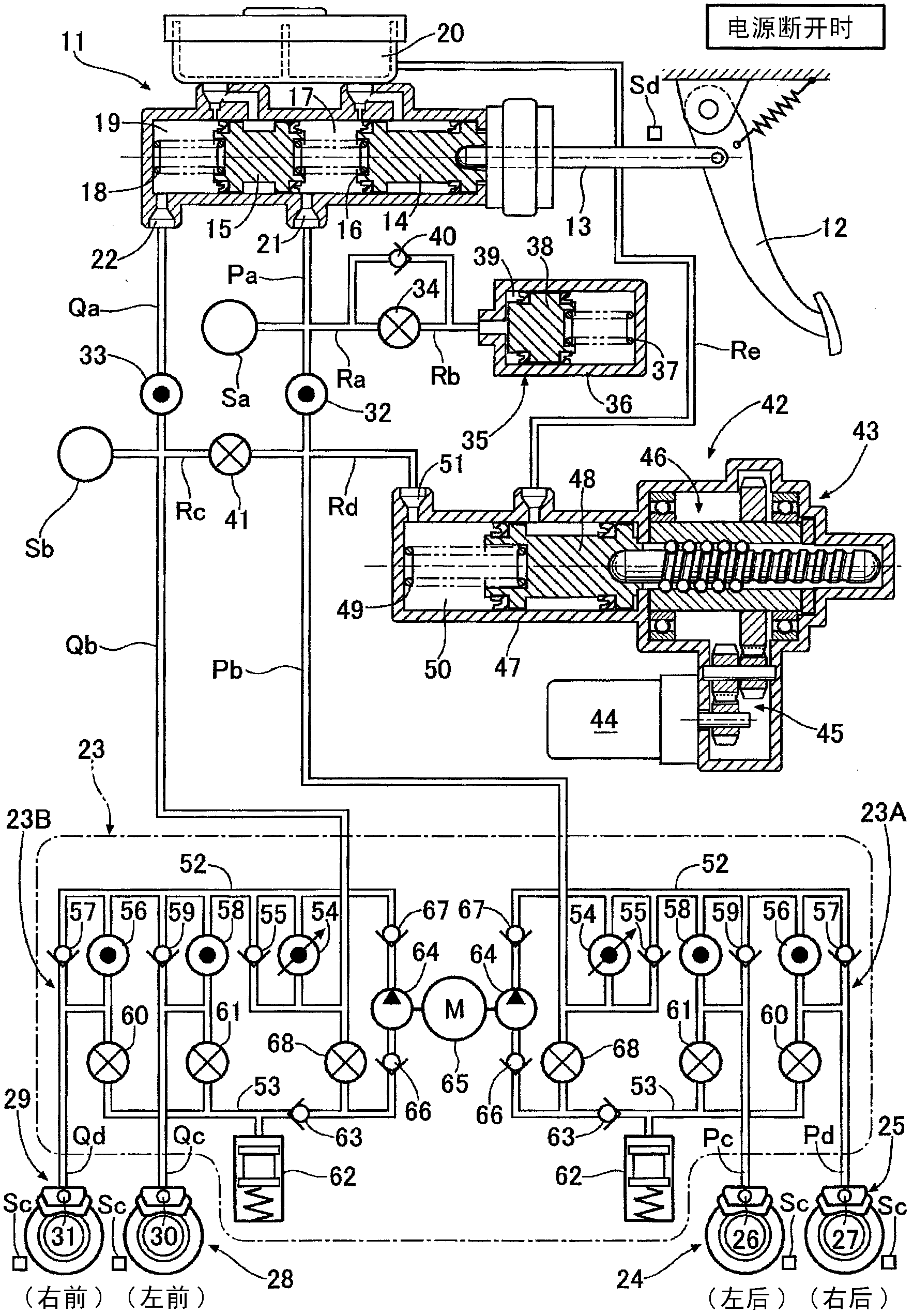

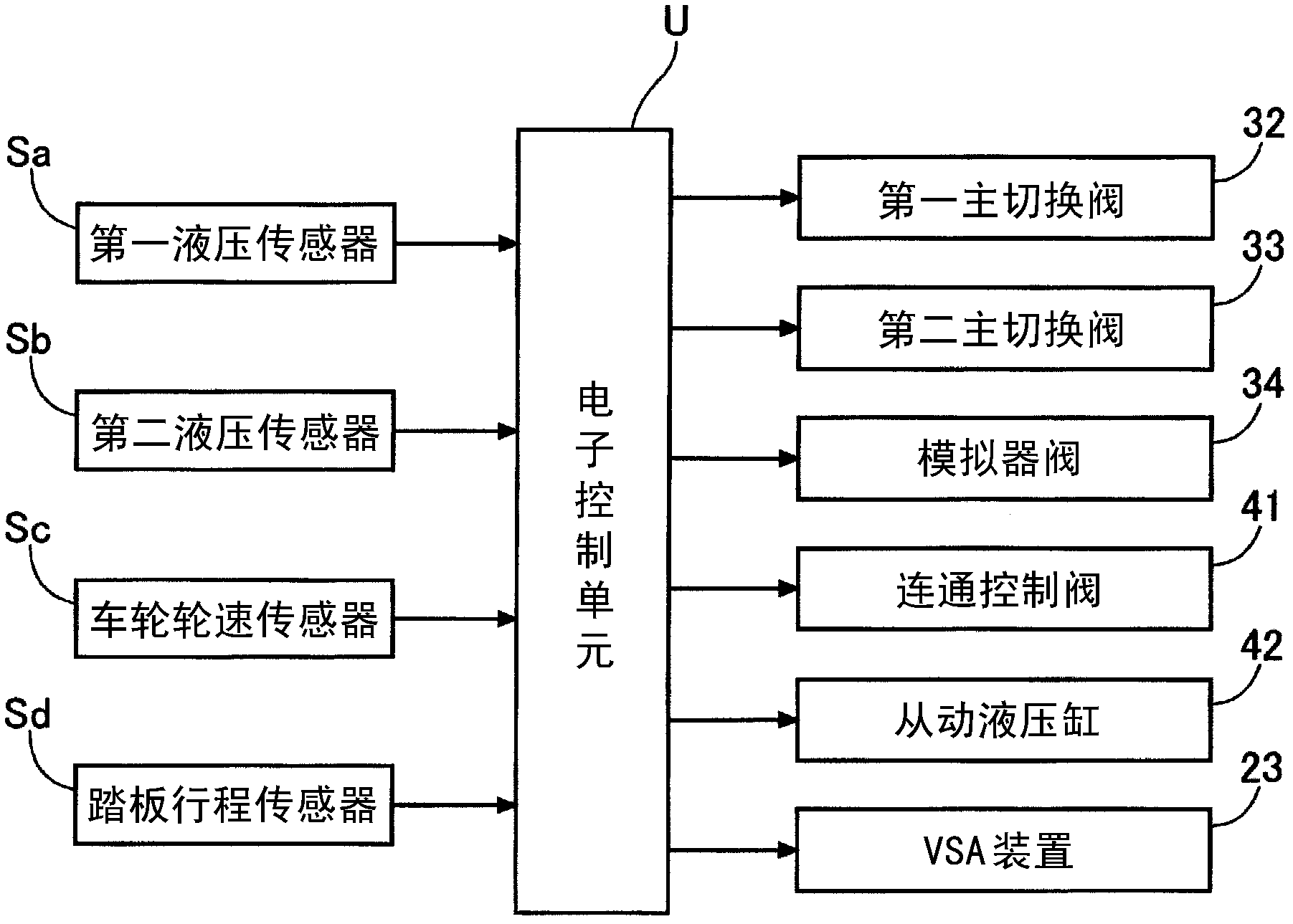

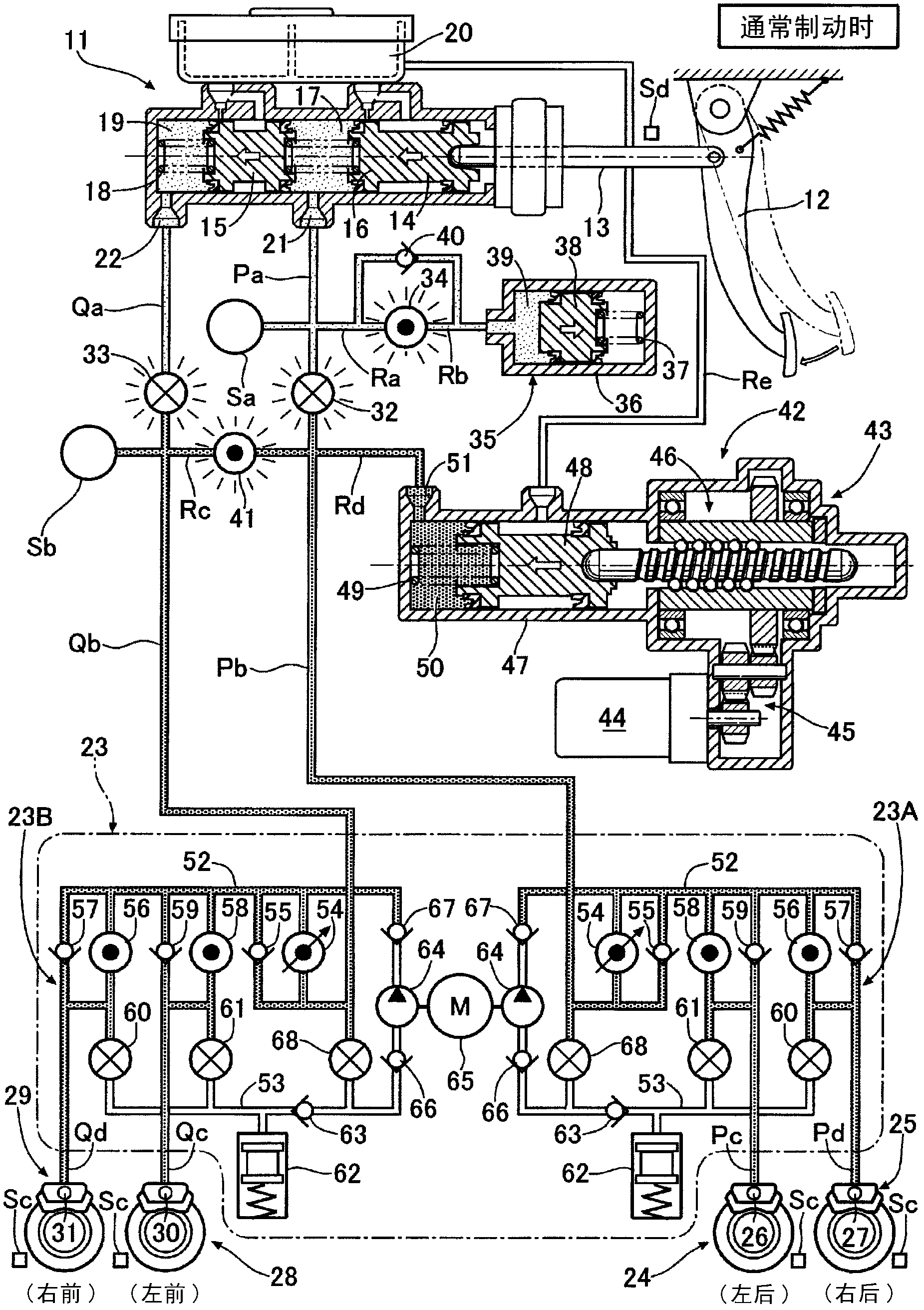

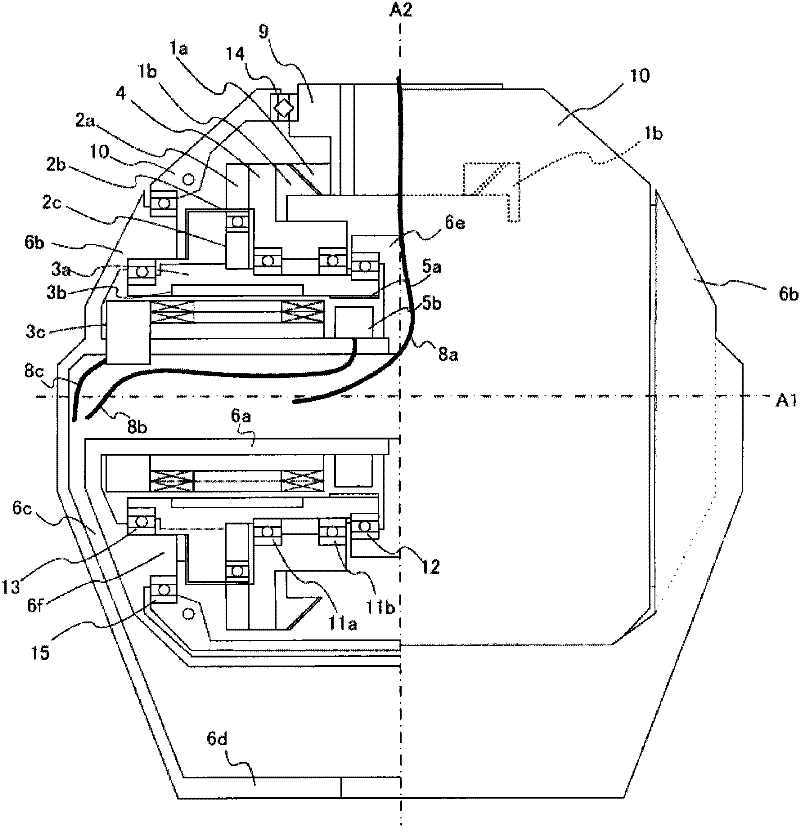

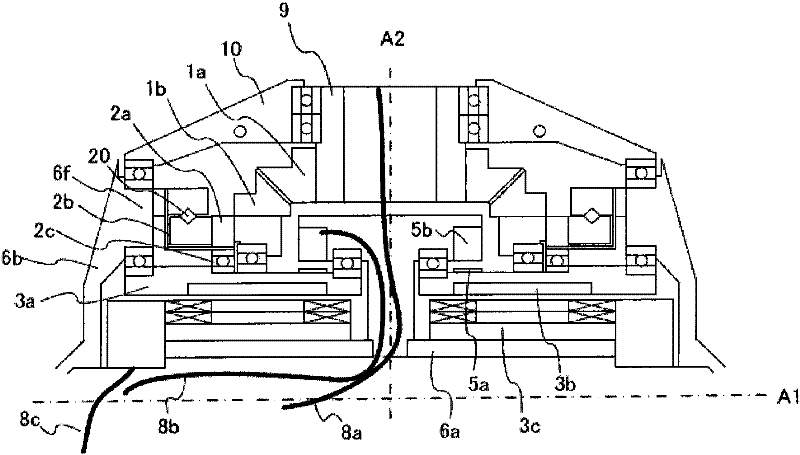

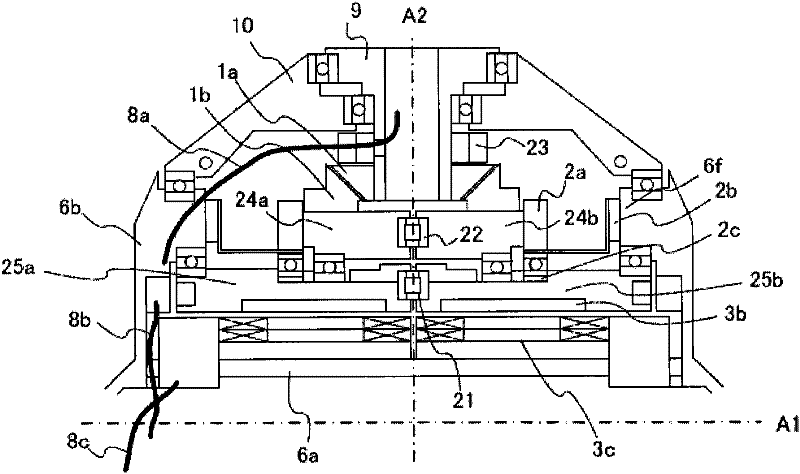

Vehicle braking apparatus

ActiveCN102556031AImprove responsivenessRealization of small size and light weightBraking action transmissionBrake action initiationsHydraulic cylinderMiniaturization

The invention provides a vehicle breaking apparatus having a hydraulic pressure source which can generate brake hydraulic pressure corresponding to a piston forward movement driven by an electric motor. The apparatus enables the electric motor small and light-weighted while the responsiveness of the brake hydraulic pressure generation is ensured. The hydraulic pressure source with BBW-type brake apparatus comprises: a slave hydraulic cylinder (42), generating brake hydraulic pressure by the forward movement of the piston (48) driven by the electric motor (44); a VSA apparatus (23), by using a pump (64), pressurizing on the brake fluid at the downstream side of the slave hydraulic cylinder (42). For the slave hydraulic cylinder (42) and the VSA apparatus (23) are selectively acted based on the operation amount of a brake pedal (12), the slave hydraulic cylinder (42) is acted when the high responsiveness of generating brake hydraulic pressure is not required, so that the miniaturization of the electric motor (44) is achieved and the VSA apparatus (23) is acted when the high responsiveness of generating brake hydraulic pressure is required, thereby ensuring the high responsiveness.

Owner:HONDA MOTOR CO LTD

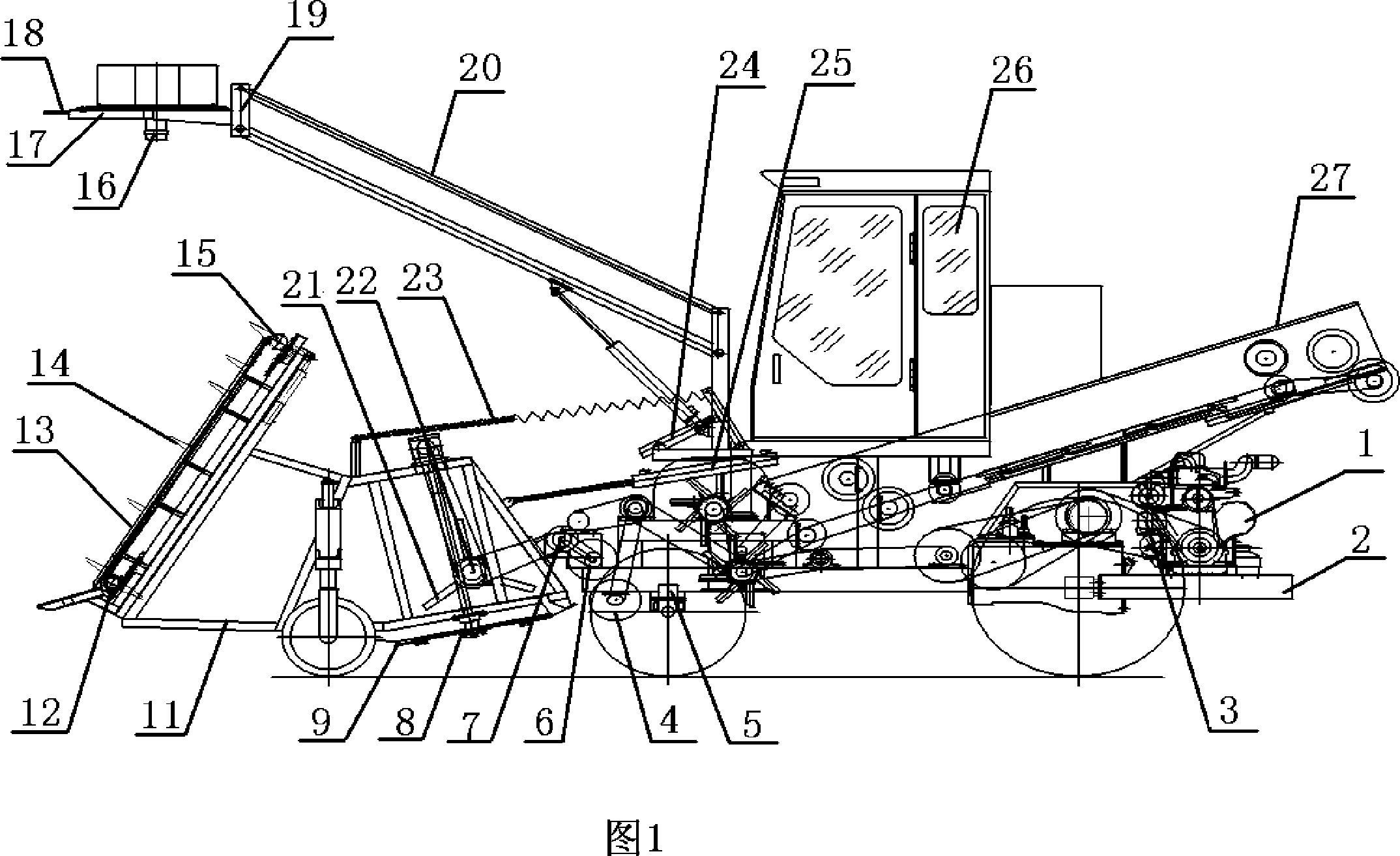

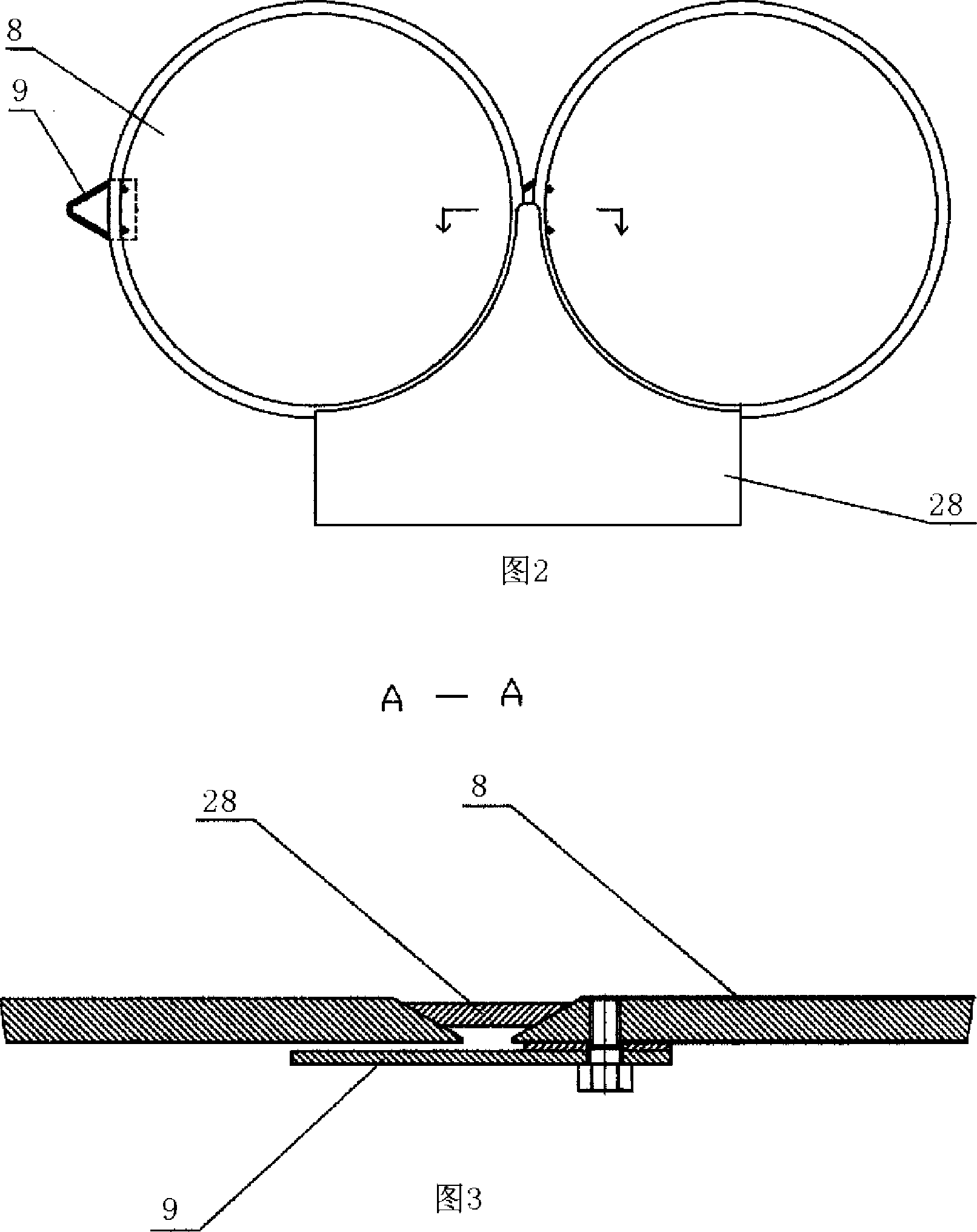

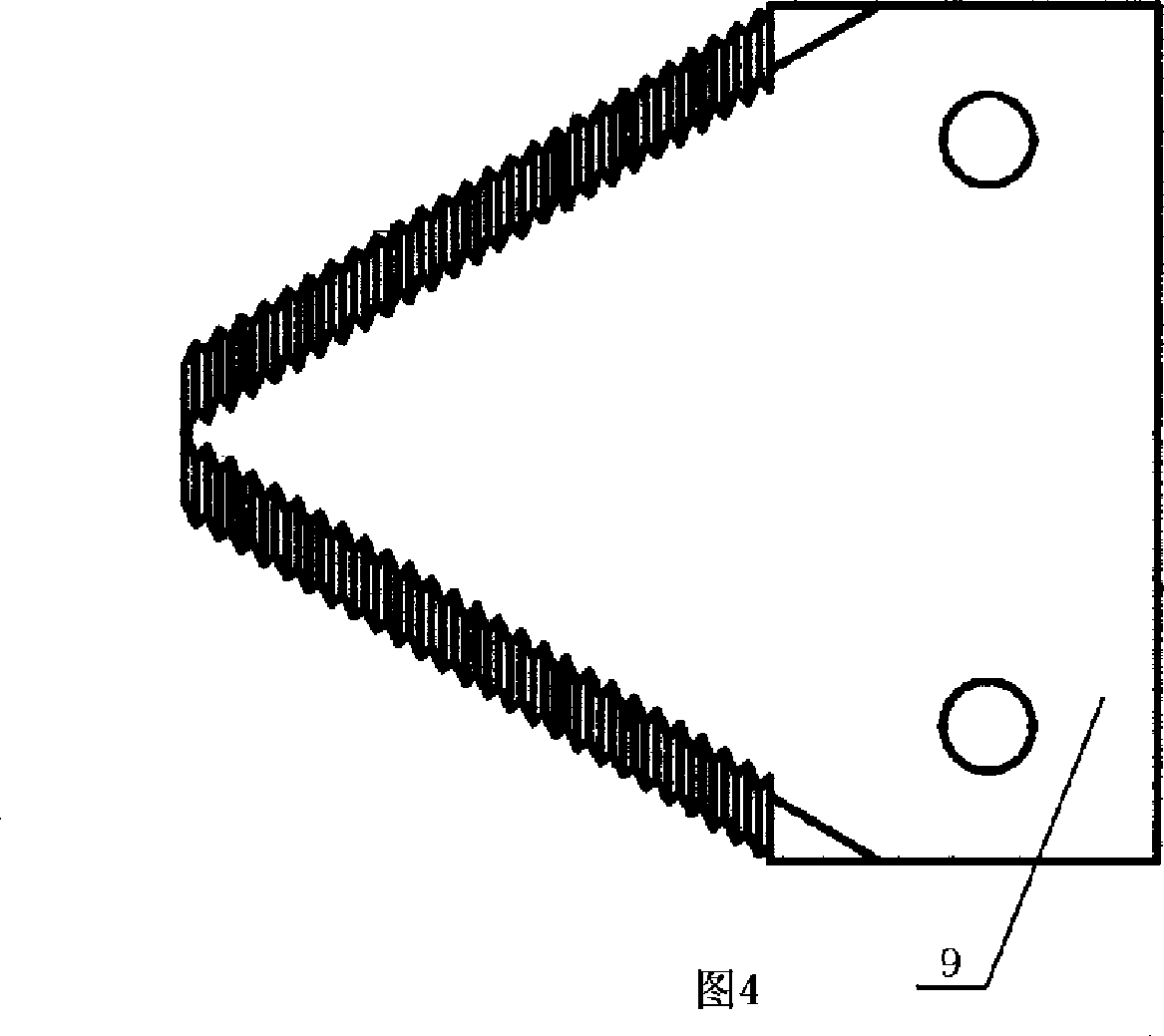

Machinery for harvesting sugarcane

InactiveCN101002526ALower the altitudeRealization of small size and light weightMowersAgricultural lifting devicesTurning framesEngineering

A sugar cane harvester is composed of a main frame assemblage with a rockerarm and a cane tip cutting unit, a harvesting platform assemblage in the front of said main frame assemblage and with two cane-holding units, a comb-shaped can pushing bar between two cane-holding units, a tooth-shaped cutting unit and a guide plate, and a leaf-stripping assemblage with a pair of horizontal delivering roller.

Owner:柳州市汉森机械制造有限公司

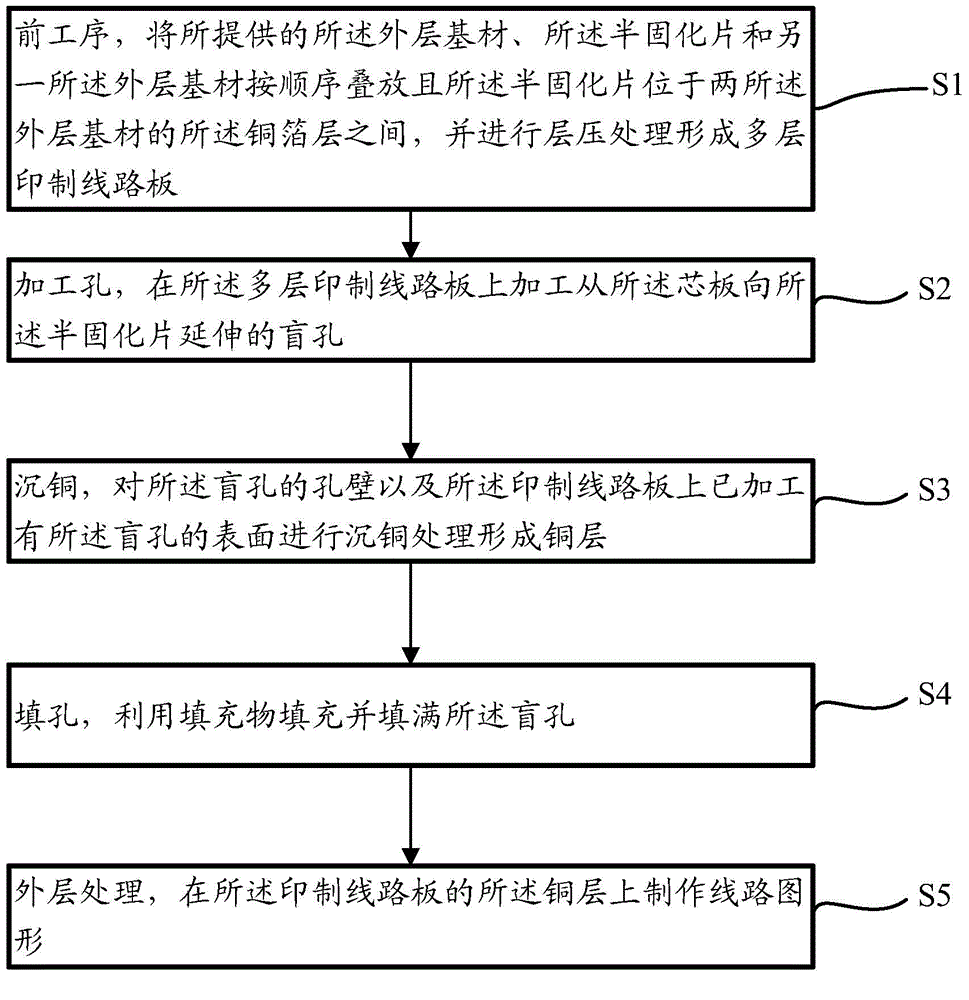

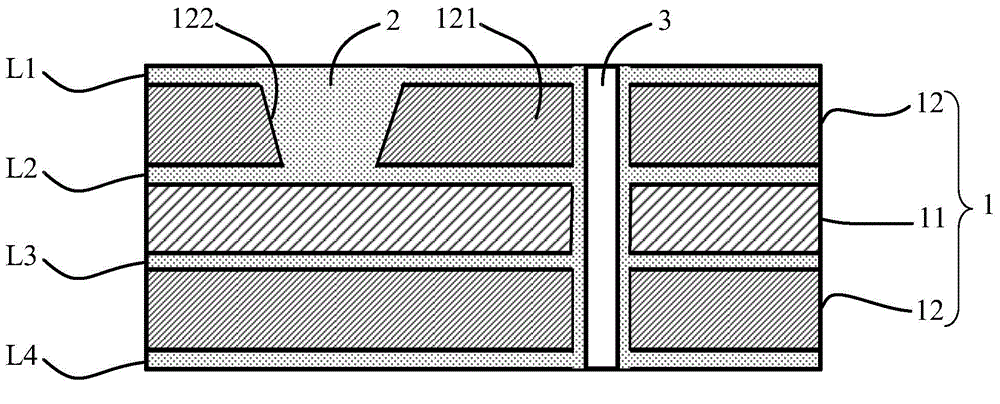

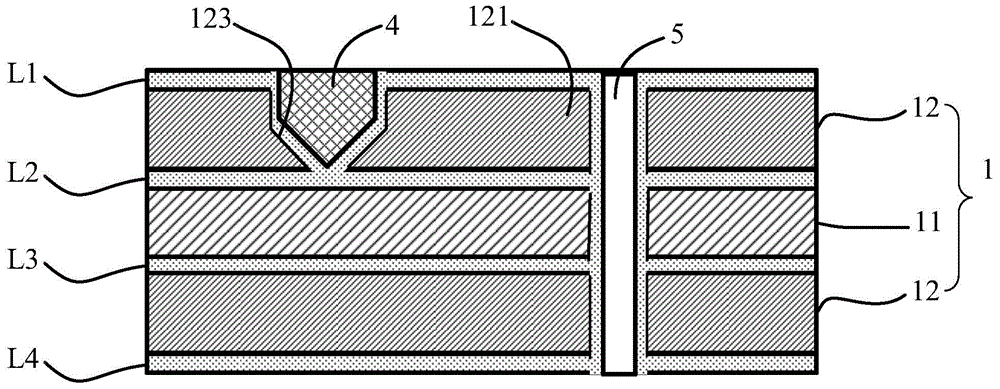

Processing method of printed circuit board

InactiveCN104427786AAchieving High Density InterconnectsRealization of small size and light weightPrinted element electric connection formationHigh densityElectrical connection

The invention is applicable to the technical field of printed circuit boards and provides a processing method of a printed circuit board and aims at solving a problem, which exists in the prior art, that before lamination, when a blind hole is drilled in a core board, core board fracture or fold is likely to happen. The method includes the following steps: a pre-procedure: laminating an outer-layer substrate, a prepreg and another outer-layer substrate sequentially and carrying out lamination processing so as to form a multi-layer printed circuit board; hole processing: processing a blind hole, which extends from the core board to the prepreg, in the multilayer printed circuit board; copper deposition: carrying out copper deposition processing on the blind-hole printed circuit board so as to form a copper layer; hole filling: using a filler to fill the blind hole fully; and outer-layer processing: manufacturing a line pattern. Through blind-hole processing on the multilayer printed circuit board after the lamination processing and hole filling processing of the blind hole, electrical connection with the inner-layer core board is realized so that a problem that in a process of hole processing in the inner-layer core board, fracture or fold happens is solved so that realization of high-density interconnection of printed circuit boards is facilitated.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

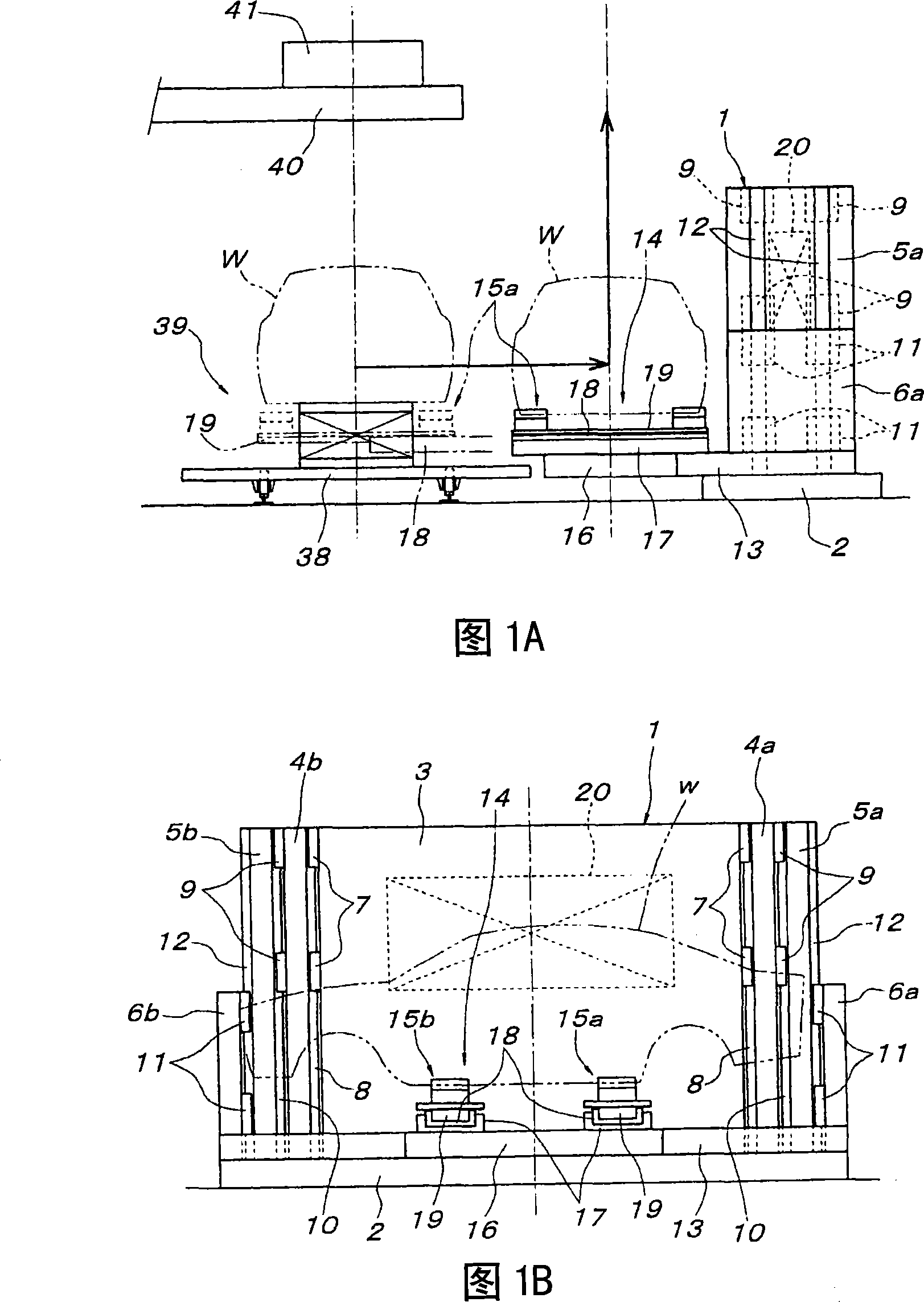

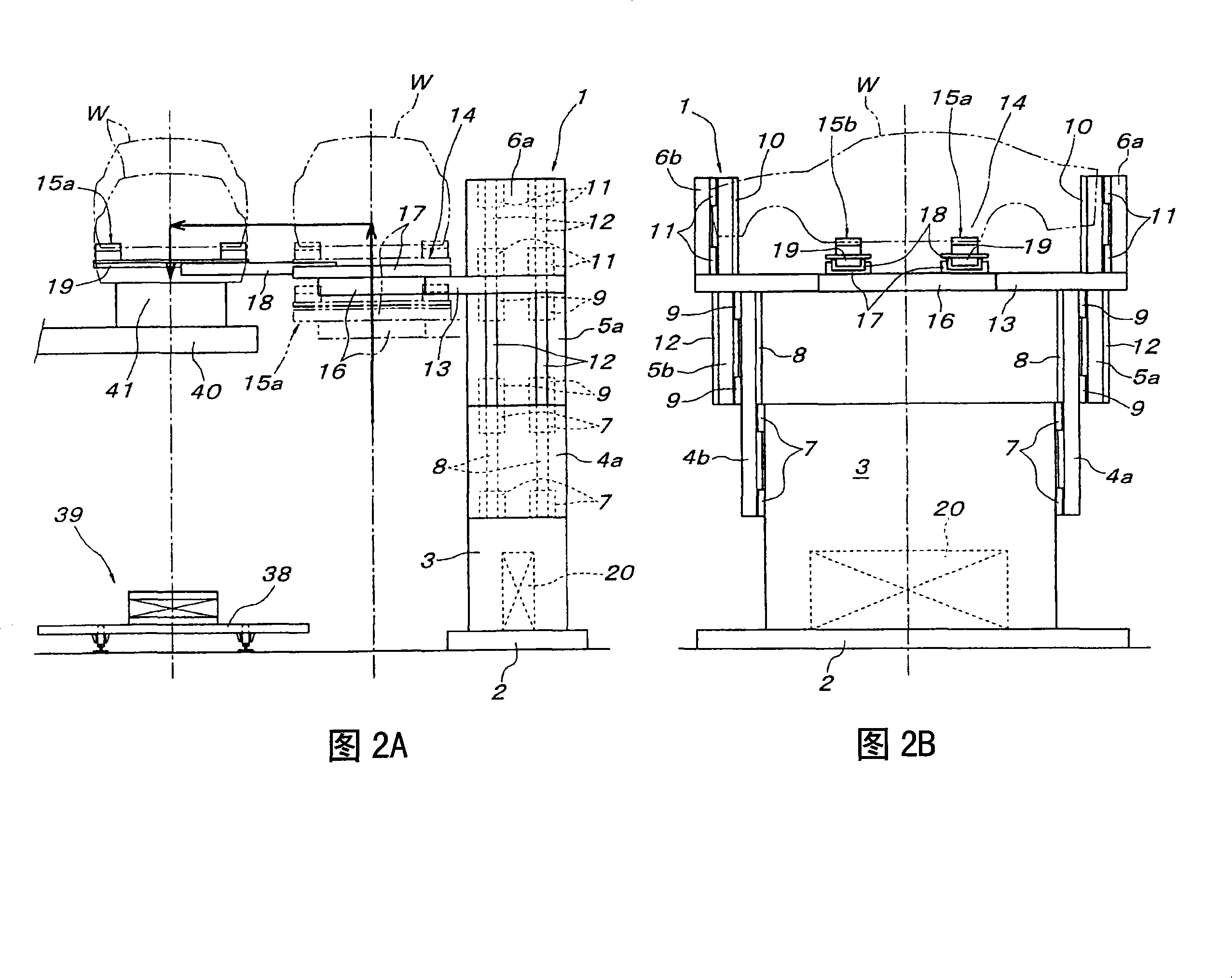

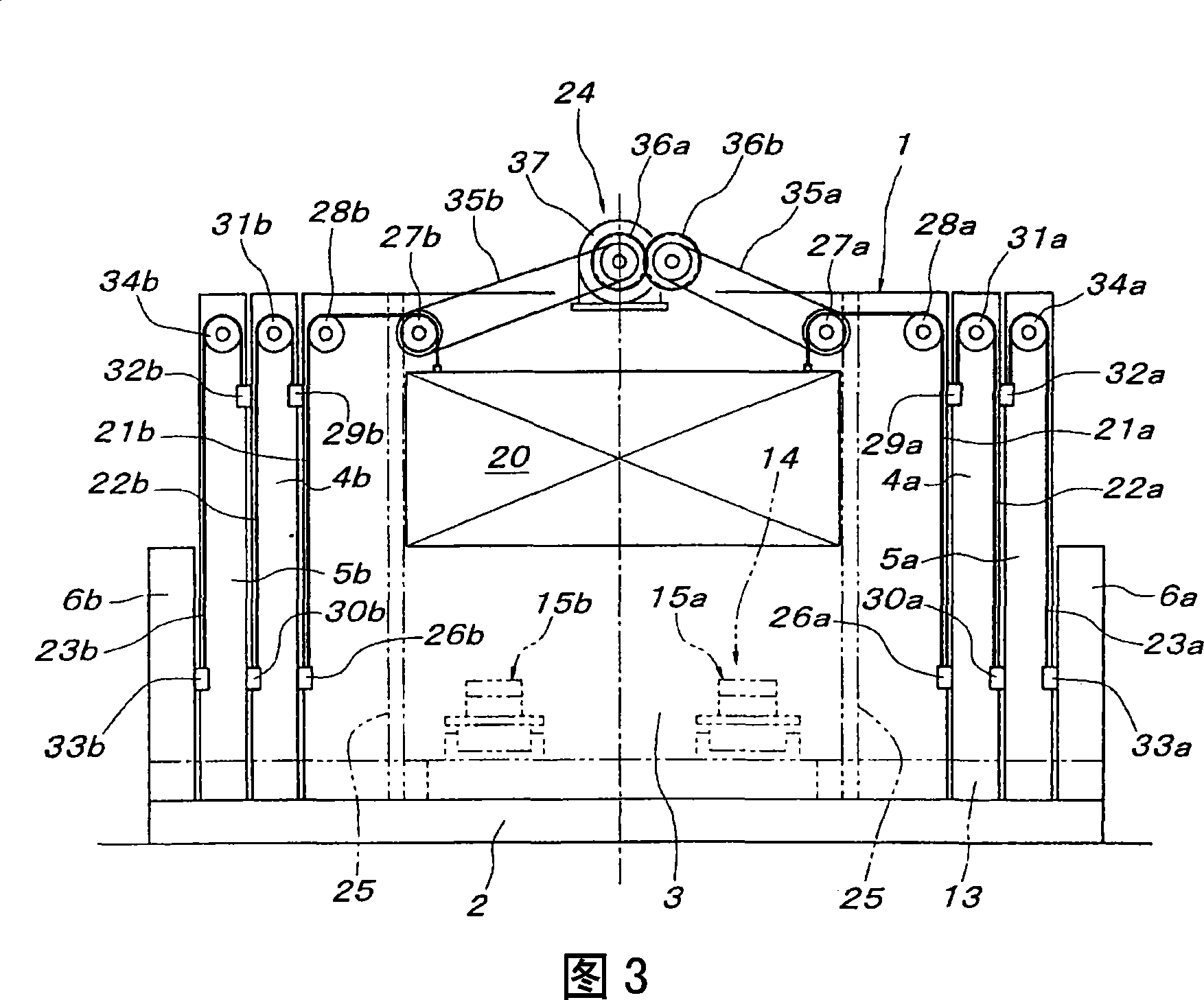

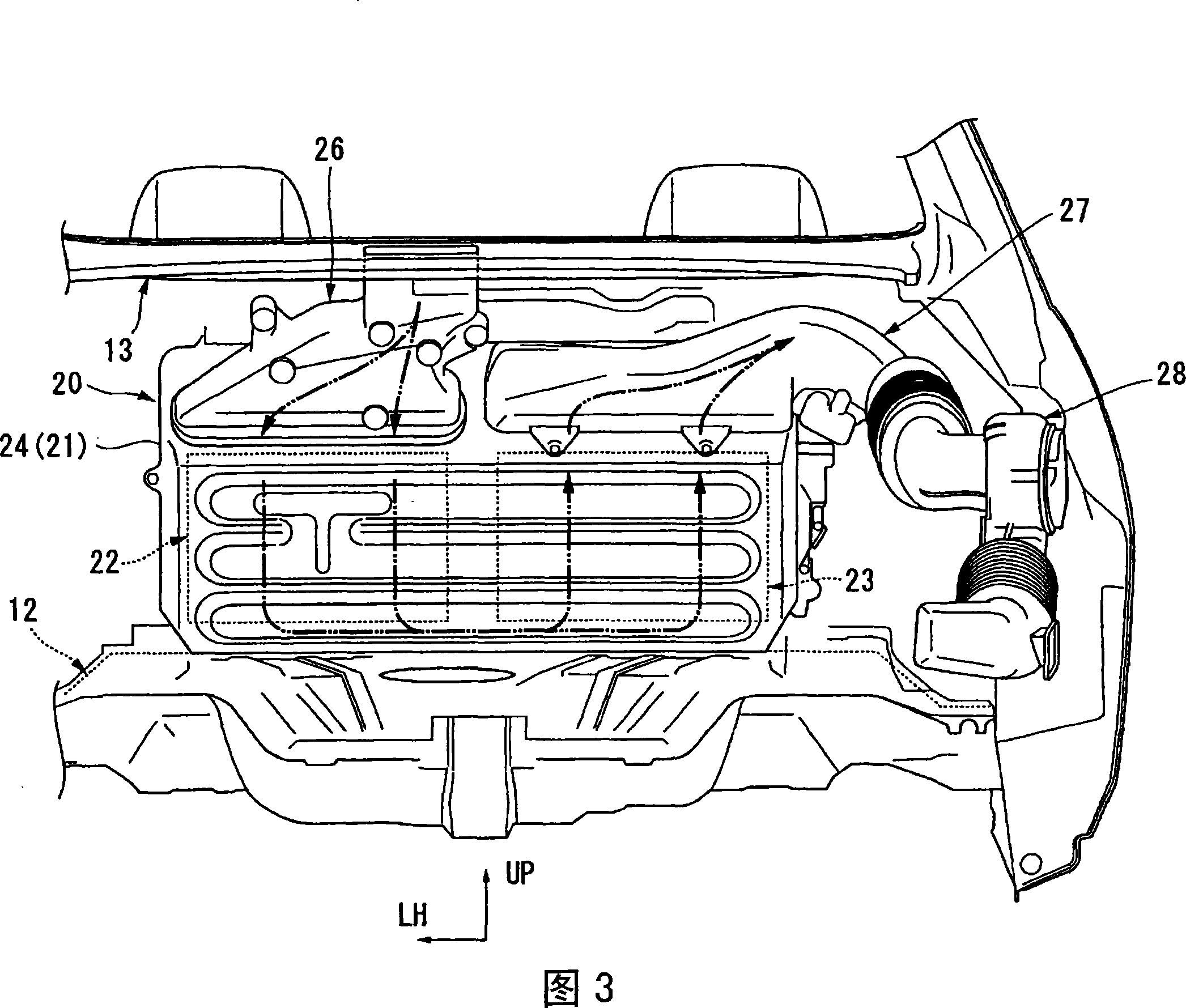

Elevating conveyance device

ActiveCN101234738AEasy to handleCompact structureLifting framesConveyor partsDistal portionAssembly line

The present invention provides a lifting and conveying device, which can improve the versatility of the lifting and conveying device that can be used in the transfer of automobile bodies in automobile assembly lines. The multi-section telescopic pillar body includes a fixed pillar part, at least one middle-section lifting pillar part, and a last-section lifting part. The transfer mechanism is arranged on the last-section lifting part. The inner lifting balance weight acts upward on the weight of the balance weight on the winding transmission part on the middle lifting pillar of the next section, and the lifting and lowering driven by the middle lifting pillar of the next section relative to the fixed pillar. The drive mechanism is composed of winding transmission parts that transform the rising motion of the middle lifting pillar part into the rising movement of the middle lifting pillar part or the last lifting part of the next stage.

Owner:DAIFUKU CO LTD

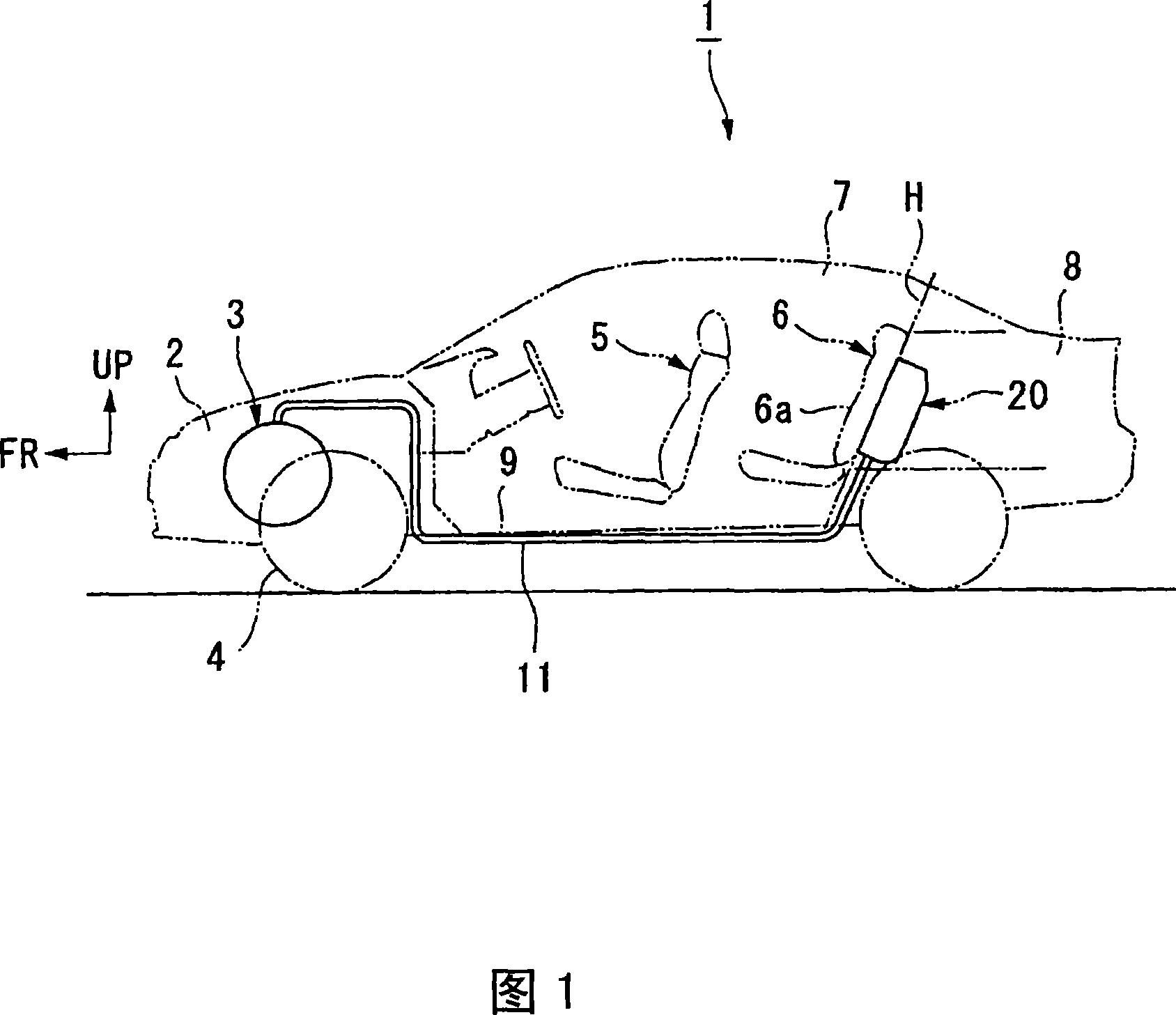

Temperature sensor mounting structure and battery module structure

ActiveCN101164181AEasy maintenanceImprove temperature detection accuracyCharging stationsElectric devicesElectrical batteryEngineering

A temperature sensor mounting structure for a battery module that is formed by connecting single cells together in series including: a temperature-measuring device that detects the temperature of the battery module; a covering device that covers the temperature-measuring device; and movement-restricting devices that are removably engaged with the battery module and restrict the movement of the covering device.

Owner:HONDA MOTOR CO LTD

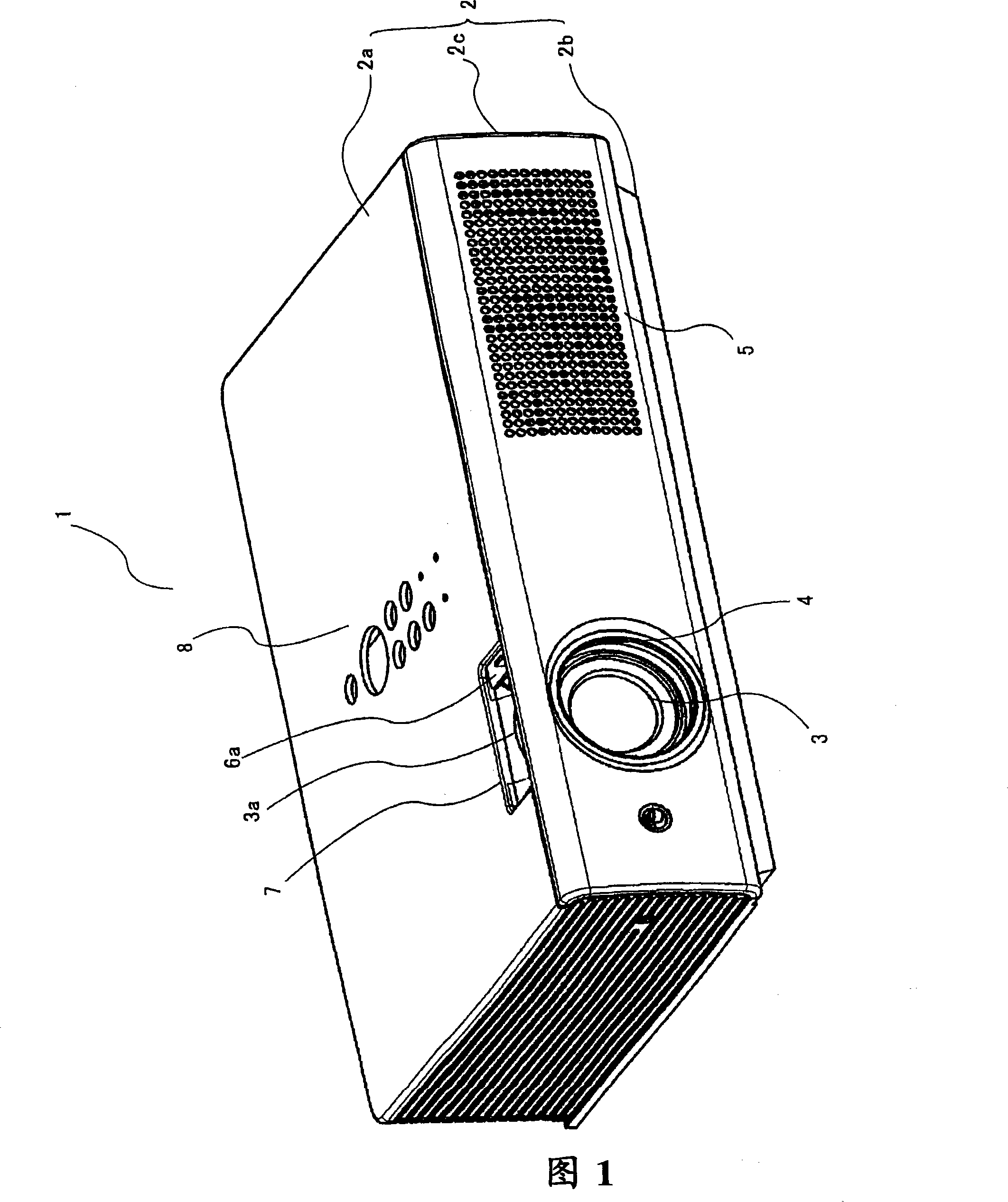

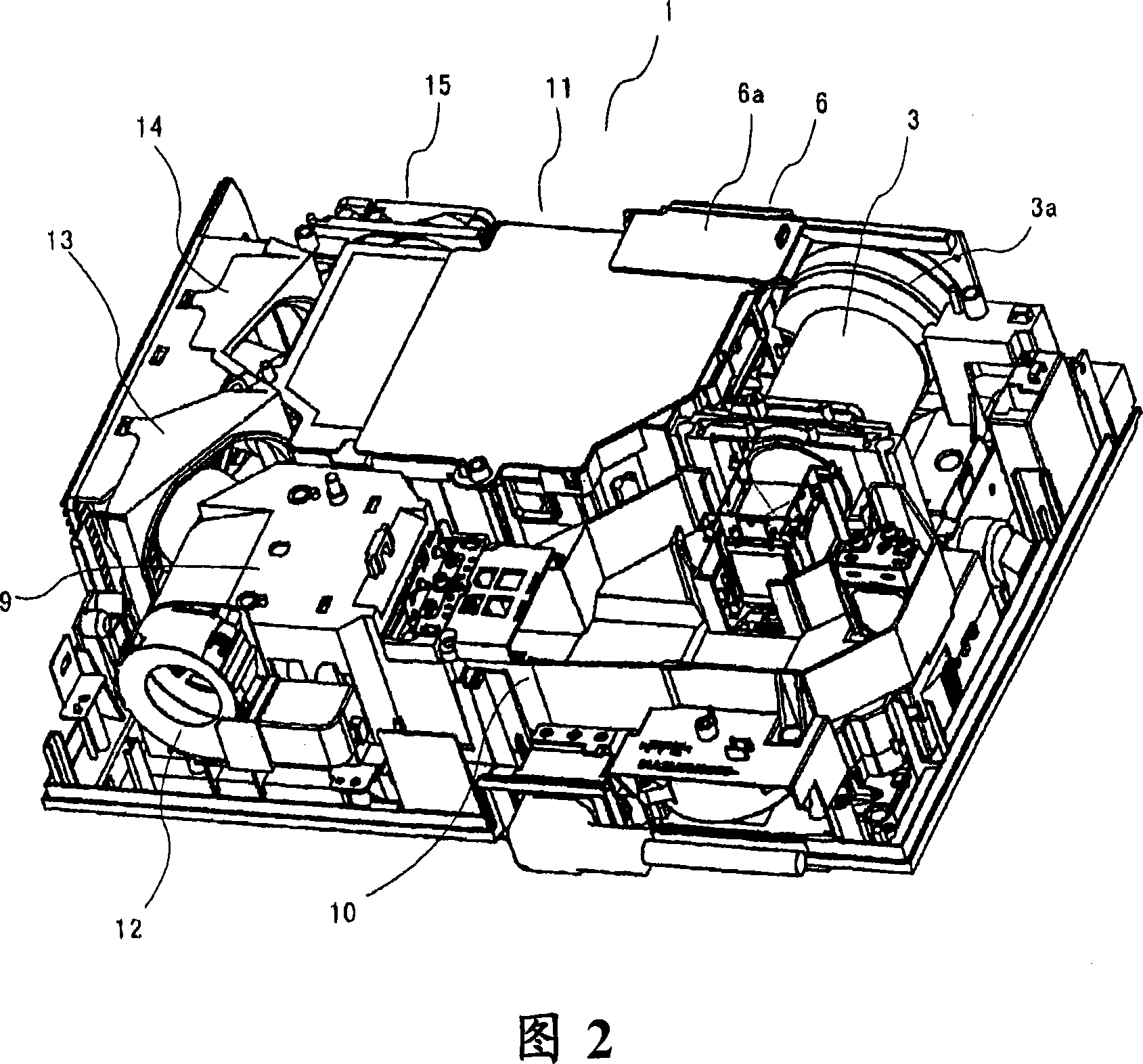

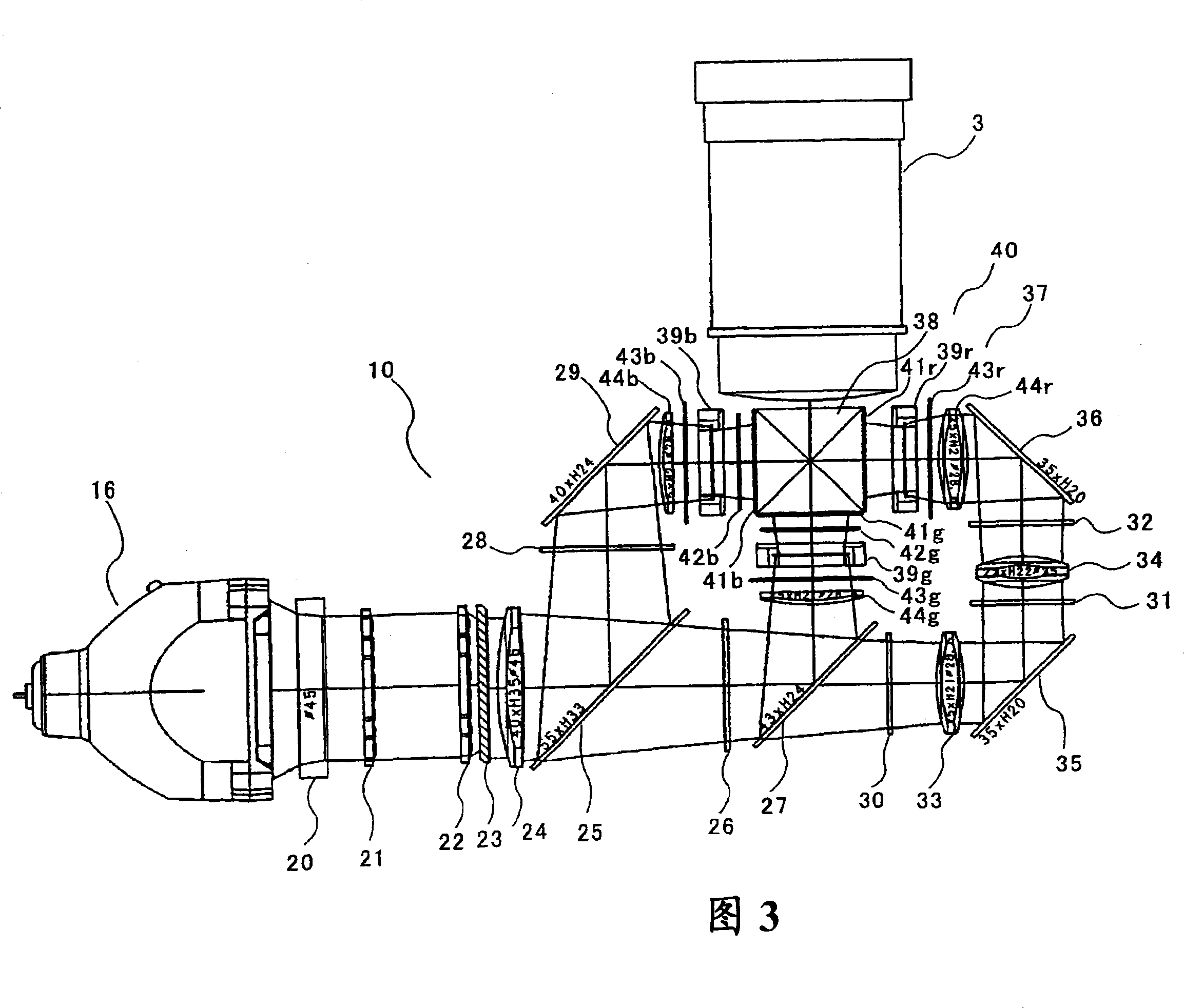

Light source lamp cooling mechanism and projection type image displaying device employing the same

ActiveCN101165589AAchieve high output powerRealization of small size and light weightProjectorsCooling/ventilation/heating modificationsEngineeringElectrical and Electronics engineering

A projection type image display apparatus of the invention is equipped with a lamp cooling mechanism, which has a duct ( 121 ) for guiding the air sent from an air intake fan ( 12 ) in the forward direction from a position lateral to a lamp ( 16 ). The duct ( 121 ) has a curved wall ( 122 ) for directing the air in the duct ( 121 ) to the air intake port ( 164 ) formed near the open end of the lamp ( 16 ). The lamp cooling mechanism has a further guide plate ( 123 ) for spreading the air stream directed by the curved section ( 122 ) over the region from the tip ( 161 b) to the luminous section ( 161 a) of the lamp ( 16 ). As a consequence, relevant sections of the lamp can be efficiently cooled, thereby simultaneously enabling uprating of power of the light source unit and downsizing and lightening of the image display apparatus without supplying the fan with a large amount of power.

Owner:SANYO ELECTRIC CO LTD

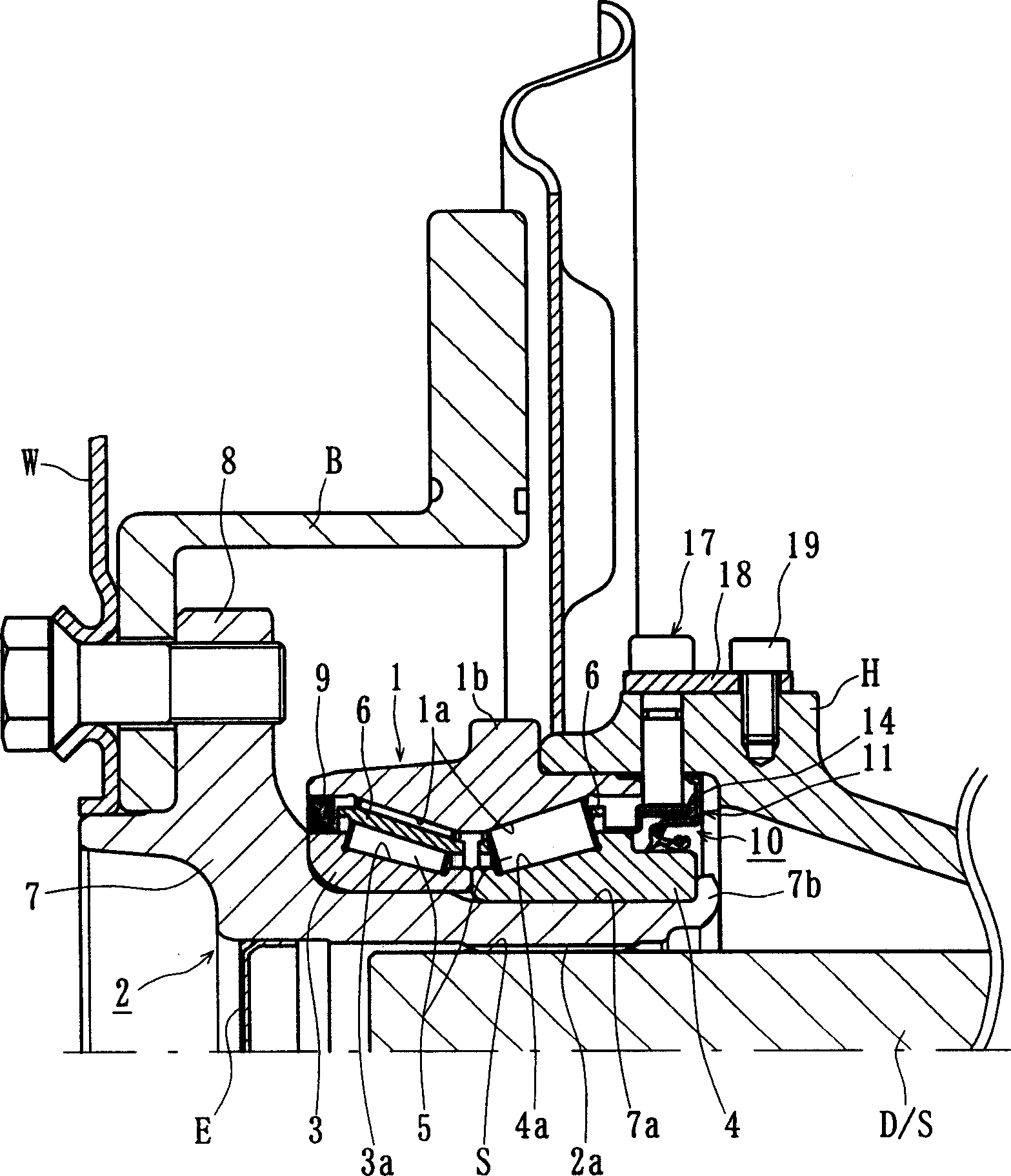

Rolling bearing for a wheel of vehicle and a semi-float type bearing apparatus having it

ActiveCN1573150AGuaranteed areaAvoid enteringEngine sealsRoller bearingsPulsarRolling-element bearing

A vehicle wheel rolling bearing has a sealing device integrated with a magnetic encoder. A semi-float type bearing apparatus has said rolling bearing which can protect a magnetic encoder and improve the sensing ability of the detecting sensor. The rolling bearing has an inner member with a wheel hub having a wheel mounting flange and an inner ring formed with inner raceway surfaces. An outer member is formed with double row outer raceway surfaces opposite the inner raceway surfaces. Double row rolling elements are between the raceway surfaces. Sealing devices include an inboard sealing device with an annular seal fitted on the outer member. A pulsar ring is mounted on the inner member and has an encoder mounted on a cylindrical holding portion. The encoder is arranged opposite to the annular seal. The encoder includes magnetic poles formed by magnetic powder with alternating polarity along its circumferential direction. A detecting sensor passes through the cylindrical portion of the seal and opposes the encoder. A predetermined air gap is kept between the encoder and detecting sensor.

Owner:NTN CORP

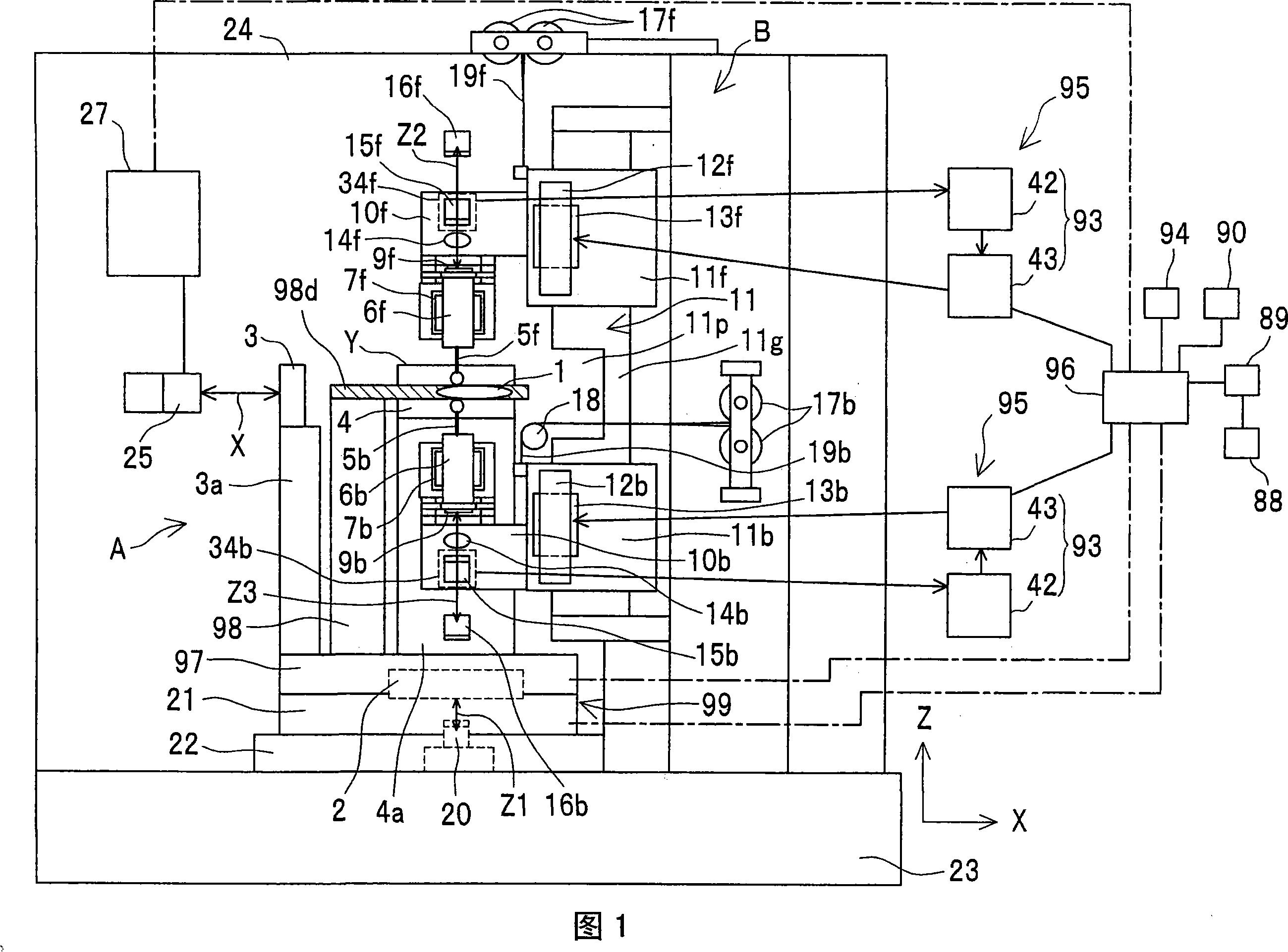

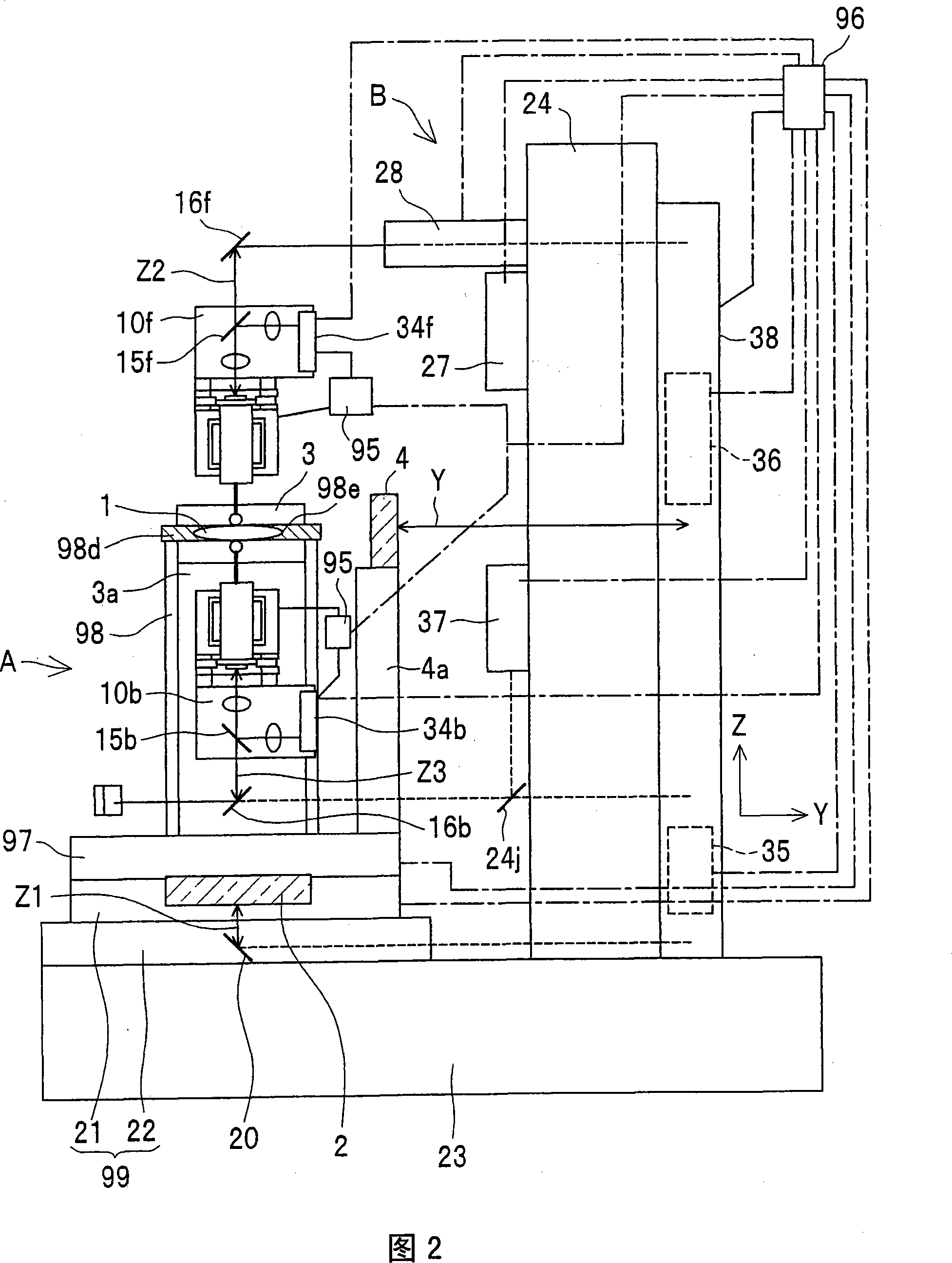

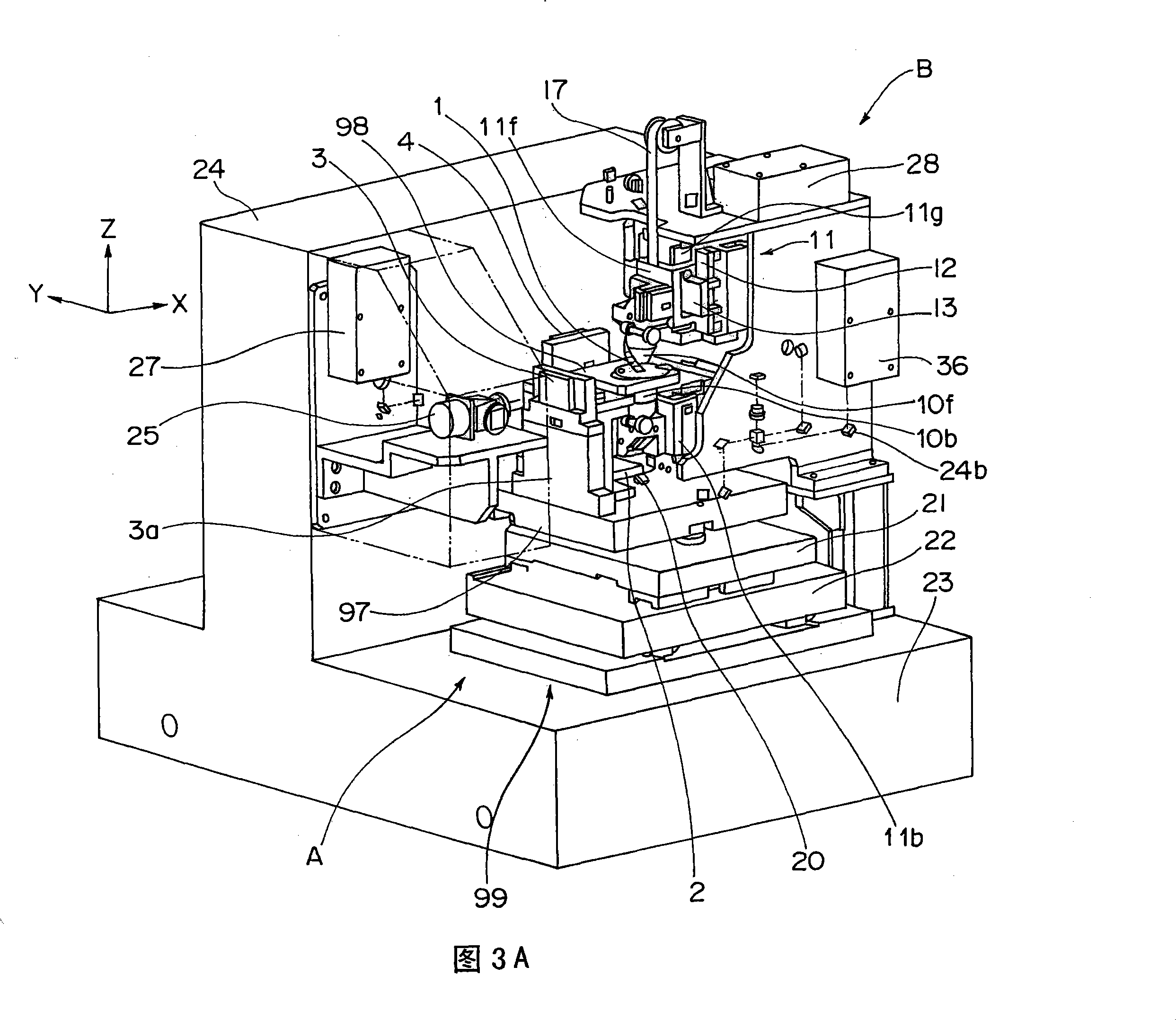

3d shape testing device

ActiveCN101173854AHalf the costImprove responsivenessMechanical counters/curvatures measurementsUsing optical means3d shapesMeasurement device

The invention provides a three-D shape measurement device. XYZ reference mirrors (2, 3, 4) of XYZ coordinates and a Z pneumatic sliding rail part (11) are formed through the sharing on the upper and lower sides, so that the upper and the lower measurement coordinate systems are made completely identical. In addition, a dislocation detecting unit for a contact pin (5) is made thinner by a diffraction grating (8), and the bearing part of a probe is made further thinner through the use of a pulley (18) and a dead load spring (17). Hereby, the structure is made simple, the miniaturization is achieved, and the manufacturing is easy.

Owner:PANASONIC CORP

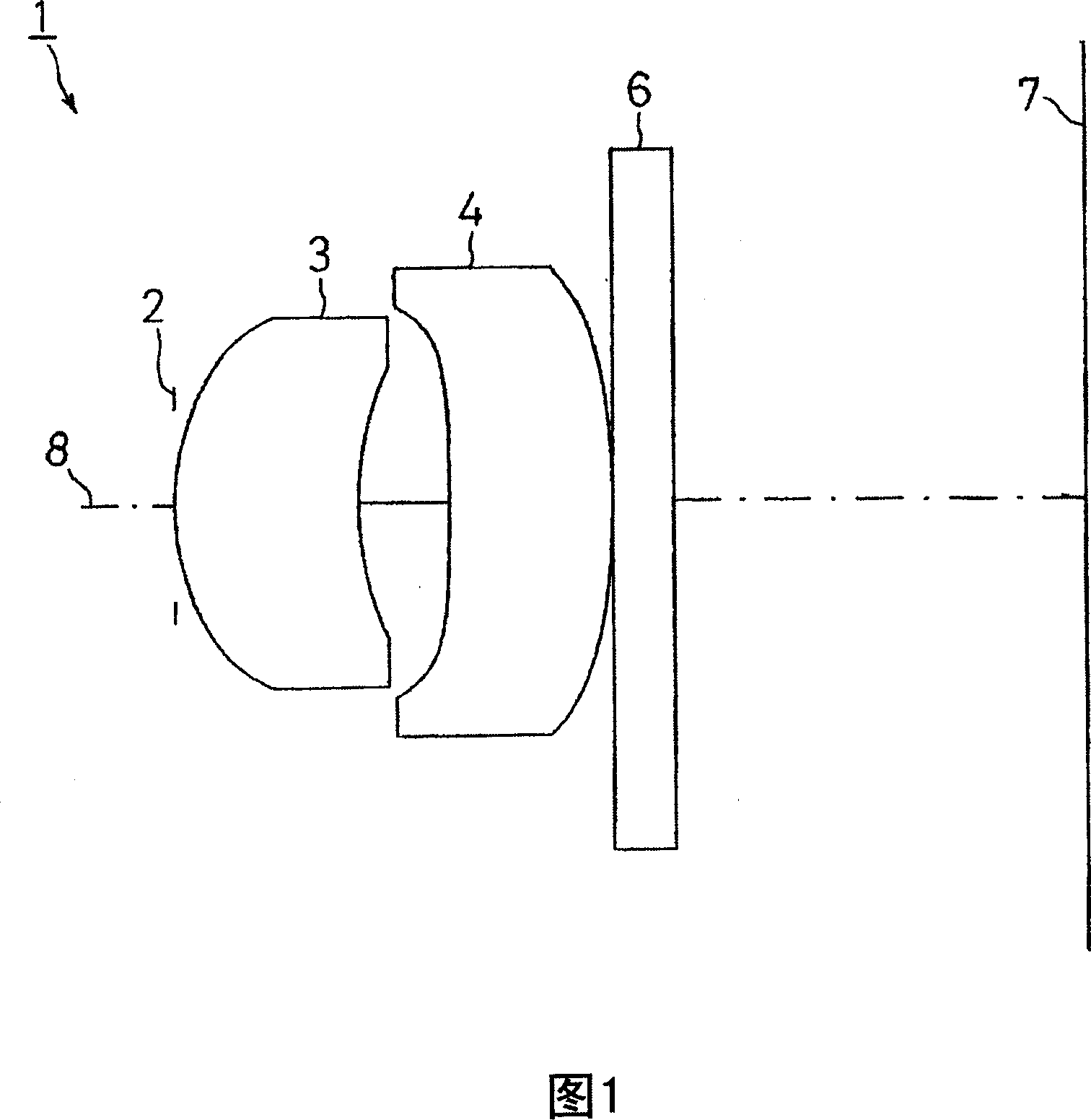

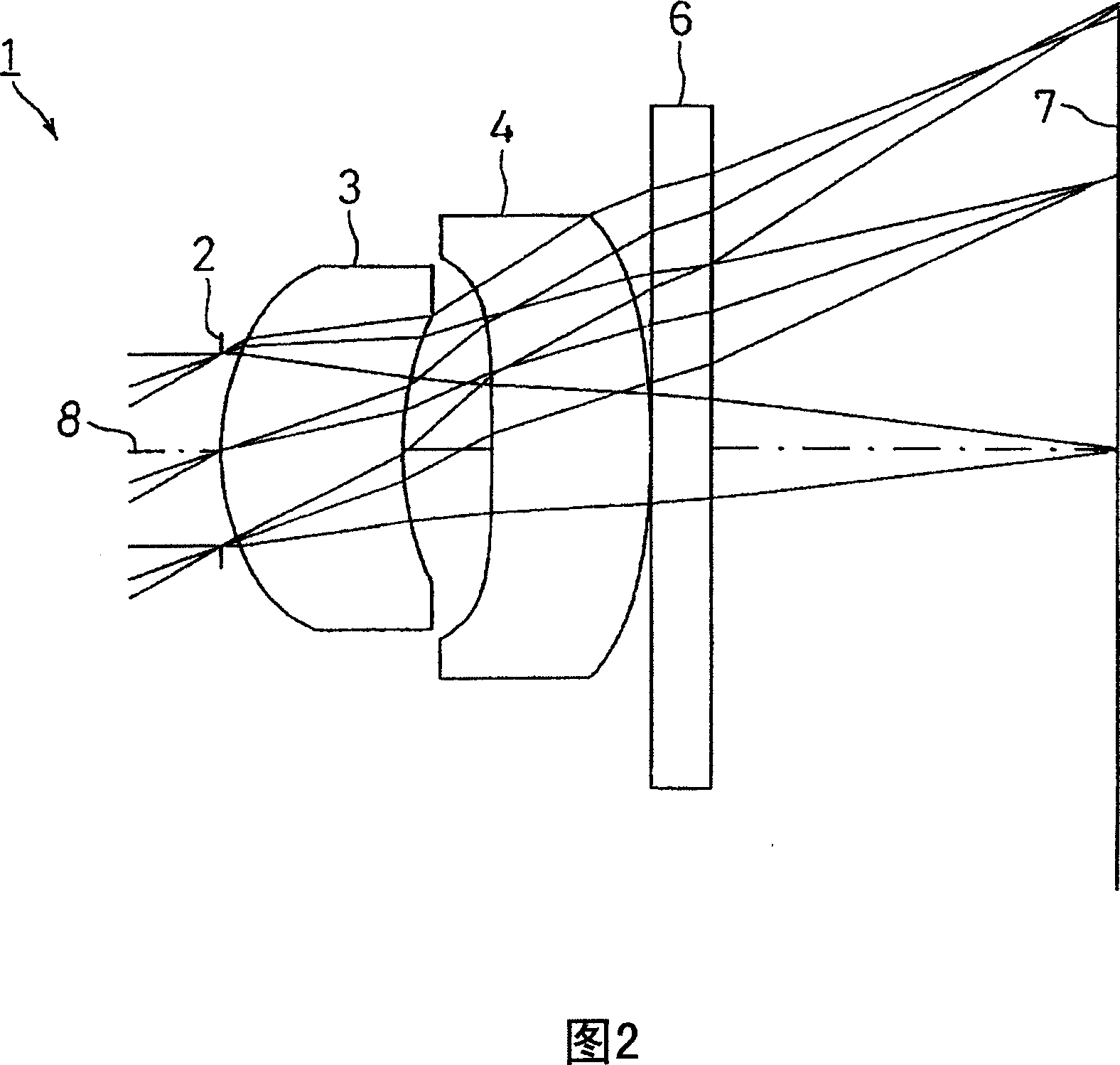

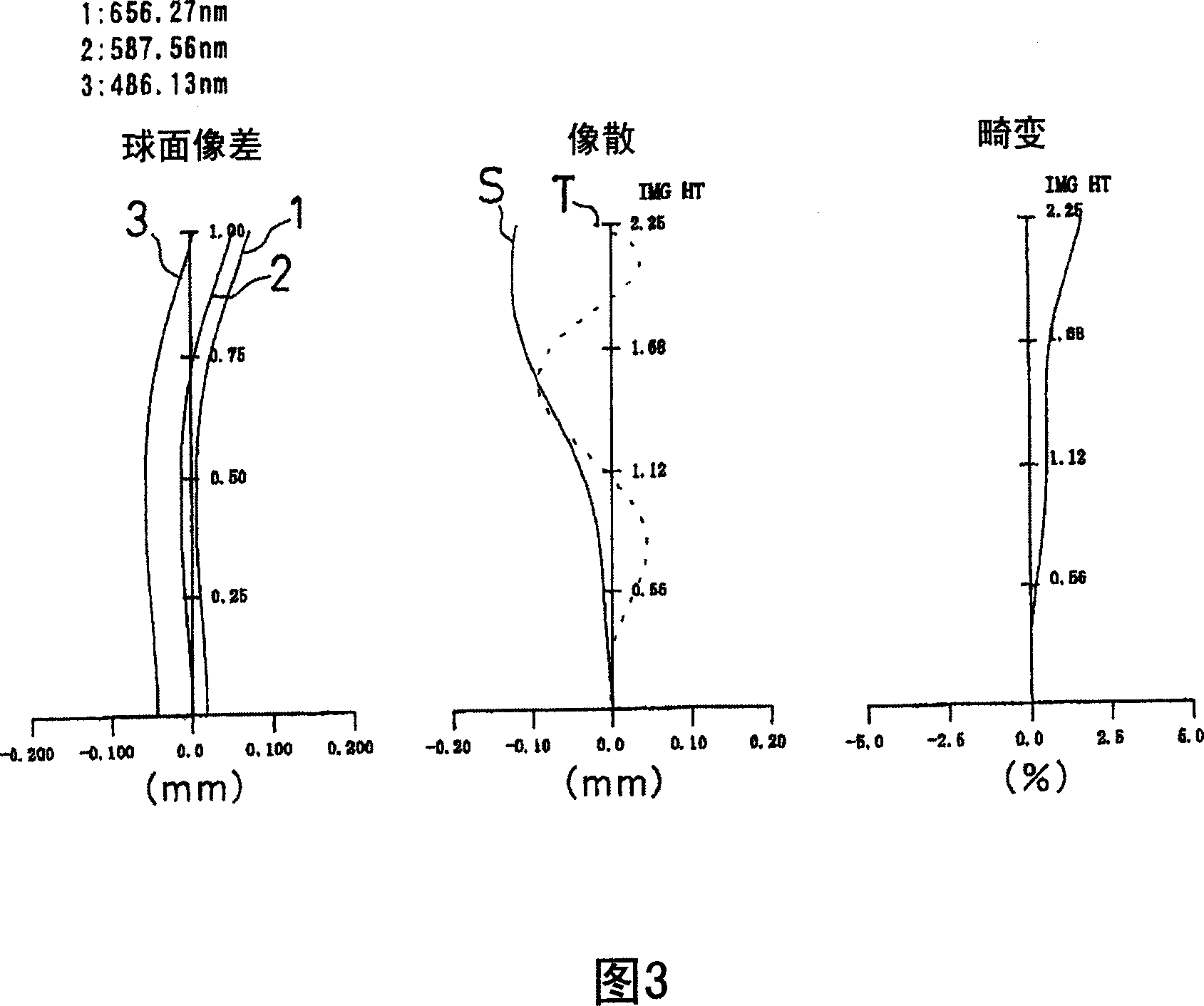

Imaging lens

It is to provide an imaging lens that can sufficiently handle the demands for reduction in size and weight and further improvement in the optical performance to improve the production. The imaging lens comprises, in order from the object towards the image side , a diaphragm, a first lens which is a meniscus lens, the convex surface of which faces the object, and a second lens which is a lens having positive power, the convex surface of which faces the image, wherein conditions expressed by each of following inequalities (1)-(6) are to be satisfied; 1.25 L / fl 0.8, 1 f 1 / f 2 0.2, 1.8 f 1 / fl 1, 0.5>d 2 / d 1 0.2, 0.35 d 1 / fl 0.1, and 0.27 d 3 / fl 0.1 (where, L: entire length of the lens system, fl: focal distance of the entire lens system, f 1 : focal distance of the first lens, f 2 : focal distance of the second lens, d 1 : center thickness of the first lens, d 2 : space between the first lens and the second lens on the optical axis, and d 3 : center thickness of the second lens).

Owner:ENPLAS CORP

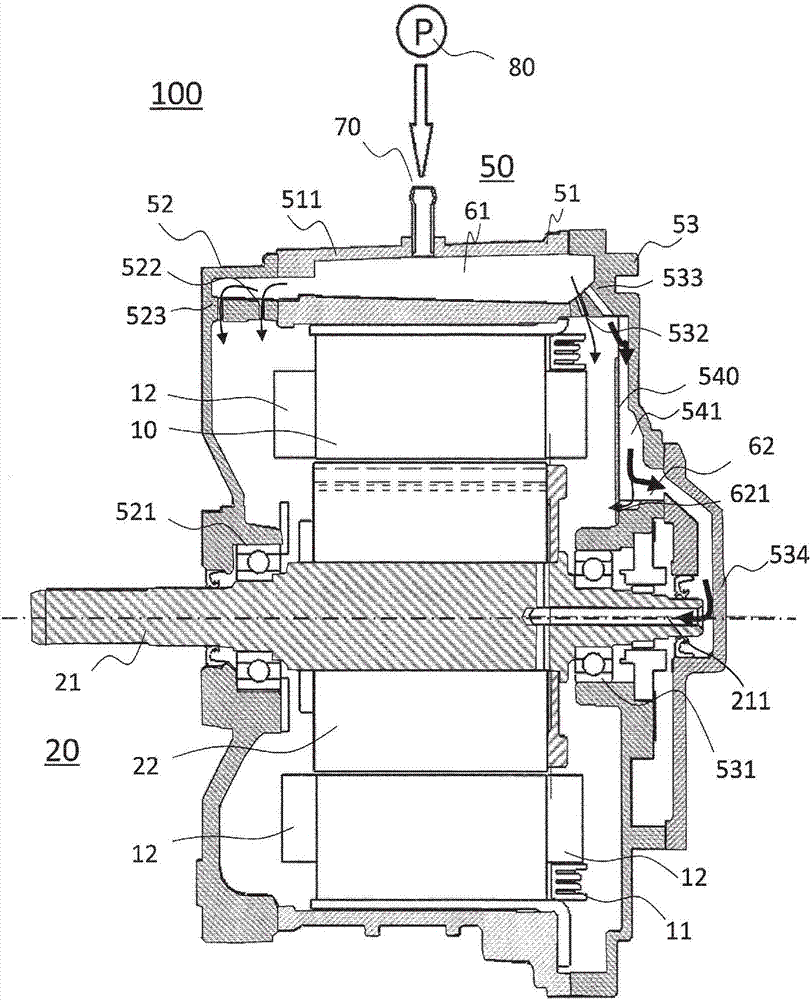

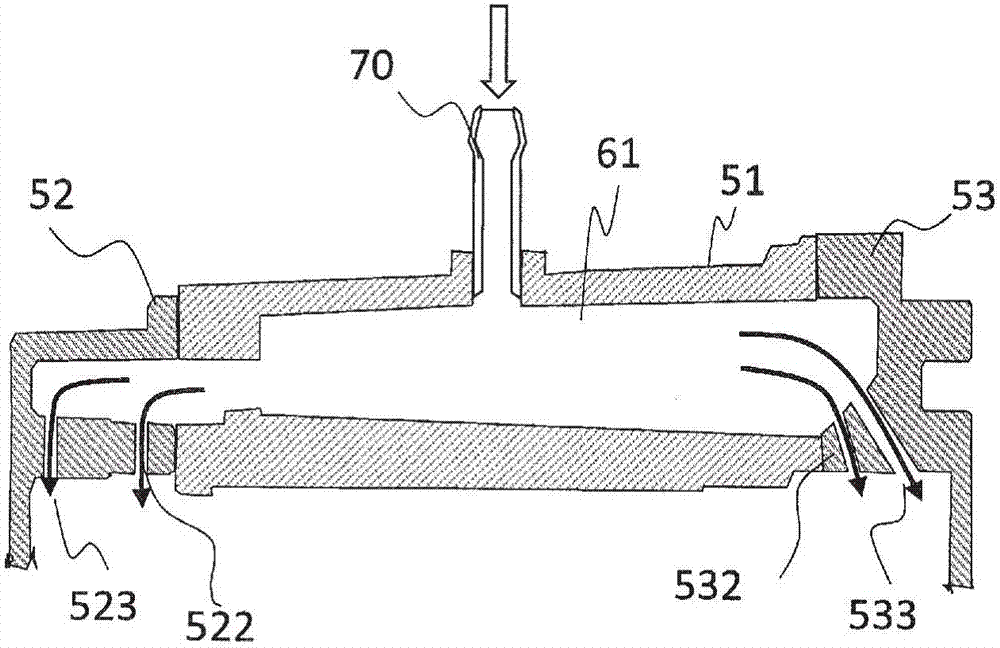

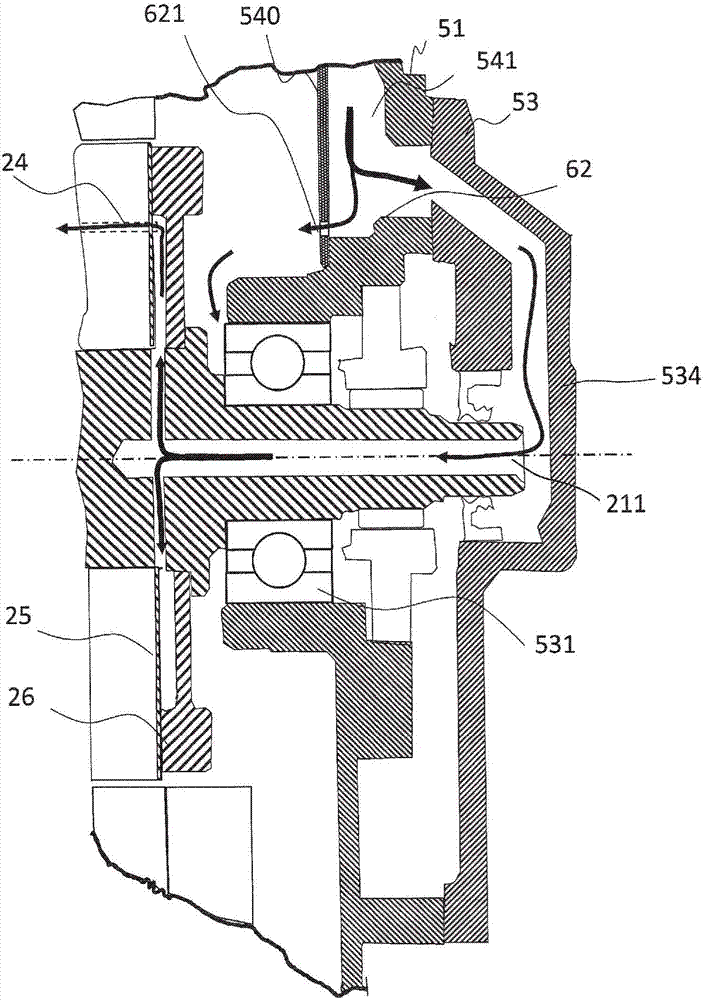

Dynamo-electric machine

InactiveCN107078606AReliable supplyRealization of small size and light weightCooling/ventillation arrangementSupports/enclosures/casingsElectric machineEngineering

In order to efficiently cool a stator and a rotor of a dynamo-electric machine, cooling oil is supplied in a pressurized state by a pump to a first reservoir provided in a top part within a housing, and after the cooling oil is sprayed from the first reservoir, the cooling oil is guided by gravity to a cooling structure for a coil end of the stator, and a cooling structure for a bearing and a rotor iron core of the rotor.

Owner:MITSUBISHI ELECTRIC CORP

Gas breaker

InactiveCN1700380AIncrease gas pressureRealization of small size and light weightHigh-tension/heavy-dress switchesAir-break switchesFilling materialsContactor

The objective is to provide a gas circuit breaker improving an arc distinguishing performance. The gas circuit breaker is provided with: a fixed contactor 1 and a movable contactor 2 contactably and separably arranged in a container filled with an insulating gas; a tubular nozzle 10 installed surrounding the contact-separation parts of the fixed contactor and the movable contactor; and a buffer room 7 to compress the insulating gas and eject it into the nozzle while interlocked with the movable contactor. A nozzle 10 is formed by a composite material composed by adding an inorganic filler to a resin of lower heat resistance than that of a fluororesin, gas pressure inside the nozzle is elevated by an abrasion gas generated from the resin of lower heat resistance than that of the fluororesin by arc energy, and the arc distinguishing performance is improved.

Owner:JAPAN AE POWER SYST

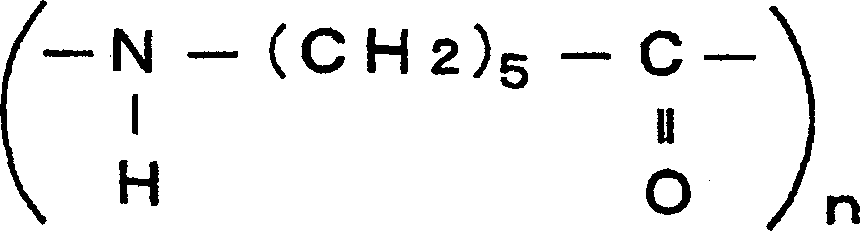

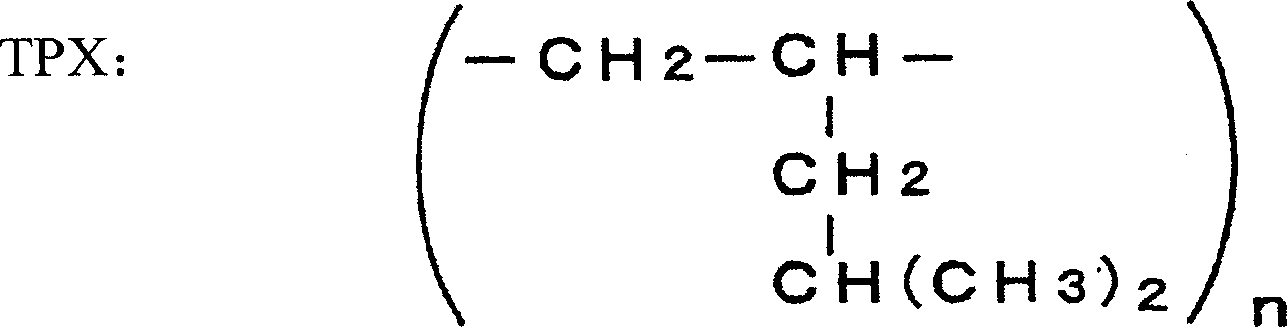

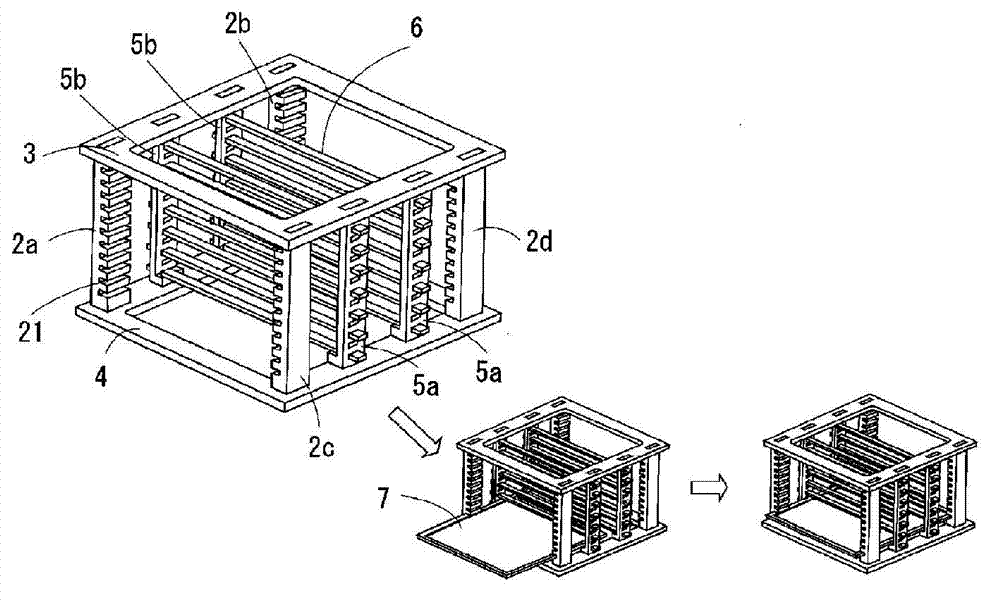

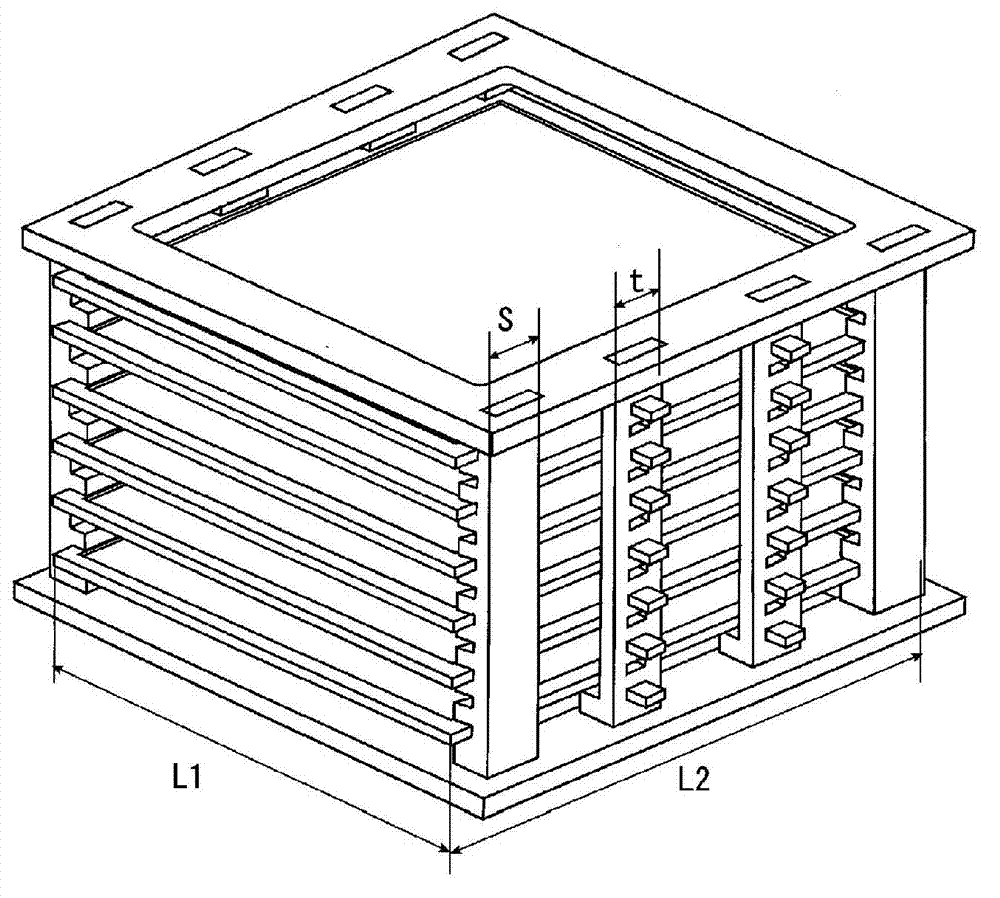

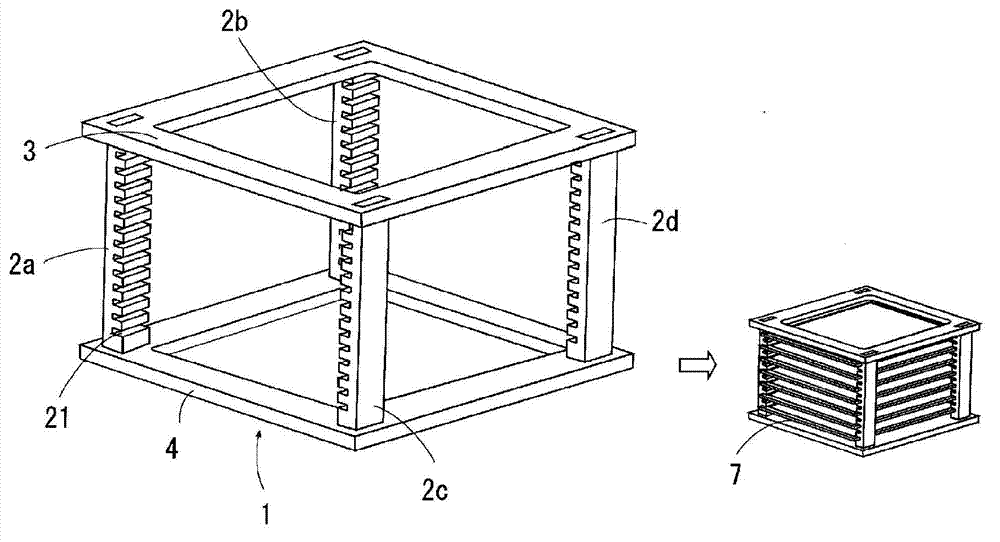

Rack for firing

ActiveCN103097845AEasy to passIncrease heat radiation rateCharge supportsCharge manipulationSetterEngineering

Provided is a rack for firing which holds a plurality of flat board-like setters at multiple levels in the perpendicular direction by means of a setter holding means, and fires electronic ceramic elements at multiple levels. The setter holding means is composed of a material composed of Si-SiC containing 0.01-30 % of Si or recrystallized SiC or Si3N4-SiC, and the setter holding means holds each of the flat board-like setters with 70-100 % of the outer circumferential side surface thereof exposed. Consequently, the rack has excellent energy efficiency, mass-production efficiency, and uniform heating characteristics at each of the multiple levels in the multiple-level firing.

Owner:NGK INSULATORS LTD +1

Articulation unit for robot and robot

InactiveCN102341221ARealization of small size and light weightPrevent splashProgramme-controlled manipulatorMechanical apparatusReduction driveGear wheel

Provided are a differential articulation unit which makes it possible to carry a heavier weight by effectively utilizing the outputs of two motors due to interference-drive and which can be made small and light-weighted, and a robot using the differential articulation unit. A cover / support structure which is a support member for covering the entirety of a set of opposed bevel gears and output bevel gears from the outside is provided to rotatably support the output bevel gears. A wave generator of a wave reduction gear is secured coaxially to the outside of a rotor of an outer rotor motor and the bevel gears are secured to a circular spline or a flex spline, which is an output member. The motor, the bevel gears, and the wave reduction gear are hollow so that a wiring passes therein.

Owner:YASKAWA DENKI KK

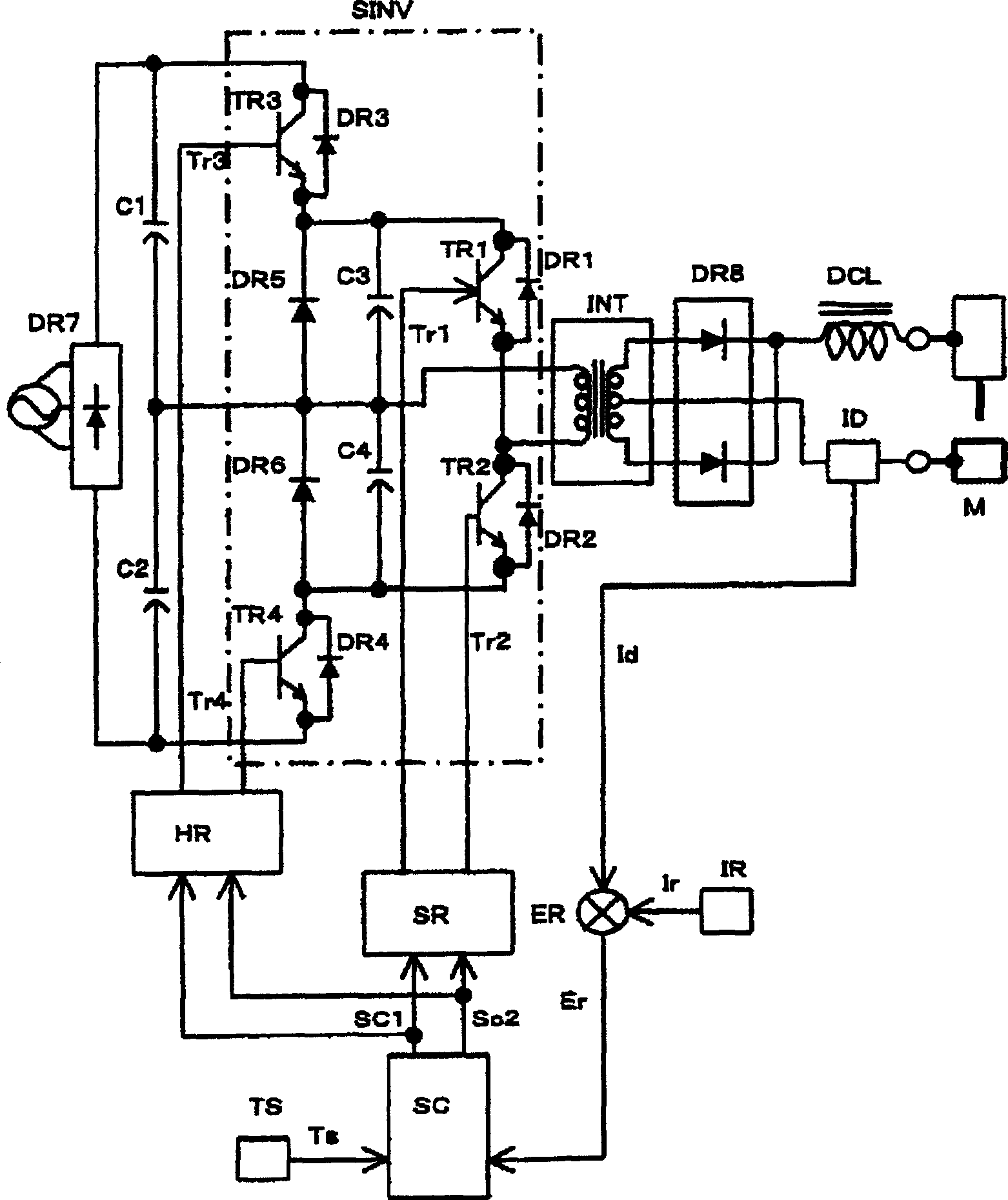

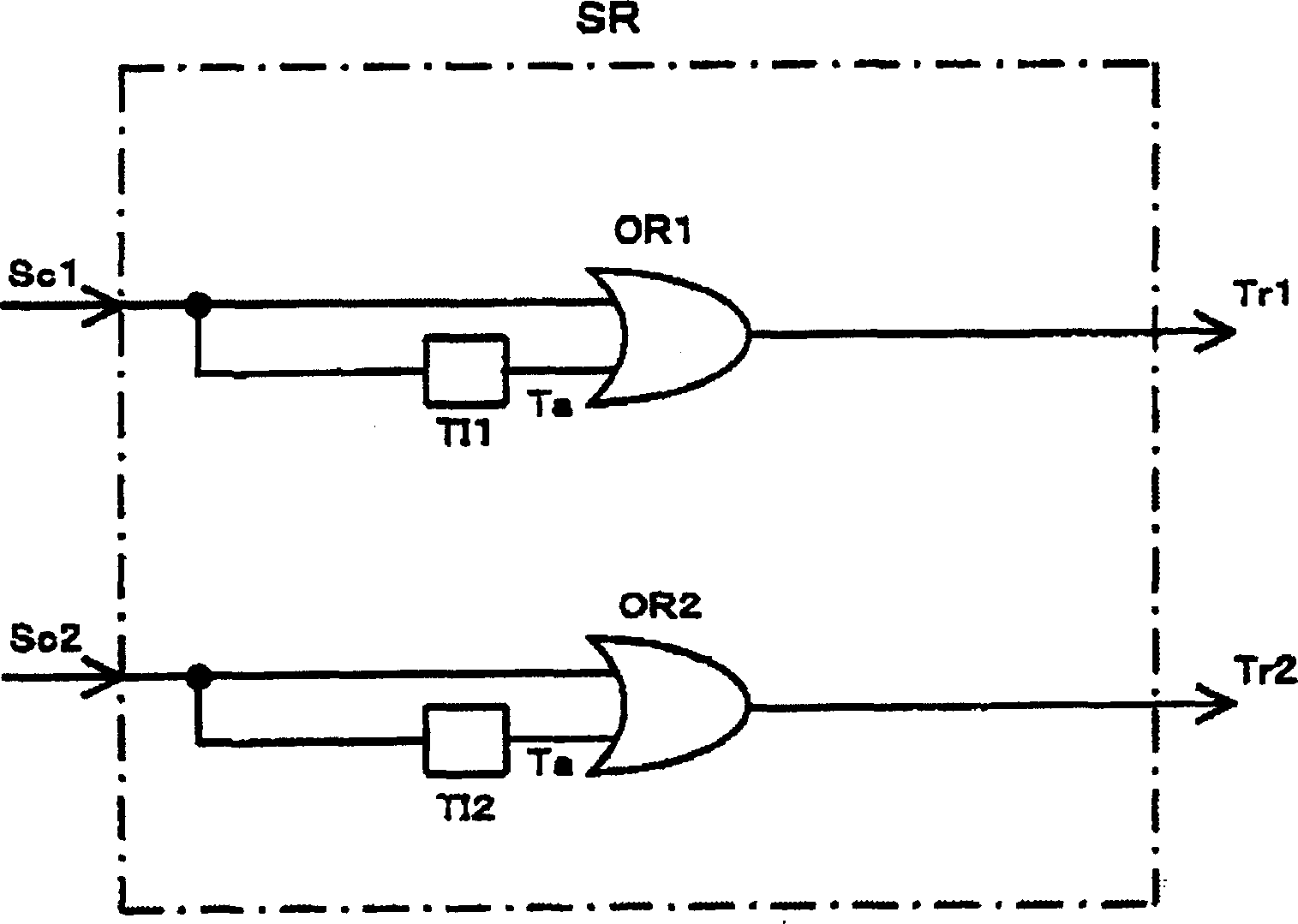

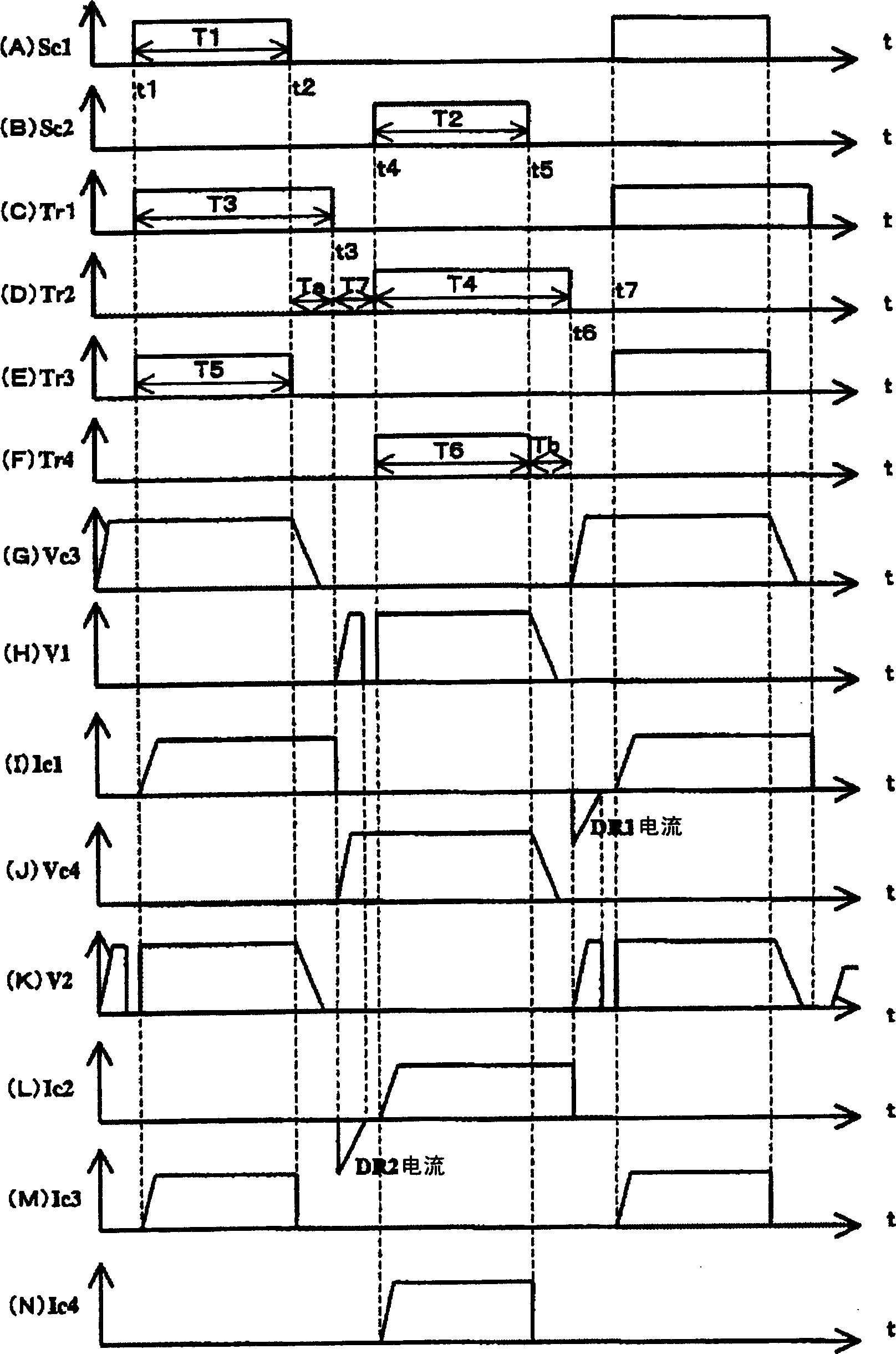

Soft-switching half-bridge inverter power supply system

InactiveCN1663728AAchieve high frequencyMiniaturizationEfficient power electronics conversionDc-dc conversionDriver circuitSoft switching

An inverter power supply system includes a half-bridge inverter circuit which includes a first switching element, a second switching element, a first auxiliary capacitor and a second auxiliary capacitor for converting a DC voltage from a DC power supply circuit to an AC voltage. An output control circuit outputs a first output control signal and a second output control signal with a phase difference of a half cycle to control the inverter circuit. An inverter driving circuit turns on the first (or second) switching element when the first (or second) output control signal turns ON while turning off the first (or second) switching element upon lapse of a first (or second) delay time for allowing the first (or second) auxiliary capacitor to discharge to apredetermined level after the first (or second) output control signal turns OFF.

Owner:DAIHEN CORP

Sheet hole punching apparatus and sheet hole punching method

ActiveCN101108492ARealize small capacityRealization of small size and light weightMetal working apparatusDrive motorEngineering

The invention relates to a paper perforating device and a paper perforating method. A transmission mechanism is provided between the driving motor and the perforating part, and the rotational force of the driving motor is transmitted to the perforating part to provide the perforating part with a linear thrust or radial direction in the perforating direction. The rotation force of the piercing part is provided with a cam mechanism on the base frame supporting the piercing part and the piercing part to transform the transmission force of the transmission mechanism so that the piercing part moves up and down in the piercing direction and rotates at the same time, driving the motor forward or reverse Running in the direction, the perforating part moves up and down between the upper and lower vertices in the perforating direction and rotates at the same time. When moving from the upper apex to the lower apex, it rotates while piercing. The invention can obviously reduce the shearing force necessary for punching, realize the small capacity, small size and light weight of the driving motor, and can punch holes quickly without accumulation of debris under the punching parts.

Owner:成行有限公司

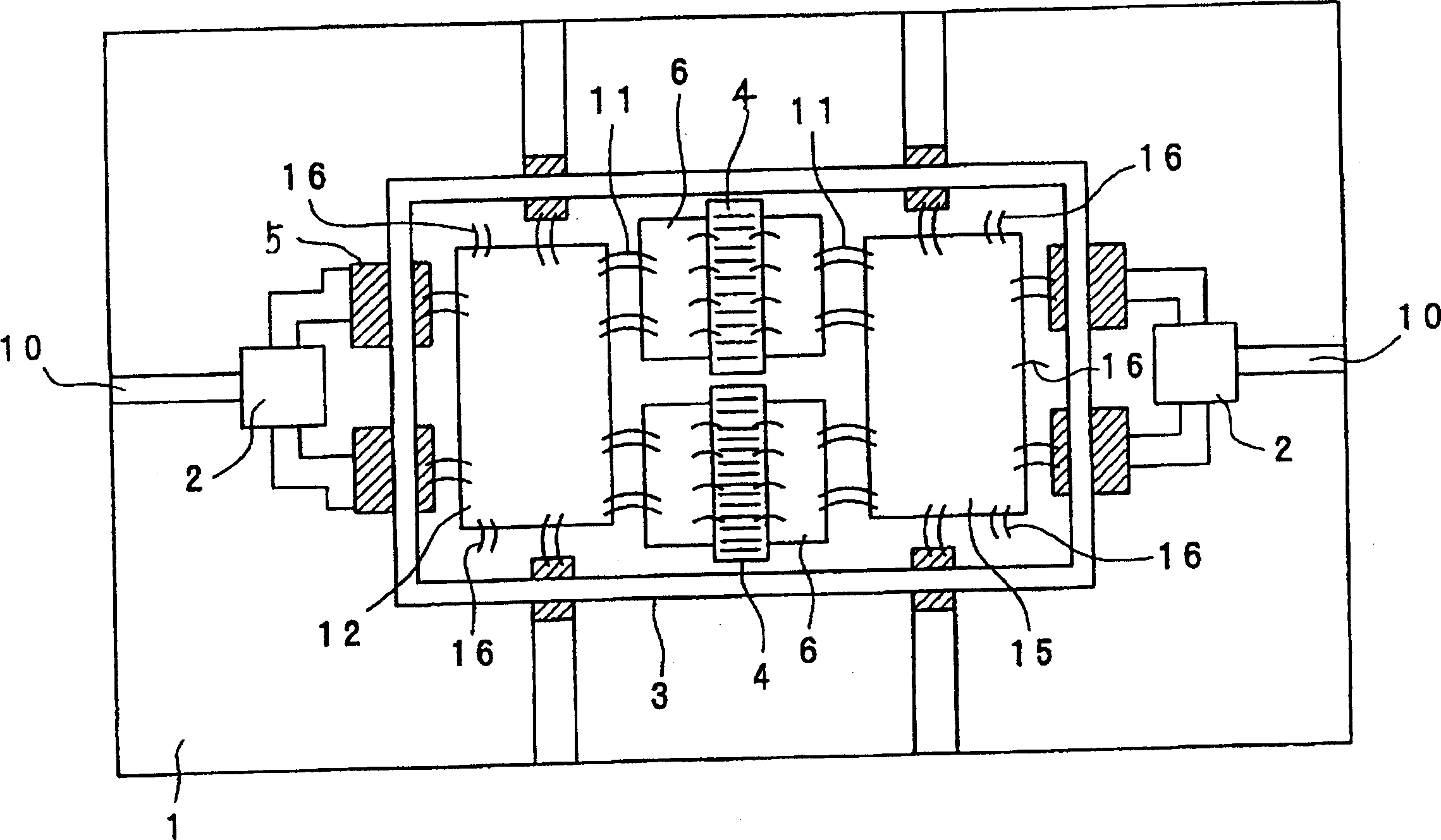

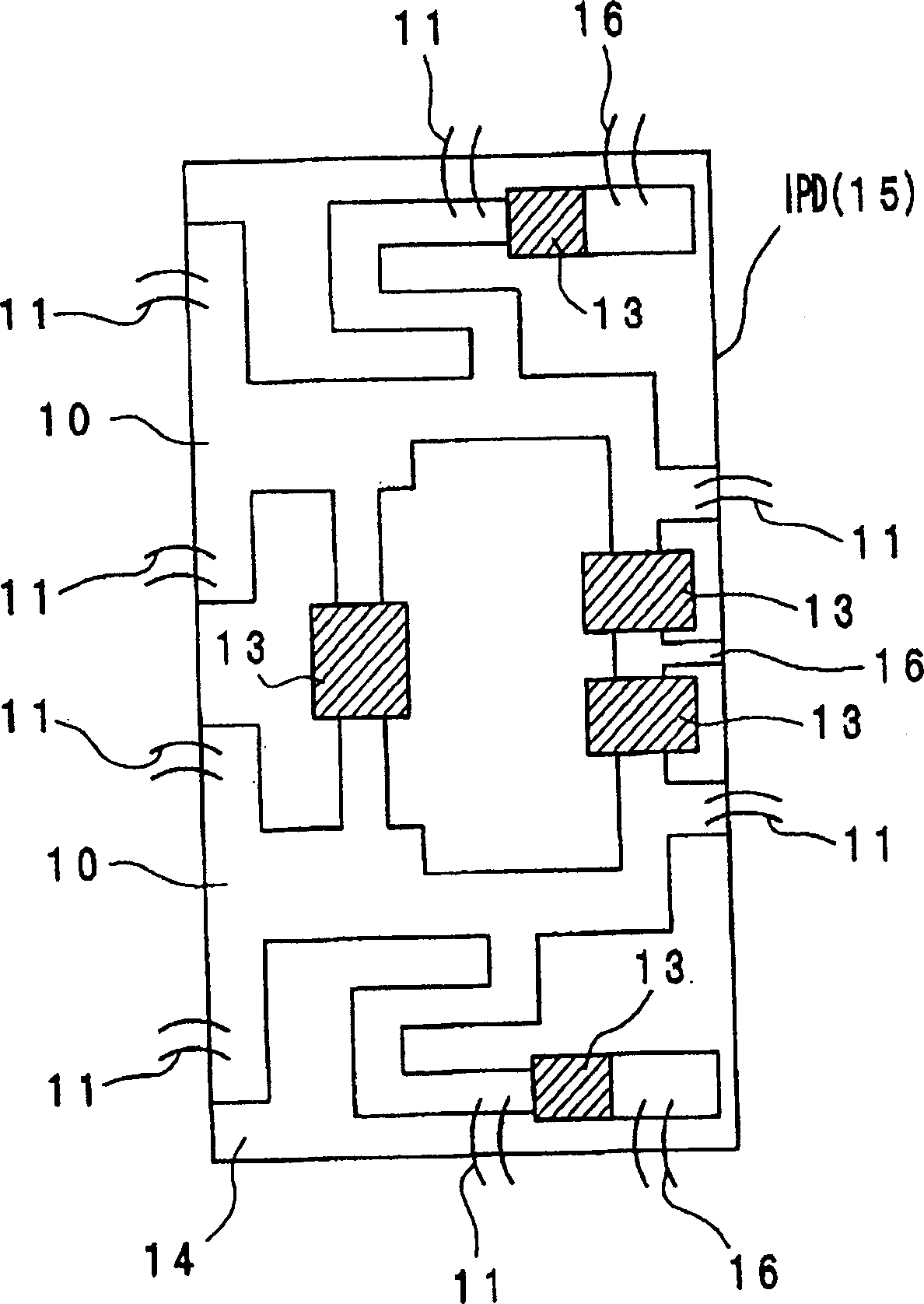

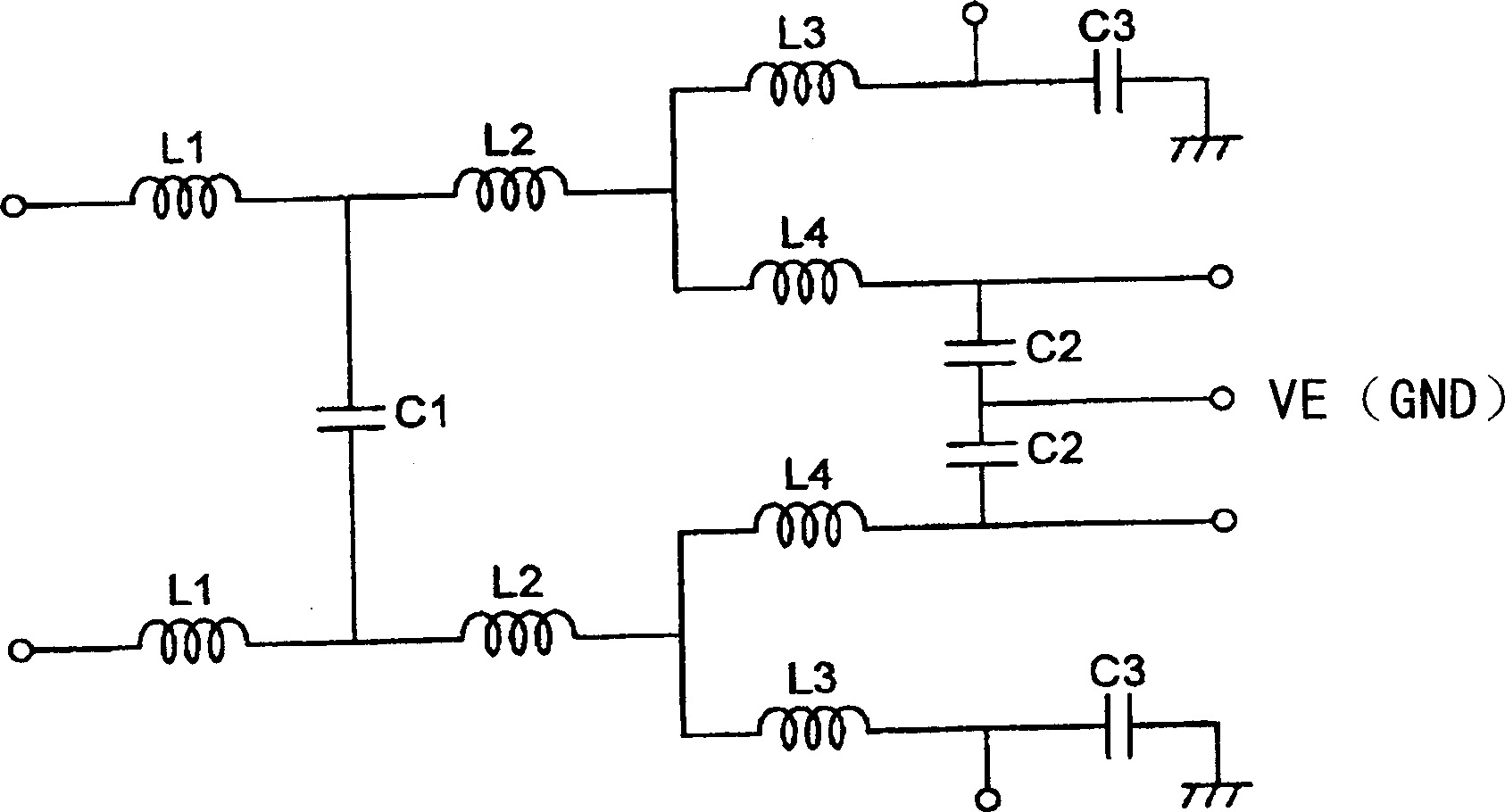

Semiconductor devices

ActiveCN1531194AEliminate discretenessSmall discreteSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipBalanced circuit

Owner:MURATA MFG CO LTD

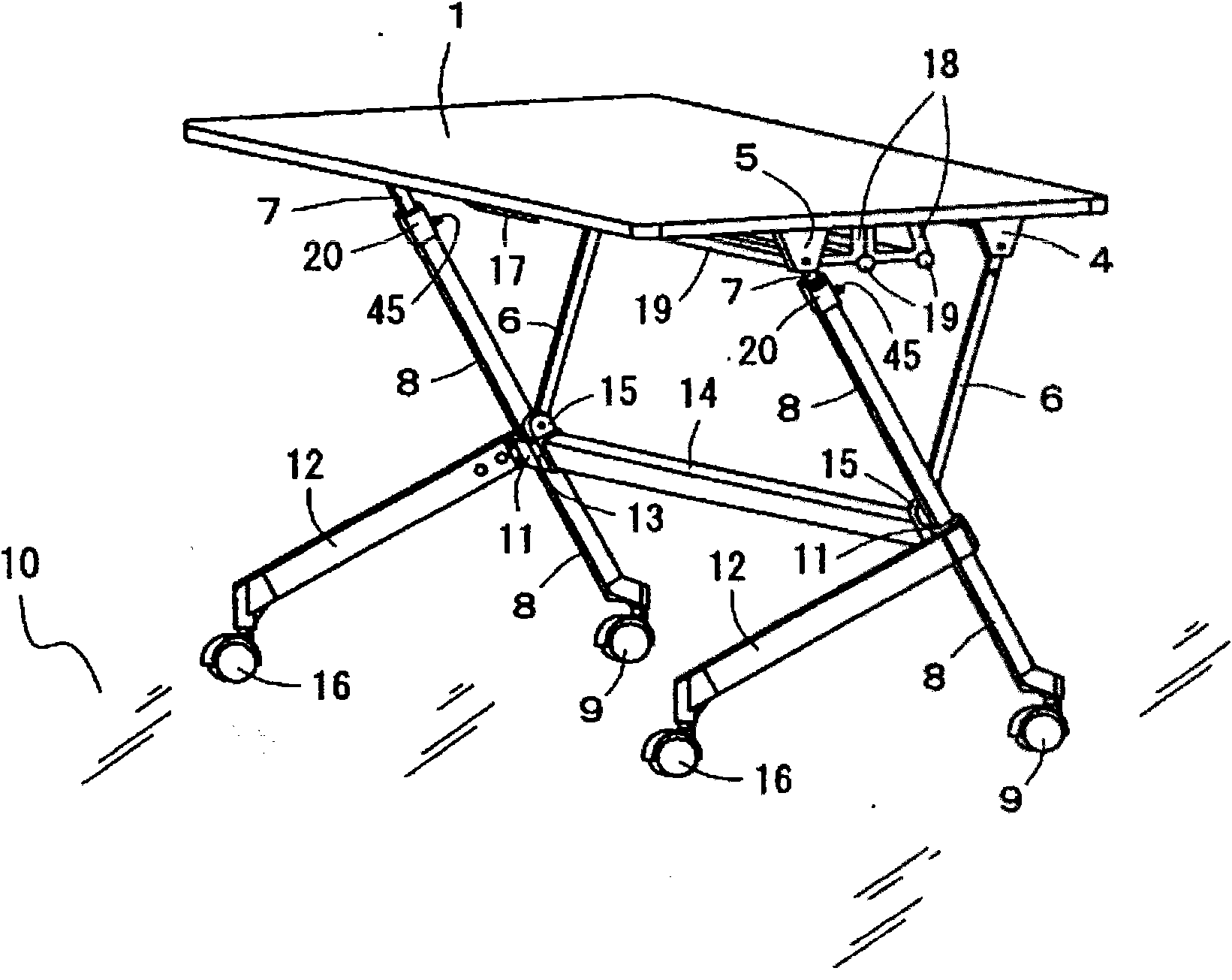

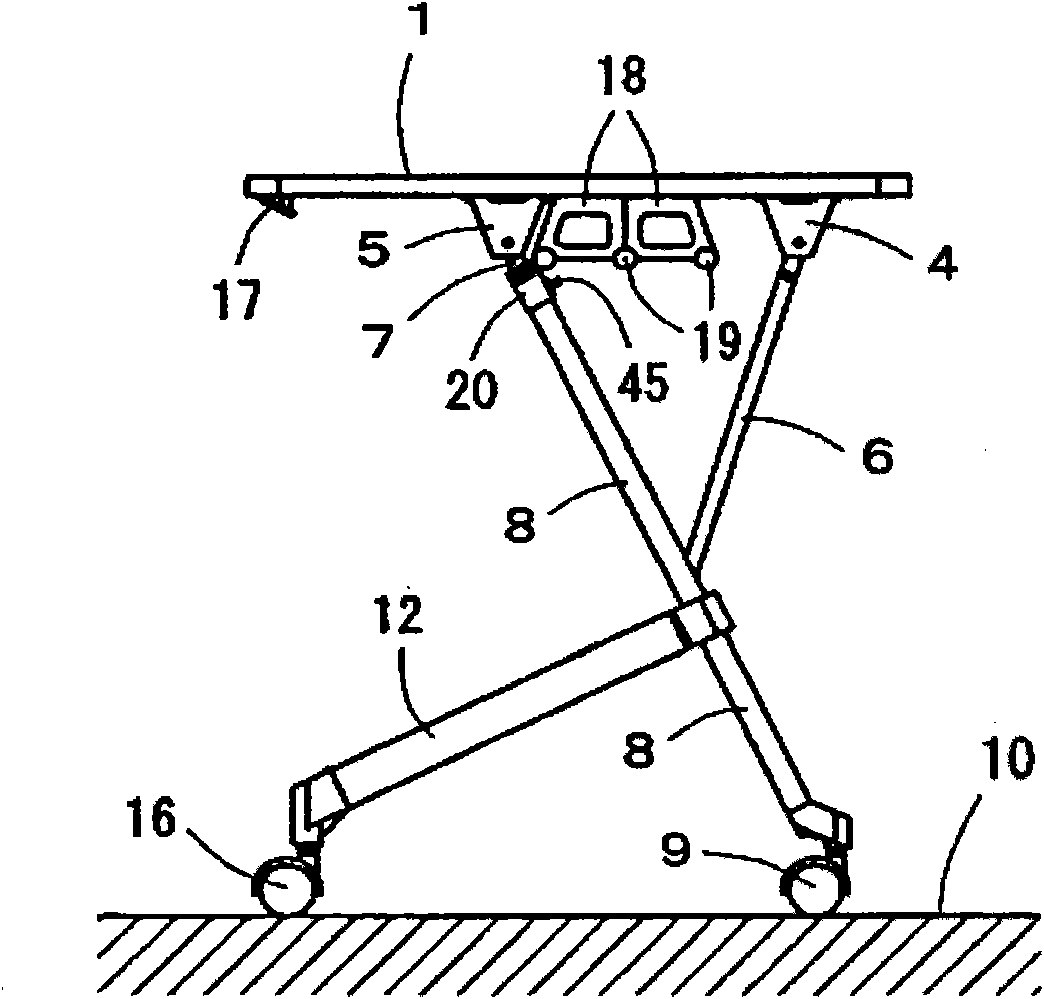

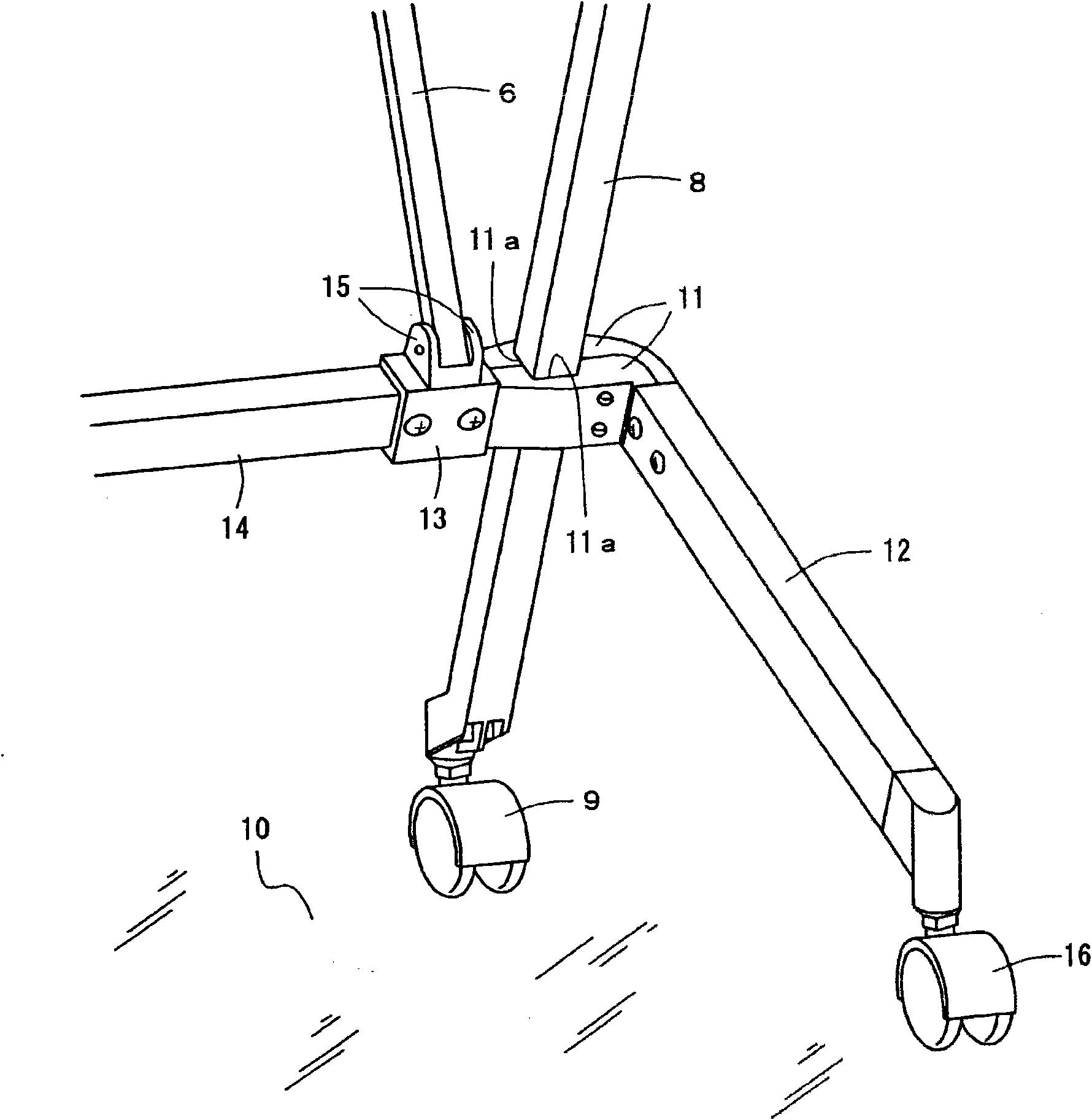

Buffer device and folding table

InactiveCN102106648AAchieve simplicityRealization of small size and light weightFoldable tablesStowable tablesBiomedical engineeringWeight light

The invention provides a buffer device and a folding table.The buffer device is simple in structure, wherein the manufacture is easy and inexpensive, and the small-sized lightweight is realized. Meanwhile, the waste treatment is performed.The folding and unfolding operation of the folding table is performed by the buffer device.The folding table is easy in structure, wherein the manufacture is easy and inexpensive, the small-sized lightweight is realized and the design is improved while ensuring the operation to be smooth and safe.A telescopic action member can be movably accommodated in the main body of the buffer device. One end of the action member is connected to a load part.The load part can be displaced.when the load part is displaced, the movement of the action member can be braked or buffered.A movable body accommodated inside the main body can move along the axial direction thereof and the action member is movably accommodated inside the movable body.A retainer of a tapered portion is arranged at the circumferential surface of the movable body.When the action member is moved, the tapered portion is detachably inserted between a clamp part arranged inside the main body and the circumferential surface of the action member.

Owner:HUIBIES FURNITURE

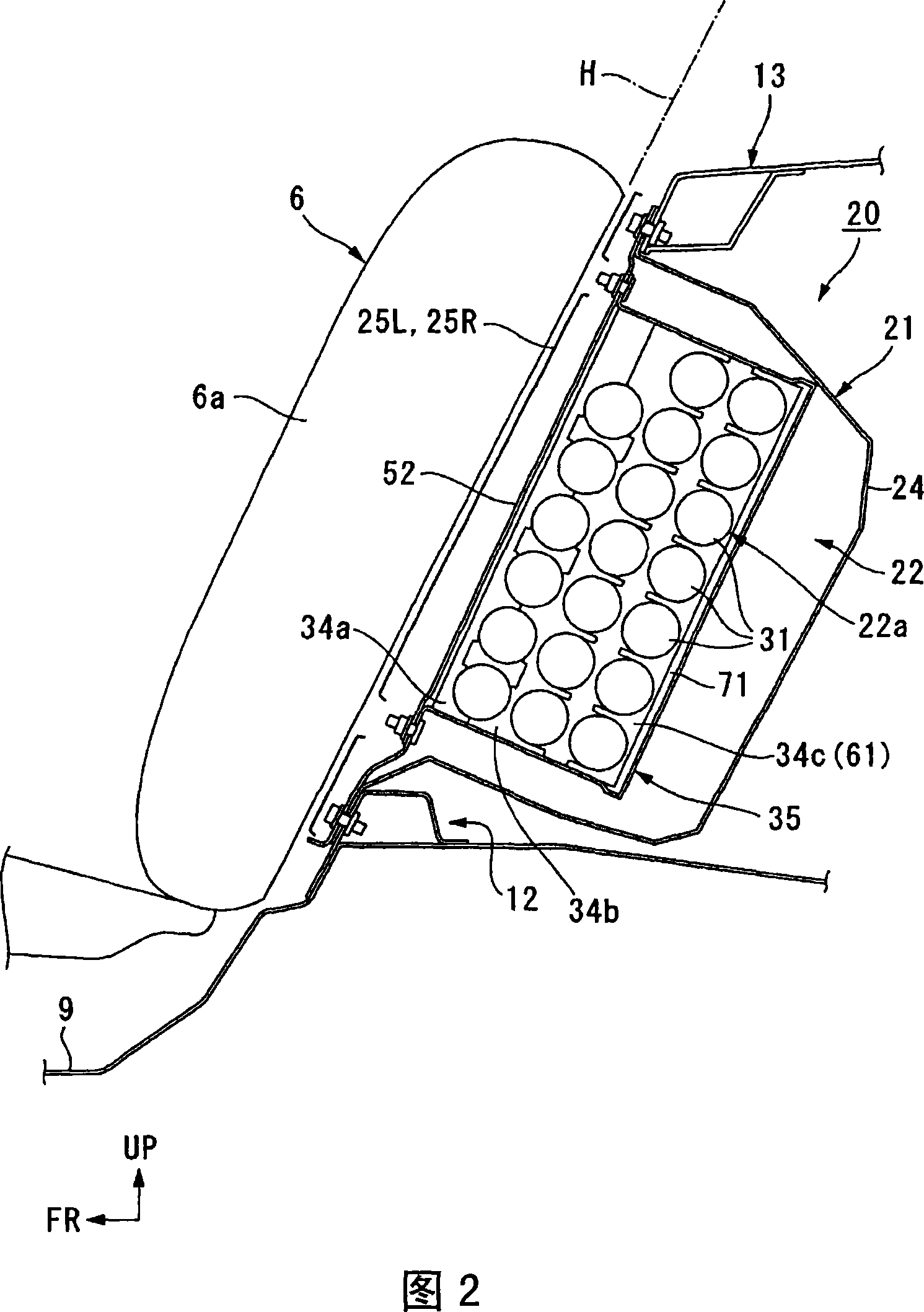

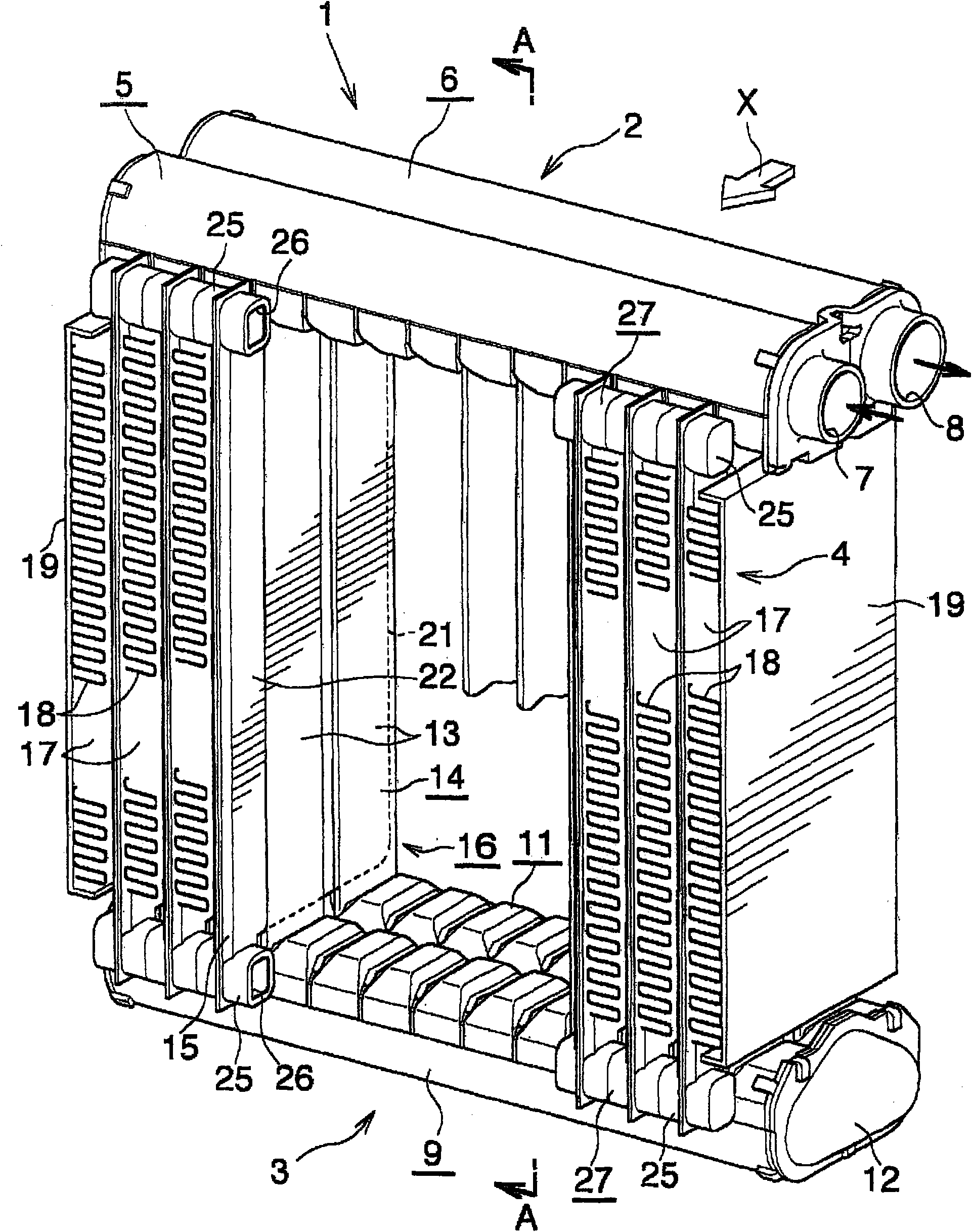

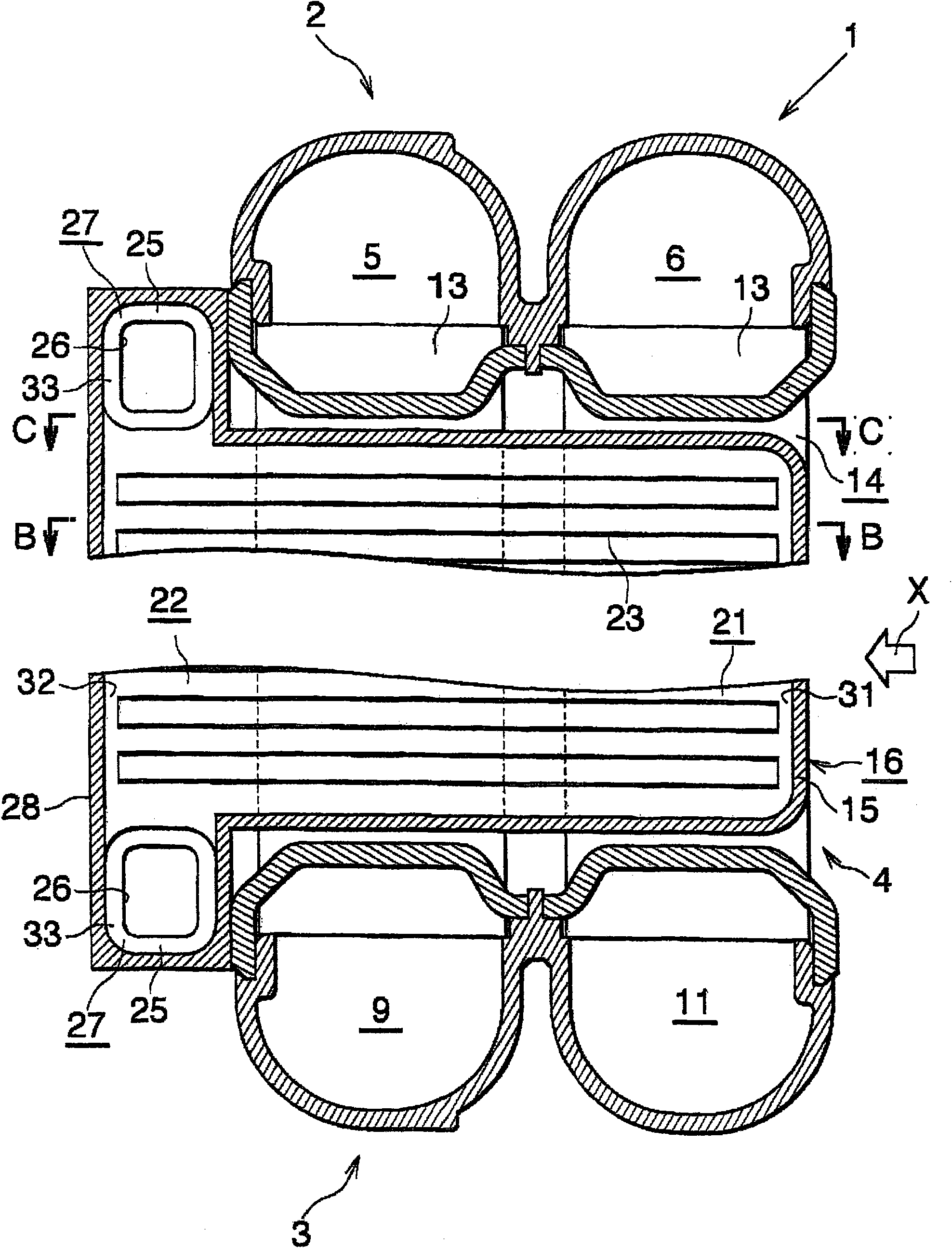

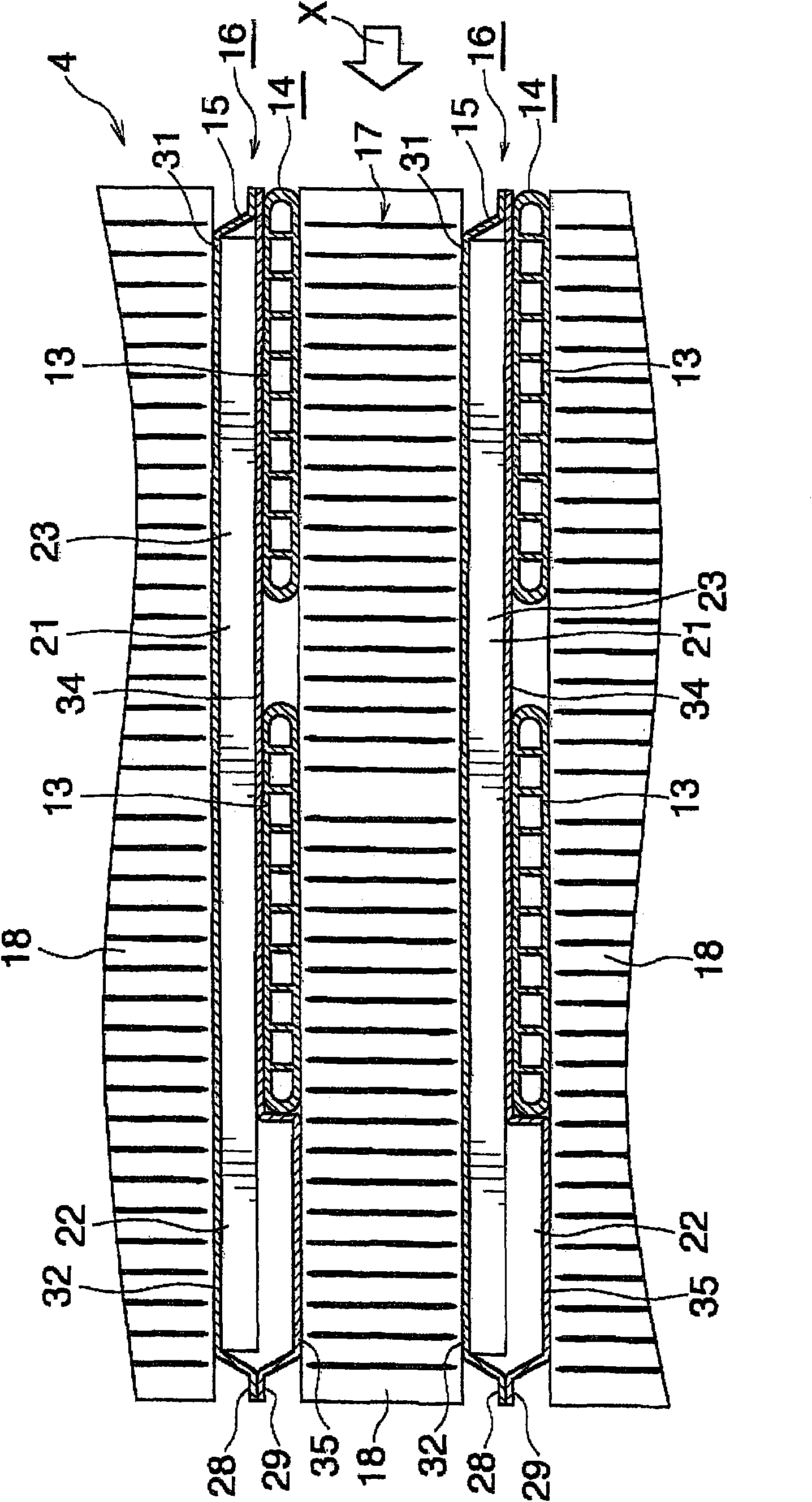

Evaporator with cool storage function

InactiveCN102109254AImprove cooling effectAvoid performance degradationHeat storage plantsEvaporators/condensersCool storageEngineering

An evaporator (1) with a cool storage function includes a plurality of flat refrigerant flow tubes (13) spaced apart from one another, and a plurality of flat cool storage material containers (15) each of which contains a cool storage material and is disposed on one side of the corresponding refrigerant flow tube (13), and is brazed to the corresponding refrigerant flow tube (13). The cool storage material container includes a container body (21) brazed to the corresponding refrigerant flow tube (13), and an internal-volume-increasing portion (22) which extends downstream from the container body, which projects downstream from the refrigerant flow tube (13), and which is greater in dimension in a thickness direction than the container body (21). An inner fin (23) extending from the container body (21) to the internal-volume-increasing portion (22) is disposed in the cool storage material container (15).

Owner:KEIHIN THERMAL TECH CORP

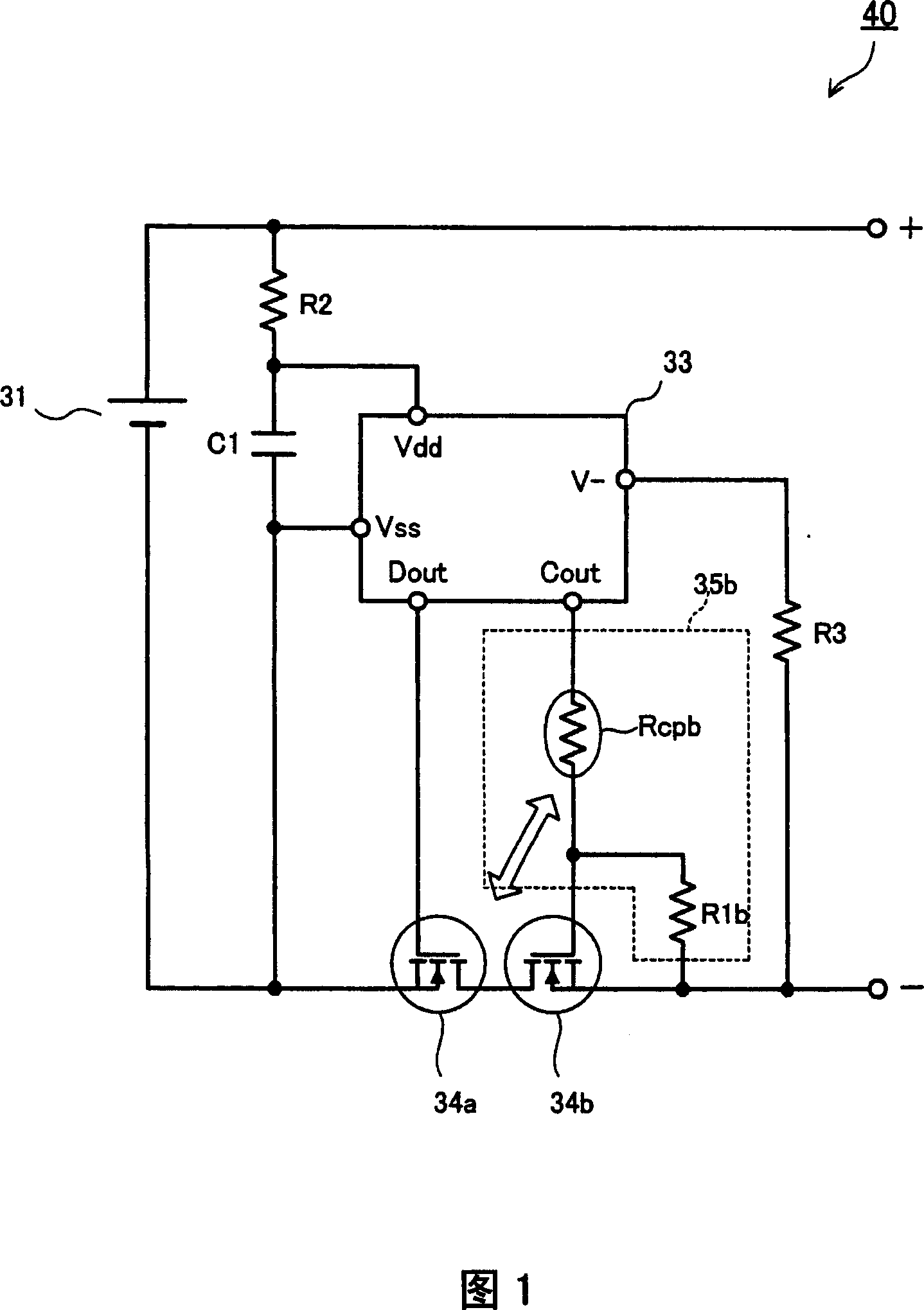

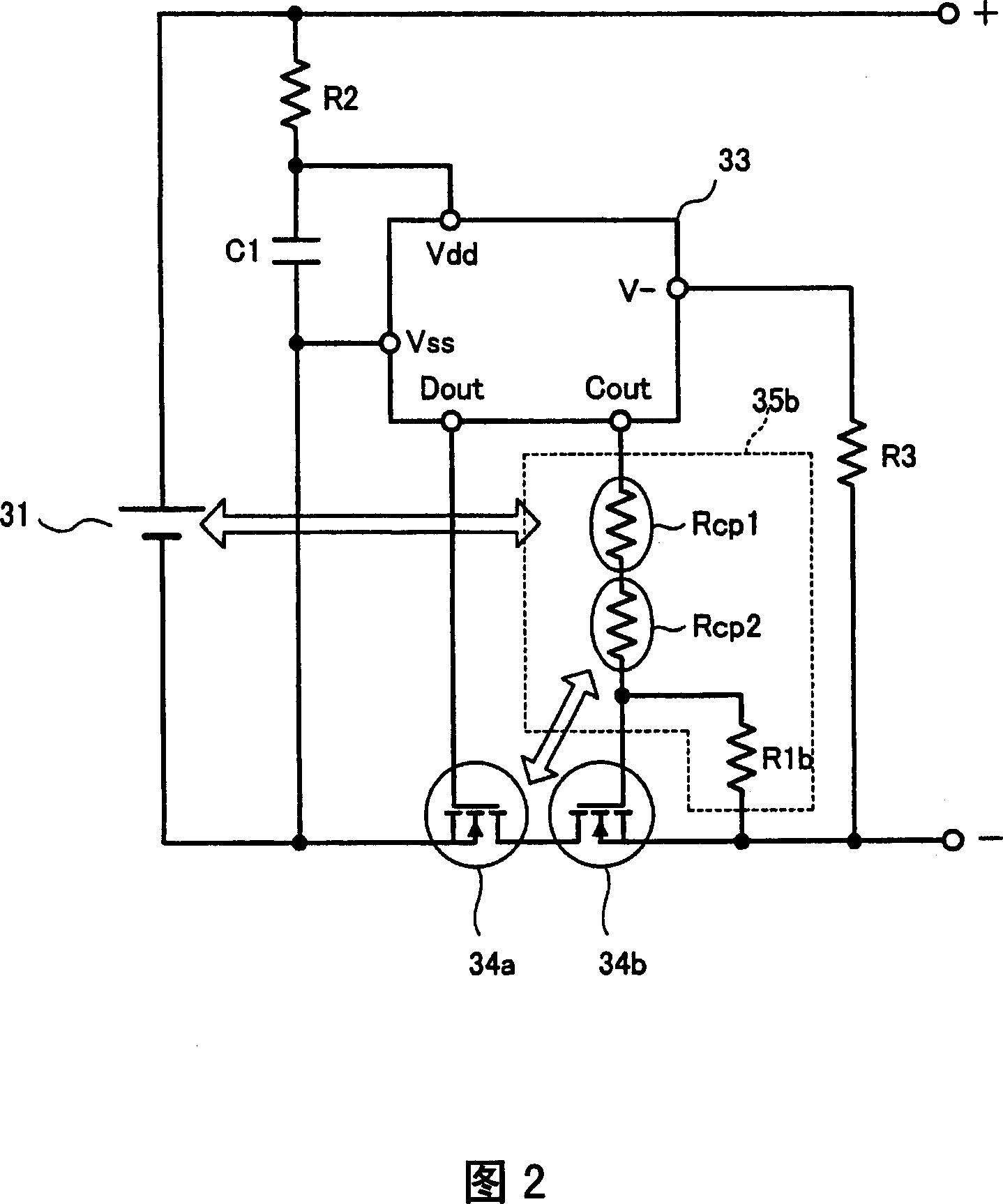

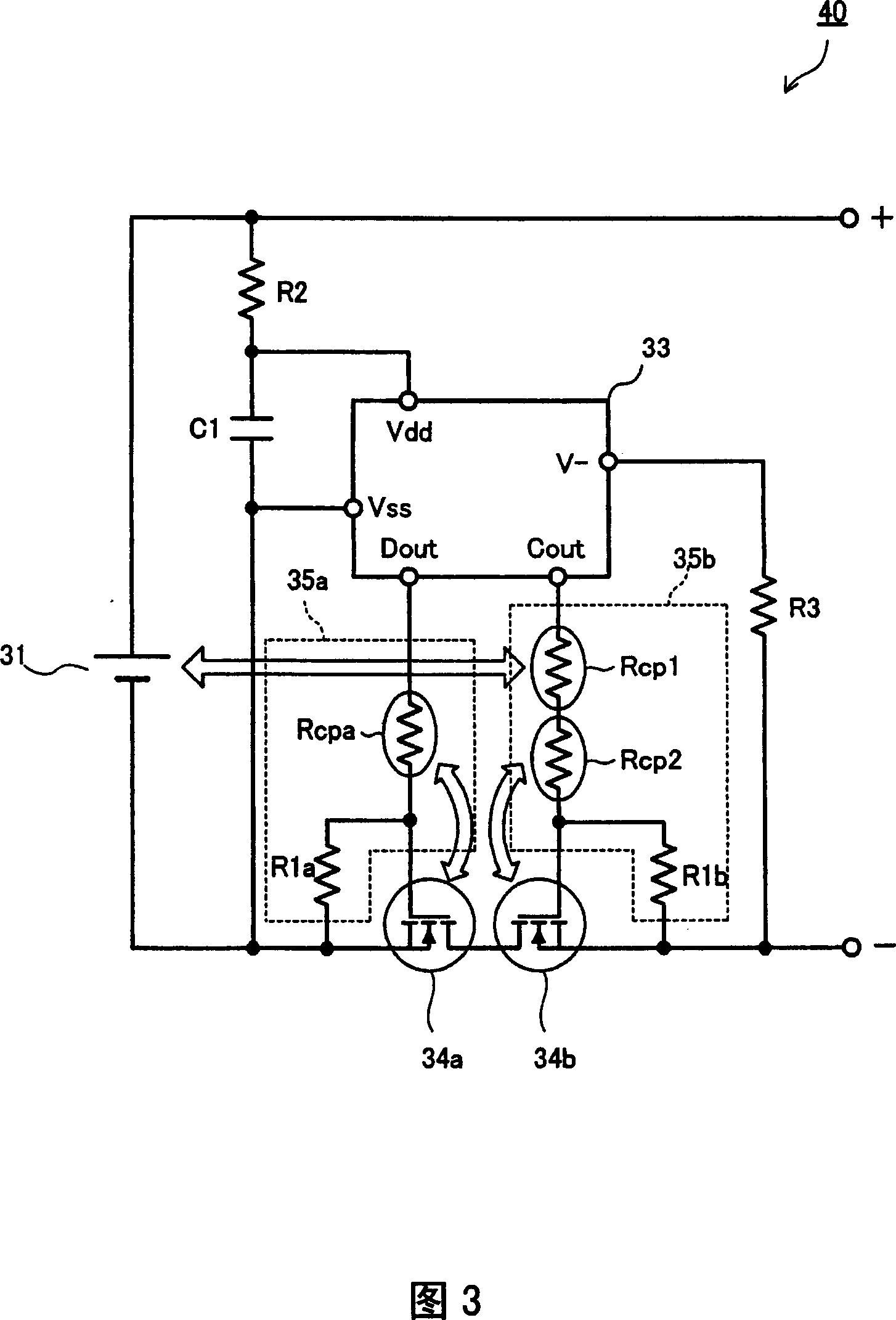

Battery pack protecting circuit and battery pack

InactiveCN1965457AReduce manufacturing costEnsure doubleBatteries circuit arrangementsEmergency protective circuit arrangementsElectrical resistance and conductanceCharge current

There are provided a first switch element (34a) for interrupting the discharging current following in a battery cell (31) and a second switch element (34b) for interrupting the charging current. A positive character thermistor (Rcpb) is inserted between a gate control terminal (Dout,Cout) of a protection control circuit (33) and the gate of at least one of the switch elements (34a,34b), while a resistor (R1b) is connected between the gate and source of that switch element. The positive character thermistor (Rcpb) is thermally coupled to the first and second switch elements (34a,34b) or to the battery cell (31). In this way, an extraordinary excessive heating state of the switch elements (34a,34b) or battery cell (31) causes a rise in the resistance of the positive character thermistor (Rcpb), which then places the switch element (34b) in an interruption state to activate a protection function.

Owner:MURATA MFG CO LTD

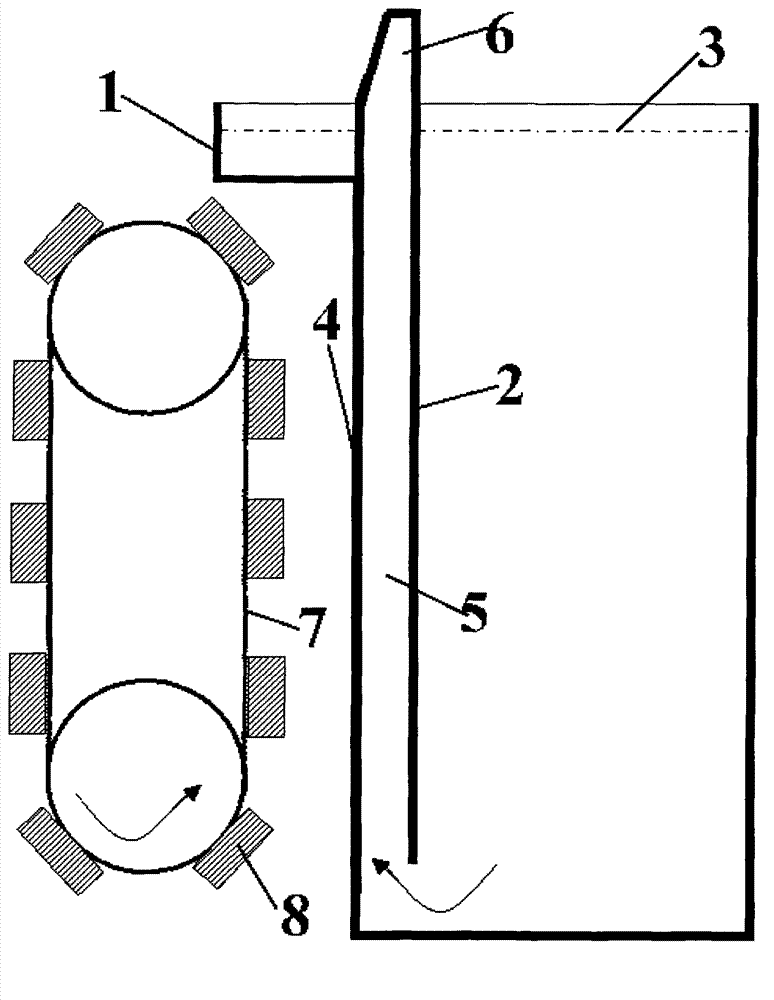

Electromagnetic pump for pumping liquid brazing filler metal

The invention provides an electromagnetic valve for pumping liquid brazing filler metal. The electromagnetic valve is characterized in that the electromagnetic pump is provided with a soldering flux groove for accommodating the liquid brazing filler metal, an iron plate which extends from the upper portion to the bottom of the soldering flux groove is arranged on the soldering flux groove, a gap is reserved between the lower portion of the iron plate and the bottom of the soldering flux groove, the liquid brazing filler metal flows through the gap, and a liquid brazing filler metal flowing channel is formed between the iron plate and the wall of the soldering flux groove, and extends towards to the top of the soldering flux groove to form a liquid brazing filler metal nozzle; and a conveying belt is arranged at a position, which is adjacent to the flowing channel, of the outer portion of the soldering flux groove, a plurality of permanent magnets are placed on the conveying belt at intervals, and the conveying belt is driven by a motor to move upwards, so that an upward moving magnetic field is generated, and upwards thrust is correspondingly generated to push the liquid brazing filler metal to be jetted out from the nozzle. Problems of complexity, large occupied space, high heating and the like caused by an existing three-phase electromagnetic pump are avoided, and the electromagnetic valve is simple, small and light.

Owner:NINGBO RUITONG NEW MATERIAL TECH +1

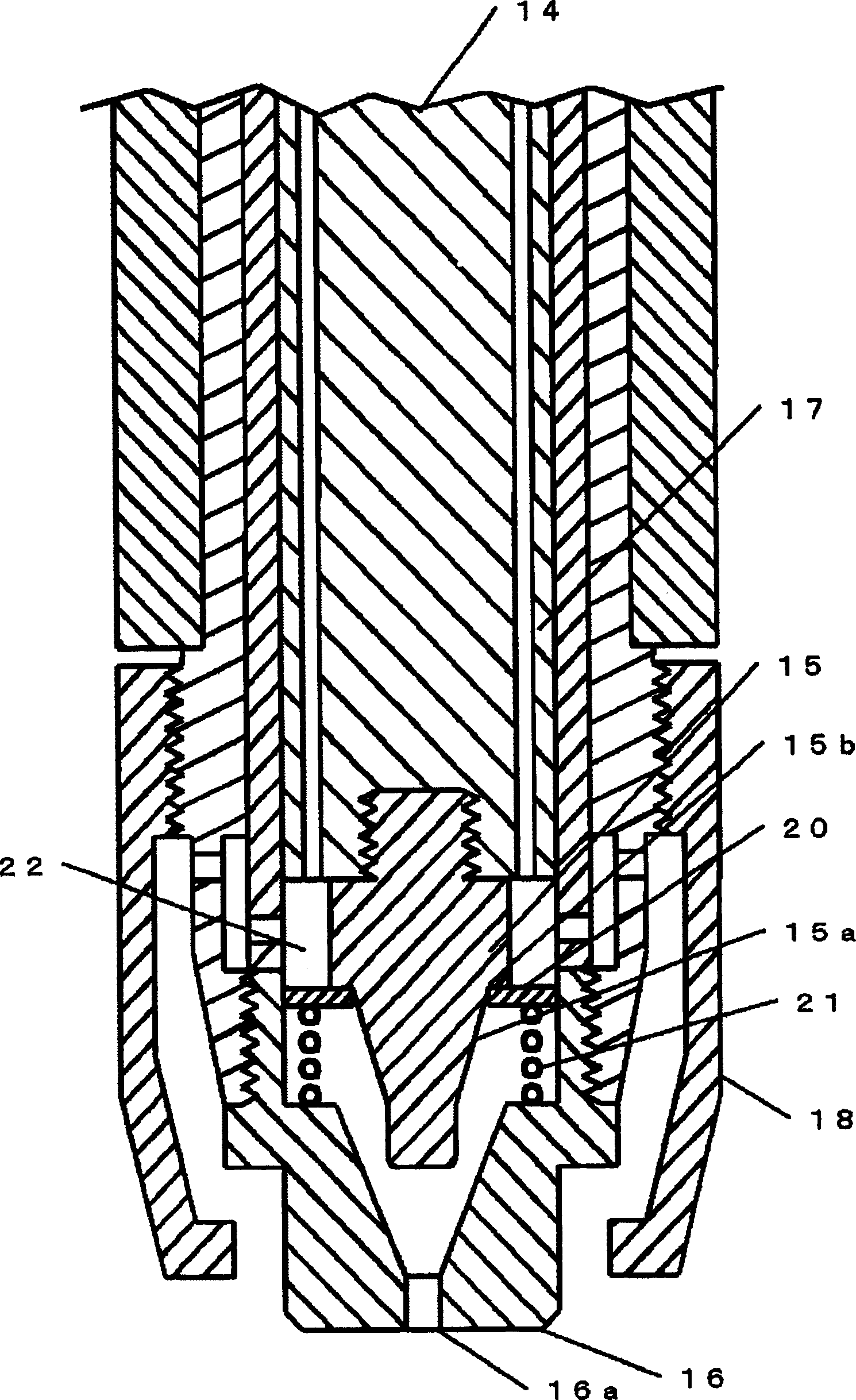

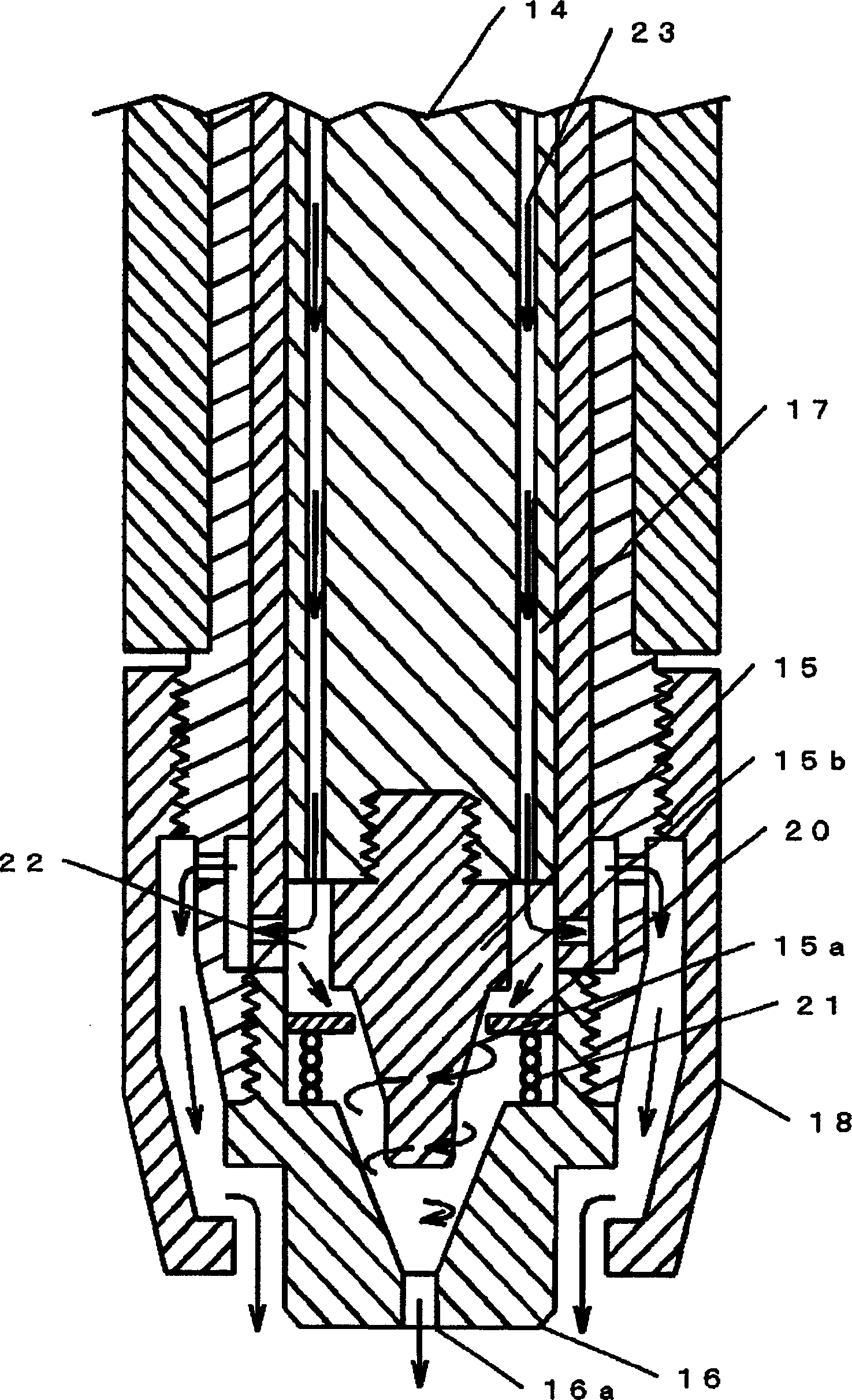

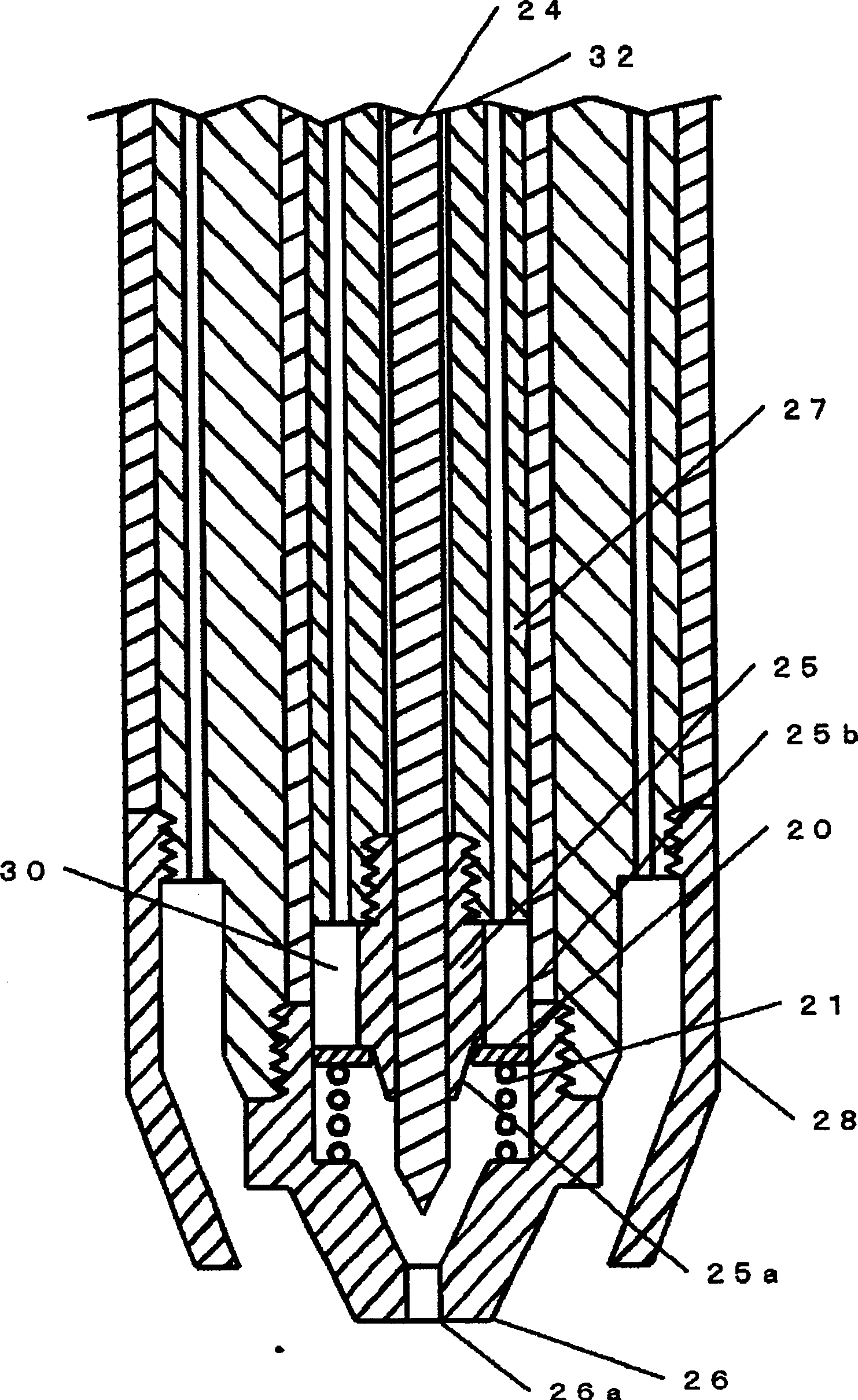

Plasma cutting torch

InactiveCN1678164ASolution to short lifeCutting stabilityPlasma welding apparatusPlasma techniqueTorchEngineering

The present invention provided a plasma torch which is stable in cutting performance, is long in service lives of an electrode and a plasma nozzle, and can be made small in size and lightening in weight are attained. The plasma torch is equipped with: an electrode provided at the axial part of a torch body, and in which a taper part is formed at the tip; a plasma nozzle fitted to the torch body; cups each surrounding the plasma nozzle and fitted to the torch body; movable rings sliding to the axial direction while the inner circumferential part is electrically contacted with the upper part of the taper part in the electrode, and the outer circumferential part is electrically contacted with the plasma nozzle; and springs each fitted to the inside face of the plasma nozzle and pushing-up the movable ring. Each sealed space is formed by the electrode, the movable ring, the plasma nozzle and the torch body, and at the time of arc starting, when plasma gas is fed to the space, the movable ring is separated from the upper part of the taper part in the electrode and moves to the lower direction, and the inner circumferential face of the movable ring is made non-contact with the taper part in the electrode, thereby generating a pilot arc.

Owner:DAIHEN CORP

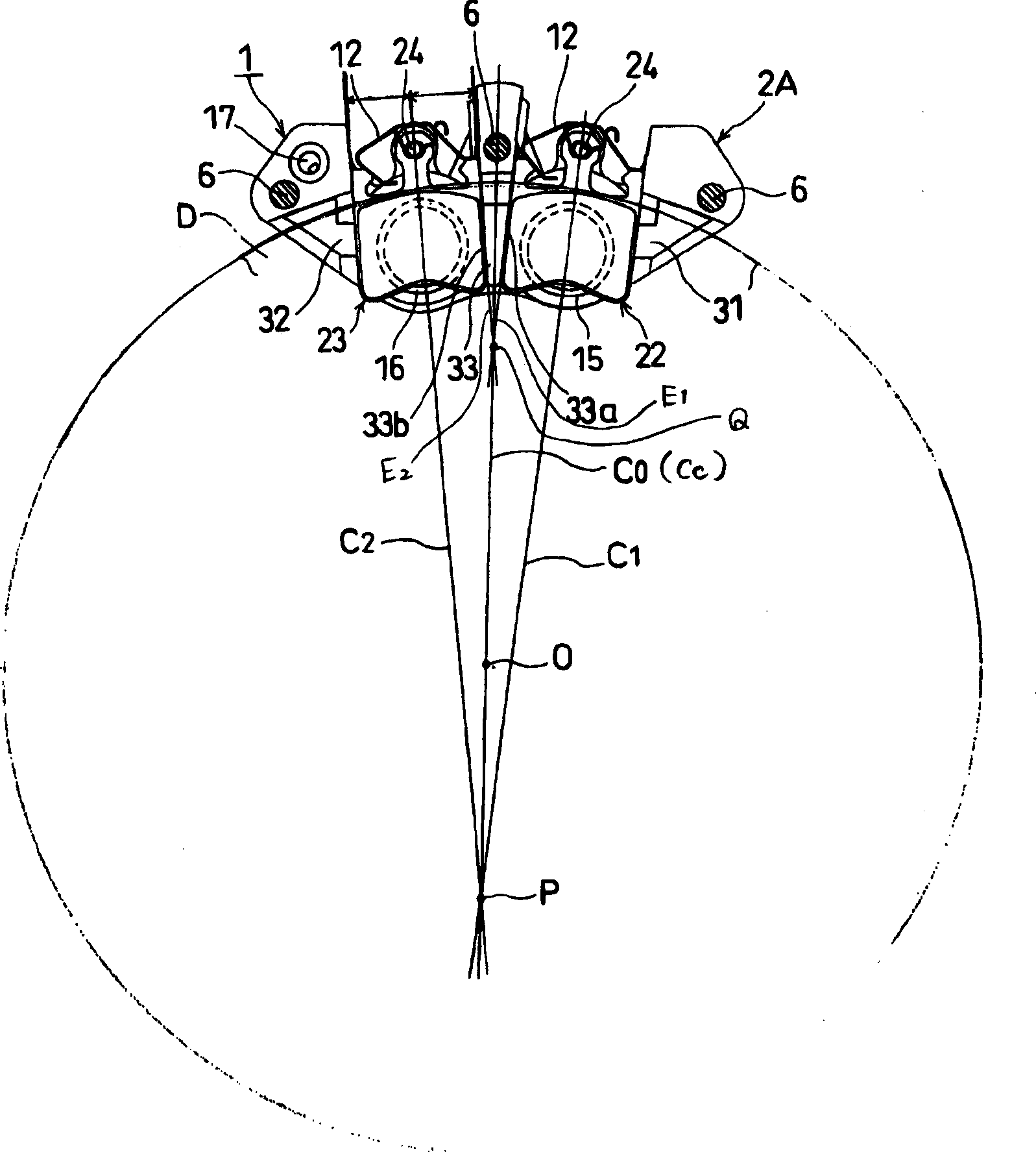

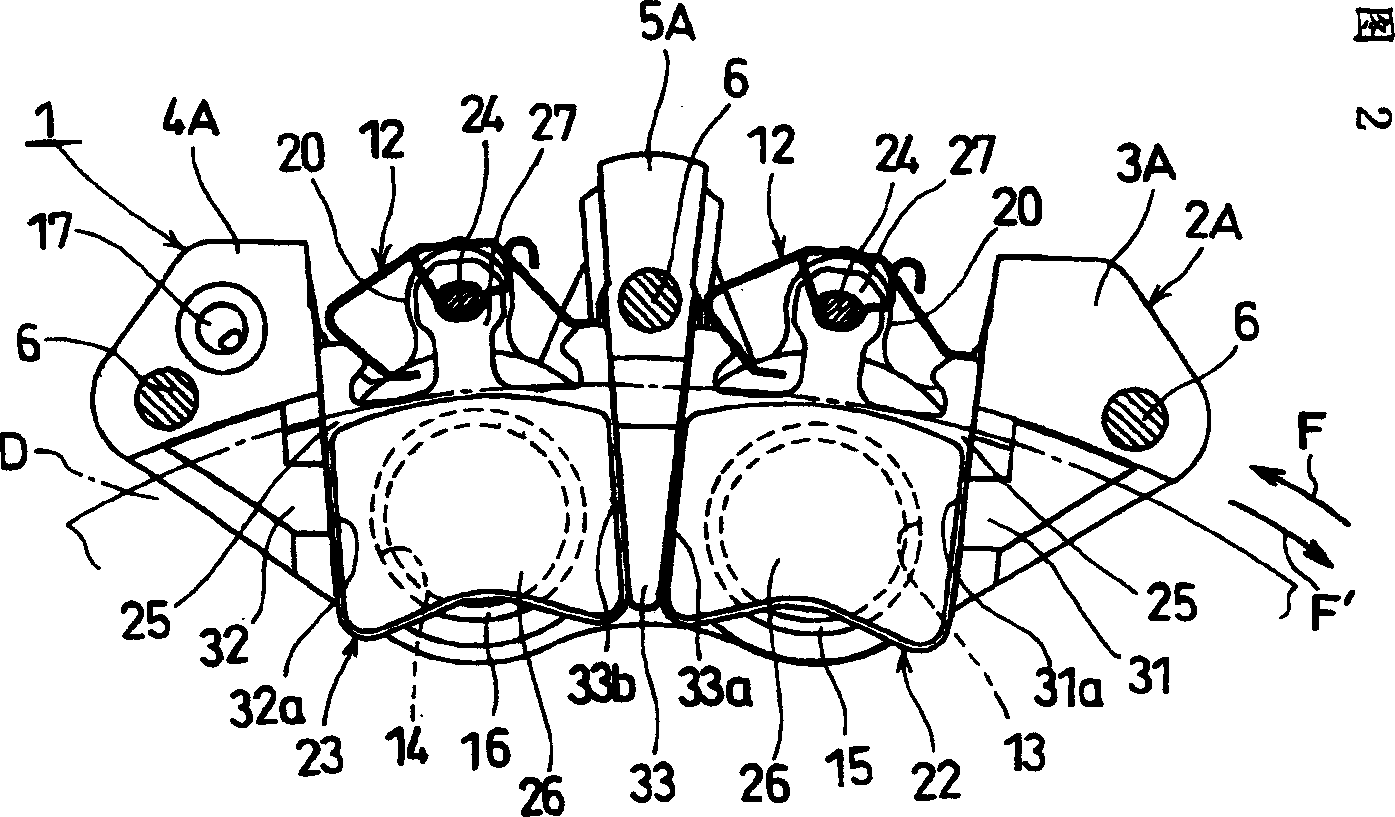

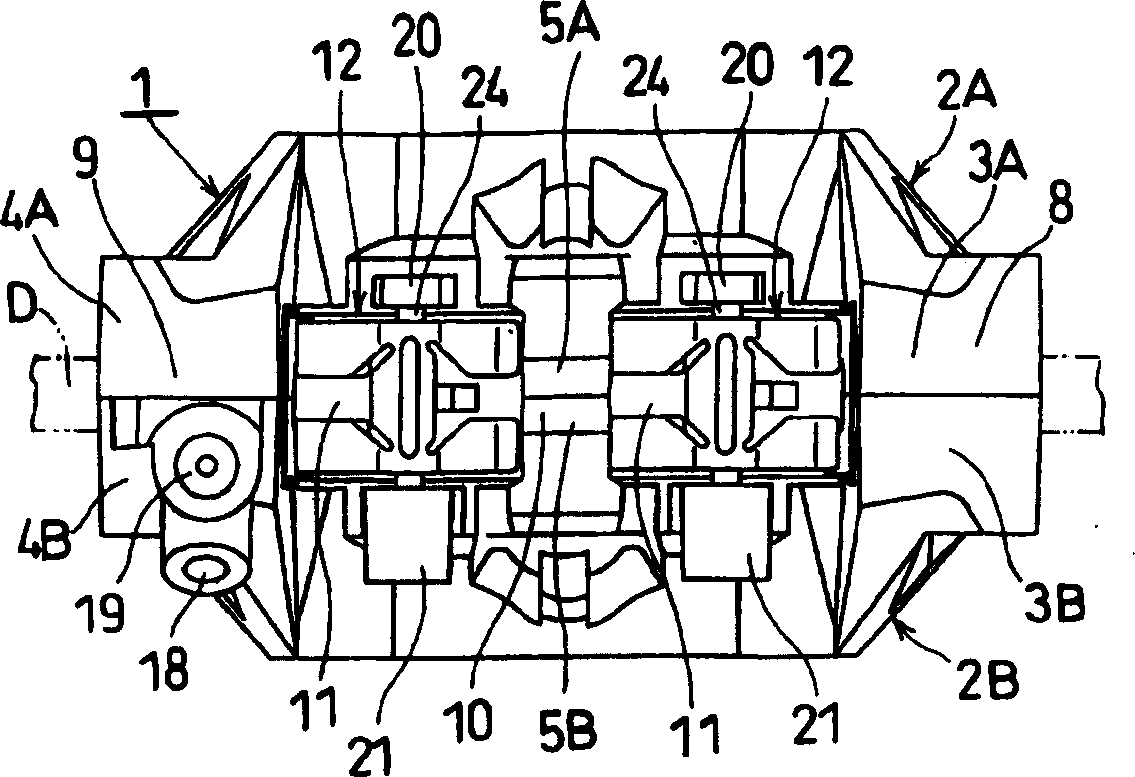

Disk-type brake

InactiveCN1375645AReduce wall thicknessRealization of small size and light weightAxially engaging brakesBrake actuating mechanismsDisc brakePiston

A disc brake, which can reduce the wall thickness of the torque receiving part between the pistons to the greatest extent without sacrificing the length, the disc brake has multiple pairs of pistons (15, 16) on both sides of the disc rotating body, through which each The advancement of the pistons (15, 16) makes many pairs of brake blocks (22, 23) crimped on the disc rotating body (D), and at the same time, the sides of each pair of brake blocks (22, 23) are supported on the support Braking forces are generated on the torque receiving parts (31, 32, 33) of the frame main body (1), and each pair of brake blocks (22, 23) is configured as follows: in the radial direction of the disc rotation body (D), in the opposite direction The rotation center (O) of the disk rotation body (D) and a point (P) in the area on the opposite side of the support frame main body (1), the centerlines of each block intersect, and the torque receiving part (33 in the middle) is reduced as much as possible ) at the front end angle of the triangle to reduce the arrangement spacing of the pistons (15, 16).

Owner:HITACHI LTD

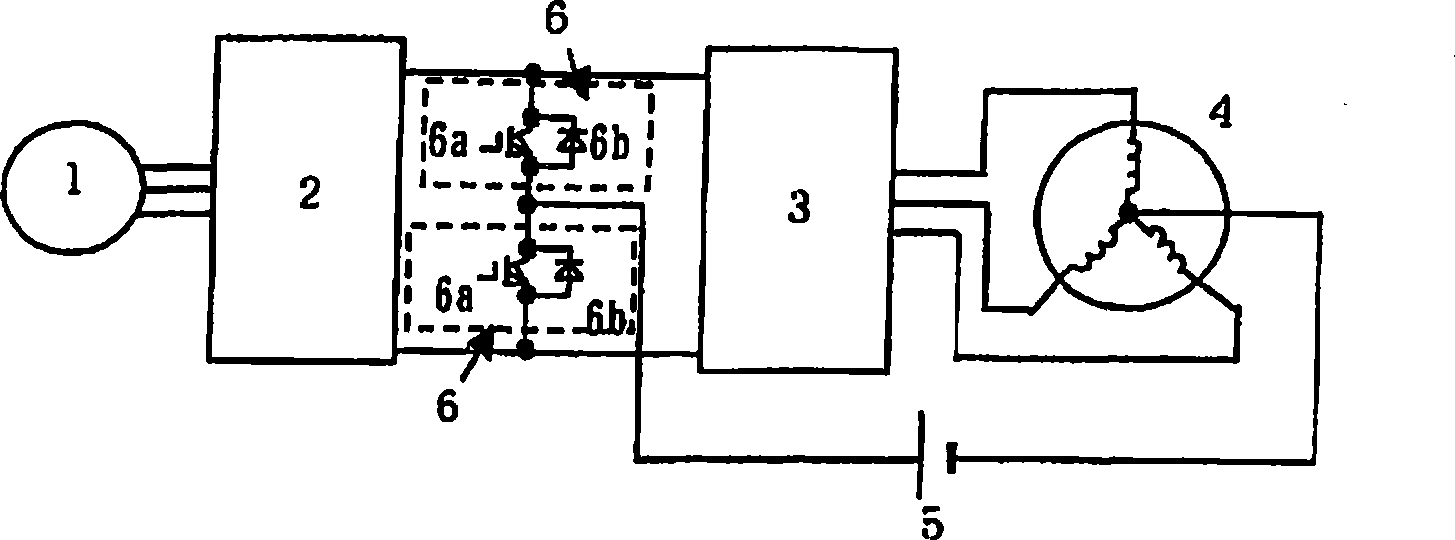

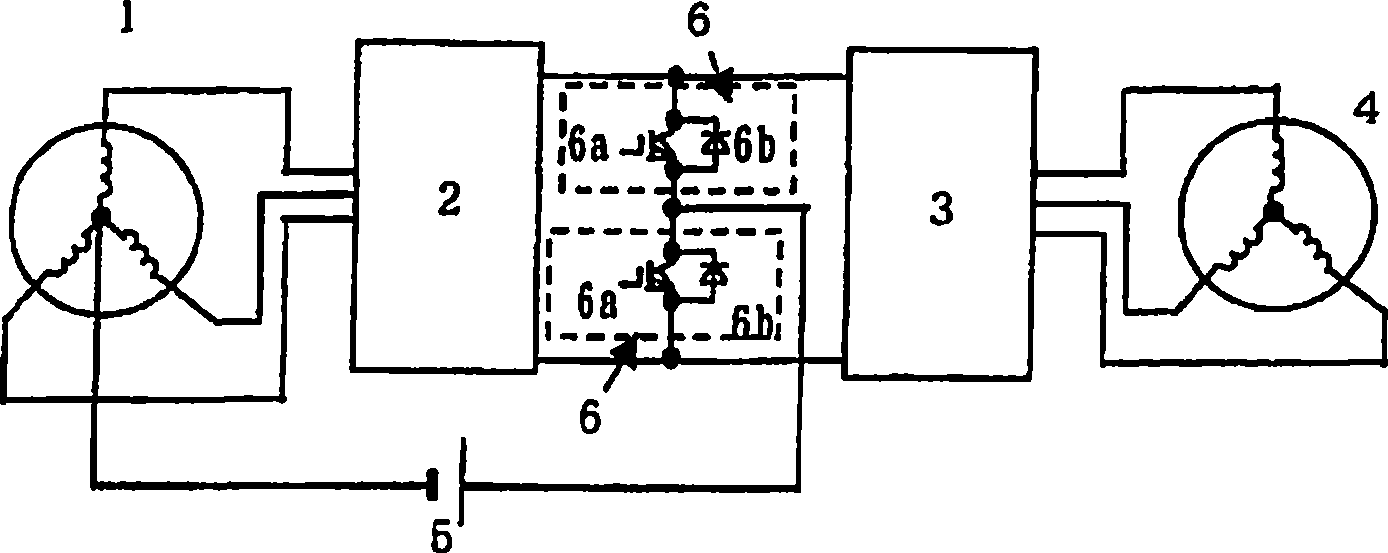

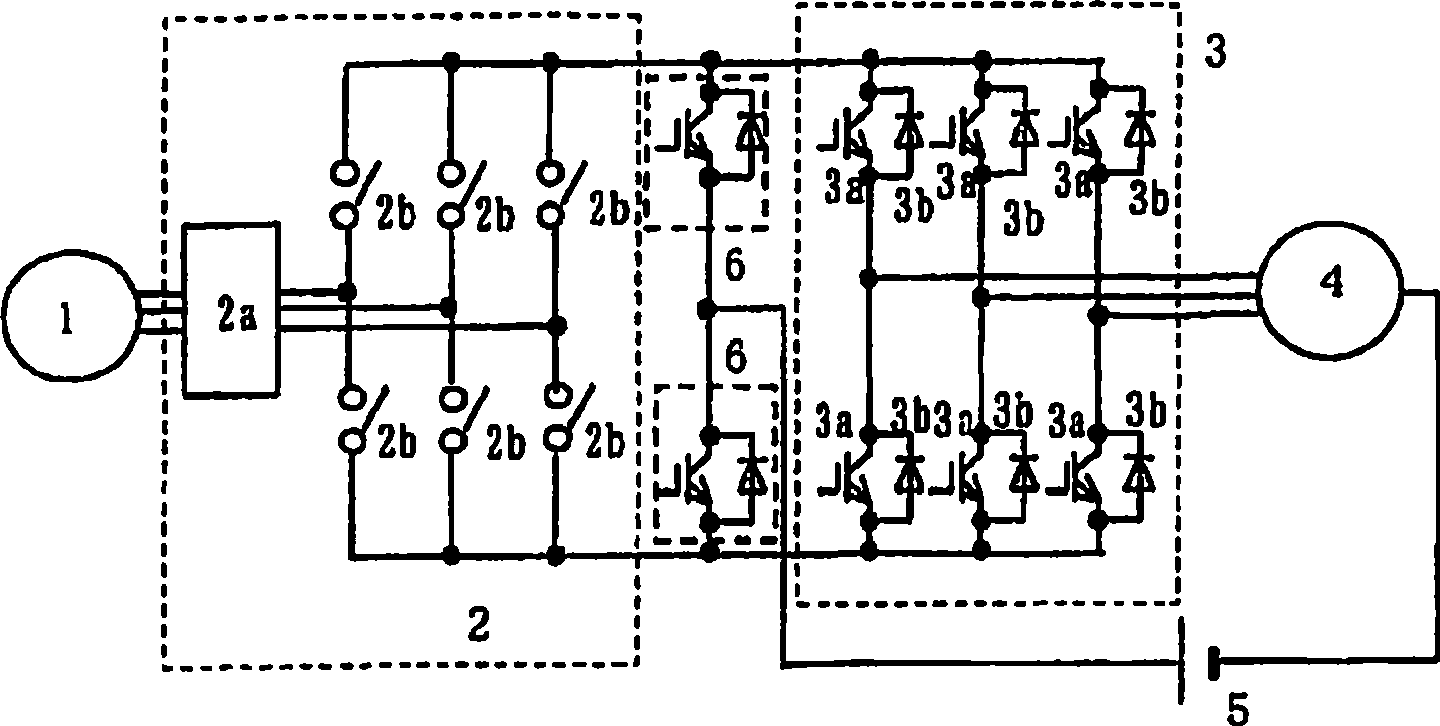

Alternating current motor drive circuit and electric vehicle drive circuit

ActiveCN101505134ARealization of small size and light weightLow costAC motor controlElectric machinesVoltage source inverterElectric vehicle

To eliminate a need for a large volumetric reactor in a direct current chopper, achieving a downsizing of the circuit. A current source rectifier circuit (2) is provided at an output of an alternating current generator (1), an alternating current motor (4) is connected to an output of the rectifier circuit (2) via a voltage source inverter (3), furthermore, two arms (6) having switching elements connected in inverse parallel to diodes are connected to the output of the rectifier circuit (2), and one terminal of a direct current power source (5) capable of a power supply and absorption is connected to a midpoint between the arms (6), while the other terminal thereof is connected to a neutral point of motor coils, achieving a solution of the problem.

Owner:NAT UNIV CORP NAGAOKA UNIV TECH +1

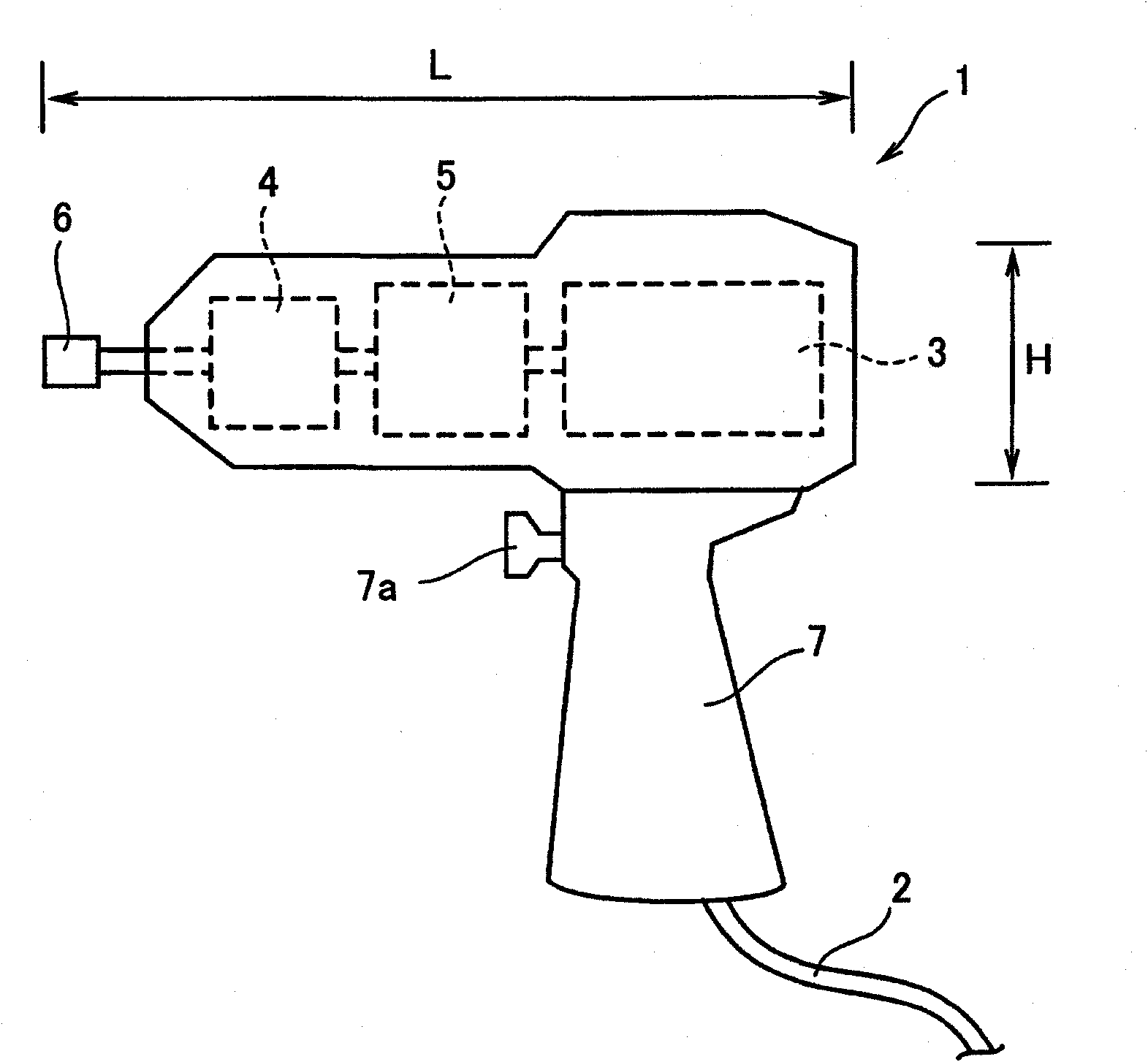

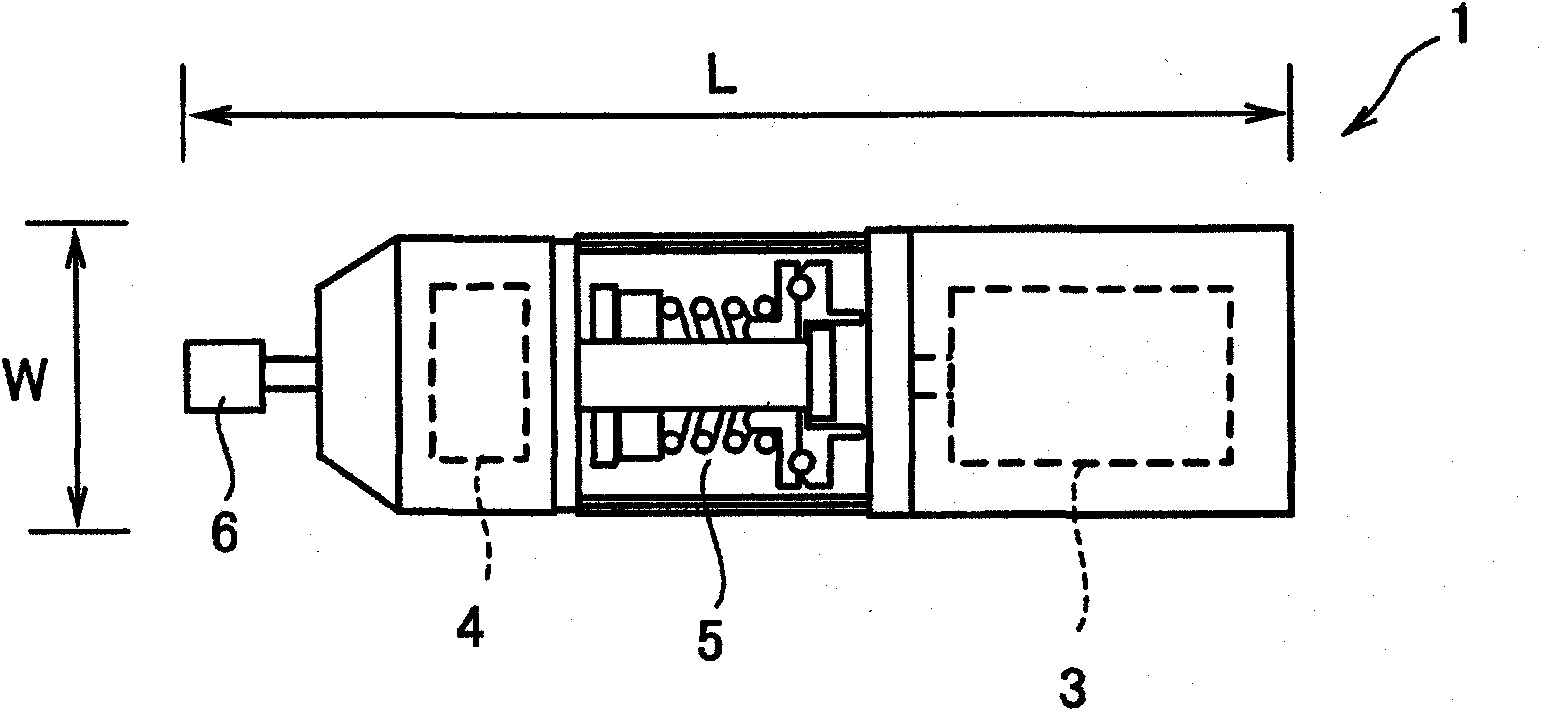

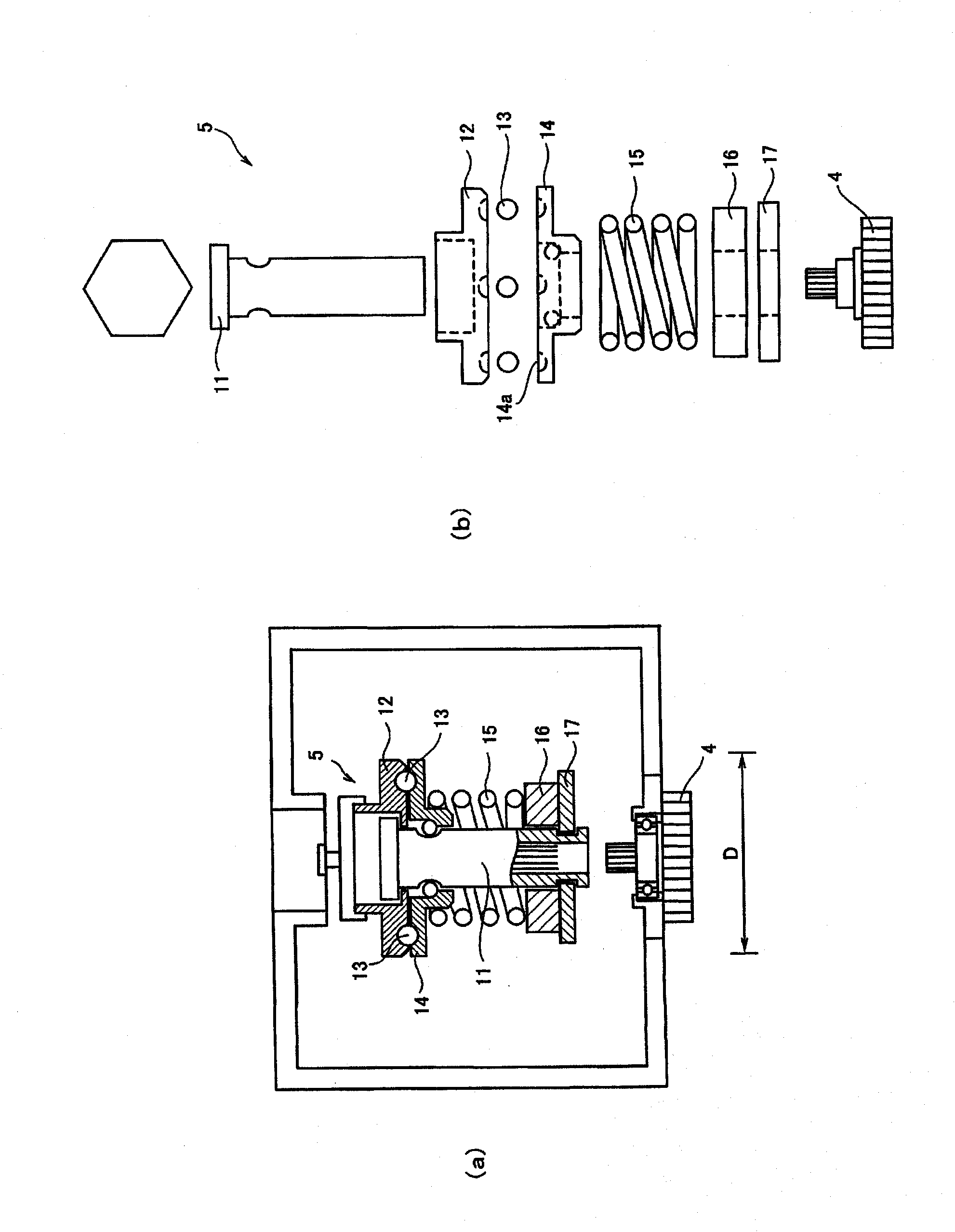

Screw tightening device and torque sensor

InactiveCN102159363AFastening is easyRealization of small size and light weightWork measurementSpannersMiniaturizationDC motor

The present invention relates to a screw tightening device having a small-sized clutch, reduced in size and weight, and easily operable. A clutch (5) is directly connected to the output side of a DC motor (3), and as a result, the output of the DC motor (3) is less than the output of conventionally used motors. This reduces the size of the DC motor (3) and the clutch (5). Accordingly, the size and weight of a device body (1) are less than those of conventional products.

Owner:HONDA MOTOR CO LTD

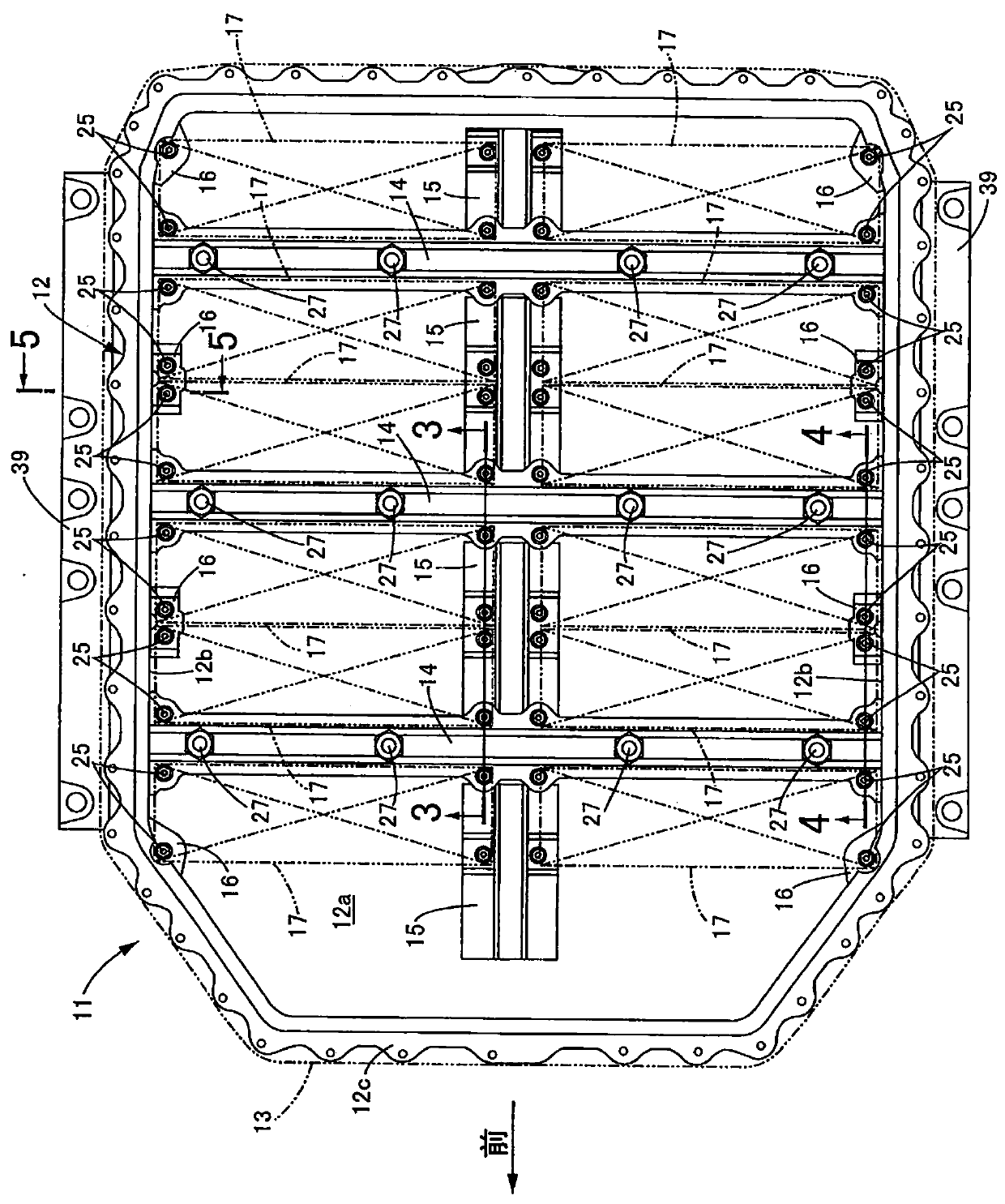

Battery pack

PendingCN110395098ARealization of small size and light weightMiniaturization in the height directionElectric propulsion mountingUnderstructuresEngineeringElectric vehicle

It is an object of the invention to reduce the dimension in the up-down direction of a battery pack housing a battery of an electric vehicle. In a battery pack, a battery driving an electric vehicle is housed inside a case. A skeleton member extending in a vehicle width direction is provided on a bottom wall of the case. The skeleton member has a hat-shaped section having an upper wall, paired side walls, and paired flanges and opening downwardly. The flange is fixed to the bottom wall. Part of the battery is supported on an upper face of the flange. Therefore, by supporting the battery by utilizing the skeleton member reinforcing the case against the impact of a side collision, it is possible to make a special battery support member unnecessary and achieve small size and light weight of the battery pack, and also to reduce the dimension in the height direction of the battery pack compared with a case where part of a battery is supported on an upper face of a skeleton member.

Owner:HONDA MOTOR CO LTD

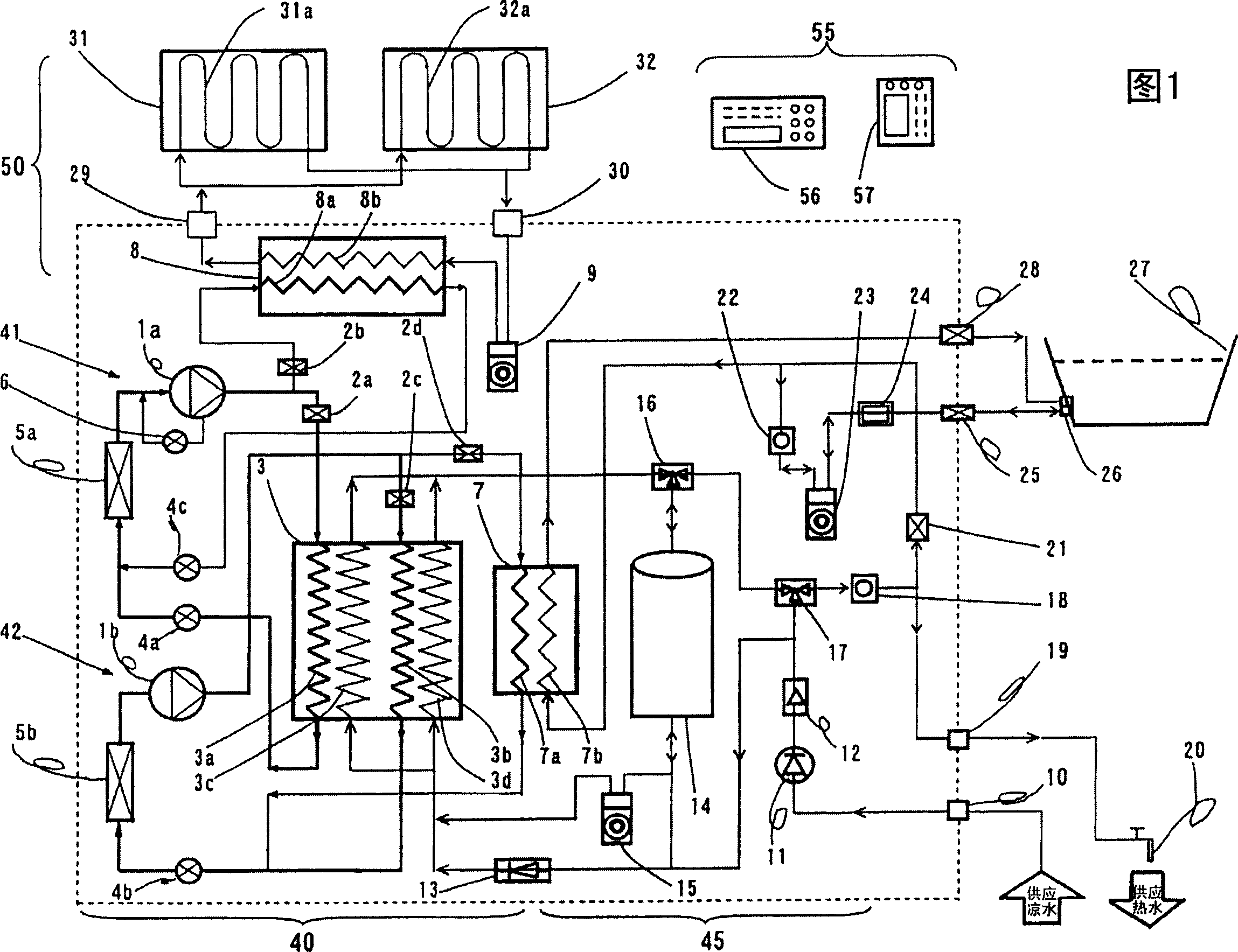

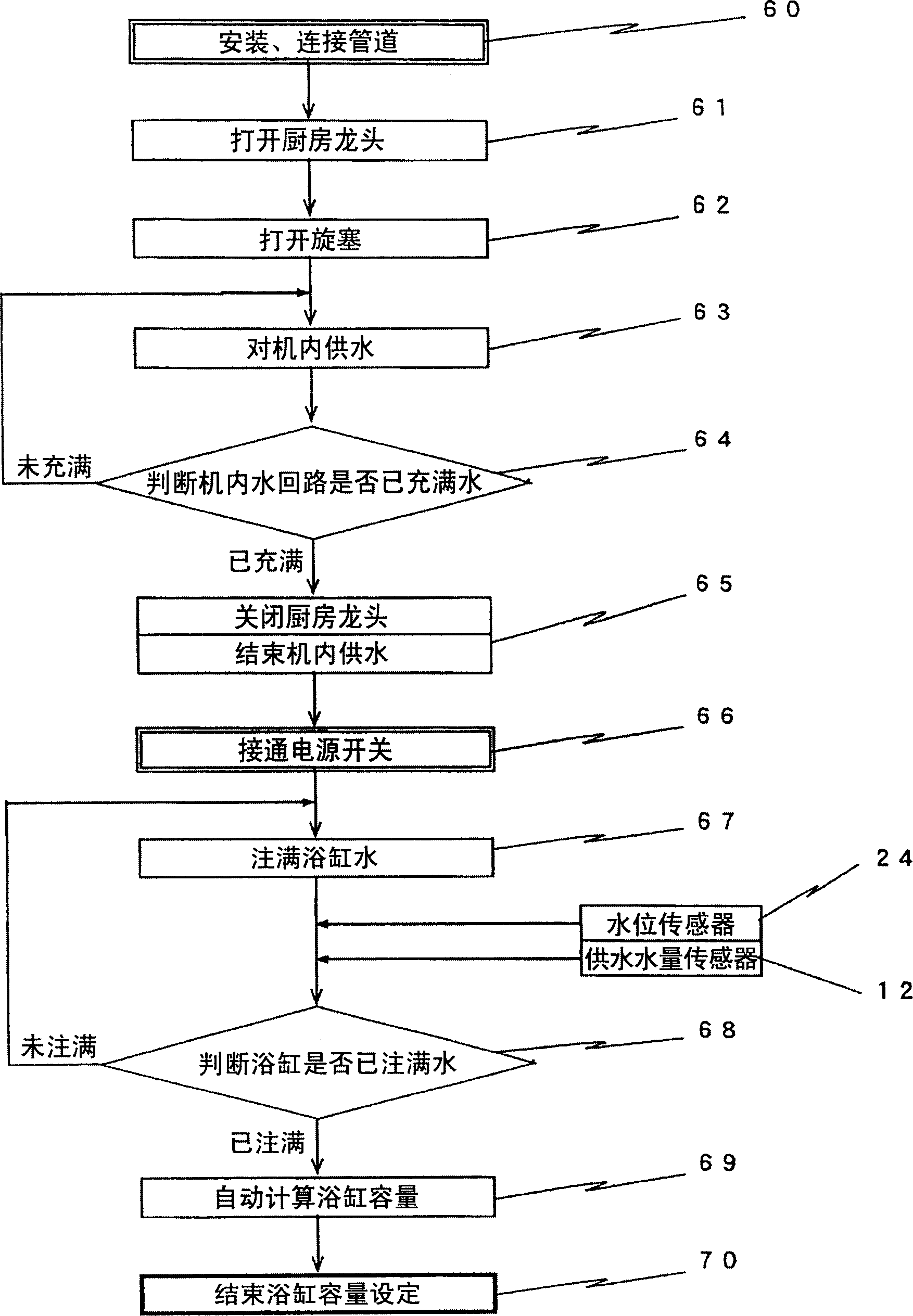

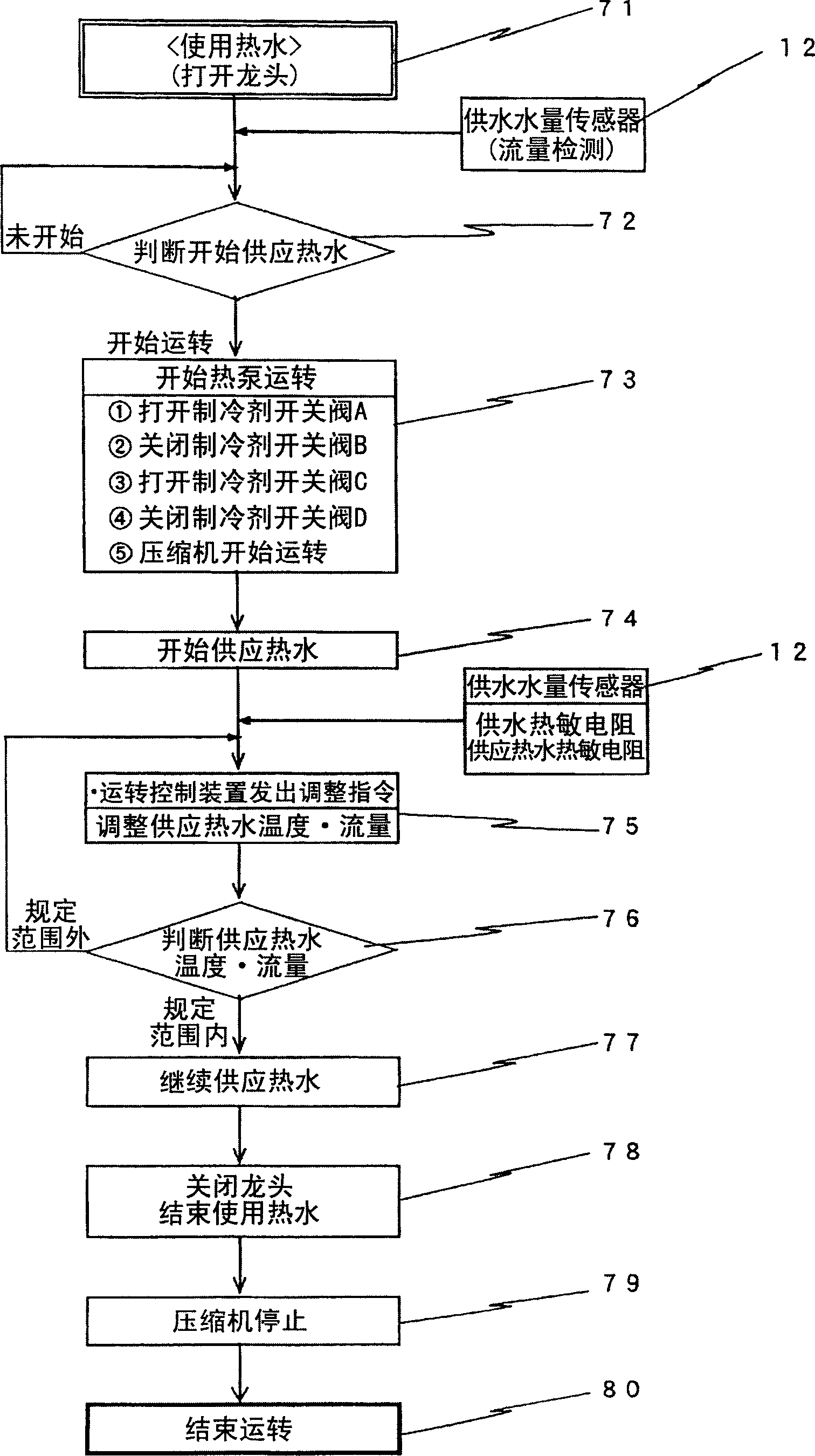

Floor heating system employing heat pump for supplying hot water

InactiveCN1912476AExpand the variable rangeEliminate slow performanceLighting and heating apparatusEnergy efficient heating/coolingLow speedProcess engineering

The problem to be solved in the invention is that, although a direct hot-water supply type is being considered in order to reduce size and weight in a heat pump hot-water supply floor heating device having a floor heating function at the same time, the difference between necessary heating capability in a hot-water supply operation and that in a floor heating operation is large, it can not be handled by conventional control of the number of revolutions of a compressor, and, in particular, separation, loss of synchronism, noise and the like of a compression mechanism part are generated in a low-speed operation in the floor heating operation. This heat pump hot-water supply floor heating device of the invention is solved the conventional problem by executing a heat pump operation in using hot water, by adding a floor heating function to a direct hot-water supply type heat pump water heater for directly supplying heating water to a used terminal, and by skillfully using control of the number of revolutions and capacity control as a control method of a compressor in response to a situation.

Owner:HITACHI APPLIANCES INC +1

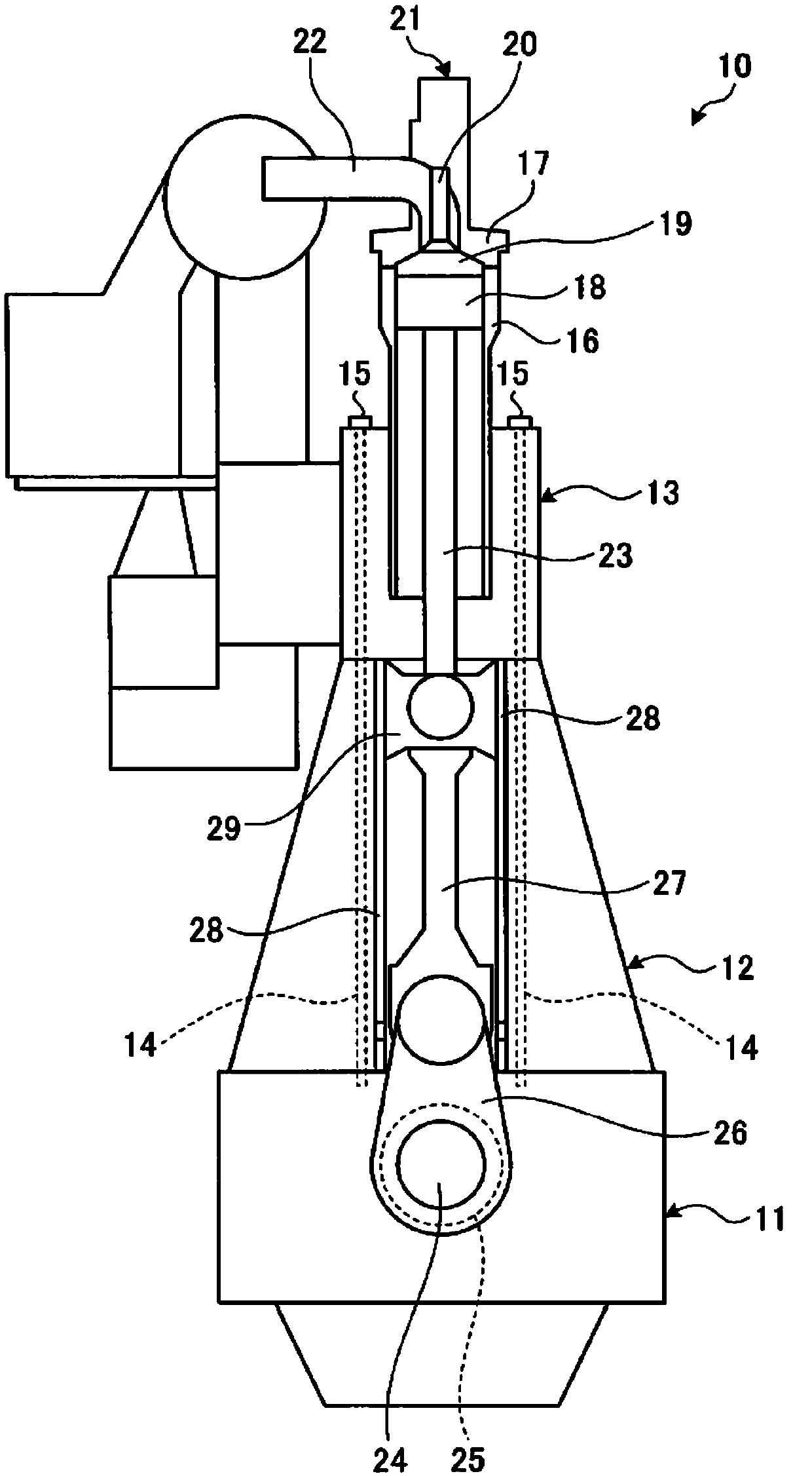

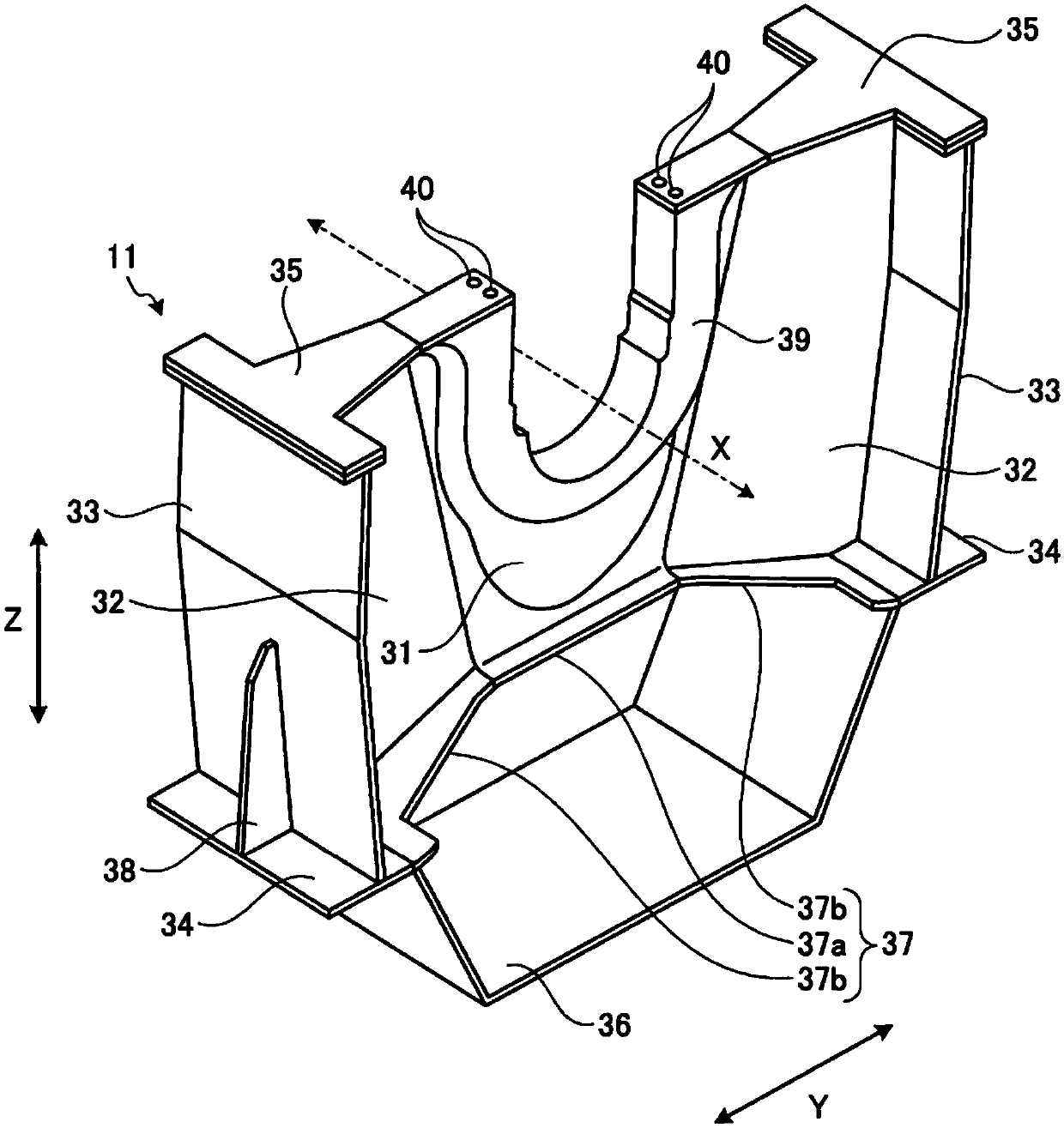

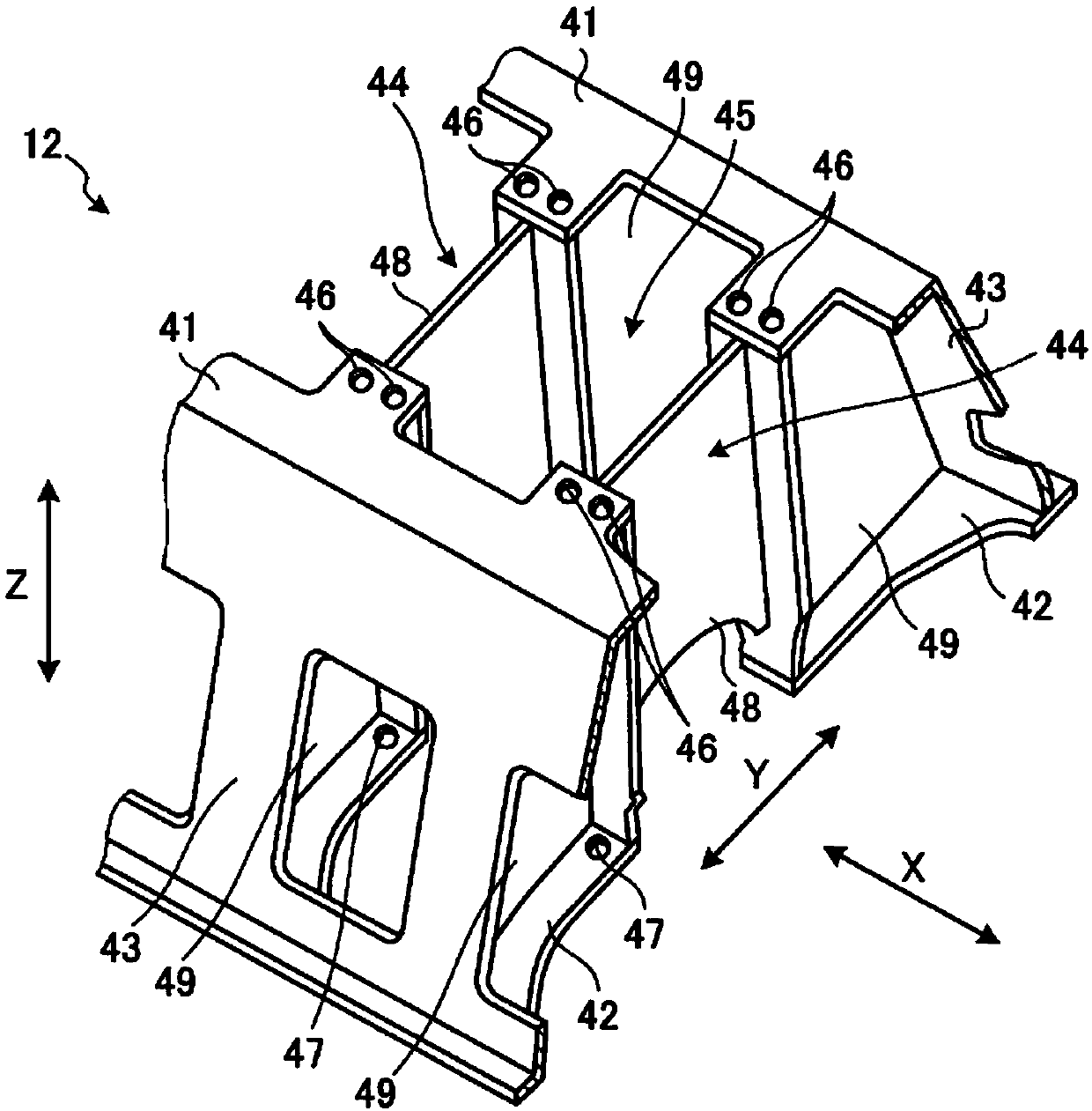

Cylinder jacket and crosshead-type internal combustion engine

ActiveCN109642514AShorten the lengthRealization of small size and light weightCasingsCylinder headsEngineeringInternal combustion engine

A cylinder jacket and a crosshead-type internal combustion engine provided with: a top plate (51) in which first through-holes (55) penetrating in the plate thickness direction are formed; a bottom plate (52) in which second through-holes (56) penetrating in the plate thickness direction and opposing the first through-holes (55) are formed; side plates (53) connecting the top plate (51) and the bottom plate (52); and attachment holes (59) which penetrate along the direction of penetration of the first through-holes (55) and the second through-holes (56), and through which a plurality of tie bolts (14) are inserted.

Owner:MITSUBISHI HEAVY IND LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com