Gas breaker

A gas circuit breaker and gas technology, applied in the direction of high-voltage air circuit breakers, circuits, electrical components, etc., can solve the problems of difficult to adjust the addition rate of inorganic filler materials, promote heat diffusion, etc., to increase gas pressure, shorten insulation distance, improve The effect of arc extinguishing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

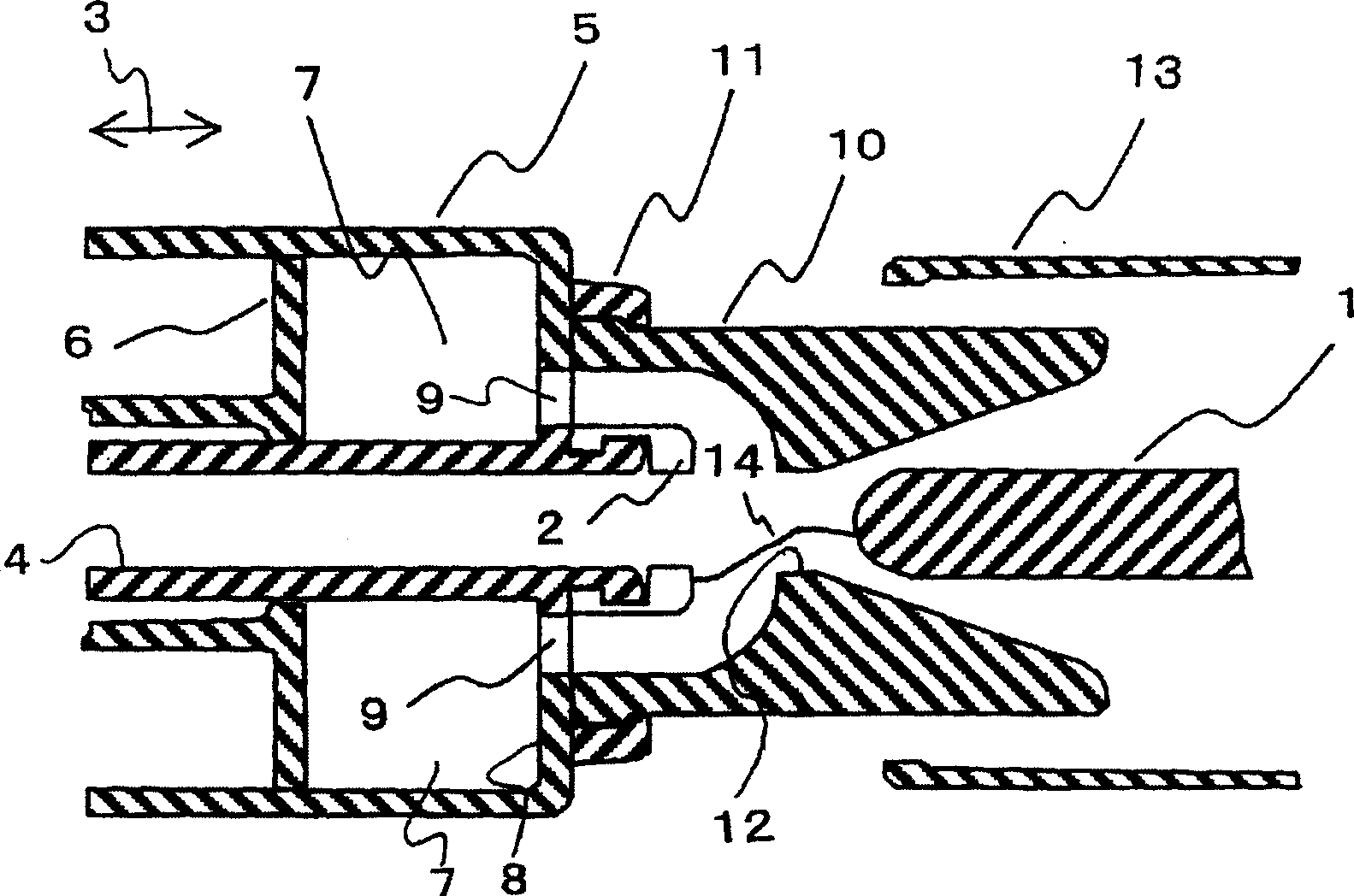

[0030] Here, the material of the nozzle 10 which is the characteristic of the present invention can be selected from the composite materials of Examples 1 to 8 shown in Table 1. According to these Examples, since the heat resistance and mechanical strength are excellent, the insulation recovery at the time of breaking is accelerated, and the arc voltage at the time of breaking is high, the breaking performance is remarkably improved. That is, it is possible to obtain a gas circuit breaker in which the breaking performance is remarkably improved by generating ablative gas.

[0031] Example

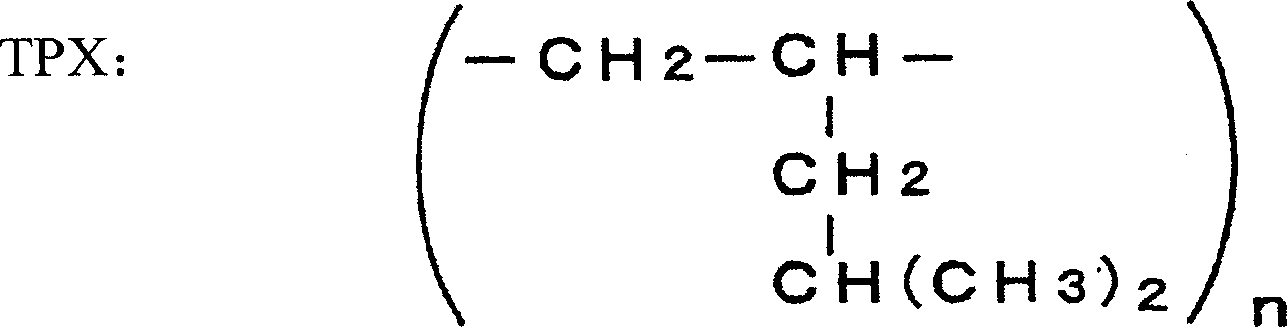

[0032] TPX: poly-4-methyl-1-pentene

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com