Patents

Literature

236results about How to "Increase gas pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

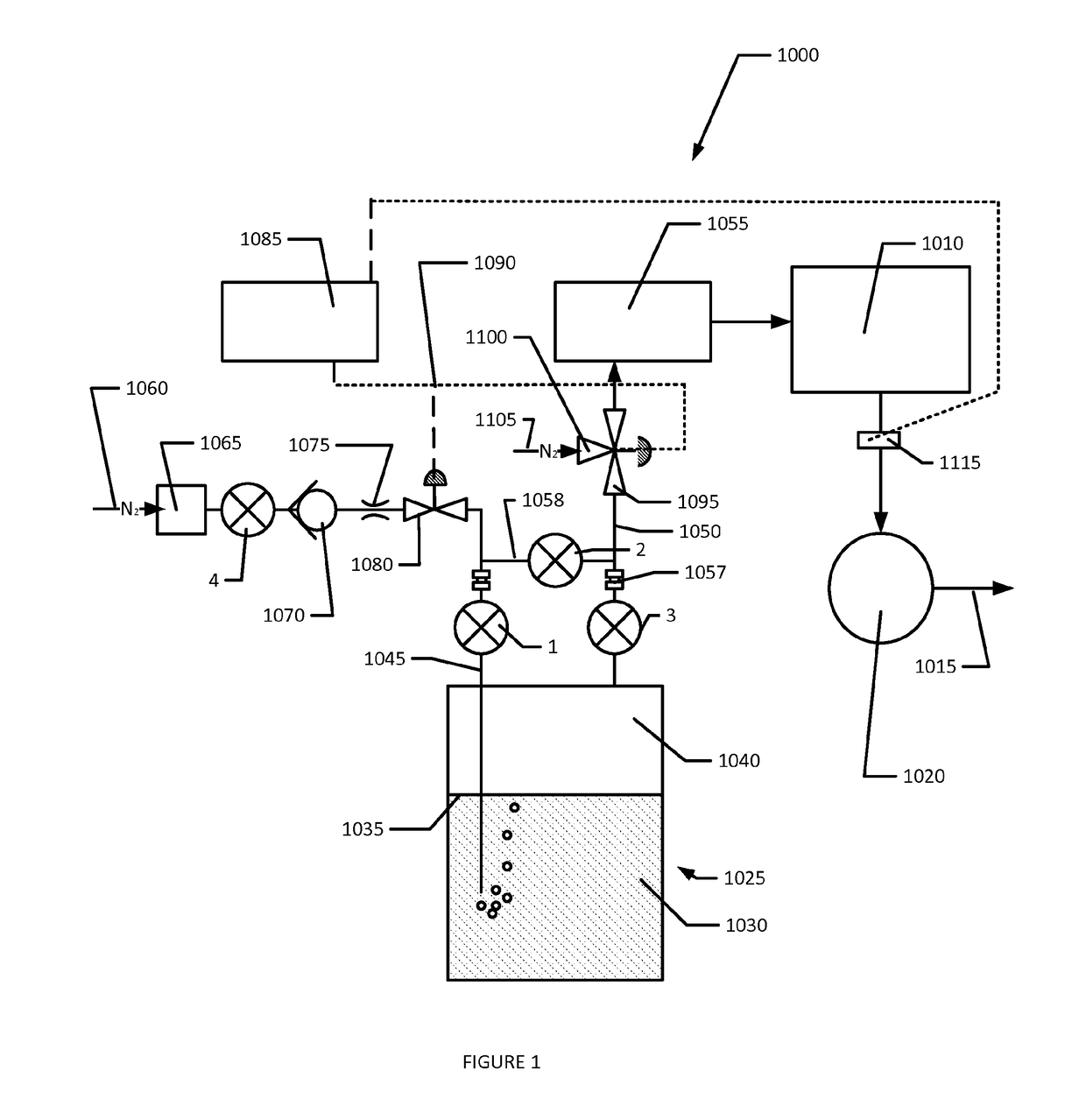

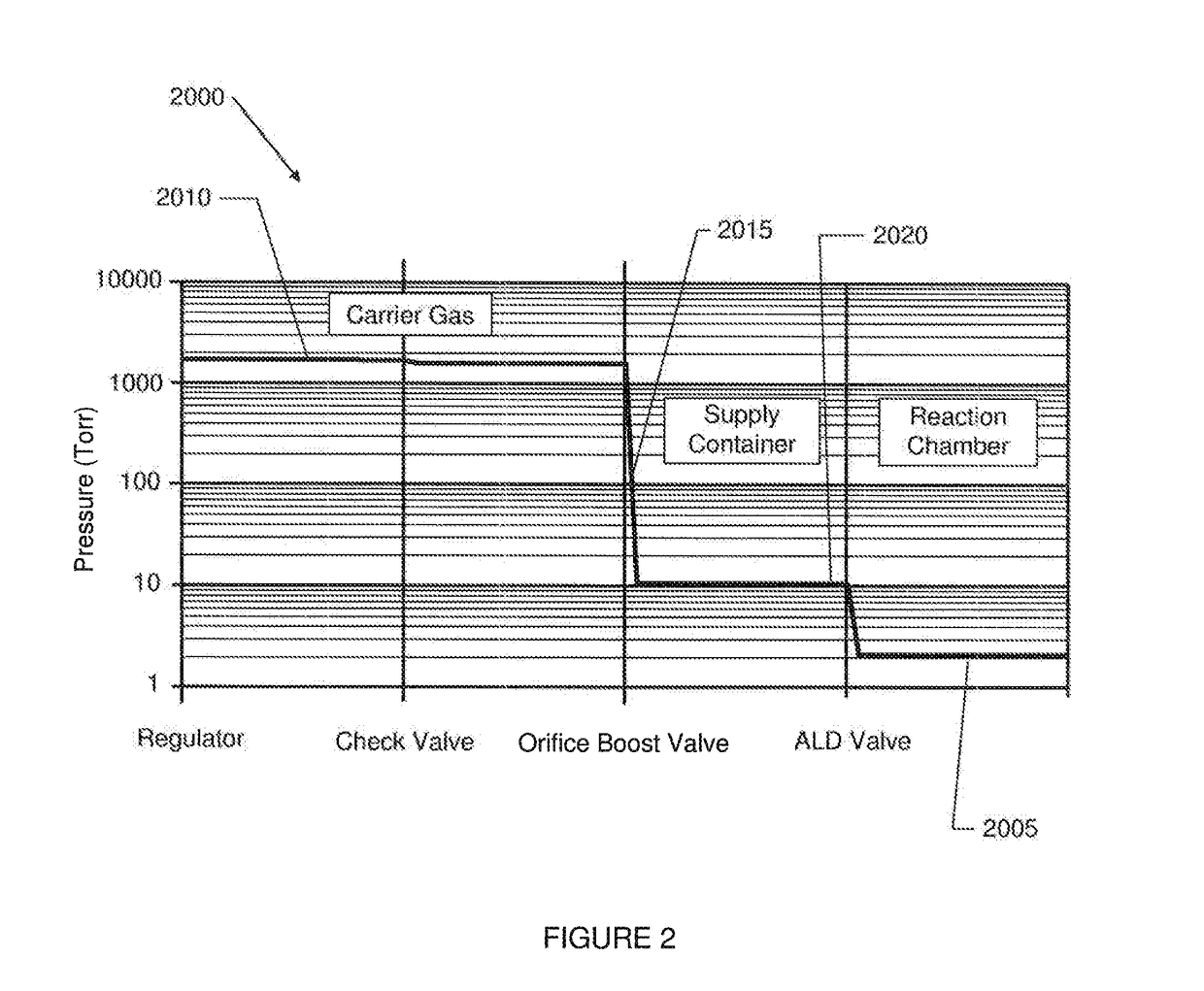

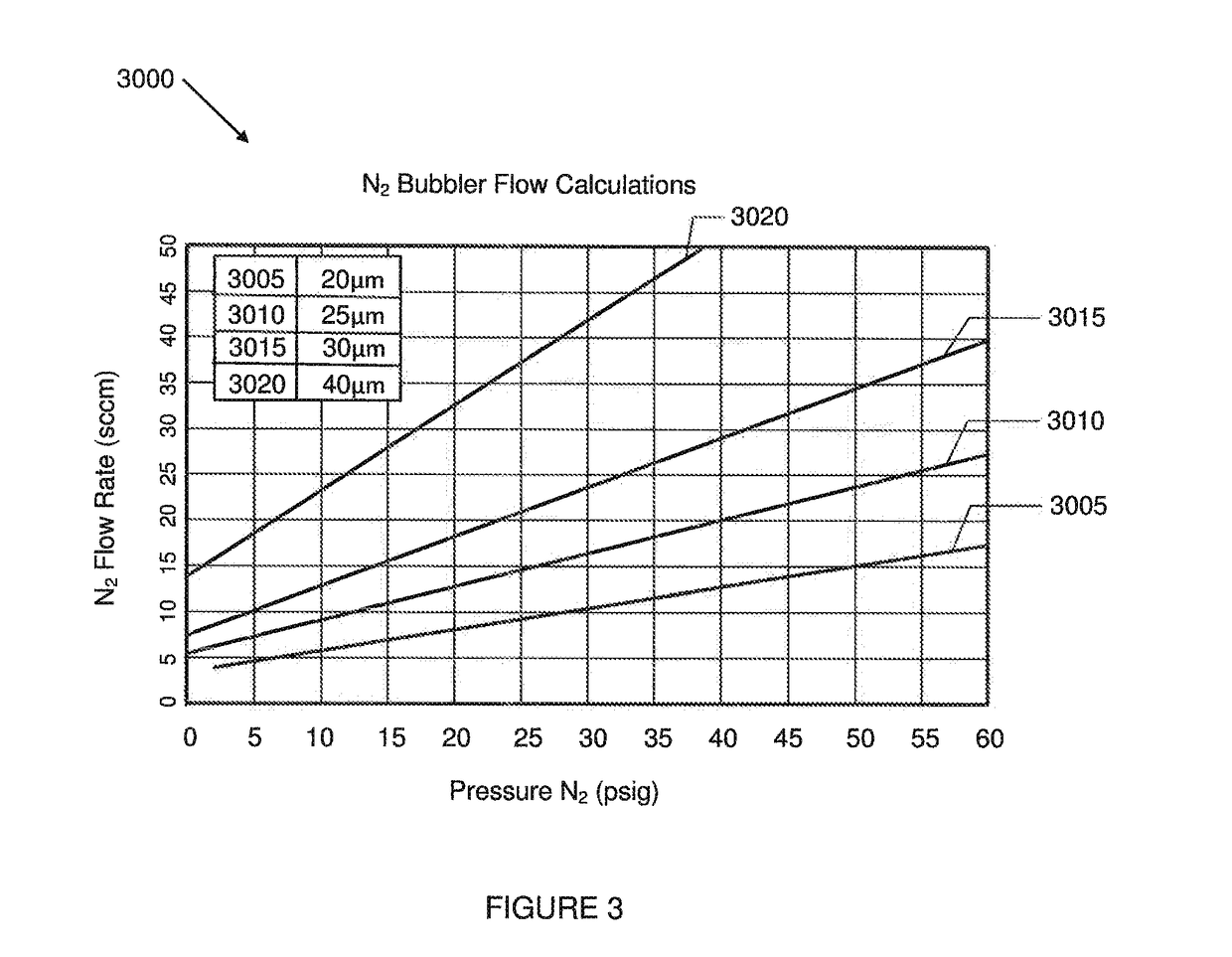

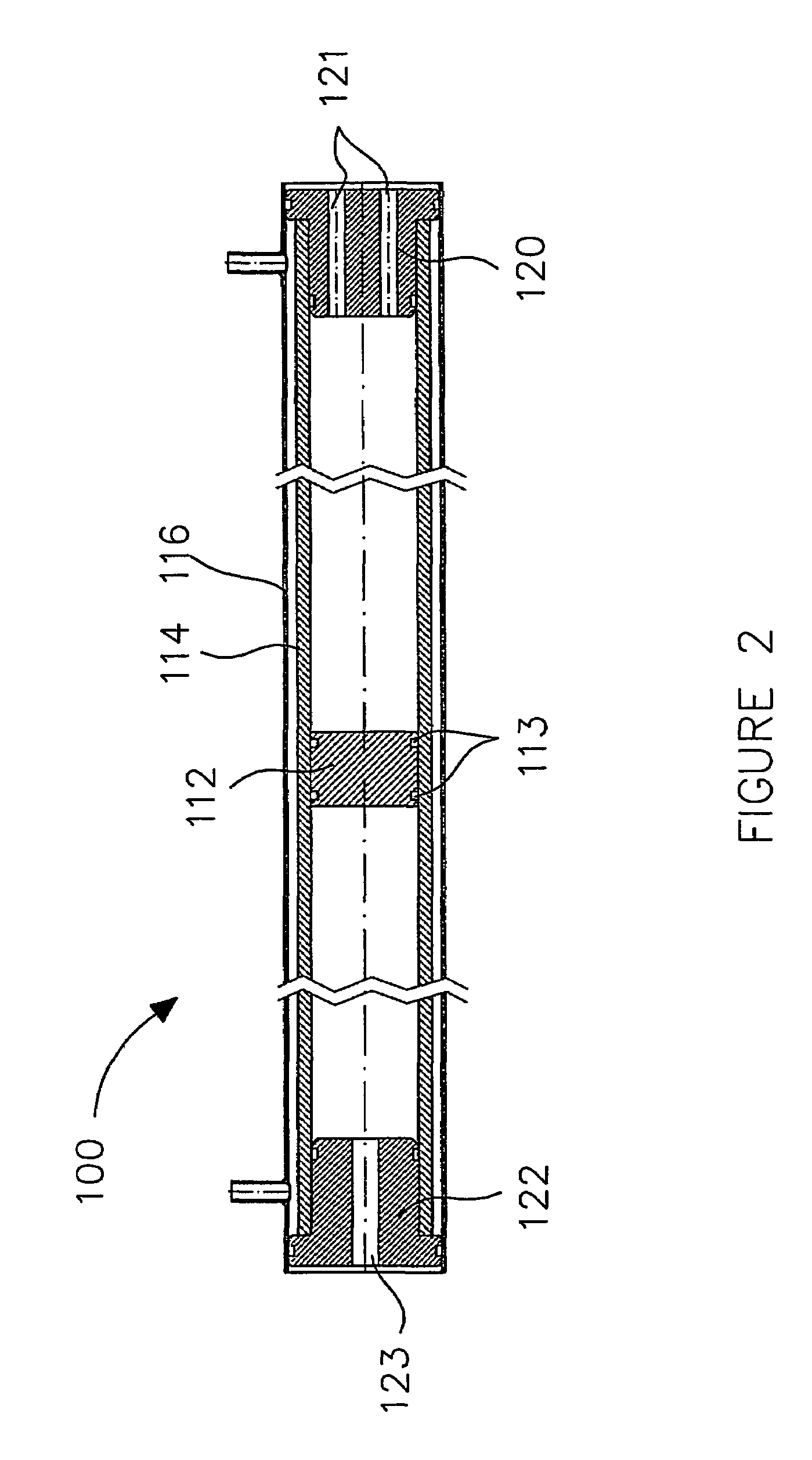

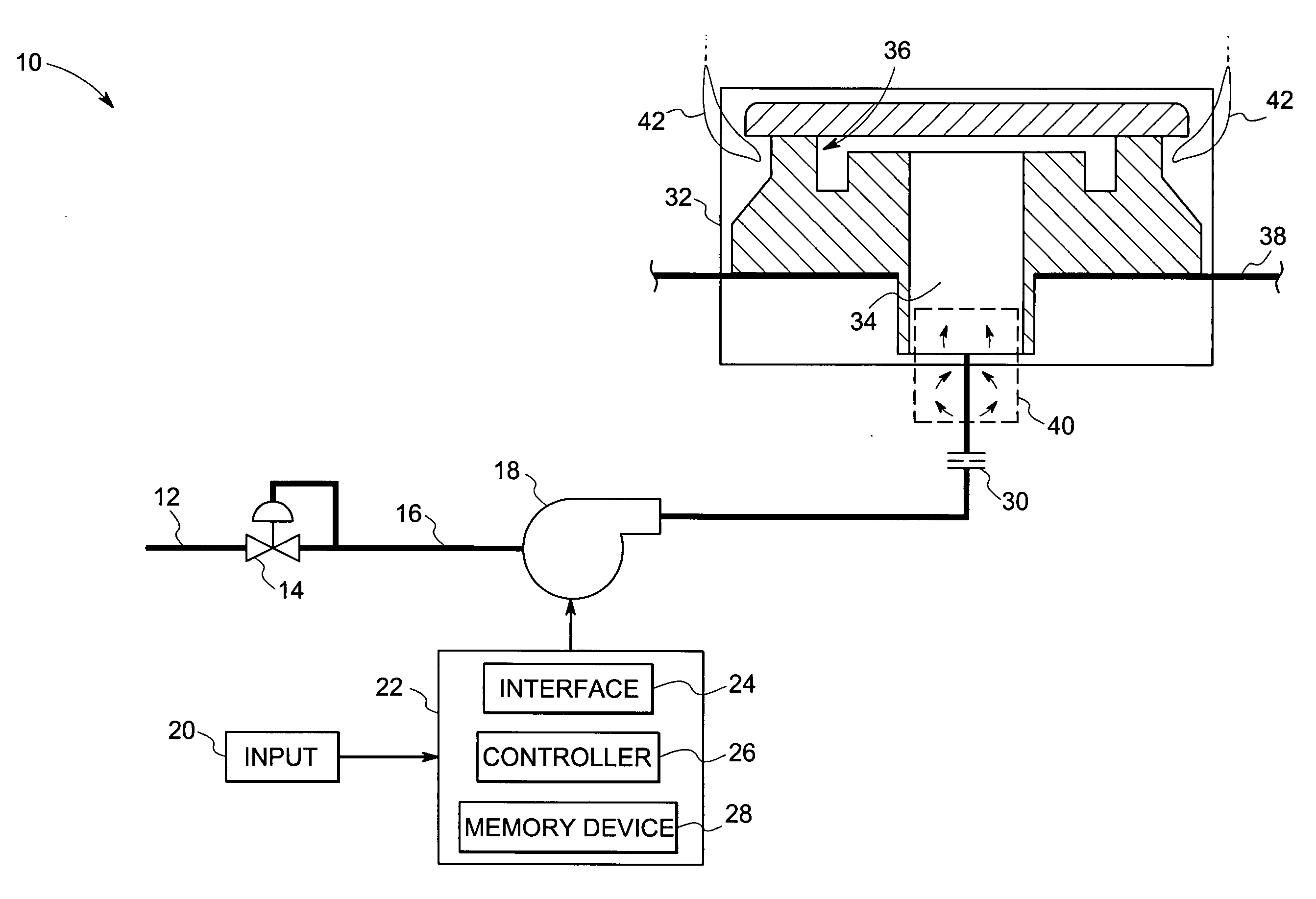

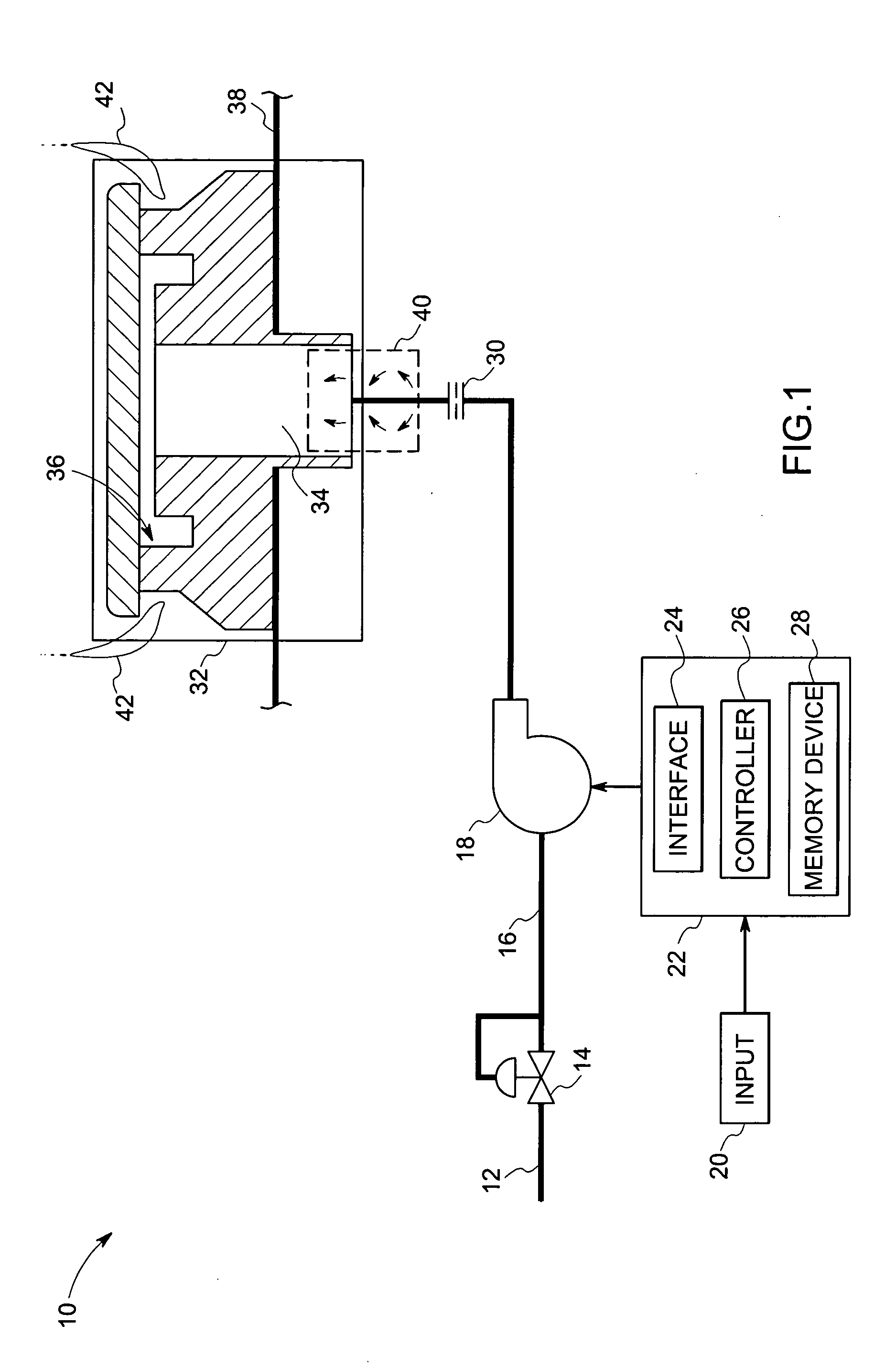

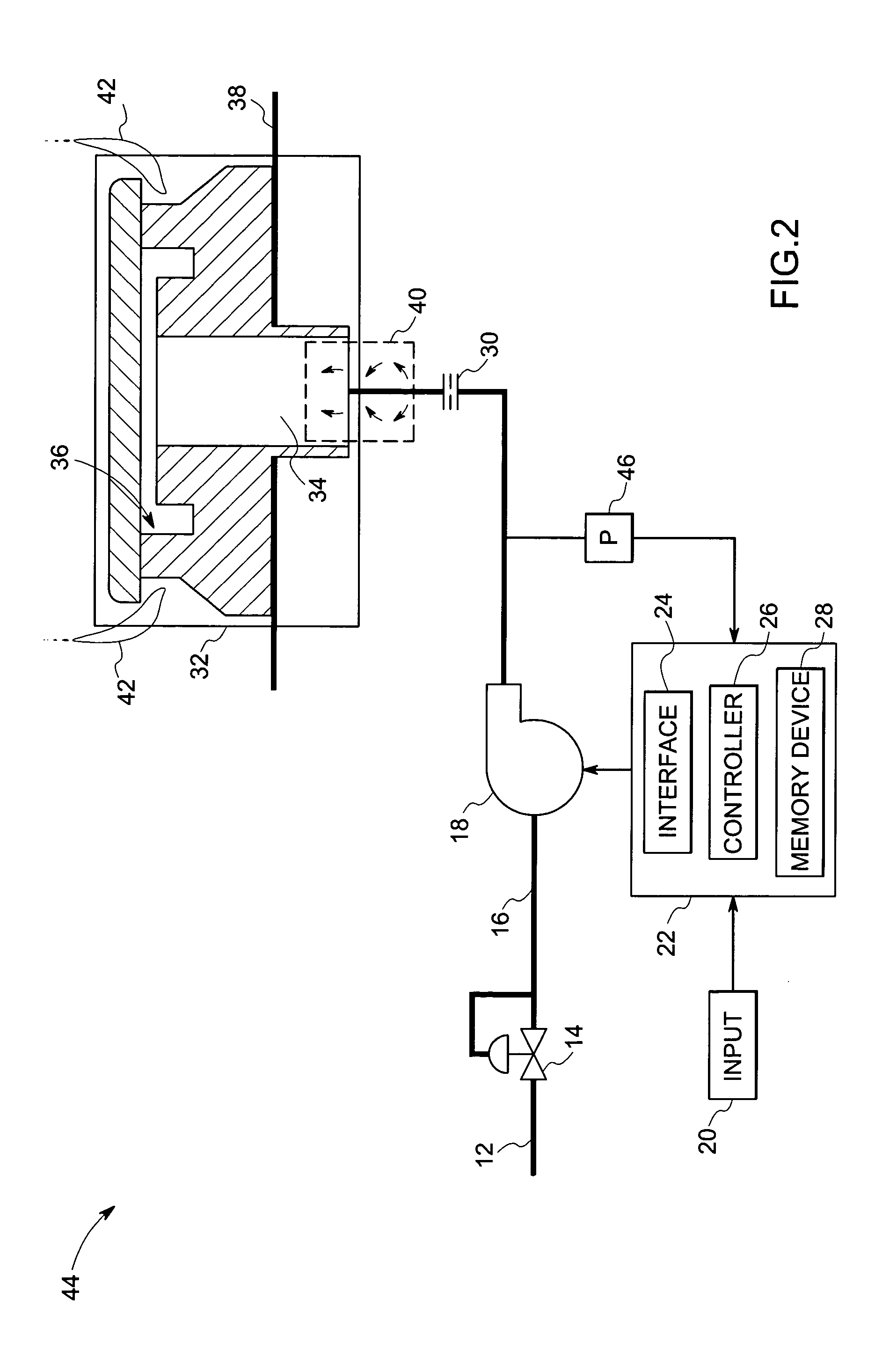

Vapor delivery system

InactiveUS20170145564A1Increase gas pressureChemical vapor deposition coatingEngineeringDelivery system

An improved ALD system usable for low vapor pressure liquid and sold precursors. The ALD system includes a precursor container and inert gas delivery elements configured to increase precursor vapor pressure within a precursor container by injecting an inert gas pulse into the precursor container while a precursor pulse is being removed to the reaction chamber. A controllable inert gas flow valve and a flow restrictor are disposed along an inert gas input line leading into the precursor container below its fill level. A vapor space is provided above the fill level. An ALD pulse valve is disposed along a precursor vapor line extending between the vapor space and the reaction chamber. Both valves are pulsed simultaneously to synchronously remove precursor vapor from the vapor space and inject inert gas into the precursor container below the fill level.

Owner:ULTRATECH INT INC

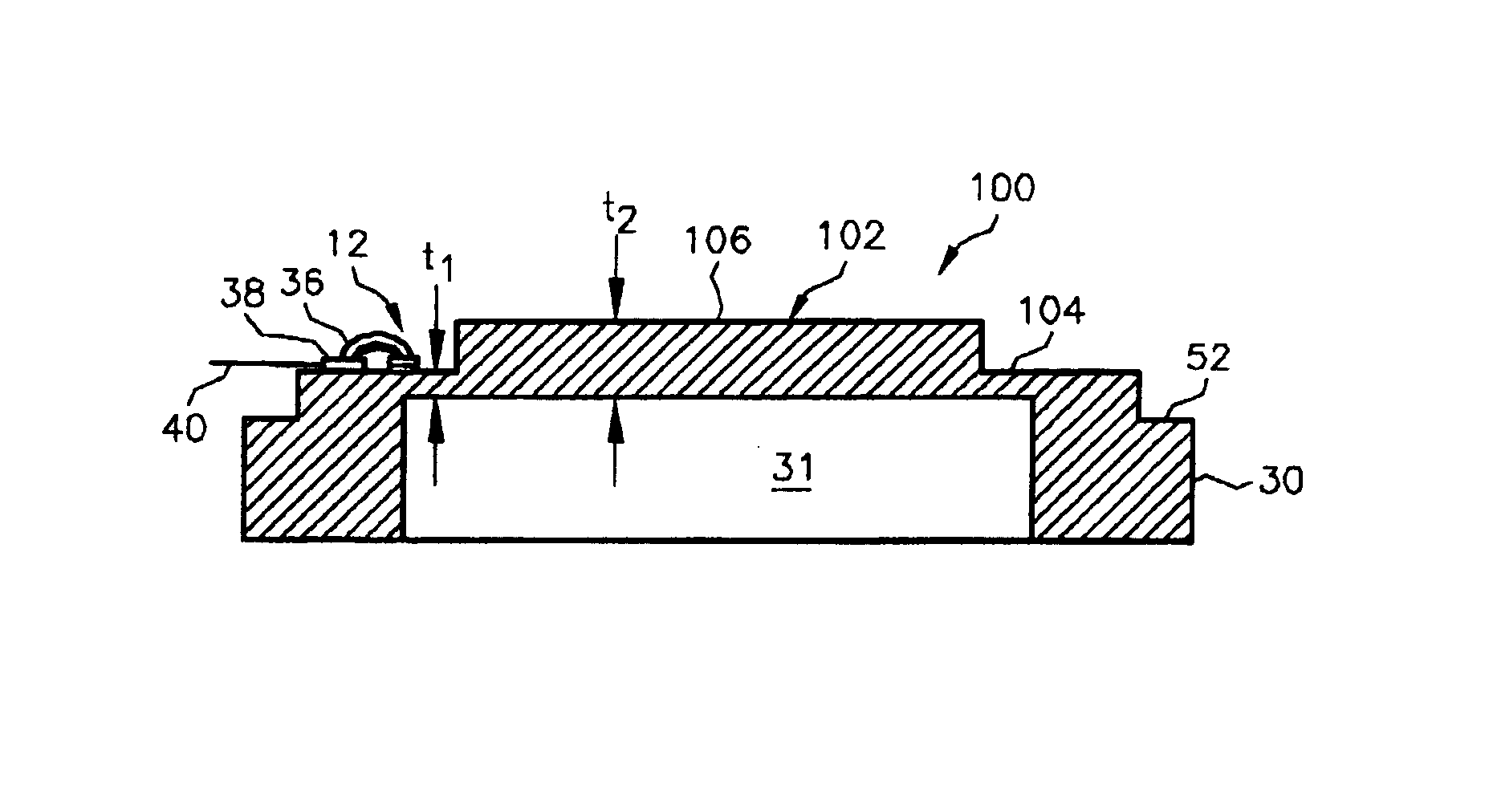

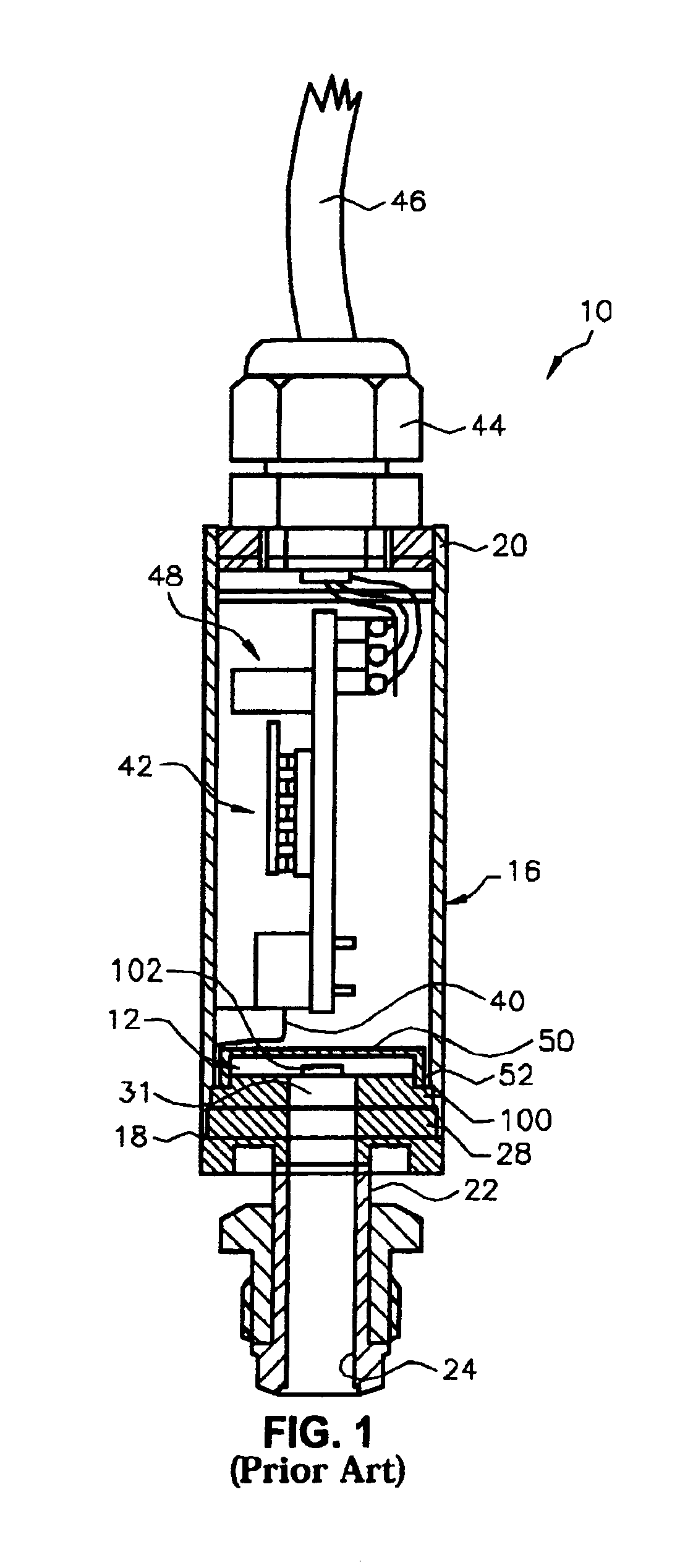

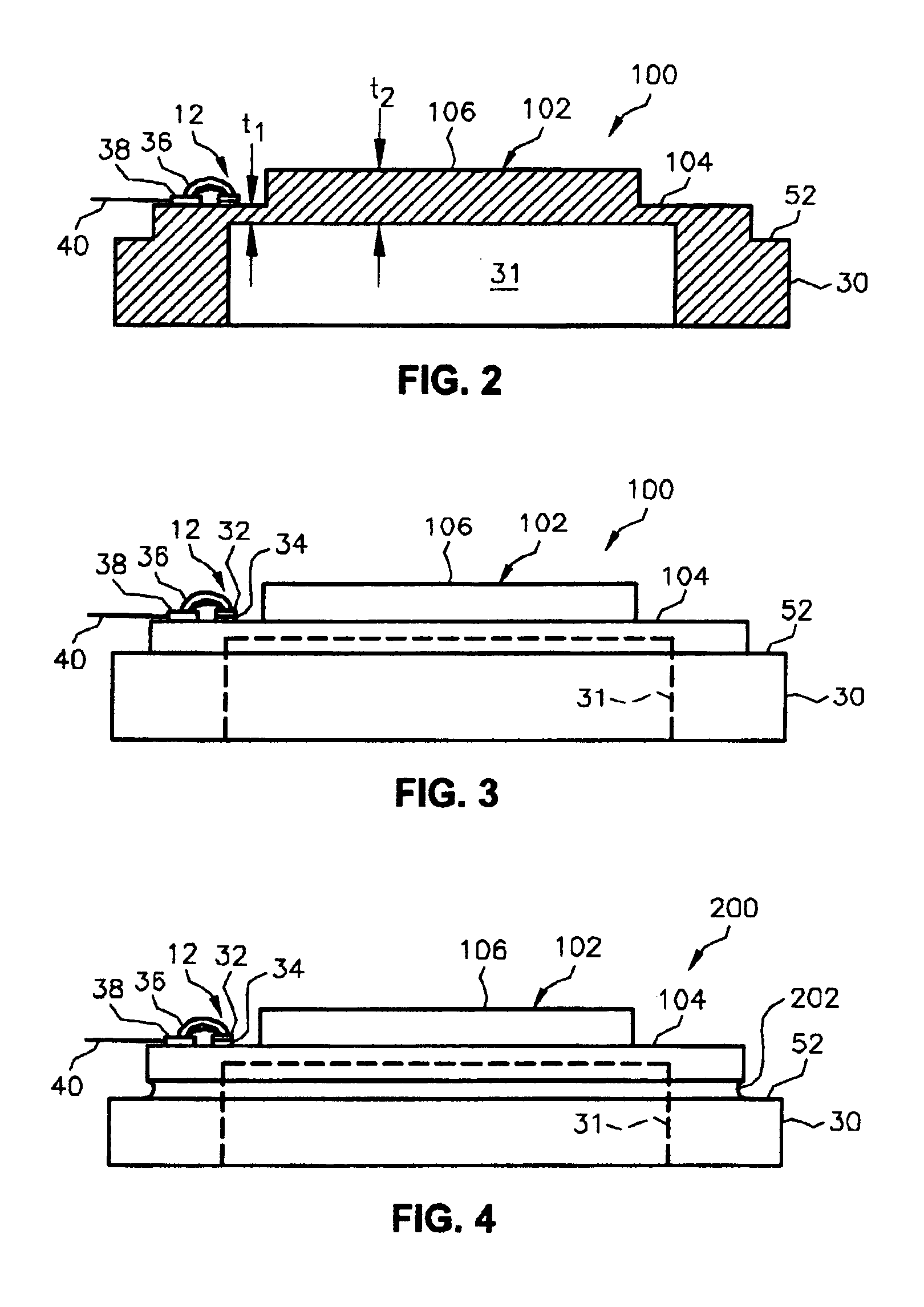

Diaphragm for bonded element sensor

ActiveUS6877380B2Improve sensor sensitivityIncrease gas pressureFluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by electric/magnetic elementsEngineeringPressure sensor

A pressure sensor device for producing a signal indicative of a pressure of a fluid to be monitored, including a housing having a fluid conduit for receiving the fluid to be monitored and a diaphragm positioned at an end of the fluid conduit. The diaphragm includes at least first and second portions, wherein a thickness of the first portion is less than a thickness of the second portion. A transducer is bonded to a surface of the first portion of the diaphragm and including piezoresistive elements for sending the signal. Preferred is a circular second portion and an annular first portion around the outer edge of the second portion. The housing is preferably tubular and includes an annular shoulder for mounting the diaphragm, along with an annular groove on the outer surface of the first portion and connecting the first portion to the annular shoulder.

Owner:HONEYWELL INT INC

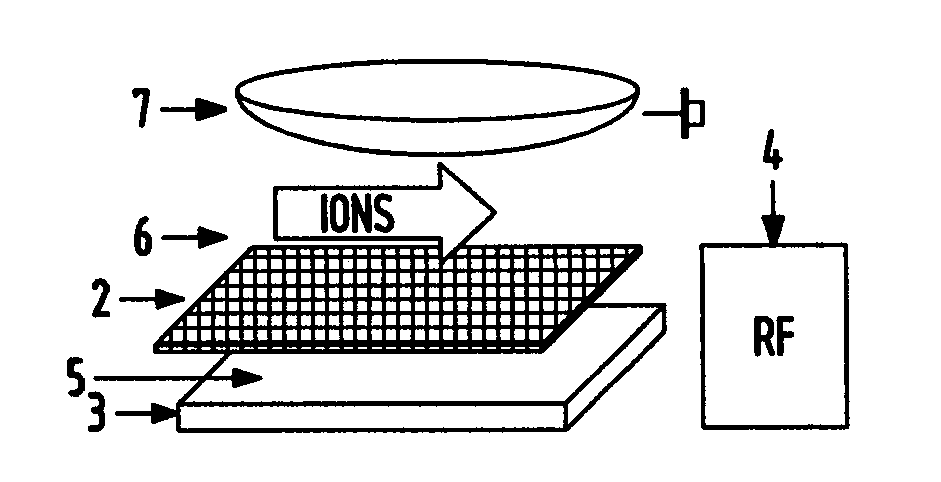

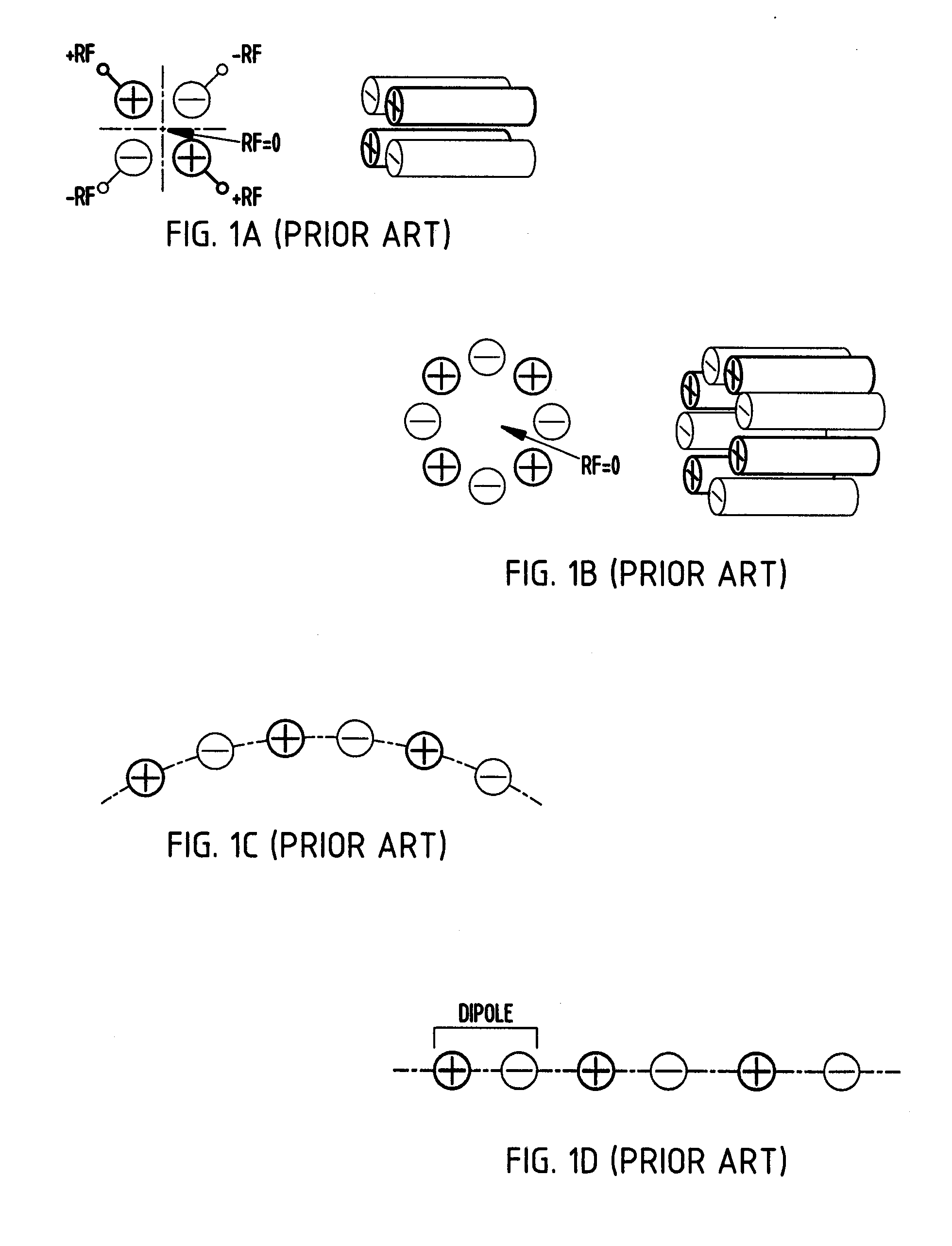

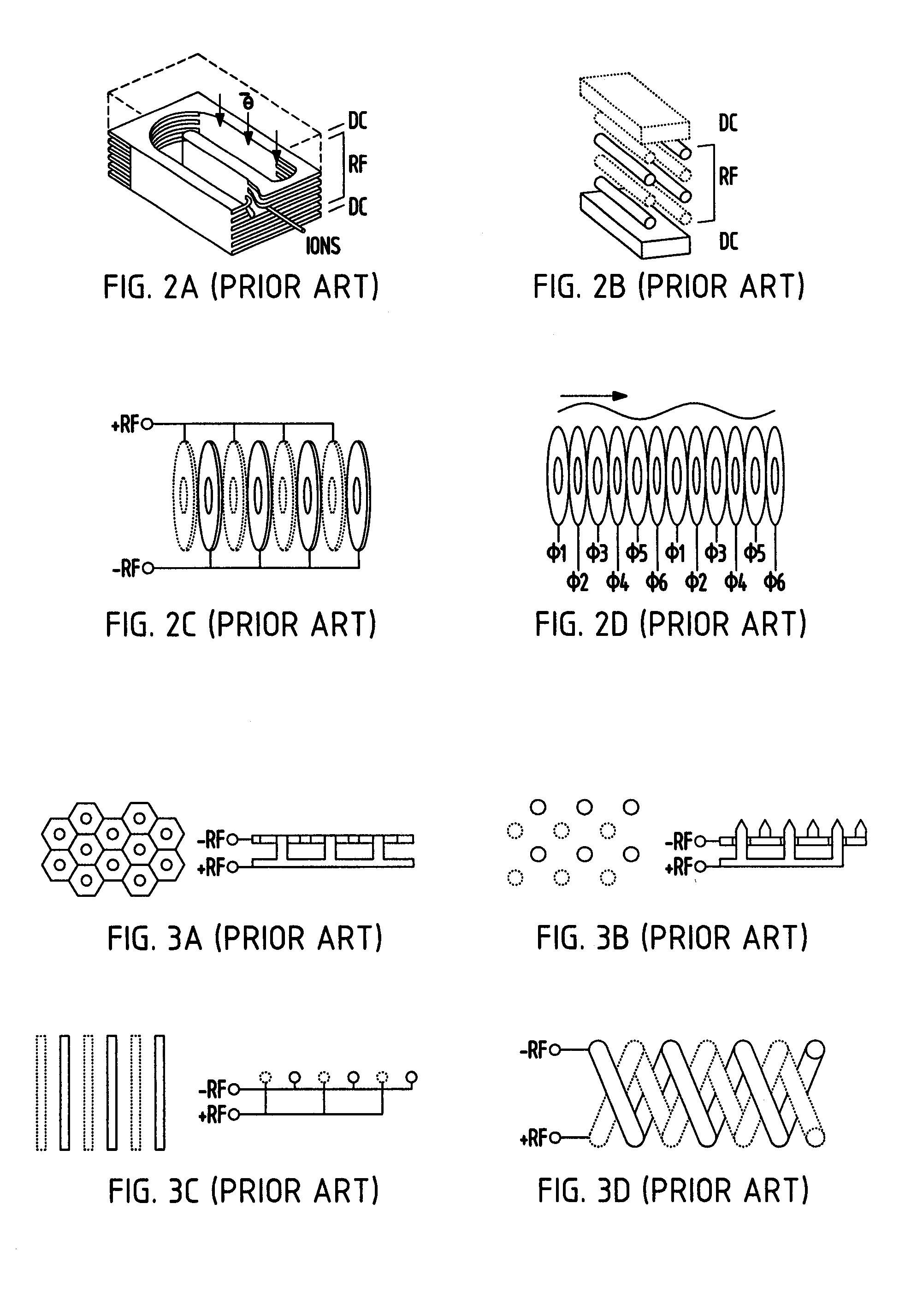

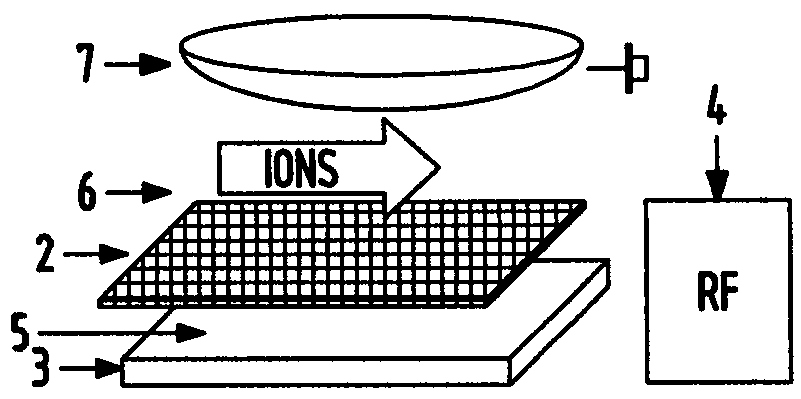

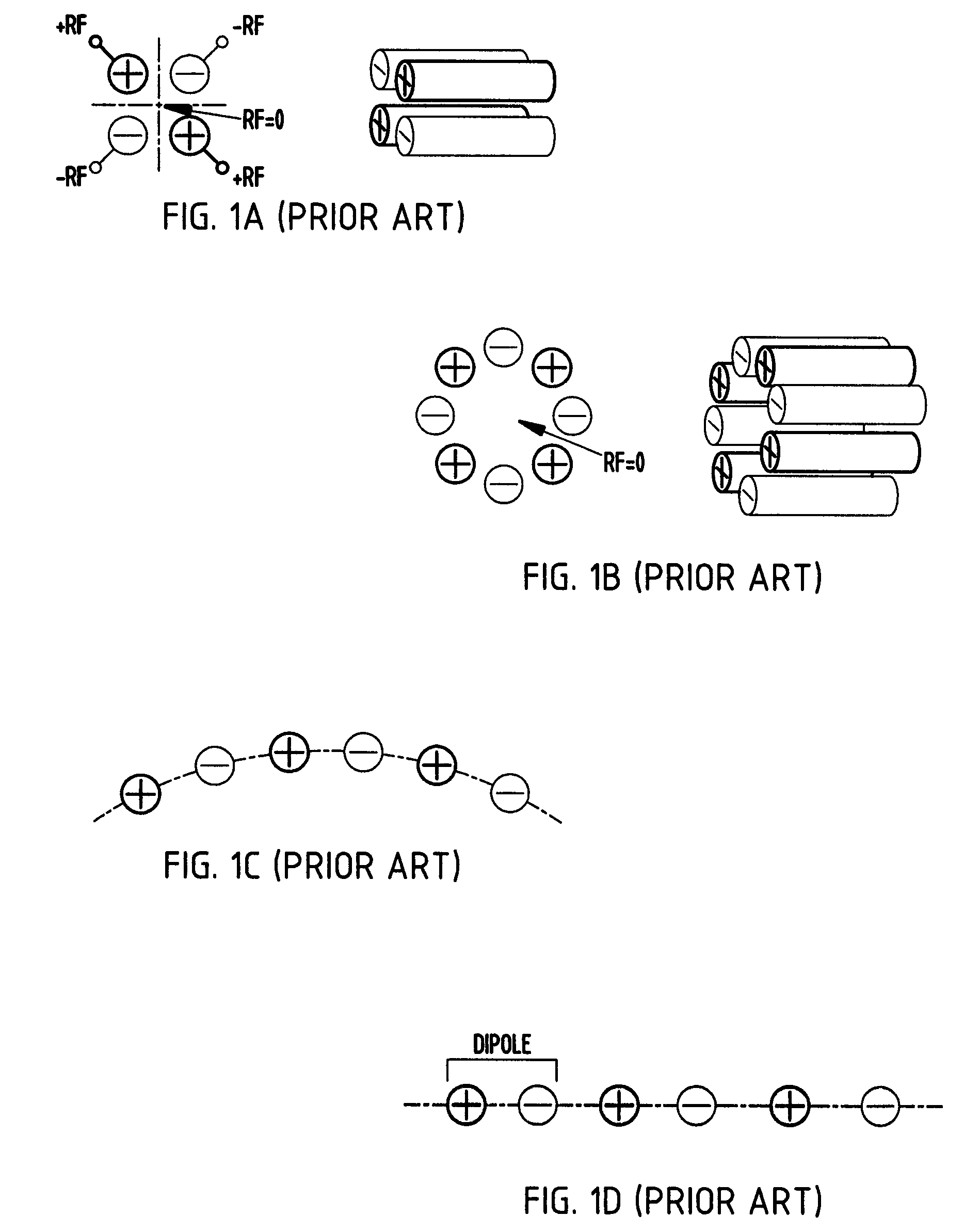

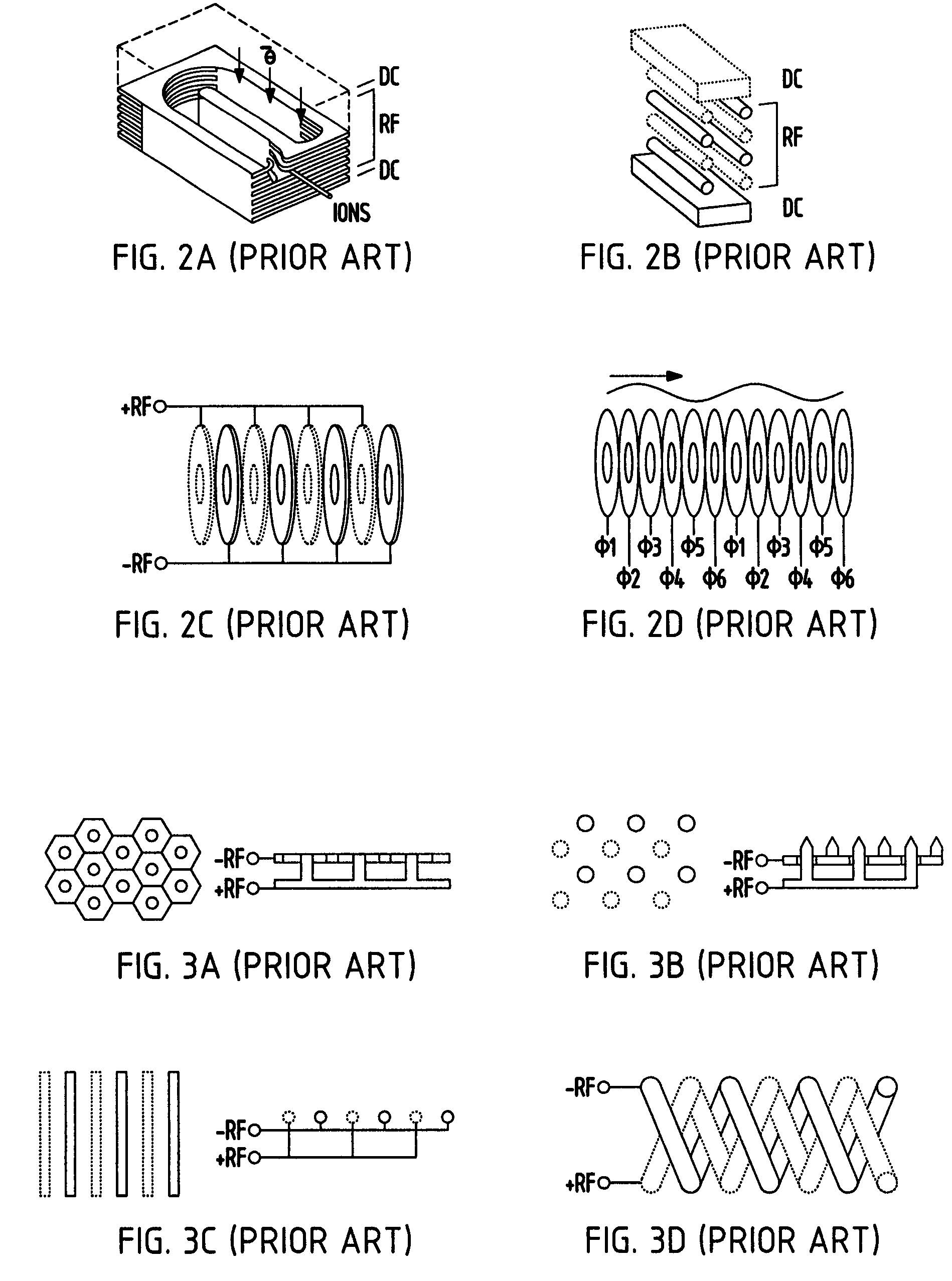

Method and apparatus for ion manipulation using mesh in a radio frequency field

ActiveUS20110192969A1Better wayEasy to buildTime-of-flight spectrometersIsotope separationIon chromatographyDesorption

Ion manipulation systems include ion repulsion by an RF field penetrating through a mesh. Another comprises trapping ions in a symmetric RF field around a mesh. The system uses macroscopic parts, or readily available fine meshes, or miniaturized devices made by MEMS, or flexible PCB methods. One application is ion transfer from gaseous ion sources with focusing at intermediate and elevated gas pressures. Another application is the formation of pulsed ion packets for TOF MS within trap array. Such trapping is preferably accompanied by pulsed switching of RF field and by gas pulses, preferably formed by pulsed vapor desorption. Ion guidance, ion flow manipulation, trapping, preparation of pulsed ion packets, confining ions during fragmentation or exposure to ion to particle reactions and for mass separation are disclosed. Ion chromatography employs an ion passage within a gas flow and through a set of multiple traps with a mass dependent well depth.

Owner:LECO CORPORATION

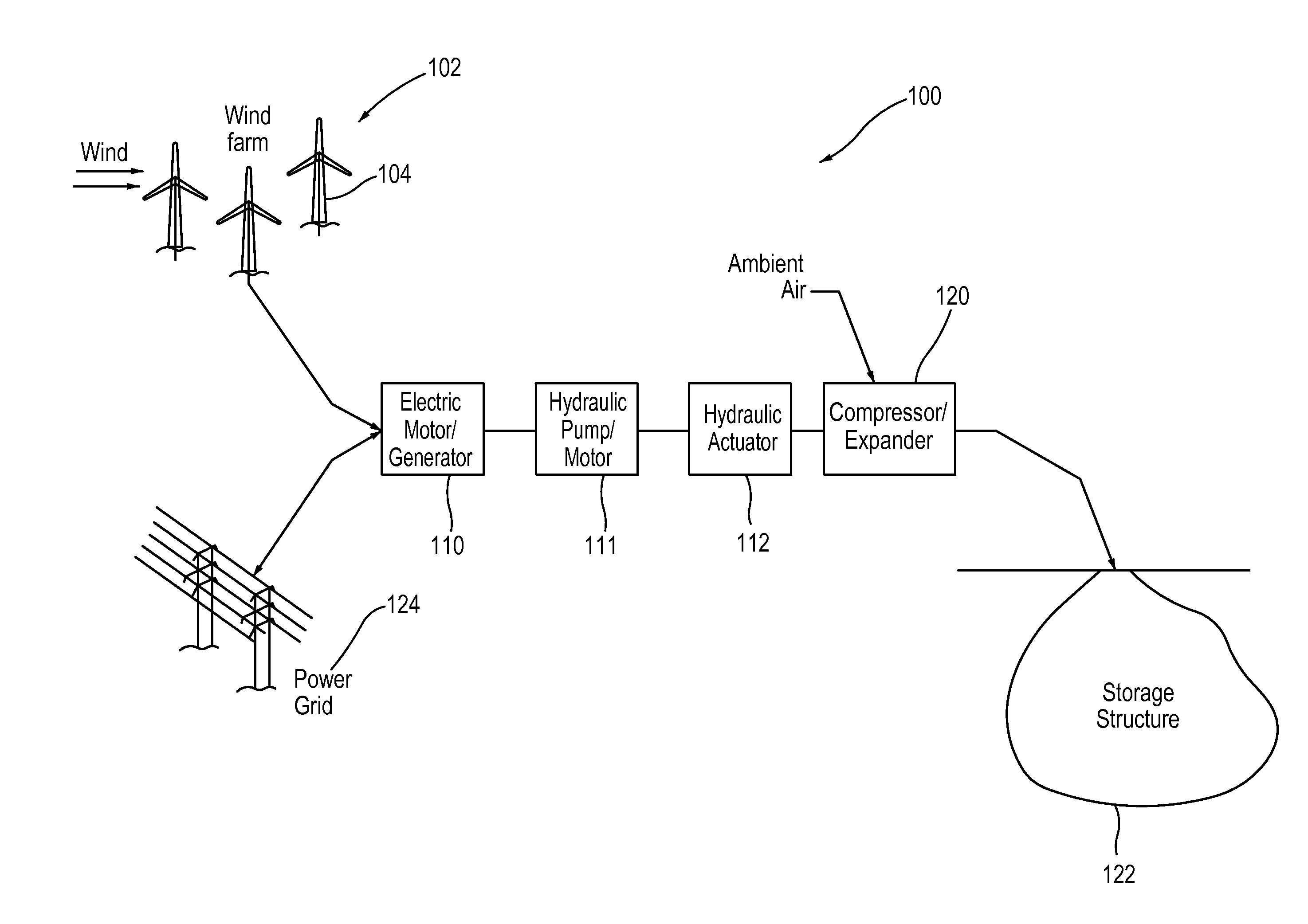

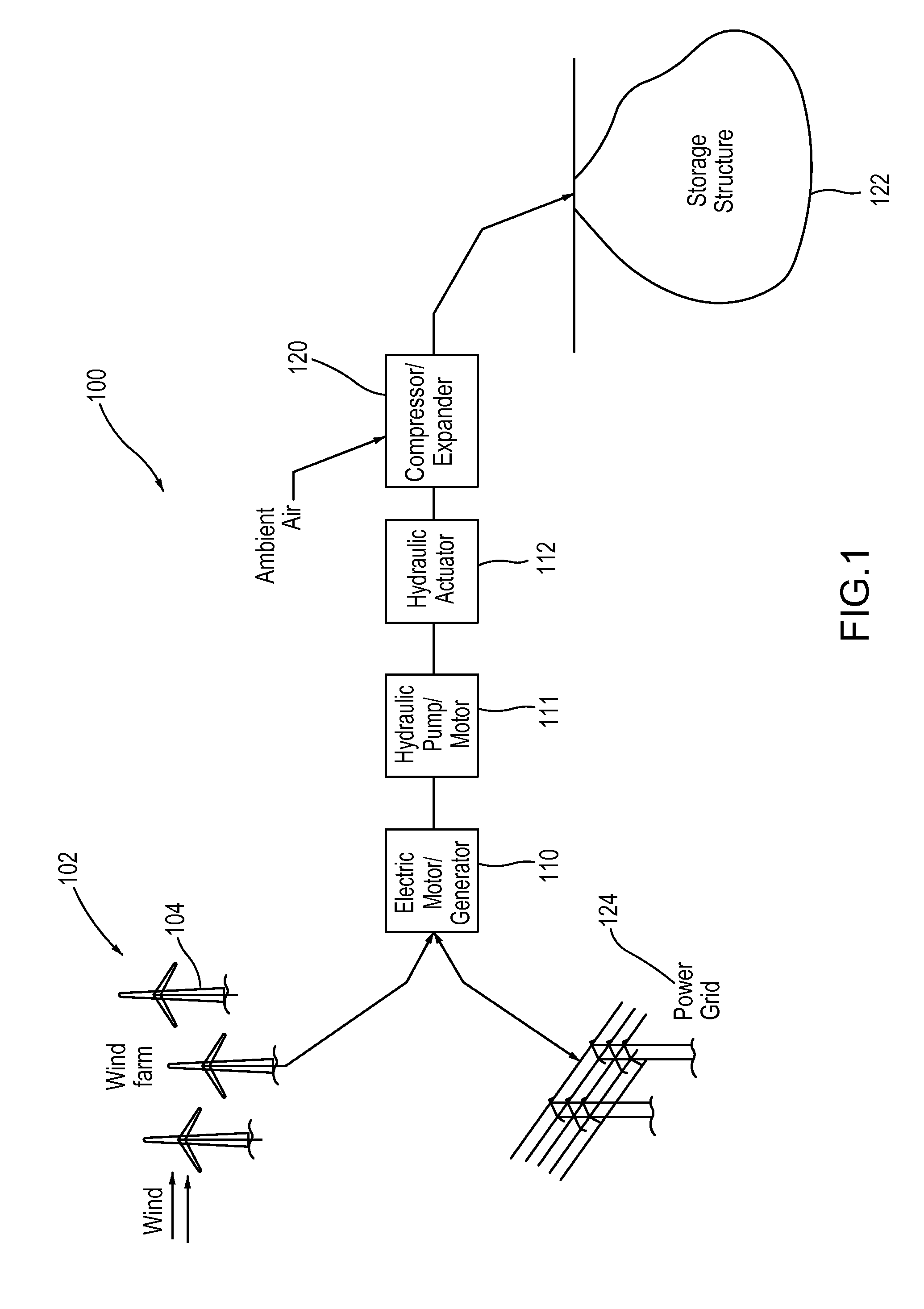

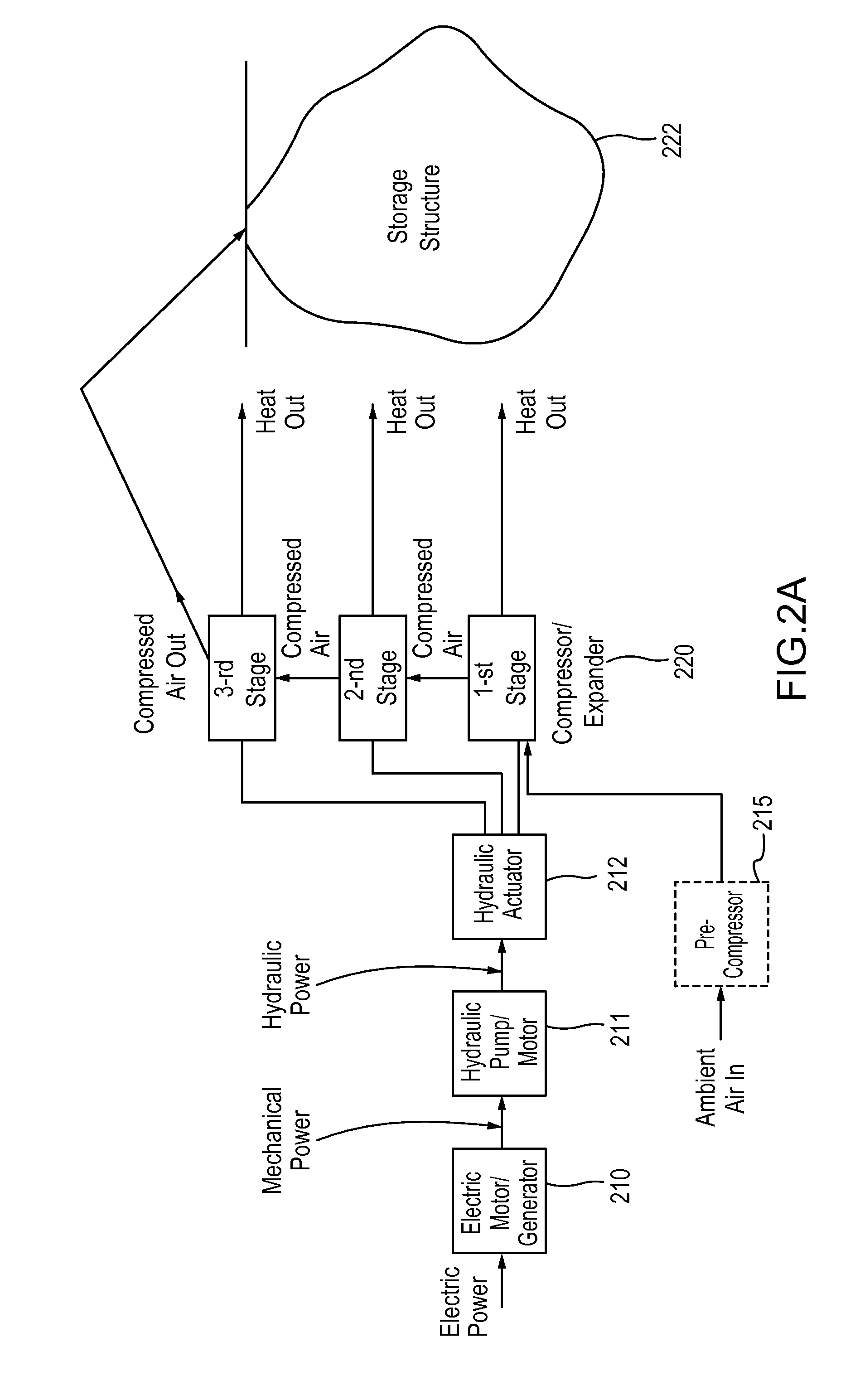

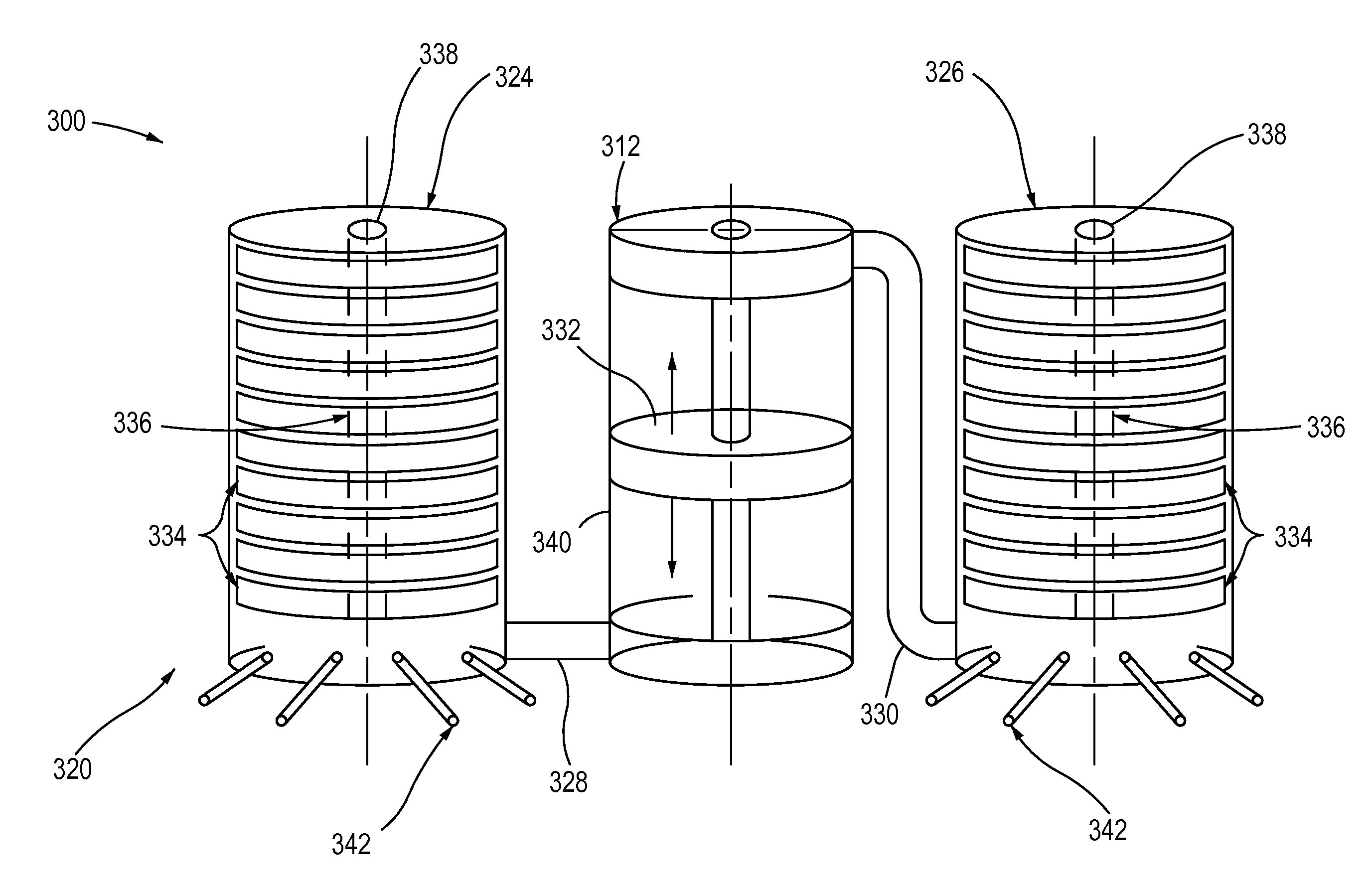

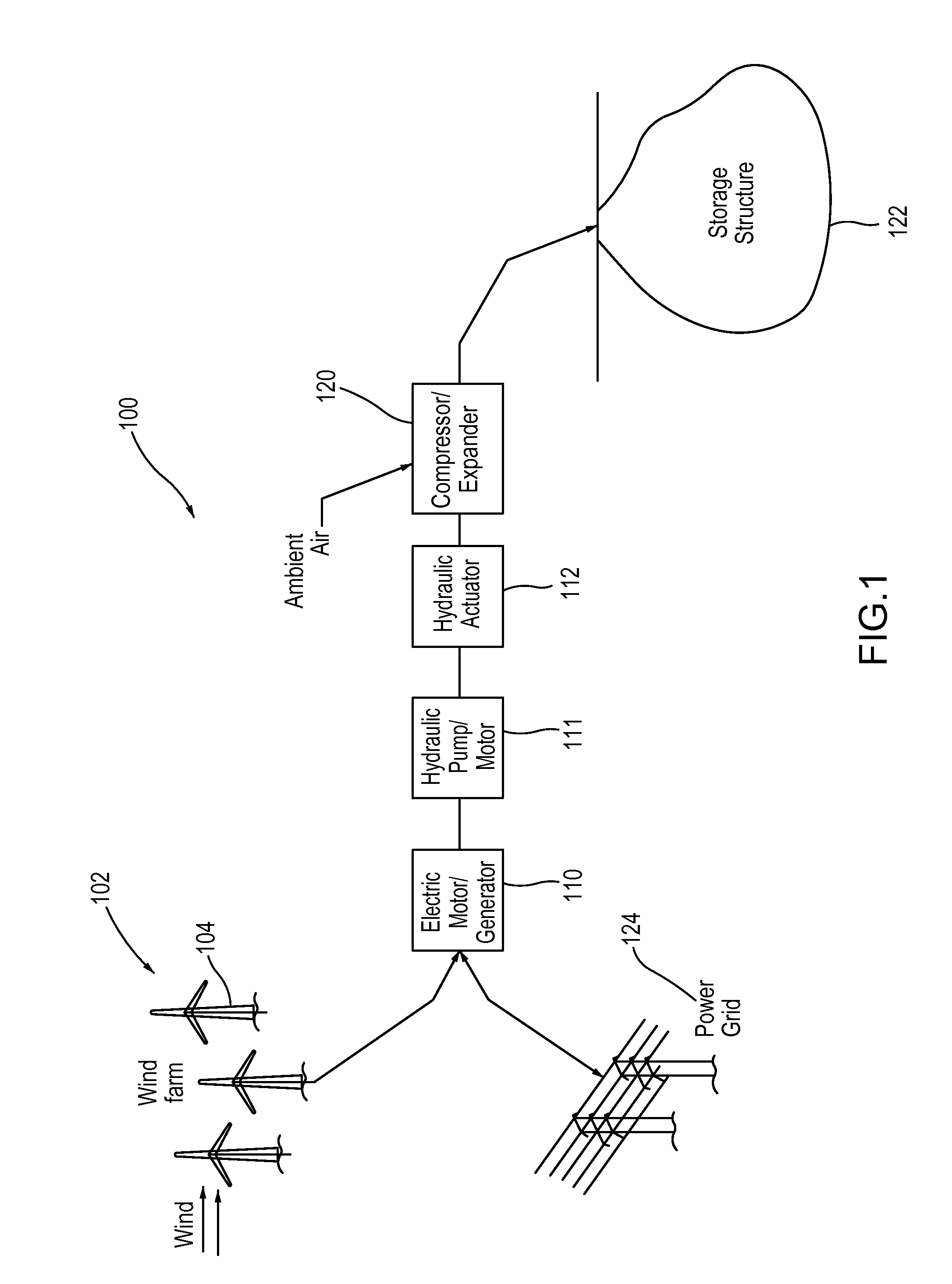

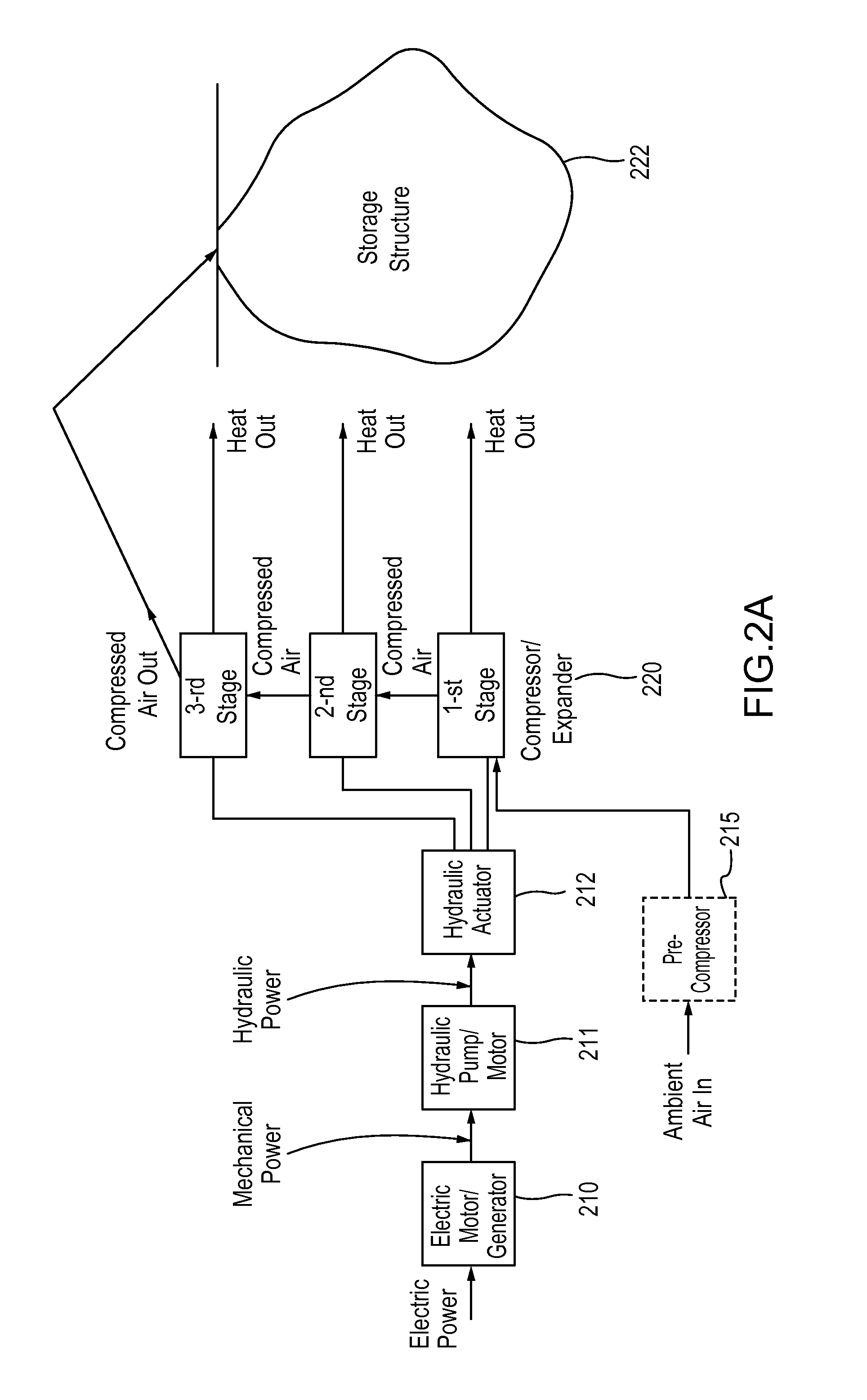

System and methods for optimizing efficiency of a hydraulically actuated system

InactiveUS20110258996A1Increase gas pressureEasy to operateFluid couplingsServomotor componentsHydraulic cylinderHydraulic pump

Systems and methods for efficiently operating a hydraulically actuated device / system are described herein. For example, systems and methods for efficiently operating a gas compression and expansion energy storage system are disclosed herein. Systems and methods are provided for controlling and operating the hydraulic actuators used within a hydraulically actuated device / system, such as, for example, a gas compression and / or expansion energy system, within a desired efficiency range of the hydraulic pump(s) / motor(s) used to supply or receive pressurized hydraulic fluid to or from the hydraulic actuators. In such a system, a variety of different operating regimes can be used depending on the desired output gas pressure and the desired stored pressure of the compressed gas. Hydraulic cylinders used to drive working pistons within the system can be selectively actuated to achieve varying force outputs to incrementally increase the gas pressure within the system for a given cycle.

Owner:GENERAL COMPRESSION

Hybrid NANO sorbent

InactiveUS20110168018A1High activityHigh rateMaterial nanotechnologyMethane captureSorbentNanostructure

The invention relates to a hybrid nano sorbent that is capable of reducing and / or removing acidic gases in a gas stream. The hybrid nano sorbent includes at least (i) a nano-structured carbonous material including at least one organic functional group, (ii) at least one metal from at least one of groups 2A, 6B, 7B, 9B or 10B of the periodic table of elements, or (iii) a combination of (i) and (ii). The method for reducing and / or removing the acidic gases in a stream is also described.

Owner:RES INST OF PETROLEUM IND RIPI

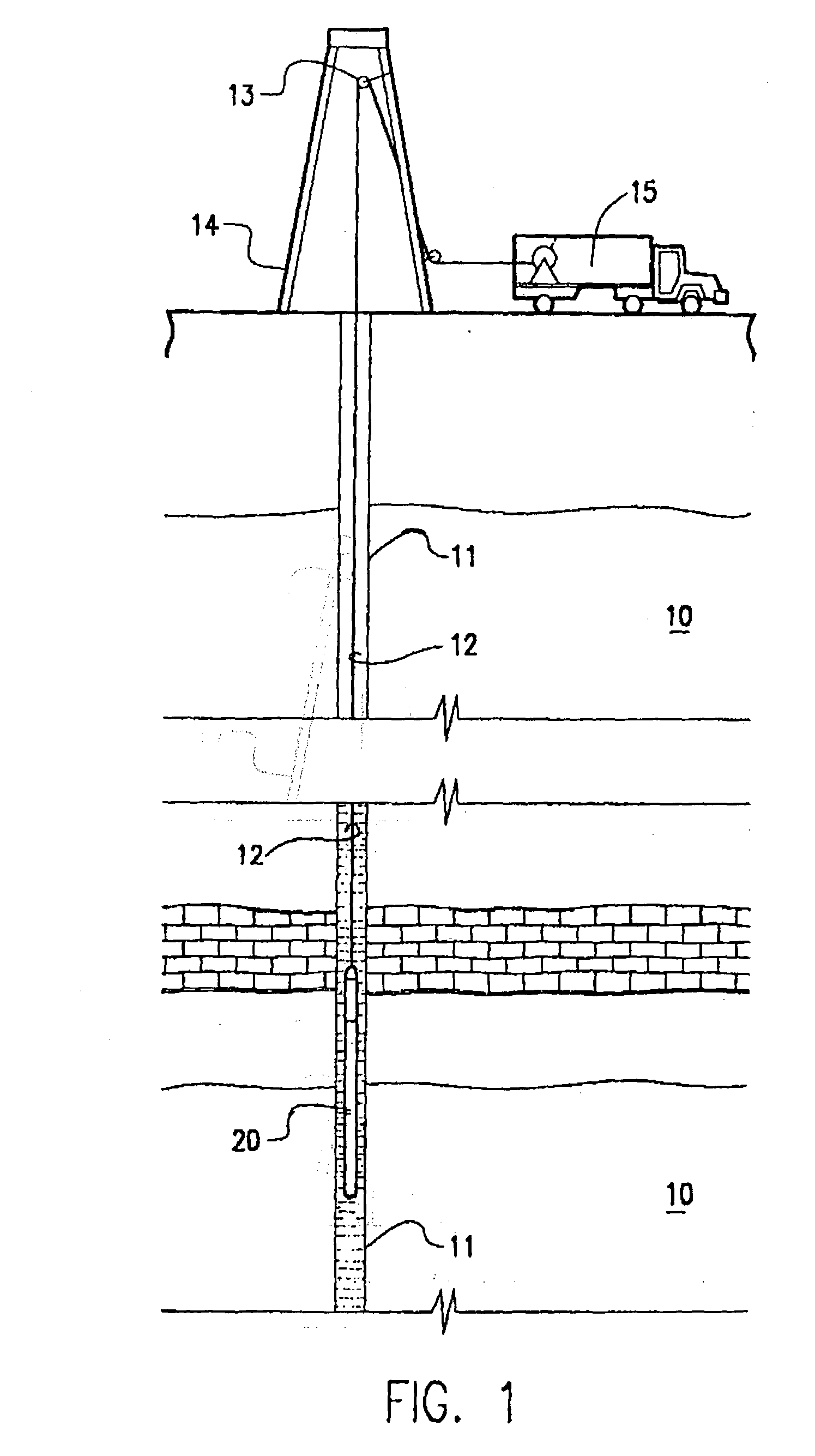

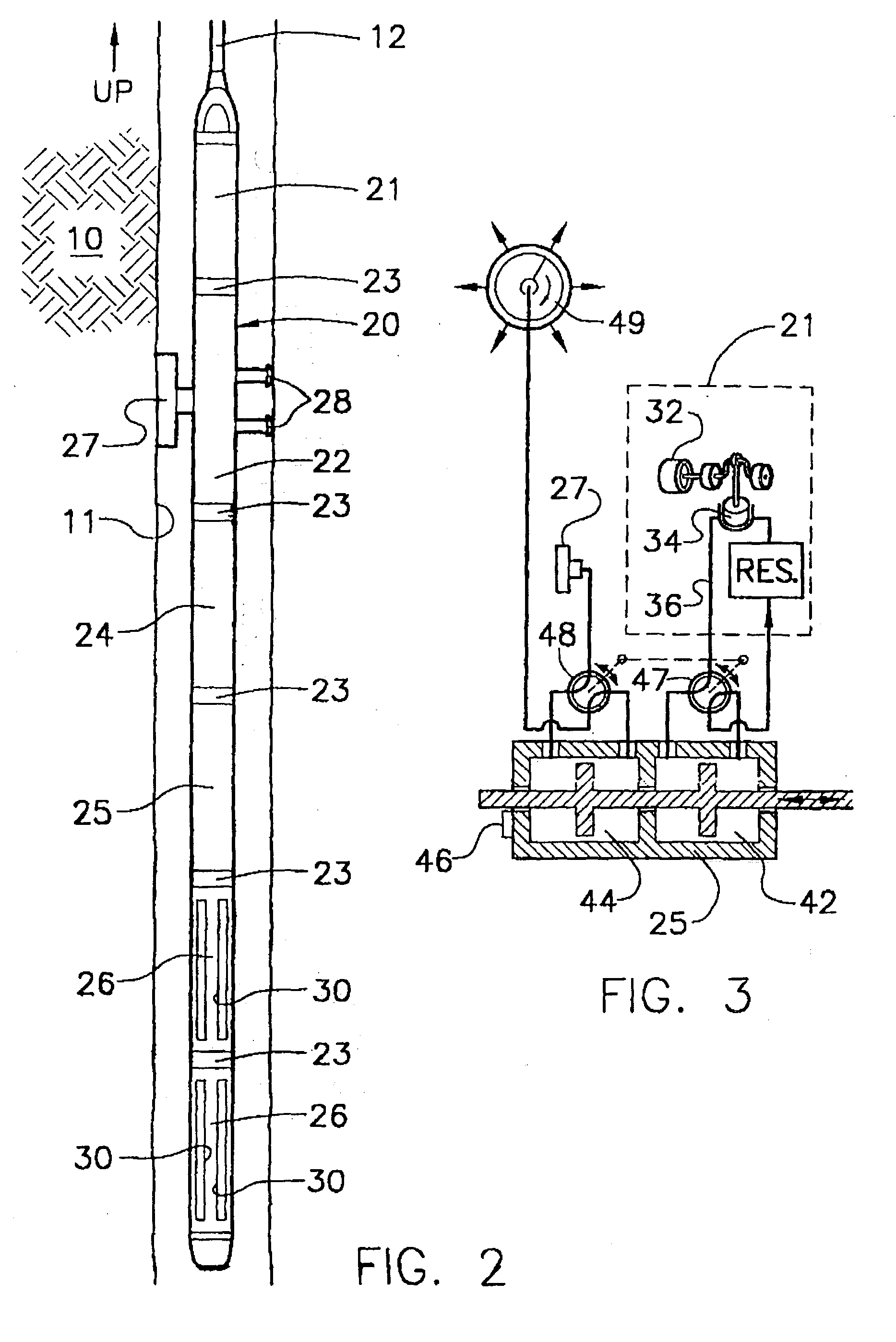

Method and apparatus for supercharging downhole sample tanks

A tank contains both Zeolite and a hydrate in a gas chamber formed beneath a piston in the sample tank. Out of safety considerations, we avoid using source cylinders of nitrogen whose pressures exceed 4000 psi. Thus, the gas chamber of the sample tank is initially pressurized by the source cylinder to no more than 4000 psi of nitrogen at room temperature at the surface. Nitrogen gas is sorbed onto the zeolite at room temperature. As the tank is heated by being lowered downhole, nitrogen desorbs from the zeolite and the gas pressure increases. However, once this tank reaches a temperature high enough to release the hydrate's water of hydration, the released water is preferentially sorbed by zeolite, displacing sorbed nitrogen, and causing the pressure in the gas volume to increase even further. Because well temperatures are not high enough to desorb water from zeolite, any water sorbed onto a Zeolite sorption site will permanently block released nitrogen from resorbing at that site. The process of lowering the tank downhole provides the necessary heating to make the entire process occur. Thus, if returned to the surface at room temperature with the original gas-chamber volume, the tank's pressure would not fall back to the original pressure (e.g., 4000 psi) but would be at a substantially higher pressure (e.g., 6000 psi or more depending on the amount of Zeolite used and gaseous nitrogen gas released).

Owner:BAKER HUGHES INC

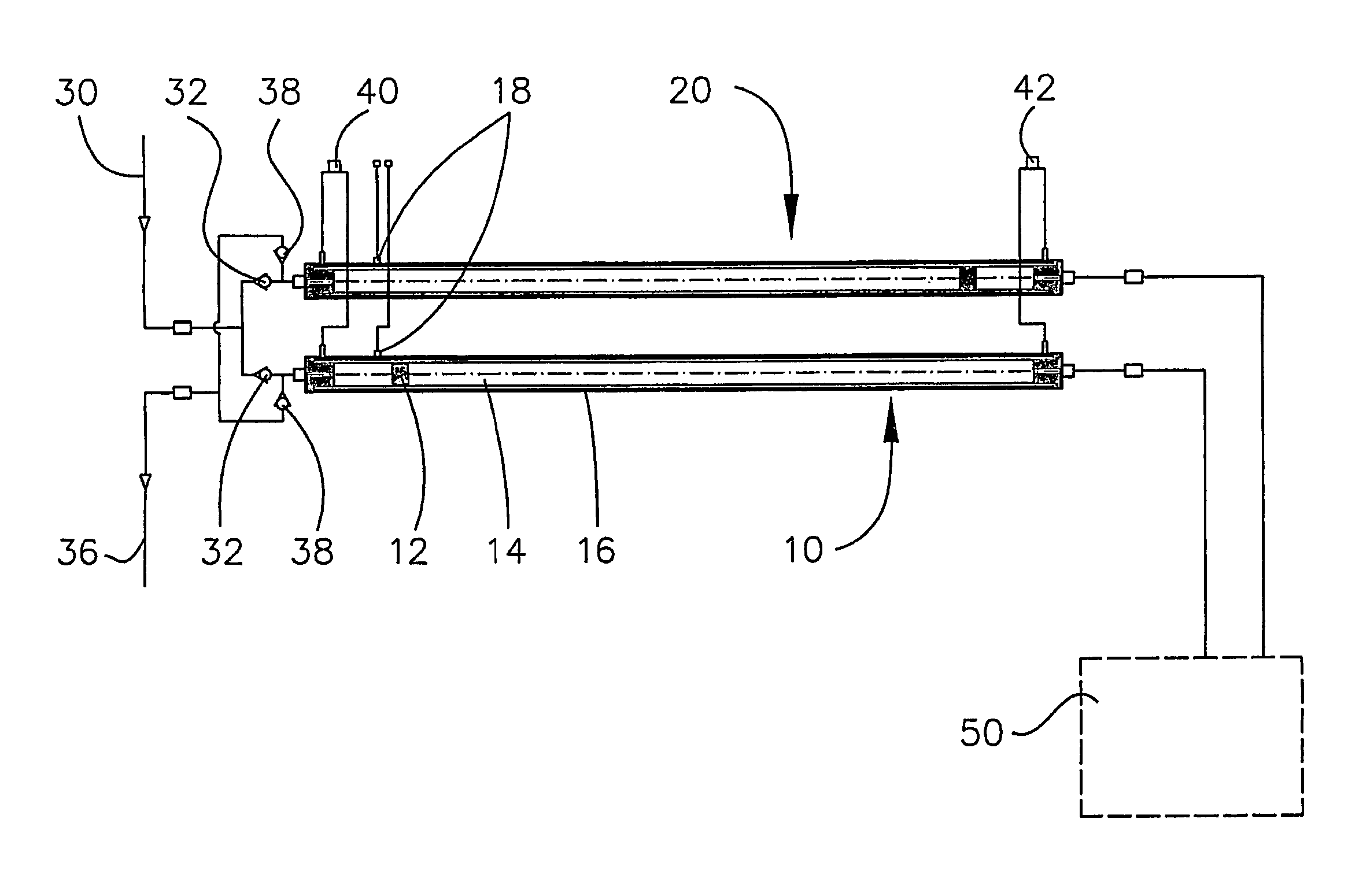

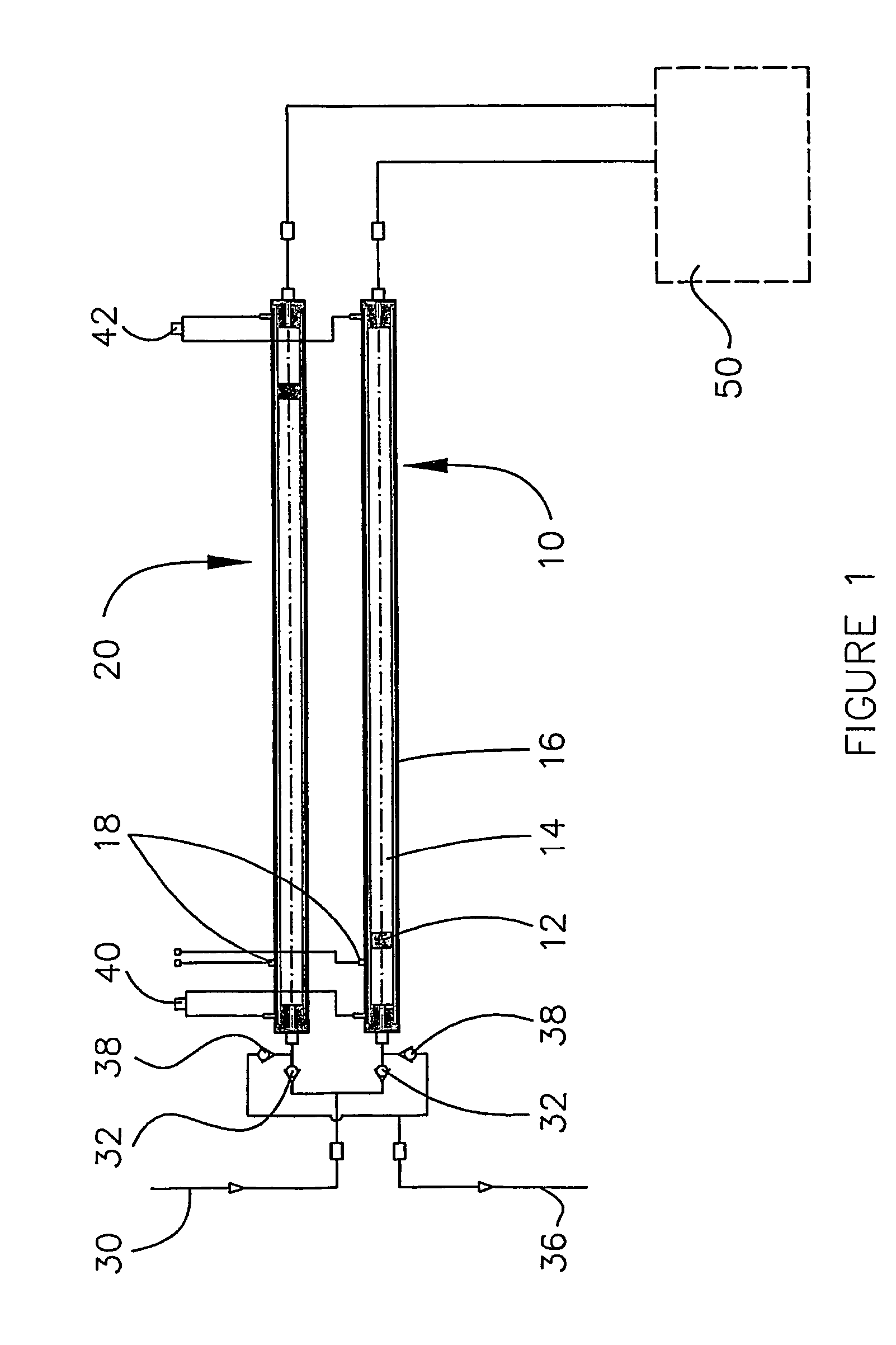

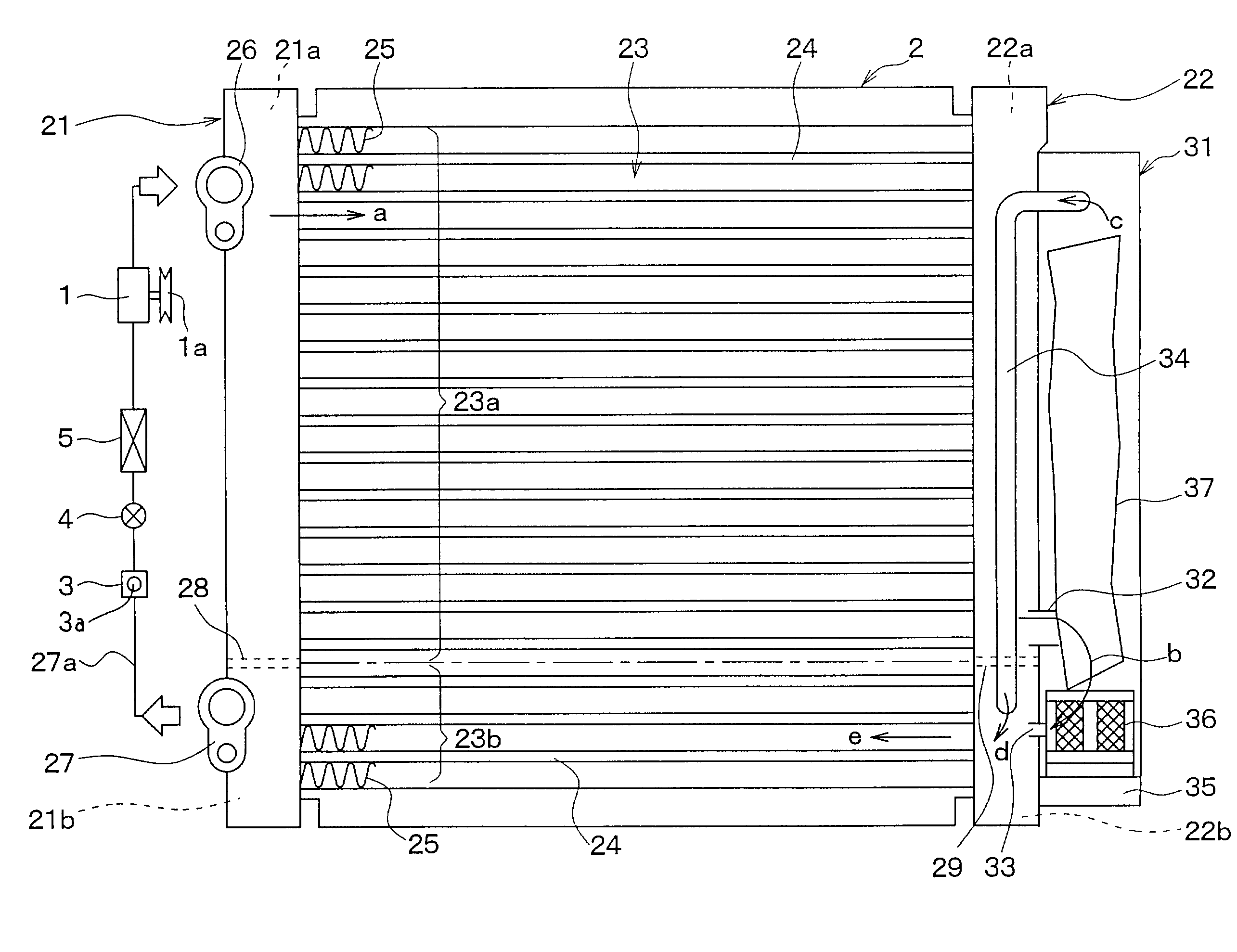

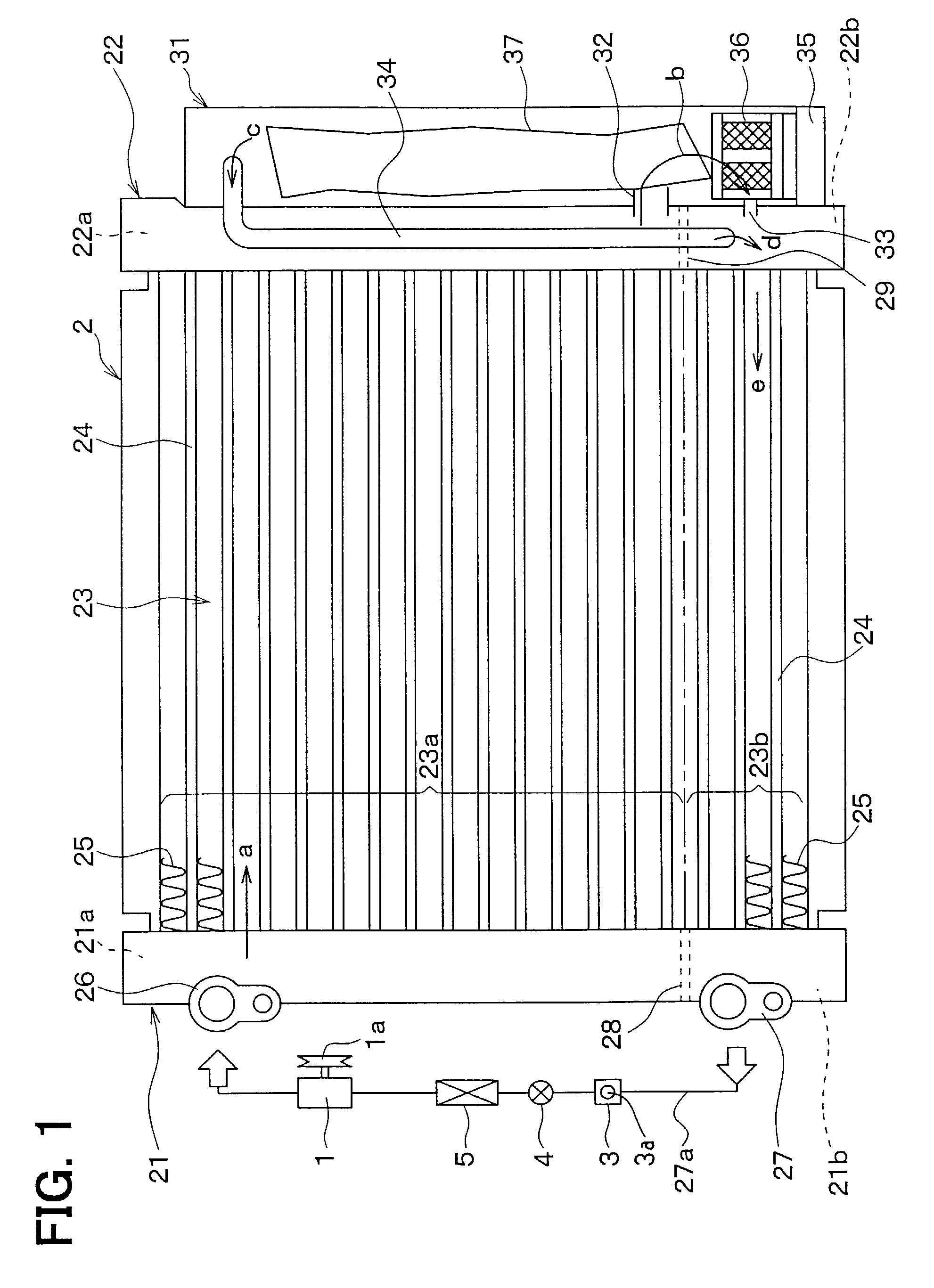

Method and apparatus for compressing a gas to a high pressure

ActiveUS7527482B2Increase volumeReduce volumePositive displacement pump componentsFlexible member pumpsElectronic controllerFoot per second

A method is provided for compressing a gas in a single cycle and in a single cylinder to a pressure of at least 17.2 Mpa with a compression ratio of at least about five to one. The method further comprises dissipating heat from the cylinder during the compression stroke whereby the gas is discharged with a temperature significantly less than isentropic. The apparatus comprises a hollow cylinder and a reciprocable free-floating piston disposed therein. The piston divides the cylinder into: (a) a compression chamber within which a gas can be introduced, compressed, and discharged; and, (b) a drive chamber, into which a hydraulic fluid can be introduced and removed for actuating the piston. The apparatus further comprises a piston stroke length to piston diameter ratio of at least seven to one. For operating the apparatus with a compression ratio of at least five to one, an outlet pressure of at least 17.2 Mpa, and a gas discharge temperature significantly less than isentropic, the apparatus can further comprise a variable displacement hydraulic pump for controlling piston velocity, an electronic controller for maintaining an average piston velocity that is less than 0.5 feet per second, and a heat dissipator for dissipating heat from the cylinder.

Owner:WESTPORT FUEL SYST CANADA INC

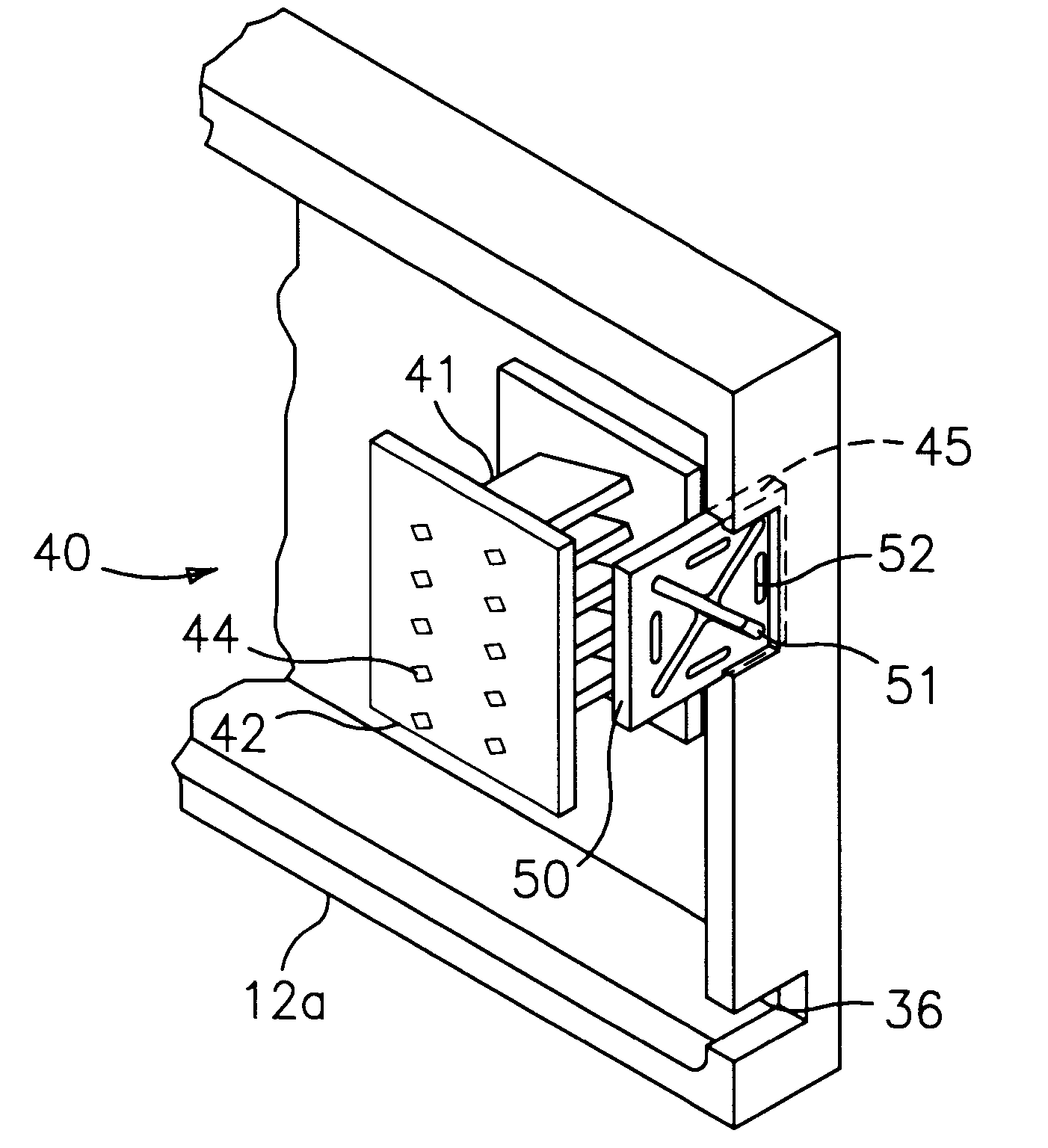

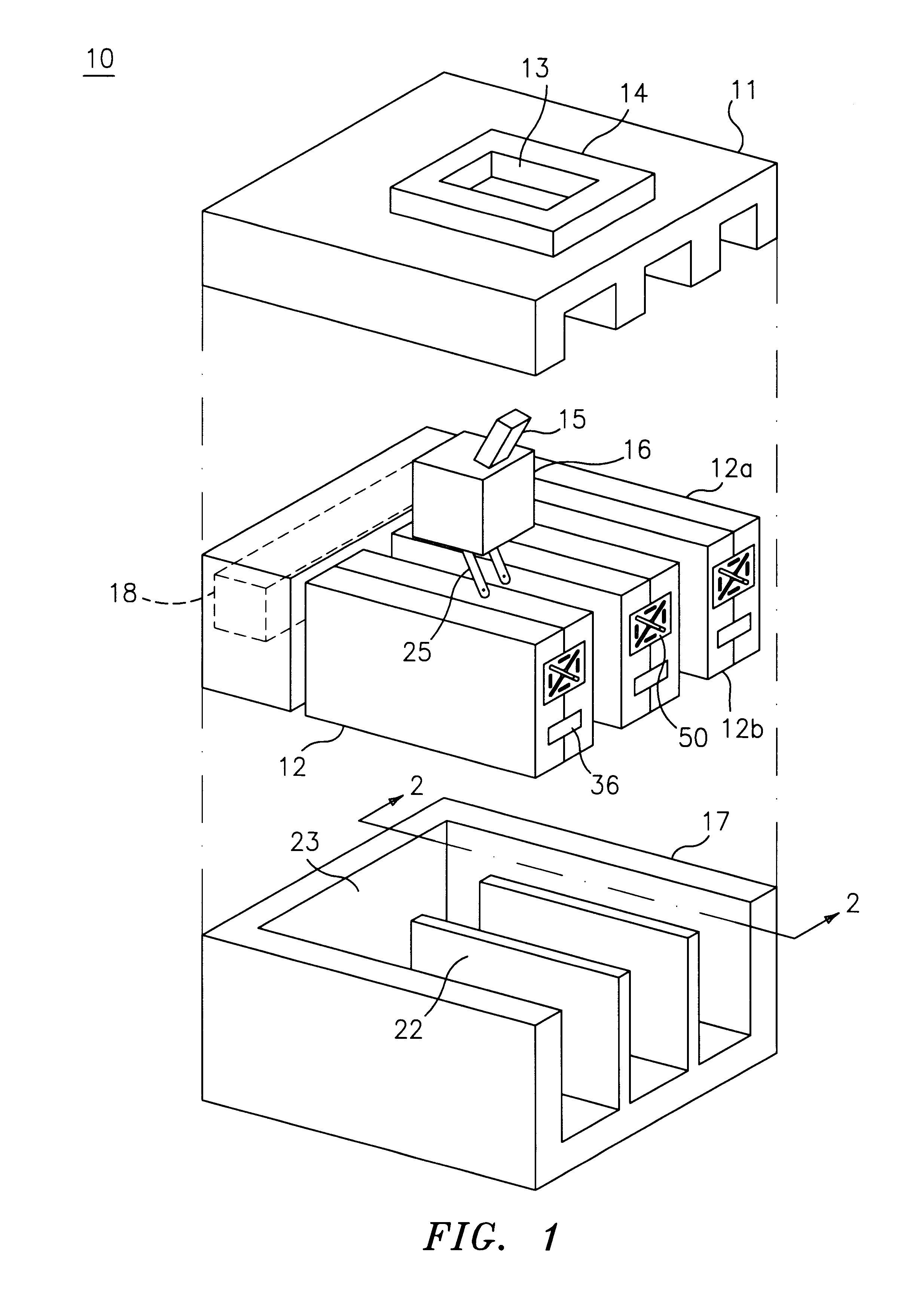

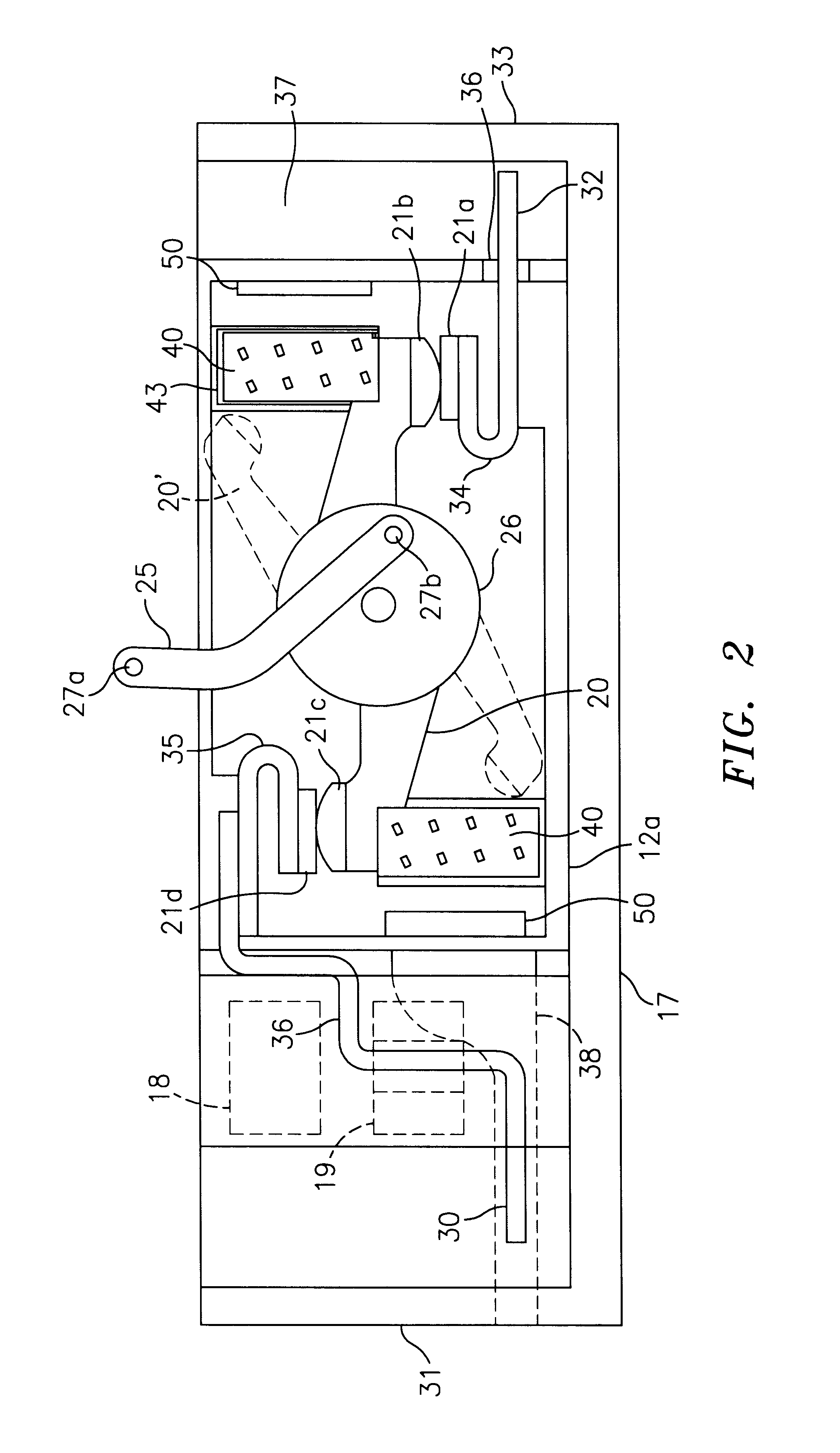

Circuit breaker arc exhaust baffle with variable aperture

InactiveUS6222147B1Reduce stressIncrease pressureProtective switch detailsHigh-tension/heavy-dress switchesCircuit breakerCircuit protection

An improved exhaust baffle for a circuit protective device such as a circuit breaker utilizes material having elastomeric characteristics to provide for variable apertures where the cross-sectional opening of the apertures is dependent on the pressure gradient across the exhaust baffle, thereby effectively controlling arc pressure and arc effluent during short circuit interruption. Fabrication of the exhaust baffle with geometric symmetry about one or more axes or planes also facilitates assembly during product construction.

Owner:ABB (SCHWEIZ) AG

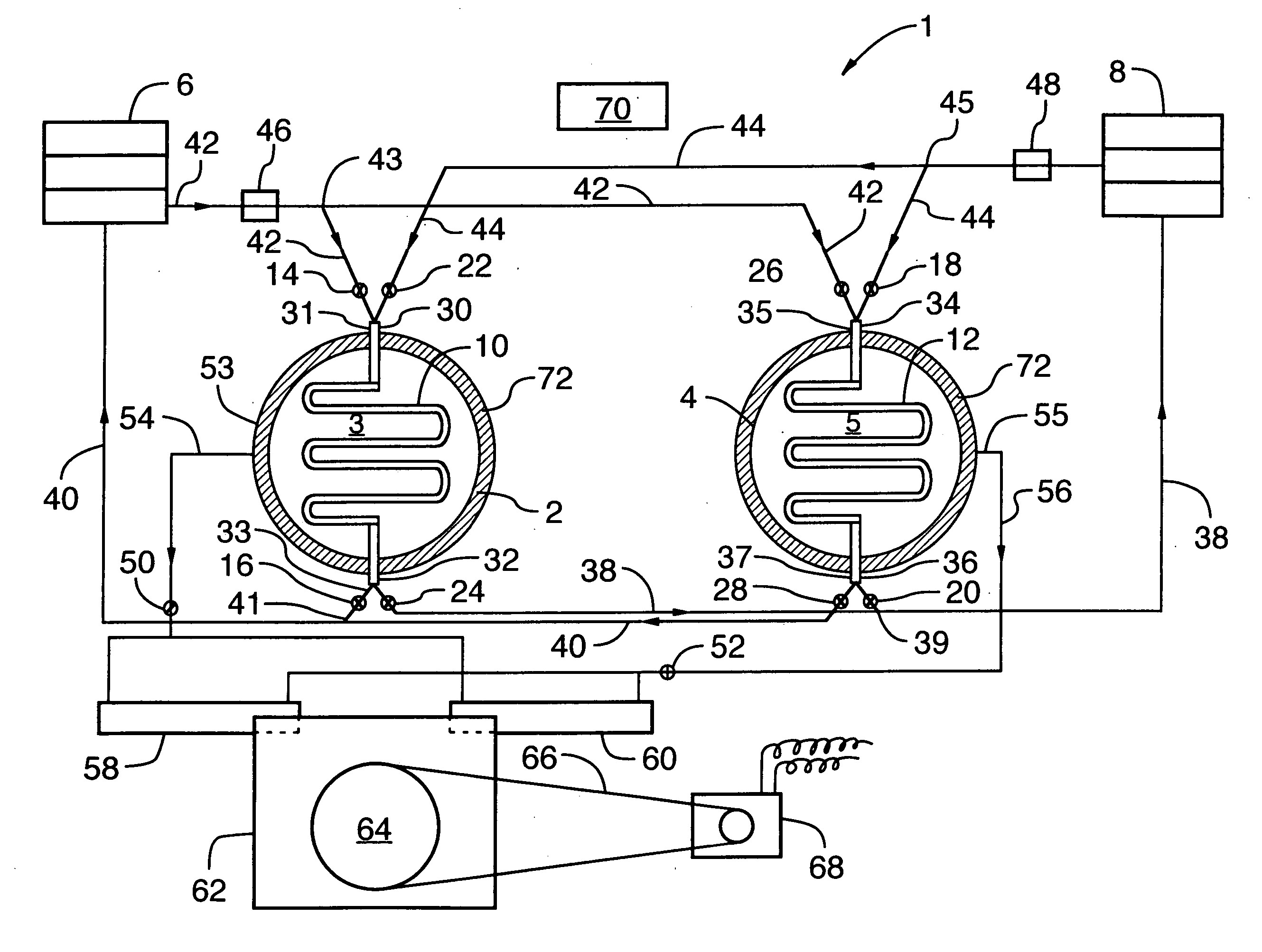

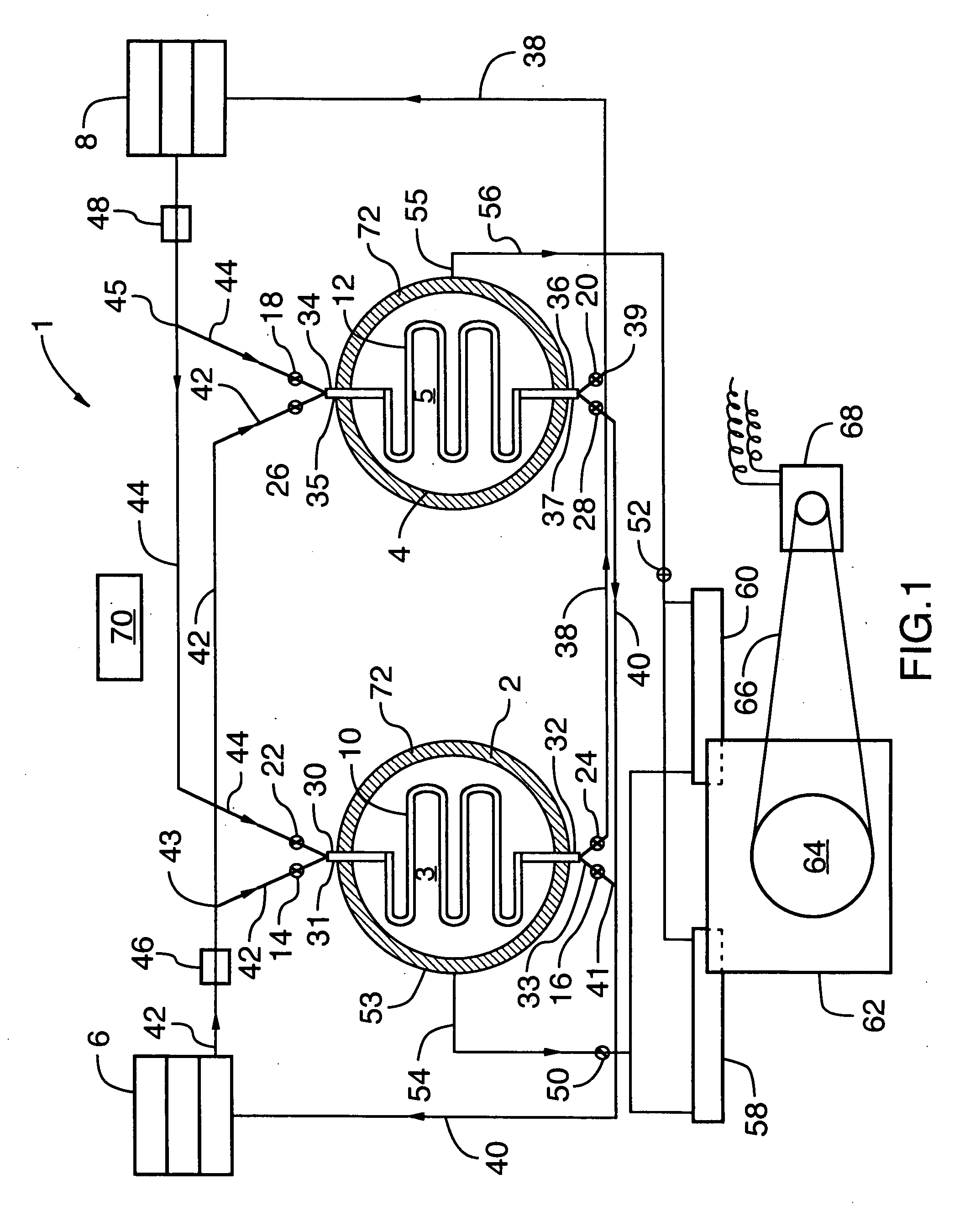

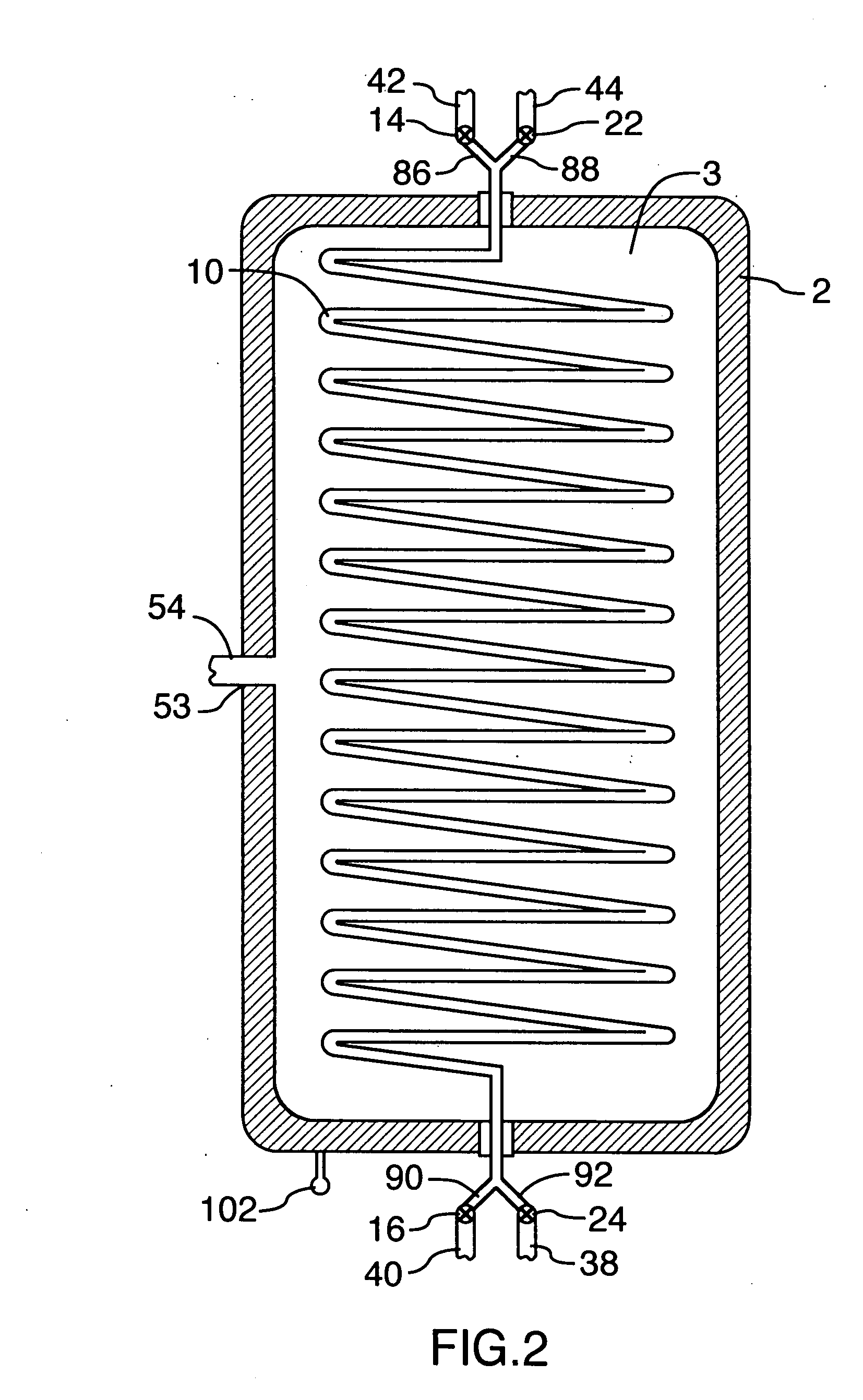

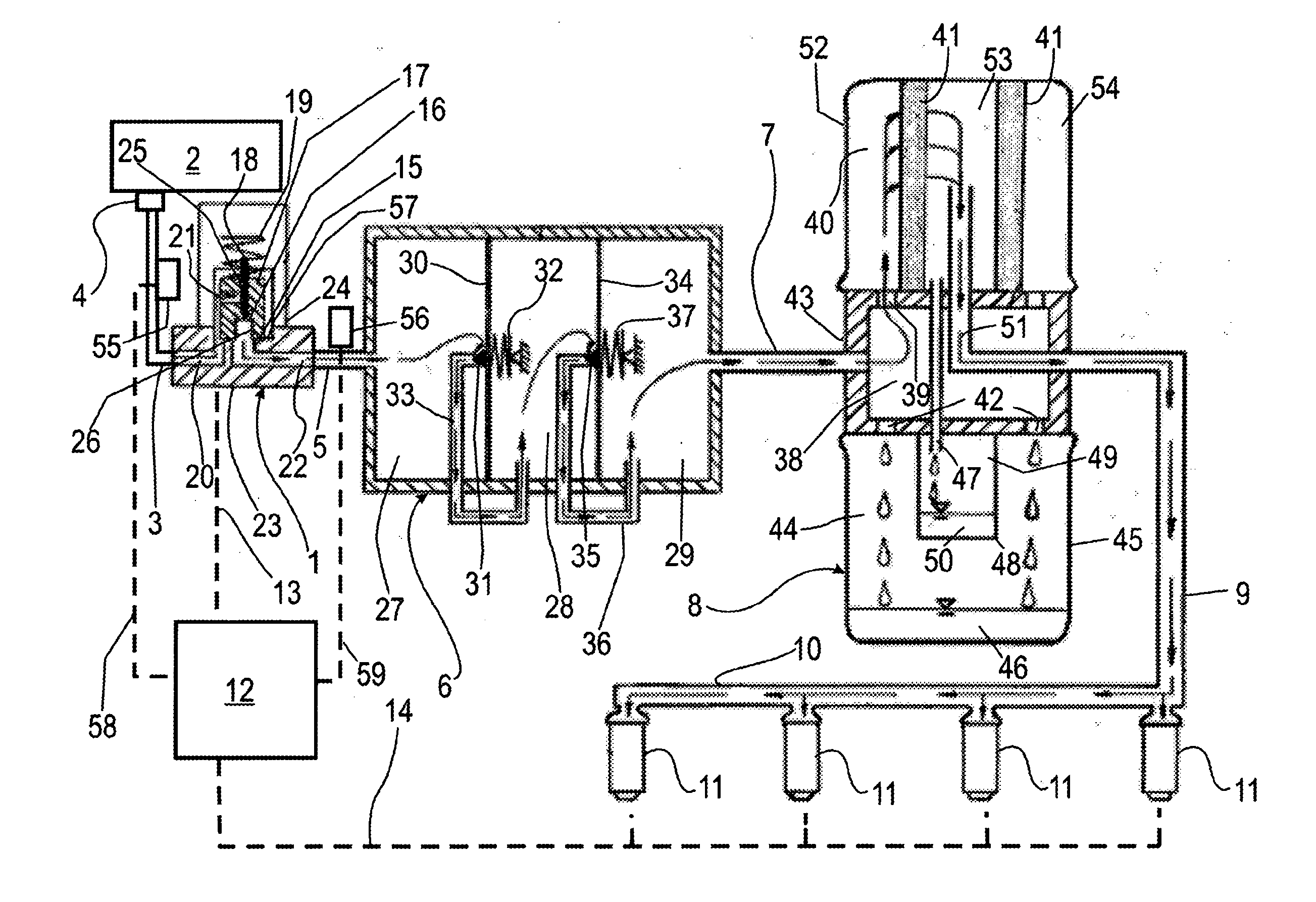

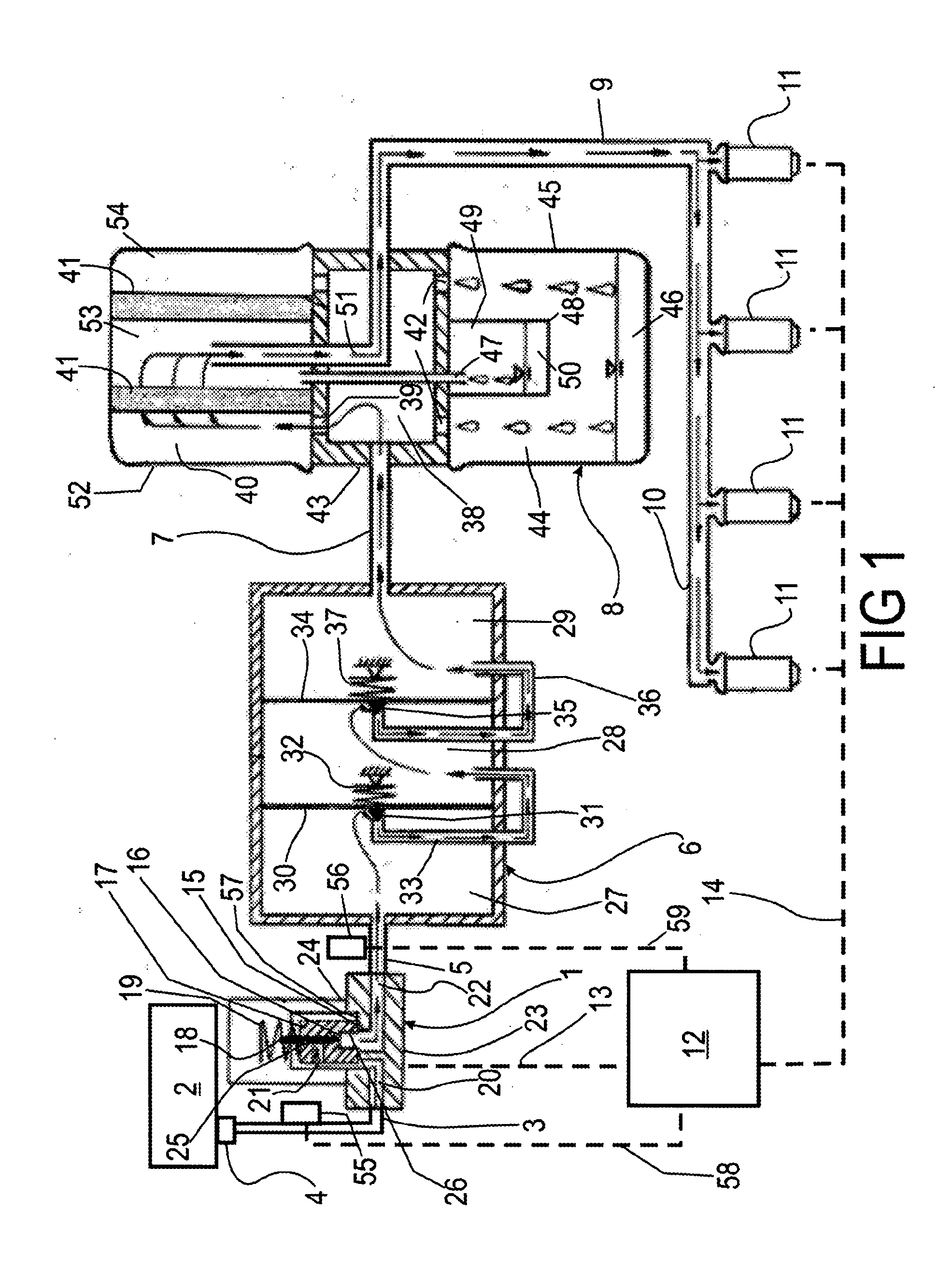

Thermal conversion device and process

ActiveUS20050198960A1Avoid flowIncrease gas pressureCatalytic crackingSteam engine plantsThermal energyPositive pressure

An apparatus and method for converting a differential in thermal energy between a first thermal source having a thermal conducting fluid and a second thermal source having a thermal conducting fluid is provided. The apparatus emplys a first vessel and a second vessel. Each of the vessels contain a gas under pressure The vessels contain heat exchanging coils that are connected to the thermal sources by fluid lines. A plurality of cooperating valves regulate the flow of the thermal conducting fluid from the first and second thermal sources to the first and second vessels. The valves alternate between first and second operating positions. In the first position, the valves permit a flow of thermal conducting fluid from the first thermal source to the first vessel and from the second thermal source to the second vessel and prevent a flow of thermal conducting fluid from the first thermal source to the second vessel and from the second thermal source to the first vessel. In the second position, the valves permit a flow of thermal conducting fluid from the first thermal source to the second vessel and from the second thermal source to the first vessel and prevent a flow of thermal energy from the first thermal source to the first vessel and from the second thermal source to the second vessel. A pressure driven actuator in fluid communication with the first and second vessels is driven into reciprocating motion between a first position and a second position by alternating positive pressure and negative pressure from the first and second vessels.

Owner:MARNOCH IAN A

Method and apparatus for ion manipulation using mesh in a radio frequency field

ActiveUS8373120B2Easy to buildSmall scaleTime-of-flight spectrometersIsotope separationIon chromatographyDesorption

Owner:LECO CORPORATION

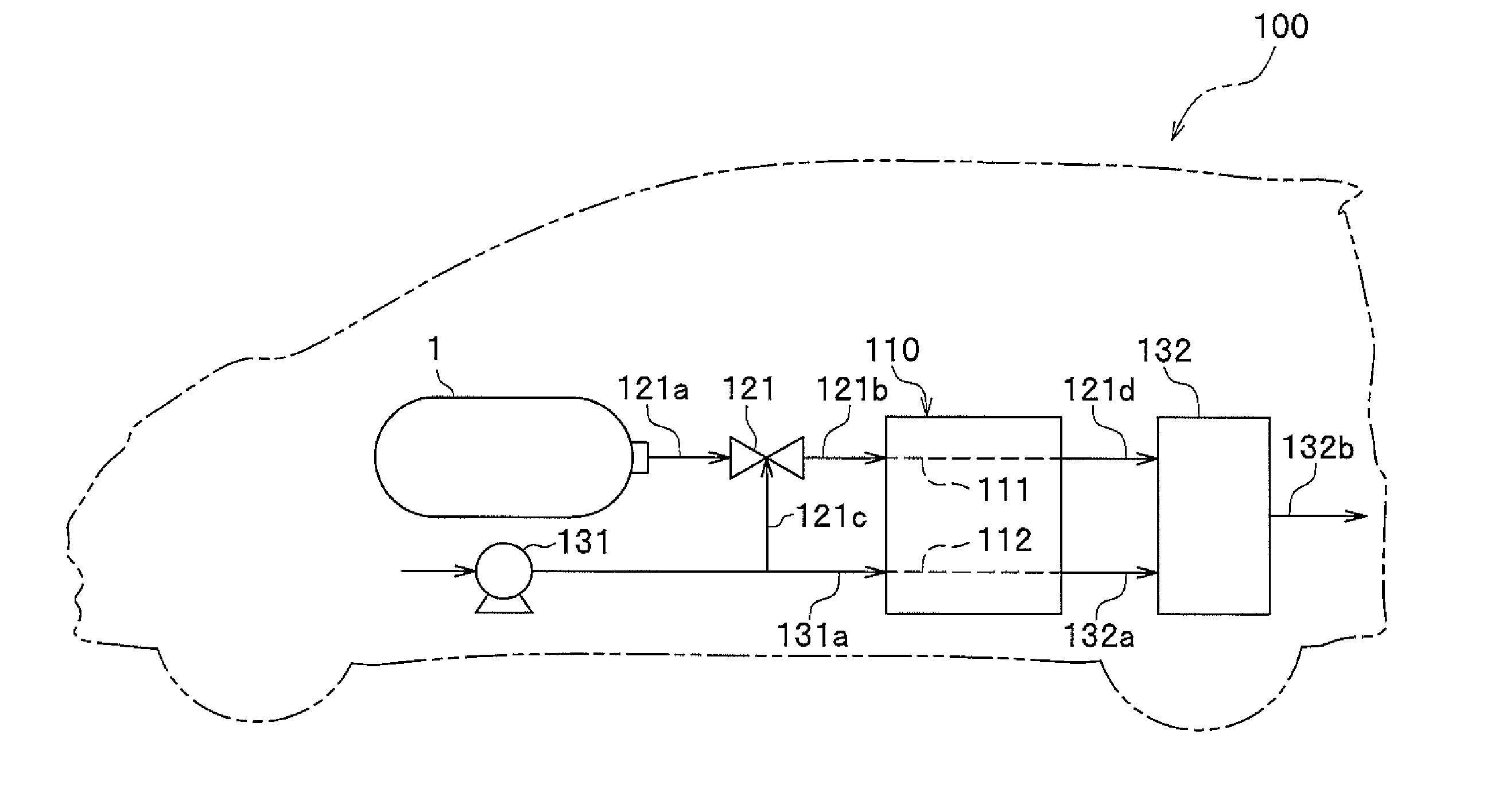

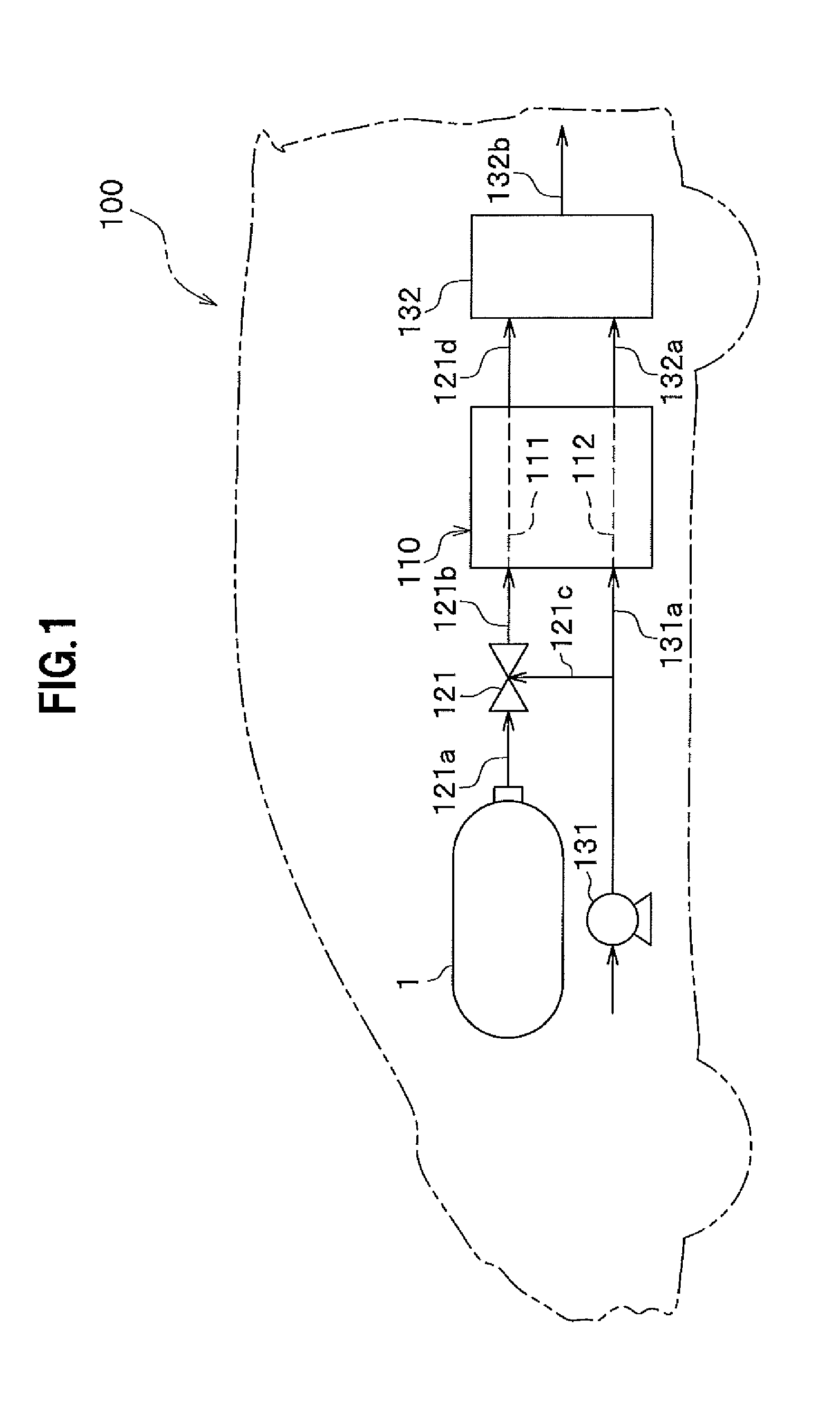

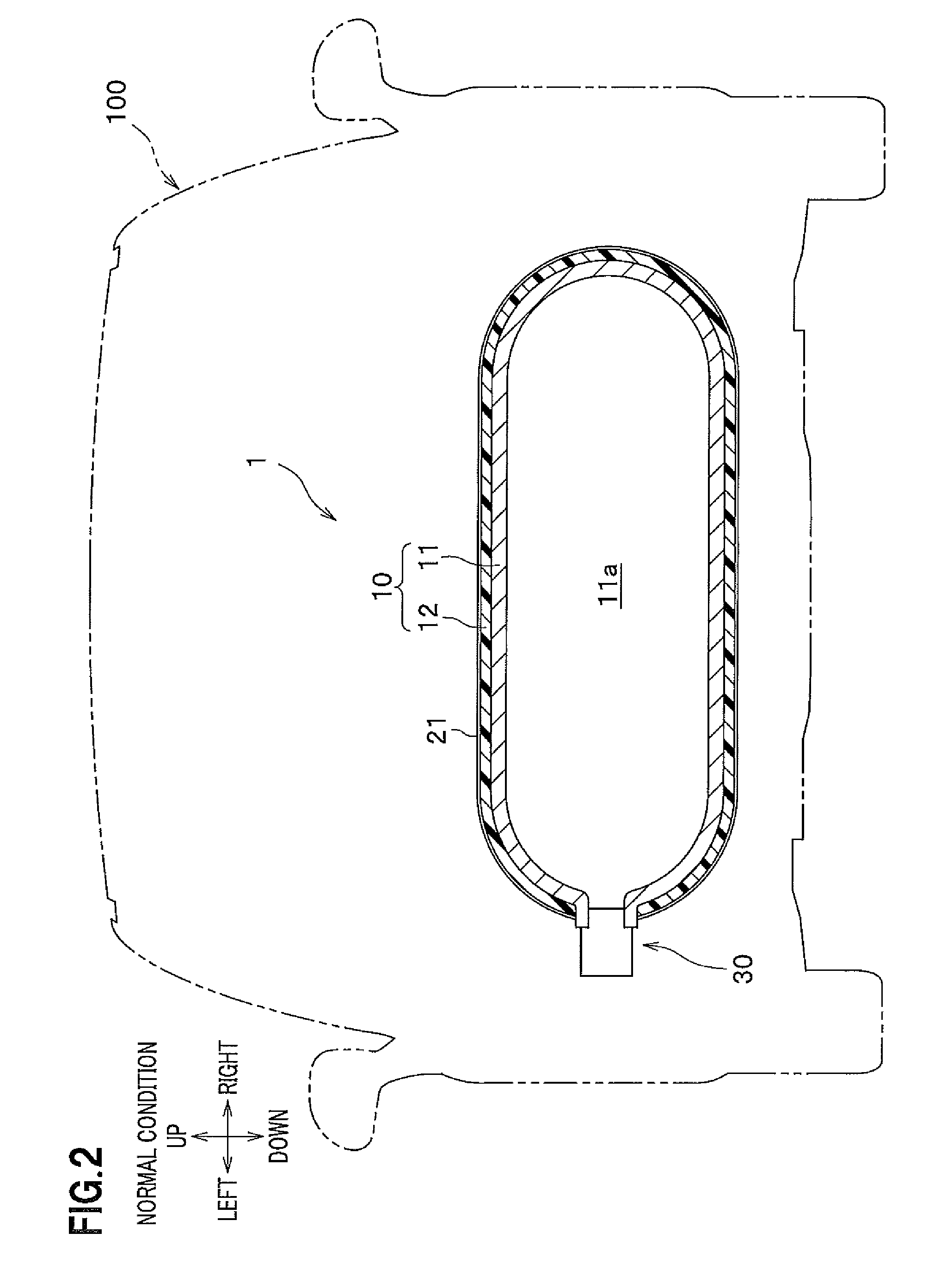

Gas tank

ActiveUS20110180551A1Reduce gas pressureIncrease gas pressureDomestic cooling apparatusLighting and heating apparatusEngineeringProduct gas

There is provided a gas tank that suppresses an increase in pressure of a gas filled therein. A hydrogen tank comprises a tank main body filled with hydrogen, a thermofoamable heat-insulating layer provided on the external surface of the tank main body, a relief valve which is provided at the left end of the tank main body and which reduces the pressure in the tank main body by releasing the hydrogen in the tank main body, and a liner which extends from the relief valve toward the right end and which detects an increase in temperature. The relief valve is thermally connected to the liner, and is actuated based on heat transferred from the liner in order to release the hydrogen in the tank main body, thereby reducing the pressure in the tank main body.

Owner:HONDA MOTOR CO LTD

Driving device for a hydroacoustic transmitter

InactiveUS6711097B1Large transmission ratioInterference problemMechanical vibrations separationSound producing devicesReciprocating motionEngineering

The invention refers to a driving device for hydroacoustic transmitters, including at least one actuating element (1), arranged to execute a reciprocating movement, wherein the movement of the actuating element (1) includes an increase and a decrease of the distance between two ends thereof, and at least one spring member (5, 27) which is connected to the actuating element (1) at said ends and which extends along a curved line between said ends, wherein the increase and the decrease of the distance between said ends result in a change of the curve of the spring member (5, 27) and thereby a movement of it. The device includes an element (12, 13, 28) for displacement of a mass, which displacement element (12, 13, 28) is connected to the spring member (5, 27) so that the movement of the latter is transmitted to the displacement element (12, 13, 28) and generates a displacement thereof, resulting in said mass displacement. Furthermore, the invention refers to the use of such a device for transmitting hydroacoustic waves in a liquid.

Owner:CETUS CORP

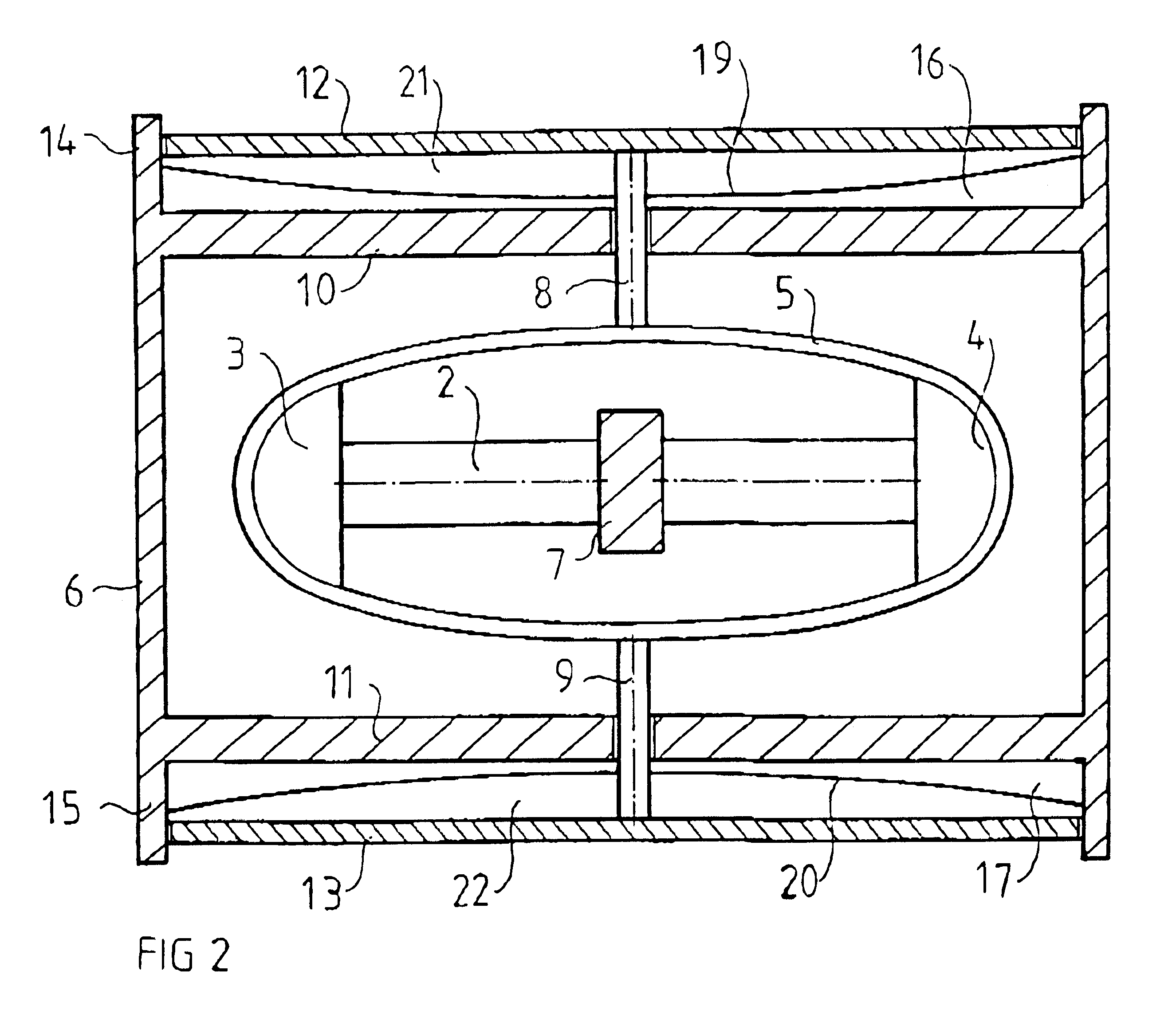

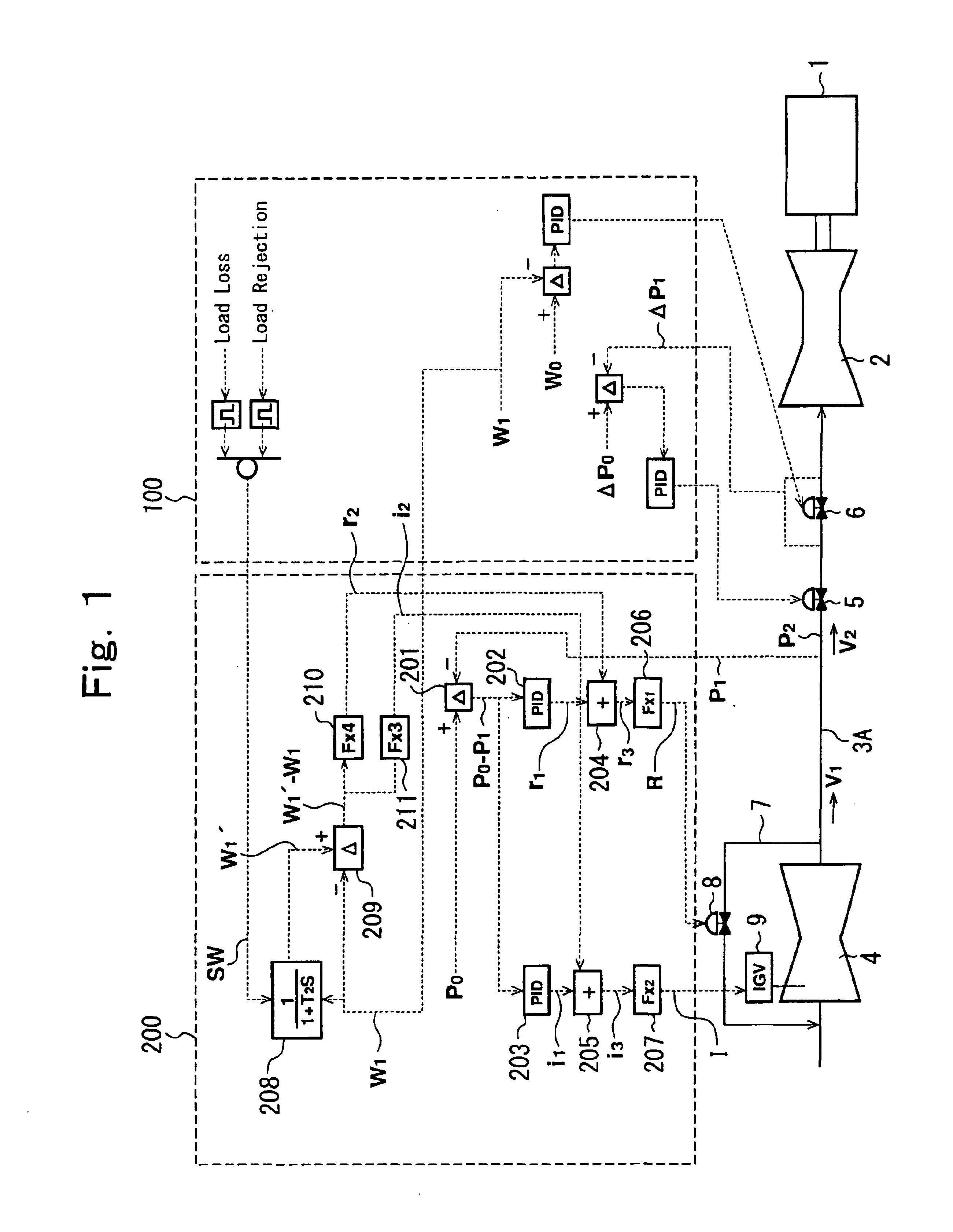

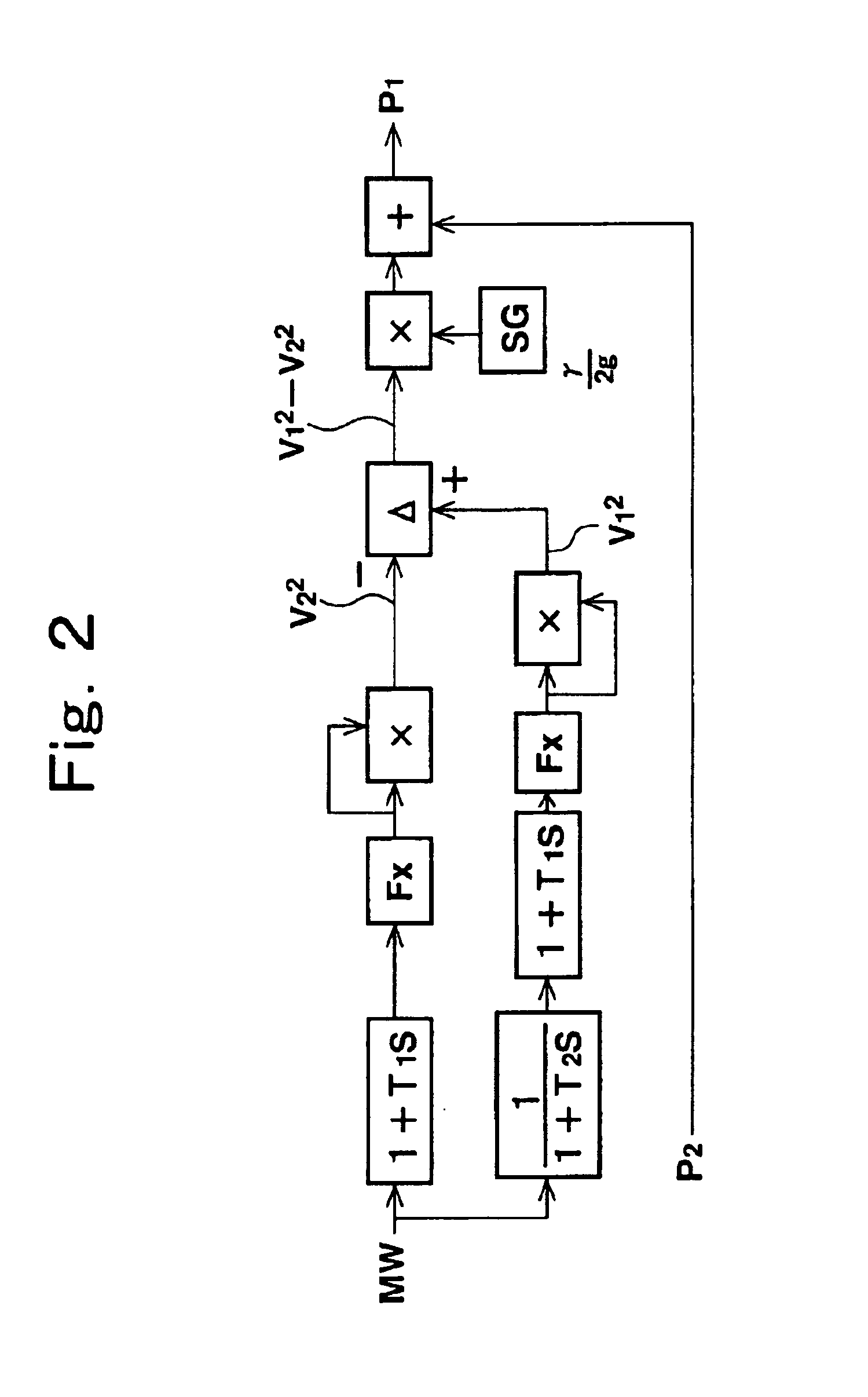

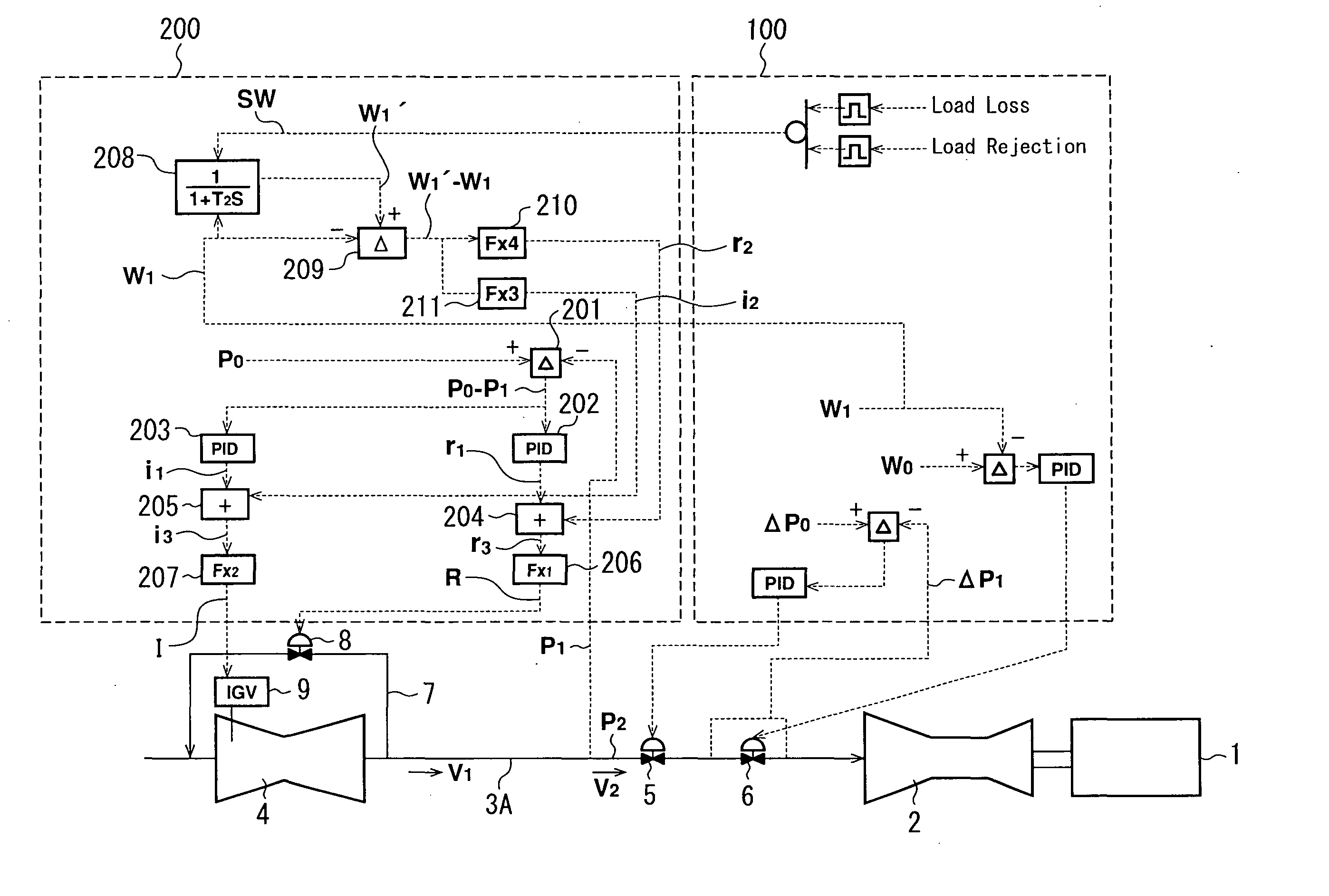

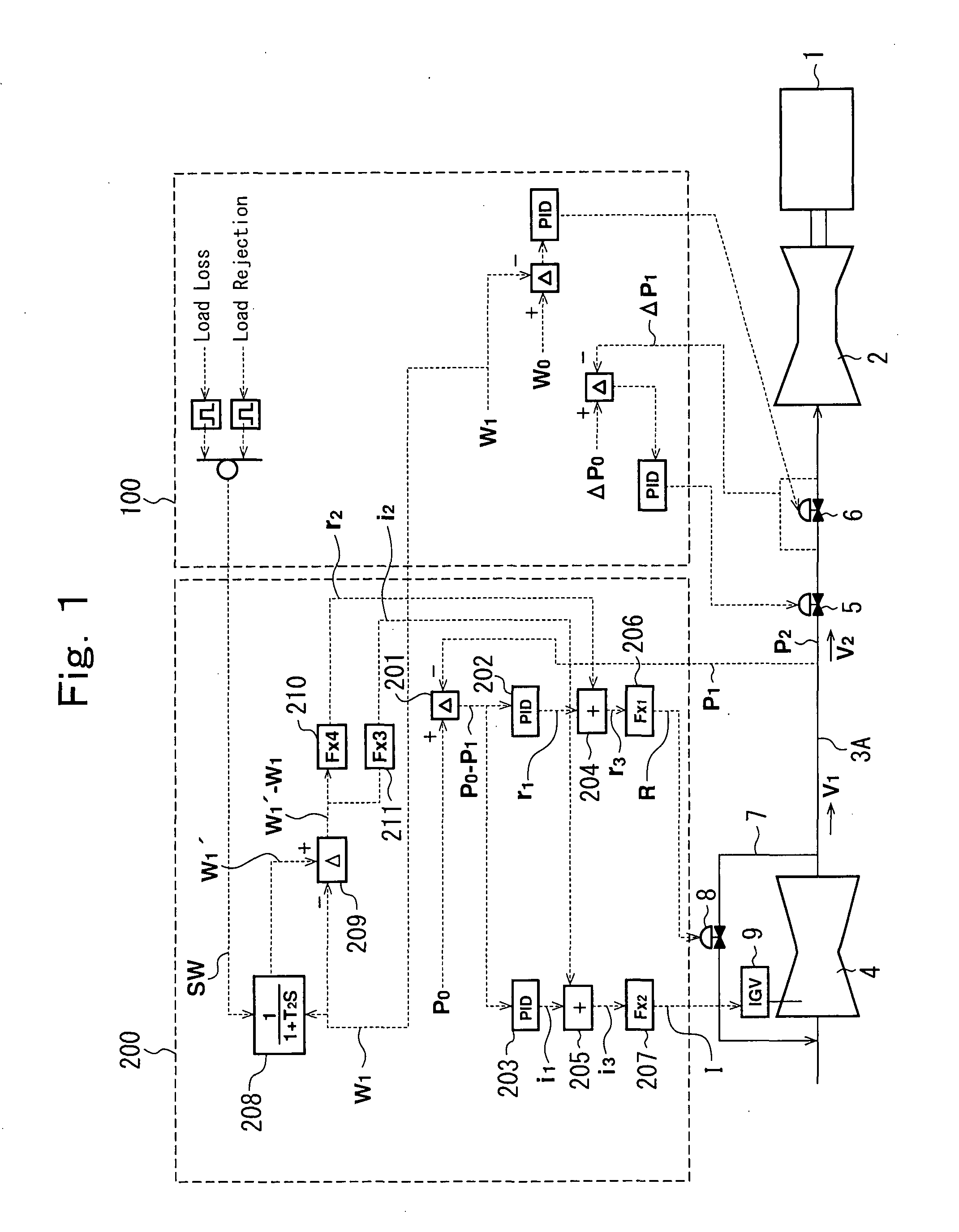

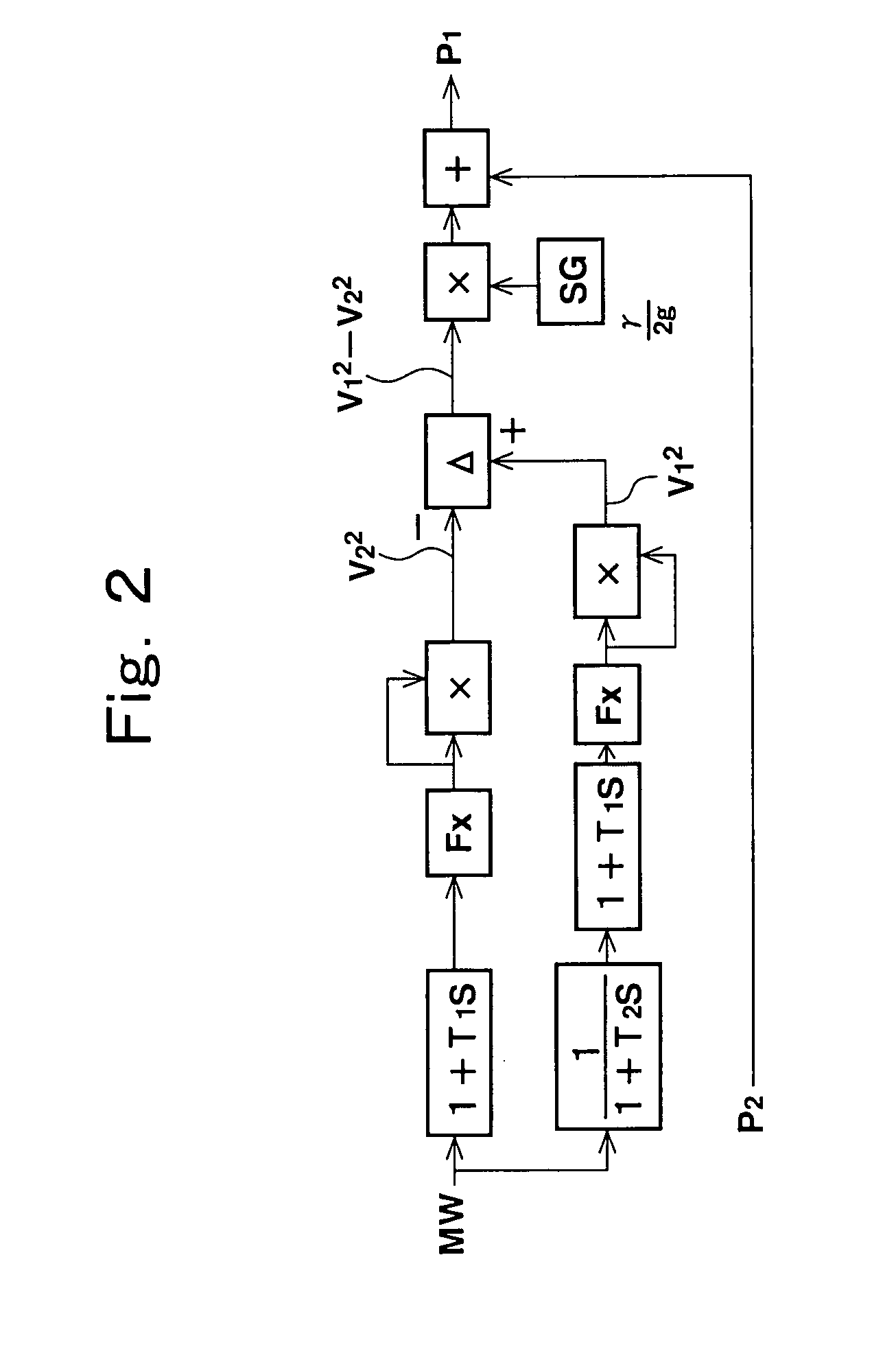

Gas compressor control device and gas turbine plant control mechanism

ActiveUS6907722B2Increase gas pressureReduce gas pressurePump componentsGas turbine plantsLoad rejectionGas compressor

A gas compressor control device and a gas turbine plant control mechanism are disclosed. A fuel gas pressurized by a gas compressor is supplied to a gas turbine via fuel gas piping. A gas turbine control device adjusts the flow rate of the fuel gas into the gas turbine by exercising opening and closing control of a pressure control valve and a flow control valve. The gas compressor control device controls a fuel gas pressure at the outlet of the gas compressor by effecting opening and closing control of a recycle valve and an IGV. If load rejection or load loss occurs, the gas compressor control device opens the recycle valve in a preceding manner and closes the IGV in a preceding manner. Thus, elevation of the fuel gas pressure at the gas compressor outlet can be prevented, and elevation of a fuel gas pressure at an inlet of the gas turbine can be suppressed, thereby ensuring stable operation.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

System and methods for optimizing efficiency of a hydraulically actuated system

InactiveUS20120057998A1Easy to operateIncrease gas pressureGas turbine plantsEfficient propulsion technologiesHydraulic cylinderHydraulic pump

Systems and methods for efficiently operating a hydraulically actuated device / system are described herein. For example, systems and methods for efficiently operating a gas compression and expansion energy storage system are disclosed herein. Systems and methods are provided for controlling and operating the hydraulic actuators used within a hydraulically actuated device / system, such as, for example, a gas compression and / or expansion energy system, within a desired efficiency range of the hydraulic pump(s) / motor(s) used to supply or receive pressurized hydraulic fluid to or from the hydraulic actuators. In such a system, a variety of different operating regimes can be used depending on the desired output gas pressure and the desired stored pressure of the compressed gas. Hydraulic cylinders used to drive working pistons within the system can be selectively actuated to achieve varying force outputs to incrementally increase the gas pressure within the system for a given cycle.

Owner:GENERAL COMPRESSION

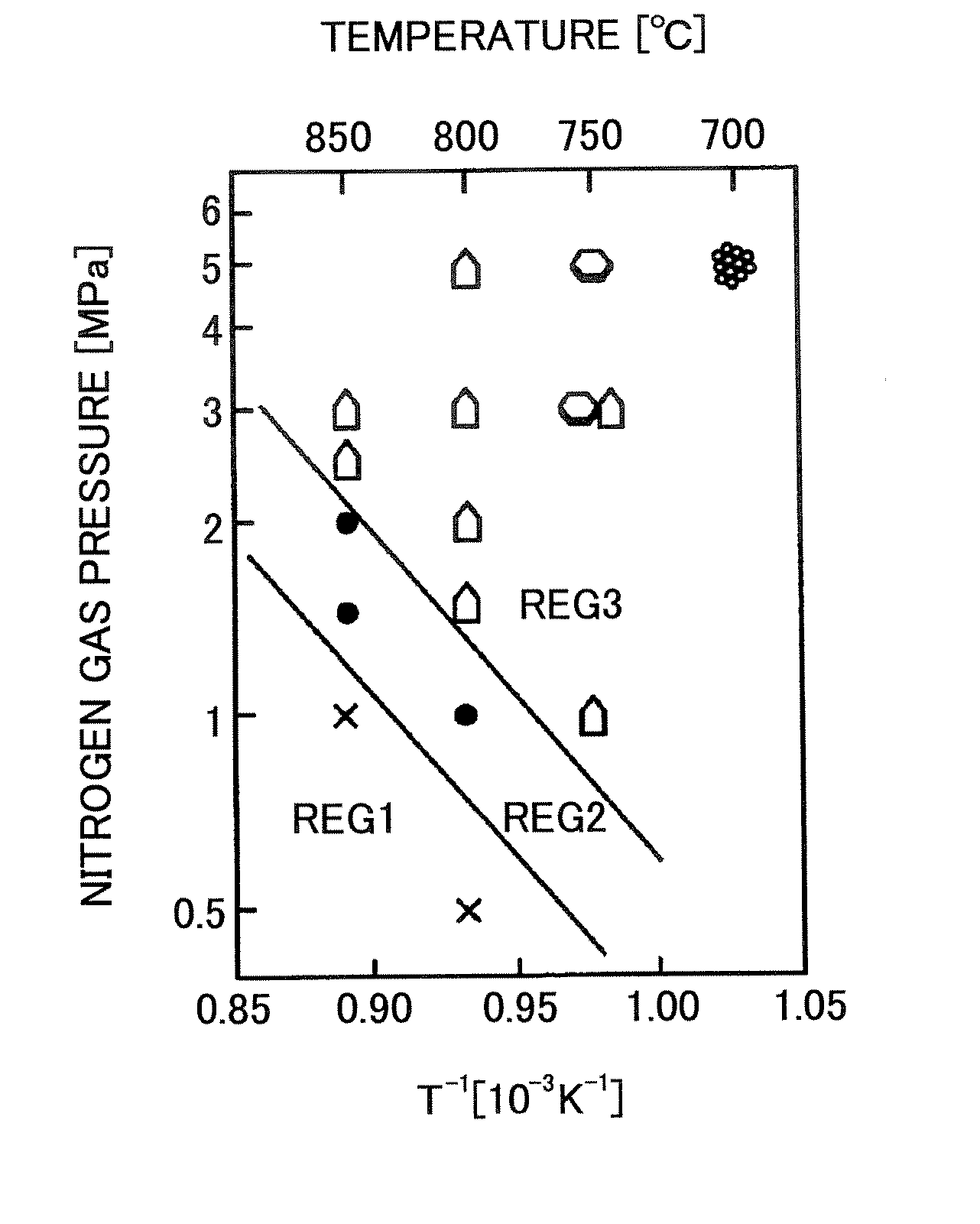

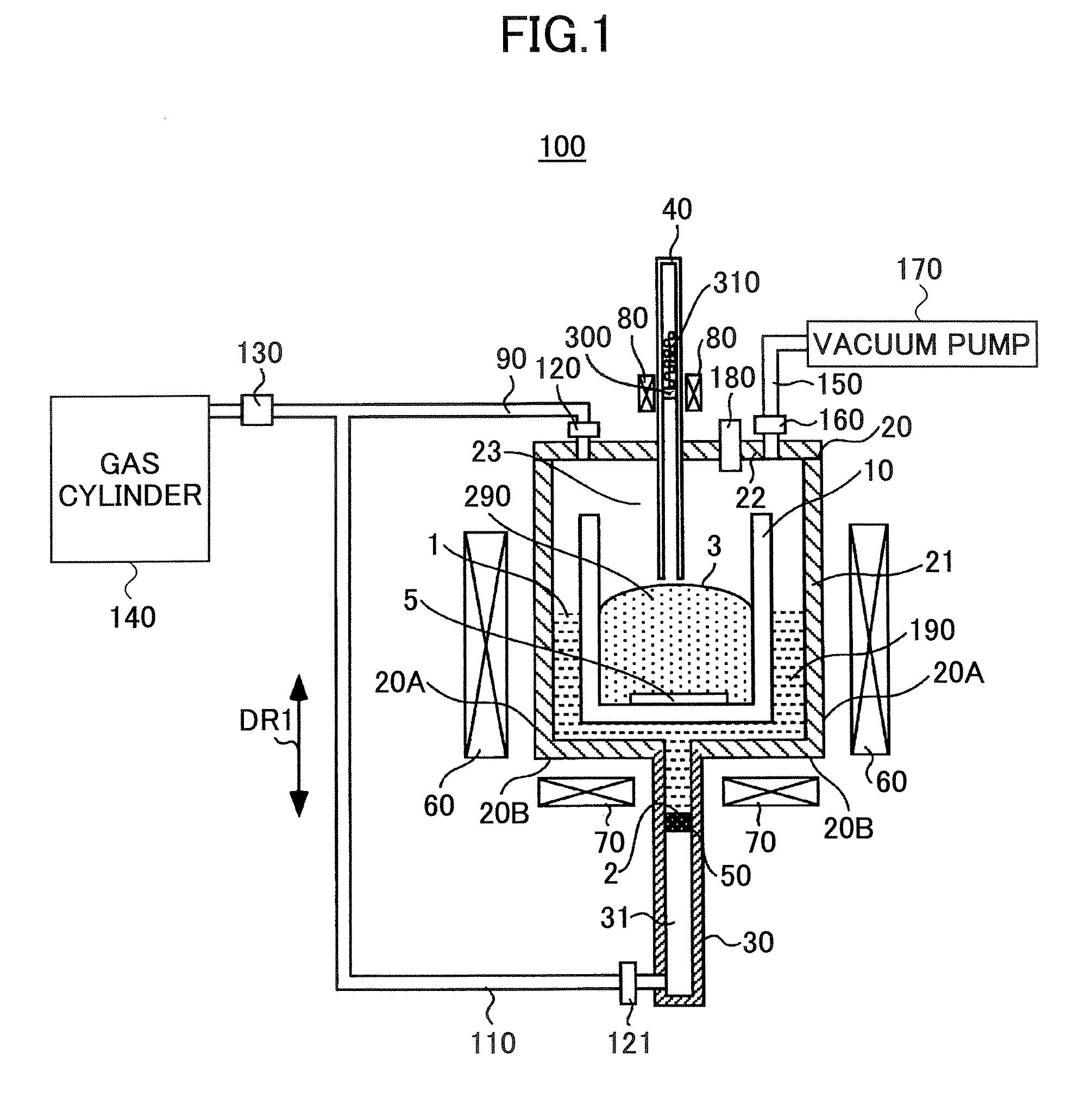

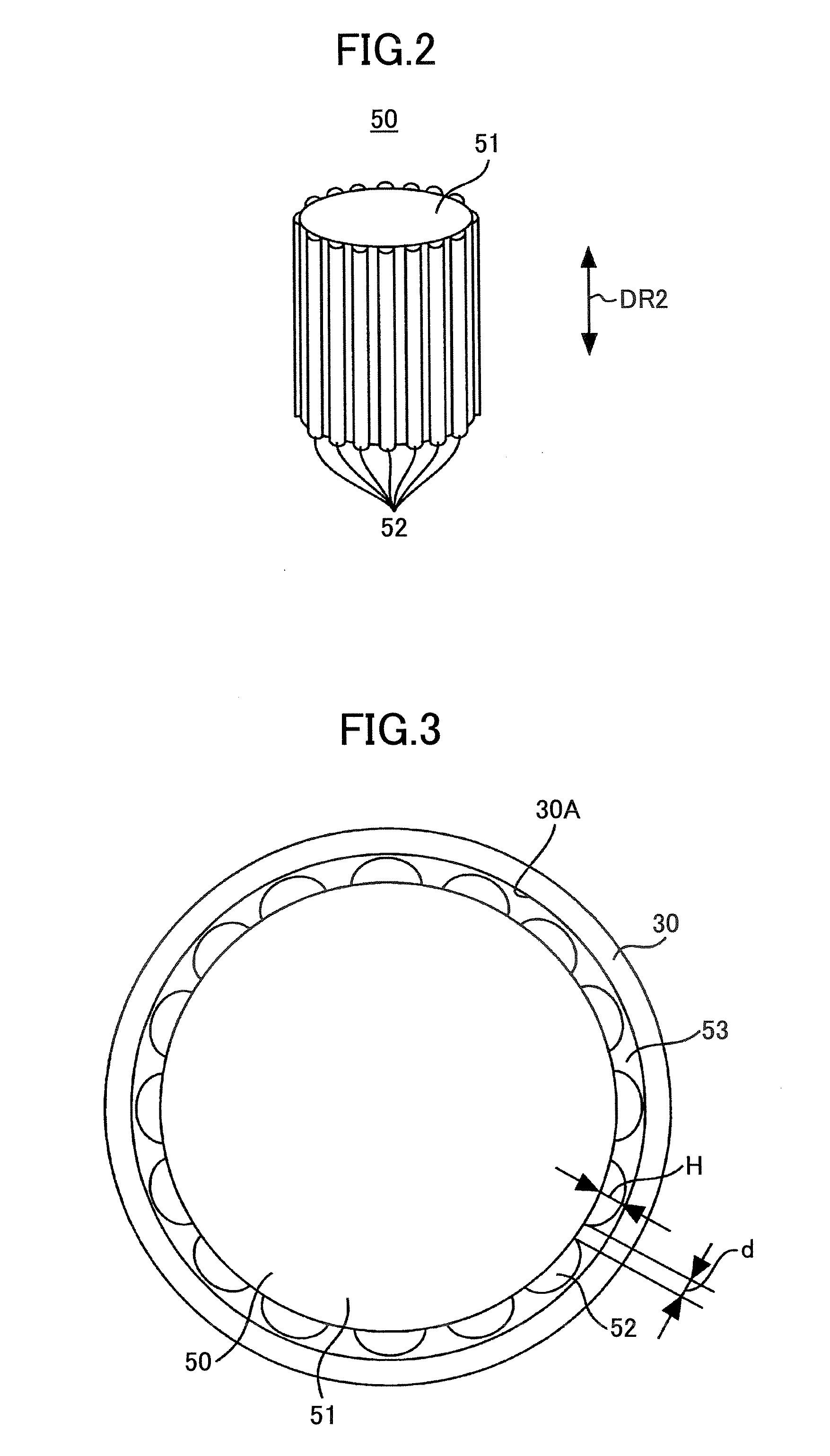

Group iii nitride crystal and manufacturing method thereof

ActiveUS20070128746A1Reduce misalignmentIncrease gas pressurePolycrystalline material growthLiquid-phase epitaxial-layer growthThreading dislocationsDislocation

A group III nitride crystal containing therein an alkali metal element comprises a base body, a first group III nitride crystal formed such that at least a part thereof makes a contact with the base body, the first group III nitride crystal deflecting threading dislocations in a direction different from a direction of crystal growth from the base body and a second nitride crystal formed adjacent to the first group III nitride crystal, the second nitride crystal having a crystal growth surface generally perpendicular to the direction of the crystal growth.

Owner:SUMITOMO CHEM CO LTD +1

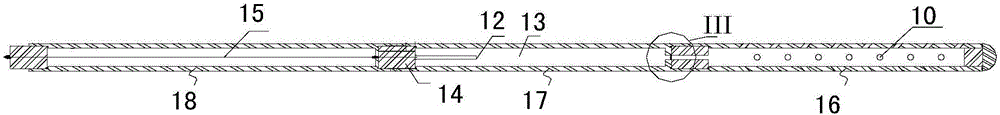

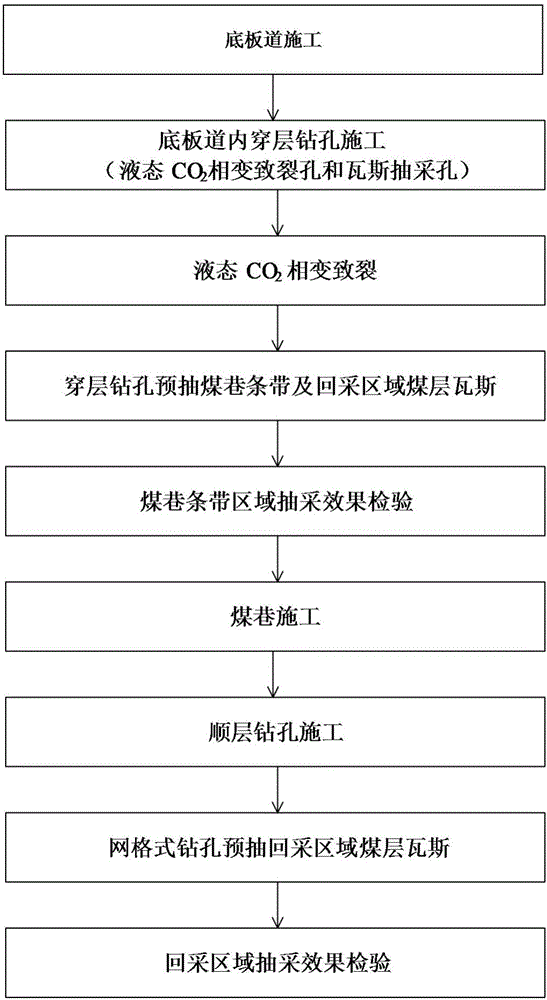

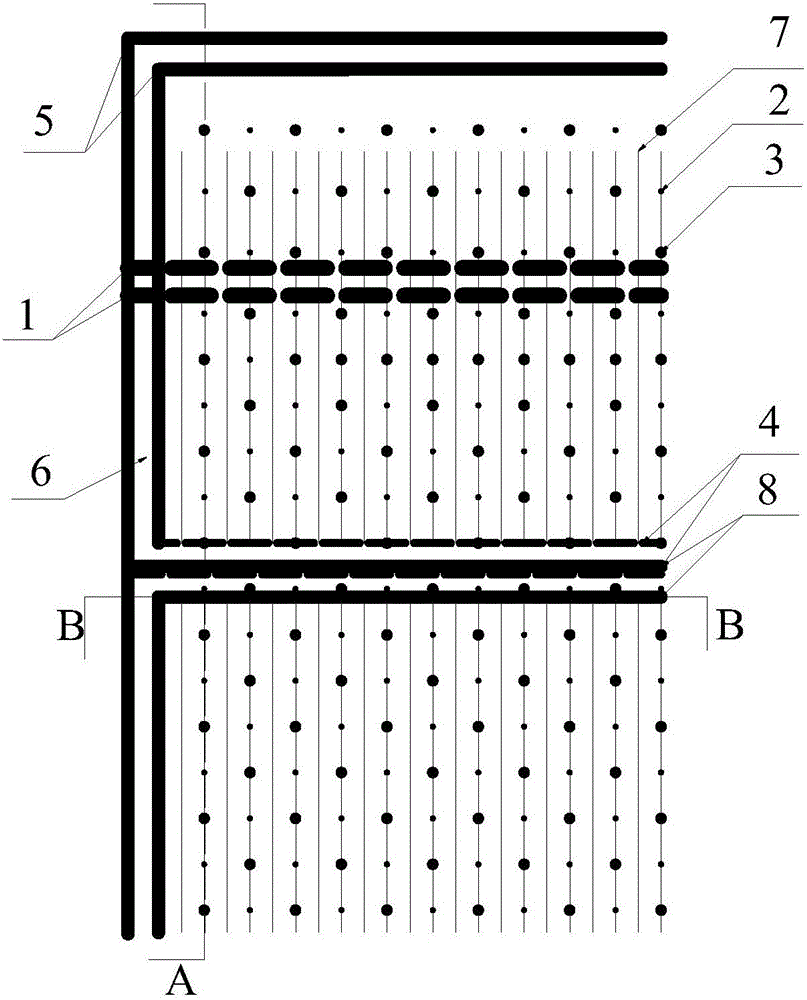

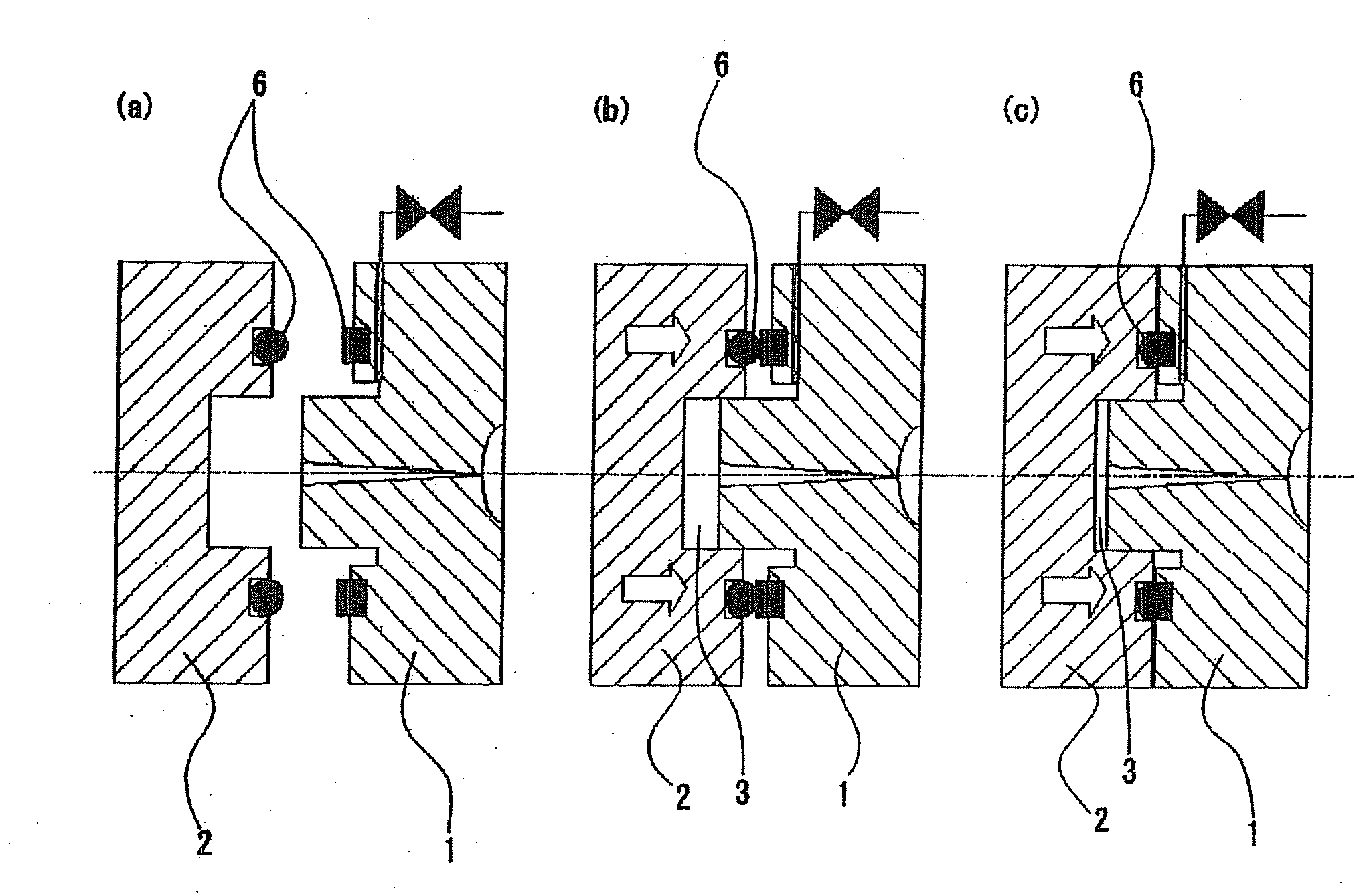

Liquid-phase CO2 phase change cracking permeability-increasing grid type gas extraction method for low-permeable coal seam

ActiveCN106194244AIncrease gas extractionEliminate outstanding hazardsFluid removalGas removalDrill holeProcess engineering

The invention discloses a liquid-phase CO2 phase change cracking permeability-increasing grid type gas extraction method for a low-permeable coal seam. The method comprises the following steps that (1) a bottom board passage is constructed; (2) crossing drilling construction is carried out in the bottom board passage; (3) liquid CO2 phase change cracking is carried out; (4) gas of coal seams of a coal roadway strip and a recovery area is pre-drained with crossing drill holes; (5) the extraction effect of the coal roadway strip area is detected; (6) coal roadway construction is carried out; (7) hole drilling down the seam is carried out; (8) gas of the coal seam in the recovery area is pre-drained with grid type drill holes; and (9) the extraction effect of the recovery area is detected. The method can improve the quantity of drainage of gas of underground coal mine, achieve the purpose of rapidly eliminating danger of outburst for high-gas low-permeable outburst coal seams, prevent coal and gas outburst accidents and guarantee safety production of the underground coal mine.

Owner:CHONGQING UNIV

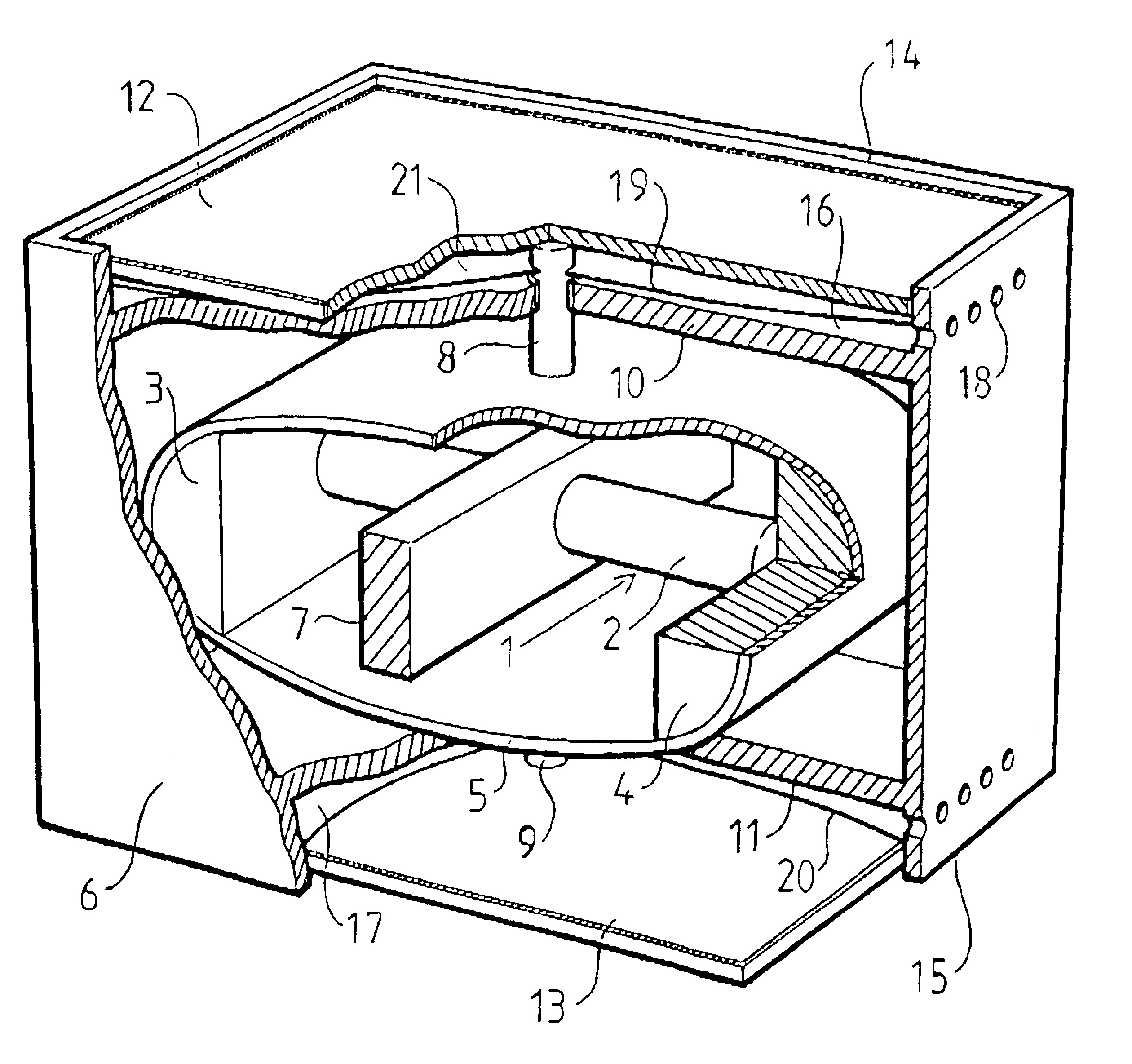

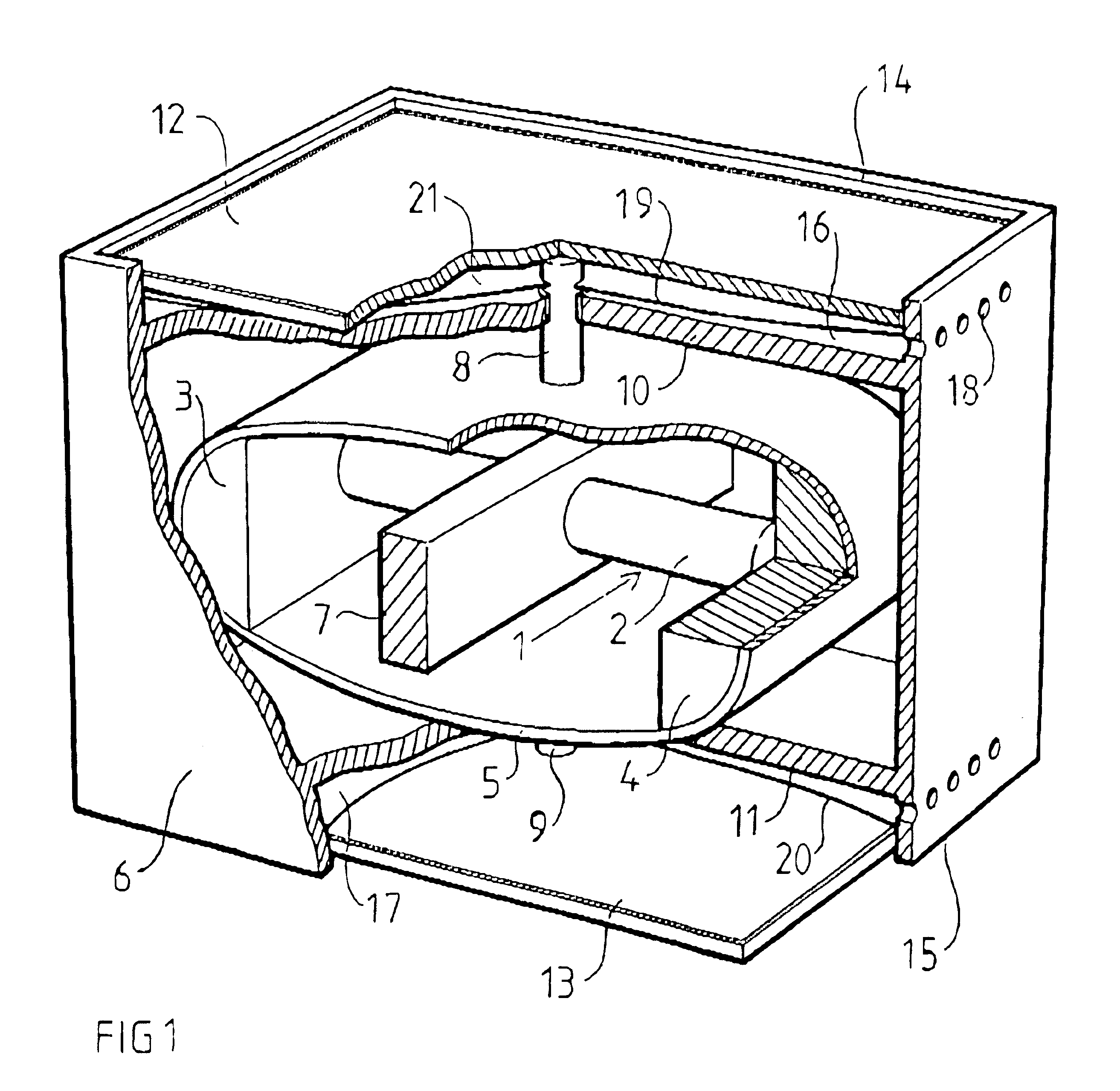

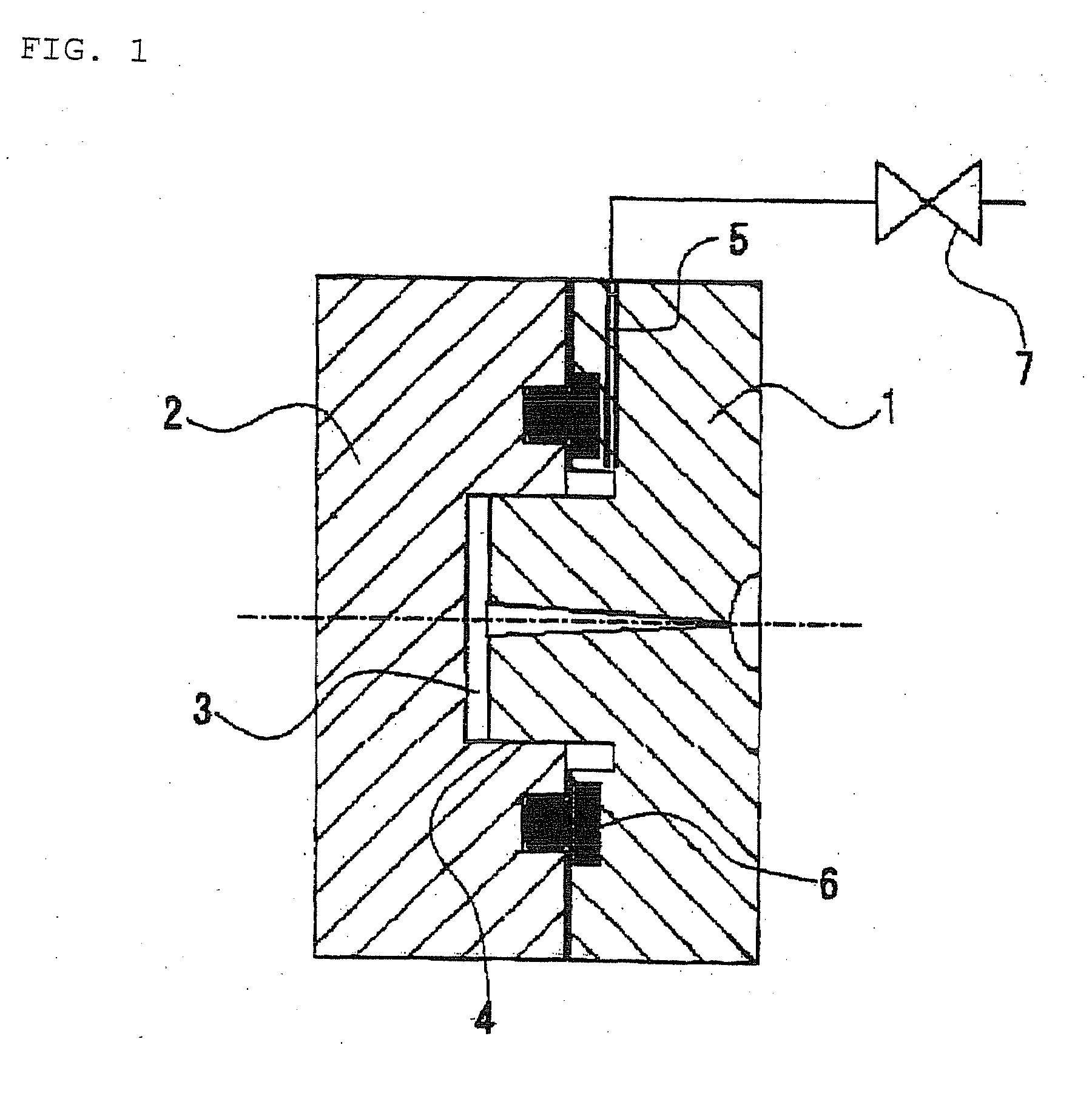

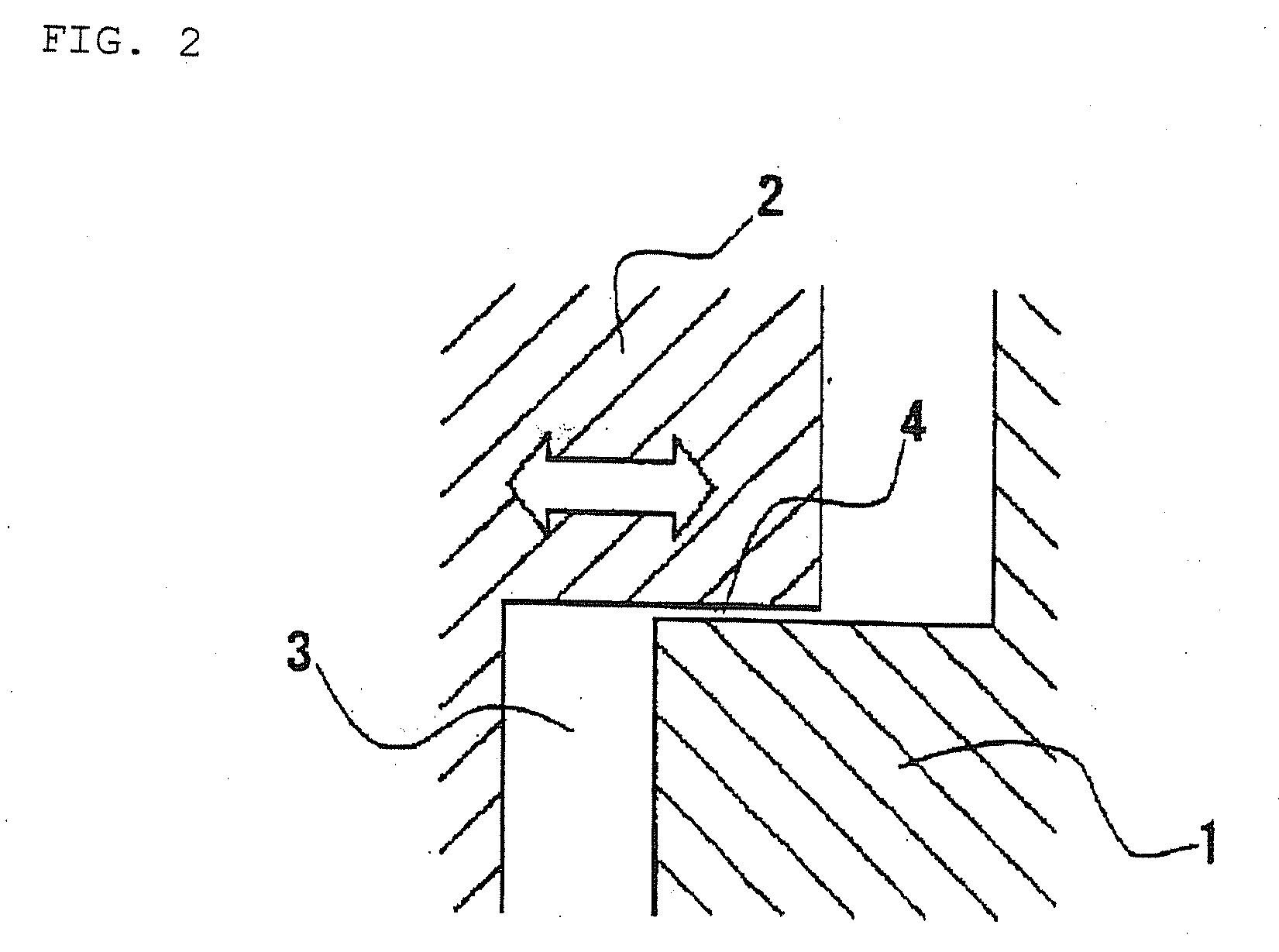

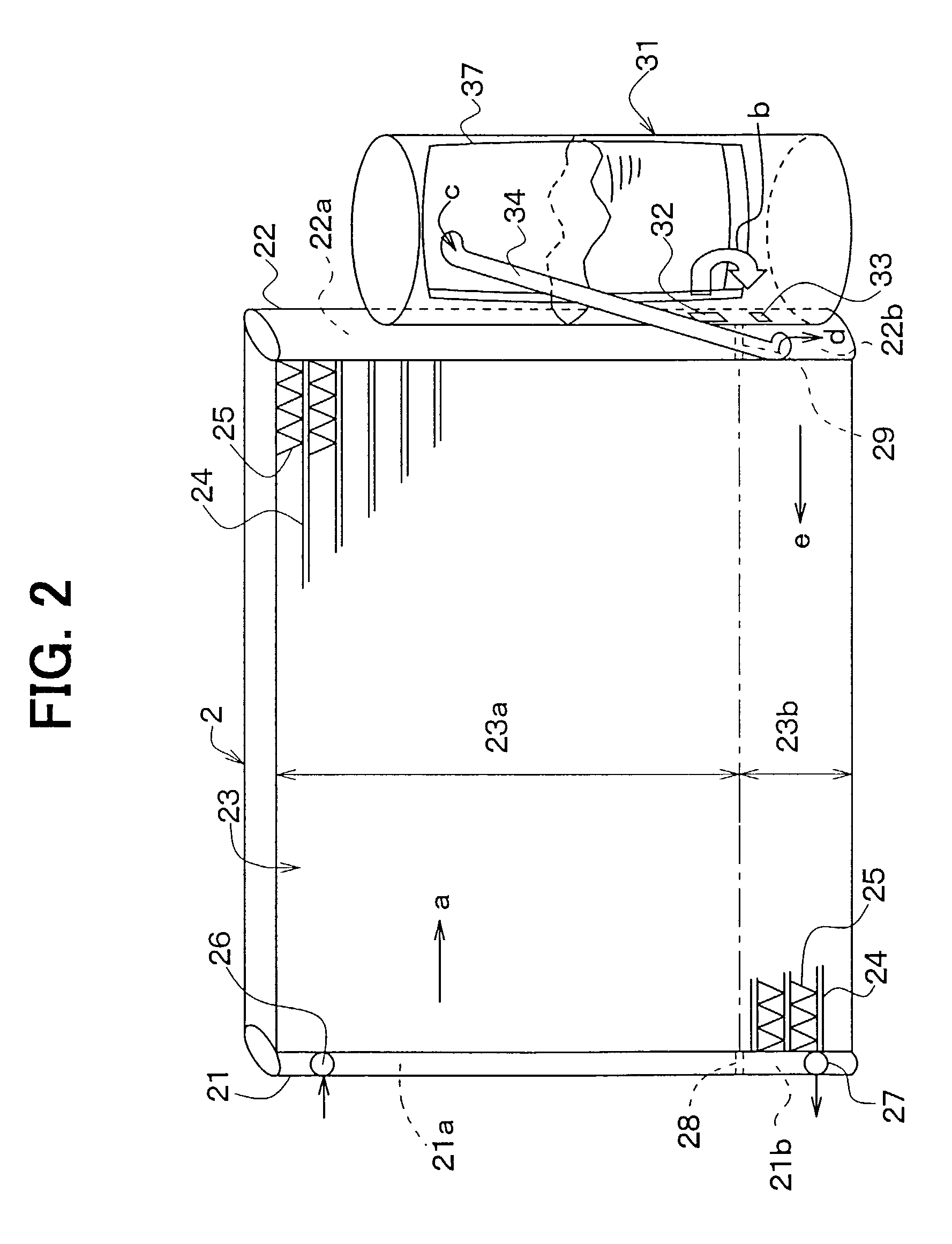

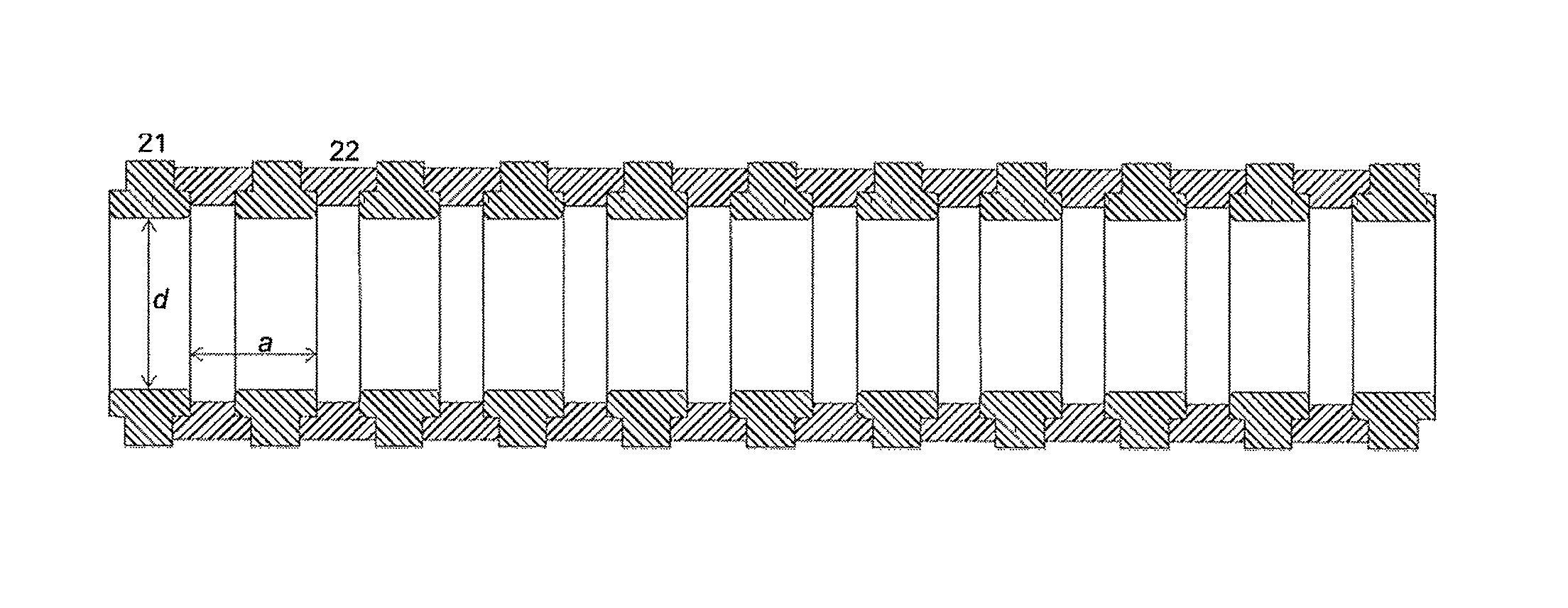

Expansion Injection Molding Process And Mold For Expansion Injection Molding

To provide an expansion injection molding process, which is freed from the occurrence of swirl marks on the surface of a molded article and by which foamed injection moldings having good appearance can be produced in a short molding cycle and at a low cost; and a mold for expansion injection molding.A movable mold 2 is moved toward a fixed mold 1, whereby a sealing member 6 set on at least one of a pair of facing surfaces of the mold 1 and mold 2 in the outside of a cavity is brought into contact with the other of the facing surfaces or a sealing member 6 set thereon to make the cavity 3 gas-sealed state. While keeping the gas-sealed state, the movable mold 2 is further moved toward the fixed mold 1 with the sealing member 6 compressed, whereby the volume of the cavity 3 is decreased to enhance the pressure in the cavity 3 to a level exceeding the atmospheric pressure. Then, a thermoplastic resin is injected into the cavity 3 of an enhanced pressure.

Owner:PRIME POLYMER CO LTD

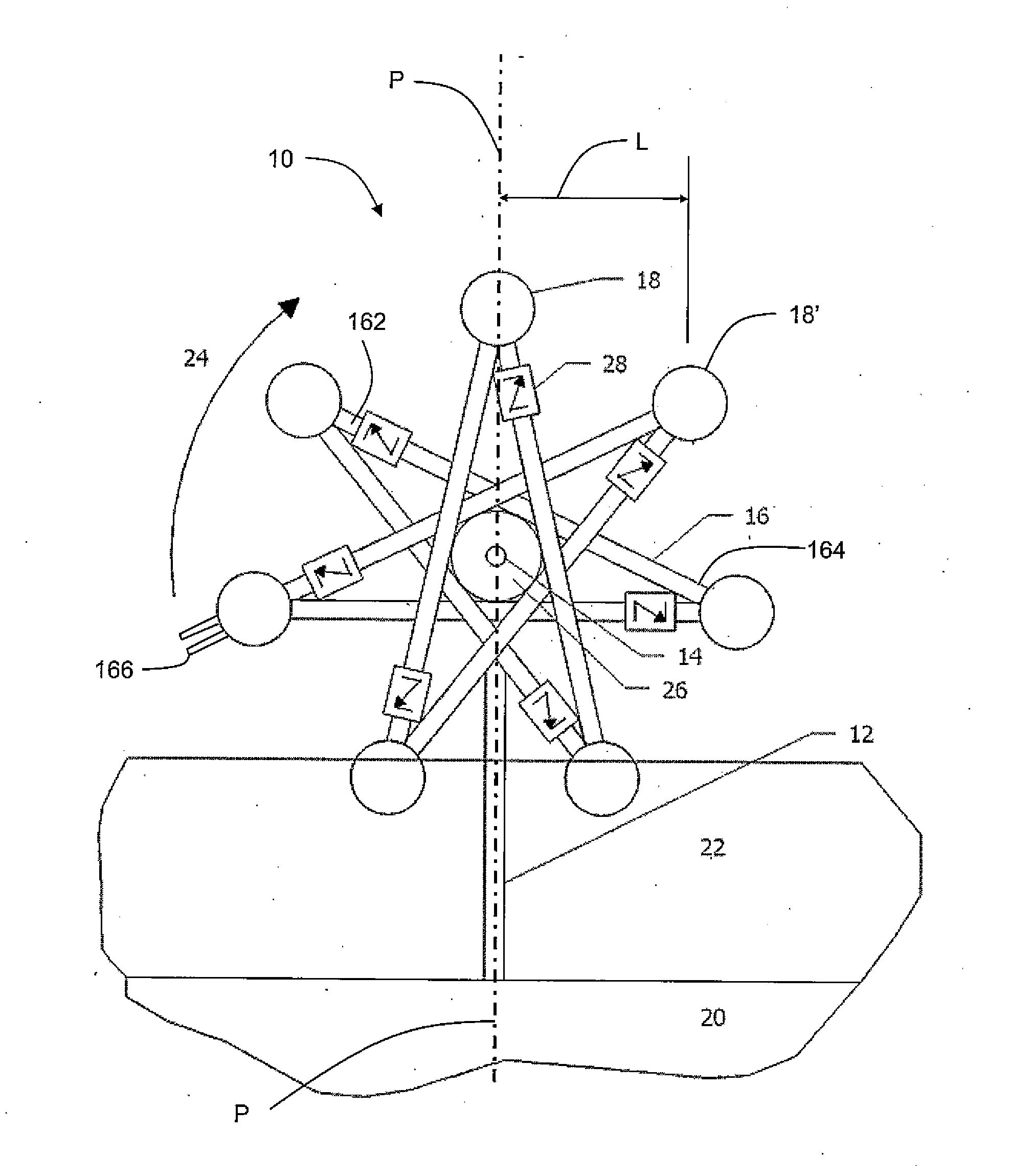

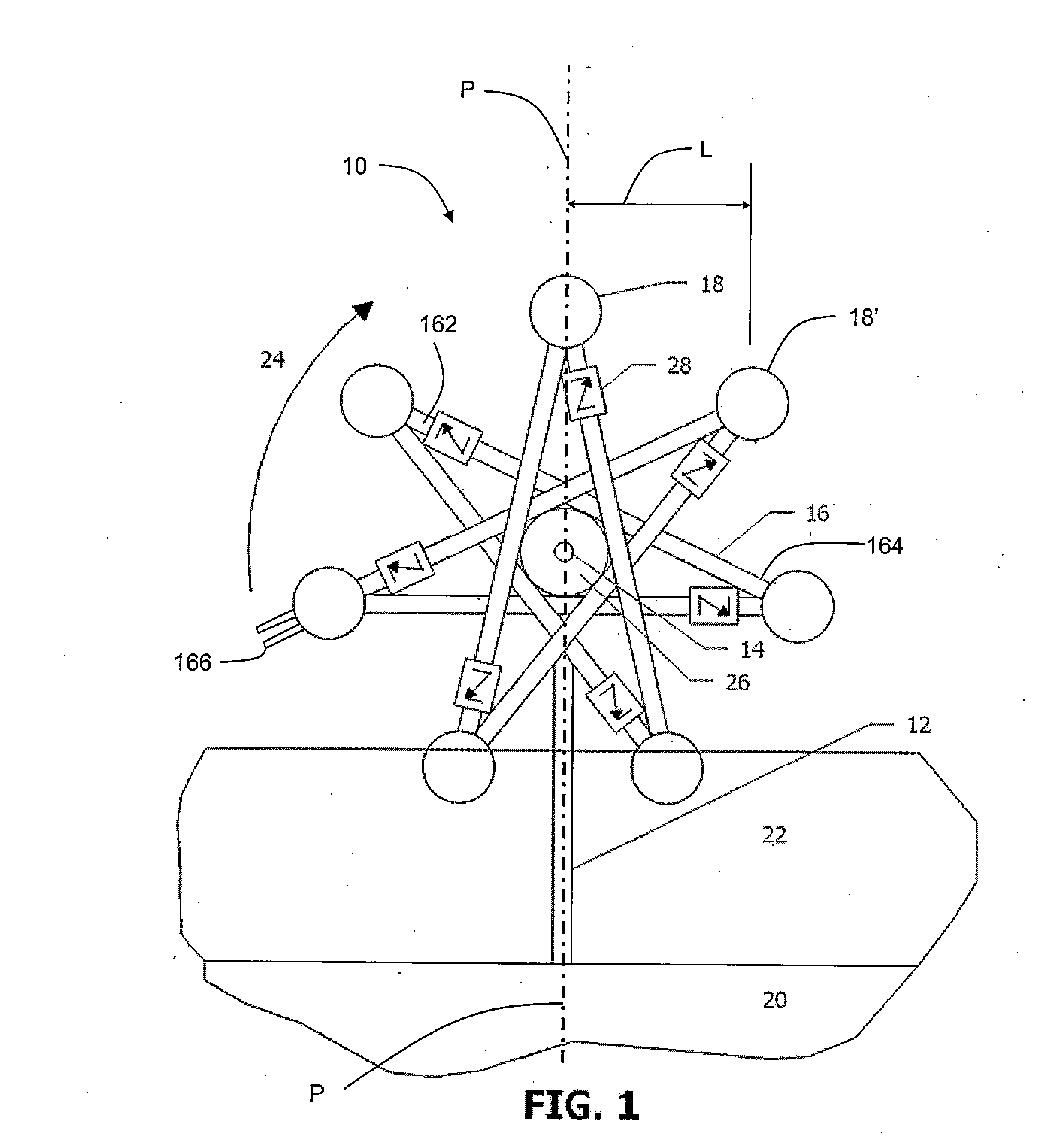

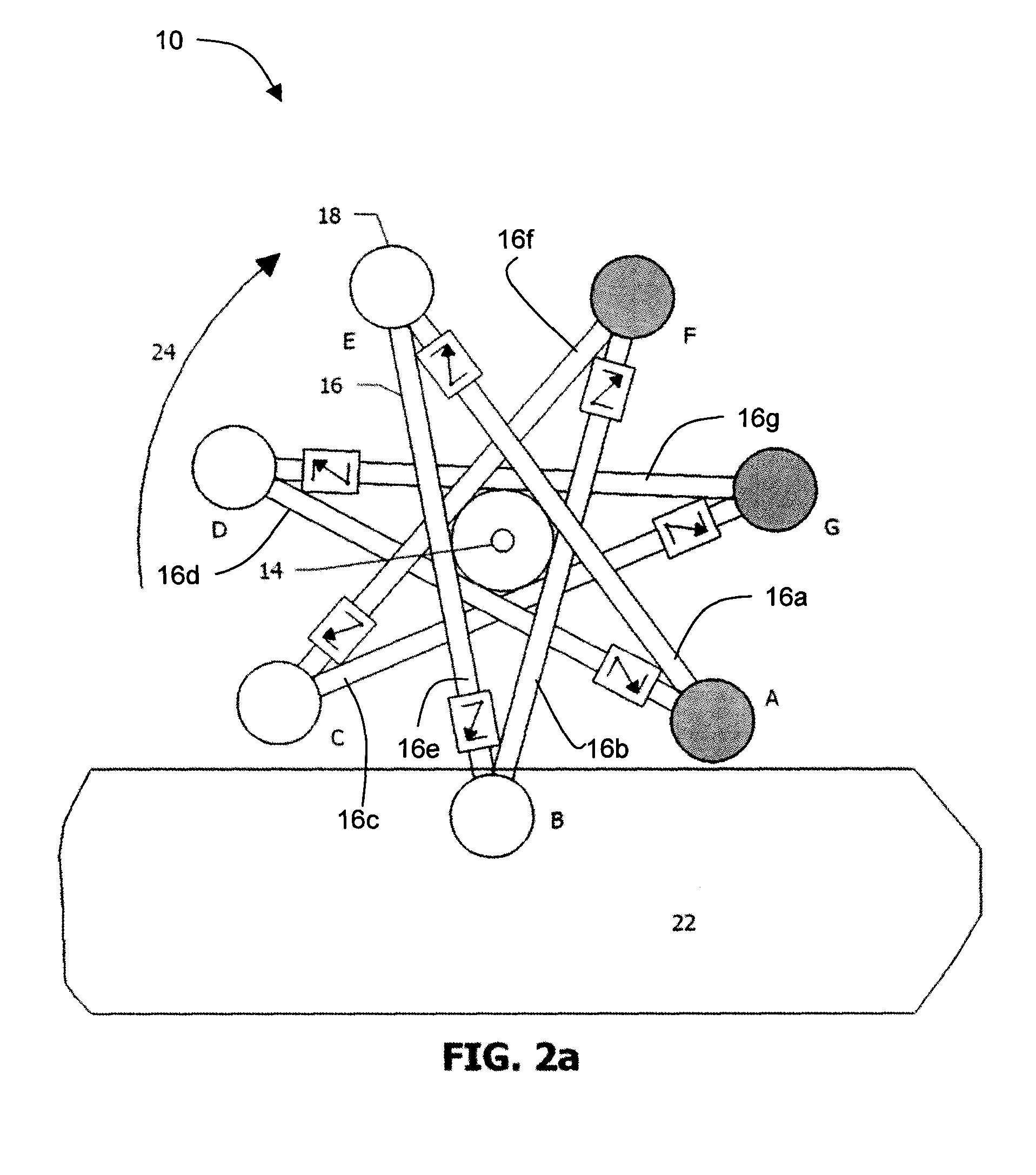

Low differential temperature rotary engines

InactiveUS20110041499A1Facilitate transferIncrease gas pressureSteam engine plantsMotorsWorking fluidCheck valve

An engine for extracting energy from a heat source, comprising a support, a shaft rotatably coupled to the support and being rotatable in a first direction, a plurality of vessels coupled to and spaced about the shaft, a working fluid provided in the plurality of vessels, and a plurality of conduits connecting the vessels together in a circuitous fluid circuit. Each conduit has an outlet end connected to one of the plurality of vessels, an inlet end connected to another one of the plurality of vessels, and a one-way check valve configured to allow the working fluid to flow out of the one vessel via the outlet end, through the conduit and into the another vessel via the inlet end. The plurality of vessels and conduits are shaped and arranged about the shaft and the working fluid is selected so that when the one vessel is heated by the heat source the working fluid in the one vessel experiences an increase in vapour pressure causing at least part of the working fluid to flow from the one vessel into the another vessel located above the one vessel so as to produce a gravitational moment that encourages rotation of the shaft in the first direction.

Owner:DYVERGA ENERGY CORP

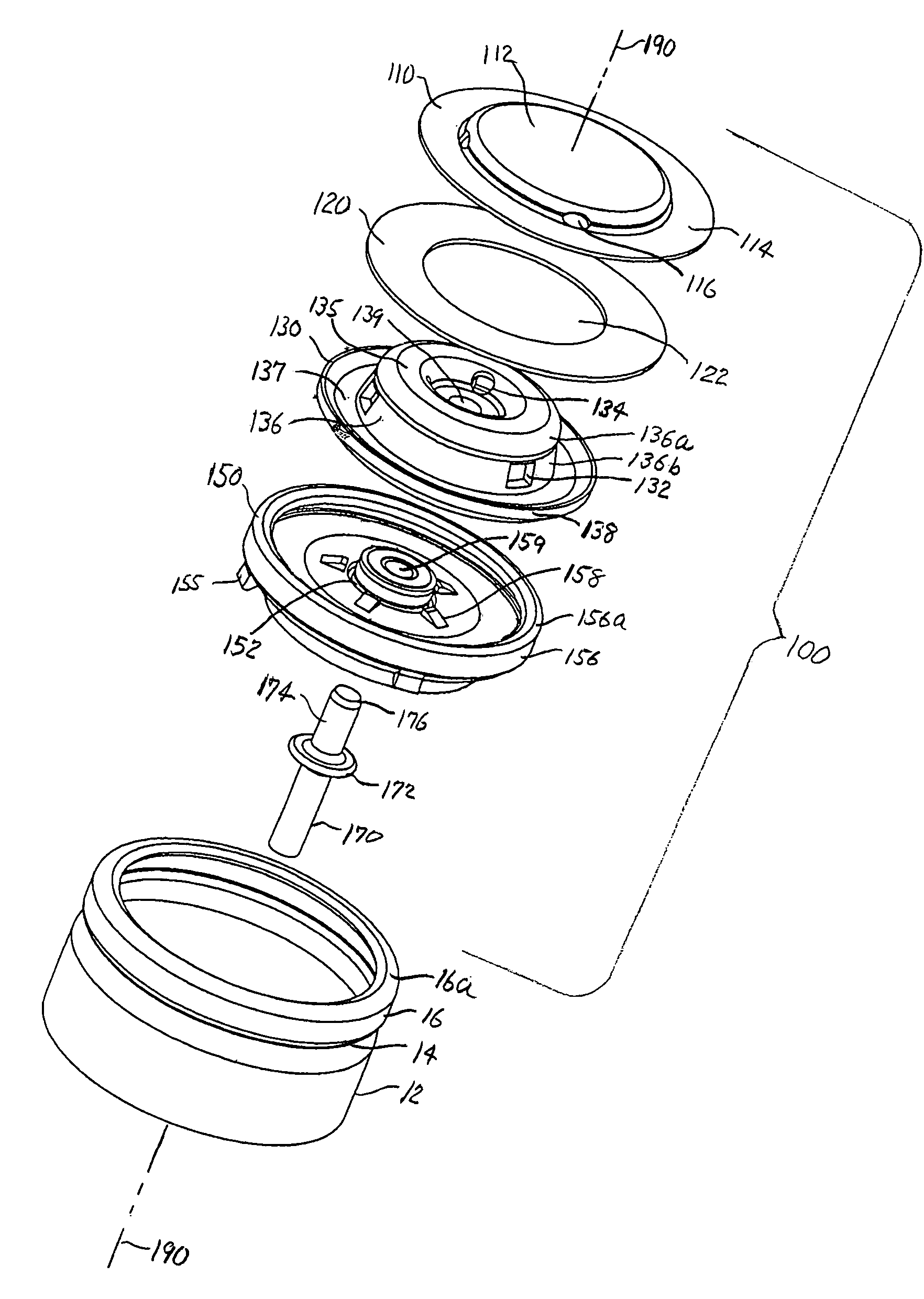

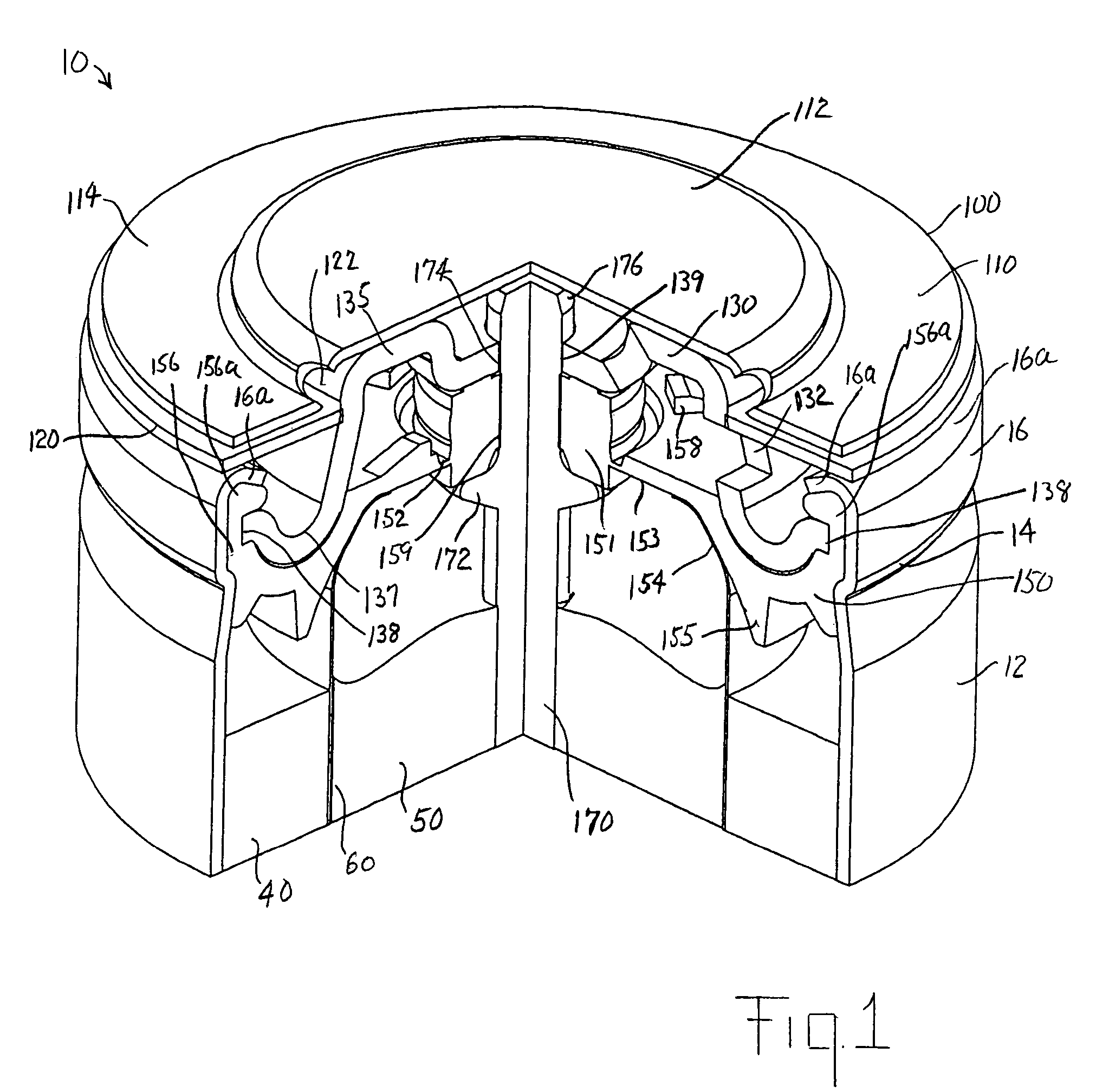

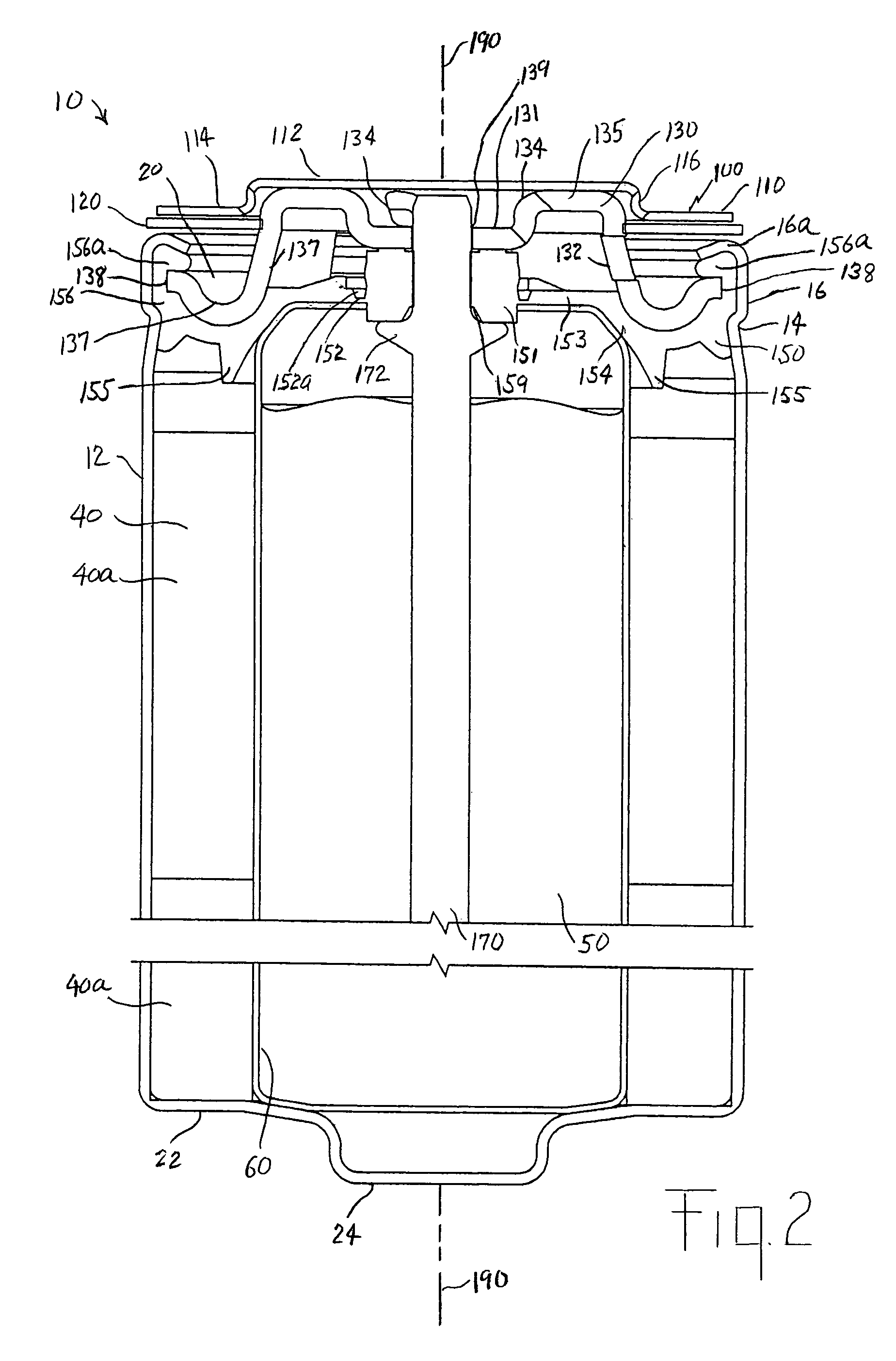

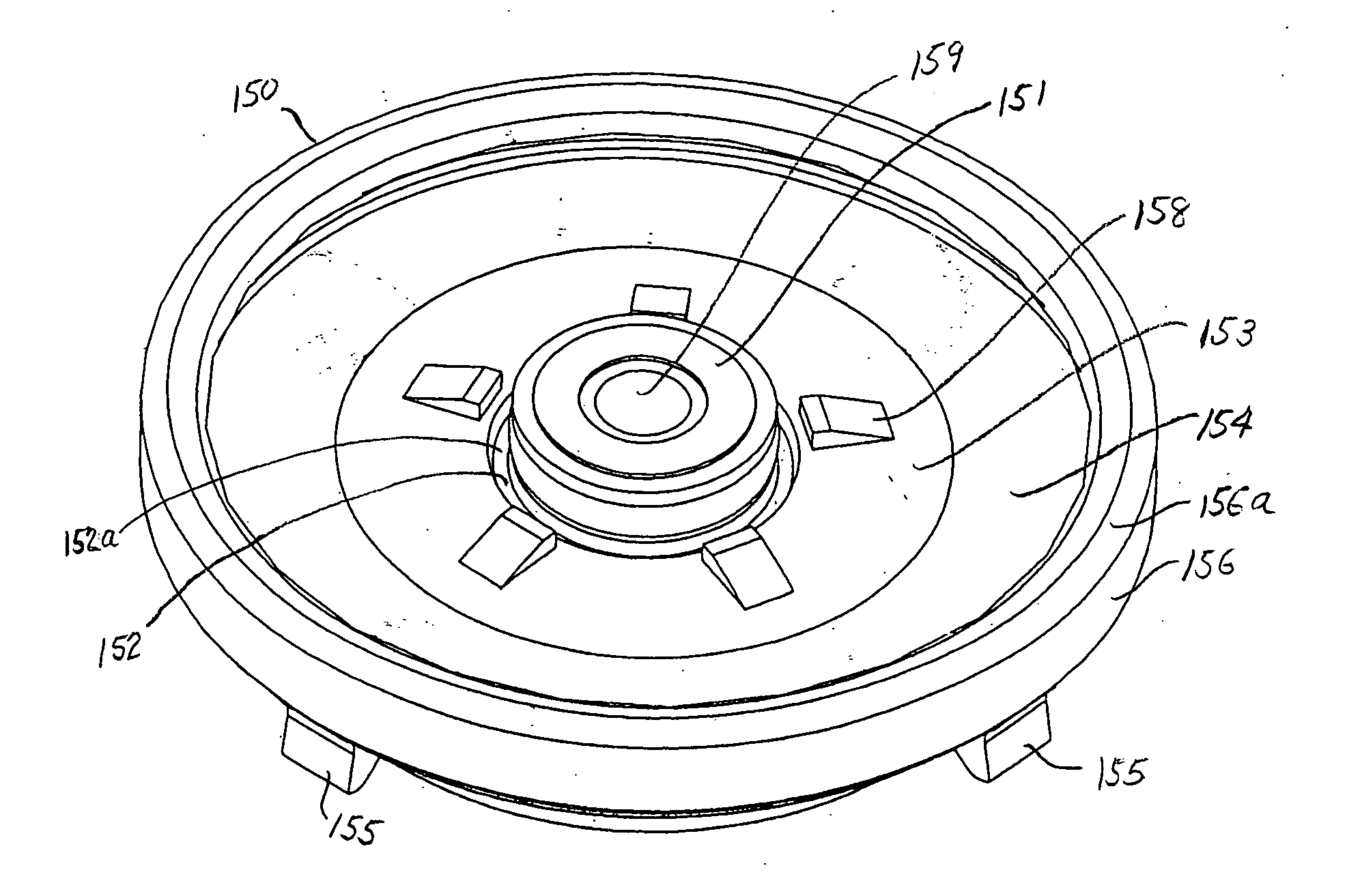

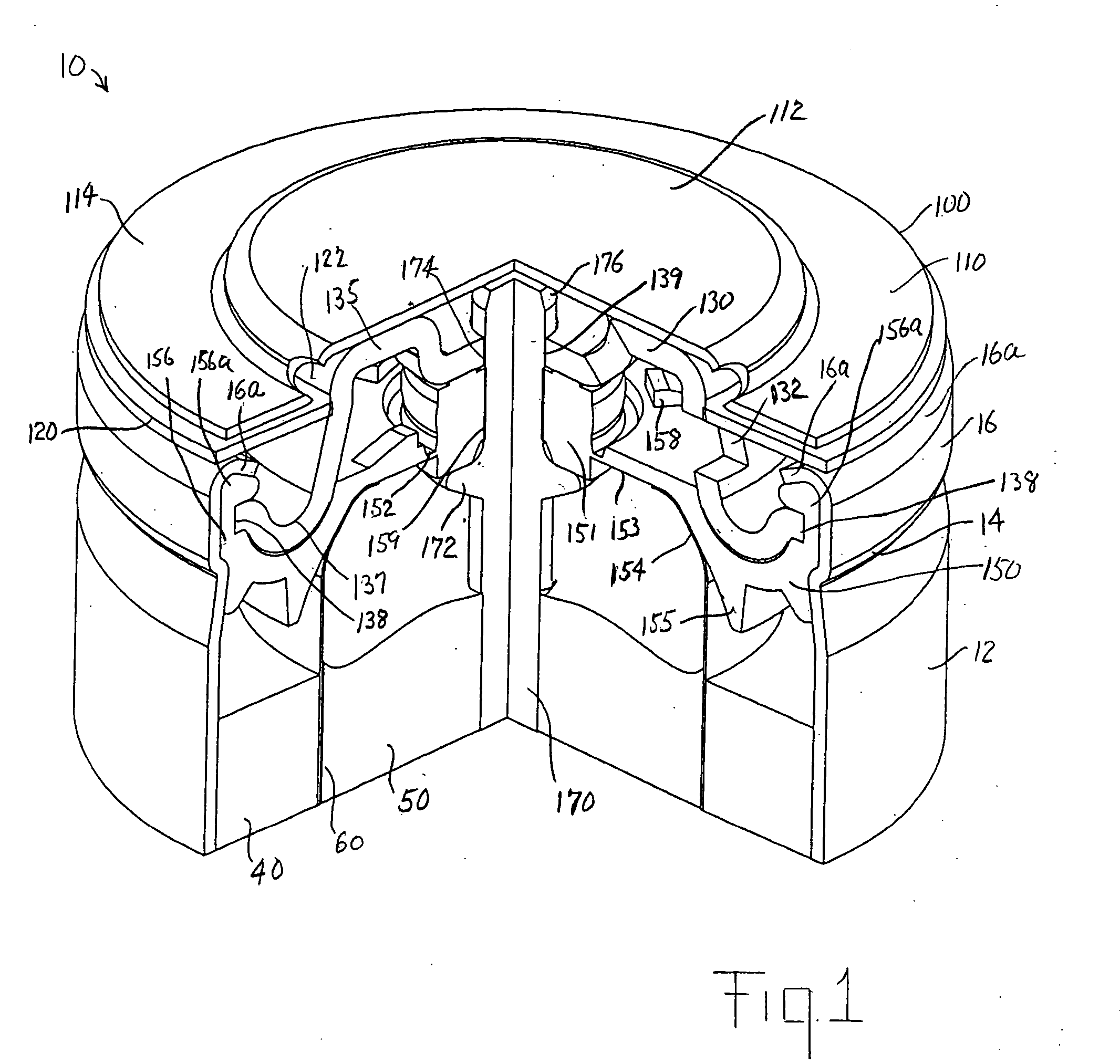

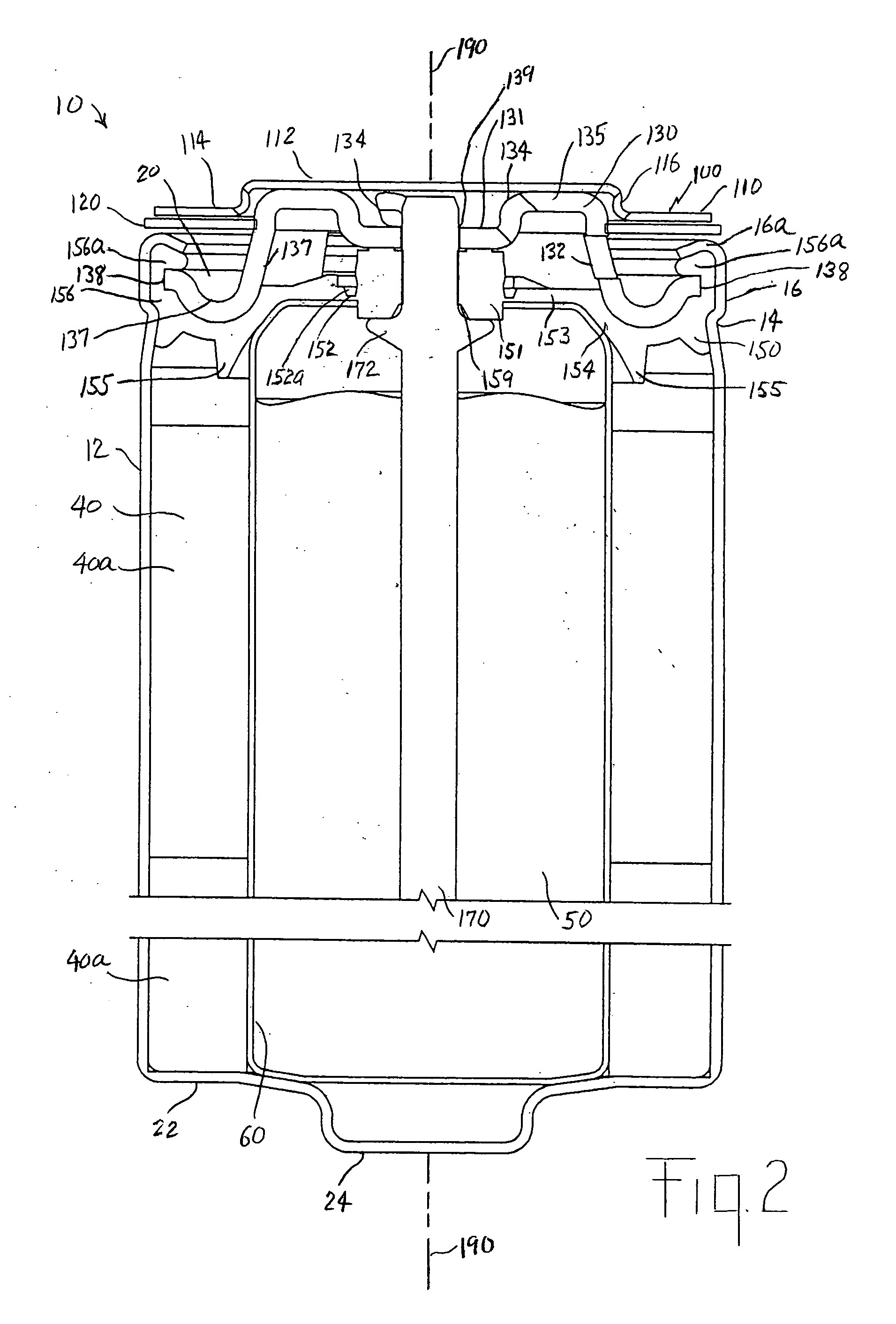

End cap assembly and vent for high power cells

ActiveUS7579105B2Preventing a catastrophic ruptureQuick releaseSmall-sized cells cases/jacketsAqueous electrolyte cellsMechanical engineeringMembrane configuration

And end cap assembly and venting system therein for closing and sealing the open end of a cell housing. The end cap assembly comprises a sealing disk underlying an end cap, and a metal support disk between the end cap and the sealing disk. The metal support disk has a plurality of primary vent apertures and a plurality of secondary vent apertures through its surface. The primary vent apertures are spaced apart along a path located at a greater distance from the central longitudinal axis of the metal support disk than the secondary vent apertures. The insulating sealing disk may have a thinned portion therein forming an rupturable membrane circumventing the central hub of the sealing disk. The insulating sealing disk may have protrusions emanating from its top surface to deflect the membrane during rupture. The venting system releases internal gases rapidly from the cell in the event of an abusive or short circuit discharge.

Owner:DURACELL U S OPERATIONS

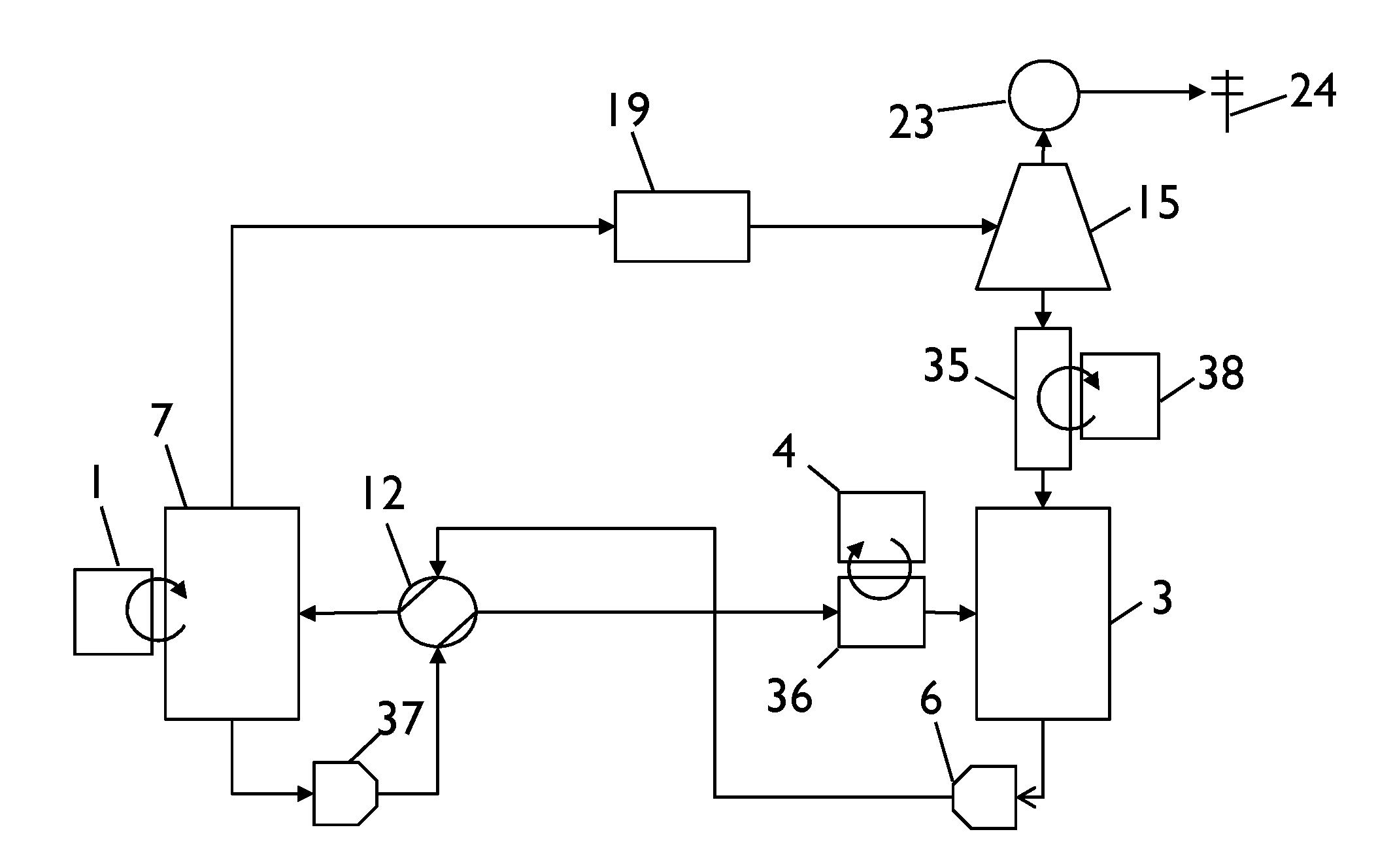

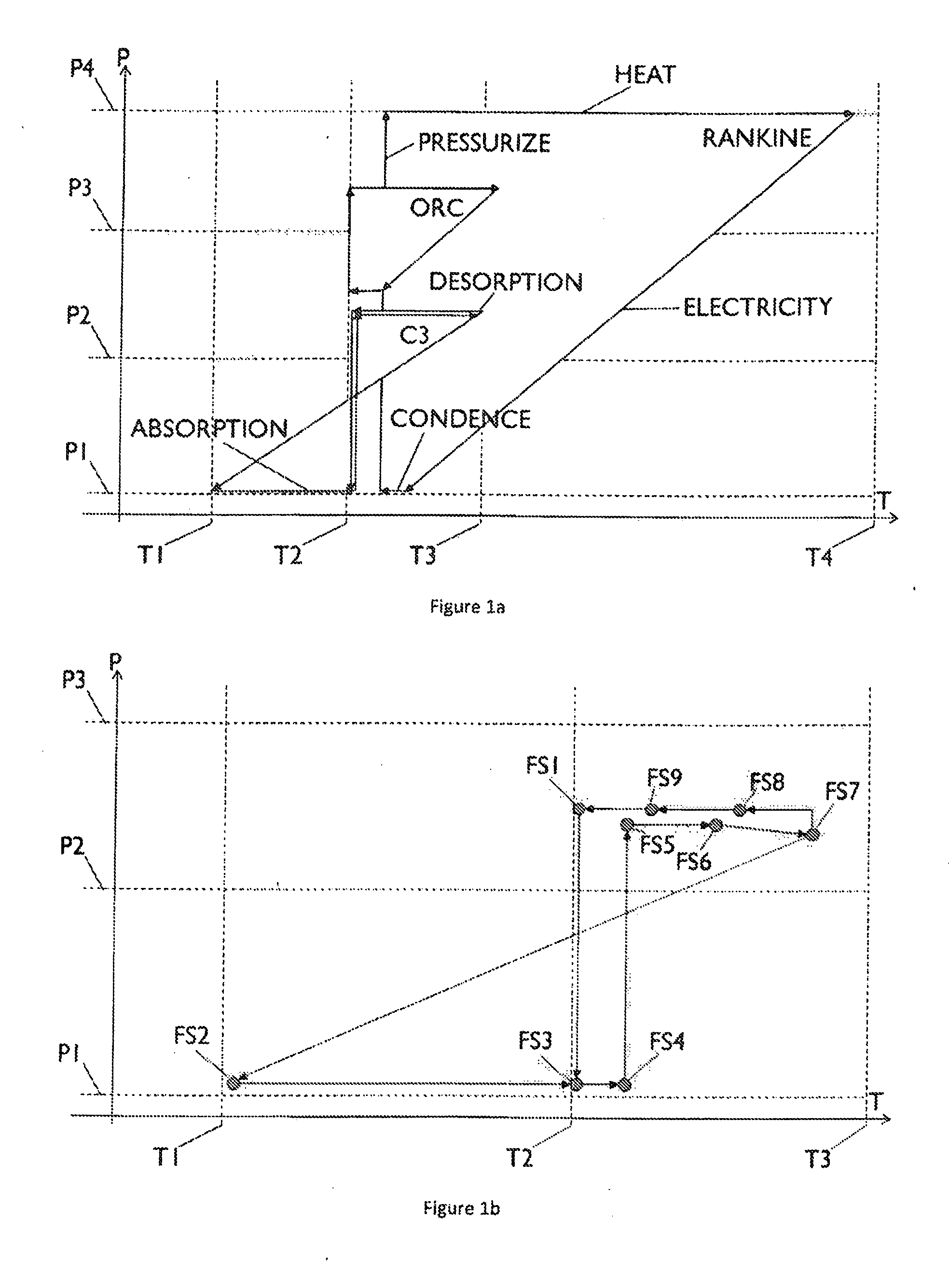

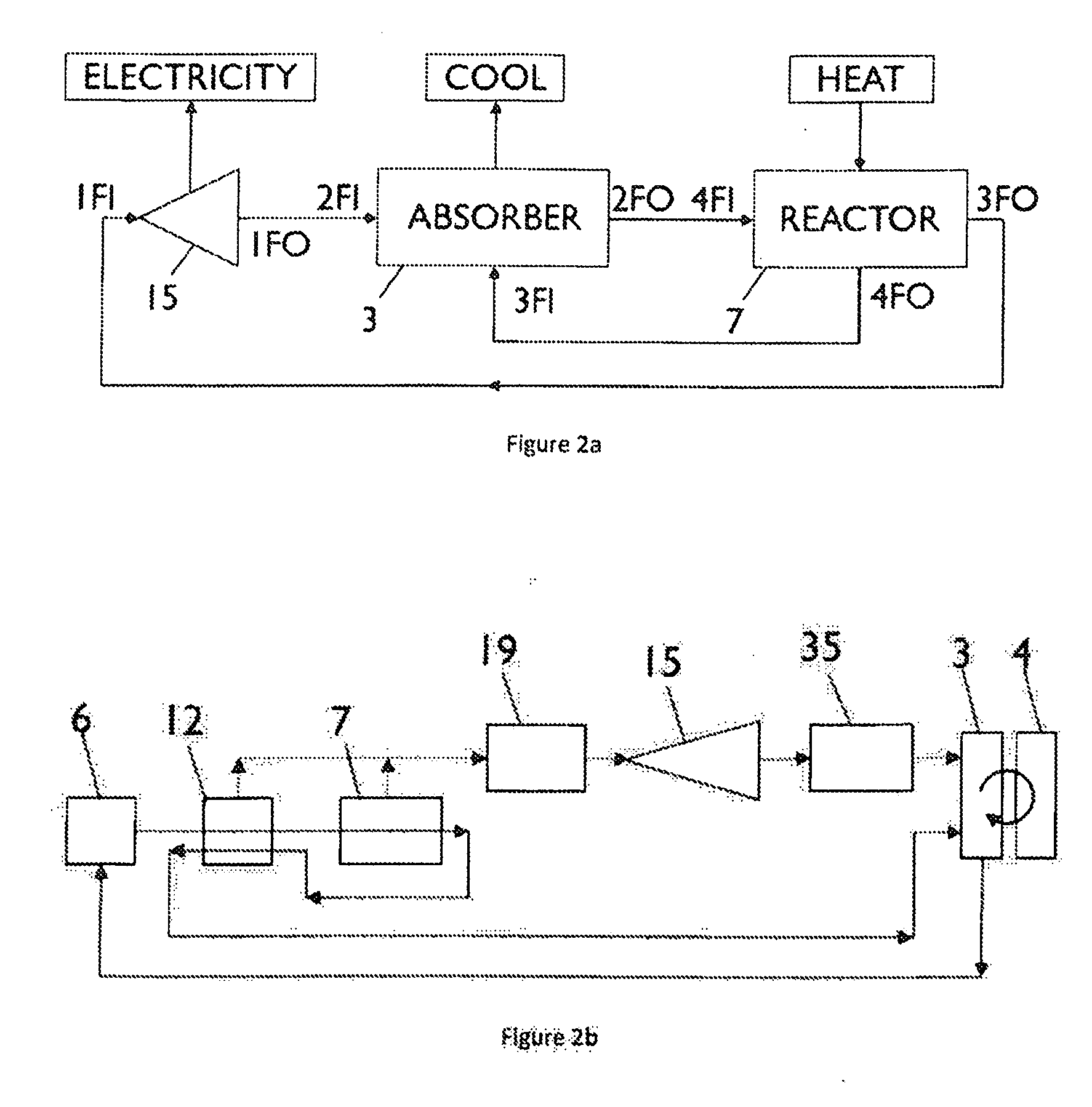

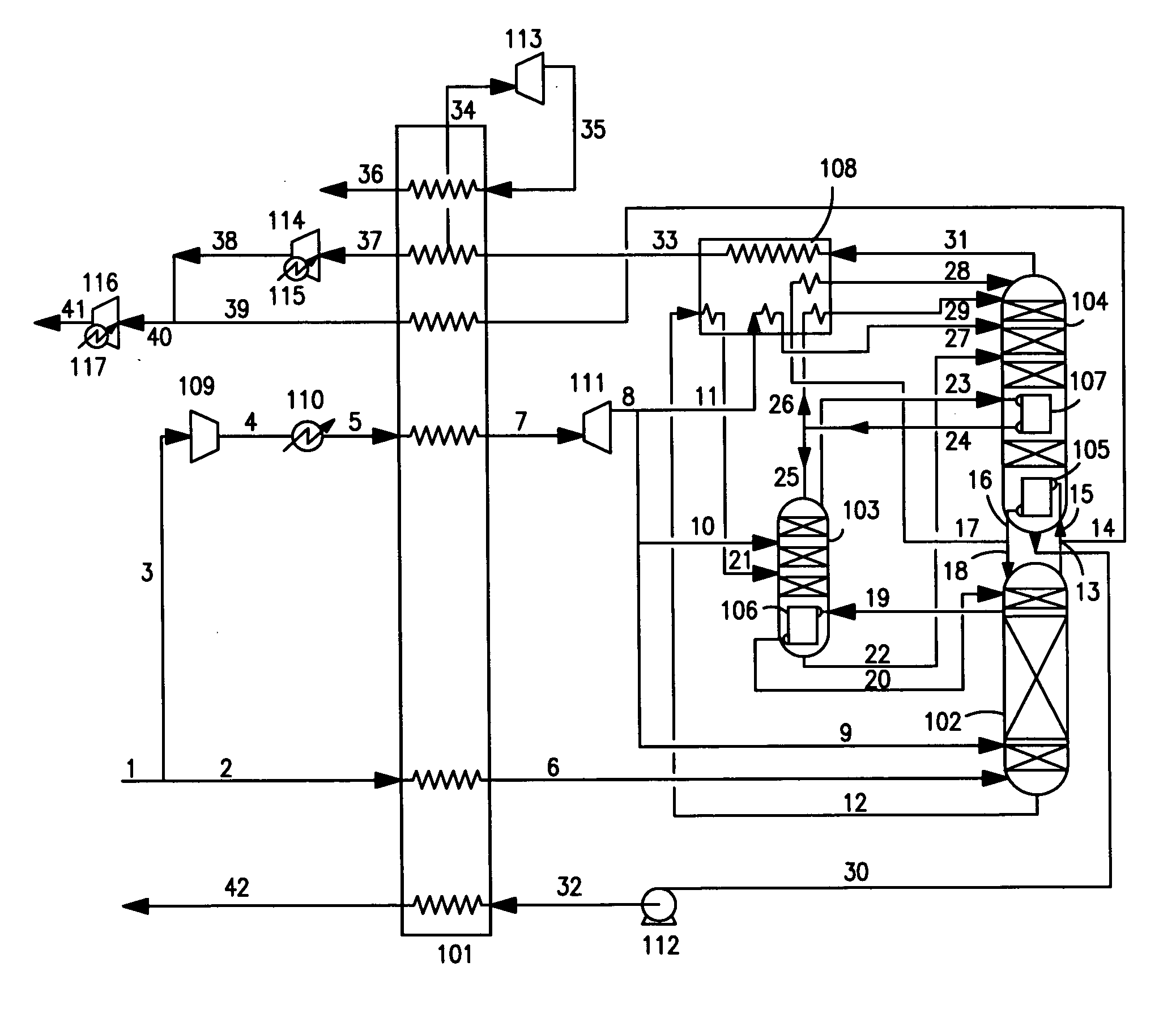

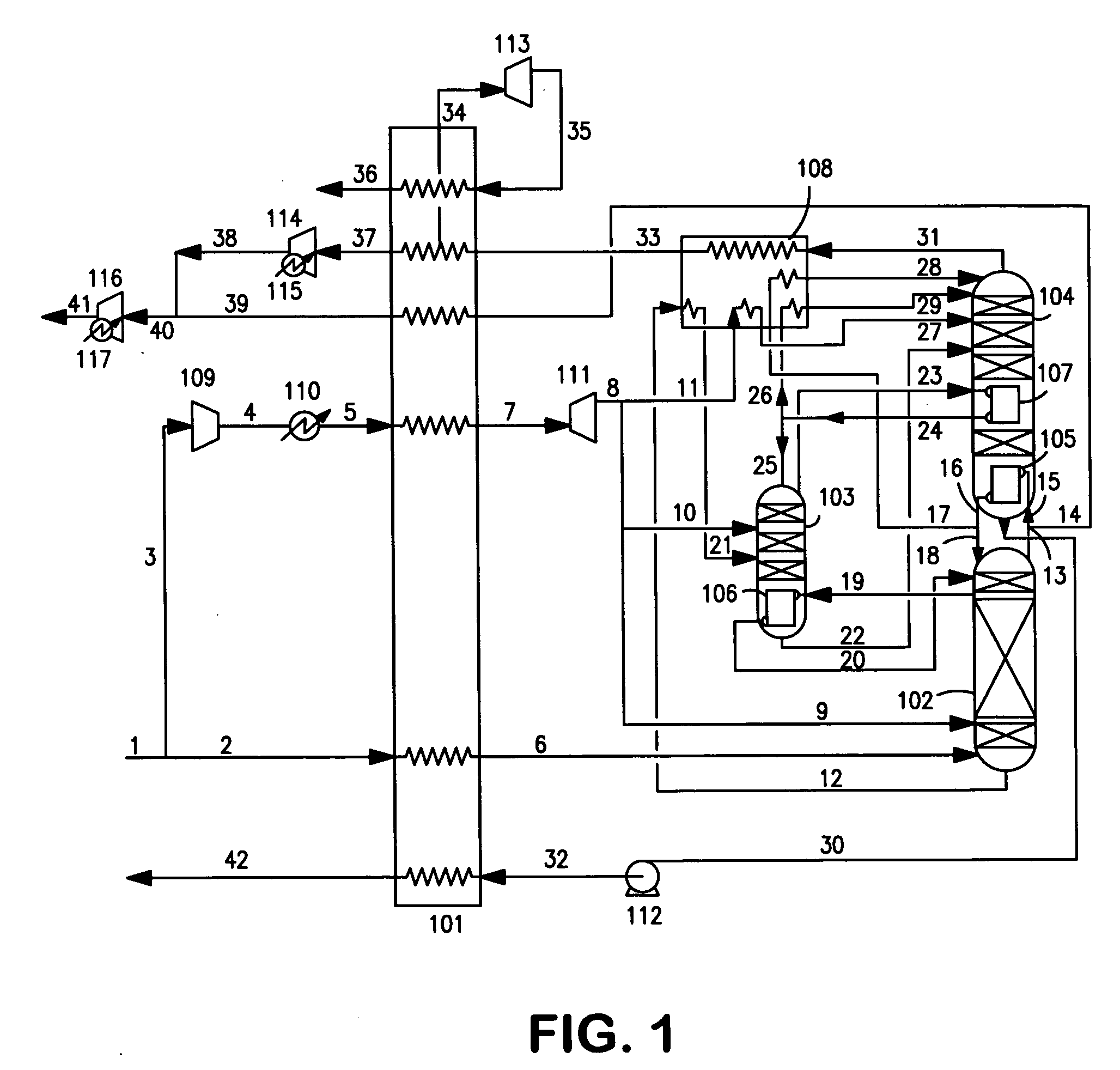

Method for conversion of low temperature heat to electricity and cooling, and system therefore

ActiveUS20130038055A1Reduce energy lossAvoiding cost driving conditionHeat pumpsCarbon compoundsProcess engineeringElectric power

A method for producing electrical energy is disclosed which uses a heat source, such as solar heat, geothermal heat, industrial waste heat or heat from power production processes, providing heat of 150 ° C. or below, further comprising an absorber system in which a working gas, primarily carbon dioxide CO2, is absorbed into an absorbent, typically an amine, further comprising a reactor which receives heat from said heat source and in which the absorbent-CO2 mixture is split into CO2 and absorbent, further comprising an expansion machine, an electricity generator and auxiliary equipment such as pumps, pipes and heat exchangers. The system according to the method allows the cost-efficient production of electrical energy and cooling using low value heat source.

Owner:CLIMEON AB

Enhanced burner performance gas range system and method

InactiveUS20050221243A1Increase pressureImprove performanceFuel supply regulationDomestic stoves or rangesProcess engineeringPressure regulator

An enhanced gas range system includes a pressure regulator adapted to regulate a gas flow from a gas feed line. The system also includes a gas fuel boost pump disposed downstream of the pressure regulator and adapted to increase pressure of the gas flow received from the gas feed line. A gas burner is disposed to receive the gas flow from the gas fuel boost pump.

Owner:GENERAL ELECTRIC CO

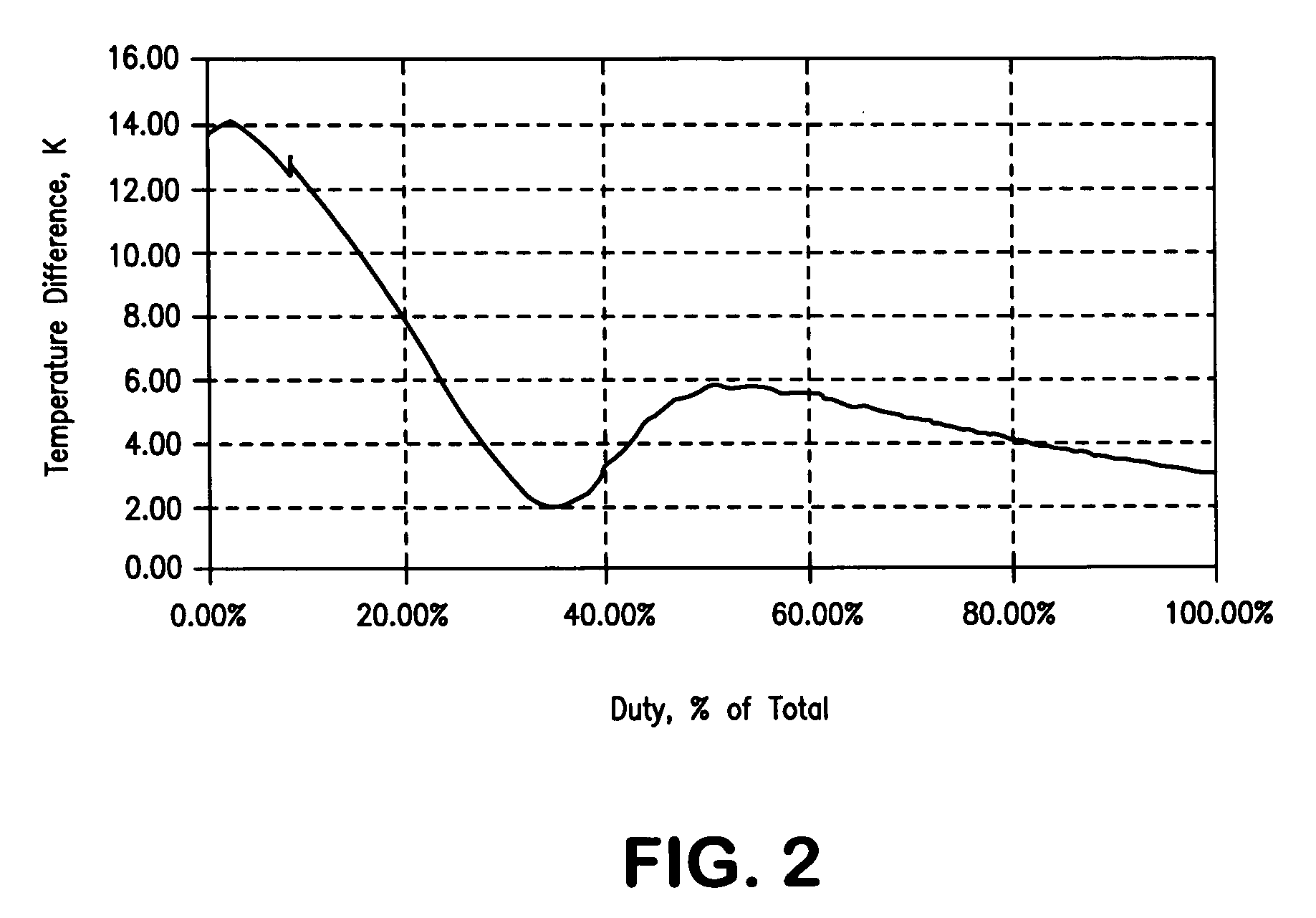

Cryogenic air separation process with excess turbine refrigeration

InactiveUS20070095100A1Increase gas pressureSolidificationLiquefactionProcess engineeringAir separation

A process for carrying out cryogenic air separation wherein liquid oxygen is pressurized and vaporized against condensing feed air to produce oxygen gas product wherein excess plant refrigeration is generated such that the aggregate warm end temperature difference of the process exceeds the minimum internal temperature difference of the primary heat exchanger by at least 2K.

Owner:PRAXAIR TECH INC

End cap assembly and vent for high power cells

ActiveUS20060188779A1Preventing a catastrophic ruptureQuick releaseSmall-sized cells cases/jacketsAqueous electrolyte cellsEngineeringMechanical engineering

And end cap assembly and venting system therein for closing and sealng the open end of a cell housing. The end cap assembly comprises a sealing disk underlying an end cap, and a metal support disk between the end cap and the sealing disk. The metal support disk has a plurality of primary vent apertures and a plurality of secondary vent apertures through its surface. The primary vent apertures are spaced apart along a path located at a greater distance from the central longitudinal axis of the metal support disk than the secondary vent apertures. The insulating sealing disk may have a thinned portion therein forming an rupturable membrane circumventing the central hub of the sealing disk. The insulating sealing disk may have protrusions emanating from its top surface to deflect the membrane during rupture. The venting system releases internal gases rapidly from the cell in the event of an abusive or short circuit discharge.

Owner:DURACELL U S OPERATIONS

Method of operating an internal combustion engine arrangement

InactiveUS20100294250A1Increase gas pressureShort time intervalElectrical controlInternal combustion piston enginesReducerEngineering

A method is provided for operating an internal combustion engine arrangement and to an internal combustion engine arrangement, which includes, but is not limited to an internal combustion engine, which can be operated with gaseous fuel, a pressure reducer for reducing the gas pressure of the gaseous fuel, which is fed to the internal combustion engine. The pressure reducer is connected on the high-pressure side in a fluid-conducting manner via a gaseous fuel line to at least one gas tank for storing gaseous fuel, and the pressure reducer is connected on the low-pressure side in a fluid-conducting manner by means of a gaseous fuel line to at least one controllable gas injection valve for regulating the gas flow of the gaseous fuel, which is fed to the internal combustion engine, a controllable high-pressure shutoff valve, which is arranged on the high-pressure side of the pressure reducer and is connected in a fluid-conducting manner to the pressure reducer, for shutting off the gas flow of the gaseous fuel which is fed to the pressure reducer from the gas tank. The high-pressure shutoff valve includes, but is not limited to a pilot valve with a relatively small opening cross-sectional area and a main valve with a relatively large opening cross-sectional area, and an electronic control device which is used at least for controlling the high-pressure shutoff valve and the at least one gas injection valve. In order to assume operation of the internal combustion engine with gaseous fuel, controlled by the electronic control device, the pilot valve of the high-pressure shutoff valve is opened in chronological order before the at least one gas injection valve.

Owner:GM GLOBAL TECH OPERATIONS LLC

Refrigerant cycle system having discharge function of gas refrigerant in receiver

InactiveUS20030051503A1Increase pressureControl pressureAir-treating devicesCompression machines with non-reversible cycleEngineeringRefrigerant

A refrigerant cycle system includes a condenser having a condensation portion for condensing refrigerant discharged from a compressor, and a receiver for separating refrigerant from the condensation portion into gas refrigerant and liquid refrigerant, and for storing the liquid refrigerant. In this system, refrigerant from the condensation portion flows into the receiver through a first communication hole, and liquid refrigerant in the receiver is discharged through a second communication hole in which a pressure loss is generated. Further, gas refrigerant at an upper side in the receiver is discharged to a downstream side of the second communication hole through a gas bypass pipe.

Owner:DENSO CORP

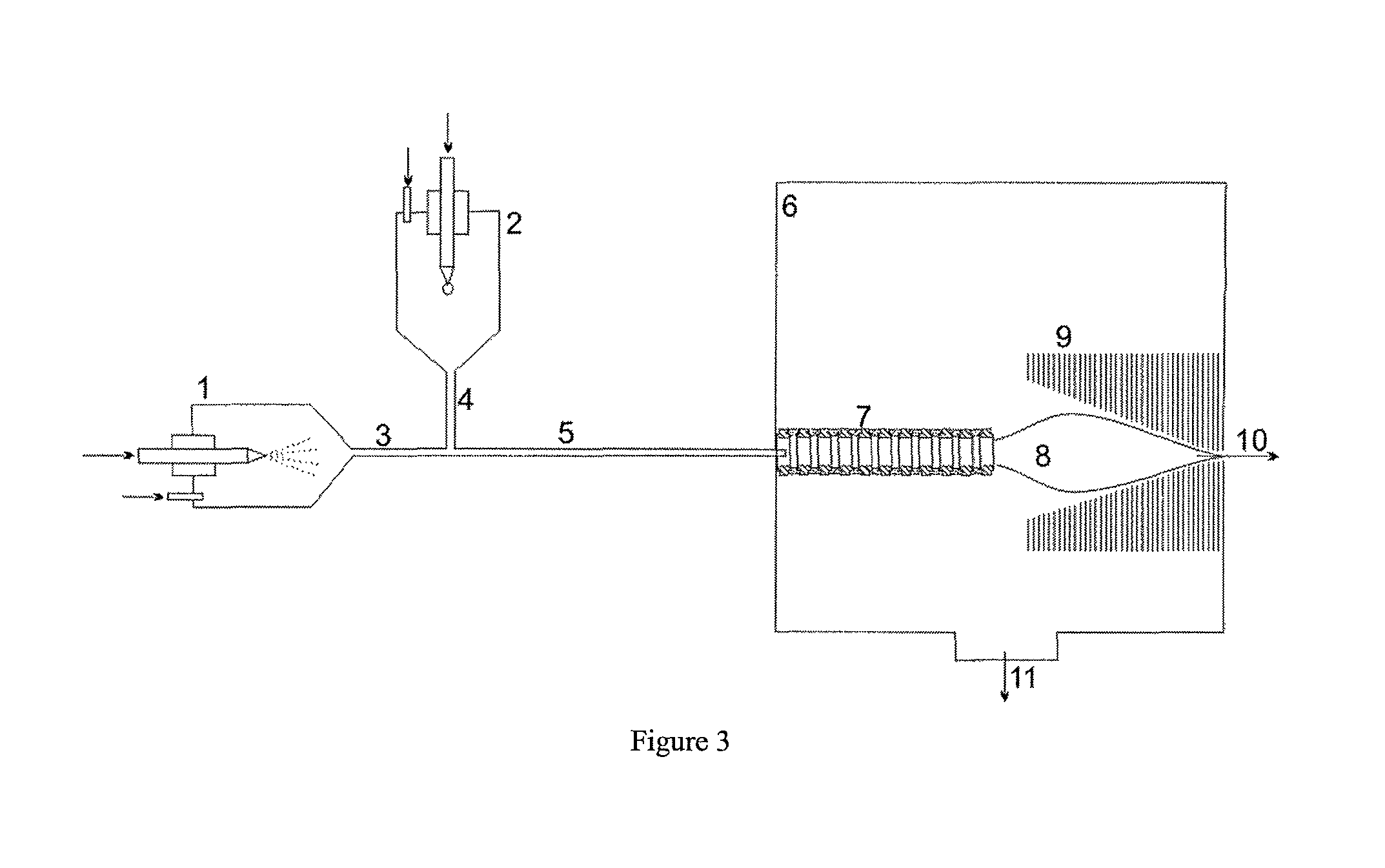

Method and device to increase the internal energy of ions in mass spectrometers

ActiveUS9324548B1Increase gas pressureEnhancing focusing effectElectron/ion optical arrangementsPrinted circuitsInternal energyChemistry

A method and a device increases (e.g., uniformly) the internal energy of ions, in order to remove water shells or adducts, to decompose clusters or molecular agglomerations, to unfold large folded ions, or to prepare ions for fragmentation with high yield. The ions can be heated at a gas pressure of a few hectopascal viscously dragged through a tube comprising on-axis RF fields with strong axial field components. The ions are introduced, as usual together with entraining gas, into a vacuum system of a mass spectrometer through a small hole or capillary, and are driven by the gas flow through the tube with the RF fields. The RF fields decelerate and re-accelerate the ions, which travel through the tube, in rapid succession mainly in forward and backward direction, thus causing high numbers of collisions with the gas molecules and heating up the ions in a uniform manner.

Owner:BRUKER DALTONIK GMBH & CO KG

Gas compressor control device and gas turbine plant control mechanism

ActiveUS20040045275A1Increase gas pressurePump componentsGas turbine plantsPipingAutomotive engineering

A gas compressor control device and a gas turbine plant control mechanism are disclosed. A fuel gas pressurized by a gas compressor is supplied to a gas turbine via fuel gas piping. A gas turbine control device adjusts the flow rate of the fuel gas into the gas turbine by exercising opening and closing control of a pressure control valve and a flow control valve. The gas compressor control device controls a fuel gas pressure at the outlet of the gas compressor by effecting opening and closing control of a recycle valve and an IGV. If load rejection or load loss occurs, the gas compressor control device opens the recycle valve in a preceding manner and closes the IGV in a preceding manner. Thus, elevation of the fuel gas pressure at the gas compressor outlet can be prevented, and elevation of a fuel gas pressure at an inlet of the gas turbine can be suppressed, thereby ensuring stable operation.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

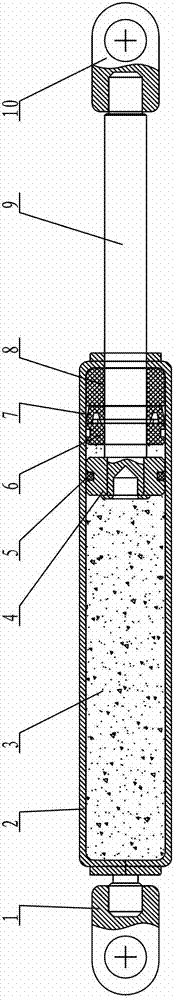

Controllable temperature-sensitive gas spring

InactiveCN102767586AThe output force value increasesReduced output forceNon-rotating vibration suppressionGas based dampersAutomatic controlGas phase

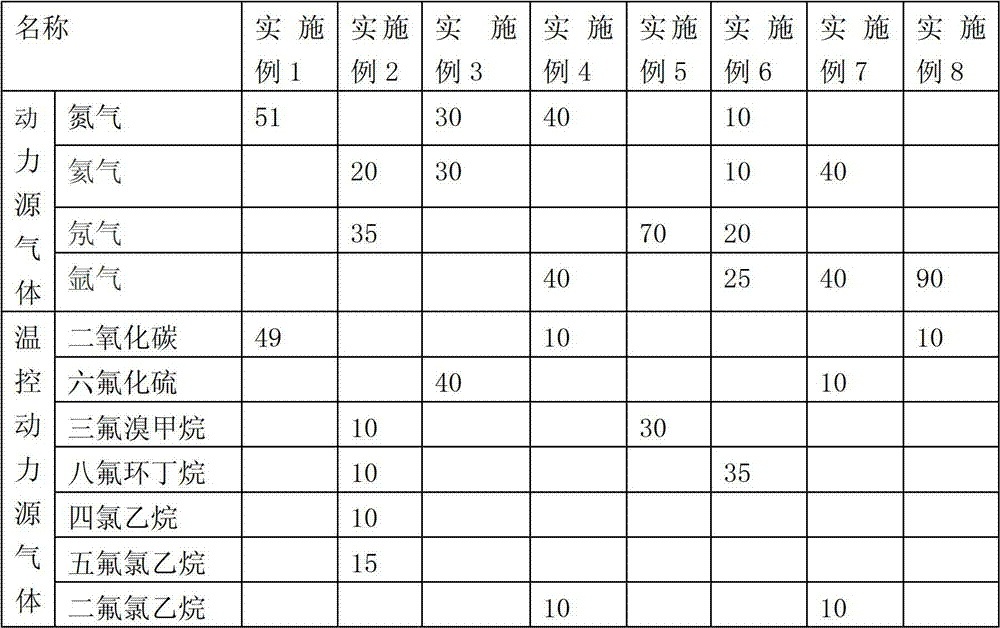

The invention relates to a controllable temperature-sensitive gas spring, comprising a cylinder, a piston and a piston rod fixedly connected with the piston, wherein the piston rod passes through a guide sealing assembly to be connected with a front connecting piece; the cylinder is inflated with compressible power source gas and at least one temperature-sensitive power source gas, wherein the liquid phase and the gas phase of the power source gas are reversible; the volume percentage ratio of the power source gas to the temperature-sensitive power source gas is 51-90%: 10-49%; and the temperature-sensitive power source gas is a liquid phase at a room temperature. The controllable temperature-sensitive gas spring is reasonable in structure; the output force of the gas in the cylinder can be changed through an environmental temperature, and the environmental pressure and the movement of the gas spring can be automatically controlled; the controllable temperature-sensitive gas spring can be used for industries of a fireproofing fire-fighting field, a high-rise ventilating field, agriculture and the like; and a ventilating field can be automatically changed, and the use field of the gas spring is expanded.

Owner:CHANGZHOU GAS SPRING

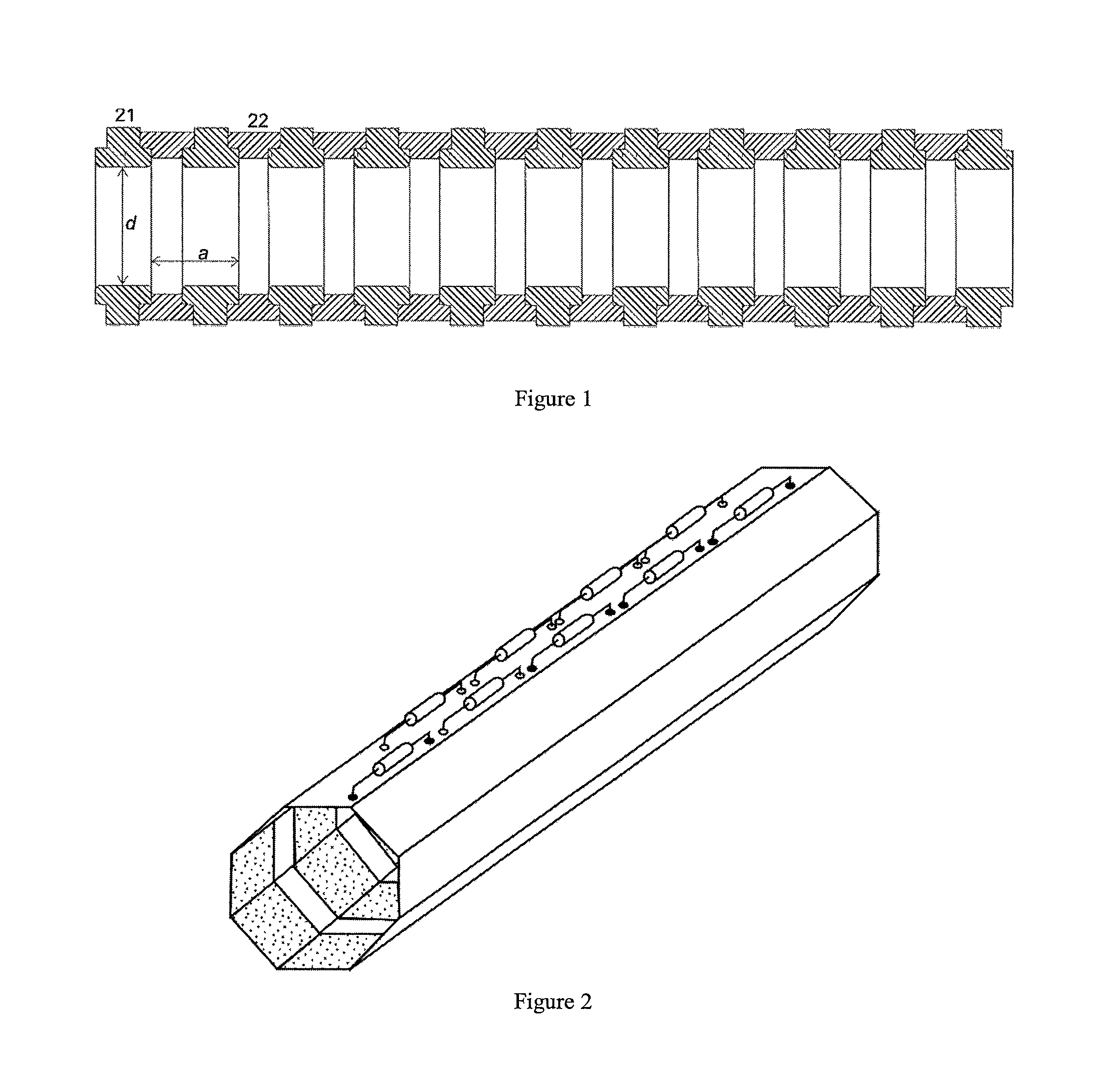

Gear-tooth block meshing switching device for linear reciprocating motion and rotational motion

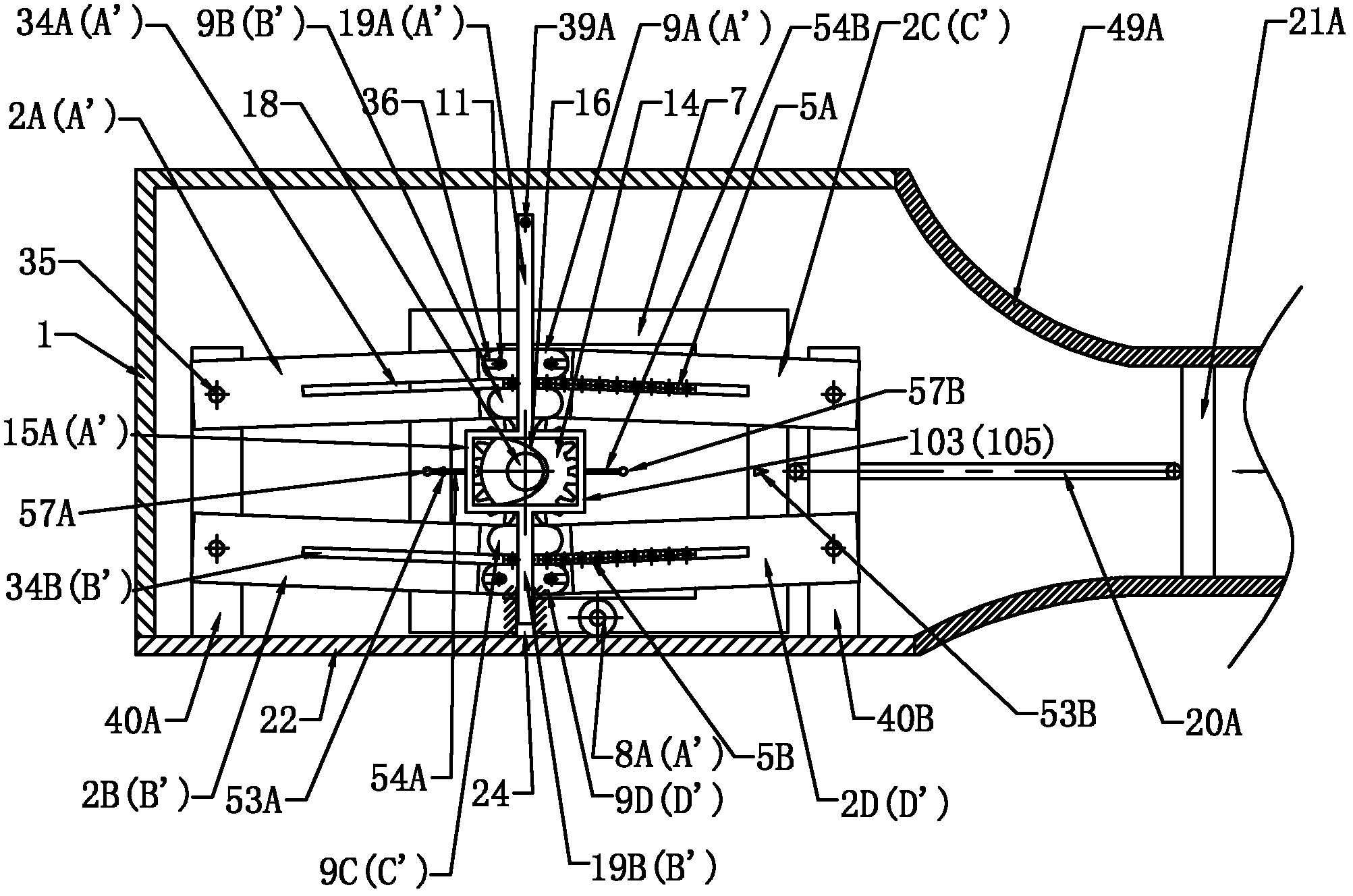

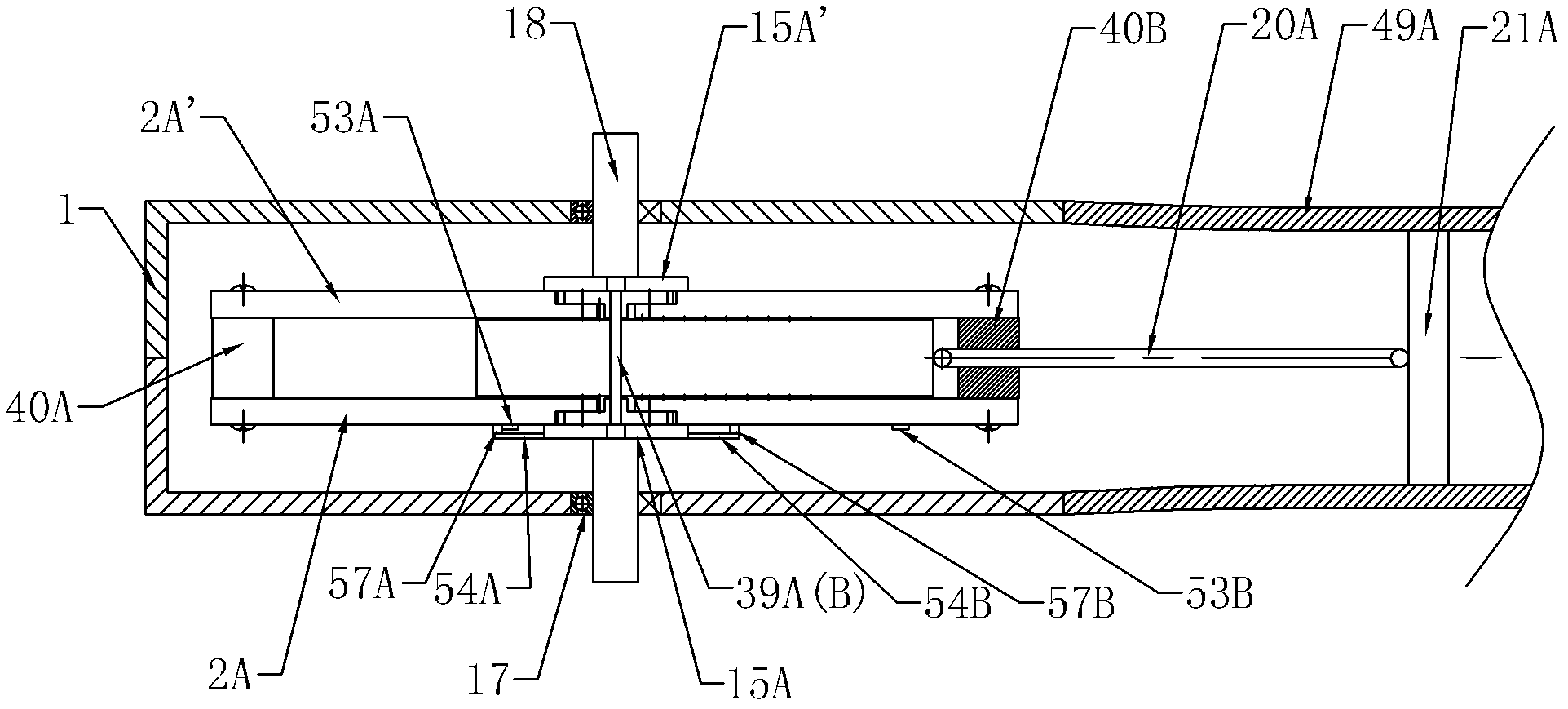

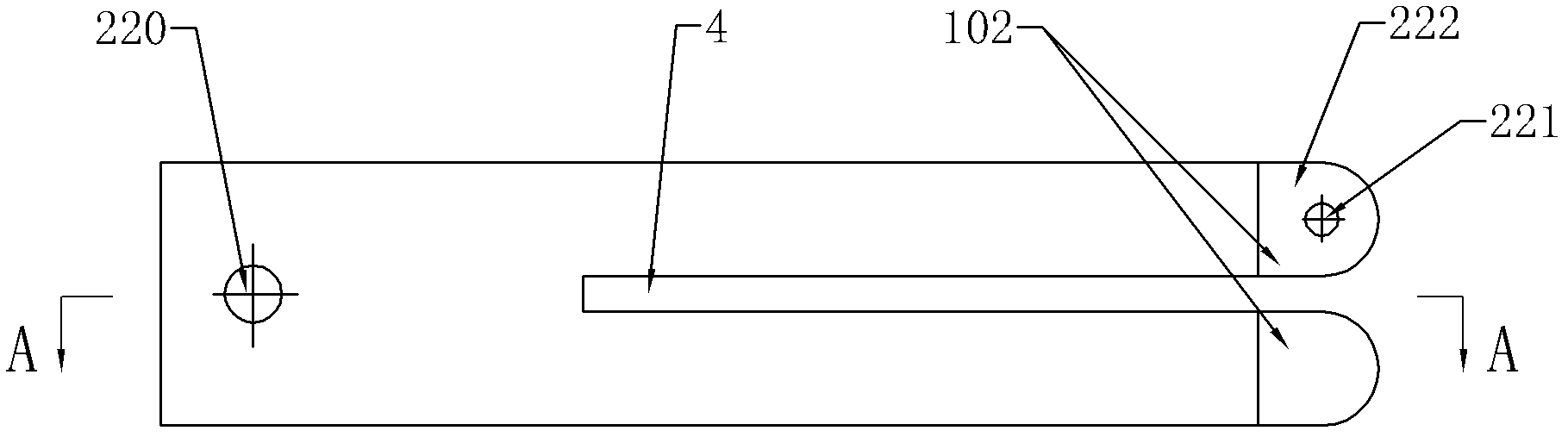

The invention provides a gear-tooth block meshing switching device for linear reciprocating motion and rotational motion. Four pairs of track plates are mounted in a casing, one ends of the track plates are hinged to the inner walls of the two sides of the casing, the other ends of the track plates are provided with track grooves respectively, and a track shifting mechanism lifter is arranged among the four pairs of track plates. Tooth block lines including a plurality of tooth blocks are mounted on a driving frame mechanism, sliding pins extending from two sides of each tooth block are respective disposed in each track groove, a gear fixedly mounted with a transmission shaft is arranged between the two tooth block lines, and the lifter driving device drives the lifter to lift or descend the track plates. Besides, a frame of the driving frame mechanism is connected with one end of a connecting rod, and the other end of the connecting rod is connected with a piston. The switching device is capable of realizing equivalent switching between linear reciprocating motion and rotational motion.

Owner:安里千

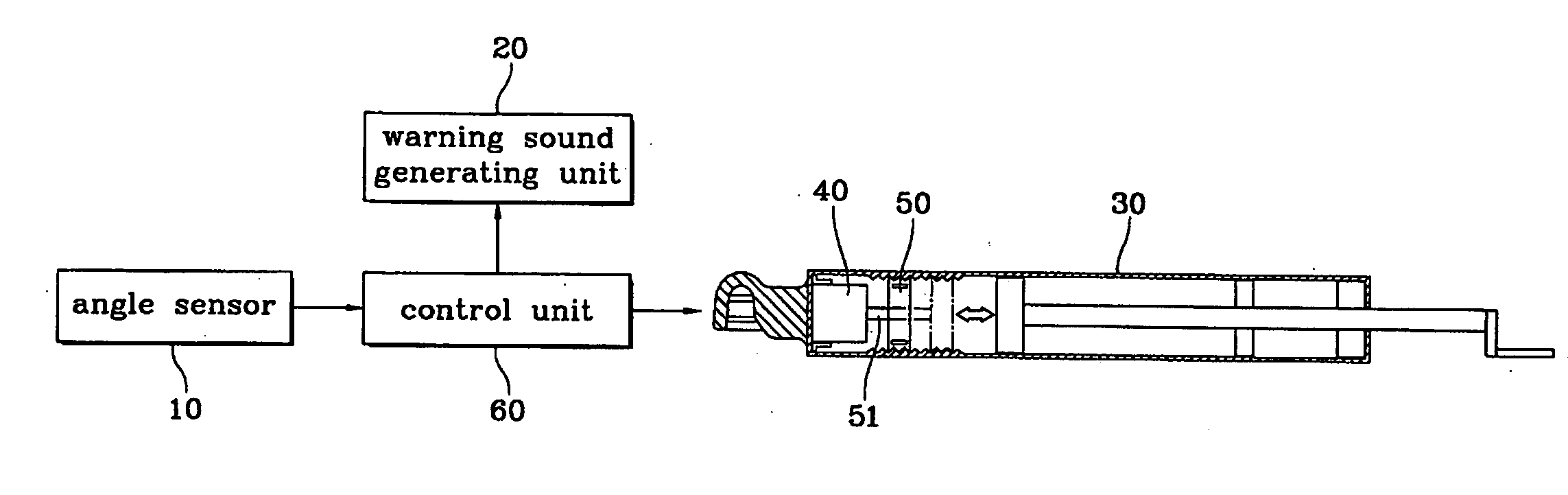

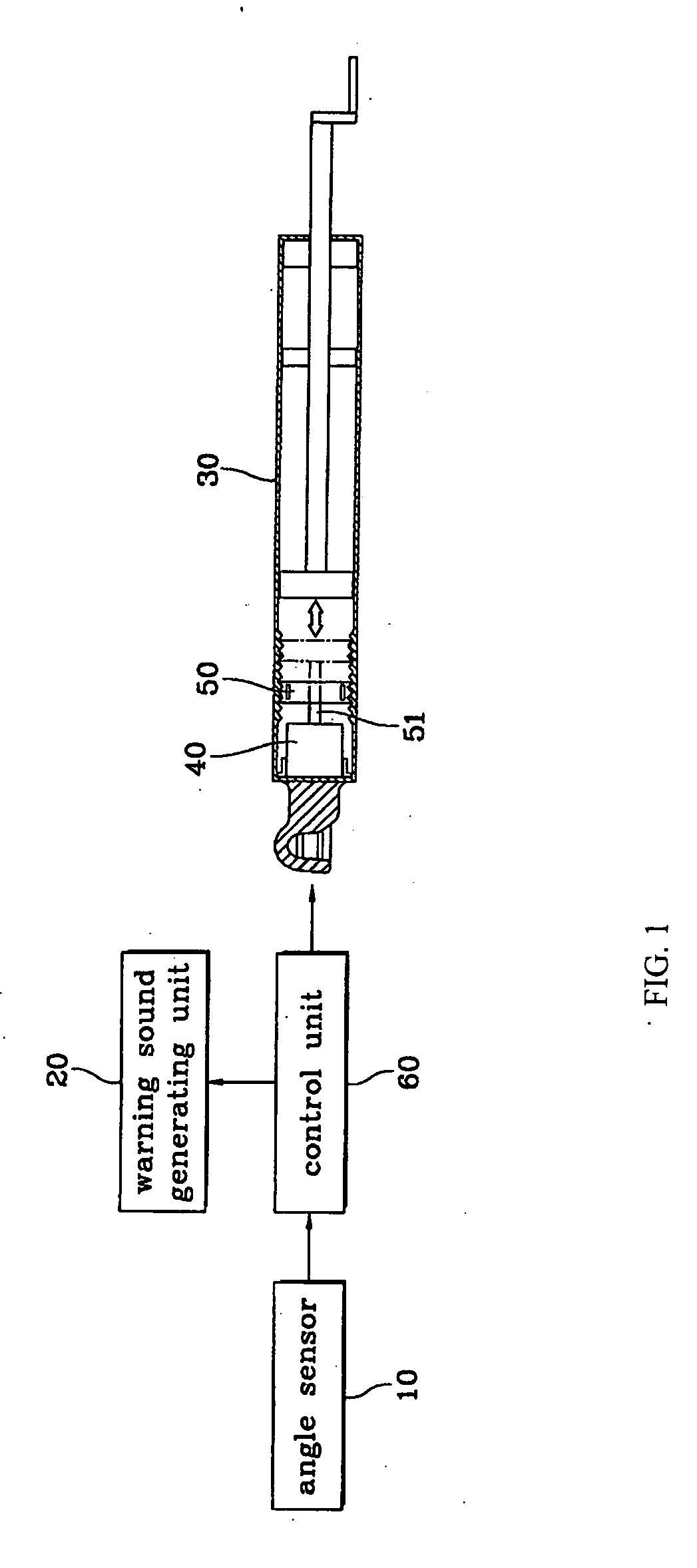

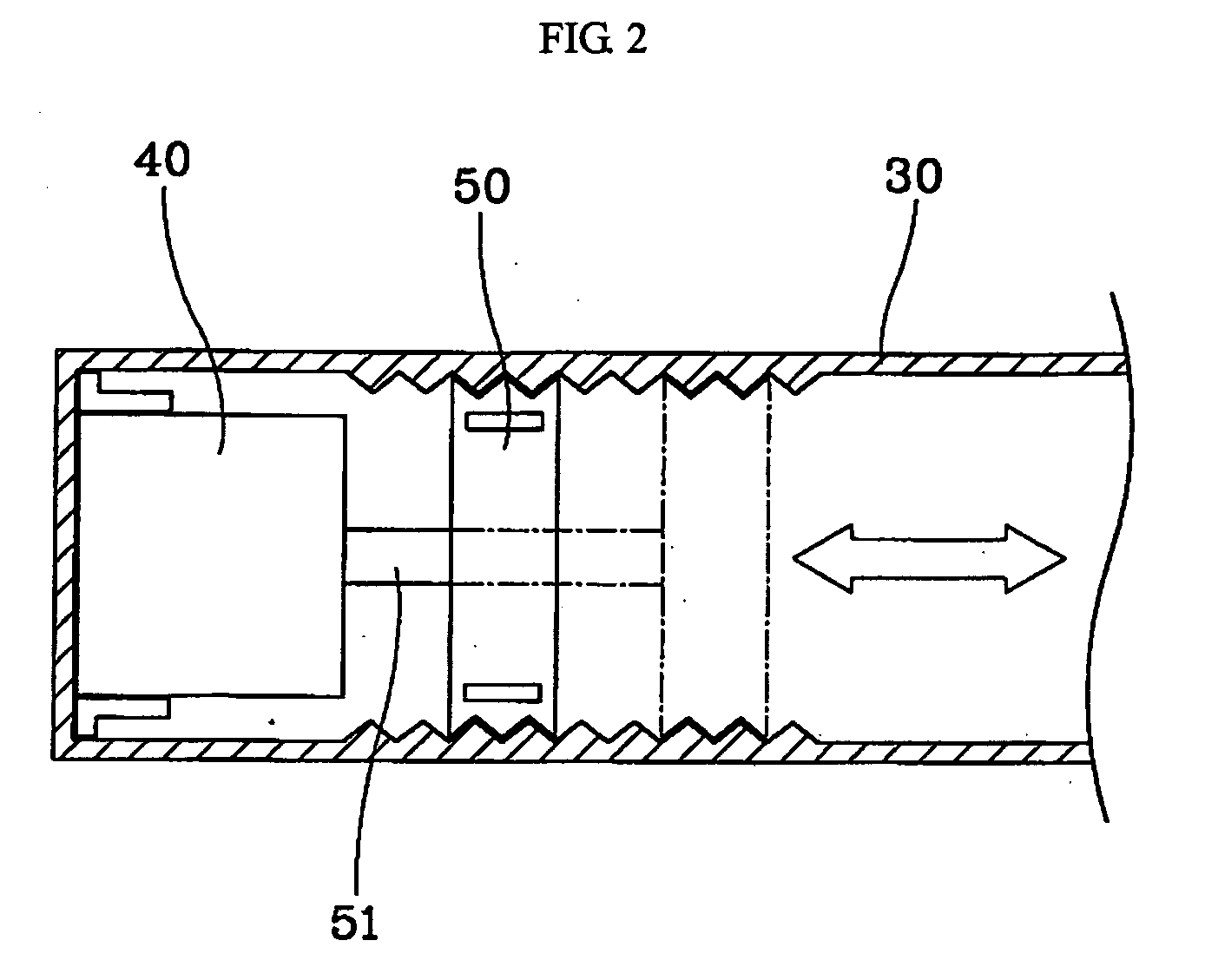

Method and system for adjusting internal pressure of gas lifter using angle sensor

InactiveUS20060028058A1High pressureReduce internal pressureSpringsOperating chairsInternal pressureEngineering

A method and system for adjusting internal pressure of a gas lifter includes measuring a variable opened angle of an openable object, such as a hood, a trunk lid or a tailgate, using an angle sensor, and adjusting the internal pressure of the gas lifter according to the measured opened angle of the openable object. The present invention helps a user easily open or close the openable object.

Owner:HYUNDAI MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com