Enhanced burner performance gas range system and method

a burner performance and gas range technology, applied in the field of gas range systems, can solve the problems of not being able to achieve the desired degree of primary entrainment, limiting secondary entrainment and flame length, and not being able to achieve the enhancement required to operate within the industry standards for emissions and fabric ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

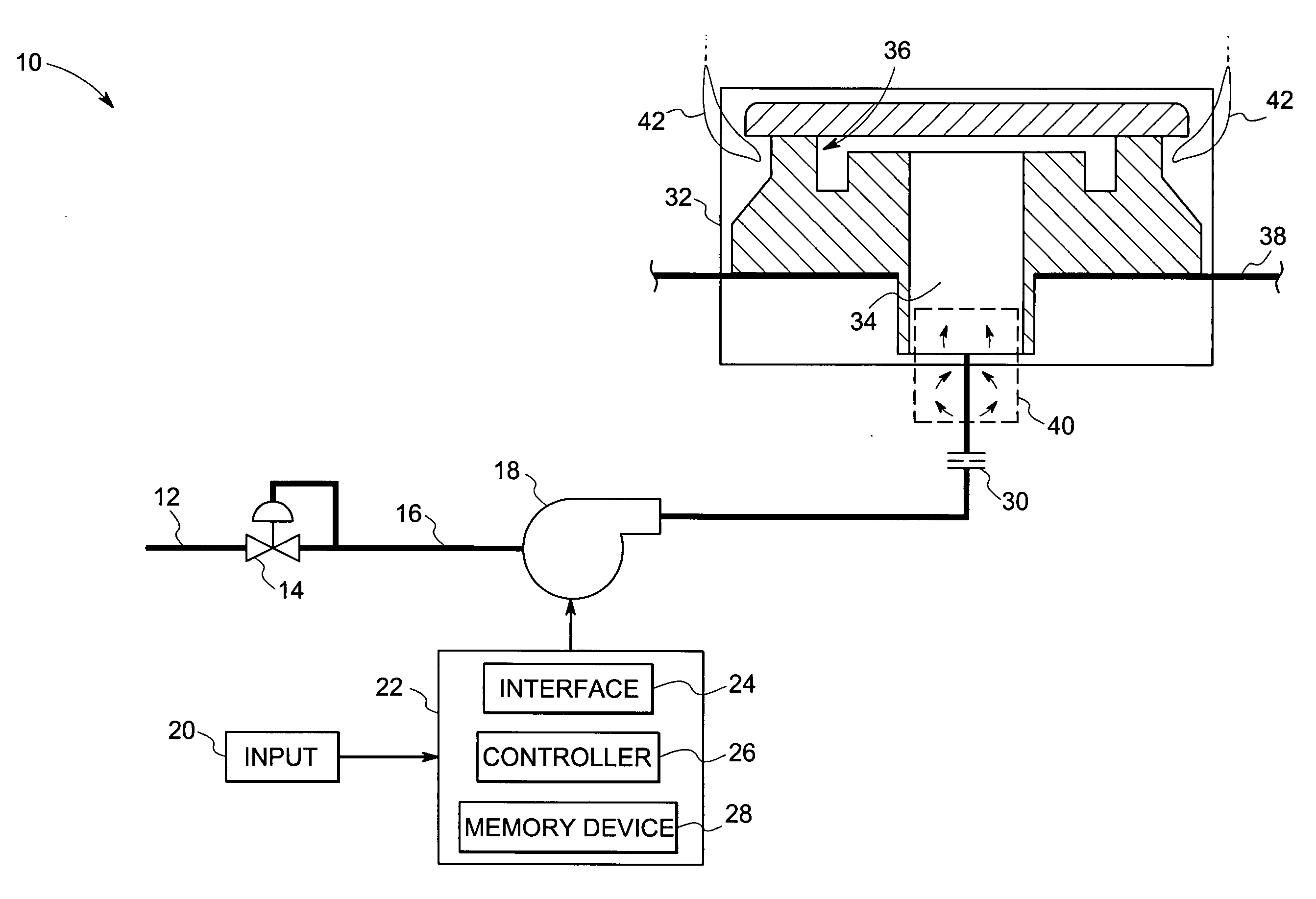

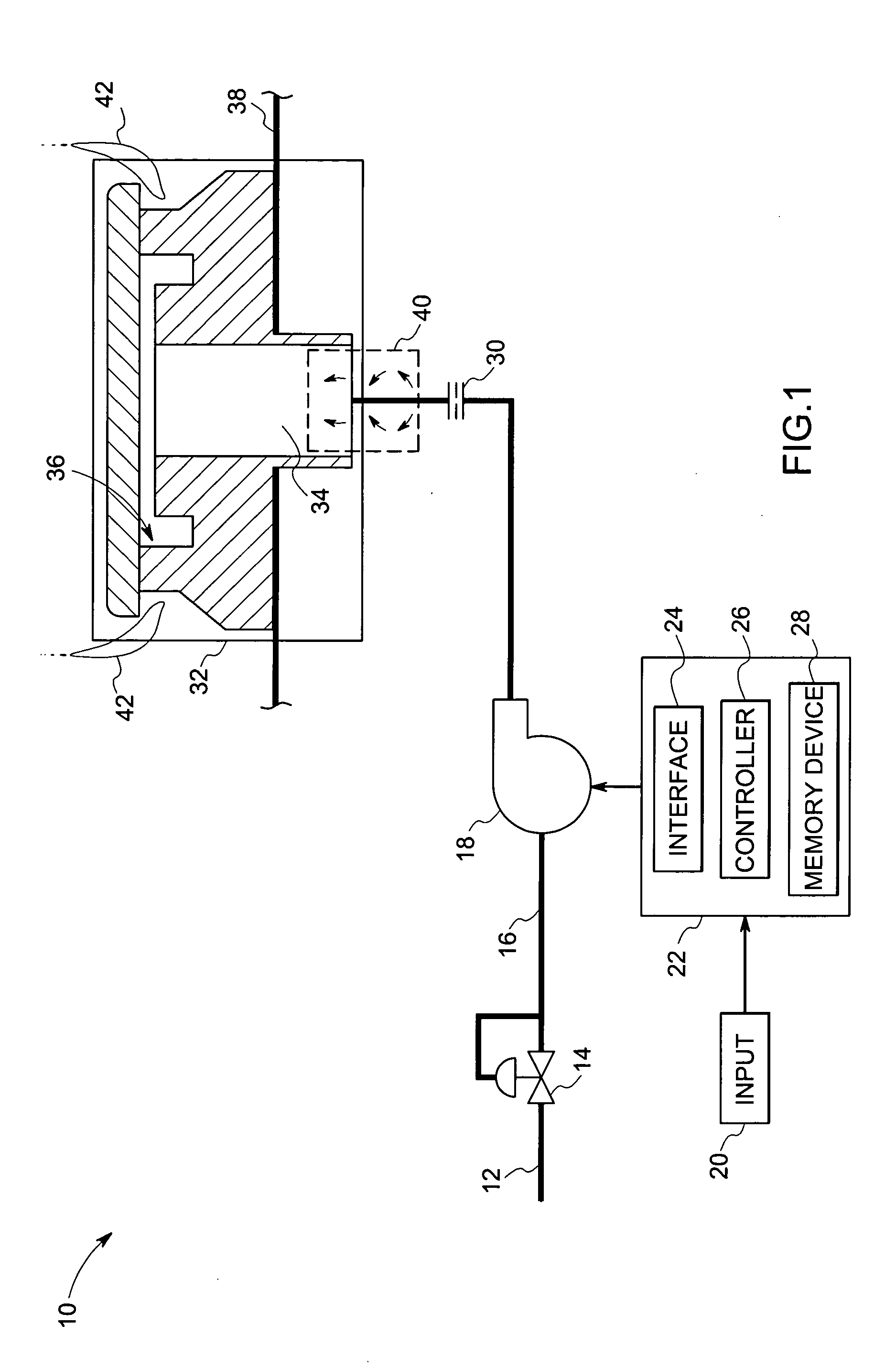

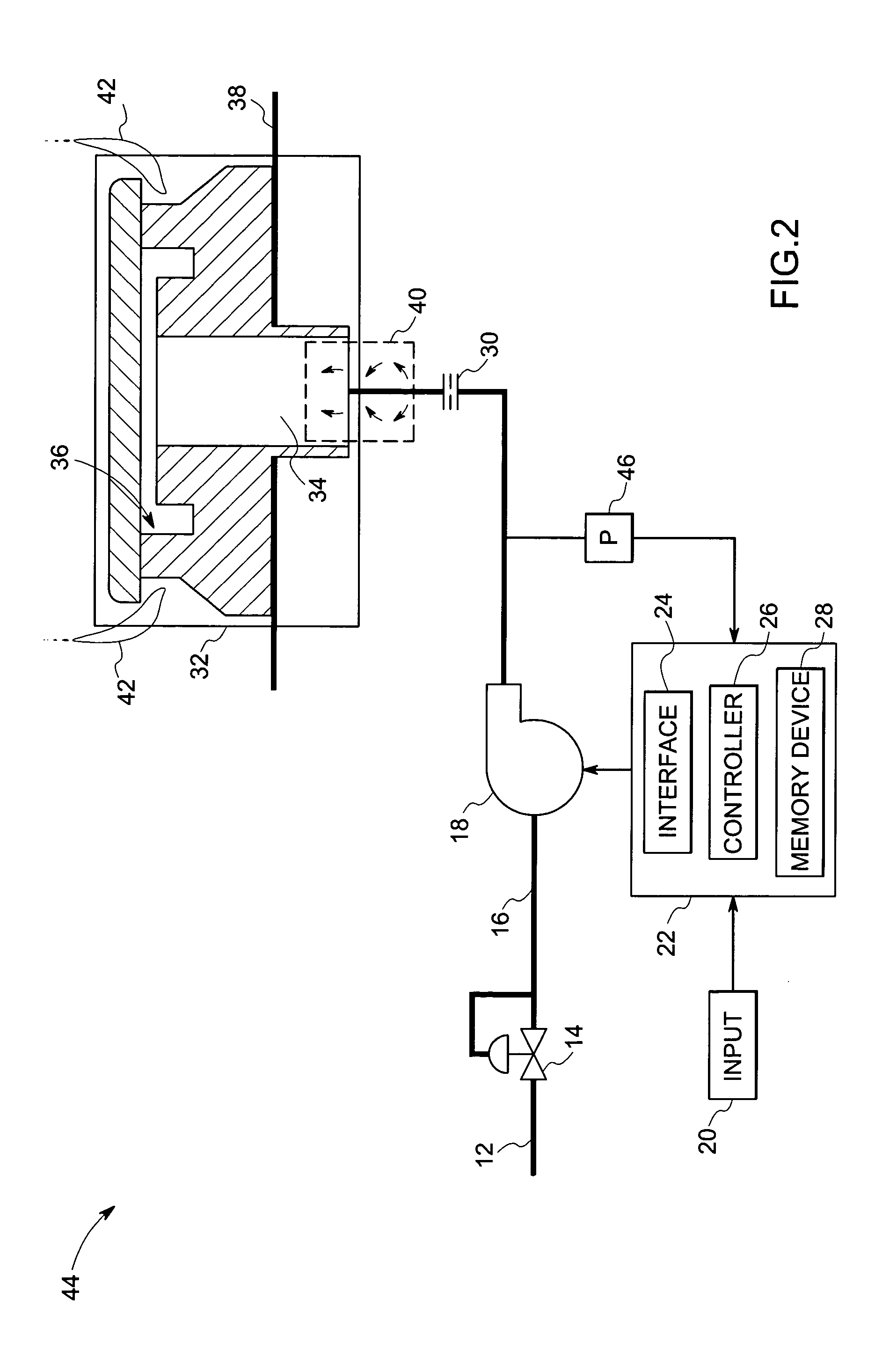

[0016]FIG. 1 illustrates a gas range system 10, according to an embodiment, for use in a gas operated cooking appliance, such as, but not limited to, gas stove, gas cookers, gas hobs, and gas ovens. In the embodiment illustrated in FIG. 1, gas range system 10 receives a supply of combustible gas from a supply line 12 via a pressure regulator 14. A conduit, such as tubing 16 then delivers the pressure regulated gas to a gas fuel boost pump 18 located downstream of the pressure regulator 14. As described in greater detail below, based upon user-defined inputs 20, flow control circuitry 22 coupled to the gas fuel boost pump 18 regulates the gas flow through the gas fuel boost pump 18. In operation, the gas range system 10 receives a gas flow from a supply, for example, a gas supply network, gas cylinder, gas tank and so forth.

[0017] Typically, the gas flow is received from the supply device at the natural gas supply pressure that may be about 5 to 10 inches of water column. This flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com