Method and apparatus for radial exhaust gas turbine

a technology of radial exhaust, which is applied in the direction of machines/engines, stators, liquid fuel engines, etc., can solve the problems of adversely affecting engine performance and/or engine efficiency, known gas turbine engines and known radial exhaust gas turbines that include an outer casing may experience high pressure losses in their exhaust diffuser sections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015]Embodiments of the present disclosure include an involute type casing for use with a radial exhaust diffuser of a gas turbine generator. The radial exhaust diffuser, when installed on the radial exhaust gas turbine facilitates reducing pressure loss in the casing generally, without increasing costs of manufacturing the casing. Flue gas discharged from vanes enters the casing and is directed towards one side of the casing.

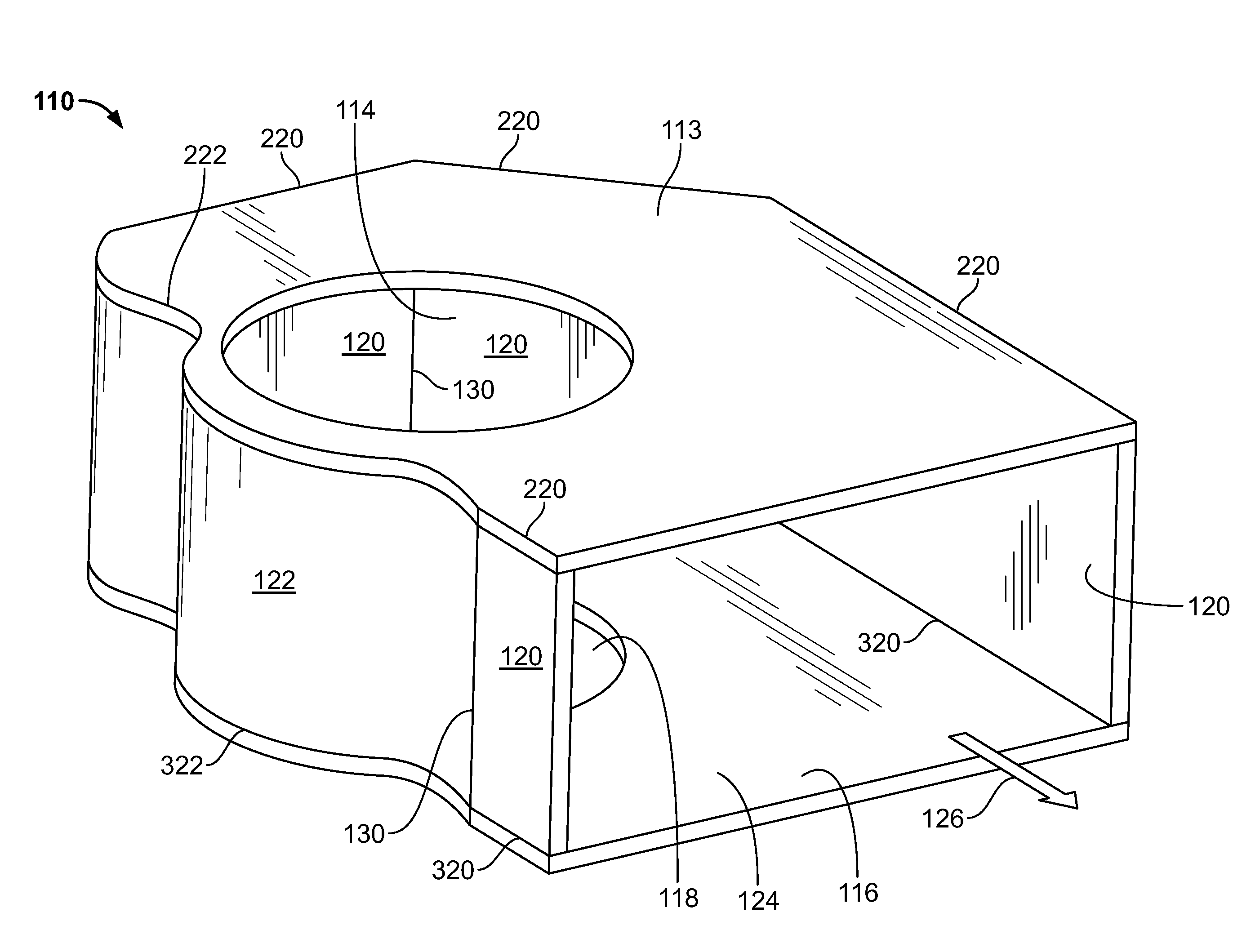

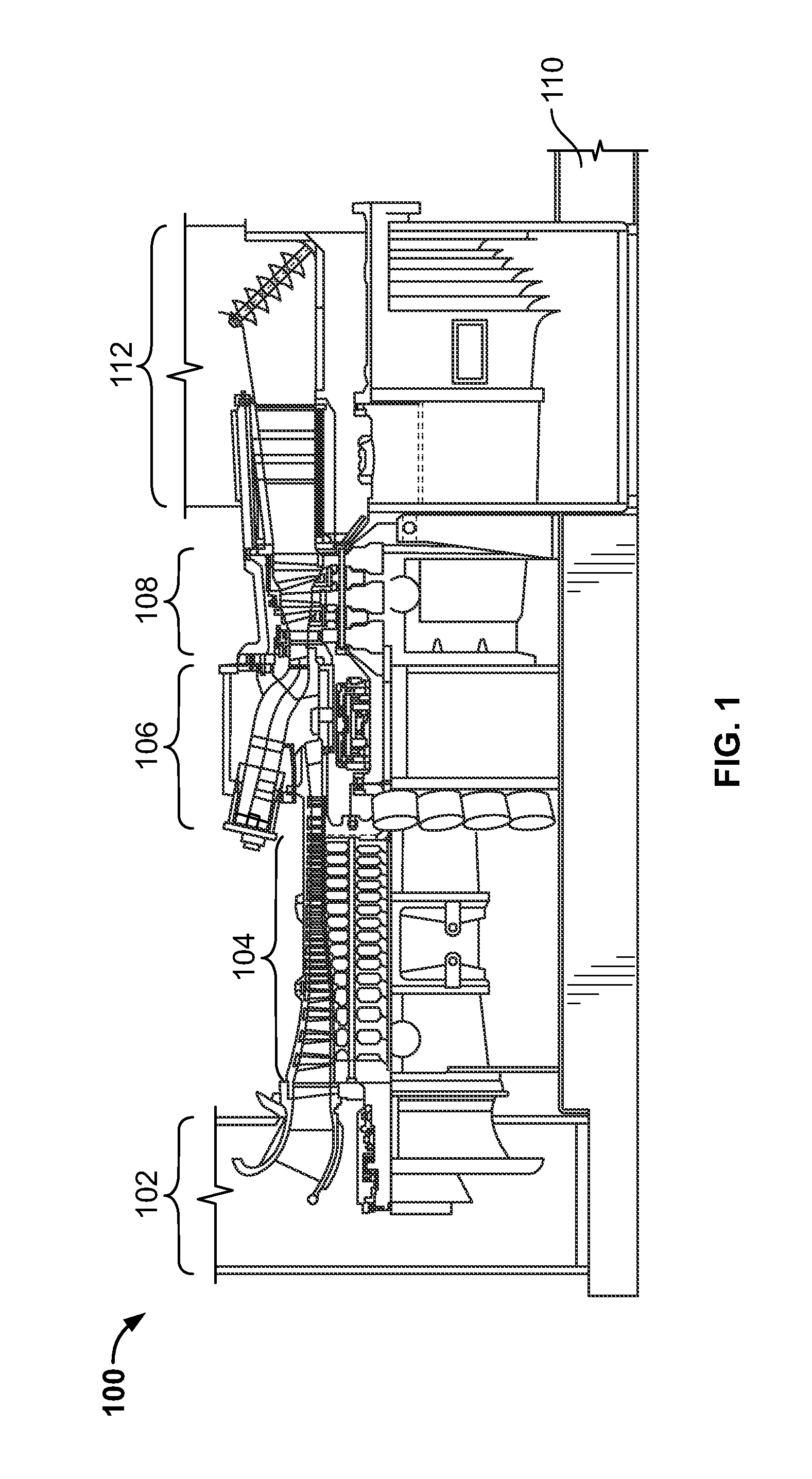

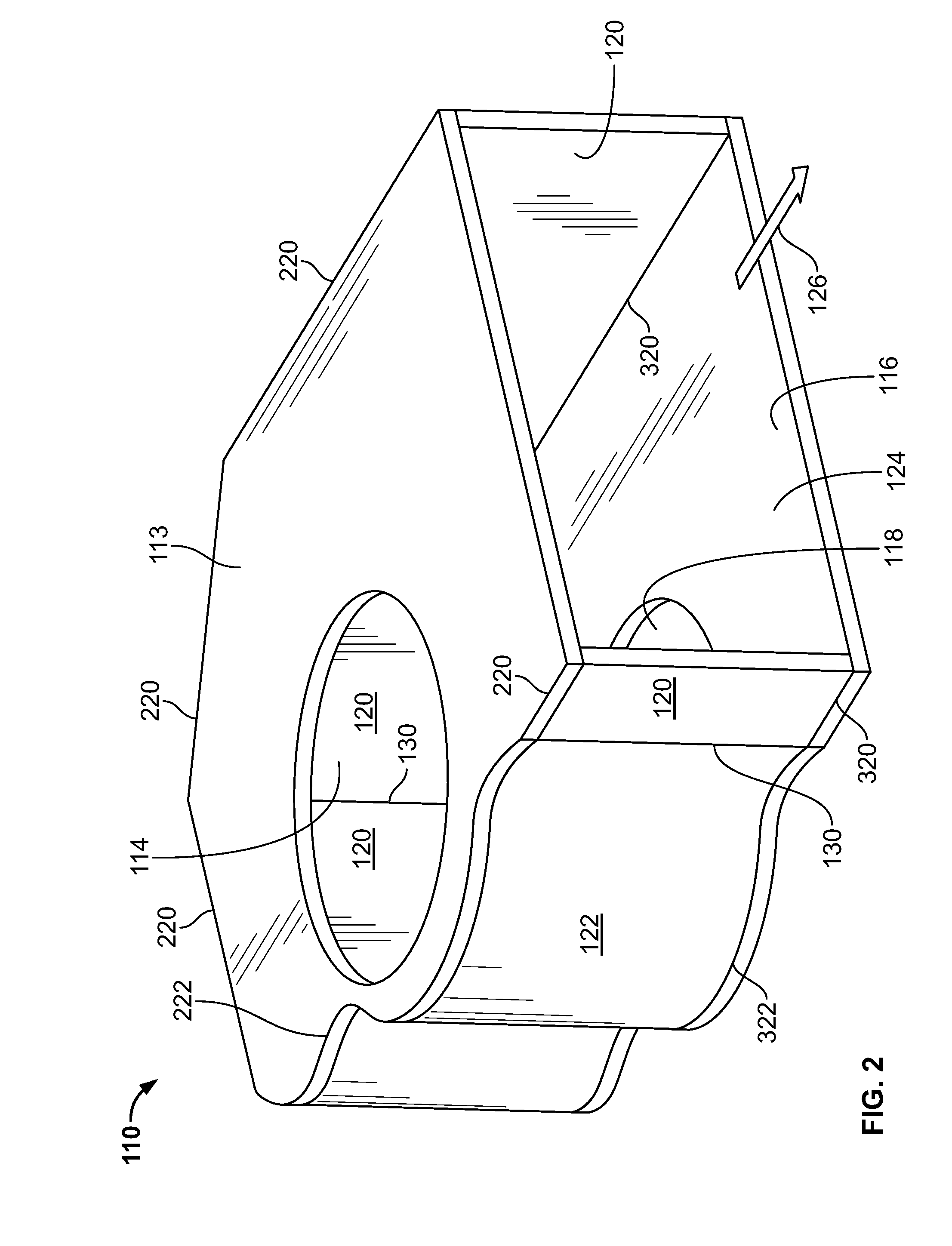

[0016]In some embodiments, and referring specifically to FIG. 1, a radial exhaust gas turbine 100 includes an inlet section 102, a compressor section 104, a combustor section 106, a turbine section 108, and an exhaust diffuser section 112. FIG. 2 and FIG. 3 illustrate respective triaxial and exploded triaxial views, respectively, of exhaust diffuser casing 110. In the illustrated embodiment, exhaust diffuser casing 110 includes a turbine engagement wall 113 that includes an entry opening 114. An exhaust diffuser engagement wall 116 is positioned opposite turbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com