Controllable temperature-sensitive gas spring

A gas spring and temperature-sensitive technology, applied in the field of gas springs, can solve the problems that gas springs cannot be used in fire-fighting places, high-rise ventilation places or agriculture and other industries, and achieve the effect of reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

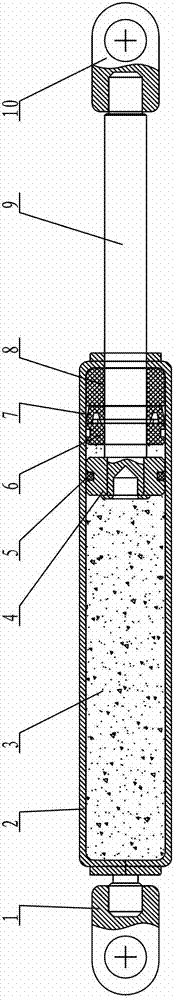

[0009] See figure 1 As shown, the controllable temperature-sensitive gas spring of the present invention includes a cylinder 2, a piston 4 and a piston rod 9 fixed to the piston 4, and the piston rod 9 passes through the guide seal assembly and is connected with the front connector 10. The cylinder of the present invention 2. The rear end is fixed with the rear cover. The rear connector 1 is connected to the rear cover of the cylinder 2, while the piston 4 is connected to the piston rod 9. The piston 4 is provided with a sealing groove, and the sealing ring 5 is arranged in the sealing groove of the piston 4. , which plays a blocking and damping role during the movement of the piston 4, and the guide seal assembly is composed of a guide sleeve 8 and a guide seal 7, and can also be used as figure 1 As shown, the guide seal assembly in the cylinder 2 consists of a guide sleeve 8, a guide seal 7 and an inner guide sleeve structure 6, the piston rod 9 connected with the piston 4 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com