Patents

Literature

42results about How to "Eliminate outstanding hazards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coal seam pre-splitting method based on gas extraction

The invention relates to a coal seam pre-splitting method based on gas extraction, which adopts a 'CO2 gas extraction device' as a tool to blast and pre-split a pre-mined coal seam, so as to increase the crack of the coal seam, drive out gas absorbed on the coal seam and extract the gas. The method particularly comprises the following steps: drilling a hole on the working surface of a pre-mined coal seam, filling CO2 gas extraction device into the drilled hole, sealing the drilled hole, detonating the CO2 gas extraction device, releasing high-pressure CO2 gas for deep-hole impact and pre-splitting of the coal seam, taking out the CO2 gas extraction device, and connecting the drilled hole with a gas extraction system to extract gas. The pre-splitting method of the invention can greatly enhance the permeability of the coal seam, promote the gas dissociation in the coal seam, and improve the underground gas extraction efficiency of the coal mine.

Owner:山西锦浩诚科技有限公司

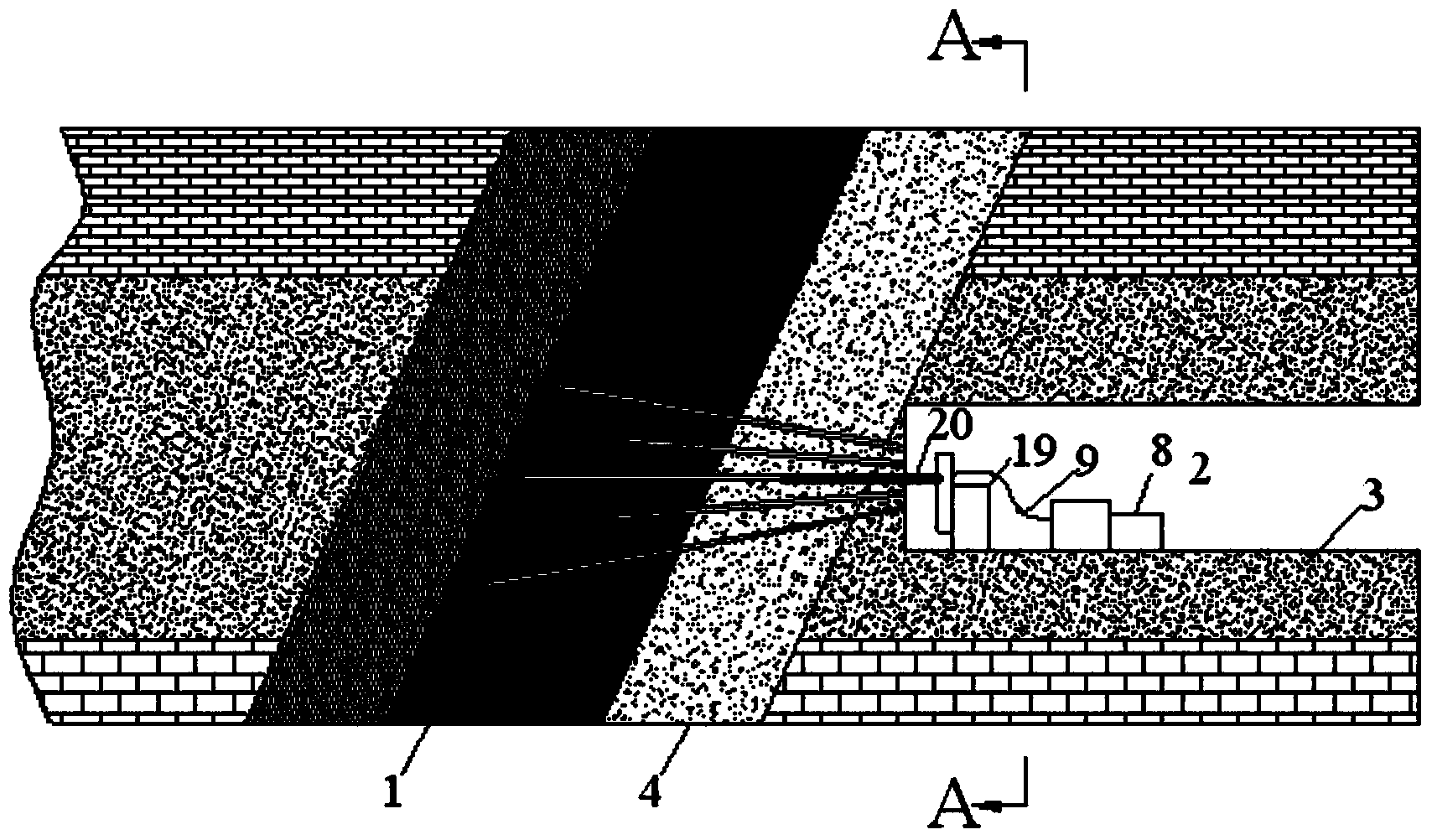

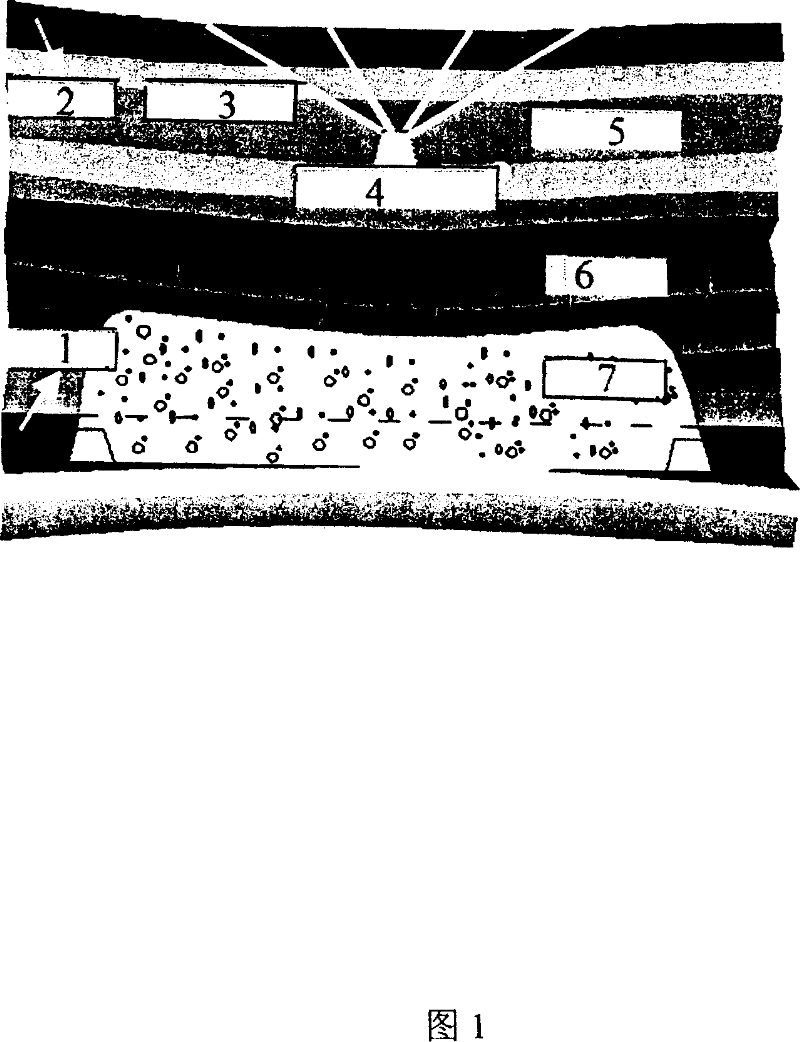

Low premeability high gas soft thick coal layer remote pressure relief gas exhausting method

ActiveCN1534164AEliminate the danger of coal and gas outburstSafe and efficient miningGas removalCoalEnvironmental geology

A remotely pressure-releasing method for sucking and exhausting gas from the low-air-permeability high-gas soft and thick coal seam is disclosed. The coal seam, which is 70m under the coal seam to be gas-exhausted and has relative interbeam distance of 30-70 times, is first mined. Under the action of pressure release and subsidence, the cracks are generated in the coal seam and the gas penetrates through the cracks and then is exhausted via predrilled holes. After the coal seam is mined, a great deal of gas is flowing along the seam and then is sucked by said predrilled holes.

Owner:HUAINAN MINING IND GRP +1

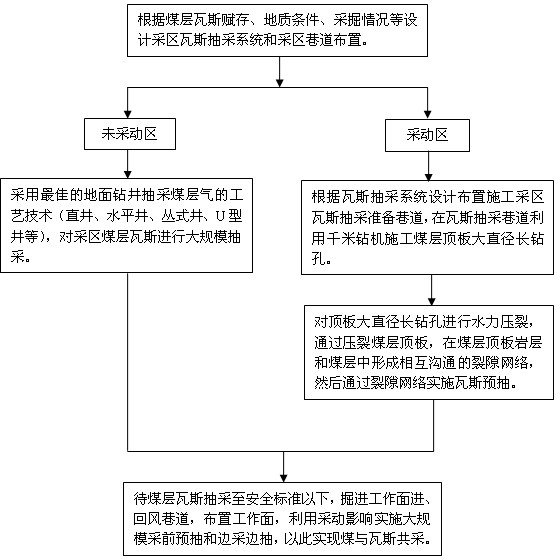

Integrated mining method for commonly mining coal and gas of high mine

The invention discloses an integrated mining method for commonly mining coal and gas of a high mine. The integrated mining method comprises the following steps of: adopting a process technology which utilizes ground drilling to drain coal bed gas for carrying out gas drainage on unmined areas, and carrying out coal mining on drainage areas when the safety standard is met; for mined areas, utilizing the space of the existing roadways and gas drainage special preparation roadways under the coal mine or additionally opening large-diameter long drilling holes which have different distances from a drill site to a coal bed top plate; selecting corresponding fracturing pump stations and fracturing process technologies to carry out fracturing treatment, forming a fracture network system communicated with the coal bed in the coal bed top plate to preextract the coal bed gas; when the preextraction meets the safety standard, firstly adopting a tunneling process to tunnel an intake airway and a return airway of a work surface; distributing a stopping work surface, then carrying out construction of the conventional drainage and drilling at the intake airway and the return airway of the work surface; and by utilizing the mine pressure rule caused by the stopping of the work surface, implementing the preextraction before mining and simultaneous mining and extraction with fracturing holes, and realizing integrated mining of the coal and the gas. In the integrated mining method, the safe high-efficiency common mining of the coal and the gas can be realized and the application prospect is wide.

Owner:HENAN COAL CHEM IND GROUP INST

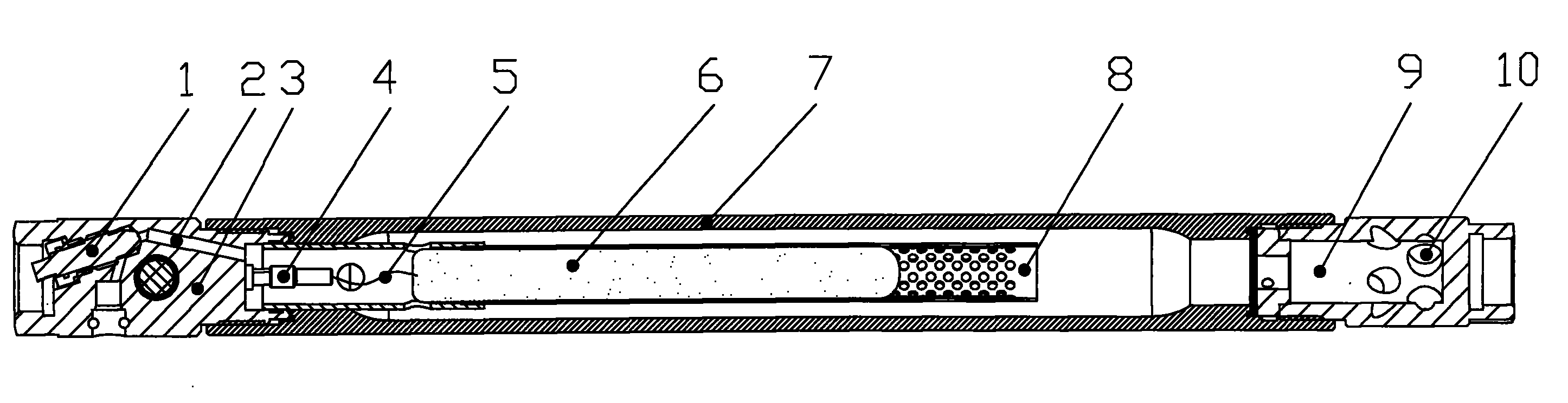

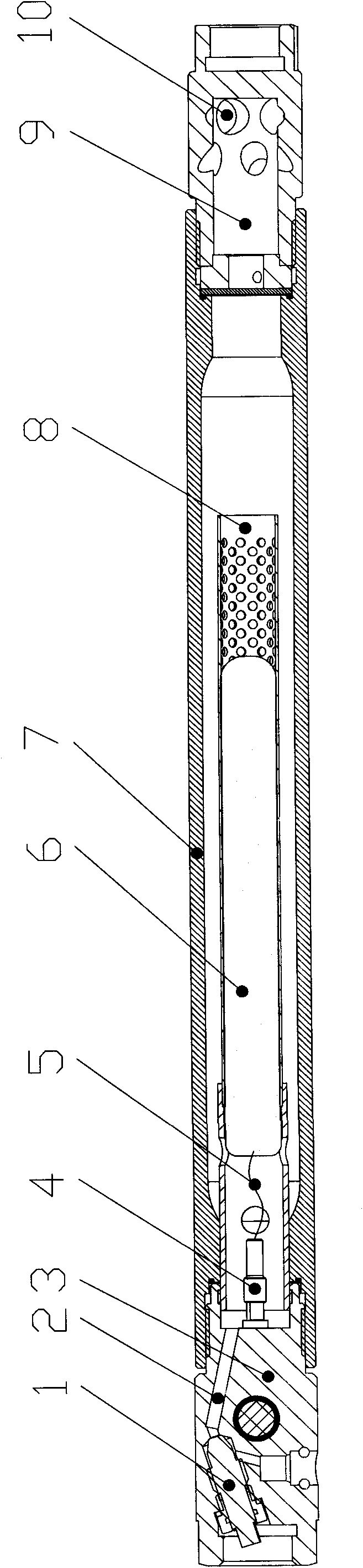

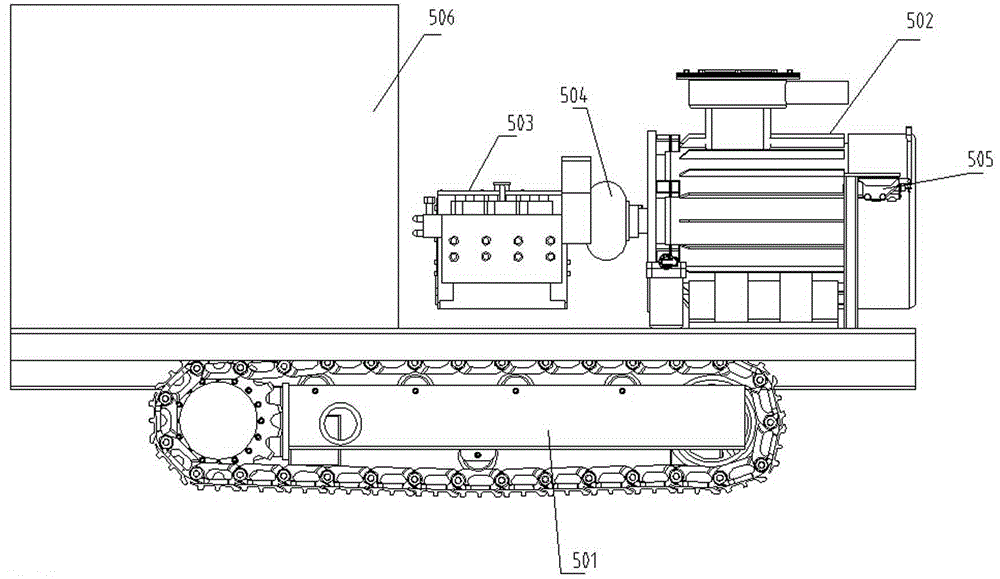

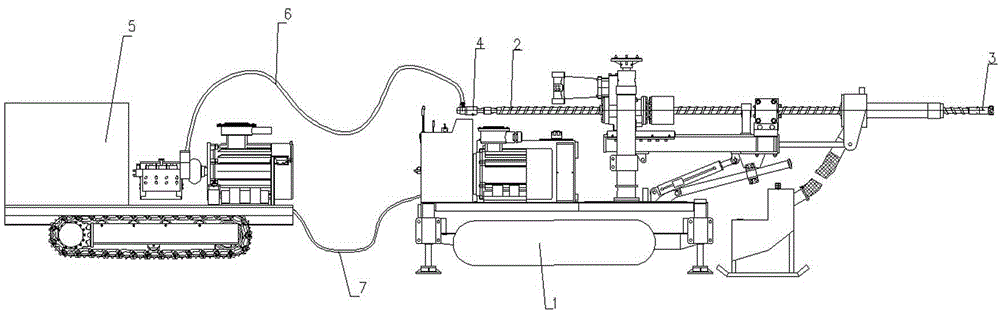

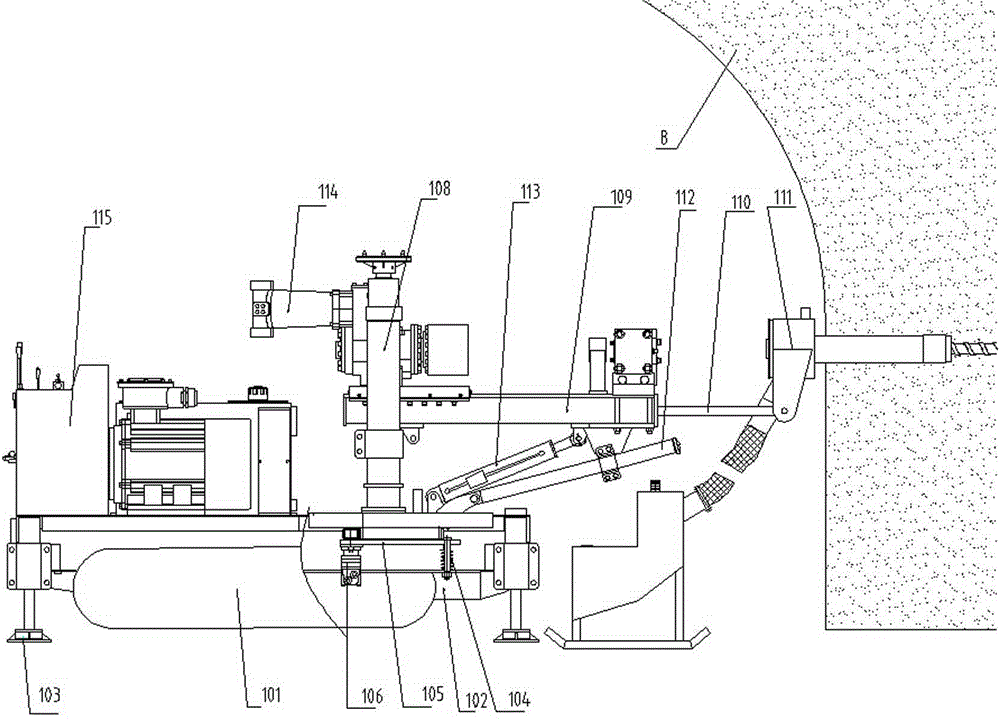

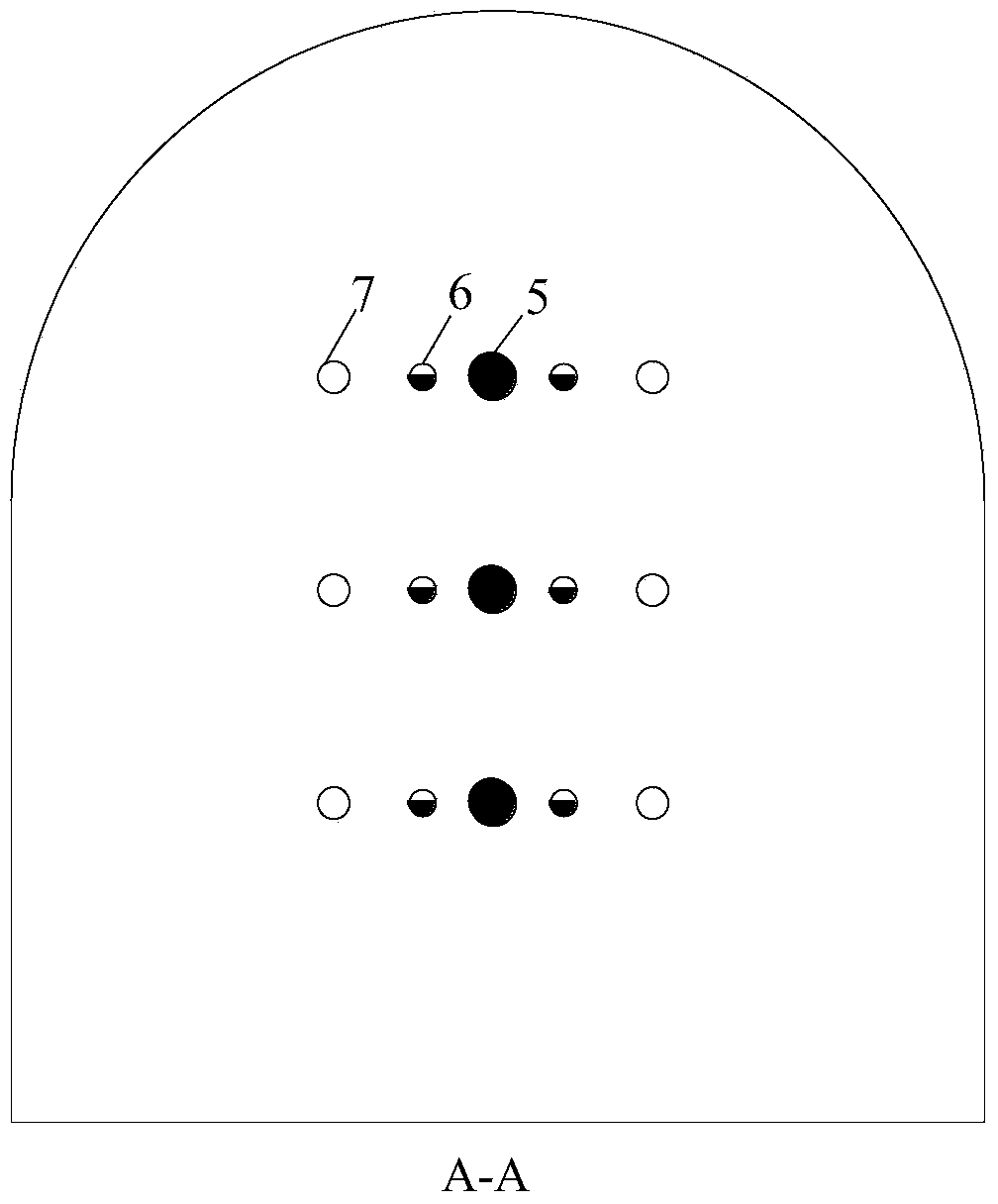

Coal mine downhole crawler type drilling and punching integrated equipment

ActiveCN104895484ASafe and efficient productionImprove extraction efficiencyConstructionsBorehole drivesPunchingDual purpose

Coal mine downhole crawler type drilling and punching integrated equipment comprises a crawler type hydraulic drilling machine, a high-pressure-resistant sealing drill stem, a drilling and punching dual-purpose drill bit, a high-pressure rotation connector and a high-pressure water pump station, wherein the body of the high-pressure-resistant sealing drill stem penetrates and is fixed in the power head inner hole of the crawler type hydraulic drilling machine, a power head provides rotation speed and torque to the body of the high-pressure-resistant sealing drill stem, one end of the high-pressure-resistant sealing drill stem is connected with the high-pressure water pump station through the high-pressure rotation connector, the high-pressure water pump station provides high-pressure water needed by punching, the other end of the high-pressure-resistant sealing drill stem is connected with the drilling and punching dual-purpose drill bit, and hydraulic operations can be performed after drilling without replacing the drill bit. The coal mine downhole crawler type drilling and punching integrated equipment has the advantages that streamlined operations of coal mine downhole gas pressure relief, drilling and punching can be completed by the equipment, safe and efficient production of outburst mines is guaranteed, coal seam coal and gas outburst danger is eliminated, a regional pre-drainage gas drilling construction period is shortened, coal seam drilling and punching and gas extraction efficiency are increased, and gas disaster prevention and control cost is reduced.

Owner:HENAN TIEFULAI EQUIP MFG CO LTD +1

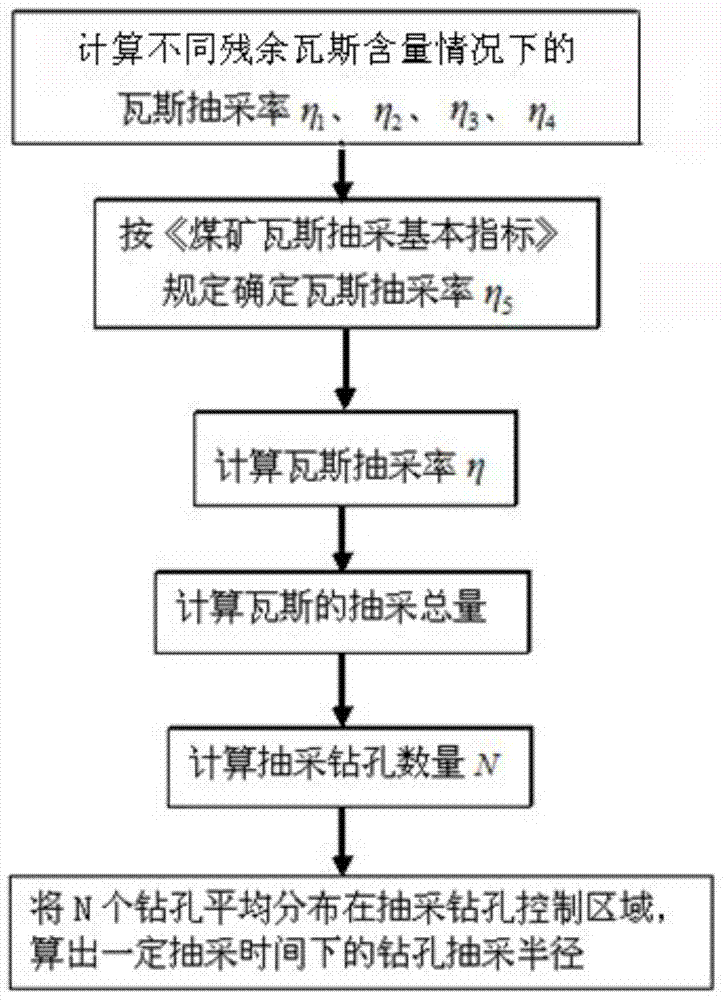

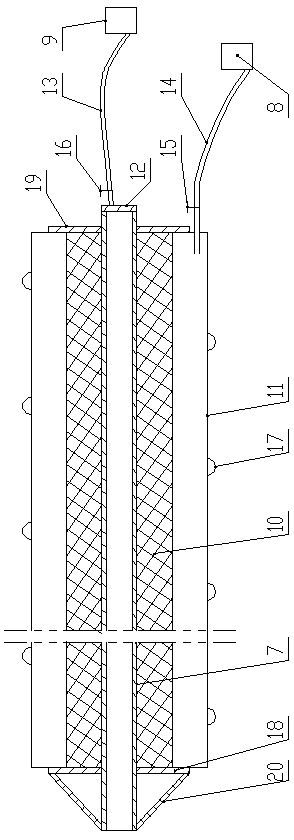

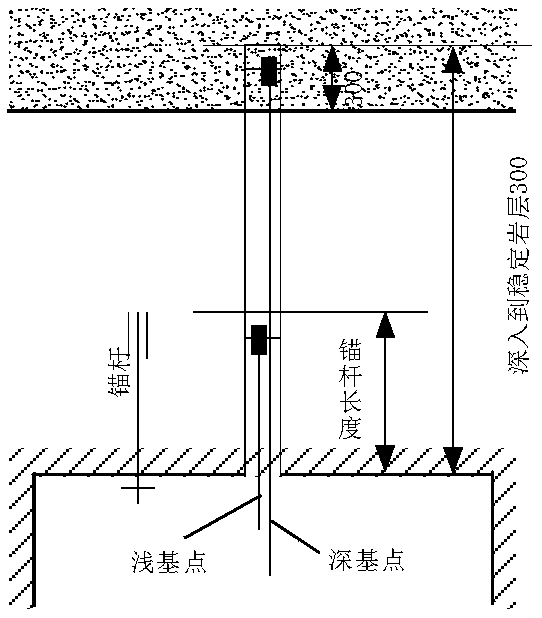

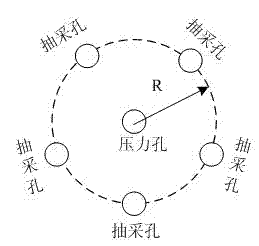

Drilled hole effective extraction radius measuring method based on gas content method

The invention provides a drilled hole effective extraction radius measuring method based on a gas content method, and belongs to the technical field of coal seam gas extraction. The method comprises the following steps that (1) the gas extraction rates under the different residual gas content conditions are respectively calculated; (2) the gas extraction rate eta 5 is determined according to the regulations of the Coal Mine Gas Extraction Basic Index; (3) the gas extraction rate eta is calculated; (4) the total extraction quantity of gas is calculated; (5) the number N of extraction drilled holes is calculated; (6) the N drilled holes are evenly distributed in an extraction drilled hole control area, and the drilled hole extraction radius within certain extraction time is calculated. The effective extraction radius can guide to design the reasonable extraction drilled holes, the aim of eliminating prominent dangerousness can be achieved through the method on the premise of meeting the pre-extraction time, and a large amount of manpower and a large number of financial resources and material resources can be saved.

Owner:CHINA COAL TECH ENG GRP CHONGQING RES INST

Slotting induced-flow pressure-relief anti-reflection method for complicated seam

ActiveCN102966372AAchieving safe miningImprove extraction efficiencyFluid removalGas removalSocial benefitsDesorption

A slotting induced-flow pressure-relief anti-reflection method for a complicated seam is suitable for gas control of high-gas high-ground-stress complicated seam regions, can improve the gas permeability and gas desorption rate of coal, solves the difficult problems of low exhausting and mining efficiencies of coal-bed gas, high drilling construction load and the like, and realizes efficient gas exhausting and mining as well as fast outburst elimination of the complicated seam. High-pressure water is jetted into drilled holes to cut and destroy the coal in a rotary manner, and the coal in the radial direction of the drilled holes is destroyed and disturbed, so that buckling failures of the coal are induced and the coal and the gas are enabled to be spouted out of the drilled holes, as a result, the gas expansion energy of the coal is released, coal cracks are expanded and the exposure surface area of the coal is increased. therefore, the gas exhausting and mining efficiencies of coal are improved, coal and gas burst risks are eliminated, the effective influence range of drilling gas exhausting and mining is improved by 1-3 times, the air permeability coefficient of coal around the drilled holes is improved by 100-200 times, the drilling methane gas exhausting and mining quantity is improved by 2-5 times within hundreds of meters, and the outburst elimination time of the coal bed is shortened by 30-50 percent. The slotting induced-flow pressure-relief anti-reflection method for the complicated seam has very good field application value and social benefits.

Owner:CHINA UNIV OF MINING & TECH

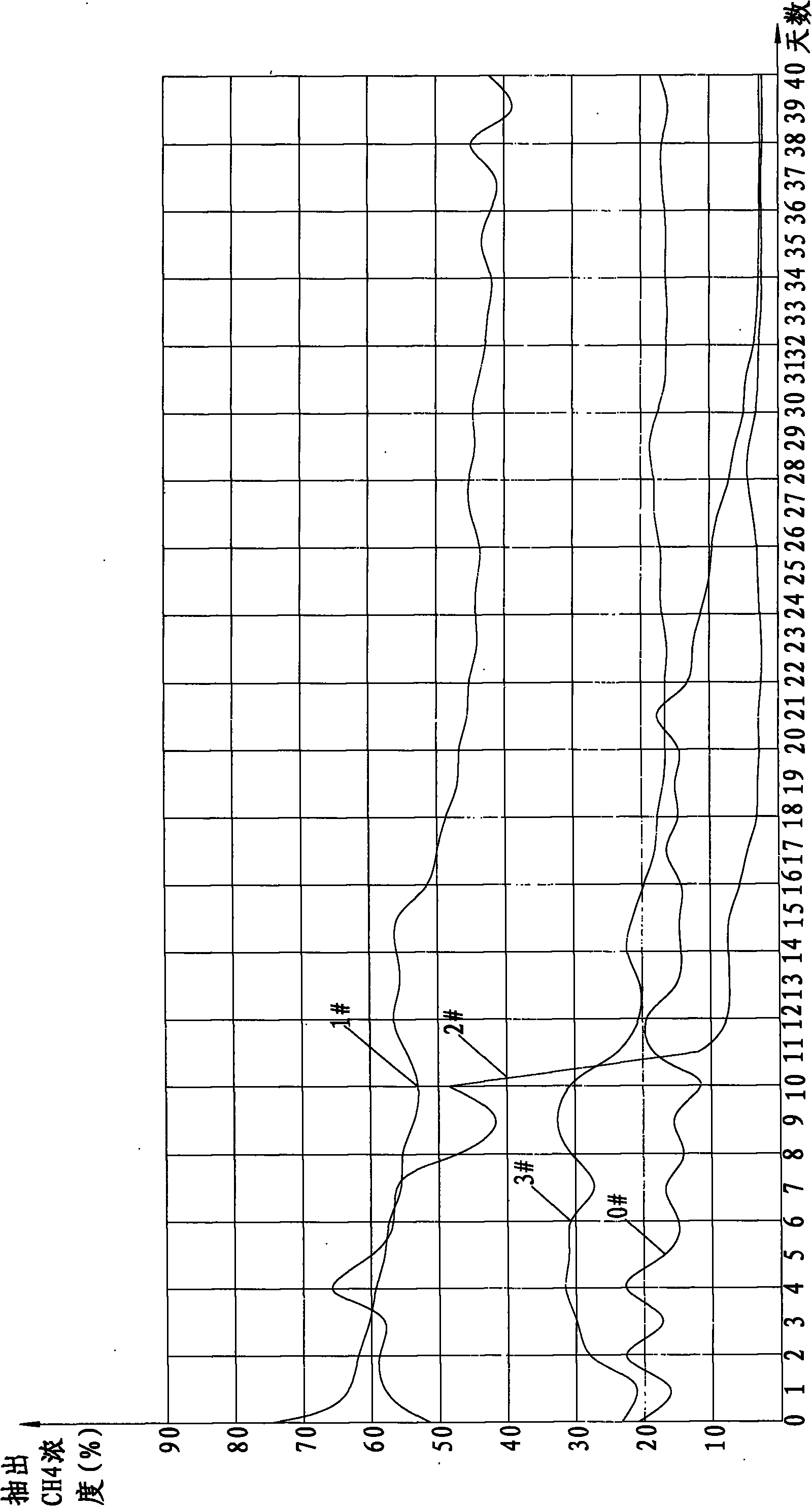

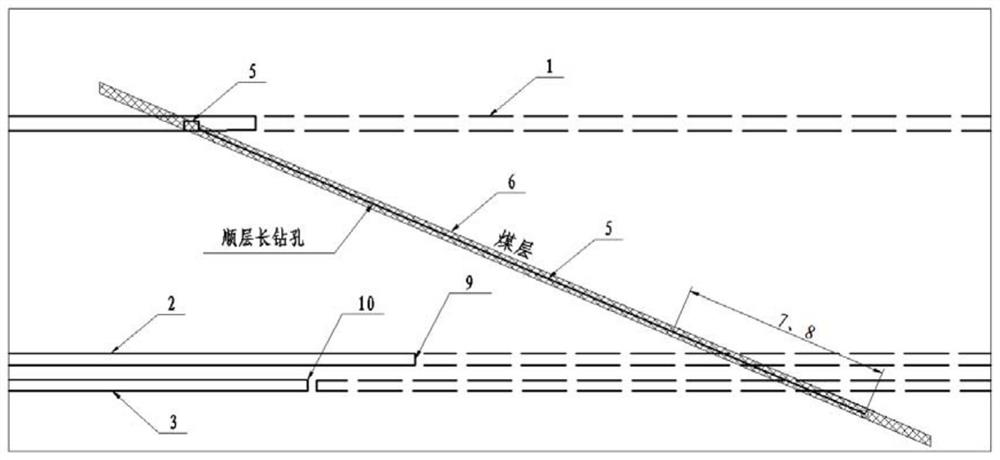

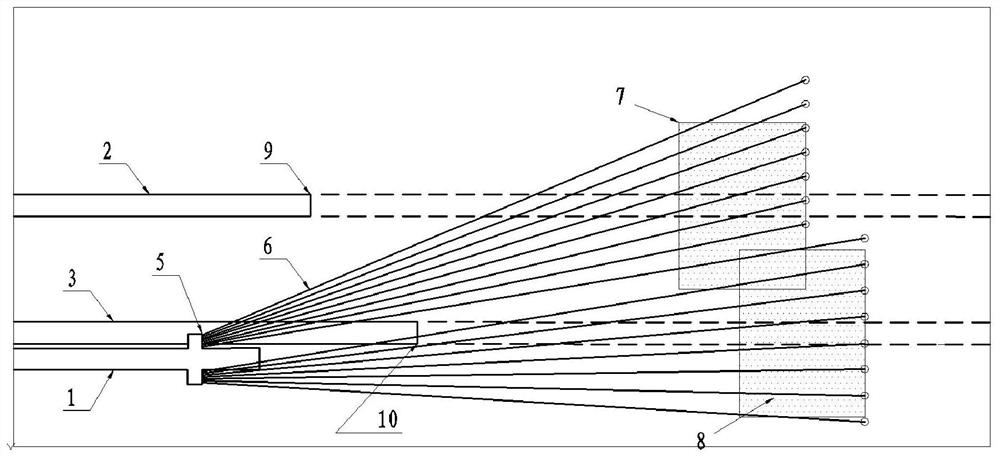

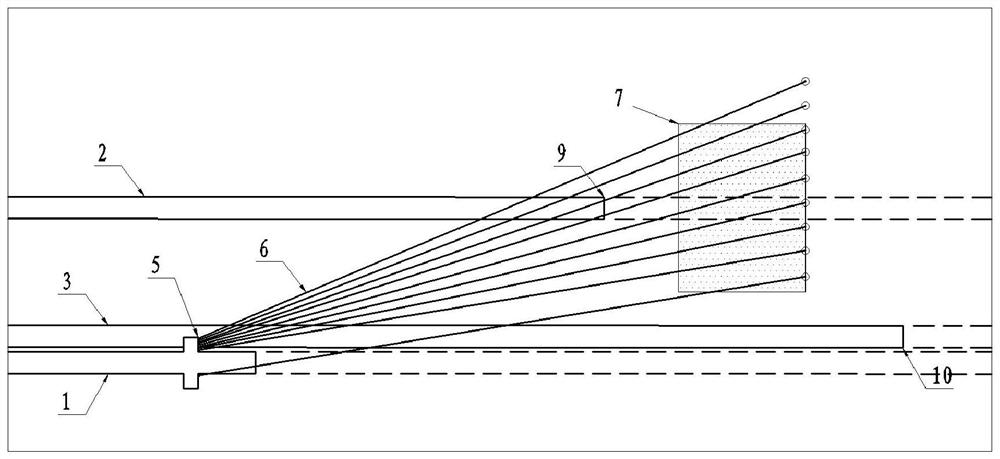

Method for extracting protruded coal-bed downward bedding long-borehole step-by-step covering area gas

InactiveCN101029575AReduce gas contentEliminate outstanding hazardsGas removalSealing/packingEngineeringGas concentration

This is a gas extraction method for a single burst coal bed of stable coal occurrence, angle less than 10o, and firm index over 0.5. Drill a hole from top working face downward along the coal bed from shallow bed to deep, from low gas concentration zone to high for pre-extraction to lower down the gas concentration.

Owner:淮北矿业股份有限公司祁南煤矿 +1

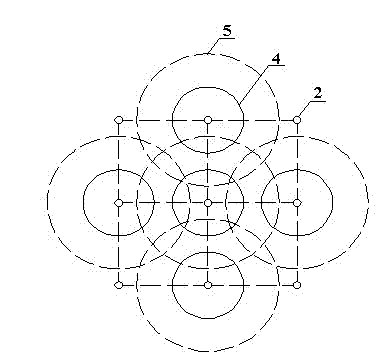

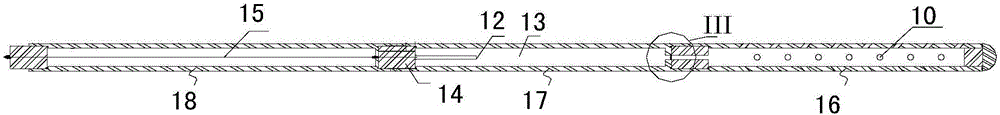

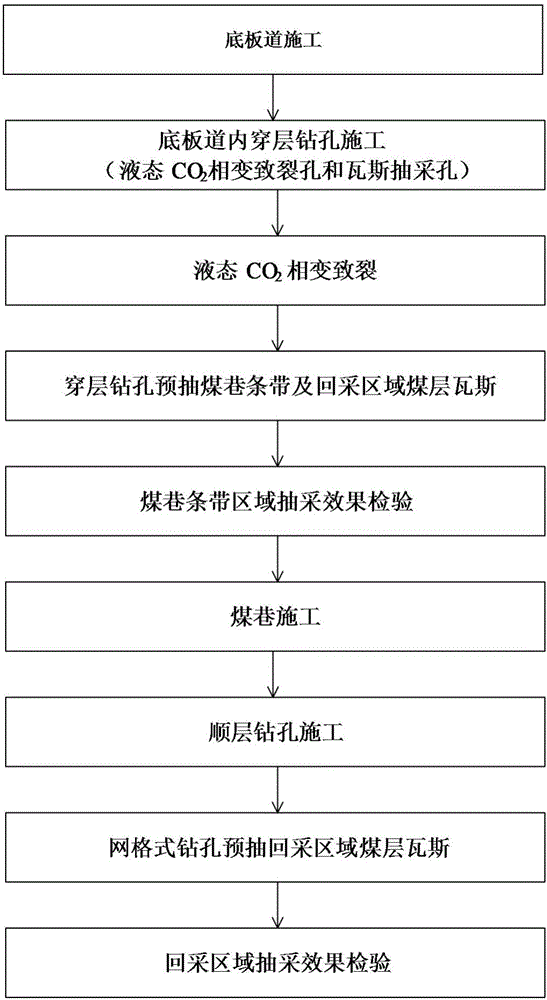

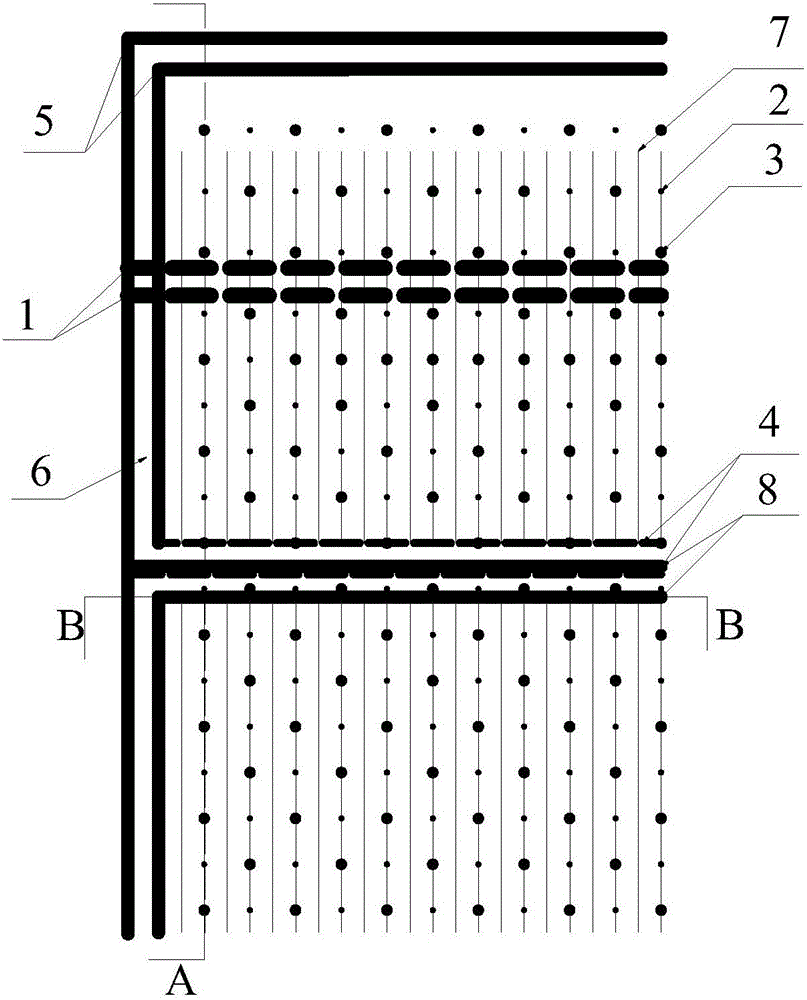

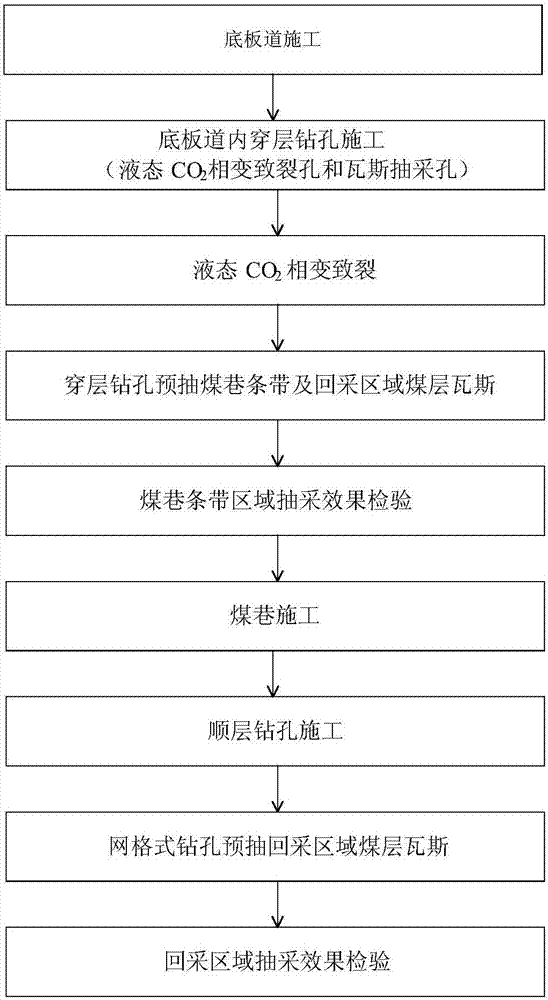

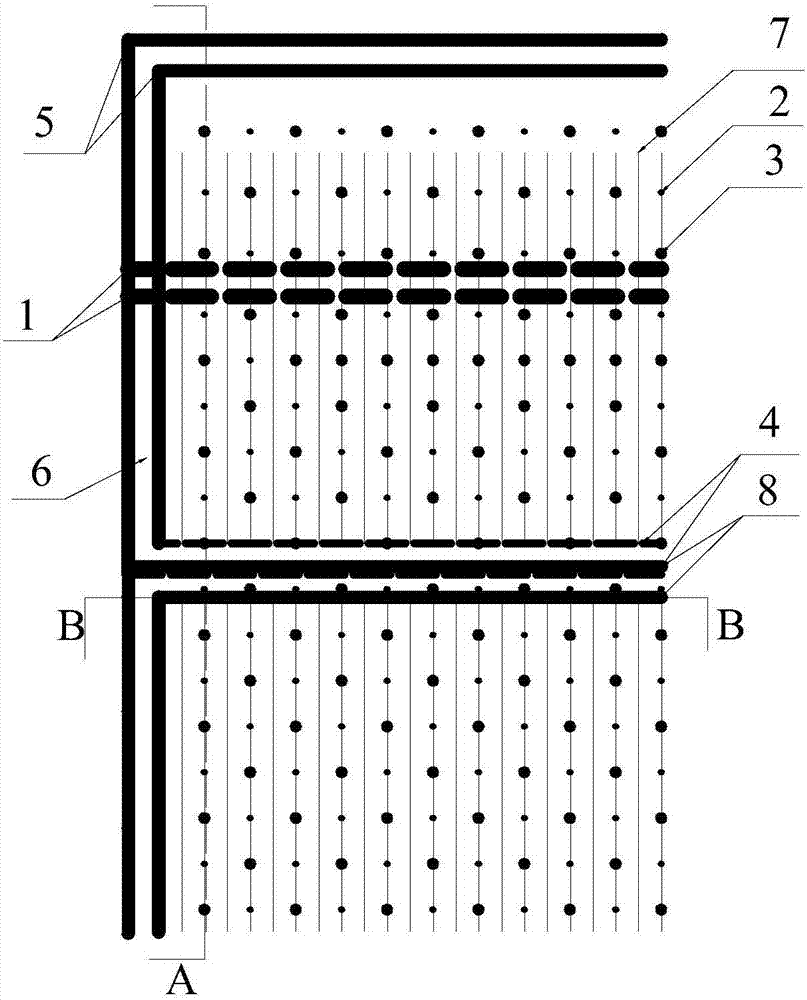

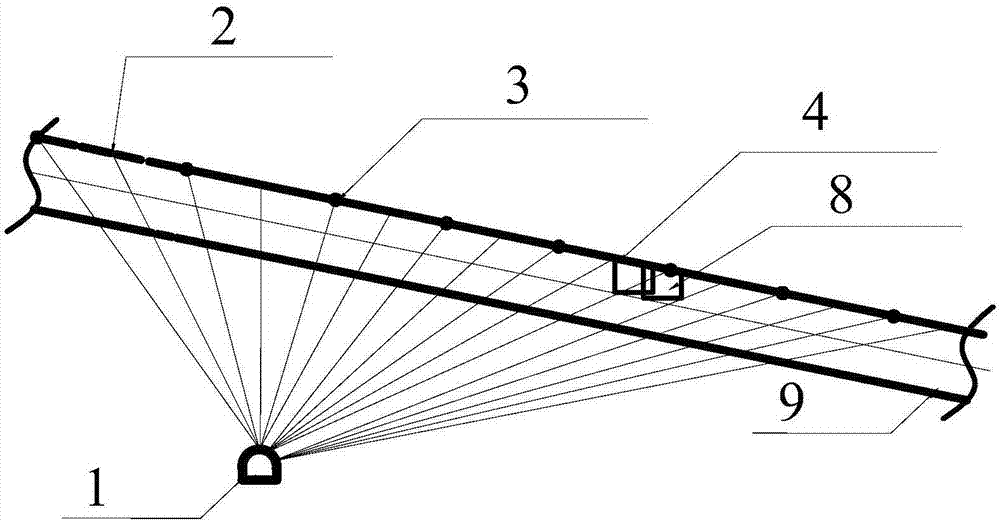

Liquid-phase CO2 phase change cracking permeability-increasing grid type gas extraction method for low-permeable coal seam

ActiveCN106194244AIncrease gas extractionEliminate outstanding hazardsFluid removalGas removalDrill holeProcess engineering

The invention discloses a liquid-phase CO2 phase change cracking permeability-increasing grid type gas extraction method for a low-permeable coal seam. The method comprises the following steps that (1) a bottom board passage is constructed; (2) crossing drilling construction is carried out in the bottom board passage; (3) liquid CO2 phase change cracking is carried out; (4) gas of coal seams of a coal roadway strip and a recovery area is pre-drained with crossing drill holes; (5) the extraction effect of the coal roadway strip area is detected; (6) coal roadway construction is carried out; (7) hole drilling down the seam is carried out; (8) gas of the coal seam in the recovery area is pre-drained with grid type drill holes; and (9) the extraction effect of the recovery area is detected. The method can improve the quantity of drainage of gas of underground coal mine, achieve the purpose of rapidly eliminating danger of outburst for high-gas low-permeable outburst coal seams, prevent coal and gas outburst accidents and guarantee safety production of the underground coal mine.

Owner:CHONGQING UNIV

Gas treatment method of rock protection layer working face under near-distance hard roof

ActiveCN106223998APrevent overrunningEliminate outstanding hazardsGas removalEngineeringProtection layer

The invention discloses a gas treatment method of a rock protection layer working face under a near-distance hard roof. When protective seam mining conditions do not exist, weak mudstone of a proper position of an outburst coal seam bottom plate serves as a protective layer, Y-type downward ventilation is adopted on the mudstone working face, and gas of a protected layer and a goaf area is extracted by means of protected layer coal roadways, bedding drilled holes, downward seam penetrating drilled holes, upward seam penetrating drilled holes and hysteretic drilled holes of a mudstone working face roadway, goaf area pipe laying and other modes. The bedding drilled holes and the seam penetrating drilled holes below the bedding drilled holes and adjacent to an outburst coal seam are formed in the pre-constructed coal roadways, and gas of a pressure release seam in an upper section area of the protected area of the mudstone working face is extracted. Pressure release gas of a lower section area corresponding to the protected seam is extracted by means of the hysteretic drilled holes of the mudstone working face, and two hysteretic seam penetrating holes facing the working face are formed in every construction place. Pipes are laid along the top of an abandoned roadway filling wall to extract and control gas in the goaf area. The protected layer coal roadways seal the roadway section by section to extract gas.

Owner:ANHUI UNIV OF SCI & TECH

High-gas mine Y-shaped ventilation method

ActiveCN105221179AEliminate outstanding hazardsImprove securityTunnel/mines ventillationGas removalEngineeringCoal

The invention provides a high-gas mine Y-shaped ventilation method. The method comprises the following steps of: before the crossheading tunneling, tunneling a floor suction roadway in a coal seam floor rock layer, wherein the position of the floor suction roadway corresponds to a working face rail crossheading and open-off cut; arranging a gas drainage pipe in a roadway; tunneling the rail crossheading and open-off cut in a working coal seam right above the floor suction roadway to form a ventilation system; excavating a coal roadway along the coal seam strike at the tail end of the rail crossheading; tunneling an air return inclined roadway in an inclined downward direction along the coal seam at the tail end of the coal roadway; communicating the floor suction roadway after the same seam position of the floor suction roadway is reached; then, building a sealing wall at the floor suction roadway in the communicating position; and building a roadway-side filling body to remain a rail roadway in the working face extraction process, and arranging a gas drainage pipeline for draining gas in a goaf. The method solves the problem of gas bursting in the working face corner gas accumulation and tunneling process; the safety is high; one roadway has multiple purposes; the mining cost is low; the working face does not pass through an abandoned roadway; and the process is simple.

Owner:TAIYUAN UNIV OF TECH

Freezing-type stone door cross-measure coal uncovering method based on hydraulic seam cutting

ActiveCN104213921AImprove flow statusImprove breathabilityUnderground miningSurface miningUltimate tensile strengthCoal

A freezing-type rock cross-measure coal uncovering method based on hydraulic seam cutting is suitable for a rock cross-measure coal uncovering operation in a high-gas outburst coal seam. The method includes following steps: (1) constructing a plurality of water injection holes into a coal uncovering operation surface at a position of the coal uncovering operation surface, wherein a minimum normal distance from the coal seam to the position is not less than 7 m; (2) performing hydraulic seam cutting to the water injection holes through a conventional hydraulic seam cutting technology; (3) when the hydraulic seam cutting is finished, connecting the water injection holes to a gas extraction pipe network to perform gas extraction; (4) when the content of gas in the coal seam is less than 8 m<3> / t, stopping the gas extraction; (5) constructing a freezing holes and a temperature measuring hole respectively at the two sides of the water injection holes; (6) sealing the holes through a capsule hole-sealing device; (7) injecting water into the coal seam through the water injection holes and closing valves when the water injection process is finished to enable the water injected into the coal seam to gradually seep into micro cracks in coal; (8) freezing the coal seam around the water injection holes through a conventional freezing technology to enable free water in the micro cracks in the coal seams to gradually convert from liquid phase into solid phase during the freezing process, so that a strength and an anti-impact performance of the coal are increased and an effect of solidification of the coal seam is achieved; and (9) uncovering the coal seam through a conventional coal uncovering method.

Owner:CHINA UNIV OF MINING & TECH

Freezing-thawing cycle anti-reflection promoting extraction safe and efficient rock cross-cut coal uncovering method

ActiveCN110056355AImprove breathabilityEliminate outstanding hazardsUnderground miningFluid removalFreeze thawingCross cut

The invention provides a freezing-thawing cycle anti-reflection promoting extraction safe and efficient rock cross-cut coal uncovering method. The freezing-thawing cycle anti-reflection promoting extraction safe and efficient rock cross-cut coal uncovering method comprises the following steps that (1) the influence radius Phi of a coal seam high-pressure water injection is measured; (2) drilling holes are constructed in a drilling field to a coal seam top plate or a bottom plate; (3) the drilling holes are divided into water injection hole bodies and freezing hole bodies, and the water injection hole bodies and the freezing hole bodies are arranged alternately; (4) hole sealing is carried out on the water injection hole bodies and the freezing hole bodies; (5) water injection is carried out on the water injection hole bodies, liquid nitrogen is injected into the freezing hole bodies to enable coal bodies on the periphery of the water injection hole bodies to be frozen, after a period of time, hot nitrogen is injected into the freezing hole bodies to enable the frozen coal bodies on the periphery of the water injection hole bodies to be unfrozen and thawed, and the liquid nitrogen is gasified; (6) gas discharged from the water injection hole bodies is extracted; (7) after gas extraction is carried out for 48 hours, the step (5) is repeated; and (8) rock cross-cut coal uncoveringoperation is carried out. According to the freezing-thawing cycle anti-reflection promoting extraction safe and efficient rock cross-cut coal uncovering method, through a coal body freezing-heat injection technology, the coal seam air permeability is effectively increased, the coal seam gas extraction effect can be greatly increased, the coal seam gas pressure is reduced, and the coal seam outburst risk is eliminated.

Owner:HENAN POLYTECHNIC UNIV

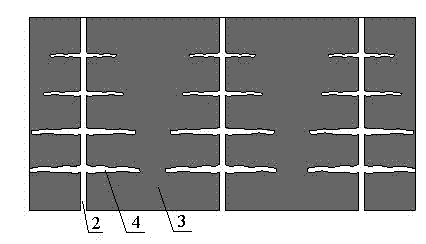

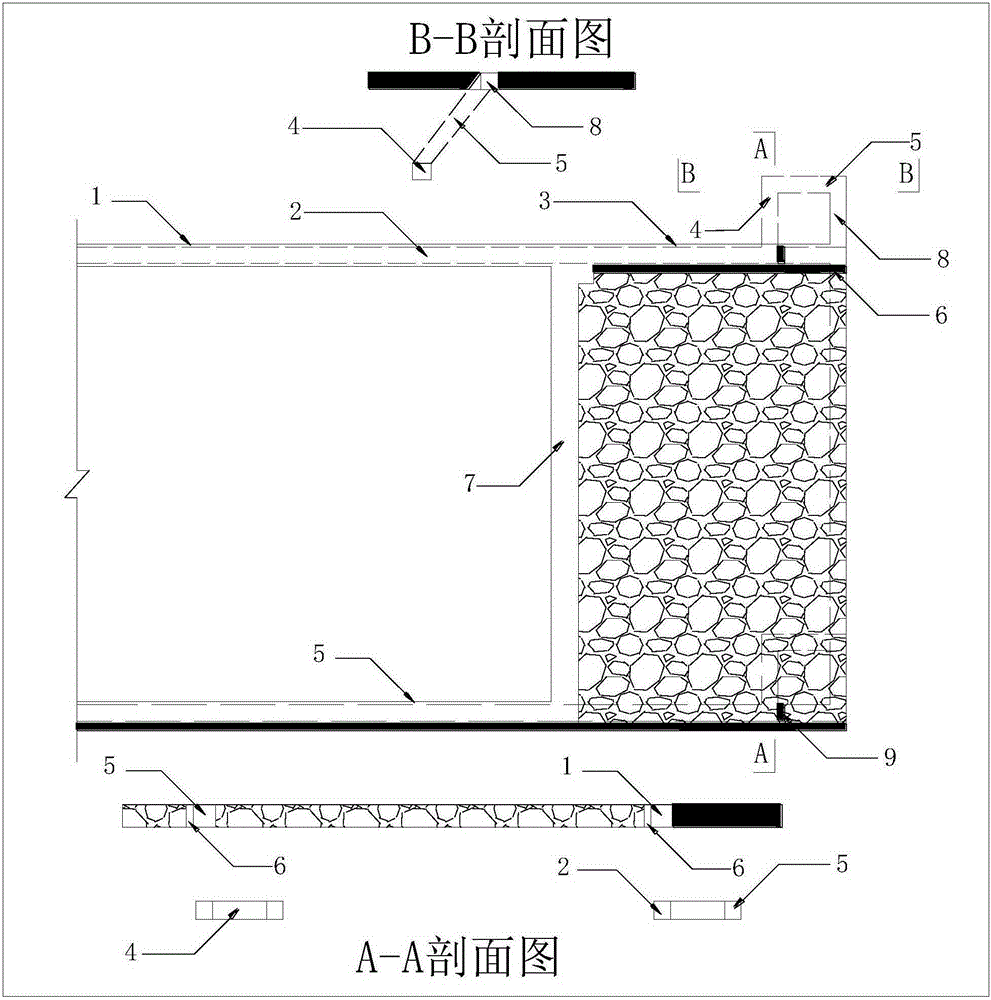

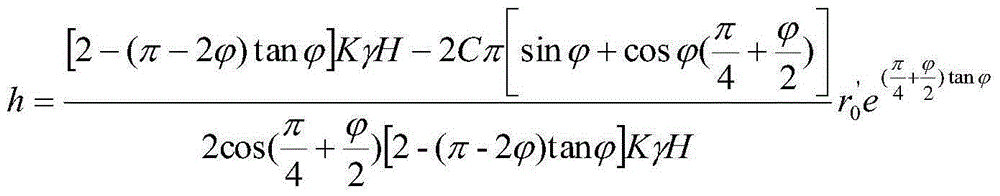

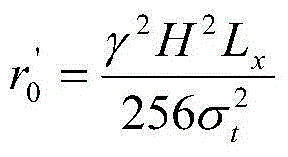

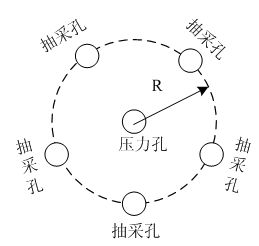

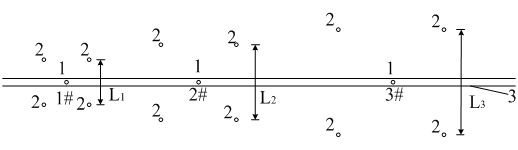

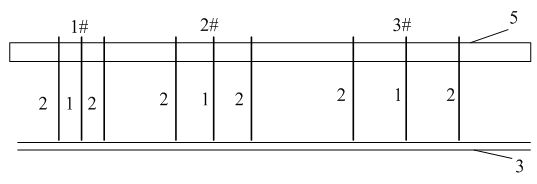

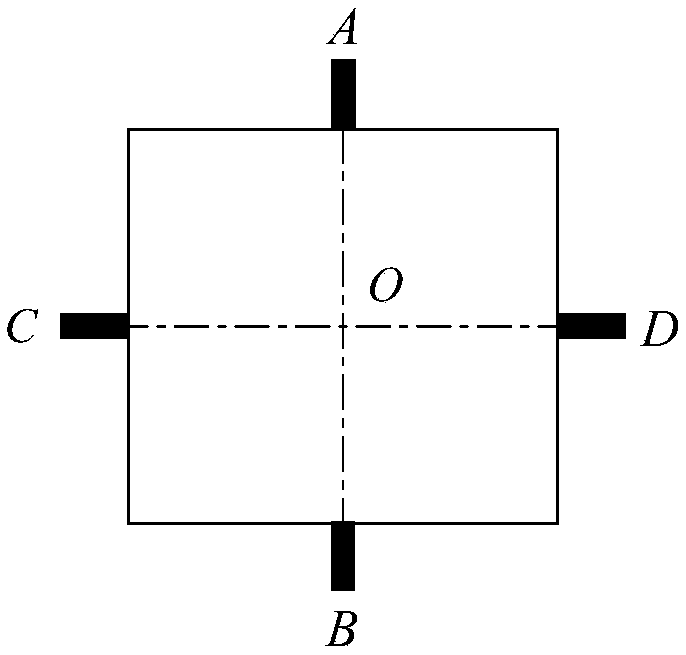

Method for determining grid type layer-through drilling intervals of floor roadway

The invention relates to a method for determining grid type layer-through drilling intervals of a floor roadway, which can accurately and quickly determine the effective intervals of layer-through drilling of an outburst coal seam within a certain period of time by adopting the arrangement of the determining drilling holes and determining the grid type layer-through drilling intervals, simultaneously arranging multiple groups of the determining drilling holes and adopting the determination of double indexes, namely residual gas pressure of a coal seam and residual gas content, so as to effectively reduce the gas content in the coal seam and eliminate the outburst risk by the determined layer-through drilling intervals on the one hand, and reduce the drilling engineering quantity to the greatest extent, shorten the construction period of drilling, and further ensure the balance of pumping, excavation and mining of the outburst coal seam on the other hand. The method is simple, the measurement speed is fast, and the determined results are accurate and reliable.

Owner:CHINA UNIV OF MINING & TECH

Centralized gas control method for coal measures in closed distance seam group

InactiveCN112412527AFacilitated releaseIncrease gas contentGas removalCoal measuresMining engineering

The invention discloses a centralized gas control method for coal measures in a closed distance seam group. The method comprises the following steps of ensuring that the pressure relief protection range covers other minable seams after a first mining layer is mined according to gas parameters and outburst danger degree of each coal seam of middle coal measures and a development range of a gas emission channel formed by movement, deformation and rupture of roof and floor rock strata of each coal seam under the influence of mining of the first mining layer; arranging a first mining face in the first mining layer, determining a mining roadway of the first mining face, and arranging a gas centralized control roadway according to the thickness of each coal seam, the interlayer spacing, the drilling construction difficulty and the control range; constructing crossing long drilling holes in the gas centralized control roadway so as to pre-extract strip gas of two roadways on the first miningface of a protective layer, and continuously drilling after the drilling holes penetrate through the first mining layer until all coal seams on the upper part of the middle coal measures are explored;and continuously constructing the crossing drilling holes so as to pre-extract gas of each coal seam in the mining area of the first mining face and a pressure relief area of the middle coal measuresin the tunneling period of the mining roadway of the first mining face, so that the gas control work amount in the mining period is reduced.

Owner:GUIZHOU PANJIANG REFINED COAL

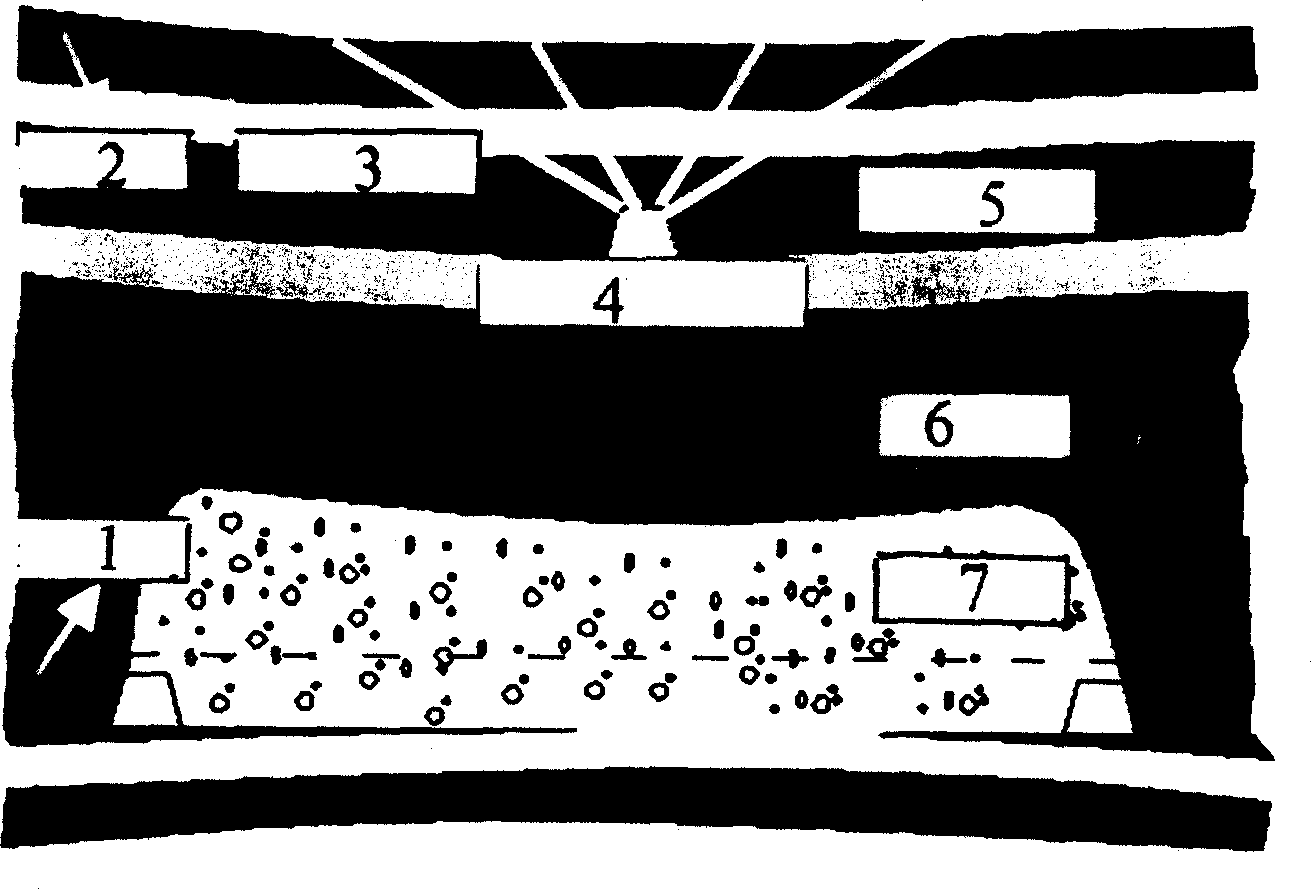

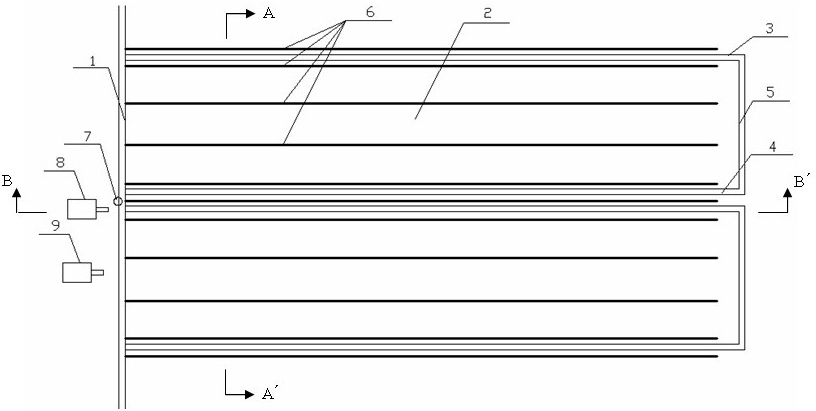

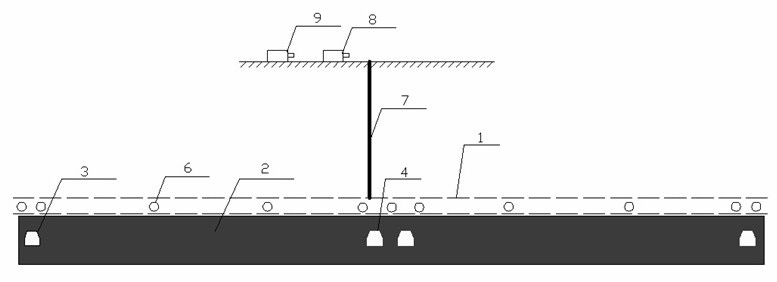

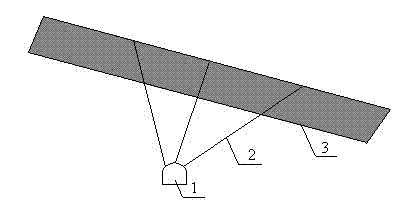

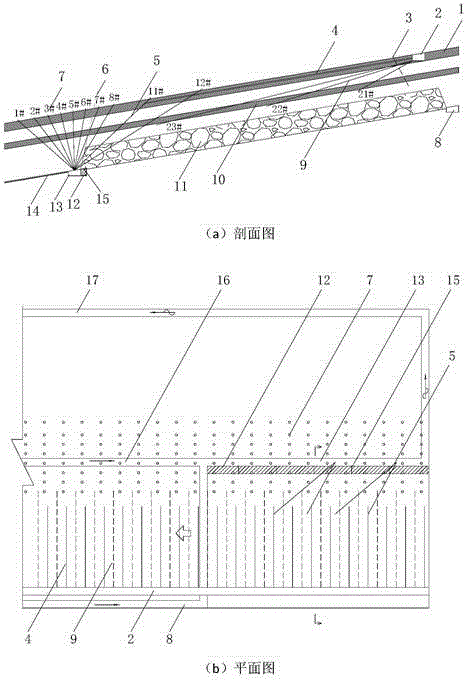

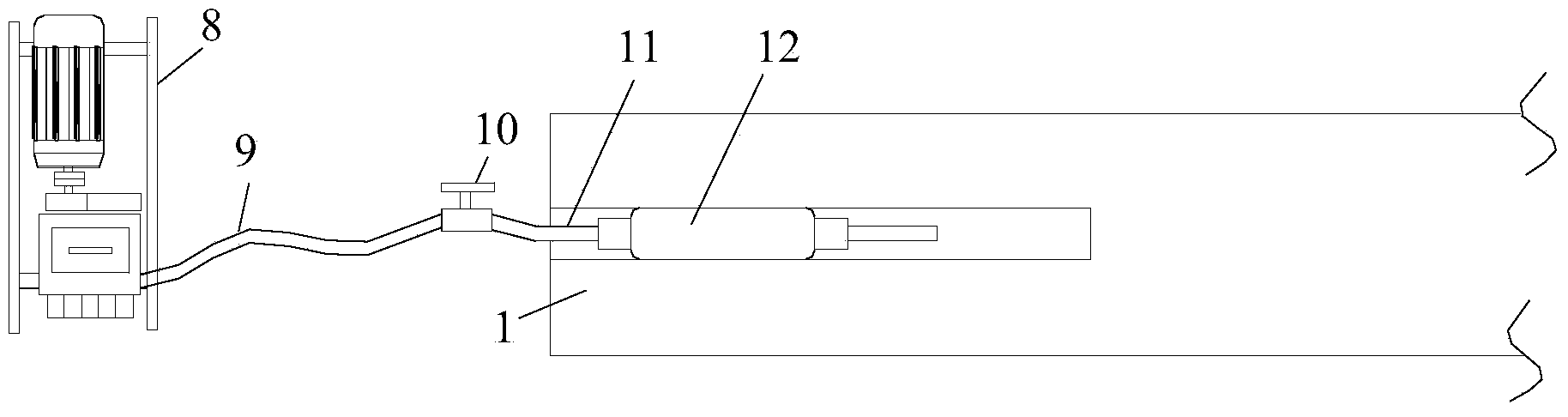

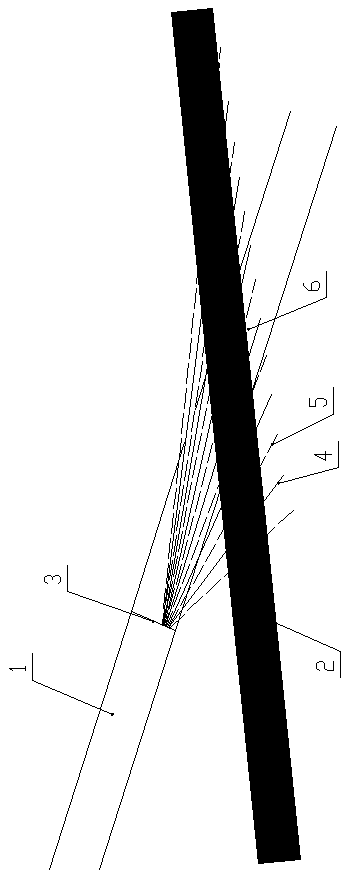

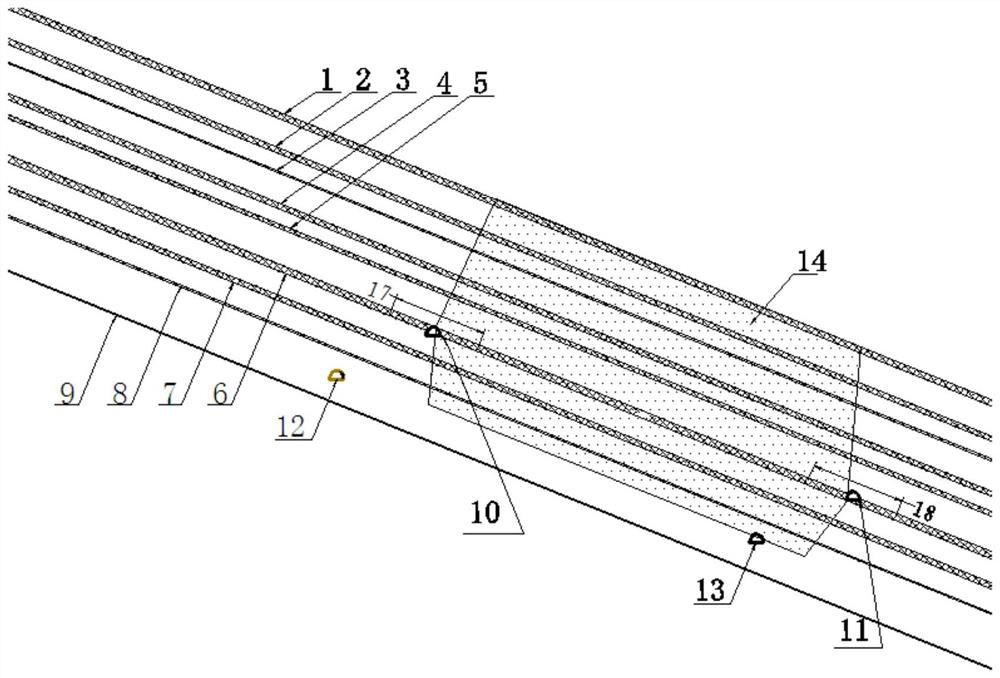

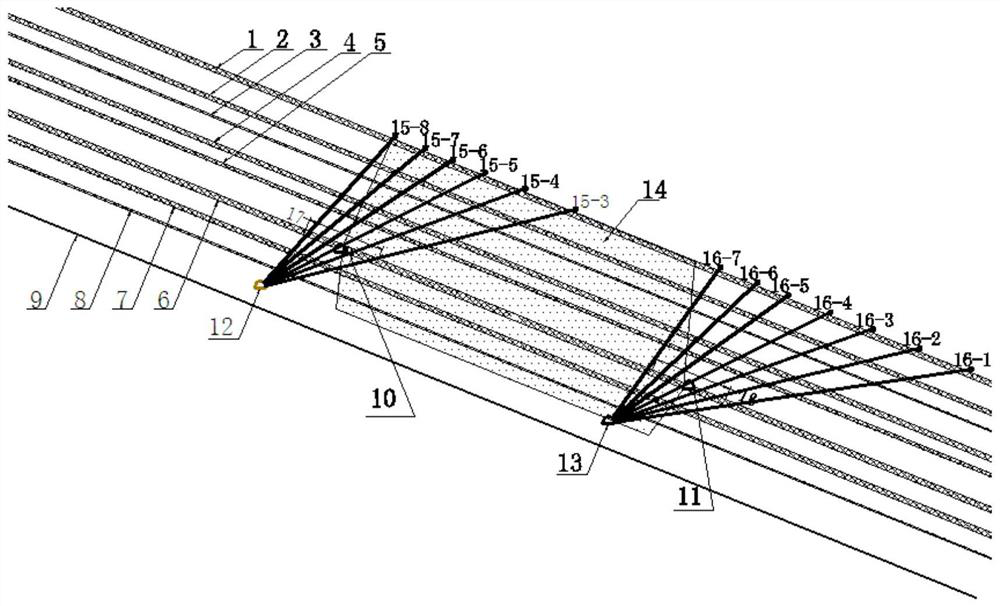

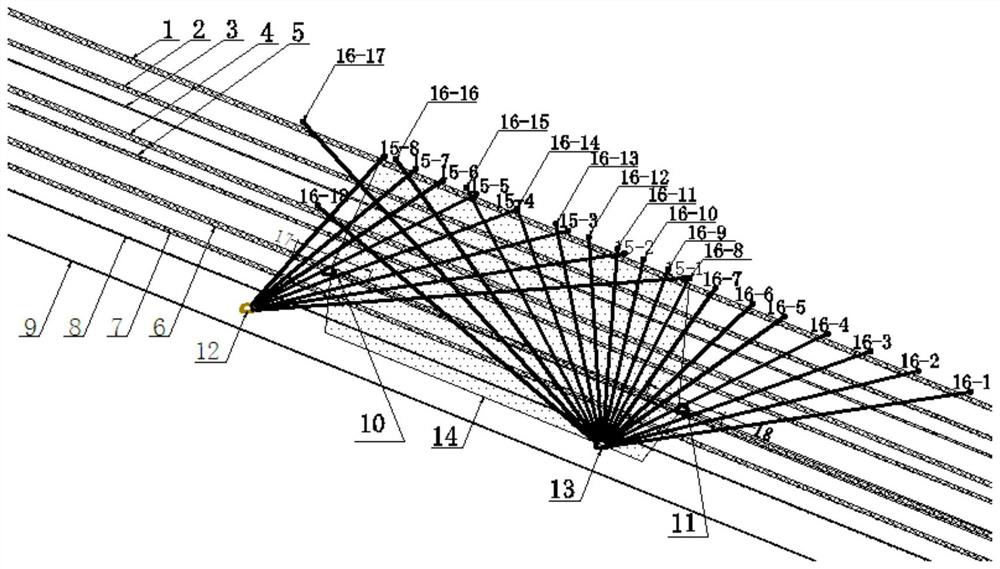

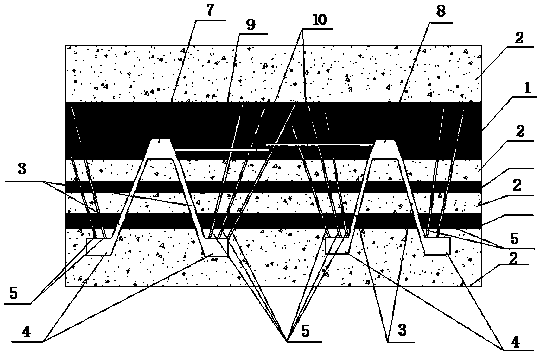

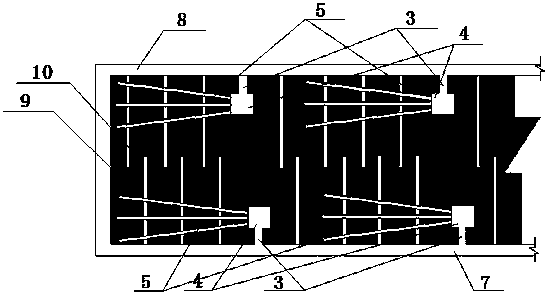

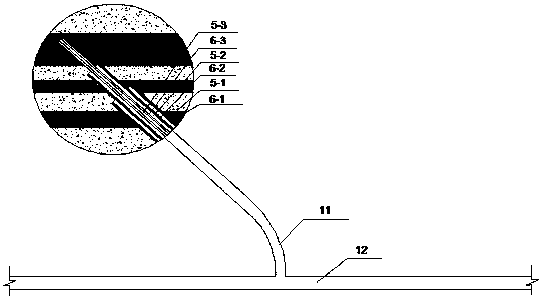

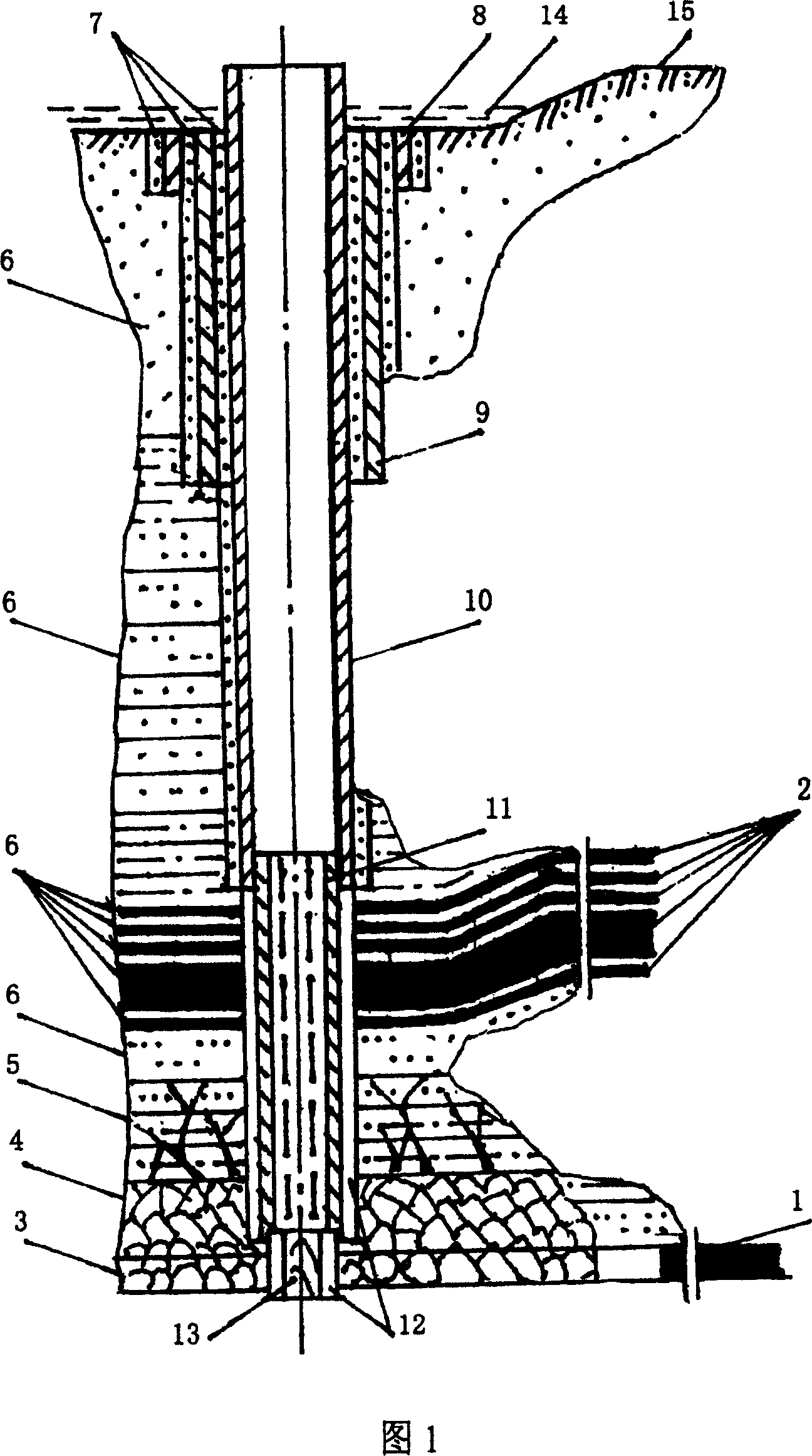

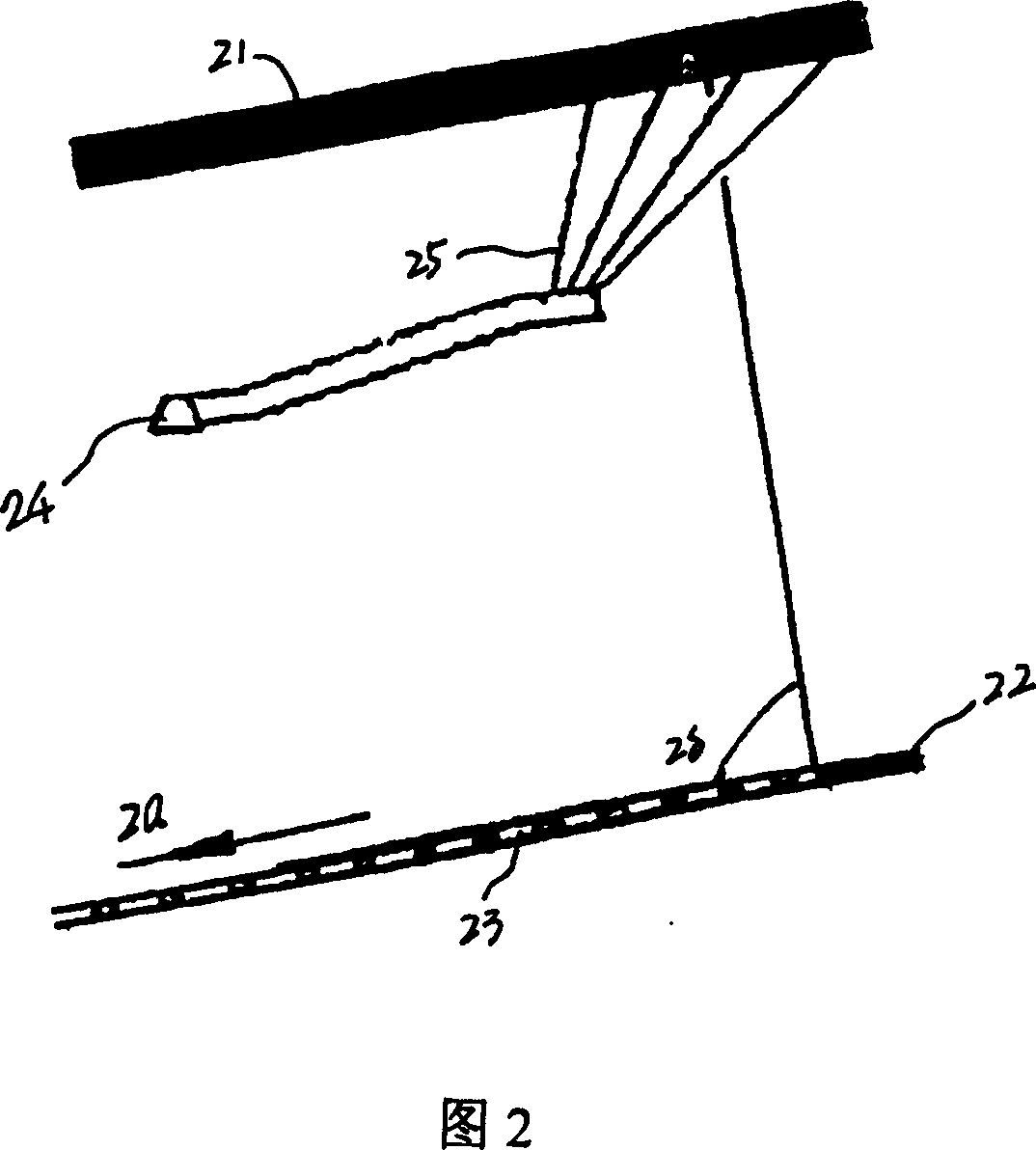

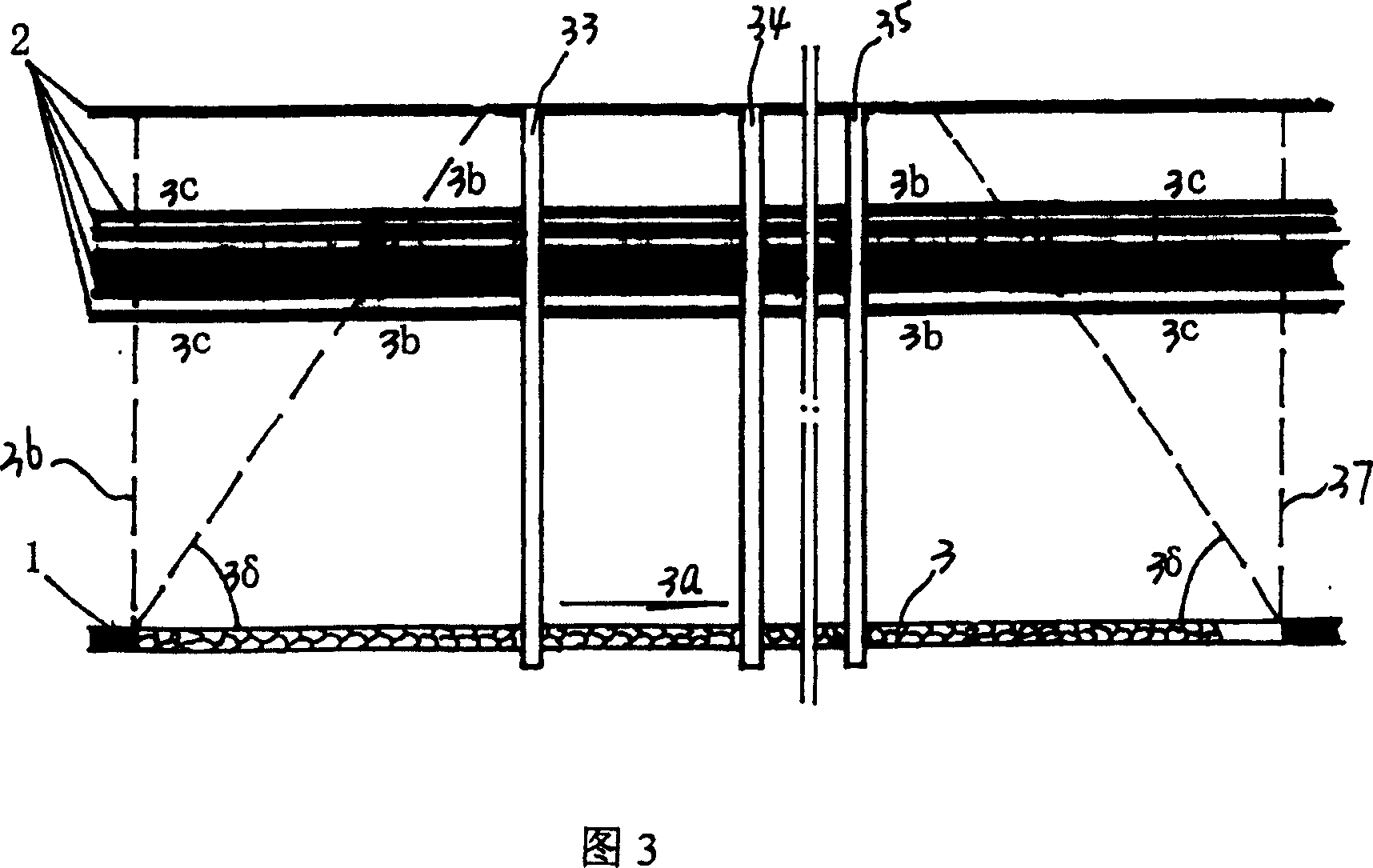

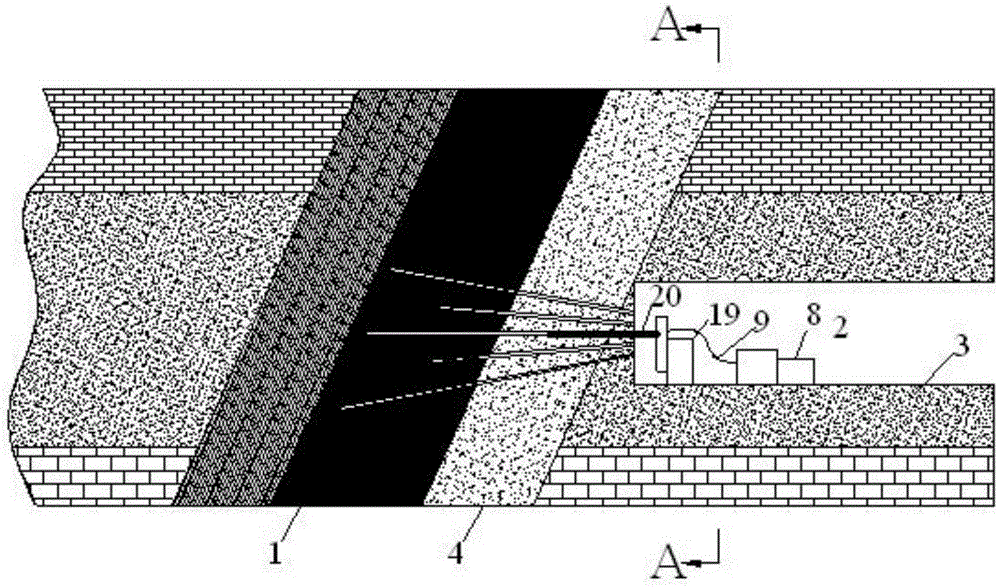

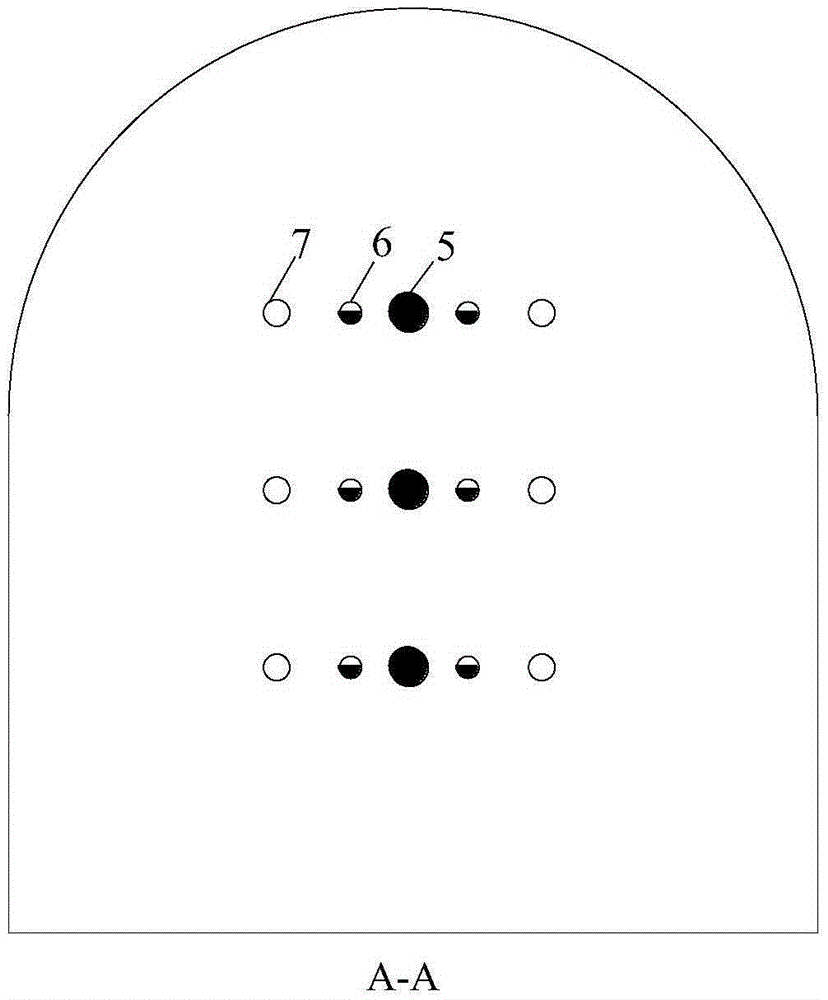

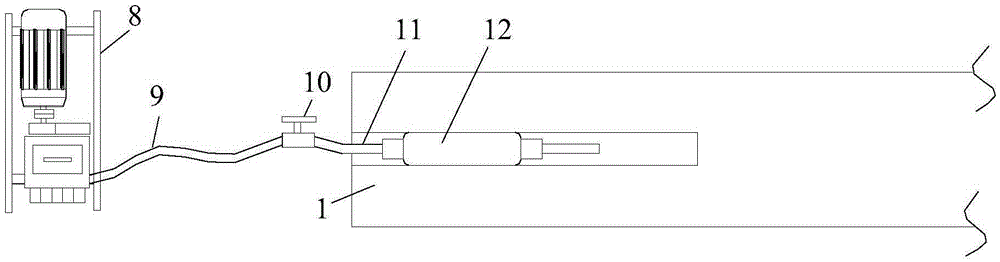

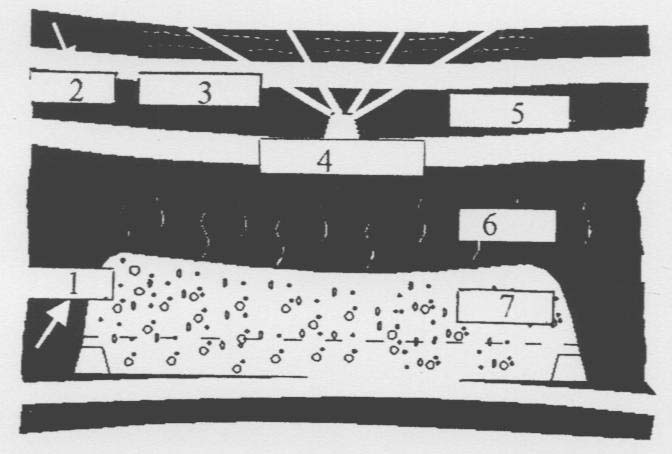

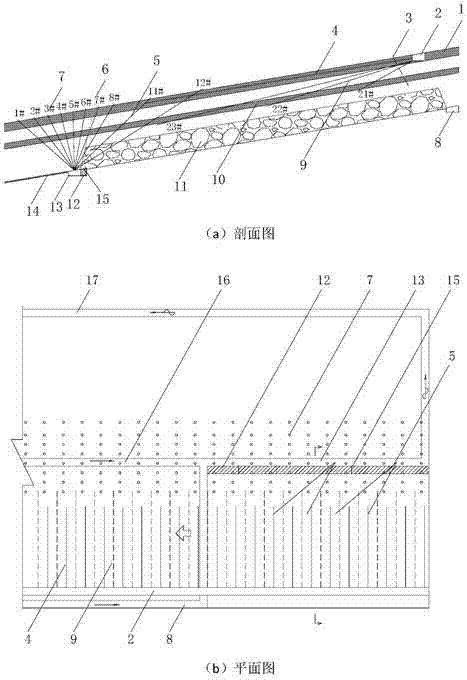

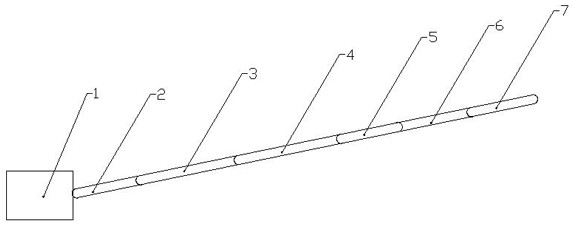

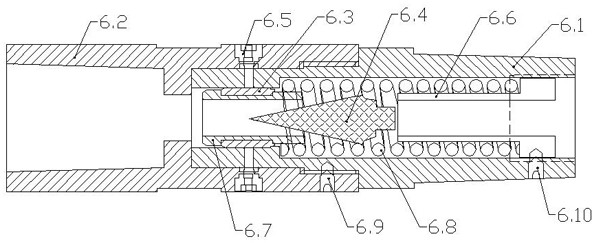

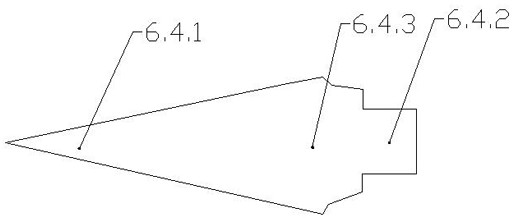

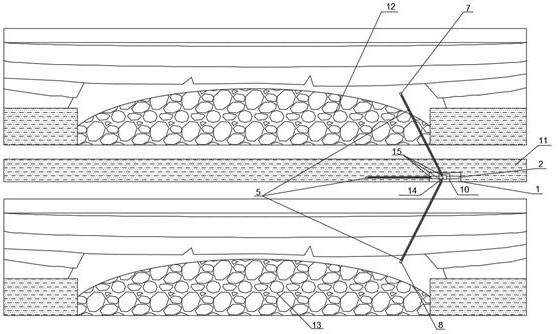

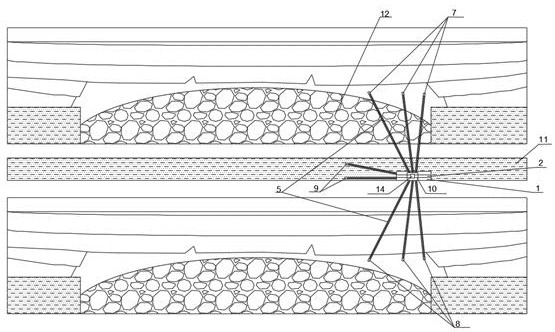

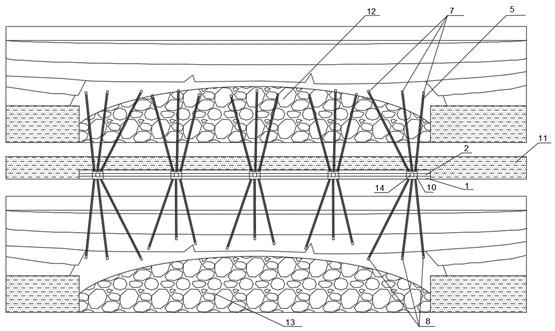

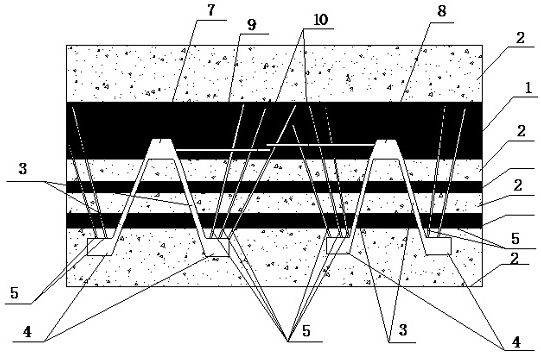

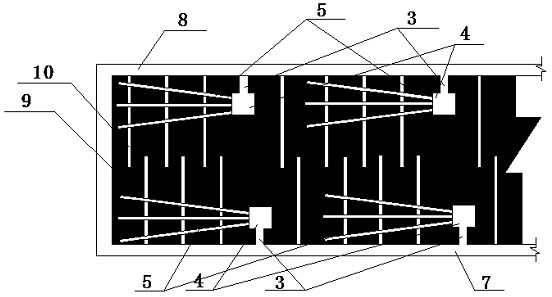

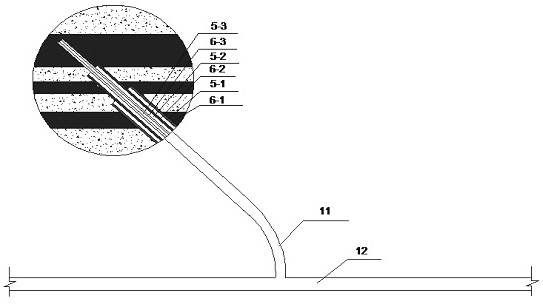

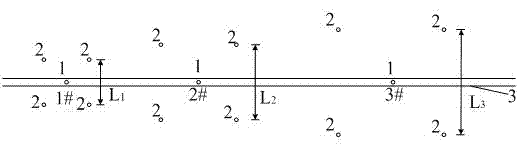

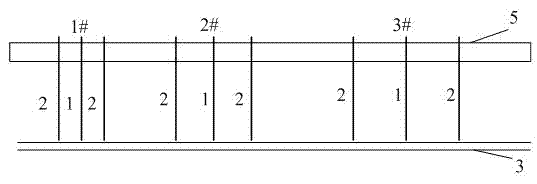

Low-level multi-step crossing hole gas extraction method for coal interbedding coal seams

ActiveCN109899105AEliminate outstanding hazardsGuaranteed sampling complianceGas removalCoalExtraction methods

The invention relates to a low-level multi-step crossing hole gas extraction method for coal interbedding coal seams. The low-level multi-step crossing hole gas extraction method is characterized in that transporting crossheadings (or air return crossheadings) are dug in the mined coal seams (1), a 0.3-1 m of inclined dip (3) penetrating into bottommost rock strata (2) of all coal interbeddings isconstructed obliquely downwards along the left (right) side of a roadway, a low-level drilling field (4) is dug, wherein the product of the length, the width and the height of the low-level drillingfield (4) is equal to 3.0 m*2.5 m*2 m, a plurality of low-level multi-step crossing holes (5) penetrating through the multiple coal seams to a mined bed are constructed in the low-level drilling fieldin the roadway tunneling direction obliquely upwards, multi-step sleeves (6-1), (6-2) and (6-3) are inserted into the low-level multi-step crossing holes (5), the sleeve (6-1) is connected with a multi-way part through a phi 120 mm of rubber hose (11), and the sleeve (6-1) is connected with a gas extraction pipeline (12) in the roadway to converge for low-level multi-step crossing hole (5) networking gas extraction operation. Gas at coal seam bottom plates is effectively extracted, the safe and efficient effects are achieved, and the low-level multi-step crossing hole gas extraction method can be used for implementation of outburst prevention measures of a working surface.

Owner:EASTERN GANSU UNIVERSITY

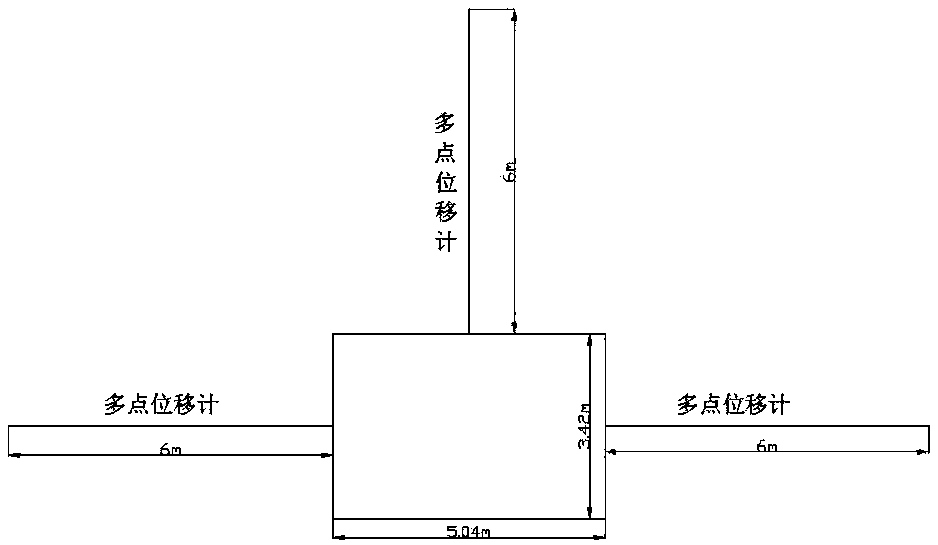

Industrial test method for pre-cracking and anti-reflection of high gas coal roadway

ActiveCN109555502AEasy extractionEliminate outstanding hazardsSurveyUnderground chambersPre crackingCoal

The invention discloses an industrial test method for pre-cracking and anti-reflection of a high gas coal roadway. The industrial test method comprises the following steps that monitoring devices forrealizing surface displacement monitoring of the roadway, roof separation monitoring of a back, deep multi-point displacement monitoring of roadway surrounding rocks and stress monitoring of a bolt and / or a cable is arranged are set positions; fracturing holes are formed in a heading face, gas drilling fields are arranged on two sides of the heading face, pre-extraction holes are formed in the drilling fields, the fracturing holes are subjected to CO2 pre-cracking, and gas is extracted from the pre-extraction holes; small guide pipe advanced grouting is performed in a driving working face; andthe gas extraction effect analysis before and after the fracturing and the permanent support effect analysis of the driving working face are performed, monitoring data acquired by the monitoring devices is combined, and the rationality of the relevant design parameters is judged.

Owner:山西潞安环保能源开发股份有限公司常村煤矿 +1

Gas pressure relief method of ground drilling extraction minery and goaf

InactiveCN1313702CLess gushAchieve destructive effectFluid removalGas removalMining engineeringWell drilling

This invention discloses a method for depressuring gas in ground drilled well and mining area. Before extracting coal a ground drilling well is drilled from ground to long distance, low breathing, high gas, projecting and soft covered seams, then extracting down seam. The gas from the up covered seam is exhausted from pipe.

Owner:HUAINAN MINING IND GRP

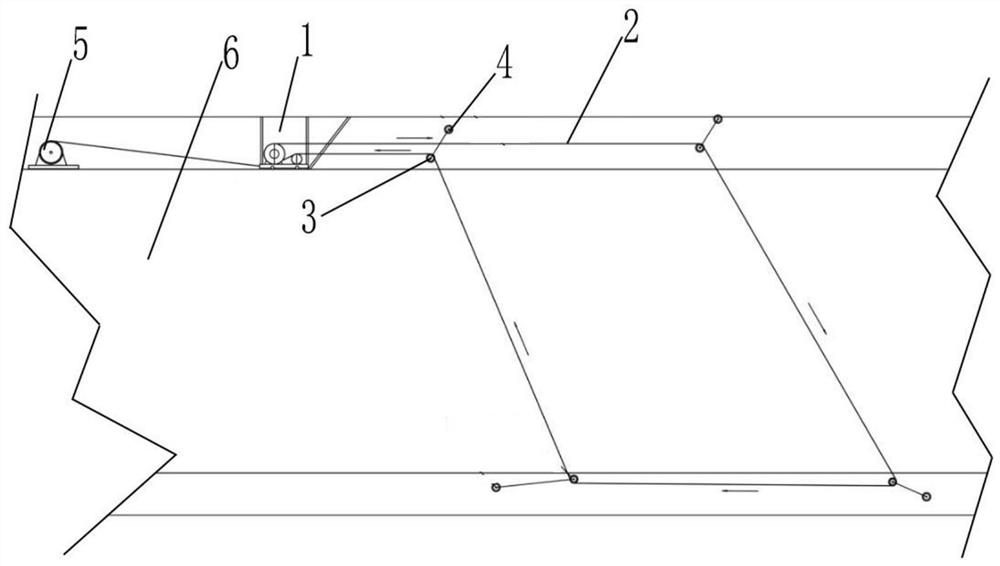

Wire saw cutting device and coal seam gas permeability-increasing pressure-relieving method

PendingCN112145223AImprove breathabilityChange the original natureSlitting machinesGas removalMining engineeringWire saw

The invention discloses a wire saw cutting device and a coal seam gas permeability-increasing pressure-relieving method, and relates to the field of coal seam gas pressure relieving. The device comprises a wire saw machine and an adjusting piece. The method comprises the steps that S1, the effective drainage radius after slotting of the wire saw machine is determined; S2, the drilling density andposition are determined according to the effective drainage radius, and drilling is conducted; and S3, the whole coal seam is subjected to cutting slotting through the wire saw machine. According to the device and the method, a large free space is formed in a coal body through whole-face cutting of a coal seam, surrounding coal bodies move, deform and generate flowing deformation in the directionof the free space, the stress balance of the coal body is continuously and repeatedly broken, and finally, the coal body is in a new balance state; when the coal body is cut, a new crack is formed inthe coal body, the new crack and a primary crack and a free space pore system expand, intersect and communicate, and the gas permeability of the coal body is improved; and after slotting, a space is provided for expansion deformation of the surrounding coal bodies, the expansion deformation causes expansion and mutual penetration of pore and crack systems in the coal body, favorable conditions areprovided for efficient desorption and high-speed flowing of gas, the original property of the coal body is changed, and the outburst risk of a coal seam area is quickly eliminated.

Owner:李章明 +3

Freezing Shimen Uncovering Coal Method Based on Hydraulic Slit

ActiveCN104213921BImprove flow statusImprove breathabilityUnderground miningSurface miningLiquid stateCross cut

Owner:CHINA UNIV OF MINING & TECH

Cross-section coal uncovering accurate outburst elimination method for rock cross-cut

InactiveCN112443351AEliminate outstanding hazardsResolution timeGas removalMining engineeringDrill site

The invention discloses a cross-section coal uncovering accurate outburst elimination method for a rock cross-cut. The method comprises the following steps that 1, drill sites are constructed on two sides of a coal uncovering position of a first rock cross-cut in an upper section, a plurality of bedding long drill holes are constructed, and the range of at least 12 meters outside two second rock cross-cut and third rock cross-cut roadway contour lines of coal to be uncovered in a lower section is controlled; 2, in the bedding long drill holes construction process, a directional drilling machine or a high-power and large-torque drilling machine is adopted to be matched with a drilling inclinometer to monitor the drilling track in real time, it is guaranteed that the constructed bedding longdrilling holes completely cover in the multiple cross-cut coal uncovering concentration gas pre-extraction area, and the gas treatment range is accurately controlled; and 3, after extraction reachesthe standard through construction of the bedding long drilled holes in the first rock cross-cut in the upper section, inspection is conducted on construction effect inspection holes when distance between driving working faces of second rock cross-cut and a third rock cross-cut in the lower section and normal line of a to-be-uncovered coal seam (4) is 7 meter, and if the residual gas content and the residual gas pressure are smaller than the specified requirements, it is confirmed that no outburst danger exists, and the second rock cross-cut and the third rock cross-cut in the lower section canbe used for directly uncovering coal.

Owner:GUIZHOU PANJIANG REFINED COAL

Low premeability high gas soft thick coal layer remote pressure relief gas exhausting method

A remotely pressure-releasing method for sucking and exhausting gas from the low-air-permeability high-gas soft and thick coal seam is disclosed. The coal seam, which is 70m under the coal seam to be gas-exhausted and has relative interbeam distance of 30-70 times, is first mined. Under the action of pressure release and subsidence, the cracks are generated in the coal seam and the gas penetrates through the cracks and then is exhausted via predrilled holes. After the coal seam is mined, a great deal of gas is flowing along the seam and then is sucked by said predrilled holes.

Owner:HUAINAN MINING IND GRP +1

A gas control method for working face of rock protective layer under close hard roof

ActiveCN106223998BPrevent overrunningEliminate outstanding hazardsGas removalEngineeringProtection layer

The invention discloses a gas treatment method of a rock protection layer working face under a near-distance hard roof. When protective seam mining conditions do not exist, weak mudstone of a proper position of an outburst coal seam bottom plate serves as a protective layer, Y-type downward ventilation is adopted on the mudstone working face, and gas of a protected layer and a goaf area is extracted by means of protected layer coal roadways, bedding drilled holes, downward seam penetrating drilled holes, upward seam penetrating drilled holes and hysteretic drilled holes of a mudstone working face roadway, goaf area pipe laying and other modes. The bedding drilled holes and the seam penetrating drilled holes below the bedding drilled holes and adjacent to an outburst coal seam are formed in the pre-constructed coal roadways, and gas of a pressure release seam in an upper section area of the protected area of the mudstone working face is extracted. Pressure release gas of a lower section area corresponding to the protected seam is extracted by means of the hysteretic drilled holes of the mudstone working face, and two hysteretic seam penetrating holes facing the working face are formed in every construction place. Pipes are laid along the top of an abandoned roadway filling wall to extract and control gas in the goaf area. The protected layer coal roadways seal the roadway section by section to extract gas.

Owner:ANHUI UNIV OF SCI & TECH

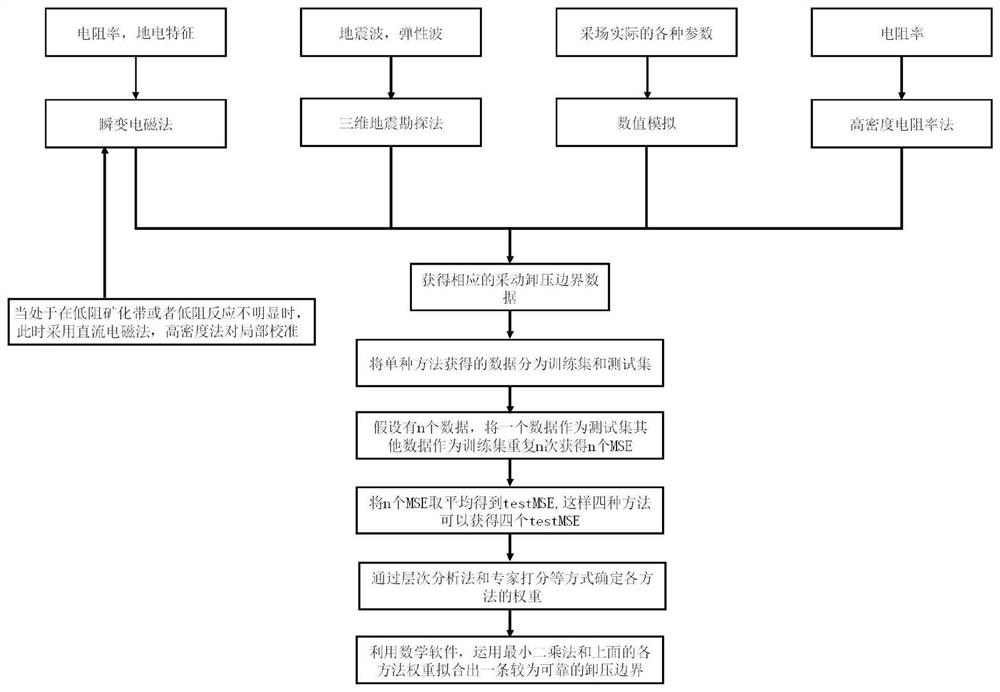

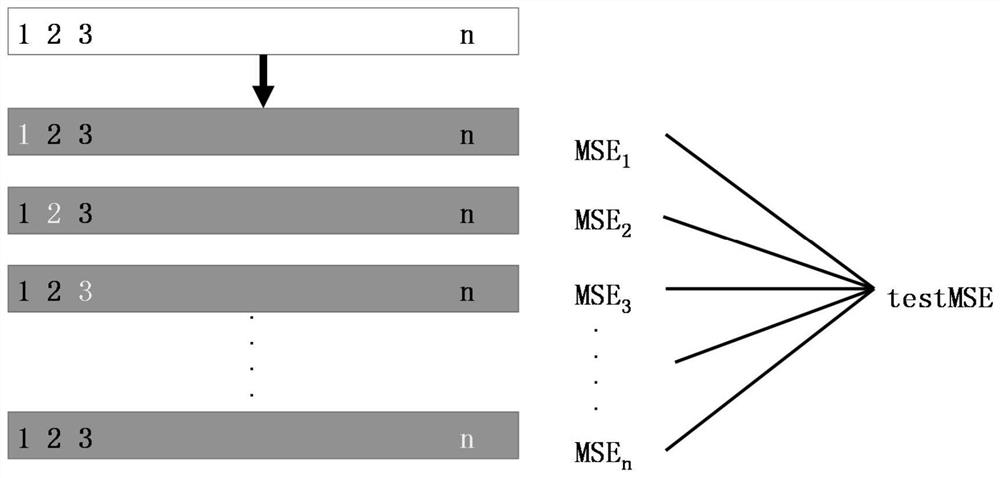

Mining pressure relief boundary detection method

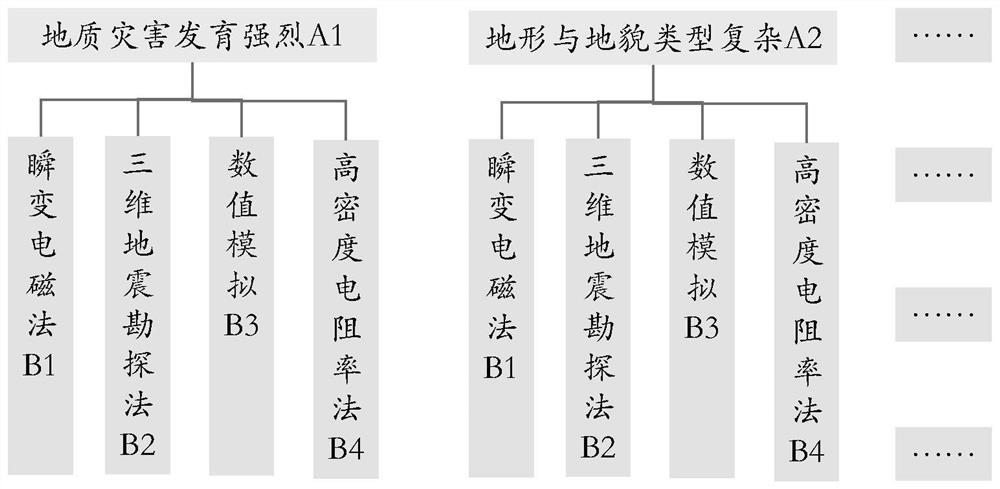

PendingCN114442189AGuaranteed effective accuracyGuaranteed accuracyGeological measurementsHigh densityBoundary detection

The invention provides a mining pressure relief boundary detection method. According to the method, a transient electromagnetic method, a seismic exploration method, a numerical simulation method and a high-density electrical method are utilized in a mining stable area to obtain corresponding mining pressure relief boundaries from different parameter angles, the data of the obtained mining pressure relief boundaries are optimized in combination with the actual condition of a stope, the accuracy of determining the boundaries by all the methods is improved, and the method is suitable for popularization and application. All the mining pressure relief boundaries after data optimization are fitted, and finally the mining pressure relief boundaries are obtained. According to the method, the complexity and variability of the geological structure are considered, the determination accuracy of the mining pressure relief boundary is improved, and the mining pressure relief boundary can be accurately obtained. The method is of great significance in eliminating coal and gas outburst danger, and provides powerful guarantee for safe mining of coal mines.

Owner:CHONGQING UNIV +1

Directional hydraulic coal digging device and method

PendingCN112412335ASolve the deconfliction taskPromoting mining safely and efficientlyLiquid/gas jet drillingDirectional drillingTool bitMining engineering

The invention belongs to the technical field of underground coal mine operation, particularly relates to a directional hydraulic coal digging device and method. The device solves the problem that coaldigging operation cannot be performed on a coal face or other long-distance, effective and all-around accurate coal digging operations. The device comprises a directional drilling machine used for achieving long-distance precise drilling and coal digging, a common high-pressure sealing drill rod, an upper non-magnetic high-pressure sealing drill rod, a high-pressure sealing exploring tube, a lower non-magnetic high-pressure sealing drill rod, a flow water jet cutter and a drill bit, wherein a water jet cutter head and a water jet cutter tail of the flow water jet cutter are detachably connected, low-pressure water enters the water jet cutter tail, then flows out of the water jet cutter head and finally enters the drill bit to achieve directional drilling operation, and high-pressure waterenters and flows to the water jet cutter tail and then is sprayed out from small cutting holes of the flow water jet cutter, so that directional hydraulic coal digging operation is realized. The directional hydraulic coal drawing method comprises the following steps of S1,carrying out directional drilling operation; and S2, carrying out directional hydraulic coal digging operation. According to the device and the method, long-distance accurate drilling and coal digging operation can be achieved, and the effect of rapid and safe outburst elimination is achieved.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

High-efficiency pre-extraction and rapid outburst elimination method of multi-source gas in the process of re-mining and excavation of leftover coal in the middle seam

ActiveCN112943347BEfficient extractionImprove extraction efficiencyFluid removalGas removalMining engineeringCoal

The invention discloses a multi-source gas high-efficiency pre-draining and rapid outburst elimination method in the process of re-mining and excavation of leftover coal in the middle layer. Gap gas; first determine the maximum danger of the three types of gas sources in the upper and lower empty areas and the coal seam, and after reasonable extraction, the roadway left in the middle of the coal seam starts to excavate, and after a certain distance is excavated, the upper and lower empty areas are carried out again. And the gas pressure measurement of the residual coal in the middle seam, determine the most dangerous gas disaster source, and then carry out gas extraction, and then cycle the maximum risk determination of the three gas sources, gas extraction and roadway re-excavation work, until the entire coal seam roadway is excavated. Finish.

Owner:TAIYUAN UNIV OF TECH

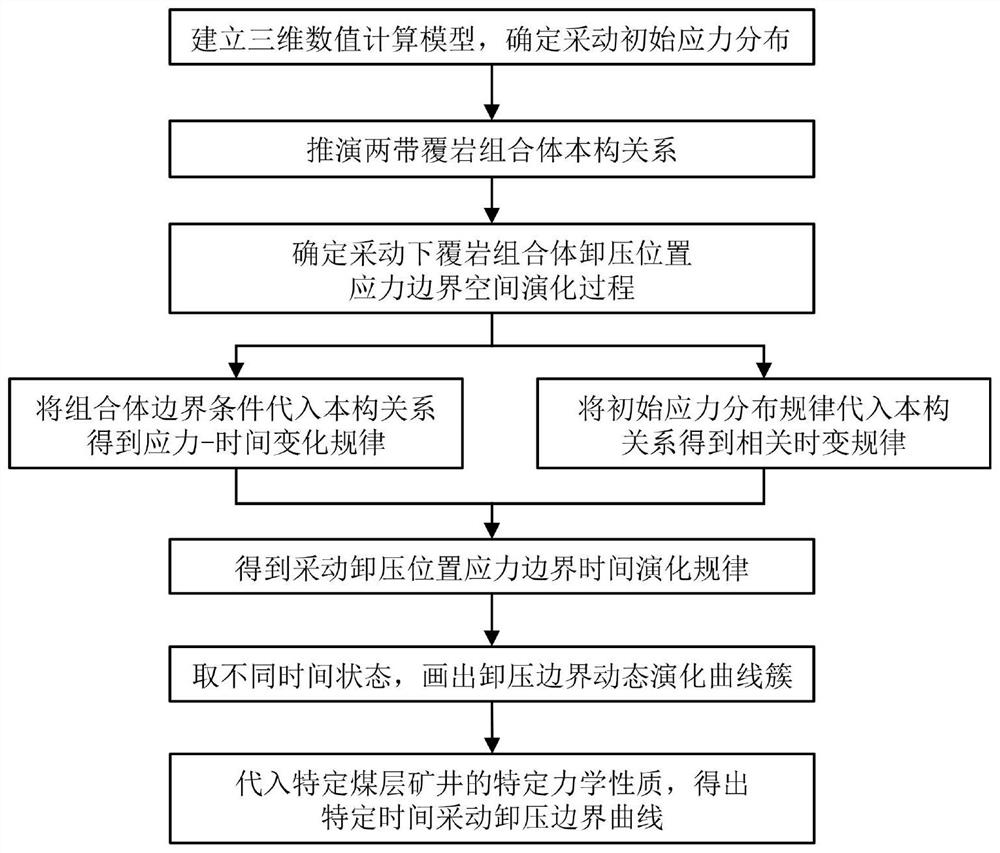

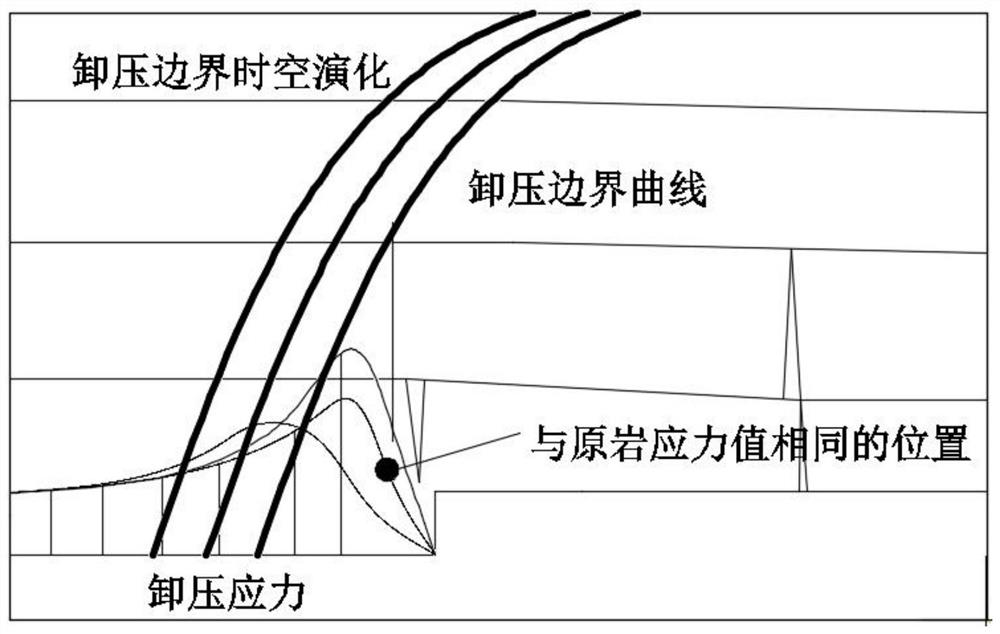

Mining pressure relief boundary space-time curve cluster determination method

PendingCN113742940AEliminate outstanding hazardsAccurate estimateDesign optimisation/simulationSpecial data processing applicationsSpacetimeNumerical models

The invention discloses a mining pressure relief boundary space-time curve cluster determination method. The method specifically comprises the following steps: calculating a three-dimensional numerical model, deducing a constitutive relation of a block-scattered combination, determining a space-time evolution process of a stress boundary of a mining-induced pressure relief position, and drawing the space-time curve cluster of the pressure relief boundary. According to the invention, the influence of time and space factors on the pressure relief boundary is fully considered, the authenticity and objectivity of the mining pressure relief boundary can be guaranteed, the more accurate mining pressure relief boundary can be obtained, and the method has important significance for determining the outburst elimination range of the protected layer.

Owner:CHONGQING UNIV

Low gas permeability coal seam liquid phase co 2 Phase change fracturing anti-reflection mesh gas drainage method

ActiveCN106194244BLarge amount of extractionEnsure safe productionFluid removalGas removalProcess engineeringPhase change

The invention discloses a liquid-phase CO2 phase change cracking permeability-increasing grid type gas extraction method for a low-permeable coal seam. The method comprises the following steps that (1) a bottom board passage is constructed; (2) crossing drilling construction is carried out in the bottom board passage; (3) liquid CO2 phase change cracking is carried out; (4) gas of coal seams of a coal roadway strip and a recovery area is pre-drained with crossing drill holes; (5) the extraction effect of the coal roadway strip area is detected; (6) coal roadway construction is carried out; (7) hole drilling down the seam is carried out; (8) gas of the coal seam in the recovery area is pre-drained with grid type drill holes; and (9) the extraction effect of the recovery area is detected. The method can improve the quantity of drainage of gas of underground coal mine, achieve the purpose of rapidly eliminating danger of outburst for high-gas low-permeable outburst coal seams, prevent coal and gas outburst accidents and guarantee safety production of the underground coal mine.

Owner:CHONGQING UNIV

Method for extracting released-gas of protected coal-bedding under unstabilized thin coal bedding set condition

InactiveCN100535396CProtection of highlighted danger areasReduce gas contentUnderground miningSurface miningGas concentrationCoal

A pressure-relief gas drainage method for protected coal seams under the condition of unstable thin coal seams. For mining areas without stable protective seams, a new protective layer is formed by mining the mineable areas of each unstable thin coal seam. The pressure relief gas drainage can effectively reduce the gas content and pressure of outburst coal seams, transform high gas outburst coal seams into low gas outburst non-outburst coal seams, eliminate the risk of coal seam outburst, and realize safe, rapid excavation and efficient recovery of coal and gas outburst coal seams . The roadway in the working face of the outburst coal seam adopts comprehensive mechanized continuous excavation, and the speed of the roadway excavation can be increased from the original 60m / month to more than 200m / month; The gas concentration at the corner of the surface can be controlled below 0.8%, and the gas concentration of the return air flow can be controlled below 0.5%, which has wide practicability in this field.

Owner:CHINA UNIV OF MINING & TECH +1

A gas drainage method for low-level and multi-stage through-bed drilling holes for coal-rock interbedded coal seams

ActiveCN109899105BEliminate outstanding hazardsGuaranteed sampling complianceGas removalMining engineeringCoal

The present invention relates to a low-level multi-stage perforated drilling method for gas drainage in coal-rock interbedded coal seams. (Right) A 0.3-1m slope downhill (3) penetrating into the bottom rock layer (2) of all coal-rock interbeds (2) is constructed on the side of the slope, and a length × width × height = 3.0m × 2.5m × 2m low-level drilling site (4), in which several low-level multi-stage through-layer drilling holes (5) are constructed obliquely upward along the roadway excavation direction to the mining layer, and inserted into multiple Step bushings (6‑1), (6‑2), (6‑3), use Ф120mm rubber hose (11) to connect the bushings (6‑1) with multi-pass, and connect with the gas pump in the roadway The mining pipelines (12) are connected and converged, and the low-level multi-stage cross-layer drilling (5) is connected to the gas extraction operation. The invention effectively drains the coal seam floor gas, is safe and efficient, and can be used for the implementation of outburst prevention measures on the working face.

Owner:EASTERN GANSU UNIVERSITY

Method for determining grid type layer-through drilling intervals of floor roadway

InactiveCN102116170BGuaranteed to highlight the dangerEliminate outstanding hazardsSurveyGas removalMining engineeringCoal

The invention relates to a method for determining grid type layer-through drilling intervals of a floor roadway, which can accurately and quickly determine the effective intervals of layer-through drilling of an outburst coal seam within a certain period of time by adopting the arrangement of the determining drilling holes and determining the grid type layer-through drilling intervals, simultaneously arranging multiple groups of the determining drilling holes and adopting the determination of double indexes, namely residual gas pressure of a coal seam and residual gas content, so as to effectively reduce the gas content in the coal seam and eliminate the outburst risk by the determined layer-through drilling intervals on the one hand, and reduce the drilling engineering quantity to the greatest extent, shorten the construction period of drilling, and further ensure the balance of pumping, excavation and mining of the outburst coal seam on the other hand. The method is simple, the measurement speed is fast, and the determined results are accurate and reliable.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com